Patents

Literature

943results about "Tungsten oxides/hydroxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

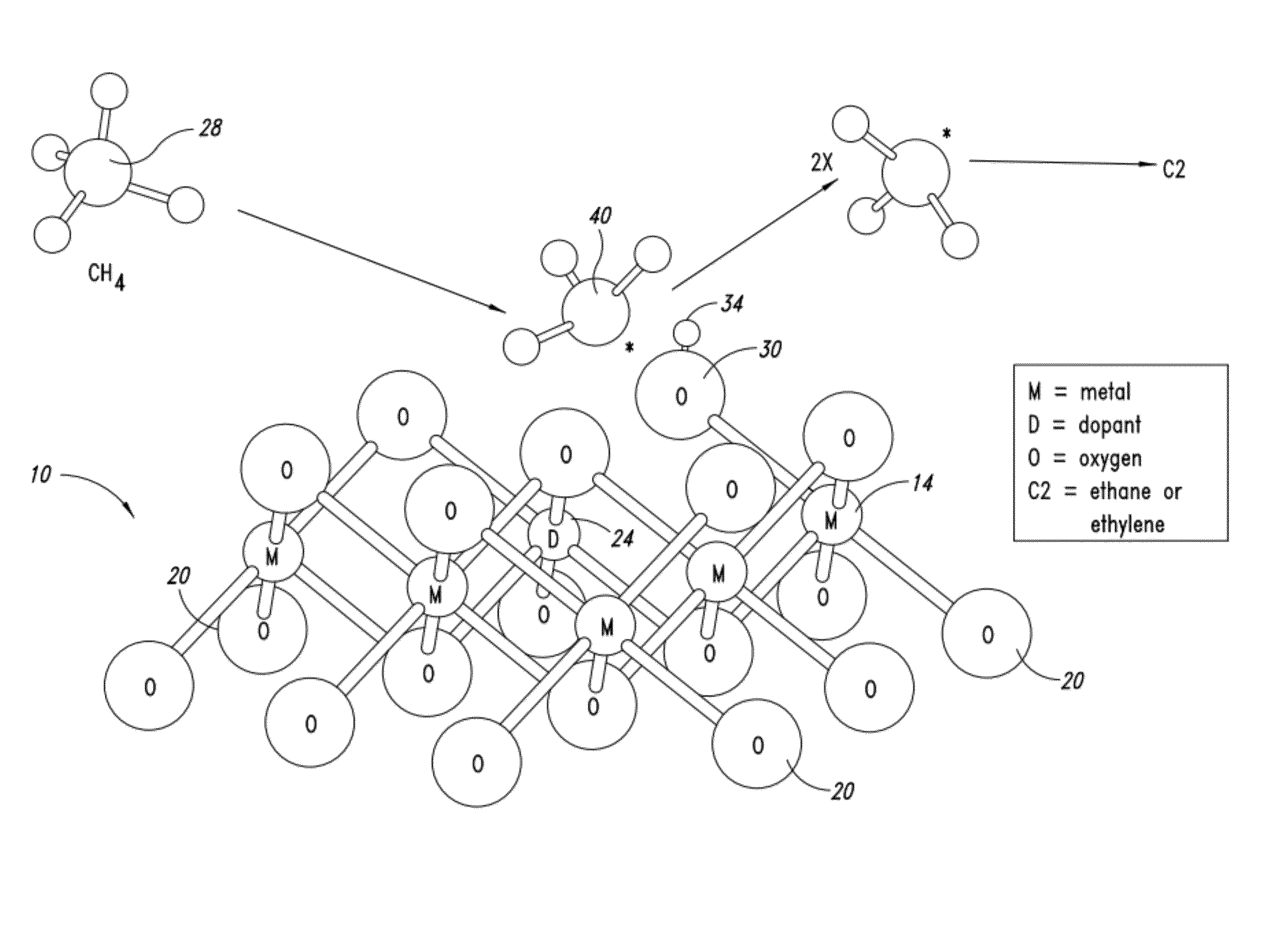

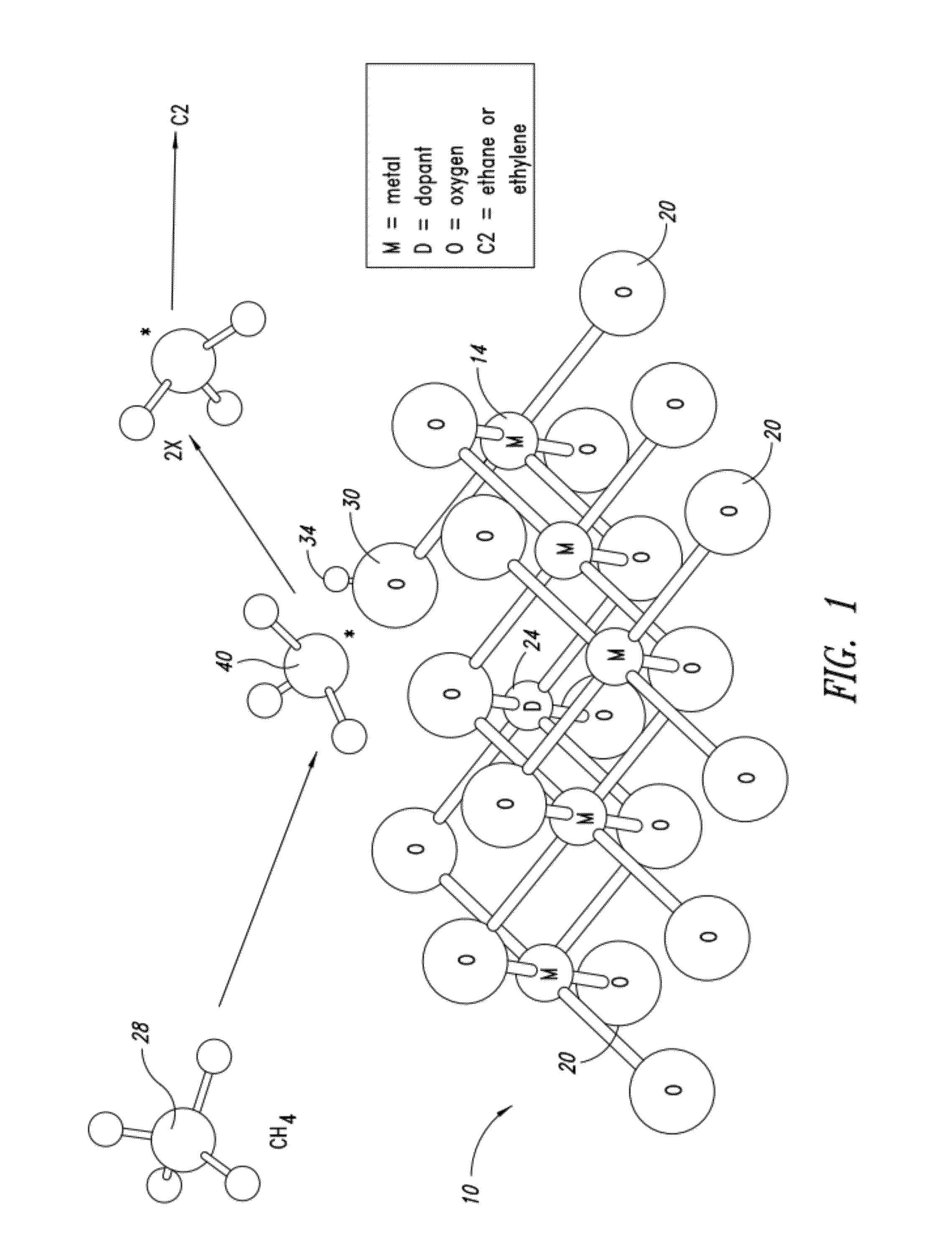

Nanowire catalysts

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

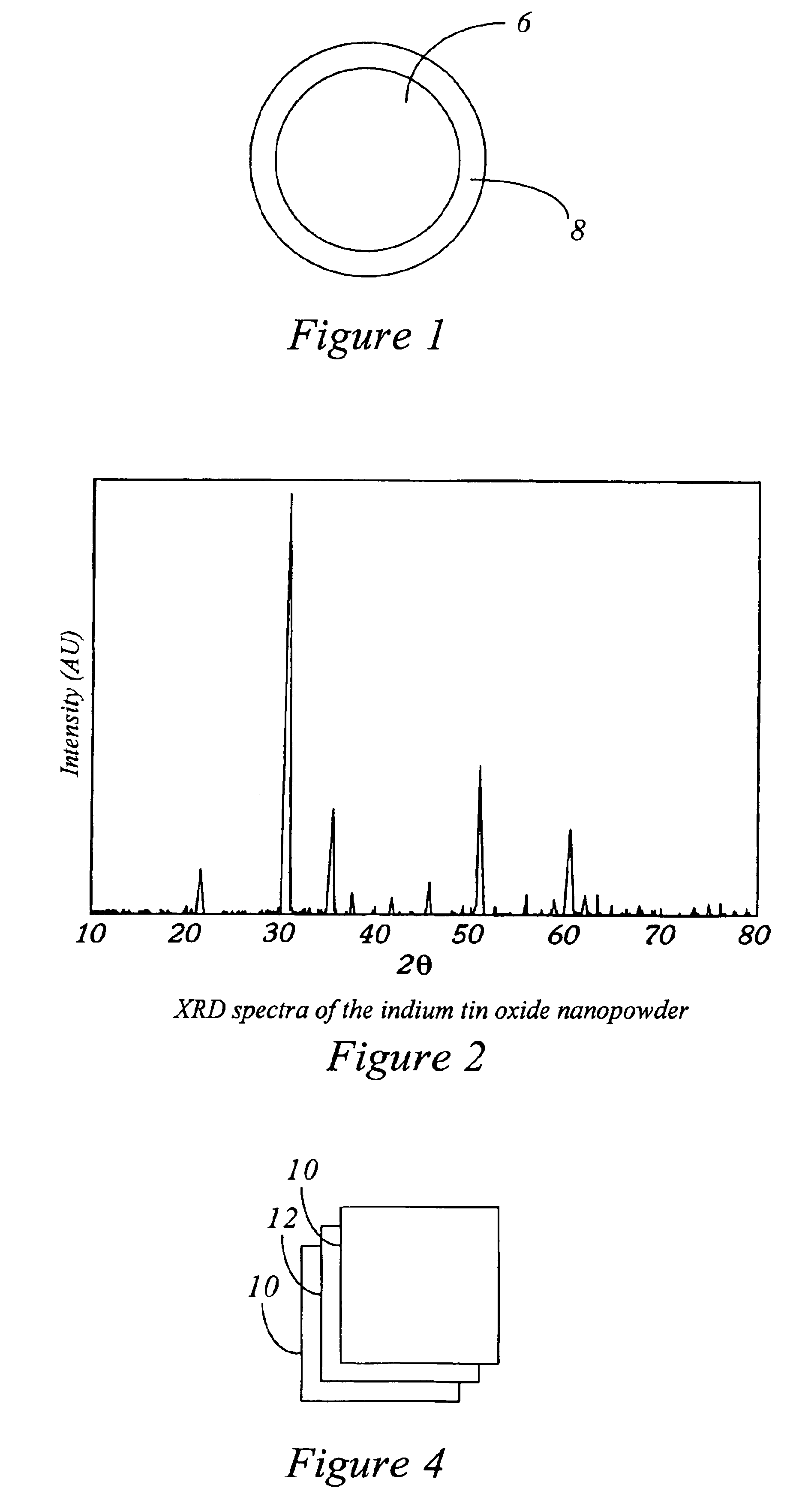

Polymer nanocomposite implants with enhanced transparency and mechanical properties for administration within humans or animals

Polymer nanocomposite implants with nanofillers and additives are described. The nanofillers described can be any composition with the preferred composition being those composing barium, bismuth, cerium, dysprosium, europium, gadolinium, hafnium, indium, lanthanum, neodymium, niobium, praseodymium, strontium, tantalum, tin, tungsten, ytterbium, yttrium, zinc, and zirconium. The additives can be of any composition with the preferred form being inorganic nanopowders comprising aluminum, calcium, gallium, iron, lithium, magnesium, silicon, sodium, strontium, titanium. Such nanocomposites are particularly useful as materials for biological use in applications such as drug delivery, biomed devices, bone or dental implants.

Owner:PPG IND OHIO INC

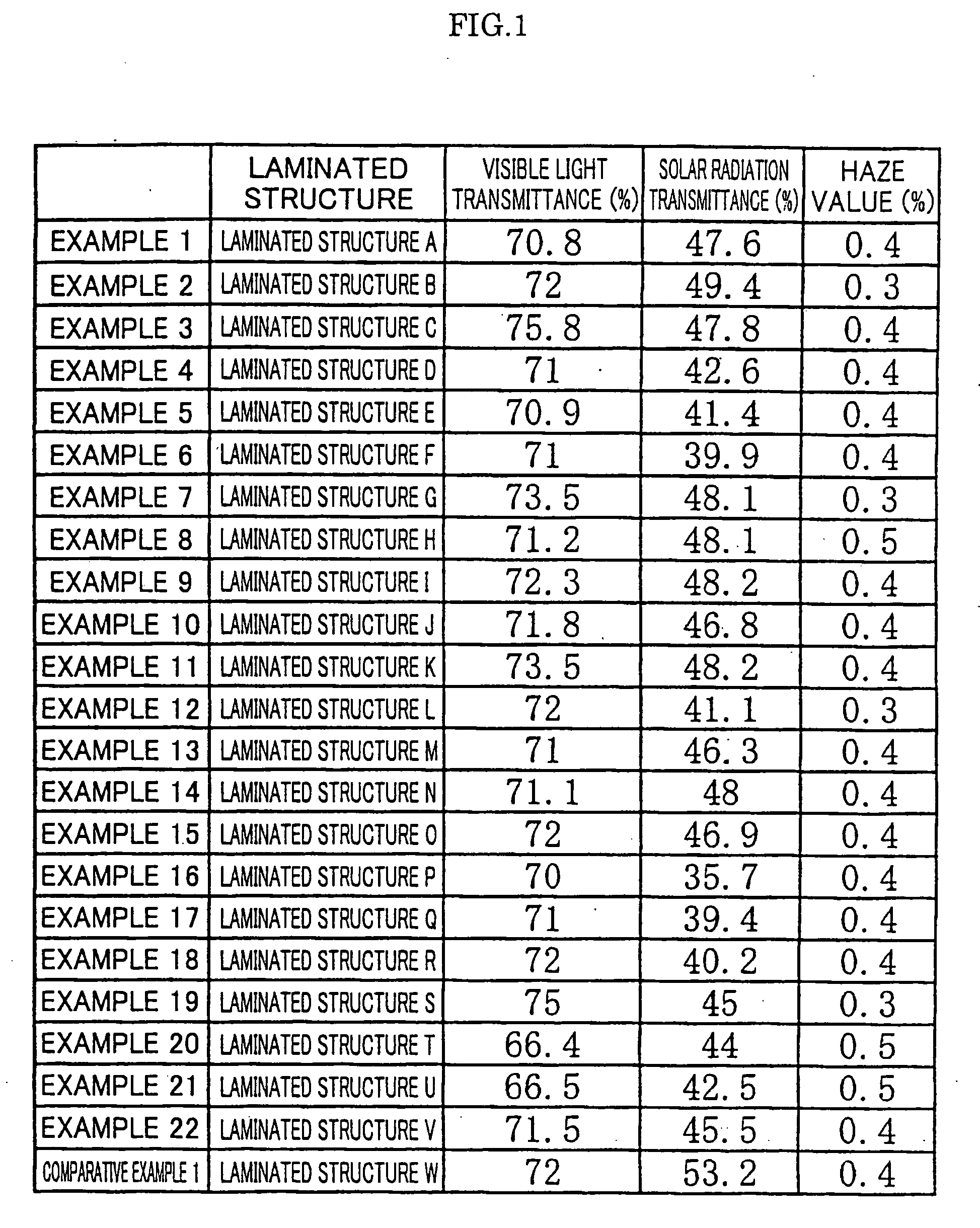

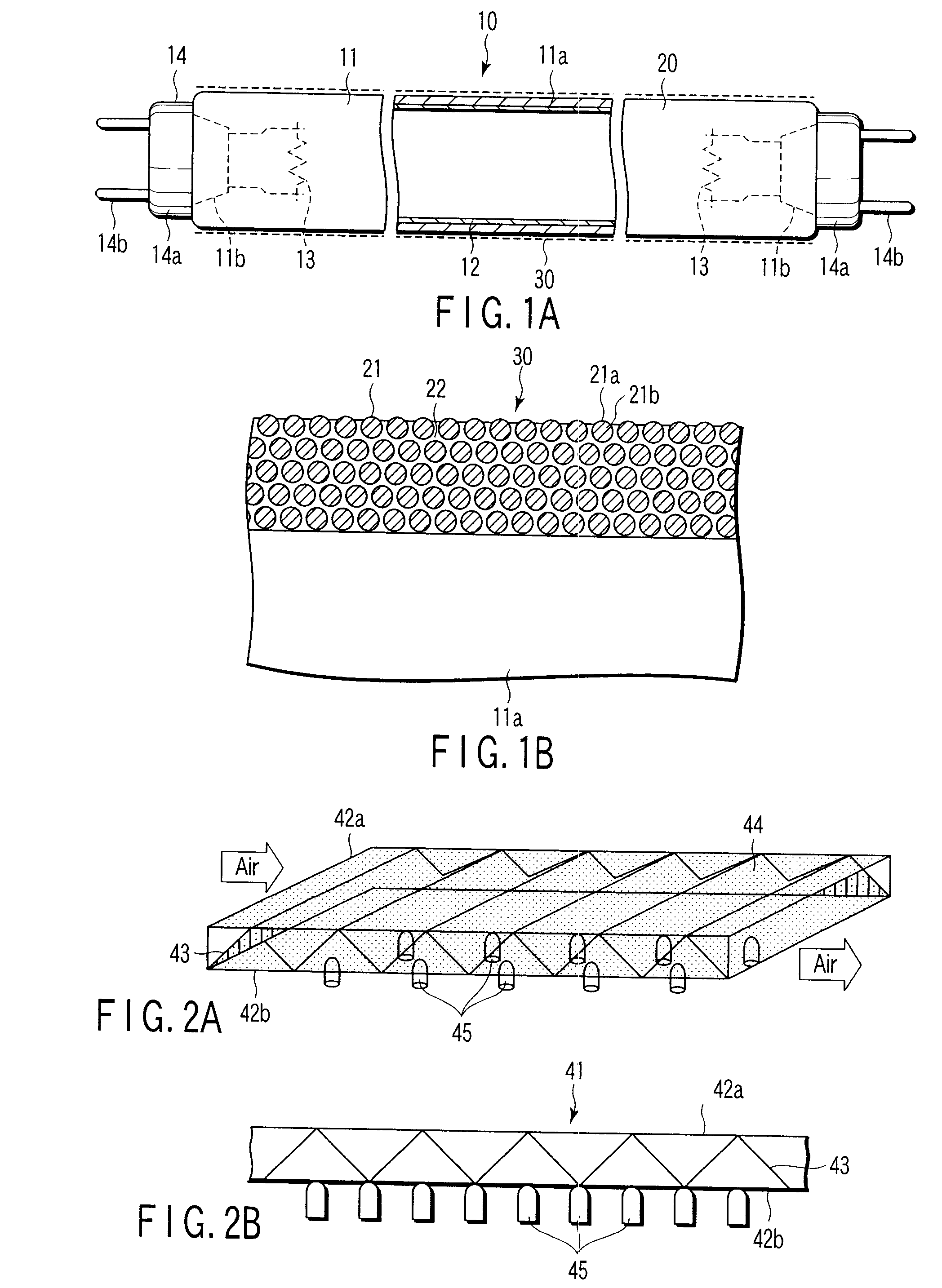

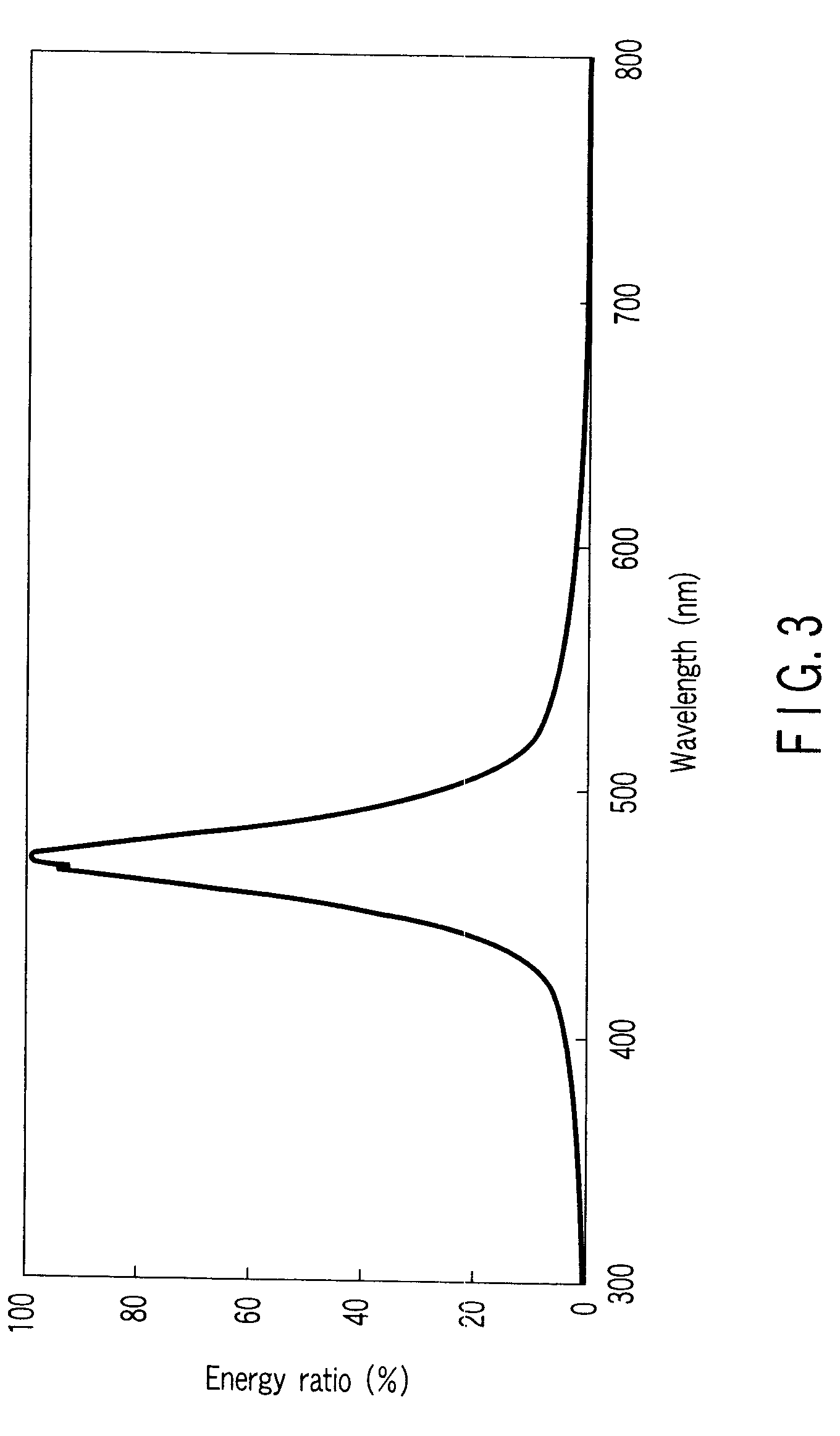

Infrared shielding material microparticle dispersion infrared shield, process for producing infrared shield material microparticle and infrared shielding material microparticle

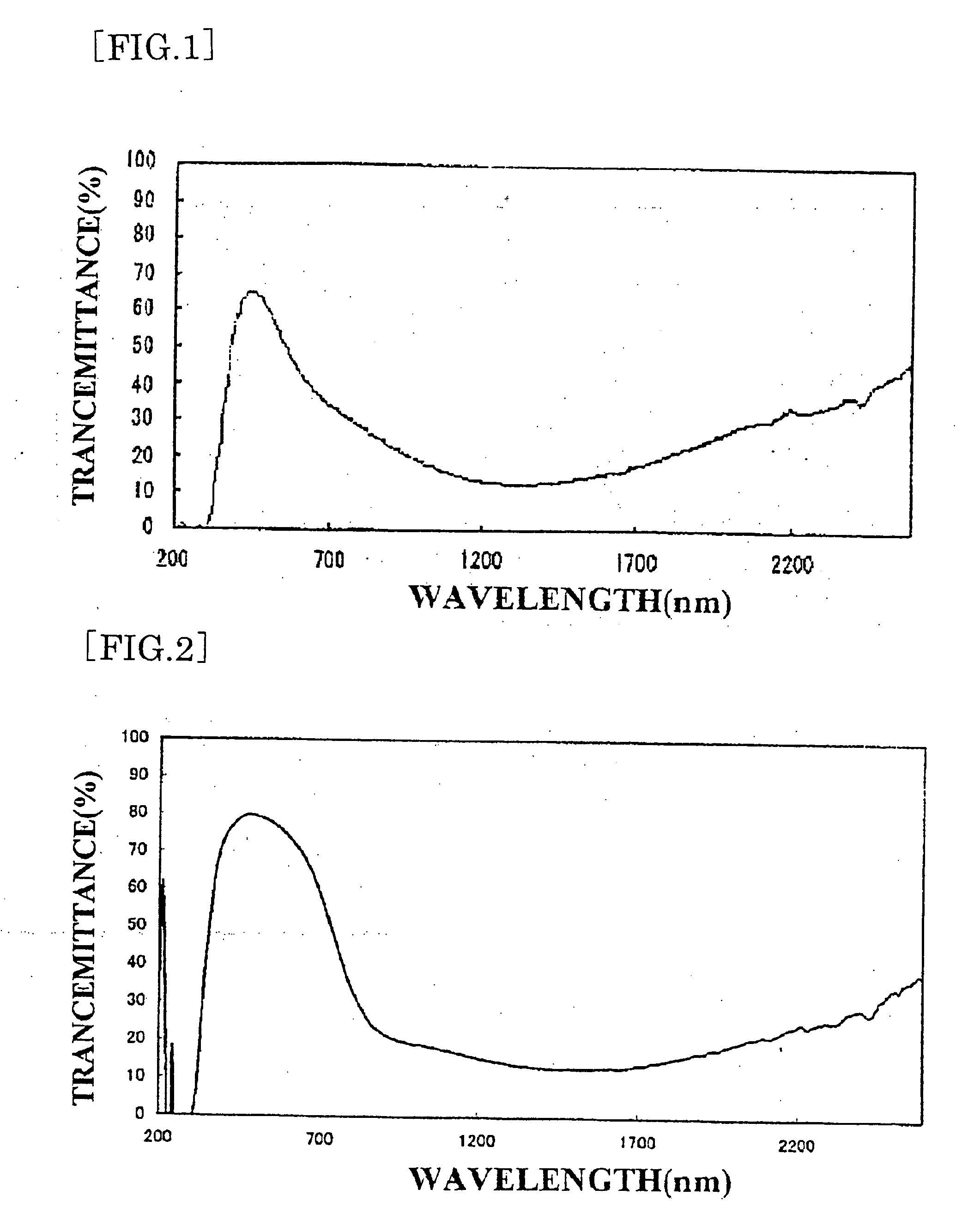

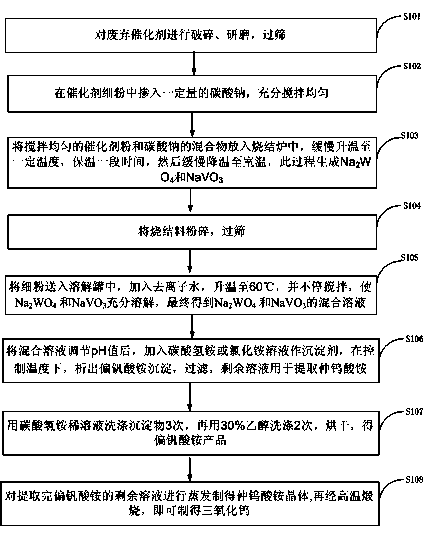

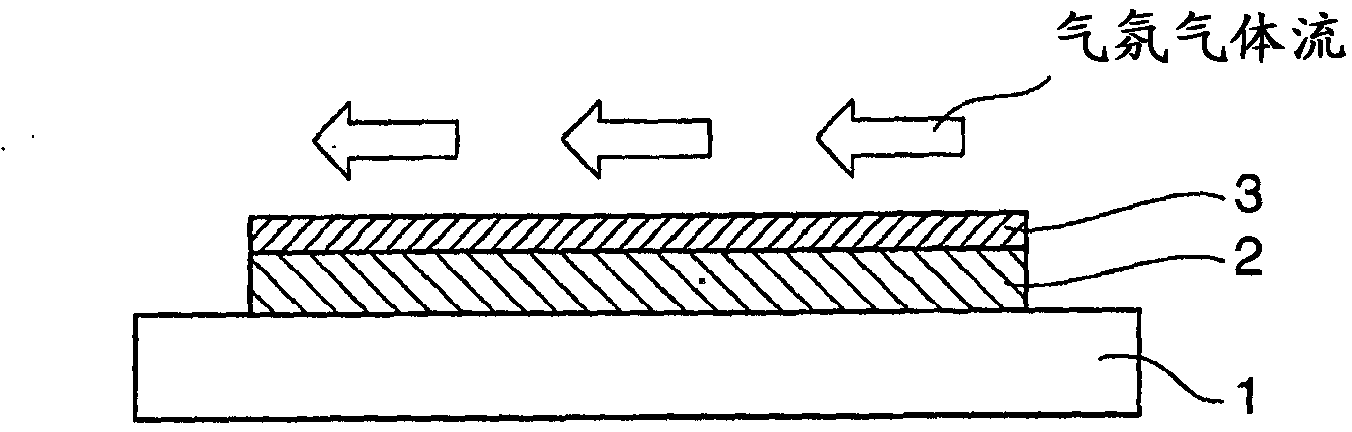

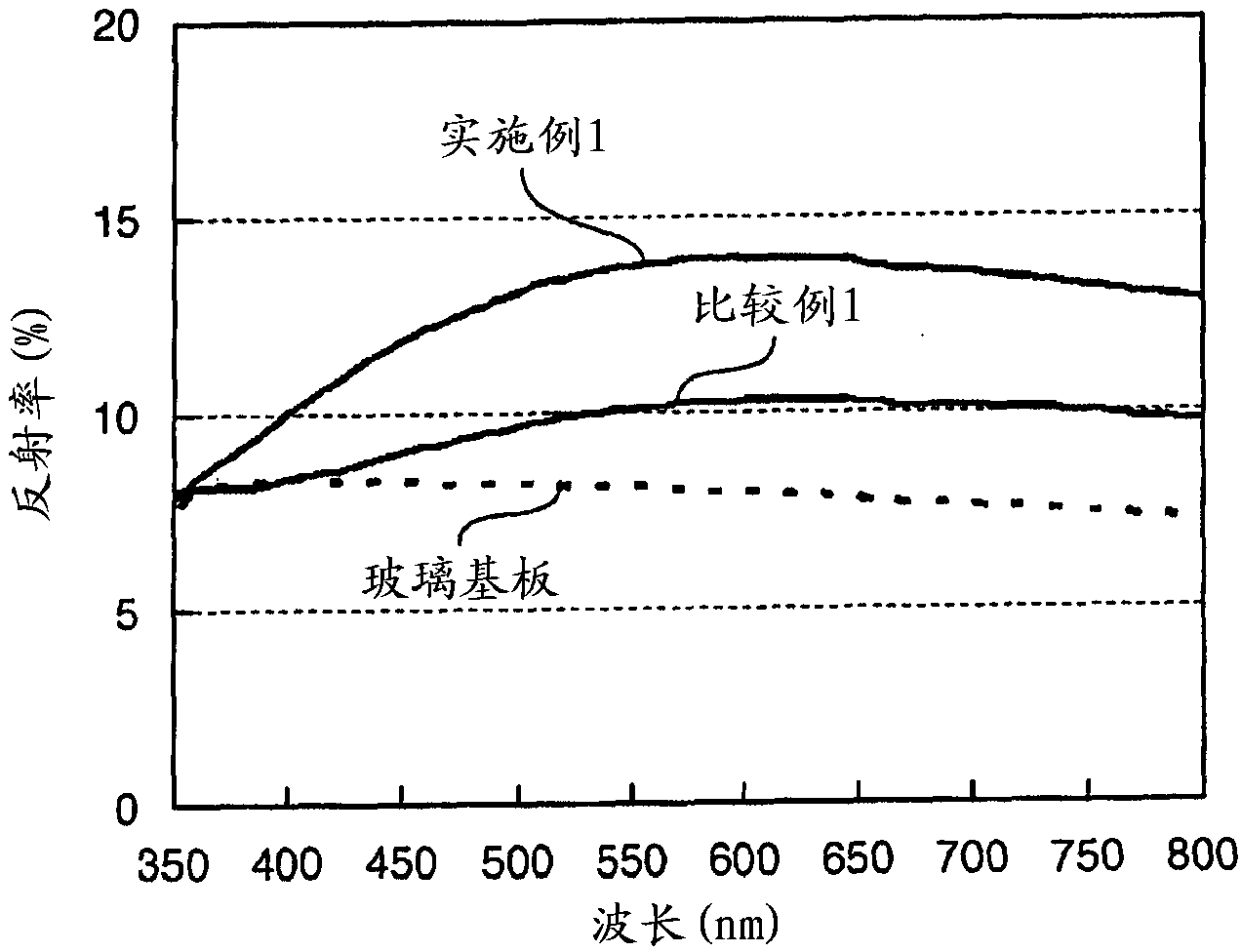

ActiveUS20060178254A1Improve featuresEffective shieldingPigmenting treatmentTungsten oxides/hydroxidesArgon atmosphereRoom temperature

To provide an infrared-shielding body sufficiently transmitting visible rays, having no half-mirror shaped appearance, requiring no large-scale apparatus when forming a film on a substrate, efficiently shutting invisible near-infrared rays with wavelength range of 780 nm or more, while eliminating a heat treatment at high temperature after film formation, and having a spectral characteristic such as transparency with no change of color tone. The starting material, which is a mixture containing a predetermined amount of a tungsten compound, is heated at 550° C. in a reductive atmosphere for 1 hour, then cooled to room temperature once in an argon atmosphere, thus producing powder of W18O49. Then, the powder, the solvent, and the dispersant are mixed, then subjected to dispersion treatment to obtain a dispersion solution. The dispersion solution and a UV-curable hardcoat resin are mixed to obtain a solution of fine particle dispersion of infrared-shielding material. The solution of the fine particle dispersion of infrared-shielding material is applied on a PET resin film to form a film, which is then cured, and an infrared-shielding film having a transmission profile shown in the figure is thereby obtained.

Owner:SUMITOMO METAL MINING CO LTD

Nanotechnology for drug delivery, contrast agents and biomedical implants

A nanocomposite structure comprising a nanostructured filler or carrier intimately mixed with a matrix, and methods of making such a structure. The nanostructured filler has a domain size sufficiently small to alter an electrical, magnetic, optical, electrochemical, chemical, thermal, biomedical, or tribological property of either filler or composite by at least 20%.

Owner:PPG IND OHIO INC

Inorganic dopants, inks and related nanotechnology

InactiveUS6849109B2Facilitated DiffusionLower transition temperatureSelenium/tellurium compundsCell electrodesIndiumCerium

Ink compositions with modified properties result from using a powder size below 100 nanometers. Colored inks are illustrated. Nanoscale coated, uncoated, whisker inorganic fillers are included. The pigment nanopowders taught comprise one or more elements from the group actinium, aluminum, antimony, arsenic, barium, beryllium, bismuth, cadmuim, calcium, cerium, cesium, chalcogenide, cobalt, copper, dysprosium, erbium, europium, gadolinium, gallium, gold, hafnium, hydrogen, indium, iridium, iron, lanthanum, lithium, magnesium, manganese, mendelevium, mercury, molybdenum, neodymium, neptunium, nickel, niobium, nitrogen, oxygen, osmium, palladium, platinum, potassium, praseodymium, promethium, protactinium, rhenium, rubidium, scandium, silver, sodium, strontium, tantalum, terbium, thallium, thorium, tin, titanium, tungsten, vanadium, ytterbium, yttrium, zinc, and zirconium.

Owner:PPG IND OHIO INC

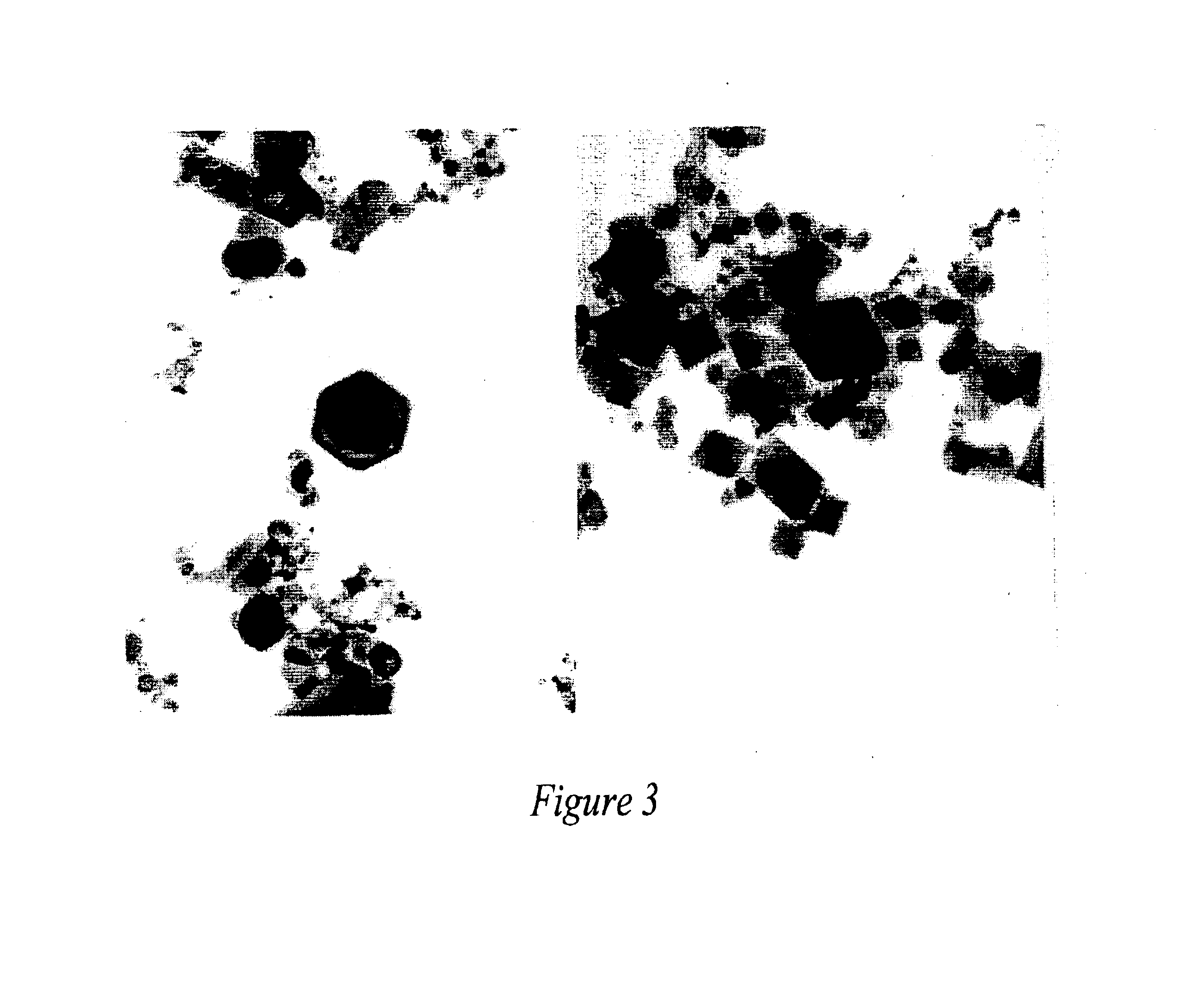

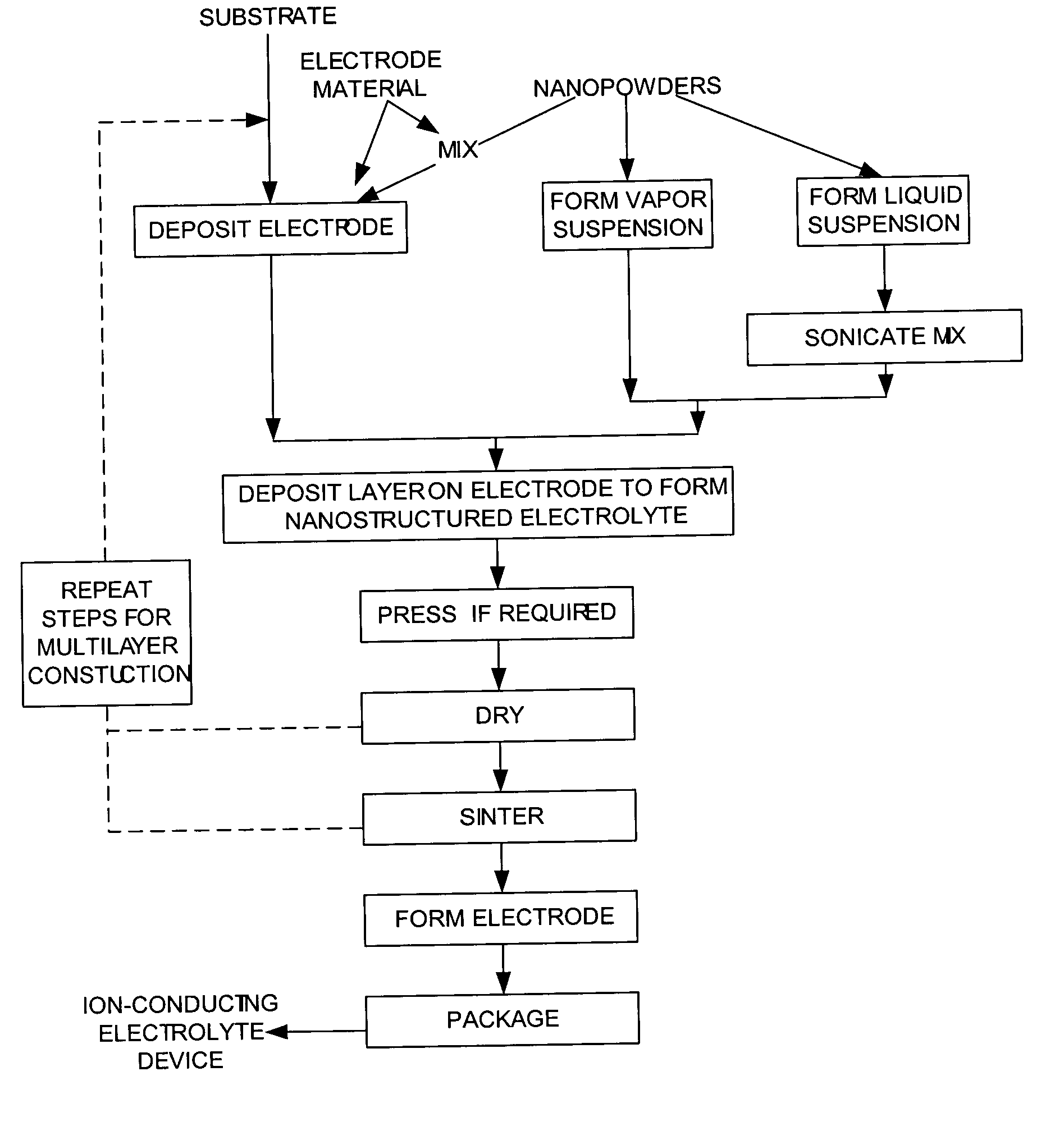

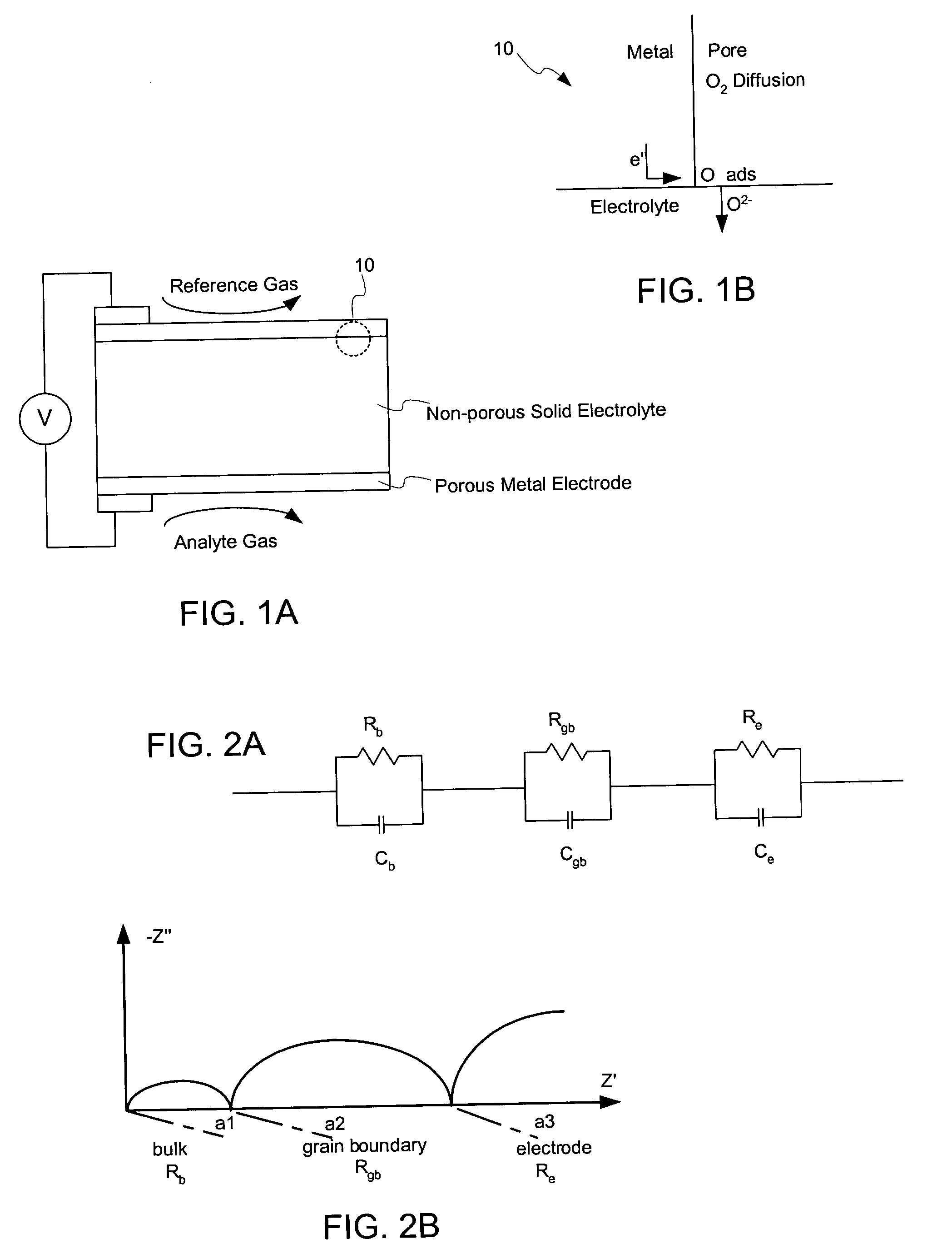

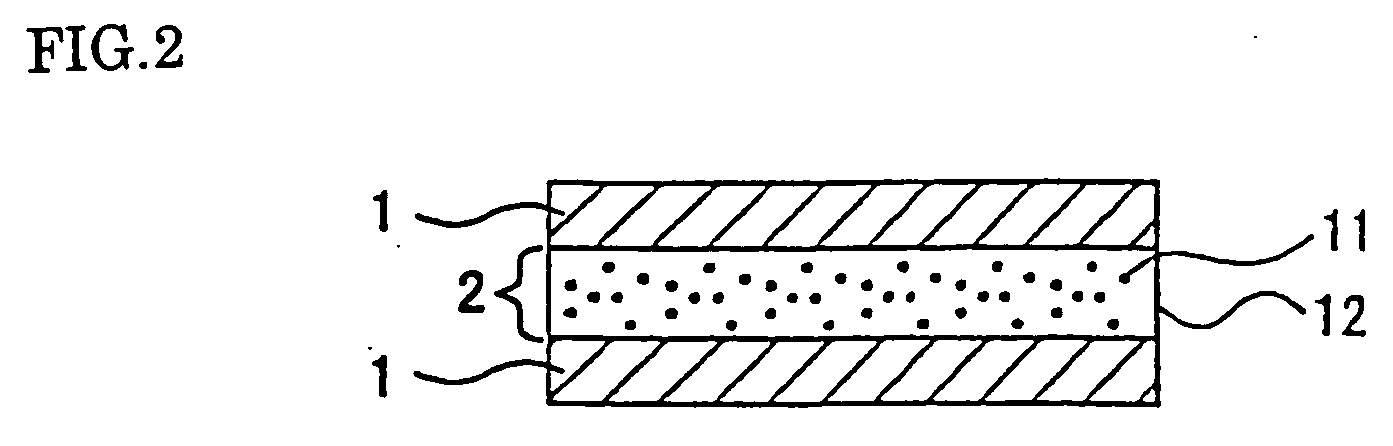

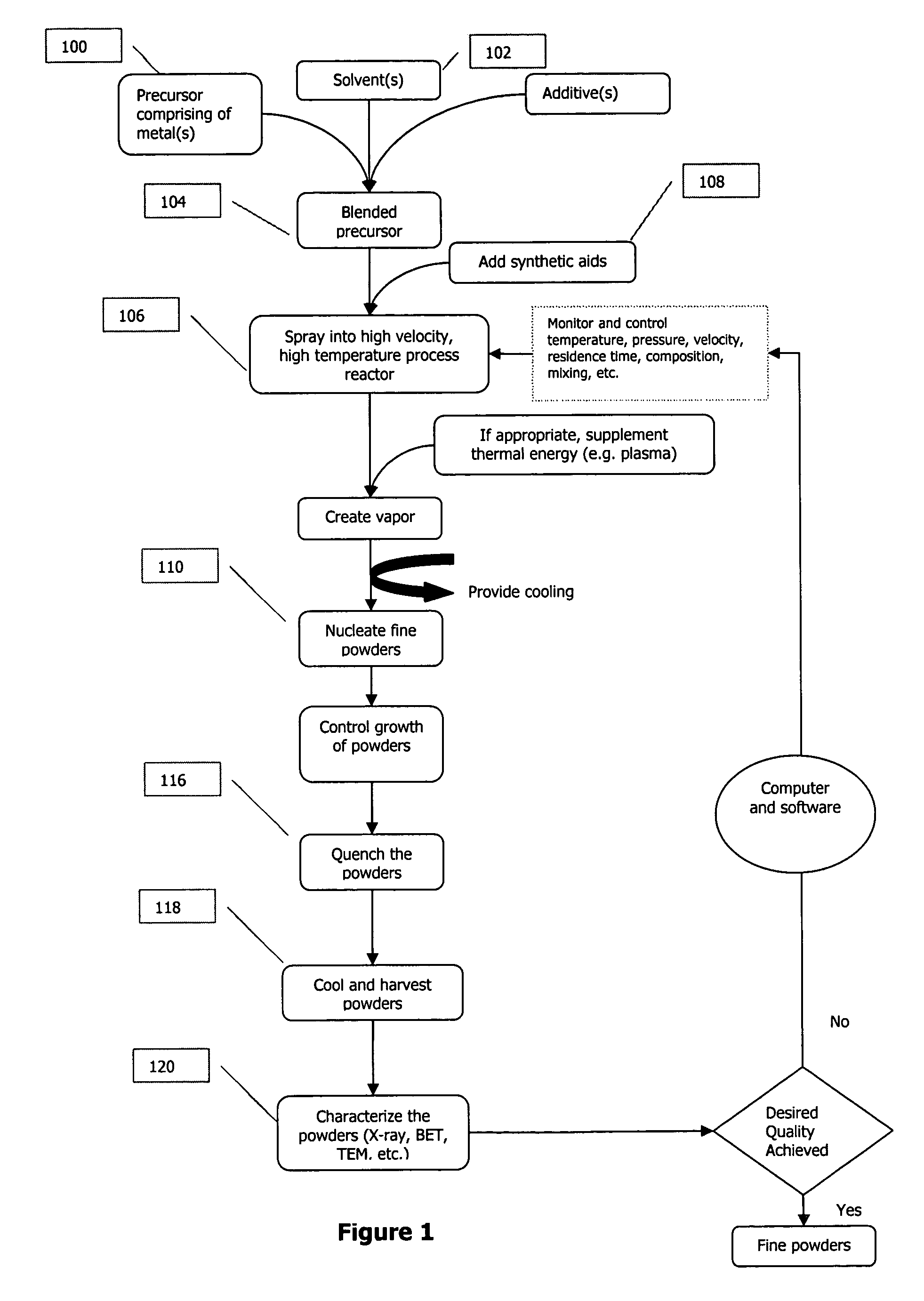

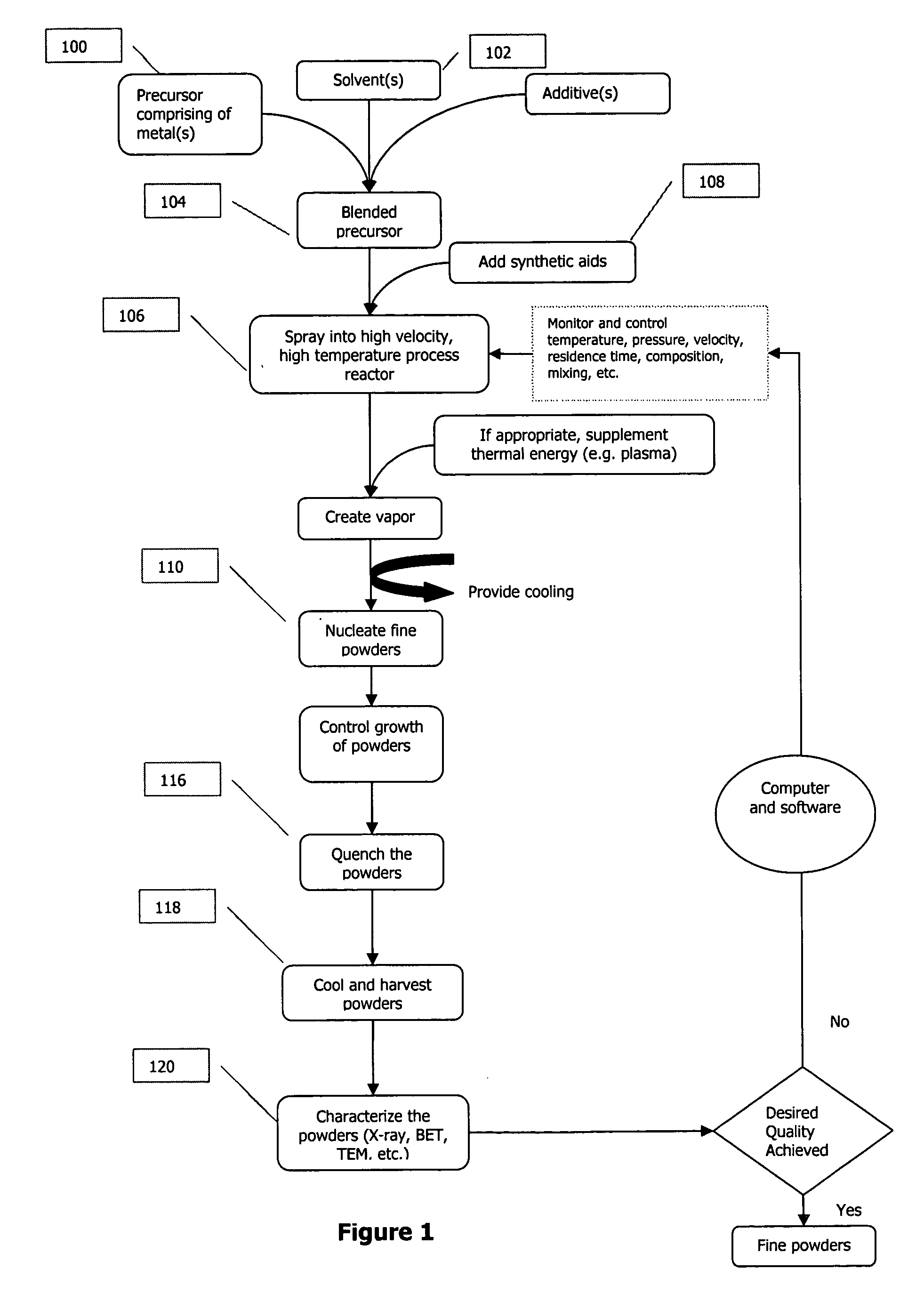

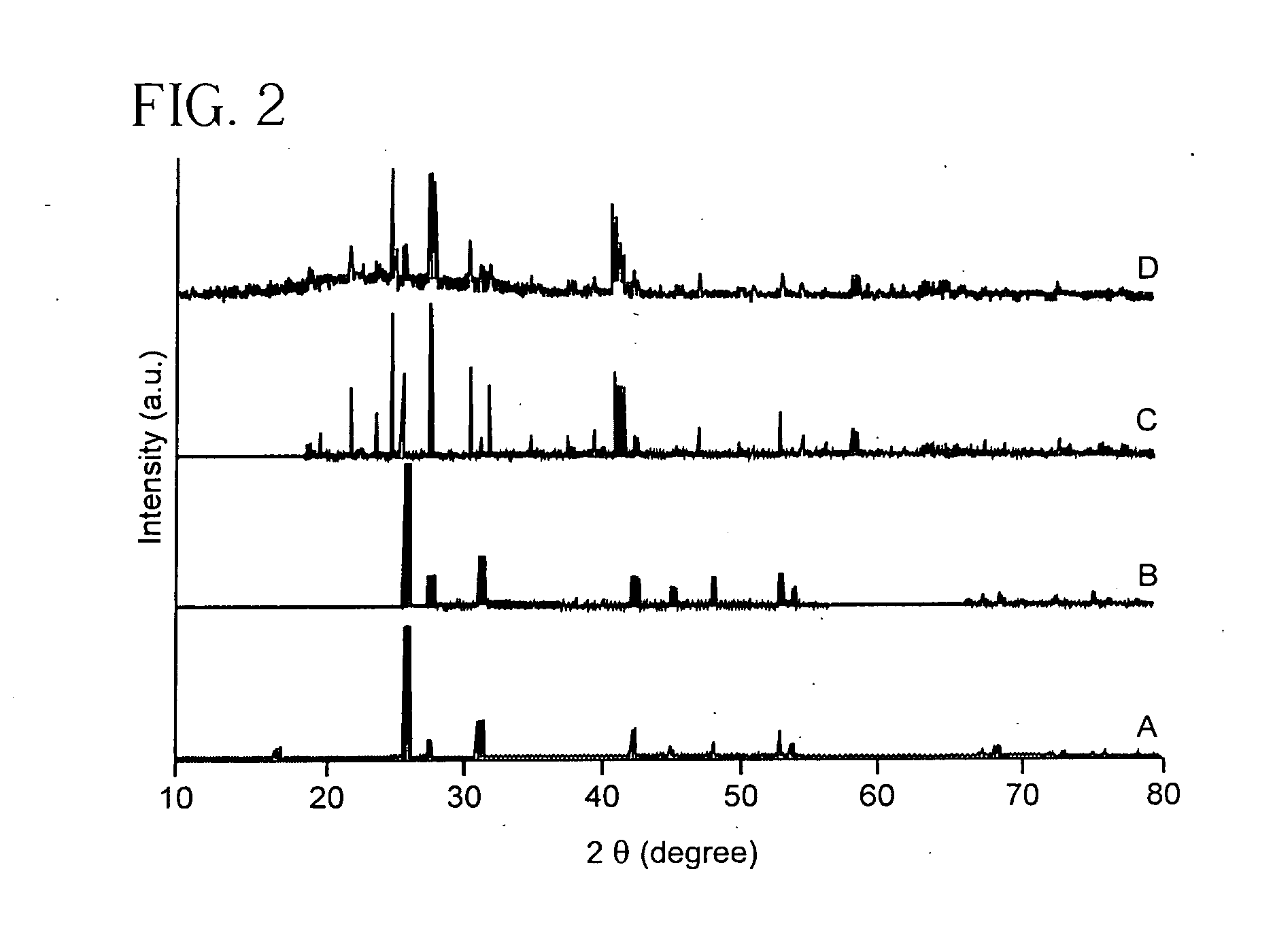

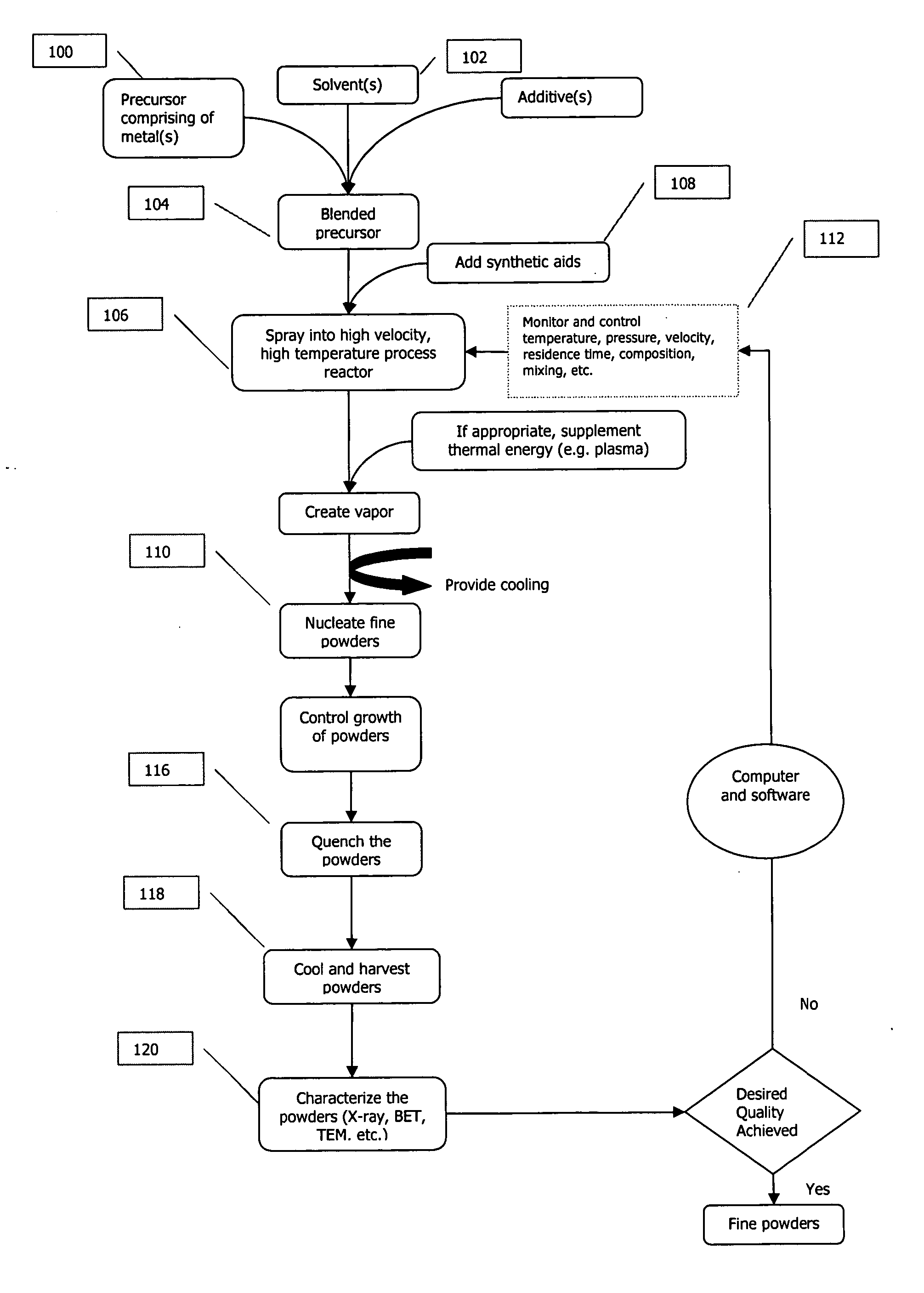

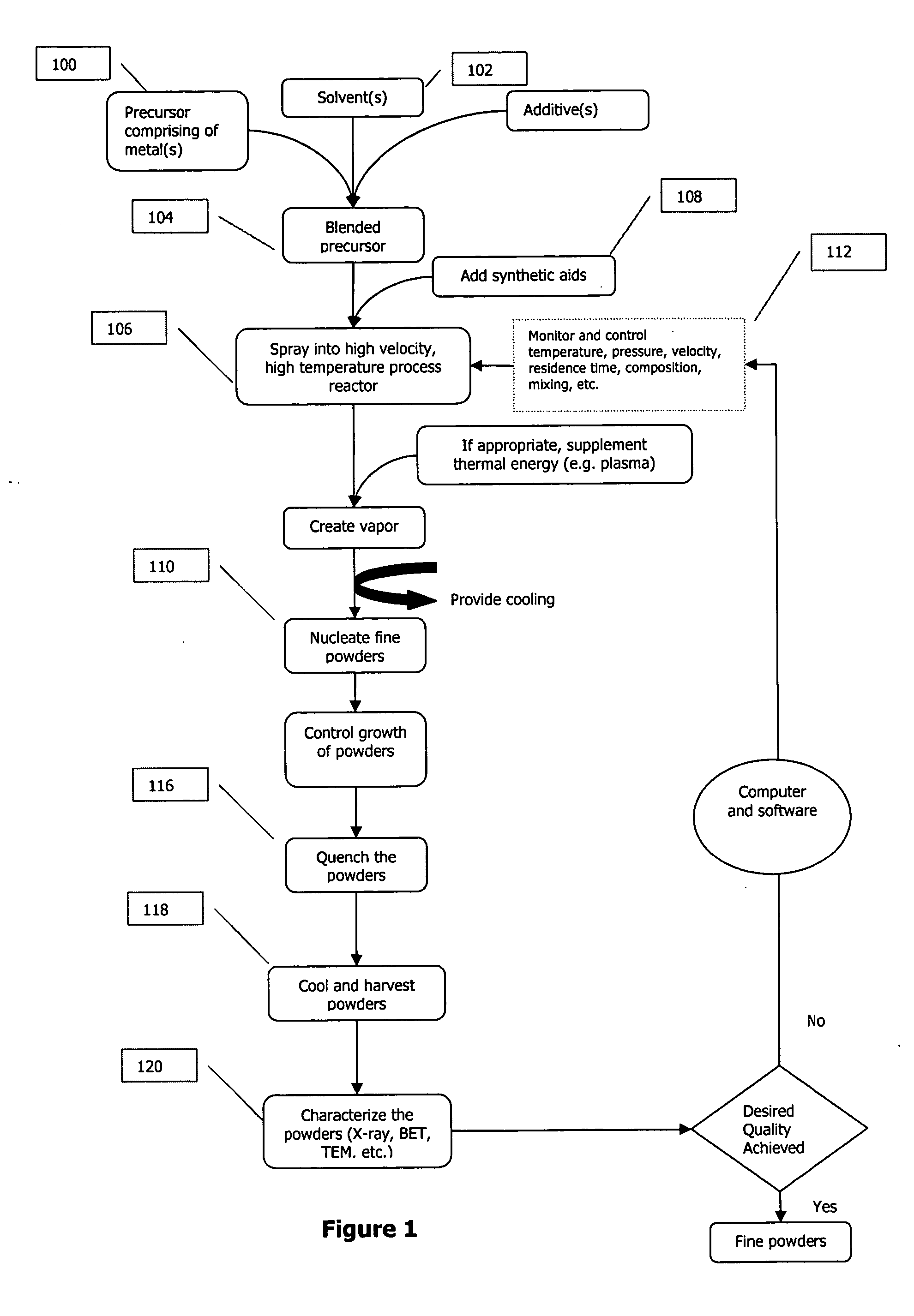

Nanostructured powders and related nanotechnology

InactiveUS7081267B2Low costReduce operating costsNitrogen compoundsSelenium/tellurium compundsThermal energyOxygen

Methods to manufacture nanoscale particles comprising metals, alloys, intermetallics, ceramics are disclosed. The thermal energy is provided by plasma, internal energy, heat of reaction, microwave, electromagnetic, direct electric arc, pulsed electric arc and / or nuclear. The process is operated at some stage above 3000K and at high velocities. The invention can be utilized to prepare nanopowders for nanostructured products and devices such as ion conducting solid electrolytes for a wide range of applications, including sensors, oxygen pumps, fuel cells, batteries, electrosynthesis reactors and catalytic membranes.

Owner:PPG IND OHIO INC

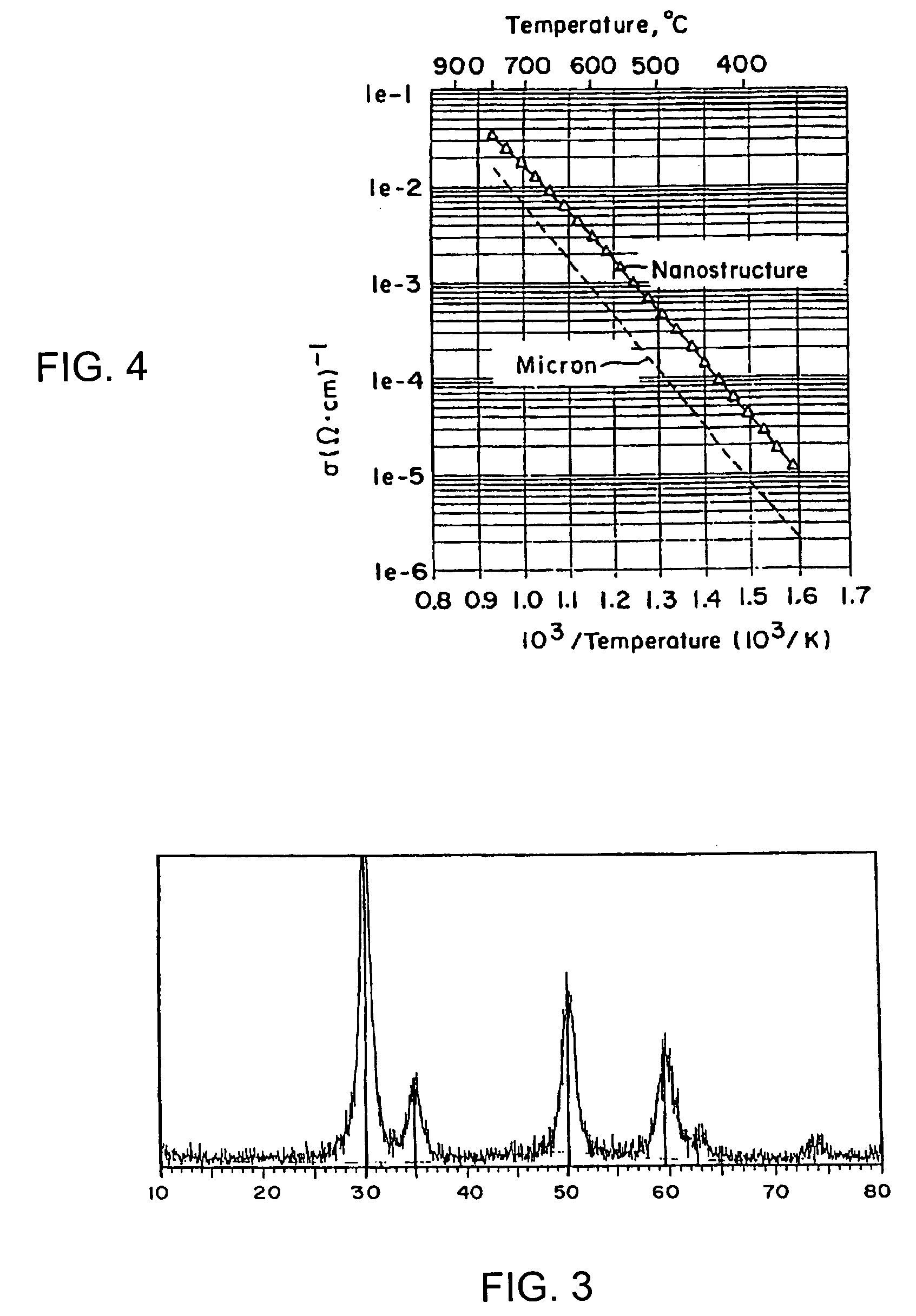

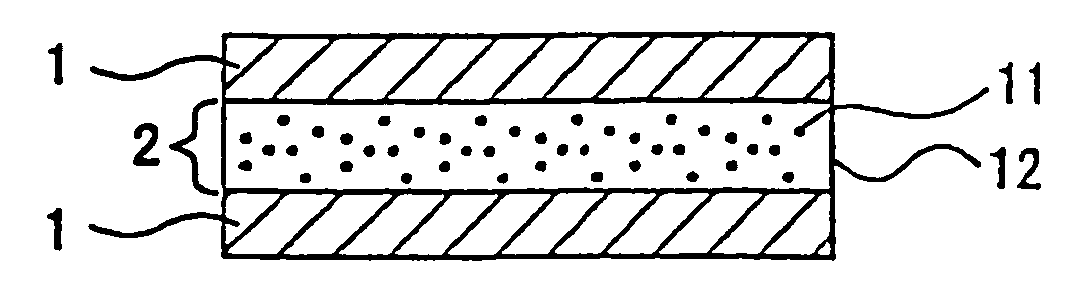

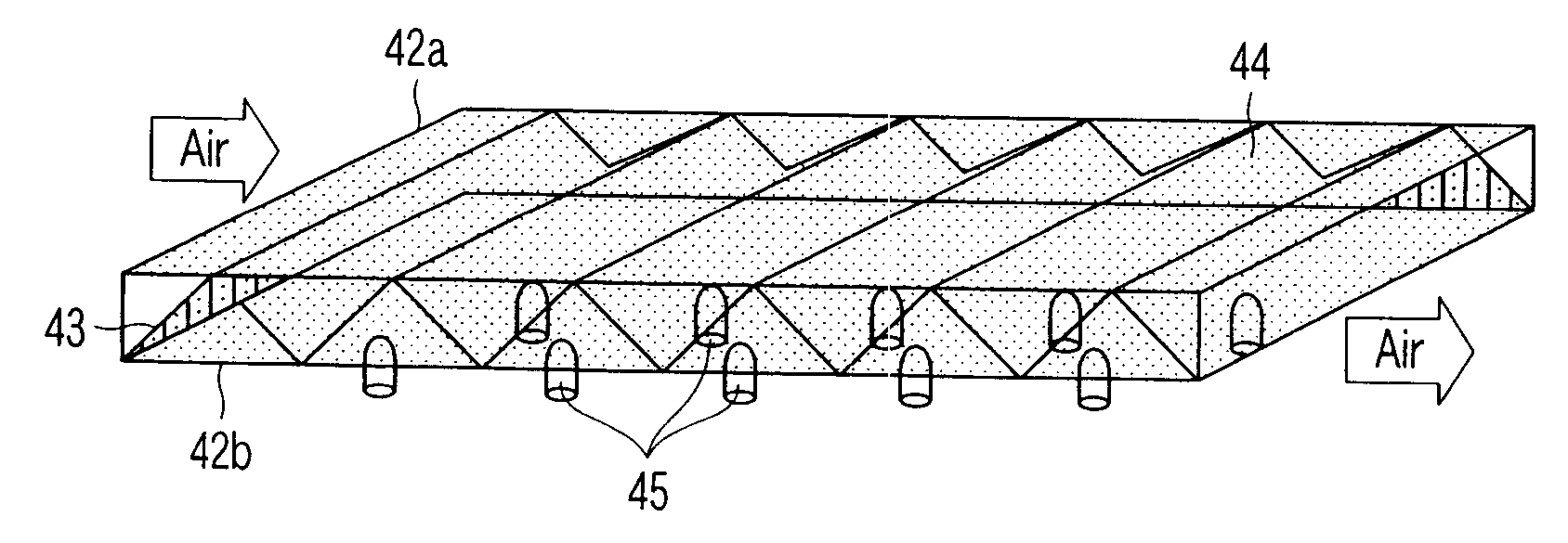

Laminated structure for shielding against solar radiation

ActiveUS20060008640A1Thin thicknessEasy to addTungsten oxides/hydroxidesSynthetic resin layered productsOptoelectronicsReducing atmosphere

To provide a laminated structure for shielding against solar radiation having high solar radiation blocking characteristics with low manufacturing costs. Fine particles 11 functioning to block solar radiation are obtained by firing tungstic acid under a reductive atmosphere, a liquid dispersion to form a solar radiation blocking material is prepared by crashing and dispersing treatment of the fine particles, a polymer base dispersing agent, and solvent, and thus prepared liquid dispersion to form a solar radiation blocking material is added to vinyl resin, which is molded into a sheet shape to obtain an intermediate film 12. Thus obtained intermediate film 12 is sandwiched between two sheets to be laminated selected from sheet-glass or plastic to obtain an intermediate layer 2, which is heated and bonded each other to prepare a laminated structure for shielding against solar radiation.

Owner:SUMITOMO METAL MINING CO LTD

Conductive particle, visible light transmissive particle dispersed conductor, method for producing same, transparent conductive thin film, method for producing same, transparent conductive article using same, and infrared shielding article

ActiveUS20070187653A1Improve conductivityGood visible light transmittanceMaterial nanotechnologyConductive materialInfraredRare-earth element

An object of the present invention is to provide an infrared-shielding nanoparticle dispersion that has a property whereby visible light is adequately transmitted, and light in the near-infrared region is adequately shielded; an infrared-shielding body manufactured using the infrared-shielding nanoparticle dispersion; a method for manufacturing infrared-shielding nanoparticles that are used in the infrared-shielding nanoparticle dispersion; and infrared-shielding nanoparticles manufactured using the method for manufacturing infrared-shielding nanoparticles. The present invention is a method for manufacturing infrared-shielding nanoparticle dispersion obtained by dispersing infrared-shielding nanoparticles in a medium, an infrared-shielding body manufactured by using the infrared-shielding nanoparticle dispersion, and infrared-shielding nanoparticles used in the infrared-shielding nanoparticle dispersion, wherein the infrared-shielding nanoparticles include a substance expressed by the general formula MXAYW(1-Y)O3 (where M is one or more elements selected from H, He, alkali metals, alkaline-earth metals, rare earth elements, Mg, Zr, Cr, Mn, Fe, Ru, Co, Rh, Ir, Ni, Pd, Pt, Cu, Ag, Au, Zn, Cd, Al, Ga, In, Tl, Si, Ge, Sn, Pb, Sb, B, F, P, S, Se, Br, Te, Ti, Nb, V, Mo, Ta, Re, Be, Hf, Os, Bi, and I; A is one or more elements selected from Mo, Nb, Ta, Mn, V, Re, Pt, Pd, and Ti; W is tungsten; O is oxygen; 0<X≦1.2; 0<Y≦1).

Owner:SUMITOMO METAL MINING CO LTD

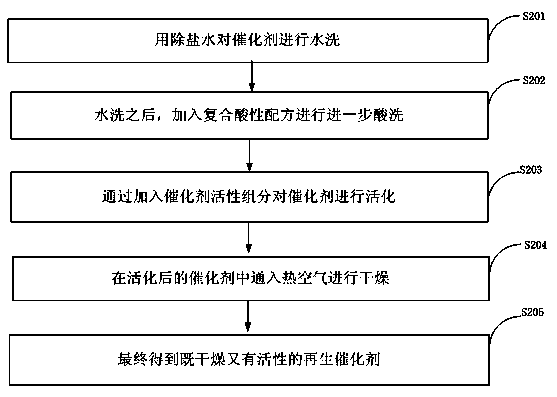

Method for extracting tungsten, titanium and vanadium from waste SCR (selective catalytic reduction) catalyst

InactiveCN102936049ASolve the pollution of the environmentLow equipment requirementsTungsten oxides/hydroxidesTitanium dioxideSlagStrong acids

The invention discloses a method for extracting tungsten, titanium and vanadium from a waste SCR (selective catalytic reduction) catalyst, which comprises the following steps: crushing the waste SCR catalyst, adding a strongly alkaline solution, and reacting; filtering, separating, then adding strong acid into the sodium tungstate and sodium vanadate mixed solution, and reacting to obtain tungstic acid and a sodium salt and vanadic acid mixed solution; regulating the pH value of the sodium salt and vanadic acid mixed solution until precipitate is separated out, thus obtaining ammonium vanadate; then adding sulfuric acid into the tungsten-and-vanadium-removed SCR catalyst, and reacting to obtain a titanyl sulfate solution and solids such as aluminum slag and the like; then adding water into the titanyl sulfate solution, and hydrolyzing to obtain titanic acid and a waste acid solution; and finally, respectively calcining the obtained ammonium vanadate, tungstic acid and titanic acid to obtain vanadium pentoxide, tungsten trioxide and titanium dioxide. According to the invention, tungsten, titanium and vanadium can be extracted from the SCR catalyst through the reaction with strong alkali and strong acid at a low temperature, the equipment requirement is low, the energy consumption is low, some products having added values can be coproduced, and no secondary pollution is generated, thereby facilitating popularization and application.

Owner:成都新智金森环保科技有限公司

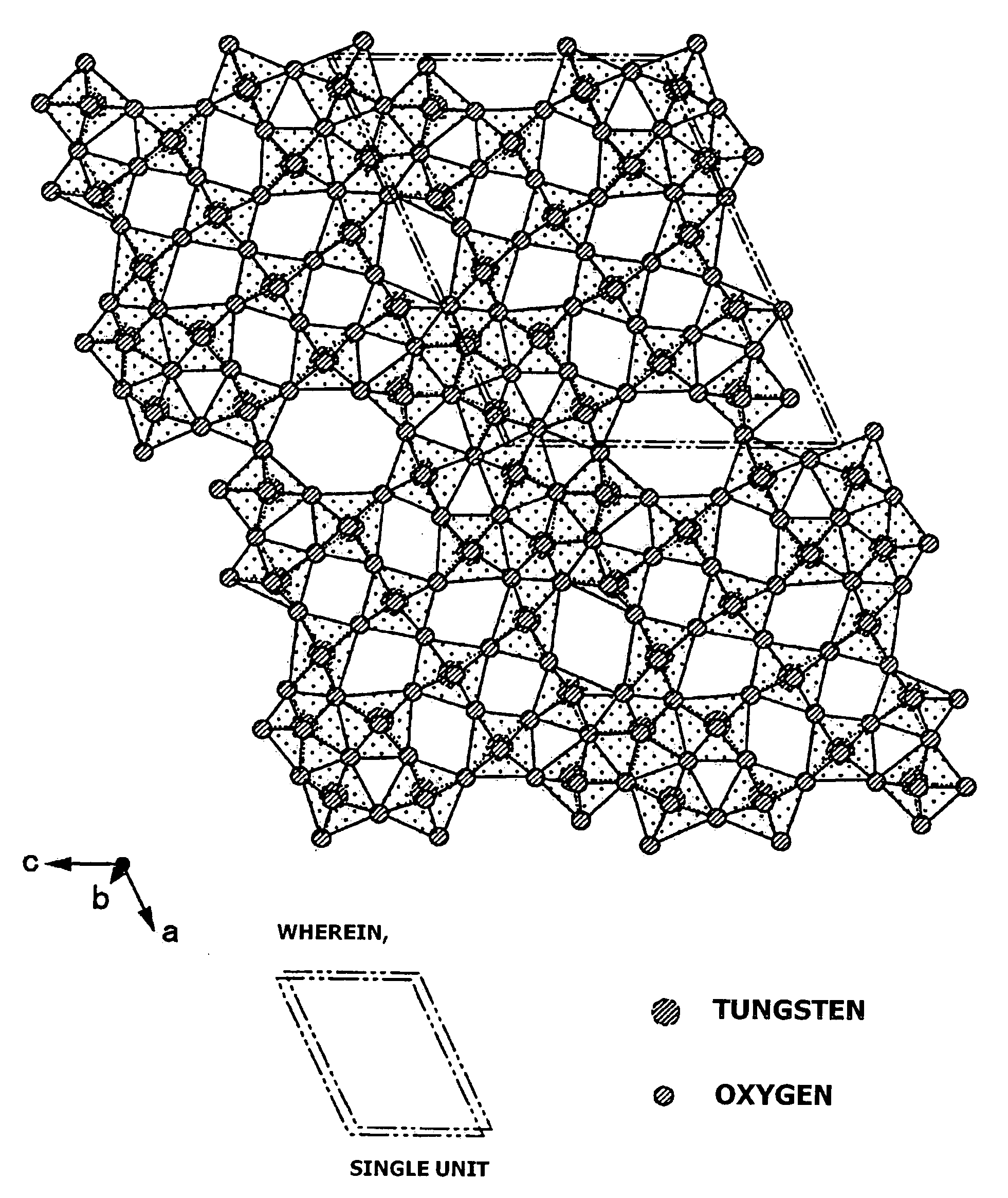

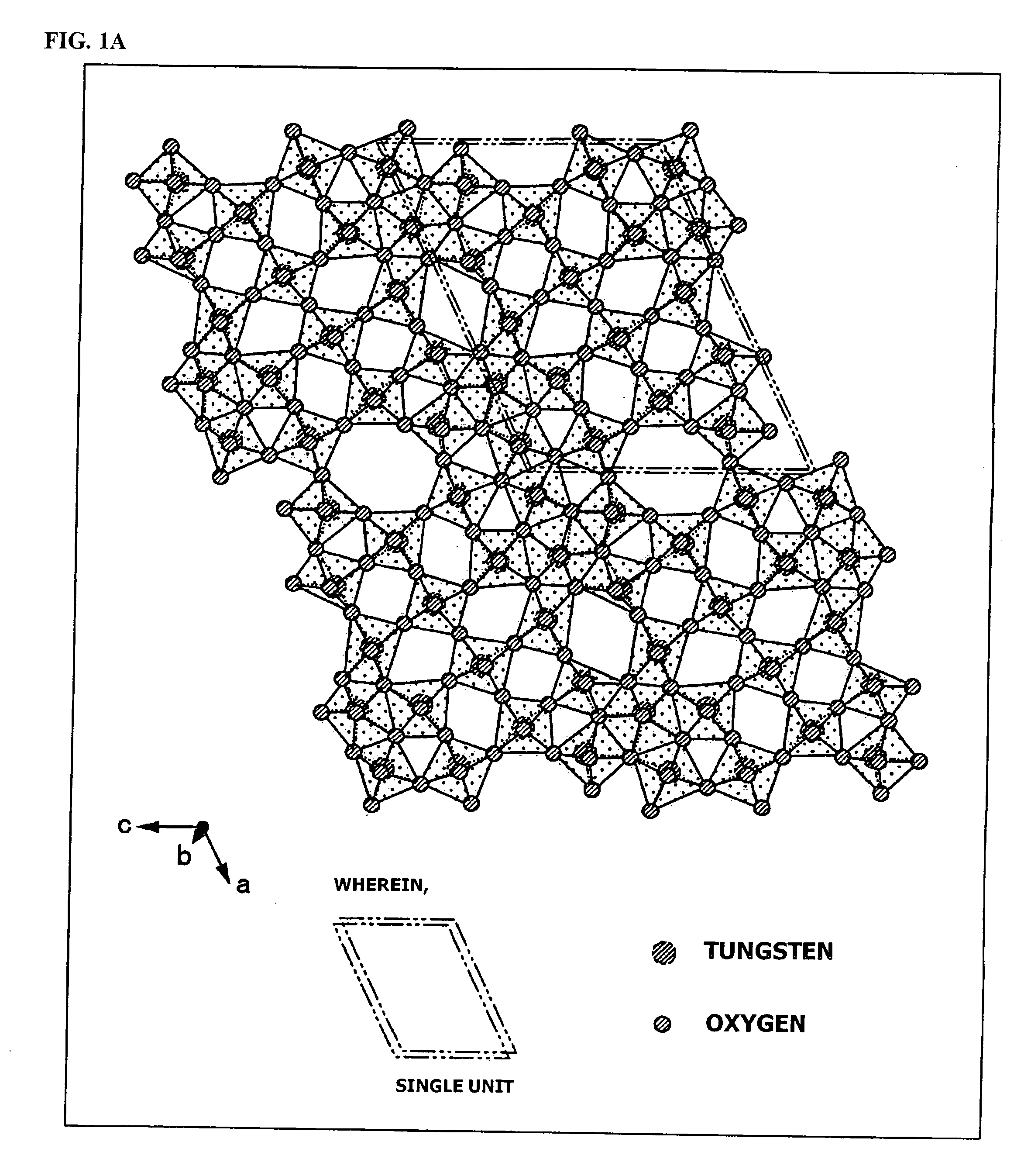

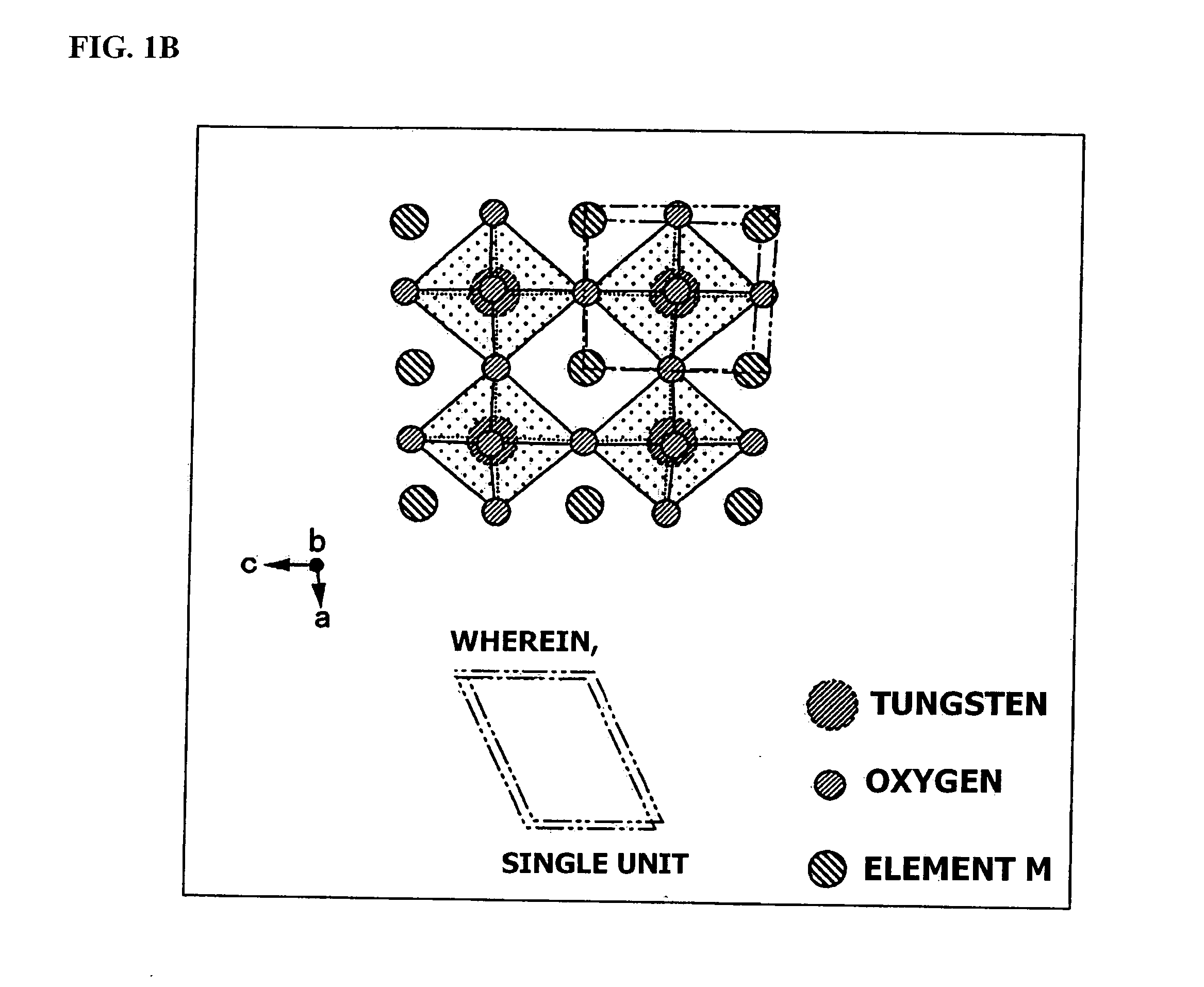

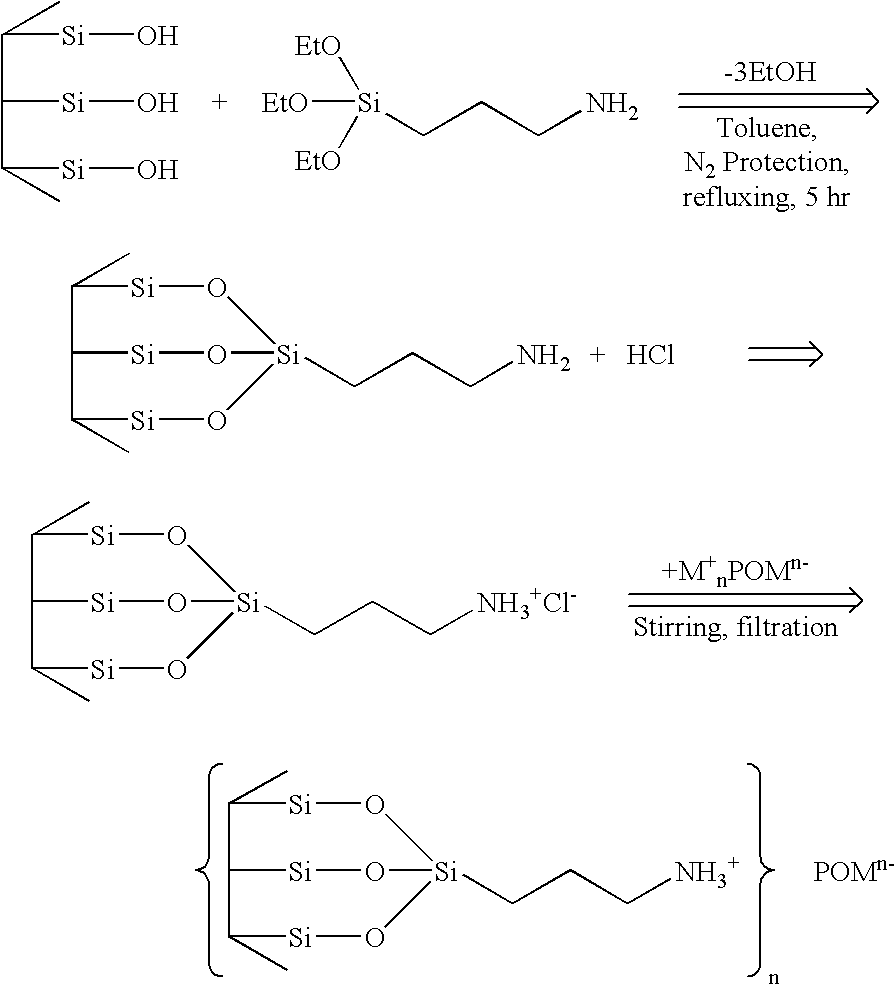

Supported polyoxometalates and process for their preparation

InactiveUS7417008B2Group 4/14 element organic compoundsOxygen/ozone/oxide/hydroxideCatalytic oxidationMesoporous silica

Owner:EXXONMOBIL CHEM PAT INC

Method for recovering tungsten trioxide and ammonium metavanadate from selective catalytic reduction (SCR) denitration catalyst

ActiveCN102557142AEmission reductionTungsten oxides/hydroxidesDispersed particle separationWarm waterAmmonium paratungstate

The invention relates to a method for recovering tungsten trioxide and ammonium metavanadate from a selective catalytic reduction (SCR) denitration catalyst. The method comprises the following steps of: crushing the SCR denitration catalyst, sieving to obtain catalyst powder, mixing with sodium carbonate, and stirring fully and uniformly; putting the mixed powder into a sintering furnace, and sintering to obtain a sintered material; keeping temperature for 1 hour, and sieving to obtain sintered material powder; pouring warm water, so that Na2WO4 and NaVO3 in the sintered material powder are dissolved fully, filtering, and removing precipitates to obtain a mixed solution of Na2WO4 and NaVO3; regulating the pH value to be 6.5-7.5, adding an ammonium bicarbonate solution or an ammonium chloride solution, and precipitating ammonium metavanadate precipitate; filtering, washing by using a diluted ammonium bicarbonate solution for 2 to 3 times, washing by using 30 percent ethanol for 1 to 2 times, and drying to obtain an ammonium metavanadate finished product; and converting the Na2WO4 in the residual solution into ammonium paratungstate, evaporating the residual solution to obtain ammonium paratungstate crystals, and calcining to obtain the tungsten trioxide. By the method, the ammonium metavanadate and the tungsten trioxide can be recovered, and the discharge of pollutants is reduced.

Owner:江苏万德环保科技有限公司

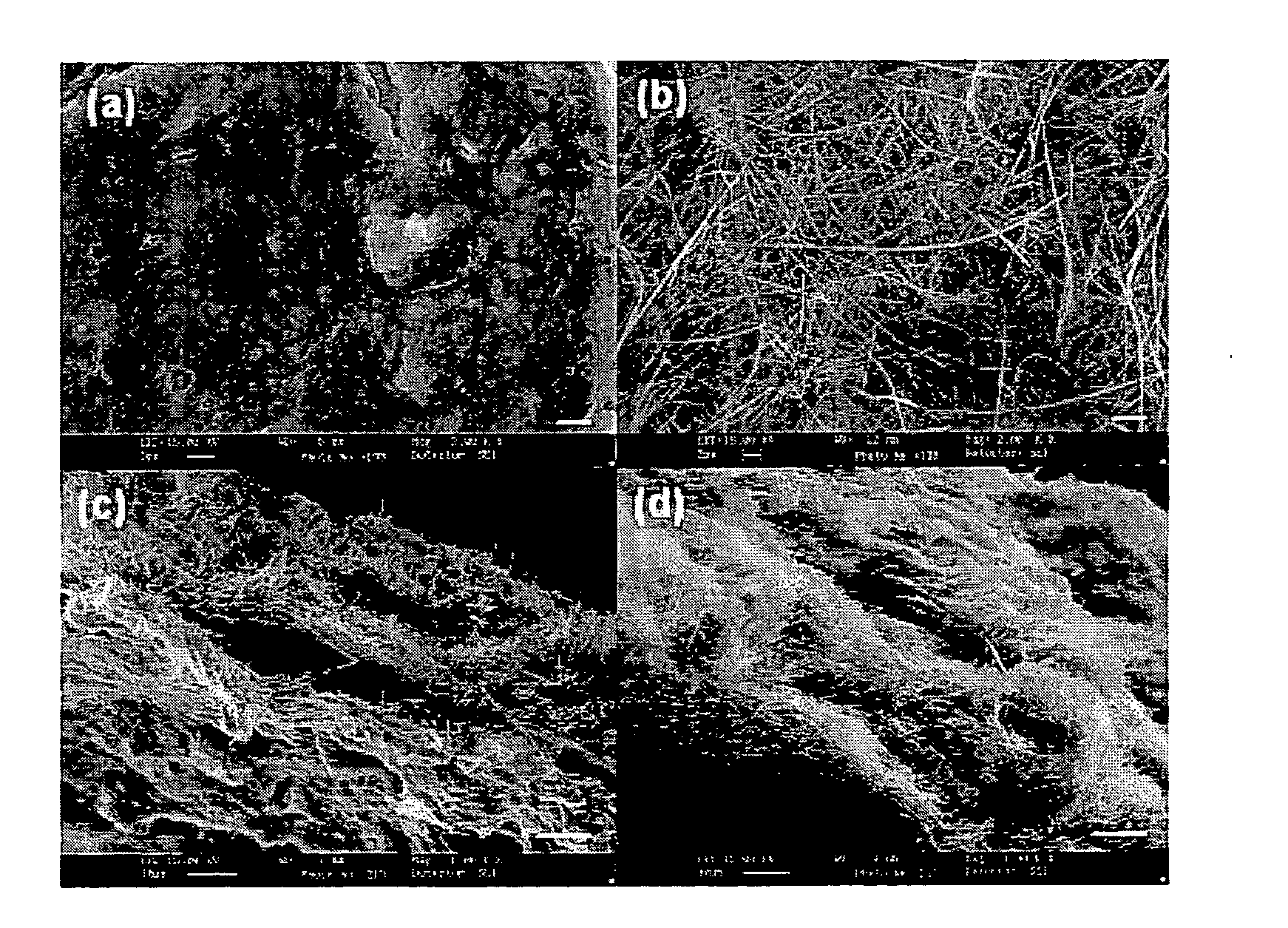

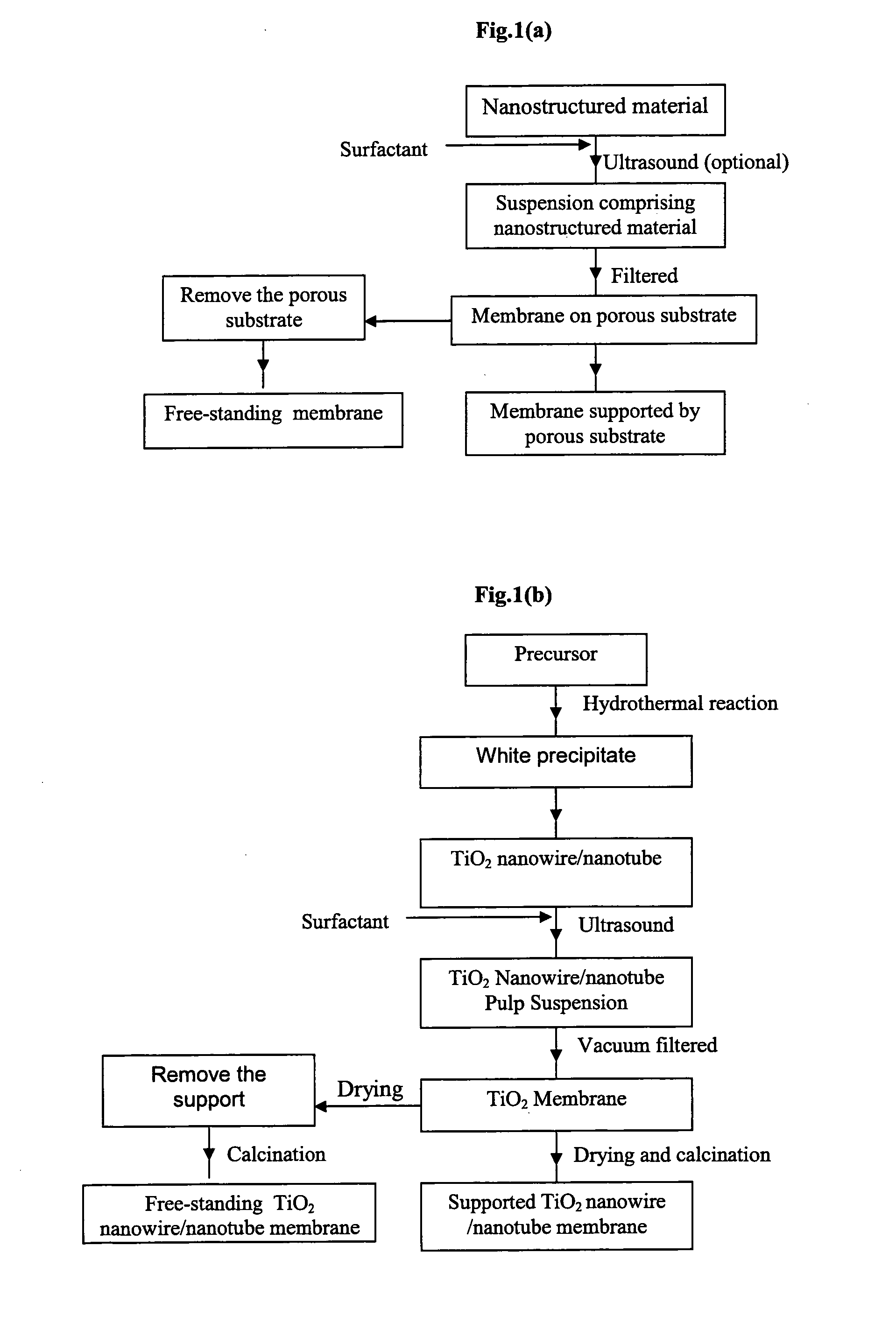

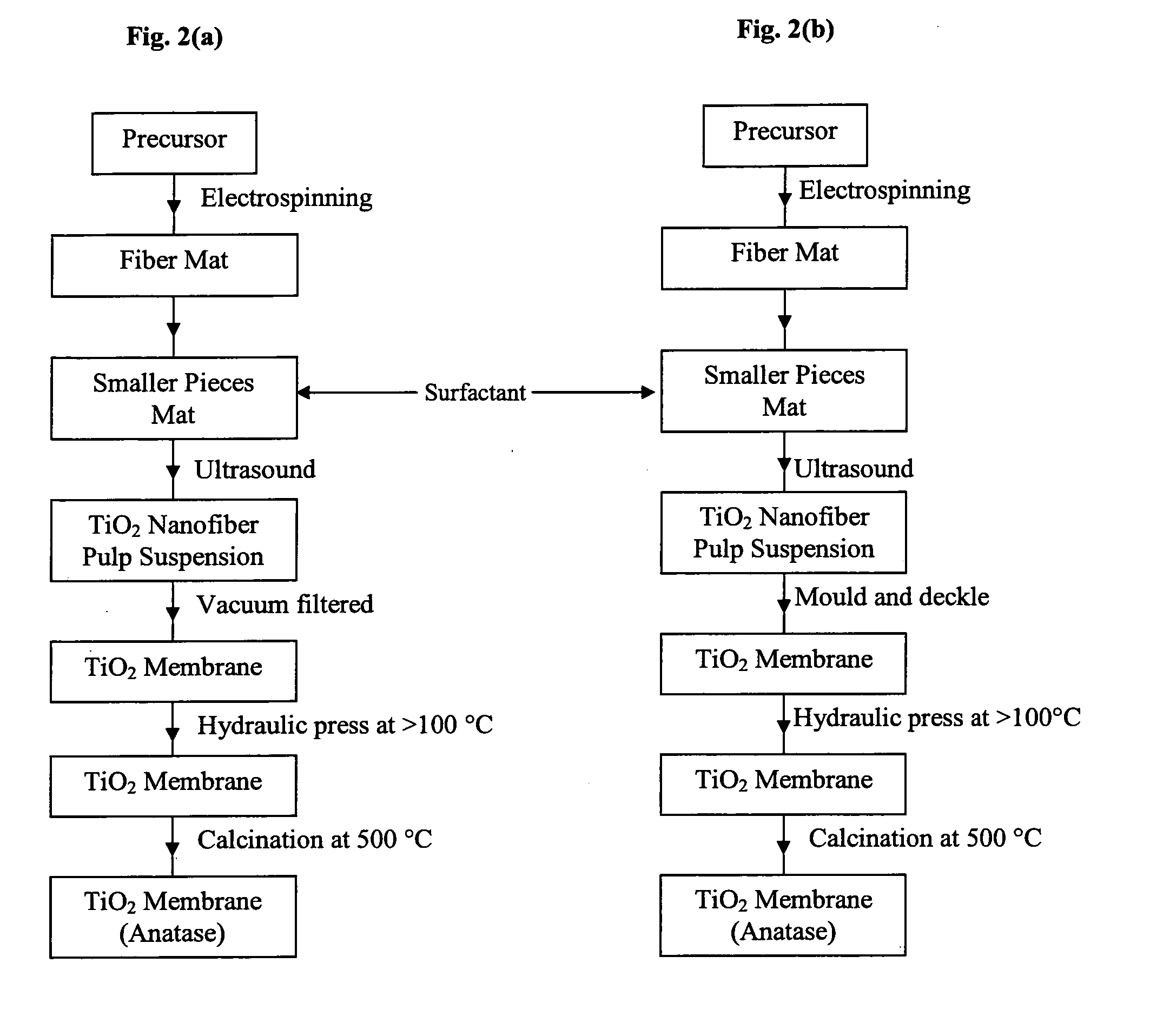

Membrane made of a nanostructured material

Owner:NANYANG TECH UNIV +1

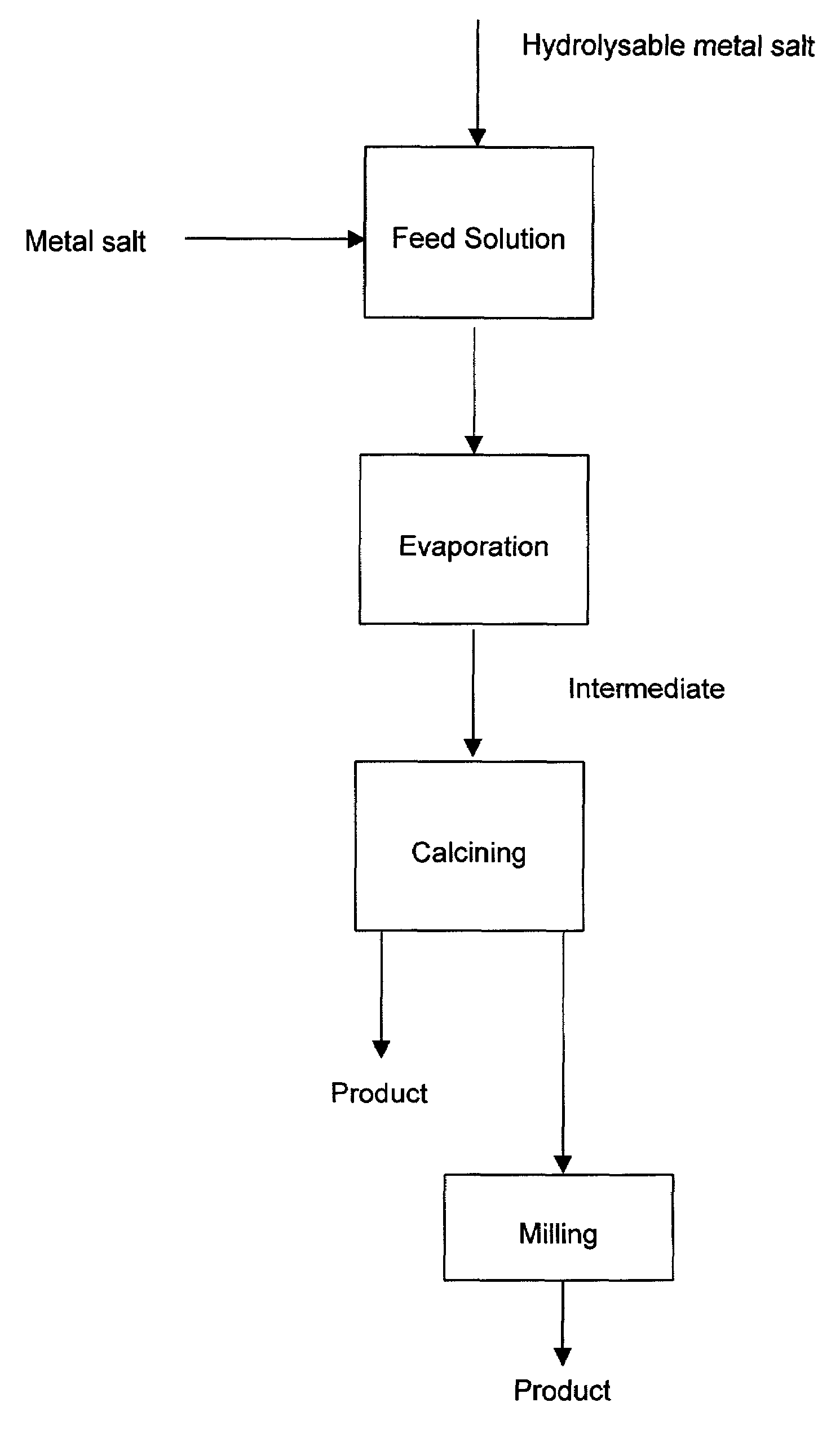

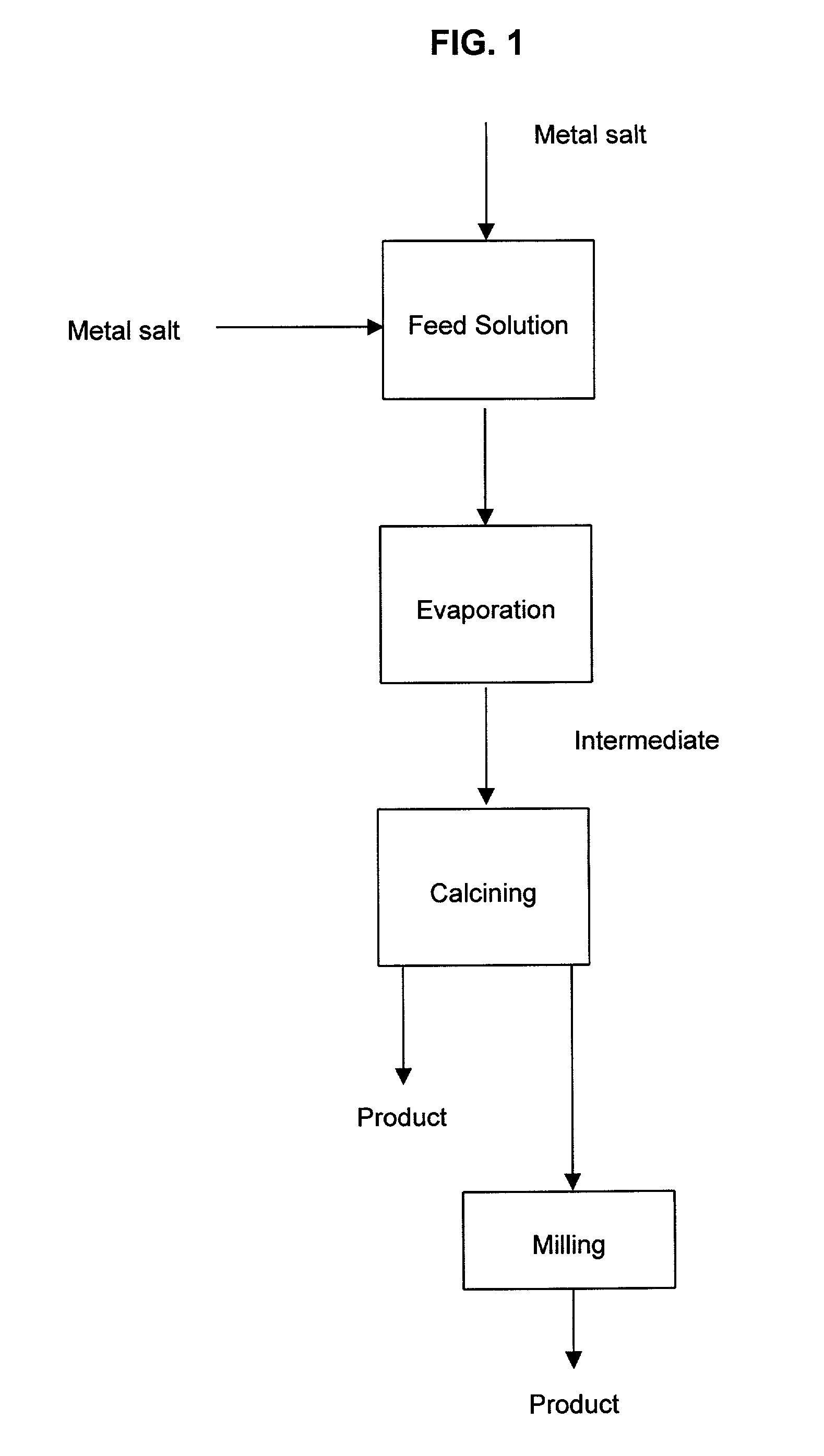

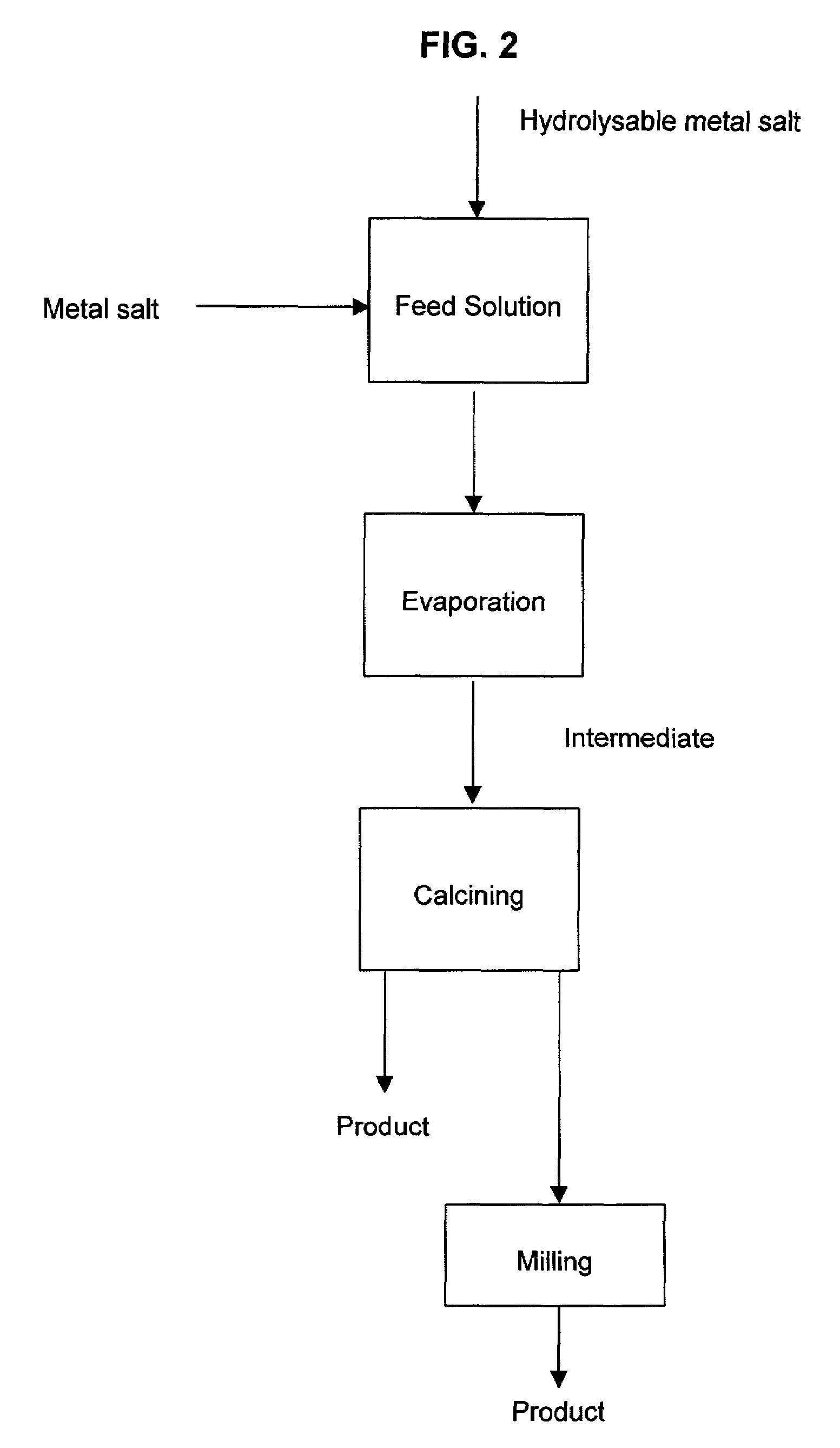

Method for producing mixed metal oxides and metal oxide compounds

A process to produce mixed metal oxides and metal oxide compounds. The process includes evaporating a feed solution that contains at least two metal salts to form an intermediate. The evaporation is conducted at a temperature above the boiling point of the feed solution but below the temperature where there is significant crystal growth or below the calcination temperature of the intermediate. The intermediate is calcined, optionally in the presence of an oxidizing agent, to form the desired oxides. The calcined material can be milled and dispersed to yield individual particles of controllable size and narrow size distribution.

Owner:ALTAIR NANOMATERIALS INC

Titanium comprising nanoparticles and related nanotechnology

ActiveUS7232556B2Increase volumeLow cost productionNitrogen compoundsGermanium dioxideNanoparticleTitanium metal

Owner:PPG IND OHIO INC

Titanium comprising nanoparticles and related nanotechnology

ActiveUS20050191492A1Increase volumeLow cost productionNitrogen compoundsGermanium dioxideNanoparticleTitanium metal

Owner:PPG IND OHIO INC

Preparation method of quantum dot self-assembling nano structural material

The invention discloses a preparation method of a super nanostructure material formed by quantum dots self-assembly. That the alcohols are used as solvent to prepare nano-metal oxides and sulphides or metal oxides and sulphides are reduced to get nano-metal is a widely used method. The super nanostructure material formed by the quantum dots self-assembly draws much attention because of the superior comprehensive properties. The application prospect is wide enough. The invention adopts a method of using the alcohols as the solvent that a super nanostructure with different appearances and is formed by the quantum dots self-assembly which is obtained by changing the condition under the existence condition of surfactant. According to the invention, precursor, namely organic metal compound is dissolved in the alcohol solvent by ultrasonic, stirring and being laid down quietly. Under the effect of the surfactant, the precursor has a nucleation and grows into a plurality of quantum dots, the size of which is similar to nano. Then the dots form a super nanostructure which has a certain shape or space structure along the defined growing direction of the surfactant.

Owner:HUAZHONG NORMAL UNIV

Method of manufacturing metal oxide film, metal oxide film, element using the metal oxide film, substrate with metal oxide film, and device using the substrate with metal oxide film

InactiveUS20130101867A1High densityHigh film strengthTantalum compoundsSemiconductor/solid-state device detailsOxygenMaterials science

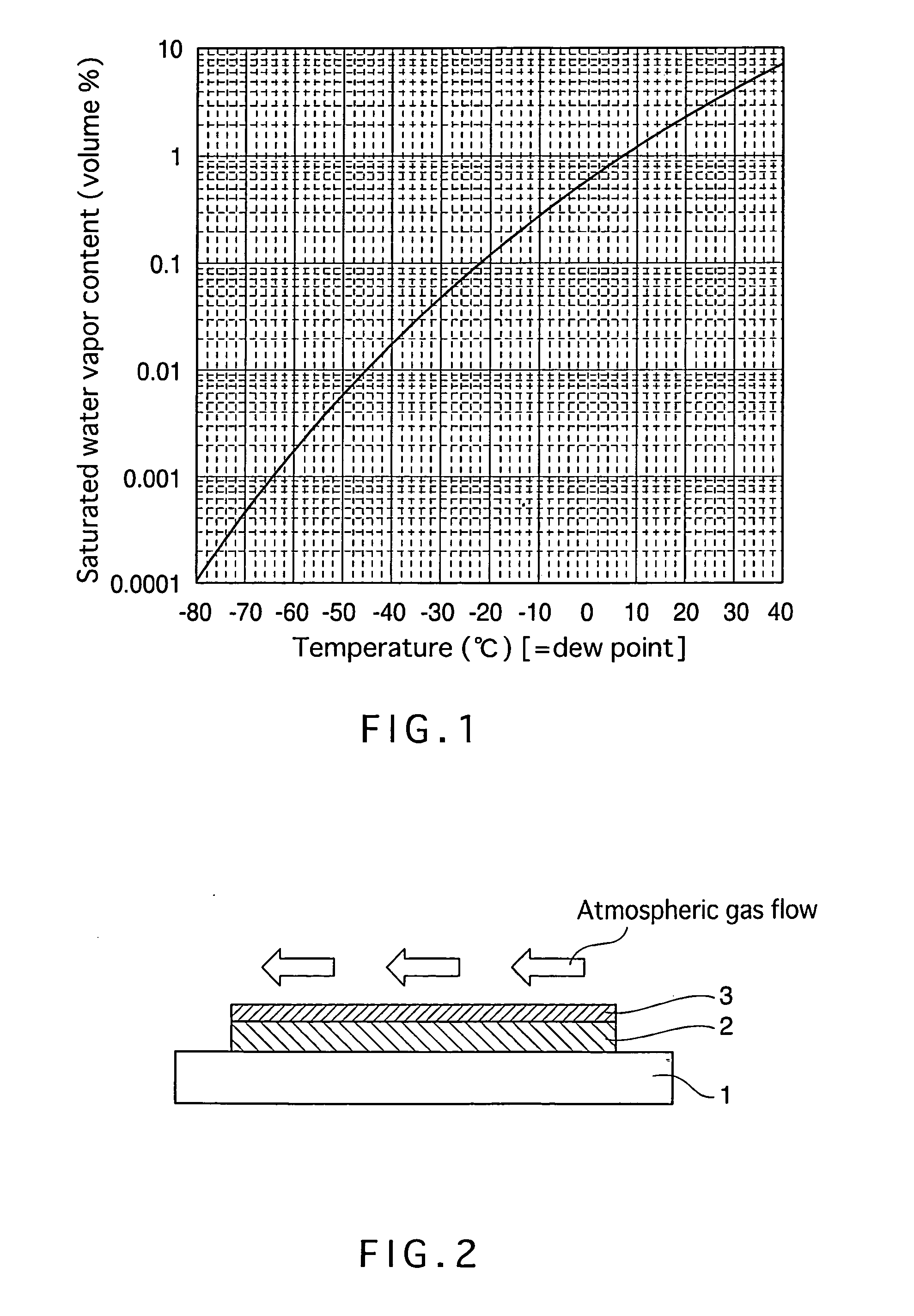

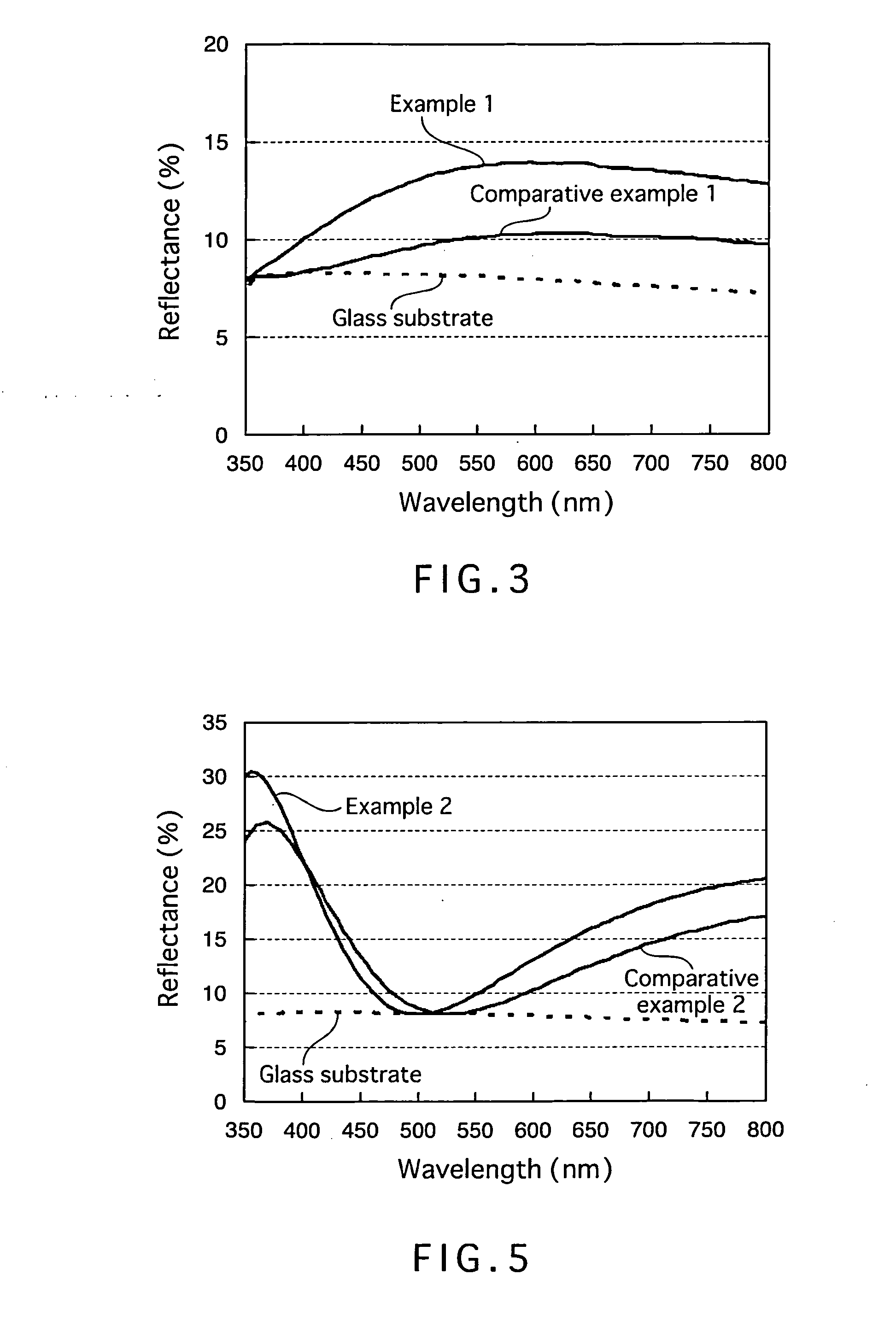

Provided is a method of manufacturing a metal oxide film to be formed through the following processes: a coating process of forming a coating film on a substrate by using a coating liquid for forming metal oxide film containing any of various organometallic compounds; a drying process of making the coating film into a dried coating film; and a heating process of forming an inorganic film from the dried coating film under an oxygen-containing atmosphere having a dew-point temperature equal to or lower than −10° C.

Owner:SUMITOMO METAL MINING CO LTD

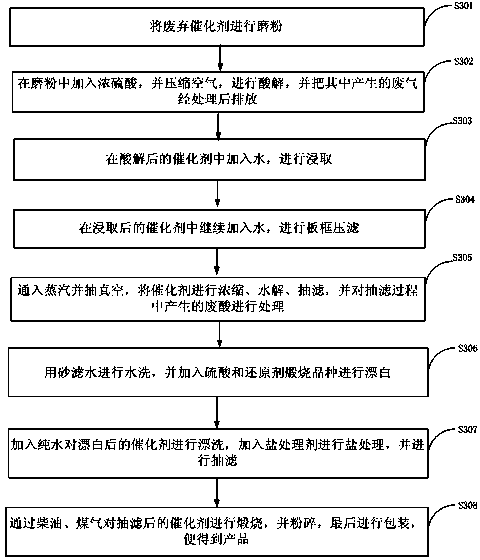

Method for regeneration and resource utilization of waste honeycombed denitrification catalyst

InactiveCN103508491ALow costRestore activityTungsten oxides/hydroxidesDispersed particle separationResource utilizationAmmonium paratungstate

The invention discloses a method for regeneration and resource utilization of a waste honeycombed denitrification catalyst. The method comprises the following steps of: crushing, grinding and sieving the waste catalyst; loading a mixture of the powdered catalyst and sodium carbonate into a sintering furnace to produce Na2WO4 and NaVO3, dissolving completely, adjusting the pH value to separate ammonium metavanadate precipitates, filtering, applying the remaining liquid to ammonium paratungstate extraction, washing the precipitates and oven-drying to obtain ammonium metavanadate, and making ammonium paratungstate crystals and tungsten trioxide. The regeneration method of the SCR catalyst comprises the following steps of: performing water-washing, pickling, activation and drying on the catalyst. The method for producing titanium pigment from the waste catalyst as raw material comprises the following steps of: performing pulverization, acidolysis and extraction on the waste catalyst, performing plate-frame pressure filtration; performing concentration, hydrolysis and suction-filtration on the catalyst, washing and blanching with sand leaching water, calcining, grinding and packaging. The method disclosed by the invention can effectively restore the activity of a deactivated catalyst and prolong the service life of the deactivated catalyst, which not only reduce the operating cost of a thermal power plant but also save the valuable rare earth resources.

Owner:YIXING YIGANG ENVIRONMENTAL PROTECTION ENG & MATERIALS

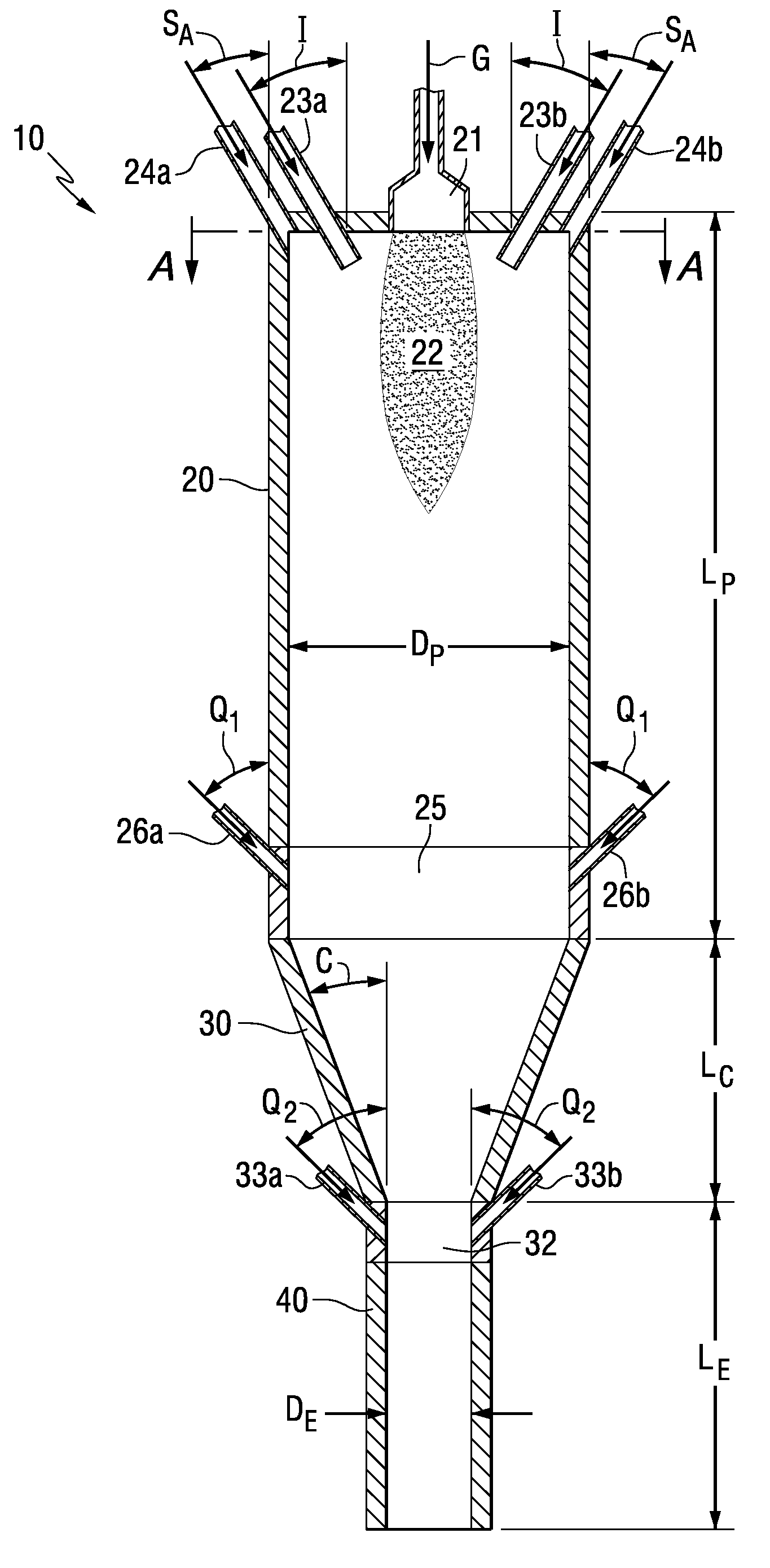

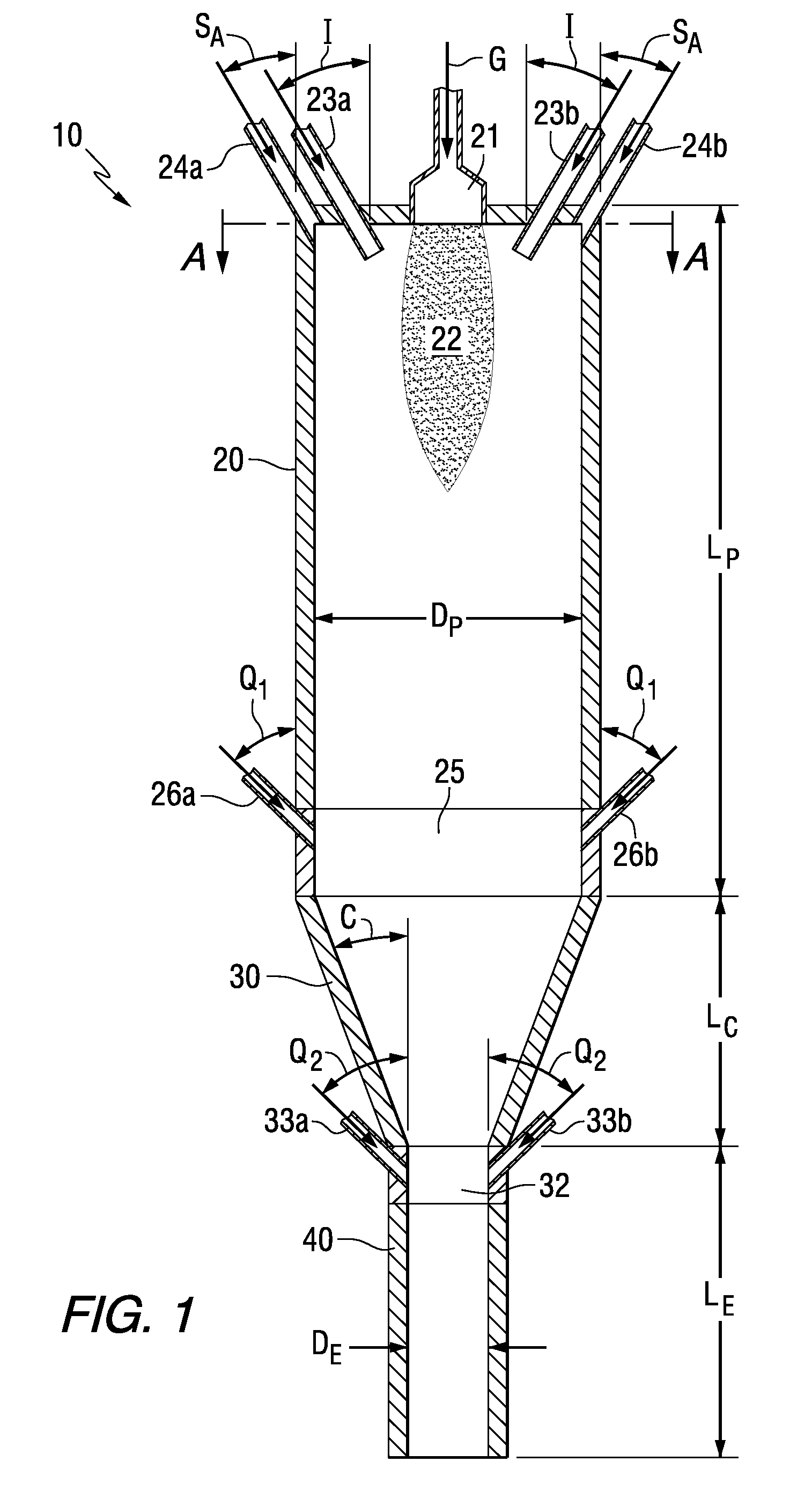

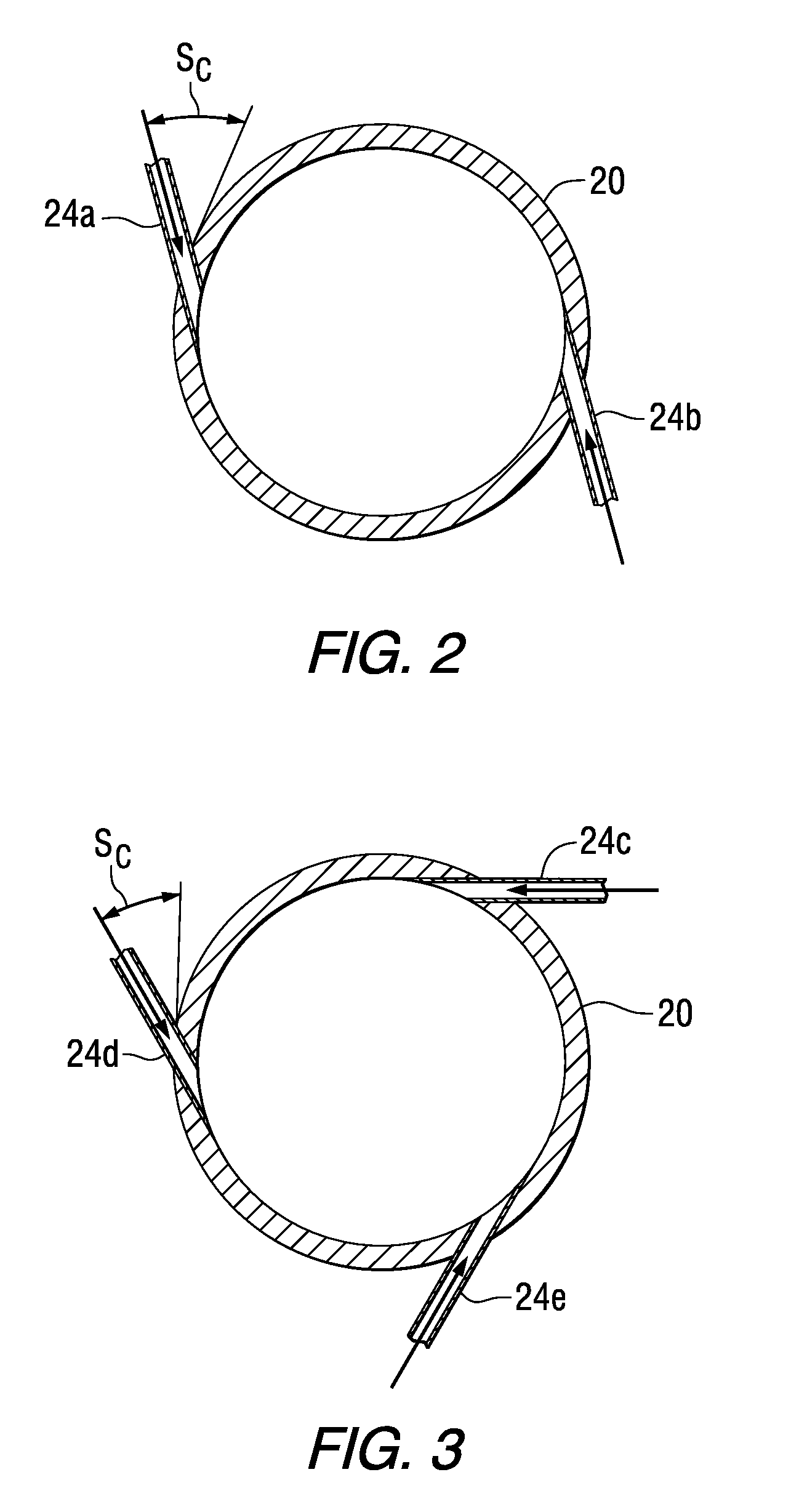

Production of Ultrafine Particles in a Plasma System Having Controlled Pressure Zones

InactiveUS20100314788A1Constant pressureMaterial granulation and coatingMaterial nanotechnologyEngineeringPlasma chamber

A system and method for making ultrafine particles are disclosed. A high temperature plasma is generated at an inlet end of a plasma chamber into which precursor materials are introduced. A converging member is located adjacent an outlet end of the plasma chamber. During operation, a substantially constant pressure and / or material flow pattern is maintained to reduce or eliminate fouling of the system.

Owner:PPG IND OHIO INC

Transparent, colorless infrared radiation absorbing compositions comprising nanoparticles

ActiveUS20100184901A1Material nanotechnologyTungsten oxides/hydroxidesNanoparticleChemical measurement

Owner:PPG IND OHIO INC

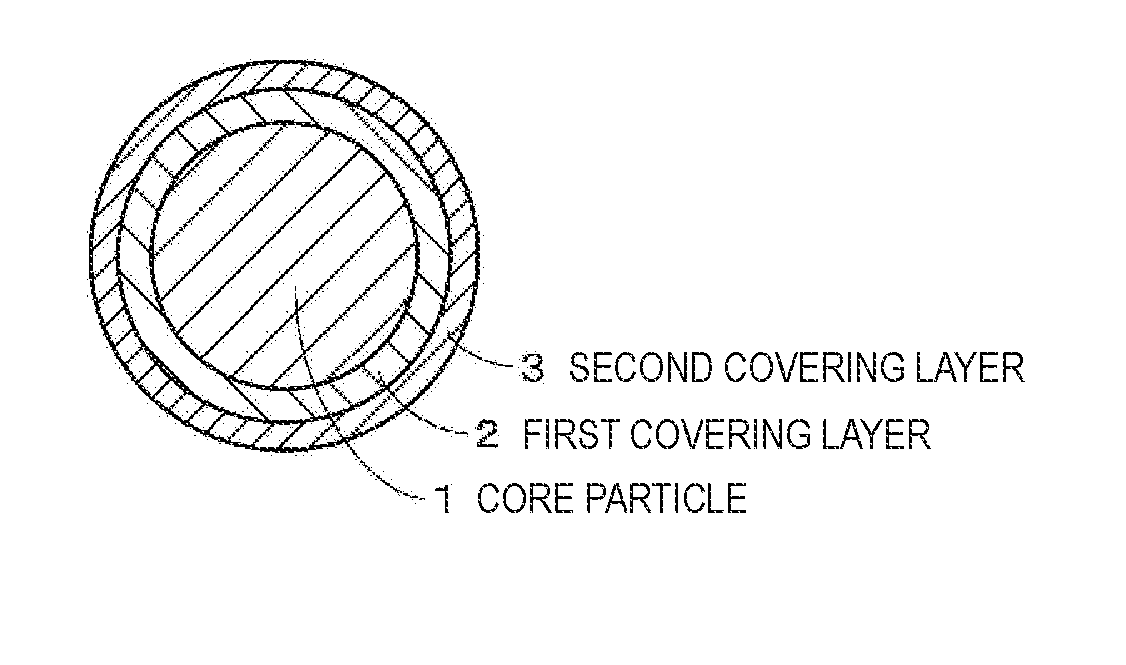

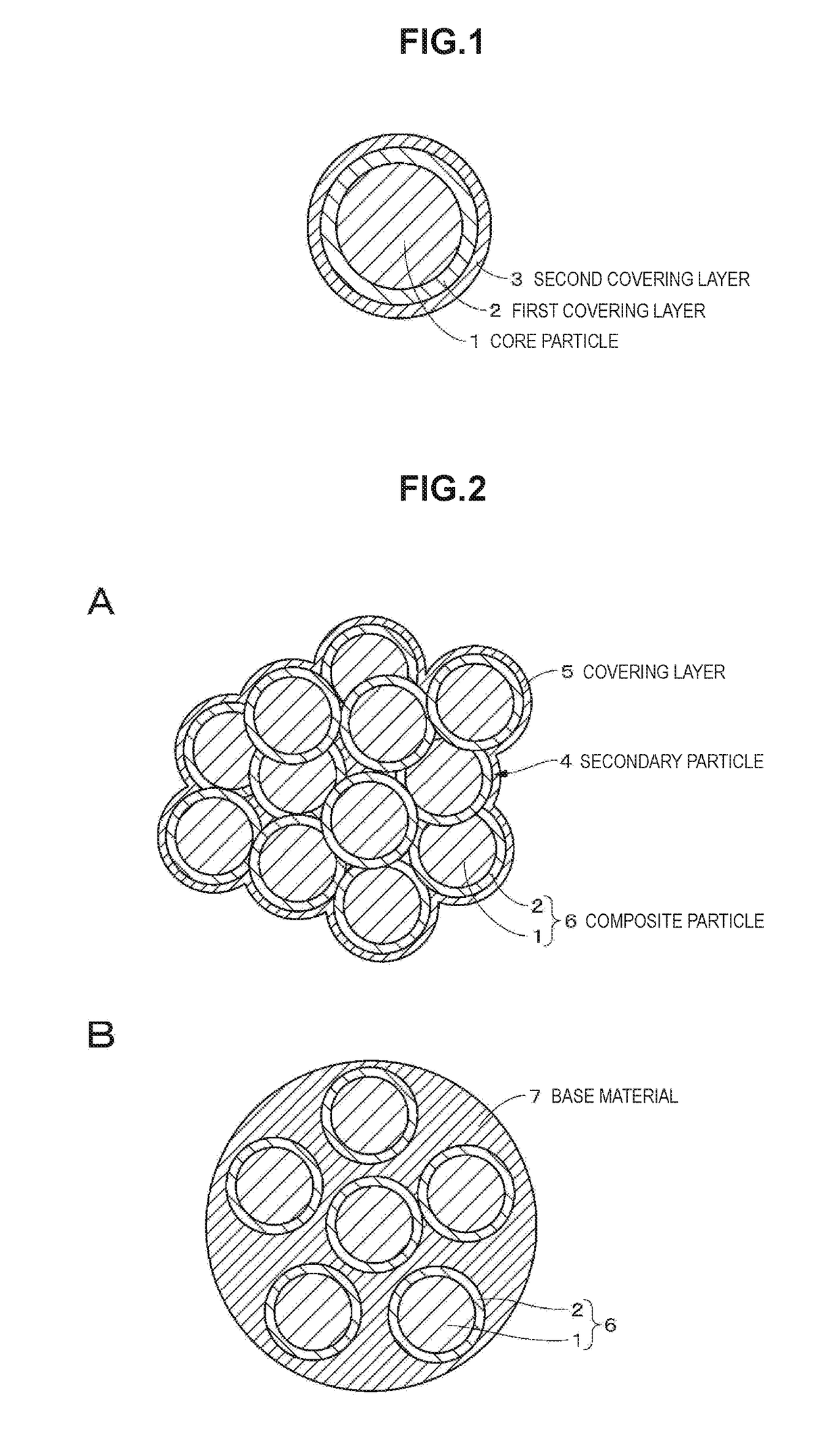

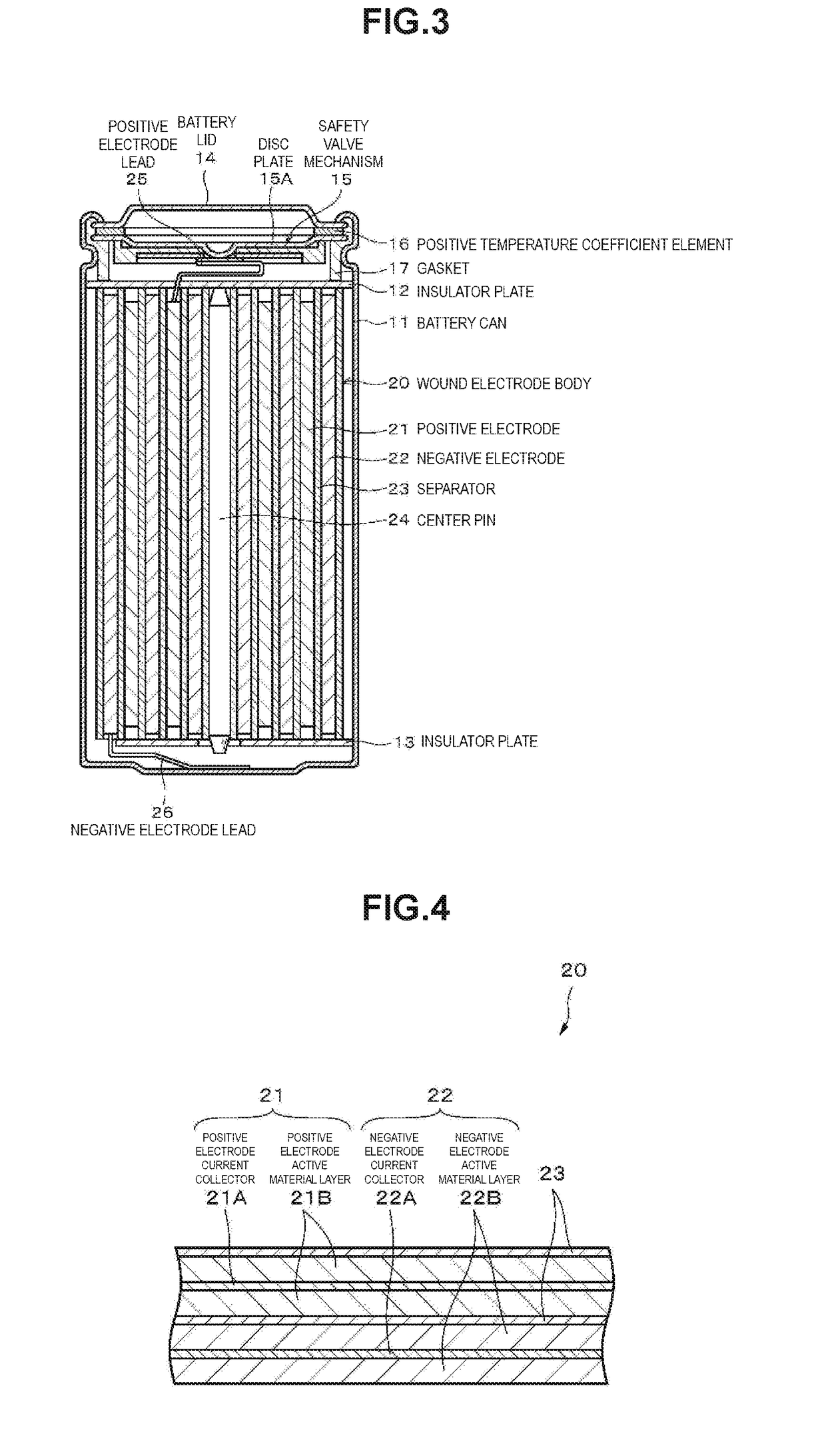

Positive electrode active material, positive electrode, battery, battery pack, electronic device, electric vehicle, power storage device, and power system

ActiveUS20170207444A1Large capacityExcellent cycle characteristicsMagnesium halidesCell electrodesFluorideCrystallinity

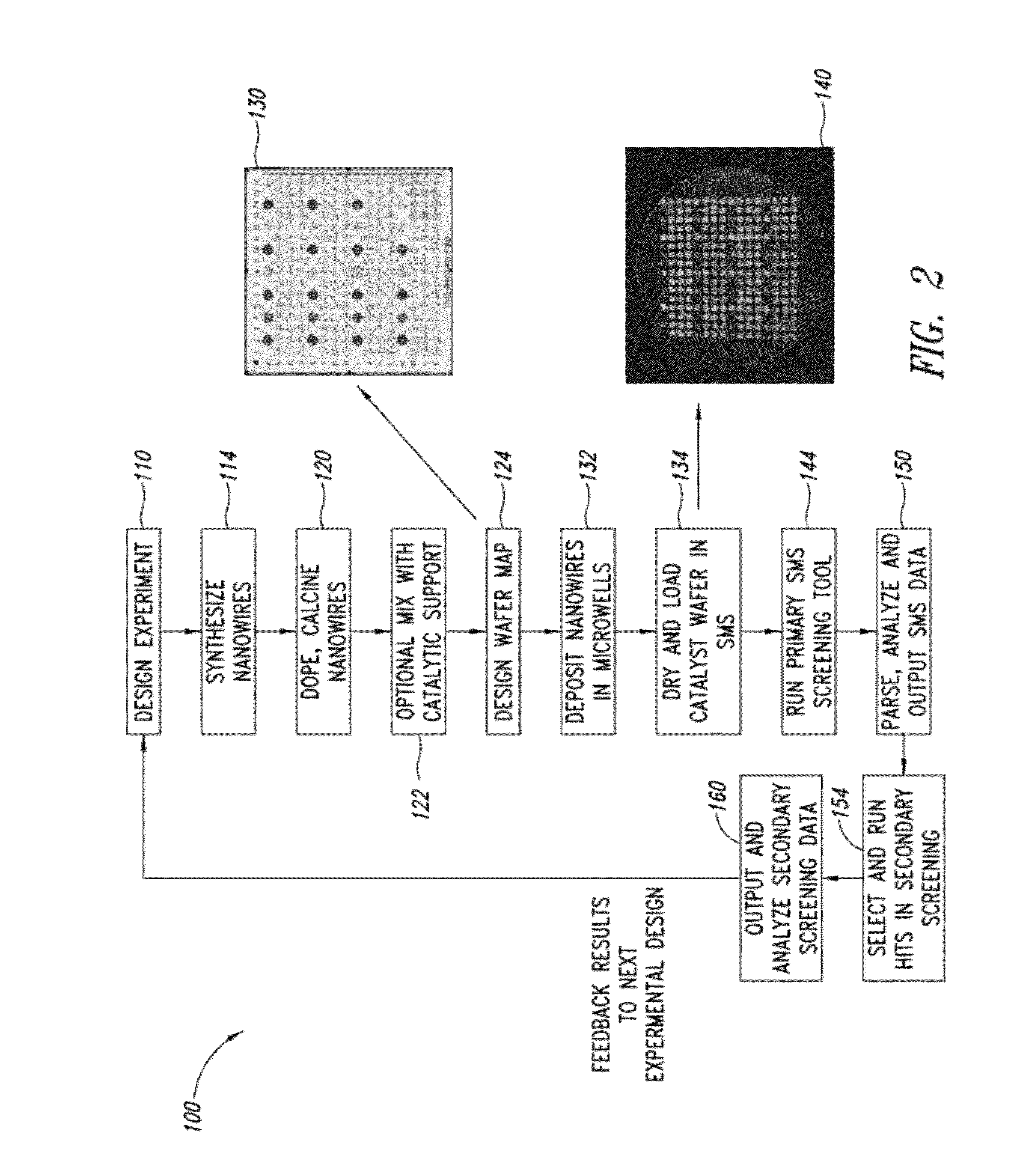

A positive electrode active material includes: a particle including a lithium composite oxide; a first layer that is provided on a surface of the particle and includes a lithium composite oxide; and a second layer that is provided on a surface of the first layer. The lithium composite oxide included in the particle and the lithium composite oxide included in the first layer have the same composition or almost the same composition, the second layer includes an oxide or a fluoride, and the lithium composite oxide included in the first layer has lower crystallinity than the lithium composite oxide included in the particle.

Owner:MURATA MFG CO LTD

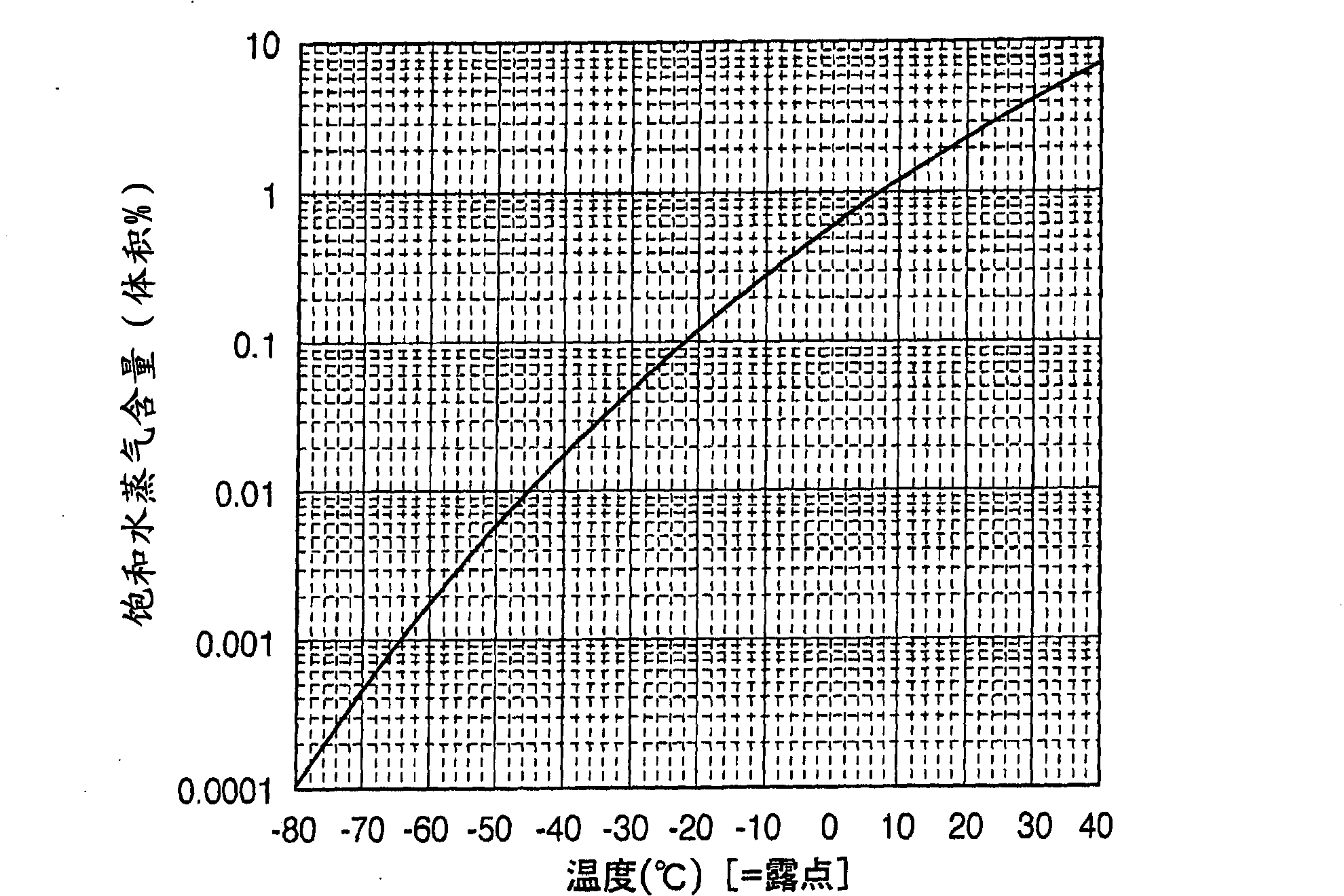

Method for producing metal oxide film, metal oxide film, element using the metal oxide film, substrate with metal oxide film, and device using the substrate with metal oxide film

InactiveCN102933496AImprove compactnessHigh strengthConductive layers on insulating-supportsTantalum compoundsPhysical chemistryThermal treatment

Disclosed are: a metal oxide film, which is formed by a coating method that is one of the methods for producing a metal oxide film, and which has a good balance between excellent transparency and high electrical conductivity, while having excellent film strength; and a method for producing the metal oxide film. Specifically disclosed is a method for producing a metal oxide film, which comprises: a coating step wherein a coating film is formed on a substrate using a metal oxide film-forming coating liquid that contains various organic metal compounds; a drying step wherein the coating film is changed into a dry coating film; and a heating step wherein an inorganic film is formed from the dry coating film. The method for producing a metal oxide film is characterized in that in the heating step, the dry coating film, which is mainly composed of the various organic metal compounds, is heated to a temperature at which at least mineralization of organic metal compound components occurs or higher in an oxygen-containing atmosphere at a temperature not higher than the temperature that is lower by 10 DEG C than the dew point, so that the organic components in the dry coating film are removed by thermal decomposition or combustion, or by thermal decomposition and combustion, thereby forming a metal oxide fine particle layer which is densely filled with metal oxide fine particles that are mainly composed of various metal oxides.

Owner:SUMITOMO METAL MINING CO LTD

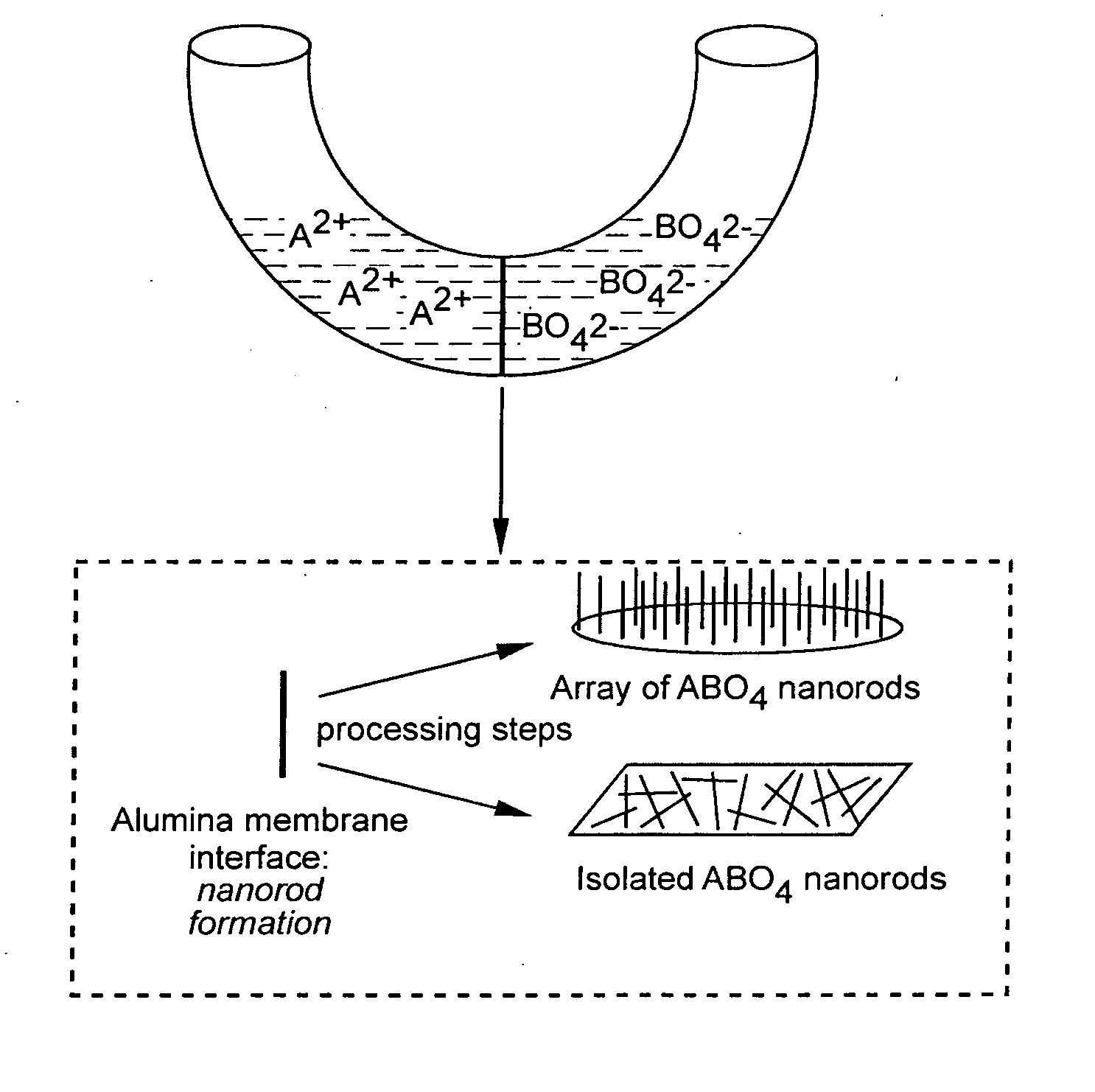

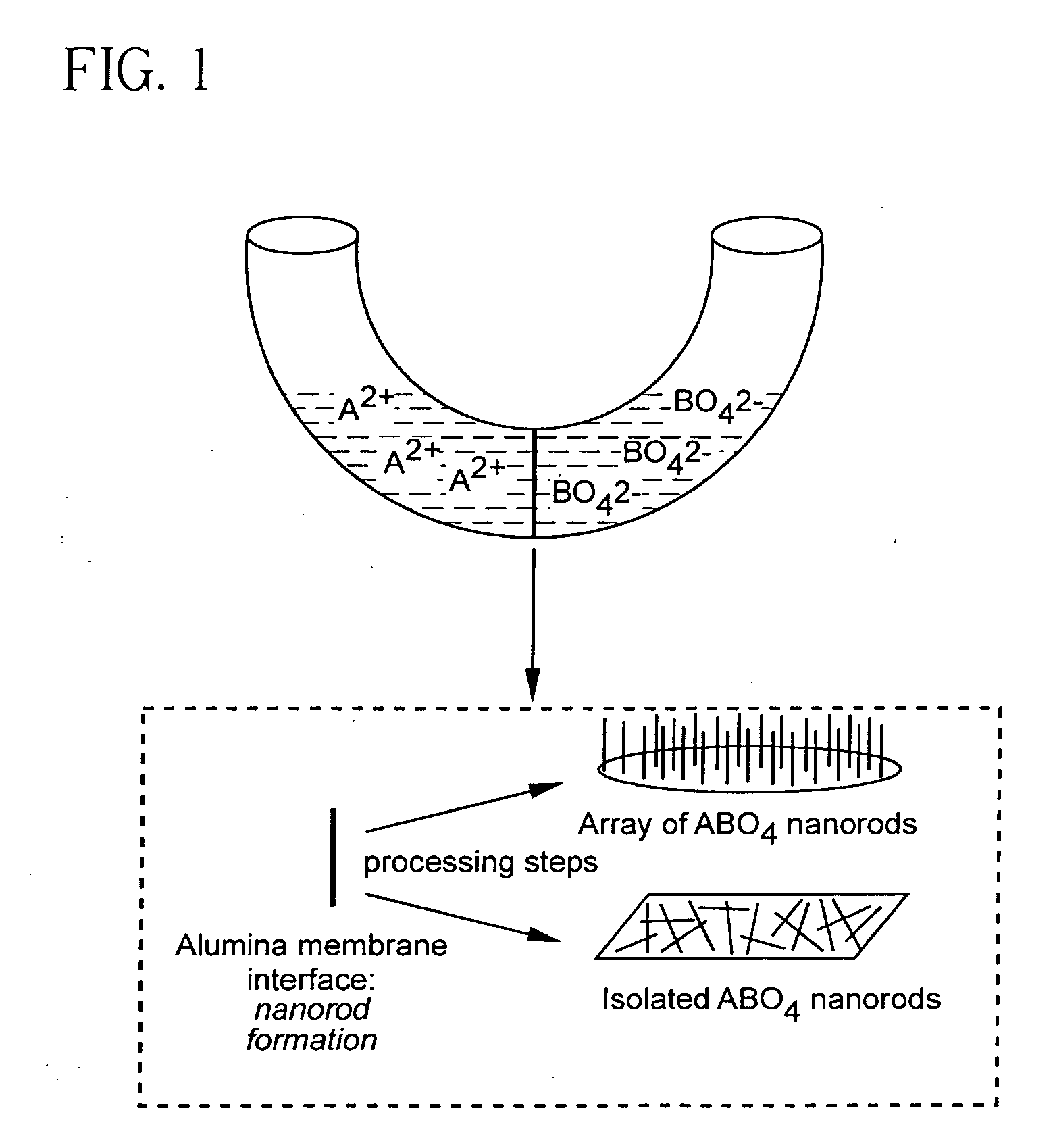

Metal oxide and metal fluoride nanostructures and methods of making same

InactiveUS20070113779A1Easy to controlOvercomes shortcomingMercury oxidesAlkali metal oxides/hydroxidesSingle crystalNanostructure

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Manufacturing methods for nanomaterial dispersions and products thereof

InactiveUS20060016371A1Increase volumeLow cost productionMaterial nanotechnologyAlkaline earth titanatesManufactured nanomaterialsApplications of nanotechnology

Methods for manufacturing nanomaterial dispersions, such as nanomaterial concentrates, and related nanotechnology are provided. The nanomaterial concentrates provided can be more cheaply stored and transported compared to non-concentrate nanomaterial forms.

Owner:PPG IND OHIO INC

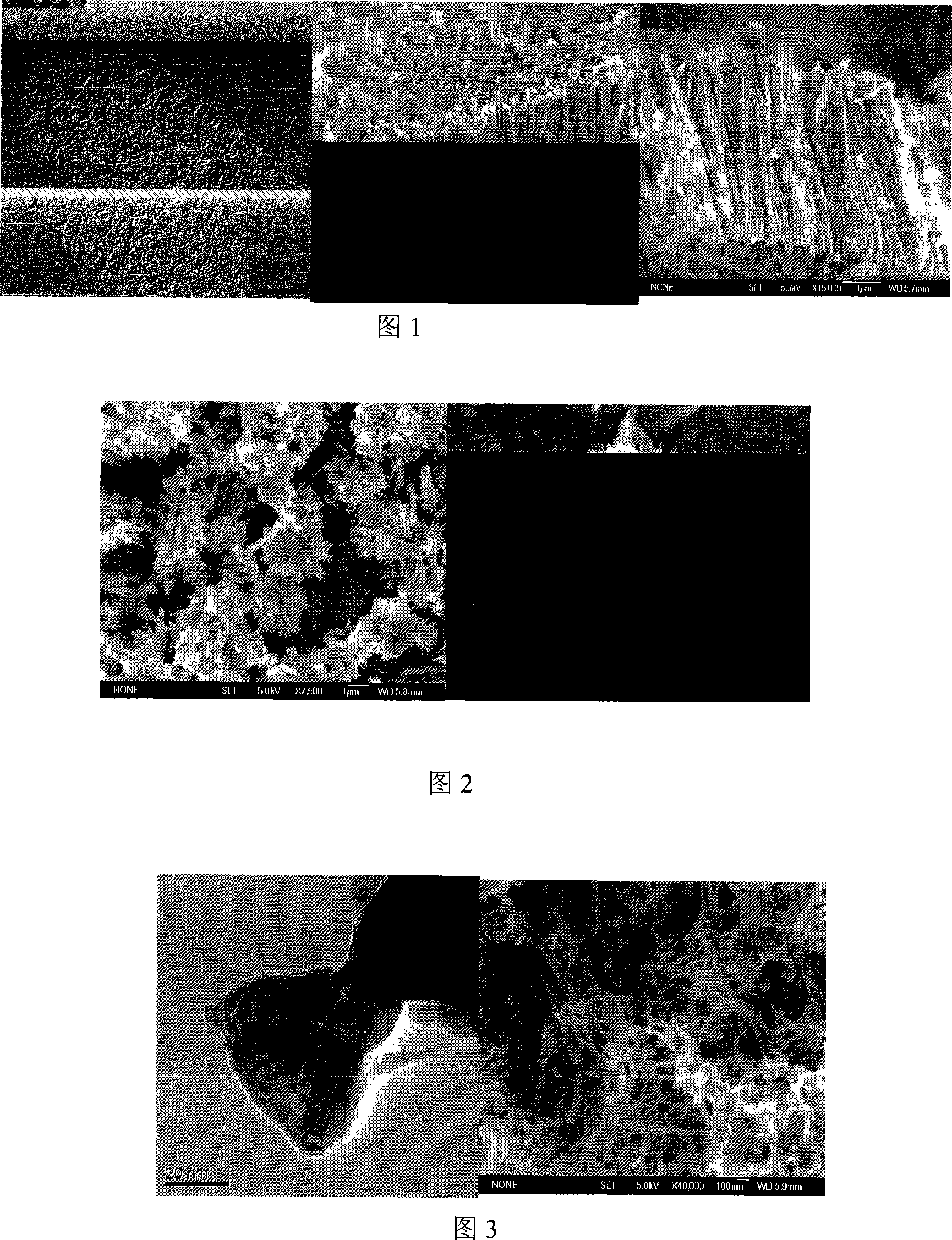

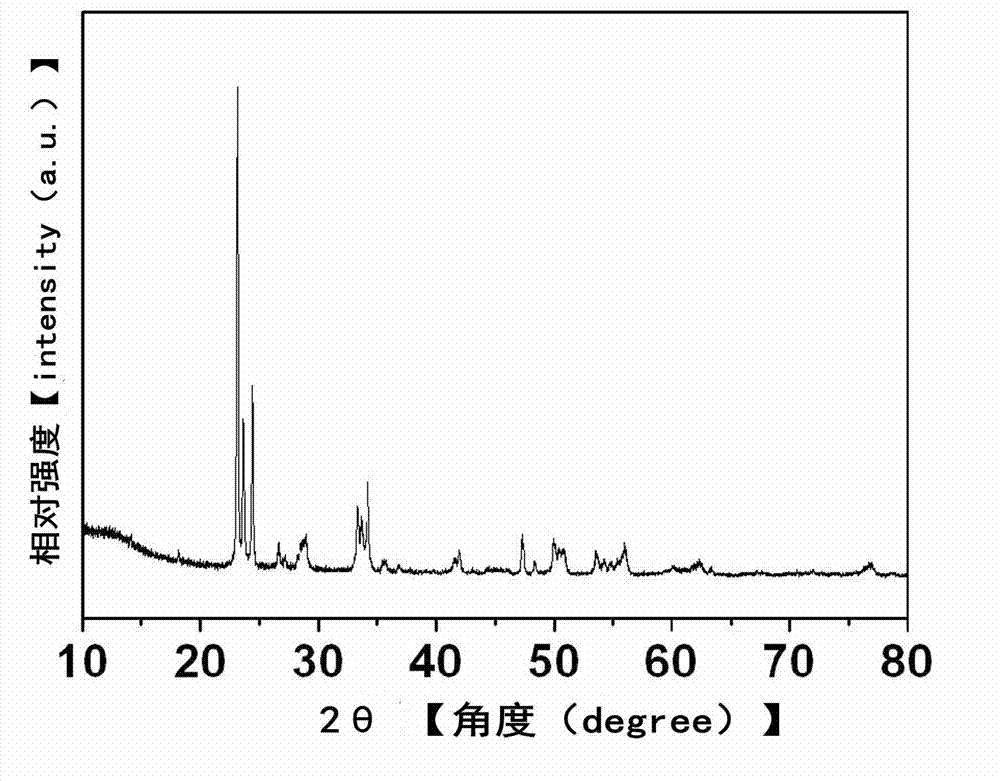

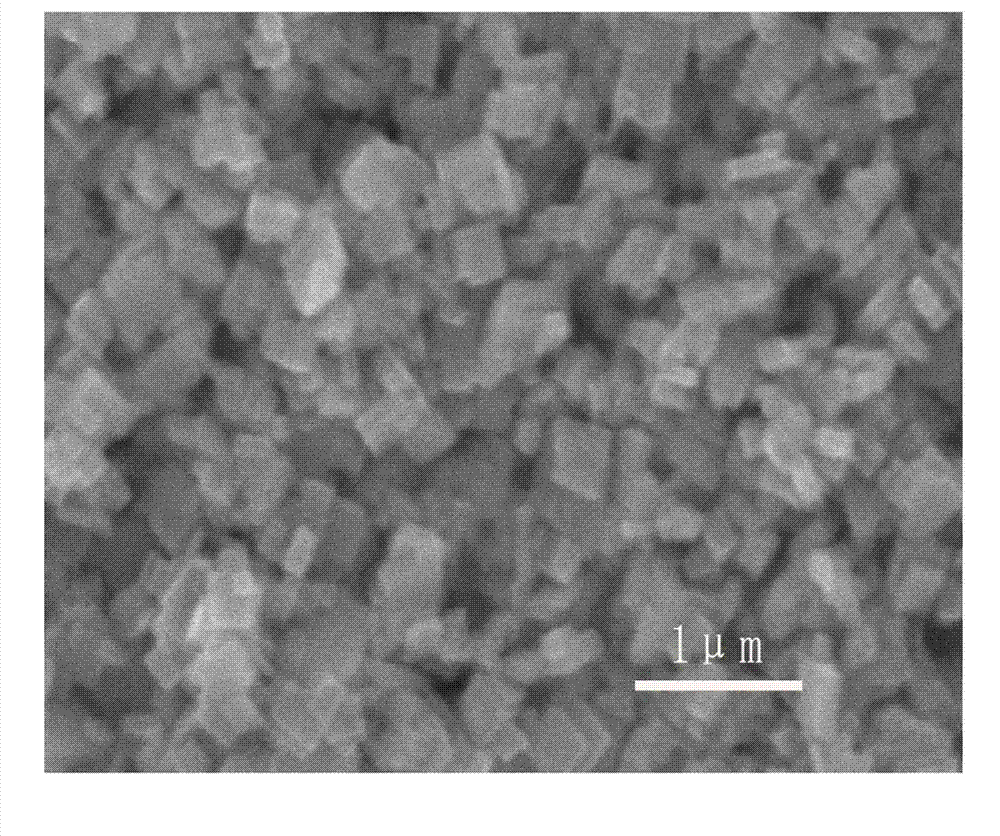

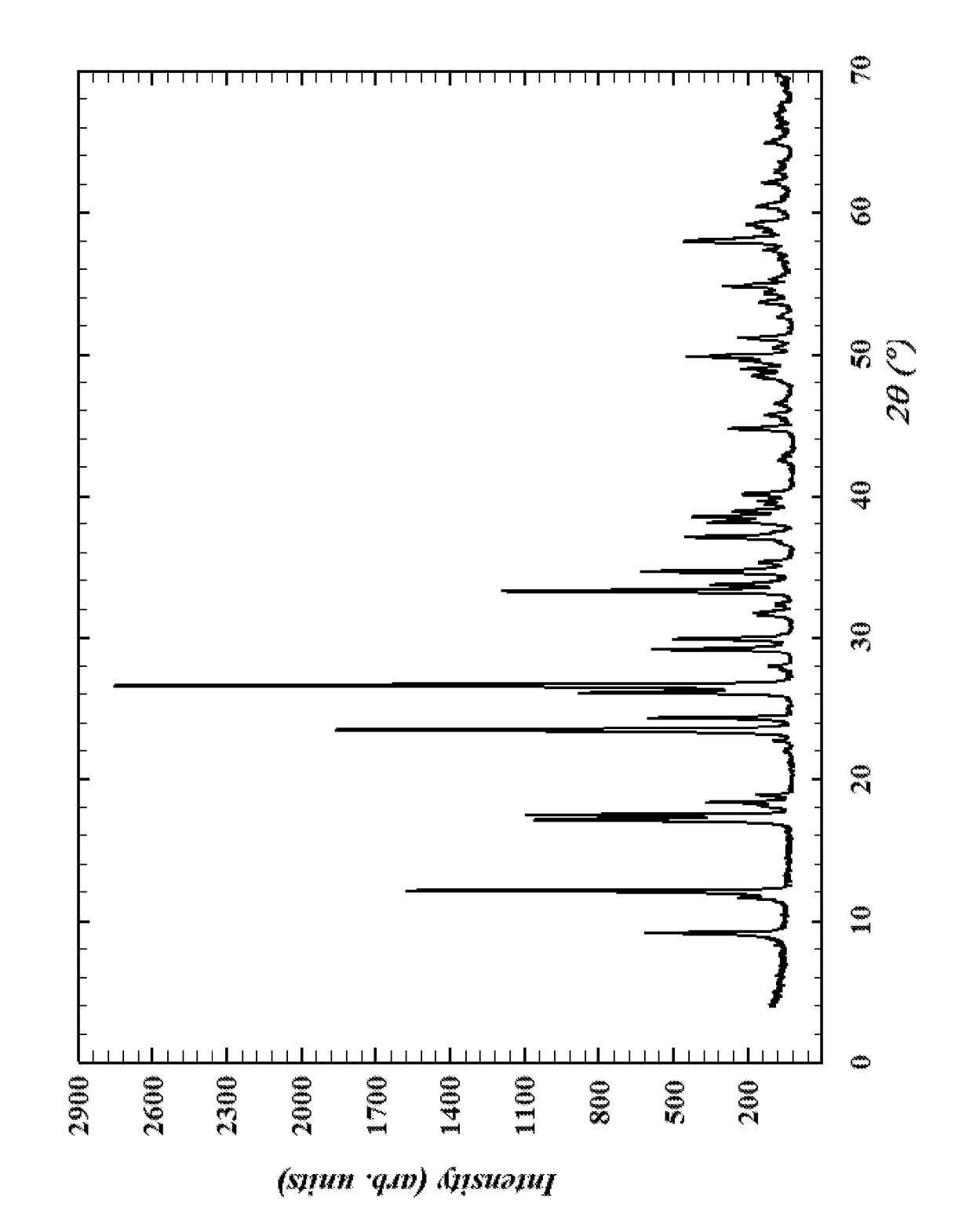

Tungsten trioxide nano-sheet prepared by hydrothermal method and application of tungsten trioxide nano-sheet

InactiveCN103030179AGood chemical stabilityMeets friendly requirementsMaterial nanotechnologyTungsten oxides/hydroxidesInorganic chemical compoundHydrothermal synthesis

The invention belongs to the technical field of preparation of inorganic nano-materials and environmental materials, relates to a preparation method of tungsten trioxide nano-sheets,, in particular to a tungsten trioxide nano-sheet prepared by hydrothermal method and application of the tungsten trioxide nano-sheet. The invention aims to provide a preparation method of tungsten trioxide nano-sheets, which has a simple process and reduces the synthesis temperature. The preparation of tungsten trioxide nano-sheets with relatively homogeneous patterns through liquid-phase hydrothermal reaction at a low temperature is implemented by stirring mixing a dilute nitric acid solution and a sodium tungstate solution to form tungstic acid precipitates and then performing hydrothermal method. Tungsten trioxide (WO3) prepared throughsimple hydrothermal synthesis reaction has a sheet-like nano-scale structure pattern and is advantageous in good chemical stability. The method has a simple process and good reproducibility. All used raw materials are inorganic compounds which are cheap and abundant and conform to the requirement for environmental friendliness. The method does not need calcination and other pretreatment processes at high temperatures and reduces the synthesis temperature, so as to reduce the energy consumption and reaction cost and to facilitate the mass production.

Owner:江苏海能动力科技有限公司

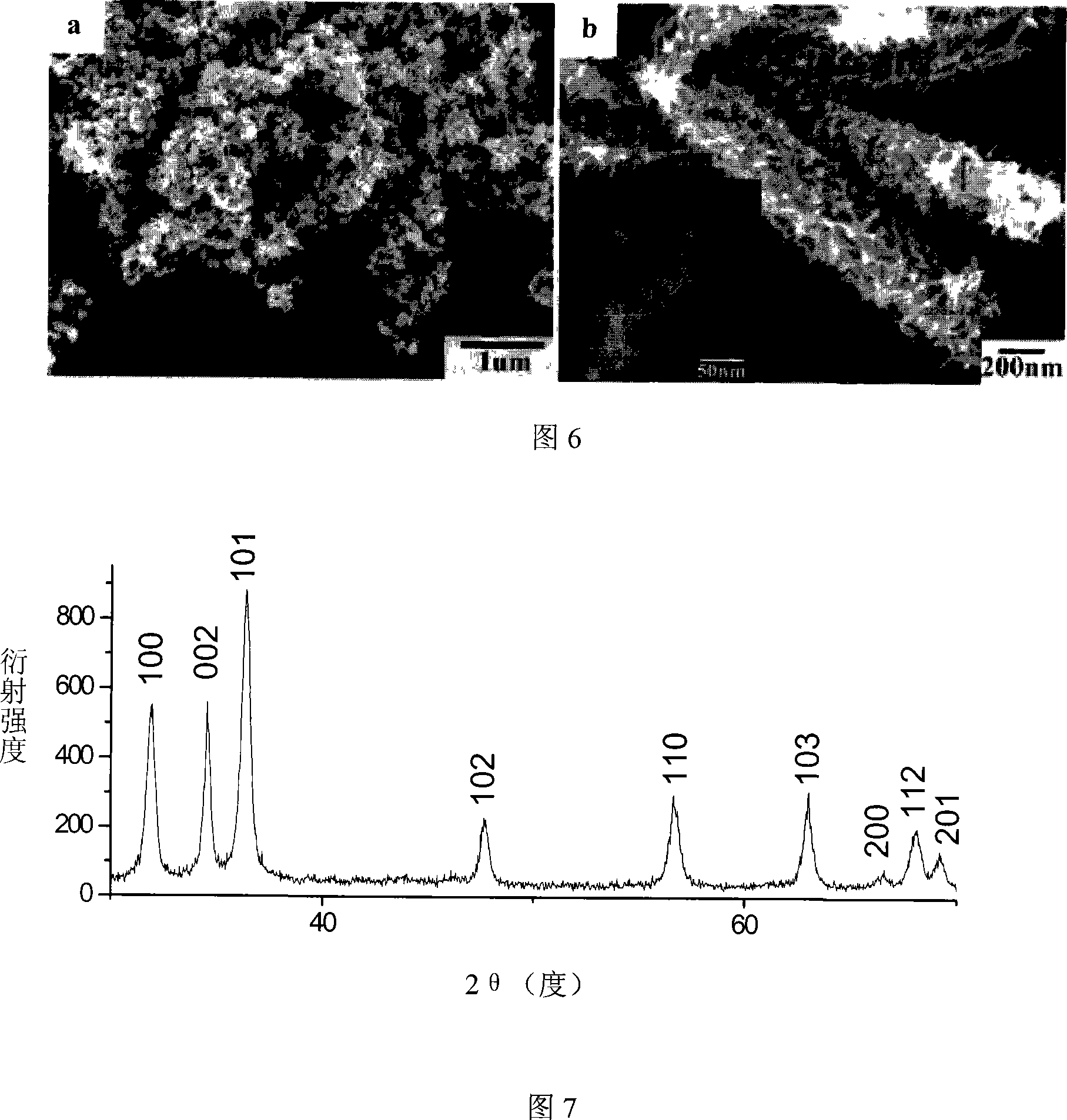

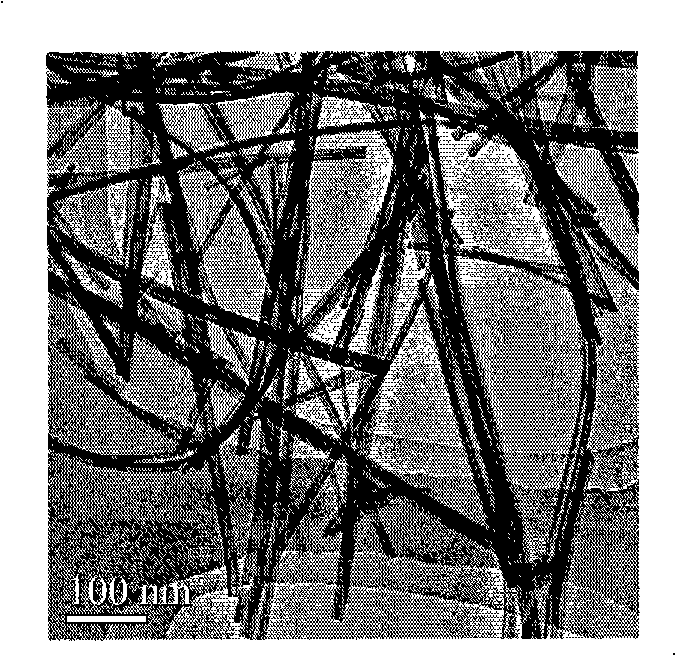

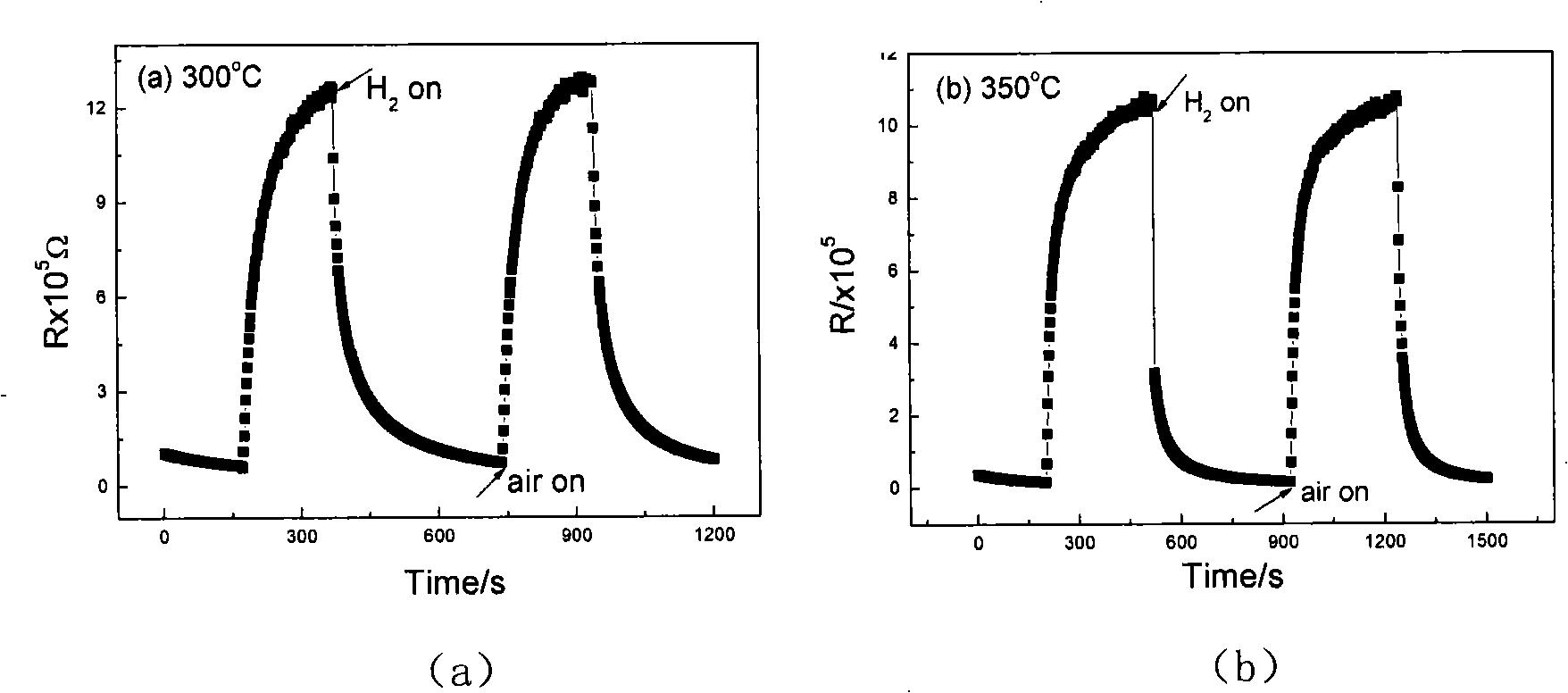

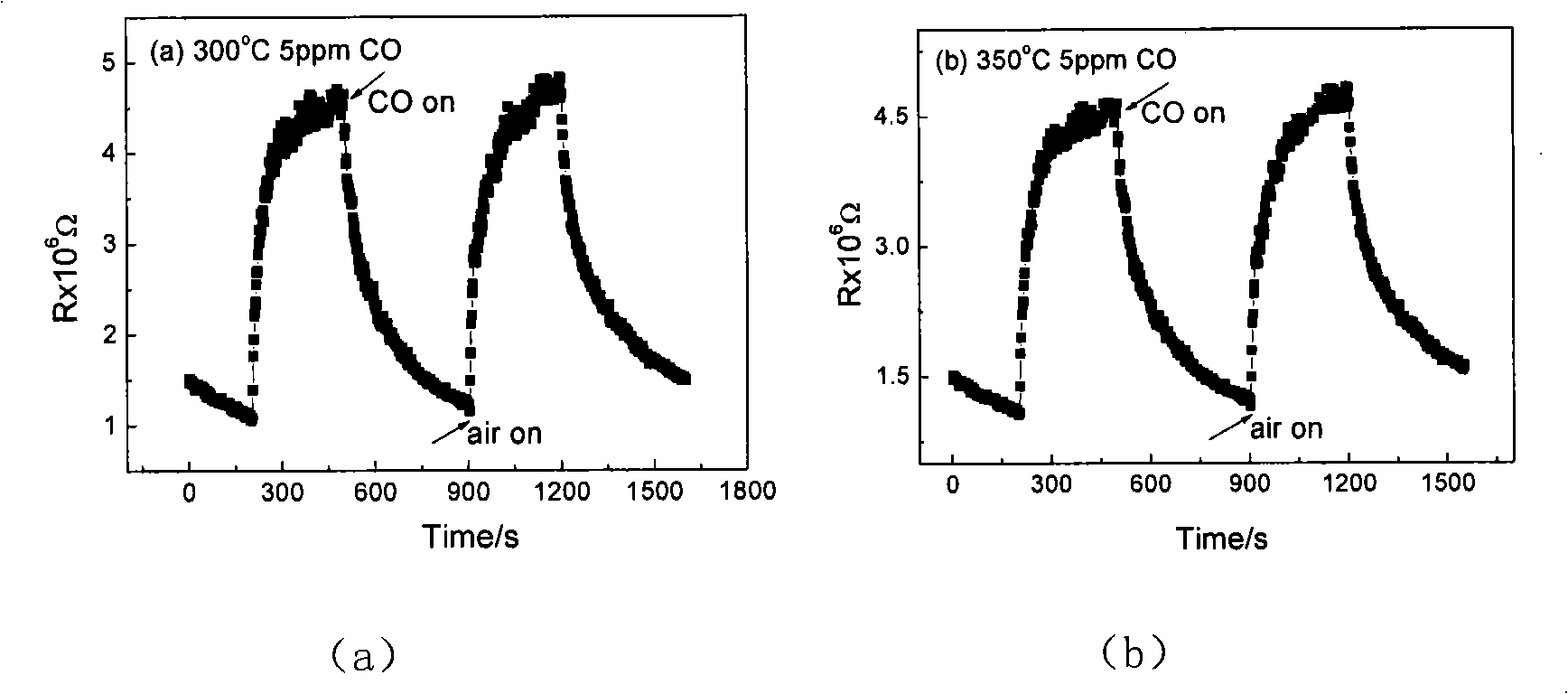

Tungstic oxide nano-wire and method for preparing tungstic oxide nano-wire gas-sensitive sensor

InactiveCN101318704AReduce consumptionLarge specific surface areaTungsten oxides/hydroxidesMaterial analysis by electric/magnetic meansAdhesiveMicellar solutions

The invention relates to a method for preparing a tungsten oxide nano-wire and a tungsten oxide nano-wire ammonia-sensitive sensor, belonging to the one dimensional nano oxide material preparation and gas-sensitive technical field. The method comprises the following steps that: sodium tungstate is dissolved in deionized water to prepare a sodium tungstate solution; a hydrochloric acid is dripped slowly to prepare a flaxen micellar solution which is then centrifugally separated; products are uniformly dispersed in a potassium sulfate solution which is then transferred into a reaction kettle for hydrothermal reaction, and then the tungsten oxide nano-wire is prepared; adhesives and frit are added into the tungsten oxide nano-wire, and then the tungsten oxide nano-wire ammonia-sensitive sensor is prepared after element sintering and ageing. The method has simple steps, easily controlled technological parameters during the preparation process, and very low energy consumption during the whole preparation process; the tungsten oxide nano-wire prepared has a large specific surface area and high thermal stability; and the tungsten oxide nano-wire ammonia-sensitive sensor prepared has high sensitivity on low-concentration (between 1 and 100 pars per million) H2, CO and NH3, good repeatability and high stability.

Owner:TSINGHUA UNIV

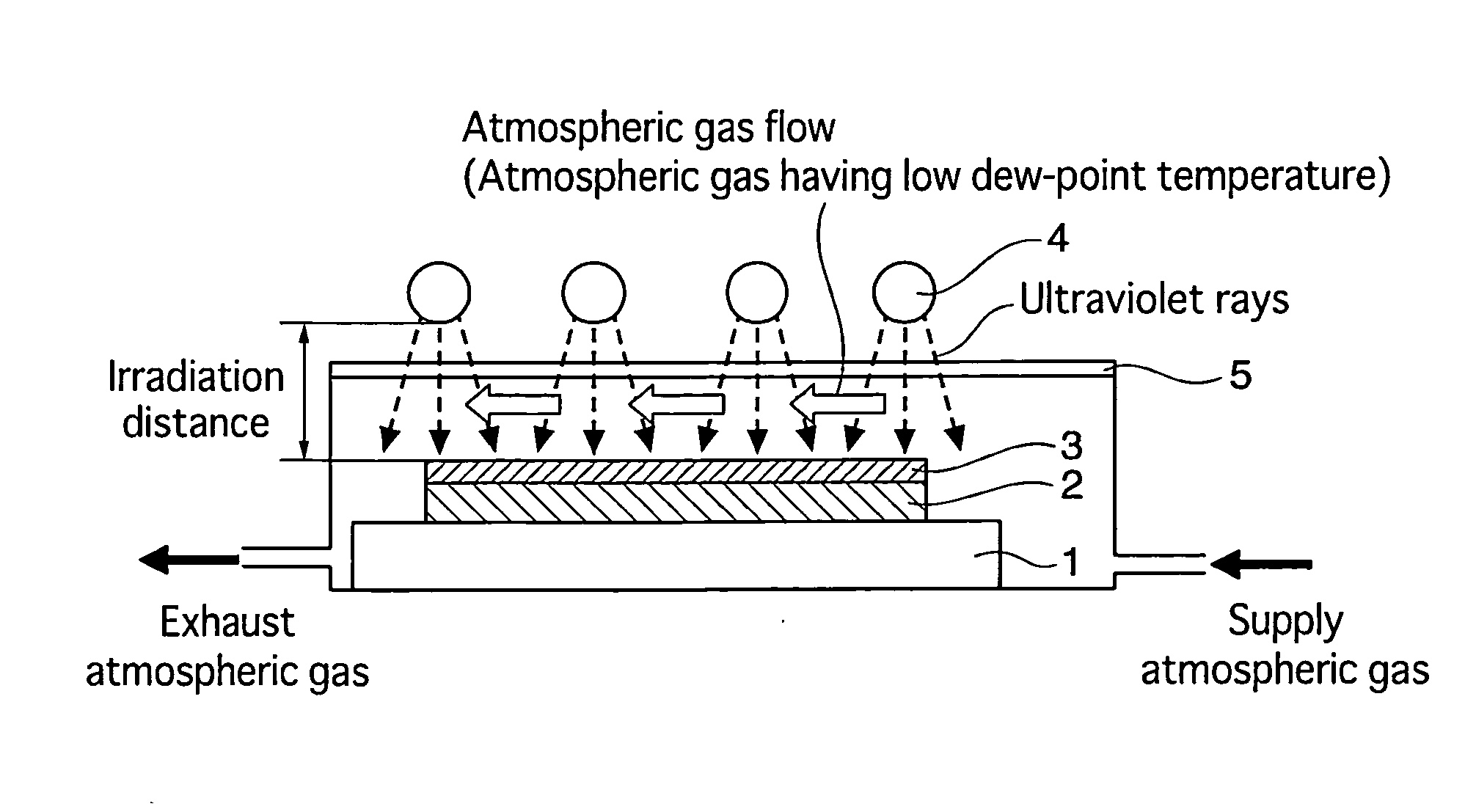

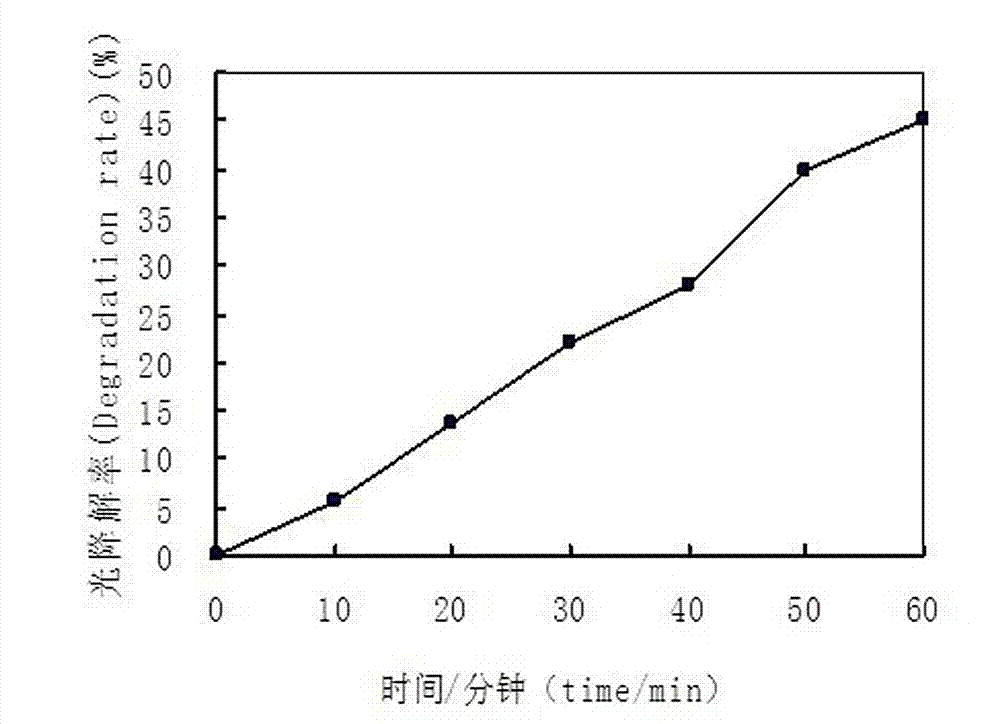

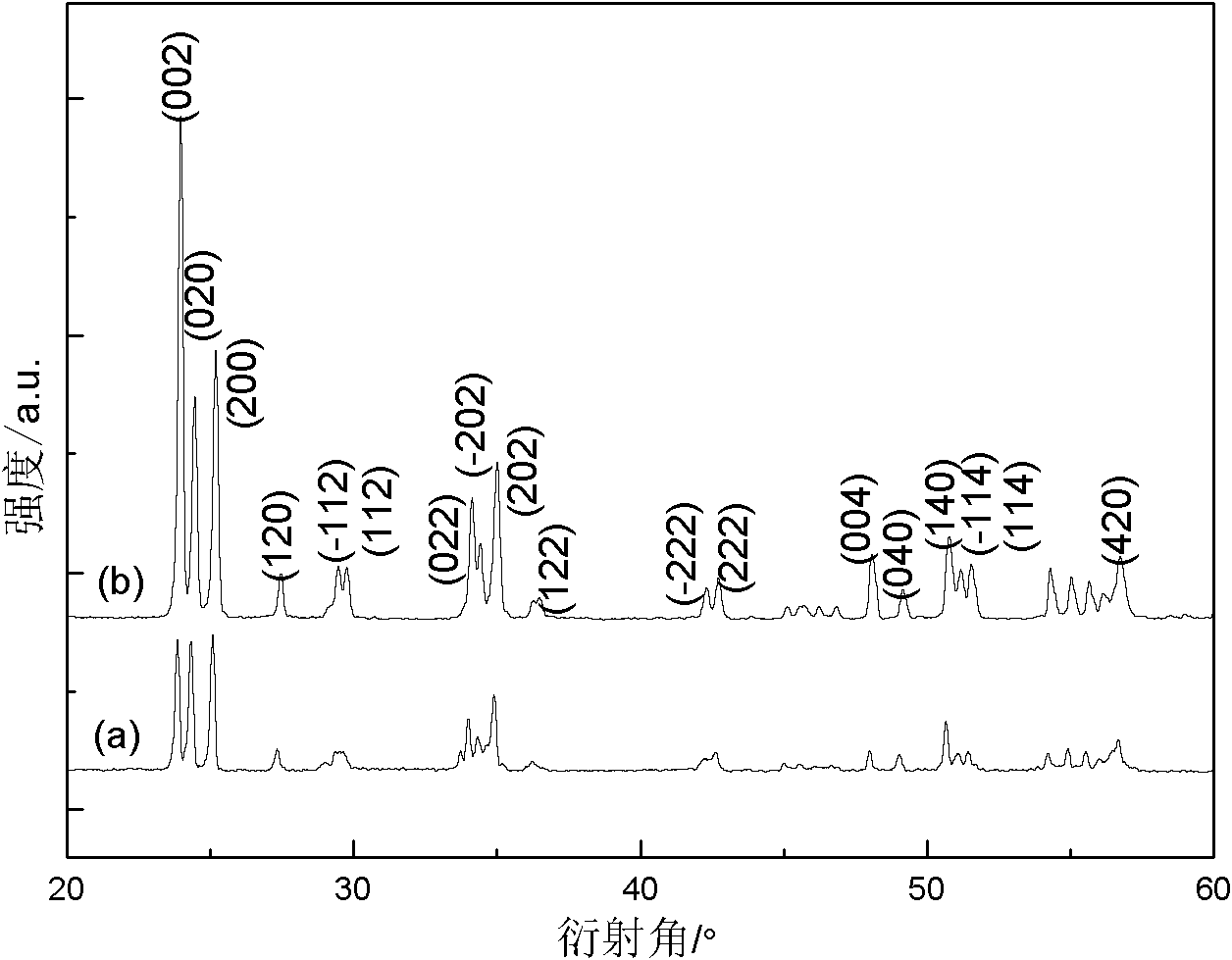

Photocatalytic material, photocatalyst, photocatalytic product, lighting apparatus, and method of producing photocatalytic material

InactiveUS20070177372A1Improve catalytic performanceImprove photocatalytic performanceMaterial nanotechnologyTungsten oxides/hydroxidesMicroparticleTungsten trioxide

A photocatalytic material containing tungsten trioxide fine particles having an average particle diameter of 0.5 μm or smaller and a crystal structure of a monoclinic crystal system as a main component.

Owner:TOSHIBA LIGHTING & TECH CORP

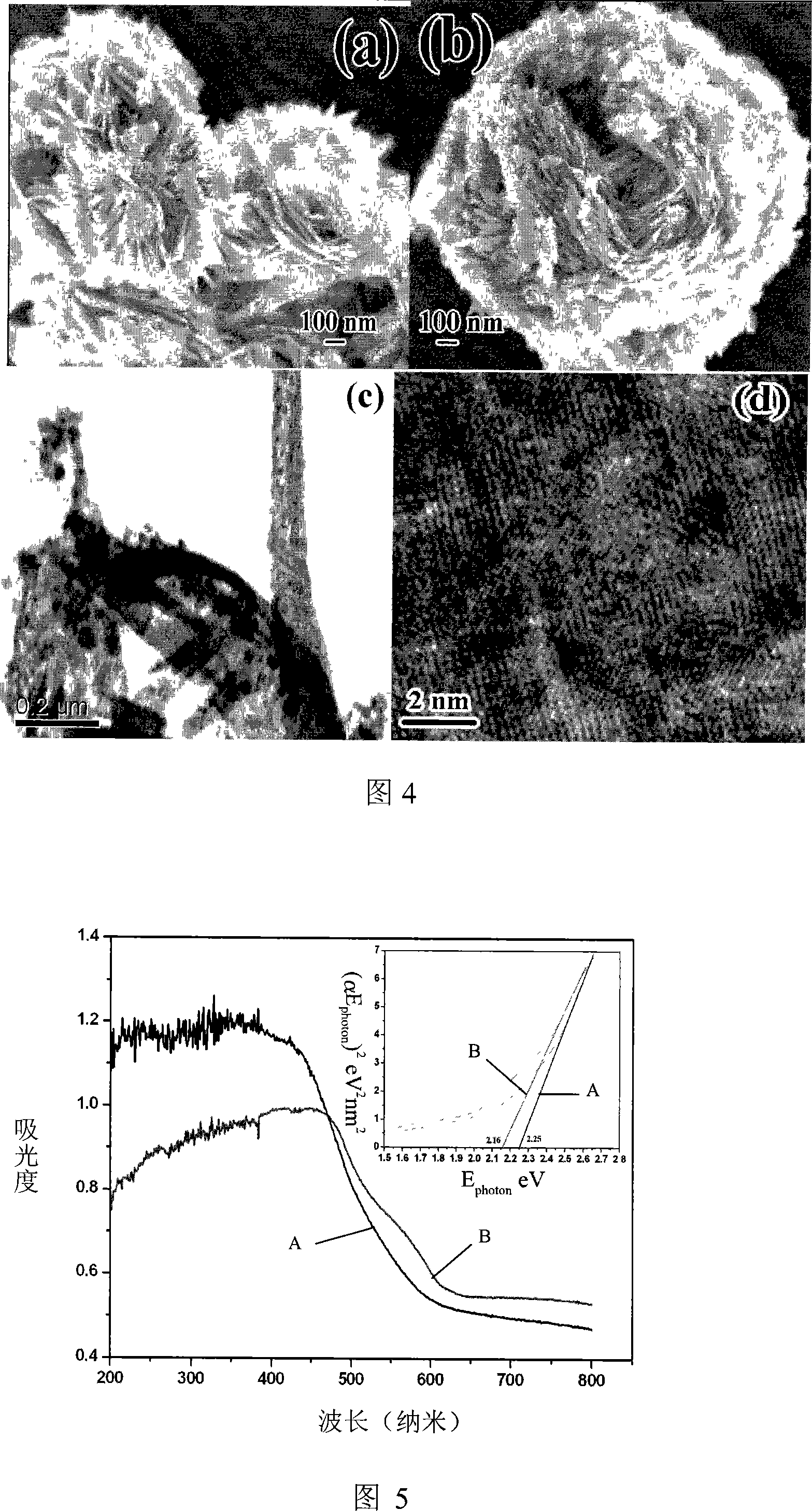

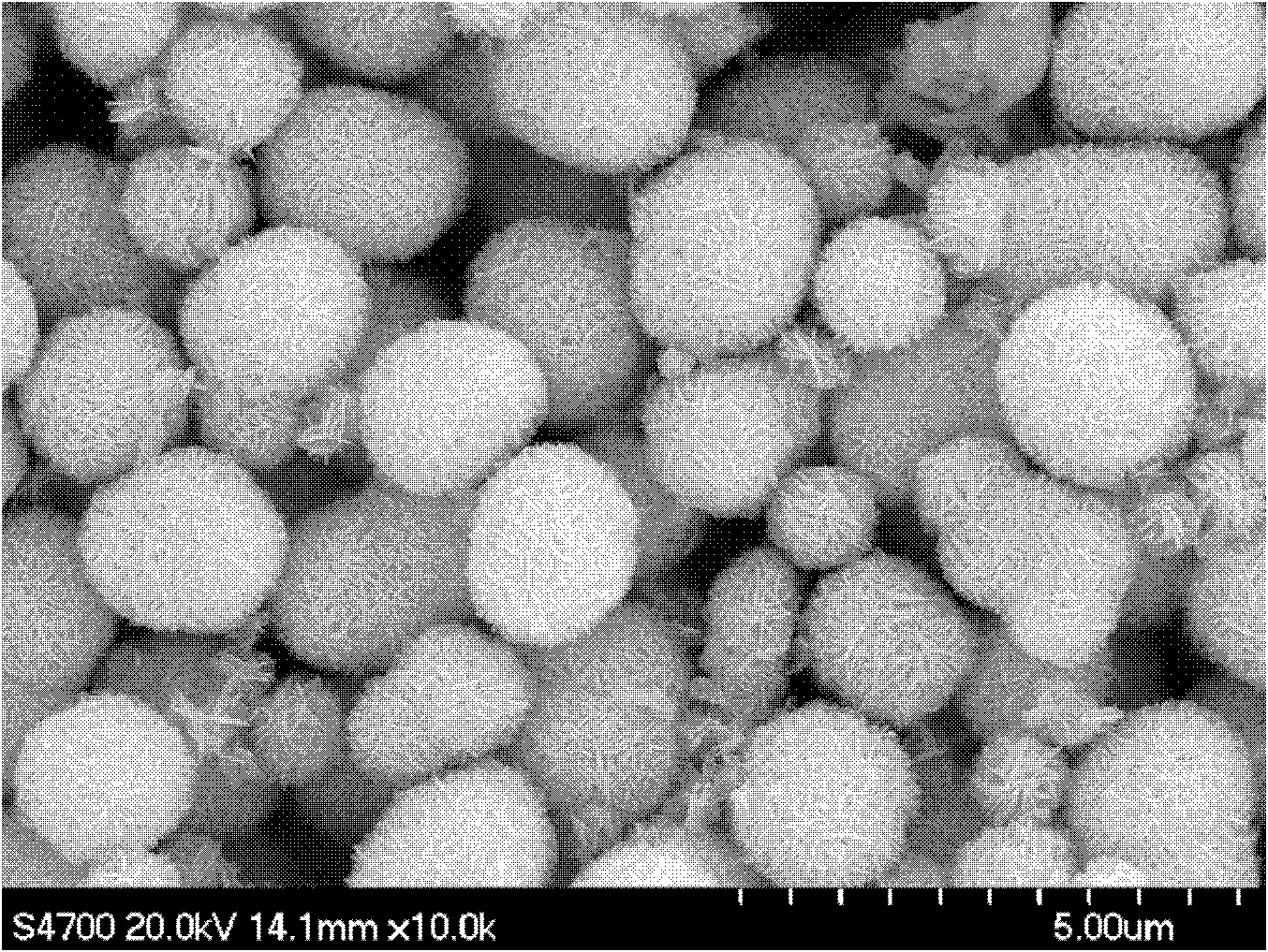

Tungsten oxide nanoflake self-assembly nanosphere and application method and application of tungsten oxide nanoflake self-assembly nanosphere

InactiveCN102757095AEasy to operateMild experimental conditionsTungsten oxides/hydroxidesNanotechnologyMicrometerNitrogen dioxide

The invention provides a tungsten oxide nanoflake self-assembly nanosphere gas-sensitive material, a preparation method and application of the gas-sensitive material. Tungsten oxide nanoflake self-assembly nanosphere is successfully prepared by an ultrasonic method under the mild condition, the diameter of the tungsten oxide nanosphere ranges from 1 micrometer to 3 micrometers, and the tungsten oxide nanosphere consists of lamella structure units in a self-assembly manner. Compared with an existing method for preparing a tungsten oxide nanometer material, the method has the advantages of simple equipment, convenience in operation, mild experimental condition, low cost and the like. The prepared tungsten oxide nanoflake self-assembly nanosphere has high sensitivity and selectivity to low-concentration NO2 at low operation temperature, and is applicable to detecting trace nitrogen dioxide in environments.

Owner:BEIJING UNIV OF CHEM TECH

Crystalline transition metal oxy-hydroxide molybdotungstate

ActiveUS20170165648A1Polycrystalline material growthTungsten oxides/hydroxidesHydrodesulfurizationPhysical chemistry

A hydroprocessing catalyst has been developed. The catalyst is a unique crystalline transition metal oxy-hydroxide molybdotungstate material. The hydroprocessing using the crystalline ammonia transition metal oxy-hydroxide molybdotungstate material may include hydrodenitrification, hydrodesulfurization, hydrodemetallation, hydrodesilication, hydrodearomatization, hydroisomerization, hydrotreating, hydrofining, and hydrocracking.

Owner:UOP LLC

Method for preparing nano tungsten trioxide powder

The invention discloses a method for preparing nanometer tungstic oxide nanopowder. The method for producing the high-quality nanometer WO3 powder with high efficiency comprises the following steps: according to the rate of 1 to 1, 13.4 to15mol / L of ammonia and deionized water are prepared into the needed ammonia solution; tungstenic acid is dissolved into the prepared ammonia solution; citric acid which has the molar ratio with the tungstenic acid by 2 to 4 times is added into the solution, is heated at the temperature of between 80 and 90 DEG C and is stirred for 8 to 12 hours to obtain a yellowish transparent gel; the prepared gel is positioned in an infrared oven for roasting till brown expanded gel is obtained; and the gel obtained by the steps is calcined in a chamber furnace at the temperature of between 550 and 650 DEG C to obtain yellow nanometer tungstic oxide powder. Compared with the prior art, the method has the advantages of simple and feasible process,, less environmental pollution, less erosion to equipment and relatively low production cost.

Owner:SOUTHWEST JIAOTONG UNIV

Popular searches

Manganese oxides/hydroxides Hydrocarbon by hydrocarbon condensation Bulk chemical production Hydrocarbon oils treatment products Aluminium oxides/hydroxides Organic-compounds/hydrides/coordination-complexes catalysts Heterogenous catalyst chemical elements Hydrocarbon preparation catalysts Catalyst activation/preparation Hydrocarbons

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com