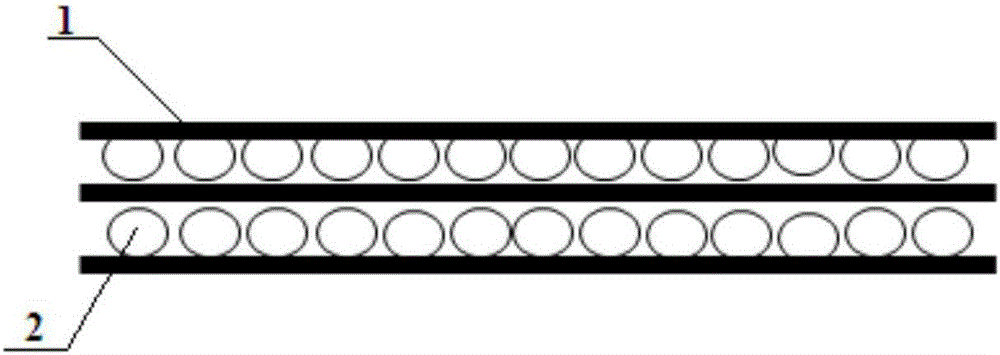

Graphene oxide-polymeric microsphere water-based lubricant additive and preparation method thereof

A technology of lubricating additives and polymers, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problems of limited application range, large friction coefficient, poor anti-wear performance, etc. The effect of improving the anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

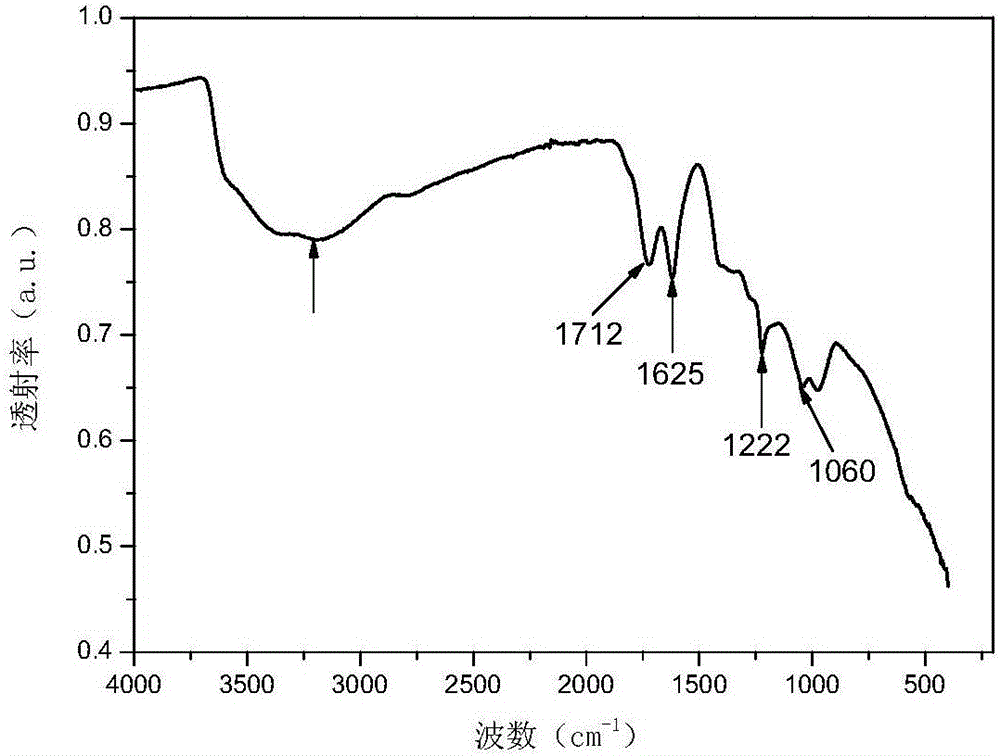

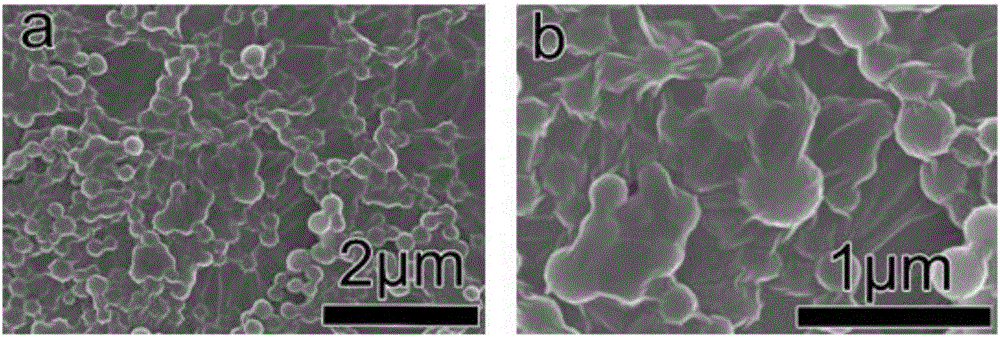

Embodiment 1

[0031] A kind of preparation method of graphene oxide-polymethyl methacrylate microsphere water-based lubricating additive, comprises the steps:

[0032] (1) Prepare graphene oxide powder by improving the Hummers method: Weigh 2.4g of natural flake graphite and 3g of sodium nitrate and place it in an Erlenmeyer flask, add 140ml of concentrated sulfuric acid to it, and place it in an ice-water bath at 0°C for 30 minutes; then Slowly add 12g of potassium permanganate under stirring conditions, and continue to stir for 3 hours; then raise the temperature to 35°C and continue to stir for 30 minutes, then slowly add 600ml of deionized water dropwise, and after the addition is completed, the temperature rises to 98°C for 15 minutes. After the reaction, add 10ml of hydrogen peroxide dropwise until the solution changes color, vacuum filter, centrifuge and wash with deionized water at a speed of 10000r / min for 5min until the pH value is 7, continue centrifuging for 4 times, take the upp...

Embodiment 2

[0038] A preparation method for graphene oxide-polyethylacrylate microsphere water-based lubricating additive, comprising the steps:

[0039] (1) Prepare graphene oxide powder by improving the Hummers method: Weigh 0.6g of natural flake graphite and 1g of sodium nitrate in a Erlenmeyer flask, add 35% concentrated sulfuric acid to it, and place it in an ice-water bath at 0°C for 30min; then Slowly add 3g of potassium permanganate under stirring conditions, and continue to stir for 3 hours; then raise the temperature to 35°C and continue to stir for 30 minutes, then slowly add 200ml of deionized water dropwise, and after the addition is completed, the temperature rises to 98°C for 15 minutes. After the reaction is over, add 2ml of hydrogen peroxide dropwise until the solution changes color, vacuum filter, centrifuge and wash with deionized water at a speed of 12000r / min for 3min until the pH value is 7, continue to centrifuge for 3 times, take the supernatant of the upper layer, ...

Embodiment 3

[0044] A kind of preparation method of graphene oxide-polystyrene microsphere water-based lubricating additive, comprises the steps:

[0045] (1) Prepare graphene oxide powder by the improved Hummers method: Weigh 0.6g of natural flake graphite and 0.6g of sodium nitrate into a three-necked flask, add 40ml of concentrated sulfuric acid to it, and place it in an ice-water bath at 2°C for 60min; Then slowly add 2g of potassium permanganate under stirring conditions, and continue to stir for 5 hours; then raise the temperature to 35°C and continue to stir for 60 minutes, then slowly add 250ml of deionized water dropwise, after the addition is completed, the temperature rises to 98°C for 30 minutes , after the reaction, add 2ml of hydrogen peroxide dropwise until the solution changes color, vacuum filter, centrifuge and wash with deionized water at a speed of 11000r / min for 4min until the pH value is 7, continue centrifuging for 5 times, take the supernatant of the upper layer, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com