Patents

Literature

344results about How to "Reduce casting costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

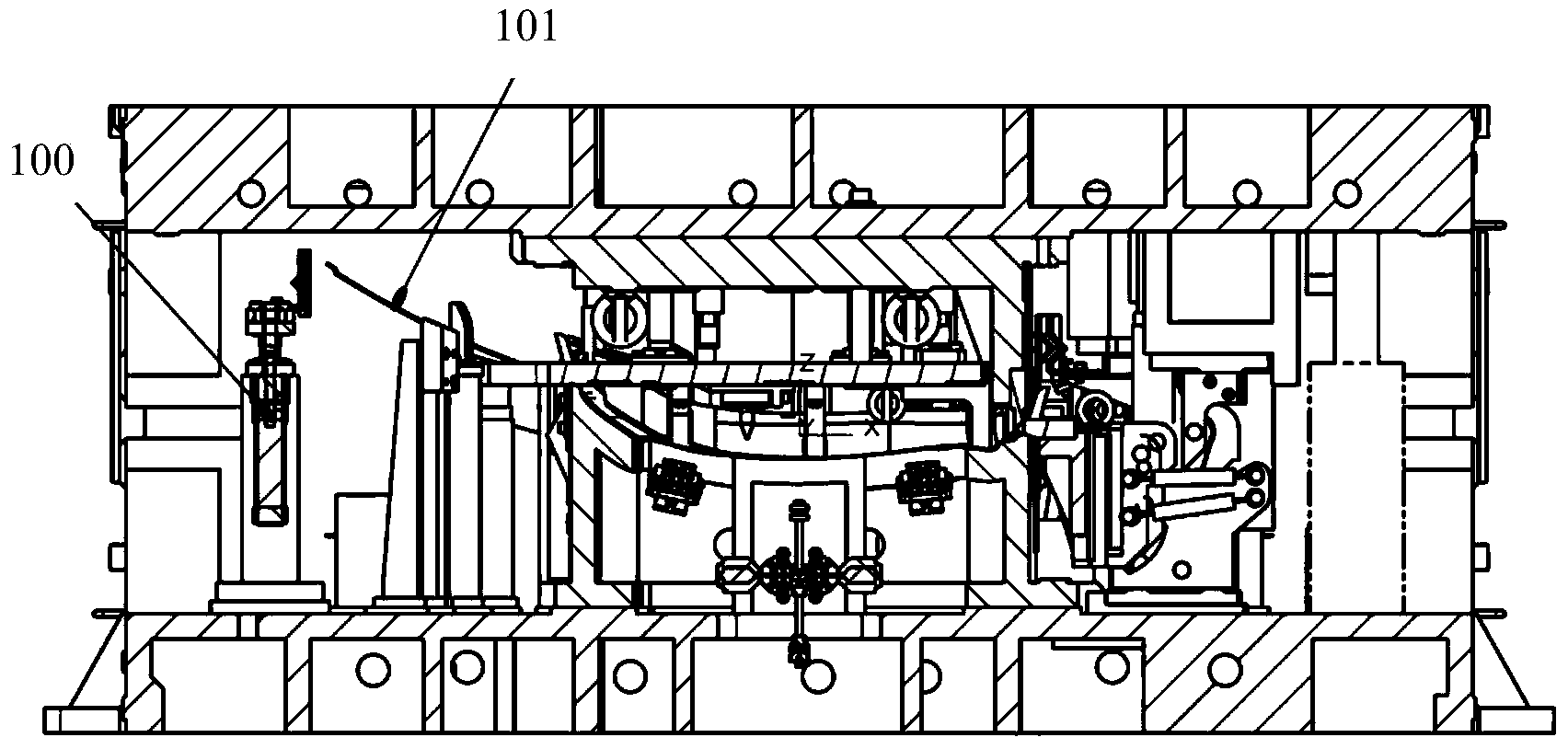

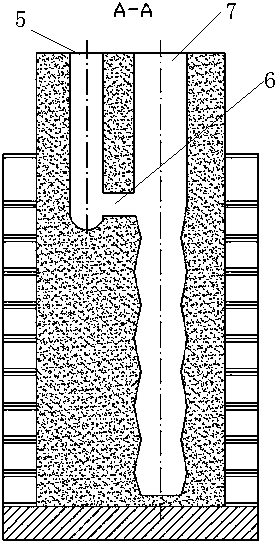

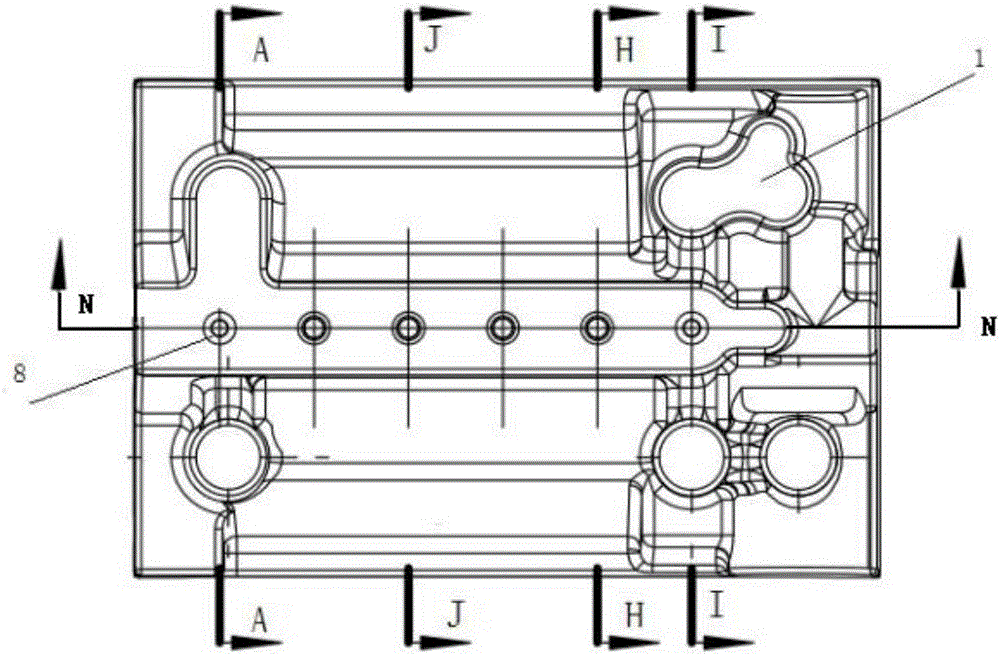

Cast sand core for cylinder cover of diesel engine

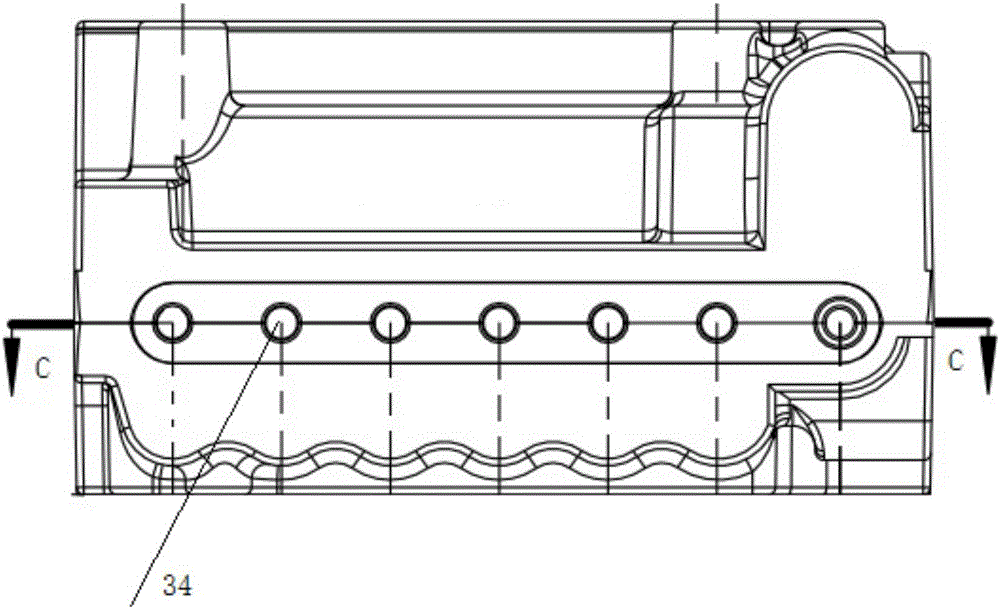

ActiveCN104707939AUniform wall thicknessNo input requiredFoundry mouldsFoundry coresInlet channelDiesel engine

The invention discloses a cast sand core for a cylinder cover of a diesel engine. The cast sand core comprises a composite overall sand core, a base plate core, an upper cover plate core and a casting auxiliary core, wherein the composite overall sand core comprises a base plate part, an air inlet channel part, an exhaust channel part, an upper water sleeve part, a lower water sleeve part, a tappet hole part and an exhaust system channel; the exhaust system channel is formed in the composite overall sand core; a sand removal window is formed in the bottom of the composite overall sand core; the base plate core comprises a core assembly frame position, a core assembly abdicating position, a sand core exhaust channel and a casting position; the core assembly frame position is used for accommodating the composite overall sand core; the sand core exhaust channel is communicated with the exhaust system channel; a first sprue is formed in the upper cover plate core; and the casting auxiliary core comprises a second sprue and a first cross gate. According to a casting method for the cylinder cover of the diesel engine by employing the composite overall sand core, the cylinder cover with an accurate shape and a uniform wall thickness can be obtained; and according to the cylinder cover of the diesel engine, the floating core phenomenon in casting of the air inlet cannel, the exhaust channel, the upper water sleeve and the lower water sleeve is avoided, a cylinder cover water cavity is free of a joint surface, a product casting is free of a water sleeve burr, and the water cavity is high in cleanliness.

Owner:GUANGXI YUCHAI MASCH CO LTD

Method for producing ultrahigh pressure switch pressure-bearing aluminum alloy tanks under low pressure through V method

ActiveCN102941333ASpeed up the flowReduce scour forceFoundry mouldsFoundry coresVacuum castingUltra high pressure

The invention discloses a method for producing ultrahigh pressure switch pressure-bearing aluminum alloy tanks under low pressure through a V method in the technical field of vacuum casting, which comprises the following processing steps: jig manufacture, low-temperature gating system manufacture, upper tank molding, lower tank molding, lower core mould assembling, casting and pressure removing and picking. The method solves the defects of slag inclusion, pores, pinholes and the like of cast caused by intensive scouring of molten metal to cast, and simultaneously can solve the problems that the cavity casting system occupies excessive molten metal, and particularly the product yield of cast with low wall thickness and large size is low.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

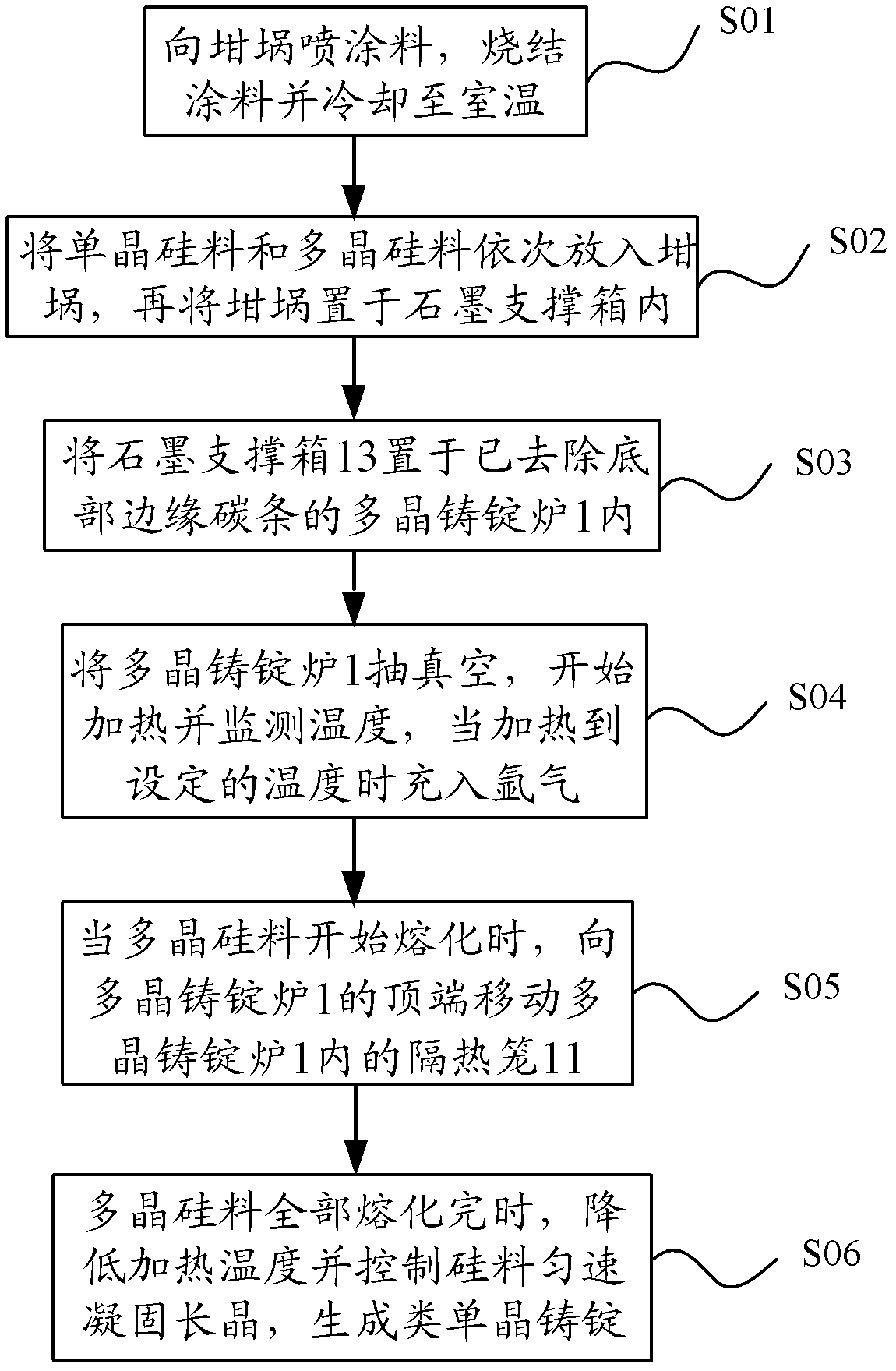

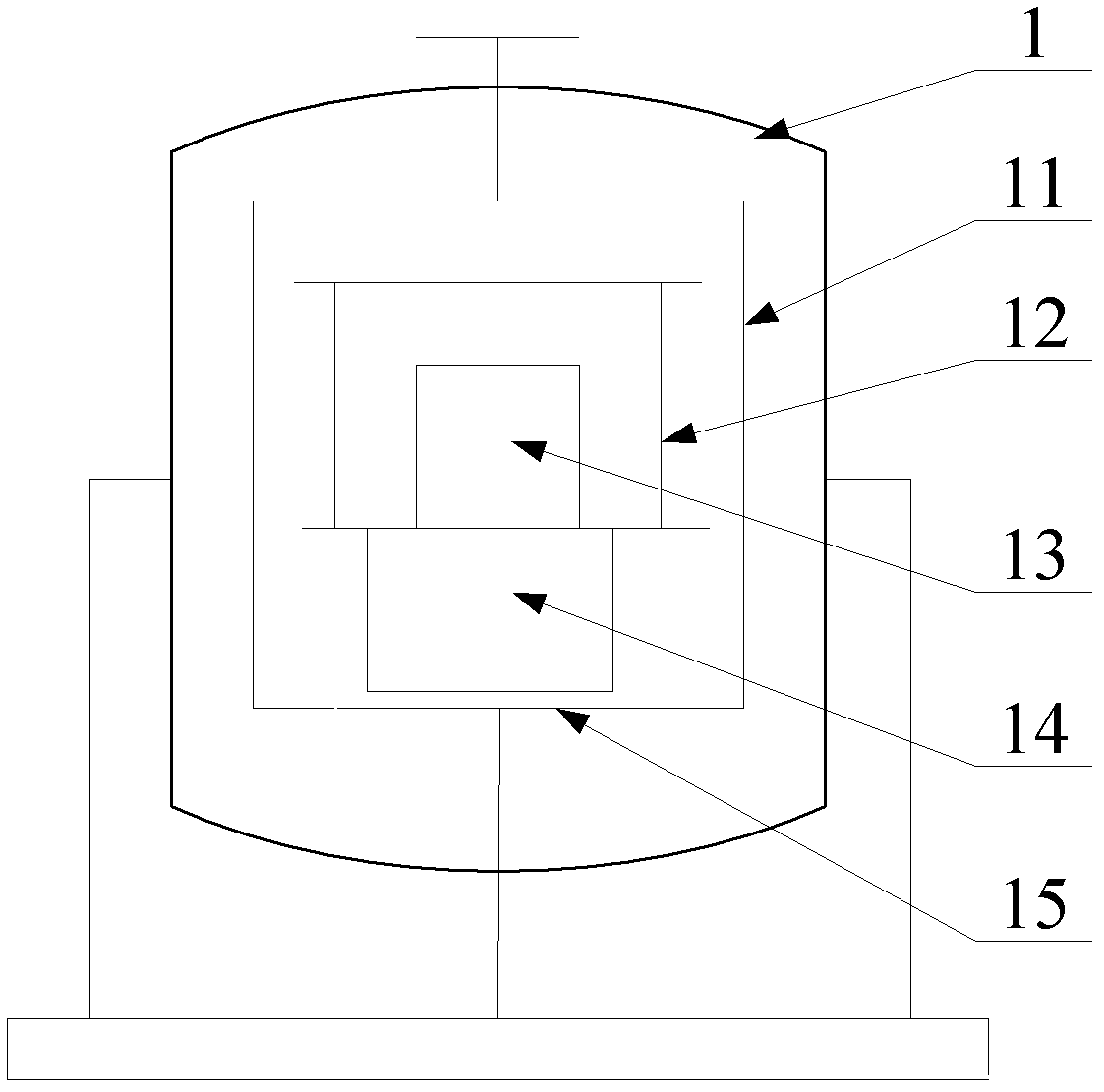

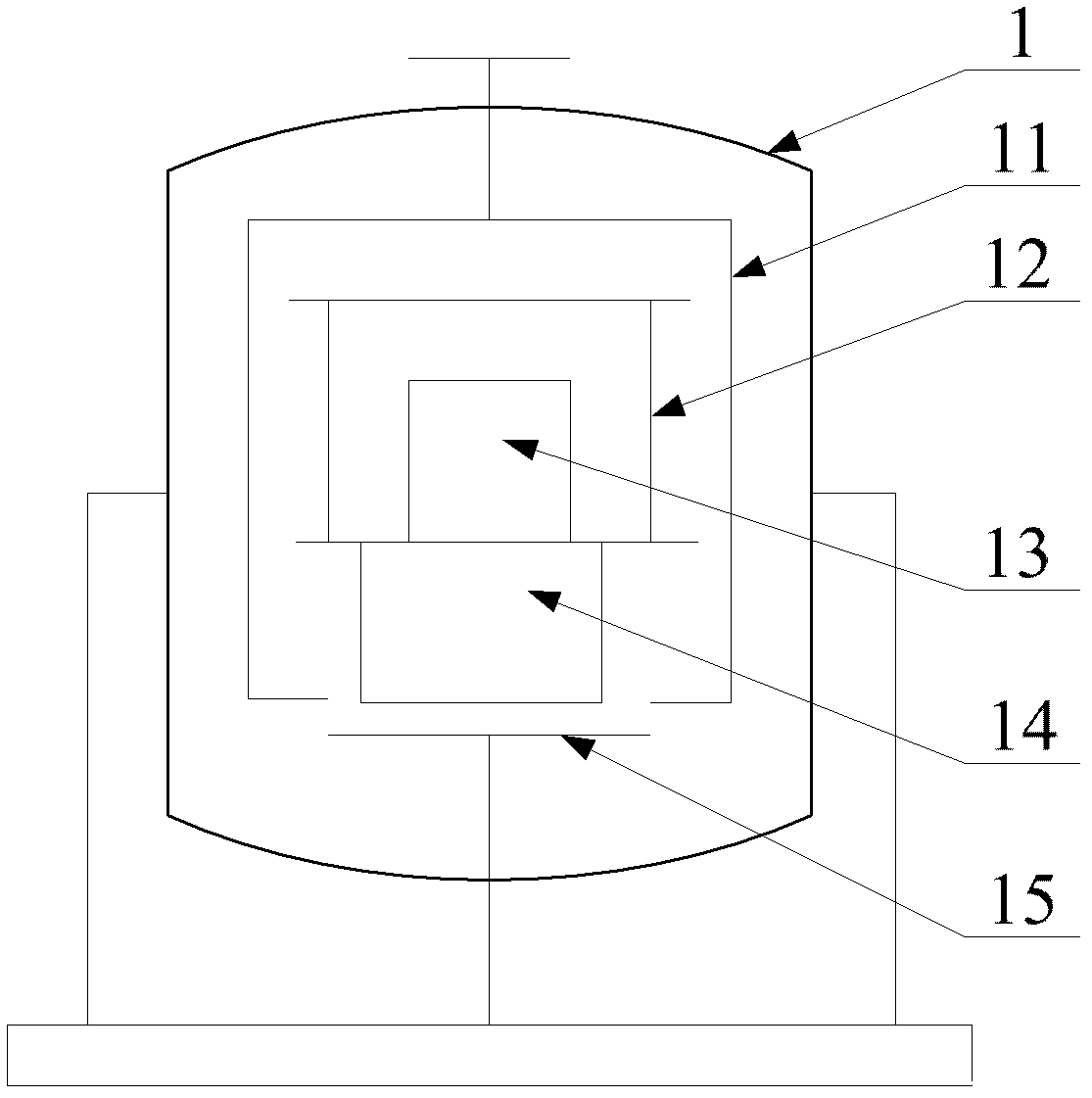

Polycrystal ingot casting furnace and method for producing single crystal-like silicon ingot by utilizing same

ActiveCN102560640AAvoid meltingImprove cooling effectPolycrystalline material growthFrom frozen solutionsCrucibleIngot casting

The invention provides a method for producing a single crystal-like silicon ingot by utilizing a polycrystal ingot casting furnace. The method comprises the following steps: spraying a coating on the inner surface of a crucible; sintering the coating and cooling to room temperature; placing a single crystal silicon material and a polycrystal silicon material into the crucible in turn, and placing the crucible into a graphite supporting box; placing the graphite supporting box into the polycrystal ingot casting furnace without bottom edge carbon bars; vacuumizing the polycrystal ingot casting furnace; heating and monitoring temperature; introducing argon when the polycrystal ingot casting furnace is heated to a preset temperature; when the polycrystal silicon material begins to smelt, moving a heat-isolating cage in the polycrystal ingot casting furnace to the top of the polycrystal ingot casting furnace; and when the polycrystal silicon material is completely smelted, reducing the heating temperature, controlling the silicon material to solidify at constant speed to grow the crystal, thereby forming the single crystal-like silicon ingot. According to the method provided by the invention, the present polycrystal ingot casting furnace is utilized to realize the production of the single crystal-like silicon ingot; the casting cost of the single crystal-like silicon ingot is reduced; the large-scale production of the single crystal-like silicon ingot is boosted; and the invention also provides the polycrystal ingot casting furnace for producing the single crystal-like silicon ingot.

Owner:YINGLI ENERGY CHINA

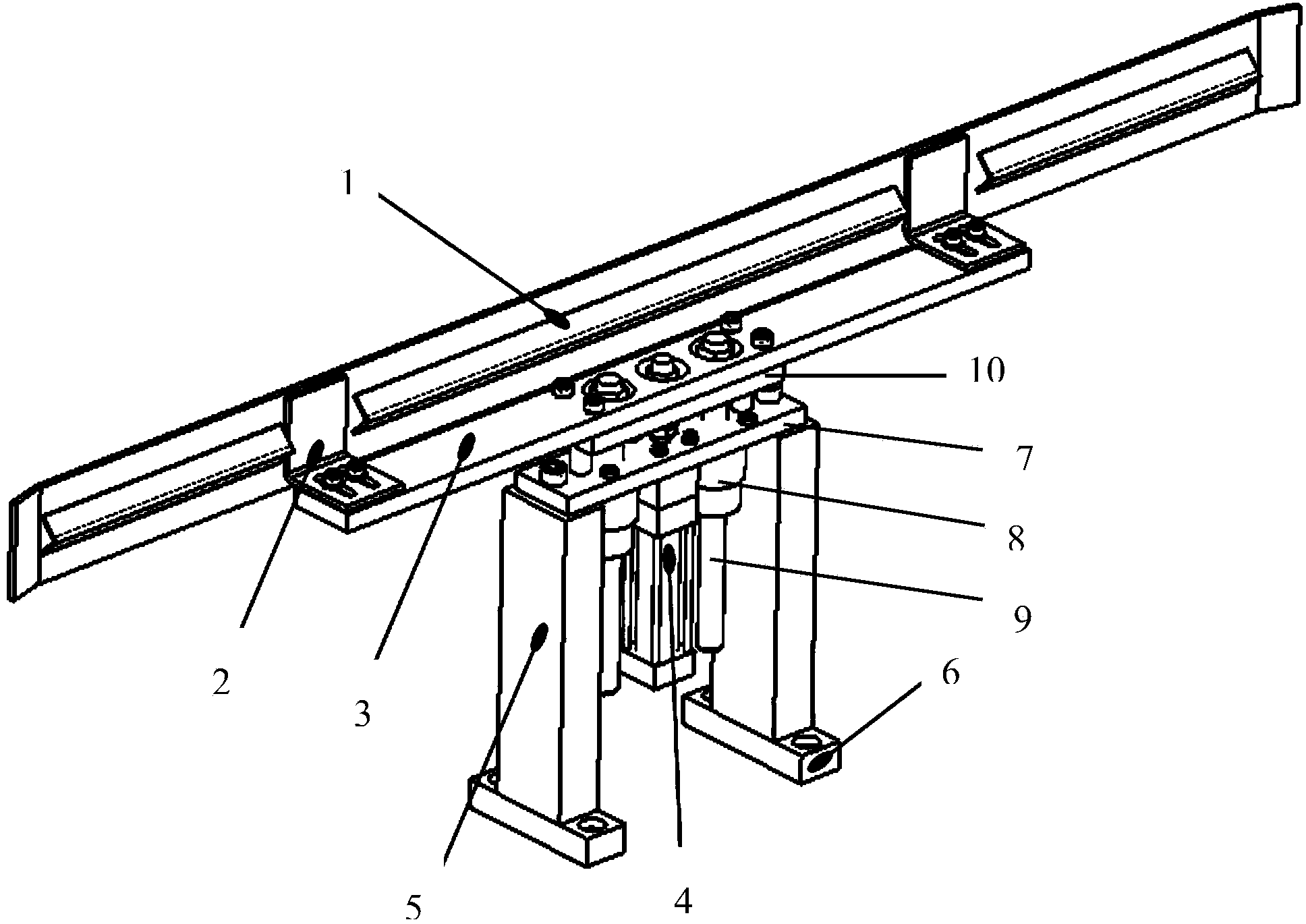

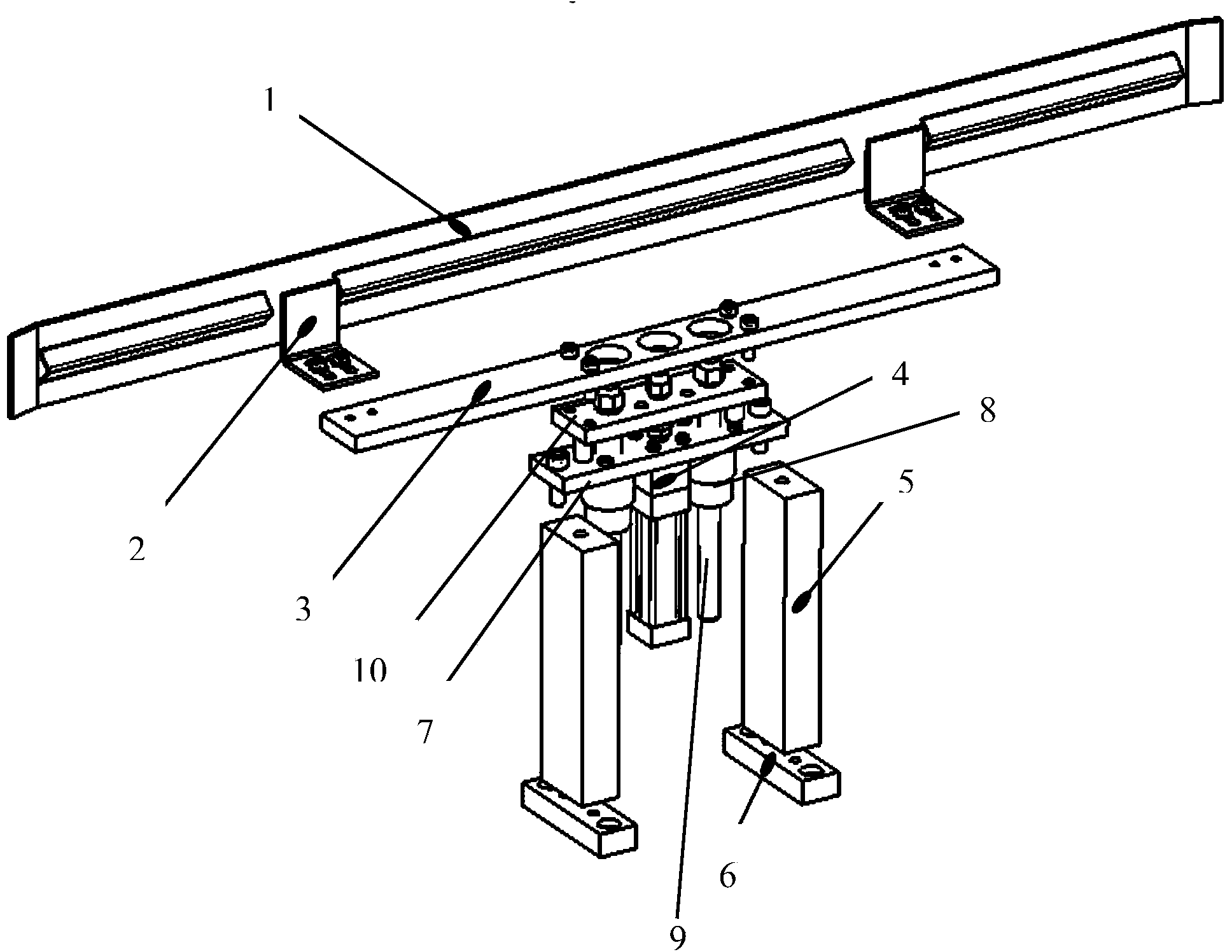

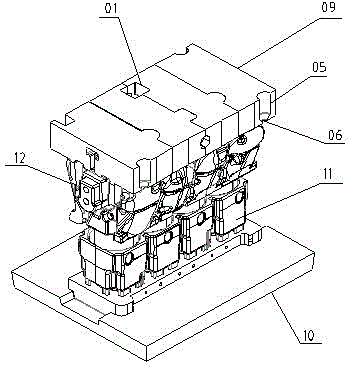

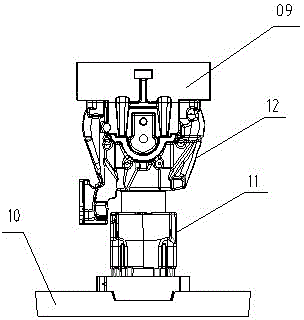

Automobile press fit die transmission and positioning mechanism

ActiveCN103817243ASmooth loading and unloadingLoading and unloading safetyShaping toolsMetal-working feeding devicesMechanical engineeringMental detachment

The invention discloses an automobile press fit die transmission and positioning mechanism, which comprises a positioning plate mounting plate, an assembly transportation positioning plate, a lifting jack and a fixing device, wherein the top surface of the positioning plate mounting plate is vertical to the stamping direction of an automobile press fit die; the assembly transportation positioning plate is mounted on the top surface of the positioning plate mounting plate and faces to a stamping piece in the automobile press fit die; the distance between the assembly transportation positioning plate and the stamping piece is adjustable; the lifting jack is capable of jacking and dropping down the positioning plate mounting plate and the assembly transportation positioning plate; the fixing device is used for fixing the lifting jack. According to the automobile press fit die transmission and positioning mechanism, the height direction and the horizontal direction of the stamping piece transportation positioning mechanism are adjustable, the loading and the discharging of the stamping piece are more stable and safer, and the space is saved; the adjustable positioning mechanism is adopted, the problem that the positioning mechanism intervenes with a press fit cutter block mounting seat and an upper die under the existing die height is solved, and the die height is reduced to 1000 mm, and therefore, the mixed routing manufacturing of different products is realized, the casting cost is reduced, the tool development expense is reduced, and the processing, the detachment, the debugging and the production are facilitated.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Method for casting automobile axle housing by V method

InactiveCN103722125AImprove casting qualityImprove yieldFoundry mouldsFoundry coresMechanical engineeringSurface film

The invention relates to a casting method and in particular relates to a method for casting an automobile axle housing by a V method. The method comprises the steps of (1) covering a model with a film; (2) adhering a casting head; (3) spraying coating on the surface film of the model; (4) drying the coating; (5) performing sand compaction; (6) rotating a sand box after the sand box is lifted out, and putting a loam core and cold iron into the sand box; (7) combining an upper box and a lower box; (8) preparing furnace burdens; (9) performing pouring. According to the method disclosed by the invention, a casting is high in casting quality, high in yield and low in casting cost.

Owner:LIUZHOU JINTE NEW WEAR RESISTANT MATERIAL CO LTD

Environment-friendly casting molding sand and preparation method thereof

ActiveCN104057013APrevent shrinkageImprove yieldFoundry mouldsFoundry coresDispersityEnvironmental resistance

The invention discloses environment-friendly casting molding sand which is made of the following raw materials in parts by weight: 200-230 parts of quartz sand, 50-60 parts of sodium bentonite, 20-30 parts of red soil, 30-40 parts of talcum powder, 20-30 parts of zinc oxide, 20-24 parts of Chinese medicine residue, 40-45 parts of straw powder, 2-3 parts of carboxymethyl cellulose, 5-8 parts of brown sugar, 1-2 parts of fatty alcohol polyoxyethylene ether, 40-50 parts of brick trash powder, 2-3 parts of boric acid, 40-45 parts of perlite, 2-3 parts of polyving alcohol, 1-2 parts of tung oil, 30-35 parts of bamboo charcoal and a proper amount of water. According to the invention, the brick trash powder is adopted, the Chinese medicine residue, the straw powder and the like are sintered at high temperate, the sand is loosened, breathable and good in collapsibility and is environmental-friendly and energy-saving, and with the combination of talcum powder, the dispersity and the plasticity are improved; due to adoption of brown sugar, tung oil and carboxymethyl cellulose as binding agents, the sand is not only good in binding effect, but also not affected in collapsibility at high temperature; the pass percent of cast pieces is improved, and the casting cost is lowered.

Owner:中合基铭实业江苏有限公司

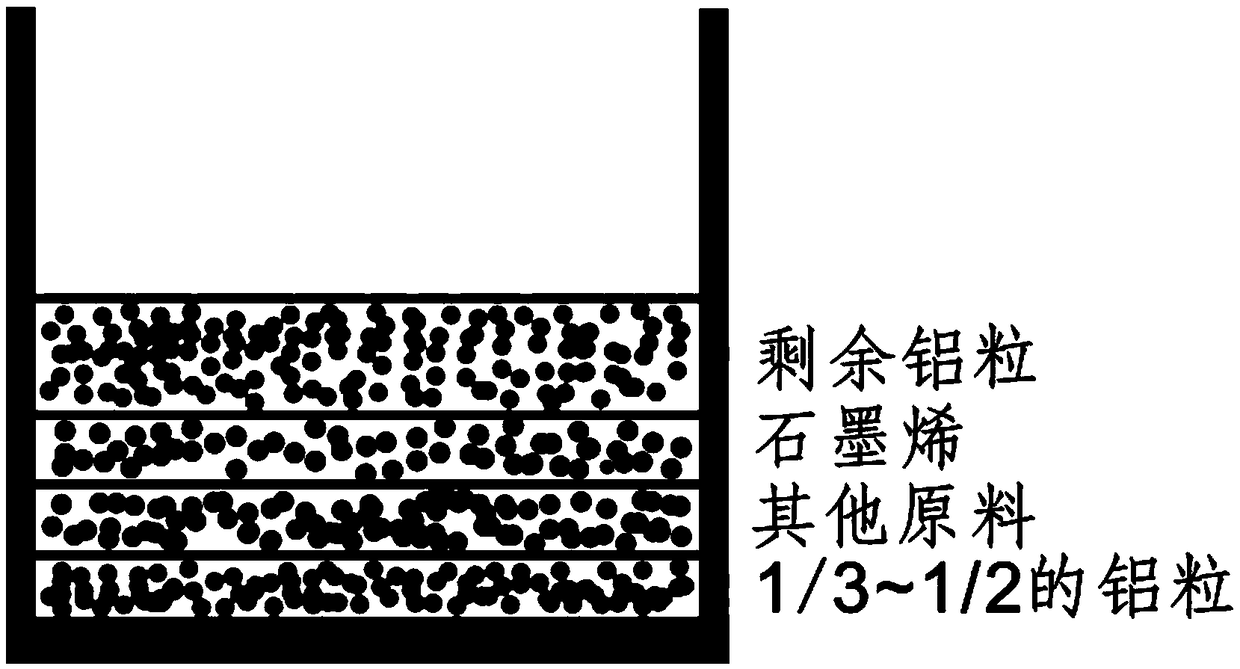

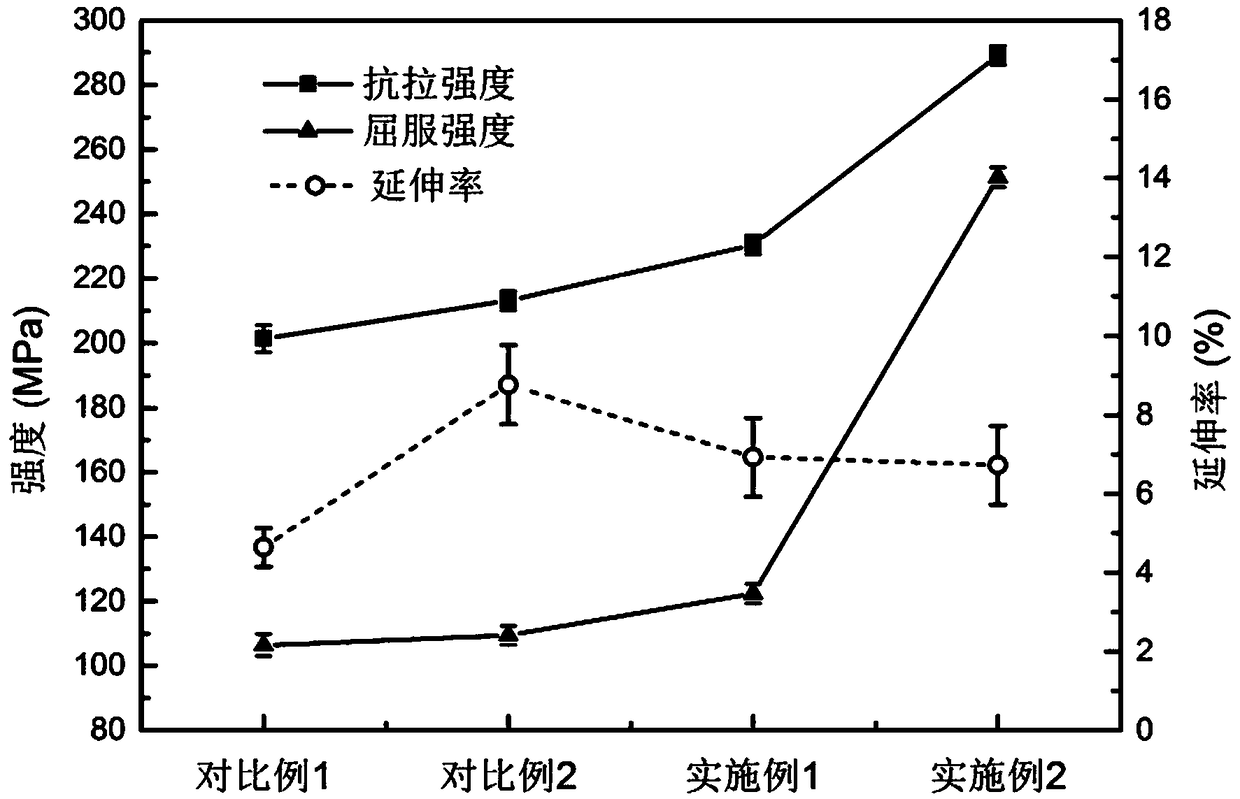

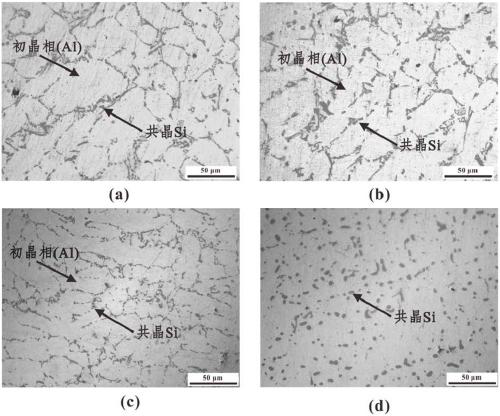

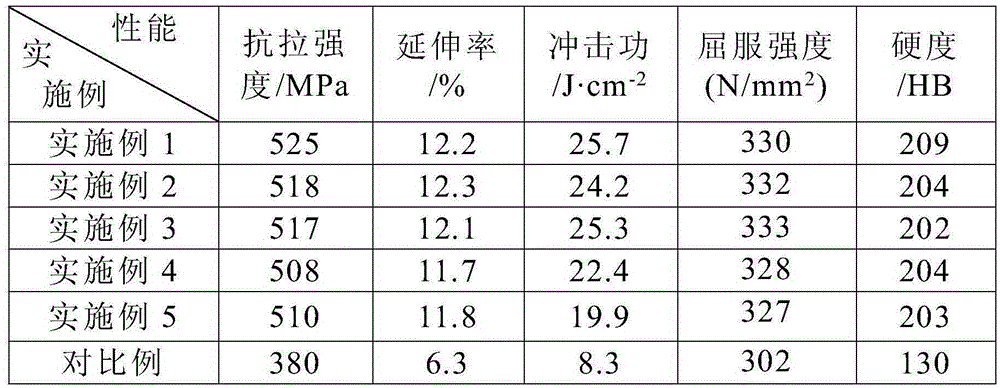

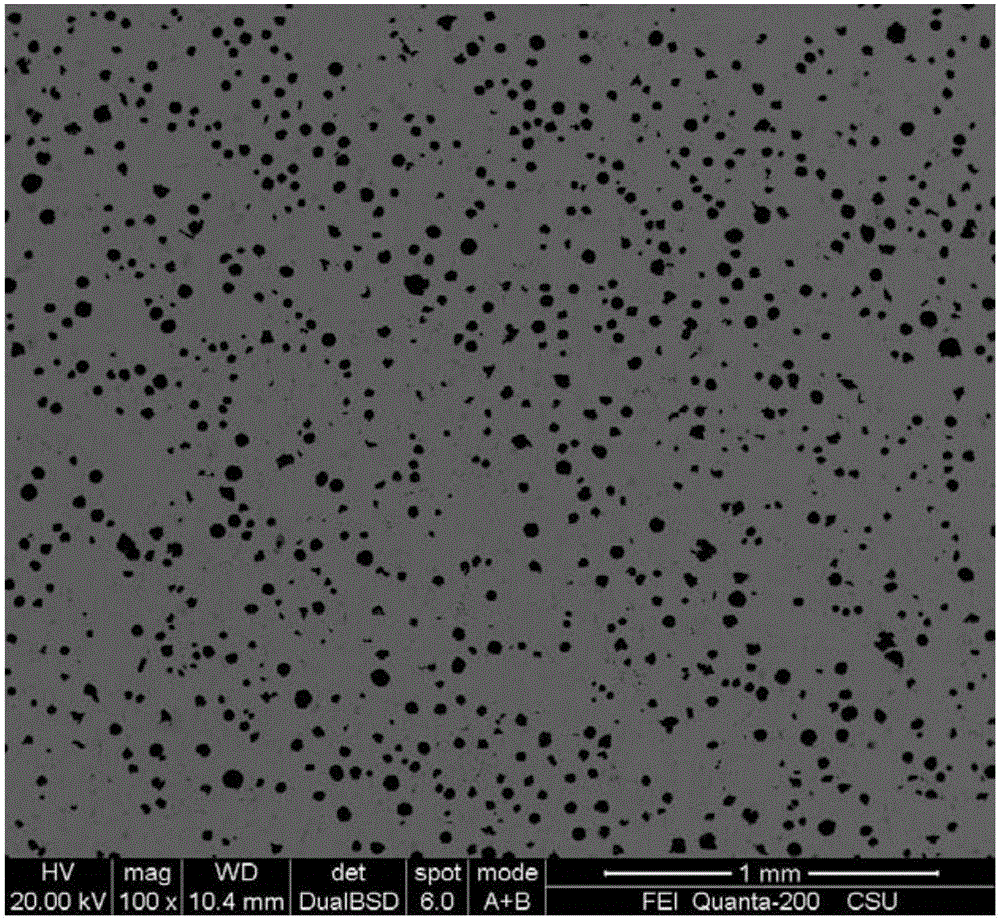

Graphene-rare earth-lanthanum reinforced Al-Si-Mg cast aluminum alloy and preparation method thereof

The invention relates to a graphene-rare earth-lanthanum reinforced Al-Si-Mg cast aluminum alloy and a preparation method thereof. The aluminum alloy comprises the following raw material in mass percent: 6.5 to 7.5% of silicon, 0.25 to 0.45% of magnesium, 0.30 to 0.50% of cerium, 0.001 to 0.005% of graphene, less than or equal to 0.05% of iron, less than or equal to 0.2% of zinc, less than or equal to 0.1% of manganese, less than or equal to 0.1% of titanium, less than or equal to 0.15% of zirconium, less than or equal to 0.1% of beryllium, less than or equal to 0.05% of tin, less than or equal to 0.1% of lead, less than or equal to 0.10% of other unavoidable elements, each of which is equal to or less than 0.03%, and the balance of aluminum. The mechanical property of the aluminum alloy is remarkably improved through uniformly adding a small amount of graphene and rare earth lanthanum in the alloy, and the comprehensive mechanical property is significantly improved when being comparedwith the prior art, so that the application range of aluminum alloy materials in the fields of automobile, aerospace and the like is greatly enlarged.

Owner:广州埃烯金属科技有限公司

Spheroidizing agent and preparation method and application thereof in spheroidal graphite cast iron smelting

The invention relates to a spheroidizing agent and a preparation method and application of the nucleating agent in spheroidal graphite cast iron smelting, and belongs to the technical field of metallurgy. The spheroidizing agent is composed of 41%-44% of Si, 7.5%-8% of Mg, 2.0%-2.5% of Y, 0.3%-0.5% of Ce, 0.1%-0.3% of Sc, 0.2%-0.6% of Mn, 3.0%-4.0% of Ca, 0.1%-0.3% of Al, 8%-15% of nano SiC with the grain size being 15-25 nm, and the balance Fe. A melting-mixing method is adopted and the spheroidizing agent is crushed to ultrafine powder with the grain size being 20-60 [mu]m. The invention further discloses the preparation method and application of the spheroidizing agent in spheroidal graphite cast iron smelting. Spheroidal graphite cast iron is obtained through spheroidizing twice by means of the spheroidizing agent, specifically, a first nucleating agent layer is placed on the side of the spheroidizing agent of a spheroidizing tundish and coated with a first spherical spheroidizing agent; the first spherical spheroidizing agent is coated with a first pig iron sheet layer; a second nucleating agent layer is overlaid on the first pig iron sheet layer, then a second spherical spheroidizing agent layer, a second pig iron sheet layer and a third nucleating agent layer are sequentially overlaid on the second nucleating agent layer, and spheroidizing and inoculation treatments are conducted by pouring in iron liquid. Obtained spheroidal graphite cast iron castings are high in strength, toughness and size stability.

Owner:宁波康发铸造有限公司

Grate bar material and production method thereof as well as combined pouring unit of sintering machine

ActiveCN103849819AReduce contentHigh hardnessFoundry mouldsFurnace typesChemical compositionBar product

The invention relates to a production method of a grate bar material of a sintering machine. The production method mainly solves the problems that a high-alloy grate bar is complex in production process, relatively high in production cost, difficult in casting flaw control, non-uniform in performance and the like in the prior art. The technical scheme of the invention is as follows: the grate bar material of the sintering machine comprises the following chemical components in percentage by mass: 1-1.5% of C, 1.5-2.5% of Si, 1.2-2.2% of Al, 2.5-3% of Mn, 11-15% of Cr, 0.3-0.8% of Mo, 0.01-0.03% of Nb, 0.01-0.03% of Ti, 0.03-0.1% of Re, less than or equal to 0.06% of P, less than or equal to 0.06% of S, and the balance of Fe and inevitable impurity elements. A sand casting process of 'one pouring with more molds' is applied, so that the aluminum content and the casting flaws of a silicon grate bar are reduced, and the production cost is reduced. A heat treatment furnace provided with a flow guide circulating fan is applied to low-temperature uniform heat treatment on a cast so as to improve the performance uniformity of casts of the same batch. By adopting the production method disclosed by the invention, a grate bar product of the sintering machine, which is good in process stability, good in performance and relatively low in production cost, can be obtained.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

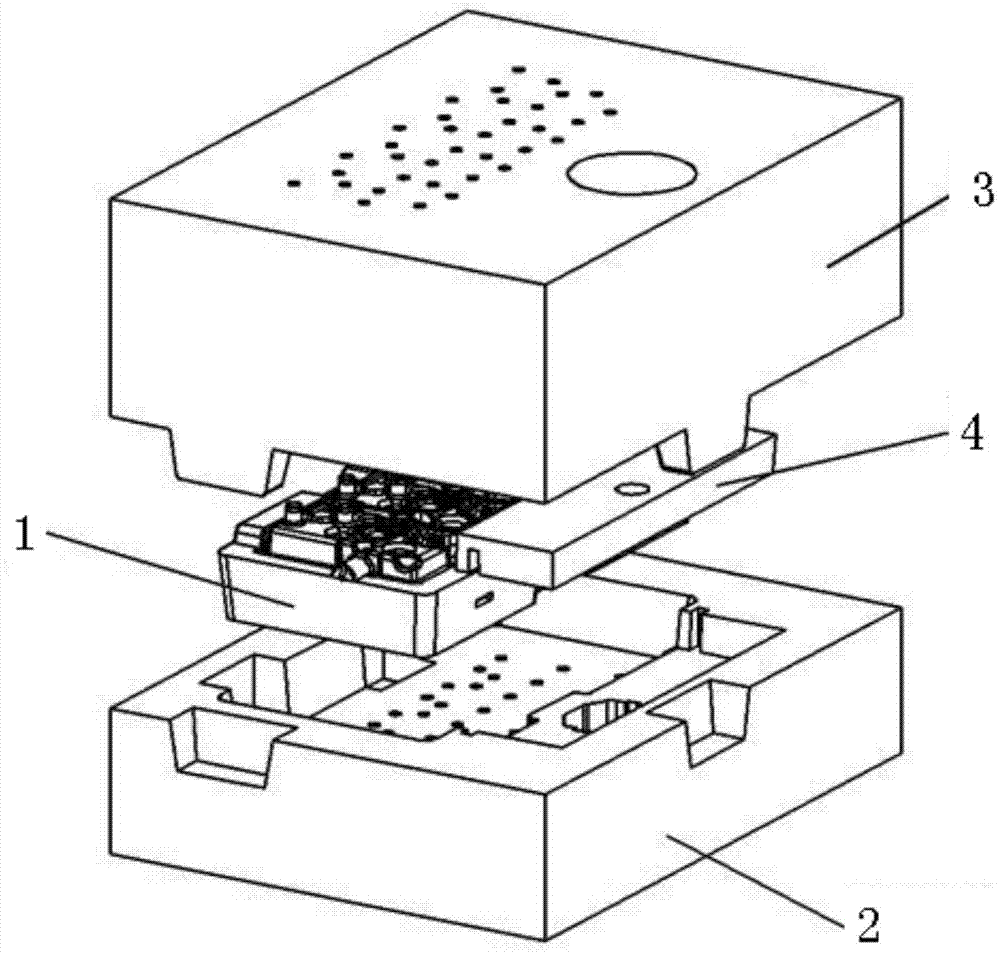

Large-duty loader hydraulic valve body casting mold and manufacturing method

ActiveCN105772646ACompact and reasonable structureStrong reliabilityFoundry mouldsFoundry coresCasting moldCasting defect

The invention discloses a large-duty loader hydraulic valve body casting mold. The large-duty loader hydraulic valve body casting mold comprises an upper shell mold body, a lower shell mold body, a sand core and a pouring and riser system. The sand core comprises a core head, a main core body and small core bodies. The main core body is composed of seven longitudinal arbors and four transverse arbors, and the longitudinal arbors and the transverse arbors are horizontally arranged in the same plane. The main core is provided with a plurality of convex blocks. Installation grooves are formed in the convex blocks. The small core bodies are fixed to the main core body through the installation grooves. The pouring and riser system comprises two exothermic and insulating risers with the diameter being 90 mm and the height being 120 mm. The large-duty loader hydraulic valve body casting mold has the advantages of being reasonable and compact in structure, high in reliability and convenient to assemble and cast, the straightness of a blank casted through a main valve hole is controlled to be smaller than 0.8 mm, assembly errors of a complex sand core are avoided, the casting defects of shrinkage cavities, shrinkage porosity, internal pores and the like of a casting piece are overcome, and the compactness of the internal structure is improved, so that leakage is avoided under a high-pressure working condition with the rated pressure being larger than or equal to 35 Mpa; and the casting qualified rate is improved greatly, and the casting cost is reduced.

Owner:NANTONG ENMAI PRECISION MACHINERY SCI & TECH CO LTD

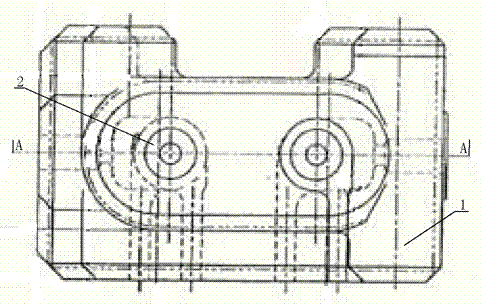

Multi-passage valve body casting

ActiveCN104776258ASimple designEasy to useFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention relates to a multi-passage valve body casting. The multi-passage valve body casting comprises a valve body, horizontal flow passages, a longitudinal flow passage and flow passage ports, the valve body is shaped like a cuboid, the two horizontal flow passages are arranged side by side in the valve body, the lower ends of the two horizontal flow passages communicate with each other via the longitudinal flow passage, the front and back of the valve body are respectively provided with two flow passage ports which communicate with the two horizontal flow passages, the middle parts of the two horizontal flow passages are respectively provided with three annular grooves, the upper ends of the annular grooves of the upper ends of the horizontal flow passages are provided with through holes, the openings of the through holes are located on the valve body, the left side of the middle annular groove of the left horizontal flow passage is provided with a through hole, the opening of the through hole is located at the left side of the valve body, the right side of the middle annular groove of the right horizontal flow passage is provided with a through hole, the upper ends of the annular grooves of the lower ends of the horizontal flow passages are provided with through holes, and the right side of the longitudinal flow passage is provided with a through hole. The multi-passage valve body casting has the following advantages: the design is simple, the multi-passage valve body casting is convenient to use and cast, and is ingenious and reasonable, the casting percent of pass is increased greatly, and the casting cost is reduced.

Owner:南通华东油压科技有限公司

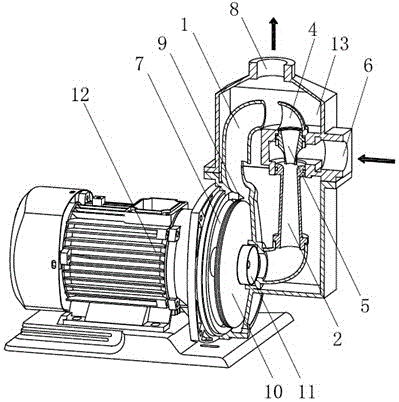

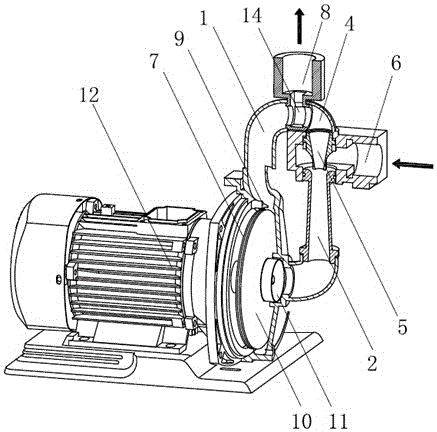

Low-noise self-priming combined pump

ActiveCN106224249AReserve large trafficKeep high headPump componentsPriming pumpLow noiseWorking fluid

The invention discloses a low-noise self-priming combined pump. According to the low-noise self-priming combined pump, diffusion guide vanes and a guide disc of a traditional self-priming jet pump are removed, a single-baffle-tongue single-outlet centrifugal vortex chamber or a multi-baffle-tongue multi-outlet centrifugal vortex chamber which is higher in hydraulic performance and efficiency is adopted, a single entry type runner is designed, centrifuged and accelerated fluid is reasonably guided into a distribution pumping chamber or a distribution tee joint, scraping among the guide vanes, the guide disc and a centrifugal impeller and strong impact of the high-speed fluid to the guide vanes and the guide disc are eliminated essentially, transitional flowing between the centrifugal vortex chamber and the distribution pumping chamber or the distribution tee joint is more smooth, and the flowing losses and flowing noise are lower. Through the reasonable arrangement of the single entry type runner, continuous supply of the working fluid at the inlet section of a spray nozzle can be guaranteed, so that negative pressure is maintained, and strong self-priming capacity is obtained. The traditional large-sized distribution pumping chamber can be replaced with the distribution tee joint, and thus the structure is more compact.

Owner:ZHEJIANG SINCONTROL PUMP IND

Green sand single box feederless foundry method for glass mold

InactiveCN102581221AIncrease profitHigh densityFoundry mouldsFoundry coresFoundryProcess engineering

The invention discloses a green sand single box feederless foundry method for a glass mold and belongs to the field of glass mold foundry. The method comprises the following steps: firstly, positioning sand cores are manufactured; then a wood pattern template provided with a pair of bottom molds, sand core matrixes, pouring gate molds as well as a filter screen gap is manufactured according to the size of the blank of the glass mold; the wood pattern template is fixed on a moulding machine, a frame is arranged on the wood pattern template in a covering manner, one positioning sand core is respectively placed on the sand core matrixes at two ends of the bottle molds, and a filter screen is placed into the filter screen gap: the frame is filled with green sand, and the moulding machine is opened. The wood pattern template and the frame filled with the green sand are over turned, and the wood pattern template is removed; a releasing agent is sprayed into the bottle cavities of the bottle molds; molten iron is poured from the pouring gate mold cavities of the pouring gate molds, the frame, a chiller sand core and the positioning sand cores are removed, and the blank is obtained after the green sand is removed; and the pouring gate iron is removed, and the glass mold is obtained. The utility model has the advantages that the raw materials are saved; the finish of the inner chamber surface and the parting surface of mold are improved; the casting cost is lowered; and the environmental conservation is achieved.

Owner:CHANGSHU WEIHENG MOLD MFG

High-toughness synthetic cast iron cylinder-sleeve material and manufacturing process

The invention discloses a manufacturing process of a high-toughness synthetic cast iron cylinder-sleeve material. The method comprises the following steps: using low-carbon steel scrap as a raw material, carrying out recarburization by adding a carburant, adding ferroalloy and fusing to obtain high-carbon high-silicon molten iron; adding a high-silicon silicon steel sheet into the surface of the molten iron to carry out silicon-increasing and carbon-reduction processing; and adding an instantaneous inoculant into the molten iron to carry out secondary instantaneous compound inoculation treatment, and pouring a blank to prepare the high-toughness synthetic cast iron cylinder-sleeve material. Casting costs of the high-toughness synthetic cast iron provided by the invention are 15-20% lower than casting costs of general alloy cast iron. Tensile strength of the prepared high-toughness synthetic cast iron cylinder-sleeve is 80-130MPa higher than tensile strength of an alloy cast iron cylinder-sleeve, and the tensile strength of the prepared high-toughness synthetic cast iron cylinder-sleeve can reach 350-420 MPa. Hardness can be controlled to 190-240, and hardness difference of the high-toughness synthetic cast iron cylinder-sleeve is shortened by 20HB in comparison with hardness difference of the alloy cast iron cylinder-sleeve and can shortened to delta HB being less than or equal to 10. Elasticity modulus E is greater than or equal to 140GPA. High-toughness synthetic cast iron can be used to reduce wall thickness of the cylinder sleeve and raise power of an engine. In addition, the elasticity modulus is high, hardness is low and processability is good, clearance between a piston and a cylinder can be decreased; noise can be reduced; and power can be increased.

Owner:FUJIAN LONGSHENG MACHINERY

Gypsum model precise casting technology

InactiveCN107812888AReduced risk of crackingReduce casting costsFoundry mouldsFoundry coresAbnormal tissue growthPorosity

The invention provides a gypsum model precise casting technology and relates to the technical field of casting technologies. The gypsum model precise casting technology comprises the following steps that gypsum slurry is prepared; grouting is carried out, a box frame in which a module is installed is placed into a grouting chamber, then vacuumizing is carried out to 0.05-0.06 MPa, and the slurry is stably poured into the box frame; roasting is carried out, step temperature rise is adopted, and heat is preserved for a certain period of time in each section, so that the temperature of the innerwall and the temperature of the outer wall are consistent; casting and casting cleaning are carried out; and after a gypsum model is dried completely, gravity casting is carried out, and for large thin-wall precise castings, great careful clearing, repairing and correcting are carried out after casting. According to the gypsum model precise casting technology, the crack risk of the castings can bereduced greatly, size precision is high, the casting cost is low, the casting quality is good, and defects of air holes, shrinkage holes, shrinkage depression, rising and the like are avoided.

Owner:泰兴市长江密封材料有限公司

Method for casting negative pressure solid cylinder sleeve

The invention relates to a method for casting a negative pressure solid cylinder sleeve, which comprises the following steps: manufacturing a foam plastic model of a cylinder sleeve; bonding a molten iron flow passage through which molten iron flows into a cavity when casting the cylinder sleeve; forming the cavity for accommodating the foam plastic model of the cylinder sleeve by using dry sand; placing the foam plastic model of the cylinder sleeve into the cavity; filling sand into the cavity and jolting to form a solid cavity; molding the cavity by negative pressure; casting molten iron into the cavity so that the foam plastic model of the cylinder sleeve disappears due to gasification and combustion; obtaining a raw casting of the cylinder sleeve blank; taking the casting of the cylinder sleeve blank out; and shaking out the sand and cleaning to obtain a required casting of the cylinder sleeve blank. The method for casting the negative pressure solid cylinder sleeve has the following advantages of: high automation degree of production equipment, small labour intensity, high production efficiency, high utilization ratio of molten metal, high yield of castings, low production cost, high production efficiency, high casting precision, low coke consumption, low sulphur dioxide emissions, and less pollution to environment.

Owner:ANHUI PROVINCE YUEXI CYLINDER

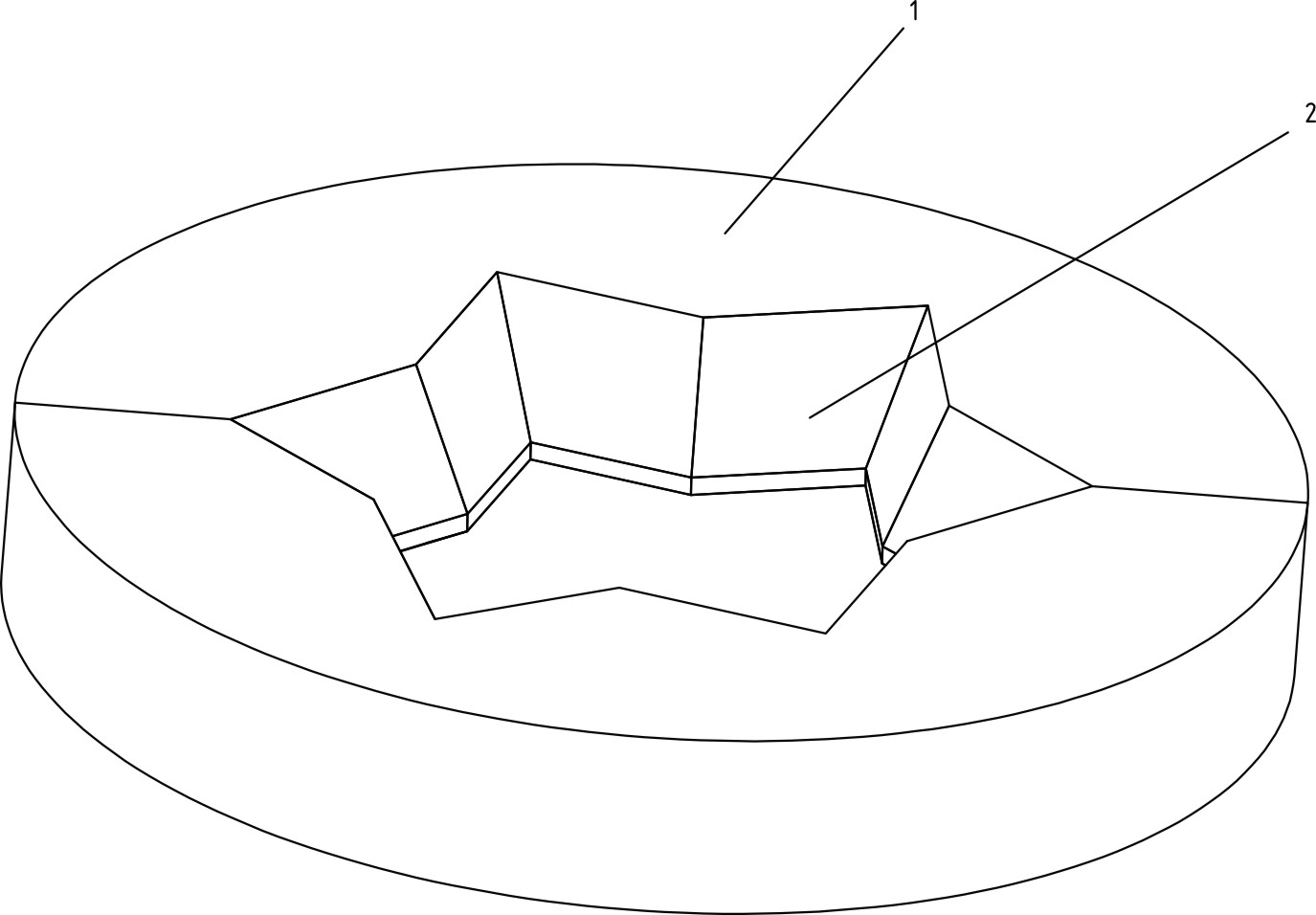

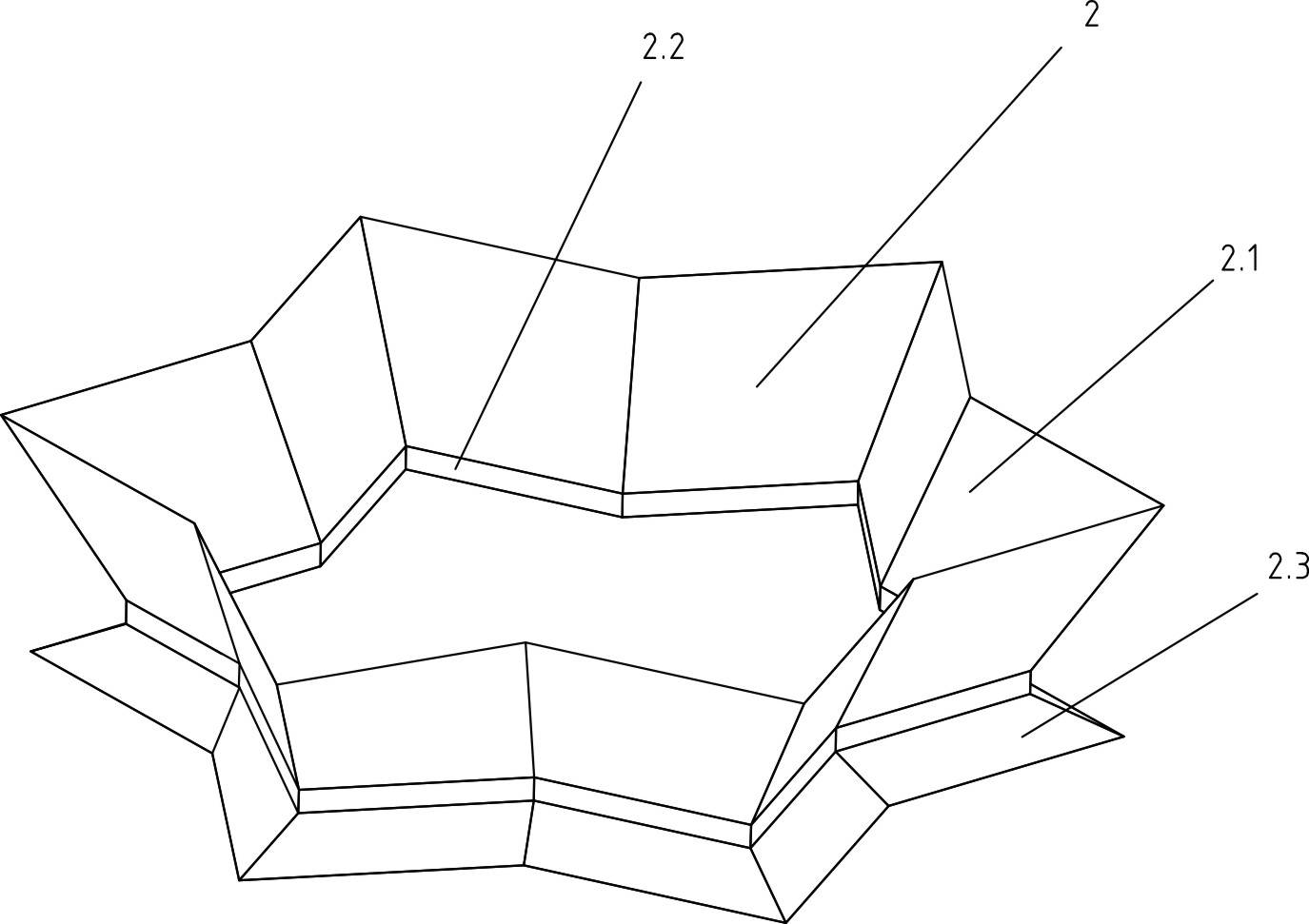

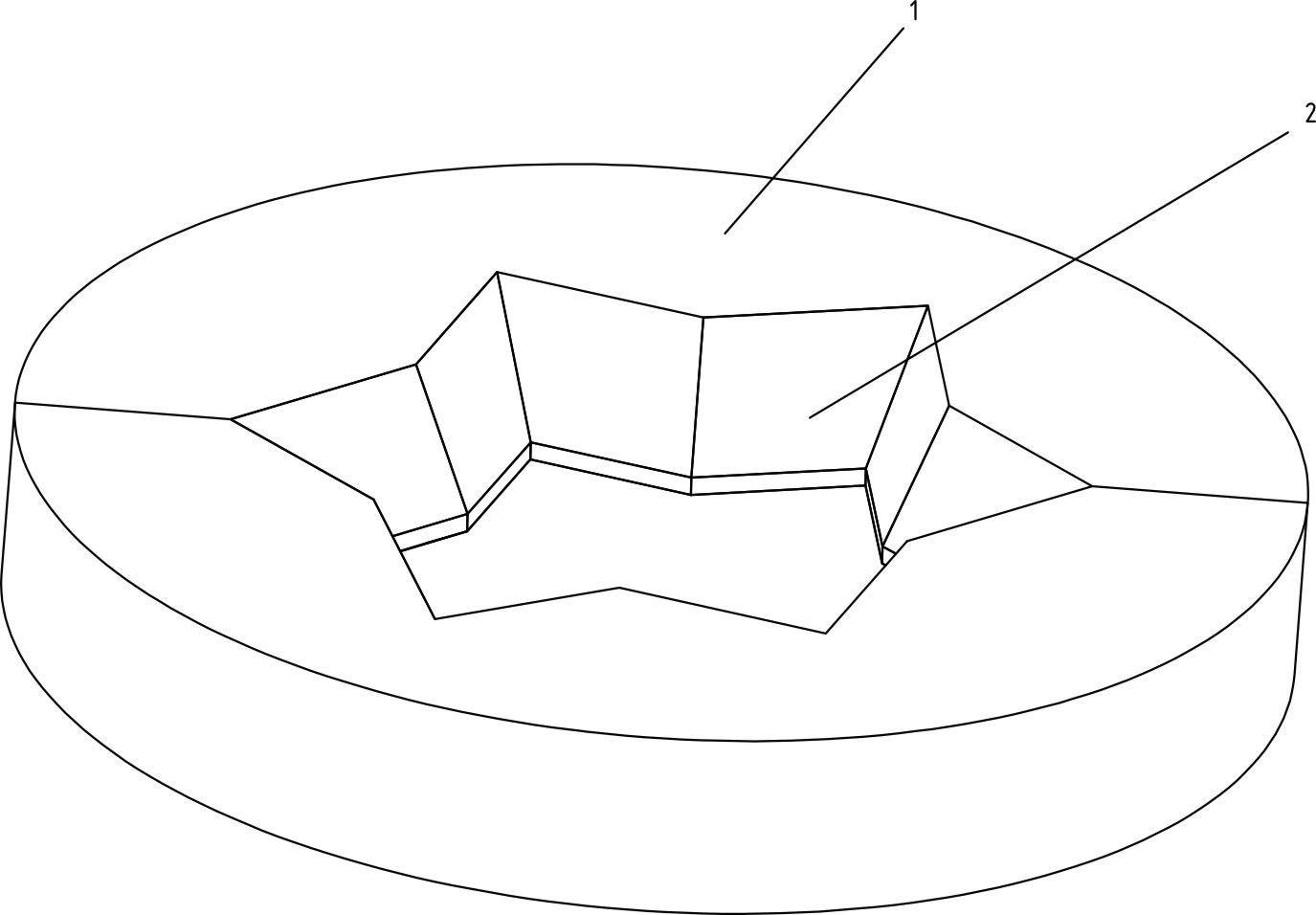

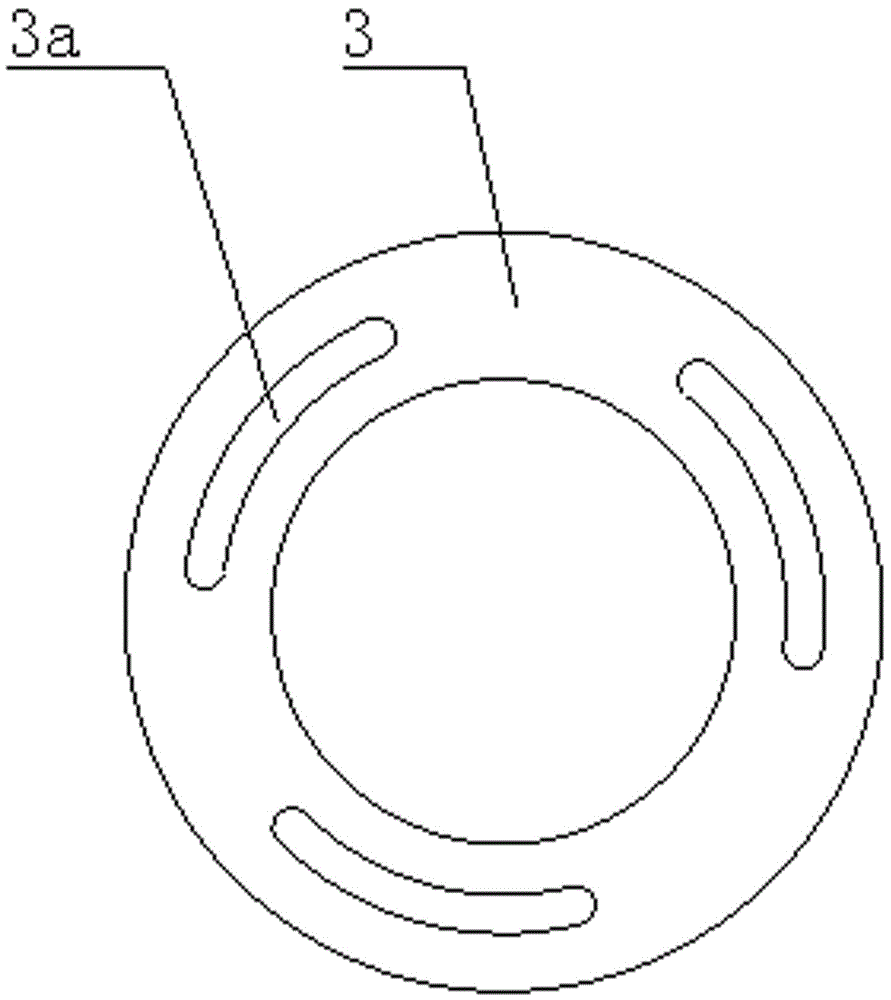

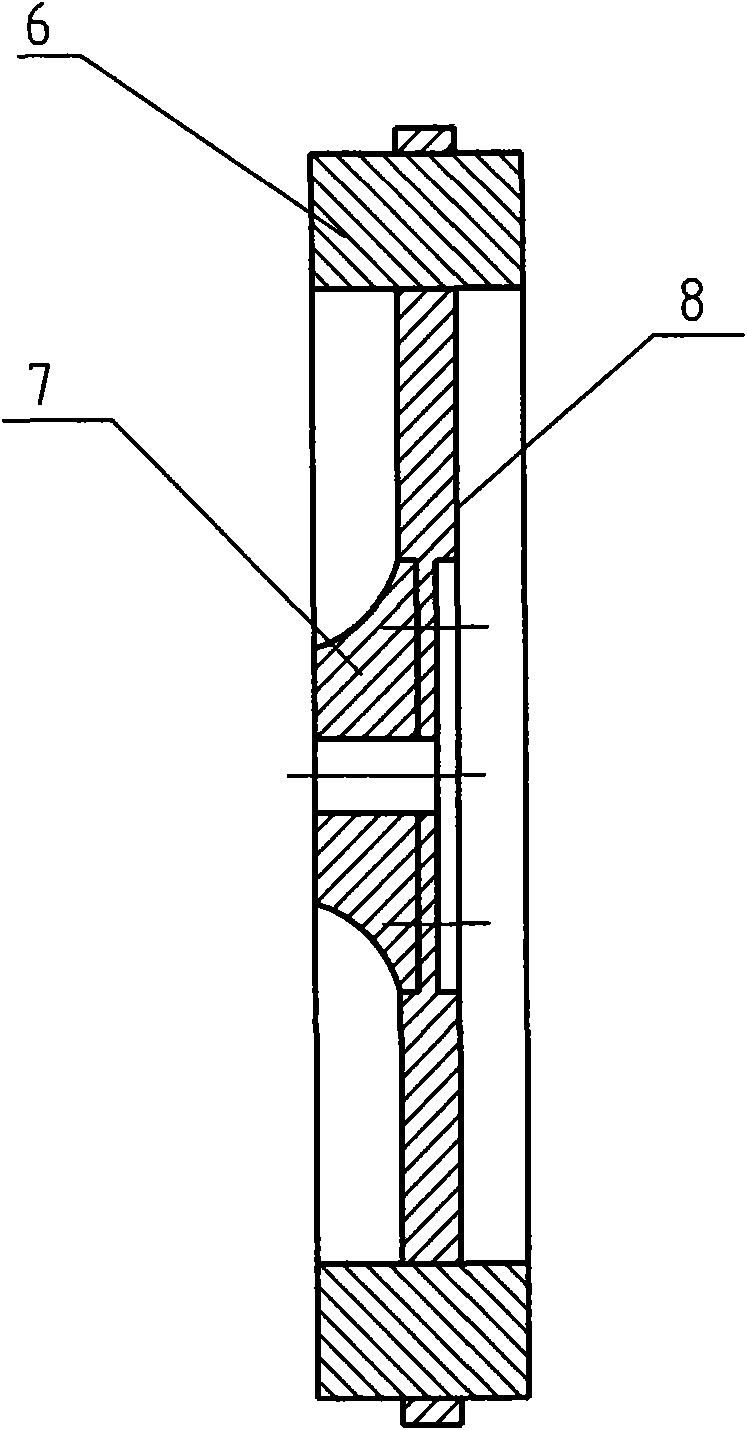

Feeder head knock-off core

ActiveCN102328030AResolve separation difficultiesReduce connection strengthFoundry mouldsFoundry coresUltimate tensile strengthMaterials science

The invention relates to the cast field, in particular relates to a knock-off core between a cast cavity and a feeder head. The feeder head knock-off core solves the technical problems that a cast feeder head and a cast main body in the existing feeder head knock-off core have high connection strength, the cast feeder head is hard to separate from the cast main body, and the separation work of the cast feeder head and the cast main body has high strength in the prior art. The invention provides a feeder head knock-off core, wherein the cast feeder head and the cast main body have low connection strength, the cast feeder head is easy to separate from the cast main body, the separation work strength of the cast feeder head and the cast main body is low, and the processing work load after the casting of the cast main body is low. The feeder head knock-off core provided by the invention comprises a knock-off core main body on which a liquid communicating hole for communicating upper and lower surfaces of the knock-off core is arranged; the liquid communicating hole comprises an upper liquid communicating hole and a lower communicating hole; and cross section outlines of the upper and lower communicating holes are in four-pointed star shape or five-pointed star shape or six-pointed star shape, and a lower opening of the upper liquid communicating hole is congruent to a small opening of the lower communicating hole.

Owner:ZHEJIANG WUJING MACHINE MFG +1

Casting device capable of being continuously used

The invention discloses a casting device capable of being continuously used. The casting device comprises a working table and further comprises a supporting frame, a top plate, a hydraulic cylinder, an upper mold hanging plate, an upper mold, a high-pressure casting box, a lower mold installation plate, a lower mold, an ejector rod, a motor, a cam disk and a high-pressure spraying device. Compared with the prior art, the upper mold and the lower mold are pushed by the hydraulic cylinder to be assembled, melted metal liquid is injected into cavities of the upper mold and the lower mold through the high-pressure casting box, after the metal liquid is solidified, and the upper mold is pulled by the hydraulic cylinder to move upwards; meanwhile, the high-pressure spraying device sprays high-pressure gas, releasing agents are mixed into the gas, the cam disk is driven by the motor to rotate, when the highest point of the cam disk reaches the top end, the ejector rod is pushed to upwards move, a casting is released from the lower mold, the casting can be smoothly related accordingly, a traditional sand mold is replaced, one mold can be repeatedly used, and the casting cost is reduced.

Owner:东至县文元瓷砖加工厂

Flange fast and firm in connection

ActiveCN106224667AQuick and efficient installationEasy to installFlanged jointsFoundry mouldsEngineeringFlange

The invention relates to a flange fast and firm in connection. The flange fast and firm in connection comprises a first flange body, a second flange body, a sealing gasket, a fastening bolt and a nut. The corresponding positions of the first flange body and the second flange body are each provided with at least two arc-shaped holes. The fastening bolt sequentially penetrates the arc-shaped holes in the first flange body and the arc-shaped holes of the second flange body and is connected with the nut in a threaded manner. The sealing gasket is arranged between the first flange body and the second flange body. The side, close to the first flange body, of the second flange body is provided with an annular connecting block. An external thread is machined on the outer side of the annular connecting block. A connecting groove matched with the annular connecting block is formed in the first flange body. An internal thread matched with the external thread of the annular connecting block is machined on the inner wall of the connecting groove. According to the flange fast and firm in connection, the first flange body and the second flange body are connected through the thread of the connecting block firstly and thereafter connected through the bolt when connected, and the two connecting manners are matched mutually, so that connection of the first flange body and the second flange body is firmer and more stable, and the problems of leakage and the like caused by infirm connection are reduced greatly.

Owner:YANCHENG FENGGONG MACHINERY

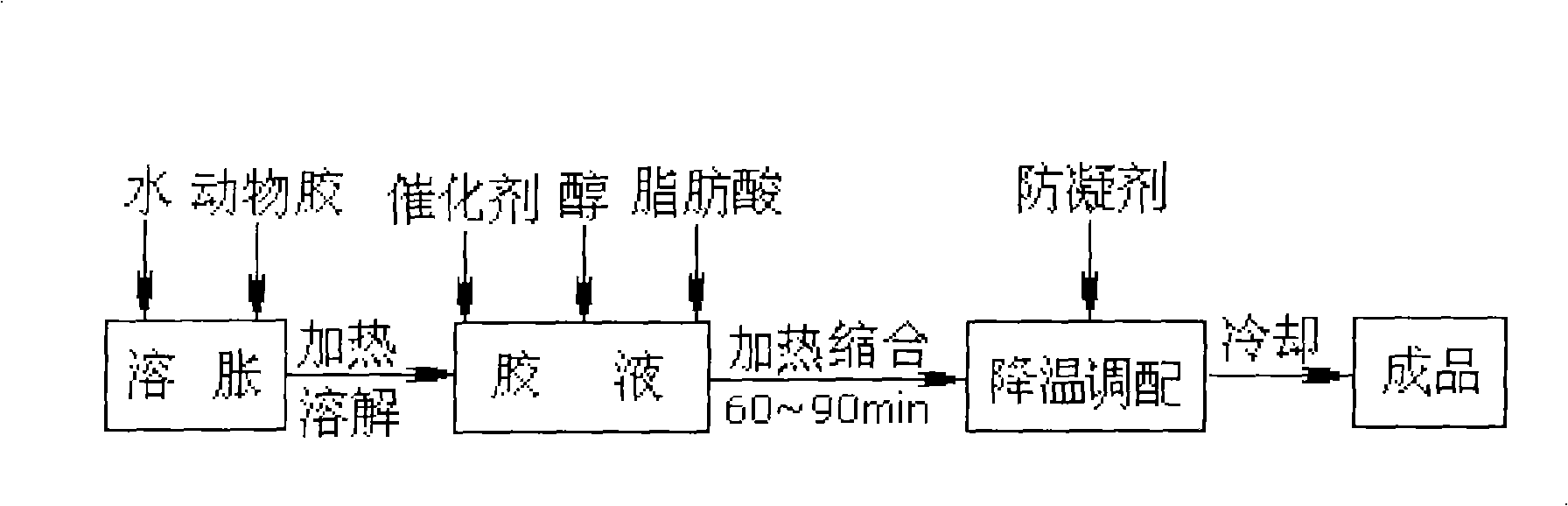

Method for preparing environment-friendly type casting adhesive agent

The invention discloses a preparation method of an environment-friendly casting binder, which relates to an improvement of a casting binder, and provides the preparation method of an environment-friendly casting binder that does not discharge noxious and harmful gases in the producing and using process. The preparation method of the environment-friendly casting binder adopts the technical proposal which comprises animal glue, fatty acid, alcohol, an anti-gelling agent and a catalyst with the content of each component by weight is: 30 to 60 units of animal glue, 20 to 40 units of fatty acid (or C12-C18 organic acid), 10 to 20 units of alcohol, 10 to 20 units of anti-gelling agent, 1 to 2 units of mineral acid catalyst and the remaining of water.

Owner:SHENYANG POLYTECHNIC UNIV

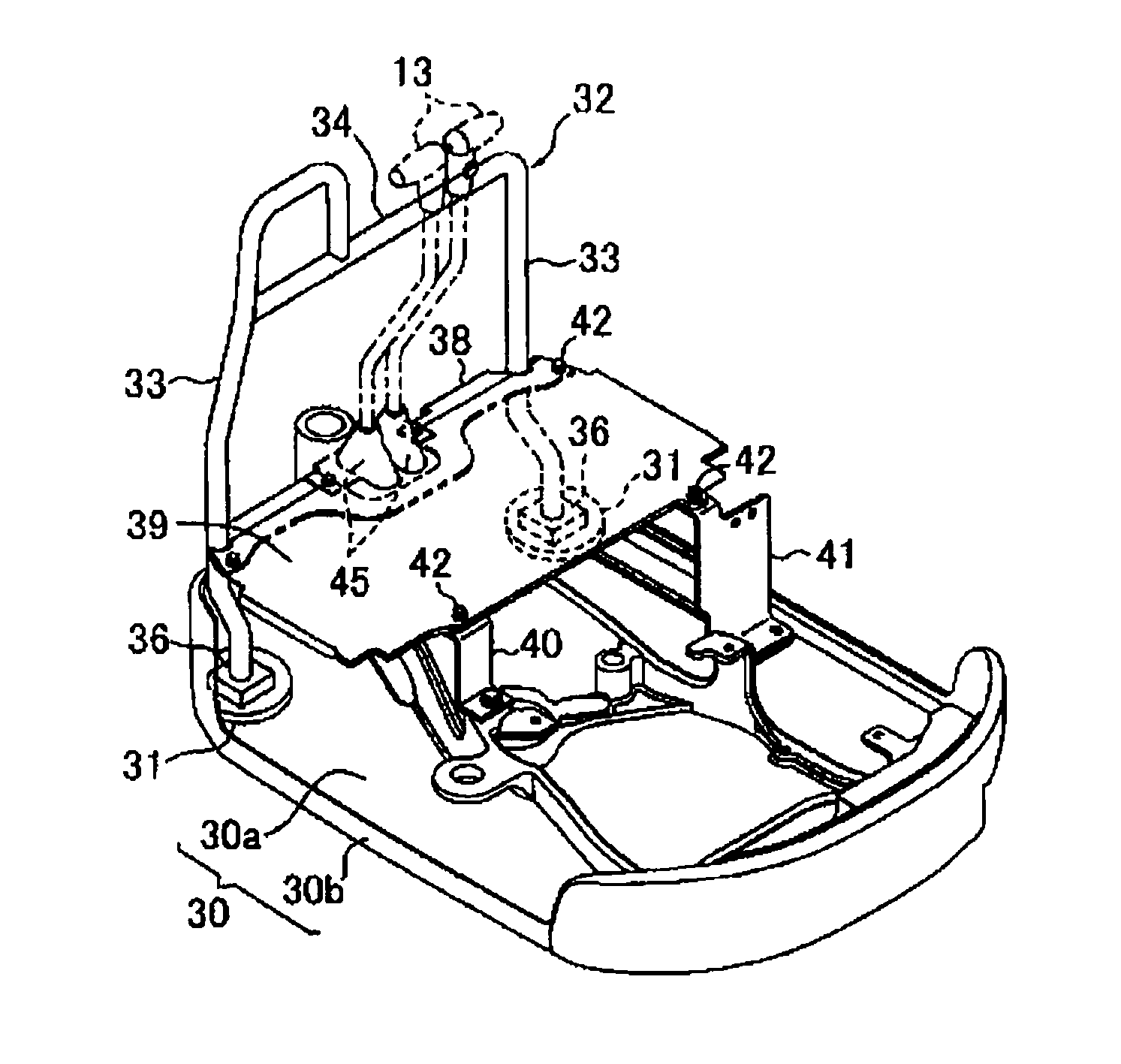

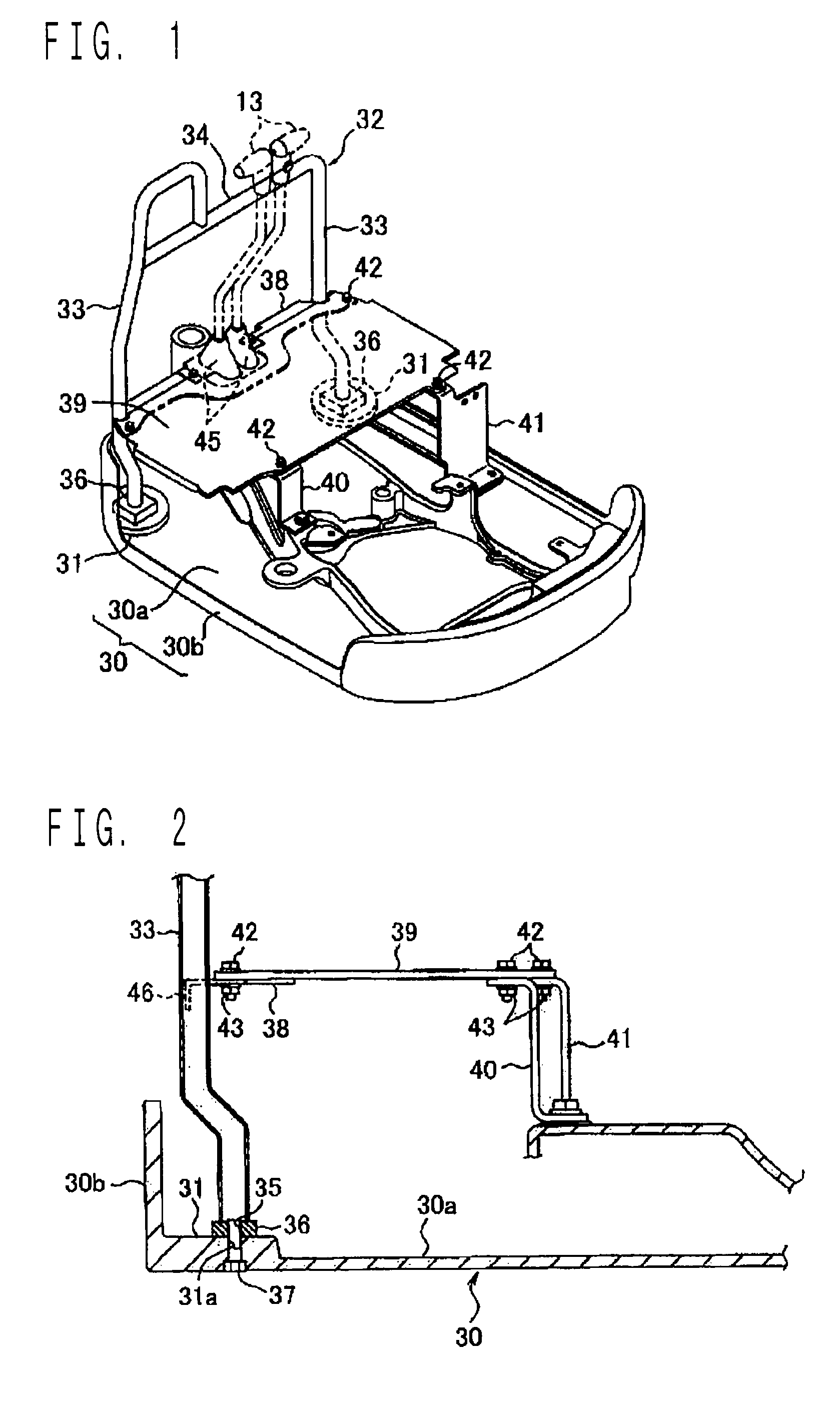

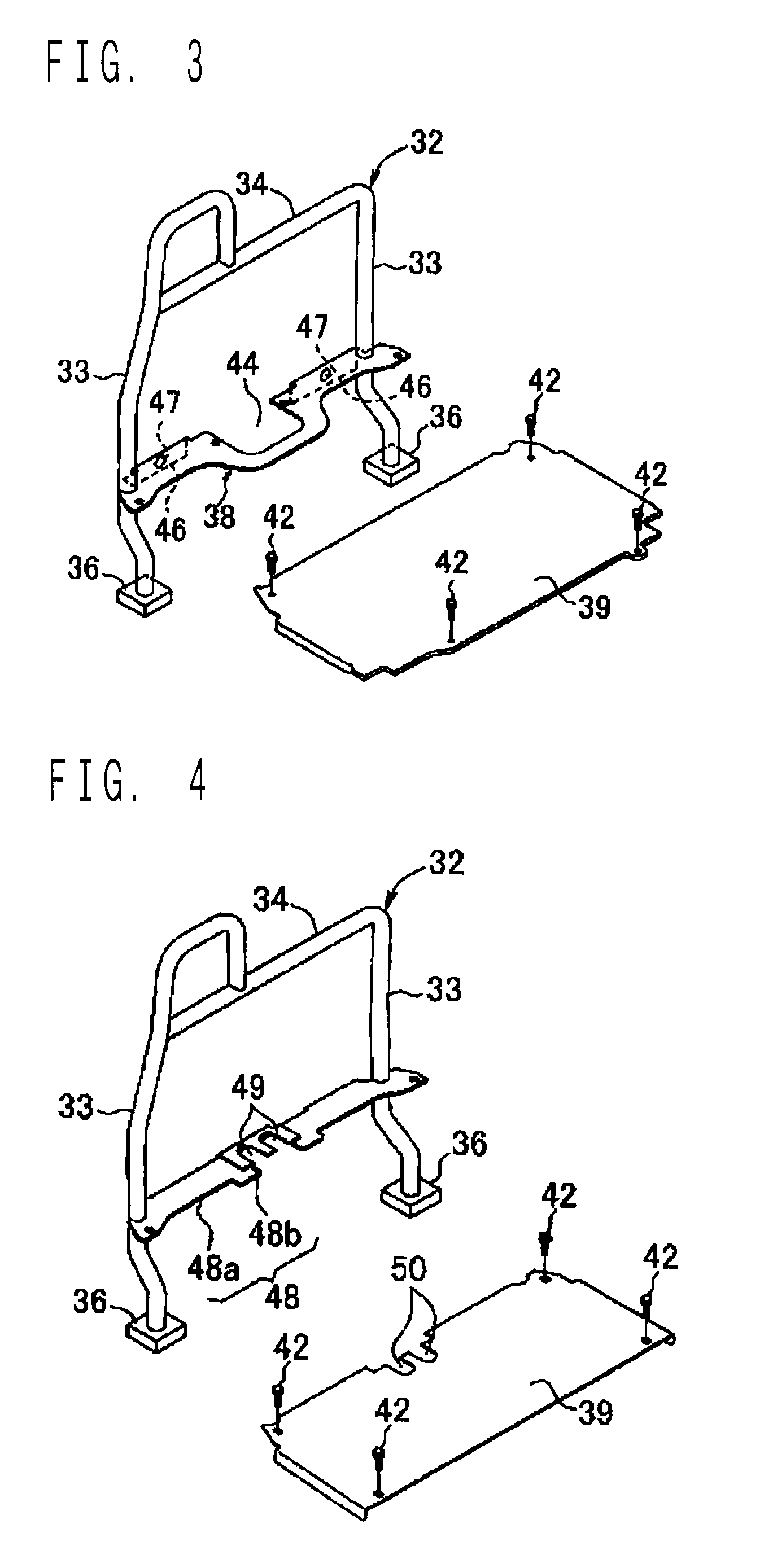

Construction machine

Handrail mounts are provided in a bottom portion of a cast upper frame, and lower ends of side supports of a handrail are attached to the above handrail mounts. A base plate for attaching a floor plate is hanged and fixed between the side supports at a higher position than the attachment position, and a front end part of the floor plate is attached to the above base plate.

Owner:KOBELCO CONSTR MASCH CO LTD

Efficient sealing flange

ActiveCN106247048AQuick and efficient installationEasy to installEngine sealsFlanged jointsScrew threadScreen filter

The invention relates to an efficient sealing flange which comprises a first flange body, a second flange body, a round filter screen, fastening bolts and nuts. The corresponding positions of the first flange body, the second flange body and the round filter screen are each provided with arc-shaped holes. Each fastening bolt sequentially penetrates the corresponding arc-shaped hole of the first flange body, the corresponding arc-shaped hole of the round filter screen and the corresponding arc-shaped hole of the second flange body to be in threaded connection with the corresponding nut. An annular connecting block is arranged on the side, close to the first flange body, of the second flange body. An external thread is manufactured on the outer side of the annular connecting block. A connecting groove is formed in the first flange body, and an internal thread is manufactured on the inner wall of the connecting groove. The surfaces of the opposite sides of the first flange body and the second flange body are covered with a first rubber sealing layer and a second rubber sealing layer correspondingly. The side, in contact with the first flange body, of each fastening bolt and the side, in contact with the second flange body, of each nut are covered with a third rubber sealing layer and a fourth rubber sealing layer correspondingly. The edge of the outer side of the round filter screen is covered with a rubber sealing ring. According to the efficient sealing flange, by means of the cooperation of the four rubber sealing layers, it is guaranteed that the sealing performance of the flange is efficient and stable, and the flange is prevented from leaking at the connecting position.

Owner:YANCHENG FENGGONG MACHINERY

Additive of green sand casting mould sand for preventing sand fusion and sand inclusion

A green sand casting addition which prevents sand adhesion and sand inclusion is characterized in that the addition comprises one of the three following components or the combination thereof: polystyrene foam recycling products, furfural scraps and feldspar powder. The addition can easily produce castings with smooth and clean surfaces, and meet the requirements for producing various castings; the addition has the advantages of simple casting process, high production efficiency, low casting cost, high precision, etc.; the addition can better solve the technical problems of the green sand castings, such as the sand adhesion, the sand inclusion, the sand scabbing, etc.; the castings have the advantages of easier cleaning, high shape stability and more beautiful appearance; and meanwhile, the addition further avoids various defects in using coal powder. Compared with the prior art, the addition has better technical effect and great foreseeable economic and social values.

Owner:SHENYANG POLYTECHNIC UNIV

Lost foam casting process of low-alloy cast steel wheel for port machinery

InactiveCN104353781AReduce casting costsMolten metal pouring equipmentsFoundry mouldsHigh volume manufacturingAlloy

The invention relates to a lost foam casting process of a low-alloy cast steel wheel for port machinery. The lost foam casting process comprises the following steps: firstly, pre-foaming and forming; secondly, preparing a coating, coating a template, and coating after assembling a casting system and the template; thirdly, designing a casting system process; fourthly, shaping; fifthly, performing the casting process steps; sixthly, finishing all castings, keeping negative pressure for 15 minutes, standing and cooling for at least 12 hours, and opening a box. According to the lost foam casting process, various technical difficulties are overcome, the application range of the lost foam casting technology is expanded, the casting cost is greatly reduced, and the concept that people often think that low-alloy cast steel is forbidden zone of lost foam casting is broken through; small-batch pilot tests and large-batch production practices show that the one-time qualification rate of casting products reaches about 95%.

Owner:WUXI LEHUA AUTOMATION TECH

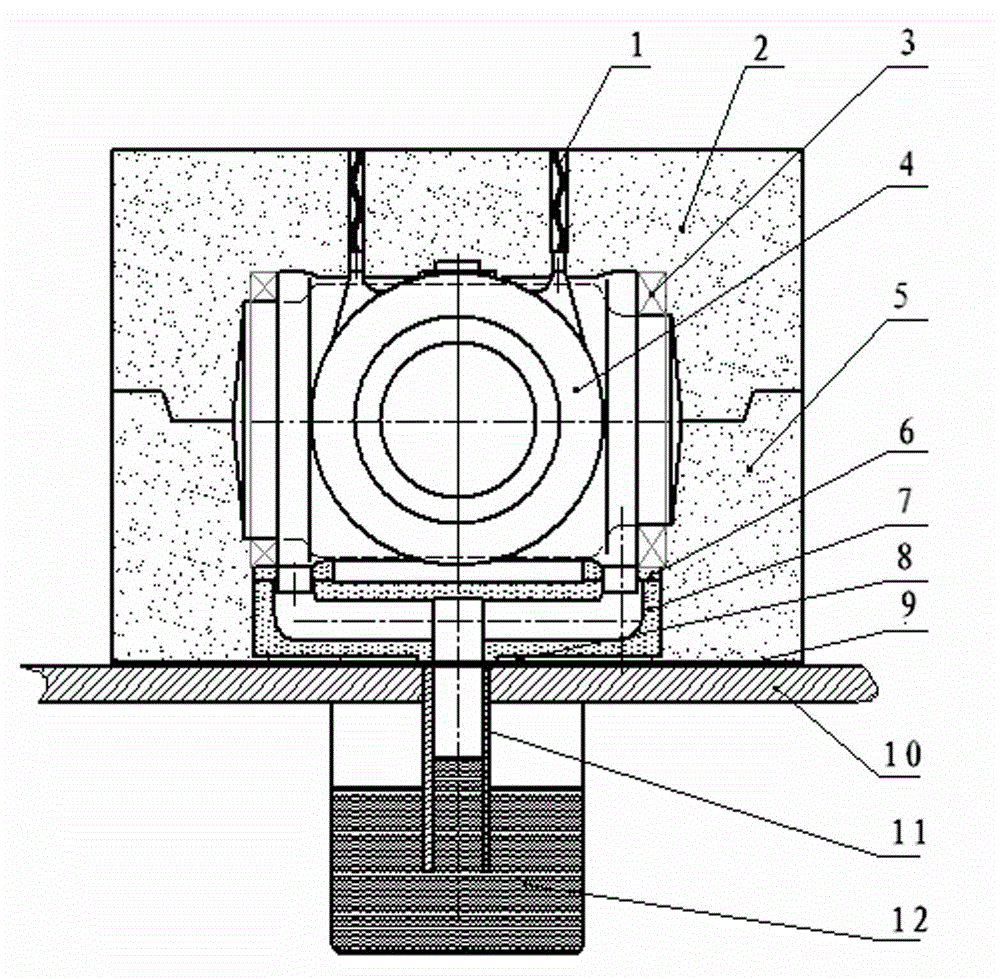

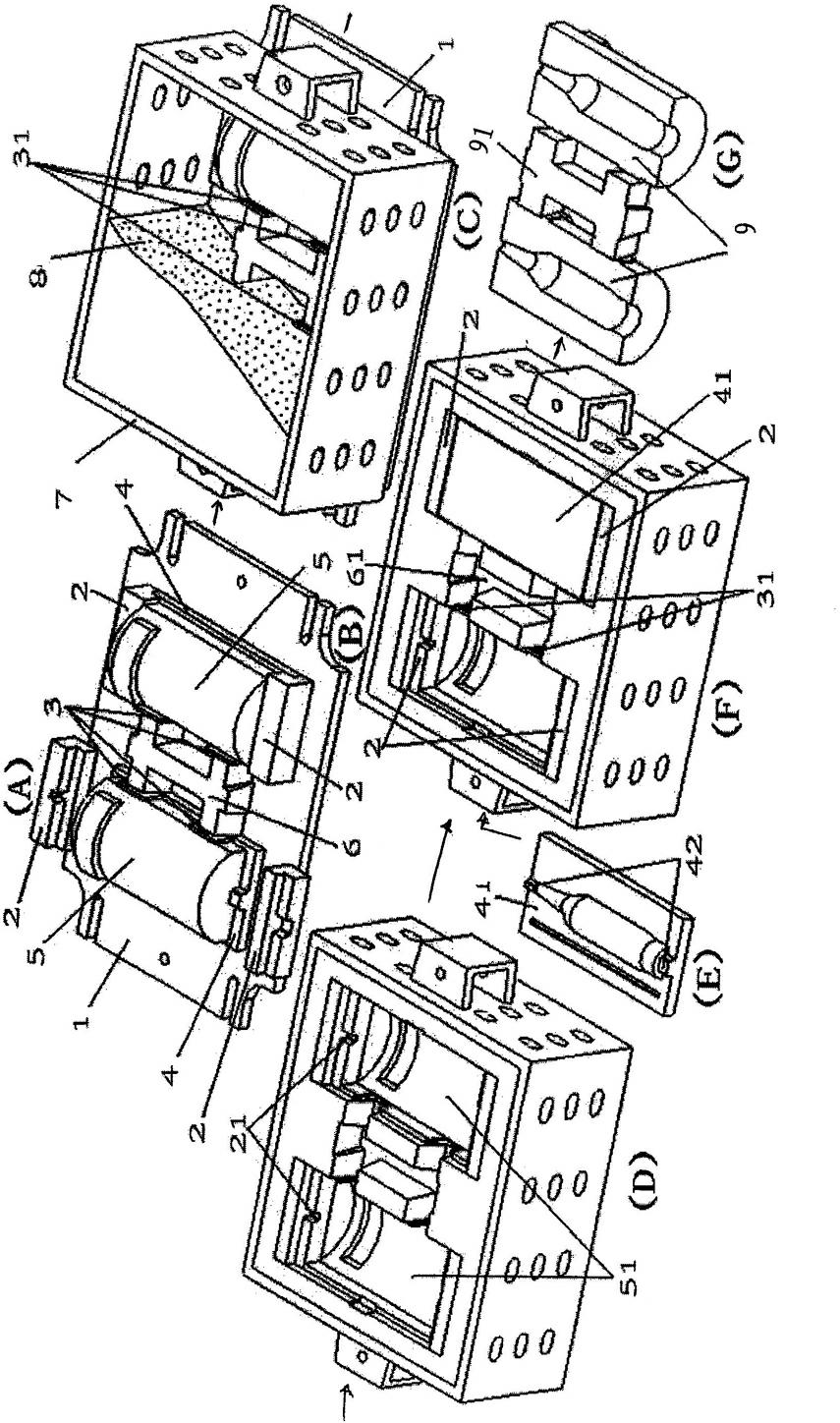

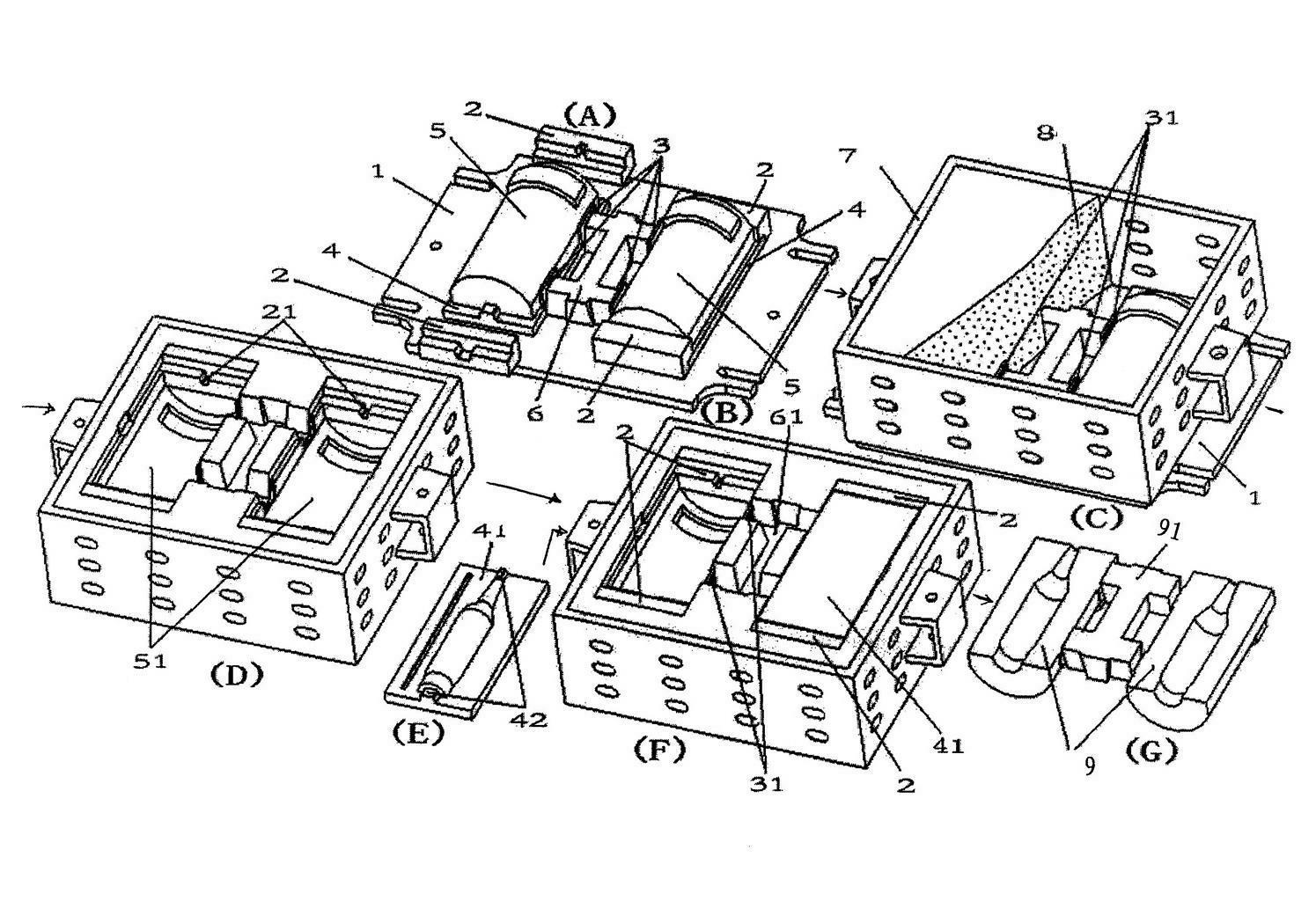

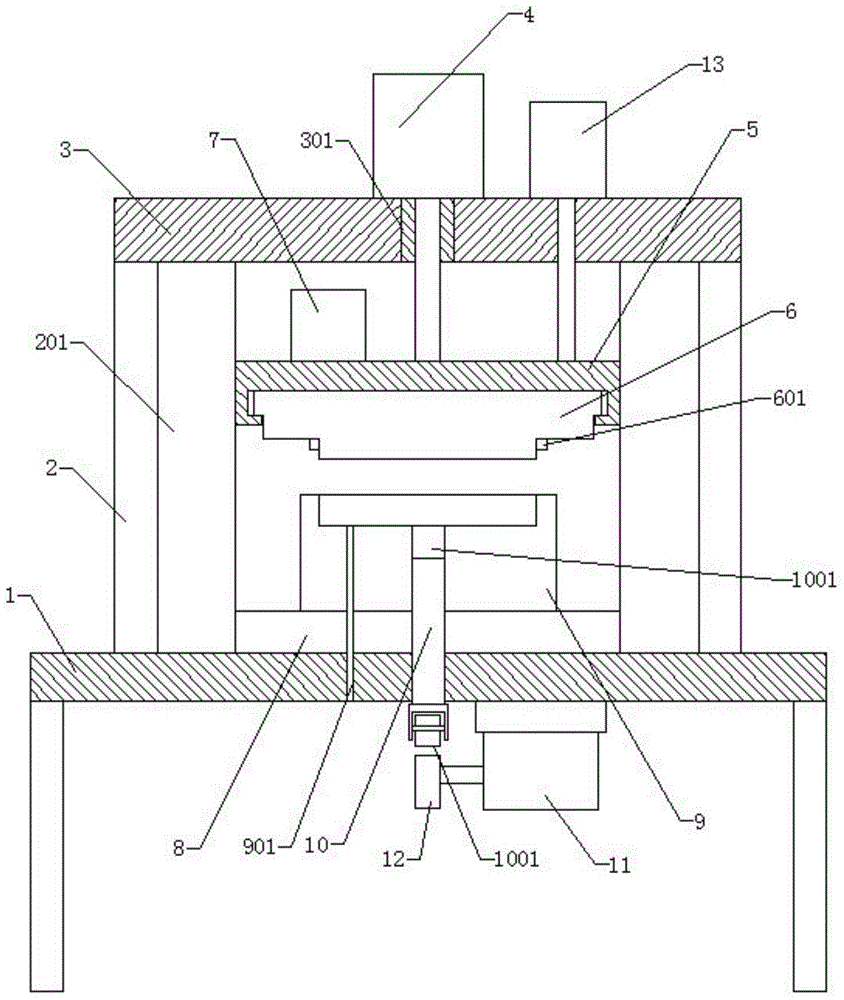

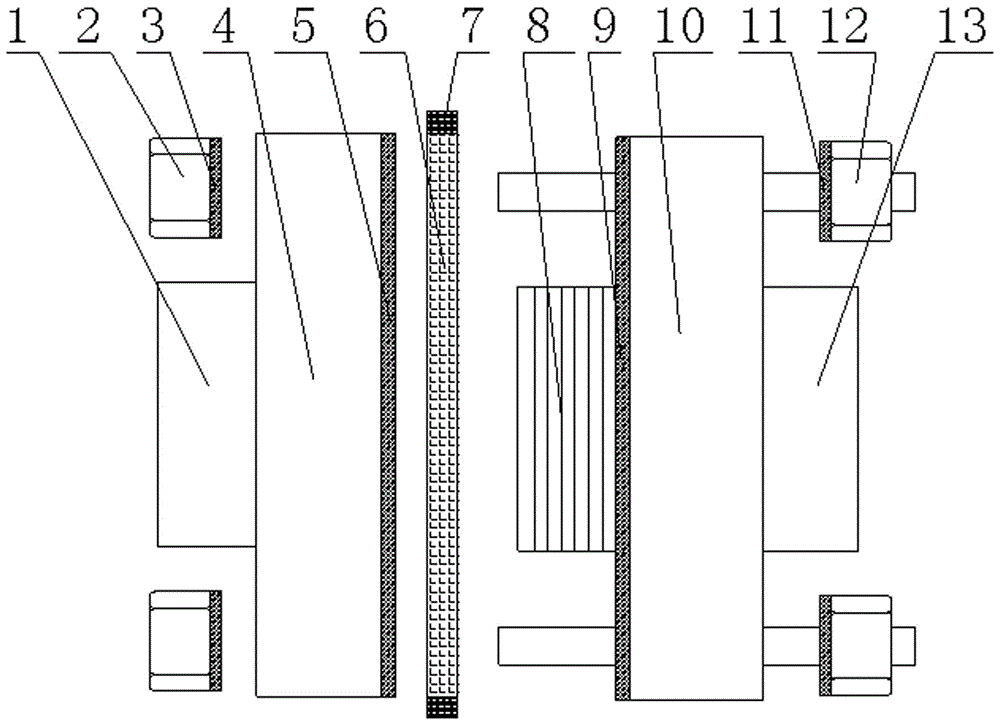

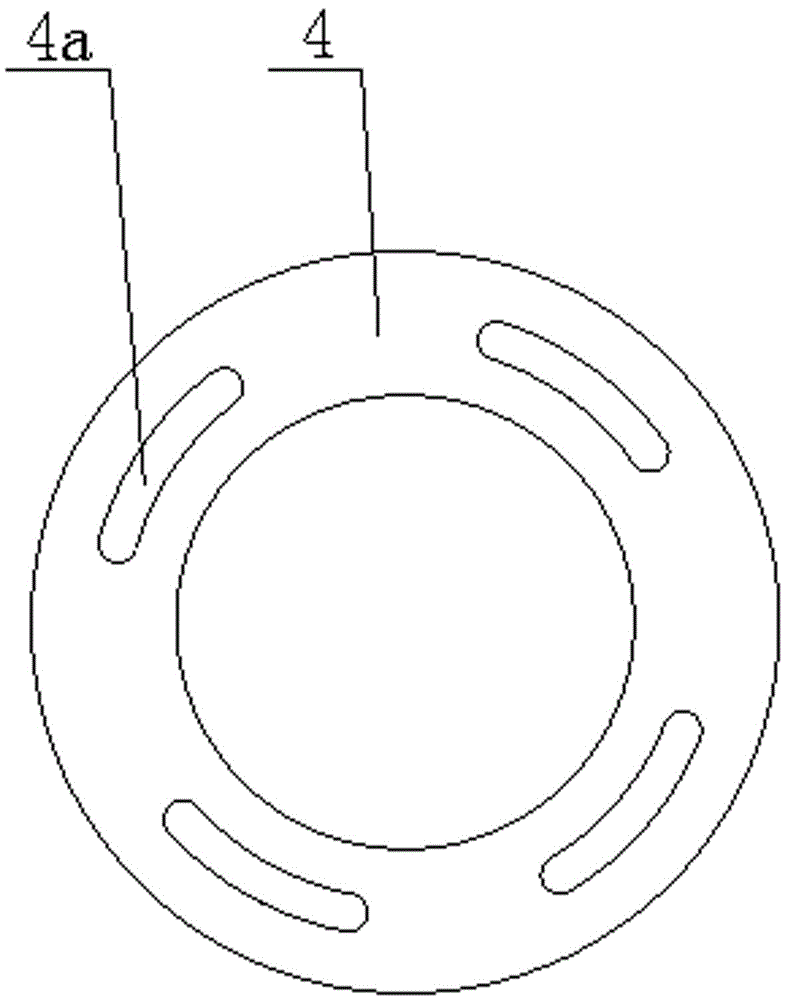

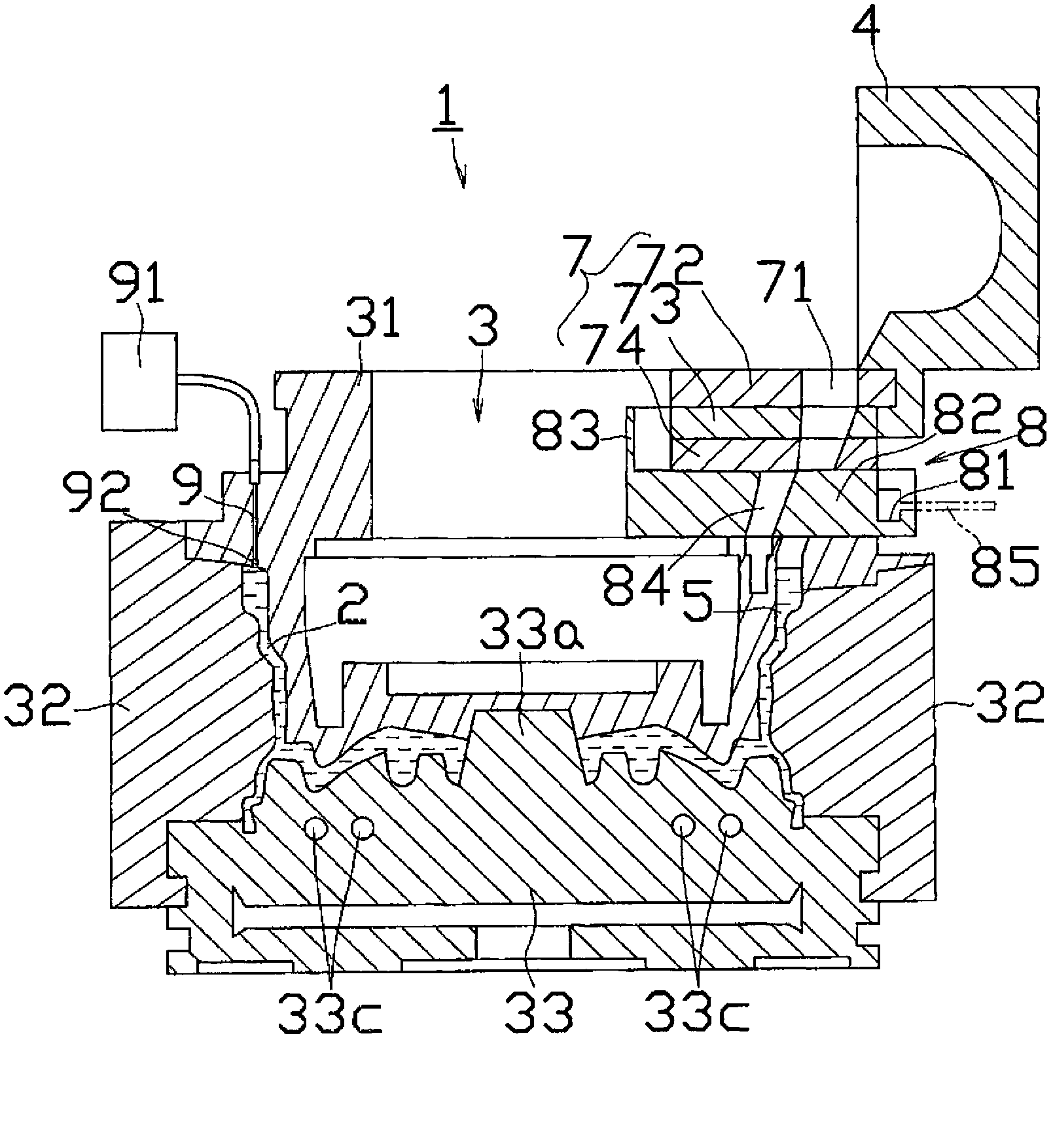

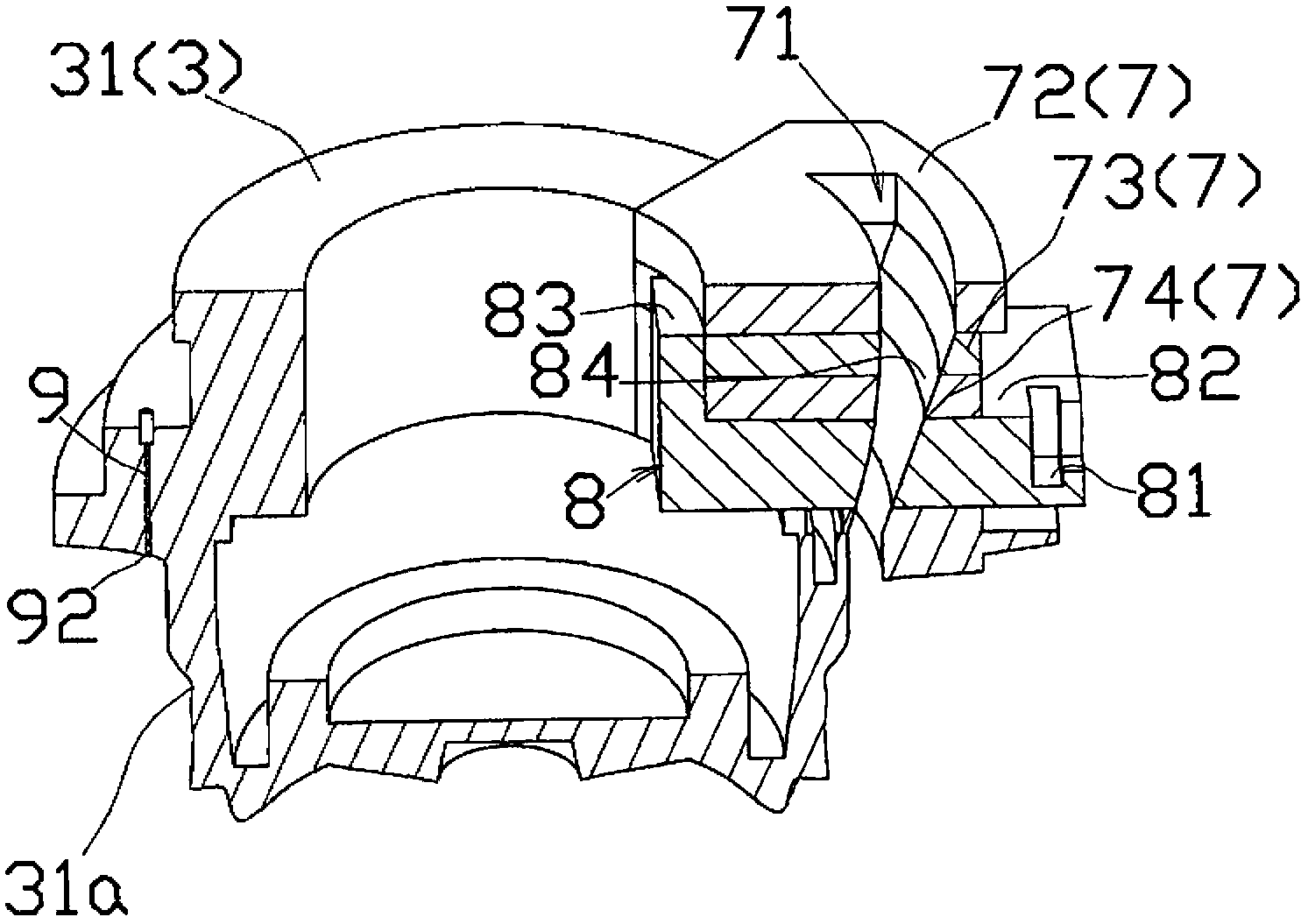

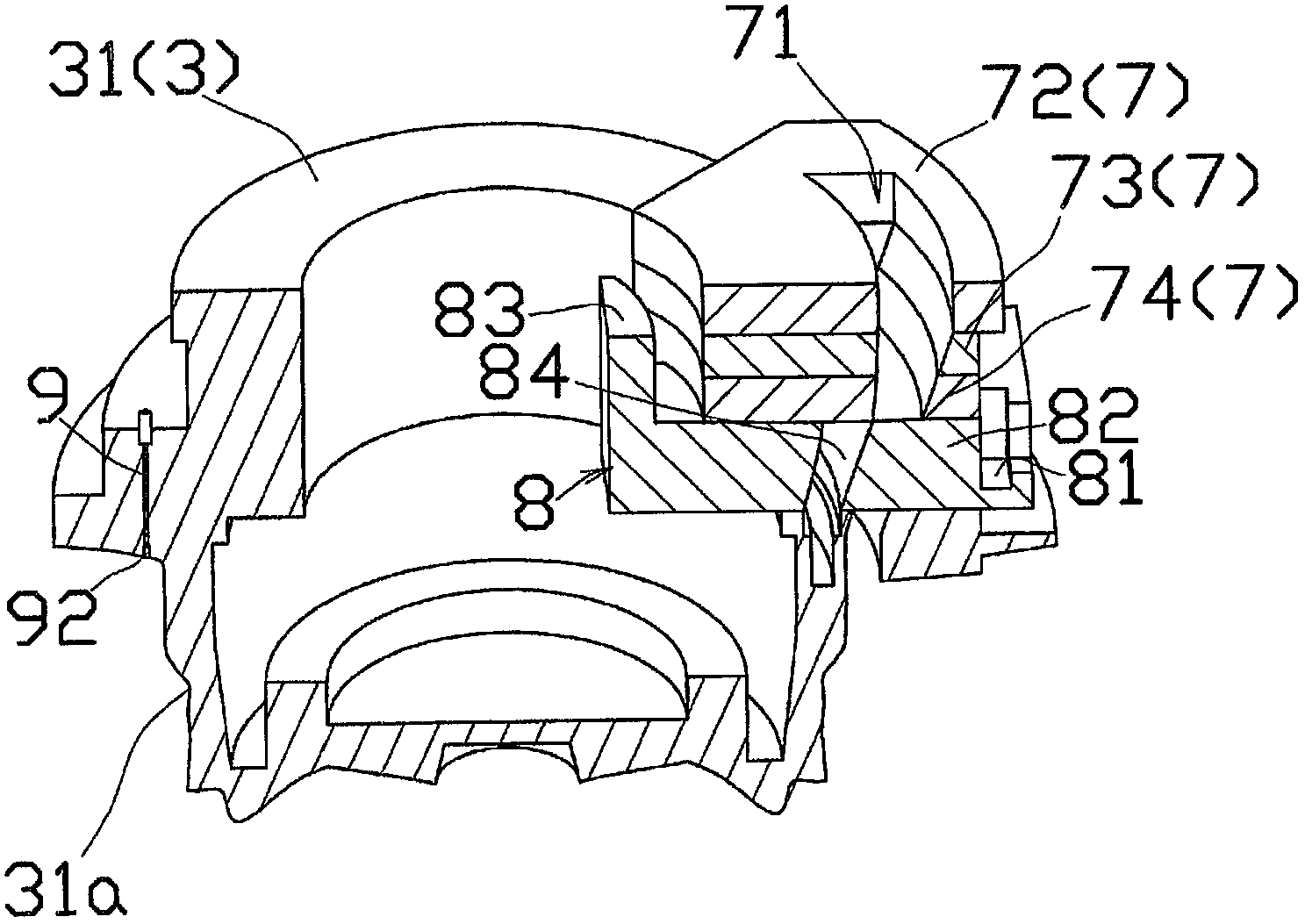

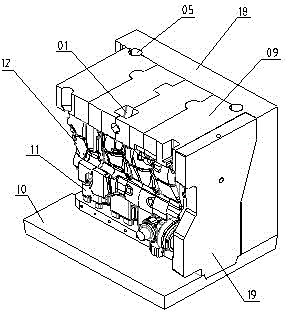

Tilt type gravity molding device

InactiveCN102712041AReduce the amount of timeReduce manufacturing costFoundry mouldsFoundry coresMetallurgyStanding Positions

A tilt type gravity molding device comprises: a mold (3) which can tilt between a fallen position and a standing position raised approximately 90 degrees from the fallen position; a pouring mold (7) in which a pouring gate (71) for guiding molten metal to the cavity (2) for forming a molded article is formed; and a bowl-like member (4) which contains the molten metal and pours the molten metal into the pouring gate (71) as the mold (3) tilts. In order to eliminate the need for a feeder head and for a reduction in the tilt speed and to enable the molten metal within the mold to be appropriately pressurized by gas, the tilt type gravity molding device also comprises: a blocking means (8) which is provided between the pouring gate (71) and the cavity (2) and which can open and close the pouring gate (71); a gas opening (9) which is provided at the upper part of the mold (3) in the standing position, prevents the molten metal from flowing to the outside of the mold (3), and permits only gas to pass therethough; and a gas supply means (91) which can supply a high-pressure gas to the gas opening (9).

Owner:MORIKAWA KANAGATA

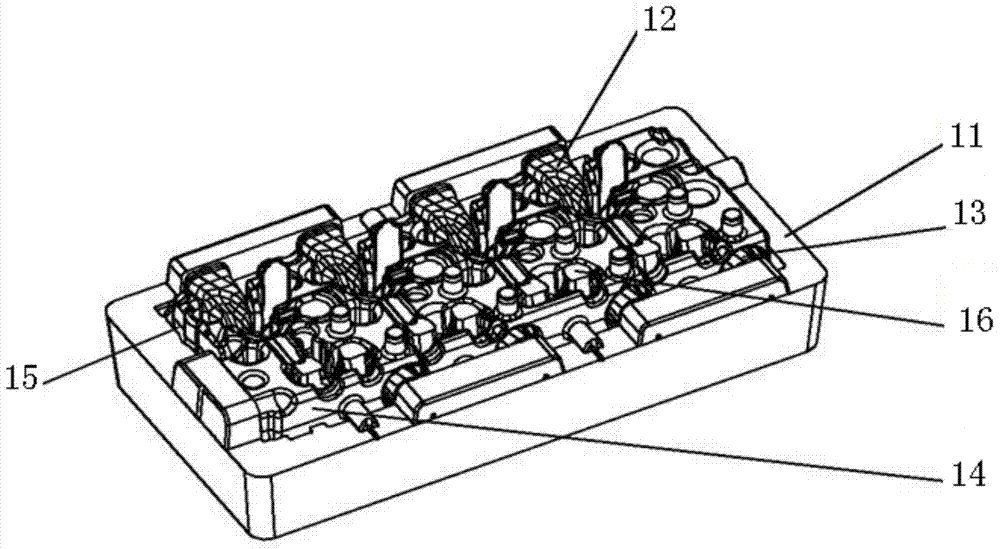

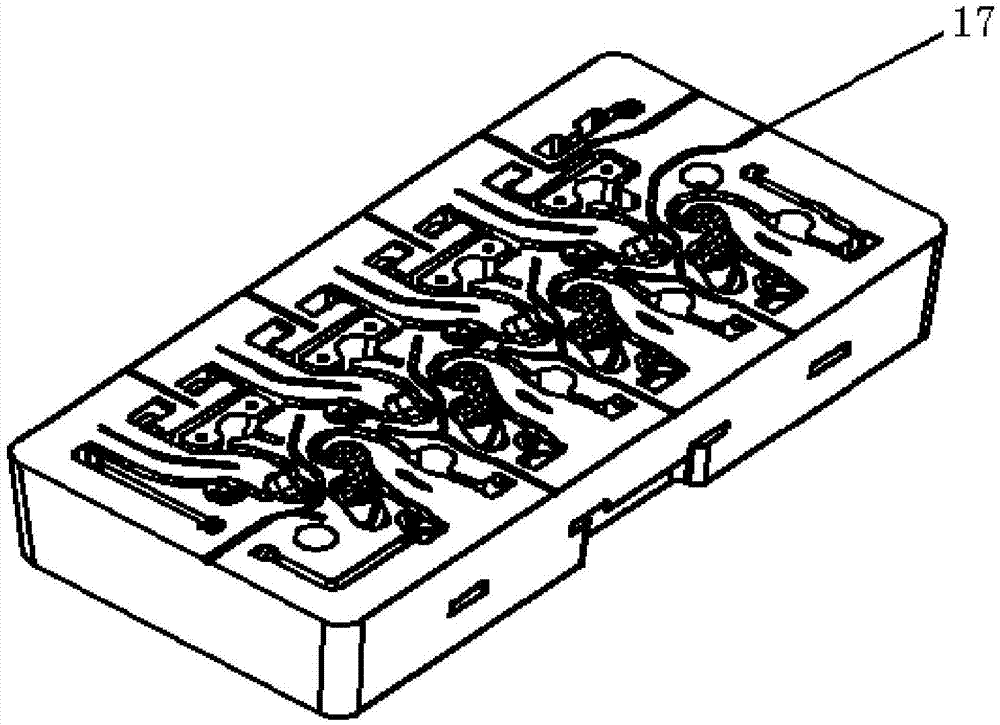

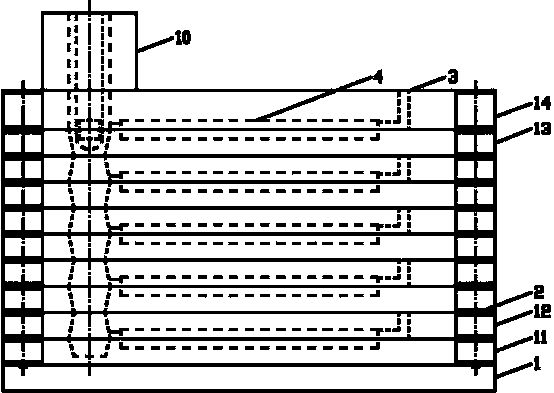

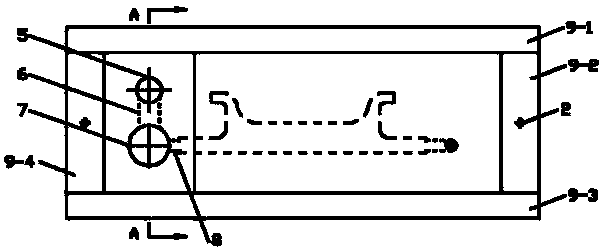

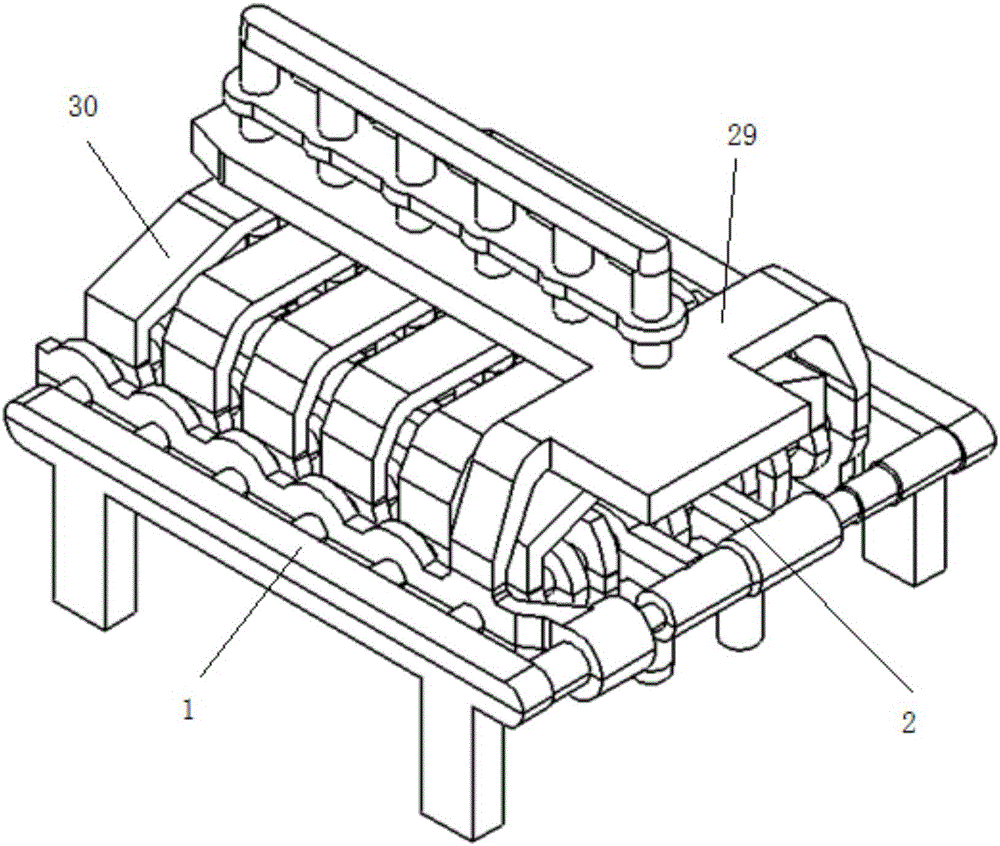

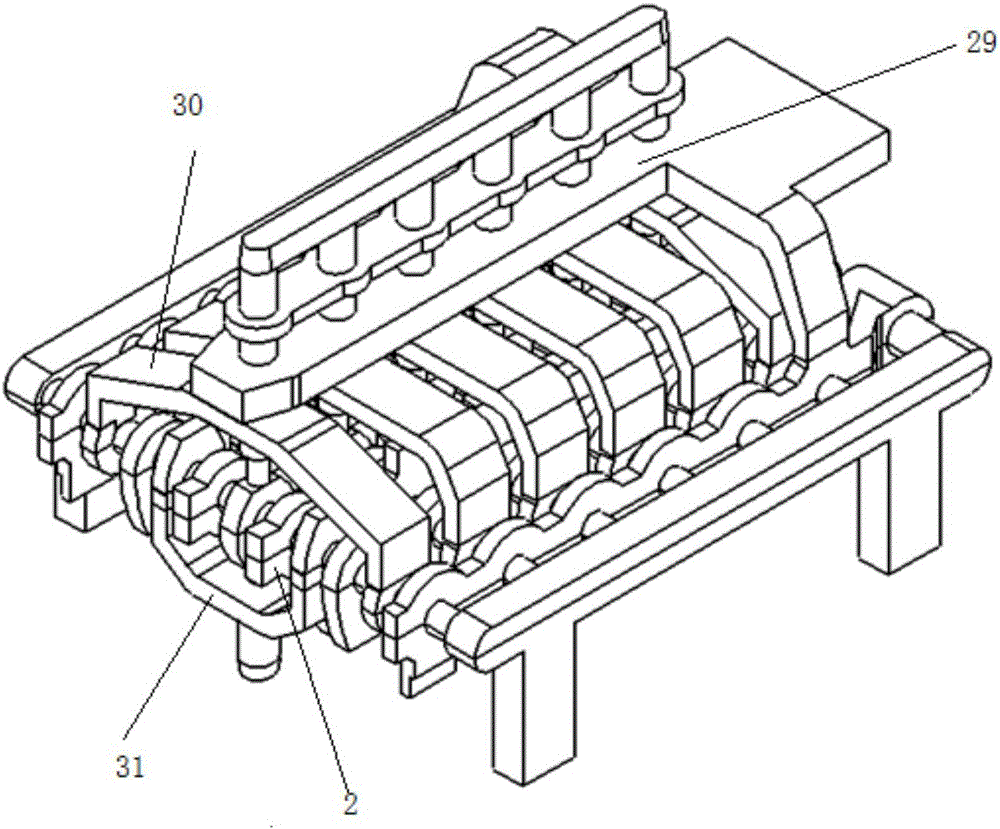

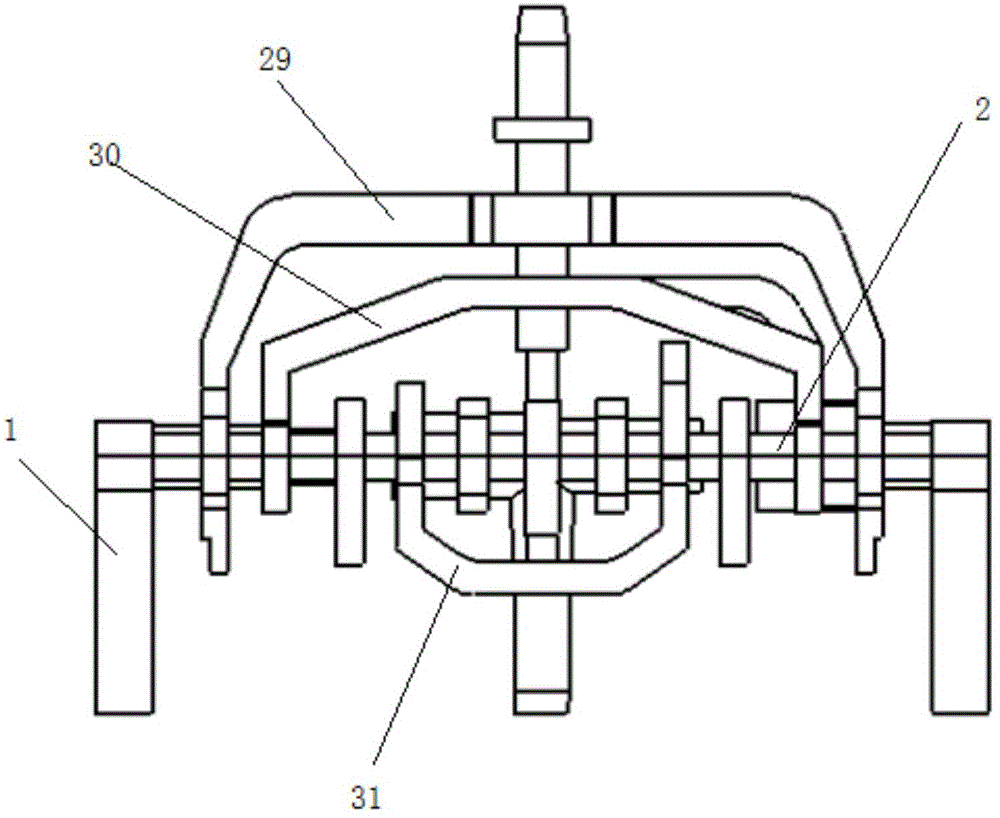

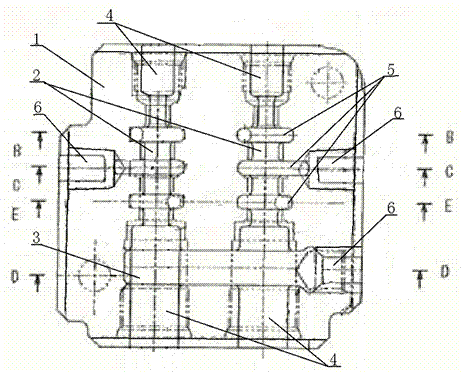

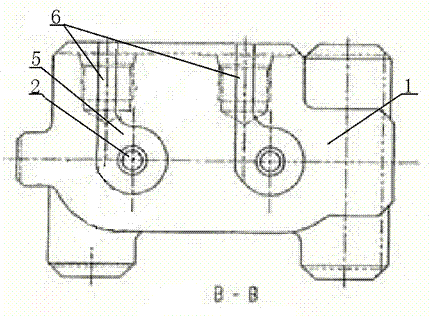

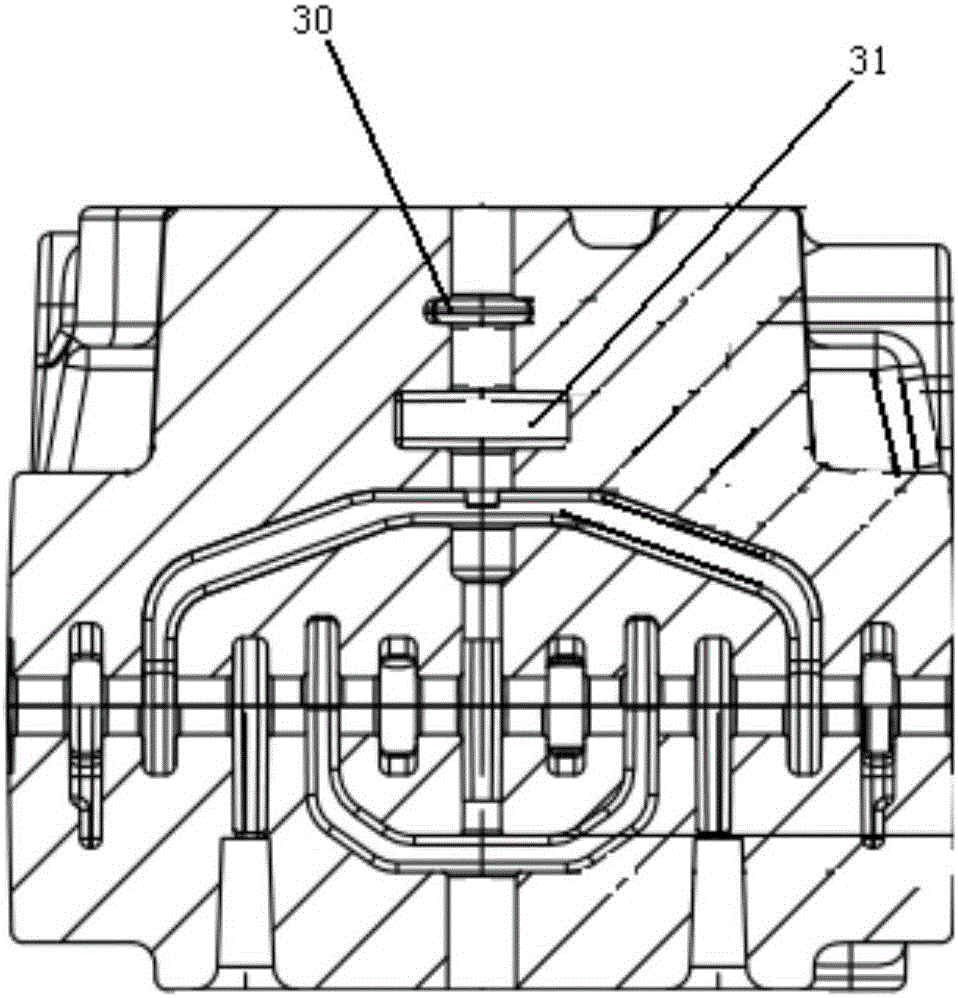

Composite casting system of crank shaft box

InactiveCN102873278AEasy to manufactureImprove production efficiencyFoundry mouldsFoundry coresSlagCrankshaft

The invention discloses a composite casting system of a crank shaft box. The composite casting system comprises a base plate core, a jacket core, a main core, an end face core, an outer cast core and a pouring system. The base plate core, the jacket core, the main core and the pouring system are sequentially overlapped from the bottom layer to the high layer to form a crank shaft box sand mould structure. The pouring system comprises two rows of pouring openings evenly arranged and gates located outside the two rows of pouring openings. The two rows of pouring openings are communicated with a pouring opening cup through a flow division pouring gate and a pouring gate cup. The gates comprise hole-shaped gates located at four corners and strip gates located between the hole-shaped gates and outside the two rows of pouring gates. The composite casting system adopts a rain type pouring system in the middle of a cast piece to conduct liquid feeding pouring from a plurality of positions of a shaft seat and reduces impact of pouring to casts, floating impurities cannot be easily adhered to the cast wall or the cast core, and the pouring system is good in slag blocking effect. The main core is arranged on the upper portion of a sand mould and on the shaft seat, and the two strip gates and the four hole-shaped gates are utilized to discharge air completely. The composite casting system does not require core drying and is stable in cast piece pouring.

Owner:SICHUAN XIANGYE MASCH CASTING CO LTD

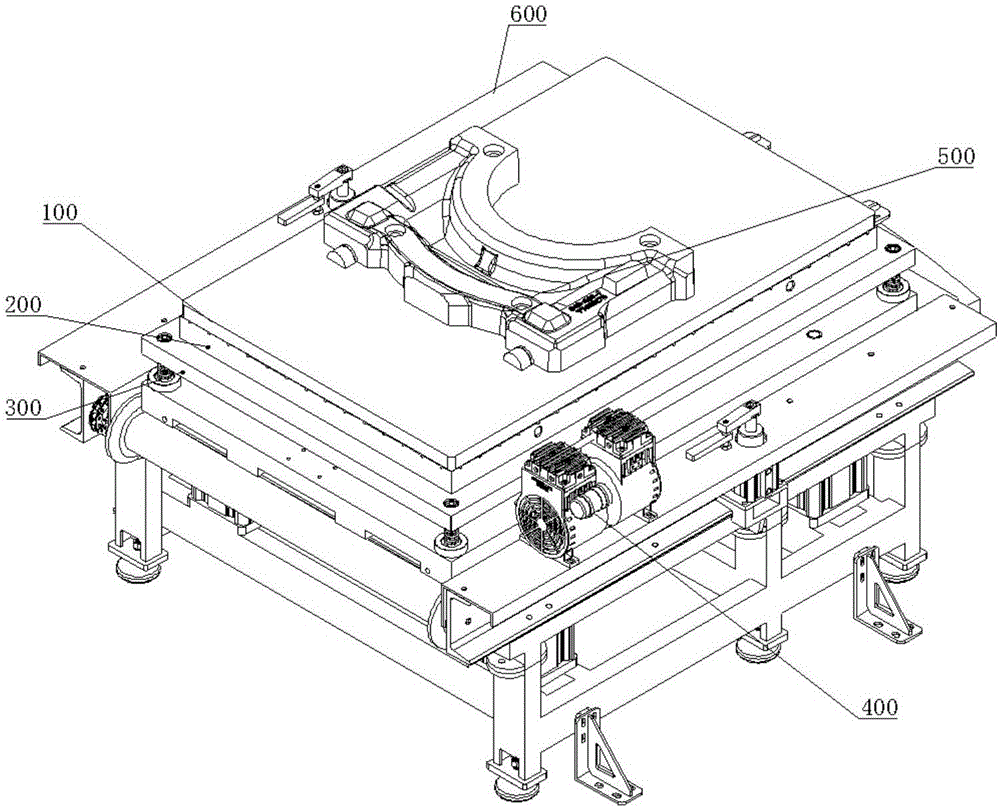

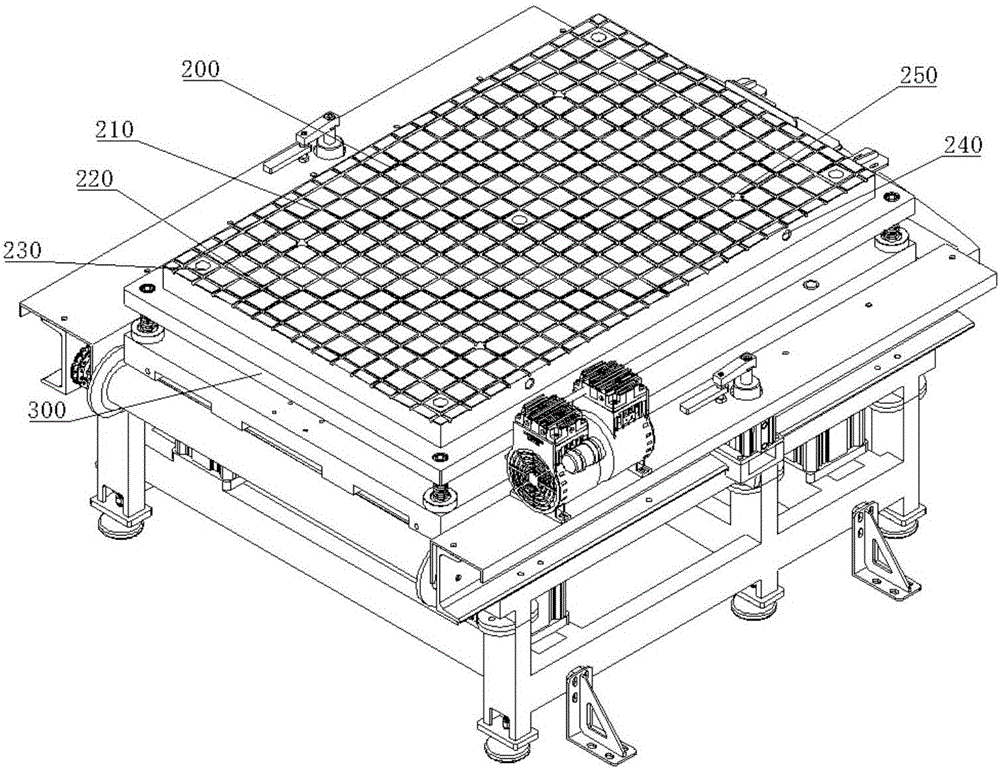

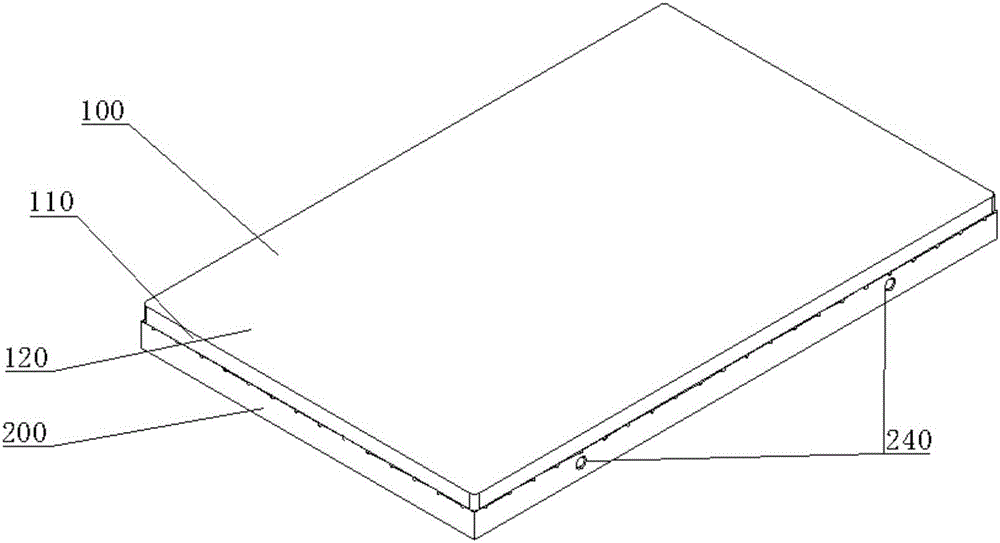

Working table for FDM printing equipment

InactiveCN106515021AHigh shape precisionReduce casting costsManufacturing heating elementsManufacturing auxillary operationsViscosityElectrical and Electronics engineering

The invention provides a working table for FDM printing equipment. The working table comprises an adsorption platform. The first face of the adsorption platform is coated with a clad layer of a first material, and the second face opposite to the first face and a heating slab are in thermal coupling, wherein the clad layer has no viscosity in a normal temperature state and is bonded to a printing mold in a heating state. According to the purpose, the working table for the FDM printing equipment can grab the mold firmly in the mold printing process, and can be disassembled conveniently.

Owner:NINGXIA KOCEL MOLD

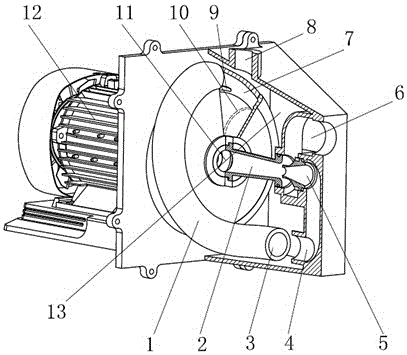

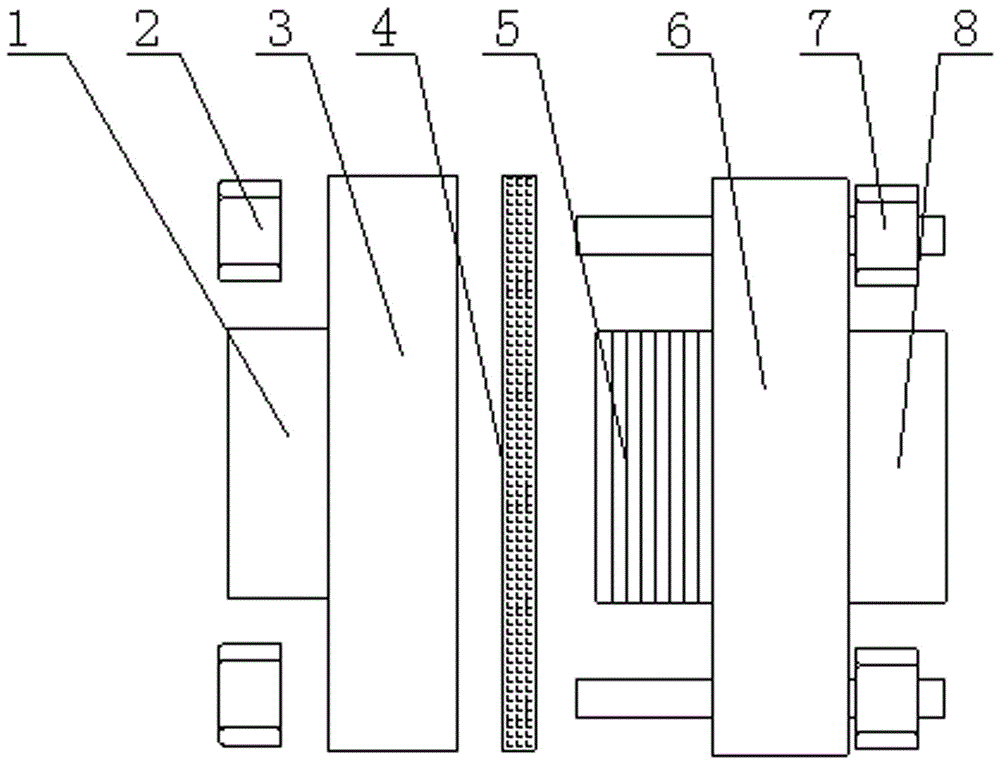

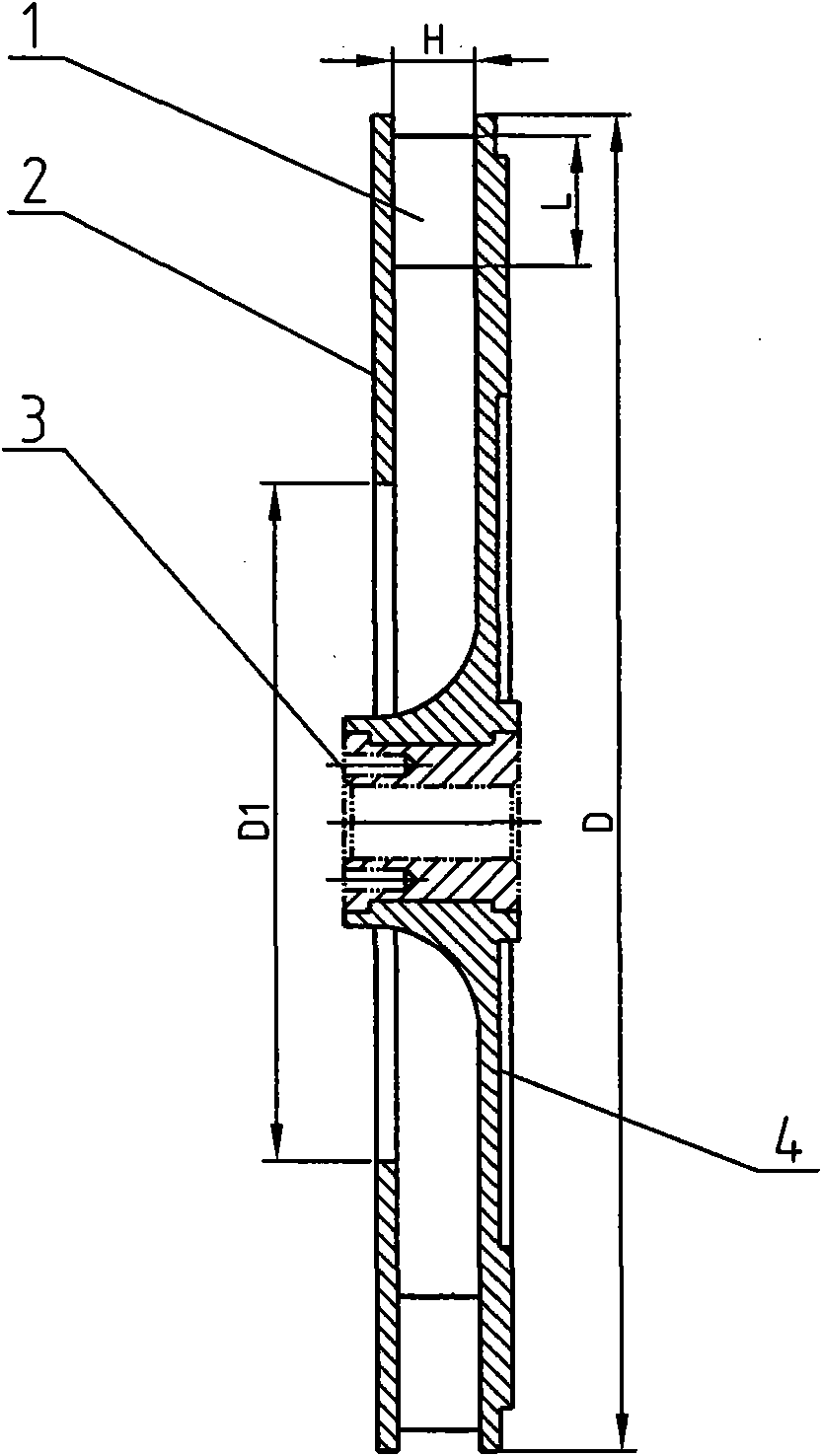

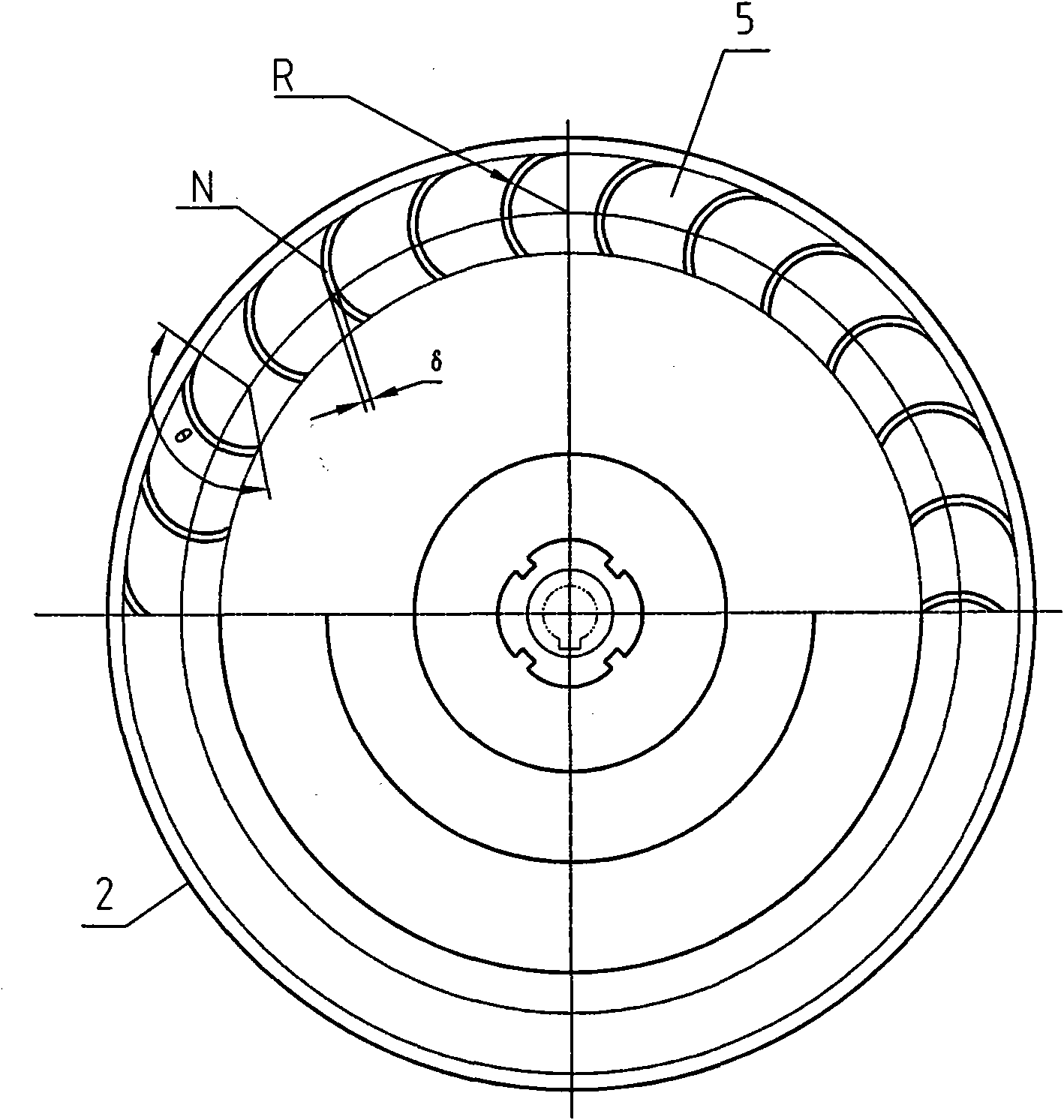

Forward skewed multi-blade impeller with narrow cavity and integral casting technique thereof

ActiveCN101787984ACompact structureReduce noisePump componentsPumpsImpellerUltimate tensile strength

The invention relates to a forward skewed multi-blade impeller with a narrow cavity, which is used for a centrifugal fan and is low in noise, and an integral casting technique thereof. The impeller comprises a base plate and a hollow front plate, and narrow blades are installed along the circumference between the base plate and the front plate. The difference lies in that the blades are arc-shaped; the radial length of each blade is 20mm-30mm; the outlet height H of the meridian plane of each blade is 10mm-20mm; the number of the blades distributed along the circumference is 20-60; and the whole impeller is integrally cast. The impeller is compact in structure, low in noise, light in weight, high in structural strength and simple and convenient in maintenance. By adopting a moveable blade mold structure to fabricate an impeller inner core blank removing mold so as to finish the integral casting of the impeller, the invention solves the technical problem of blank removal failure of a closed impeller with a narrow cavity and has the advantages of high casting precision and good quality of the impeller, low casting cost and high production efficiency. The technique is widely applicable for integral casting of various multi-blade impellers, with the effect obviously better than that of similar products.

Owner:CHINA SHIP DEV & DESIGN CENT +1

Spheroidal graphite cast iron and preparation method thereof

InactiveCN106435337AStable spheroidization rateImprove mechanical propertiesTrace elementMaterials science

The invention provides spheroidal graphite cast iron. The spheroidal graphite cast iron comprises, by mass, 3.35%-3.7% of C, 2.3%-2.7% of Si, 0.35%-0.55% of Mn, 0-0.035% of P, 0-0.015% of S, 0.016%-0.018% of Re, 0.02%-0.04% of Mg and 0.55%-0.85% of Nb, and the total amount of trace elements including Cu, Zn, Sn, Mo, Al and Zr is smaller than or equal to 0.22%. The tensile strength of the spheroidal graphite cast iron is larger than 750 MPa, the yield strength is about 560 MPa, and the percentage elongation after fracture is 7.5% or above. The invention further discloses a preparation method of the spheroidal graphite cast iron. According to the preparation method of the spheroidal graphite cast iron, the processes of normalizing as well as hardening and tempering heat treatment are omitted, and the prepared spheroidal graphite cast iron has high strength and high plasticity at the same time.

Owner:长沙金龙铸造实业有限公司

Large-duty loader hydraulic valve body casting

ActiveCN105782500AHighly integratedCompact and reasonable structureMultiple way valvesValve housingsEngineeringMechanical engineering

The invention discloses a large-duty loader hydraulic valve body casting. The large-duty loader hydraulic valve body casting comprises a valve body, perpendicular runners, horizontal runners, auxiliary runners and runner openings. The valve body is internally provided with the six perpendicular runners, the seven horizontal runners and four horizontal transverse runners. The perpendicular runners from the first one to the sixth one communicate with the four transverse runners, and the second transverse runner and the third transverse runner communicate with the seventh longitudinal runner; the first transverse runner communicates with the seventh longitudinal runner through an inclined runner, the fourth transverse runner does not communicate with the seventh longitudinal runner, and the six perpendicular runners communicate with the midpoint of the perpendicular runners from the first one to the sixth one; and the multiple auxiliary runners are formed between the horizontal runners and the perpendicular runners, and the seven horizontal longitudinal runners are provided with a plurality of oil grooves. The large-duty loader hydraulic valve body casting has the advantages of being high in integration level, reasonable and compact in structure, high in reliability, convenient to cast, use and maintain, safe, capable of saving energy, long in service life and wide in application range, the casting qualified rate is increased greatly, and the casting cost is reduced.

Owner:南通华东油压科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com