Patents

Literature

80 results about "Polyethylacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blends of amorphous and semicrystalline polymers having shape memory properties

InactiveUS20040122174A1High modulusImprovement in critical temperatureDental impression compositionsPoly(methyl methacrylate)Ethyl acrylate

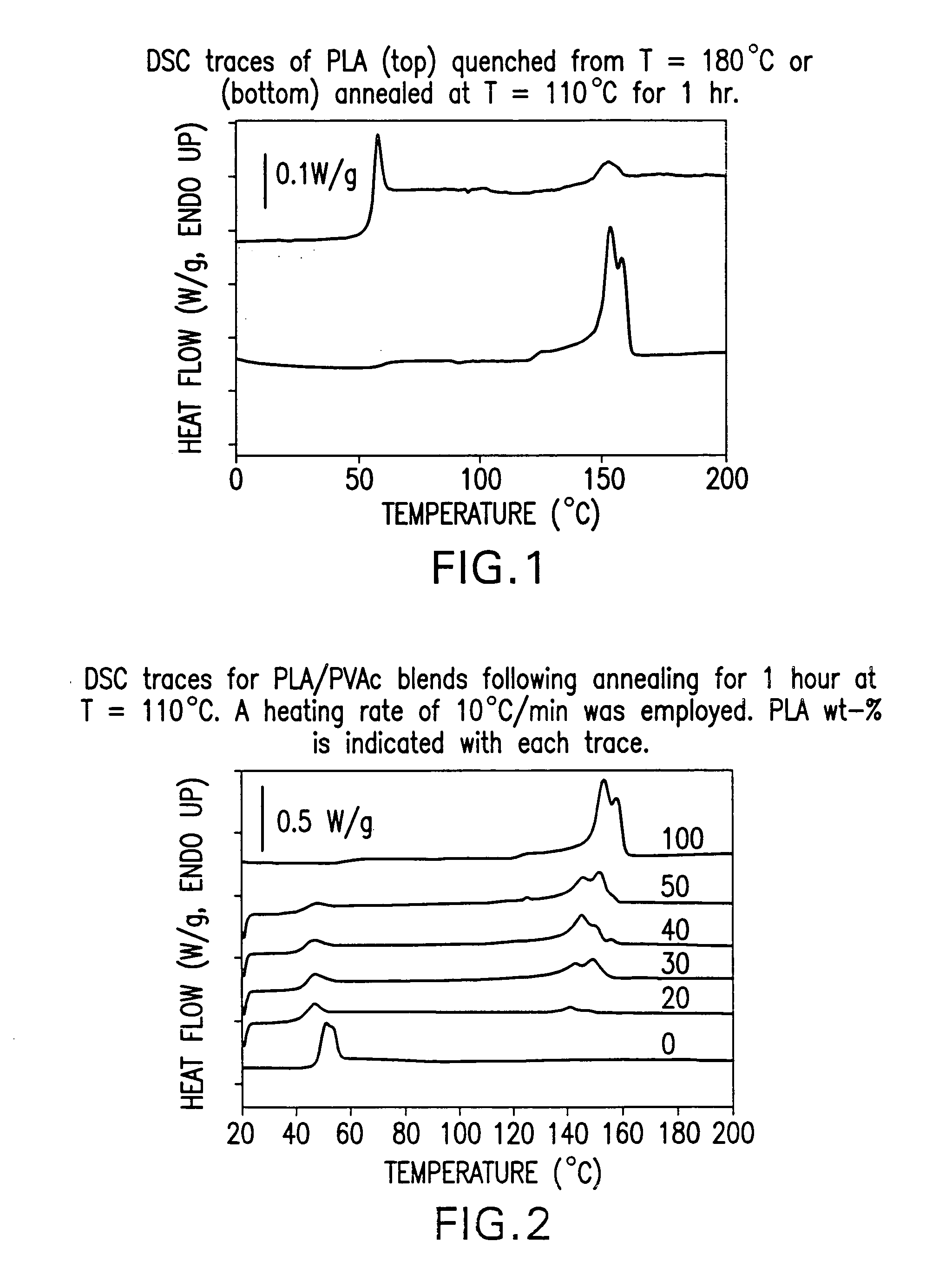

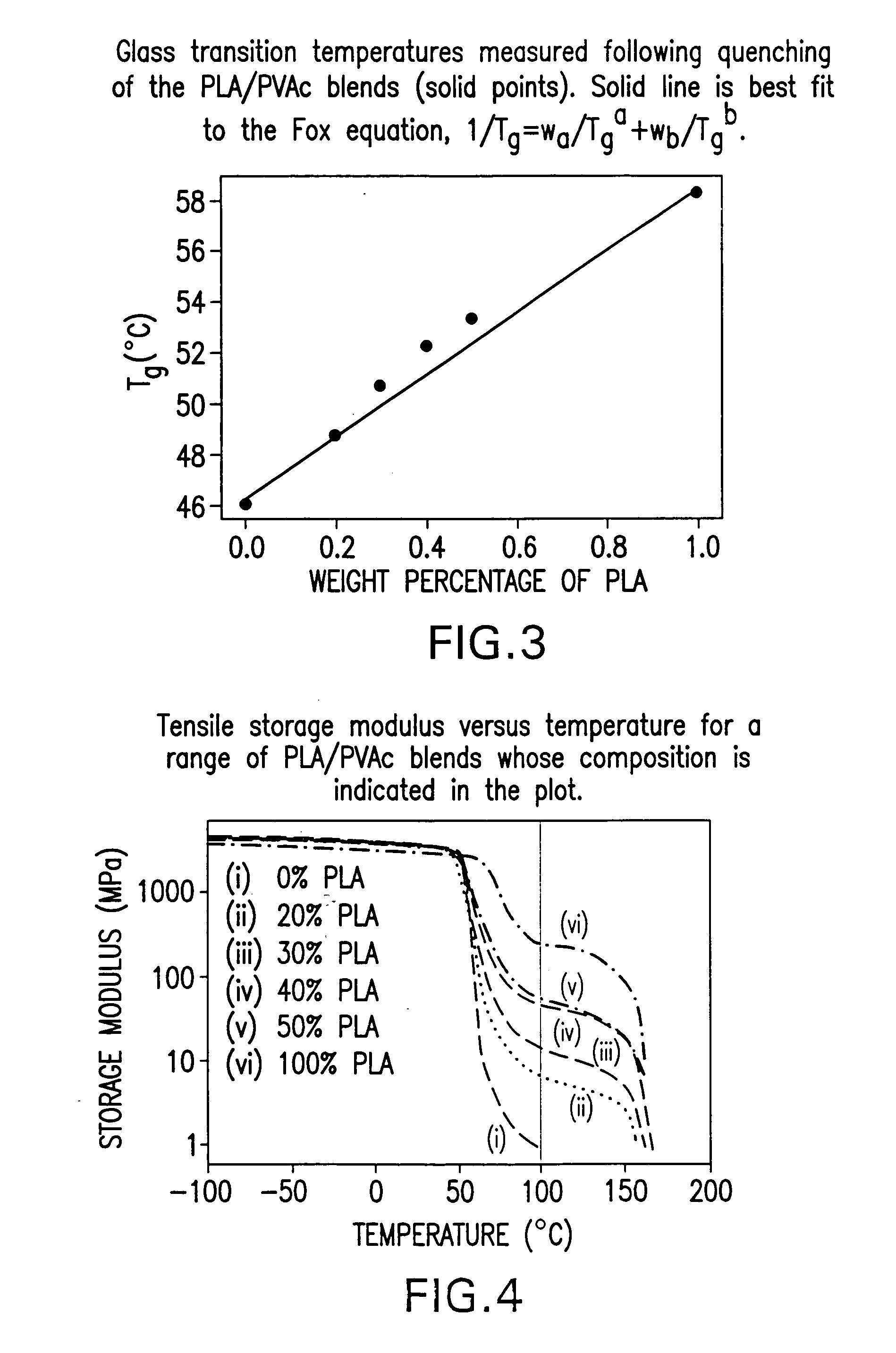

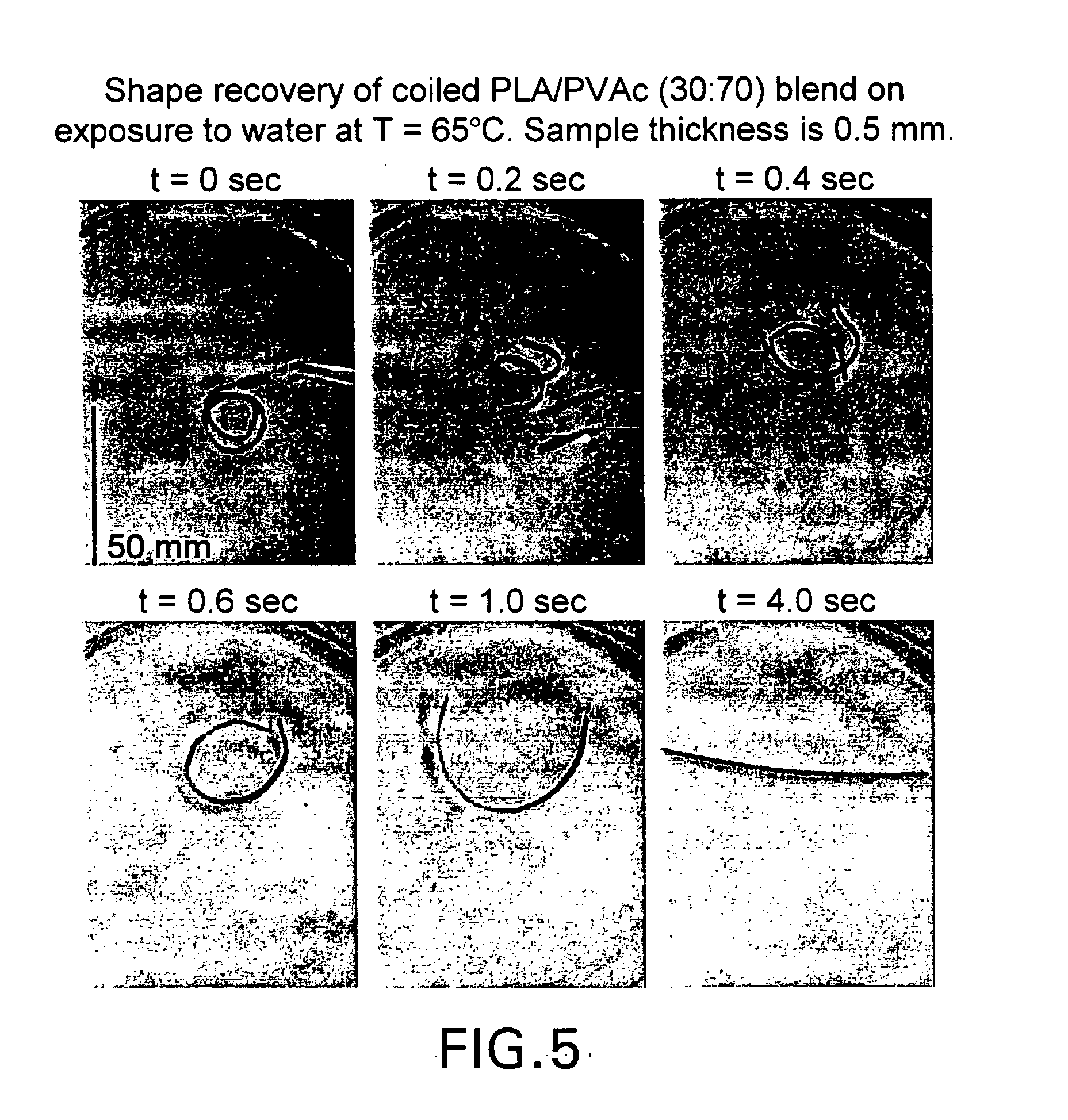

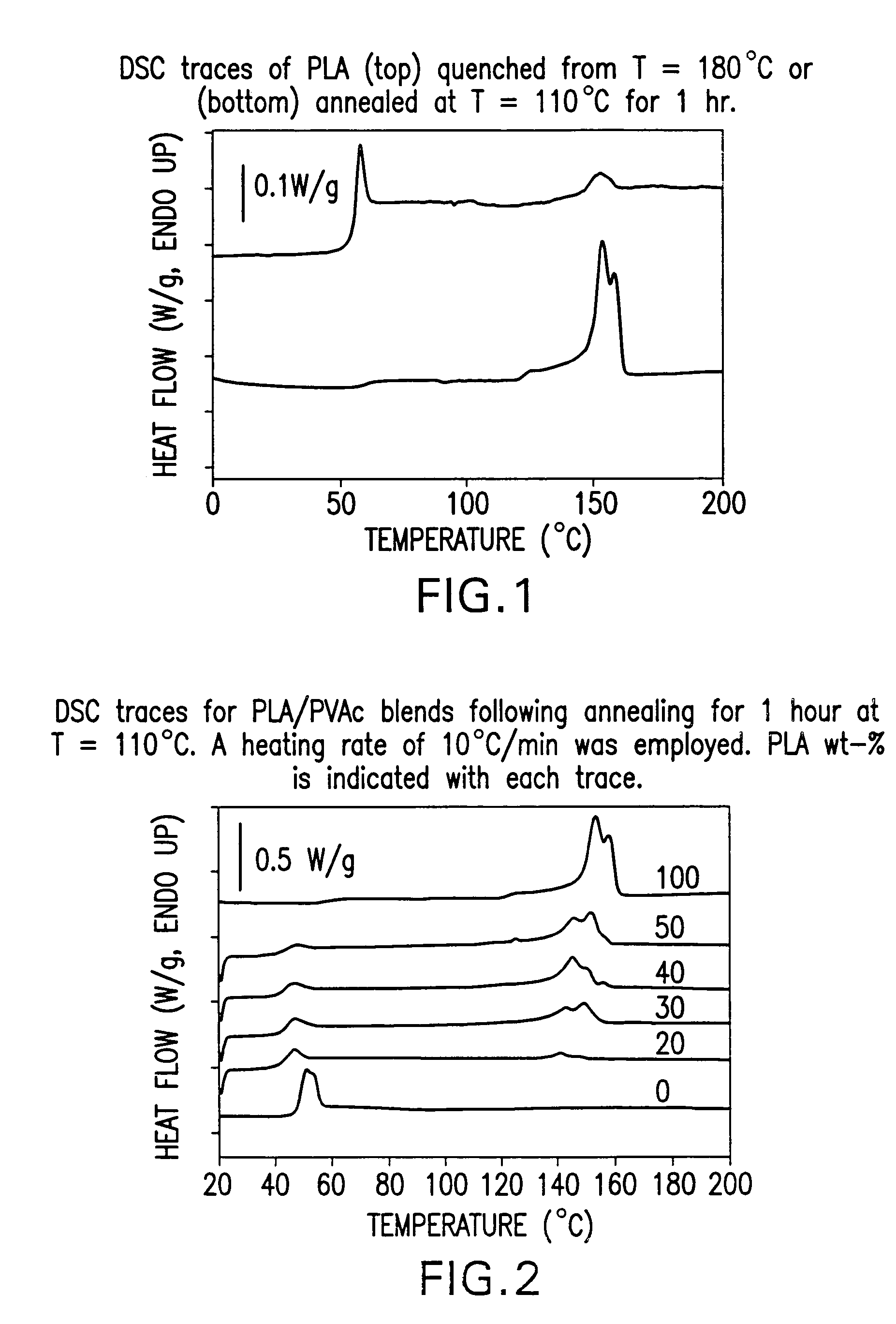

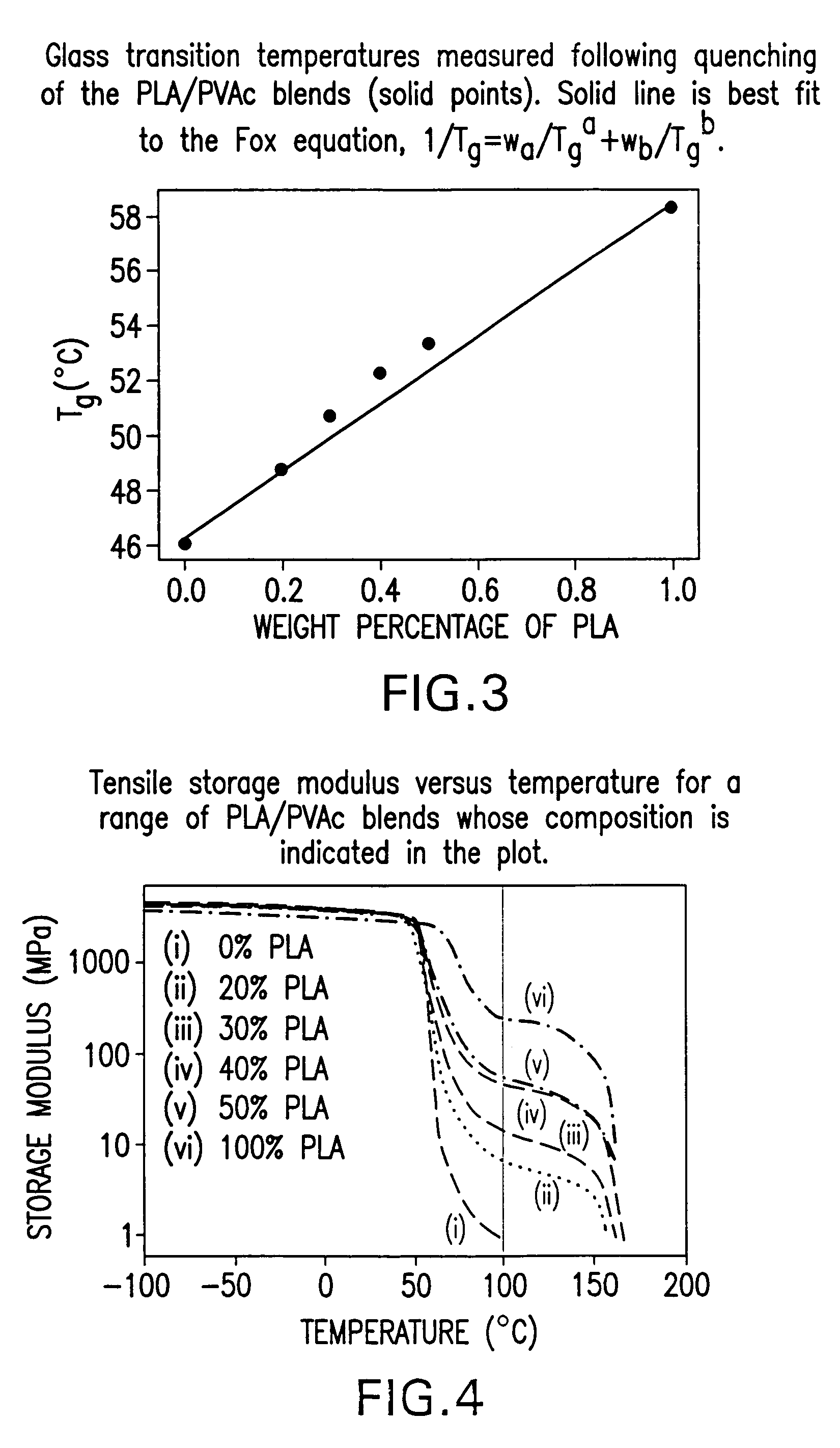

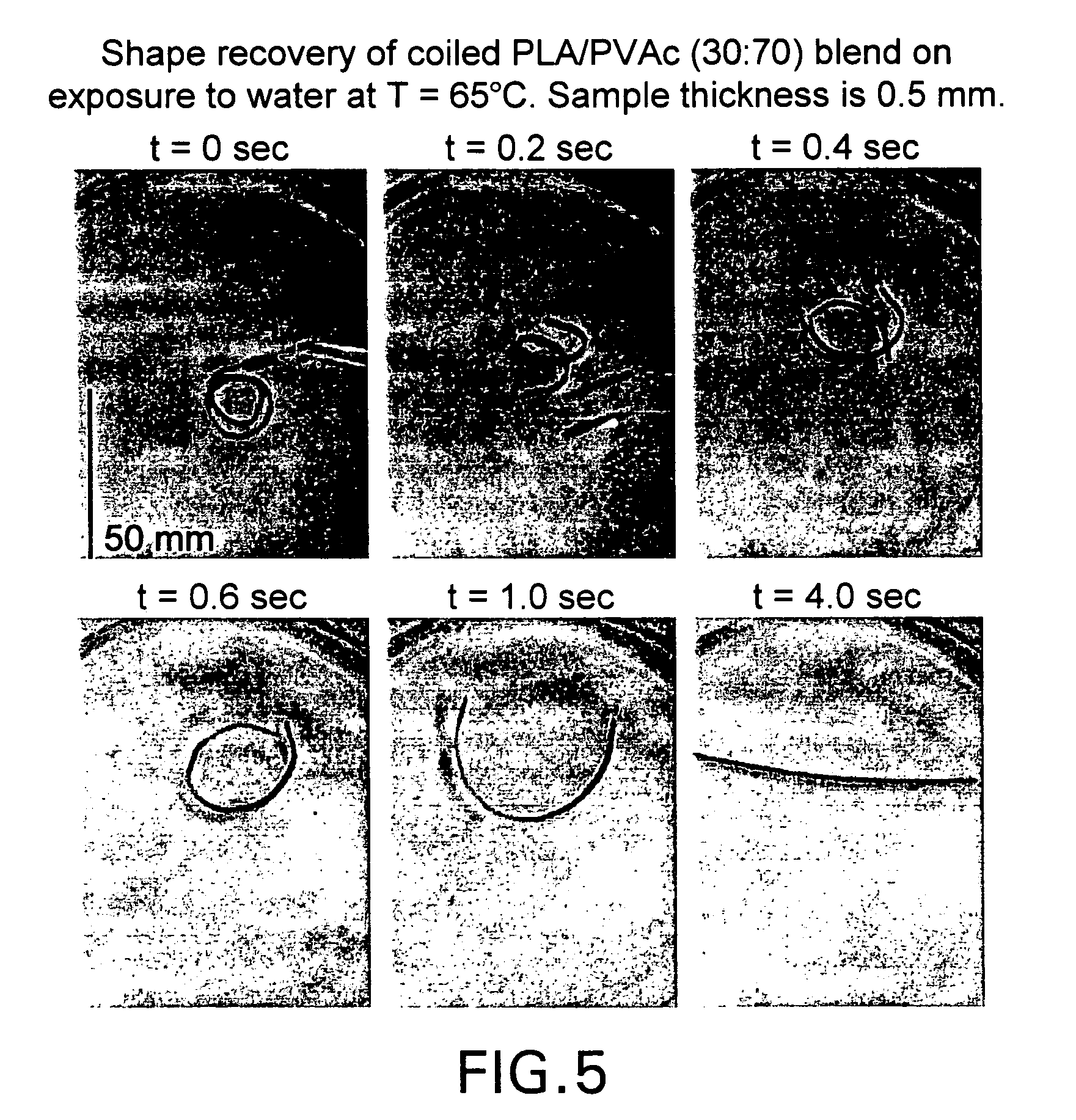

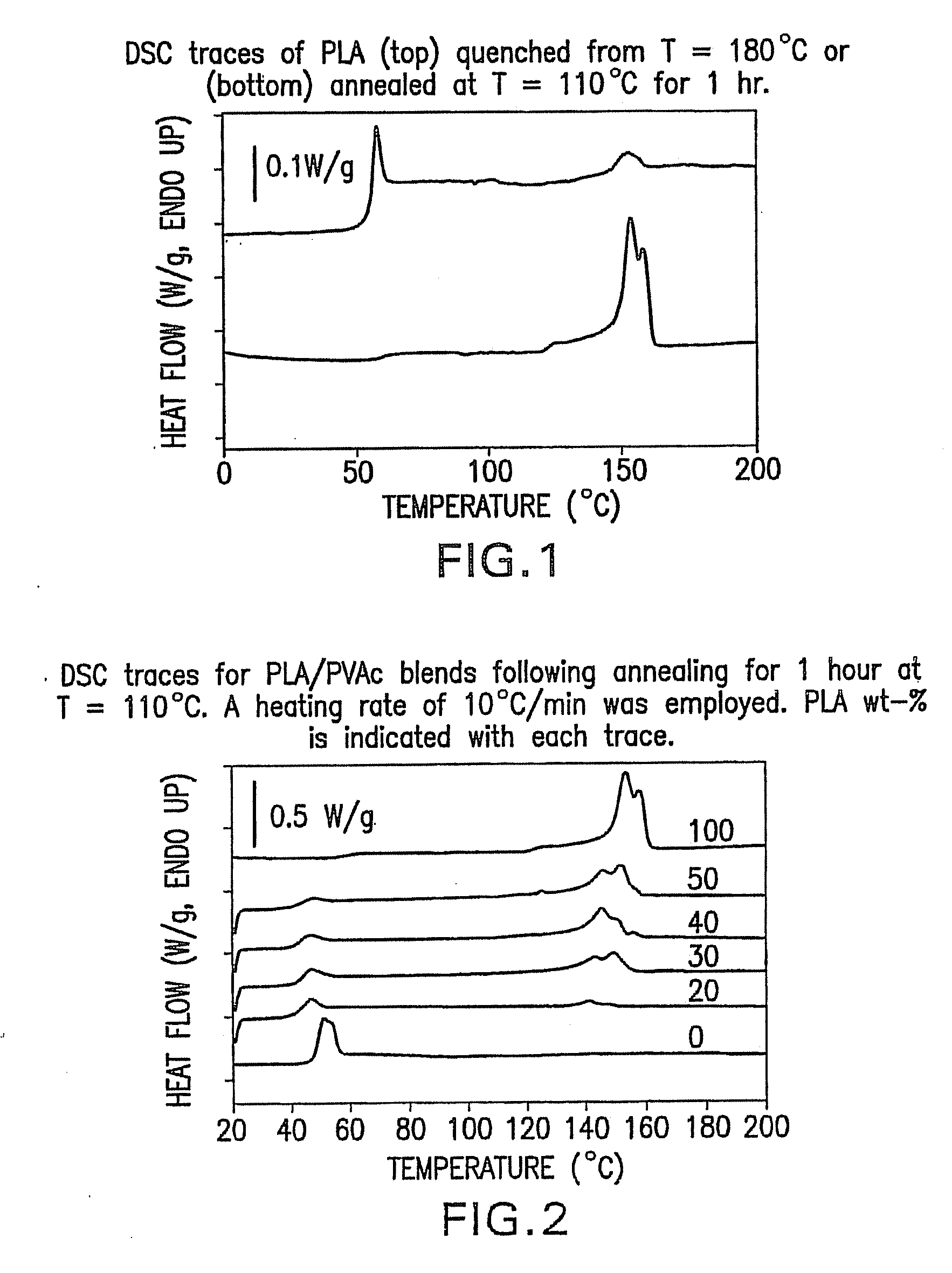

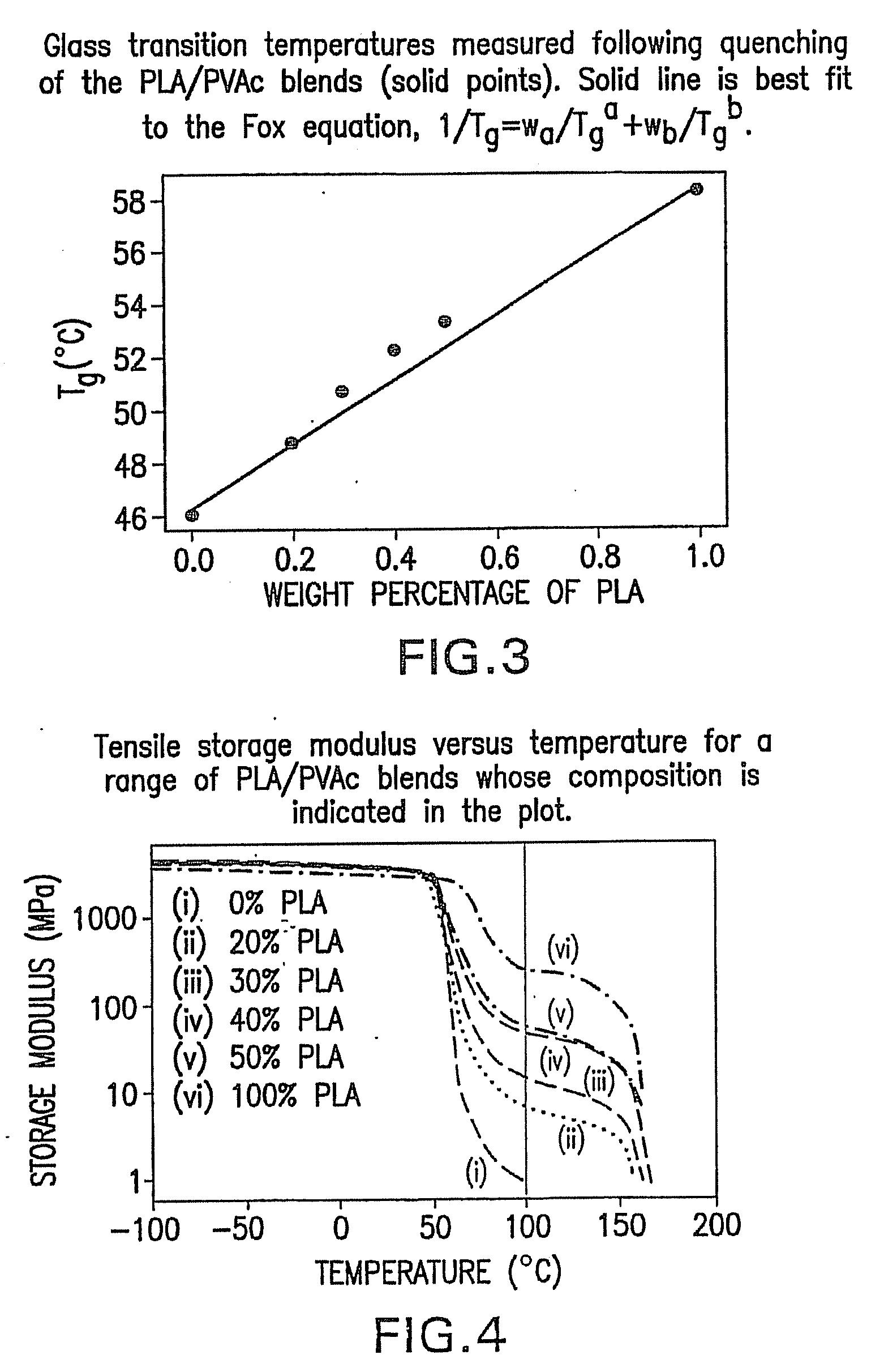

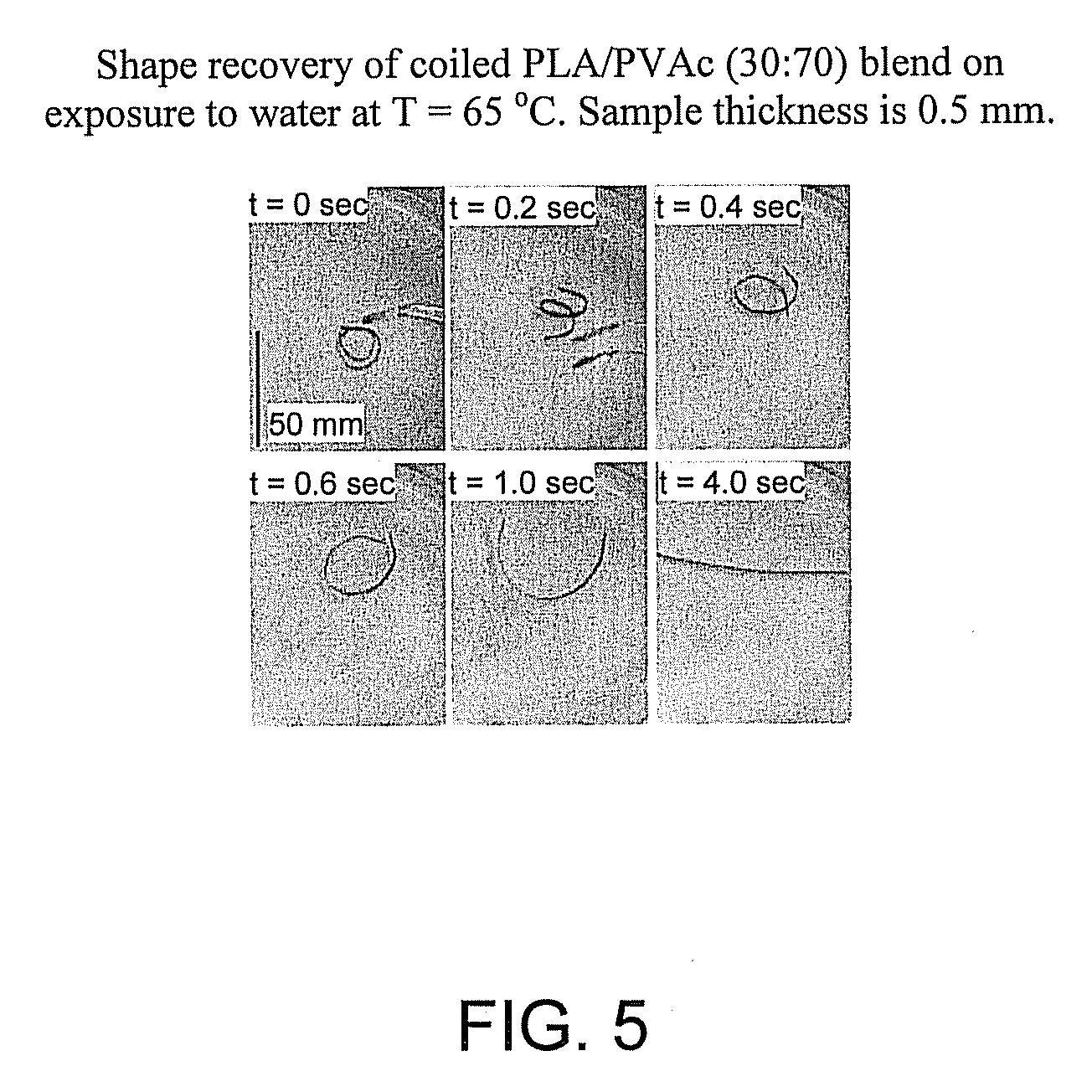

Blends of amorphous and semicrystalline polymers having shape memory properties were prepared by blending a crystalline polymer such as poly(vinylidene fluoride), polylactide, poly(hydroxxybutyrate), poly(ethylene glycol) polyethylene, polyethylene-co-vinyl acetate, poly(vinyl chloride), poly(vinylidene chloride) and copolymers of poly(vinylidene chloride) and poly(vinyle chloride) and an amorphous polymer such as poly(vinyl acetate), poly methyl acrylate, poly ethyl acrylate, atactic poly methyl methacrylate, isotactic poly methyl methacrylate, syndiotactic poly methyl methacrylate and other poly alkyl methacrylates. The method for preparing the polymeric materials and applications thereof, for example, as smart medical devices, are also disclosed.

Owner:UNIV OF CONNECTICUT

Blends of amorphous and semicrystalline polymers having shape memory properties

InactiveUS7208550B2High modulusDental impression compositionsPoly(methyl methacrylate)Glycol synthesis

Blends of amorphous and semicrystalline polymers having shape memory properties were prepared by blending a crystalline polymer such as poly(vinylidene fluoride), polylactide, poly(hydroxxybutyrate), poly(ethylene glycol) polyethylene, polyethylene-co-vinyl acetate, poly(vinyl chloride), poly(vinylidene chloride) and copolymers of poly(vinylidene chloride) and poly(vinyle chloride) and an amorphous polymer such as poly(vinyl acetate), poly methyl acrylate, poly ethyl acrylate, atactic poly methyl methacrylate, isotactic poly methyl methacrylate, syndiotactic poly methyl methacrylate and other poly alkyl methacrylates. The method for preparing the polymeric materials and applications thereof, for example, as smart medical devices, are also disclosed.

Owner:UNIV OF CONNECTICUT

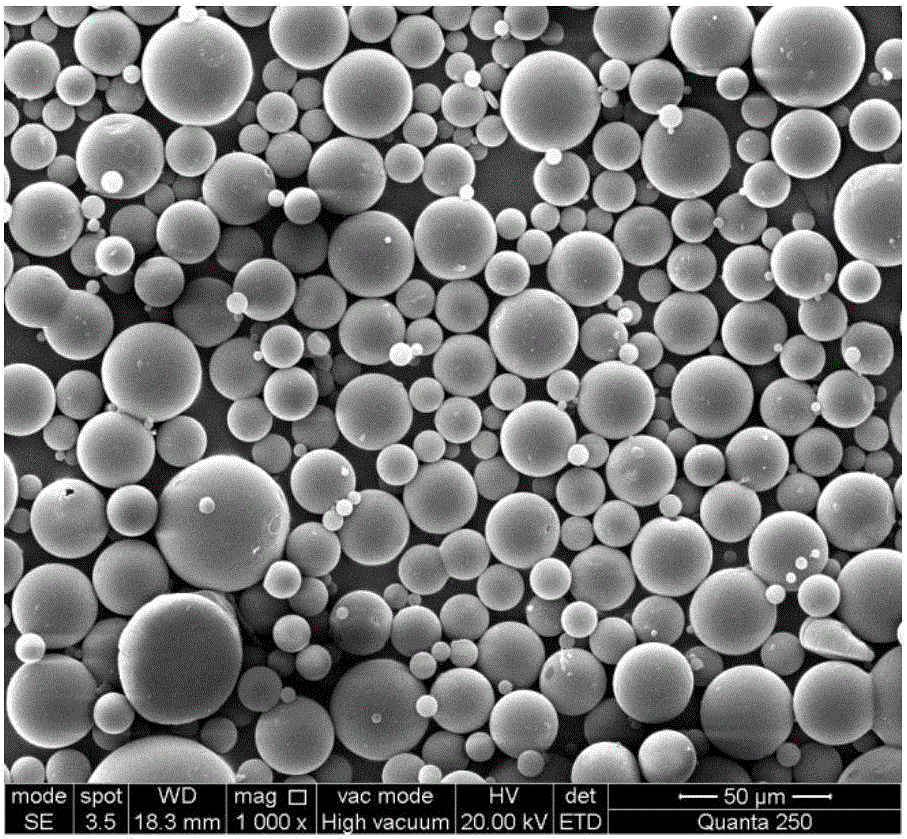

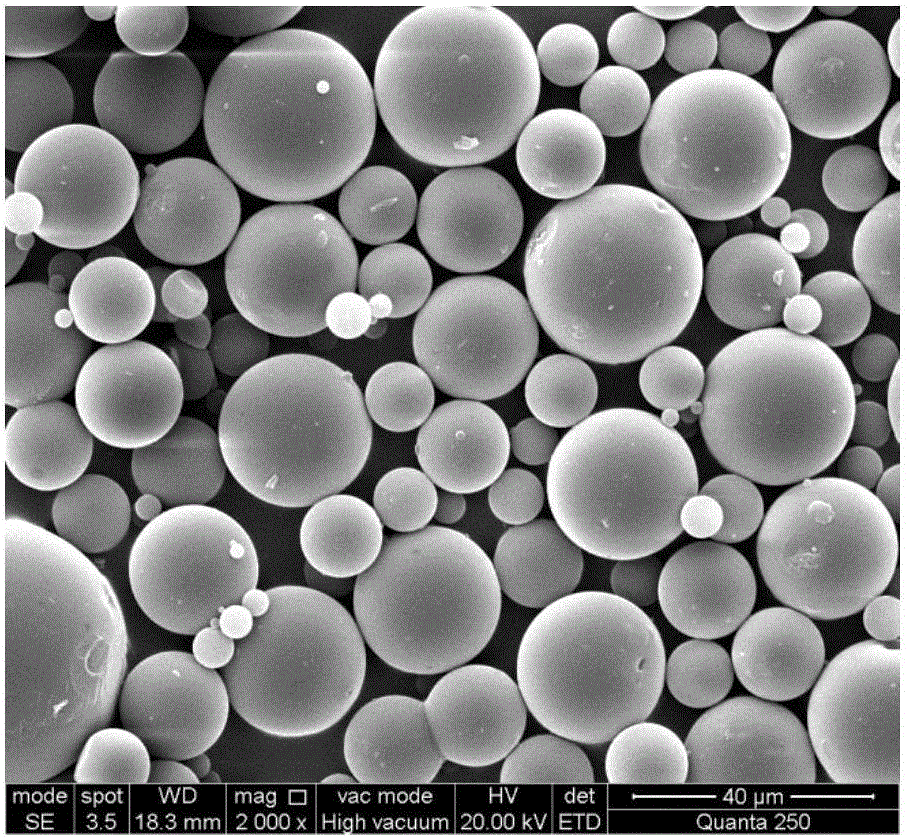

Inorganic hydrous salt phase change microcapsule energy-storage material and preparing method

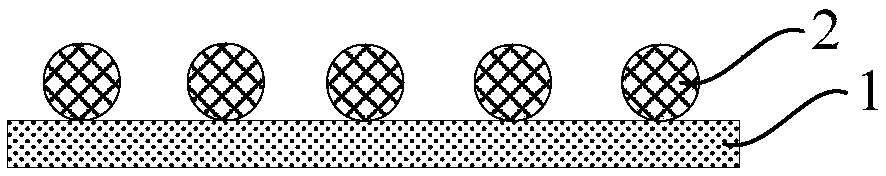

InactiveCN106221674AAchieve solidificationImprove heat transfer efficiencyHeat-exchange elementsCalcium Chloride HexahydrateSodium Thiosulfate Pentahydrate

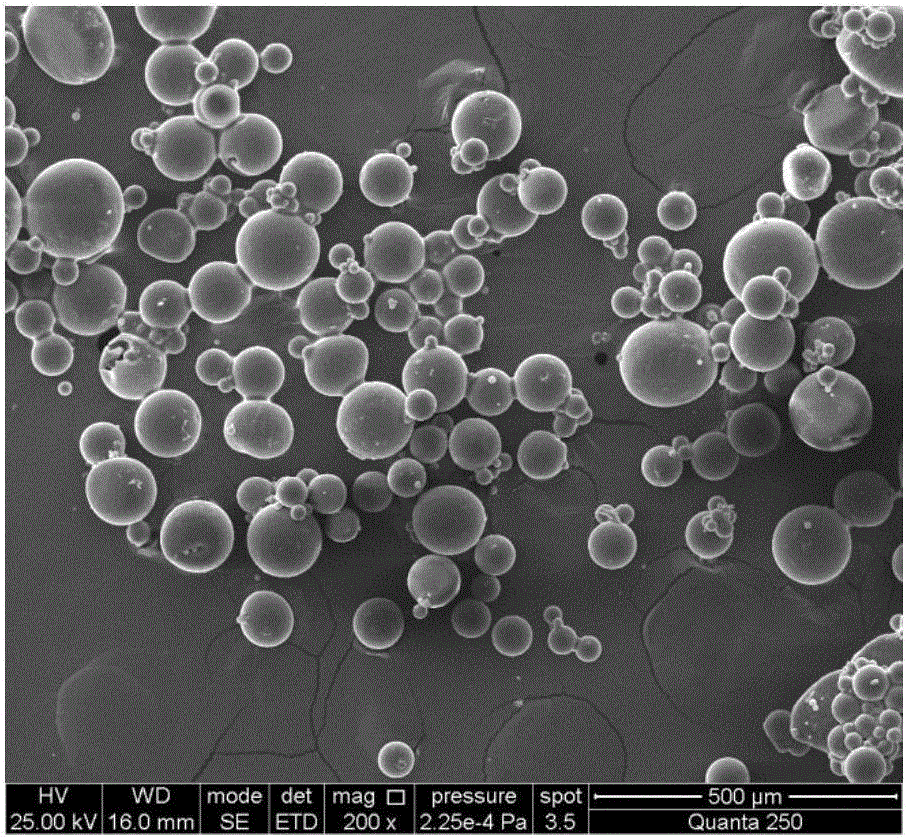

The invention relates to a preparing method of an inorganic hydrous salt phase change microcapsule energy-storage material and belongs to preparing methods of energy-storage materials. The energy-storage material comprises a core material and a wall material, wherein the core material is prepared from one or more of calcium chloride hexahydrate, sodium sulfate decahydrate, sodium thiosulfate pentahydrate, disodium hydrogen phosphate dodecahydrate, sodium acetate trihydrate and sodium carbonate decahydrate inorganic hydrous salt, and the wall material is prepared from one or more of polystyrene, polymethyl methacrylate, poly(ethyl acrylate), polyurethane, cellulose acetate butyrate (CAB) and a diphenylmethane diisocyanate polymer, the core material accounts for 30-80% of the microcapsule energy-storage material by mass, and the wall material is prepared from the polymer and accounts for 20-70% of the microcapsule energy-storage material by mass. The phase change point of the obtained phase change microcapsule energy-storage material ranges from 20 DEG C to 90 DEG C, and the particle size ranges from 1 micrometer to 100 micrometers. The phase change microcapsule energy-storage material prepared with the method is high in encapsulation rate, good in sealing performance, large in phase change latent heat value, simple in preparing method and large in industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

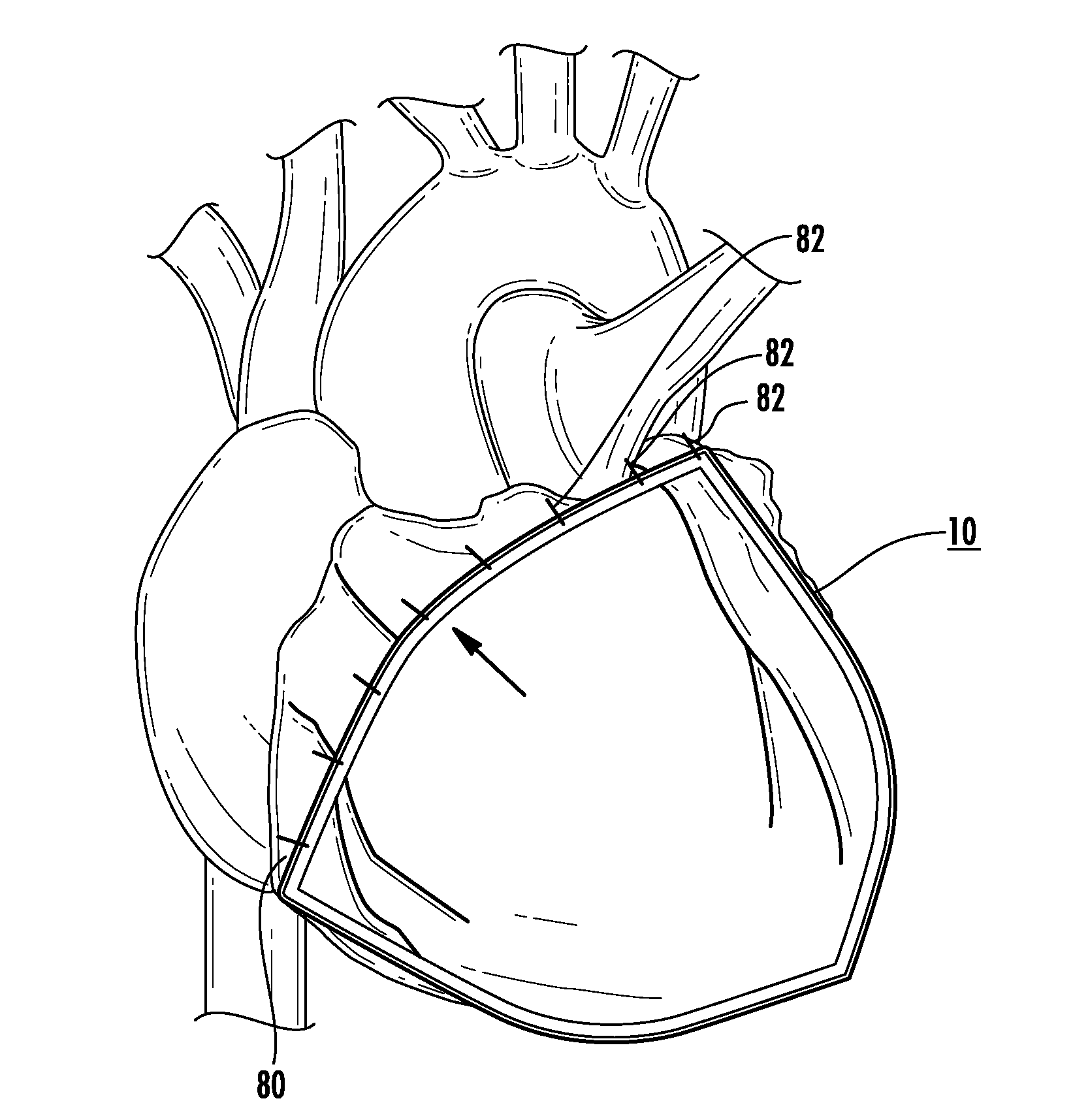

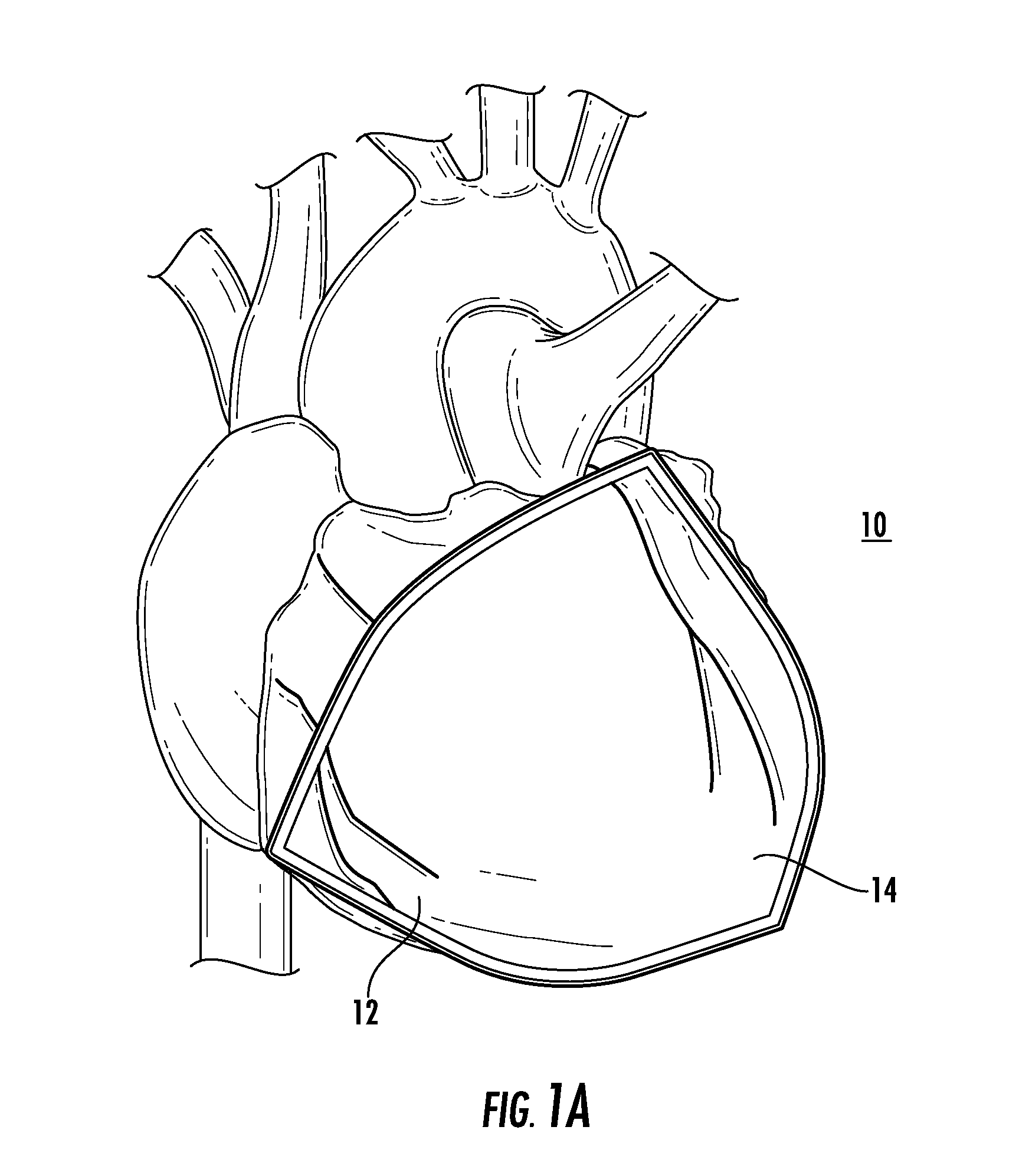

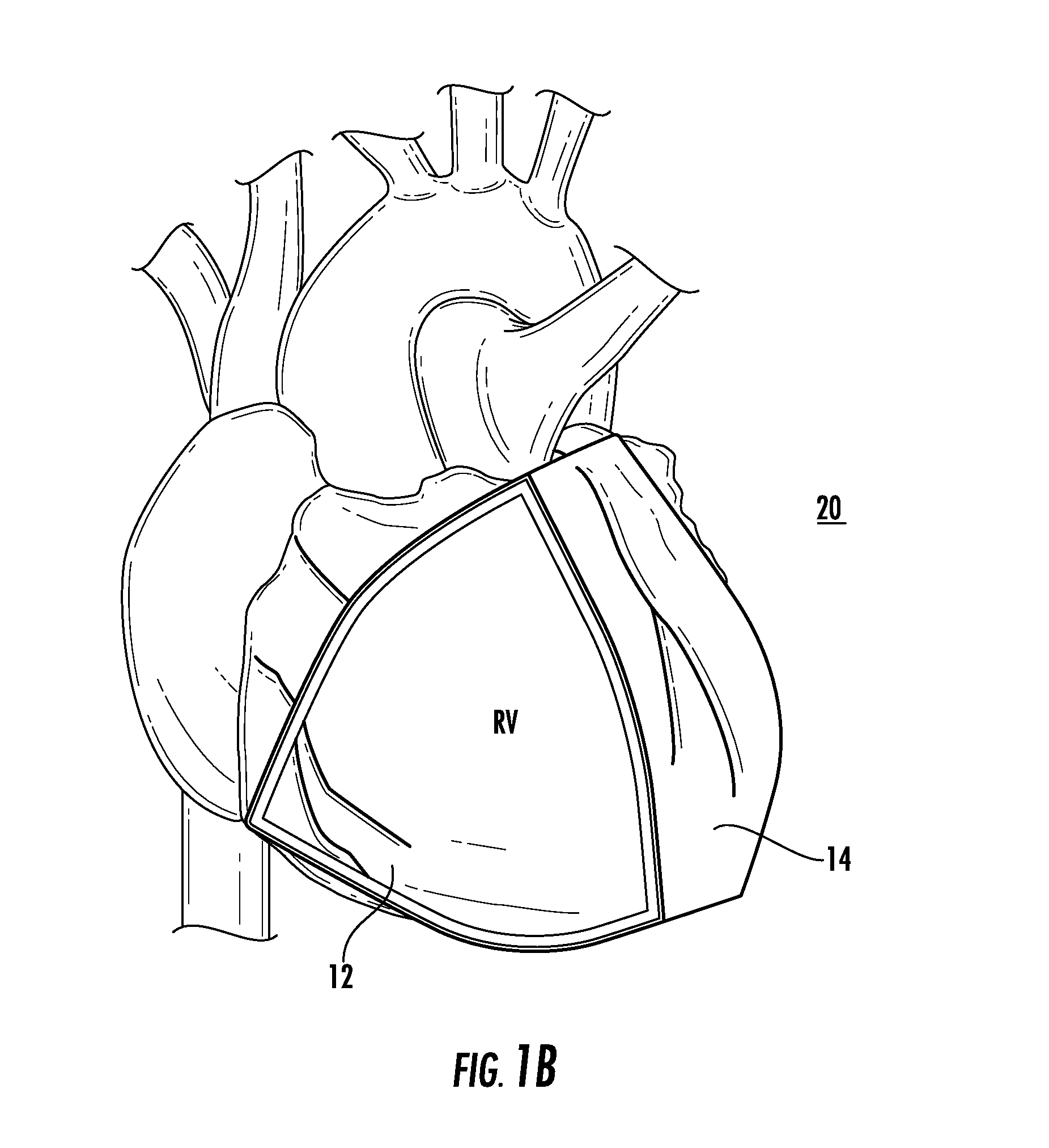

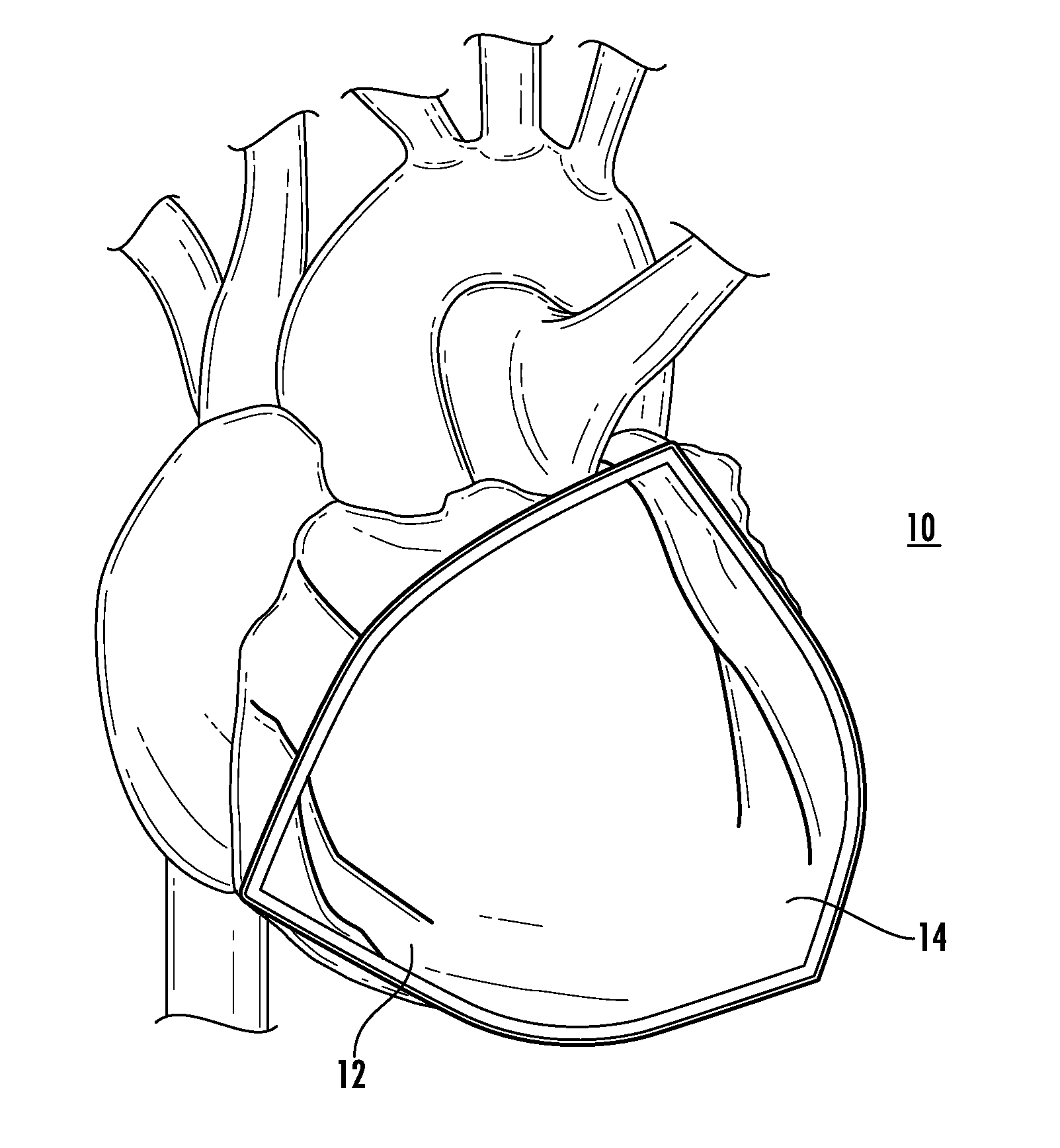

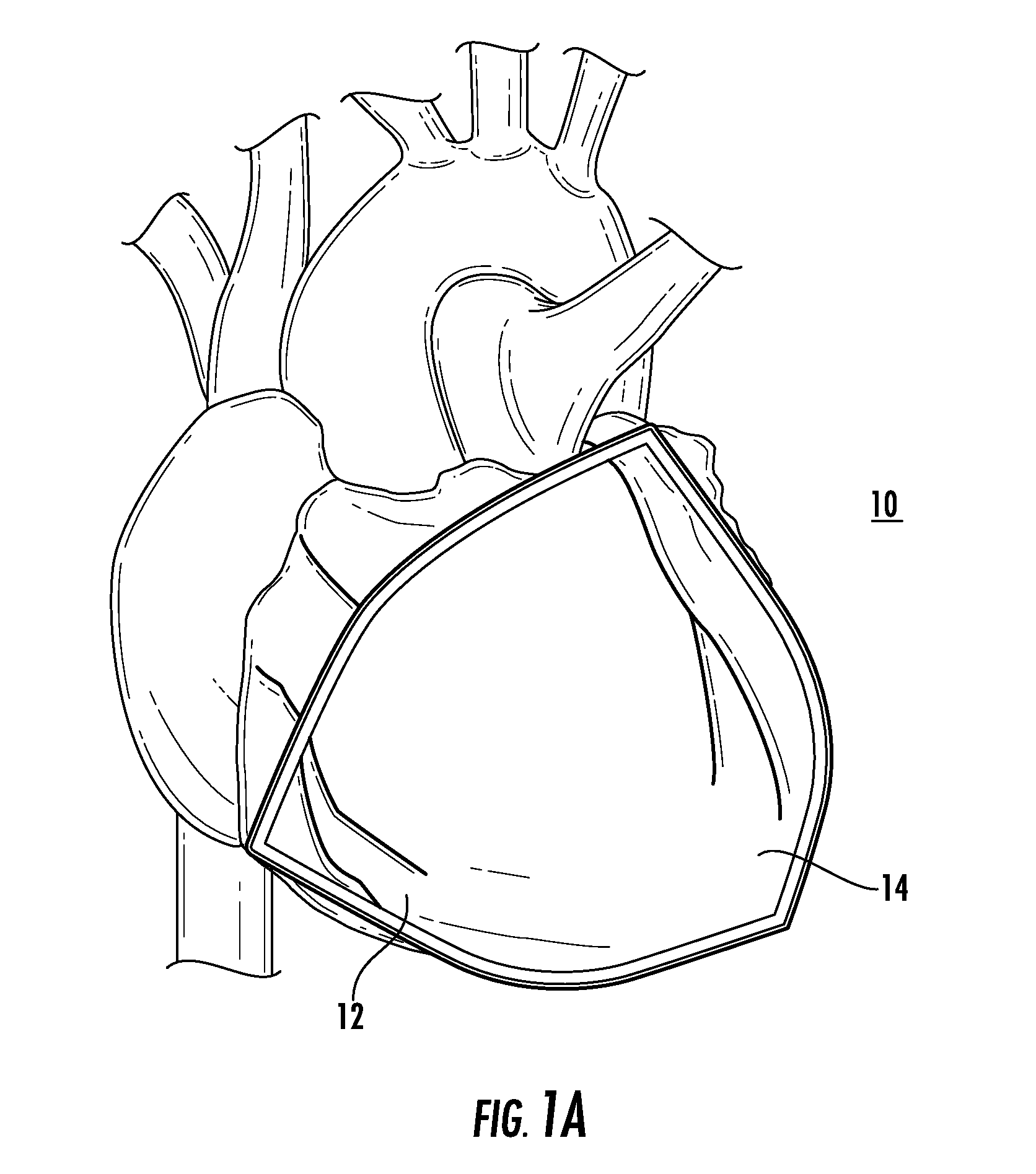

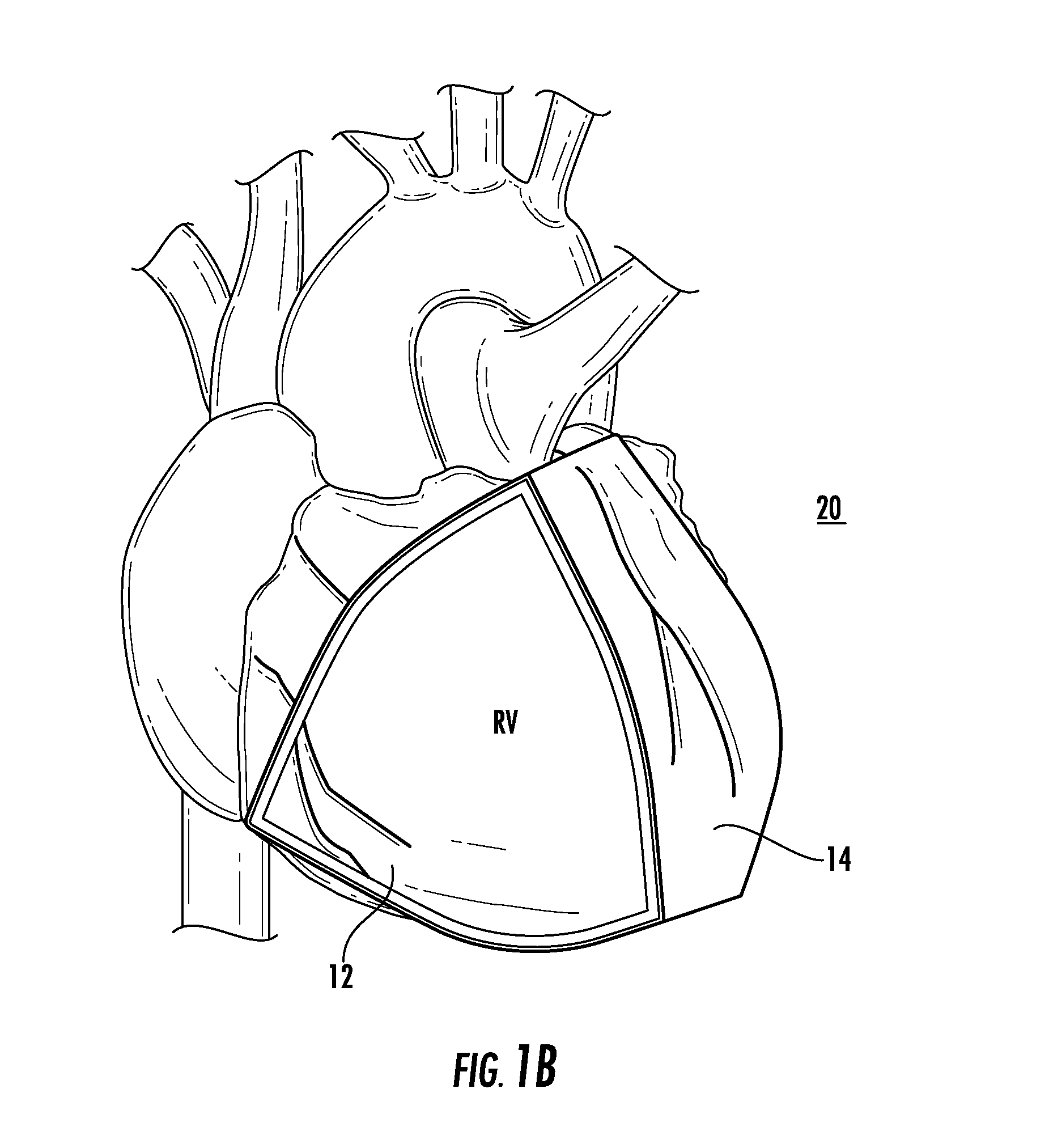

Bioactive implant for myocardial regeneration and ventricular chamber restoration

InactiveUS20130116789A1Limit chronic dilationRestore native elliptical shapeHeart valvesPharmaceutical delivery mechanismProsthesisCardiac muscle

Bioactive implant for myocardial regeneration and ventricular chamber support including an elastomeric microporous membrane. The elastomeric microporous membrane being at least one non-degradable polymer and at least one partially degradable polymer. The non-degradable polymer is selected from polyethylacrylate and polyethylacrylate copolymerized with a hydroxyethylacrylate comonomer. The partially degradable polymer is selected from caprolactone 2-(methacryloyloxy)ethyl ester and caprolactone 2-(methacryloyloxy)ethyl ester copolymerized with ethylacrylate. The elastomeric microporous membrane further includes a nanofiber hydrogel, and cells. The bioactive implant, having one or two helical loops, contributes to the restauration of the heart conical shape. Cardiac wrapping by ventricular support bioprostheses of the present invention, having reinforcement bands spatially distributed as helicoids, recovers the sequential contraction of the myocardium resulting in the successive shortening and lengthening of the ventricles, therefore improving the ejection (systolic function) and suction of blood (diastolic function).

Owner:INSTITUT QUIMIC DE SARRIA +3

Blends of amorphous and semicrystalline polymers having shape memory properties

InactiveUS20070135578A1High modulusDental impression compositionsPolyethylene glycolPoly(methyl methacrylate)

Owner:UNIV OF CONNECTICUT

Road waste asphalt regenerant and preparation method

The invention discloses a road waste asphalt regenerant and a preparation method. The regenerant comprises base oil, a plasticizer and a reinforcer, wherein the ratio of the three components is 1:1:1. The base oil is waste engine oil, the plasticizer is 6101 epoxy resin and the reinforcer is polyacrylic ester which is prepared from polymethyl acrylate, polyethyl acrylate and polybutyl acrylate in the ratio of 1:1:1. The preparation method comprises the following steps: mixing certain amount of road ageing asphalt and 10-25 percent of the road waste asphalt regenerant together; stirring and evenly mixing under the condition of 140 to 160 DEG C to obtain the road regenerated asphalt. The regenerant is used to directly save a large amount of sandstones and asphalt resources, and effectively save a large amount of land resources occupied by exploring the sandstones and waste materials at the same time; and a main raw material of the road waste asphalt regenerant is the waste engine oil which has low prices, so the road waste asphalt regenerant has certain commercial value.

Owner:BEIJING UNIV OF CHEM TECH

Polymer optical fiber used for luminous fabric, luminous fabric, and manufacturing method for luminous fabric

ActiveCN105133084AHigh mechanical strengthGood chemical resistanceOptical fibre with multilayer core/claddingWoven fabricsPolytetramethylene terephthalateSilanes

The invention relates to a polymer optical fiber used for a luminous fabric, the luminous fabric, and a manufacturing method for the luminous fabric. The polymer optical fiber comprises an inner core layer and an outer core layer, wherein the inner core layer consists of polybutylene terephthalate, ETPI (Epoxidized Trans-1,4-polyisoprene), SBS (Styrene Butadiene Styrene), polyethylene acrylate, n-butyl acrylate, polycarbonate, methacryloyloxyethyl silane, vinylsilane, aroyl phosphine oxide, and 2,4-dihydroxy benaophenonel; the outer core layer consists of methacrylic acid n-propyl ester, tetrafluoroethylene, 1,3,5-trimethyltris-1,5-(3,3-trifluoropropyl)-cyclotrisiloxane, vinyltriethoxysilane, methacryloxy propyl trimethoxyl silane, double benzoyl phenyl phosphine oxide, alpha-hydroxyalkyl phenyl ketone, and nanosilicon dioxide. The polymer optical fiber disclosed by the invention is not easy to break, and the luminous fabric made from the polymer optical fiber has the characteristics of high brightness and long service life.

Owner:徐州国宏包装有限公司

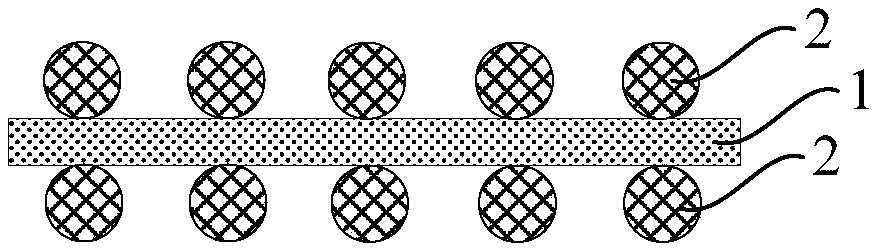

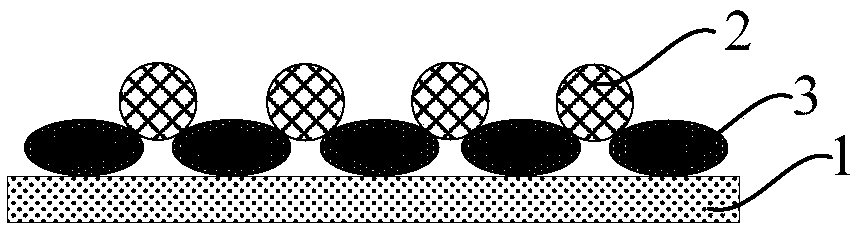

A lithium ion battery isolation film and a preparation method thereof

InactiveCN109037555AImprove adhesionThe overall thickness is thinCell seperators/membranes/diaphragms/spacersPorous substratePolymer science

The invention provides a lithium ion battery isolation film, which includes a porous substrate and a polymer coating coated on at least one side surface of the porous substrate; and the material of the polymer includes at least one of polyacrylic acid, polymethacrylic acid, polymethyl acrylate, styrene copolymer, neopentyl glycol diacrylate, polytetrafluoroethylene, polyimide, polyamide, polyester, polysulfone and polyacrylonitrile. The polymer has good bonding performance, the prepared polymer coating prepared by the invention is thin in thickness, uniform and continuous in distribution, andthe adhesion among the porous substrate, the inorganic coating and the positive and negative electrode sheets can be improved, thereby improving the hardness of the battery cell. In addition, the polymer particles have a large number of micro-pores between them, and the polymer particles swelling in the electrolyte is small, which can ensure that the obtained isolation film has good air permeability and battery cyclicity.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

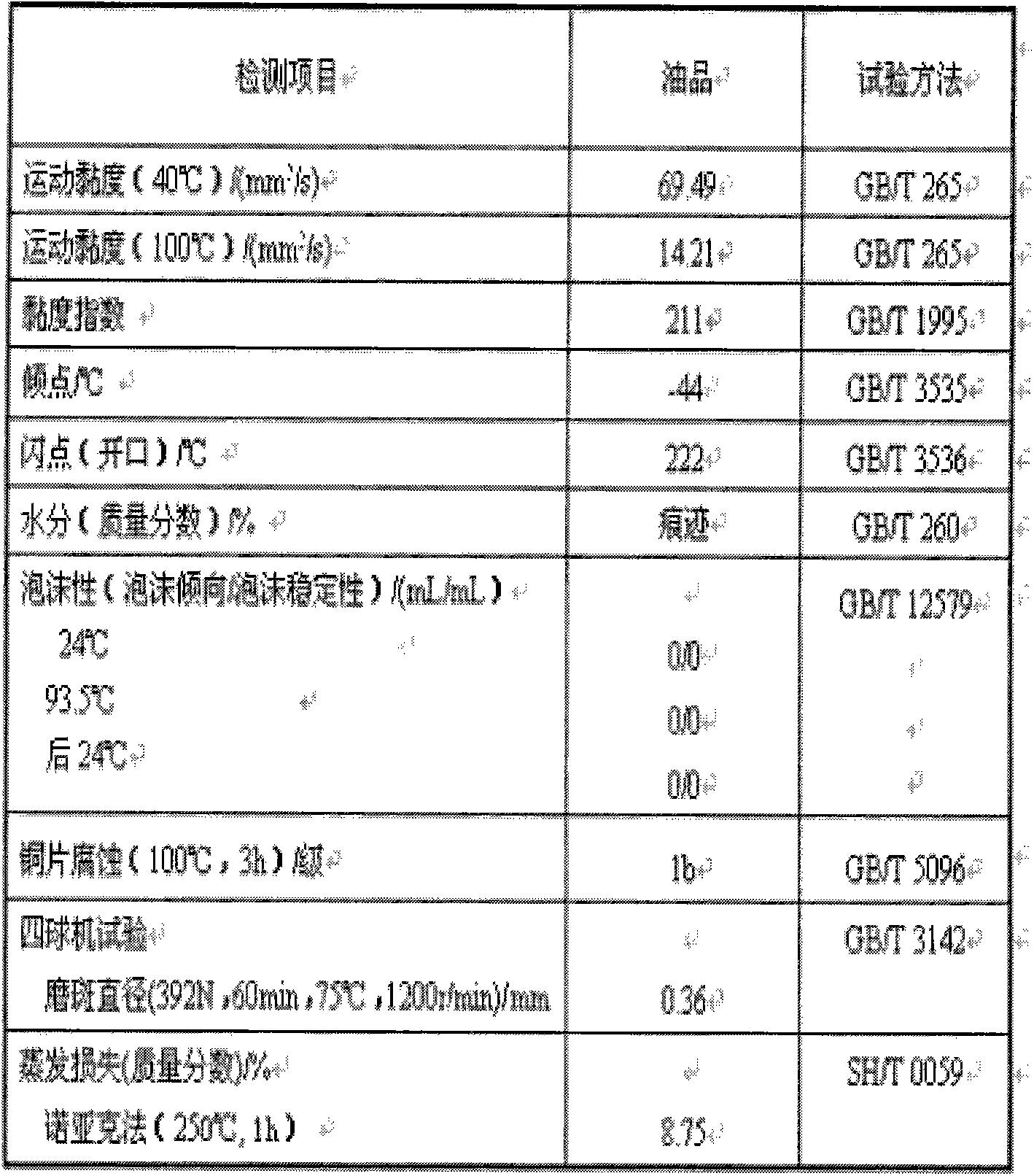

Lube-oil composition with ricinoleic oil as raw material

ActiveCN1896202AGood weather resistanceImprove low temperature fluidityAdditivesBase-materialsAlkylphenolAromatic amine

A lube-oil composition as castor oil consists of decanedioic acid-2-octester 47-50 proportion, polyvinyl glycol-ester sebate 28-30 proportion, methyl-polyacrylate 5.8-6.5 proportion, alkylphenol calcium 5.2-5.5 proportion, mono-succimide or diene-succimide 5.5-6.5 proportion, alkyl amino sulfate calcium orthophosphate 1.4-1.8 proportion, dimeric alkyl monosulfide aromatic amine 5.0-5.4 proportion, benzothiazole or benzotriazole 0.1-0.15 proportion, polyacrylate ethyl ester 0.3-0.5 proportion. It is cheap, non-toxic and low-volatile, has excellent degradative and lubricating performances, higher viscosity index and less consumption.

Owner:TIANJIN DIHENG BIO ENERGY CO LTD

Heat-resistant high-strength organic glass and preparation method thereof

The invention discloses heat-resistant high-strength organic glass and a preparation method thereof. The organic glass is prepared from the following raw materials in parts by weight: methyl methacrylate, methacrylamide, acrylonitrile, isophorone diisocyanate, ethylene glycol dimethacrylate, triallyl isocyanurate, glycerol, acetyl tributyl citrate, dibutyl phthalate, high-density polyethylene, glass fibers, carbon fibers, polyvinyl alcohol fibers, modified montmorillonite, nano silicon dioxide, ammonium persulfate, azodiisobutyronitrile, di-iso-decylphthalate, polyethylene acrylate, ethyl p-hydroxybenzoate and sodium stearate. The invention provides the heat-resistant high-strength organic glass and the preparation method thereof. The organic glass has high strength, high vitrification temperature, good heat resistance, long service life and good economic benefit.

Owner:蚌埠承永玻璃制品有限公司

Epoxy resin packaging material for dry-type transformer and preparation method thereof

InactiveCN105400138AImprove mechanical propertiesImprove insulation performanceSodium BentoniteTransformer

The invention discloses an epoxy resin packaging material for a dry-type transformer and a preparation method thereof. The preparation method comprises the steps that 1, epoxy resin, red brick powder, vinyl trimethoxy silane, nanosilicon dioxide, nano aluminum oxide, bentonite, carbonized tantalum, glass fiber, silk and polyacrylic acid ethylester are heated, fused, cooled and solidified to obtain modified epoxy resin; 2, the modified epoxy resin, an organic solvent, pentaerythritol triarylate, dodecyl dimethyl tertiary amine, polyacrylic acid, zinc phosphate, silica powder, a fire retardant and a plasticizer are mixed and thermally treated, and then are cooled and ground to obtain the epoxy resin packaging material. The epoxy resin packaging material obtained through the method has the excellent electrical performance and mechanical performance.

Owner:WUHU JINNIU ELECTRIC

Heat-resistant epoxy resin paint

The invention discloses heat-resistant epoxy resin paint. The heat-resistant epoxy resin paint comprises the following raw materials in parts by weight: 132-145 parts of modified epoxy resin, 21-25 parts of phenolic resin, 18-24 parts of zinc dialkyl dithiophosphate, 2-3 parts of polyacrylic acid, 1-3 parts of phthalic acid diethylene glycol diacrylate, 2-4 parts of pentaerythritol triacrylate, 0.8-1 part of N-(beta-aminoethyl)-gamma-aminopropyl trimethoxysilane(triethoxysilane), 1-1.2 parts of poly(ethyl acrylate), 0.2-0.4 part of tert-butyl hydroperoxide, 0.6-1 part of 8-hydroxyquinoline, 0.2-0.6 part of cobalt acetylacetonate, 0.1-0.2 part of defoaming agent poly(ethylene glycol) methyl ether and 0.5-0.8 part of dodecyl dimethyl tertiary amine. The heat-resistant epoxy resin paint disclosed by the invention adopts an aqueous emulsion finished product prepared from the modified epoxy resin as a main film-forming substance, the whole production process is smooth and easy to control, the consistency of the finished product is greatly improved, and the batch stability is good; and the phthalic acid diethylene glycol diacrylate and the pentaerythritol triacrylate are selected as solvents, the odor of the product is greatly improved, and the environmental pollution in production and use is reduced.

Owner:TONGLING SANJIA TRANSFORMER

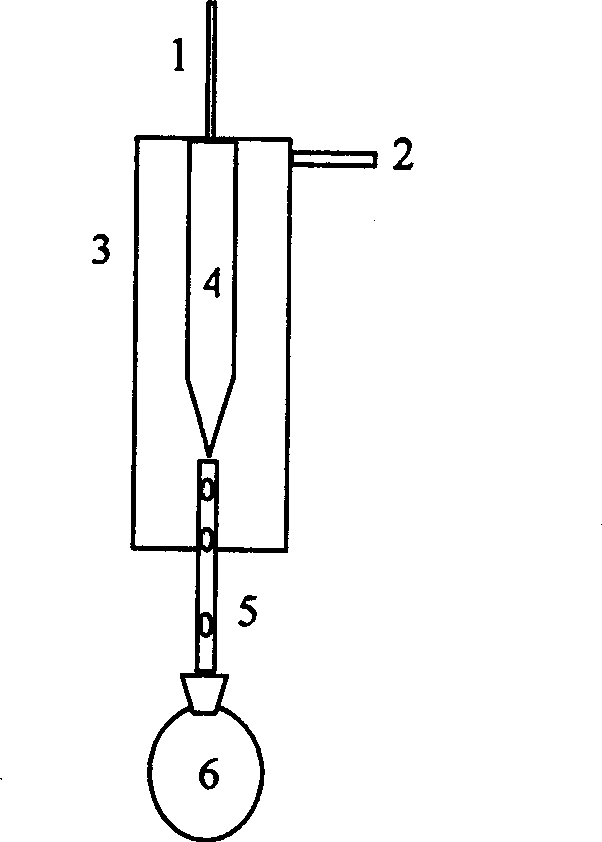

Polymer microsphere encoded by nano-gold and method for preparing same

The invention discloses a polymer microsphere encoded by nano-gold and method for preparation, which comprises nano gold particles and ethylene polymer, the ethylene polymer can be polyphenylacetylene, or polymethyl methacryate, of polyacrylonitrile, or polyethylene, or polypropylene, or polyethyl acrylate. The preparation method comprises dissolving the ethylene polymer in organic solvent, forming ethylene polymer solution, dropping into polyvinyl alcohol solution through a droplet formation apparatus, finally volatilizing the organic solvent to obtain the polymer microballoon.

Owner:SOUTHEAST UNIV

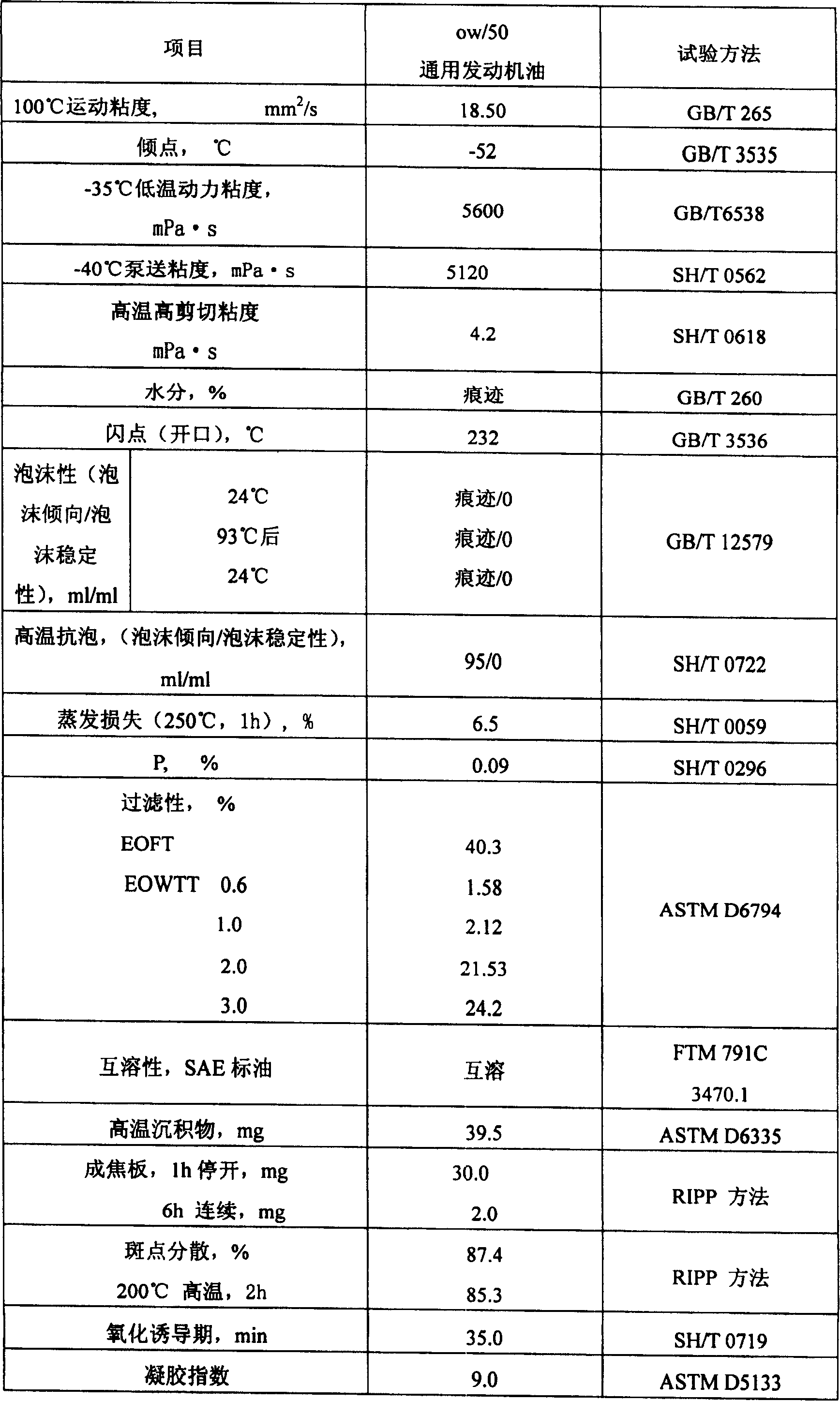

Lubricating oil for motor and preparation method thereof

InactiveCN104830440APlay a role in lubrication protectionWill not corrodeAdditivesPolyethylene oxideAntioxidant

The invention discloses a lubricating oil for motor and a preparation method thereof. The lubricating oil comprises a base oil, an antioxidant, heptadecenyl imidazoline alkenyl succinic acid salt, tricresyl phosphate, polyethyl acrylate, methyl silicone oil, polyethylene oxide, and lithium 12-hydroxystearate, wherein the polyethylene oxide has a weight average molecular weight of 1000-3000, and the polyethyl acrylate has weight average molecular weight of 2000-4000. The lubricating oil has excellent viscosity, kinematic viscosity index and pH value of 6-8l; while the preparation method of the lubricating oil is simple; and the raw materials are easily available.

Owner:ANHUI YUANFENG PIPELINE TECH CO LTD

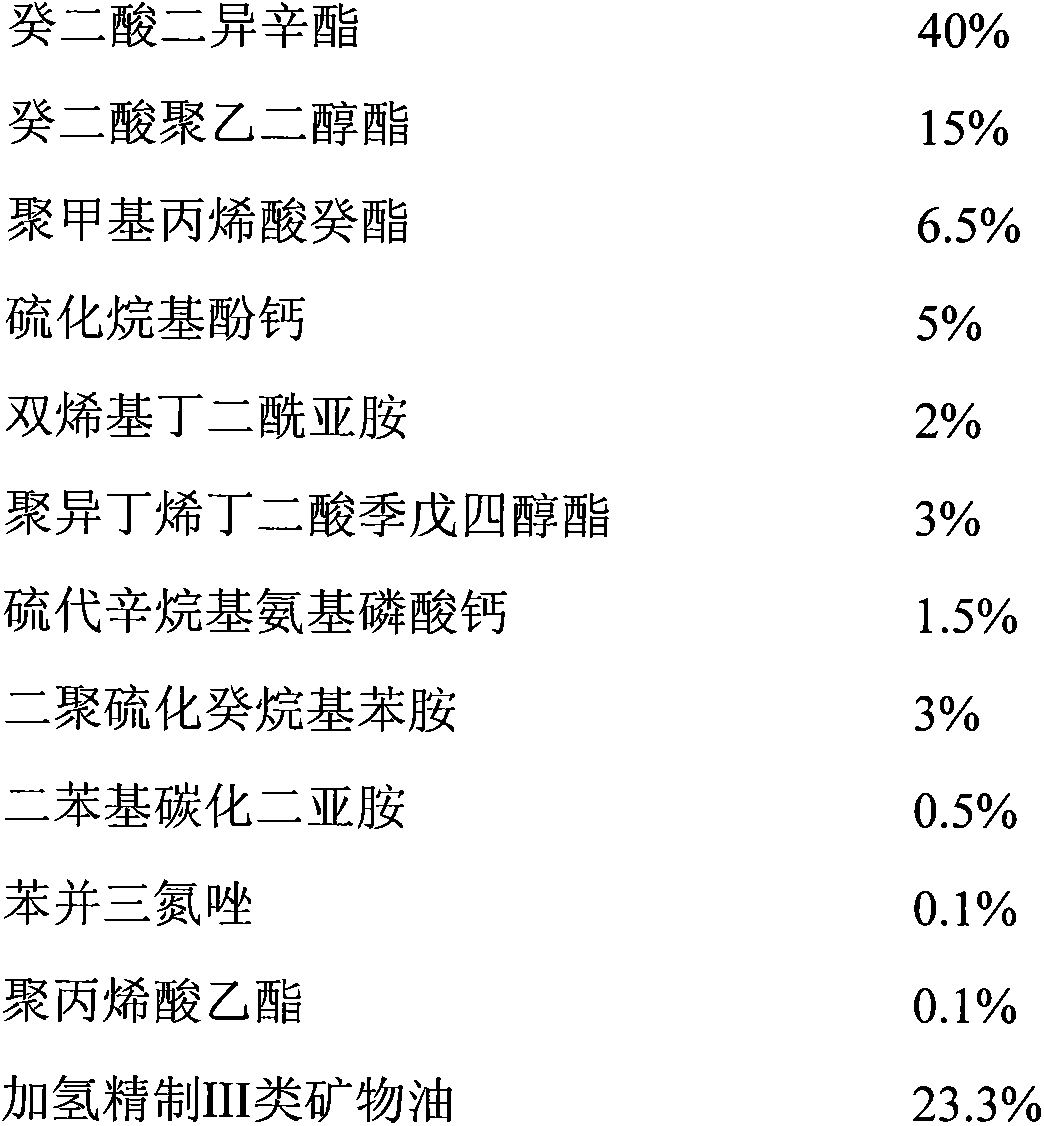

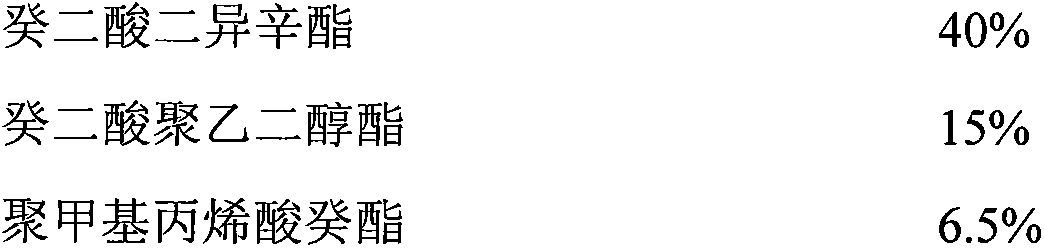

Castor-based derivative automotive lubricant and preparation method thereof

The invention provides a castor-based derivative automotive lubricant, comprising, by mass, 30 to 40% of diisooctyl sebacate, 10 to 15% of polyethyleneglycol sebacate, 5 to 10% of a viscosity index improver, 1 to 5% of sulfurized calcium alkyl phenolate, 1 to 5% of a composite ash-free dispersant, 1 to 3% of calcium alkylamino-sulfophosphate, 0.5 to 5% of dipoly(alkyl arylamine) sulfide, 0.1 to 2% of carbodiimide, 0.05 to 0.15% of benzotriazol or 2-mercaptobenzothiazole and 0.1 to 0.2% of poly(ethyl acrylate) with low molecular weight, with the balance being hydrorefined group III mineral oil. The lubricant provided by the invention has excellent antioxidation performance, enables generation amount of oil sludge in the process of usage to be substantially decreased, has an ultra long service life, provides optimal protection for the engine of a taxi and reduces consumption of fuel oil. The invention further provides a preparation method for the castor-based derivative automotive lubricant.

Owner:TIANJIN DIHENG BIO ENERGY CO LTD

Preparation method of reversible photochromic microcapsule material

InactiveCN108126635AWill not affect the visible effectEvenly distributedTenebresent compositionsMicroballoon preparationSolubilityCholesterol

The invention discloses a preparation method of a reversible photochromic microcapsule material. A three-layer microcapsule material, which takes spiropyrane, cholesterol ester and butyl acrylate graft as a core, polyethyl acrylate as an inner shell and polymethyl methacrylate as an outer shell, is prepared. The photochromic material is grafted with butyl acrylate, so that the stability can be enhanced, the defects that a spiropyrane compound is liable to oxidation and the fatigue resistance is low can be overcome, and cholesterol ester liquid crystal layered molecules are distributed more evenly. The polyethylene acrylate serves as the inner shell, so that the photochromic molecules in the core can be protected well and external stress generated by shearing in the processing process can be avoided. The outermost layer of polymethyl methacrylate has high rigidity, forms a hard shell on the outermost side of the capsule and forms a first protective layer. In addition, the solubility parameter of the polymethyl methacrylate is close to that of PVC, the polymethyl methacrylate and the PVC have high compatibility, the photochromic material can be dispersed into the PVC system uniformlyand the effect can be exerted well.

Owner:YIXING GUANGHUI PACKAGE

Epoxy resin encapsulating material for dry type transformer and preparation method for epoxy resin encapsulating material

The invention discloses an epoxy resin encapsulating material for a dry type transformer and a preparation method for the epoxy resin encapsulating material. The preparation method comprises the steps: (1) carrying out heating melting on epoxy resin, red brick dust, vinyl trimethoxysilane, nano aluminum nitride, nano aluminum oxide, bentonite, calcium carbide, carbon fibers, natural silk and ethyl polyacrylate, and carrying out cooling curing, so as to prepare modified epoxy resin; and (2) mixing the modified epoxy resin, an organic solvent, pentaerythritol triacrylate, dodecyldimethyl tertiary amine, polyacrylic acid, zinc phosphate, silicon powder, a flame retardant and a plasticizer, carrying out heat treatment, and then, carrying out cooling and grinding, thereby preparing the epoxy resin encapsulating material. The epoxy resin encapsulating material prepared by the method has excellent electrical properties and mechanical properties.

Owner:WUHU JINNIU ELECTRIC

Lube-oil composition with ricinoleic oil as raw material

A lube-oil composition as castor oil consists of decanedioic acid-2-octester 47-50 proportion, polyvinyl glycol-ester sebate 28-30 proportion, methyl-polyacrylate 5.8-6.5 proportion, alkylphenol calcium 5.2-5.5 proportion, mono-succimide or diene-succimide 5.5-6.5 proportion, alkyl amino sulfate calcium orthophosphate 1.4-1.8 proportion, dimeric alkyl monosulfide aromatic amine 5.0-5.4 proportion, benzothiazole or benzotriazole 0.1-0.15 proportion, polyacrylate ethyl ester 0.3-0.5 proportion. It is cheap, non-toxic and low-volatile, has excellent degradative and lubricating performances, higher viscosity index and less consumption.

Owner:TIANJIN DIHENG BIO ENERGY CO LTD

Forest litter sampling and profile structure image acquisition method

InactiveCN102095692AWithdrawing sample devicesPreparing sample for investigationPorosityLiquid state

The invention discloses a forest litter sampling and profile structure image acquisition method. The method comprises the steps: spraying liquid-state polyethylene acrylate on the litters at the collection spot, wherein the polyethylene acrylate can naturally volatilize after complete permeation; fixing the litters at the collection spot; cutting off the peripheral edges of a die; taking out the die to complete the sampling of the forest litters; heating paraffin to liquid state in a container; soaking the litter die in the paraffin liquid completely to enable the paraffin liquid to permeate in the gap of the litter die; naturally cooling to obtain solidified paraffin; cutting the solidified paraffin; polishing with a plane; placing the profile of the polished litter die in boiling water to dissolve the paraffin on the profile to obtain the profile structure of the litter die; and scanning the profile by a scanner to obtain the profile structure image. In the method, the litters can be sampled, processed and scanned to obtain the profile structure image of the litters without destructing the natural structure, thereby establishing the foundation for the profile porosity calculation of the forest litters and other related researches.

Owner:DALIAN UNIVERSITY

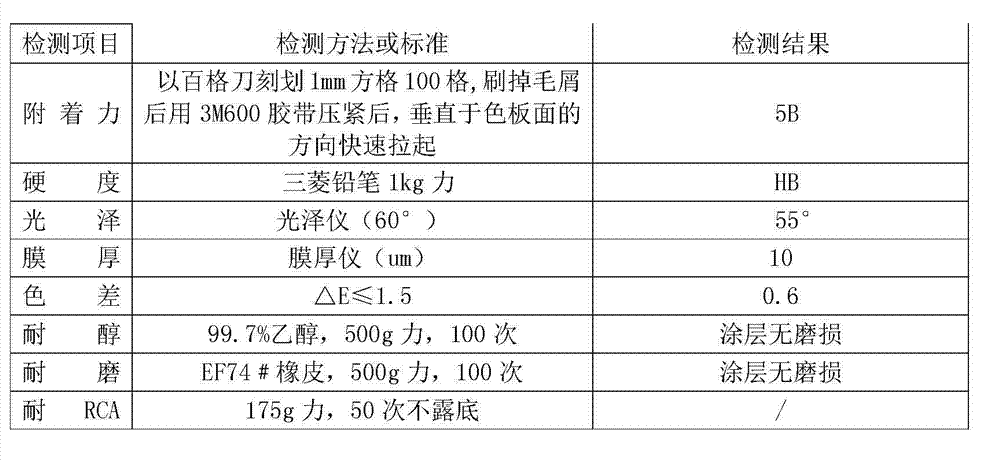

Interior decoration facing powder coating

InactiveCN104861788AEliminate formaldehydeRegulate humidityRosin coatingsUnspecified rubber coatingsEnvironmental resistanceGlycerol

The invention discloses an interior decoration facing powder coating, and belongs to the technical field of coatings. The interior decoration facing powder coating is prepared from the following constituents in parts by weight: 30-60 parts of diatom ooze, hydroxyethylmethylcellulose, poly(ethyl acrylate), 1-10 parts of polyoxyethylene, 2-10 parts of rubber, 0.5-2 parts of solvent blue, and 0.1-1 part of rosin glycerol ester 138. The interior decoration facing powder coating disclosed by the invention is prepared from the constituents according to the proportion; when sprayed to the room surface, the interior decoration facing powder coating is convenient to spray, good in spraying effect, capable of improving the aesthetic feeling of the decorative facing, non-toxic and environment-friendly; the obtained decorative facing is strong in stereoscopic impression; the interior decoration facing powder coating is a novel environment-friendly pollution-free green product, and is favored by consumers.

Owner:湖州大周高分子材料有限公司

Environment-friendly epoxy resin paint for transformer

ActiveCN103013297AImprove consistencyImprove surface qualityPretreated surfacesEpoxy resin coatingsEpoxyBenzoyl peroxide

The invention discloses environment-friendly epoxy resin paint for a transformer. The environment-friendly epoxy resin paint comprises raw materials in parts by weight: 118-125 parts of modified epoxy resin, 18-26 parts of phenolic resin, 13-18 parts of alkenyl succinic acid ester, 3-4 parts of phthalate glycol acrylate, 1-2 parts of pentaerythritol triacrylate, 0.3-0.6 part of phenylamine methyl triethoxysilane, 0.3-0.4 part of isopropyl three (dioctyl pyrophosphoric acid acyl oxygen radicals) titanate, 0.9-1.2 parts of polyacrylic acid ethyl acrylate, 1-2 parts of polyacrylic acid, 0.2-0.4 part of benzoyl peroxide, 0.2-0.6 part of 2,6-butylated hydroxytoluene and 0.1-0.2 part of polydimethylsiloxane serving as an antifoaming agent. By the environment-friendly epoxy resin paint, a modified finished product prepared by the modified epoxy resin is used as a main film-forming substance, so that the whole process is stable and easy to control, the consistency of a finished product is greatly improved, and the batch stability is good; and the phthalate glycol acrylate and the pentaerythritol triacrylate are used as solvents, so that the smell of a prepared finished product is greatly improved, and the environment pollution to production and application is reduced.

Owner:TONGLING SANJIA TRANSFORMER

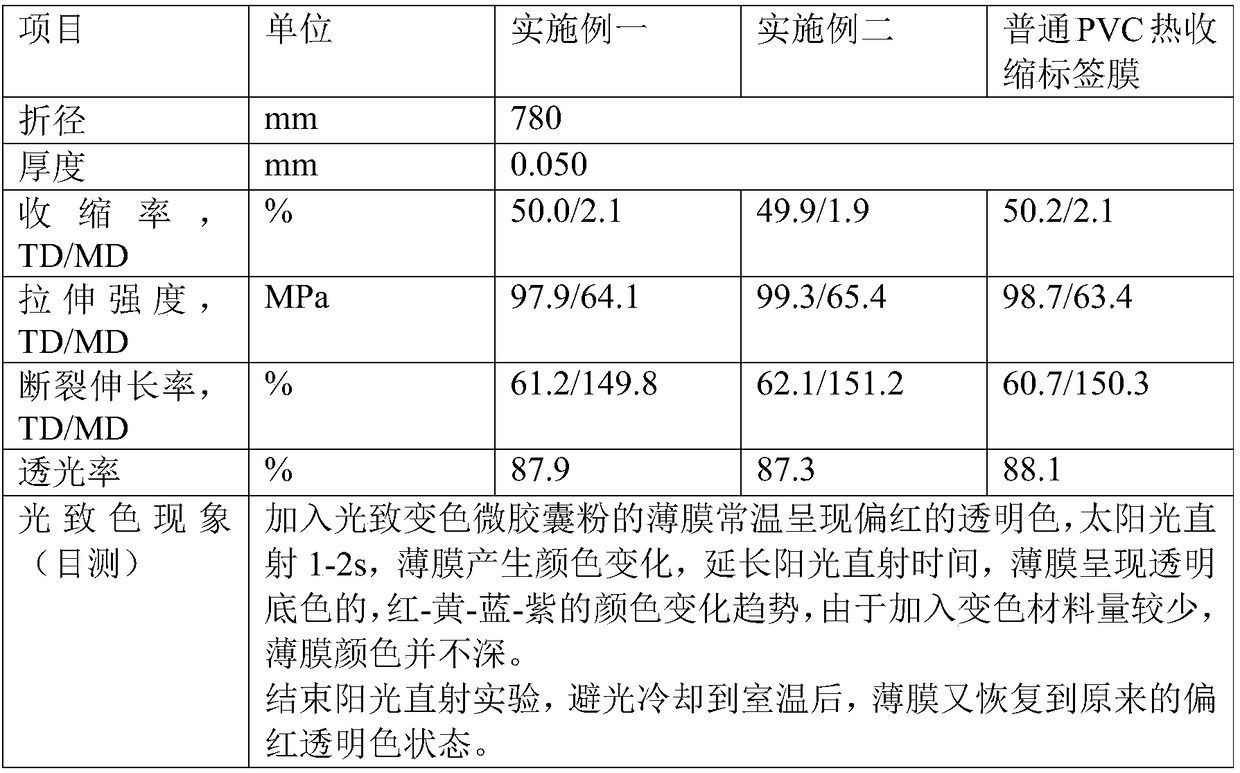

Photochromic PVC thermal contraction label film and preparation method thereof

ActiveCN108192240AWill not affect the visible effectEvenly distributedTenebresent compositionsSolubilityBlow molding

The invention discloses a photochromic PVC thermal contraction label film and a preparation method thereof. The method comprises the following steps: preparing a three-layer microcapsule material taking spiropyrane, cholesterol ester and butyl acrylate graft as a core, polyethylene acrylate as a inner shell and polymethyl methacrylate as a shell, then adding the microcapsule material into PVC resin material and additives, performing mixing and blow molding, and finally obtaining the thermal contraction label film. In addition, as the solubility parameters of polymethyl methacrylate and PVC aresimilar to each other, and polymethyl methacrylate and PVC have good compatibility, photochromic materials can be uniformly dispersed into a PVC system, and effect can be properly realized.

Owner:YIXING GUANGHUI PACKAGE

Dual-component silvery primer

InactiveCN103087620AGood solvent releaseGood low temperature dryingPolyurea/polyurethane coatingsQuality levelAcrylic resin

The invention discloses a dual-component silvery primer which consists of components A and B, wherein the component A is composed of the following raw materials in parts by weight: 70-78 parts of hydroxy acrylic resin, 4-6 parts of ferrocene, 10-15 parts of talcum powder, 6-10 parts of aluminum silver paste, 4-7 parts of glycol ether acetate, 5-6 parts of n-butyl acetate, 2-4 parts of zinc stearate, 1-3 parts of modified asbestos powder, 0.8-1 part of vinyl tri (beta-methoxy ethyoxy) silicane, 0.8-1 part of hydroquinone, 0.6-0.8 part of zinc dialkyl dithiophosphate, 0.4-0.6 part of ethyl polyacrylate and 0.4-0.6 part of diethylamine. The primer disclosed by the invention has an excellent solvent release performance, and is capable of effectively preventing generation of prickly heat bubbles; through participation of toluene diisocynate tripolymer and ethidene diamine, the primer is excellent in low-temperature drying performance; and through a reasonable formula, the primer has a comparatively rapid drying speed and good storage stability, and hardness, solid content and viscosity of the primer are kept at comparatively high quality levels as well.

Owner:中山市依高化工有限公司

Jasmine essence capsule for leather

ActiveCN107083457AImprove mechanical propertiesCover up the smellEssential-oils/perfumesLeather/skins/hides/pelt chemical treatment apparatusNano sio2Microemulsion

Owner:SHANGHAI INST OF TECH

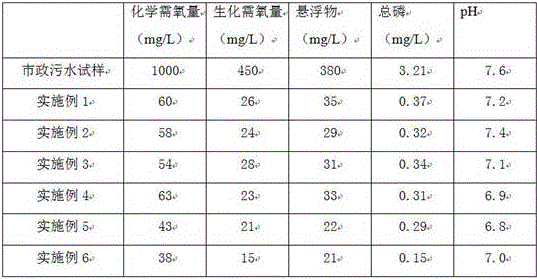

Preparation method of municipal sewage treating agent

The invention provides a preparation method of a municipal sewage treating agent.The method comprises the steps of firstly, picking dry straw, pulverizing the straw, adding a solution of sodium cyanoborohydride, ammonium ceric nitrate and gelatin, mixing the materials to be uniform, raising the temperature, then adding poly(ethyl acrylate), polyacrylonitrile and glutaraldehyde, raising the temperature, lowering the temperature, and conducting filtering, so that solid matter is obtained; then adding etidronic acid and polyhydric alcohol phosphate ester to water, conducting stirring, adding isothiazolinone, sepiolite, starch xanthate, magnesium sulfate heptahydrate, chitosan, N, N-dimethyl methylene diphosphonic acid, lecithin and lignin, and mixing the materials to be uniform, so that a mixture (I) is obtained; finally, adding a sodium hydroxide solution to the mixture (I) to adjust pH to 6.0-7.0, adding organic acid and the obtained solid matter, mixing the materials to be uniform, and then leaving the mixture standing still, so that the municipal sewage treating agent is obtained.By means of the municipal sewage treating agent, the chemical oxygen demand of sewage can be lowered to 63 mg / L, the biochemical oxygen demand can be lowered to 28 mg / L, suspended solids can be decreased to 35 mg / L, and total phosphorus can be decreased to 0.37 mg / L.

Owner:刘平

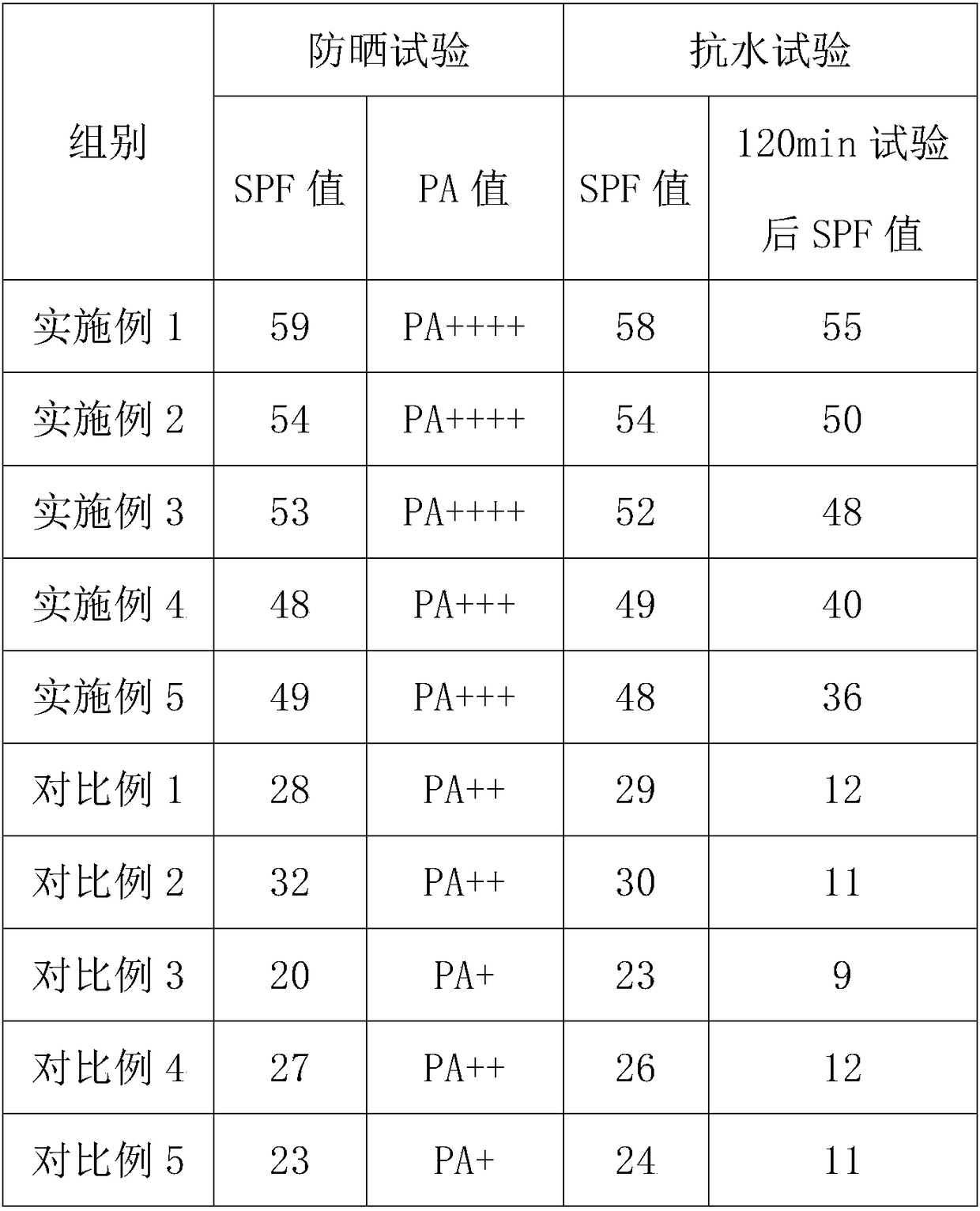

Fullerene sunscreen cream

InactiveCN109316395AGood sun protectionImprove water resistanceCosmetic preparationsToilet preparationsBetaineInonotus obliquus

The invention discloses fullerene sunscreen cream which is prepared from the following raw materials: a water phase of deionized water, inonotus obliquus extractive, titanium dioxide, 1,3-butanediol and glycine betaine; an oil phase of fullerene, hydroxyl benzoxazole, hydroxyl ethylurea, hydroxyl moxybenzone, iso-octyl p-methoxycinnamate, Vaseline, stearyl alcohol, glycerol monostearate, polyethylene acrylate, benzene and a preservative. According to the fullerene sunscreen cream disclosed by the invention, a compounding effect of the oil phase and the water phase which are prepared accordingto different ingredient contents is utilized, so that the produced sunscreen cream has an excellent sunscreen effect, an excellent water-resistant effect and good stability and can effectively block irradiation of ultraviolet rays to the skin; the fullerene and the inonotus obliquus extractive are added into the raw materials to achieve a synergistic effect on effects of the sunscreen cream. In addition, the fullerene sunscreen cream has no stimulation or damage to the skin in a use process and has good use safety.

Owner:广州雷诺生物科技有限公司

Modified polyvinyl chloride cable material with favorable antioxidation and anti-aging effects and preparation method thereof

InactiveCN104761853AImprove antistatic performanceImprove flame retardant performanceInsulatorsCarbon nanotubePolyvinyl chloride

The invention discloses a modified polyvinyl chloride cable material with favorable antioxidation and anti-aging effects. The invention is characterized in that the polyvinyl chloride cable material is prepared from the following raw materials in parts by weight: 13-15 parts of carbon nanotube, 12-14 parts of polyethylacrylate, 1.2-1.3 parts of titanate coupling agent TC-F, 5-7 parts of flame retardant DOPO, 0.03-0.04 part of lauroyl peroxide, 67-70 parts of polyvinyl chloride resin SG, 10-12 parts of light calcium carbonate, 1-1.2 parts of dimethyl fumarate, 8-10 parts of DBP (dibutyl phthalate), 2-3 parts of polyethylene wax, 0.5-0.8 part of bis thiodipropionic acid, 0.8-1.2 parts of 2,6-di-tert-butyl-4-methylphenol, 2-3 parts of monoglyceryl stearate and 7-9 parts of assistant. The formula is special, and the carbon-nanotube-base polymer is added into the cable material to enhance the antistatic property and flame retardancy of the polyvinyl chloride. The 2,6-di-tert-butyl-4-methylphenol and the like are added to obviously enhance the antioxidation and anti-aging effects.

Owner:HEXIAN ELECTRICAL POWER WIRE & CABLE

High polymer material formulation of three-dimensional gold stamping electrified aluminium hot stamping foil coating and preparation method thereof

ActiveCN101717605ASimple preparation processThree-dimensional hot stamping is clearPolyurea/polyurethane coatingsPolyvinyl butyralHot stamping

The invention relates to a high polymer material formulation of three-dimensional gold stamping electrified aluminium hot stamping foil coating and a preparation method thereof. The high polymer material formulation comprises the components based on the parts by weight: 10-20 parts of modified polyurethane, 1-5 parts of polyformaldehyde, 5-10 parts of poly ethyl acrylate, 5-10 parts of poly alkylene oxide resin, 5-15 parts of cellulosic resin, 8-20 parts of acrylic resin, 30-60 parts of butanone, 5-10 parts of acetic ether, 5-10 parts of n-propyl acetate and 1-20 parts of polyvinyl butyral. The preparation method comprises: 1) according to the requirement of the formulation, firstly putting all solvents into a reaction kettle, heating to 20-45 DEG C and then stirring; 2) keeping stirring, sequentially putting the modified polyurethane, the polyformaldehyde, the poly ethyl acrylate, the poly alkylene oxide resin, the cellulosic resin, the acrylic resin and the polyvinyl butyral into the reaction kettle according to the proportion, and stirring for 0.5-2.0h; 3) after all solid is dissolved and evenly mixed together, stopping the blend and curing for 3-5h; 4) measuring the content of the solid and adjusting to theoretical value; and 5) slowly stirring and cooling to 20 DEG C. The invention has the characteristics of simple preparation technique, clear three-dimensional hot stamping, good effect of stamping, good ductility of a formed film of the product and the like.

Owner:ZHEJIANG HENGFENG PACKING

Bioactive implant for myocardial regeneration and ventricular chamber restoration

InactiveUS8968417B2Limit chronic dilationRestore native elliptical shapeHeart valvesPharmaceutical delivery mechanismSystolic functionCaprolactone

Bioactive implant for myocardial regeneration and ventricular chamber support including an elastomeric microporous membrane. The elastomeric microporous membrane being at least one non-degradable polymer and at least one partially degradable polymer. The non-degradable polymer is selected from polyethylacrylate and polyethylacrylate copolymerized with a hydroxyethylacrylate comonomer. The partially degradable polymer is selected from caprolactone 2-(methacryloyloxy)ethyl ester and caprolactone 2-(methacryloyloxy)ethyl ester copolymerized with ethylacrylate. The elastomeric microporous membrane further includes a nanofiber hydrogel, and cells. The bioactive implant, having one or two helical loops, contributes to the restauration of the heart conical shape. Cardiac wrapping by ventricular support bioprostheses of the present invention, having reinforcement bands spatially distributed as helicoids, recovers the sequential contraction of the myocardium resulting in the successive shortening and lengthening of the ventricles, therefore improving the ejection (systolic function) and suction of blood (diastolic function).

Owner:INSTITUT QUIMIC DE SARRIA +3

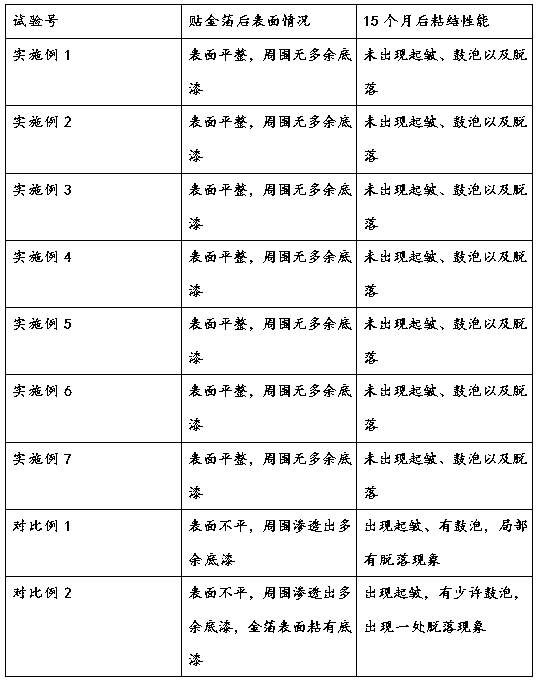

Gold leaf pasting method for archaeological restoration

InactiveCN108528123AWon't wrinkleWon't hurtDecorative surface effectsPriming paintsParaffin waxEther

The invention discloses a gold leaf pasting method for archaeological restoration. The gold leaf pasting method comprises the steps of treating a to-be-gilded surface, applying primer to the to-be-gilded surface, absorbing primer with untreated Xuan paper, and pasting gold leaves, wherein the primer is prepared from the following raw materials according to mass ratio: 13.7% to 18.5% of urushiol, 0.1% to 0.3% of subtractive agent, 3% to 6% of polyethylene acrylate, 7% to 9% of gum, 6% to 8% of sodium silicate, 8% to 12% of acetic ether, 4% to 6.5% of paraffin, 9% to 14% of vegetable oil and thebalance of deionized water.

Owner:余其姝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com