Method for detecting air gap on a blast furnace shell

A blast furnace shell and air gap technology, which is applied in the detection field of blast furnace shell air gap, can solve the problems of lack of management tools and technical means, the timeliness, accuracy and comprehensiveness of furnace shell longevity management cannot be guaranteed, and achieve The effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

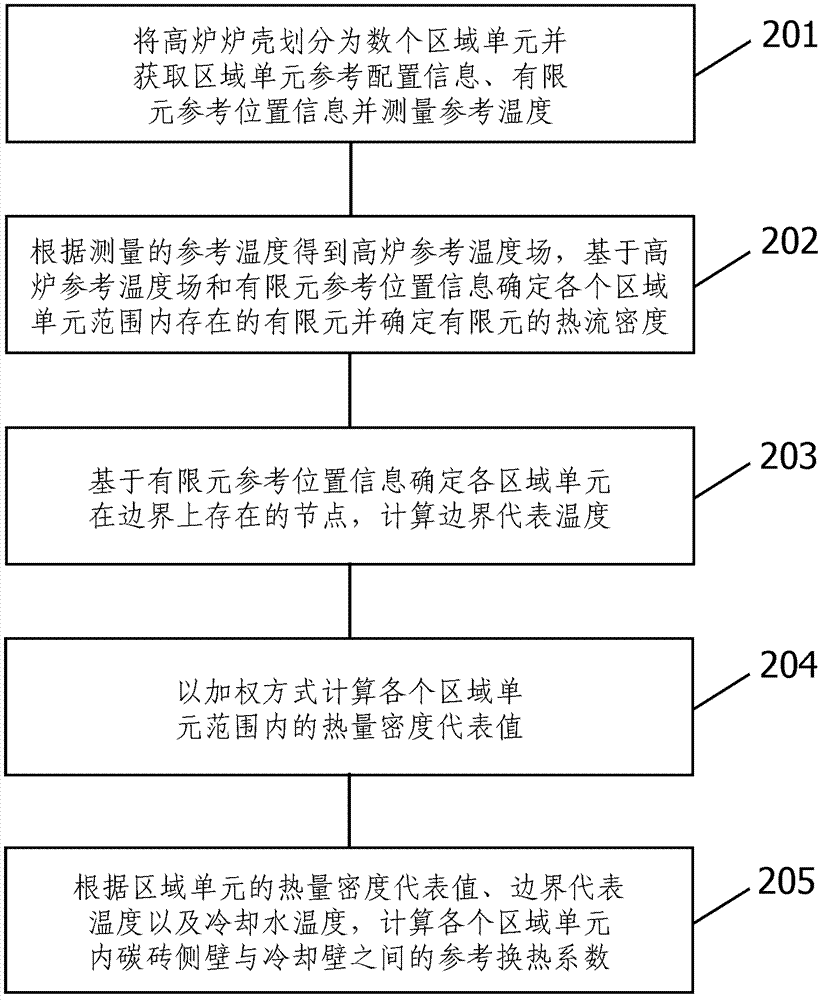

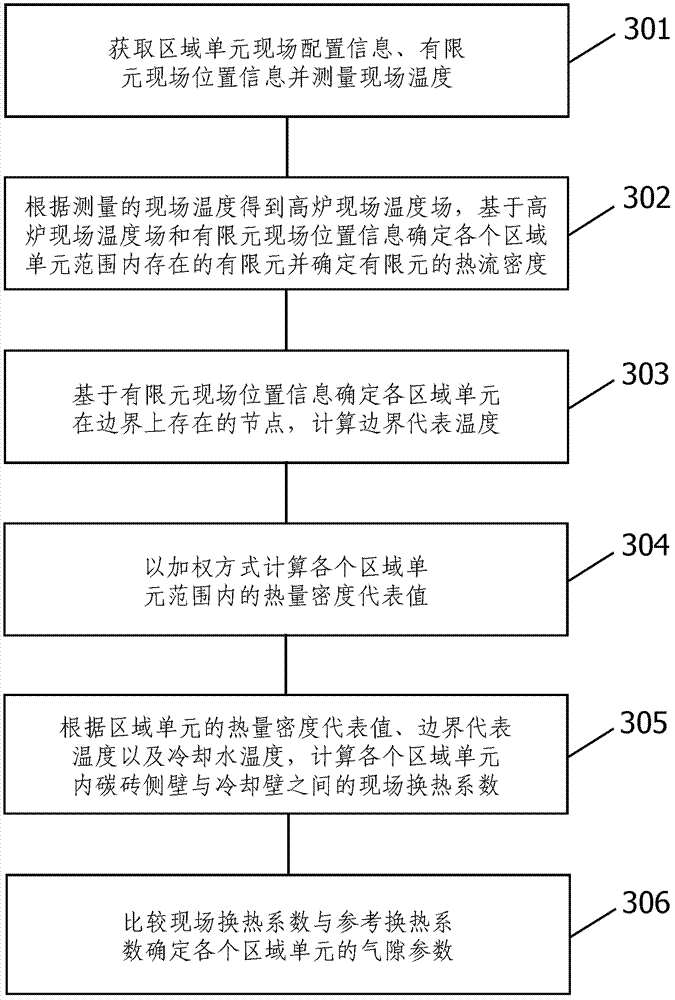

[0028] In blast furnace production, due to the slow change of the heat transfer state of the furnace shell, the furnace shell is considered to be in a steady state of heat transfer. According to the theory of heat transfer, based on the thermocouple information and the properties of the refractory material of the furnace shell, the erosion line of the refractory material of the furnace shell is calculated , The position of the solidification line, and the temperature field in the refractory material of the furnace shell can be simulated and calculated. Based on the finite element results of the temperature field of the side wall of the furnace shell, the present invention comprehensively calculates the determination index of the air gap of the side furnace shell to reflect the probability and size of the air gap of the furnace shell.

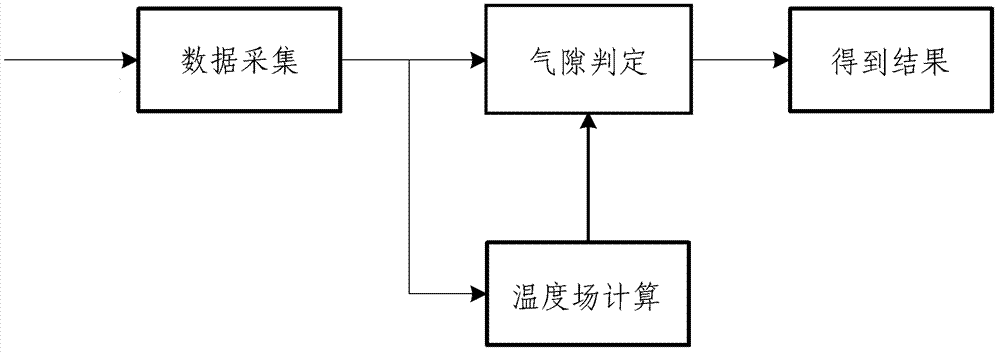

[0029] figure 1 The realization principle of the detection method for the blast furnace shell air gap according to an embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com