Material receiving and transmitting integrated machine

An all-in-one machine and input mechanism technology, applied in conveyors, transportation and packaging, etc., can solve the problems of time-consuming, manpower, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

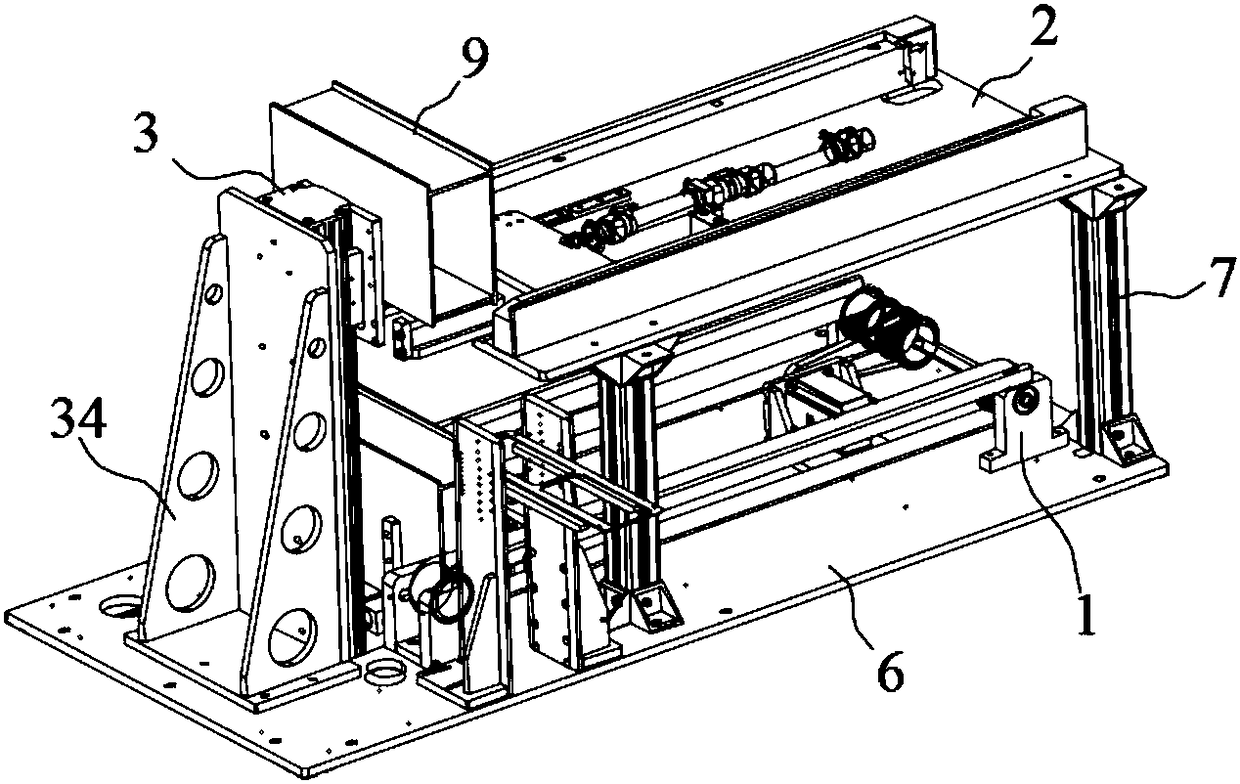

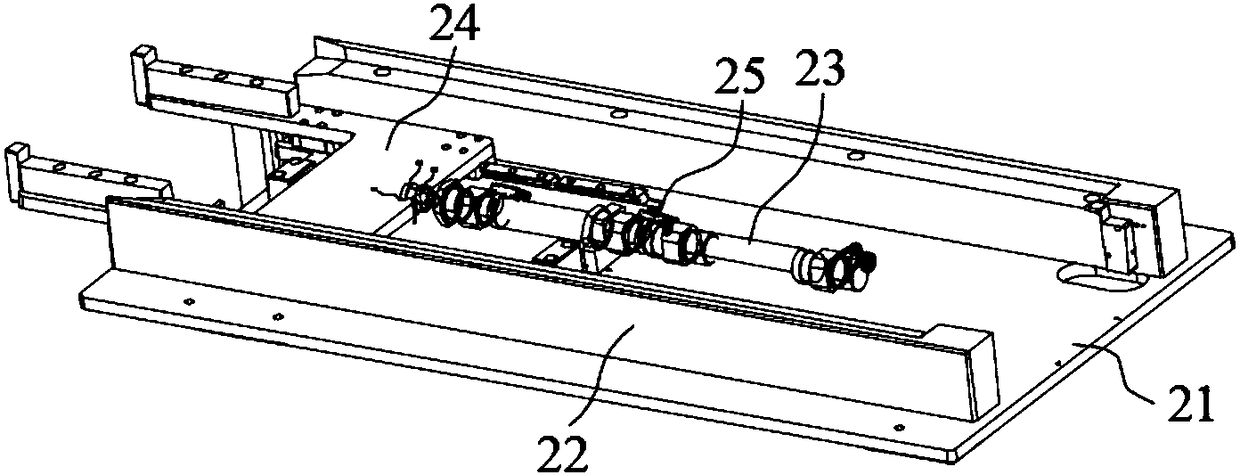

[0022] Embodiment 1: An all-in-one machine for receiving and transmitting materials, including a horizontal input mechanism 1, a horizontal output mechanism 2, a vertical transmission mechanism 3, a base 6 and a magazine 9, the horizontal input mechanism 1 is installed on the upper surface of the base 6, and the The horizontal output mechanism 2 is installed on the base 6 through several support columns 7 and is located directly above the horizontal input mechanism 1, and the vertical transmission mechanism 3 is installed on the upper surface of the base 6 and is located at the rear end of the horizontal input mechanism 1 and the horizontal output mechanism 2 ;

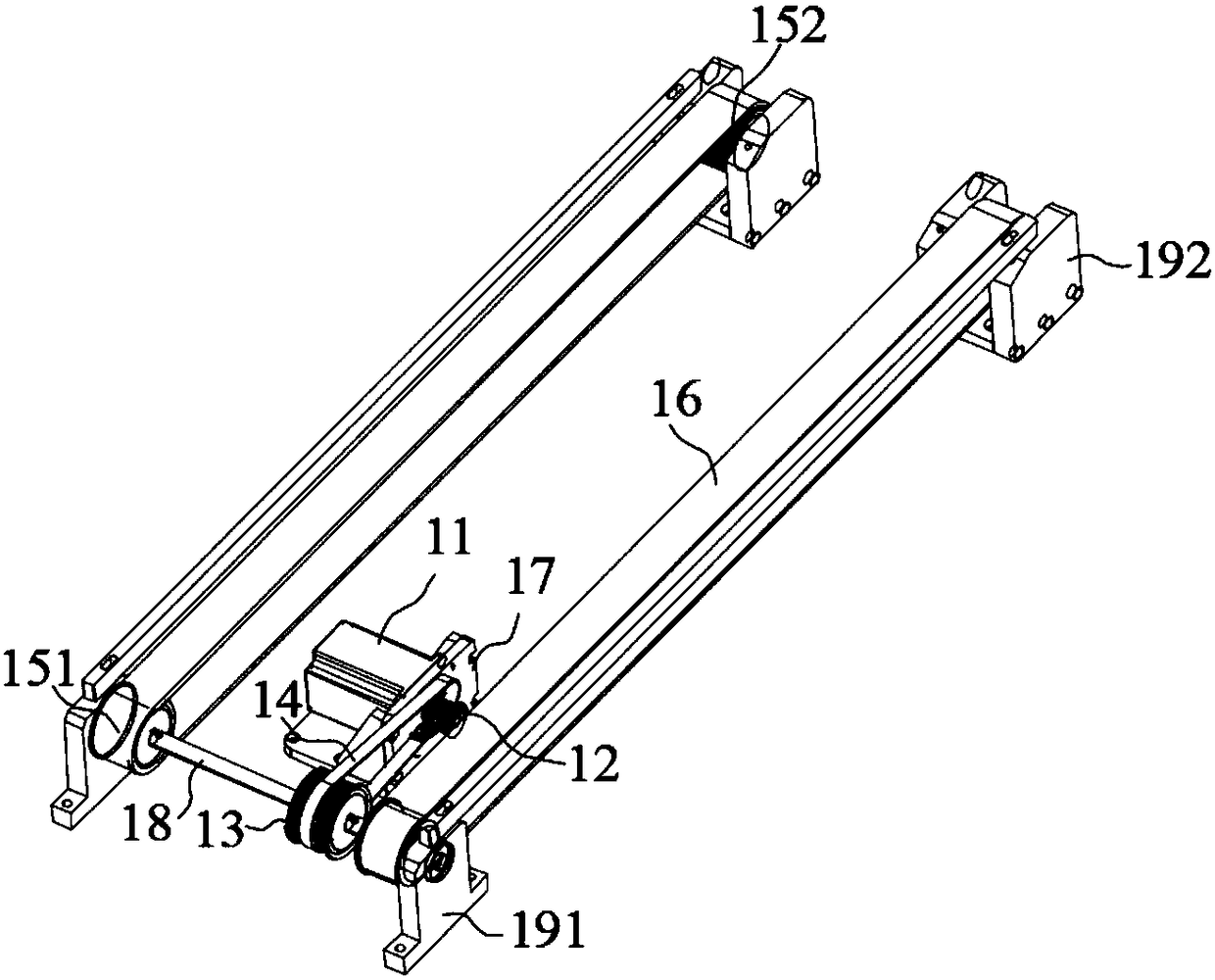

[0023] The horizontal input mechanism 1 further comprises a horizontal motor 11, a driving wheel 12, a driven wheel 13, a transmission belt 14, 2 front-end conveying wheels 151, 2 rear-end conveying wheels 152 and a conveying belt 16, and the horizontal motor 11 passes through a The motor base 17 is fixedly installed ...

Embodiment 2

[0027] Embodiment 2: An all-in-one machine for receiving and transmitting materials, including a horizontal input mechanism 1, a horizontal output mechanism 2, a vertical transmission mechanism 3, a base 6 and a magazine 9, the horizontal input mechanism 1 is installed on the upper surface of the base 6, and the The horizontal output mechanism 2 is installed on the base 6 through several support columns 7 and is located directly above the horizontal input mechanism 1, and the vertical transmission mechanism 3 is installed on the upper surface of the base 6 and is located at the rear end of the horizontal input mechanism 1 and the horizontal output mechanism 2 ;

[0028] The horizontal input mechanism 1 further comprises a horizontal motor 11, a driving wheel 12, a driven wheel 13, a transmission belt 14, 2 front-end conveying wheels 151, 2 rear-end conveying wheels 152 and a conveying belt 16, and the horizontal motor 11 passes through a The motor base 17 is fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com