A sofa plank cutting machine

A cutting machine and wood board technology, applied in the field of machinery, can solve the problems of low work efficiency and high labor intensity, and achieve the effects of recycling, accurate cutting of saw blades, and clean processing and production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

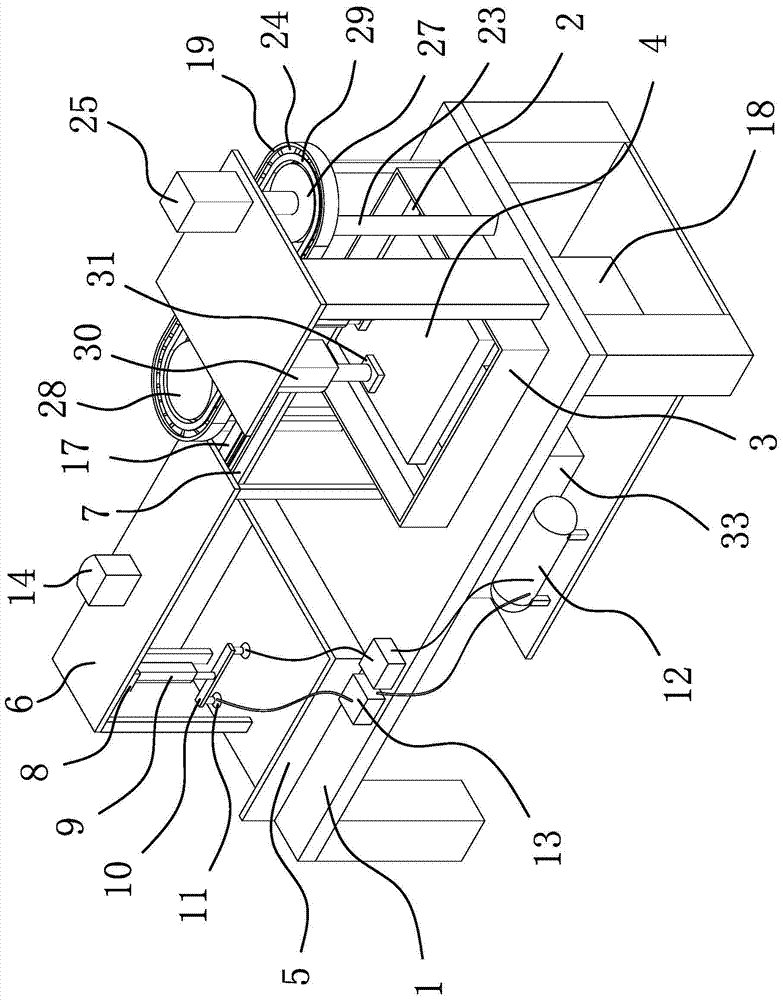

[0043] like figure 1 As shown, a sofa wood cutting machine includes a frame 1, a worktable 2 is fixed on the frame 1, and a protective plate 3 is fixed around the worktable 2 by screws. Under the action of the protective plate 3, the saw can be The outgoing wood chips are uniformly collected on the workbench 2 and processed in a centralized manner, so as to reduce the dust pollution caused by the wood chips to the surrounding environment as much as possible.

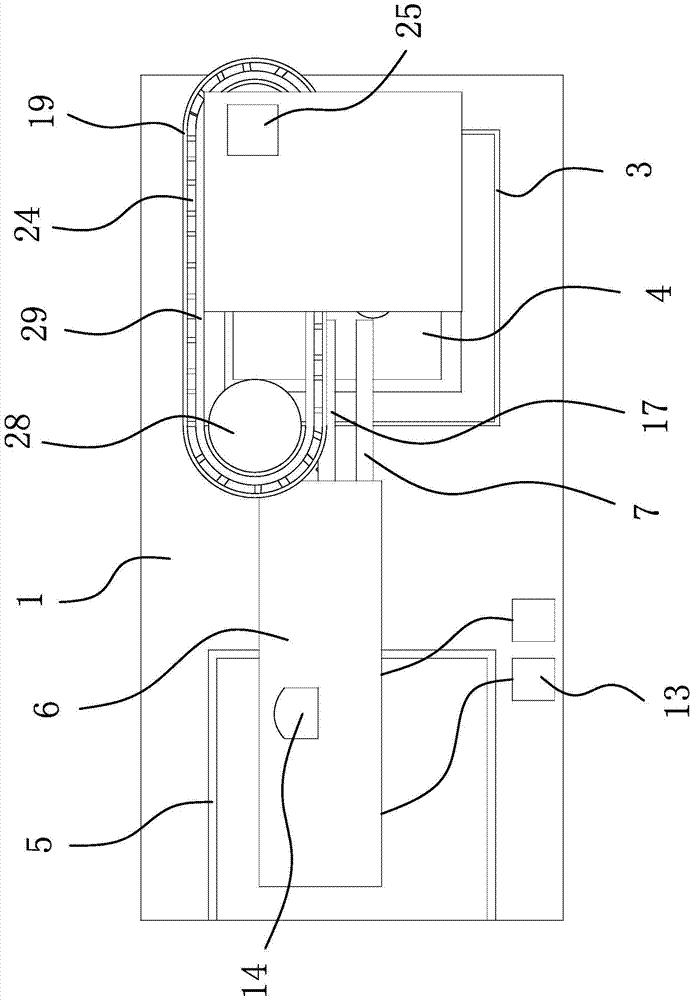

[0044] like figure 2 As shown, the middle part of the workbench 2 is provided with an installation square hole, and a lifting platform 4 is arranged in the installation square hole. The lifting platform 4 is smaller than the installation square hole, so that the lifting platform 4 can be lifted up and down in the installation square hole. The upper side of the square platform 4 is a horizontal plane, and the lower side of the lifting square platform 4 is connected with a lifting structure that can drive it up and down....

Embodiment 2

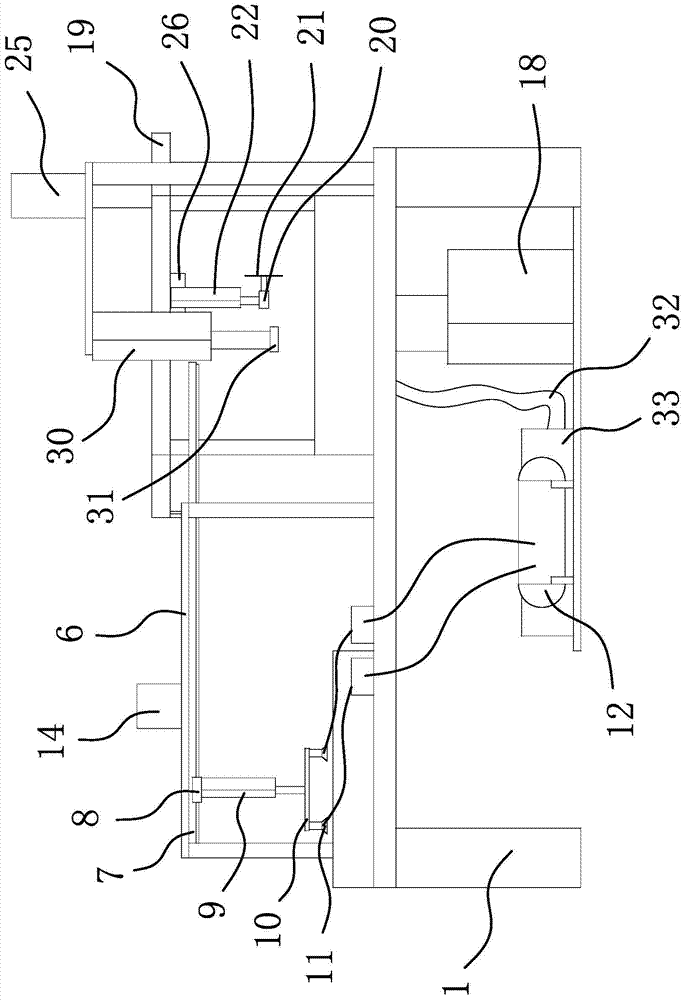

[0058]The structure and principle of this embodiment are basically the same as the first embodiment, the difference is that in the first embodiment, the drive structure includes a drive motor 14, a gear 15, a rack 16 and a second guide rail 17, and the drive motor 14 is fixed on On the connecting bracket 6, the gear 15 is fixed on the output shaft of the drive motor 14, the second guide rail 17 is fixed on the connecting bracket 6, the rack 16 is arranged in the second guide rail 17, and one side of the rack 16 has teeth, The teeth of the bar 16 are meshed with the gear 15, and the other side of the rack 16 is fixed with the slider 8; and in the second embodiment, the driving structure is a driving cylinder, and the cylinder body of the driving cylinder is fixed on the connecting bracket 6 , the piston rod of the drive cylinder is fixed with the slide block 8 by screws. The piston rod of the drive cylinder stretches out, and the slide block 8 slides from the top of the placeme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com