Patents

Literature

89 results about "Paraffin liquid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

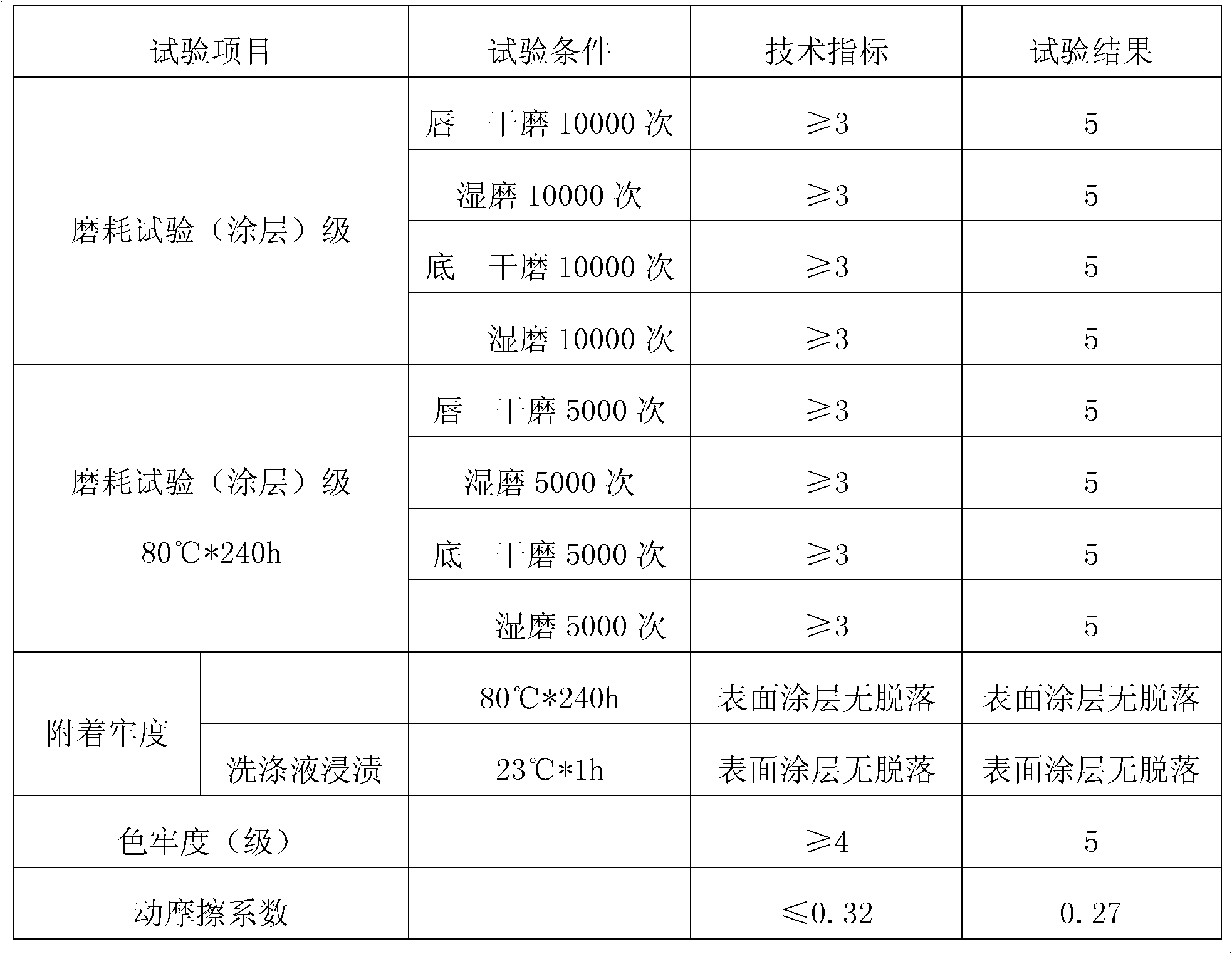

Aqueous bi-component coating of vehicle rubber and plastic sealing strip and preparation method thereof

InactiveCN101824271AStrong adhesionAttachment meetsPolyurea/polyurethane coatingsPolyamide coatingsCross-linkPolyurethane dispersion

The invention relates to an aqueous bi-component coating of a vehicle rubber and plastic sealing strip and a preparation method thereof. A component A takes aqueous polyurethane as matrix resin, and a component B is a cross-linking agent. The component A contains the following components in percentage by weight: 26-55 percent of aliphatic aqueous polyurethane dispersoid, 0-5 percent of polyamide paraffin slurry, 0-20 percent of aqueous ethylene paraffin liquid, 0-12 percent of aqueous resin containing active functional group, 1-10 percent of functional material, 5-10 percent of slipping agent, 0.1-2 percent of stuffing, 0-3 percent of pigment slurry, 1.5-6 percent of special assistant and 15-45 percent of solvent, and the component B contains the following components in percentage by weight: 70-100 percent of hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate and 0-30 percent of diethylene glycol butylether acetate. The invention has the advantages that after thecross-linking reaction is carried out on the aqueous resin composition and the cross-linking agent, the aqueous bi-component coating has excellent adhesiveness and meets the adhering requirements on treated rubber and plastic surfaces, has superstrong abrasive resistance and moderate flexibility, can enhance the slipping performance and the abrasive resistance with glass, resists high temperature, does not deform or separate out and has permanent slipping effect.

Owner:吕相洋

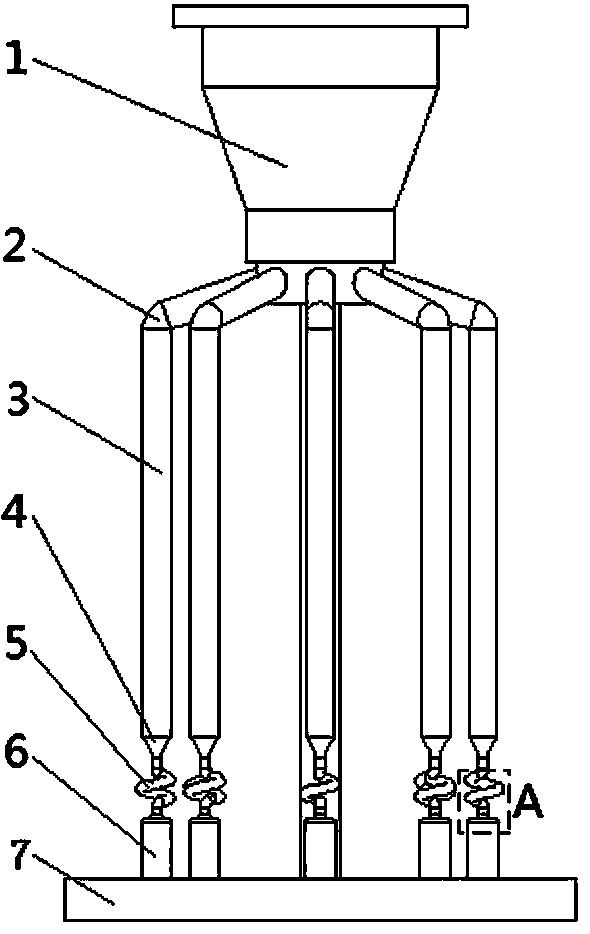

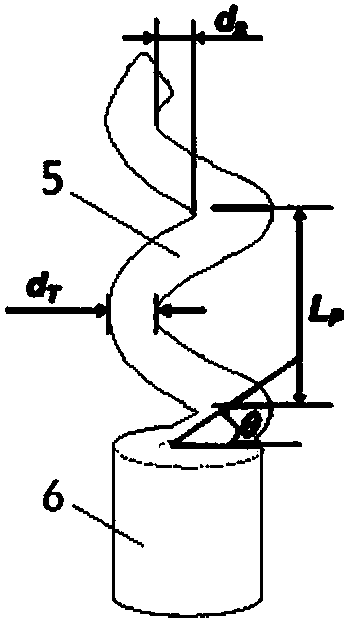

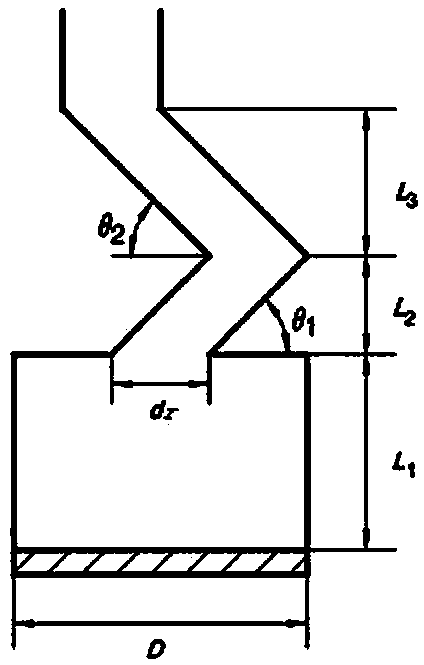

Method for preparing wax mold of monocrystal spiral crystal selector

The invention provides a method for preparing a wax mold of a monocrystal spiral crystal selector. The wax mold of the monocrystal spiral crystal selector comprises a seeding section wax mold, a spiral crystal selecting section wax mold and a transition section wax mold which are sequentially connected from bottom to top. The method comprises the following steps: firstly, manufacturing the seeding section wax mold and the transition section wax mold; winding on a screw corresponding to the size of the required spiral crystal selecting section by a plastic welding rod, sizing for a moment, immersing into 58# refined paraffin liquid at 68 DEG C, taking out after 4-7 seconds so as to obtain the spiral crystal selecting wax mold; connecting two ends of the spiral crystal selecting wax mold with the bottom of the transition section wax mold and the top of the seeding section wax mold respectively by utilizing bonding wax which is heated to be 130 DEG C. According to the invention, the crystal selector wax mold which meets the requirement can be prepared rapidly; compared with the traditional method using a wax injector and a wax mold, the method has the characteristics of no need of wax injector equipment, no need of machining the wax mold, low expense, simplicity in operation, short consumption time, high efficiency, high yield and the like.

Owner:DONGFANG TURBINE CO LTD

Bamboo chopstick processing method

InactiveCN105291238ASave energyGuaranteed anti-corrosion performanceWood treatment detailsReed/straw treatmentSulfurMildew

The invention discloses a bamboo chopstick processing method. The bamboo chopstick processing method comprises the following steps: a bamboo is sawn to a bamboo cylinder; the bamboo cylinder is processed to a bamboo piece, and is processed to a bamboo chopstick blank; one end of the bamboo chopstick blank is sharpened; the wet disinfection and the blenching are performed; the preservative treatment is performed; the carbonizing treatment is performed; the drying and the disinfection are performed; the polishing is performed; and the sorting and the packing are performed. Compared with the mildew prevention and the disinfection of chopsticks smoked by sulfur and boiled by hydrogen peroxide, the bamboo chopstick processing method is safer and more reliable; as ozone cannot leave any poisonous substances on the chopsticks, and an ozone disinfection method saves more energy, the excellent mould preventing, bleaching and disinfecting effects can be obtained only by consuming less electric energy without needing heating; bamboo chopsticks are dip in paraffin liquid or tung oil under high temperature, so that the corrosion preventing effect of the chopsticks in later use is effectively guaranteed; the bamboo chopsticks prepared by the method has such performances as corrosion prevention, insect prevention, mildew prevention and damp prevention, and such natural colors as faint yellow and brown are given to the bamboo chopsticks; and the bamboo chopstick processing method increases the mechanical degree, quickens the production speed, and improves the production efficiency.

Owner:安徽泓浩竹科技股份有限公司

Manufacturing technology of ceramic water tap housing

InactiveCN101201132AWill not polluteAvoid pollutionValve housingsParaffin waxManufacturing technology

The invention relates to a manufacture art for a housing of a ceramics tap, which is prepared according to the following steps: firstly 10 to 20 portions of raw talcum, 60 to 70 portion of ripe talcum, 10 to 15 portion of clay, 5 to 10 portion of TiO or BaCO3 or the mixture of the two to carry through mixing are prepared and mixed together; then the original mixed raw materials can be calcined to 1320 to 1390 degrees, rubbed for 28 to 36 hours and then sifted to get ultrafine powder with 250 to 300 meshes; then the powder can be added into a paraffin liquid, the weight of which is 15 to 20 percent of that of the powder to make slurry; then the slurry can be shaped into a roughcasts of tap shells in required shape through an injection moulding technics forming technology; then roughcasts can be calcined, dewaxed, polished and glazed; finally roughcasts can be calcined to 1280 to 1350 degrees and cooled naturally. The invention can not generate any pollution during the manufacture and using processes and the product has the advantages of high temperature resistance, abrasion resistance, rust resistance and light weight, etc.

Owner:闽清中瓷卫浴有限公司

Preparation method of polyurethane waterproof coating

InactiveCN103709922AStable film performanceColor adjustablePolyurea/polyurethane coatingsSlagChlorinated paraffins

The invention discloses a preparation method of an environmental-protection polyurethane waterproof coating. The preparation method comprises the following steps: 1) preparing a component A, namely a polyurethane prepolymer; 2) preparing a component B, namely a pigment filler; and 3) adding the pigment filler into 20-30 parts of the polyurethane prepolymer, adding a thickening agent, stirring for 1-2 h, and discharging to obtain the environmental-protection polyurethane waterproof coating. The new-generation double-component environmental-protection color polyurethane waterproof coating which contains no any solvent, has high solid content, has no pollution during a construction process, and has stable film coating performance, adjustable colors and excellent cost performance is prepared with a chlorinated paraffin liquid and industrial waste slag fly as a mixed filler.

Owner:江苏民扬塑胶科技有限公司

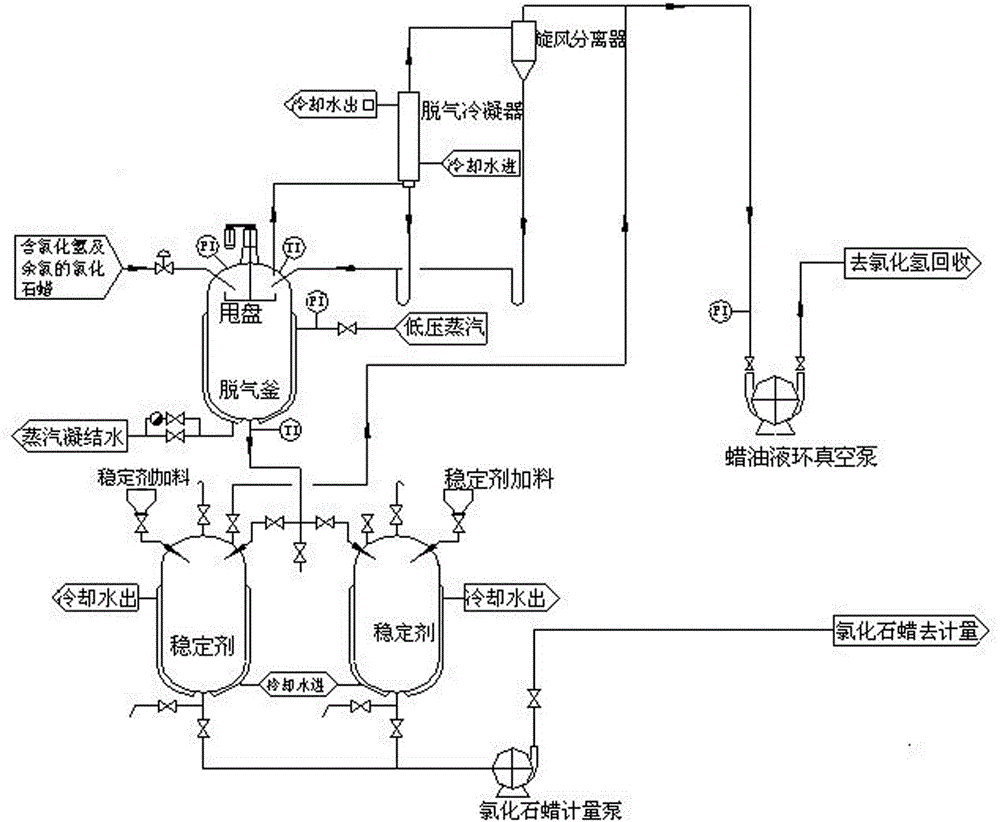

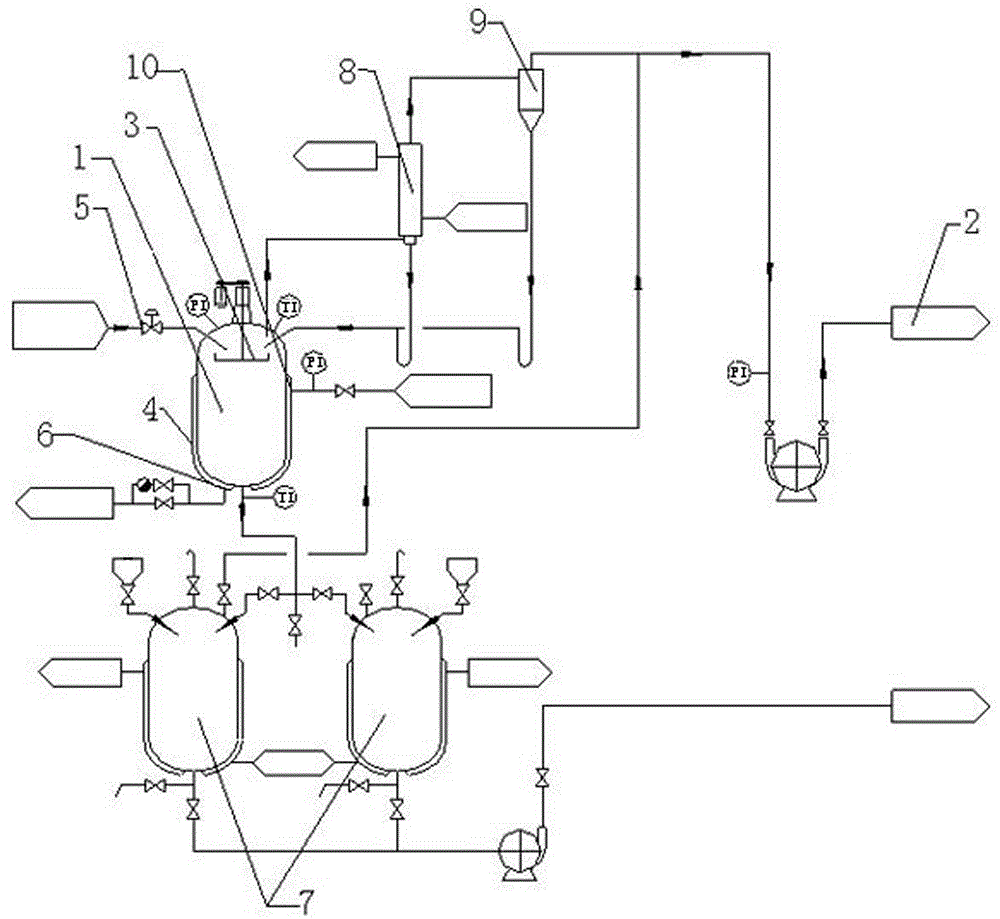

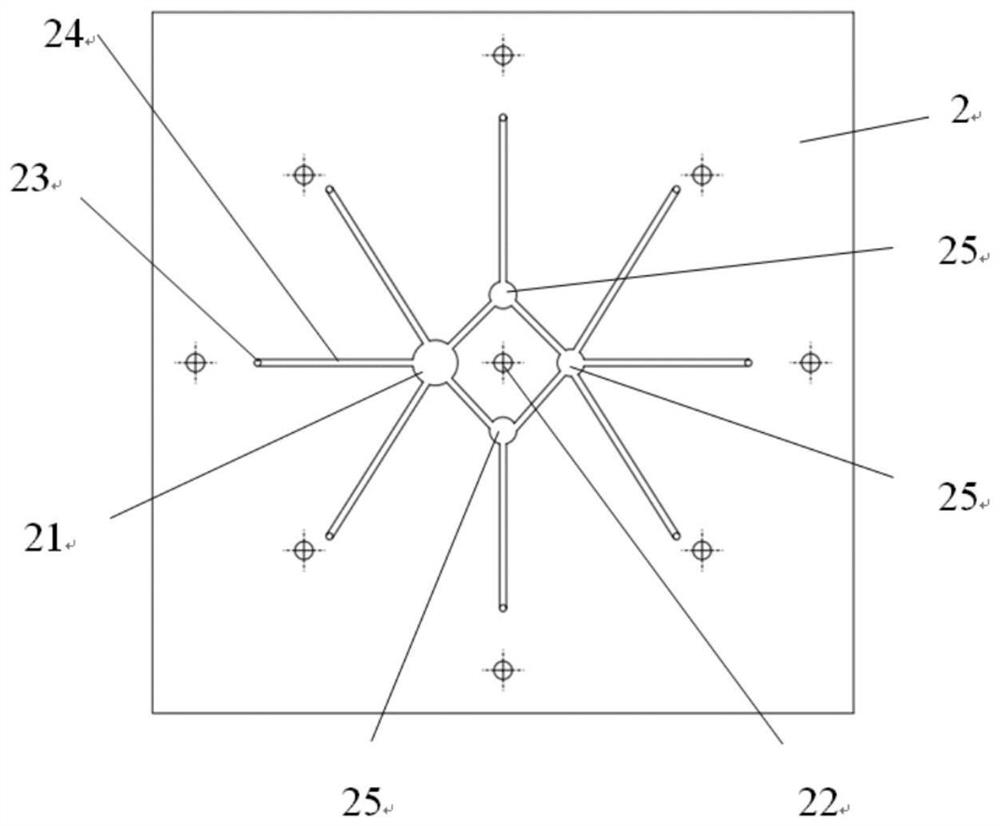

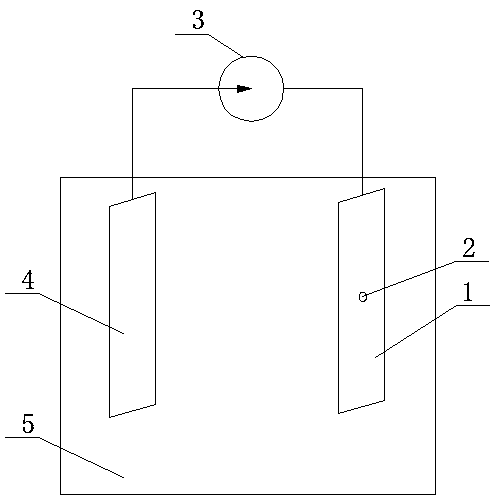

Method and device for removing hydrogen chloride and residual chlorine from liquid chlorinated paraffin

ActiveCN104415580AReduce partial pressureEvenly arrangedLiquid degasificationWax physical treatmentChlorinated paraffinsHydrogen chloride

The invention relates to a method for removing hydrogen chloride and residual chlorine from liquid chlorinated paraffin, which comprises the following steps: (1) turning on a vacuum device, vacuumizing a degassing kettle; (2) turning on a throwing disc of the degassing kettle; (3) injecting steam or heat transfer media into the jacket of the degassing kettle; (4) opening a liquid chlorinated paraffin feed valve on the degassing kettle, allowing the liquid chlorinated paraffin to flow into the rotating throwing disc; (5) heating the chlorinated paraffin liquid film during continuous falling through the degassing kettle jacket; (6) allowing the liquid chlorinated paraffin with hydrogen chloride and residual chlorine removed to flow out from the bottom of the degassing kettle, adding a stabilizing agent into the liquid chlorinated paraffin with hydrogen chloride and residual chlorine removed, stirring uniformly, and metering by a chlorinated paraffin metering pump. The method is simple in process, easy to control, continuous in production, large in productivity, simple in equipment investment, stable in quality of the prepared product, and easy for tail gas treatment, can continuously and automatically remove a large amount of hydrogen chloride and residual chlorine in liquid chlorinated paraffin, and guarantee the continuous production of liquid chlorinated paraffin.

Owner:DANYANG CITY AUX CHEM PLANT

Metal fiber polyporous material subsequent processing method

InactiveCN101134257AGuaranteed machining accuracyIntegrity guaranteedElectrical-based auxillary apparatusMachined surfaceParaffin oils

The present invention discloses post-treating process of porous metal fiber material, and the process includes heating solid paraffin to form paraffin liquid, soaking the porous metal fiber material into the paraffin liquid for paraffin to fill the pores of the porous metal fiber material, taking out the porous metal fiber material and cooling fast, eliminating the surface solidified paraffin and wire electrode cutting, eliminating residual oil stain in the machined surface of the porous metal fiber material, heating in boiled water to eliminate paraffin, and final stoving. The process has the advantages of simple operation, low cost, etc. and can ensure the machining precision and maintain the integrity and stability of the pore structure effectively.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

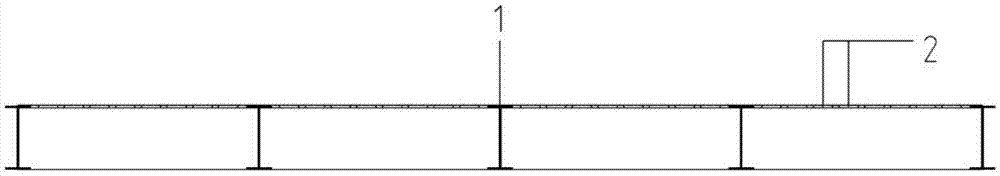

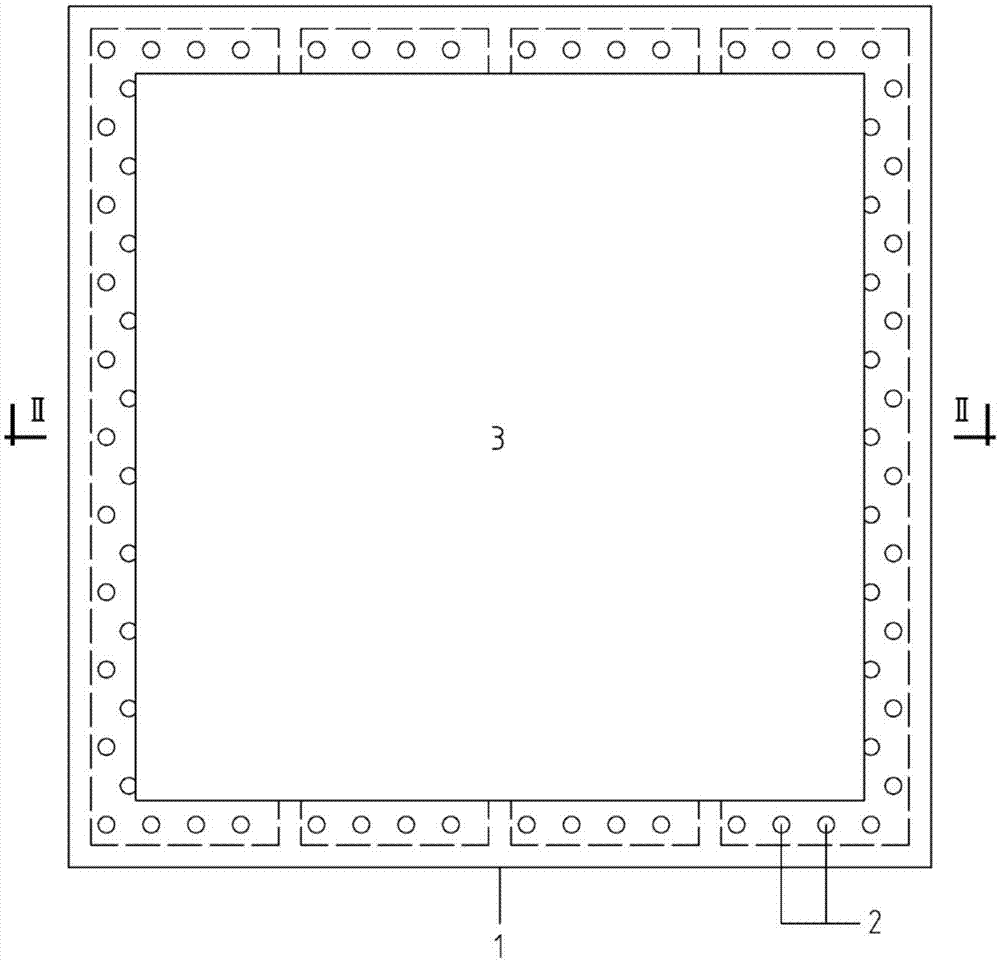

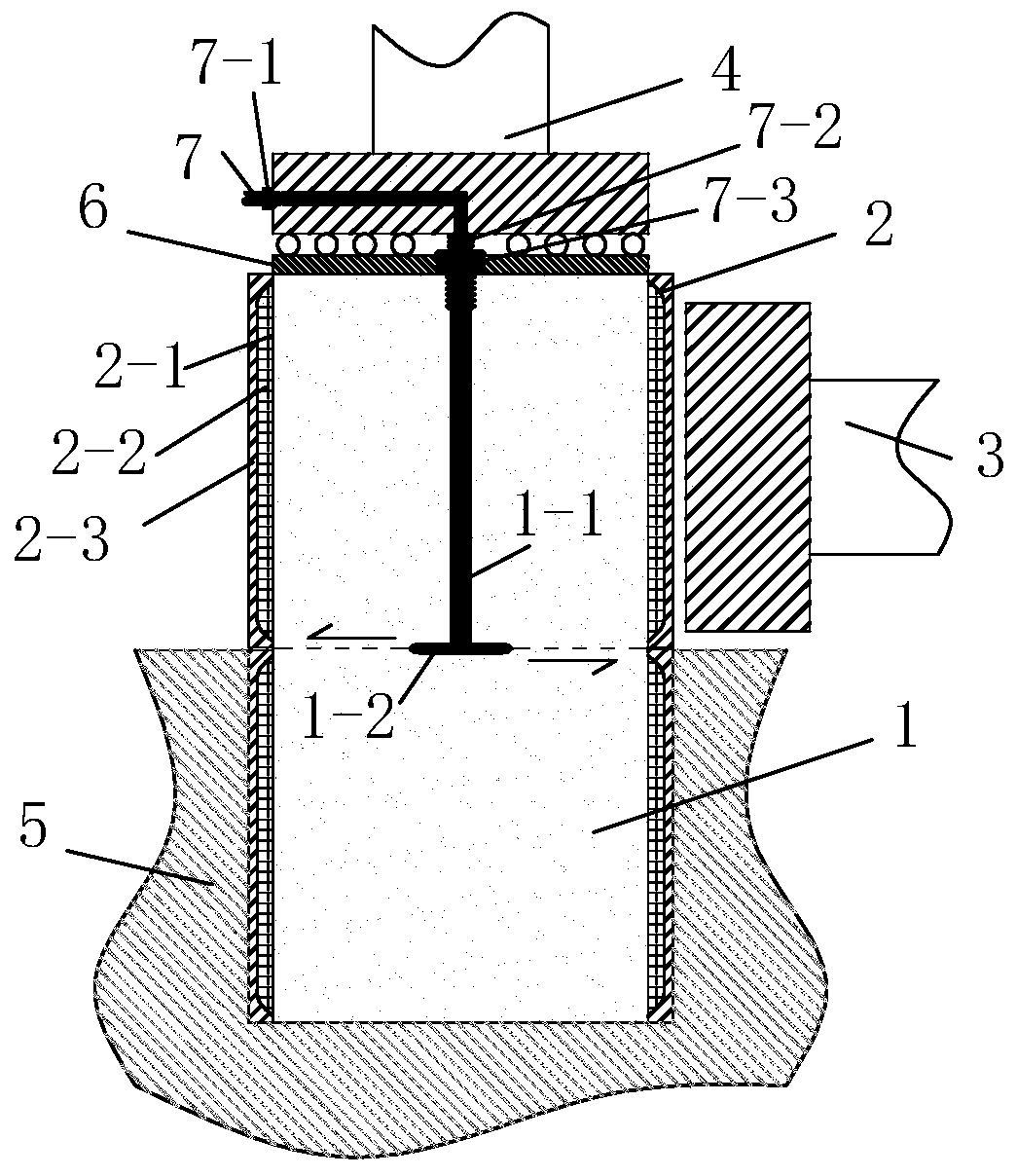

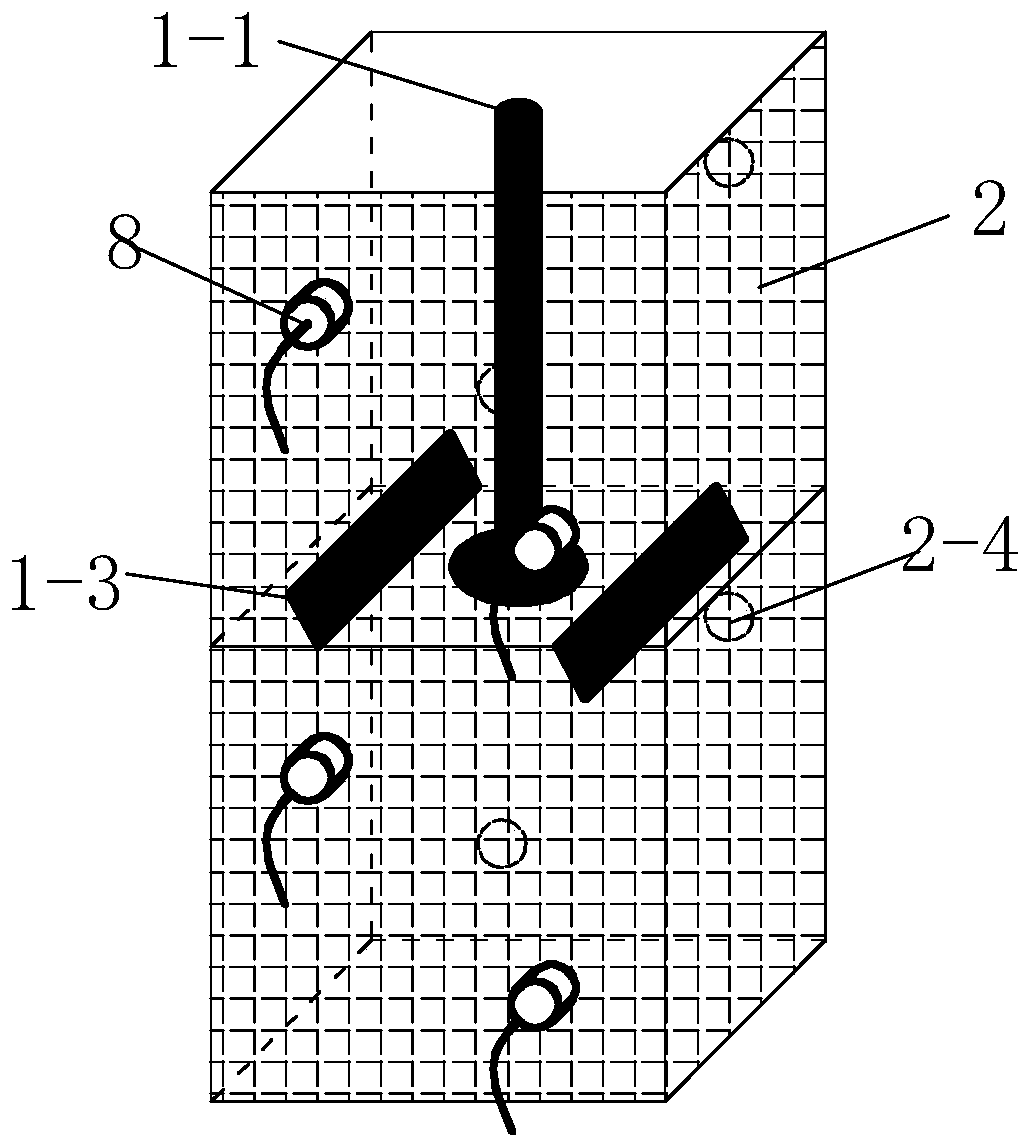

Method for pasting face bricks in prefabrication of concrete floor and concrete wallboard

The invention provides a method for pasting face bricks in prefabrication of a concrete floor and a concrete wallboard, and belongs to the technical field of construction engineering. The method includes the steps that a bottom mold for the prefabricated concrete floor or concrete wallboard is manufactured, a single-sided adhesive plastic film is laid on the bottom mold for the prefabricated concrete floor or concrete wallboard, a face brick positioning grid and the face bricks are placed on the bottom mold, laid with the single-sided adhesive plastic film, for the prefabricated concrete floor or concrete wallboard, and hot paraffin liquid is poured onto the bottom mold; and a side mold for the prefabricated concrete floor or concrete wallboard is mounted, steel bar materials of the prefabricated concrete floor or concrete wallboard are bound, concrete of the prefabricated concrete floor or concrete wallboard is poured, and after the needed strength is achieved through curing, construction is completed. By means of the method, the pasting quality of the face bricks for a wall surface or a building surface can be remarkably improved, pasting materials are saved, manpower is reduced, and the construction cost of construction engineering is lowered. According to the method, the production process and equipment are simple, operation is easy, the bonding strength is high, finished product protection is facilitated, and the face bricks are flat and clean in appearance; the method has positive significance to development of prefabricated and assembled type concrete buildings.

Owner:江苏亿科博建筑科技有限公司

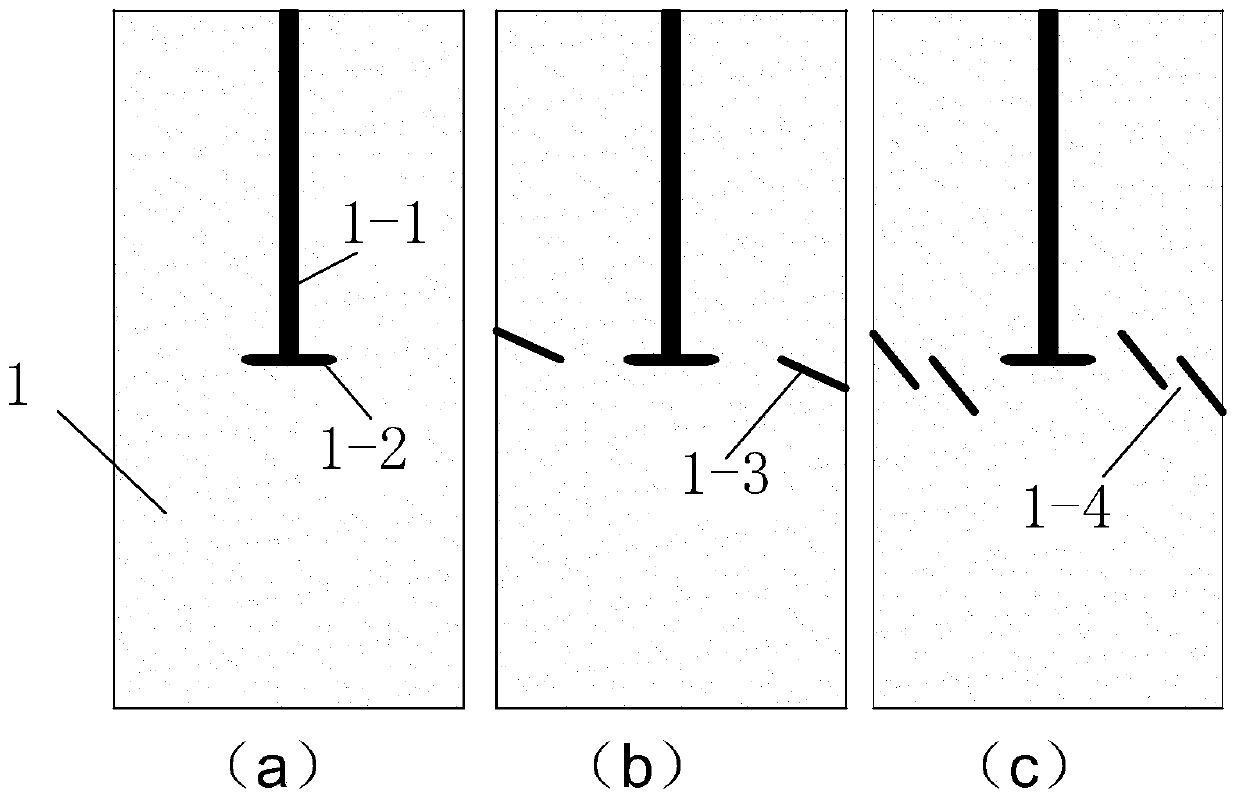

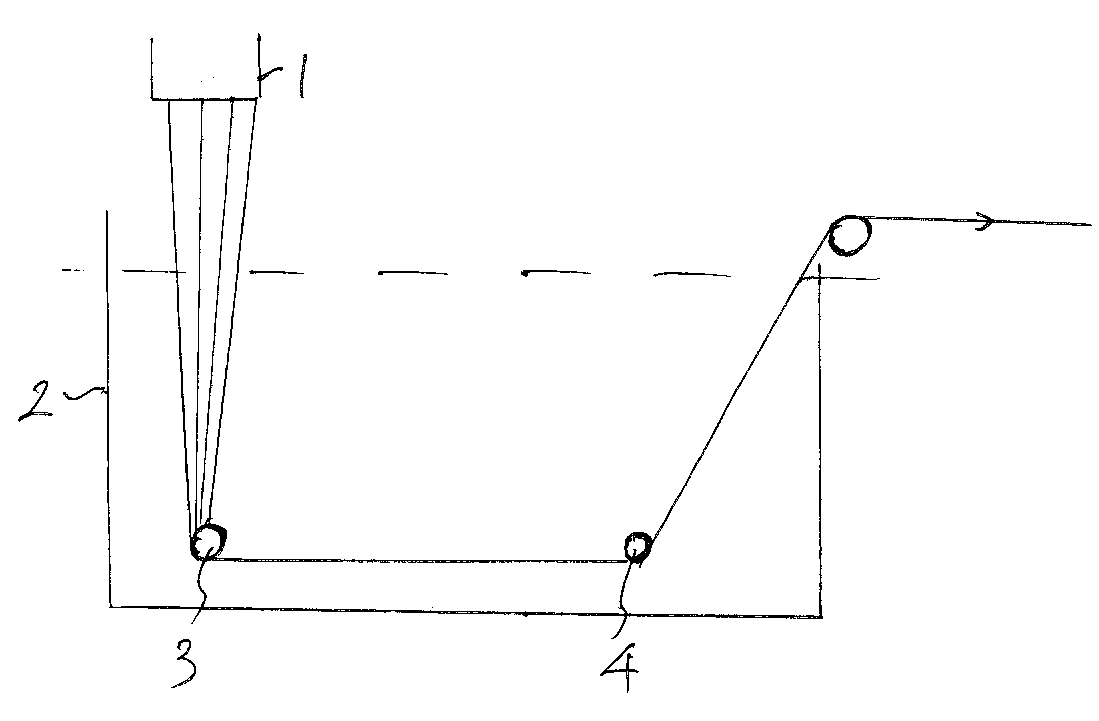

Water injection fracturing shear test system and method for simulating hot dry rock of geothermal system

The invention discloses a water injection fracturing shear test system and method for simulating hot dry rock of a geothermal system, and belongs to the technical field of water injection fracturing shear tests of the dry hot rock of an enhanced geothermal system (EGS). The water injection fracturing shear test method comprises the steps that firstly, a double-opening stainless steel mold is utilized to manufacture a paraffin reverse mold containing water injection drilling holes and cracking cracks; secondly, gypsum, water and a standard mold are utilized to manufacture large-sized rock-like test pieces containing the paraffin reverse mold and different forms of primary cracks; then, the test pieces are placed in an upper heating sleeve and a lower heating sleeve and placed in a direct shear test machine, and paraffin liquid is poured out after the power is turned on and heating is performed; and finally, an acoustic emission sensor, a water injection pipe and a sliding clamp are installed, the test machine is operated to apply axial stress and shear stress, and appropriate water injection parameters, temperature parameters and loading prestress parameters are selected for testing. The water injection fracturing shear test system and method truly reflect the excitation process of a hot dry rock reservoir, and provide an effective indoor test means for studying the propagation mechanism of water injection fracturing shear cracks of the hot dry rock.

Owner:SHANDONG UNIV OF SCI & TECH

Production method of foamed candle

The invention relates to a production method of a foamed candle. The method is characterized by comprising the technological steps of: (1) melting paraffin so as to obtain a paraffin liquid at a temperature of 75-85DEG C, and filling the paraffin liquid into a foaming machine; (2) initiating a cooling water pump and the foaming machine which is maintained at a low speed running state, thus obtaining a paraffin liquid at a temperature of 65-75DEG C; (3) cooling the paraffin liquid to a temperature of 57-59DEG C; and initiating the foaming machine to run at a high speed, thus obtaining a foamed paraffin liquid; (4) injecting the foamed paraffin liquid obtained in step (3) into a die or container, the center of which is inserted with a cotton wick, cooling the foamed paraffin liquid for 12-15min so as to obtain a solid candle; covering the solid candle with a layer of paraffin liquid at a temperature of 75-85DEG C and with thickness of 1-2mm, and flattening the surface of the paraffin liquid; continuing to conducting cooling for 12-15min, then carrying out demoulding, thus obtaining the foamed candle. The method of the invention adopts mechanical foaming which is easy to operate and has no need for other substances as boosting agents.

Owner:无锡市灵山香烛工艺制品有限公司

Molding method of liquid cooling polymer monofilament

InactiveCN102851754AHigh strengthImprove roundnessFilament/thread formingMonocomponent polyesters artificial filamentFiberParaffin wax

The invention discloses a molding method of liquid cooling polymer monofilament. The method includes that polymer melt ejected by a spinneret plate component enters a liquid box to perform liquid cooling molding and is delivered out of the liquid box through front and back winding rollers in the liquid box to enter a sequence process; the front and back winding rollers are on a same horizontal plane, and the distance between the front and back winding rollers is in a range of 50cm to 200cm, wherein liquid temperature in the liquid box is in a range of 5 DEG C to 95 DEG C, the distance between a spinneret end of the spinneret plate component and the liquid level of liquid box is in a range of 1cm to 10cm, and the distance between the roller in the liquid box and the liquid level is in a range of 10cm to 150cm; the liquid in the liquid box is a circulation liquid with a flow rate of 25-150kg / h, and the liquid in the liquid box is a mixture of water, triethylene glycol liquid or paraffin liquid. The molding method has the advantages that the process is simple, the operation is convenient, and molded fibers have high strength, roundness and uniformity, and the like; and the method is particularly suitable for being used by paper making molding nets, filter fabrics, special screens and the like.

Owner:马海燕

Method for processing yak horn comb blank

The invention discloses a method for processing an yak horn comb blank, which comprises the following steps: (1) preparing the primary yak horn comb blank: choosing an yak horn with the shape and thickness suitable for making a comb, cutting off leftover materials, making the yak horn into the primary yak horn comb blank by cutting the yak horn from the middle part along the direction extending towards the ox-head from the tip of the yak horn, and storing for later use; (2) heating and softening: putting the made primary yak horn comb blank into a paraffin liquid which is melted and is at 120-150 DEG C, and heating and softening for 2-3 minutes; and (3) preparing the yak horn comb blank: putting the softened primary yak horn comb blank into a pressing machine for flattening and straightening the primary yak horn comb blank, and obtaining the yak horn comb blank after cooling the flattened and straightened primary yak horn comb blank. By using the method provided by the invention, the phenomenon that a large amount of water is sucked in the process of preparing the yak horn comb blank is completely eradicated, the original organic matters of the raw materials are protected well, the yak horn comb blank cannot be easily carbonized in the preparation process, the prepared product is difficult to deform and is not brittle, the yak horn comb blank can be produced in batch, and the quality and the service life of the yak horn comb blank are promoted.

Owner:雅安市长益生物科技有限公司

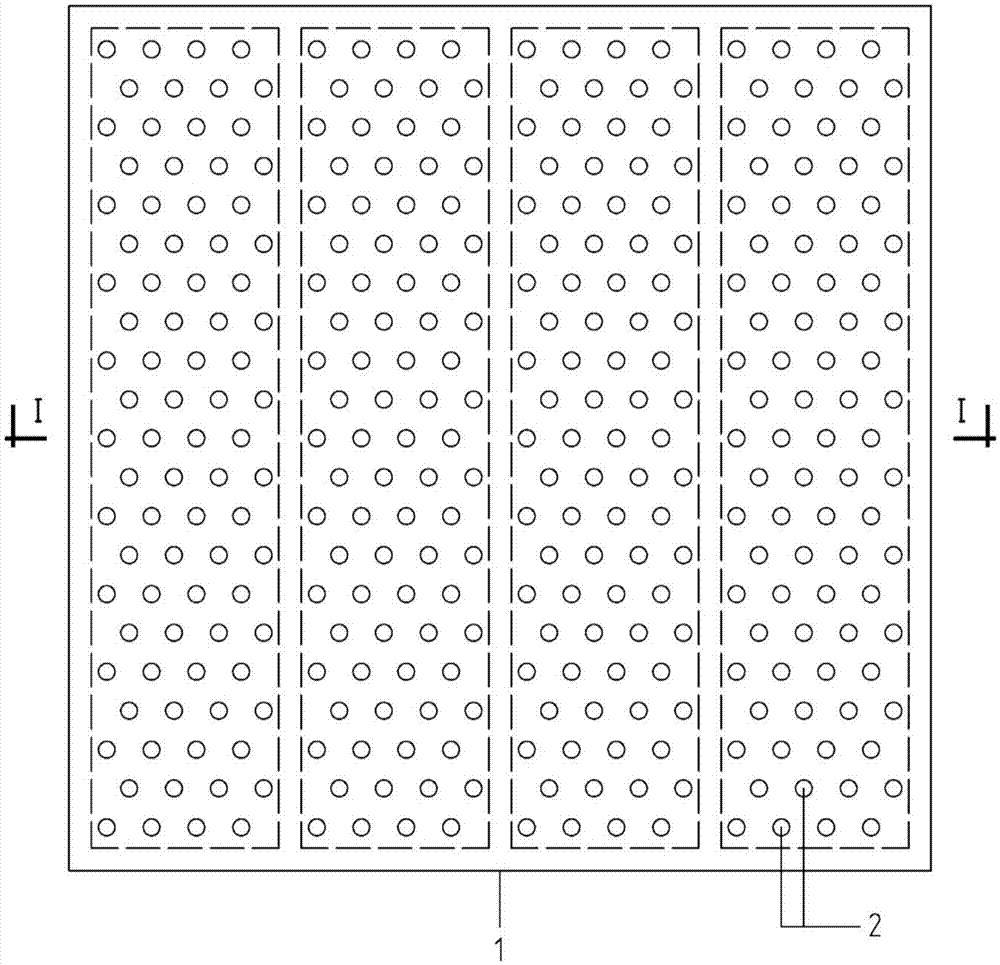

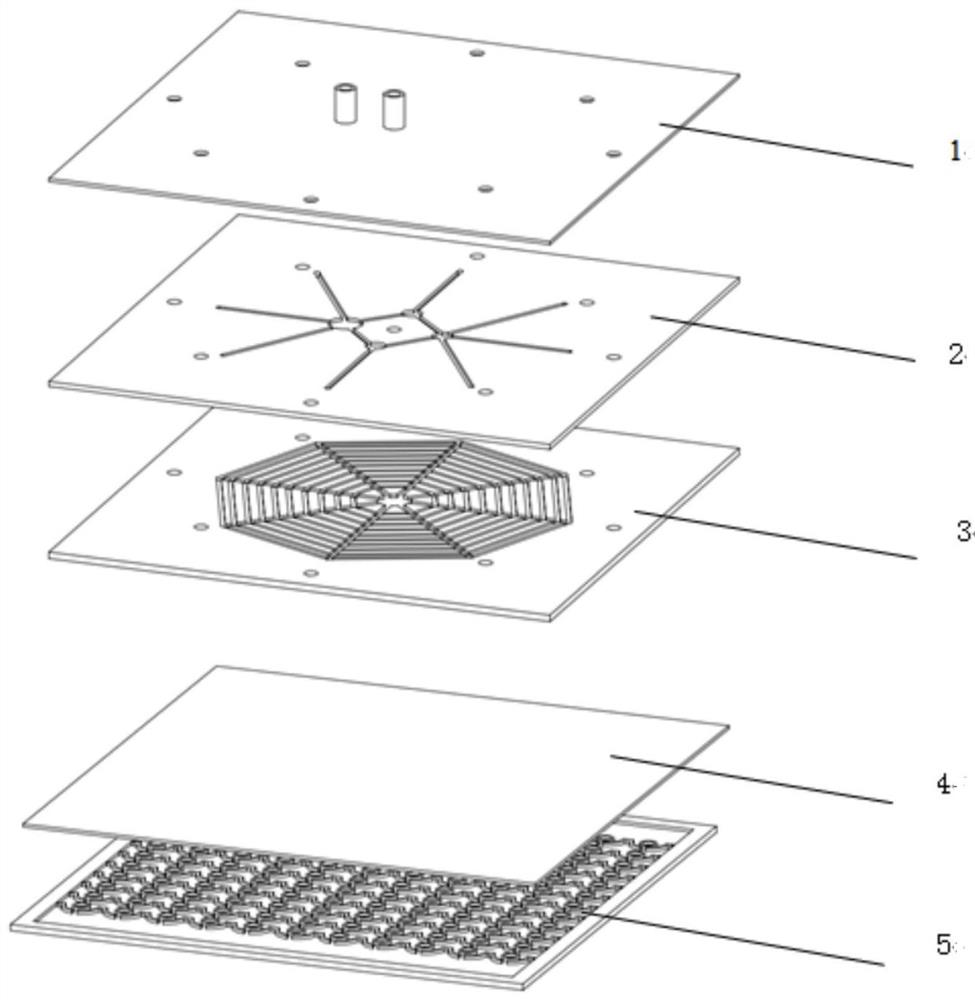

Liquid cooling heat dissipation device and heat dissipation system

ActiveCN111883497AImprove cooling effectCool down in timeSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsLiquid storage tank

The invention discloses a liquid cooling heat dissipation device and a heat dissipation system, the liquid cooling heat dissipation device comprises a paraffin liquid cooling heat dissipation device and a micro-channel heat dissipation cold plate, one surface of the paraffin liquid cooling heat dissipation device is connected with a heat source, and the other surface of the paraffin liquid coolingheat dissipation device is connected with the micro-channel heat dissipation cold plate; the heat dissipation system comprises a liquid cooling heat dissipation device, a circulating water pump, a sensing system, a controller, a liquid storage tank and a fan, wherein the paraffin liquid cooling heat dissipation device and the micro-channel heat dissipation cold plate are combined for use; meanwhile, the heat dissipation system is adopted for intelligent control, so timely cooling can be effectively conducted according to the temperature change of a heat source, and the heat dissipation degreeof the heat dissipation system is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Micro-carbonization method for solid wood floor

InactiveCN108972813AImprove bending strengthImprove impact toughnessWood treatment detailsThermal wood treatmentSolid woodMicrowave

The invention discloses a micro-carbonization method for a solid wood floor. The micro-carbonization method includes: cutting to obtain a solid wood floor slab, standing and drying the solid wood floor slab in a vacuum environment of 60-80 DEG C for 60-90 minutes, wherein the excess pressure of the vacuum environment is 0-9KPa; performing microwave drying to allow the water content of the solid wood floor slab to lower to below 6%; rising the temperature to 160-200 DEG C in a humidified environment in a carbonization chamber to perform carbonization; after the carbonization, transferring the solid wood floor slab to a vacuum environment of 60-80 DEG C, and standing for 30-45 minutes; soaking into paraffin liquid for 45-60 seconds, and taking out. By the micro-carbonization method, the obtained micro-carbonized solid wood floor is dampproof, mothproof, corrosion-resistant, stable in performance, uniform in carbonization and good in mechanical performance such as bending strength, impacttoughness and nail-holding ability, and the usability of the micro-carbonized solid wood floor is increased.

Owner:苏州燕泥地热地板科技有限公司

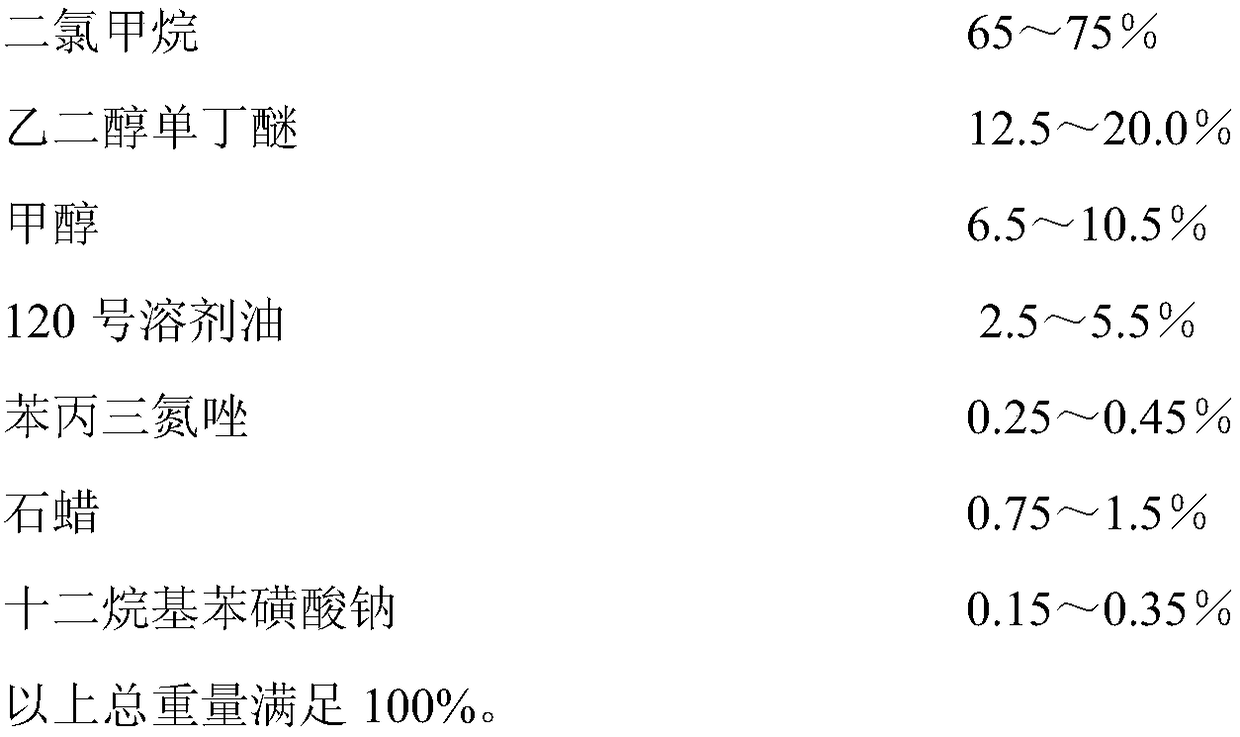

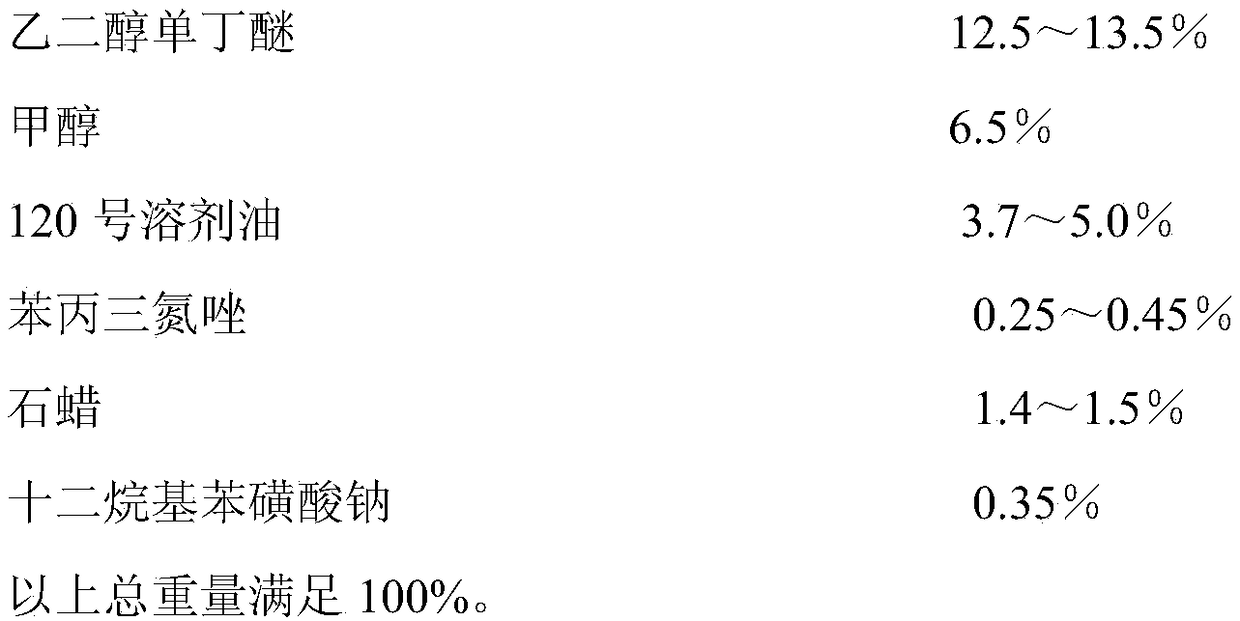

Normal-temperature glue detergent and preparation method thereof

InactiveCN108865463AQuick washImprove performanceOrganic detergent compounding agentsSurface-active detergent compositionsEtherBenzotriazole

The invention discloses a normal-temperature glue detergent and a preparation method thereof. The normal-temperature glue detergent disclosed by the invention is prepared from the following ingredients in percentage by weight: 65% to 75% of dichloromethane, 12.5% to 20.0% of ethylene glycol monobutyl ether, 6.5% to 10.5% of methanol, 2.5% to 5.5% of 120# solvent oil, 0.25% to 0.45% of benzotriazole, 0.75% to 1.5% of paraffin and 0.15% to 0.35% of sodium dodecylbenzene sulfonate. According to the normal-temperature glue detergent and the preparation method thereof, the dichloromethane serves asa primary solvent, the ethylene glycol monobutyl ether, the methanol and the 120# solvent oil serve as cosolvents, the sodium dodecylbenzene sulfonate serves as an anionic surfactant, and the paraffin serves as a penetrant; after the normal-temperature glue detergent is sprayed onto the surface of a glue film, the primary solvent and the other cosolvents rapidly dissolve part of the glue film onthe surface of the film, paraffin liquid rapidly penetrates into the film and is rapidly cured after solvent volatilization, the glue film is isolated from the original surface, and thus, the originalglue film is very easy to peel off.

Owner:SHANGHAI INST OF TECH

Forest litter sampling and profile structure image acquisition method

InactiveCN102095692AWithdrawing sample devicesPreparing sample for investigationPorosityLiquid state

The invention discloses a forest litter sampling and profile structure image acquisition method. The method comprises the steps: spraying liquid-state polyethylene acrylate on the litters at the collection spot, wherein the polyethylene acrylate can naturally volatilize after complete permeation; fixing the litters at the collection spot; cutting off the peripheral edges of a die; taking out the die to complete the sampling of the forest litters; heating paraffin to liquid state in a container; soaking the litter die in the paraffin liquid completely to enable the paraffin liquid to permeate in the gap of the litter die; naturally cooling to obtain solidified paraffin; cutting the solidified paraffin; polishing with a plane; placing the profile of the polished litter die in boiling water to dissolve the paraffin on the profile to obtain the profile structure of the litter die; and scanning the profile by a scanner to obtain the profile structure image. In the method, the litters can be sampled, processed and scanned to obtain the profile structure image of the litters without destructing the natural structure, thereby establishing the foundation for the profile porosity calculation of the forest litters and other related researches.

Owner:DALIAN UNIVERSITY

Field in-situ sampling method for granular mixtures

InactiveCN105527117AOvercome extraction difficultiesFacilitate the analysis of physical and mechanical propertiesWithdrawing sample devicesParaffin waxSoil science

The invention discloses a field in-situ sampling method for granular mixtures. The field in-situ sampling method overcomes the problem of incapability of sampling an ideal in-situ sample due to proneness to disturbance of a granular mixture accumulative layer in the prior art. The field in-situ sampling method provided by the invention comprises the following steps: (1) digging out a slope surface with an angle of 35 to 45 DEG from the top of a granular mixture slope to the bottom of the slope and respectively digging out one surface at the top, medium and bottom of the slope for sampling; and (2) respectively pouring two places of each plane with paraffin liquid obtained after melting of paraffin and virgin rubber of cyanoethyl acrylate and taking out cemented bodies of granular mixtures after solidification of the paraffin liquid and the virgin rubber. According to the invention, sampling is carried out via two processes, so a granular mixture accumulative layer is not disturbed, optimal samples are obtained, and subsequent determination operation is facilitated.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Machining method of bamboo toothpicks

The invention discloses a machining method of bamboo toothpicks. The method includes: sawing bamboo into sections, and cutting into bamboo chips; machining the bamboo chips into circular wires; soaking the circular wires into complex enzyme preparation solution; performing preservation treatment; carbonizing; drying and sterilizing; sawing off the circular wires into circular toothpick strips, and polishing; grinding to form one or two pointed ends; packaging. The machining method has the advantages that the method uses bamboo as the raw material, environment protection is achieved, and the bamboo grows fast and is short in growth cycle; the circular wires are soaked in the complex enzyme preparation solution to completely degrade protein, fat, starch, pectin, tannin and pigment in the circular wires, the defects such as color changing and mildewing, caused by the protein, the fat, the starch and the like, of the toothpicks are overcome, the toothpicks are soaked into paraffin liquid or tung oil under high temperature to effectively guarantee the anticorrosion effect of the toothpicks; carbonizing allows the toothpicks to have corrosion resistance, insect resistance, mildew resistance, dampness resistance and the like.

Owner:安徽泓浩竹科技股份有限公司

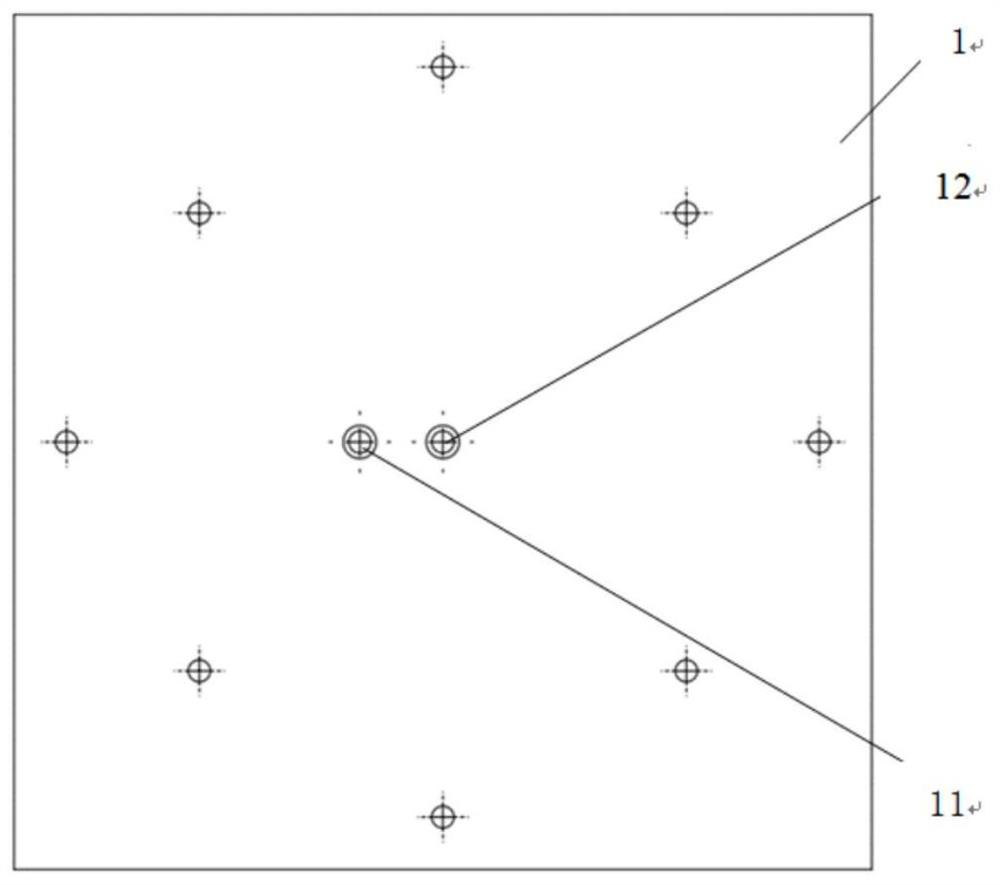

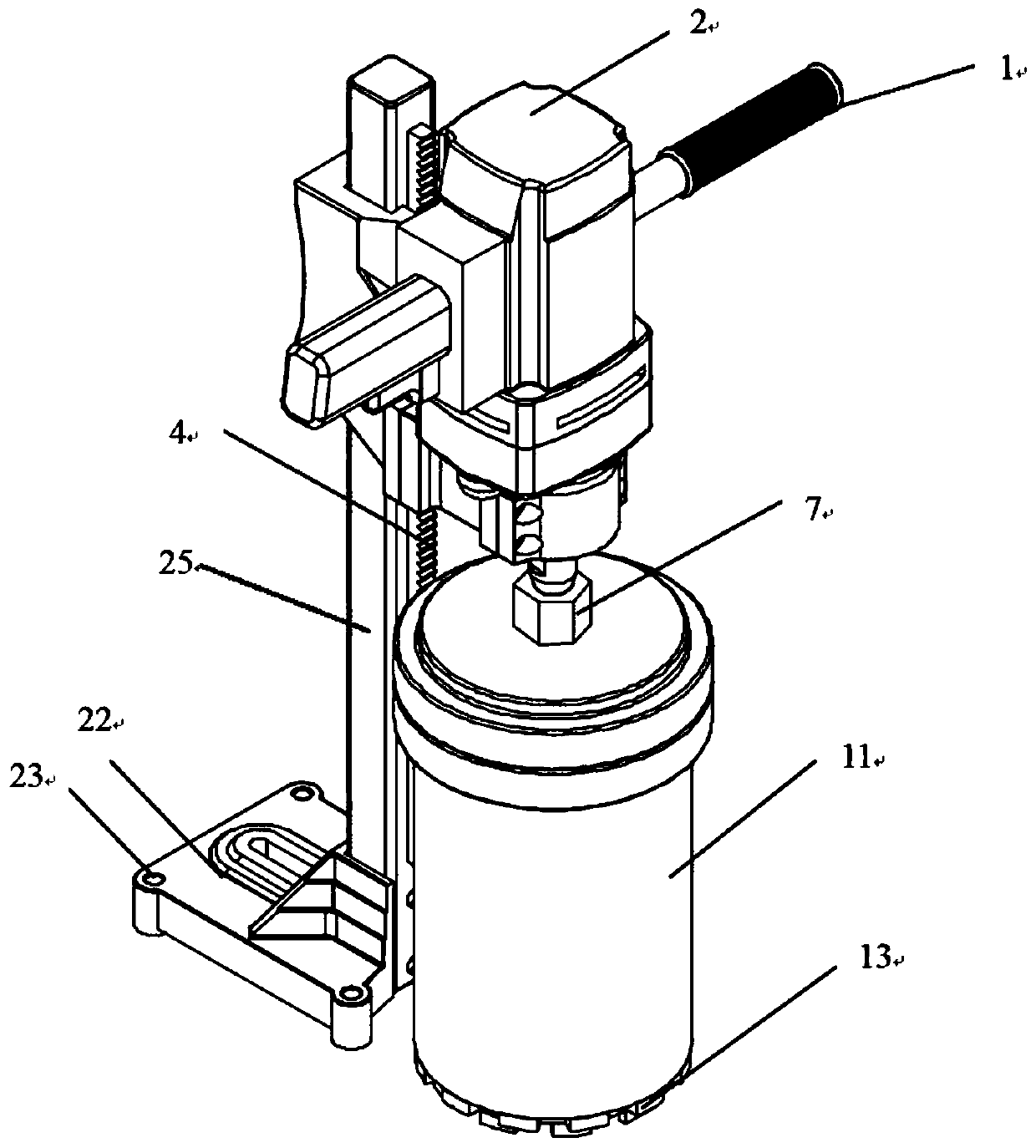

Device and method for extracting rock core by drilling fractured rock mass

The invention discloses a device and method for extracting a rock core by drilling fractured rock mass, and belongs to the field of geotechnical engineering. The device comprises a driving device, a drill bit and a paraffin injection system, wherein the driving device is used for providing power for driving the drill bit, the drill bit comprises a cutting barrel and a paraffin screening barrel, the paraffin screening barrel is rotationally connected into the cutting barrel, a paraffin supply gap is formed between the cutting barrel and the paraffin screening barrel, the cutting barrel is fixedly connected to the power output end of the driving device, the paraffin injection system comprises a paraffin liquid distribution channel and a supply device, one end of the paraffin liquid distribution channel communicates with the supply device, the other end communicates with the paraffin supply gap, the paraffin sieve barrel is of a sieve-shaped structure, and the supply device is used for supplying liquid paraffin injected into the sampling rock core. According to the device and method for extracting the rock core by drilling the fractured rock mass, in-situ sampling can be carried out on the fractured rock mass, the integrity of the drilled rock core can be kept more completely, the success rate and the operation efficiency of core drilling operation on the fractured rock mass are improved, and the condition of carrying out a rock mechanics experiment on a later-stage fractured rock sample can be better met.

Owner:NORTHEASTERN UNIV

Immunofluorescence staining method for paraffin embedded three-dimensional suspension cell clusters

PendingCN111207987AIntegrity guaranteedEasy to storePreparing sample for investigationAntigenStaining

The invention relates to an immunofluorescence staining method of paraffin embedded three-dimensional suspension cell clusters. The method comprises the following steps: pretreating the three-dimensional suspension cell clusters, immersing into paraffin liquid to embed sections, carrying out antigen repair, and carrying out immunofluorescence staining. According to the method provided by the invention, cells in the cell cluster are fully dyed, the result is accurate, the overall protein expression and distribution condition of the suspension cell cluster can be observed, and sample observationcan be carried out only by a common fluorescence microscope.

Owner:DONGGUAN HEC BIOPHARMACEUTICAL R&D CO LTD +1

Preparation method of color emulsion type shoe polish

InactiveCN103571340AAppropriate compositionEasy to makePolishing compositionsParaffin waxShoe polish

The invention discloses a preparation method of color emulsion type shoe polish, which is implemented by the following steps of (1) weighing the following components in percentage by mass: 35-40% of paraffin, 35-40% of insect wax, 20-30% of turpentine and 0.1-0.2% of dye, wherein the total proportion of the three is 100%, and 2-4% of pure water is also included except the 100%; (2) heating to melt the paraffin, adding one part of turpentine and sufficiently and uniformly stirring to obtain paraffin liquid; (3) heating to melt the insect wax, adding another part of turpentine, and uniformly stirring to obtain insect wax liquid; (4) heating to melt the dye, and uniformly stirring with the remaining turpentine to obtain dye liquid; (5) mixing the thee mixtures obtained by the steps (2), (3) and (4) together, pouring the pure water, sufficiently and uniformly stirring and cooling to obtain the color emulsion type shoe polish. The method disclosed by the invention is simple in preparation and has better adaptability.

Owner:西安佳迅科技有限公司

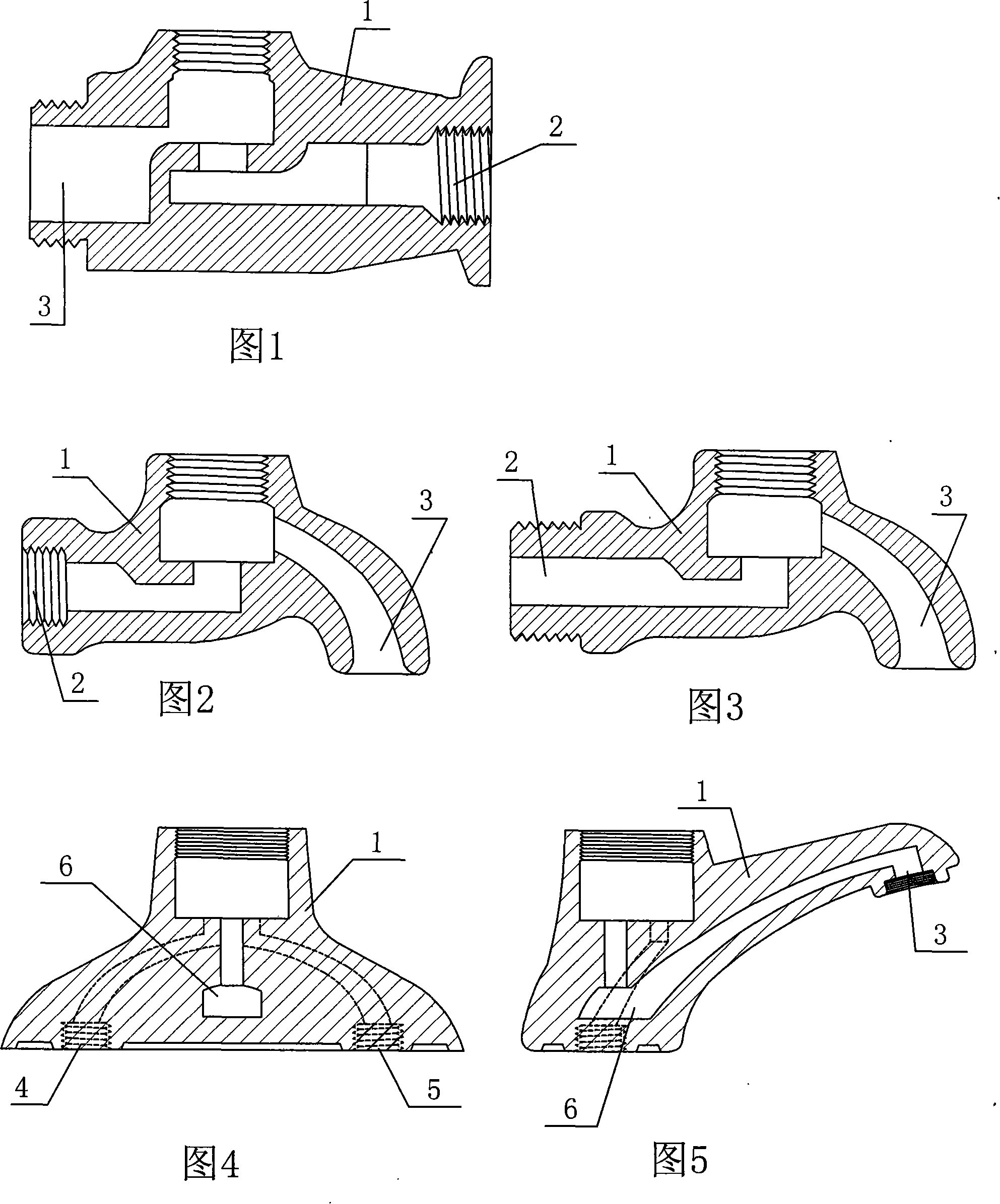

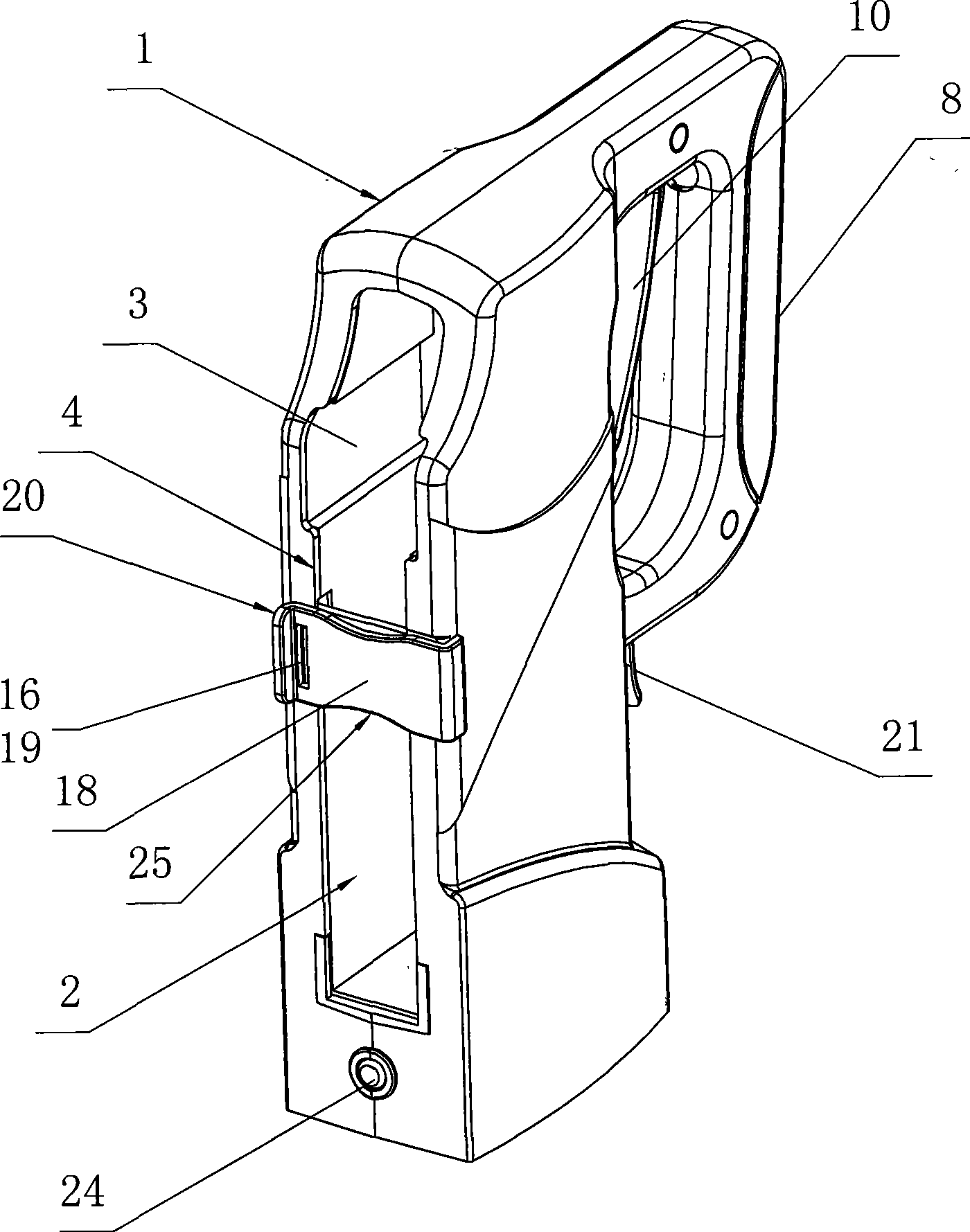

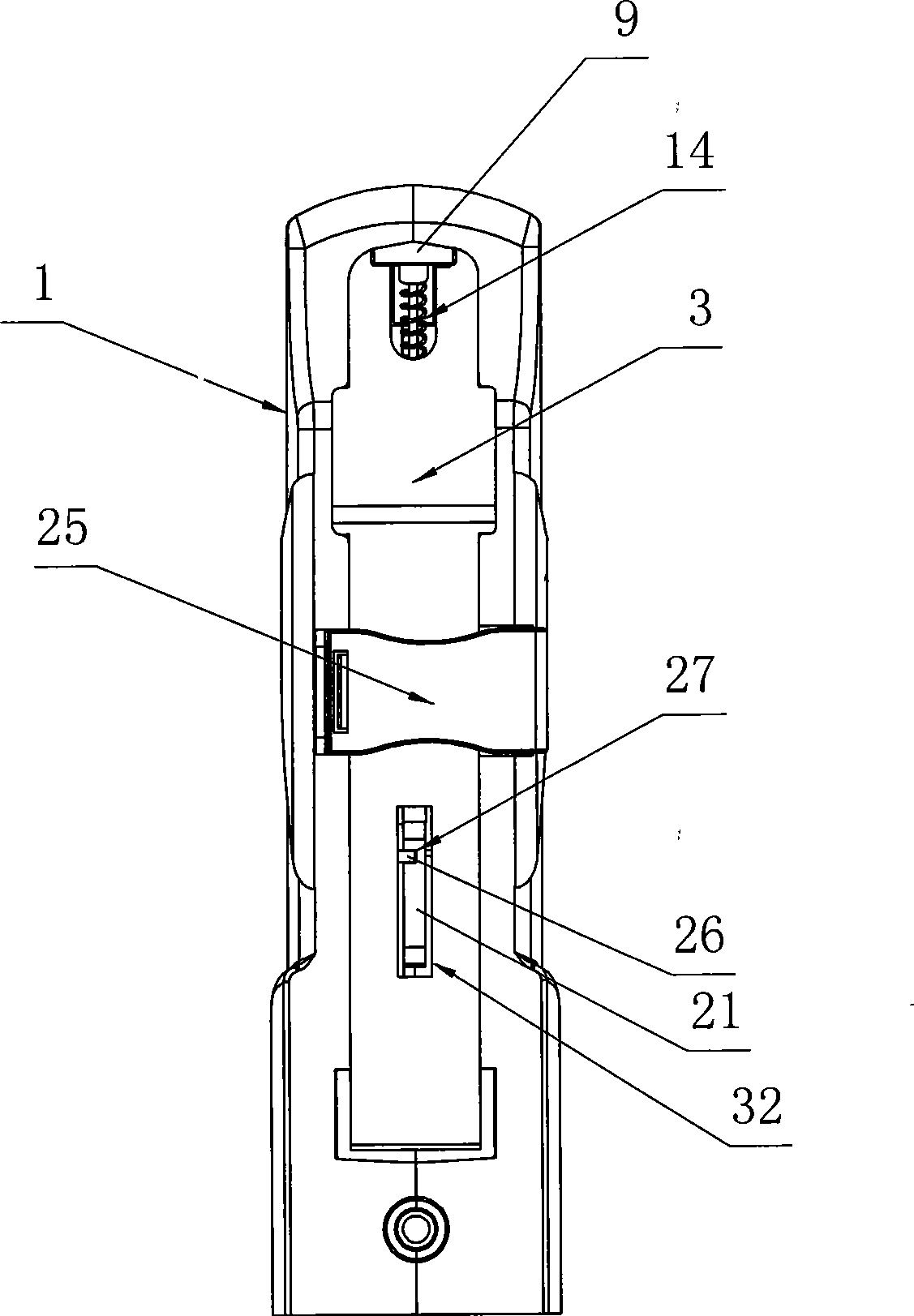

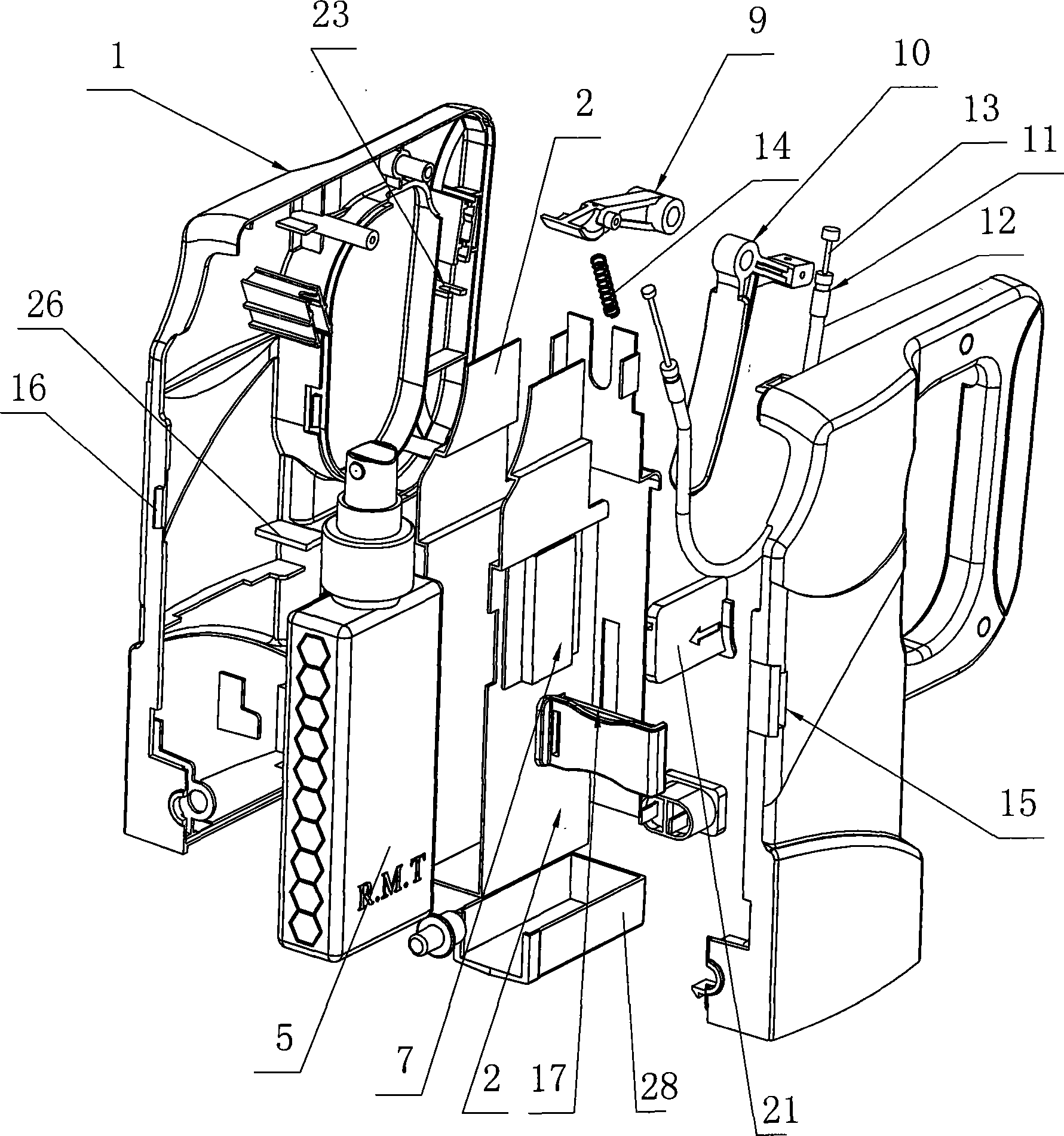

Human body keritherapy film-spraying device

InactiveCN101390783AImprove the heating effectEasy to useTherapeutic coolingTherapeutic heatingParaffin oilsEngineering

The invention discloses a human body paraffin therapy film-spraying machine which comprises a shell; the shell is provided with a hollow cavity chamber used for holding a paraffin liquid bottle; an insertion hole used for the placement of the paraffin liquid bottle is opened on the wall of the cavity chamber; a heater is additionally arranged on the inner wall of the shell; a spraying-pressing mechanism is arranged on the top part of the cavity chamber. The film-spraying machine integrates the functions of heating and film-spraying together and has simple heating and spraying operations; compared with the prior art which requires the paraffin to be preheated and then taken out for film-spraying, the human body paraffin therapy film-spraying machine has the advantages that the application of the film-spraying machine is convenient; the heating function and the film-spraying function are integrated together; the carrying of the film-spraying machine is convenient so that the film-spraying machine is applicable to families or individuals, and the paraffin therapy can be conducted anywhere and at any time; when the film-spraying machine is in use, the paraffin and the heater are not separated to ensure the paraffin to be heated continuously, so as to ensure the paraffin to maintain the optimum human body contact temperature.

Owner:江山

Production method of one-step method polypropylene foam material

ActiveCN103509245AImprove interface strengthImproved resistance to shock loadsCarvacryl acetateAzodicarbonamide

The invention provides a production method of a one-step method polypropylene foam material. The raw materials comprise polypropylene, polyethylene, azodicarbonamide, zinc oxide, zinc stearate, silicon dioxide, dicumyl peroxide, pentaerythritol triacrylate, ethylene-vinyl acetate copolymer, alpha crystal form nucleating agent, maleic anhydride grafted polypropylene, liquid paraffin and liquid acetone. The production method comprises the following steps: 1. mixing polypropylene, polyethylene, silicon dioxide, ethylene-vinyl acetate copolymer, alpha crystal form nucleating agent and maleic anhydride grafted polypropylene together for standby; 2. dissolving dicumyl peroxide in the liquid acetone; 3. mixing pentaerythritol triacrylate, liquid paraffin and the standby material together; 4. mixing the azodicarbonamide, zinc oxide and zinc stearate with the mixture uniformly; 5. extruding and foaming the material through an extruder; 6. compounding non-woven fabric on the two sides of the foam material and rolling to obtain the finished product. The material has high performance for absorbing impact load, good rebound resilience and heat-resisting performance, and can be recycled.

Owner:湖北南泽汽车复合材料有限公司

Auxiliary article for moxibustion and preparation method thereof

InactiveCN106620593APlay multiple therapeutic rolesImprove clinical efficacyDevices for heating/cooling reflex pointsAntipyreticWater bathsEvaporating dish

The invention discloses an auxiliary article for moxibustion and a preparation method thereof. The auxiliary article is prepared from the following raw materials in parts by weight: 2-10 parts of dried ginger fine powder, and 2-10 parts of paraffin. The preparation method comprises the following steps: pulverizing dried ginger slices, and performing mesh screening to obtain dried ginger fine powder, or adding water to perform extract so as to obtain a dried ginger water extract for later use; putting paraffin into an evaporating dish, and performing water bath heating until the paraffin is completely molten into liquid; putting the dried ginger fine powder or the ground dried ginger water extract and the obtained paraffin liquid into a container together, stirring them uniformly, and then performing standing; and filtering the liquid after standing, and pouring the filtered liquid into a pre-customized mold for cooling so as to obtain a medicine cake with a certain height. The auxiliary article disclosed by the invention is prepared by mixing ginger and paraffin, and is used by matching with moxibustion and moxa to give play to effects of the moxa, the traditional Chinese medicines and the paraffin, thereby achieving multiple treatment effects. Under the action of the ginger and the dissolved paraffin, the auxiliary article shows extraordinary performance of effects of harmonizing spleen and stomach, promoting blood circulation to remove blood stasis, promoting qi circulation to relieve pain and relieving arthritis, and the effect is obviously superior to that of conventional mild moxibustion.

Owner:杨子萱 +1

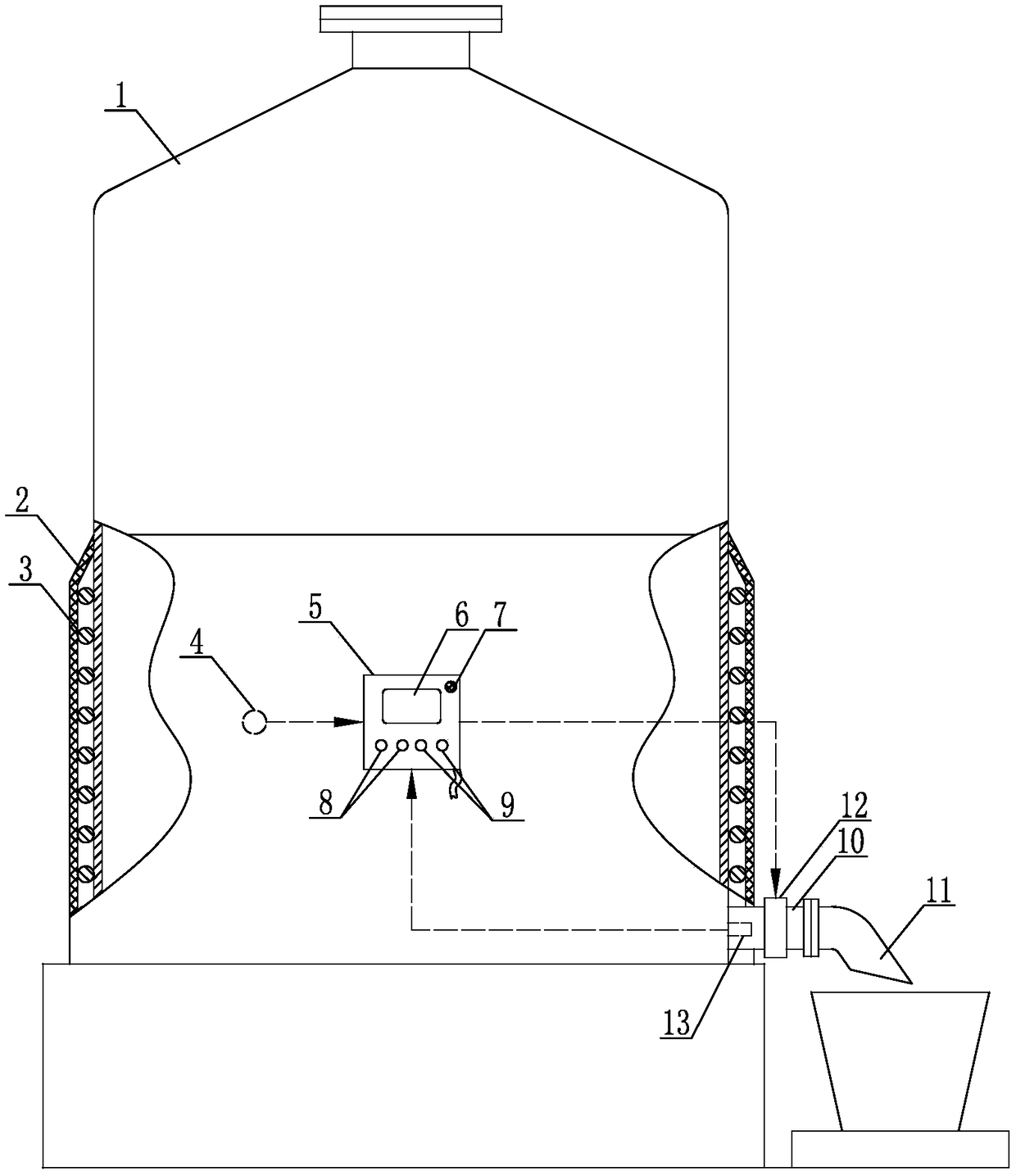

Viscous-proof chlorinated paraffin liquid storage tank for rubber compound mixing

InactiveCN109484777ARealize quantitative automatic dischargePrevent outflowLarge containersTank wagonsMicrocontrollerBiochemical engineering

The invention discloses a viscous-proof chlorinated paraffin liquid storage tank for rubber compound mixing. The liquid storage tank comprises a liquid storage tank body and a taking opening; the lower part of the liquid storage tank body is coated with a tank body heat insulating sleeve; electric heating pipes are clamped between the tank body heat insulating sleeve and the liquid storage tank body; a temperature sensor is packaged inside the tank body heat insulating sleeve; a microcontroller is inlaid in the surface of the liquid storage tank body and is in series connection with a power supply wire of the electric heating pipes; and an automatic discharging device is mounted at the taking opening and is in signal connection with the microcontroller. The tank body heat insulating sleeveand the electric heating pipes are separately arranged at part of the outer side of the liquid storage tank body and only heat chlorinated paraffin close to the taking opening, so that the conditionthat a raw material inside cannot flow out successfully due to increase of the viscosity during discharging in winter is prevented, and the electric energy can be saved due to the fact that the electric heating pipe is arranged partially; and through cooperation of the automatic discharging device and the microcontroller, quantitative and automatic discharging of the chlorinated paraffin can be realized, and manual control is not required, so that the liquid storage tank is easy to use, and the taking error is small.

Owner:潍坊潍星联合橡塑有限公司

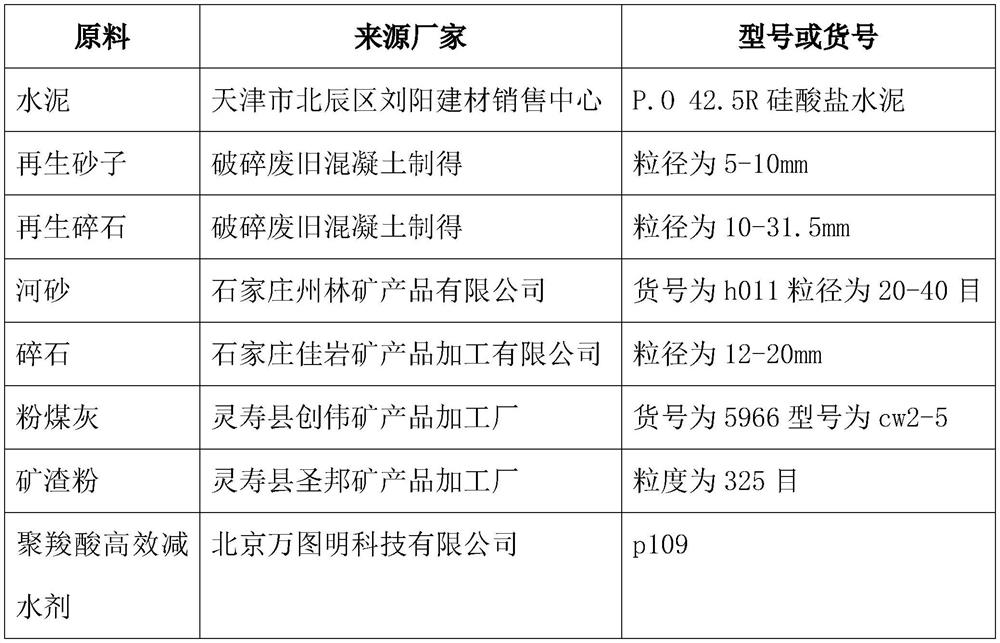

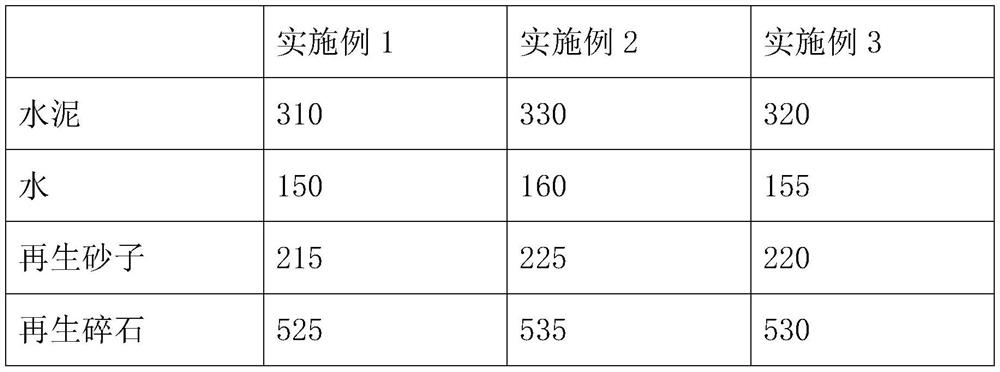

High polymer environment-friendly recycled concrete and preparation method thereof

ActiveCN113651579AHigh apparent densityNot prone to discrete phenomenaSolid waste managementPolymer scienceSuperplasticizer

The invention relates to the field of concrete, and particularly discloses high polymer environment-friendly recycled concrete and a preparation method thereof. The high polymer environment-friendly recycled concrete is prepared from a concrete mixture, wherein the concrete mixture comprises the following components: cement; water; regenerating coarse aggregate; natural coarse aggregate; coal ash; slag powder; a polycarboxylate superplasticizer; a viscosity modifier; paraffin; and a liquid accelerator which has the advantages that the bleeding rate and the strength performance are not easily influenced by the regenerated aggregate; in addition, the invention also discloses a preparation method of the high polymer environment-friendly recycled concrete, which comprises the following steps: step 1, crushing construction waste; step 2, pouring the liquid accelerator; step 3, coating paraffin; step 4, mixing the components to form the concrete mixture; and step 5, curing and forming to obtain the high polymer environment-friendly recycled concrete which has the advantage of being convenient to prepare.

Owner:深圳市永恒业混凝土有限公司

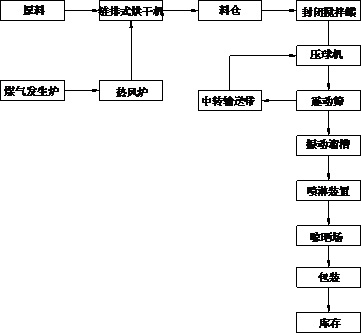

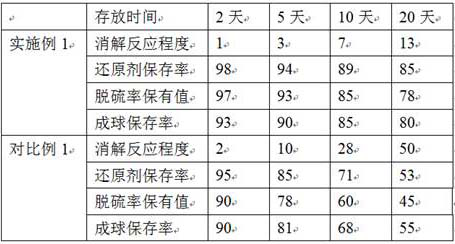

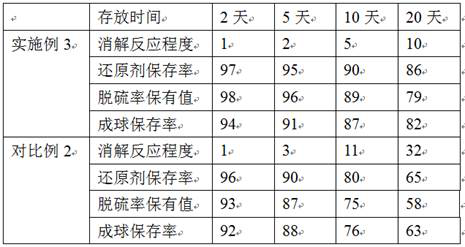

Anti-pulverization production technology of synthetic slag lotion

PendingCN112322838AEasy to useExtended inventory cycleProcess efficiency improvementParaffin waxSlag

The invention provides an anti-pulverization production technology of a synthetic slag lotion, and belongs to the technical field of metal smelting. The technology sequentially comprises the followingsteps of preparing, drying, feeding, stirring, conveying, ball pressing, screening, film attaching, airing and packaging. According to ball pressing, when materials to be conveyed are loaded in a buffering hopper of a ball pressing machine fully, the ball pressing machine begins to be started for pressing balls. According to screening, the extruded materials are all conveyed to a vibrating sieve,the screened materials are conveyed to the ball pressing machine, and circular pressing is carried out. According to film attaching, qualified balls on the sieve are conveyed to a sieve vibrating chute, spraying devices are arranged at the upper fixing position and the lower fixing position of the chute, and when the balls fall through the chute and pass through the spraying devices, and the spraying devices spray paraffin liquid to surfaces of balls. According to airing, the finished balls subjected to spraying are spread flatly and aired, and thus the paraffin liquid fully wets the surfacesof the balls and is solidified into films. According to the technology, the problems of occurrence of digestion reaction and ball pulverization can be effectively relieved, and the inventory period is prolonged.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

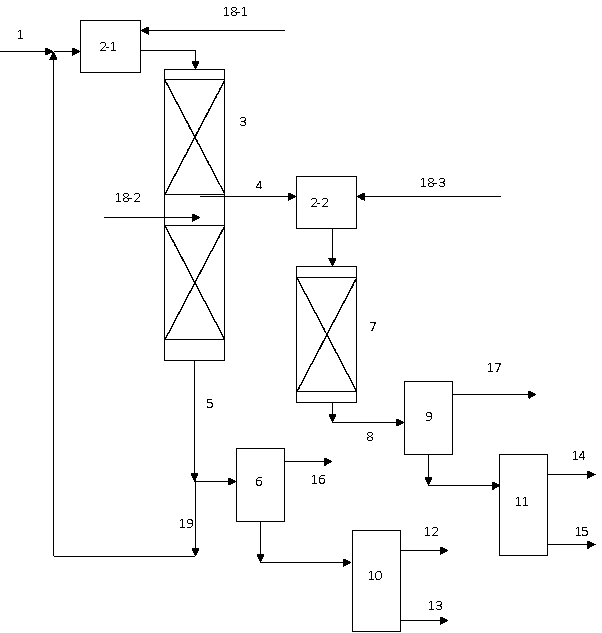

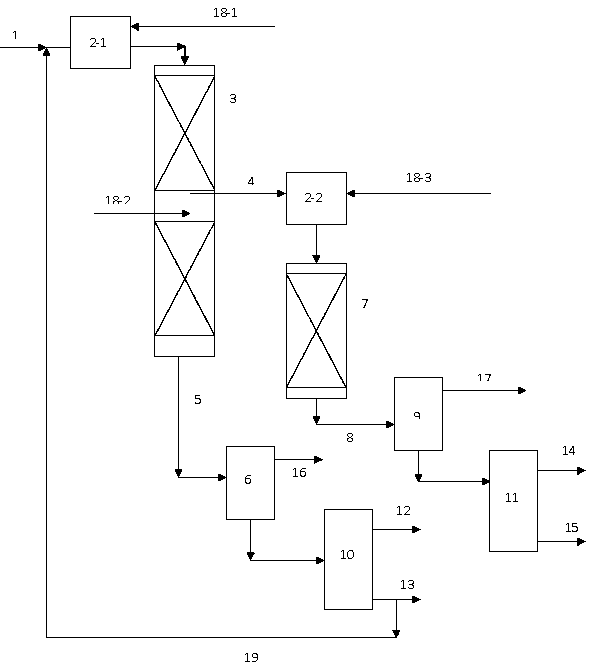

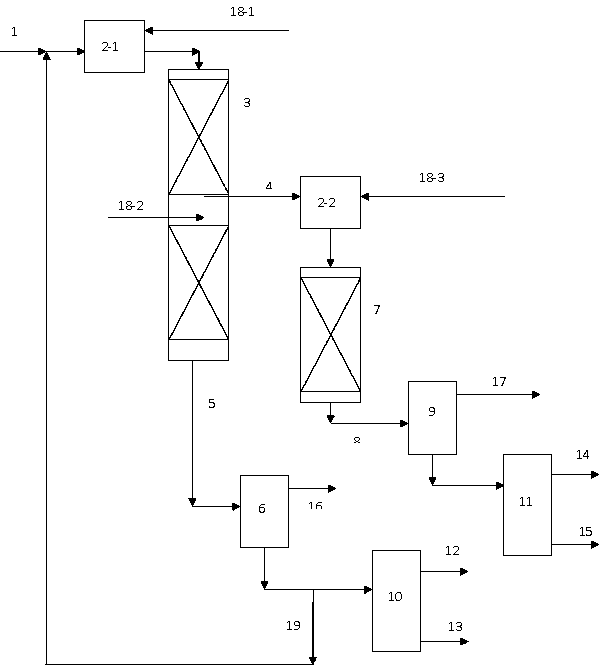

Flexible paraffin liquid phase hydrogenation process

ActiveCN109988608AEffective distributionFlexible productionPetroleum wax refiningTreatment with hydrotreatment processesParaffin waxIsomerization

The invention discloses a flexible paraffin liquid phase hydrogenation process. A paraffin raw material and circulating oil enter a liquid-phase hydrofining reactor under a liquid-phase hydrogenationcondition; the material passing through an upper hydrofining catalyst bed layer is divided into two streams; one material stream is extracted out of the liquid-phase hydrofining reactor from the middle of the bed layer, and fed into a liquid-phase hydroisomerization reactor for isomerization reaction; the other material stream continues flowing downward to pass through a lower hydrofining catalystbed layer; and an obtained hydrofining reaction material and an obtained hydroisomerization reaction material are subjected to gas-liquid separation and fractionation separately to obtain paraffin products with different specifications. The invention provides the hydrogenation process for simultaneously producing more than two paraffin products with different specifications on one set of liquid-phase hydrogenation process equipment for the first time, heat carried by a part of hydrofined materials can be fully utilized, and coupling operation of the liquid-phase hydrofining reactor and the liquid-phase hydroisomerization reactor is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

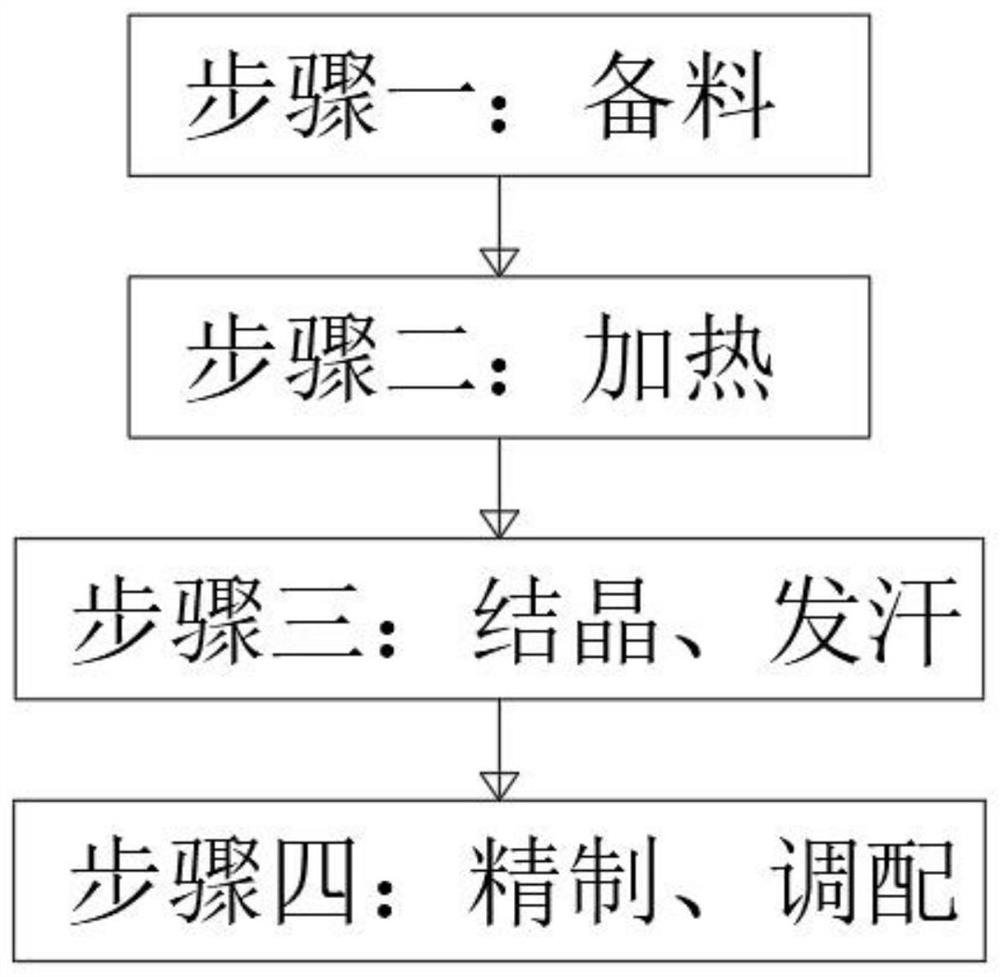

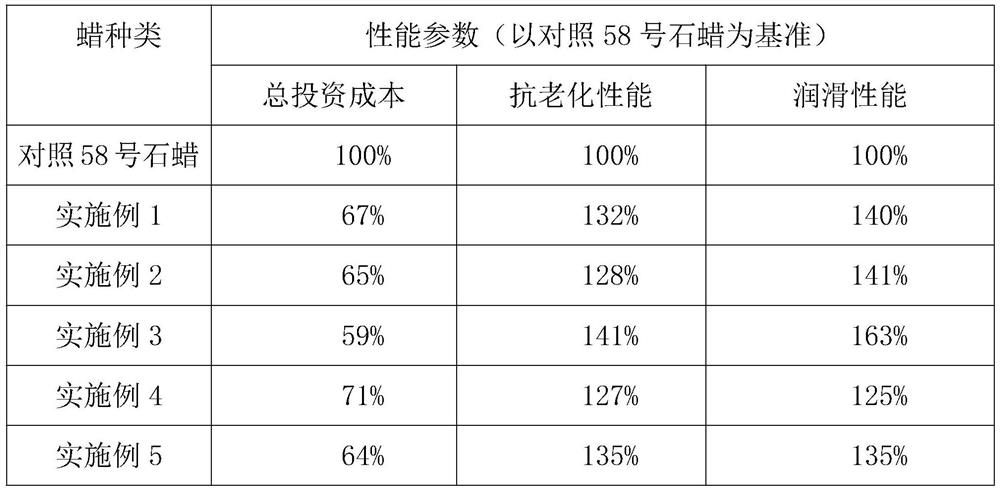

Rubber wax based on new material technology

The invention discloses rubber wax based on a new material technology. The technical scheme mainly comprises that the rubber wax is prepared according to the following steps: step 1, preparing materials: preparing the following component raw materials in parts by weight: 20-50 parts of soap wax, 30-55 parts of mixed paraffin, 35-48 parts of microcrystalline wax, 25-35 parts of protective wax and 1-5 parts of a rubber wax auxiliary agent; and step 2, conducting heating: separately putting the soap wax, the mixed paraffin, the protective wax and the microcrystalline wax into a reaction kettle, conducting heating until melting to obtain a soap wax liquid, a mixed paraffin liquid and a microcrystalline wax liquid, separately adding an oil-soluble substance capable of being decomposed to generate gas into the soap wax liquid, the mixed paraffin liquid and the microcrystalline wax liquid, and after adding is completed, injecting the soap wax liquid, the mixed paraffin wax liquid and the microcrystalline wax liquid into a sweating device through a hopper. The reaction device is low in investment, the production process is simple, the operation cost is low, and no solvent pollutes the environment.

Owner:上海鑫曾化工科技有限公司

Method for preparing corrosion pit in metal material sample

PendingCN111398001AFast preparationGood effectPreparing sample for investigationParaffin waxElectrolysis

The invention discloses a method for preparing a corrosion pit on a metal material sample. The method comprises the following steps: marking the position where the corrosion pit needs to be prepared on the sample, and processing a blind hole at the marked position; carrying out ultrasonic cleaning on the sample with the machined blind hole, drying the sample subjected to ultrasonic cleaning, immersing the sample into heated and melted paraffin liquid until the surface of the sample is completely sealed by paraffin, taking out the sample from the paraffin liquid, and removing the paraffin at the position of the blind hole; taking a lead plate as a cathode, taking the sample as an anode, taking a mixed solution of 5-10% of sodium chloride and 8-20% of hydrochloric acid as an electrolytic solution, placing the lead plate and the sample in the electrolytic solution in parallel, and performing constant-current electrolysis by using a direct-current power supply to accelerate the corrosion of the blind hole position, thereby obtaining the target corrosion pit. According to the preparation method, rapid preparation of various types of common metal material corrosion pits can be achieved,the sizes of the corrosion pits can be manually controlled, and the problems that an existing metal material corrosion pit preparation method is long in period and does not have universality are solved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com