Patents

Literature

281results about How to "Won't inhale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

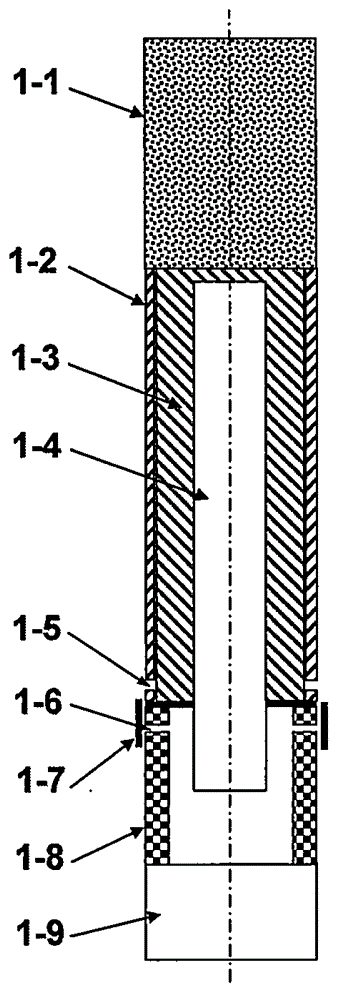

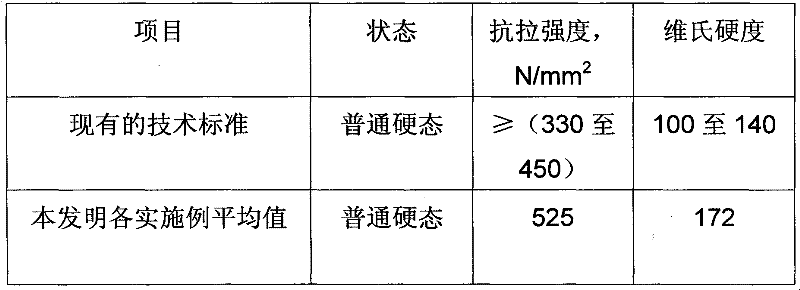

Heating type low-temperature cigarette and manufacturing method thereof

InactiveCN103549657AEfficient heatingReduce processing costsCigar manufactureCigarette manufactureProcess engineeringCombustion chamber

The invention relates to a heating type low-temperature cigarette and a manufacturing method thereof. A low-temperature heat source comprises a vacuum heat pipe and a combustion chamber, wherein the combustion chamber is used for generating heat, the heat pipe is used for heat conduction, the heat absorption segment of the heat pipe is placed in the combustion chamber, the heat emission segment of the heat pipe is wrapped or filled with shredded tobacco, a moveable sliding block is arranged between the air outlet hole of the combustion chamber and the air inlet hole of the shredded tobacco, and the moveable sliding block is used for controlling air for combustion in the combustion chamber and air for smoke suction alternately to desynchronize combustion and smoke suction so as to prevent combustion exhaust from entering a smoker; when the heat source device and the low-temperature shredded tobacco are separated in an assembled manner, the heating type low-temperature cigarette can completely replace the traditional cigarette because the smoker can still light and smoke the separated cigarette when necessary. The heating type low-temperature cigarette has the advantage that the heat source device is efficient and safe, low in cost and can meet the demands of various cigarette consumer groups after being combined with low-temperature cigarettes.

Owner:黄争鸣

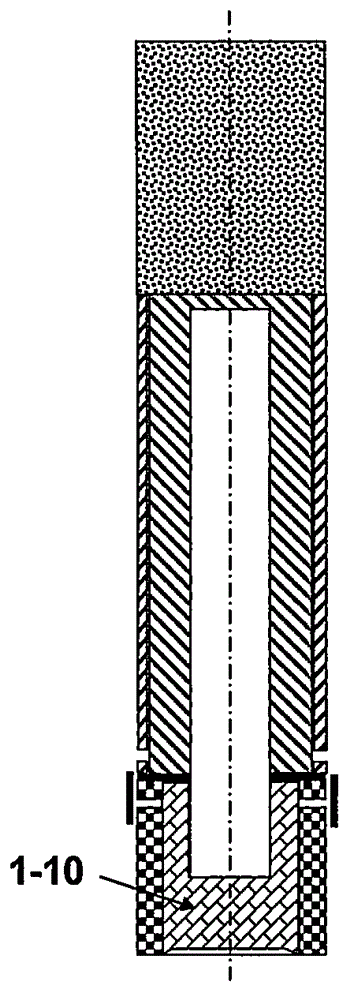

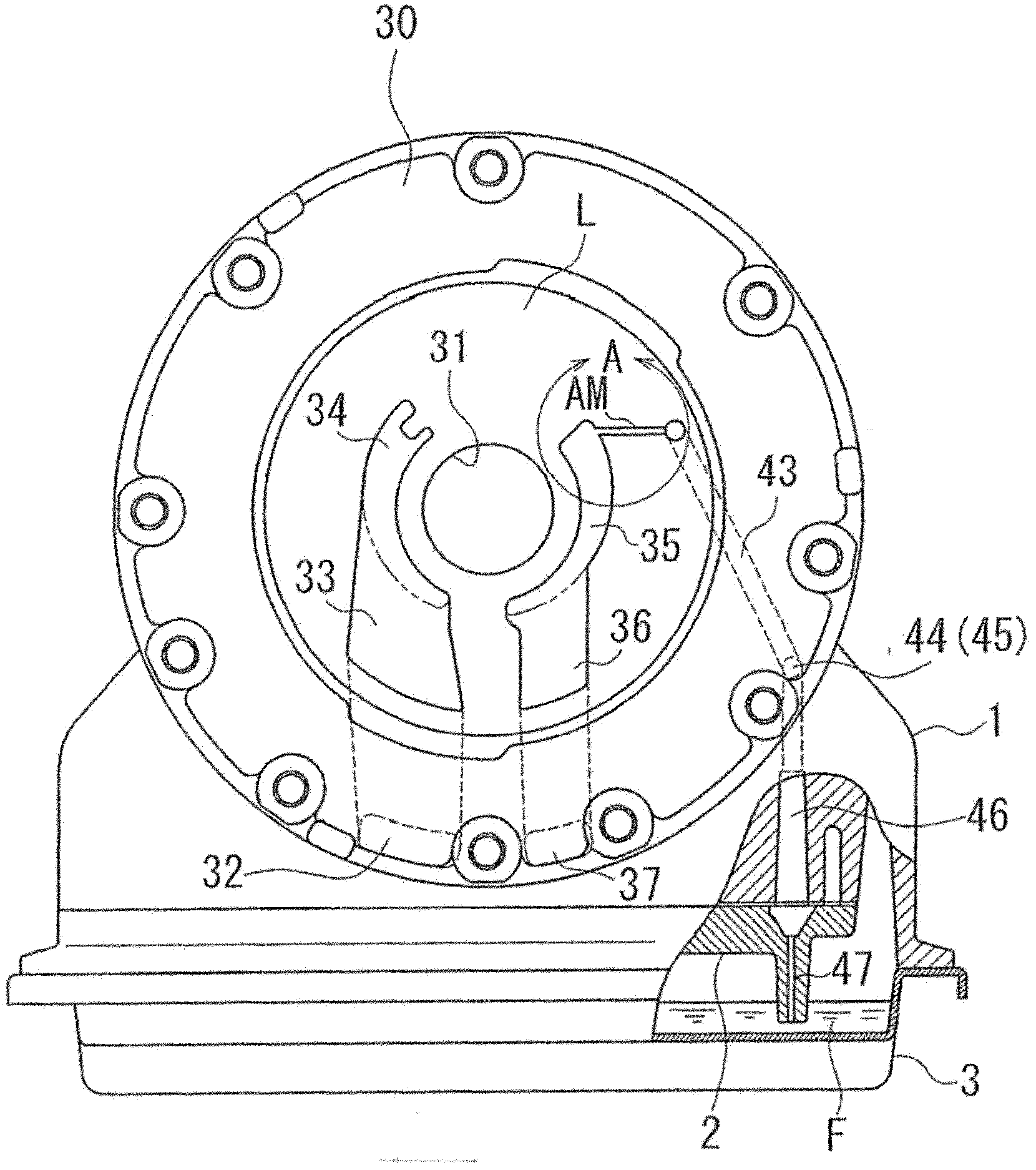

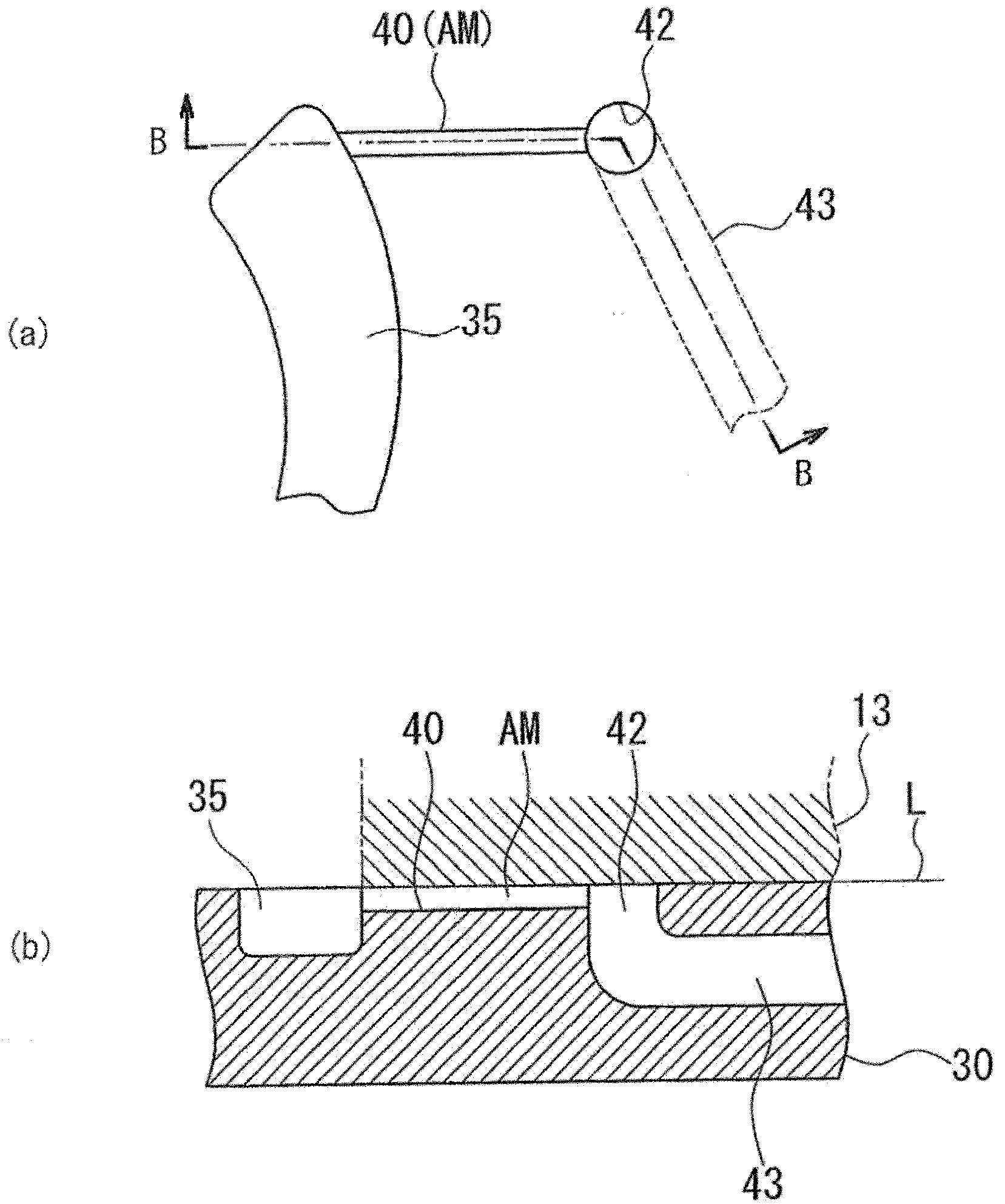

Air vent structure of oil pump of automatic transmission

ActiveCN102146917AWon't inhaleAvoid dischargeGear lubrication/coolingGearing controlAutomatic transmissionResponsivity

An air vent structure of an oil pump of automatic transmission. In a hybrid vehicle loaded with a primary pump and a secondary pump, the air is not sucked from an air vent of the primary pump when the secondary pump works. A suction oil path and a discharge oil path of the primary pump (10M) and the secondary pump (10S) are connected in parallel. In the discharge oil paths (17M, 17S), the accumulators 20M, 20S are disposed upstream of junction G to cut off the discharge oil path driving the pump on the stop side. An air vent (AM) is disposed on a discharge port 35 of the primary pump (10M) and is communicated with thw oil (F) of an oil pan (3) through a communication passage (50). Therefore, the state of the primary pump filled with the oil maintains a certain period because the main discharge passage 17M is cut off, even if the primary pump (10M) stops and the responsivity of recovering the operation is enhanced; and in addition, the air vent (AM) is communicated with the oil pan, there is impossible to suck the air in operation later.

Owner:JATCO LTD +1

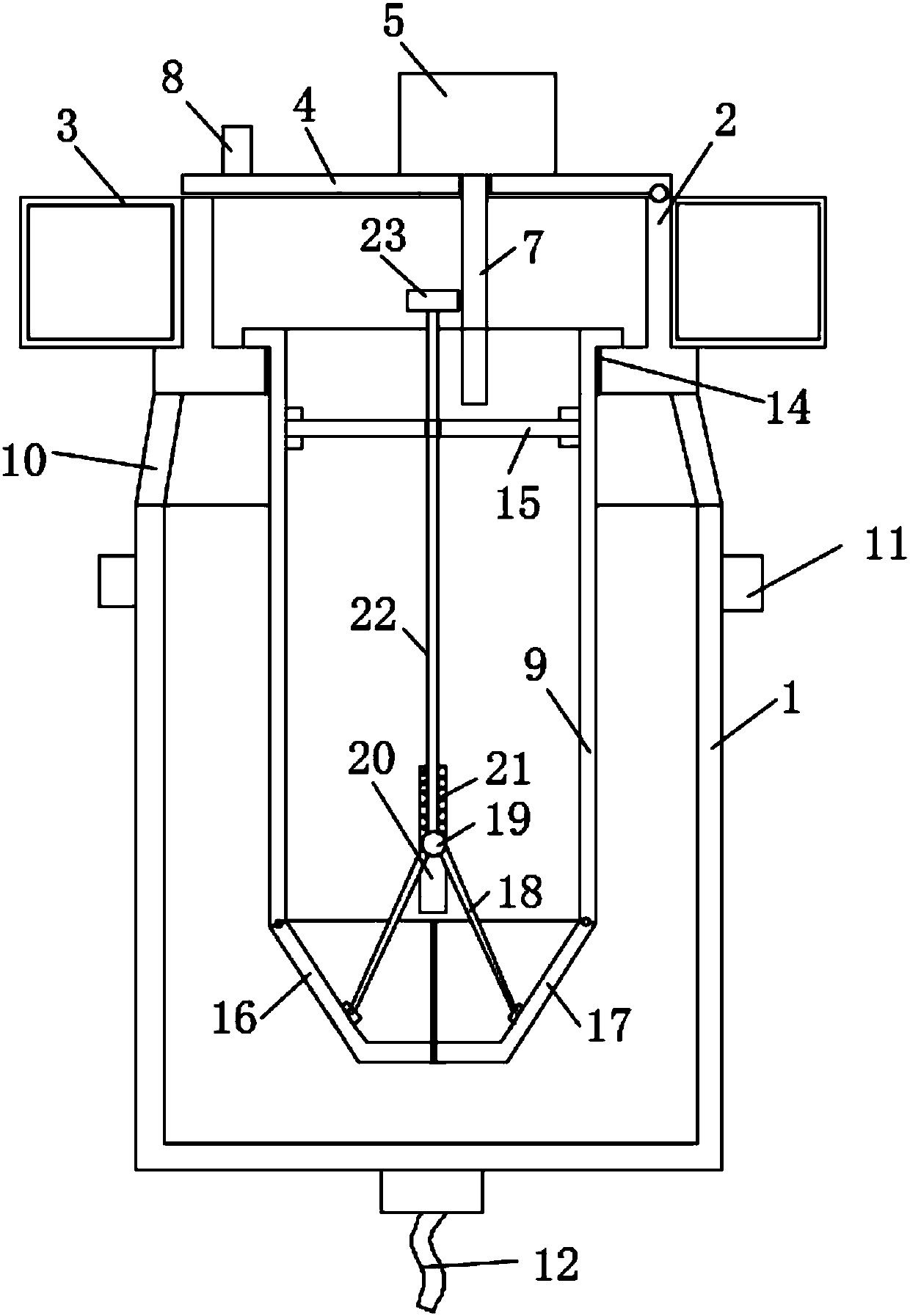

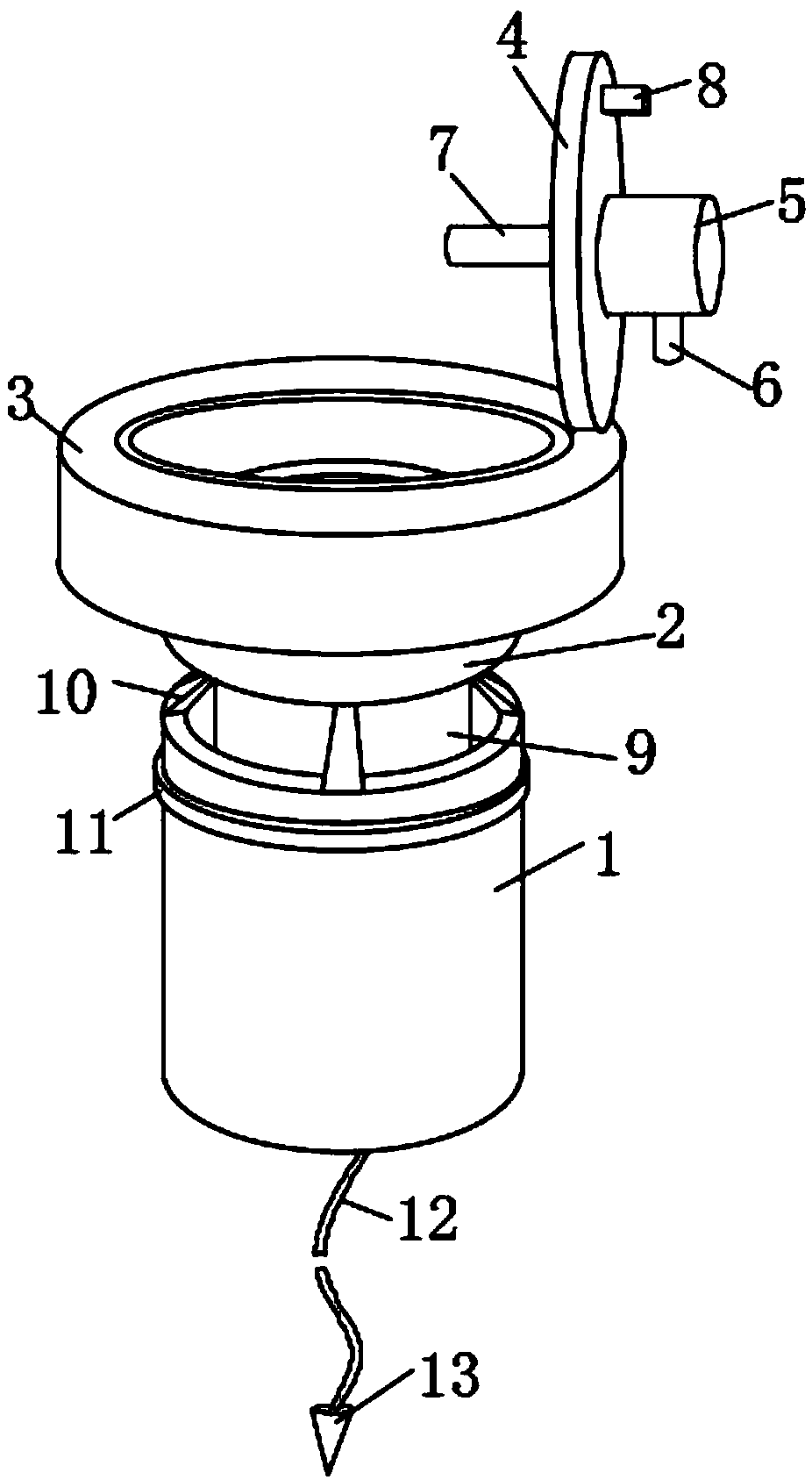

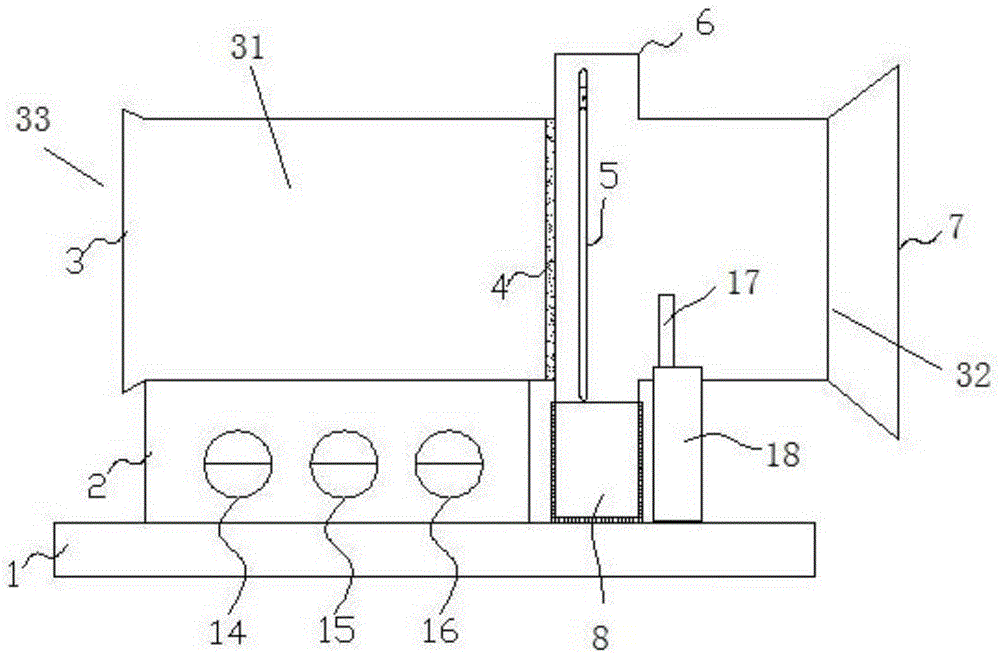

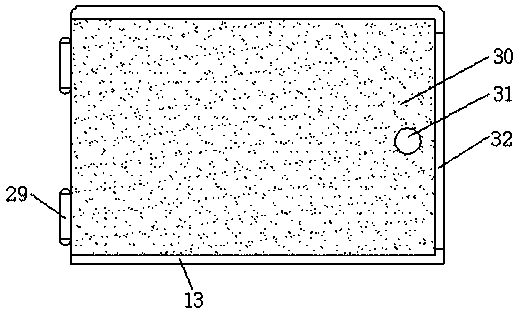

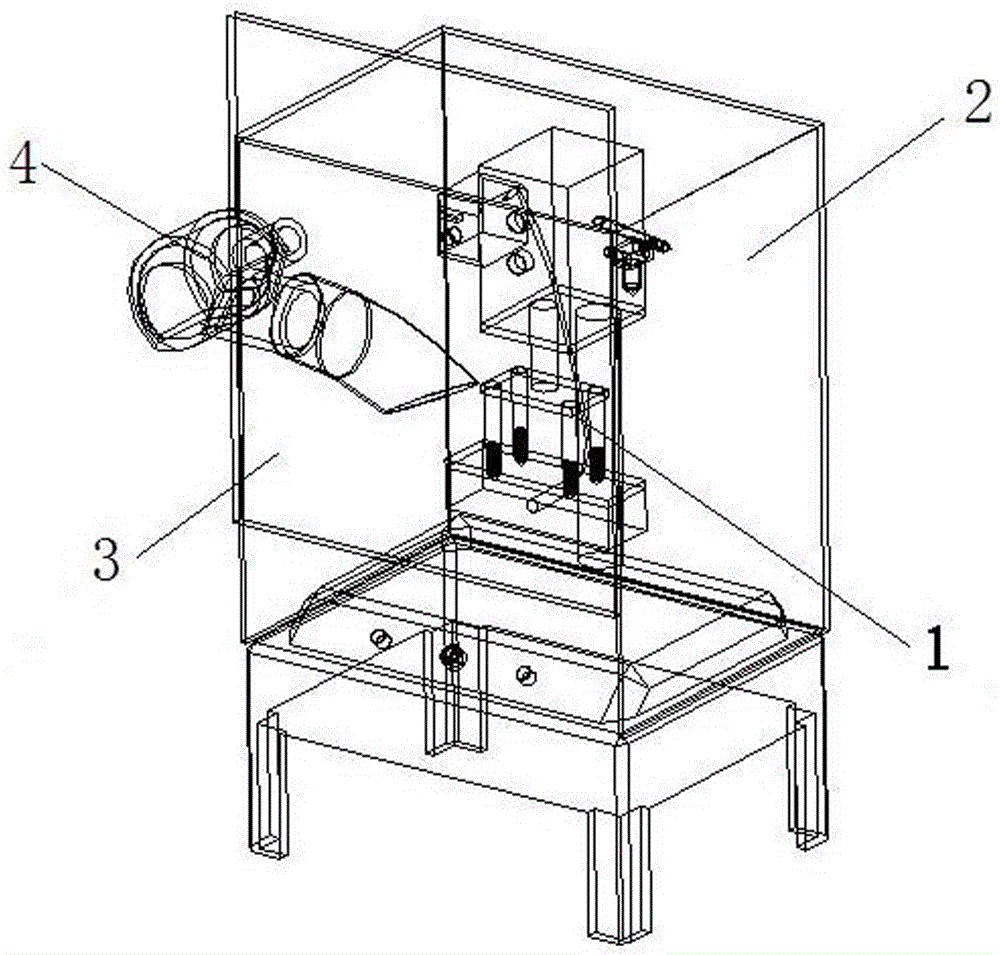

Water surface floating waste cleaning device for fish aquaculture

InactiveCN107628207AImprove cleanlinessEasy to operateWater cleaningAnimal repellantsWater flowPulp and paper industry

The invention provides a water surface floating waste cleaning device for fish aquaculture. The cleaning device comprises a device body, an outer cylinder is fixedly connected with an inner cylinder through a connecting plate, a movable cover plate is hinged to one side end of the upper end surface of the inner cylinder through hinges, a water pump is fixedly mounted on the upper end surface of the movable cover plate, an inserting opening is formed in the inner bottom surface of the inner cylinder, and a waste containing cylinder is arranged in the inserting opening. According to the device,the water pump is started, water in the waste containing cylinder is pumped out by a water absorption pipe, water pressure of the waste containing cylinder is reduced, water on the periphery of the cleaning device can enter the outer cylinder through a waste inlet, water in the waste containing cylinder can be continuously discharged through a discharge pipe of the water pump under the action of aseparating net, waste entering the waste containing cylinder along with water flow is stored in the waste containing cylinder through the separating net, water floating objects are cleaned, the wastecontaining cylinder can be conveniently lifted, and waste in the waste containing cylinder is treated.

Owner:陈志强

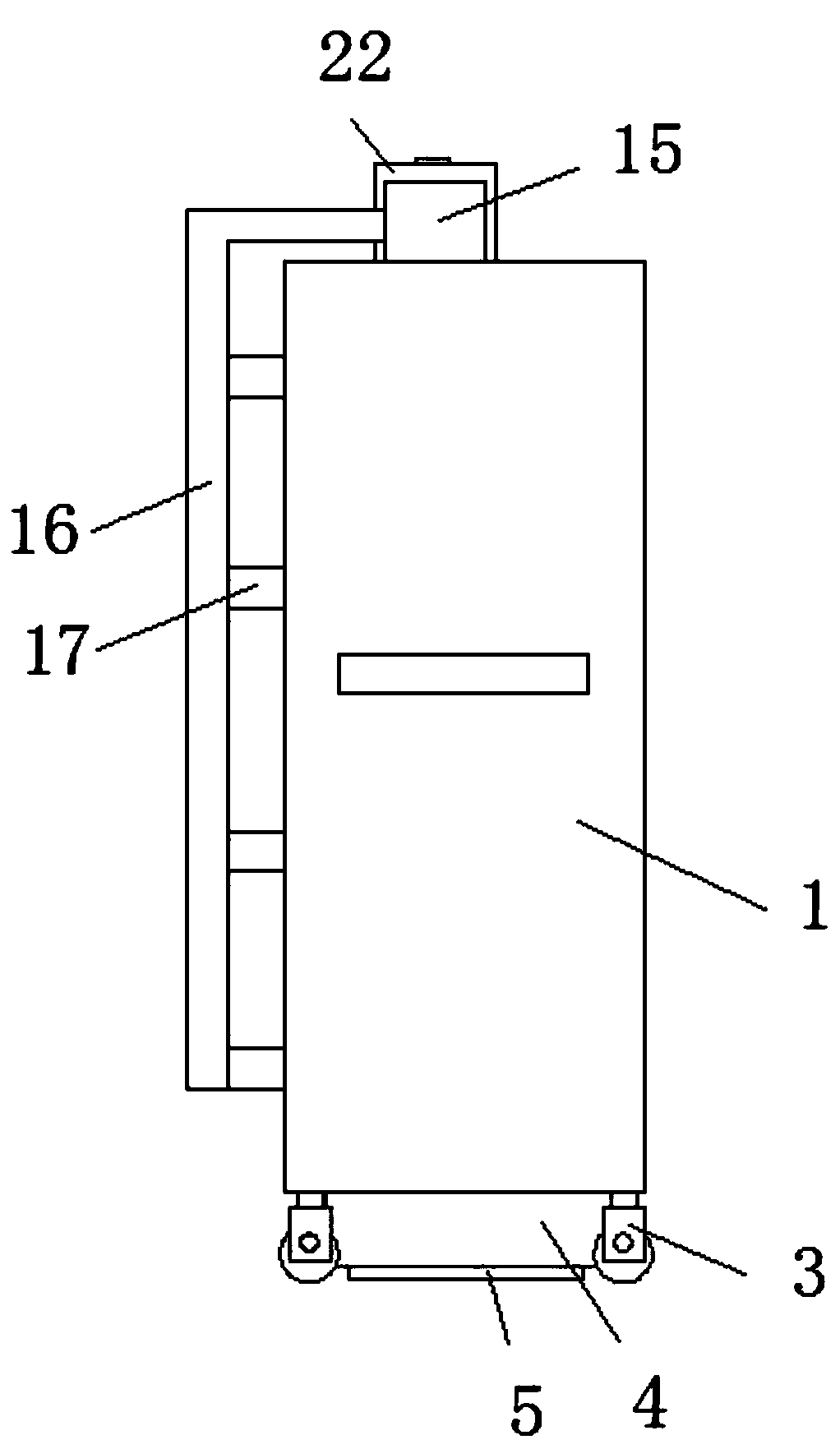

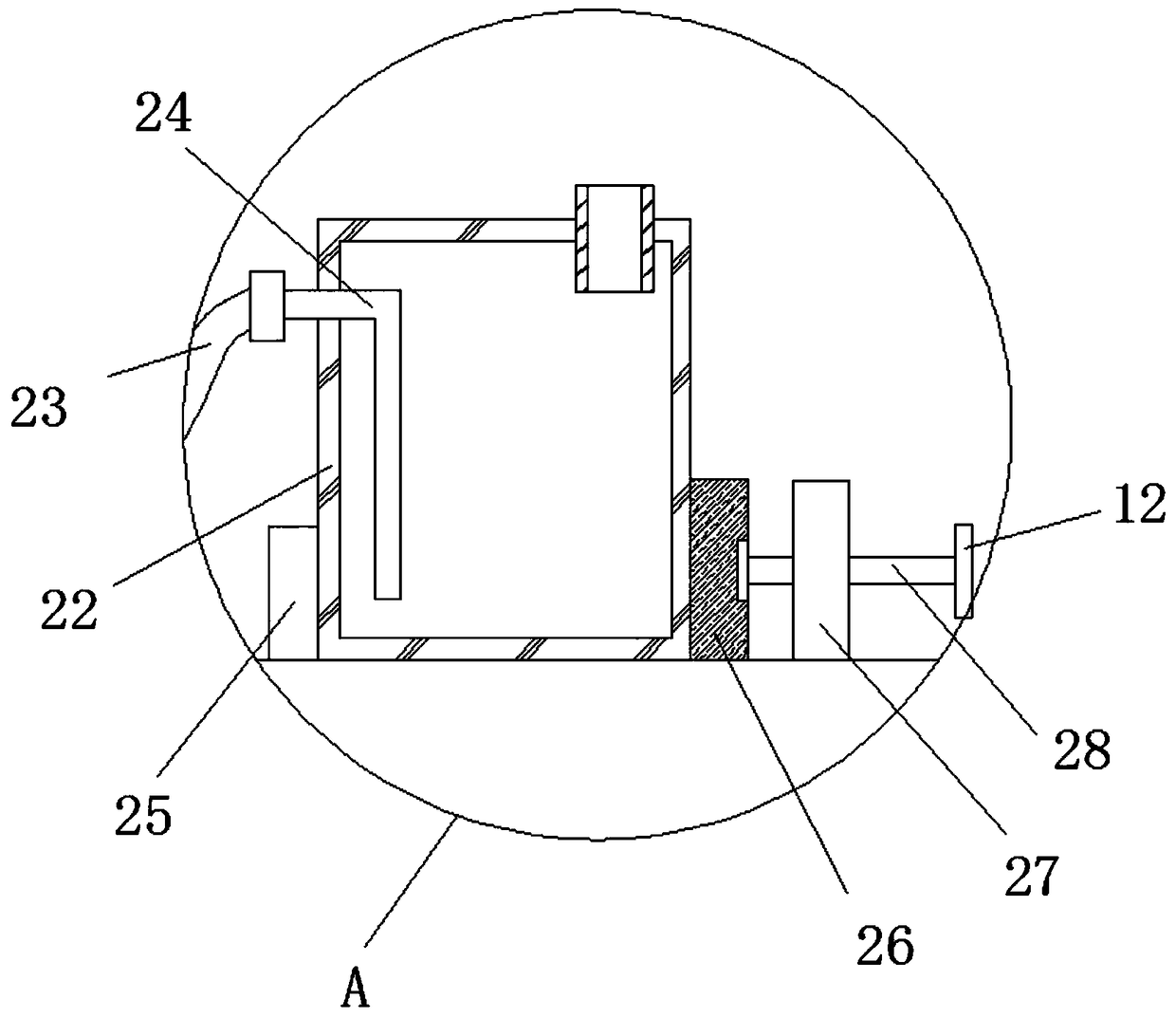

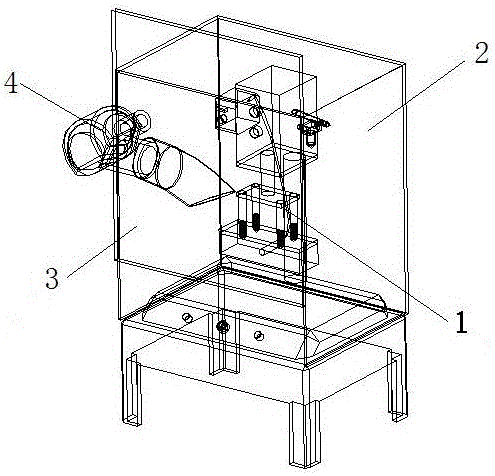

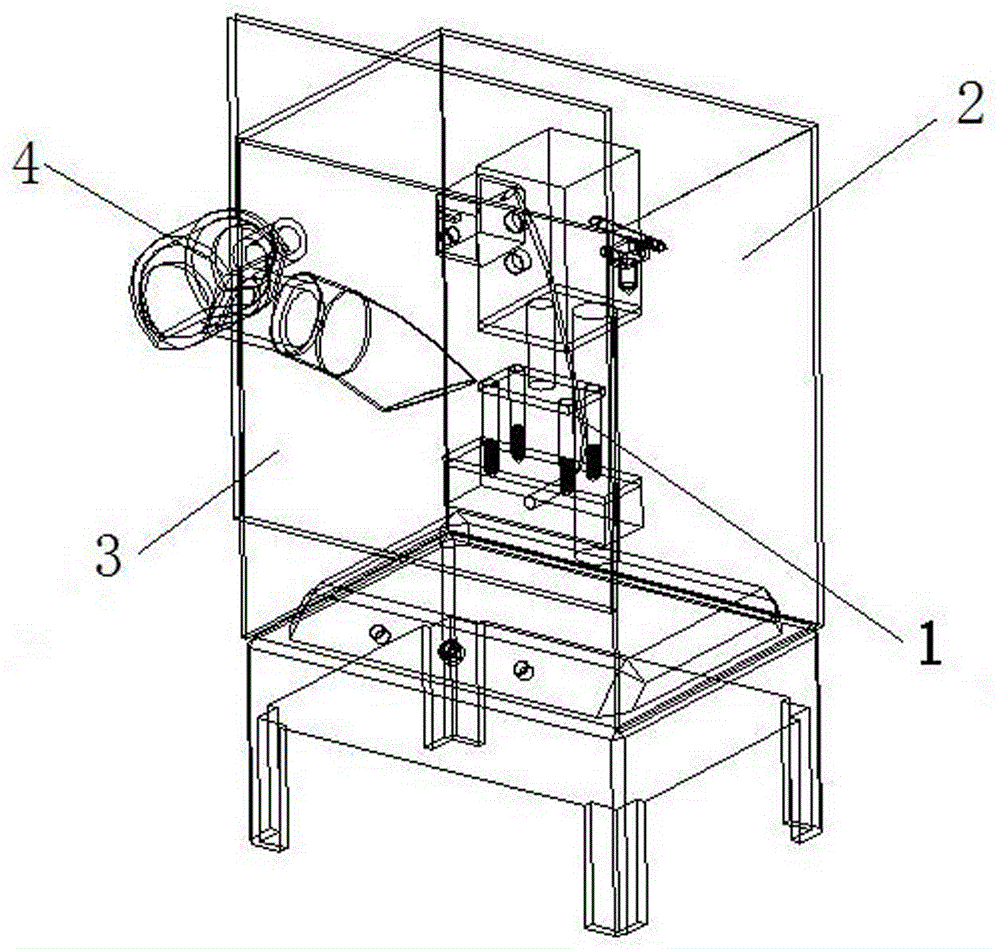

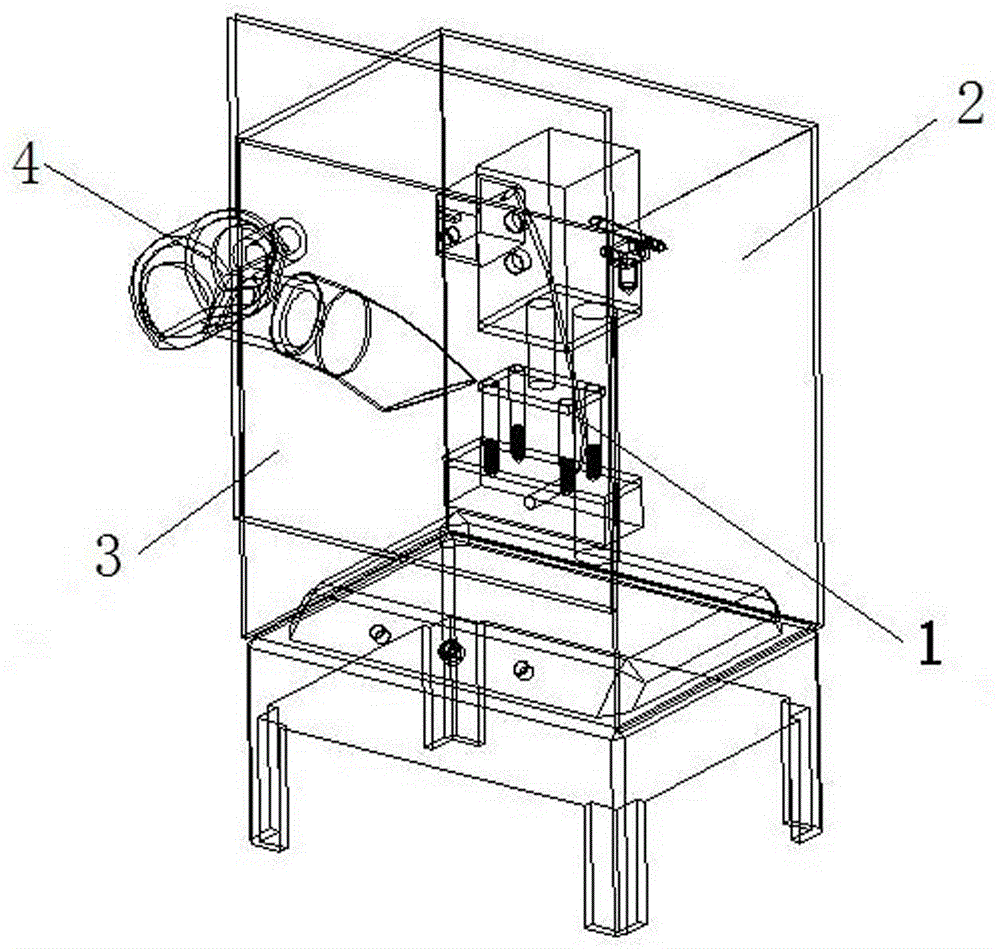

Novel hot melt welding machine

InactiveCN104786484AEasy to operateOperation will not affectDirt cleaningToxic gasWorking environment

The invention discloses a novel hot melt welding machine and relates to the technical field of automobile part manufacturing. The novel hot melt welding machine comprises a main engine and an isolation hood, wherein the isolation hood is arranged outside the main engine; a perspective window is formed in the front side of the isolation hood; and an exhaust fan is arranged on the rear of the isolation hood. According to the novel hot melt welding machine disclosed by the invention, toxic gases produced during hot melting of plastics can be timely eliminated under the condition that the operations of the staff are not influenced, and the operating environment of operators is greatly improved.

Owner:合肥凯蒙新材料有限公司

Dust removal device

InactiveCN105477951AEasy to remove dustReduce labor intensityDispersed particle filtrationTransportation and packagingEngineeringDust fall

Owner:周桂灵

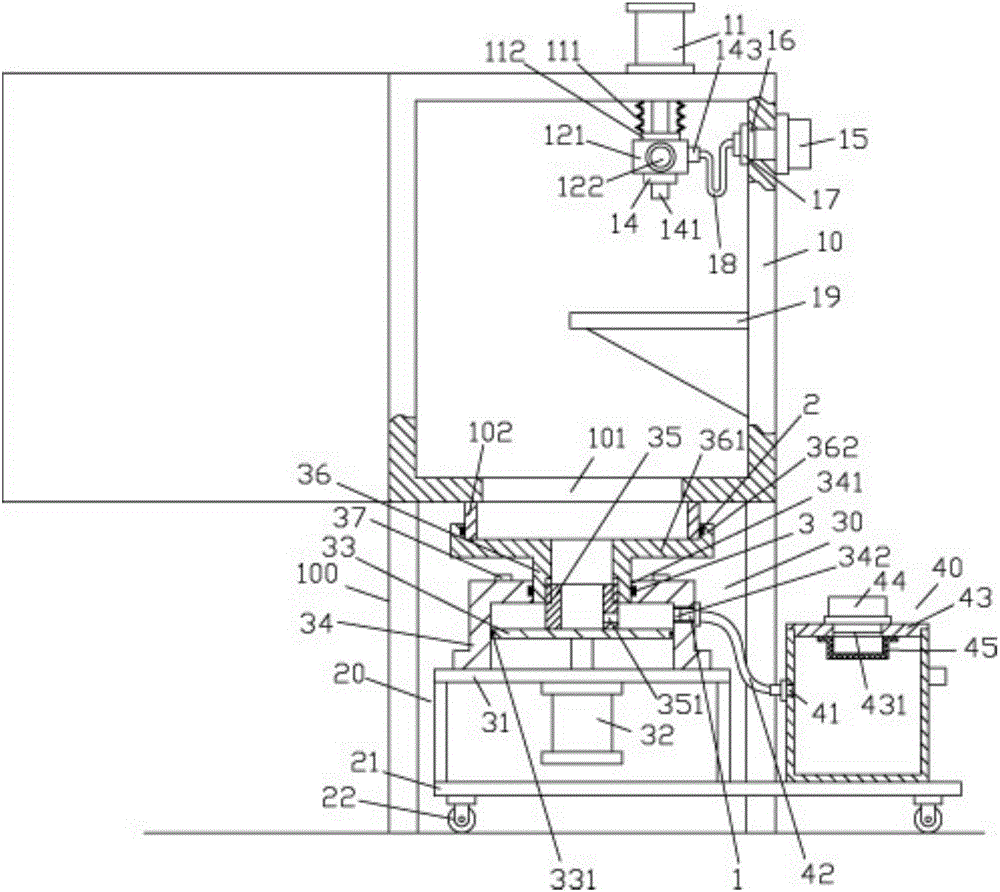

Laser drilling waste collecting mechanism

ActiveCN106392340AImprove cleanlinessReduce the impactLaser beam welding apparatusEngineeringLaser drilling

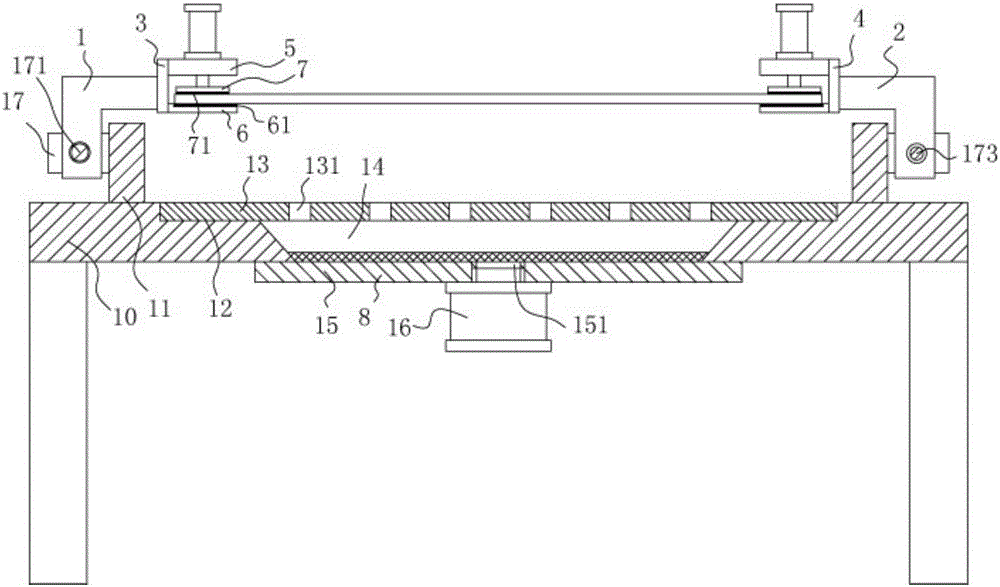

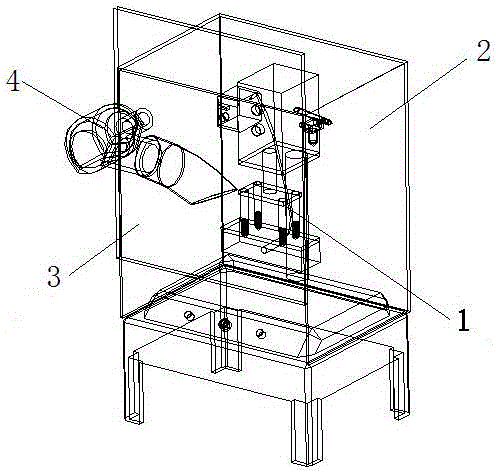

The invention discloses a laser drilling waste collecting mechanism which comprises a laser drilling rack; a processing box body is arranged on the upper part of the laser drilling rack; at least two telescopic air cylinders are fixedly arranged on the top plate of the processing box body; pushing rods of the telescopic air cylinders downwards pass through the top plate of the processing box body vertically, and are fixedly equipped with a rotary connecting frame; a rotary rod is positioned below the rotary connecting frame; the two ends of the rotary rod are hinged on the vertical plates hinged at the two sides of the rotary connecting frame; a rotary regulating motor is fixedly arranged on the outer side wall of one vertical plate; the output shaft of the rotary regulating motor is a spline shaft; the spline shaft is in plug bush in a spline hole in one end of the rotary rod; an air blowing box is fixedly arranged on the rotary rod; and a plurality of gas jetting tubes are connected on the bottom surface of the air blowing box. The laser drilling waste collecting mechanism disclosed by the invention can be used for automatically collecting waste without manual processing, so that cleanliness of a laser equipment operation environment is guaranteed, and operation of the laser drilling waste collecting mechanism is guaranteed to be normal; and moreover, people do not inhale waste, so that influence on health is reduced.

Owner:郑招才

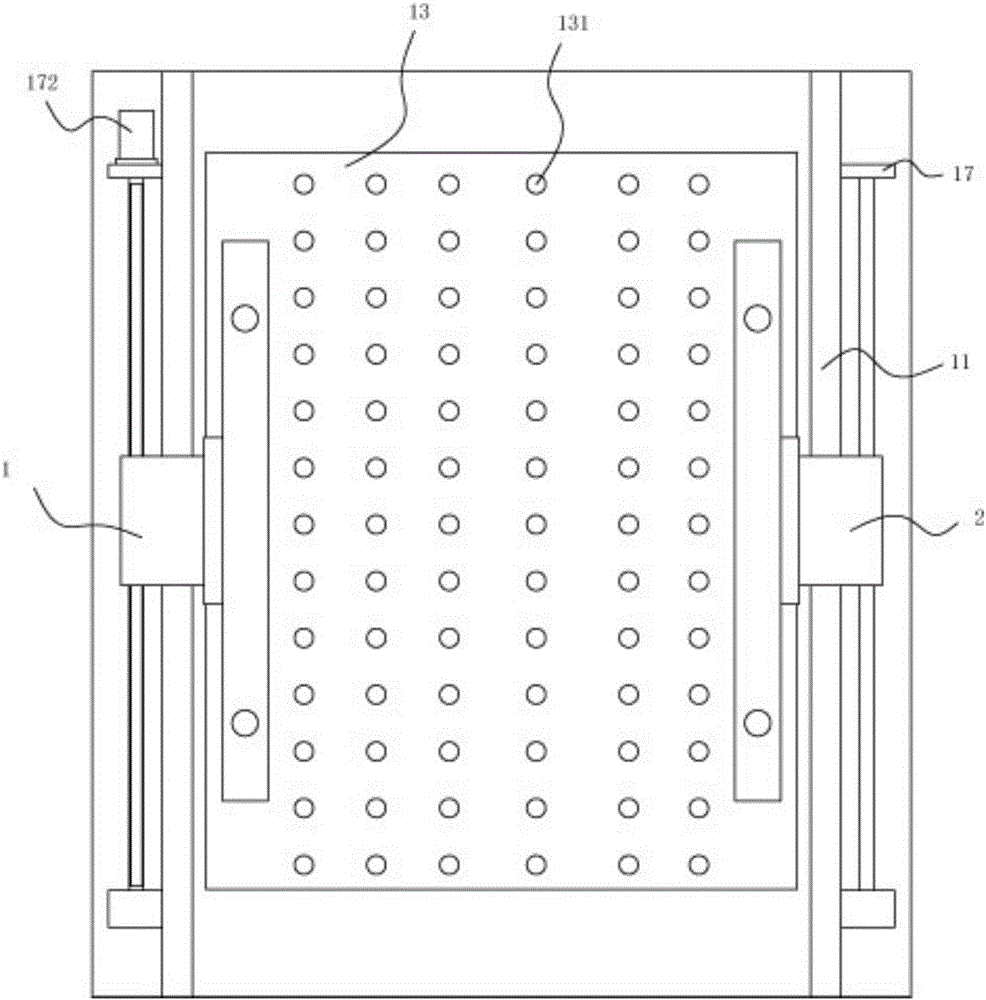

Plate material conveying mechanism for plate material environment-friendly dust collection equipment

InactiveCN106429423AWill not be damagedWon't inhaleConveyorsCleaning using gasesAgricultural engineering

Owner:盐城捷尔达环保设备有限公司

Vertical-adsorption type environment-friendly dust suction mechanism for boards

ActiveCN106392758AGuaranteed adsorption effectWon't inhaleMaintainance and safety accessoriesArchitectural engineeringTyping environment

Owner:XUANCHENG YANGLIUQING CHEM CO LTD

Novel hot melt welding machine

InactiveCN105563802AEasy to operateOperation will not affectDirt cleaningToxic gasWorking environment

The invention discloses a novel hot melt welding machine, and relates to the technical field of automobile component processing. The machine comprises a main engine and a shielding cover, the shielding cover is arranged outside the main engine, the front side of the shielding cover is provided with a perspective window, and the back side of the shielding cover is provided with a fan. The novel hot melt welding machine can timely eliminate toxic gases generated in hot melting of plastics without influencing the operation of employees, and greatly improves the working environment of the operating personnel.

Owner:合肥光裕机械有限责任公司

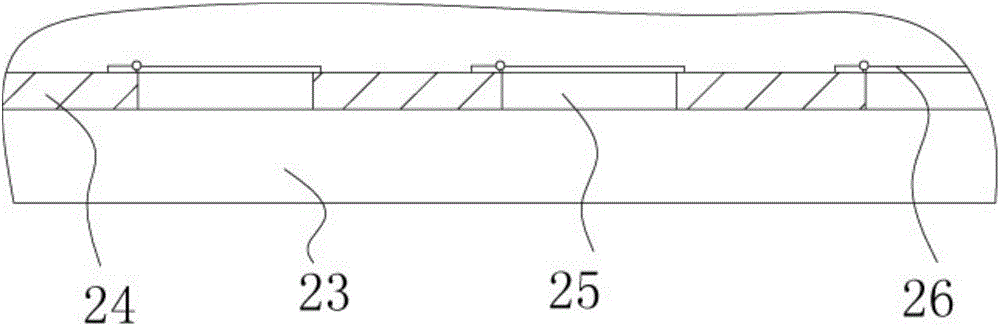

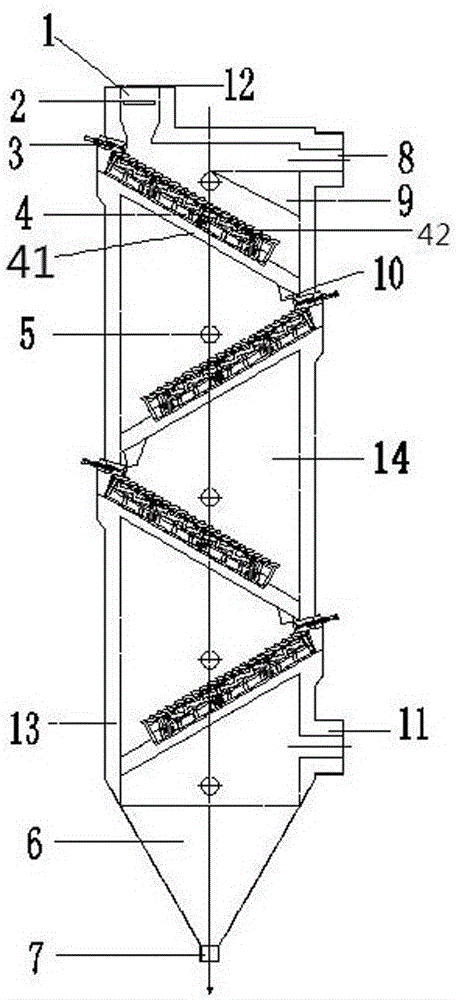

Closed-loop steel sintered red ore cooling device and process method thereof

ActiveCN106123609AIncrease productionGood qualityHandling discharged materialCooling methodsCold air

The invention discloses a closed-loop steel sintered red ore cooling device. The device comprises a device body, a heat exchange cavity arranged in the device body, a feeding inlet formed in the upper end of the device body, a uniform distributor arranged at the lower end of the feeding inlet, a discharging outlet formed in the lower end of the body, a uniform temperature device and at least one fire grate. The uniform temperature device is arranged on the device body and communicates with a cold air outlet. The at least one fire grate is movably installed in the heat exchange cavity. Each fire grate and the heat exchange cavity form an obliquely-downward angle, and the fire grates are parallel to each other. A pushing device is arranged at the front end of each fire grate. A hopper is arranged at the tail end of each fire grate. The device replaces a cooling section of an original sintering machine or a ring cooling machine. Compared with an original cooling mode, the device is high in yield, good in quality and low in energy consumption. Compared with the original cooling mode, the yield of a marching type sintering machine can be increased by 30%-40%, zone firing is increased by 5%-10%, and energy consumption only accounts for about 50% of the original cooling mode.

Owner:BEIJING RUIDA HONGXIN TECH CO LTD

Air filter

InactiveCN105617784AWill not affect healthDust removal is simpleDispersed particle filtrationTransportation and packagingPhysical healthAir filter

The invention provides an air filter. The air filter comprises a base, a fan bracket, a fan, a dust removing structure, a dust brushing structure, a rotary closing cover, a motor, a water drenching pipe and a water pump, wherein the fan comprises an air draught tube and fan blades, and the air draught tube has an air inlet and an air outlet; the dust removing structure is arranged at the middle part of the air draught tube and comprises a filter screen and a dust collecting chamber, and the dust collecting chamber is lower than the air draught tube in position; the dust brushing structure is used for brushing away dust attached to one side, facing to the air inlet, of the filter screen and enabling the dust to fall into the dust collecting chamber; the water drenching pipe is mounted above the dust brushing structure and is used for flushing the dust brushed away from the filter screen inside the dust collecting chamber; the water pump is used for supplying water to the water drenching pipe. According to the air filter provided by the invention, the dust removing structure is arranged at the middle part of the air draught tube, and the dust brushing structure is arranged, so that when the filter screen needs dust removal, the dust brushing structure is started up to clean the filter screen, and the dust removal can be carried out without detaching the filter screen, is easy and is low in labor intensity; the dust cannot fly around, cannot be inhaled by workers and cannot affect the physical health of the workers.

Owner:周桂灵

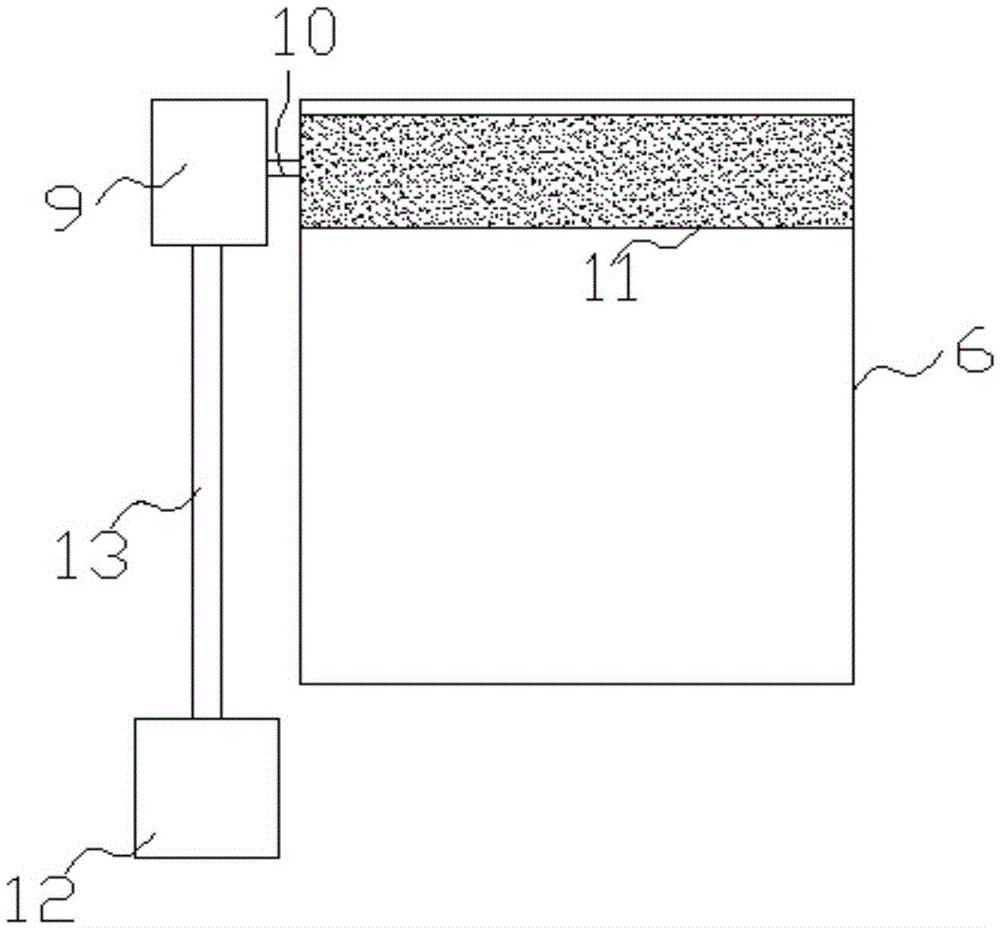

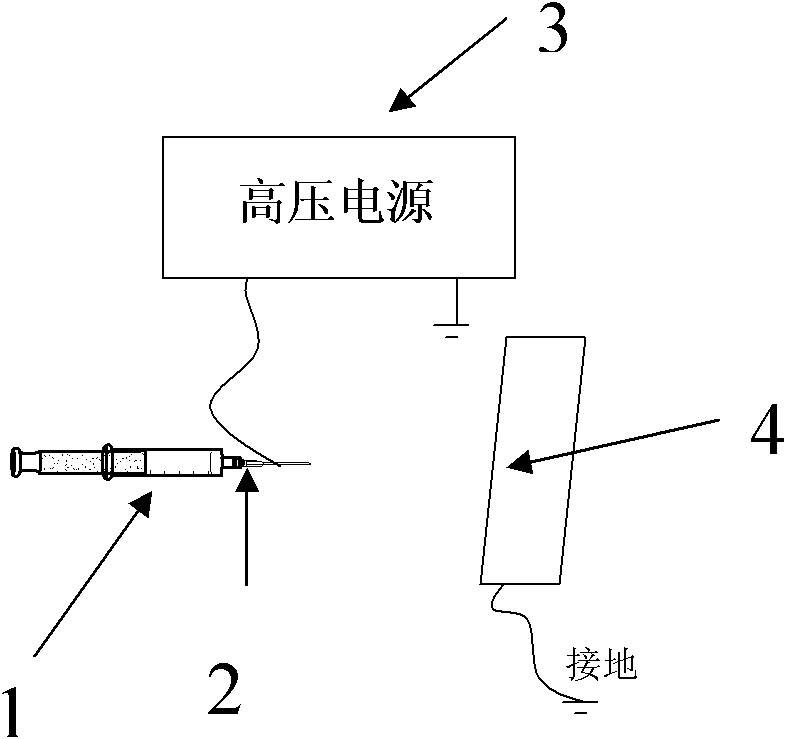

Nano porous fiber filter tip additive material for reducing amount of released formonitrile in cigarette smoke, preparation method and application

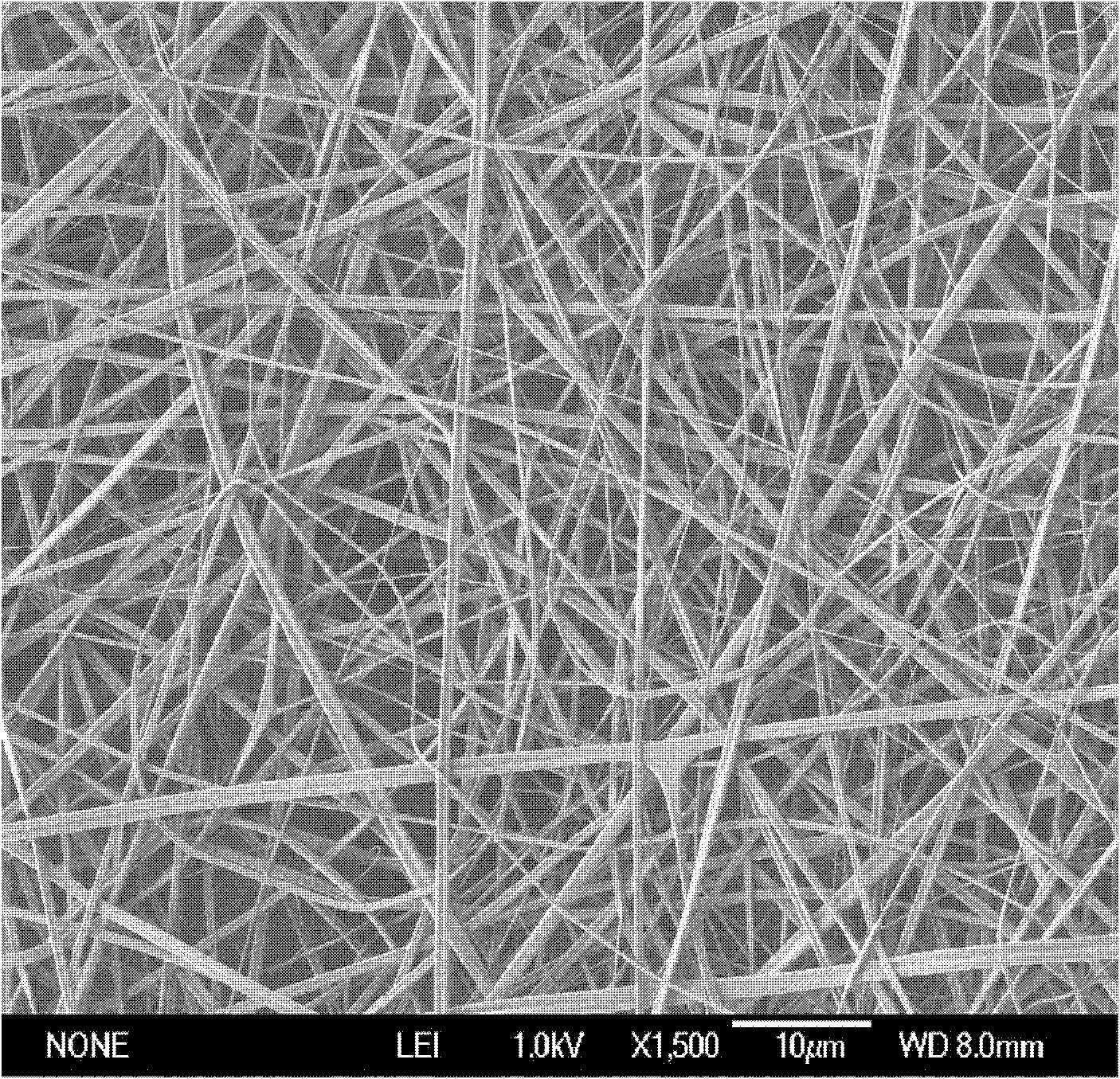

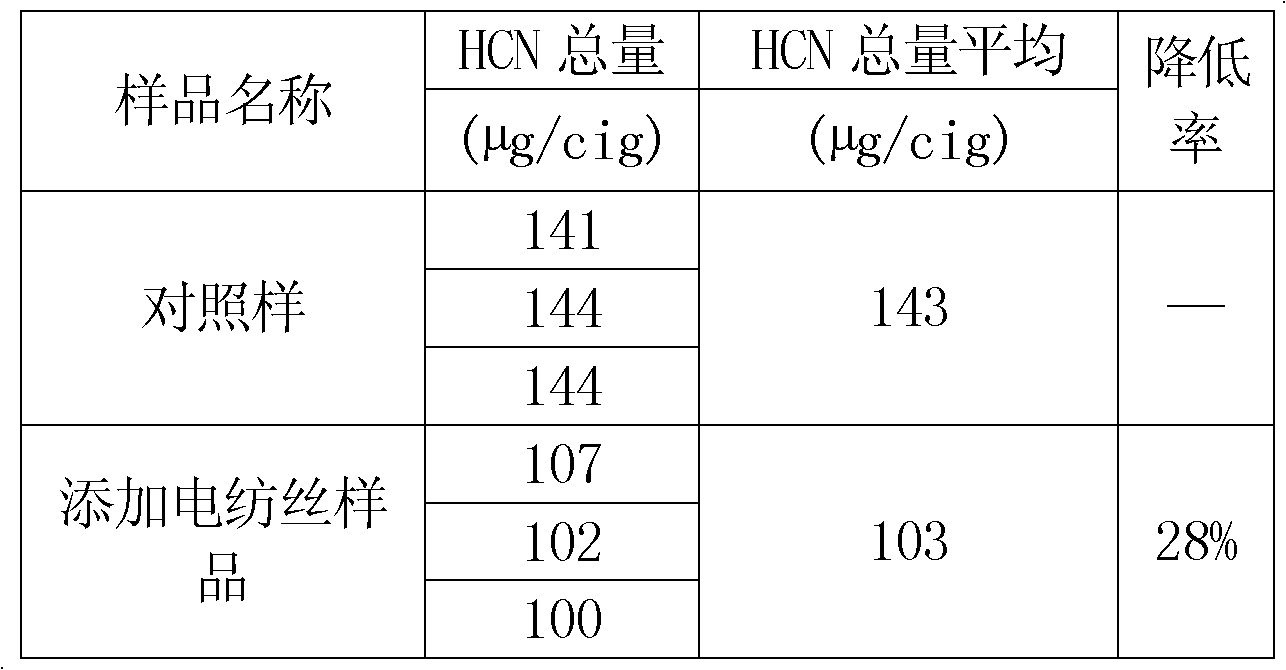

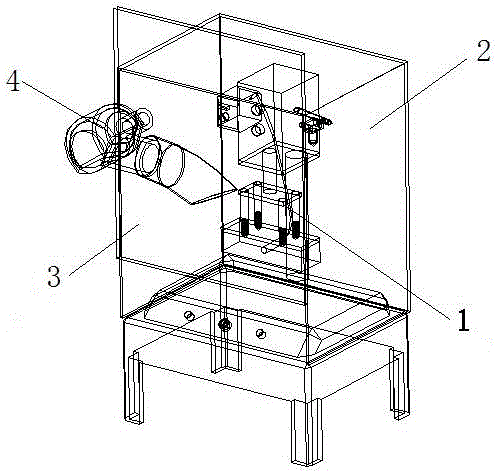

ActiveCN102423138ARich in basic sitesEfficient removalInorganic material artificial filamentsTobacco smoke filtersFiberNanofiber

The invention relates to a nano porous fiber filter tip additive material for selectively reducing the amount of released formonitrile in cigarette smoke, a preparation method and application, and the material, the method and the application belong to the field of cigarette harm and tar reduction. The invention is characterized in that the nano fiber material is a porous TiO2 nano fiber with a large special surface and a high length-to-diameter ratio obtained by the electrospinning technology. The nano fiber material can adsorb the formonitrile under the normal temperature, and when being added into a cigarette filter stick, the material can reduce the content of the formonitrile in the mainstream smoke of a cigarette by more than 40 percent, and does not affect the smoking quality of the cigarette. The preparation technique is simple, and the material can be used for selectively reducing the harm of cigarettes.

Owner:HONGTA TOBACCO GRP

Novel hot melt welding machine

InactiveCN105563801AEasy to operateOperation will not affectDirt cleaningAgricultural engineeringWorking environment

The invention provides a novel hot melt welding machine, and relates to the technical field of vehicle part processing. The novel hot melt welding machine comprises a host machine and a separation shield, wherein the separation shield is arranged outside the host machine, the front surface of the separation shield is provided with a perspective window, and the back surface of the separation shield is provided with an exhaust fan. According to the present invention, with the novel hot melt welding machine, in the case of no influence on the operation of the staff, the toxic gas generated during the hot melting of the plastic can be timely discharged so as to substantially improve the working environment of the operator.

Owner:HEFEI KAIRUIDE NEW ENVIRONMENTAL PROTECTION BUILDING MATEIRAL CO LTD

Welding apparatus

InactiveCN105562416AEasy to operateOperation will not affectDirt cleaningWorking environmentEngineering

A welding apparatus relates to the technical field of automobile part and component processing and comprises a main engine and a separation cover. The separation cover is arranged outside the main engine; the front surface of the separation cover is provided with a transparent window; and an air-drafting fan is mounted behind the separation cover. Without effects on worker operation, poisonous gas produced during plastic hot melting can be timely discharged, so work environment of operators can be greatly improved.

Owner:FEIXI FAERDA METAL PROD CO LTD

Desulfurization-denitration purification tower for flue gas

InactiveCN110252110AWon't inhaleImprove securityGas treatmentDispersed particle filtrationFlue gasEngineering

The invention provides a desulfurization-denitration purification tower for flue gas. The desulfurization-denitration purification tower for flue gas comprises a purification tower. The outer side surface of the bottom of the purification tower is connected with a discharge pipe; the part, close to a central position, of the outer side surface of the purification tower communicates with two L-shaped tubes arranged in parallel; the other end of one of the L-shaped tubes is connected with a liquid feeding funnel; two parallel filter screens are arranged inside the purification tower at a position near the center of the tower; the two filter screens are rotatably connected to the inner side surface of the purification tower through a rotating shaft; one end of the rotating shaft penetrates the side surface of the purification tower and is connected with belt pulleys; the two belt pulleys are in transmission connection via a belt; the outer side walls of one of the filter screens is equipped with a rotary snapping mechanism; and the rotary snapping mechanism includes a U-shaped snapping bar, a spring and a rotating tube. The desulfurization-denitration purification tower for flue gas provided by the invention has improved safety, does not need manual disassembling of the filter screens for regular cleaning, realizes the rotation operation of the filter screens via rotary snapping mechanism, and is simple and convenient to operate.

Owner:耿静

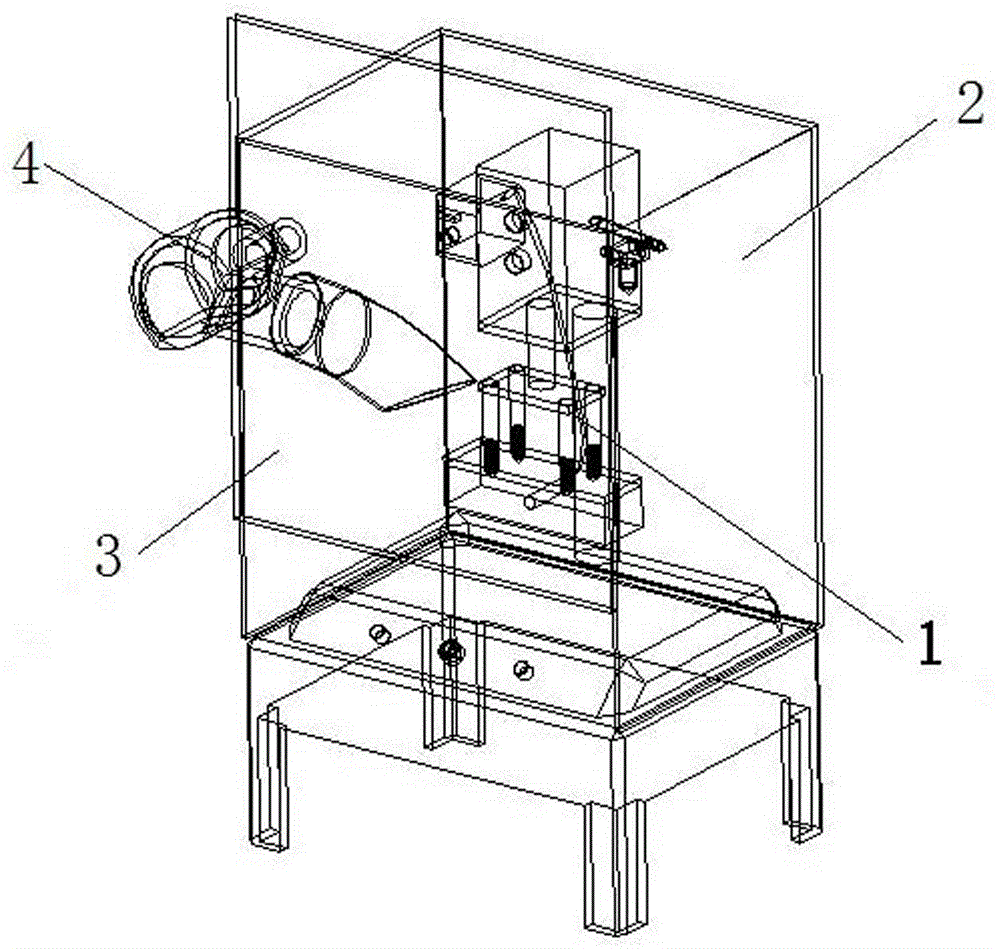

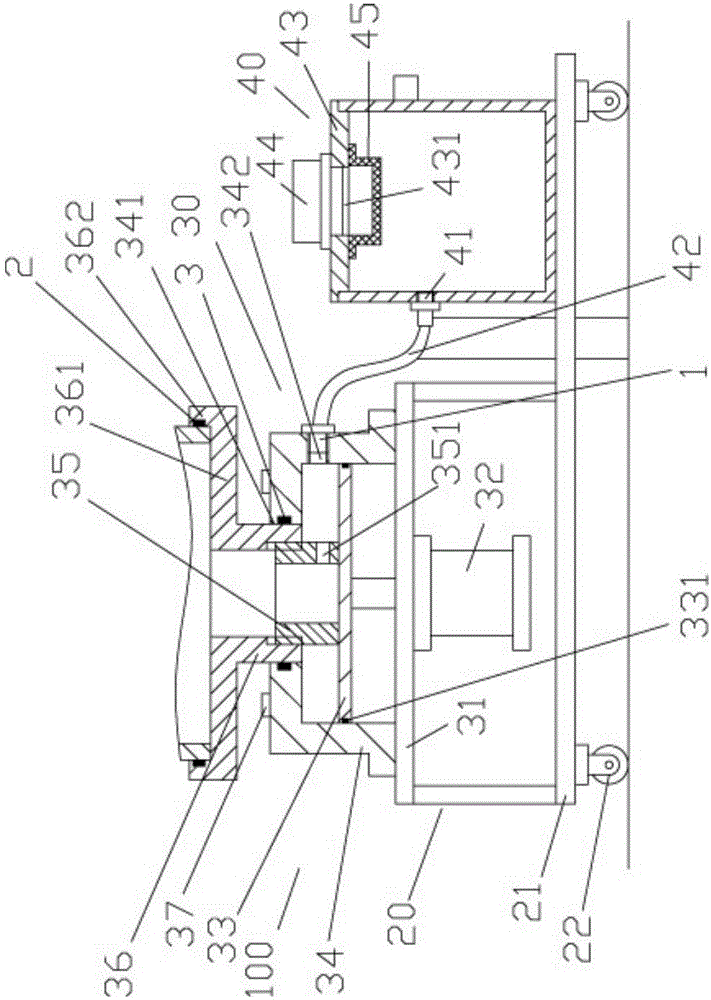

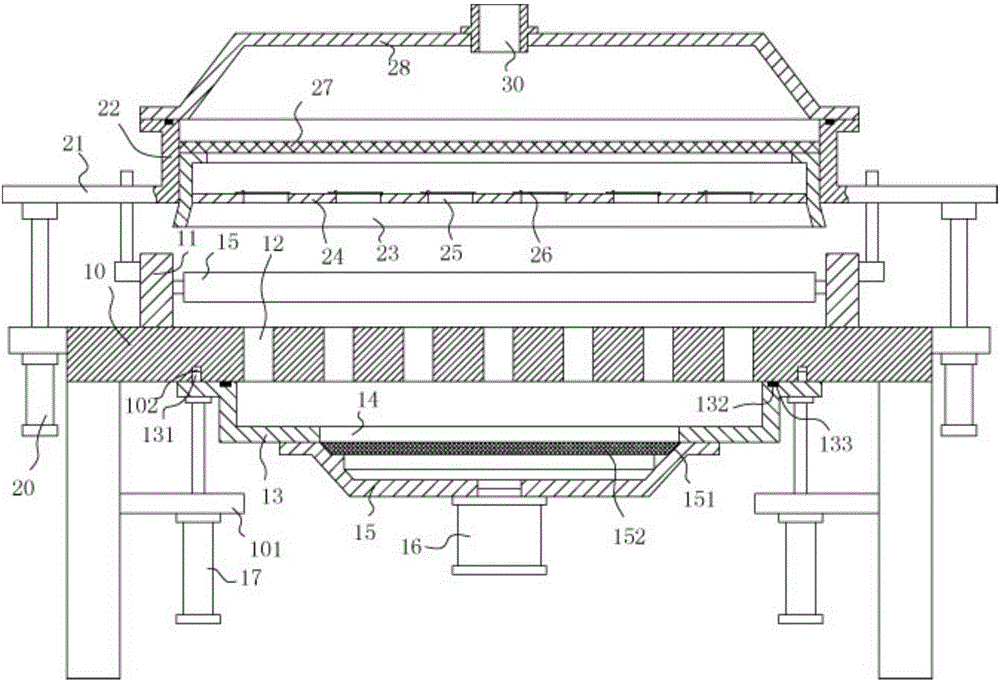

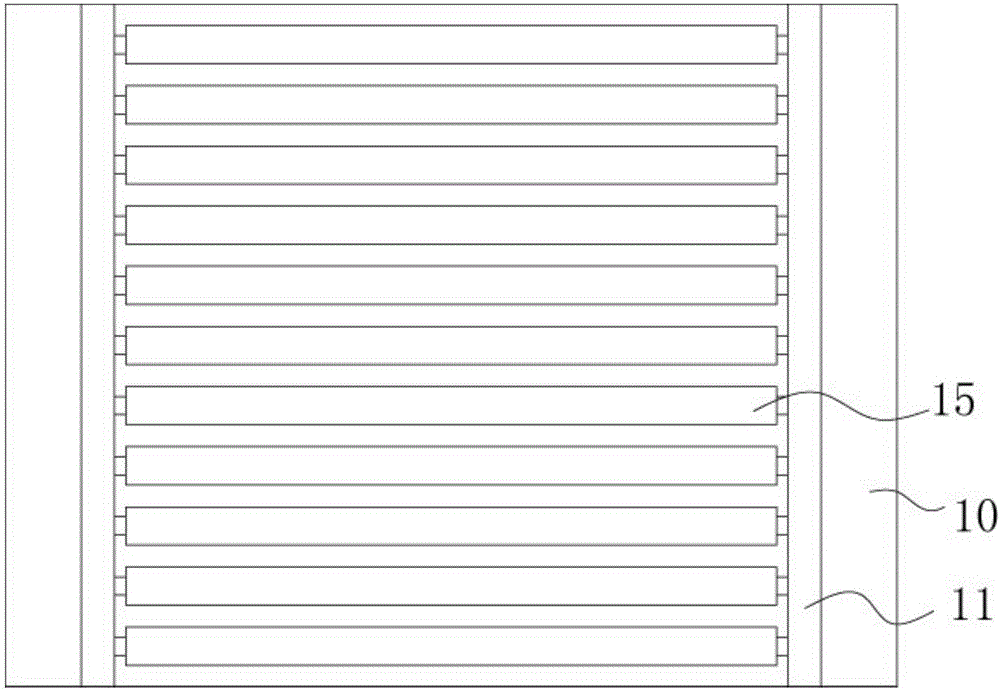

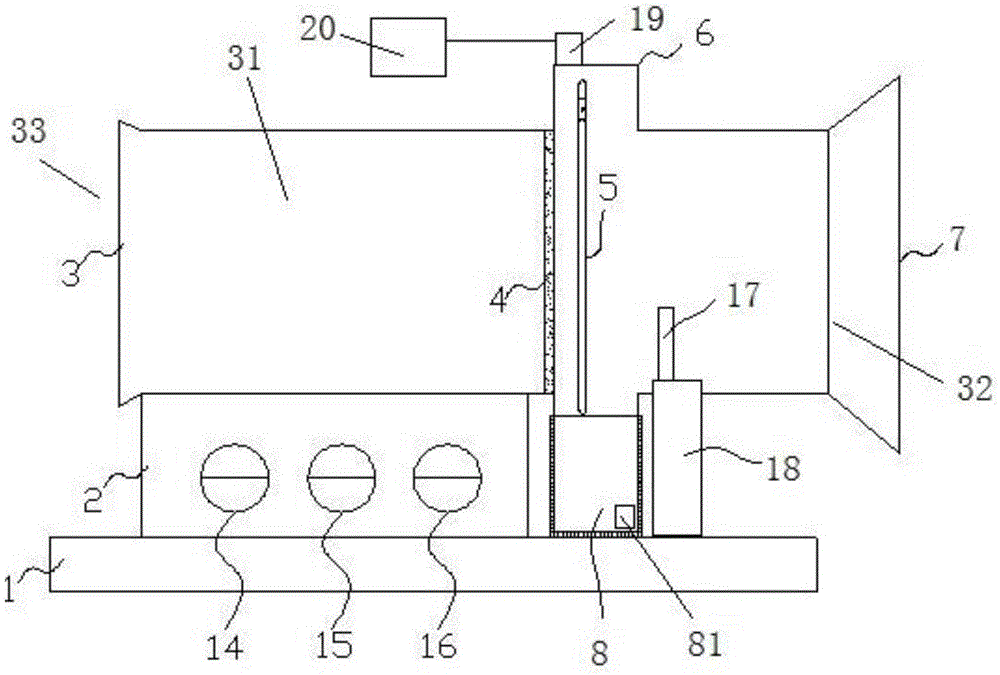

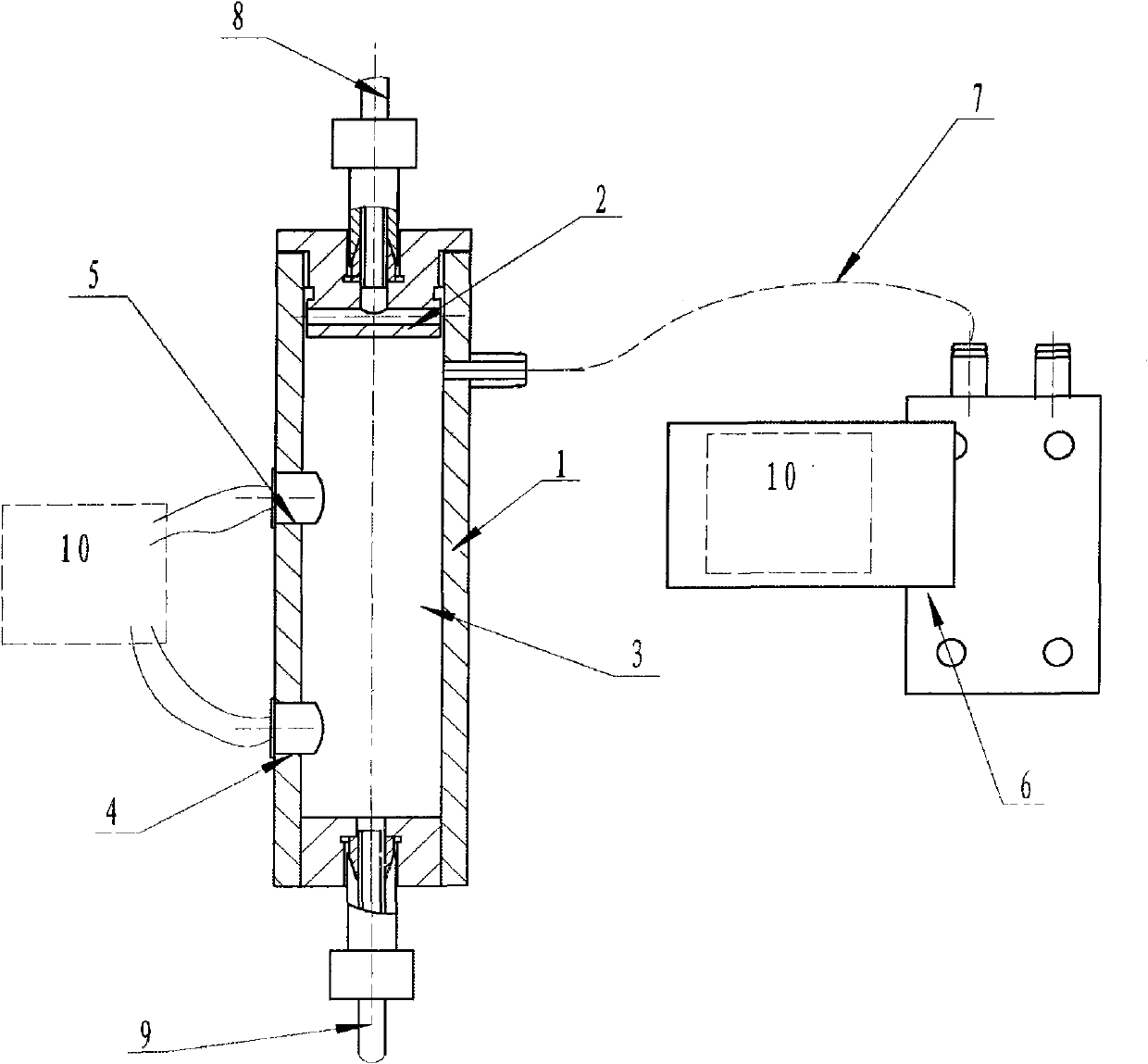

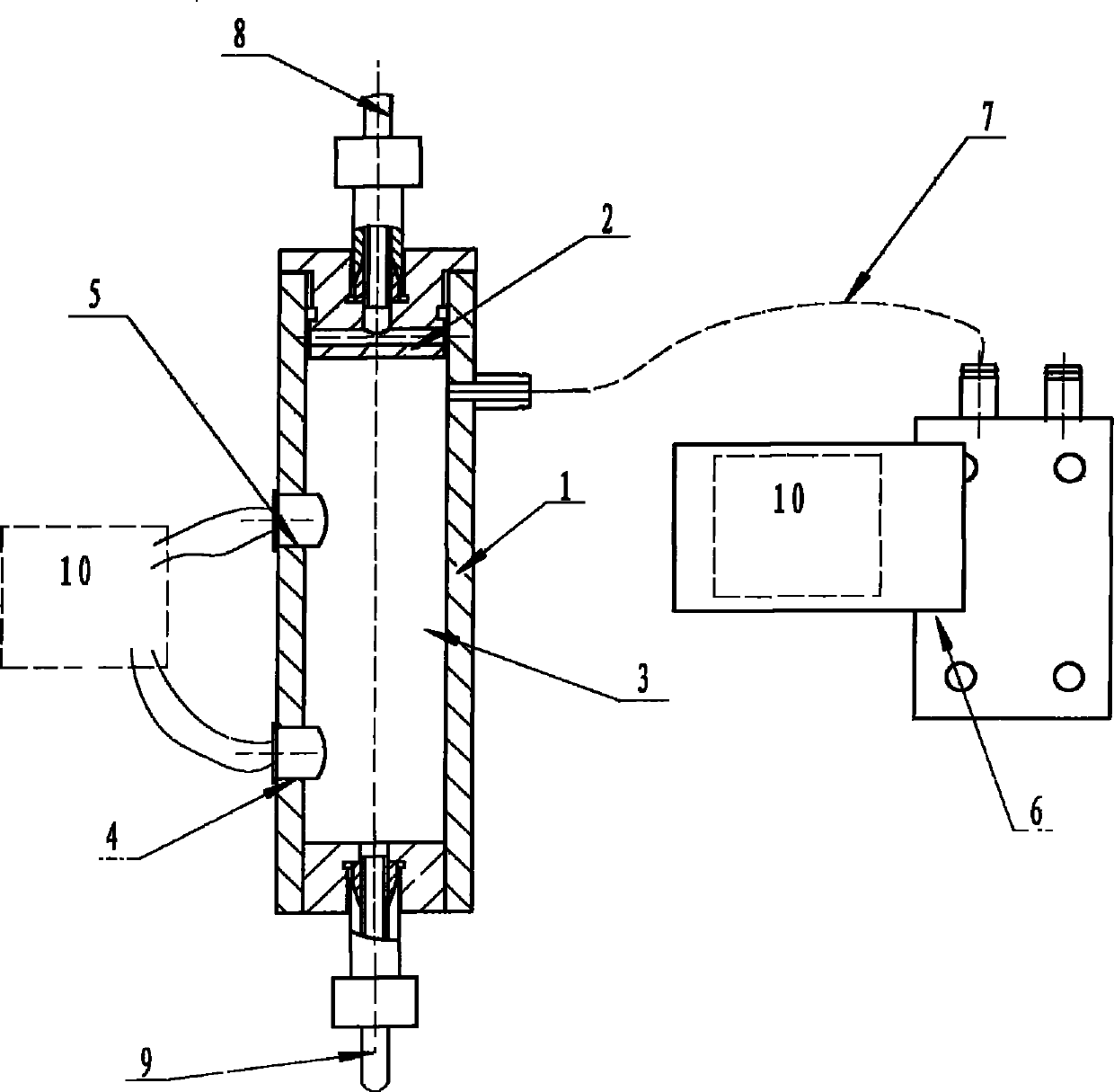

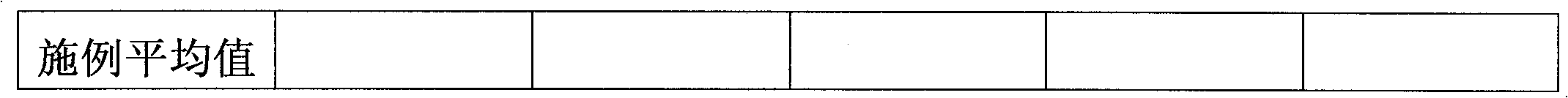

Automatic refractory brick material pouring and stamping device

ActiveCN111203957AIncrease productivityWon't inhaleFeeding arrangmentsAuxillary shaping apparatusStructural engineeringManufacturing engineering

The invention relates to an automatic material pouring and stamping device, and particularly relates to an automatic refractory brick material pouring and stamping device. The invention aims to provide the automatic refractory brick pouring and stamping device which can automatically pouring powder and automatically stamping and can also push out manufactured refractory bricks. The automatic refractory brick material pouring and stamping device comprises an operating table, a bottom plate, fixed blocks, transmission wheels, a material conveying vehicle, a storage bin, a supporting block and the like; a feeding port is formed in the operating table, the bottom plate is arranged in the feeding port, the two fixing blocks are fixedly connected to the operating table, the material conveying vehicle is placed in the operating table, and four transmission wheels are arranged on the material conveying vehicle. According to the automatic refractory brick material pouring and stamping device, apressure block is driven by an air cylinder to manufacture the refractory bricks, manual participation is not needed in the use process, and only the powder needs to be placed in the storage bin, sothat the raw materials can be automatically conveyed and poured.

Owner:山东沈耐新材料科技有限公司

Planar polishing equipment for mobile phone shell

InactiveCN109590879AReduce pollutionEasy to cleanPolishing machinesGrinding drivesWater vaporSpray nozzle

The invention discloses planar polishing equipment for a mobile phone shell, and relates to the technical field of polishing. The planar polishing equipment comprises a bottom plate, wherein the uppersurface of the bottom plate is fixedly connected with the lower surface of the base; the upper surface of the base is provided with a groove; and the right side face of the inner wall of the groove is fixedly connected with a first pressing plate. According to the planar polishing equipment for the mobile phone shell, a dust collection air blower, a connecting tube, a box body, a filter plate, awater pump, a first water pipe, a second water pipe and spray nozzles, water ejected from the spray nozzles can remove water vapor in the gas and some toxic and harmful gas pollutants while dust-containing dust gas particles can be removed at the same time, so that gas in a box body can pass through the filter plate and can be discharged; and crumbs produced by polishing the mobile phone shell body through a polishing wheel can be fallen into a collection box through a through hole, so that the crumbs and the dust can be effectively treated, pollution to an environment is reduced, and moreover, the crumbs and the dust can be effectively collected and also can be conveniently cleared up by the working personnel.

Owner:湖南融灏实业有限公司

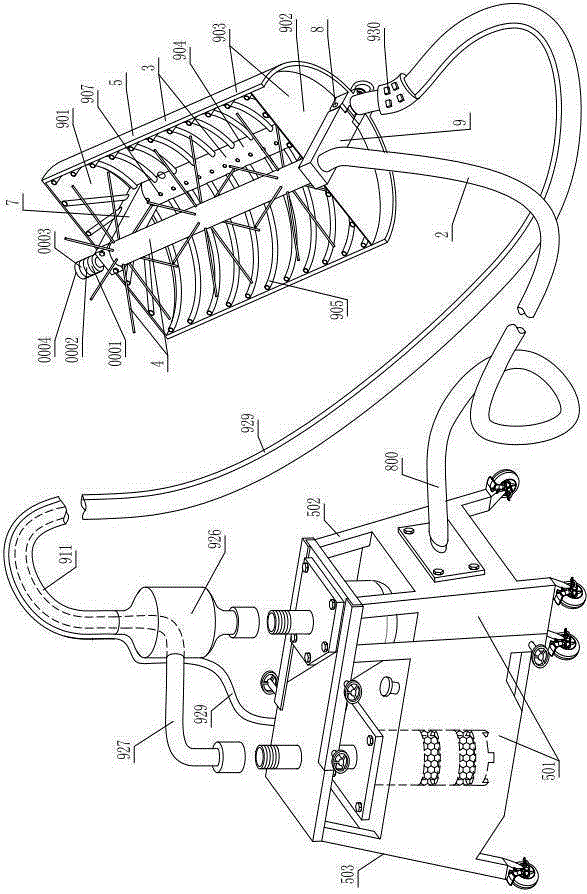

Full-automatic mobile phase bubble separation device

ActiveCN101991974APrevent direct drippingNormal supplyFoam dispersion/preventionPerfusionEngineering

The invention discloses a full-automatic mobile phase bubble separation device, which comprises a tubular capturing trap, wherein a mobile phase liquid dripping passage is formed in an upper cover at the upper end of the tubular capturing trap; a guide device is arranged at the lower end of the upper cover, and a clearance is formed between the guide device and the periphery of the tubular capturing trap; the lower end opening of the mobile phase liquid dripping passage is positioned on the outer wall of the guide device; the mobile phase liquid dripping passage is connected with an upper perfusion pipe, and the lower end of the tubular capturing trap is provided with a mobile phase liquid drop outlet and connected with a lower perfusion pipe; and upper and lower liquid level sensors are arranged on the side walls of the tubular capturing trap respectively, the side wall of the tubular capturing trap is provided with an air outlet and connected with an air extraction pressure-keeping pump through a pipeline, and the upper and lower liquid level sensors are electrically connected with the air extraction pressure-keeping pump through a control loop. The device realizes separation of visible bubbles and liquid in the falling process of the mobile phase liquid drops, enables the mobile phase liquid drops to slowly flow down along the inner wall of the tubular capturing trap, and can effectively prevent the mobile phase liquid drops from directly dripping into the liquid level at the lower end of the tubular capturing trap.

Owner:ANHUI WAYEE SCI & TECH CO LTD

Selling rack for cotton yarn selling

InactiveCN108741977AAchieve the limitAvoid a collapsed situationShop accessoriesShow shelvesYarnEngineering

The invention discloses a selling rack for cotton yarn selling. The selling rack for cotton yarn selling comprises a selling rack body and multiple supporting plates, wherein multiple fixed blocks arefixedly connected to the upper surfaces of the supporting plates, the adjacent sides of every two adjacent fixed blocks in the fixed blocks are each fixedly connected with a stretchable rod, the opposite sides of every two adjacent stretchable rods in the stretchable rods are each fixedly connected with a baffle, the rod walls of the stretchable rods are sleeved with springs, and the two ends ofeach spring are fixedly connected with the side wall of the corresponding baffle and the side wall of the corresponding fixed block respectively. By means of the selling rack for cotton yarn selling,the condition that due to careless touching of customers, cotton yarn stacked on the selling rack is collapsed can be avoided, workers do not need to newly put the cotton yarn, time and labor are saved, the labor intensity of the workers is reduced, the moving speed of the selling rack is increased, the stability of the selling rack is guaranteed, dust adhesion of the cotton yarn on the selling rack is avoided, the cotton yarn is protected and cannot be contaminated to be blackened, the quality of the cotton yarn is improved, and the selling efficiency of the cotton yarn is guaranteed.

Owner:徐州锦翔纺织有限公司

Thread added cigarette holder capable of reducing harmfulness of cigarettes

InactiveCN102771894AEasy to joinSolve pollutionTobacco smoke filtersPolycyclic aromatic hydrocarbonFiber

The invention discloses a thread added cigarette holder capable of reducing harmfulness of cigarettes and a production process of the thread added cigarette holder. The thread added composite cigarette holder is composed of a conventional acetic acid fiber cigarette holder A and a thread added acetic acid fiber cigarette holder B, wherein cotton threads are wrapped in the thread added acetic acid fiber cigarette holders B and infused with carbon nano tube solutions, and the weight of added carbon nano tubes in each of the thread added acetic acid fiber cigarette holders B is between 1mg and 10mg. The thread added cigarette holder capable of reducing harmfulness of the cigarettes and the production process have the advantages that the problem that indoor environments are polluted when the carbon nano tubes are added to the acetic acid fiber cigarette holders is effectively solved; by means of the control of the number of added threads, the added amount of the nano tubes in the cigarette holders can be conveniently and quantitatively adjusted; the production process is simple, capable of being combined with cigarette holder forming processes and applicable to mass production; harmful substances of polycyclic aromatic hydrocarbon, phenol and the like in cigarette smoke can be further reduced on the basis that cigarette tar is effectively reduced; and the number of the added threads and the positions of the threads in filter sticks can be controlled so that patterns with certain shapes can be structured on end surfaces of the filter sticks, and the cigarette holder is provided with anti-fake functions.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Saw dust collecting device for wood processing workshop

InactiveCN111152315AReduce the size of the air intakeLess attractiveBark-zones/chip/dust/waste removalStructural engineeringIndustrial engineering

The invention discloses a saw dust collecting device for a wood processing workshop. The saw dust collecting device comprises a support, wherein a slant threaded shaft penetrates through the top of the support, a friction block is fixedly connected to the bottom of the slant threaded shaft, air stop blocks penetrate through the top of the friction block, and triangular blocks are fixedly connectedto the opposite sides of two bearing rods. Friction plates are arranged below the friction block, pitch varying rods are fixedly connected to the opposite sides of two slide blocks, compression rodsare fixedly connected to the opposite sides of the two pitch varying rods, compression cylinders are slidably connected to the opposite sides of the two compression rods, unloading rods are fixedly connected to the bottoms of the friction plates, bearing blocks are fixedly connected to the opposite sides of the two unloading rods through connecting rods, and squeezing rods are rollably connected to the two sides of each bearing block. According to the saw dust collecting device for the wood processing workshop, through the cooperative use of the support and the friction block, the effect thatwhen saw dust is recycled, dust is unlikely to get inhaled is achieved.

Owner:林锡贵

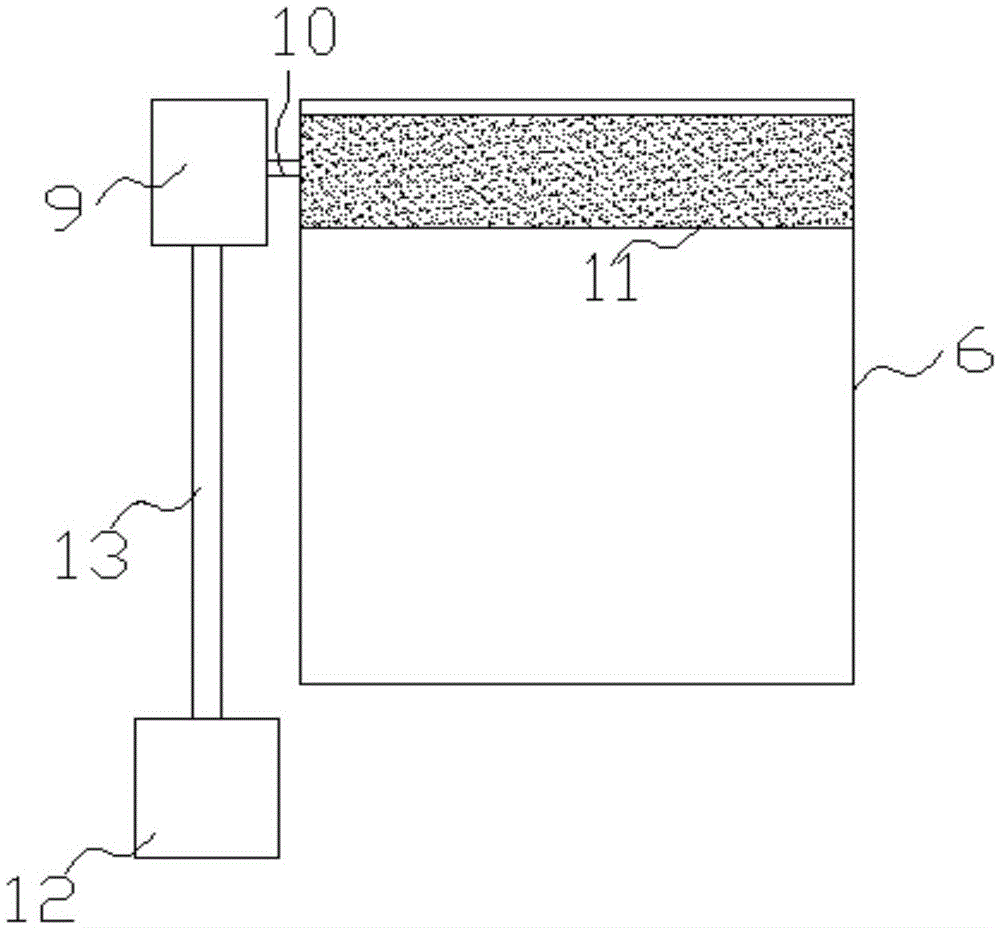

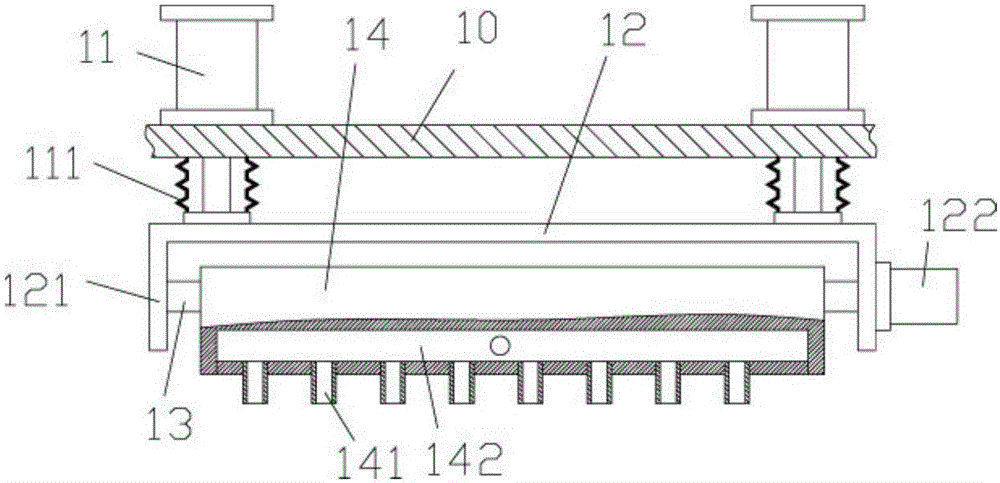

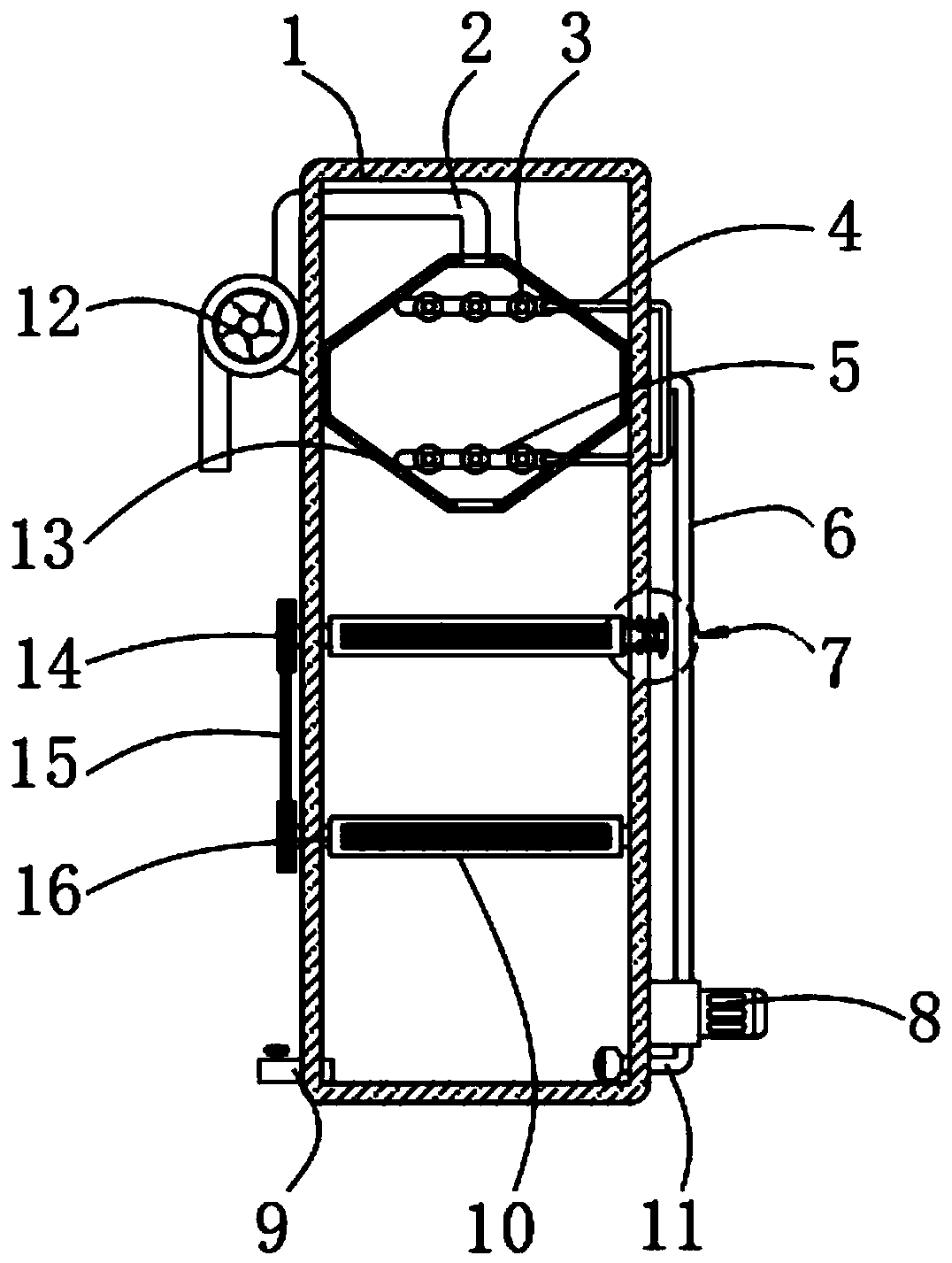

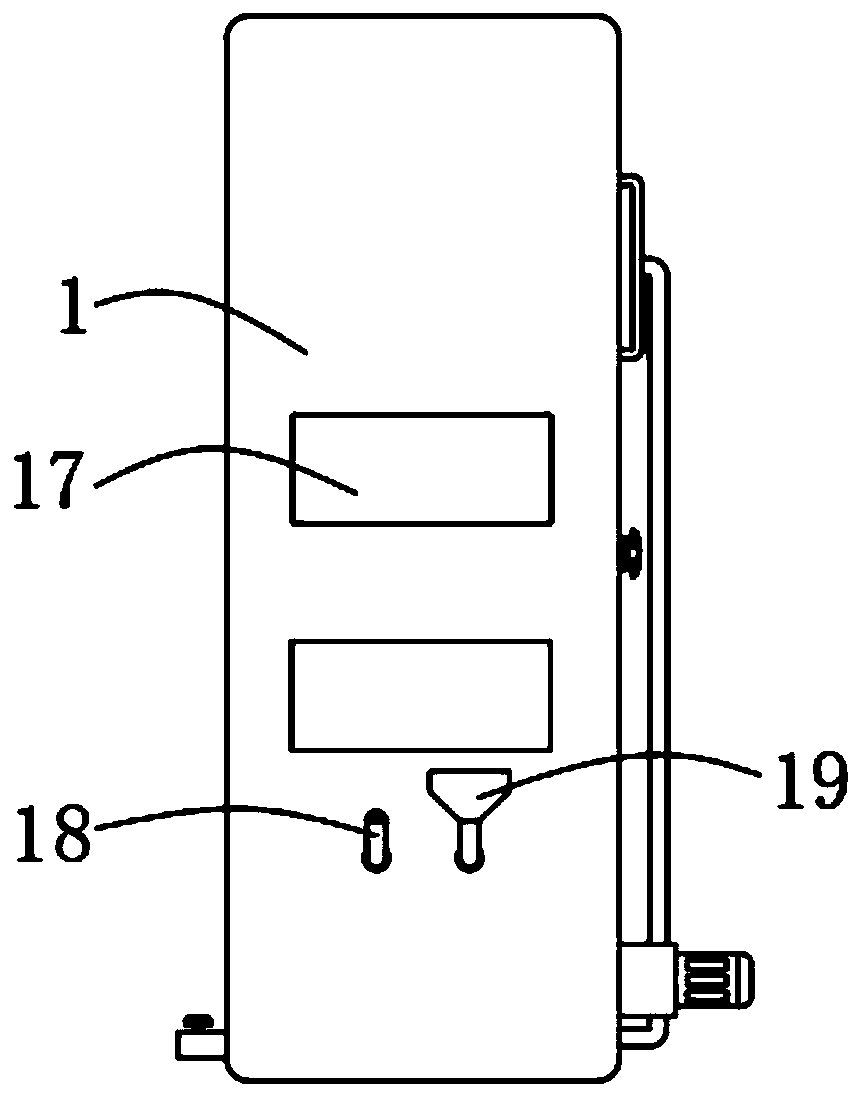

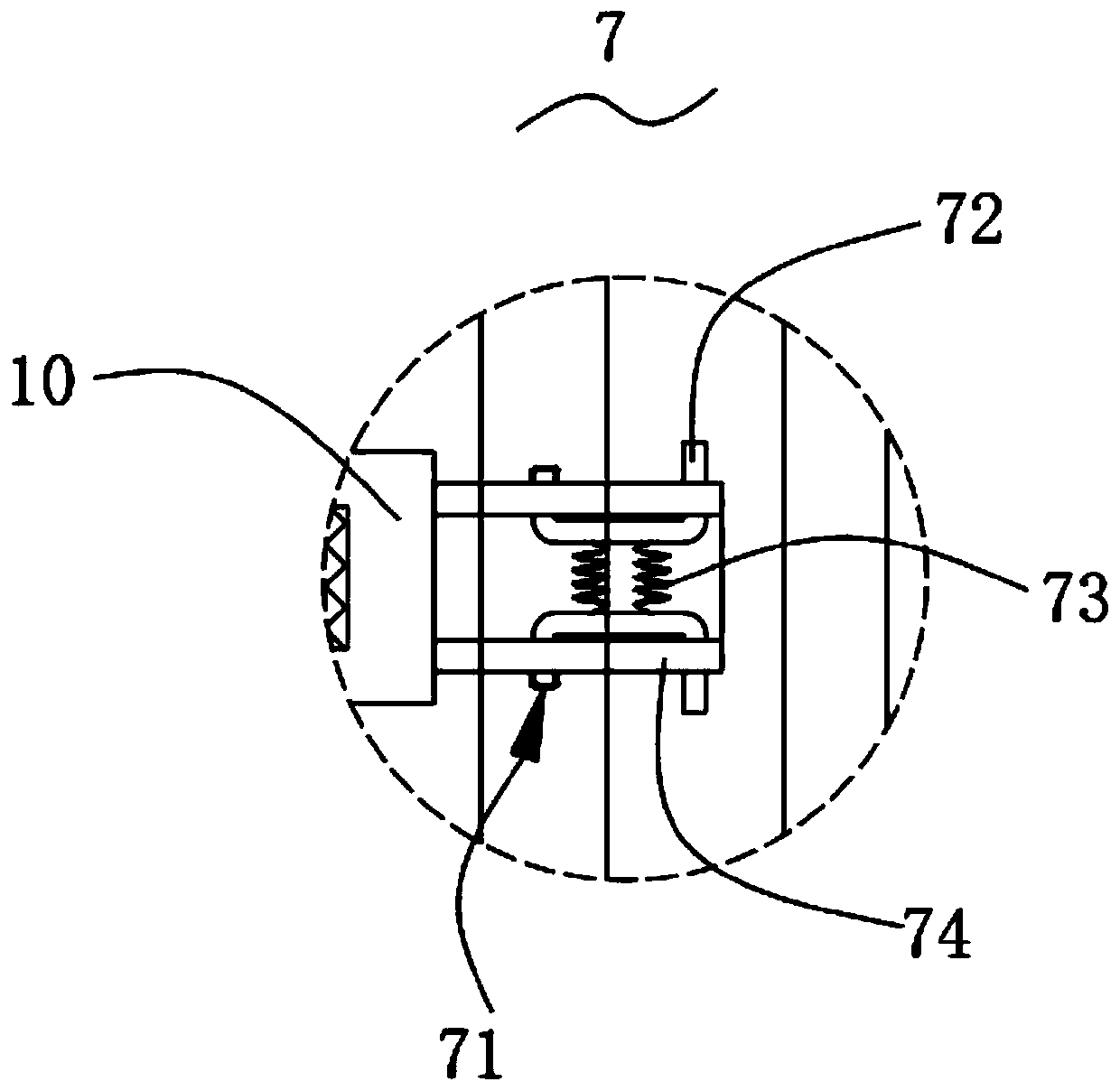

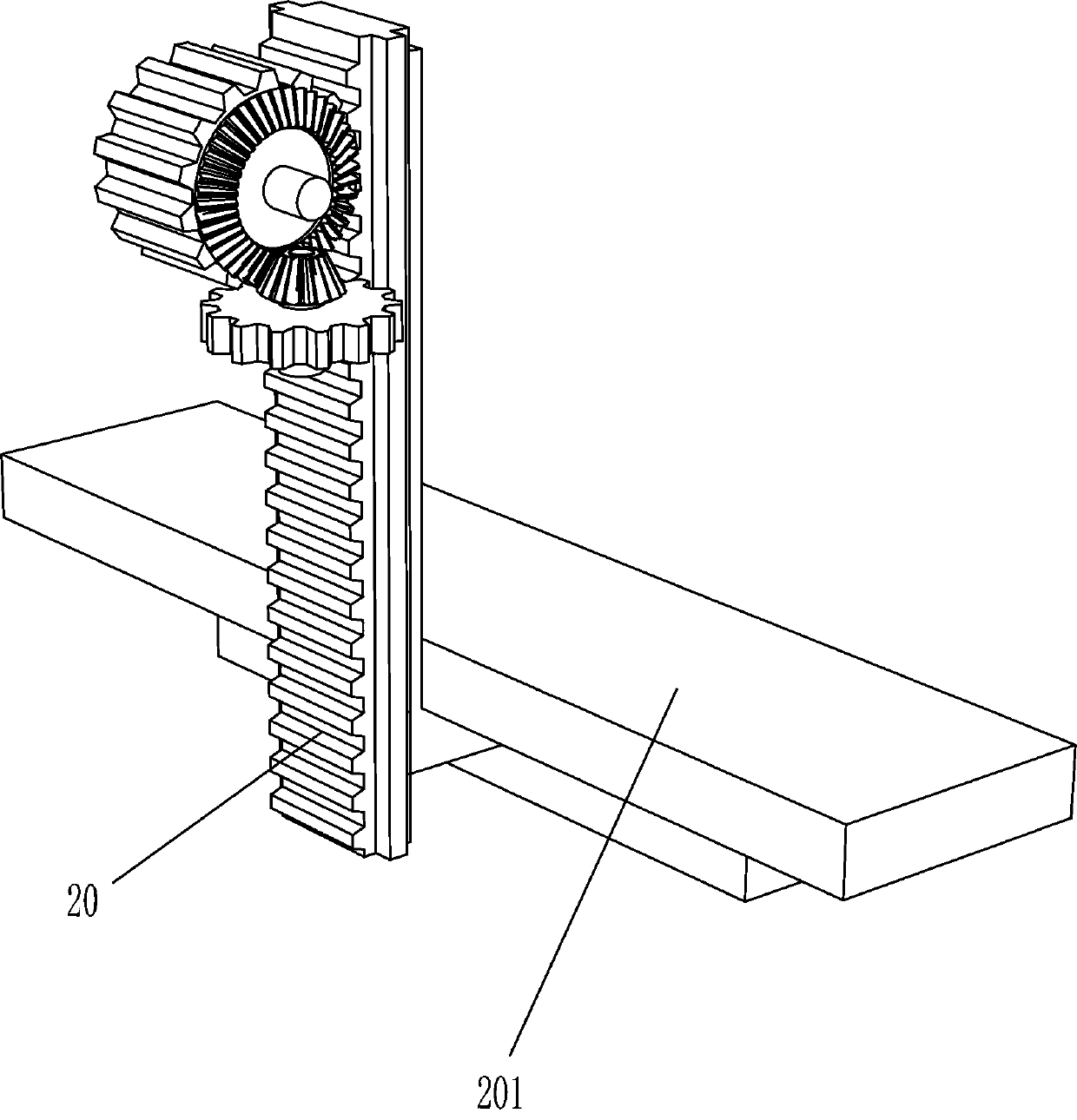

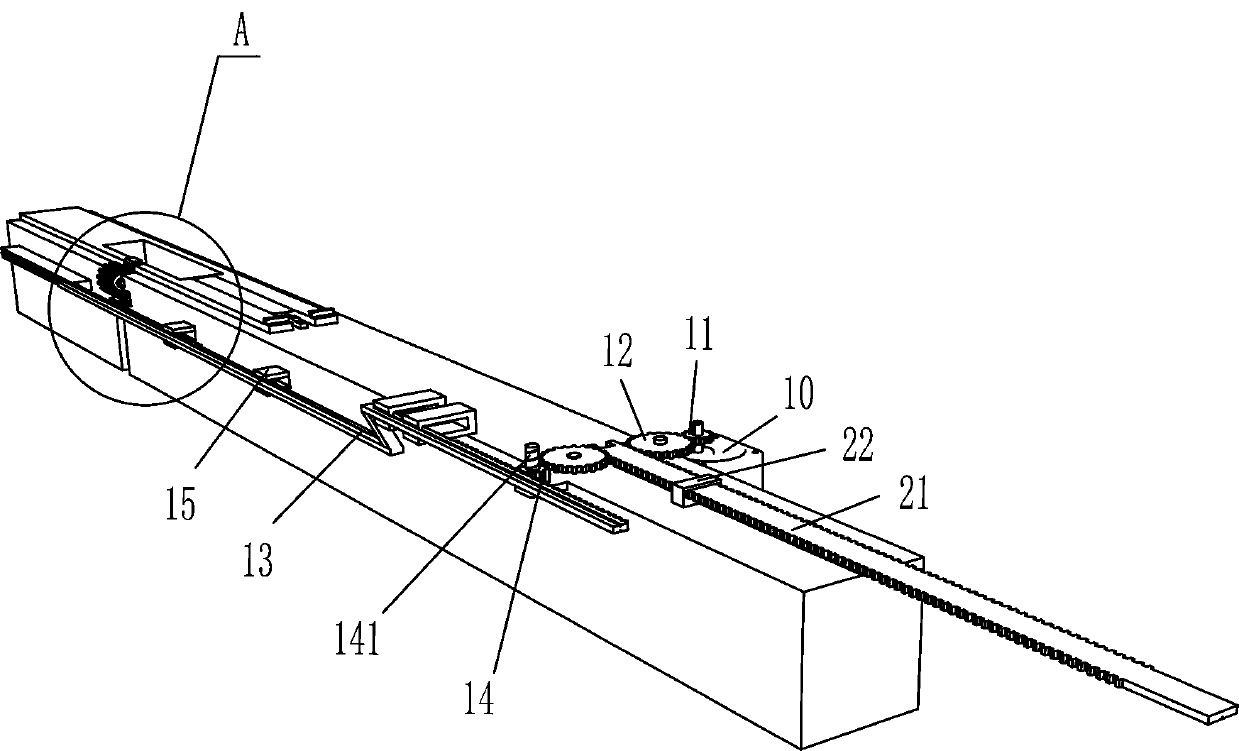

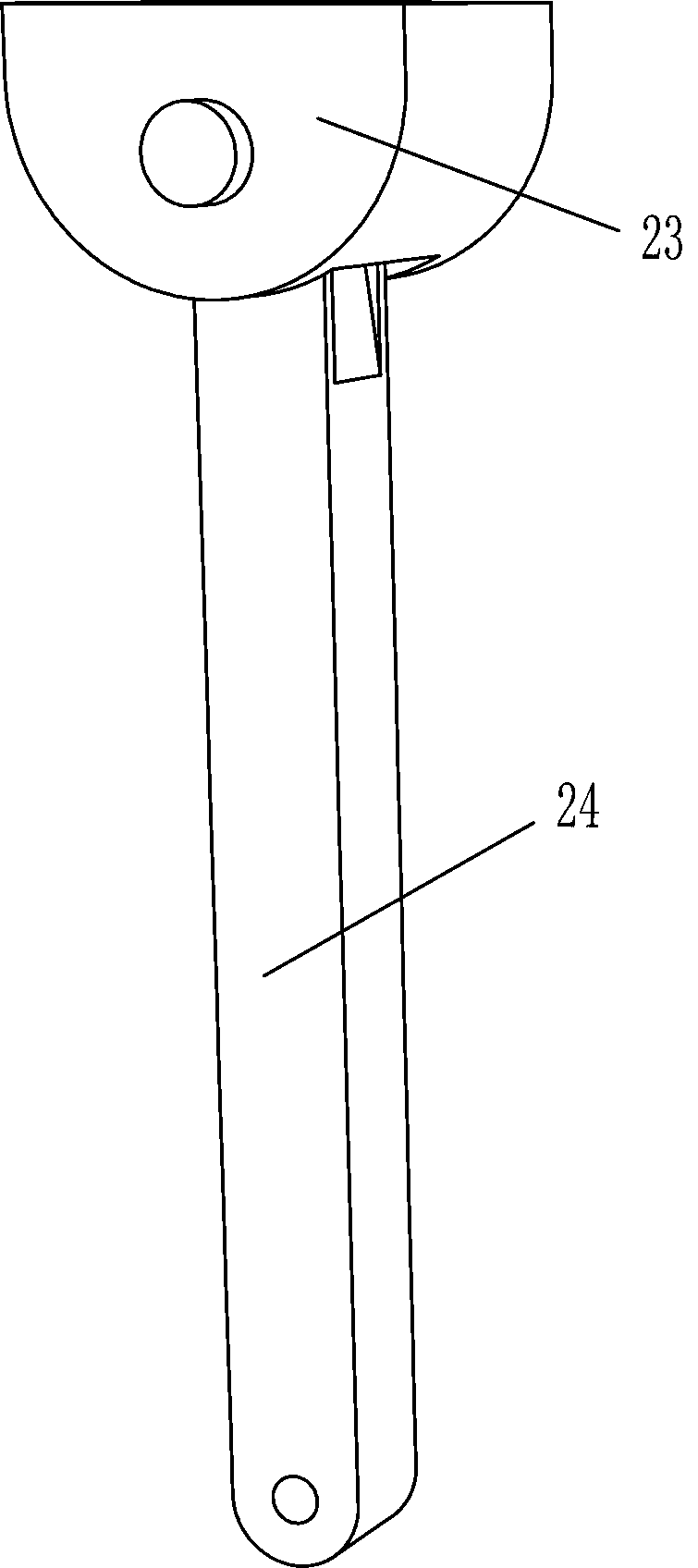

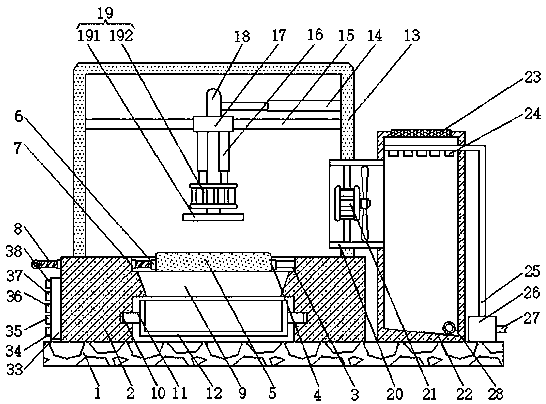

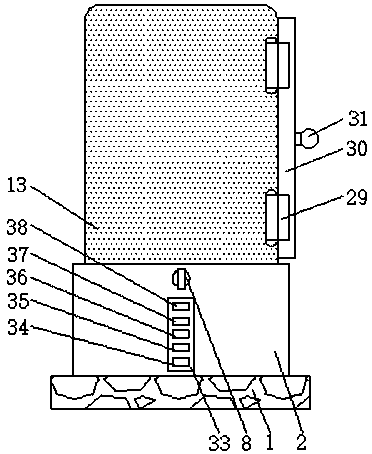

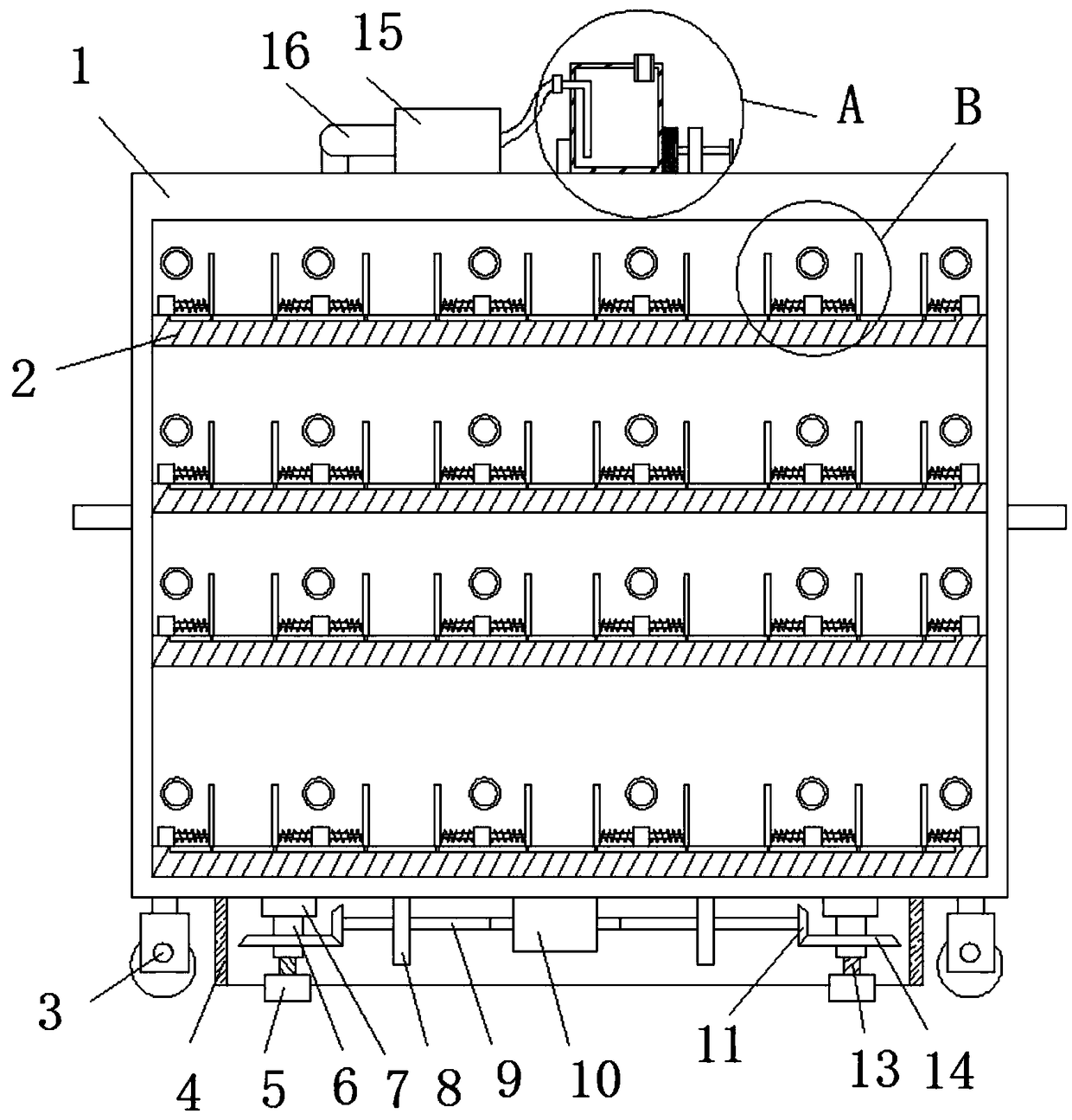

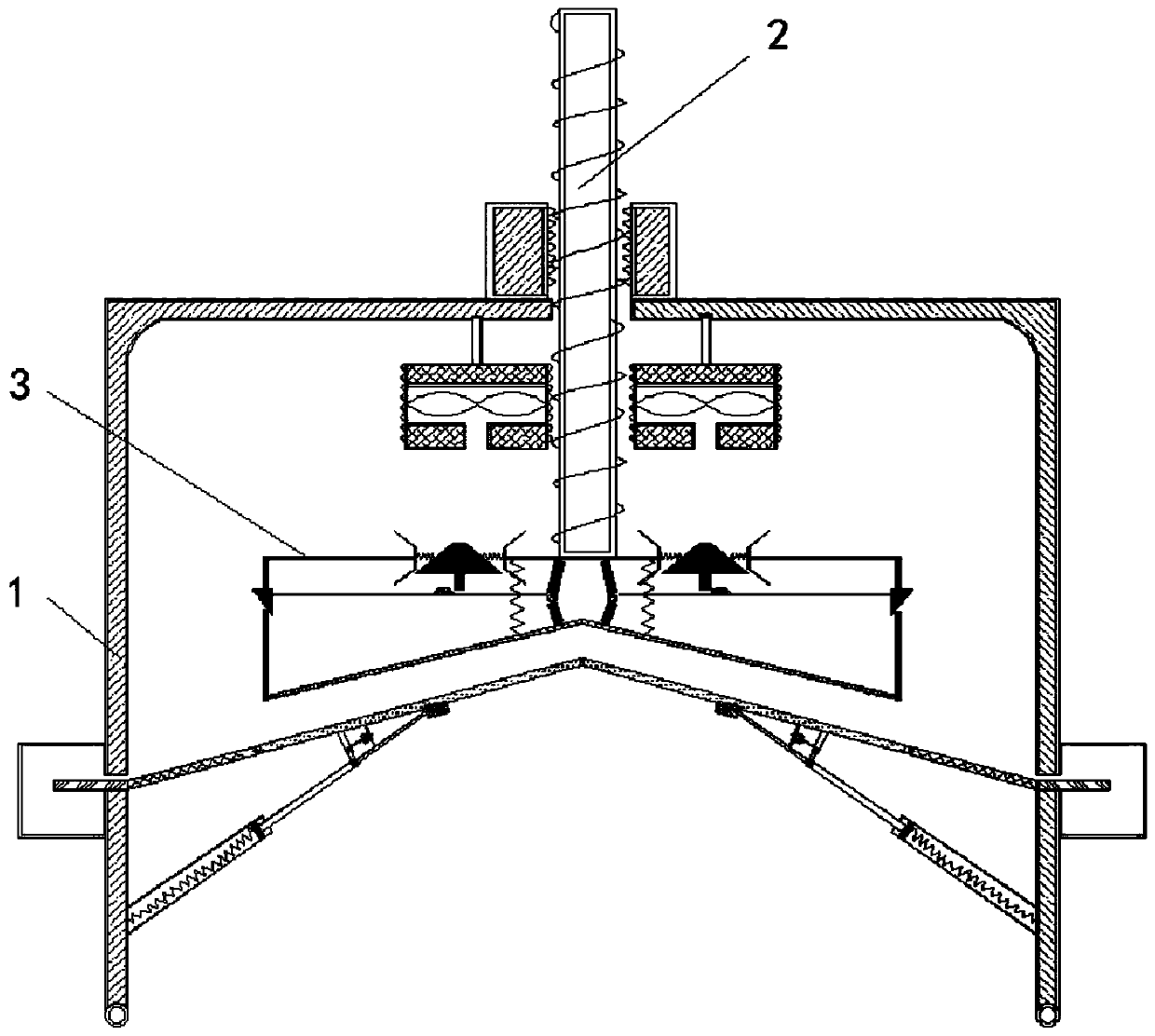

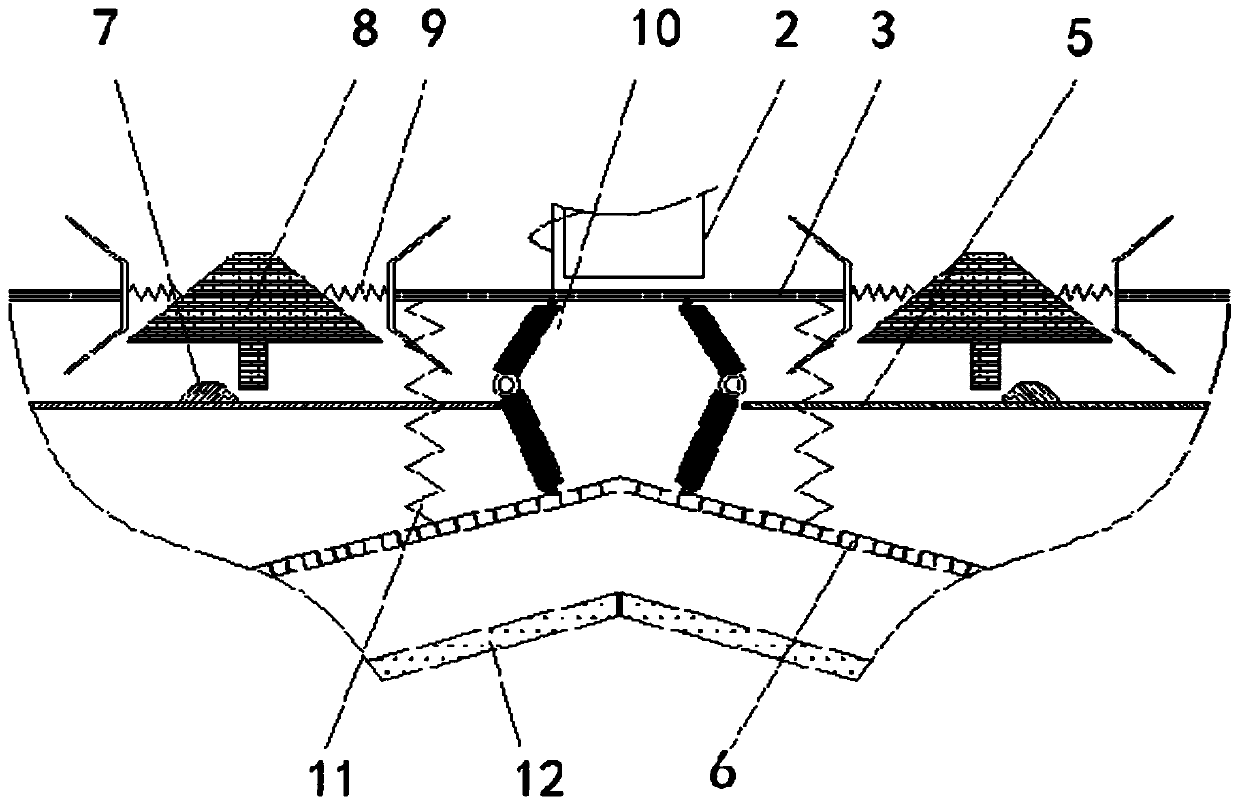

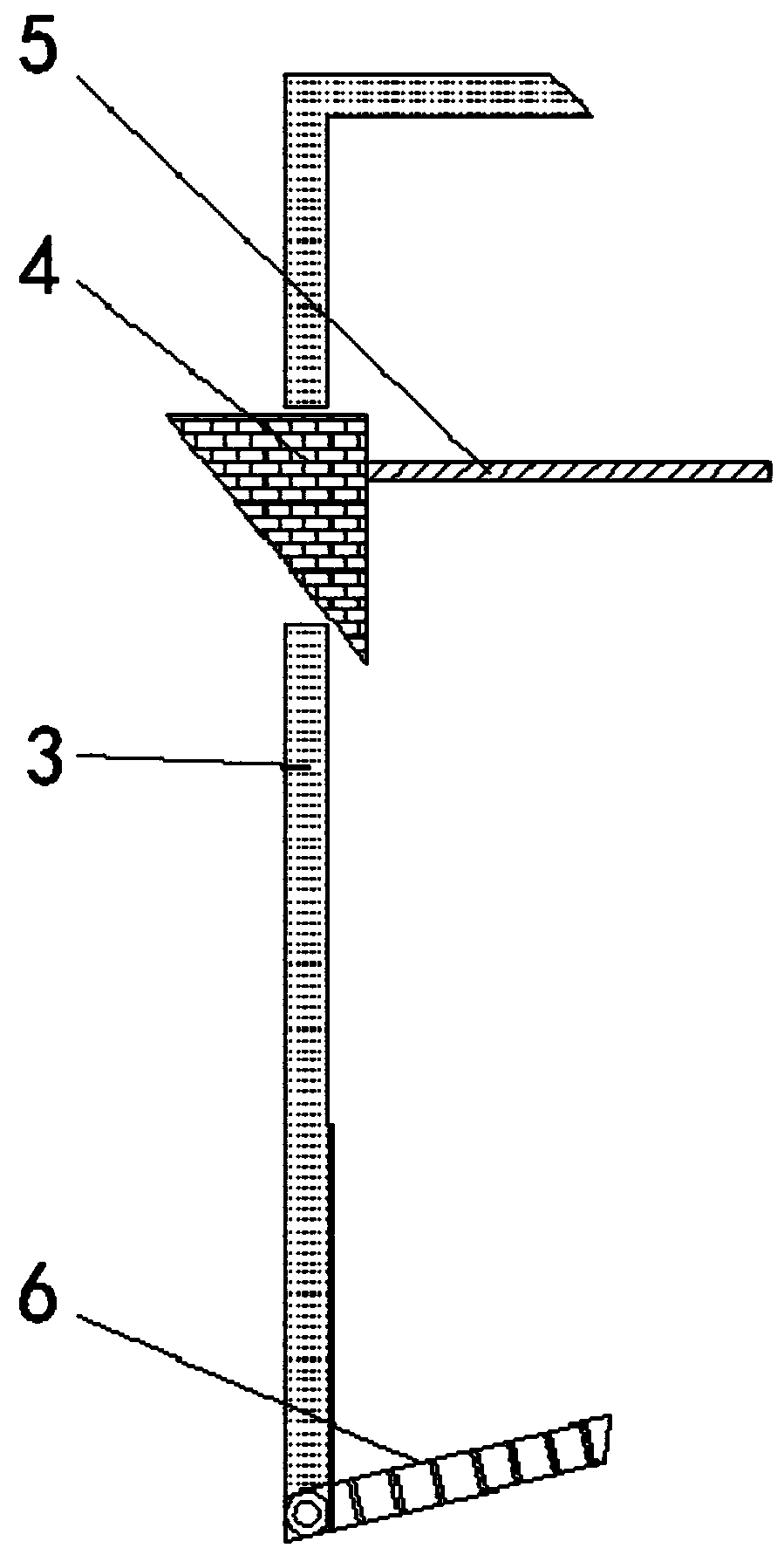

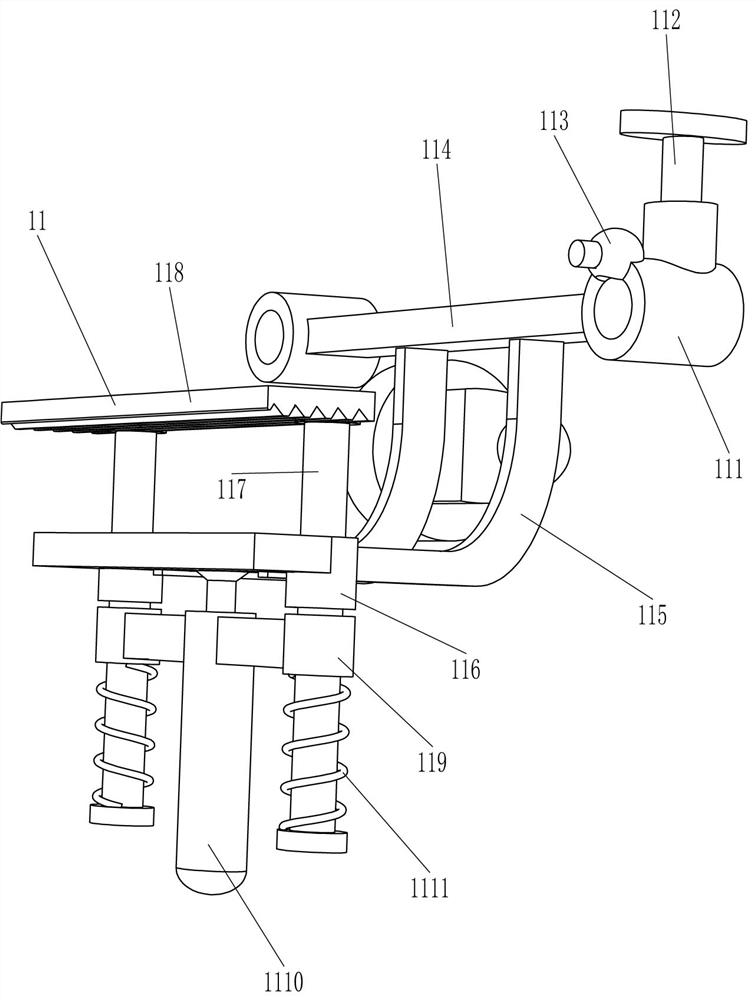

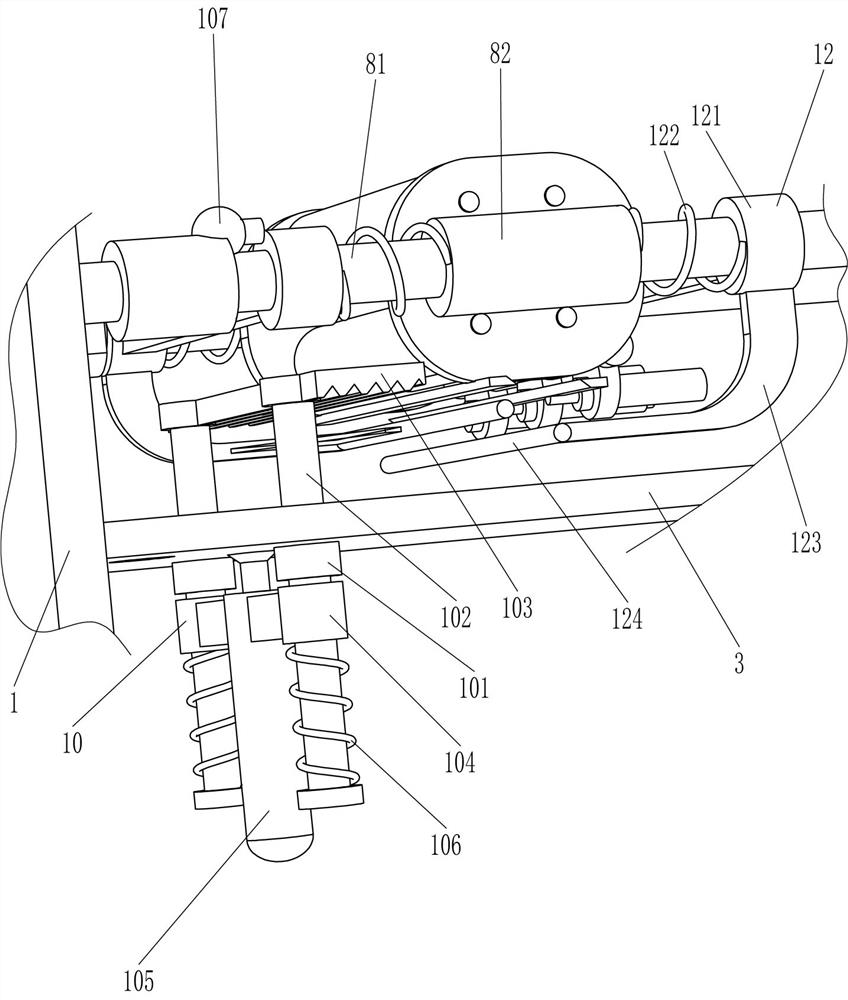

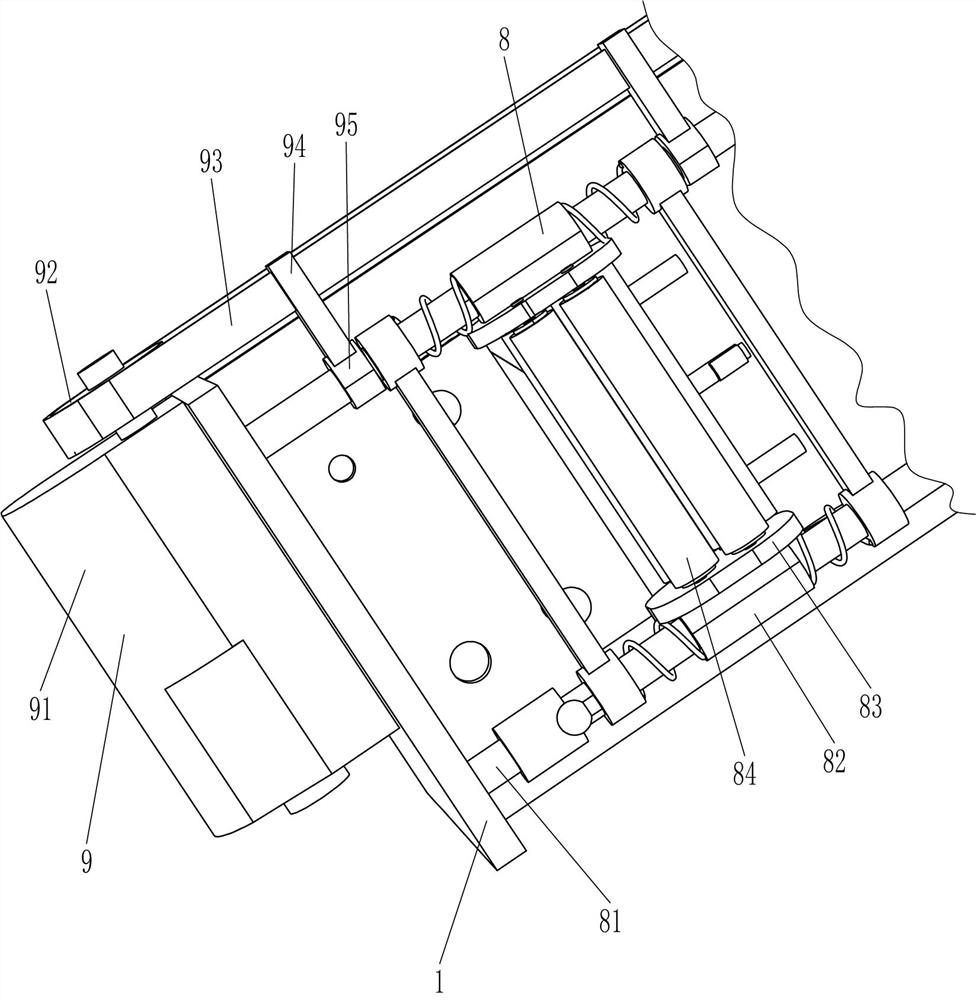

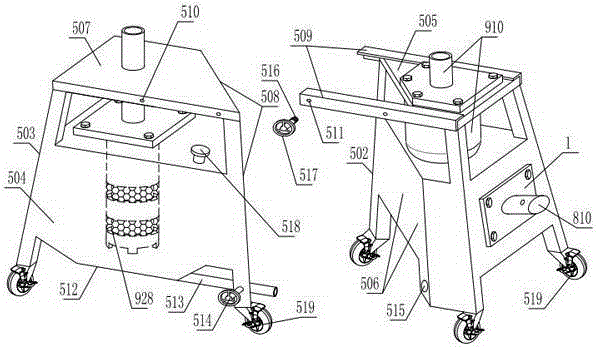

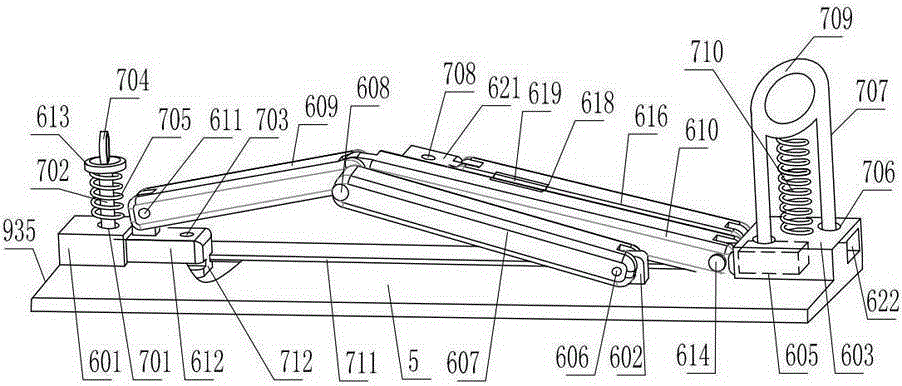

Adjustable plaster bandage folding machine for orthopedics department

The invention relates to a plaster bandage folding machine, in particular to an adjustable plaster bandage folding machine for the orthopedics department. The technical problem to be solved is to provide the adjustable plaster bandage folding machine for the orthopedics department, which can prevent people from inhaling plaster powder. According to the technical scheme, the adjustable plaster bandage folding machine for the orthopedics department comprises a mounting frame and a discharging mechanism, wherein a transverse plate is fixedly connected to the upper portion of the mounting frame; and the discharging mechanism is mounted on the mounting frame, and the discharging mechanism is used for discharging the plaster bandages. The discharging mechanism can be driven to move left and right through a moving mechanism to fold a plaster bandage, and people do not need to make close contact with the plaster bandage in the plaster bandage folding process, so that people do not inhale plaster powder; and the plaster bandage can be plugged below a first toothed plate and a second toothed plate through a plugging mechanism, manual operation is replaced, and hands of people are prevented from being pressed.

Owner:CHANGZHOU NO 2 PEOPLES HOSPITAL

Welding machine

The invention provides a welding machine and relates to the technical field of automobile part machining. The welding machine comprises a main engine and an isolating hood. The isolating hood is arranged outside the main engine. A viewing window is arranged in the front of the isolating hood, and a draft fan is arranged on the back of the isolating hood. Under the circumstance of not influencing operation of staff, toxic gas generated in the plastic hot-melting process can be eliminated in time, and the working environment of operators is improved greatly.

Owner:HEFEI YONGTAI FIREPROOF DOOR CO LTD

Welding machine

The invention relates to a welding machine and relates to the technical field of automobile part processing. The welding machine comprises a main engine and an isolation sleeve, the isolation sleeve is arranged outside the main engine, a perspective window is arranged in the front side of the isolation sleeve, and a drawing fan is arranged in the rear of the isolation sleeve. Under the condition of not affecting operation of personnel, toxic gas produced during hot melting of plastics can be timely removed, and working environment of the operating personnel is greatly improved.

Owner:REFONE AUTO POWER

Method for processing yak horn comb blank

The invention discloses a method for processing an yak horn comb blank, which comprises the following steps: (1) preparing the primary yak horn comb blank: choosing an yak horn with the shape and thickness suitable for making a comb, cutting off leftover materials, making the yak horn into the primary yak horn comb blank by cutting the yak horn from the middle part along the direction extending towards the ox-head from the tip of the yak horn, and storing for later use; (2) heating and softening: putting the made primary yak horn comb blank into a paraffin liquid which is melted and is at 120-150 DEG C, and heating and softening for 2-3 minutes; and (3) preparing the yak horn comb blank: putting the softened primary yak horn comb blank into a pressing machine for flattening and straightening the primary yak horn comb blank, and obtaining the yak horn comb blank after cooling the flattened and straightened primary yak horn comb blank. By using the method provided by the invention, the phenomenon that a large amount of water is sucked in the process of preparing the yak horn comb blank is completely eradicated, the original organic matters of the raw materials are protected well, the yak horn comb blank cannot be easily carbonized in the preparation process, the prepared product is difficult to deform and is not brittle, the yak horn comb blank can be produced in batch, and the quality and the service life of the yak horn comb blank are promoted.

Owner:雅安市长益生物科技有限公司

Welding machine

InactiveCN104827659AEasy to operateOperation will not affectDirt cleaningWorking environmentHot melt

The invention discloses a welding machine, and relates to the technical field of automobile part machining. The welding machine comprises a host and an insulation cover, wherein the host is externally provided with the insulation cover; the frontage surface of the insulation cover is provided with a perspective window; the rear surface of the insulation cover is provided with a draught fan. According to the invention, under the condition of not affecting the operation of workers, toxic gases generated by hot melting plastics can be discharged time, and the working environment of operators is improved greatly.

Owner:合肥凯蒙新材料有限公司

Production method of T2 copper strap used for automobile radiator

The invention discloses a production method of a T2 copper strap used for an automobile radiator, which belongs to the field of material processing, and solves the problems of the prior art that the process flow of the T2 copper strap production process is longer and the required equipment is expensive. The production method of the T2 copper strap used for the automobile radiator comprises the following steps: batching and melting raw material, and covering dry wood coal on liquid raw material; transferring the liquid raw material covered with the dry wood coal into a heat preserving furnace with the temperature of 1100 DEG C to 1150 DEG C for 30 to 45 minutes, then performing horizontal continuous casting, the casting temperature being 1220 DEG C to 12050 DEG C, and adopting drawing, stopping and returning process; milling and cold rolling cogging, then performing intermediate annealing and rough rolling to reduce-second intermediate annealing-surface cleaning and passivating-cold finish rolling-low temperature heat treatment on finished product-surface cleaning and passivating-bending and flattening, and obtaining the required T2 copper strap. With the invention, the existing homogenizing anneal procedure can be omitted, the additionally arranged expensive equipment can be avoided, the complexity of the process is reduced, and the cost can be saved.

Owner:宁波市鄞州锡青铜带制品有限公司

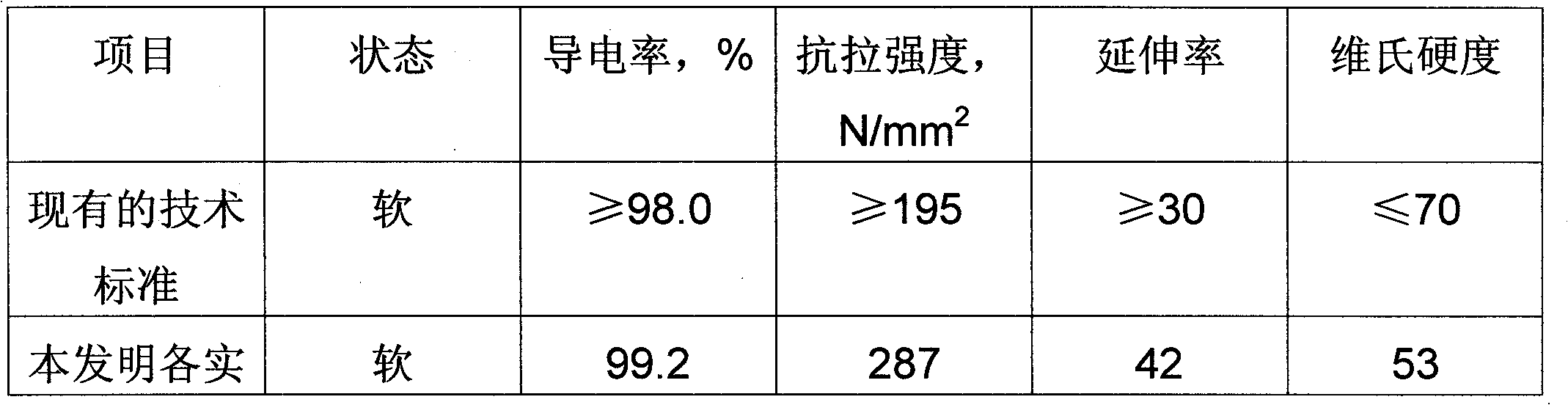

Method for preparing high-electric-conductivity pure copper strips for transformer

InactiveCN102321810AShort production processHigh cold working rateProcess efficiency improvementSurface cleaningTransformer

The invention discloses a method for preparing high-electric-conductivity pure copper strips for a transformer, belonging to the field of material manufacturing, for solving problems of longer preparation process and expensive required devices of the high-electric-conductivity pure copper strips in the prior art. The preparation method of the high-electric-conductivity pure copper strips for the transformer comprises the following steps of: distributing materials, melting materials, adding a copper phosphor intermediate alloy, and covering dry charcoal on liquid raw materials; transferring the liquid raw materials covered with dry charcoal in a heat preservation furnace at the temperature of 1180 DEG C-1280 DEG C, and keeping the temperature for 25-30 minutes; then carrying out horizontal continuous casting at the casting temperature from 1100 DEG C to 1200 DEG C by adopting pulling, stopping and returning technologies; and carrying out face milling, intermediate annealing after cold rolling and cogging, as well as roughing and reduction, secondary intermediate annealing, surface cleaning and passivation, cold finishing rolling, low-temperature thermal treatment for finished products, surface cleaning and passivation, stretch bending leveling, thus the required high-electric-conductivity pure copper strips are obtained. According to the invention, the existing uniform annealing working procedure is omitted, expensive devices are not required to be purchased additionally, the technology complexity is lowered, and the cost is lowered.

Owner:宁波市鄞州锡青铜带制品有限公司

Novel hot melt welding machine

A novel hot-melt welding machine relates to the technical field of auto parts processing. It includes a host and an isolation cover, the host is provided with an isolation cover, a perspective window is arranged on the front of the isolation cover, and an exhaust fan is arranged at the back of the isolation cover. The invention can timely remove the poisonous gas generated when hot-melting plastics without affecting the operation of employees, thereby greatly improving the working environment of operators.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

Electric equipment anti-flashover blowing cleaner

InactiveCN106623115AReasonable structureImprove protectionDirt cleaningCleaning using toolsEngineeringElectric equipment

The invention discloses an electric equipment anti-flashover blowing cleaner. The electric equipment anti-flashover blowing cleaner comprises a cleaning head driven by a power device through a transmission hose; the cleaning head includes a rotating brush vertically arranged; one side of the rotating brush is coated with a protective cover with C-shaped cross section; the outer side of the protective cover is fixed with a handle; the upper end of the inner side of the protective cover is fixed with an upper rod for transversely extending; the end part of the upper rod is rotationally matched with the upper end of the rotating brush through an upper connecting device; the lower end of the inner side of the protective cover is hinged with a lower rod capable of swinging up and down through a horizontal shaft; and the lower rod is rotationally matched with the lower end of the rotating brush through a lower connecting device. The electric equipment anti-flashover blowing cleaner has the advantages of: reasonable structure, capability of quickly finishing the wiping task according to the shape of wiping equipment, capability of freely and quickly switching two modes of near wiping and far wiping without changing the position of operators, random adjustment of the wiping angle, capability of removing stubborn dirt, no dead angles in wiping, time and labor saving, good protection of wiping persons, incapability of sucking and staining dust, generation of no problem of the dirt entering eyes, no falling of the wiped dust dirt onto lower equipment, no limitation by the wiping height, capability of independently finishing the wiping task by one person, and high wiping effect.

Owner:刘刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com