Automatic refractory brick material pouring and stamping device

A technology of punching device and refractory brick, applied in the direction of supply device, forming indenter, auxiliary forming equipment, etc., can solve the problems of complex production process, time-consuming and laborious, dust inhalation, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

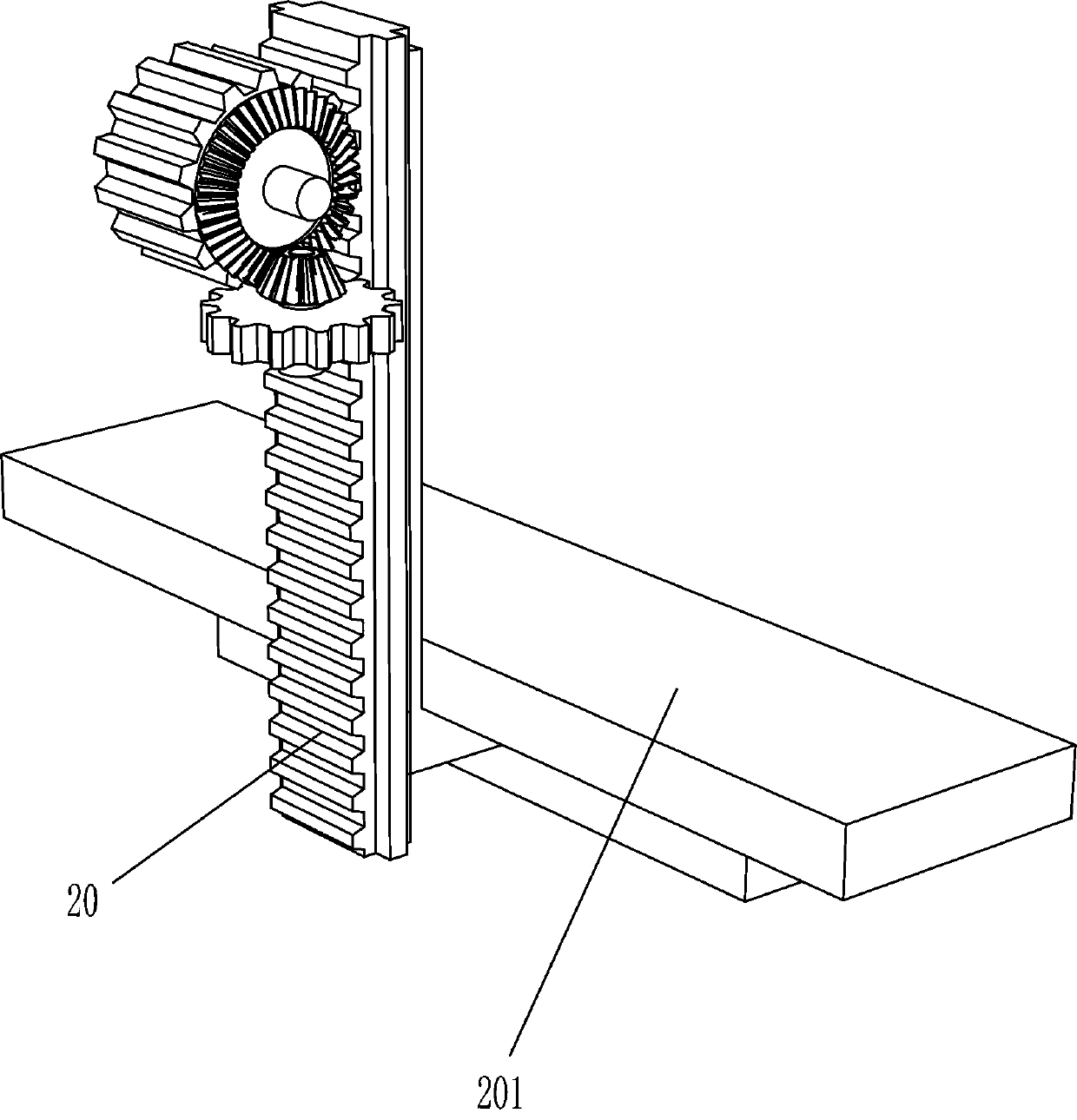

[0023] A kind of refractory brick automatic pouring stamping device, such as Figure 1-4 As shown, it includes an operation table 1, a bottom plate 201, a fixed block 3, a transmission wheel 4, a material transport vehicle 5, a storage bin 6, a support block 7, a cylinder 8 and a pressing block 9, and the right part of the operation table 1 has a feeding Bottom plate 201 is provided at the bottom of port 2 and feed port 2, and two fixed blocks 3 are fixedly connected to operating platform 1, and fixed block 3 is located near the position of feeding port 2. Four transmission wheels 4 are installed on the material transport vehicle 5, a storage bin 6 is fixedly connected to the upper side of the left part of the operation platform 1, a support block 7 is fixedly connected to the rear side of the operation platform 1, and a cylinder is fixedly connected to the upper and lower sides of the support block 7 8. A pressure block 9 is fixedly connected to the lower end of the cylinder ...

Embodiment 2

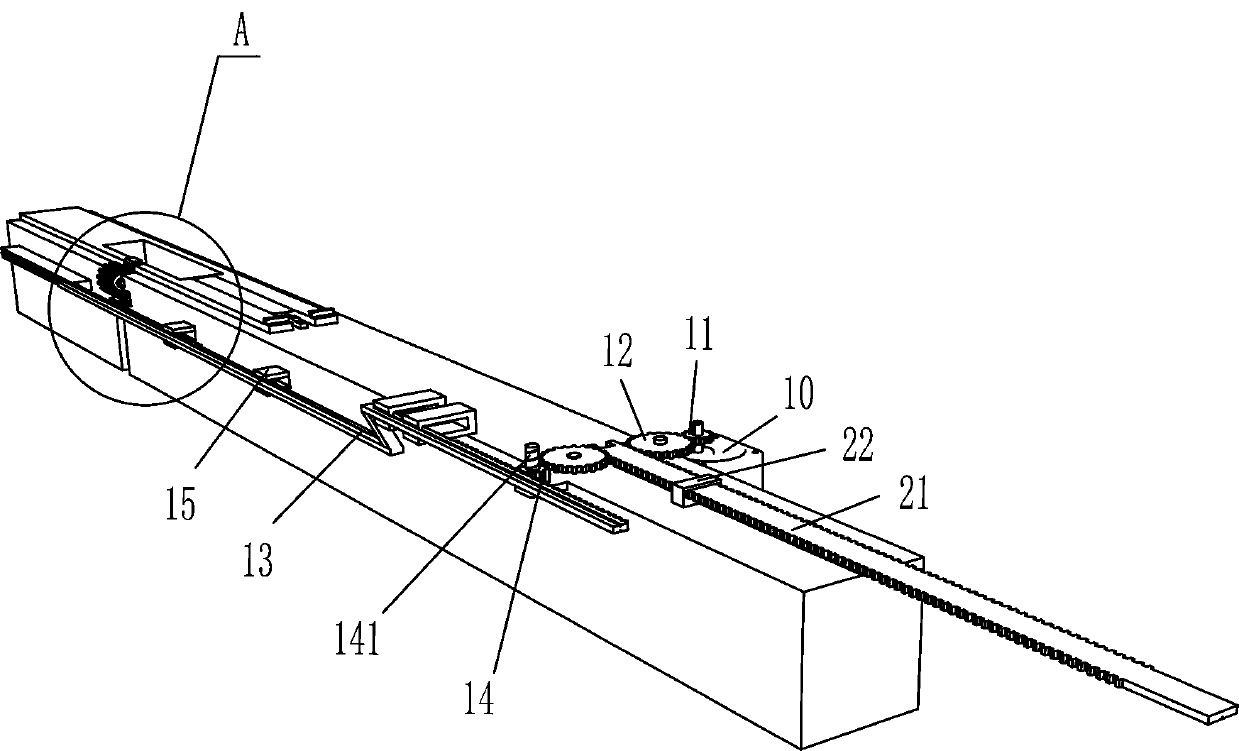

[0028] On the basis of Example 1, such as figure 2 As shown, it also includes a rotating motor 10, a second gear 11, a first gear 12, a third rack 21 and a fixed sleeve 22, and a rotating motor 10 is fixedly connected to the console 1 on the side away from the stamping mechanism. A second gear 11 is fixedly connected to the output shaft of the rotating motor 10, and two first gears 12 are rotatably connected to the console 1, and the first gear 12 on one side near the rotating motor 10 meshes with the second gear 11, A fixed sleeve 22 is fixedly connected to the operating table 1, and a third rack 21 is slid through the fixed sleeve 22. The third rack 21 meshes with the first gears 12 on both sides, and the first gear 12 at the rear Mesh with threaded gear 14.

[0029]Start the rotating motor 10, the rotating motor 10 drives the first gear 12 on the front side to rotate through the second gear 11, the first gear 12 drives the third rack 21, and the third rack 21 drives the f...

Embodiment 3

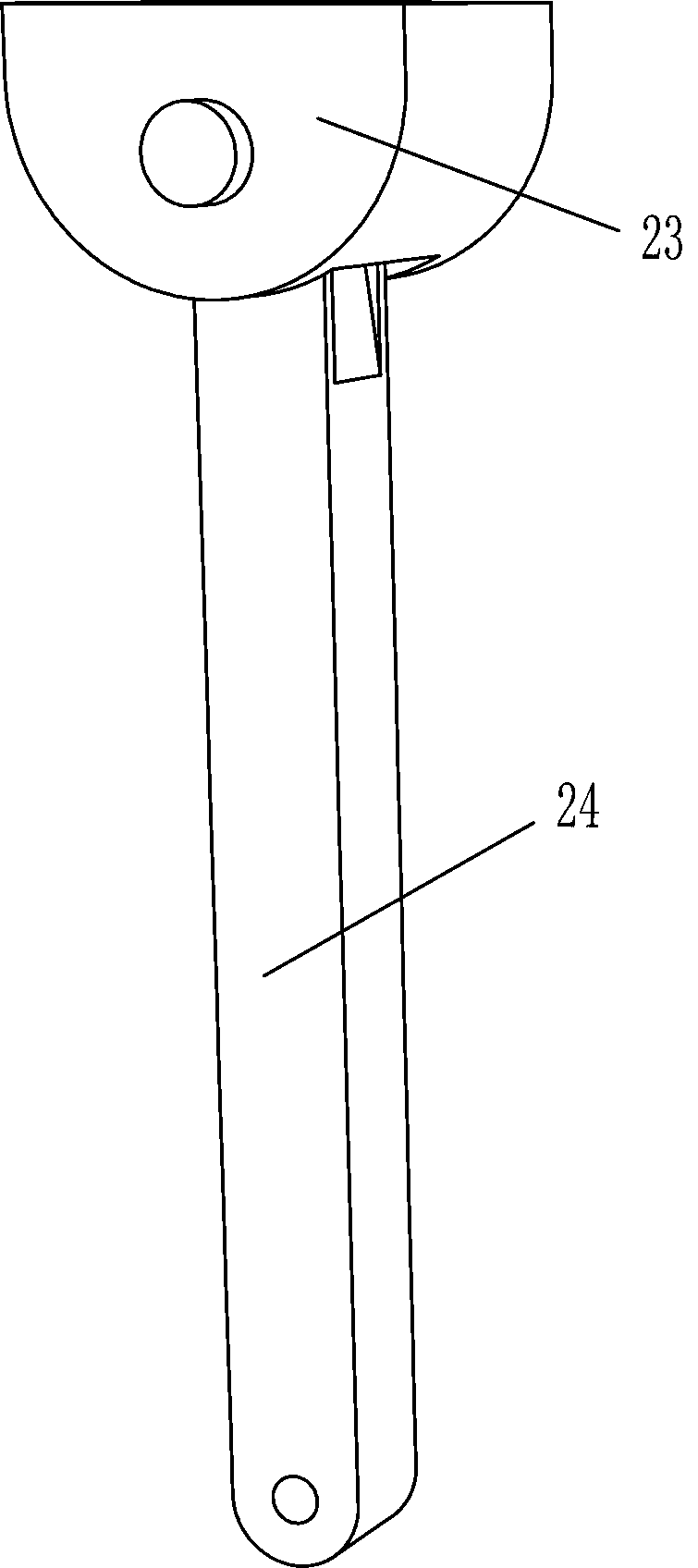

[0031] On the basis of Example 2, such as Figure 5-9 Shown, also comprise connecting block 23, rotating bar 24, fixed bar 25, pushing block 26, recessed block 27 and fixing plate 28, material delivery vehicle 5 lower sides are fixedly connected with connecting block 23, and connecting block 23 is hinged with rotating block. Rod 24, the left end of rotating rod 24 is hinged with the left end of the third rack 21, the right part of the material transport vehicle 5 is fixedly connected with a fixed rod 25, the right part of the fixed rod 25 is fixedly connected with a push block 26, and the upper side of the console 1 is fixedly connected with a concave Block 27, the upper side of the console 1 is fixedly connected with a fixed plate 28, and the concave block 27 is located in the middle of the fixed plate 28.

[0032] It also includes a slant plate 29, a support plate 2901, a trapezoidal block 30, a fixed shaft 31, a fitting plate 32 and a second spring 33. The upper side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com