Preparation method of oxidized graphene/sodium lignin sulfonate modified polyurethane rigid foam material

A technology of sodium lignosulfonate and rigid foam, applied in the field of preparation of polyurethane rigid foam materials, can solve the problems of poor compatibility, poor dispersibility of graphene oxide and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

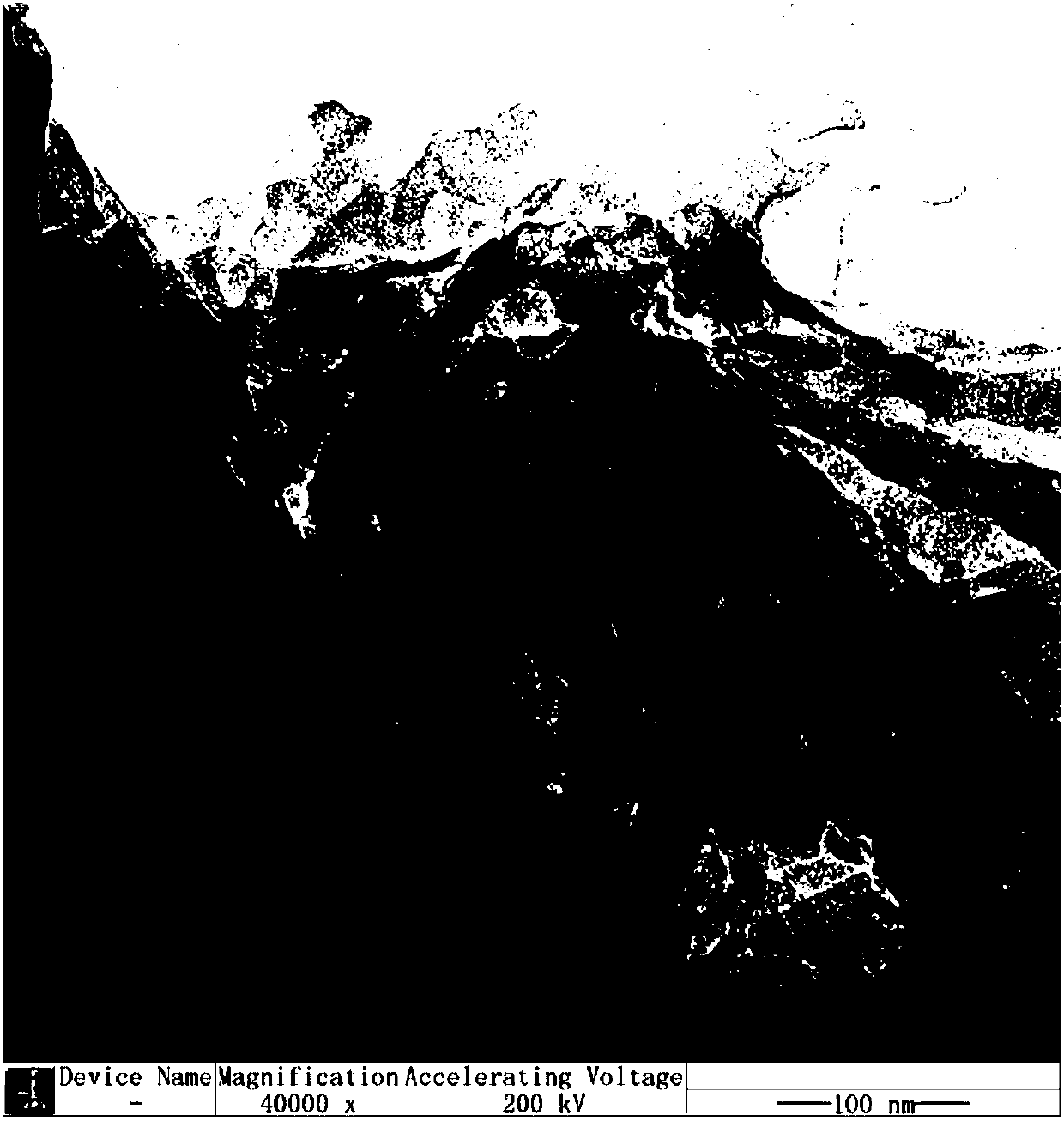

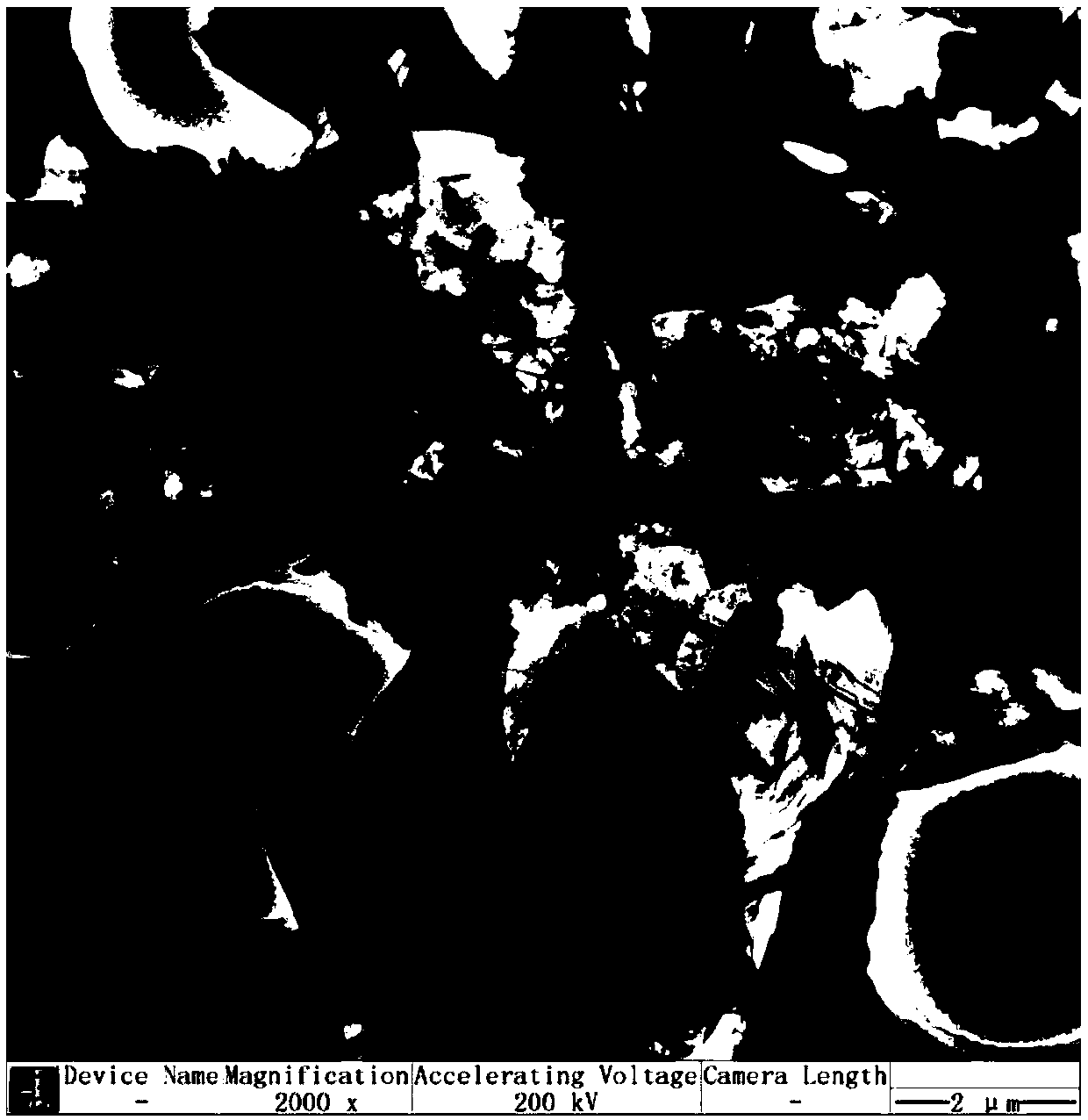

Image

Examples

specific Embodiment approach 1

[0065] Specific embodiment one: the preparation method of graphene oxide / sodium lignosulfonate modified polyurethane rigid foam material in this embodiment is carried out according to the following steps:

[0066] Step 1: Sodium lignosulfonate solvent liquefaction:

[0067] Mix polyethylene glycol, glycerol and concentrated sulfuric acid to obtain a mixed solution A, stir the mixed solution A, add sodium lignosulfonate powder to the mixed solution A while stirring, and then heat the mixed solution A to React at 80-120°C for 30-60 minutes, stop heating after the reaction, and cool to room temperature naturally to obtain lignin liquefaction products;

[0068] Described glycerol and Polyethylene Glycol mass ratio are (1~2):9;

[0069] The mass ratio of the concentrated sulfuric acid to polyethylene glycol is 1:(9~30);

[0070] The polyethylene glycol is polyethylene glycol 400;

[0071] The mass percent composition of sulfuric acid in the concentrated sulfuric acid is 98%;

...

specific Embodiment approach 2

[0091] Embodiment 2: This embodiment is different from Embodiment 1 in that: the foaming catalyst described in Step 3 is triethylenediamine. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0092] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the chain extension catalyst described in step three is dibutyltin dilaurate. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com