Curing oven and tubular column conveying and rotating device and method used in curing oven

A technology of rotating device and curing furnace, which is applied in the direction of the device, furnace and furnace material for coating liquid on the surface, which can solve the problems of easy falling off, thin coating thickness and affecting large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] see Figure 1 to Figure 6 , the present invention provides a technical solution: a curing furnace, comprising:

[0080] An outer casing 1, a heating rod 2 is arranged inside the outer casing;

[0081] Also includes:

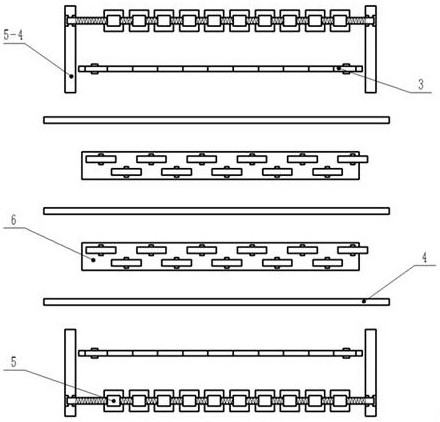

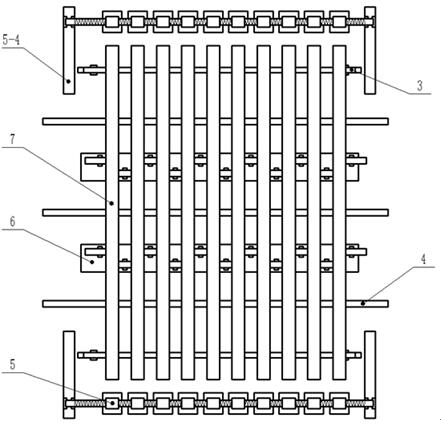

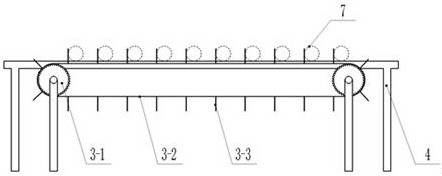

[0082] The pipe string conveying rotating device, the pipe string conveying rotating device is arranged inside the outer casing; the pipe string conveying rotating device includes a pipe feeding device 3, an auxiliary supporting lifting device 6, and a clamping rotating device 5, and the auxiliary supporting lifting device It is located on the inner side of the tube delivery device, and the tube delivery device is located on the inner side of the clamping and rotating device.

[0083] Further, there are two tube delivery devices, which are the front tube delivery device and the rear tube delivery device, and are arranged symmetrically to each other;

[0084] Two auxiliary support lifting devices are provided, which are respectively a front auxiliary sup...

Embodiment 2

[0114] see Figure 1 to Figure 6 , the present invention provides a technical solution: a curing furnace, comprising:

[0115] An outer casing 1, a heating rod 2 is arranged inside the outer casing;

[0116] Also includes:

[0117] The pipe string conveying rotating device, the pipe string conveying rotating device is arranged inside the outer casing; the pipe string conveying rotating device includes a pipe feeding device 3, an auxiliary supporting lifting device 6, and a clamping rotating device 5, and the auxiliary supporting lifting device It is located on the inner side of the tube delivery device, and the tube delivery device is located on the inner side of the clamping and rotating device.

[0118] Further, there are two tube delivery devices, which are the front tube delivery device and the rear tube delivery device, and are arranged symmetrically to each other;

[0119] Two auxiliary support lifting devices are provided, which are respectively a front auxiliary sup...

Embodiment 3

[0141] see Figure 1 to Figure 6 , the present invention provides a technical solution: a curing furnace, comprising:

[0142] An outer casing 1, a heating rod 2 is arranged inside the outer casing;

[0143] Also includes:

[0144] The pipe string conveying rotating device, the pipe string conveying rotating device is arranged inside the outer casing; the pipe string conveying rotating device includes a pipe feeding device 3, an auxiliary supporting lifting device 6, and a clamping rotating device 5, and the auxiliary supporting lifting device It is located on the inner side of the tube delivery device, and the tube delivery device is located on the inner side of the clamping and rotating device.

[0145] Further, there are two tube delivery devices, which are the front tube delivery device and the rear tube delivery device, and are arranged symmetrically to each other;

[0146] Two auxiliary support lifting devices are provided, which are respectively a front auxiliary sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com