Pulp injecting device and method for pulp molding

A grouting device and pulp molding technology, applied in separation methods, chemical instruments and methods, textiles and papermaking, etc., can solve problems such as slow injection of slurry, inaccurate injection volume, and limited development, so as to improve efficiency, The effect of increasing production speed and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are now described in detail with accompanying drawings as follows. The embodiments described in the accompanying drawings are only used to illustrate the technical solutions of the present invention and are not limiting this invention.

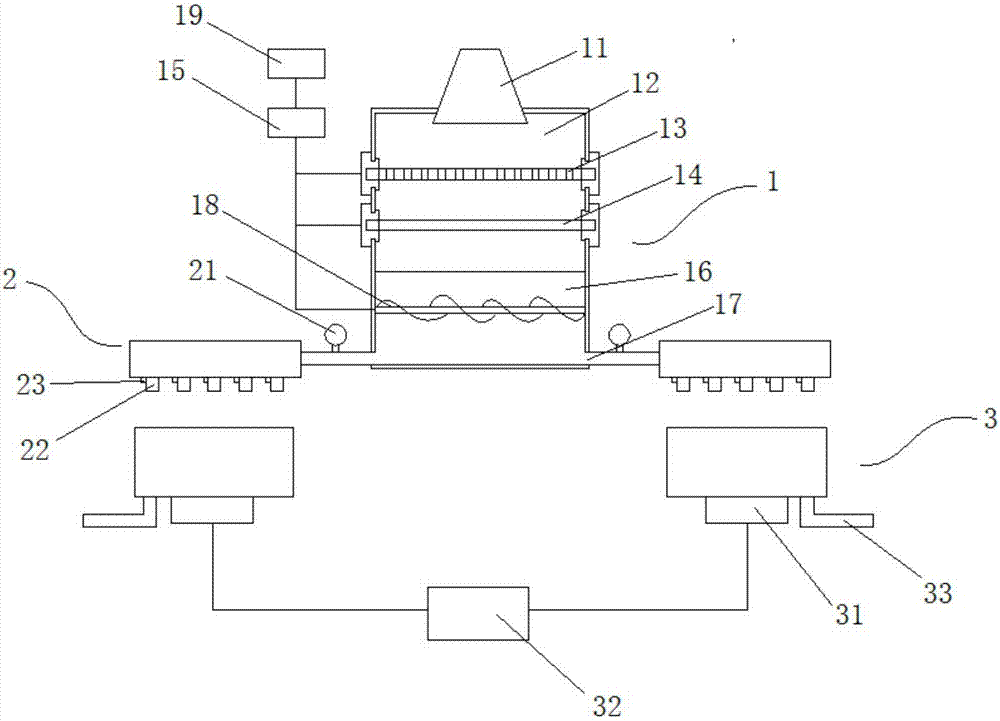

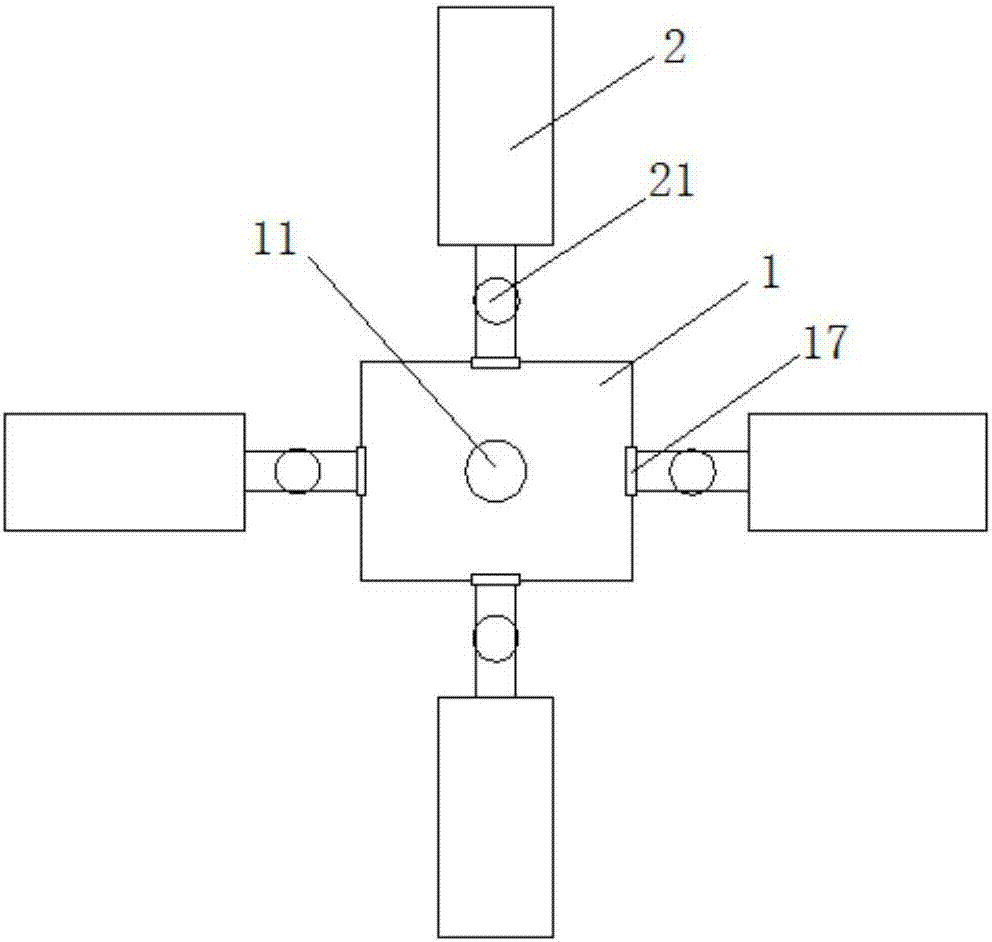

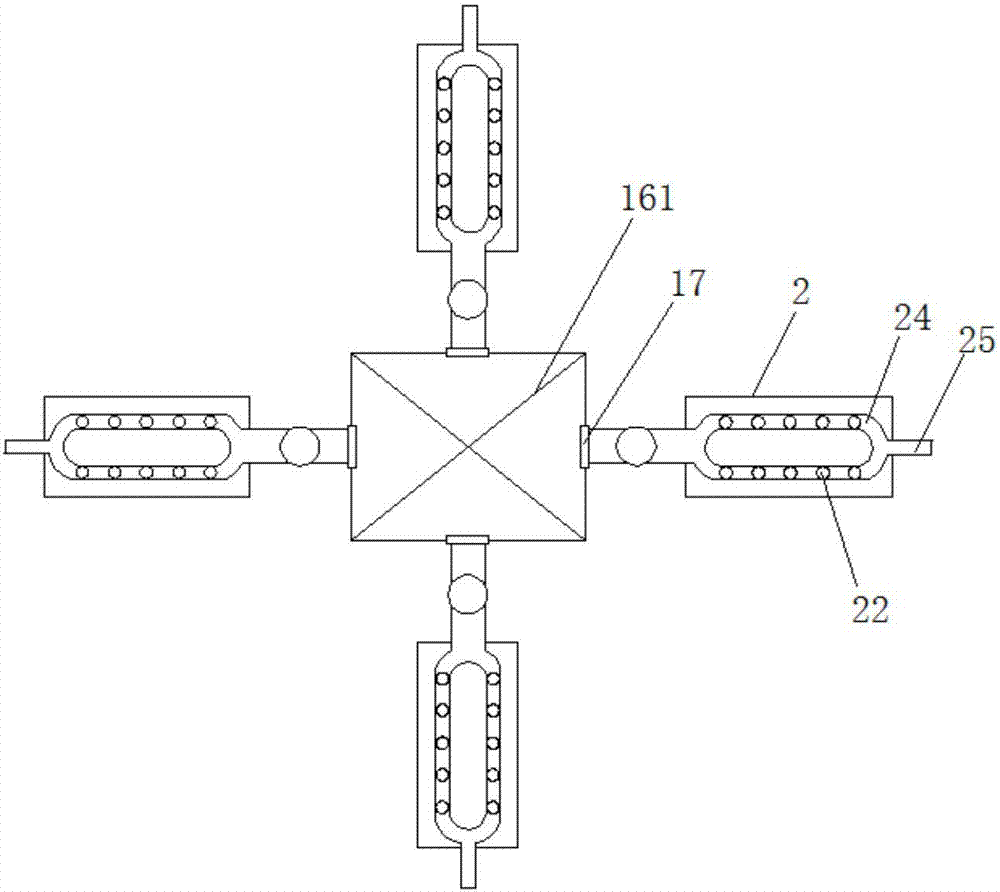

[0018] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the grouting device of the present invention; the grouting device includes a grouting box 1, a grouting box 2 and a slurry tank 3; wherein, the grouting box 1 is a square box and the top is provided with a grouting inlet 11 , the upper part in the square box is a filter cavity 12, the filter cavity 12 is provided with a first vibrating filter membrane 13 and a second vibrating filter membrane 14, preferably, the first vibrating filter membrane 13 is a large-aperture filter membrane, and the second vibrating filter membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com