Patents

Literature

61results about How to "Automate shipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent sales terminal with online shopping function, sales system and method

InactiveCN104915875ASafe and stable operationMeet the needs of operational security managementCoin-freed apparatus detailsBuying/selling/leasing transactionsCommunication interfaceMan machine

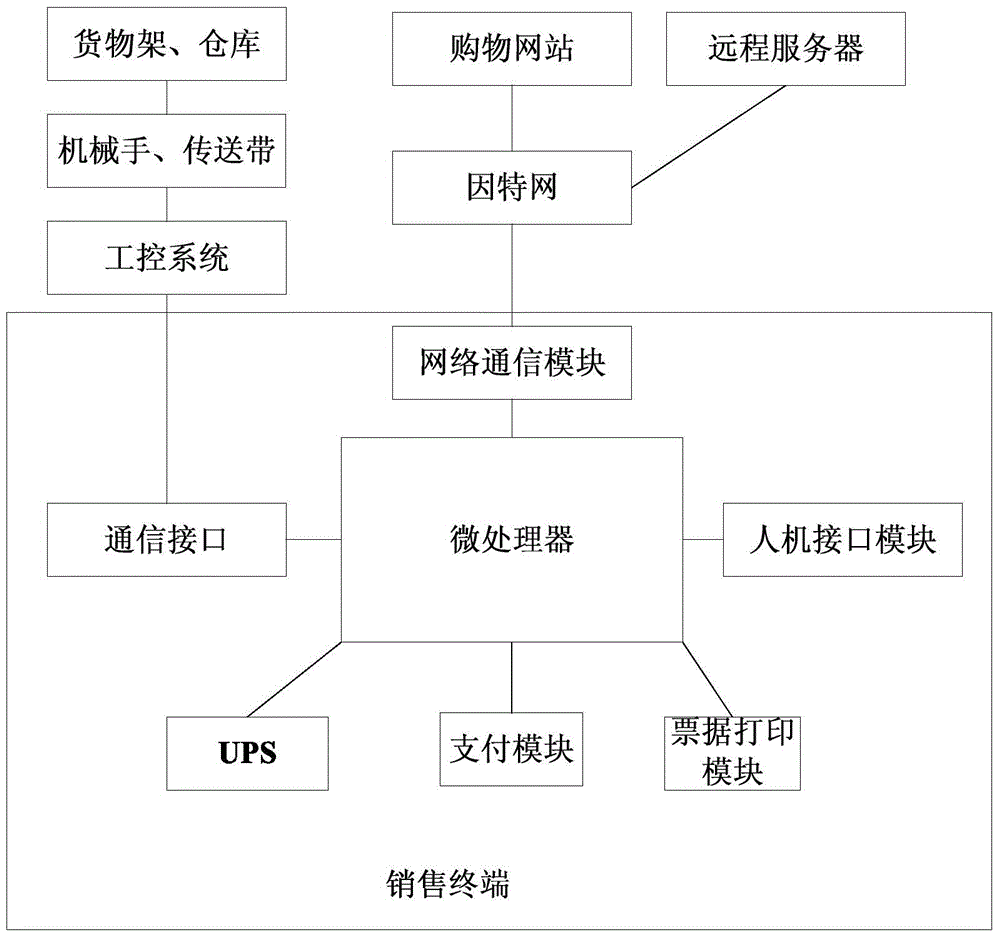

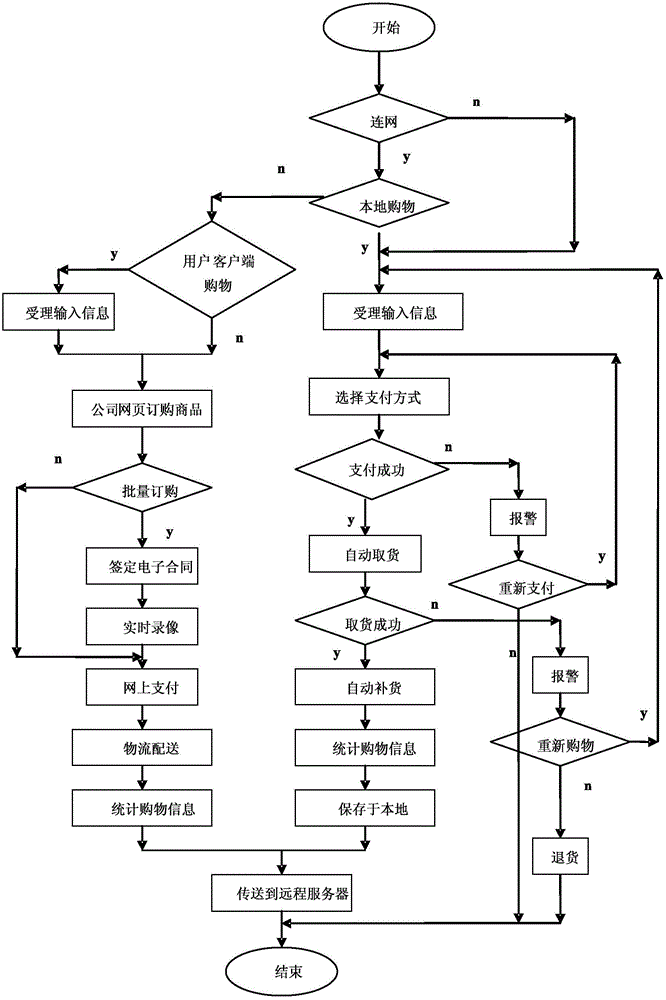

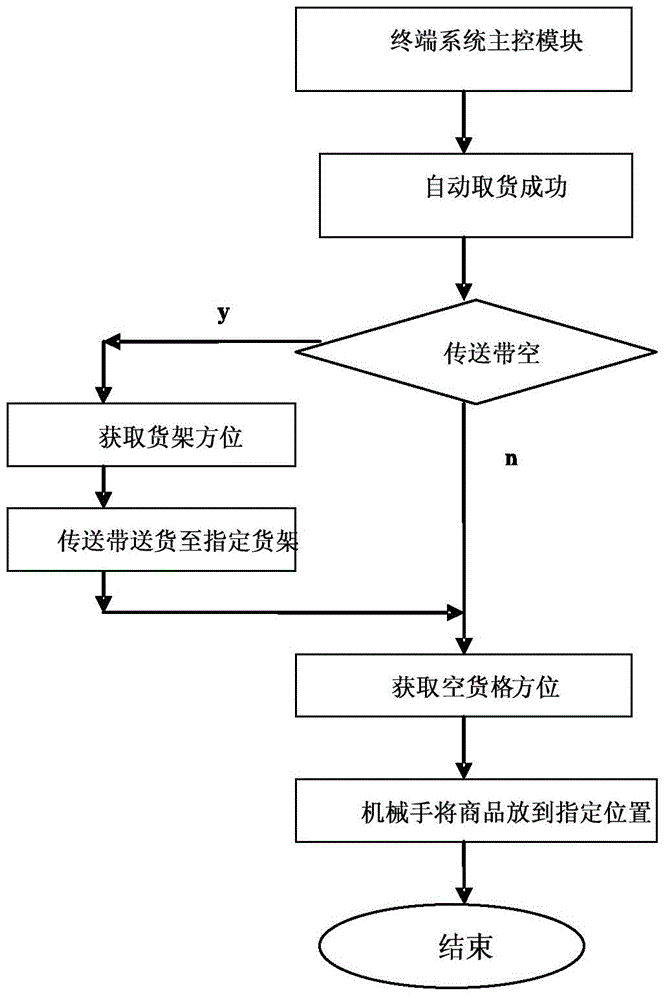

The invention discloses an intelligent sales terminal with an online shopping function, a sales system and a method. Disclosed by the invention is an intelligent safe sales terminal, a sales system and an implementation method which are based on network technologies, not only can carry out shopping on a local sales terminal, but also can order goods through the network. The intelligent sales terminal comprises a microprocessor, a man-machine interface module, a storage device, a network communication interface and a local communication interface, wherein the man-machine interface module, the storage device, the network communication interface and the local communication interface are connected with the microprocessor; and the man-machine interface module comprises a display screen and a device used for data input. The sales system comprises the intelligent sales terminal and a remote shopping website. The sales system also can comprise an automatic replenishment system and a remote server. The intelligent sales terminal with the online shopping function, the sales system and the method are easy to implement and can provide great convenience for shopping of customers.

Owner:向亦斌

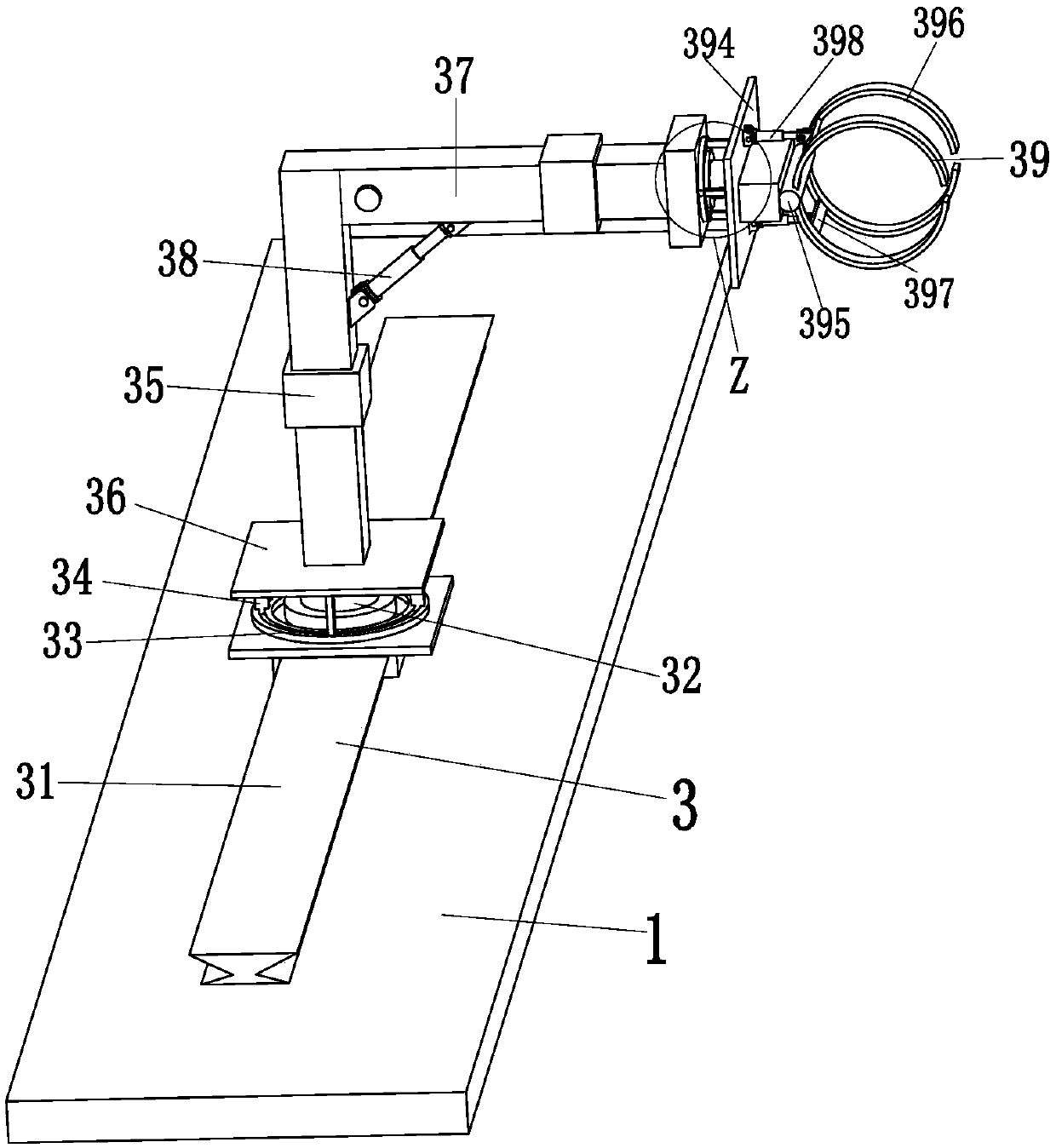

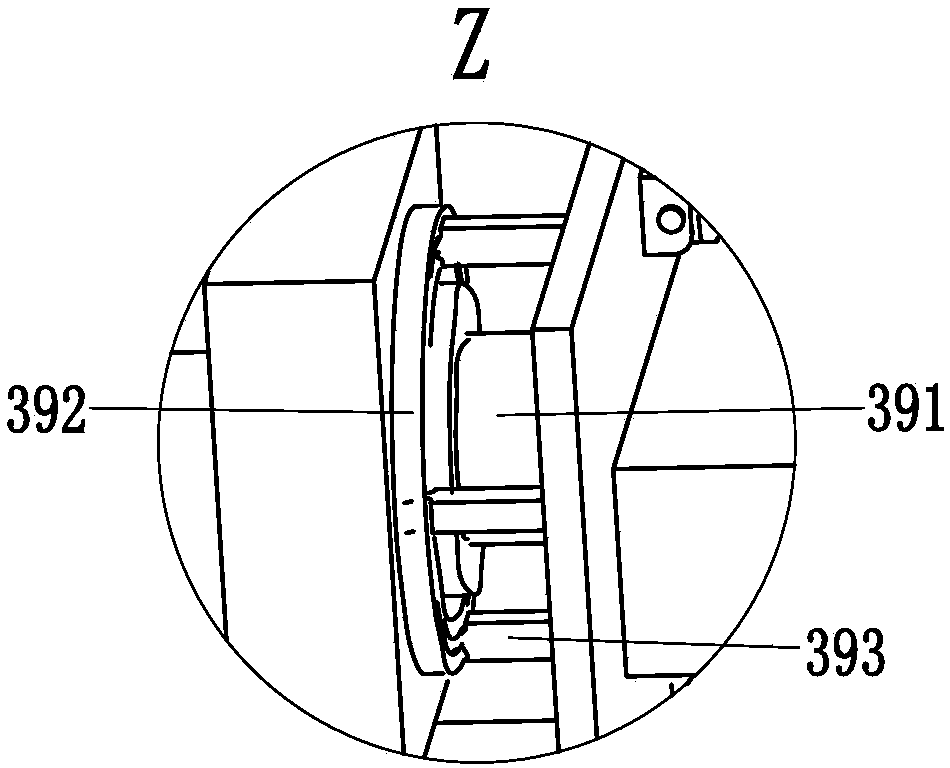

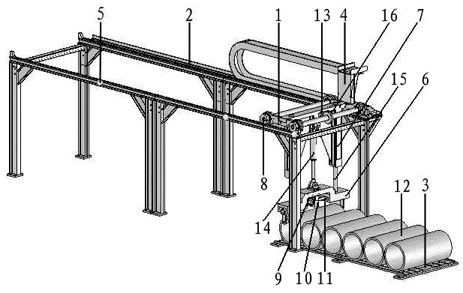

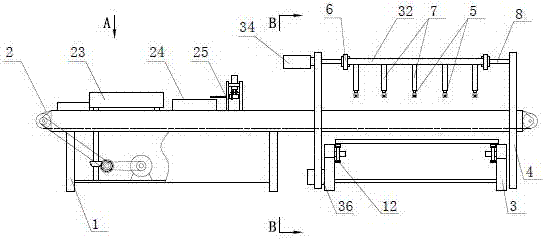

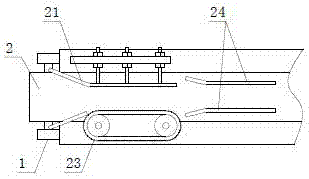

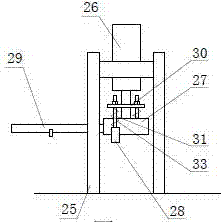

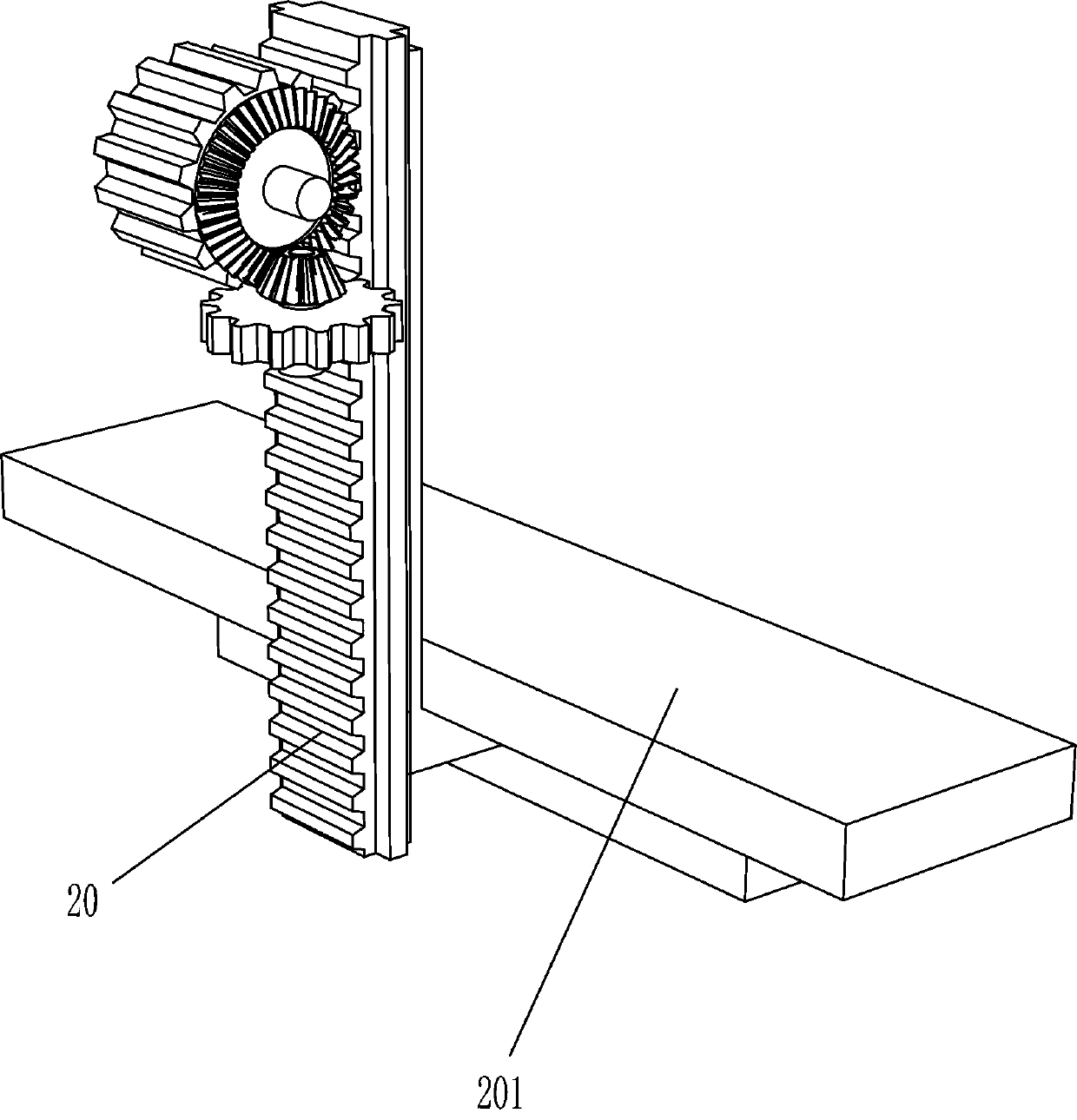

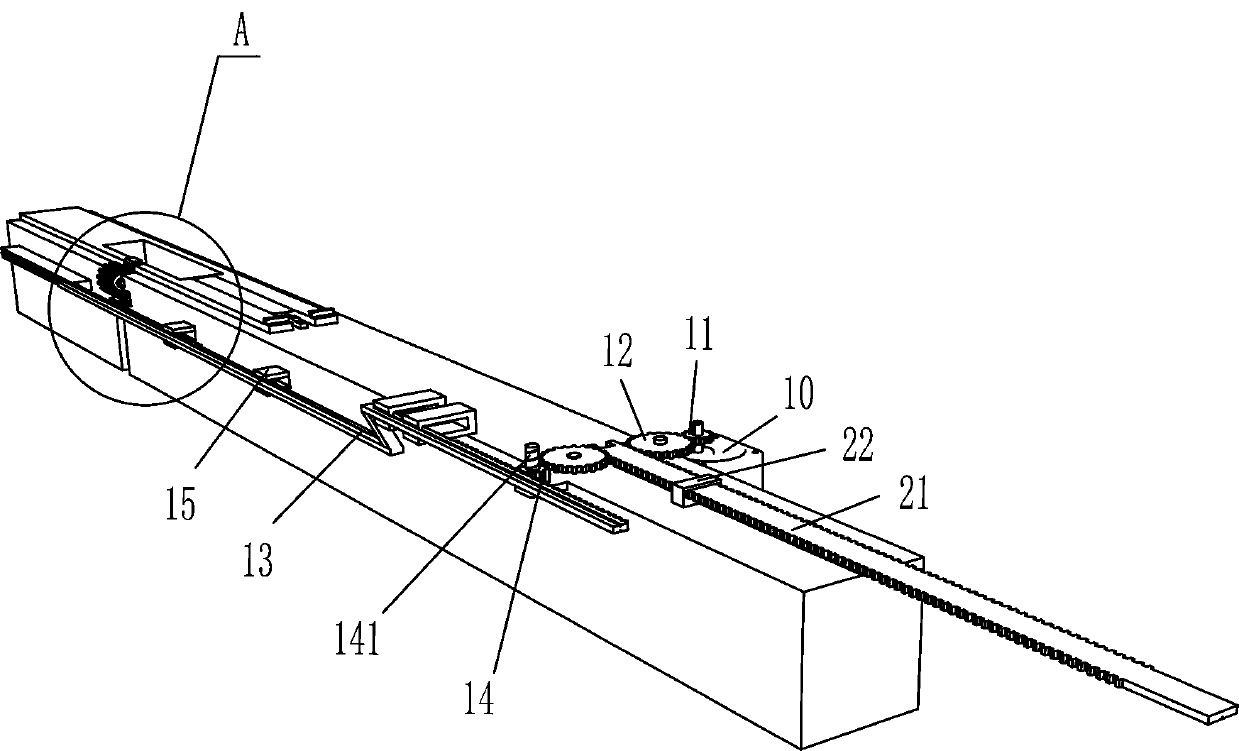

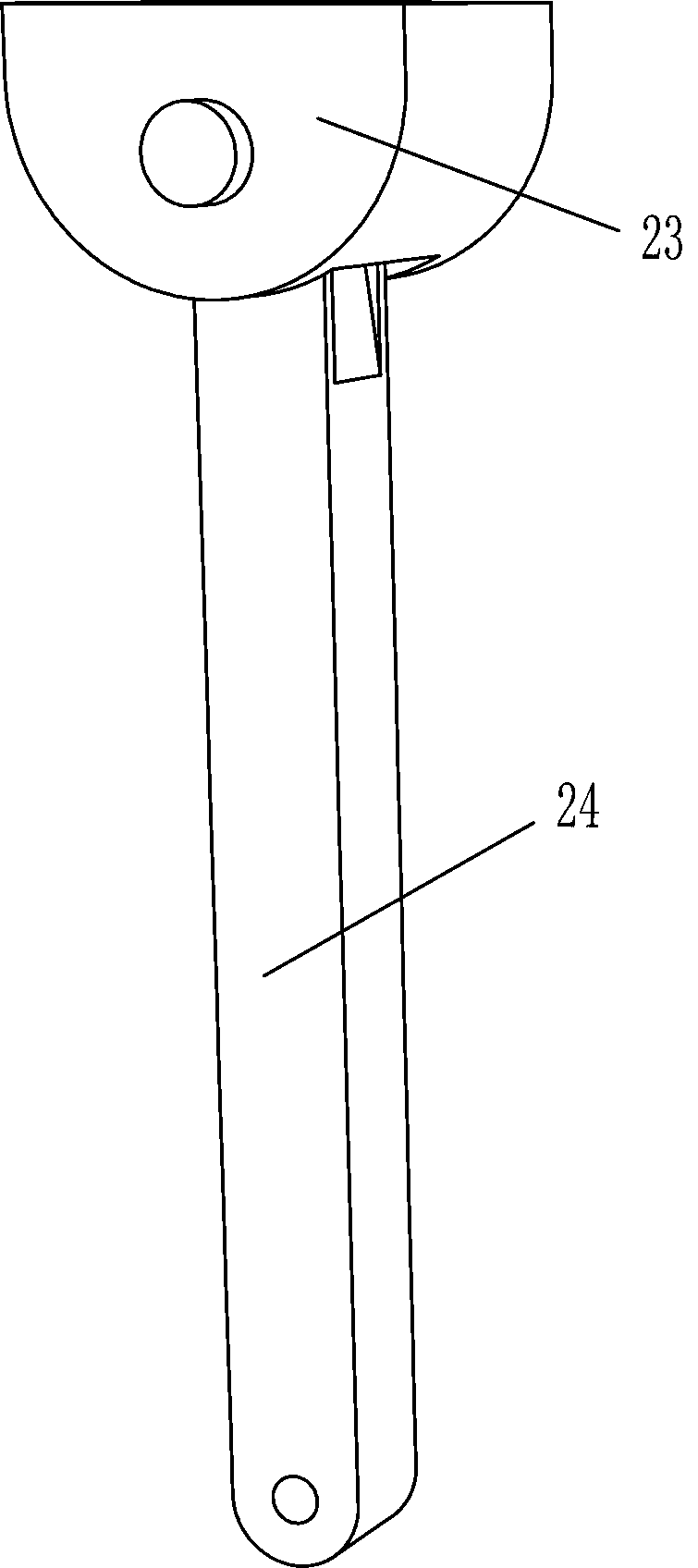

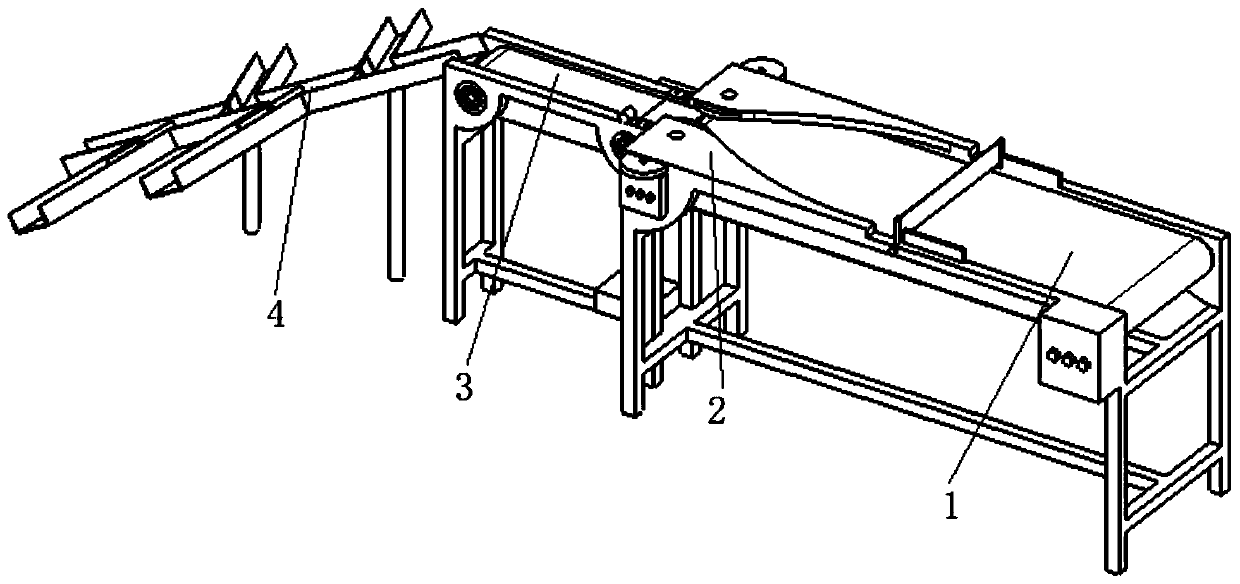

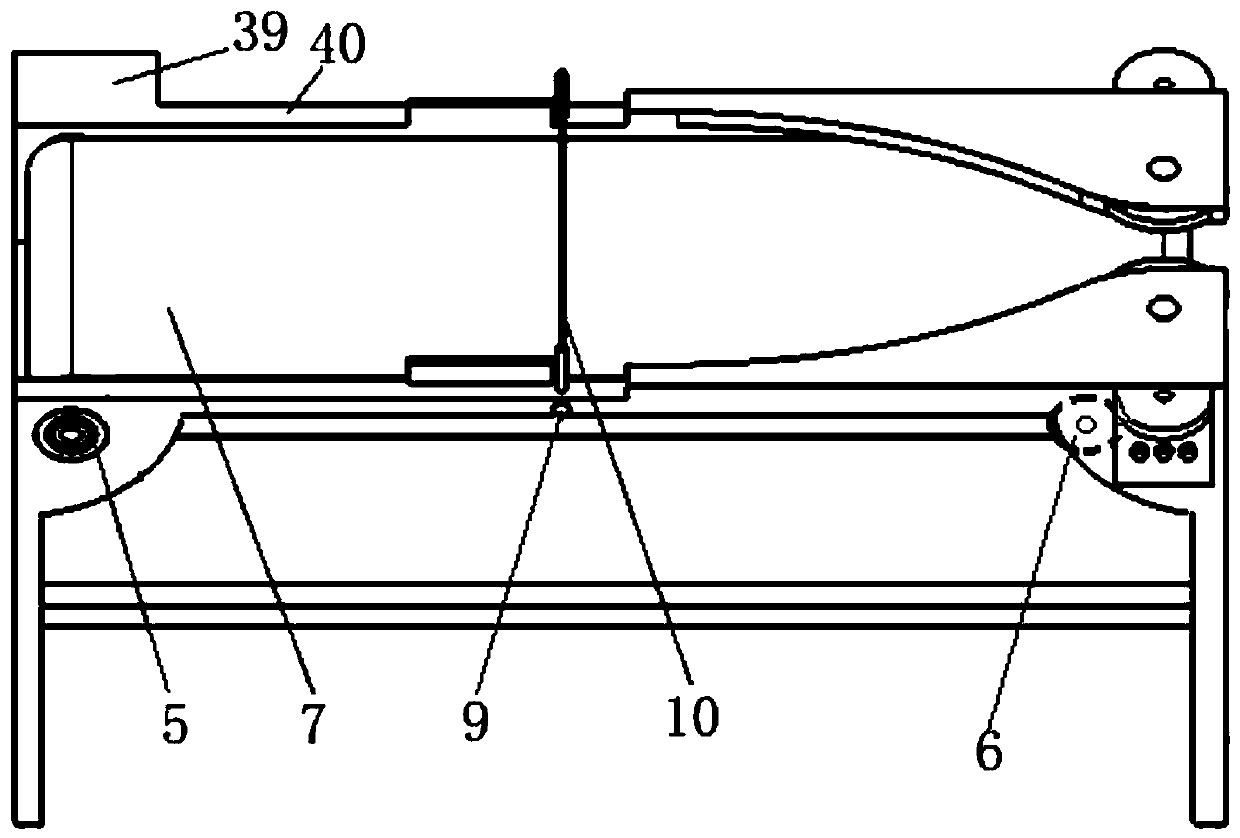

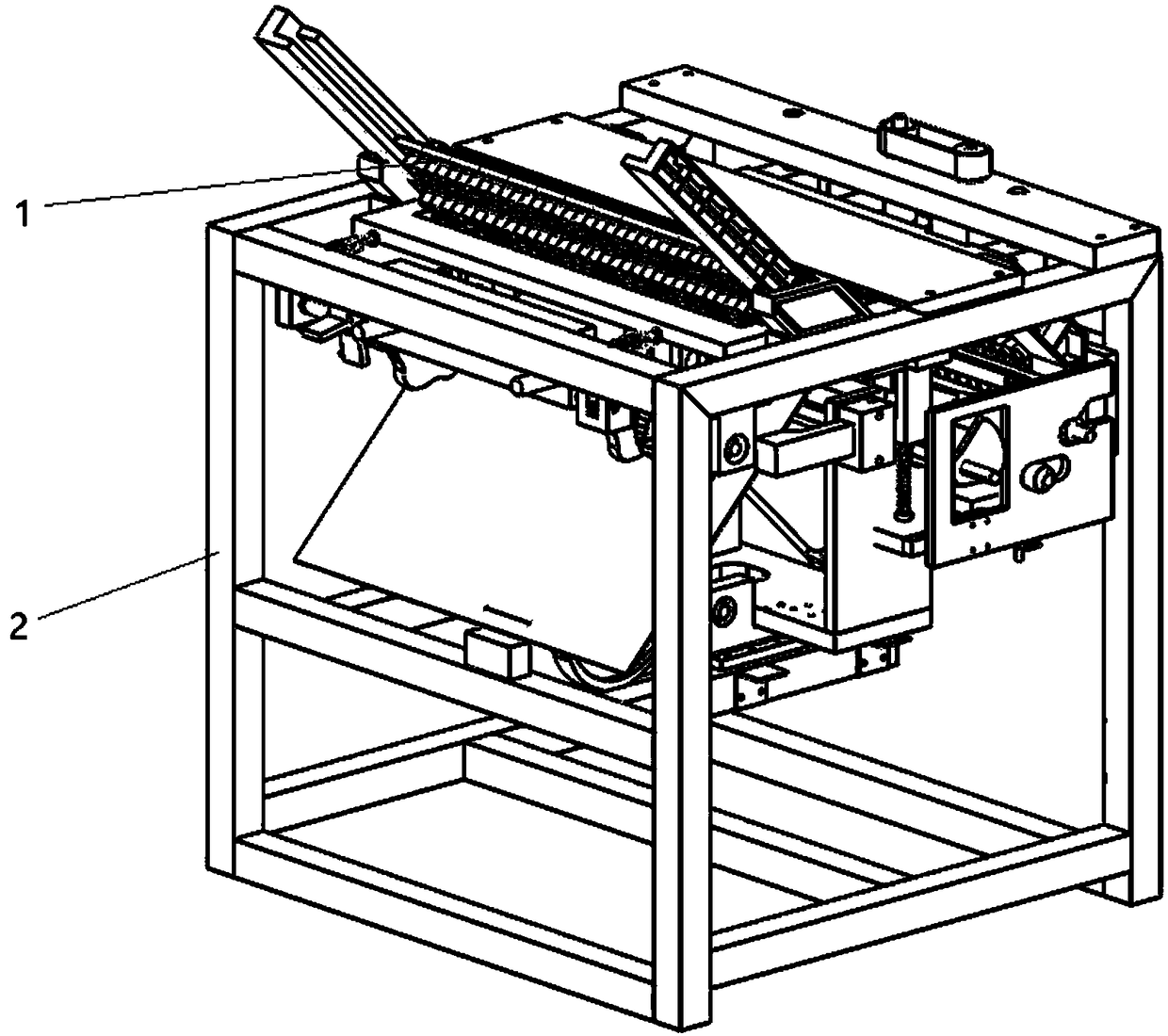

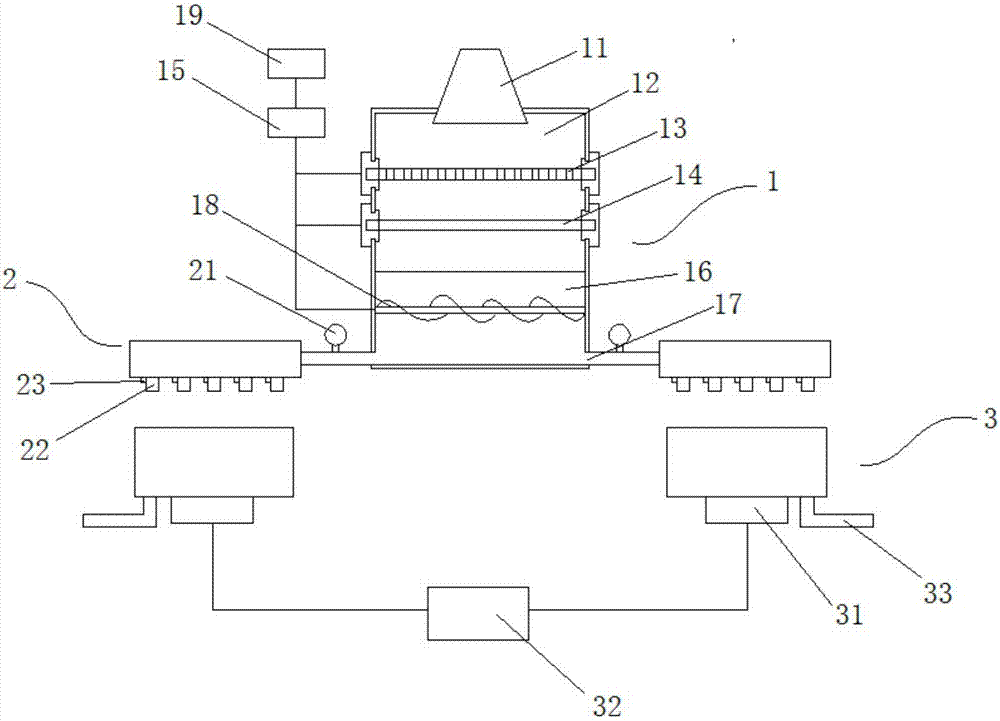

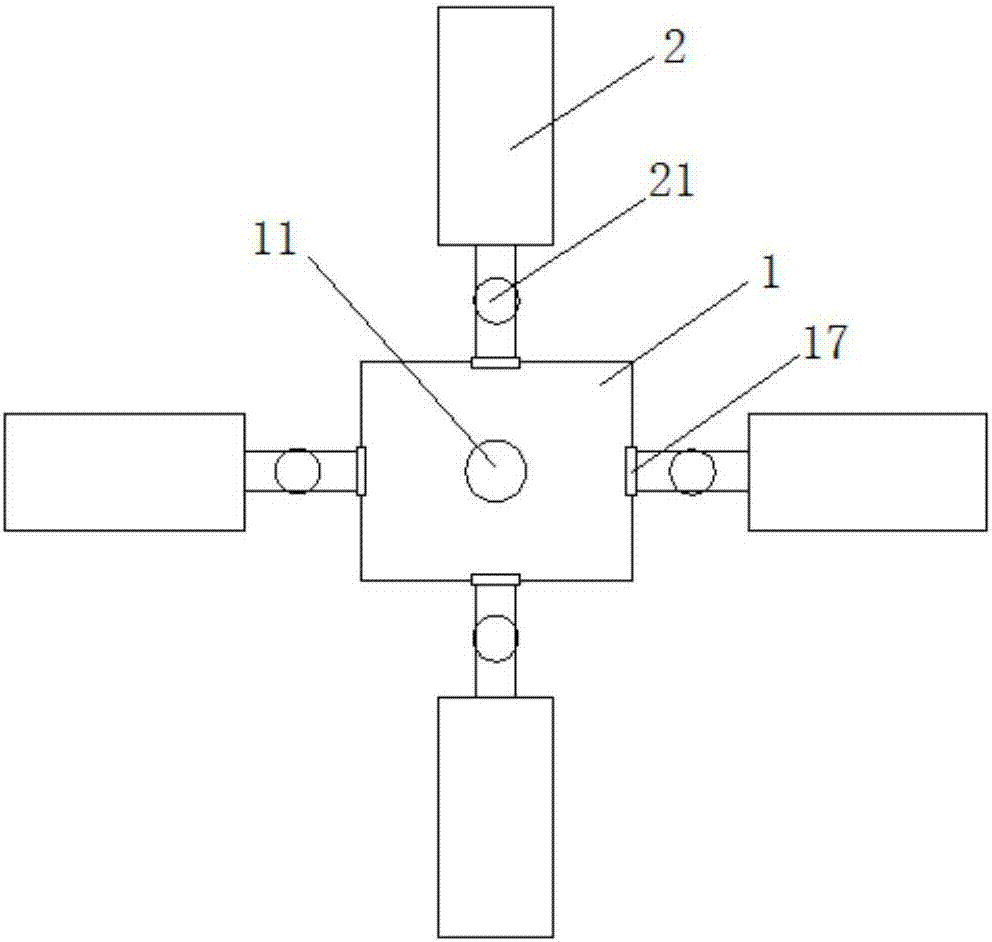

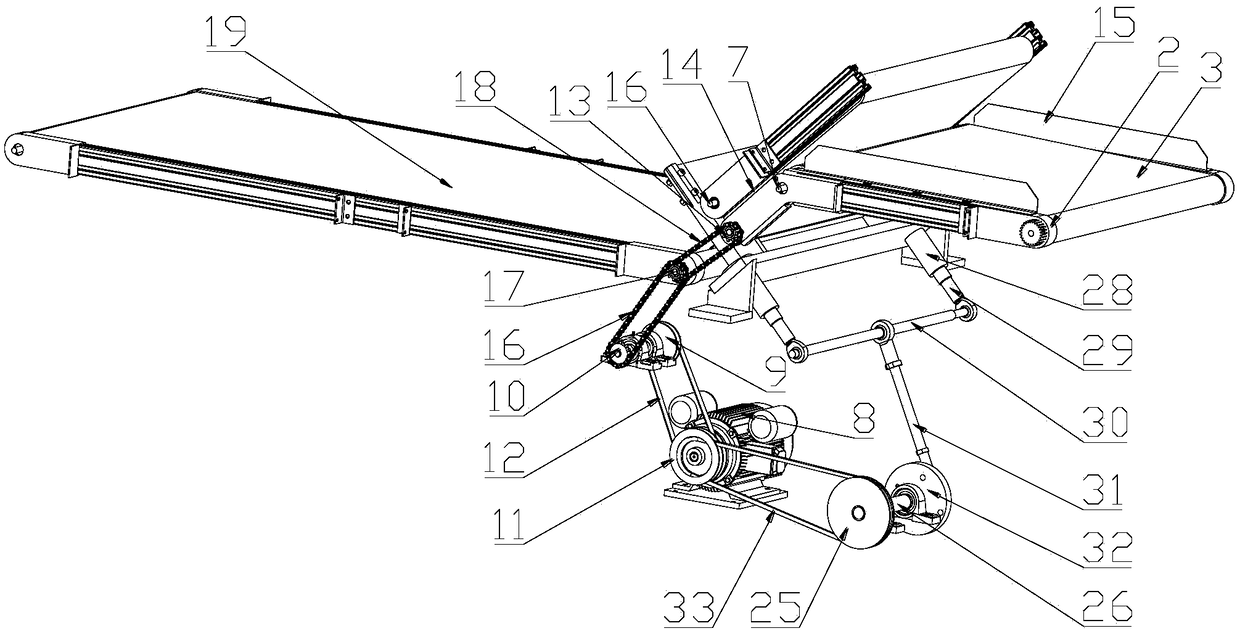

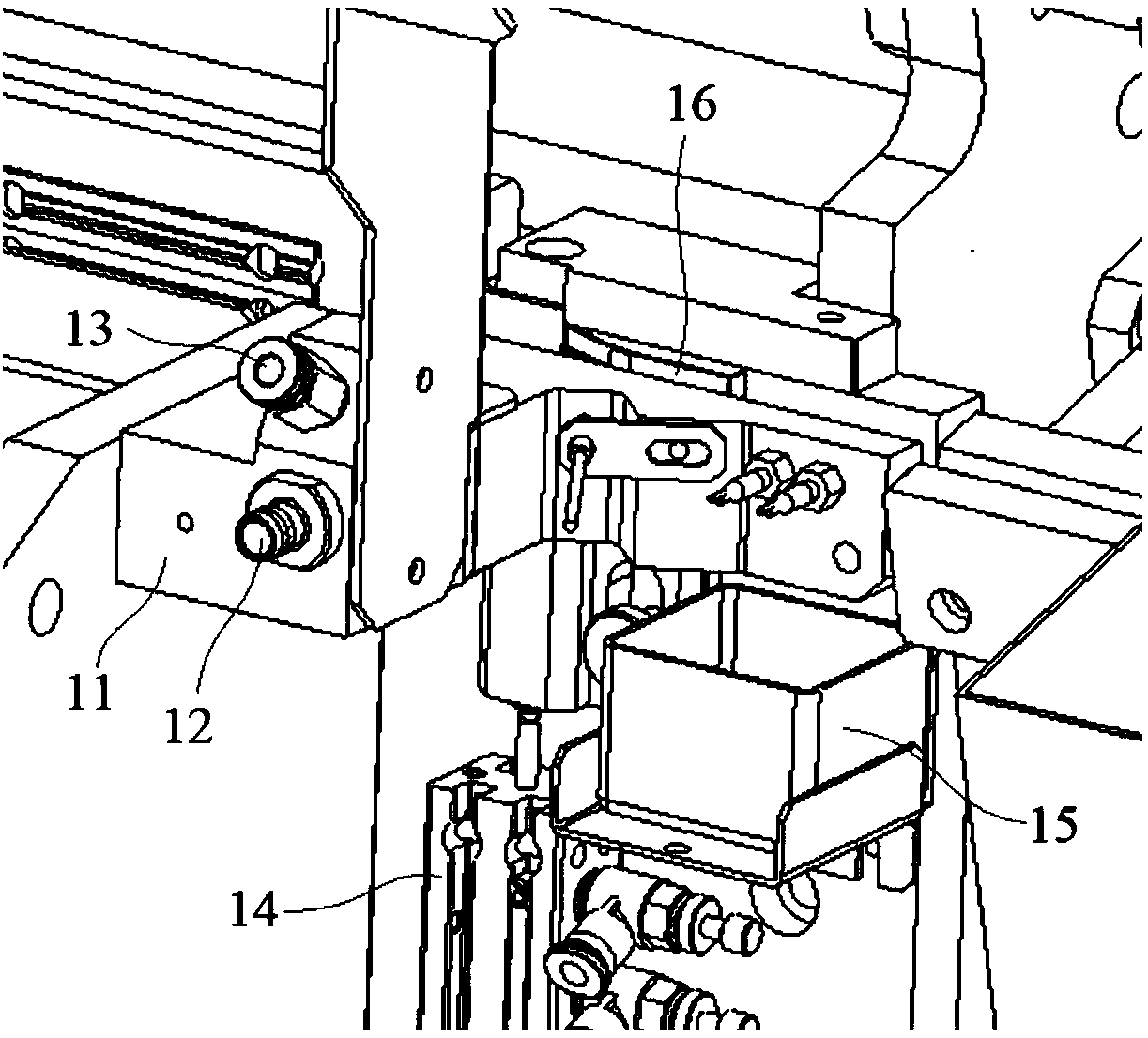

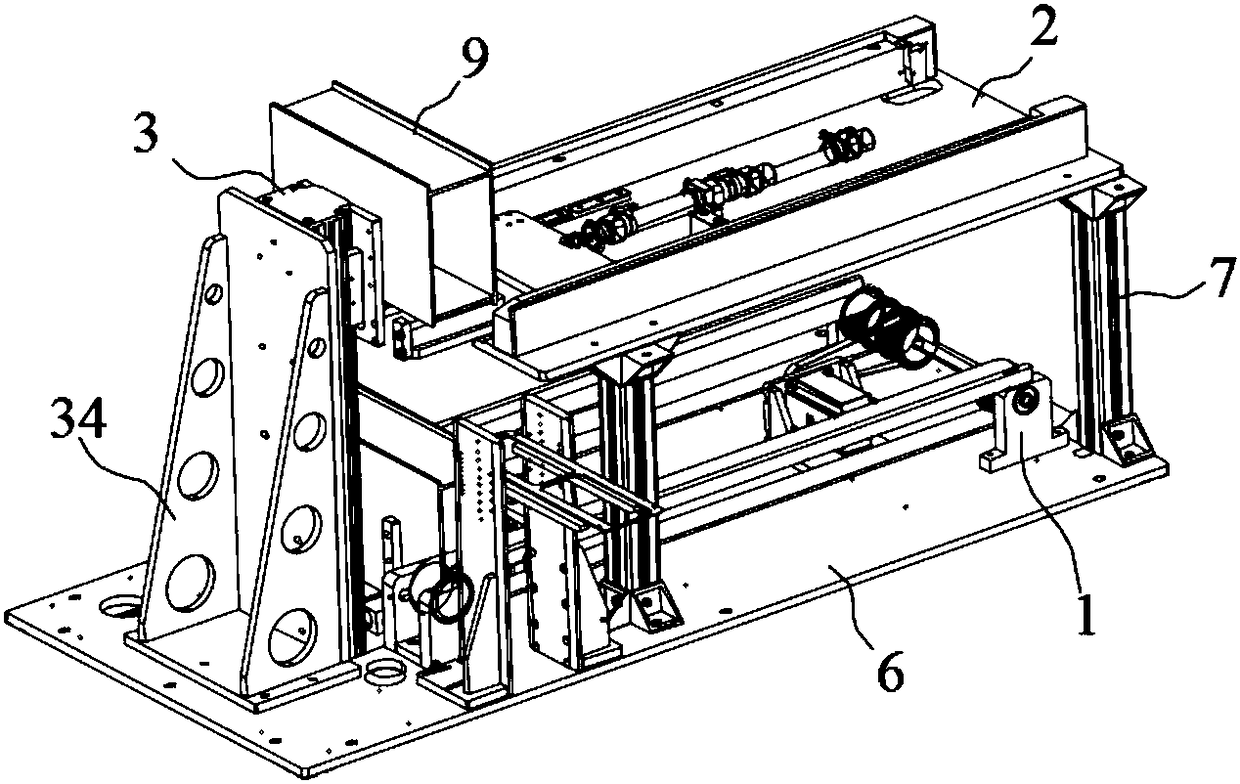

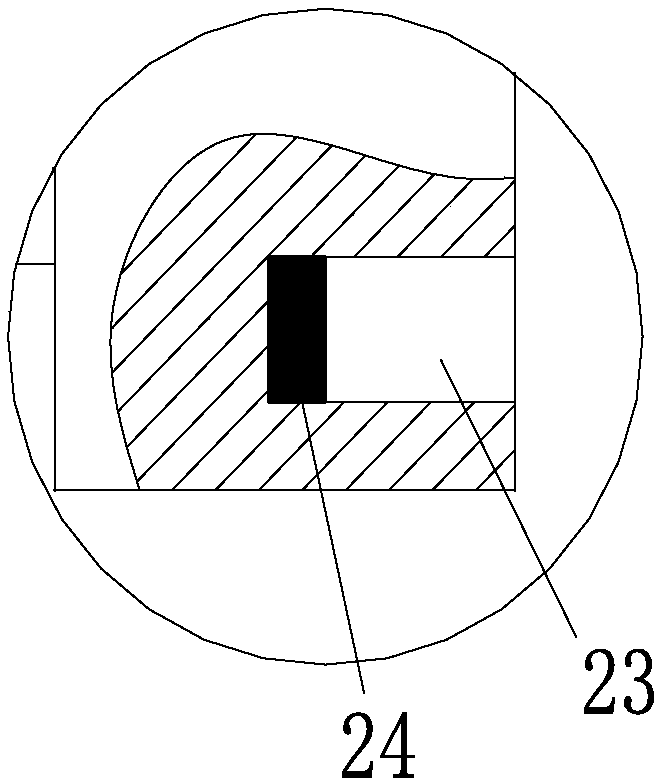

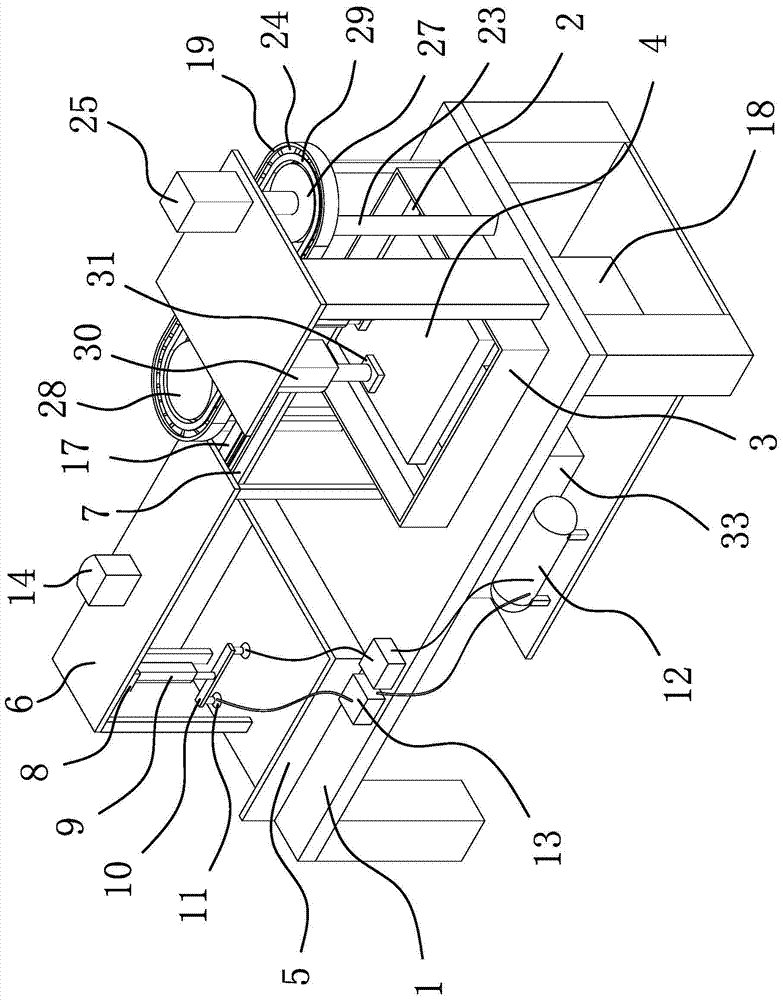

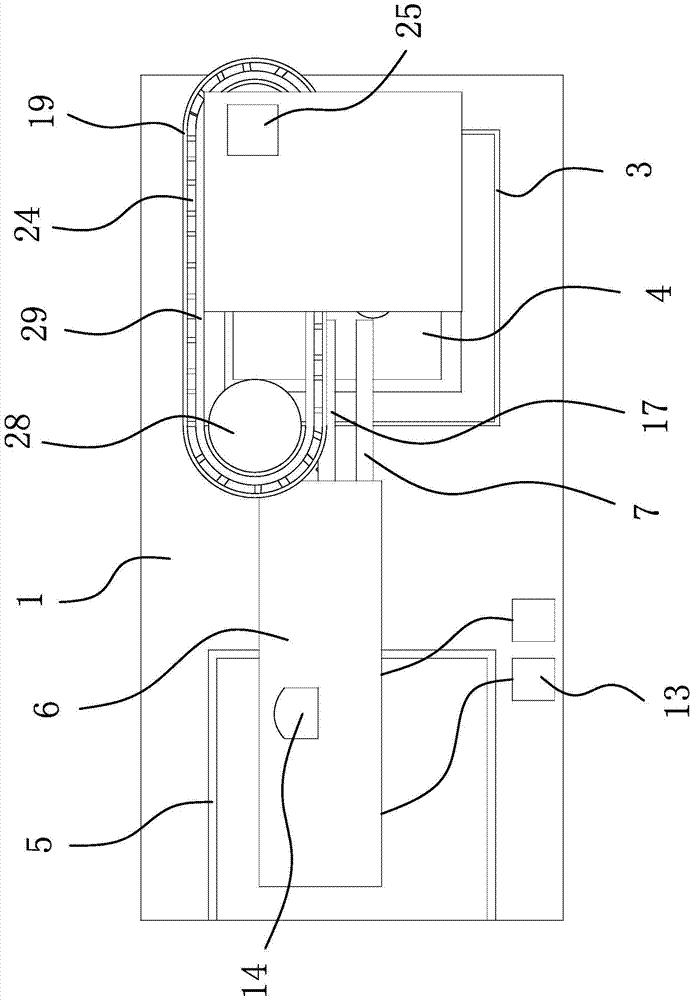

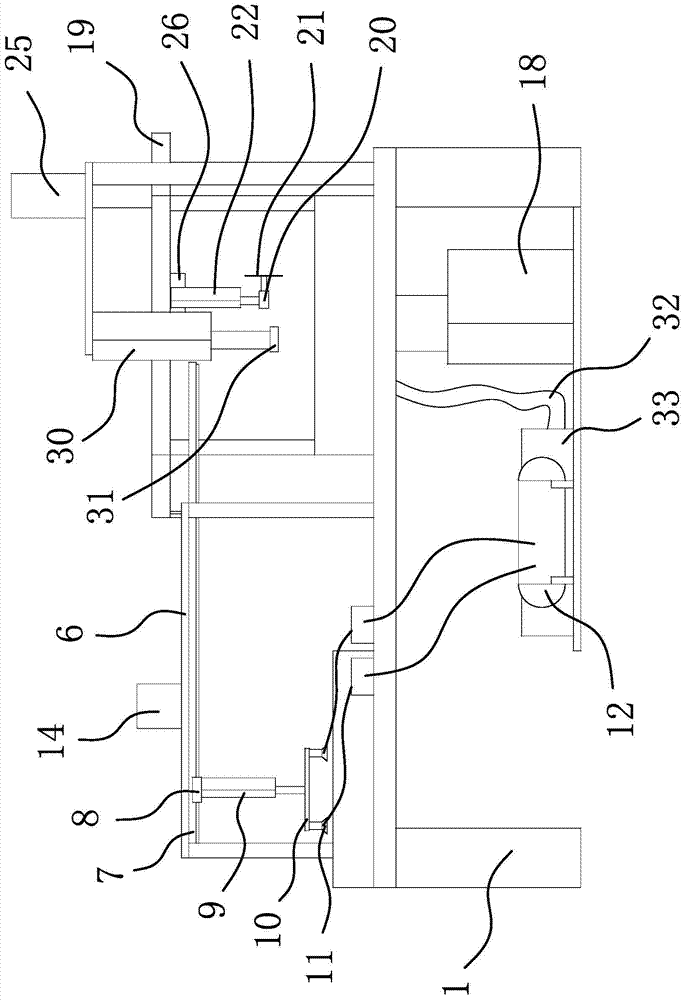

Automatic polishing, correction and assembly equipment for chemical heat energy exchange steel pipe machining

InactiveCN107891333AImprove grinding effectAutomate shippingEdge grinding machinesGrinding carriagesAfter treatmentPosition error

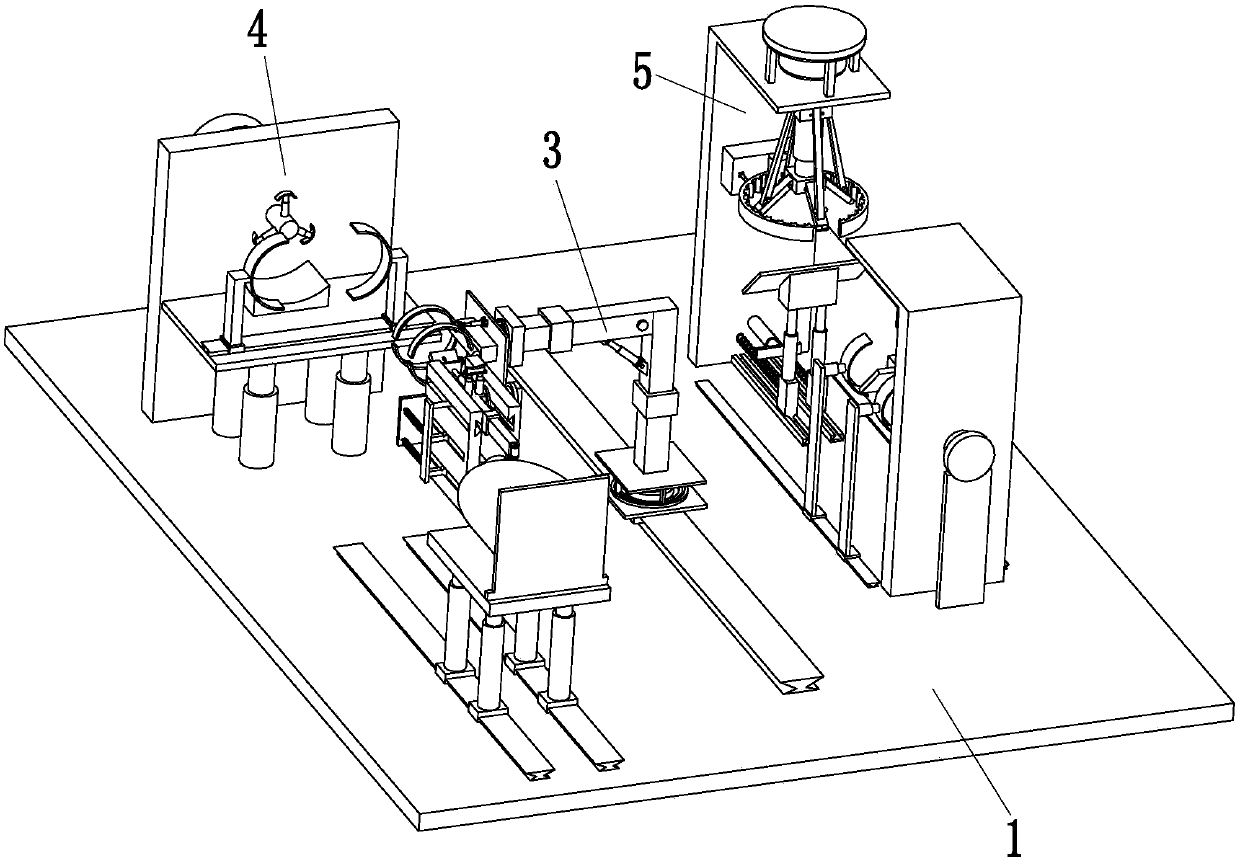

The invention relates to an automatic grinding, straightening and splicing equipment for chemical heat exchange steel pipe processing, which includes a supporting base plate, a clamping device, a grinding device and a fixing device. The clamping device is installed on the middle of the supporting base plate, and the grinding device is installed on the On the top of the left end of the base plate, the fixing device is installed on the top of the right side of the supporting base plate. The invention can solve the problems existing in the welding of the existing steel pipes, such as the need to manually grind the cut of the steel pipe, the poor grinding effect of the cut of the steel pipe, the need to manually correct the position of the steel pipe before welding the steel pipe, and the position of the steel pipe after correction. The cut steel pipes are cut and polished, the polished steel pipes are automatically transported, the steel pipes are automatically corrected and spliced together. The position is corrected, and there is no error in the position of the steel pipe after correction.

Owner:范满香

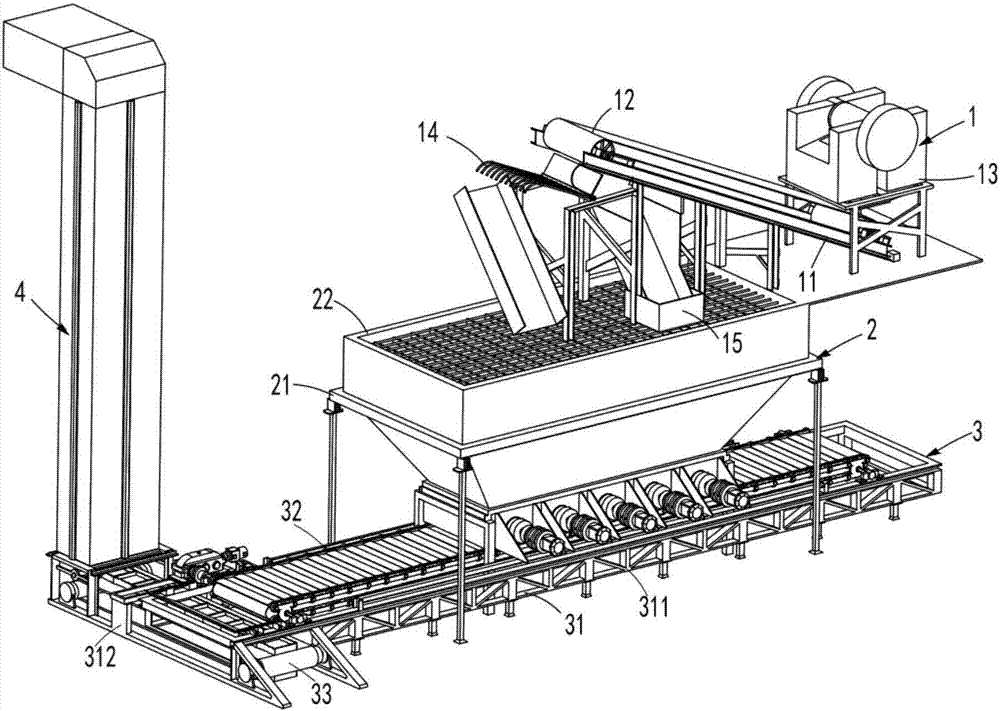

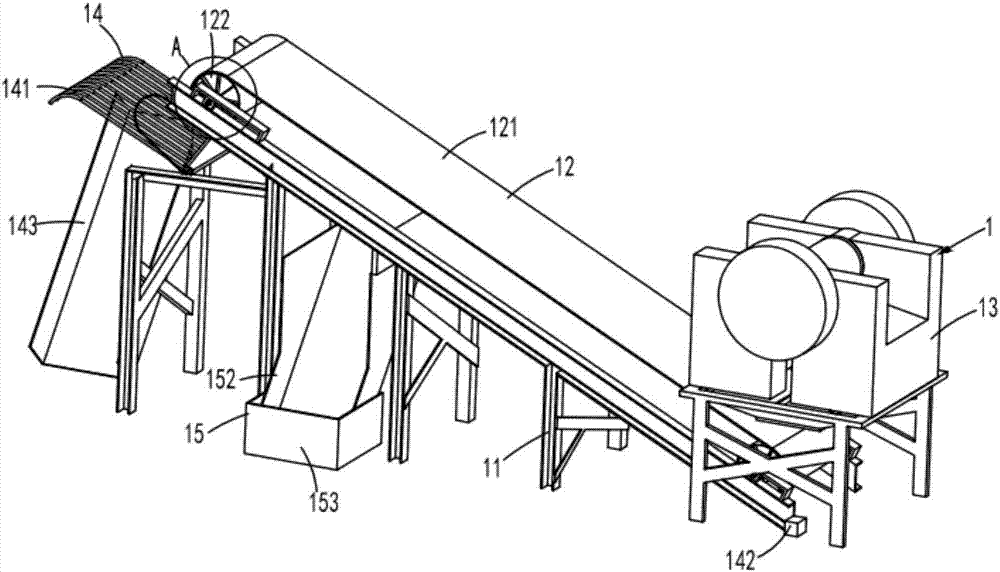

Heavy metal pollution soil treatment system and process

InactiveCN107309256ASimple structureClean thoroughlyContaminated soil reclamationMagnetic separationSoil treatmentPollution soil

The invention discloses and provides a heavy metal polluted soil treatment system and process, aiming to solve the screening problem of magnetic heavy metal pollutants in polluted soil, which includes a first crushing and screening mechanism, a second crushing and screening mechanism, and a transfer and conveying mechanism And the lifting mechanism, through the oblique lifting and throwing of the heavy metal contaminated soil after the initial crushing to the screening rake with magnetic adsorption, the secondary crushing of the heavy metal contaminated soil is carried out by the screening rake, and the heavy metal contaminated soil is sucked out by magnetic adsorption The magnetic heavy metals contained in it improve the quality and efficiency of heavy metal pollutants in the subsequent treatment process.

Owner:浙江明境环保科技集团有限公司

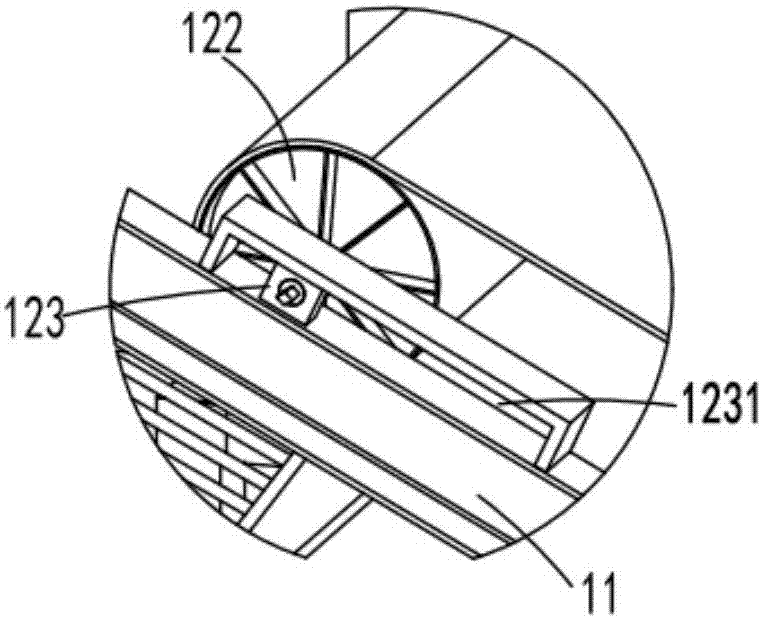

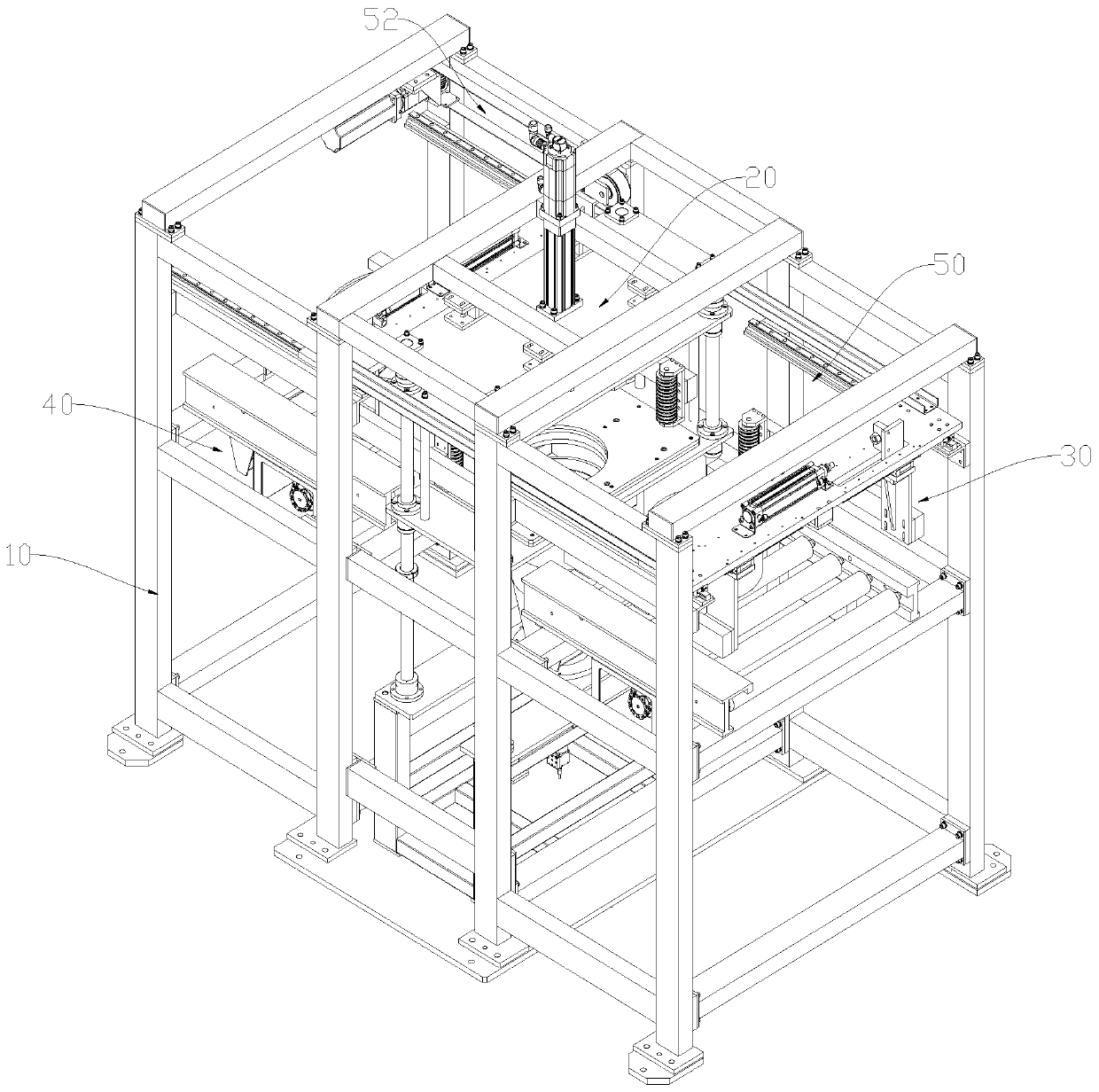

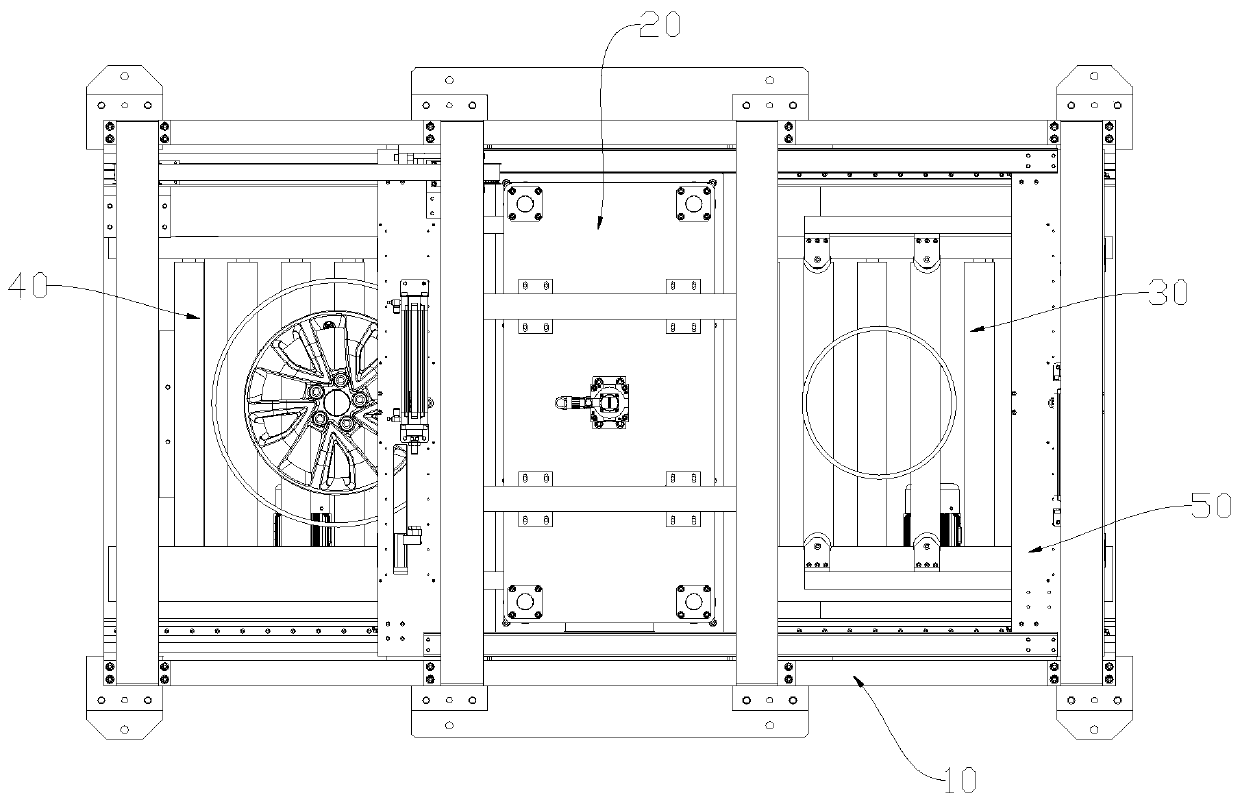

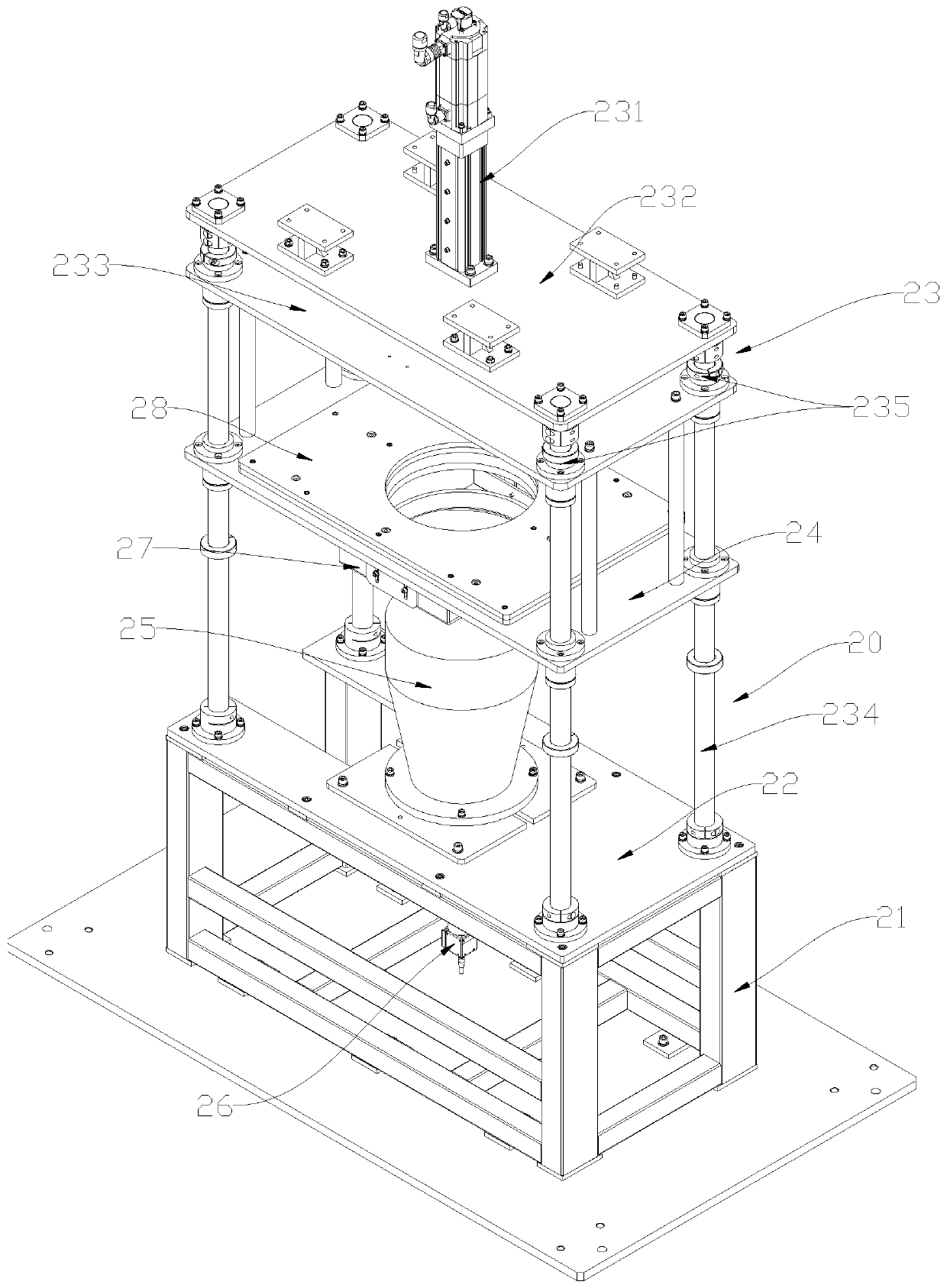

Device for detecting wheel hub and automobile component product

PendingCN110375653ARealize non-contact online detectionThe measurement results are objectiveUsing optical meansControl systemData acquisition

An embodiment of the invention discloses a device for detecting a wheel hub and an automobile component product. The device comprises a frame body, a lifting and lowering detecting device, a first workpiece conveying mechanism, a second workpiece conveying mechanism and a workpiece clamping and moving mechanism. The lifting and lowering detecting device comprises a bracket, a lens fixing plate, alifting and lowering device, a backlight source, a detecting platform, a lens and a camera. The lens is disposed on the lens fixing plate, the camera is disposed under the lens, the detecting platformis disposed above the lens, and the detecting platform is provided with a window penetrating the thickness direction of the detecting platform, a lower surface of the detecting platform is provided with a front light source, and the lifting and lowering device is respectively connected to the lens fixing plate and the detecting platform. Through the cooperation of the camera, the lens and the combined light source, the non-contact online detection is achieved, the automatic data acquisition, processing and automatic identification are completed by a vision system and a control system in the whole process, human subjective factors are reduced, the manual processing is not needed, the detection efficiency and detection accuracy are improved, and the labor cost is reduced.

Owner:长沙精锐智能科技有限公司

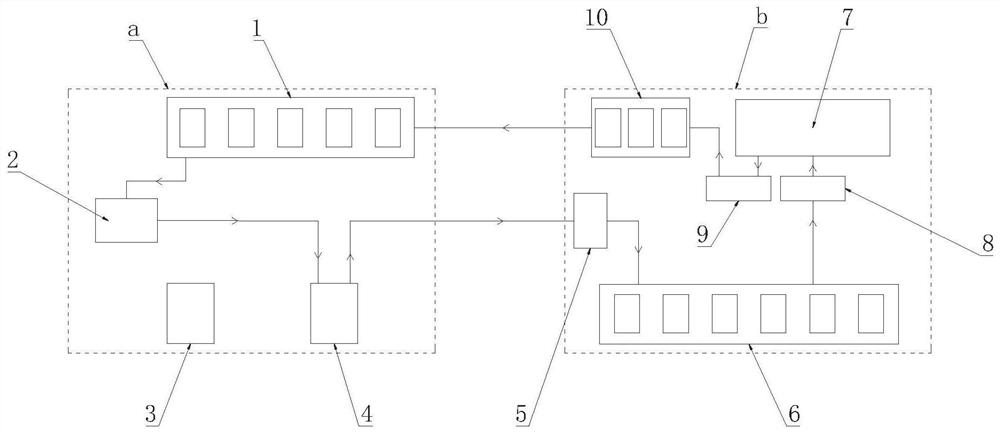

AGV based automatic transportation system of warping yarn rack

PendingCN106516626AGuaranteed accuracyAutomate shippingWarping machinesOther manufacturing equipments/toolsYarnEngineering

The invention discloses an AGV based automatic transportation system of a warping yarn rack. The AGV based automatic transportation system comprises an AGV body and a magnetic strip laid on the ground. A magnetic inductor corresponding to the magnetic strip is arranged at the lower end of the AGV body. The upper end of the AGV body is detachably connected with a bottom plate. A walking mechanism is arranged at the lower end of the bottom plate. A bearing rack is arranged at the upper end of the bottom plate. A first moving rack is arranged on one side of the bearing rack. Fixed shafts are arranged at the upper end and the lower end of the bearing rack. First lead screws corresponding to the fixed shafts are fixed to the upper end and the lower end of the first moving rack. The first lead screws penetrate the fixed shafts. A second air cylinder is fixed to the bearing rack. According to the AGV based automatic transportation system, by means of combination of the AGV body and the bearing rack, automatic transporting of spools is achieved; by means of combination of the first moving rack, a second moving rack and a lifting oil cylinder, automatic yarn feeding and collecting are achieved; and by means of combination of a locating device and a guide rail, yarn feeding accuracy is guaranteed, and the AGV based automatic transportation system is suitable for popularization.

Owner:广州赫伽力智能科技有限公司

Conveying device of juice extractor

InactiveCN105329606AAutomate food deliverySolve the problem that ingredients cannot be confirmed on siteConveyorsControl devices for conveyorsMotor driveEngineering

The invention discloses a conveying device of a juice extractor. The conveying device comprises a conveying basket and a conveying chain. The conveying basket is connected with the conveying chain, and a motor drives a transmission gear and further drives the transmission chain to rotate; the conveying device further comprises a lower-layer tray, and a transmission belt is arranged on the bottom face of the lower-layer tray; the conveying device further comprises an upper-layer tray, and the upper-layer tray is higher than the lower-layer tray and comprises a bottom face and a fence connected with the bottom face; a transmission belt is also arranged on the bottom face of the upper-layer tray, and the fence is provided with an opening; and a containing groove is formed in one side of the lower-layer tray. The problem that when a traditional juice extruding device carries out production, a consumer cannot confirm the food material on site is solved; and meanwhile, enough raw materials are ensured, and food material conveying automation can be achieved.

Owner:SHANGHAI JUANG IND

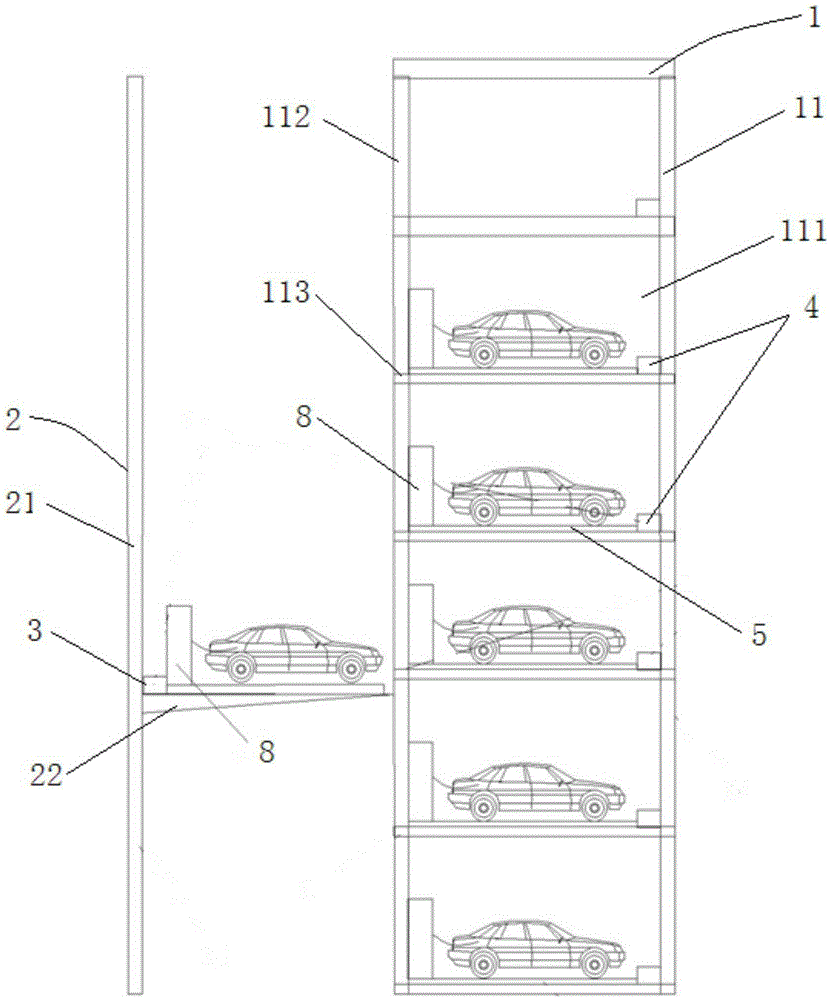

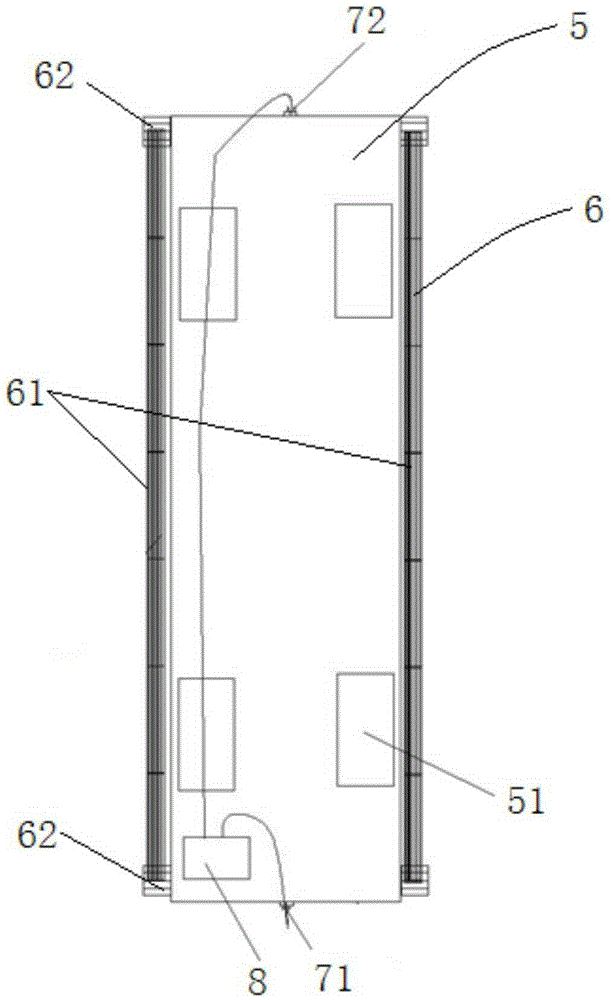

Chargeable mechanical stereoscopic garage

ActiveCN105332533AConvenient high-level transportationAutomate shippingParkingsElectricityElectric machinery

The invention provides a chargeable mechanical stereoscopic garage. The chargeable mechanical stereoscopic garage comprises a building, a car lifting unit, a first socket, multiple second sockets, multiple car carrying plates, multiple car conveying units, first plugs, second plugs, multiple charging piles and an external power grid. The building comprises multiple floors, each floor is provided with a car parking unit, and a car inlet is formed in one end of each floor. The car lifting unit comprises a lifting arm, and a supporting plate is arranged on one side of the lifting arm. The first socket is arranged on the upper surface of the supporting plate. The second sockets are arranged at the other ends of the car parking units respectively. The car carrying plates are each in a plate body shape. Each car conveying unit comprises two conveying tracks and drive motors. Each first plug and each second plug are arranged at the two ends of the corresponding car carrying plate in the width direction respectively. Each charging pile is arranged at one end of the upper surface of the corresponding car carrying plate. The power supply ends of the charging piles are electrically connected with the first plugs and the second plugs. The external power grid is electrically connected with the first socket and the second sockets. The chargeable mechanical stereoscopic garage is simple in structure and high in operation automation degree, the number of parking places is obviously increased, cars can be charged in the parking and fetching processes, the garage is small in occupied area, charging is convenient, and charging efficiency is high.

Owner:SUZHOU ZOYO ELEVATOR

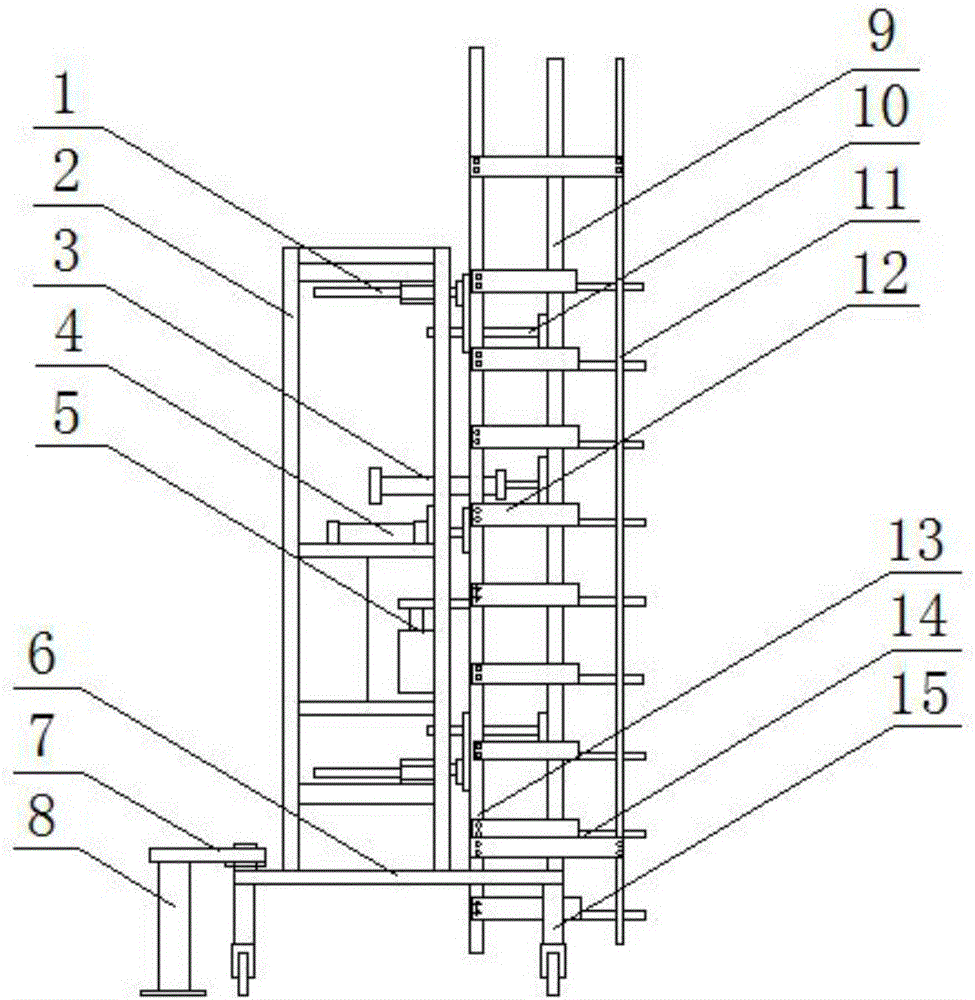

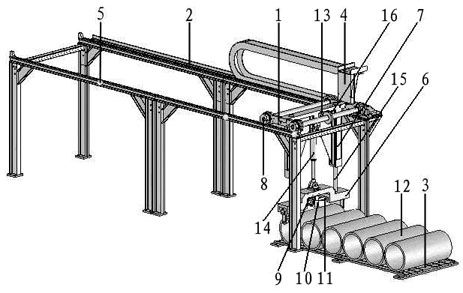

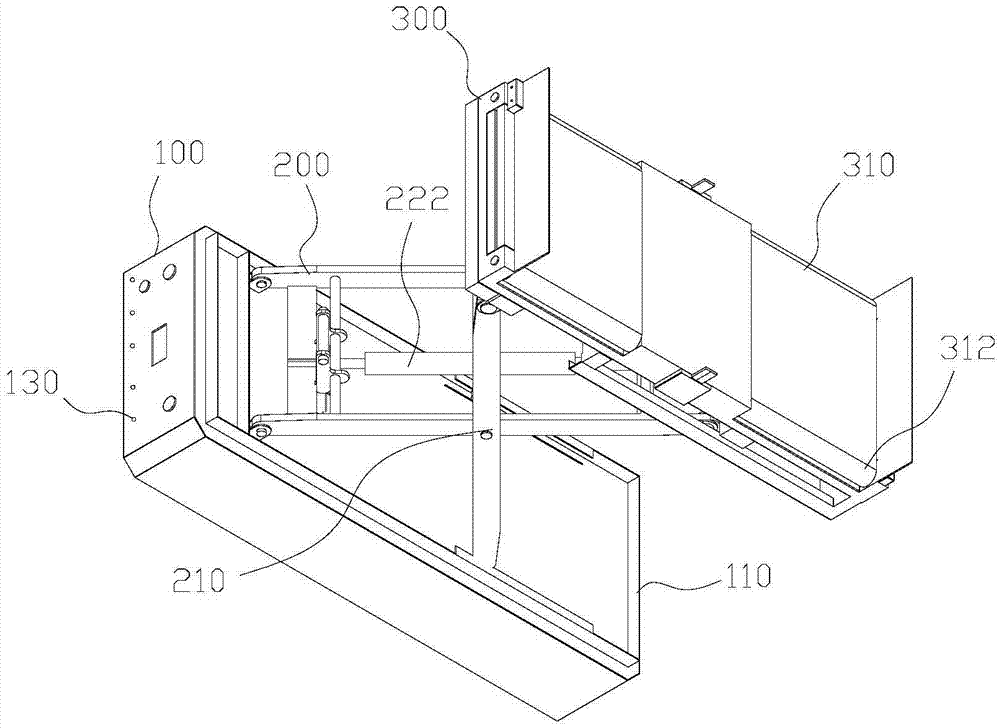

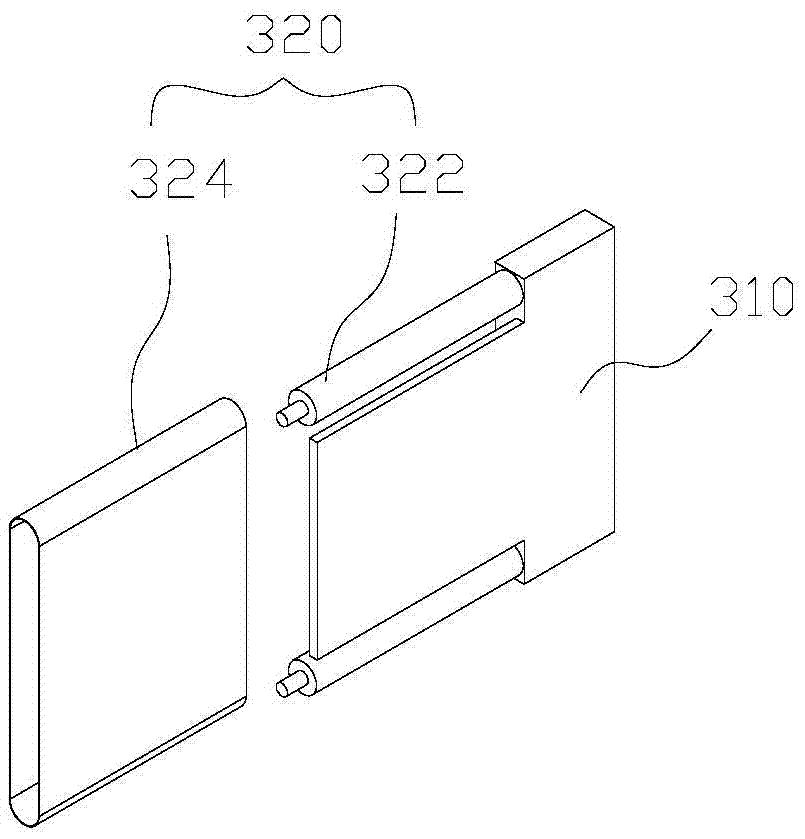

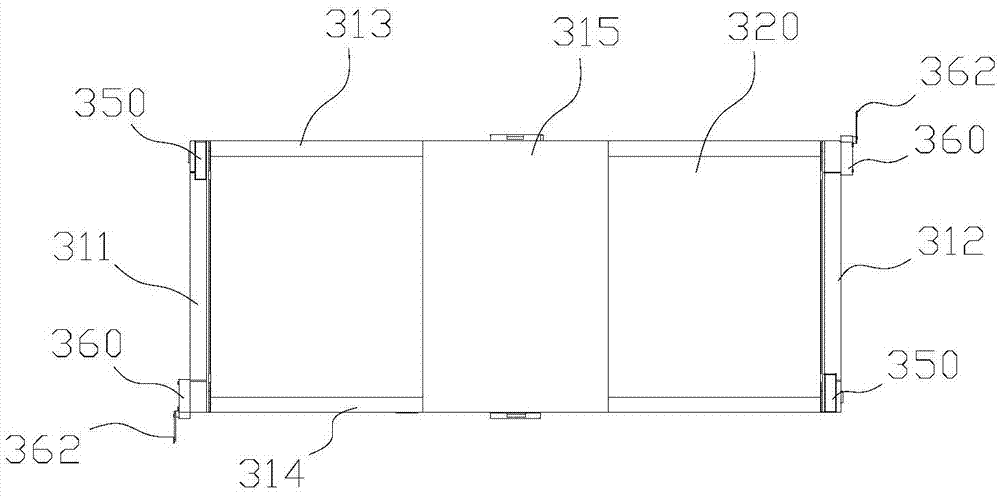

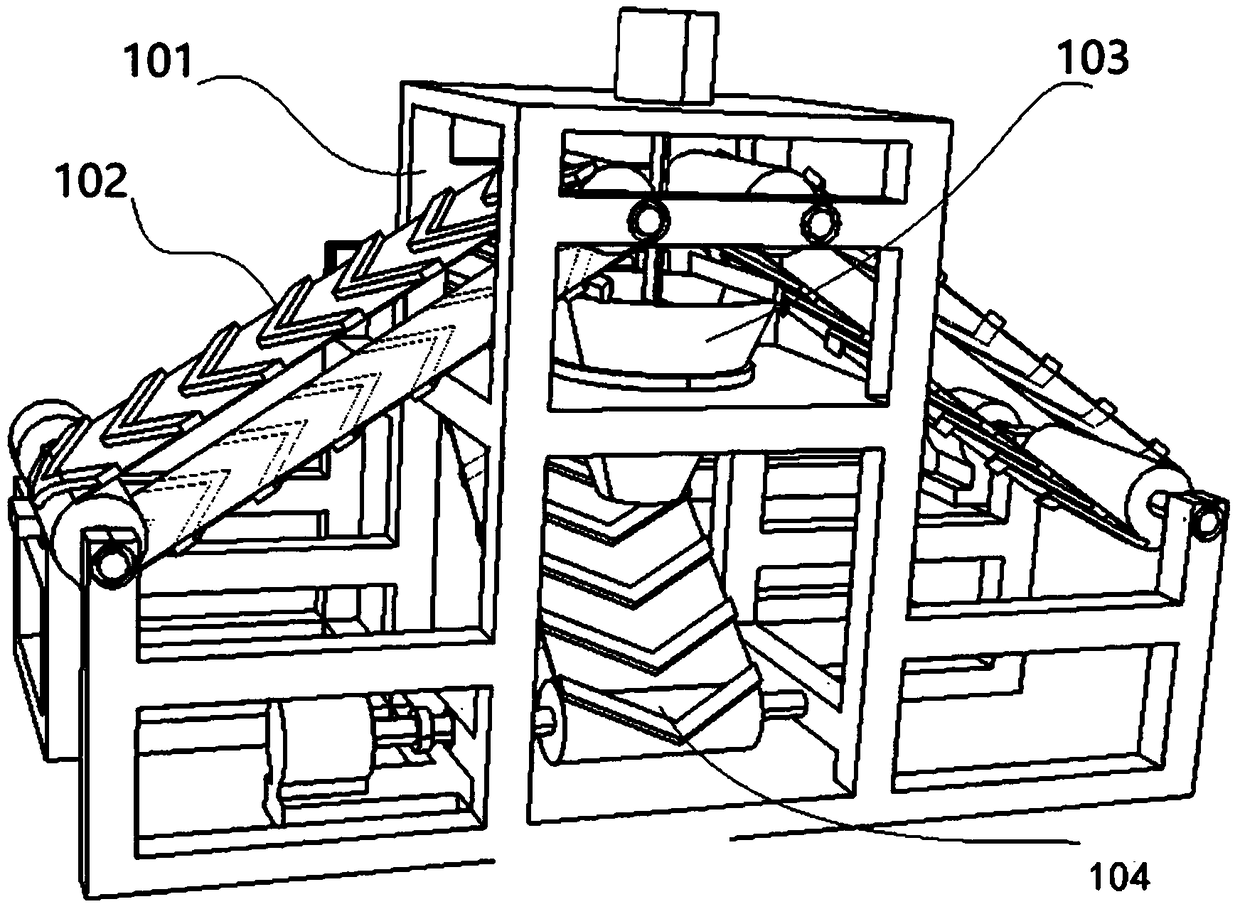

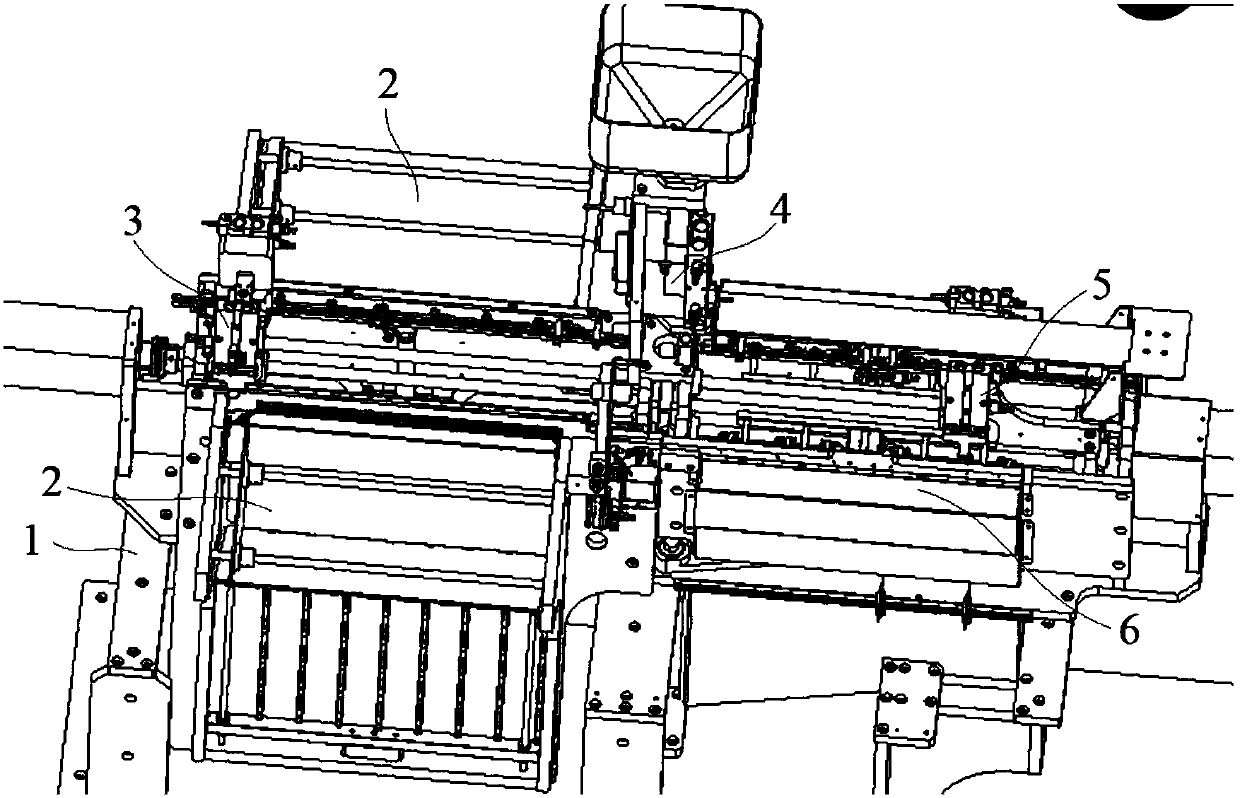

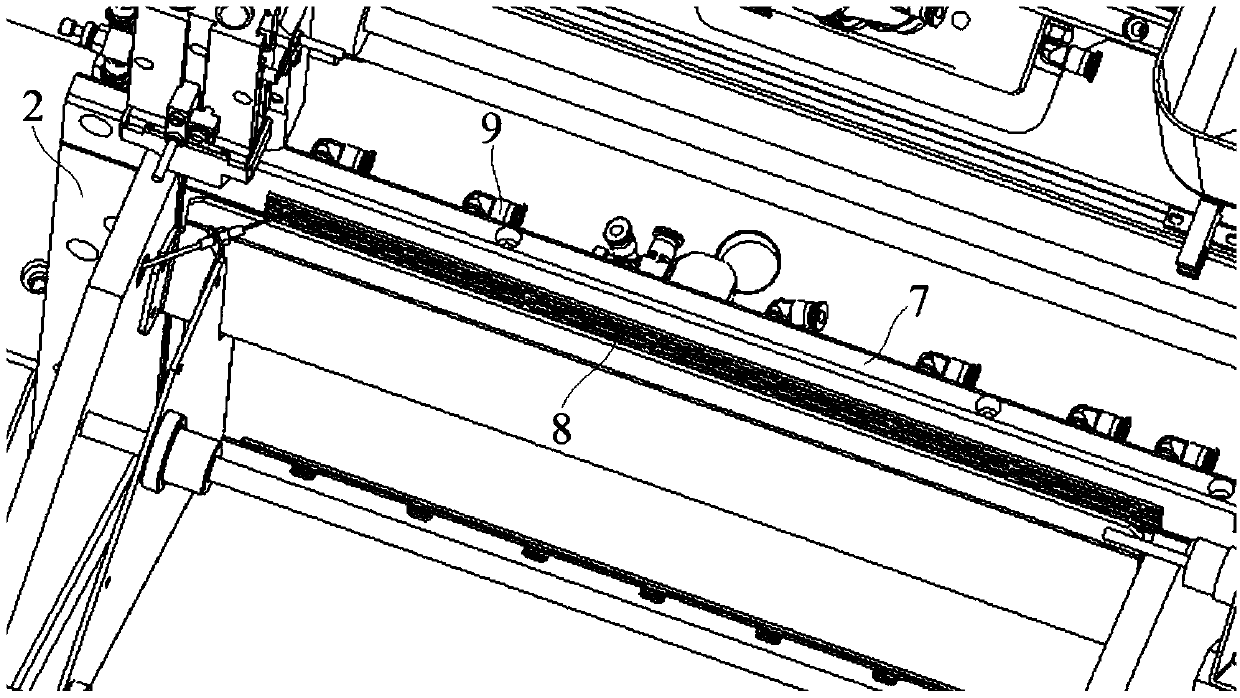

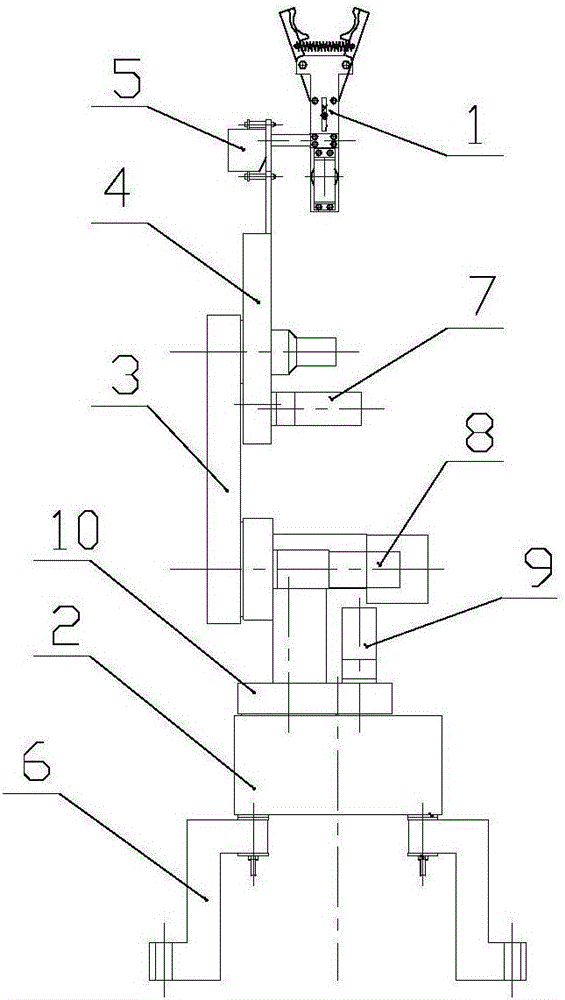

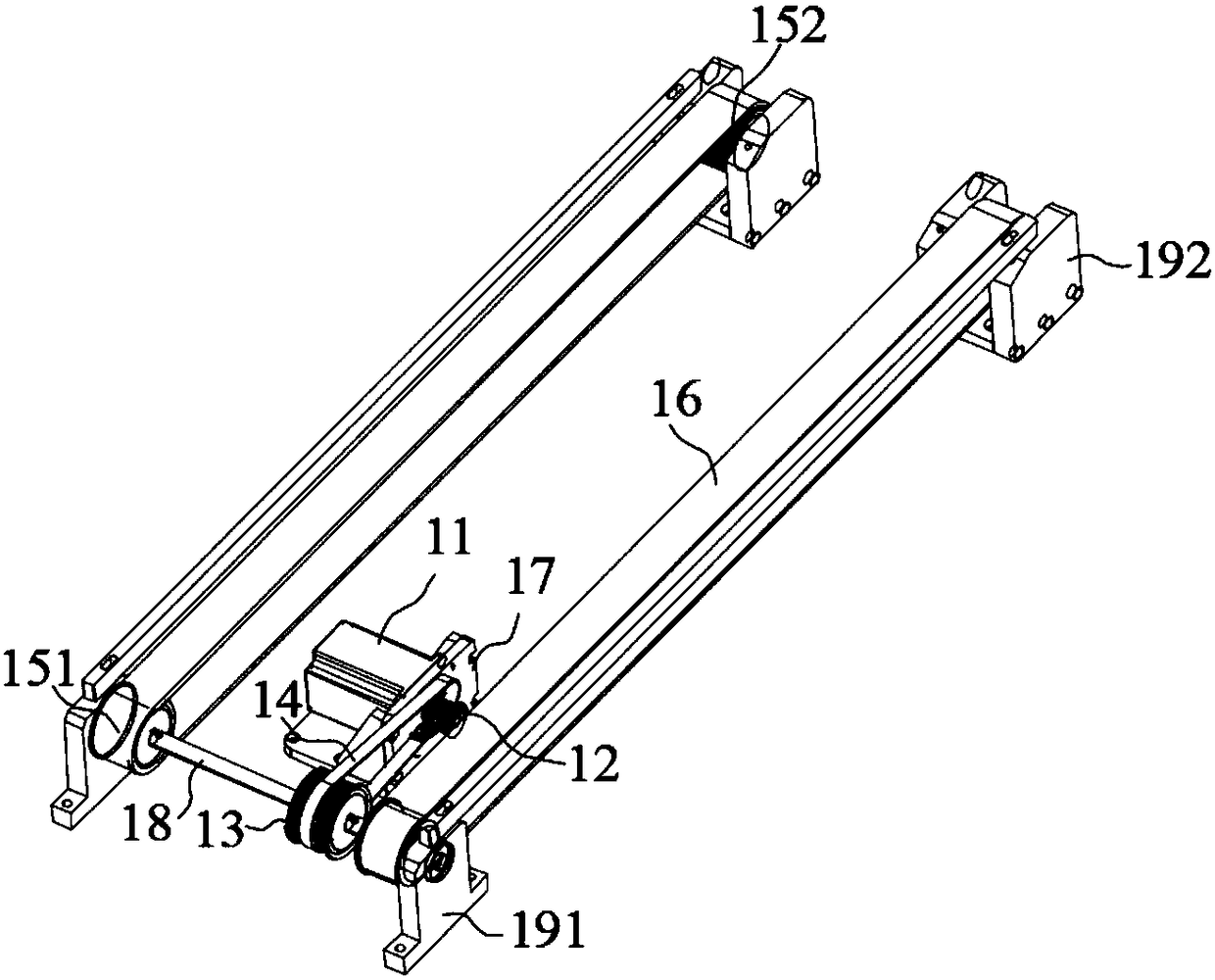

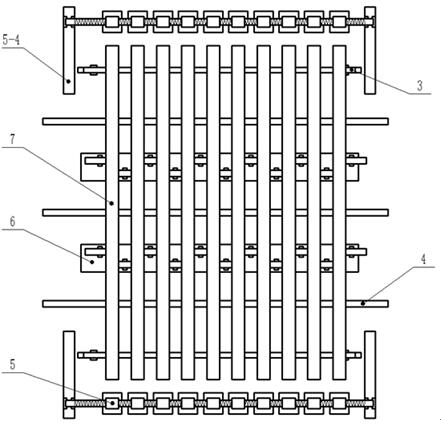

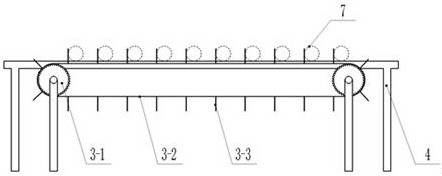

Multistation automatic upper sleeve system

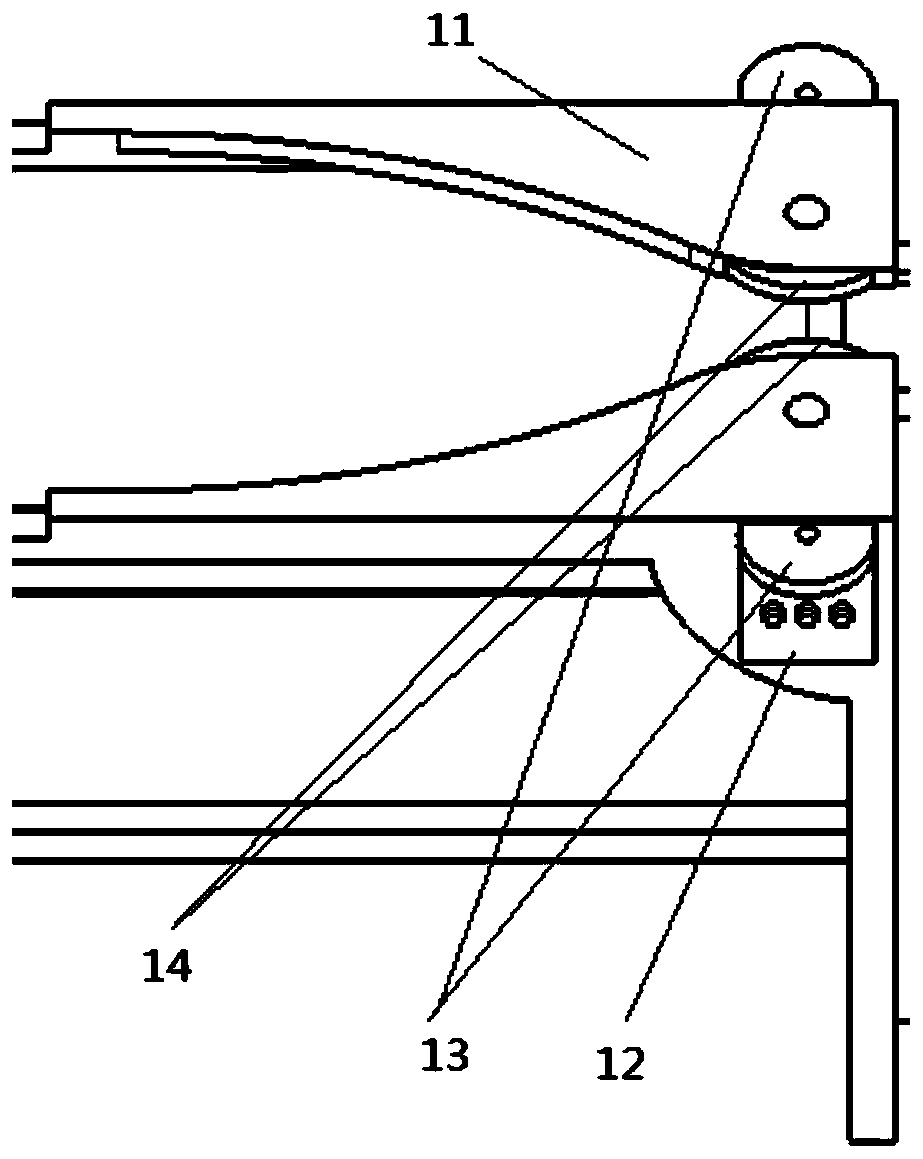

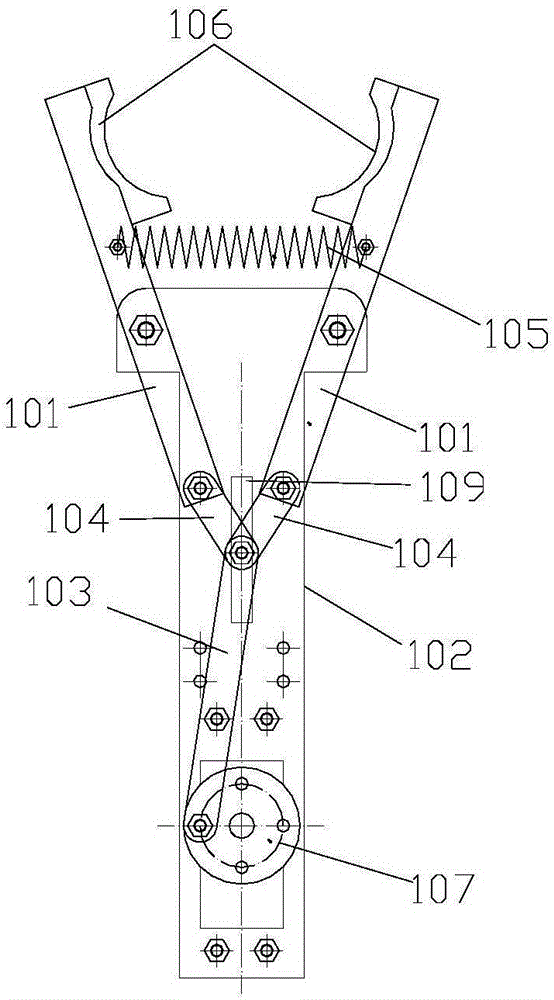

ActiveCN101885013ARealize the clamping functionRealize lifting functionIndustrial engineeringElectrical and Electronics engineering

The invention belongs to the field of metallurgical equipment, in particular to a multistation automatic upper sleeve system, an outlet of which is provided with a full continuous cold mill train of two coiling machines. The multistation automatic upper sleeve system at least comprises a body, a rail body and a sleeve storage bracket, wherein the rail body and the sleeve storage bracket are fixed on a foundation by foundation bolts, the body comprises a clamping mechanism, a lifting mechanism and a cross travelling trolley, the cross travelling trolley of the body is connected with the rail body through a roller wheel in a rolling way; the clamping mechanism and the lifting mechanism are respectively connected with the cross travelling trolley, the clamping mechanism is used for clamping a sleeve of the sleeve storage bracket; the lifting mechanism is used for upwards moving the sleeve clamped by the clamping mechanism, then the cross travelling trolley on the rail body completes the conveying of the sleeve along the rail body, and when the multistation automatic upper sleeve system does not work, the cross travelling trolley stops at the end part of the rail body. The multistation automatic upper sleeve system meets the working condition of an upper sleeve on a station and upper sleeves on two stations and more than two stations.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

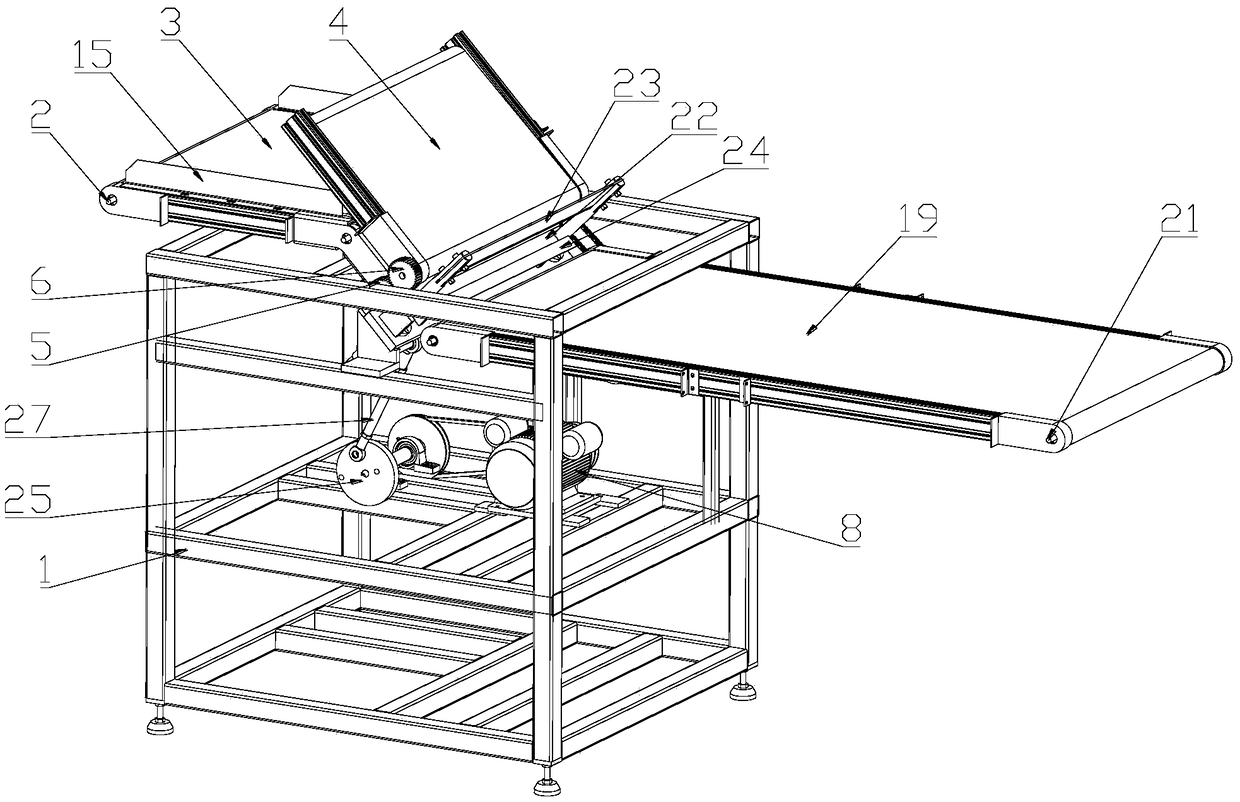

Baked wheaten cake making, forming and conveying all-in-one machine

InactiveCN107136155AAutomatically put in placeFully automatedConveyorsPre-baking dough treatmentReciprocating motionEngineering

The invention discloses a baked wheaten cake making, forming and conveying all-in-one machine which comprises a making and forming frame. A conveying belt driven by a making and conveying power device and arranged longitudinally is installed on the making and forming frame, a speed reducing and arrangement device and a press forming device which are sequentially arranged from back to front are installed on the making and forming frame, the back of the making and forming frame is connected with a baked wheaten cake conveying rack, a tray conveying device capable of conveying baked wheaten cake trays is installed on the baked wheaten cake conveying rack, a baked wheaten cake transferring frame is installed between the making and forming frame and the baked wheaten cake conveying rack, a negative-pressure sucking disc is fixedly installed on the baked wheaten cake transferring frame, and a transfer driving device for driving the negative-pressure sucking disc to perform reciprocating motion between the front section of the making and forming frame and the baked wheaten cake conveying rack is also installed on the baked wheaten cake transferring frame. The baked wheaten cake making, forming and conveying all-in-one machine achieves baked wheaten cake forming, automatic conveying and arrangement of baked wheaten cake doughs and automatic conveying of baked wheaten cake trays and has the advantages of improving the labor efficiency and saving labor cost.

Owner:王晓聪

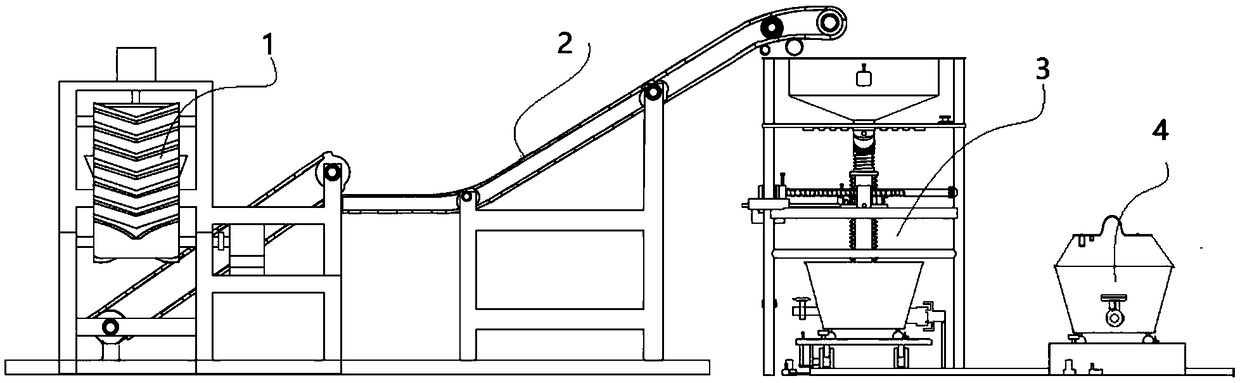

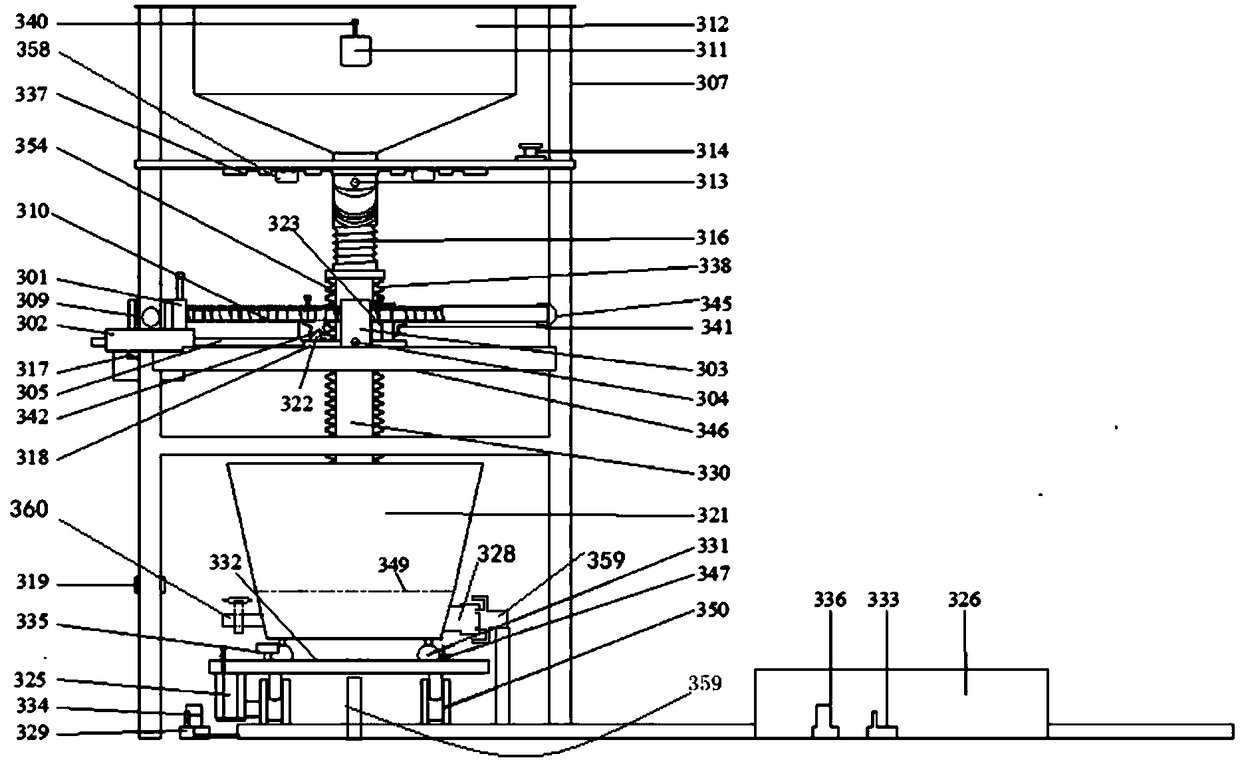

Automatic refractory brick material pouring and stamping device

ActiveCN111203957AIncrease productivityWon't inhaleFeeding arrangmentsAuxillary shaping apparatusStructural engineeringManufacturing engineering

The invention relates to an automatic material pouring and stamping device, and particularly relates to an automatic refractory brick material pouring and stamping device. The invention aims to provide the automatic refractory brick pouring and stamping device which can automatically pouring powder and automatically stamping and can also push out manufactured refractory bricks. The automatic refractory brick material pouring and stamping device comprises an operating table, a bottom plate, fixed blocks, transmission wheels, a material conveying vehicle, a storage bin, a supporting block and the like; a feeding port is formed in the operating table, the bottom plate is arranged in the feeding port, the two fixing blocks are fixedly connected to the operating table, the material conveying vehicle is placed in the operating table, and four transmission wheels are arranged on the material conveying vehicle. According to the automatic refractory brick material pouring and stamping device, apressure block is driven by an air cylinder to manufacture the refractory bricks, manual participation is not needed in the use process, and only the powder needs to be placed in the storage bin, sothat the raw materials can be automatically conveyed and poured.

Owner:山东沈耐新材料科技有限公司

Automatic feeding device

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Long-strip-shaped fish product sorting mechanism based on detection type and control method

PendingCN110694932AImprove work efficiencyReduce operating costsFish sortingFish work-tablesProcess engineeringBiotechnology

The invention relates to a long-strip-shaped fish product sorting mechanism based on the detection type. The long-strip-shaped fish product sorting mechanism comprises a conveying mechanism, a sequencing mechanism, an accelerating mechanism and a sorting mechanism body which are sequentially installed and connected. The conveying mechanism is used for flat laying products and conveying the products to the sequencing mechanism. The sequencing mechanism adjusts the positions of the products and sequences the products. The accelerating mechanism accelerates the products on a conveying belt so that every two adjacent products can keep a certain distance away from each other and then enter the sorting mechanism body. The sorting mechanism body classifies and sorts the products through the detection type. A control method of the long-strip-shaped fish product sorting mechanism based on the detection type includes the five steps. Continuous operation is performed through an assembly line, andthe fish products are automatically conveyed, sequenced, separated and sorted. The fish sorting work efficiency is greatly improved, operation cost is reduced, and the long-strip-shaped fish productsorting mechanism is suitable for application and popularization.

Owner:SHANGHAI OCEAN UNIV

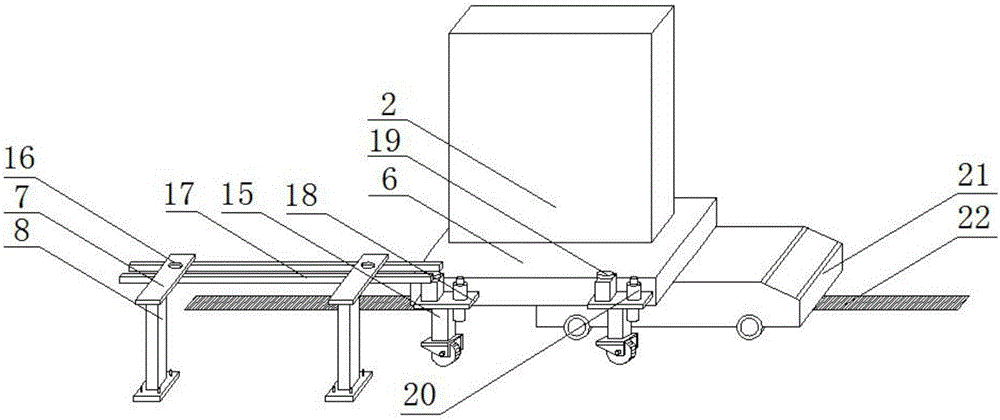

High-radioactive nuclear industry waste microwave heating treatment equipment

PendingCN108231232AReduce lossExtended service lifePortable shielded containersRadioactive decontaminationIndustrial wasteScrap

The invention belongs to the technical field of high-radioactive nuclear industry waste microwave heating treatment and particularly relates to high-radioactive nuclear industry waste microwave heating treatment equipment with an aim to solve problems that in a microwave heating device, high-radioactive liquid waste usually contains more solid waste resulting in proneness to pipe clogging, influence of process efficiency and increasing of radiation risks in the prior art. The technical scheme includes that the high-radioactive nuclear industry waste microwave heating treatment equipment comprises a sealed box, a microwave heating hole is arranged in the top of the sealed box, a lifting device is arranged under the microwave heating hole, a sealing door is arranged on the sealed box, a first conveying device used for conveying a barrel containing high-radioactive liquid waste to the lifting device or away form the same is arranged n the sealed box, a second conveying device is arrangedon the outside of the sealed box, and the first conveying device and the second conveying device are matched in height and are respectively located on two sides of the sealing door. The high-radioactive nuclear industry waste microwave heating treatment equipment is applied to microwave evaporation of the high-radioactive liquid waste.

Owner:四川固力铁环保工程有限责任公司

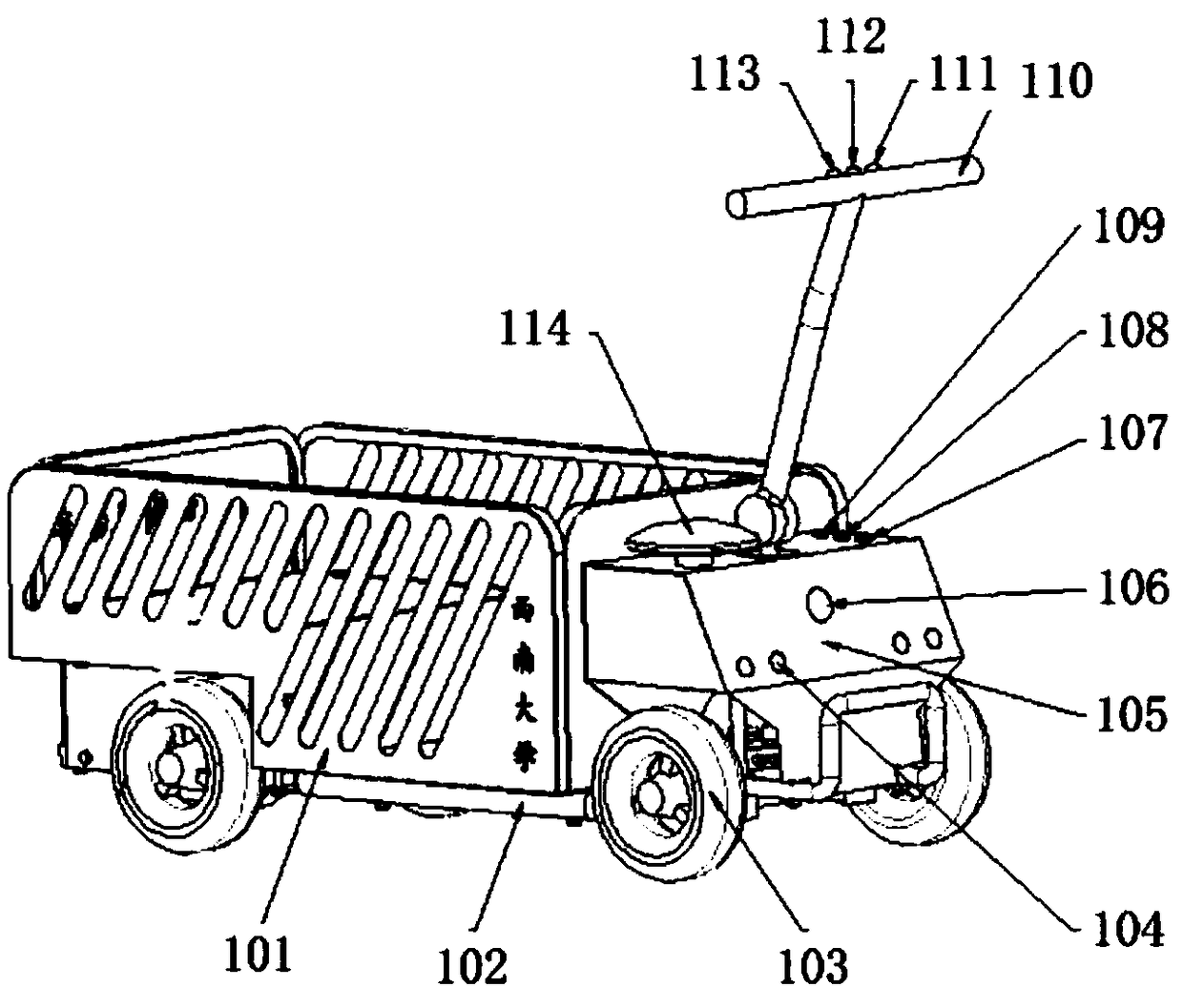

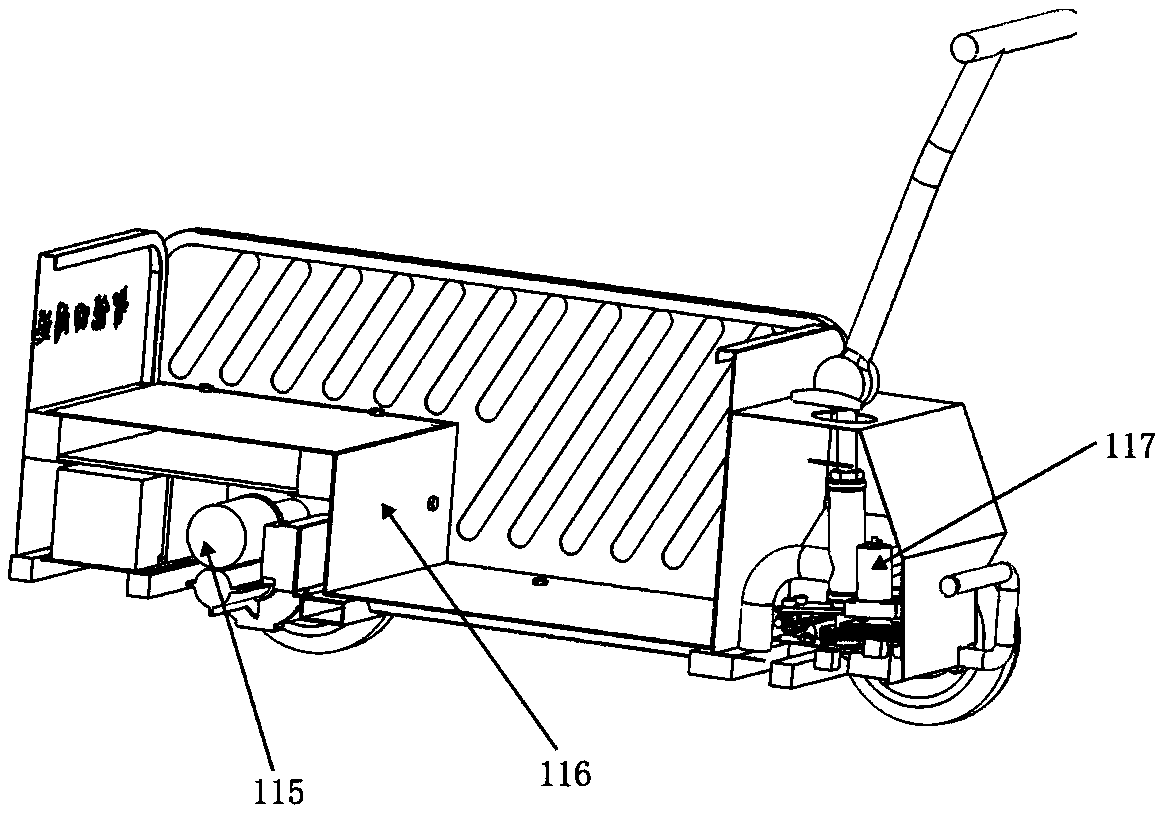

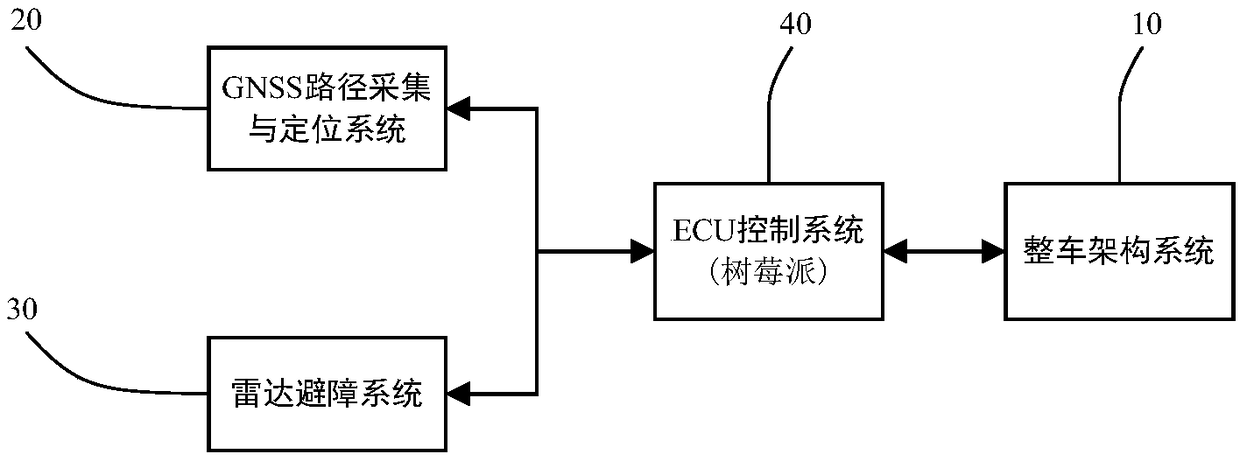

Transport vehicle capable of be driven automatically on field road

PendingCN108614568AAutomate shippingPosition/course control in two dimensionsVehiclesRadarControl system

The invention provides a transport vehicle capable of be driven automatically on a field road. The transport vehicle comprises a vehicle architecture system, a GNSS path acquisition and positioning system, a radar obstacle avoidance system and an ECU control system. The vehicle architecture system includes design and manufacture parts of the overall mechanism to realize loading and transporting ofagricultural materials and agricultural products. The GNSS path acquisition and positioning system is used for collecting, processing, and storing field road information and determining the real-timeposition and attitude of the transport vehicle. The radar obstacle avoidance system is used for detecting whether an obstacle exists in a front predetermined distance. The ECU control system determines the position of the transport vehicle relative to the road according to the information sent by the GNSS path acquisition and positioning system and the radar obstacle avoidance system and planninga safe and reliable driving path for tracking. Therefore, the field-road transport vehicle is able to convey the agricultural materials and agricultural products automatically to a destination alongthe planned route without any manual operation.

Owner:SOUTHWEST UNIVERSITY

Jelly extracting machine

The invention relates to a jelly extracting machine, which comprises a machine frame, wherein the machine frame is provided with a pushing mechanism, a feeding mechanism and an extracting device, wherein a royal jelly queen cup strip can move in the feeding mechanism, the pushing mechanism and the extracting device are sequentially arranged on the moving route of the royal jelly queen cup strip, the pushing mechanism is used for pushing the royal jelly queen cup strip to move along the feeding mechanism, and the extracting device is used for gathering larva and extracting jelly from the royaljelly queen cup strip, so that the automation of jelly extracting is achieved, and the working efficiency is improved.

Owner:杭州余杭飞瑞五金制品有限公司

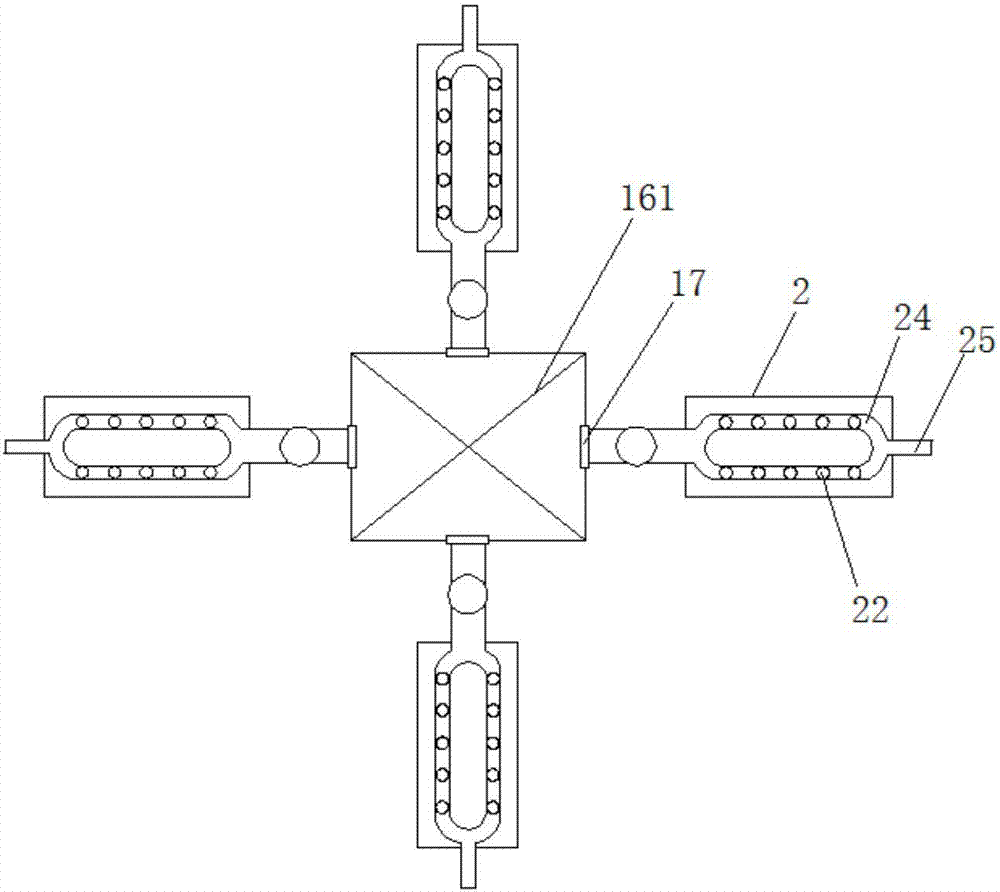

Pulp injecting device and method for pulp molding

PendingCN107326750AAutomate shippingImprove product qualityTextiles and paperMoving filtering element filtersMolded pulpElectric machinery

The invention provides a pulp injecting device and method for pulp molding. The pulp injecting device comprises a pulp supply box, pulp injecting boxes and pulp tanks, wherein the pulp injecting boxes are arranged on four sides below the pulp supply box, the pulp supply box is communicated with the pulp injecting boxes through pipelines, each pipeline is provided with an electromagnetic flow valve used for controlling pulp flow, one pulp tank is correspondingly arranged below each pulp injecting tank and used for receiving pulp, and the pulp tanks are connected with a motor to achieve lifting so as to conveying the pulp. The pulp injecting device has the advantages that the automatic pulp injecting and pulp injecting quantified control in the pulp molding process are achieved, impurities in the pulp are removed in advance through two vibration filter membranes before the pulp injecting, product quality is increased, pulp injecting efficiency is increased by the multi-directional pulp injecting, production speed is increased, automatic pulp conveying is achieved through the motor, and labor cost is saved.

Owner:GEOTEGRITY ENVIRONMENTAL PROTECTION TECH XIAMEN CO LTD

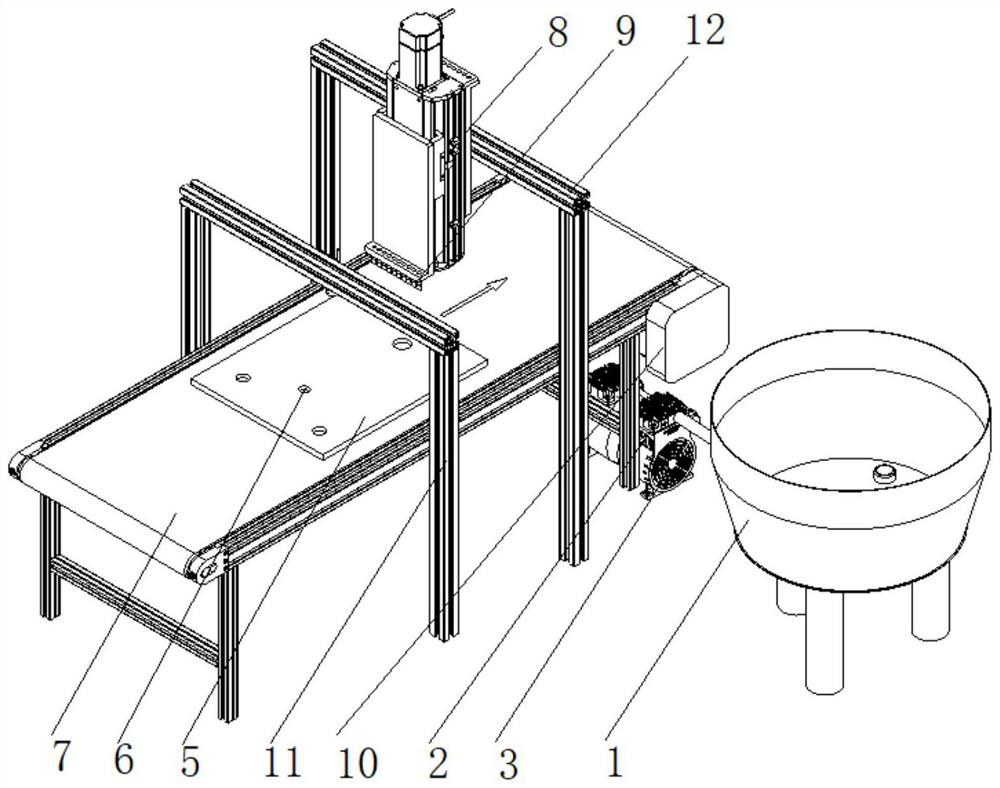

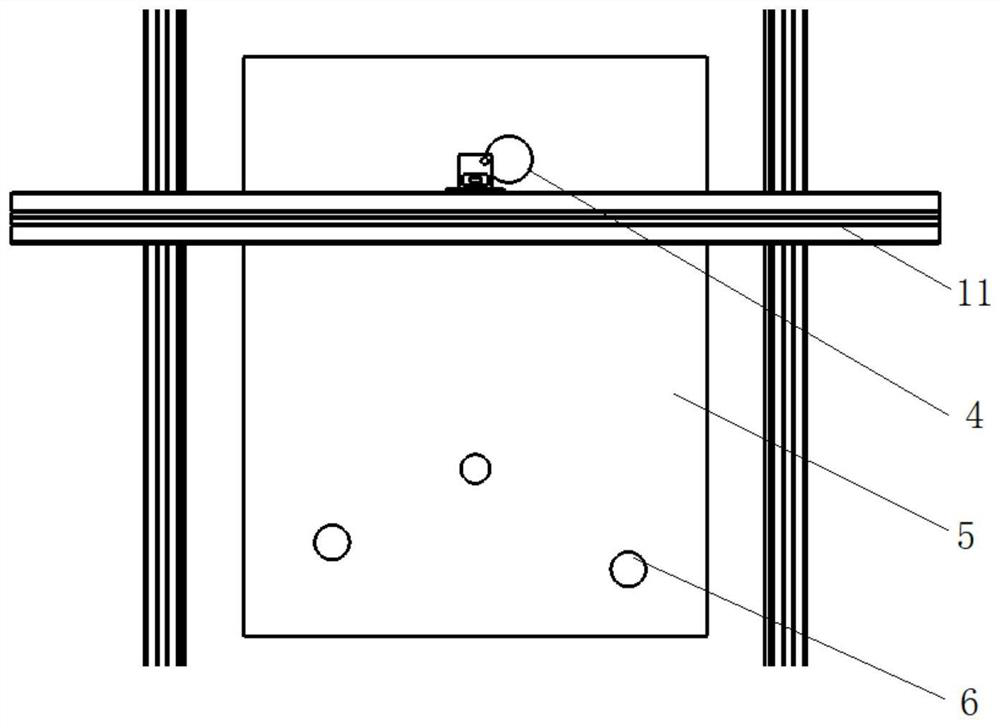

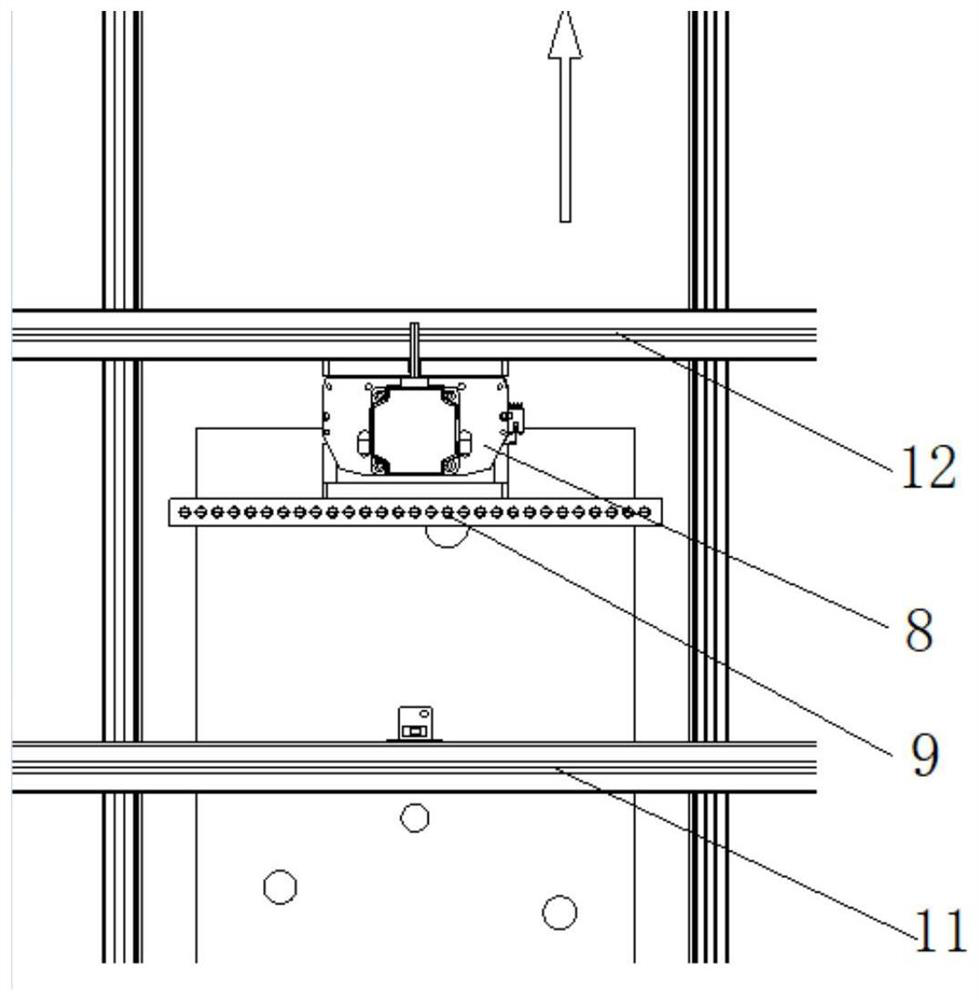

Automatic hole filling mechanism for veneer

PendingCN112643823APrecise position controlPrecise size controlIrregularity removal devicesControl systemCoating system

The invention provides an automatic hole filling mechanism for a veneer. The automatic hole filling mechanism is composed of a veneer moving system, a glue discharging system, a hole positioning system, an automatic coating system and a control system, and the veneer moving system comprises a conveying belt and a conveying belt motor for driving the conveying belt; the hole positioning system comprises a camera fixing frame located above the conveying belt and a CCD camera installed on the camera fixing frame; the glue discharging system comprises a mixed glue storage barrel, a glue pump connecting pipe externally connected to the mixed glue storage barrel, and a glue discharging pump mounted at the other end of the glue pump connecting pipe; and the automatic coating system comprises a lifting mechanism fixing frame, a lifting device and a plurality of glue spraying heads, wherein the lifting device is installed on the lifting mechanism fixing frame, the multiple glue spraying heads are installed at the bottom of the lifting mechanism fixing frame and closely connected side by side, each glue spraying head is provided with a control valve, and the glue spraying heads are connected with glue outlets of the glue pump through hoses. According to the automatic hole filling mechanism, manual veneer cutting and hole filling are omitted, automatic hole filling of the veneer is achieved, and the veneer laying efficiency is greatly improved.

Owner:天津源启晟科技发展有限公司

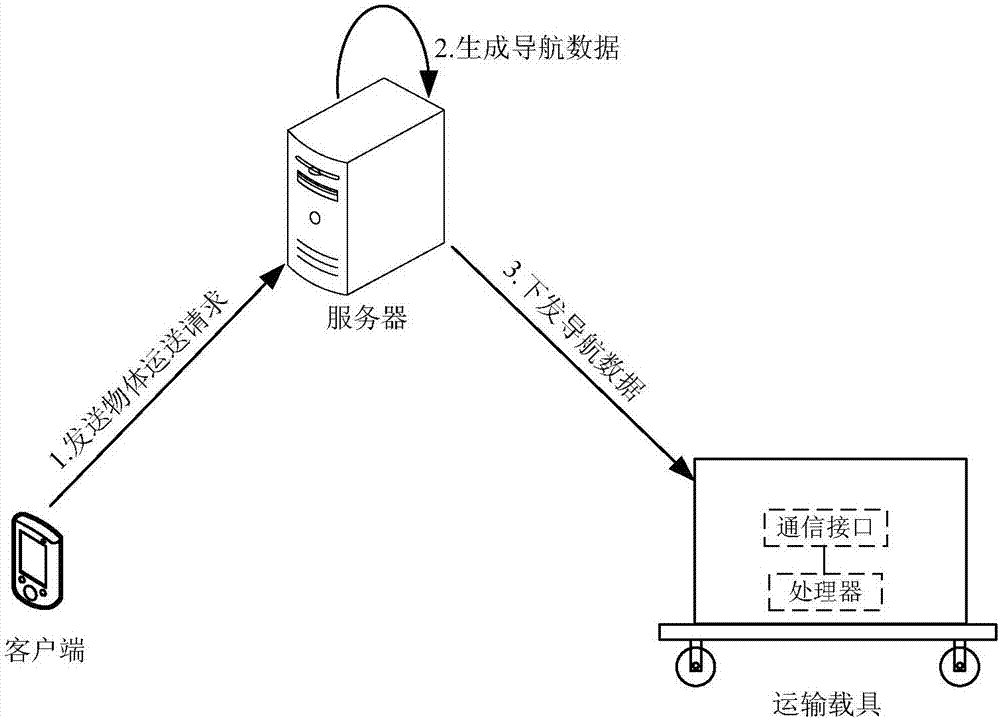

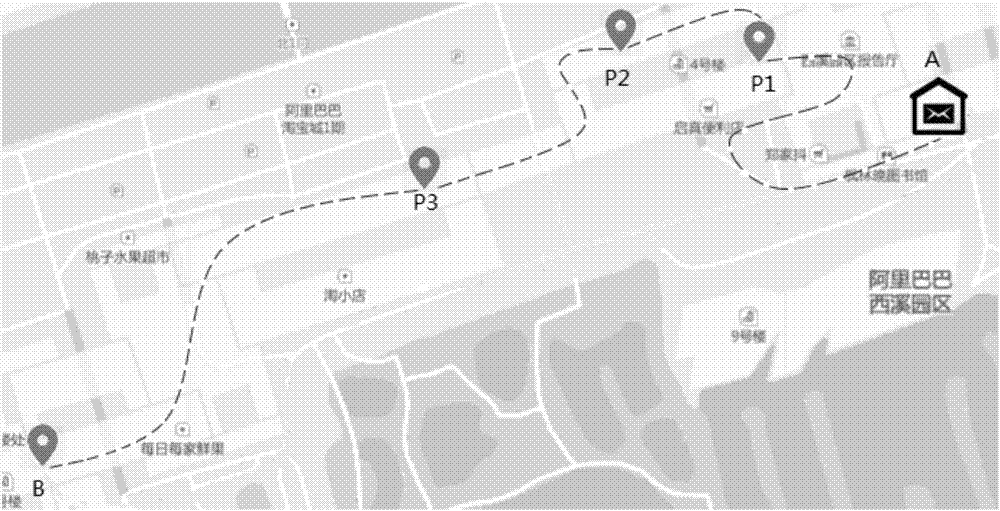

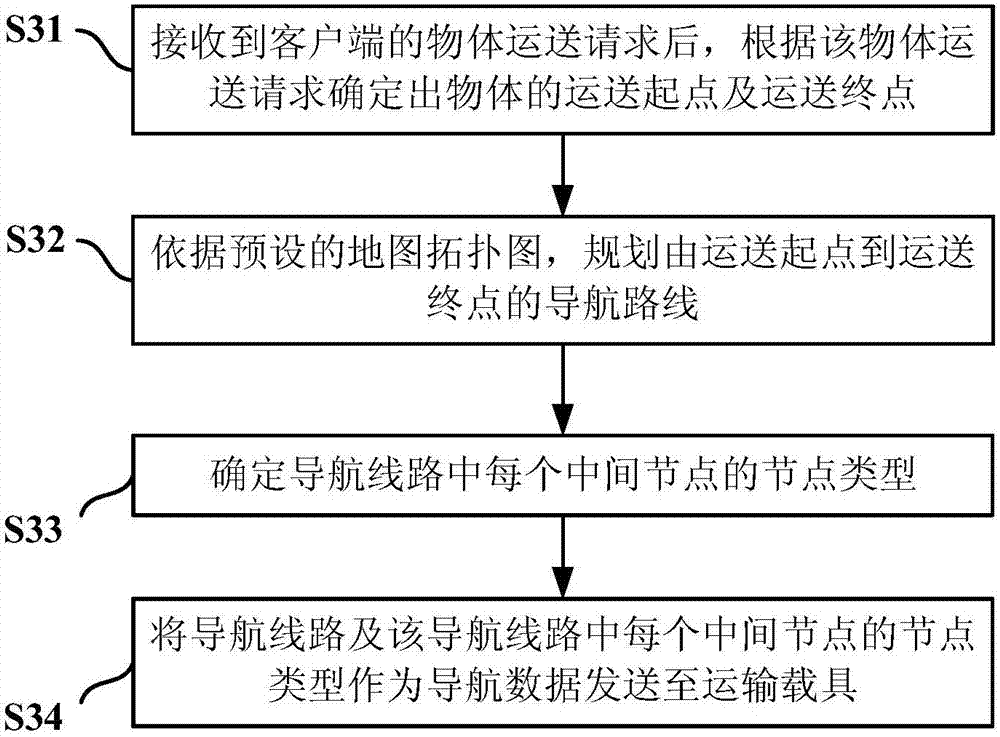

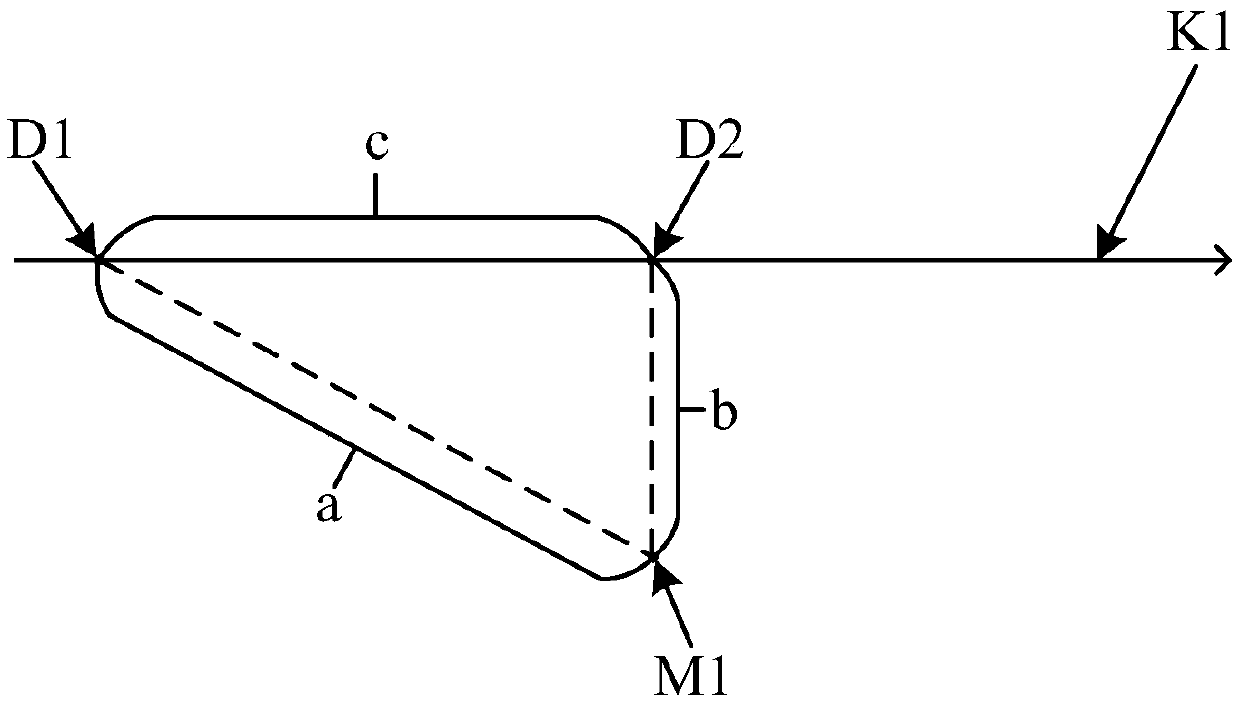

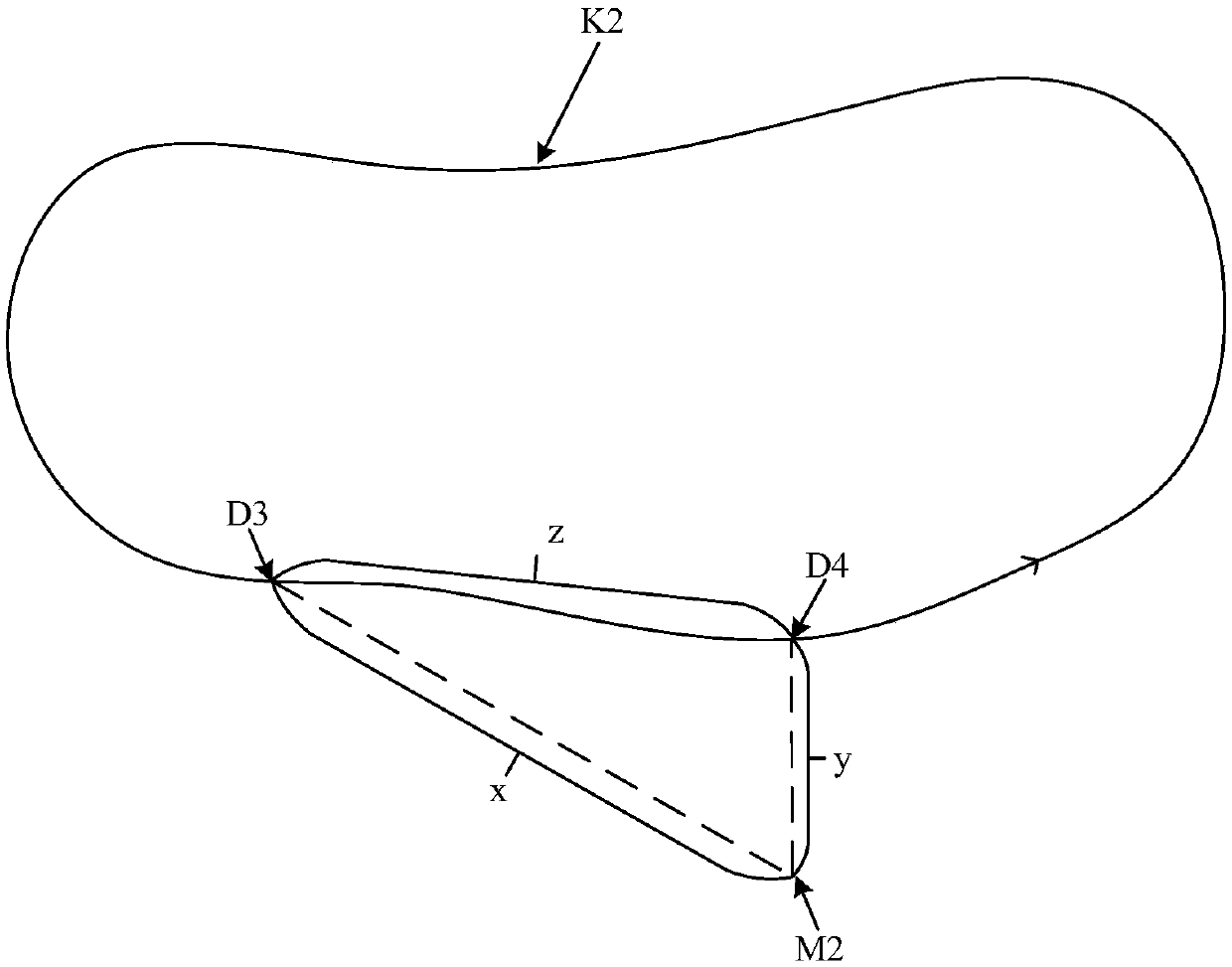

Navigation data generating method and device and goods conveying method and device

InactiveCN107957268AAutomate shippingReduce labor costsInstruments for road network navigationConveyorsComputer scienceMarine navigation

The invention provides a goods conveying system. The goods conveying system comprises a server and a conveying carrier, wherein the server is used for generating navigation data according to a goods conveying request of a user, the navigation data comprises navigation routes and the type of every intermediate node, and the node type is used for indicating actions to be executed by every intermediate node; the conveying carrier achieves goods conveying according to the navigation data. The goods conveying system can achieve automatic goods conveying to save labor and cost. Besides, the invention also provides a navigation data generating method and device and a goods conveying method and device.

Owner:CAINIAO SMART LOGISTICS HLDG LTD

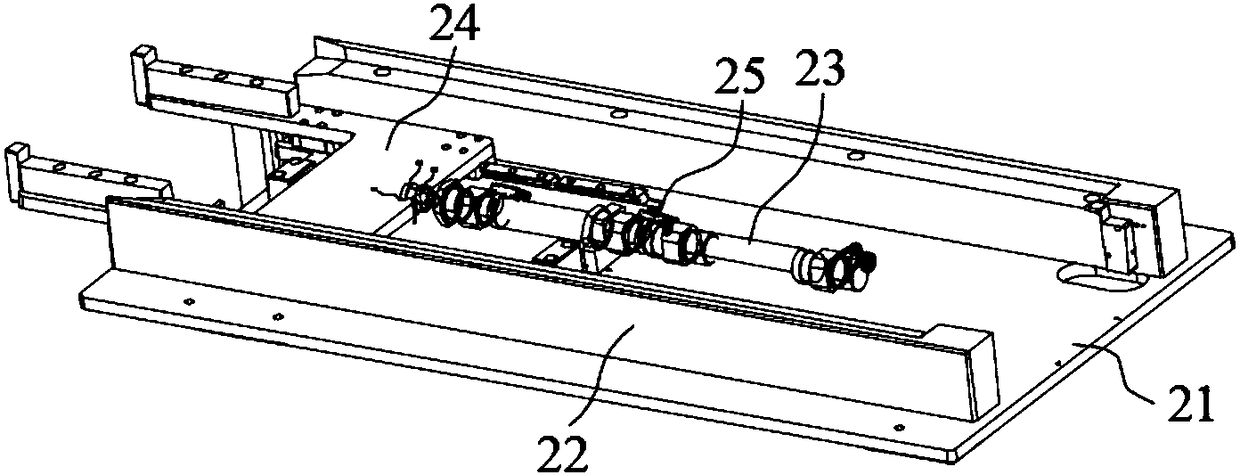

Full-automatic liquor steaming equipment based on feeding upon steam

PendingCN109439502AAdd evenlyFast reciprocating motionAlcoholic beverage preparationElectricitySteaming

The invention provides full-automatic liquor steaming equipment based on feeding upon steam, and belongs to the field of full-automatic liquor steaming equipment. The full-automatic liquor steaming equipment comprises a V-shaped automatic stirring device, a liquor steaming raw material conveyor belt, a feeding-upon-steam liquor steaming device and a track steamer device. The full-automatic liquorsteaming equipment has the advantages that a micro-pressure film electric contact pressure sensor and an infrared thermal imager are integrated to accurately judge the steaming state of steamed liquorin an unclosed area, misjudgment caused by many different factors is eliminated, and feeding-upon-steam is realized for the first time in the field of liquor steaming; the circulating track steamer is adopted, so that continuous liquor steaming is realized, the utilization rate of the sensor and the equipment is increased, the liquor steaming speed is increased, and equipment support is providedfor efficiency improvement of automatic liquor steaming and baijiu brewing.

Owner:ANHUI AGRICULTURAL UNIVERSITY

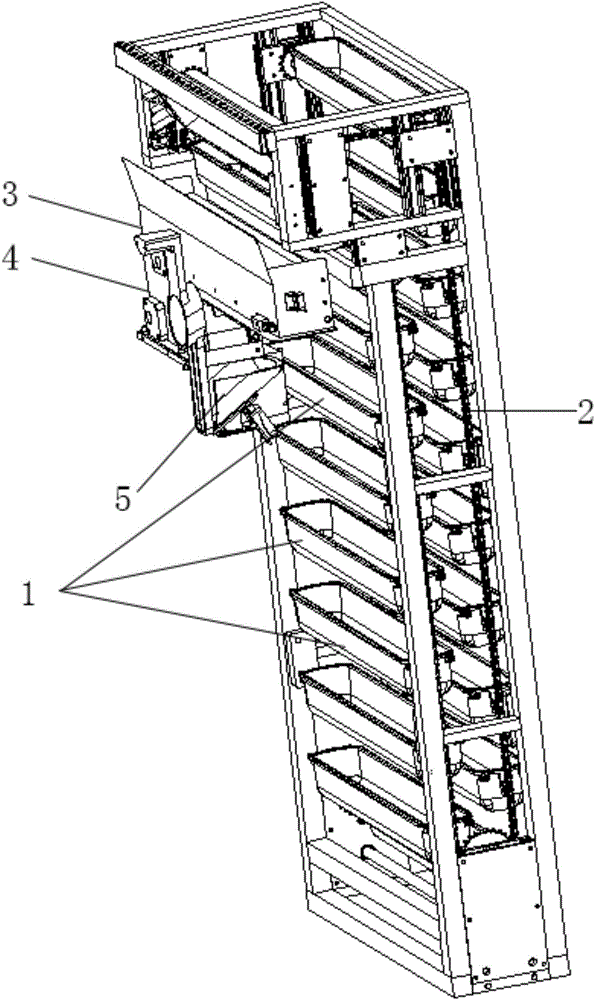

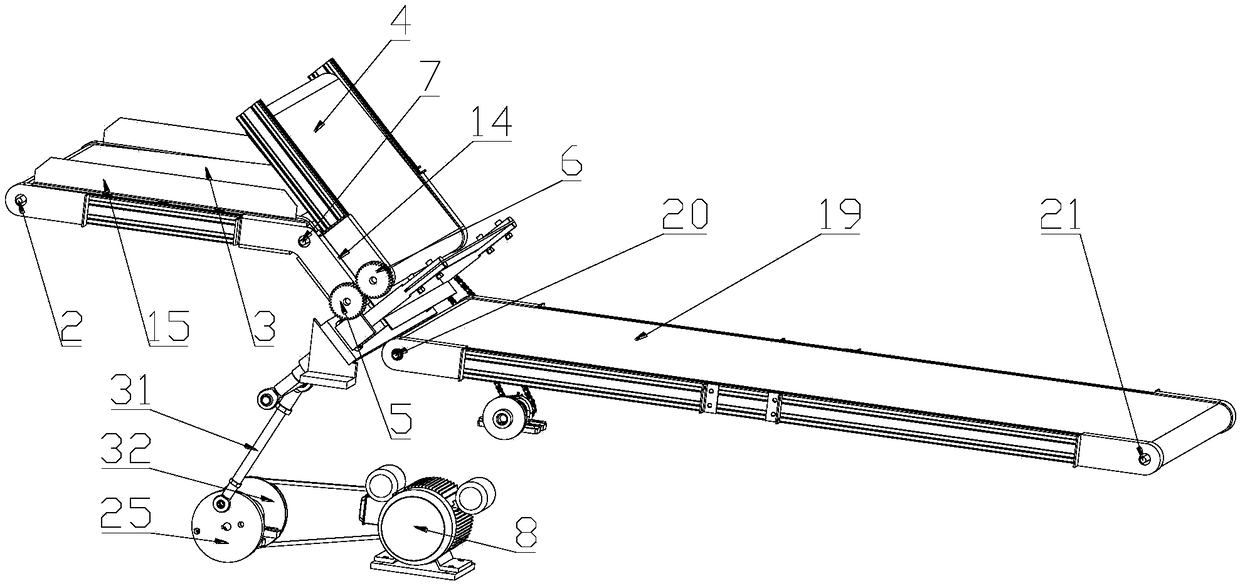

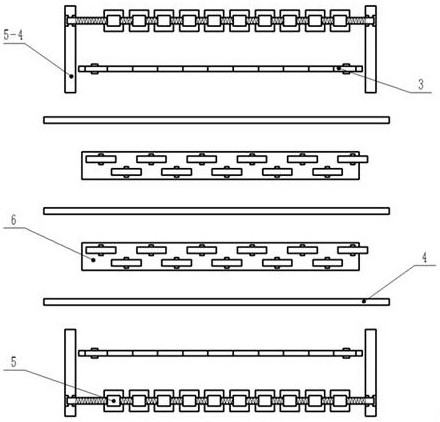

Integrated folium mori shredding machine

PendingCN109366544AAutomate shippingNot easy to dropMetal working apparatusEngineeringMechanical engineering

The invention discloses an integrated folium mori shredding machine which comprises a first linear conveying mechanism, a second linear conveying mechanism and a third linear conveying mechanism. Thesecond linear conveying mechanism is located above the discharging end of the first linear conveying mechanism. The conveying direction of the first linear conveying mechanism is opposite to that of the second linear conveying mechanism. An automatic feeding gap is formed between the first linear conveying mechanism and the second linear conveying mechanism. A folium mori cutting mechanism is arranged at an outlet of the automatic feeding gap. The third linear conveying mechanism is arranged below the folium mori cutting mechanism. The conveying direction of the third linear conveying mechanism is the same as that of the first linear conveying mechanism. By means of the machine, folium mori can be automatically conveyed, the folium mori conveying amount is stable and constant, folium moriis not prone to falling off, the three linear conveying mechanisms and the folium mori cutting mechanism share one drive mechanism, and the folium mori cutting cost and the folium mori conveying costare greatly reduced.

Owner:重庆京渝瑞基测控仪器仪表制造有限公司

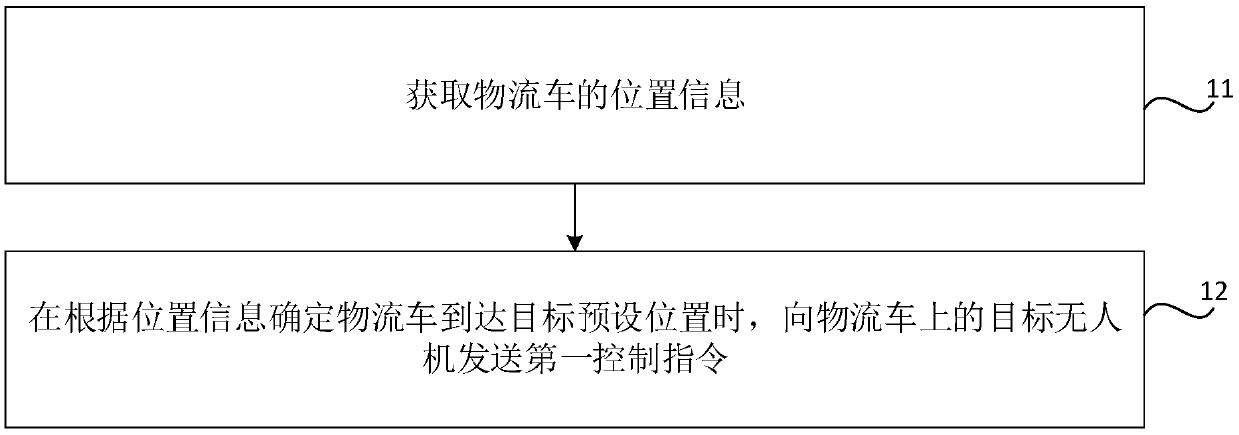

Goods transportation method and device, medium and electronic device

ActiveCN110968105ARealize automatic collectionAutomate shippingPosition/course control in three dimensionsLogistics managementUncrewed vehicle

The invention relates to a cargo transportation method and device, a medium and an electronic device, and the method is applied to a server, and the method comprises the steps: obtaining the positioninformation of a logistics vehicle, and the logistics vehicle travelling according to a preset travel route; determining that the logistics vehicle reaches a target preset position according to the position information; sending a first control instruction to a target unmanned aerial vehicle on the logistics vehicle, wherein the server is connected with the target unmanned aerial vehicle to controlthe target unmanned aerial vehicle to take goods from a target cargo cabinet or convey the goods to the target cargo cabinet, the server stores a corresponding relation between target preset positions and the target cargo cabinet, and each target preset position is located on the preset driving route. Thus, automatic collection and automatic conveying of the goods can be achieved, manual intervention is not needed, manpower is saved, the goods conveying efficiency is improved, and the cost can be reduced.

Owner:BYD CO LTD

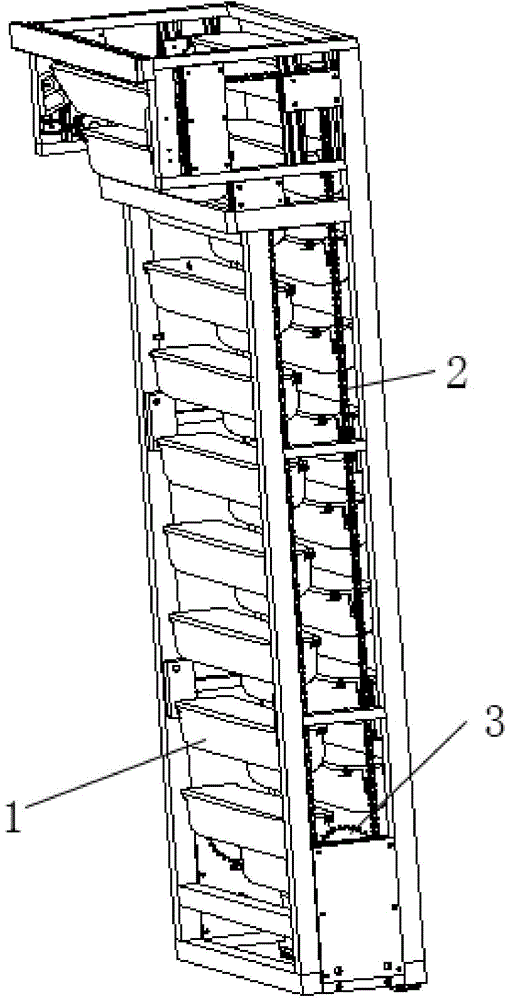

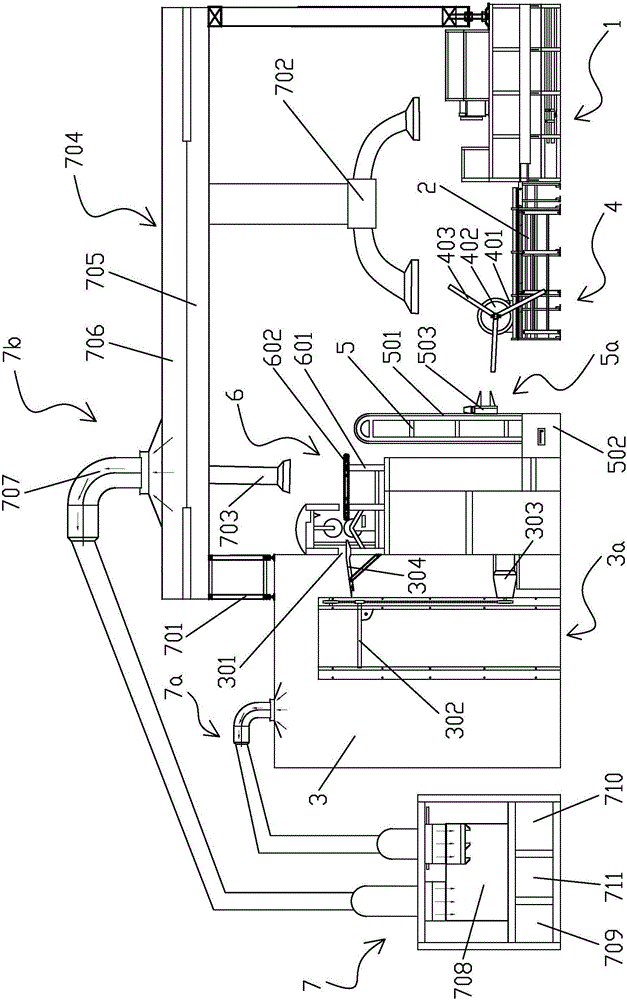

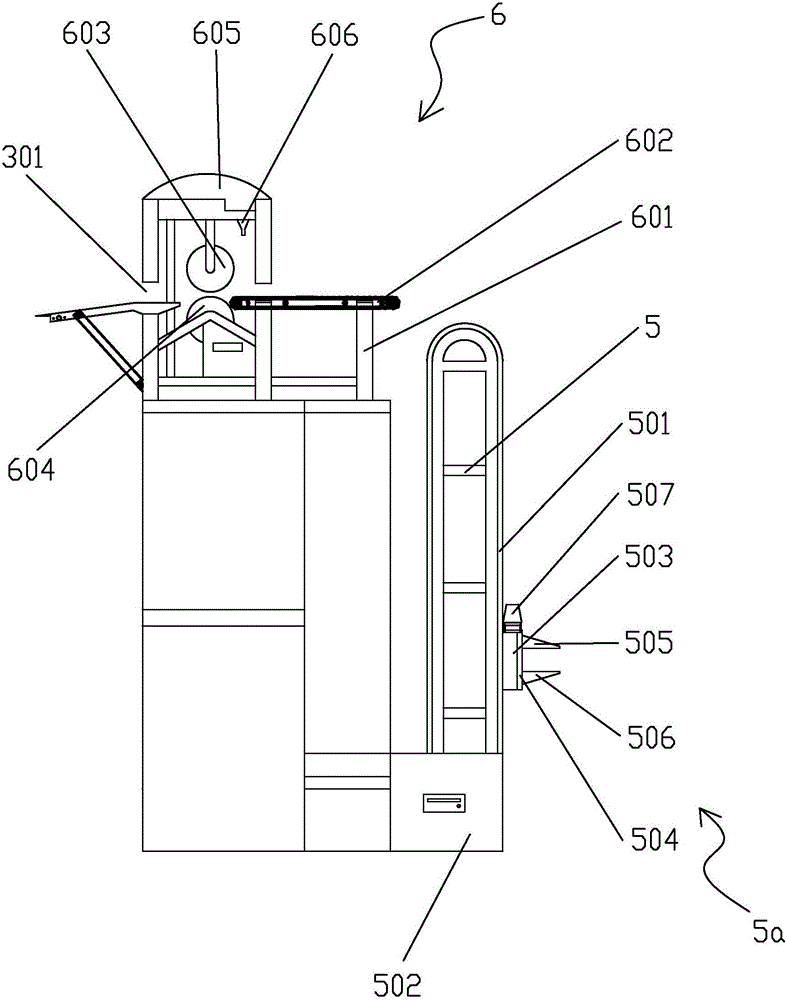

Panel automatic machining and storing and intelligent dust treatment integrated system

InactiveCN105965628ACompact structureHigh degree of automationSpraying apparatusDirt cleaningTreatment centerMachining

The invention discloses a panel automatic machining and storing and intelligent dust treatment integrated system. The system comprises a panel arranging device, an automatic conveying and trimming device and a panel intelligent storage cabin, wherein an automatic panel overturning device capable of automatically overturning a trimmed panel is arranged on the automatic panel overturning device, a first bracket is arranged on one side of the automatic panel overturning device, a lifting conveying chain is arranged on the first bracket, an automatic panel clamping device is arranged on the lifting conveying chain, a power device driving the lifting conveying chain to raise and fall is arranged on the first bracket, a compact oil sealing device for sealing oil is arranged on one side of the upper end part of the first bracket, a dust centralized treatment center is arranged next to the panel intelligent storage cabin, a warehouse dust absorbing device connected to the dust centralized treatment center is arranged on the panel intelligent storage cabin, a fixed rack is arranged on the panel intelligent storage cabin, a production dust absorbing device connected to the dust centralized treatment center is arranged on the fixed bracket, and a first dust absorption part and a second dust adsorption part are arranged on the production dust absorbing device.

Owner:江永县大众木业有限责任公司

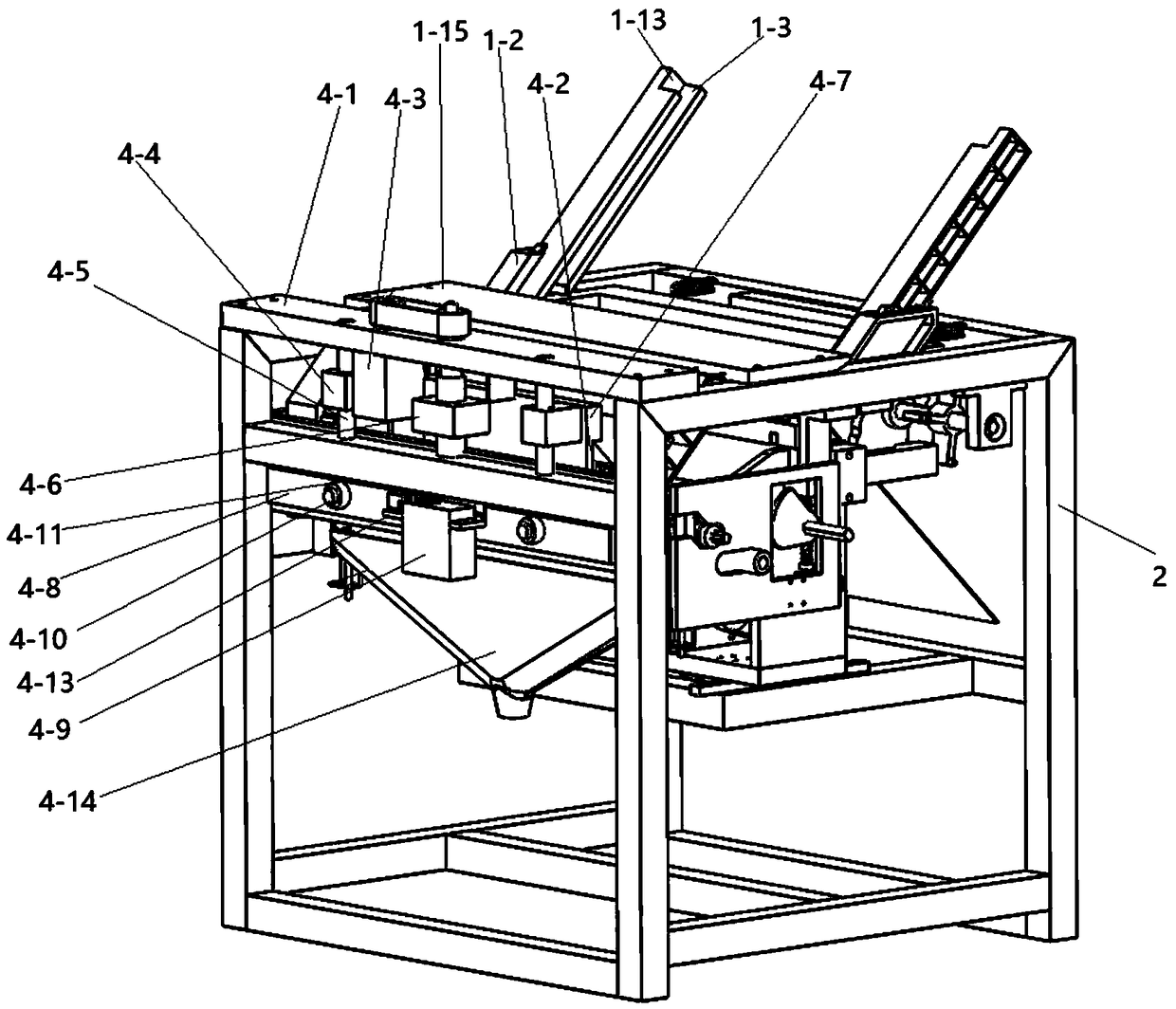

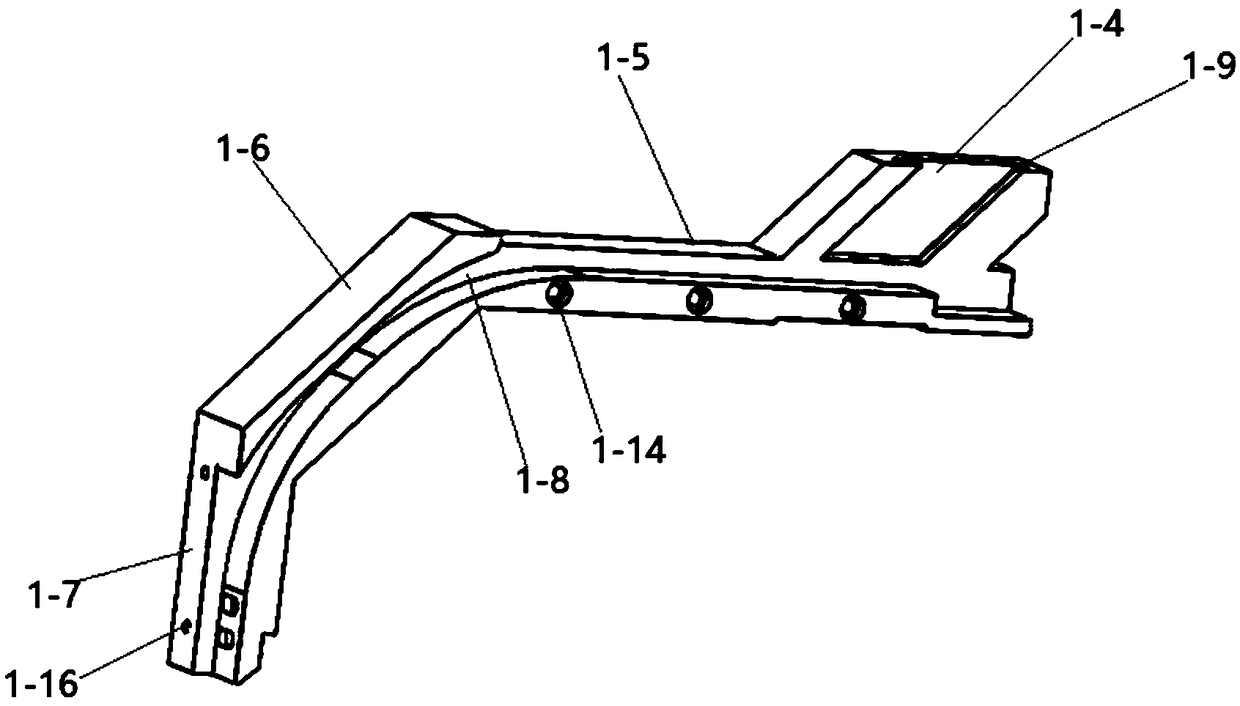

Automatic ball loading device for sliding rail

ActiveCN110465787AGuaranteed stabilityRealize automatic bead loading functionMetal working apparatusEngineeringSteel ball

The invention discloses an automatic ball loading device for a sliding rail. The automatic ball loading device comprises a rack, a loading inclined hopper, a ball strip pushing-in mechanism, a steel ball feeding mechanism, a ball strip pushing-out mechanism and a material distributing mechanism. The loading inclined hopper is obliquely arranged on the side surface of the rack. The ball strip pushing-in mechanism and the ball strip pushing-out mechanism are arranged above the rack and located at the two ends of the rack correspondingly. The material distributing mechanism is arranged on the rack and is positioned at one end of the ball strip pushing-out mechanism. A discharging motor is arranged on the end surface of one end, far away from the loading inclined hopper, of the rack. A plurality of gas holes are connected with a plurality of blowing nozzles correspondingly. A steel ball mounting mechanism is provided with a through ball mounting hole. One end of the ball mounting hole is connected with the steel ball feeding mechanism through a ball feeding leather hose. A ball outlet is formed in the other end of the ball mounting hole. An air blowing hole is formed above one end, connected with the steel ball feeding mechanism, of the ball mounting hole. A ball blocking mechanism is arranged below the ball outlet of the ball mounting hole. According to the automatic ball loadingdevice, due to the arrangement of a wedge-shaped strip, a steel ball can be better squeezed into a ball groove of a feeding belt, and simpleness, convenience and good effect are realized.

Owner:昆山棠赢电子科技有限公司

Inter-process material automatic conveying method

ActiveCN113219983AAutomate shippingAvoid human involvementElectric/hybrid propulsionPosition/course control in two dimensionsProcess equipmentParking space

The invention discloses an inter-process material automatic conveying method. The method comprises the steps: 1) conveying empty skip cars on a sizing workshop empty skip car storage position to loading parking spaces in sizing process equipment through a sizing workshop AGV, and performing loading operation; 2) transporting the loaded full-material vehicle to a weighbridge for weighing through a sizing workshop AGV; (3) reading relevant information of the corresponding full-material vehicle through a forming workshop AGV and conveying to a forming workshop full-material vehicle storage position to be stored; (4) the forming workshop AGV conveys the corresponding full-material trolley to forming process equipment; (5) the forming workshop AGV conveys the empty skip cars on the forming process equipment to a forming workshop empty skip car storage position, and then the sizing workshop AGV conveys the empty skip cars on the forming workshop empty skip car storage position to the sizing workshop empty skip car storage position to be stored; and 6) circulating the steps 4) and 5) until the work order is completed. According to the inter-process material automatic conveying method, inter-process material transferring can be automatically completed.

Owner:BEIJING TIEKE SHOUGANG RAIL TECH CO LTD

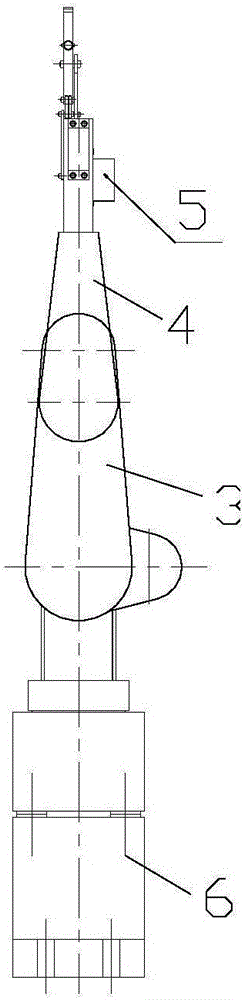

Feeding robot

The invention discloses a feeding robot. The feeding robot comprises a base, a rotation bearing, a first arm, a second arm and a manipulator; the rotation bearing is mounted on the base and driven by a rotation motor to rotate in the horizontal plane; the first arm is mounted on the rotation bearing and driven by a first motor to rotate in the vertical plane; the second arm is connected with the first arm in a pivotal mode and driven by a second motor to rotate in the vertical plane; the manipulator is mounted on the second arm and used for clamping a workpiece; and a controller controls the motors to enable the rotation bearing, the first arm and the second arm to rotate to a certain form, the manipulator moves to a workpiece storing position and then clamps the workpiece, and the motors are controlled again through the controller to enable the rotation bearing, the first arm and the second arm to rotate to another form, then the manipulator drives the workpiece to move to an appointed position, and thus workpiece automatic transporting is achieved.

Owner:防城港市海洋局

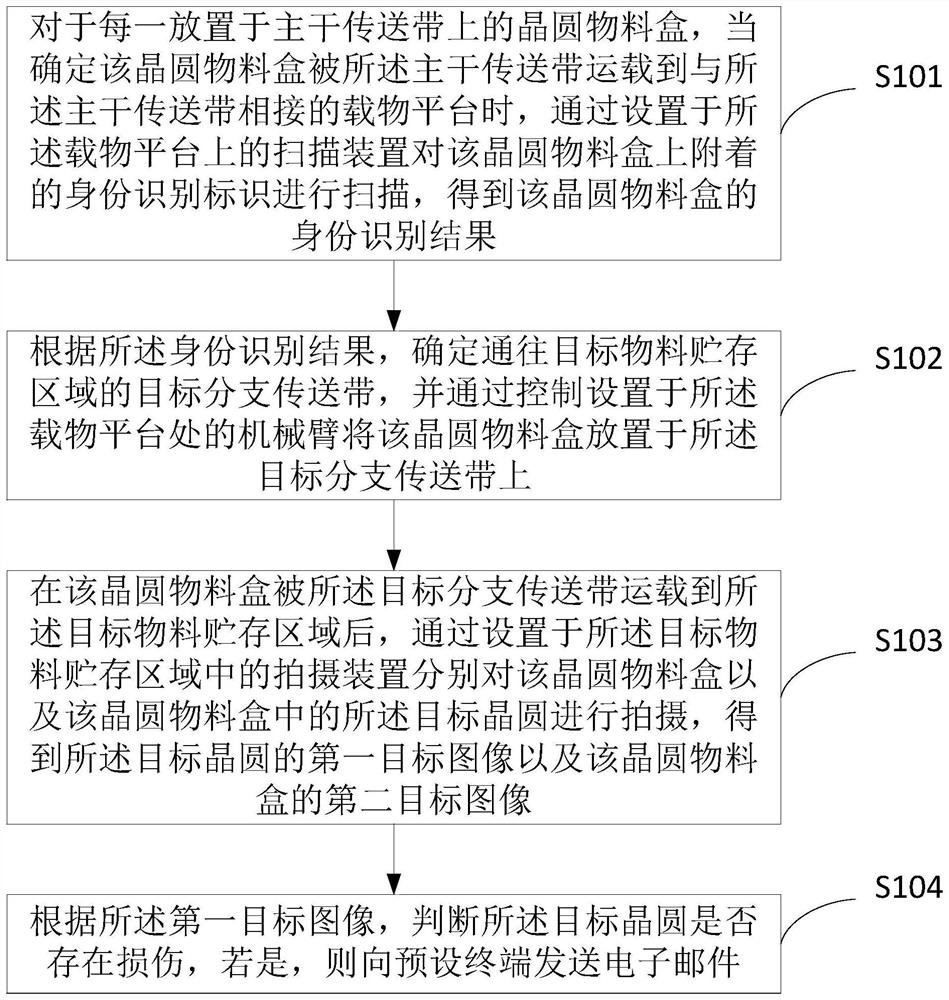

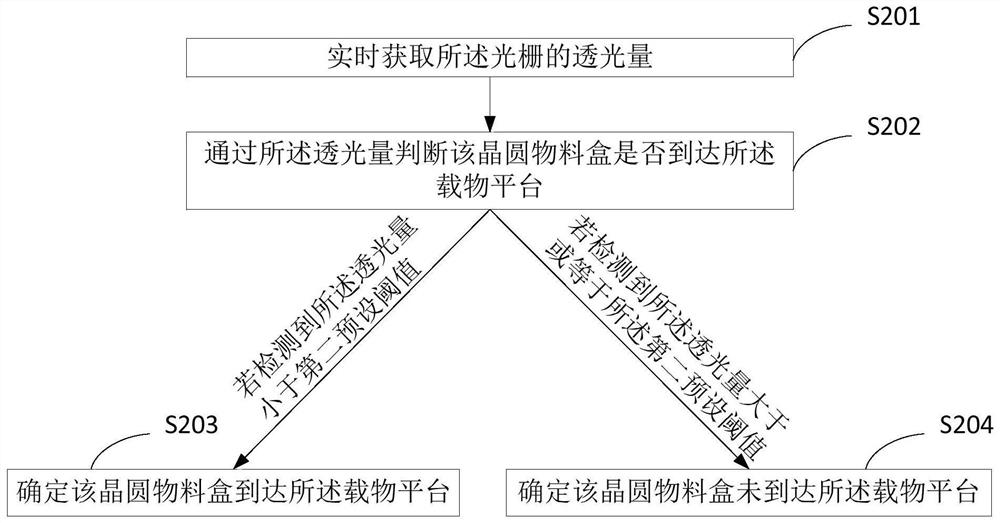

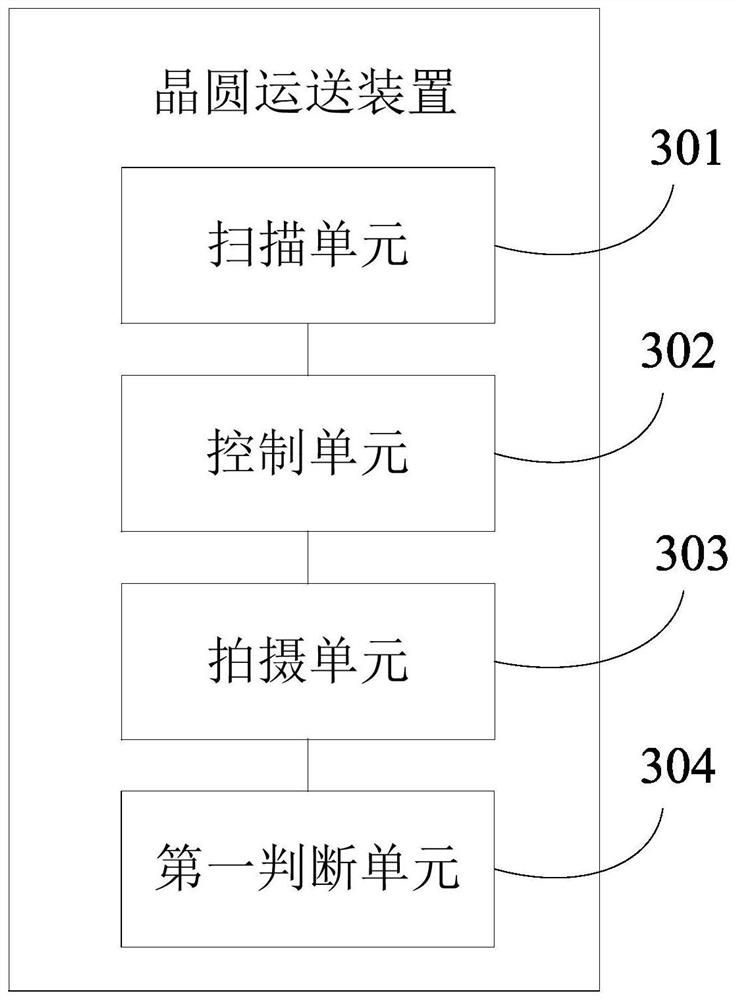

Wafer conveying method and device, electronic equipment and storage medium

ActiveCN114408452AReduce processing stepsAutomate shippingConveyorsSemiconductor/solid-state device manufacturingWaferElectronic mail

The invention provides a wafer conveying method and device, electronic equipment and a storage medium, and the method comprises the steps: for each wafer material box, when the wafer material box is conveyed to a carrying platform by a main conveying belt, scanning an identification mark on the wafer material box, and obtaining an identification result; according to the recognition result, a target branch conveying belt leading to the target material storage area is determined, and the wafer material box is placed on the target branch conveying belt through a mechanical arm; after the wafer material box is carried to a target material storage area, shooting the wafer material box and a target wafer to obtain a target image; and according to the target image, judging whether the target wafer is damaged, and if yes, sending an E-mail to a preset terminal. According to the invention, automatic conveying of the wafer material box can be realized, and when the wafer in the wafer material box is damaged in the conveying process, a worker is notified by a mail, so that subsequent use of the damaged wafer for processing operation and the like is avoided.

Owner:赛美特科技有限公司

Material receiving and transmitting integrated machine

The invention discloses a material receiving and transmitting integrated machine which comprises a horizontal input mechanism, a horizontal output mechanism, a vertical conveying mechanism, a base anda material case. The horizontal input mechanism further comprises a carrier plate, two strip-type seats, a horizontal cylinder and a case receiving plate, the lower surface of the carrier plate is fixedly connected with a plurality of supporting columns, the two strip-type seats are arranged on the upper surface of the carrier plate in parallel, the horizontal cylinder is installed in the middleof the upper surface of the carrier plate through a connection seat and is parallel to the two strip-type seats, the case receiving plate is movably mounted on the upper surface of the carrier plate through two parallel guide rails and located between the two strip-type seats, the horizontal cylinder and the case receiving plate are connected in a clamped manner, and a nut is movably arranged on ascrew rod in a sleeving manner and is fixedly connected with the material case base through a connecting block so as to drive the material case base to move up and down. The material receiving and transmitting integrated machine can completely replace manual conveying, transverse horizontal conveying can be achieved, longitudinal conveying can be achieved, the operation flow is simplified, and the automation and intelligence level of the machining line are improved.

Owner:JIANGSU A KERR BIOLOGICAL RECOGNITION TECH CO LTD

Curing oven and tubular column conveying and rotating device and method used in curing oven

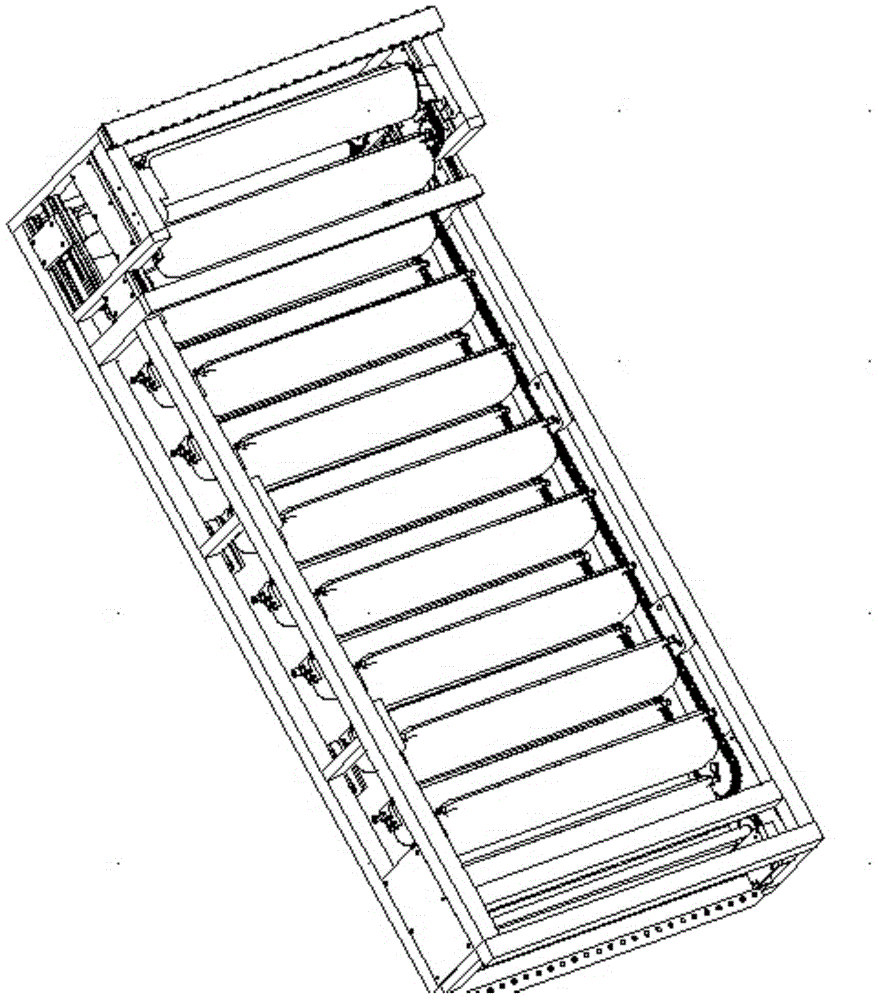

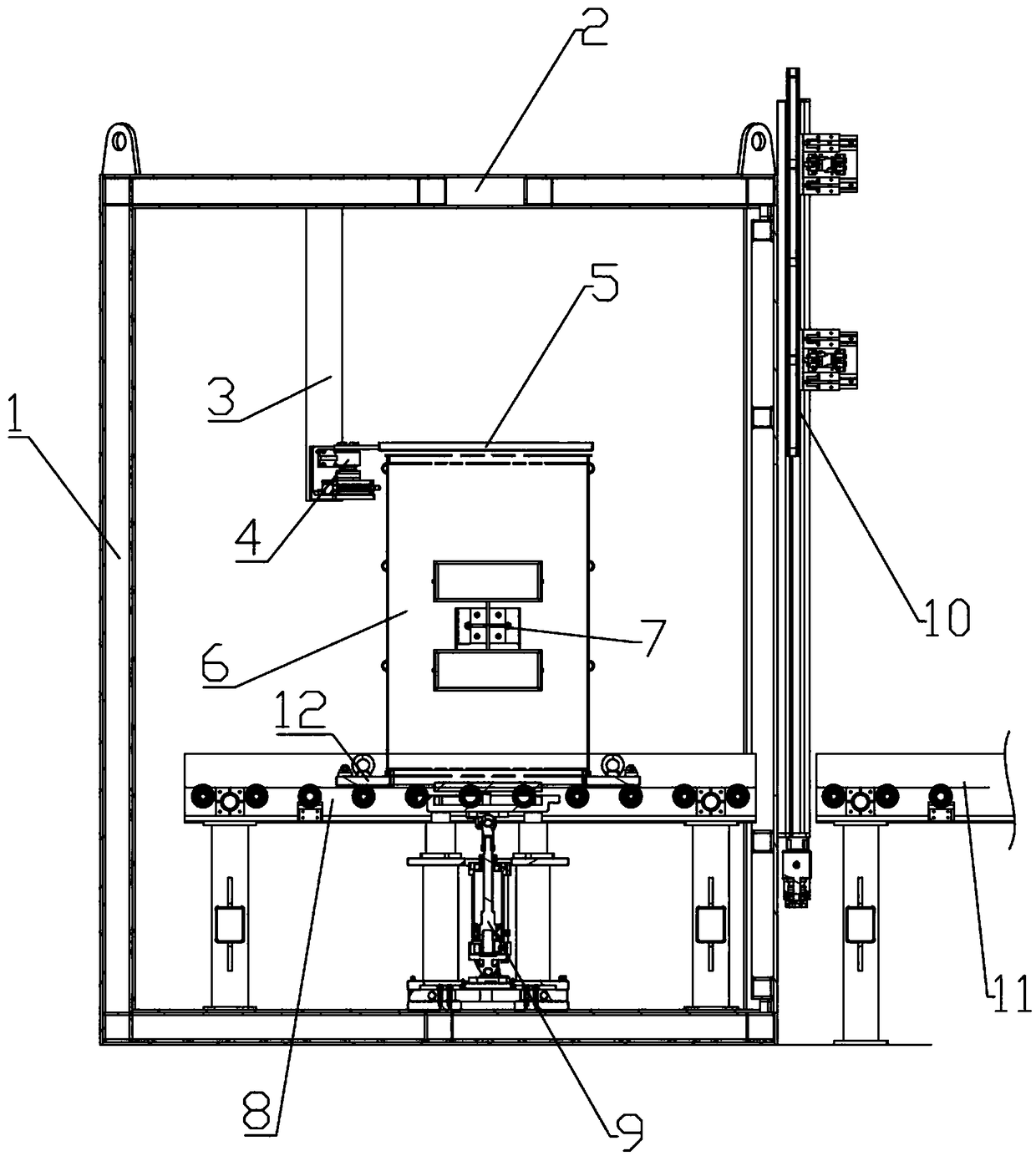

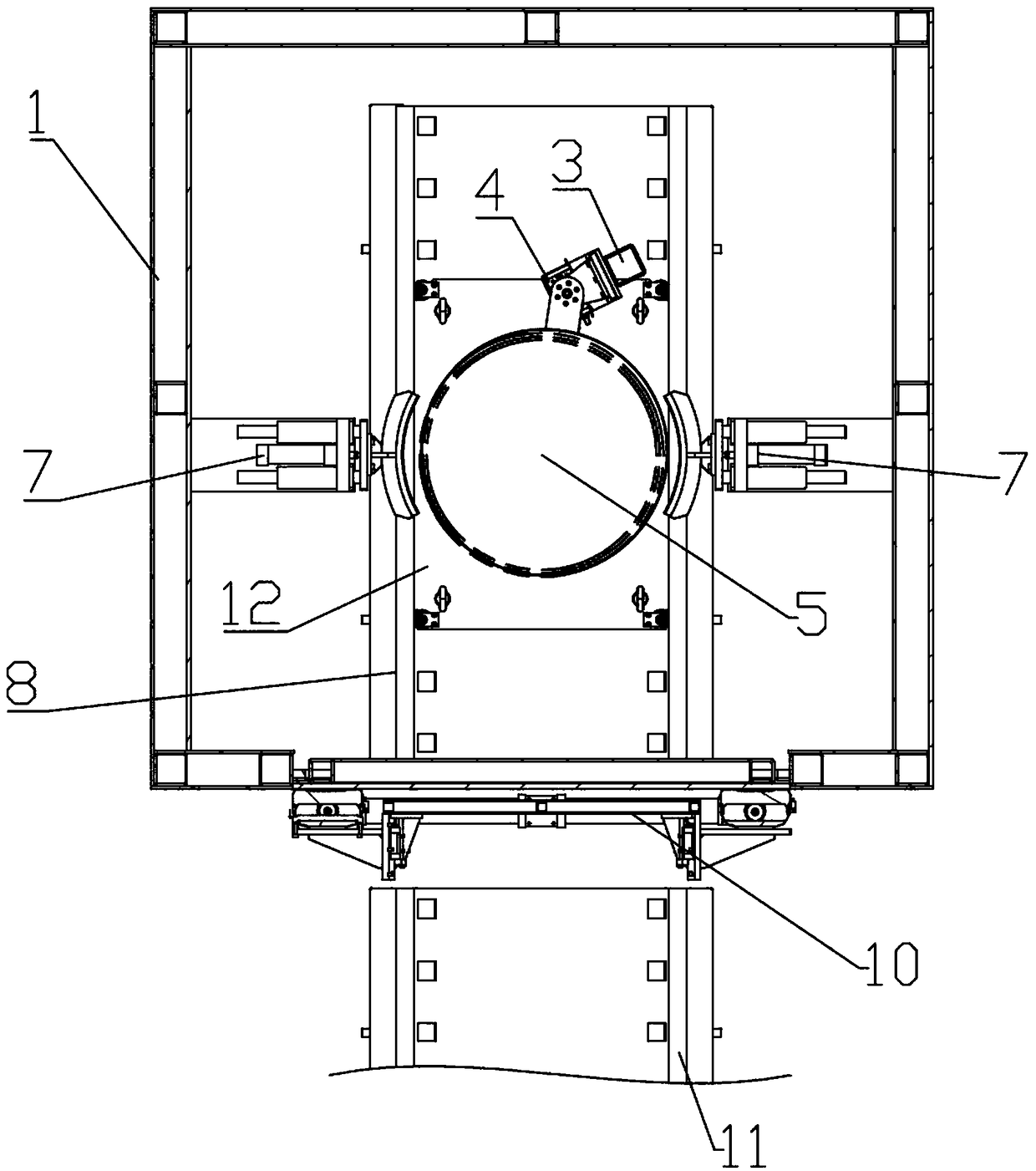

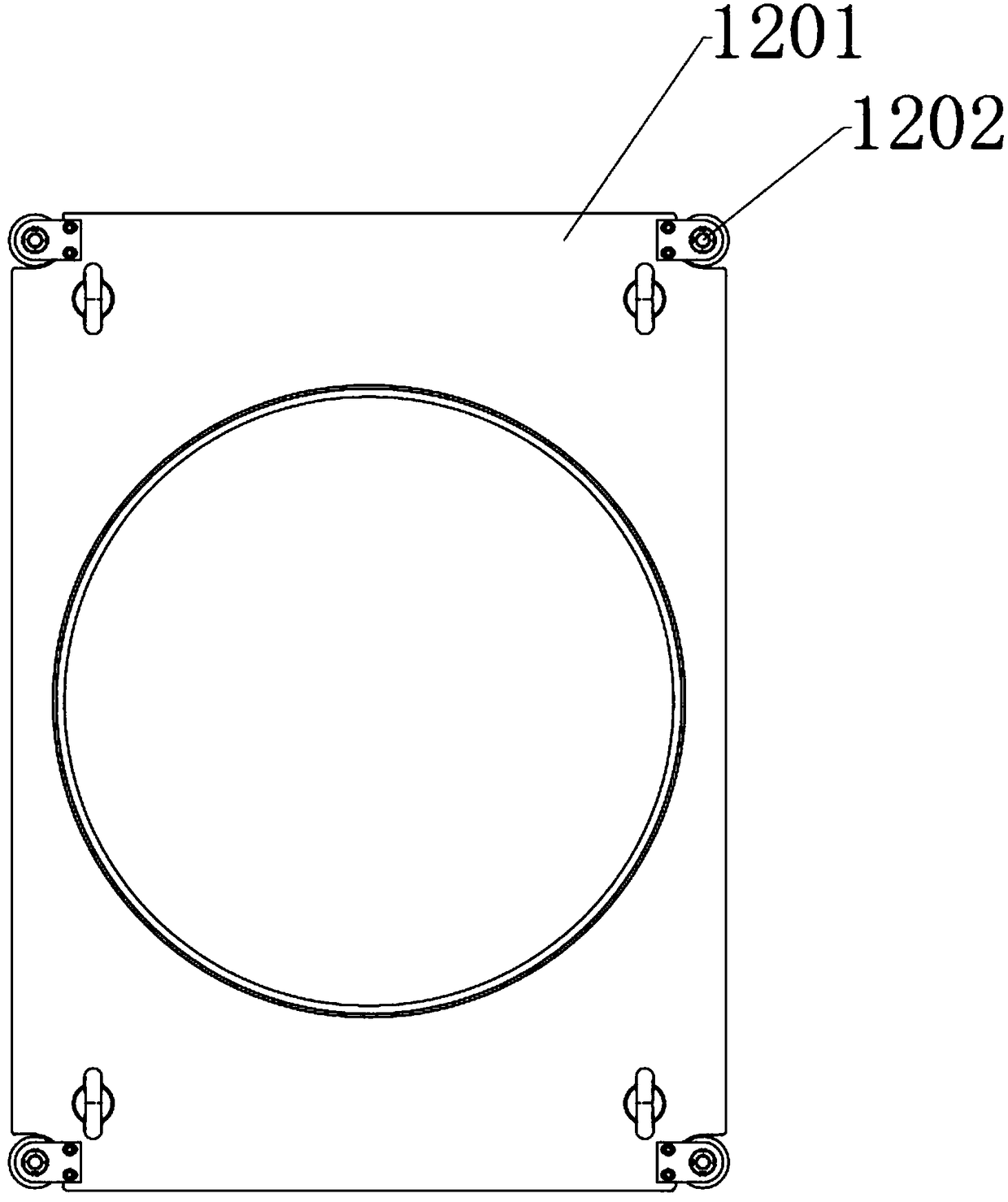

ActiveCN112815716AGuaranteed heating temperatureGuaranteed insulation effectPretreated surfacesCharge manipulationComposite materialEngineering

The invention discloses a curing oven and a tubular column conveying and rotating device and method used in the curing oven. The curing oven comprises: an outer shell, wherein a heating rod is arranged in the outer shell; the tubular column conveying and rotating device, wherein the tubular column conveying and rotating device is arranged in the outer shell. The tubular column conveying and rotating device comprises a tube conveying device, an auxiliary supporting and lifting device and a clamping and rotating device, wherein the auxiliary supporting and lifting device is located on the inner side of the tube conveying device, and the tube conveying device is located on the inner side of the clamping and rotating device. According to the curing oven, the functions of automatic conveying, clamping, rotating and curing of an oil tube can be achieved, the oil tube obtained after solvent-free liquid spraying is kept in the rotating state in the curing process, it is guaranteed that a sprayed coating is free of sagging and cured evenly, and the spraying quality of the internally-coated oil tube is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

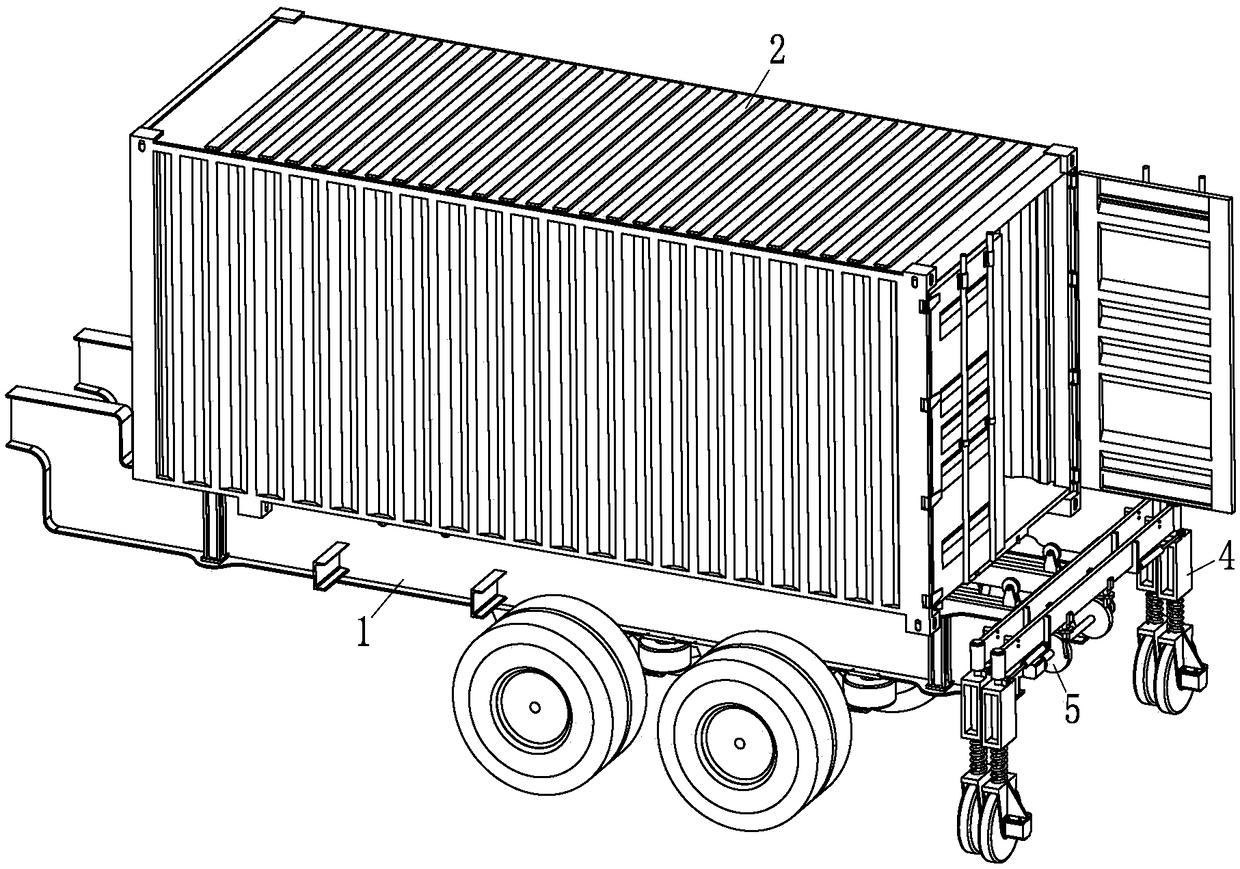

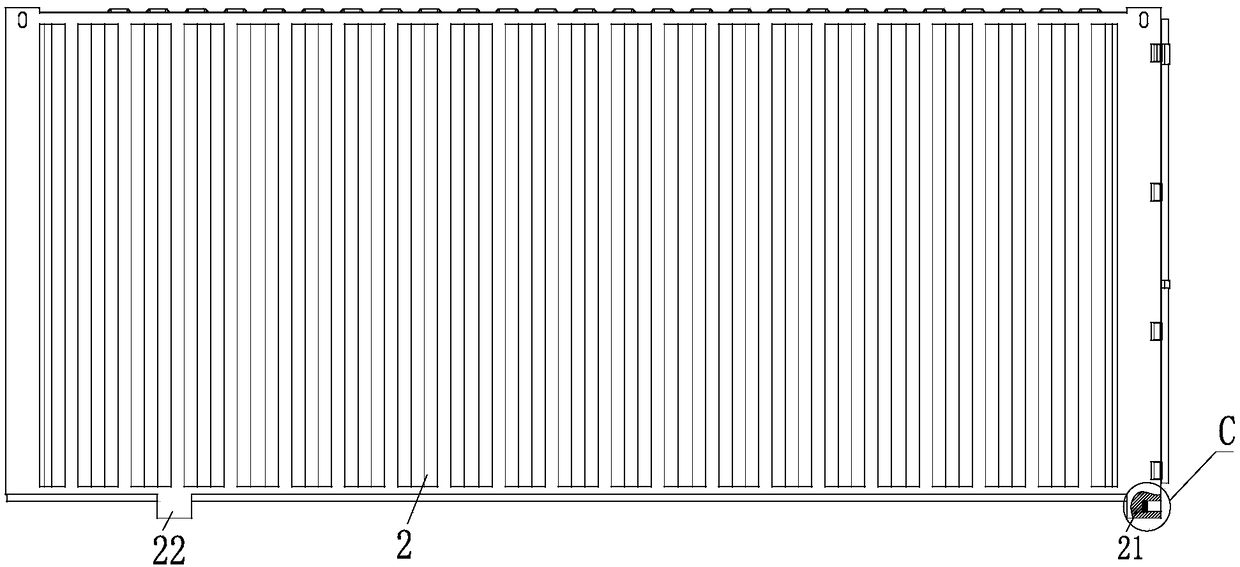

A semi-trailer container automatic running mechanism

The invention relates to the field of semitrailers, in particular to an automatic walking mechanism of a semitrailer container. The automatic walking mechanism comprises a frame, a container body, a container conveying device and a frame conveying device. The container conveying device and the frame conveying device are located behind the frame. The container body is the body for the container. The container conveying device comprises a forward conveying device and a backward conveying device. The forward conveying device and the backward conveying device each comprise a main conveying frame, a rotating shaft, a rotating frame, a rotating hydraulic rod, a connecting wheel hydraulic rod, a wheel frame, a spring and a container conveying wheel. The forward conveying device further comprises a forward conveying motor and a motor frame. The frame conveying device comprises a rotating disc, a connecting shaft, a supporting frame, a frame conveying motor, a first sliding rod, a second sliding rod, a connecting rod and a limiting plate. Automatic conveying of the container can be achieved, the container get away from the semitrailer horizontally and moved to the designated container placement region, no manual operation is needed, and the semitrailer body and cargos inside the container are effectively protected.

Owner:浙江国正安全技术有限公司

A sofa plank cutting machine

ActiveCN105500463BAutomate shippingFor precise cuttingFeeding devicesCircular sawsEngineeringWood plank

Owner:HAINING JIALIAN SOFA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com