High polymer environment-friendly recycled concrete and preparation method thereof

A technology of recycled concrete and high polymer, applied in the field of concrete, can solve the problems of discrete recycled aggregates, increased concrete bleeding rate, poor compatibility between recycled aggregates and natural aggregates, etc., and achieves the effect of good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

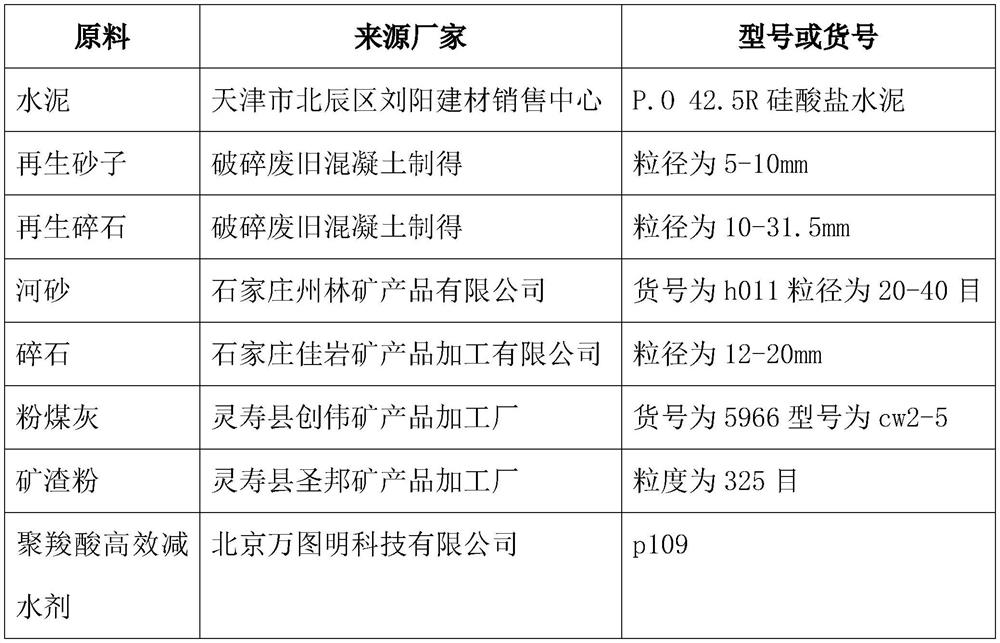

Method used

Image

Examples

Embodiment 1

[0065] This embodiment discloses a high polymer environmentally friendly recycled concrete, which is made of concrete mixture, and the concrete mixture includes the following components:

[0066] 310kg of cement; 150kg of water; 215kg of recycled sand; 525kg of recycled crushed stone; 445kg of river sand; 1075kg of crushed stone; 50kg of fly ash; 110kg of slag powder; Accelerator 10kg.

[0067] This embodiment also discloses a preparation method of high polymer environment-friendly recycled concrete, comprising the following steps:

[0068] Step 1, crush construction waste, remove metal, wood, glass, plastic and other substances in construction waste through magnetic separation and manual sorting, and screen out waste concrete blocks with a particle size greater than 10mm, and add them to the jaw crusher for further crushing , and then screen out aggregates with a particle size of 5-10mm as recycled sand, and filter out aggregates with a particle size of 10-31.5mm as recycled...

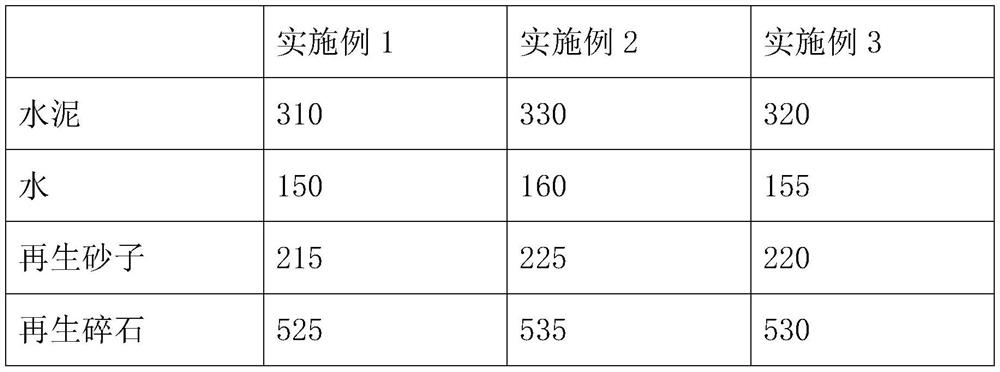

Embodiment 2-3

[0074] The difference with embodiment 1 is:

[0075] The pressure control in the container in step 2 is 5MPa, and the consumption of each component of concrete mixture is different, and the consumption of each component of embodiment 1-3 is detailed in Table 2, and the unit of the consumption of each component is kg.

[0076] Table 2

[0077]

[0078]

Embodiment 4

[0080] The difference from Example 3 is that in step 4, 4 kg of xanthan gum is replaced with 1 kg of sodium caseinate and 3 kg of starch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com