Method for producing metal oxide film, metal oxide film, element using the metal oxide film, substrate with metal oxide film, and device using the substrate with metal oxide film

一种氧化物膜、制造方法的技术,应用在稀土金属氧化物/氢氧化物、镧系元素氧化物/氢氧化物、氧气/臭氧/氧化物/氢氧化物等方向,能够解决难致密化、致密性低、膜强度低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0258] [Preparation of coating solution]

[0259] Hafnium n-butoxide (liquid at room temperature) [Hf(OC 4 h 9 ) 4 ] (molecular weight = 470.95) 10g, N-methyl-2-pyrrolidone (NMP) 14g, diethylene glycol monoethyl ether (ethyl carbitol) 25g, hydroxypropyl cellulose (HPC; low molecular weight type) 1g Mix, heat to 120°C, stir for 60 minutes to dissolve, then mix 43g of ethanol (EA) and 7g of isopropanol (IPA) into 50g of the obtained solution, stir well until uniform, and make n-butanol A coating liquid for forming a metal oxide film comprising 10% by weight of hafnium and 1% by weight of hydroxypropyl cellulose. The viscosity (25° C.) of the coating liquid for forming a metal oxide film is about 10 mPa·s.

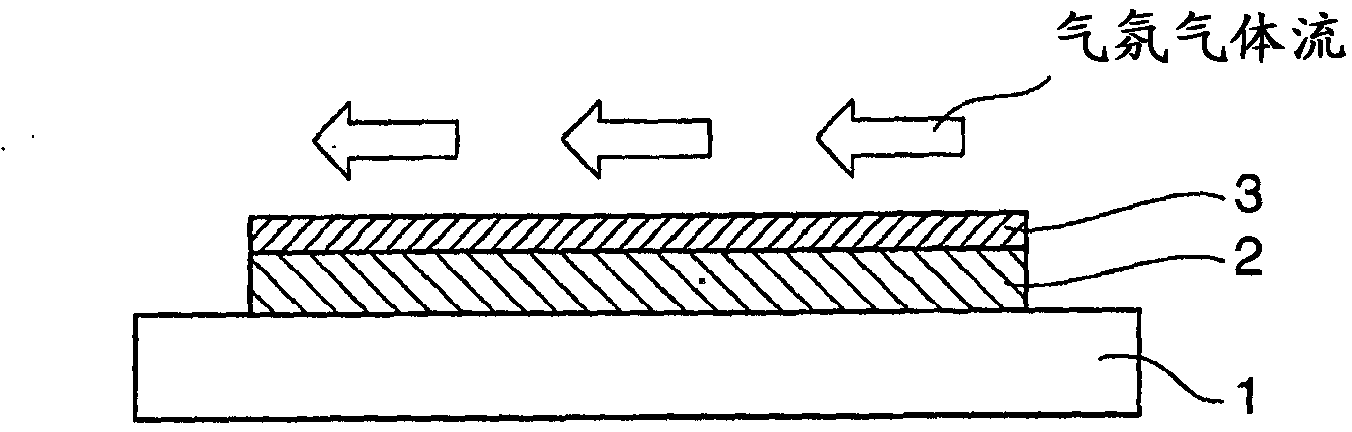

[0260] [Production of metal oxide film]

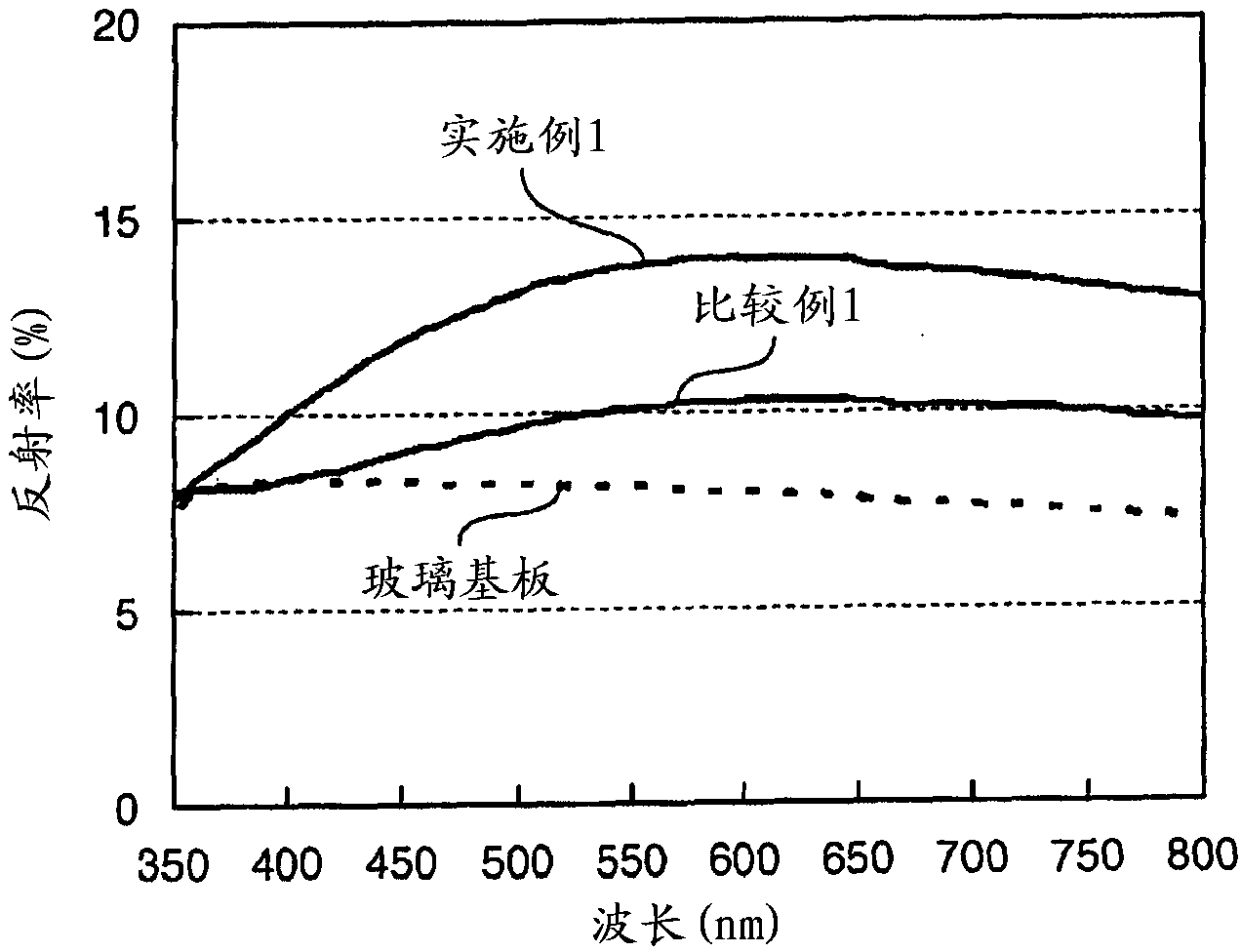

[0261] The prepared coating solution for forming a metal oxide film was applied on a soda-lime glass substrate (10cm×10cm×thickness 3mm; haze value = 0.26%, visible light transmittance = 91.1%, refractive index = 1.53) at 25°C ov...

Embodiment 2

[0277] [Preparation of coating solution]

[0278] Niobium n-butoxide (liquid at room temperature) [Nb(C 4 h 9 o) 5 ] (molecular weight = 458.12) 10g, N-methyl-2-pyrrolidone (NMP) 14g, diethylene glycol monoethyl ether (ethyl carbitol) 25g, hydroxypropyl cellulose (HPC; low molecular weight type) 1g Mix, heat to 120°C, stir for 60 minutes to dissolve, then mix 43g of ethanol (EA) and 7g of isopropanol (IPA) into 50g of the obtained solution, stir well until uniform, and make n-butanol A coating solution for forming a metal oxide film comprising 10% by weight of niobium and 1% by weight of hydroxypropyl cellulose. The viscosity (25° C.) of the coating liquid for forming a metal oxide film is about 10 mPa·s.

[0279] The prepared coating solution for forming a metal oxide film was applied on a soda-lime glass substrate (10cm×10cm×thickness 3mm; haze value = 0.26%, visible light transmittance = 91.1%, refractive index = 1.53) at 25°C over the entire After forming a spin coating...

Embodiment 3

[0283] [Preparation of coating solution]

[0284] Zirconium n-butoxide (liquid at room temperature) [Zr(C 4 h 9 O) 4 ] (molecular weight = 383.68) 10g, N-methyl-2-pyrrolidone (NMP) 14g, diethylene glycol monoethyl ether (ethyl carbitol) 25g, hydroxypropyl cellulose (HPC; low molecular weight type) 1g Mix, heat to 120°C, stir for 60 minutes to dissolve, then mix 43g of ethanol (EA) and 7g of isopropanol (IPA) into 50g of the obtained solution, stir well until uniform, and make n-butanol A coating liquid for forming a metal oxide film comprising 10% by weight of zirconium and 1% by weight of hydroxypropyl cellulose. The viscosity (25° C.) of the coating liquid for forming a metal oxide film is about 10 mPa·s.

[0285] Except for using the coating solution for forming a metal oxide film, film formation was carried out in the same manner as in Example 2, and a zirconia (ZrO 2 ) The metal oxide film of Example 3 with the main component.

[0286] Various characteristics of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

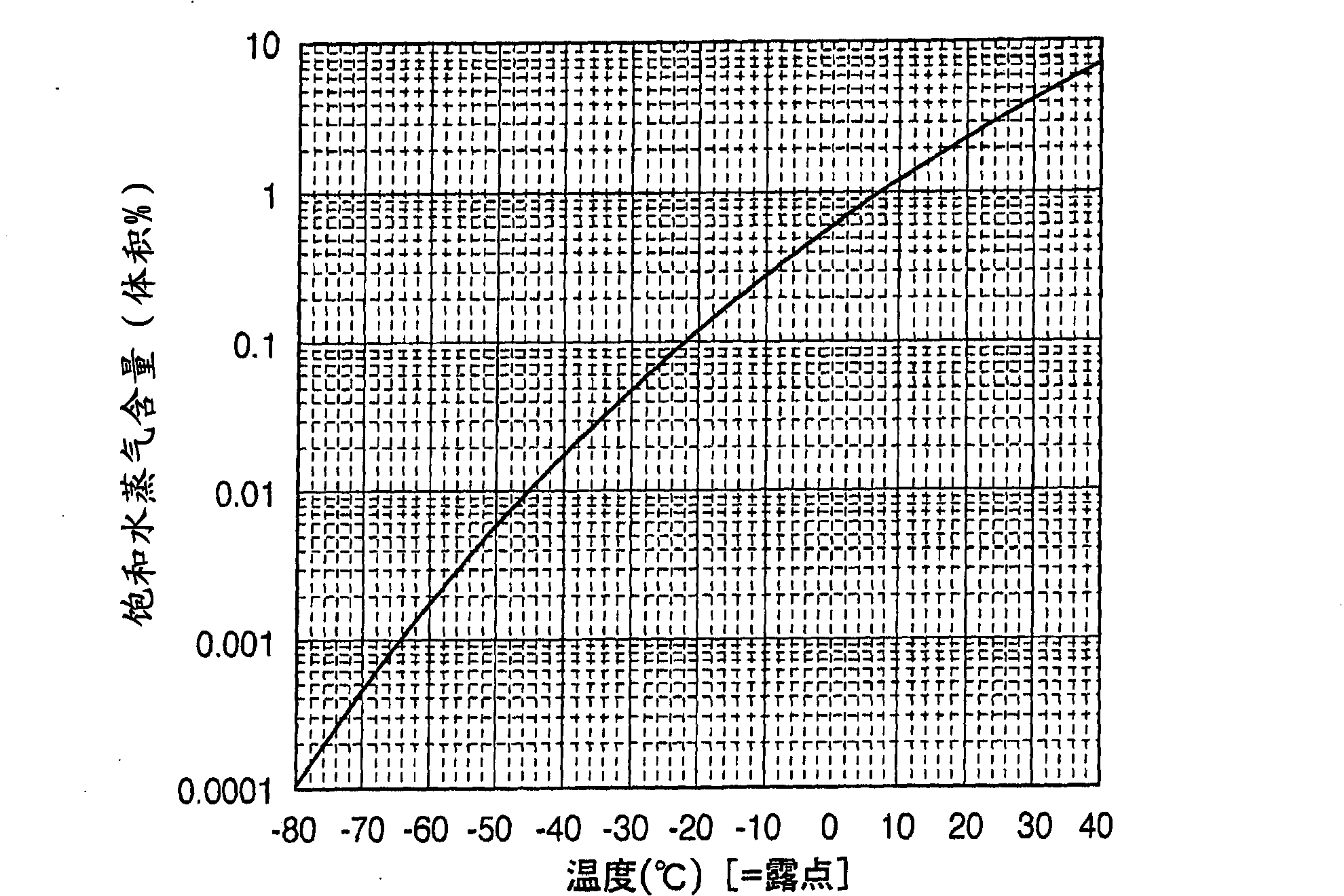

| humidity | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com