A method for swirling and blowing refining of low-pressure casting aluminum alloy melt with argon protection

An aluminum alloy melt and argon protection technology, which is applied in the field of argon blowing and refining aluminum alloy melt, can solve the problems of differences in refining effects, etc., and achieve the effects of reducing oxidation slag inclusions and suction, isolating contact, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]Taking a casting with a size of 560×245×190mm as an example, the material is ZL114A, there are 11 oil pipes in total, there are many bosses, and the shapes are different. The 3D printing sand mold + low-pressure pouring method is adopted, and there are many sand mold blocks. The implemented Specific steps are as follows:

[0045] Step 1: The surface of the aluminum alloy used materials must be dry blasted, and the used materials are baked at 450°C for 1 hour before use.

[0046] Step 2: Add the aluminum alloy material baked in step 1 into the 150Kg graphite crucible, use a bell jar to cover the mouth of the crucible during the materialization process, and pass argon gas into the aluminum alloy crucible at the center of the upper end of the bell jar. The gas inlet should be 5cm higher than the upper end of the crucible.

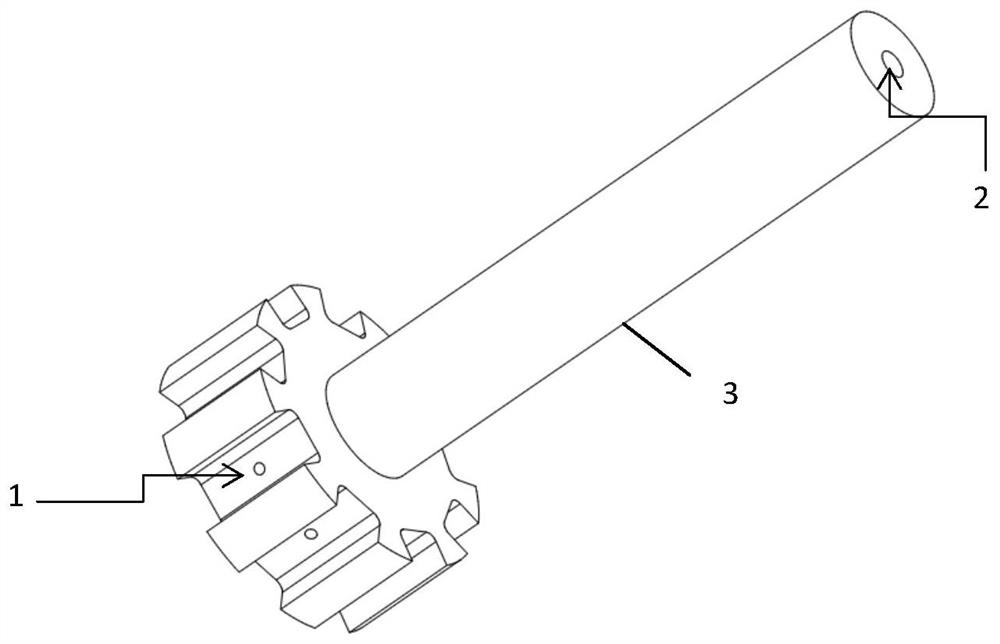

[0047] Step 3: Improve the argon cyclone blowing refining device, and improve the structure of the refining device: there are vent holes 2 along the ax...

Embodiment 2

[0058] Taking a casting with a size of 150×130×57mm and an overall wall thickness of 8mm as an example, the material is ZL105, and there are two hydraulic channels in the casting. The specific steps are as follows:

[0059] Step 1: The surface of the aluminum alloy used materials must be dry blasted, and the used materials are baked at 450°C for 1 hour before use.

[0060] Step 2: Add the aluminum alloy material baked in step 1 into the 150Kg graphite crucible, use a bell jar to cover the mouth of the crucible during the materialization process, and pass argon gas into the aluminum alloy crucible at the center of the upper end of the bell jar. The gas inlet should be 5cm higher than the upper end of the crucible.

[0061] Step 3: Improve the argon cyclone blowing refining device, and improve the structure of the refining device: there are vent holes 2 along the axis of the graphite rod 3, and the diameter of the vent hole 2 is 14mm, and there are 9 vent holes evenly distribute...

Embodiment 3

[0072] by size Take a casting with an overall wall thickness of 16mm as an example. The material is ZL114A. The casting is in the shape of a basin with a large curvature and a hollow inner cavity. Its implementation specific steps are as follows:

[0073] Step 1: The surface of the aluminum alloy used materials must be dry blasted, and the used materials are baked at 450°C for 1 hour before use.

[0074] Step 2: Add the aluminum alloy material baked in step 1 into the 150Kg graphite crucible, use a bell jar to cover the mouth of the crucible during the materialization process, and pass argon gas into the aluminum alloy crucible at the center of the upper end of the bell jar. The gas inlet should be 5cm higher than the upper end of the crucible.

[0075] Step 3: Improve the argon cyclone blowing refining device, and improve the structure of the refining device: there are vent holes 2 along the axis of the graphite rod 3, and the diameter of the vent hole 2 is 14mm, and there...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com