[0004] (1) There are problems in the selection of basic data in the existing hearth

monitoring methods or systems: they all collect the

water temperature difference of the hearth cooling wall or the temperature of the

thermocouple in the

brick lining alone to judge the working state of the hearth, but rely solely on the hearth When judging the hearth

erosion by using the

heat flow of

water temperature difference in the stave, the

heat flow of the stave can only reflect the average

erosion degree of the

brick lining in front of the whole stave, and the hearth burn-through is often point burn-through rather than surface burn-through; relying on bricks alone When the lining

thermocouple temperature is used to judge the hearth erosion, due to the limited number of thermocouples, the places without thermocouples will lose the basis for erosion judgment, and at the end of the furnace service (the blast furnace hearth needs to be monitored), the thermocouples in the brick lining are often already More damage, so the accuracy of erosion monitoring will be greatly reduced due to insufficient basic data

[0005] (2) The existing hearth

monitoring methods or systems have problems in basic data collection: most of the collected data are directly used for hearth working state diagnosis, and there is a lack of filtering of erroneous data, such as basic data errors will directly lead to wrong judgment results and may undermine the accuracy of

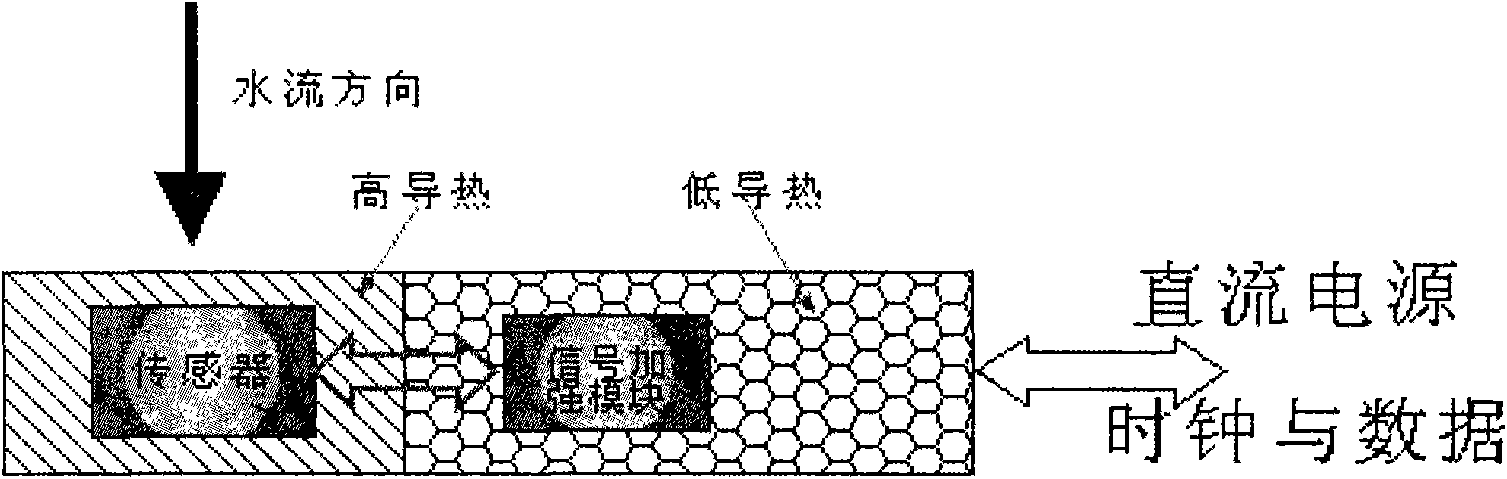

continuous monitoringIn addition, most of the traditional multi-module circuit

analog signal transmission is used in the collection of

cooling water temperature, the data accumulation error is large and the transmission process is susceptible to interference

[0006] (3) There are problems in the calculation

model selection of existing hearth

monitoring methods or systems when inferring hearth erosion: most of them use one-dimensional or two-dimensional,

rectangular coordinates (rectangular), and steady-state calculation models that do not include the

latent heat of solidification of molten iron. The three-dimensional design and erosion

asymmetry of the hearth bottom of the blast furnace, the geometric shape is approximately cylindrical, and the

slag-iron shell forms and releases the solidification

latent heat.

[0007] (4) There is a gap in the existing hearth monitoring method or

system when judging whether there is an

abnormality in the hearth: through the research on the erosion mechanism of the hearth hearth bottom and the erosion monitoring and damage investigation of dozens of blast furnaces in China (the applicant of this patent has long been committed to

Blast furnace longevity technology and erosion monitoring research, undertook and completed the national "Eighth Five-Year Plan", "Ninth Five-Year Plan", "Eleventh Five-Year Plan",

Natural Science Foundation projects and Shougang, Taiyuan Iron and Steel, Tangshan Iron and Steel, Panzhihua Iron and Steel Co., Ltd. and many factory association projects), we found that after the blast furnace was put into production, with the gradual temperature rise of the

refractory material at the bottom of the hearth, tapping operation, corrosion of

zinc and alkali metals, thermal stress changes, and the removal of

moisture and

volatiles in the filling and ramming materials, the hearth The reasons for the obvious change in the working state of the furnace bottom and the intensification of erosion are often due to the occurrence of abnormal conditions, such as ring cracks in the hearth carbon bricks, air gaps between carbon bricks and the cooling system, gas flow, abnormal changes in the

thermal conductivity of

refractory materials, and furnace bottom seepage. Iron, etc., but the existing erosion monitoring methods or systems have not judged and warned these abnormal situations

[0008] (5) The existing hearth monitoring methods or systems have problems in the display and early warning function: most of them only display a single hearth bottom erosion line, and lack the display of different temperatures at various parts of the hearth bottom; When the system is in an unresponsive state, it does not support man-

machine dialogue; when performing historical query on the state of the hearth, it can only provide

data query and lacks an intuitive query display of the inner shape of the hearth erosion; , hearth is not active and other real-time early warning prompt function

[0009] (6) There is a gap in the existing hearth monitoring methods or systems in guiding hearth maintenance: most of them can only make judgments on the severity of hearth erosion or the remaining thickness of brick lining, but fail to diagnose the cause of increased erosion , it is impossible to guide targeted hearth maintenance and production operation adjustment

[0010] In summary, the existing hearth bottom monitoring and early warning methods or systems still have defects in basic

data selection, erosion calculation

model selection, and early warning prompts for hearth working status. There is still a gap in cylinder maintenance, which has not been organically combined with the safe and efficient production of blast furnaces

Login to View More

Login to View More  Login to View More

Login to View More