Patents

Literature

1149results about "Checking devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

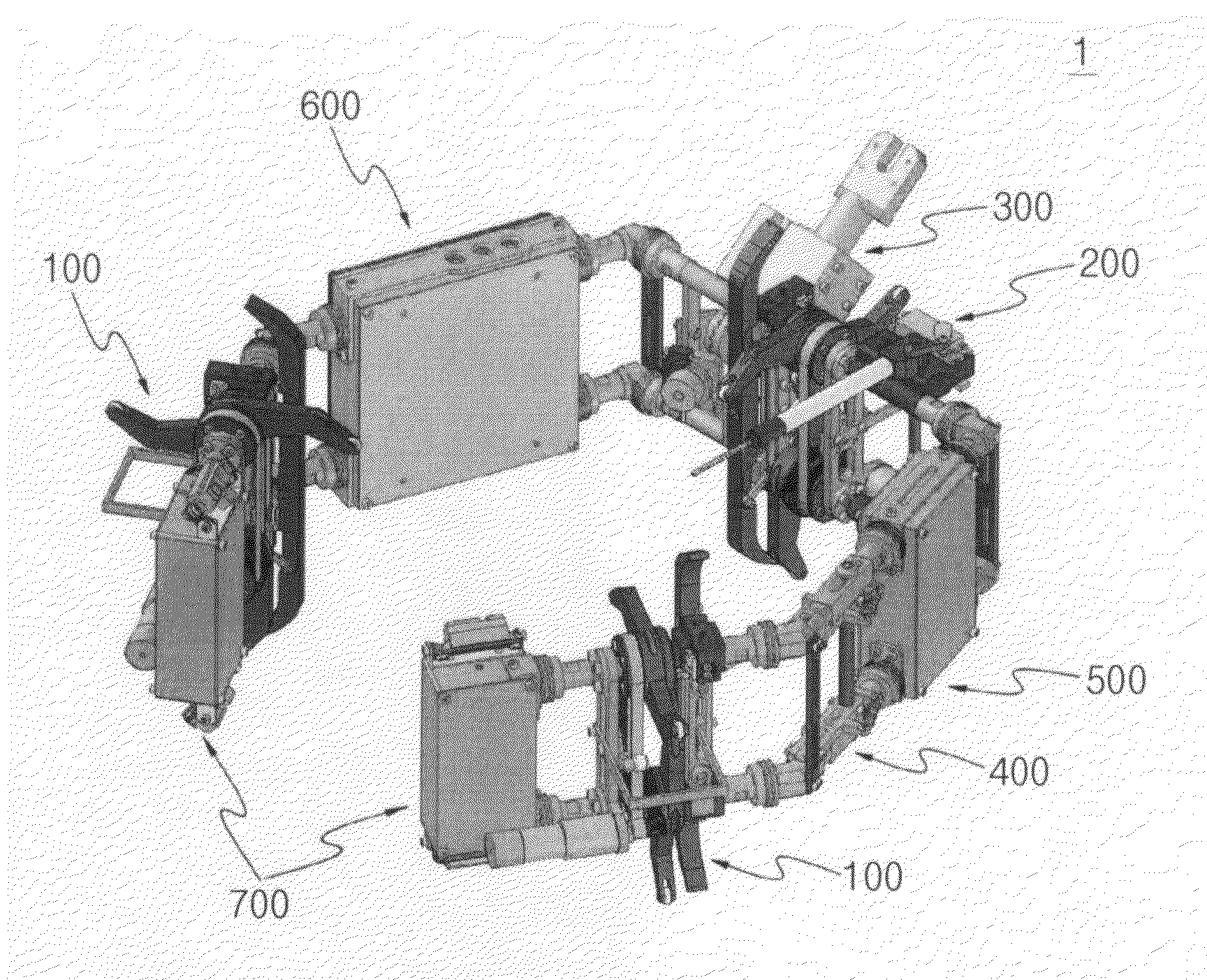

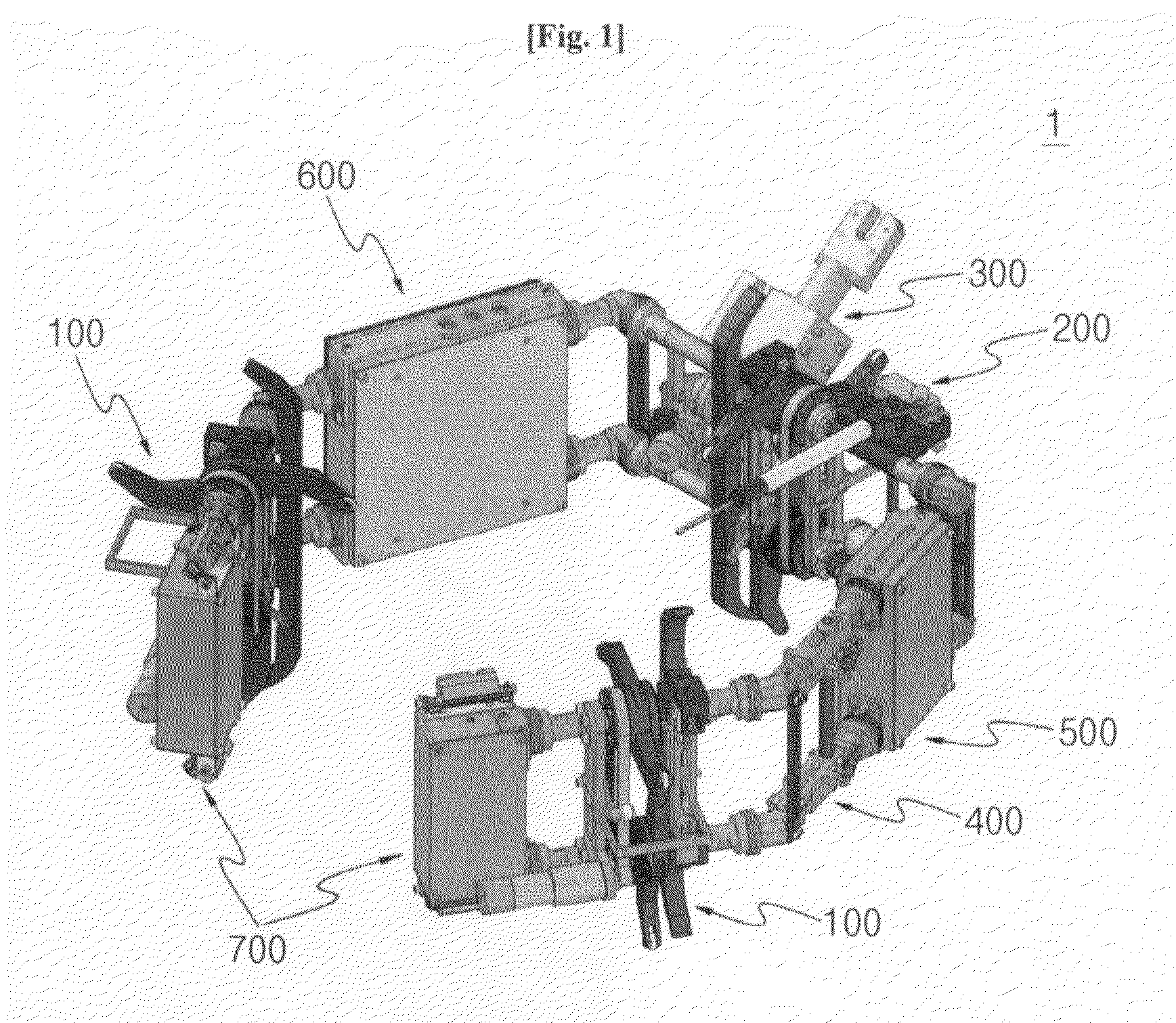

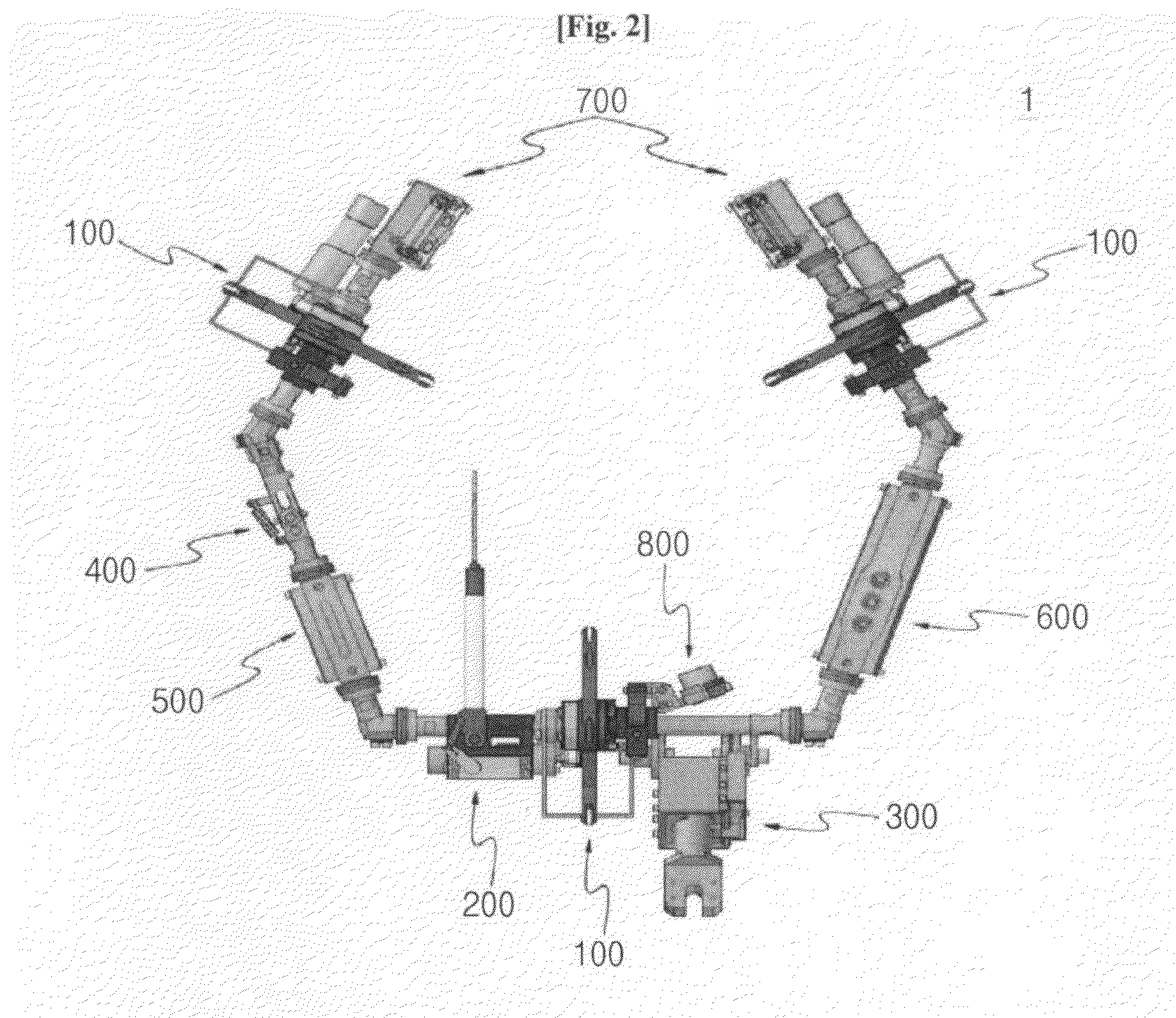

Robot mechanism for inspection of live-line suspension insulator string

ActiveUS20100100239A1Inspection is accurateProgramme controlVibration measurement in solidsControl theoryElectric wire

Disclosed herein is a robot mechanism for inspection of a live-line suspension insulator string. A robot body of the robot mechanism reciprocates along the live-line suspension insulator string and includes upper and lower robot frames configured to encircle the insulator string, a battery module provided to either end of the robot body, an actuation module for moving the robot body along the insulator string, an inspection module for electrically inspecting an insulator, a connection module for coupling the robot body to an installation / dismantlement mechanism, a wing opening / closing module for manually separating the robot body from the insulator string, a measurement module for measuring electrical properties of the insulator, a controller for controlling operation of the robot body, and a crack detection unit for detecting cracks formed in the insulator.

Owner:KOREA ELECTRIC POWER CORP

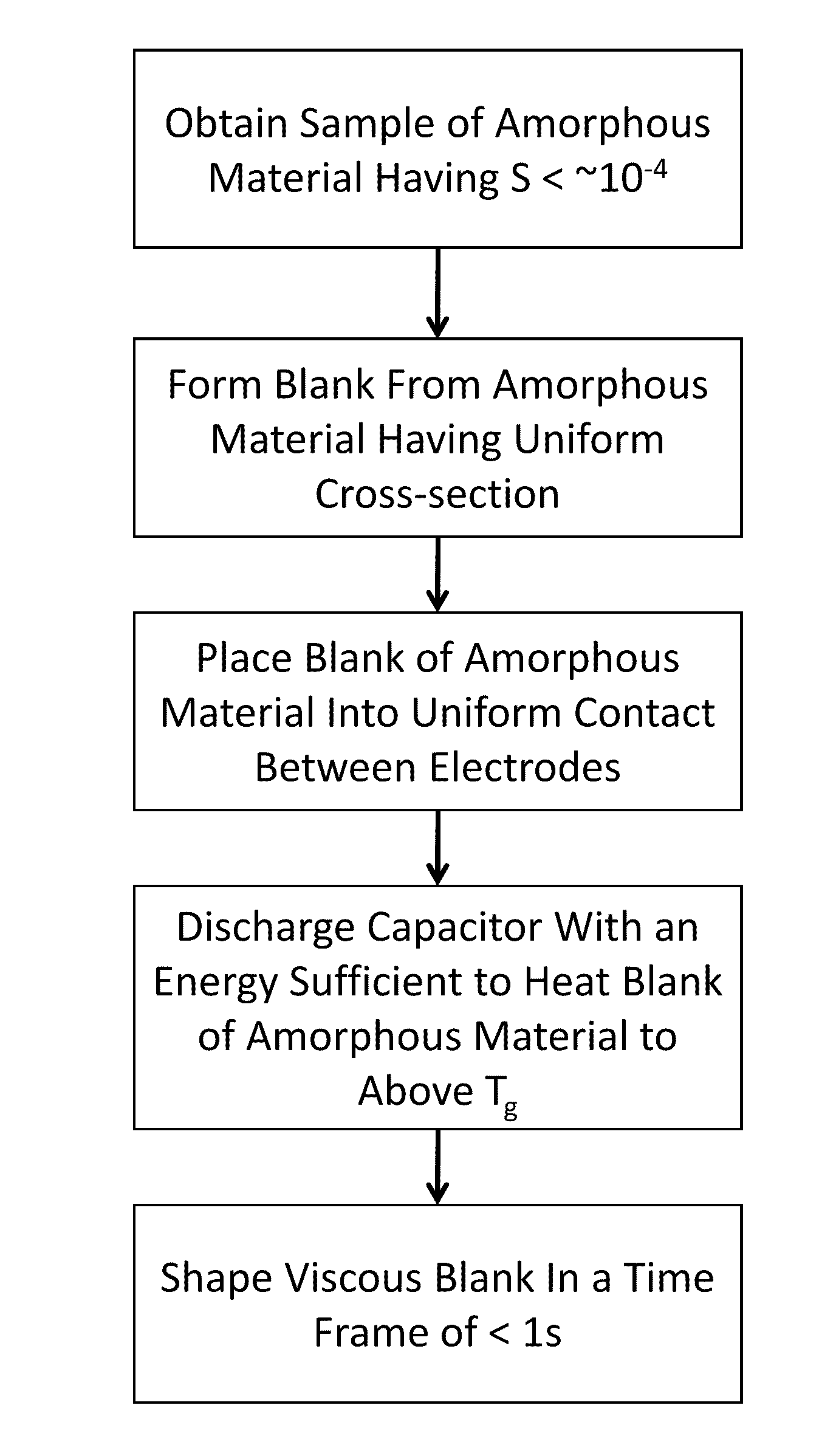

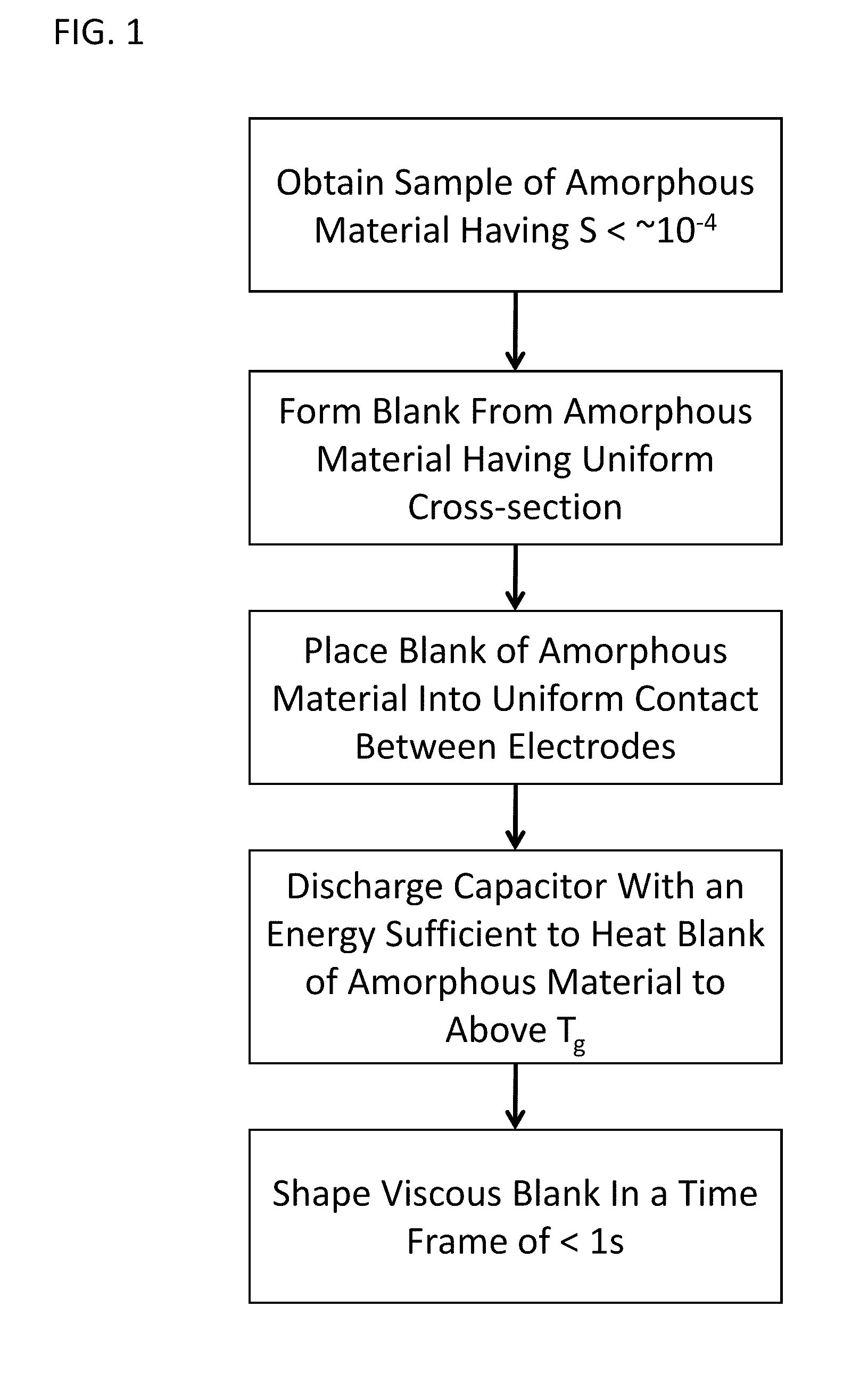

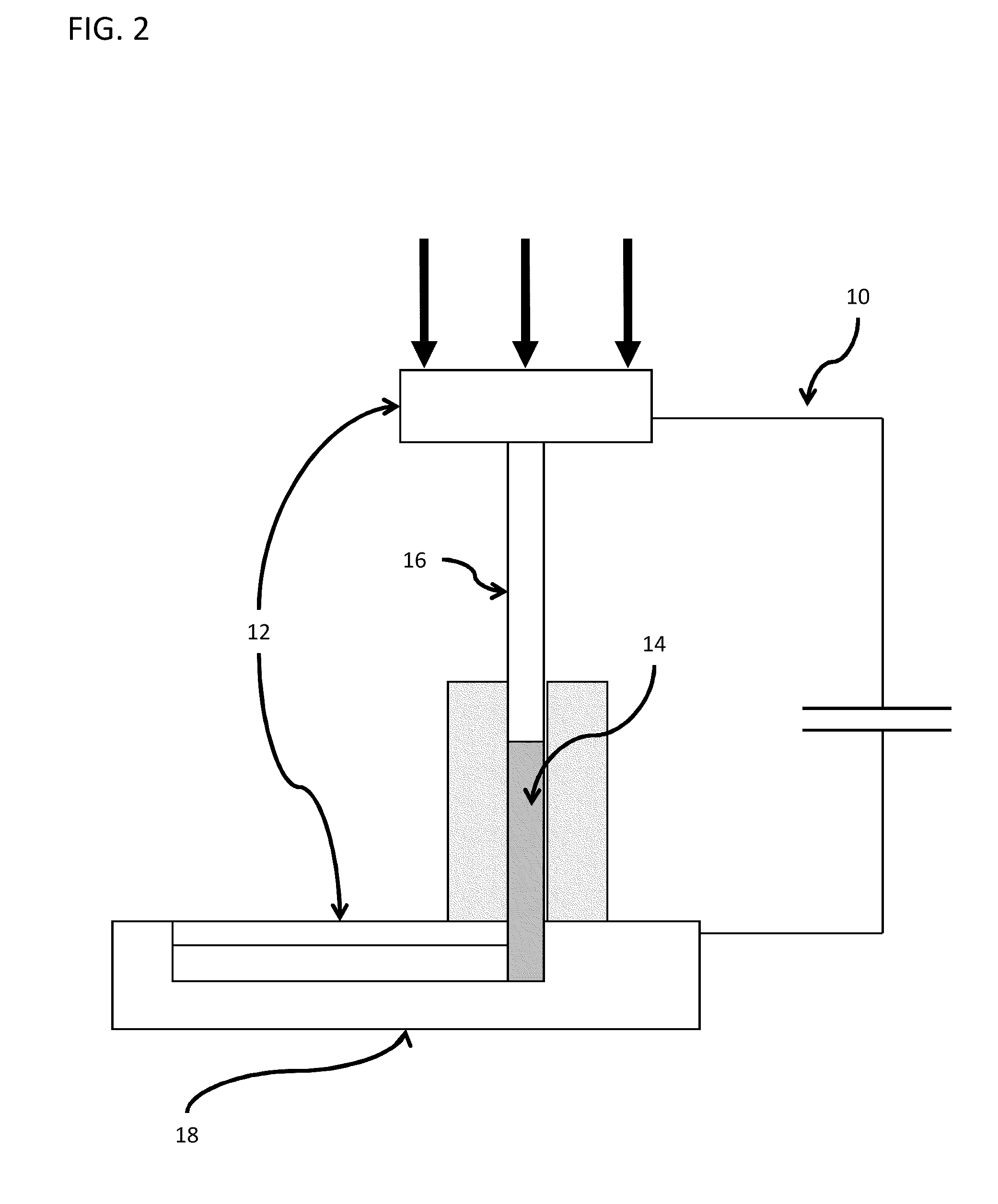

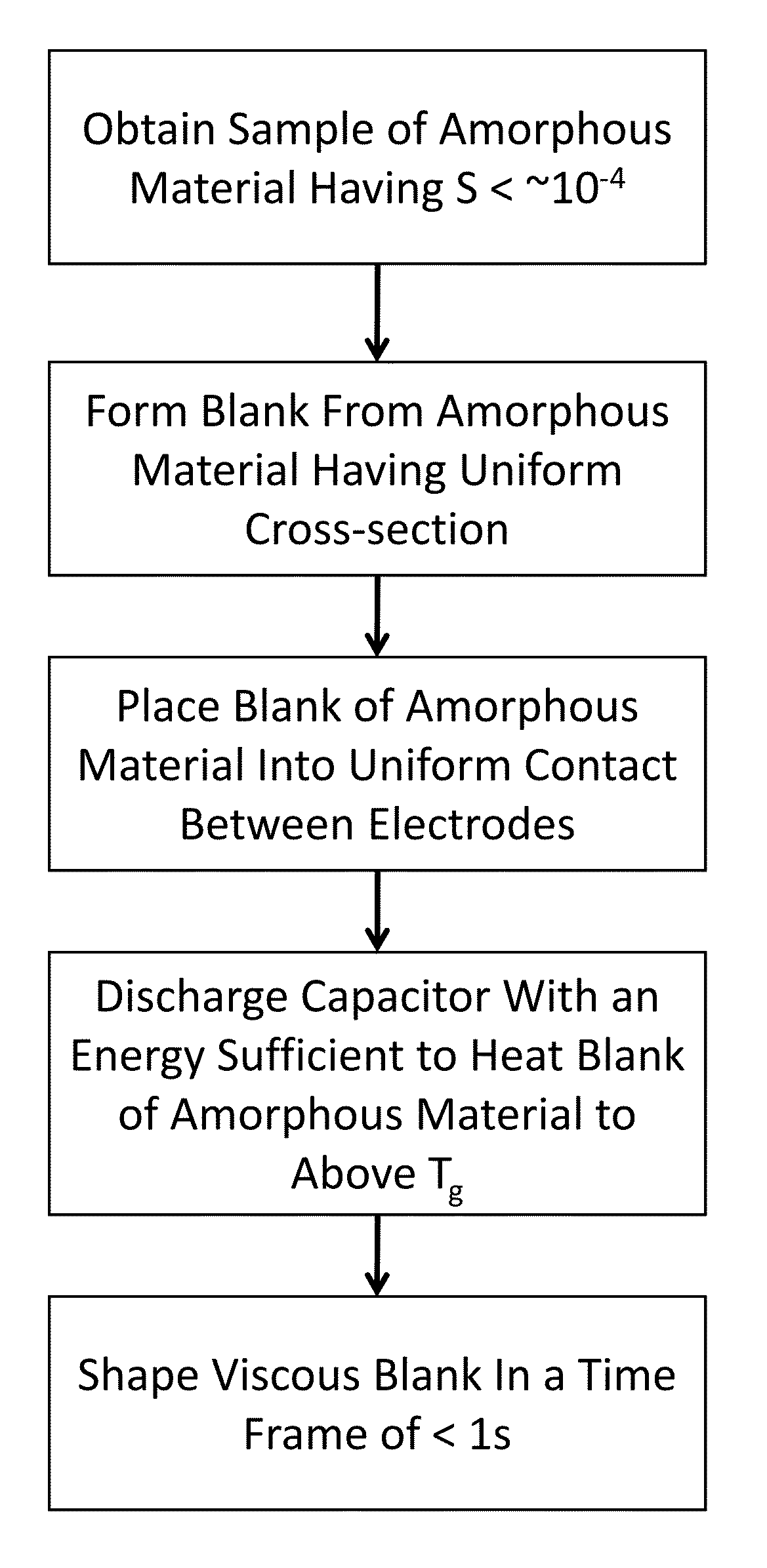

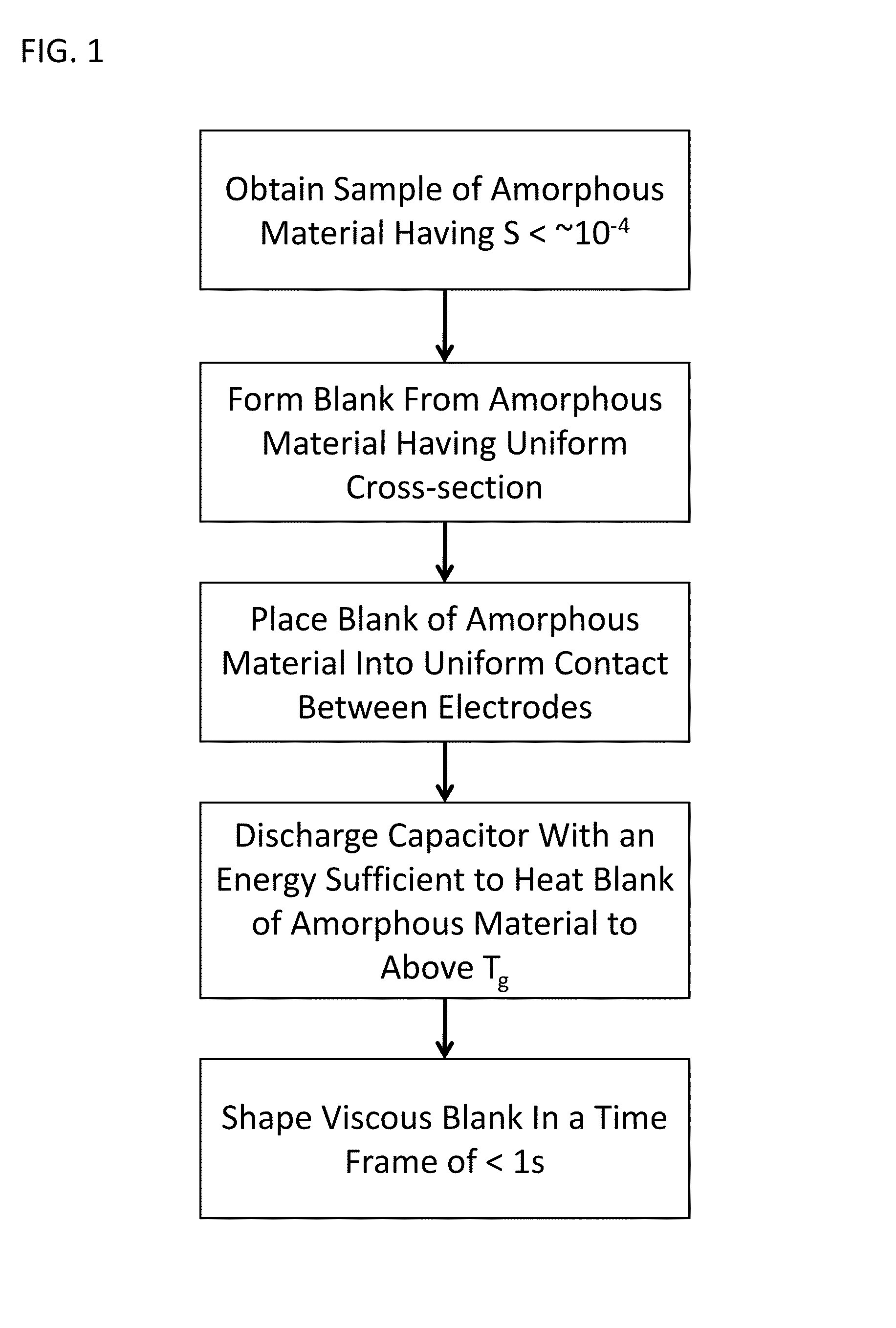

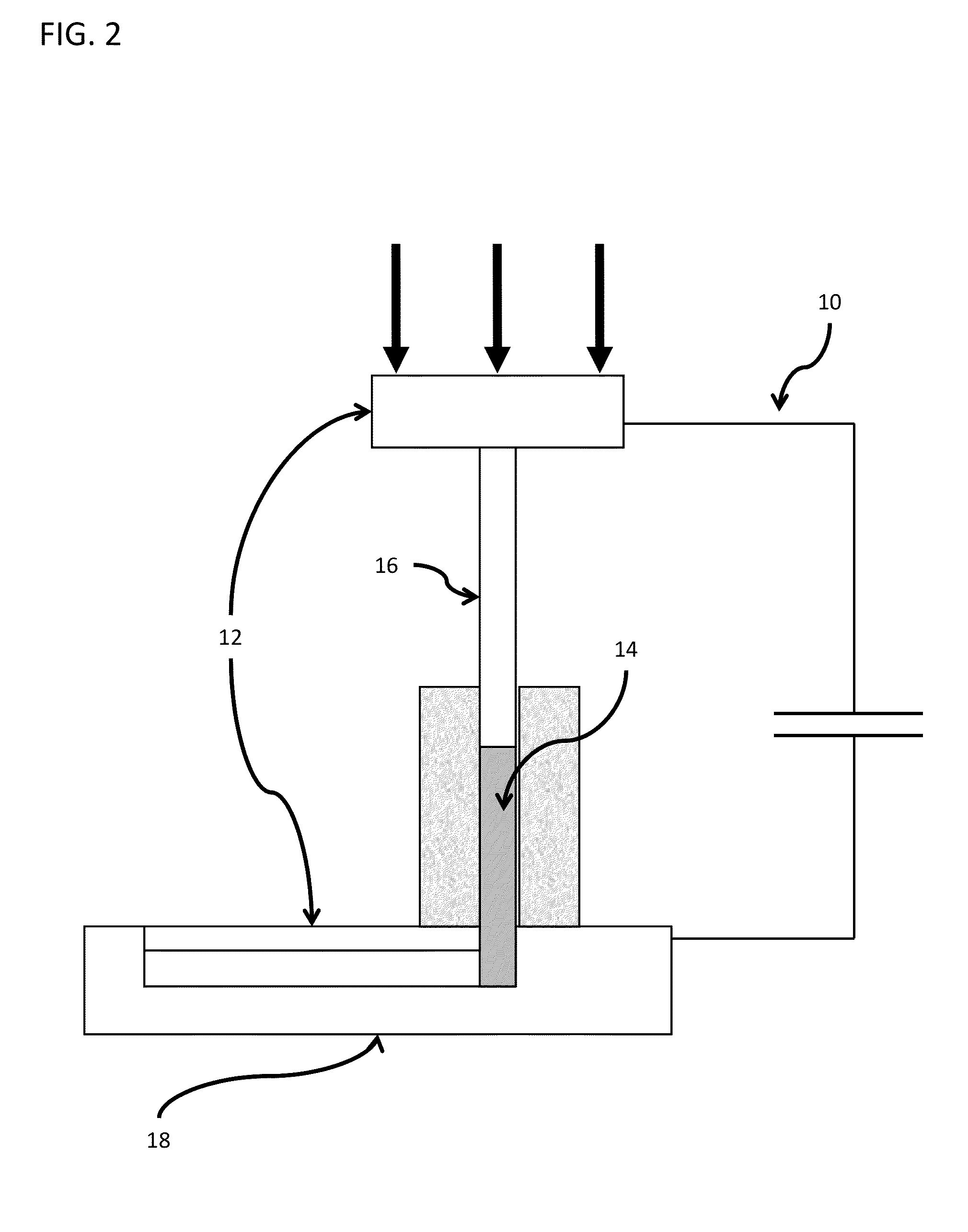

Forming of metallic glass by rapid capacitor discharge

ActiveUS20090236017A1Avoid failureAvoid thermal transport and development of thermalDielectric heatingShaping toolsAlloyGlass transition

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool are provided. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous material and the equilibrium melting point of the alloy in a time scale of several milliseconds or less. Once the sample is uniformly heated such that the entire sample block has a sufficiently low process viscosity it may be shaped into high quality amorphous bulk articles via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, and blow molding in a time frame of less than 1 second.

Owner:CALIFORNIA INST OF TECH

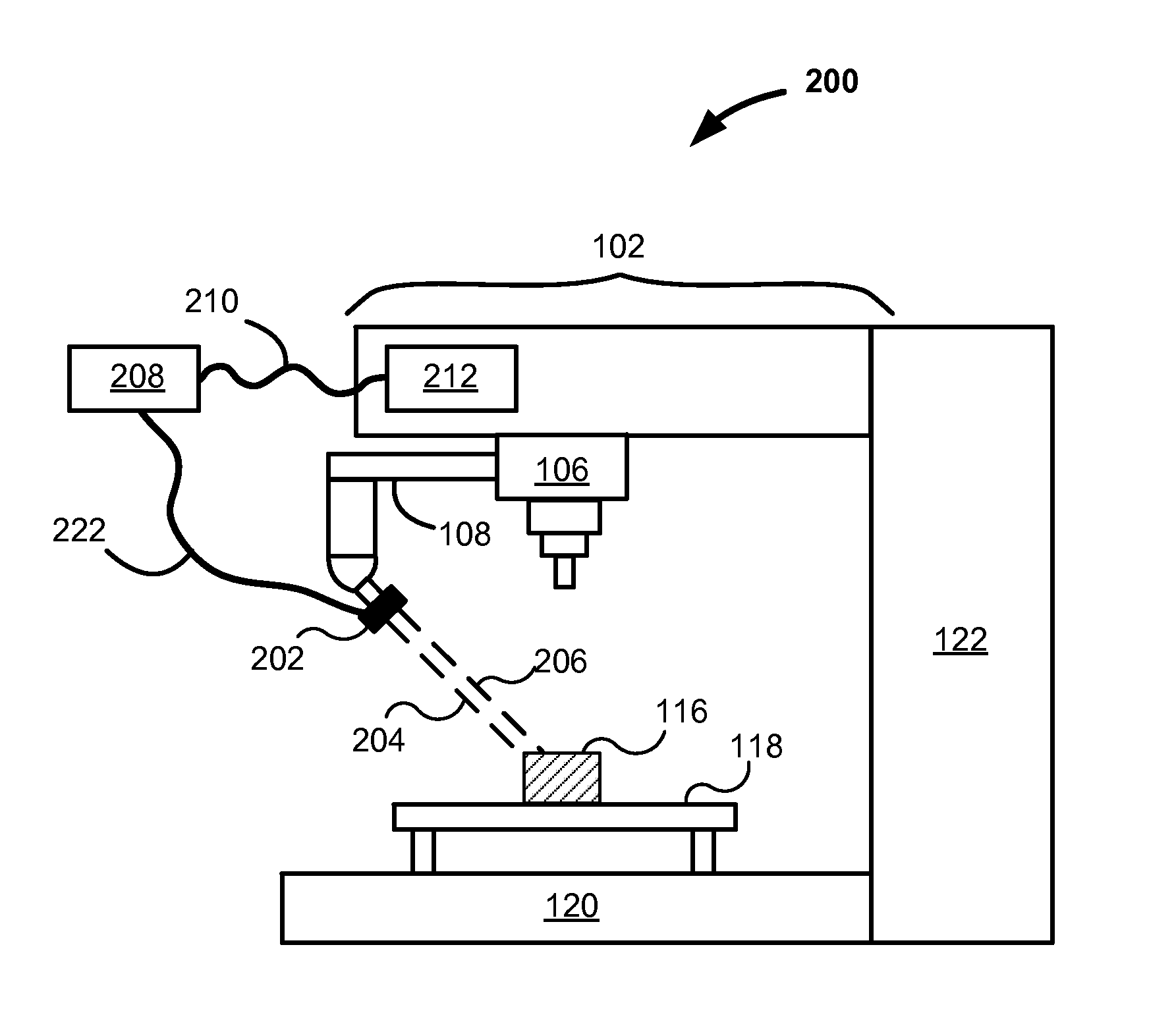

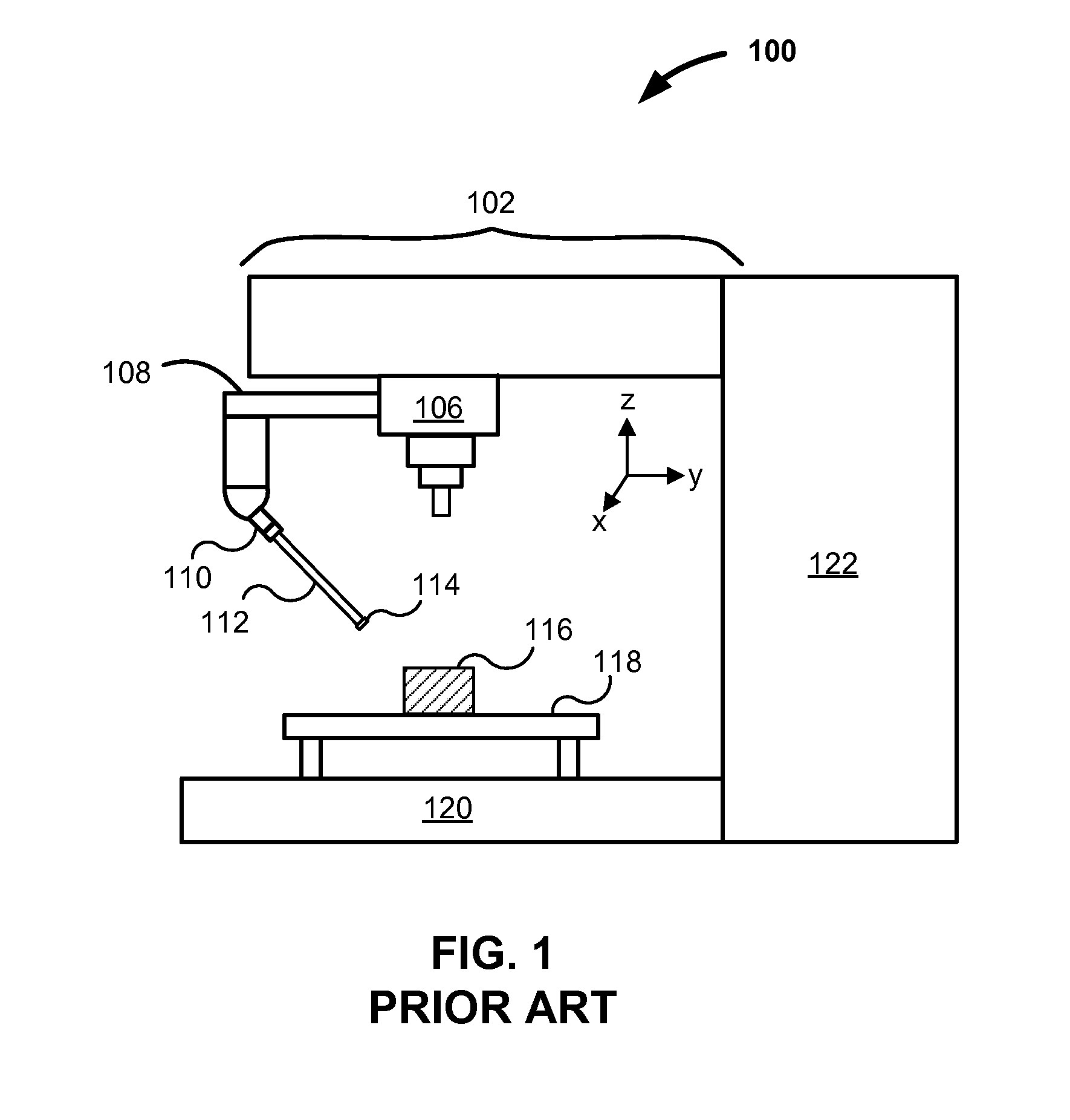

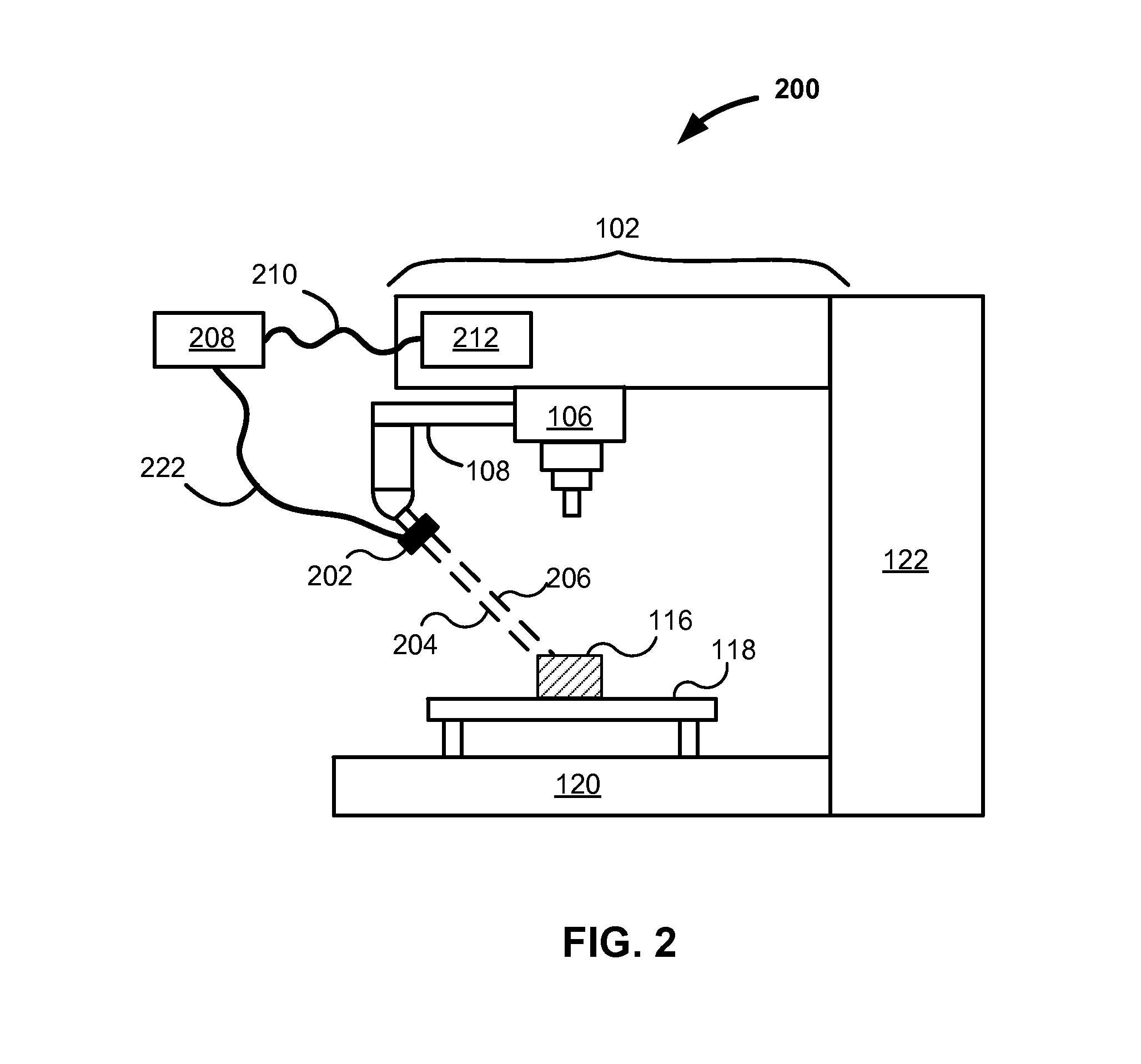

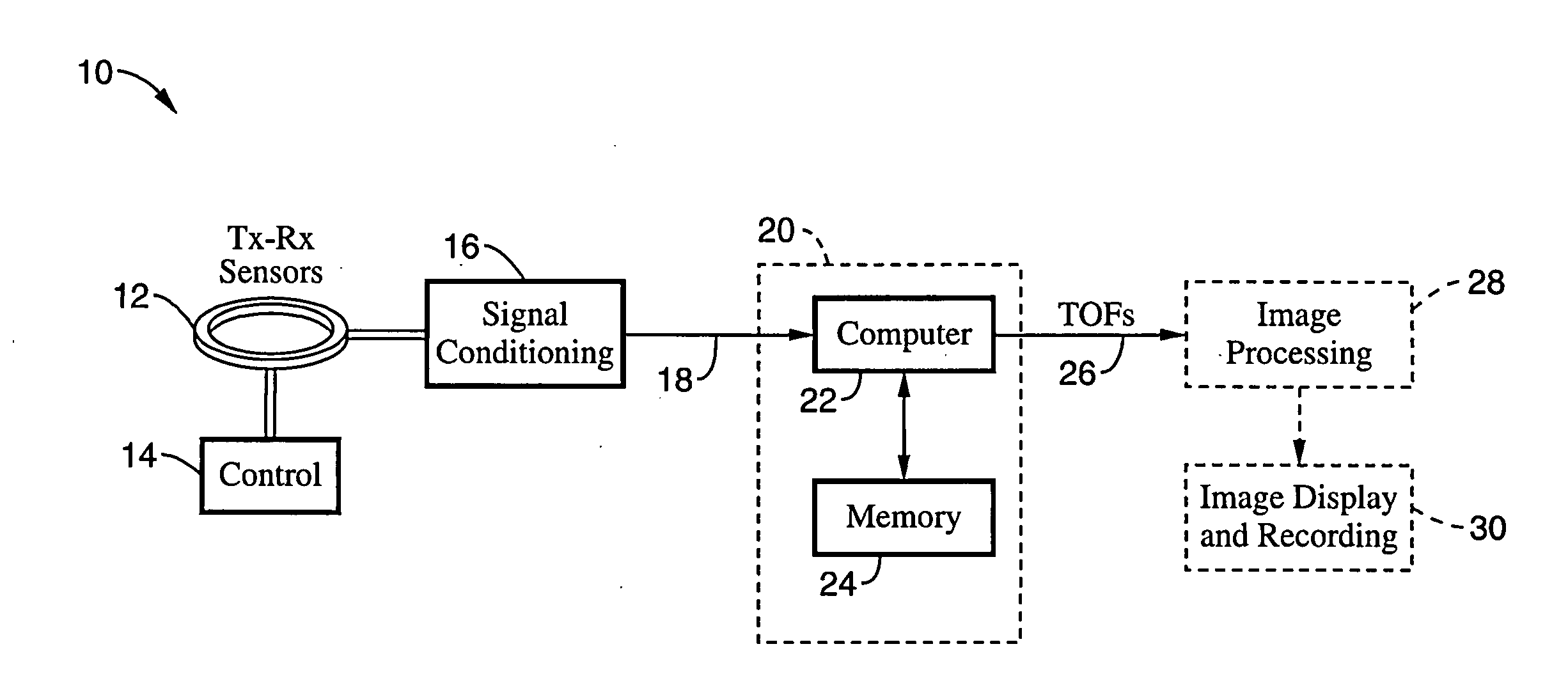

High Speed Metrology with Numerically Controlled Machines

ActiveUS20140157610A1Accurate verificationTight stack-up toleranceVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesNumerical controlMetrology

Systems, apparatuses and methods are described for integrating an electronic metrology sensor with precision production equipment such as computer numerically controlled (CNC) machines. For example, a laser distance measuring sensor is used. Measurements are taken at a relatively high sample rate and converted into a format compatible with other data generated or accepted by the CNC machine. Measurements from the sensor are synchronized with the position of the arm of the machine such as through the use of offsets. Processing yields a detailed and highly accurate three-dimensional map of a workpiece in the machine. Applicable metrology instruments include other near continuously reading non-destructive characterization instruments such as contact and non-contact dimensional, eddy current, ultra-sound, and X-Ray Fluorescence (XRF) sensors. Various uses of measurements include: multiple component matching, correction of machine drift, closed loop control of machines, and verification of product tolerances via substantially complete serialized dimensional quality control.

Owner:GRALE TECH

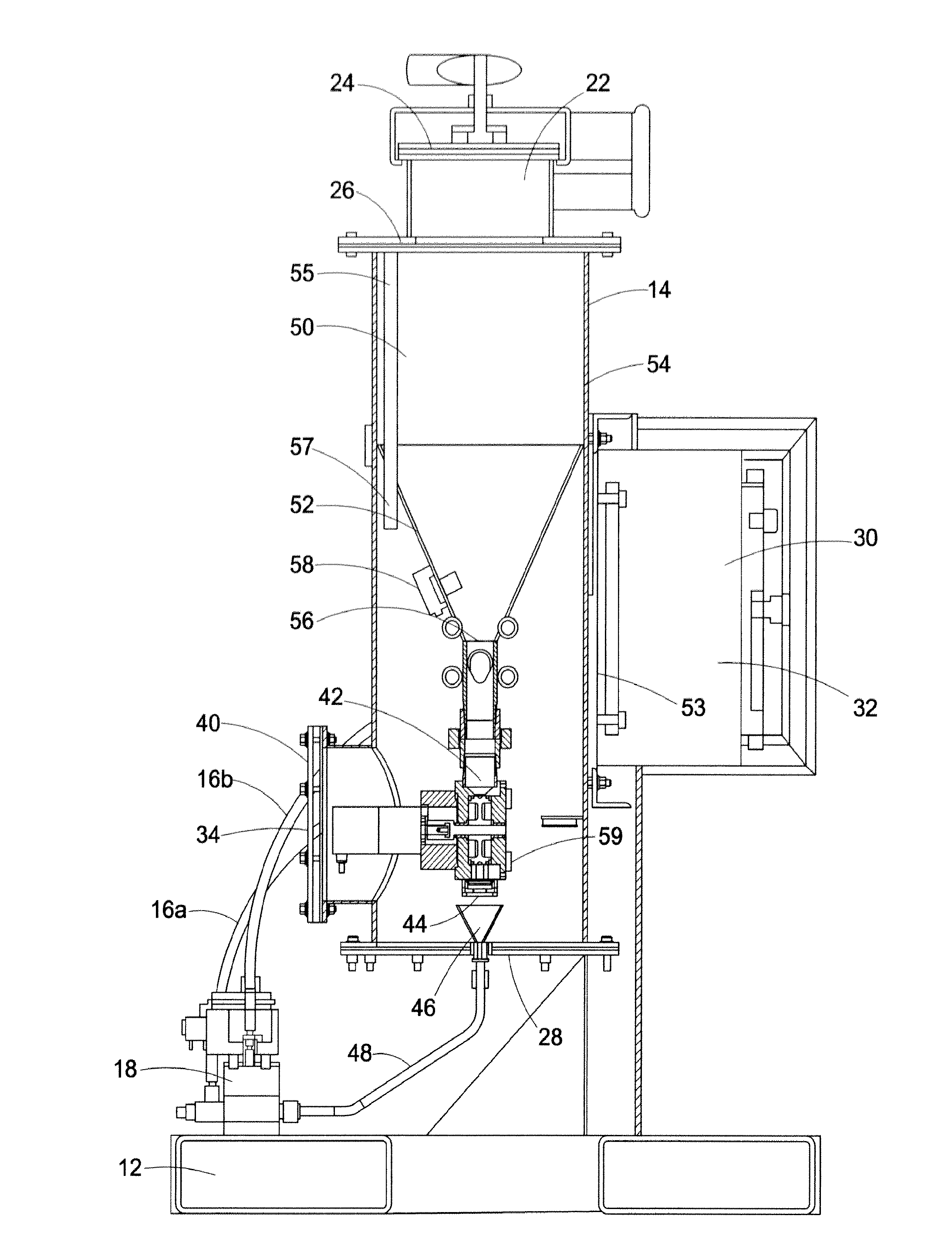

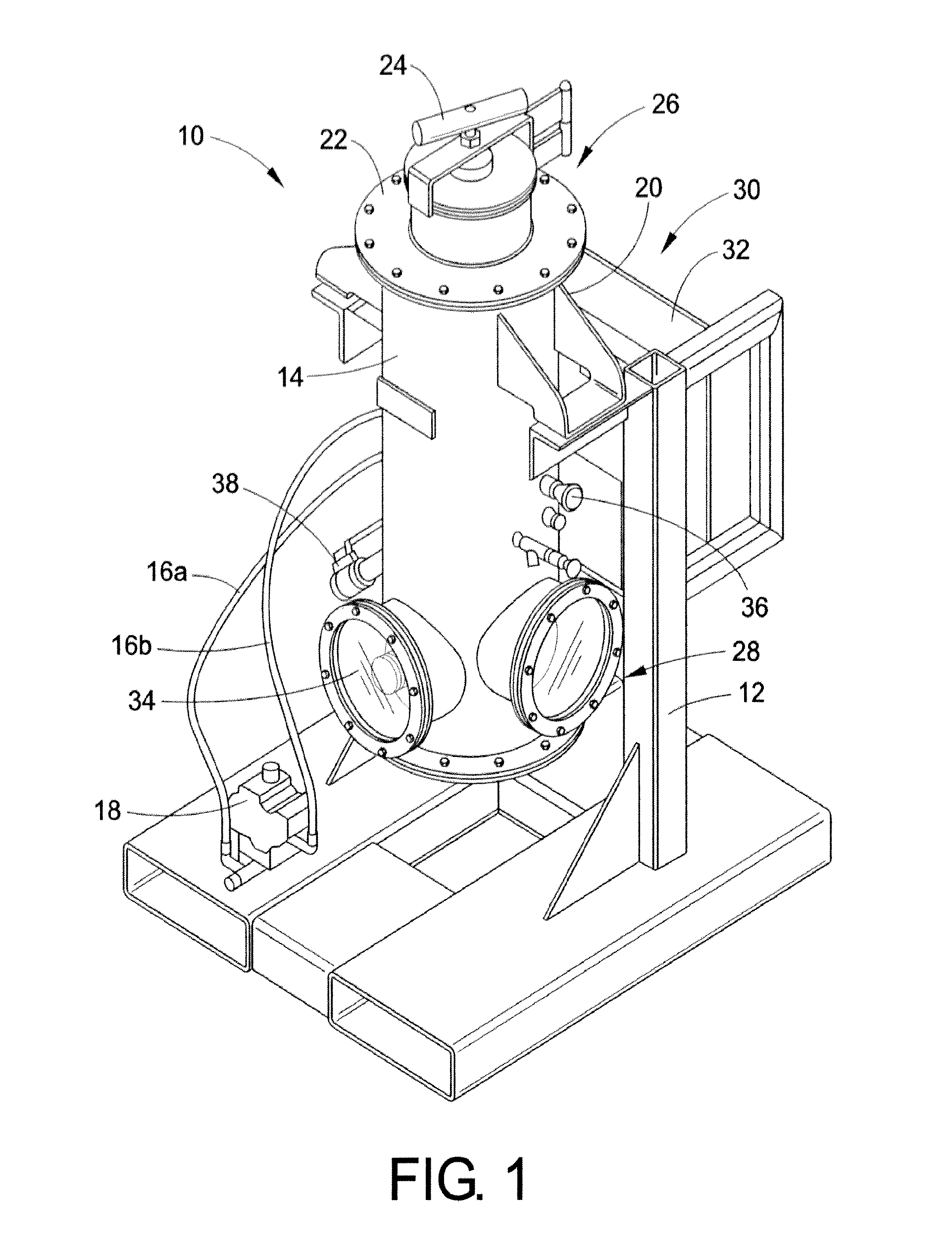

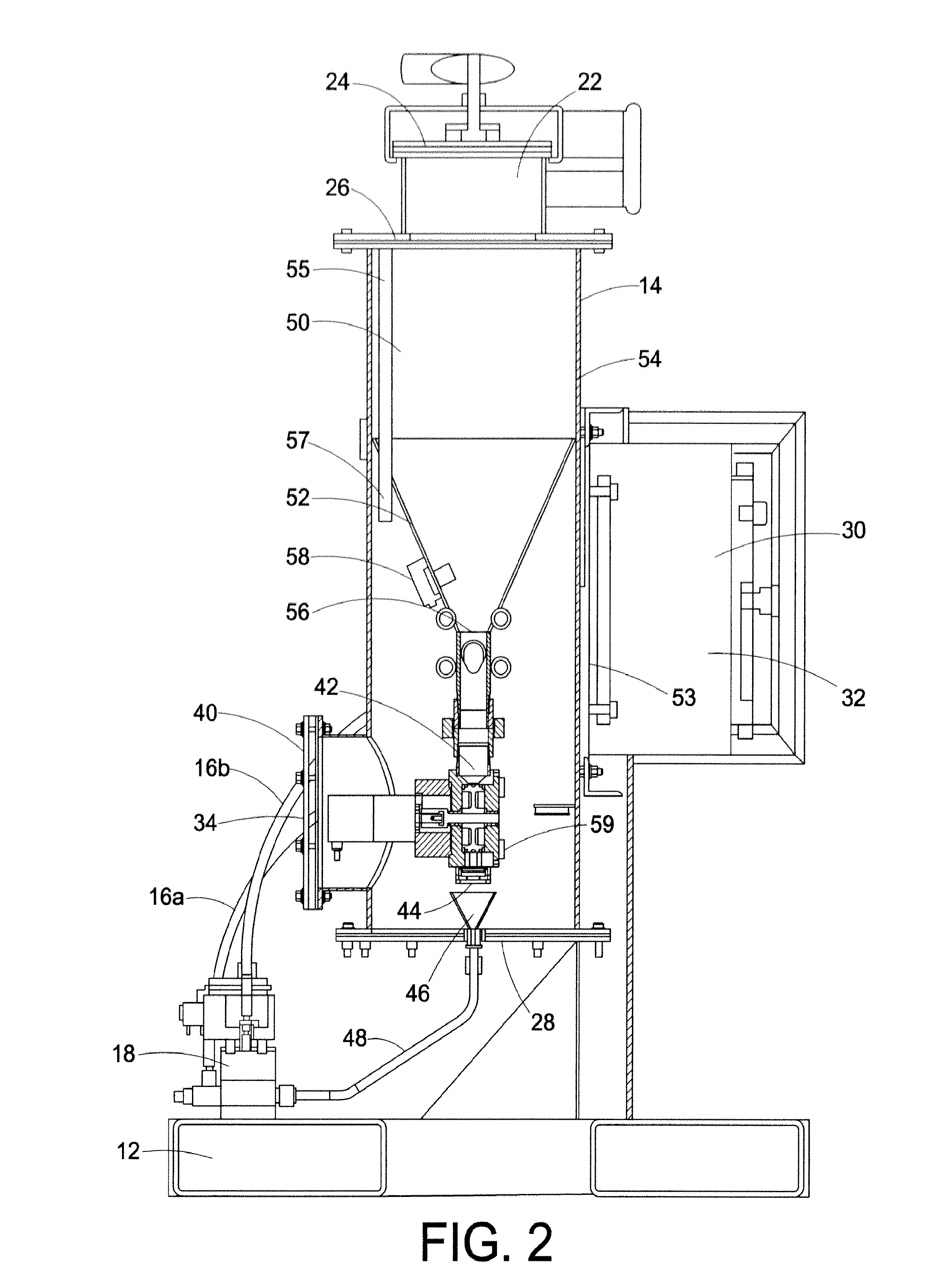

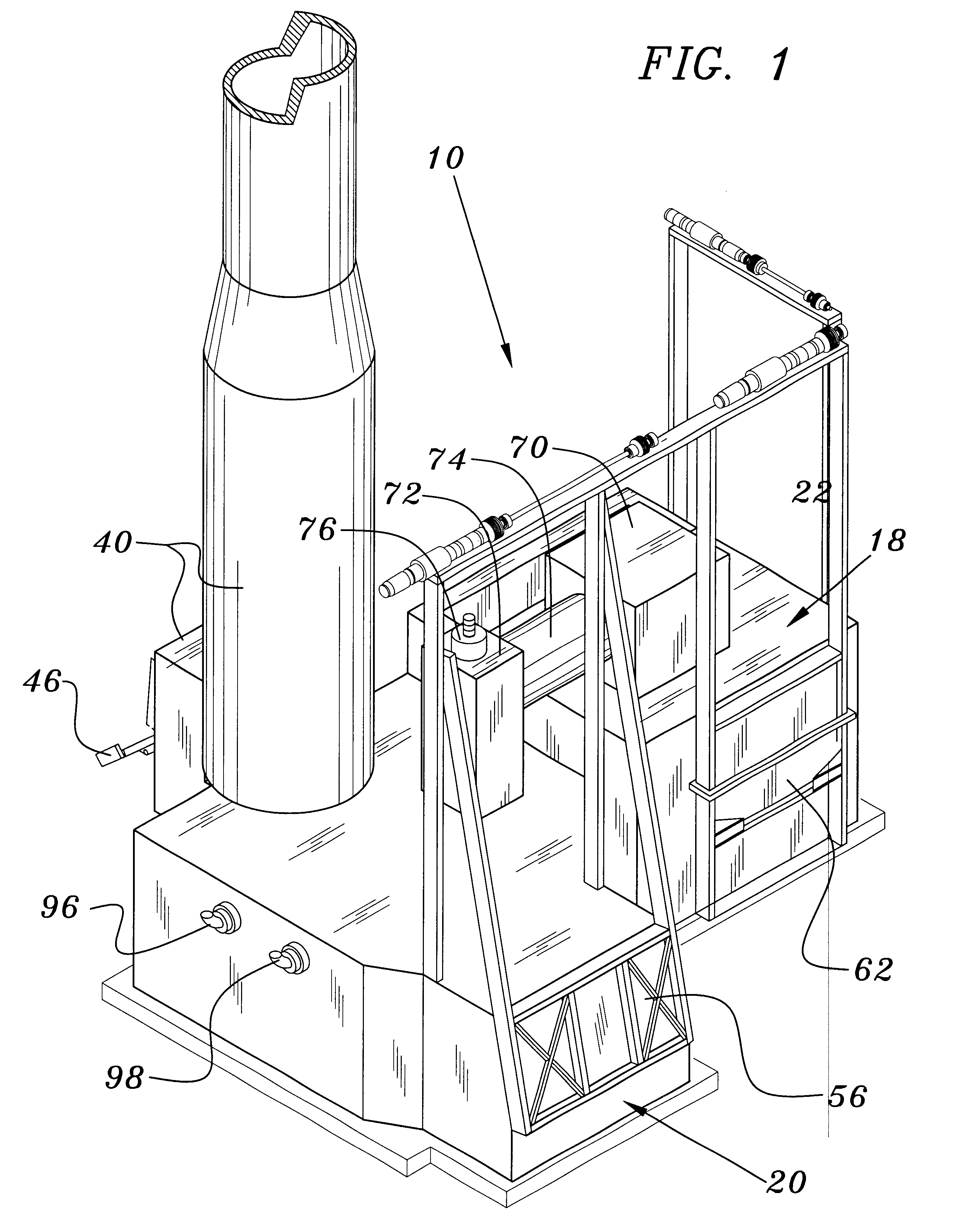

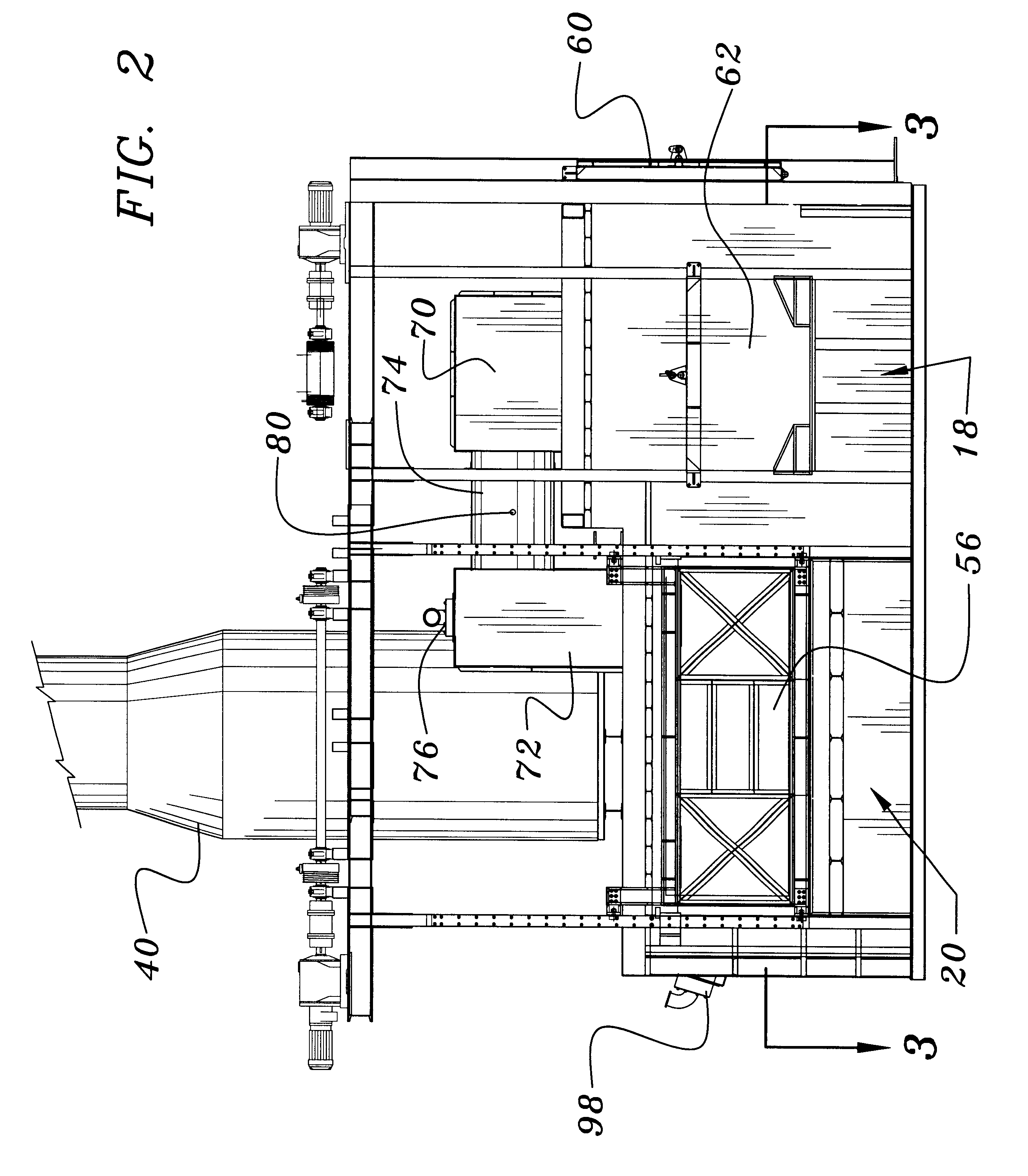

Flux injection assembly and method

ActiveUS20140083253A1Safely store and measureAvoid pollutionCharge manipulationBlast furnace detailsEngineeringInjector

A flux injector apparatus and method adapted to distribute a predetermined amount of flux to an associated pool of molten aluminum. The flux injector apparatus includes a pressurized tank adapted to store and feed the flux under pressure. A feed mechanism operative to discharge a predetermined amount of flux to an outlet and a controller for monitoring and operating the apparatus. The feed mechanism includes a housing having an inner wall defining a cavity with an inlet and an outlet. A feed wheel is positioned within the cavity and operative to receive a predetermined amount of flux from the inlet, translate the flux within the cavity and discharge the predetermined amount of flux through the outlet of the pressurized tank.

Owner:PYROTECK INC

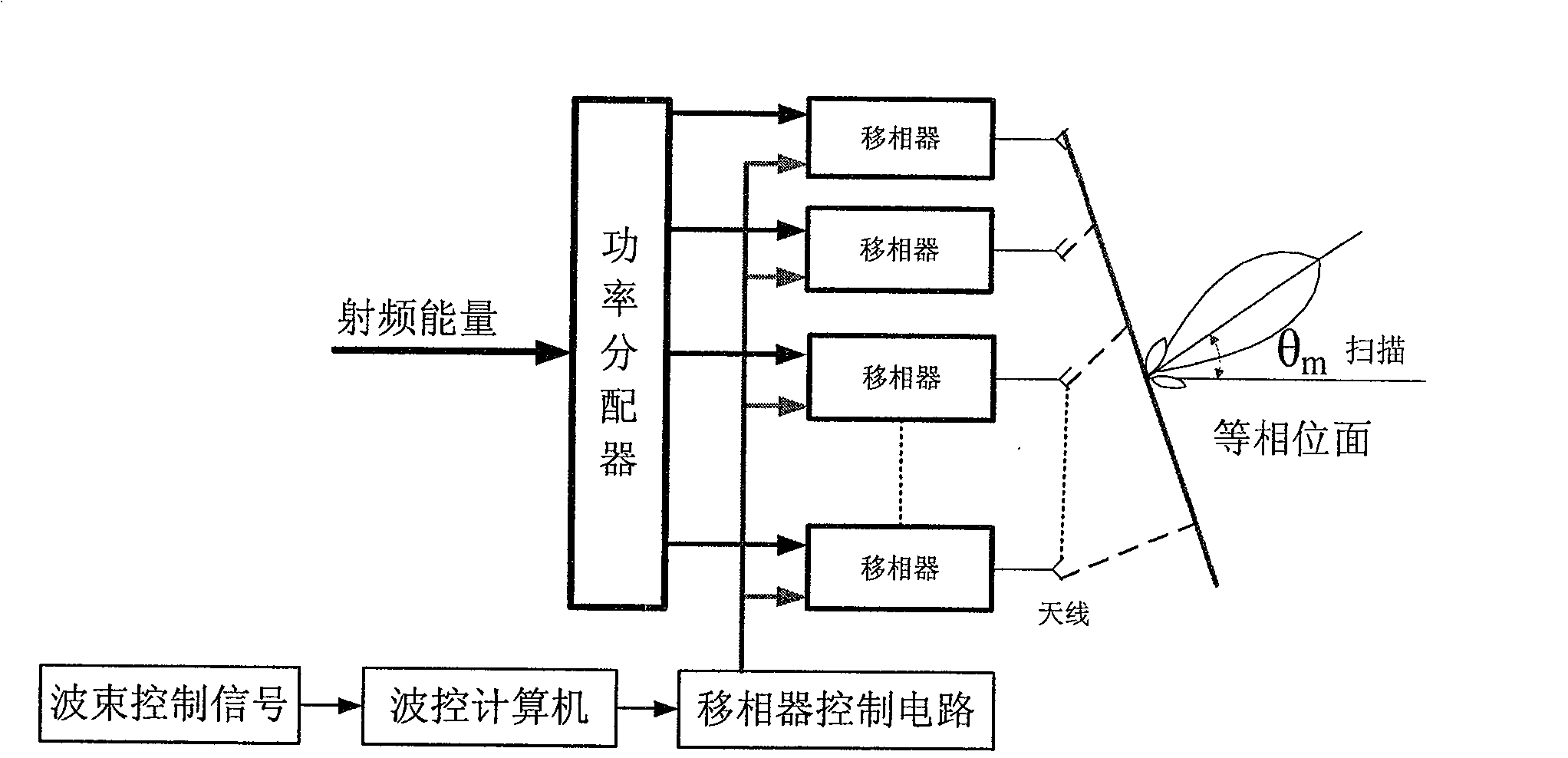

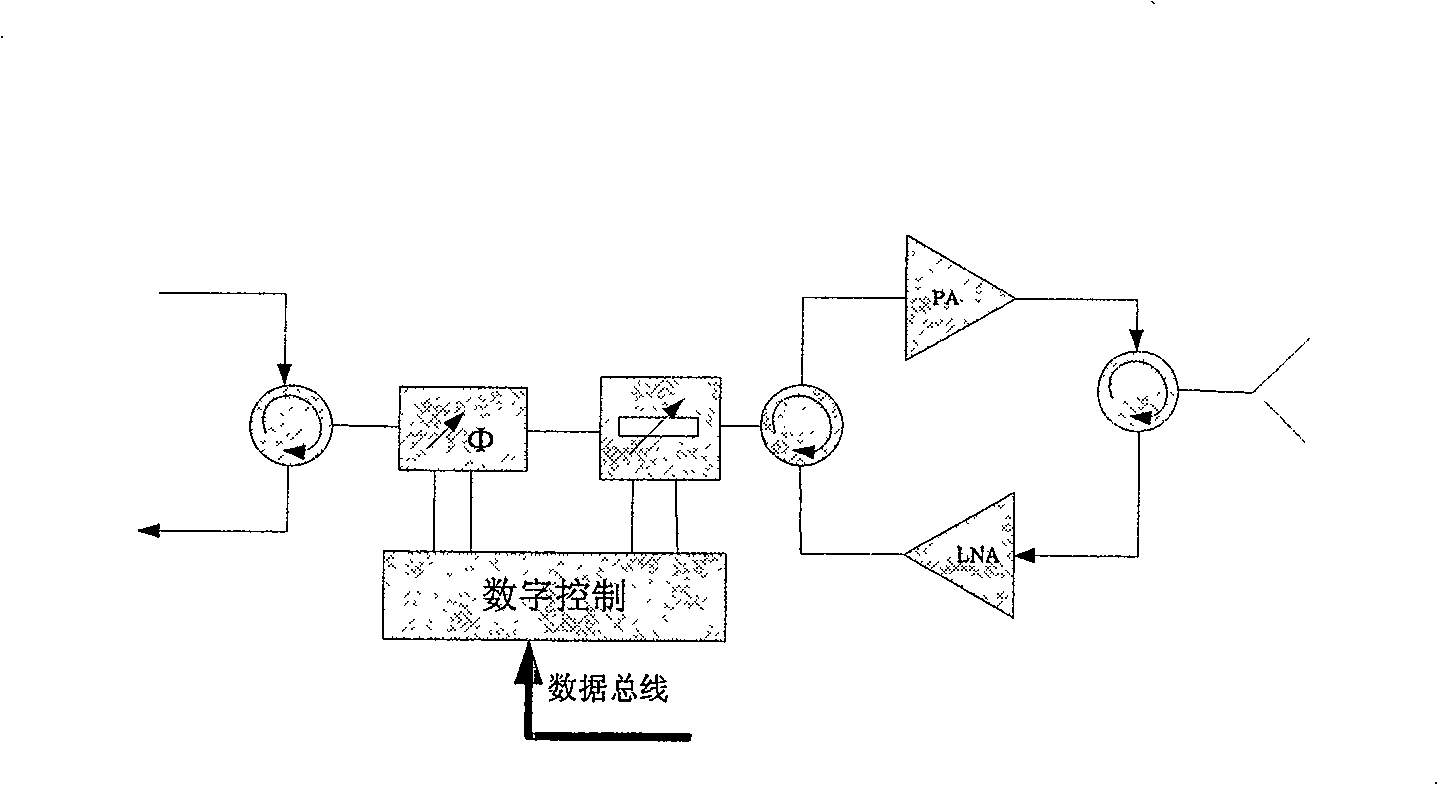

High furnace burden face measurement and control system based on industrial phased array radar

InactiveCN101492750ASolve bottlenecksFast scanningMachines/enginesLevel indicators3d imageControl system

A system for measuring and controlling blast furnace level based on an industrial phased array radar relates to the industrial phased array radar used in the fields of metallurgy, chemical engineering, cement building materials. The system includes an industrial phased array radar body, a radar electromagnetic shield and an interlock cloth control system; wherein the industrial phased array radar body is in charge of obtaining level information; the electromagnetic shield is in charge of protecting the industrial phased array radar body in a high-temperature and high-pressure dust atmosphere; and the interlock cloth control system is in charge of carrying out analysis and judgment and charging task according to the level height data transmitted by the interlock cloth control system to control the final level shape to be in a predetermined shape. The inventive system can be applied in severe atmosphere of darkness, high temperature and dustiness to precisely describe the height information of each solid level point and obtain the kind and time of charging at different moments by the interlock with PLC or DCS; so that the shapes of a plurality of level layers and 3D images of solid levels are obtained.

Owner:UNIV OF SCI & TECH BEIJING

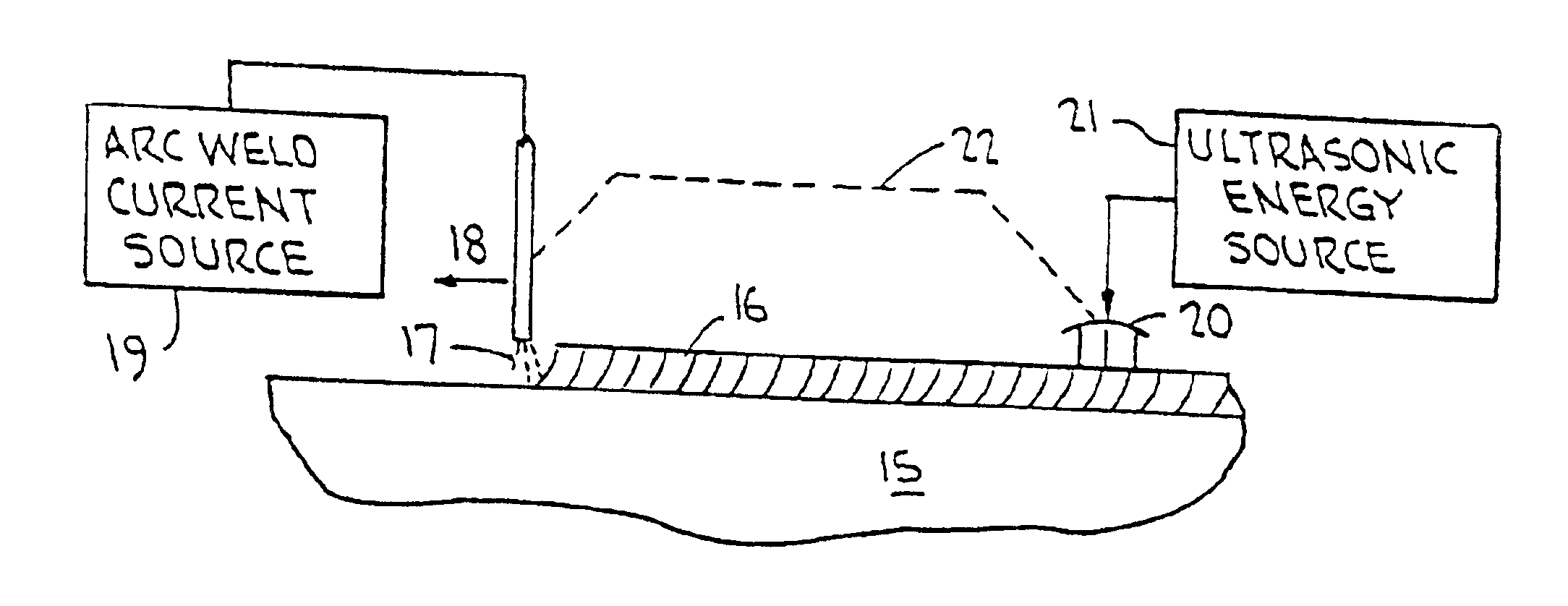

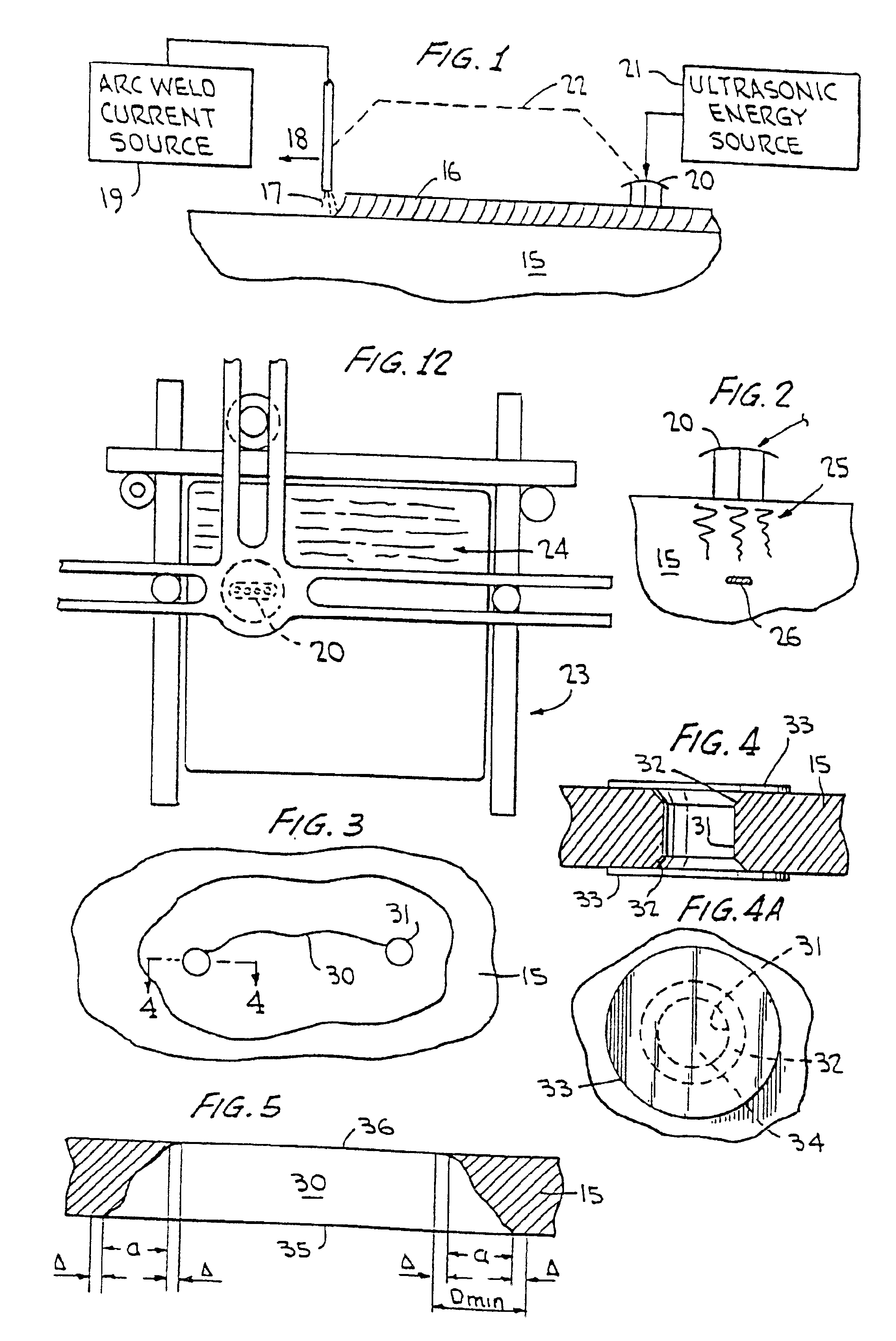

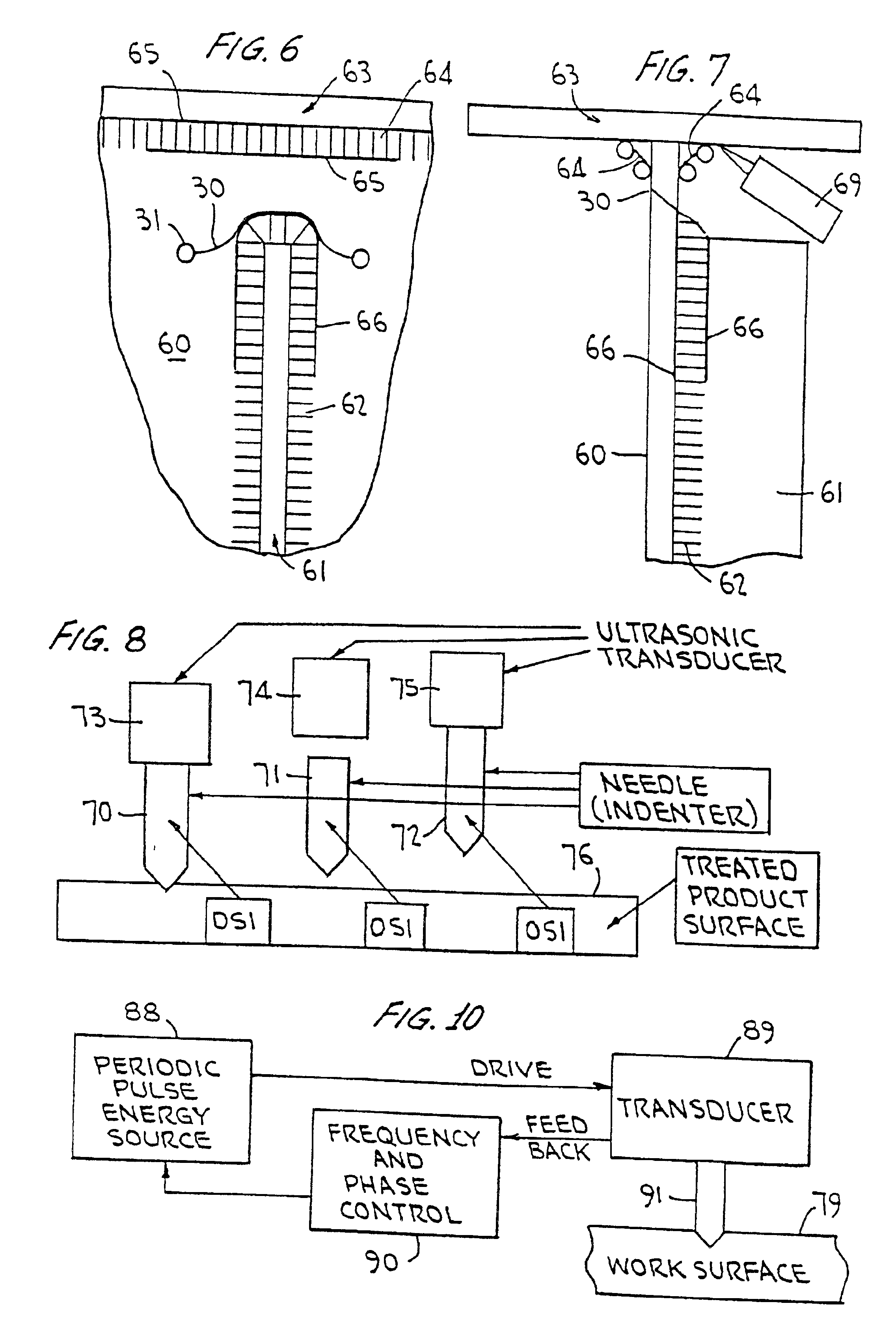

Ultrasonic impact methods for treatment of welded structures

InactiveUS6843957B2Improve corrosion fatigue strengthIncreased durabilityBlast furnace detailsHigh frequency current welding apparatusUltrasonic sensorEngineering

This invention provides methods of treatment for work products of materials such as steel, bronze, plastic, etc. and particularly welded steel bodies by pulse impact energy, preferably ultrasonic, to relax fatigue and aging and extend expectant life. The treatment may occur (a) at original production, (b) during the active life period for maintenance or (c) after failure in a repair stage. The ultrasonic treatment improves the work product strength. In welded products residual stress patterns near the weld sites are relaxed and micro-stress defects such as voids and unusual grain boundaries are reduced. The basic method steps are non-destructive in nature, inducing interior pulse compression waves with ultrasonic transducers and accessory tools impacting an external product surface with enough impulse energy to heat and temporarily plasticize the metal interior and relax stresses. The nature of the work product interior structure being treated is determined by sensing the mechanical movement at the impact surface of the work body to produce feedback frequency and phase signals responsive to input impact signals. These signals automatically conform driving pulse energy frequency and phase to the input transducers to match the mechanical resonance frequency of the working transducers and increase efficiency of energy transfer. Such feedback signals also are available for automated procedures which can improve product quality and consistency.

Owner:PROGRESS RAIL SERVICES

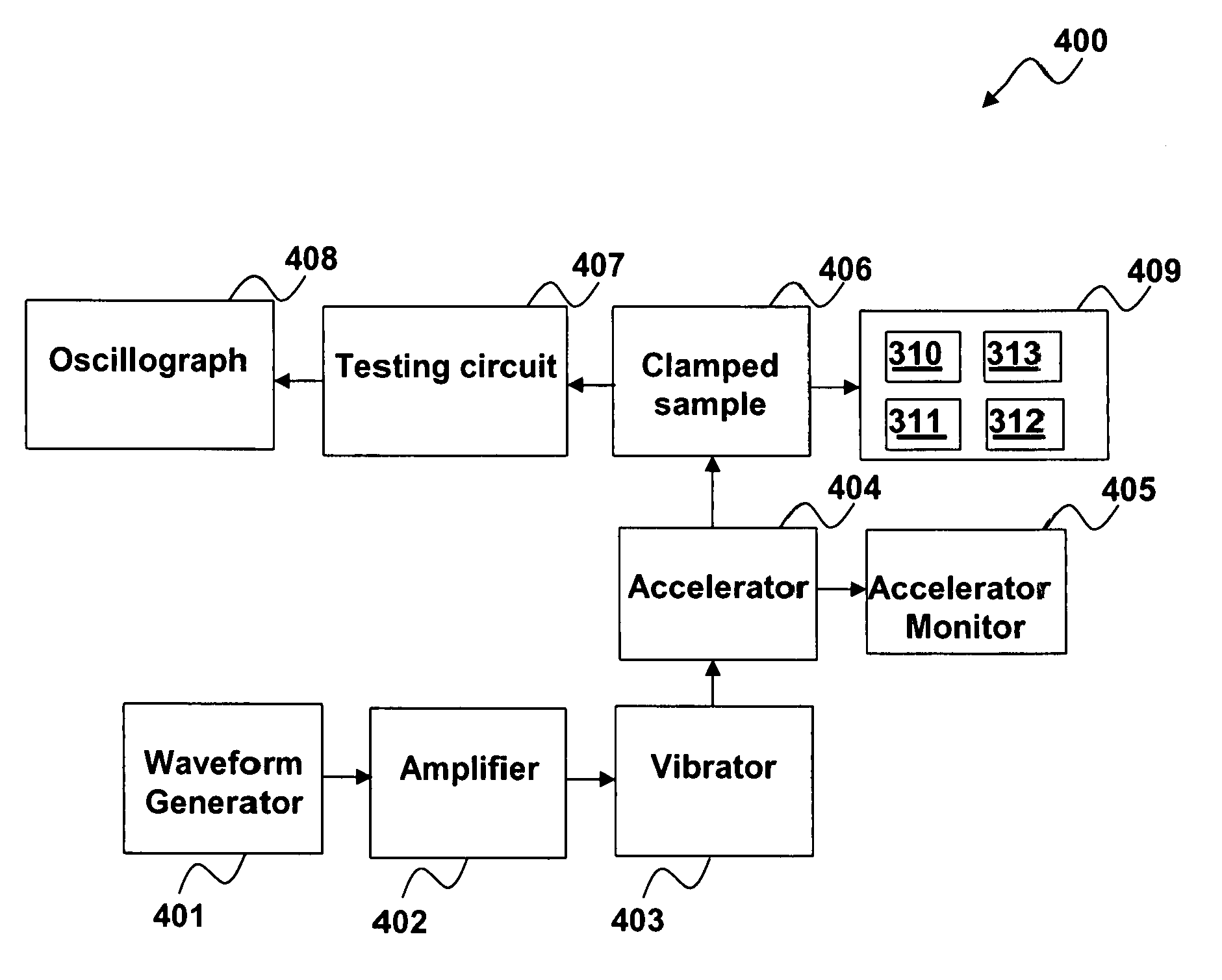

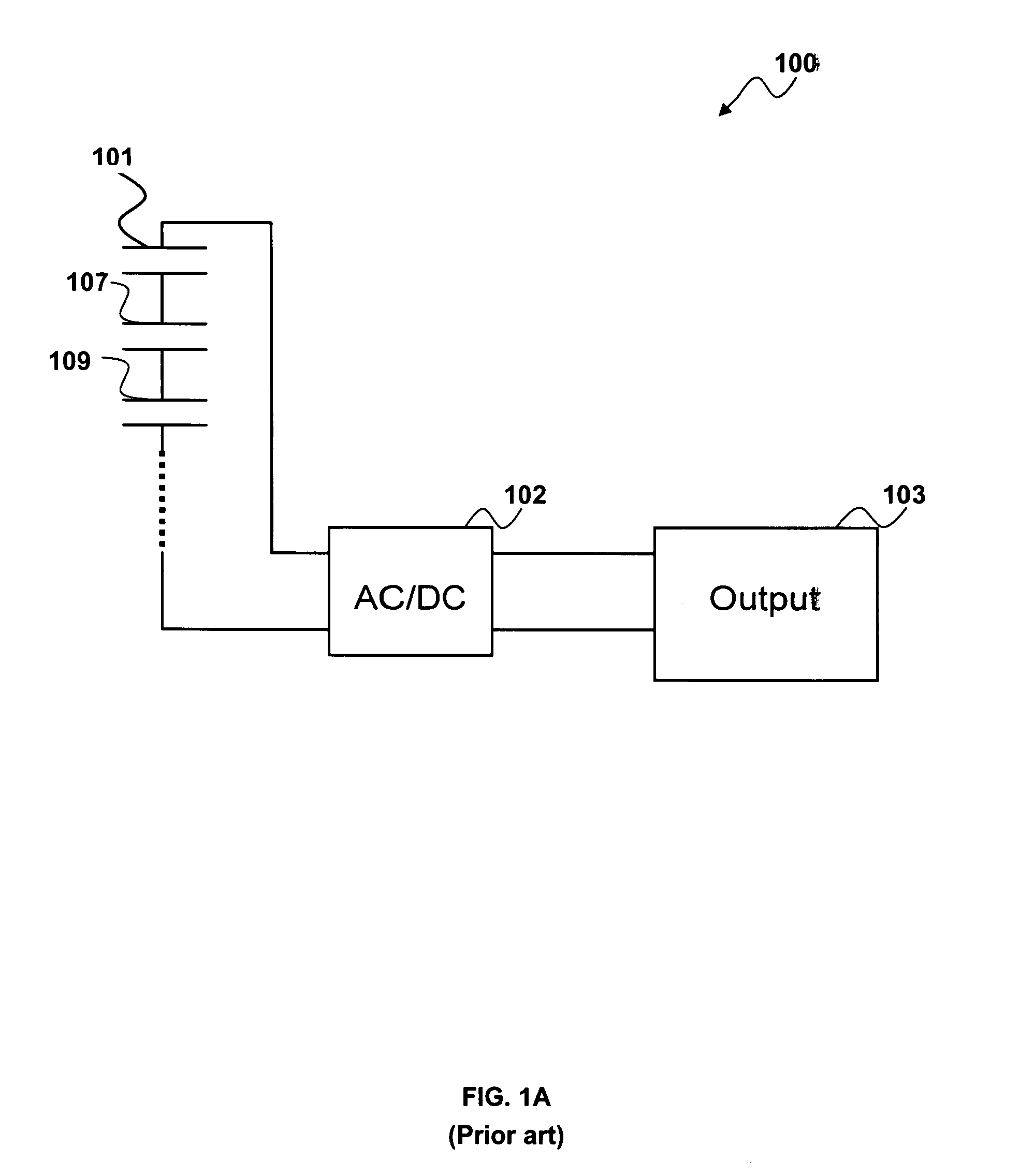

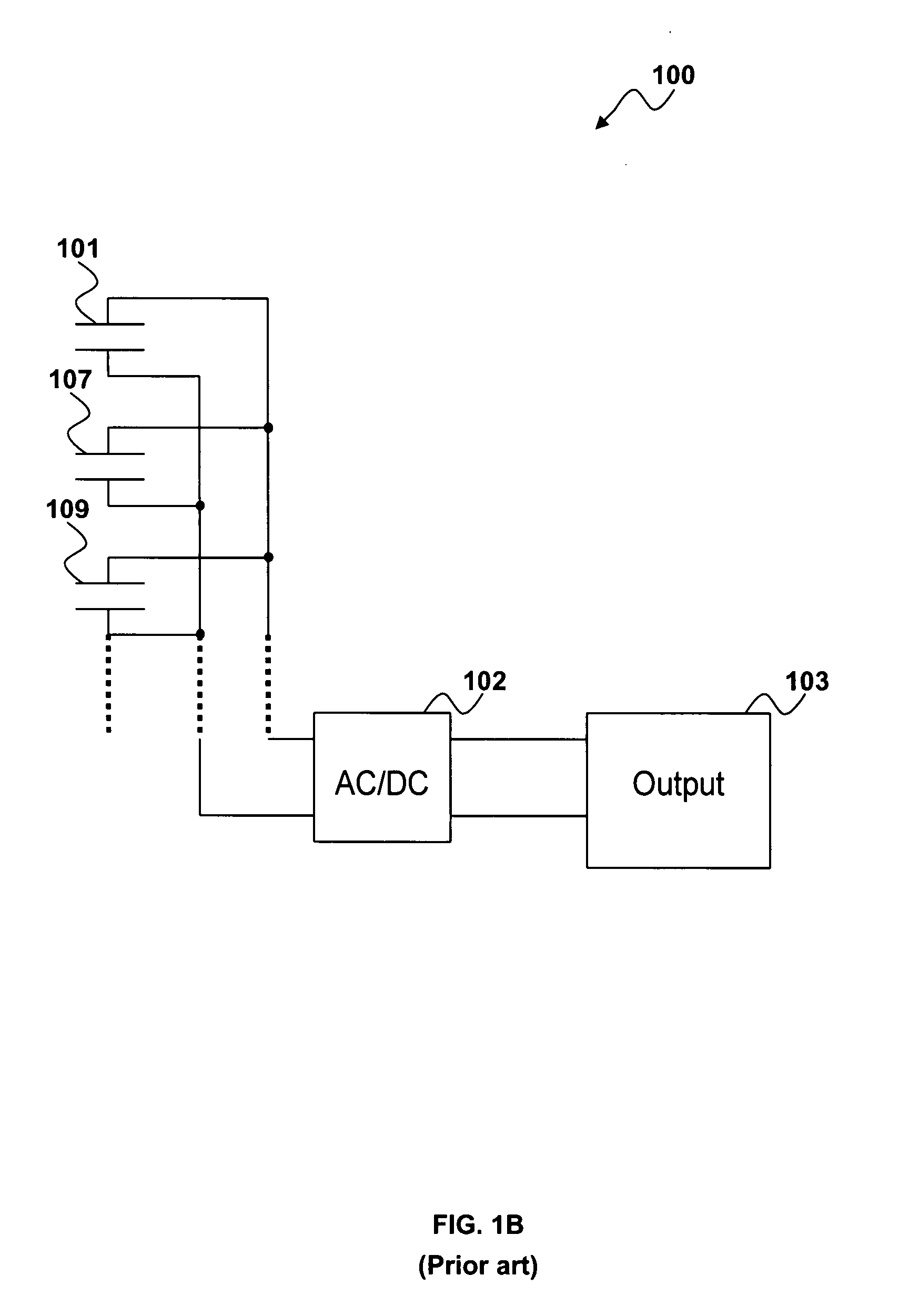

Electrical connection of energy harvesting devices

InactiveUS20080264144A1High outputHigh voltageVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricityElectrical connection

An energy harvesting system and method. An array of cantilevers with PZT films is electrically connected to an energy harvesting device that converts vibration energy to electrical energy. An AC output signal provided by the cantilevers can be rectified to a DC output, thereby avoiding impairment in total electrical output. The DC output terminals can be connected in parallel and / or in series in order to achieve a higher voltage and / or a higher current that prevents the output from different cantilevers from counteracting one another. The connection circuitry includes one or more rectifying components integrated with one or more micro-cantilevers into a single integrated circuit chip. An oscillograph can be utilized to monitor the DC output voltage signal from an associated testing circuit.

Owner:HONEYWELL INT INC

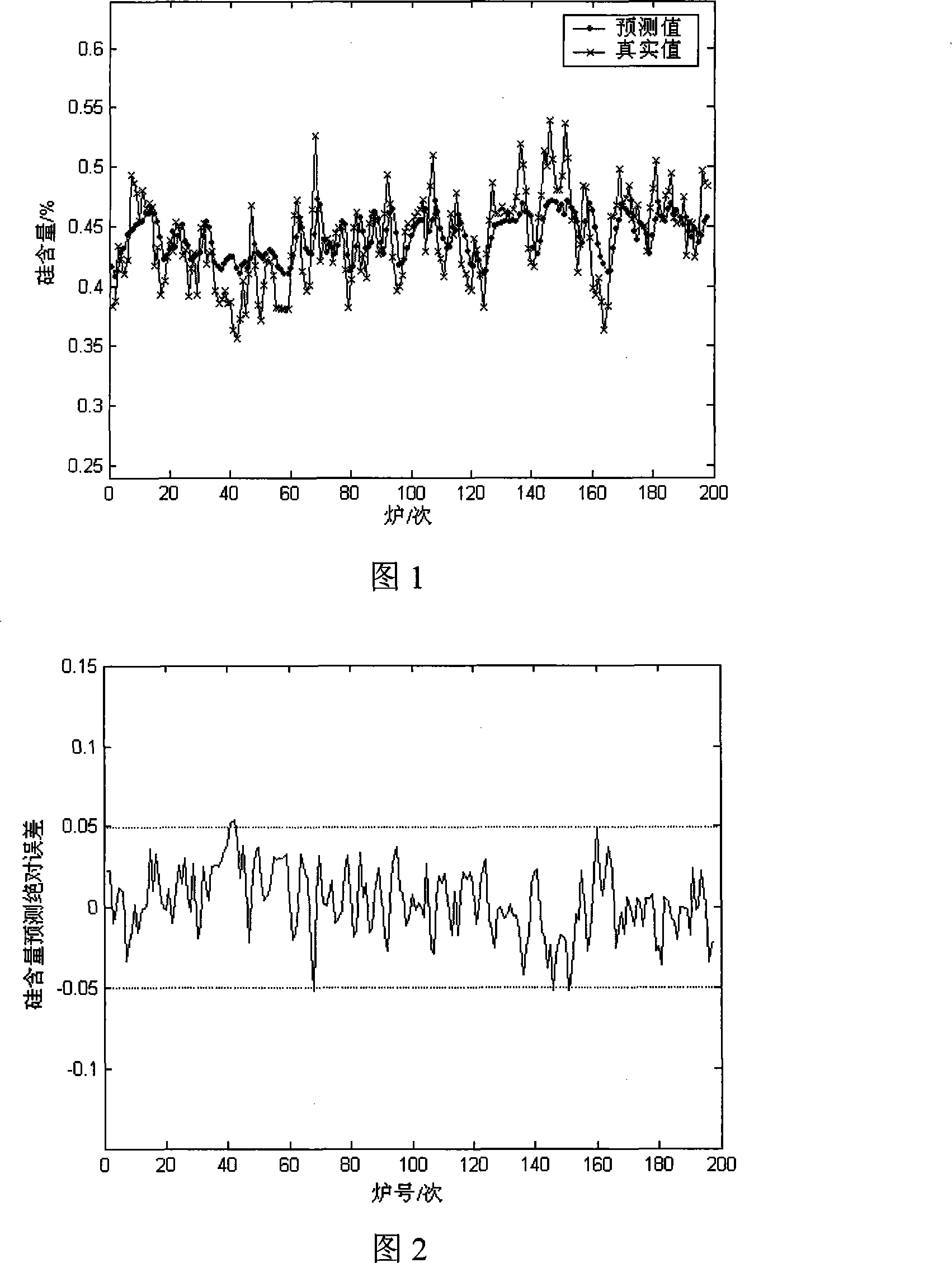

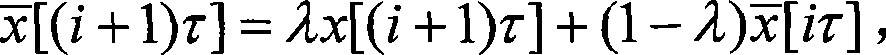

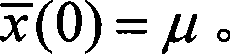

Blast furnace molten iron silicon content feature analysis and prediction method

InactiveCN101211383AImprove forecast hit rateEliminate dependenciesGenetic modelsChecking devicesFeature extractionFiltration

The invention discloses a characteristics analysis and forecast method for blast furnace molten iron silicon content. Blast furnace technological parameters in a forecast module for blast furnace molten iron silicon content are deemed as input variables; after exponential weight mobile average filtration and normalized pre-process for sample data of the input variables, the invention can use an improved dynamic separate composition analysis method for conducting characteristic extraction for the sample data of the input variables, so as to eliminate relevance between production technological parameters; a dynamic recurrence module for forecast of the blast furnace molten iron silicon content is established using the least square support vector machine arithmetic, so as to bring in a genetic arithmetic to optimize module parameters. The invention has common universality for molten iron silicon content forecast in blast furnace smelting process, so as to gain rather good forecast accuracy and improve the forecast hit ratio for blast furnace molten iron silicon content.

Owner:ZHEJIANG UNIV

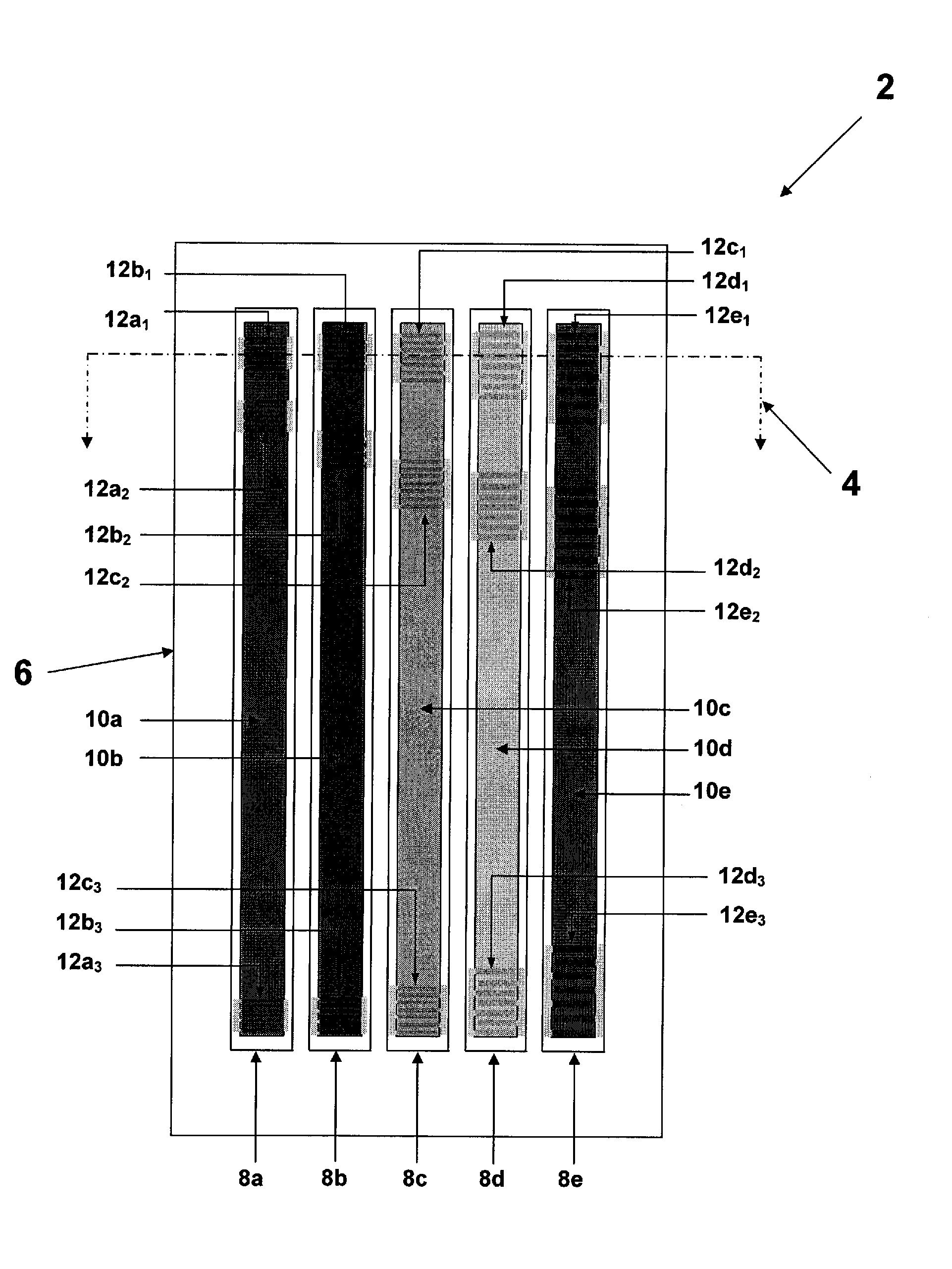

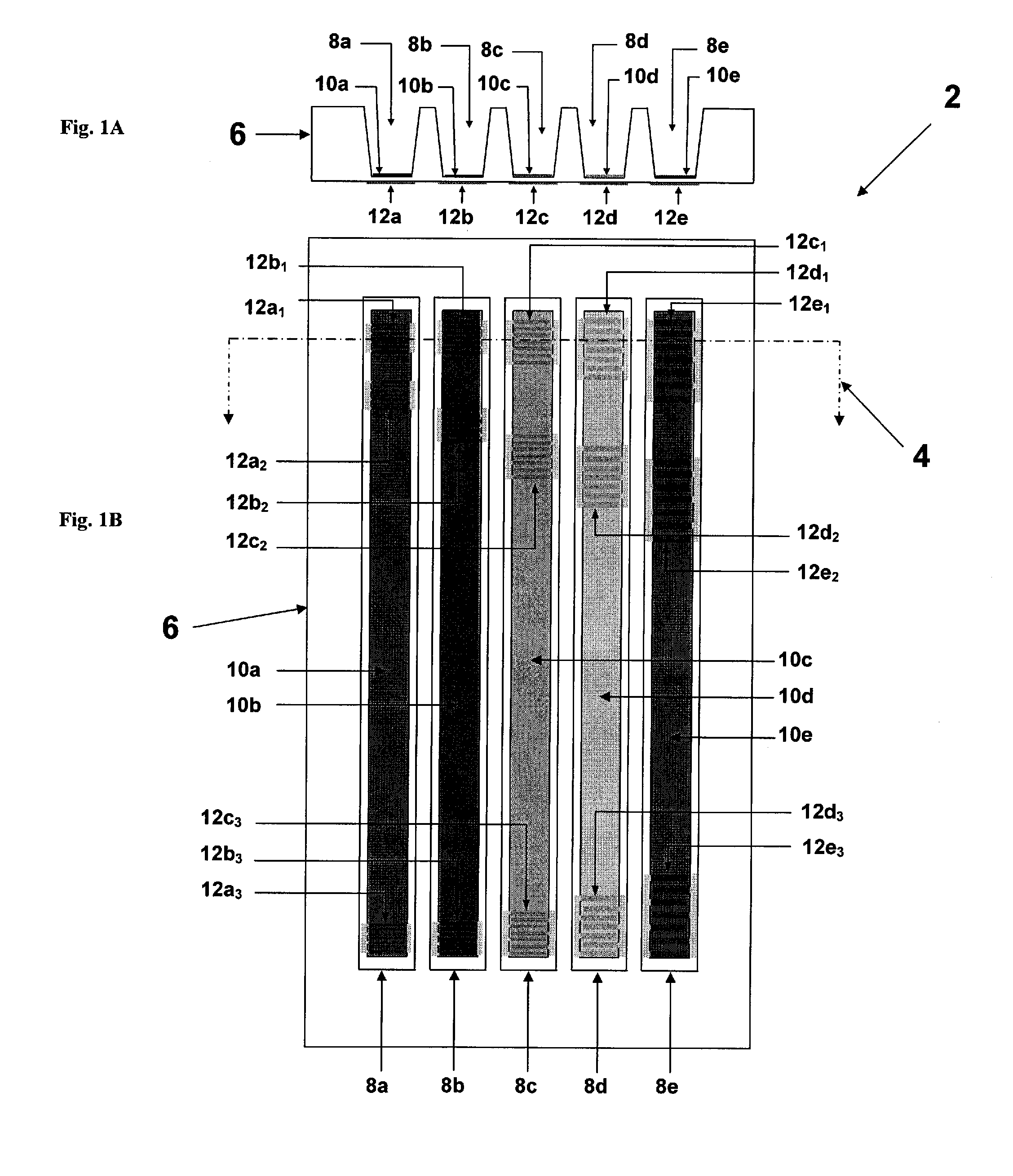

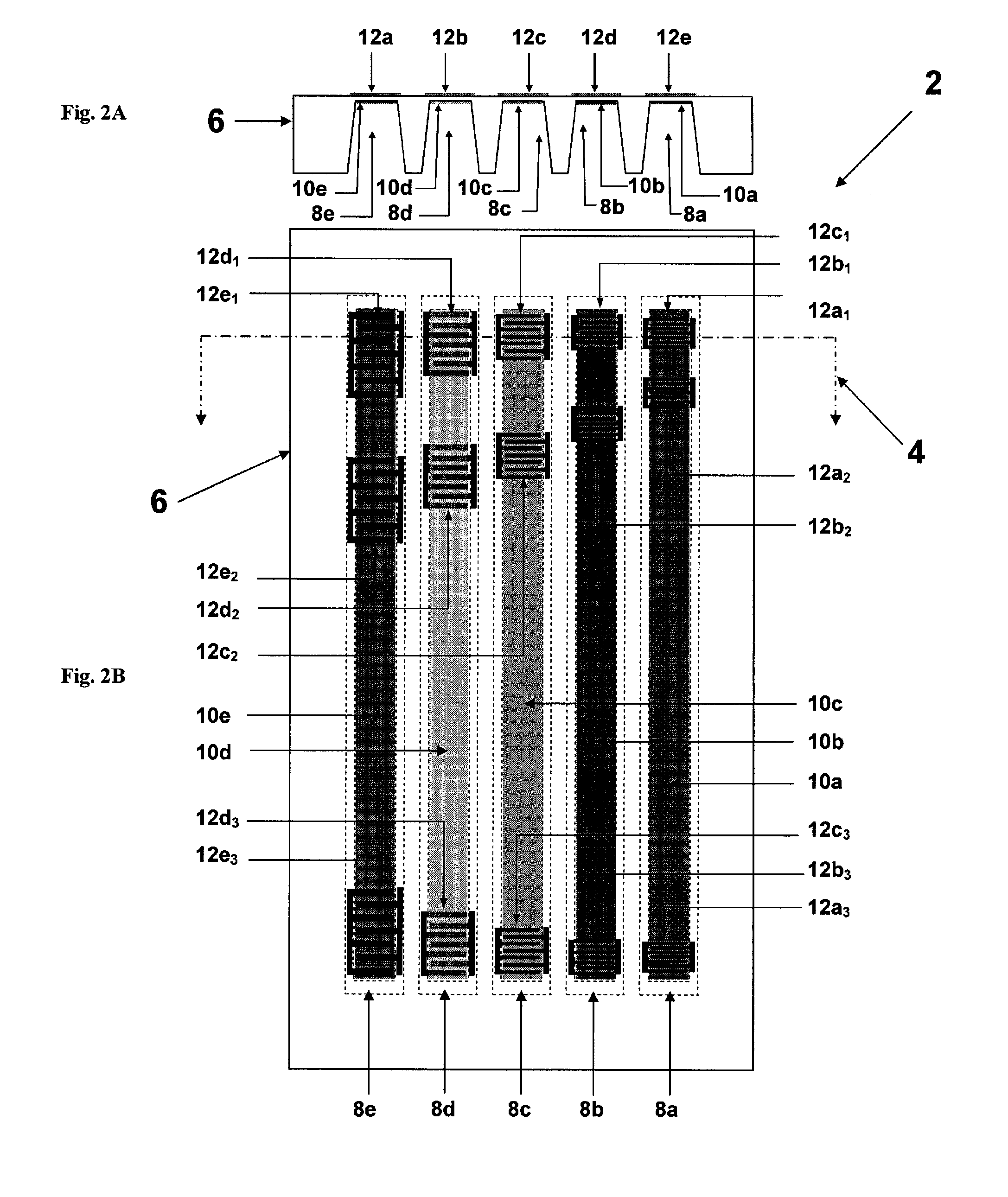

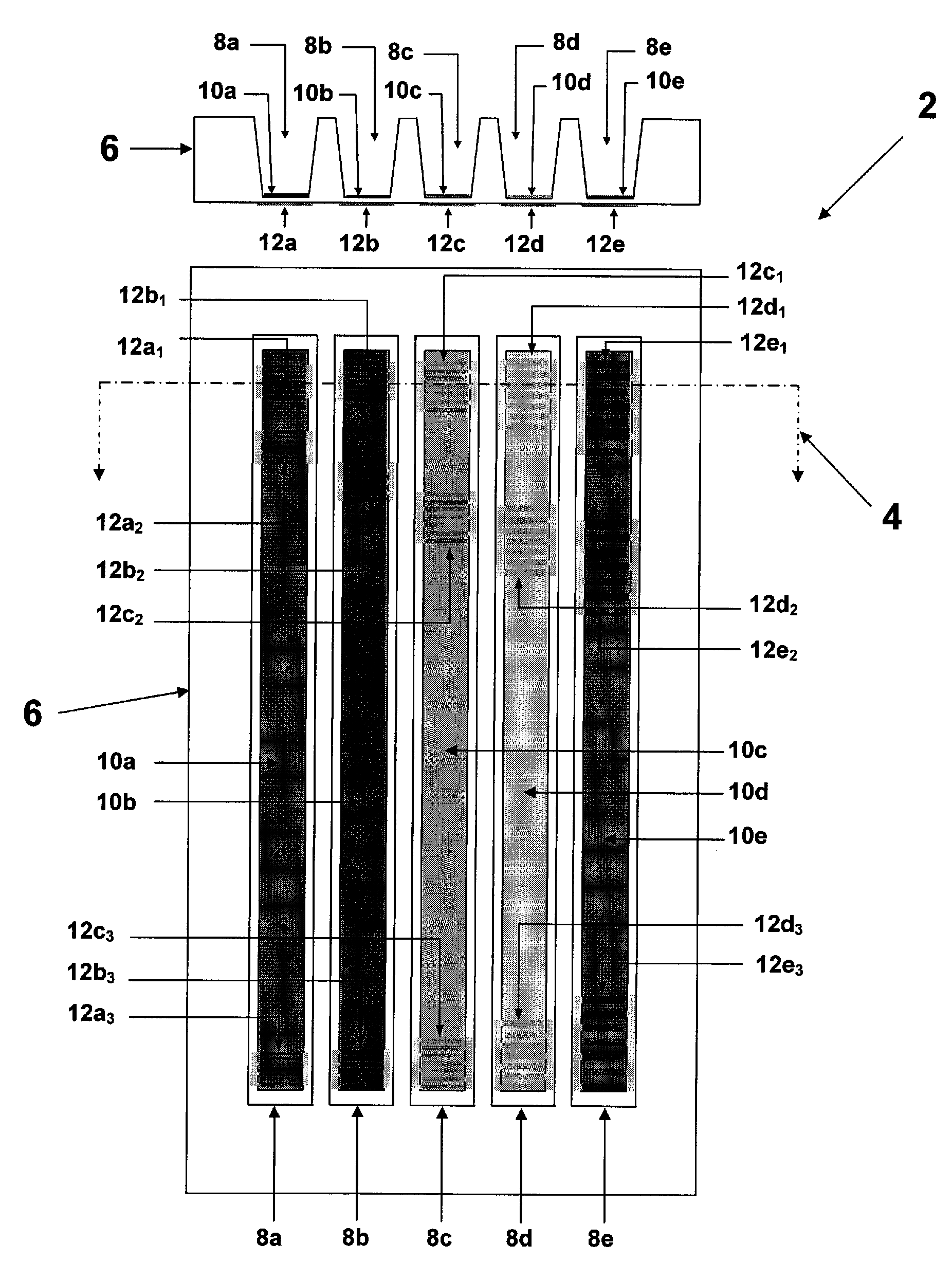

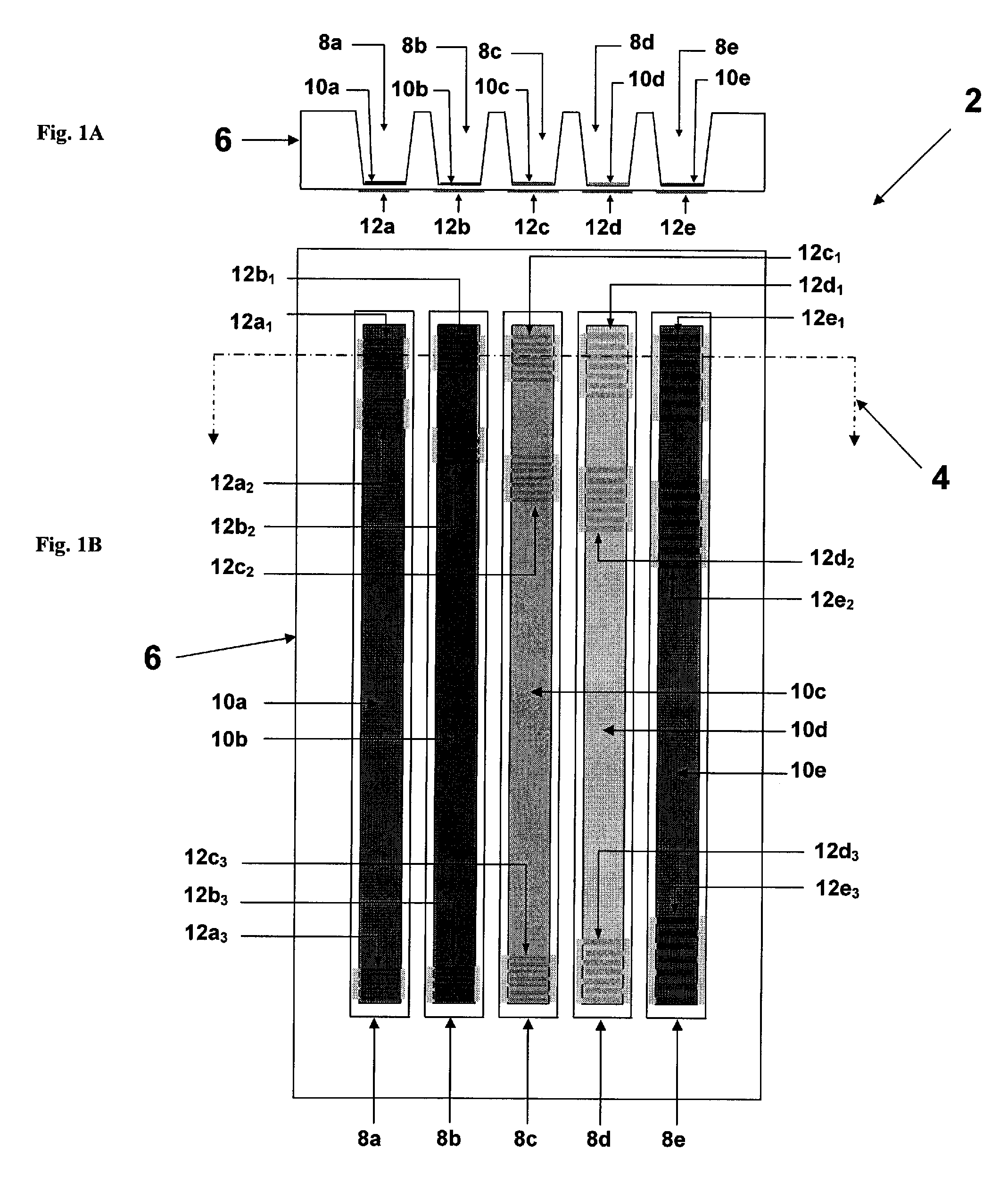

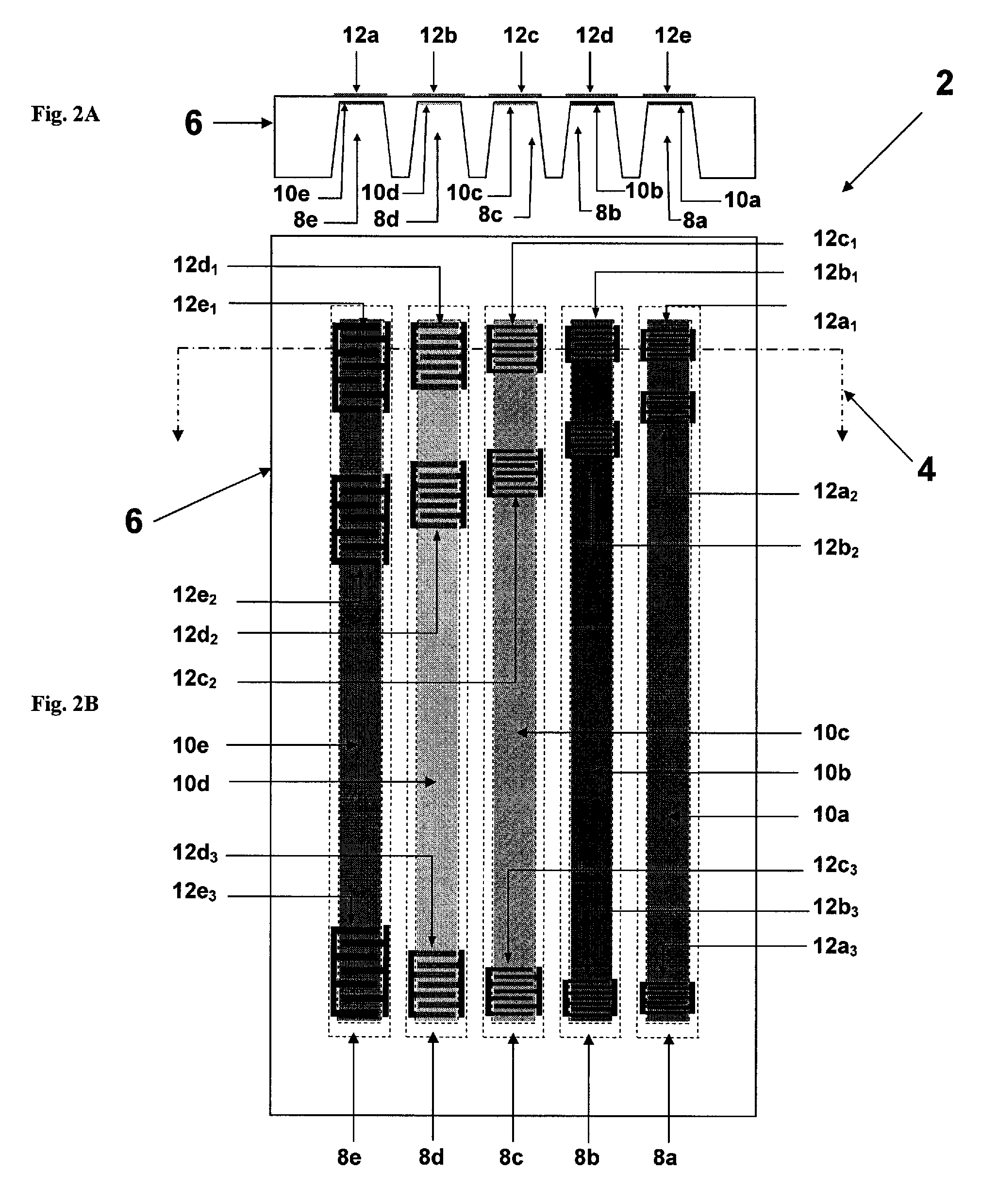

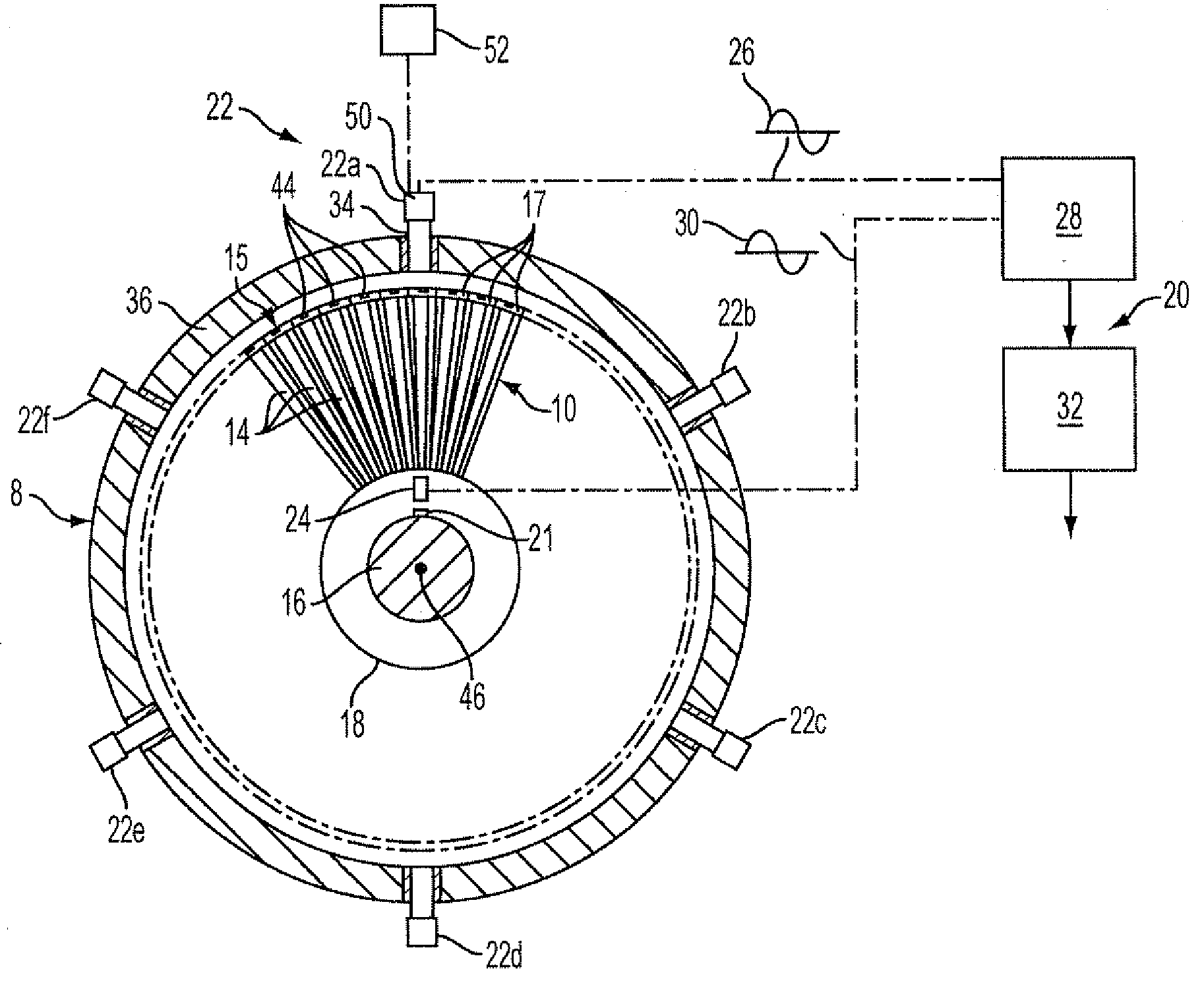

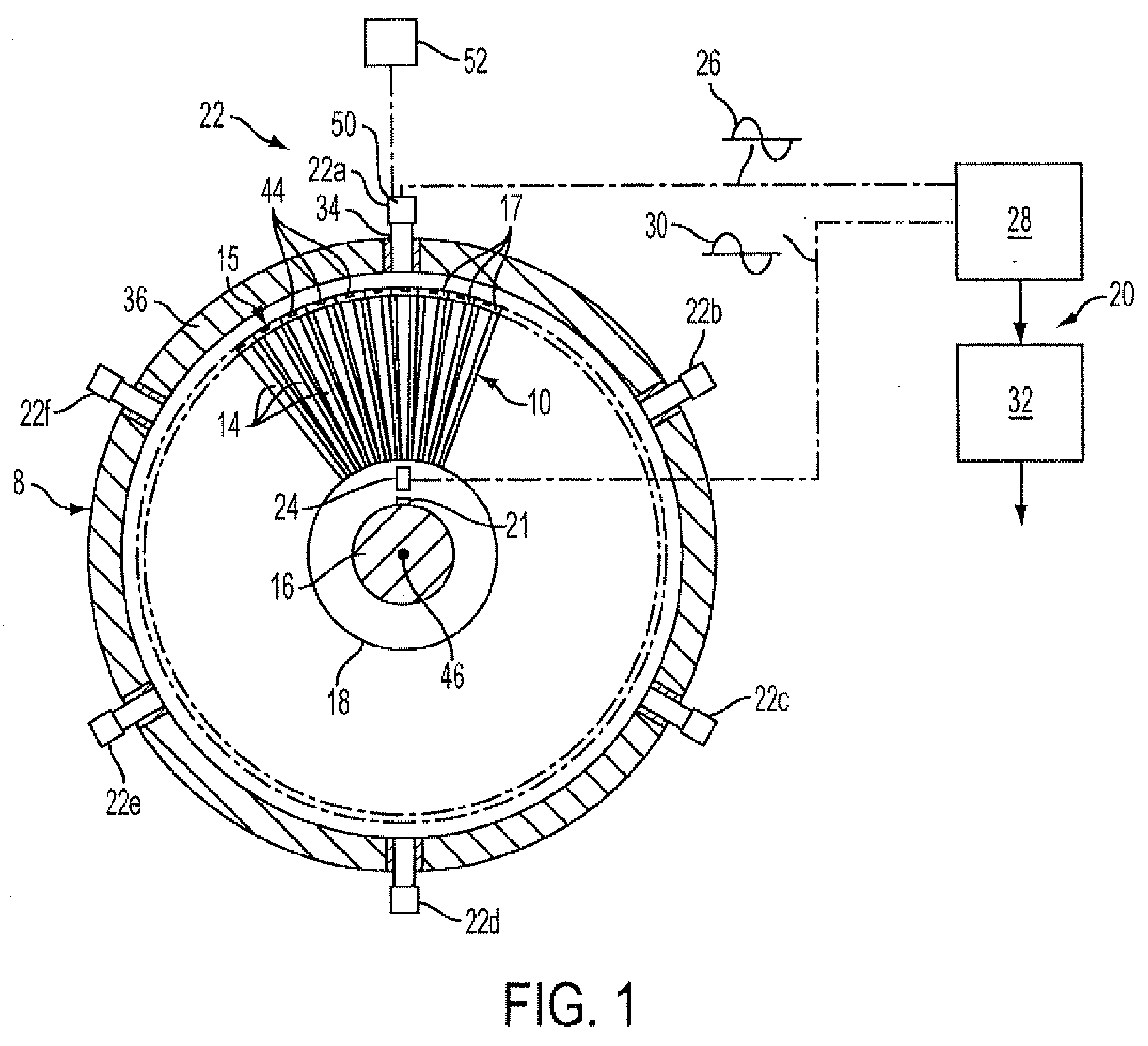

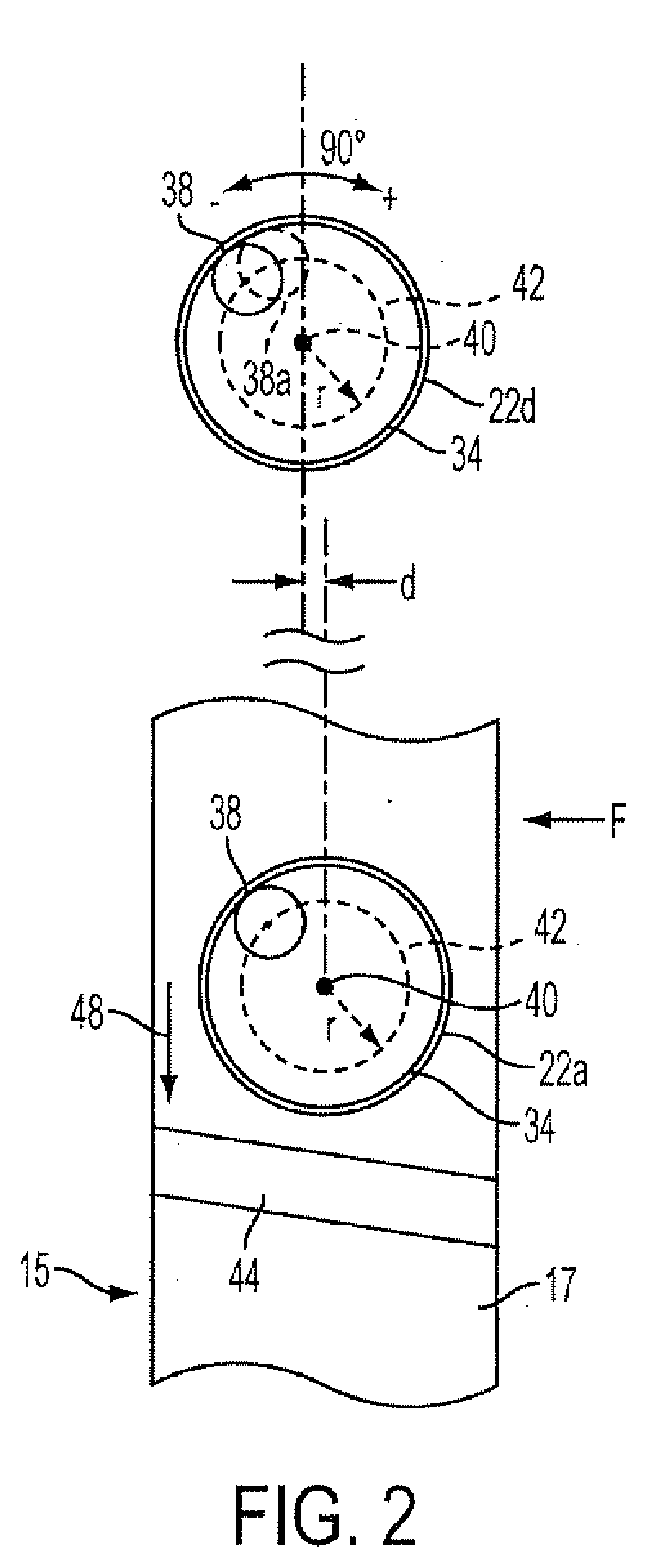

Acoustic wave array chemical and biological sensor

ActiveUS20080156100A1Simultaneous measurementImprove sensor sensitivityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSensor arrayAnalyte

An acoustic wave sensor array device is provided for the detection, identification, and quantification of chemicals and biological elements dispersed in fluids. The sensor array device is capable of the simultaneous characterization of a fluid for multiple analytes of interest. A substrate has a plurality of channels formed therein and a sensor material layer applied in a bottom of the channels. The sensor material layer has a shear acoustic wave speed lower than a shear acoustic wave speed in said substrate. The channels may have the same material in each channel or different materials in at least two of the channels. A surface acoustic wave transducer and at least one surface acoustic wave reflector, or at least two transducers is formed on a surface of the substrate opposite the channels at a portion of the substrate that is thinned by the channels, so that the acoustic tracks of the surface acoustic wave device extend along the channels. The response of the surface acoustic wave depends on the response of the sensor material to a sensed fluid supplied to the channels.

Owner:SENSANNA

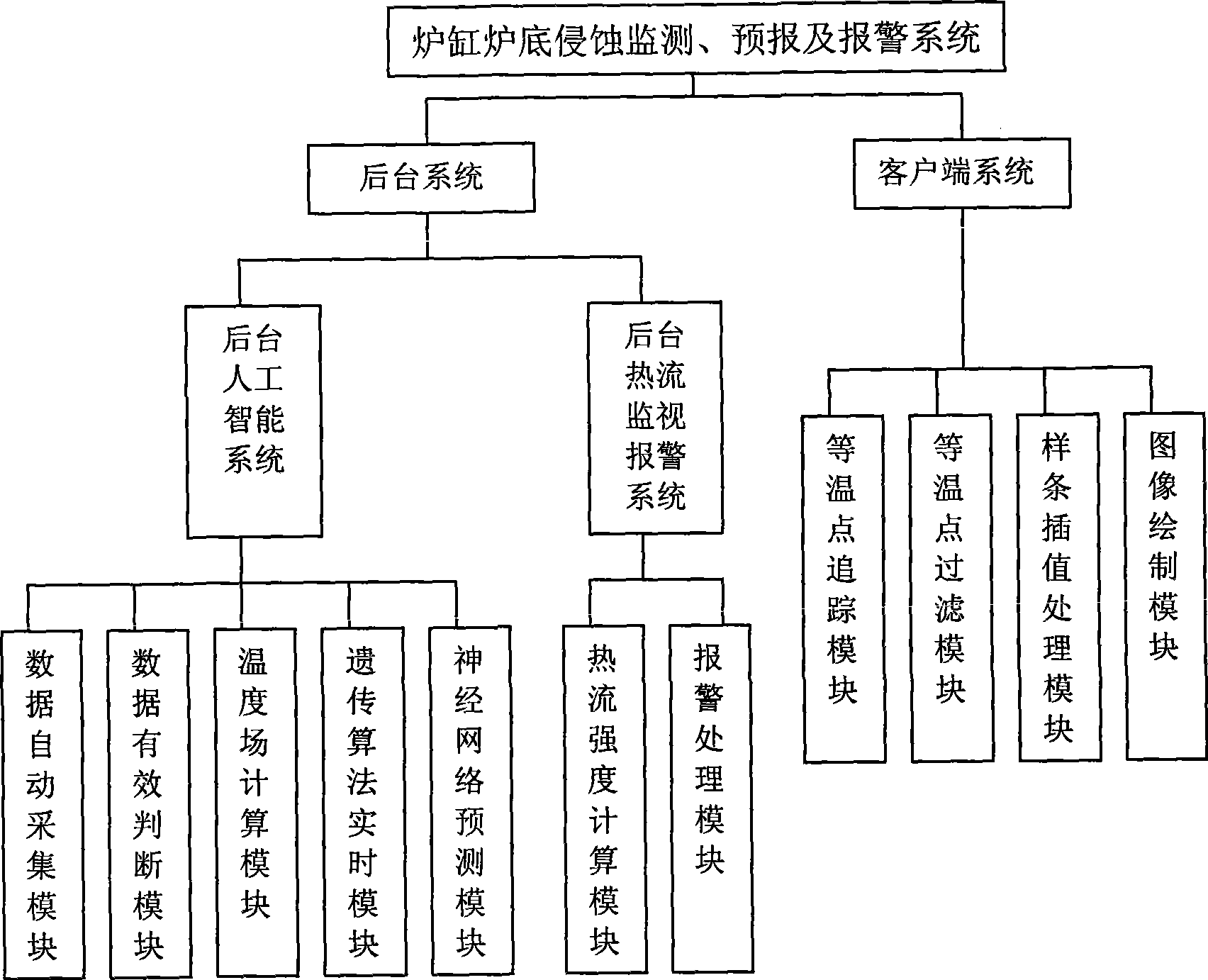

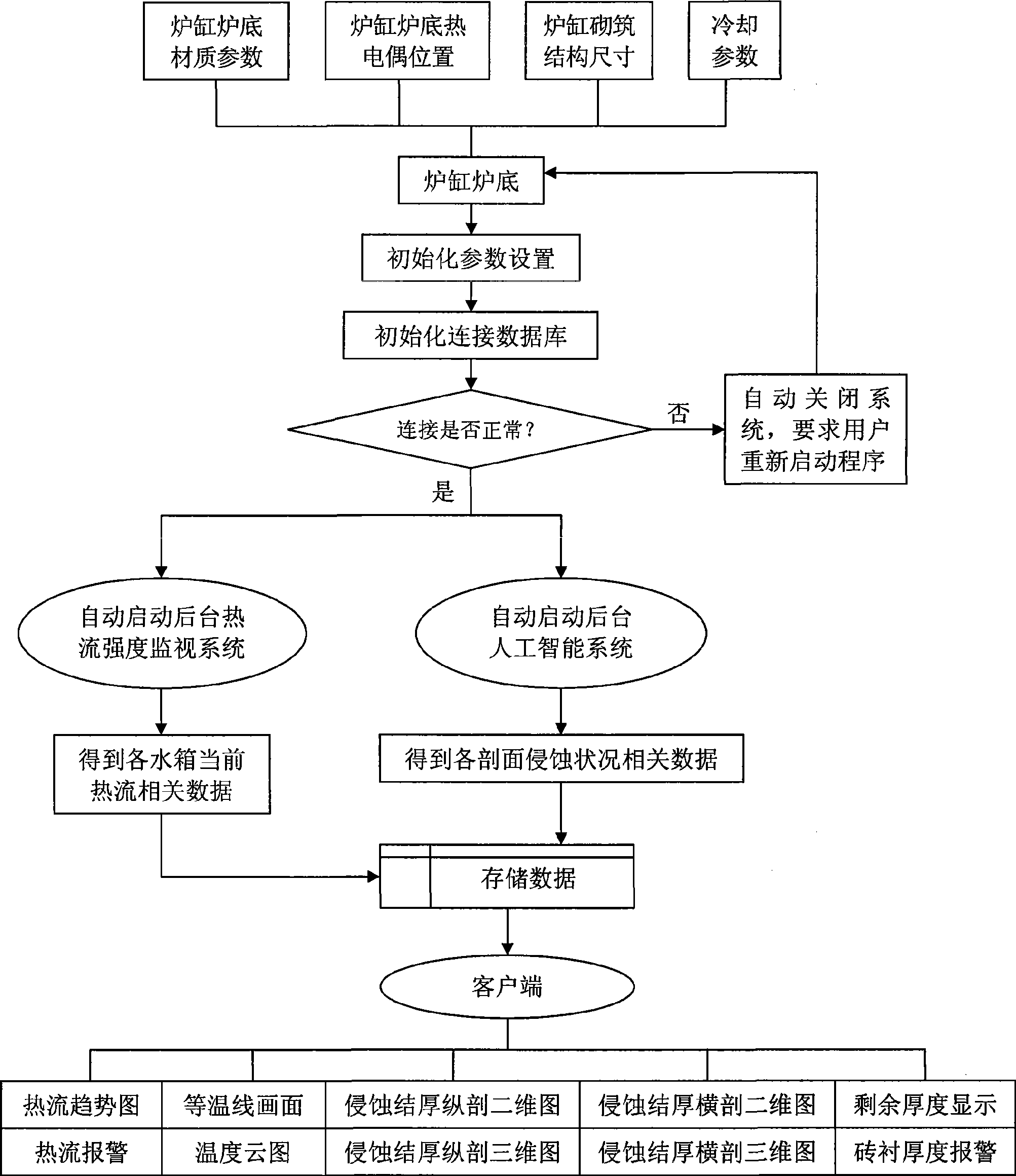

Monitoring, prediction and alarm system for blast furnace hearth and bottom

InactiveCN101457268ARealize online monitoring and alarmImplement storageThermometers using electric/magnetic elementsUsing electrical means3d imageData acquisition

A monitoring, forecasting and alarm system of the bottom and hearth of a blast furnace belongs to the longevity technical field of blast furnaces. The system comprises online monitoring and forecasting hardware and software processing modules; the online monitoring and forecasting hardware consists of a thermocouple and a cooling system which are laid at the furnace hearth and the furnace bottom, and a database of the blast furnace production process is connected by the Ethernet; the software processing modules comprise a data acquisition module, a data validity judgment module, a temperature field computation module, an improved genetic algorithm module, a B-P neural network module, a database, an isotherm, an erosion and thickening image display module, a 3D imaging module, a heat flow monitoring and alarm module and a historical data query module; and the software processing modules are operated on an industrial control computer. The monitoring, forecasting and alarm system has the advantages of low investment, reliability and visualization. The system provides an objective and quantized basis for the erosion and thickening erosion condition of the furnace hearth and the furnace bottom in the blast furnace ironmaking process, and helps a blast furnace operator timely know the condition of the furnace hearth and the furnace bottom and take effective furnace protection measures so as to prolong the service life of the blast furnace.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

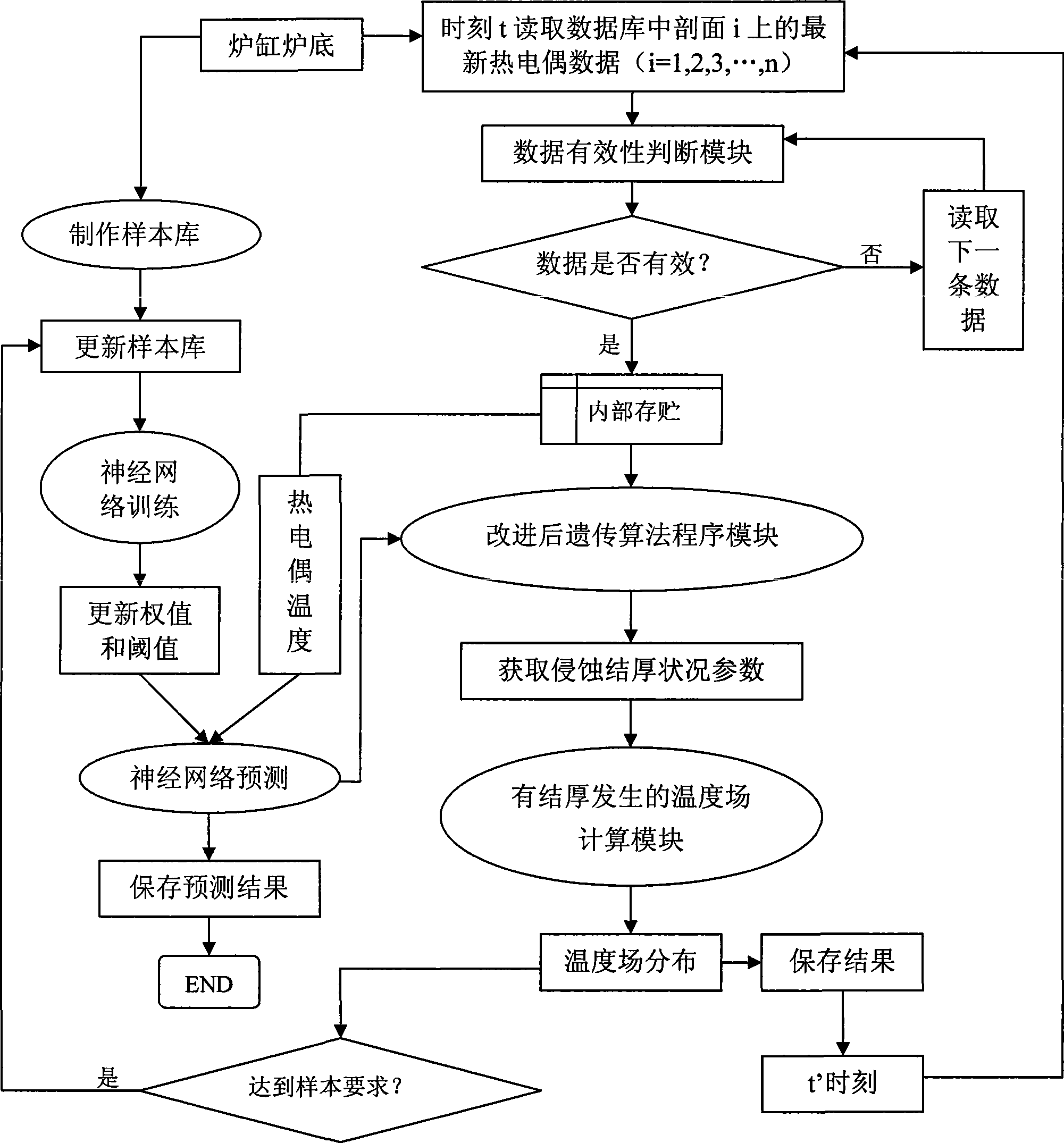

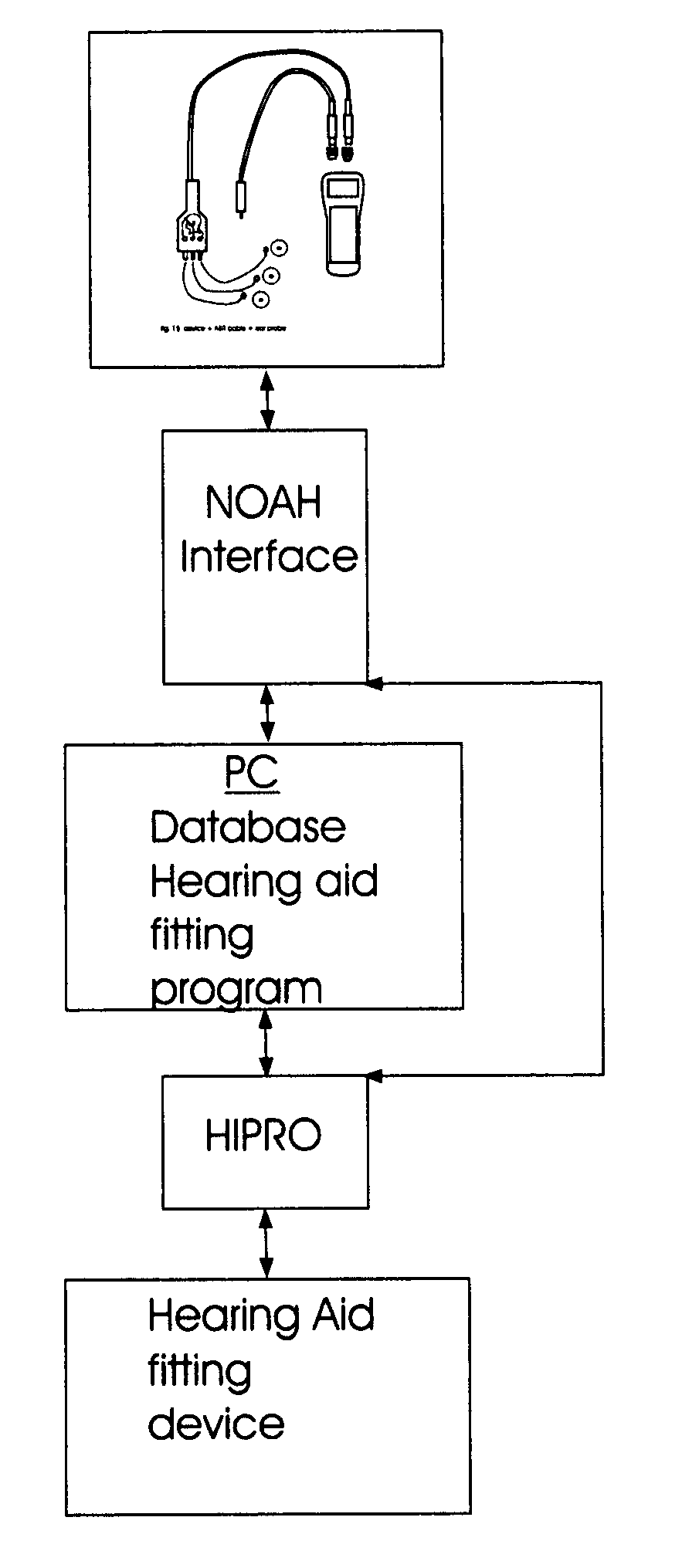

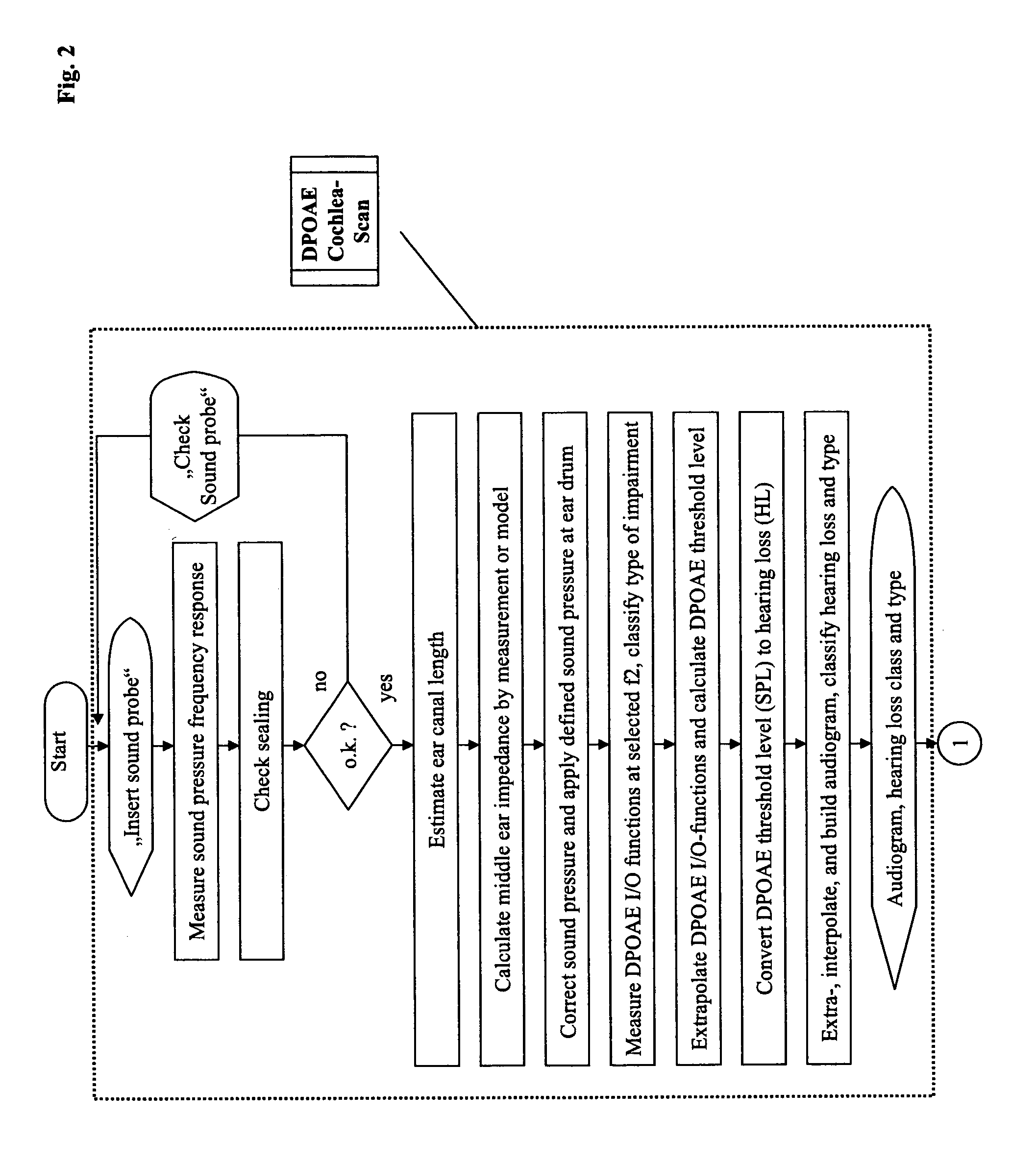

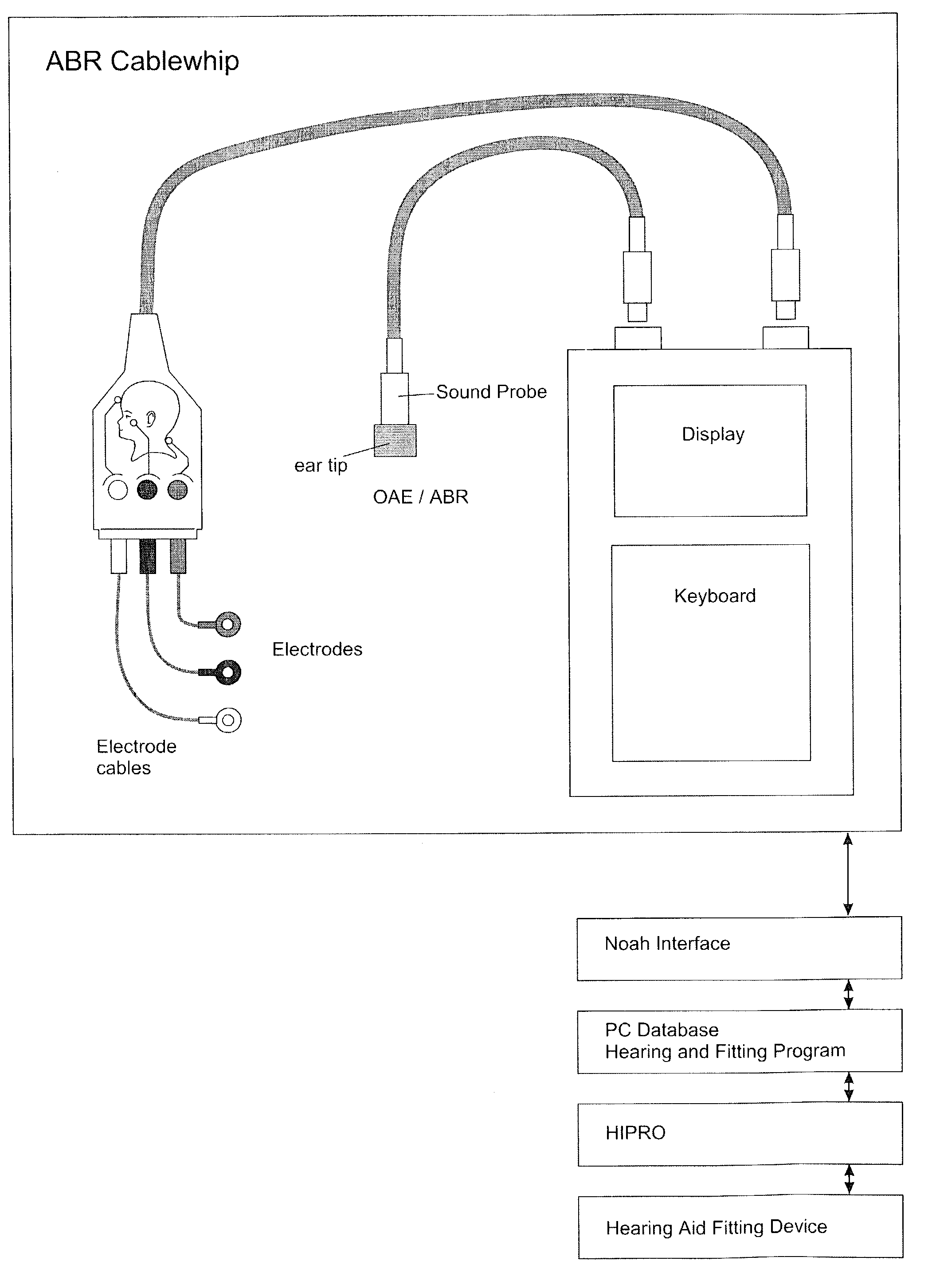

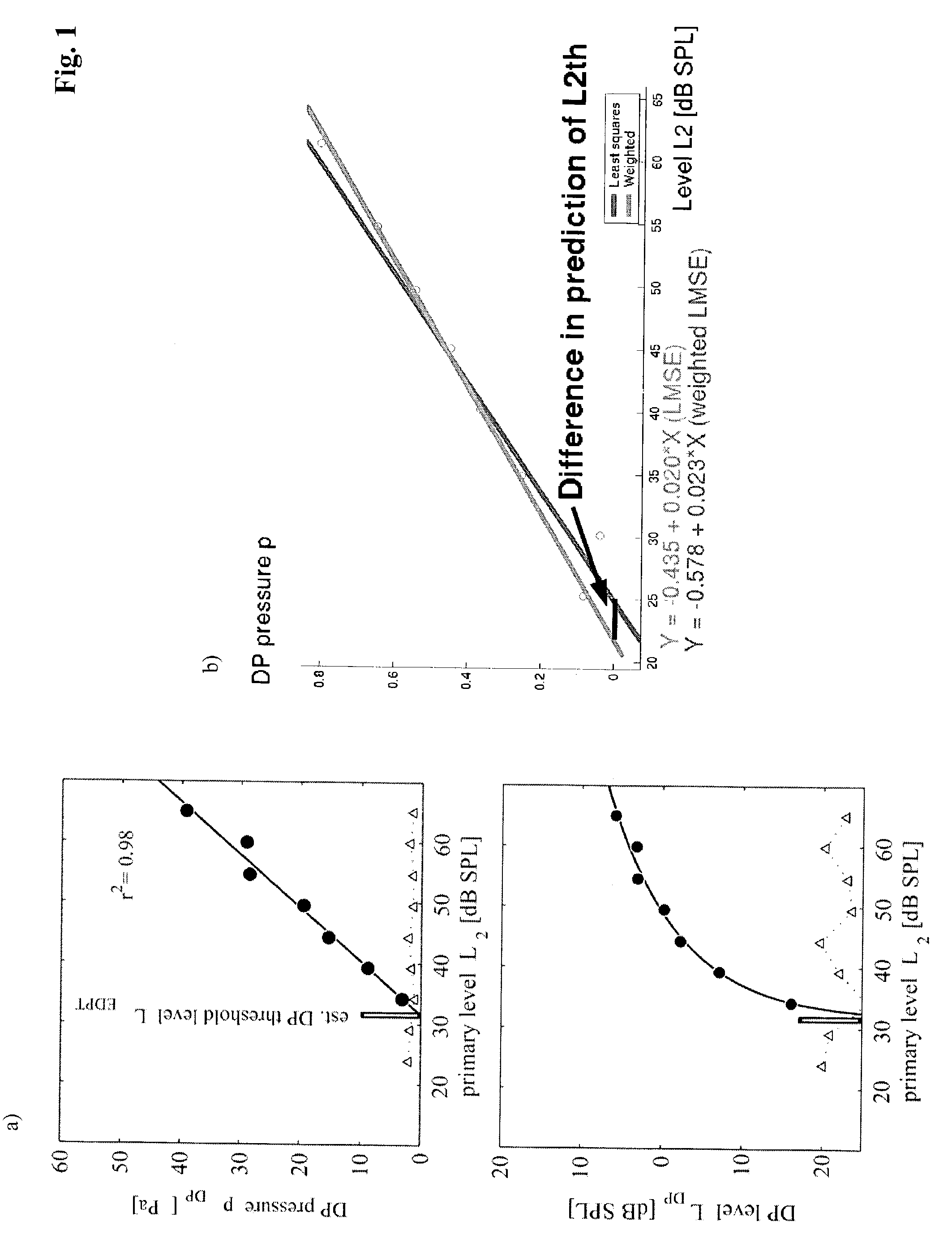

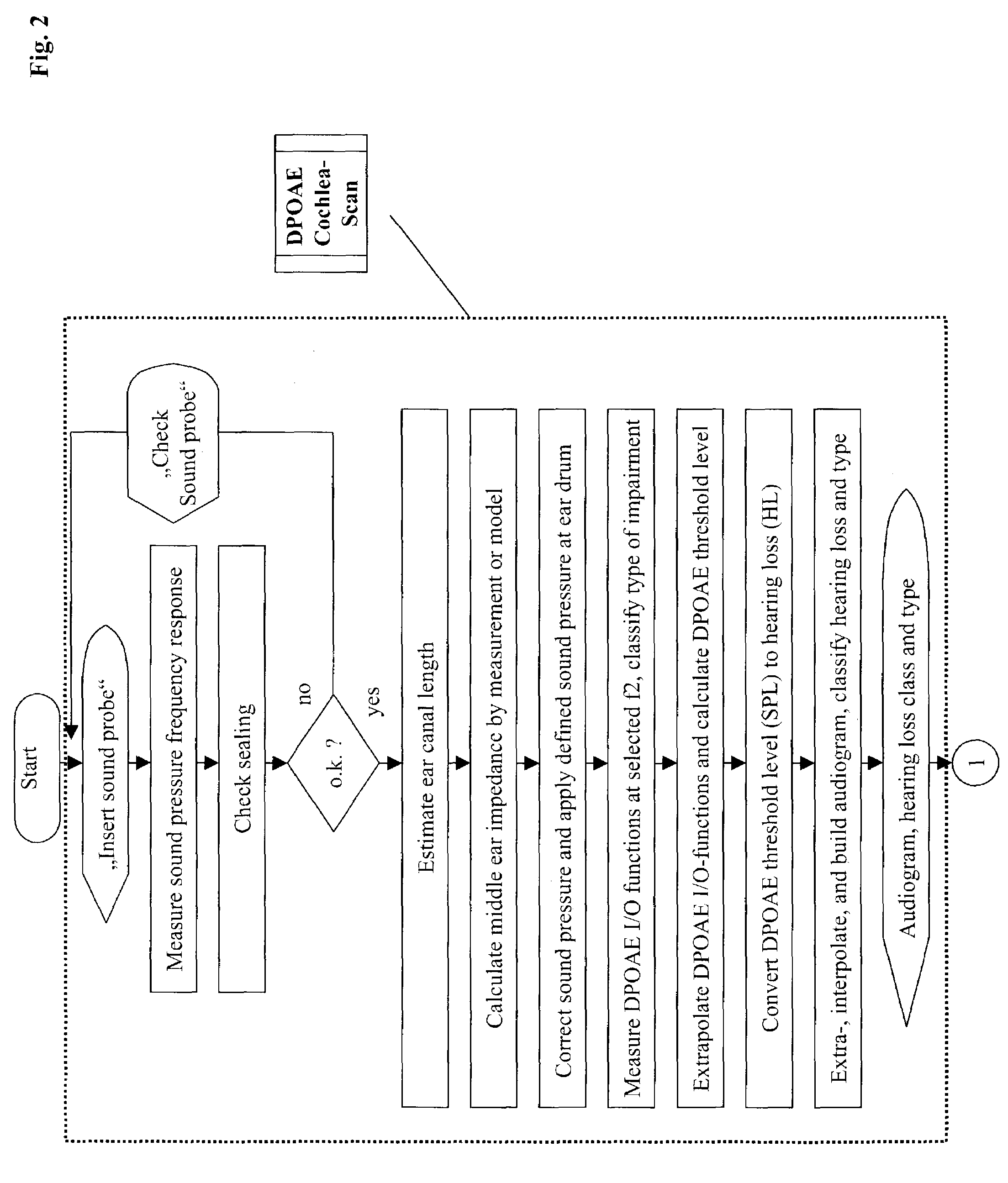

Method and apparatus for automatic non-cooperative frequency specific assessment of hearing impairment and fitting of hearing aids

ActiveUS20070156063A1High frequency resolutionMany timesVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSmall brainstemHearing perception

A method and device for automatically assessing loss of hearing sensitivity and compression (recruitment) with user defined frequency resolution by means of extrapolated DPOAE I / O functions and ABRs as well as for automatically fitting hearing aids without any cooperation of the subject tested using a device having a display screen attached to a handheld device generating and collecting otoacoustic emission signals and brain stem response signals into a programmed with a clinical audiogram with fitting parameters for hearing aids calculated on the basis of assessed hearing threshold and compression and identifying the type of hearing required for the individual.

Owner:NATUS MEDICAL

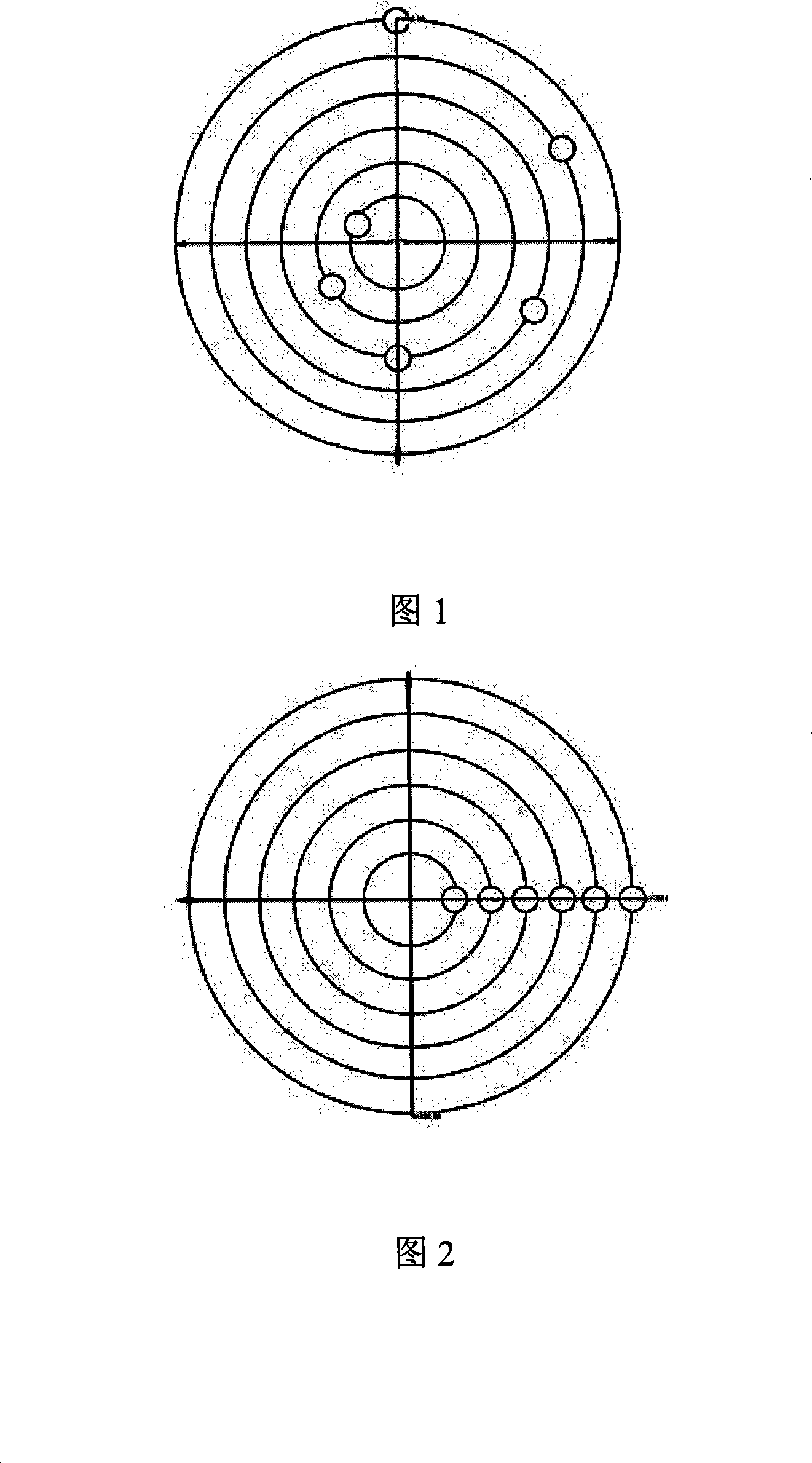

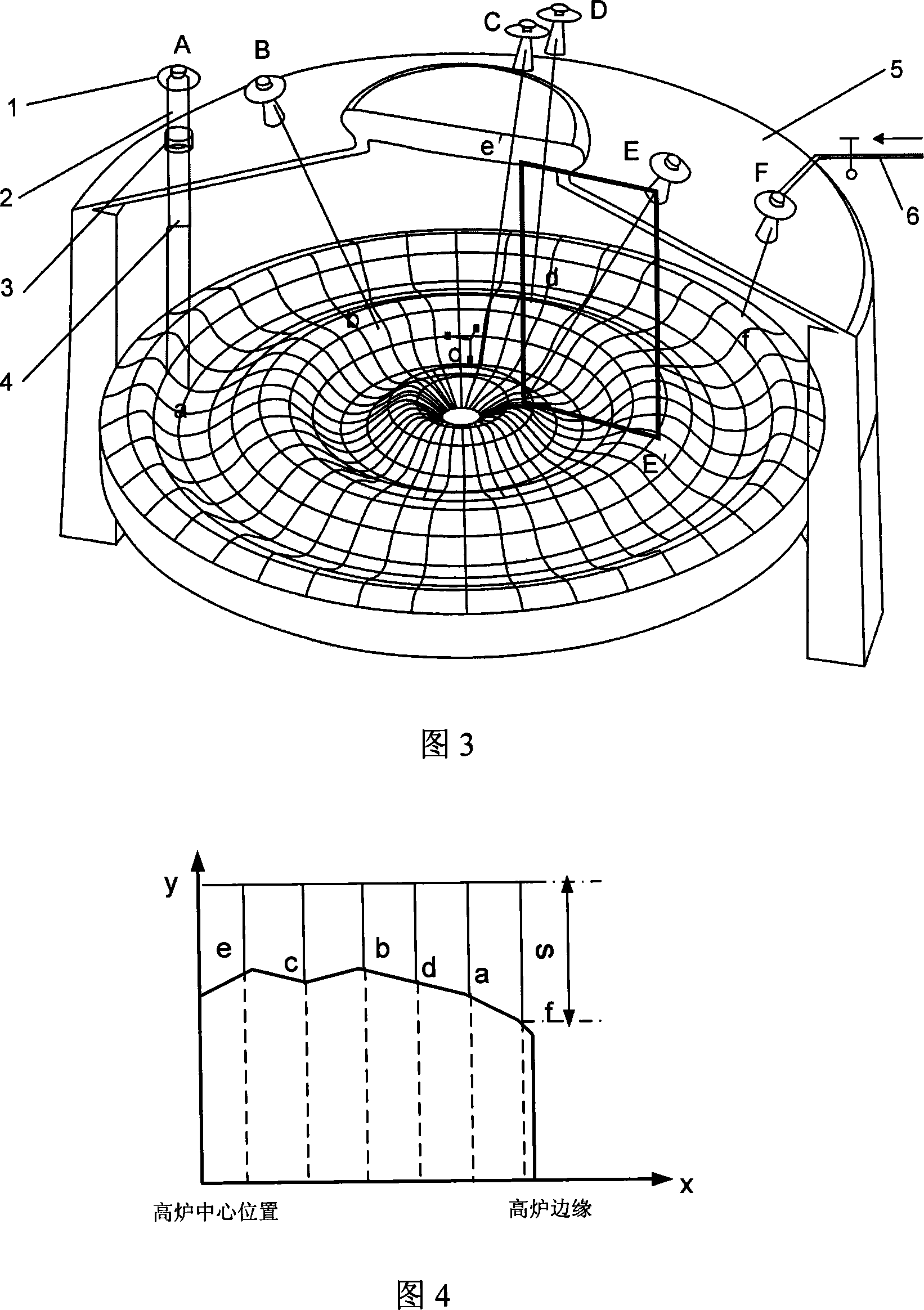

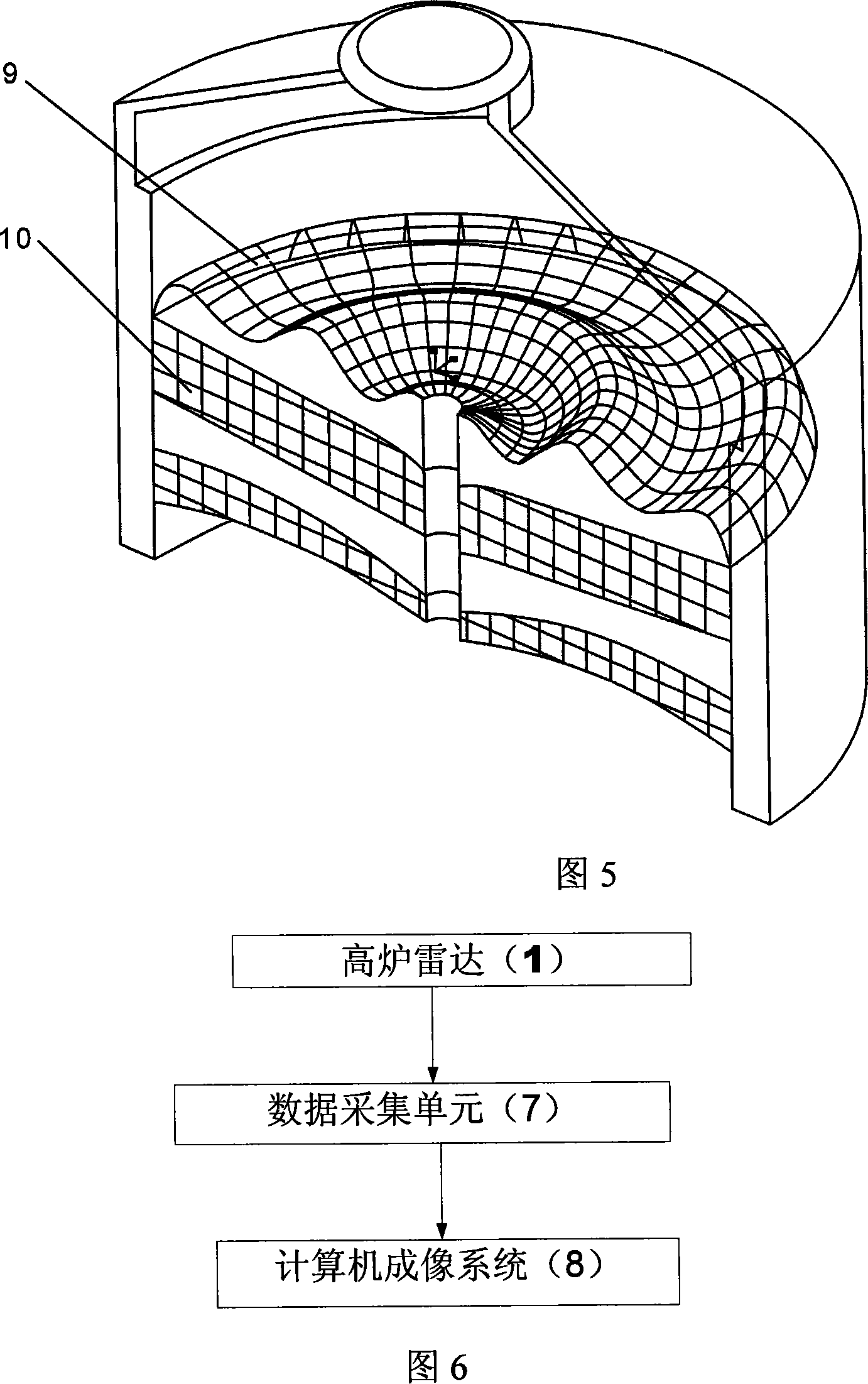

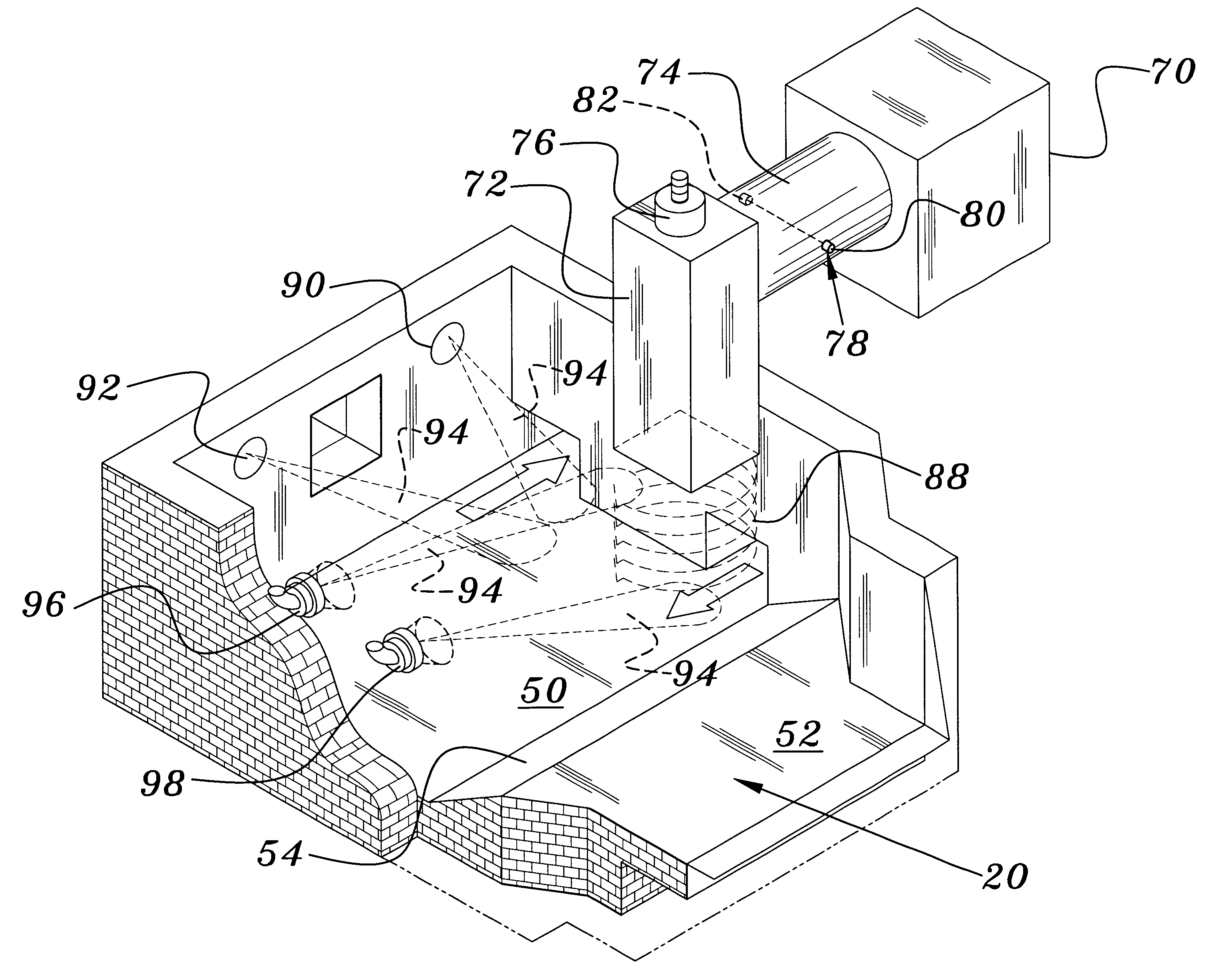

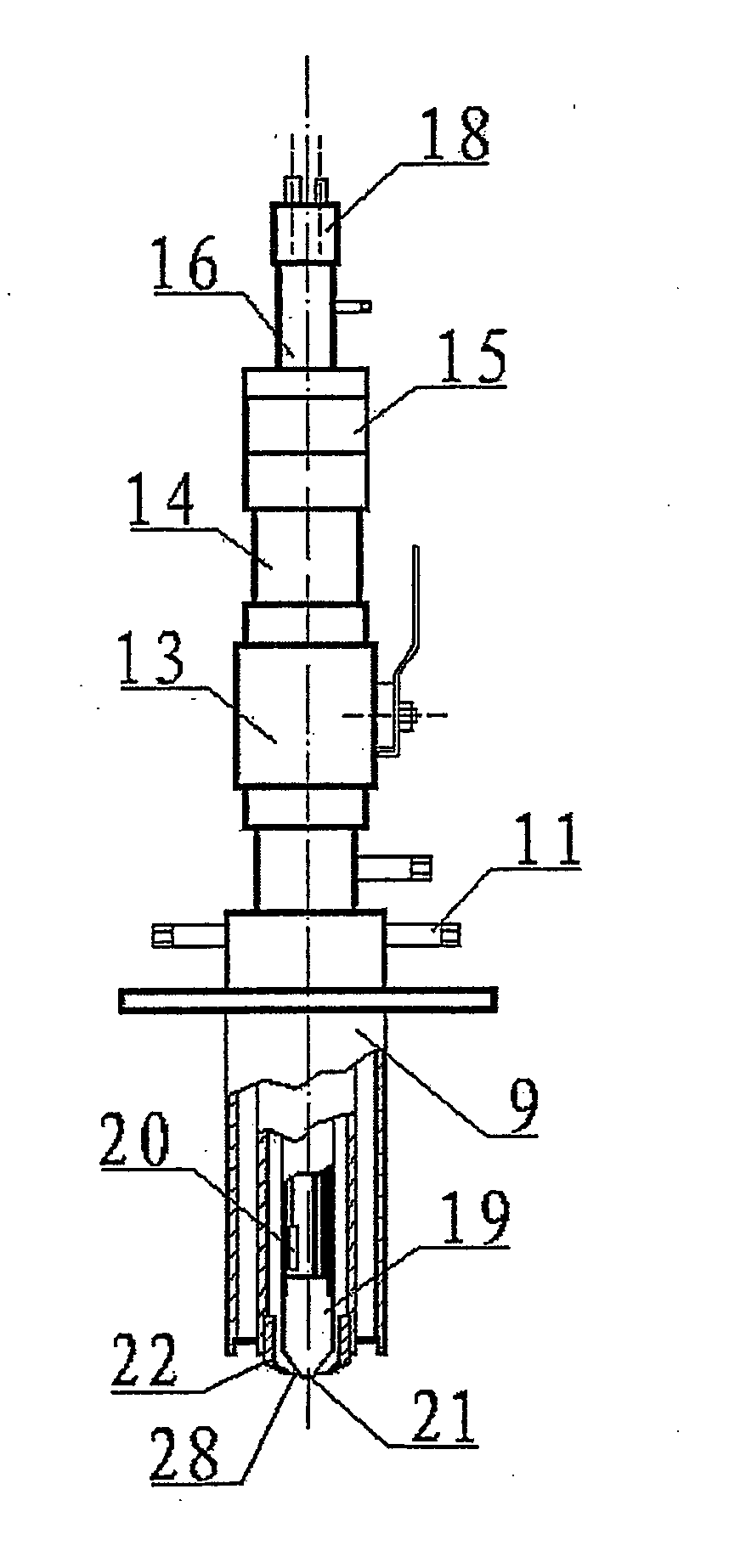

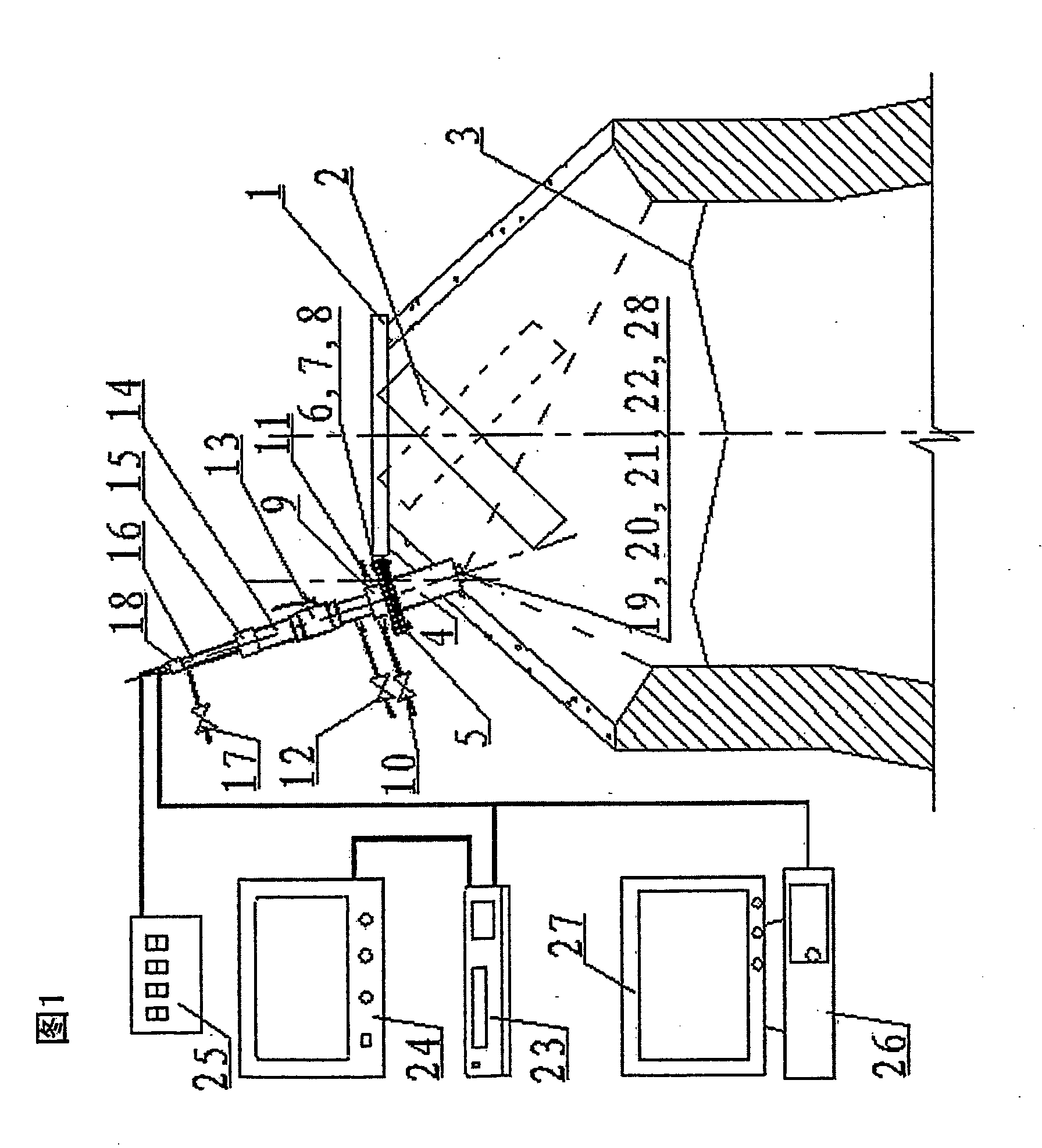

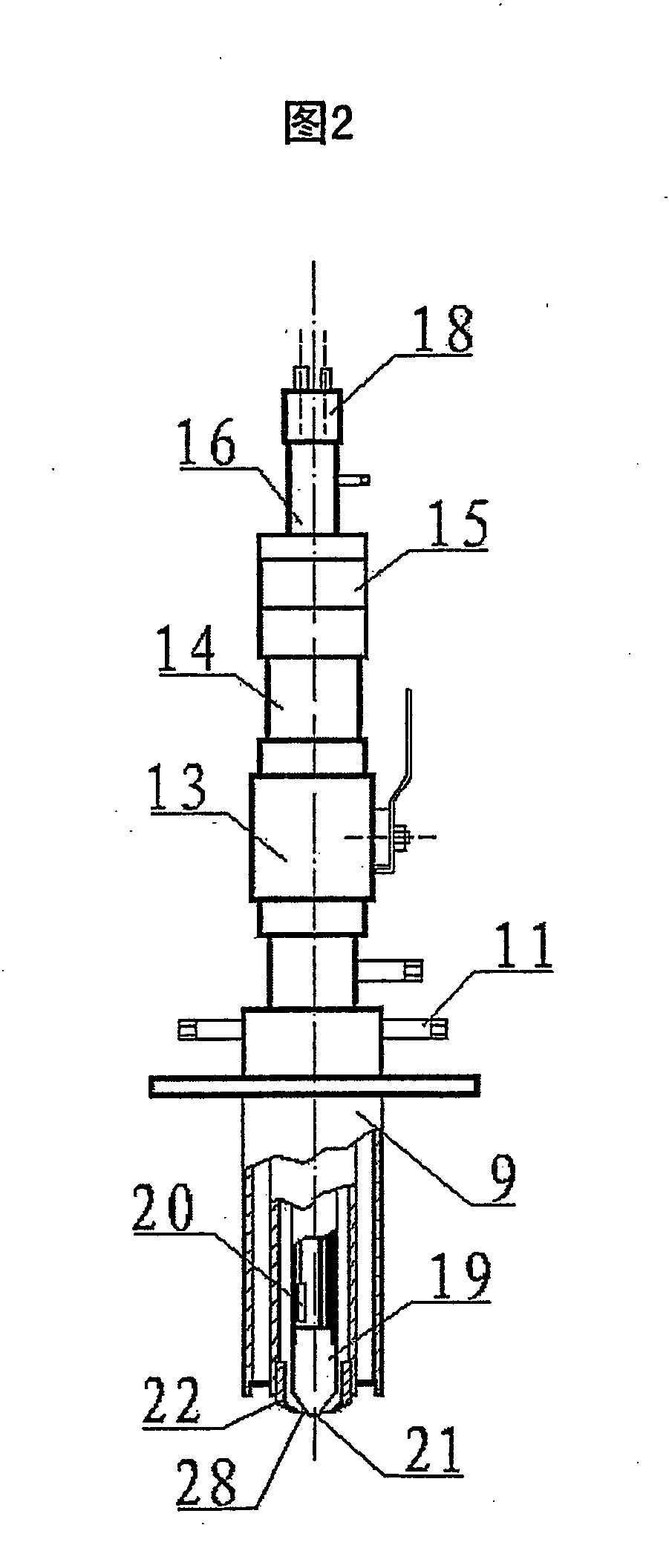

Dynamic stereo monitoring system and detection method for charge surface shape in blast furnace

The dynamic stereo monitoring system and detection method for charge surface shape in blast furnace belongs to the field of electronic measurement technology and computerized 3D technology. The dynamic stereo monitoring system includes radar, sleeves, a valve, a blast furnace, a radar data acquiring unit with a 24 channel signal access terminal board and a data acquisition board, and an imaging system comprising an industrial control computer and complementary monitoring software. The detection process includes the following steps: the real-time communication between the radar and radar data acquiring unit, converting inclined measured data into vertical curve data, and creating the 3D charge surface shape data. The present invention can realize the on-line real-time monitoring of charge surface shape in blast furnace under harsh operation condition.

Owner:北京普瑞玛仪表有限公司

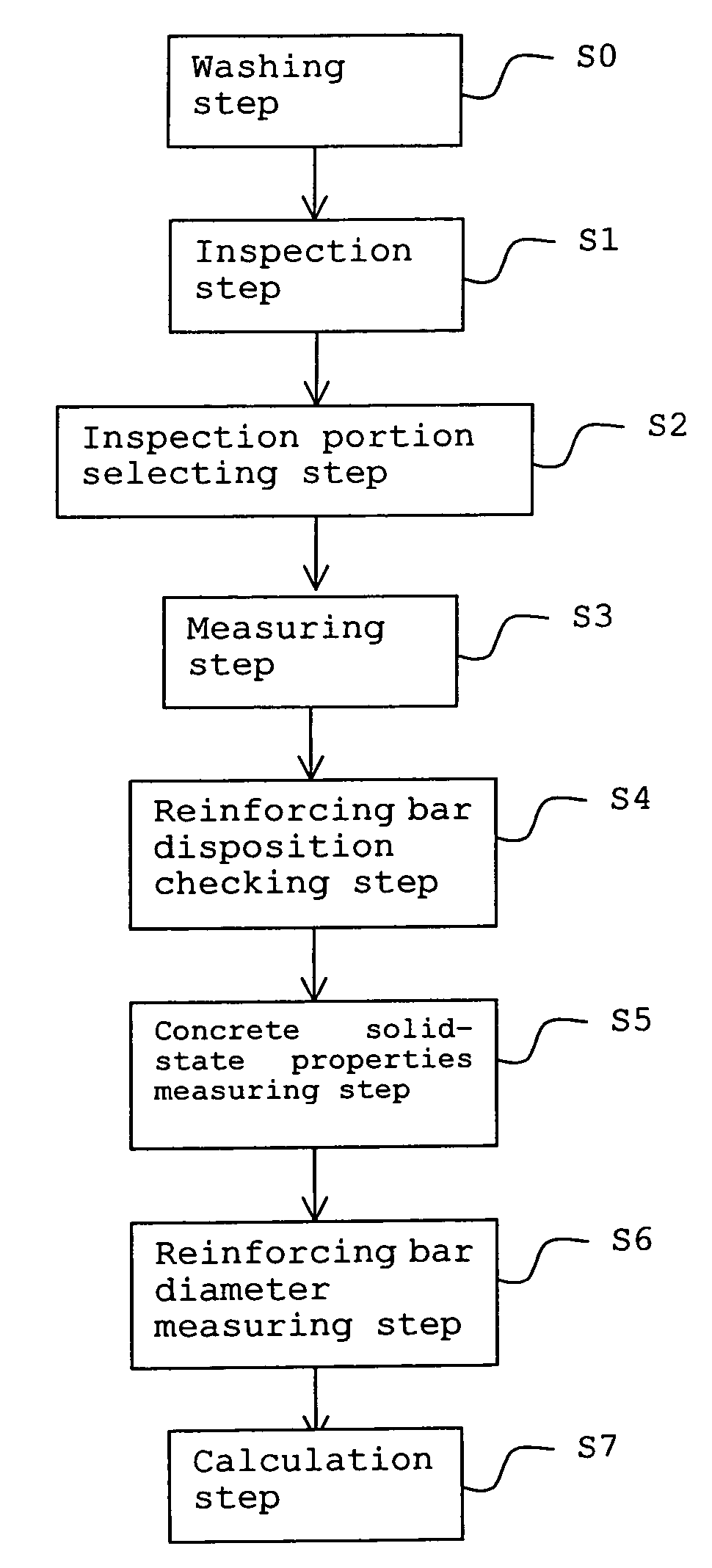

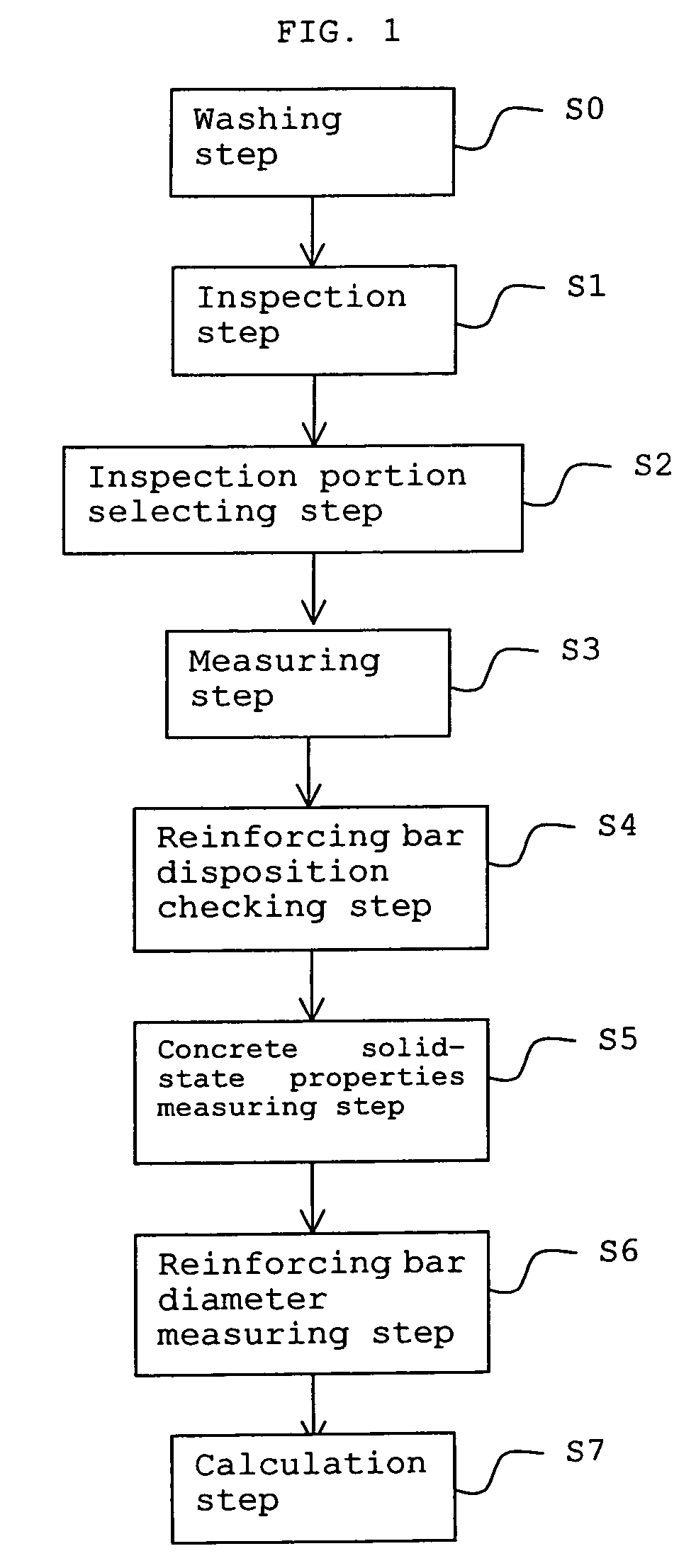

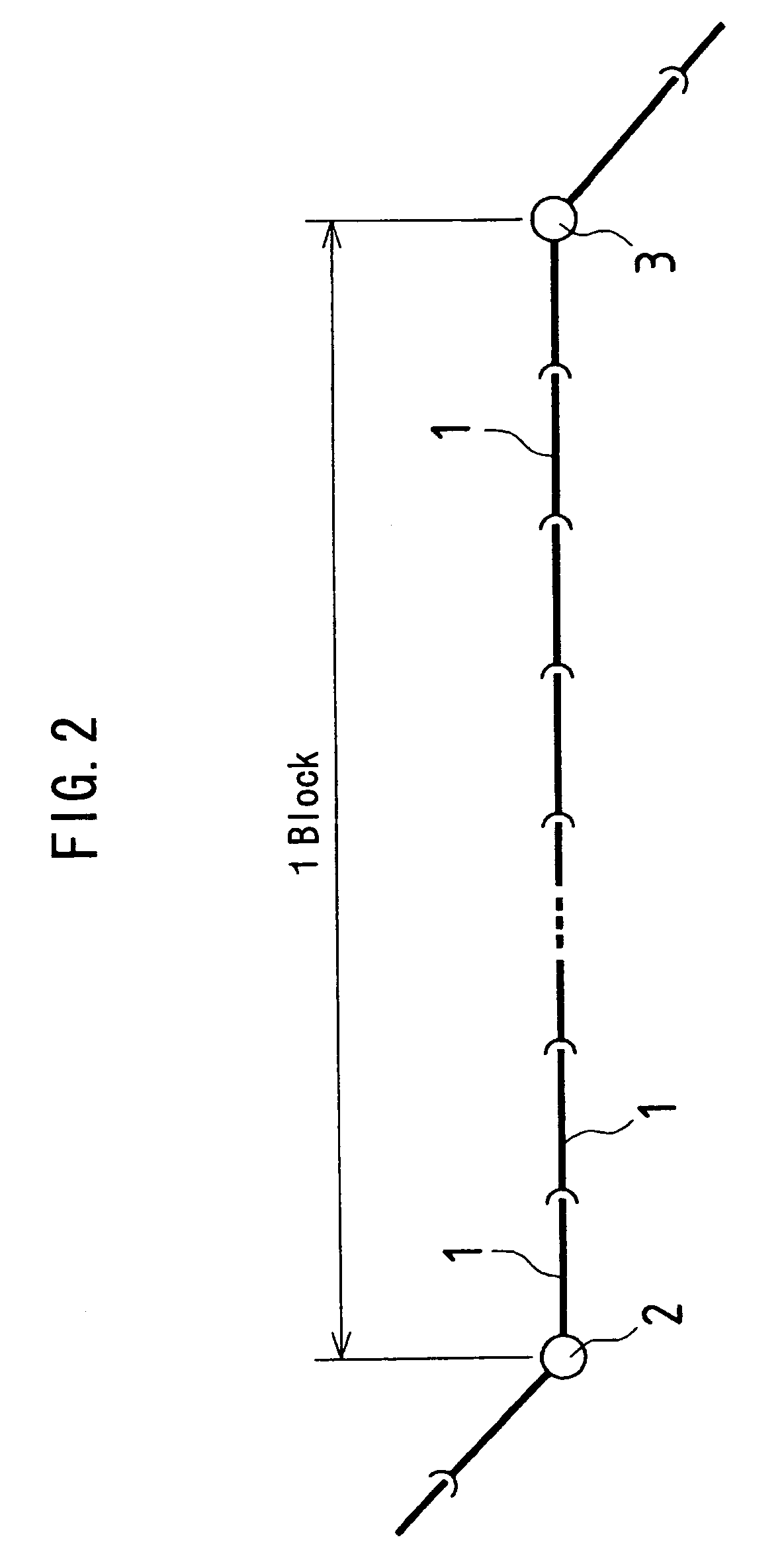

Method and equipment for inspecting reinforced concrete pipe

InactiveUS7360462B2Shorten operation timeImprove accuracyVibration measurement in solidsDetection of fluid at leakage pointReinforced concreteStructural analysis

Deterioration of reinforced concrete pipes is checked and the deterioration progress level is classified. Based on the inspection result, a portion to be inspected in detail in an inspection area is selected. With respect to the selected portion to be inspected in detail, the pipe thickness and the diameter of reinforcing bars are measured and the location of reinforcing bars in the portion to be inspected in detail are checked. Using the data of the thickness of a pipe, the diameter of the reinforcing bar and disposition of the reinforcing bars, structural analysis is carried out and the strength of the reinforced concrete pipe is calculated. The calculation result is used as information for evaluating the deterioration state of the reinforced concrete pipe.

Owner:SEKISUI CHEM CO LTD

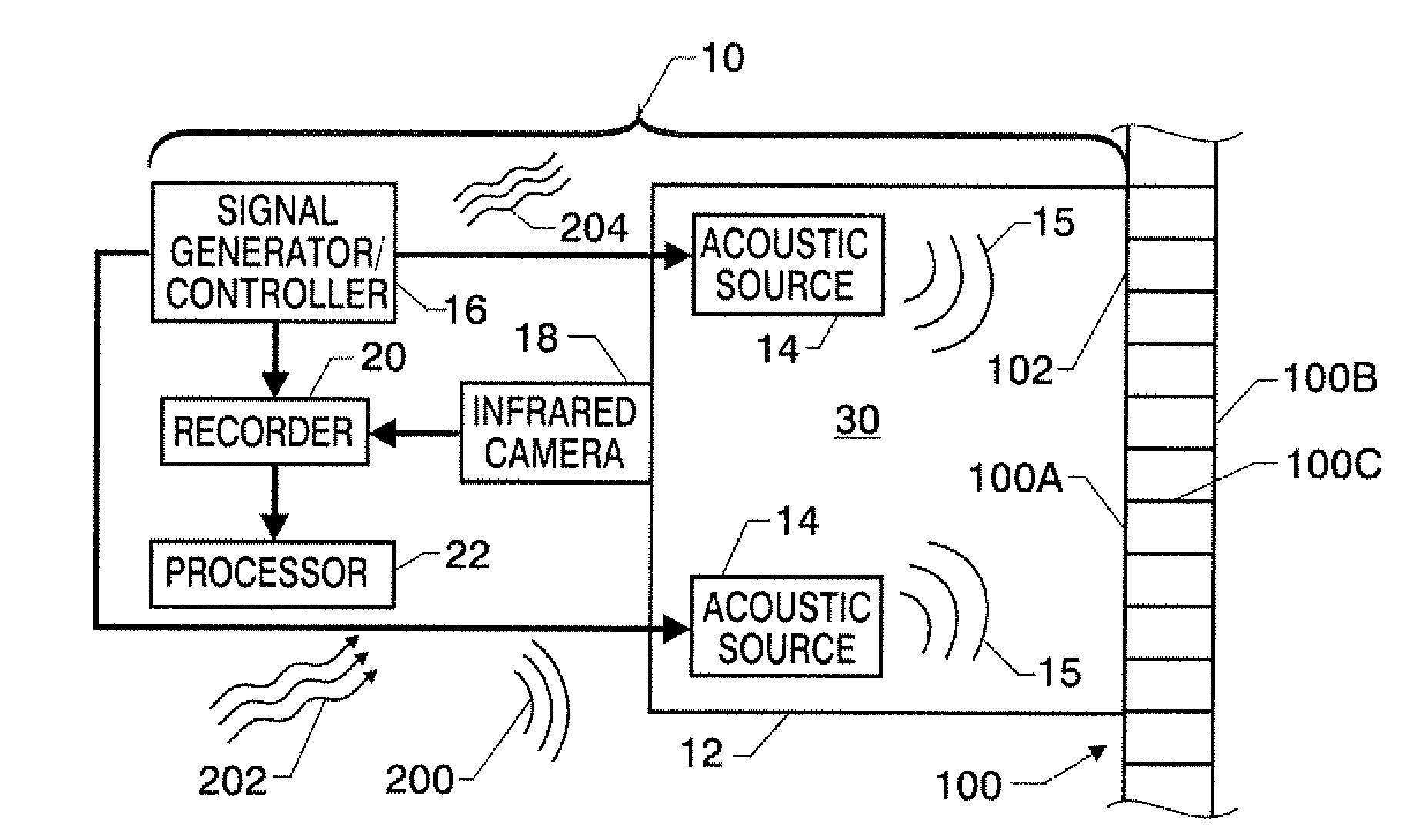

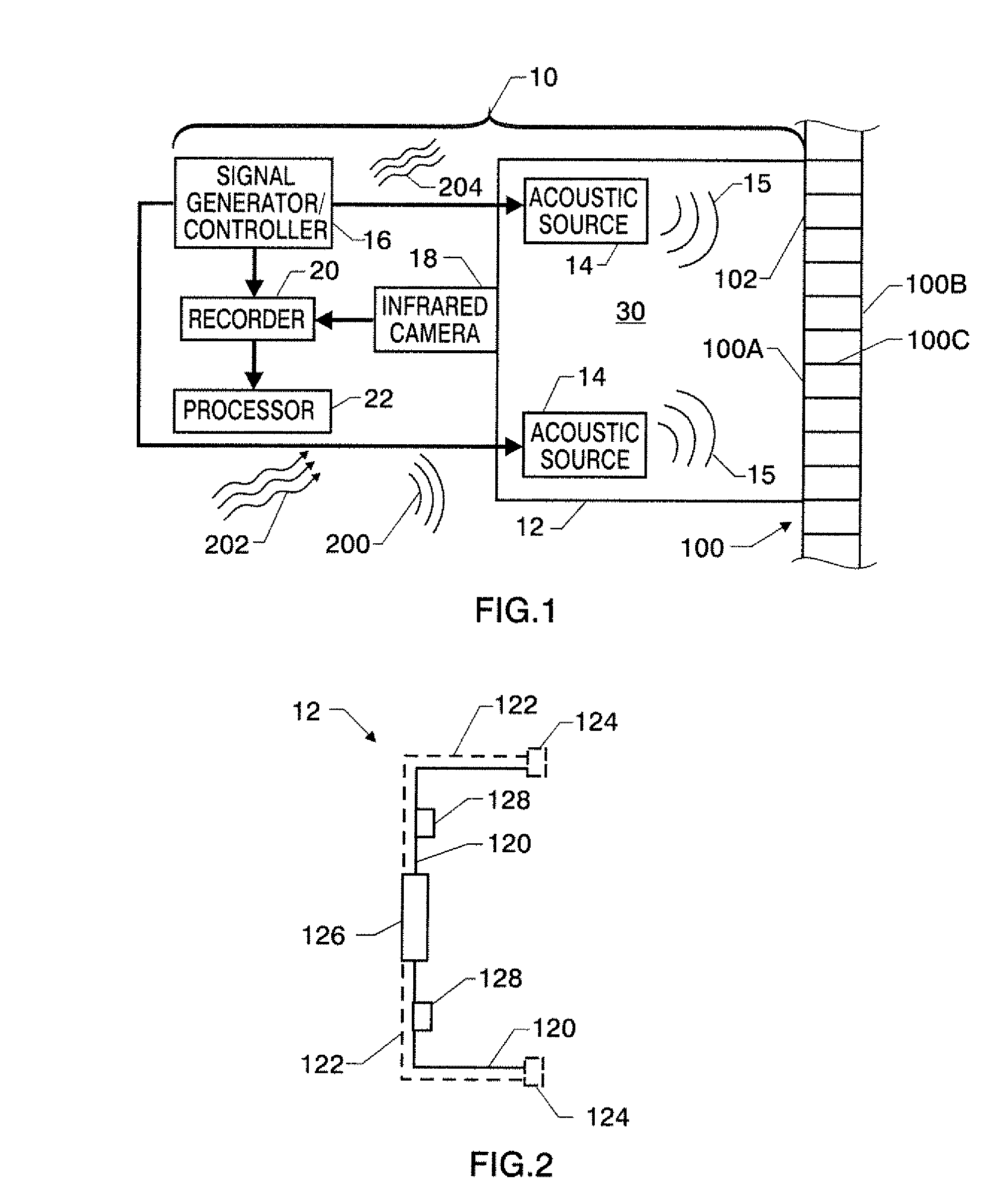

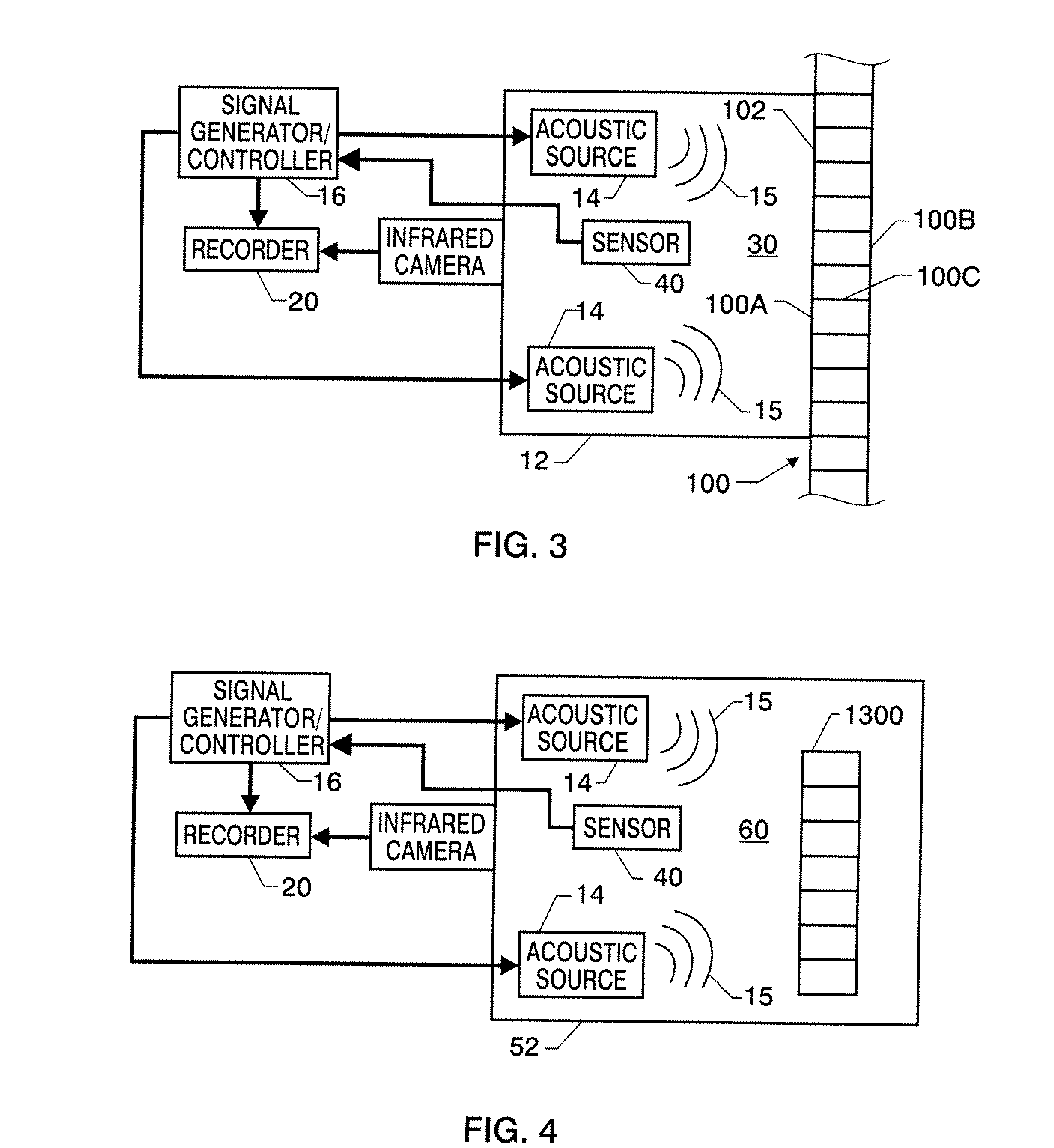

Air-Coupled Acoustic Thermography for In-Situ Evaluation

InactiveUS20100019153A1High-degree of flaw/damage sensitivityGood repeatabilityVibration measurement in solidsRadiation pyrometrySound sourcesAir coupled

Acoustic thermography uses a housing configured for thermal, acoustic and infrared radiation shielding. For in-situ applications, the housing has an open side adapted to be sealingly coupled to a surface region of a structure such that an enclosed chamber filled with air is defined. One or more acoustic sources are positioned to direct acoustic waves through the air in the enclosed chamber and towards the surface region. To activate and control each acoustic source, a pulsed signal is applied thereto. An infrared imager focused on the surface region detects a thermal image of the surface region. A data capture device records the thermal image in synchronicity with each pulse of the pulsed signal such that a time series of thermal images is generated. For enhanced sensitivity and / or repeatability, sound and / or vibrations at the surface region can be used in feedback control of the pulsed signal applied to the acoustic sources.

Owner:NASA

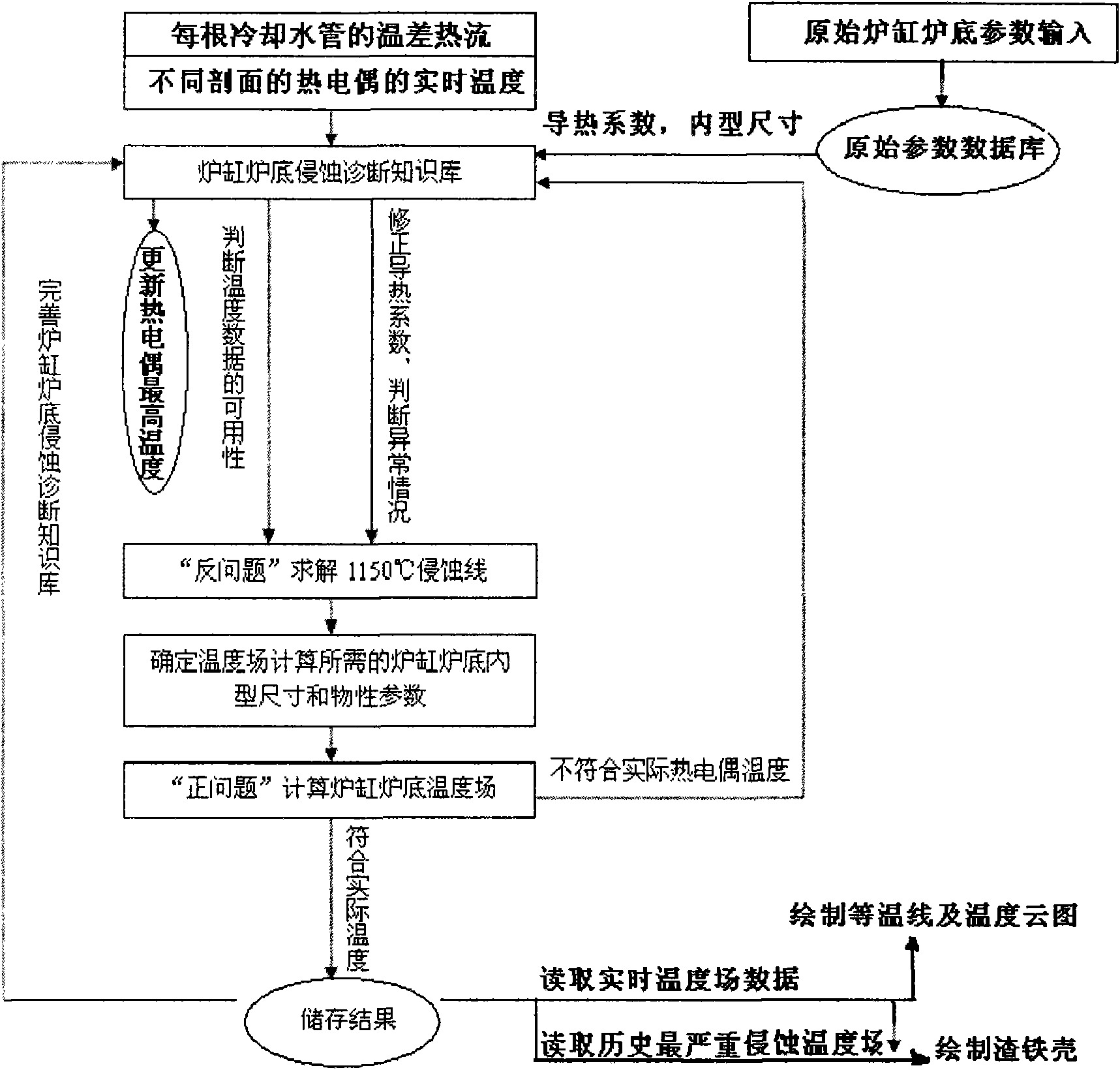

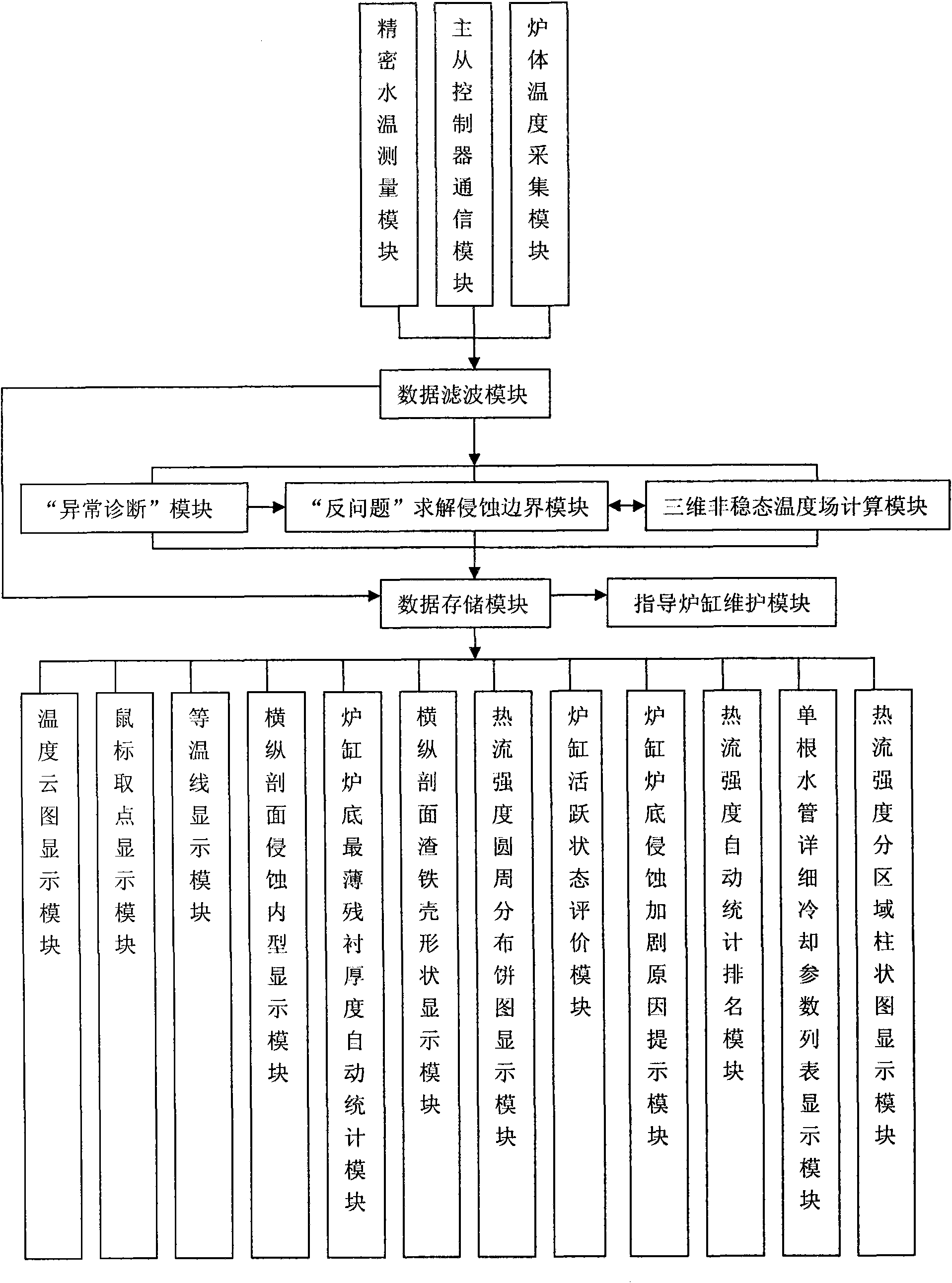

Three-dimensional unstable state monitoring and abnormity diagnosis and maintenance system of blast furnace hearth

InactiveCN101886152ATake sensitivity into considerationFully consider follow-upBlast furnace detailsChecking devicesSlagData acquisition

The invention relates to a three-dimensional unstable state monitoring and abnormity diagnosis and maintenance system of a blast furnace hearth, belonging to the technical field of online monitoring, diagnosis, prewarning and maintenance of the blast furnace. The three-dimensional unstable state monitoring and abnormity diagnosis and maintenance system of the blast furnace hearth comprises a data acquisition module, a data filtering module, a hearth and furnace bottom corrosion and accretion calculation module, an abnormality diagnosis module, a prewarning displaying module and a hearth-guiding and maintaining module. Water temperature of a cooling wall of the hearth and galvanic couple temperature of a furnace body can be collected and filtered in real time; by combining the two data together and using pro and con questions of the heat transmission science in combination with the standard of abnormity diagnosis, the influence of the abnormity possibly occurring in the production of the thermal conductivity coefficient variation of refractories, the ring shake, the air gap, and the like on distribution and corrosion of a temperature field is comprehensively judged, a gradient-regularization method and a chaos optimization method are combined to solve, the online monitoring on the three-dimensional unstable state temperature field of the hearth and the furnace bottom, the internal corrosion type, the slag-metal skull variation and the hot state of the hearth is realized, the abnormal circumstance and the corrosion deterioration causes are diagnosed in real time, and the hearth maintenance means is pertinently guided according to the corrosion deterioration causes. The system is successfully applied to industry.

Owner:HEBEI SHOUGANG QIAN AN IRON & STEEL CO LTD +1

Verification of Continuity

InactiveUS20070107517A1Simple and cost-effectiveMinimizing chanceVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesCouplingComplex system

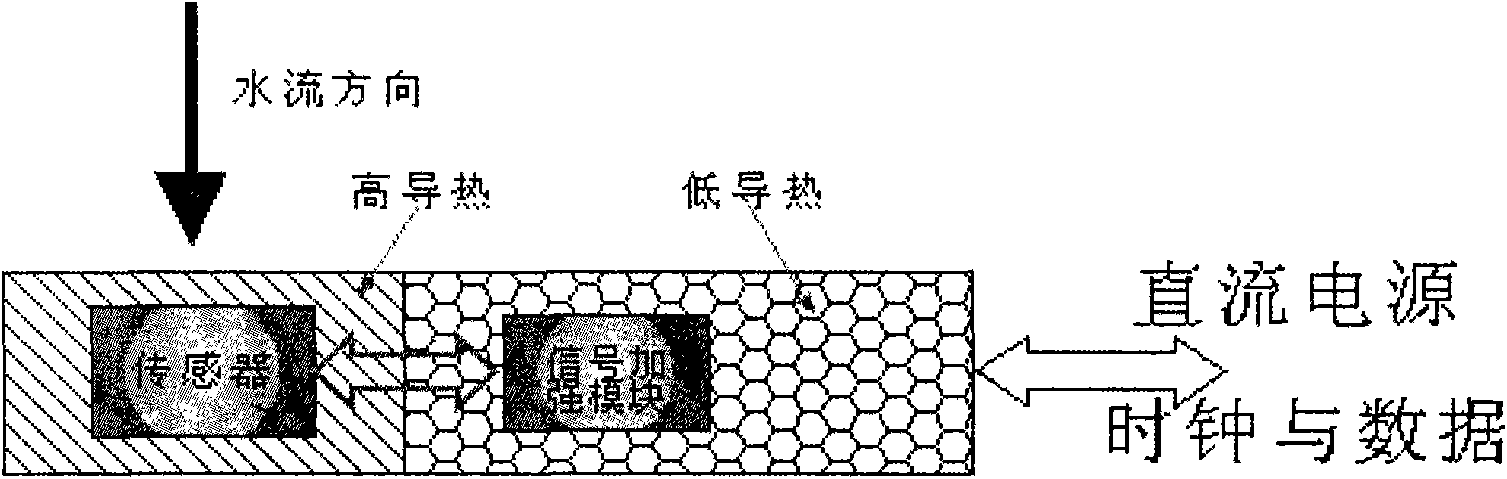

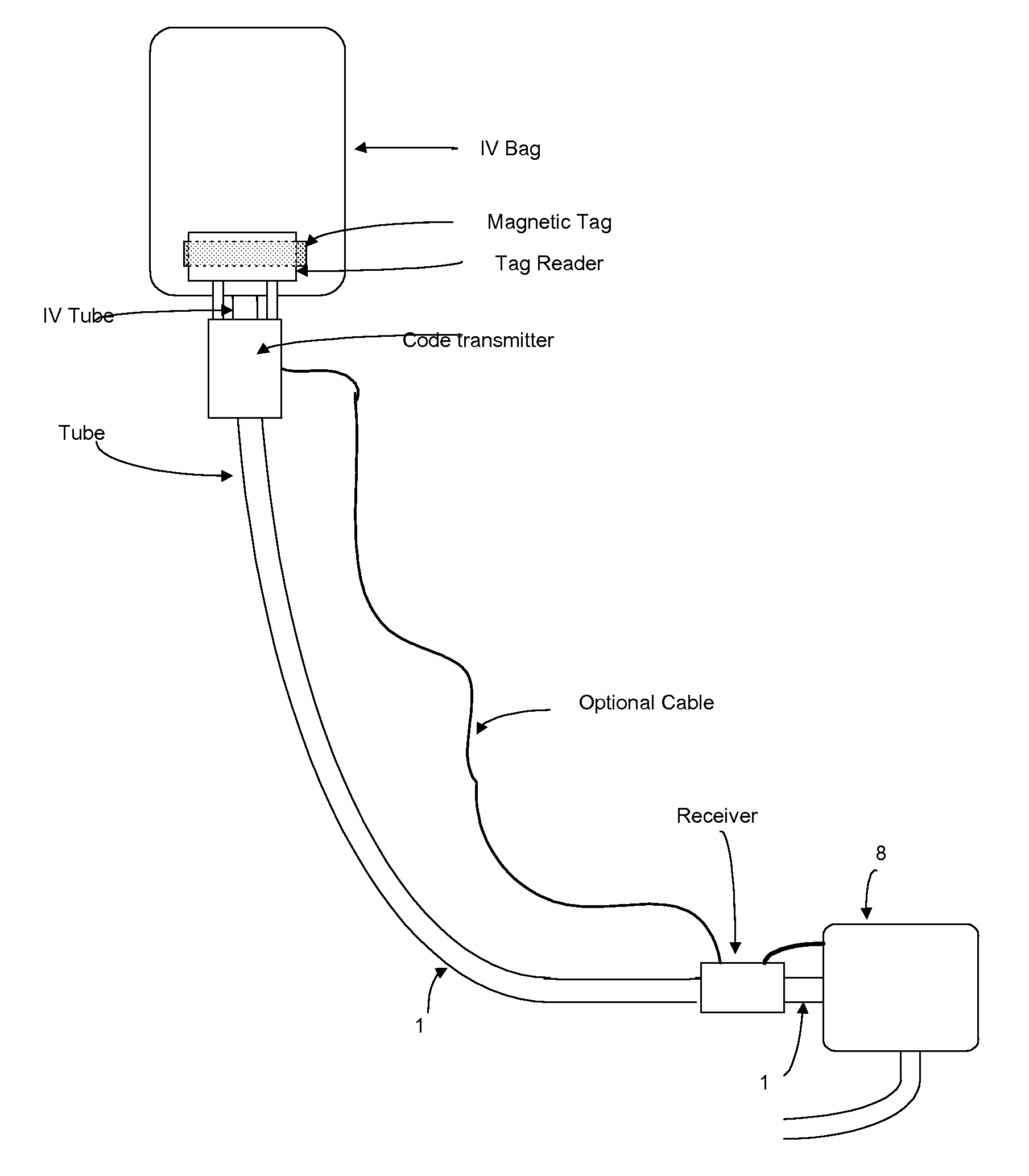

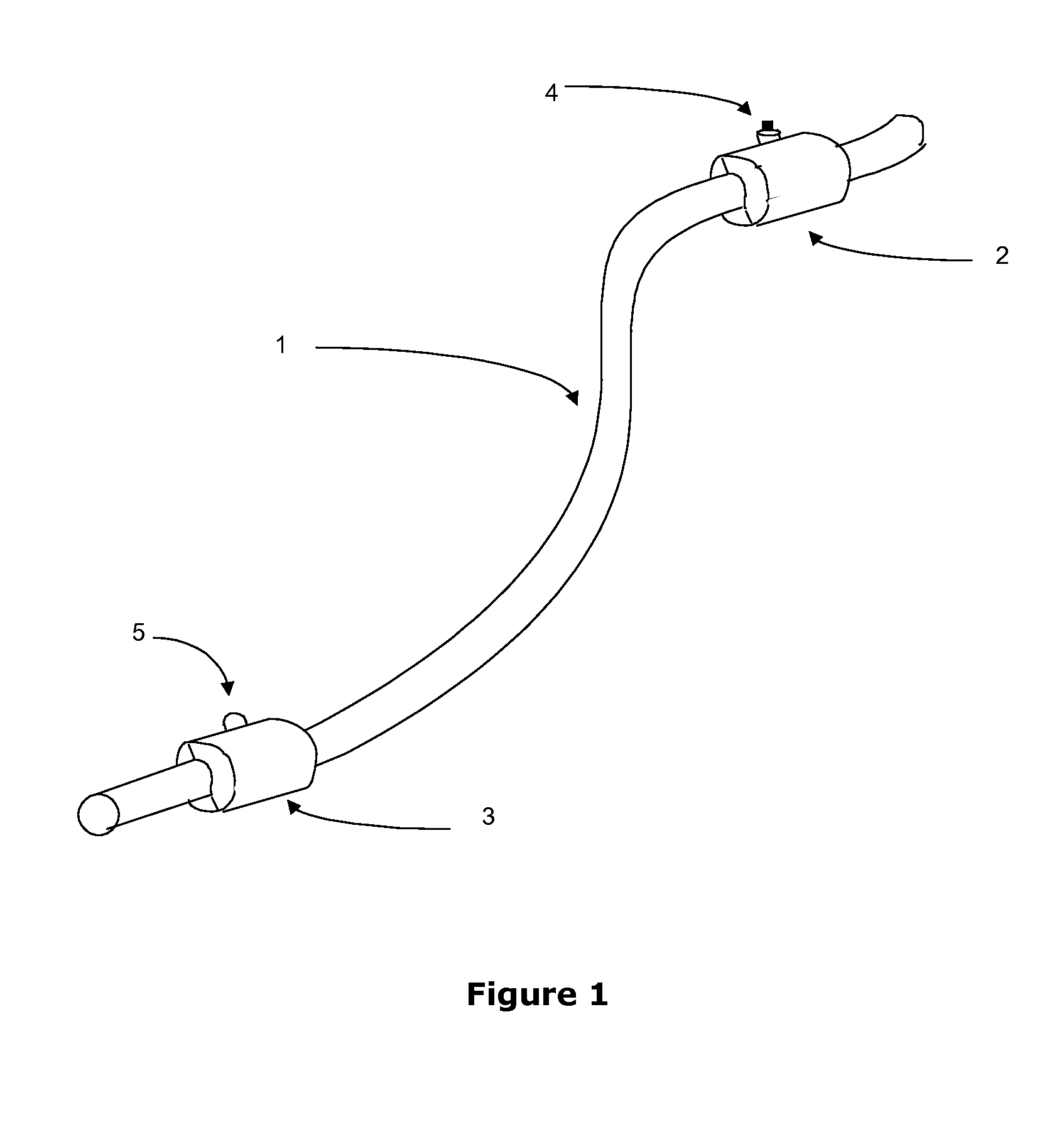

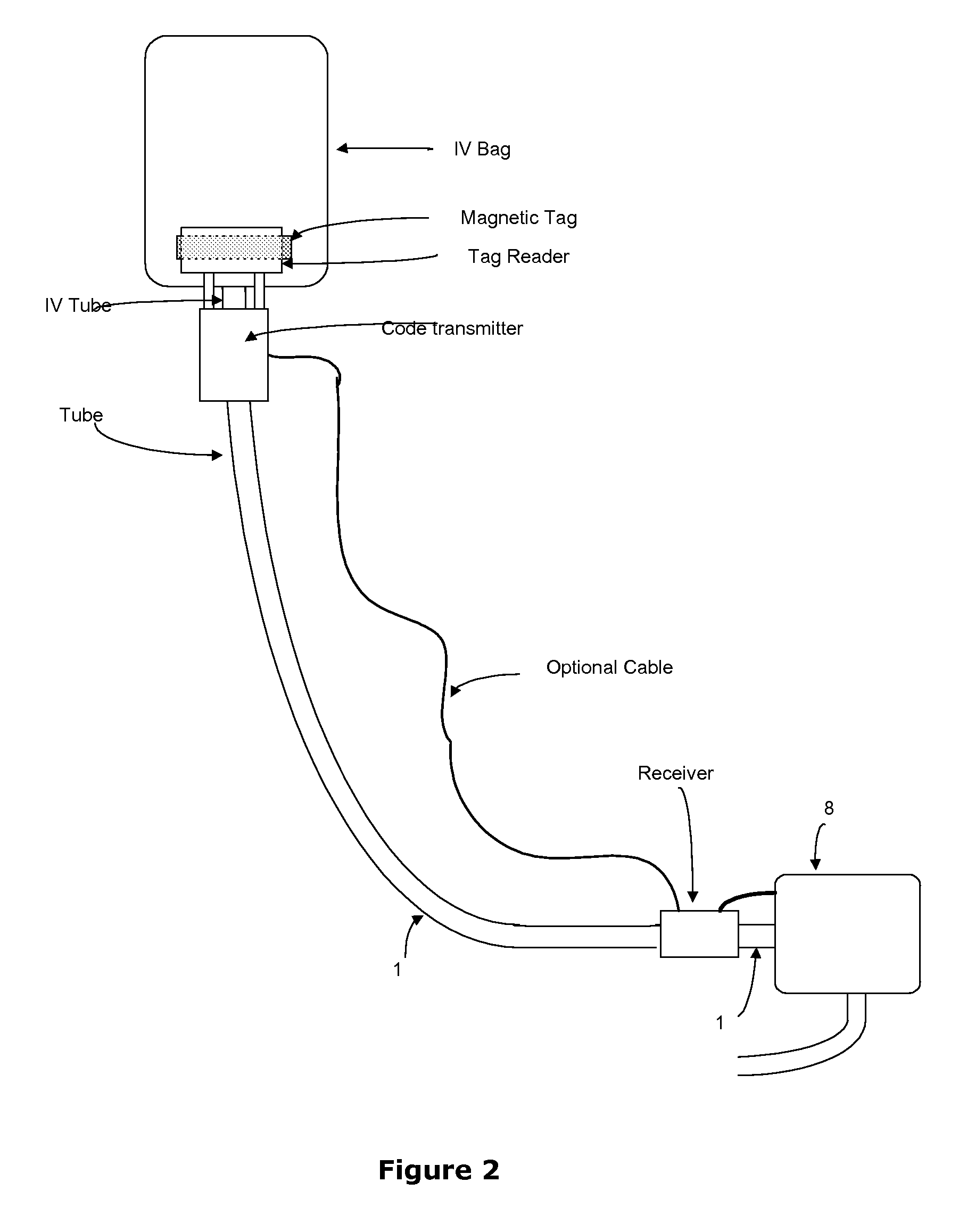

Techniques are described for eliminating the potential continuity errors in fluid connection devices, such as tubes, which can arise in complex systems where many tubes are used. The techniques are based upon the use of ultrasound, light or pressure waves being transmitted along the connecting device using a transmitter and a receiver at either end. Methods are described to cover the external coupling of the transmitter and / or the receiver into the tubing thereby eliminating the need to compromise the connection. The described apparatus can be external to the system or integrated within it. The potential to carry information along the connection device is also disclosed.

Owner:ARNOLD DAVID HOWARD +1

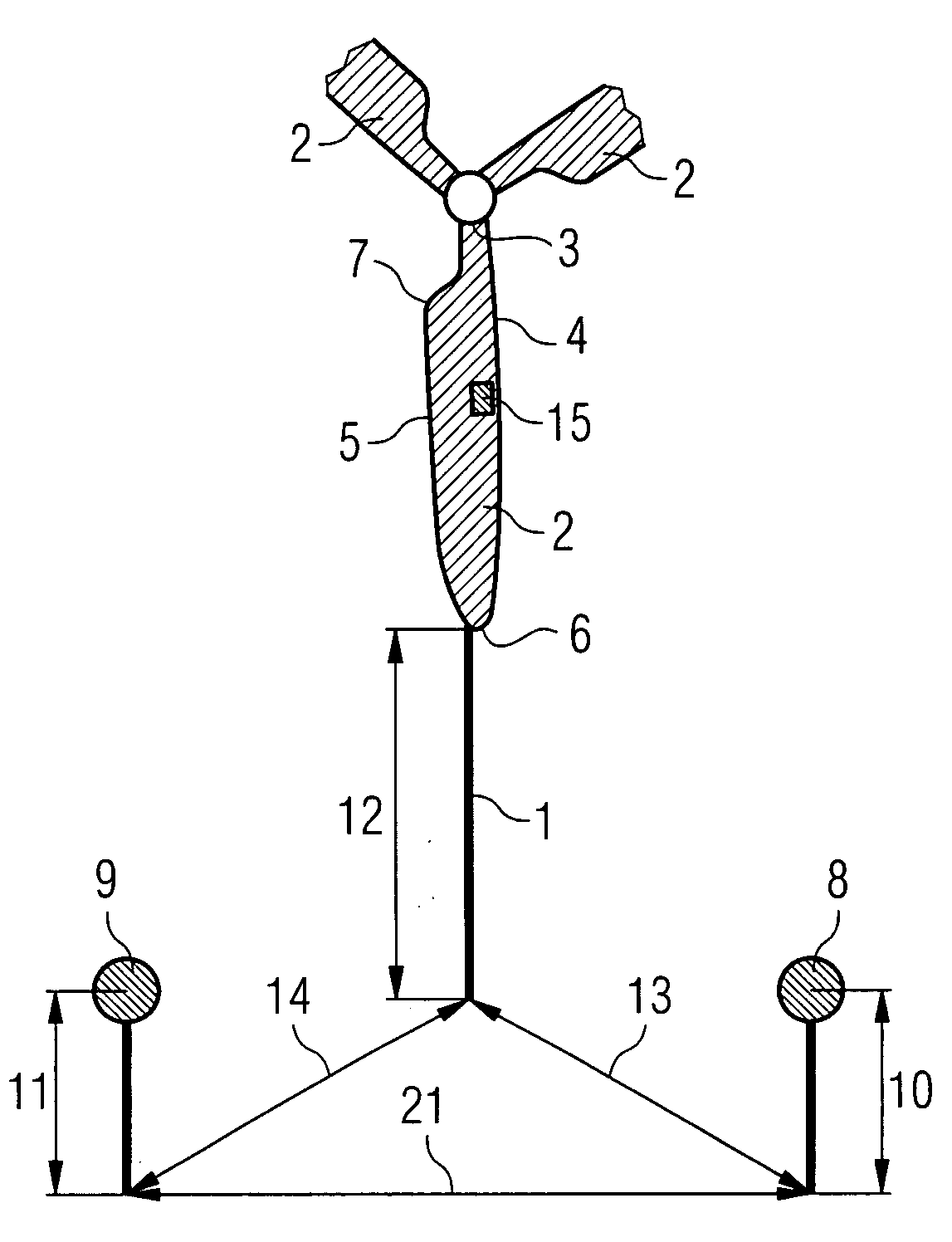

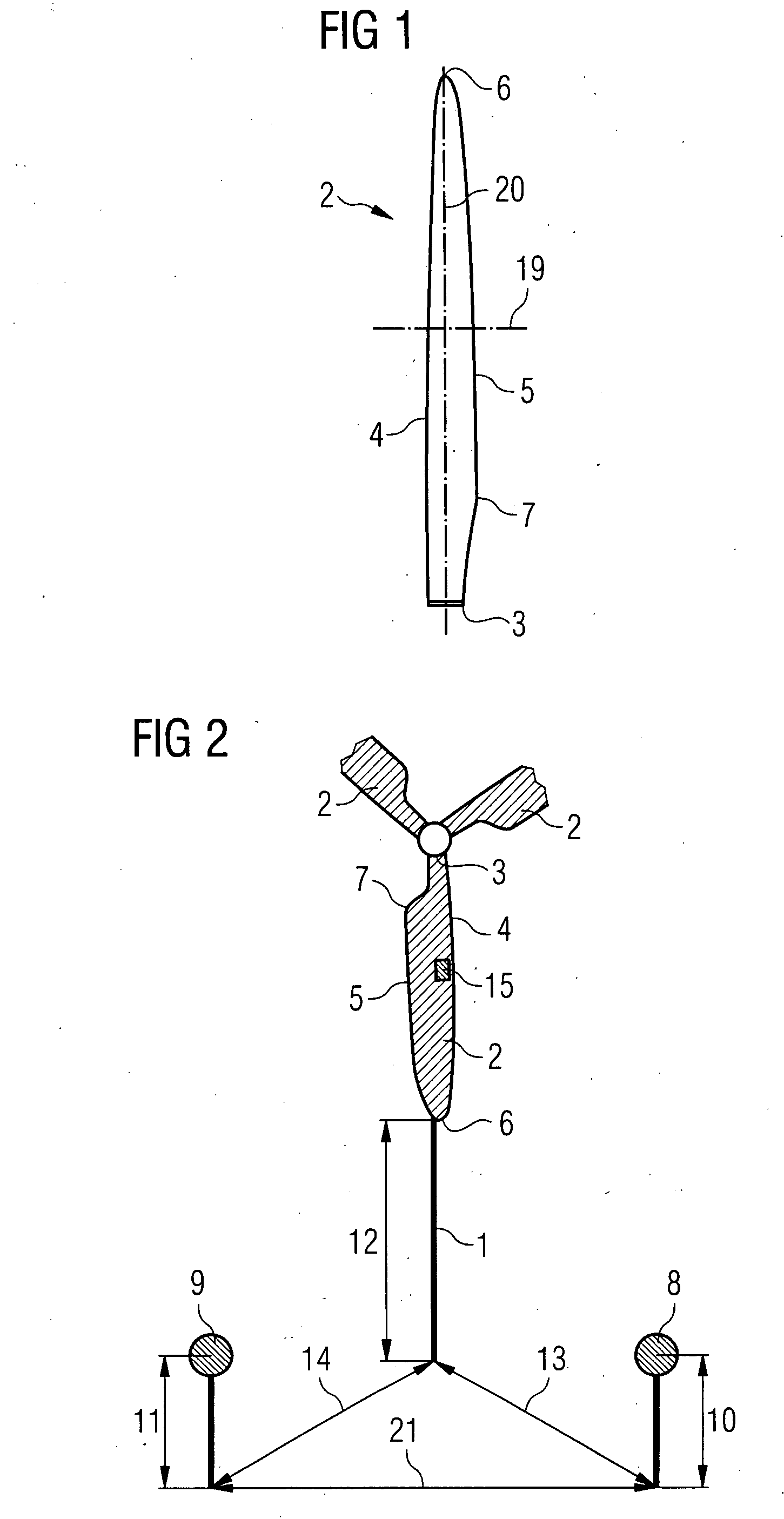

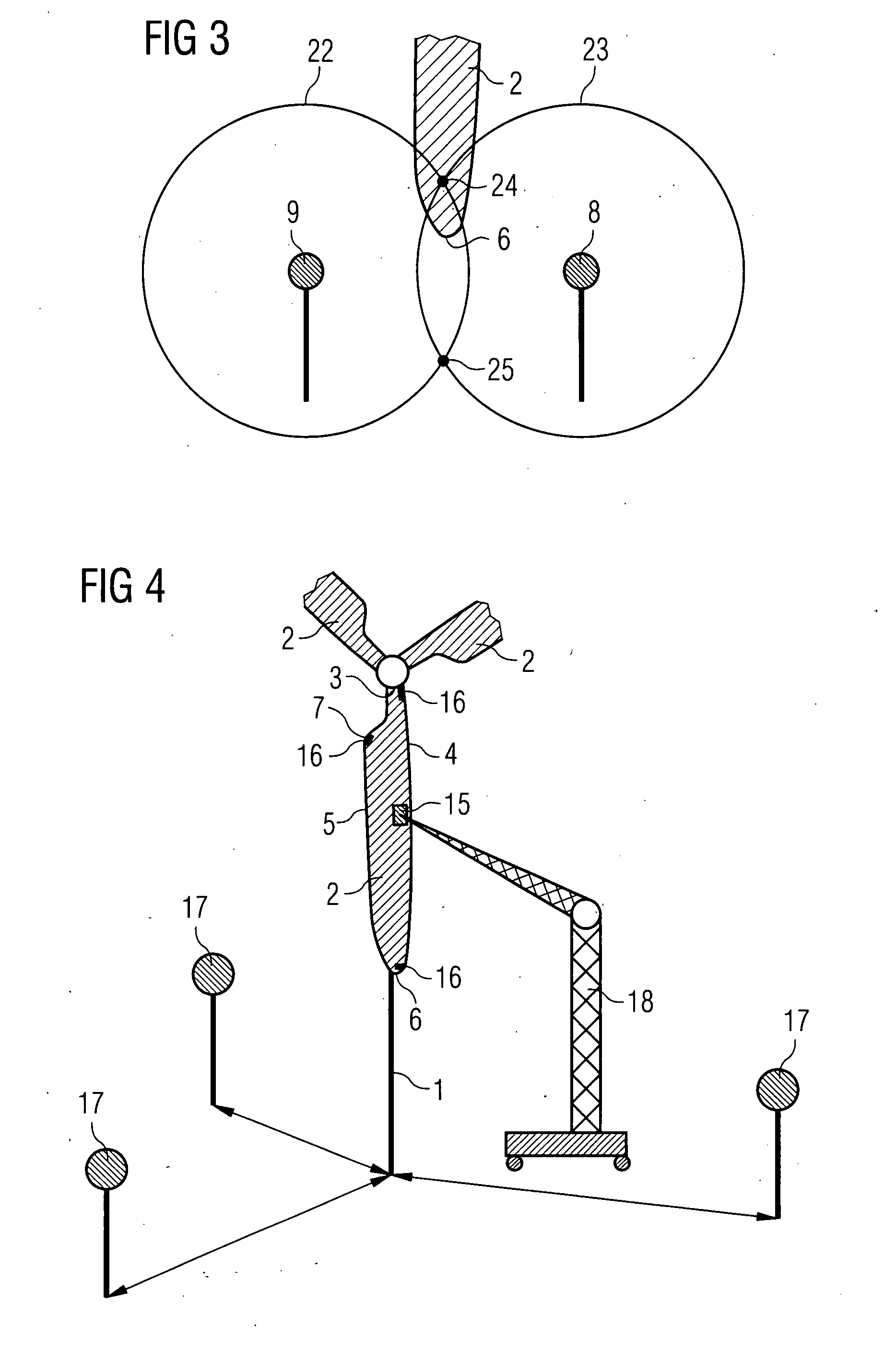

Method of non-destructively testing a work piece and non-destructive testing arrangement

InactiveUS20080141778A1Eliminate needExact correlationVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructivePositioning system

A method of non-destructively testing a work piece is disclosed, wherein the work piece is placed within an active field of a positioning system; a frame of reference of the work piece is established based on the geometry of the work piece in the coordinates of the positioning system; the geometry of the work piece is detected by determining the position of specific transponders, which are fixed to the work piece, by the positioning system or the geometry of the work piece is detected by scanning at least parts of the contour of the work piece with a transponder of the positioning system; testing data is acquired for the work piece with a non-destructive testing probe, which comprises a transponder of the positioning system, while the position of the testing probe is recorded by the positioning system; the position of the testing probe is transformed into an intrinsic position defined with respect to the frame of reference of the work piece; and the intrinsic position of the testing probe is assigned to the testing data recorded at the respective position. Moreover, a non-destructive testing arrangement is provided.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

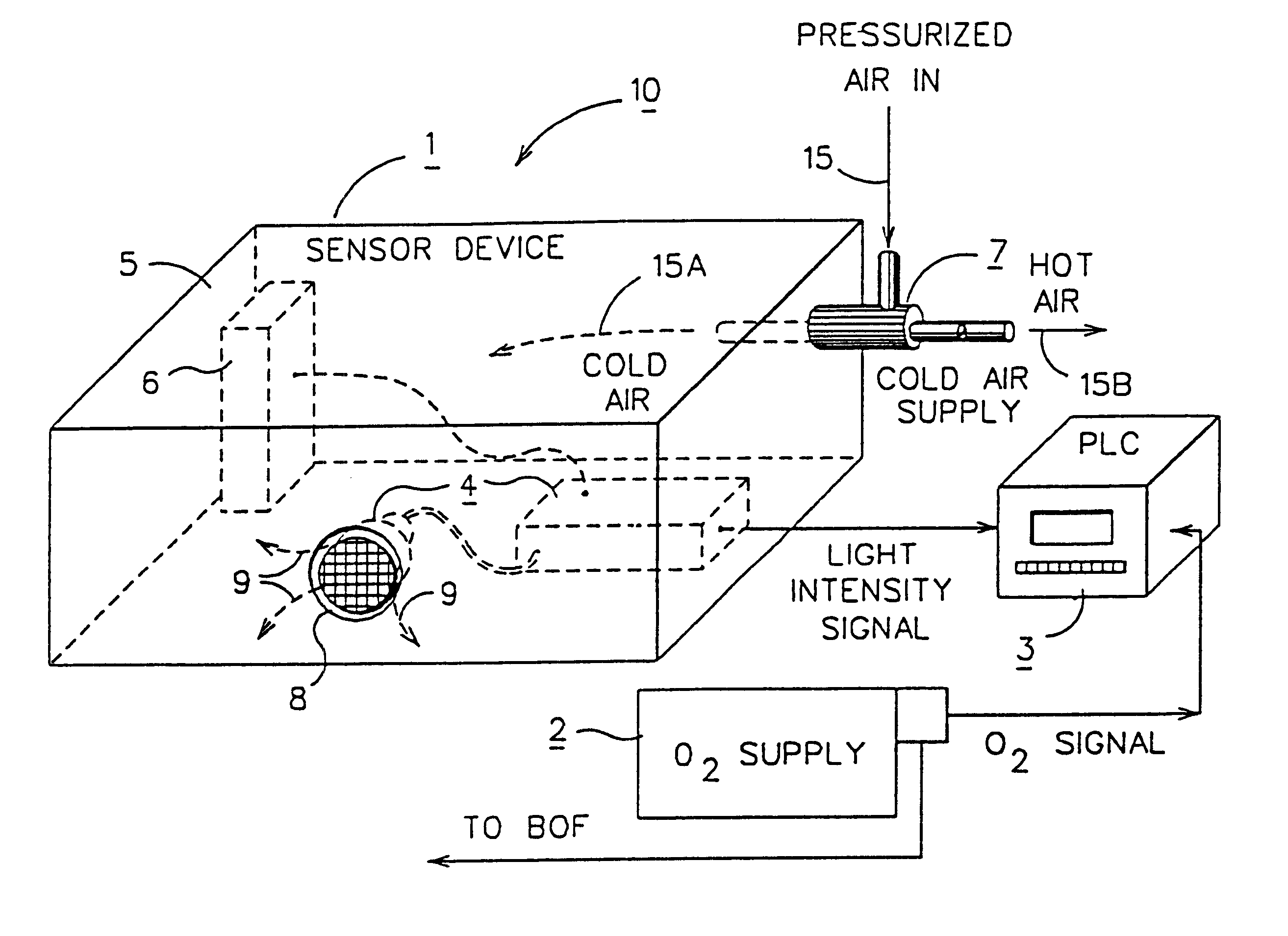

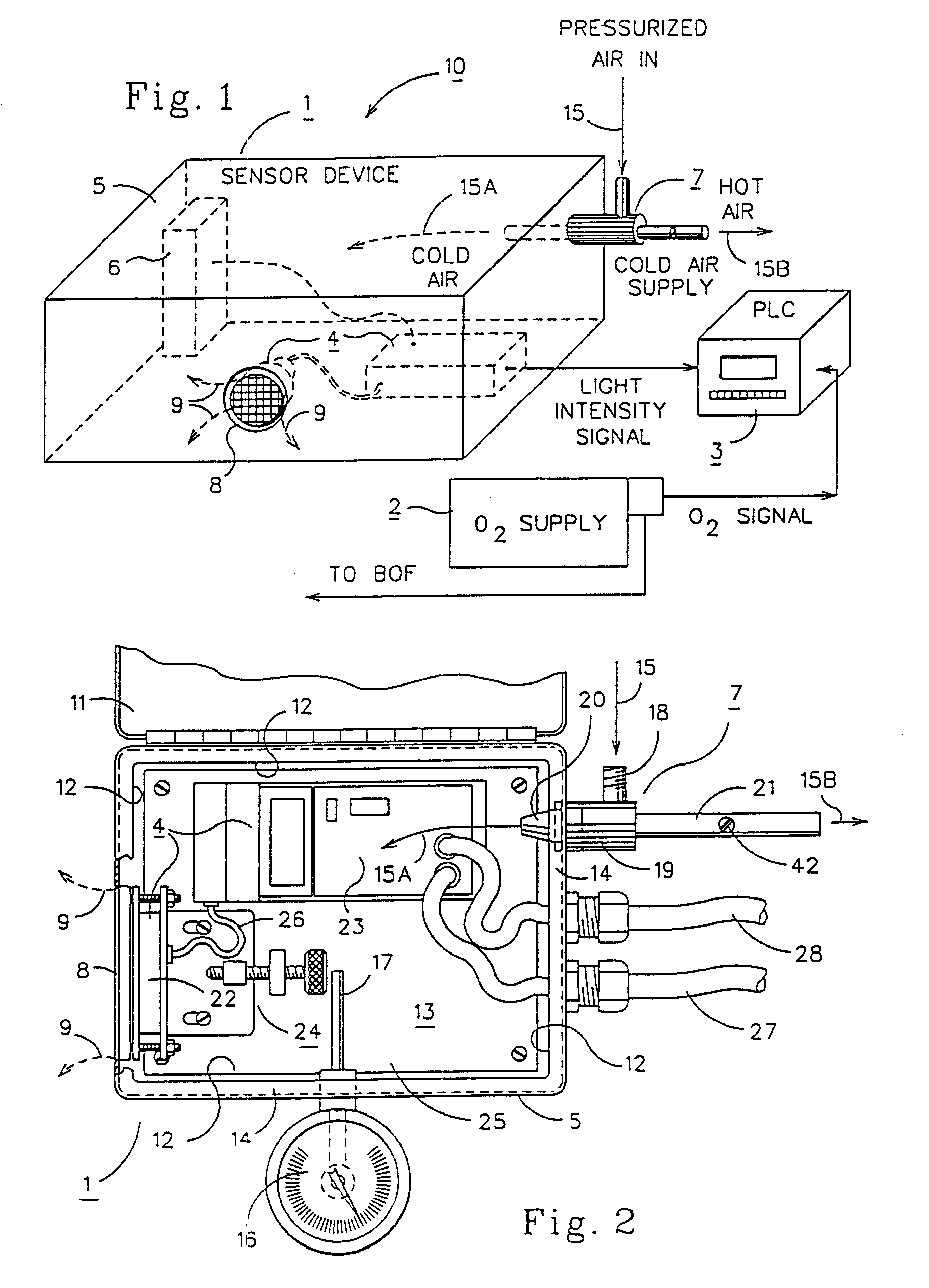

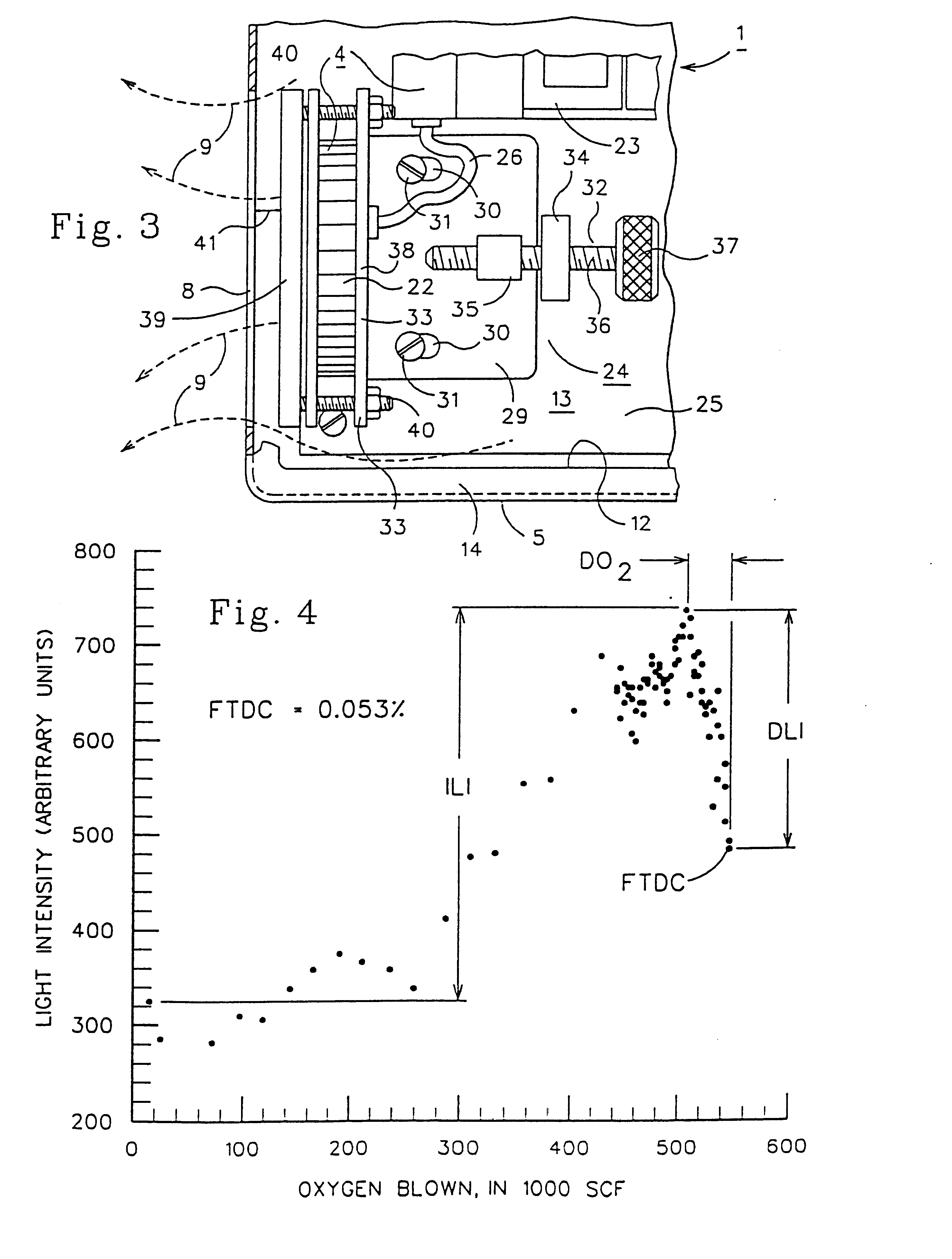

Method and apparatus to determine and control the carbon content of steel in a BOF vessel

InactiveUSRE37922E1Avoid accumulationAccurately determined and controlledPhotometryMaterial analysis by optical meansSteelmakingProgrammable logic controller

Apparatus for determining in-blow % carbon content and / or the First Turn Down Carbon of a BOF heat includes a light sensor housed within a temperature regulated case having a sighting window including air wipe means to shield the light sensor from steelmaking dust and fume. The apparatus also includes a means to generate a signal that corresponds to the amount of oxygen blown into the BOF during a heat, and a programmable logic controller. The logic controller is programmed to continuously process oxygen blown signals from the signal generating means, and light intensity signals received from the light sensor. The program calculates continuous in-blow % carbon content of the heat based upon the difference in light intensity from a point of maximum light intensity emitted from the BOF vessel in relation to the amount of oxygen blown into the BOF vessel during the same period of time.

Owner:ISG TECH

Method and apparatus for automatic non-cooperative frequency specific assessment of hearing impairment and fitting of hearing aids

ActiveUS7223245B2High frequency resolutionMany timesVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesImage resolutionHearing perception

A method and device for automatically assessing loss of hearing sensitivity and compression (recruitment) with user defined frequency resolution by means of extrapolated DPOAE I / O functions and ABRs as well as for automatically fitting hearing aids without any cooperation of the subject tested using a device having a display screen attached to a handheld device generating and collecting otoacoustic emission signals and brain stem response signals into a programmed with a clinical audiogram with fitting parameters for hearing aids calculated on the basis of assessed hearing threshold and compression and identifying the type of hearing required for the individual.

Owner:NATUS MEDICAL

Acoustic wave array chemical and biological sensor

ActiveUS7500379B2Simultaneous measurementVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesSensor arrayAnalyte

An acoustic wave sensor array device is provided for the detection, identification, and quantification of chemicals and biological elements dispersed in fluids. The sensor array device is capable of the simultaneous characterization of a fluid for multiple analytes of interest. A substrate has a plurality of channels formed therein and a sensor material layer applied in a bottom of the channels. The sensor material layer has a shear acoustic wave speed lower than a shear acoustic wave speed in said substrate. The channels may have the same material in each channel or different materials in at least two of the channels. A surface acoustic wave transducer and at least one surface acoustic wave reflector, or at least two transducers is formed on a surface of the substrate opposite the channels at a portion of the substrate that is thinned by the channels, so that the acoustic tracks of the surface acoustic wave device extend along the channels. The response of the surface acoustic wave depends on the response of the sensor material to a sensed fluid supplied to the channels.

Owner:SENSANNA

Apparatus and method for reclaiming scrap metal

An apparatus and method for reclaiming contaminated scrap metal, more particularly an improved reverberatory furnace designed for melting scrap. The amount of hydrocarbons volatilized from the melting of contaminated scrap is measured and the fumes are passed into the main hearth for burning. As the amount of fuel value contained within the fumes increases, the amount of fuel provided to the burner is proportionally reduced while the amount of oxygen is kept constant. This will ensure that the amount of fuel and the amount of oxygen present within the furnace is completely burned without excessive free oxygen or unburned fuel building up within the furnace or furnace exhaust. The burner will be operating under lean fuel conditions or under fuel rich conditions such that the flame temperature is lower than at stoichiometric firing, whereby the burners create reduced NOx.

Owner:ANTARES CAPITAL LP AS AGENT

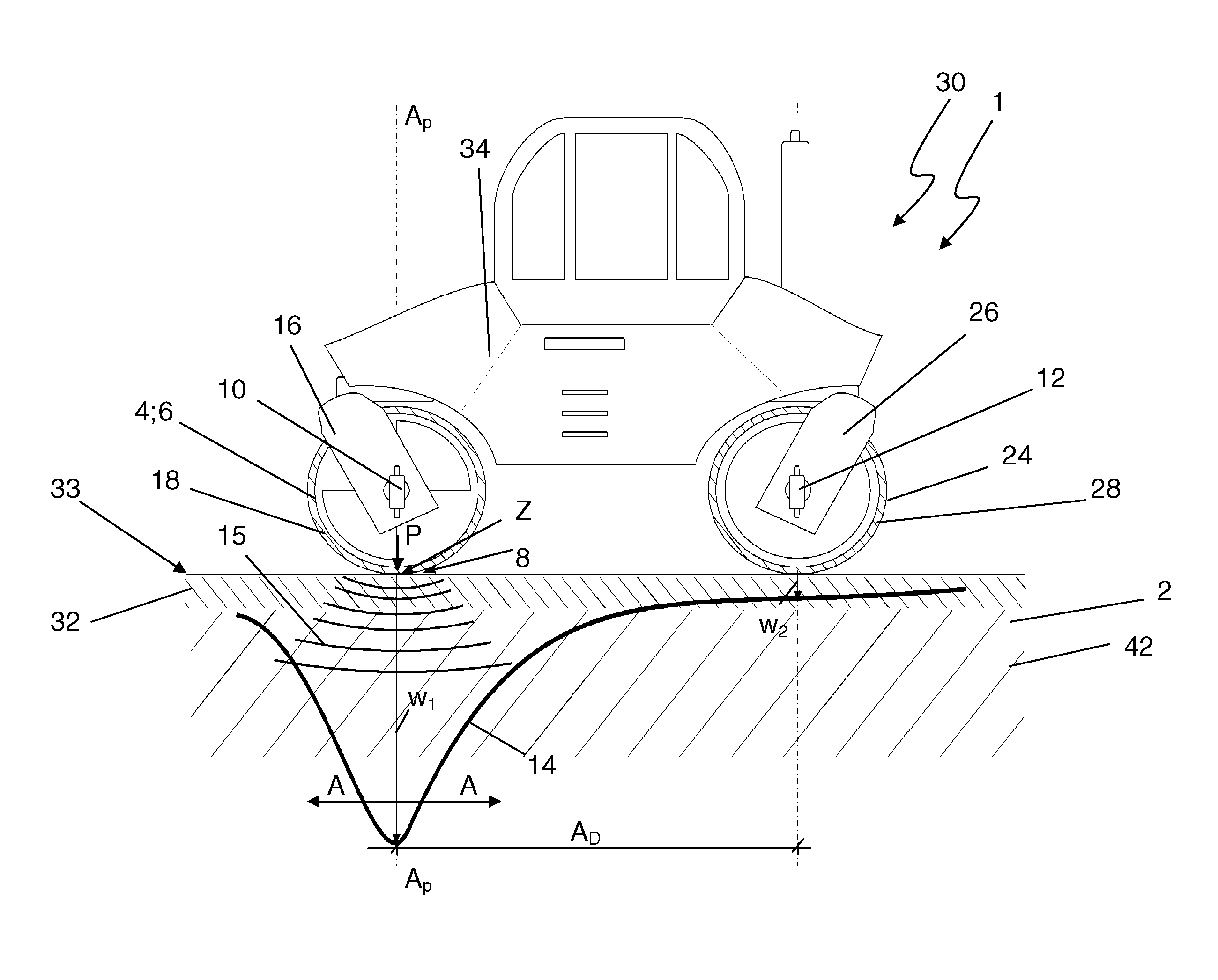

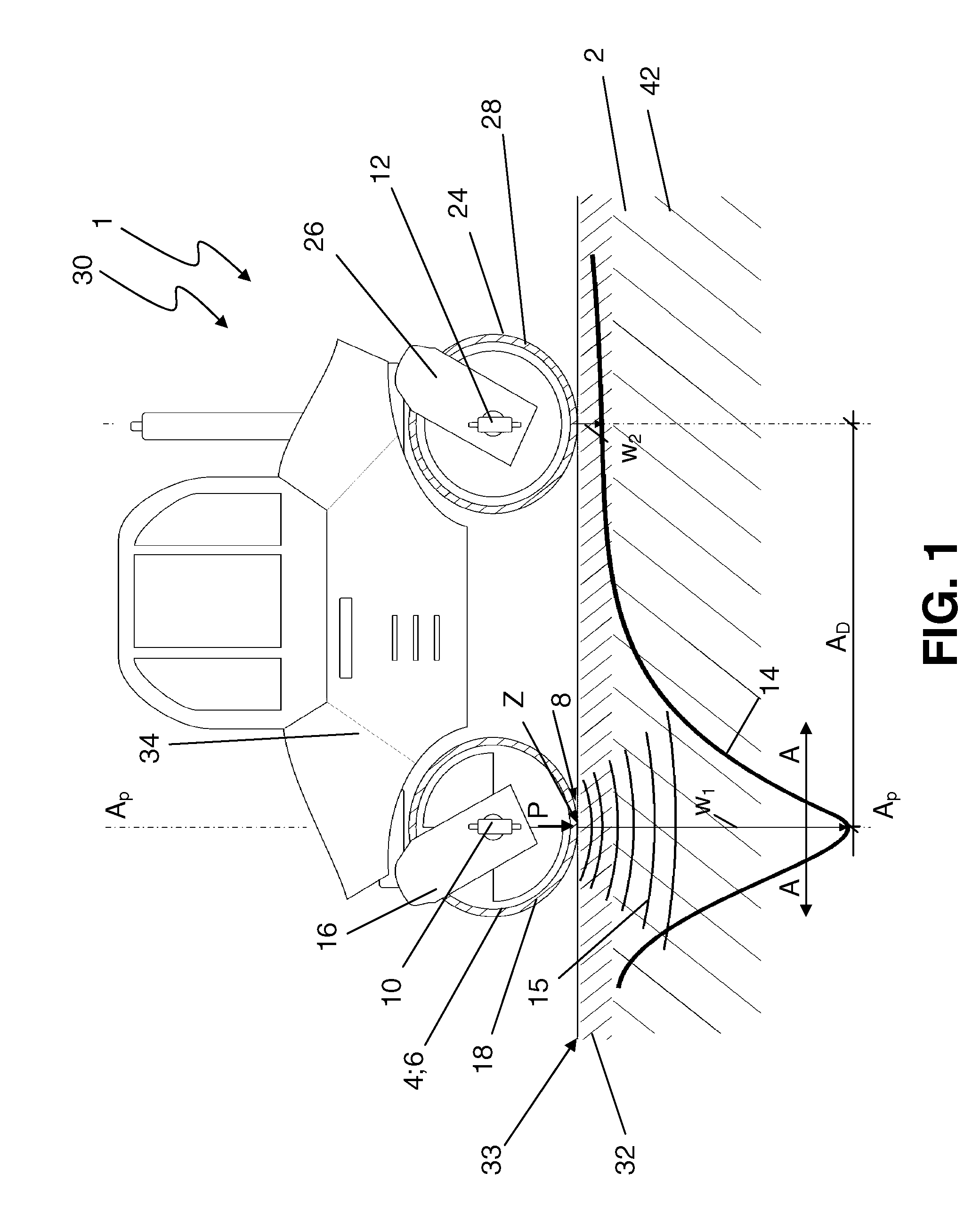

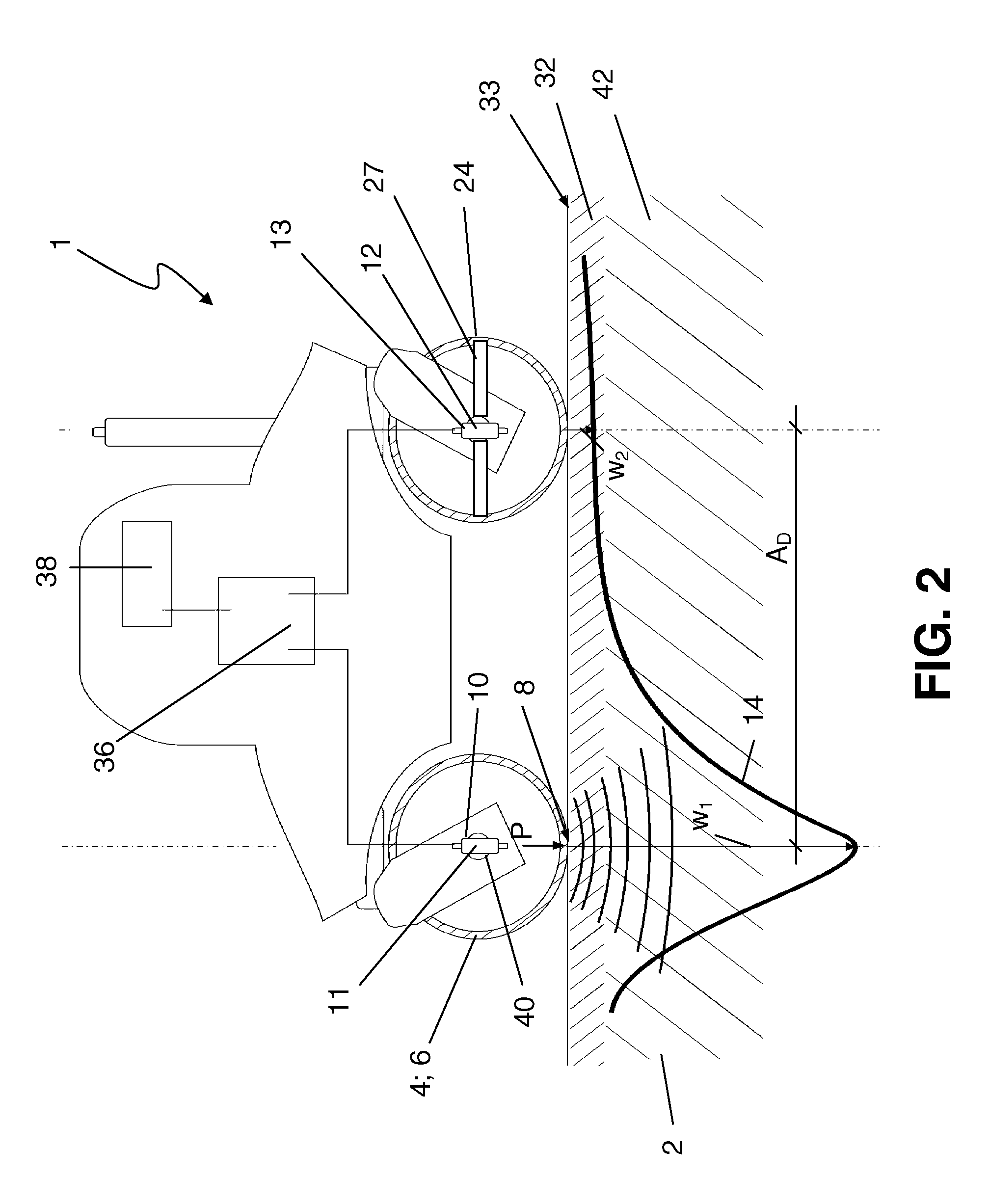

Drivable device for compacting a soil layer structure and method for ascertaining a layer modulus of elasticity of an uppermost layer of this soil layer structure

ActiveUS8671760B2Rapid and cost-effective detection and monitoringAccurate detectionVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringElastic modulus

Owner:BOMAG

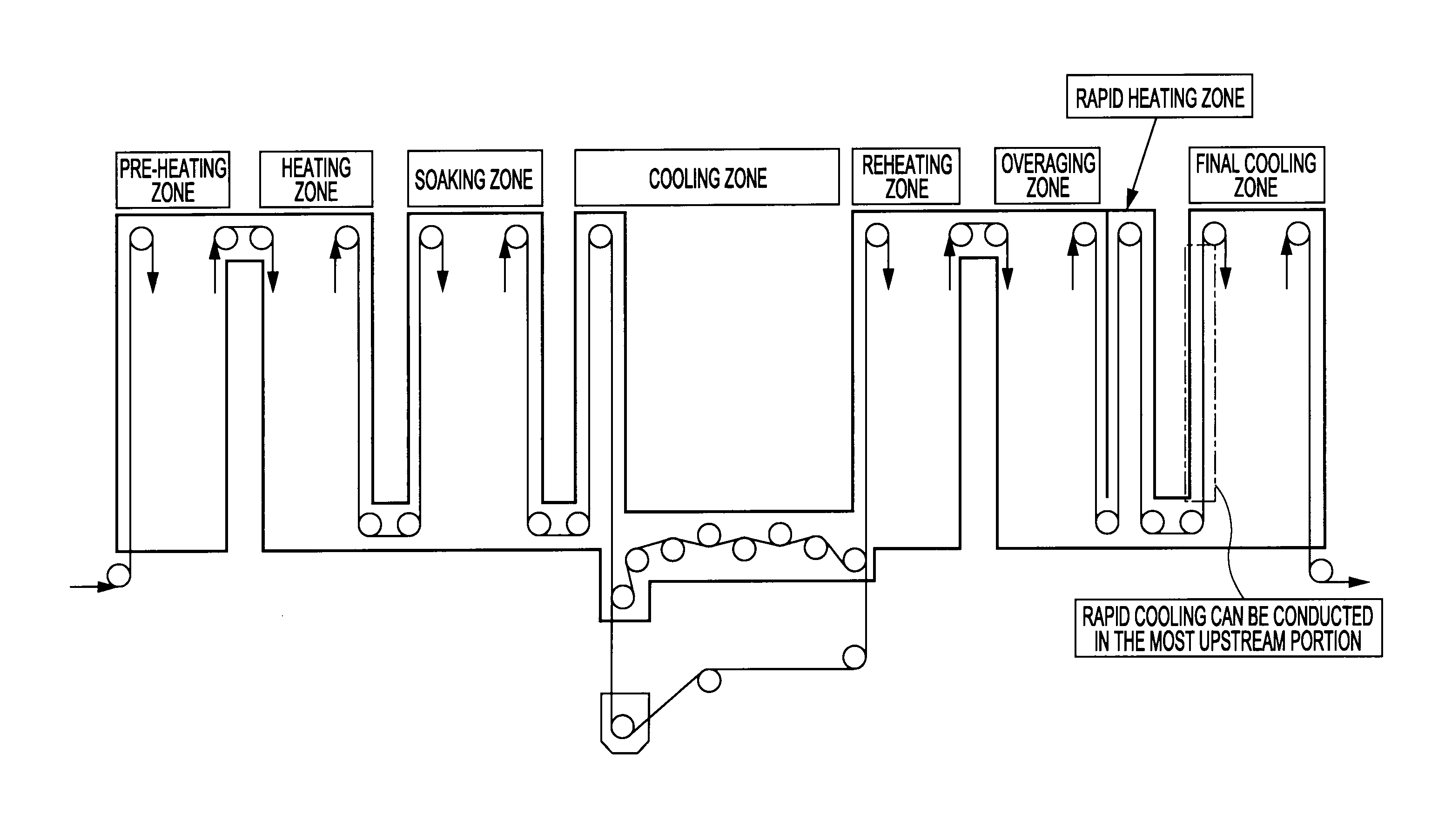

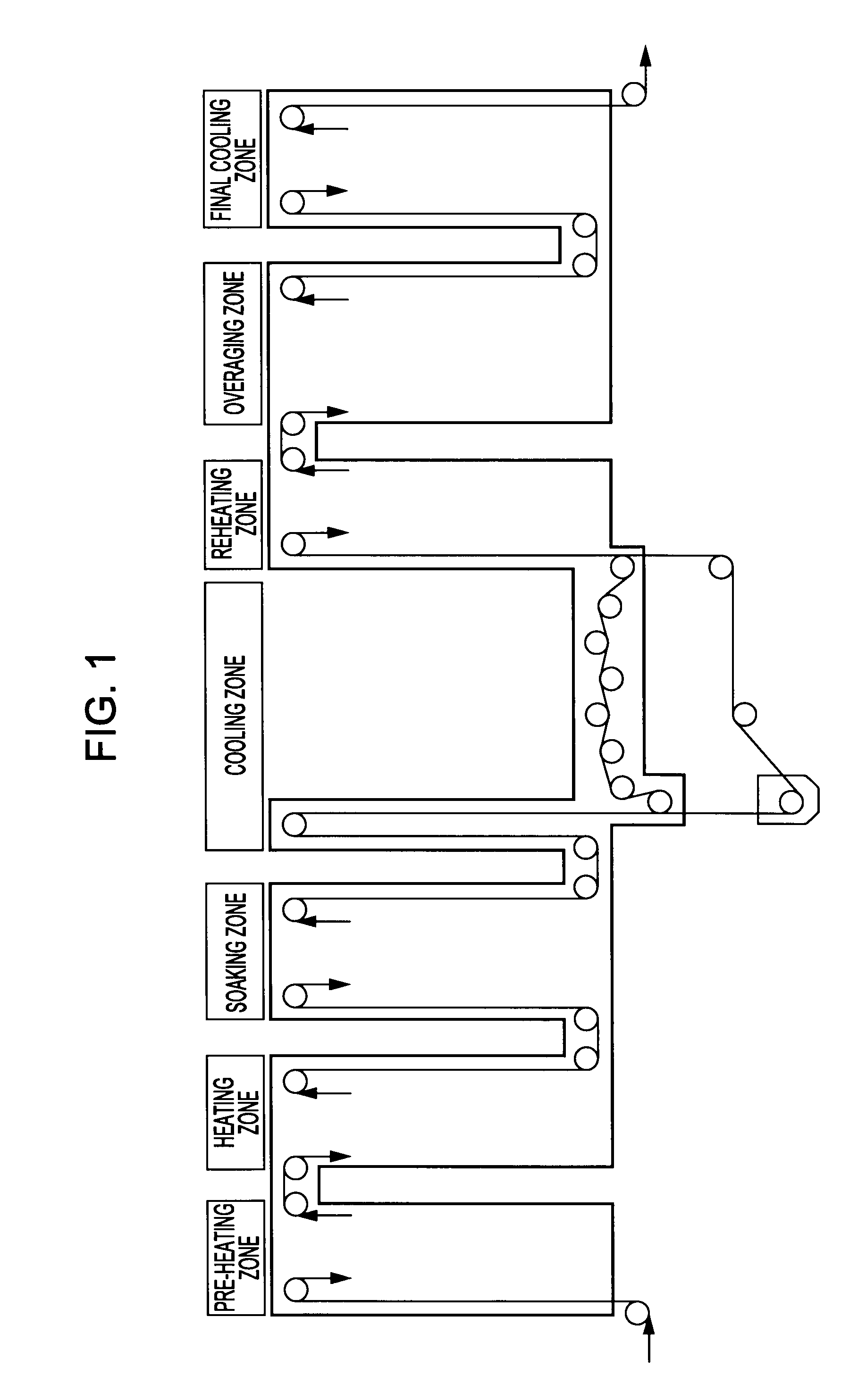

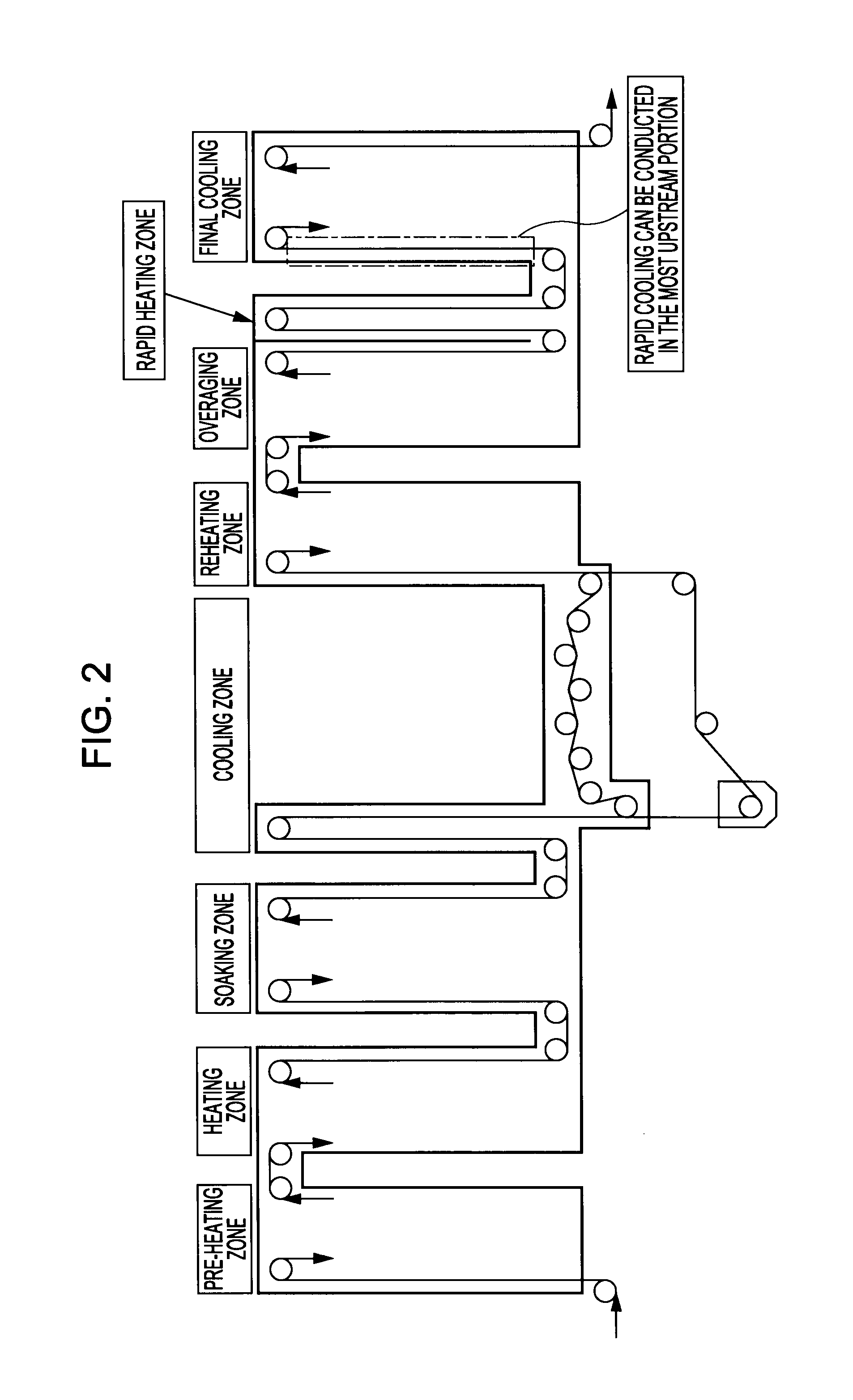

Steel-sheet continuous annealing equipment and method for operating steel-sheet continuous annealing equipment

ActiveUS20100237548A1Heating fastRapid coolingBlast furnace detailsIncreasing energy efficiencySheet steelContinuous annealing

Steel-sheet continuous annealing equipment includes, in sequence, a pre-heating zone, a heating zone, a soaking zone, a cooling zone, a reheating zone, an overaging zone, and a final cooling zone, and further includes a rapid heating region and a rapid cooling region that are provided within a range from the reheating zone to the final cooling zone (including the reheating zone and the final cooling zone), the rapid heating region allowing rapid heating of a steel sheet at a heating rate of 15° C. / s or more and the rapid cooling region allowing rapid cooling, at a cooling rate of 10° C. / s or more, of the steel sheet that has been rapidly heated in the rapid heating region. Various steel-sheet products ranging from mild steel sheets to ultrahigh-tensile steel sheets can be produced by performing a heat treatment with such steel-sheet continuous annealing equipment.

Owner:KOBE STEEL LTD

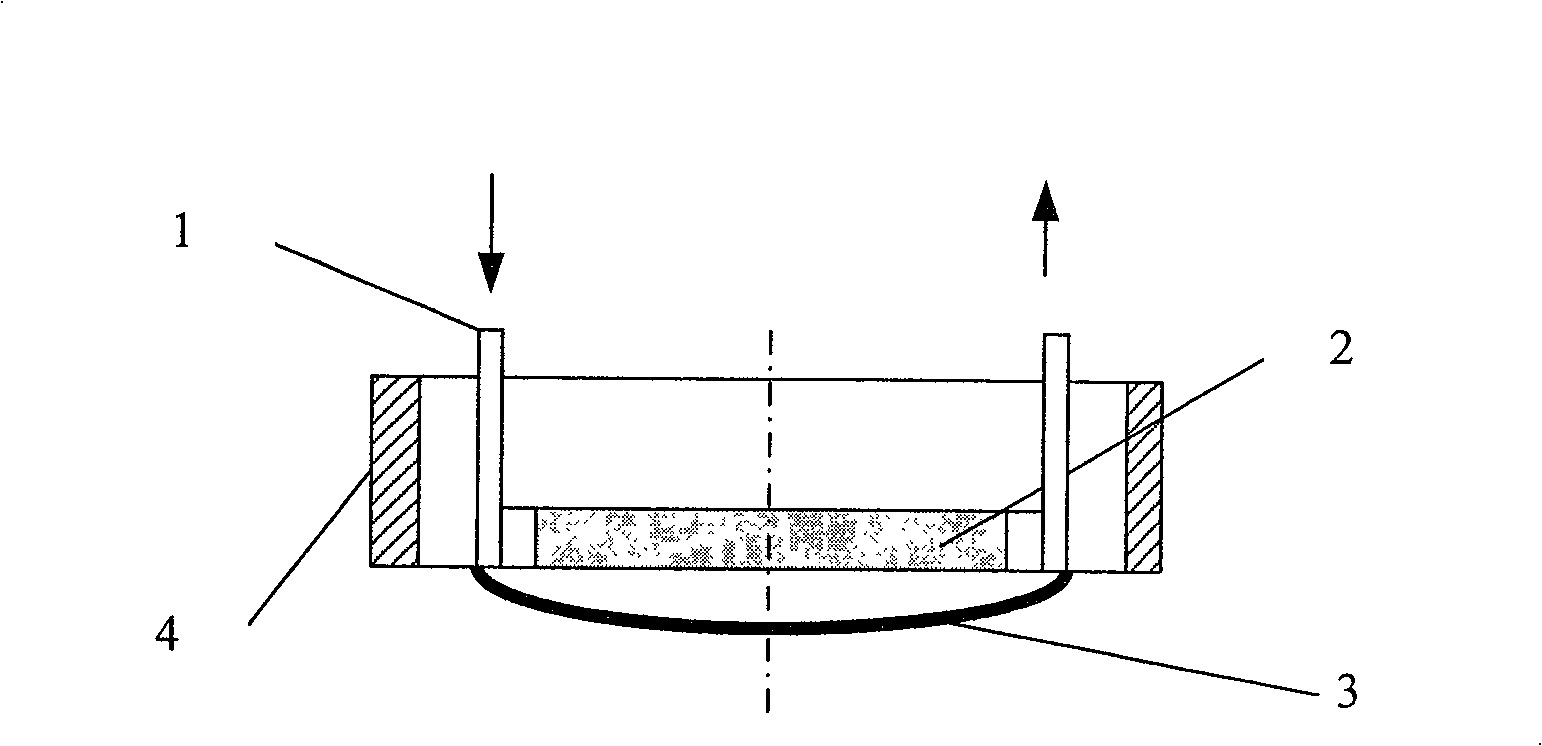

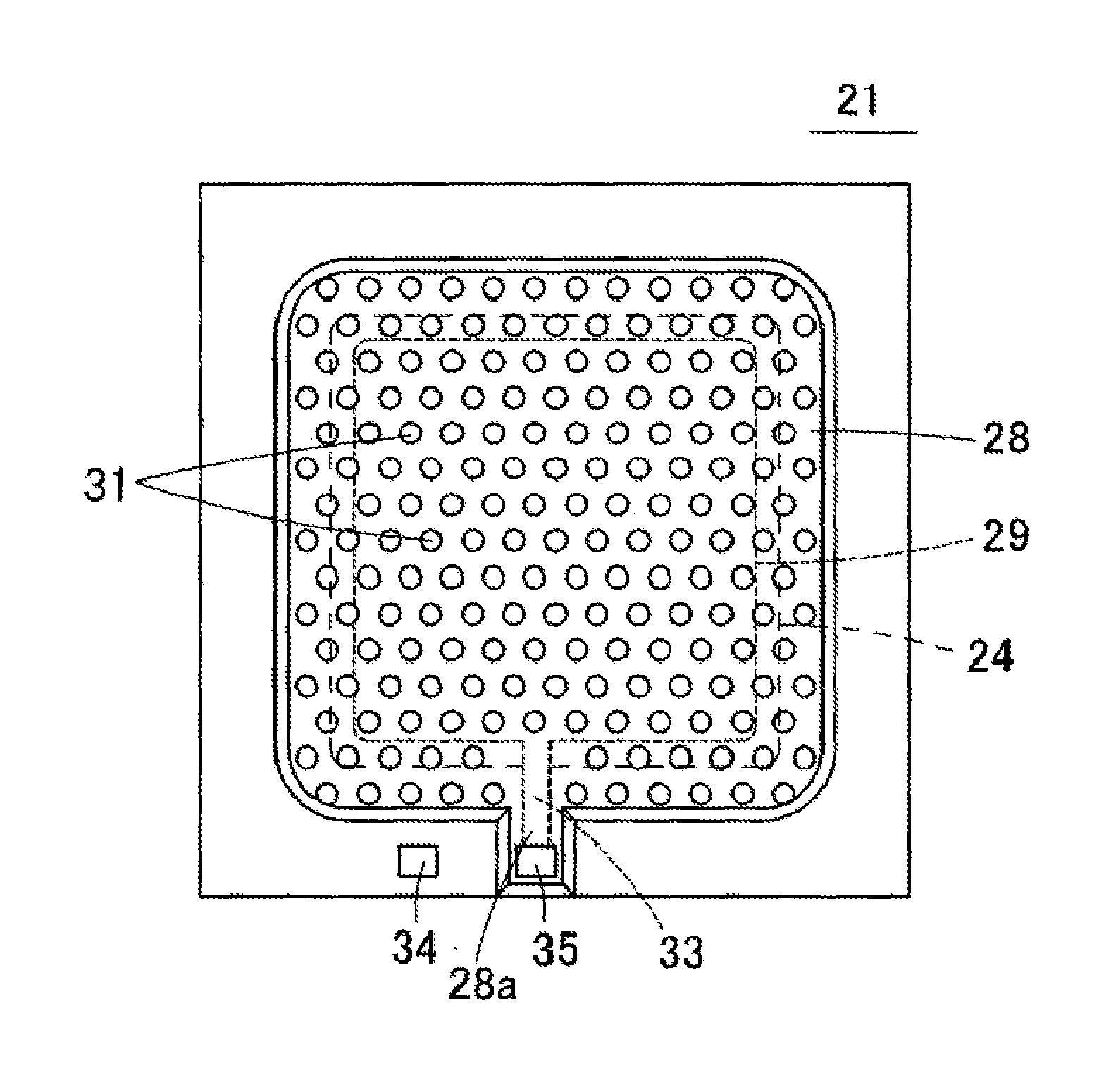

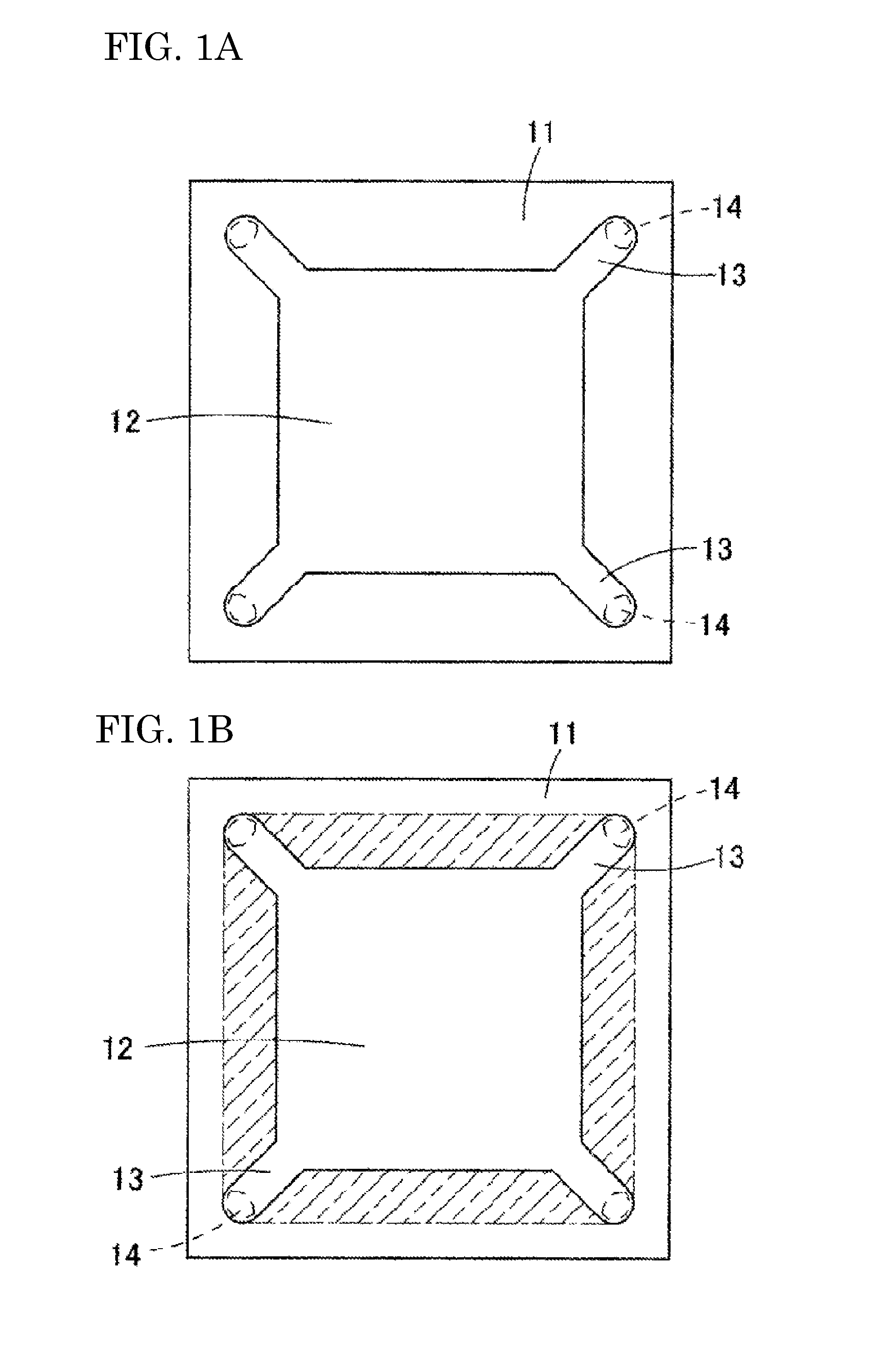

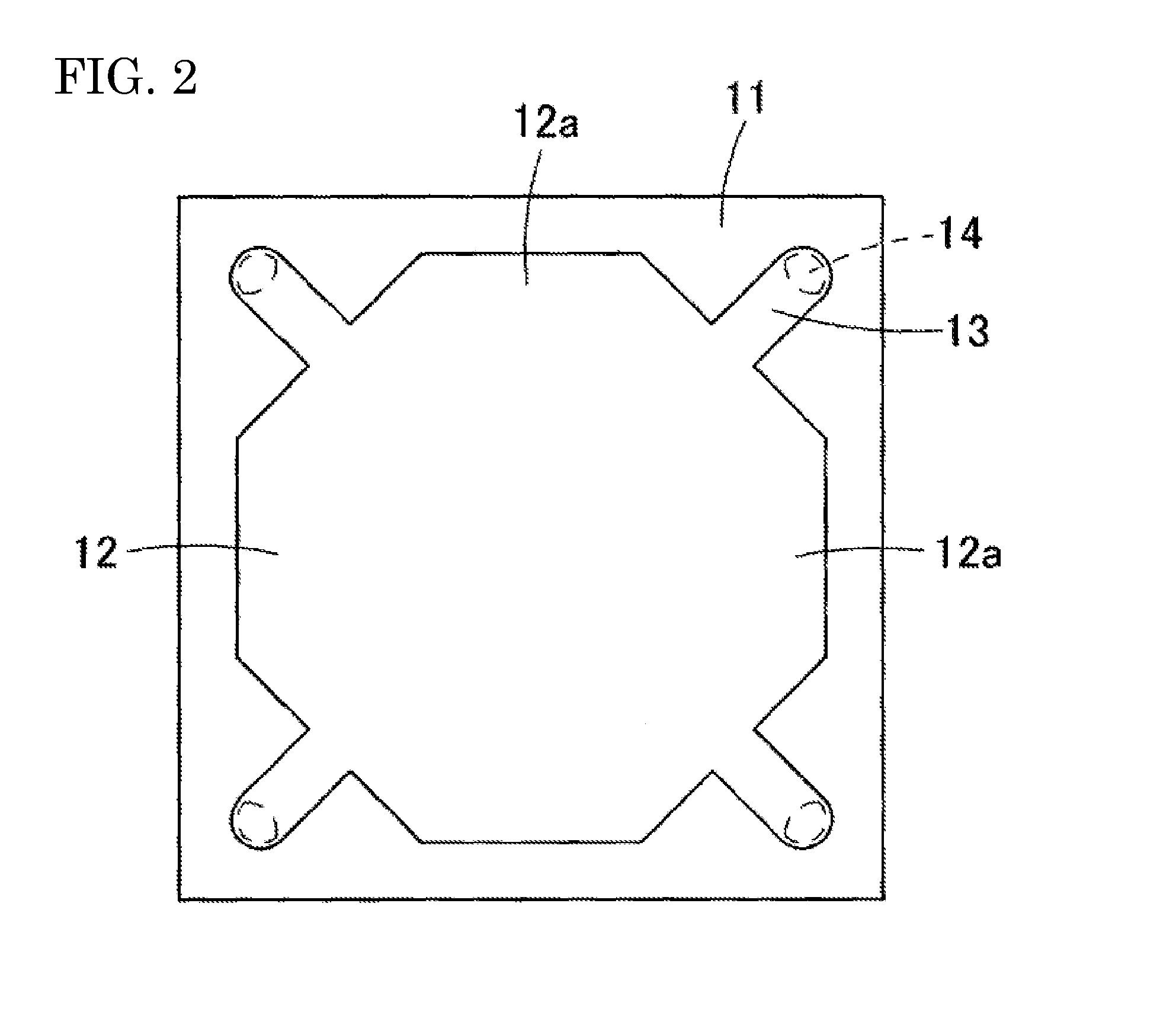

Capacitive sensor, acoustic sensor and microphone

ActiveUS20150369653A1High sensitivitySmall sensor sizeVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesDiagonalCapacitive sensing

A chamber that penetrates vertically is formed in a silicon substrate. A diaphragm is arranged on the upper surface of the silicon substrate so as to cover the upper opening of the chamber. Leg pieces are provided in corner portions of the diaphragm, within the diaphragm. The diaphragm and the leg pieces are separated by slits, and the leg pieces extend in the diagonal directions of the diaphragm. The leg pieces are connected to the diaphragm at the ends on the outer peripheral side of the diaphragm, and the ends on the central side of the diaphragm are supported by anchors provided on the upper surface of the silicon substrate. A back plate is provided above the silicon substrate so as to cover the diaphragm, and a fixed electrode plate is provided on the lower surface of the back plate so as to oppose the diaphragm.

Owner:MMI SEMICON CO LTD

Forming of metallic glass by rapid capacitor discharge

ActiveUS8613813B2Avoid thermal transport and development of thermalHeating evenlyDielectric heatingShaping toolsAlloyGlass transition

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool are provided. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous material and the equilibrium melting point of the alloy in a time scale of several milliseconds or less. Once the sample is uniformly heated such that the entire sample block has a sufficiently low process viscosity it may be shaped into high quality amorphous bulk articles via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, and blow molding in a time frame of less than 1 second.

Owner:CALIFORNIA INST OF TECH

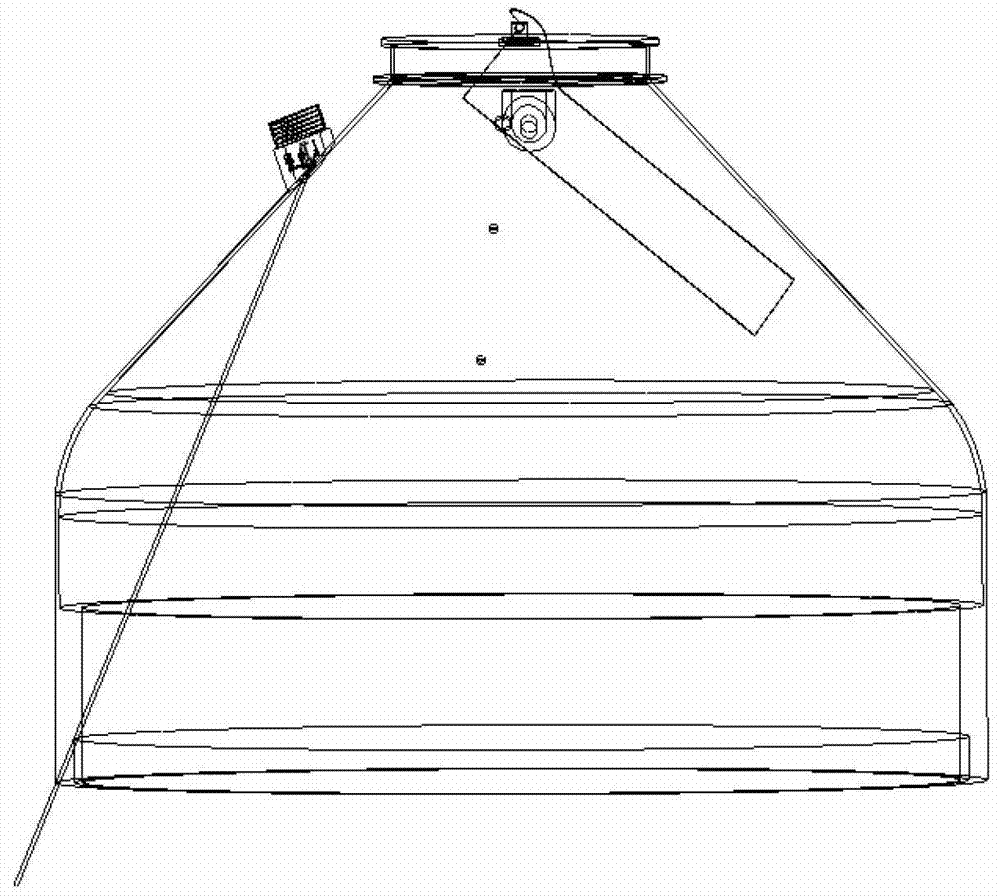

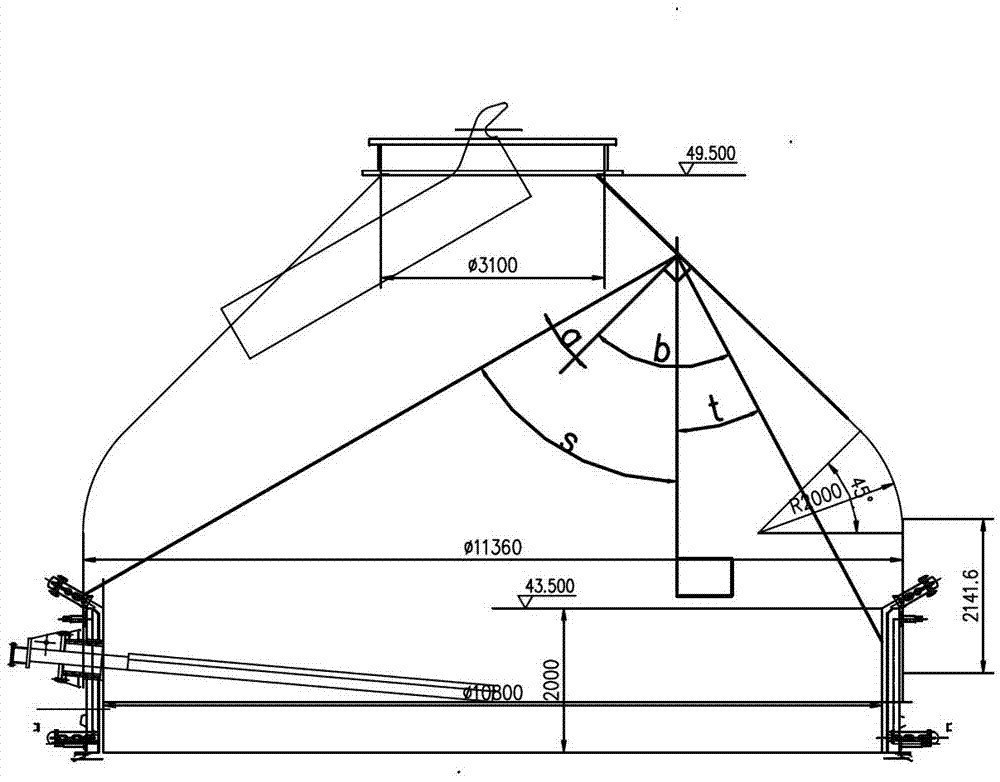

Novel mechanical scanning radar device for measuring shape of shaft furnace charge level

ActiveCN102864263AExtend working lifeSafe and stable long-term workChecking devicesEngineeringRadar signal processing

Owner:北京普瑞玛仪表有限公司

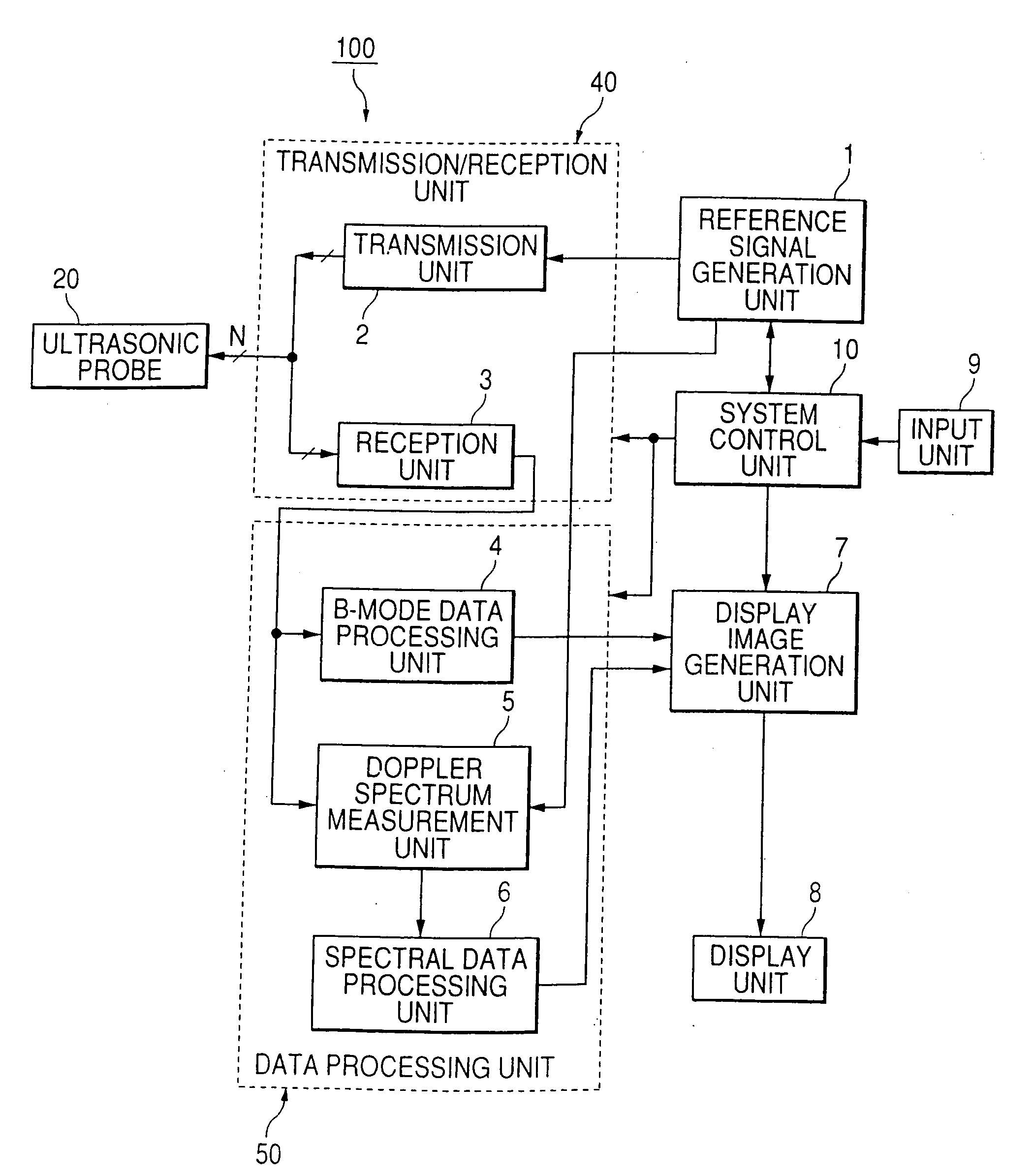

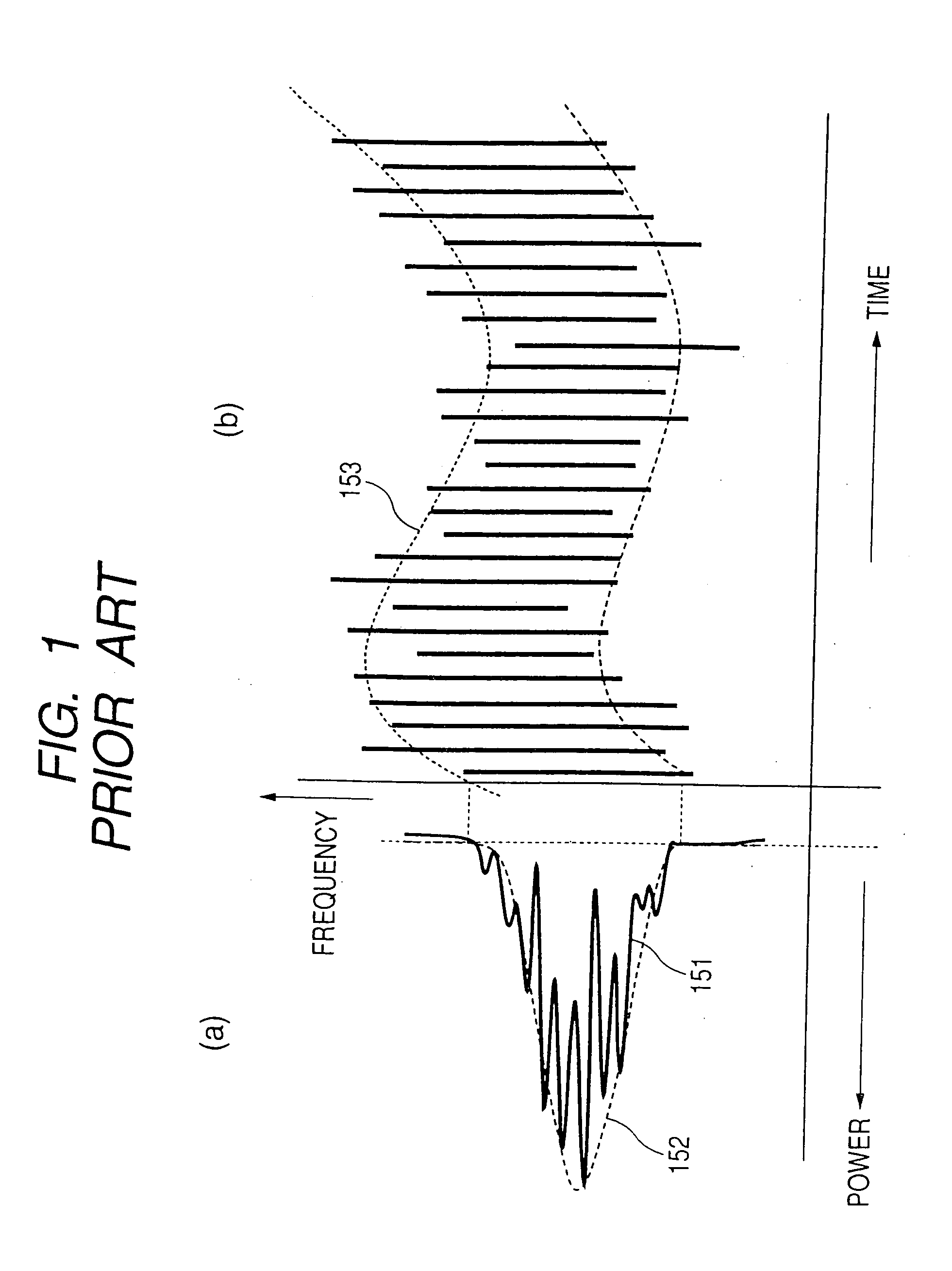

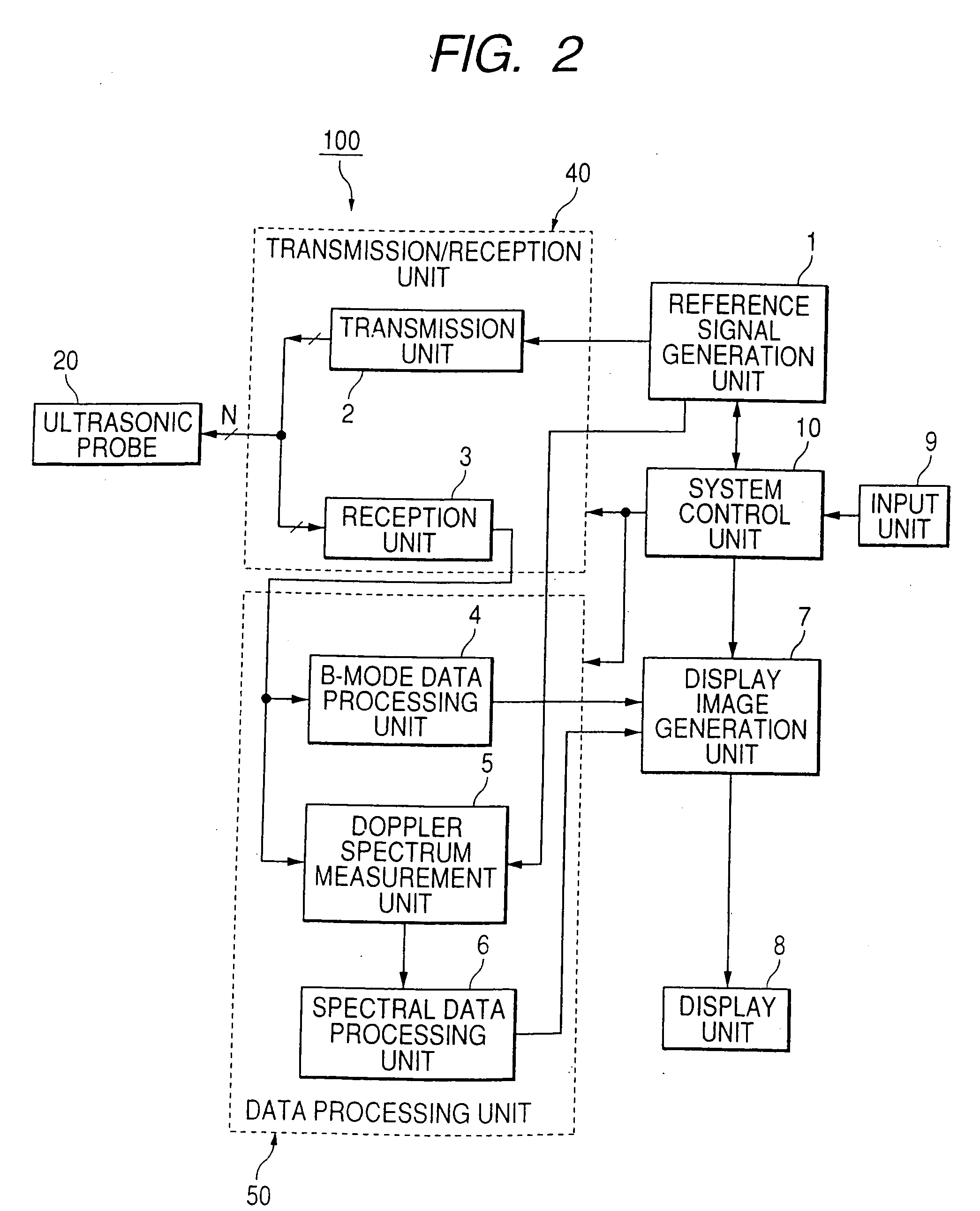

Ultrasound doppler diagnostic apparatus and image date generating method

InactiveUS20050080329A1Improve discontinuityDisplay clearVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound dopplerDiagnostic equipment

An ultrasonic Doppler diagnostic equipment comprising a spectrum measurement unit which measures a Doppler spectrum, a decision unit which determines processing conditions of an average process on the basis of power values of spectral components in the Doppler spectrum, an average process unit which performs the average process of the Doppler spectrum on the basis of the processing conditions determined by the decision unit, and a display unit which displays a Doppler spectral image on the basis of the Doppler spectrum subjected to the average process by the average process unit. According to the configuration, the ultrasonic Doppler diagnostic equipment can improve discontinuities in those spectral components of small power values which are susceptible to interference noise, in the Doppler spectral image, and it can generate image data of high resolution.

Owner:TOSHIBA MEDICAL SYST CORP

Method of Matching Sensors in a Multi-Probe Turbine Blade Vibration Monitor

InactiveUS20090078052A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesTurbine bladeHarmonic

A method of matching sensors in a multi-probe blade vibration monitor for a turbine. The method includes providing at least two probes mounted in a casing of the turbine adjacent to a rotating blade structure of the turbine. Targets are provided on radially outer portions of the blade structure. Each of the probes includes a sensor generating signals corresponding to target passing events, and a set of synchronous harmonics of the rotational speed of the rotor are produced for each sensor. The position of the sensors is adjusted such that the sets of harmonics of the sensors are substantially matched, indicating that the positions of the sensors are matched.

Owner:SIEMENS ENERGY INC

Plug-in kiln video camera and image processing system

ActiveUS20060050147A1Reduces investment in equipmentReduce operating costsTelevision system detailsColor television detailsImaging processingState of charge

The present invention provides a video camera plugged into kiln to monitor and an image processing system using the camera. The video camera is composed of a camera body, a video recorder, a monitor, and a digial thermometer; the image processing system is composed of the camera body mentioned above, a computer and a color monitor. Especially, the present invention is used to monitor material surface during the smelting in a blast furnace; process the image by a computer, describing quantificationally the airflow and temperature distribution of the material surface; monitor the operation state of charging chute or bell, the material stream, and the abnormality in the furnace such as pipeline and material collapse. The advantages of the present invention: Micro camera used to obtain IR image in the furnace, pint-sized, low cost, easy installation, simple maintenance, long service life, and the maintenance performed without stopping production.

Owner:UNIV OF SCI & TECH BEIJING +1

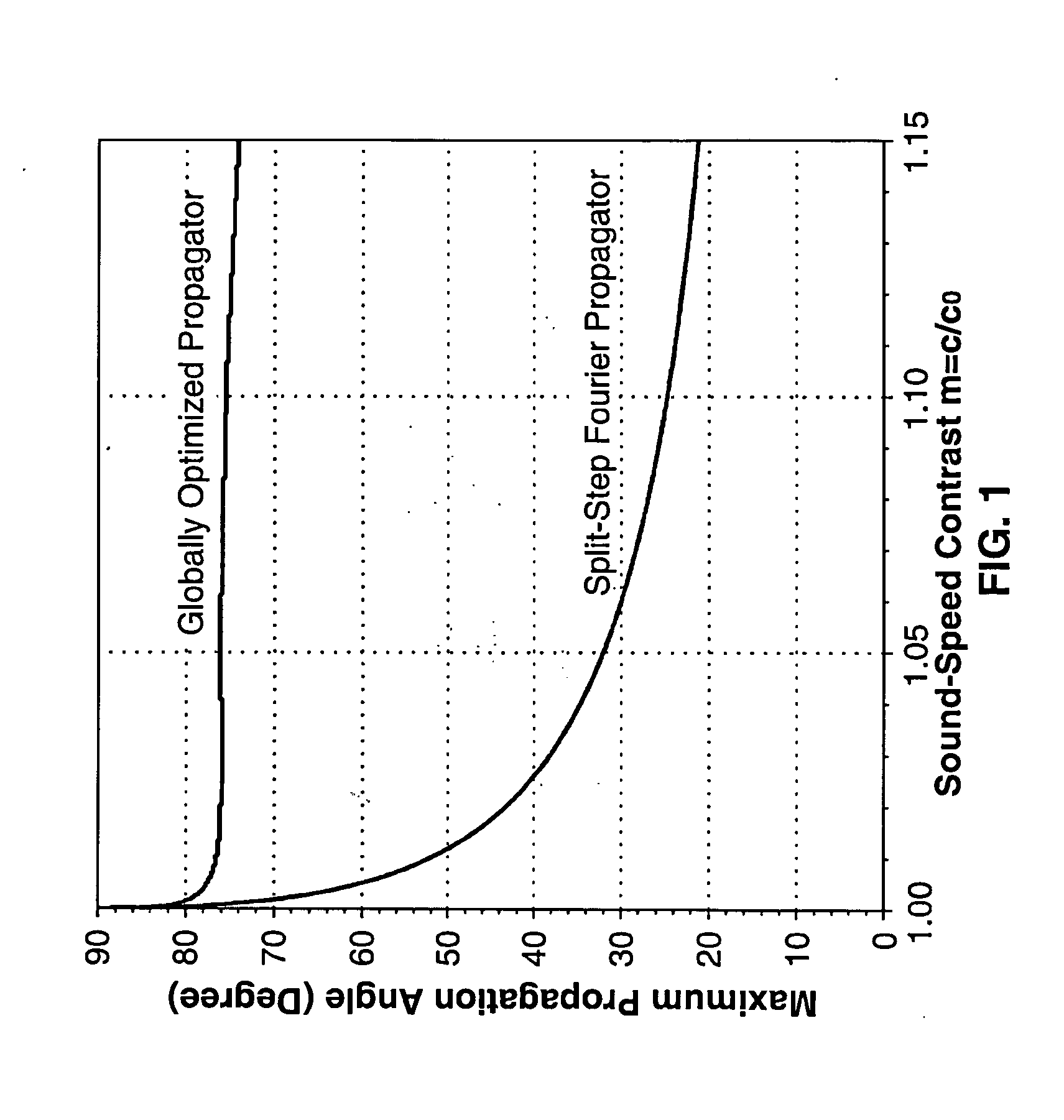

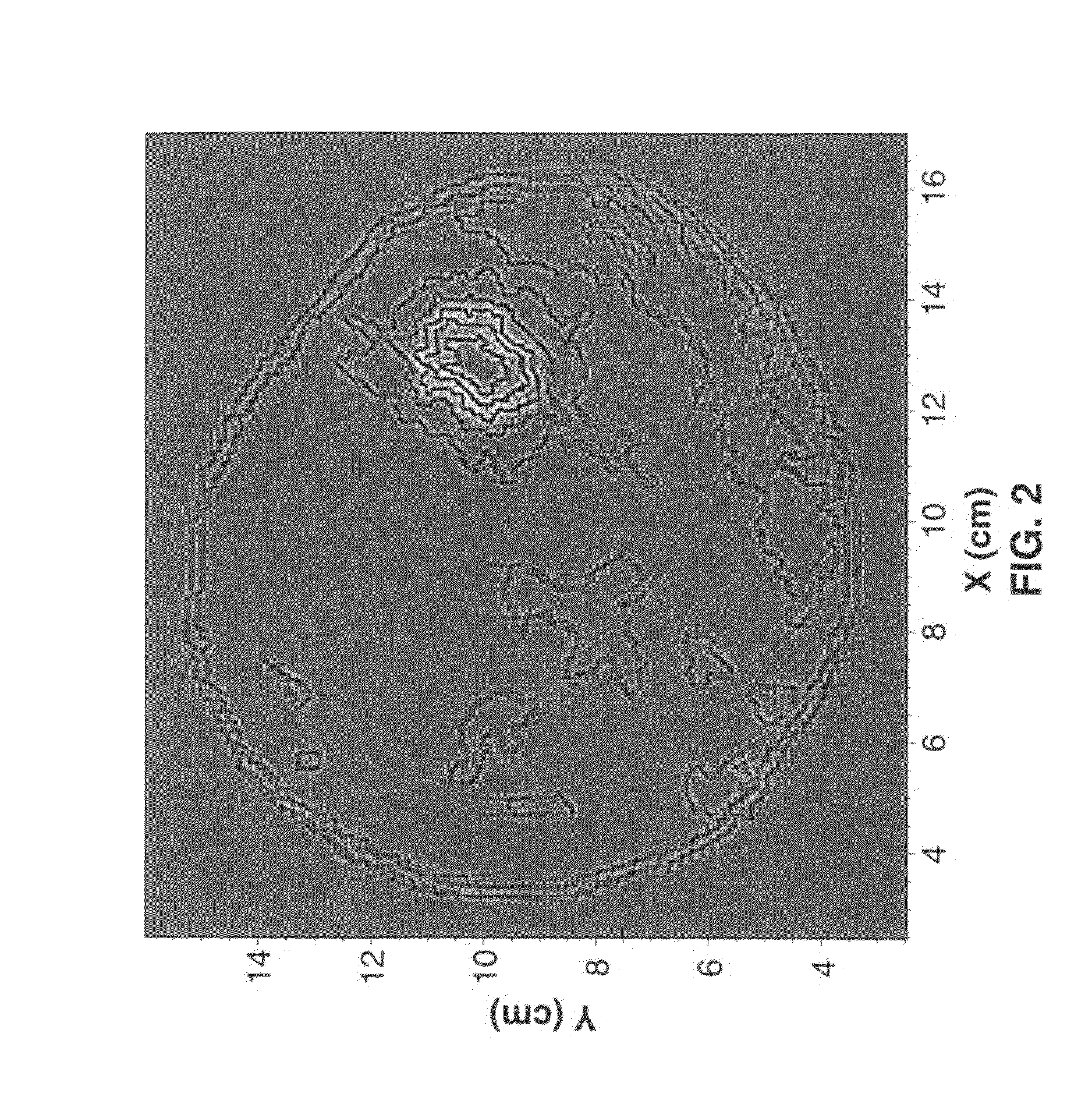

High-resolution wave-theory-based ultrasound reflection imaging using the split-step fourier and globally optimized fourier finite-difference methods

InactiveUS20130251222A1Quality improvementImprove resolutionVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesFrequency waveImaging quality

Methods for enhancing ultrasonic reflection imaging are taught utilizing a split-step Fourier propagator in which the reconstruction is based on recursive inward continuation of ultrasonic wavefields in the frequency-space and frequency-wave number domains. The inward continuation within each extrapolation interval consists of two steps. In the first step, a phase-shift term is applied to the data in the frequency-wave number domain for propagation in a reference medium. The second step consists of applying another phase-shift term to data in the frequency-space domain to approximately compensate for ultrasonic scattering effects of heterogeneities within the tissue being imaged (e.g., breast tissue). Results from various data input to the method indicate significant improvements are provided in both image quality and resolution.

Owner:TRIAD NAT SECURITY LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com