Patents

Literature

33results about How to "Reduce oxidation slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

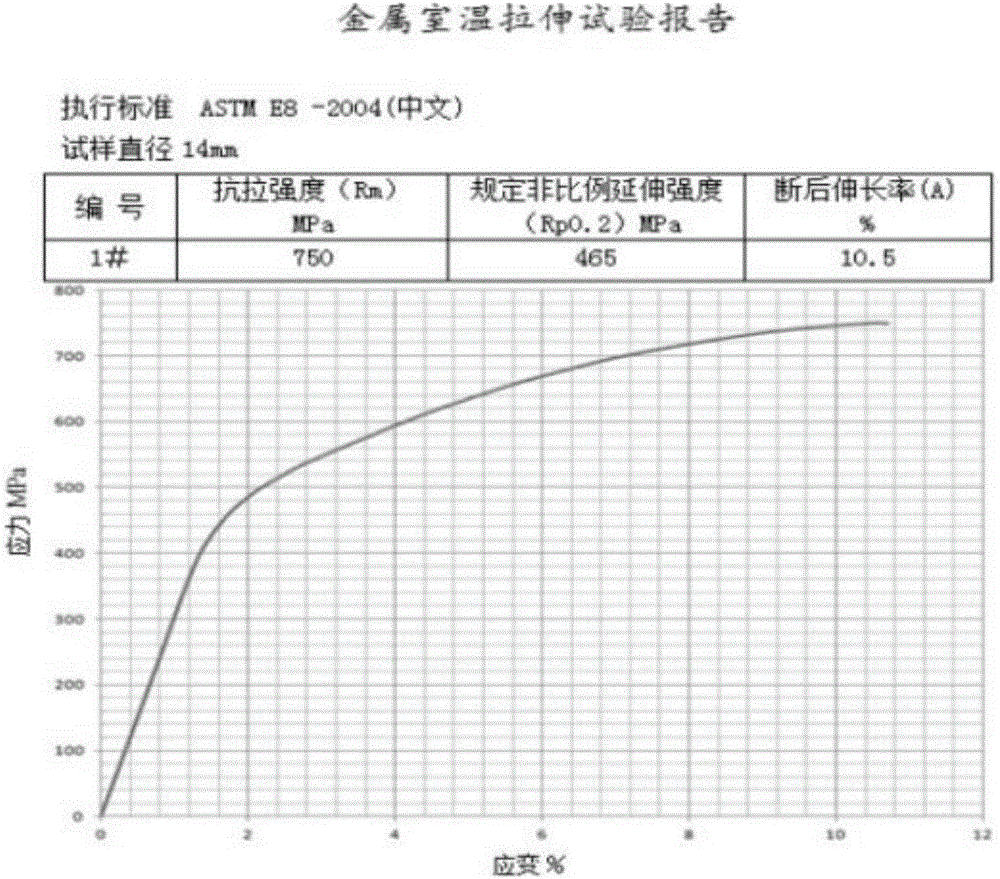

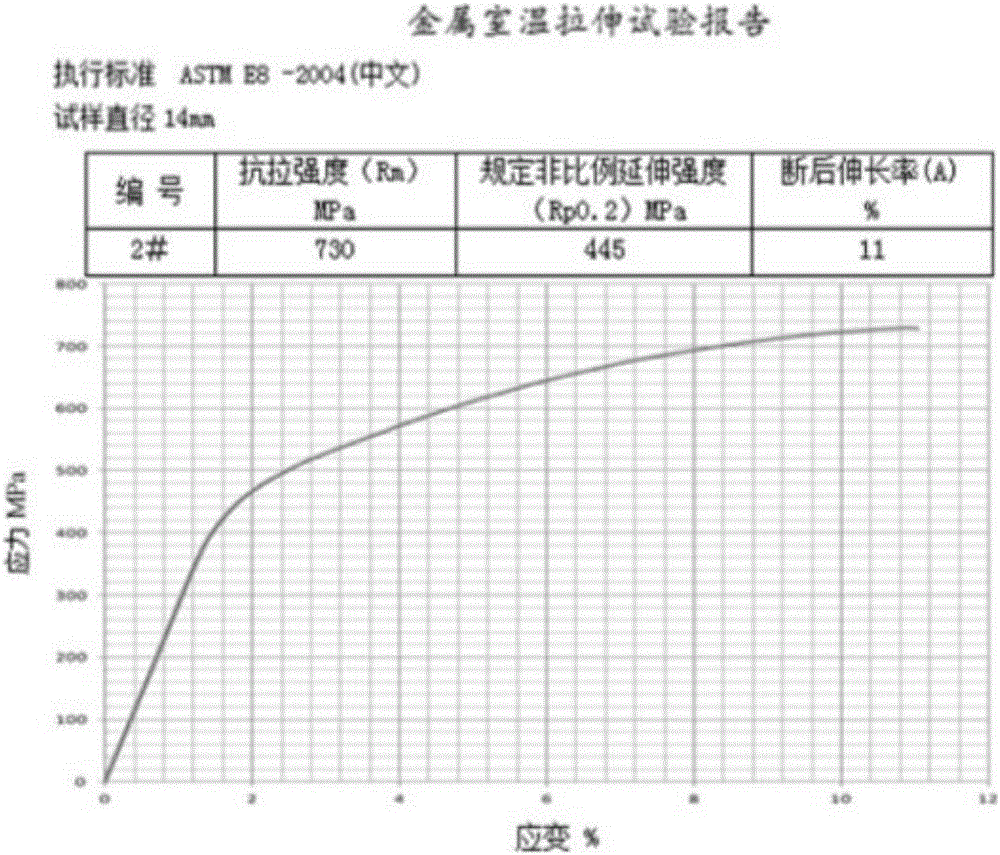

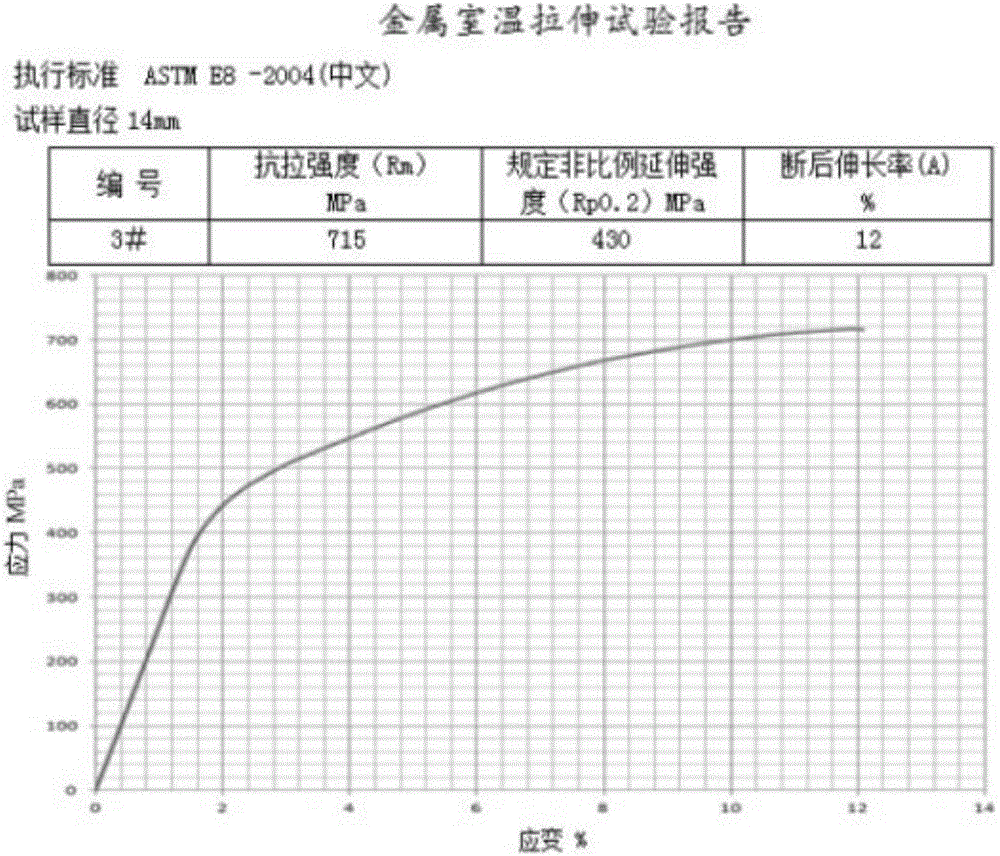

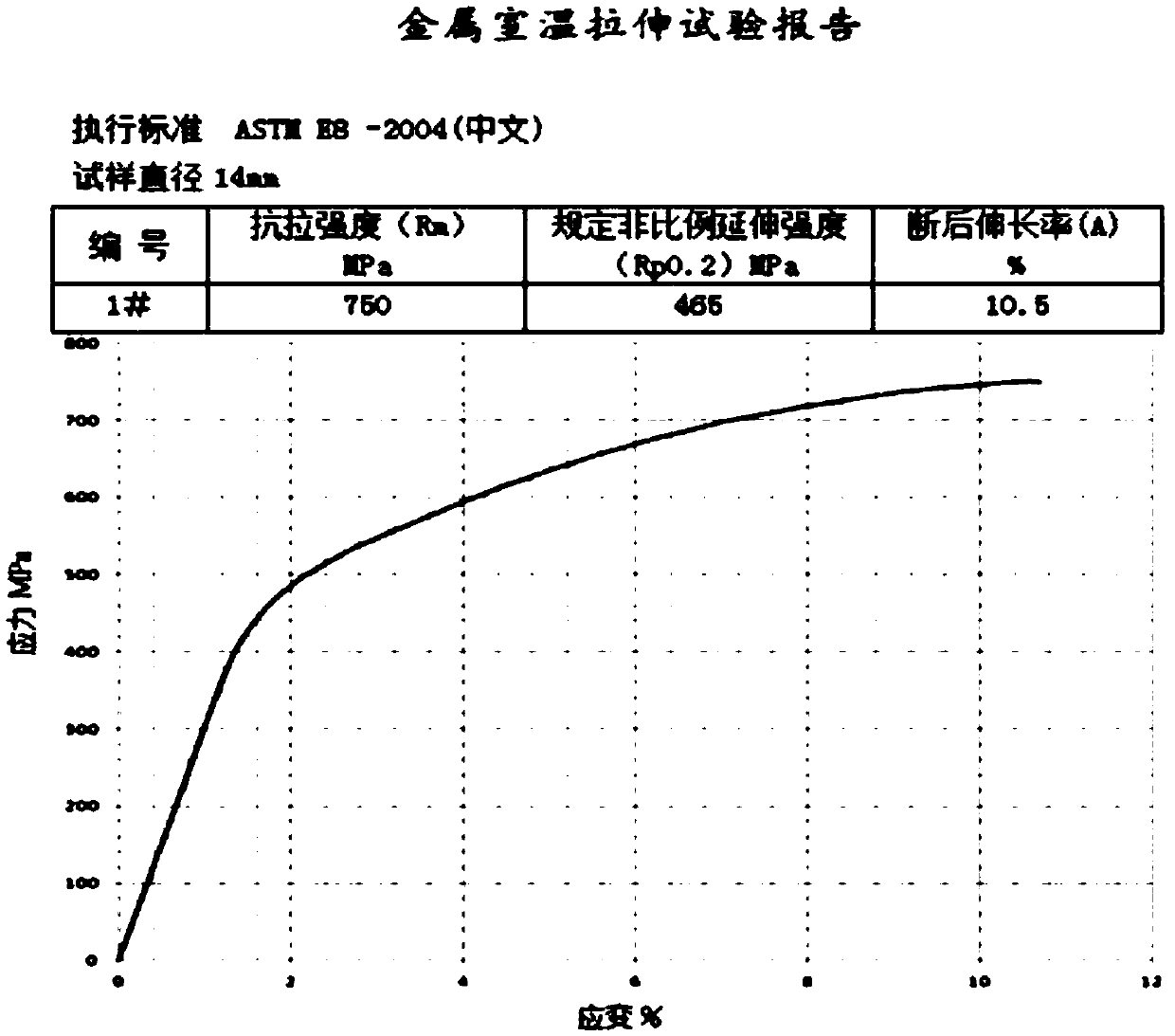

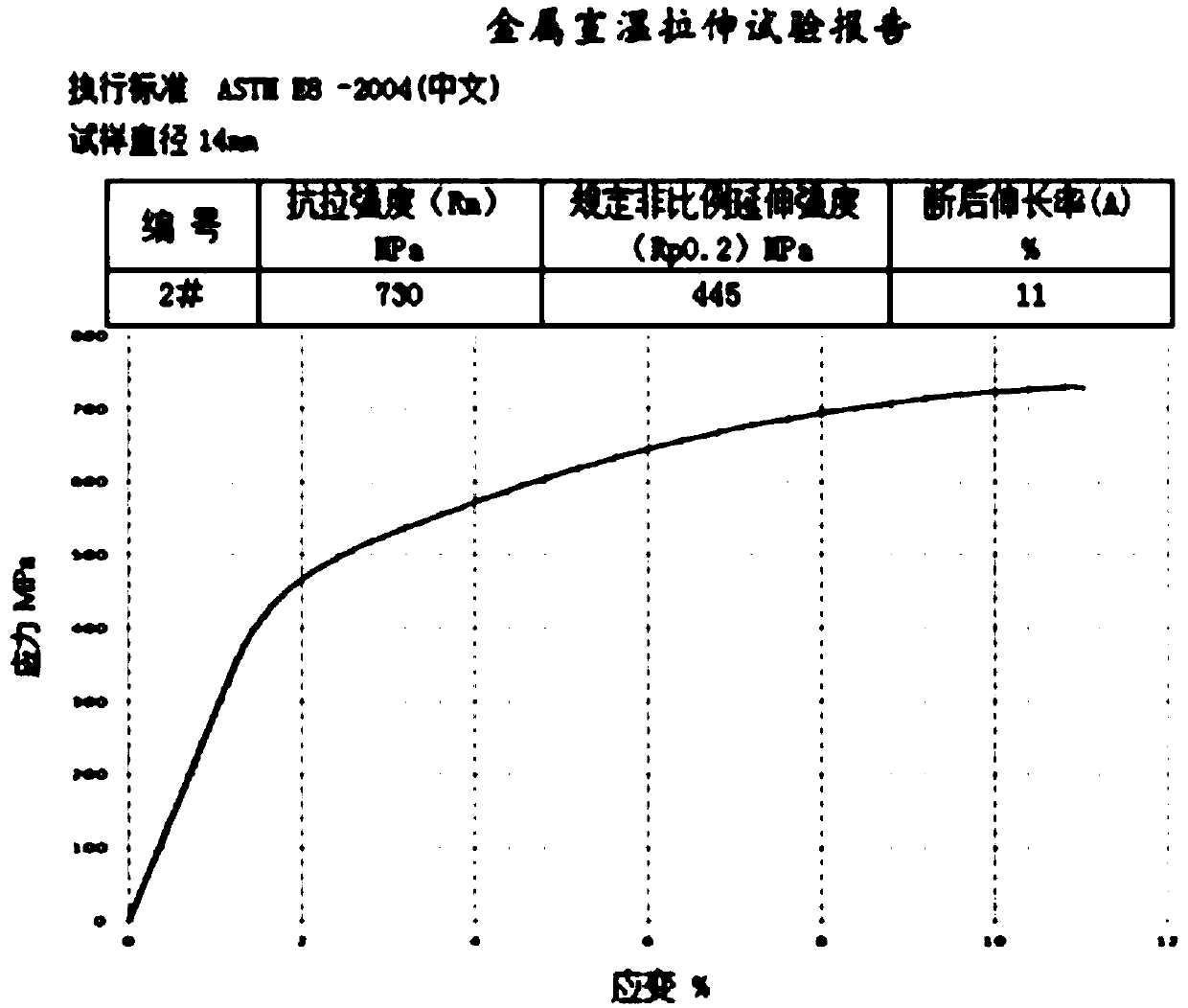

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

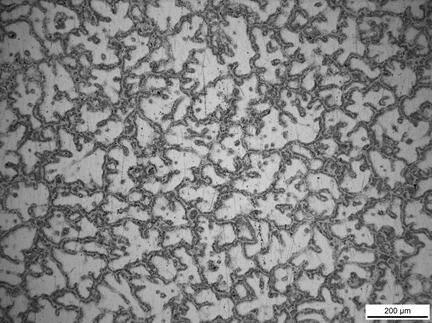

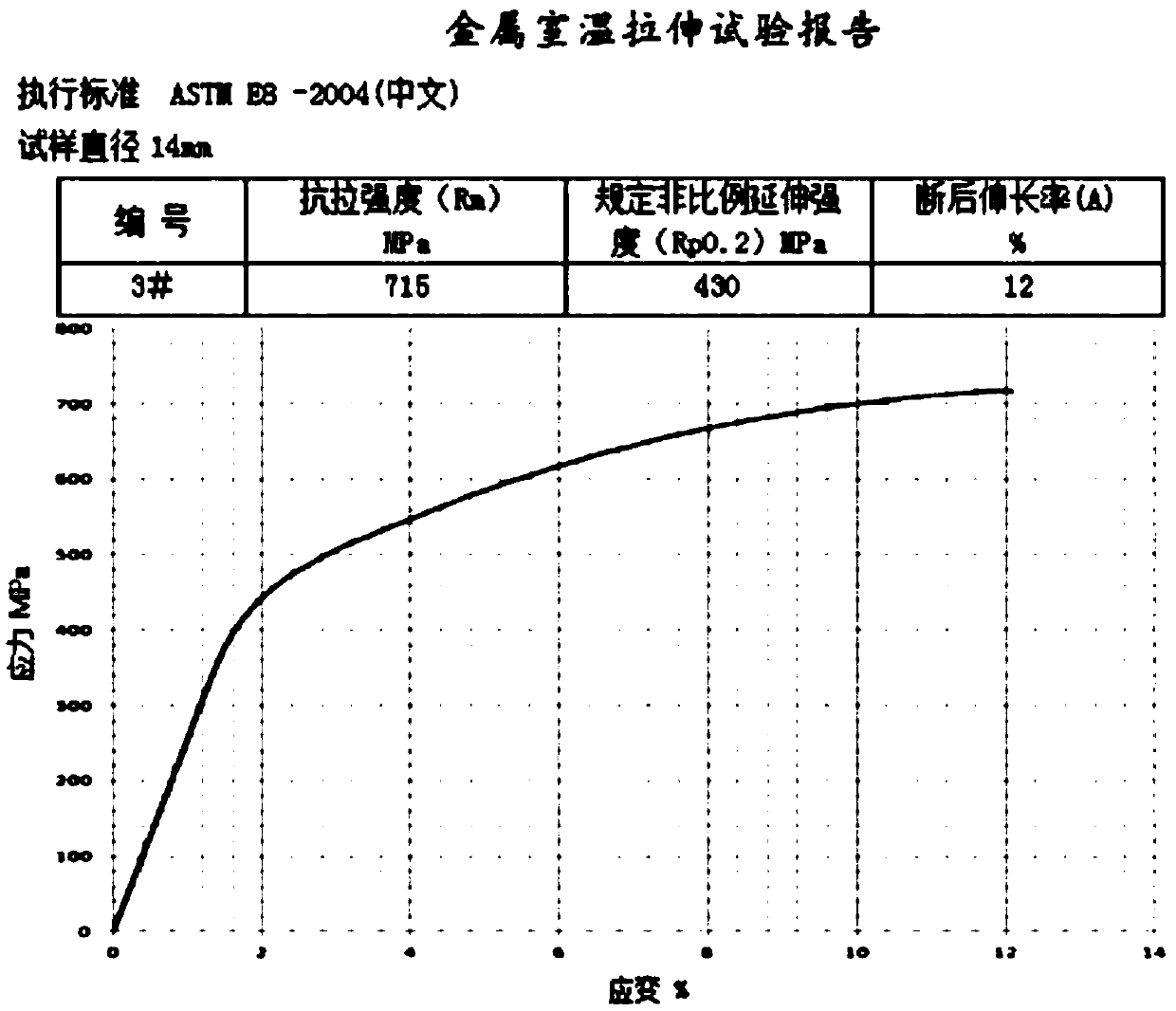

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

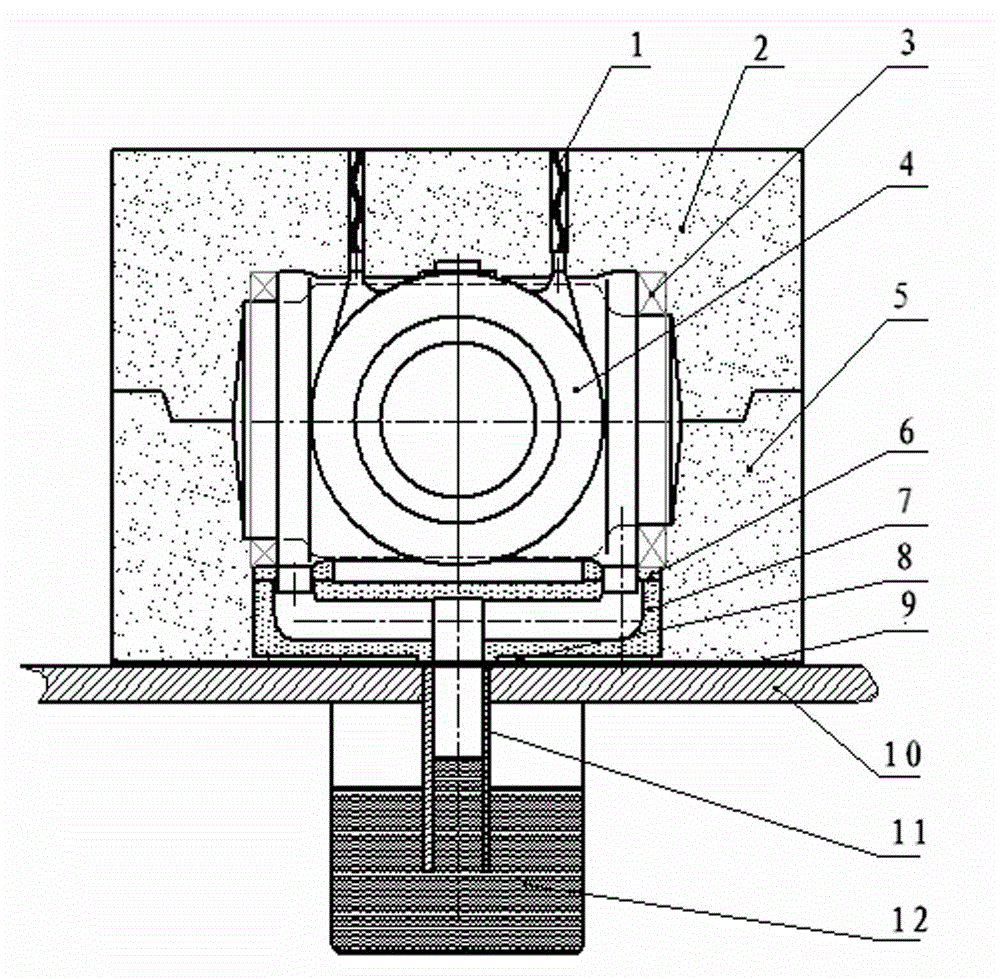

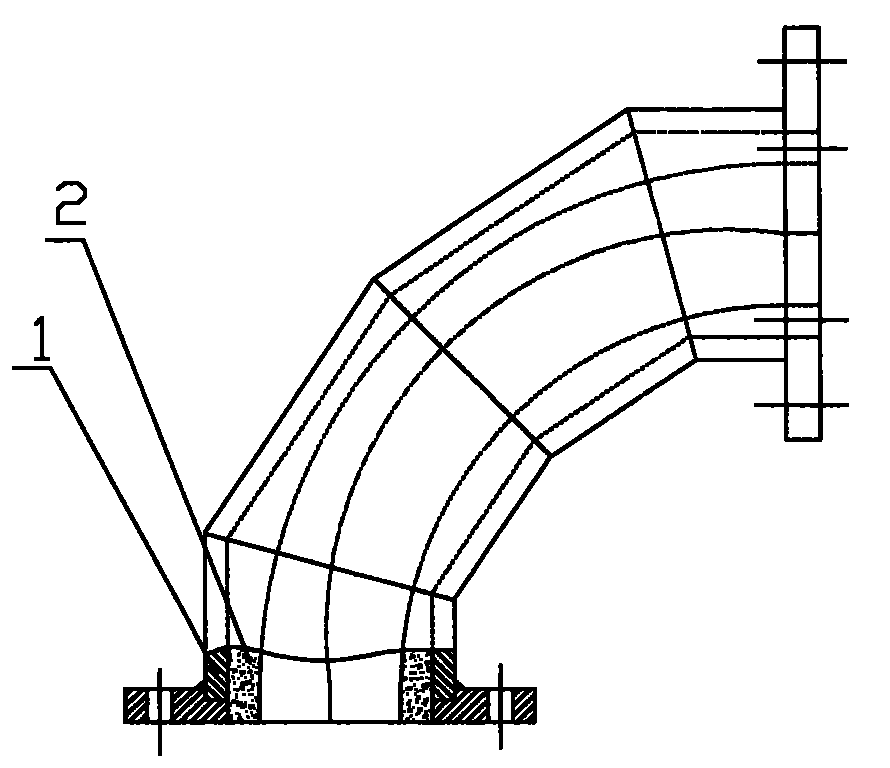

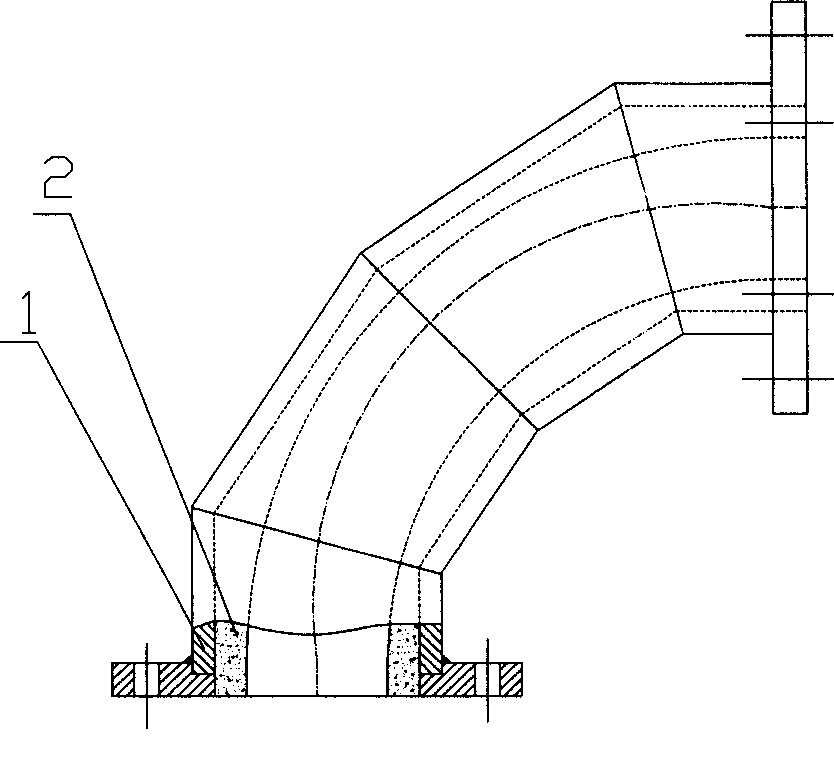

Method for producing ultrahigh pressure switch pressure-bearing aluminum alloy tanks under low pressure through V method

ActiveCN102941333ASpeed up the flowReduce scour forceFoundry mouldsFoundry coresVacuum castingUltra high pressure

The invention discloses a method for producing ultrahigh pressure switch pressure-bearing aluminum alloy tanks under low pressure through a V method in the technical field of vacuum casting, which comprises the following processing steps: jig manufacture, low-temperature gating system manufacture, upper tank molding, lower tank molding, lower core mould assembling, casting and pressure removing and picking. The method solves the defects of slag inclusion, pores, pinholes and the like of cast caused by intensive scouring of molten metal to cast, and simultaneously can solve the problems that the cavity casting system occupies excessive molten metal, and particularly the product yield of cast with low wall thickness and large size is low.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

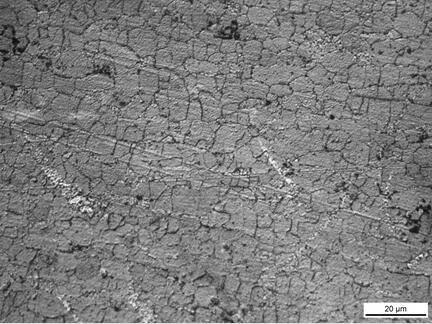

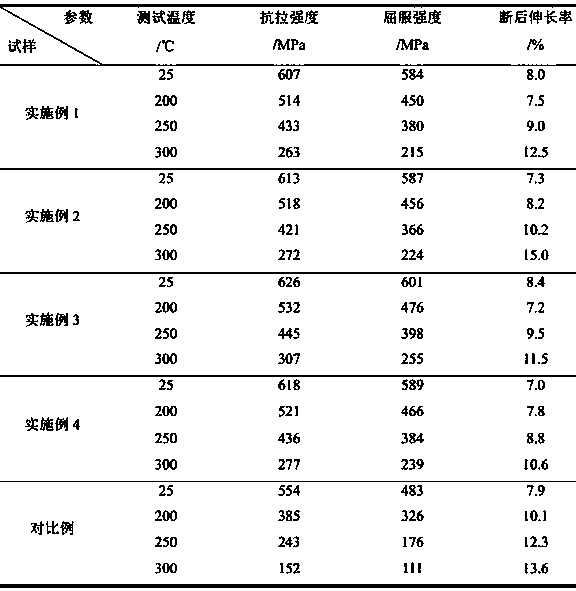

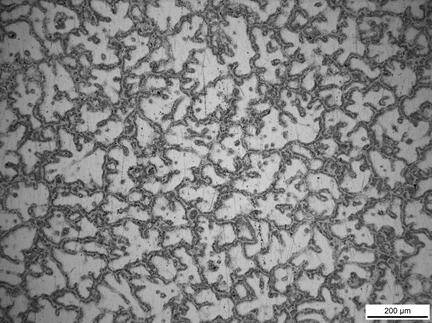

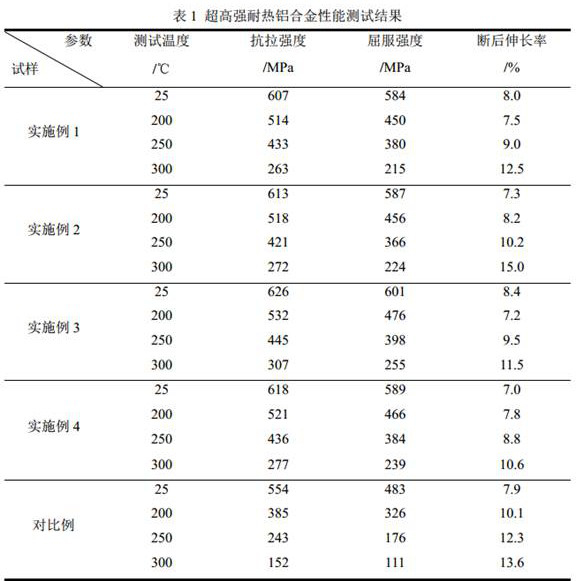

Ultrahigh-strength and heat-resistant aluminum alloy and preparation method thereof

ActiveCN109898000AInhibit growthSuppress coarseningFurnace typesHeat treatment furnacesYttriumScandium

The invention provides an ultrahigh-strength and heat-resistant aluminum alloy and a preparation method, and the alloy aims at overcoming the defects of an existing heat-resistant aluminum alloy. Theultrahigh-strength and heat-resistant aluminum alloy comprises the following components in percentage by mass: 5.9-7.2% of copper, 0.60-1.50% of silver, 0.6-0.9% of magnesium, 0.1-0.5% of chromium, 0.1-0.5% of molybdenum, 0.09-0.3% of zirconium, 0.07-0.12% of scandium and / or 0.07-0.12% of erbium and / or 0.07-0.12% of yttrium, and the balance aluminum, wherein the mass ratio of copper to magnesiumis 7-10. According to the ultrahigh-strength and heat-resistant aluminum alloy, the separating out of a strengthening phase in the alloy and the distribution are controlled by means of microalloying,deforming, thermal treatment and the like based on the abovementioned mixing ratio of the alloy, so that the density of the strengthening phase in the alloy is improved, and the alloy remains a largeamount of fine dispersed strengthening phases under high temperature, and as a result, the alloy strength and heat resistance are improved.

Owner:郑州轻研合金科技有限公司

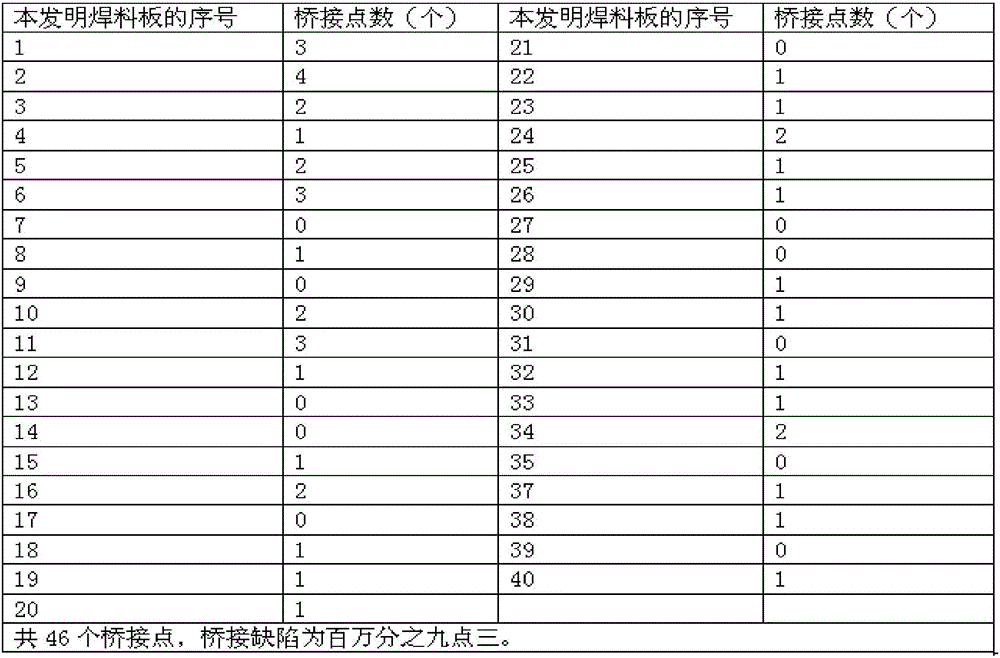

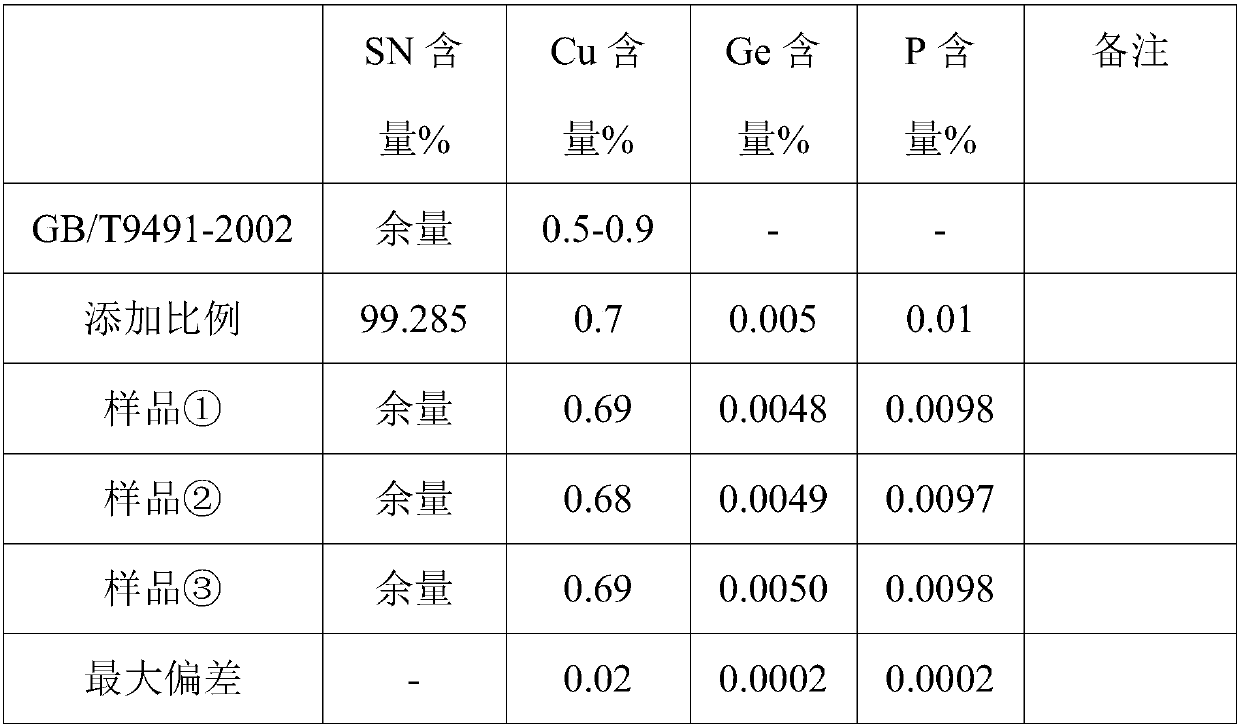

Lead-free high-temperature antioxidant solder and preparation method thereof

ActiveCN106271187AImprove protectionAvoid poisoningWelding/cutting media/materialsSoldering mediaIndiumSlag

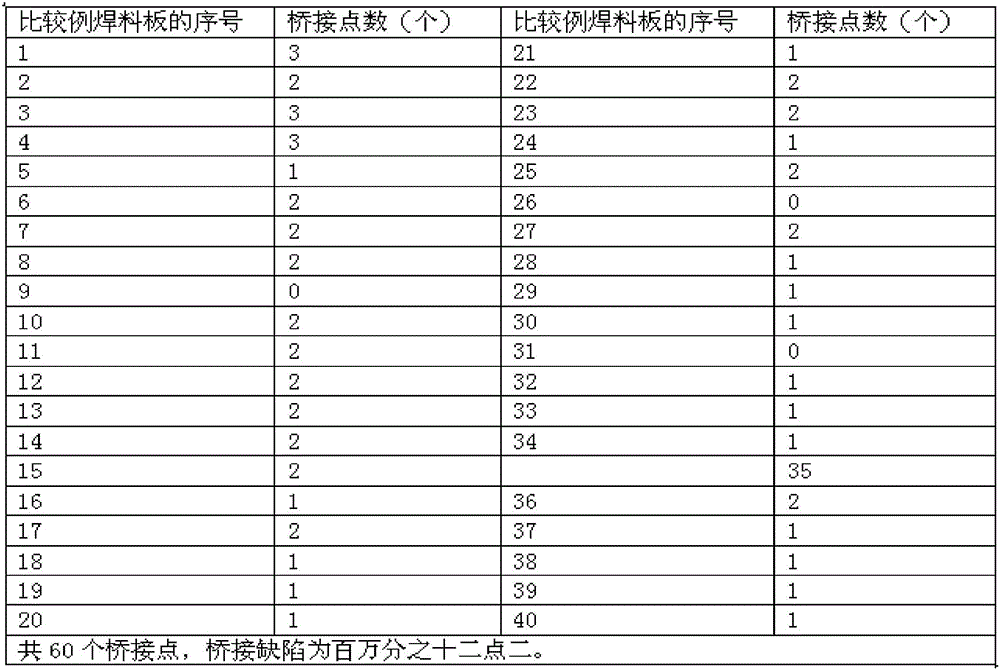

The invention discloses lead-free high-temperature antioxidant solder. The solder is prepared from the following ingredients by weight percent: 0.001 to 5.0% of silver, 0.001 to 11% of copper, 0.001 to 0.1% of nickel, 0.001 to 0.1% of indium, 0.001 to 0.15% of phosphorus, 0.001 to 0.08% of germanium and the balance of tin. The invention further provides a preparation method of the lead-free high-temperature antioxidant solder. Compared with the prior art, the lead-free high-temperature antioxidant solder can generate little oxidizing slag at high temperature (250 DEG C to 510 DEG C) soldering and can keep the surface of a solder machine bright and free of oxidation at the temperature. The solder can't be oxidized for 50 seconds at the temperature of 500 DEG C, so that the soldering efficiency is greatly improved and the high temperature oxidization resistance is excellent. In soldering, the solder has fewer soldering defects compared with an ordinary Sn-Ag-Cu system, the surface of a solder joint is bright, the solder joint is full, continuous soldering is avoided, and the soldering quality is effectively improved. The solder is environmentally friendly and safe.

Owner:THOUSAND ISLAND METAL FOIL

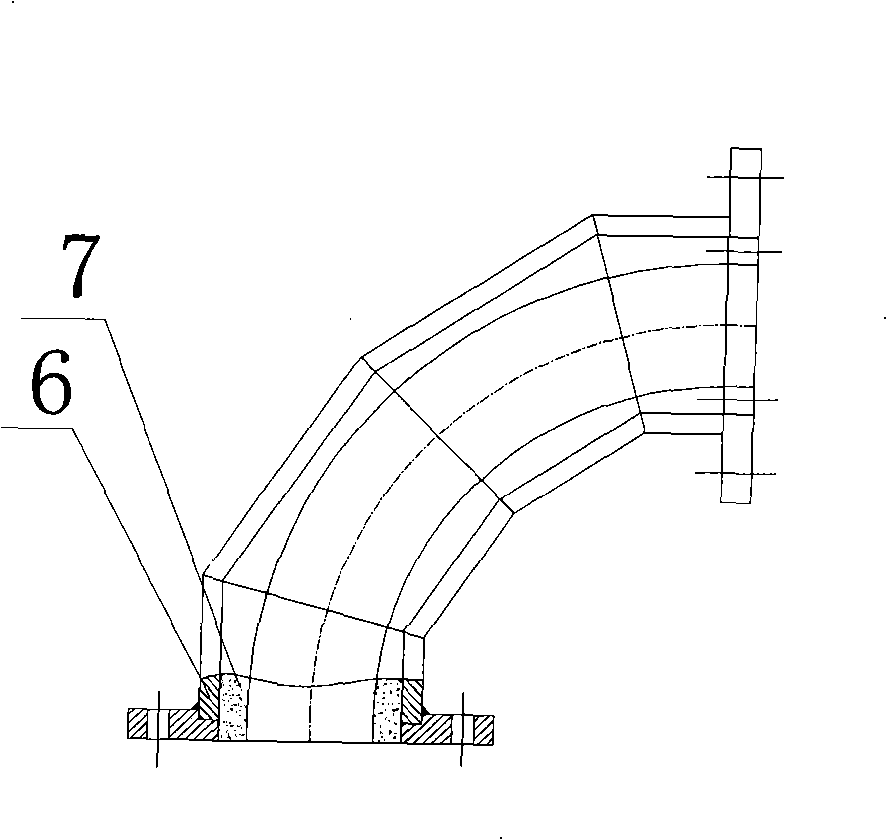

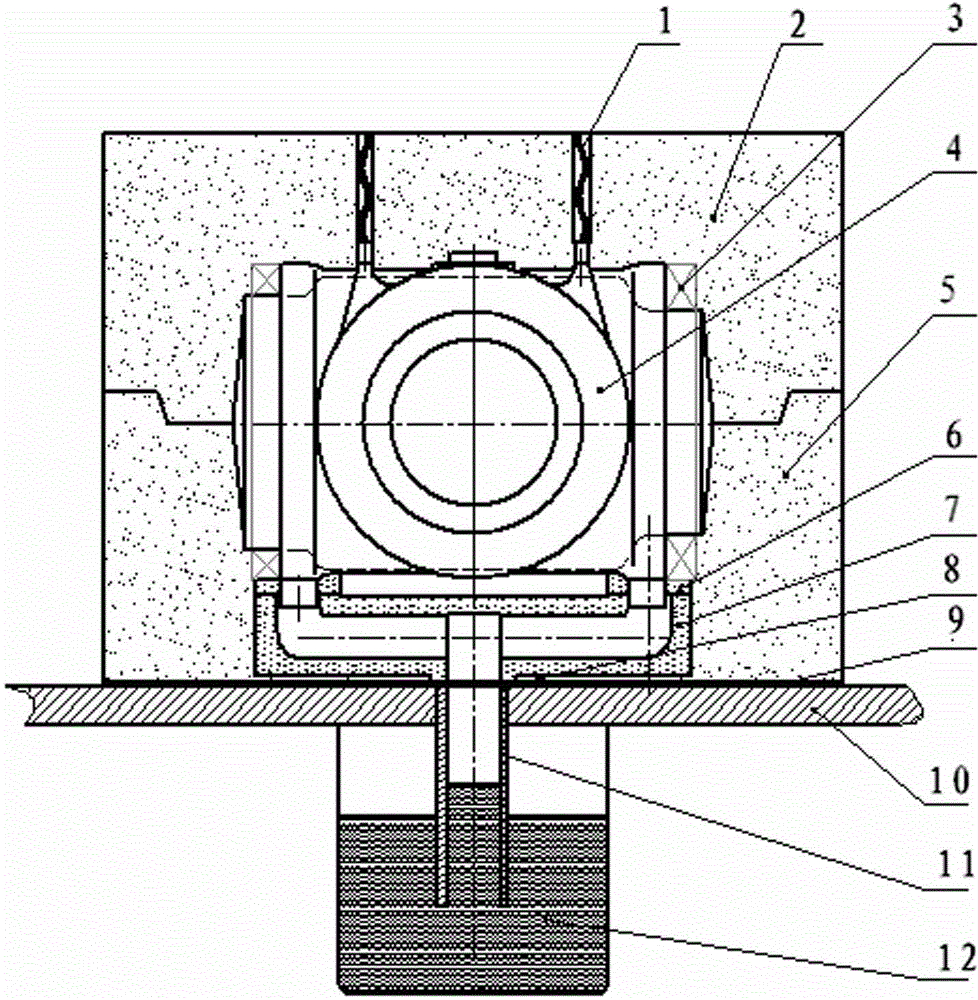

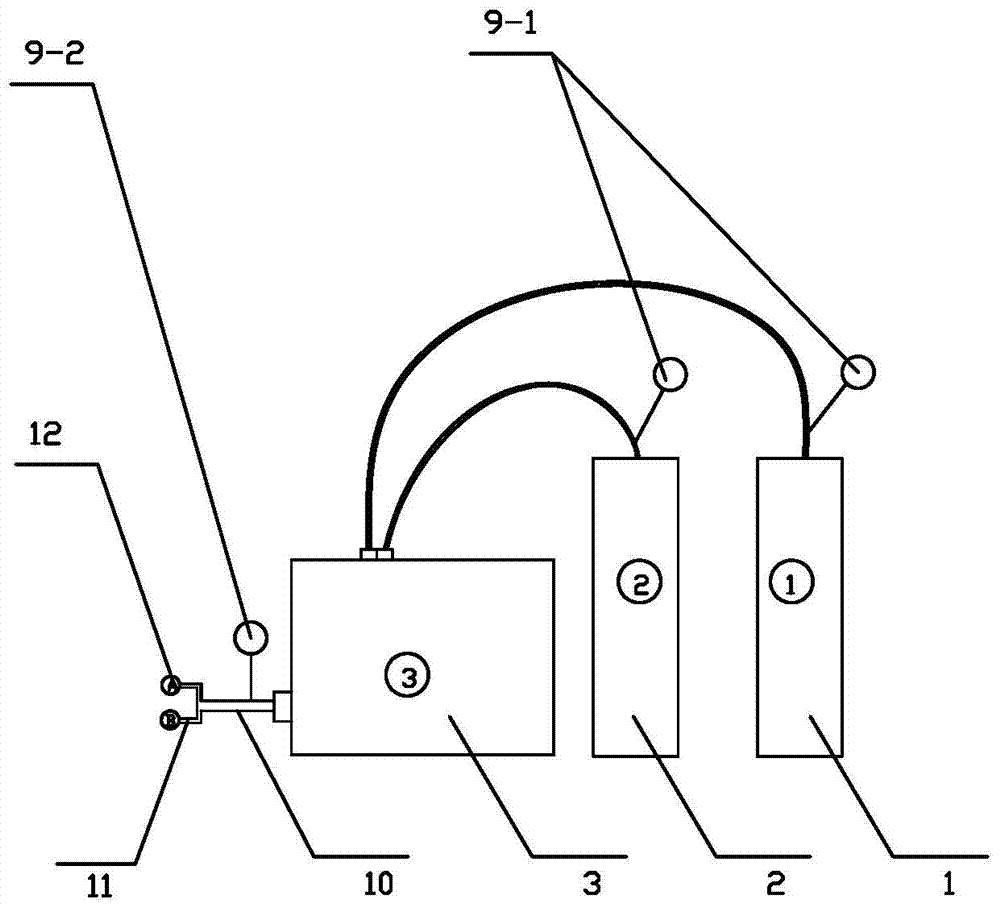

Mold filling differential pressure determining method based on vacuum differential pressure casting classified pressurizing mold filling

InactiveCN109128096AReduce oxidation slagReduce casting defects such as air entrainmentDesign optimisation/simulationCAD numerical modellingLiquid stateSlag

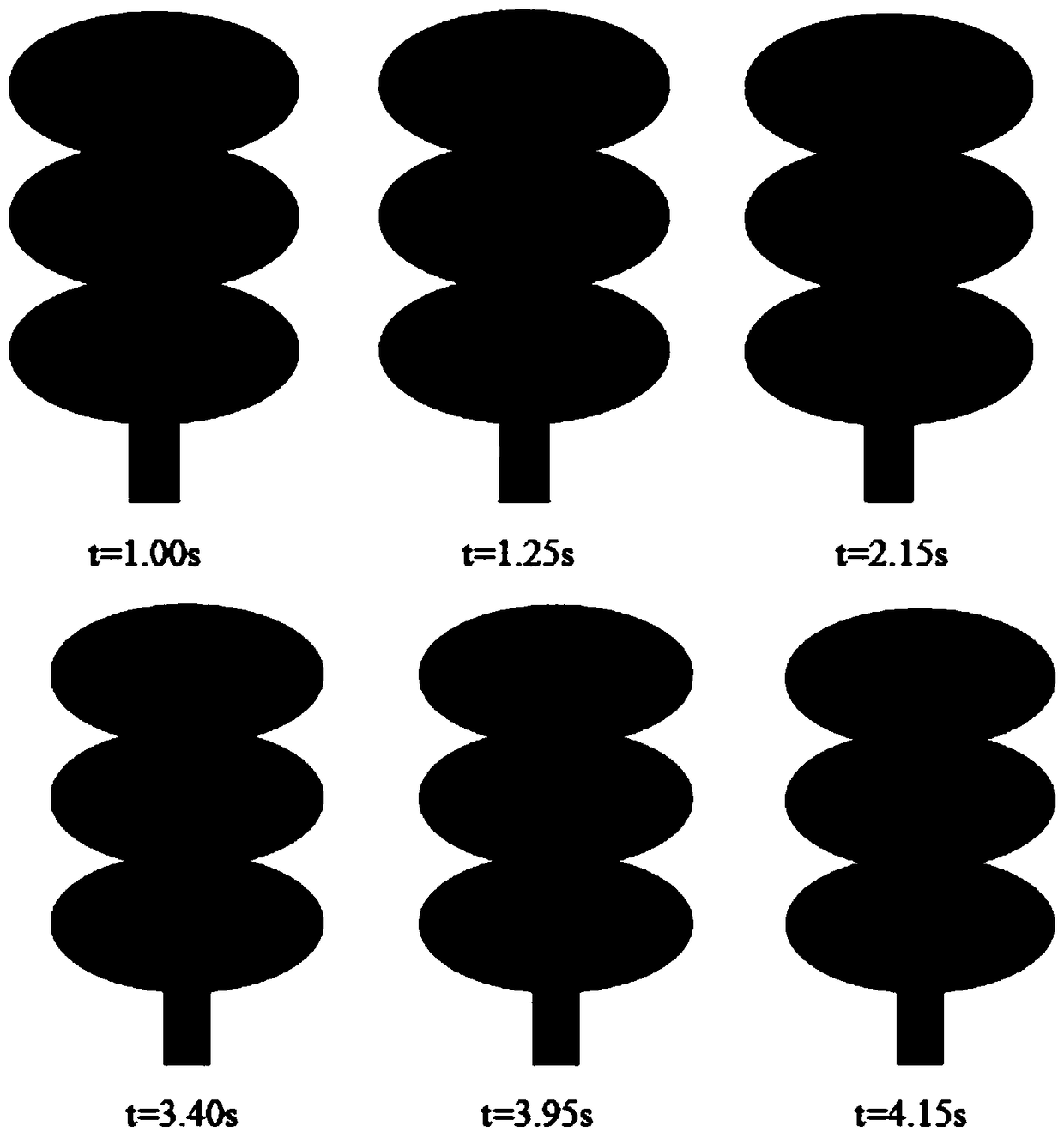

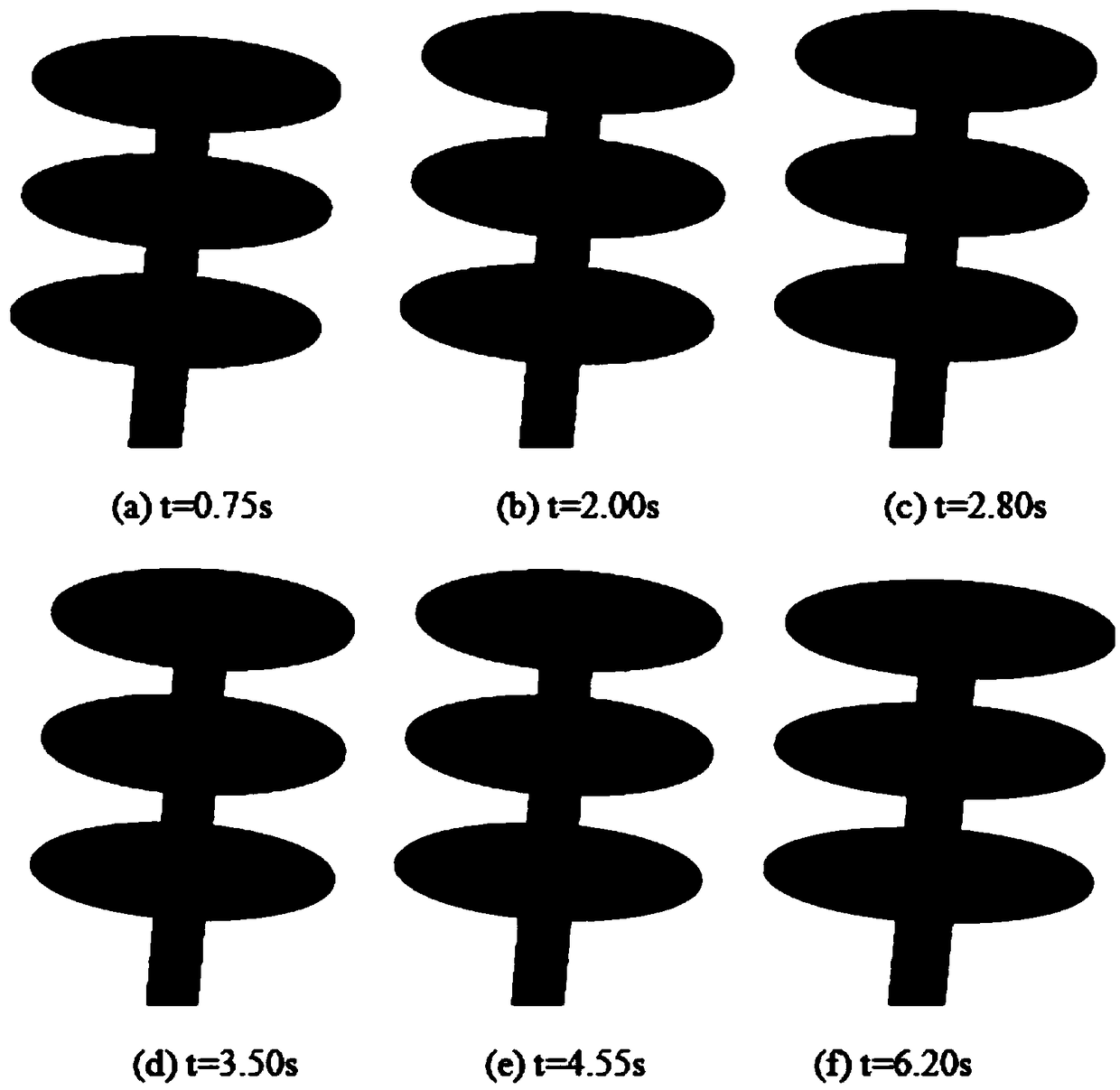

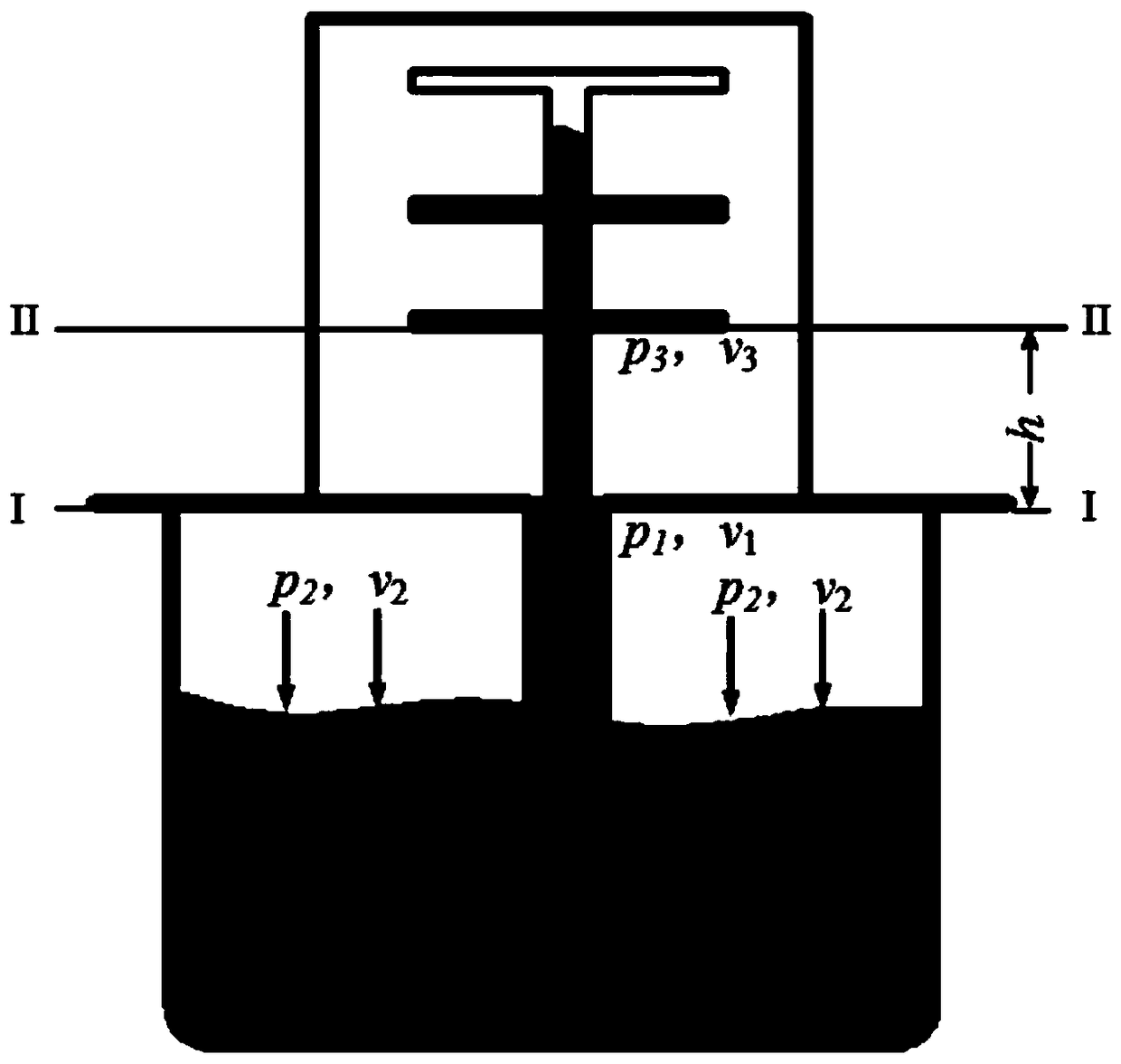

The invention discloses a mold filling differential pressure determining method based on vacuum differential pressure casting classified pressurizing mold filling. Under the condition that it is guaranteed that the inner mold filling flow state of a liquid ascending pipe is laminar flow, the mold filling pressure and the mold filling speed of liquid metal in the liquid ascending pipe are determined, and the classified pressurizing mold filling differential pressure needed at the position of a classified mold filling section is calculated in combination with the shape, the height, the wall thickness and the complex degree at the position of a casting mold filling section according to the principles of energy conservation, mass conservation and continuity. The mold filling differential pressure determining method has the advantages that a good mold filling flow state in the liquid ascending pipe can be guaranteed, the classified pressurizing mold filling differential pressure is determined according to the mold filling section feature, and accordingly, the stability of the mold filling flow state at the position of the mold filling section can be obviously improved. The vacuum differential pressure casting classified pressurizing mold filling differential pressure can be scientifically determined, and important significance is achieved for achieving stability and the sequence ofthe flow state in the mold filling process and reducing oxidization slag inclusions, gas wrapping and other casting defects happening to castings.

Owner:NANCHANG HANGKONG UNIVERSITY

Covering agent applicable to smelting of copper alloy containing easily oxidized alloying elements and application of covering agent

The invention belongs to the technical field of copper alloy machining, and relates to a covering agent applicable to smelting of a copper alloy containing easily oxidized alloying elements, and application of the covering agent. The coving agent consists of the following components in mass percent: 50-80% of sodium borate and 20-50% of cullet, wherein the sodium borate and the cullet are added respectively, and the cullet is added firstly, and then the sodium borate is added with the time interval not less than 10 min. Through the covering agent, vacuum smelting can be replaced by common smelting, the copper alloy containing easily oxidized alloying elements can be smelted by a common electric induction furnace, large-size ingot castings can be easily prepared and continuously cast, and the alloy quality of the copper alloy subjected to smelting is better. The covering agent related to the invention has the characteristics of low cost, environmental protection and energy conservation.

Owner:洛阳双瑞达特铜有限公司

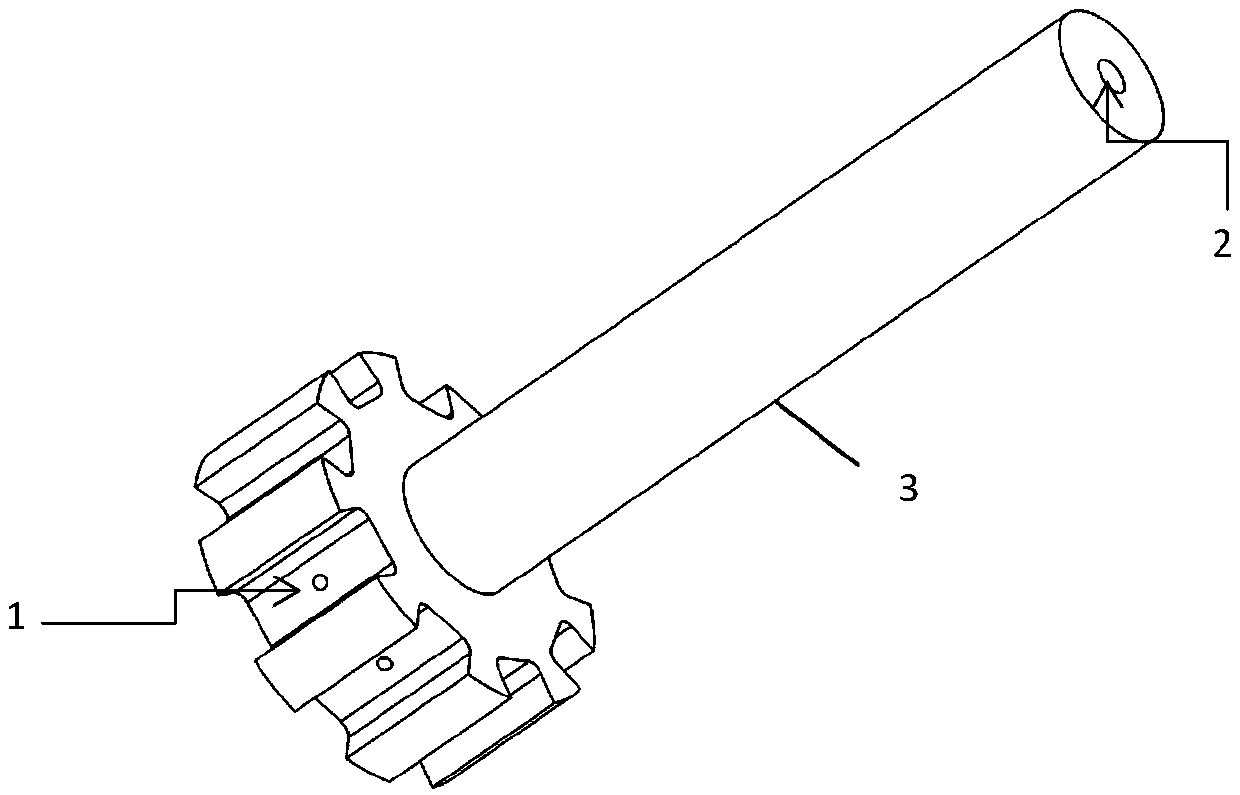

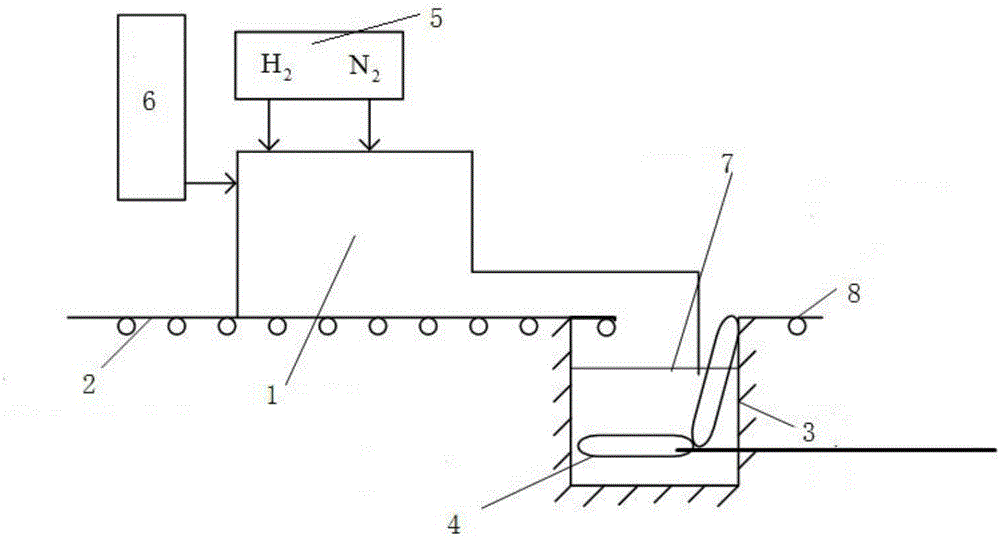

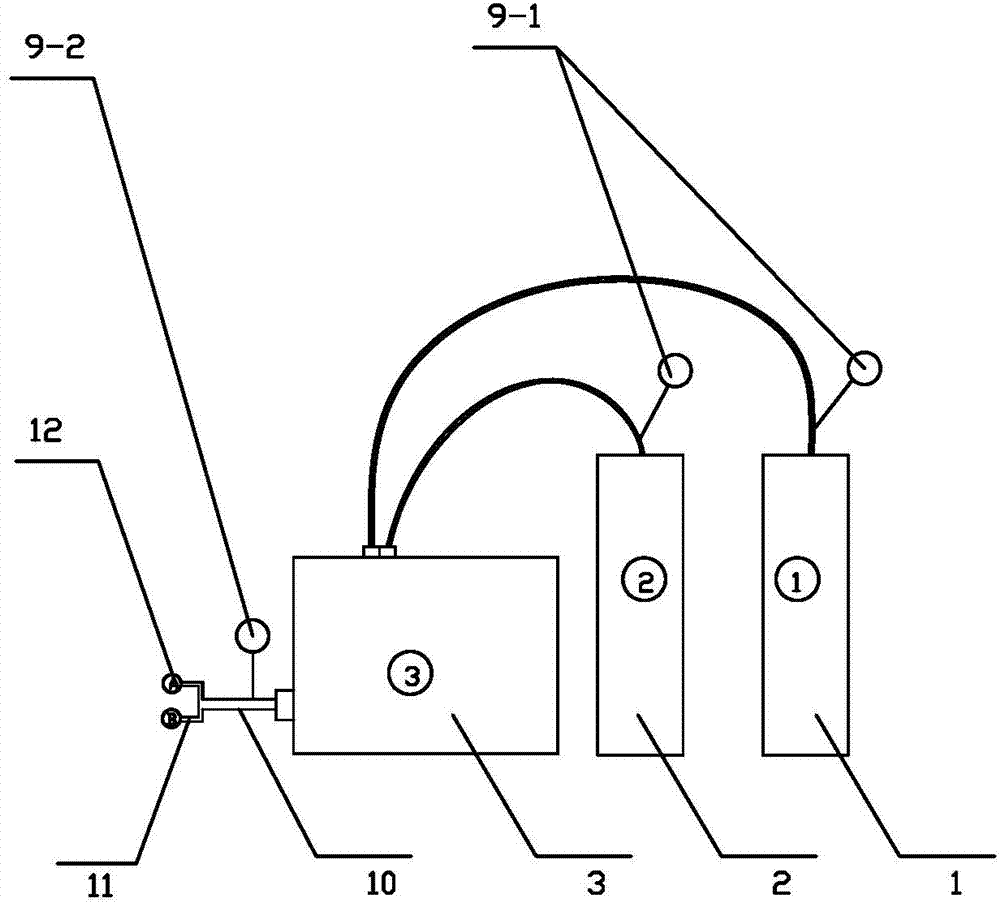

A method for swirling and blowing refining of low-pressure casting aluminum alloy melt with argon protection

ActiveCN109628773BSolve the problem of large melt contentImprove compactnessPressure castingHydrogen content

The invention discloses an argon gas protection rotary blowing refining method for low-pressure casting of aluminum alloy melt. The method comprises the following steps that an aluminum alloy materialis melted; a refining device is adopted for carrying out argon gas blowing refining on molten aluminum after melting is finished, and molten aluminum alloy metal is left to stand after refining is finished; and a mold shell model waits to be poured; and a casting is poured by adopting a low-pressure casting device connected with an air compressor through a low-pressure casting process. The problem that the content of the aluminum alloy melt casted by low-pressure casting is large is solved, the density and pressure bearing capacity of the aluminum alloy are improved, the situation that the metallurgical quality is unstable and even scrapping occurs due to the fact that the aluminum alloy melt is large in gas content is avoided, so that the production cost of castings is greatly reduced; and the hydrogen content of every 100 g of a sample after refining is less than 0.1 mL, and the production efficiency is improved while the gas content of the aluminum alloy melt is reduced.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD +1

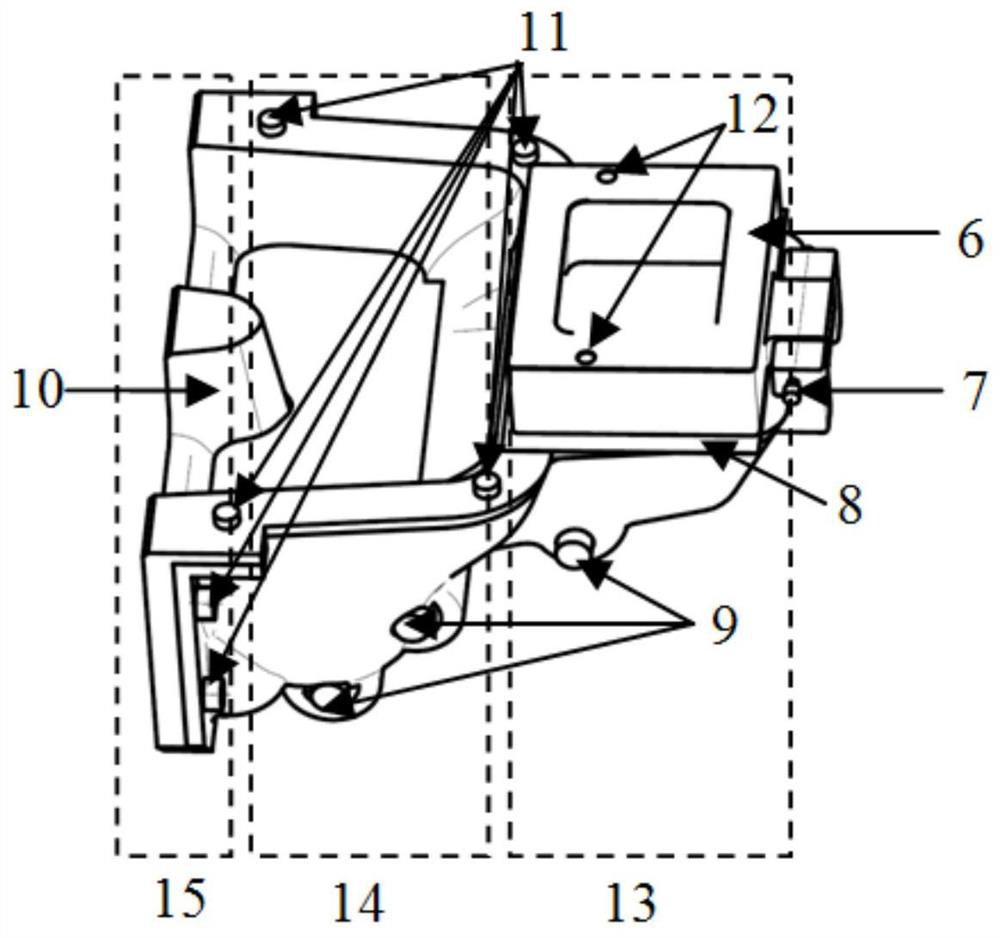

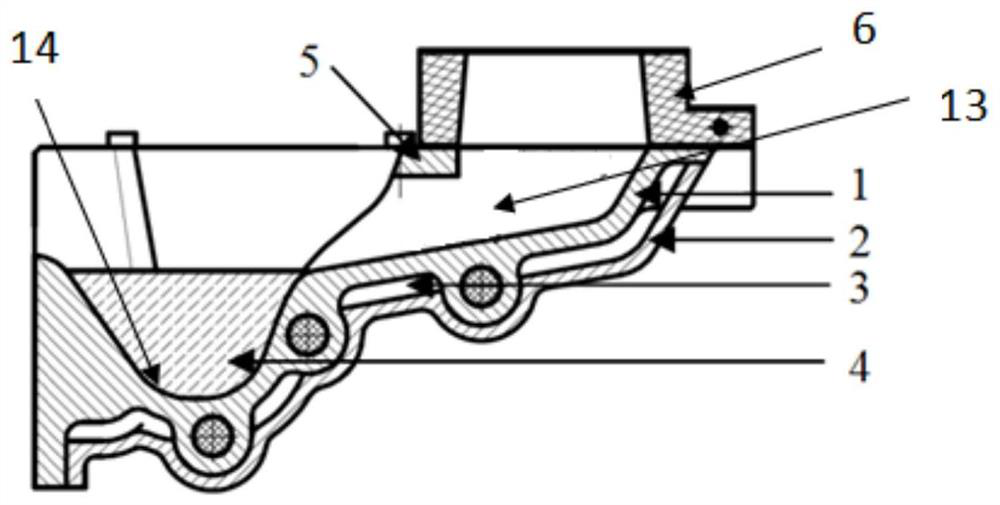

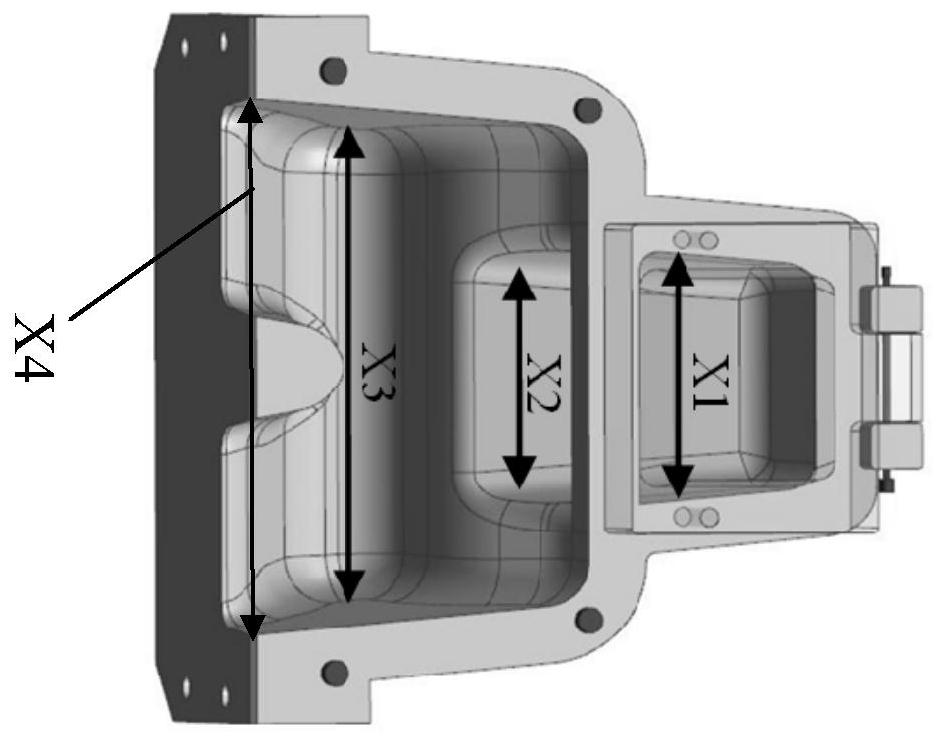

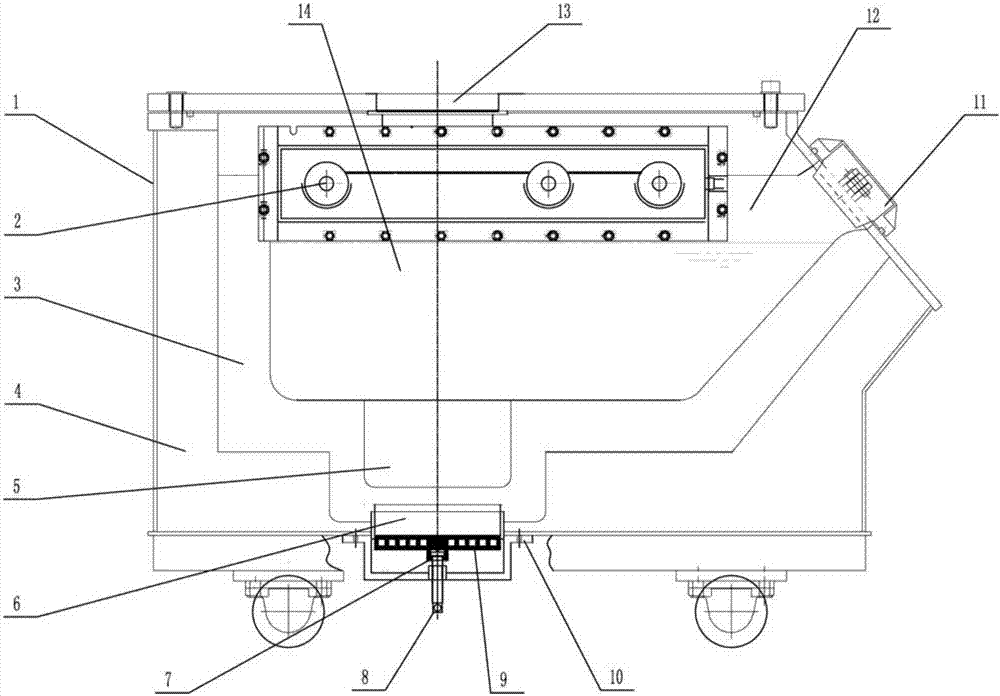

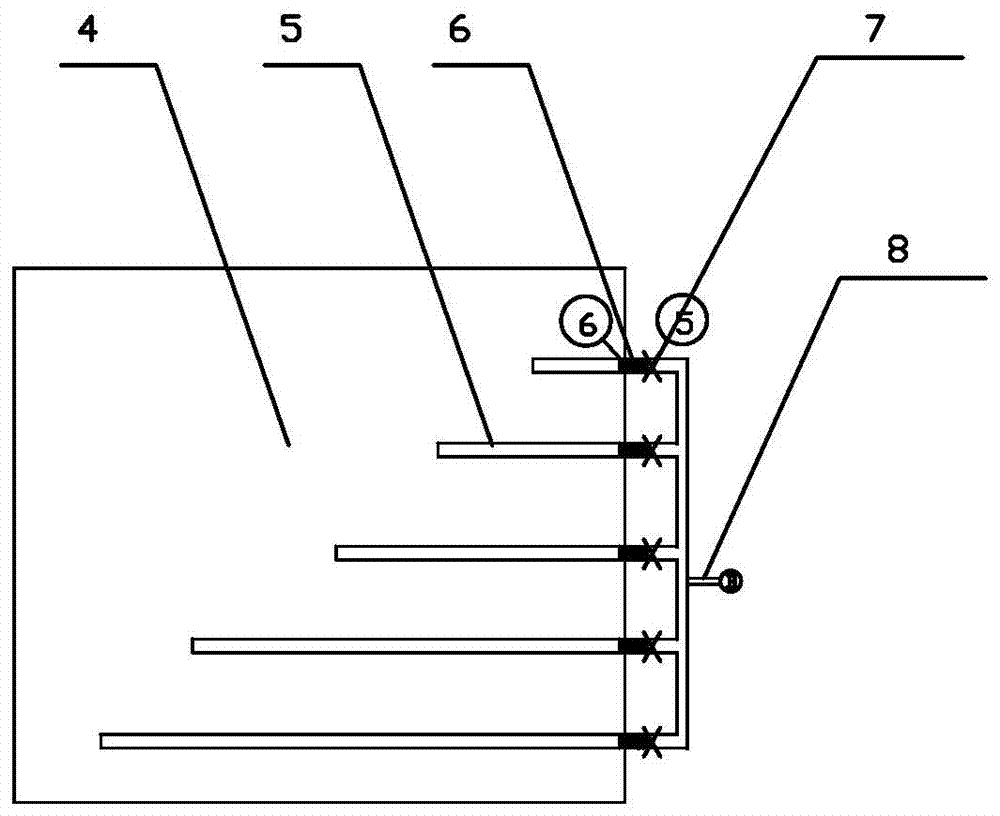

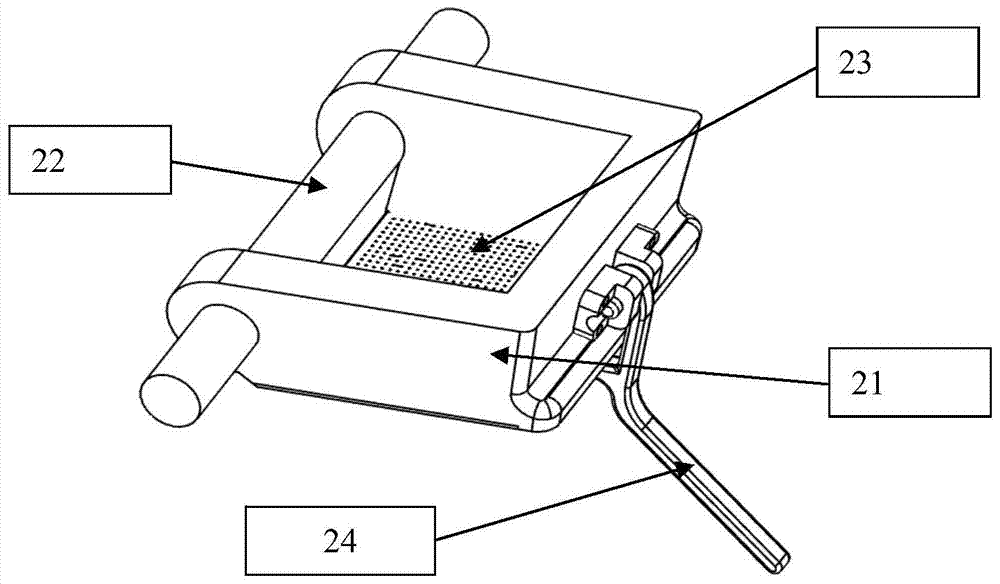

Open type heating and heat preservation hopper for reducing oxide inclusions and pouring method

ActiveCN112658214AReduce oxidation inclusionsReduce secondary oxidationFoundry mouldsProcess efficiency improvementEngineeringCasting mold

The invention relates to an open type heating and heat preservation hopper for reducing oxide inclusions and a pouring method. The problems that in the prior art, the oxide inclusion defect of a casting poured by a hopper for tilting casting is serious, and the heat preservation effect of the hopper is not ideal are solved. The open type heating and heat preservation hopper comprises a hopper outer lining, a hopper body and a pouring cup; a cavity with an opening in the top is formed in the hopper body, and the cavity is sequentially divided into a liquid inlet cavity and a liquid containing cavity according to the flowing direction of molten metal; by designing the shape of the cavity wall of the liquid inlet cavity and the shapes and the sizes of a liquid inlet and a liquid outlet, it is ensured that the liquid inlet cavity is approximately filled with the molten metal in the flowing process below the pouring cup, and meanwhile it is ensured that the molten metal stably enters the liquid containing cavity; by designing the structures and shapes of a pouring gate and the liquid containing cavity, the stability of the process of filling a casting mold cavity with the molten metal is guaranteed; by using the open type heating and heat preservation hopper for pouring, the oxide inclusion defect of the casting can be effectively reduced, the temperature of the molten metal in the open type heating and heat preservation hopper can be maintained in the pouring process, the heat loss of the molten metal in the hopper is reduced, and the quality of the casting is ensured.

Owner:XIAN AERO ENGINE CONTROLS

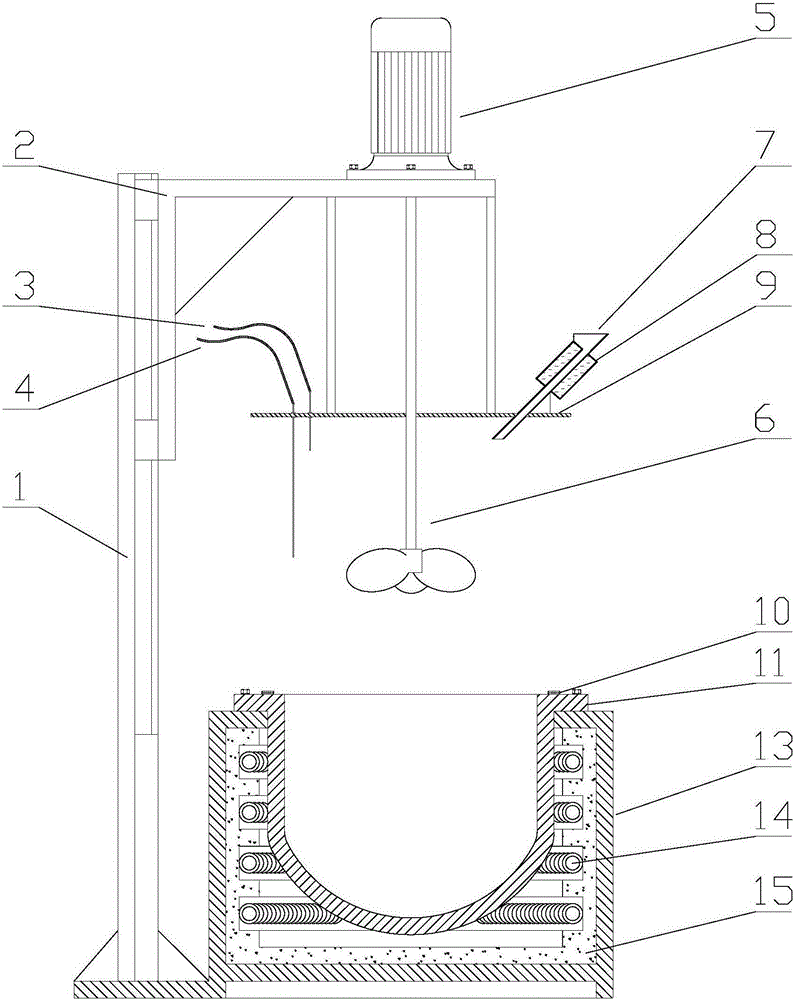

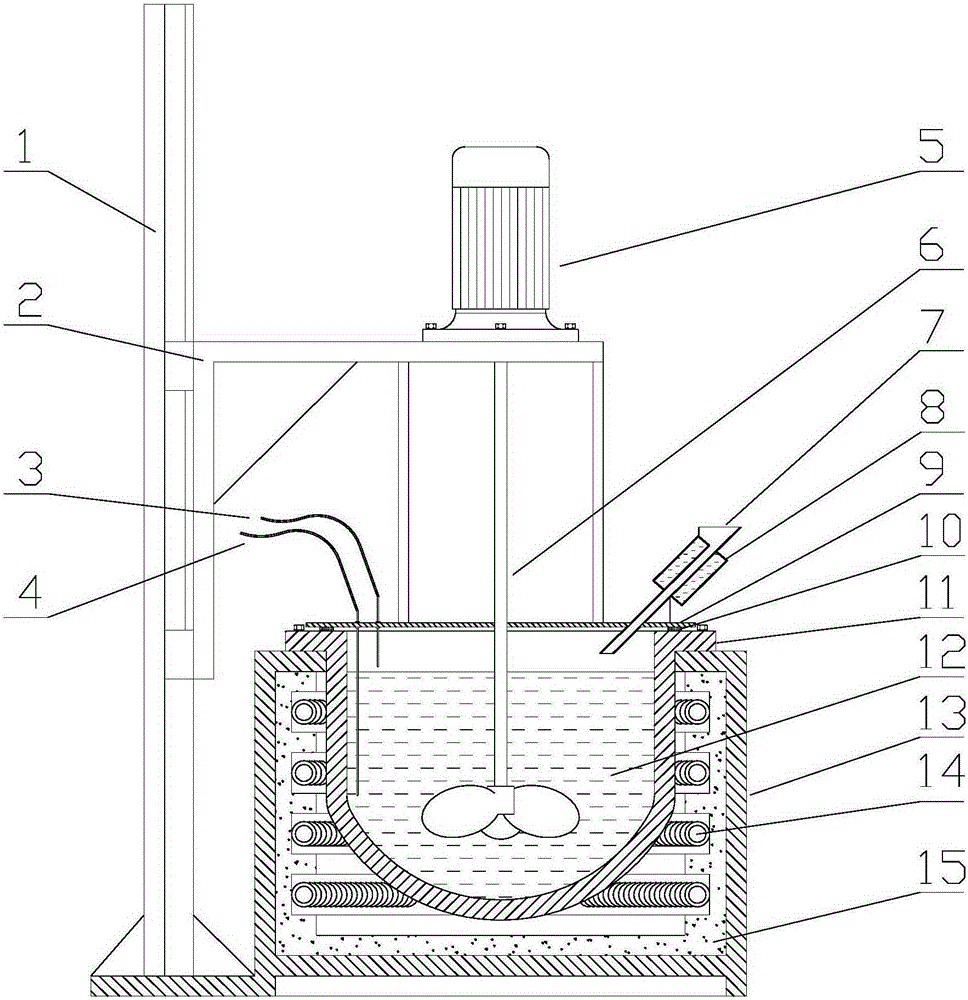

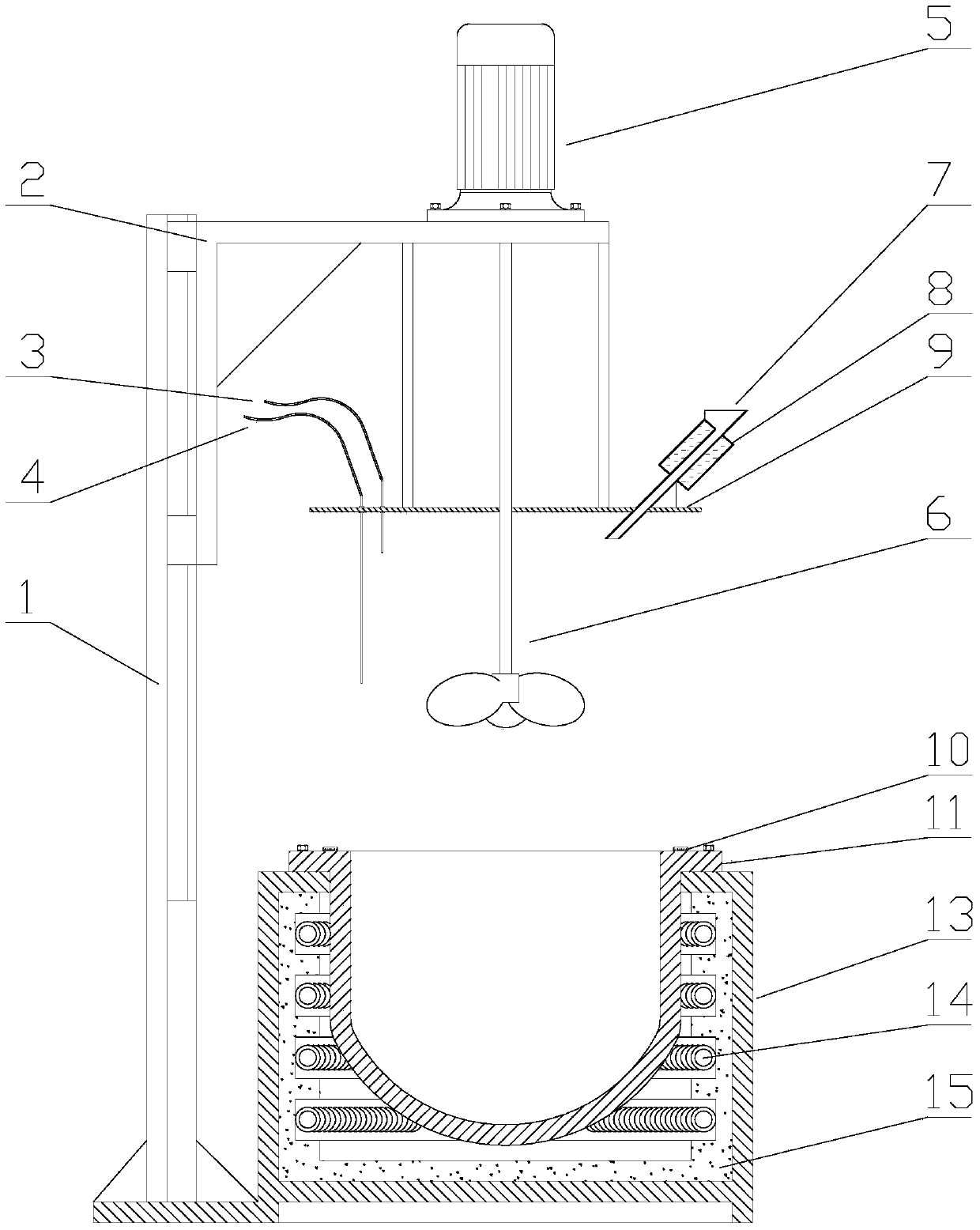

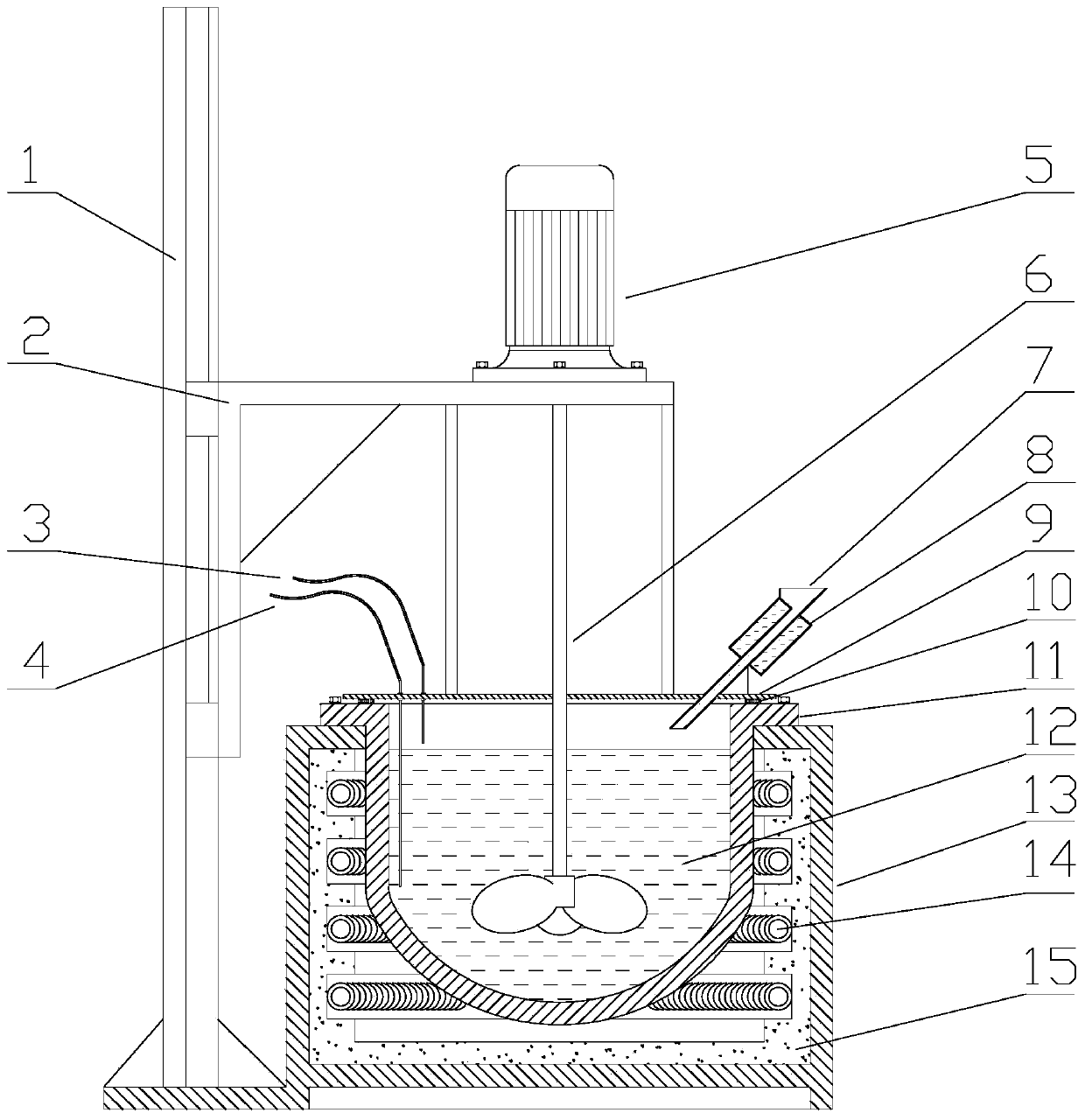

Smelting device and preparing method for antioxidant tin solder alloy

The invention provides a smelting device for antioxidant tin solder alloy. The smelting device for the antioxidant tin solder alloy comprises a furnace body, a furnace cover, a stirring machine, a stirring support, a guide rail support, a feeding system, a temperature control system, a nitrogen system and a lifting system. The furnace cover is fixed to the liftable stirring support. The feeding device, a thermoelectric couple and a nitrogen pipe are installed on the furnace cover. A stirring shaft passes through the center of the furnace cover. A cooling device is arranged at the front end of the feeding device. The stirring support is fixed to the guide rail support through a sliding rail and can move up and down. The guide rail support and the furnace body are fixed together. The exterior of the furnace body is made of metal. The interior of the furnace body is made of refractory heat-insulation materials. Electric heating wires are fixed in grooves built through refractory materials. A stainless steel or iron-cast crucible is arranged on the furnace body. According to the smelting device for the antioxidant tin solder alloy, by the adoption of the way that the furnace cover can rise and fall, nitrogen in the furnace body is at the positive pressure, a microelement feed inlet is formed, and the cooling device is arranged, the alloy element of tin solder can be effectively controlled, and the oxidation resistance is improved and stabilized.

Owner:GUANGDONG TTIN METAL IND CO LTD

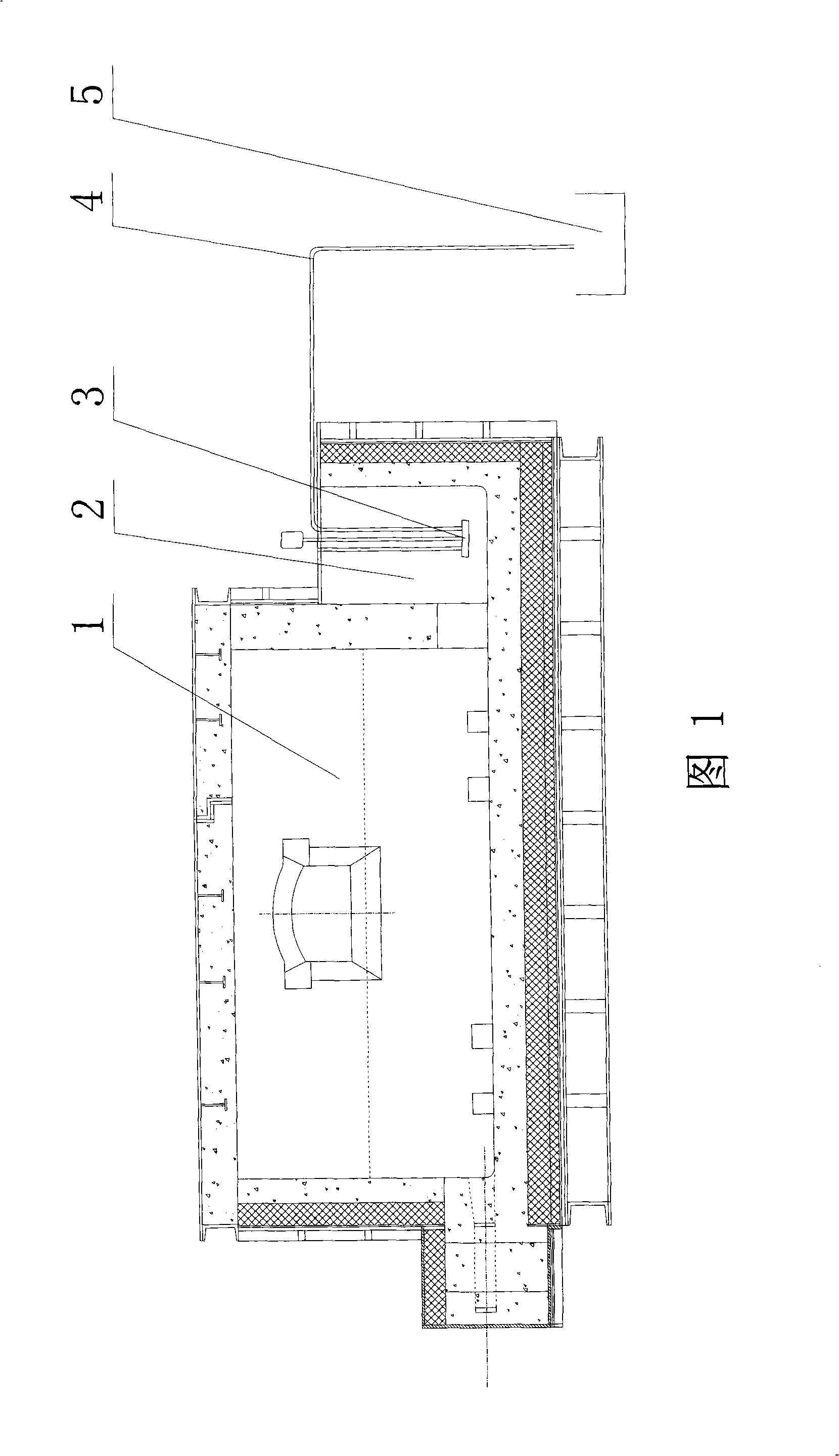

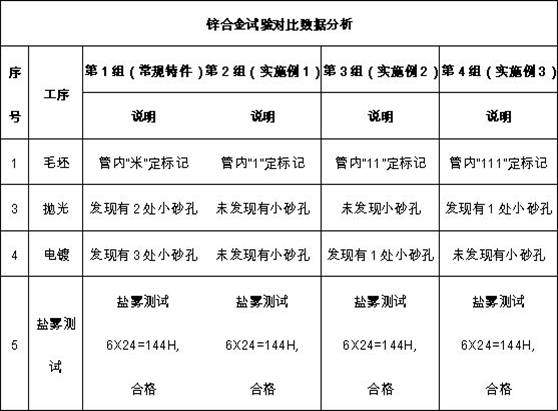

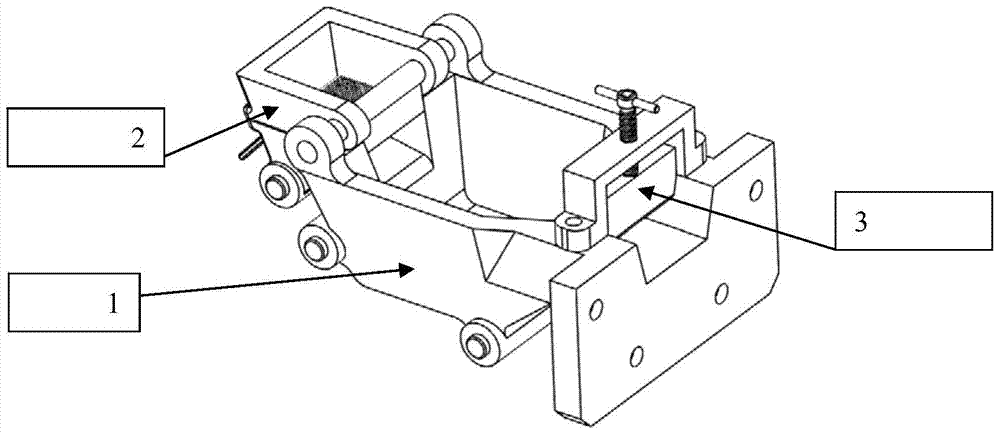

Enclosed type method and device for conveying zinc alloy liquor and casting zinc alloy ingot

InactiveCN101406936AReduce oxidation slagStable and reliable casting flowMolten metal conveying equipmentsAlloy elementSlag

The invention relates to a method and a device for casting a zinc alloy pig. The method comprises the following steps: melting solid zinc into zinc liquid and adding an alloying element into the zinc liquid to alloy the zinc liquid, then pumping out the zinc liquid, and casting the zinc alloy pig through a pipeline in an airtight conveying mode. The device comprises a melting device, a conveyer, a casting device, and a pumping device, wherein the pumping device is an immersible pump type zinc liquid pump which is arranged in an airtight container communicated with the melting device. The method allows the zinc liquid to flow under the airtight condition, reduces the slag rate in the process of alloy casting, improves the quality of an alloy product, cancels the operations of blow on and stop off, reduces potential safety hazards in the production process, reduces the labor intensity of workers, improves the labor productivity, and realizes the automation of casting flow control.

Owner:ZHUZHOU SMELTER GRP

Argon gas protection rotary blowing refining method for low-pressure casting of aluminum alloy melt

ActiveCN109628773AImprove density and pressure bearing capacityAvoid unstable or even scrapped metallurgical qualityHydrogen contentAluminium alloy

The invention discloses an argon gas protection rotary blowing refining method for low-pressure casting of aluminum alloy melt. The method comprises the following steps that an aluminum alloy materialis melted; a refining device is adopted for carrying out argon gas blowing refining on molten aluminum after melting is finished, and molten aluminum alloy metal is left to stand after refining is finished; and a mold shell model waits to be poured; and a casting is poured by adopting a low-pressure casting device connected with an air compressor through a low-pressure casting process. The problem that the content of the aluminum alloy melt casted by low-pressure casting is large is solved, the density and pressure bearing capacity of the aluminum alloy are improved, the situation that the metallurgical quality is unstable and even scrapping occurs due to the fact that the aluminum alloy melt is large in gas content is avoided, so that the production cost of castings is greatly reduced; and the hydrogen content of every 100 g of a sample after refining is less than 0.1 mL, and the production efficiency is improved while the gas content of the aluminum alloy melt is reduced.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD +1

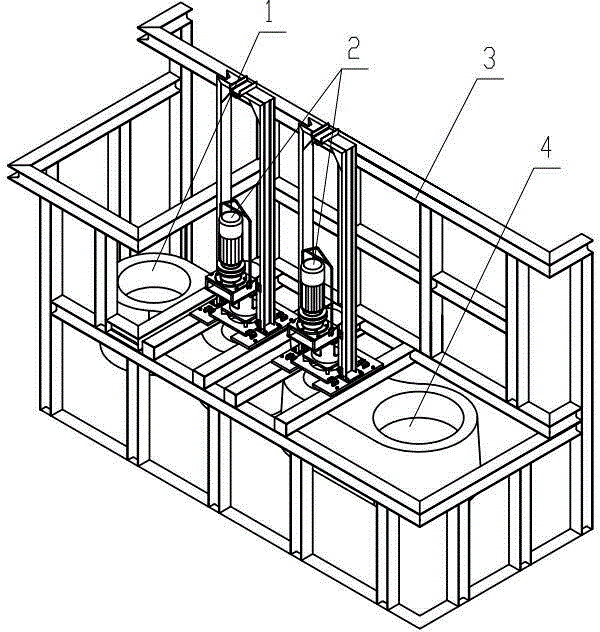

Aluminum ingot and aluminum scrap double fusion system alloy furnace

The invention discloses an aluminum ingot and aluminum scrap double fusion system alloy furnace. The furnace comprises a fusion furnace body, and an aluminum scrap fusion pool, an aluminum ingot fusion pool and a double mechanical stirring system which are positioned behind the fusion furnace body; and the double mechanical stirring system comprises an aluminum scrap stirring system and an aluminum ingot stirring system, the aluminum scrap stirring system is connected with the aluminum scrap fusion pool, and the aluminum ingot stirring system is connected with the aluminum ingot fusion pool. The aluminum ingot and aluminum scrap double fusion system alloy furnace can realize simultaneous fusion of aluminum scraps and aluminum ingots, makes the aluminum scraps, aluminum ingots and an aluminum liquid in the fusion furnace body form double annular cycle, avoids the abuse of multi-time opening of a furnace door for adding aluminum ingots and removing slag in the alloy aluminum melting process, reduces heat loss in the fusion furnace, avoids impact of frequent opening of the furnace door on a refractory material nearby the furnace door, prolongs the service life of the refractory material nearby the furnace door, reduces wastes of the raw material industrially-pure aluminum and the cost investment, reduces the labor intensity of workers in high temperature environment, and creates comprehensive values and benefits for aluminum alloy production enterprises.

Owner:BAODING ANBAONENG METALLURGICAL EQUIP CO LTD

Knotting type heat preservation furnace used for continuously preparing aluminum alloy semi-solid slurry

The invention provides a knotting type heat preservation furnace used for continuously preparing aluminum alloy semi-solid slurry. The knotting type heat preservation furnace comprises a furnace body,a hearth and a heater; the hearth and the heater are located in the furnace body, the heater is arranged on the top of the hearth, a slurry making groove is formed in the bottom of the hearth, the heater heats molten aluminum in the hearth through heat radiation, the temperatures of the molten aluminum in the hearth forms a temperature gradient gradually reduced from the molten aluminum liquid level to the molten aluminum deep position, and semi-solid slurry is generated in the slurry making groove. The furnace is used for continuously preparing the semi-solid slurry, oxide inclusions in theslurry are few, and quality inside the casting can be further improved; the slurry making groove in the furnace body is large in use depth, the molten aluminum utilization rate can be up to 80% or above, molten aluminum is added, slagging off is conveniently operated, the effect on the prepared slurry is very little, and the normal production is not affected.

Owner:FUJIAN RHEOMET LIGHT METAL CO LTD

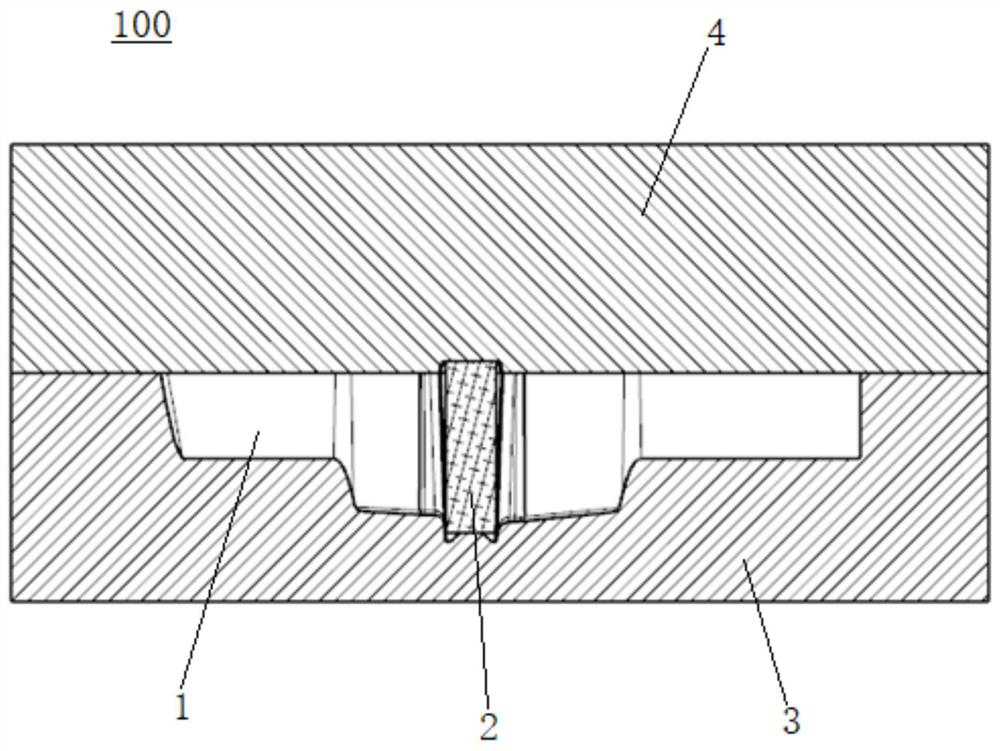

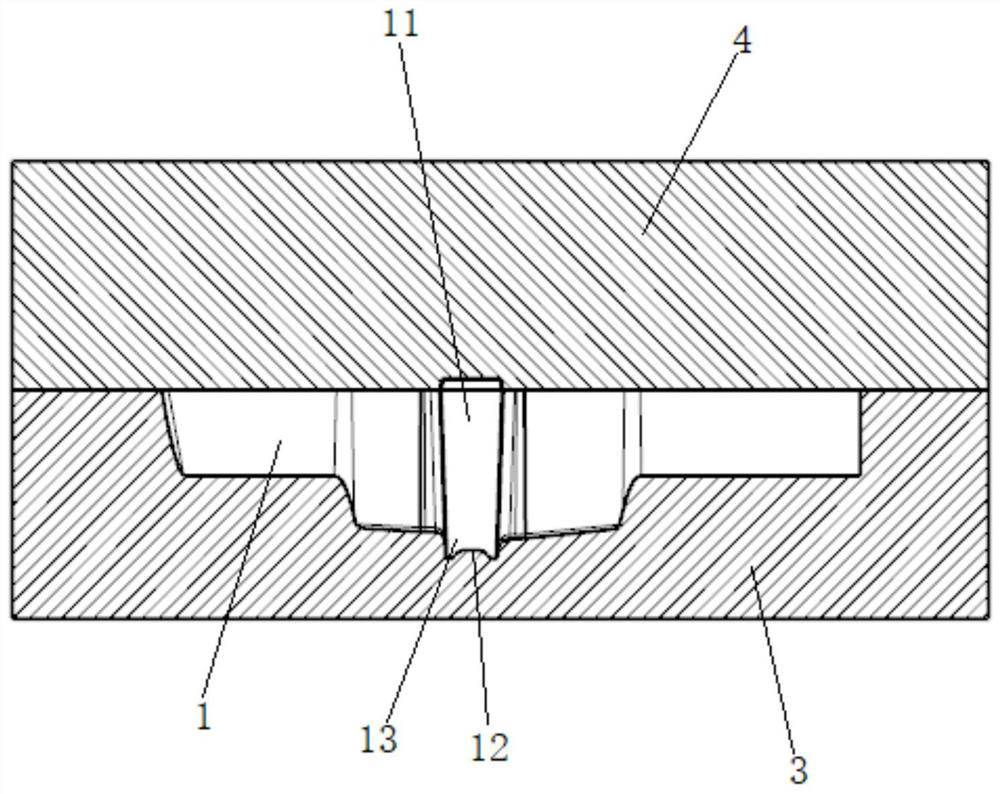

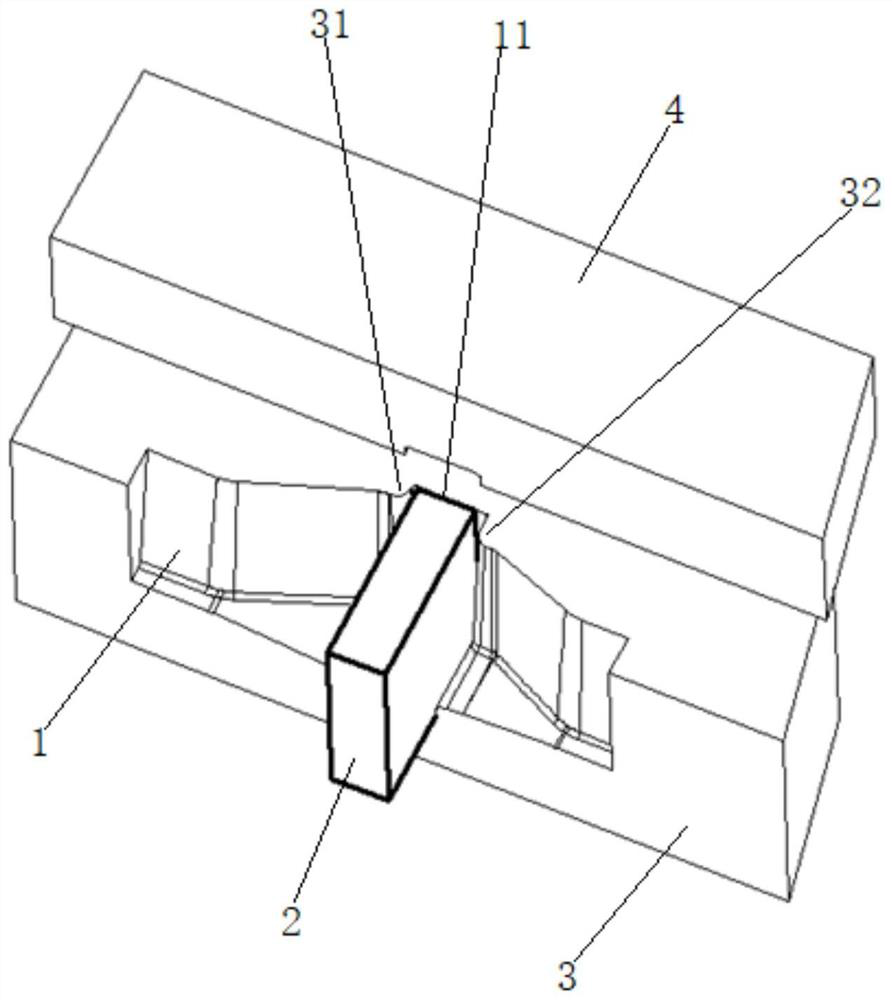

Molten iron dross filtering structure in casting mold

PendingCN112589055AImprove positional stabilityImprove sealingFoundry mouldsFoundry coresHoneycombEngineering

The invention discloses a molten iron dross filtering structure in a casting mold. The molten iron dross filtering structure comprises a honeycomb filter screen block arranged in a pouring gate, the periphery of the honeycomb filter screen block is attached to the surface of the inner wall of the pouring gate, the pouring gate is jointly formed by a lower mold and an upper mold in a surrounding manner, the upper surface of the honeycomb filter screen block protrudes out of the upper surface of the lower mold, the upper portion of the honeycomb filter screen block is embedded into the lower surface of the upper mold, and the width of the part, on the water inlet side of the honeycomb filter screen block, of the pouring gate is larger than that of the part, on the water outlet side, of the pouring gate. According to the molten iron dross filtering structure, position stability of a filter screen and the sealing performance of the filter screen and the periphery of the pouring gate can beguaranteed, it is guaranteed that molten iron can effectively pass through the filter screen to achieve dross filtering, and the casting forming quality is improved.

Owner:苏州勤堡精密机械有限公司

A kind of ultra-high-strength heat-resistant aluminum alloy and its preparation method

ActiveCN109898000BInhibit growthSuppress coarseningFurnace typesHeat treatment furnacesHeat resistanceUltimate tensile strength

Owner:郑州轻研合金科技有限公司

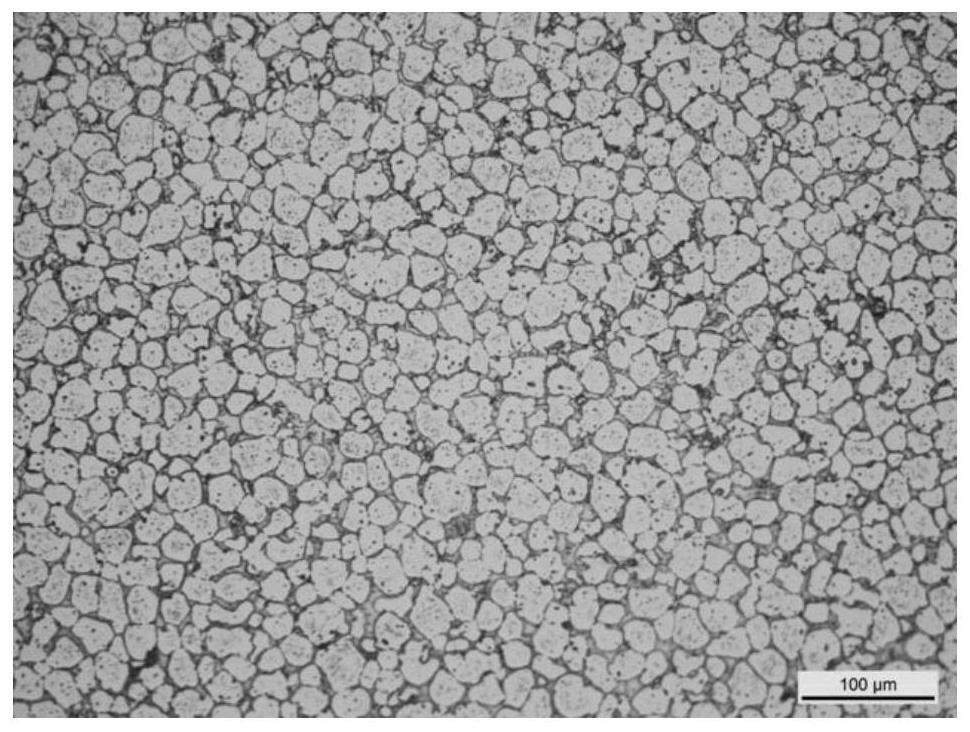

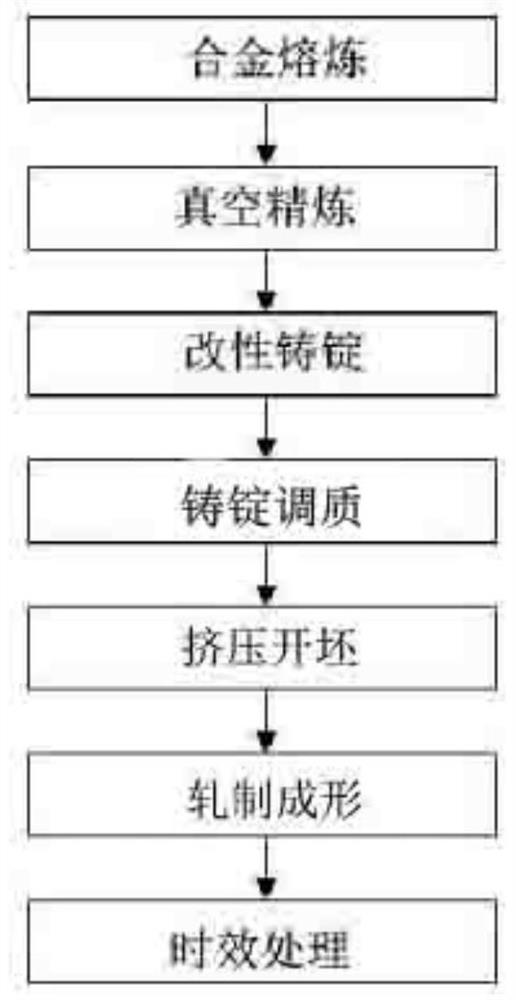

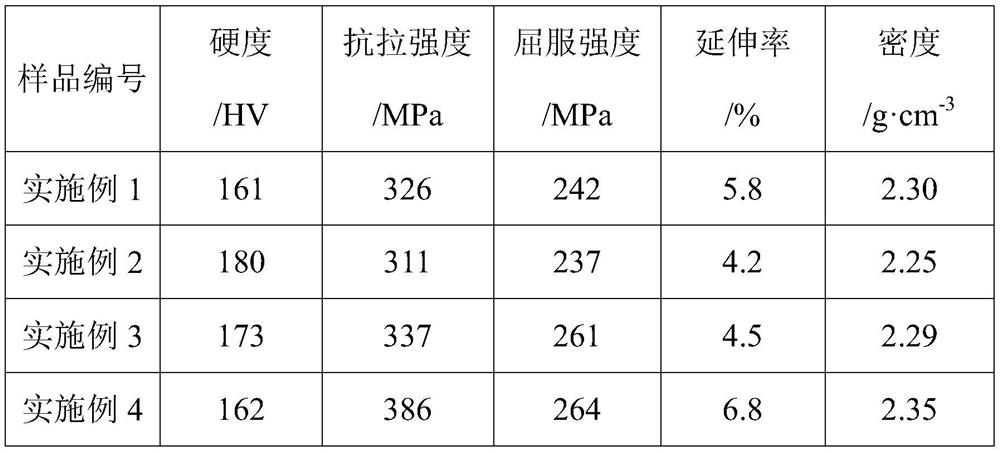

A kind of ultra-low density aluminum-lithium alloy and preparation method thereof

The invention provides an ultra-low density aluminum-lithium alloy, which is composed of the following components in mass percentage: magnesium: 9.0%-12.5%, lithium: 2.1%-3.5%, beryllium: 0.01%-0.1%, manganese: 0.1%- 0.5%, zinc: 0.1%‑0.5%, rare earth: 0.05%‑0.5%, and the balance is aluminum. The preparation method includes seven steps of alloy smelting, vacuum refining, ingot modification, ingot quenching and tempering, extrusion blanking, rolling forming and aging treatment. The aluminum alloy material involved in the present invention has good rigidity and plastic toughness, and the density is only 2.3g / cm 3 , is the aluminum alloy structural material with the lowest density at present, and can achieve a weight reduction effect of more than 20% by replacing traditional aluminum alloys, and has broad application prospects in aerospace and high-end civil fields where the demand for lightweight is urgent.

Owner:郑州轻研合金科技有限公司

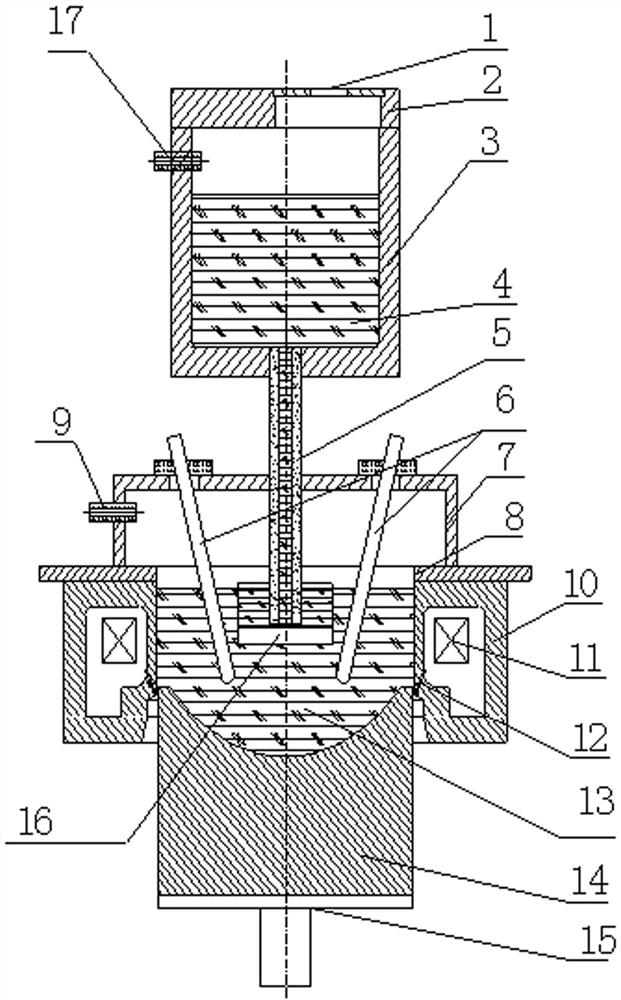

Semi-continuous casting device

The invention relates to a semi-continuous casting device. The semi-continuous casting device is composed of a liquid inlet, a heat preservation cover, a heat preservation cup, molten metal, a liquidguide pipe, an ultrasonic vibration rod, a protective cover, a platform, a protective gas pipe, a crystallizer, an electromagnetic coil, cooling water holes, crystallizer molten metal, a casting rod,a dummy ingot device, a flow limiting block, a heat preservation cup protective gas inlet pipe and the like. The semi-continuous casting device is used for semi-continuous casting of light alloys, gasprotection is adopted to prevent the molten metal from being oxidized, and electromagnetic stirring and ultrasonic vibration modes are adopted in the solidification process to jointly refine crystalgrains. According to the semi-continuous casting device, the defects that in a traditional semi-continuous casting process, the molten metal is prone to being oxidized, slagging and other factors damaging the quality of transmitted liquid are overcome, and the electromagnetic stirring and ultrasonic vibration combined mode is adopted in the casting rod solidification process, so that internal quality of the casting rod is better.

Owner:湖北启宏热工设备有限公司

A kind of high-strength and high-toughness cast qt700-10 and its production method

ActiveCN106811676BIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

A kind of smelting device and preparation method of anti-oxidation tin solder alloy

The invention provides a smelting device for an anti-oxidation tin solder alloy, which includes a furnace body, a furnace cover, a mixer, a stirring support, a guide rail support, a feeding system, a temperature control system, a nitrogen system, and a lifting system. The furnace cover is fixed on a liftable On the stirring support, the furnace cover is equipped with a feeding device, a thermocouple, and a nitrogen pipe, and the stirring shaft passes through the center of the furnace cover; the front end of the feeding device is equipped with a cooling device; the stirring support is fixed on the guide rail support through slide rails, and can move up and down; the guide rail support It is fixed with the furnace body; the outside of the furnace body is made of metal, and the inside is made of refractory and heat-insulating materials. The heating wire is fixed in the groove made of refractory materials, and the furnace body is made of stainless steel or cast iron crucible. The smelting device of the tin solder anti-oxidation alloy of the present invention adopts the mode of raising and lowering the furnace cover, nitrogen positive pressure in the furnace, trace element feeding port and cooling device, the alloy composition of the tin solder can be effectively controlled, and the oxidation resistance performance is improved and stabilized.

Owner:GUANGDONG TTIN METAL IND CO LTD

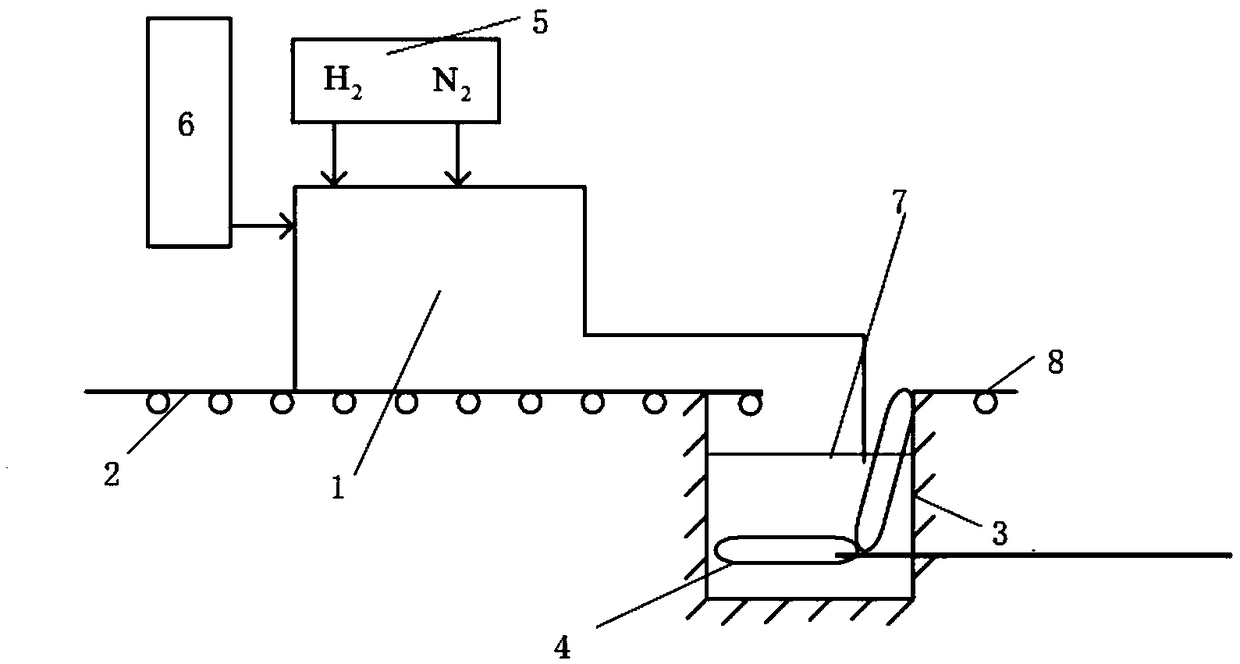

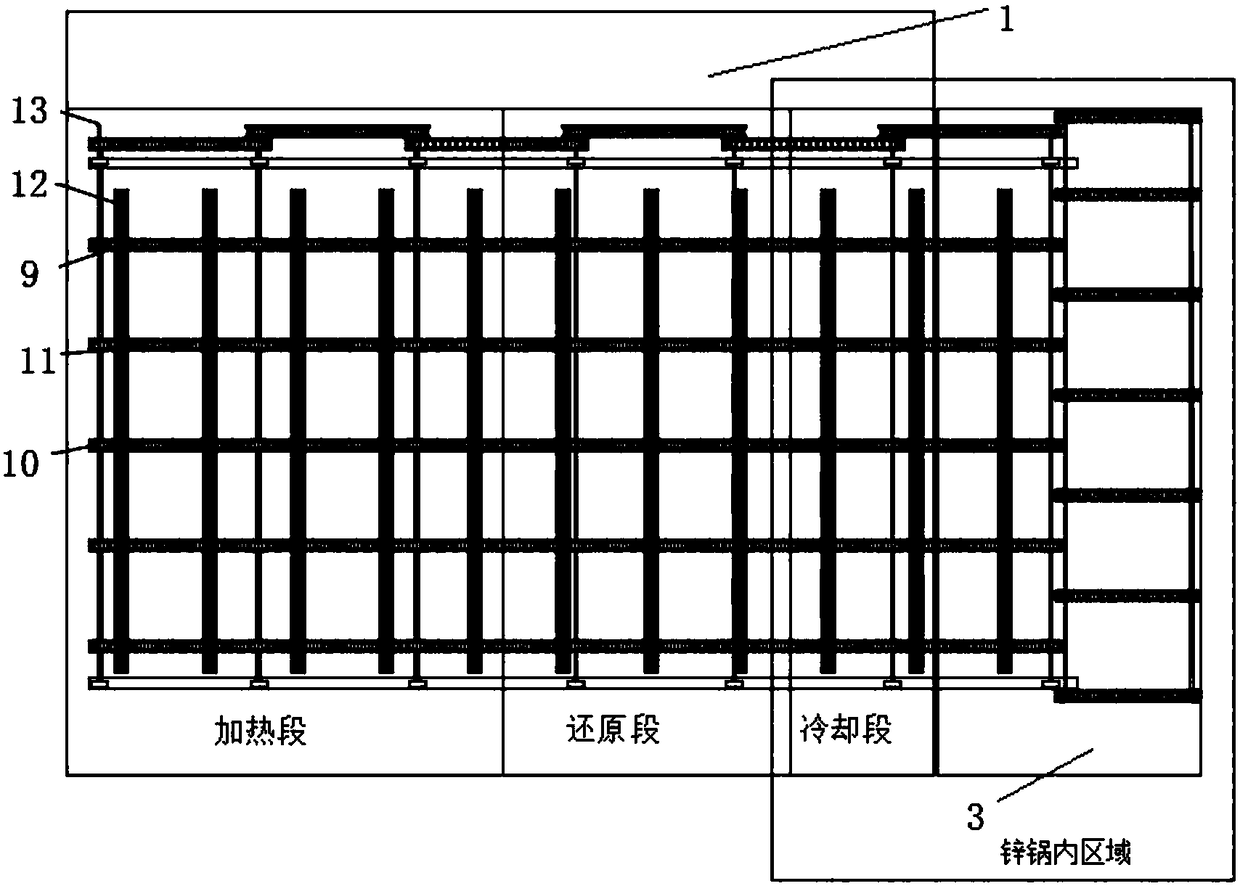

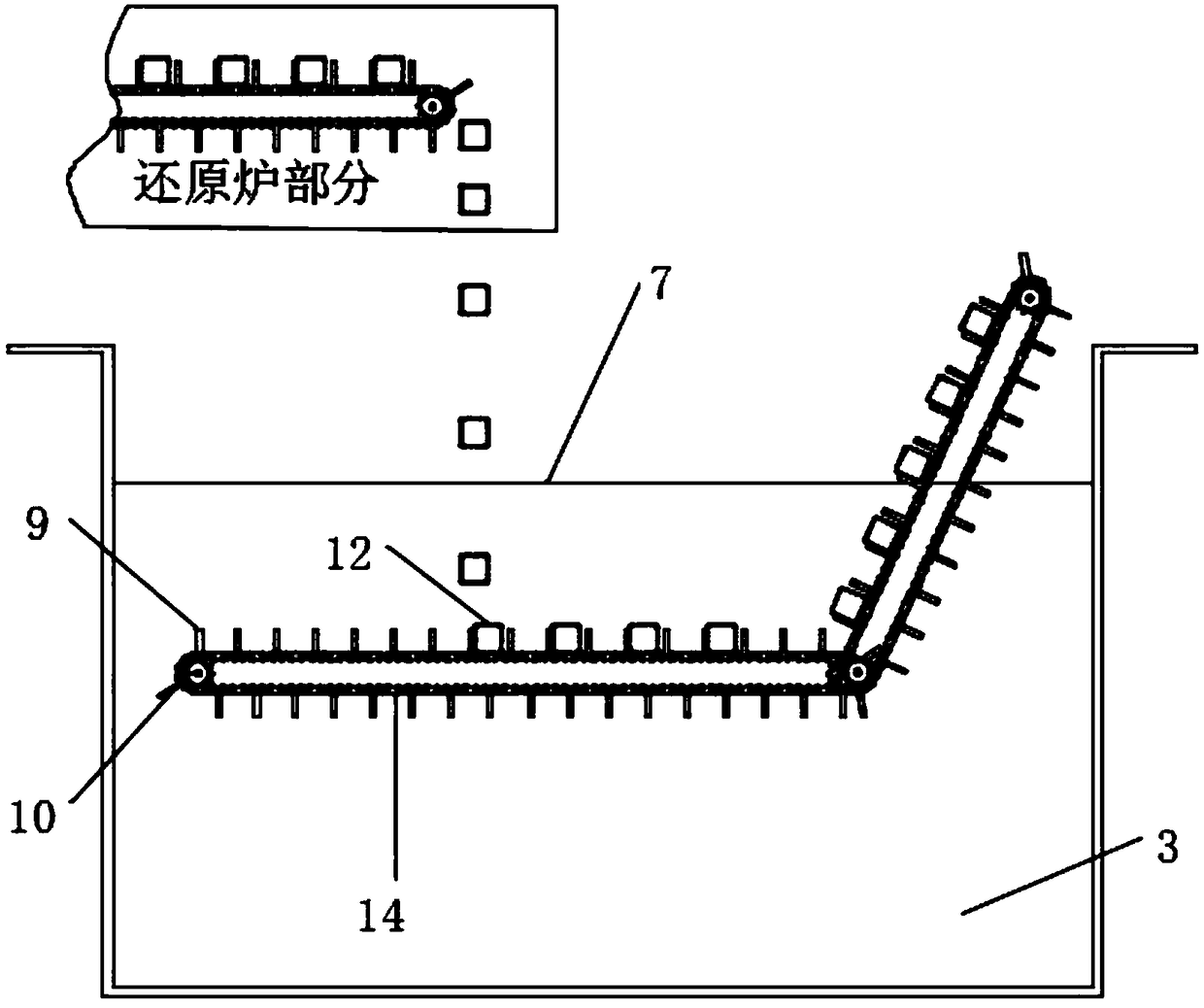

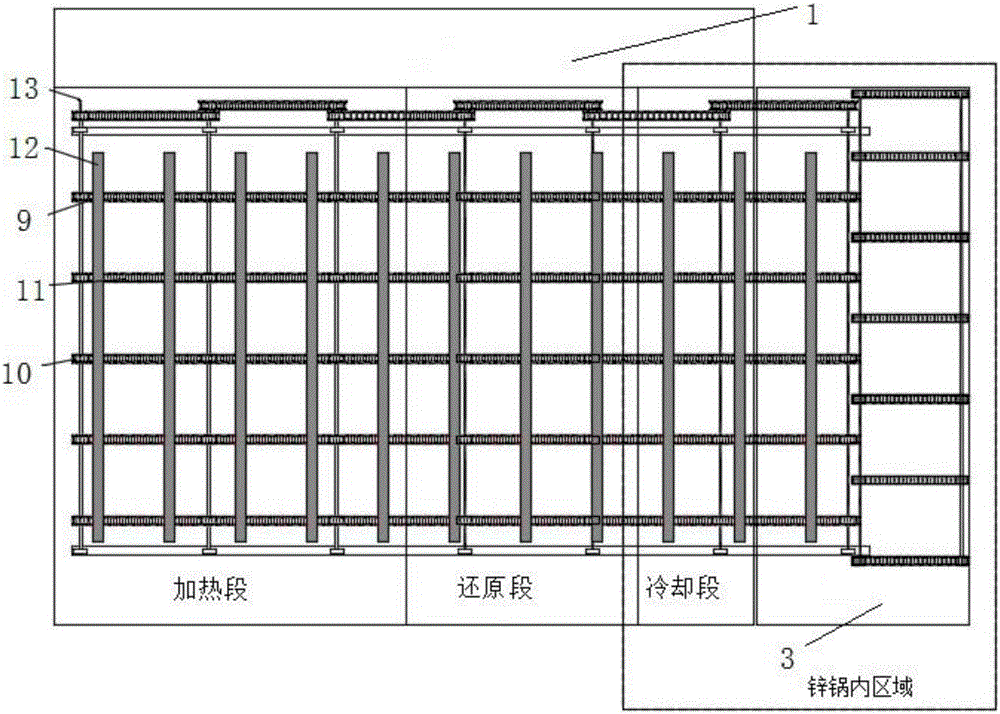

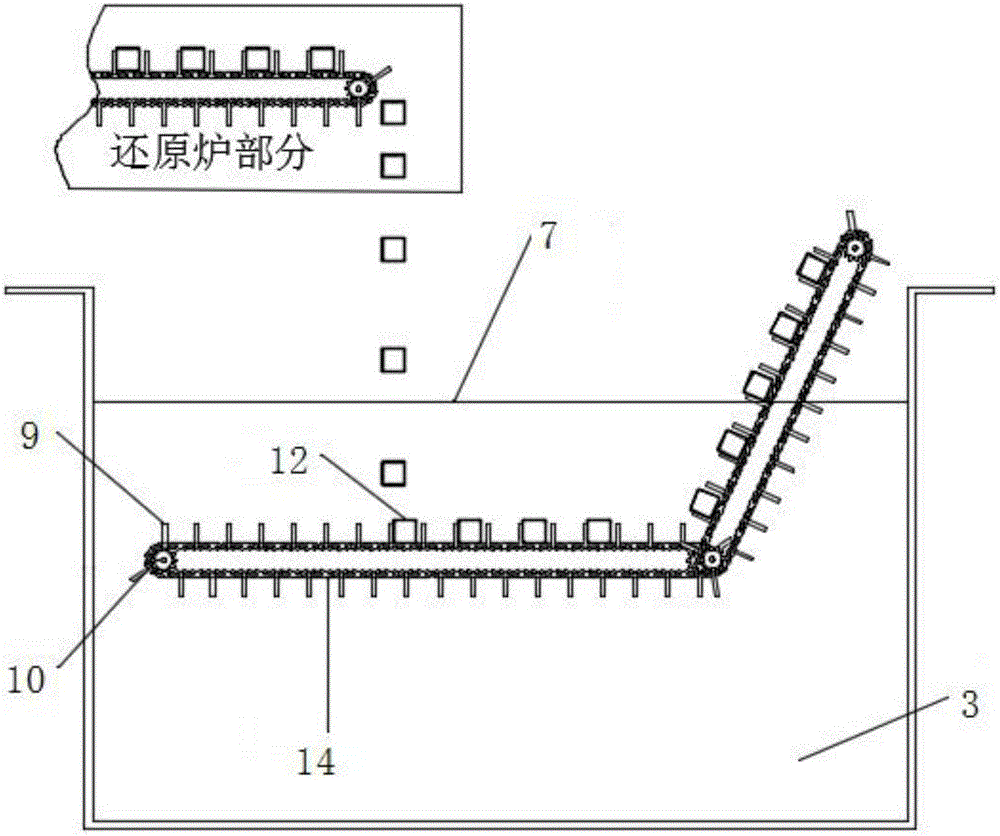

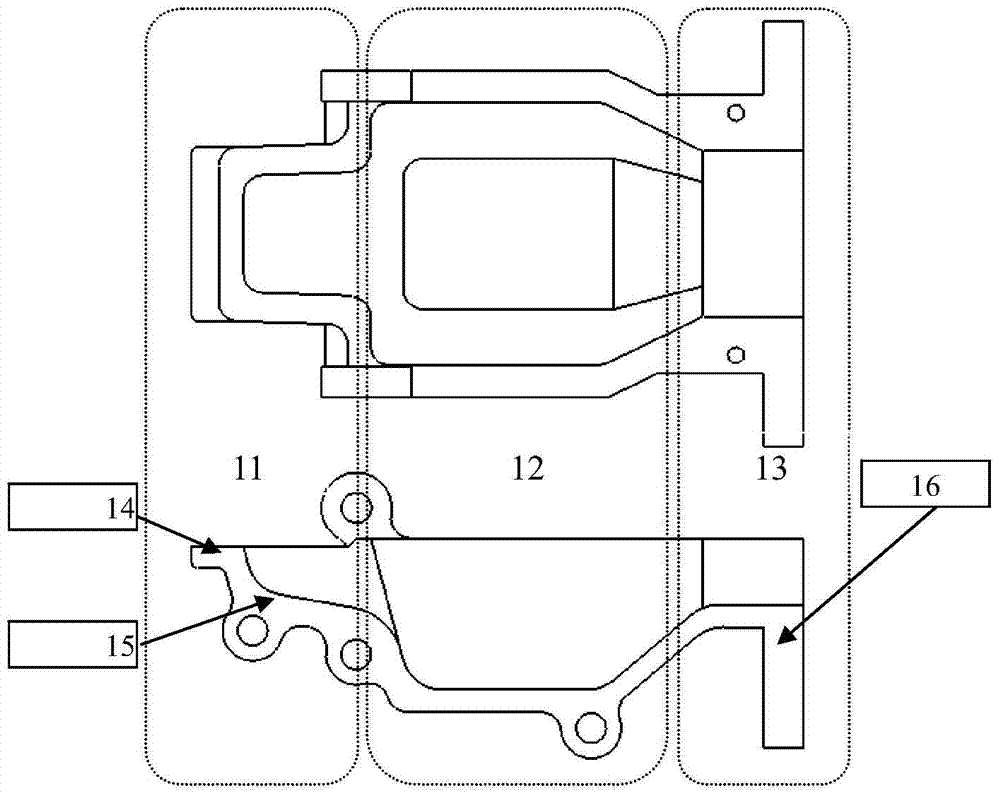

Device and method for continuous galvanizing of profiles and pipes

InactiveCN106119753BAvoid formingReduce oxidation slagHot-dipping/immersion processesSlagControl system

The invention provides a device and a method for continuous galvanizing of a profile and a pipe, and belongs to the technical field of galvanizing of the profiles and the pipes. The device consists of a reducing furnace, a galvanized part transmission device, a hot galvanizing zinc pot, a transmission device in the zinc pot, a protective gas supply device and a control system. By the use of the device, galvanizing assistant fluid is not needed to be coated on the surface of a galvanized part, so that formation of zinc soil due to retention of the galvanizing assistant fluid on zinc liquid is avoided; due to the efficient reducing furnace and the transmission device in the zinc pot, the production time can be greatly shortened; and protective gas in the zinc pot further reduces oxidized slag of the high-temperature zinc liquid, so that the production cost is effectively reduced.

Owner:UNIV OF SCI & TECH BEIJING +1

Smelting method of zinc alloy

The invention discloses a smelting method of a zinc alloy. The smelting method comprises the following steps: taking 99.0%-99.35% by weight of a Zn-Al4 alloy, 0.55%-0.9% by weight of an AlTi-5B intermediate alloy and 0.05%-0.15% by weight of ZnCl2 as raw materials for smelting; a power frequency coreless induction furnace is used as smelting equipment; a zinc liquid pump, a silicon carbide ceramic infusion tube with the output hole diameter of 45-50 mm and an H13 steel crucible serve as smelting tools, and the zinc alloy is manufactured through the three steps of raw material and equipment preparation, pre-preparation and smelting. The method is low in metal loss, controllable in cost, small in pollution, good in compactness and good in uniformity.

Owner:贵州省鑫泰增材制造有限公司

V method, low pressure production method of ultra-high pressure switch pressure aluminum alloy tank body

ActiveCN102941333BSpeed up the flowReduce scour forceFoundry mouldsFoundry coresVacuum castingUltra high pressure

The invention discloses a method for producing ultrahigh pressure switch pressure-bearing aluminum alloy tanks under low pressure through a V method in the technical field of vacuum casting, which comprises the following processing steps: jig manufacture, low-temperature gating system manufacture, upper tank molding, lower tank molding, lower core mould assembling, casting and pressure removing and picking. The method solves the defects of slag inclusion, pores, pinholes and the like of cast caused by intensive scouring of molten metal to cast, and simultaneously can solve the problems that the cavity casting system occupies excessive molten metal, and particularly the product yield of cast with low wall thickness and large size is low.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

Aluminum bronze casting molten casting process

InactiveCN110090919AImprove casting qualityConvenient to avoid slagFoundry mouldsFoundry coresWaxSlag

The invention discloses an aluminum bronze casting molten casting process. The process includes the following steps: preparation of a wax mold, preparation of a form shell, dewaxing, form shell roasting and forming casting. The preparation of the wax mold includes melting paraffin and forming the paraffin into the wax mold. The wax mold includes a U-shaped flow channel and multiple part bodies. The U-shaped flow channel is composed of a first direct flow section, a second direct flow section and an arc connection section. The arc connection section is connected to a ceramic filter. The multiple part bodies are symmetrically arranged on the two sides of the second direct flow section. During the forming casting, a bottom pouring type casting process is adopted to pour molten liquid metal upward from the bottom of the first direct flow section through the first direct flow section, and the liquid metal flows through the ceramic filter, is finally injected to the part bodies and formed into a part to be prepared. The process optimizes the form of the flow channel, reduces a large amount of casting defects caused by turbulent flows in a conventional signal flow channel, and is more convenient to slag avoidance.

Owner:ZHENJIANG ZHONGYUAN ELECTRIC

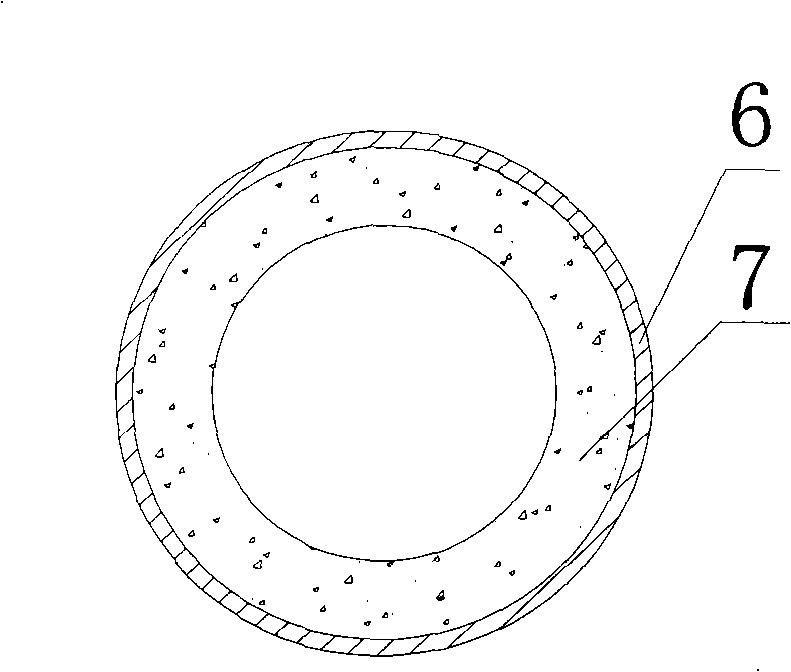

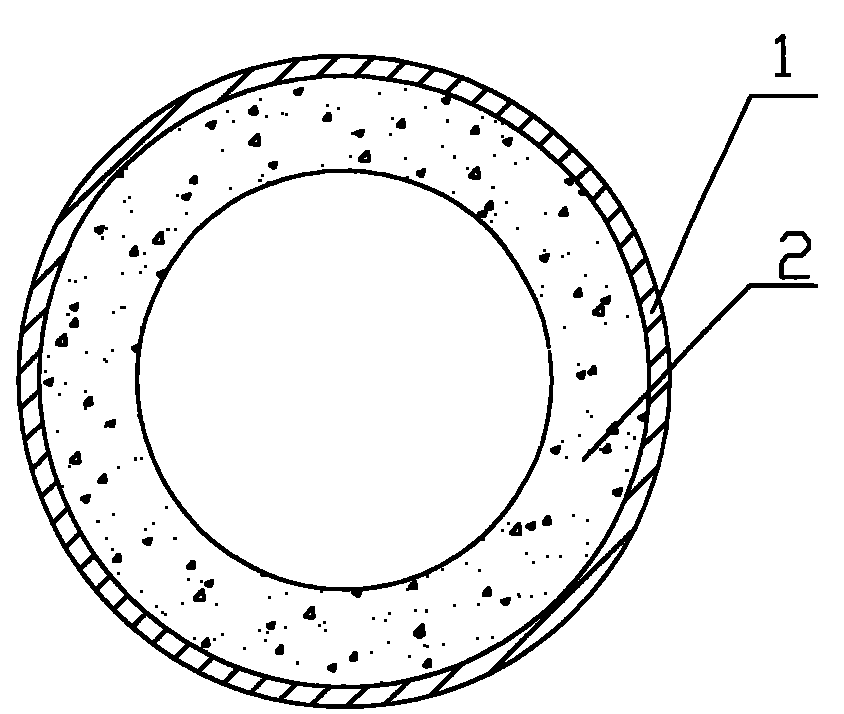

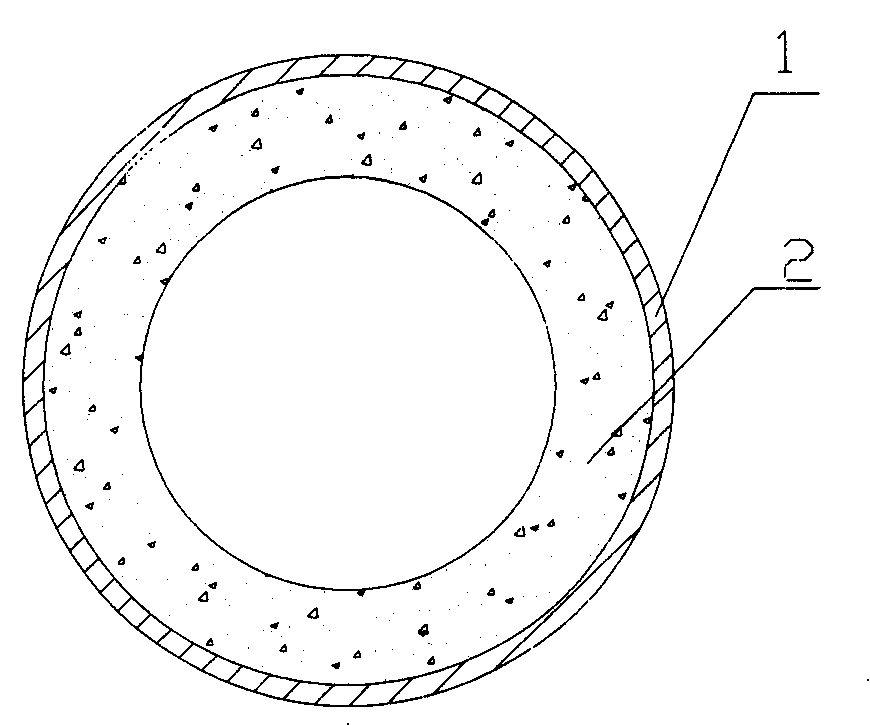

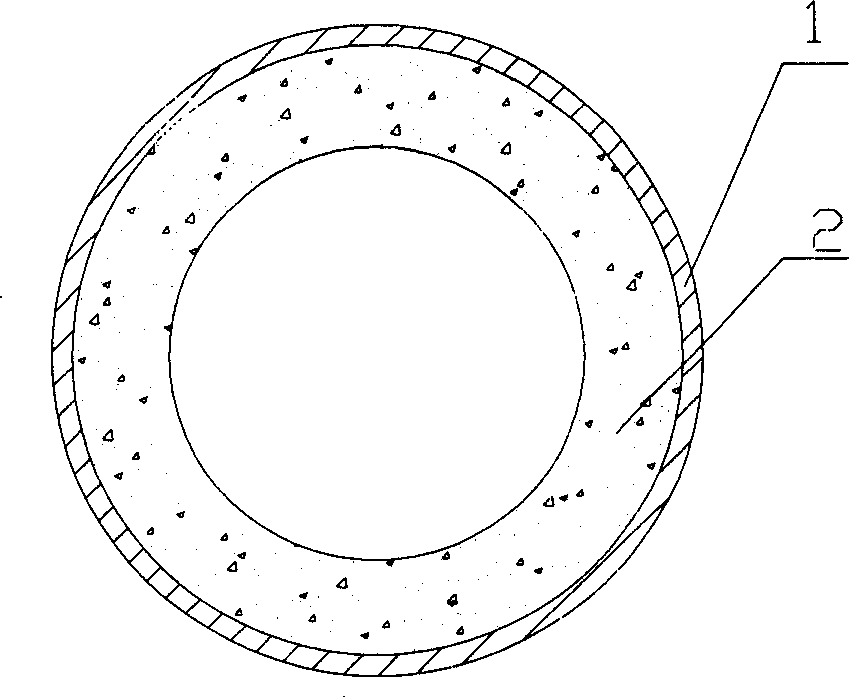

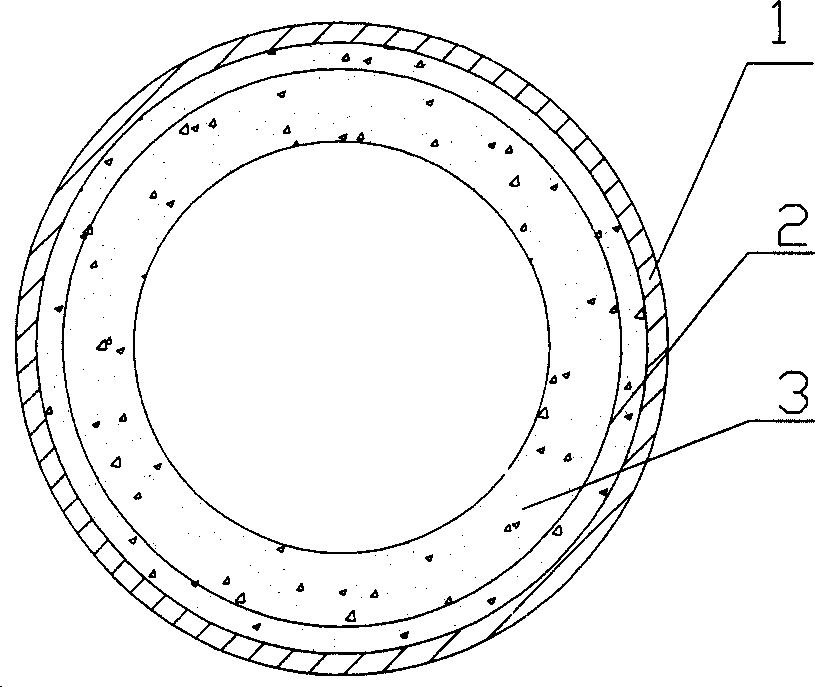

Transfer pipe for zinc alloy melt and manufacturing method thereof

ActiveCN101446372BGuaranteed StrengthCreate pollutionRigid pipesPipe protection against damage/wearThermal insulationSlag

Owner:ZHUZHOU SMELTER GRP

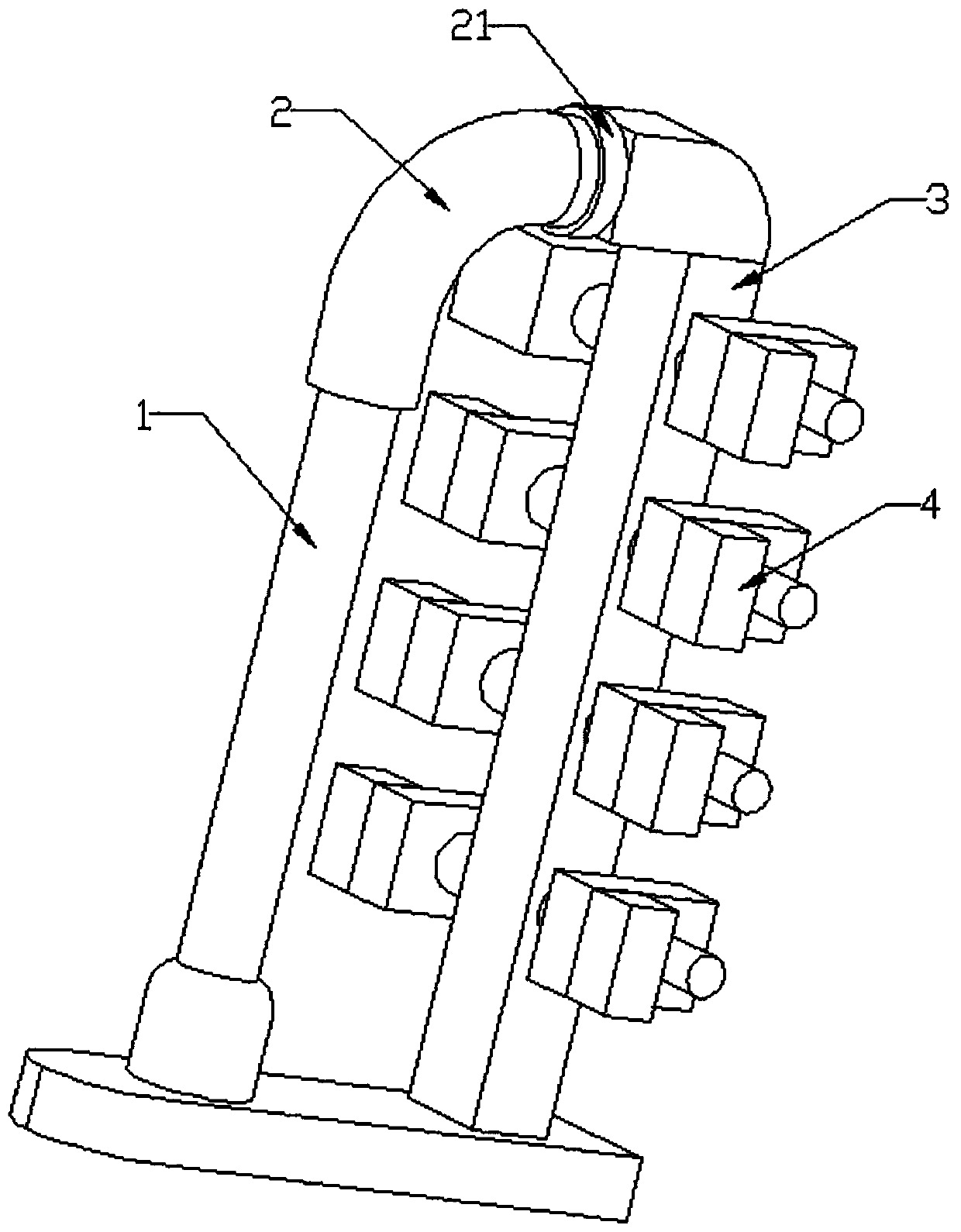

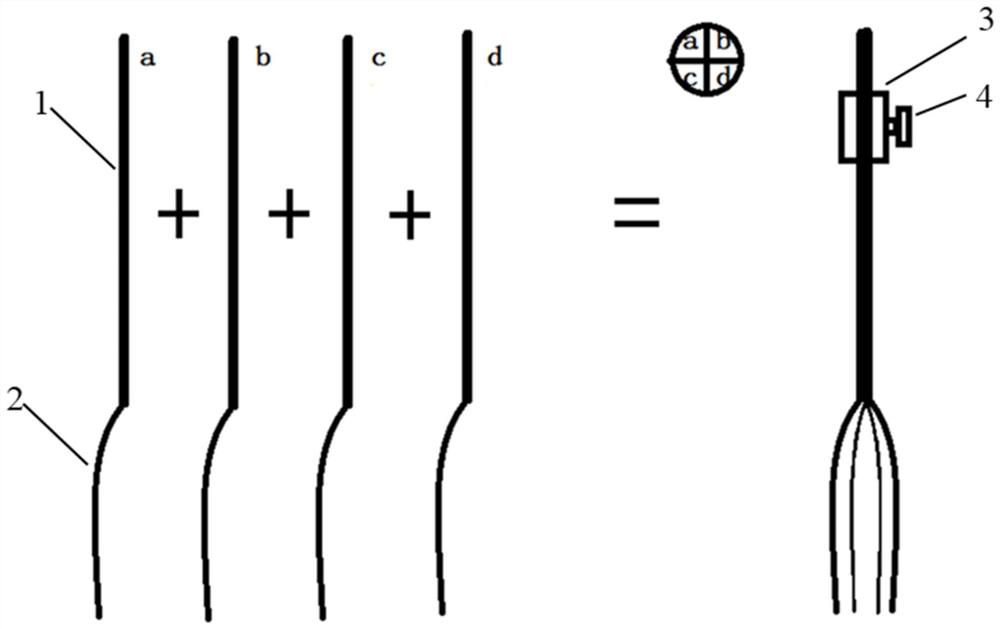

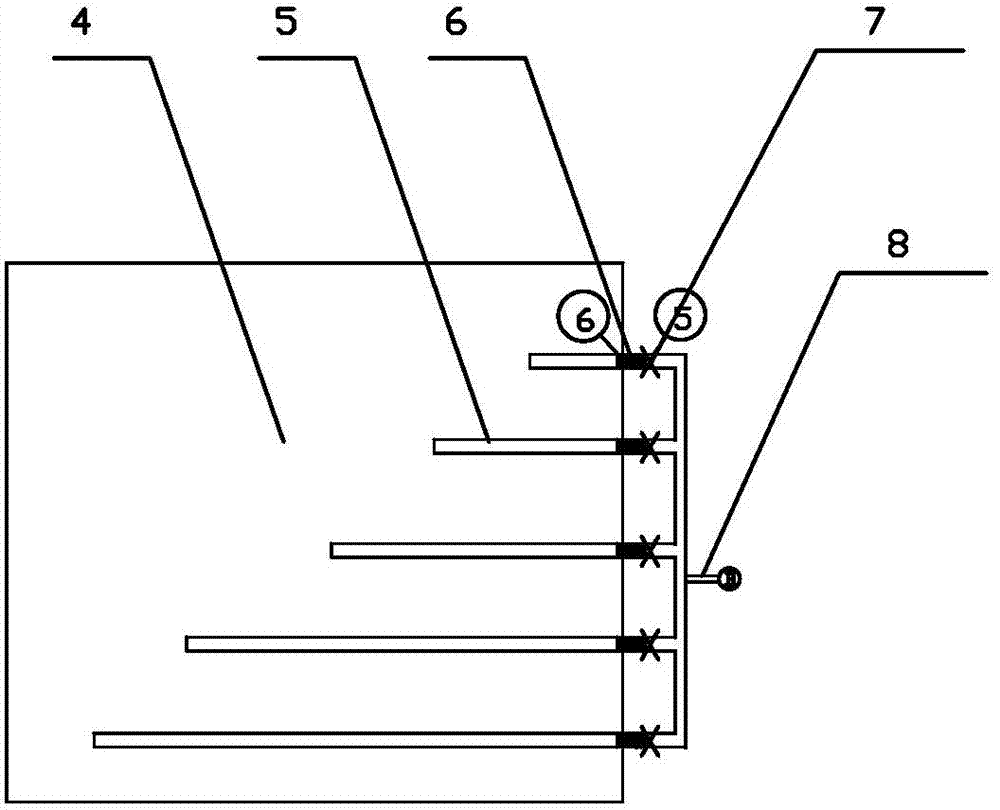

Process and device for welding magnesium alloy sheets

ActiveCN103706973AHigh tensile strengthPromote oxidationWelding/cutting auxillary devicesAuxillary welding devicesSlagHelium

The invention relates to a process and a device for welding magnesium alloy sheets. The magnesium alloy sheets are protectively welded by the aid of mixtures, and the mixtures comprise, by volume, 70-80% of argon and 20-30% of helium. The process includes controlling pressure gauges at openings of an argon tank and a helium tank during welding and filling the 70-80% of argon and the 20-30% of helium into a gas mixer; selecting grooves of a welding platform according to the lengths of weld joints of magnesium sheets; opening gas inlet pipe valves corresponding to the selected grooves during welding, closing gas inlet pipe valves corresponding to the unselected grooves, butting the magnesium sheets to the upper sides of the selected grooves and welding the magnesium sheets after 5-second gas filling time elapses. The lengths of the selected grooves are larger than the lengths of the weld joints by 10-30mm. The process and the device have the advantages that the degree of welding fusion and the surface quality can be improved, the shortcoming of oxidation of back surfaces of magnesium alloy sheets can be overcome, oxidation conditions of welding spots and surrounding materials of the welding spots can be improved, oxidation slag inclusion due to oxidation can be reduced, and the tensile strength of welded magnesium alloy can be improved.

Owner:山东宏泰科技有限公司

Transfer pipe for zinc alloy melt and manufacturing method thereof

ActiveCN101446372AGuaranteed StrengthCreate pollutionRigid pipesPipe protection against damage/wearThermal insulationSlag

The invention relates to a transfer pipe for melting metals and manufacturing method thereof, especially a transfer pipe for zinc alloy melt and manufacturing method thereof. The invention is lining an inside lining layer made from the refractory material on the inner surface. The inside lining layer is directly cast on the refractory material on the inner surface; the invention also sets the steel tube integrated into the pipeline by the amorphous refractory ramming refractory steel construction fixed on the inner surface of the structure. Since the invention of refractory material used in steel-lined floor structure of the refractory layer does not melt in the liquid zinc alloy, non-polluting liquid zinc alloy. It has high strength, high temperature, good thermal insulation performance characteristics, the same time, the invention also has good thermal insulation to reduce the liquid metal in contact with air, thus reducing the oxidation of liquid metal, therefore, can be greatly reduced when the casting alloy oxide slag.

Owner:ZHUZHOU SMELTER GRP

A stirring device and container for preparing magnesium-based composite materials

ActiveCN109718682BEnhancing Chaotic Mixing BehaviorImprove the mixing effectRotary stirring mixersMagnesium matrix compositeMechanical engineering

The invention provides a stirring device and a container for preparing magnesium-based composite materials, comprising a stirring shaft and a plurality of sickle-shaped blades fixed on the bottom end of the stirring shaft; the length direction of the sickle-shaped blades is along the axis of the stirring device to the settings. The invention relates to a split paddle combined with a plurality of sickle-shaped paddles, and a flexible stirring device with a specific structure that the length direction of the sickle-shaped paddles is arranged along the axial direction of the stirring device. The stirring device provided by the present invention has a good stirring effect, and can fully contact the entire melt during the stirring process, avoiding the formation of a ring-shaped "dead zone" at the bottom of the melt and reducing the stirring effect; the stirring paddle is easy to clean, and the melt brought out is less, And it adopts a split design, which can fully clean up the magnesium melt attached to each paddle. The stirring device for preparing magnesium-based composite materials provided by the present invention has a simple manufacturing process, can be mass-produced, is suitable for industrialization, and is expected to be widely used in the field of preparing magnesium-based composite materials.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Device and method for continuous galvanizing of profile and pipe

InactiveCN106119753AAvoid formingReduce oxidation slagHot-dipping/immersion processesControl systemSlag

The invention provides a device and a method for continuous galvanizing of a profile and a pipe, and belongs to the technical field of galvanizing of the profiles and the pipes. The device consists of a reducing furnace, a galvanized part transmission device, a hot galvanizing zinc pot, a transmission device in the zinc pot, a protective gas supply device and a control system. By the use of the device, galvanizing assistant fluid is not needed to be coated on the surface of a galvanized part, so that formation of zinc soil due to retention of the galvanizing assistant fluid on zinc liquid is avoided; due to the efficient reducing furnace and the transmission device in the zinc pot, the production time can be greatly shortened; and protective gas in the zinc pot further reduces oxidized slag of the high-temperature zinc liquid, so that the production cost is effectively reduced.

Owner:UNIV OF SCI & TECH BEIJING +1

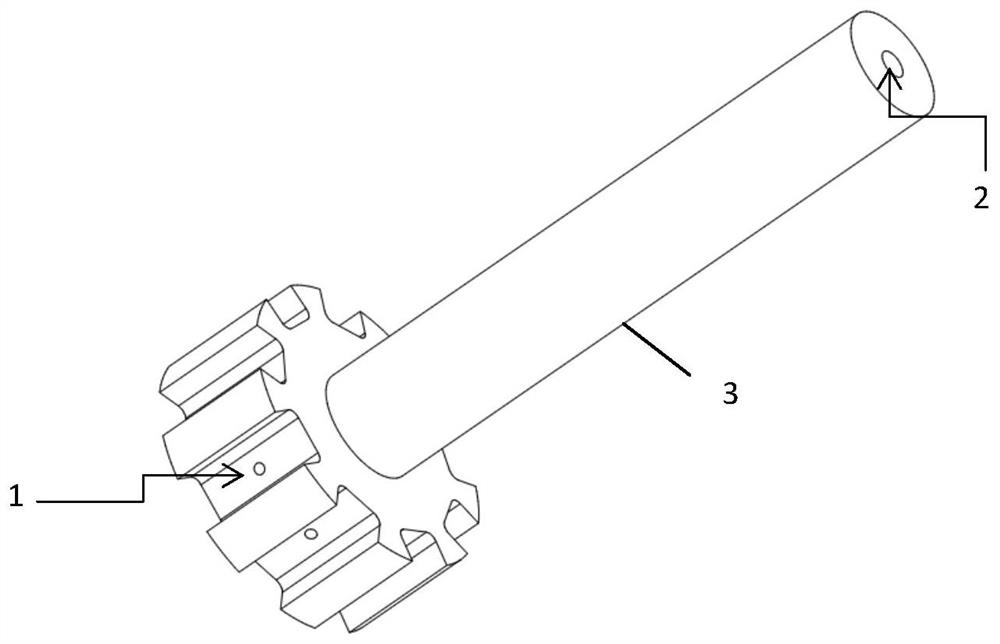

Gravity Tilt Casting Sprue Basin

ActiveCN104525865BControl Inflow FlowReduce flow rateFoundry mouldsFoundry coresStable stateMolten metal

A gravity tilting casting sprue basin, comprising a sprue basin body, the sprue basin body includes a bottom of the body and a side wall extending outward along the edge of the bottom of the body; the sprue basin body is divided into The liquid inlet area, the liquid holding area and the gate; the bottom of the body is correspondingly divided into the bottom of the liquid inlet area, the bottom of the liquid holding area and the bottom of the gate which are smoothly connected; the bottom of the liquid inlet area is an impact slope. The invention provides a gravity tilting casting sprue basin capable of improving the flow characteristics of molten metal in the sprue basin and realizing steady pouring of molten metal.

Owner:XIAN AERO ENGINE CONTROLS

Magnesium Alloy Sheet Welding Process and Its Device

ActiveCN103706973BHigh tensile strengthPromote oxidationWelding/cutting auxillary devicesAuxillary welding devicesSlagProduct gas

The invention relates to a process and a device for welding magnesium alloy sheets. The magnesium alloy sheets are protectively welded by the aid of mixtures, and the mixtures comprise, by volume, 70-80% of argon and 20-30% of helium. The process includes controlling pressure gauges at openings of an argon tank and a helium tank during welding and filling the 70-80% of argon and the 20-30% of helium into a gas mixer; selecting grooves of a welding platform according to the lengths of weld joints of magnesium sheets; opening gas inlet pipe valves corresponding to the selected grooves during welding, closing gas inlet pipe valves corresponding to the unselected grooves, butting the magnesium sheets to the upper sides of the selected grooves and welding the magnesium sheets after 5-second gas filling time elapses. The lengths of the selected grooves are larger than the lengths of the weld joints by 10-30mm. The process and the device have the advantages that the degree of welding fusion and the surface quality can be improved, the shortcoming of oxidation of back surfaces of magnesium alloy sheets can be overcome, oxidation conditions of welding spots and surrounding materials of the welding spots can be improved, oxidation slag inclusion due to oxidation can be reduced, and the tensile strength of welded magnesium alloy can be improved.

Owner:山东宏泰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com