Patents

Literature

90 results about "SHELL model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The SHELL model is a conceptual model of human factors that clarifies the scope of aviation human factors and assists in understanding the human factor relationships between aviation system resources/environment (the flying subsystem) and the human component in the aviation system (the human subsystem).

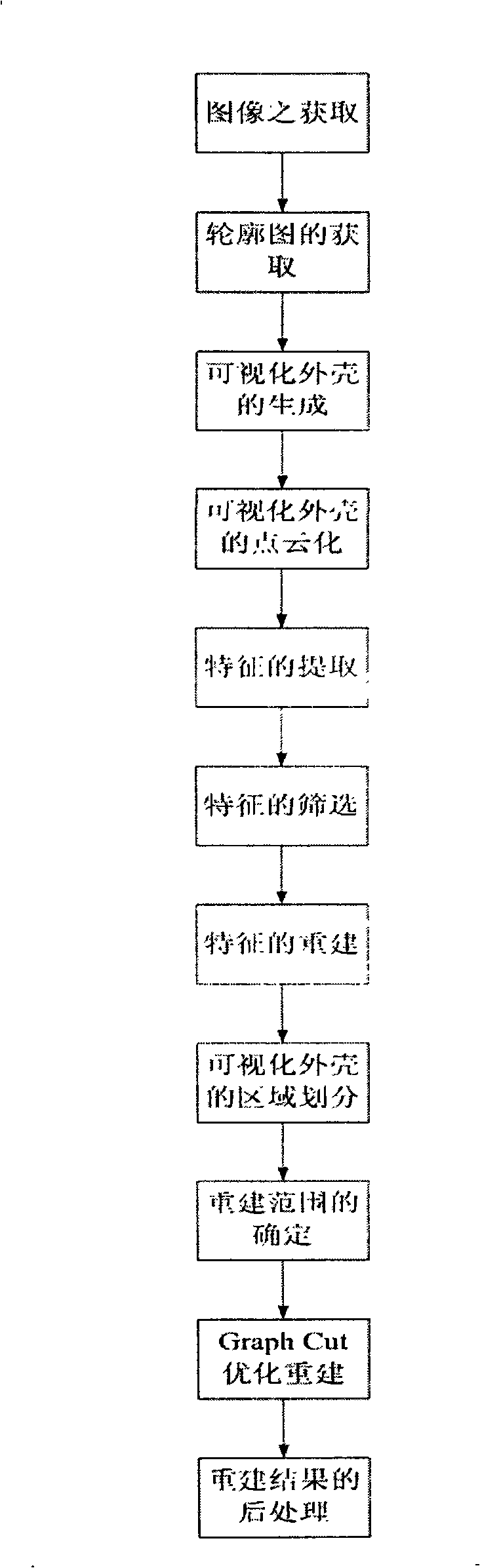

Interactive multi-vision point three-dimensional model reconstruction method

InactiveCN101271591AImprove accuracyReduce processing timeImage analysisImage data processing detailsViewpointsPoint cloud

The invention relates to a three-dimensional reconstruction algorithm introducing an interactive operation for a user, belonging to the technical field of a computer multimedia. The method is as followings: the user utilizes a plurality of cameras to obtain a two-dimensional image Ii of a plurality of viewpoints of an object and extracts a contour map of the object; the computer obtains a visual shell model of a real scene according to a geometric parameter of every camera and the contour map, and turns the visual shell model into a point cloud form; a two-dimensional characteristic in the image is extracted to optimize a part of a real surface model corresponding to the characteristics; the user divides the image Ii into a region of a smoothness and the region of a subsidence; a nonuniform weighted graph is set up according to the areas selected above to find out a minimal cut of the image to obtain the optimized scene surface model. Combined with an auxiliary operation of the user, the three-dimensional reconstruction algorithm is capable of reconstructing the high-quality three-dimensional model of the object relatively fast according to the multi-view image which is shot of the actual object and the camera parameter corresponding to each image.

Owner:安徽沃孚医疗科技有限公司

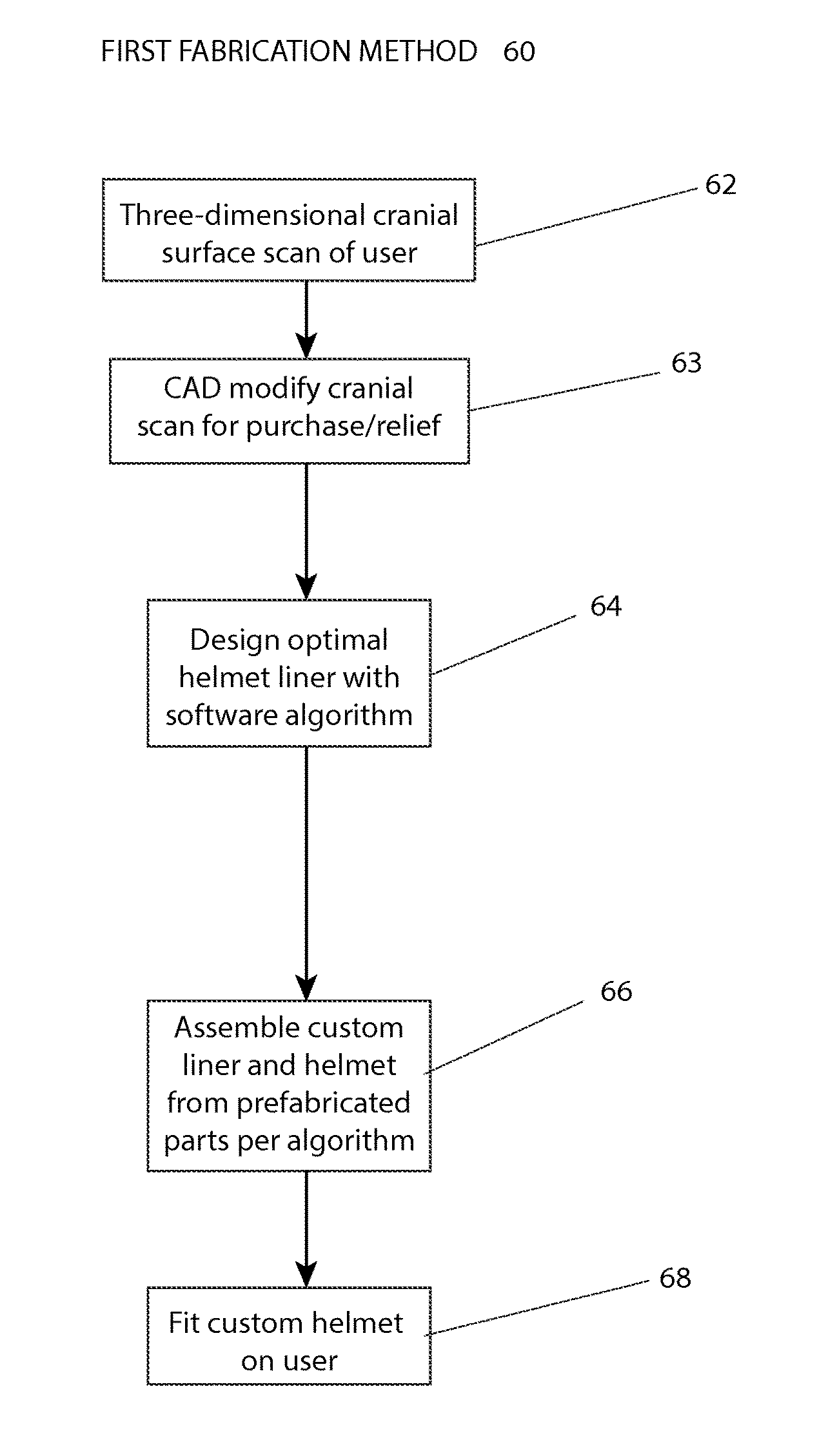

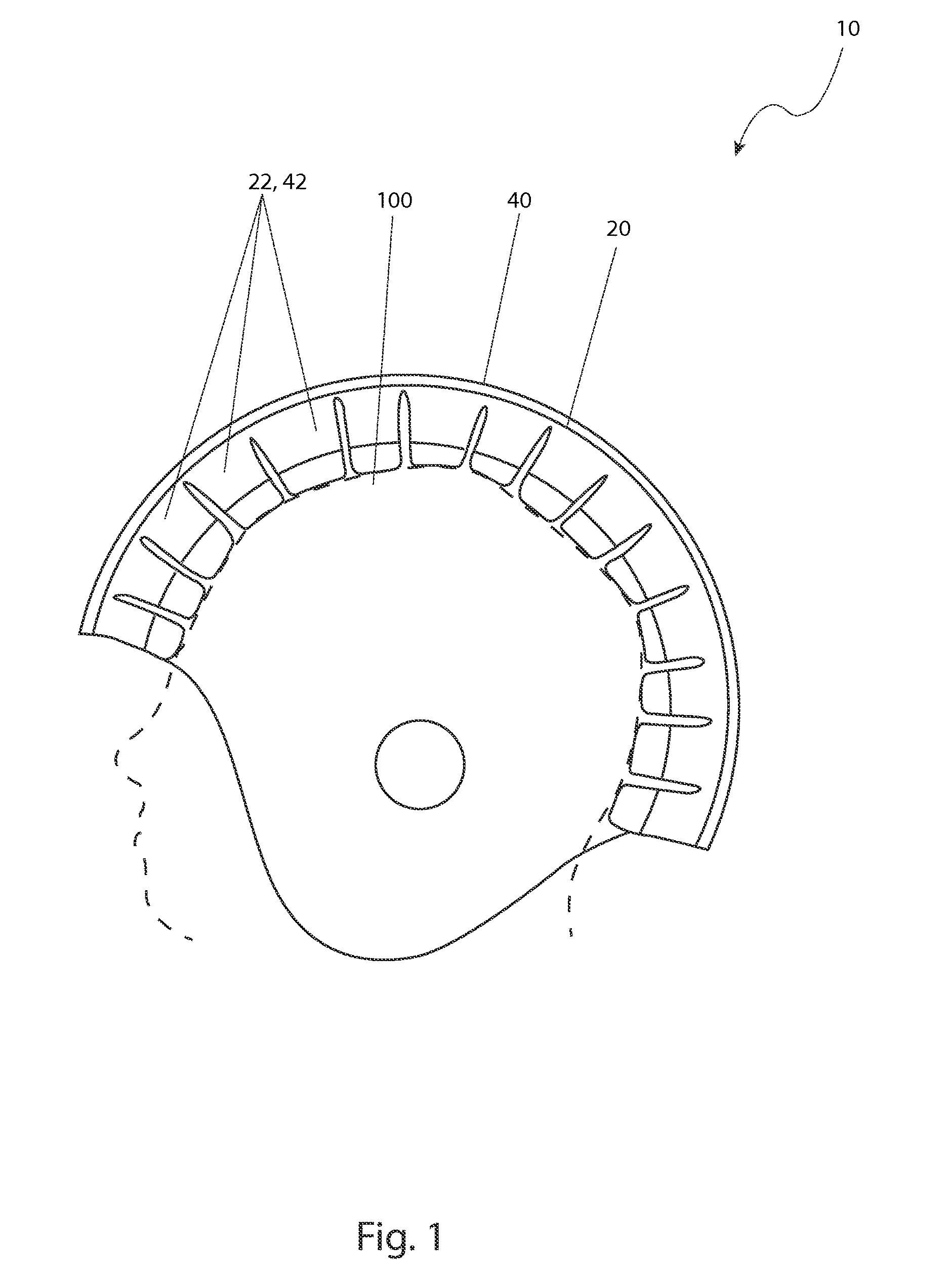

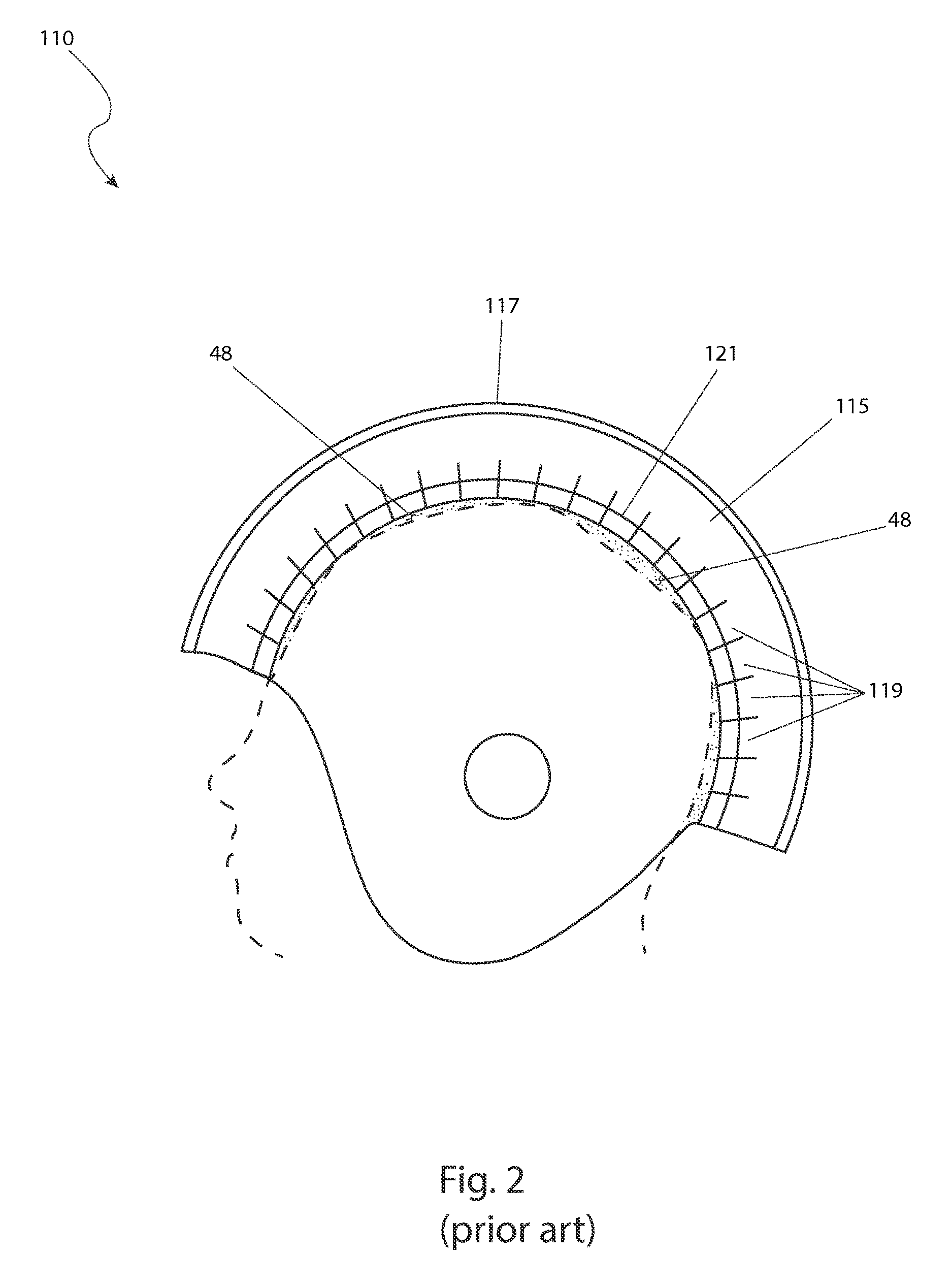

Method for customizing and manufacturing a composite helmet liner

InactiveUS9545127B1Reduction and elimination of air gapEnhanced surface pressure distributionHelmetsHelmet coversComputer Aided DesignThree-dimensional space

A method for producing a customized helmet including a computer designed composite helmet liner to be incorporated into existing and new helmet designs is provided by scanning a user's cranial region, creating a computer rendering surface model of the scan, modifying the surface model using computer aided design software, overlaying and aligning an outer helmet shell model onto the modified cranial model to define the custom liner three-dimensional space to configure the composite liner with a software algorithm including shock absorbing segments having optimal sizes, shapes, and materials, fabricating the liner in a heat sealing process to include an optional encapsulating or serial air bladder, and assembling the liner and outer helmet shell together.

Owner:SANDIFER ALAN T

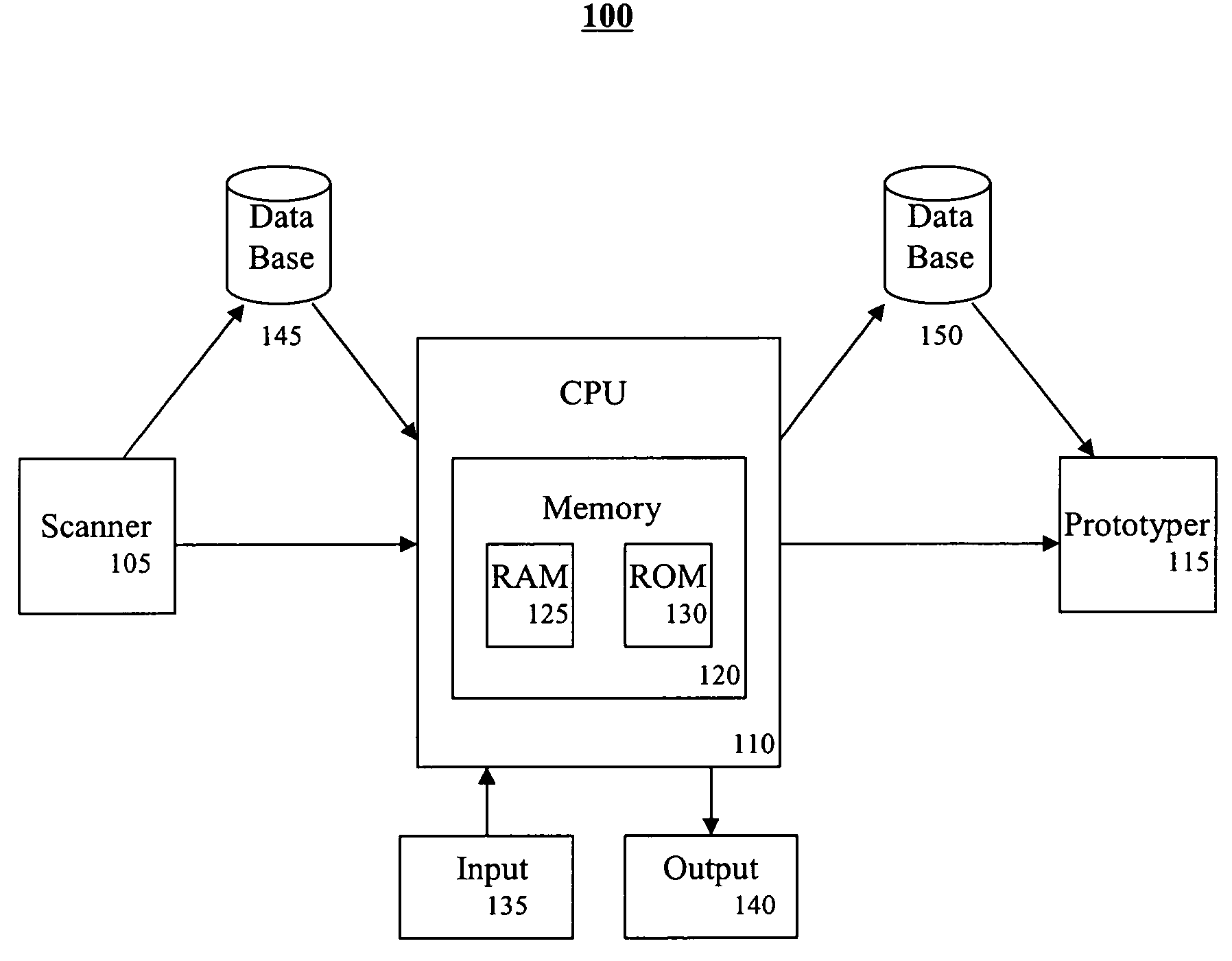

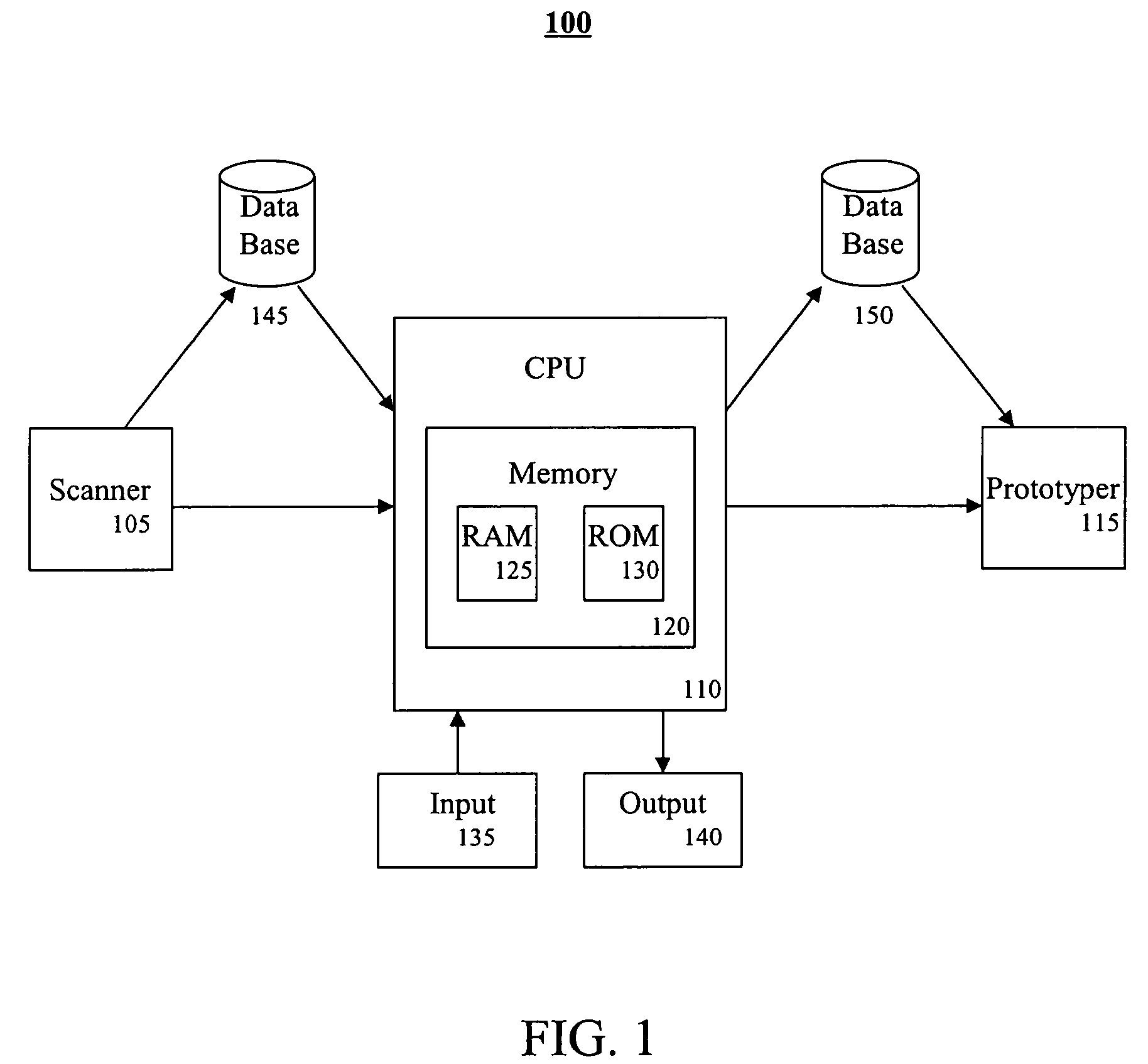

Interactive binaural shell modeling for hearing aids

ActiveUS20040165740A1Additive manufacturing apparatusHearing aid design aspectsSHELL modelComputer science

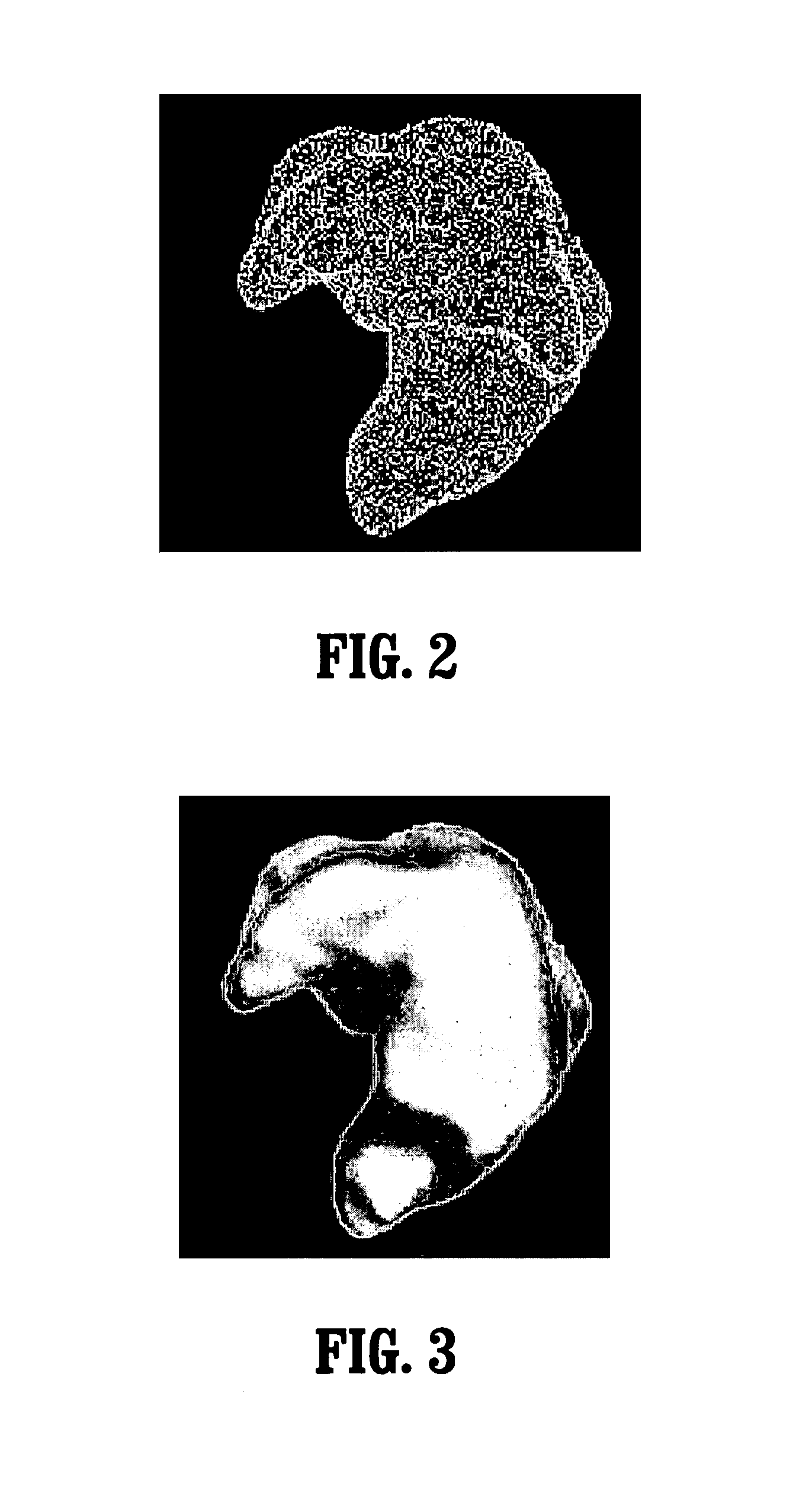

A system and method for modeling binaural shells for hearing aids, wherein the system is configured to load data associated with a first and a second ear shell. The system is further configured to register the data associated with the first and the second ear shells and process the first ear shell. The system is also configured to store data associated with processing the first ear shell and then map the data associated with processing the first ear shell to the second ear shell. Subsequently, the mapped second ear shell is interactively adjusted by an operator to compensate for an inconsistency in the mapped second ear shell.

Owner:SIEMENS CORP

Interactive binaural shell modeling for hearing aids

ActiveUS7084870B2Additive manufacturing apparatusHearing aid design aspectsComputer scienceSHELL model

Owner:SIEMENS CORP

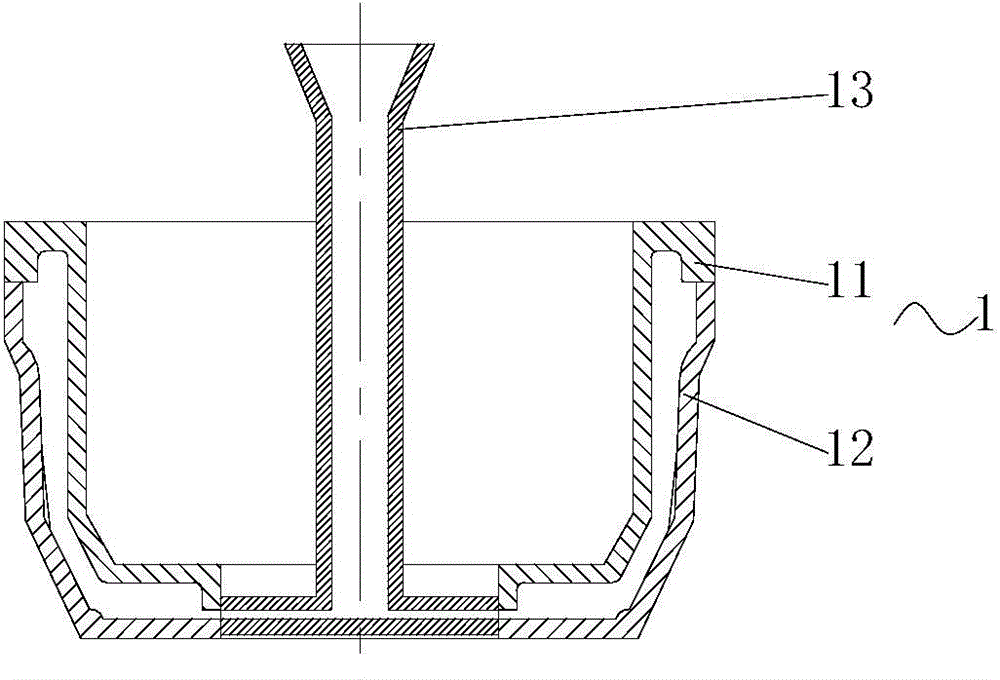

Preparation method of oxide ceramic composite shell for precision casting of titanium alloy

ActiveCN104001856ASolve the material redissolving in waterSolve the breathability problemFoundry mouldsFoundry coresOxide ceramicWax

Owner:张勇弢

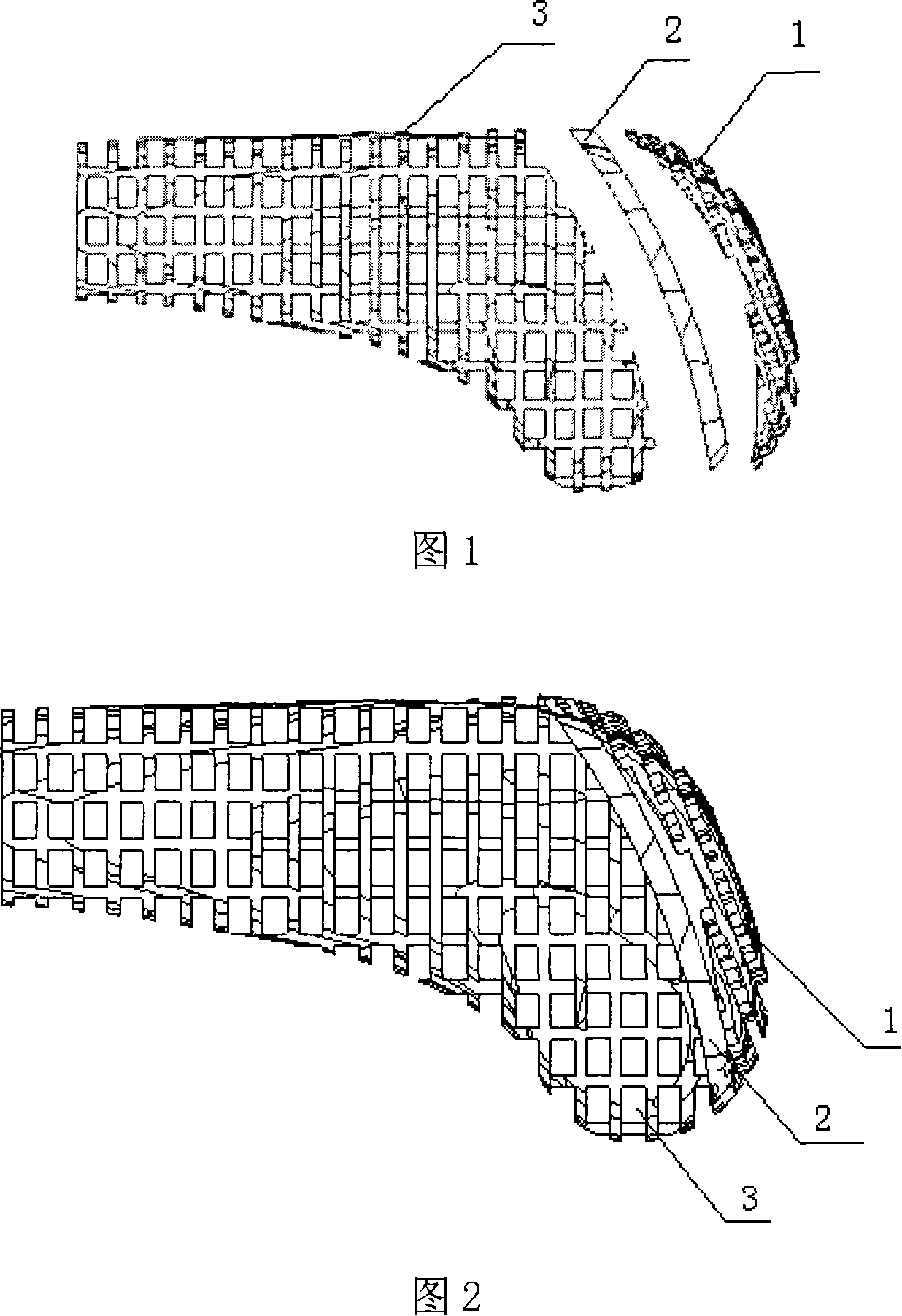

Bionic artificial semi- joint body and manufacturing technique thereof

InactiveCN101108145APrecise thickness controlPrecisely control the areaJoint implantsPolyurethane elastomerManufacturing technology

A simulation manual semi-joint body and fabrication technics are provided, which forms a shell model through reverse engineering and 3D design software and the divides the bone layer into three parts, namely upper, middle and lower layer; then designing the internal pipe column negative structure according to the funvtions of each layer and finally combining the model of each layer and the shell model to form the negetive model. The invention shapes the false body model by adopting the speedy shaping and exact photocureable forming machine, fills the ceramics slurry into the false body model and solidifies it in vacuum high temperature stove and then places the solidified ceramics body in polyurethane solution module; then pumping the vacuum, placing the module still and then taking out the ceramics after the polyurethane fully solidified; shaping it, thus achieving the bone layer material serving as the ceramics part; the soft bone layer elastomer is made of manual semi-joint body of the polyurethane elastomer. The invention reduces the rubbing damage for side joints and strengthens the activity capacity of the joints when the soft bone layer contacting the side joints.

Owner:XI AN JIAOTONG UNIV

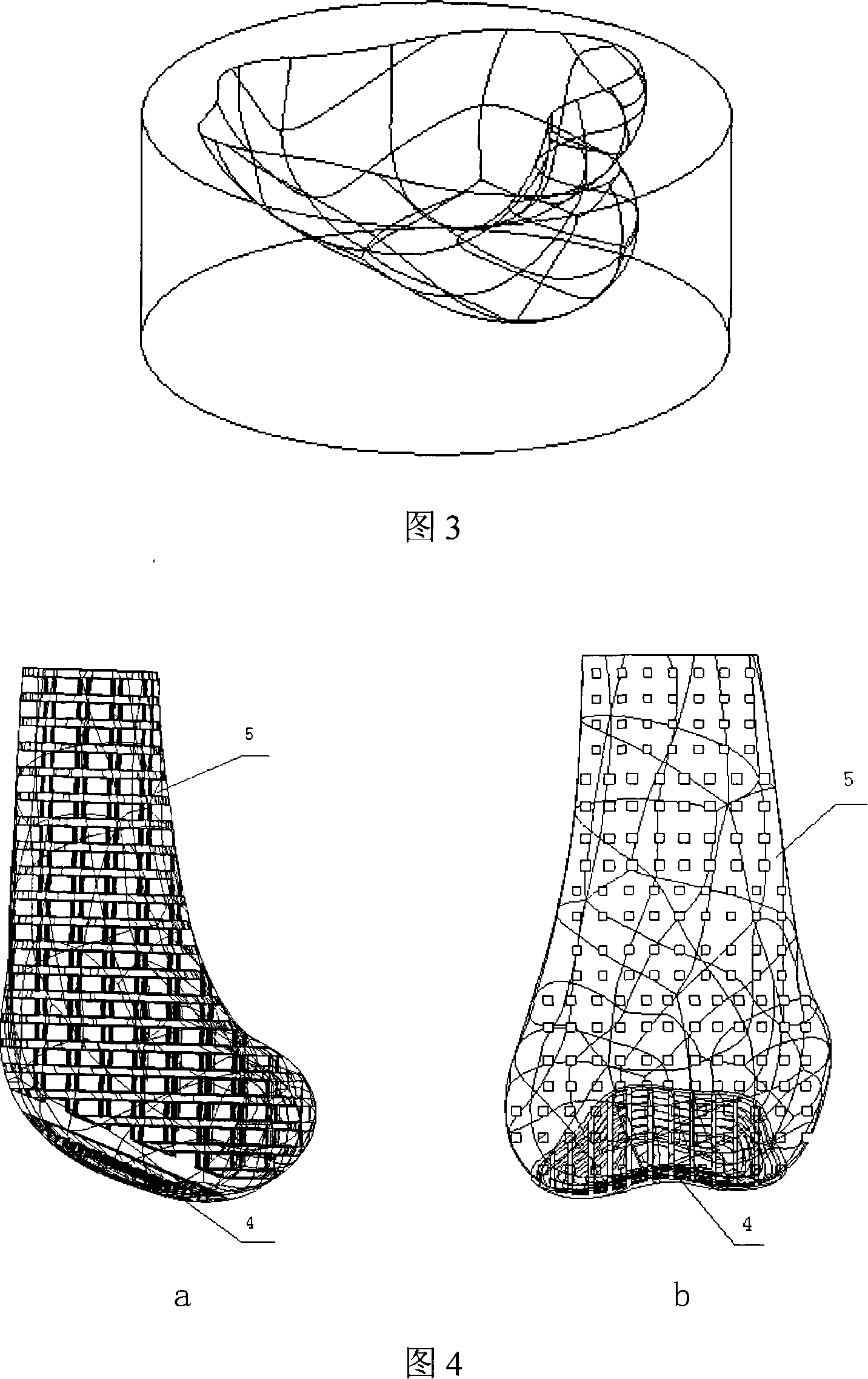

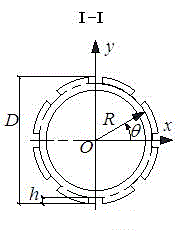

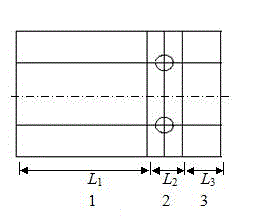

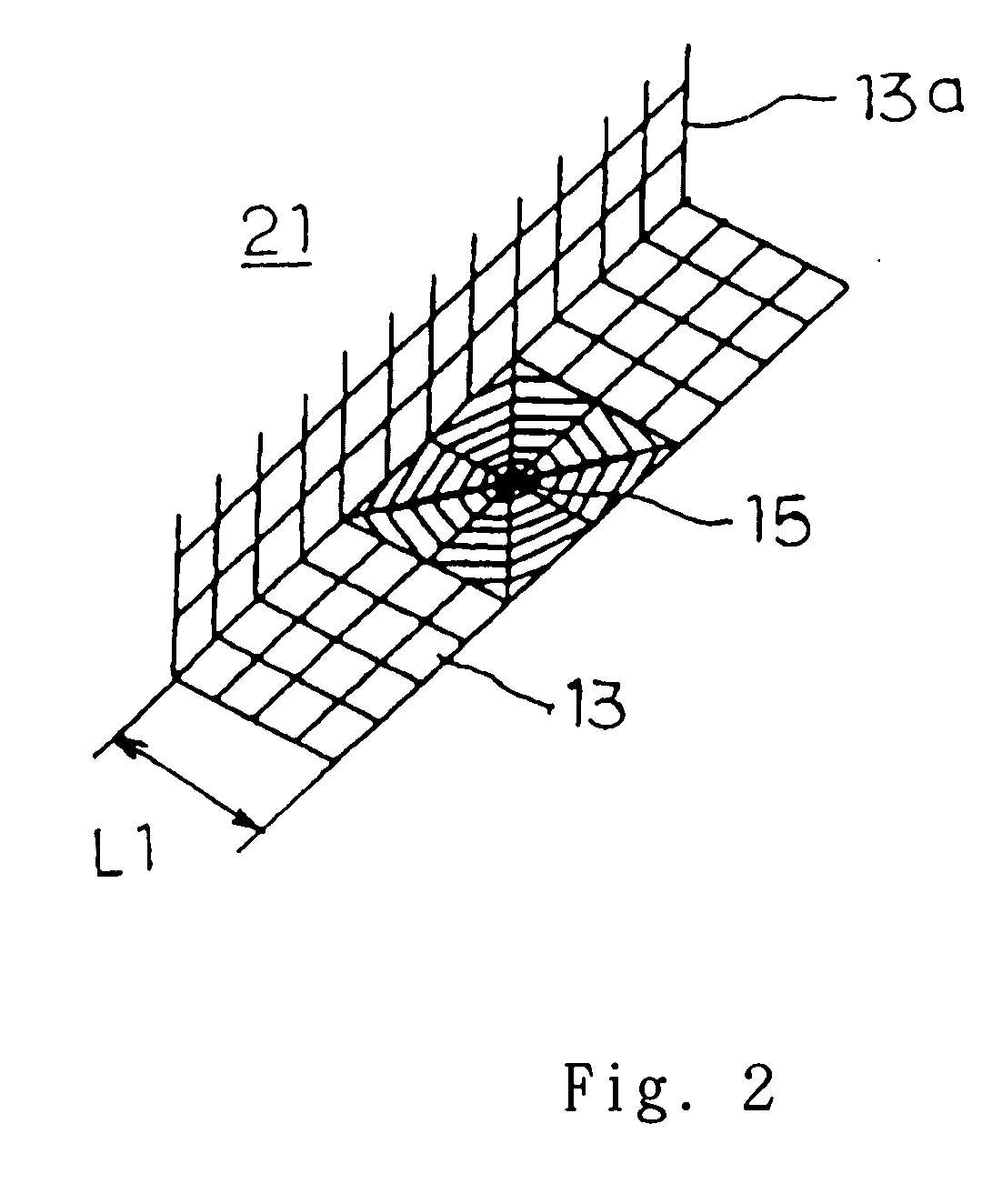

Automatic generation method for quadrilateral finite element mesh of pitting corrosion damage cylindrical shell

ActiveCN104484489ASolve the problem of fine pitting damage descriptionHigh solution accuracySpecial data processing applicationsElement modelScale structure

The invention discloses an automatic generation method for a quadrilateral finite element mesh of a pitting corrosion damage cylindrical shell. The automatic generation method for the quadrilateral finite element mesh of the pitting corrosion damage cylindrical shell includes that carrying out parameterization set on key geometrical sizes of a pitting corrosion damage cylindrical shell model in a finite element software, constructing three standard basic segments of an end perfecting region, a pitting corrosion region and a pitting corrosion spacer region of the cylindrical shell through segregate expression, constructing the whole geometrical model of the pitting corrosion damage cylindrical shell with a multi-layer pitting corrosion region, the pitting corrosion spacer region and the end perfecting region through copying, translation and division methods, grouping the geometrical model according to pit positions and size characteristics of each region, setting the mesh division number of the region boundary of each grouping object, using mapping MAPPED and AMAP to divide the whole cylindrical shell model, and generating the whole finite element model of the quadrilateral mesh unit. The automatic generation method for the quadrilateral finite element mesh of the pitting corrosion damage cylindrical shell solves the microscopic pitting corrosion damage description problem in a macro-scale structure and improves the solving precision and solving efficiency of the simulating calculation.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

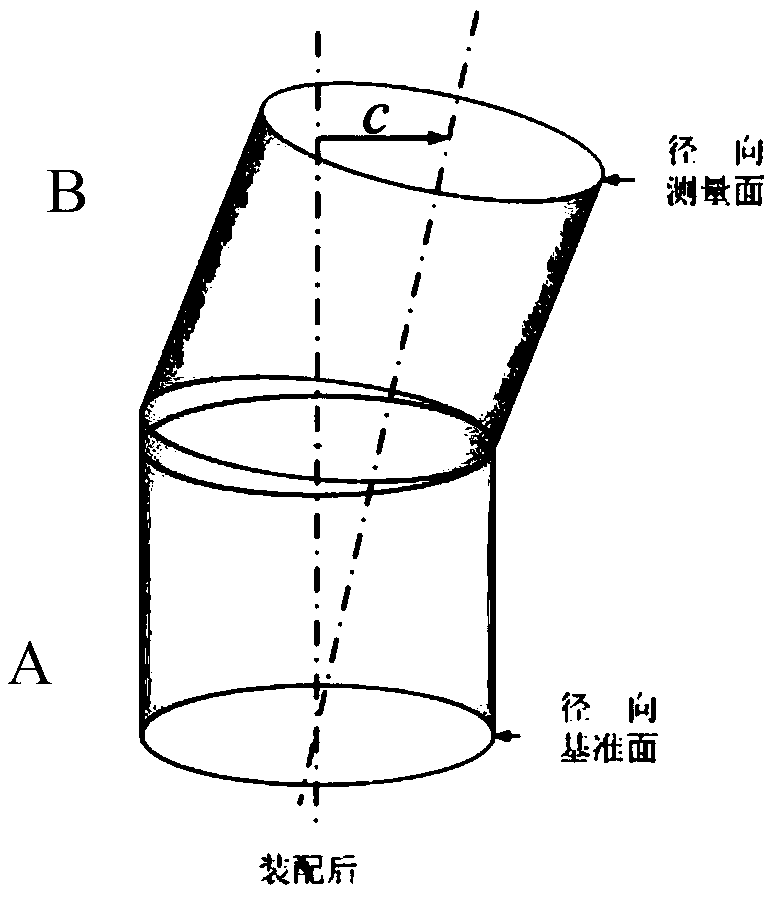

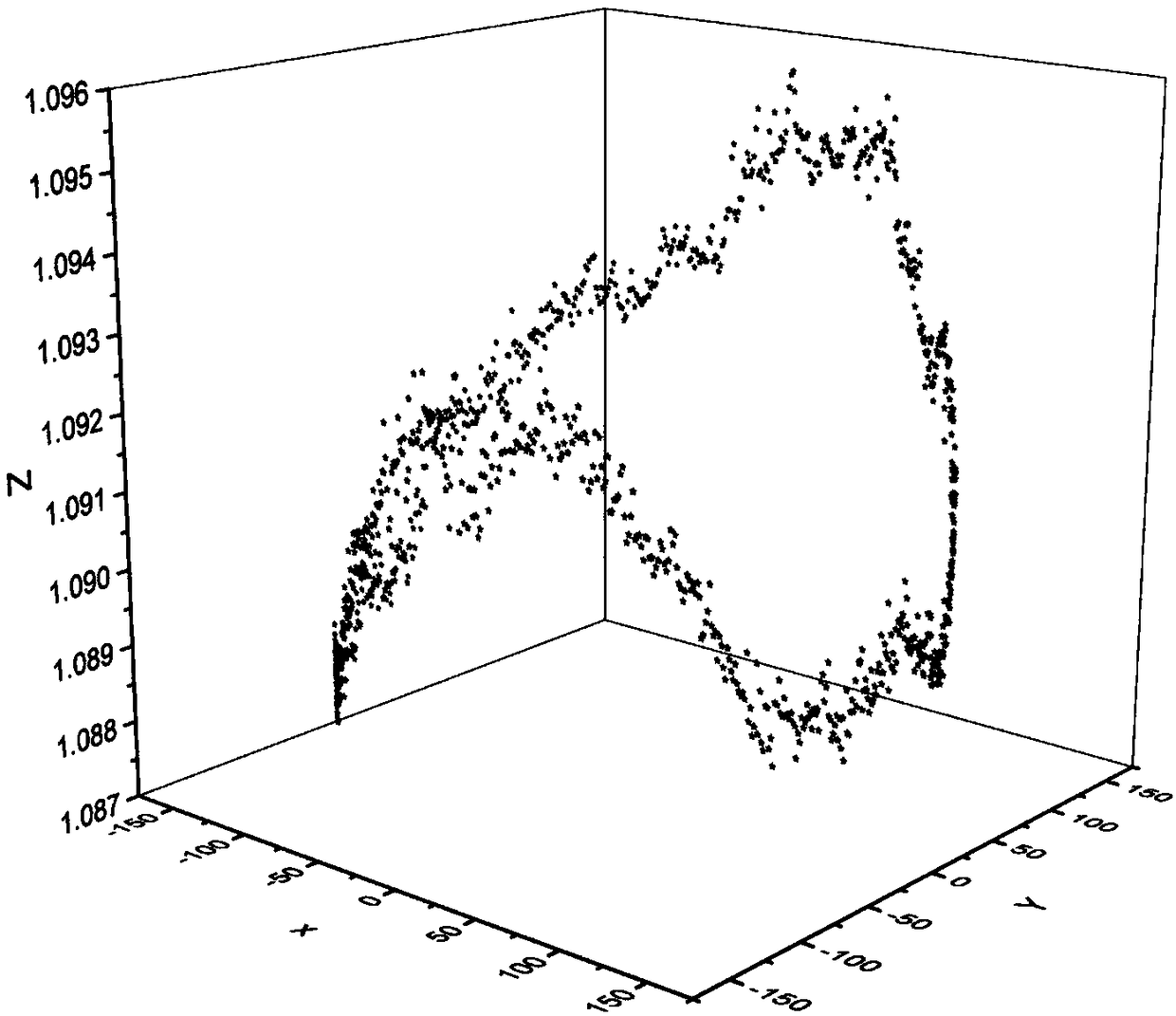

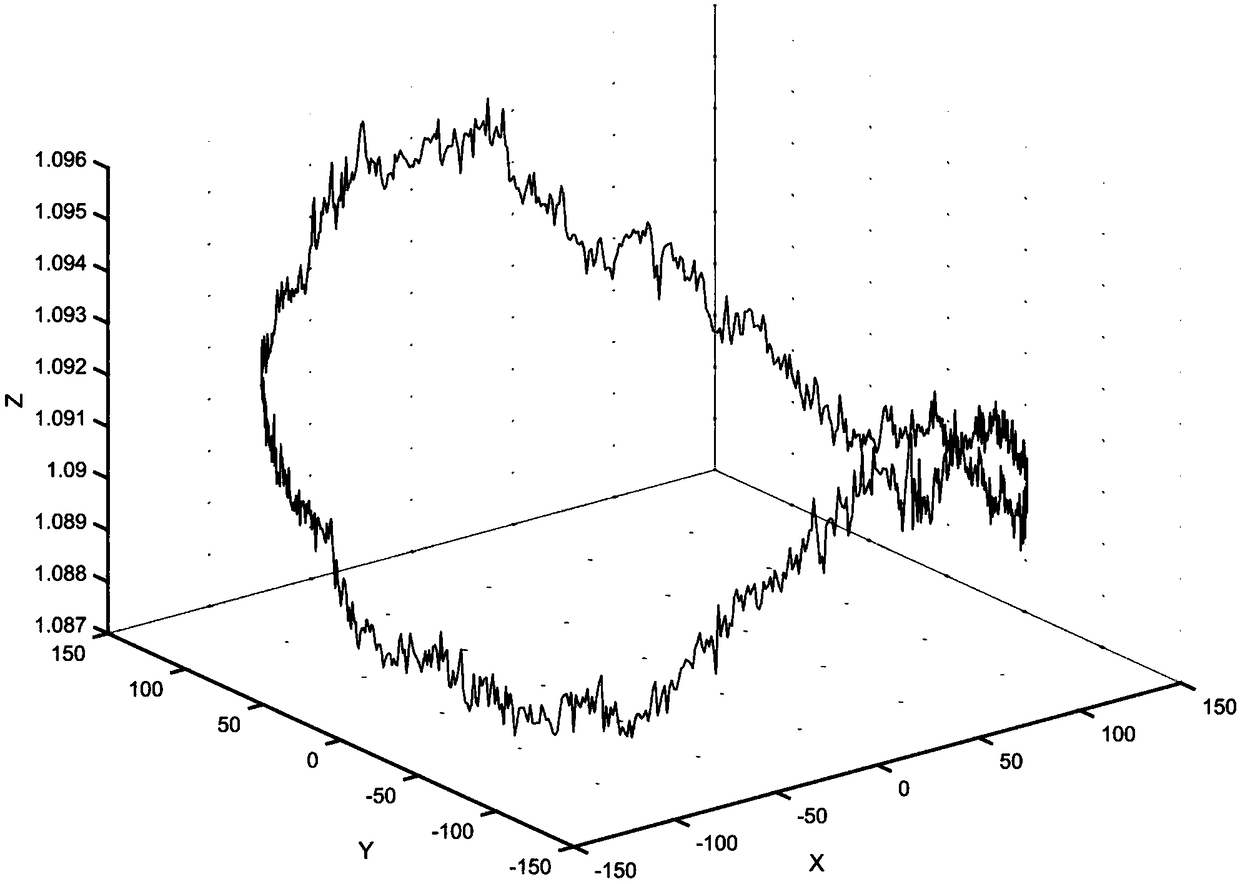

A finite element method for calculating the deflection of the assembly axis of a rotor considering contact elastic deformation

ActiveCN109408887AForecast skewImprove computing efficiencyGeometric CADDesign optimisation/simulationElement modelExtended finite element method

The invention provides a finite element analysis method for calculating the deflection of the assembly axis of a rotor considering the contact elastic deformation, wherein the relationship between theend face runout and the inclination amount is calculated by the finite element analysis method under the condition of considering the contact deformation of the mating surface. Considering such an ideal shell stacking model, the contact part of two shells is tangent to each other when they are initially modeled and assembled, and the two 3D curves are fitted according to the measured end-jump data, which can fully reflect the end-jump topography of the joint surface. The shell stacking model proposed by the invention is based on the finite element analysis method, considers the elastic deformation in the assembly process, and more accurately predicts the axis deflection than the algorithm. Compared with the general finite element analysis model, the shell model proposed in this inventionhas higher computational efficiency, and the finite element model can be optimized continuously to reduce the time of analysis and to give consideration to both analysis efficiency and accuracy.

Owner:DALIAN UNIV OF TECH

Manufacturing method of brake drum

The invention discloses a manufacturing method of a brake drum. The manufacturing method mainly comprises the following steps: respectively manufacturing an upper mould shell model, a lower mould shell model and a sprue cup shell model on a core shooting machine, then assembling to form an integral film-coated sand shell model; placing a sand box on a ramming platform; putting dried sand into the sand box, and ramming to form a bottom sand layer; placing the assembled film-coated sand shell model into the sand box, putting the dried sand into the sand box, and ramming; coating a back film, vacuumizing; and pouring, releasing a negative pressure, opening the box, drawing and removing a casting head of a casting of the brake drum. The manufacturing method achieves the characteristic of combining advantages of two processes by combining a V-method casting process and a film-coated sand shell model casting process.

Owner:江西弘旺汽车制动器制造有限公司

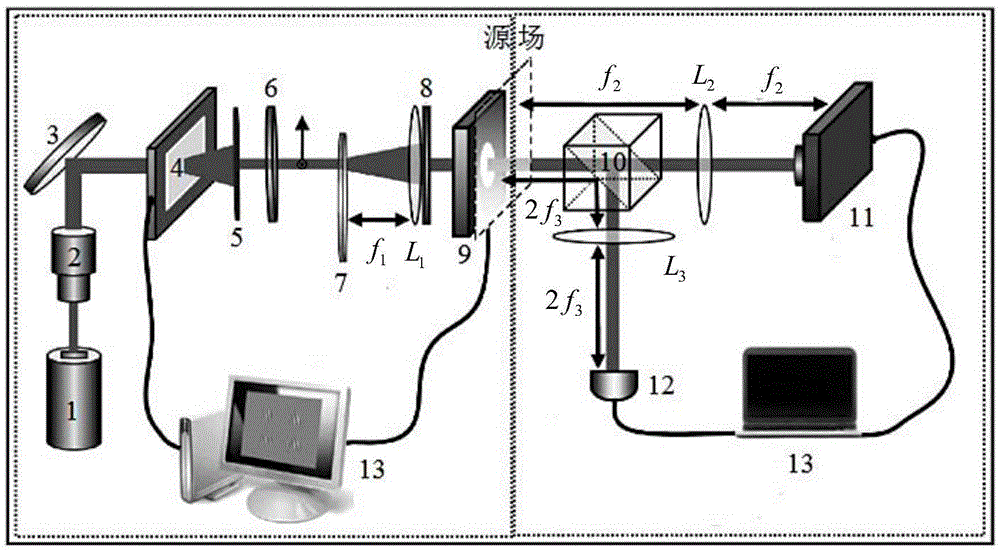

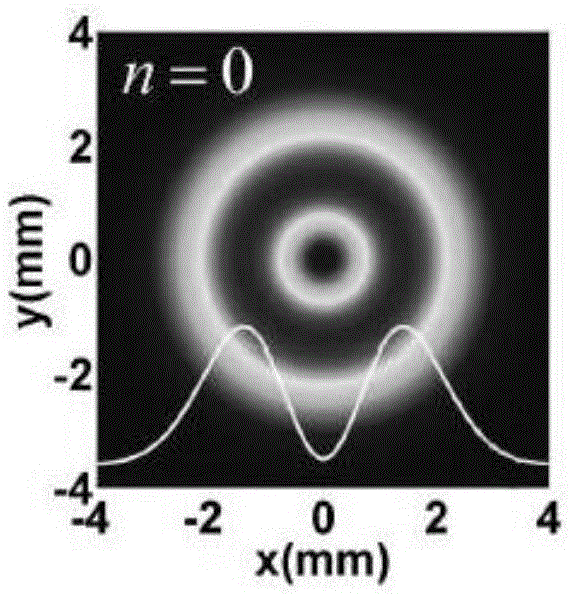

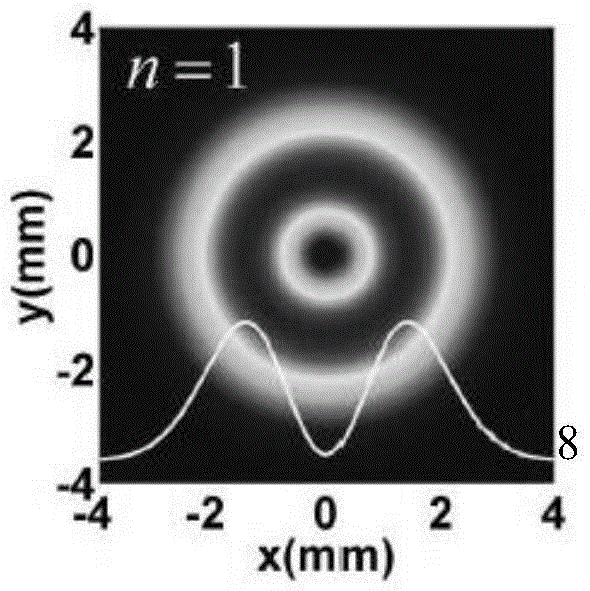

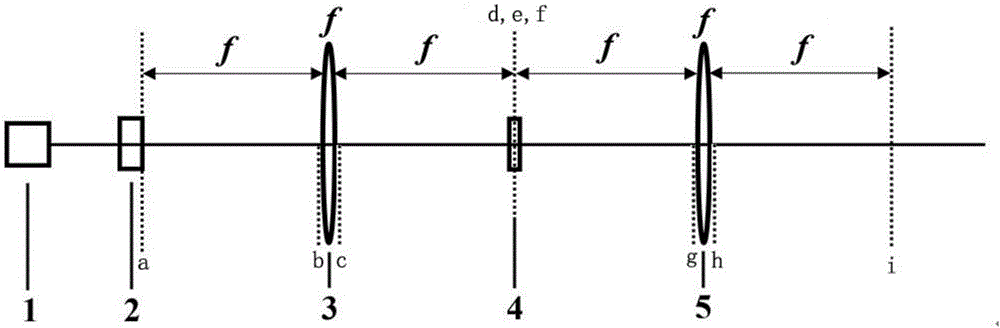

Method and apparatus for generation of radial polarized cosine Gaussian Shell Model (GSM) light beam

The invention relates to a method and apparatus for generation of a radial polarized cosine Gaussian Shell Model (GSM) light beam. The method comprises the steps: performing beam expanding on laser, and modulating the correlation characteristics of the light beam through a spatial light modulator to obtain a light beam with the correlation characteristics of cosine Gaussian; performing space polarization regulation and control on the light beam to obtain a radial polarized beam; reducing the spatial correlation characteristics of the radial polarized beam to obtain a noncoherent cosine Gaussian correlation beam; obtaining a linearly polarized cosine Gaussian correlation Gaussian beam after the noncoherent cosine Gaussian correlation beam is focused through a lens and is filtered through a Gaussian amplitude filter plate; and obtaining a radial polarized cosine GSM light beam after the linearly polarized cosine Gaussian correlation Gaussian beam passes through a radial polarized light converter. The invention provides a novel light beam generation method, further promoting the research on transmission, imaging and matter interaction for a special coherence light beam, and expanding the types of light beams.

Owner:NANJING UNIV OF SCI & TECH

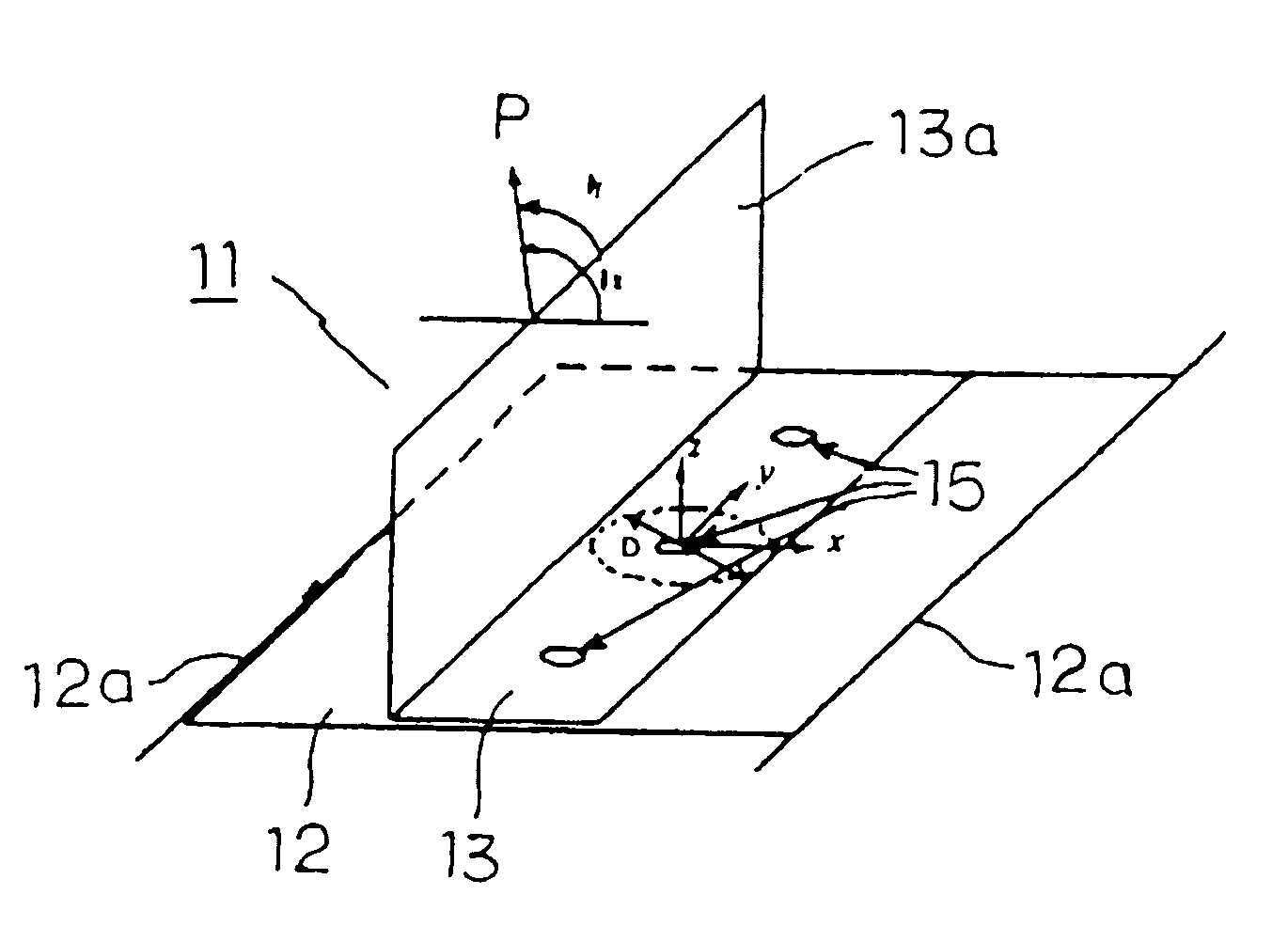

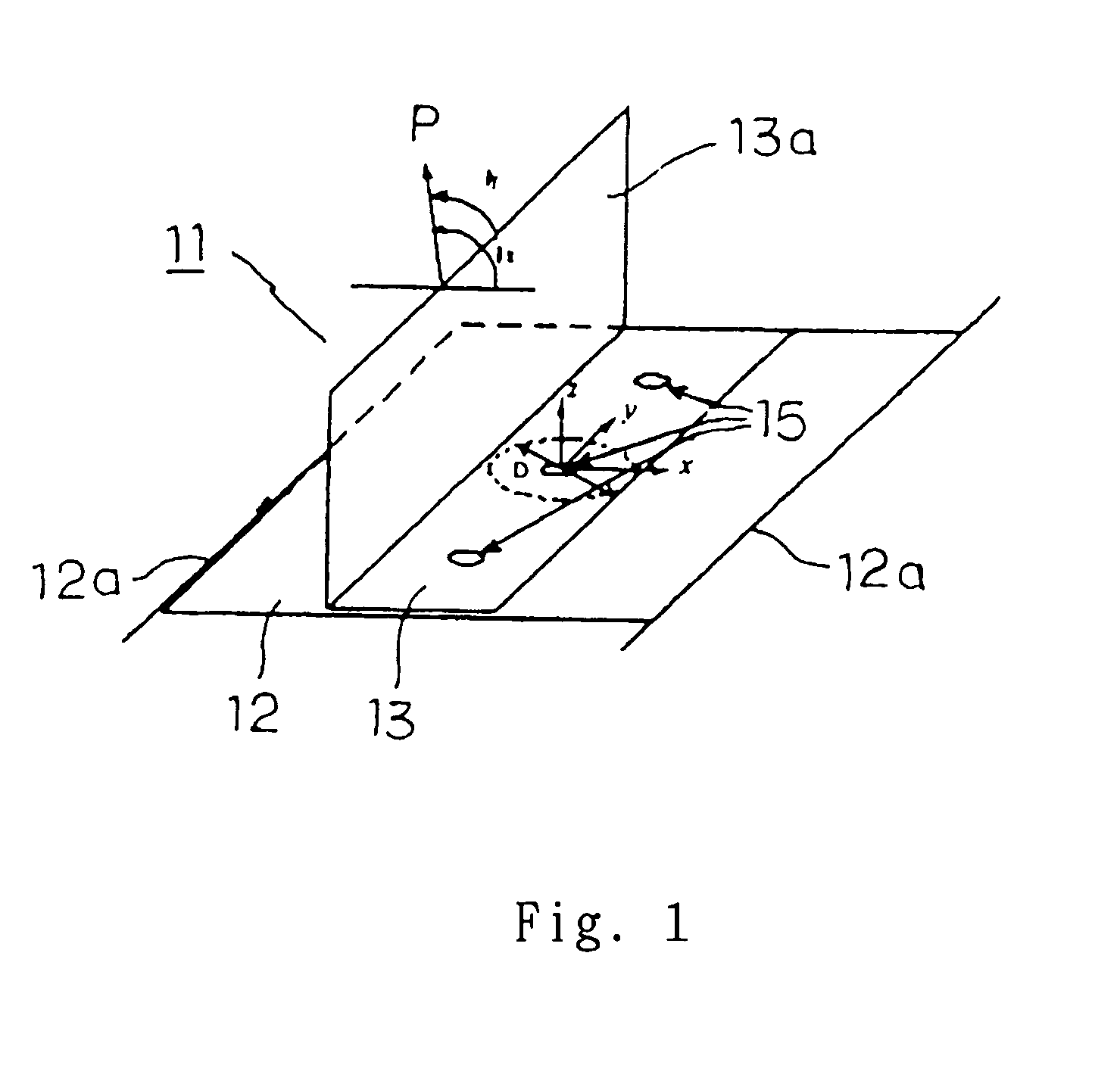

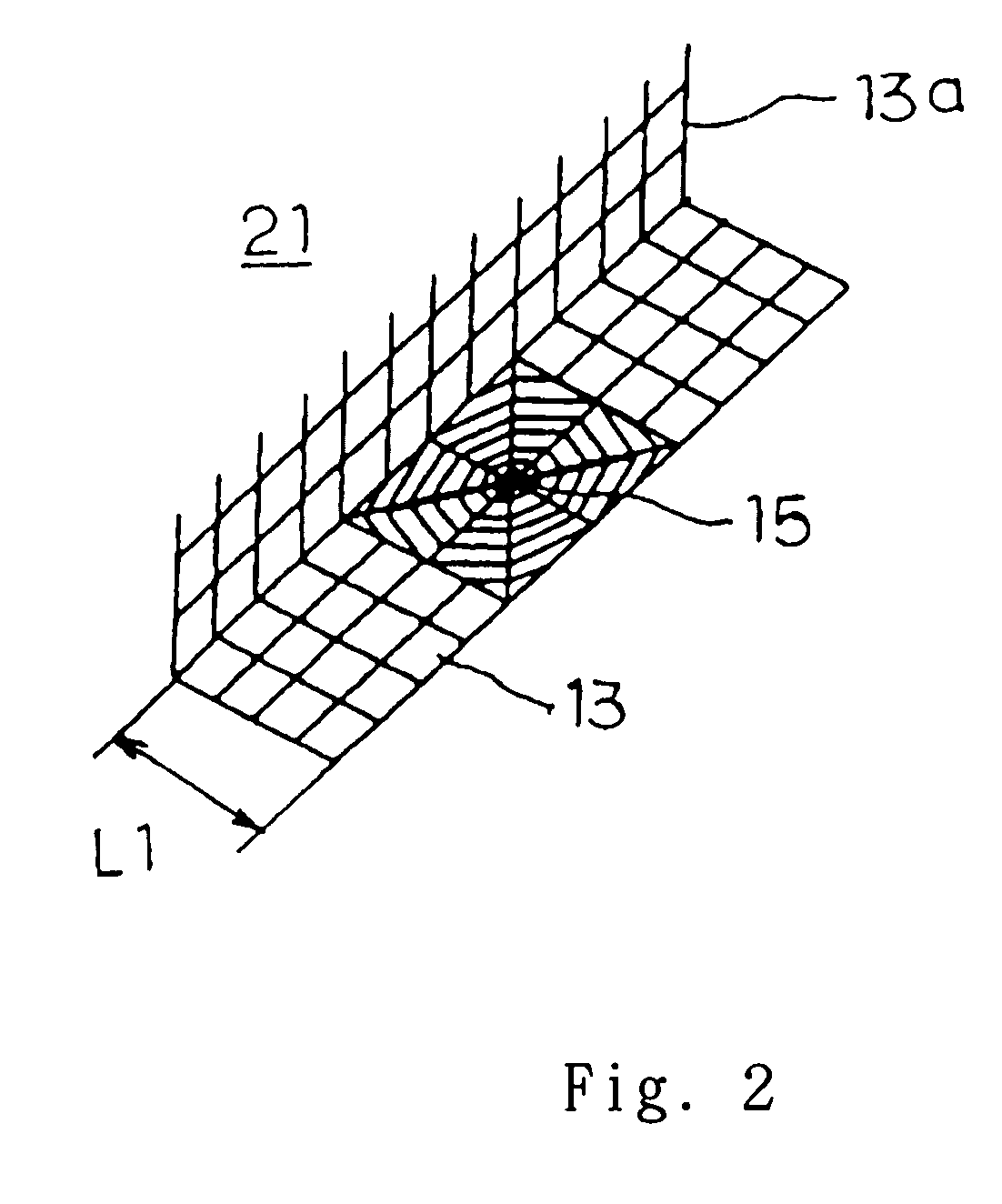

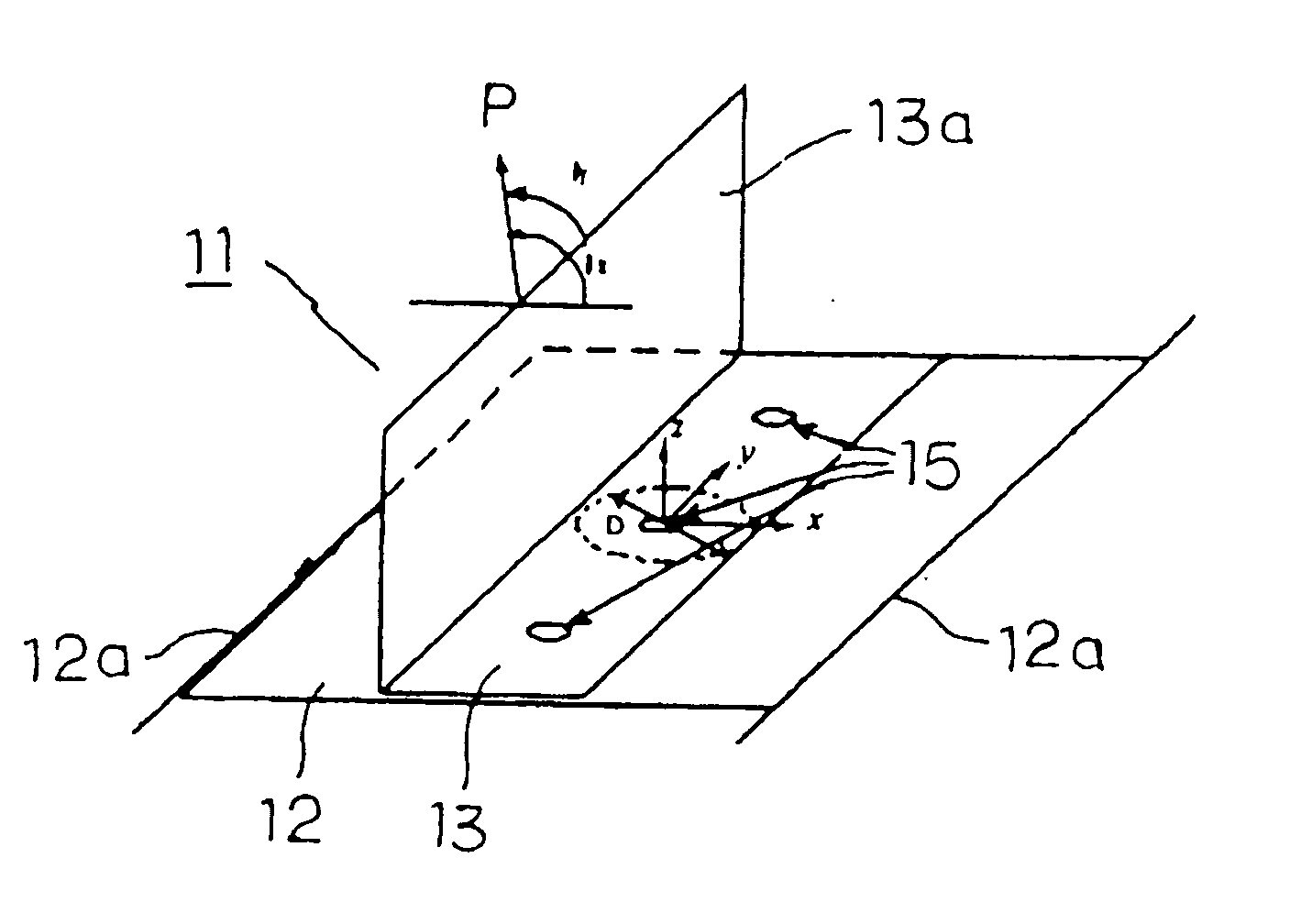

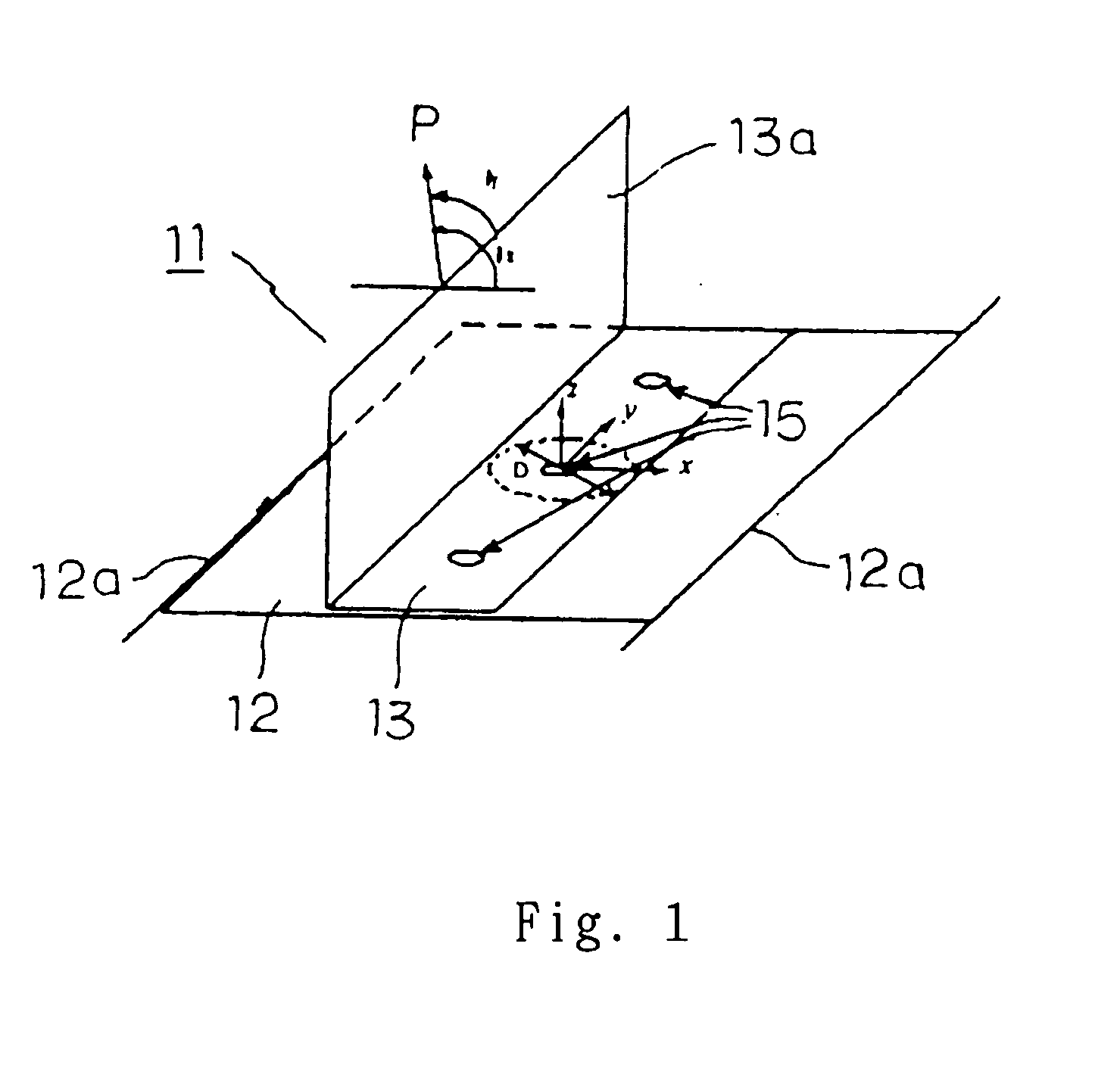

Fatigue life estimating method for spot welded structure

InactiveUS7752917B2Good estimateSimple structureMaterial strength using steady bending forcesUsing mechanical meansFinite element methodEngineering

A fatigue life estimating method for a spot welded structure is provided comprising the steps of providing a shell model of a spot welded structure for a finite element method analyzing process, calculating the nominal structural stress on a nugget as the center of the spot welded structure using a disk bending theory and a two-dimensional elastic theory of the elastodynamics with the partial loads exerted on the nugget and the deflection on the circumference of a circle, D in diameter, in which the nugget is located, which have been calculated by the finite element method analyzing process of the shell model, and estimating the fatigue life of the spot welded structure from the nominal structure stress. According to the method, the fatigue life of the spot welded structure can be estimated easily, readily, and accurately.

Owner:NIHON UNIVERSITY

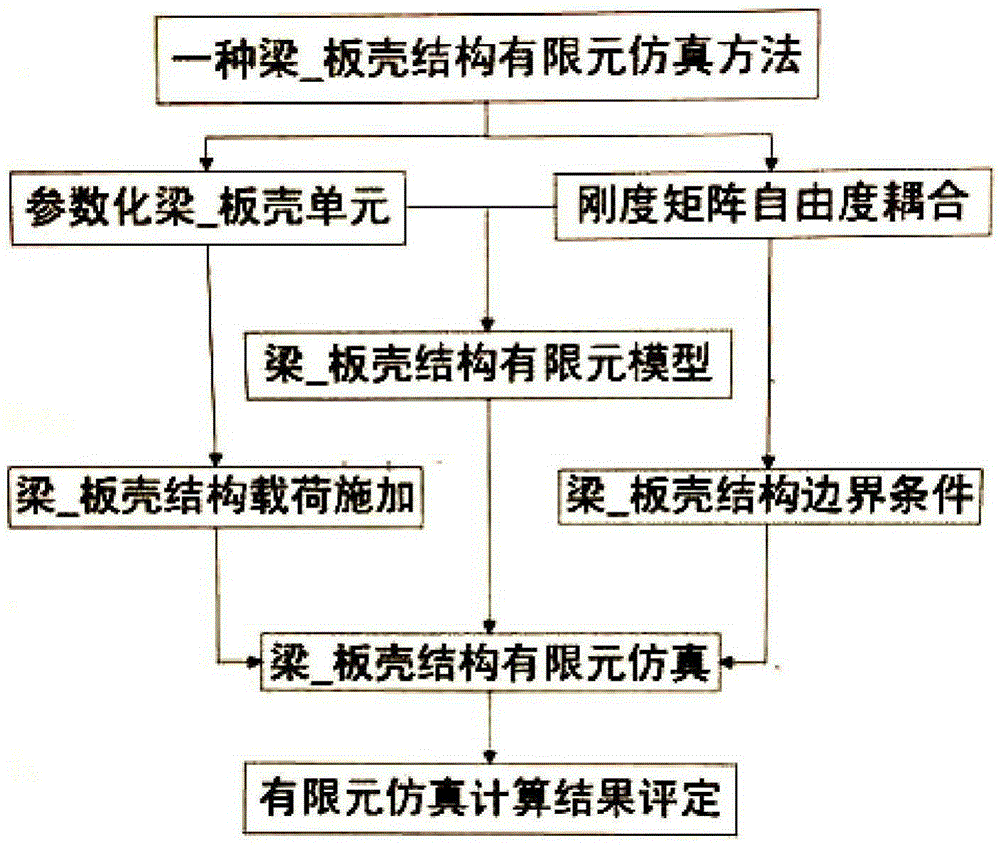

Finite element simulation method of beam_plate shell structure

InactiveCN105302994AImprove mesh qualitySimple resultSpecial data processing applicationsElement modelEngineering

The invention relates to a finite element simulation method of a beam_plate shell structure. The finite element simulation method comprises the steps of establishing the research of a beam unit and a plate shell unit, and a finite element model; determining the boundary conditions of a beam_plate shell model; carrying out strength calculation and mode analysis; and evaluating the calculation result, wherein the establishment of the research of the beam unit and the beam_plate shell unit and the finite element model comprises the steps of researching the beam unit and setting real constants based on cross-section shape, namely carrying out parameterization on the beam_plate shell unit; researching the characteristics of the plate shell unit and the coupling characteristics of plate shell unit and the beam unit, namely coupling stiffness matrix degree of freedom; and creating the finite element model of the beam_plate shell structure by applying the parameterized beam_plate shell unit and the stiffness matrix degree of freedom. The finite element simulation method has the advantages of good grid quality, intuitive result and the like, and is beneficial to promoting the design level, shortening the design period, reducing the experiment expense, and reducing the potential fault danger.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Fatigue life estimating method for spot welded structure

InactiveUS20090211366A1Troublesome taskGood estimateMaterial strength using steady bending forcesUsing mechanical meansFinite element methodEngineering

A fatigue life estimating method for a spot welded structure is provided comprising the steps of providing a shell model of a spot welded structure for a finite element method analyzing process, calculating the nominal structural stress on a nugget as the center of the spot welded structure using a disk bending theory and a two-dimensional elastic theory of the elastodynamics with the partial loads exerted on the nugget and the deflection on the circumference of a circle, D in diameter, in which the nugget is located, which have been calculated by the finite element method analyzing process of the shell model, and estimating the fatigue life of the spot welded structure from the nominal structure stress.According to the method, the fatigue life of the spot welded structure can be estimated easily, readily, and accurately.

Owner:NIHON UNIVERSITY

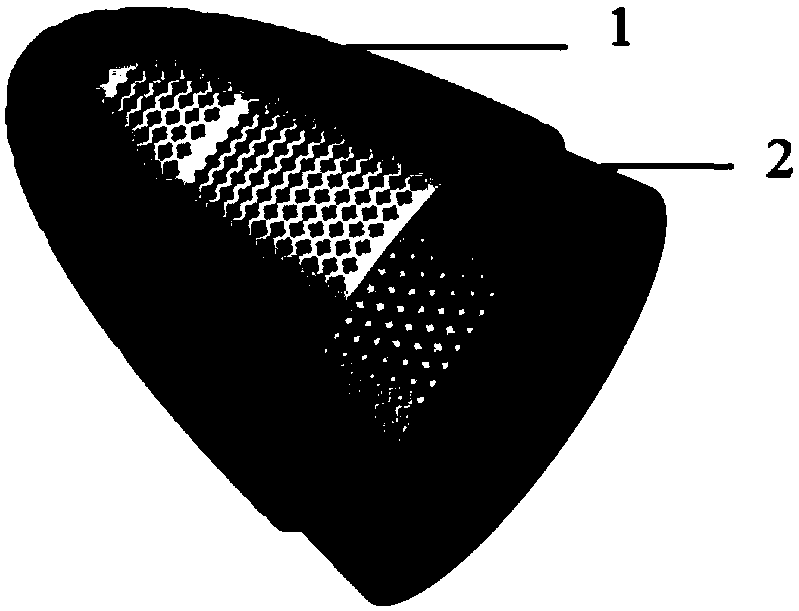

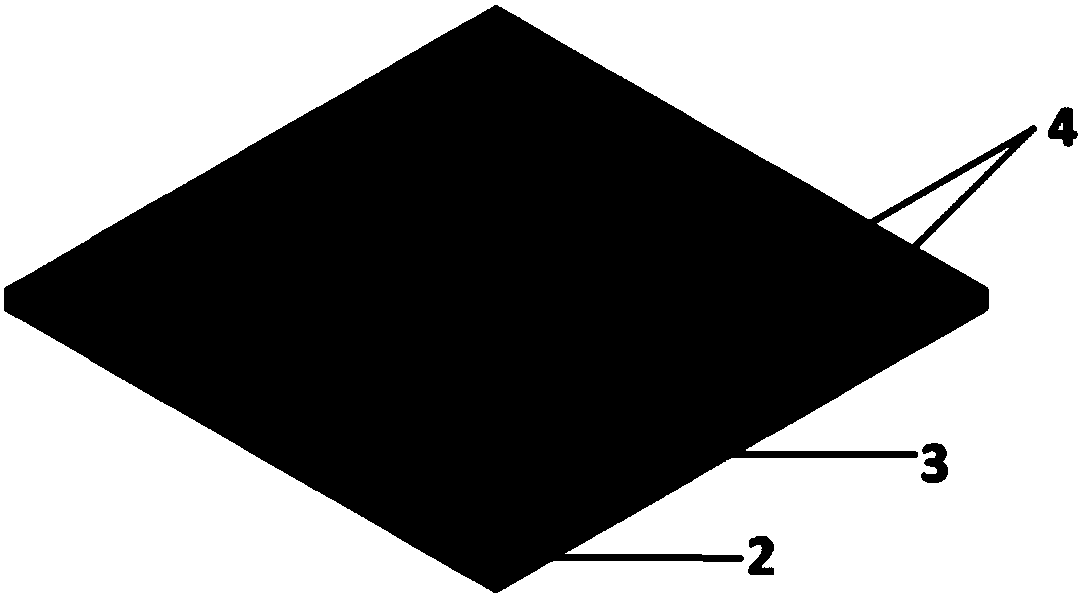

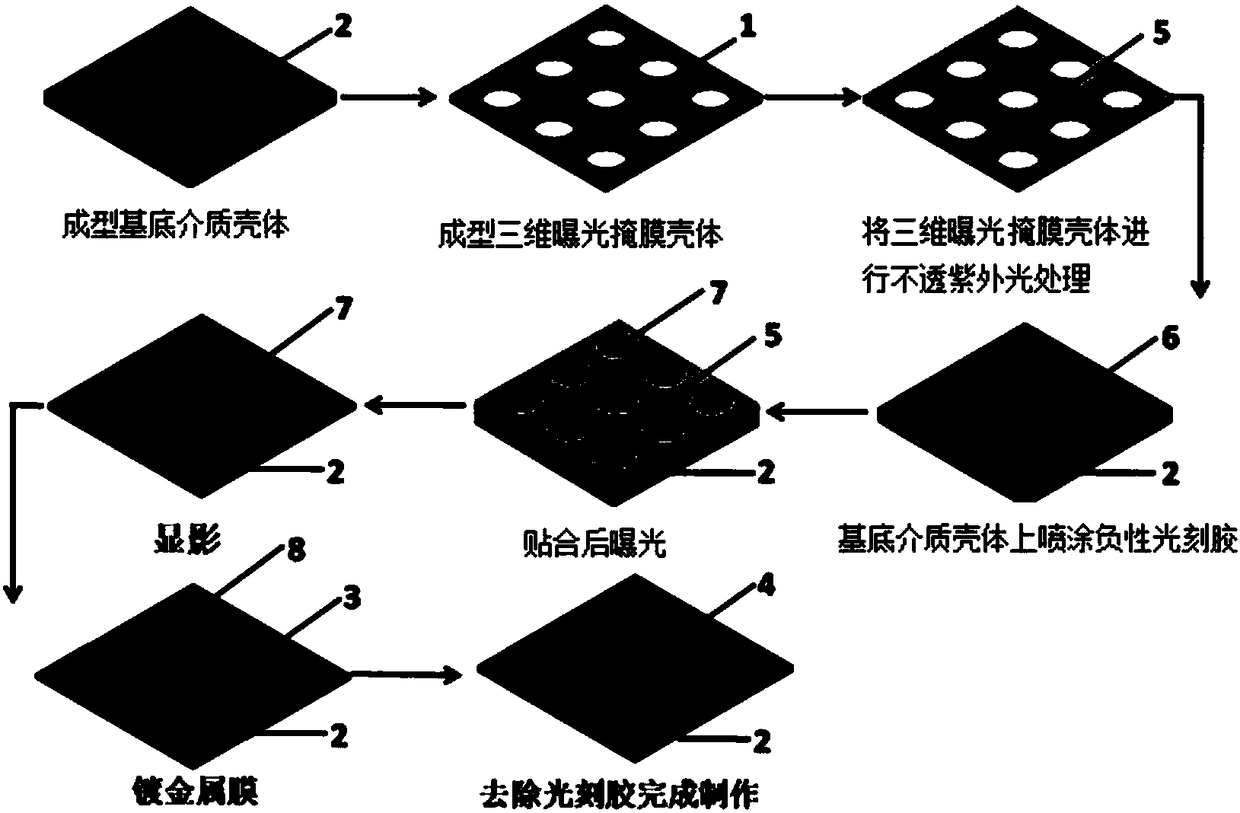

Manufacturing method of curved frequency selective surface array

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

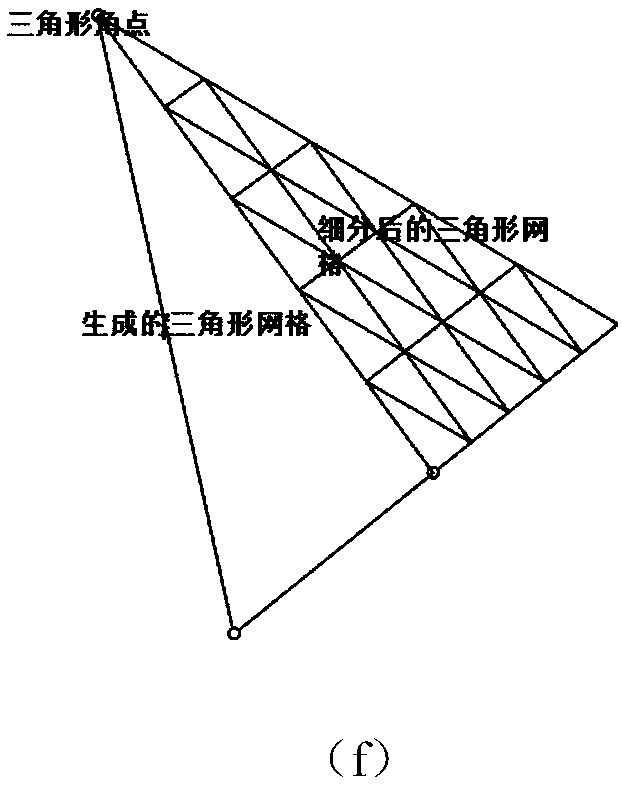

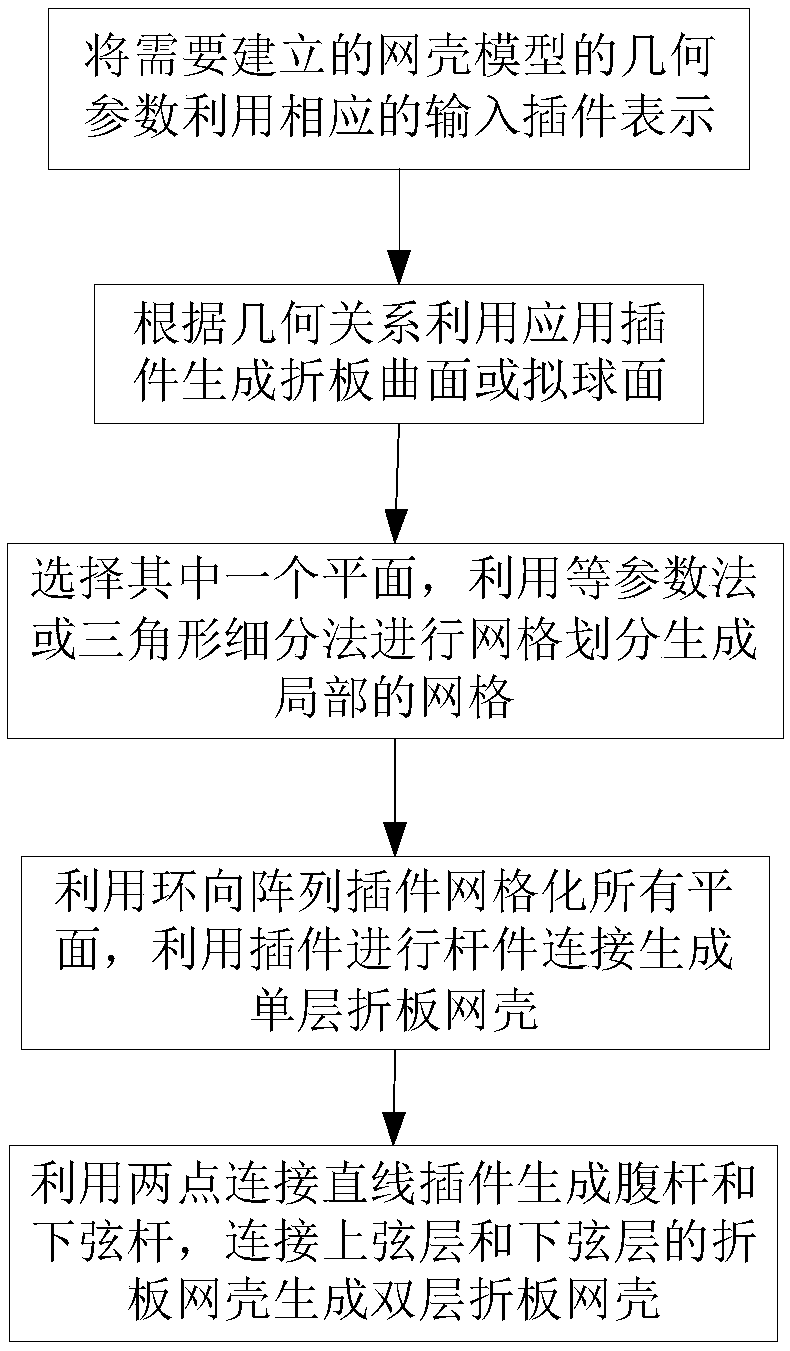

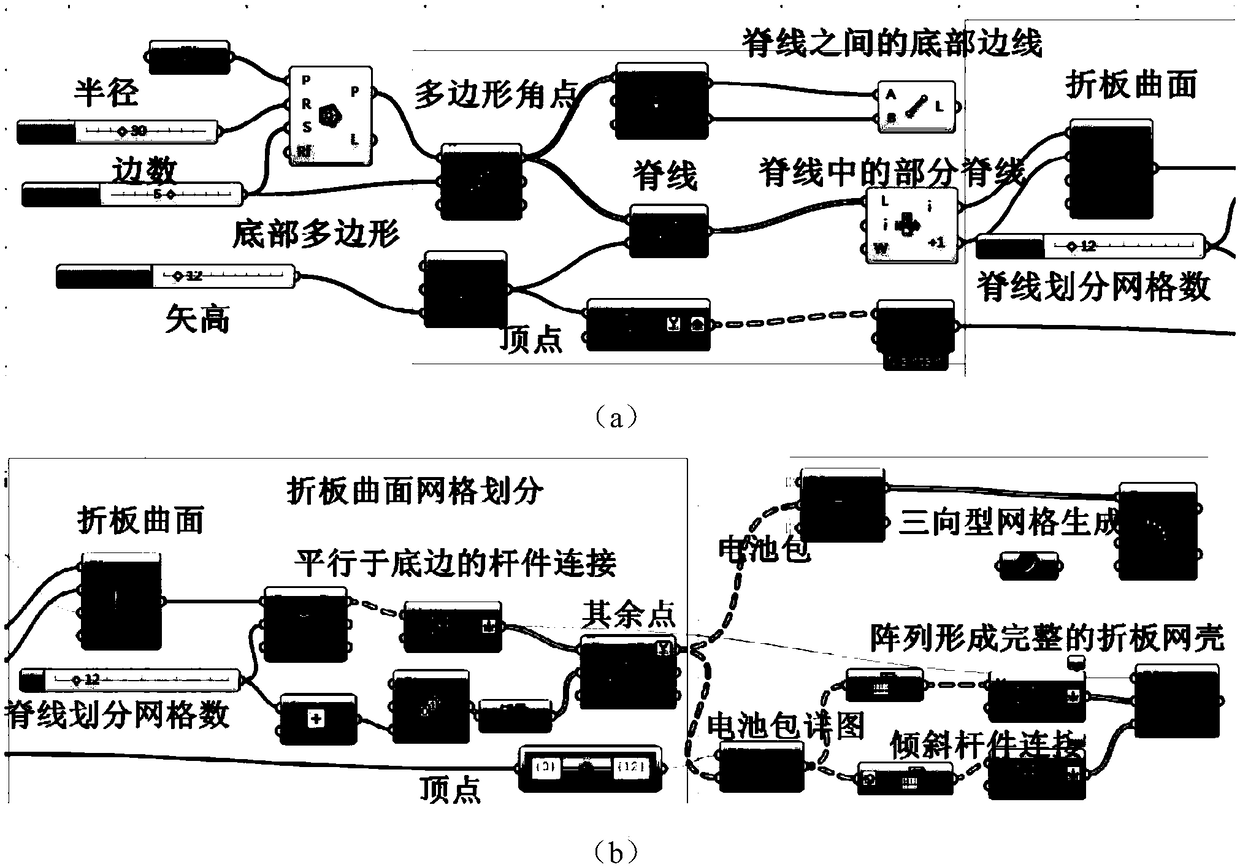

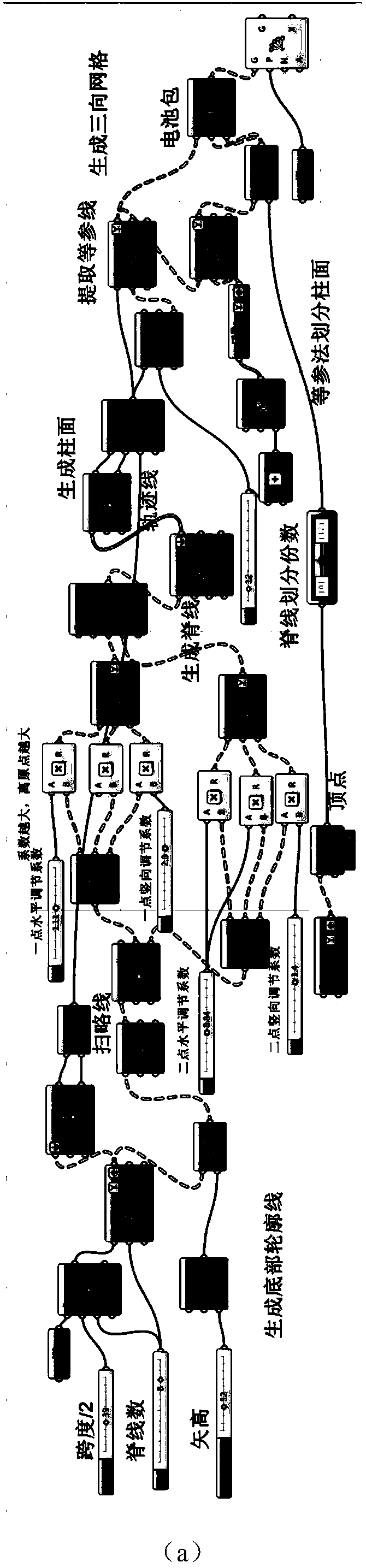

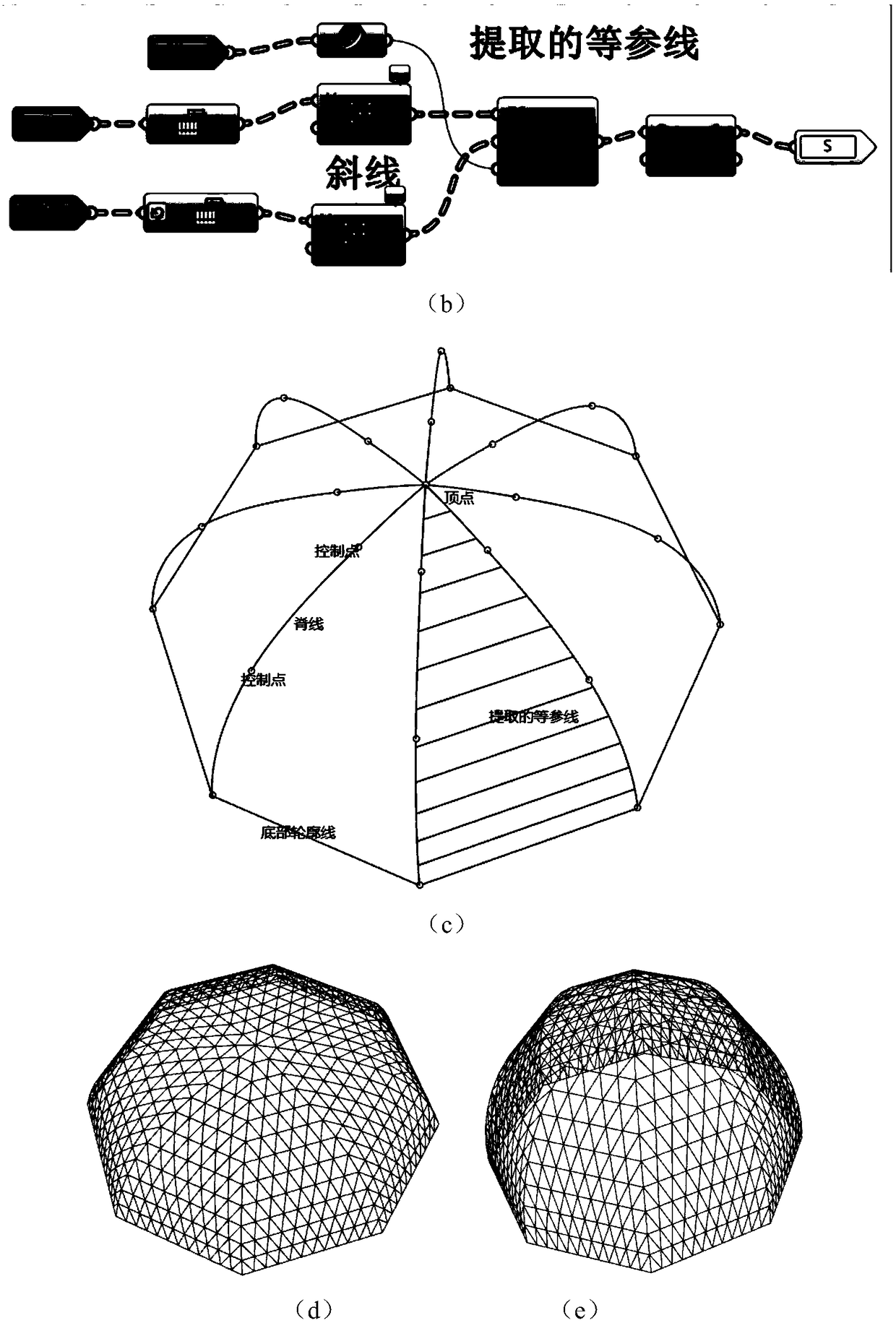

Parametric modeling method of folded plate reticulated shell based on grasshopper

ActiveCN109190231ASimple forceSimple designGeometric CADDesign optimisation/simulationGrasshopperSimulation

The invention provides a parametric modeling method of a folded plate reticulated shell based on grasshopper, which is used for solving the problems of modeling difficulty, low modeling efficiency andlow repetition utilization rate of the existing space folded plate reticulated shell with complex modeling. The invention comprises the following steps: expressing the geometrical parameters of a lattice shell model to be established by corresponding input plug-ins; generating a flap surface or quasi-spherical surface by using the application plug-ins according to geometrical relation; selectingone of the planes and using an isoparametric method or subdivision method to mesh a folded surface to generate local meshes; gridding all the planes by the circumferential array plug-in, and generating the single-layer folded latticed shell by connecting the bars with the plug-in. The invention has the advantages of simple design method, new model can be established by changing the parameter valuein the model, the modeling efficiency can be improved, the force analysis and the structural design optimization of the complex space reticulated shell structure under different types and different parameters are improved greatly and conveniently, and the use of the complex space reticulated shell structure is promoted.

Owner:HENAN ENG DESIGN CONSULTANTS OF CSCEC

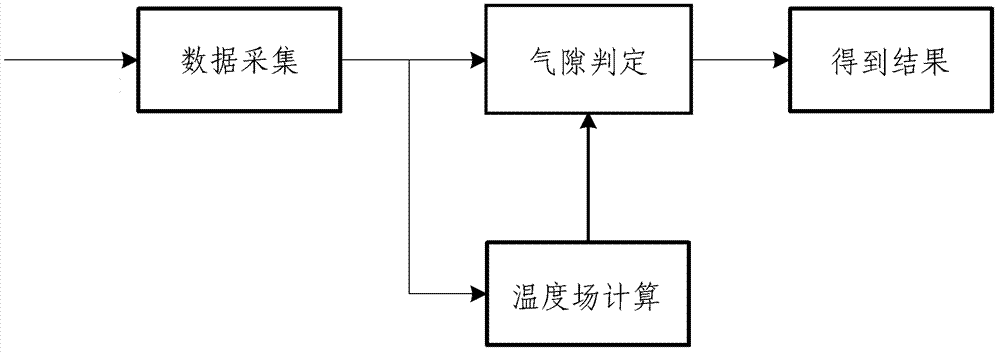

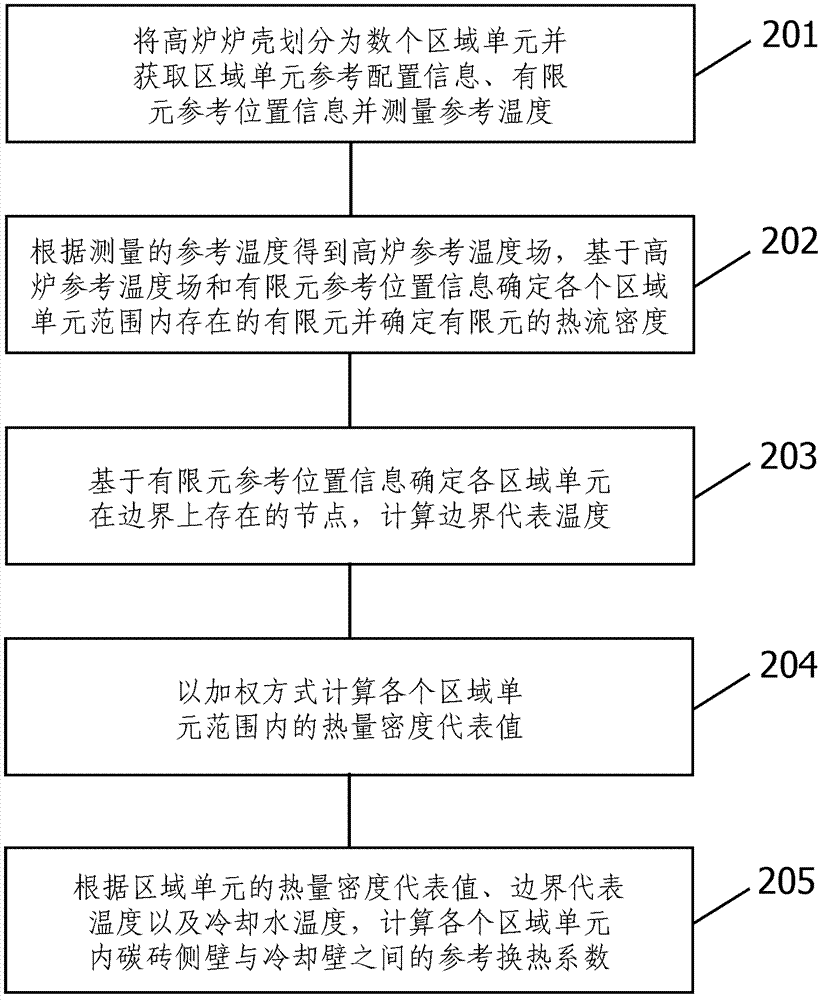

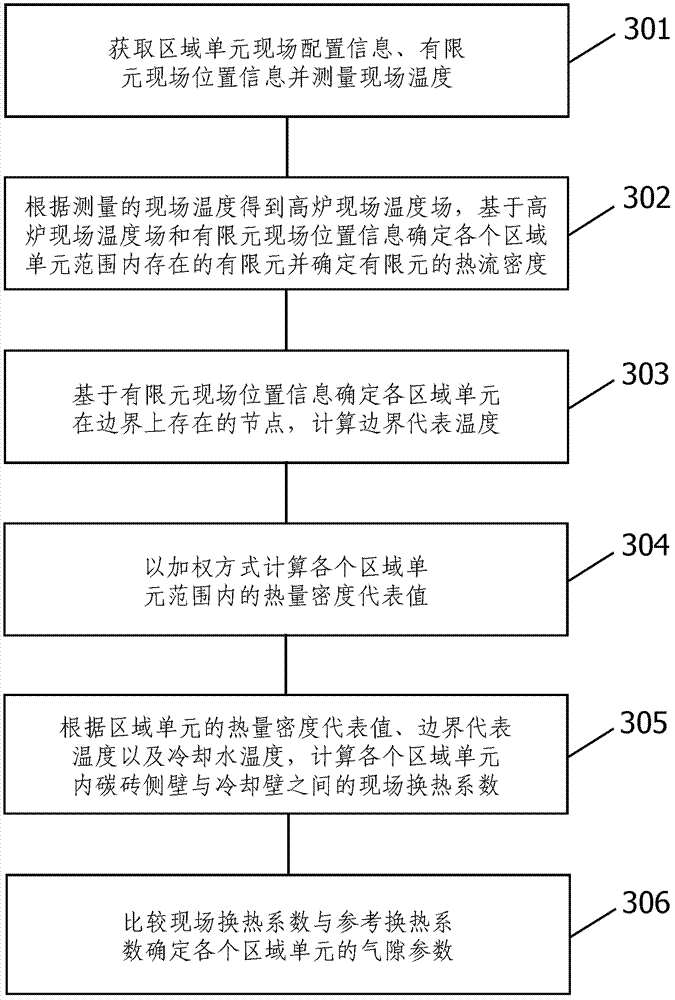

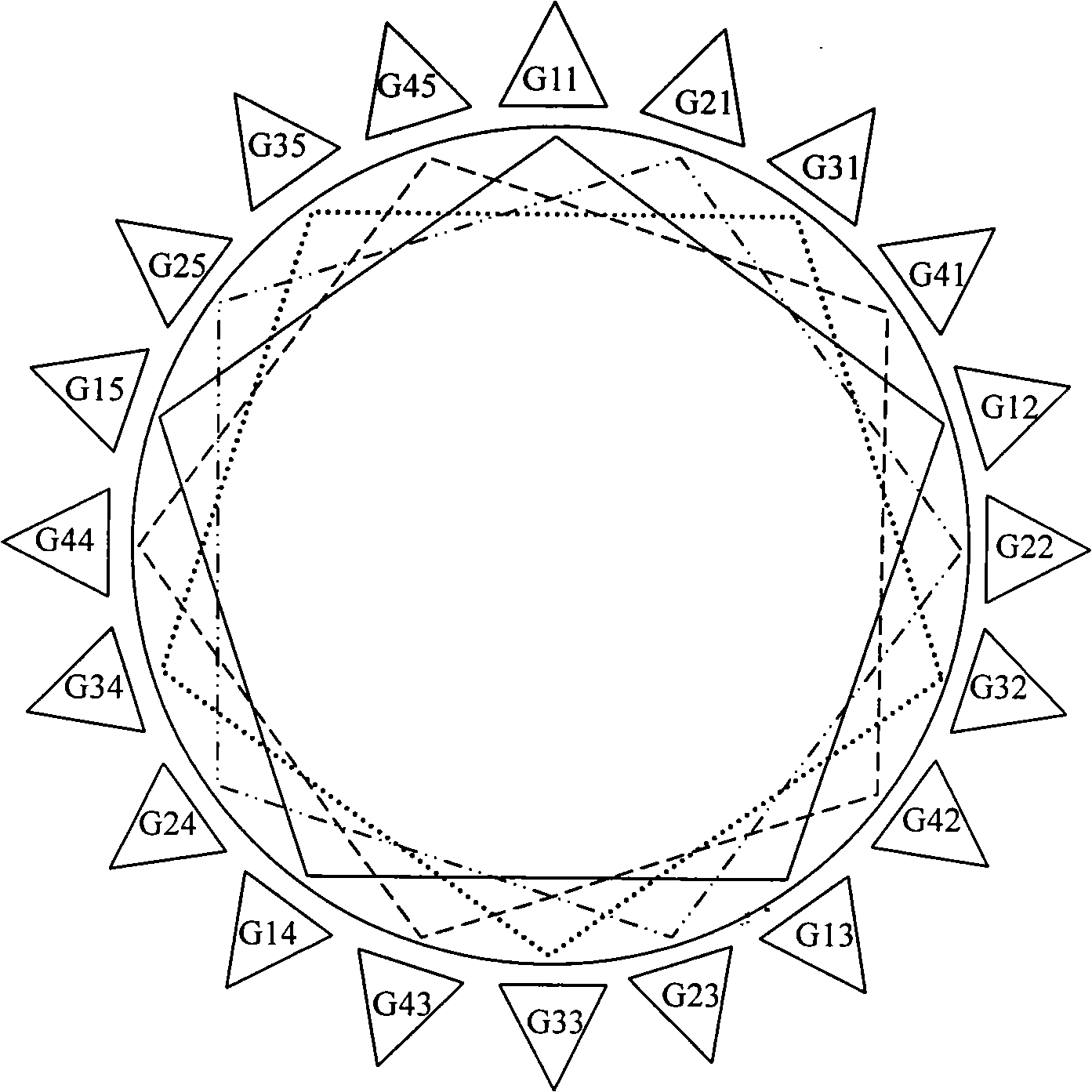

Method for detecting air gap on a blast furnace shell

ActiveCN103088176ATimely reflection of air gap parametersAccurate detectionChecking devicesReference configurationSHELL model

The invention discloses a method for detecting air gap on a blast furnace shell. The method comprises steps of: establishing a blast furnace shell model; dividing the blast furnace shell into a plurality of regional units; collecting reference configuration information and finite element reference position information in the regional units, and measuring reference temperature; calculating to obtain a reference heat transfer coefficient of the blast furnace shell model based on the above reference configuration information, the finite element reference position information and measured reference temperature; determining an air gap parameter of the blast furnace shell based on the blast furnace shell model; collecting on-site configuration information, finite on-site element position information in the regional units, and measuring an on-site temperature; calculating to obtain an on-site heat transfer coefficient based on the on-site configuration information, finite on-site element position information and measured on-site temperature; and comparing the on-site heat transfer coefficient with the reference heat transfer coefficient to obtain air gap parameter of the blast furnace shell. The method provided by the invention can effectively and timely reflect the air gap parameter of the blast furnace shell, show the change of the heat transfer coefficient of the blast furnace shell, and provide direct evidence for gap detection.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

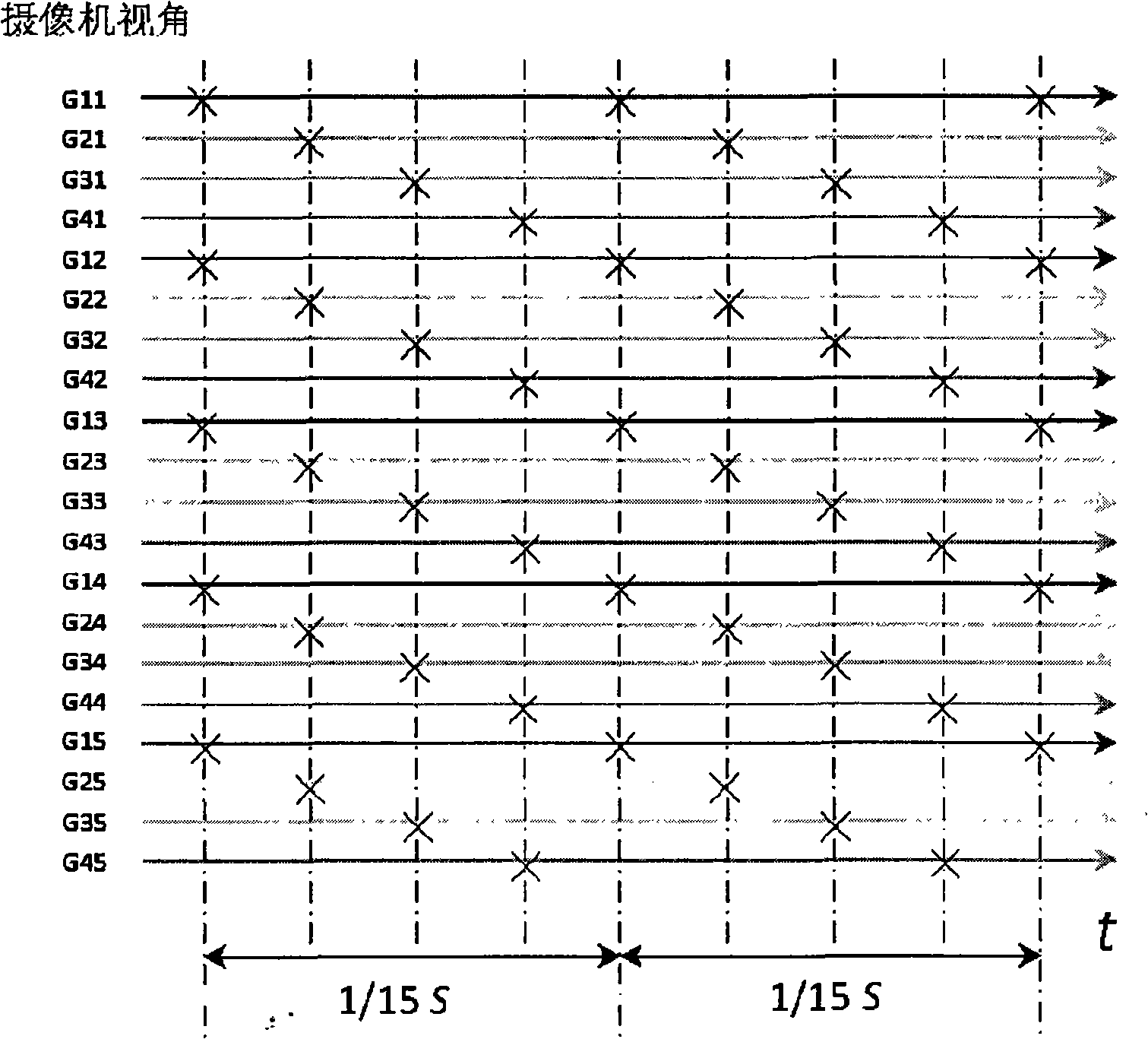

Method for modeling high-speed moving object adopting ring shaped low frame rate camera array

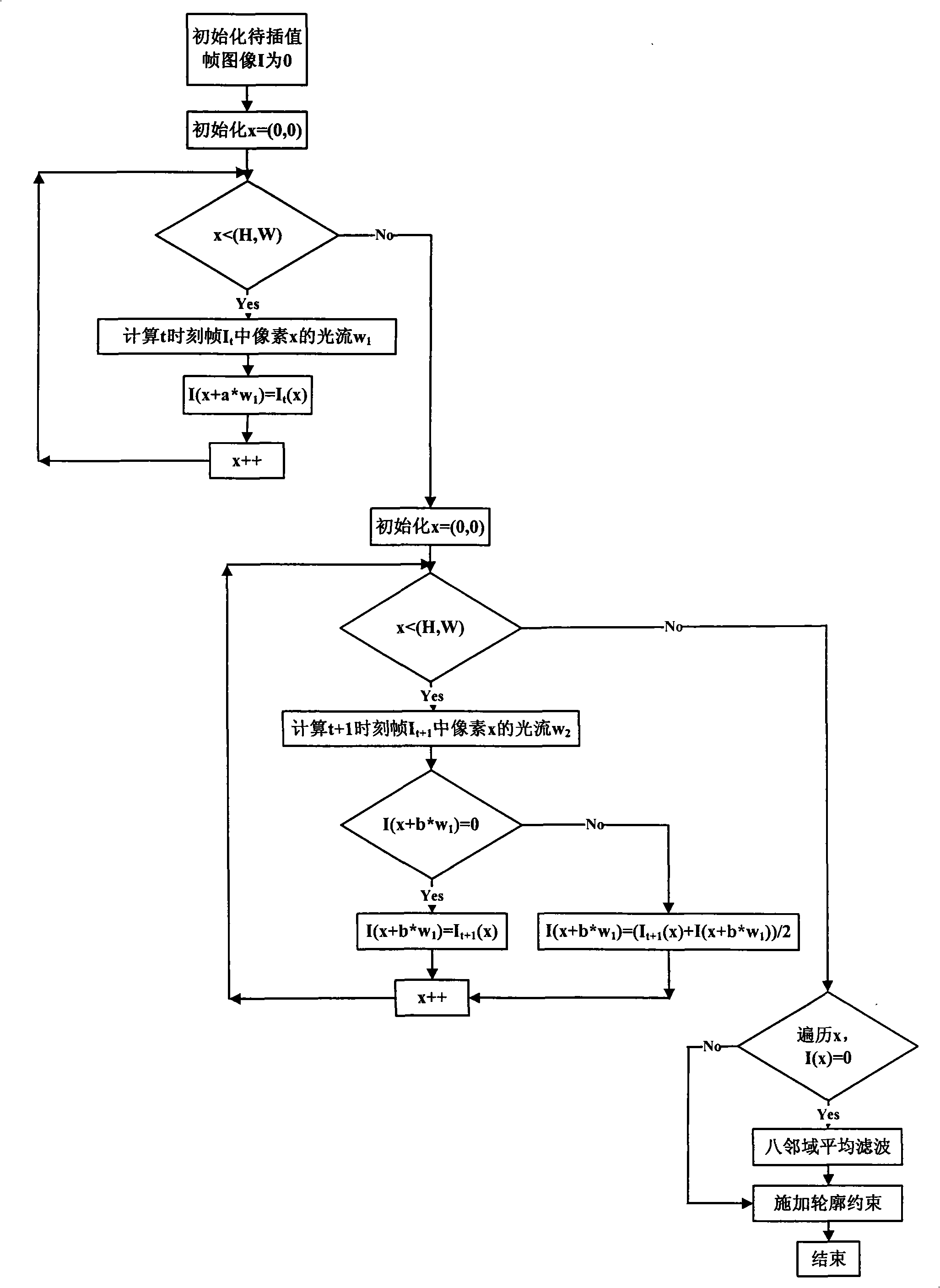

InactiveCN101271579AAvoid the need for synchronizationAchieve captureImage analysis2D-image generationSHELL modelOptical flow

The invention relates to a method adopting a ring type low frame rate camera array to catch a high-speed moving object and model, belonging to the technical field of a computer multimedia. The method includes that: the ring type camera array is divided into groups in a uniform spacing; each group of cameras acquires the moving object in a ring type field; an acquisition time difference between the adjacent groups of cameras is 1 / (fm) second; by utilizing a bi-directional optical flow prediction method, a (group count-1) frame is interpolated out between the adjacent two frames of a sequence shot by each camera; a contour constraint is added to a result of the interpolation to improve the result of the interpolation; at each moment, a visual shell model is established and rendered by using an image of each visual angle and the interpolation image. The method which adopts the ring type low frame rate camera array to catch the high-speed moving object and model is capable of using the low frame rate camera to realize the catching of the high-speed movement and the modeling of a three-dimensional dynamic scene.

Owner:广东清立方科技有限公司

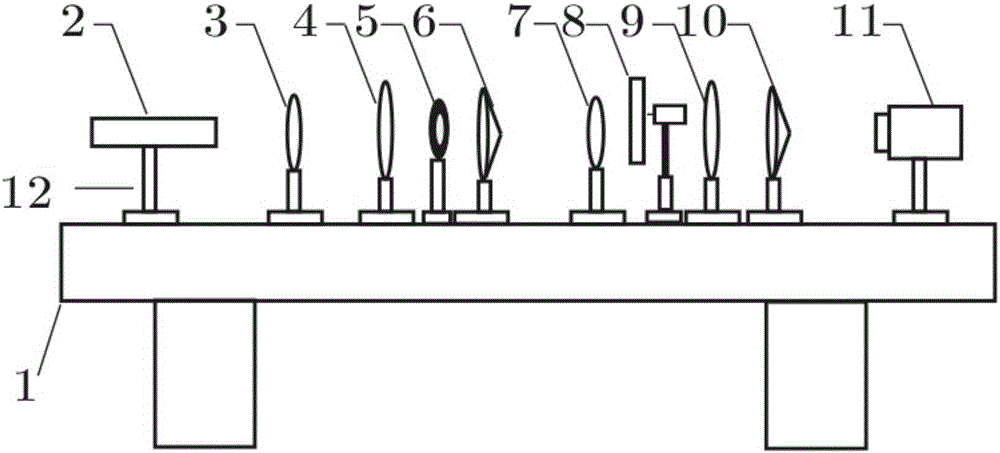

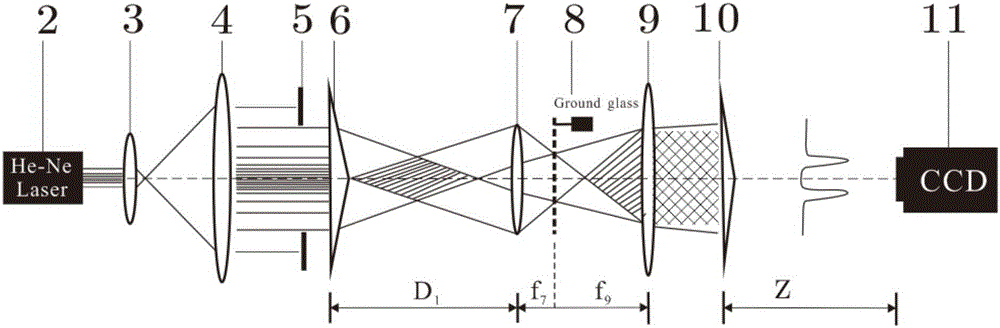

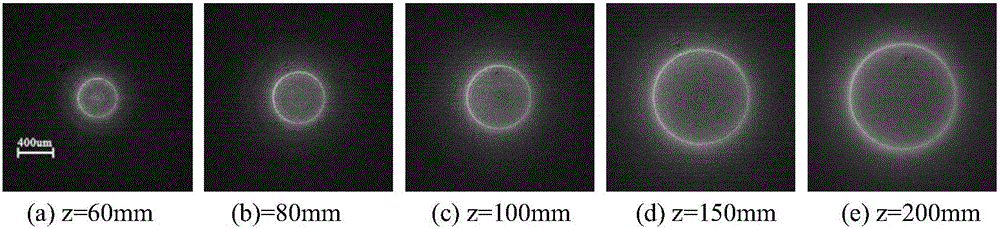

Optical system for generating hollow beam by focusing Bessel-Shell model light field through axicons

The invention discloses an optical system for generating a hollow beam by focusing a Bessel-Shell model light field through axicons.The optical system comprises an optical platform.A laser device is placed on the optical platform.A collimation and beam expanding system, an aperture diaphragm, the first axicon, a first thin lens, rotary ground glass, a second thin lens and the second axicon are sequentially placed along an optical path of the laser device.By means of the technology, the hollow beam of the size increasing along with increase of the distance can be generated, and the hollow beam has a self-reconstruction characteristic.The optical system has the advantages that the optical structure is simple, optical elements are cheap, and the generated hollow beam is high in quality; a powerful means will be provided for people to trap particles of different sizes and numbers on multiple layers.

Owner:HUAQIAO UNIVERSITY

Composite mold shell preparation method for reducing recrystallization tendency of high-temperature single-crystal alloy casting

ActiveCN107243601AResolve the compromiseSolve the shortcomings of poor collapsibilityFoundry mouldsFrom frozen solutionsSingle crystalSuperalloy

The invention belongs to the casting field, relates to a composite mold shell preparation method for reducing the recrystallization tendency of a high-temperature single-crystal alloy casting. The preparation method is suitable for preparing a shell of the investment precision casting high-temperature alloy casting for investment casting. The preparation method comprises the following steps: pressing a wax mold; preparing a surface layer coating, a transition layer coating, a middle layer coating and a back layer coating; sequentially immersing the wax mold into the coatings, scattering corresponding sand and preparing a shell model after the wax mold is dried; dewaxing the shell model; and roasting the shell model. According to the technical scheme, the defects of poor deformability and collapsibility of an existing shell are overcome, after a composite mold shell is used as a mold shell of the investment precision casting, the casting residual stress of the shrinkage blocking area of the high-temperature single-crystal alloy casting is remarkably reduced, and therefore the casting recrystallization defect caused by subsequent heat treatment is eliminated, the single crystal integrity of a casting blank is ensured, and the qualification rate of the casting is remarkably improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

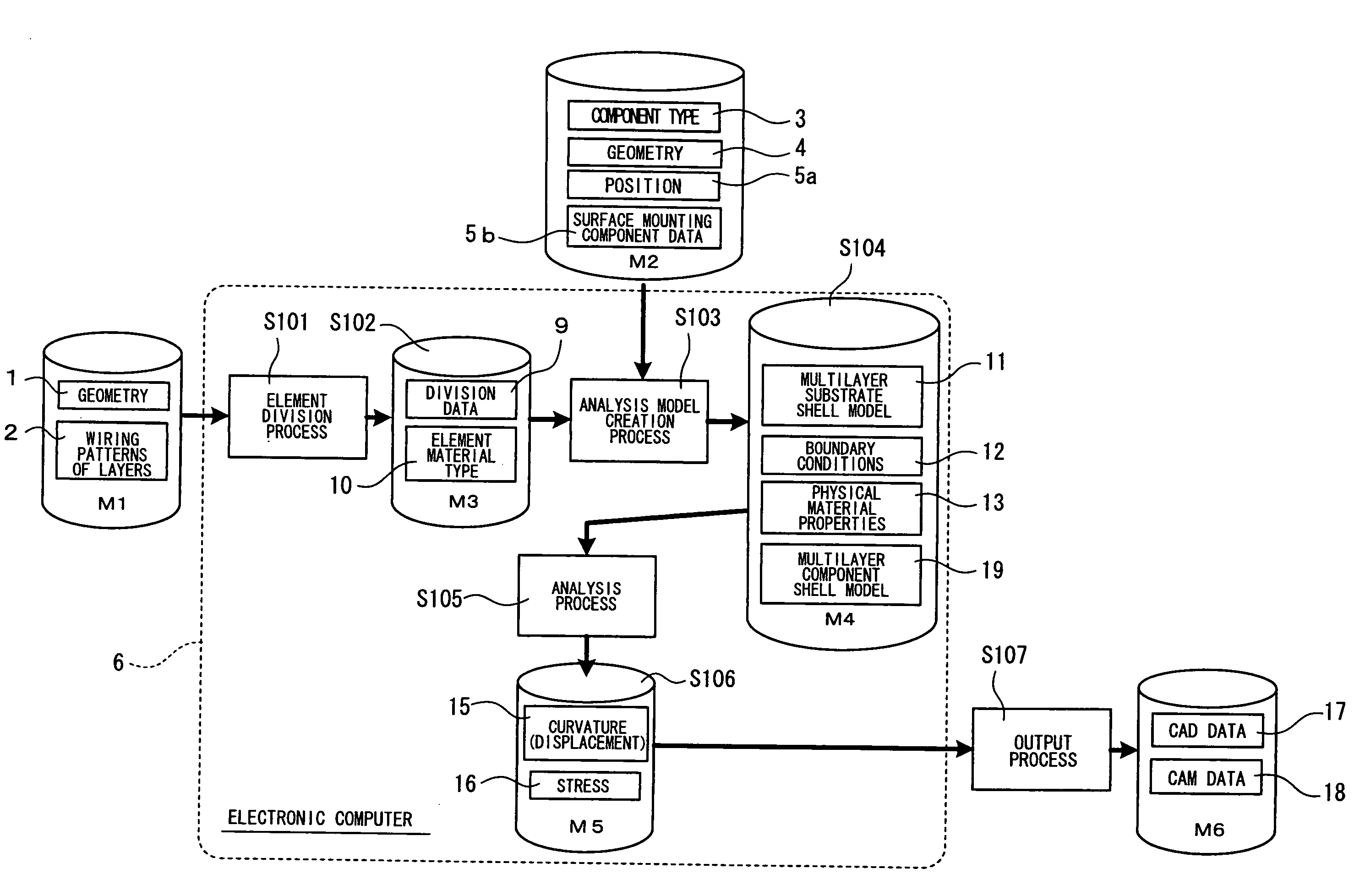

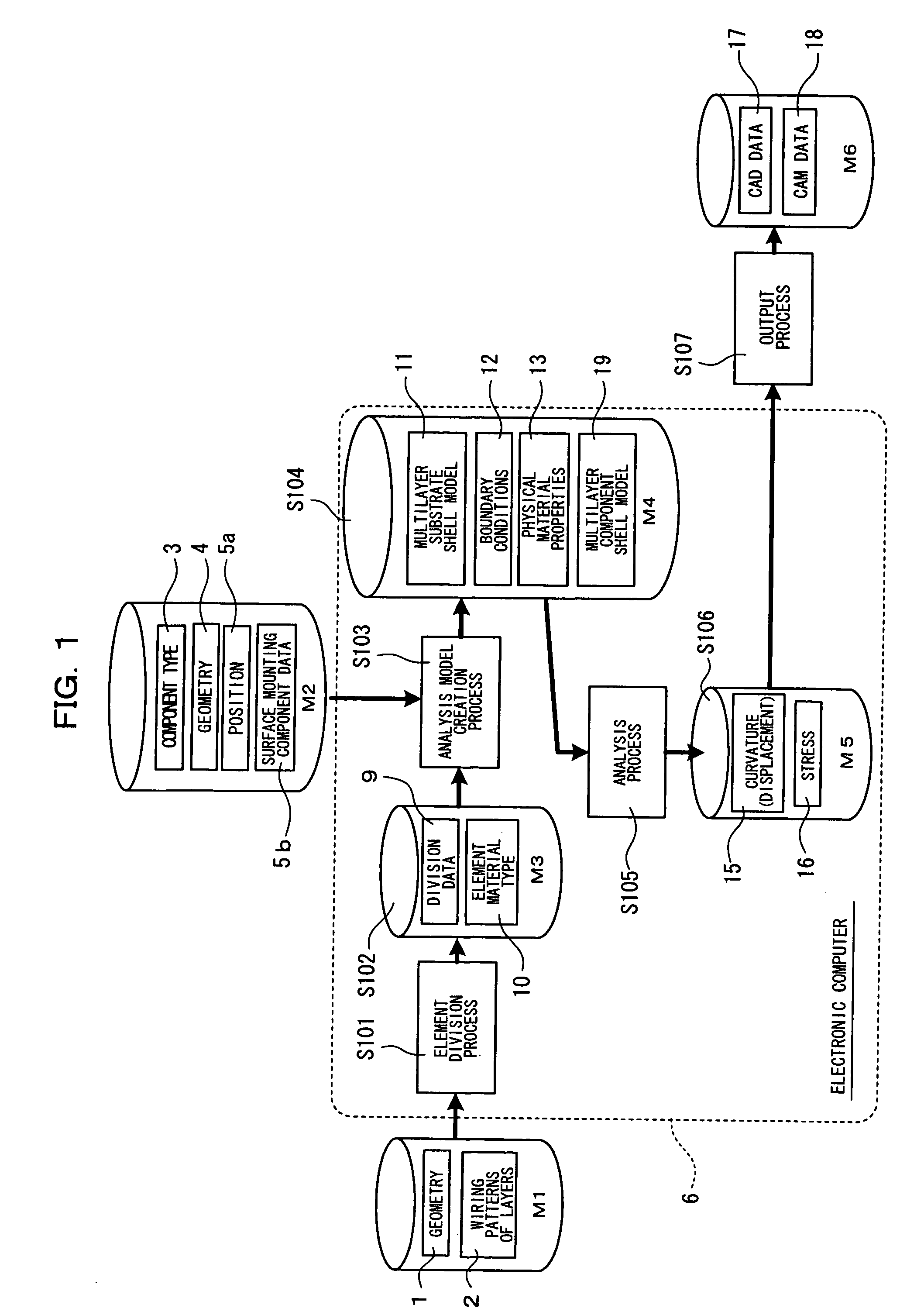

Method for Analyzing Component Mounting Board

InactiveUS20080168413A1Printed circuit assemblingDetecting faulty computer hardwareNeutral planeEngineering

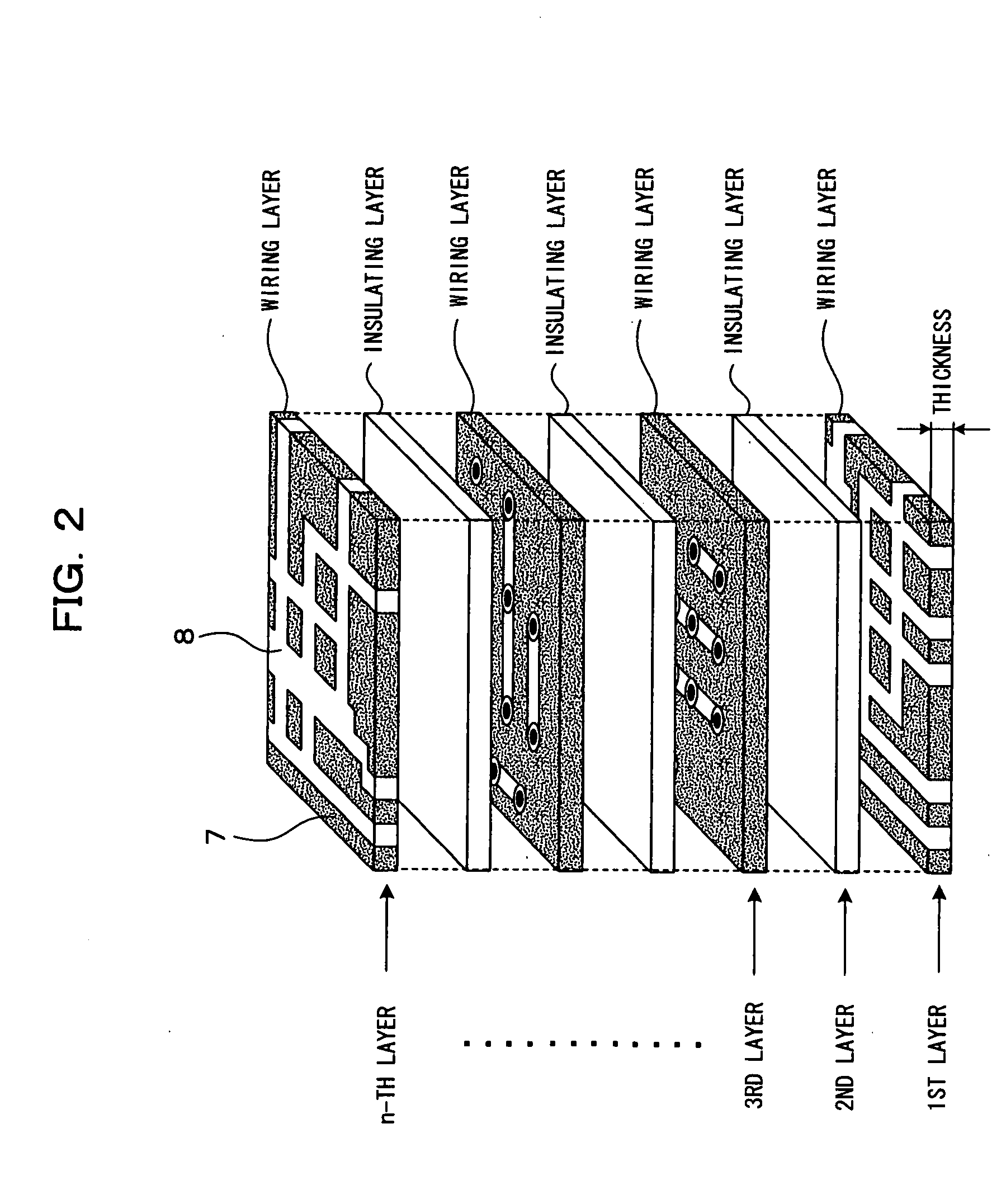

A method for analyzing a component mounting board comprising a step (A) for forming a multilayer substrate shell model of a multilayer wiring board, a step (B) for forming a multilayer component shell model divided by element division lines based on the bonding position of a component to the surface of the multilayer wiring board, step (C) for redividing the mounting position of the component in the multilayer substrate shell model, and step (D) for forming an analysis model by bonding the neutral plane of the substrate and the neutral plane of the component through one of a beam element and a solid element, i.e. a bonding element equivalent to mounting conditions of the component, wherein precision of analysis is enhanced while reducing computation cost by performing calculation while imparting boundary conditions to the analysis model.

Owner:GK BRIDGE 1

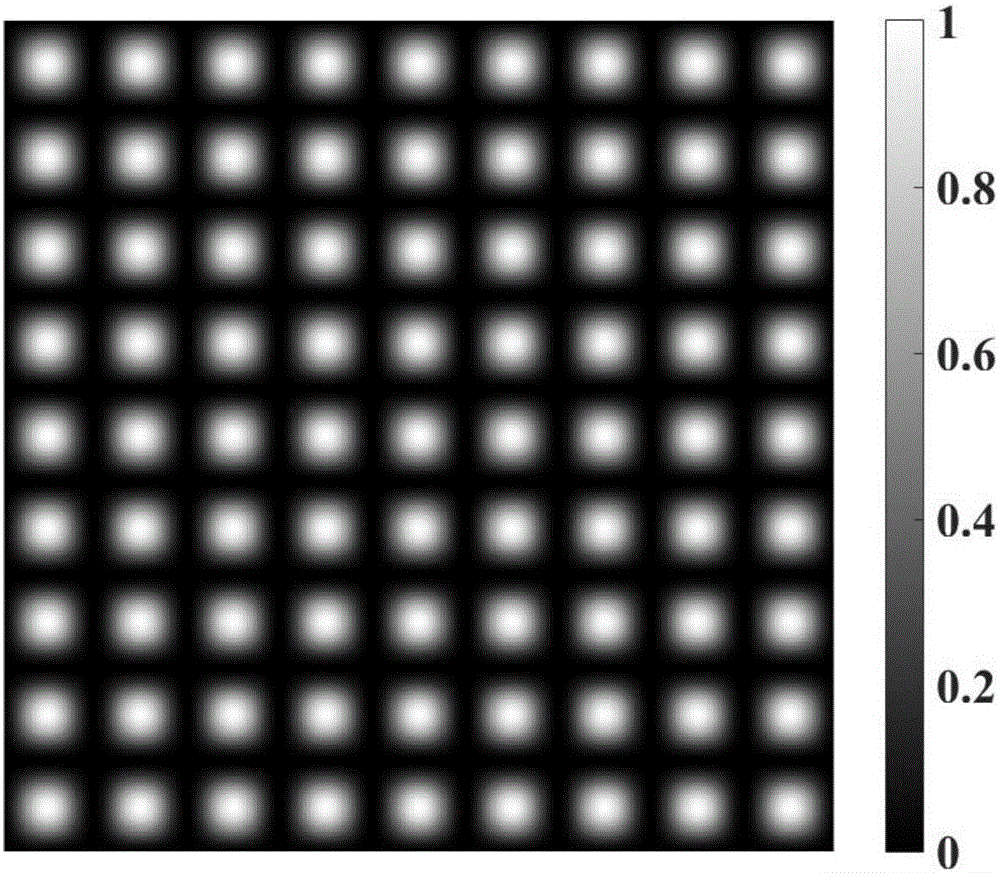

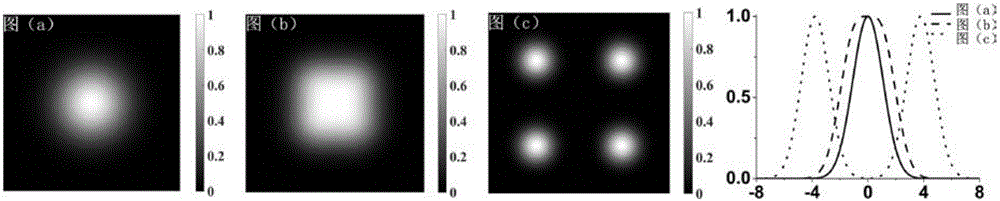

Gaussian Shell model (GSM) shaping method and system

ActiveCN106444048ARich varietyModulate light intensityOptical elementsUltrasound attenuationLight spot

The invention discloses a Gaussian Shell model (GSM) shaping method. After a GSM beam is expanded through a beam expanding mirror and the size of a light spot is changed, the GSM beam vertically enters a first thin lens, and is focused on an amplitude attenuation piece. The light beam from the amplitude attenuation piece is outputted through a second film lens in a collimation manner, thereby obtaining a special part coherent beam. The method can achieve the simultaneous or independent modulation of the light intensity and coherence of the GSM beam, can obtain a result that the distribution of the light intensity and coherence is non-Gaussian distribution, and greatly increases the types of light beams. The invention also discloses a GSM shaping system.

Owner:SUZHOU UNIV

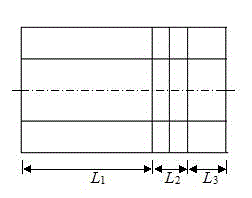

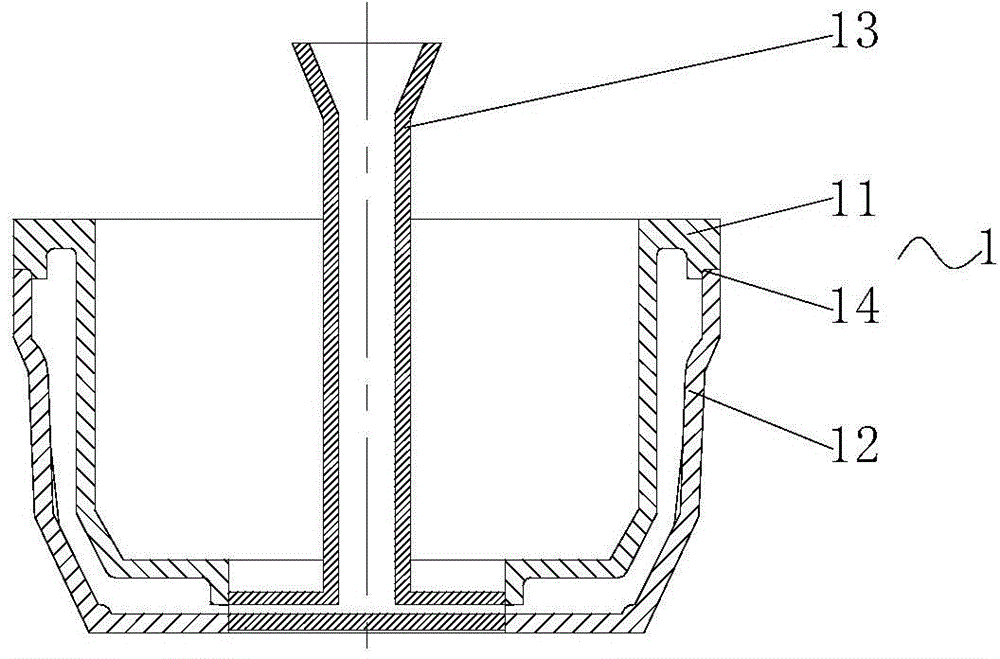

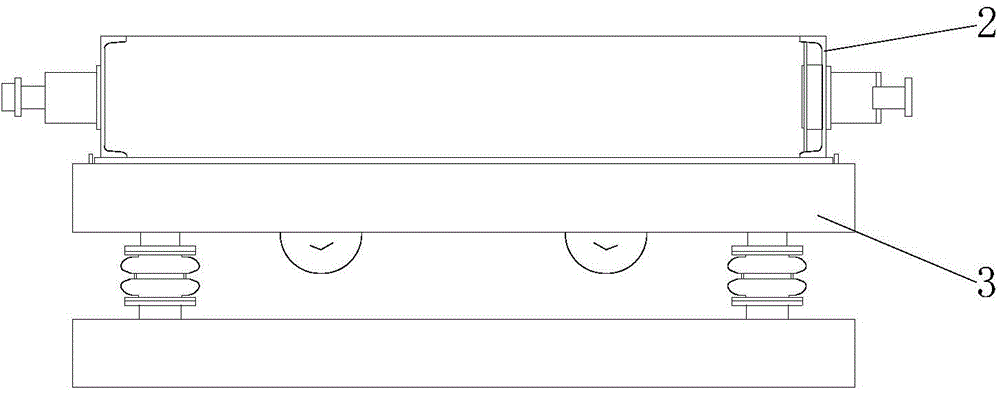

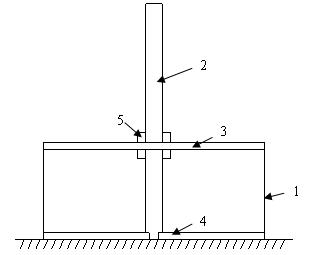

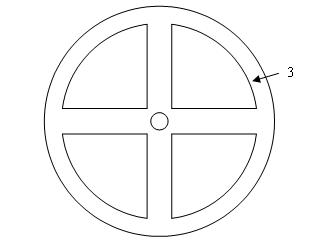

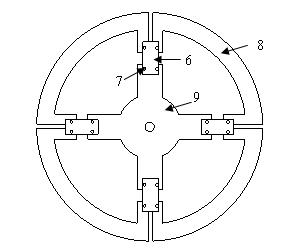

Boundary simulation device and method for thin-walled cylindrical shell structure experiment

The invention discloses a boundary simulation device and method for a thin-walled cylindrical shell structure experiment. The device comprises a central support bar, an upper ring plate and a detachable lower ring plate. A thin-walled cylindrical shell model is manufactured with the upper ring plate and the lower ring plate as templates, and a glass cement is coated on the bottom boundary of the thin-walled cylindrical shell model, The lower ring plate is shifted inward by loosening bolts on the detachable lower ring plate, and then the same glass cement is coated at the inner side of the model by a circle to create a bottom fixed boundary condition. The top of the thin-walled cylindrical shell model is fixed on the upper ring plate by adopting an aluminium strip at the top of the thin-walled cylindrical shell to create a top fixed boundary condition. The device can be detached flexibly, and plays the roles of serving as a template in the manufacturing process of a test piece and creating the bottom and the top boundary conditions for the test piece. The device can simulate a floating roof shell when the top boundary is loosened, and simulate a fixed roof shell when the top boundary is restrained.

Owner:ZHEJIANG UNIV

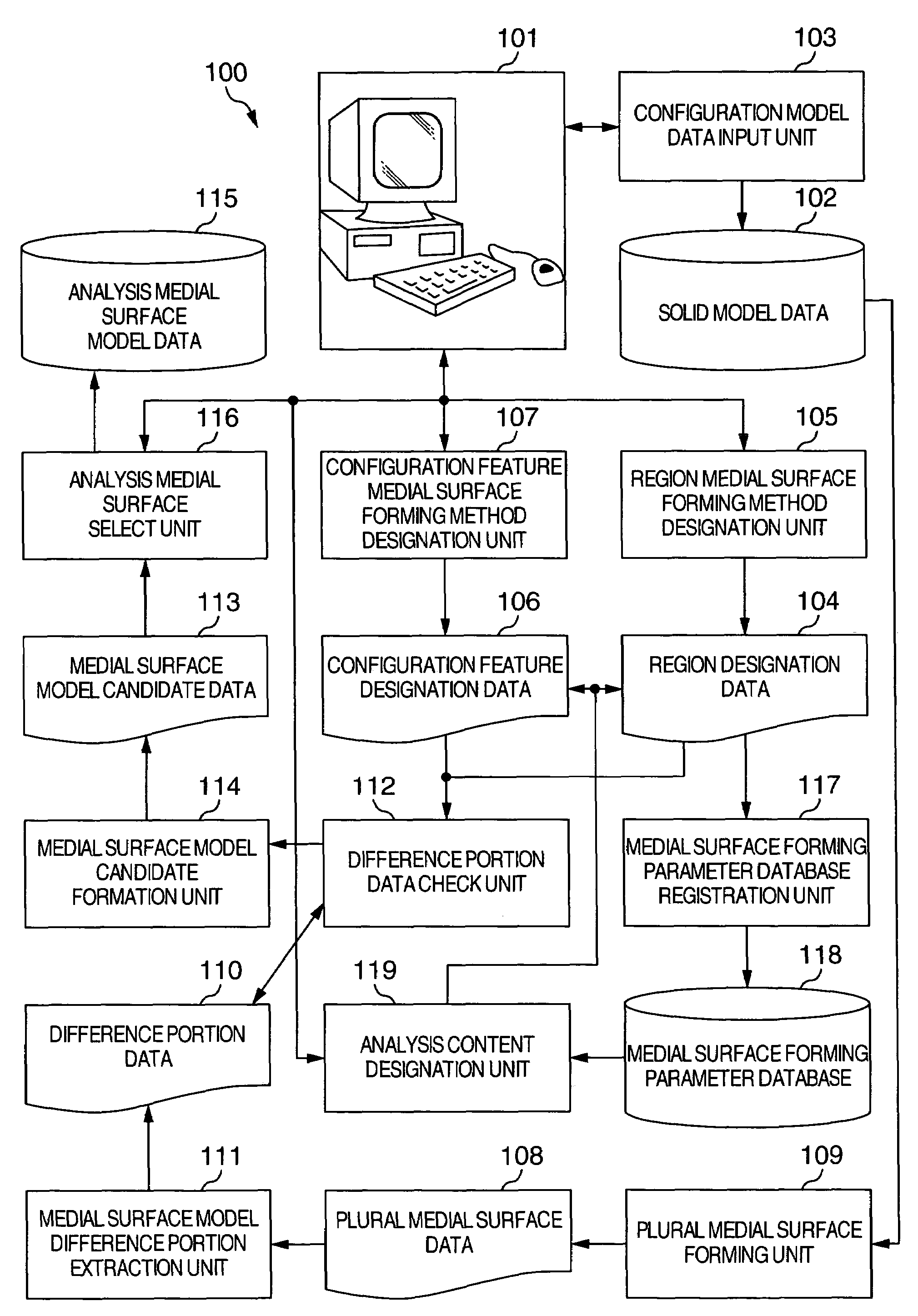

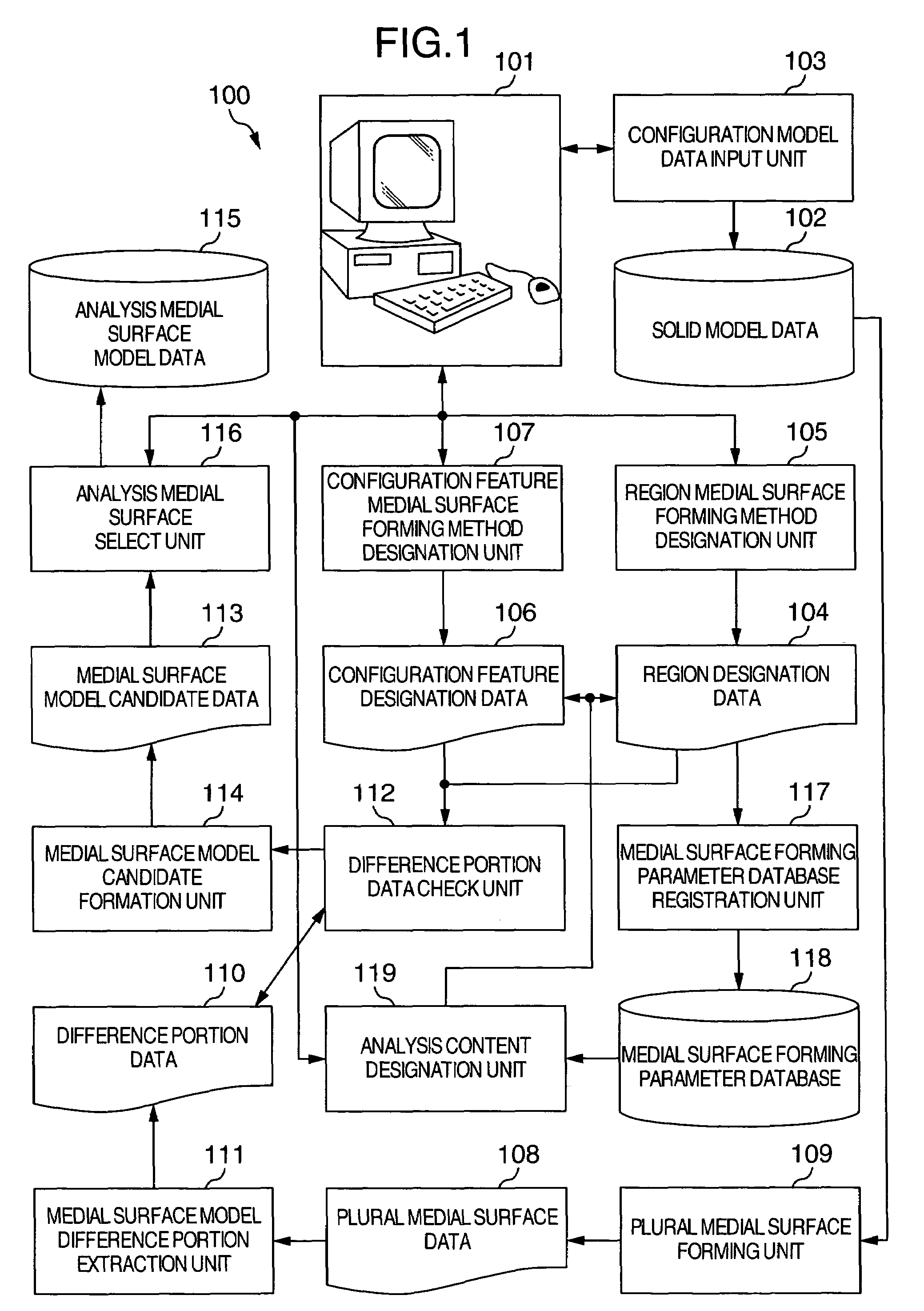

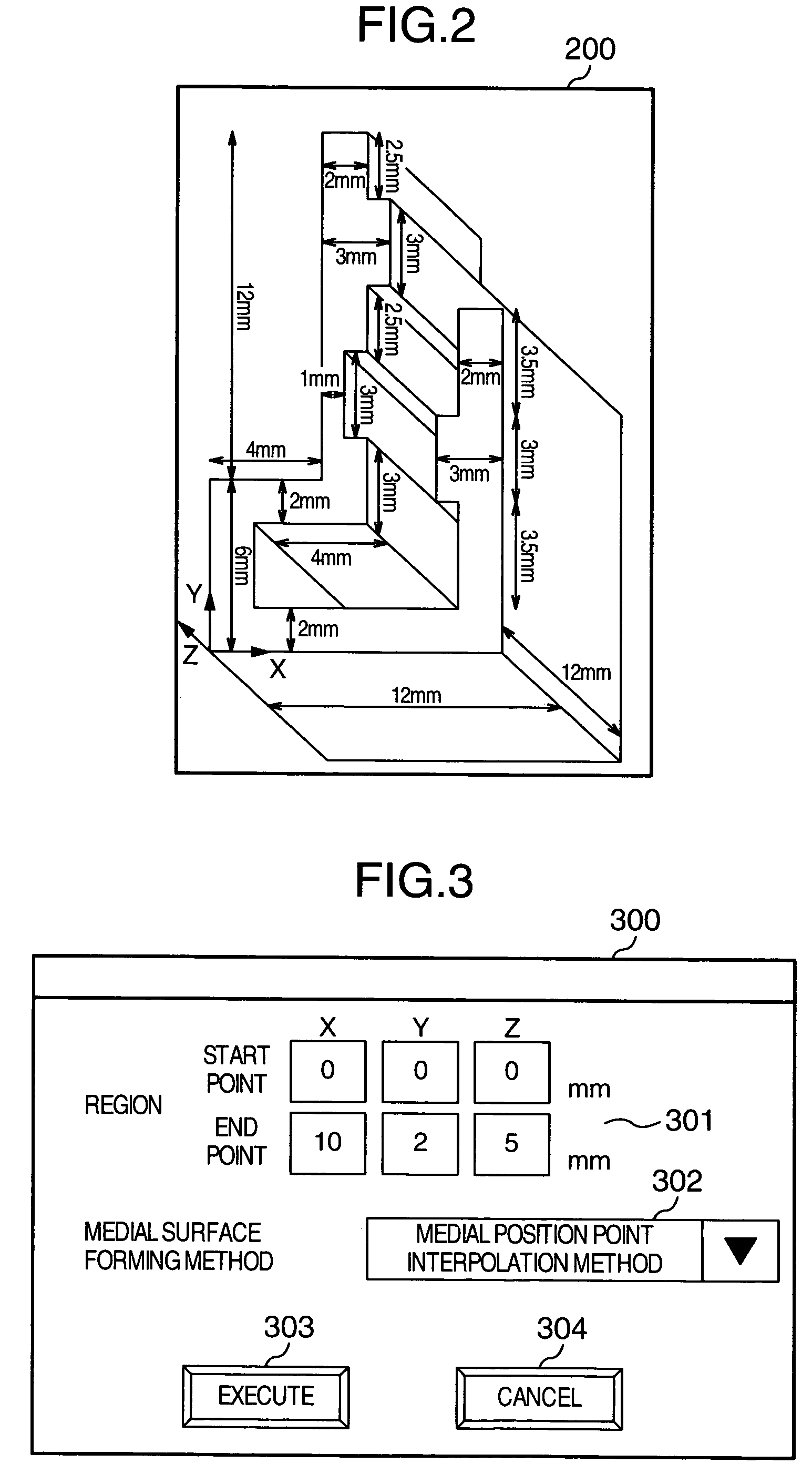

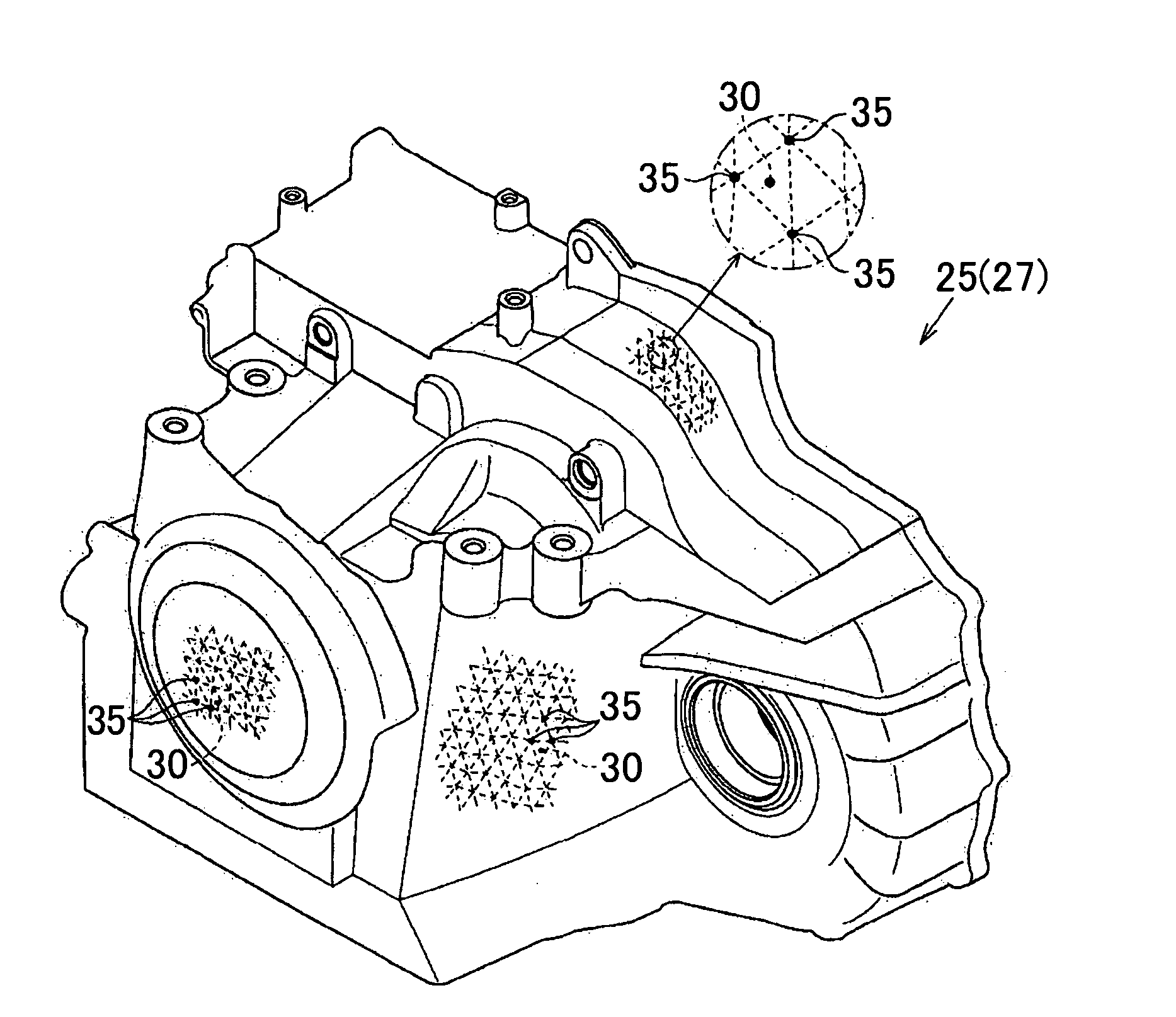

Analytical shell model forming apparatus

InactiveUS7363197B2High precisionShorten the timeDesign optimisation/simulationSpecial data processing applicationsMedial surfaceEngineering

An analytical shell model forming apparatus includes a medial surface forming unit for approximating a solid model to a plurality of shell models. An extracting unit compares a plurality of formed medial surface models and extracts difference portions. A model candidate forming unit forms a plurality of medial surface model candidates suitable for analysis by combining the extracted difference portions. A select unit selects a medial surface model matching boundary conditions, constraint conditions and the like from the plurality of model candidates. The selected medial surface model is presented to an operator as an analysis medial surface model.

Owner:HITACHI LTD

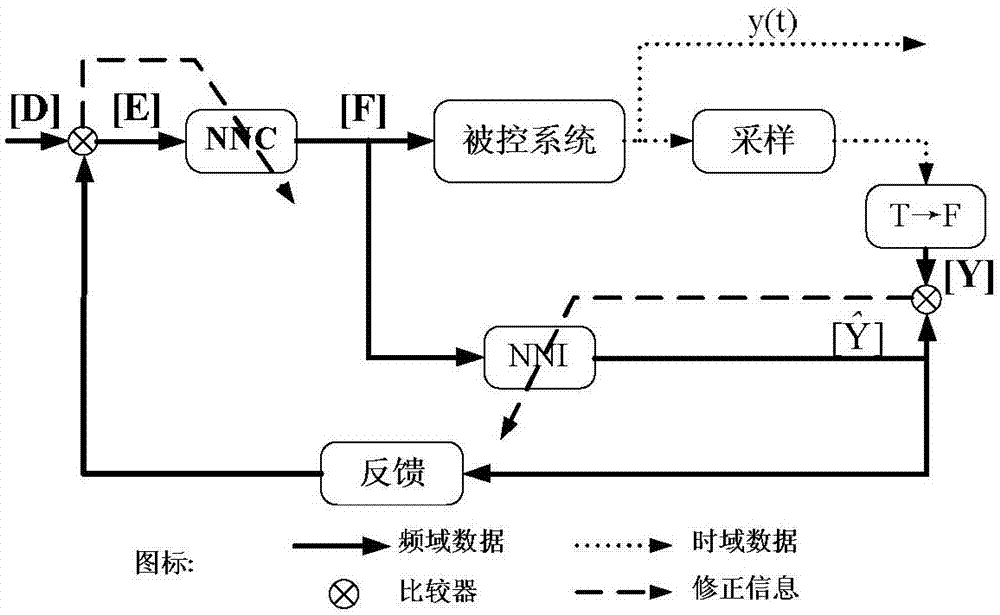

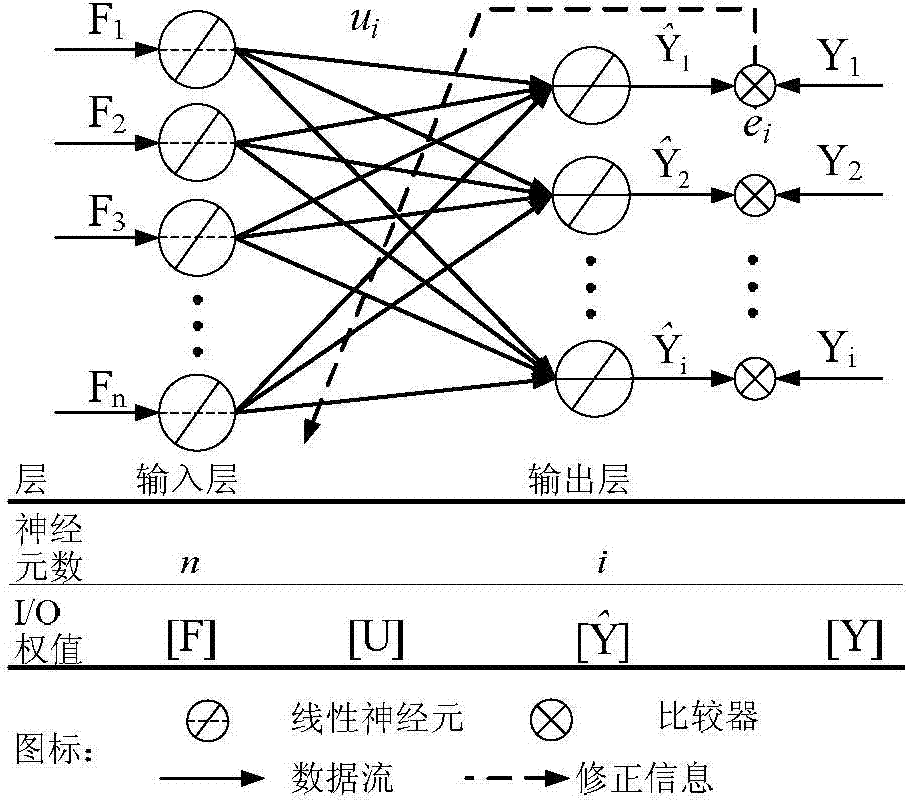

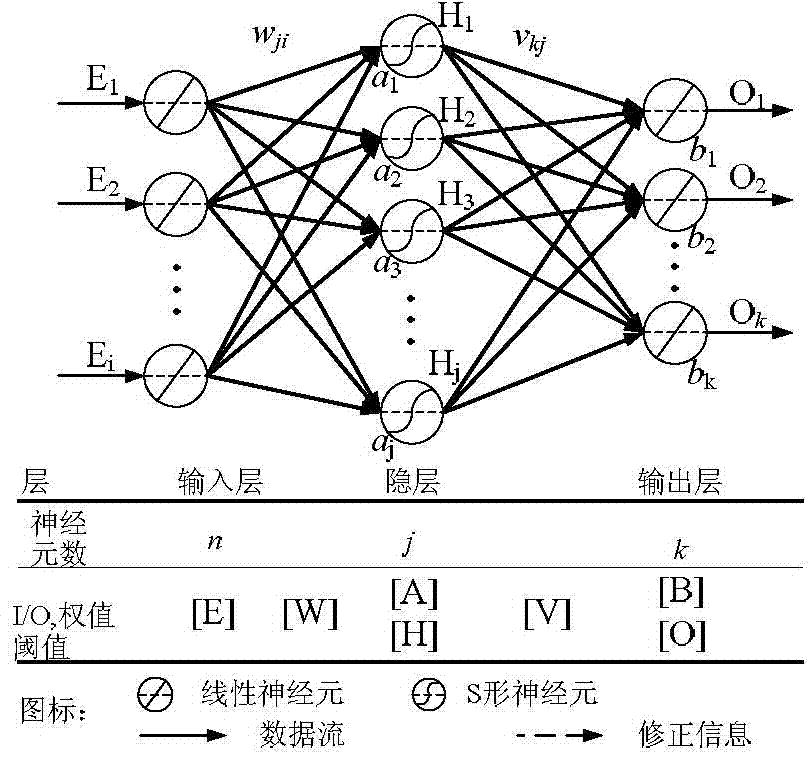

Method for controlling consistency of vibration of surfaces of shell structures on basis of neural networks

ActiveCN104238367AAchieve Vibration Consistency ControlEnhanced inhibitory effectAdaptive controlAlgorithmComputer module

The invention discloses a method for controlling the consistency of vibration of the surfaces of shell structures on the basis of neural networks. The method includes firstly, constructing vibration consistency control architectures on the basis of a neural network optimization algorithm; secondly, deducing weight and threshold iterative formulas of identifiers and controllers on the basis of a gradient descent process; thirdly, further computing global errors and frequency-point errors, combining the global errors and the frequency-point errors with one another and creating a novel error judgment criterion for judging difference between control effects and targets; fourthly, synchronously controlling the consistency of vibration response of multiple points of the surfaces of the shell structures so as to cooperatively controlling the vibration response of the multiple points of the surfaces of the shell structures. Each control architecture mainly comprises two core modules which are the corresponding identifier and the corresponding controller respectively, the identifiers are used for identifying controlled shell models and predicting the vibration response, and the controllers are used for implementing excitation parameter optimization and control targets. The weight and threshold iterative formulas are used for optimizing and updating loop parameters.

Owner:XI AN JIAOTONG UNIV

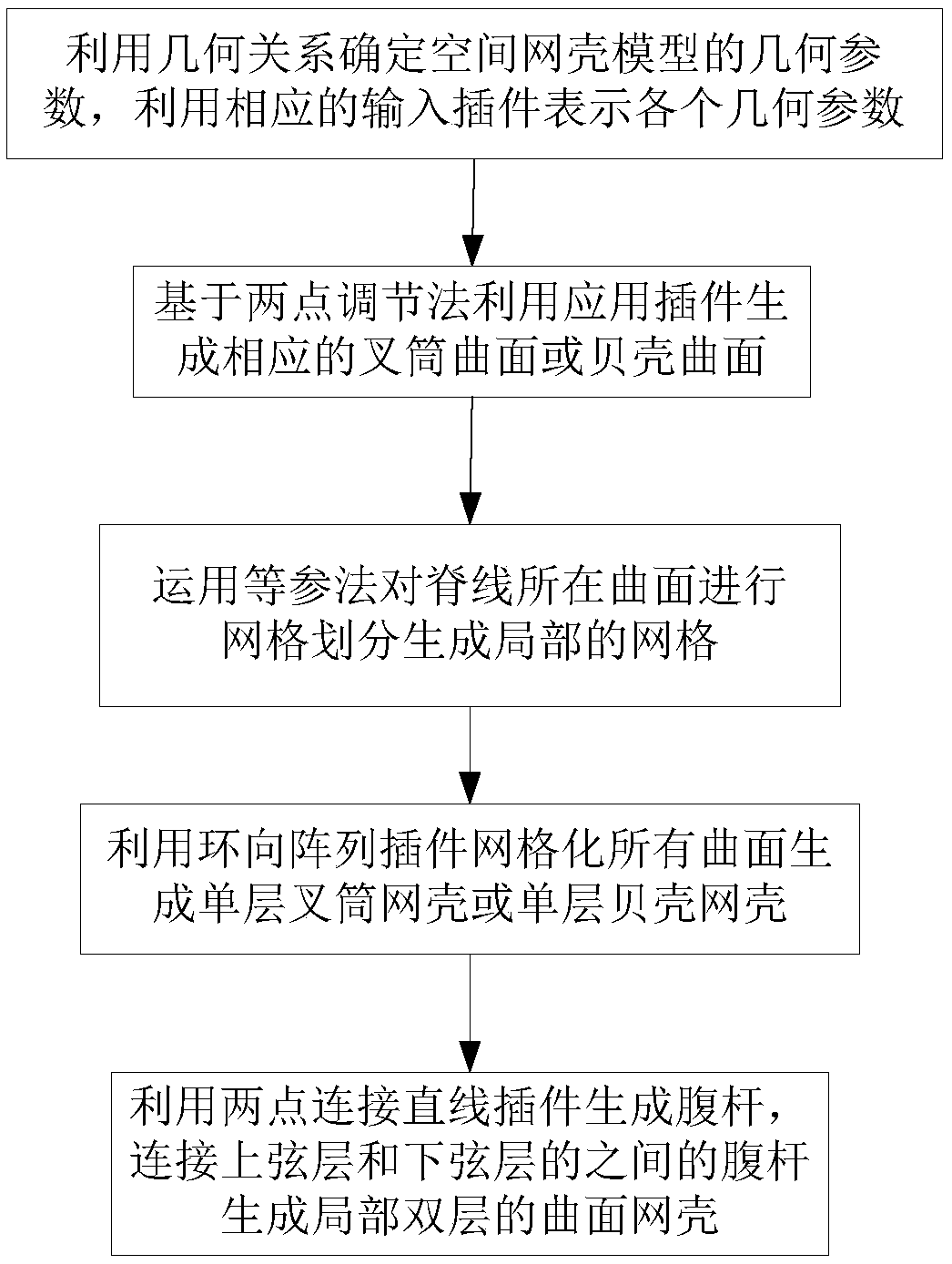

Parametric modeling method of spatial reticulated shell based on grasshopper

ActiveCN109165445ASpeed up the build processHigh speedGeometric CADDesign optimisation/simulationGrasshopperDesign software

The invention provides a parametric modeling method of a spatial reticulated shell based on grasshopper, which is used for solving the modeling difficulty of the existing complex-shaped spatial latticed shell structure, the modeling efficiency is low, and the repeated utilization ratio is low. The method comprises the following steps: determining the geometric parameters of the spatial lattice shell model by using the geometric relationship, and expressing each geometric parameter by using the corresponding input plug-in; based on the two-point adjustment method, generating the corresponding fork-cylinder surface or shell surface by using the application plug-in; using the isoparametric method to mesh the surface of the ridge to generate the local mesh; generating a single-layer fork-cylinder reticulated shell or a single-layer shell reticulated shell by gridding all the curved surfaces of the ring array plug-in. The invention can greatly improve the generation and modification speed of the model by using the parametric modeling, and improves the working efficiency. The design method is simple and efficient. It is very convenient for the analysis and optimization of spatial latticed shell structure with complex shape under different types and different parameters by using finite element design software.

Owner:HENAN ENG DESIGN CONSULTANTS OF CSCEC

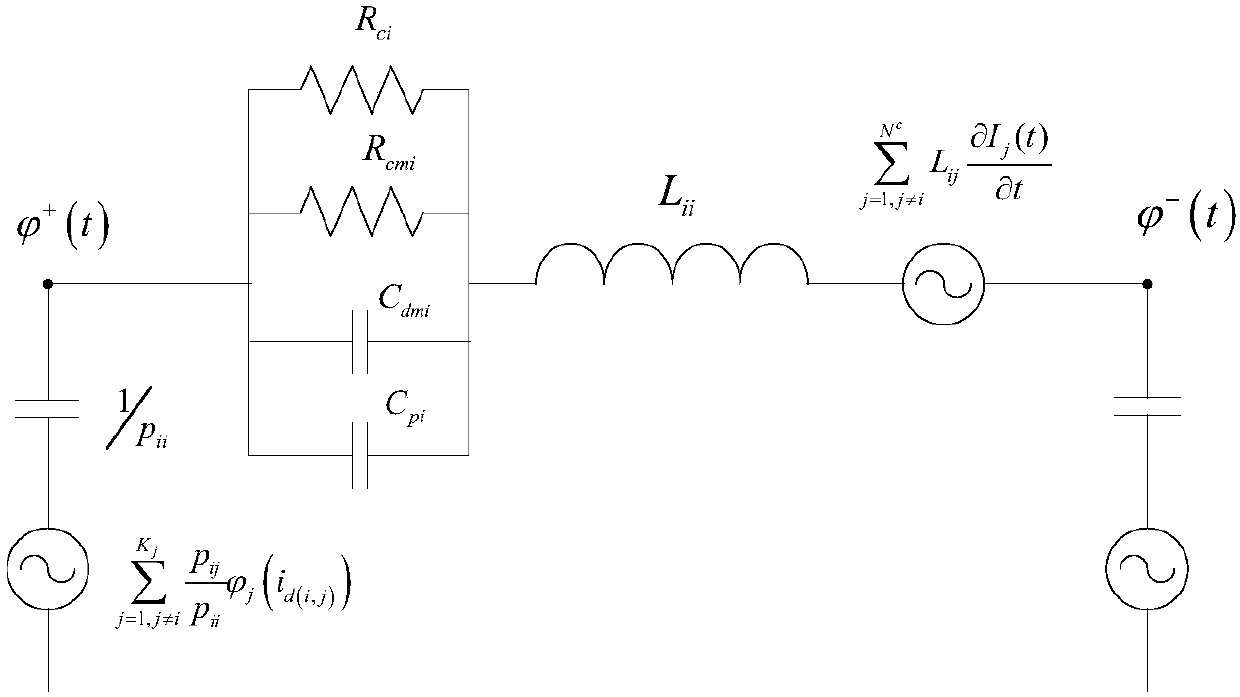

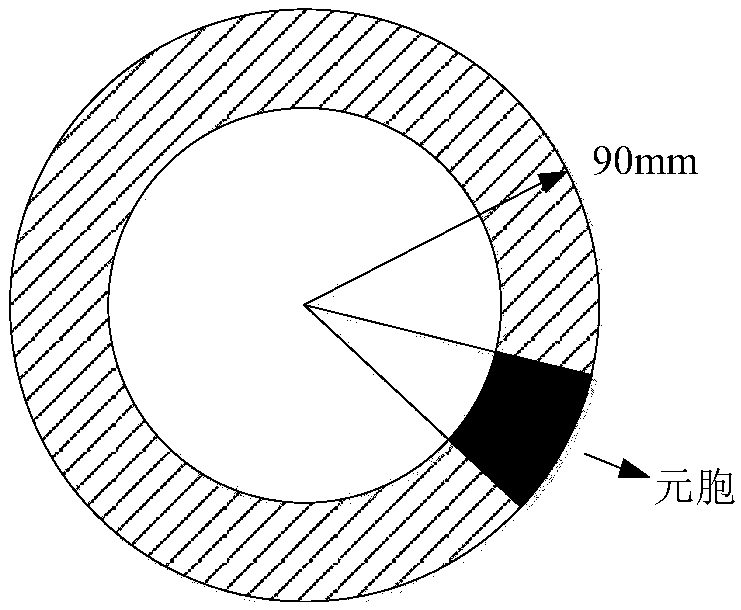

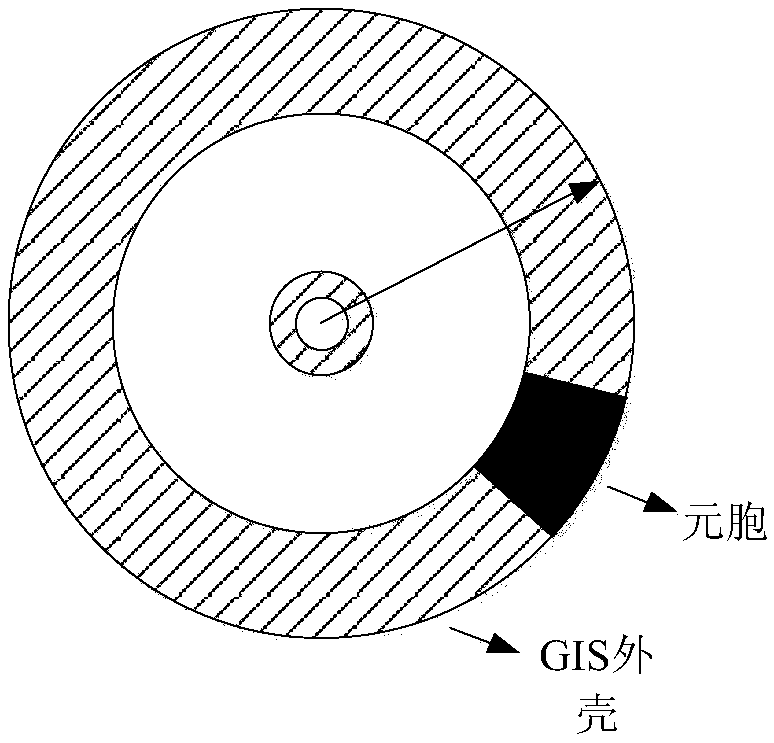

GIS (Gas Insulated Switchgear) shell circulating current and transient grounding potential rise (TGPR) modeling and analysis method based on PEEC method

InactiveCN107846013ASimple processSuppressed circulationSpecial data processing applicationsAc network circuit arrangementsTransient stateGrounding grid

The invention discloses a GIS (Gas Insulated Switchgear) shell circulating current and transient grounding potential rise (TGPR) modeling and analysis method based on a PEEC method. On the basis of the circulating current and transient grounding potential rise generation mechanism in the GIS system, the PEEC method is adopted to build a GIB busbar and shell model, an equivalent model is further built for simulation, the relation curve between amplitude of GIS inter-phase circulating current and grounding grid circulating current and a grounding point is obtained, and according to the relationcurve, influence factors for the shell circulating current and the TGPR are determined. Power grid protection and control adjustment are facilitated.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

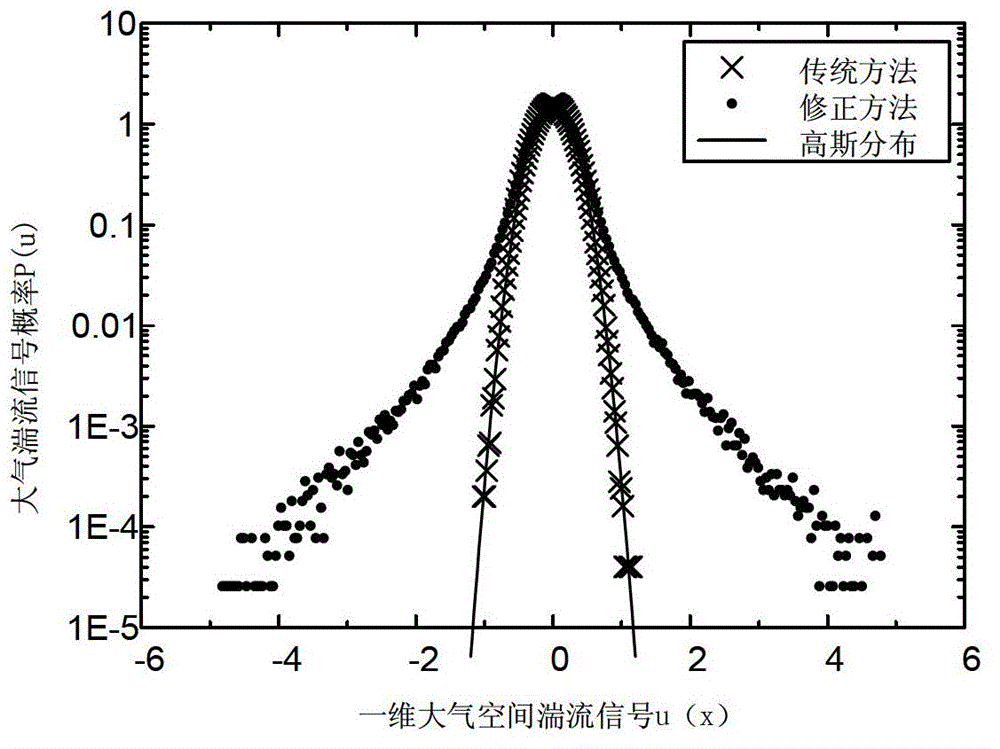

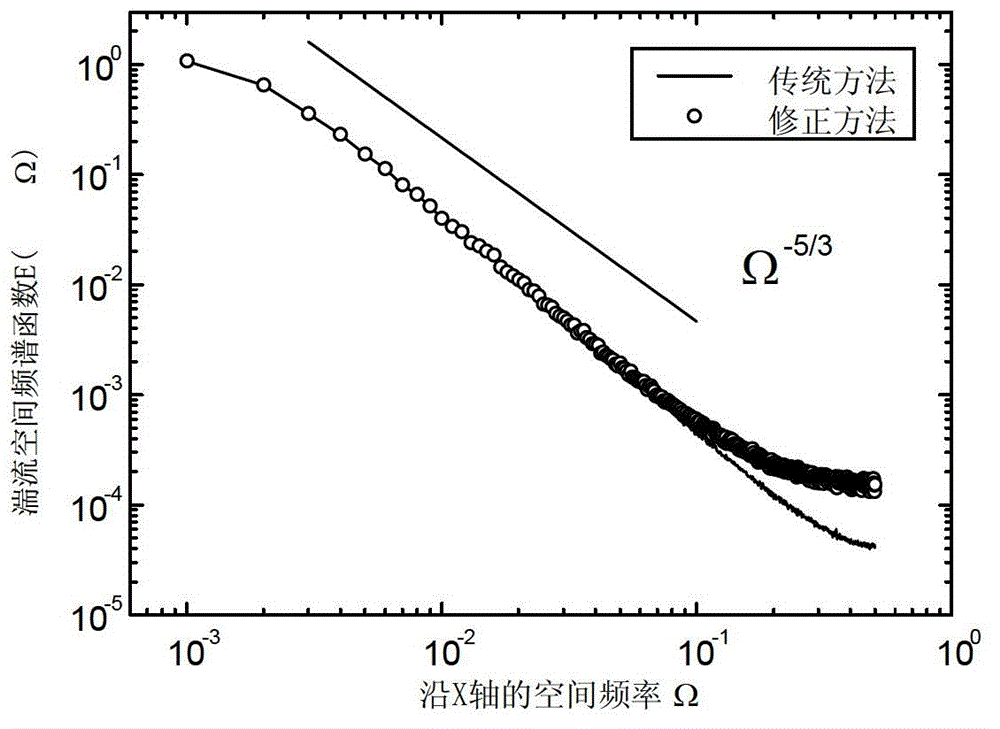

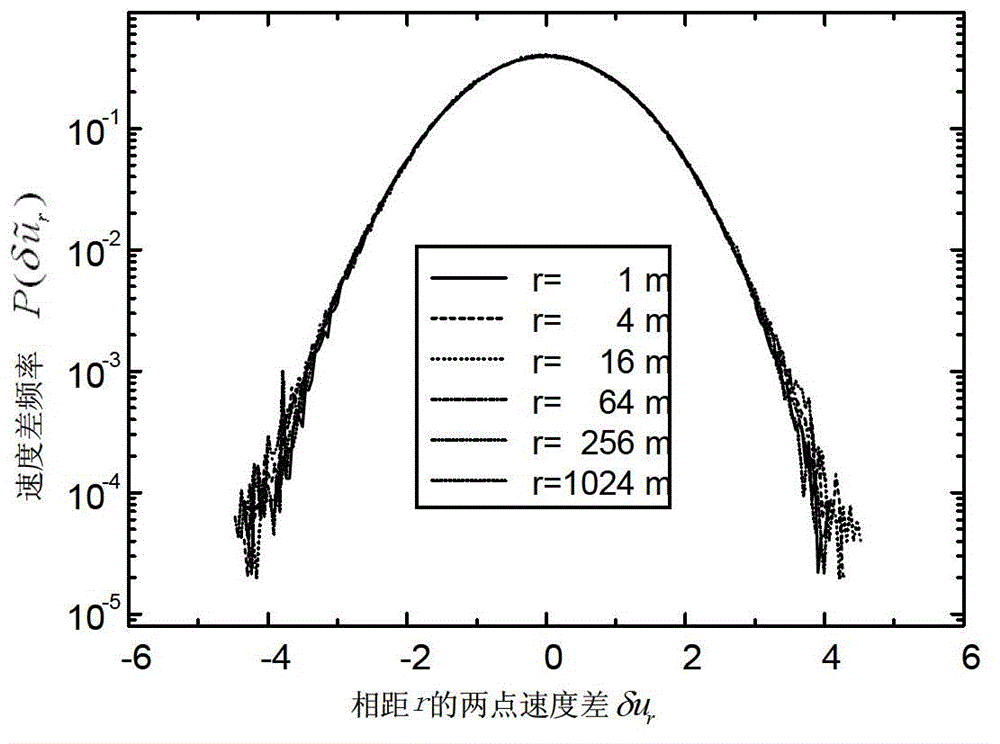

Method for correcting numerical simulation of atmospheric turbulences

InactiveCN102915391AIn line with the actual atmospheric turbulence characteristicsSustainable transportationSpecial data processing applicationsAviationEnergy transfer rate

The invention discloses a method for correcting numerical simulation of atmospheric turbulences and belongs to the field of interdisciplinary branches of aviation and mechanics. The method includes: firstly, implementing numerical simulation of atmospheric turbulences for a traditional Dryden model by iteration; secondly, performing shell model numerical simulation to obtain a physical quantity capable of reflecting turbulence singular scale features, namely energy transfer rate; and thirdly, introducing the energy transfer rate and correcting the traditional Dryden model numerical simulation signals. The defects of traditional atmospheric turbulence signals are made up, the actual features of atmospheric turbulences are more conformed, and more reasonable atmospheric turbulence signals can be provided for simulation modeling of a flight simulation system of a flight simulator.

Owner:BEIHANG UNIV

Steel structure box girder simulation method

InactiveCN109356018AUnderstanding Internal Force DeformationUnderstand force changesBridge structural detailsBridge erection/assemblyWireless transmissionCrucial point

The invention provides a steel structure box girder simulation method. The method comprises the following steps of 1, erecting a steel box die, wherein framework modeling, box beam shell modeling andbox beam transverse clapboard modeling are involved; 2, utilizing software for secondary development to quickly generate a model; 3, utilizing a program for generating a 3D axis, a horizontal curve and a key sectional sketch for the steel box beam; 4, utilizing the program for automatically completing overall erection of the steel box beam model; 5, selecting an optimal result for installation, and meanwhile, updating key data in real time in the installing process. Based on a BIM technology and numerical simulation, a wireless transmission technology is utilized for selecting key points whichcan reflect the actual state of the steel box beam and control the safety of the steel box beam, and thus internal force deformation of beam sheets in the hoisting process and stress change of structures in the hanging process are timely and accurately known. By analyzing monitored data and grasping the change rule, the whole process of hanging and installing the steel box beam is guided, and smooth proceeding of construction is ensured.

Owner:CHONGQING CONSTR RESIDENTIAL ENG +1

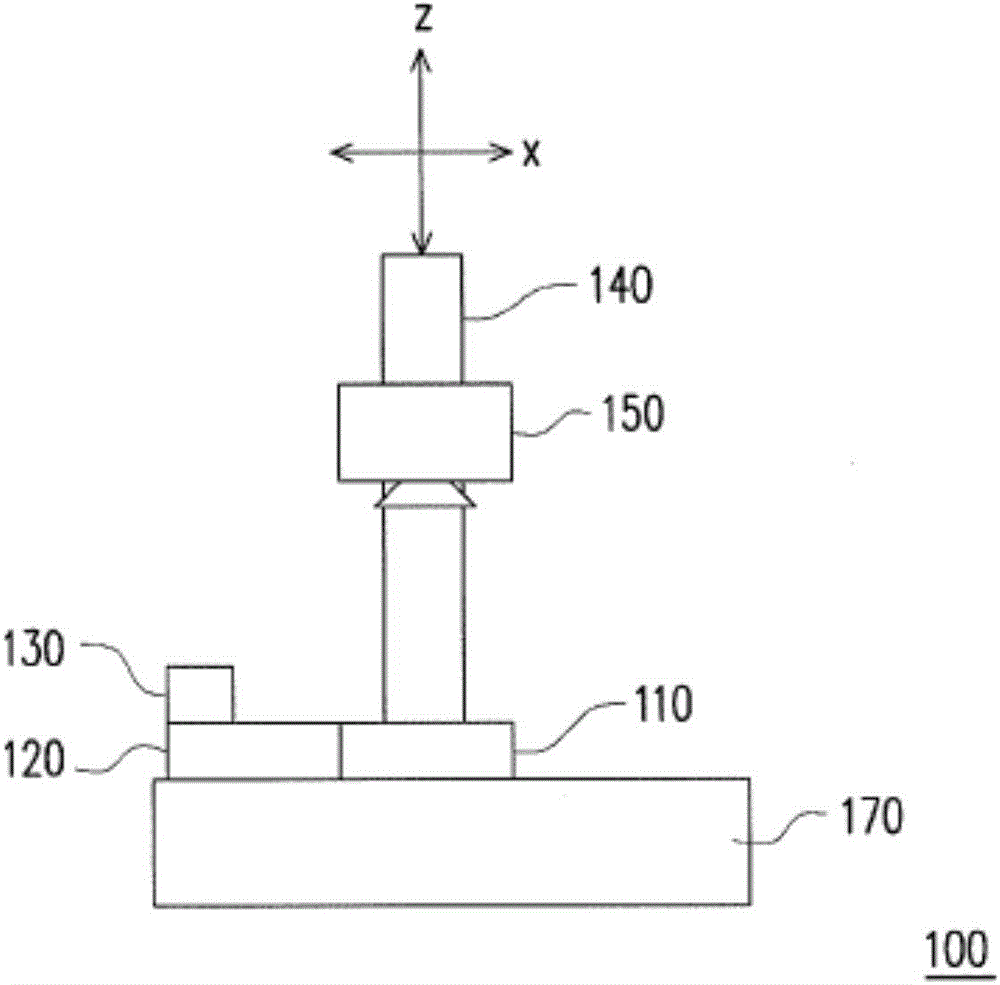

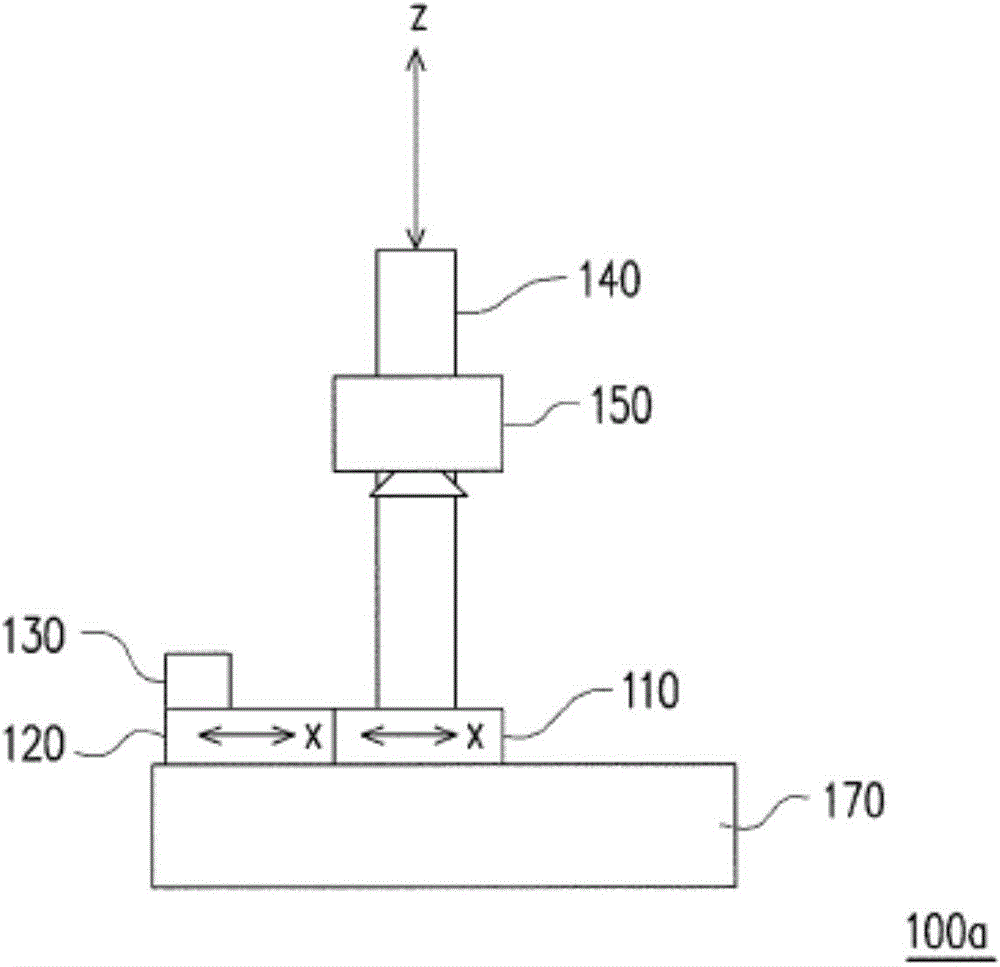

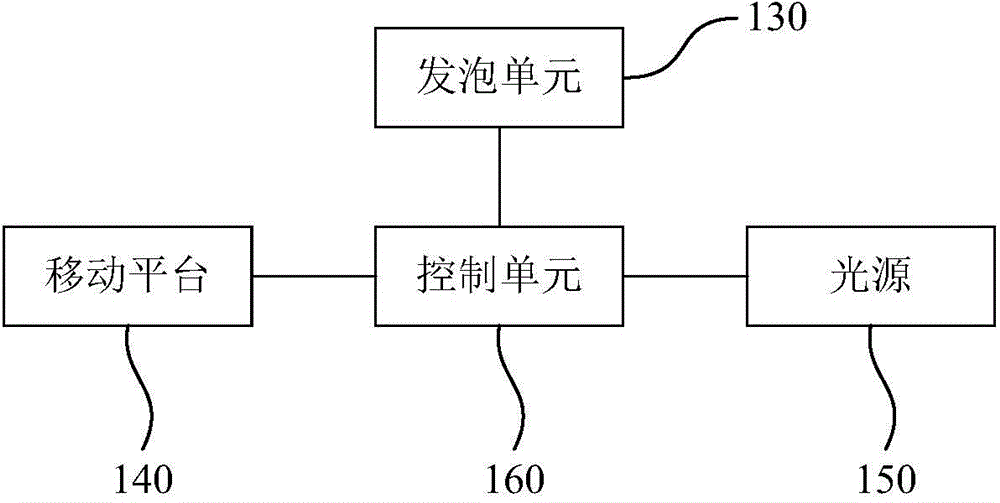

Three-dimensional printing apparatus and method for three-dimensional printing

InactiveCN105563820AReduce usageImprove structural rigidityAdditive manufacturing apparatus3D object support structuresSHELL model3D printing

A method for three-dimensional printing for forming a three-dimensional structure on a moving platform is provided. The three-dimensional structure includes a shell portion and a foamy filling portion. The method includes the following: a digital shell model of the three-dimensional structure is built. Next, the digital shell model is sliced into a plurality of cross-section information. Next, a corresponding liquid forming material is cured on the moving platform according to the cross-section information to form a plurality of shell layers. Next, foaming process is performed on the liquid forming material to form a foamy forming material. Next, the foamy forming material located within the corresponding shell layers is cured to form a plurality of foamy filling layers. Afterward, the shell layers and the foamy filling layers are alternately formed on the moving platform and stacked to form the three-dimensional structure. A three-dimensional printing apparatus adopting the method is also provided.

Owner:XYZPRINTING +2

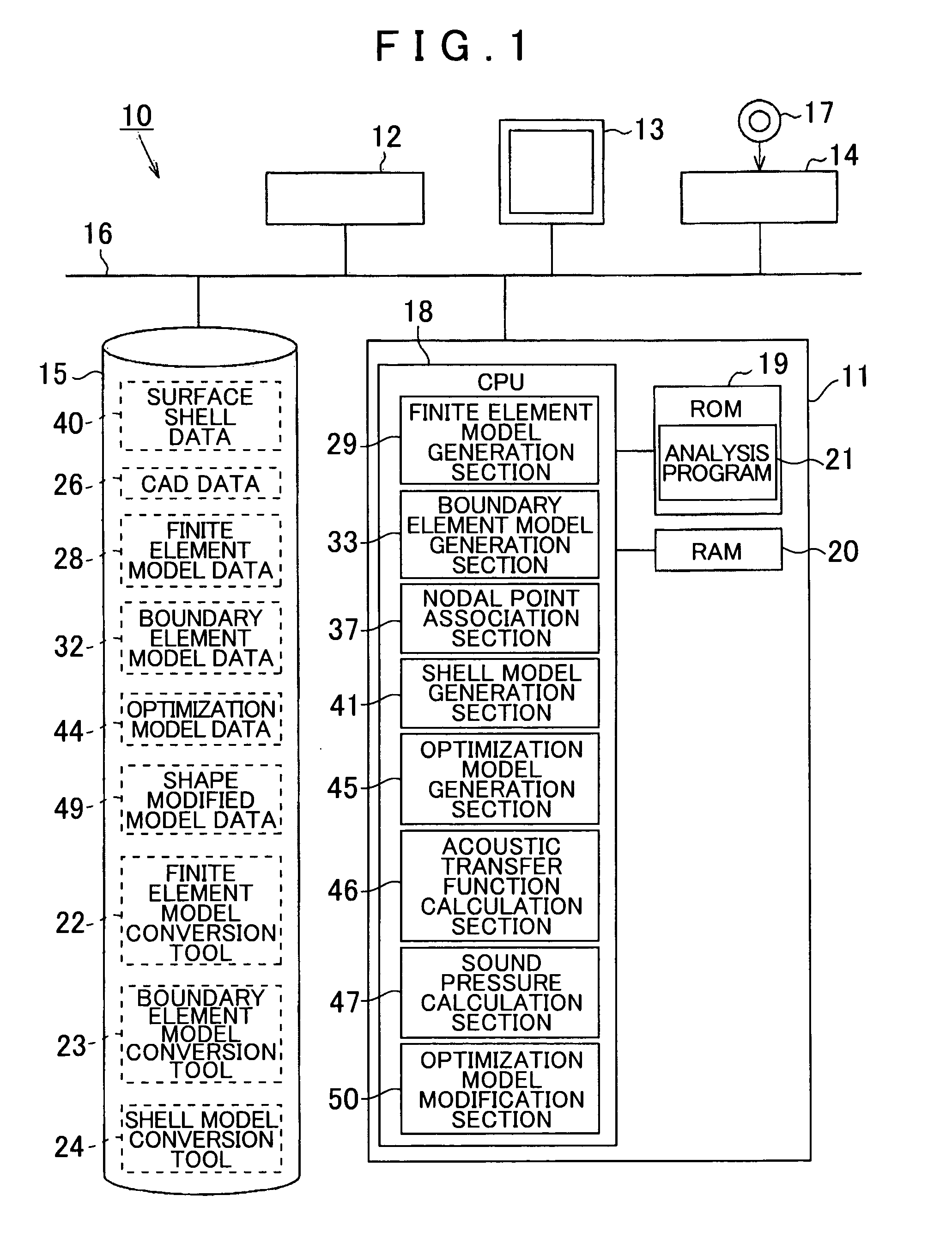

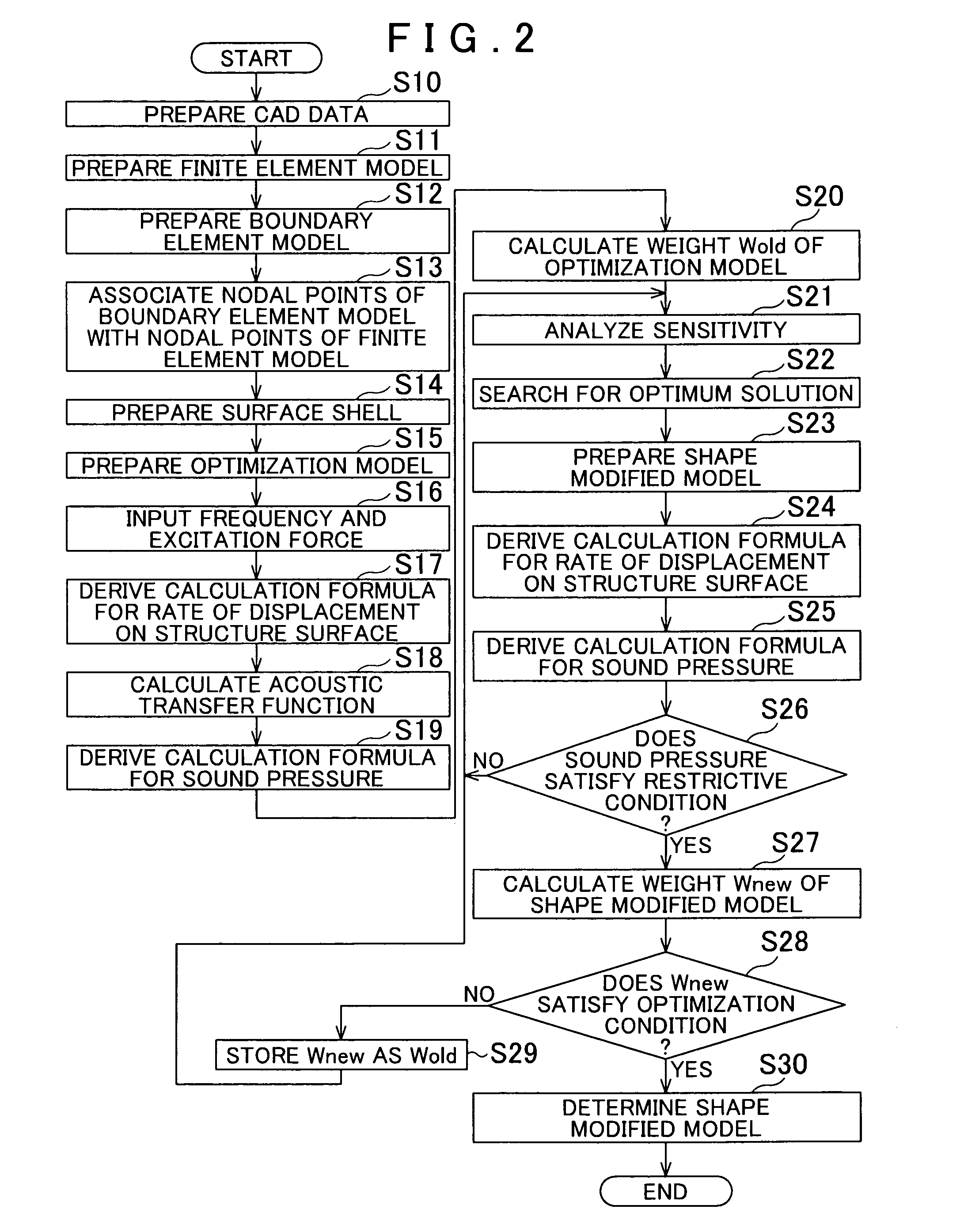

Apparatus, method, and program for optimization model analysis

InactiveUS20110125464A1Weight increaseReduce weightGeometric CADDesign optimisation/simulation3d shapesNODAL

An optimization model analysis apparatus configured with a finite element model generation unit that generates on the basis of a structural configuration of a design model having a 3D shape a finite element model for analyzing acoustic characteristics of the design by a finite element method. The apparatus is configured with a shell model generation unit that generates a model by dividing a surface of the finite element model into a plurality of plate elements having a polygonal shape; an optimization model generation unit that superimposes the shell model on the surface of the finite element model to generate an optimization model; and an optimization model modification unit that displaces nodal points which serve as vertexes of the plate elements in a direction intersecting a plane of the plate elements by displacing at least one of the nodal points in a direction of reducing a thickness of the optimization model.

Owner:AISIN AW CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com