Complex lithium grease and preparation method thereof

A technology of complex lithium-based grease, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of limiting the application of lithium-complex grease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

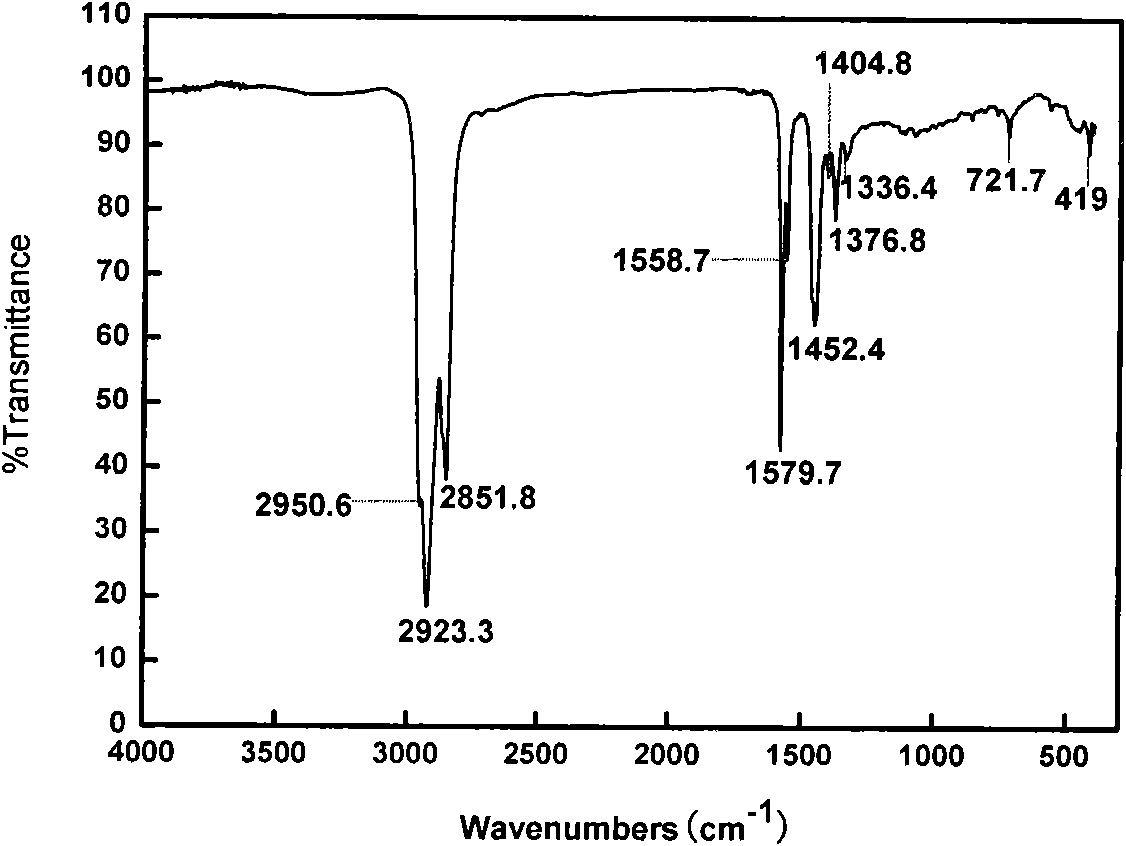

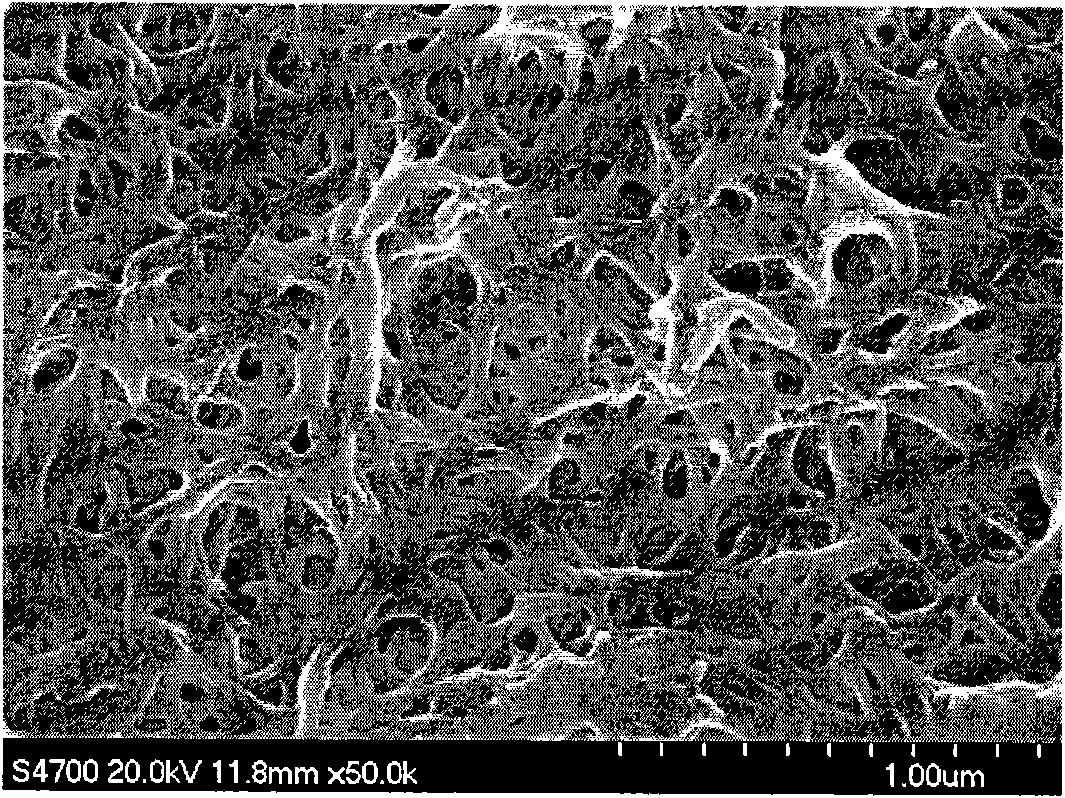

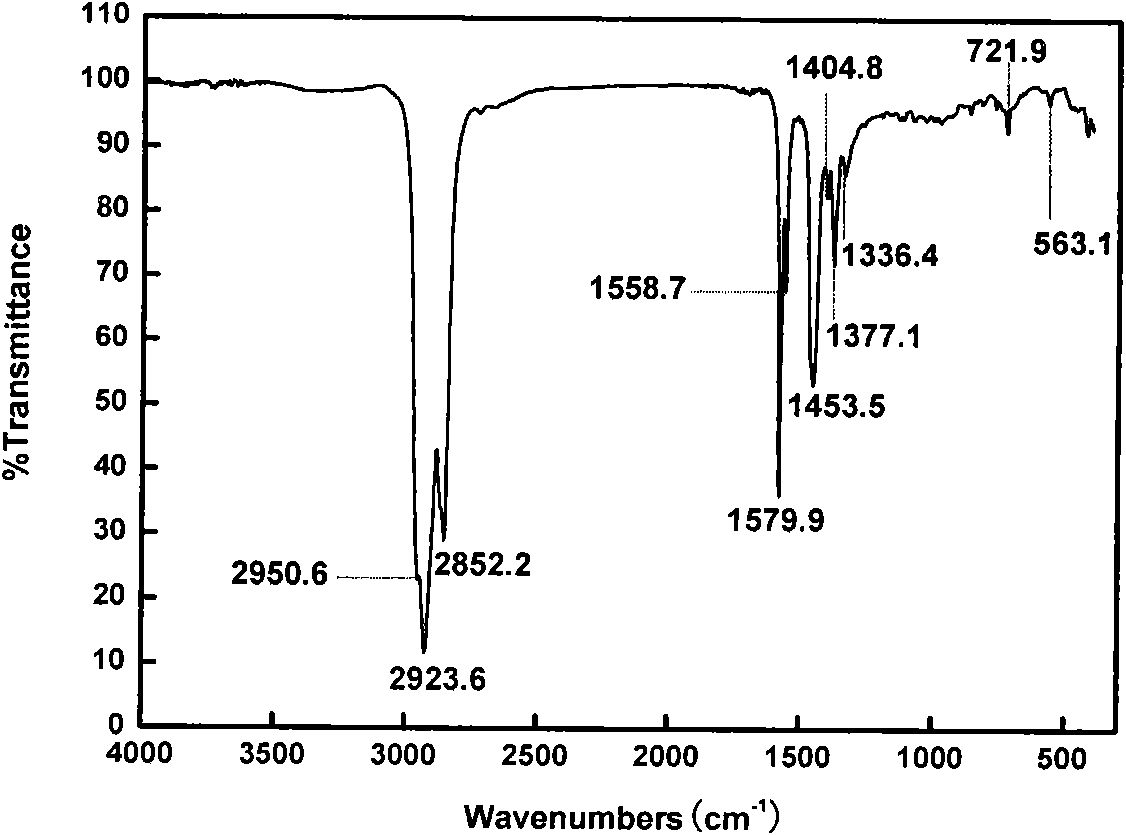

Image

Examples

Embodiment 1

[0037] Embodiment 1, the preparation of the complex lithium base lubricating grease that is made up of minus second-line base oil, complex lithium base thickener, surfactant and additive

[0038] Using naphthenic base oil (at 100°C, the kinematic viscosity is 8.01mm 2 / s) as a grease base oil. Get 33.2g of 12-hydroxystearic acid, 11.2g of sebacic acid, 3.4g of boric acid, 130g of naphthenic base oil and 2g of cetyltrimethylammonium bromide into the reactor, fully stir and slowly Raise the temperature to 100° C. and add a heated 10% aqueous solution containing 12 g of lithium hydroxide monohydrate, saponify at a constant temperature for 2 hours, and add water appropriately during the saponification process. After saponification, the temperature is raised to 140°C for dehydration and compounding. After the dehydration is complete, slowly add 80g of naphthenic base oil to dilute and continue to heat up. Gradually raise the temperature to 220°C for high-temperature refining. Sti...

Embodiment 2

[0039] Embodiment 2, the preparation of the complex lithium base lubricating grease that is made up of minus second-line base oil, complex lithium base thickener, surfactant and additive

[0040] This embodiment is an enlarged experiment to embodiment 1. Get 12-hydroxystearic acid of 166g, 56g sebacic acid, 17g boric acid, 650g naphthenic base oil (when 100 ℃, kinematic viscosity is 8.01mm 2 / s) and 10g hexadecyltrimethylammonium bromide drop into the reactor, fully stir and slowly heat up, rise to 102 ℃ and add heated 10% aqueous solution containing 60g lithium hydroxide monohydrate, Saponify at constant temperature for 2 hours, and add water appropriately during the saponification process. After saponification, the temperature is raised to 142°C for dehydration and compounding. After the dehydration is complete, slowly add 400g of naphthenic base oil to dilute and continue to heat up, and gradually raise it to 222°C for high-temperature refining, stir thoroughly for 10 min...

Embodiment 3

[0041] Embodiment 3, the preparation of the complex lithium base lubricating grease that is made up of three line base oil, complex lithium base thickener, surfactant and additive

[0042] Using naphthenic base oil minus the third line (at 100°C, the kinematic viscosity is 19.98mm 2 / s) as a grease base oil. Get 33.2g of 12-hydroxystearic acid, 11.2g of sebacic acid, 3.4g of boric acid, 130g of naphthenic base oil and 2g of cetyltrimethylammonium bromide into the reactor, fully stir and slowly Raise the temperature to 104° C. and add a heated 10% aqueous solution containing 12 g of lithium hydroxide monohydrate, saponify at constant temperature for 2 hours, and add water appropriately during the saponification process. After saponification, the temperature is raised to 144°C for dehydration and compounding. After the dehydration is complete, slowly add 80g of naphthenic base oil minus the third line to dilute and continue to heat up, gradually raising to 224°C for high-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com