Patents

Literature

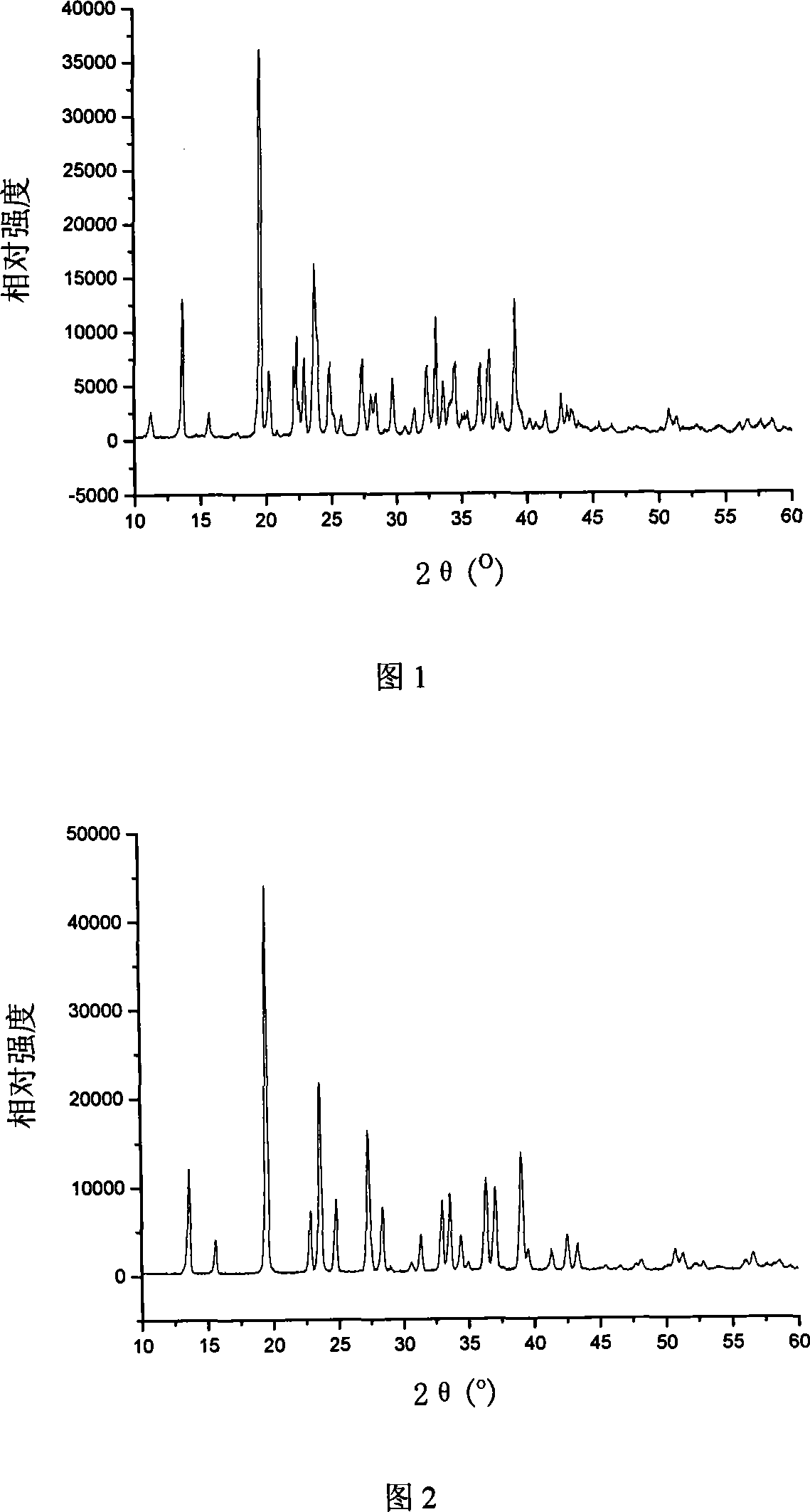

330 results about "Lithium borate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium borate, also known as lithium tetraborate is an inorganic compound with the formula Li₂B₄O₇. A colorless solid, lithium borate is used in making glasses and ceramics.

Non-aqueous electrolytic solution

InactiveUS20060236528A1Improve battery performancePrevent overchargingNon-aqueous electrolyte accumulatorsFinal product manufactureLithiumEngineering

Owner:FERRO CORP

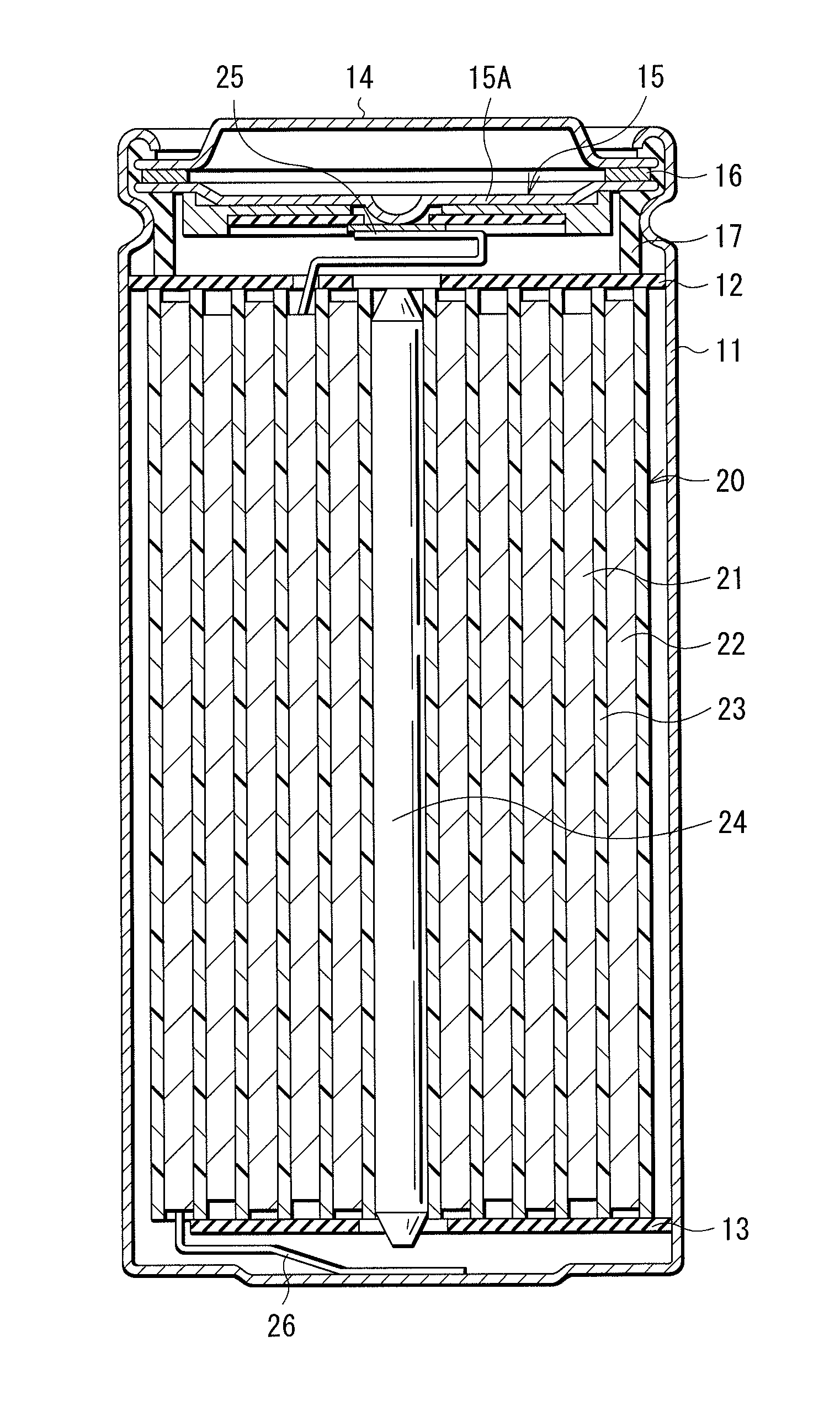

Battery

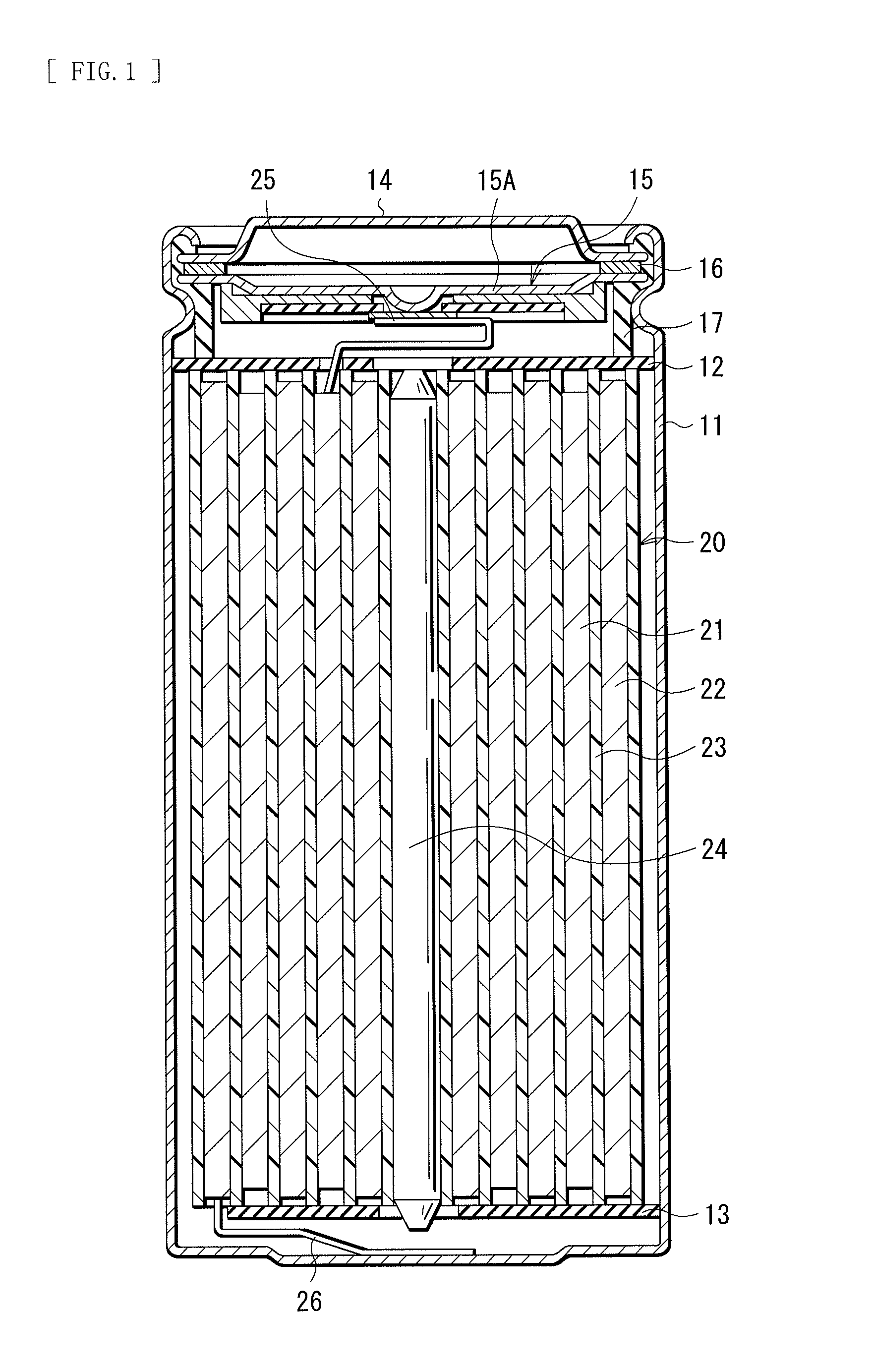

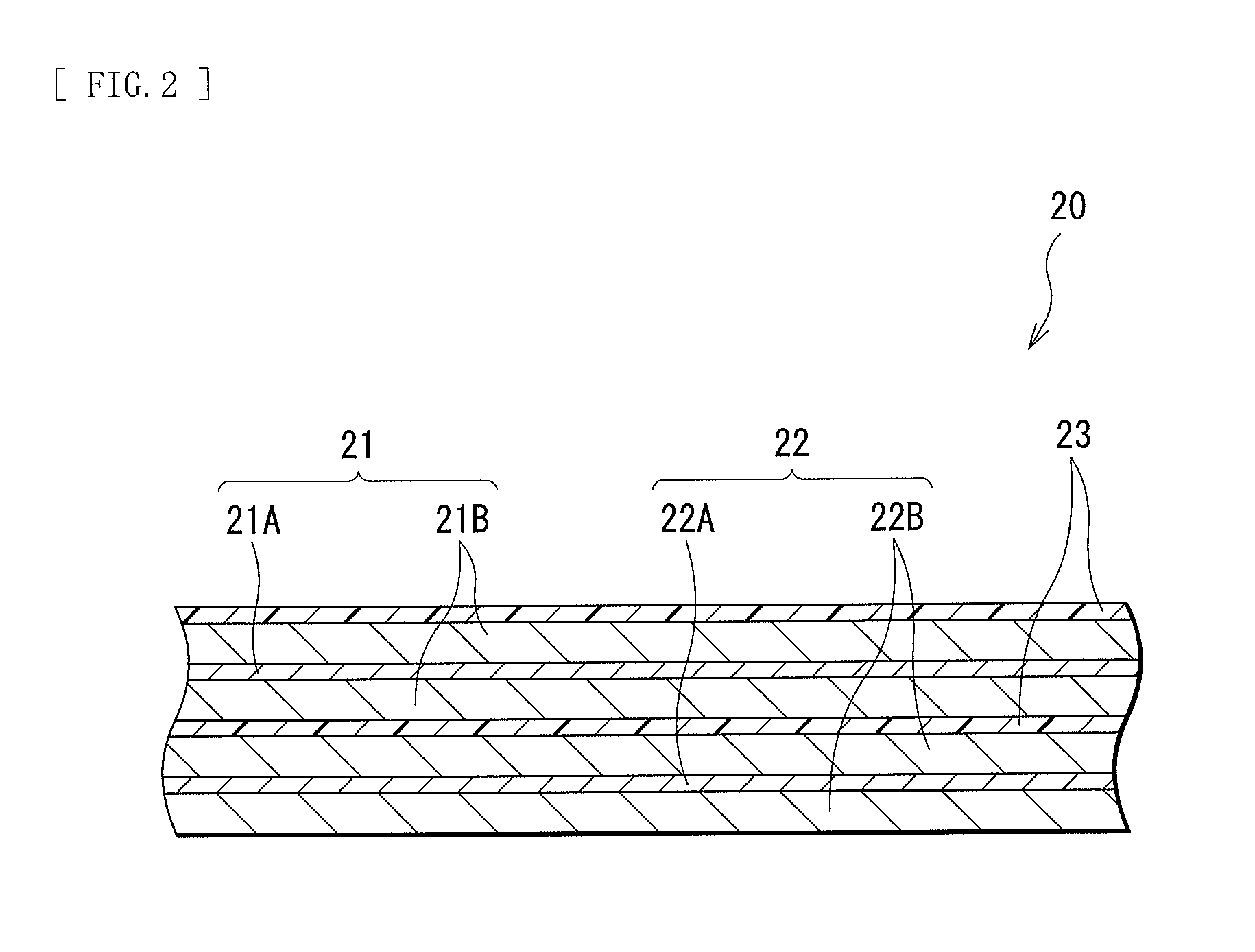

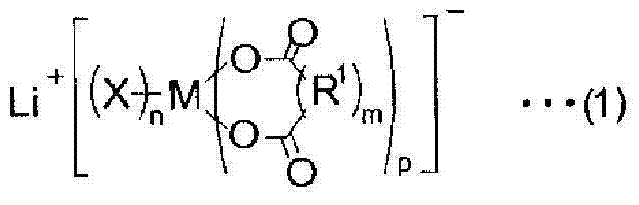

ActiveUS20050095503A1Large capacityImprove featuresElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesDecompositionAlloy

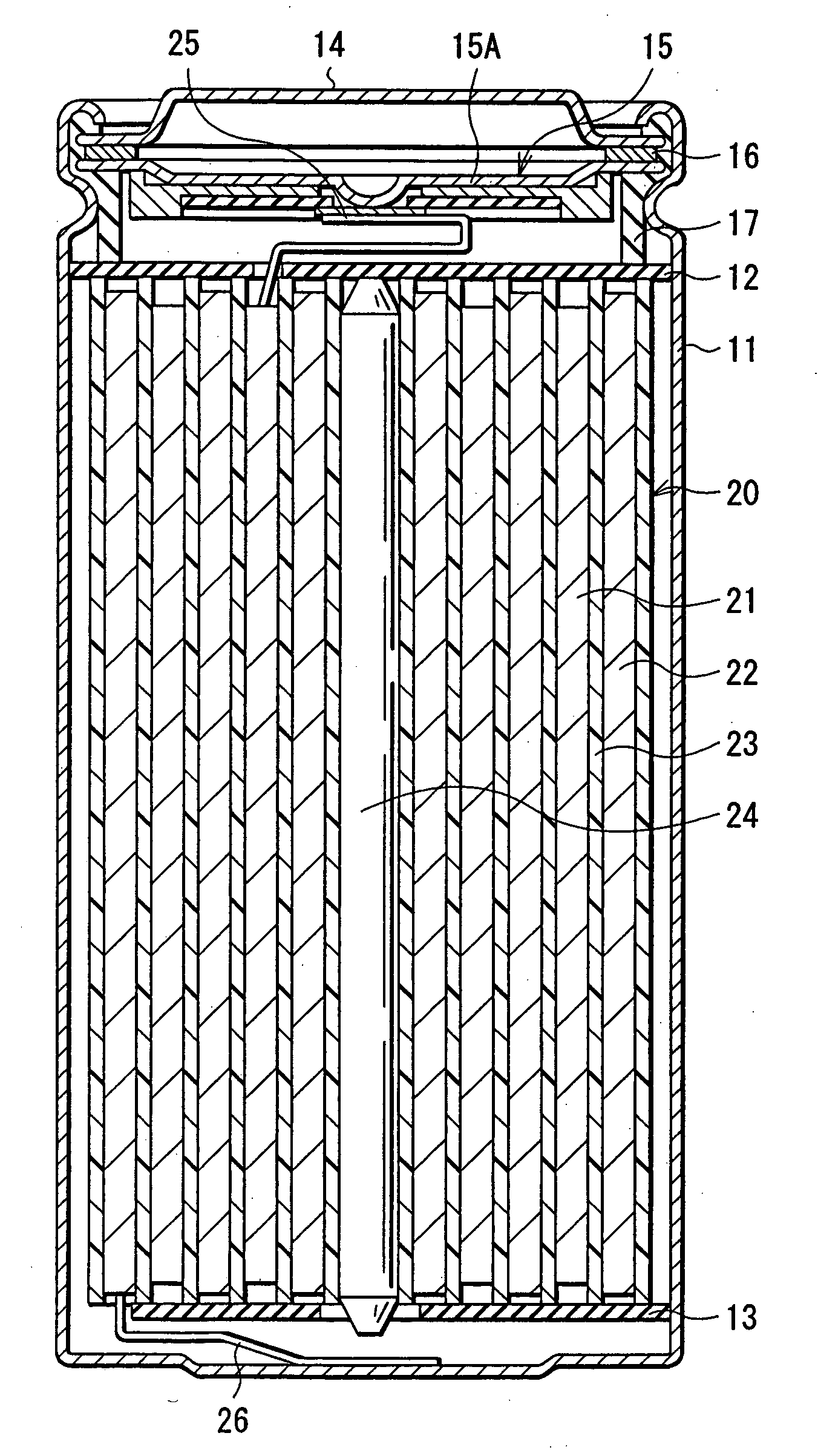

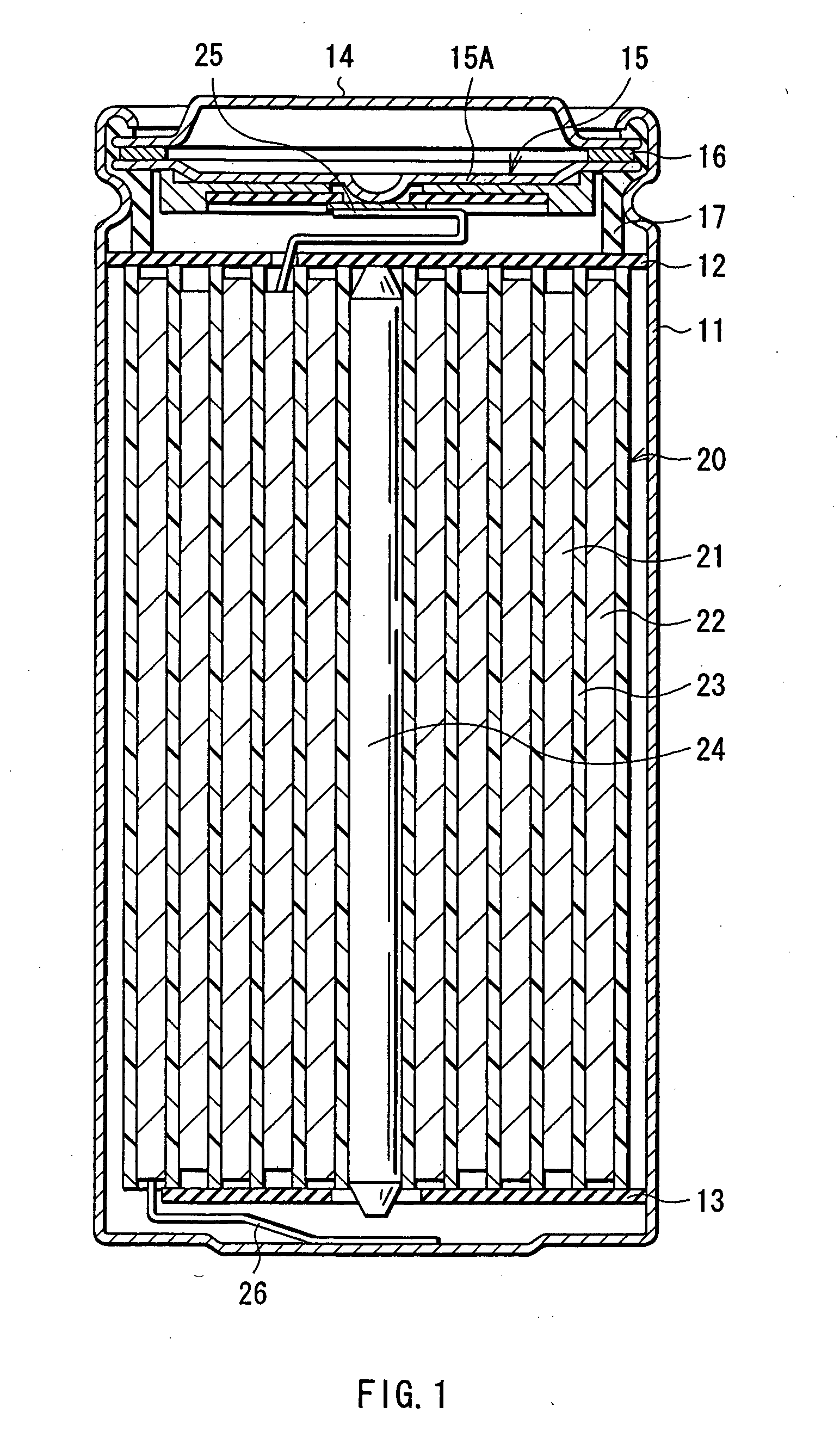

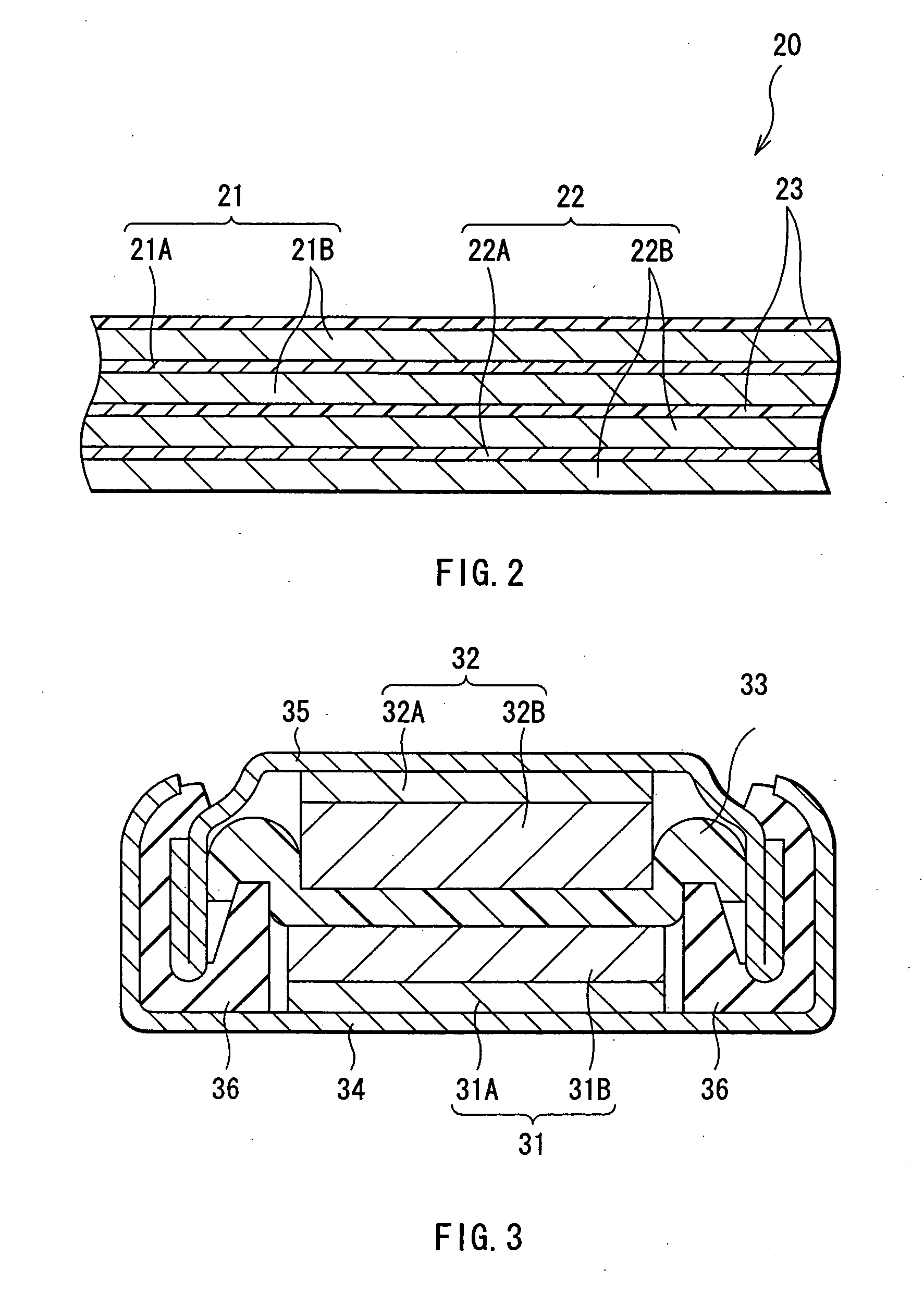

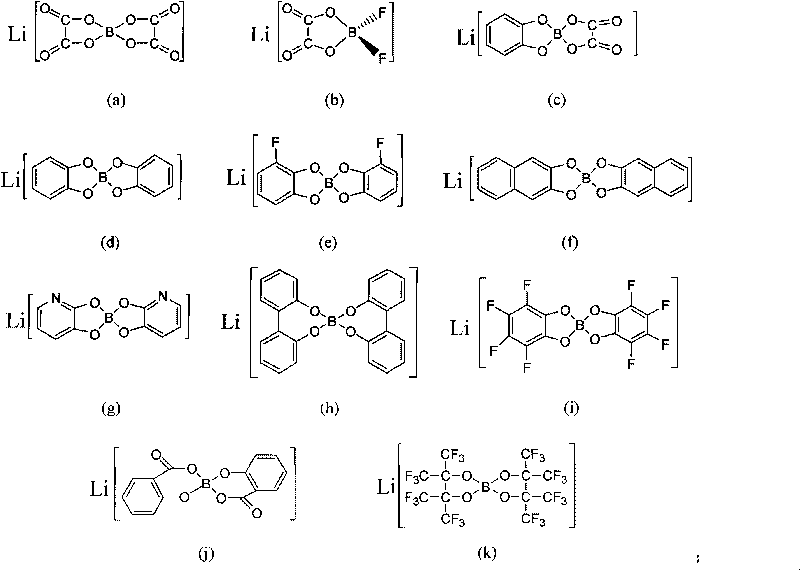

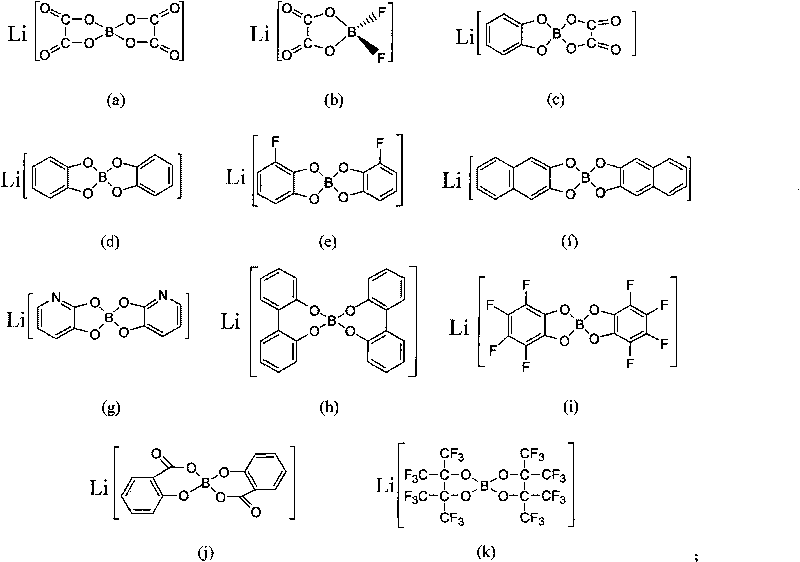

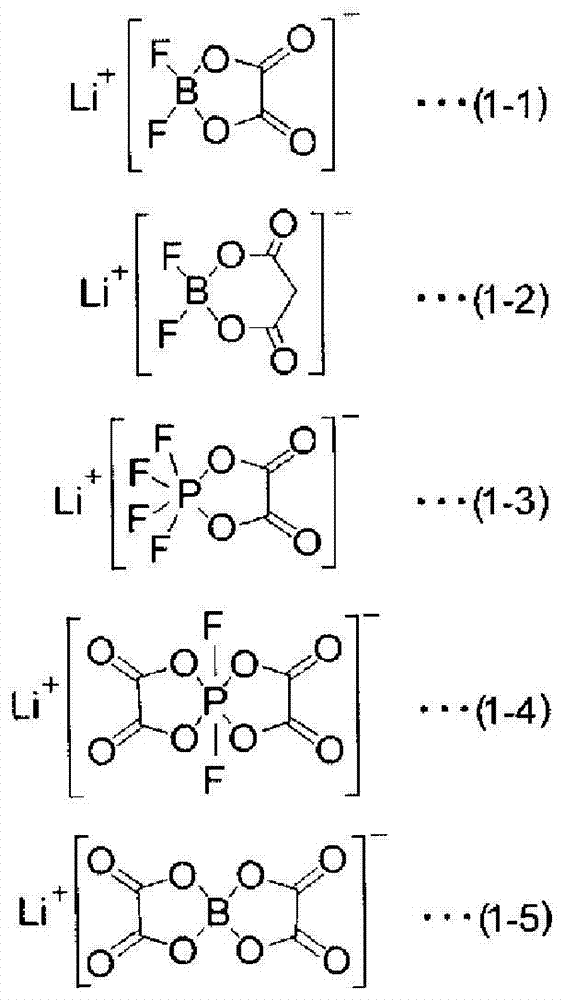

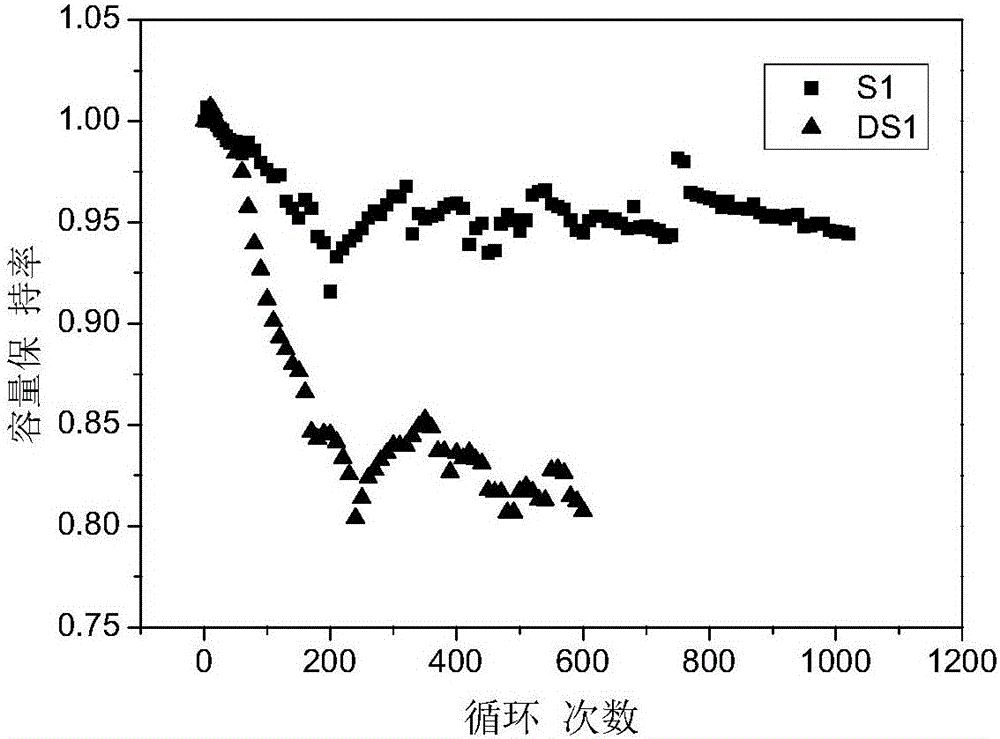

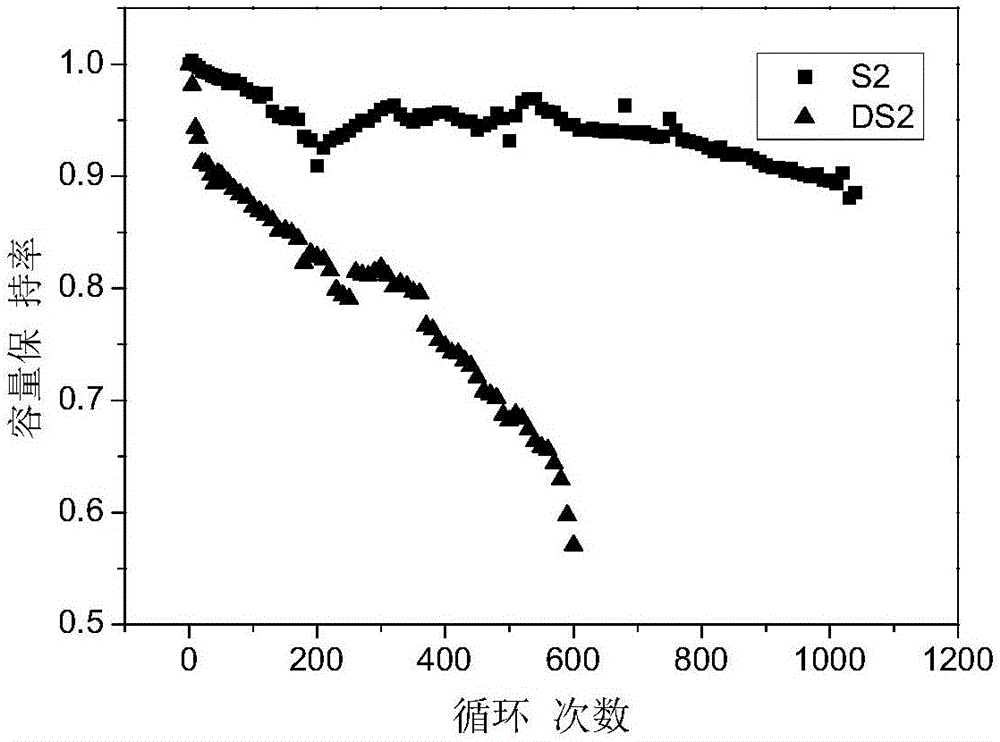

A battery is provided which has a high capacity and can improve battery characteristics, such as cycle characteristics. The battery includes a spirally wound electrode body, wherein a cathode and an anode are wound with a separator in between. The anode includes, for example, simple substances, alloys, compounds of metal elements or metalloid elements capable of forming an alloy with Li, the like and combinations thereof. An electrolytic solution wherein an electrolyte salt is dissolved in a solvent is impregnated in the separator. For the electrolyte salt, a light metallic salt having B—O bond or P—O bond, such as difluoro[oxalato-O,O′]lithium borate and tetra fluoro[oxalato-O,O′]lithium phosphate, can be used. By forming a stable coating, decomposition reaction of the solvent can be inhibited, and reaction between the anode and the solvent can be prevented.

Owner:SONY CORP +1

Composite lithium-base grease and method for making same

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

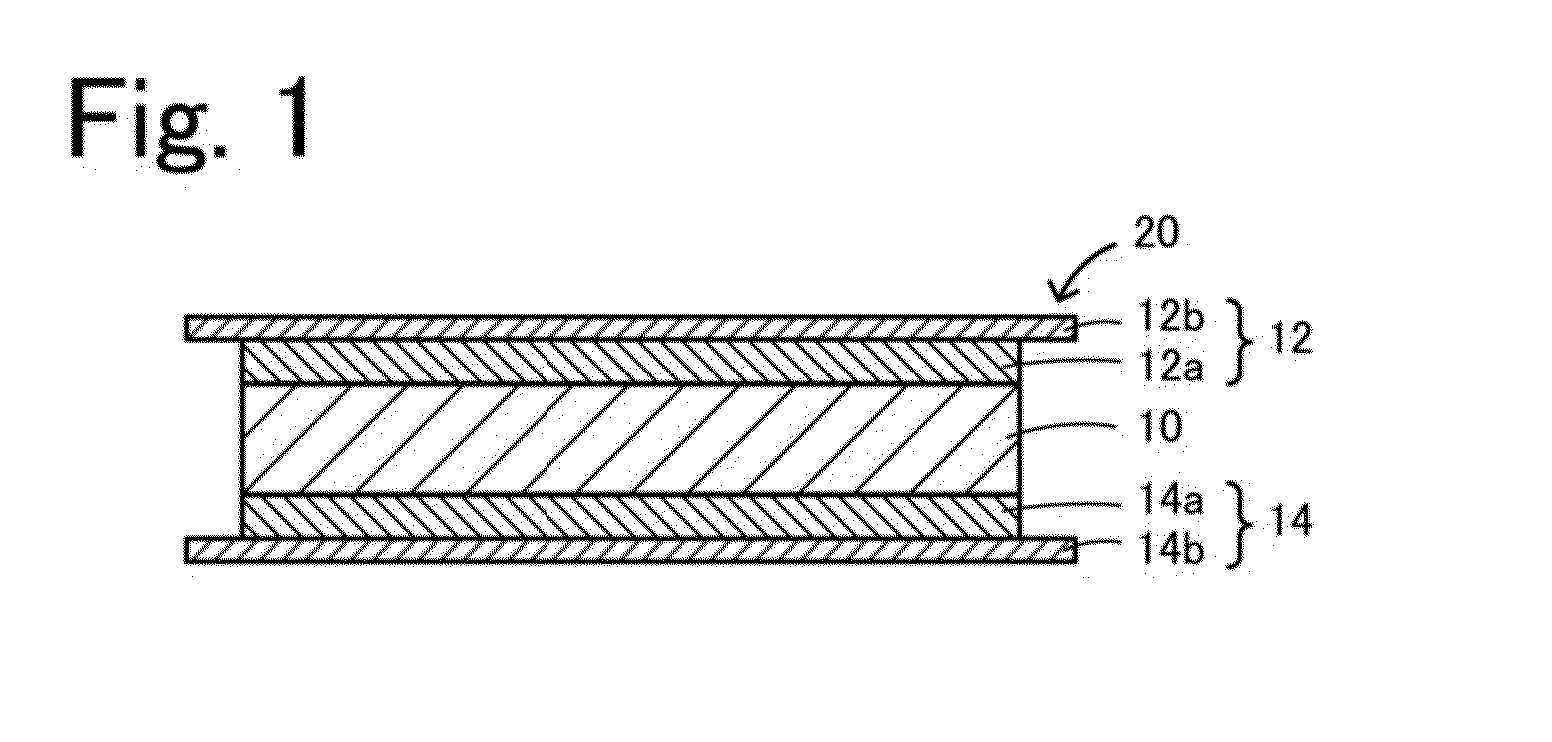

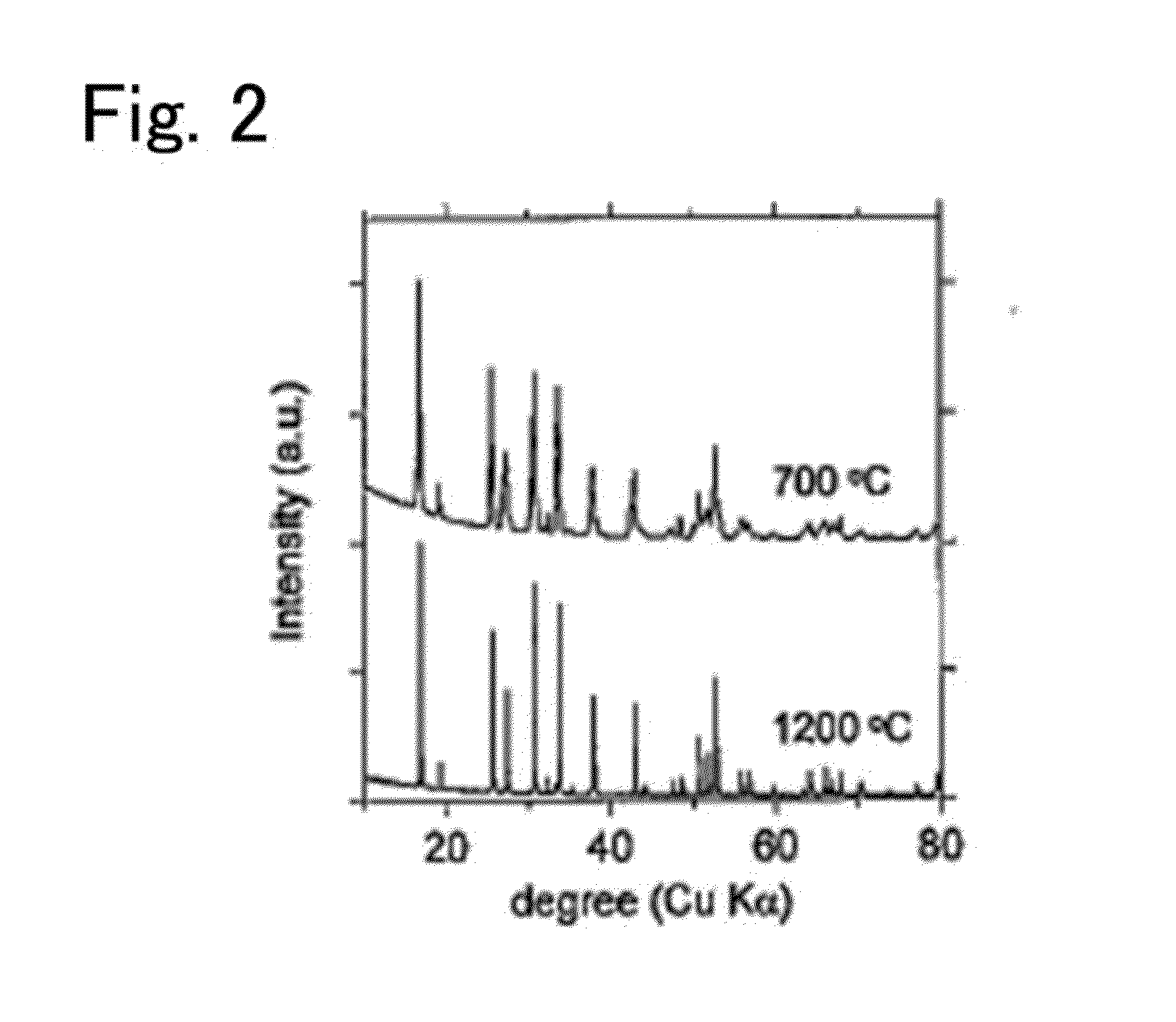

Garnet-type ion conducting oxide, complex, lithium secondary battery, manufacturing method of garnet-type ion conducting oxide and manufacturing method of complex

ActiveUS20150056519A1Reduce the temperatureAccelerates dissolution and diffusionElectrode thermal treatmentFinal product manufactureElectrolyteLithium borate

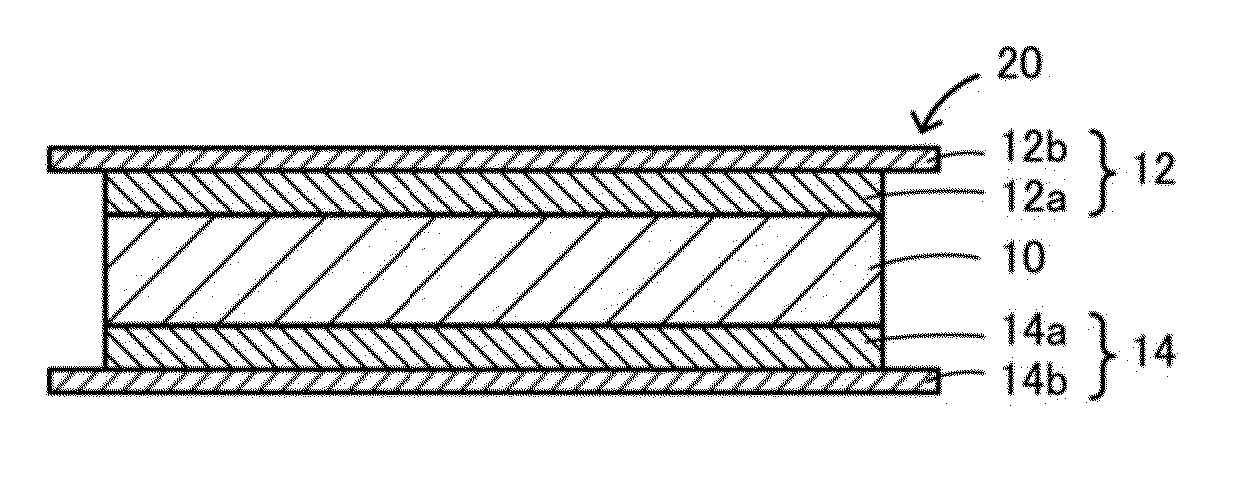

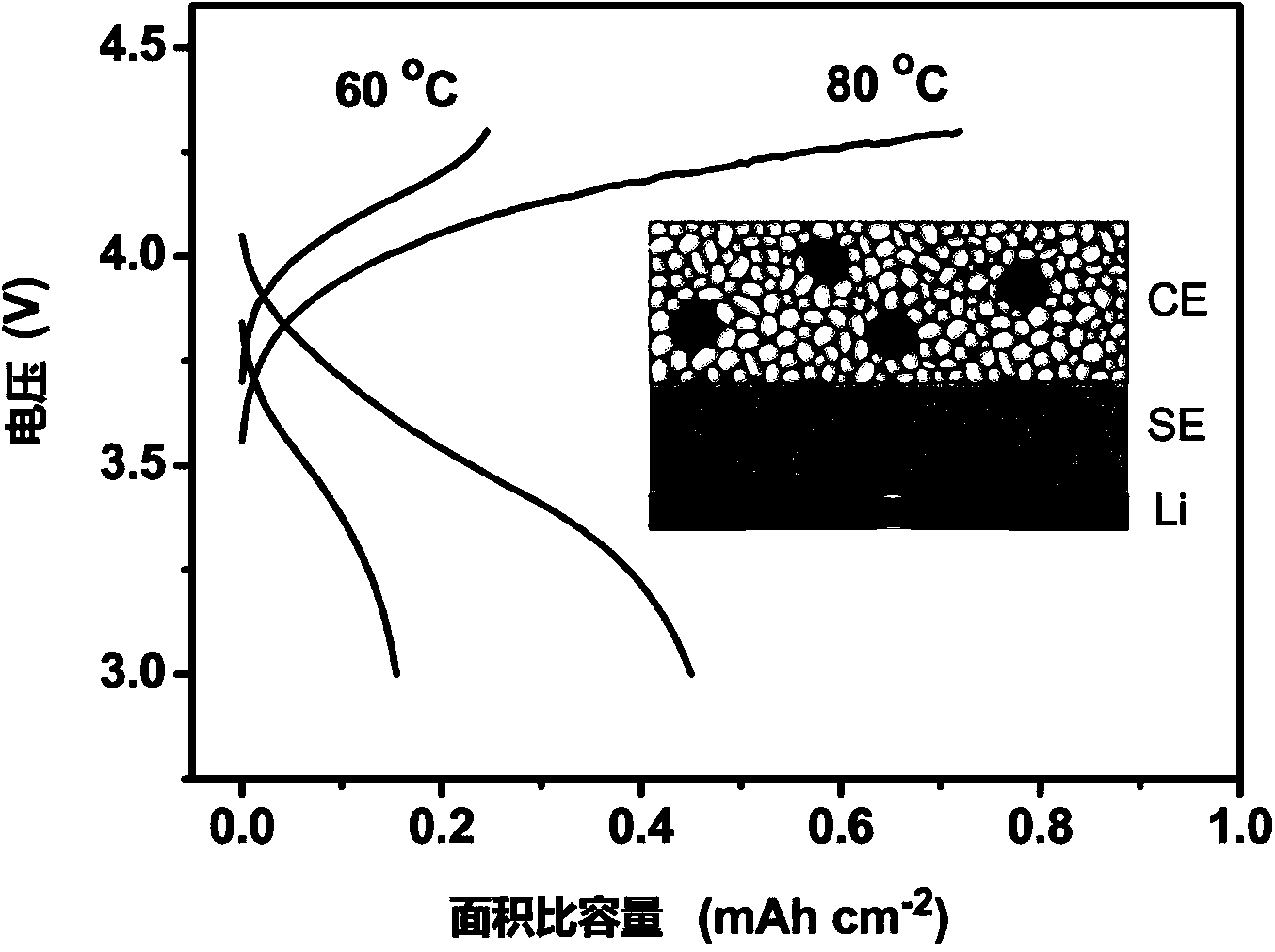

An all-solid lithium secondary battery 20 includes a solid electrolyte layer 10 composed of a garnet-type oxide, a positive electrode 12 formed on one surface of the solid electrolyte layer 10 and a negative electrode 14 formed on the other surface of the solid electrolyte layer 10. This all-solid lithium secondary battery 20 includes an integrally sintered complex of the solid electrolyte layer 10 and the positive electrode active material layer 12a. This complex is obtained by integrally sintering a stacked structure of an active material layer and a solid electrolyte layer. The solid electrolyte layer includes: abase material mainly including a fundamental composition of Li7+X−Y(La3−x,Ax) (Zr2−Y,TY)O12, wherein A is one or more of Sr and Ca, T is one or more of Nb and Ta, and 0≦X≦1.0 and 0≦Y<0.75 are satisfied, as a main component; and an additive component including lithium borate and aluminum oxide.

Owner:TOYOTA CENT RES & DEV LAB INC

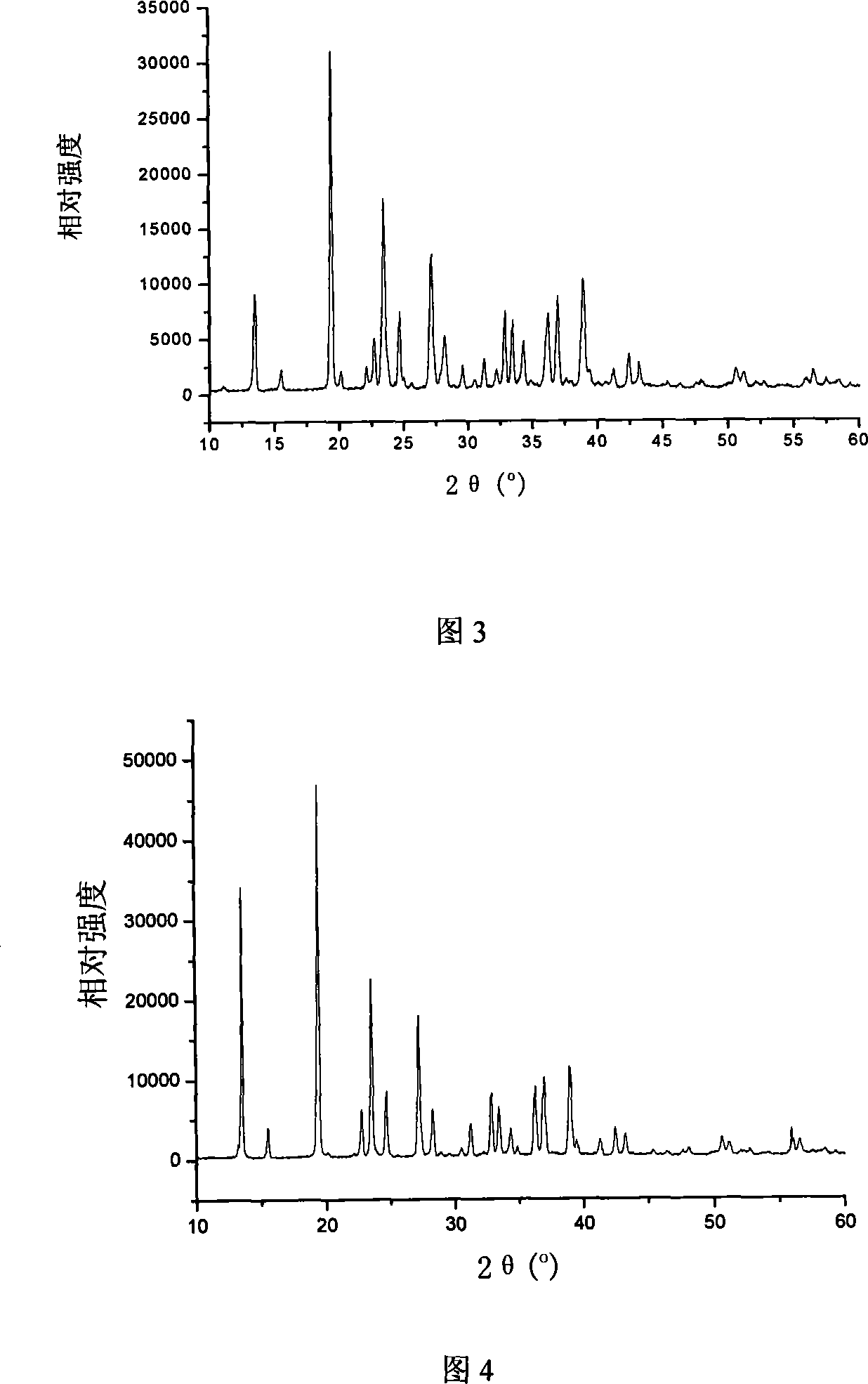

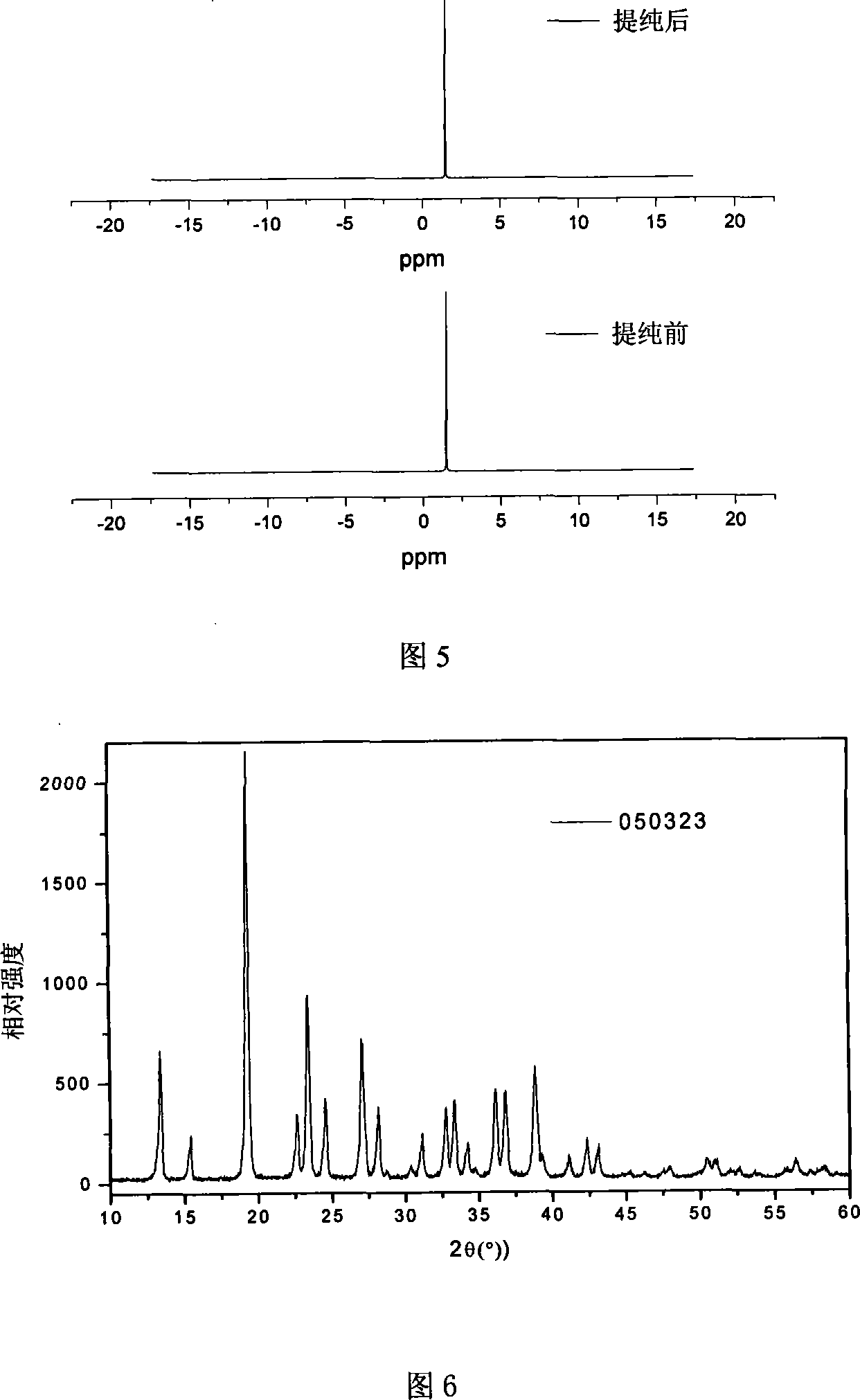

Method for synthesizing dioxalate group lithium borate

InactiveCN1687081AImprove high temperature cycle performanceInhibition of electrochemical co-intercalationGroup 3/13 element organic compoundsChemical reactionSynthesis methods

Owner:SHANDONG HIYI CHEM TECH

Bearing lubricating grease and preparation method thereof

ActiveCN102977978AHigh dropping point temperatureNot collapseLubricant compositionLithium hydroxideAntioxidant

The invention relates to bearing lubricating grease comprising the following components of: (a) a compound thickening agent formed by lithium 12-hydroxystearate soap, lithium binary acid soap and lithium borate, (b) an additive, and (c) base oil, wherein the compound thickening agent is formed by soapnifying 12-hydroxystearic acid, binary acid and boric acid with lithium hydroxide; and the additive amount of the boric acid is 1-5 parts by weight while the weight of the base oil is 100 parts by weight, wherein the additive is one or combination of at least two of an antioxidant, an antirusting agent, an anti-wear reagent at extreme pressure and a metal passivator. The dropping point temperature of the bearing lubricating grease provided by the invention is more than or equal to 300 DEG C, and the bearing lubricating grease provided by the invention does not collapse or fade and has the characteristics of long service life, silence and high temperature resistance.

Owner:安徽意博润滑科技有限公司

Synthesis technique for obtaining difluoro oxalate lithium borate and di-oxalate lithium borate

ActiveCN101643481AImprove performanceSimple processGroup 3/13 element organic compoundsOxalateOrganic solvent

The invention discloses a synthesis technique for simultaneously obtaining difluoro oxalate lithium borate and di-oxalate lithium borate with outstanding performances, comprising the following steps:1. reacting fluorinated compound, boracic compound, lithium-containing compound and oxalate-containing compound in a reaction medium at 100 DEG C with reaction pressure of 0.1-1MPa, wherein the mol ratio of lithium, fluorine, boron and oxalate ions is 5-9:5-9:-2-3:3-4, and generating a reaction solution containing difluoro oxalate lithium borate and di-oxalate lithium borate; 2. carrying out initial separation on the difluoro oxalate lithium borate and di-oxalate lithium borate in the reaction solution, then carrying out further extraction separation by using organic solvent capable of extracting difluoro oxalate lithium borate or di-oxalate lithium borate; and 3. respectively carrying out recrystallization and vacuum drying to obtain the difluoro oxalate lithium borate and di-oxalate lithium borate of battery level. The invention is suitable for industrially producing two types of lithium salts with excellent performance used for lithium ion batteries.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

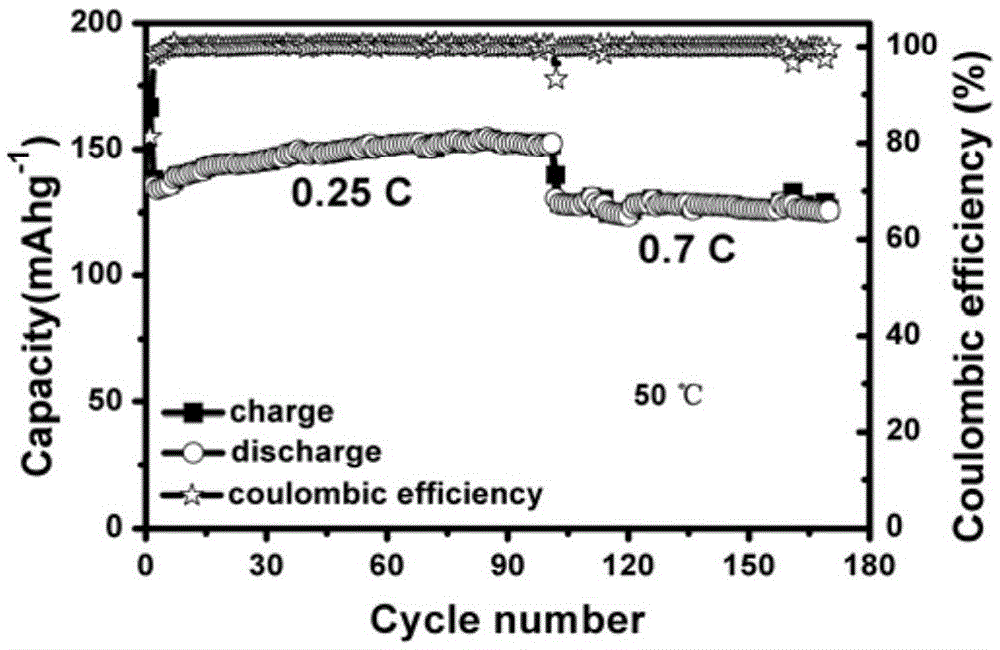

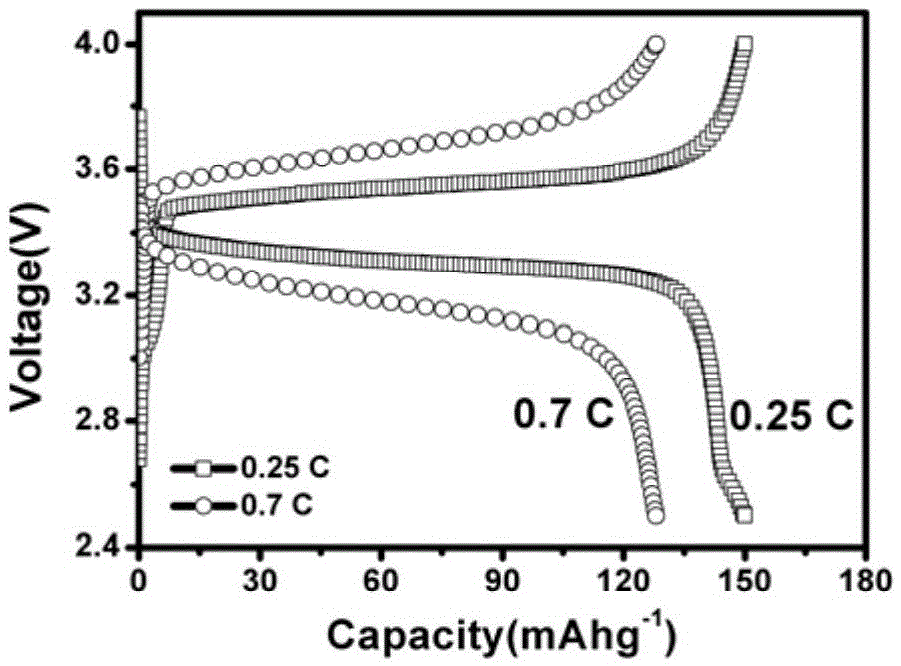

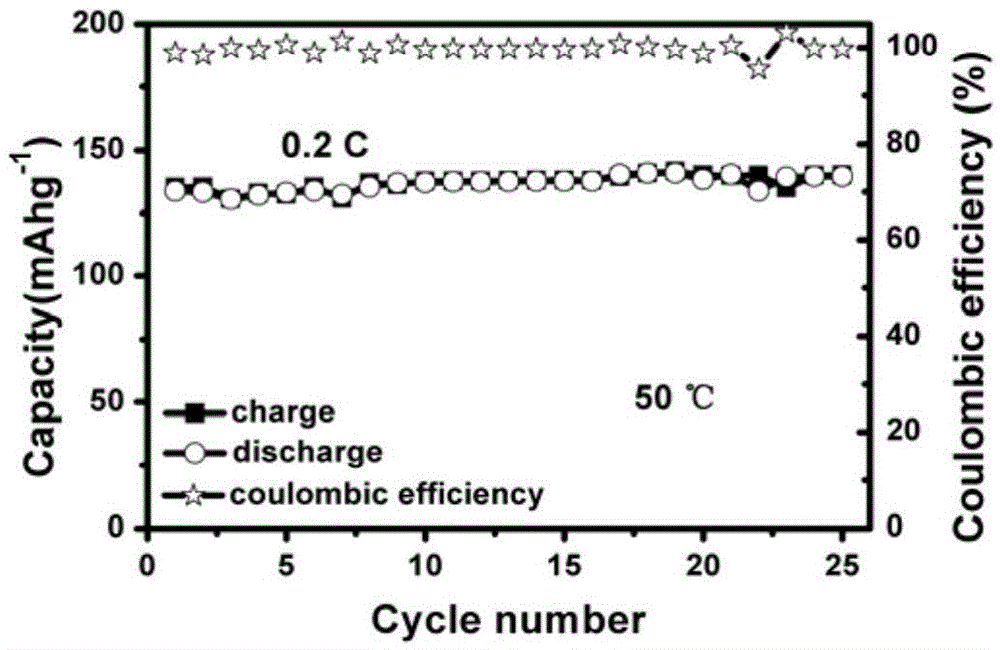

Composite positive electrode of lithium ion battery as well as preparation method and application to all-solid-state battery thereof

ActiveCN103956458AShorten migration distanceIncrease energy densityCell electrodesSecondary cellsSolid state electrolyteTin dioxide

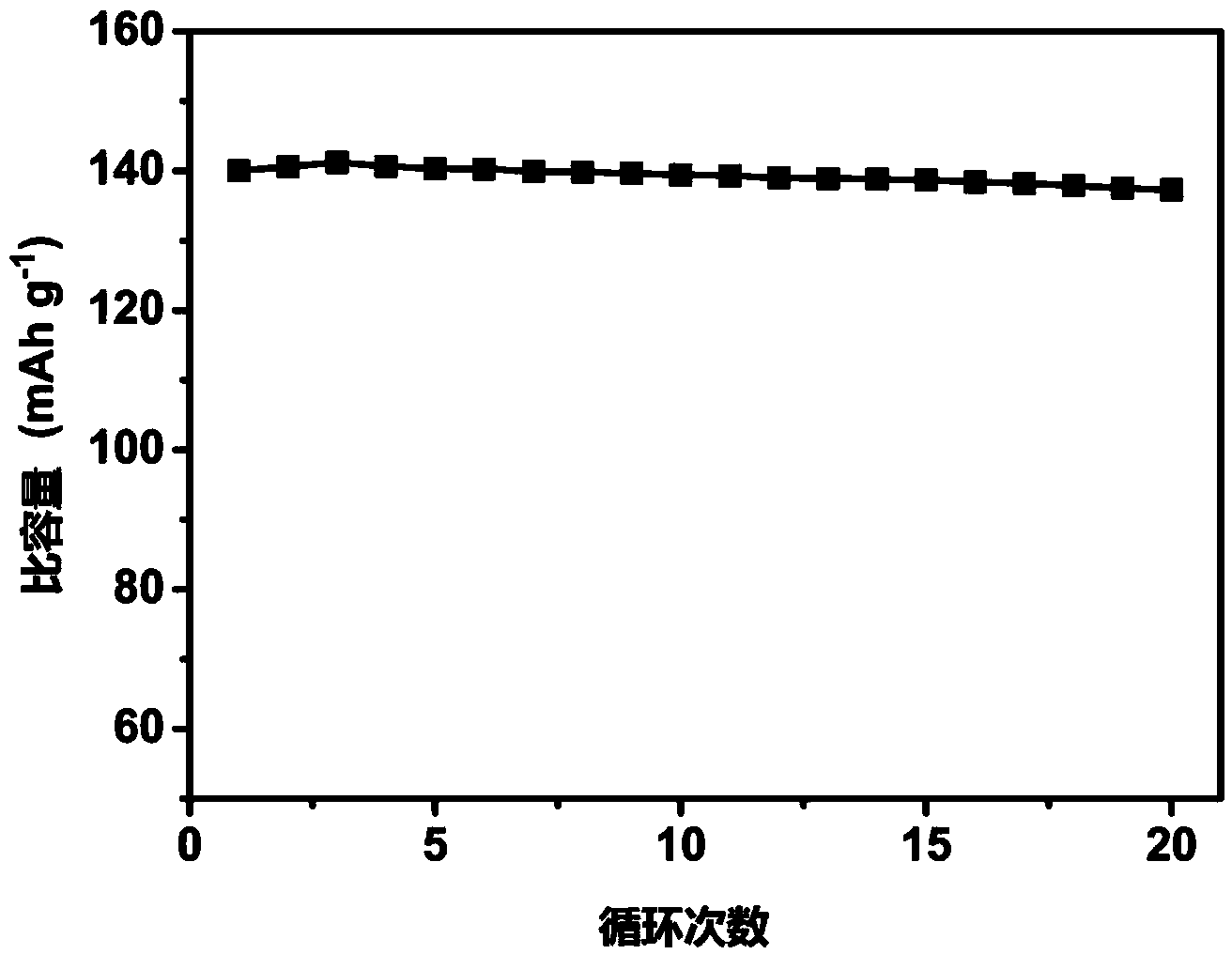

The invention discloses a composite positive electrode of a lithium ion battery as well as a preparation method and application to an all-solid-state battery thereof. The composite positive electrode of the lithium ion battery comprises a positive active material, inorganic solid electrolyte and a conductive oxide additive, wherein the positive active material is any one of lithium cobaltate, lithium manganate, lithium iron phosphate and nickel-cobalt-manganese ternary material; the inorganic solid electrolyte is at least one of lithium borate, lithium metaborate and lithium fluoride; the conductive oxide additive is any one of indium tin oxide, indium oxide, tin dioxide, zinc oxide, nickel oxide and ferroferric oxide. The method comprises the steps of (1) mixing the positive active material, the inorganic solid electrolyte and the conductive oxide additive, carrying out ball milling, drying, and carrying out tabletting to obtain a ceramic piece; and (2) sintering the ceramic piece to obtain the composite positive electrode. The composite positive electrode is good in mass ratio capacity, area ratio capacity and cycle performance, can be used for preparing the all-solid-state lithium ion battery, and can be used at high temperature.

Owner:TSINGHUA UNIV

Preparation of lithium ionic secondary cell

InactiveCN101420048AReduced rate discharge capabilityImprove high temperature storage performanceCell electrodesFinal product manufactureHigh temperature storageBattery capacity

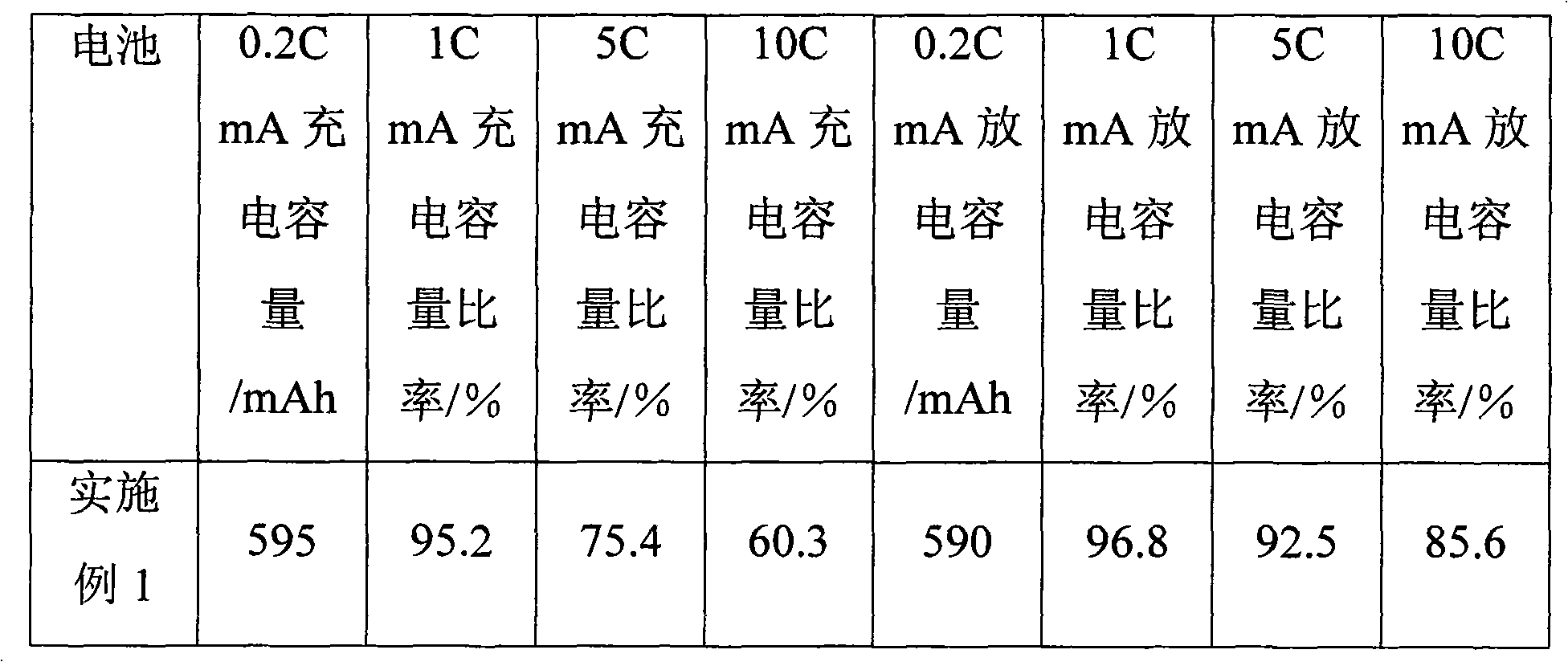

The invention relates to a preparation method of a lithium-ion secondary battery. The method comprises: an electrode unit is arranged in a battery shell, and then electrolyte solution is poured in; wherein, the method for pouring the electrolyte solution comprises two times of filling; the method of filling comprises: one part of the electrolyte solution is poured in a battery shell for carrying out one-time filling, then the battery shell is sealed temporarily for carrying out formation; additives are added in the remaining part of the electrolyte solution, then the additives and the remaining part of the electrolyte solution are filled together in the battery shell undergoing formation for two-time filling; the additives are double oxalic acid lithium borate. The lithium-ion secondary battery prepared by the method of the invention satisfactory battery capacity, high-temperature storage performance, low-temperature discharge performance, multiplying power discharging performance and cycle performance.

Owner:BYD CO LTD

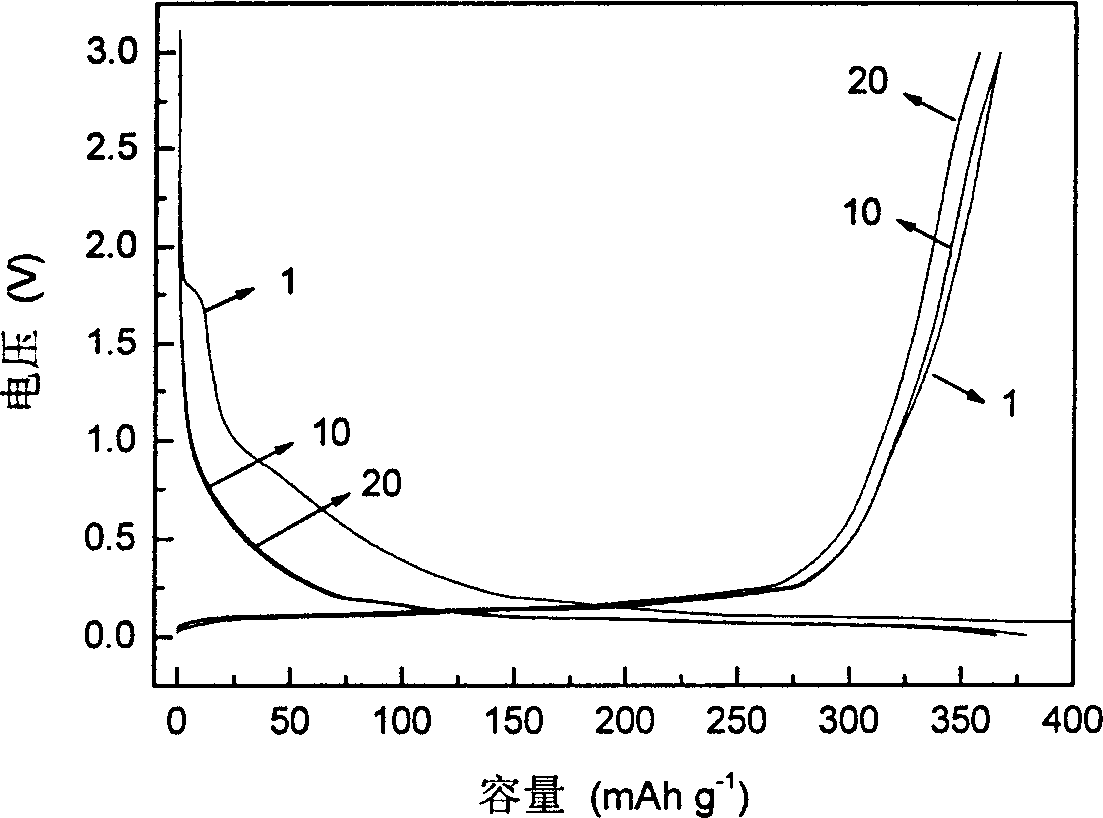

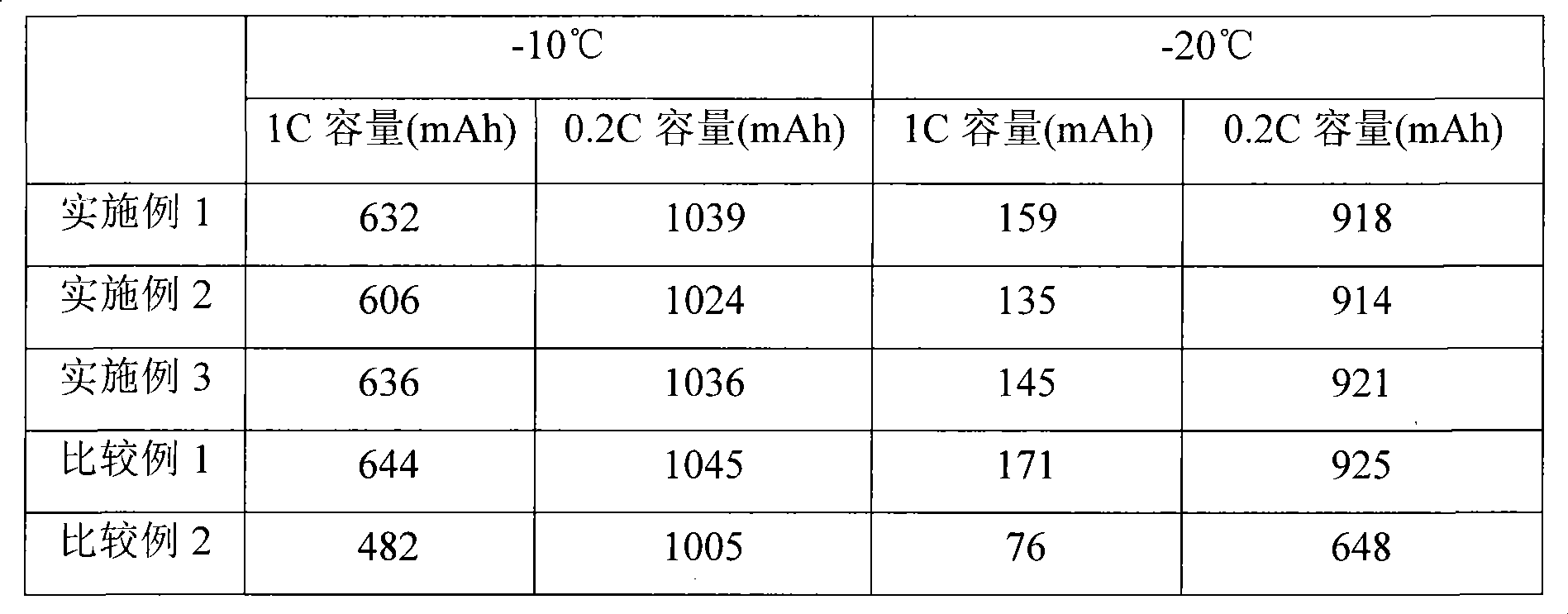

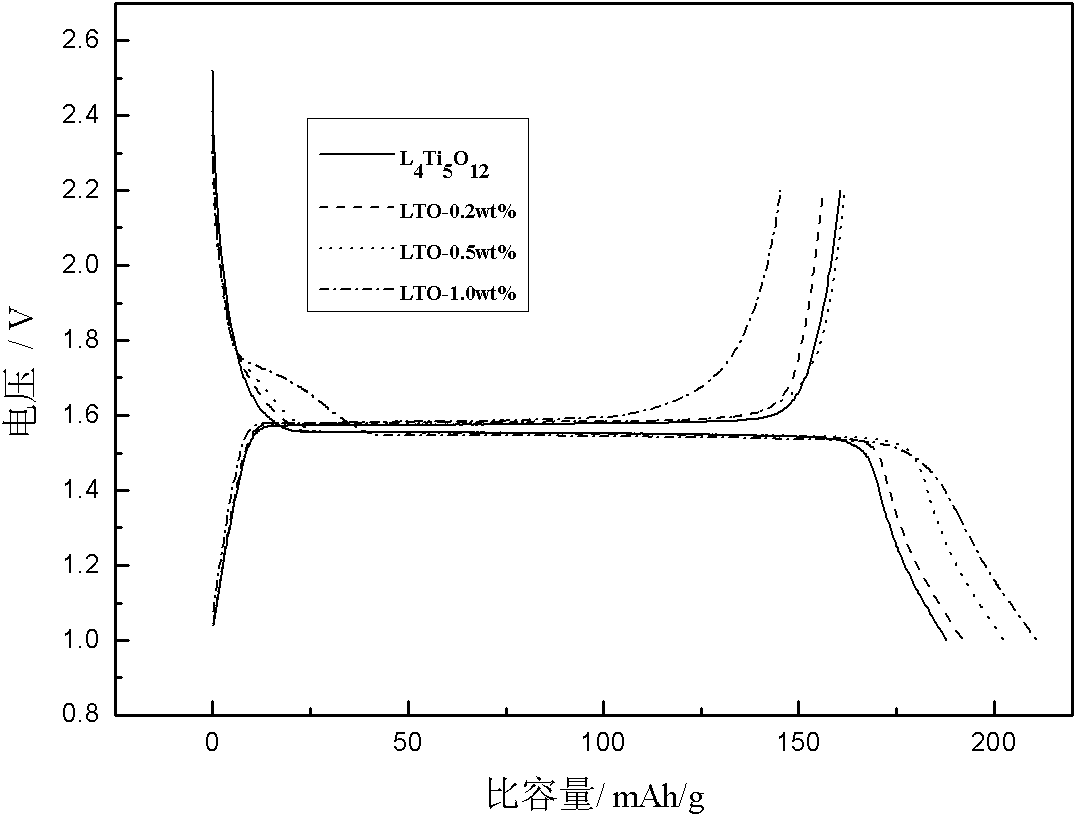

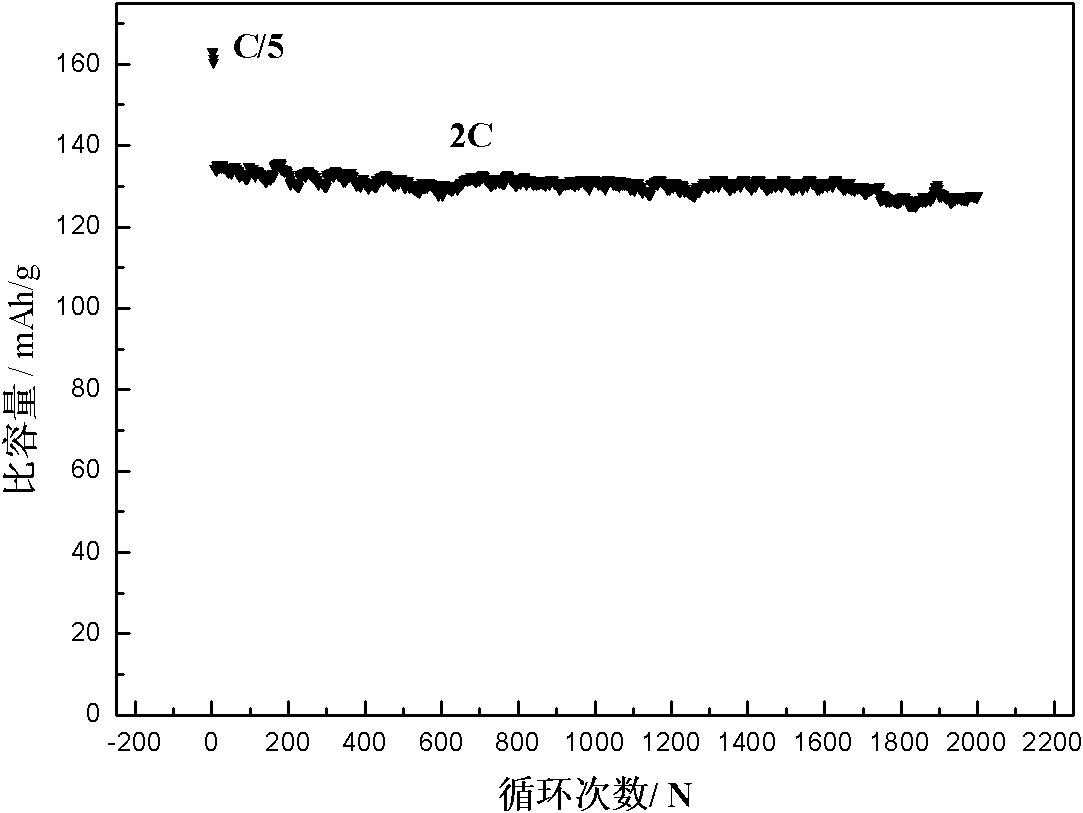

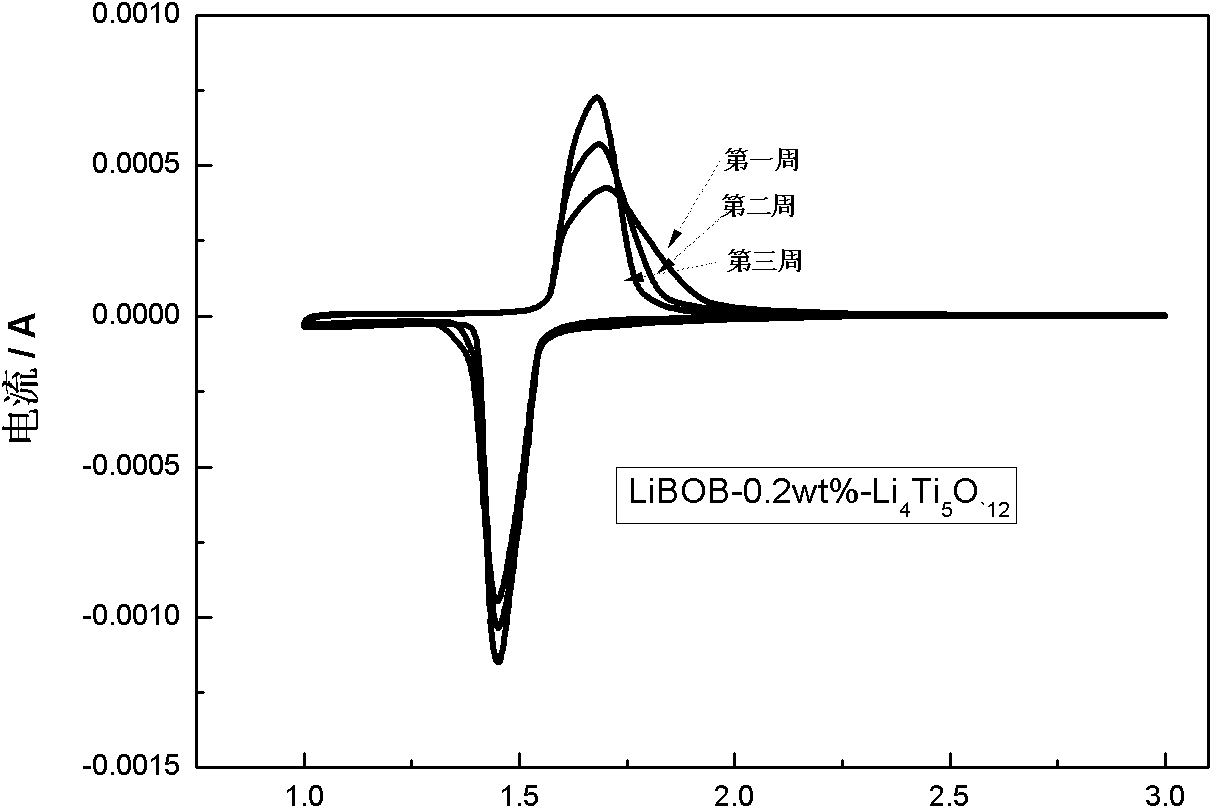

Electrolyte system for preventing spinel lithium titanate radical lithium ion secondary battery from flatulence

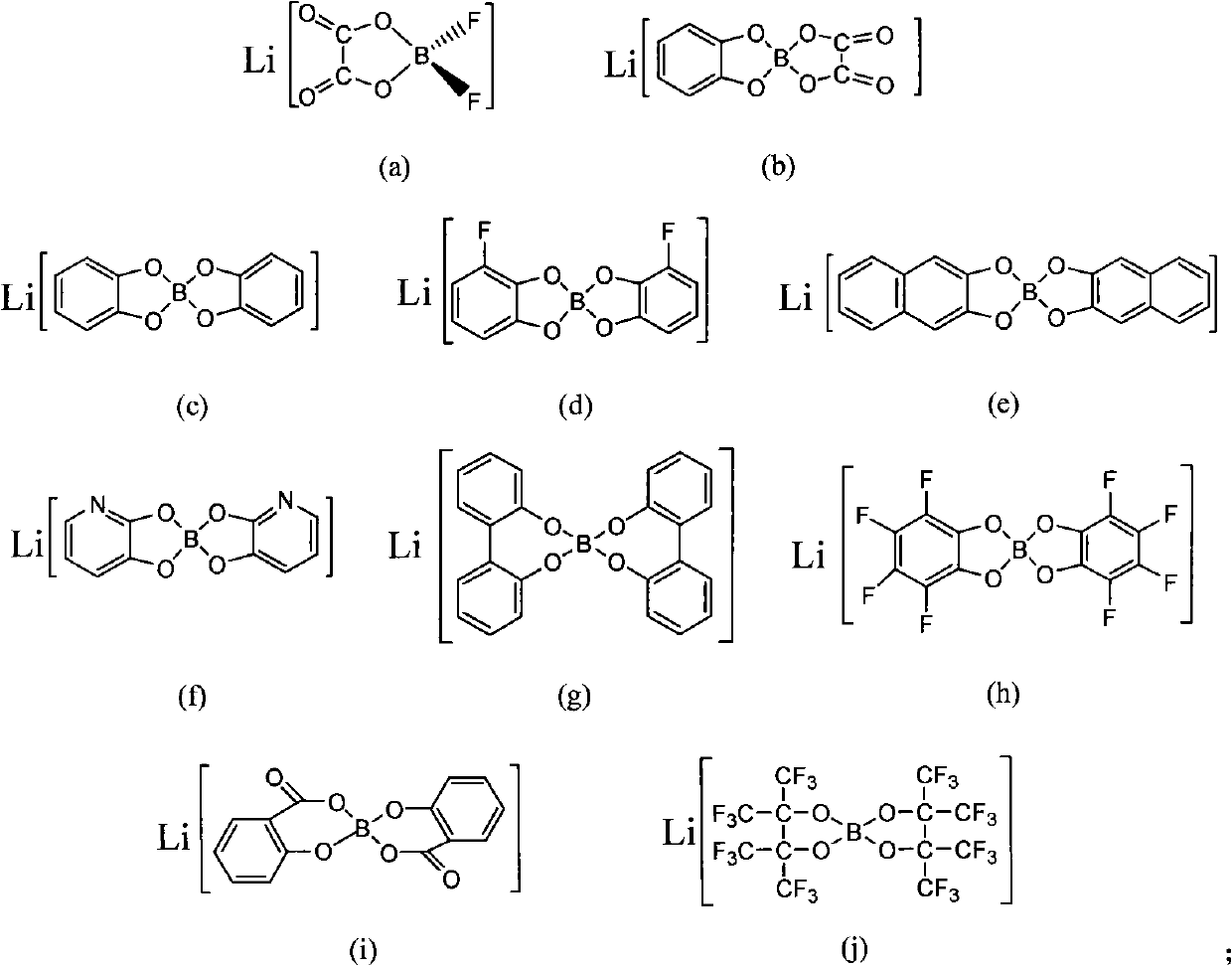

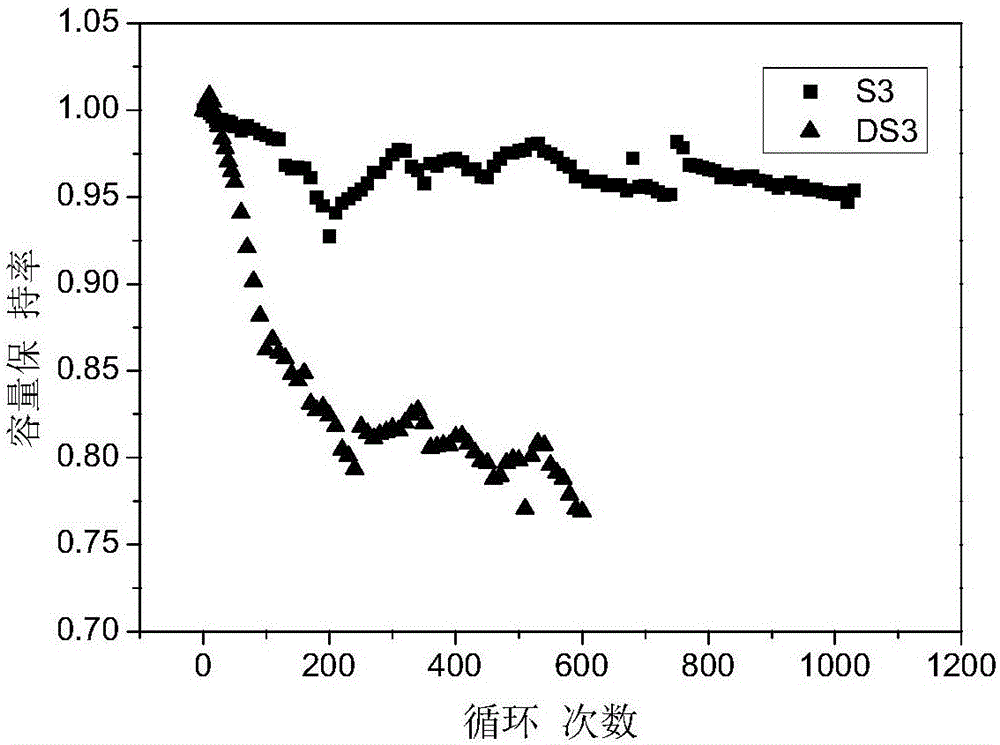

The invention discloses an electrolyte system for preventing a spinel lithium titanate radical lithium ion secondary battery from flatulence. An additive is added into the organic electrolyte system; the additive forms a layer of solid electrolyte interface film on the surface of a Li4Ti5O12 electrode in the battery cyclic process due to the reduction reaction of the organic electrolyte system, so as to prevent a lithium titanate electrode from direct contact with the organic electrolyte, thus the flatulence is prevented; the additive consists of one or more of organic lithium borate salt or boron radical compound as negative iron accepter; and the addition amount of the additive is 0.001-30 wt% of the total electrolyte system. The electrolyte system disclosed by the invention adopts the organic lithium borate salt as the film forming additive of the organic electrolyte, forms a layer of stable SEI (solid electrolyte interface) film on the surface of an active material in the battery cyclic process due to the reduction reaction of the organic electrolyte system, thus the flatulence generation phenomena due to the side reaction of the electrolyte and the active material is prevented, and the cyclic life of the battery is improved.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

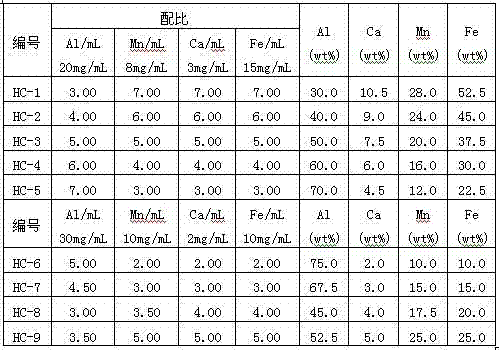

X-ray fluorescence spectroscopy analysis fusion sample preparation method of aluminum, manganese, calcium and iron alloy

InactiveCN102607934AEliminate sources of errorImprove analytical accuracyMaterial analysis using wave/particle radiationPreparing sample for investigationFluorescenceManganese

The invention discloses an X-ray fluorescence spectroscopy analysis fusion sample preparation method of an aluminum, manganese, calcium and iron alloy, which comprises the steps of: firstly, coating a uniform protection wall layer in a platinum crucible by using lithium tetraborate, then placing an aluminum, manganese, calcium and iron sample, an oxidizing agent, a lithium borate solvent and a releasing agent into the platinum crucible in which the protection wall is coated, uniformly mixing, and then pre-oxidizing the aluminum, manganese, calcium and iron sample; and finally, melting the pre-oxidized aluminum, manganese, calcium and iron sample, and cooling to obtain an aluminum, manganese, calcium and iron sample glass fuse piece, wherein the aluminum, manganese, calcium and iron sample is a detection sample or calibration sample of the aluminum, manganese, calcium and iron alloy, and the sample glass fuse piece is a detection sample glass fuse piece or calibration sample glass fuse piece of the aluminum, manganese, calcium and iron alloy. On the premise of no corrosion to the valuable platinum crucible, the glass fuse piece can be prepared, and the prepared sample is excellent and uniform, thus the mineral effect and the grain size effect are completely eliminated.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Low temperature type lithium ion battery electrolyte with high temperature property and lithium ion battery

InactiveCN101867064AEasy to manufactureEasy to operateSecondary cellsCell component detailsOxalateOrganic solvent

The invention discloses a low temperature type lithium ion battery electrolyte with high temperature property and lithium ion battery. The electrolyte is made by uniformly mixing and confecting electrolytic salt, non-water organic solvent, alkali additive and film-forming additive, the electrolytic salt is mixed lithium salt made by uniformly mixing lithium tetrafluoroborate and lithium bis(oxalate)borate, and the mol ratio of the two is 96-73: 4-27, the concentration of the mixed lithium salt solution formed by the electrolytic salt and the non-water organic solvent is 0.8-1.2mol / L; the alkali additive is heptamethyldisilazane and the mass ratio of the hepatmethyldisilazane and the non-water organic solvent is 0.1-8%; the mass ratio of the film-forming additive and the non-water organic solvent is 0.1-5%; and the lithium ion battery comprises an anode, a cathode, a diaphragm and low temperature type lithium ion battery electrolyte with high temperature property. The invention has reasonable design, simple preparation method steps and convenient implementation, and the prepared electrolyte and lithium ion battery have favourable comprehensive performances.

Owner:XIAN SAFTY ENERGY TECH

Titanium composite, preparation method thereof and application thereof

ActiveCN101901905AImprove performanceEasy to preparePigmenting treatmentAlkali titanatesLithium chlorideHigh rate

Owner:BYD CO LTD

Complex lithium grease and preparation method thereof

The invention provides complex lithium grease and a preparation method thereof. The complex lithium grease comprises grease base oil, complex lithium thickening agents and surfactants with mass part ratio of (290-1450):(50.4-251.3):(2-10), wherein the grease base oil is at least one of vacuum second line base oil, vacuum third line base oil and vacuum fourth line base oil; the complex lithium thickening agents are formed by C12-C24 fatty acid lithium and auxiliary acid lithium with mass part ratio of (34-70):(16.4-81.3); and the auxiliary acid lithium is any two of C1-C22 fatty acid lithium, lithium borate, lithium phosphate, aromatic acid lithium, lithium naphthenate, dicarboxylic acid lithium and polybasic acid lithium. The invention also provides the preparation method of the complex lithium grease. The surfactants are added to the complex lithium grease to have synergistic effect with soap molecules of the complex lithium grease and further improve the arrangement of the soap molecules and the capability of curing the base oil, thus increasing the dropping point of the grease.

Owner:CHINA NAT OFFSHORE OIL CORP +2

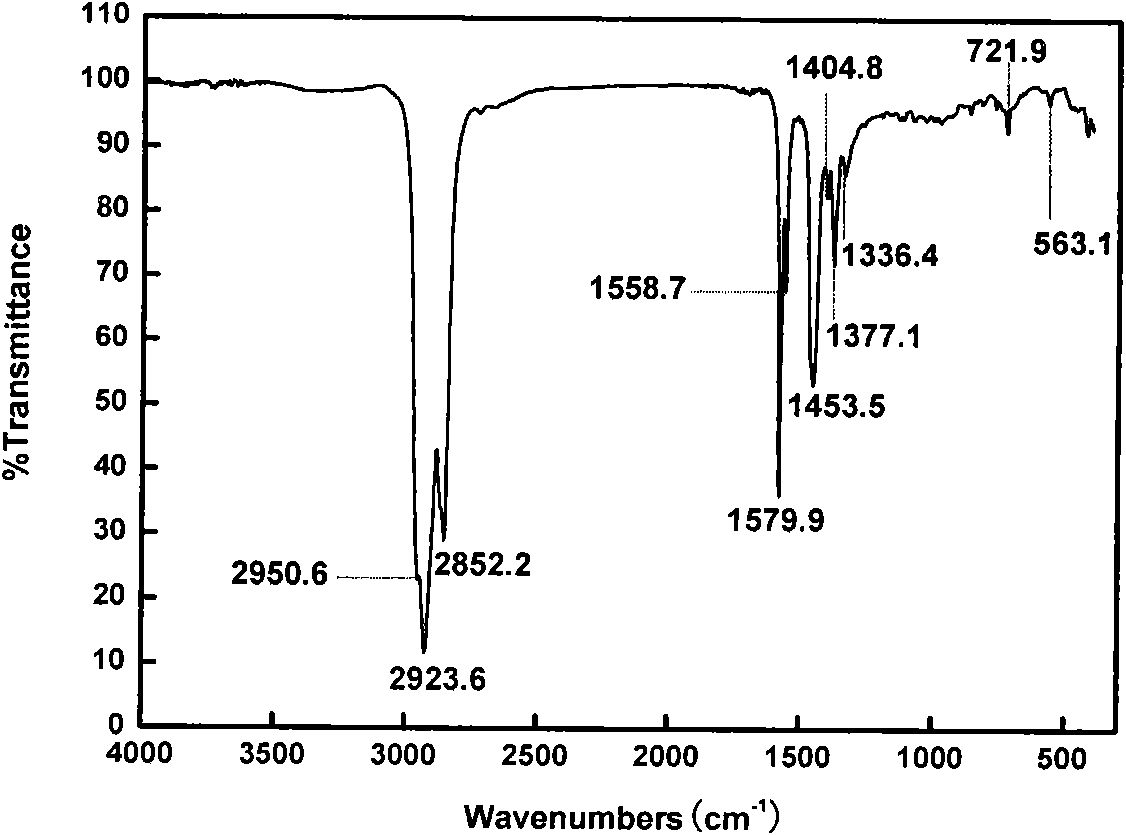

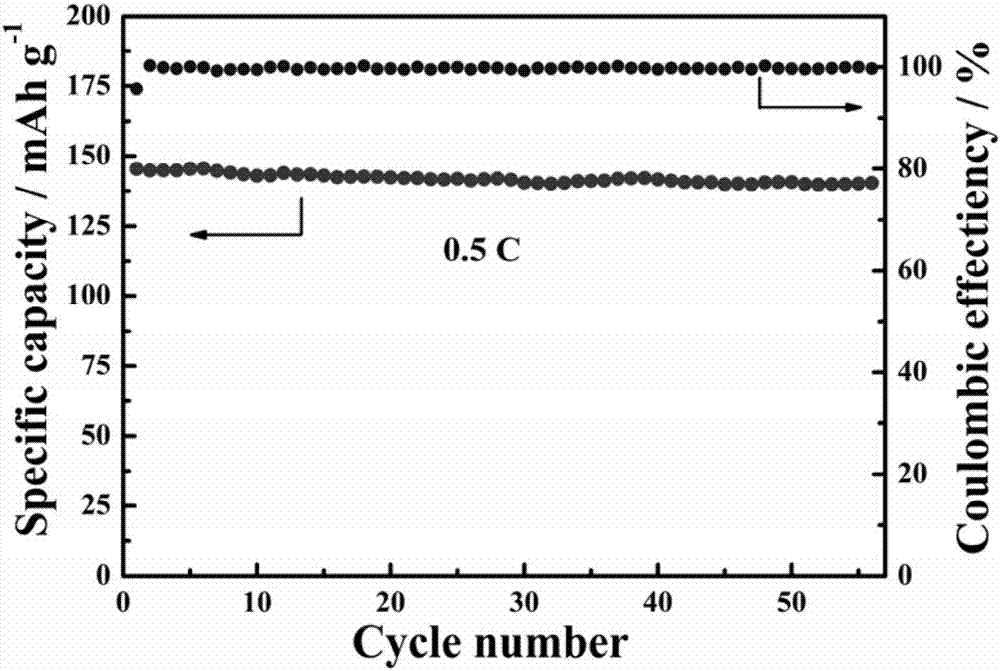

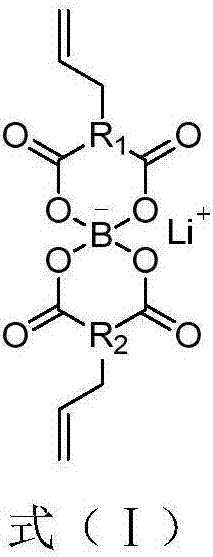

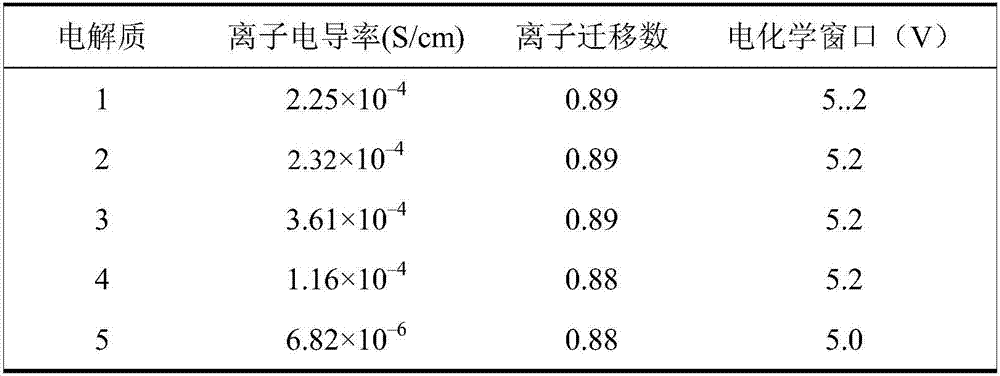

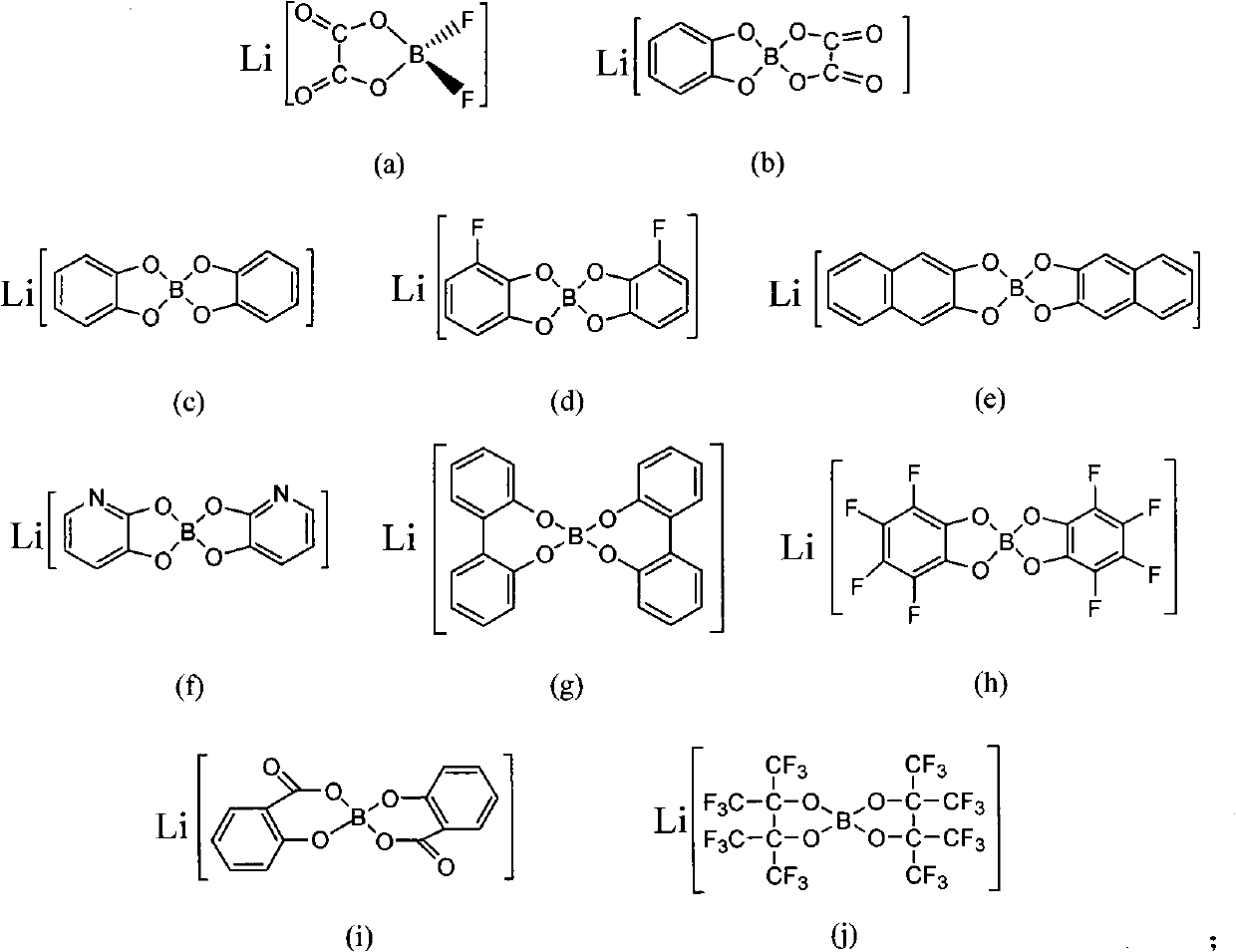

Lithium single ion conduction polymer electrolyte based on functionalized lithium borate

ActiveCN106935904AEasy to synthesizeRaw materials are cheap and easy to getSolid electrolytesCell electrodesHigh rateElectrochemical window

The invention discloses a lithium single ion conduction polymer electrolyte based on functionalized lithium borate. A double-bond-containing functionalized lithium borate and a sulfydryl-containing compound are subjected to an alkene-sulfydryl click reaction, or the double-bond-containing functionalized lithium borate and the sulfydryl-containing compound and a double-bond-containing polyether are subjected to a poly-alkene-sulfydryl click reaction to prepare a linear or network-shaped all-solid-state or gel catalyst. The lithium single ion conduction polymer electrolyte prepared by the invention has the advantages of simple and easily implemented synthesis, low-cost and easily available raw materials, high room-temperature conductivity, high lithium ion mobility, wide electrochemical window, and the like; and a lithium battery assembled by the electrolyte provided by the invention has high safety, high rate capability, long cycle life and stability.

Owner:SUN YAT SEN UNIV +1

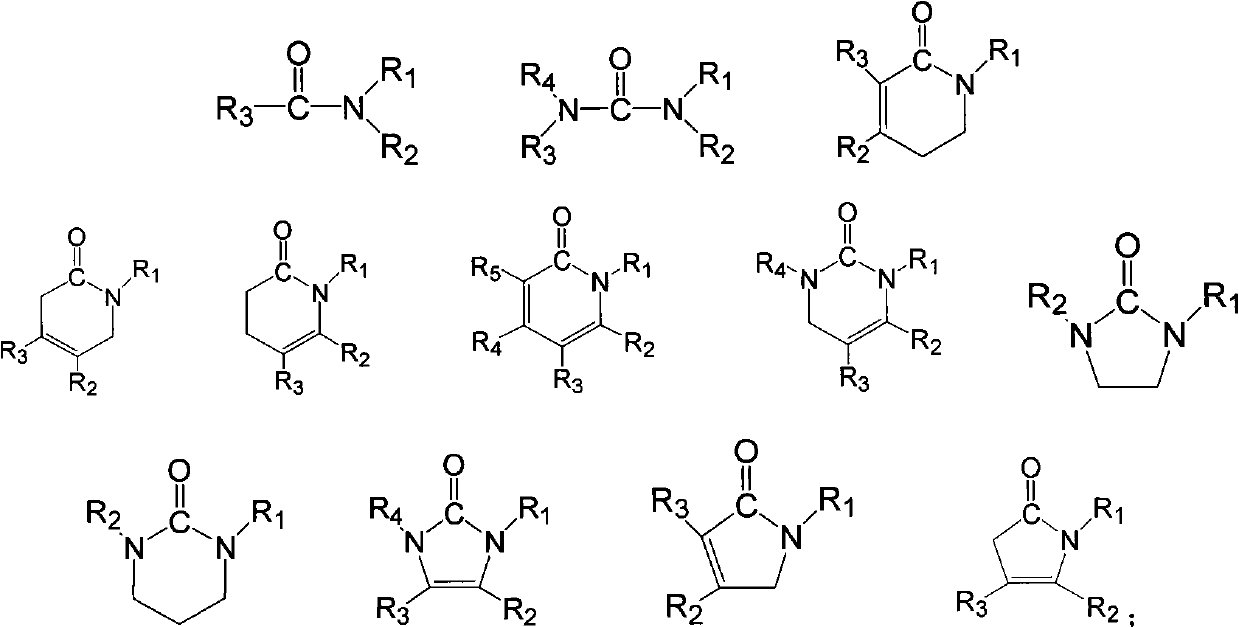

Ionic-liquid-base polymer electrolyte

An ionic liquid material, which is formed by the reaction of organic lithium borates or lithium aluminates and organic compounds containing amido functional groups, is used as a base and compounded with polymer materials to obtain the all-solid-state or gel-state polymer electrolyte material. The polymer electrolyte material has the advantages of favorable thermostability and favorable electrochemical performance. The addition reaction is carried out by regulating the composition of the ionic liquid and the proportion of ionic liquid to polymers and adding a right amount of plasticizer; or the conducting salts and the polymer materials containing amido functional groups are compounded to directly prepare the gel-state or all-solid-state polymer electrolyte with favorable performance. The polymer electrolyte has wide application prospects in the fields of chemical energy sources and especially new electrochemical energy storage systems aiming at high power, high energy density and high security requirement.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

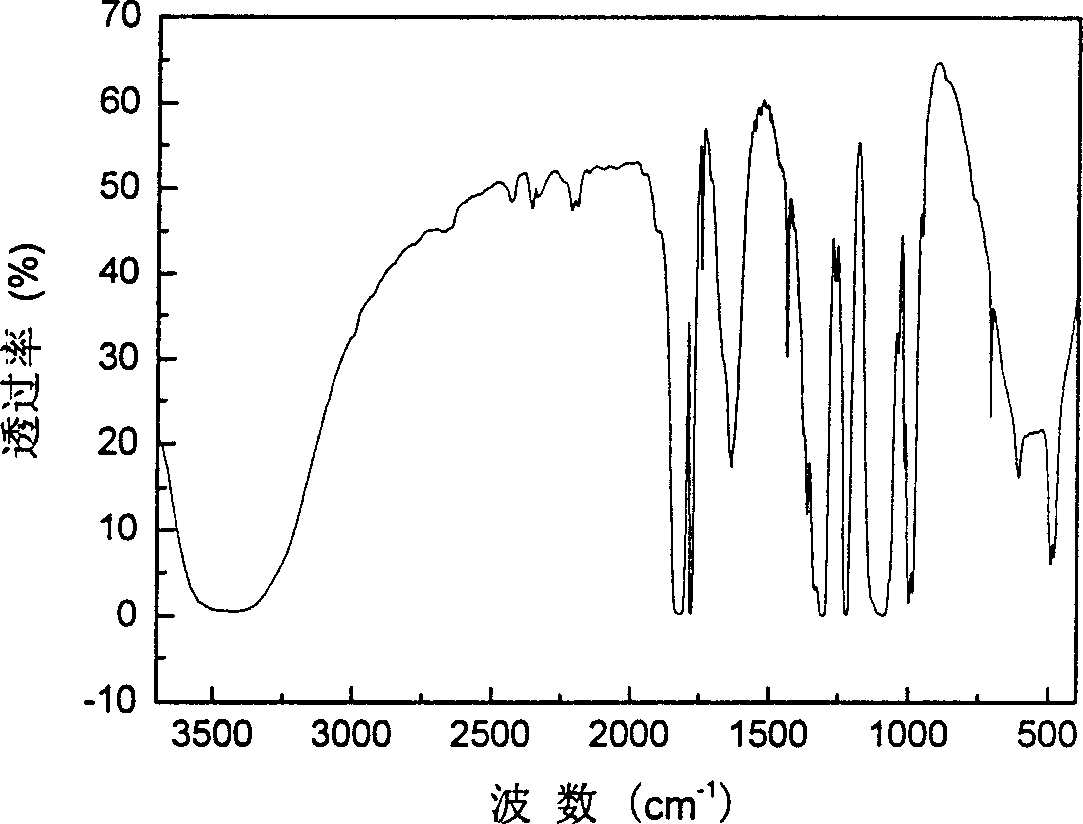

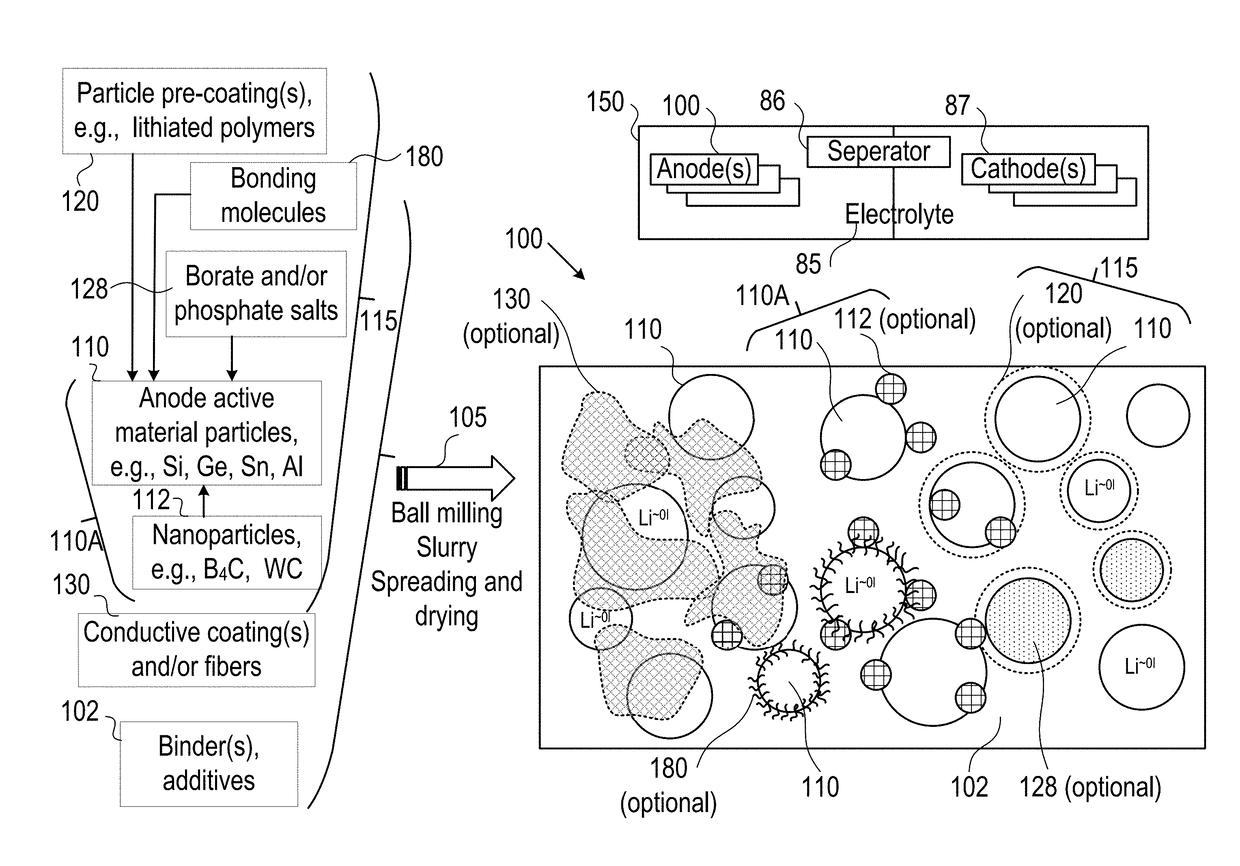

Microwave process of synthesizing lithium dioxalate borate

InactiveCN101020690AHigh yieldLess impuritiesGroup 3/13 element organic compoundsOxalateProportional control

The present invention is microwave process of synthesizing LiB(C2O4)2 material, and belongs to the field of lithium borate material technology. The process includes mixing oxalic acid and LiOH.H2O in ratio of (2.5-1.8) to 1 or oxalic acid and Li2CO3 in ratio of (4.1-3.8) to 1 mechanically in a stirrer of 12000 rpm; adding H3BO3 in the ratio to LiOH.H2O of (0.8-1) to 1 and the ratio to Li2CO3 of (1.9-2) to 1 before further stirring for 1-10 min; and setting mixture into beaker and setting the beaker in a microwave oven of 2.45 GHz frequency and 700 W maximum power for two stage synthesis of power of 100-400 W and 200-600 W separately. Compared with common solid phase synthesis process, the present invention has the advantages of fast heating, short synthesis process, low power consumption, and high product yield and purity.

Owner:SHANDONG HIRONG POWER SUPPLY MATERIAL

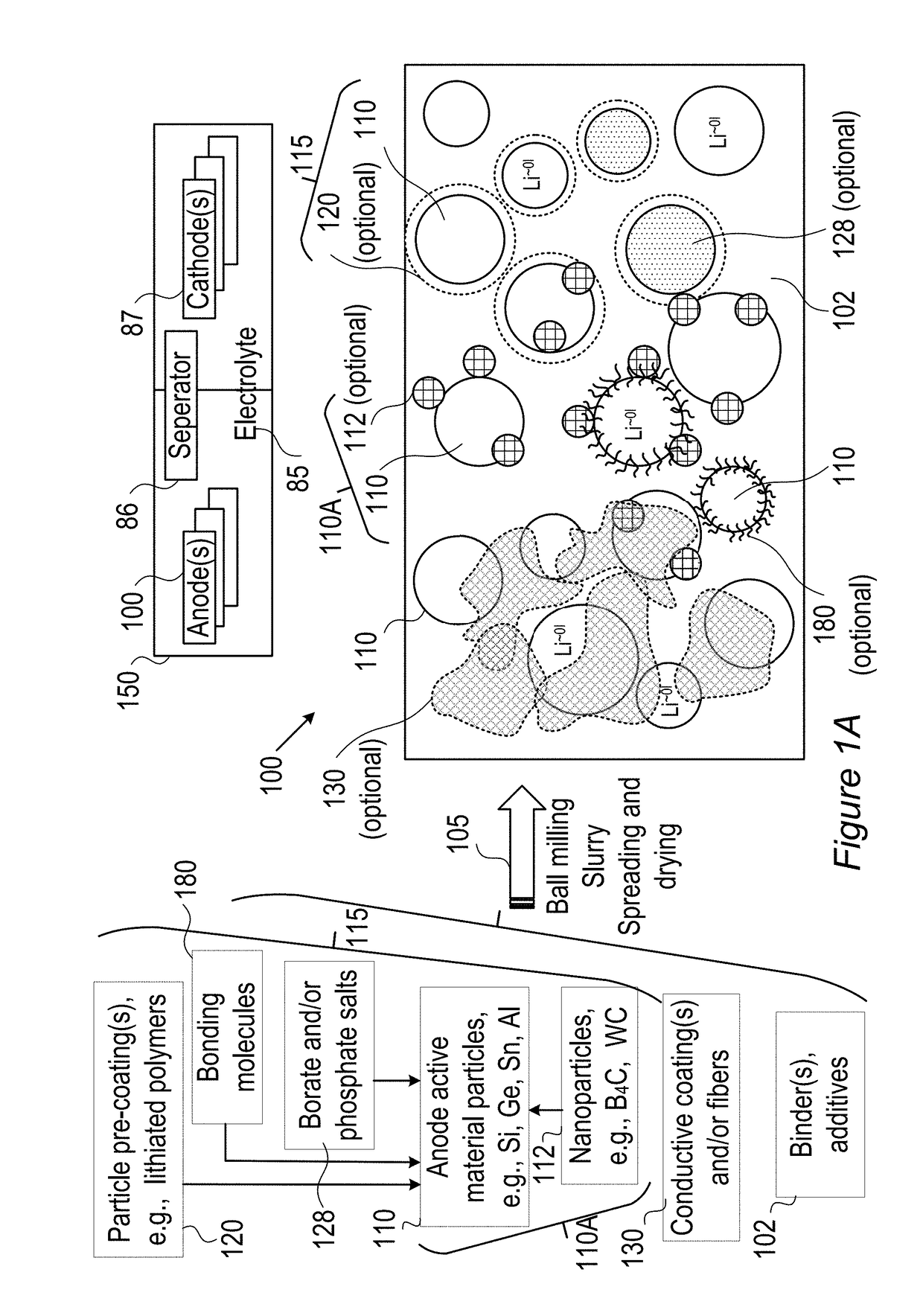

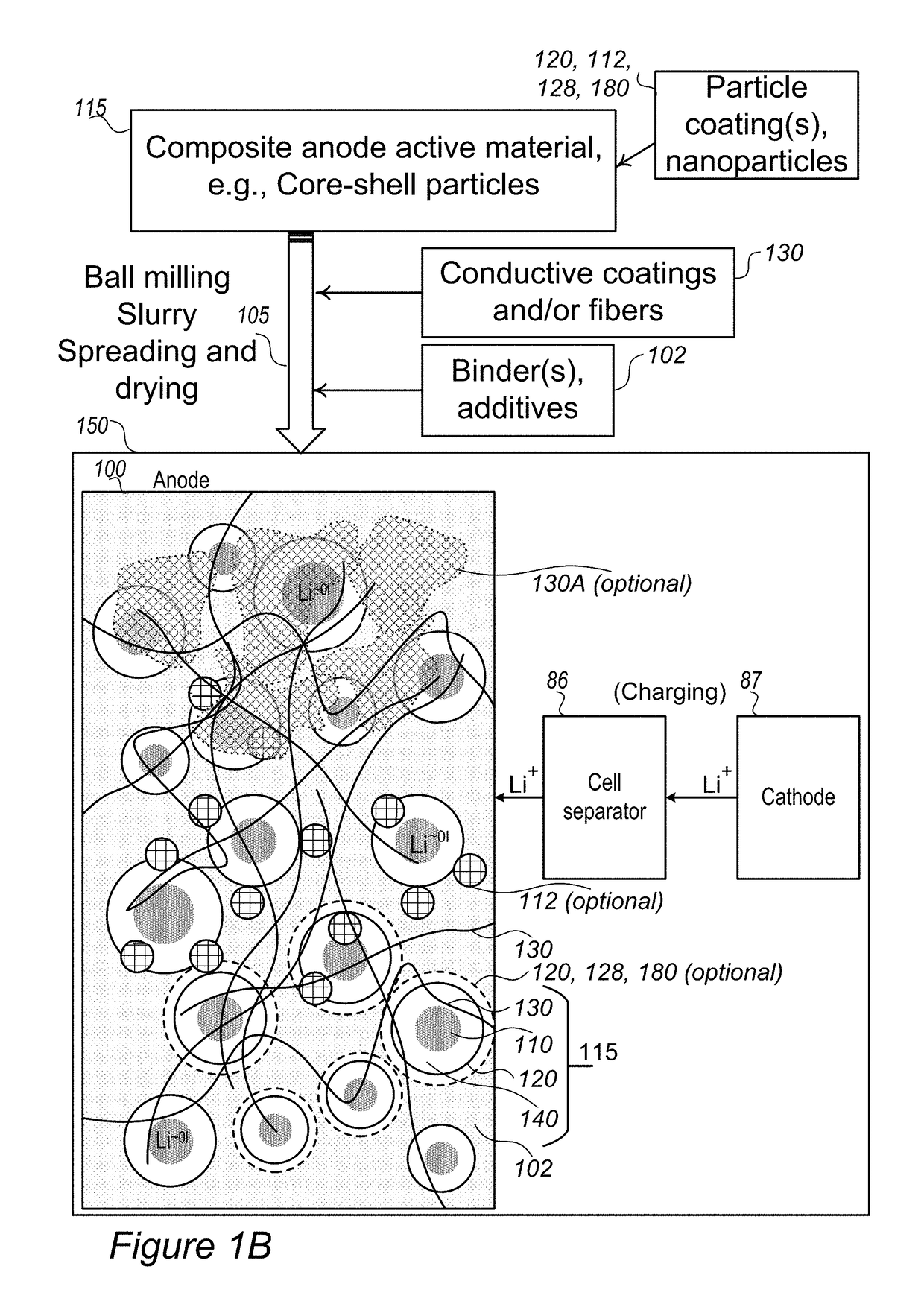

Lithium borates and phosphates coatings

Improved anodes and cells are provided, which enable fast charging rates with enhanced safety due to much reduced probability of metallization of lithium on the anode, preventing dendrite growth and related risks of fire or explosion. Anodes and / or electrolytes have buffering zones for partly reducing and gradually introducing lithium ions into the anode for lithiation, to prevent lithium ion accumulation at the anode electrolyte interface and consequent metallization and dendrite growth. Various anode active materials and combinations, modifications through nanoparticles and a range of coatings which implement the improved anodes are provided.

Owner:STOREDOT

All-solid-state battery of skeleton supported alloy anode and preparation method thereof

InactiveCN105470466ASlow responseMake up for the short board of safety performanceCell electrodesLi-accumulatorsMetallic lithiumSolid state electrolyte

The invention discloses an all-solid-state battery of a skeleton supported alloy anode and a preparation method thereof. The skeleton supported alloy anode material is higher in heat stability relative to metallic lithium; and moreover, after the treatment of a small amount of added inorganic solid electrolyte powder, when free Li in the gaps of lithium borate compound (Li7B6) particles on the surface layer of the alloy anode material is completely consumed, the transfer path of lithium ions can be maintained continuously because of the existence of the lithium ion conductor, and the disconnection problem of the transfer path of the lithium ions appearing between the anode and the electrolyte in the charging and discharging process of the all-solid-state battery is prevented. The skeleton supported alloy anode material is applied to the all-solid-state battery system, and a metallic lithium dead level on the anode side of the all-solid-state battery can be solved, so that the all-solid-state battery has the advantages of good cyclicity and high cycle efficiency (100%), and is extremely suitable for being applied to large-capacity all-solid-state batteries.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

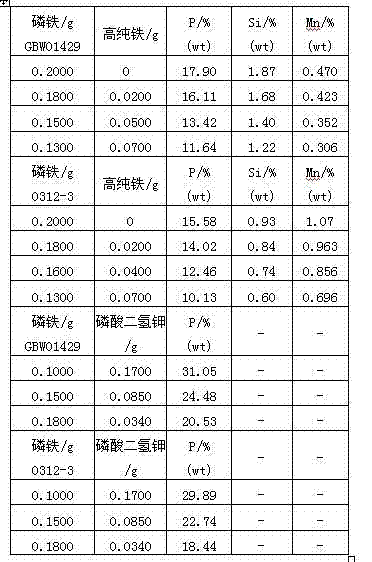

Preparation method of ferroalloy calibration samples for X-ray fluorescence spectrum analysis

InactiveCN102818722ASolving No Standard SamplesSolve the problem of insufficient standard samplesMaterial analysis using wave/particle radiationPreparing sample for investigationX-rayAlloy

The invention discloses a preparation method of ferroalloy calibration samples for X-ray fluorescence spectrum analysis. The preparation method is characterized in that firstly, high-pure metal and / or standard reagents are weighed according to the alloy proportioning, then, the high-pure metal and / or standard reagents are dissolved into solution by solvents, next, the solution is quantificationally transferred into a platinum yellow crucible and is melted after being mixed with lithium borate, oxidants and release agents, the cooling is carried out, and a ferroalloy calibration sample glass fuse piece is obtained. The method has the advantages that the ferroalloy calibration samples to be measured are compounded by reference or standard substances with similar element composition and content range, and the problem of no ferroalloy standard sample to be measured or standard sample insufficiency is solved. The ferroalloy calibration sample glass fuse piece obtained by the method is used for the X-ray fluorescence spectrum analysis, the result is accurate and reliable, and the application range of an X-ray fluorescence spectrum analysis method is expanded.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

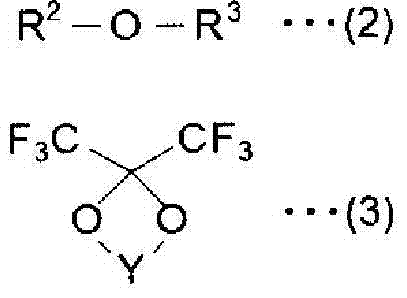

Secondary battery, electrolytic solution, battery pack, electronic device, and electrical vehicle

ActiveUS20130052543A1Good chemical stabilityImprove featuresAlkaline accumulatorsOrganic electrolyte cellsImideCarboxylic acid

A secondary battery capable of improving cycle characteristics, conservation characteristics, and load characteristics is provided. The secondary battery includes a cathode, an anode, and an electrolytic solution. A separator provided between the cathode and the anode is impregnated with an electrolytic solution. The electrolytic solution includes one or more of a dicarbonic ester compound, a dicarboxylic compound, a disulfonic compound, a monofluoro lithium phosphate, and difluoro lithium phosphate and one or more of fluorinated lithium phosphate, fluorinated lithium borate, and imide lithium.

Owner:MURATA MFG CO LTD

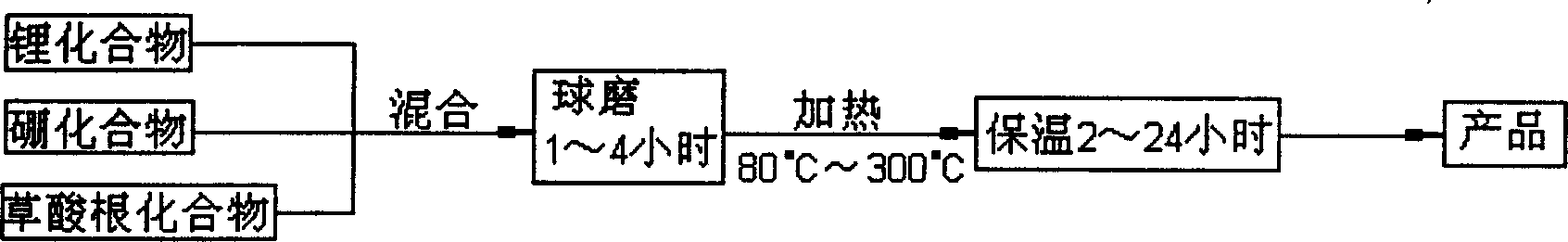

Preparation method of electrolyte double-oxalate based lithium borate for lithium ion battery

InactiveCN103030657AWell mixedIncrease responsivenessGroup 3/13 element organic compoundsOxalateSynthesis methods

The invention provides a preparation method of electrolyte double-oxalate based lithium borate for lithium ion battery and relates to a preparation method of battery level double-oxalate based lithium borate (LiBOB), which is applicable for the field of lithium ion battery and the like. A liquid phase synthesis method is used. The preparation method comprises the following steps of adding reaction raw materials consisting of a lithium compound, a boron compound, an oxalate compound and a solvent into a reaction kettle according to a ratio, heating and reacting under normal pressure, adding a water-carrying agent during the reaction process, and separating out water, thereby obtaining the product. The preparation method is simple in technology and full in reaction; and the double-oxalate based lithium borate product prepared by the preparation method is high in yield and high in purity, thus the preparation method is suitable for large-scale industrial production.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

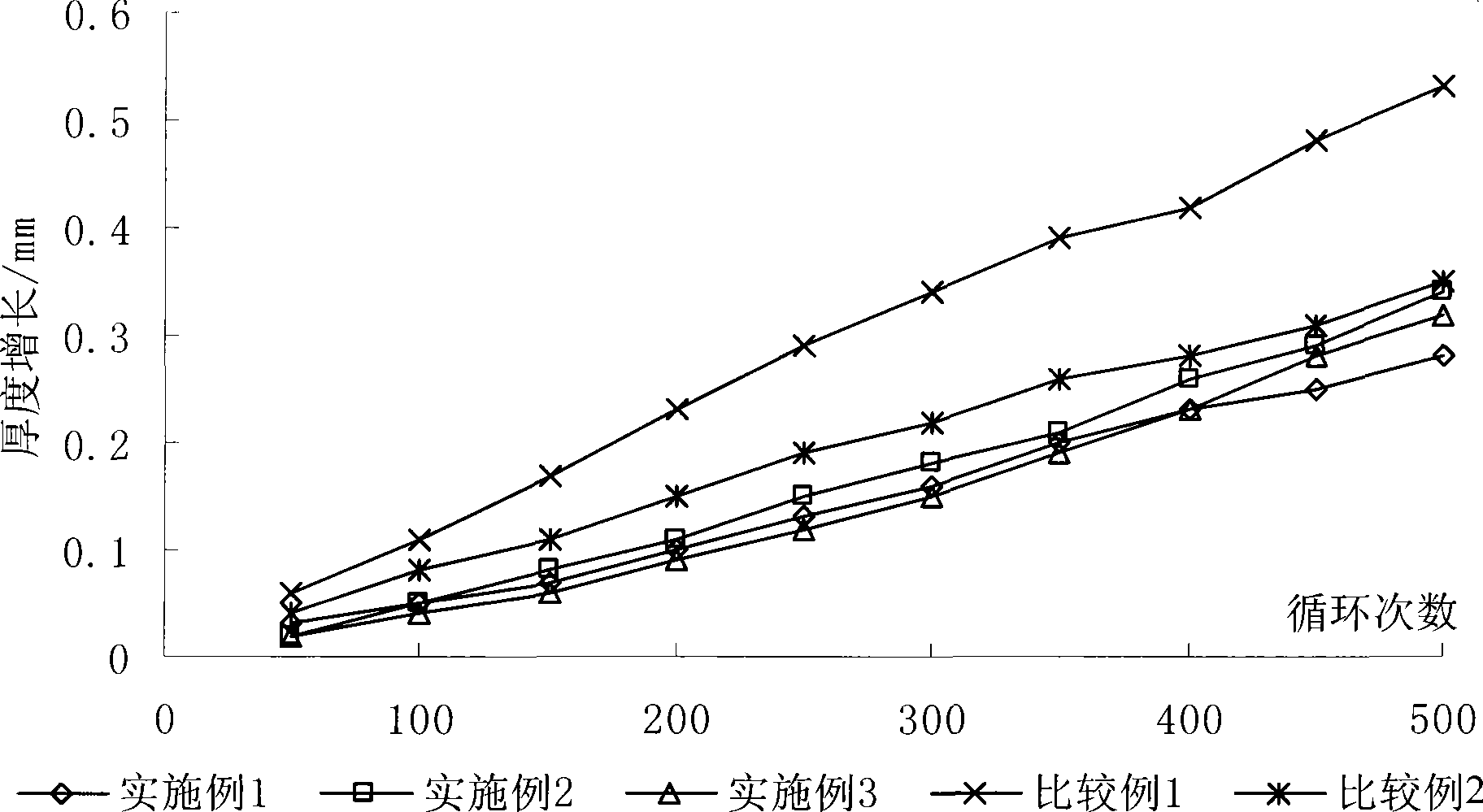

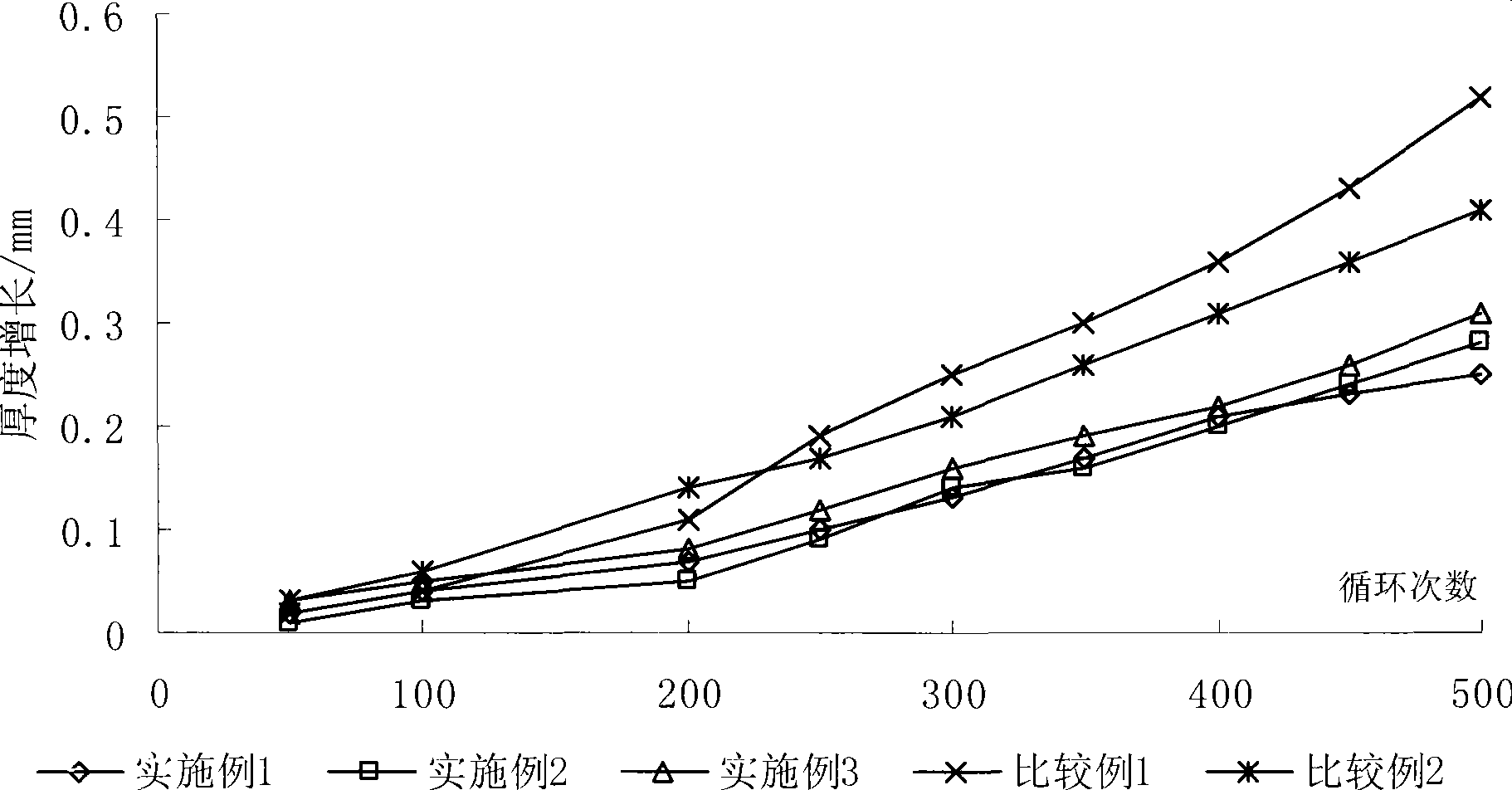

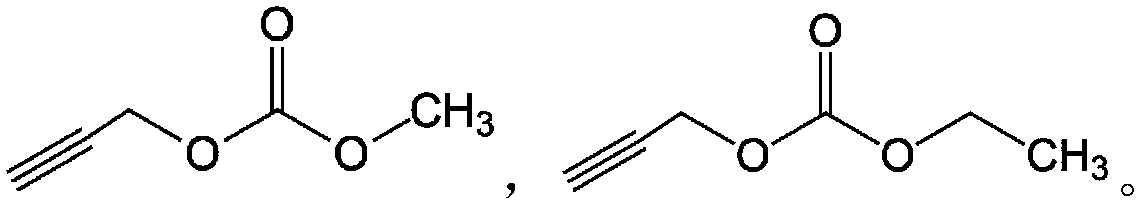

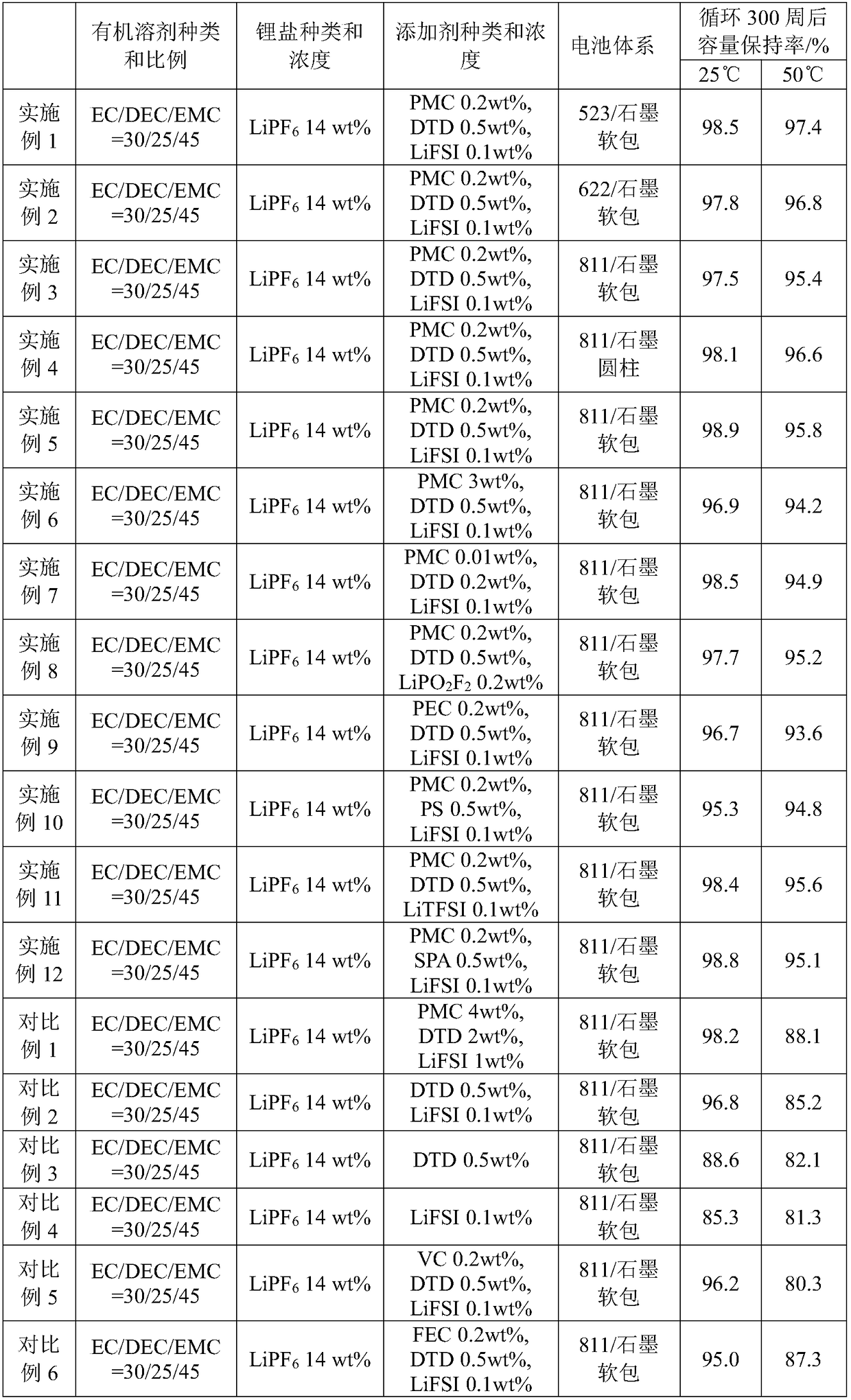

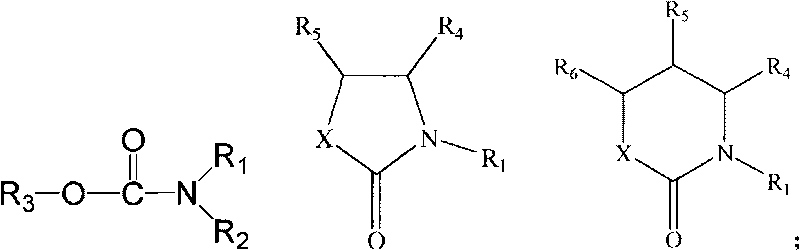

Composite lithium ion battery electrolyte and lithium ion battery comprising same

ActiveCN109361017AImprove cycle performanceInhibit side effectsSecondary cellsOrganic electrolytesMethyl carbonateLithium-ion battery

The invention discloses composite lithium ion battery electrolyte and a lithium ion battery comprising the same. The composite lithium ion battery electrolyte comprises an organic solvent, lithium salt and an additive. The organic solvent is at least two of propylene carbonate (PC), ethyl methyl carbonate (EMC), dimethyl carbonate (DMC), dipropyl carbonate (DPC), allyl ethyl carbonate (AEC), allylmethyl carbonate (AMC) and the like; and the additive is selected from at least two of unsaturated carbonate, sulfur-containing organic matters, lithium borate dioxalate, lithium difluorophosphate and fluoro-imide salt. For the respective physical and chemical characteristics of the organic solvent and the additive, the types of the additive are screened and combined, by adjustment on an electrolyte additive, the ratio by which respective advantages can be played and respective shortcomings can also be suppressed is found out, the high-voltage capacity of the battery is improved, and the cycle life of the battery is prolonged.

Owner:산산어드밴스드머테리얼스(취저우)컴퍼니리미티드

Ionic liquid compound electrolyte material

InactiveCN101740813AHybrid capacitor electrolytesFinal product manufactureComposite electrolyteElectrochemical window

The invention relates to an ionic liquid compound electrolyte material. Organic lithium borate / lithium aluminate and organic compound having the structure of carbamic acid ester compose the ionic liquid material which is used as a substrate, the composition and ratio of lithium salt to organic compound of the ionic liquid system are adjusted, and addition reaction with high molecular material and organic solvent is carried out to prepare all-solid-state or gel state polymer compound electrolyte. The electrolyte material has excellent thermostability, broad electrochemical window and high ion conductivity, is superior to existing non-aqueous organic liquid electrolyte applied to commercialized lithium ion battery especially in the aspect of safety, and has wide application prospect in lithium ion battery, electrochemical super capacitor, etc.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Solid-phase production method of lithium-borate-base electrolyte

ActiveCN105732682AReduce labor intensitySimple production processFinal product manufactureGroup 3/13 element organic compoundsBoron containingCarboxylic acid

The invention discloses a solid-phase production method of a lithium-borate-base electrolyte. The method comprises the following steps: by using a solid boron-containing compound, a solid lithium-containing compound and a solid organic carboxylic acid as raw materials and a vacuum stainless steel kneader as a reactor, stirring and heating the raw materials under micro-positive or negative pressure to perform pre-synthesis reaction, and keeping the temperature to perform synthesis reaction; and in the vacuum state, keeping the temperature for drying and dewatering, thereby finishing the production steps. The method has the advantages of simple control in production operation and high conversion rate, solves the problems of high complexity and low efficiency in other multistep solid-phase reaction processes, can produce multiple solid lithium-borate-base electrolytes, and is suitable for industrial production.

Owner:CHAOYANG GUANGDA CHEM

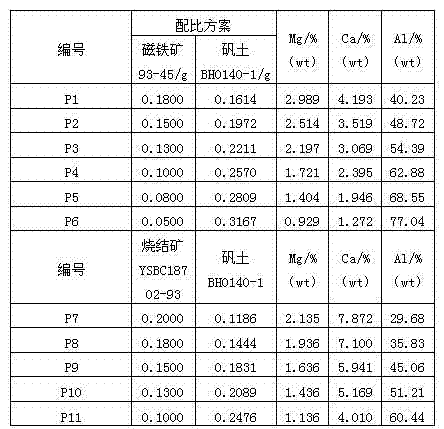

Vitrification reagent for preparing glass melt piece for X fluorescence analysis and use method thereof

ActiveCN101509847AShorten the analysis cycleQuick analysisMaterial analysis using wave/particle radiationPreparing sample for investigationPlatinumVitrification

The invention provides a glass reagent for preparing glass fuse pieces used for metallurgical flux X-ray fluorescence analysis, consisting of anhydrous lithium tetraborate or mixture of anhydrous lithium tetraborate and lithium metaborate, and boric acid. A method for preparing the glass fuse pieces includes: firstly adding the anhydrous lithium tetraborate or the mixture of anhydrous lithium tetraborate and lithium metaborate in the metallurgical flux, then fusing at a high temperature for 12-15mins in a platinum yellow pot, preparing the glass fuse pieces after cooling; or fully mixing the boric acid with the anhydrous lithium tetraborate or the mixture of the anhydrous lithium tetraborate and lithium metaborate in advance, preparing the fast fused glass reagent and then mixing with the metallurgical flux, then fusing at the high temperature for 12-15mins in the platinum yellow pot, and preparing the glass fuse pieces after cooling. The glass reagent has accurate and stable analysis results, and greatly shortens the analysis period of the metallurgical fusing agent.

Owner:MAANSHAN IRON & STEEL CO LTD

Fast-charging high-power winding column type lithium ion battery

InactiveCN102157753AIncrease contact areaImprove migration speedSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrolytic agentMethyl carbonate

The invention discloses a fast-charging high-power winding column type lithium ion battery which comprises a positive pole piece, a negative pole piece and a porous isolating membrane, the positive pole piece, the negative pole piece and the porous isolating membrane are wound into a column type core body in sequence, a metal case is sheathed outside the core body, and an electrolytic liquid is injected into the metal case. The fast-charging high-power winding column type lithium ion battery is characterized in that a positive pole material is one or more than one of lithium cobalt oxide, lithium manganese oxide, three-element material, aluminum-doped nickel cobalt lithium, lithium iron phosphate and lithium vanadate; a negative pole material is one or more than one of graphite and lithium titanate. The positive current collector is a pretreated aluminum foil or aluminum mesh with the thickness of 8-30 micrometers; and the negative current collector is a copper foil, a copper mesh, a nickel-plated iron foil or a nickel-plated iron mesh with the thickness of 8-30 micrometers. An electrolyte in the electrolytic liquid is one or a mixture of lithium hexafluorophosphate and biethyl diacid lithium borate; and a solvent in the electrolytic liquid is a mixture of two or more than two of EC (Ethylene Carbonate), PC (Propylene Carbonate), DMC (Dimethyl Carbonate), DEC (Diethyl Carbonate), EA (Ethyl Acetate) and the like. In the invention, not only can high-power output of the battery be realized, but also the fast charging of the battery can be realized, and safety performance is high.

Owner:贵州航天电源科技有限公司

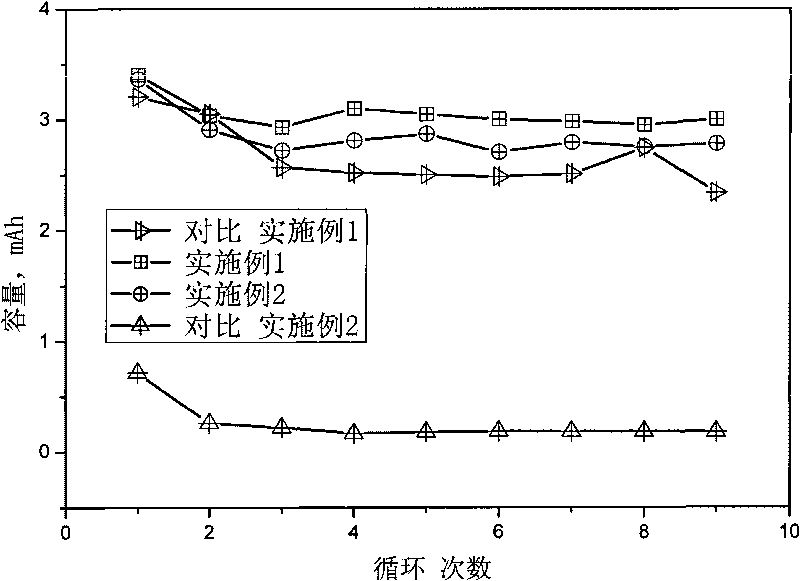

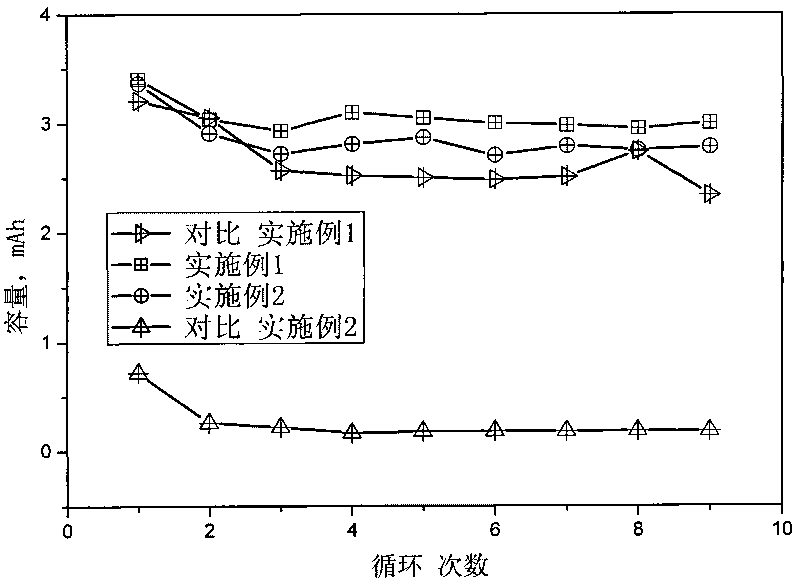

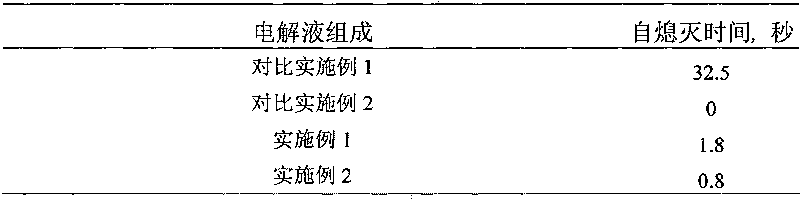

Flame-retardant electrolyte for lithium ion batteries and preparation method and application thereof

ActiveCN101702445AImprove securityIncrease concentrationFinal product manufactureElectrolyte accumulators manufacturePhosphateHeat stability

The invention discloses a flame-retardant electrolyte for lithium ion batteries and a preparation method and application thereof. In the invention, the preparation method comprises the following steps: mixing cyclic carbonate, chain carbonate and dimethoxy methyl phosphate according to the volume ratio of 1:1:(0.35-0.5), purifying the mixture, and then, adding lithium salts with the concentration of 0.8-1.2mol / L; and then, adding lithium borate diacetate the quality of which is equivalent to 5-10% of the quality of the lithium salts to obtain the flame-retardant electrolyte for lithium ion batteries. The flame-retardant electrolyte of the invention can not be burnt or fired and can effectively improve the safety performance of the lithium ion batteries; and the heat stability of the flame-retardant electrolyte is obviously improved, and after the energy is stored for more than 3 months at 85 DEG C, color of the electrolyte can not be changed, and the electrolyte can not be precipitated. The initial discharge capacity, the cycle performance and the conductivity of the lithium ion batteries prepared from the flame-retardant electrolyte of the invention are equivalent to the initial discharge capacity, the cycle performance and the conductivity of the lithium ion batteries prepared from the standard electrolyte. The flame-retardant electrolyte of the invention has lower cost and good application prospect.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Nonaqueous electrolyte solution for secondary batteries and lithium ion secondary battery

InactiveCN104737356AImprove stabilityReduced responseCell electrodesElectrolytesAqueous electrolyteCarboxylic acid

To provide a non-aqueous electrolyte solution for secondary batteries, which has a low reactivity with a positive electrode and a negative electrode and which is excellent in stability to prevent thermal runaway of a secondary battery and excellent also in battery properties such as cycle properties and rate properties, and a lithium ion secondary battery employing such a non-aqueous electrolyte solution. A non-aqueous electrolyte solution for secondary batteries, comprising a lithium salt composed of a specific complex such as lithium difluoro(oxalato)borate, a fluorinated solvent (A) containing at least one member selected from the group consisting of a fluorinated ether compound, a fluorinated chain carboxylic acid ester compound and a fluorinated chain carbonate compound, and a cyclic carboxylic acid ester compound (B); and a lithium ion secondary battery employing such a non-aqueous electrolyte solution.

Owner:ASAHI GLASS CO LTD

Electrolyte for high-capacity lithium ion battery, preparation method and lithium ion battery

InactiveCN106299324AImprove shrinkageImprove high temperature resistanceCell electrodesSecondary cellsHigh temperature storageSolvent

The invention discloses an electrolyte for a high-capacity lithium ion battery. The electrolyte is prepared from an non-aqueous solvent, lithium hexafluorophosphate, an anode film forming additive, an air bulking inhibiting additive, a cathode surface film stabilizer and a moisture stabilizer; the anode film forming additive is prepared from one or two of fluoroethylene carbonate and vinylene carbonate which account for 1%-15% of the total mass of the electrolyte; the air bulking inhibiting additive is prepared from a sultone compound accounting for 0.5%-5% of the total mass of the electrolyte; the cathode surface film stabilizer is prepared from a lithium borate salt compound accounting for 0.2%-3% of the total mass of the electrolyte; the moisture stabilizer is prepared from one or two of triphenyl phosphite and triphenyl phosphate which account for 0.1%-1% of the total mass of the electrolyte. The electrolyte can improve the normal-temperature cycle performance and the high-temperature storage performance of the battery. Meanwhile, the invention discloses a preparation method of the electrolyte and the high-capacity lithium ion battery adopting the electrolyte.

Owner:GUANGZHOU TINCI MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com