Molding method of liquid cooling polymer monofilament

A technology of liquid cooling and forming method, applied in the direction of filament/thread forming, single-component polyester rayon filament, single-component polyamide rayon filament, etc., can solve the defects of fiber strength, roundness and uniformity , affecting work performance and other issues, to achieve the effect of convenient operation, high roundness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

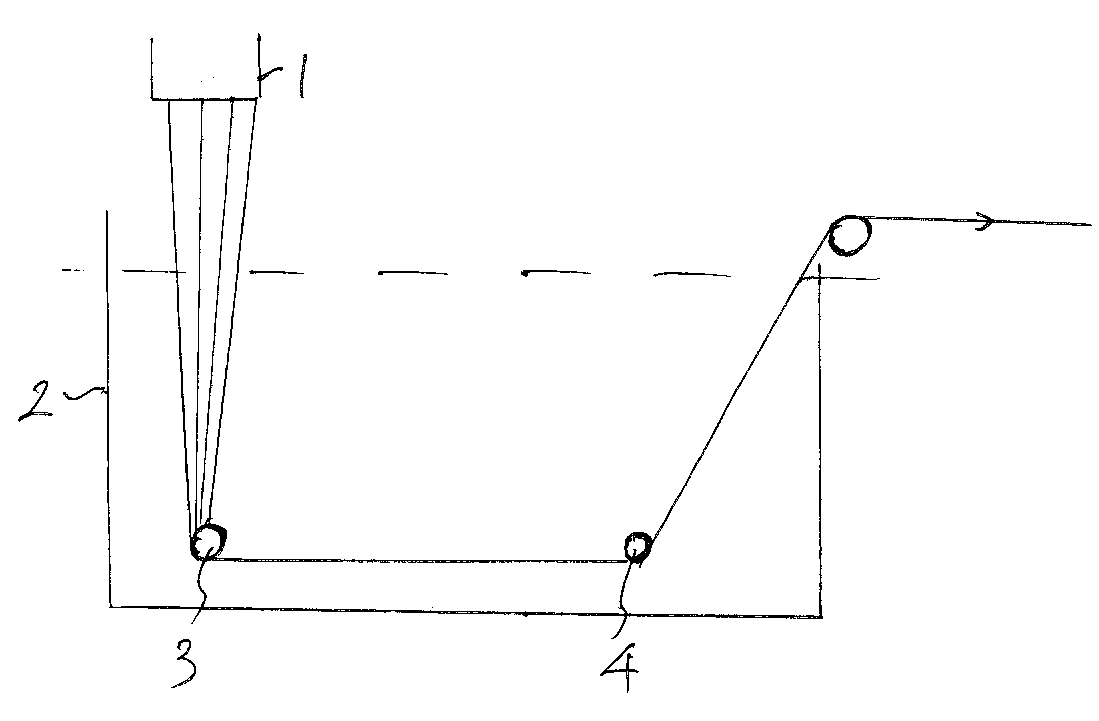

[0013] A liquid-cooled polymer monofilament forming method, the polymer melt sprayed from the spinneret assembly 1 is directly entered into the liquid tank 2 for liquid cooling and forming, and is passed through the front and rear winding rollers 3 in the liquid tank , 4 Convey the liquid tank and enter the subsequent process; the front and rear winding rollers are located on the same horizontal plane, the polymer is PET, the diameter of the monofilament is 0.8mm, the distance between the front and rear winding rollers is 100~150cm, the liquid The temperature of the liquid in the tank is 50~75°C, the distance between the spinneret end of the spinneret assembly and the liquid surface of the liquid tank is 3~7cm, the distance between the roller in the liquid tank and the liquid surface is 105~150cm; the liquid in the liquid tank It is circulating fluid, the flow rate of circulating fluid is 150~250kg / h, and the liquid in the liquid tank is triethylene glycol liquid. Tensile stre...

Embodiment 2

[0015] The polymer is PA6, the diameter of the single filament is 0.3mm, the distance between the front and rear winding rollers is 50~70cm, the temperature of the liquid in the liquid tank is 5~25°C, the spinneret end of the spinneret assembly and the liquid in the liquid tank The distance between the surface is 4~8cm, the distance between the roller in the liquid tank and the liquid surface is 35~50cm; the liquid in the liquid tank is circulating fluid, the flow rate of circulating fluid is 30~100kg / h, and the liquid in the liquid tank is three Glycol solution. All the other are with embodiment 1.

Embodiment 3

[0017] The polymer is a thermoplastic polyester elastomer, the diameter of the single filament is 0.5mm, the distance between the front and rear winding rollers is 160~200cm, the temperature of the liquid in the liquid tank is 35~65°C, the spinneret assembly spinneret end The distance from the liquid surface of the liquid tank is 2~9cm, and the distance between the roller in the liquid tank and the liquid surface is 25~70cm; the liquid in the liquid tank is circulating fluid, and the flow rate of circulating liquid is 80~120kg / h. The liquid used is water or paraffin liquid. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com