Indoor test method forming artificial hard shell layer by microbial curing silty-fine sand

An indoor test and curing powder technology, which is applied in the field of indoor test of artificial hard shell, can solve problems such as hindrance to later construction, toxicity, and damage to the original structure of the foundation soil, so as to reduce the amount of sand used, improve the bearing capacity, and solve environmental problems. problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

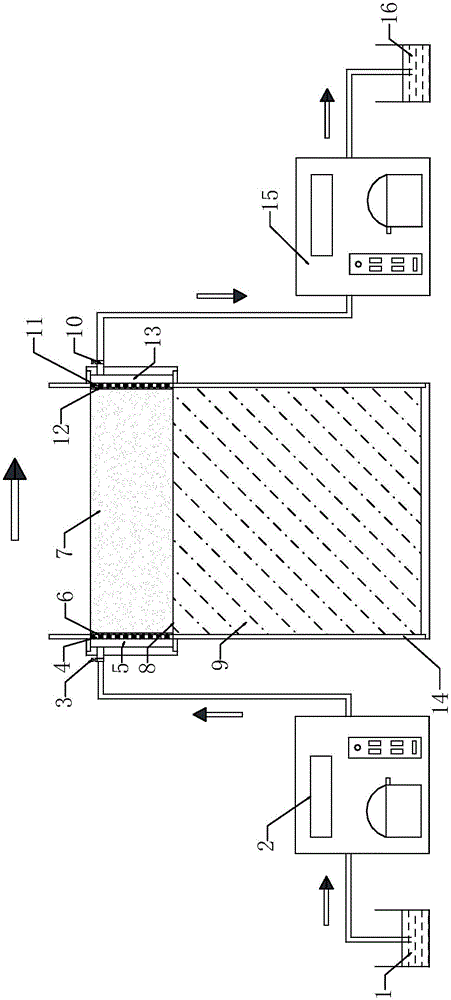

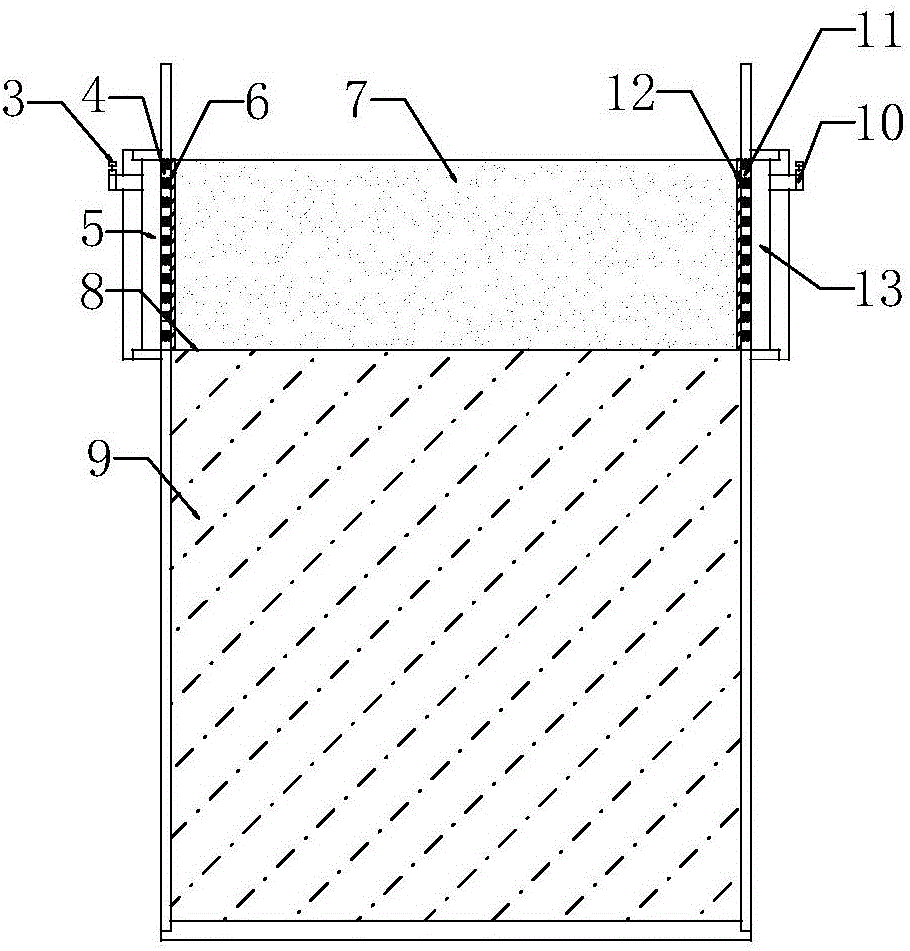

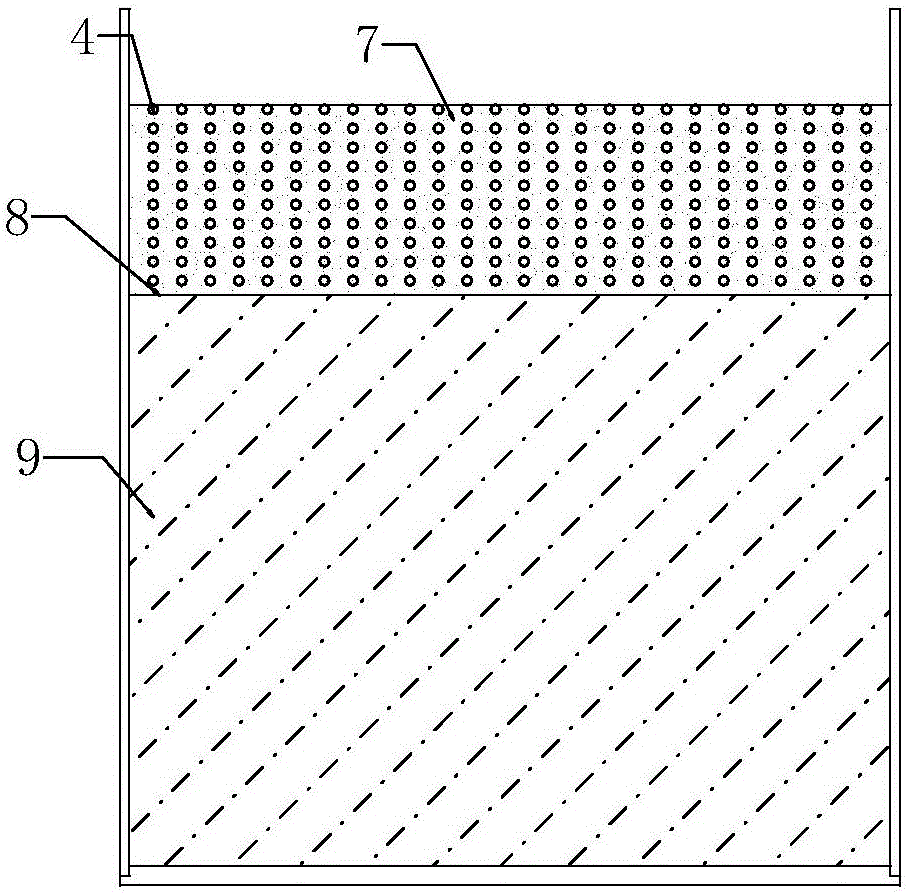

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0026] see Figure 1 ~ Figure 4 , a kind of indoor test method that adopts microbiological solidified silty sand to form artificial hard shell layer, this method adopts curing device to finish, and described curing device comprises test box 14, and the middle and lower part of described test box 14 is the mud holding area, and the upper part is In the silt and fine sand storage area, an anti-seepage film 8 is provided between the mud storage area and the silt and fine sand storage area, and a group of multiple Uniformly distributed liquid inlet holes 4 and a group of uniformly distributed liquid outlet holes 11, the liquid inlet hole group and the liquid outlet hole group are arranged opposite to each other, and a geotextile I6 is arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com