Patents

Literature

759results about "Tantalum compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified oxygen reduced valve metal oxides

InactiveUS6639787B2Maintain good propertiesWear minimizationOxide/hydroxide preparationLiquid electrolytic capacitorsFluidized bedPhysical chemistry

Owner:GLOBAL ADVANCED METALS USA

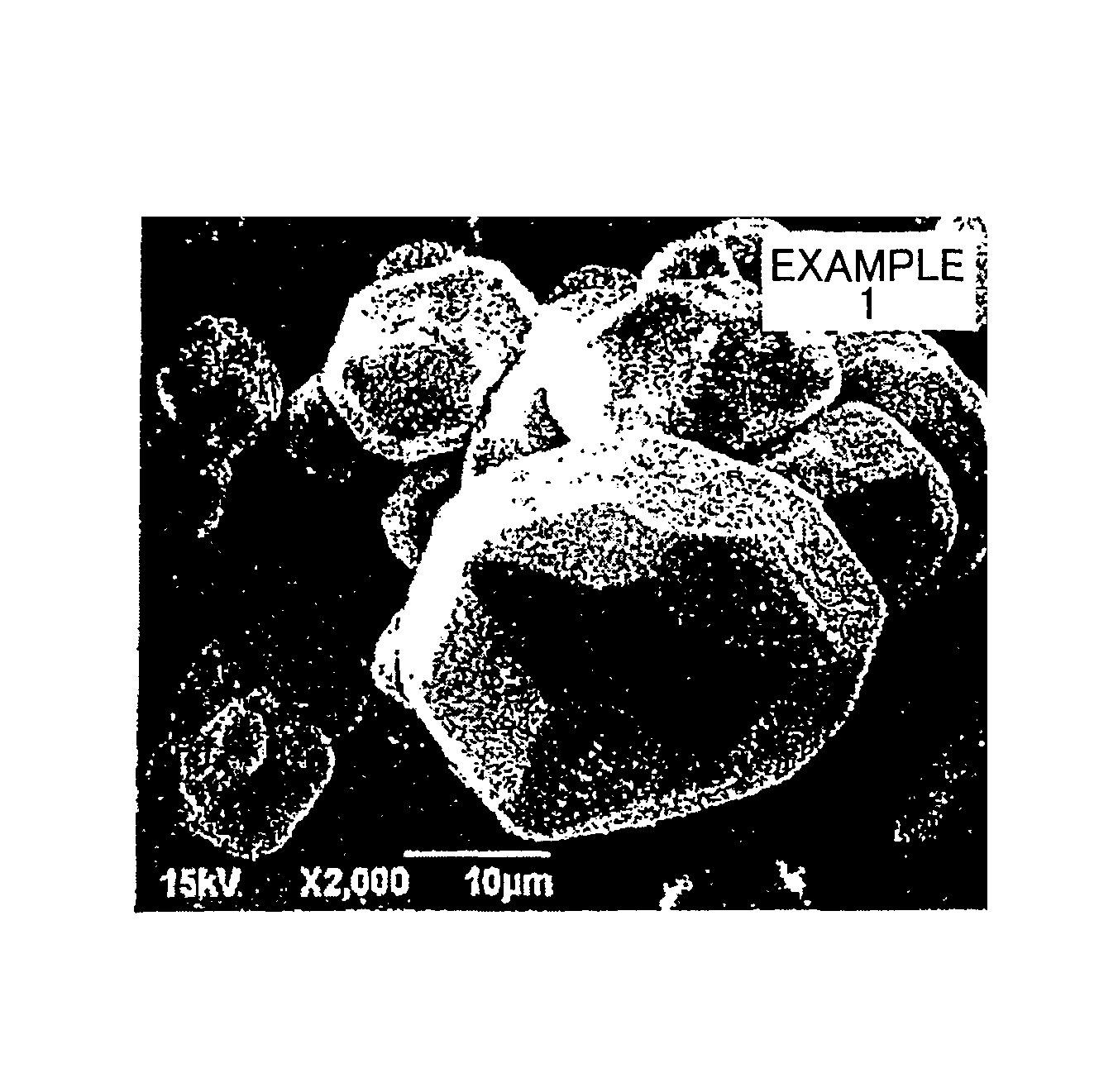

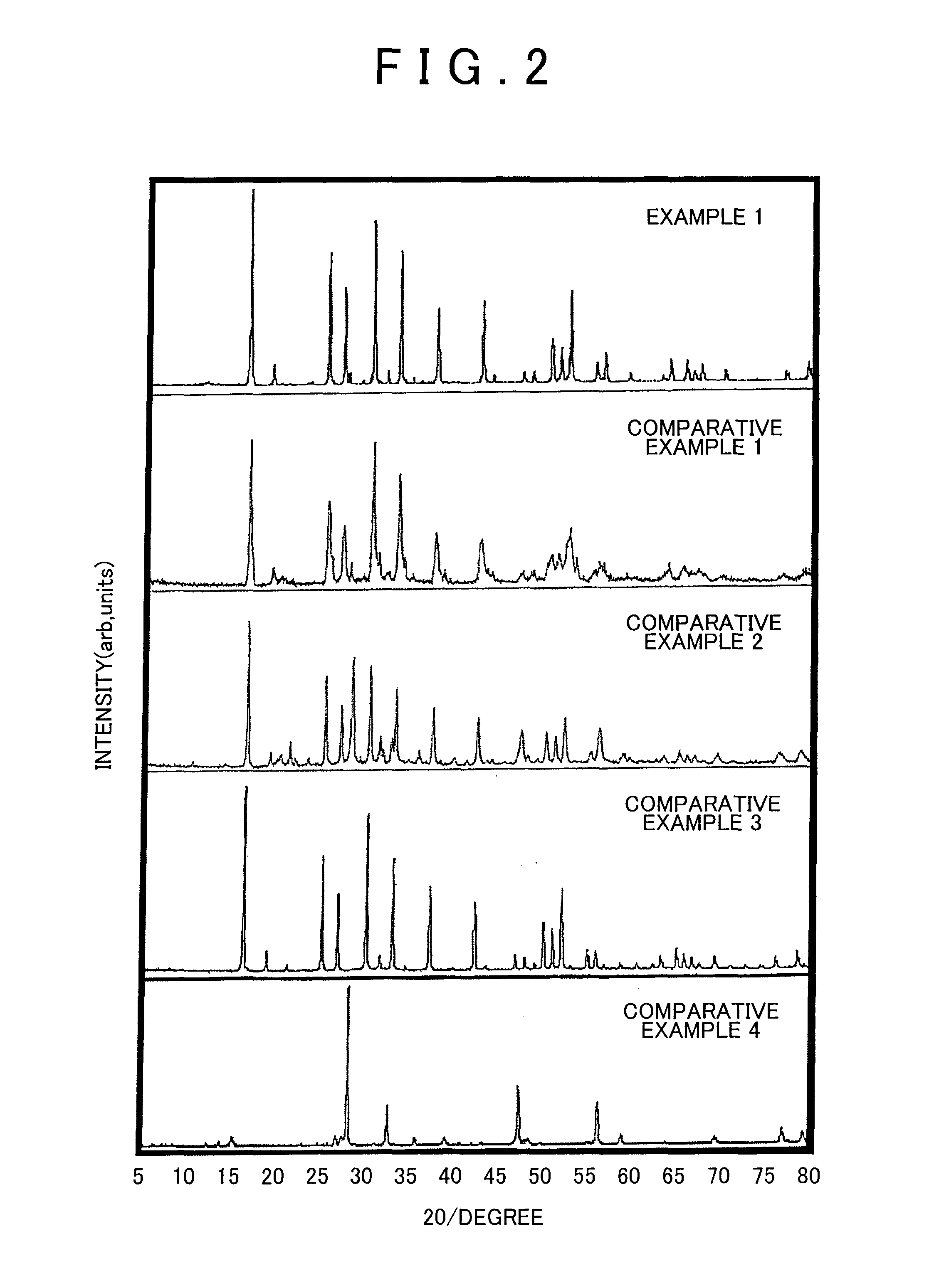

Niobium suboxide powder

ActiveUS20050013765A1High currentReduce residual currentOxide/hydroxide preparationLiquid electrolytic capacitorsCapacitorTungsten

A niobium suboxide powder comprising 100 to 600 ppm of magnesium is described. The niobium suboxide powder may (alternatively or in addition to 100 to 600 ppm of magnesium) further include 50 to 400 ppm of molybdenum and / or tungsten. The niobium suboxide powder is suitable for the production of: capacitors having an insulator layer of niobium pentoxide; capacitor anodes produced from the niobium suboxide powder; and corresponding capacitors.

Owner:TANIOBIS GMBH

Process for producing niobium suboxide

ActiveUS20050019581A1Increase capacityIncrease volumeLiquid electrolytic capacitorsTantalum compoundsHydrogenNiobium

A method is described for preparing a niobium suboxide represented by the formula, NbOx, in which 0.7<x<1.3. The method involves reacting NbOy (in which y<1.8<2.1) with a stoichiometric amount of niobium metal, in the presence of hydrogen. The niobium suboxide produced by such method may be used to fabricate anodes for solid electrolyte capacitors.

Owner:TANIOBIS GMBH

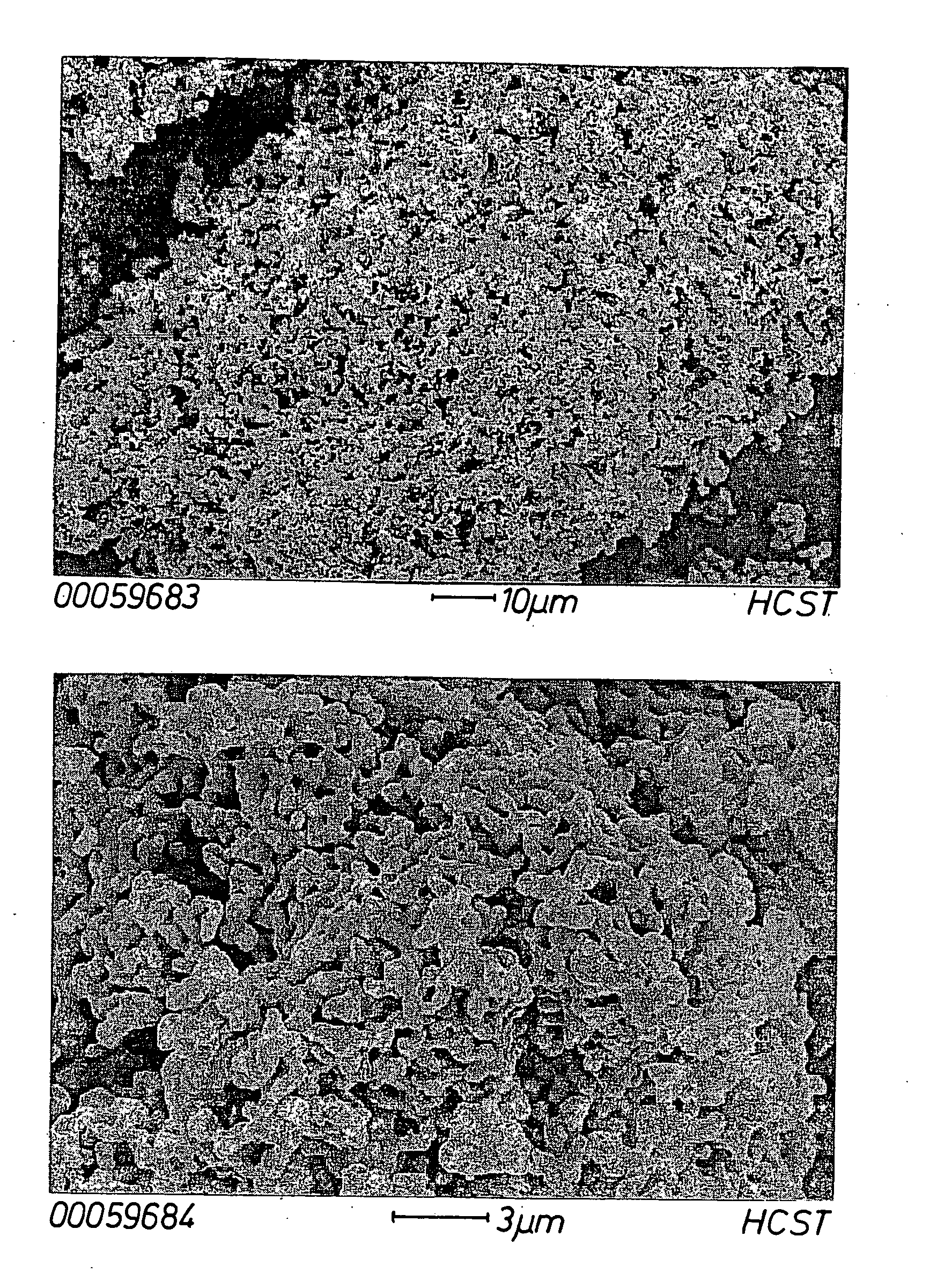

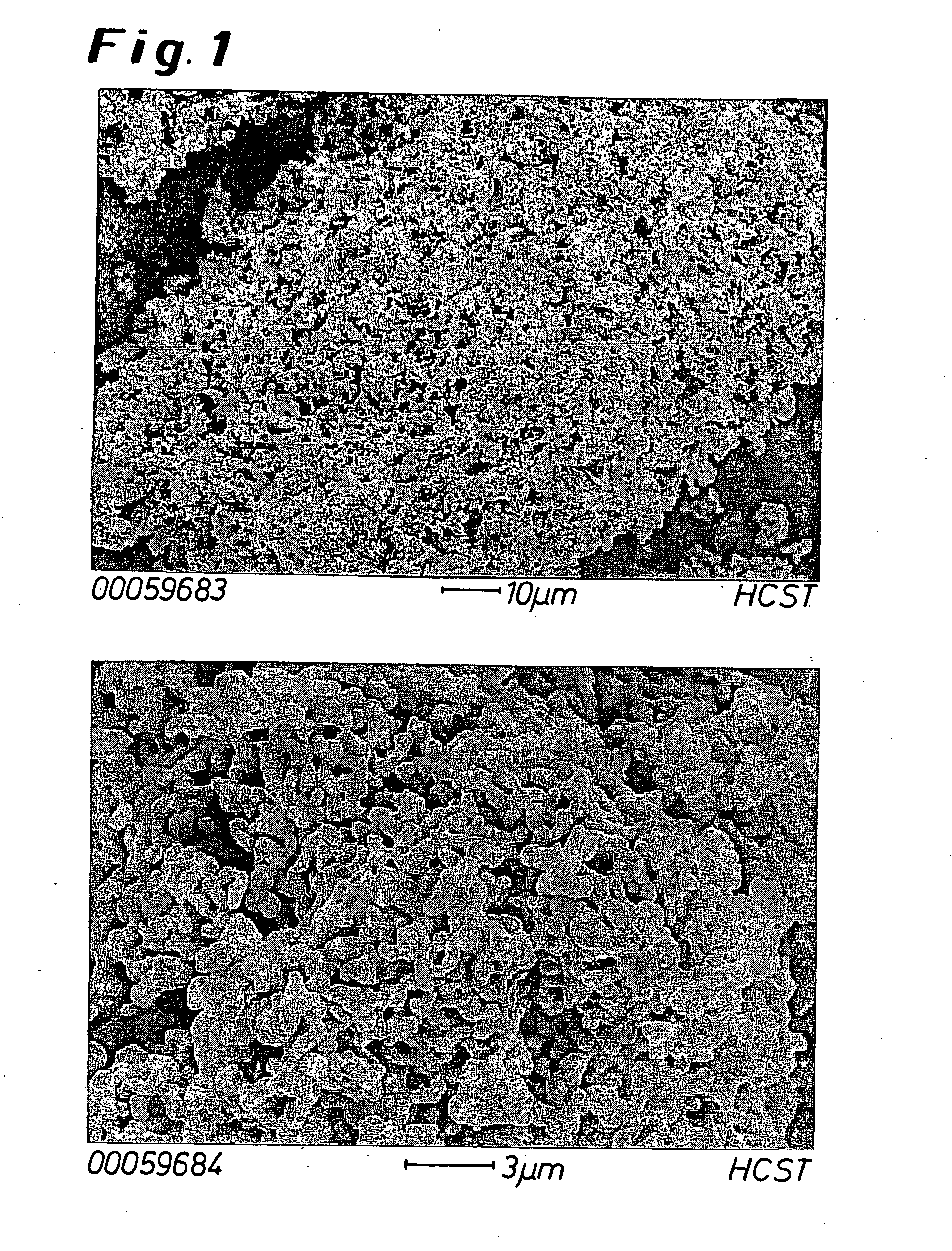

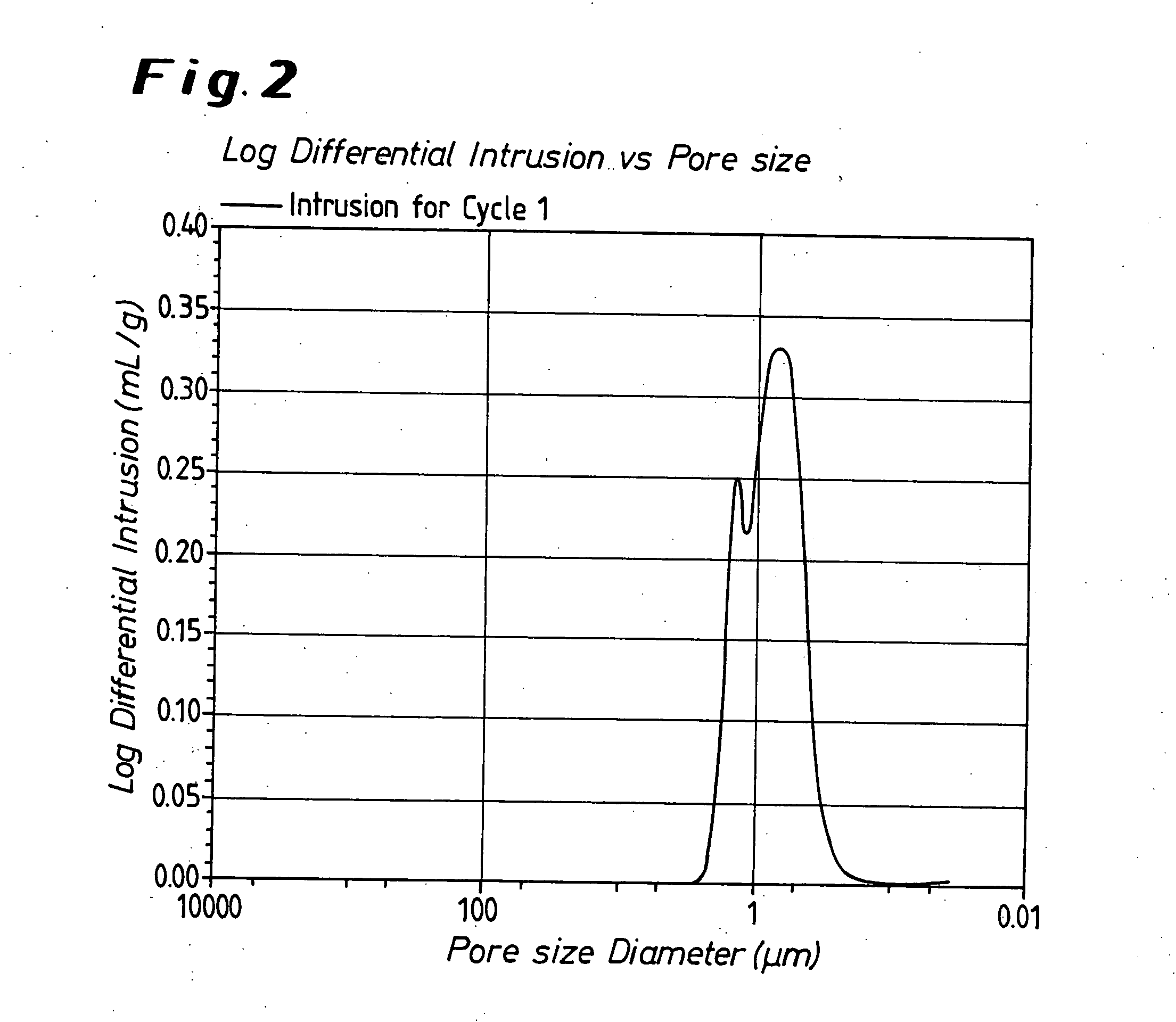

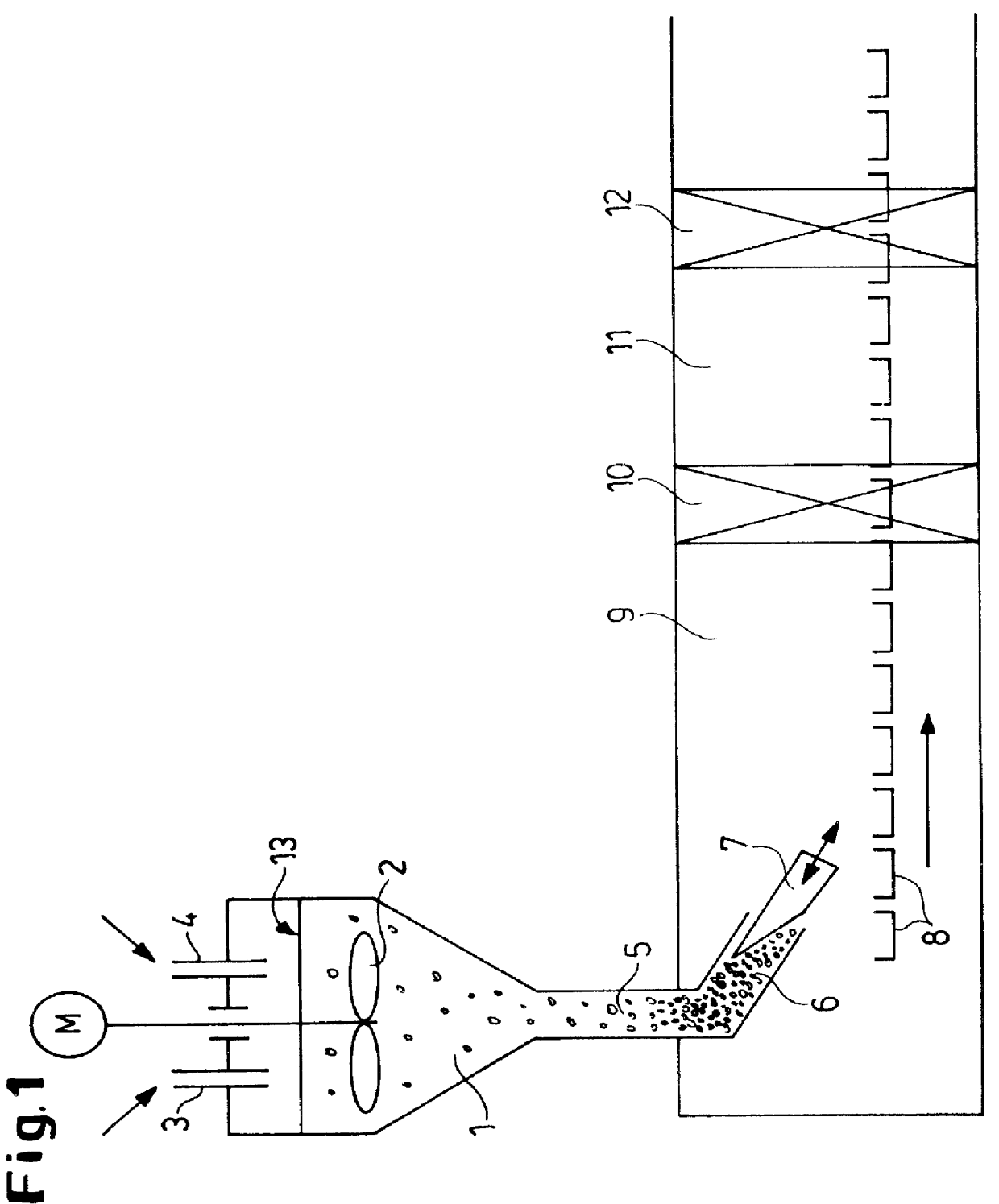

Niobium powder and a process for the production of niobium and/or tantalum powders

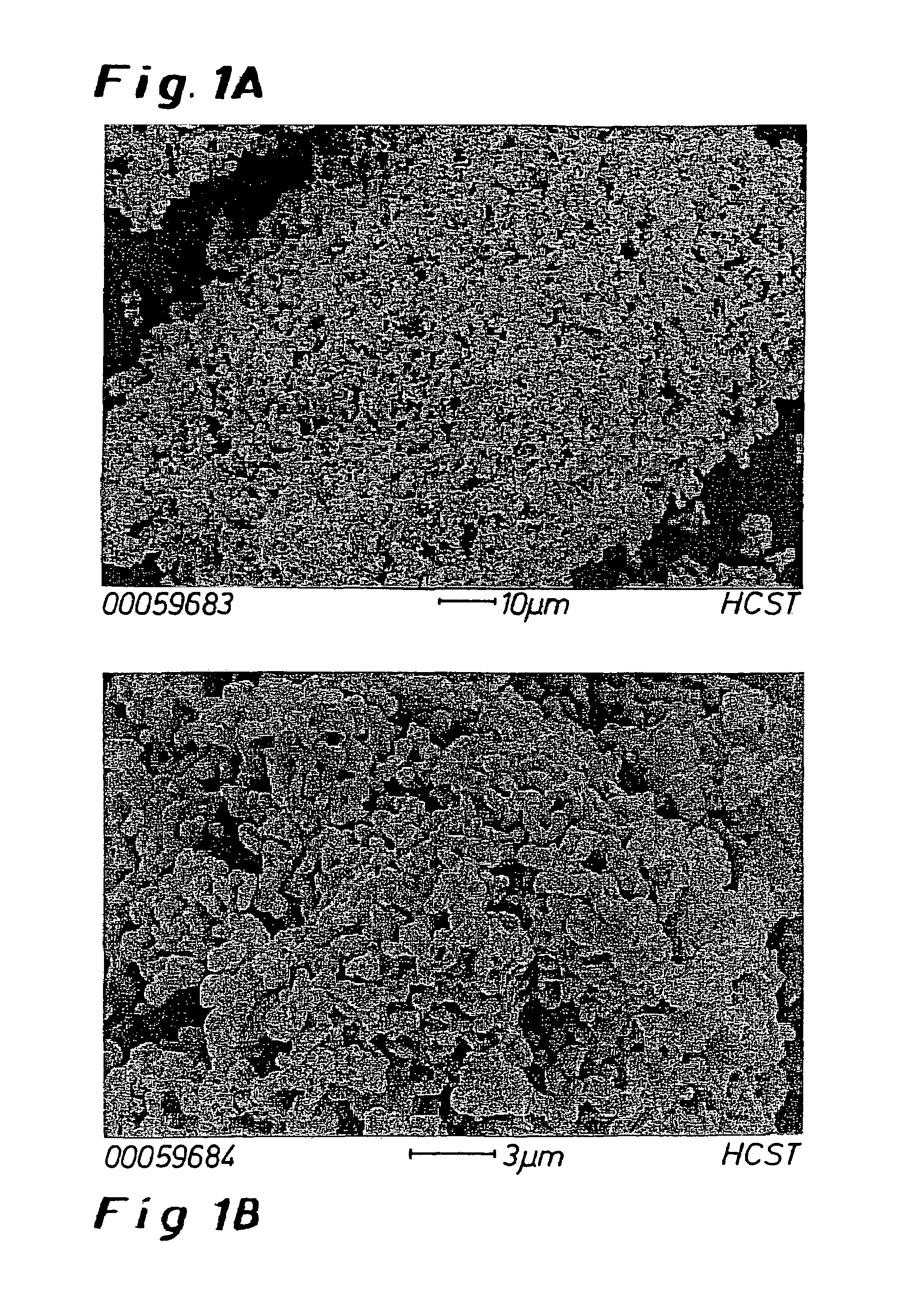

InactiveUS6136062APrevent local overheating effectStirring speed is fastElectrolytic capacitorsTantalum compoundsMischmetalRare earth

The process comprises the reduction of niobium and / or tantalum oxides by means of alkaline earth metals and / or rare earth metals, wherein the first reduction stage is carried out as far as an average composition corresponding to (Nb, Ta)Ox where x=0.5 to 1.5 and before the second stage the reduction product from the first stage is freed from alkaline earth oxides and / or rare earth metal oxides which are formed (and optionally from excess alkaline earth metal and / or rare earth metal) by washing with mineral acids.

Owner:H C STARCK TANTALUM & NIOBIUM GMBH

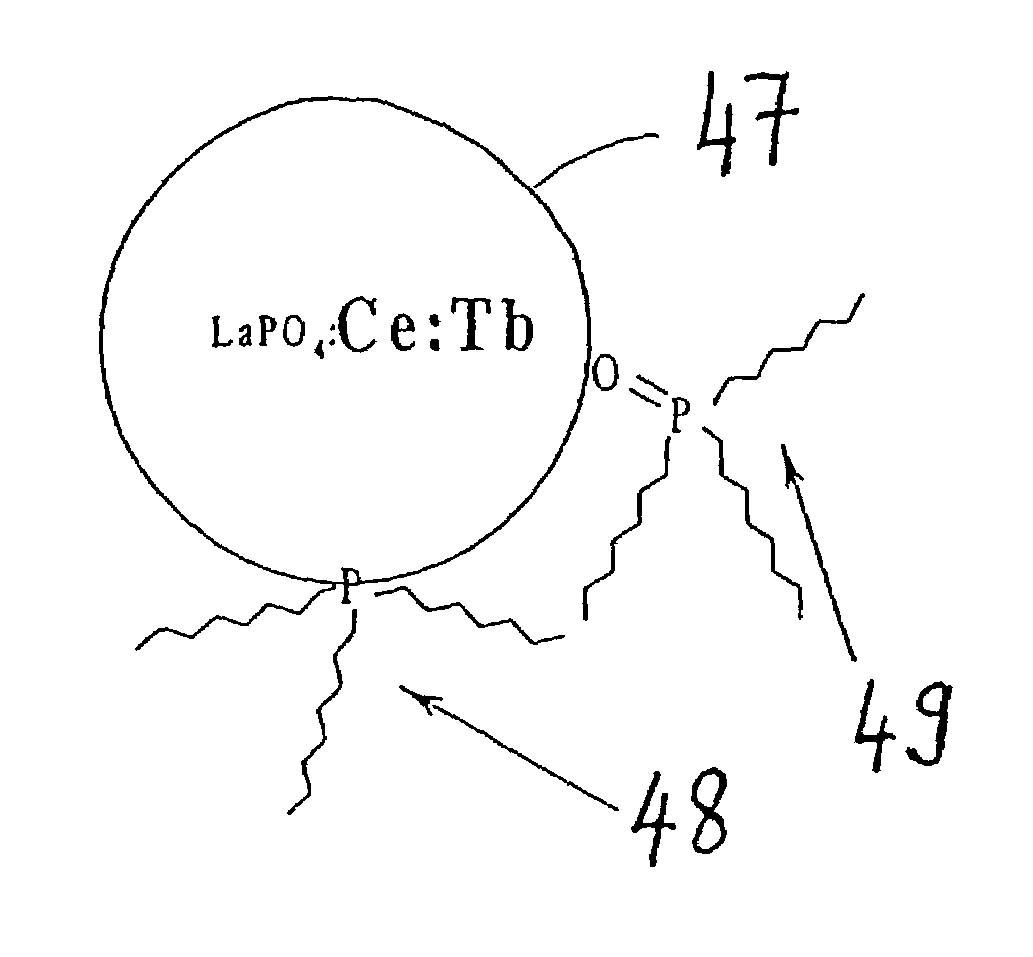

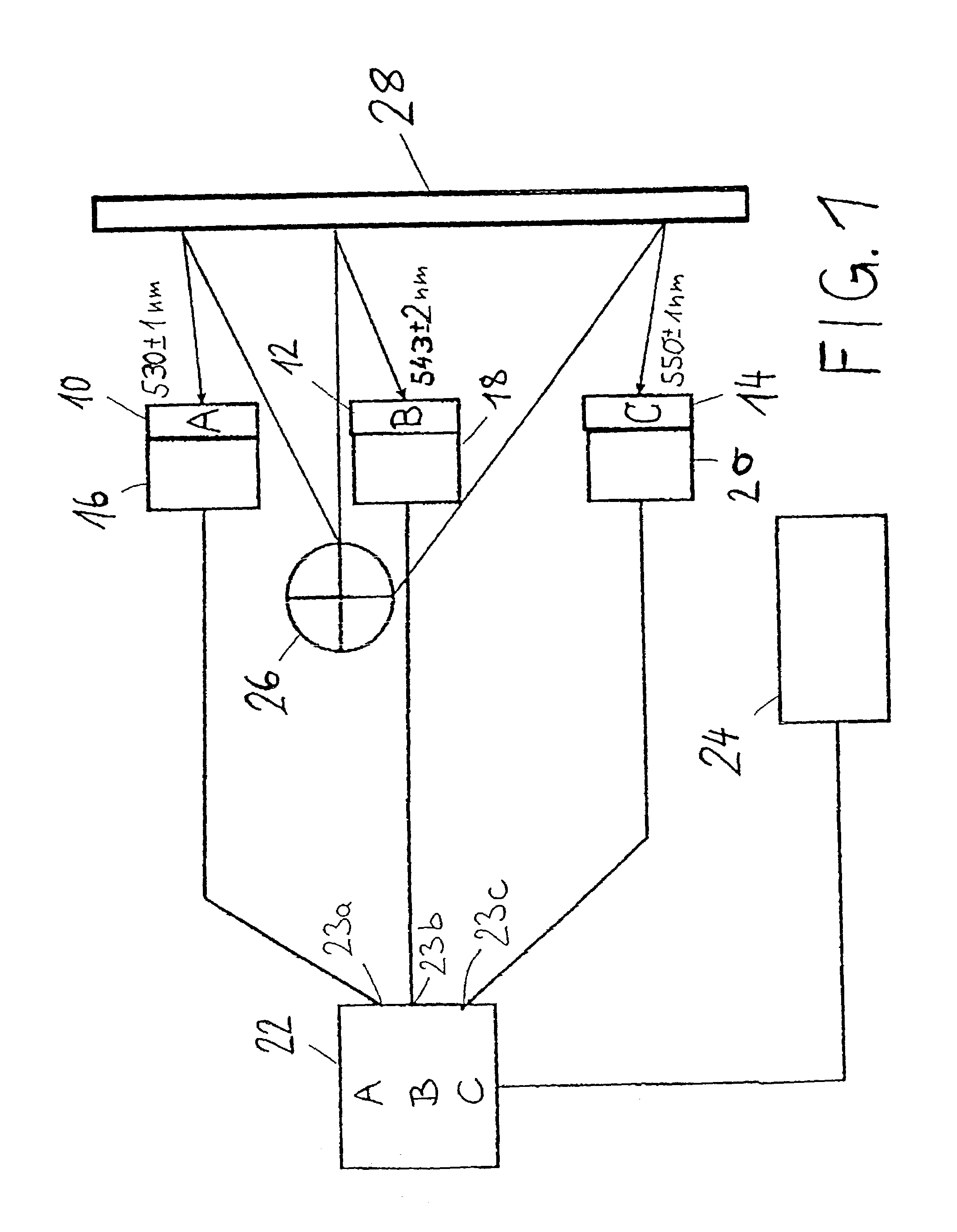

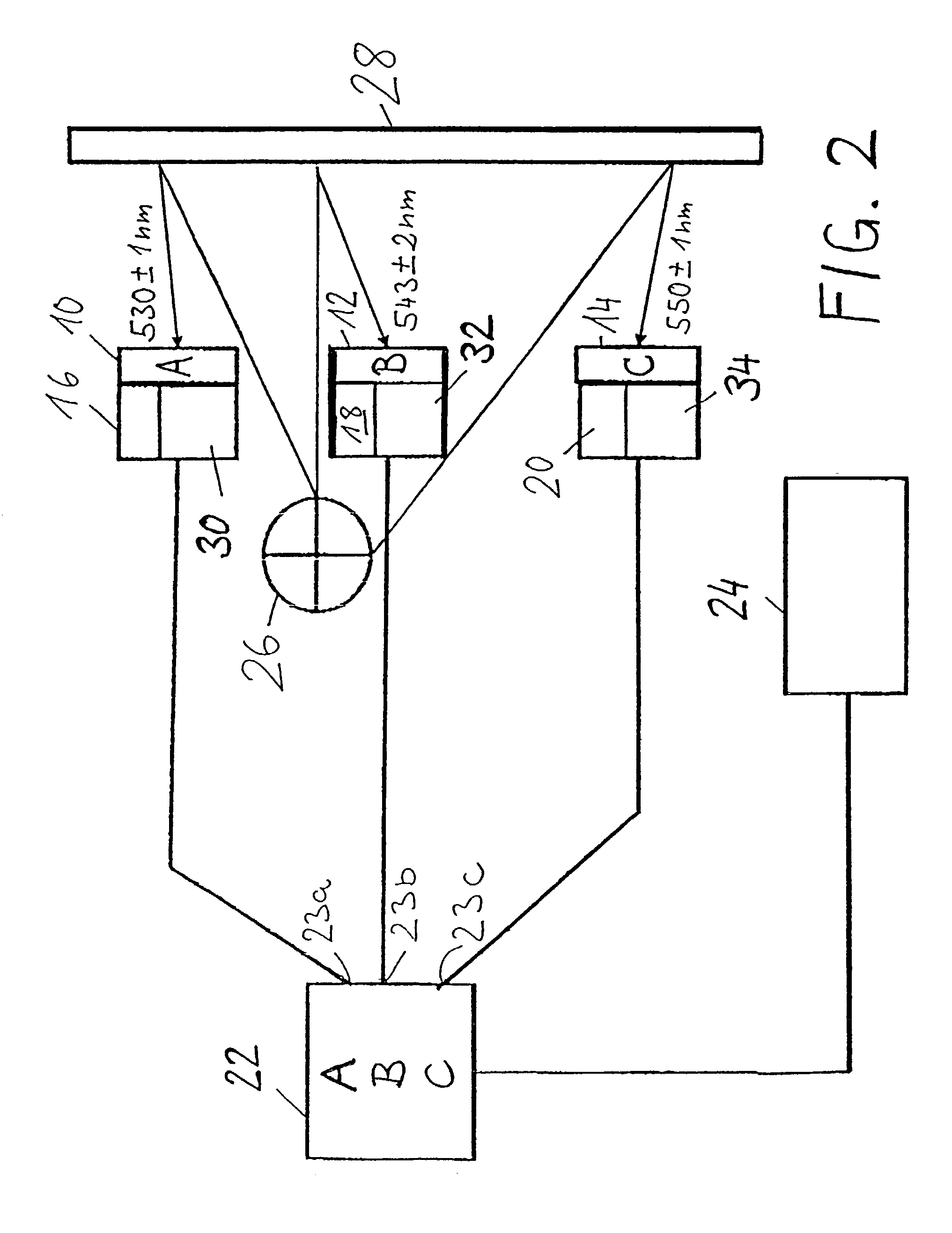

Synthesis of nanoparticles

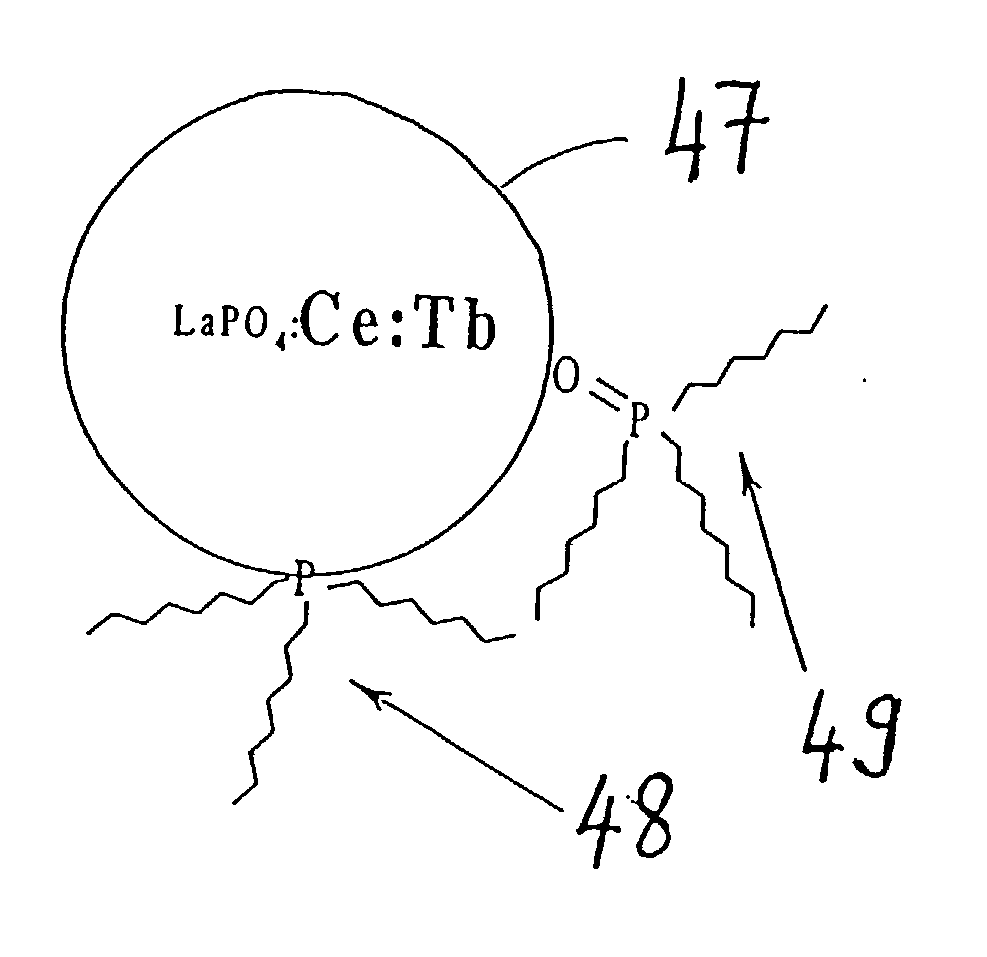

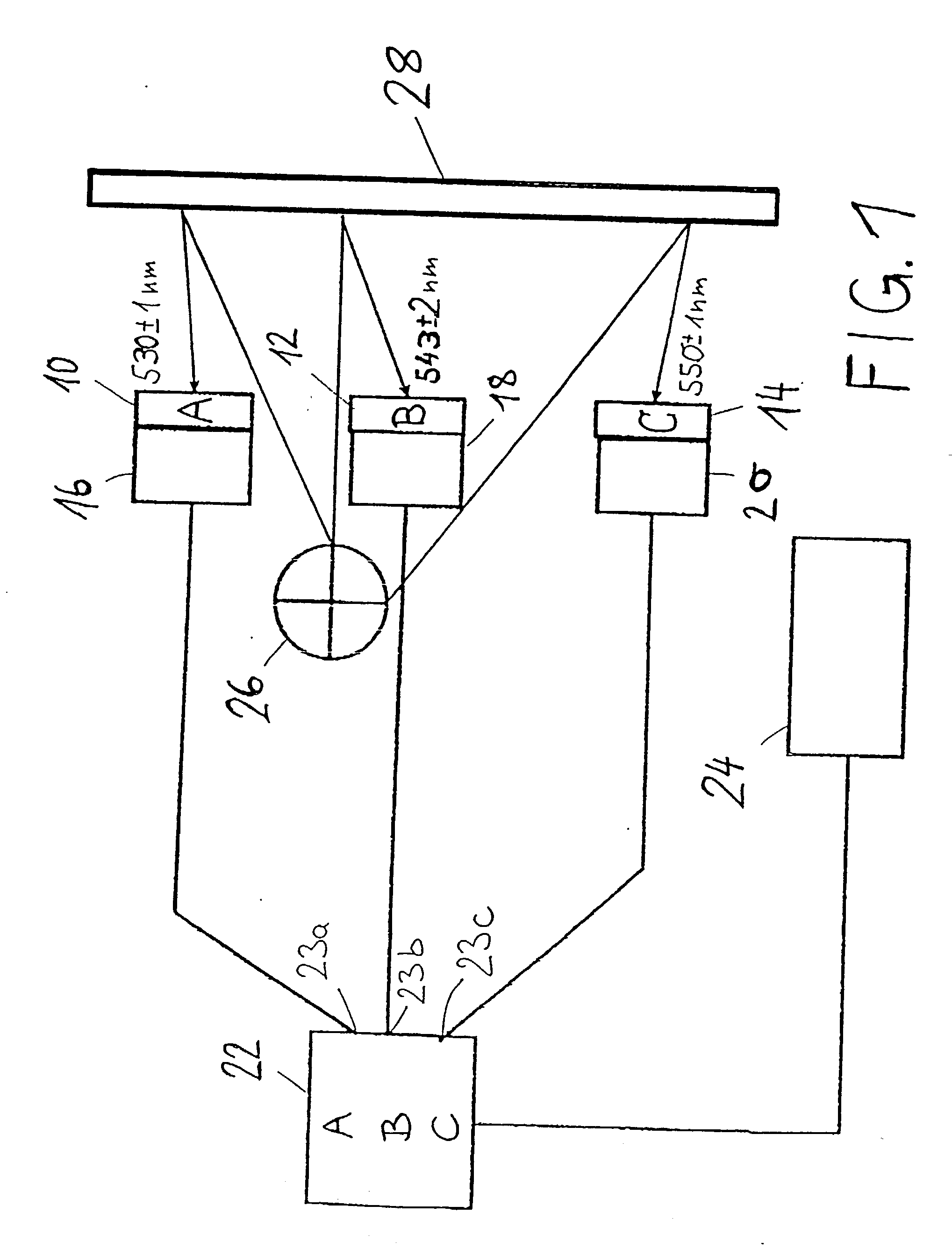

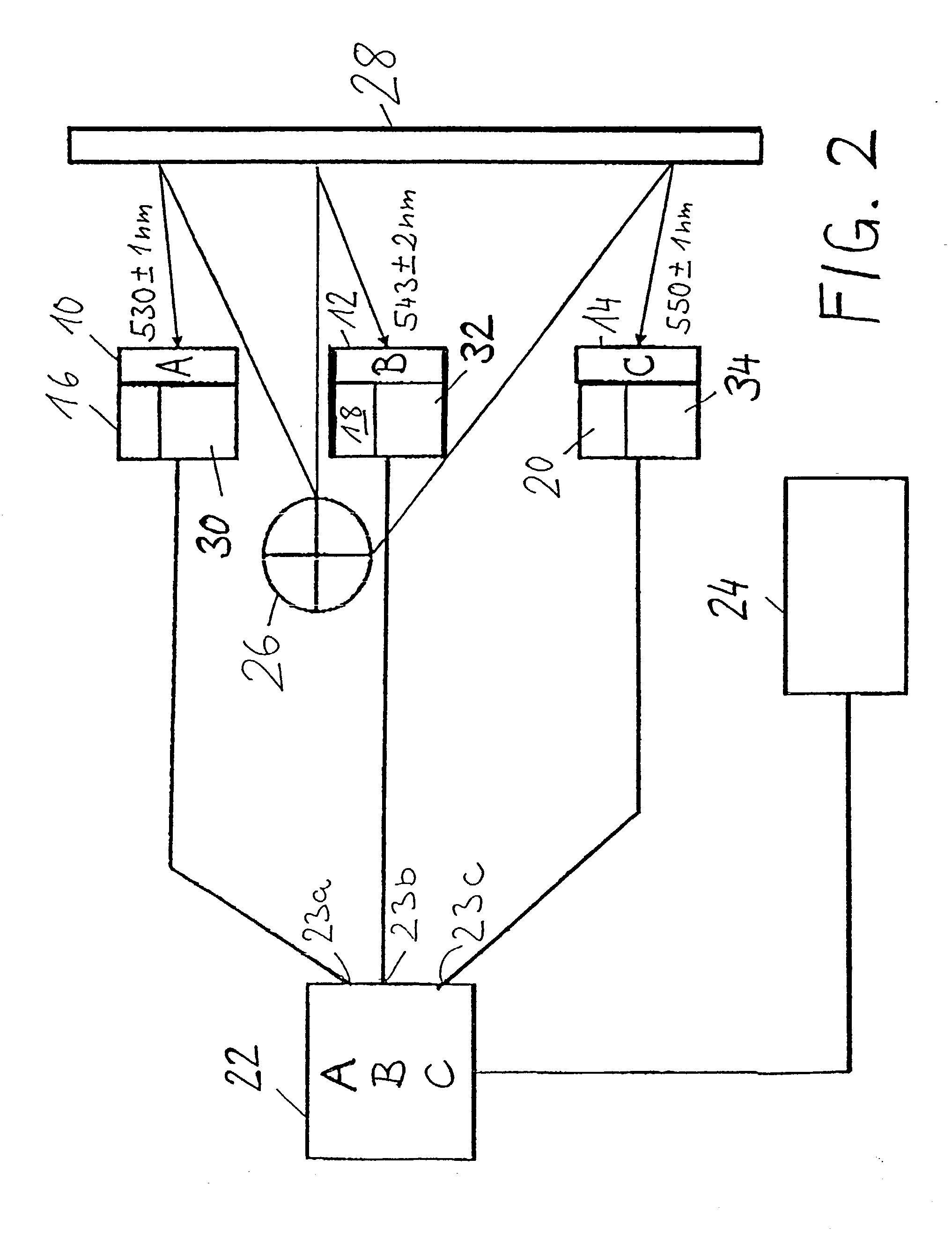

InactiveUS20030032192A1High sensitivityIncreasing efficiency of collectorOptical radiation measurementMaterial nanotechnologyDopantOrganic solvent

The present invention relates to methods for the preparation of inorganic nanoparticles capable of fluorescence, wherein the nanoparticles consist of a host material that comprises at least one dopant. The synthesis of the invention in organic solvents allows to gain a considerably higher yield compared to the prior art synthesis in water. All kinds of objects can advantageously be marked and reliably authenticated by using an automated method on the basis of a characteristic emission. Further, the size distribution of the prepared nanoparticles is narrower which renders a subsequent size-selected separation process superfluous.

Owner:CENT FUR ANGEWANDTE NANOTECH

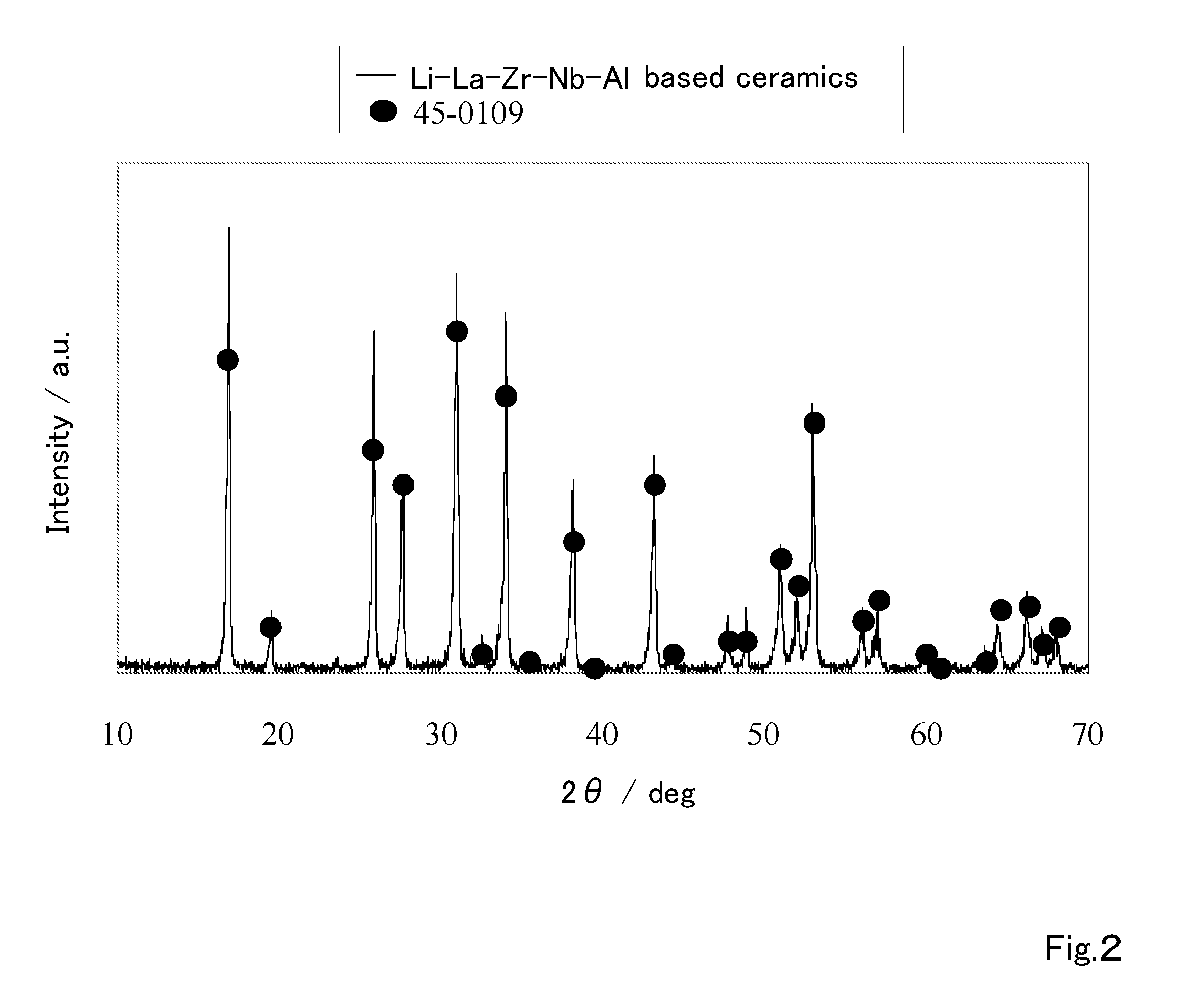

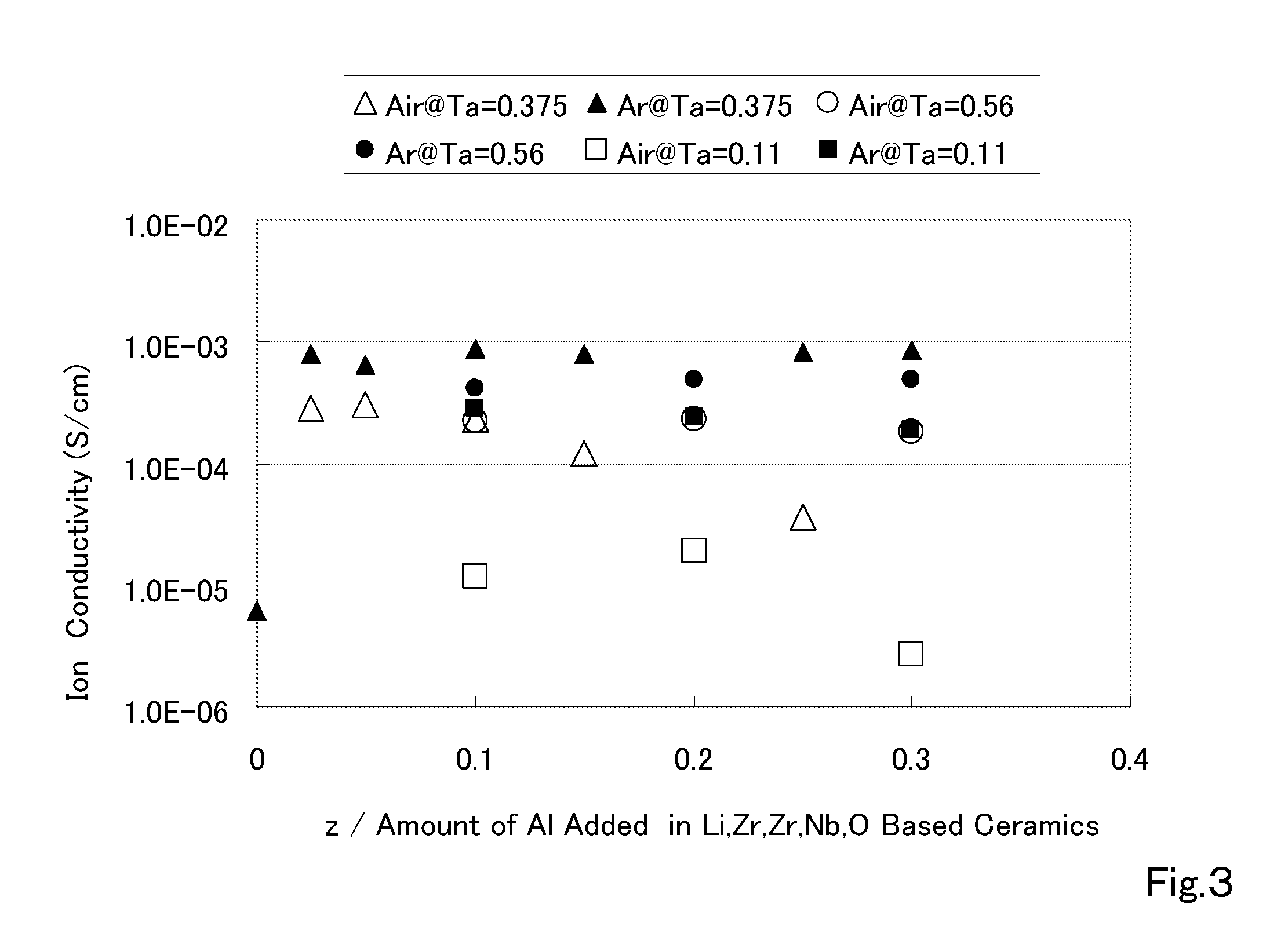

Ceramic material and preparation method therefor

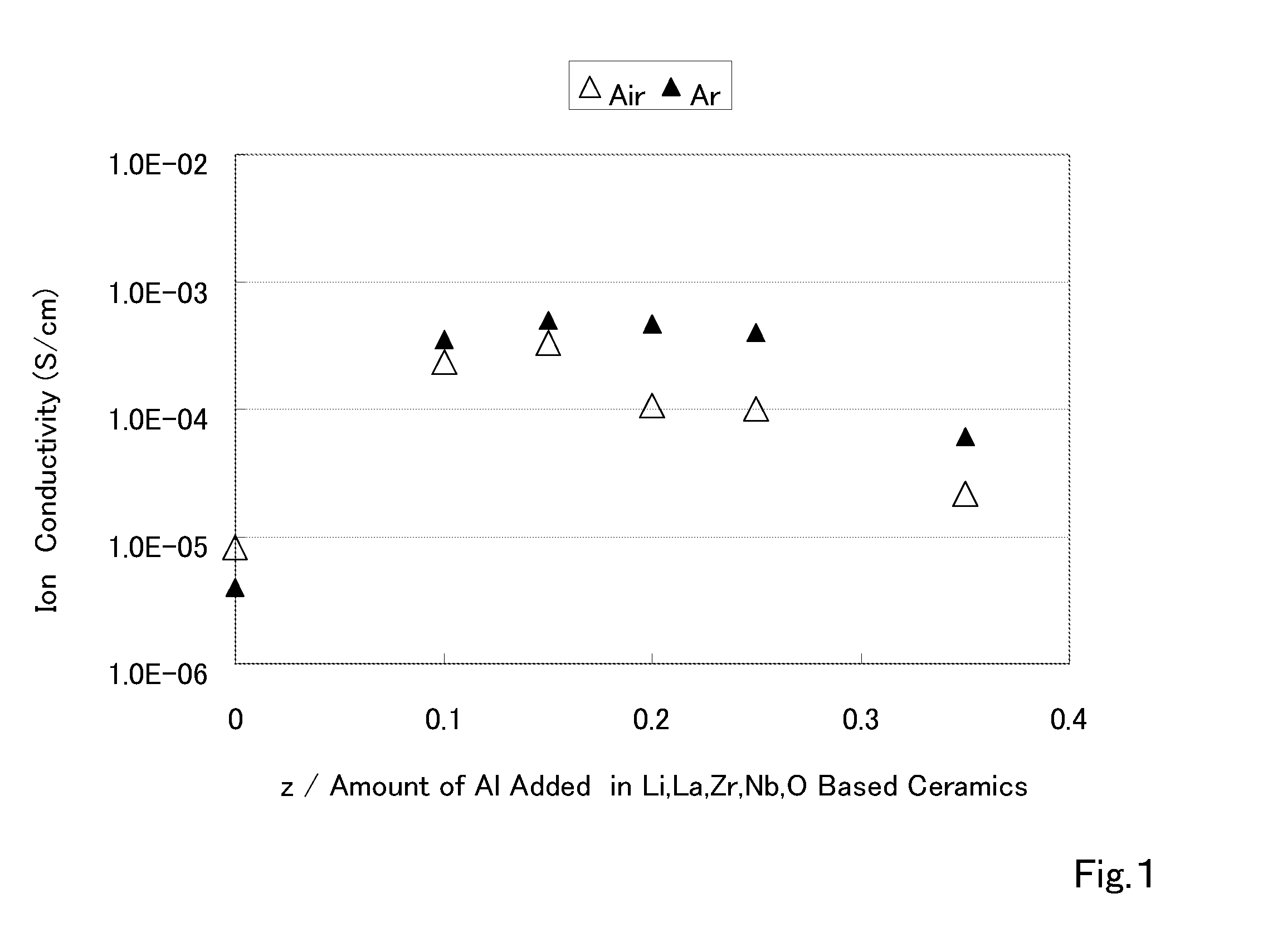

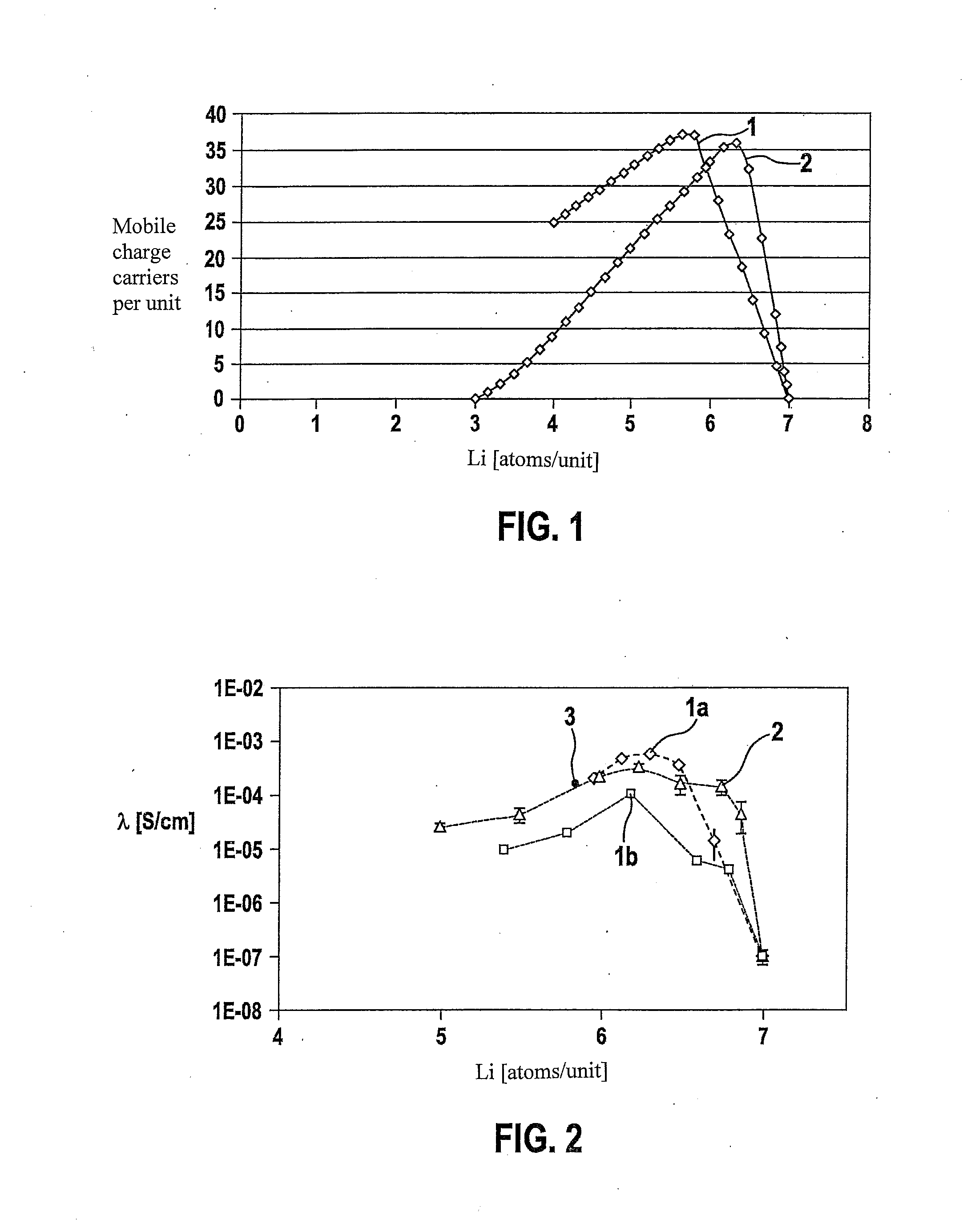

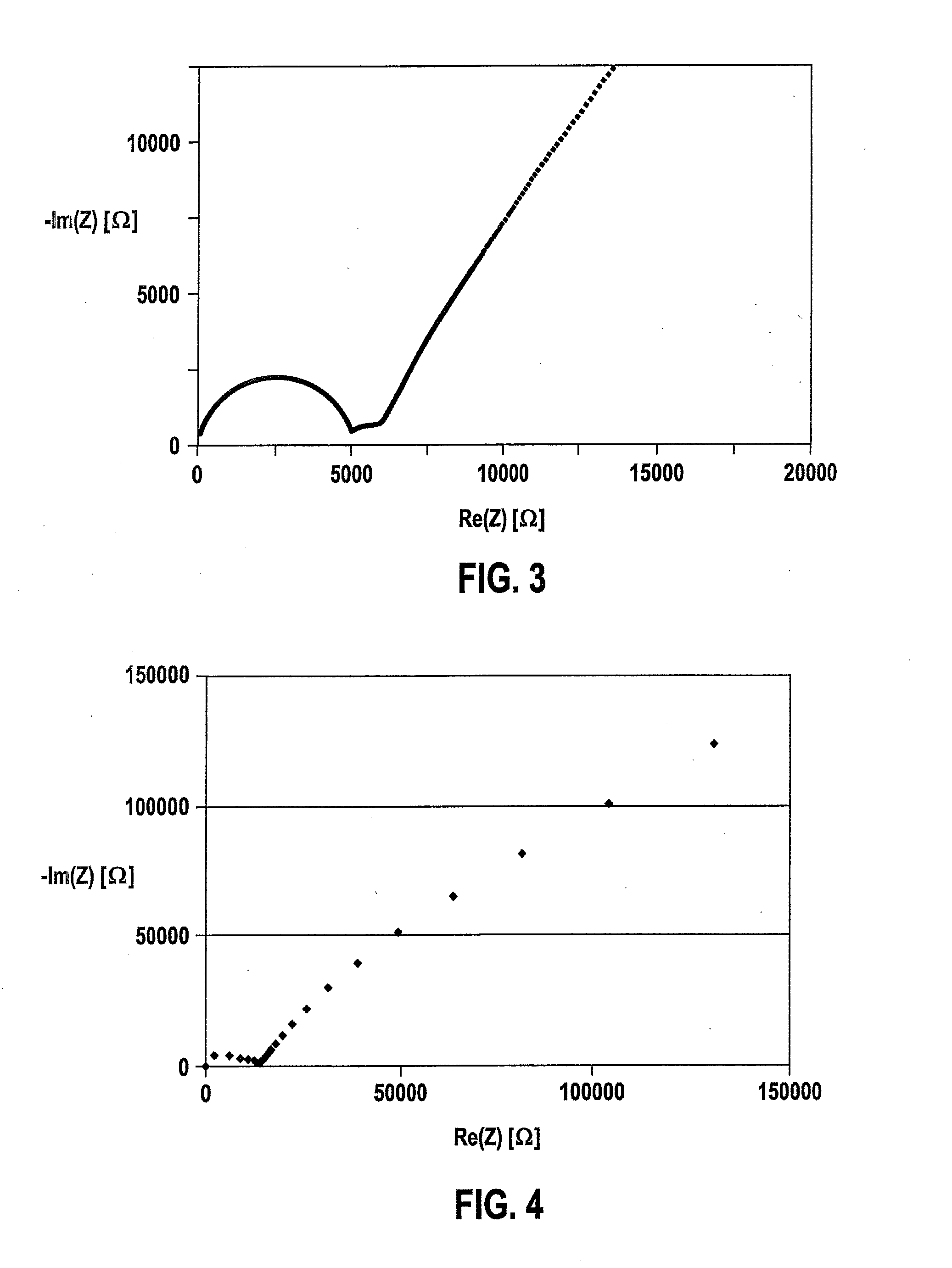

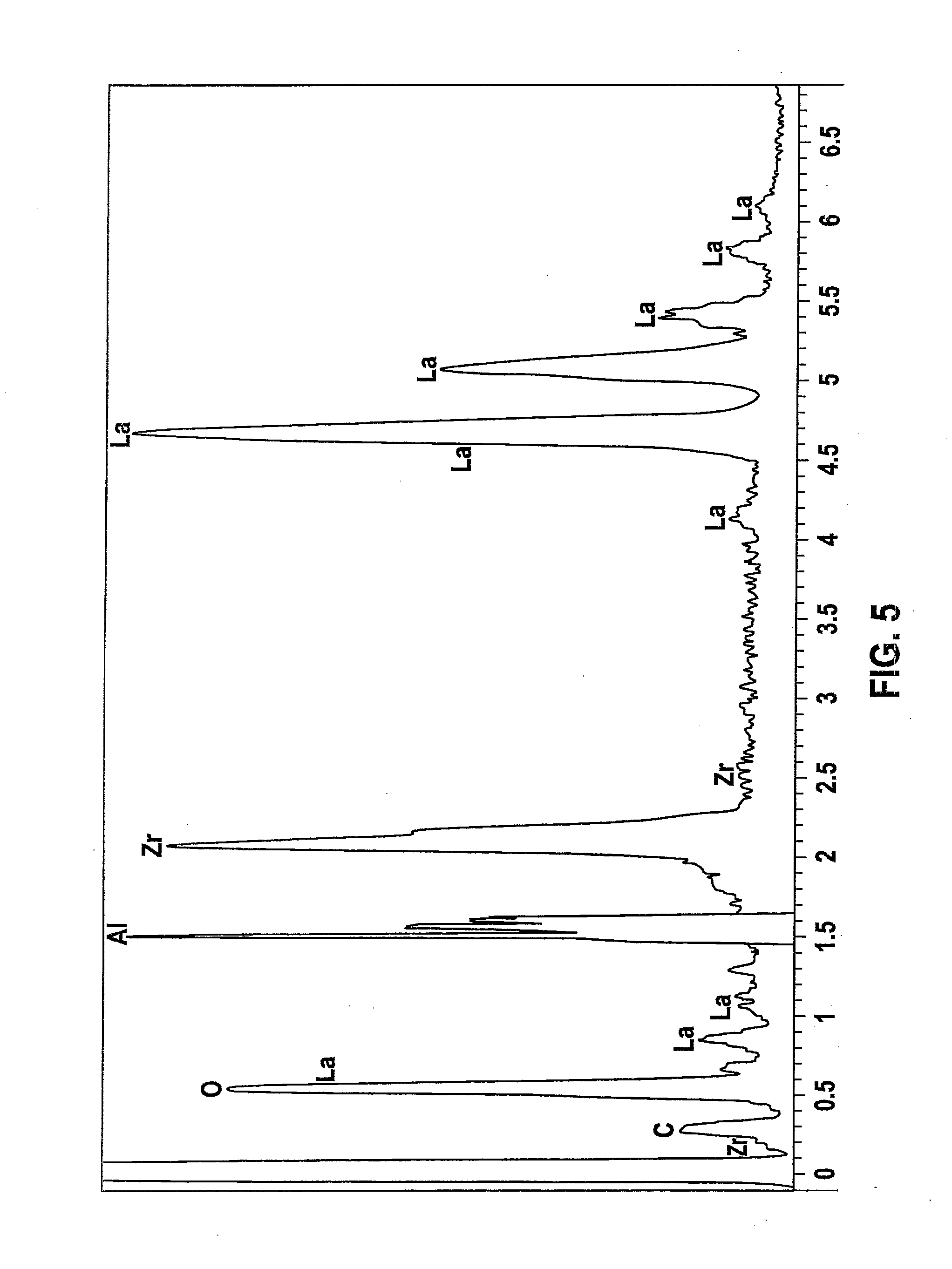

ActiveUS20110053002A1Demonstrating compactnessDemonstrating conductivityFinal product manufactureTantalum compoundsSolid state electrolyteMetallurgy

The present invention provides a ceramic material capable of demonstrating compactness and Li ion conductivity to an extent that enables the use of the ceramic material as a solid-state electrolyte material for a lithium secondary battery, or the like. A ceramic material containing Li, La, Zr, Nb and / or Ta, as well as O and having a garnet-type or garnet-like crystal structure is used.

Owner:NGK INSULATORS LTD

Vapor deposition of metal oxides, silicates and phosphates, and silicon dioxide

InactiveUS6969539B2Good step coverageNarrow structureOxygen/ozone/oxide/hydroxideAluminium silicatesAlkylphosphatePhosphate

Metal silicates or phosphates are deposited on a heated substrate by the reaction of vapors of alkoxysilanols or alkylphosphates along with reactive metal amides, alkyls or alkoxides. For example, vapors of tris-(ter-butoxy)silanol react with vapors of tetrakis(ethylmethylamido)hafnium to deposit hafnium silicate on surfaces heated to 300° C. The product film has a very uniform stoichiometry throughout the reactor. Similarly, vapors of diisopropylphosphate react with vapors of lithium bis(ethyldimethylsilyl)amide to deposit lithium phosphate films on substrates heated to 250° C. supplying the vapors in alternating pulse produces these same compositions with a very uniform distribution of thickness and excellent step coverage.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Process for producing niobium suboxide

ActiveUS7341705B2Increase capacityLiquid electrolytic capacitorsTantalum compoundsNiobiumPhysical chemistry

A method is described for preparing a niobium suboxide represented by the formula, NbOx, in which 0.7<x<1.3. The method involves reacting NbOy (in which y<1.8<2.1) with a stoichiometric amount of niobium metal, in the presence of hydrogen. The niobium suboxide produced by such method may be used to fabricate anodes for solid electrolyte capacitors.

Owner:TANIOBIS GMBH

Niobium suboxide powder

ActiveUS7381396B2Reduce residual currentReduce volatilityOxide/hydroxide preparationLiquid electrolytic capacitorsTungstenSuboxide

A niobium suboxide powder comprising 100 to 600 ppm of magnesium is described. The niobium suboxide powder may (alternatively or in addition to 100 to 600 ppm of magnesium) further include 50 to 400 ppm of molybdenum and / or tungsten. The niobium suboxide powder is suitable for the production of: capacitors having an insulator layer of niobium pentoxide; capacitor anodes produced from the niobium suboxide powder; and corresponding capacitors.

Owner:TANIOBIS GMBH

Sintered bodies based on niobium suboxide

Disclosed are sintered bodies that include: (a) 30 to 100 mol % of NbOx, wherein 0.5<x<1.5; and (b) 0 to 70 mol % of MgO. The sintered bodies may be used as inert apparatuses in the production of niobium suboxide powder or niobium suboxide anodes, or as chemically resistant components in chemical apparatuses.

Owner:H C STARCK GMBH

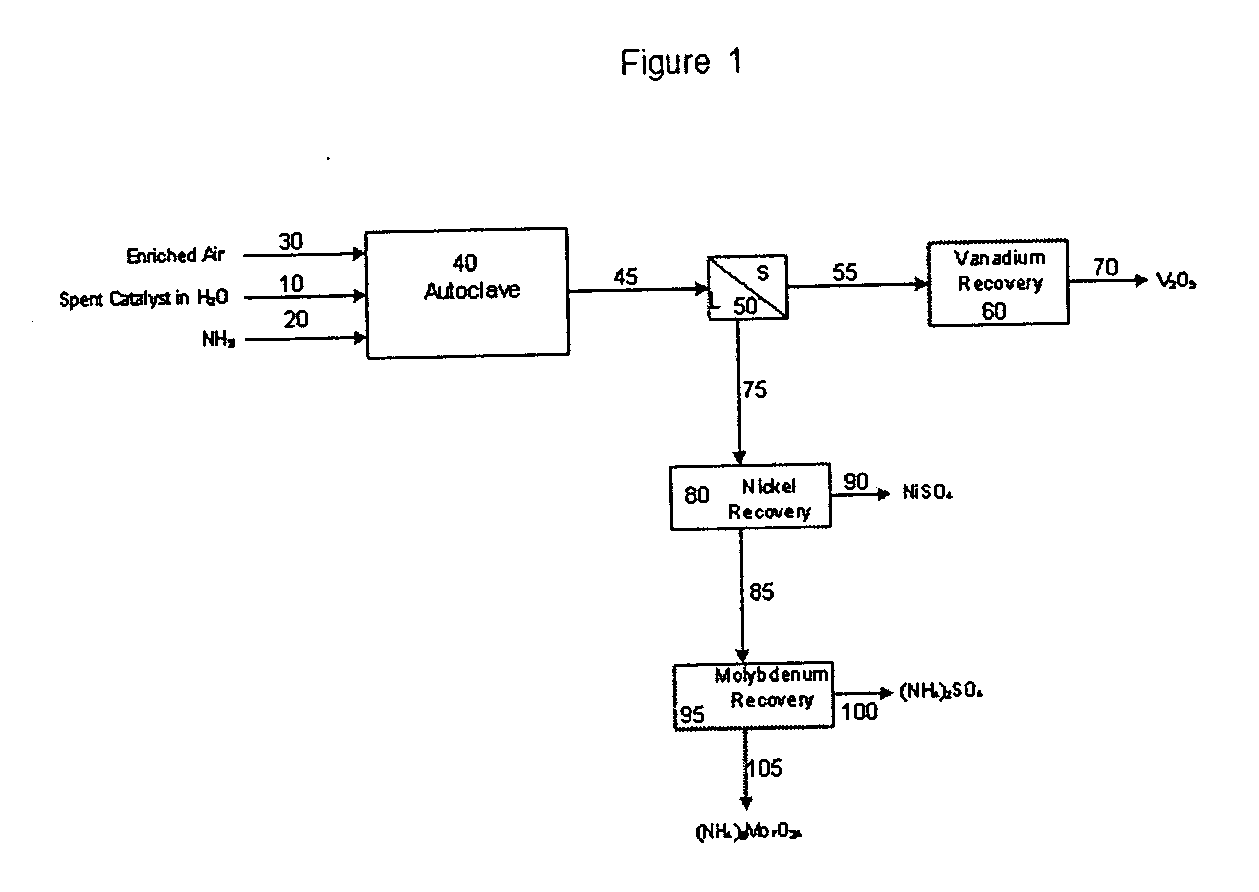

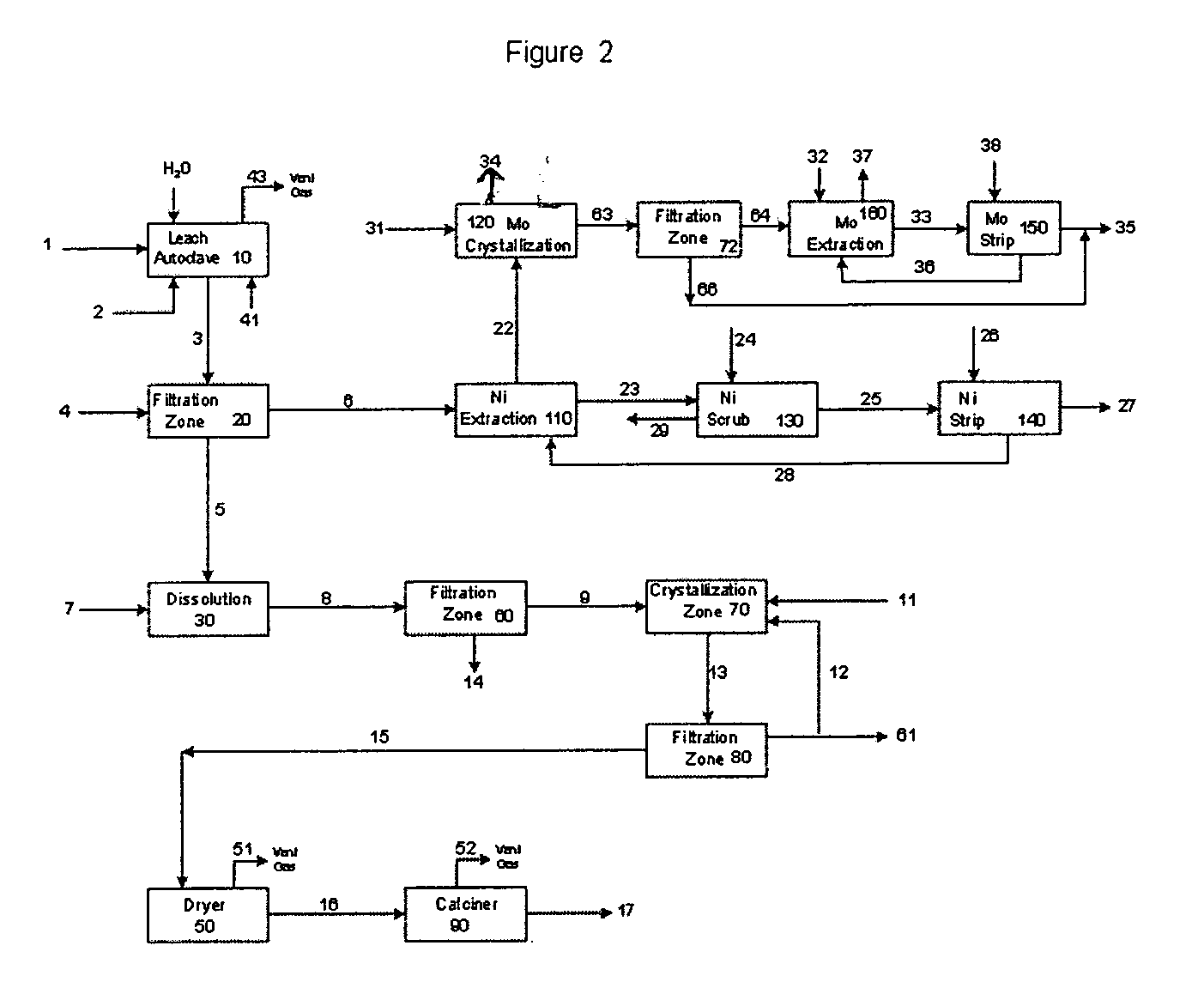

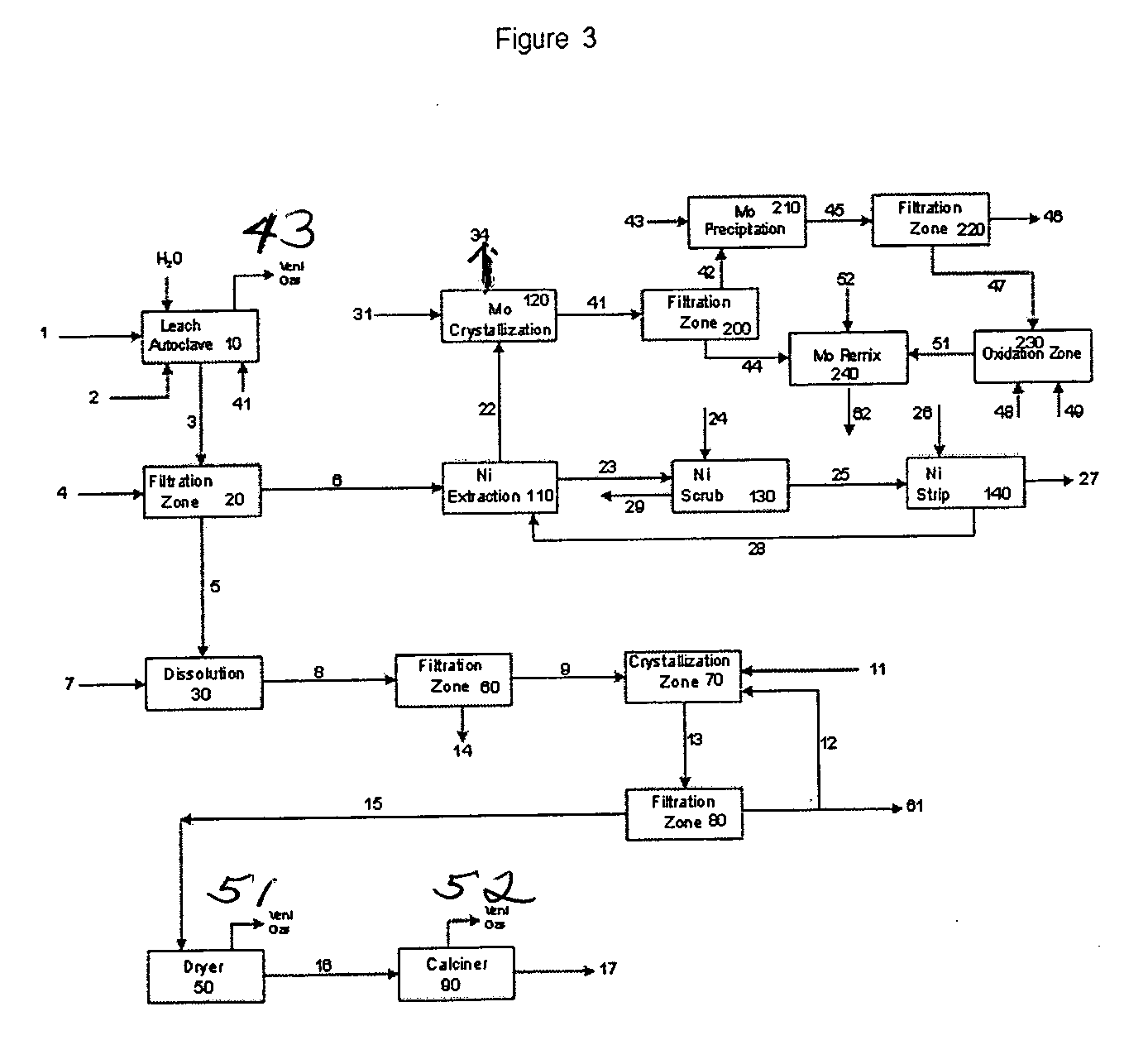

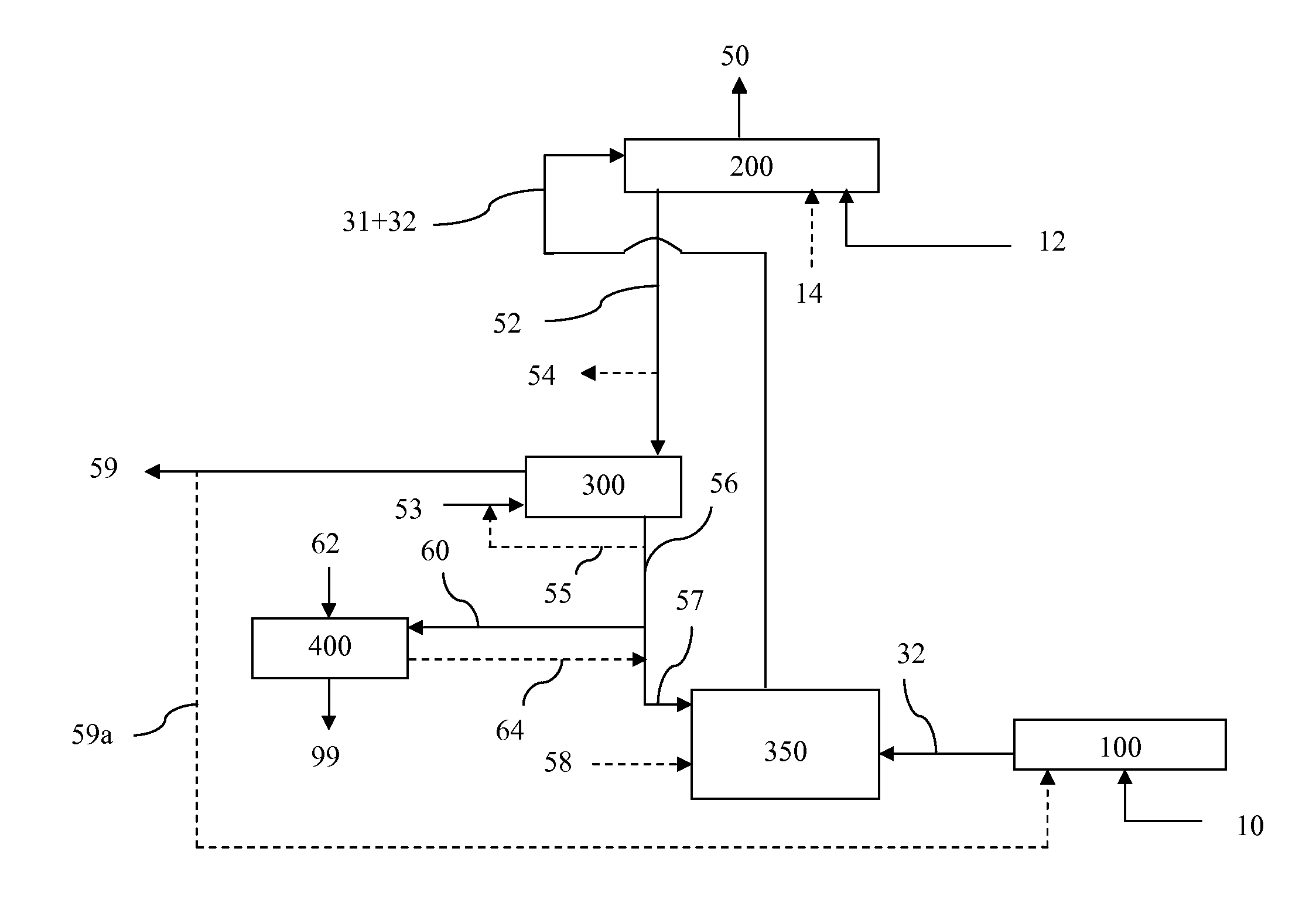

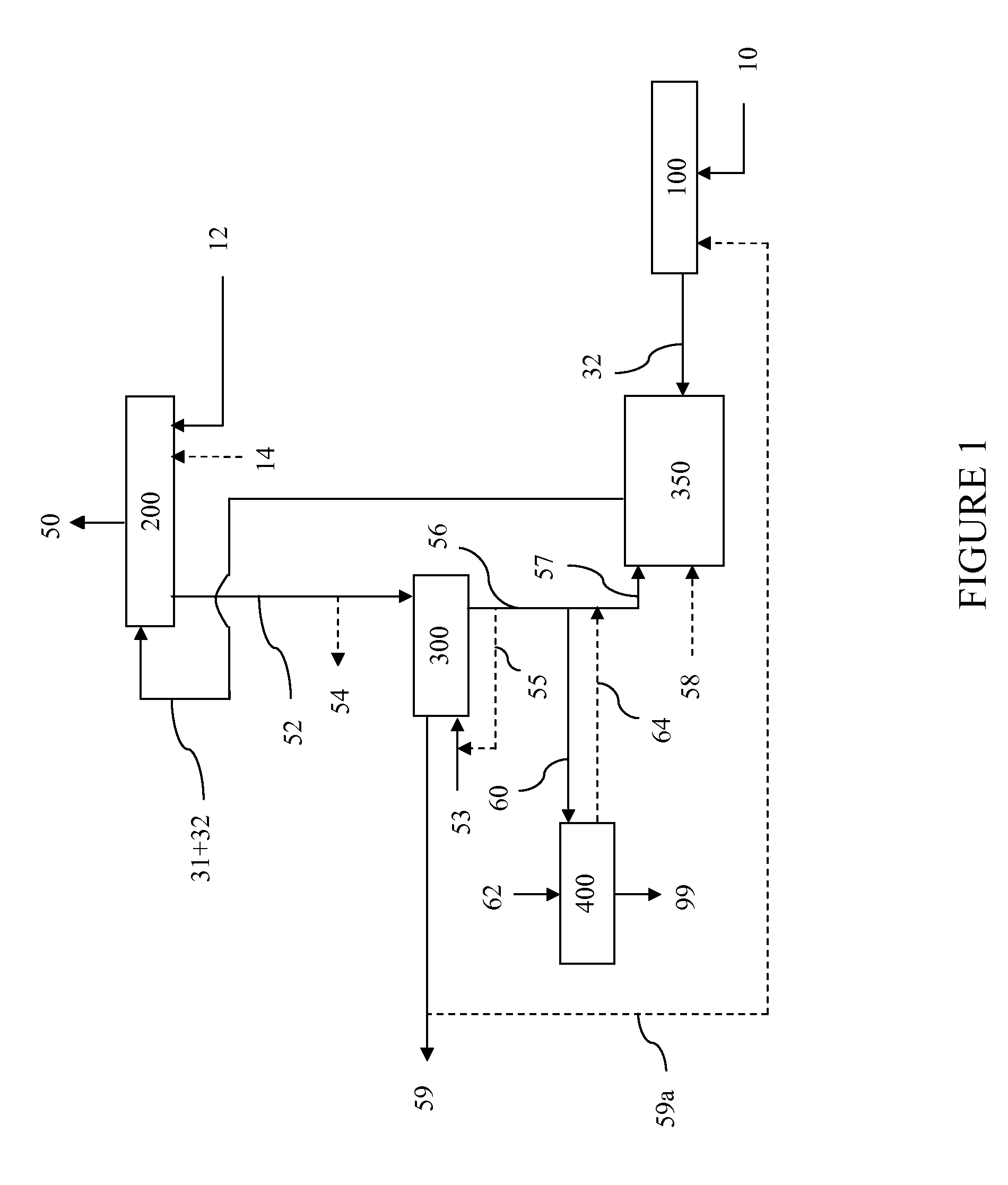

Process for metals recovery from spent catalyst

The process of this invention is directed to the removal of metals from an unsupported spent catalyst. The catalyst is subjected to leaching reactions. Vanadium is removed as a precipitate, while a solution comprising molybdenum and nickel is subjected to further extraction steps for the removal of these metals. Molybdenum may alternately be removed through precipitation.

Owner:CHEVROU USA INC

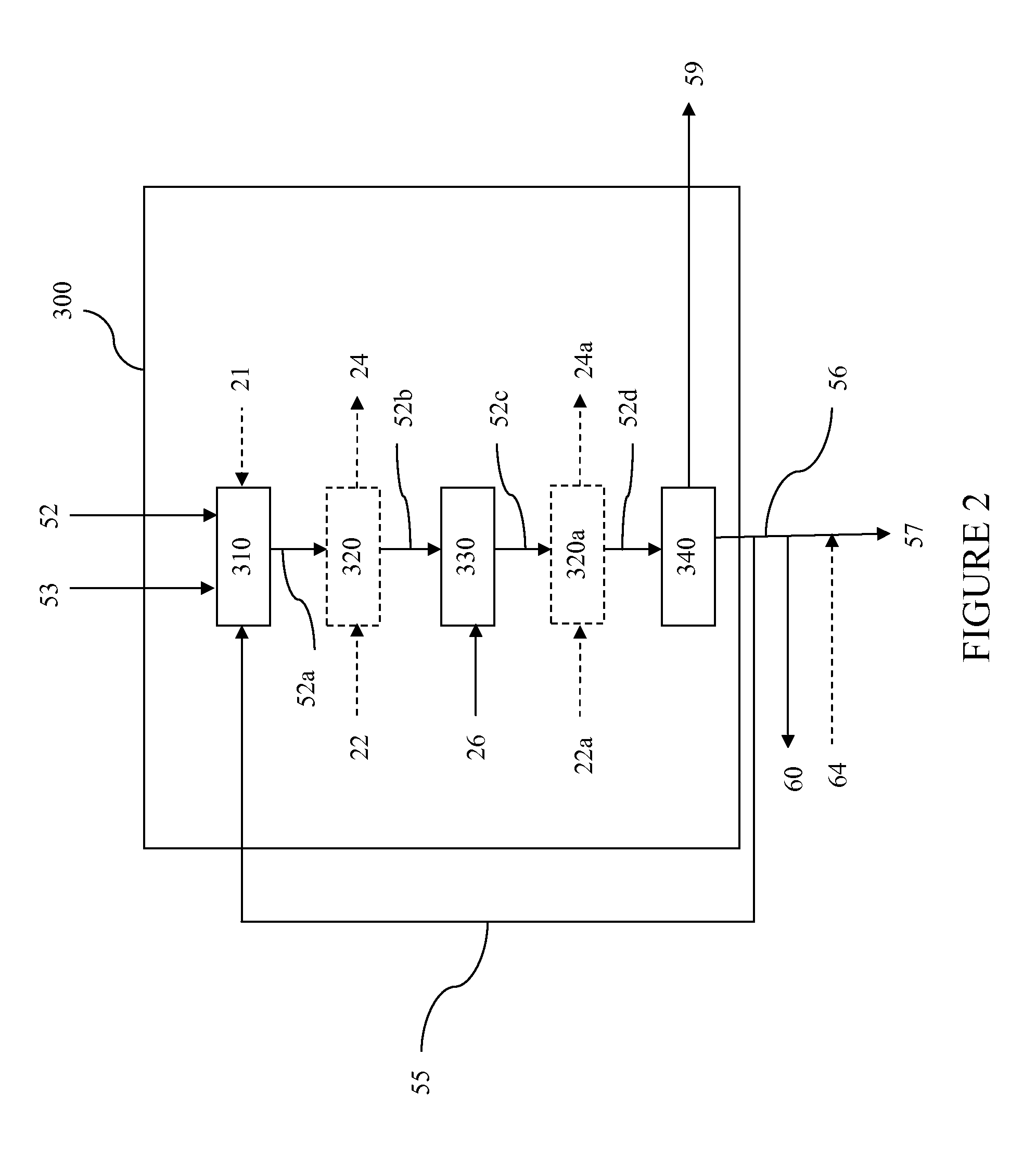

Hydromethanation of a carbonaceous feedstock with vanadium recovery

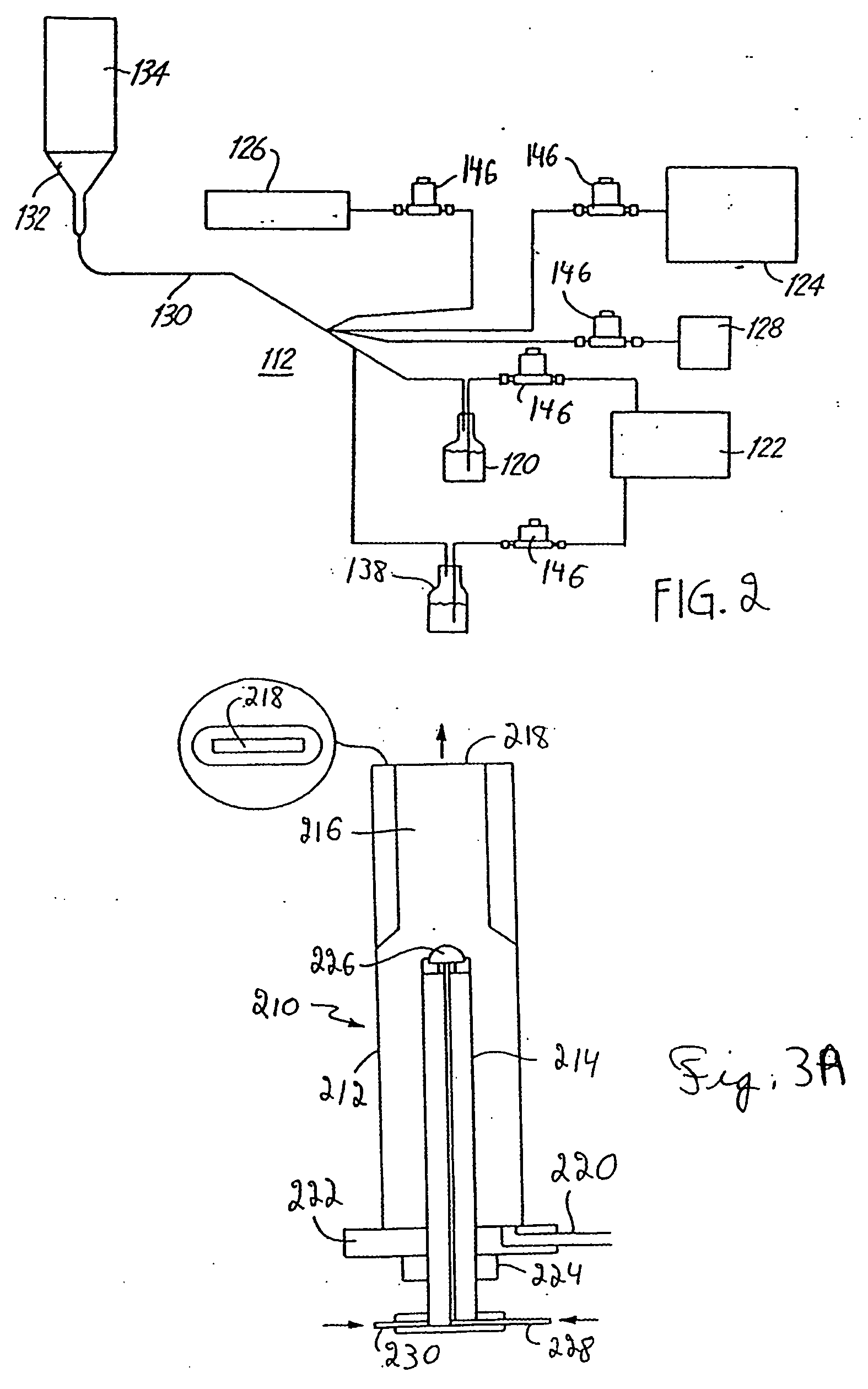

ActiveUS20110262323A1Easy to understandSolvent extractionOrganic compound preparationMaterials scienceHydromethanation

Owner:SURE CHAMPION INVESTMENT LTD

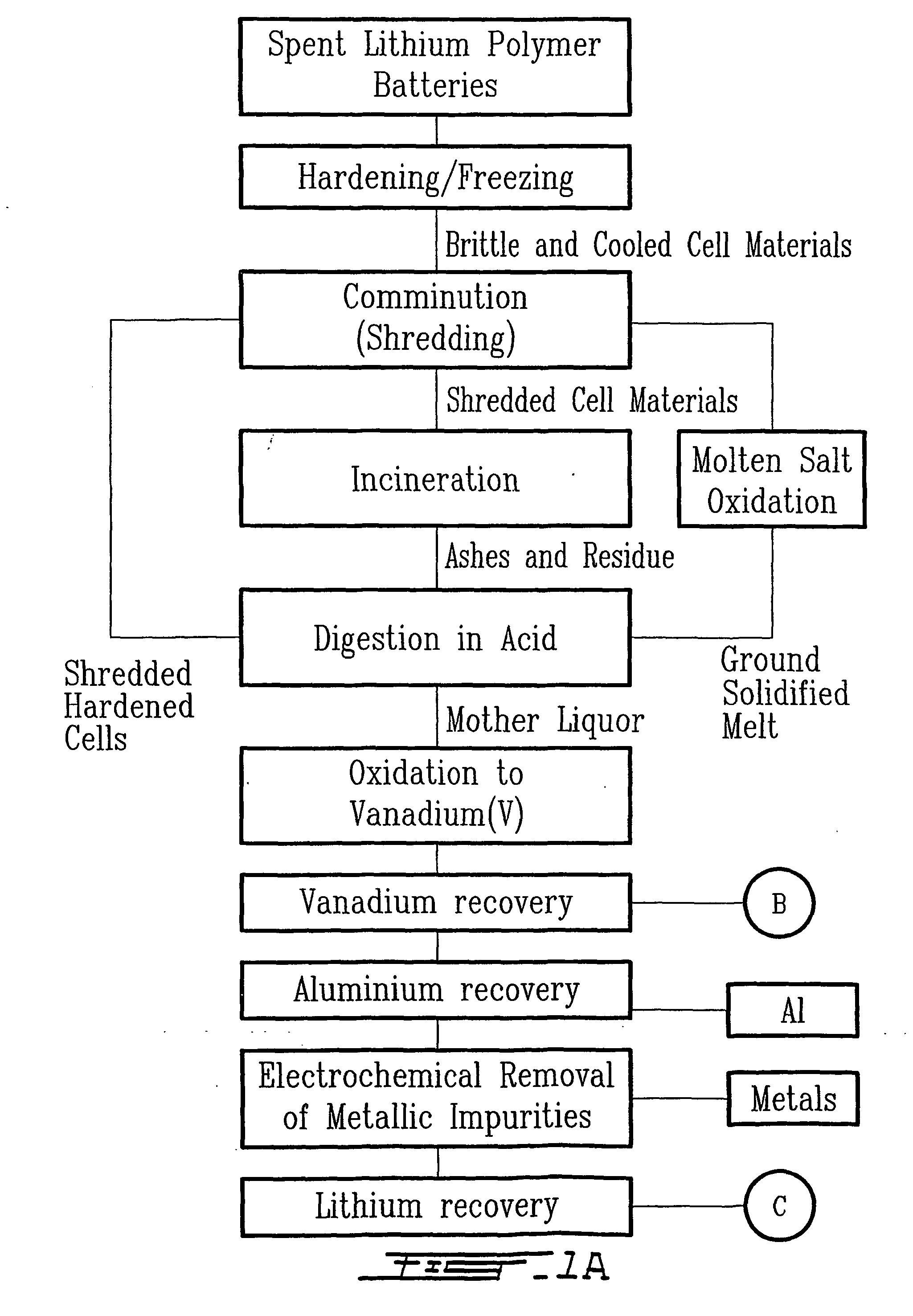

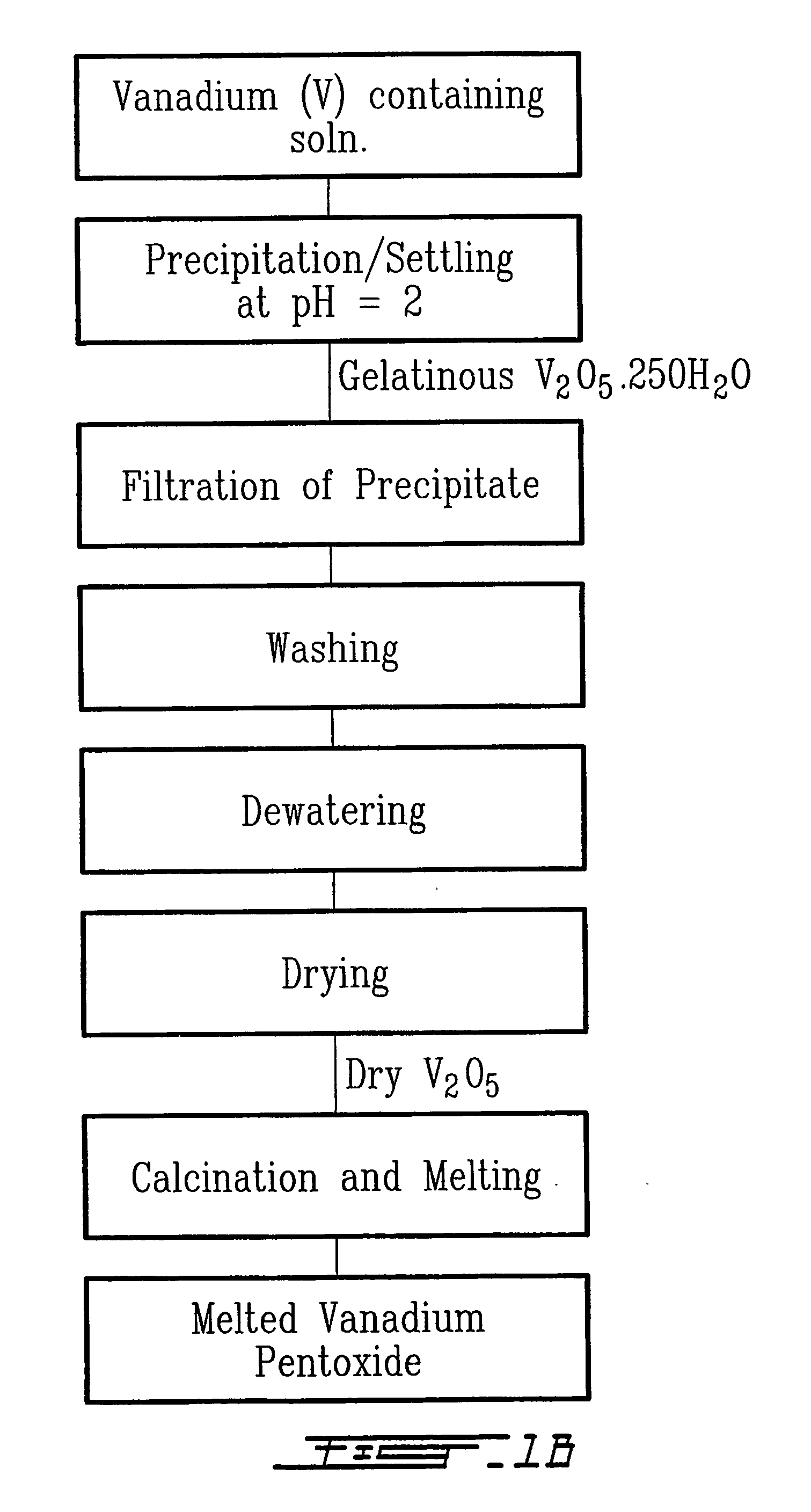

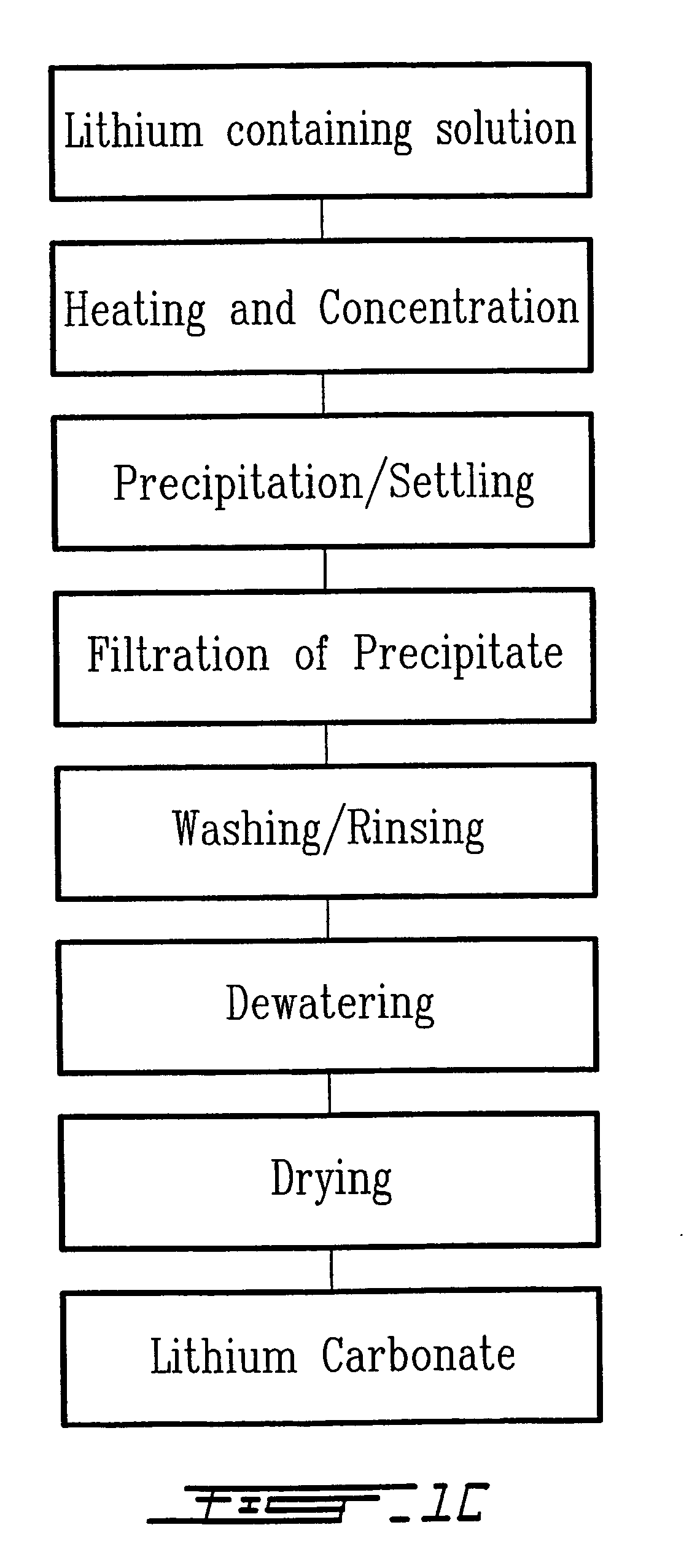

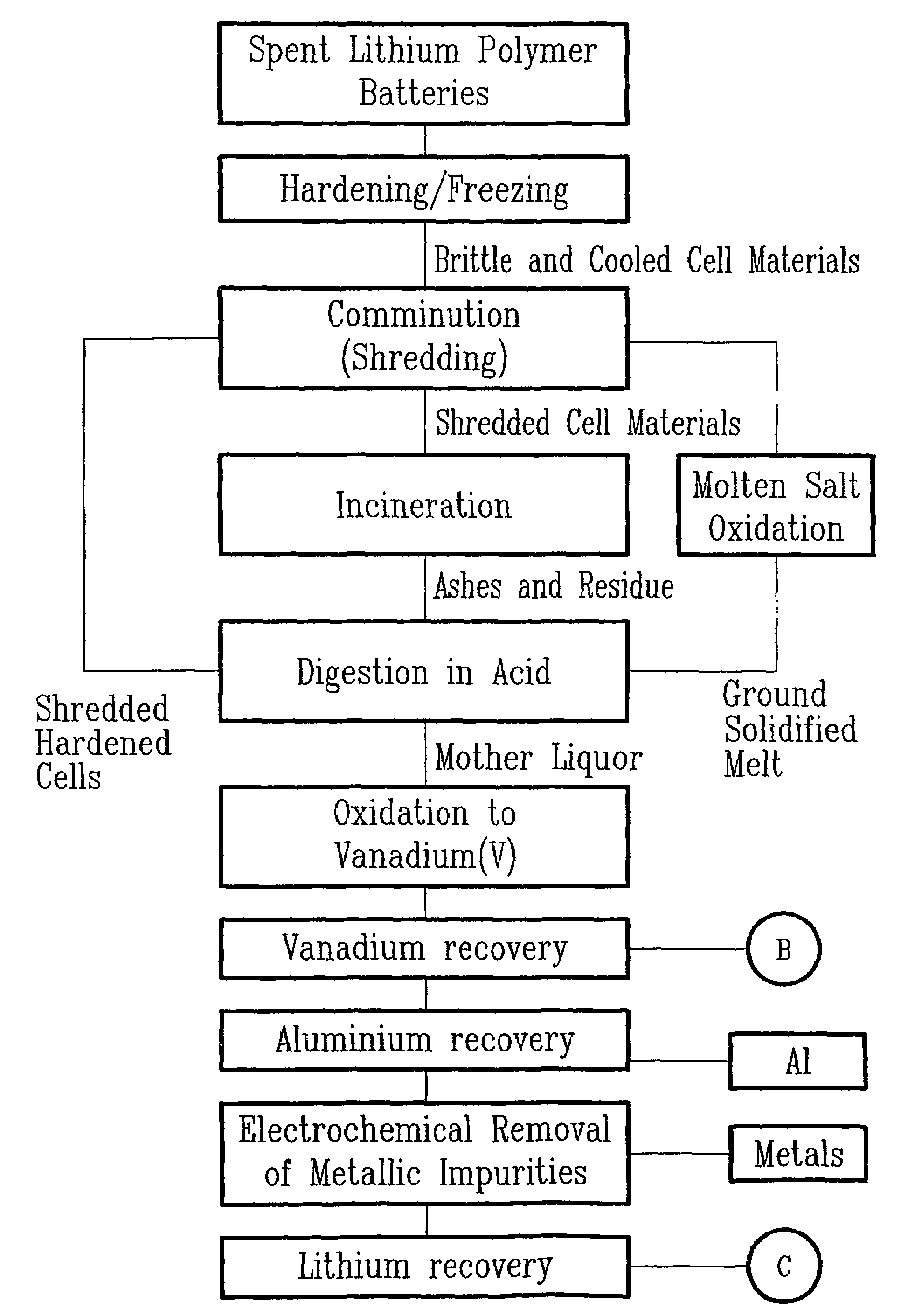

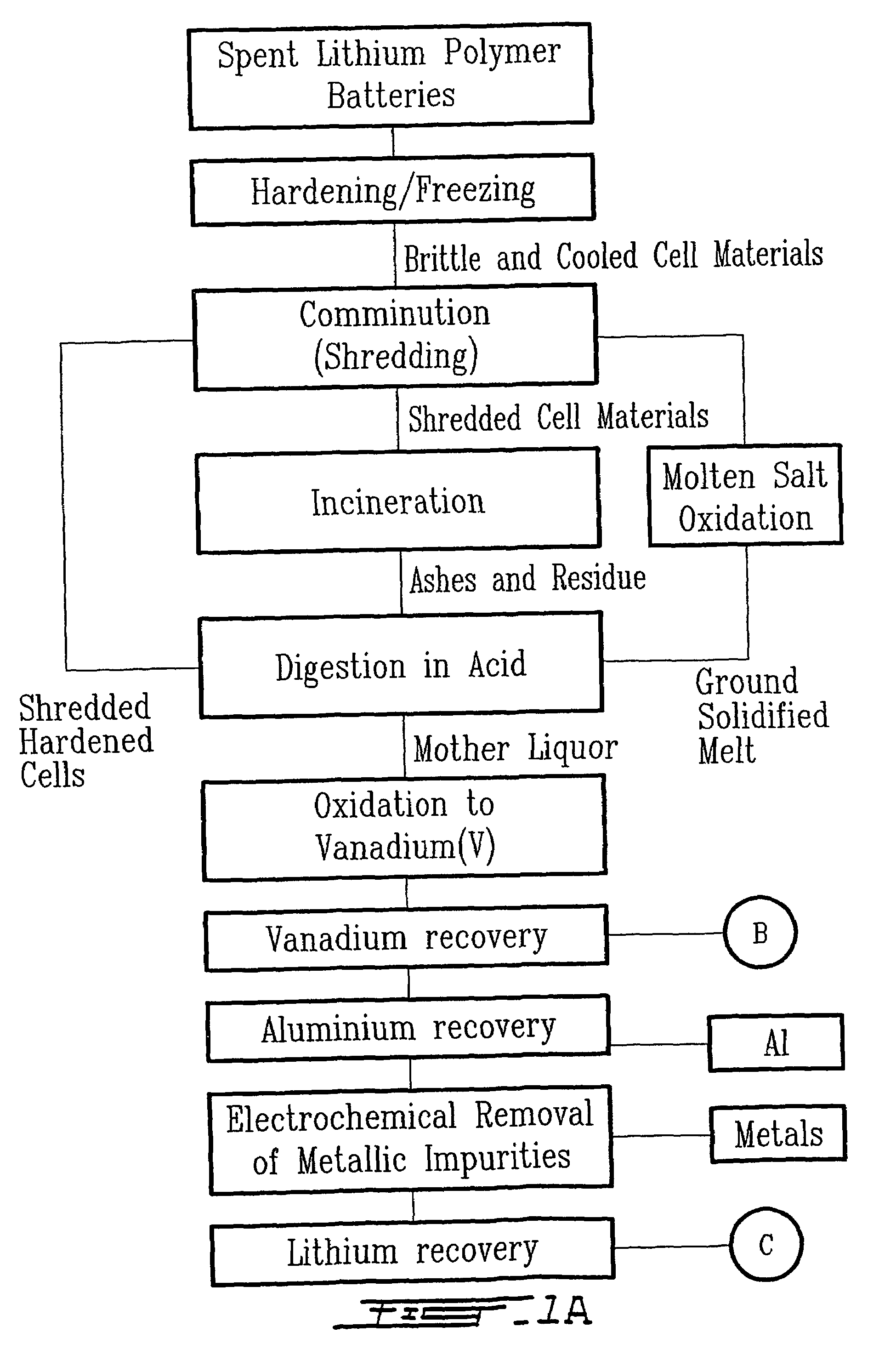

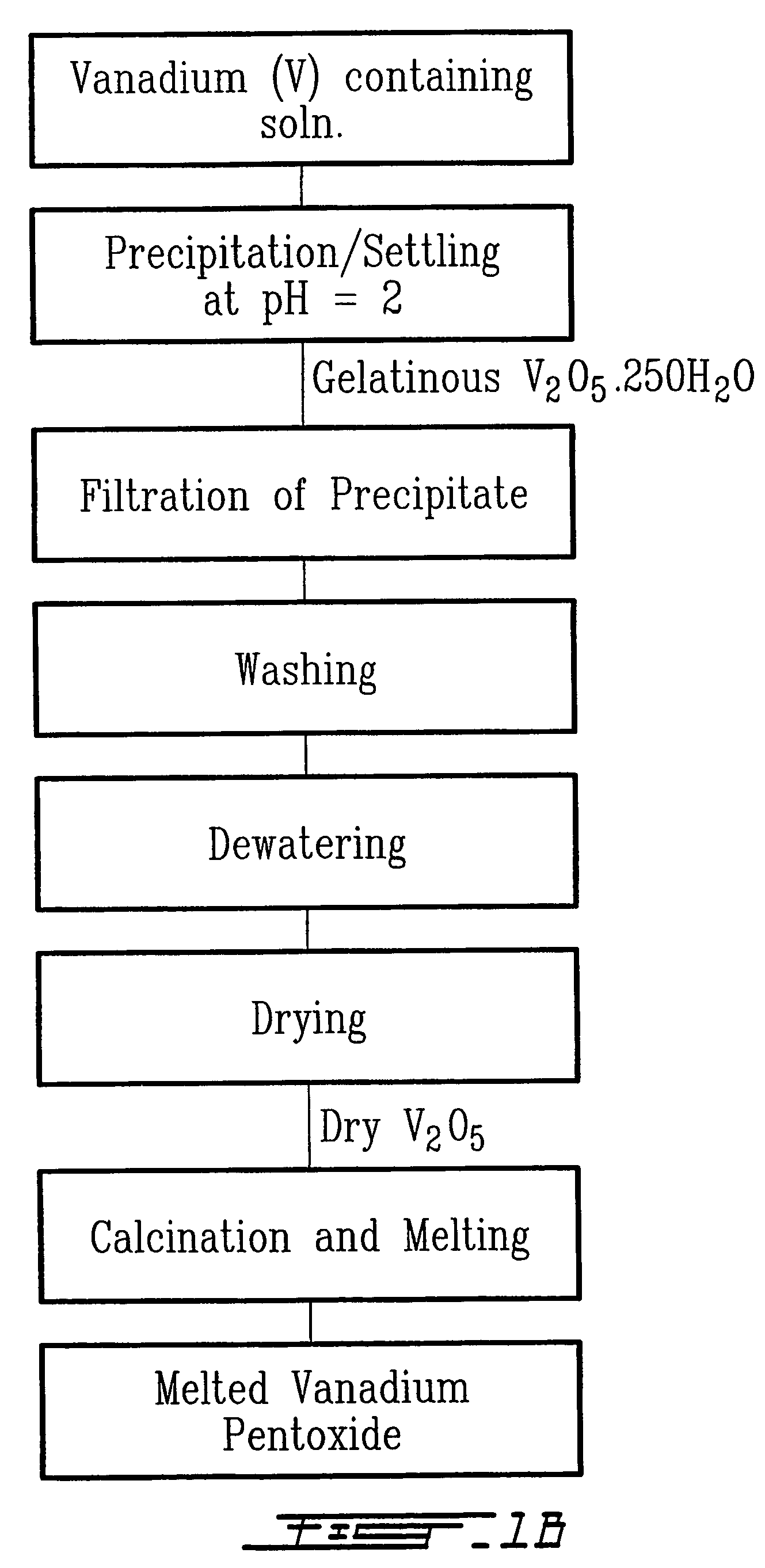

Method for recycling spent lithium metal polymer rechargeable batteries and related materials

The method relates to a pyrometallurgical and hydrometallurgical process for the recovery and recycling of lithium and vanadium compounds from a material comprising spent rechargeable lithium batteries, particularly lithium metal gel and solid polymer electrolyte rechargeable batteries. The method involves providing a mass of the material, hardening it by cooling at a temperature below room temperature, comminuting the mass of cooled and hardened material, digesting with an acid its ashes obtained by incineration, or its solidified salts obtained by molten salt oxidation, or the comminuted mass itself, to give a mother liquor, extracting vanadium compounds from the mother liquor, separating heavy metals and aluminium therefrom, and precipitating lithium carbonate from the remaining solution.

Owner:AVESTOR

Lithium ion-conducting garnet-like compounds

ActiveUS20140295287A1Loss can be compensatedImprove stabilityTantalum compoundsZirconium compoundsLithiumCompound a

A lithium ion-conducting compound, having a garnet-like crystal structure, and having the general formula: Lin[A(3-a′-a″)A′(a′)A″(a″)][B(2-b′-b″)B′(b′)B″(b″)][C′(c′)C″(c″)]O12, where A, A′, A″ stand for a dodecahedral position of the crystal structure, where A stands for La, Y, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm and / or Yb, A′ stands for Ca, Sr and / or Ba, A″ stands for Na and / or K, 0<a′<2 and 0<a″<1, where B, B′, B″ stand for an octahedral position of the crystal structure, where B stands for Zr, Hf and / or Sn, B′ stands for Ta, Nb, Sb and / or Bi, B″ stands for at least one element selected from the group including Te, W and Mo, 0<b′<2 and 0<b″<2, where C and C″ stand for a tetrahedral position of the crystal structure, where C stands for Al and Ga, C″ stands for Si and / or Ge, 0<c′<0.5 and 0<c″<0.4, and where n=7+a′+2·a″−b′−2·b″−3·c′−4·c″ and 5.5<n<6.875.

Owner:ROBERT BOSCH GMBH

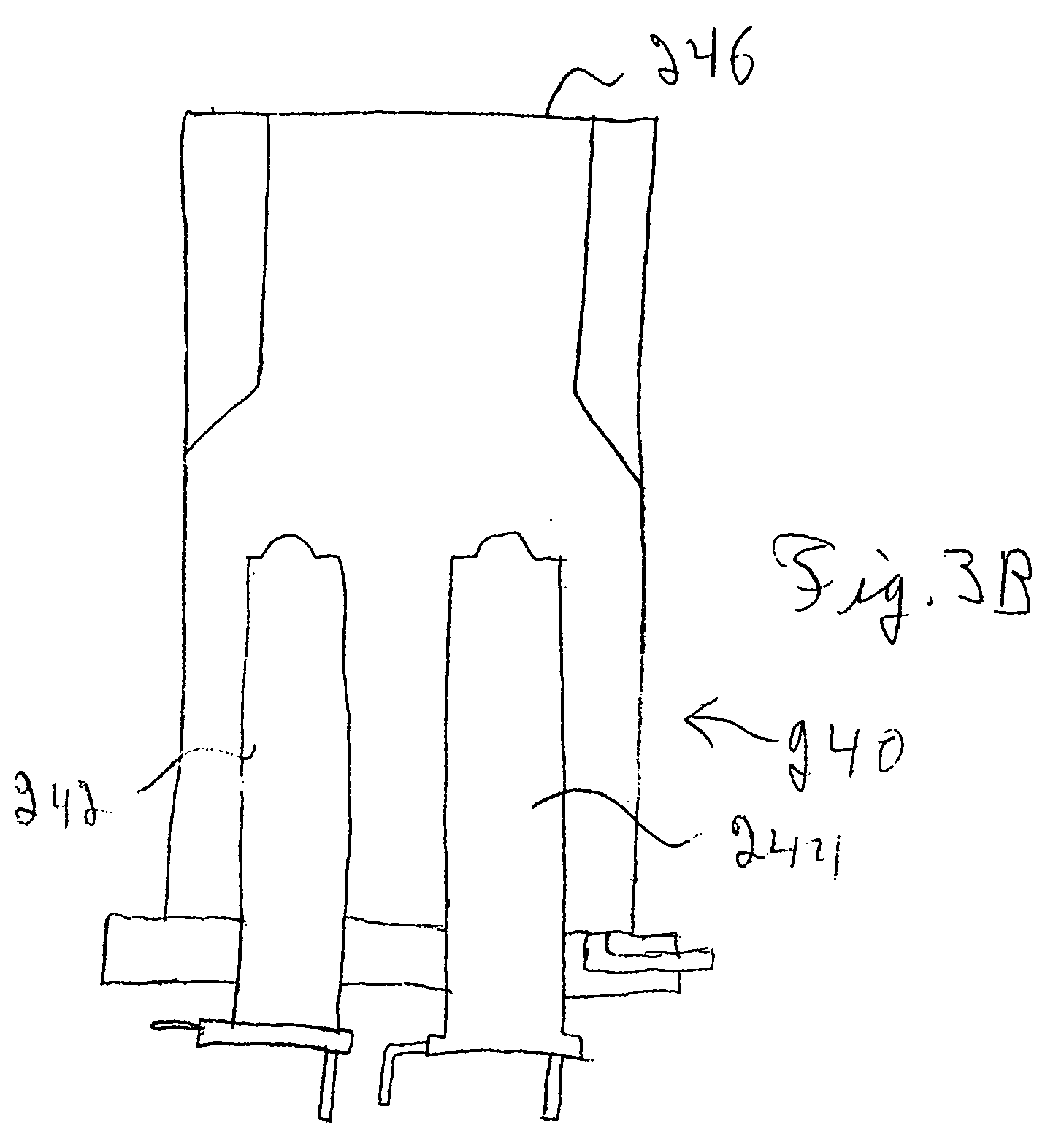

Nanoparticle production and corresponding structures

InactiveUS20060147369A1Material nanotechnologyCarbon compoundsProduction rateNanoparticle Production

Methods are described that have the capability of producing submicron / nanoscale particles, in some embodiments dispersible, at high production rates. In some embodiments, the methods result in the production of particles with an average diameter less than about 75 nanometers that are produced at a rate of at least about 35 grams per hour. In other embodiments, the particles are highly uniform. These methods can be used to form particle collections and / or powder coatings. Powder coatings and corresponding methods are described based on the deposition of highly uniform submicron / nanoscale particles.

Owner:NEOPHOTONICS CORP

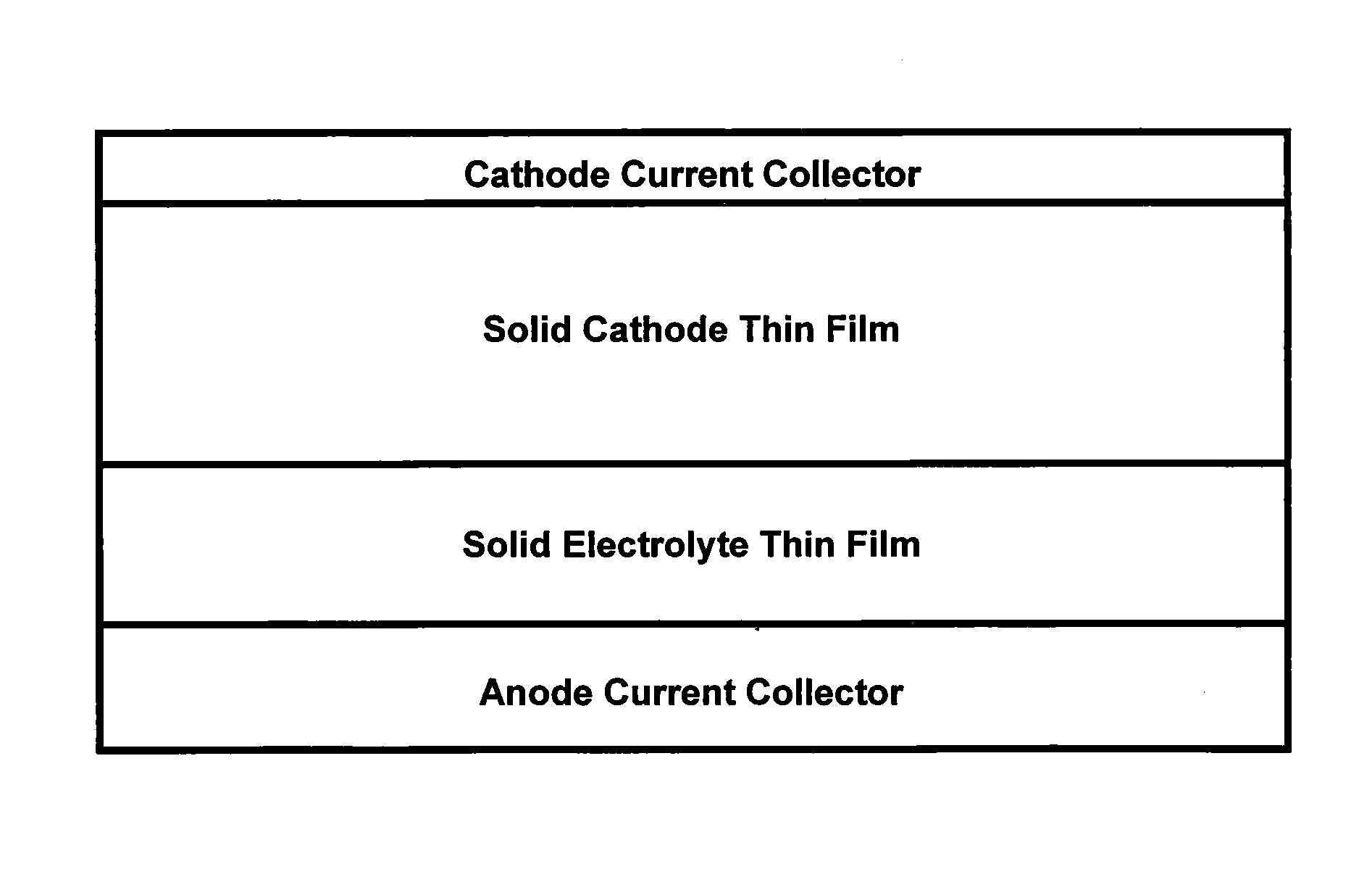

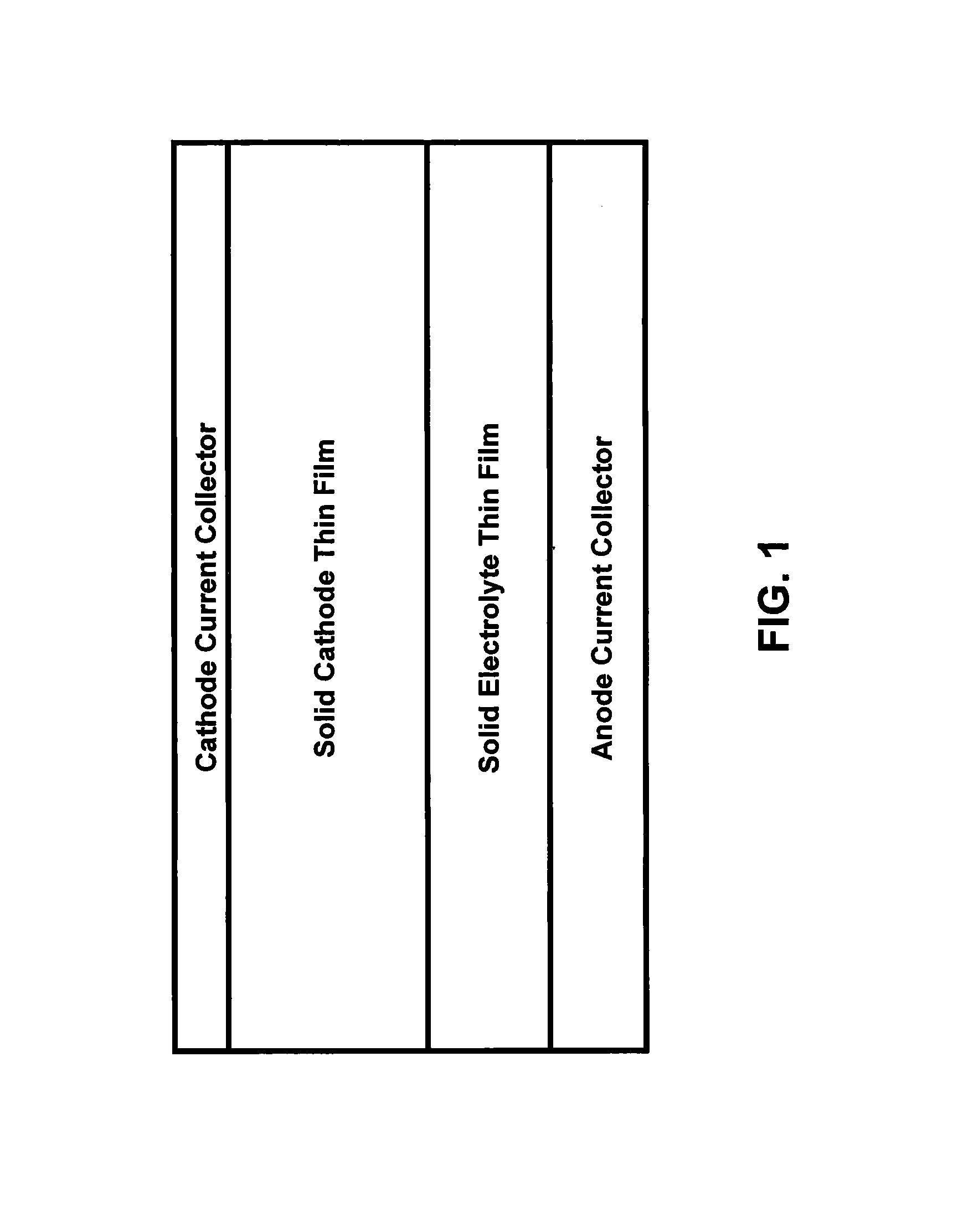

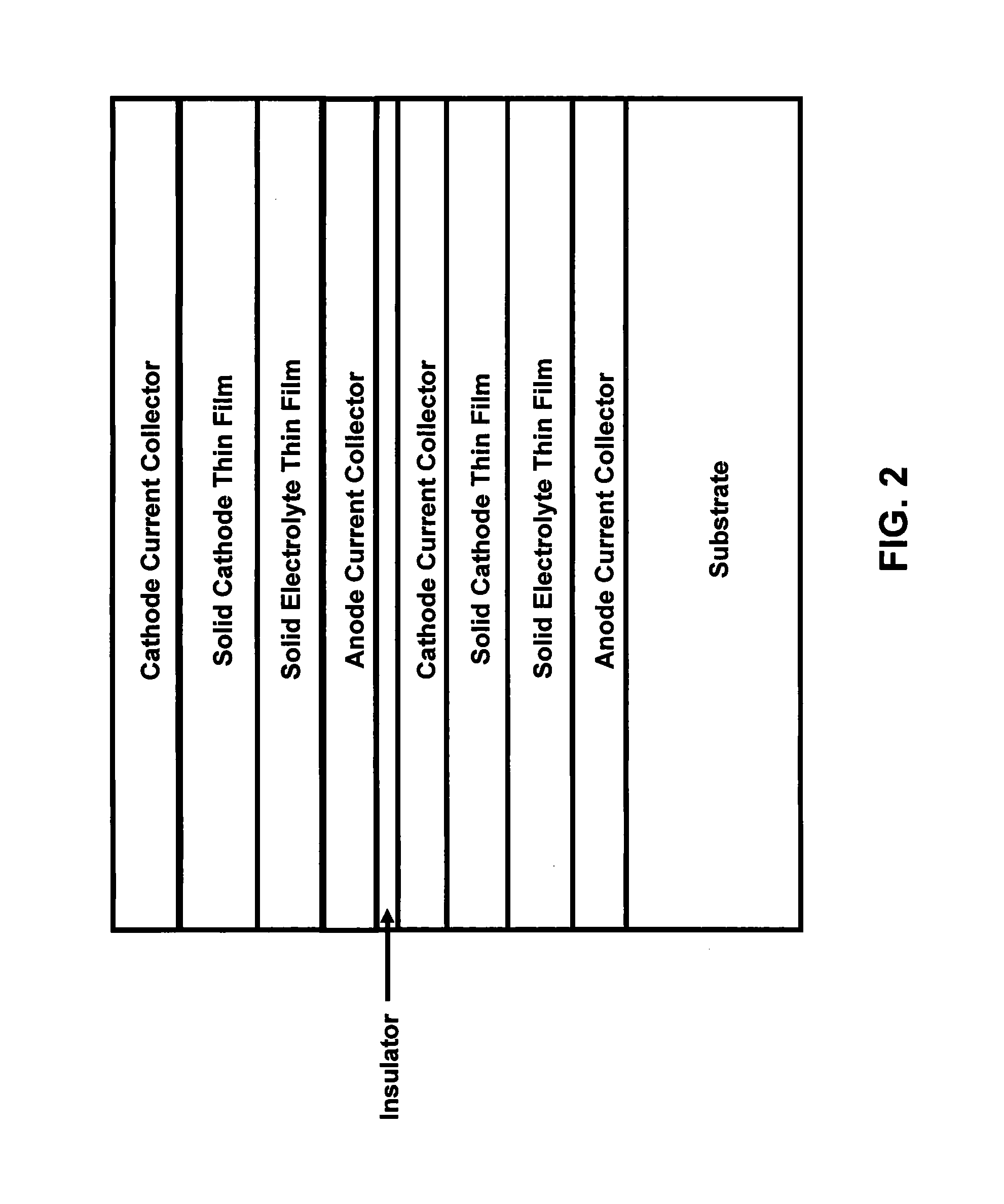

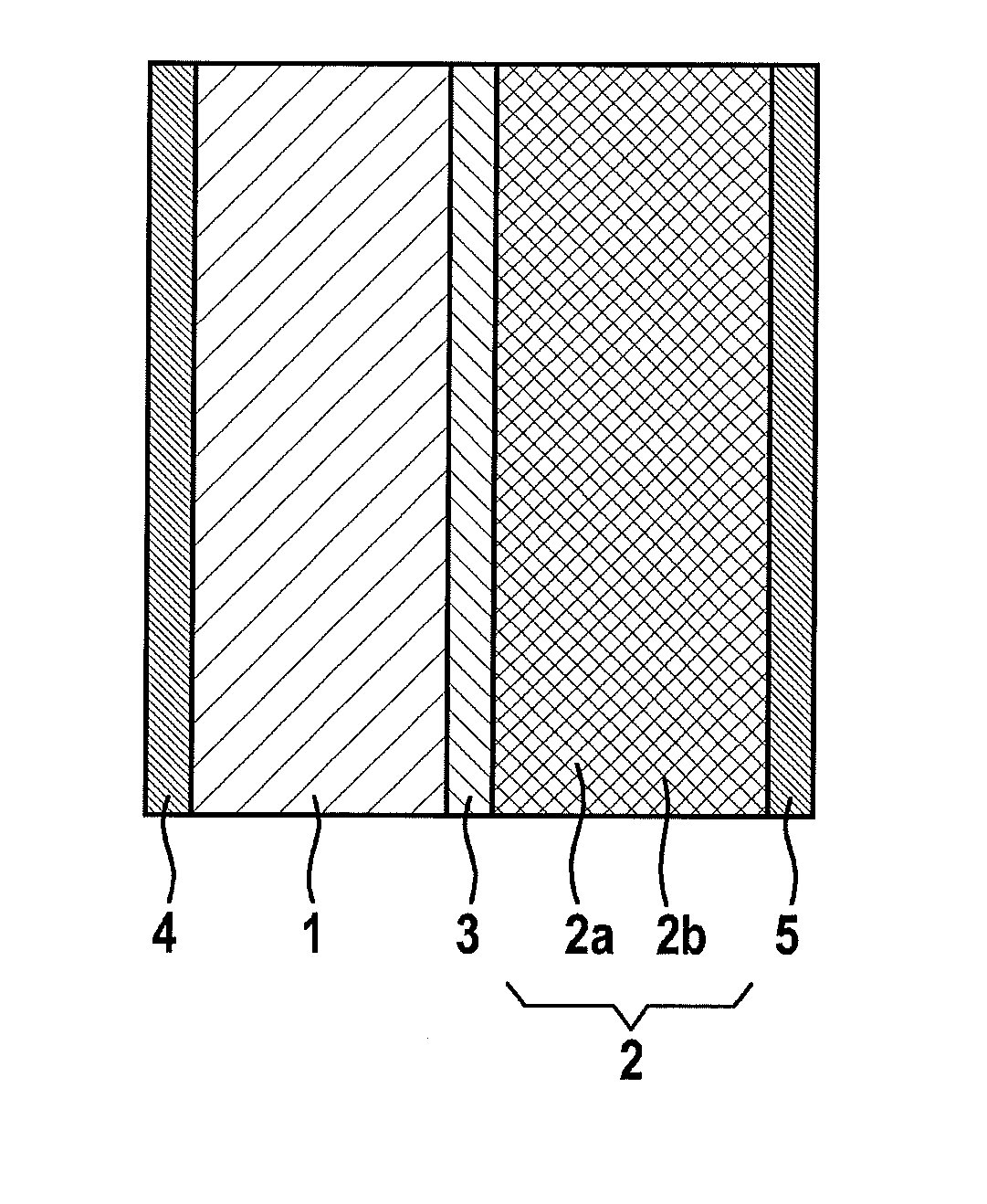

Solid-state lithium battery

ActiveUS8877388B1Low form factor requirementsIncrease powerTantalum compoundsPrinted batteriesLanthanumLithium.free

The present invention is directed to a higher power, thin film lithium-ion electrolyte on a metallic substrate, enabling mass-produced solid-state lithium batteries. High-temperature thermodynamic equilibrium processing enables co-firing of oxides and base metals, providing a means to integrate the crystalline, lithium-stable, fast lithium-ion conductor lanthanum lithium tantalate (La1 / 3-xLi3xTaO3) directly with a thin metal foil current collector appropriate for a lithium-free solid-state battery.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Method for producing fine particles of metal oxide

A method for producing fine particles of metal oxide characterized in that metal halide is hydrolyzed in the presence of organic solvent. According to this invention, under hydrolysis of titanium tetrachrolide, anatase type titanium oxide can be obtained by selecting hydrophilic organic solvent, and rutile type titanium oxide can be obtained by selecting hydrophobic organic solvent.

Owner:SHOWA DENKO KK

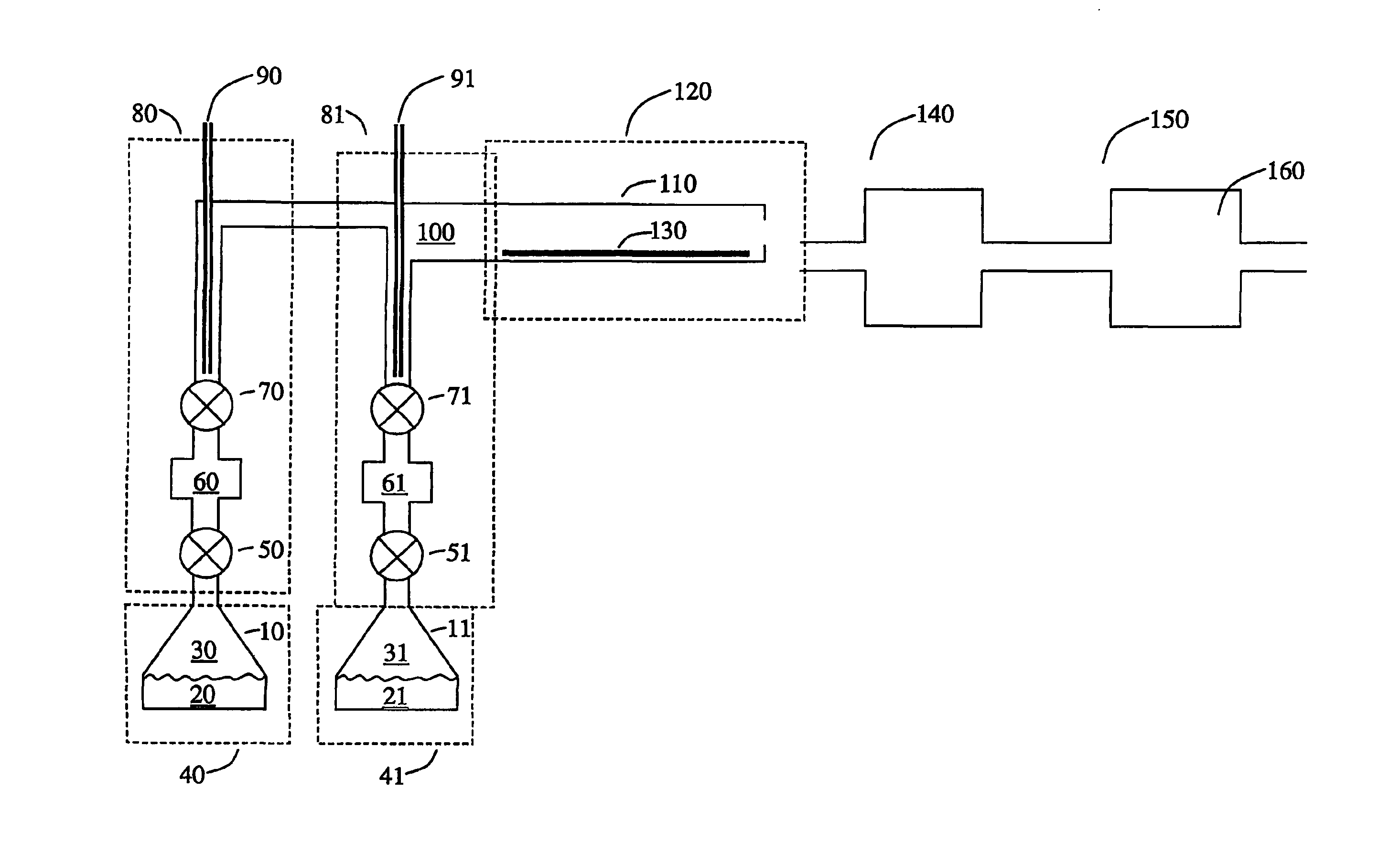

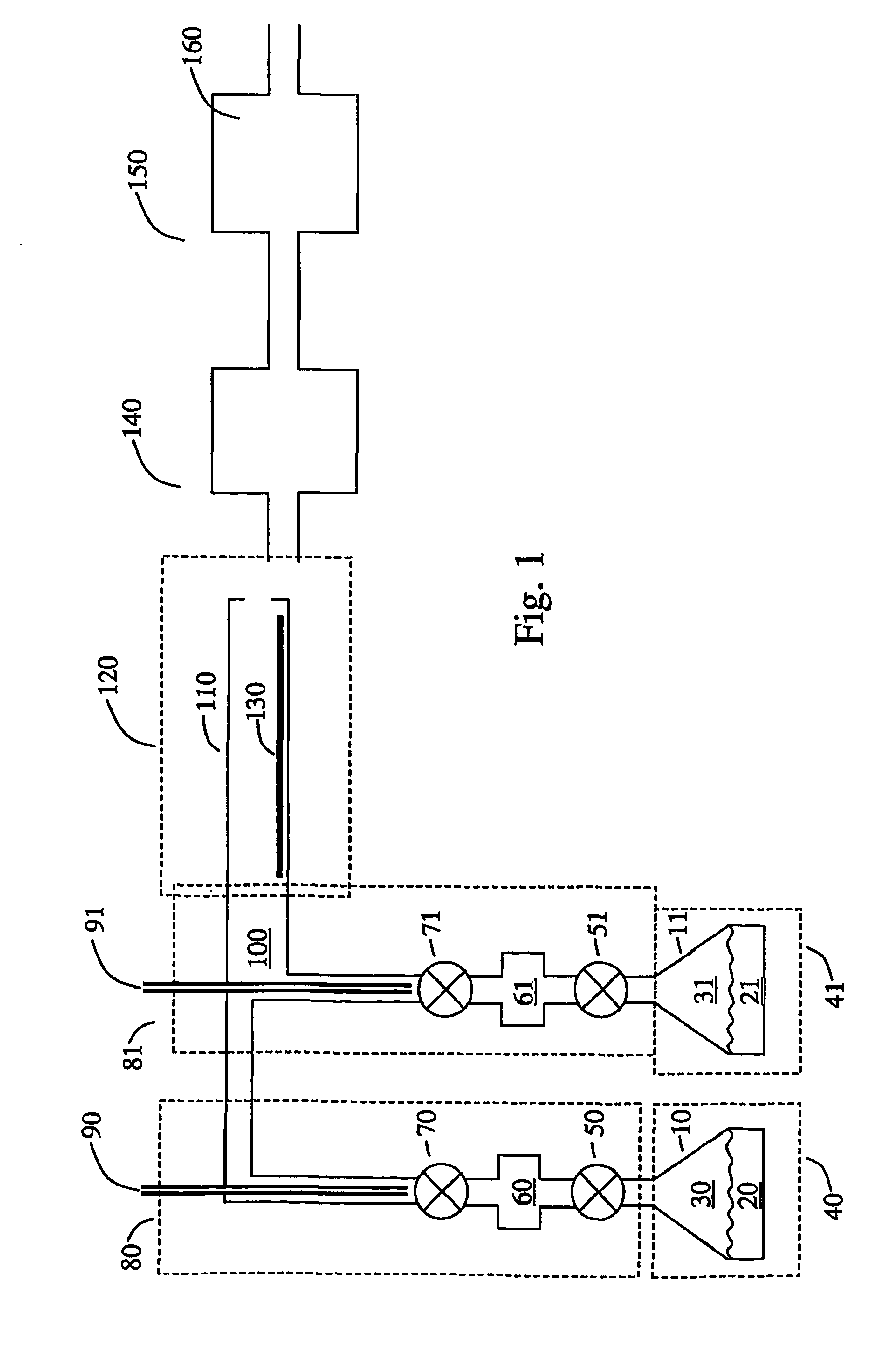

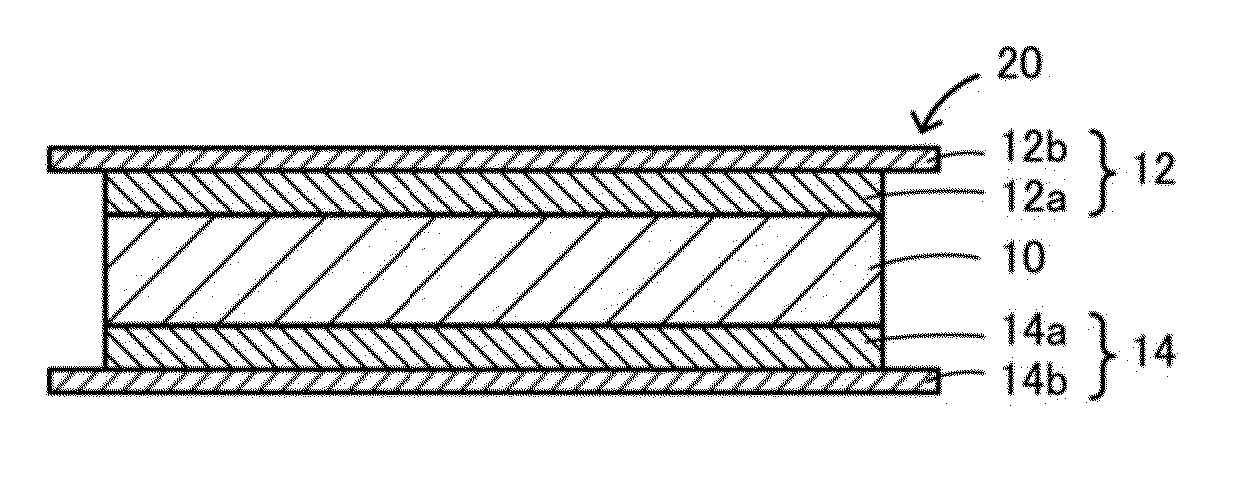

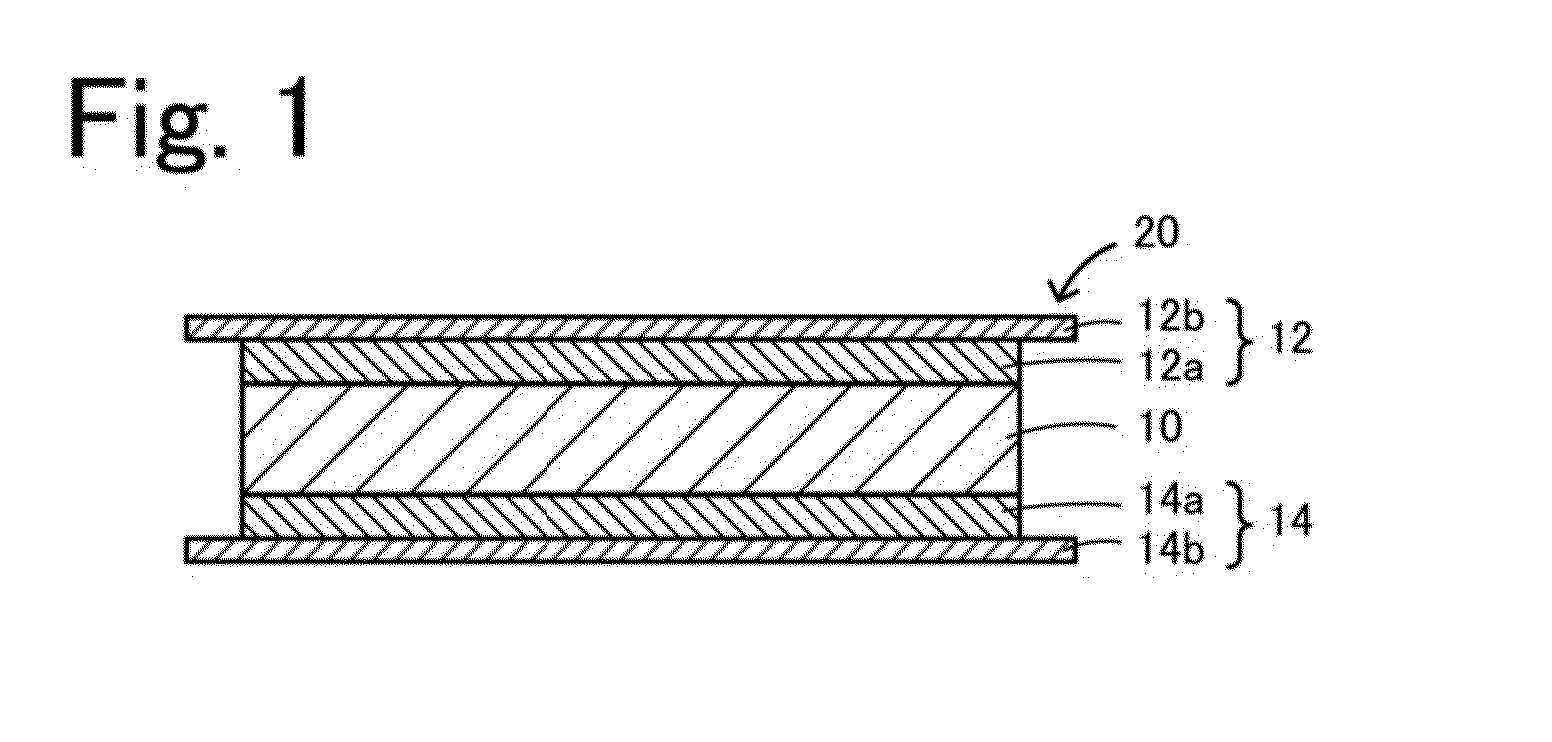

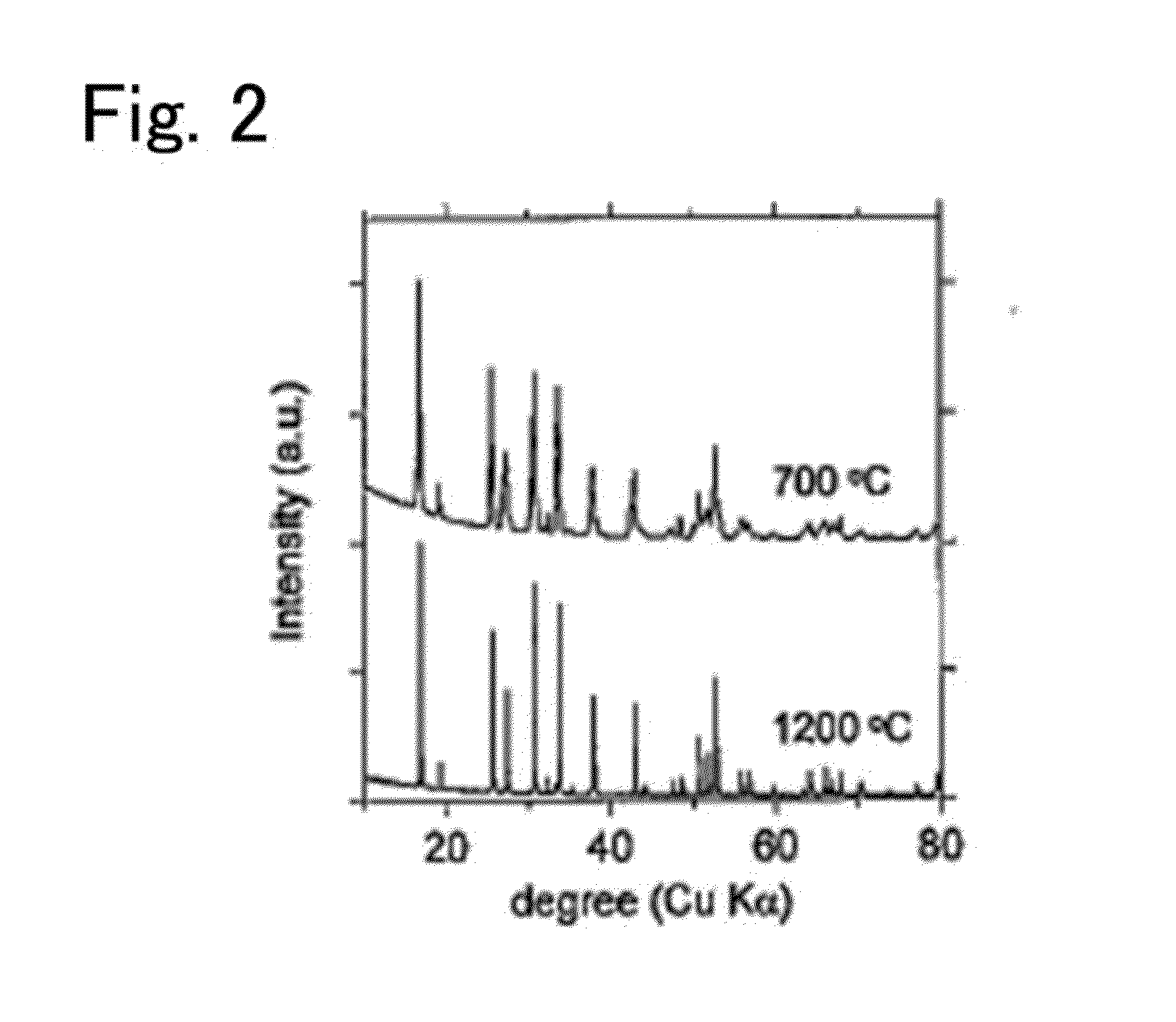

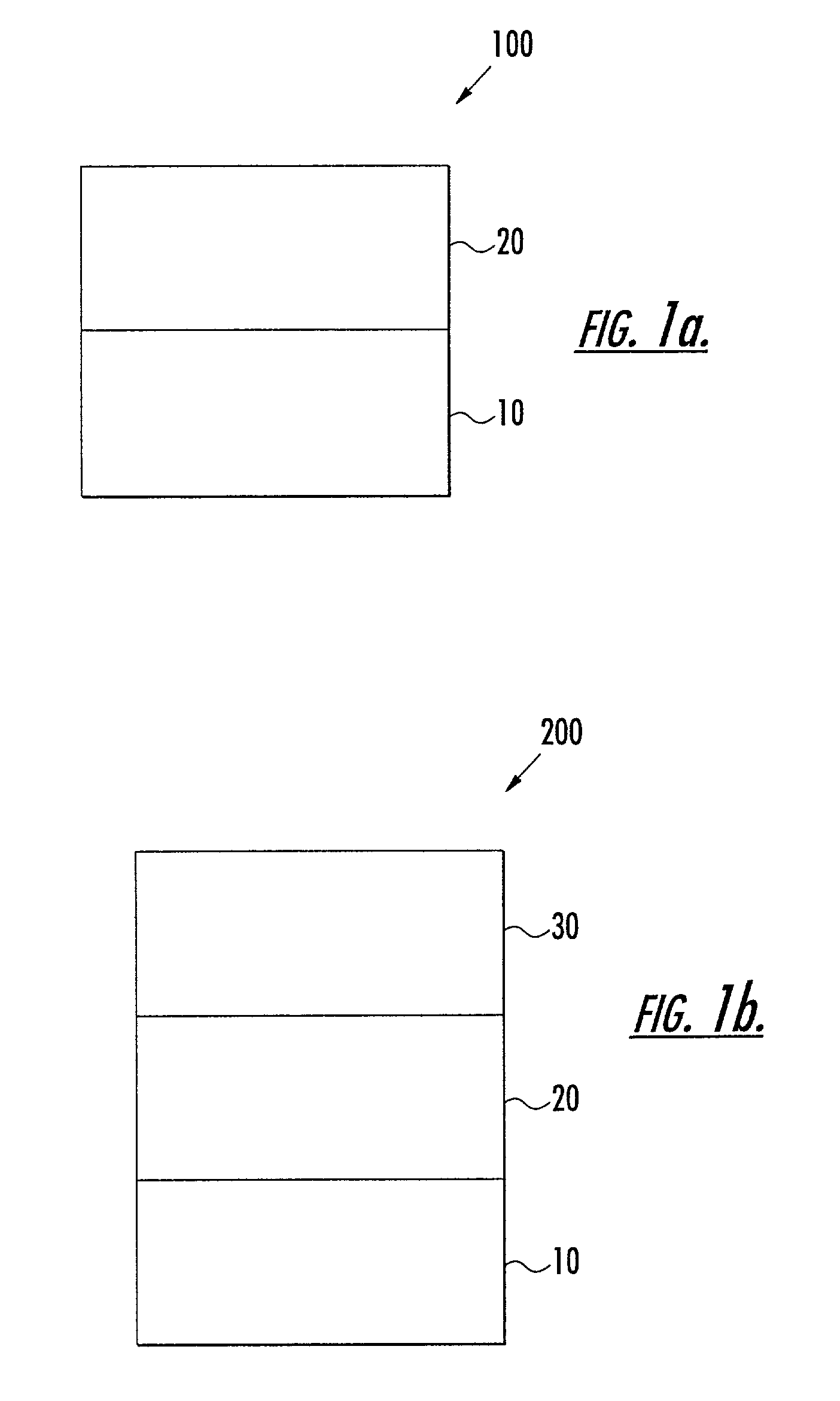

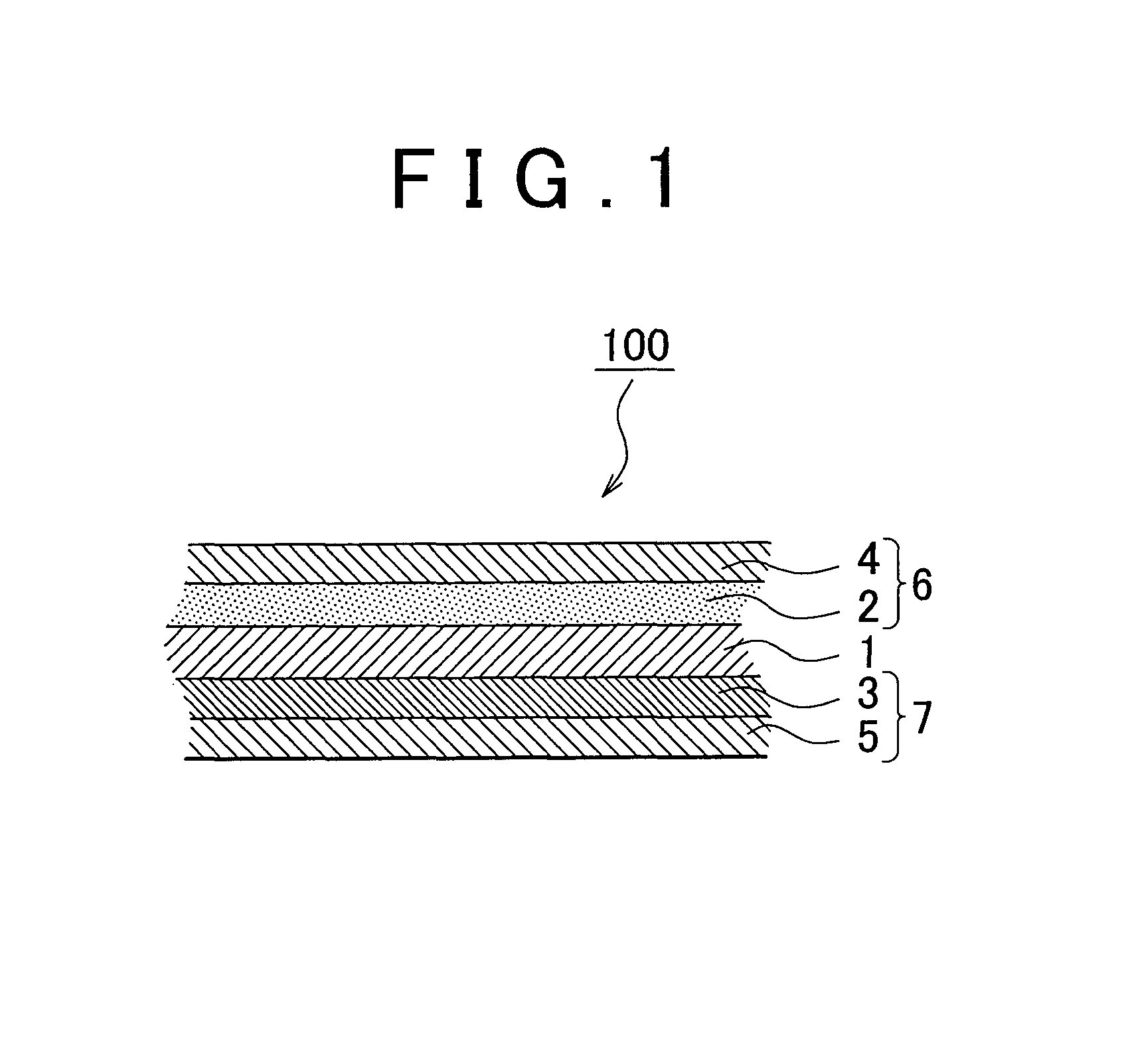

Garnet-type ion conducting oxide, complex, lithium secondary battery, manufacturing method of garnet-type ion conducting oxide and manufacturing method of complex

ActiveUS20150056519A1Reduce the temperatureAccelerates dissolution and diffusionElectrode thermal treatmentFinal product manufactureElectrolyteLithium borate

An all-solid lithium secondary battery 20 includes a solid electrolyte layer 10 composed of a garnet-type oxide, a positive electrode 12 formed on one surface of the solid electrolyte layer 10 and a negative electrode 14 formed on the other surface of the solid electrolyte layer 10. This all-solid lithium secondary battery 20 includes an integrally sintered complex of the solid electrolyte layer 10 and the positive electrode active material layer 12a. This complex is obtained by integrally sintering a stacked structure of an active material layer and a solid electrolyte layer. The solid electrolyte layer includes: abase material mainly including a fundamental composition of Li7+X−Y(La3−x,Ax) (Zr2−Y,TY)O12, wherein A is one or more of Sr and Ca, T is one or more of Nb and Ta, and 0≦X≦1.0 and 0≦Y<0.75 are satisfied, as a main component; and an additive component including lithium borate and aluminum oxide.

Owner:TOYOTA CENT RES & DEV LAB INC

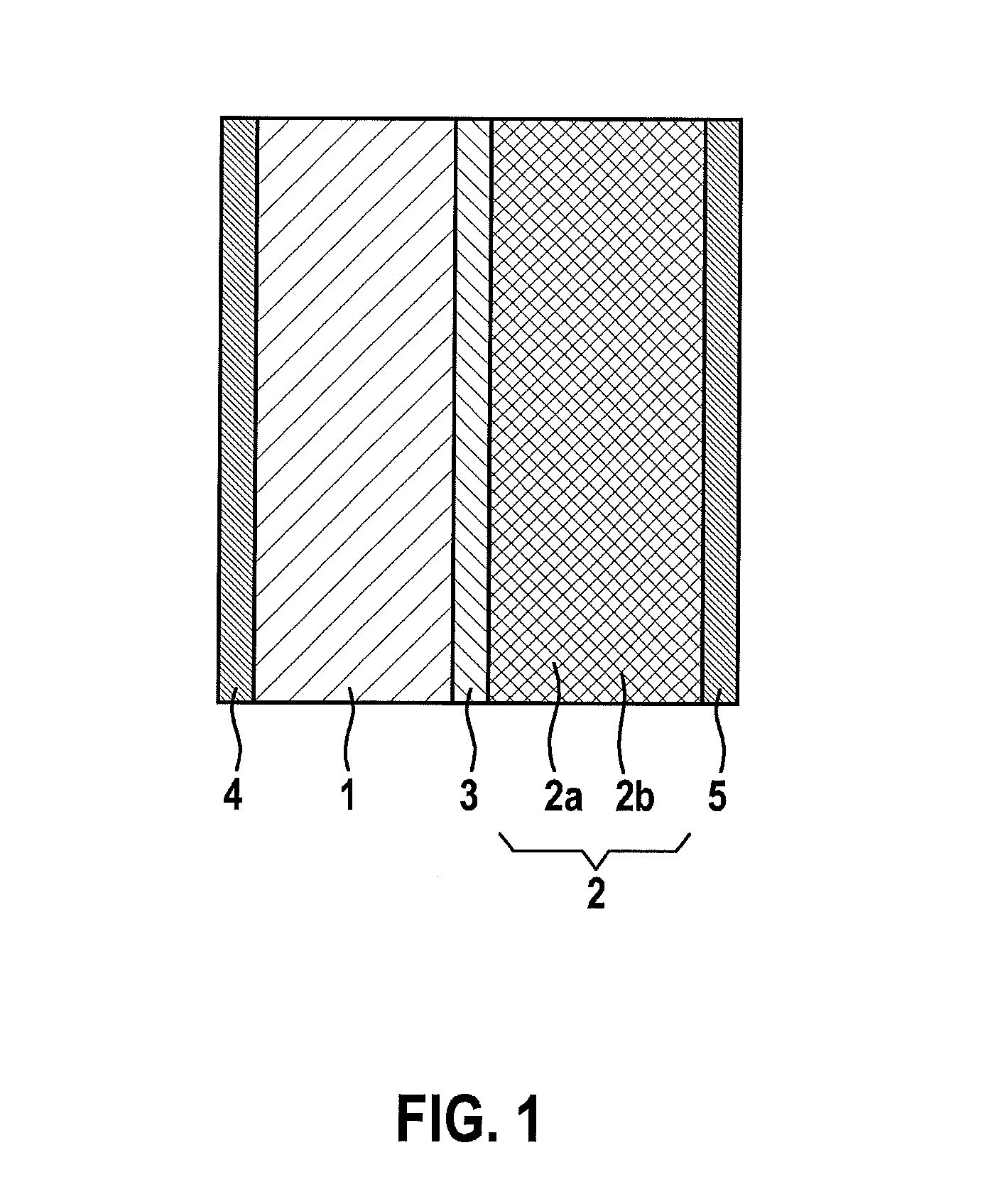

All-solid-state cell

ActiveUS20150044576A1Transportation is highImprove cycle stabilityAlkali titanatesTantalum compoundsAll solid stateSolid state electrolyte

An all-solid-state cell, which includes a lithium-containing anode, a cathode and a lithium ions-conducting solid-state electrolyte separator situated between the anode and the cathode. To improve the safety and cycle stability of the cell, the cathode includes a composite material including at least one lithium titanate and at least one lithium ions-conducting solid-state electrolyte. Furthermore, the invention relates to a corresponding all-solid-state battery and a mobile or stationary system equipped with it.

Owner:ROBERT BOSCH GMBH

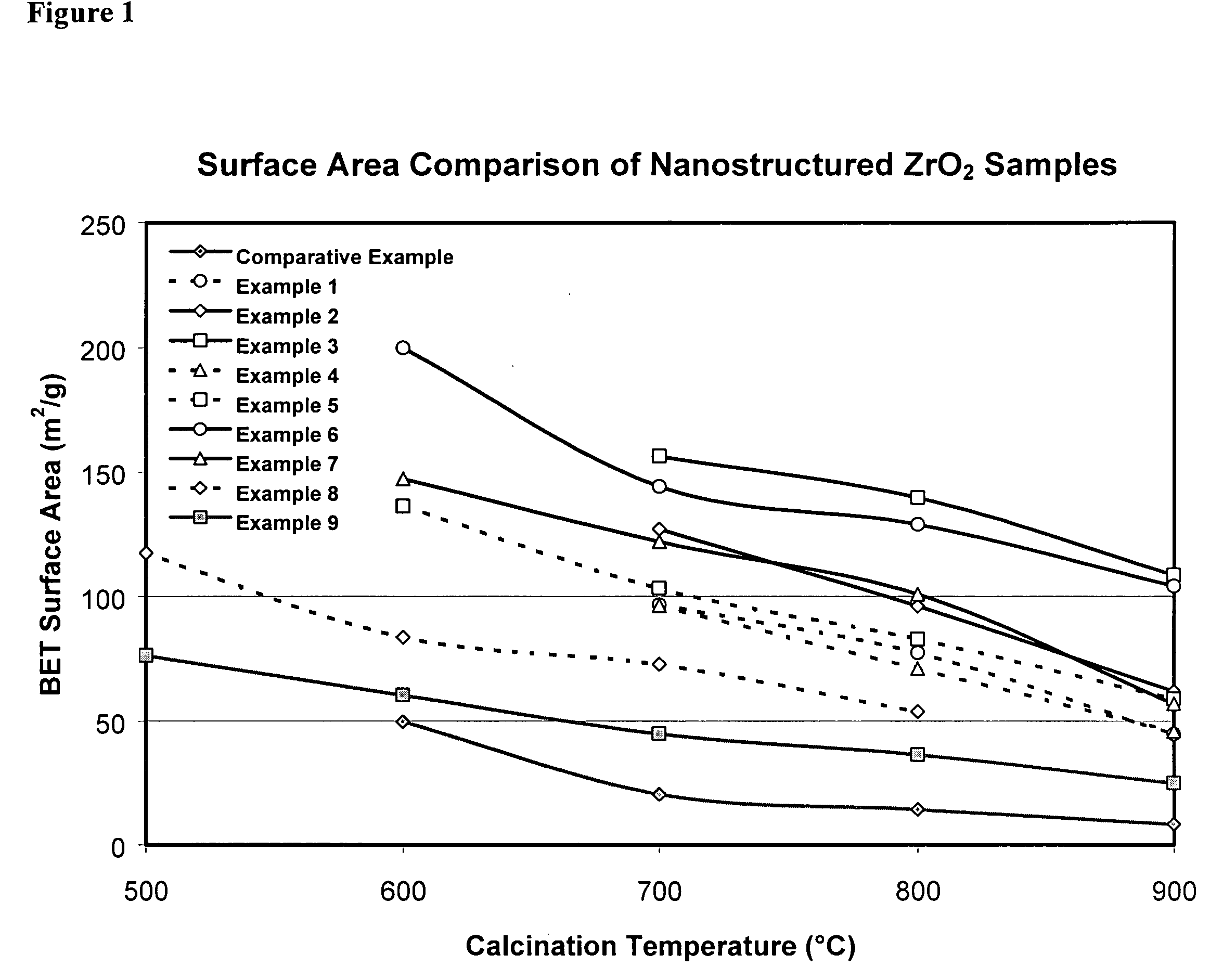

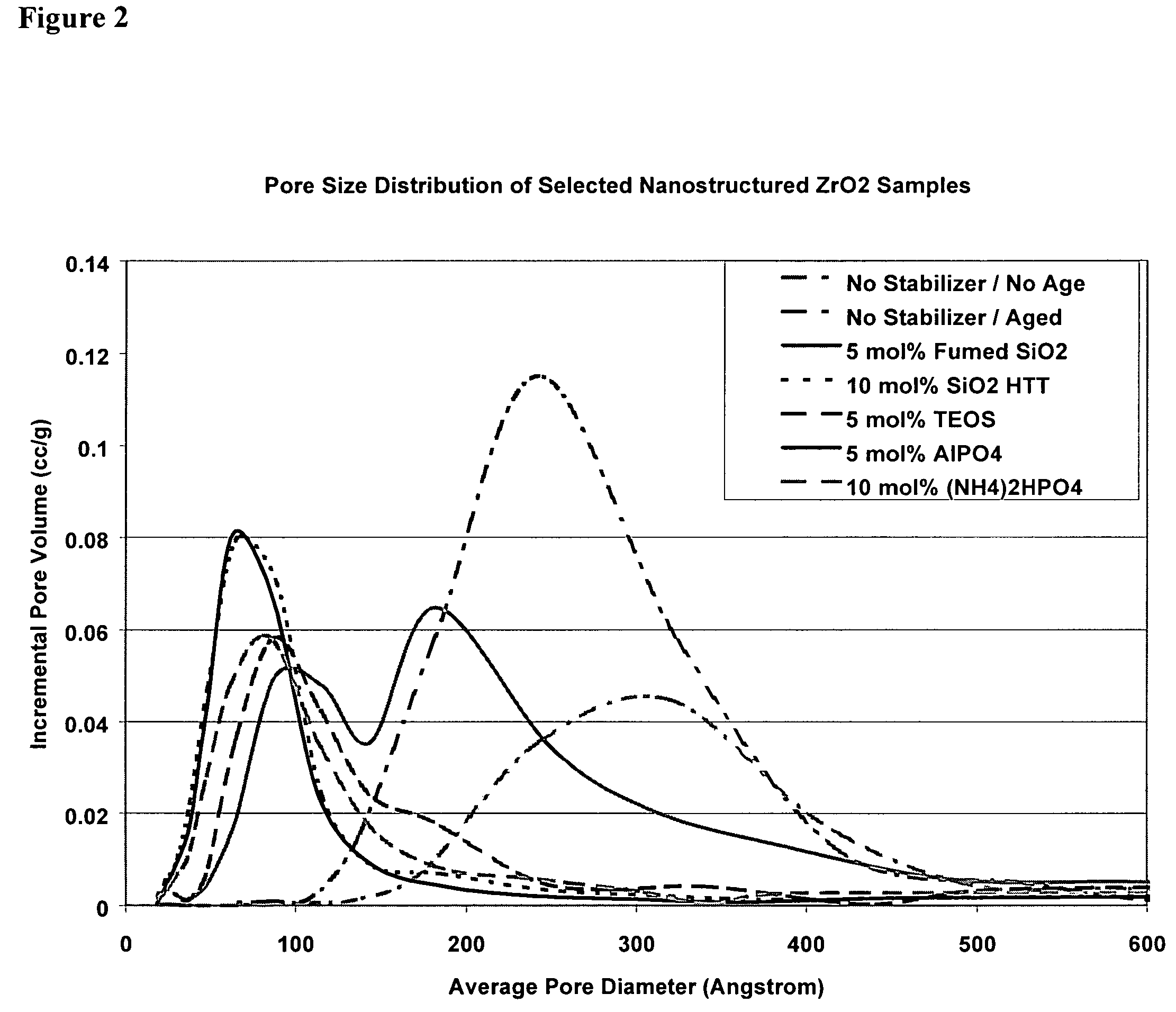

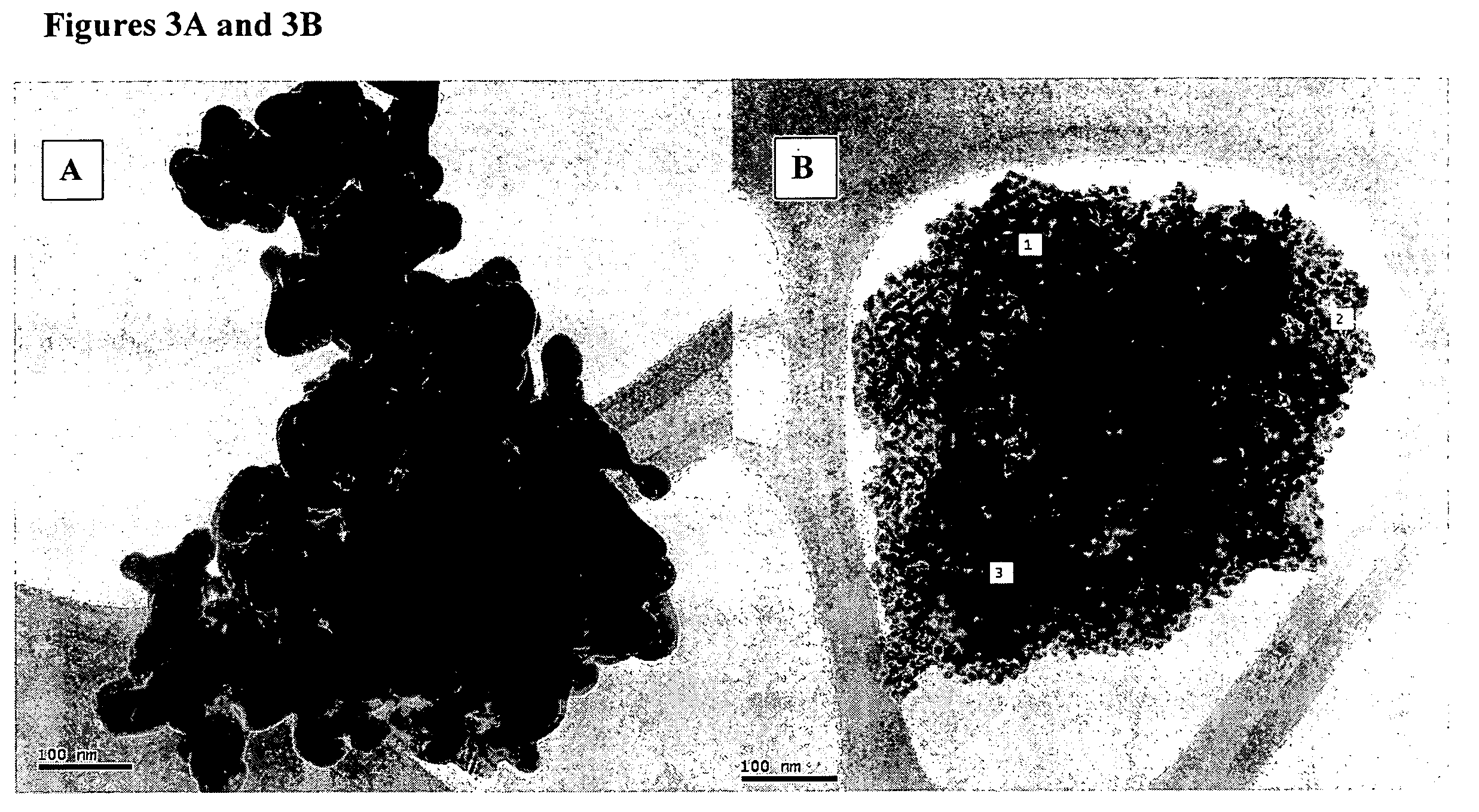

Nano-structured particles with high thermal stability

ActiveUS20050175525A1Large specific surface areaImprove thermal stabilityMaterial nanotechnologyNanostructure manufactureNanoparticleThermal stability

The present invention is directed to producing nano-structured particles that have high specific surface-areas and high thermal stability. By aging nanoparticle precursors, and processing them under appropriate conditions, one is able to generate nano-structured particles that may be used in catalysts. By adding a stabilizing agent one is able to further improve the high thermal stability. These nano-structured particle products are particularly advantageous in applications as catalysts or catalyst supports that operate at high temperatures.

Owner:TRONOX LLC

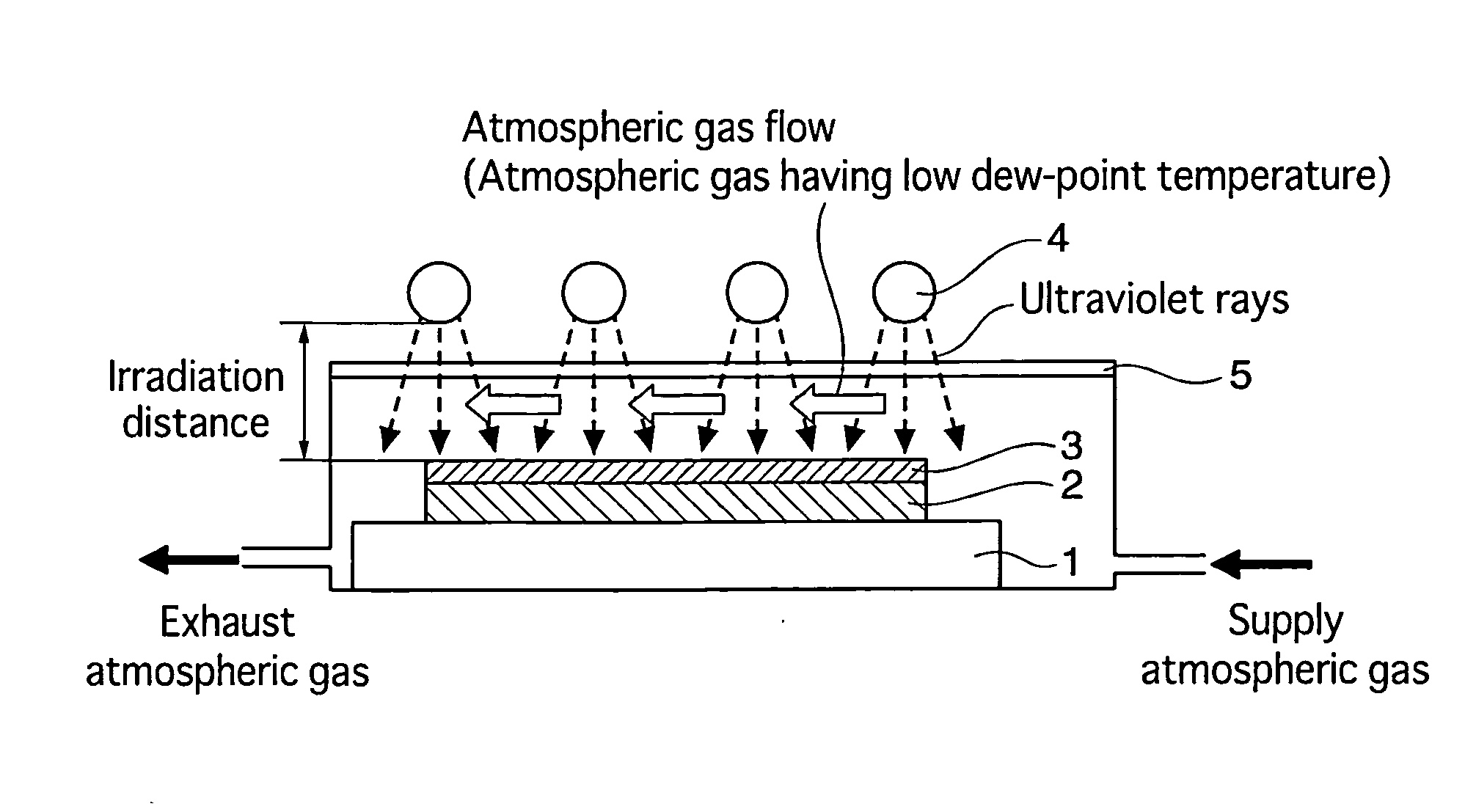

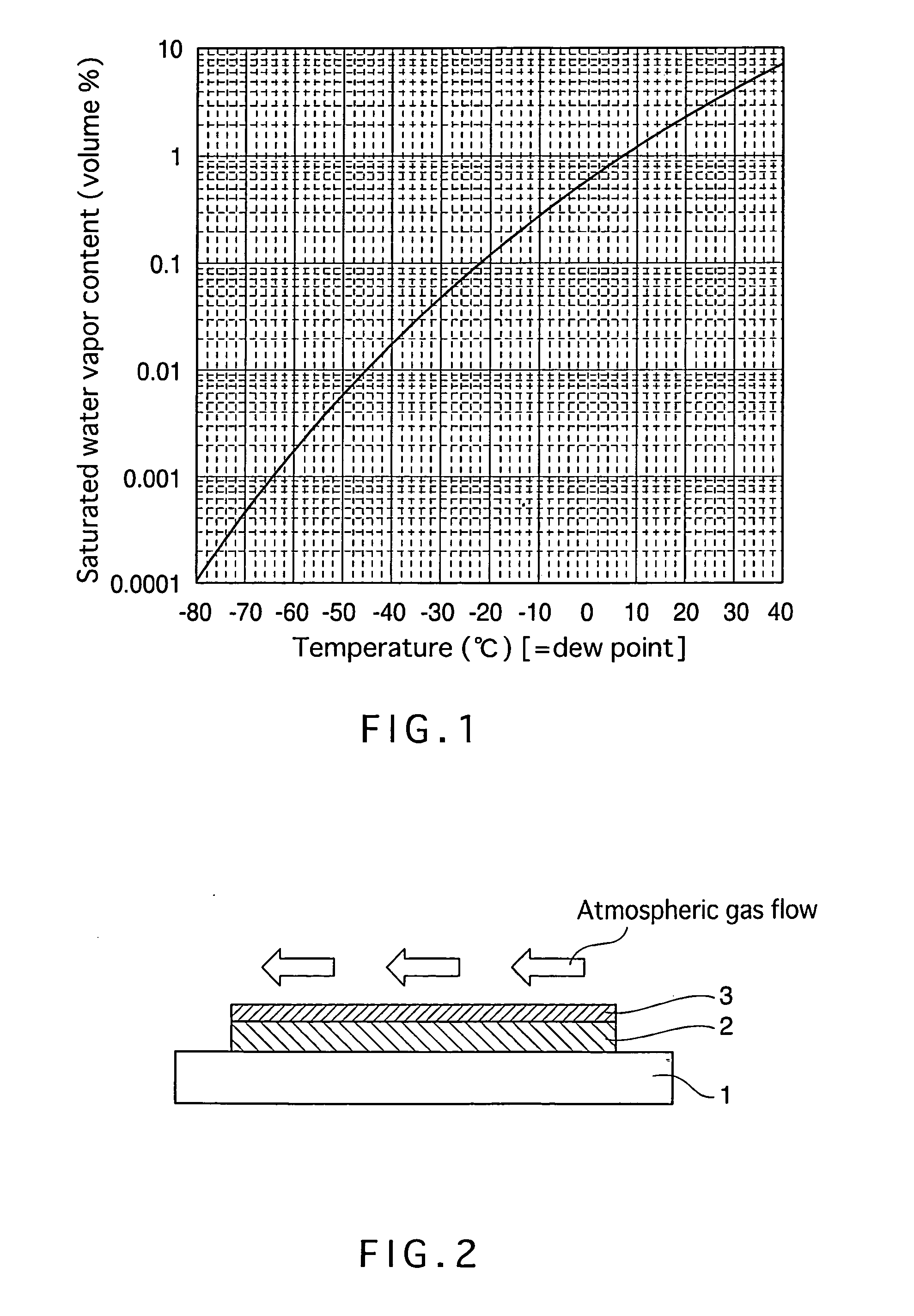

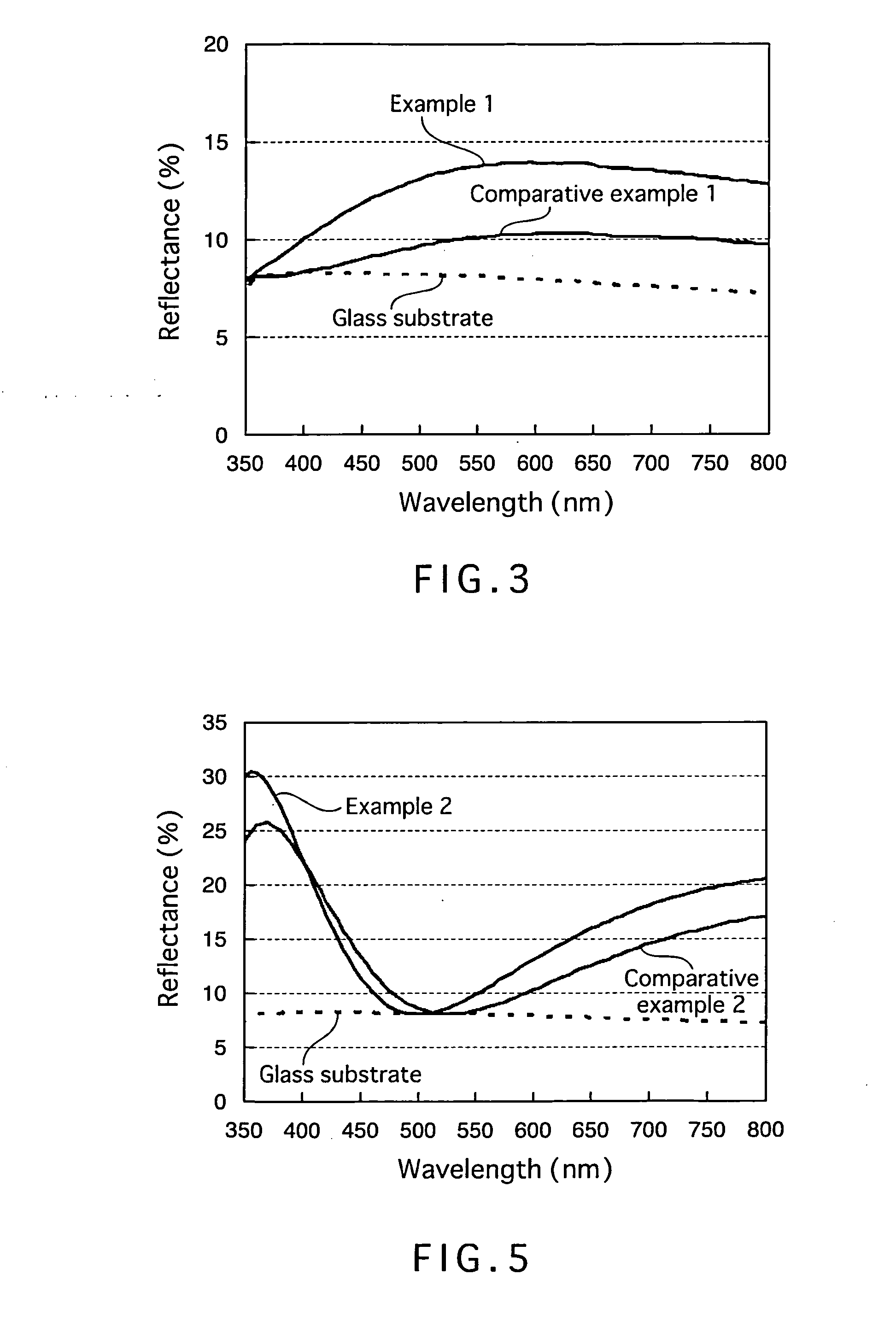

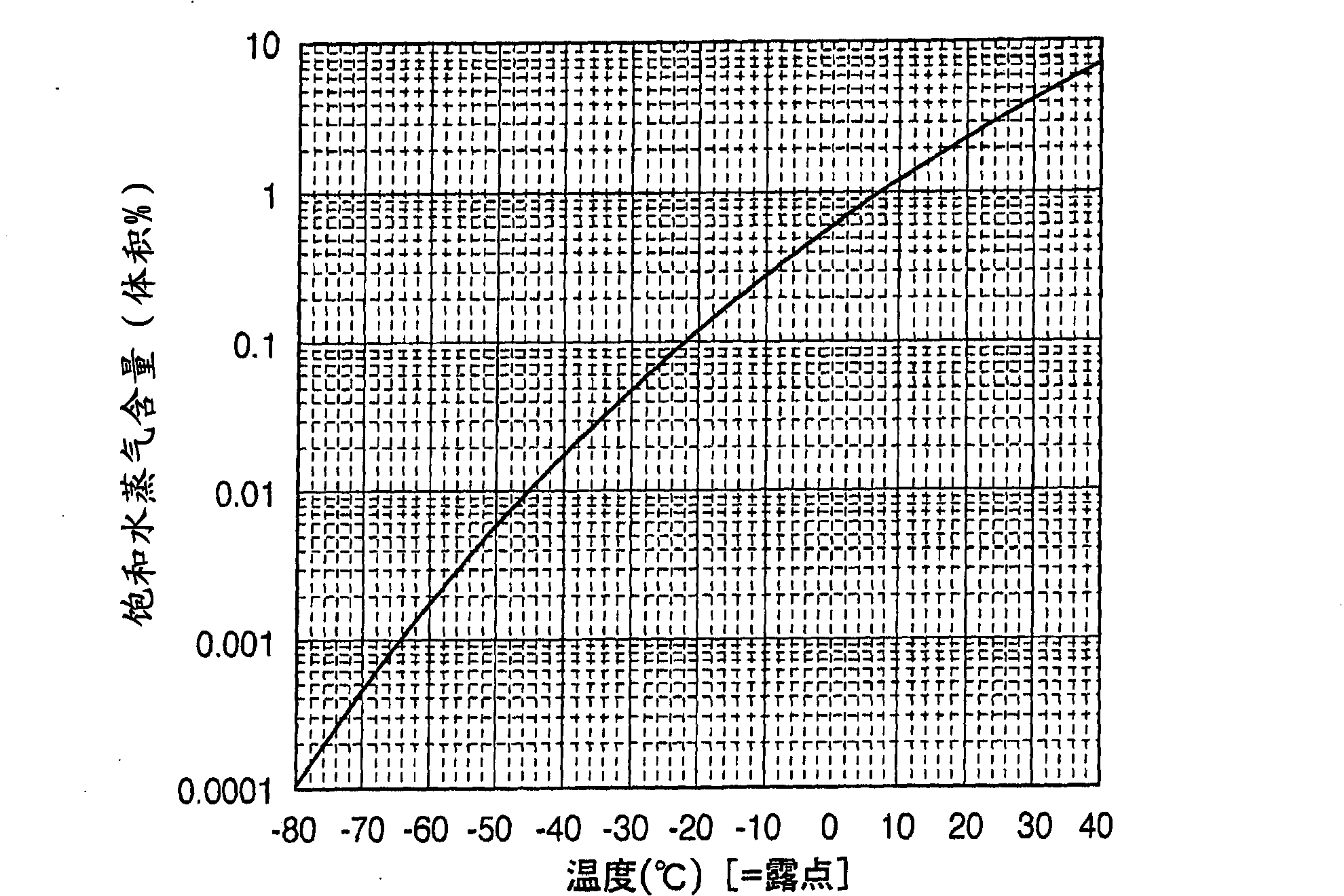

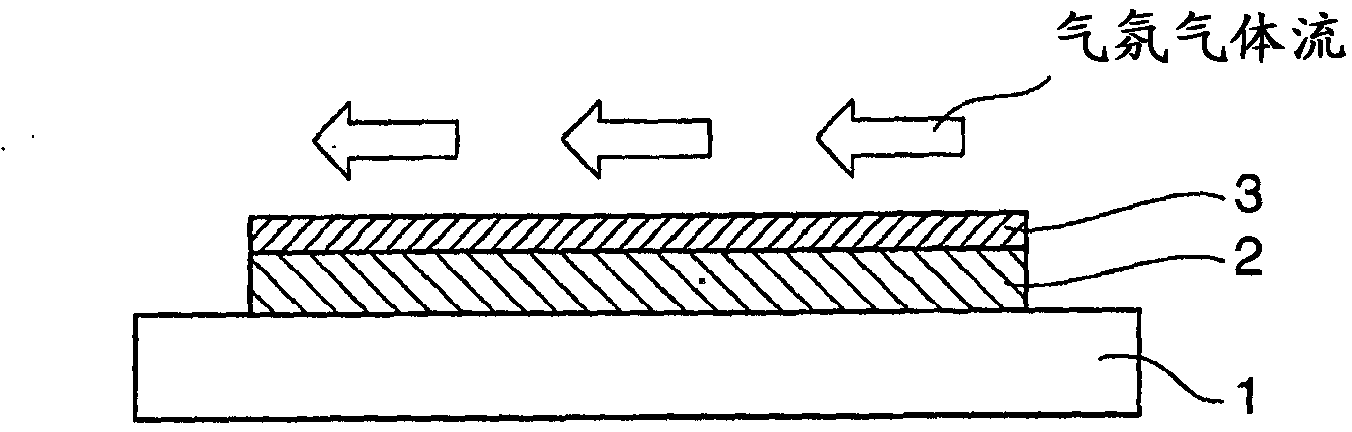

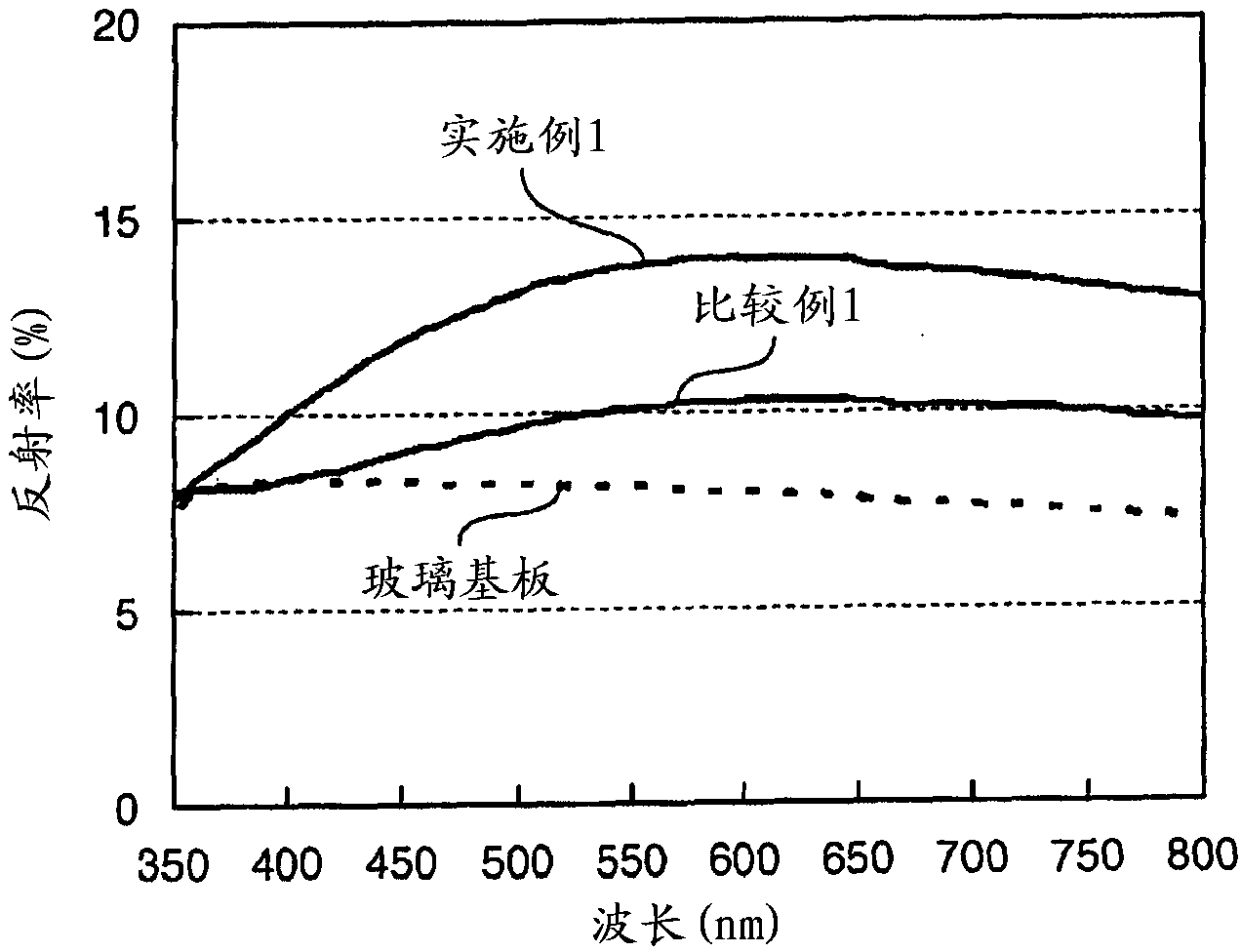

Method of manufacturing metal oxide film, metal oxide film, element using the metal oxide film, substrate with metal oxide film, and device using the substrate with metal oxide film

InactiveUS20130101867A1High densityHigh film strengthTantalum compoundsSemiconductor/solid-state device detailsOxygenMaterials science

Provided is a method of manufacturing a metal oxide film to be formed through the following processes: a coating process of forming a coating film on a substrate by using a coating liquid for forming metal oxide film containing any of various organometallic compounds; a drying process of making the coating film into a dried coating film; and a heating process of forming an inorganic film from the dried coating film under an oxygen-containing atmosphere having a dew-point temperature equal to or lower than −10° C.

Owner:SUMITOMO METAL MINING CO LTD

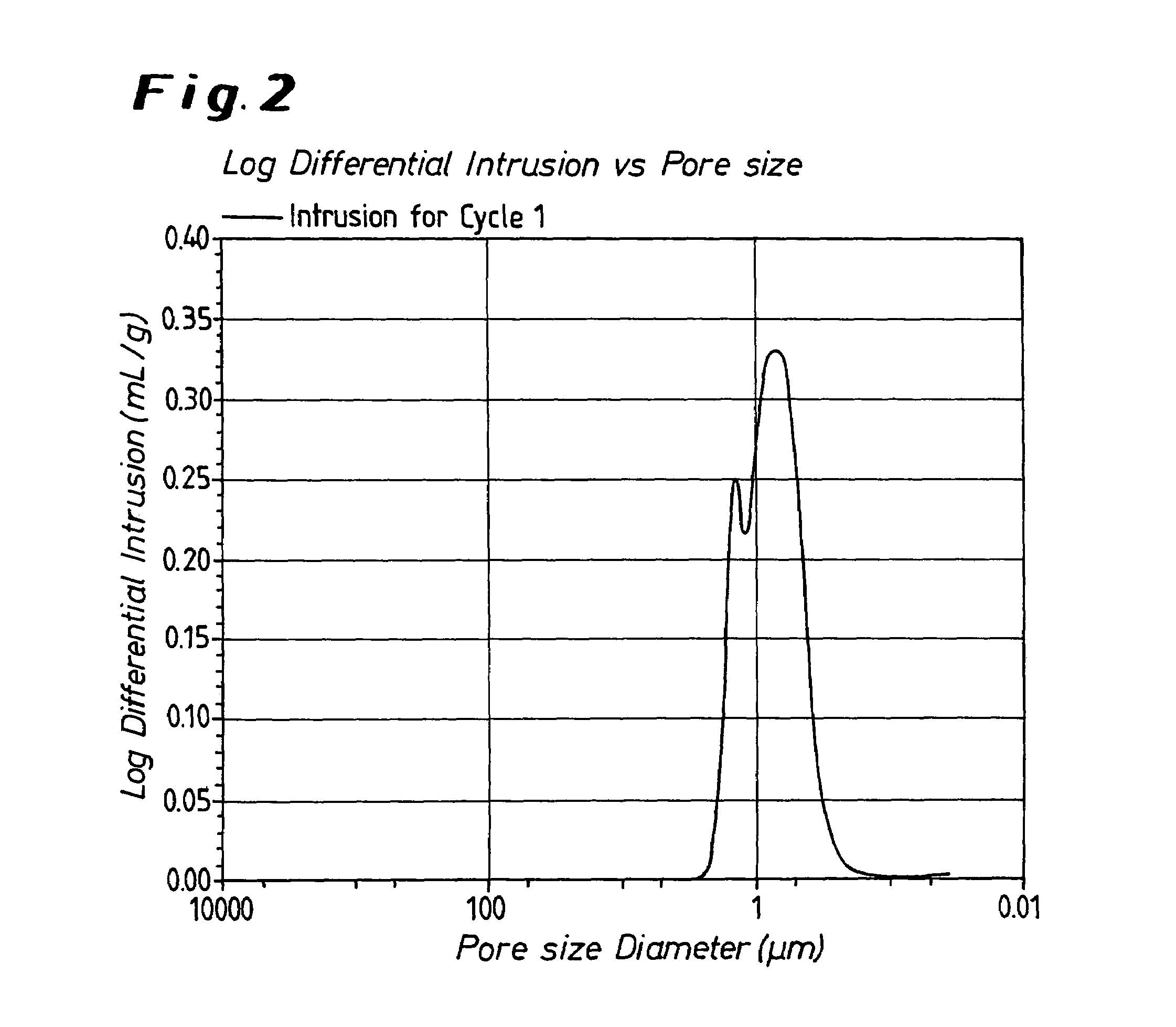

Vanadium redox battery electrolyte

InactiveUS20040241552A1Loss in Coulombic efficiencyEvolution of hydrogen is thereby avoidedTantalum compoundsRegenerative fuel cellsVanadium redox batterySlurry

The present invention relates generally to the production of a vanadium electrolyte, including a mixture of trivalent and tetravalent vanadium ions in a sulphuric acid solution, by the reactive dissolution of vanadium trioxide and vanadium pentoxide powders, the surface area and particle size characteristics being controlled for complete reaction to produce the desired ratio of V(III) to V(IV) ions in the solution. The solution may be suitable for direct use in the vanadium redox battery, or the solution can provide an electrolyte concentrate or slurry which can be reconstituted by the addition of water or sulphuric acid prior to use in the vanadium redox battery.

Owner:UNISEARCH LTD

Novel non-crystalline oxides for use in microelectronic, optical, and other applications

InactiveUS20020024108A1Oxide/hydroxide preparationTantalum compoundsCrystalline oxideField-effect transistor

The invention relates to non-crystalline oxides of formulas (I) and (II), and methods of forming the same, along with field effect transistors, articles of manufacture, and microelectronic devices comprising the non-crystalline oxides.

Owner:NORTH CAROLINA STATE UNIV

Synthesis of nanoparticles

Owner:CENT FUR ANGEWANDTE NANOTECH

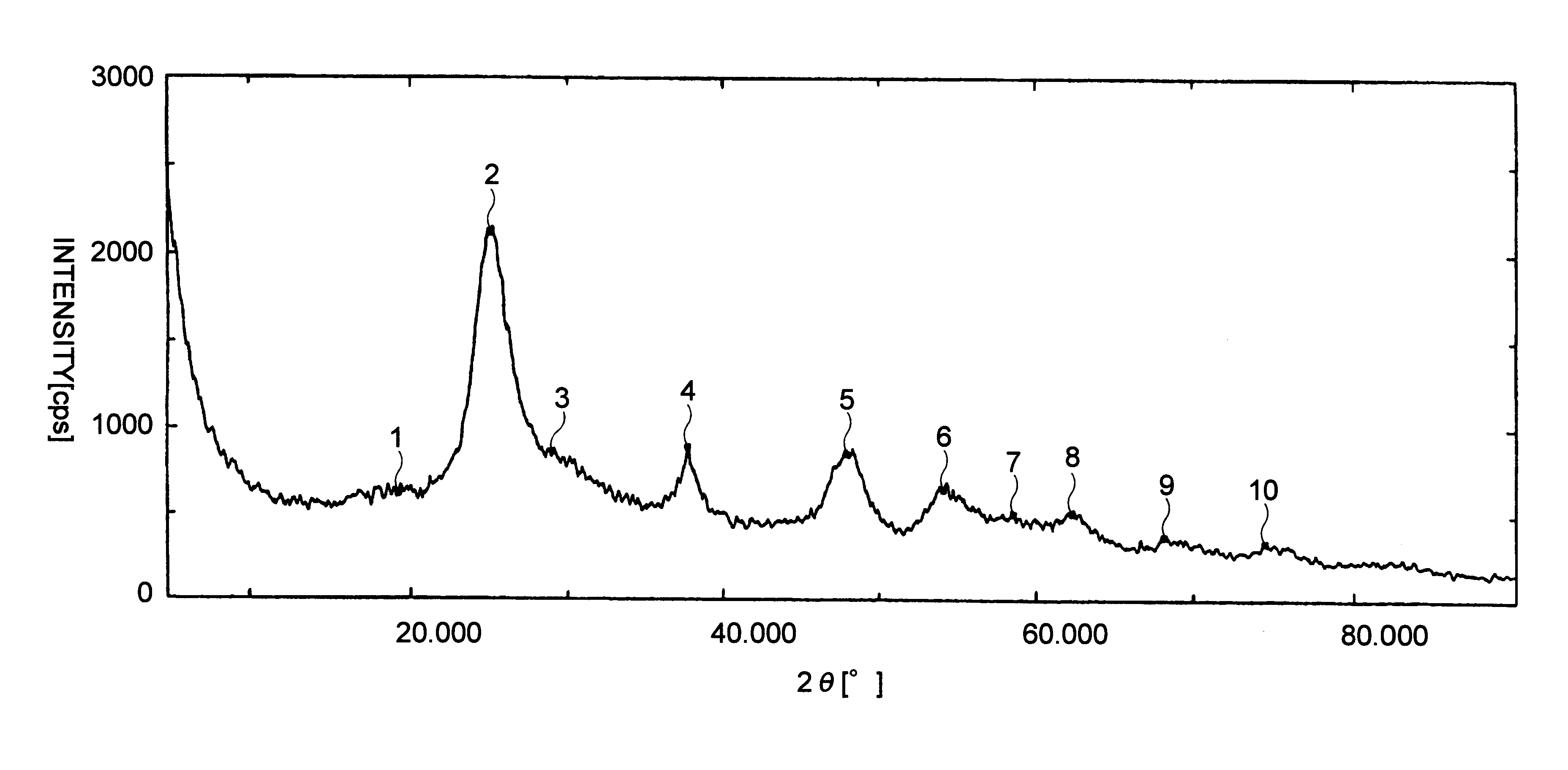

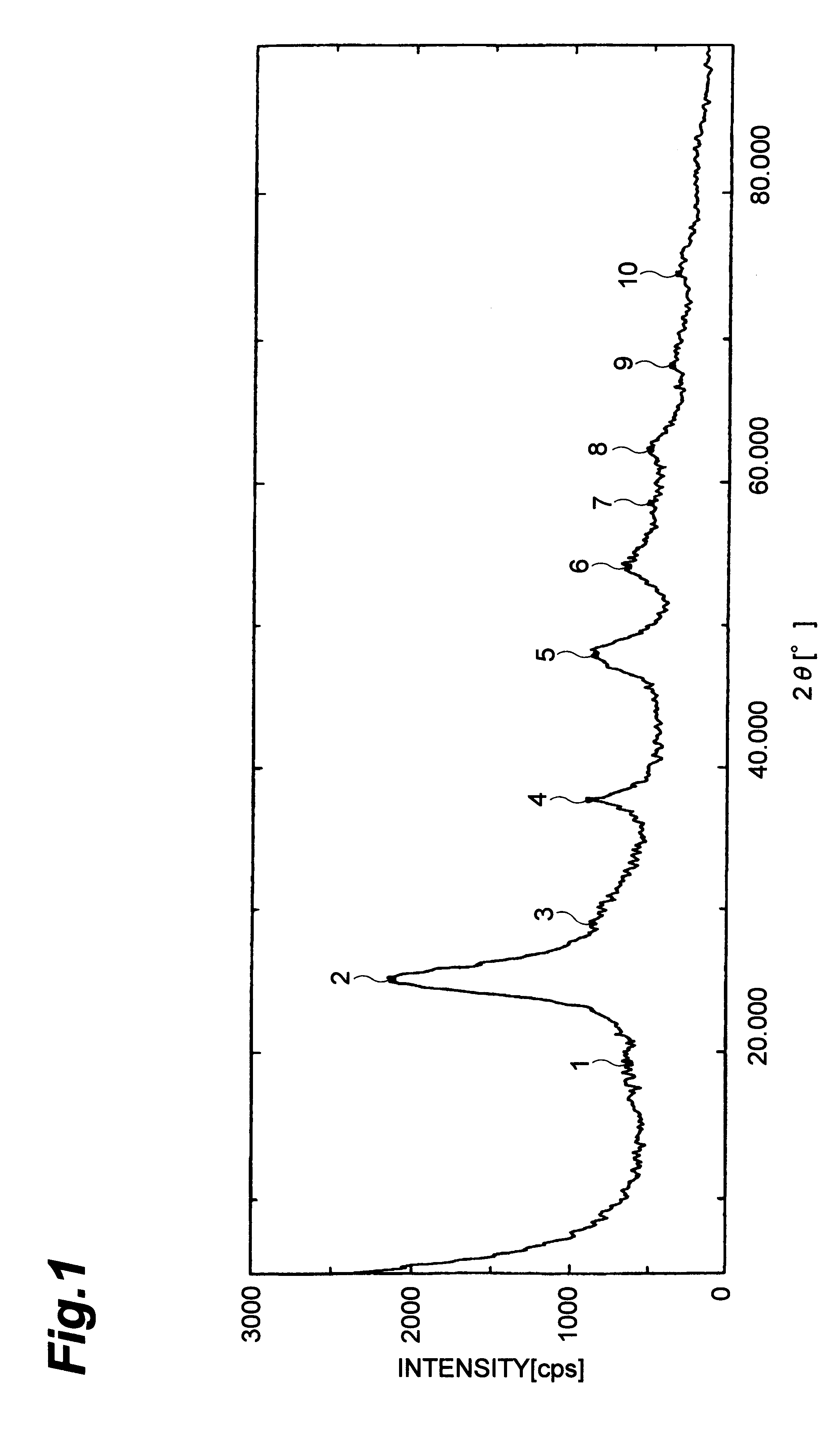

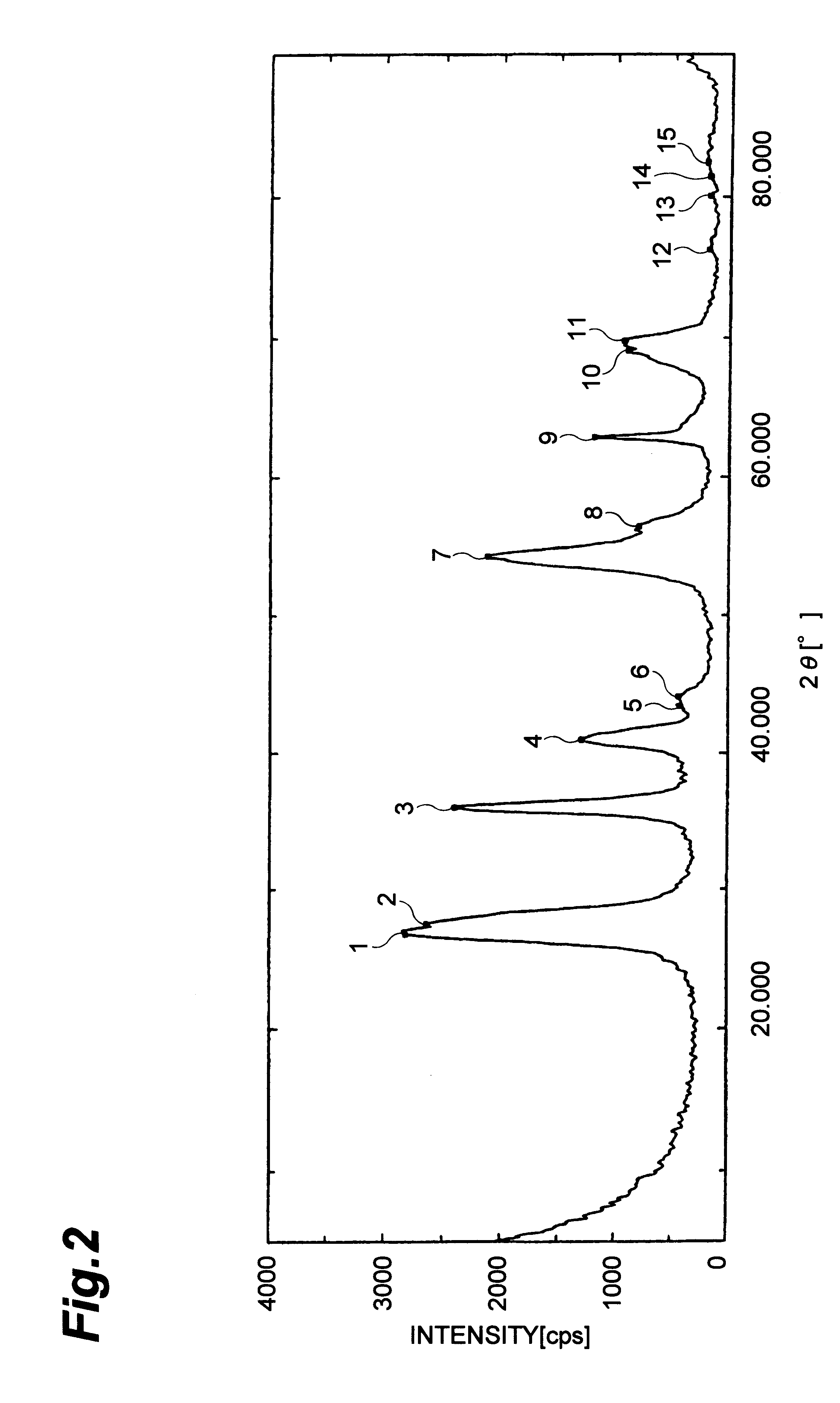

Garnet-type solid electrolyte, secondary battery containing garnet-type solid electrolyte, and method of producing garnet-type solid electrolyte

ActiveUS9034526B2Few crystal defectHigh crystallinityTin compoundsTantalum compoundsLithiumLanthanum

Owner:TOYOTA JIDOSHA KK +1

Thin film dielectrics with perovskite structure and preparation thereof

InactiveUS20050136292A1High thermodynamic stabilityLow temperature reactionTantalum compoundsFixed capacitor dielectricDielectric layerCapacitor

Methods of making a ternary oxide and a perovskite-related ternary oxide structure are described. The methods include reacting a binary oxide with a metal oxide or a metal hydroxide to form a ternary oxide dielectric layer on a substrate. Powders, anodes, pressed articles, and capacitors including the ternary oxide or perovskite-related ternary oxide structure as a dielectric layer or other layers are further described.

Owner:CABOT CORP

Method for producing metal oxide film, metal oxide film, element using the metal oxide film, substrate with metal oxide film, and device using the substrate with metal oxide film

InactiveCN102933496AImprove compactnessHigh strengthConductive layers on insulating-supportsTantalum compoundsPhysical chemistryThermal treatment

Disclosed are: a metal oxide film, which is formed by a coating method that is one of the methods for producing a metal oxide film, and which has a good balance between excellent transparency and high electrical conductivity, while having excellent film strength; and a method for producing the metal oxide film. Specifically disclosed is a method for producing a metal oxide film, which comprises: a coating step wherein a coating film is formed on a substrate using a metal oxide film-forming coating liquid that contains various organic metal compounds; a drying step wherein the coating film is changed into a dry coating film; and a heating step wherein an inorganic film is formed from the dry coating film. The method for producing a metal oxide film is characterized in that in the heating step, the dry coating film, which is mainly composed of the various organic metal compounds, is heated to a temperature at which at least mineralization of organic metal compound components occurs or higher in an oxygen-containing atmosphere at a temperature not higher than the temperature that is lower by 10 DEG C than the dew point, so that the organic components in the dry coating film are removed by thermal decomposition or combustion, or by thermal decomposition and combustion, thereby forming a metal oxide fine particle layer which is densely filled with metal oxide fine particles that are mainly composed of various metal oxides.

Owner:SUMITOMO METAL MINING CO LTD

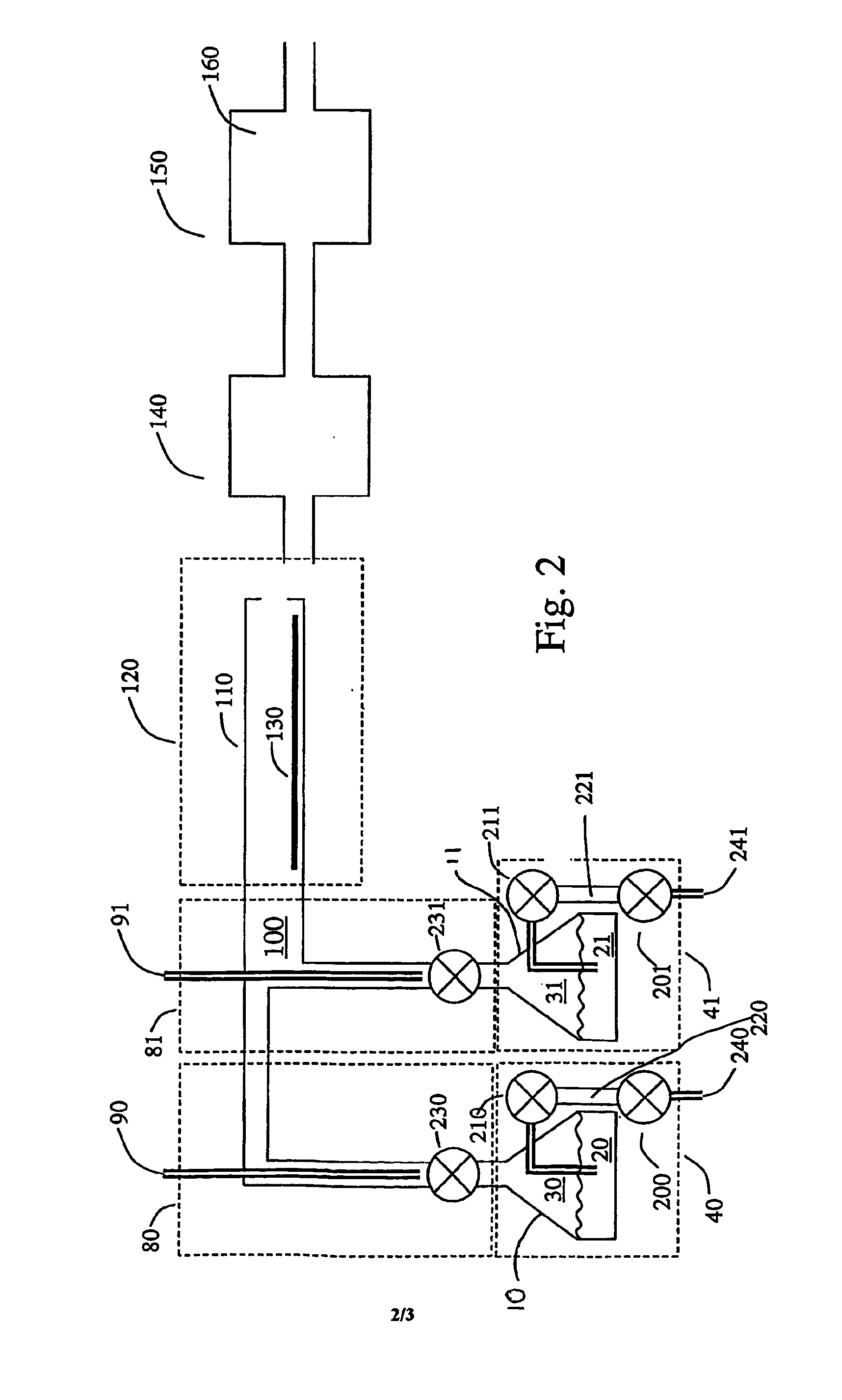

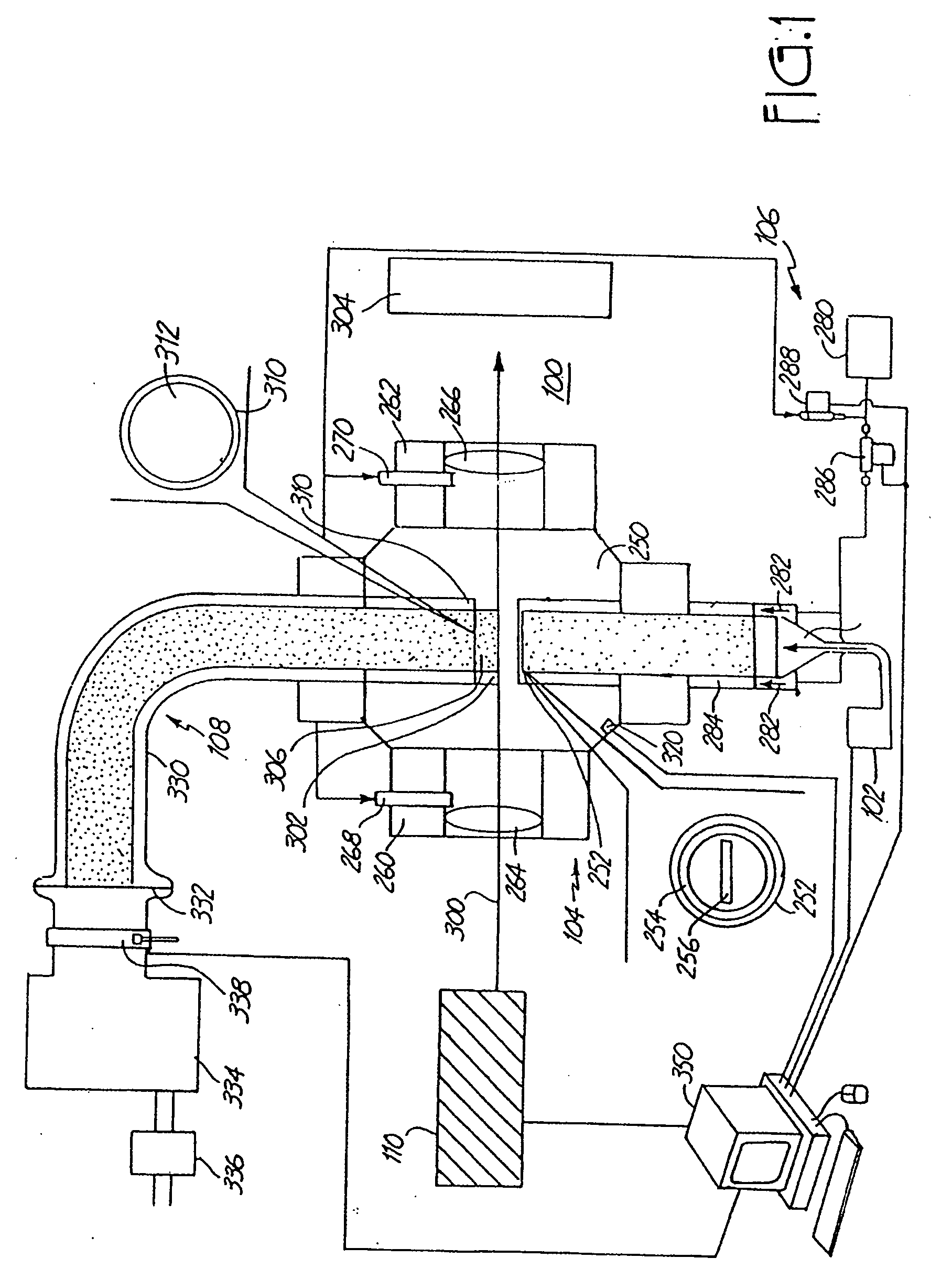

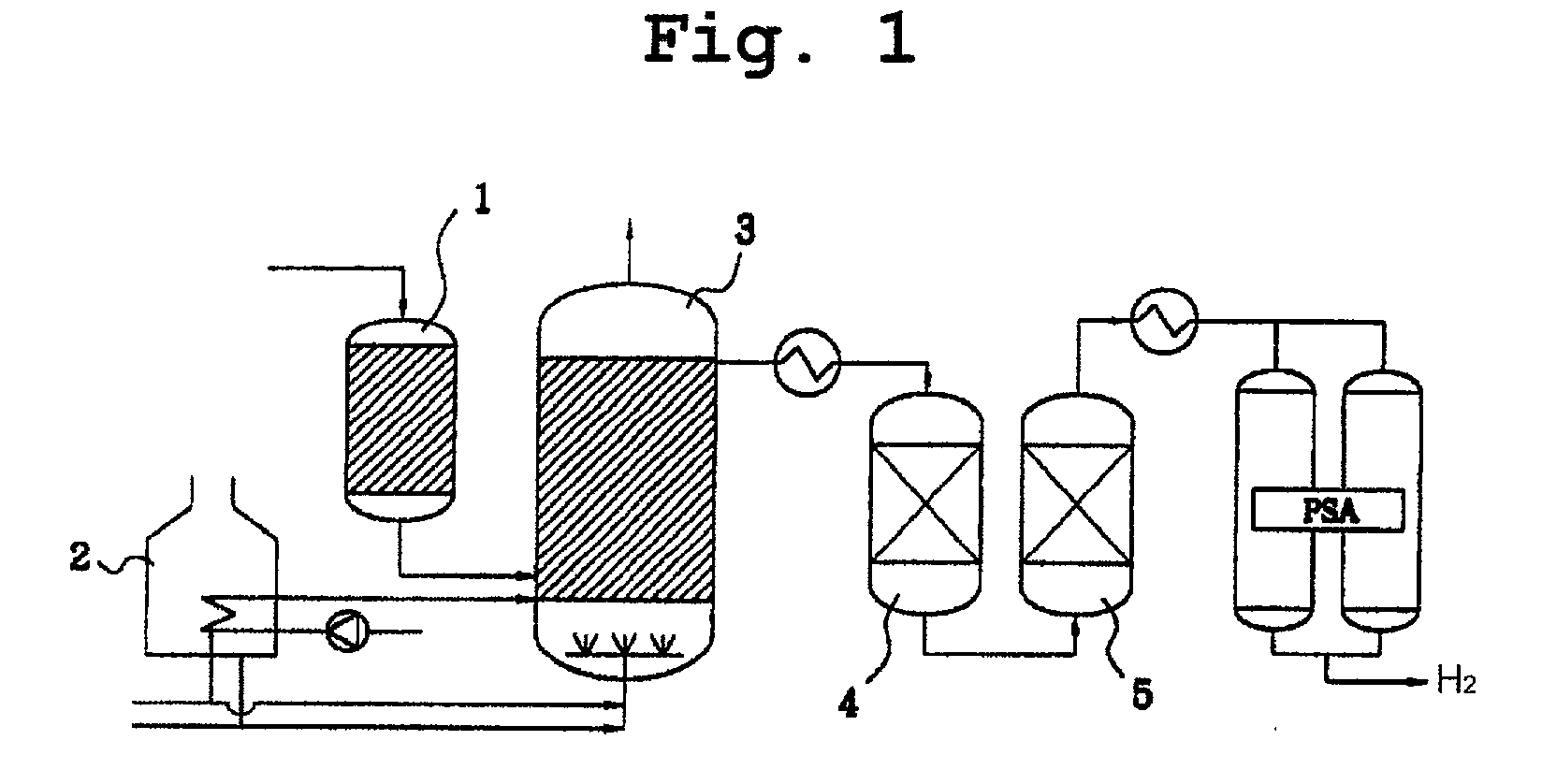

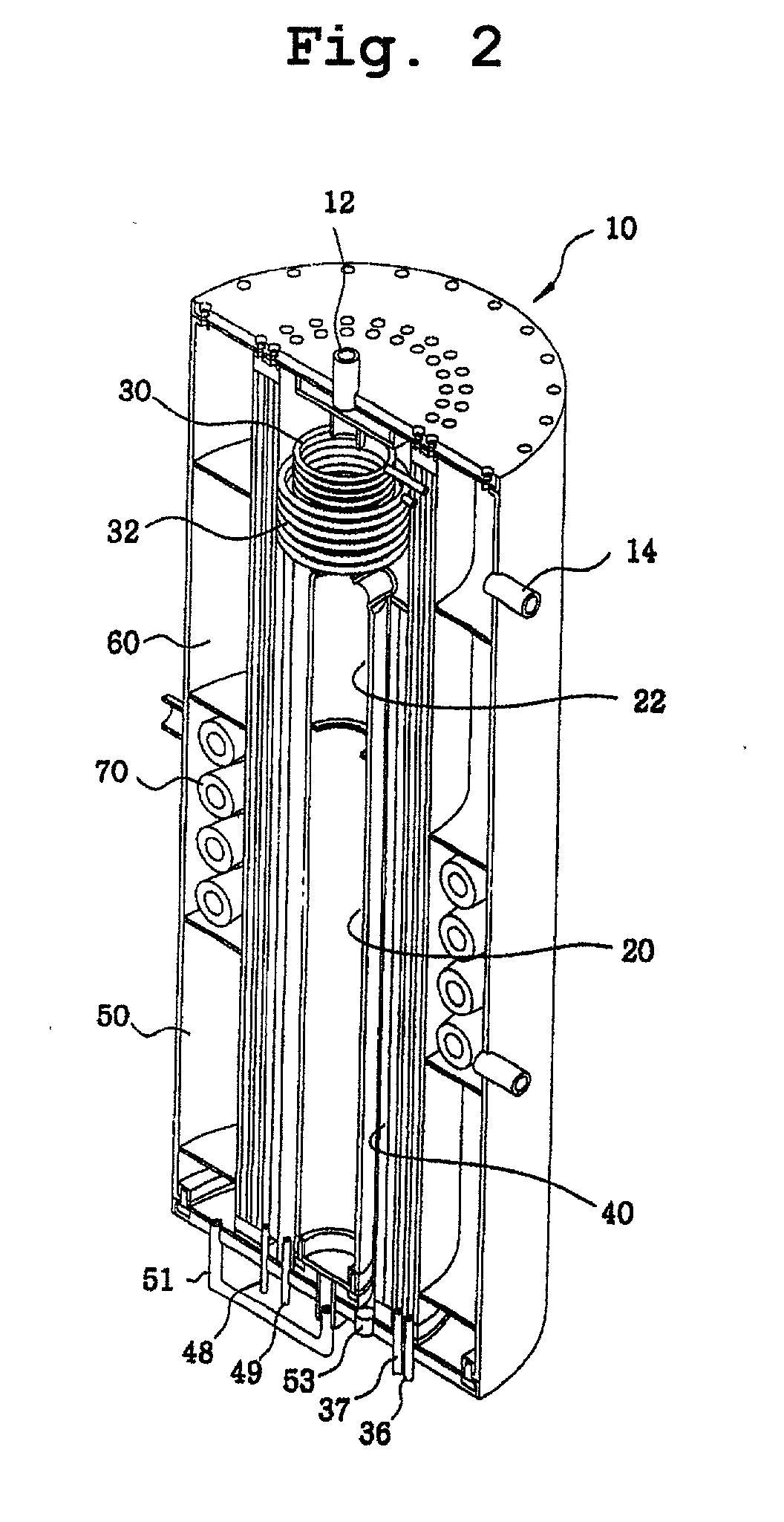

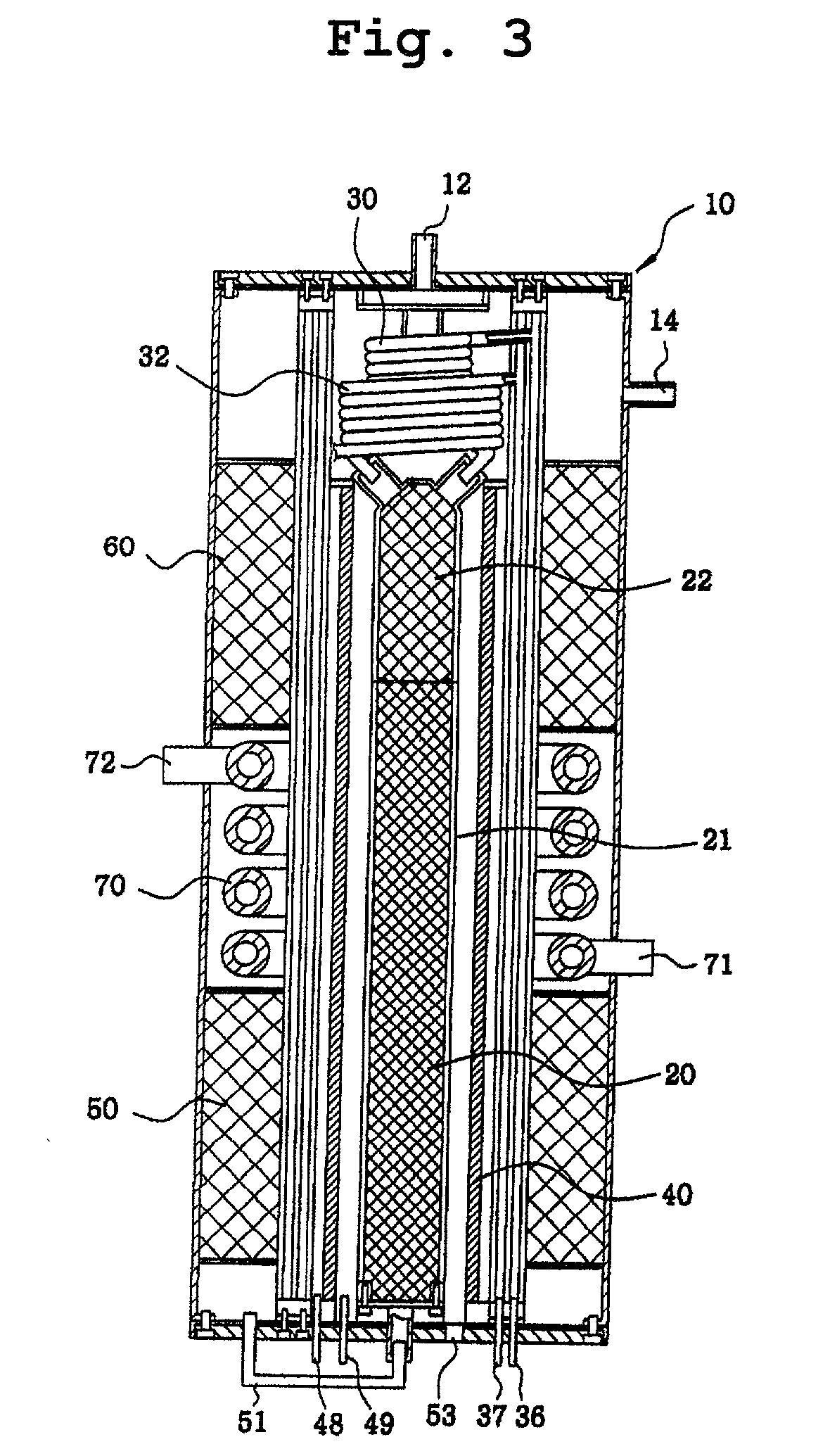

Compact steam reformer

Disclosed is a compact steam reformer which integrally comprises a housing; a reforming reactor having an upper mixing compartment for mixing natural gas and steam and a lower compartment for accommodating a catalyst bed; a natural gas feeding coiled pipe through which natural gas is introduced while being heated; a steam generating coiled pipe in which pure water is converted to steam by the exhaust; a metal fiber burner for heating the reforming reactor; a high-temperature converter for primarily removing carbon monoxide from a synthetic gas; a low-temperature converter for secondarily reducing the carbon monoxide level of the synthetic gas; and a heat exchanger, provided between the high-temperature converter and the low-temperature converter, for cooling the gas effluent from the high-temperature converter. The steam reformer enjoys the advantage of being easy to install in situ and being fabricated at low cost. Also, the cylindrical metal fiber burner can provide heat uniformly over the reforming reactor without a temperature gradient, thereby maximizing the reforming efficiency. The reformer has such a structure as to utilize the heat of the burner exhaust in generating steam, bringing about an effect of reducing the cost of the reformer because no additional steam generators are required.

Owner:KOREA GAS CORPORATION +2

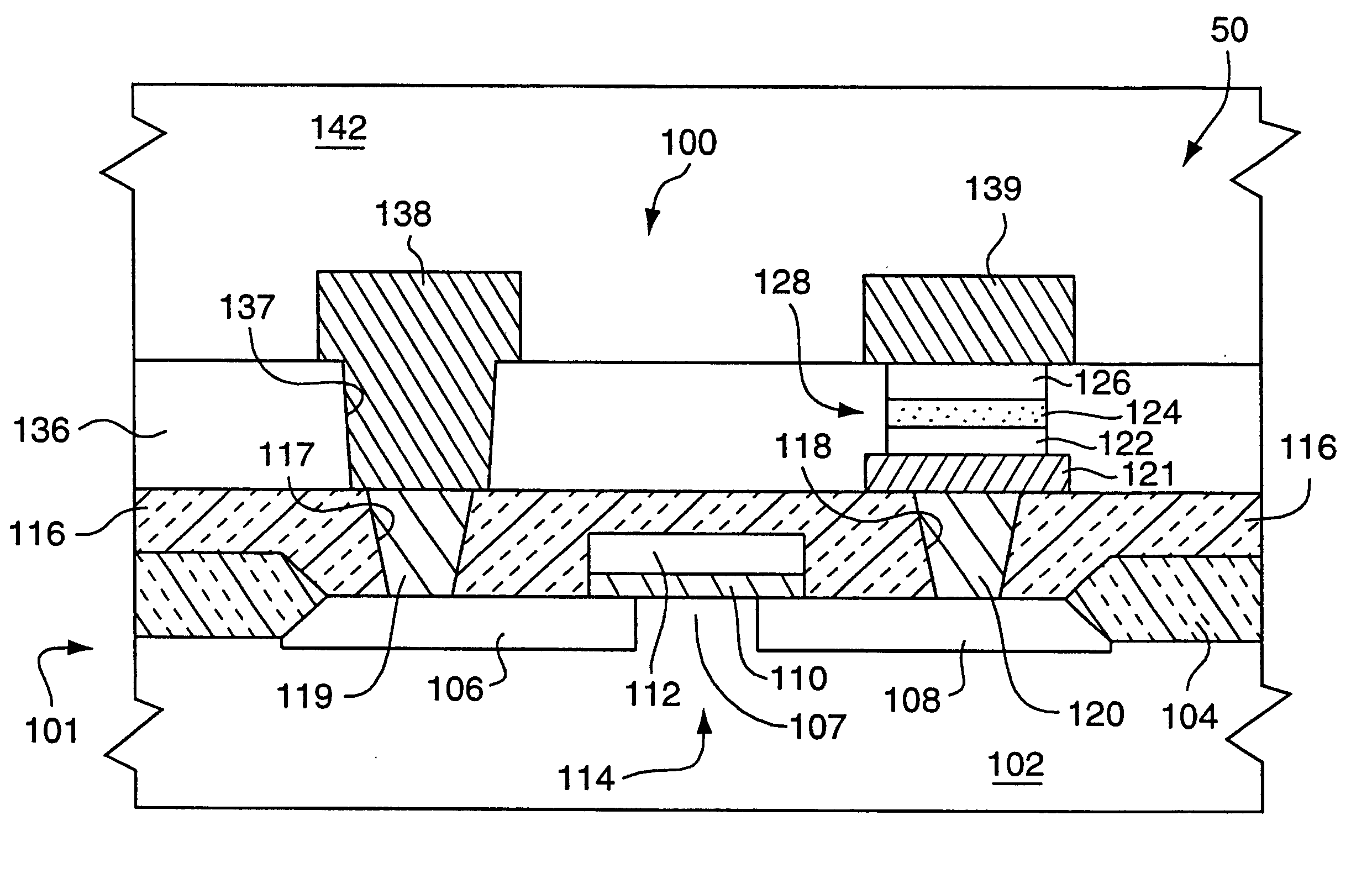

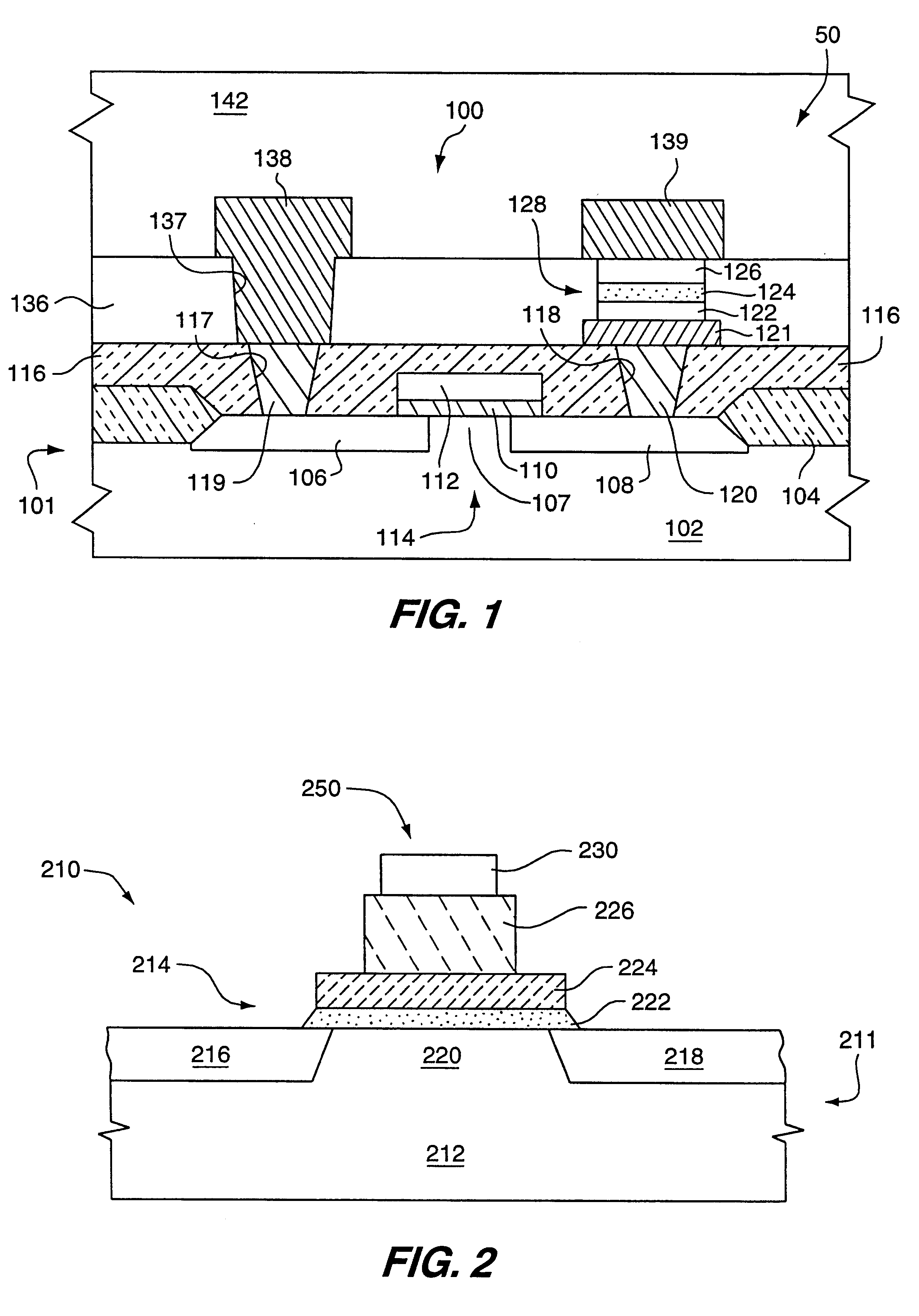

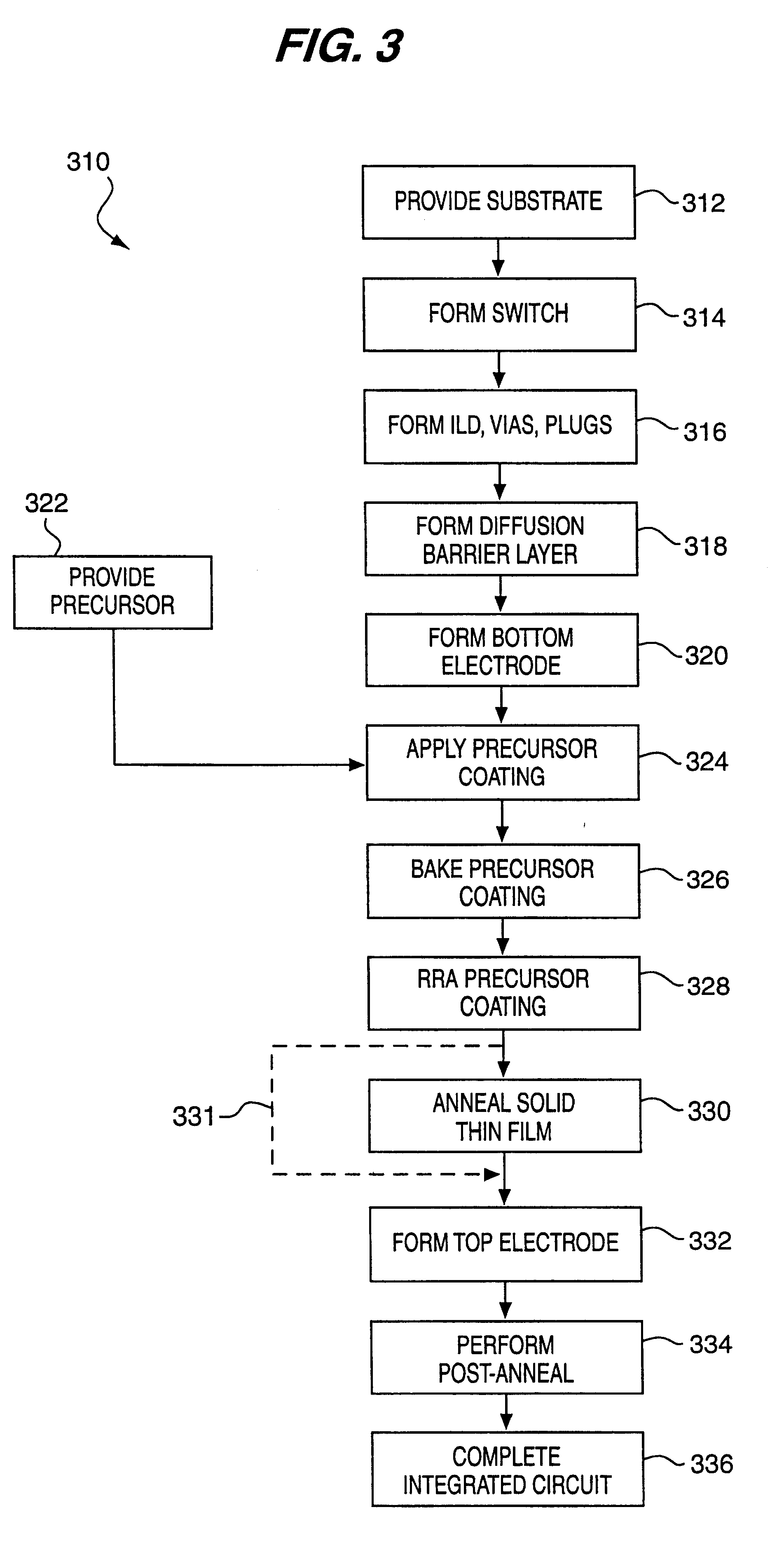

Low temperature rapid ramping anneal method for fabricating layered superlattice materials and making electronic devices including same

A liquid precursor for forming a layered superlattice material is applied to an integrated circuit substrate. The precursor coating is annealed in oxygen using a rapid ramping anneal ("RRA") technique with a ramping rate of 50.degree. C. / second at a hold temperature of 650.degree. C. for a holding time of 30 minutes.

Owner:SYMETRIX +1

Method for recycling spent lithium metal polymer rechargeable batteries and related materials

The method relates to a pyrometallurgical and hydrometallurgical process for the recovery and recycling of lithium and vanadium compounds from a material comprising spent rechargeable lithium batteries, particularly lithium metal gel and solid polymer electrolyte rechargeable batteries. The method involves providing a mass of the material, hardening it by cooling at a temperature below room temperature, comminuting the mass of cooled and hardened material, digesting with an acid its ashes obtained by incineration, or its solidified salts obtained by molten salt oxidation, or the comminuted mass itself, to give a mother liquor, extracting vanadium compounds from the mother liquor, separating heavy metals and aluminium therefrom, and precipitating lithium carbonate from the remaining solution.

Owner:AVESTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com