Patents

Literature

61results about How to "Reduce the amount of sand used" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

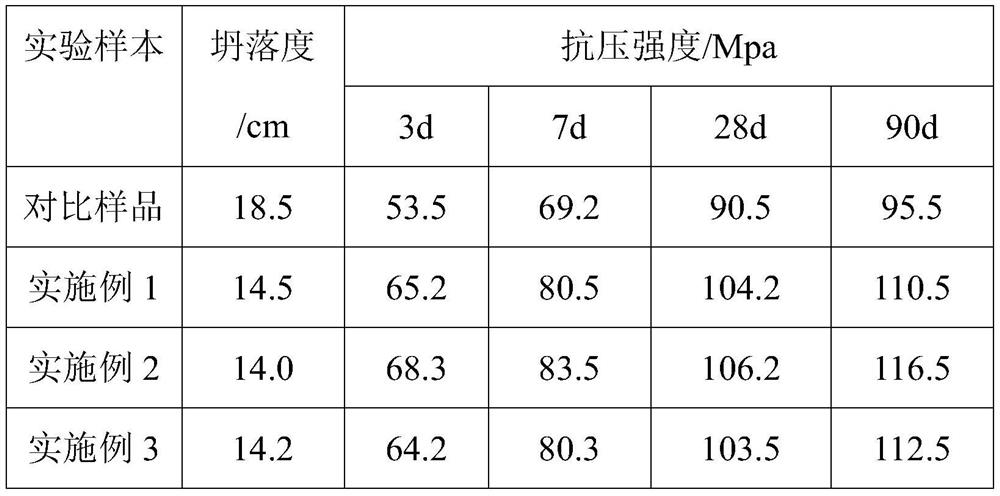

Indoor test method forming artificial hard shell layer by microbial curing silty-fine sand

ActiveCN106168550AGuaranteed uniformityGuaranteed SaturationPreparing sample for investigationPeristaltic pumpCarrying capacity

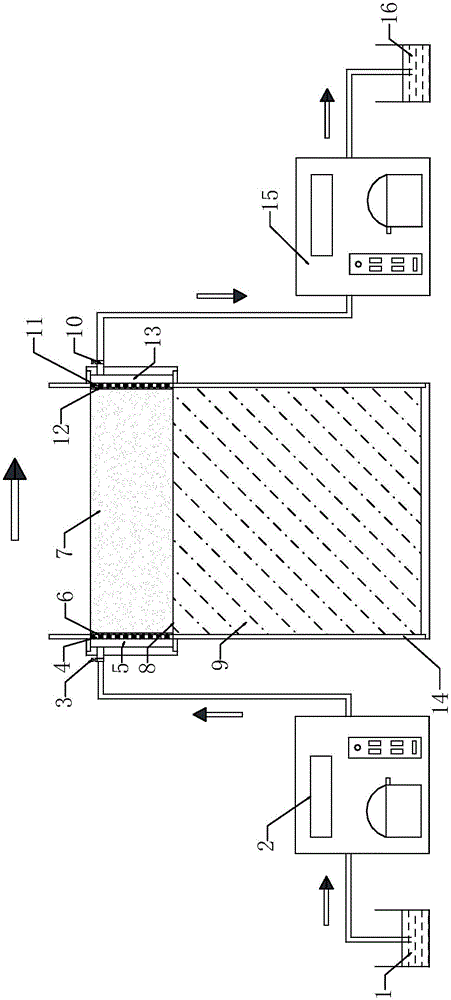

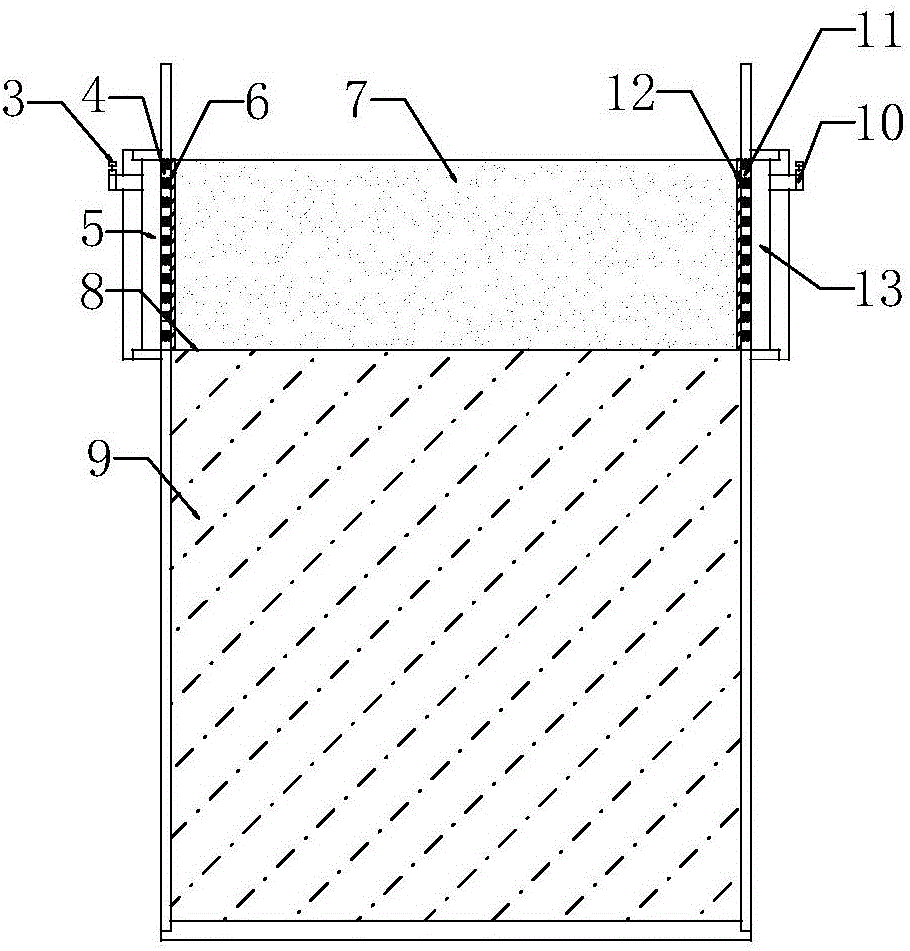

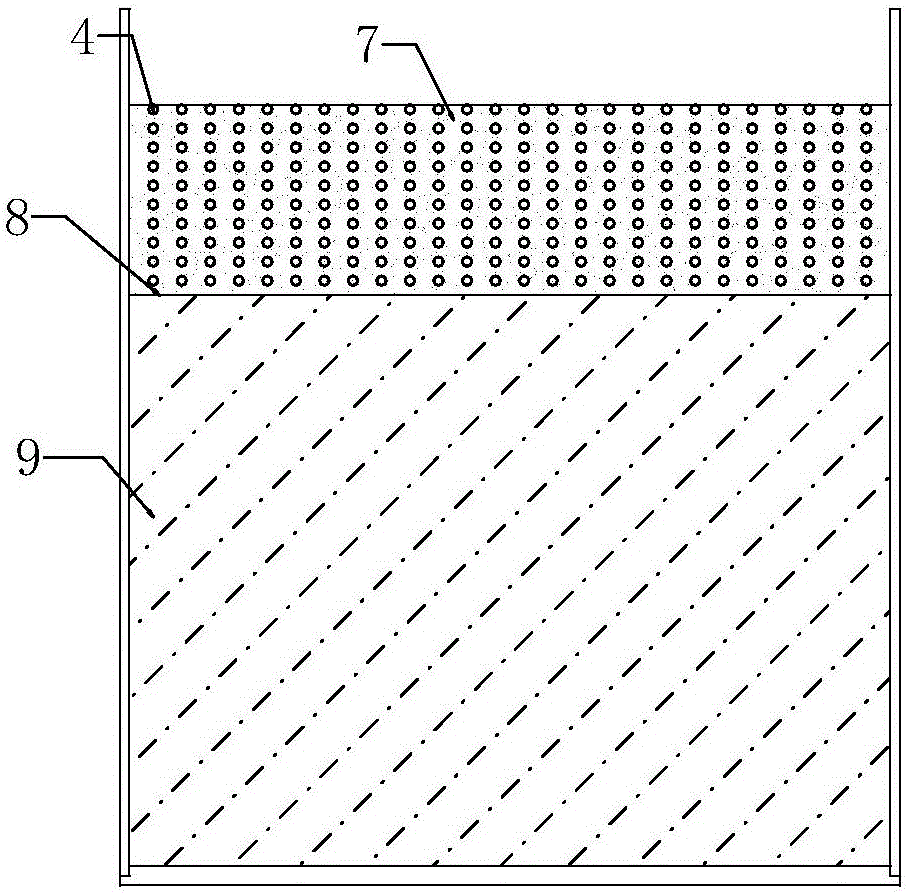

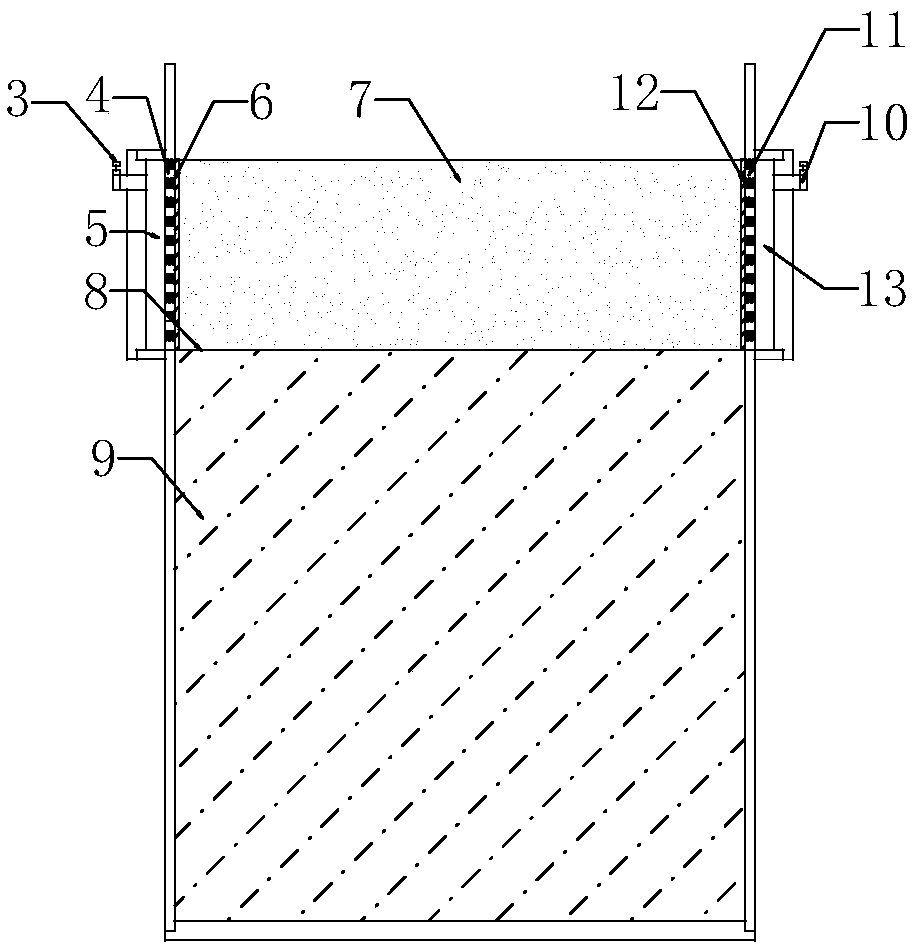

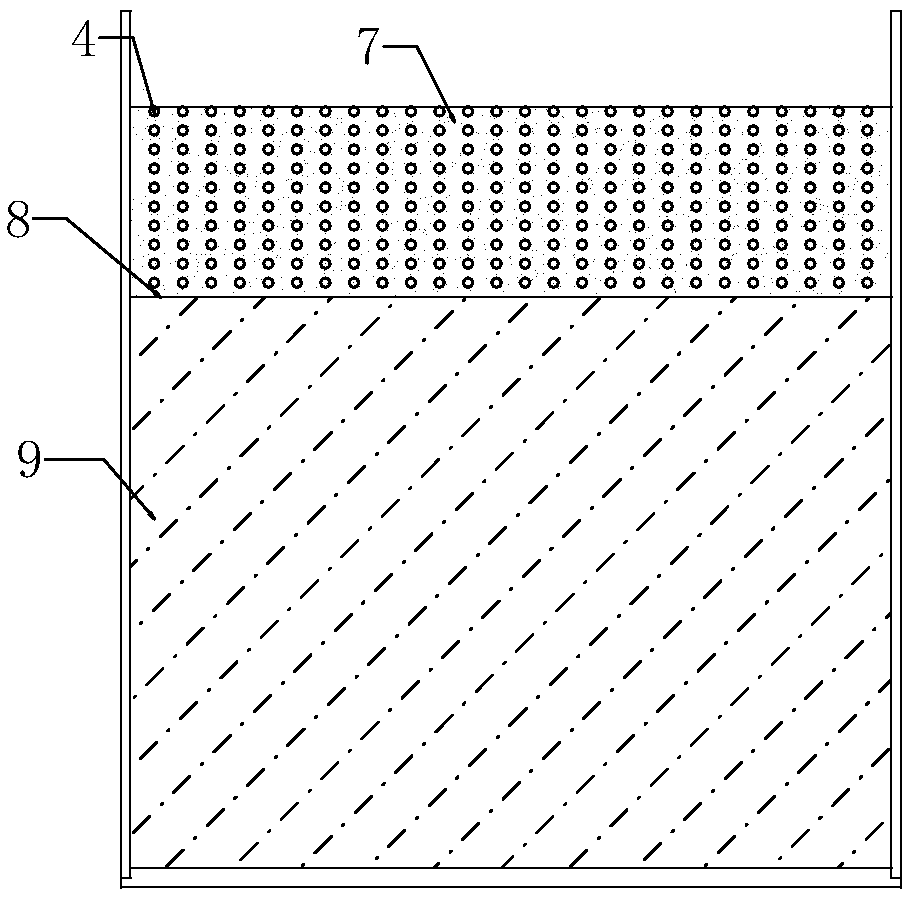

The invention discloses an indoor test method forming an artificial hard shell layer by microbial curing silty-fine sand. Silty-fine sand is paved on slurry which is thick enough, the slurry is separated from the silty-fine sand by a seepage-proofing thin film, liquid is injected into the left side by a liquid injecting peristaltic pump until a sand layer is saturated, liquid on the right side is extracted by a liquid extracting peristaltic pump to form horizontal laminar flow, the flow velocity of liquid injection and extraction is controlled, so that liquid injection and extraction are balanced, and silty-fine sand layers are cemented and cured by MICP (microbial induced calcium carbonate precipitation) technology to form the hard shell layer. The hard shell layer has high rigidity and strength, the carrying capacity of a soft soil foundation can be multiply improved, sand consumption is greatly decreased, the hard shell layer is resistant to liquefaction, and the requirement of basic carrying capacity can be met.

Owner:TIANJIN UNIV

Grinding ball specialized for mine

The invention discloses a grinding ball specialized for a mine. The grinding ball specialized for the mine comprises the following chemical components in percentage by weight: 1.0-2.9 of C, 5.0-11.5 of Cr, 0.3-0.9 of Si, 0.4-0.8 of Mn, no more than 0.8 of W, 0.05-0.20 of Y, no more than 0.08 of S, no more than 0.08 of P and the balance Fe. In the process of casting, yttrium-base heavy rare earth copper modificator with adding amount accounting for 0.1-0.3 of the molten iron. The grinding ball specialized for the mine of the invention is smelted by using a medium frequency electric furnace and casted by using a metal mould; raw materials use high quality steel pig iron and high quality waste steel and are modified by using ferrochrome, ferromanganese and ferrosilicon; after each chemical component in the molten iron reaches the requirement of the grinding ball specialized for the mine, the yttrium-base heavy rare earth copper modificator is directly added into a foundry ladle; and then the molten iron is poured into the metal models to produce the grinding ball specialized for the mine.

Owner:宁国市南洋机械有限公司

Method for producing novel light-weight wall material by mixing coal slag

The invention discloses a method for producing a novel light-weight wall material by mixing coal slag. The coal slag produced by a thermal power plant replaces 20-100% of sand. On the one hand, the consumption of the sand is reduced, the production cost is lowered greatly, resources are saved, waste materials are recycled, and the environmental pollution is relieved. On the other hand, early hydration heat of concrete mixed with the coal slag is reduced, the sulfate resistance of the concrete is improved, and the impermeability has the direct bearing on the carbonization resistance, freezing resistance and erosion resistance of the concrete and further has an important effect on shrinkage and creepage of the concrete. In addition, the coal slag is lighter than the sand, so that the volumetric weight of the concrete mixed with the coal slag is reduced; a wall is light in deadweight; the mounting efficiency is improved; for mechanical properties, compression resistance and a suspension force of the light-weight wall material mixed with the coal slag are greatly higher than those of a light-weight wall material used for construction and produced by mixing no coal slag; and the method has very good economic and social benefits.

Owner:江苏建华新型墙材有限公司

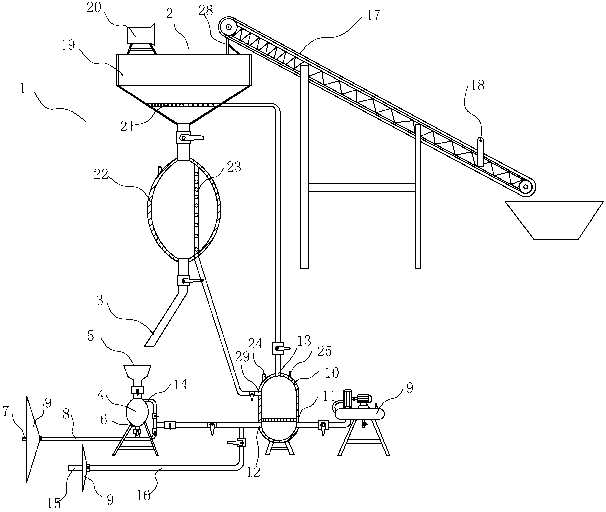

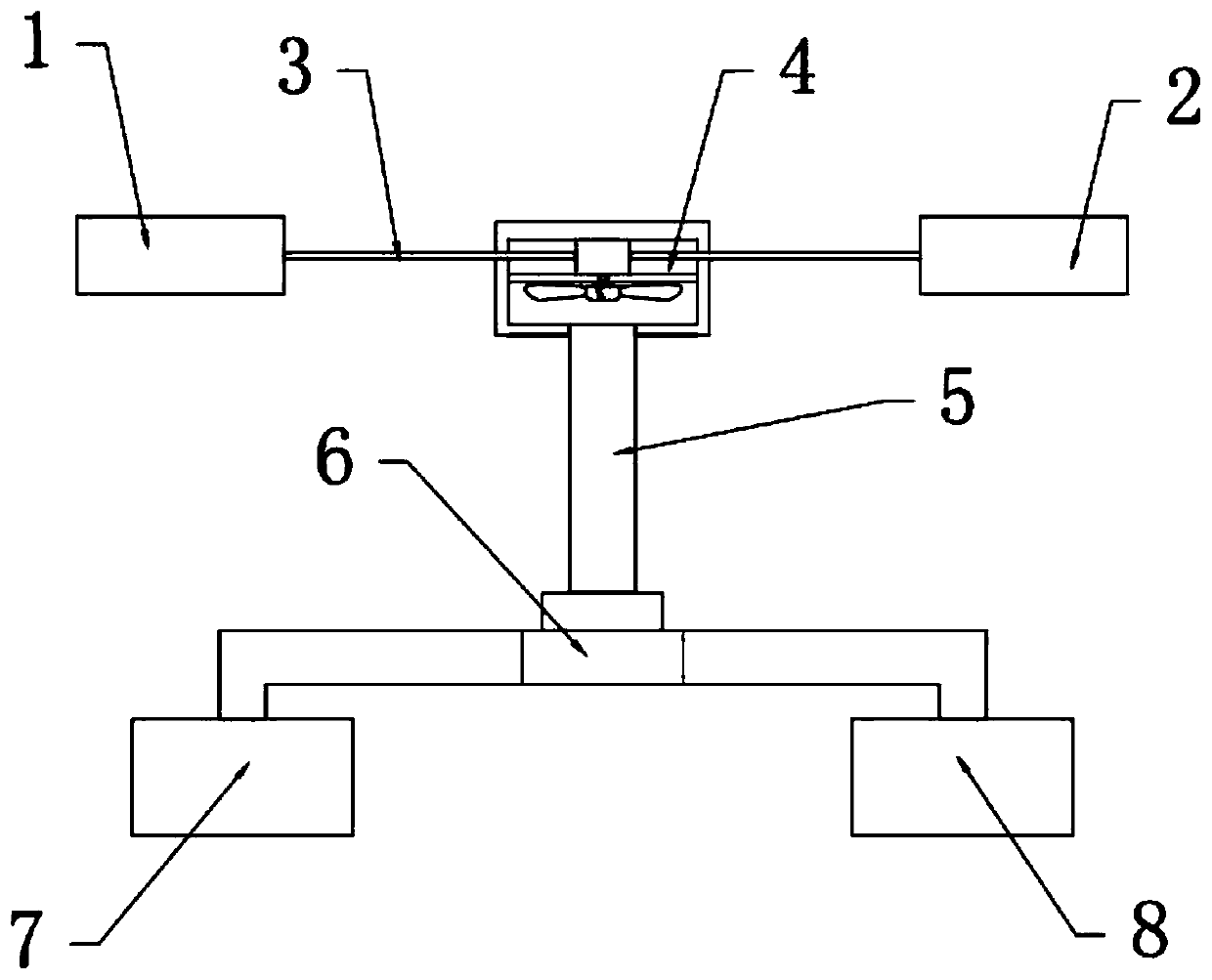

Sand blasting rust removal apparatus

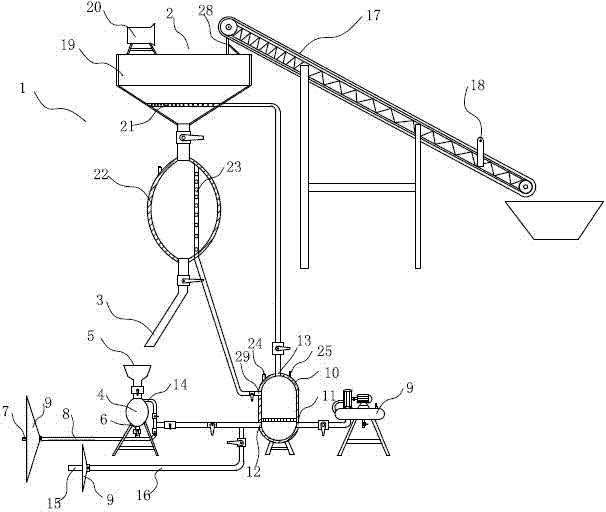

ActiveCN103223641AGood surface effectReduce rustAbrasive machine appurtenancesAbrasive blasting machinesSand blastingDry sand

The present invention discloses a sand blasting rust removal apparatus, which comprises: a wet sand conveying device, a wet sand drying device, a dry sand tank, a sand blasting head, an air compressor, an air heating tank, and a hot air nozzle. During sand blasting rust removal operation, dry sand enters the dry sand tank, air is conveying into the air heating tank through the air compressor to be heat to form high pressure hot air, the dry sand is directly blasted on a steel workpiece under a high pressure hot air effect to carry out rust removal operation, a surface effect of the rust-removed steel workpiece is good, an anticorrosion standard of paints is achieved, the hot air nozzle can directly blow the high pressure hot air to the steel workpiece so as to produce a good rust removal effect and reduce a use amount of the sand, and rust removal can be performed only by using the high pressure hot air without the dry sand if the rust of the workpiece is less. In addition, the surface of the rust-removed workpiece is heated, paint adhesion is strong, and an anticorrosion effect is strong.

Owner:SHANDONG ELECTRIC POWER CONSTR NO 2

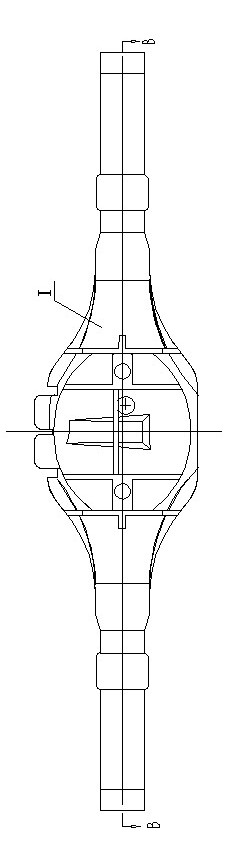

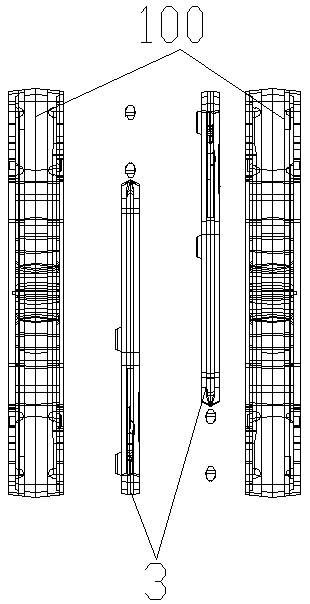

Sand lined metal mold casting method for manufacturing sand core for middle and rear axle castings for automobile

ActiveCN102527945ASmooth exhaustLow gas productionFoundry mouldsMoulding machinesSand castingCasting mold

The invention discloses a sand lined metal mold casting method for manufacturing a sand core for middle and rear axle castings for an automobile. The method is characterized by comprising the following steps of: dividing a middle and rear axle sand core into three sections, namely a left sand core, a middle sand core and a right sand core, and manufacturing the sand cores in a hollow mode respectively; and assembling the three sections of sand cores, forming a through hole in the middles of the three sections of sand cores, arranging a steel pipe of which the diameter is matched with that of the through hole in the through hole, forming a plurality of air vents on the steel pipe, and assembling the steel pipe and the three sections of sand cores to form a whole sand core. Therefore, in the process of pouring the castings, gases generated in the sand core can be discharged into the steel pipe through the air vents, are introduced to a sand core head through the steel pipe, pass througha gap between the sand core head and a casting mold and are smoothly discharged out of the casting mold. The method can be used for producing middle and rear axle castings through sand lined metal mold casting and also can be used for common sand casting production and resin sand casting production.

Owner:浙江省机电设计研究院有限公司

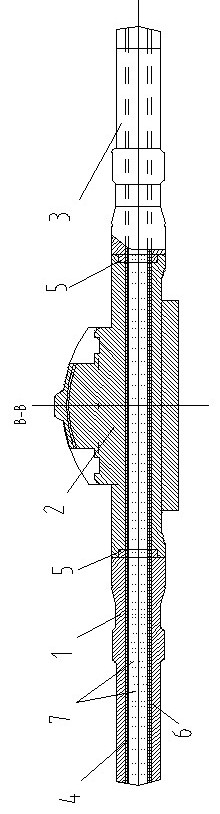

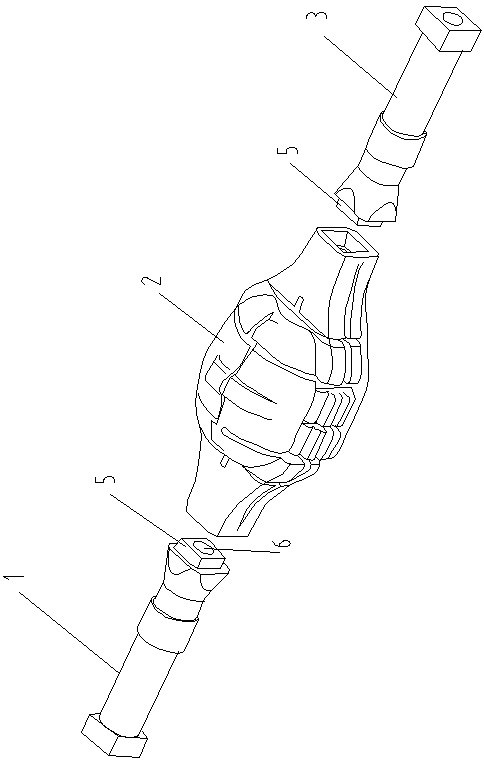

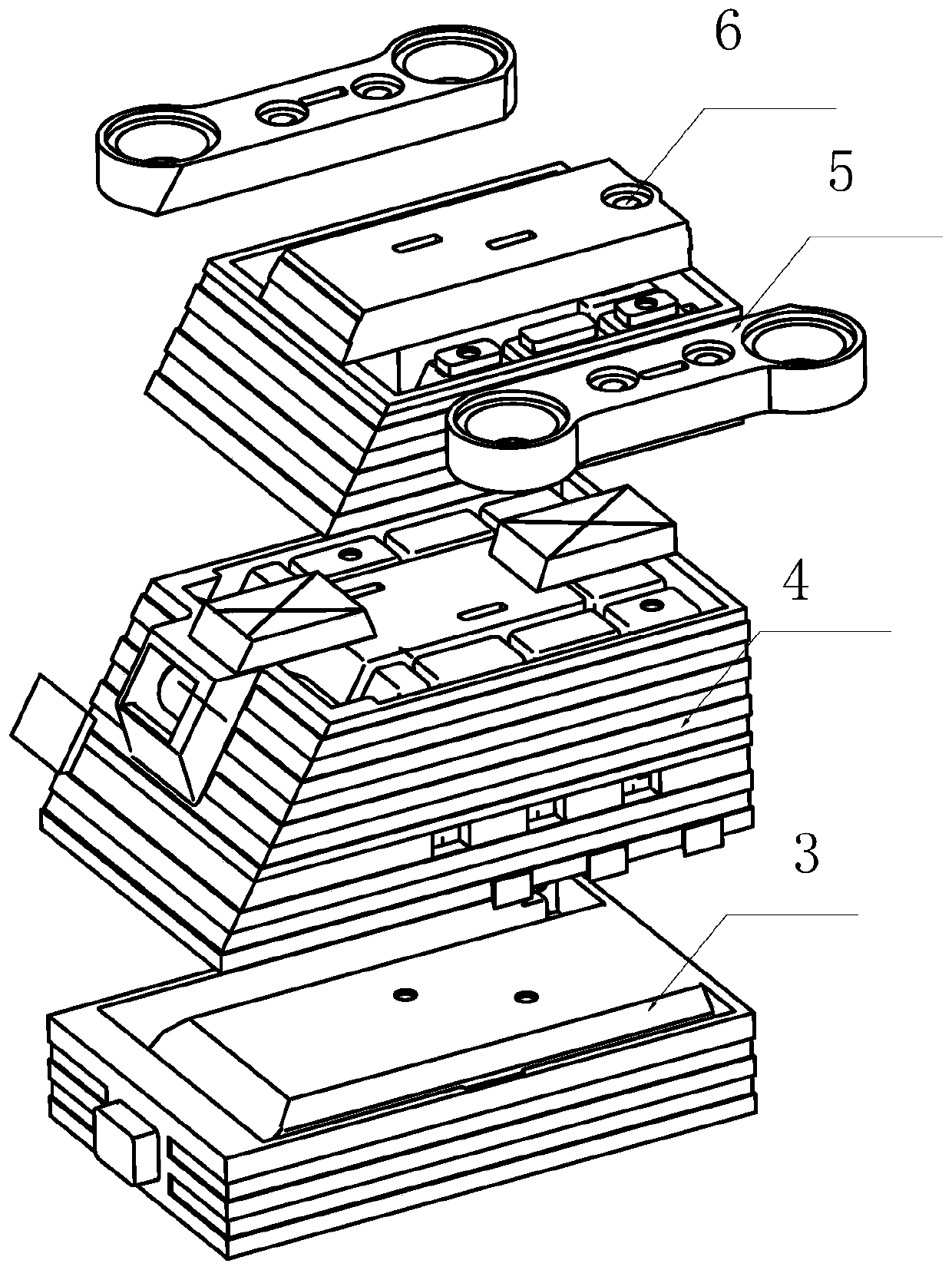

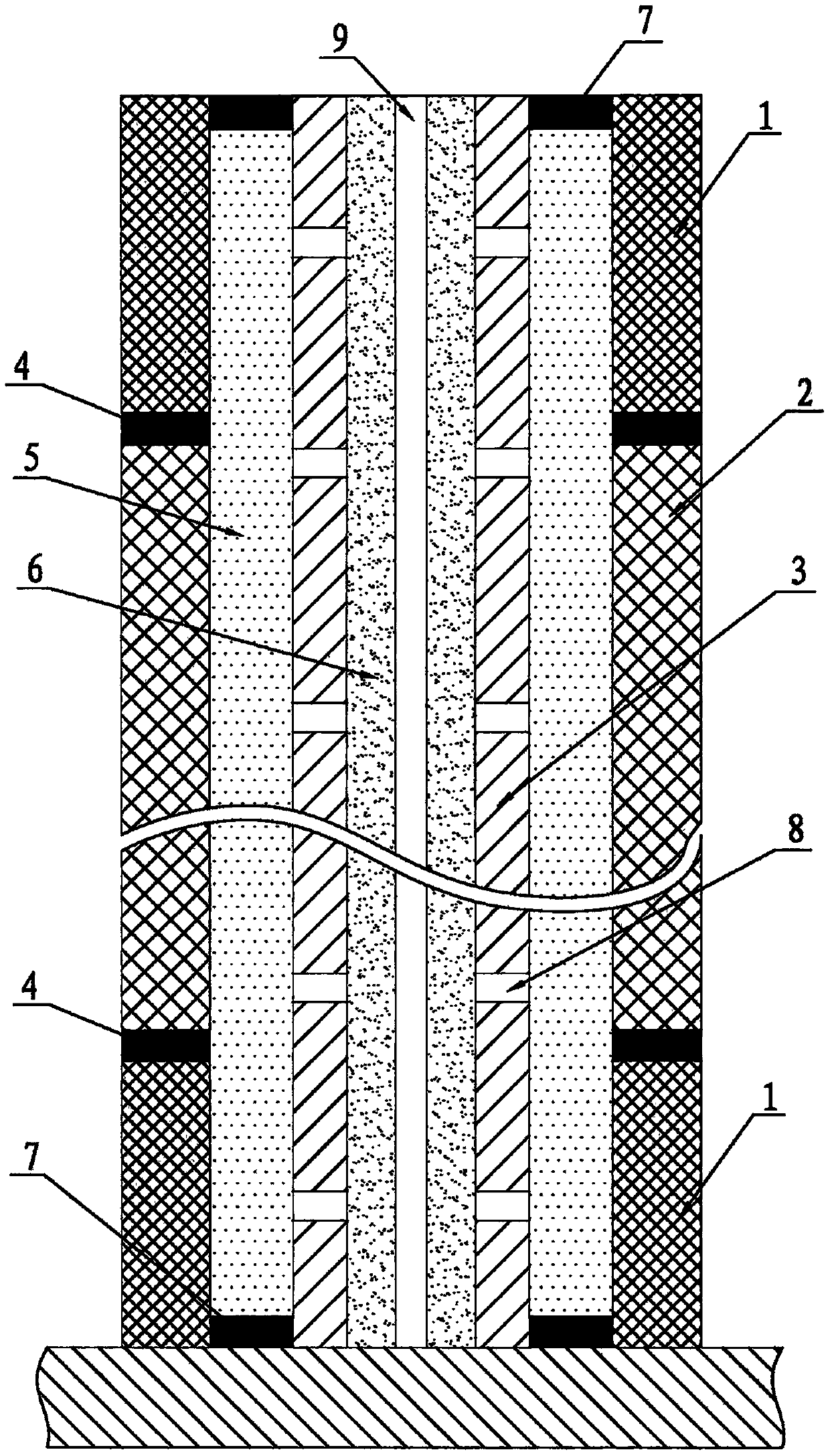

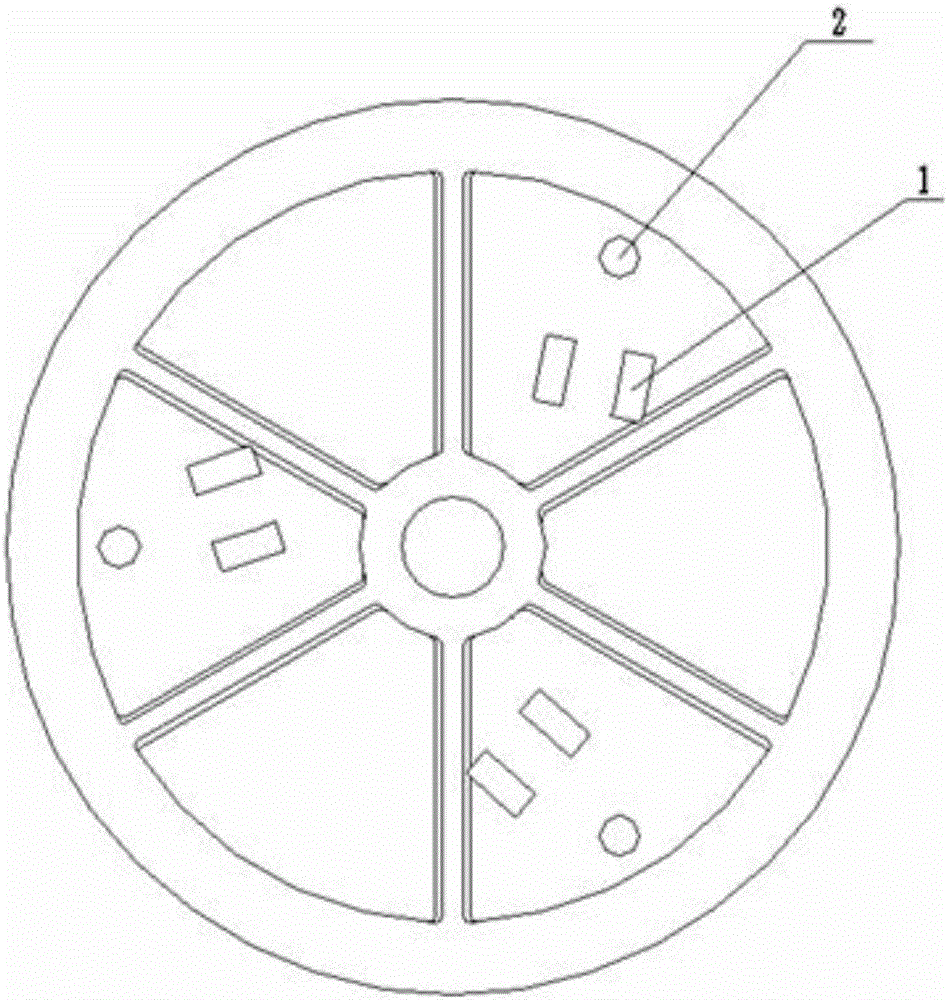

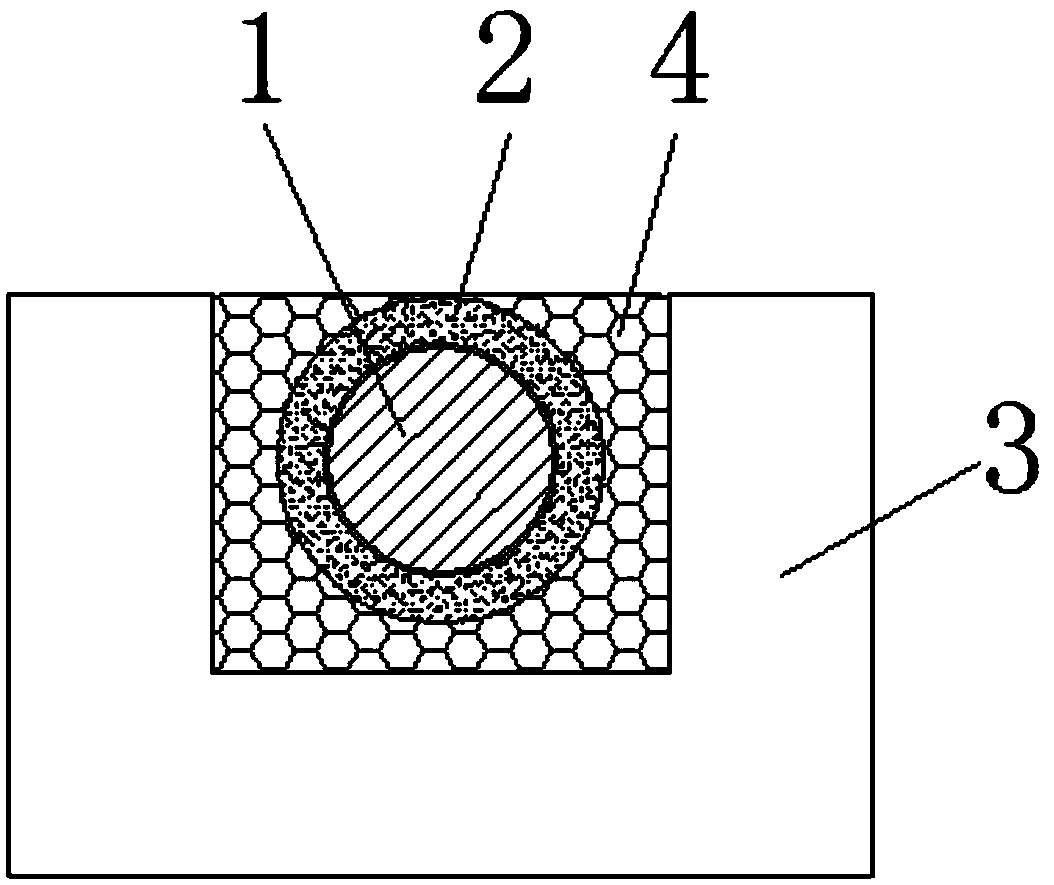

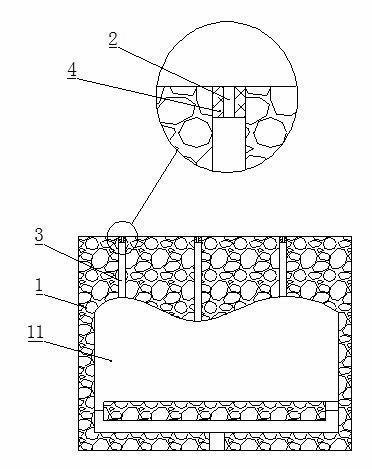

Sand core used for sand casting and preparing method thereof

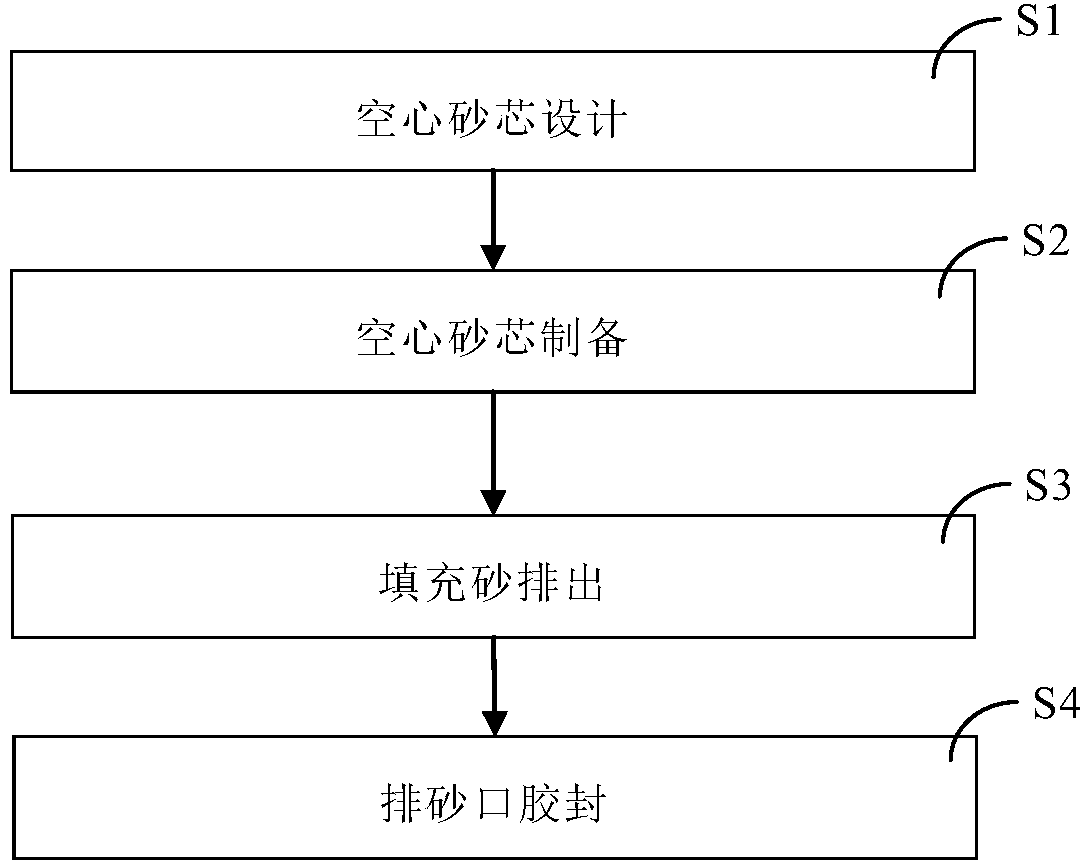

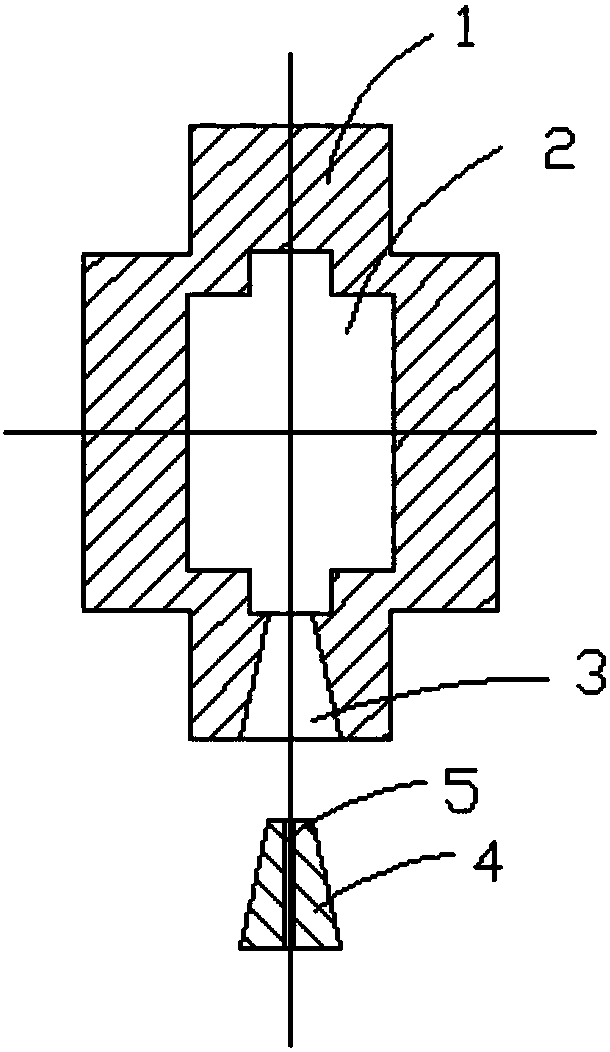

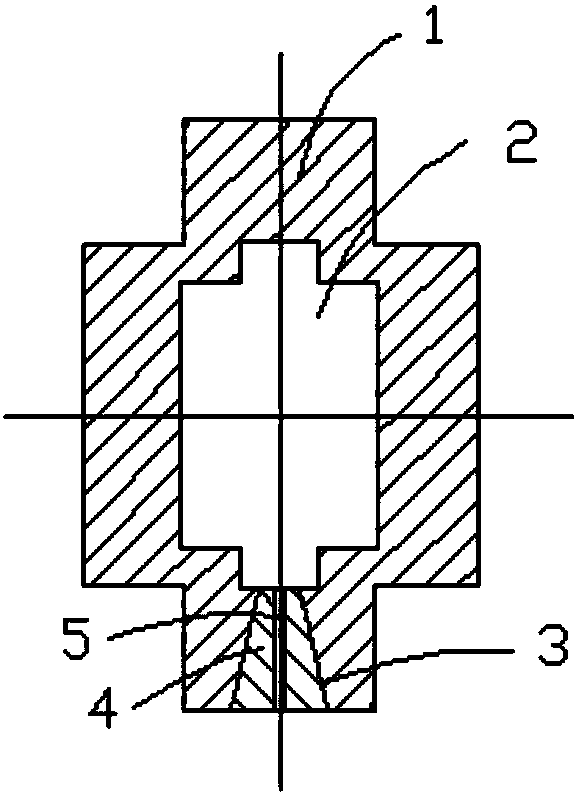

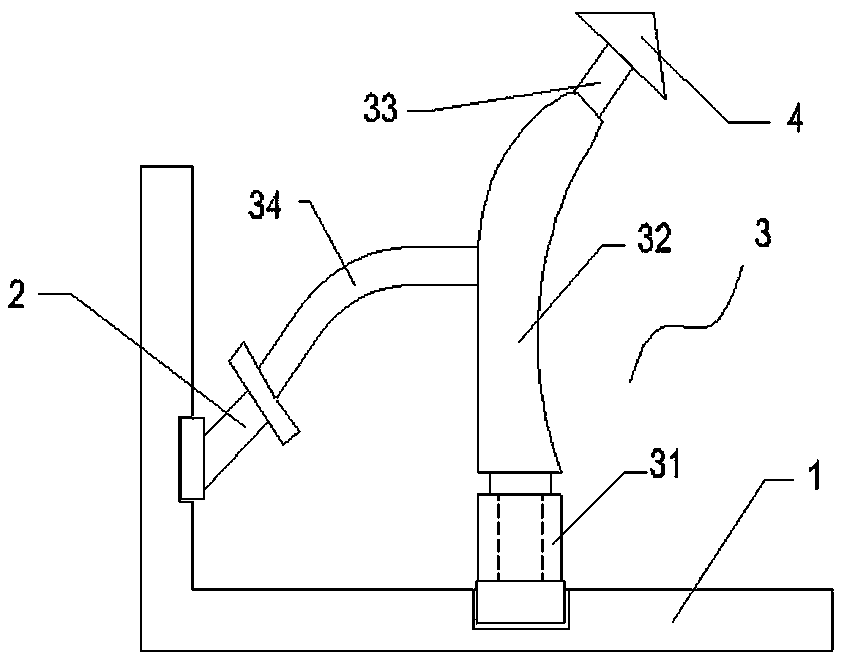

PendingCN110625071AReduce casting costsReduce the amount of sand usedAdditive manufacturing apparatusFoundry mouldsPistonSand casting

The invention discloses a sand core used for sand casting and a preparing method thereof. The method comprises the following steps of S1, sand core (1) design; S2, sand core (1) preparing; S3, fillersand discharging and S4, glue sealing of a sand discharging opening (3). A cavity (2) is formed in the sand core (1), the sand discharging opening (3) is formed in one end of the sand core (1), a sanddischarging piston (4) is arranged on the sand discharging opening (3), and an exhaust hole (5) is formed in the sand discharging piston (4). According to the preparing method of the sand core used for sand casting, the use amount of moulding sand and resin can be greatly reduced, the resin gas volume is reduced, the decoring and sand shakeout efficiency can be improved, the regeneration efficiency of a used sand machine is improved, resource consumption, waste discharge and cost are reduced, production efficiency of the casting can be improved, and the feasible technology and method of greencasting is achieved.

Owner:北京瑞泓翔宏大科技发展有限公司

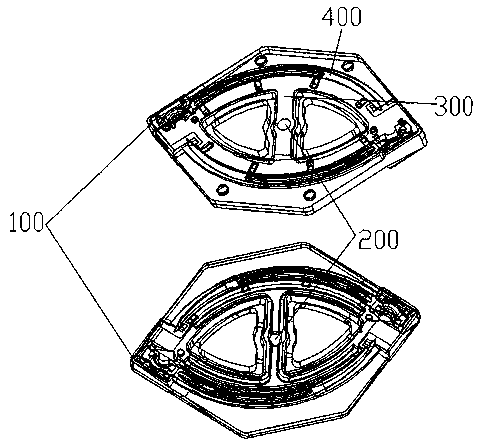

Pouring sand mould of arc needles for pasture collection machinery and pouring method

PendingCN109261896AReduce thicknessReduce sand ratioFoundry mouldsFoundry coresPastureMaterials science

The invention provides a pouring sand mould of arc needles for pasture collection machinery and a pouring method. The pouring sand mould includes an upper shell body, a lower shell body and core assemblies; the upper shell body is of an arc structure, and a first straight pouring gate is formed in the arc structure and is communicated with a pouring cup for storing pouring liquid; the lower shellbody is of an arc structure matched with the upper shell body, and a second main pouring gate penetrating through the upper and lower ends of the lower shell body is formed in the portion, corresponding to the first straight pouring gate, of the lower shell body; after the upper shell body and the lower shell body are buckled, at least one first mould cavity is formed, the mould cavities are in arc shapes, the first straight pouring gate and the second straight pouring gate are both communicated with the mould cavities, and after the mould cavities are subjected to pouring, arc needle castingsare formed; the core assemblies are arranged inside the mould cavities and are used for assisting the mould cavities in forming the arc needle castings. According to the pouring sand mould of the arcneedles for the pasture collection machinery and the pouring method, the sand mould is changed into a shell type from an overlapping type; an allowance gate is additionally formed, during pouring, sand consumption is reduced, and the finished product rate is increased.

Owner:西安合力汽车配件有限公司

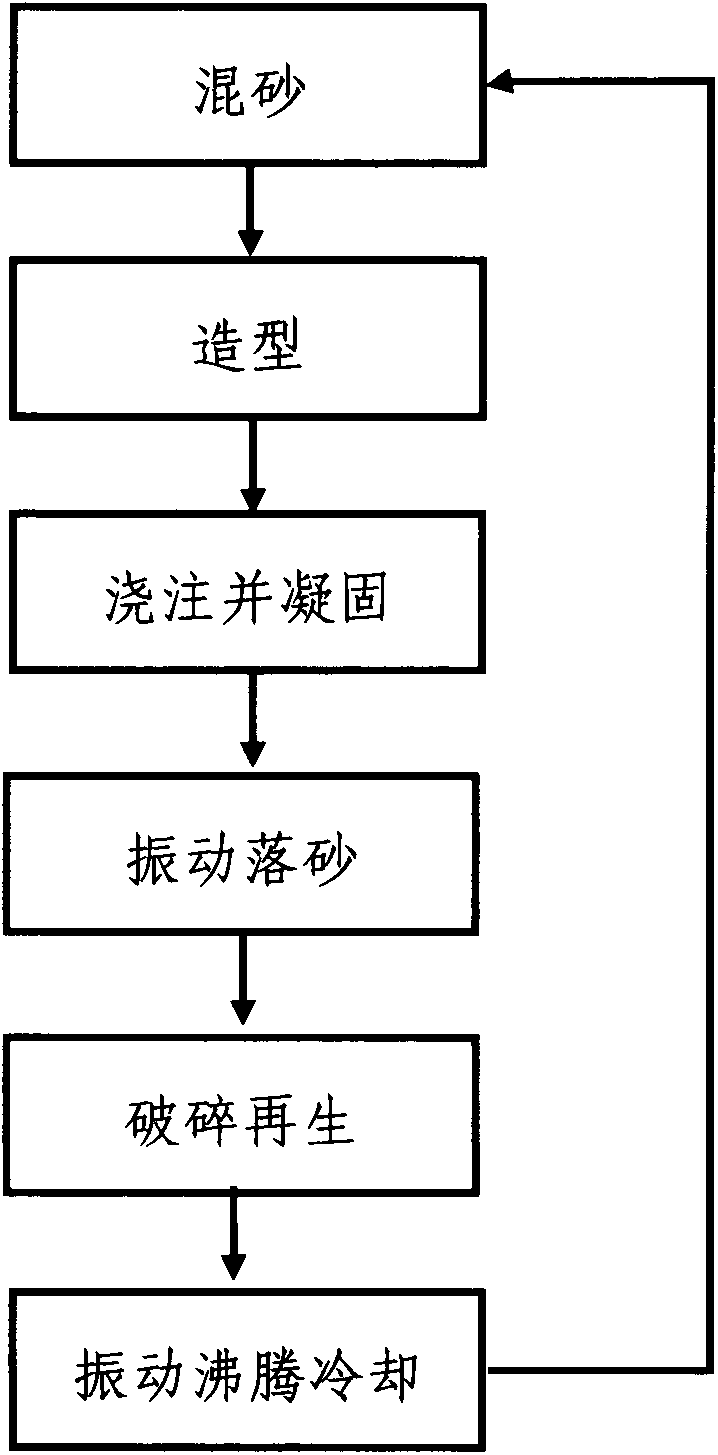

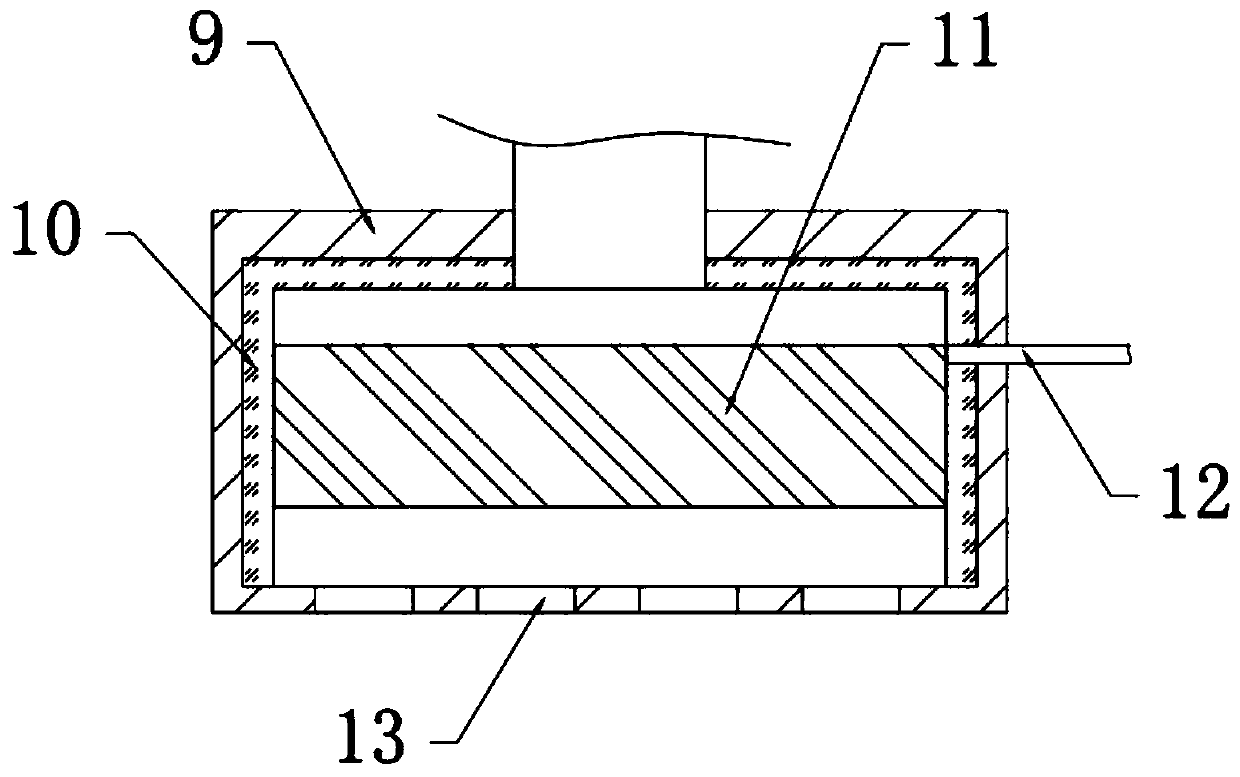

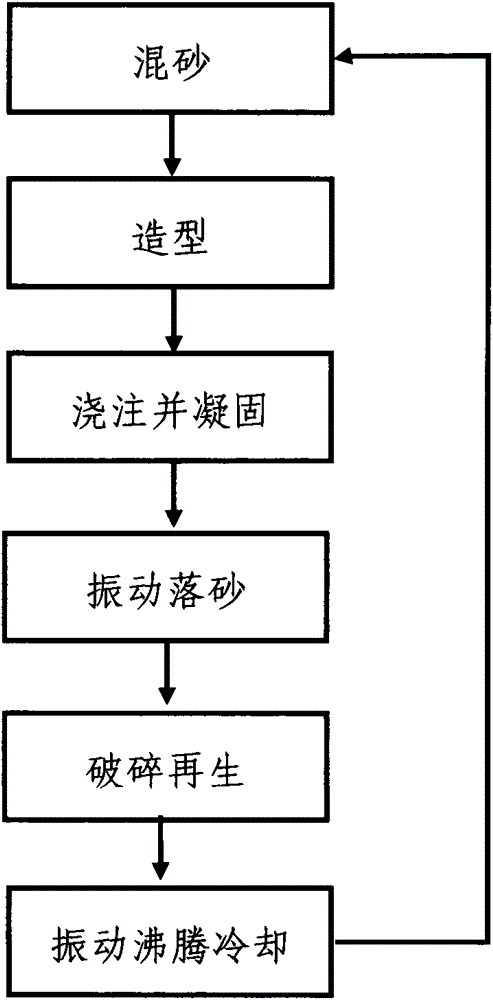

Glass bottle die casting piece manufacturing process cyclically using molding sand

ActiveCN103817287AHigh strengthImprove impact resistanceFoundry mouldsMould handling/dressing devicesDie castingBreakage rate

The invention discloses a glass bottle die casting piece manufacturing process cyclically using molding sand. According to the invention, a manufactured glass bottle die casting piece has an accurate size and no subcutaneous blowholes; sand discharging of castings is convenient after molding, used sand can be regenerated and reused and has a low breakage rate and small loss in the process of regeneration of the used sand, and the reuse rate of the used sand is high; the process produces little dust, little pollution and no phenol and formaldehyde.

Owner:CHANGSHU WEIHENG MOLD MFG

Method for producing sand coated iron mould of steel casting

InactiveCN107042284AFine granularityHigh dimensional accuracyFoundry mouldsFoundry coresSurface finishFoundry

The invention discloses a method for producing a sand coated iron mould of a steel casting. The method is used for manufacturing of the complex steel casting. The method comprises the steps of manufacturing a coated sand core and upper and lower sand coated iron mould models for casting casting; putting internal chillers in the coated sand core and the upper and lower sand coated iron mould models; putting the coated sand core into the upper and lower sand coated iron mould models; carrying out model assembly and pouring; and turning a box to take out the casting. According to the method, the characteristic that a sand shell does not separate from the iron mould models is applied, chilling points are manually controlled through controlling thickness of the iron mould and the sand shell, the sand shell does not deform, a pouring system can be simplified, shrinkage cavities, heat cracks and other casting defects of the multi-hot spot complex steel casting are eliminated, inherent quality of the casting is dense, size precision of the casting is high, surface finish is close to that of precision casting, the casting is uniform and consistent and free of flash and burr, the deformation amount is low, the qualification rate of a casting product is greatly increased, the utilization amount of coated sand can be greatly decreased, the method has the obvious advantages that less casting sand is utilized and energy consumption is low, energy consumption during the mould manufacturing process and exhaust and waste residue discharge during the casting process are reduced, the working environment can be greatly improved, and labor intensity is reduced.

Owner:襄阳金德合金磨料有限公司

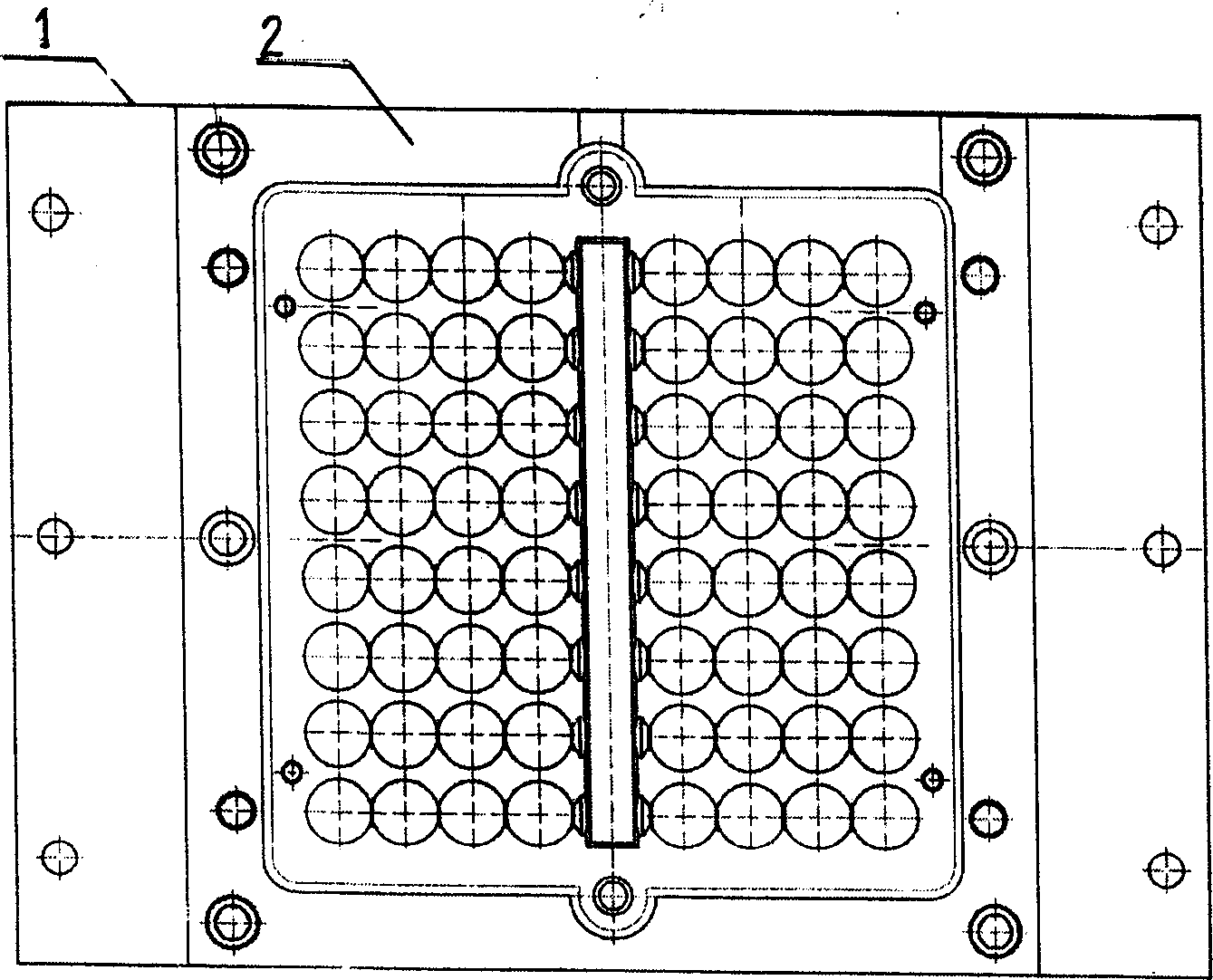

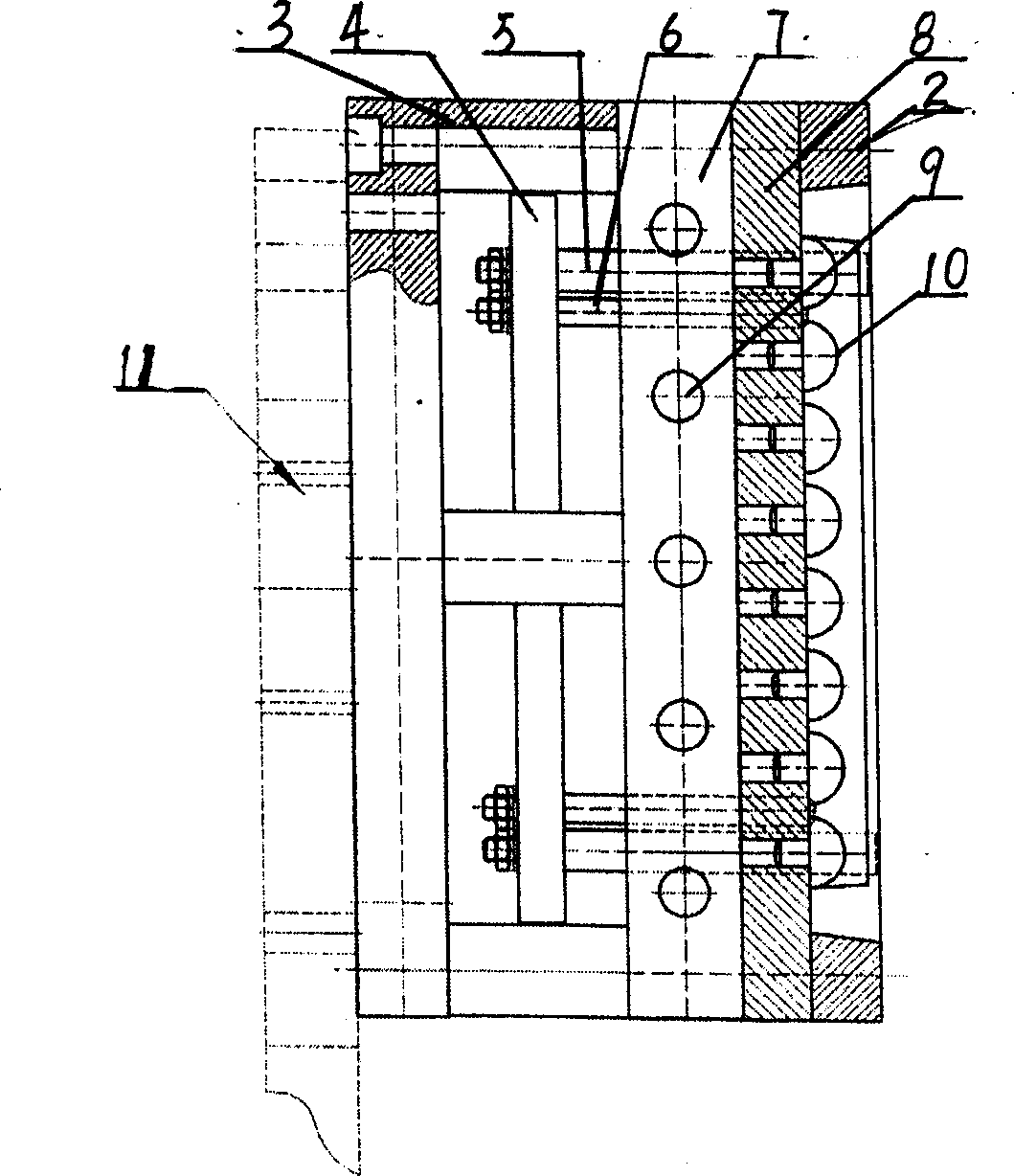

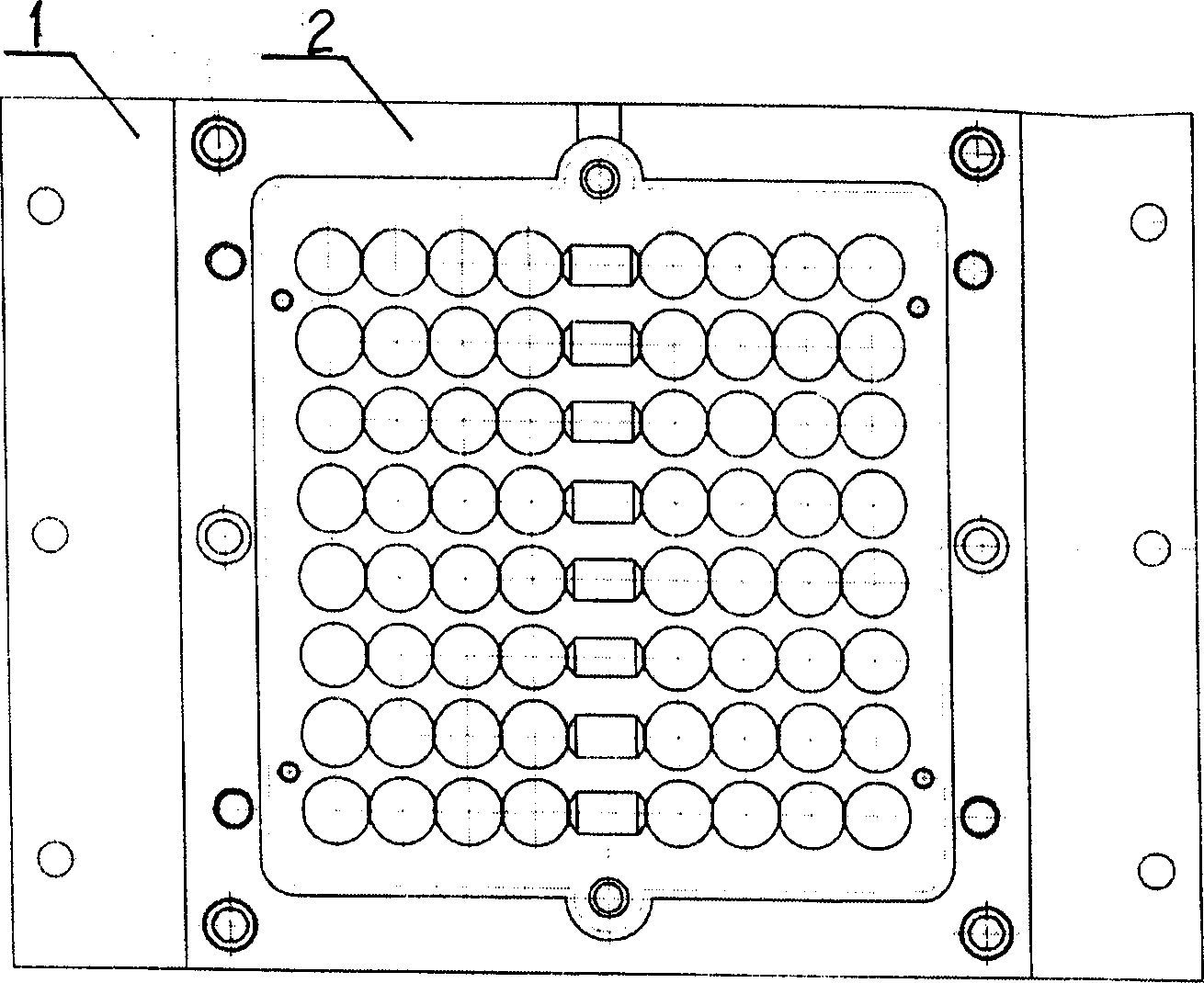

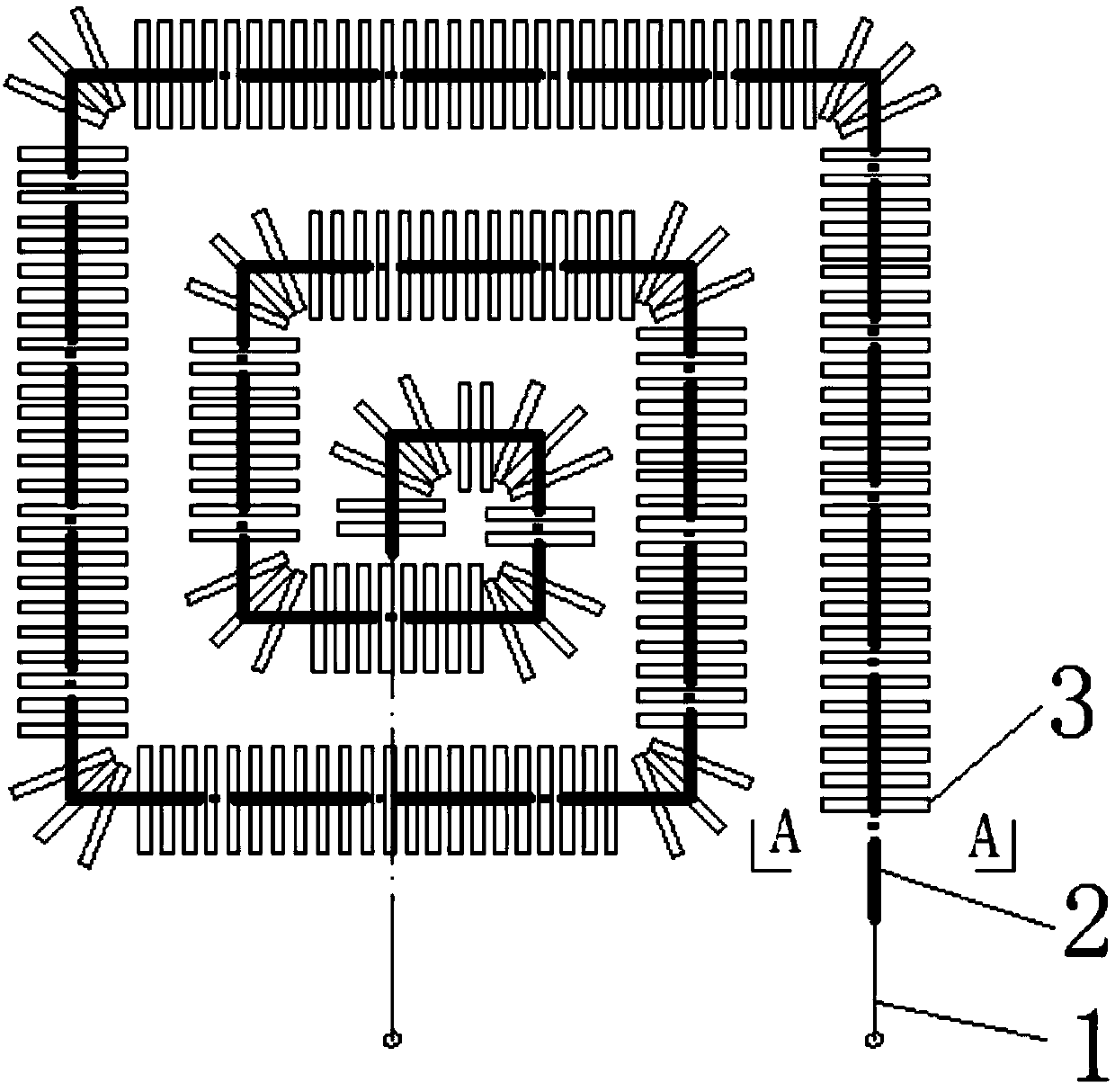

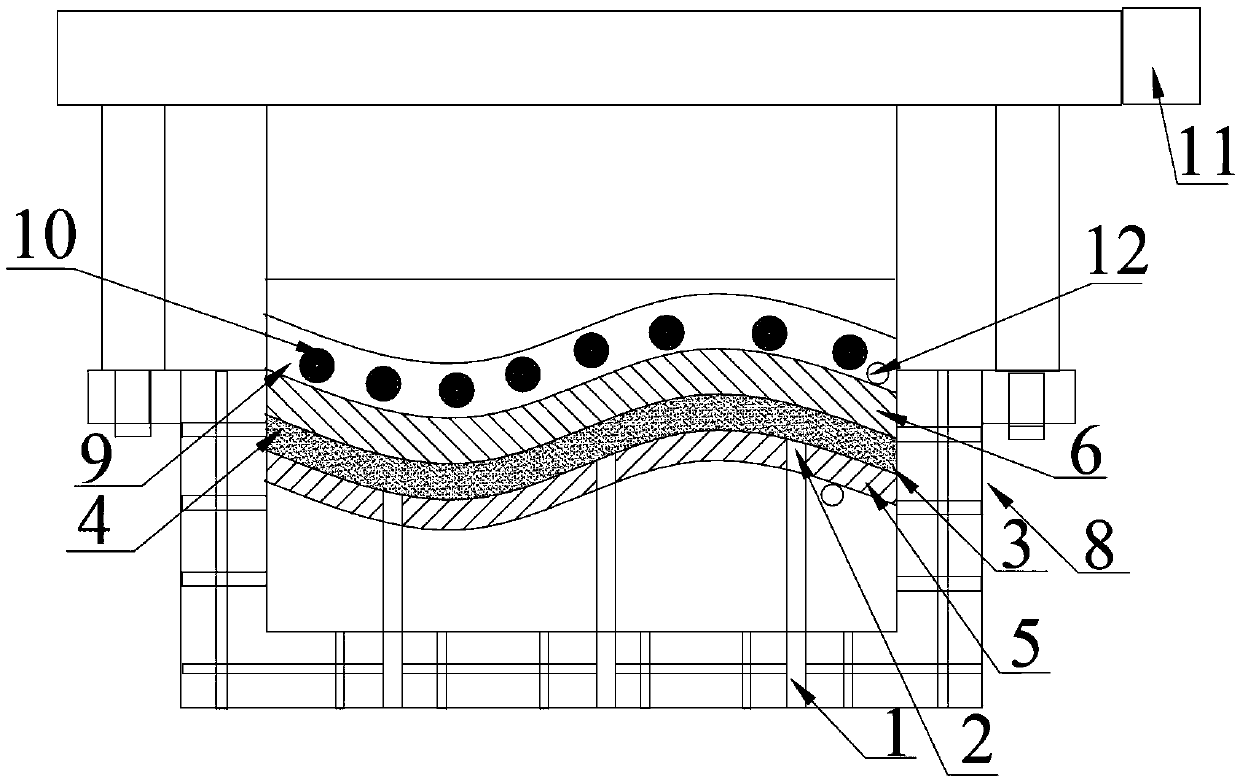

Stack cast ball and cast forging mould of production line

InactiveCN1748903AImprove product qualityImprove the authenticity rateFoundry mouldsFoundry coresElectric heatingManufacturing line

The casting mold includes upper mold and lower mold, and each of the upper mold and lower mold includes movable mold and static mold. The movable mold includes fixing board on the movable mold plate, electric heating board on the fixing board, mold board combination on the heating board, sand box on the mold board combination with sand jetting port, and casting ball or casting-forging mold fixed on the mold board combination. The static mold includes fixing board on the static mold plate, electric heating board on the fixing board, and base board on the heating board. The assembled movable mold and static mold are fixed directly mold jetting machine, sand is jetted into the closed mold via the sand jetting port to form sand mold with the sand box-mold board combination, and after heating to cure with the heating board, open the mold. The present invention has laminated sand molds and results in high casting quality, high production efficiency, low labor strength and low casting cost.

Owner:姜庆志

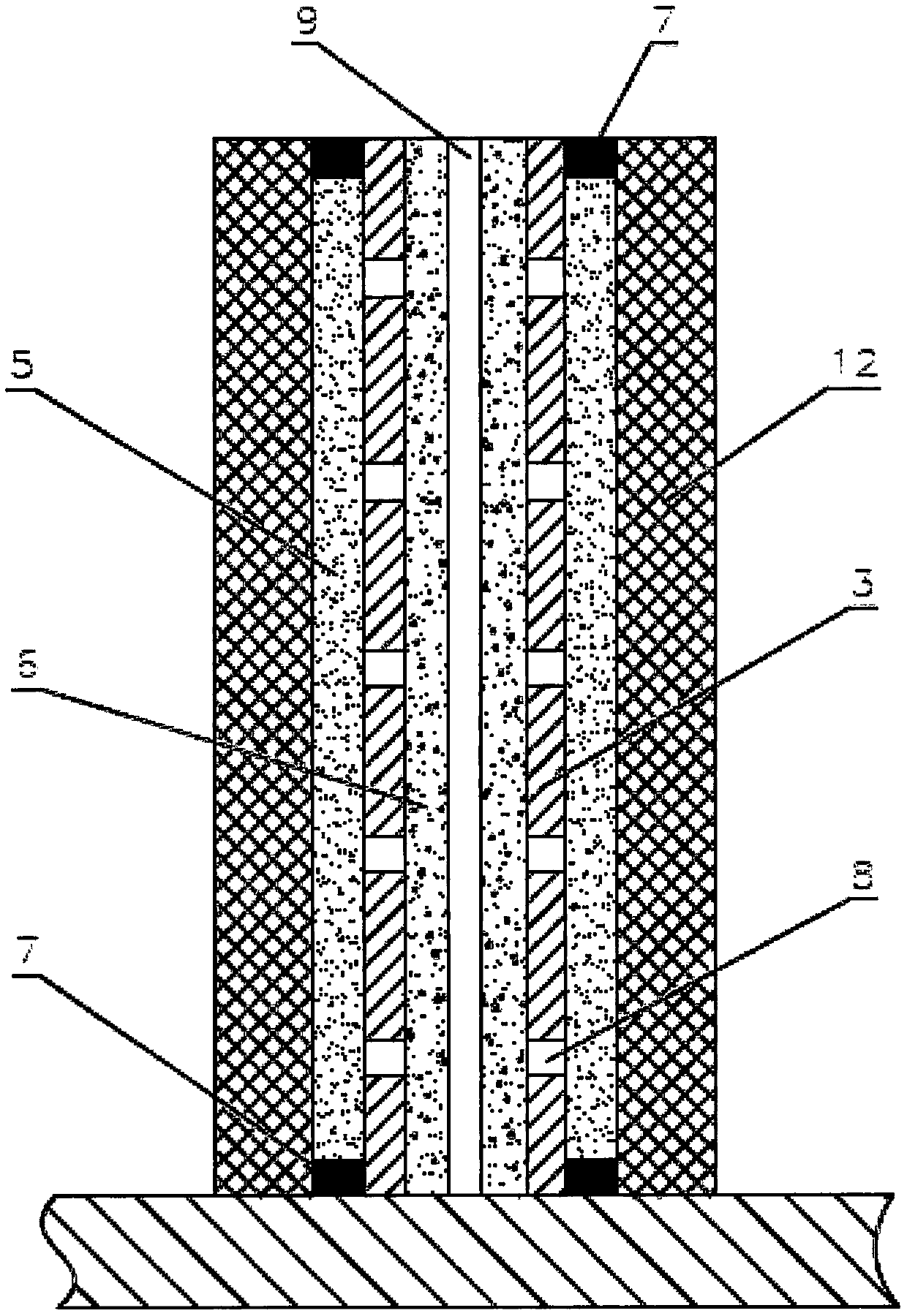

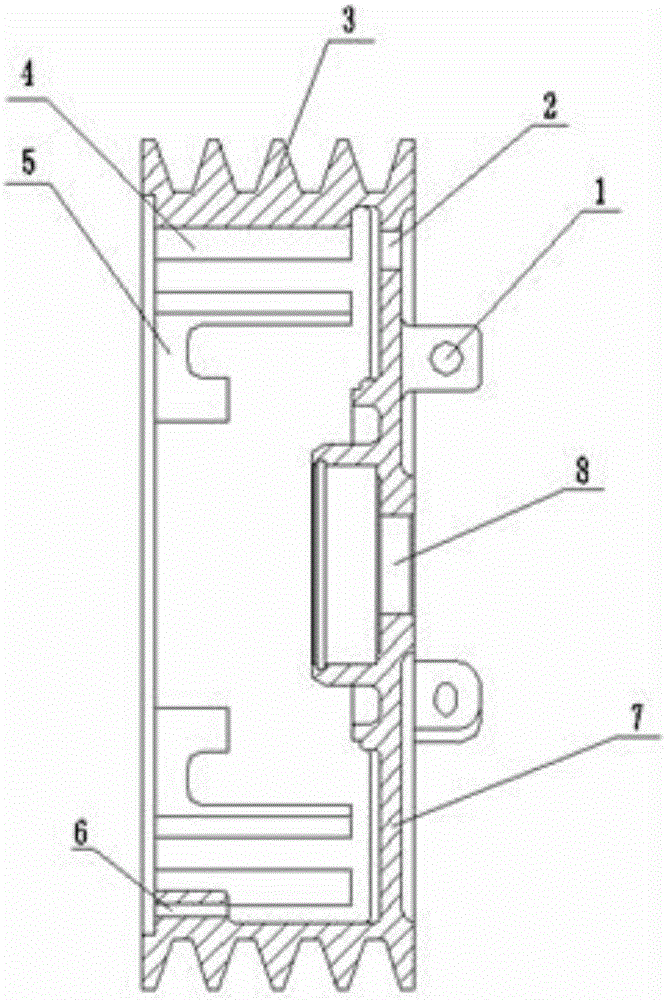

Chain wheel sand mould and method for pouring chain wheel by using chain wheel sand mould

PendingCN109332585AReduce one processImprove work efficiencyFoundry mouldsFoundry coresEngineeringSprocket

The invention discloses a chain wheel sand mould and a method for pouring a chain wheel by using the chain wheel sand mould. The chain wheel sand mould comprises an upper shell, a lower shell and a sand core, wherein the middle portion of the upper shell is provided with a first middle hole, the upper shell is provided with an annular protrusion, a pouring ring is formed between the annular protrusion and the edge of the upper shell, the annular protrusion is provided with a first pouring channel, and the side of the upper shell is provided with a first sprue communicating with the pouring ring; the middle portion of the lower shell is provided with a second middle hole, the upper and lower surfaces of the second middle hole are provided with a first pouring cavity and a second pouring cavity correspondingly, and the position, corresponding to the first sprue, of the side of the lower shell is provided with a second sprue communicating with the second middle hole; the end of the secondpouring cavity is closed, and the lower shell is provided with a second pouring channel; the sand core is arranged on the annular protrusion in a sleeving manner; and the inner wall of the sand coreis provided with a gear cavity.

Owner:西安合力汽车配件有限公司

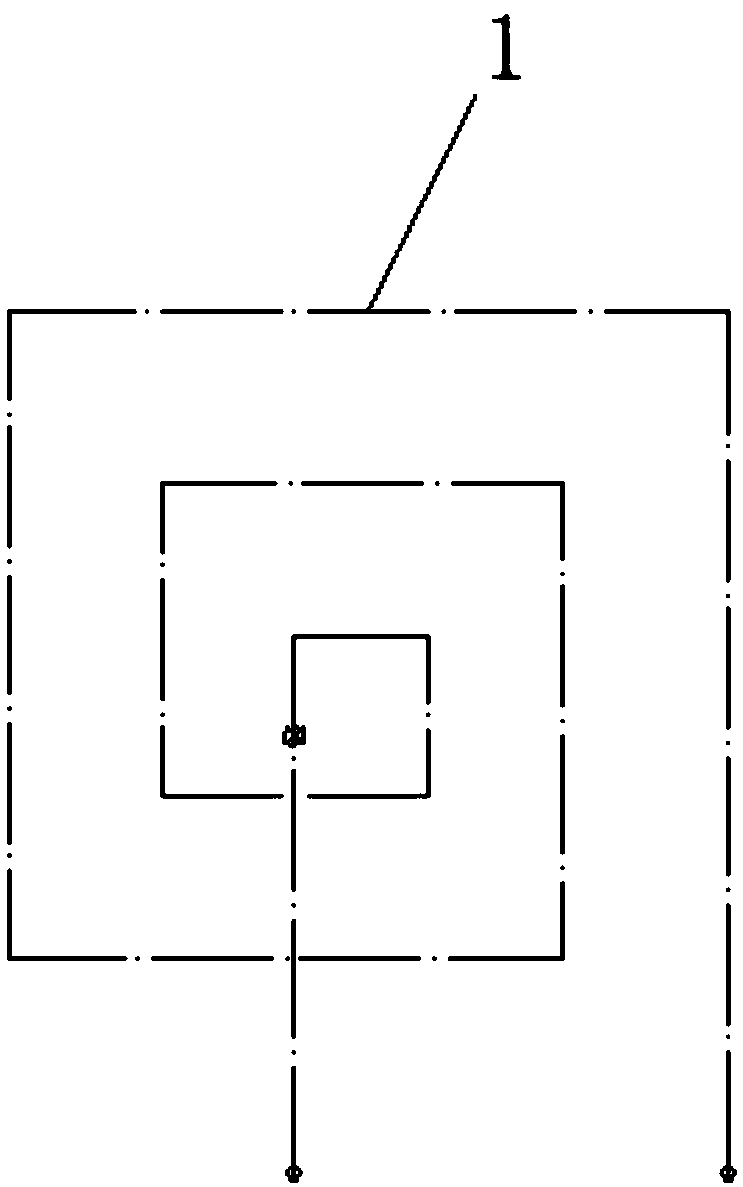

Forming method of combined sand core

ActiveCN111496192ASimplify core assembly processFast preparationAdditive manufacturing apparatusFoundry mouldsStructural engineeringMechanical engineering

The invention provides a forming method of a combined sand core. The forming method comprises the following steps of forming a complex structure by 3D printing, forming an outer contour by using a manual sand core, and splitting an inner cavity core of an inner part of a casting as an integral inner cavity sand core; splitting the highest surface and the lowest surface of an outer sand core alongthe outer contour of the casting; splitting the sand core by 3D printing to form a 3D sand core and placing a core box frame on the outer side; burying resin sand in hollow parts of the core box frameand the 3D sand core, and transferring a lower core to assemble the core through a hoisting and conveying structure arranged on the outer contour after hardening; determining a position relationshipbetween the inner cavity cores through a matched concave-convex positioning structure, wherein the inner cavity sand cores are connected to the outer sand cover through a square door structure; arranging a pouring system; and after mold assembling, carrying out pouring after being fastened by a clamping mechanism. The forming method has the characteristic of fast manufacturing. The forming methodis of significant meaning in developing a product quickly and lowering the cost without a conventional wooden die, the sand use amount of a single product is reduced greatly, the ability of a 3D formed casting is improved, the core splitting and assembling process of the casting is simplified, the cost is saved, and the casting quality is improved.

Owner:KOCEL EQUIP

Rail surface air drying machine

InactiveCN110525455AAvoid idlingImprove operational efficiencyRailway cleaningLocomotivesEngineeringSnow

The invention relates to the technical field of train accessory machinery, particularly to a rail surface air drying machine, which includes a first switch and a second switch, wherein both the firstswitch and the second switch are electrically connected with a fan through wires; an air outlet pipe is fixedly connected with the output end of the fan, and the other end of the air outlet pipe is fixedly connected with two position change-over switches; the output ends on the two sides of the two position change-over switches are respectively connected with a first heater case and a second heater case through pipelines. According to the invention, through arranging the fan and the heater cases, the rail surface is changed to be dry and clean to enable the engine in traction to be in a stableand steady running speed without being affected by rain and snow and unclean steel rain surface, as a result, the running speed is improved, idle sliding of the engine is avoided, and running behindschedule and slope stopping and slowing down are fundamentally avoided.

Owner:丁红卫

Sand-mold molding method for water turbine blade

ActiveCN106607559AReduce usageReduce manufacturing difficultyFoundry mouldsFoundry coresWater turbineAerospace engineering

A sand-mold molding method for a water turbine blade includes the following steps of model manufacturing, molding with the model, box closing and box erecting. By means of the sand-mold molding method for the water turbine blade, the sand consumption can be lowered, the production cost can be reduced, and the molding production cycle can be shortened.

Owner:KOCEL STEEL

Manufacturing process of glass bottle mold castings with recyclable molding sand

ActiveCN103817287BHigh strengthImprove impact resistanceFoundry mouldsMould handling/dressing devicesDie castingBreakage rate

The invention discloses a glass bottle die casting piece manufacturing process cyclically using molding sand. According to the invention, a manufactured glass bottle die casting piece has an accurate size and no subcutaneous blowholes; sand discharging of castings is convenient after molding, used sand can be regenerated and reused and has a low breakage rate and small loss in the process of regeneration of the used sand, and the reuse rate of the used sand is high; the process produces little dust, little pollution and no phenol and formaldehyde.

Owner:CHANGSHU WEIHENG MOLD MFG

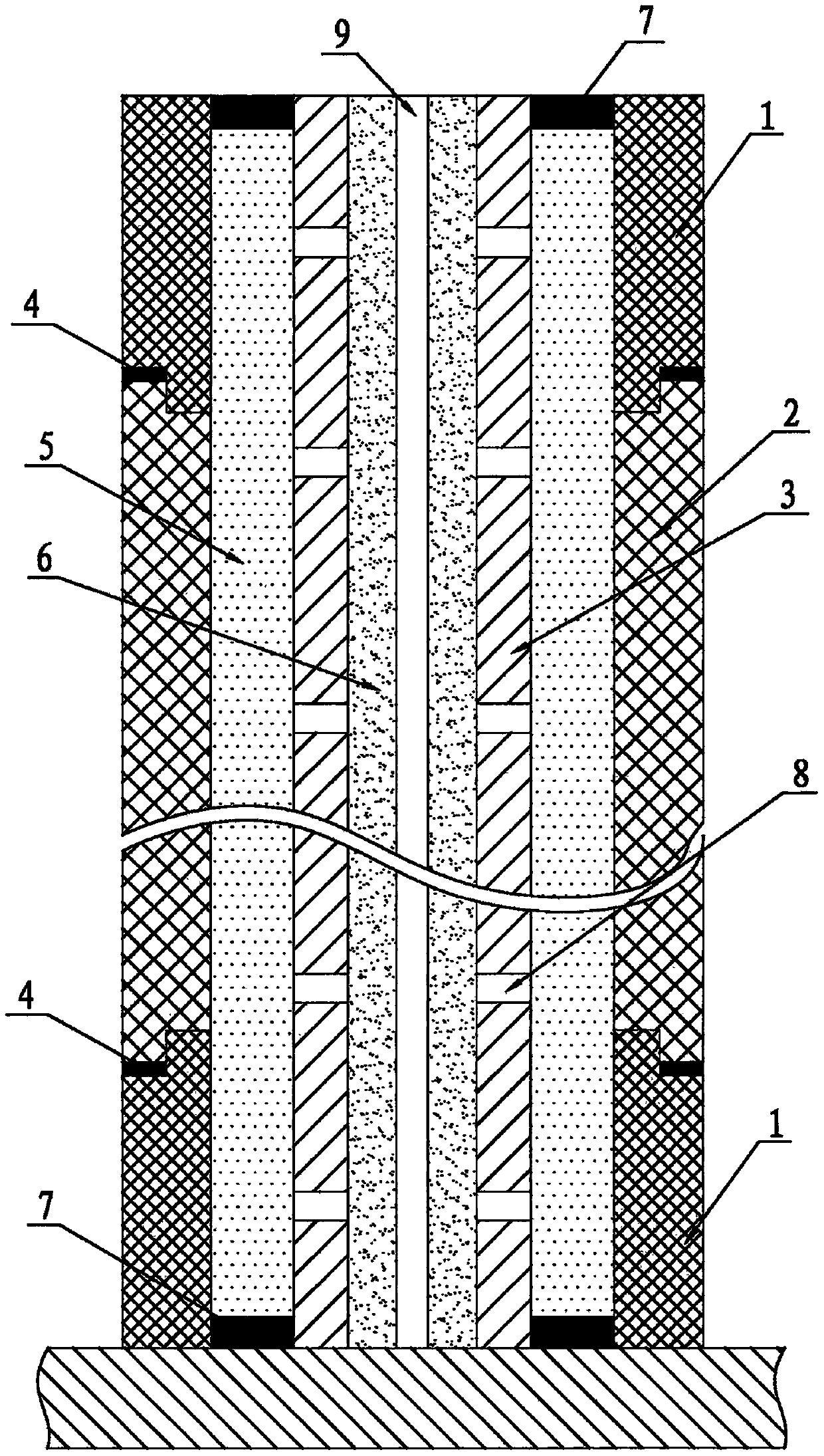

Casting long and thin hole forming sand core structure

InactiveCN109954838AGuarantee the shape qualityReduced dimensional accuracyFoundry mouldsFoundry coresButt jointSteel tube

The invention discloses a casting long and thin hole forming sand core structure. End portion fireproof casing pipes, a transition fireproof casing pipe, a process steel pipe, a casing pipe bonding resin layer, an outer sand core layer, an inner sand core layer and end face sealing layers are included. The transition fireproof casing pipe is arranged between the end portion fireproof casing pipes,the transition fireproof casing pipe and the end portion fireproof casing pipes are in butt joint through the casing pipe bonding resin layer to form a hollow fireproof casing pipe. The process steelpipe is coaxially arranged in an inner hole of the fireproof casing pipe. A ventilation hole is formed in a pipe body of the process steel pipe. The outer sand core layer is arranged between an innerhole of the process steel pipe and the inner hole of the fireproof casing pipe. The inner sand core layer is arranged in the inner hole of the process steel pipe. The end face sealing layers are arranged at the two ends of the outer sand core layer. An air outlet channel is arranged at the center of the inner sand core layer. According to a long and thin casting hole sand core of the structure, the defects that an ordinary sand core is low in surface fireproof degree and is prone to burning losses, burning through, washing damage or washing fracture through high-temperature molten iron can beeliminated, sand discharging and process steel pipe recycling and repeated usage are facilitated, the sand usage amount is small, and the casting cost is low.

Owner:KEHUA HLDG

Casting production method of large spheroidal graphite cast iron grinding disc with cavity

ActiveCN111618246AReduce manufacturing costAvoid fire riskFoundry mouldsFoundry coresDuctile ironCeramic materials

The invention provides a casting production method of a large spheroidal graphite cast iron grinding disc with a cavity. The method is characterized in that a mold is divided into two parts accordingto the height of a first layer of sand box during molding; after a lower mold is produced, the sand boxes are detached layer by layer, the second part of the mold is hoisted away, and the first part of the mold is turned over to produce an upper mold; and after the upper mold is produced, all the sand boxes are combined again, then a sand core is hoisted into a pouring mold again, and finally molten iron pouring is carried out. According to the method, the mold is divided into two parts, and the sand core is placed in the upper mold, so that the problems of flat firing and sand core floating are effectively prevented.

Owner:大连华锐重工铸业有限公司 +1

A method for producing lightweight new wall material by mixing coal slag

ActiveCN103467013BLight weightReduce early heat of hydrationSolid waste managementSocial benefitsSlag

The invention discloses a method for producing a novel light-weight wall material by mixing coal slag. The coal slag produced by a thermal power plant replaces 20-100% of sand. On the one hand, the consumption of the sand is reduced, the production cost is lowered greatly, resources are saved, waste materials are recycled, and the environmental pollution is relieved. On the other hand, early hydration heat of concrete mixed with the coal slag is reduced, the sulfate resistance of the concrete is improved, and the impermeability has the direct bearing on the carbonization resistance, freezing resistance and erosion resistance of the concrete and further has an important effect on shrinkage and creepage of the concrete. In addition, the coal slag is lighter than the sand, so that the volumetric weight of the concrete mixed with the coal slag is reduced; a wall is light in deadweight; the mounting efficiency is improved; for mechanical properties, compression resistance and a suspension force of the light-weight wall material mixed with the coal slag are greatly higher than those of a light-weight wall material used for construction and produced by mixing no coal slag; and the method has very good economic and social benefits.

Owner:江苏建华新型墙材有限公司

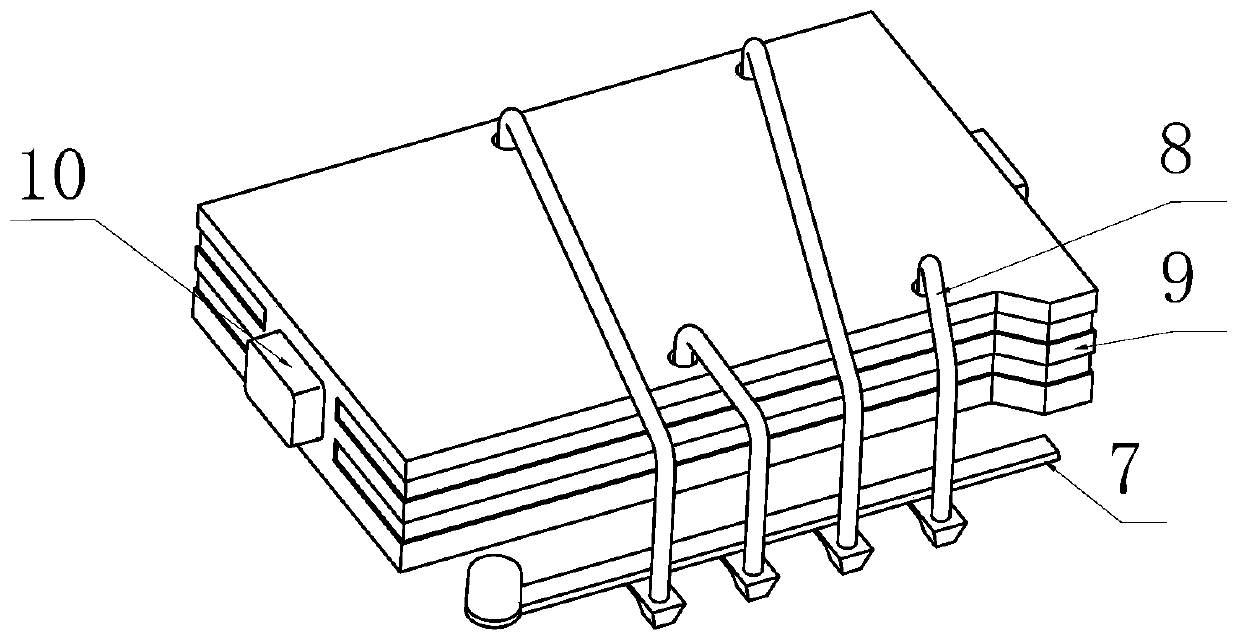

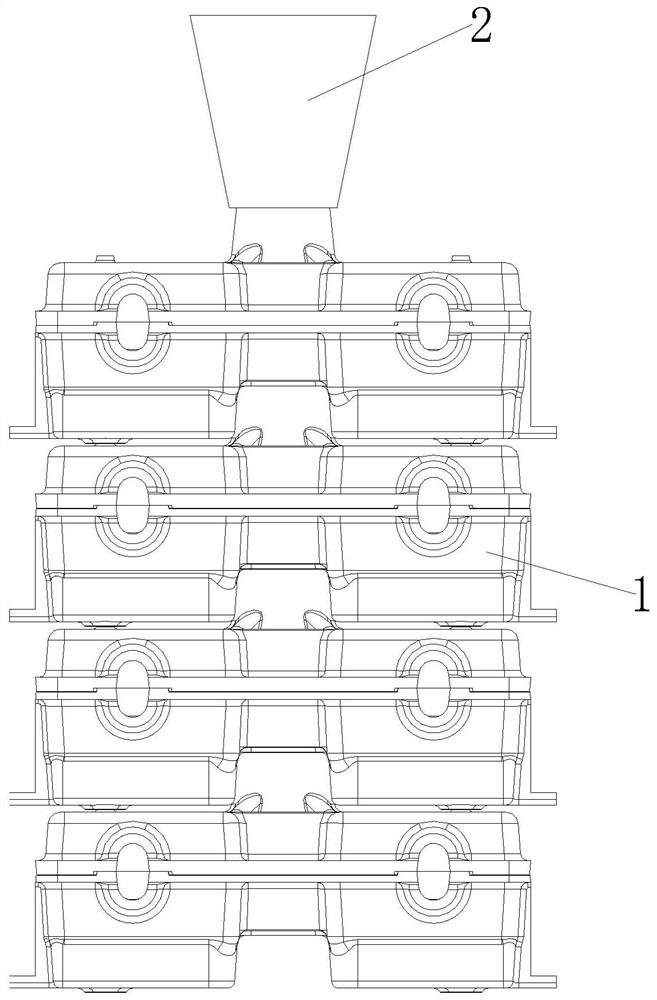

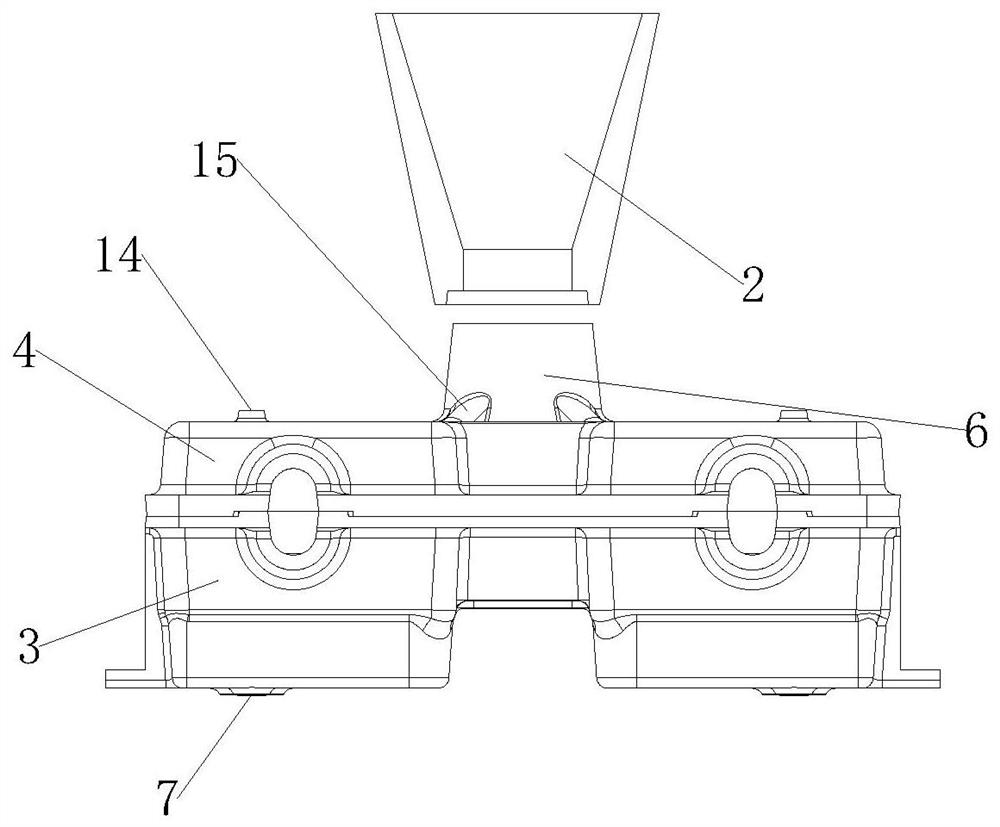

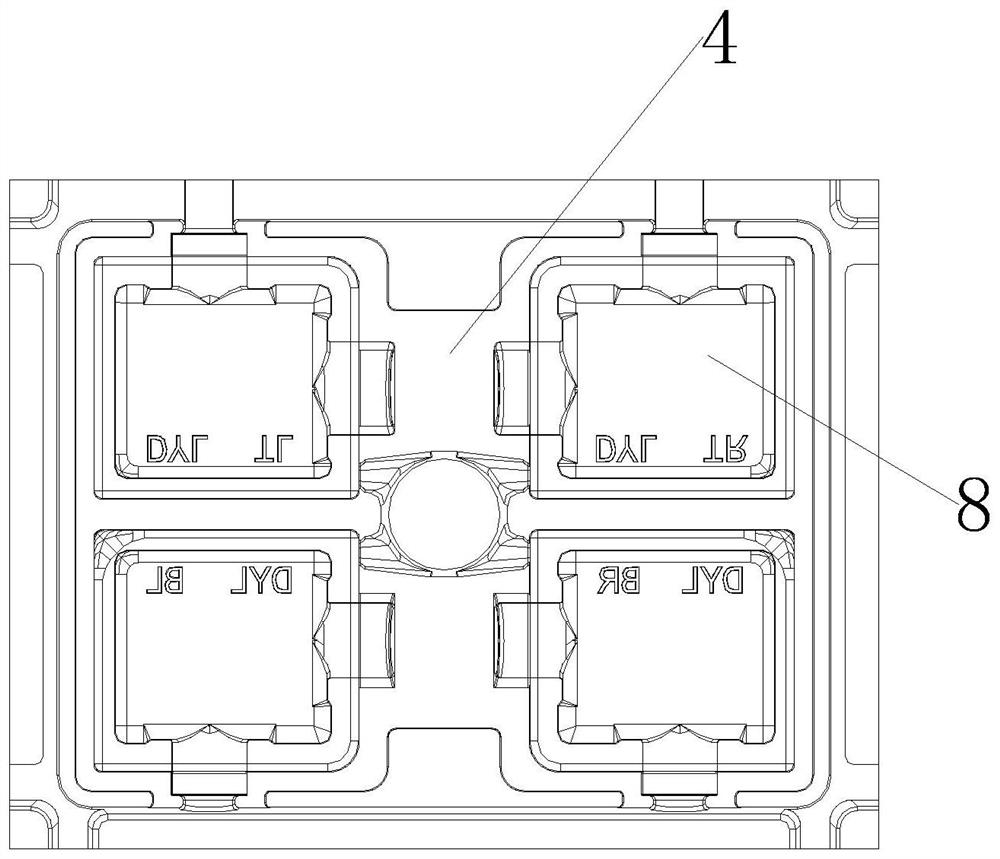

Multi-layer combined type container corner fitting precoated sand shell mold and pouring process

PendingCN112642996AIncrease profitImprove finished product efficiencyFoundry mouldsFoundry coresWhole bodyMolten steel

The invention discloses a multi-layer combined type container corner fitting precoated sand shell mold and a pouring process, and particularly relates to the technical field of container corner fitting precoated sand shells and pouring processes. The multi-layer combined type container corner fitting precoated sand shell mold comprises a corner fitting precoated sand shell whole body and a movable pouring cup, and the number of the layers of the precoated sand shell whole body is one to four. According to the combined type container corner fitting precoated sand shell and the pouring process, two layers, three layers, four layers and at most four layers can be arranged as a group to pour 16 corner fitting castings, the finished product efficiency of the corner fitting castings can be improved through sand shell pouring, the overall finished product efficiency of the corner fitting precoated sand shell is improved, the molten steel pouring frequency and weight are reduced, a chilling block is arranged in the sand shell in the shell manufacturing process, the distance between the sand shell and the chilling block is 3-4 mm, the chilling block is not in direct contact with molten steel in the casting process, shrinkage cavities of corner piece castings cannot be generated due to the fact that the molten steel is cooled too fast, and the problems that according to an existing container corner piece precoated sand shell and pouring process, the molten steel utilization rate is low, the finished product percent of pass is low and cost is high are solved.

Owner:JIANGSU YAWEI POUNDRY MATERIAL TECH CO LTD

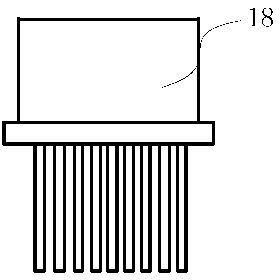

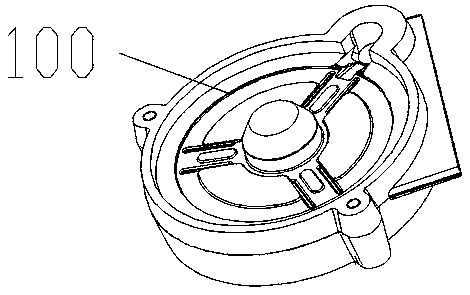

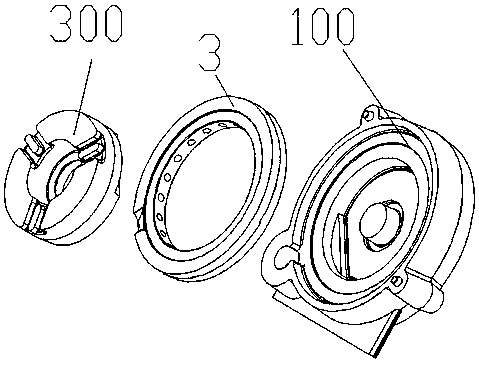

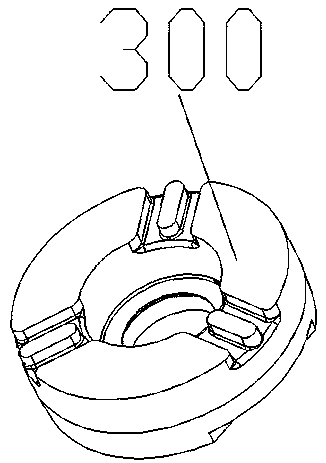

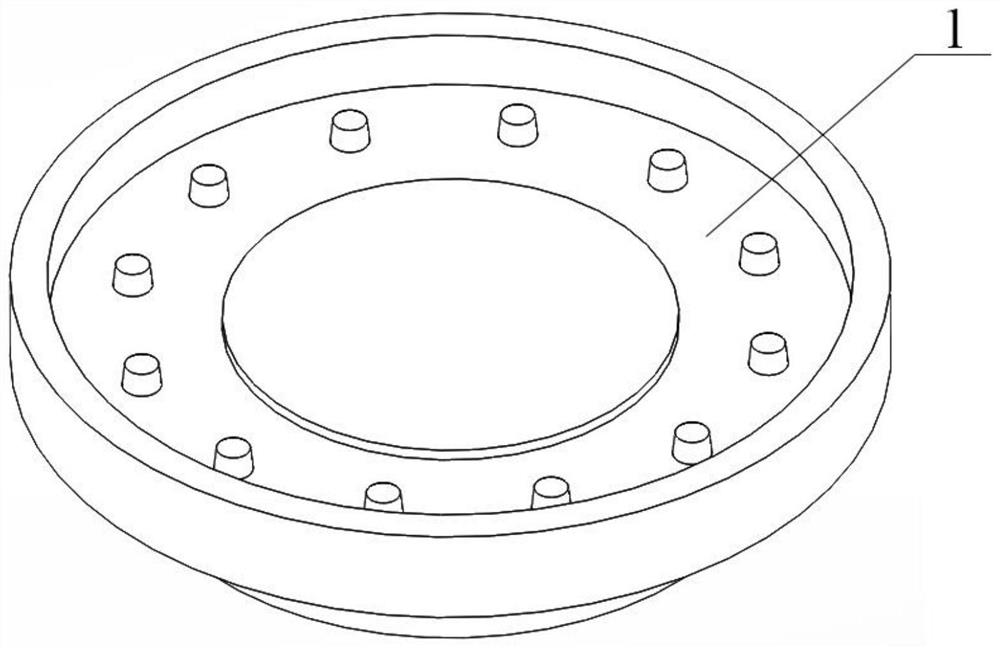

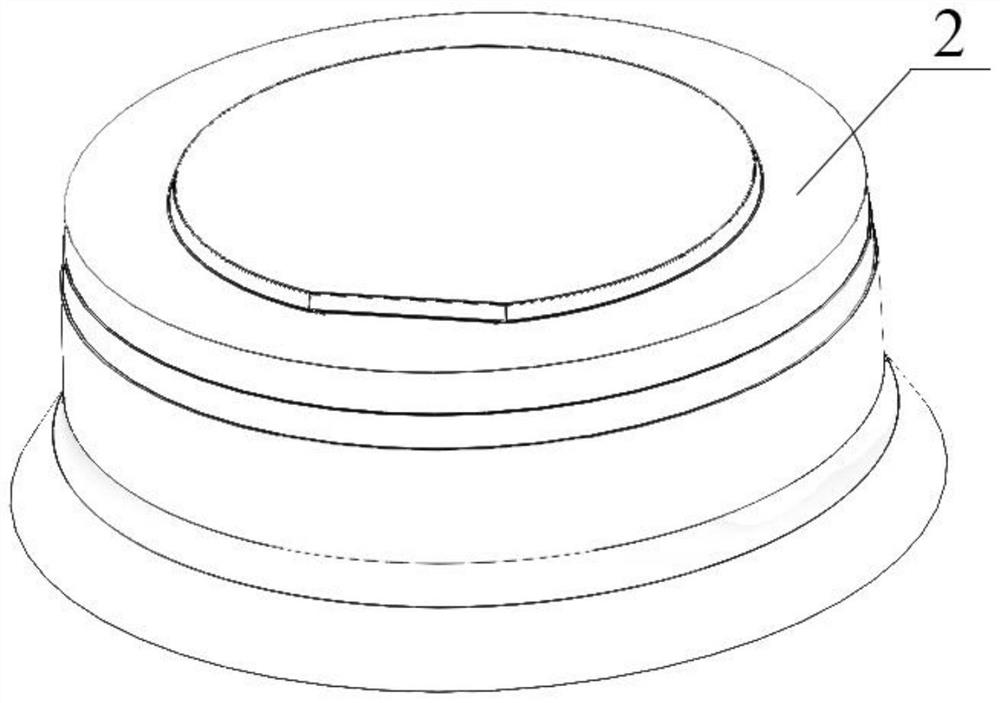

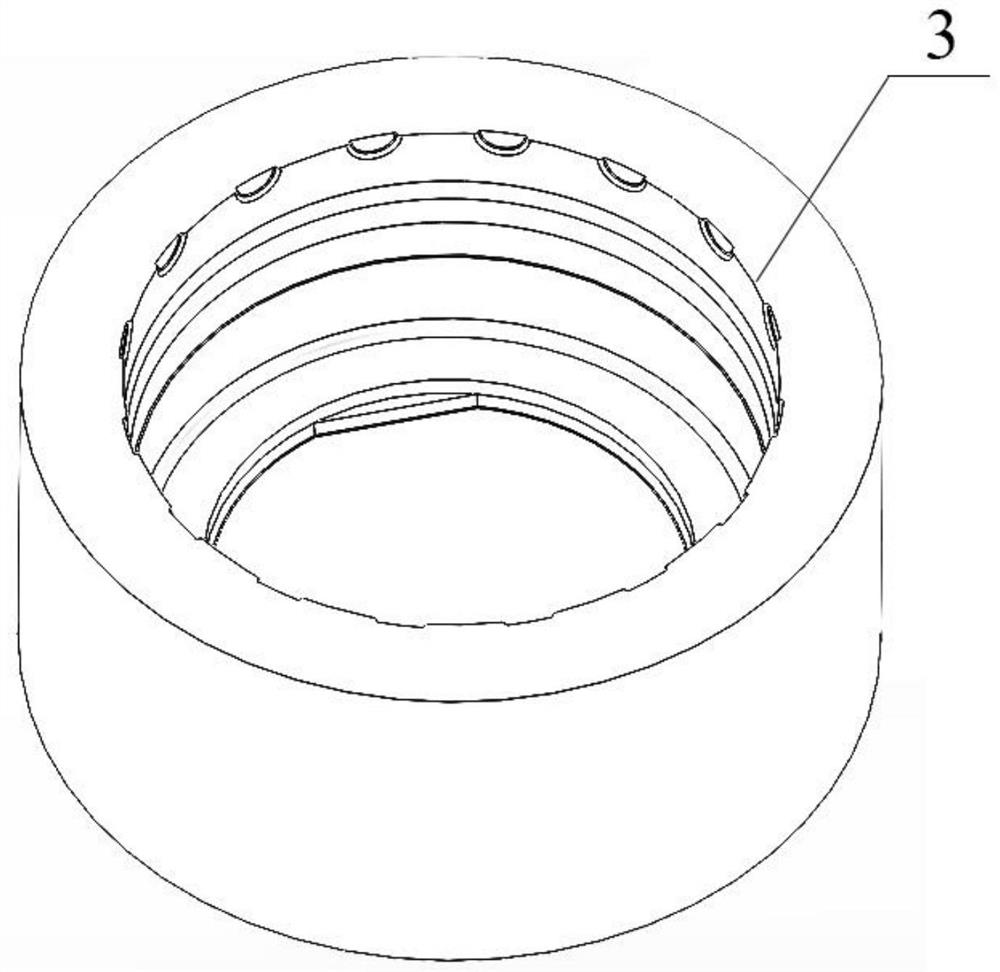

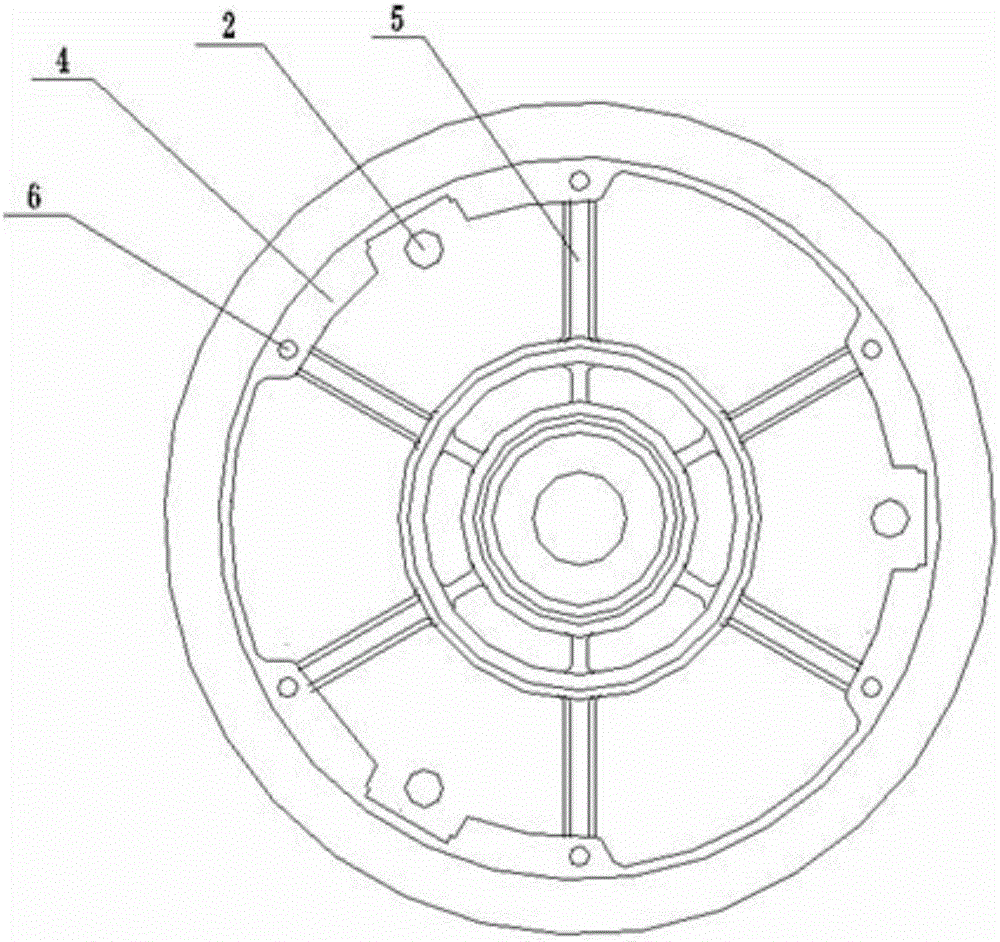

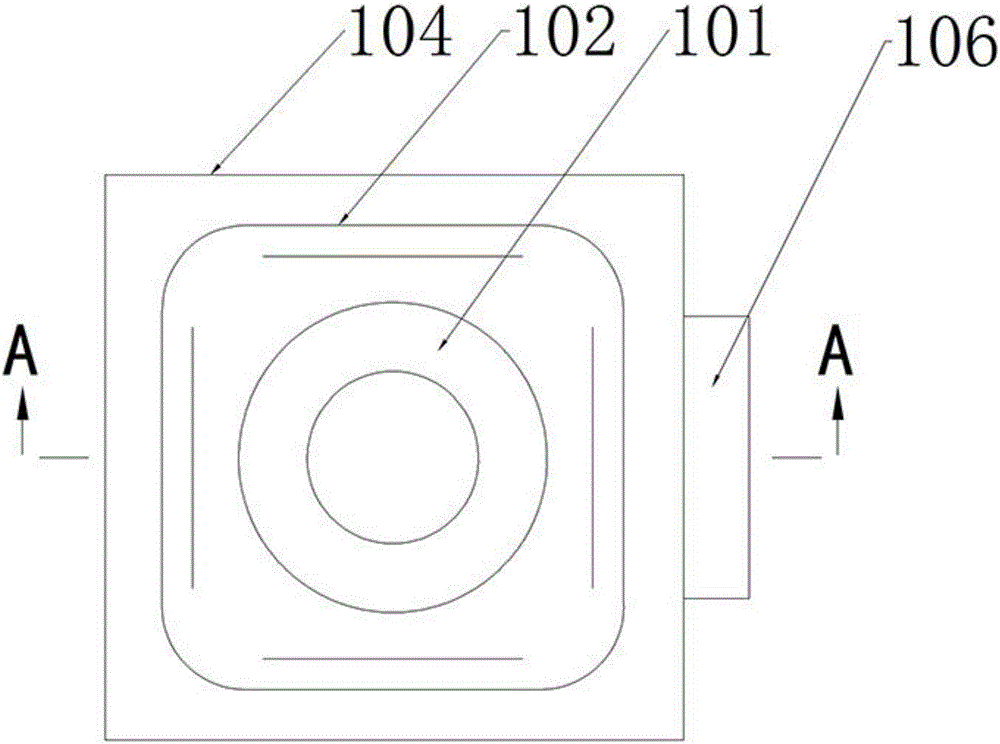

Belt pulley

InactiveCN106641189AImprove working conditionsReduce the amount of sand usedFoundry mouldsPortable liftingShell moldingEngineering

The invention provides a belt pulley. The belt pulley is in the basic shape of a circular ring, a flexible movable block with an annular opening is arranged on the outer diameter of the circular ring, a clutch supporting surface is arranged at one side of the circular ring, a bearing hole is formed in the middle of the clutch supporting surface, fan-shaped grooves are formed in the outer wall of the clutch supporting surface, and convex lugs are arranged in grooves which are arranged at intervals; a pressing disc limiting groove is formed in the inner wall of the circular ring of the inner side of the clutch supporting surface, grooves are formed in the middles of convex portions of the pressing disc limiting groove, installation holes are formed in the two sides of each convex portion, lever separation holes are formed in the portions, corresponding to the grooves, of the clutch supporting surface, and clutch plate installation platforms are arranged at the positions, corresponding to the installation holes, of the inner diameter of the pressing disc limiting groove. According to the belt pulley, a direct casting shaping process method is adopted, a complete groove-shaped cavity is obtained by adopting a precoated sand shell molding process, a groove shape is directly cast, a process method which is free of cutting or needs an extremely little amount of cutting is obtained, and method is low in cost, simple, easy to operate and suitable for being used by most enterprises.

Owner:山东时风(集团)有限责任公司

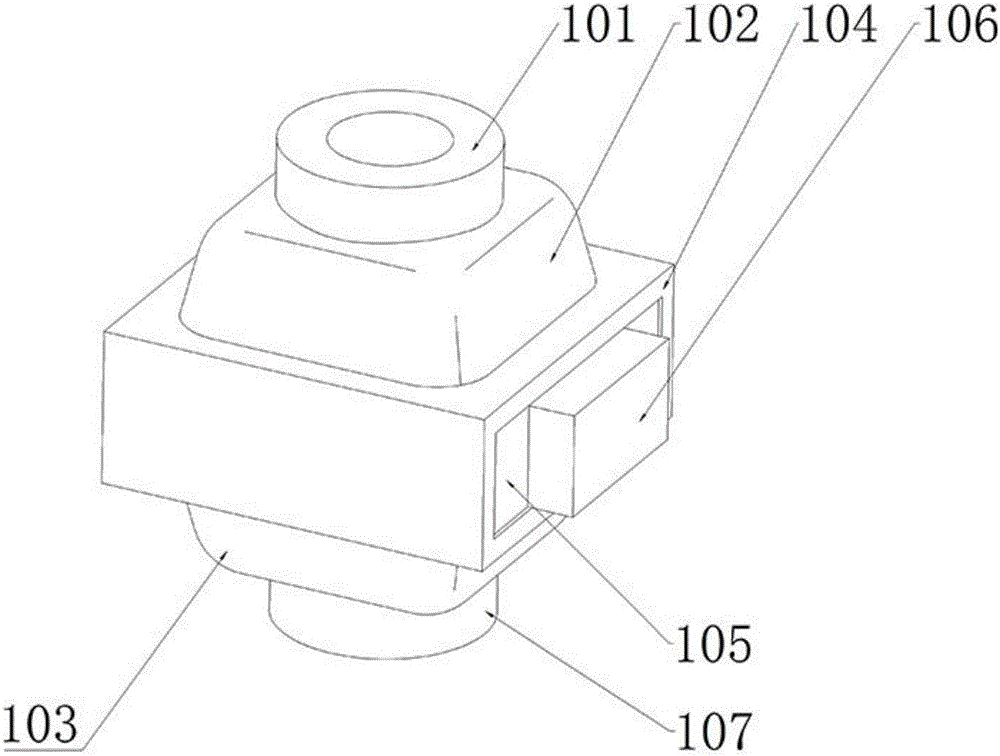

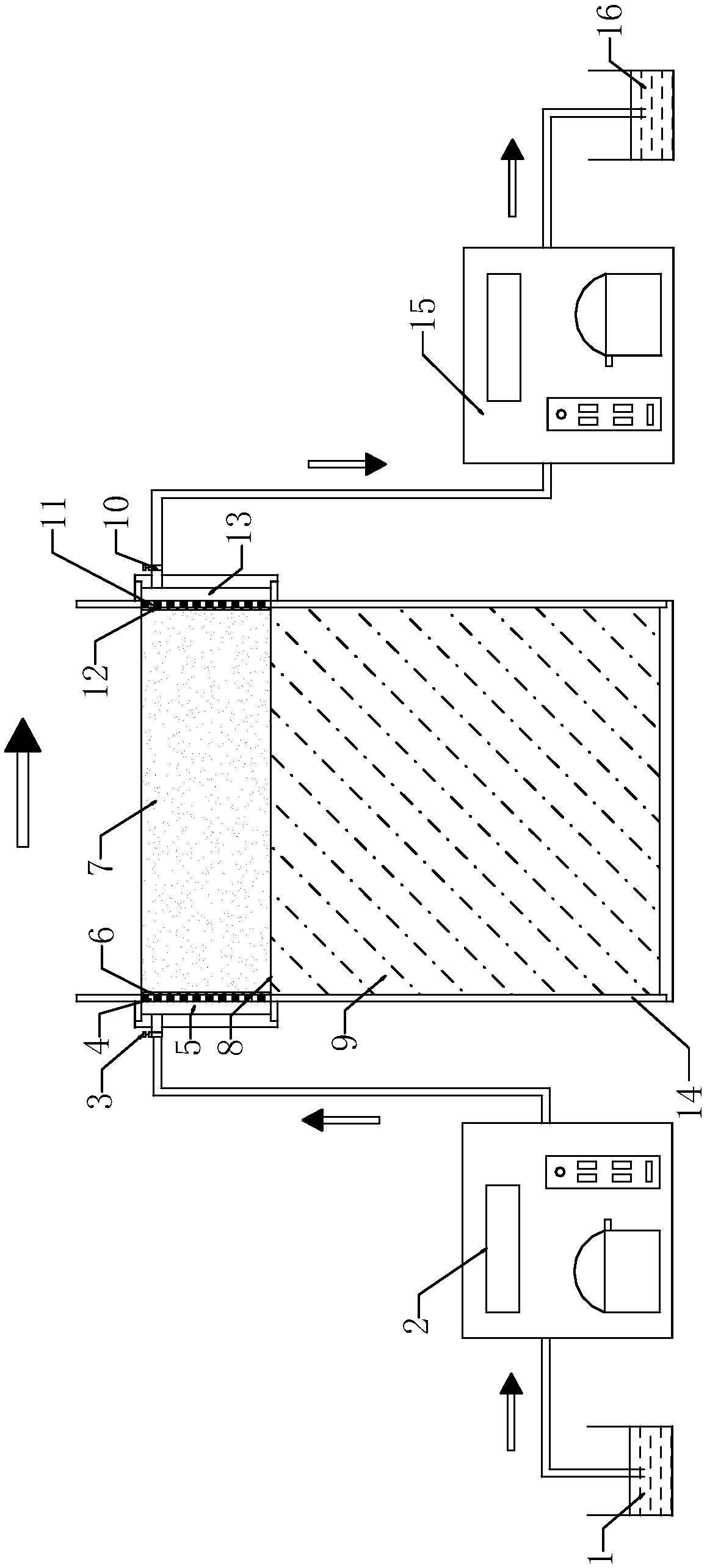

Filter for casting and filtering system comprising same

ActiveCN106670389AImprove filtration capacityFlexible structureFoundry mouldsFoundry coresFilter systemCasting

The invention provides a filter for casing. The filter comprises a flow inlet, an upper liquid storing area, a lower liquid storing area, a filter screen groove, a window, a sticky core and a flow outlet, wherein the flow inlet is formed in the top of the filter and used for guiding molten iron into the filter; the upper liquid storing area and the lower liquid storing area are arranged below the flow inlet and used for reducing flow speed of iron liquid and enlarging the contact area between the molten iron and a filter screen, the filter screen groove is formed between the upper liquid storing area and the lower liquid storing area, the cross section of the filter screen groove is rectangular, the boundary size of the filter screen groove is larger than the section size of the liquid storing areas, the filter screen groove is used for bearing a filter screen, the window is arranged on the side face of the width direction of the filter screen groove, and used for inserting the filter screen into the filter screen groove, the sticky core is installed on the window in a clearance fit manner, the flow outlet is formed in the lower portion of the lower liquid storing area, the flow outlet and the flow inlet are distributed symmetrically with the filter screen groove as an axis, and the flow outlet is used for connecting flow input points of a casting cavity. A filtering system utilizes the multiple filters to be combined in many forms to be suitable for producing castings of different structure shapes and various weights.

Owner:NINGXIA KOCEL MOLD

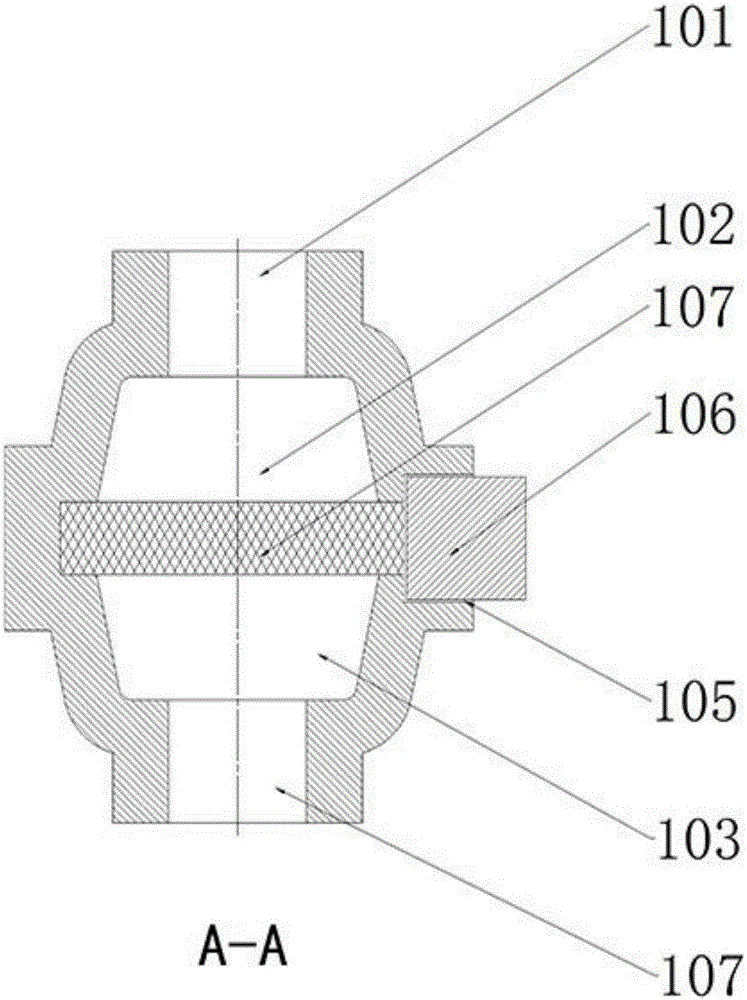

Concrete formula for high-strength pipe pile and mixing and curing process thereof

The invention discloses a concrete formula for a high-strength tubular pile and a mixing and curing process thereof. The formula comprises 380-430 kg / m <3> of cement, 80-150 kg / m <3 > of a mineral admixture, 1100-1300 kg / m <3> of coarse aggregate, 400-500 kg / m <3> of fine aggregate, 6-8 kg / m <3> of a water reducing agent and 1-2 kg / m <3> of polyethylene particles or polystyrene particles, and the polyethylene particles or polystyrene particles contain reinforced fibers. According to the concrete formula for the high-strength tubular pile and the mixing and curing process of the concrete formula, the sand consumption and the water consumption can be reduced, meanwhile, the concrete has good flowability, the strength and the toughness of the tubular pile are improved, and meanwhile, the pore defects in the tubular pile are reduced.

Owner:FUJIAN DADI CONCRETE PILE

Method for using maximized core iron in casting parts

InactiveCN101352751AImprove rigidityReduce the amount of sand usedFoundry mouldsFoundry coresVolumetric Mass DensityMaximum size

The invention relates to a method of using a maximum core iron in casting a casting. The method comprises the following steps: a. the maximum size of the core iron is made into a size less than that of a core cavity opening of the casting to be cast; b. the thickness of a sand-faced layer is made to be a thickness not less than 2.5-3mm. The method for using the maximum core iron in casting the casting can eliminate shrinkage pores and shrinkage around a sand core, improve the density of the periphery of the core and prevent leakage from the casting.

Owner:SHANXI MOFAN MACHINERY MFG

Laboratory test method for forming artificial hard crust by microbiologically solidified silt and fine sand

ActiveCN106168550BGuaranteed uniformityGuaranteed SaturationPreparing sample for investigationPeristaltic pumpMicroorganism

The invention discloses an indoor test method forming an artificial hard shell layer by microbial curing silty-fine sand. Silty-fine sand is paved on slurry which is thick enough, the slurry is separated from the silty-fine sand by a seepage-proofing thin film, liquid is injected into the left side by a liquid injecting peristaltic pump until a sand layer is saturated, liquid on the right side is extracted by a liquid extracting peristaltic pump to form horizontal laminar flow, the flow velocity of liquid injection and extraction is controlled, so that liquid injection and extraction are balanced, and silty-fine sand layers are cemented and cured by MICP (microbial induced calcium carbonate precipitation) technology to form the hard shell layer. The hard shell layer has high rigidity and strength, the carrying capacity of a soft soil foundation can be multiply improved, sand consumption is greatly decreased, the hard shell layer is resistant to liquefaction, and the requirement of basic carrying capacity can be met.

Owner:TIANJIN UNIV

Sand blasting rust removal apparatus

ActiveCN103223641BReduce rustStrong adhesionAbrasive machine appurtenancesAbrasive blasting machinesSand blastingDry sand

The present invention discloses a sand blasting rust removal apparatus, which comprises: a wet sand conveying device, a wet sand drying device, a dry sand tank, a sand blasting head, an air compressor, an air heating tank, and a hot air nozzle. During sand blasting rust removal operation, dry sand enters the dry sand tank, air is conveying into the air heating tank through the air compressor to be heat to form high pressure hot air, the dry sand is directly blasted on a steel workpiece under a high pressure hot air effect to carry out rust removal operation, a surface effect of the rust-removed steel workpiece is good, an anticorrosion standard of paints is achieved, the hot air nozzle can directly blow the high pressure hot air to the steel workpiece so as to produce a good rust removal effect and reduce a use amount of the sand, and rust removal can be performed only by using the high pressure hot air without the dry sand if the rust of the workpiece is less. In addition, the surface of the rust-removed workpiece is heated, paint adhesion is strong, and an anticorrosion effect is strong.

Owner:SHANDONG ELECTRIC POWER CONSTR NO 2

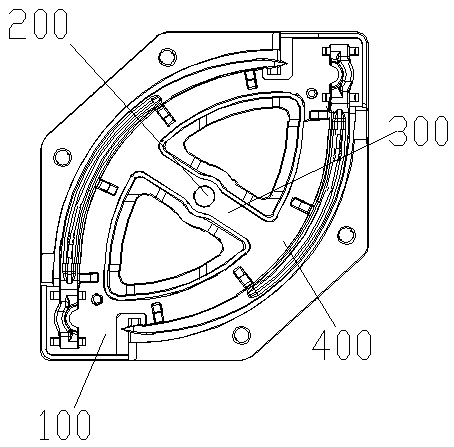

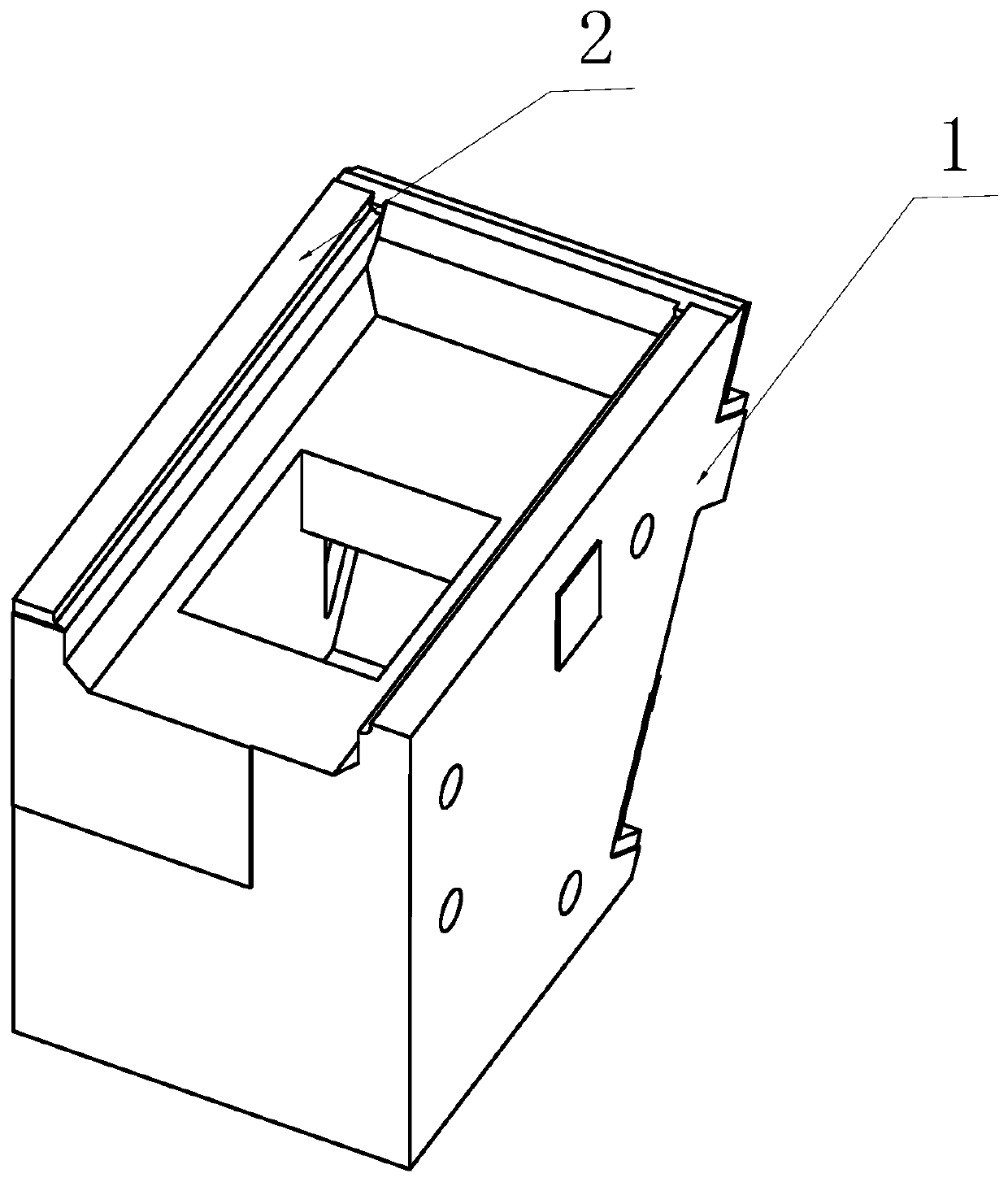

Split type sand core for back cover casting of construction machinery

PendingCN108746502AEasy to produceReduce glitchesFoundry mouldsFoundry coresMaterials scienceCasting

The invention relates to a split type sand core for back cover casting of construction machinery. The split type sand core is characterized by comprising a sand core seat, a sand mold, a sand core group and a sand core group connecting block. The sand mold is arranged on the sand core seat, one end of the sand core group is connected with the sand core group connecting block, the other end of thesand core group is connected with the sand core seat, and the side edge of the sand core group is connected with the sand mold. The combination between the sand mold and the sand core group is used asa casting for an engineering machinery back cover, a hollow type sand core structure is adopted to enable the sand core to be relatively light, and the use amount of sand is reduced, the cost is reduced, a reasonable typing position is chosen, the number of core assemblies is minimized by reducing the use of movable blocks, and the production process of construction machinery back cover is simplified; and a spilt type structure is adopted, burrs of the casted construction machinery back cover are less, and subsequent processing is convenient.

Owner:江苏力源金河铸造有限公司

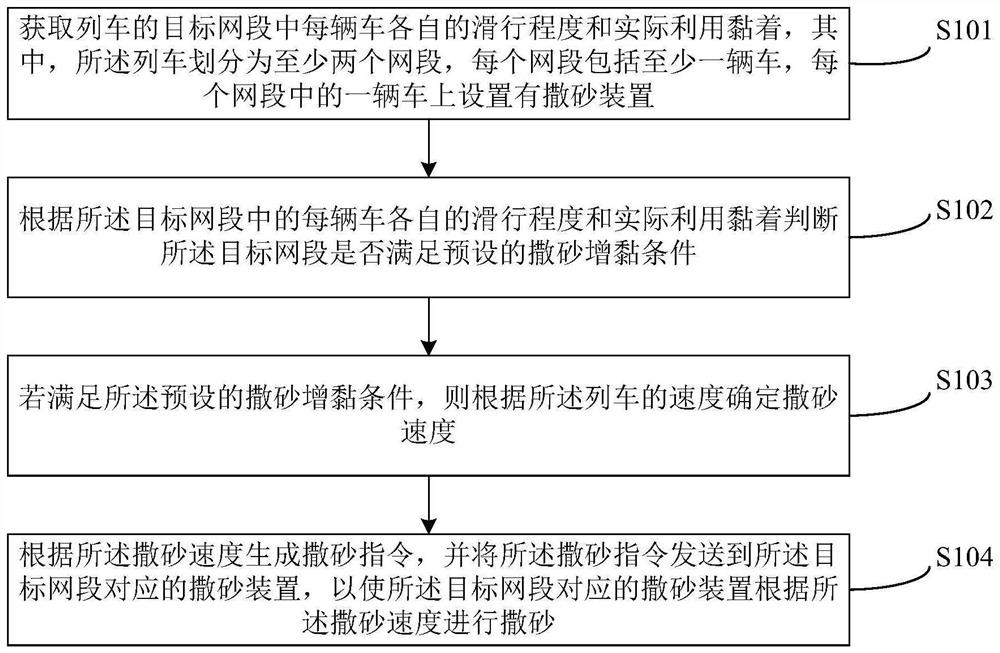

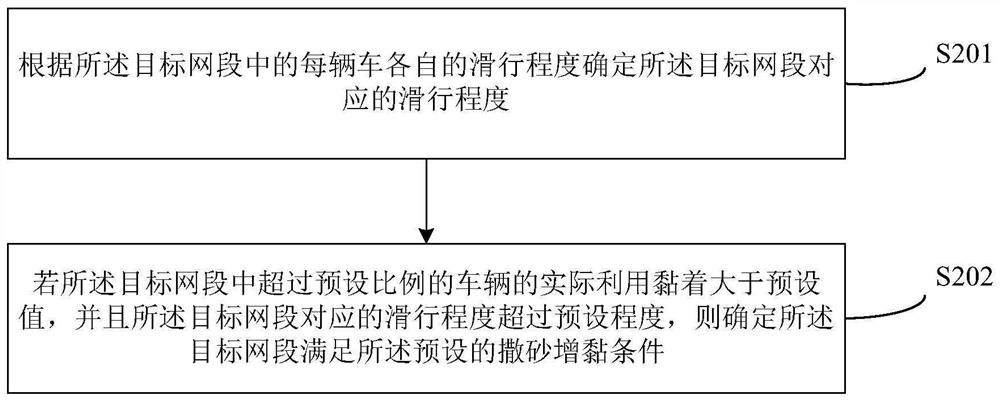

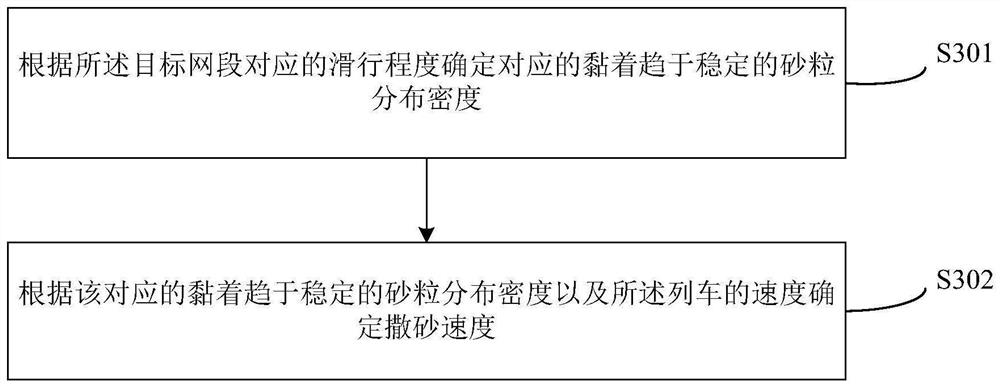

Train sliding viscosity increasing method and device

ActiveCN114274985AReduce the cost of sandImprove availabilityLocomotivesMechanical engineeringNetwork segment

The embodiment of the invention discloses a train sliding viscosity increasing method and device.The method comprises the steps that the sliding degree and actual utilization adhesion of each train in a target network segment of a train are obtained, the train is divided into at least two network segments, each network segment comprises at least one train, and a sanding device is arranged on one train in each network segment; judging whether the target network segment meets a preset sanding tackifying condition or not according to the respective sliding degree of each vehicle in the target network segment and the actual utilization adhesion; if the preset sanding tackifying condition is met, the sanding speed is determined according to the speed of the train; and a sanding instruction is generated according to the sanding speed, and the sanding instruction is sent to a sanding device corresponding to the target network section, so that the sanding device corresponding to the target network section carries out sanding according to the sanding speed. The sand spraying tackifying agent has the beneficial effect of improving the sand spraying tackifying effect of the train.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

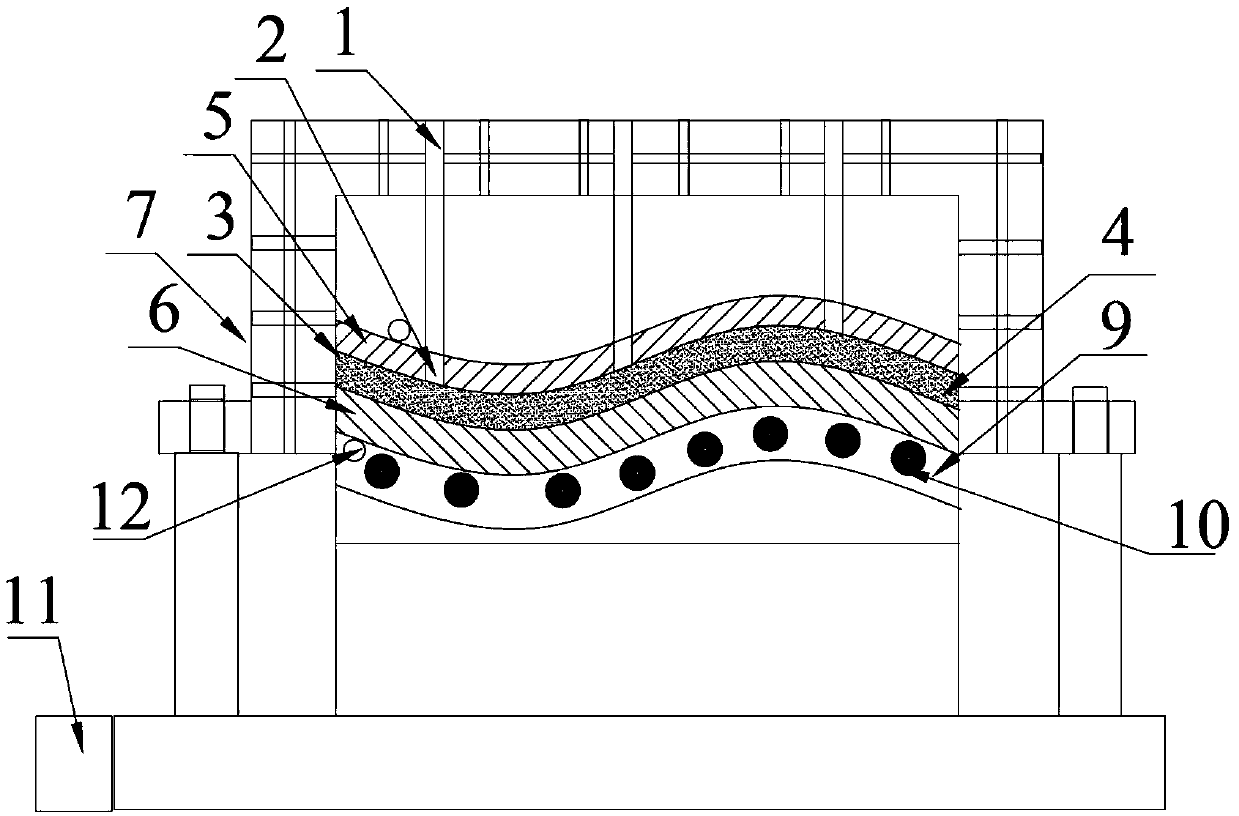

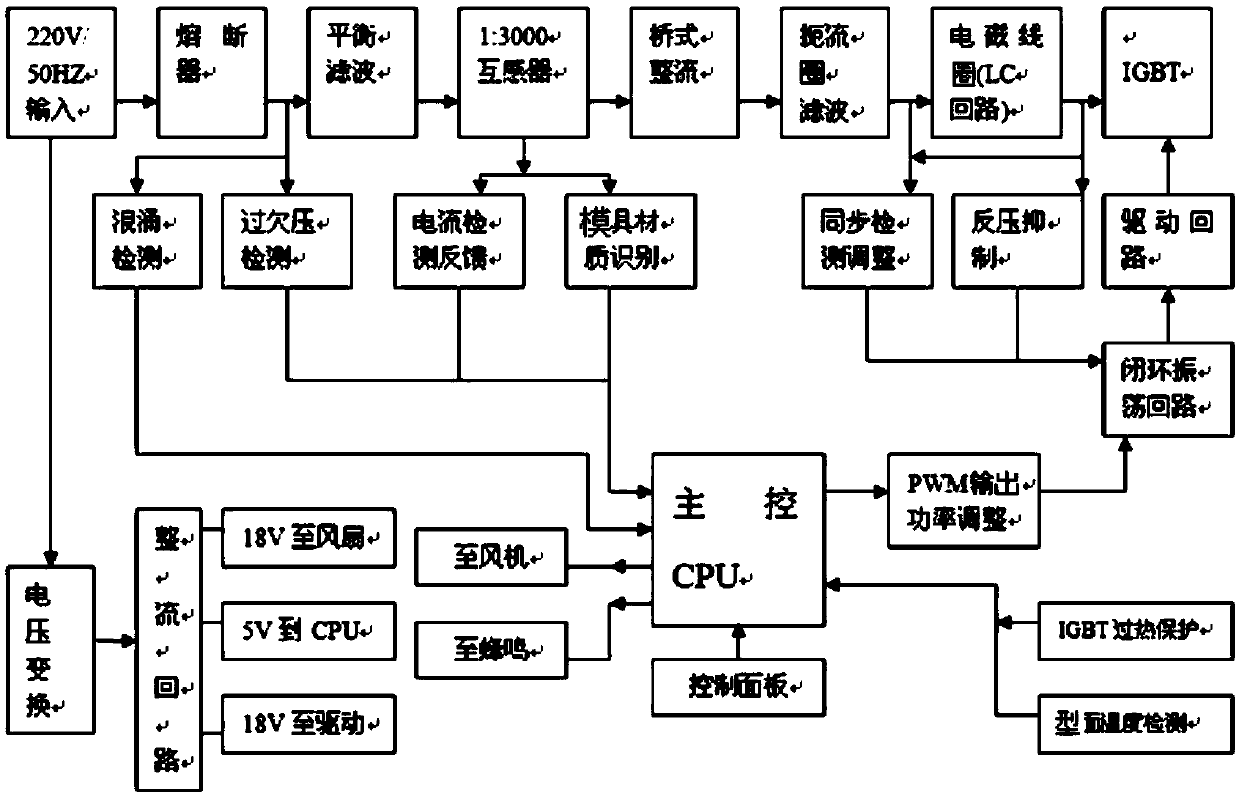

Electrical heating assembly for electromagnetic induction heating

ActiveCN110769535AGood magnetic conductivityEfficient heatingCoil arrangementsInduction heating apparatusEngineeringCondensed matter physics

The invention relates to the technical field of electrical heating, and discloses an electrical heating assembly for electromagnetic induction heating. The electrical heating assembly comprises a wire, wherein the wire is arranged in a winding way from a central part to outside according to the same winding direction, a distance is kept between adjacent wire segments after winding of the coil, aninsulator is arranged at the periphery of the wire, a magnetic conductor encircles the periphery of the insulation body, an opening is formed in the magnetic conductor along a winding path of the wireand is used for controlling a magnetic path direction, and the opening of the magnetic conductor faces a heating part of a to-be-heated object. By the electrical heating assembly, the heating capability of the electromagnetic induction heating device is improved, and the application range of the electromagnetic induction heating device is further expanded.

Owner:江阴市惠尔信精密装备股份有限公司

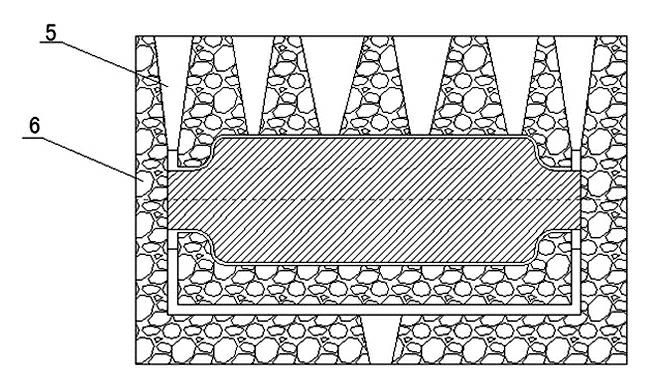

Casting sand mold forming method

ActiveCN110756744AReduce dosageImprove the finishFoundry mouldsMoulding machinesSurface finishCasting

The invention discloses a casting sand mold forming method. The sand mould forming method comprises the following steps of spraying precoated sand into a cavity between non-heated cold molds from a sand shooting hole in a sand box through a sand shooting pipe until the cavity between the cold molds is sprayed with the precoated sand to form a precoated sand layer, then heating the precoated sand layer in the cavity through a heating device arranged below one sides of the cold molds, and solidifying and molding the precoated sand layer in the cavity. The casting sand mold forming method has theadvantages that the method is simple, the sand amount used for making the sand mold model can be greatly reduced, the surface finish of the casting can be greatly improved, the manufacturing efficiency of the sand mold model can be improved, the labor can be greatly saved, the working environment is improved, environmental pollution cannot be caused, and the energy consumption is reduced; and thetechnology that the precoated sand is first injected into the cold model cavity, and then the precoated sand layer is heated, solidified and molded is mainly adopted, so that the heating energy consumption is saved, the heating time is shortened, and the dosage of the precoated sand is also reduced.

Owner:江阴市惠尔信精密装备股份有限公司

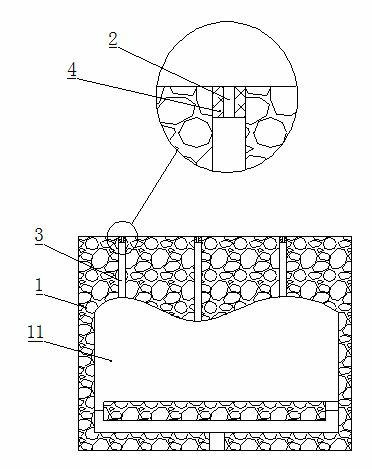

Low-pressure casting filling-mold air exhaust structure for sand mold and setting method for low-pressure casting filling-mold air exhaust structure

The invention relates to a method for setting a low-pressure casting filling-mold air exhaust channel for a sand mold. The method comprises the following steps of: vertically drilling at least one deep hole for communicating the highest point of a cavity and the outside in the sand mold; downwards smearing a section of pasty fire resistant material layer in an orifice at the upper end of the deephole; drilling a small-aperture shallow hole communicated with the deep hole in the fire resistant material layer; and heating and hardening the fire resistant material layer, wherein when aluminum liquid rises steadily, the air in the cavity is exhausted from the small-aperture shallow hole; and when the aluminum liquid continuously rises through the deep hole in the sand mold and overflows fromthe small-aperture shallow hole, the aluminum liquid overflowing the plane of the sand mold is solidified quickly due to the relatively small aperture of the small-aperture shallow hole. Therefore, the air can be exhausted steadily during mold filling; after mold filling, the cavity is closed quickly, so that pressurization, pressure retention and crystallization are realized conveniently, and a reliable guarantee is supplied for improving the quality of a product. Furthermore, the height of a cover box sand mold is effectively reduced to 100 to 120 millimeters, the sand using amount of a cover box is reduced greatly, and the cost is saved.

Owner:NANTONG L S LIGHT METAL FORMING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com