Patents

Literature

330results about How to "Uniform curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

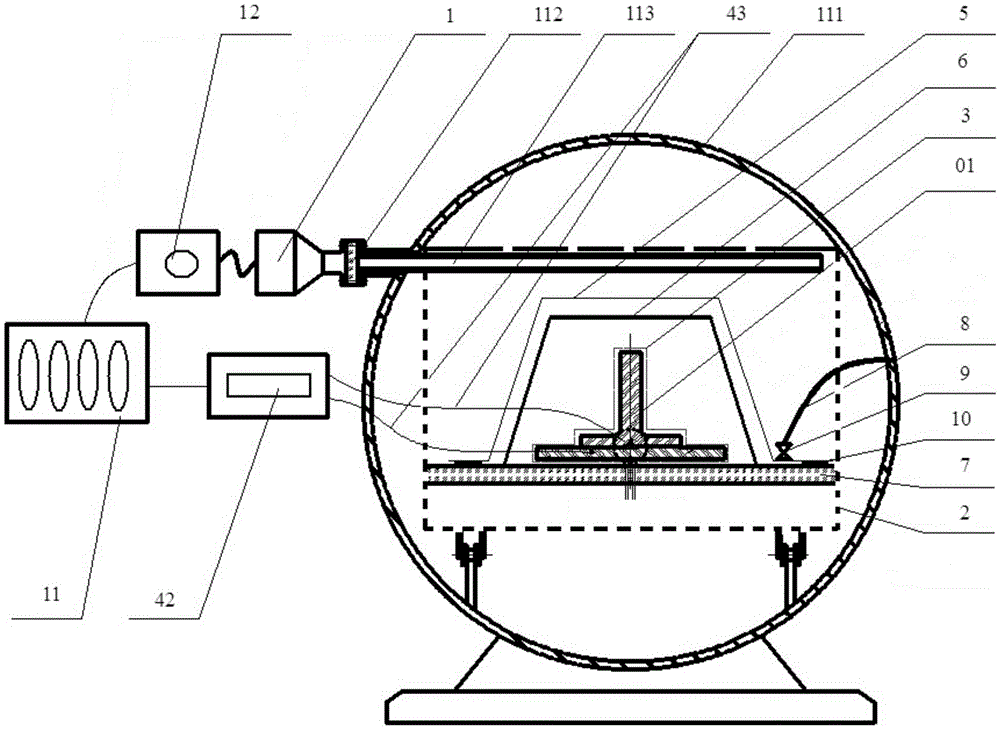

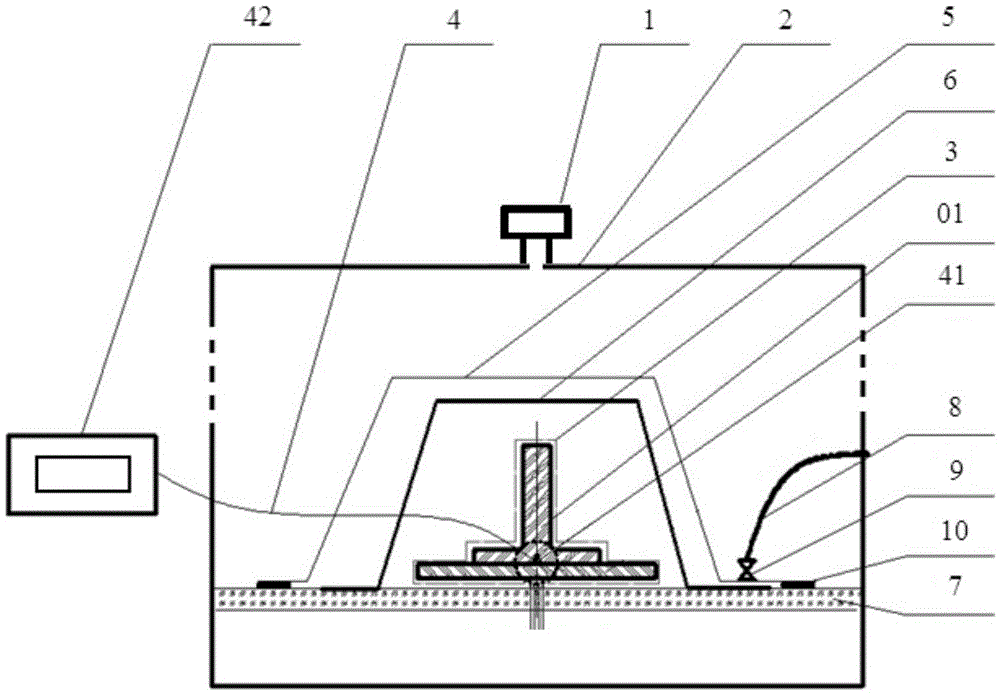

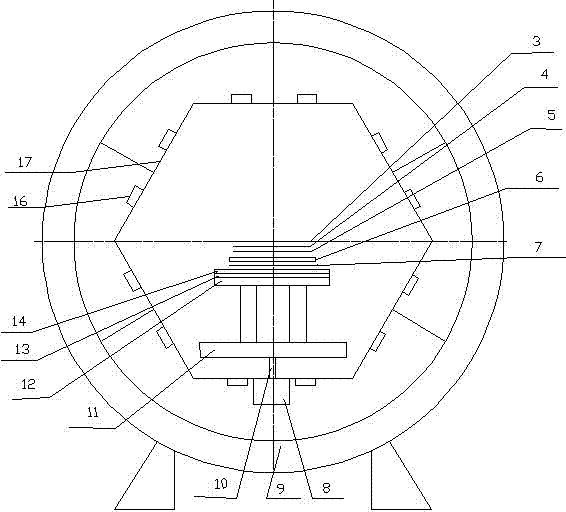

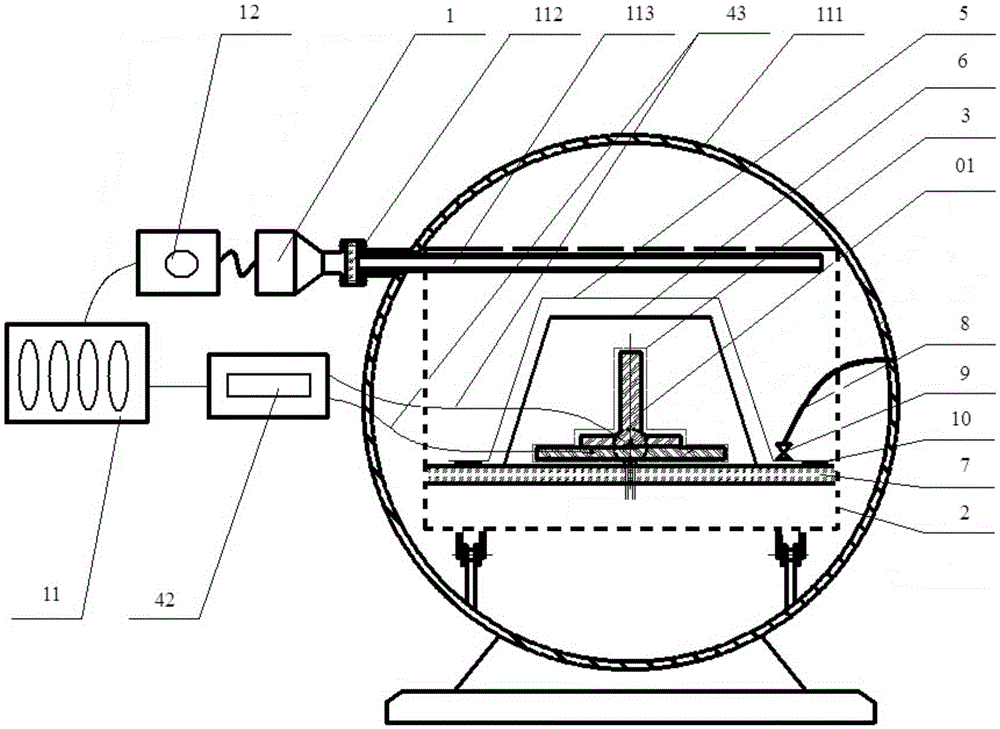

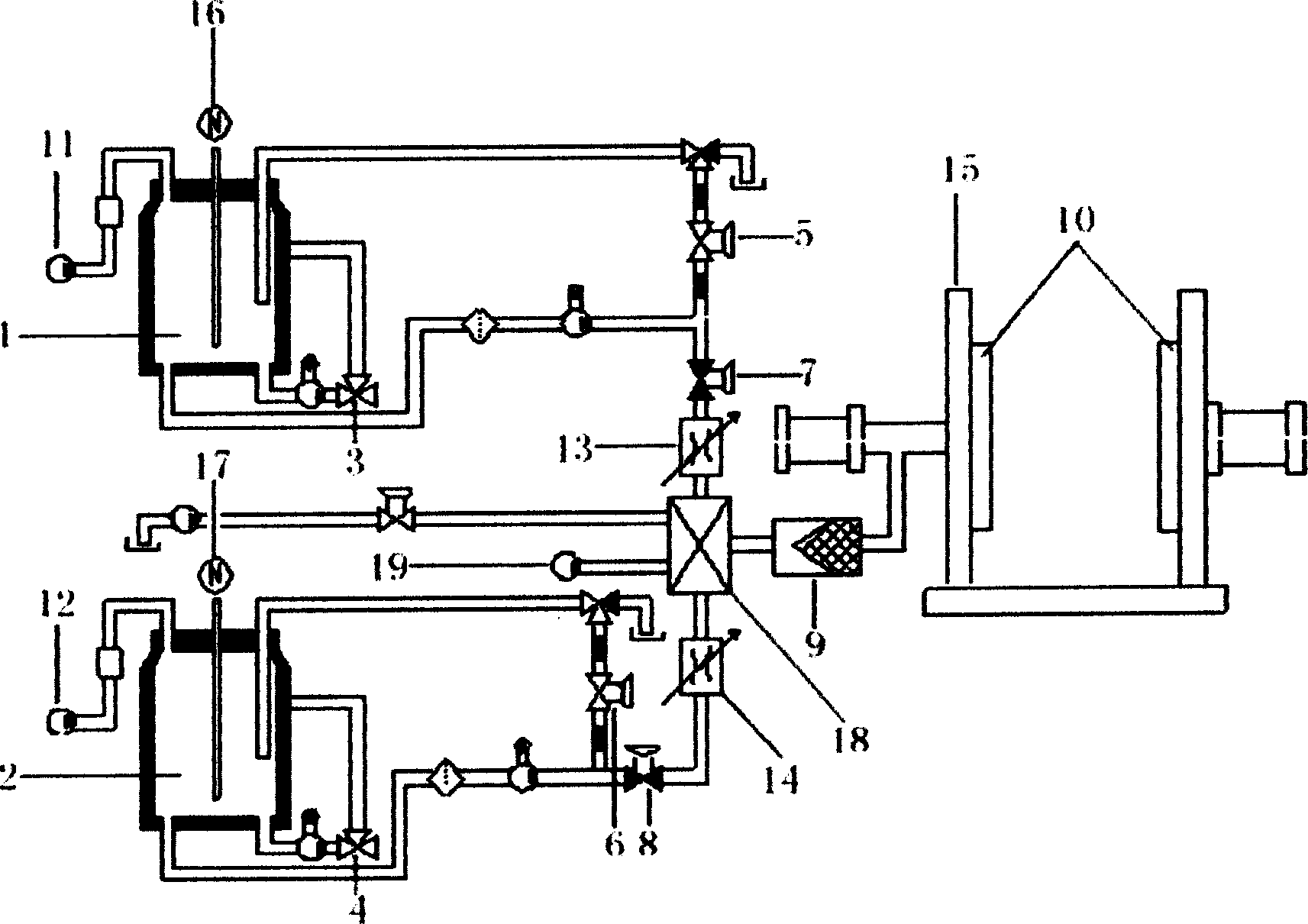

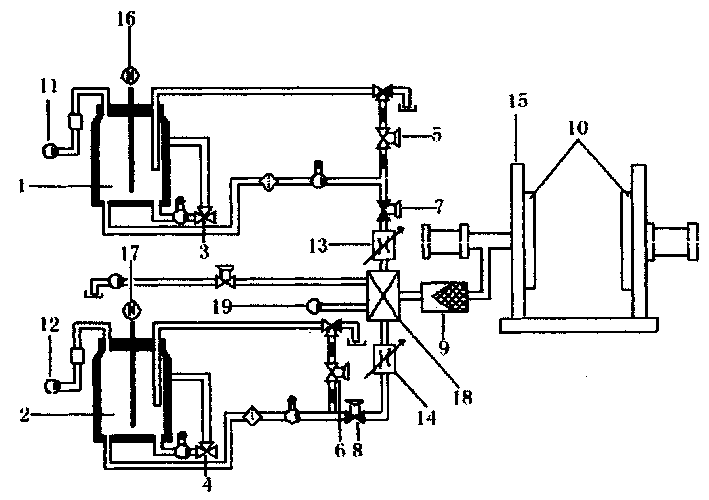

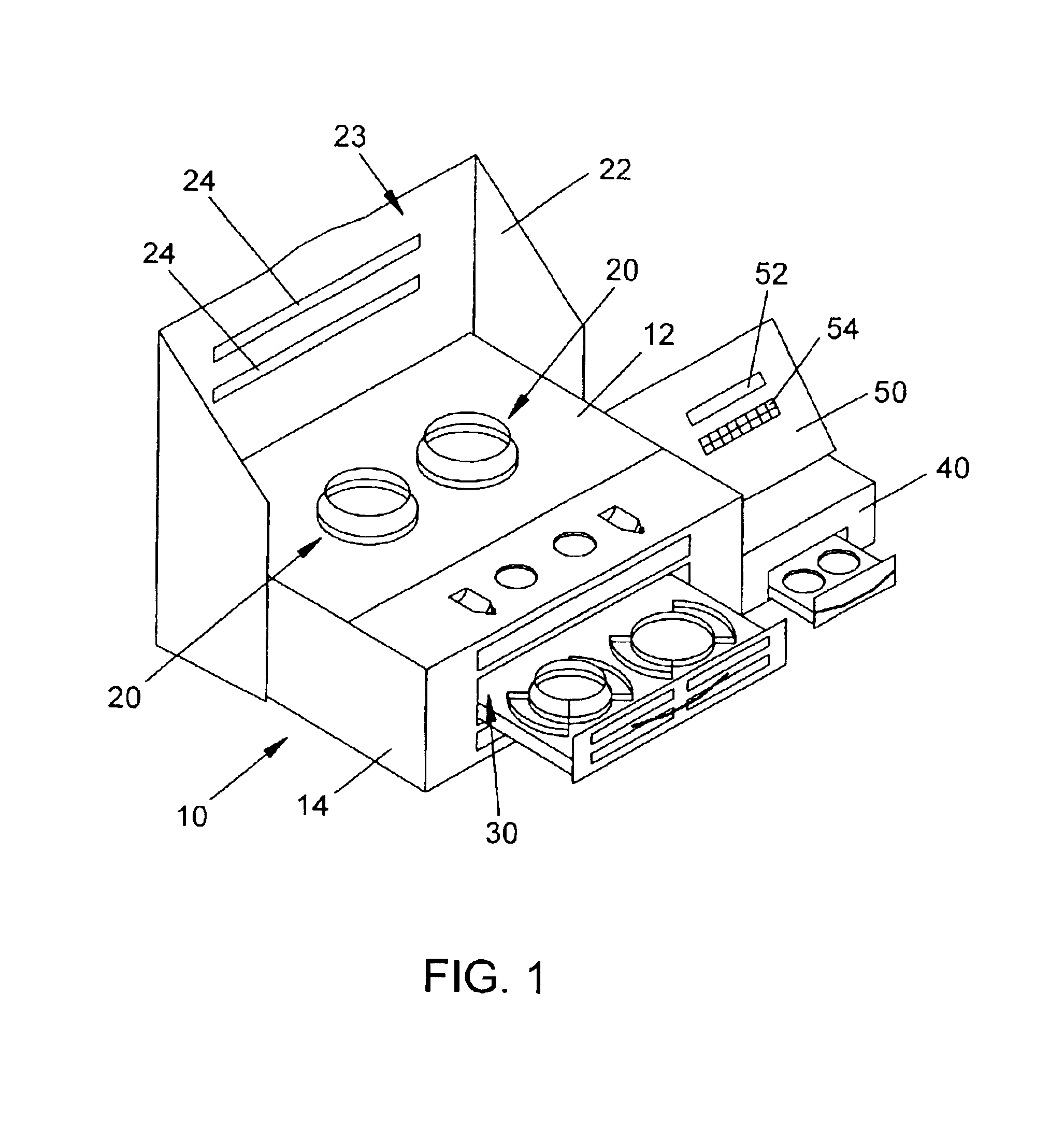

Composite energy field heating device

ActiveCN105666895AImprove performanceUniform and controllable heating and curing processMicrowave cavityAviation

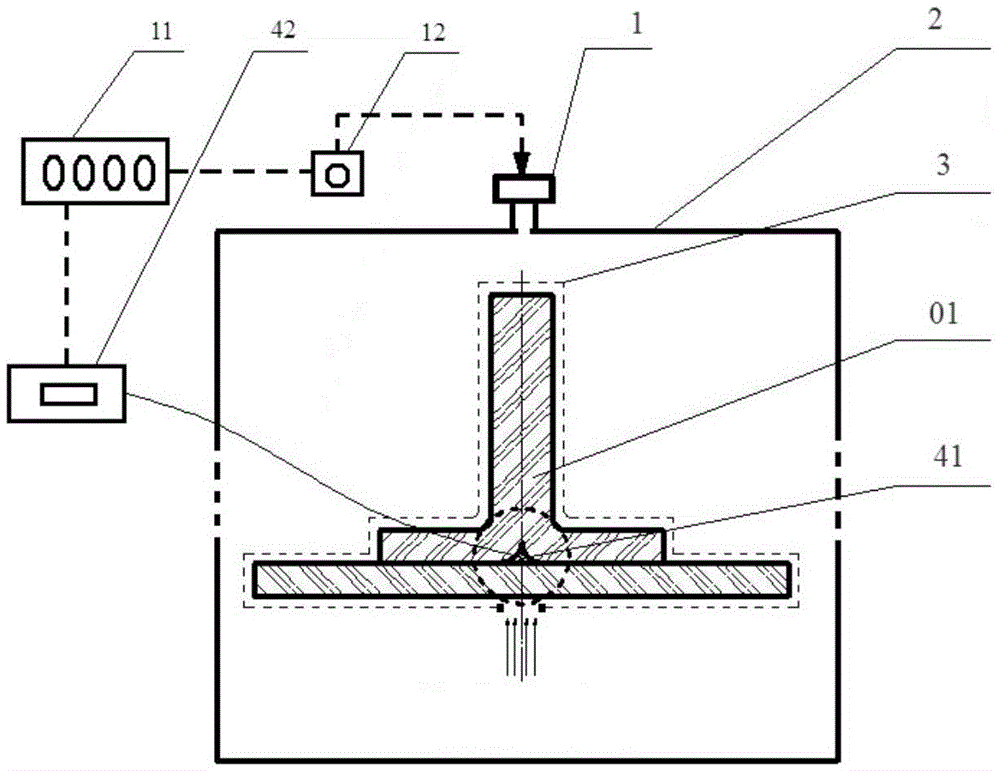

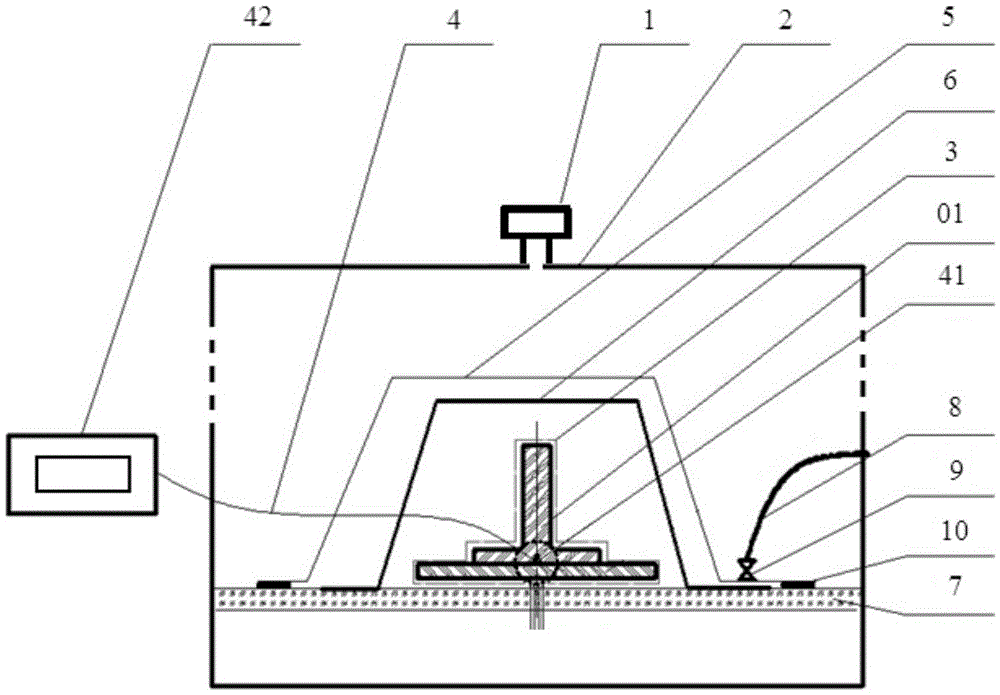

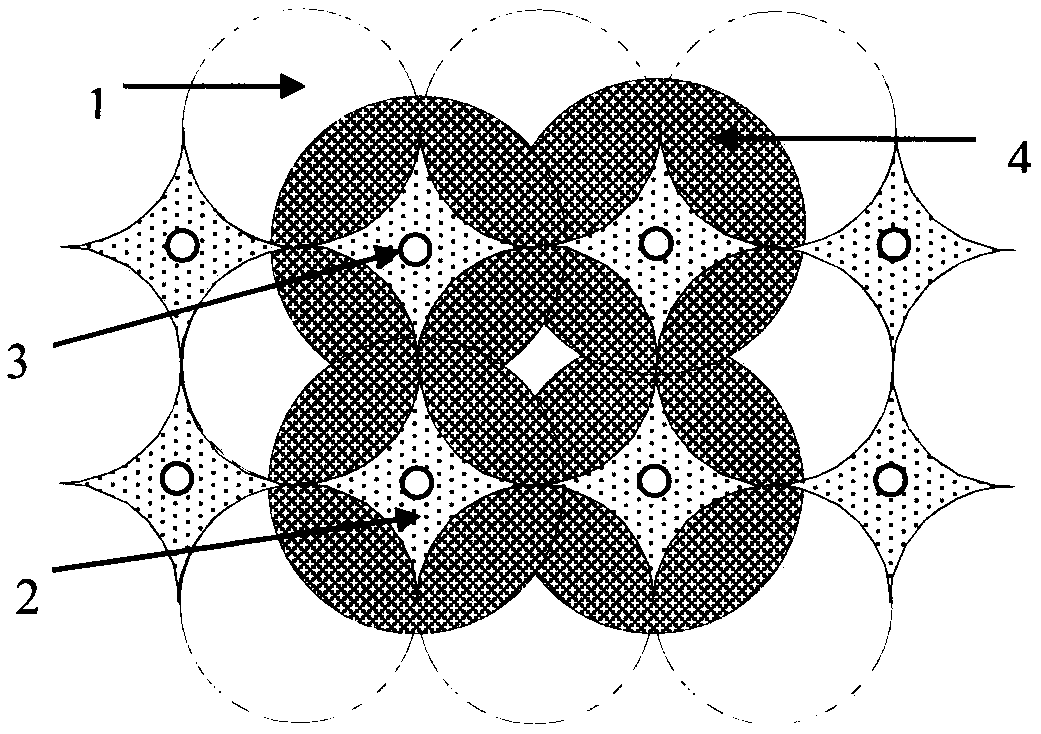

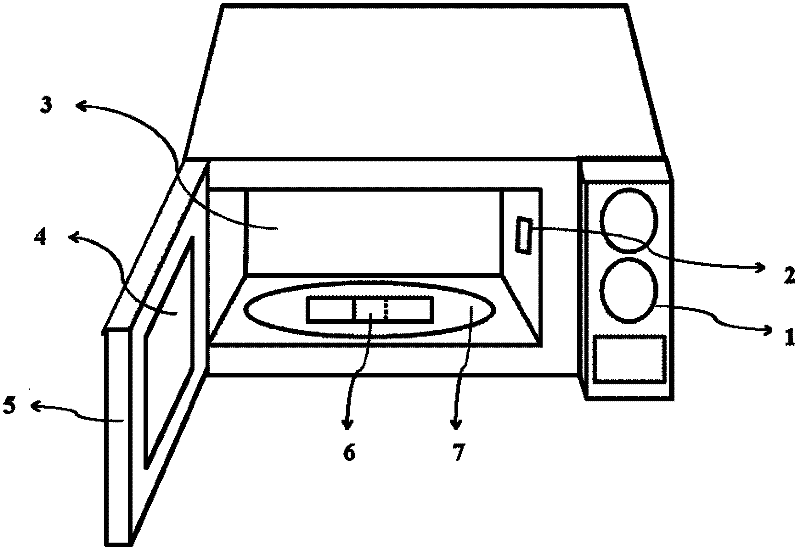

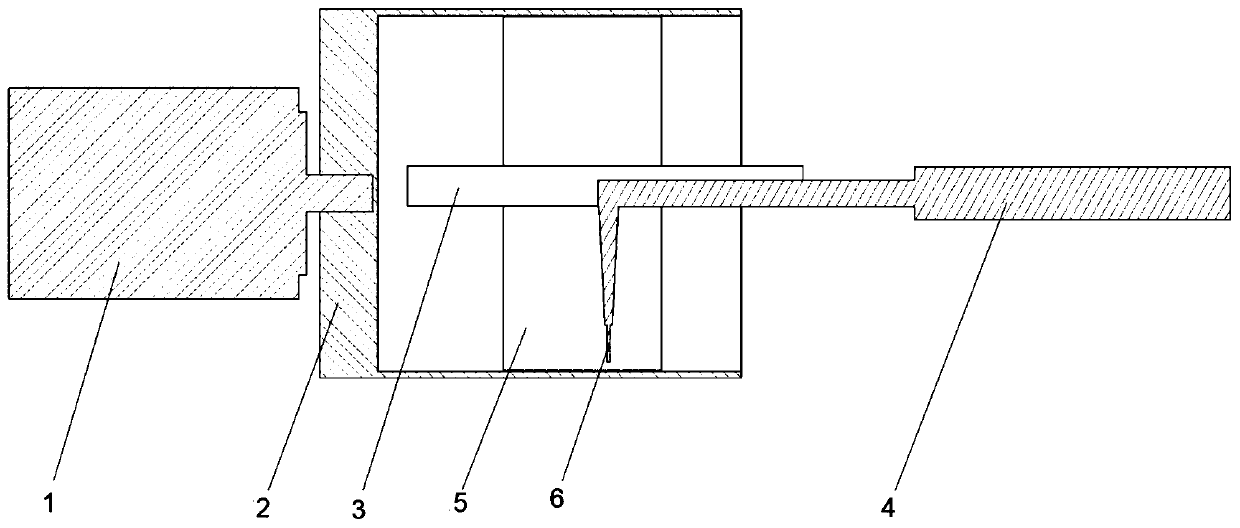

The invention provides a composite energy field heating device. The composite energy field heating device comprises a microwave heating device and a hot-pressing tank, wherein the microwave heating device comprises a microwave generator, a microwave cavity and a microwave local shielding part; the microwave generator is used for sending microwaves into the microwave cavity; a wave absorbing material is arranged in the microwave cavity; the microwave local shielding part is positioned in the microwave cavity, and is used for covering the outer surface of the wave absorbing material; the microwave local shielding part is composed of a shielding microwave region and a transmission microwave region; the transmission microwave region comprises one or more seams, so that microwaves in the microwave cavity can enter the wave absorbing material through the seams for being absorbed; the microwave cavity is integrally arranged in the hot-pressing tank; a ventilating window or a ventilating wall which consists of one or more metal honeycomb plates is arranged on the microwave cavity; and the ventilating window or the ventilating wall can be used for enabling smooth air flow inside and outside the microwave cavity in the hot-pressing tank while shielding the microwaves. The composite energy field heating device can truly realize consistent temperature on all parts in the wave absorbing material, so that high-quality cured products are provided for the aviation and aerospace fields.

Owner:CENT SOUTH UNIV

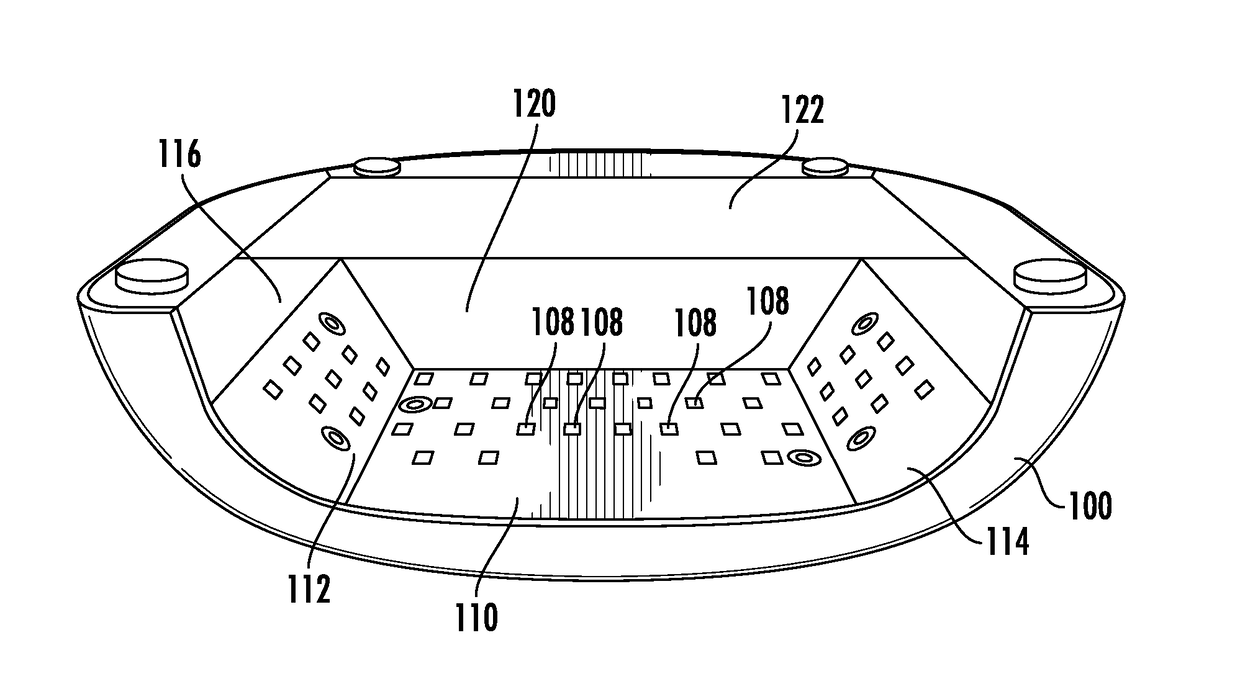

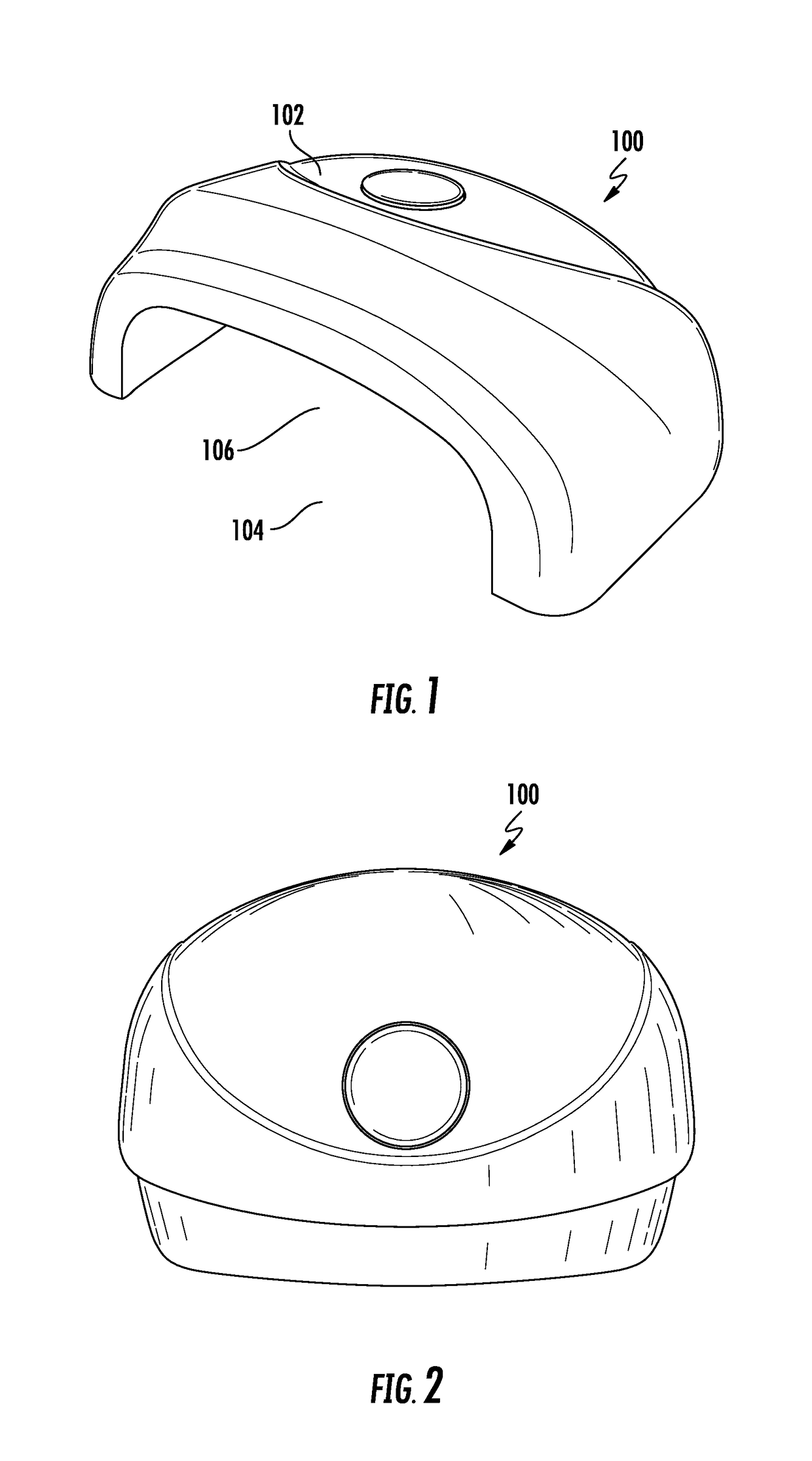

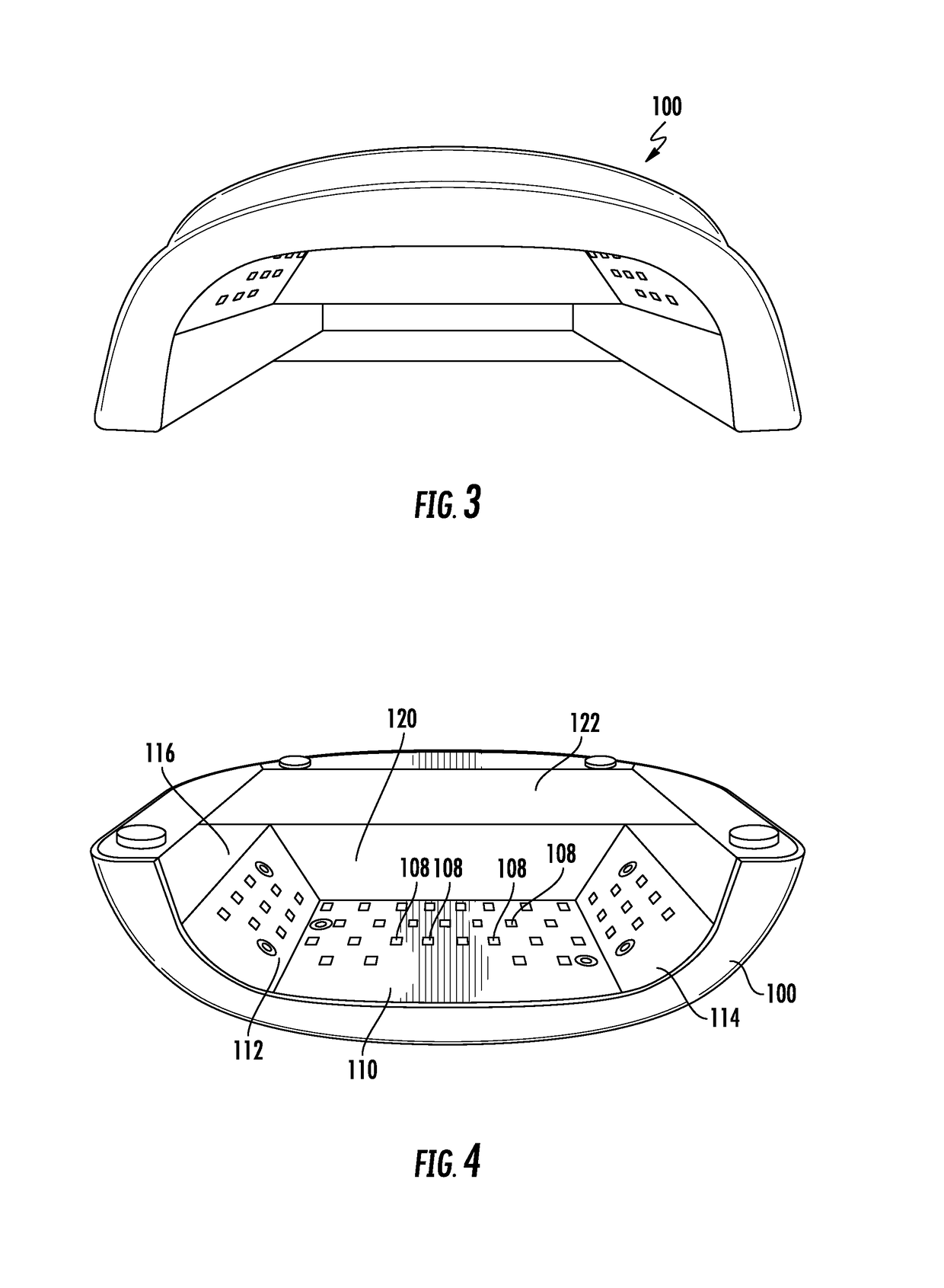

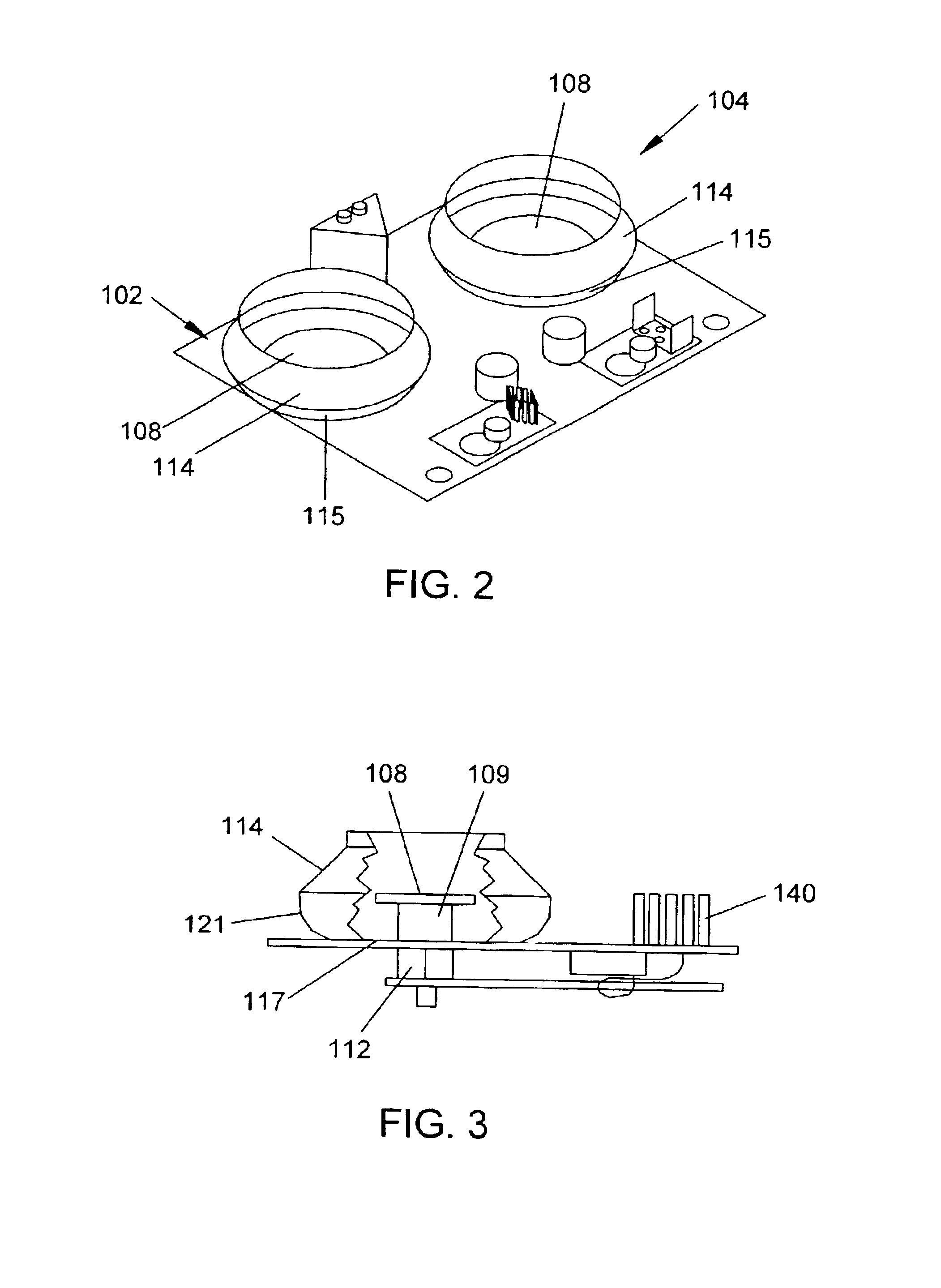

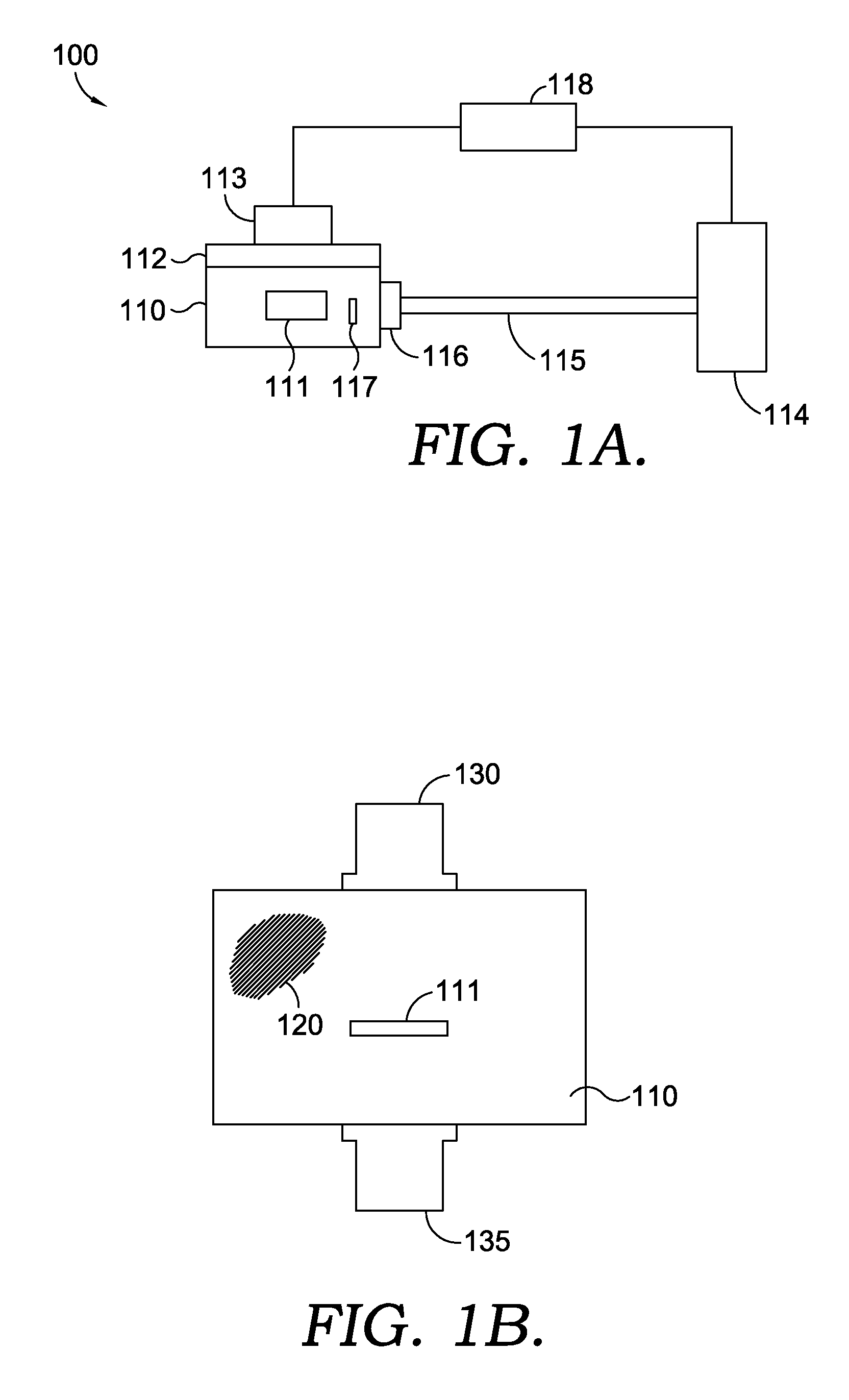

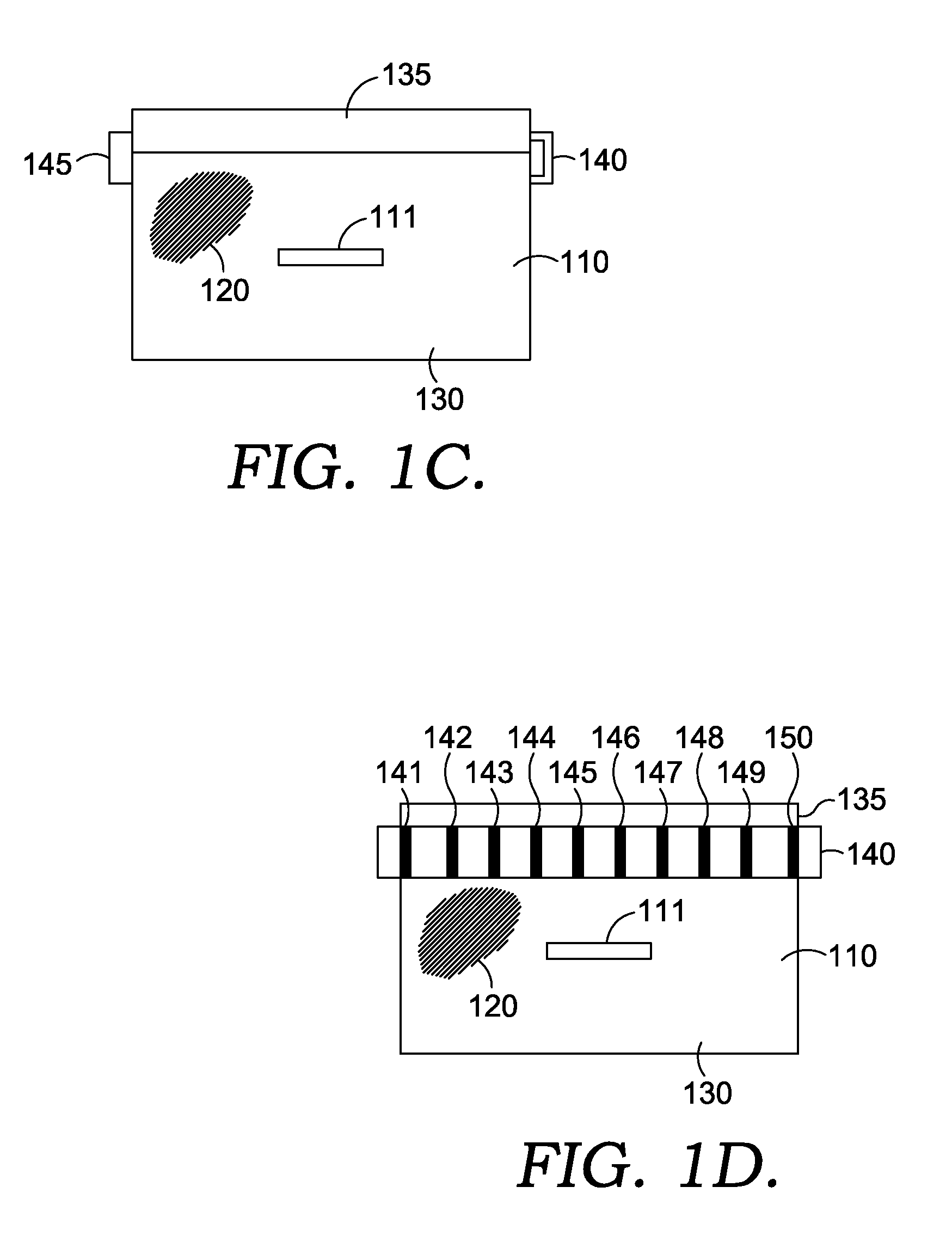

Nail lamp with light emitting diodes and rechargeable battery

ActiveUS10117494B1Low powerEasy to transportManicure/pedicureIrradiation devicesElectrical batteryUltraviolet lights

A nail lamp for curing UV-curable nail gel uses light emitting diodes (LEDs) that emit ultraviolet light and are relatively lower power. The nail lamp is powered from an exterior power source, such as a wall socket, or by a rechargeable battery pack. A battery compartment of the nail lamp holds the battery pack, which is removable without disassembling the nail lamp. The nail lamp is easily transportable to different locations and can be used even when a wall socket is unavailable. A curing time of the nail lamp is user-selectable. The nail lamp can also include detection sensors to detect a person's hand or foot in a treatment chamber and automatically turn on or off the LEDs.

Owner:LECHAT

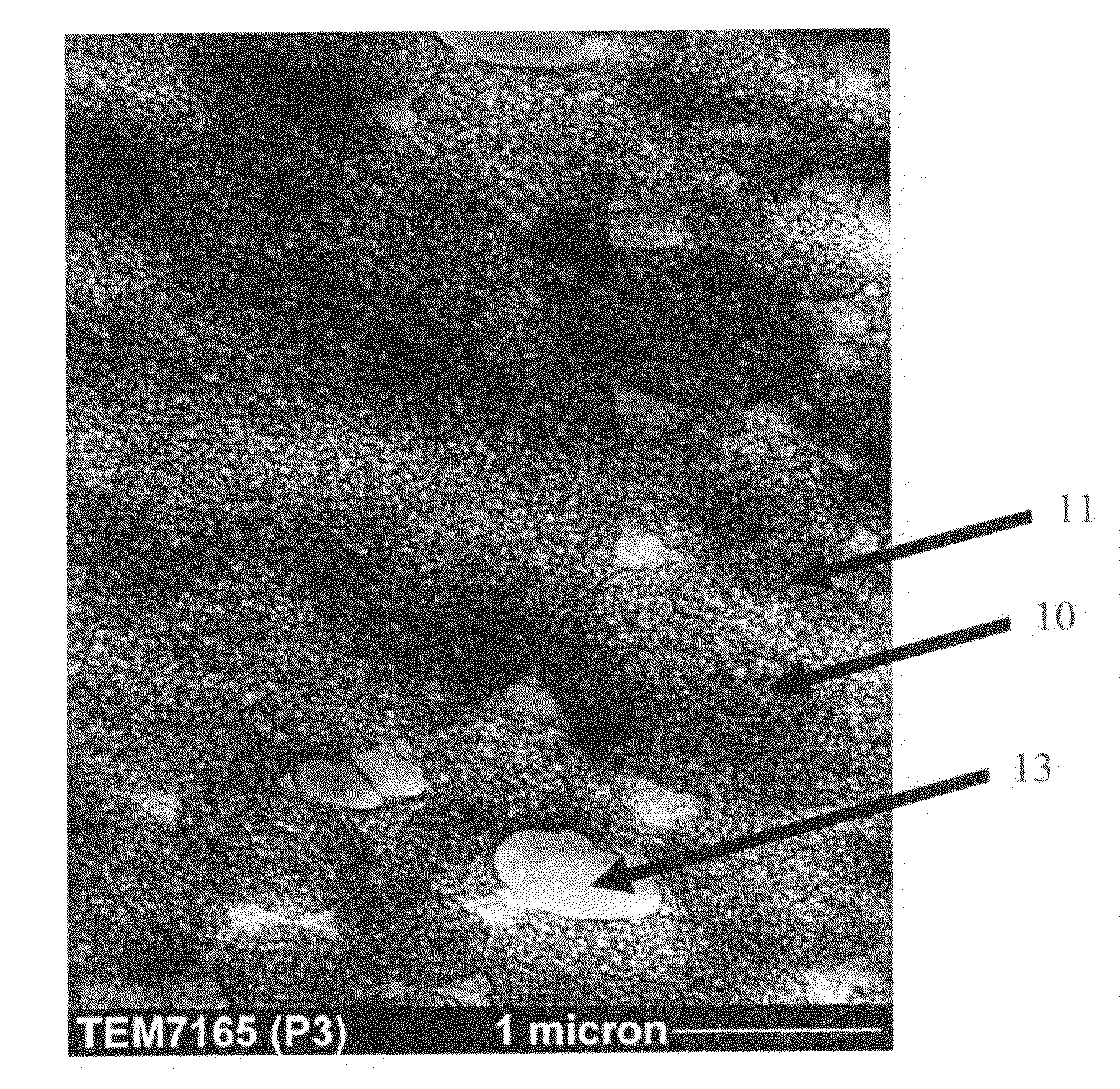

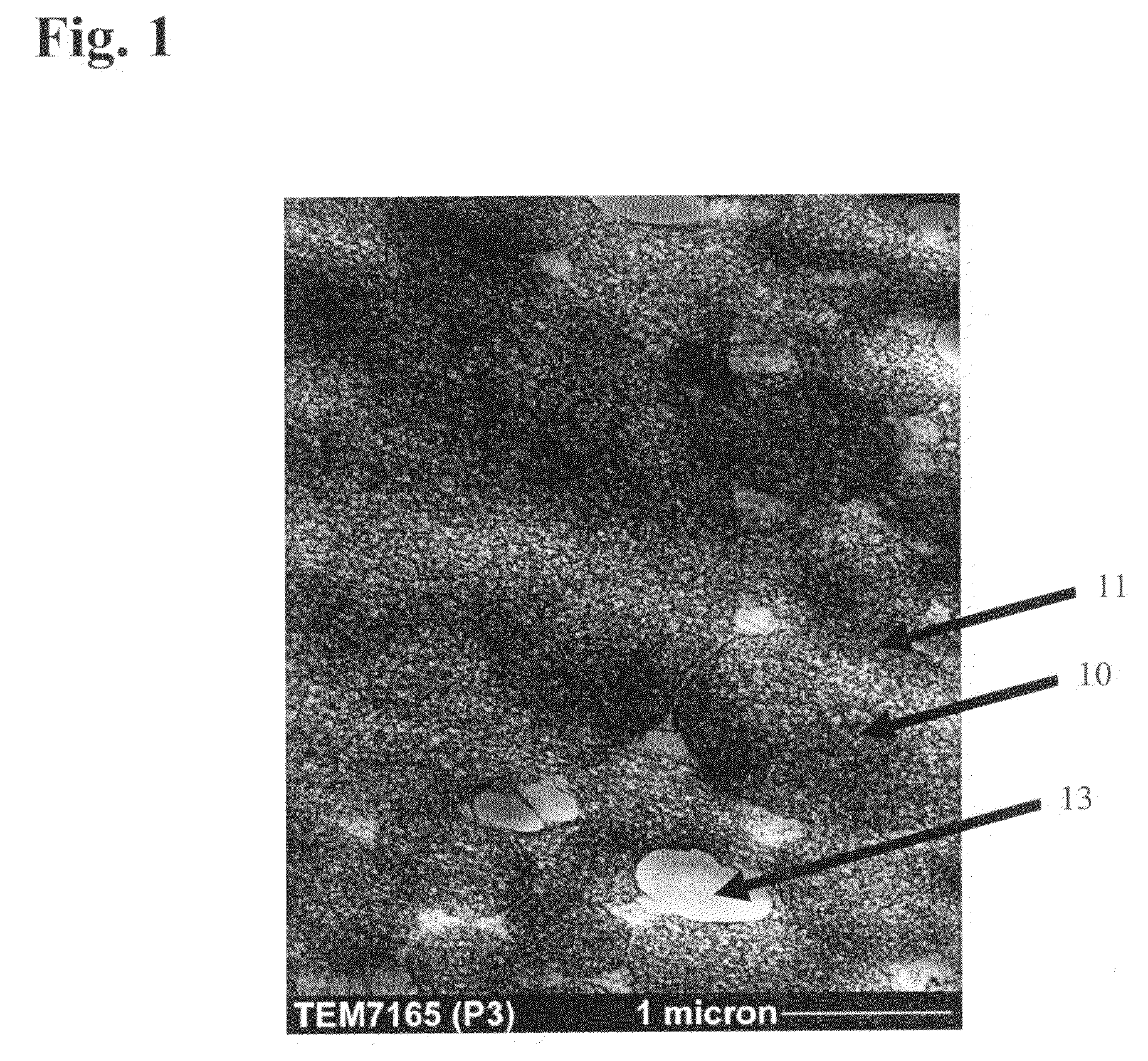

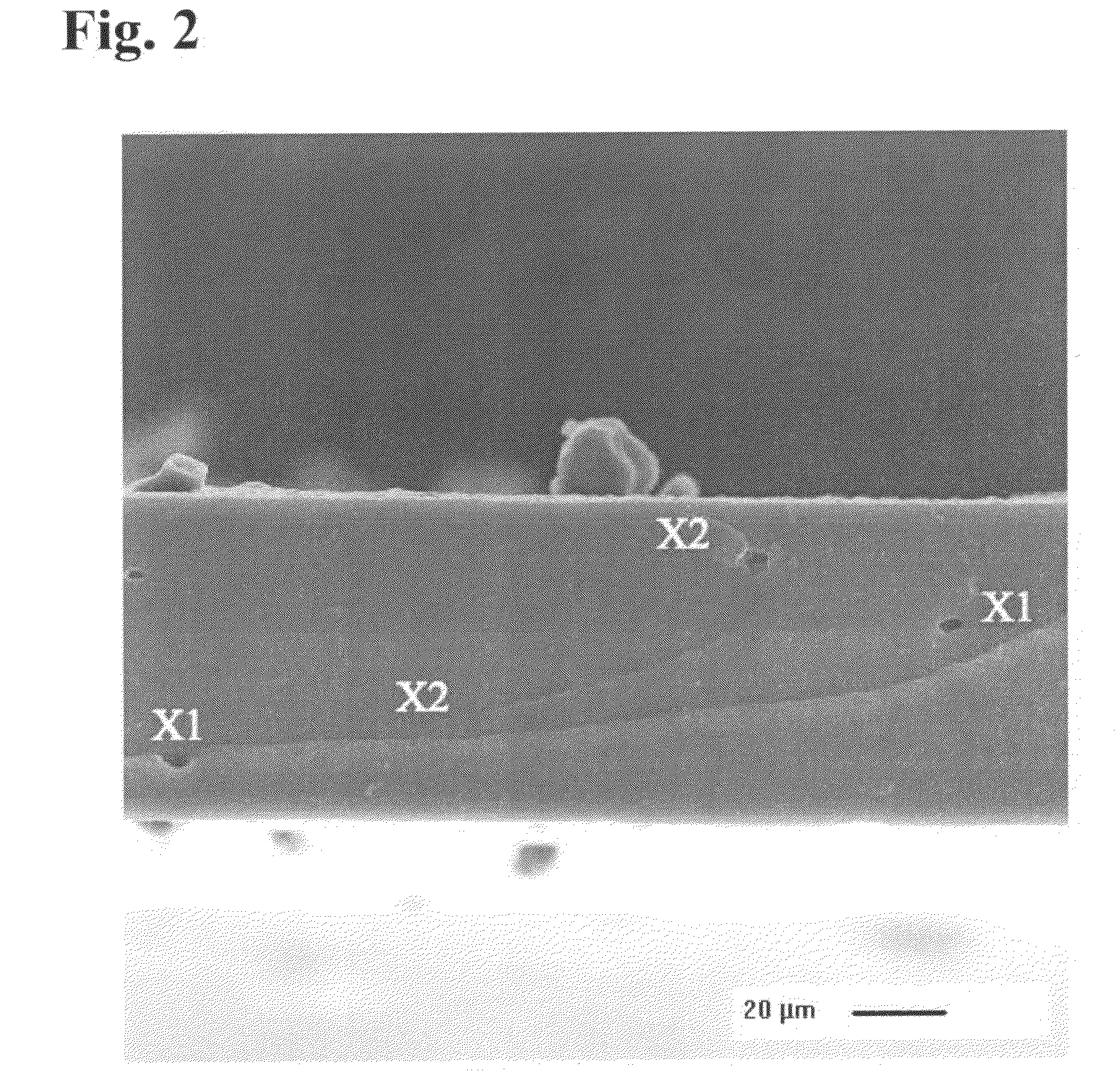

Dip-formed synthetic polyisoprene latex articles with improved intraparticle and interparticle crosslinks

ActiveUS8087412B2Uniform curingMale contraceptivesSynthetic resin layered productsCross-linkVulcanization

A synthetic polyisoprene latex emulsion has pre-vulcanization composition and post vulcanization composition. The pre-vulcanization composition comprises soluble sulfur with high S8 ring structure that is catalytically broken by a zinc dithiocarbamate. Surfactants present in the pre-vulcanization composition wets synthetic polyisoprene particles and permeates small sized sulfur and accelerator molecules into the interior of these particles thereby pre-vulcanizing the particles. The degree of pre-vulcanization is verified by isopropanol index test. The latex emulsion has post-vulcanization composition with accelerators that crosslink inter-particle region during post vulcanization cure cycle. The dipped synthetic polyisoprene article is substantially uniformly cured both in the inter-particle and intra-particle regions and reliably exhibits high cross link density, uniform distribution of double bonds in TEM and zinc segregation at the boundaries or original particles by electron microprobe analysis. The films exhibit high tensile strength, tensile modulus, tear strength, burst pressure and burst volume.

Owner:LIFESTYLES HEALTHCARE PTE LTD

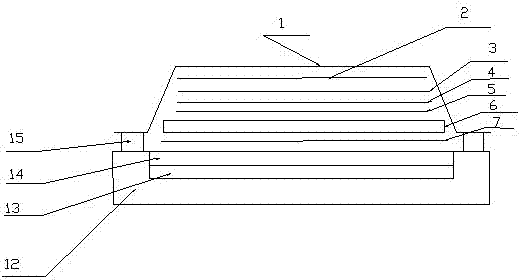

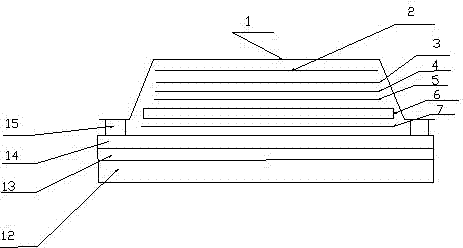

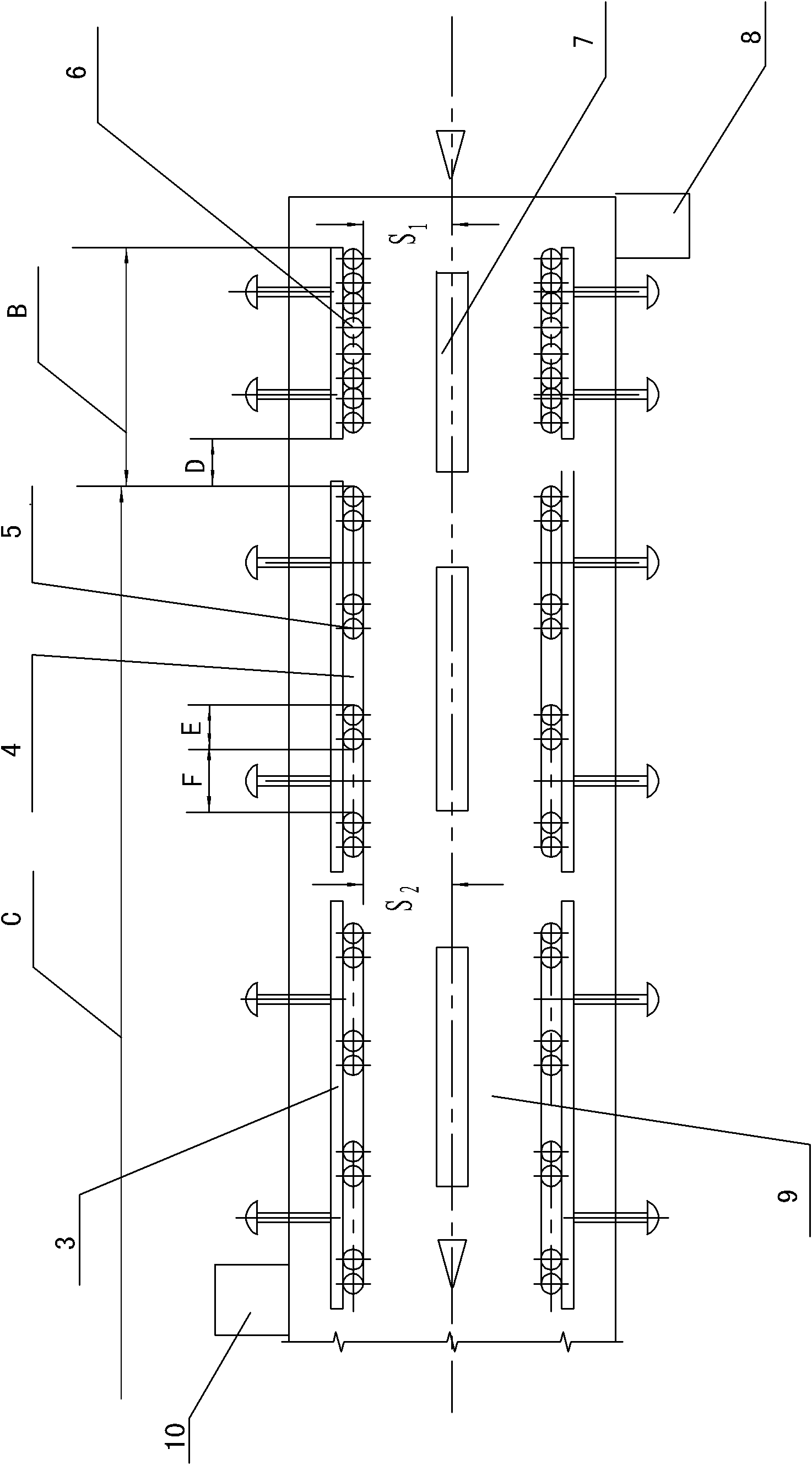

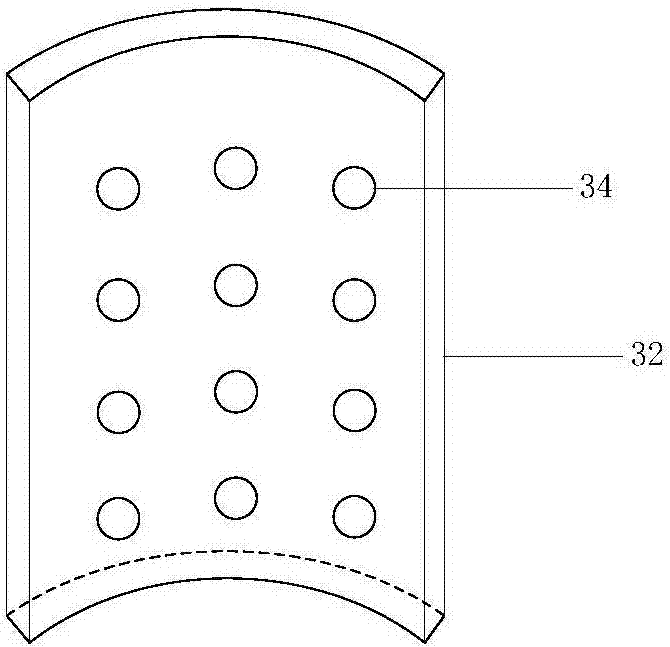

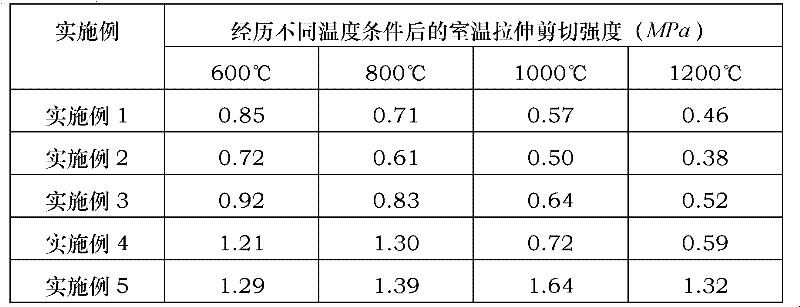

Microwave high-pressure intermittent curing method for fiber-reinforced resin base composite material and die

The invention relates to a method for processing a fiber-reinforced composite material structural piece and a matched die. The method and the die are used for processing high-thickness or large-size fiber-reinforced composite material structural piece. By the method, under a high-pressure inert gas environment, a composite material prefabricated piece which is in a moving state and is placed on a light-mass die is heated and cured by a microwave magnetron with linearly adjustable power in an intermittent manner by a plurality of warming rate modes, so that the quality and the performance of the structural piece are improved. Compared with the conventional technology for curing the composite material structural piece by a thermal pressing tank, the fiber-reinforced composite material structural piece with high performance, high size stability and high geometric precision has the advantages that the time is shortened, and the energy consumption is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

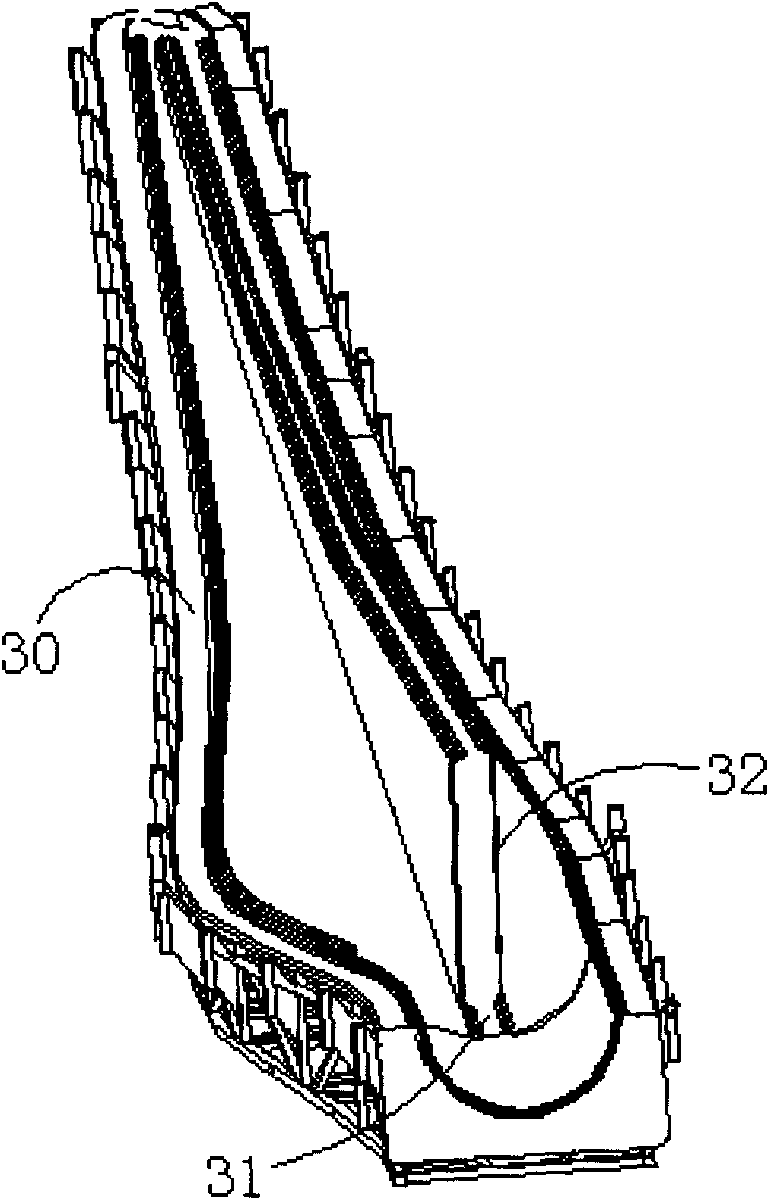

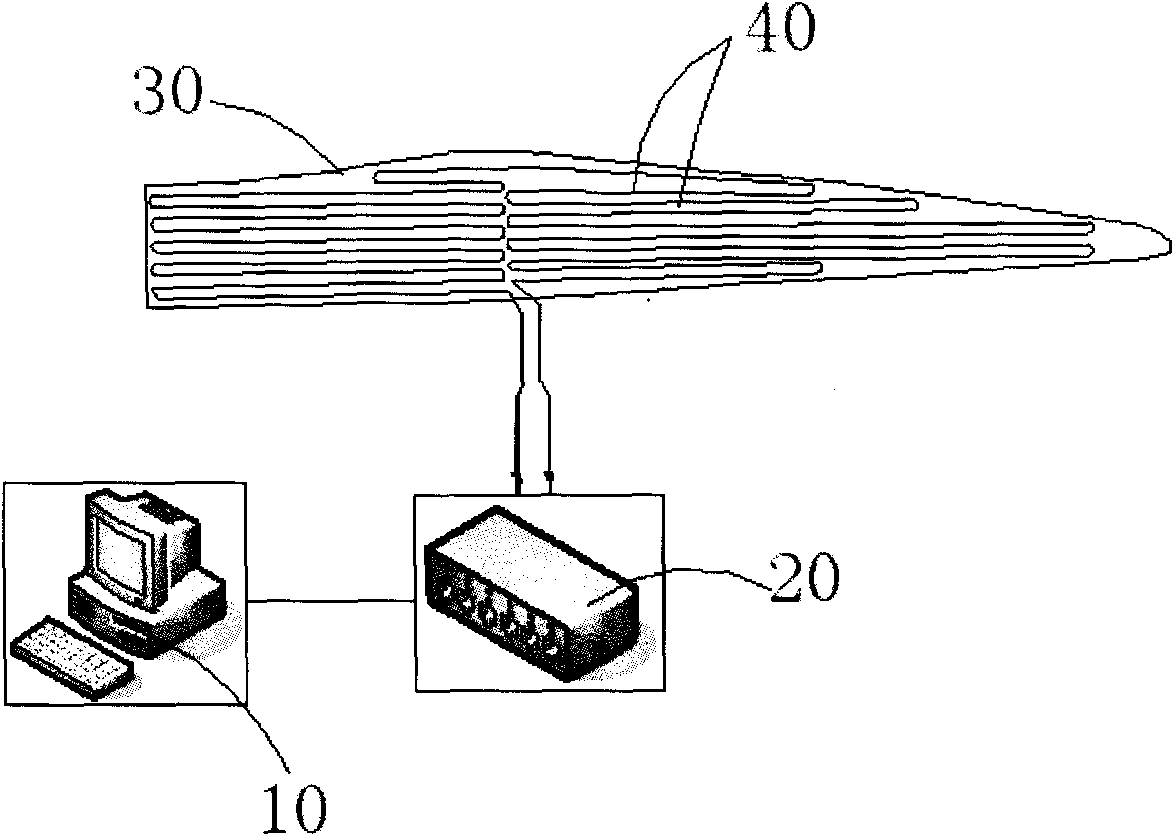

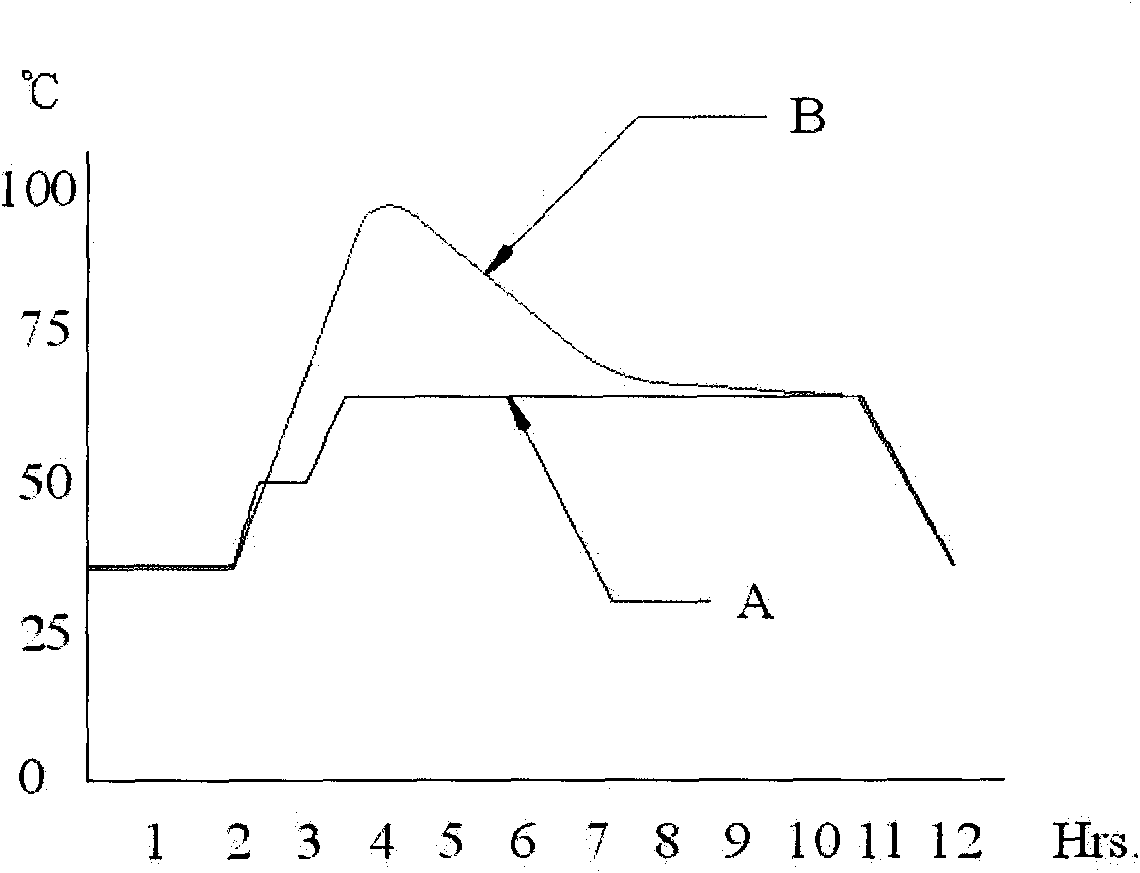

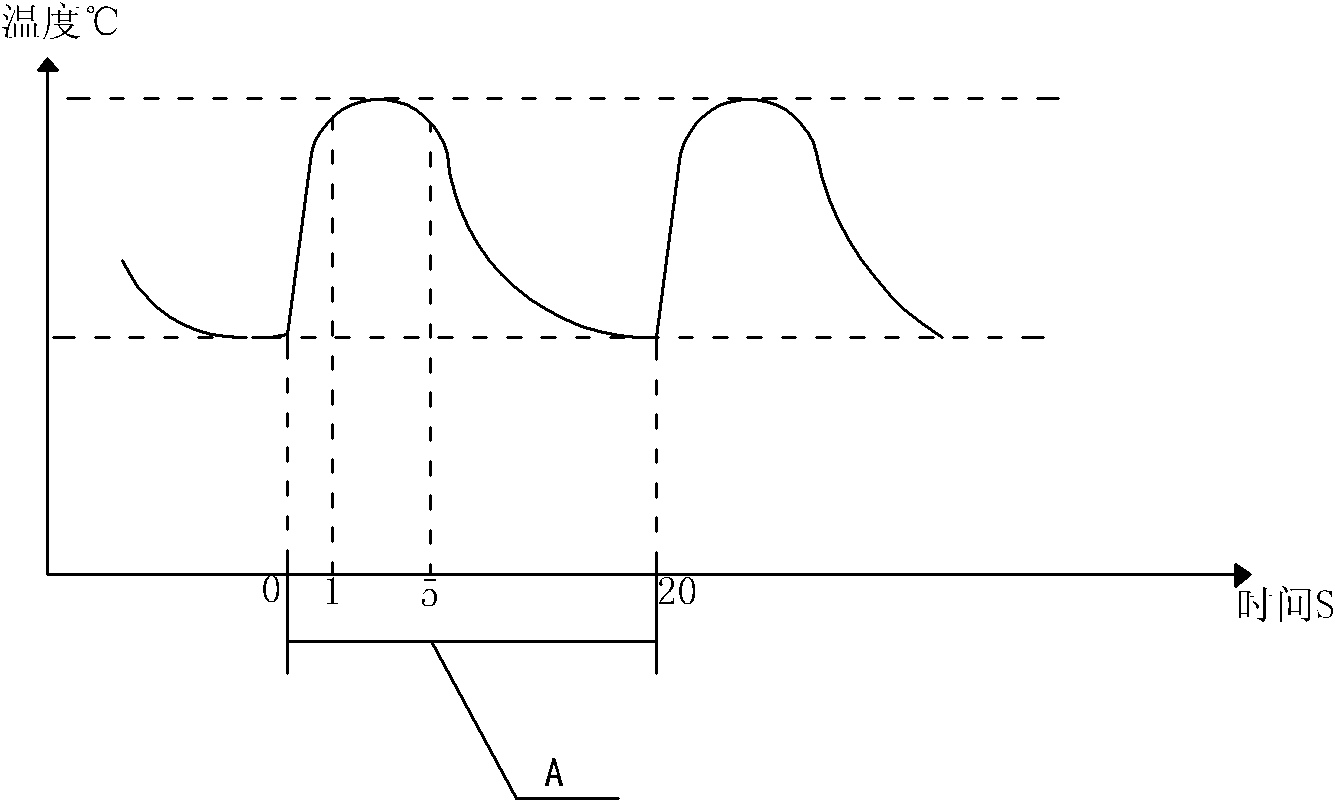

Intelligent segmental temperature control system of wind power blade die

The invention relates to an intelligent segmental temperature control system of a wind power blade die, which is provided based on the technical theory that segmental temperature control is bound to be carried out based on the differences on the formed region thickness of a designed blade structure and the energy-saving purpose can be achieved by lowering the dependence on external heating in a curing manufacturing procedure by utilizing the reaction exothermic character of a matrix material. To achieve the purpose, the invention adopts the technical measures of the construction of a die segmental temperature control pipeline, which ensures that each temperature segment can be heated or cooled independently based on requirements on thermal energy in the curing manufacturing procedure; the establishment of an intelligent temperature control system, wherein temperature and hardness data of the die and a blade shell can be captured to judge whether heating setting, exothermic peak initiating temperature and the states of completion degree, gel curing degree and the like are completed or conform to design values; and antecedent technical measures, wherein energy consumption is saved by utilizing the reaction heat of materials per se to heat and reaction and temperature control are combined to match the design of a temperature curve, which are helpful for obtaining the blades with uniform curing and excellent quality and can improve the production efficiency as a characteristic.

Owner:上海力仓实业有限公司

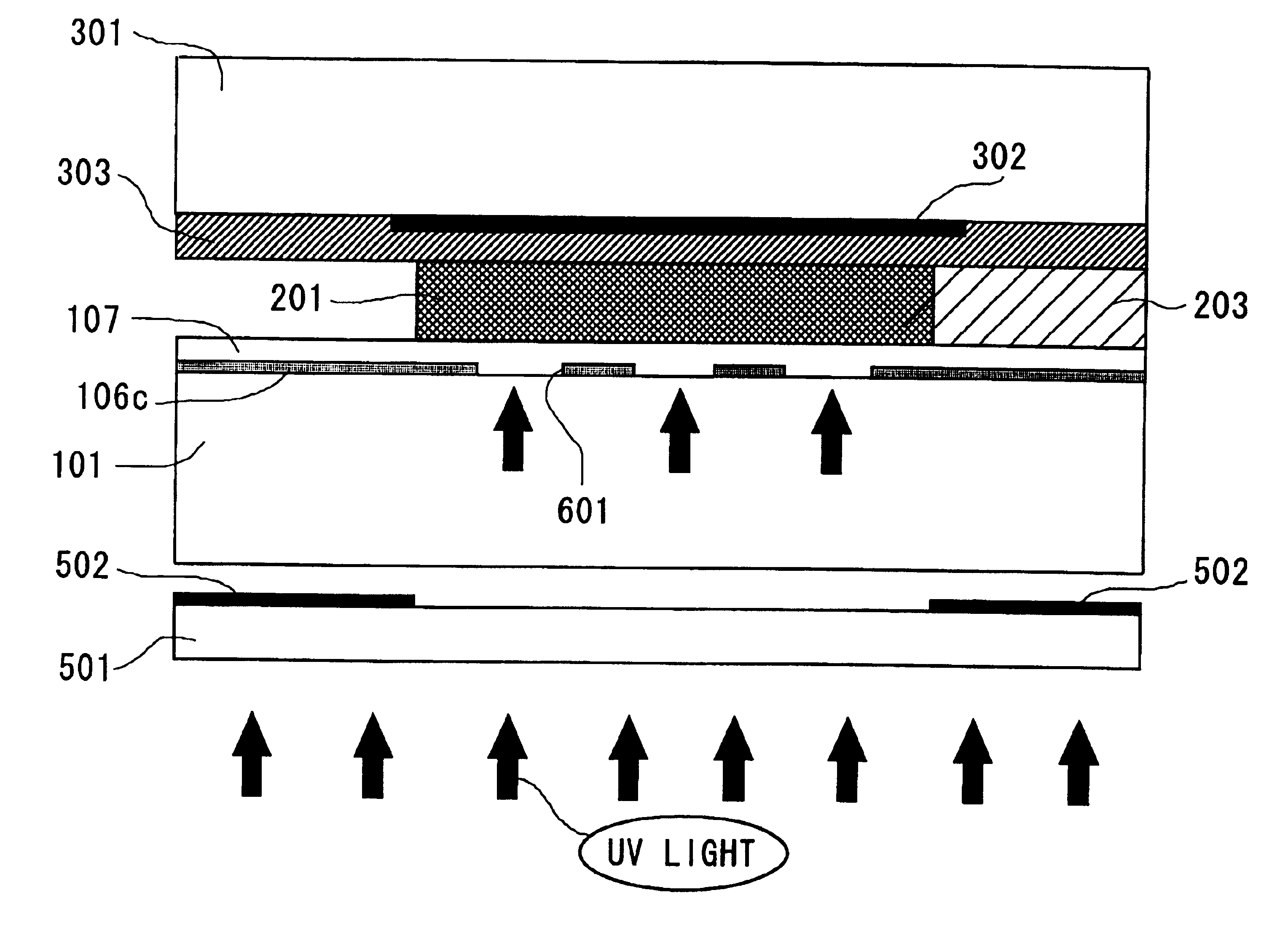

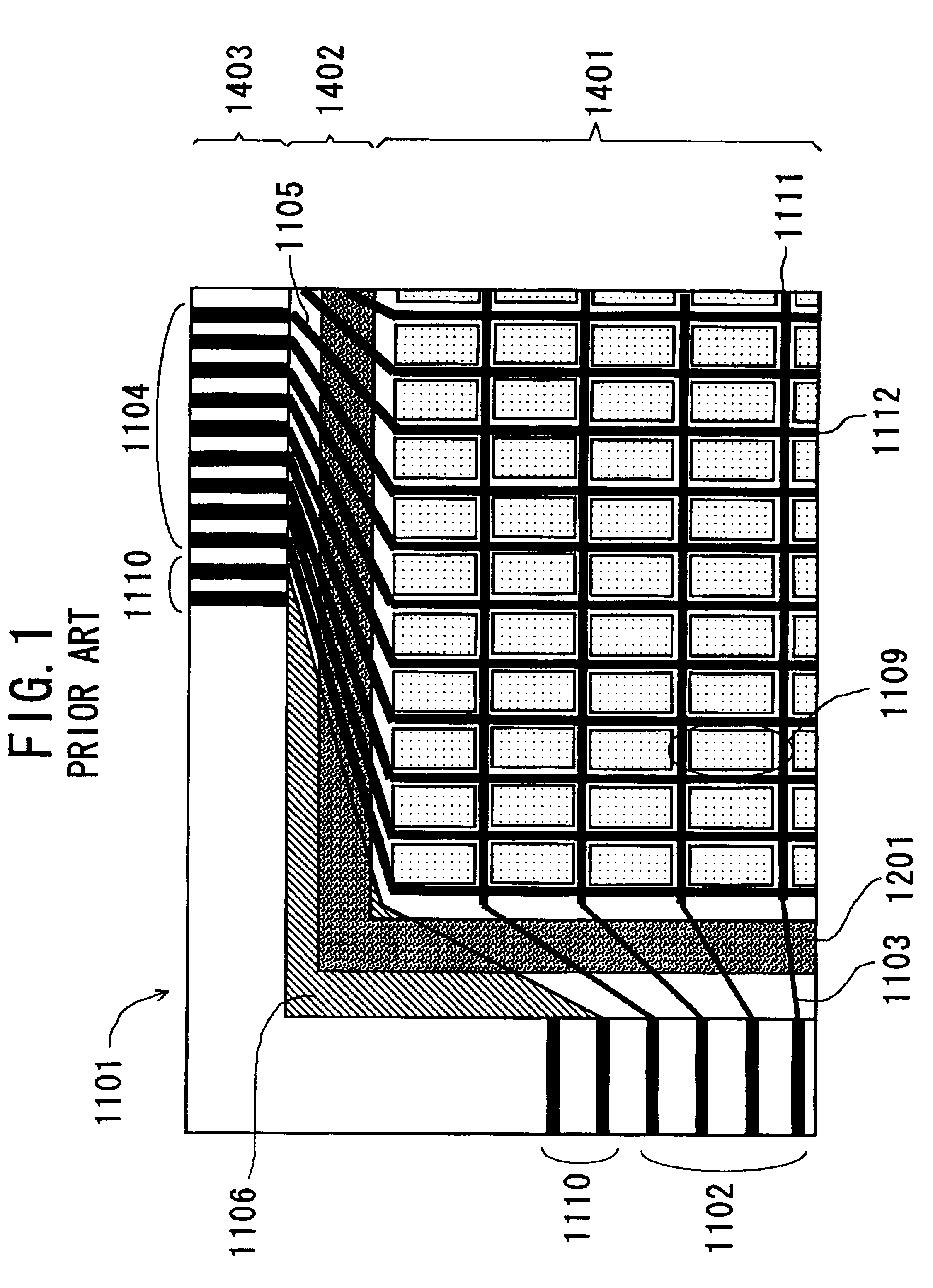

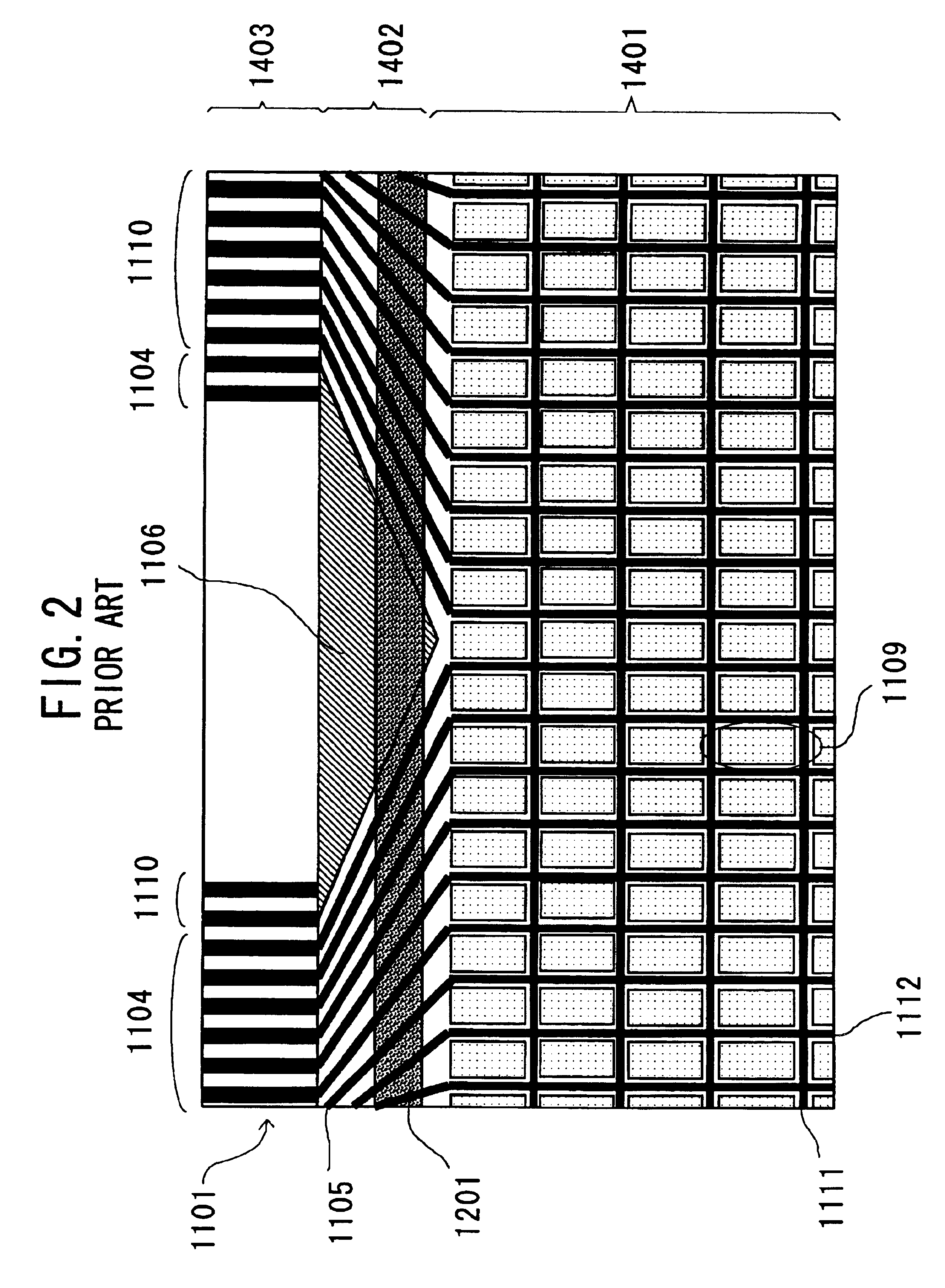

Liquid-crystal display device and method of fabricating same

InactiveUS6882398B2Uniform curingImprove display characteristicsNon-linear opticsLiquid-crystal displayEngineering

A LCD device that receives curing light sufficiently to thereby realize approximately uniform curing of the material of the sealing member without eliminating the conductive light-blocking members. A first substrate has a display area and a peripheral area located to surround the display area. The display area includes pixels arranged regularly. The peripheral area includes a sealing member, wiring lines connected to the pixels, and conductive light-blocking members. A second substrate is coupled with the first substrate. A liquid crystal layer is formed between the first and second substrates. The sealing member is formed to overlap with the wiring lines and the light-blocking members in such a way that a non-overlapping area of the sealing member with the wiring lines and the light-blocking members is equal to 25% per unit area of the sealing member or greater.

Owner:GOLD CHARM LTD

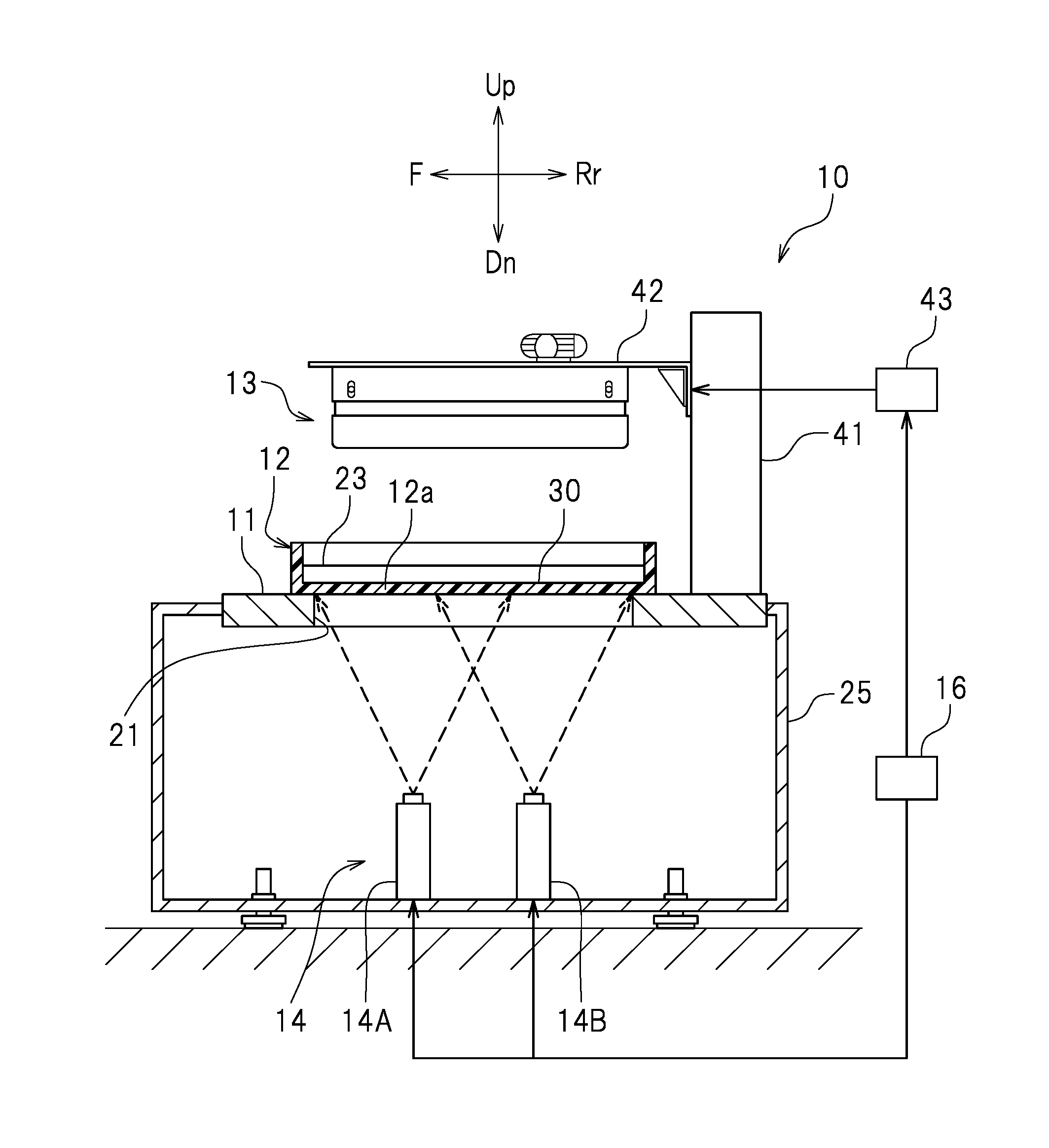

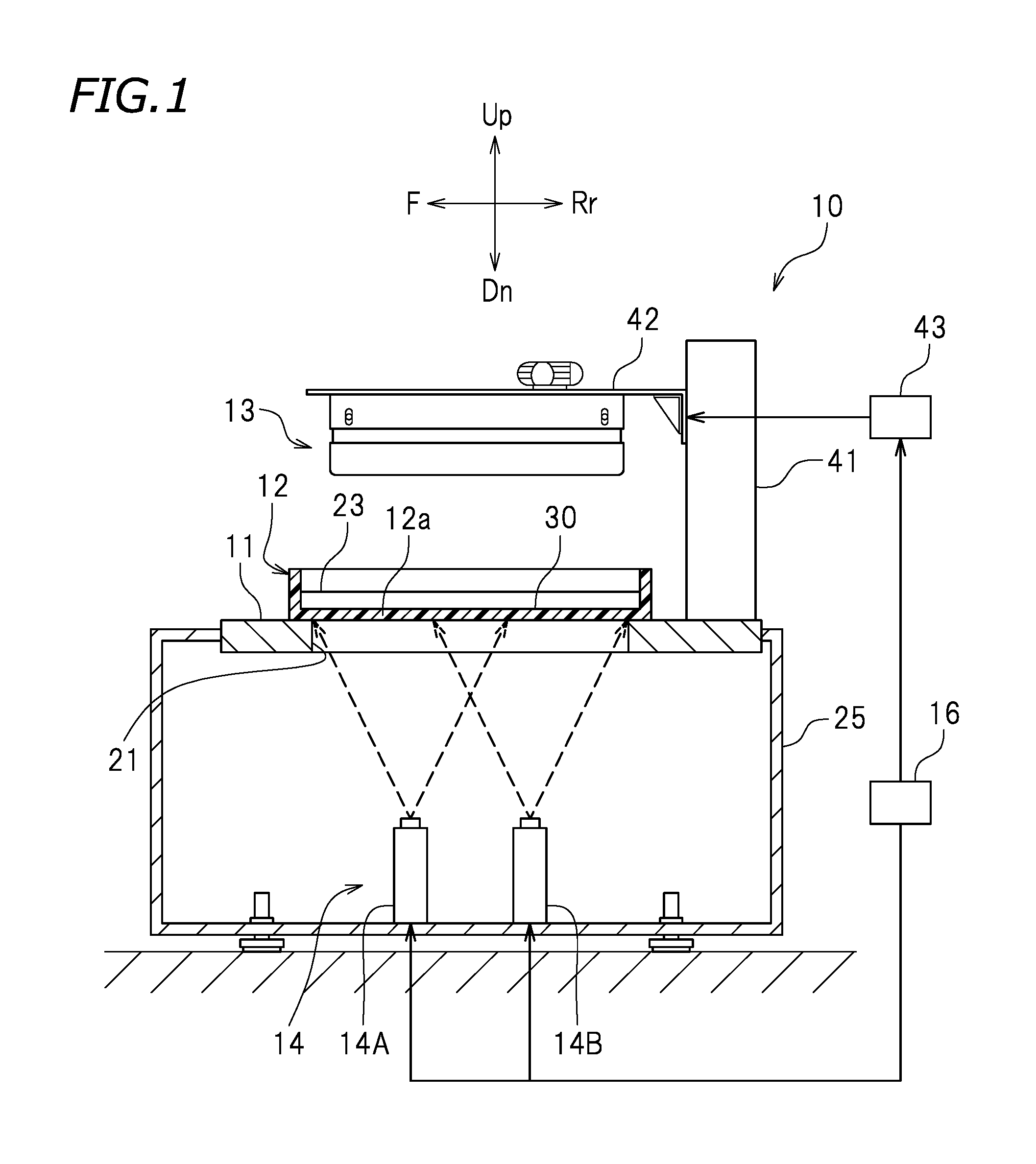

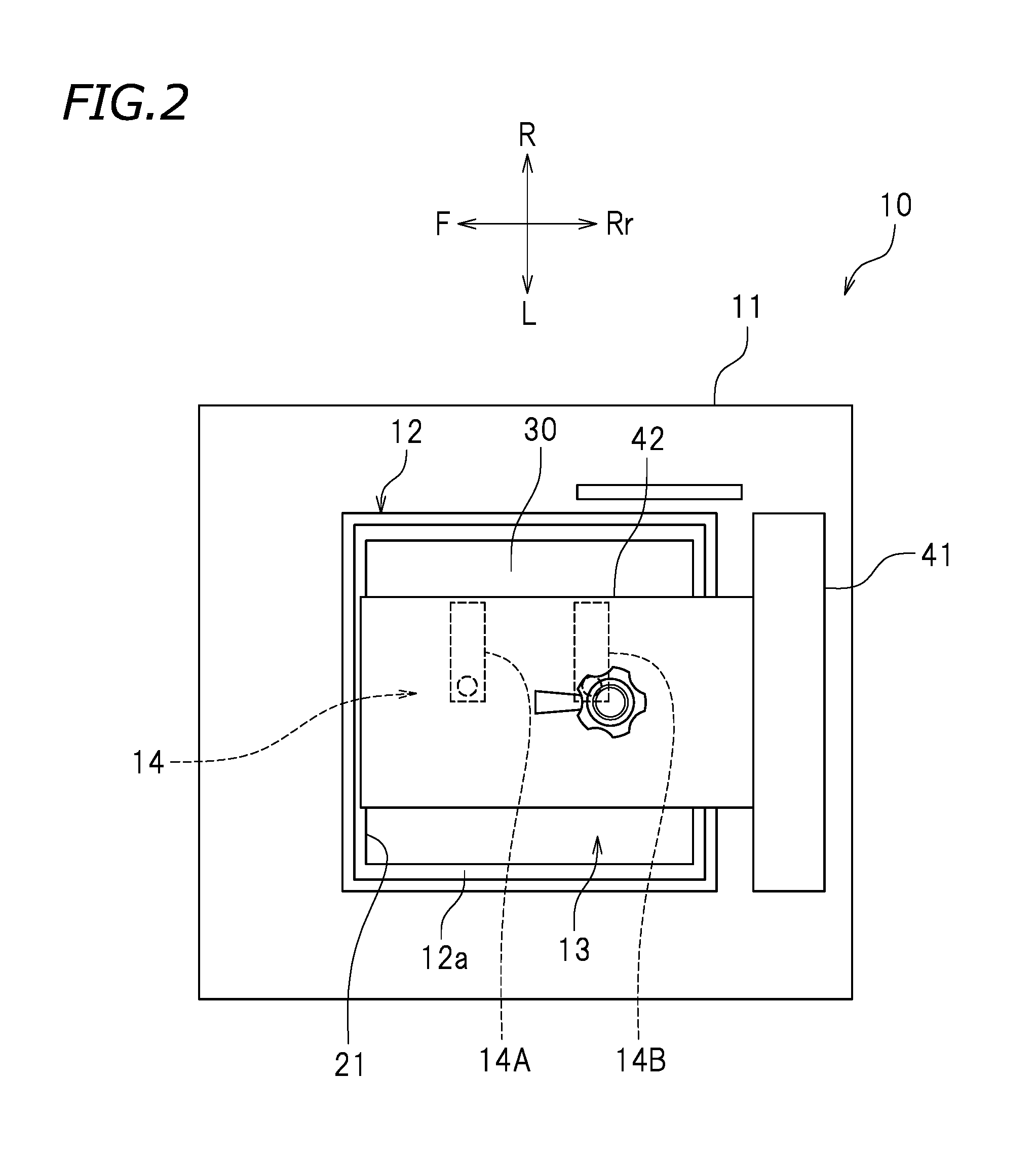

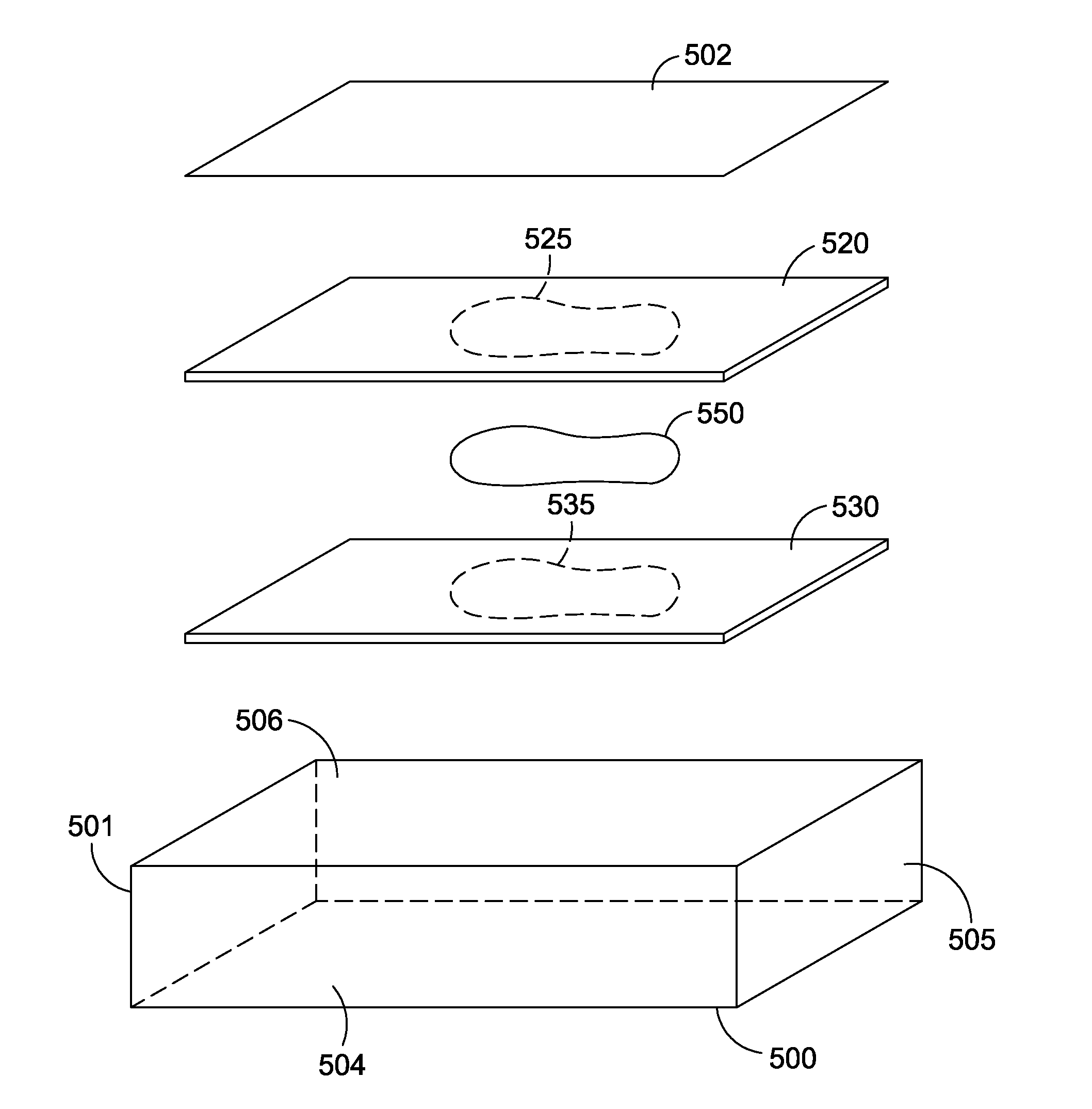

Three-dimensional printing apparatus

InactiveUS20160368221A1Reliably cureEliminate and reduce such variationAdditive manufacturing apparatus3D object support structuresElectrical and Electronics engineering3D printing

A three-dimensional printing apparatus includes a controller to control first and second projectors that apply equal or substantially equal total amounts of optical energy. The controller performs first and second projecting operations. The first projecting operation involves simultaneously projecting first and second cross-sectional sub-images from the first projector onto first and second areas of an image projecting surface, respectively, and the second and third cross-sectional sub-images from the second projector onto the second and third areas of the image projecting surface, respectively. The second projecting operation involves simultaneously projecting the first cross-sectional sub-image from the first projector onto the first area and the third cross-sectional sub-image from the second projector onto the third area. The controller equalizes the number of times the first to third cross-sectional sub-images are to be respectively projected onto the first to third areas.

Owner:ROLAND DG CORP

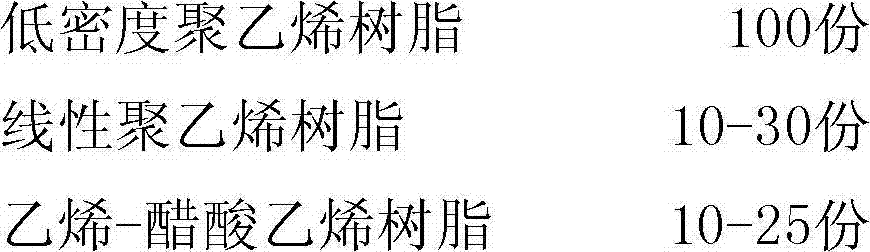

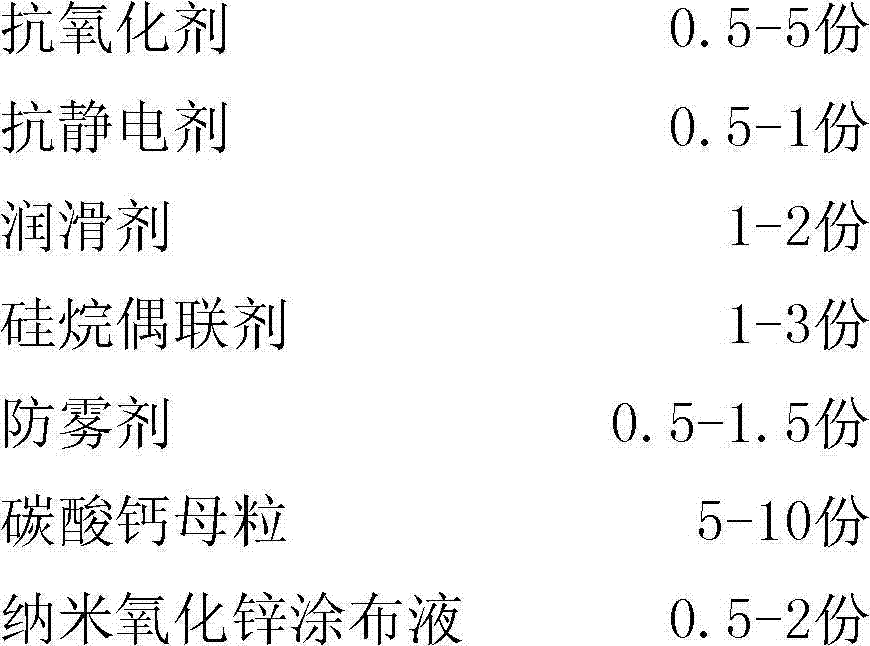

Anti-mildew modified atmosphere packaging film for fruits and vegetables and preparation method for mildew-proof modified atmosphere packaging film

ActiveCN102886950AFixed uniformGood permeabilityFruit and vegetables preservationSynthetic resin layered productsChemistryAntioxidant

The invention discloses an anti-mildew modified atmosphere packaging film, which is prepared from the following components in parts by weight: 100 parts of low density polyethylene resin, 10 to 30 parts of linear polyethylene resin, 10 to 25 parts of ethylene-vinyl acetate resin, 0.5 to 5 parts of antioxidant, 0.5 to 1 part of antistatic agent, 1 to 2 parts of lubricant, 1 to 3 parts of silane coupling agent, 0.5 to 1.5 parts of anti-fogging agent, 5 to 10 parts of calcium carbonate master batch and 0.5 to 2 parts of nano zinc oxide coating solution. The invention also discloses a preparation method for the packaging film. The packaging film prepared by the method has an anti-oxidation function, an anti-fog function, an antibacterial function, an anti-mildew function and a fruit and vegetable respiration adjustment function, the refreshing time of fruits and vegetables can be prolonged, and the quality of the fruits and the vegetables can be improved.

Owner:TIANJIN JIEDONG FRESH PRESERVATION TECH PRODIVITY PROMOTION CENT

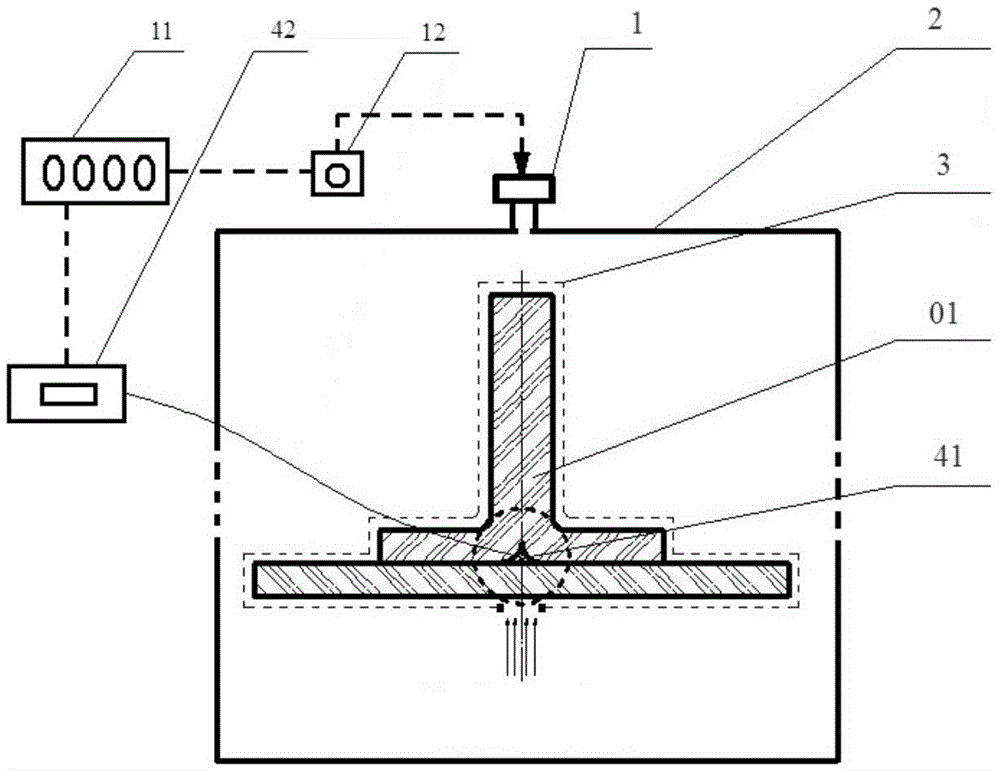

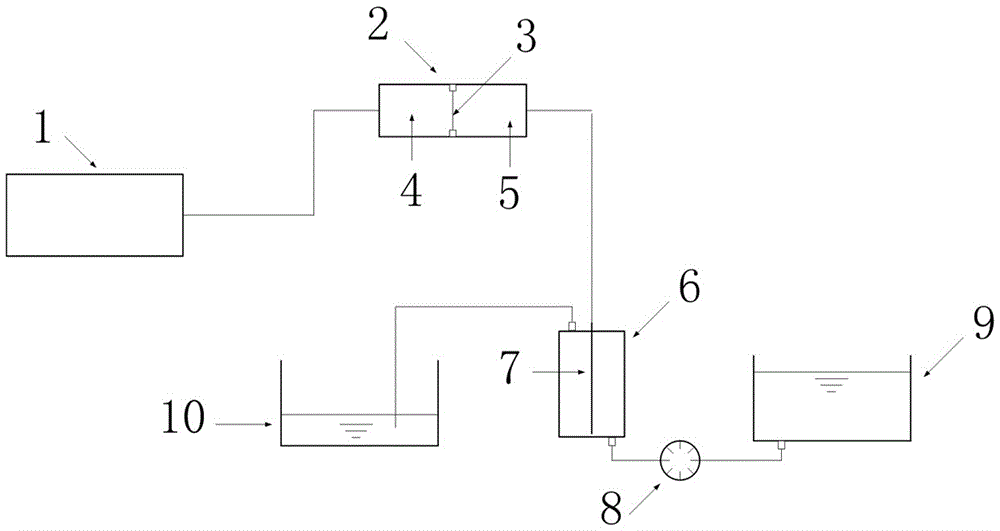

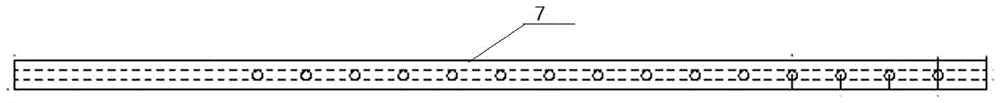

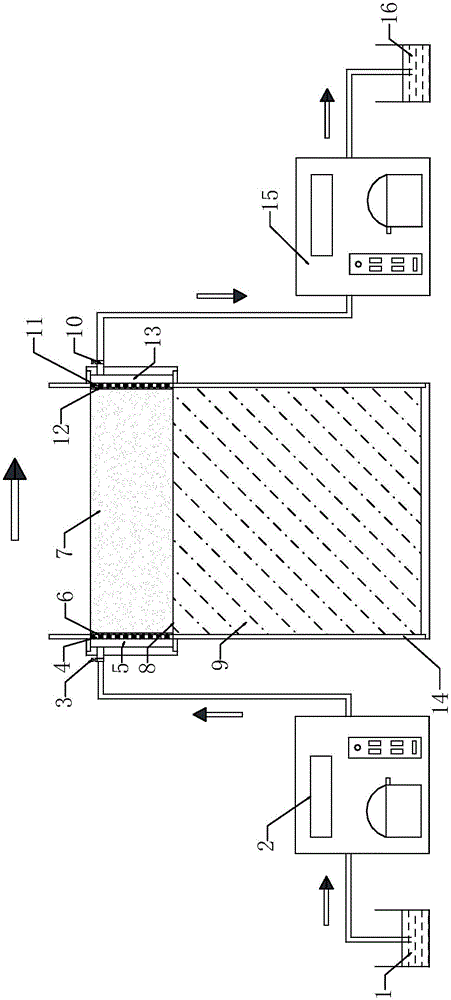

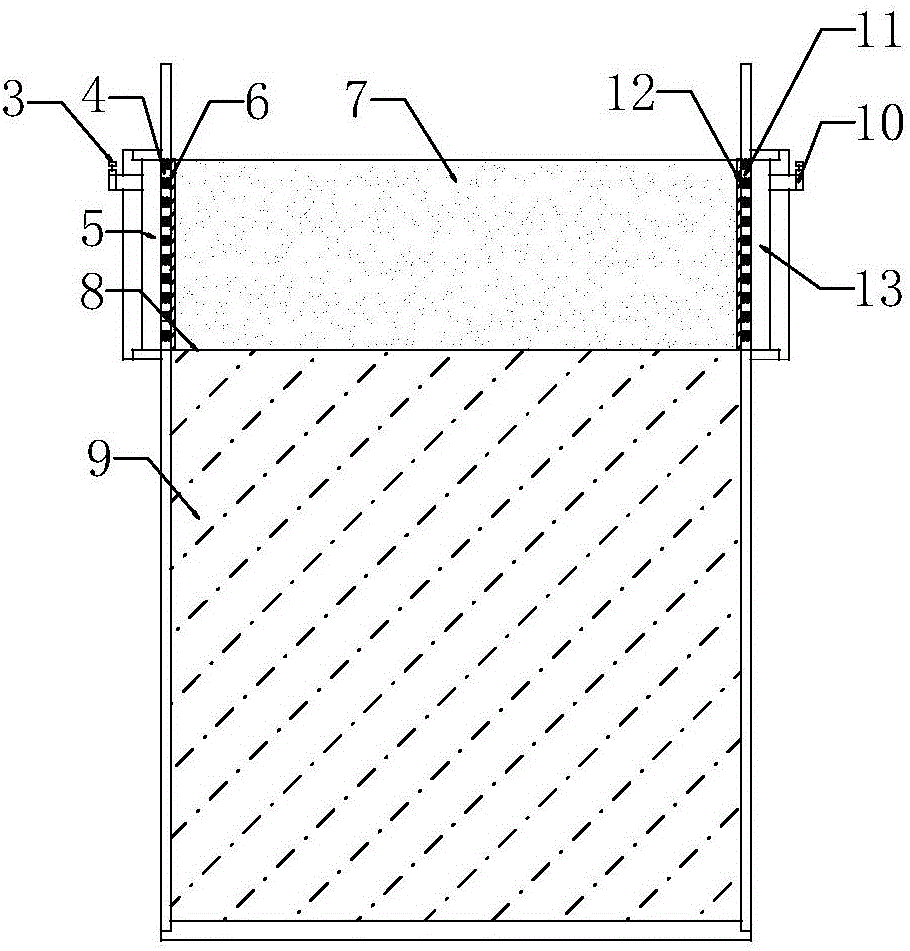

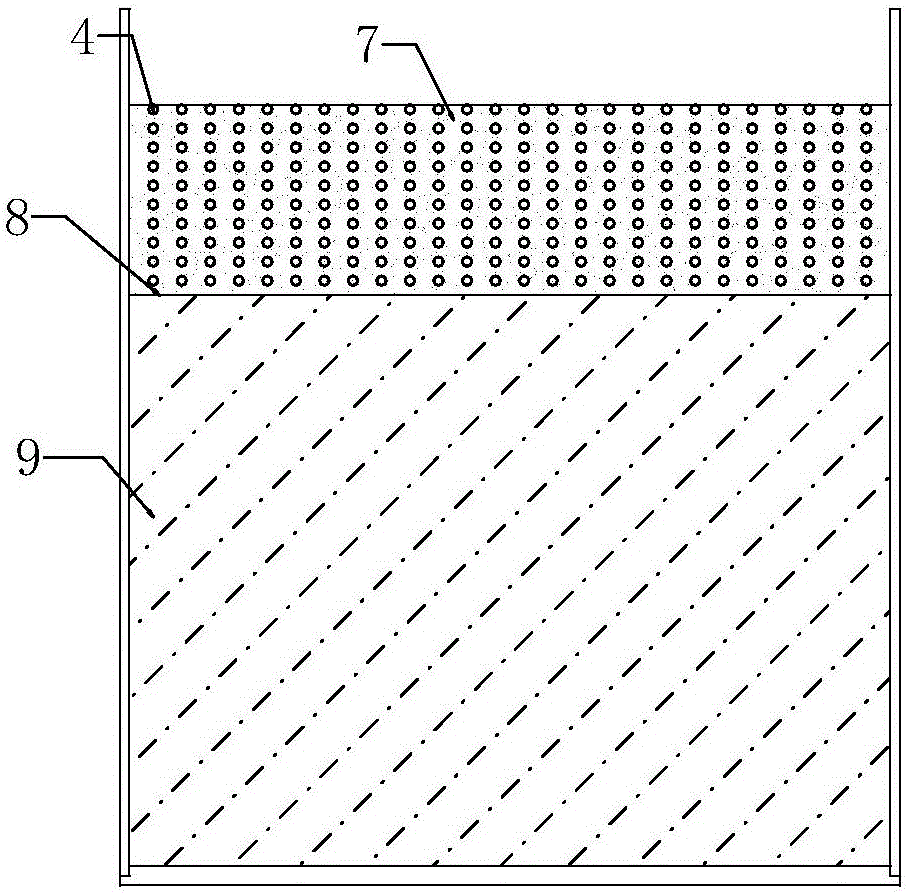

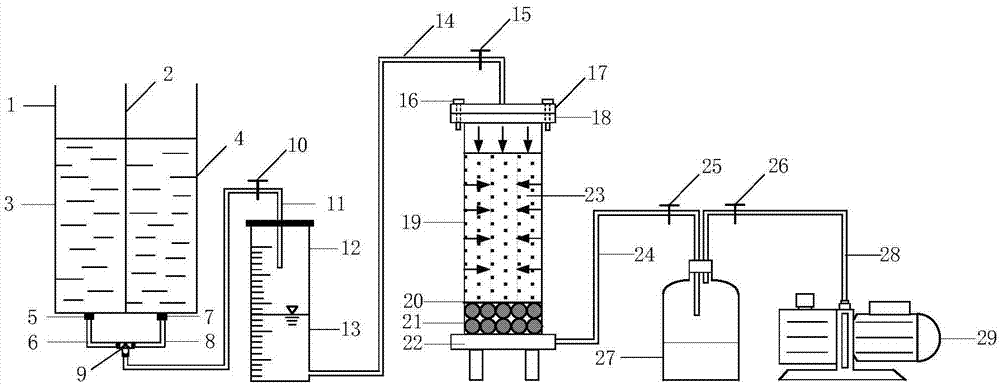

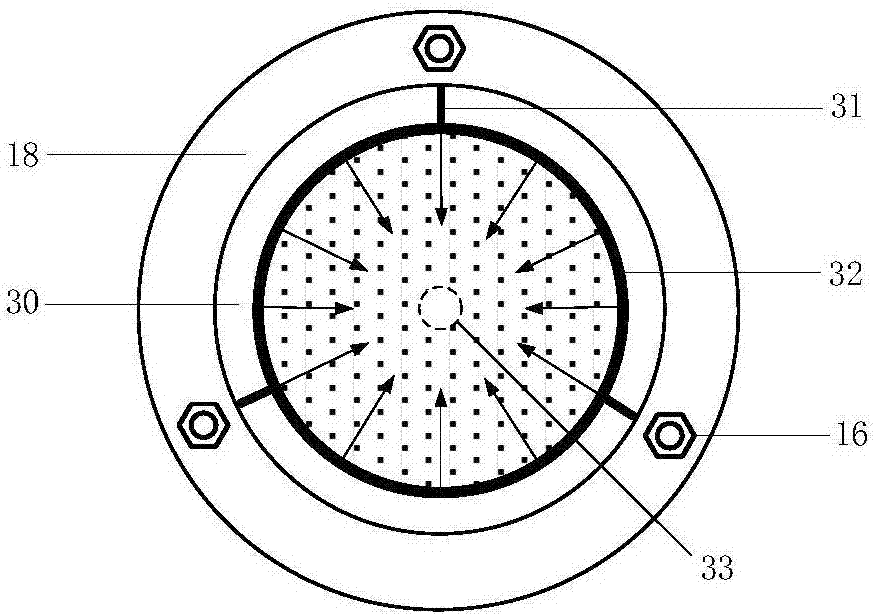

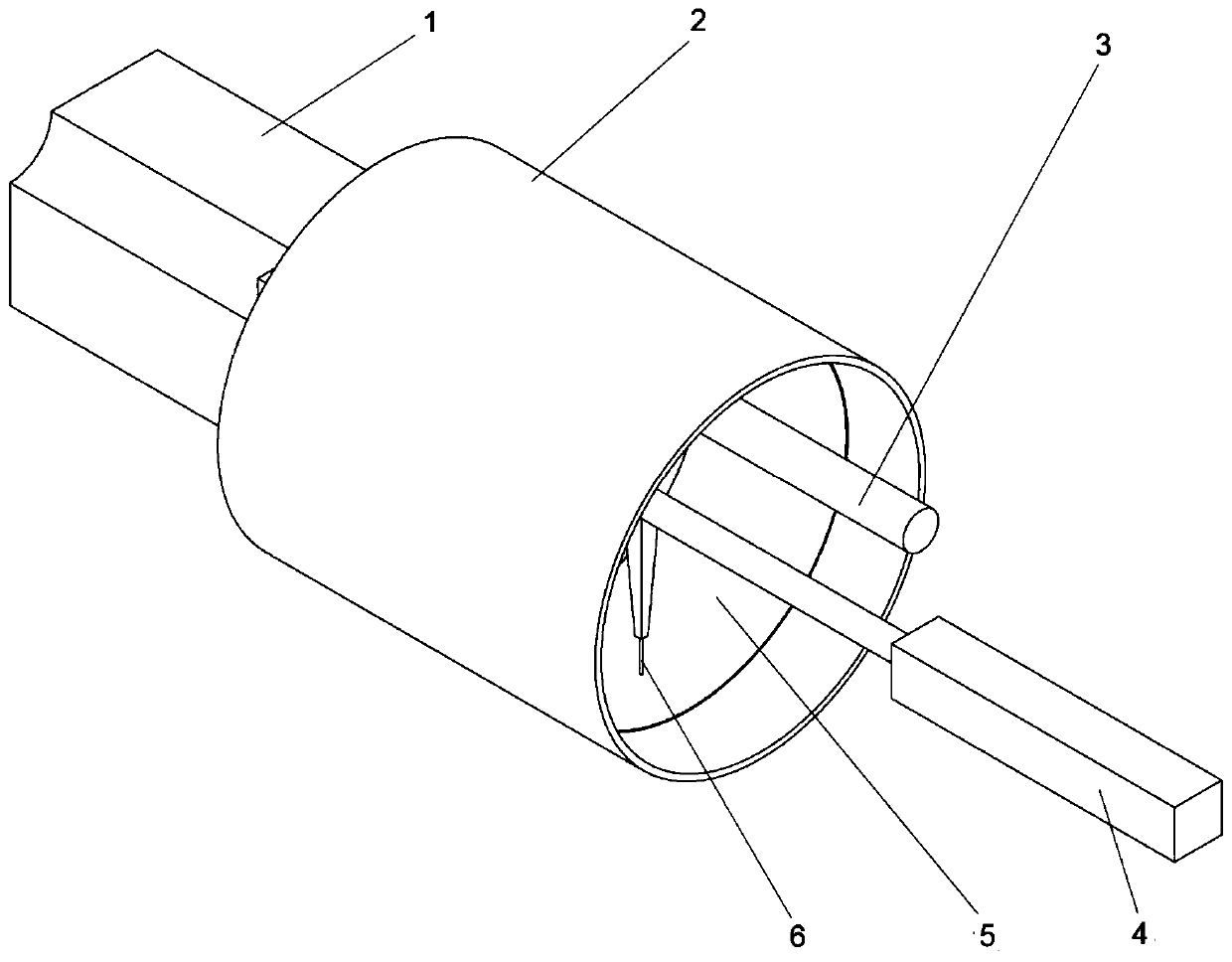

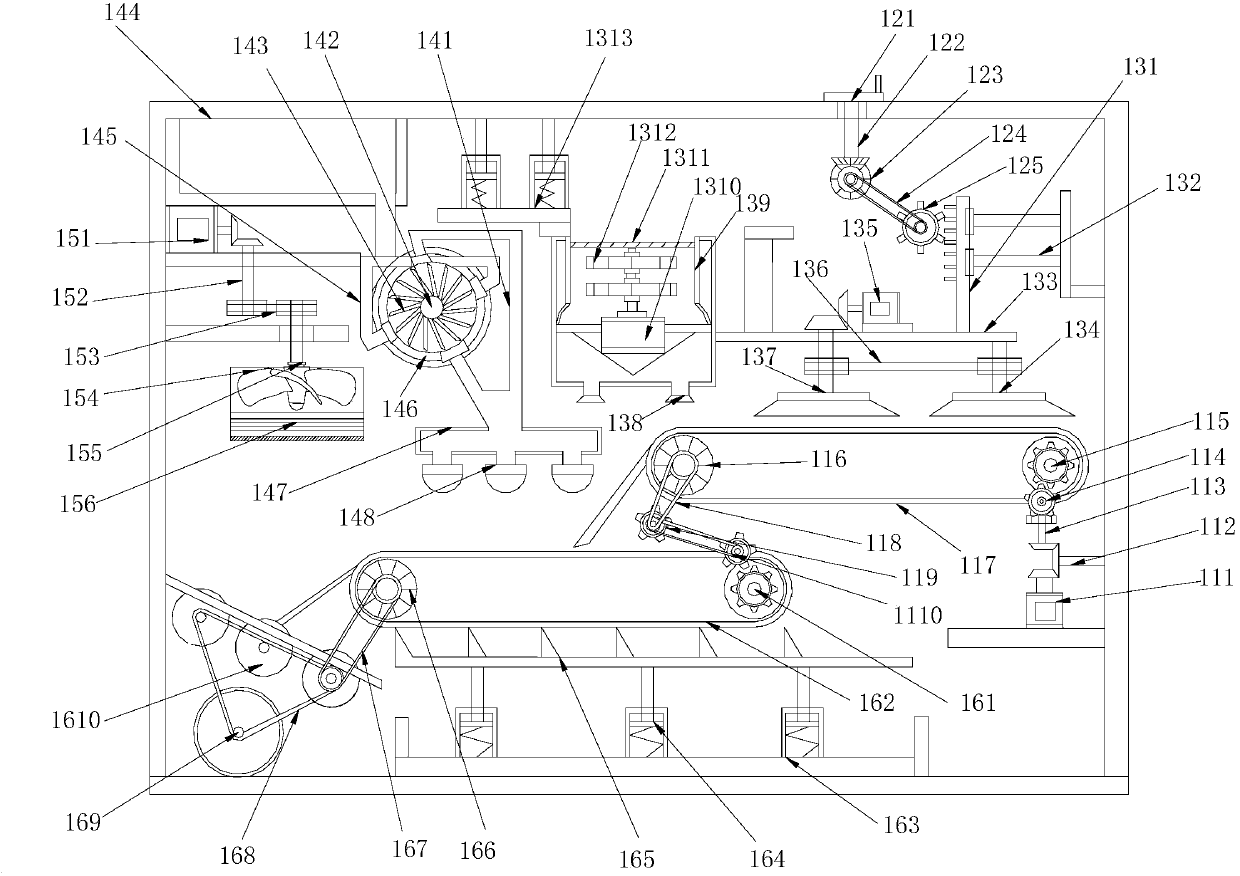

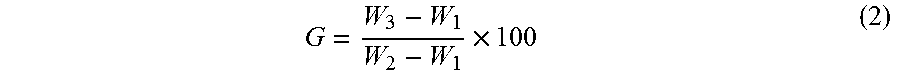

Penetration type microorganism uniformly-cured sandy soil sample preparation device and sample preparation method thereof

ActiveCN105424438AReduce disturbanceUniform curingPreparing sample for investigationMicroorganismTest sample

The invention discloses a penetration type microorganism uniformly-cured sandy soil sample preparation device. The penetration type microorganism uniformly-cured sandy soil sample preparation device comprises a capillary tube needle injection device, a microorganism solution pressure supplying device, a nutrient solution pressure supplying device and a liquid collection container, wherein the capillary tube needle injection device comprises a capillary tube needle and an organic glass splitting die; and the capillary tube needle is inserted into a sandy soil test sample to inject a microorganism solution. The microorganism solution pressure supplying device comprises a pressure controller and a solution isolation device, wherein the pressure controller carries out injection compression until the microorganism solution is injected into the capillary tube needle by the solution isolation device. The nutrient solution pressure supplying device comprises a water pump and a nutrient solution container; and the nutrient solution is pressurized by the water pump and then is injected to the sandy soil test sample from the bottom of the splitting die. After the microorganism solution and the nutrient solution are mixed, the mixed solution is discharged out from the top of the test sample to the liquid collection container; and meanwhile, calcium carbonate sediment generated by mixing the microorganism solution and the nutrient solution in the test sample can be used for reinforcing the sandy soil test sample. With the adoption of the penetration type microorganism uniformly-cured sandy soil sample preparation device, the calcium carbonate sediment can be relatively uniformly distributed in the sandy soil test sample.

Owner:西安银鼎科技有限公司

Light mixing cured coating composition and preparation method thereof

InactiveCN101709196AImprove physical and chemical propertiesExcellent system performanceEpoxy resin coatingsUltraviolet lightsSpray coating

The invention discloses a light mixing cured coating composition which comprises epoxy acrylic acid monoester, ultraviolet light-heat mixing curing agent or ultraviolet light free radical-cation mixing curing agent, pigmented filler, reactive diluent, dispersing agent, defoaming agent and flatting agent. The invention also discloses a preparation method of the light mixing cured coating composition. The coating composition of the invention has small cure shrinkage and high bonding strength, can be applied to dark systems, can be used for coating some components with complicated structures, and can be used for coating surfaces of wood products, plastics, metals and the like by the construction methods of brush coating, spray coating, curtain coating, roller coating and the like.

Owner:SHENZHEN POLYTECHNIC

Composite energy field heating method

The invention provides a composite energy field heating method. The composite energy field heating method comprises the steps that a microwave heating device is used for carrying out fixed-point heating or directional heating on a wave absorbing material, and an autoclave is used for overall heating the wave absorbing material. The method is completed through a composite energy field heating device. The composite energy field heating device comprises the microwave heating device and the autoclave. The microwave heating device comprises a microwave generator, a microwave cavity and a microwave local shielding part. The microwave generator sends microwaves into the microwave cavity. The interior of the microwave cavity is used for containing the wave absorbing material. The microwave local shielding part is located in the microwave cavity and used for covering the outer surface of the wave absorbing material, and is composed of a microwave shielding area and a microwave transmitting area. The microwave transmitting area comprises one or more clearances so that the microwaves in the microwave cavity can enter the wave absorbing material through the clearances to be absorbed by the wave absorbing material. The composite energy field heating method can really achieve temperature consistency of all the portions in the wave absorbing material, and a high-quality cured product can be provided for the field of aerospace.

Owner:CENT SOUTH UNIV

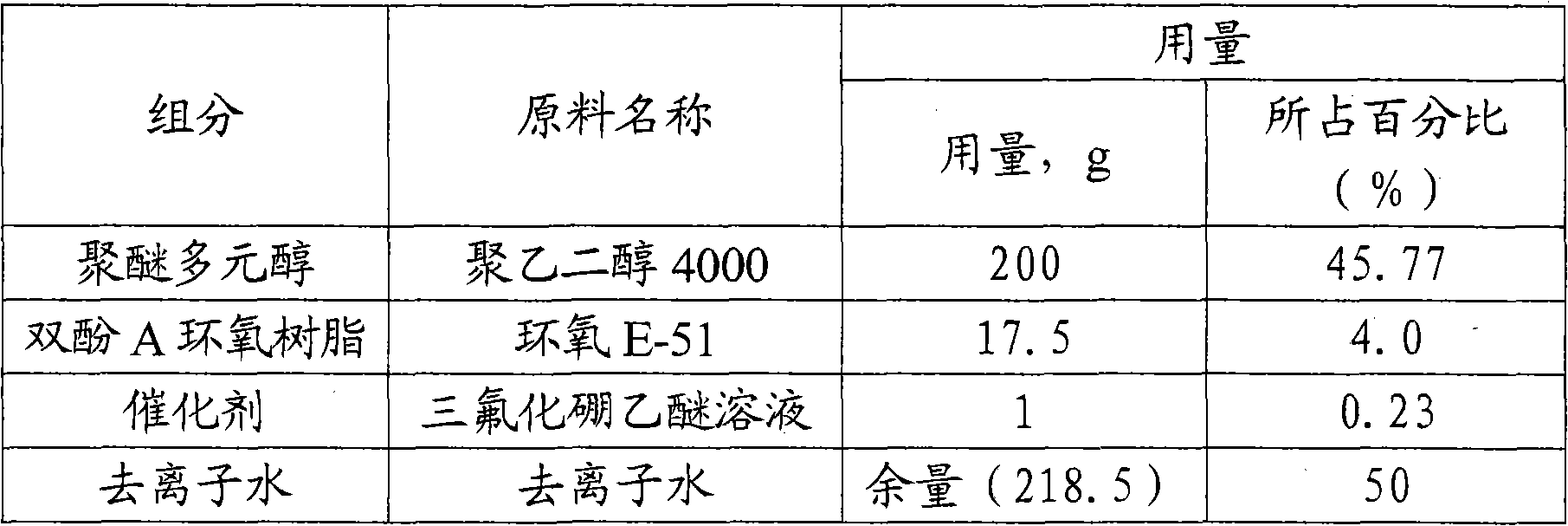

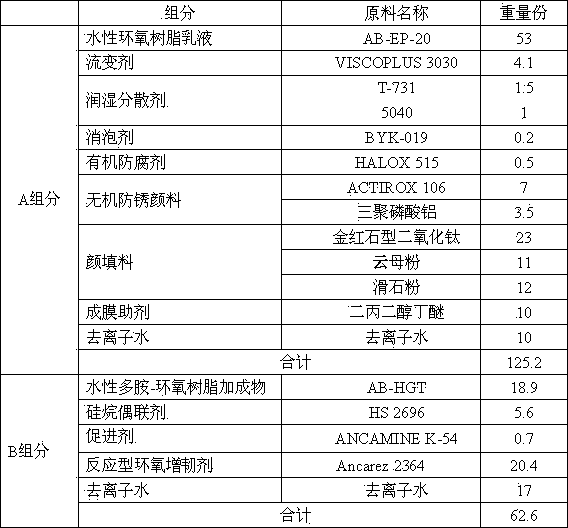

Two-component water epoxy radiation-resistant paint for nuclear power plant

ActiveCN101781509AAppropriate combinationReasonable dosageShieldingRadiation-absorbing paintsSolventIon

The invention relates to a two-component water epoxy radiation-resistant paint for a nuclear power plant. The paint comprises a component A and a component B, wherein the component A contains the following raw materials by weight percent: 30-50 percent of amine terminated water amine-epoxy adduct, 20-40 percent of pigment, 5-15 percent of filler, 0.05-0.5 percent of defoaming agent, 0.1-1 percent of wetting dispersant, 1-10 percent of cosolvent and rest percent of deionized water; and the component B contains the following raw materials by weight percent: 40-60 percent of epoxy-polyacrylic ester interpenetrating network polymer, 5-10 percent of emulsifier and rest percent of deionized water. The weight ratio of the component A to the component B is 2.5-3.5:1. The amine terminated water amine-epoxy adduct, the epoxy-polyacrylic ester interpenetrating network polymer and the emulsifier in the component B are self-made. The paint is environment-friendly, satisfies the requirement on the nuclear grade paint of the nuclear power plant and passes the simulation DBA test.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Indoor test method forming artificial hard shell layer by microbial curing silty-fine sand

ActiveCN106168550AGuaranteed uniformityGuaranteed SaturationPreparing sample for investigationPeristaltic pumpCarrying capacity

The invention discloses an indoor test method forming an artificial hard shell layer by microbial curing silty-fine sand. Silty-fine sand is paved on slurry which is thick enough, the slurry is separated from the silty-fine sand by a seepage-proofing thin film, liquid is injected into the left side by a liquid injecting peristaltic pump until a sand layer is saturated, liquid on the right side is extracted by a liquid extracting peristaltic pump to form horizontal laminar flow, the flow velocity of liquid injection and extraction is controlled, so that liquid injection and extraction are balanced, and silty-fine sand layers are cemented and cured by MICP (microbial induced calcium carbonate precipitation) technology to form the hard shell layer. The hard shell layer has high rigidity and strength, the carrying capacity of a soft soil foundation can be multiply improved, sand consumption is greatly decreased, the hard shell layer is resistant to liquefaction, and the requirement of basic carrying capacity can be met.

Owner:TIANJIN UNIV

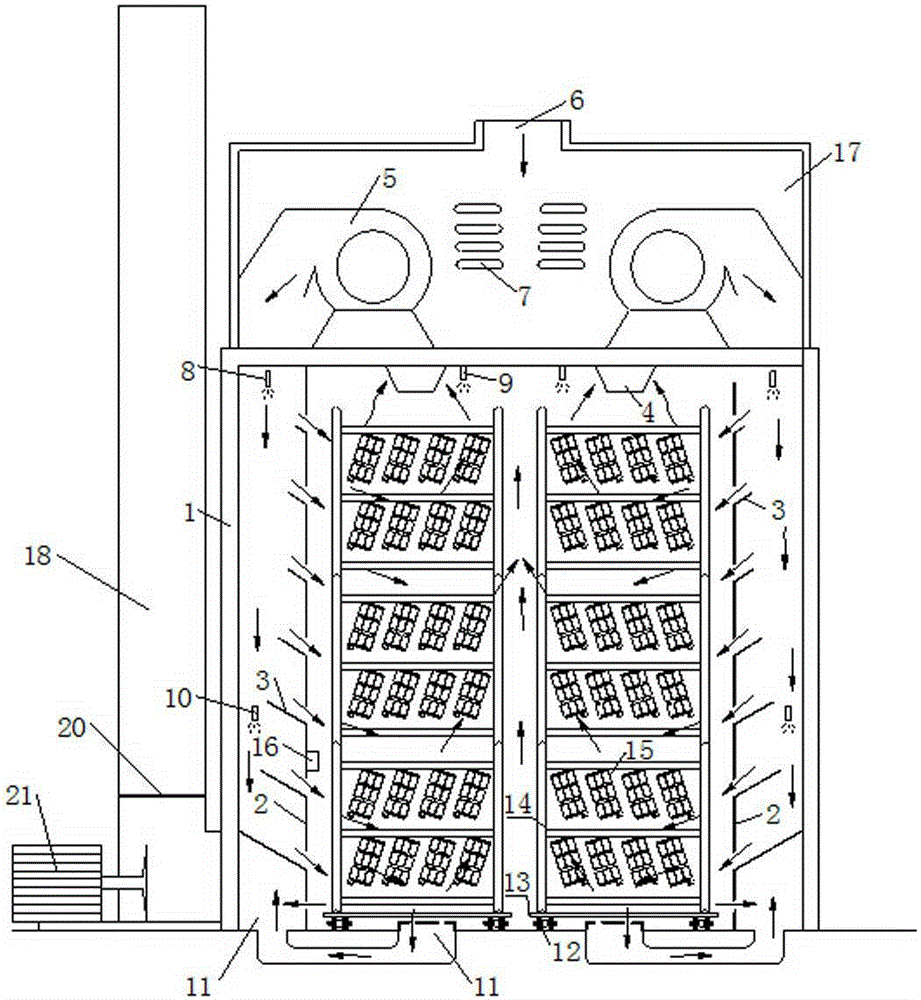

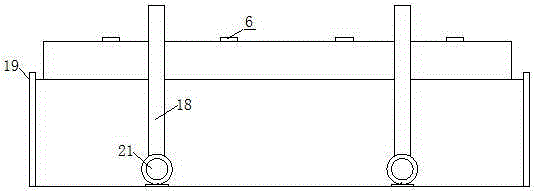

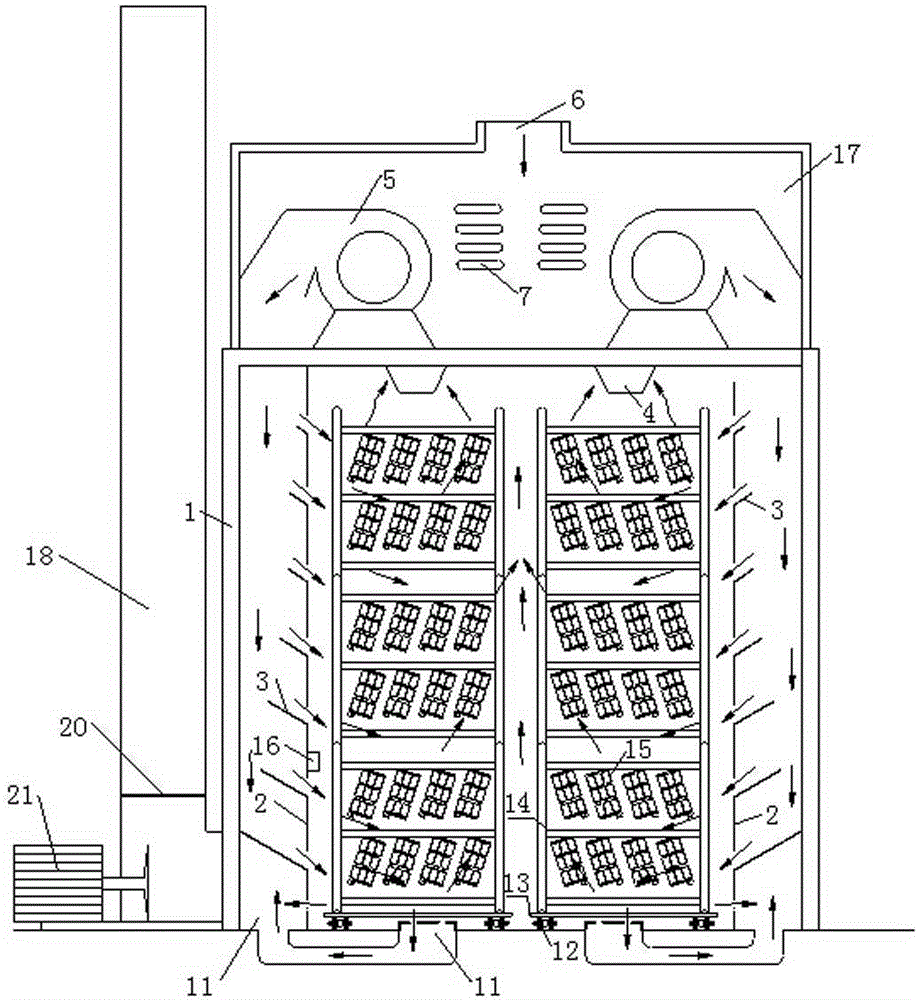

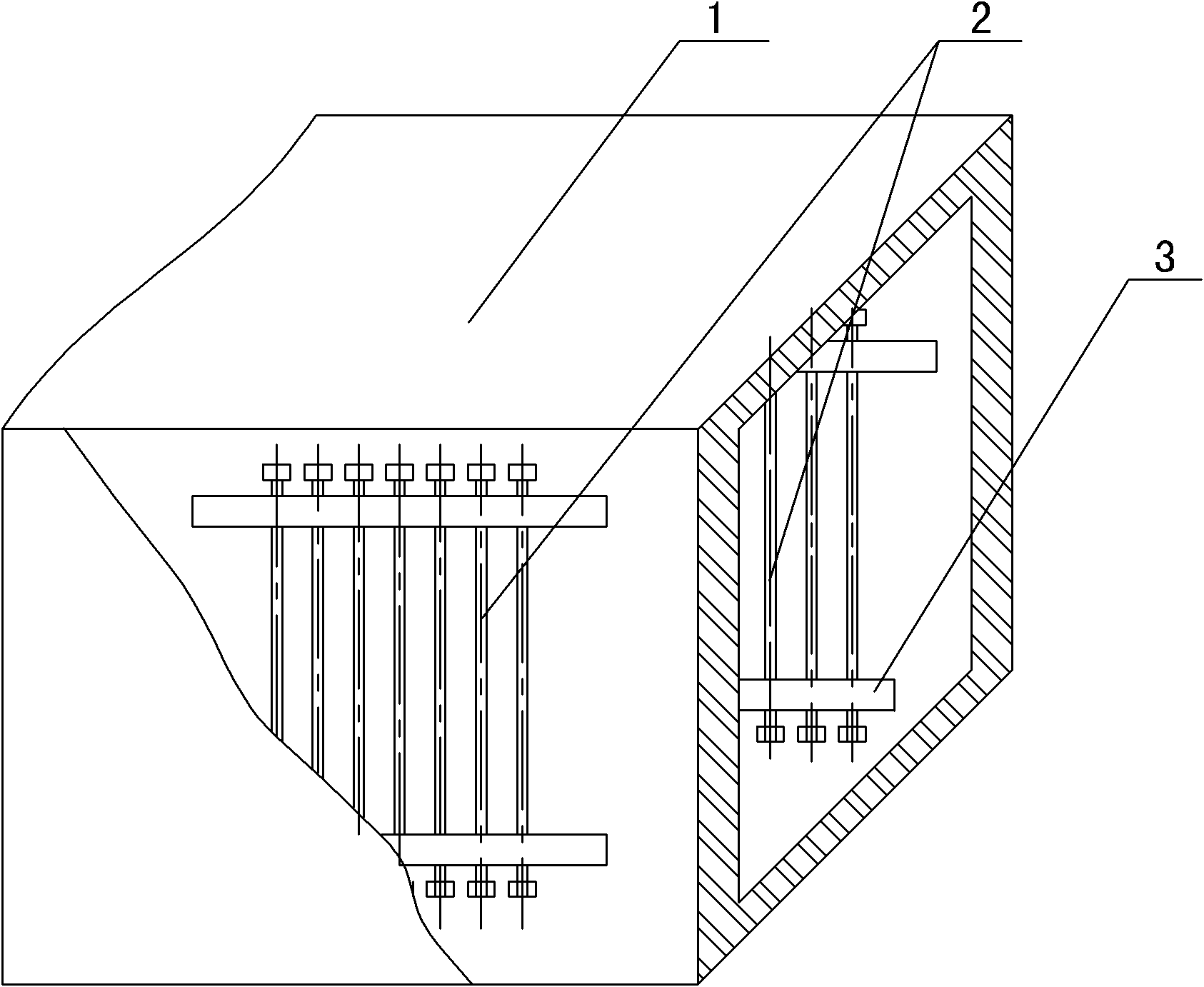

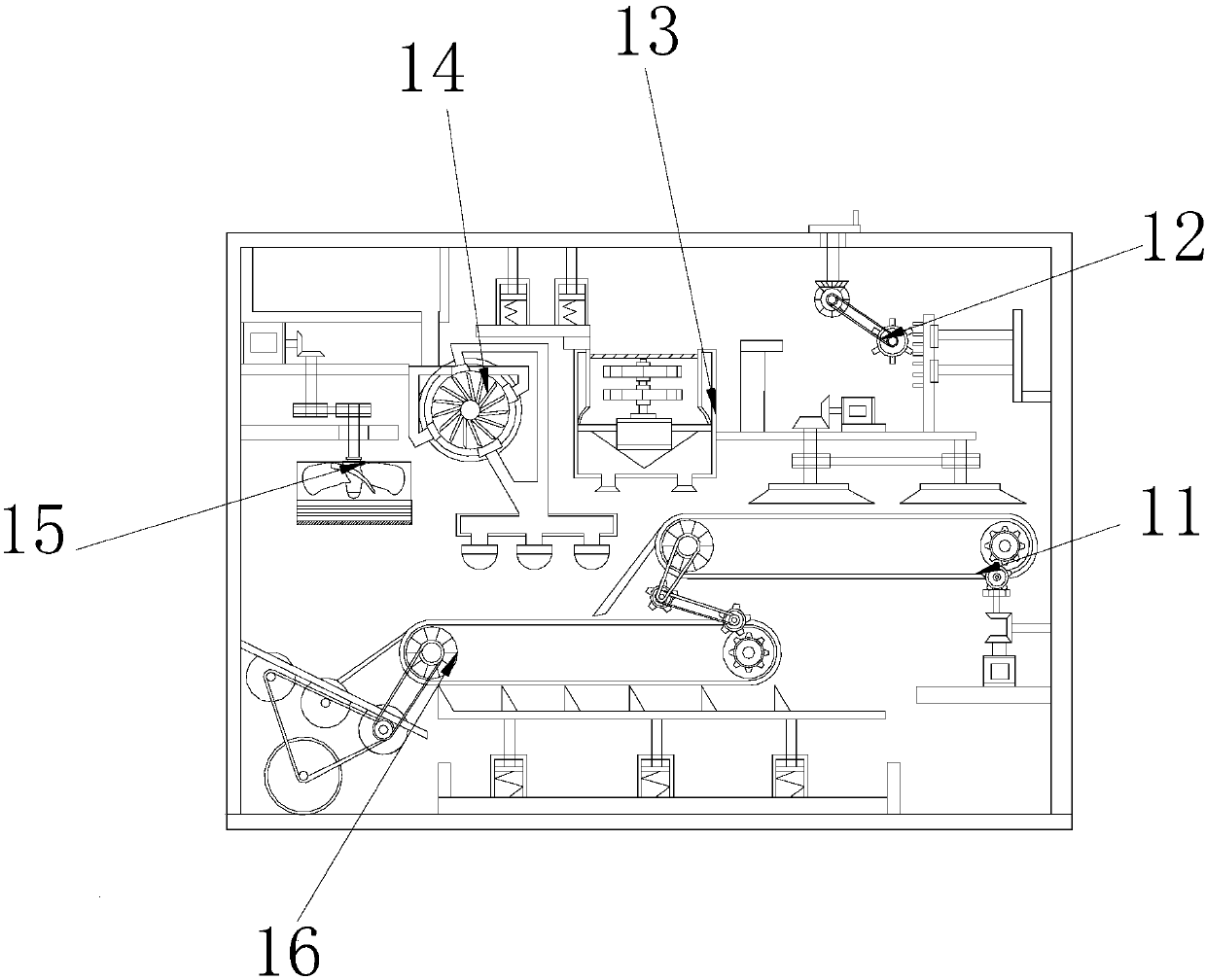

High-temperature curing chamber and curing technology for battery pole plates

ActiveCN105185950AUniform curingReduce varianceElectrode thermal treatmentProgrammable logic controllerEngineering

The invention discloses a high-temperature curing chamber for battery pole plates. The high-temperature curing chamber comprises a curing chamber and a drying chamber, wherein the curing chamber is divided into a primary chamber and an auxiliary chamber; wind distribution screens are arranged at the left side and the right side of the primary chamber; curing racks and a curing rack tray are arranged at the middle part of the primary chamber; wind shields are arranged on the wind distribution screens; steam humidifying sprinklers are arranged at the inner sides of the wind distribution screens; temperature and humidity sensors are arranged at the outer sides of the wind distribution screens; atomizing humidifying sprinklers, circulating air outlet pipes and plate-feeding atomizing humidifying sprinklers are arranged at the top of the curing chamber; circulating fans are arranged at the left side and the right side of the auxiliary chamber; an air intake door is arranged at the top of the auxiliary chamber; steam heating pipes are arranged at the middle part of the auxiliary chamber; and the atomizing humidifying sprinklers and the steam humidifying sprinklers are reduced from the curing chamber to form the drying chamber. Technological parameters of various stages are set through a programmable logic controller (PLC); the pole plates are fed into the curing chamber, and directly enter the rapid drying chamber after being cured; and the pole plates are cured after being dried in the rapid drying chamber. The curing chamber has the characteristics of curing uniformity, energy conservation and consumption reduction; according to the high-temperature curing technology, the curing time is shortened; the equipment utilization rate is increased; and meanwhile, the energy consumption is reduced.

Owner:江苏海宝新能源有限公司

Infrared pulse radiation heating method for curing board surface powder and equipment for implementing method

InactiveCN102580902AAvoid heat damageShort curing timeDrying solid materials with heatPretreated surfacesPhysical chemistryMedium density fiberboard

The invention relates to an infrared pulse radiation heating method for curing board surface powder and equipment for implementing the method, which belong to the field of infrared technology application. The heating method uses the new concept of a medium-wave infrared pulse radiation heating unit, and pulsed high-temperature curing is performed for artificial MDF (medium density fiberboard) surface powder coatings by the aid of short-time pulsed high temperature, so that heat damage of a board surface is avoided. By the aid of a pulsed high-temperature curing accumulation effect, coated film curing time is greatly shortened, the heat absorption capacity of a board matrix is greatly decreased, and an MDF is ensured to be at the temperature lower than 100 DEG C during discharge. By the aid of the equipment for implementing the method, effective heating space and the length of a drying tunnel can be reduced, MDF surfaces in an automatic coating production line are ensured to be in the same heated state, coated films are uniformly cured, and an energy-saving effect is extremely remarkable.

Owner:SHANDONG LANGFARBE POWDER COATING TECH

Cermic Sizing material fast and controllable solidfying colloied state shaping method and device

InactiveCN1513811AUniform curingShort curing timeCeramic shaping apparatusCement mixing apparatusSizingInternal stress

A process and apparatus for controllable fast solidification of shaped colloidal ceramics are disclosed. Said apparatus is composed of two vacuum storage tanks for different ceramic slurries, mixing system, diaphragm-type metering unit, high-pressure opposite jetting mixer, static mier, and mould. Said process includes stirring two ceramics slurries in vacuum state respectively, fostly injecting them in static mixer, high-pressure opposite jetting mixing, injecting in vacuum mould, and fast reaction and solidification. Its advantages are uniform solidifying and no internal stress.

Owner:TSINGHUA UNIV

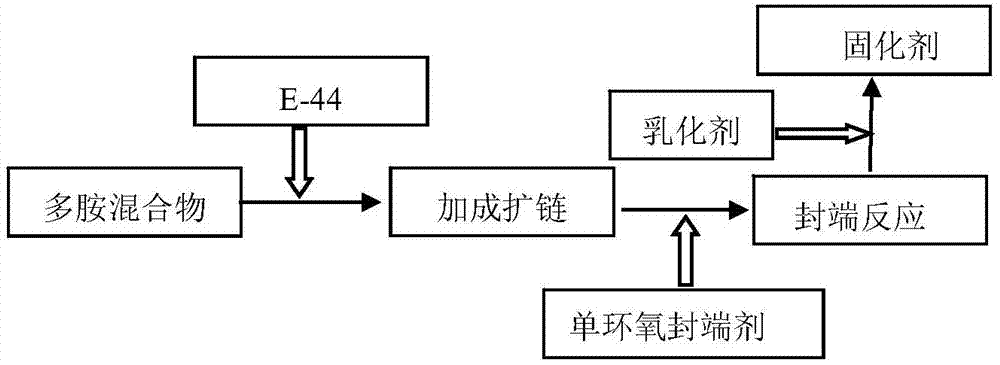

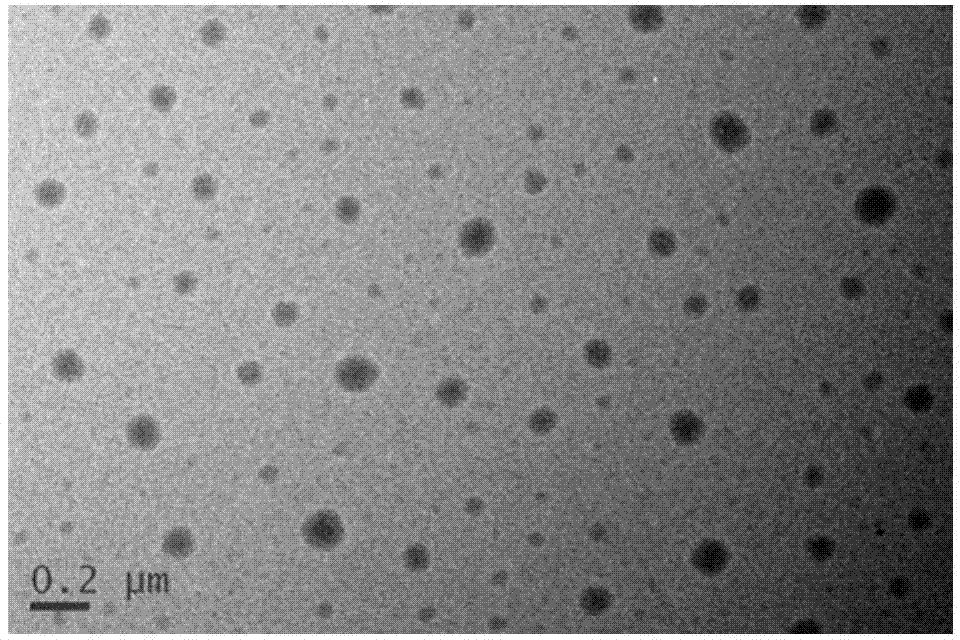

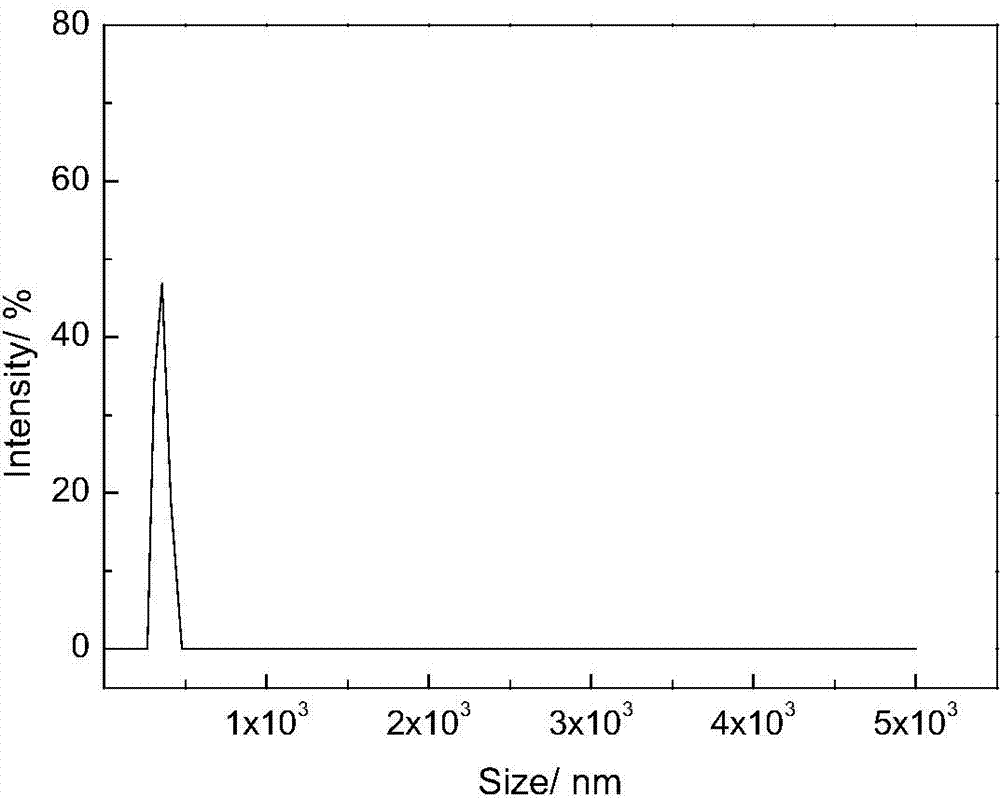

Expoxy resin polyamine curing agent and waterborne epoxy curing agent emulsion

The invention belongs to the technical fields of chemical organic synthetic materials and chemical process, and relates to an expoxy resin polyamine curing agent and a waterborne epoxy curing agent emulsion. The expoxy resin polyamine curing agent with hydrophilic epoxy resin is obtained by modifying polyamine; the expoxy resin polyamine curing agent is prepared into the curing agent emulsion through a reverse inversion method, wherein. According to the invention, an expoxy resin chain segment is introduced to the curing agent emulsion, so that the curing agent emulsion has good compatibility with an expoxy emulsion, thus the solidification uniformity curing is promoted, a solidifying cured membrane is uniform and compact, and the comprehensive mechanical property of the solidifying cured membrane is improved.

Owner:SINOHYDRO BUREAU 8 CO LTD +1

Plastic lens system, compositions, and methods

InactiveUS6964479B2Reduce light intensityLight transmissibility can be alteredOptical articlesEye diagnosticsEyeglass lensesFunctional monomer

Owner:VISION DYNAMICS

Microbial grouting test device and test method for uniformly solidifying silty soil

ActiveCN107255705AOvercome the disadvantage of uneven depth distributionAvoid wastingSolid waste managementEarth material testingMicroorganismSoil science

The invention discloses a microbial grouting test device and a test method for uniformly solidifying silty soil. The device comprises a cementing liquid supply device, a grouting device and a negative pressure liquid extraction device, wherein the grouting device consists of a grouting barrel body consisting of an inner barrel and an outer barrel; an interlayer cavity is formed between the inner barrel wall and the outer barrel wall; a grouting hole is formed in the inner barrel wall; the top of the barrel body is communicated with the cementing liquid supply device through a liquid supply pipe; the bottom of the barrel body is communicated with the negative pressure liquid extraction device through a liquid discharging pipe; cementing liquid vertically flows into an inner cavity of the inner barrel from the top of the inner barrel and transversely flows into the inner cavity of the inner barrel through the interlayer cavity and the grouting hole; a silty soil layer for grouting is arranged above the inner cavity of the inner barrel, and a coarse sand filtering layer is arranged below the inner cavity of the inner barrel. The test device disclosed by the invention can realize automatic supplying of the cementing liquid, so that a large number of sediments in a liquid supply measuring barrel can be reduced; meanwhile, migration of the cementing liquid in a whole soil sample is realized, so that local blockage of calcium carbonate is prevented; the uniformity of distribution of the calcium carbonate in the whole test sample is improved; the solidifying effect is enhanced.

Owner:HOHAI UNIV

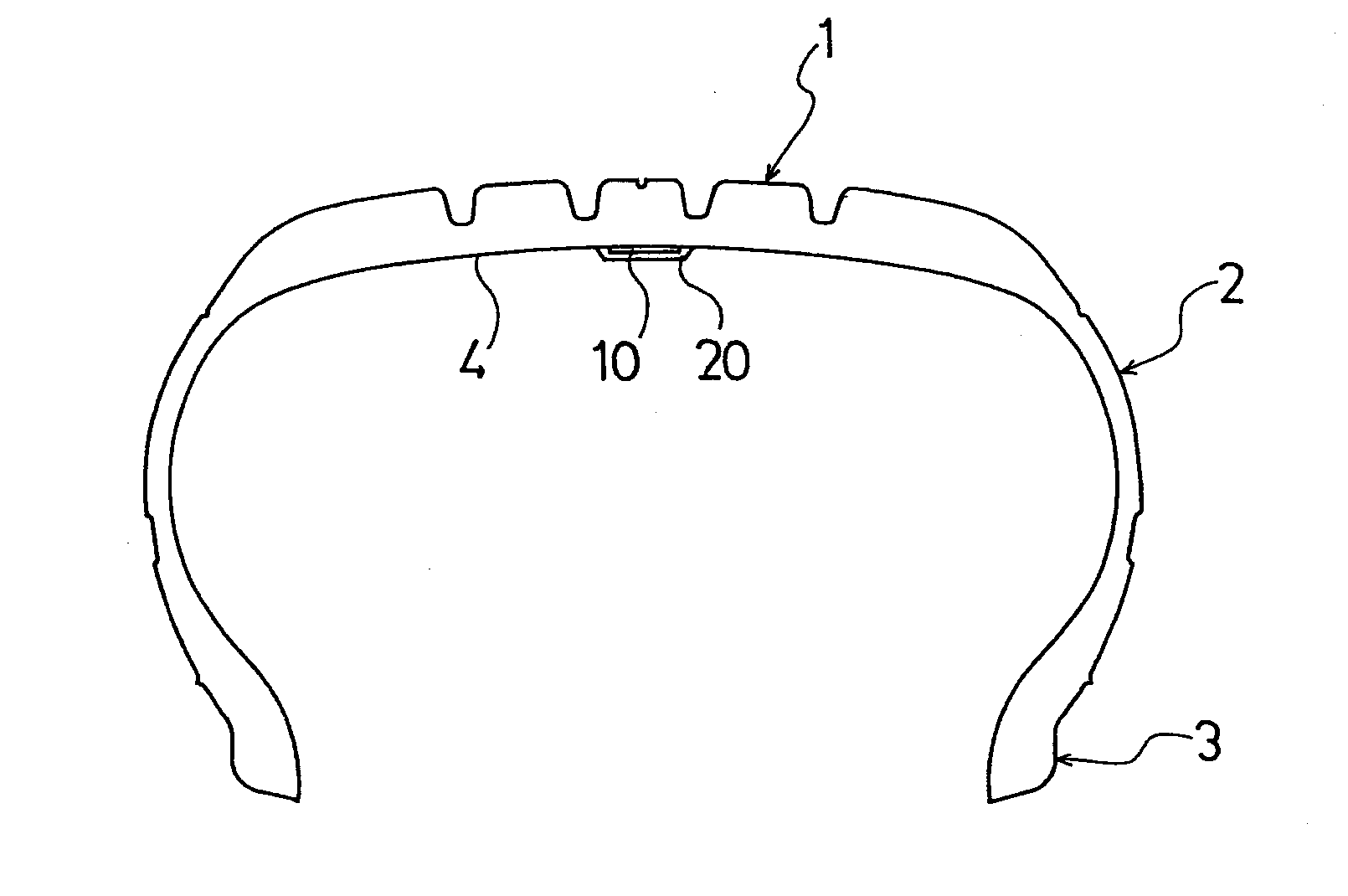

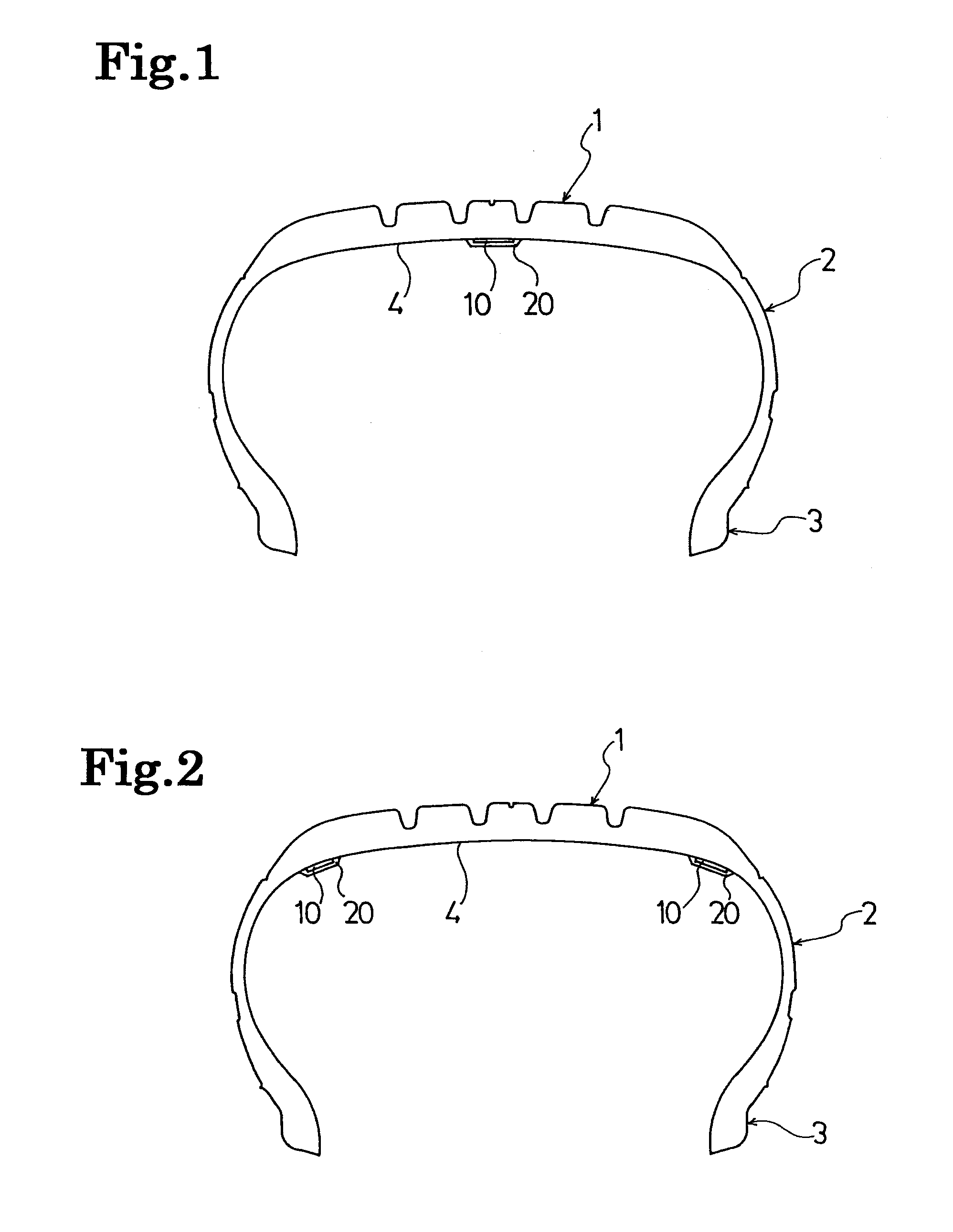

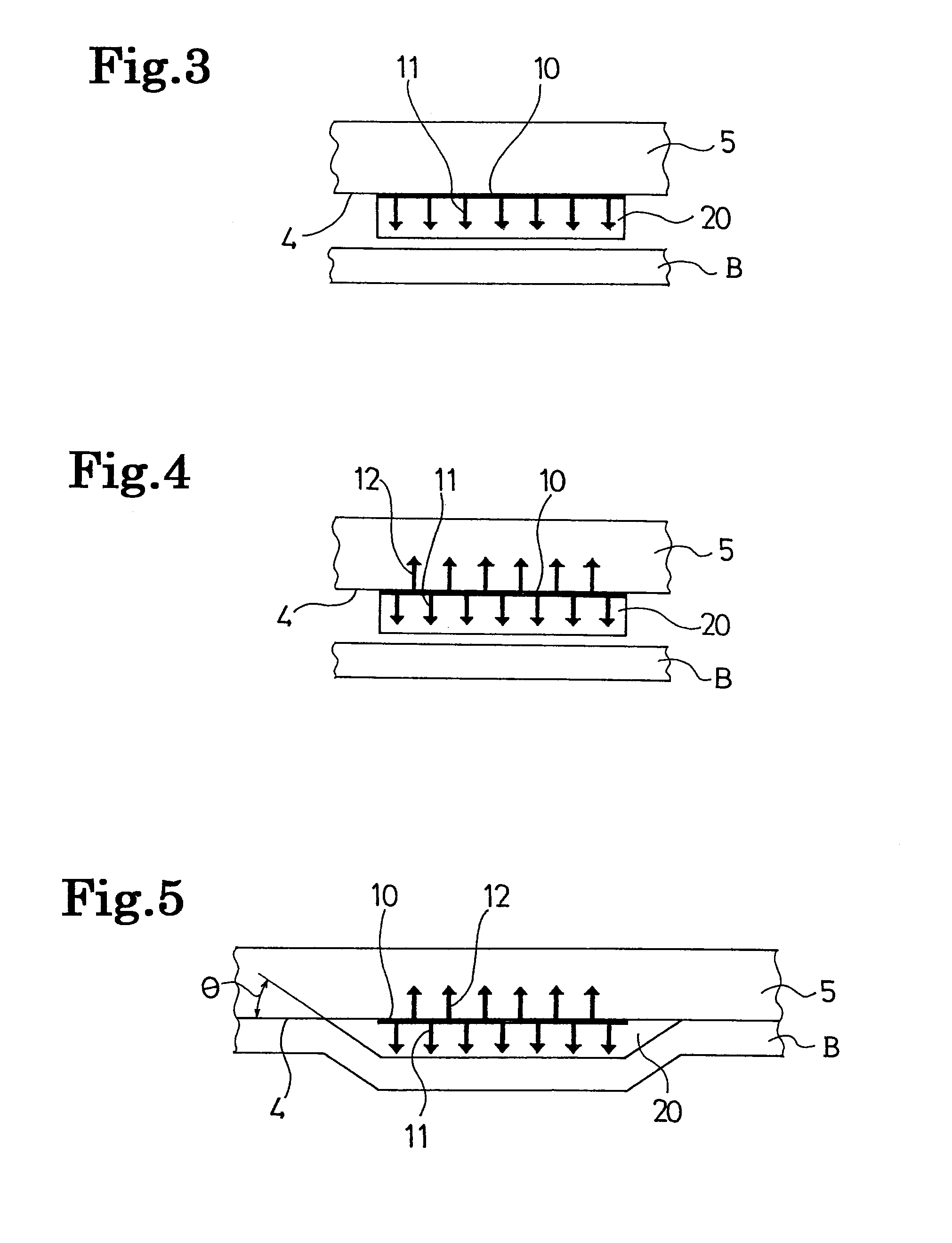

Pneumatic tire with surface fastener and method of producing the same

ActiveUS20110290395A1Avoid squeezingImprove the protective effectSlide fastenersTyresEngineeringFastener

A pneumatic tire with a surface fastener having engagement elements that are prevented from being crushed during curing, and a method of producing such a pneumatic tire. Uncured rubber is filled between the engagement elements of the surface fastener to form a protective rubber layer in which the engagement elements are buried. Then, the surface fastener having the protective rubber layer is placed on an uncured tire so that the surface opposite the surface having the engagement elements is in intimate contact with the inner surface of the tire, and after that the uncured tire having the surface fastener is cured by a curing machine equipped with a bladder.

Owner:YOKOHAMA RUBBER CO LTD

Double-component aqueous epoxy coating

InactiveCN1632016AExcellent nuclear power performanceImprove performanceEmulsion paintsEpoxy resin coatingsEpoxySolvent

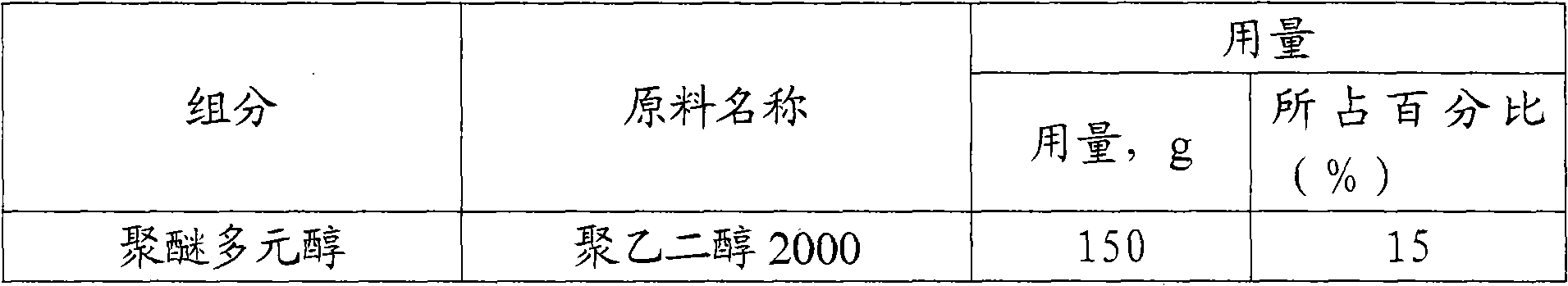

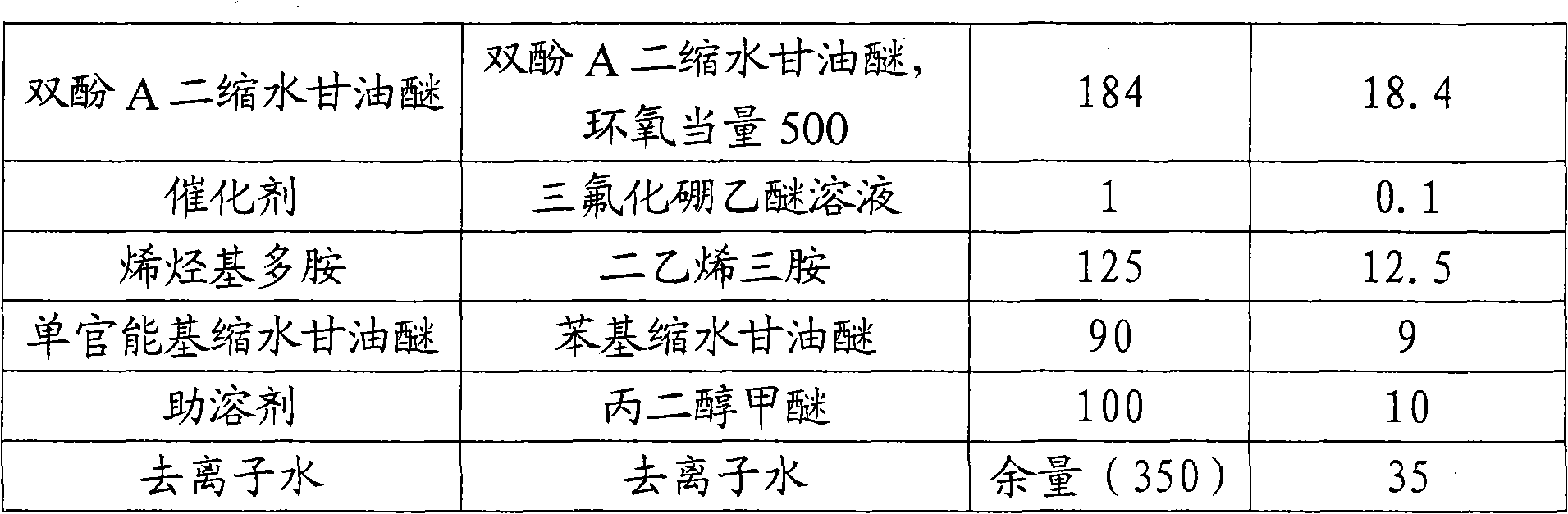

The invention relates to a hydrophilic epoxy coating with double components containing component A: hydrophilic amine-epoxy addition compound 30-50%, color 20-40%,filler 0-15%, inhibitor 0-1%, dispersant 0.1-1%,water without ion 15-30%,and dissolving assistant 1-8%; component B:shrinked glycerol ether of double phenol A 70-85%;hydrophilic amine-epoxy addition compound 5-12%;polyphenol 5-10%;catalyst 0.01-1%. The compoment an and B are mixed by the mass ratio of 2.0-3.33:hydrophilic epoxy, the hydrophilic amine-epoxy addition compound is prepared by alkene group polyamine 15-20%,epoxide 5-12%,glycerol ether of double phenol A 20-30%,acetic acid 1-8%,dissolving assistant 15-20% and deionized water 20-30%.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Construction method of microbial stirring grouting pile

InactiveCN110130318AEven distribution of microorganismsUniform solidified soilBulkheads/pilesSoil preservationUreaChemistry

The invention relates to a construction method of a microbial stirring grouting pile. The construction method solves the problems of strength and uniformity of a microbial reinforced foundation, and is characterized by comprising the following steps that a, according to the ratio of adding 100-220g of nano calcium sulphate per liter of bacterial solution, the bacterial solution is mixed with nanocalcium sulfate to prepare into a suspension; b, the suspension prepared in the step a is stirred into a foundation to be reinforced to prepare tightly arranged cylindrical bacterium-containing soil body stir zones 1, and the usage amount of the suspension is 0.9 time the pore volume of soil bodies of the bacterium-containing soil body stir zones 1; c, grouting pipes 3 are inserted into the centers of aseptic zones 2 between the cylindrical bacterium-containing soil bodies; d, a mixed solution of calcium chloride and urea is injected into the foundation through the grouting pipes 3 and standing is performed for 6-24h to form solidified pile bodies 4; and e, the step d is repeated for 4-8 times to complete construction of the microbial stirring grouting pile.

Owner:NANJING FORESTRY UNIV

Microwave solidification type bonding agent and microwave solidification method thereof

InactiveCN102352190AFast curingUniform curingNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentEpoxyCarbon composites

The invention discloses a microwave solidification type bonding agent and a microwave solidification method thereof. The bonding agent is prepared by adopting aluminum dihydrogen phosphate solution and phenolic resin as base materials, adopting compounds of two kinds of materials or several kinds of materials from magnesium oxide, zinc oxide, ferric oxide and zirconium oxide as solidification agents, adopting aluminum oxide as fillings and adopting boron carbide micro particles and ultra-fine silicon dioxide powder as modified fillings. All ingredients are mixed according to a certain proportion and are stirred at a high speed for obtaining the bonding agents. After the bonding agent is adopted for bonding devices, the convenient and fast solidification can be carried out under the microwave radiation effect. The bonding agent has excellent heat resistance performance, can be used for bonding ceramics, graphite, plastics, glass, epoxy resin, carbon / carbon composite materials and the like and has the characteristics that the temperature gradient of a solidified glue layer is small, the solidification is uniform, and the solidification time is short.

Owner:BEIHANG UNIV

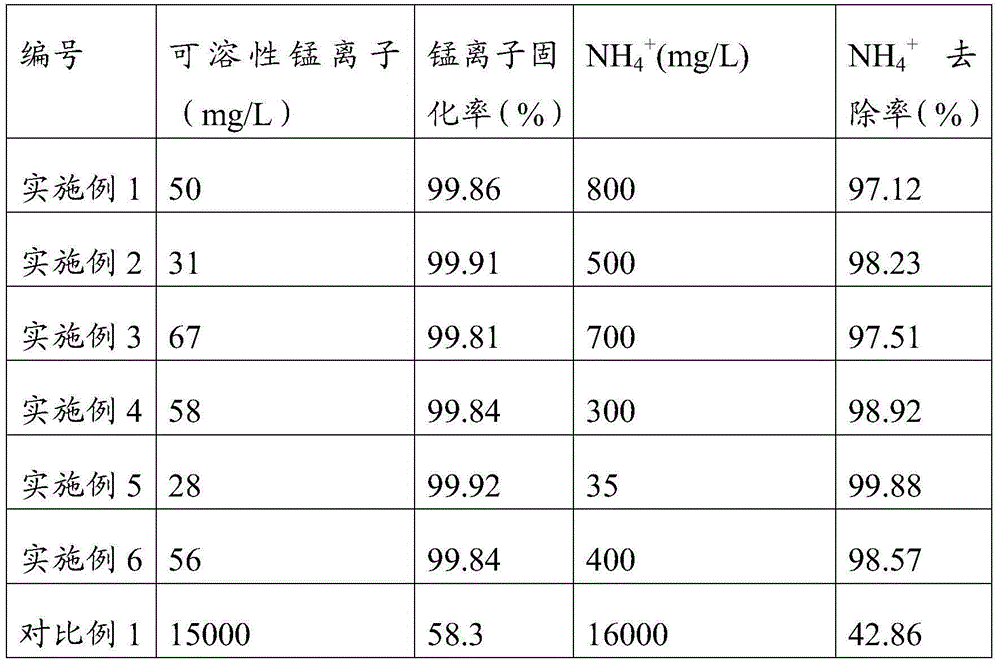

Hazard-free treatment technology for electrolytic manganese residues

ActiveCN104357662AReduce wasteThreat to healthProcess efficiency improvementElectrolysisWater resources

The invention discloses a hazard-free treatment technology for electrolytic manganese residues. The technology comprises the following steps: washing the manganese residues in a high-pressure manner by using slurry water, and basically enabling the manganese residues to form slurry liquid; injecting the manganese residue slurry liquid into a filter chamber of a membrane press filter to be filtered to obtain a filter cake, and performing two-section acid leaching on the filter cake under a prepressing state; keeping the prepressing state, and injecting multi-stage washing liquid into the filter chamber to be washed in a multi-section manner; injecting alkali liquid of which the pH is 9 to 10.5 into the filter chamber to solidify manganese ions, and inflating the air into a filter liquid passage in a stage manner during the solidifying treatment; performing the high-pressure press filtering on substances in the filter chamber, and after the solidifying treatment is finished, discharging the residues. Through the adoption of the technology provided by the invention, the soluble manganese ions in the electrolytic manganese residues can be further extracted, and at the same time, the manganese ions in the filter cake are converted into the insoluble manganese to be deposited, so that the remained manganese ions in the waste residues cannot be permeated into the ground surface or the underground water to pollute the underground water resources in the stacking process.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

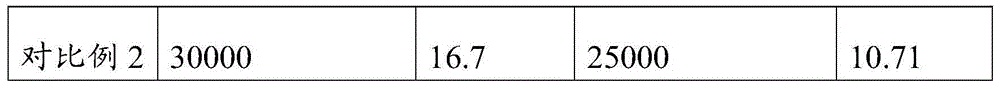

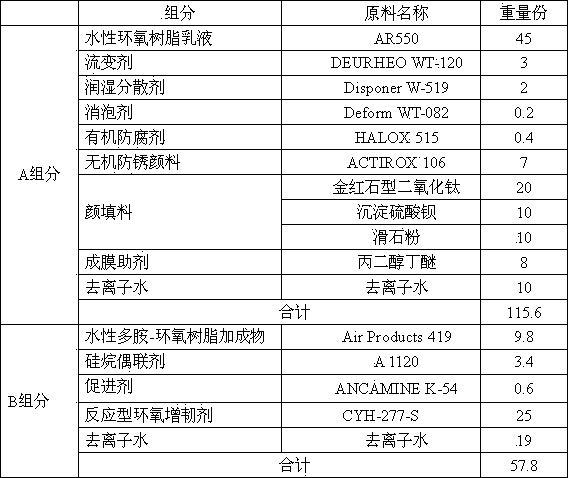

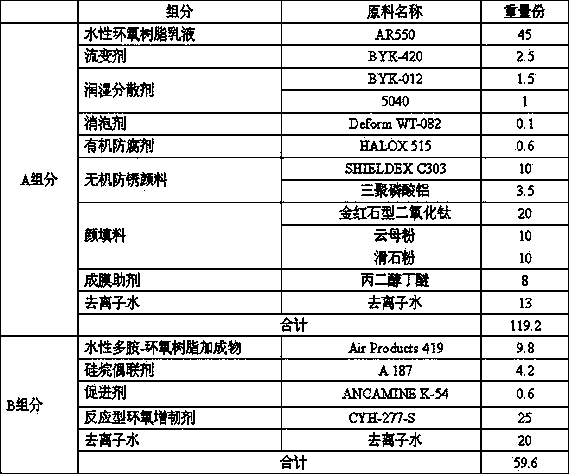

Aqueous epoxy corrosion-resistant coating for mechanical equipment and preparation method of aqueous epoxy corrosion-resistant coating

InactiveCN104277660ASpeed up the reaction processAvoid coating film brittle defectsAnti-corrosive paintsEpoxy resin coatingsIonEmulsion

The invention relates to an aqueous epoxy corrosion-resistant coating for mechanical equipment. According to the aqueous epoxy corrosion-resistant coating, a component A comprises an aqueous epoxy resin emulsion, a rheological agent, a wetting and dispersing agent, a defoaming agent, an organic preservative, an inorganic anti-rust pigment, a pigment filler, deionized water and a film-forming aid, a component B comprises an aqueous polyamine-epoxy resin adduct, deionized water, a silane coupling agent, a promoter and a reactive epoxy toughening agent, and the aqueous epoxy corrosion-resistant coating is prepared by preparing the component A, preparing the component B and mixing the component A and the component B. Test results show that under the situation of coating a 150mu m wet film, the surface drying time is less than 40min, the solid drying time is less than 12h, the thickness of a dry film is 80mu m, a coating has no cracks under the impact condition of 120kg.cm, an anti-flash rust agent which produces harm to a human body or an environment is eliminated, and the aqueous epoxy corrosion-resistant coating is environment-friendly and high in safety.

Owner:洛阳双瑞防腐工程技术有限公司

Microwave Bonding Of EVA And Rubber Items

ActiveUS20140262010A1Short widthUniform curingMechanical working/deformationSolesMicrowaveEngineering

Aspects of the present invention relate to systems and methods for customizing microwave energy distribution within a chamber to accommodate various load characteristics. Aspects of the present invention customized configurations of ports, deflectors, waveguides, conducting rods, and slots to shape and distribute energy.

Owner:NIKE INC

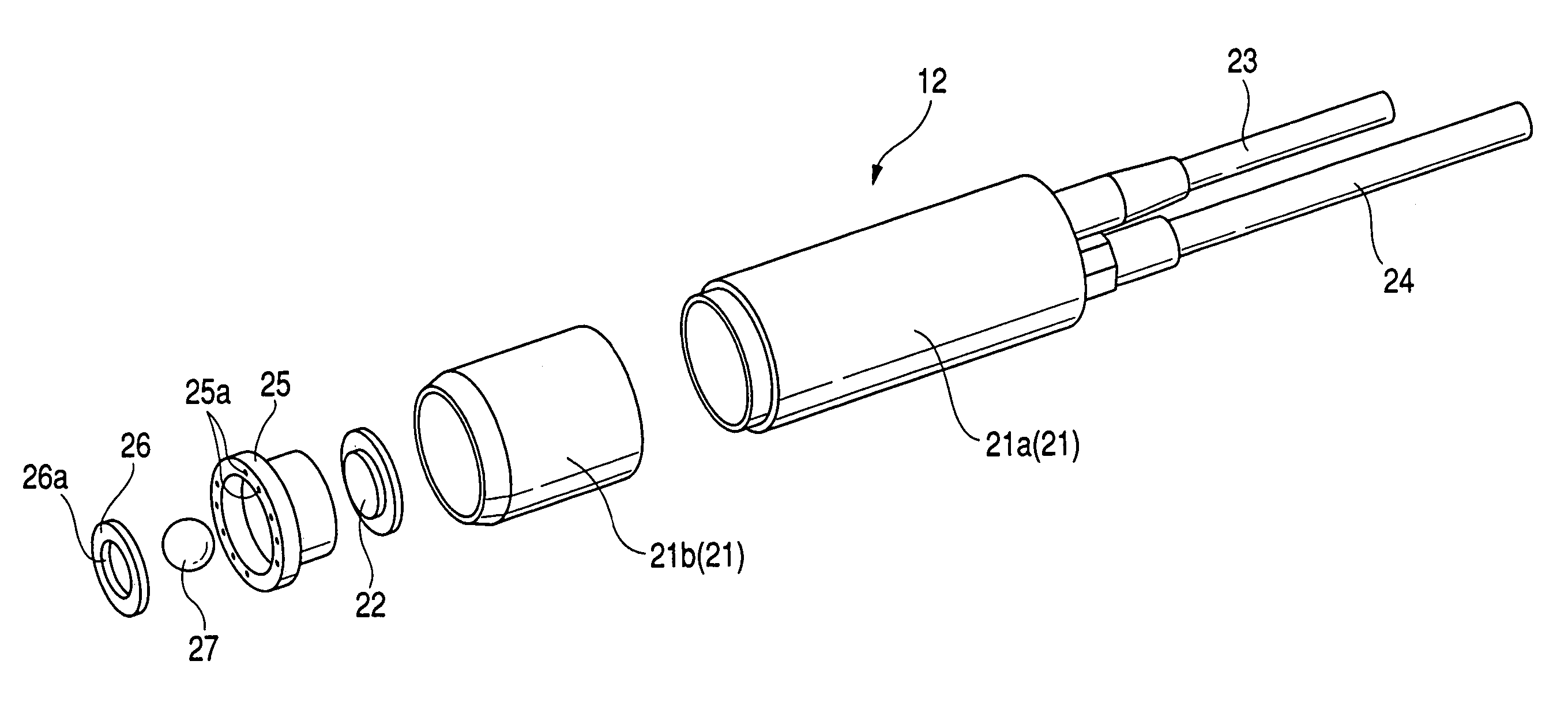

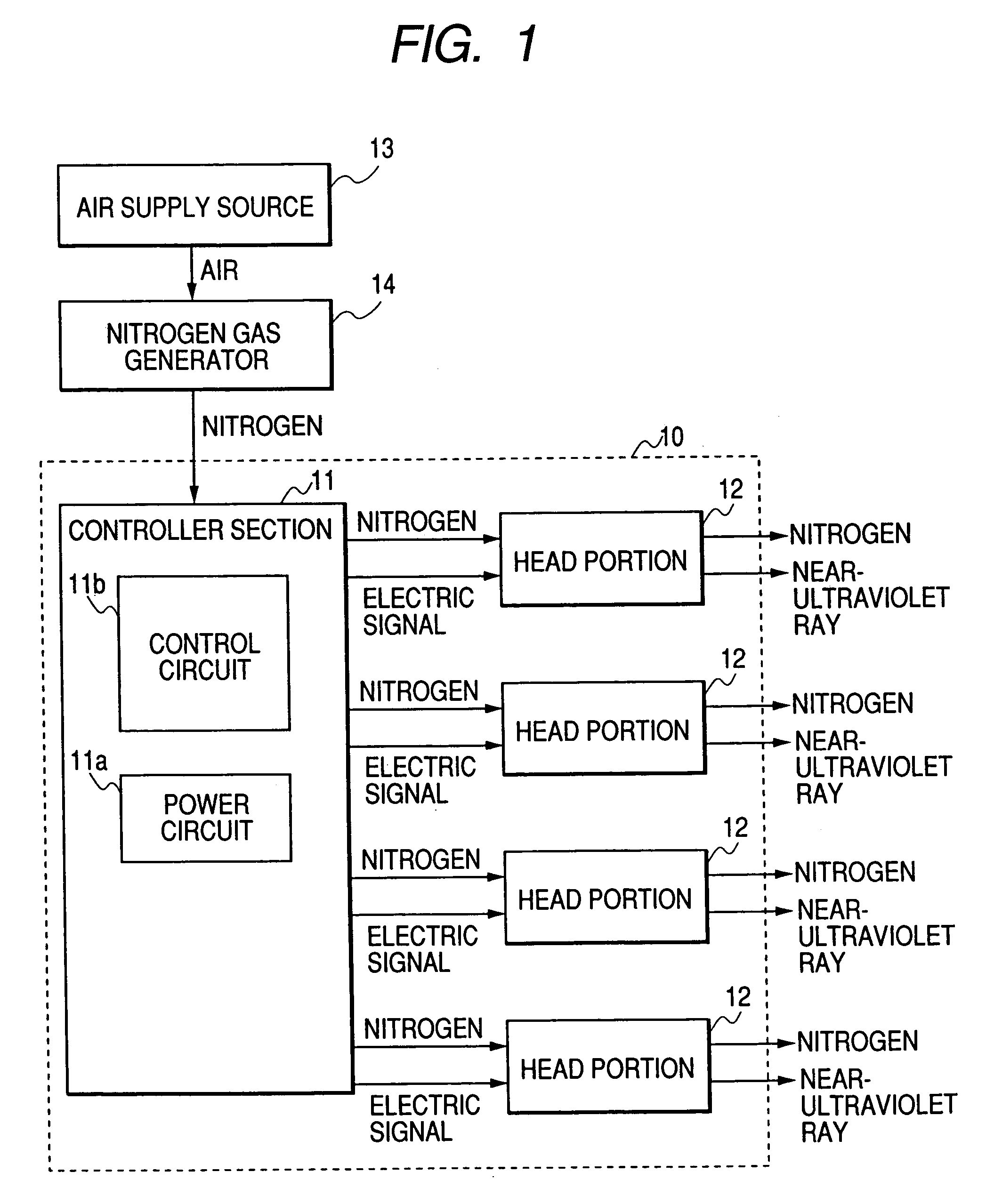

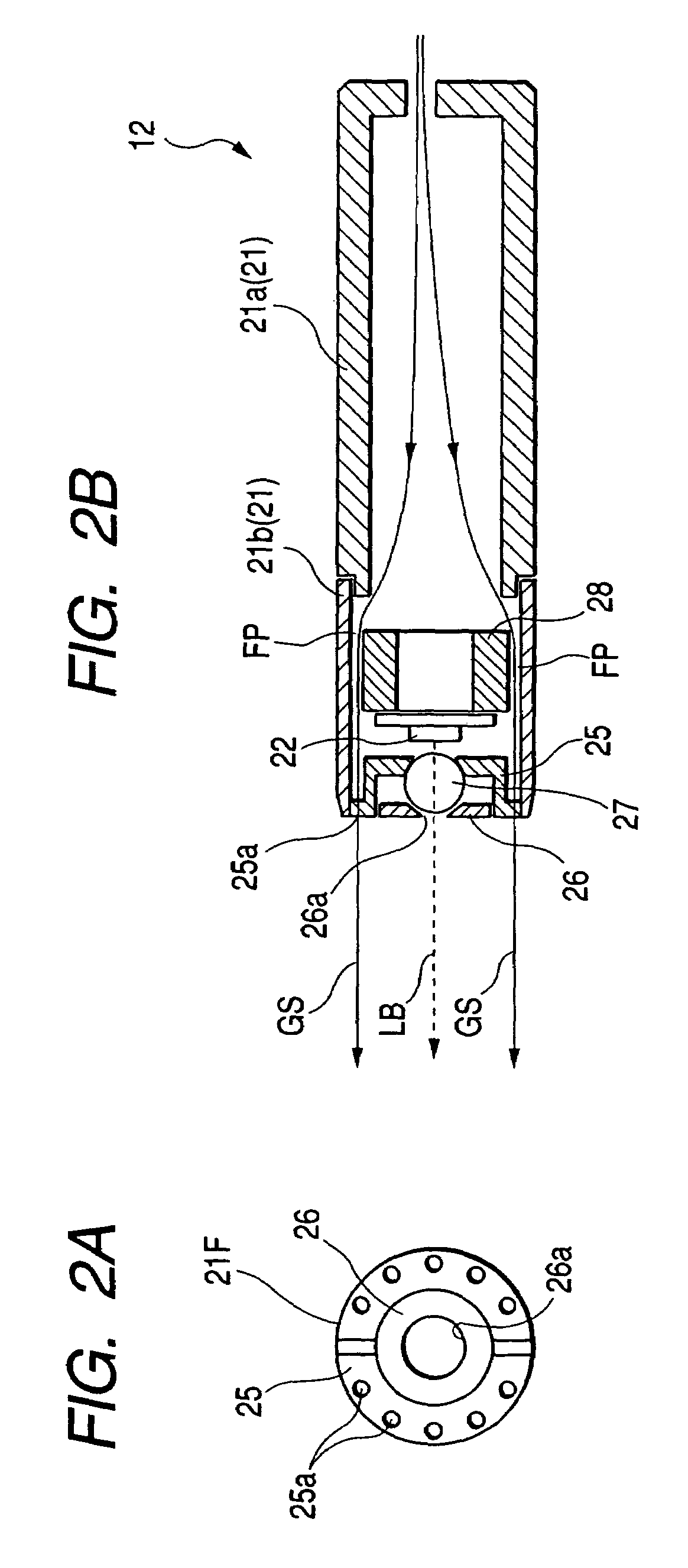

Ultraviolet irradiating device

InactiveUS7173266B2Reduce manufacturing costEasy to operateAdhesive processesLiquid surface applicatorsUV curingUltraviolet

In an ultraviolet irradiating device in which a controller section and plural head portions used to cure ultraviolet curable resin used in the adhesion of a part are connected by an electric cable, each of the plural head portions has a sleeve-shaped housing and a light emitting diode which is arranged within this housing and emits a near-ultraviolet ray. The ultraviolet irradiating device is constructed such that the near-ultraviolet ray emitted from the light emitting diode is irradiated to the exterior from a near-ultraviolet ray irradiating port arranged on the tip face of the housing. The controller section has a power circuit and a control circuit for individually controlling the operations of the light emitting diodes of the plural head portions.

Owner:KEYENCE

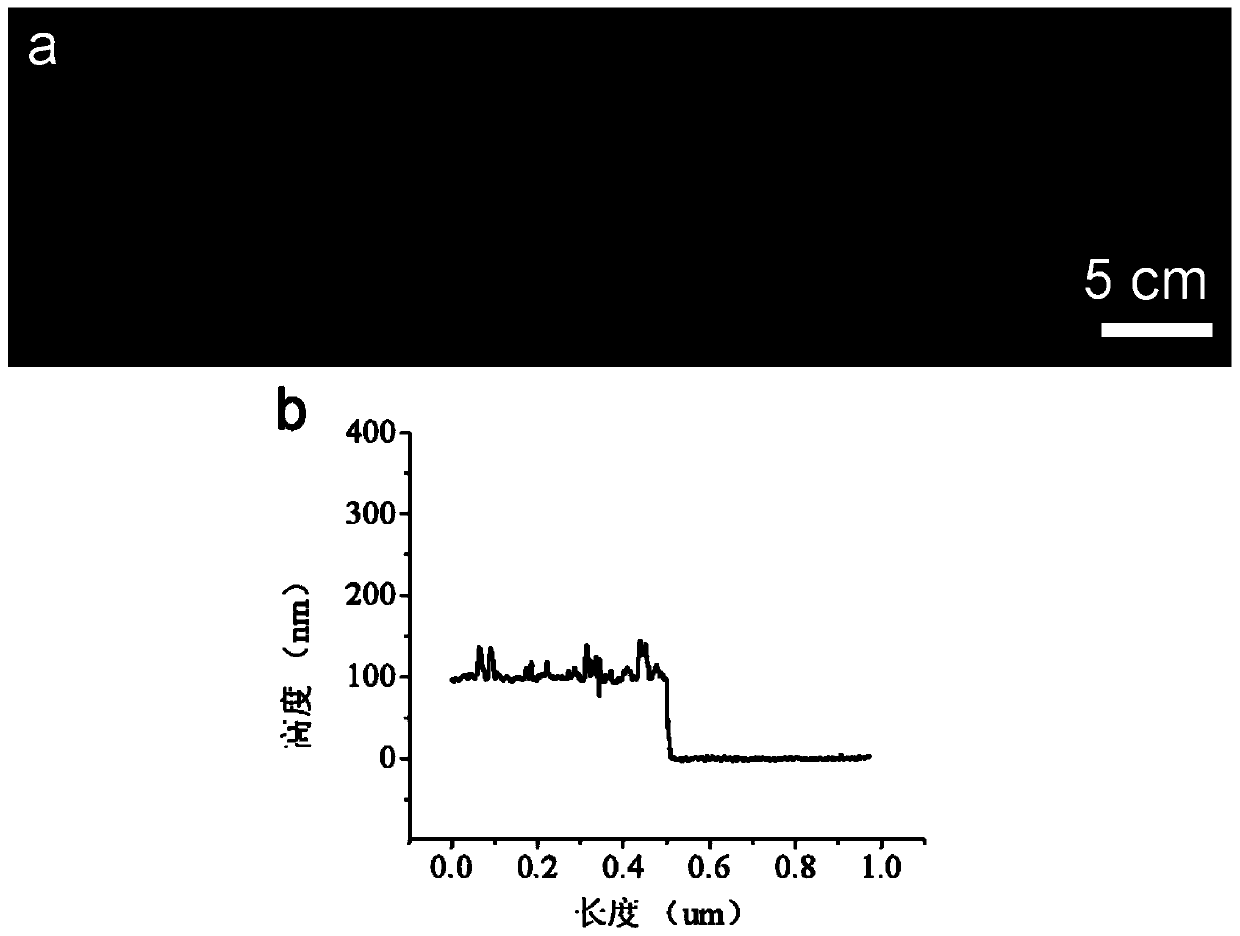

Film making method capable of precisely controlling film thickness and area of nanometer-thickness film

PendingCN110274803AEfficient and precise control of preparationControllable shapeMaterial nanotechnologyMaterial analysis using wave/particle radiationSpray nozzleEngineering

The invention relates to the field of preparation and application of a film material, in particular to a film making method capable of precisely controlling the film thickness and area of a nanometer-thickness film, thereby realizing high-efficiency control preparation of a nanometer-thickness film material with the uniform and consistent thickness. On the basis of the basic principle of a rotary centrifugal type film forming method, a printing spraying nozzle or pin head with a small aperture is used based on a base rotating device; under the conditions of the constant film forming liquid pressure and the controllable motion track, a certain amount of film forming liquid is sprayed on the surface of a film forming base at a certain rate in a micro liquid column manner, so that a uniform liquid film with the controllable thickness, shape, and area is formed; and thus a solid film material is obtained by controlling curing conditions. With the provided method, the high-efficiency and precise control preparation of the nanometer-thickness film material with the uniform thickness is realized. The film making method can be applied to technical fields of photoelectric devices, energy storage devices, protective functional coatings, catalytic materials, composite materials and the like widely.

Owner:深圳烯材科技有限公司

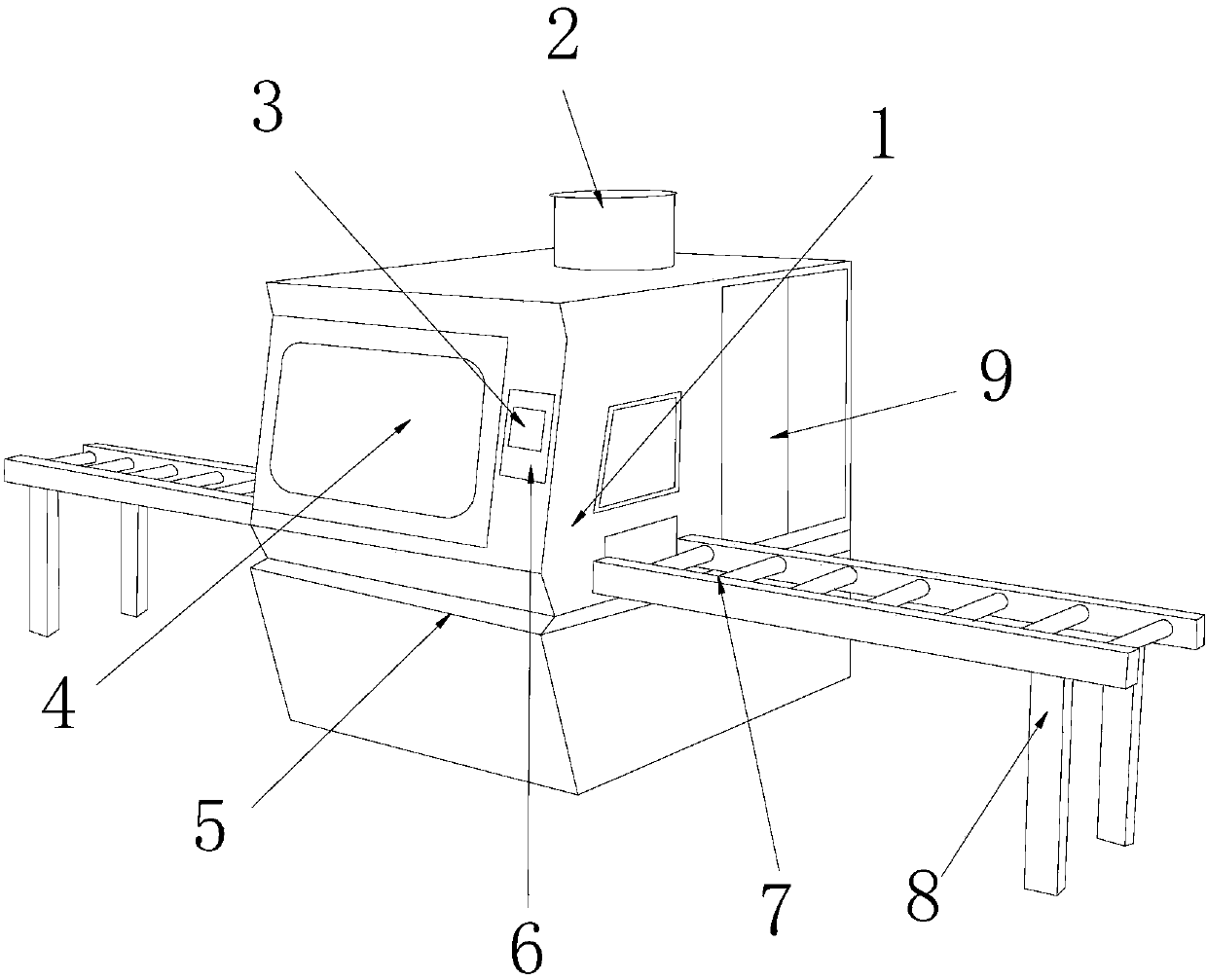

Novel environmental-friendly oil paint equipment with automatic uniform spraying function

ActiveCN108031600AEvenly paintedQuality improvementPretreated surfacesDirt cleaningToughened glassMachining time

The invention discloses novel environmental-friendly oil paint equipment with an automatic uniform spraying function. The novel environmental-friendly oil paint equipment structurally comprises a paint spraying device, a top cover, a display screen, tempered glass, a machine body, a control panel, a conveying frame, support feet and a containing cabinet. The paint spraying device is mounted in themachine body. The conveying frame is mounted on the left side and the right side of the machine body. The support feet are sequentially connected into a rectangular structure and perpendicularly arranged at the bottom of the conveying frame. The bottom of the top cover is fixedly connected with the top of the machine body. The side face of the tempered glass is embedded into the surface of the front end of the machine body. According to the novel environmental-friendly oil paint equipment with the automatic uniform spraying function, matter attached to the surface of a machined object can beremoved and absorbed, and concave-convex blocks generated after paint spraying are prevented; and meanwhile the automatic uniform spraying can be achieved by the adoption of the equipment, the paint spraying quality is improved, the paint is blow-dried through hot air, the solidification speed of the oil paint is increased, the machining time is shortened, and the production efficiency is improved.

Owner:NANTONG HAIYU MACHINERY EQUIP

Double Initiated Fast Crosslinking EVA Adhesive Film

ActiveUS20160272852A1Increase the speed of encapsulationImprove packaging efficiencyFilm/foil adhesives without carriersPhotovoltaic energy generationMethacrylateCross-link

The invention provides a dual-initiated and fast cross-linked EVA (ethylene / vinyl acetate copolymer) film for the encapsulation of solar modules, which greatly enhances the speed of the encapsulation. The EVA film is mainly prepared from the following raw materials: 100 parts by mass of ethylene / vinyl acetate copolymer, 0.01 to 1.5 parts by mass of a free-radical photoinitiator, 0.01 to 1.5 parts by mass of a free-radical thermal initiator, 0.5 to 10 parts by mass of an auxiliary cross-linking agent, 0.1 to 5 parts by mass of a tackifier and 0.01 to 5 parts by mass of a light stabilizer. The present invention adds photothermal dual-initiated free-radical initiators and the auxiliary cross-linking agent of multi-functional acrylates or methacrylates to the EVA and use a thermal-UV dual curing process to prepare the solar module. The curing time is shorten to 5 to 10 min and the yield is high; meanwhile, the EVA film has advantages of uniform curing, high crosslink density, high bonding strength between the film and glass, and good anti-aging property.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com