Damp-proof mattress and manufacture method thereof

A manufacturing method and mattress technology, applied to mattresses, spring mattresses, beds, etc., can solve problems such as troublesome maintenance, inability to guarantee sleep quality, and physical influence on sleep mood, etc., and achieve the effect of reducing temperature difference and preventing humidity from increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

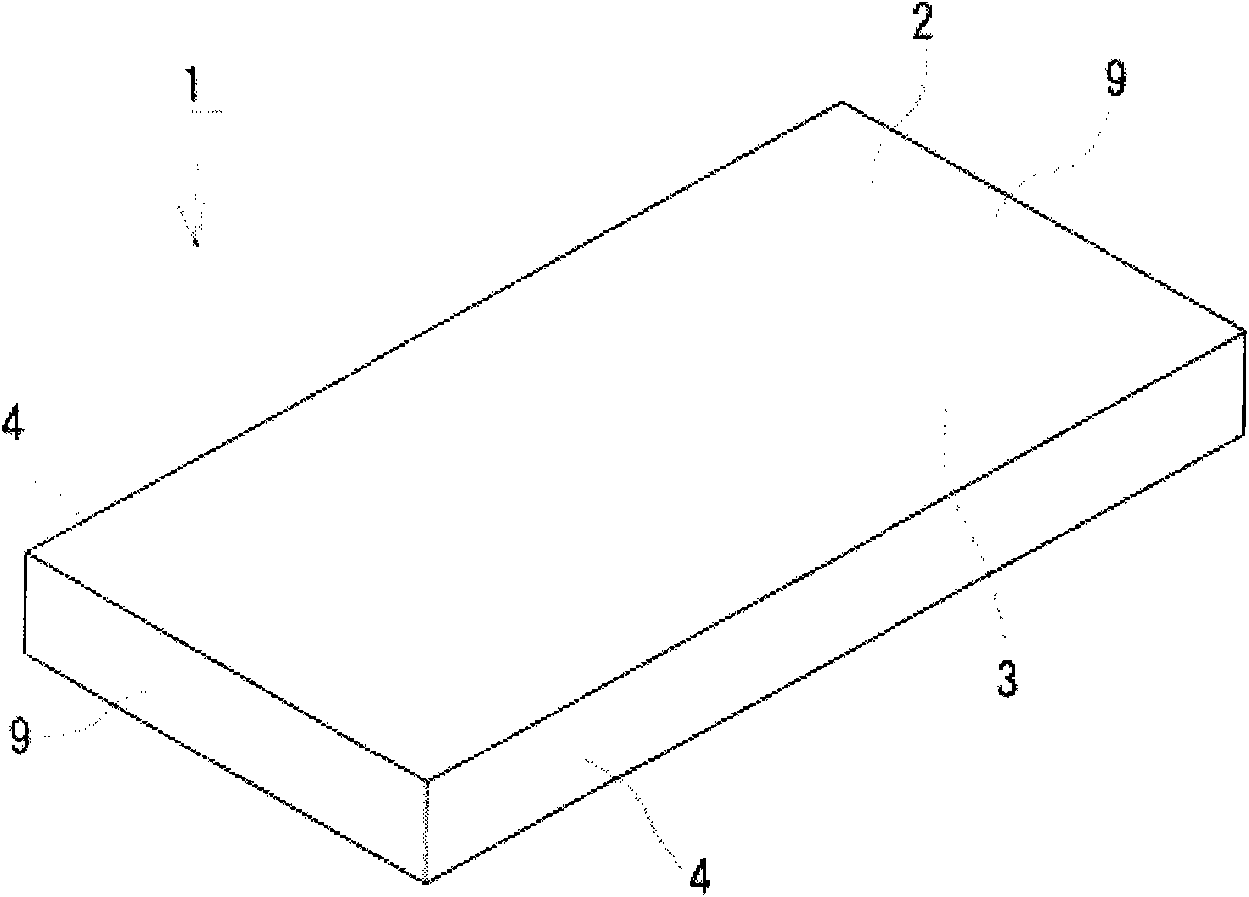

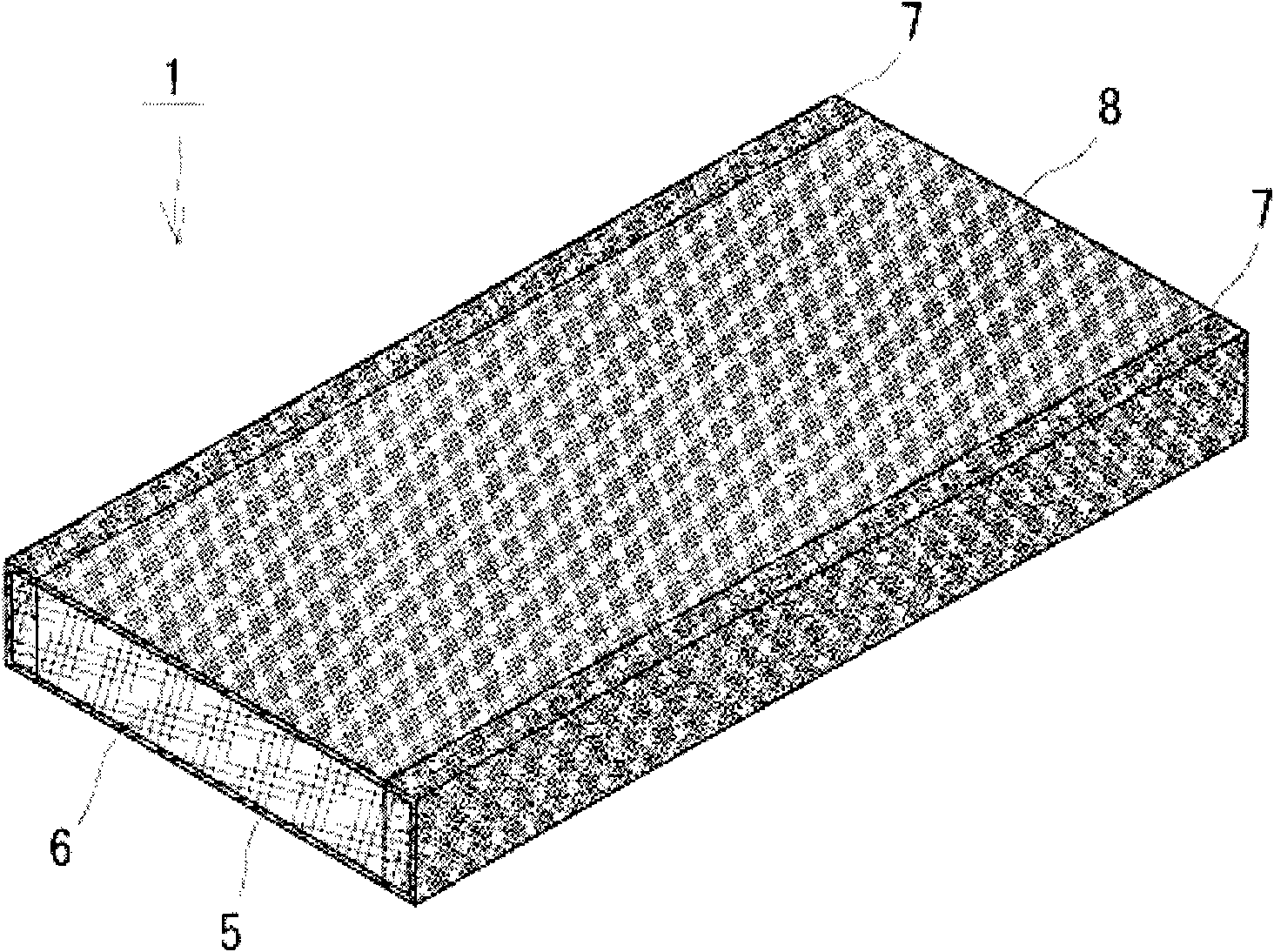

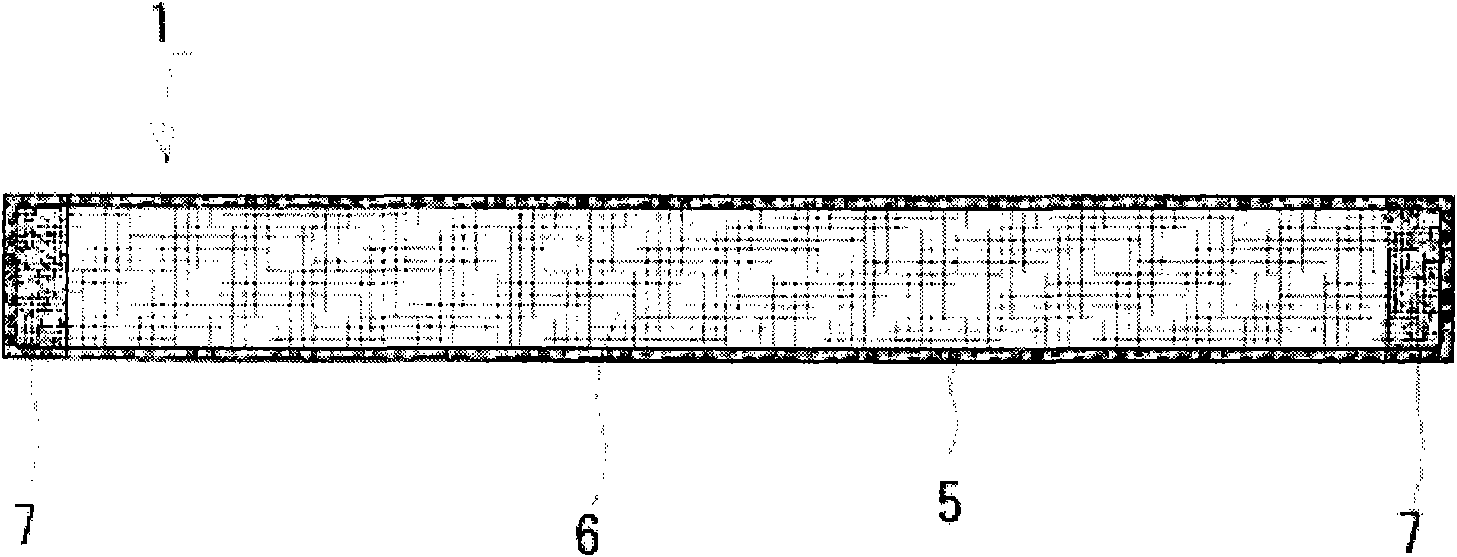

[0052] The implementation method of the moisture-proof mattress 1 is described according to FIG. 1 . The raw material or main raw material of the moisture-proof mattress 1 is renewable thermoplastic resin, and a plurality of continuous lines are disorderly wound into a ring shape and partially welded to form a plate-shaped three-dimensional network structure. Since the continuous lines are randomly wound into a ring shape, the moisture-proof mattress 1 becomes a spring-like structure, and the whole itself has elasticity.

[0053] Four of the top surface 2, the bottom surface 3, and the left and right sides 4 of the moisture-proof mattress 1 are formed in the molding stage of the three-dimensional network structure (refer to FIG. 1(a)). The front and rear end faces 9 are not formed at this stage, but are formed by cutting the three-dimensional network structure. This molding process compresses and melts the linear raw material, thereby forming a surface firm portion 5 having a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com