Patents

Literature

204results about How to "Drop point high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

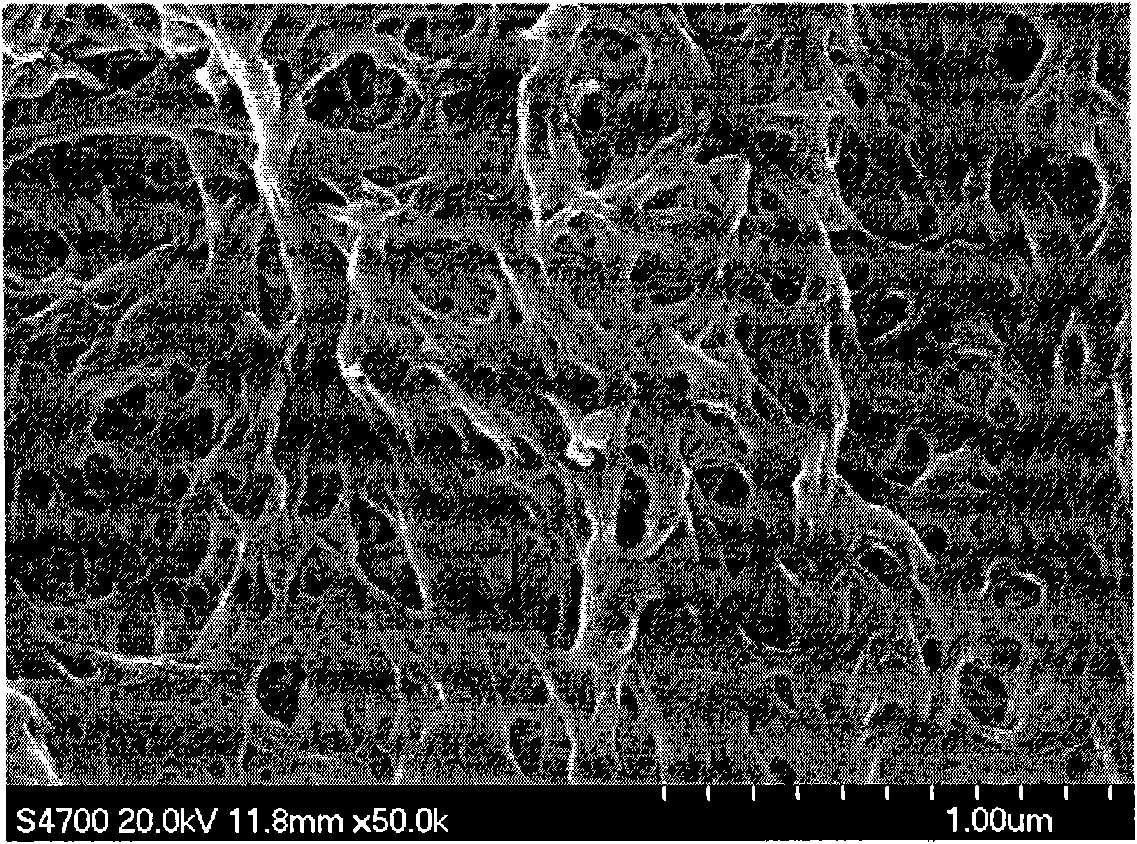

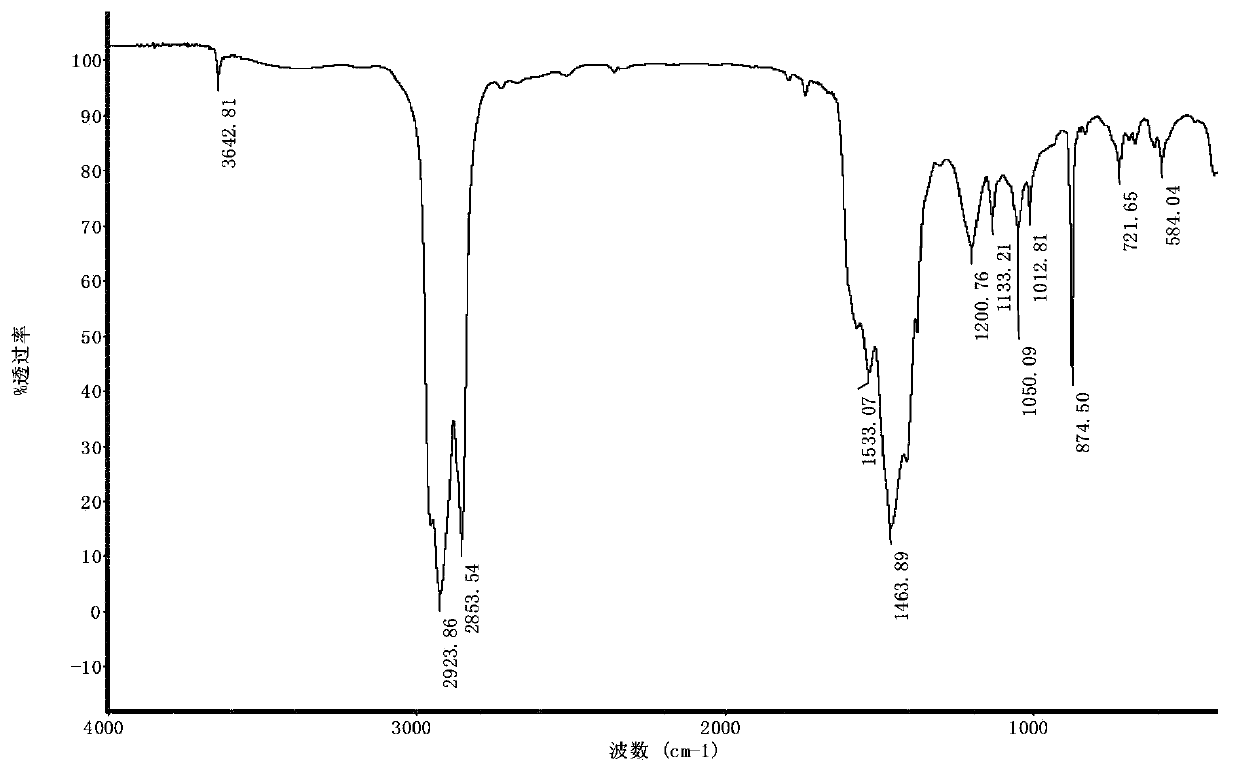

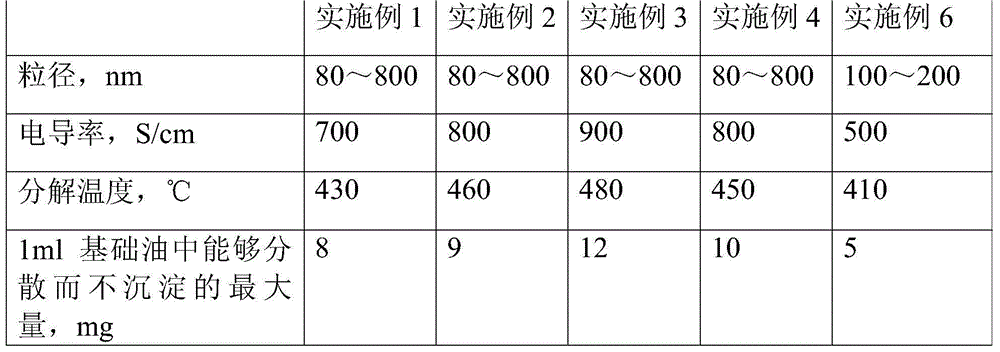

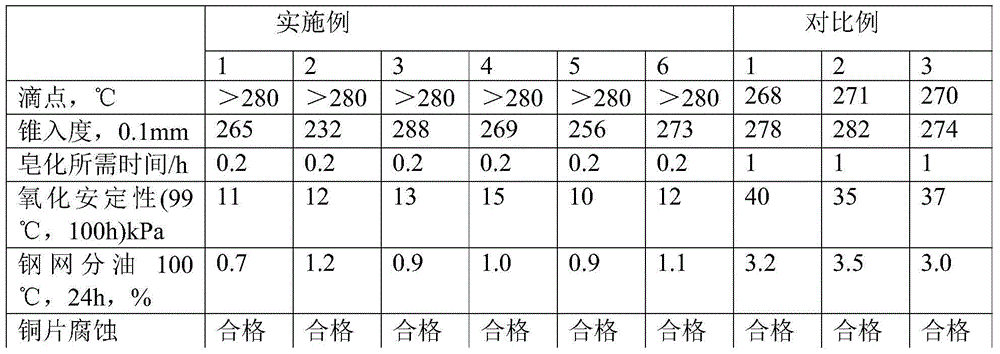

Polyurea grease composite

ActiveCN1657599AImprove extreme pressure and anti-wear performanceGood extreme pressure and anti-wear propertiesThickenersComposition BBase oil

Two lubricating polyurea-ester compositions with high stability and extreme-pressure antiwear performance contain proportionally basic oil, urea-based thickening agent, Ca-based thickening agent and extreme-pressure agent for composition A, or the composition A plus inorganic Ca salt for composition B.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite lithium-base grease and method for making same

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Lubricating grease and preparation method thereof

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of octapolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the octapolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steel rope grease with high dropping point and preparation method of steel rope grease

InactiveCN102618371AAlleviate lubrication and corrosion problemsExtended service lifeLubricant compositionAntioxidantBase oil

The invention relates to steel rope grease with high dropping point and a preparation method of the steel rope grease. The steel rope grease with high dropping point comprises the following compositions in percentage by weight: 65%-85% of base oil, 5%-20% of thickening agent, 2%-15% of adhesion agent, 1%-6% of rust inhibitor, 0-5% of antioxidant, 0-5% of polar additive and 0.5%-6% of solid lubricant. According to the steel rope grease, the dropping point of the steel rope grease is high (no less than 100 DEG C), the adhesion property is good (a slump test is qualified), the low temperature performance is good, superior adhesion property and oil film forming capacity are realized, and comprehensive performances such as waterproofing, corrosion resistance, oxidation resistance and wear resistance are also realized; and high-quality steel rope grease products required by the imported steel rope products can be partially replaced by the steel rope grease, so that the production cost is reduced for enterprises, the lubrication and corrosion resistant problems of the steel rope can be relieved, and the service life of the steel rope can be greatly prolonged.

Owner:HENAN COAL SCI RES INST

Lubricating grease and preparation method thereof

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of bipolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the bipolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite lithium grease and preparation method thereof

InactiveCN101705141ADrop point highStrong antioxidant performanceLubricant compositionChemistryLithium hydroxide monohydrate

The invention provides composite lithium grease and a preparation method thereof. The composite lithium grease comprises the following components by weight percent: 4-10 percent of hydroxyl fatty acid of C12-C14, 1-4 percent of dibasic acid of C4-C18, 1-4 percent of lithium hydroxide, 0.1-1 percent of organic amine antioxidant, 0.3-1 percent of anti-corrosion rust inhibitor, 1-5 percent of antiwear extreme pressure additive and the balance of base oil. The preparation method comprises the following steps of mixing the base oil with the hydroxyl fatty acid of C12-C14and the dibasic acid of C40C18, heating the mixture to 80-115 DEG C, and adding lithium hydroxide monohydrate aqueous solution to perform saponification reaction, then carrying out dehydration, raising the temperature to 130-180 DEG C to carry out constant-temperature refining, raising the temperature to 200-220 DEG C to carry out highest temperature refining, adding the residual base oil and the additives, cooling and grinding to obtain the composite lithium grease. The composite lithium grease has the advantages of high dropping point, favorable high temperature performance, mechanical stability, antiwear and extreme pressure property, corrosion and rust resistance, and the like.

Owner:南通山浦润滑油科技有限公司

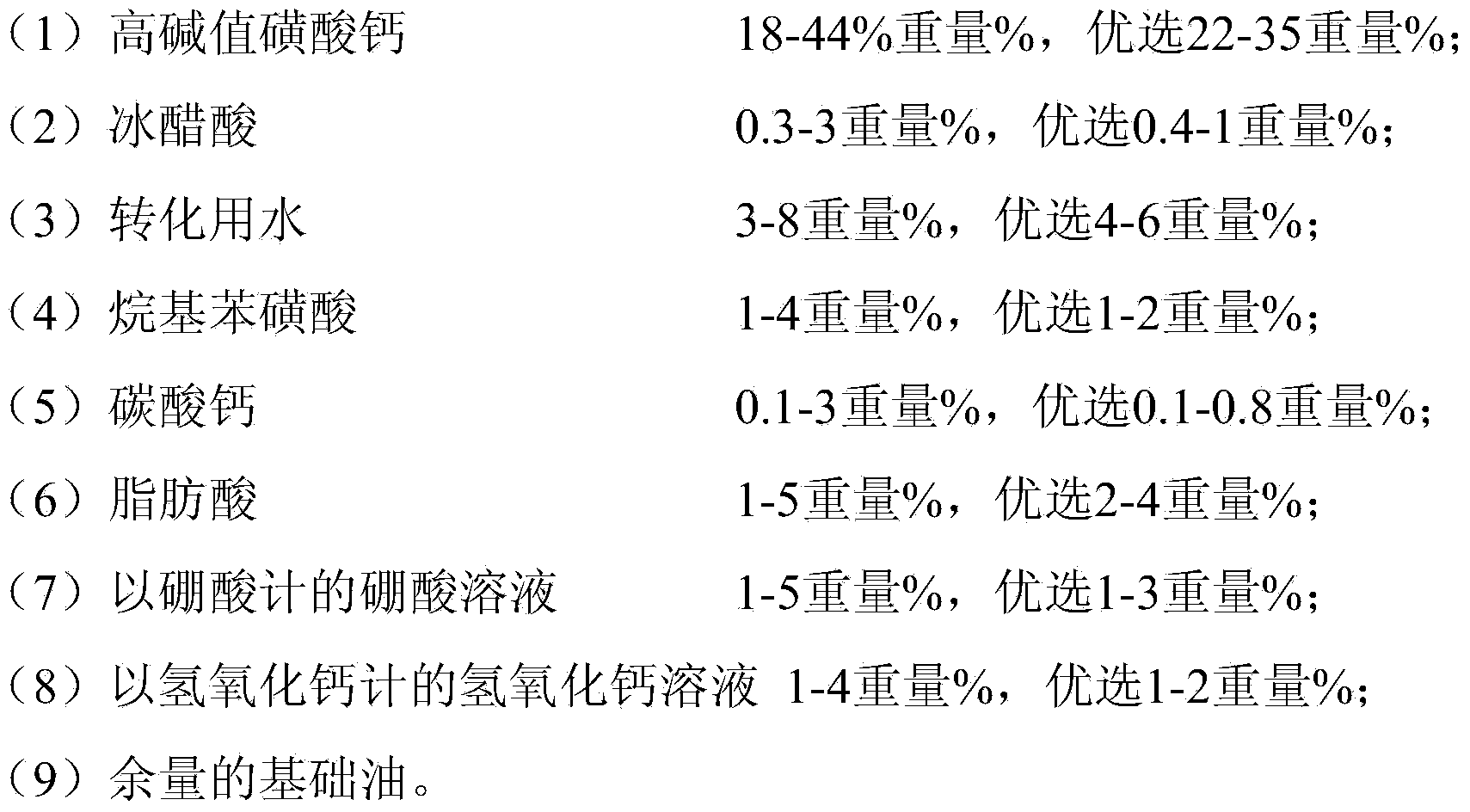

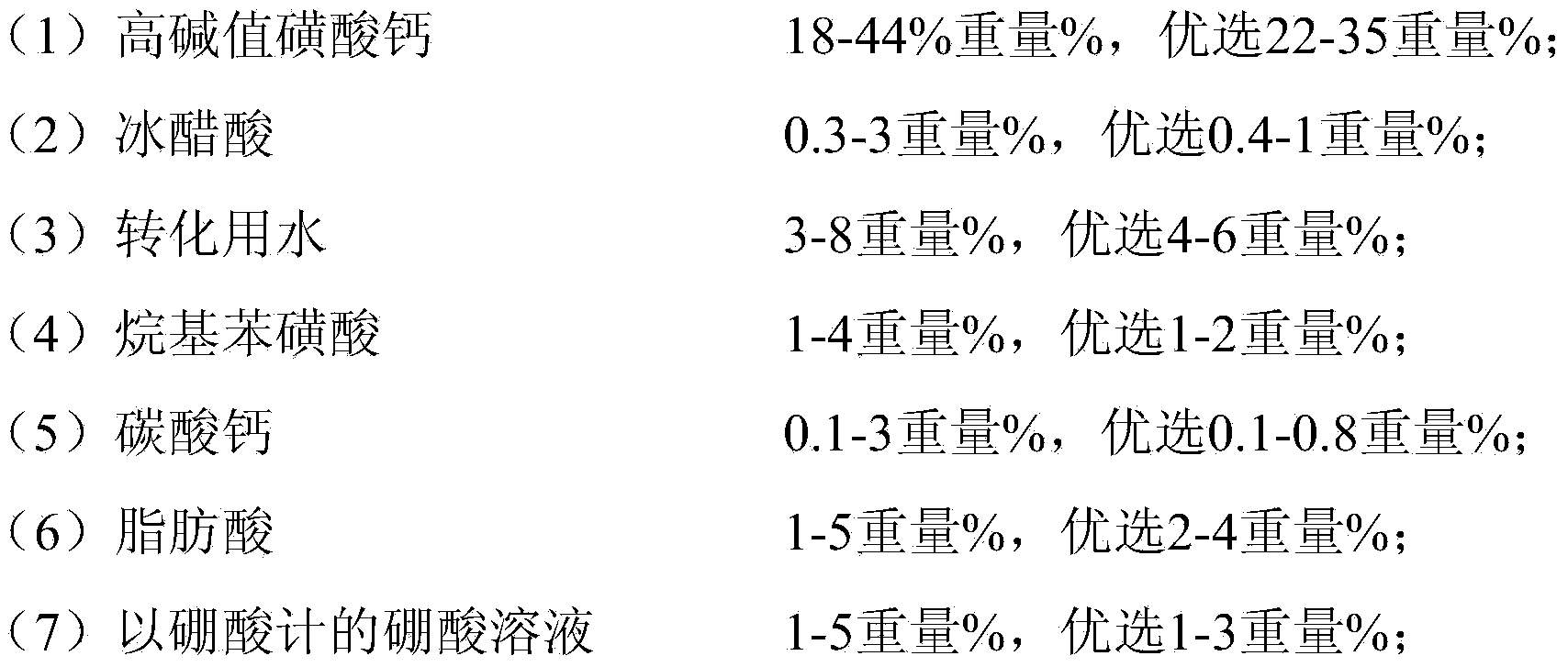

Composite calcium sulfonate lubricating grease composition and preparation method thereof

ActiveCN103740435ADrop point highGood extreme pressure and anti-wear propertiesThickenersChemistryBenzene

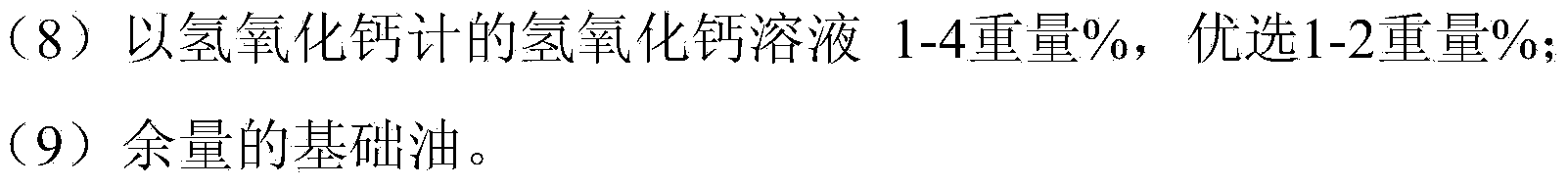

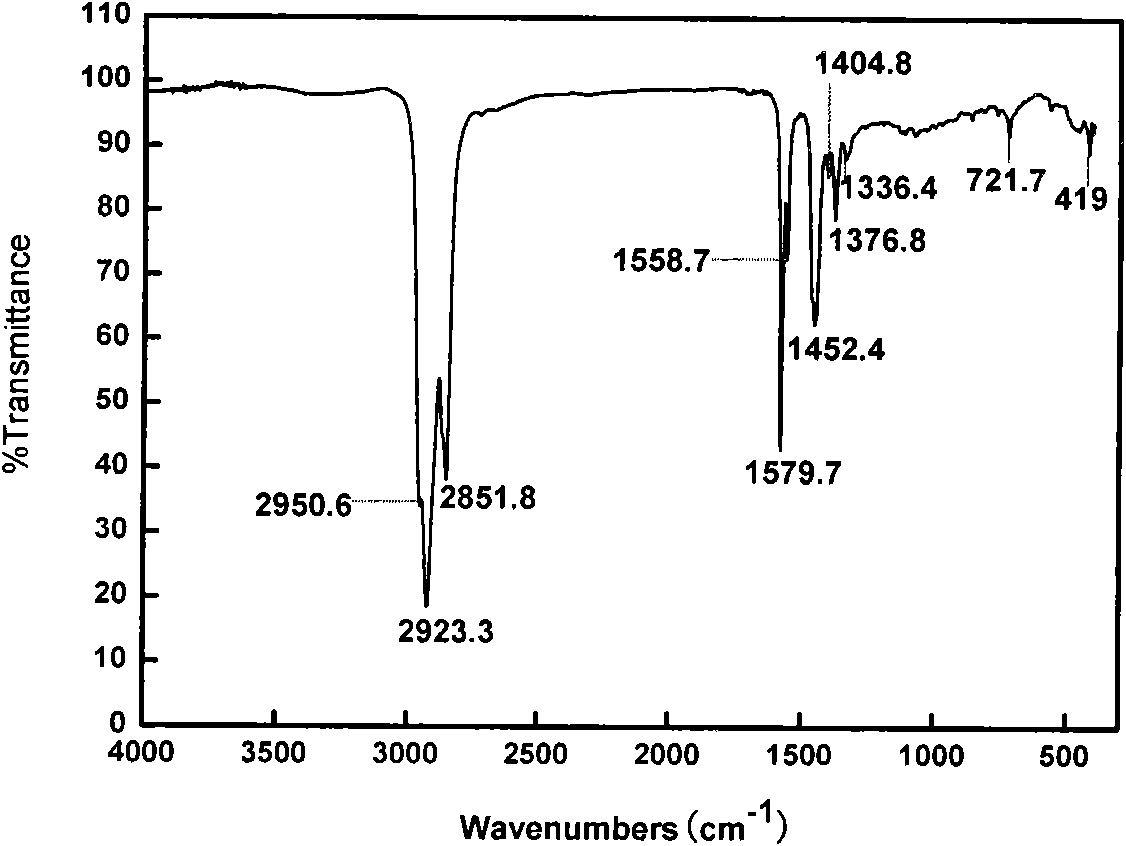

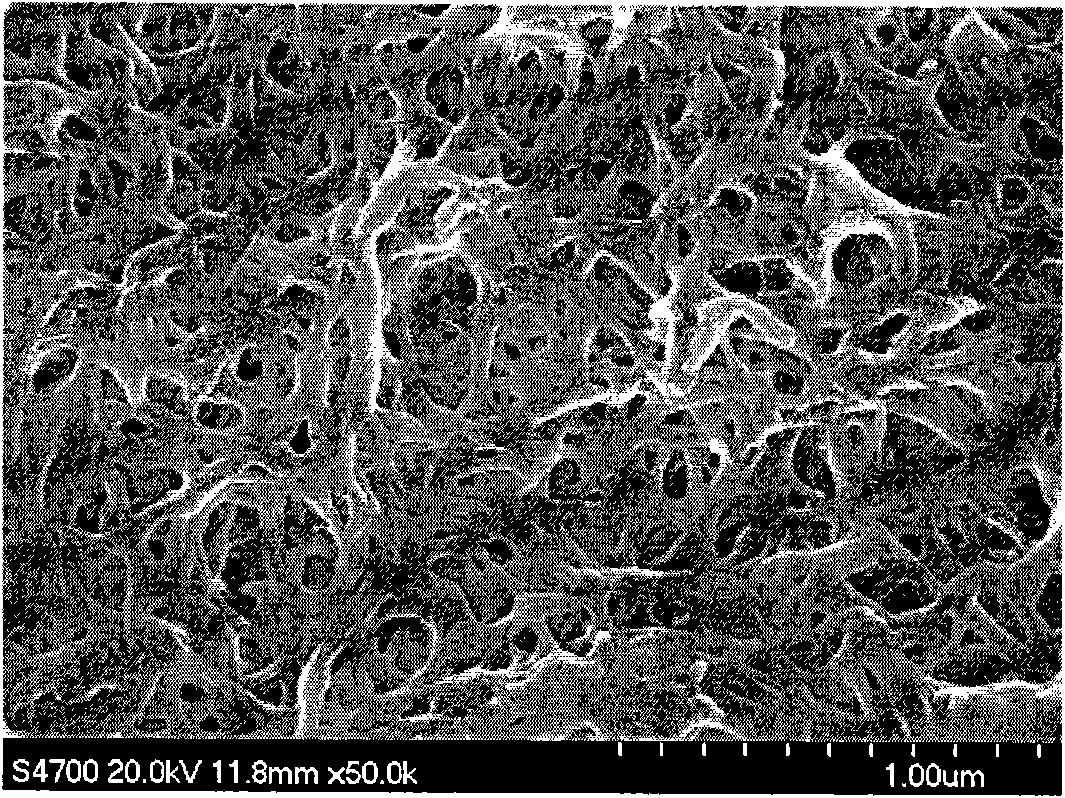

The invention relates to a composite calcium sulfonate lubricating grease composition and a preparation method thereof. The composite calcium sulfonate lubricating grease composition is prepared from the following raw materials in percentage by weight: 18 to 44 percent of high-base-number calcium sulfonate, 0.3 to 3 percent of glacial acetic acid, 3 to 8 percent of water for conversion, 1 to 4 percent of alkyl benzene sulfonic acid, 0.1 to 3 percent of calcium carbonate, 1 to 5 percent of fatty acid, 1 to 5 percent of a boric acid solution counted by using boric acid, 1 to 4 percent of a calcium hydroxide solution counted by using calcium hydroxide and the balance of base oil. The composite calcium sulfonate lubricating grease composition has the advantages of high dropping point, good extreme pressure antiwear property, excellent colloid stability and mechanical stability, and has a wide application range. The invention further relates to the preparation method for the composite calcium sulfonate lubricating grease composition.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Complex lithium grease and preparation method thereof

The invention provides complex lithium grease and a preparation method thereof. The complex lithium grease comprises grease base oil, complex lithium thickening agents and surfactants with mass part ratio of (290-1450):(50.4-251.3):(2-10), wherein the grease base oil is at least one of vacuum second line base oil, vacuum third line base oil and vacuum fourth line base oil; the complex lithium thickening agents are formed by C12-C24 fatty acid lithium and auxiliary acid lithium with mass part ratio of (34-70):(16.4-81.3); and the auxiliary acid lithium is any two of C1-C22 fatty acid lithium, lithium borate, lithium phosphate, aromatic acid lithium, lithium naphthenate, dicarboxylic acid lithium and polybasic acid lithium. The invention also provides the preparation method of the complex lithium grease. The surfactants are added to the complex lithium grease to have synergistic effect with soap molecules of the complex lithium grease and further improve the arrangement of the soap molecules and the capability of curing the base oil, thus increasing the dropping point of the grease.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Environment-friendly lubricating grease and preparation method thereof

InactiveCN101058762AImprove performanceIncreased working penetrationThickenersAdditivesBase oilOrganic chemistry

The invention discloses an environment-friend lubricating grease and making method, which comprises the following parts: 15-95% basic oil, 5-85% thickener, 0. 01-5% additive. The making method comprises the following steps: 1. blending the basic oil and thickener; stirring; heating until the thickener is dissolved in the basic oil; insulating 0-8h; 2. heating the composition; stirring; insulating 0-5min; 3. cooling the composition; adding the additive; grinding or cutting. The invention improves the awl-in degree, dripping point, oxidizing stability and environment friendness, which simplifies the technique.

Owner:HARBIN INST OF TECH

Filling oil-containing semi-solid composition for fibre-otpical composite overhead earth wire

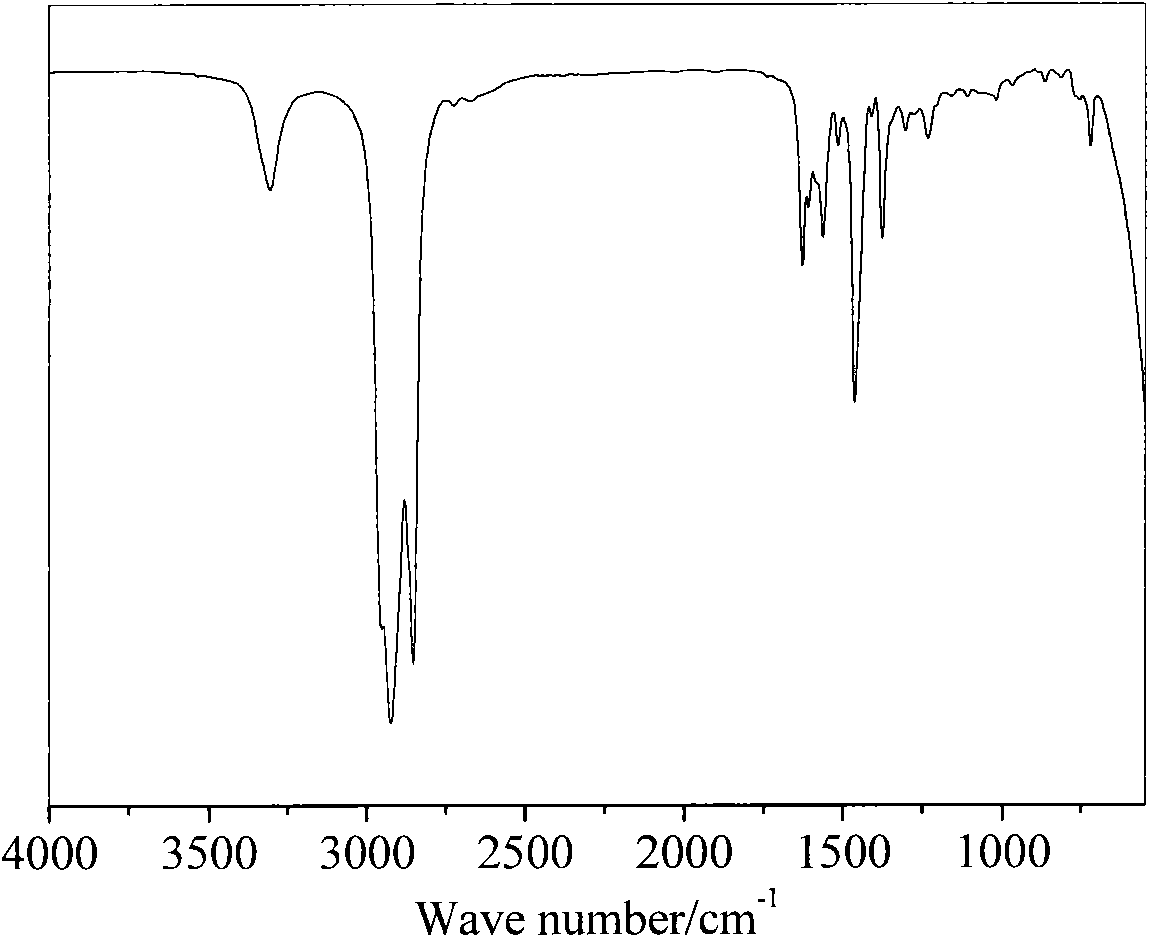

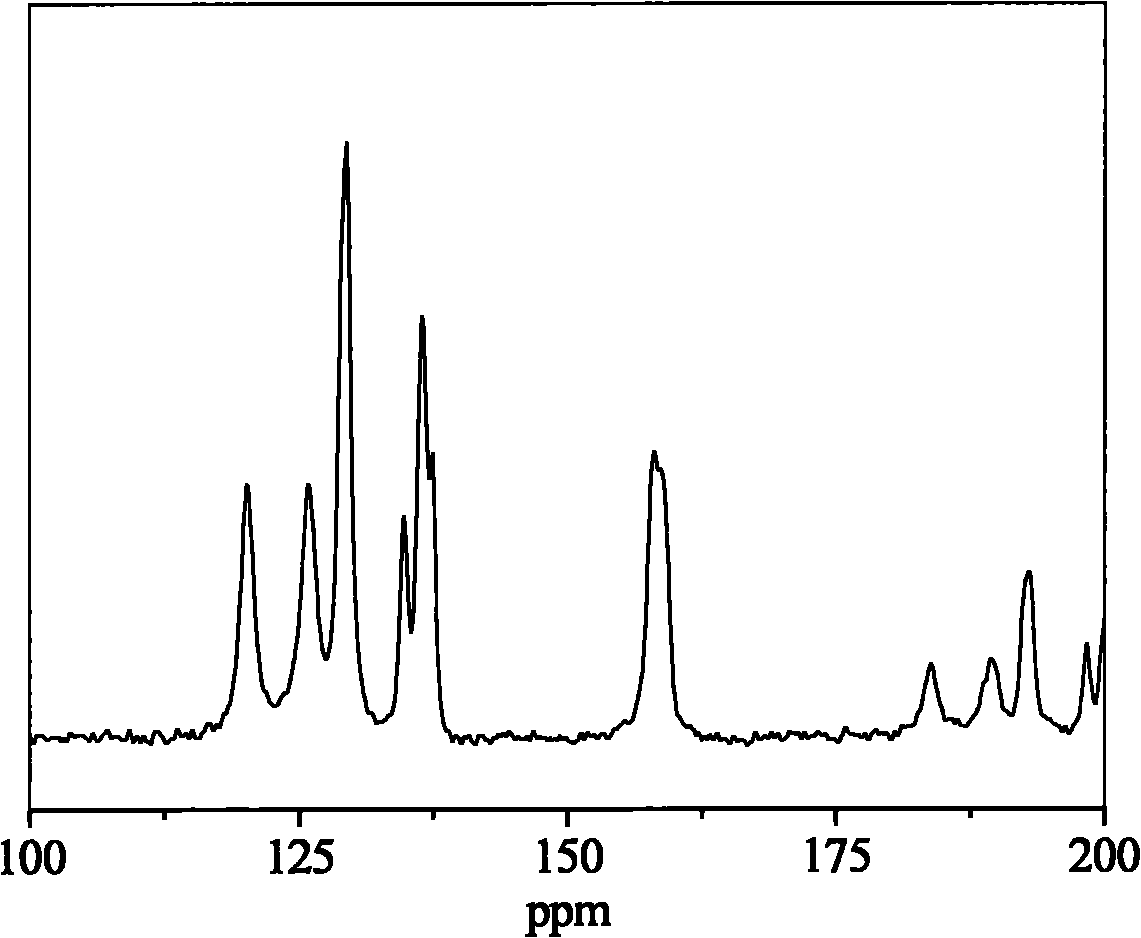

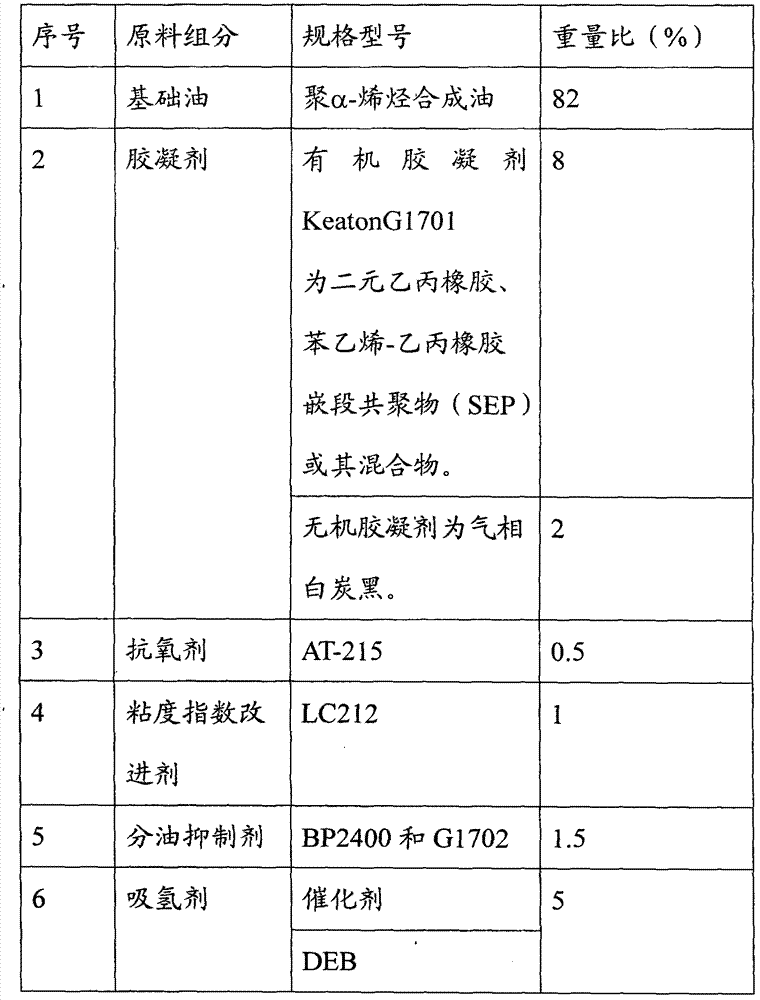

A filling grease for composite fibre-optical overhead earth wire is prepared by mixing 36®|hydrogenated white oil and PAO-8 synthesized oil with PriCO-3002 polybasic alcohol ester and viscosity exponential improver Lc-212, adding into additive OB fluorescent brightening agent, grease-separating inhibitor BP2400 and G1702, raising temperature, stirring, adding into organic thickening agent gas-phase carbon white H20, raising temperature, thickening, adding into antioxidant AT-215 and inorganic thickening agent SEP1650, raising temperature, thickening, shearing, circulation feeding back, cooling to normal temperature, homogenizing, degassing, filtering and obtaining the grease. It achieves good hydrogen absorption and stable fibre-optical transmitting performance.

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

Special-purpose lubricating agent

InactiveCN101104830ANo pollutionImprove extreme pressure performanceThickenersAdditivesAntioxidantCrusher

The invention relates to a special lubricant named as HP800 Special Lubricant which is used for the open gear and support roller that are oiled by injection method. The lubricant takes composite calcium sulphonate and composite aluminium as the thickener; the base oil of the lubricant is synthetic oil; and in addition tackifier, extreme pressure agent and antioxidant are also added in. Wherein the weight-portion of each component are: the base oil: 50-64, the thickener: 20, the tackifier :5-10, the extreme pressure agent: 10-25,and the antioxidant: 1. The invention is suitable for lubrication of the open gear, the support roller of all kinds of umbrella ball mill, mixer, rotary kiln, imported umbrella excavator, crusher, and coal grinding machine; and has very high extreme-pressure performance, excellent viscosity and protection performance, thereby the invention can substitute import products of the same kind and has the advantages of thick oil-film, non-oil-swinging and environmental-protection.

Owner:辽宁海华科技股份有限公司

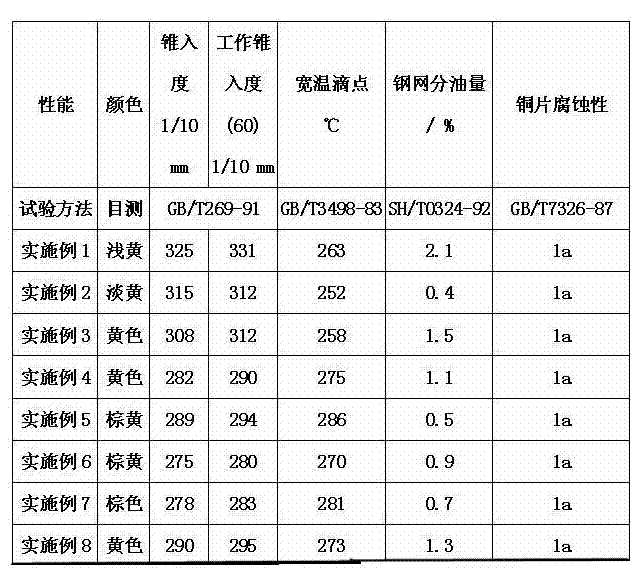

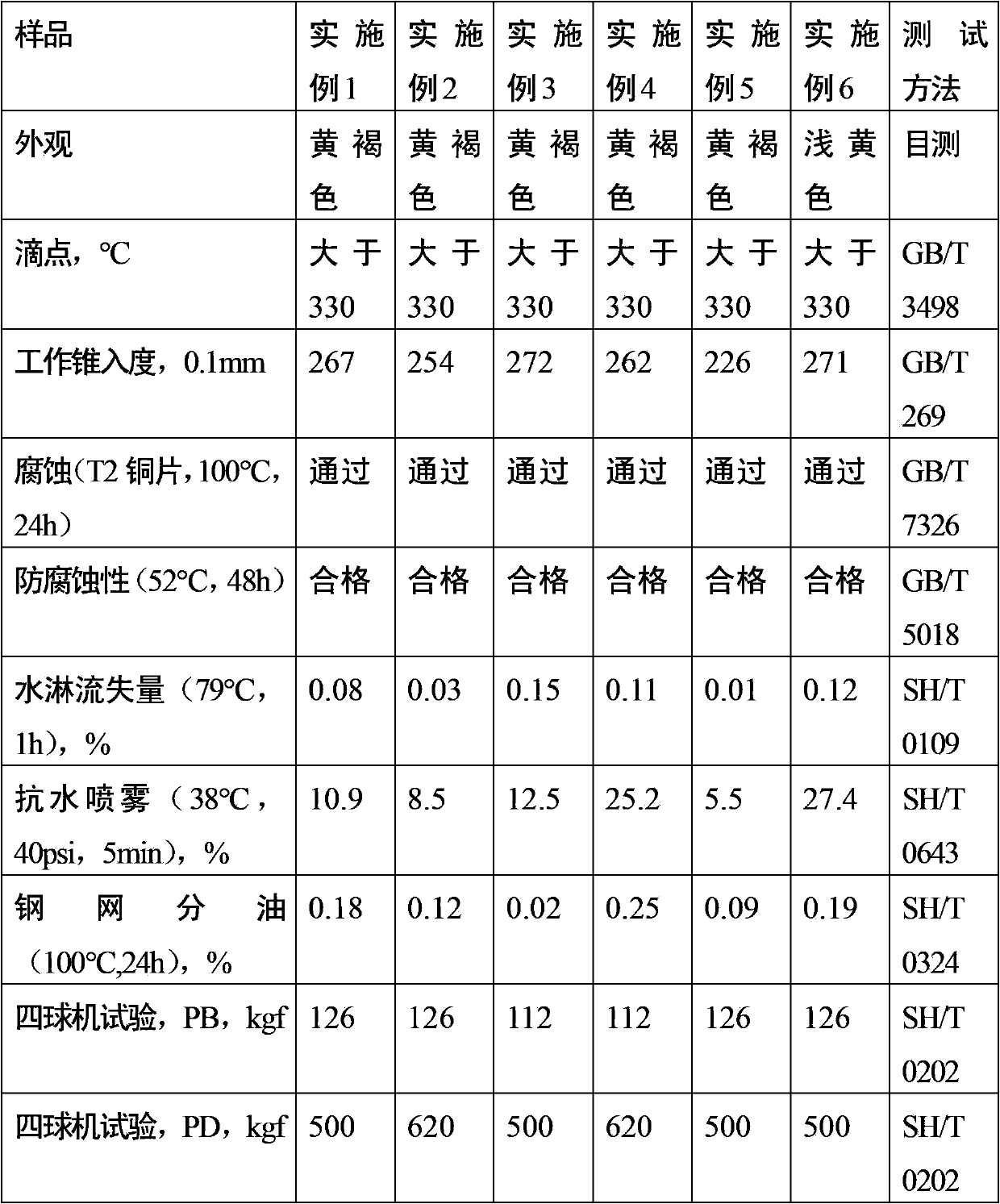

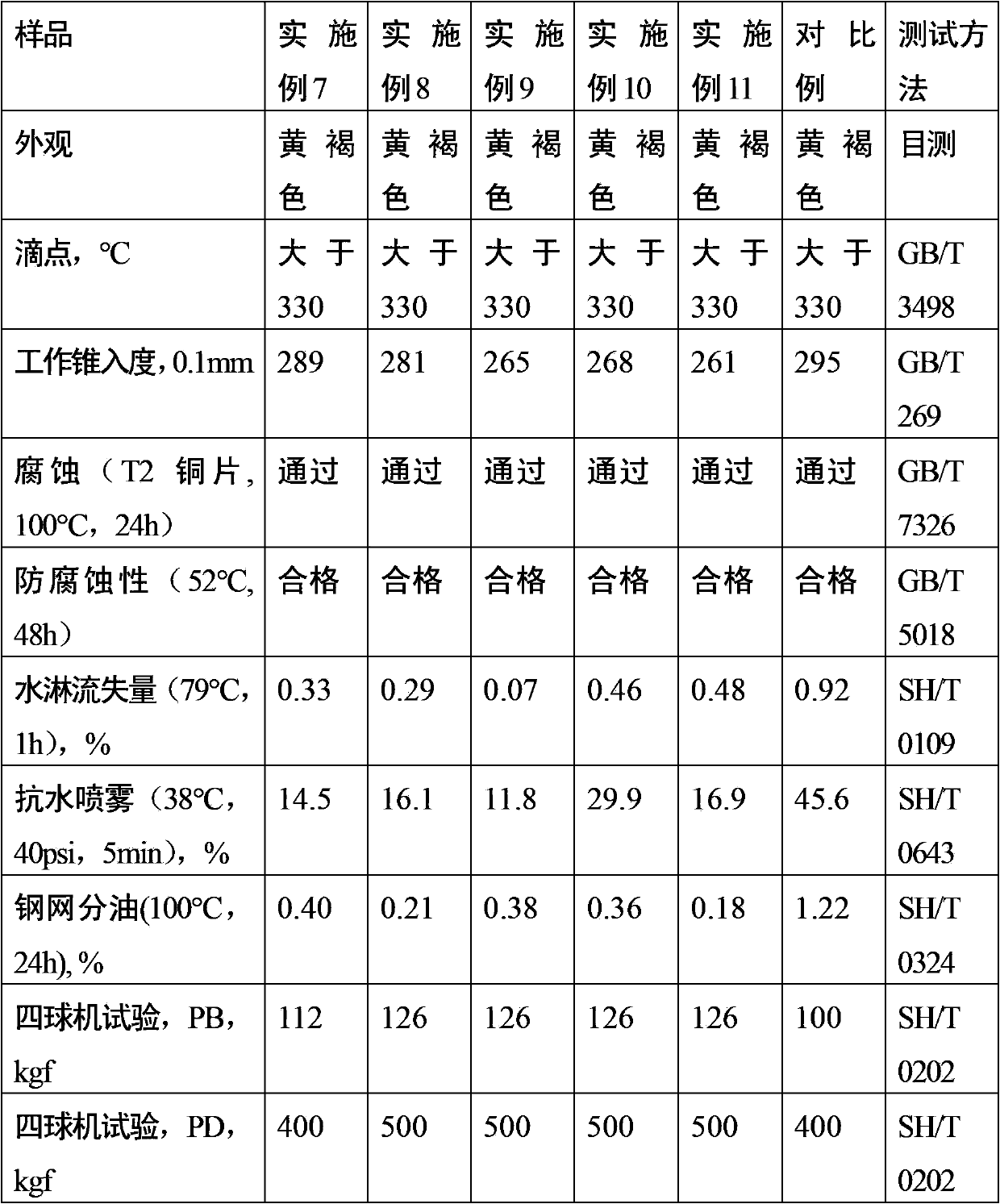

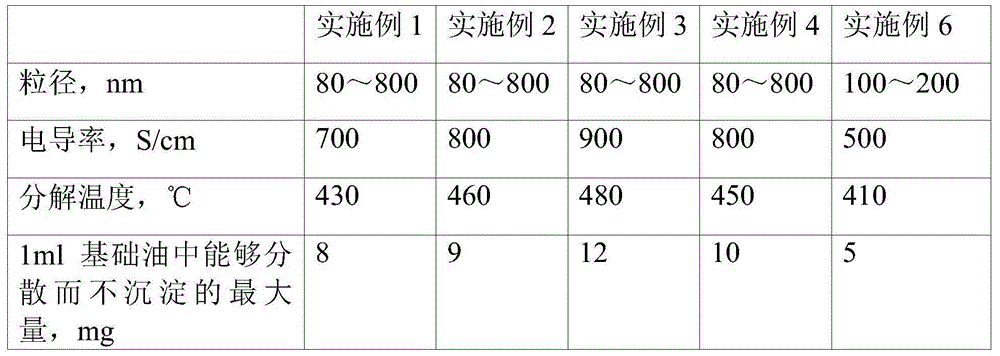

Preparation of high dropping point carbamido grease lubricant and obtained product

The invention provides a preparation process for high drop point ureido grease, wherein, the base oil, the solid additive powder, the organic amine and the diisocyanate are mixed between 50 DEG C and 100 DEG C to react, then added with the quench oil when the temperature rises between 160 DEG C and 220 DEG C and is then cooled to be taken out of a kettle. The grease obtained by the invention is taken as one hundred percent of total weight and comprises the following compositions: the weight of the base oil accounts for 70 to 90 percent, the ureido thickening agent produced by the reaction of the organic amine and the diisocyanate has a weight accounting for 5 to 25 percent, and the weight of the solid additive powder accounts for 0.1 to 10 percent. The grease obtained by the process has a drop point which is more than 330 DEG C and has good extreme pressure anti-abrasion performance as well as corrosion resistance performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

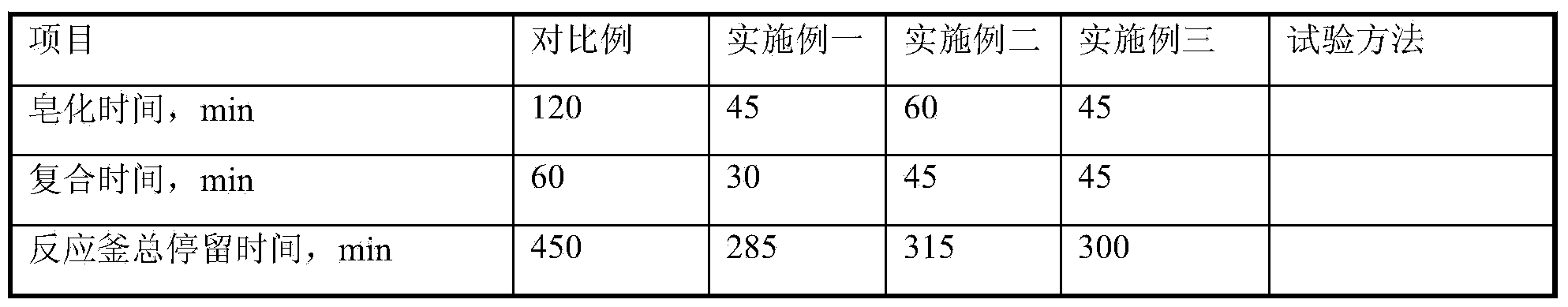

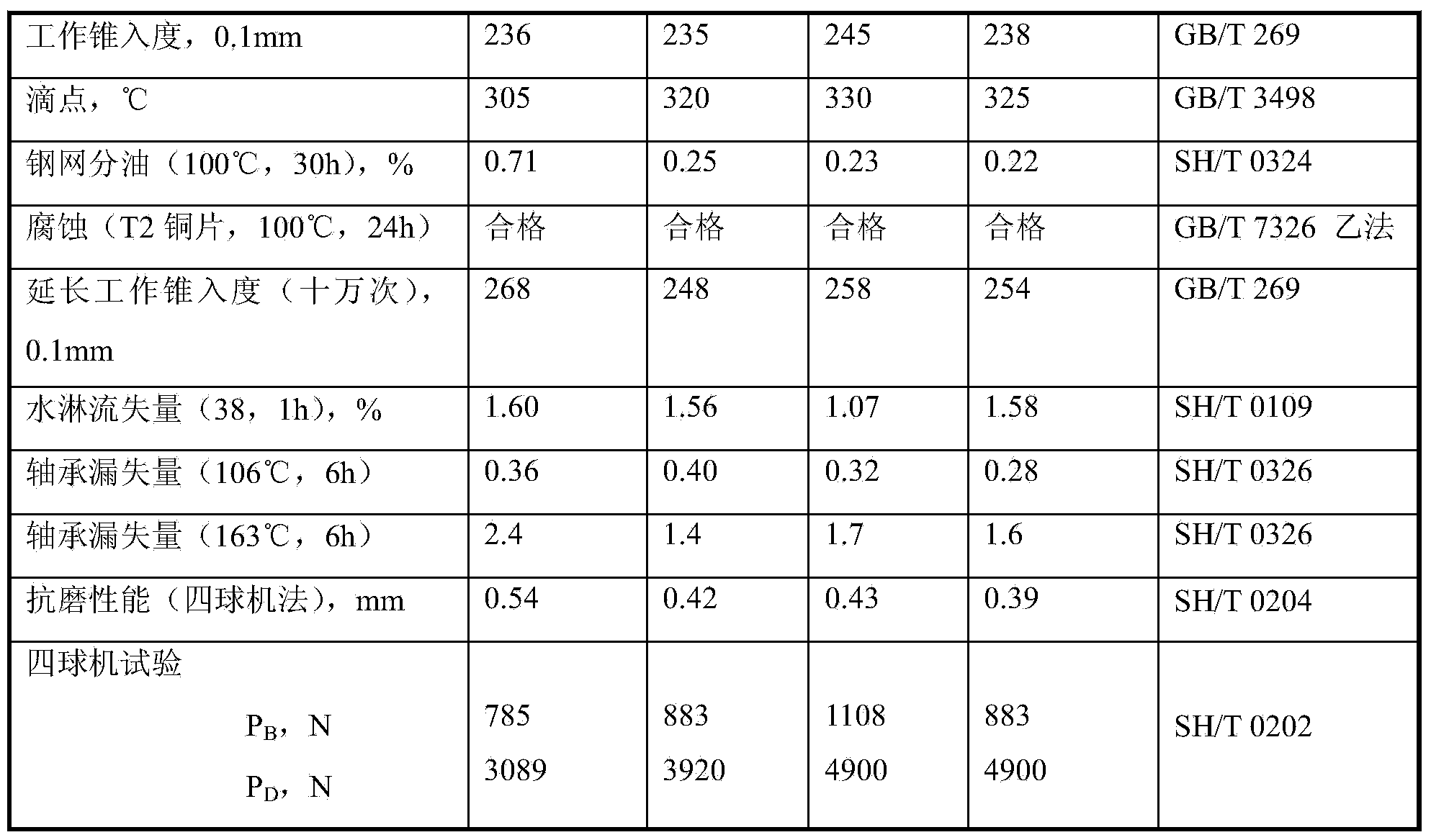

Lubricating grease for hub bearing of heavy load truck and preparation method thereof

InactiveCN103450978AEliminates tendency to overflowSlow dehydration stepThickenersThiocarbamateChemical industry

The invention relates to a lubricating grease and a preparation method thereof, particularly relates to a lubricating grease for a hub bearing of a heavy load truck and a preparation method thereof, and belongs to the technical field of a chemical industry. The lubricating grease is prepared from the following raw materials: (A) base oil which accounts for 60-85% of total weight of the lubricating grease, (B) a thickening agent, which is C12-C22 unitary organic acid which accounts for 7-12% of total weight of the lubricating grease, 0.5-3% of sebacic acid, 0.2-1% of boric acid, and 3-5% of lithium hydroxide oil solution, (C) an additive, which is thiocarbamate which accounts for 0.5-3% of total weight of the lubricating grease, 2-5% of sulfide olefin cottonseed oil, 2-4% of dialkyl dithiocarbamate salt, 0.5-2.5% of molybdenum dialkyl dithiophosphate, 0.3-2% of antirust agent and 0.3-1% of antioxidant. The lubricating grease has the beneficial effects that the production time is shortened; the lubricating grease is more controllable in process, stable in product quality, less in seepage loss of a high-temperature bearing, and prominent in extreme pressure property; lubricating protection can be better provided for hubs of the heavy load truck; the lubricating requirements of the hub bearing of the heavy load truck under various working conditions can be met; the grease exchange period of the hub bearing is prolonged.

Owner:JIANGSU LOPALTECH

High-temperature grease and preparation method thereof

The invention relates to a high-temperature grease and a preparation method thereof, which are widely applied to equipment bearings of production lines in steel mills and steel works. The high-temperature grease contains the following components in weight parts: 45 to 81.5 parts of high-viscosity mineral oil, 4 to 10 parts of polyurea, 10 to 30 parts of high-base number calcium petrolem sulfonate, 1 to 3 parts of transforming agent, 1 to 3 parts of anti-rust agent, 1 to 3 parts of extreme-pressure additive, 0.5 to 1 part of antioxidant, and 1 to 5 parts of thickening agent. The high-viscosity mineral oil is 150BS. The high-temperature grease has higher dropping point, does not turn thin or has lower thinning degree after meeting water; the antirust performance is as good as the new grease after meeting water; and the extreme-pressure performance thereof is reduced by a lower degree or does not reduce after meeting water.

Owner:辽宁海华科技股份有限公司

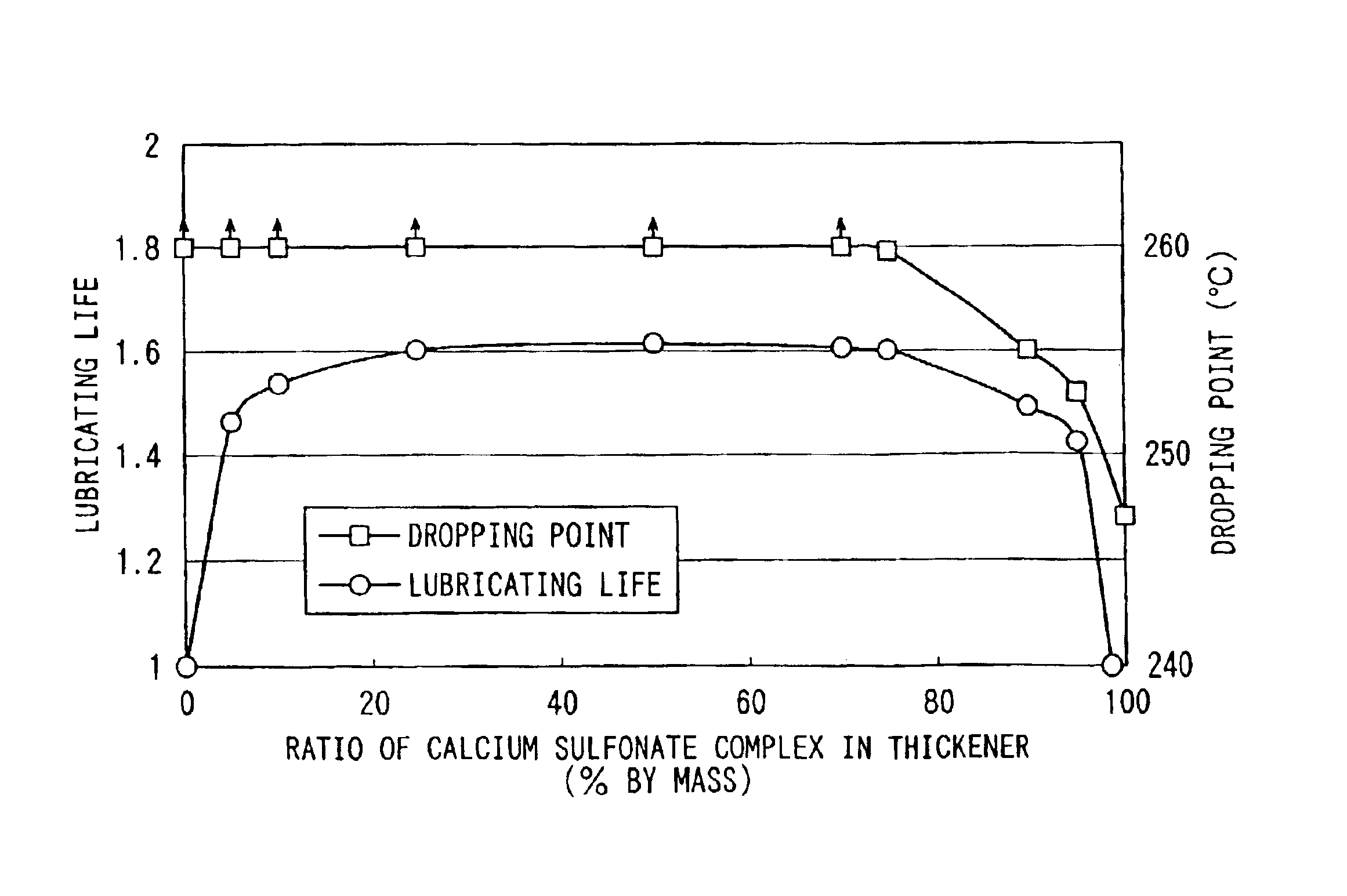

Grease composition and rolling apparatus

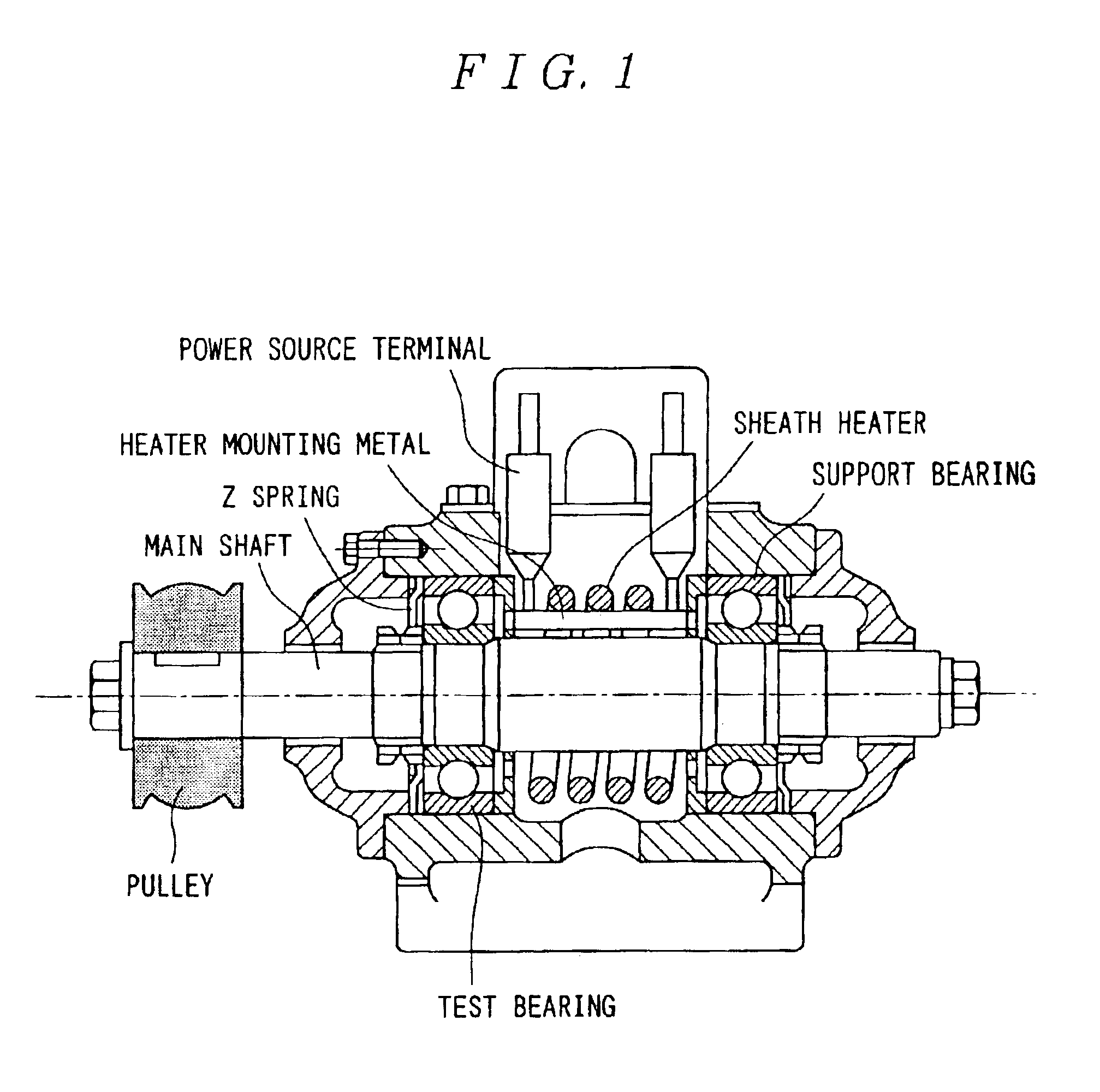

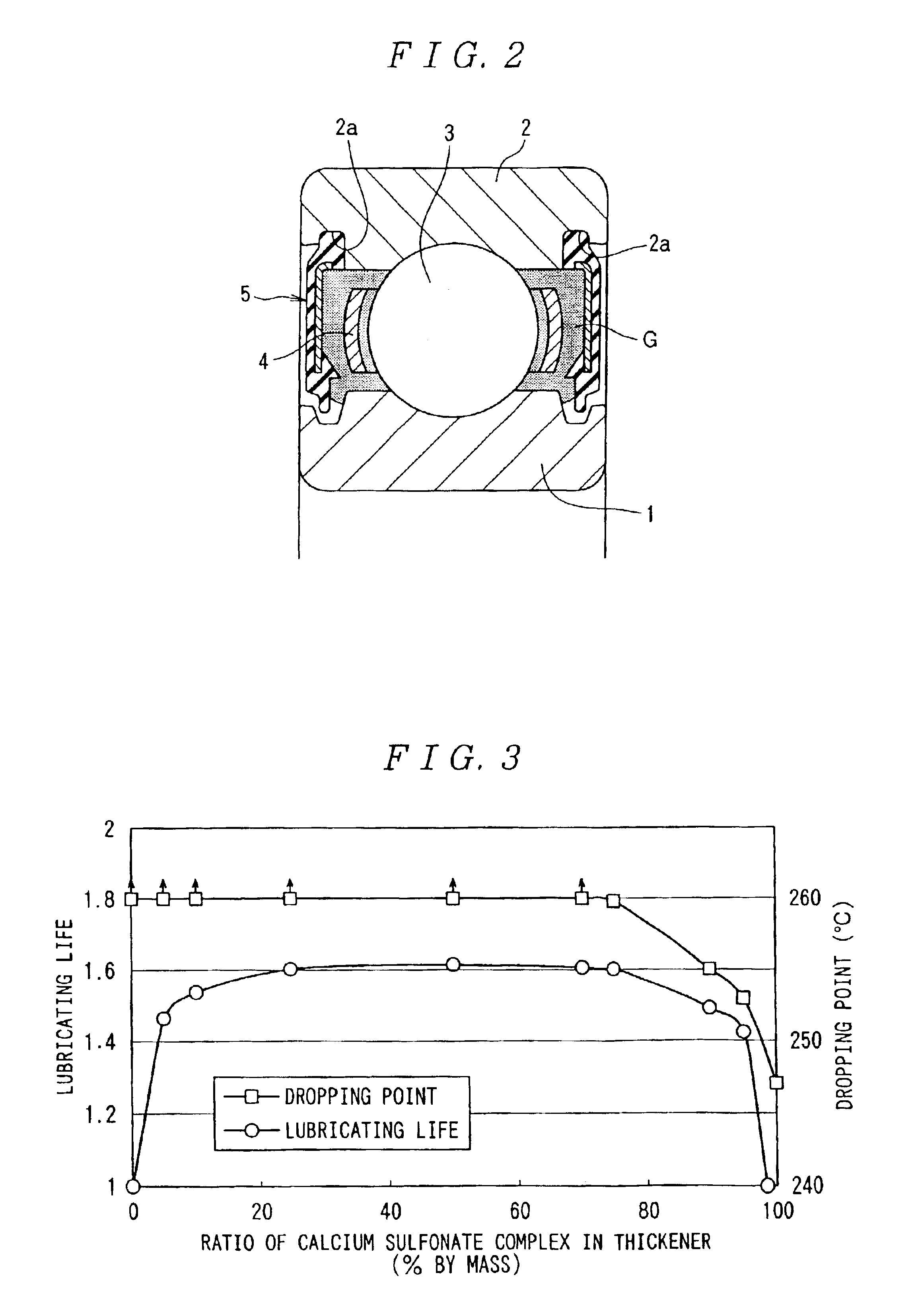

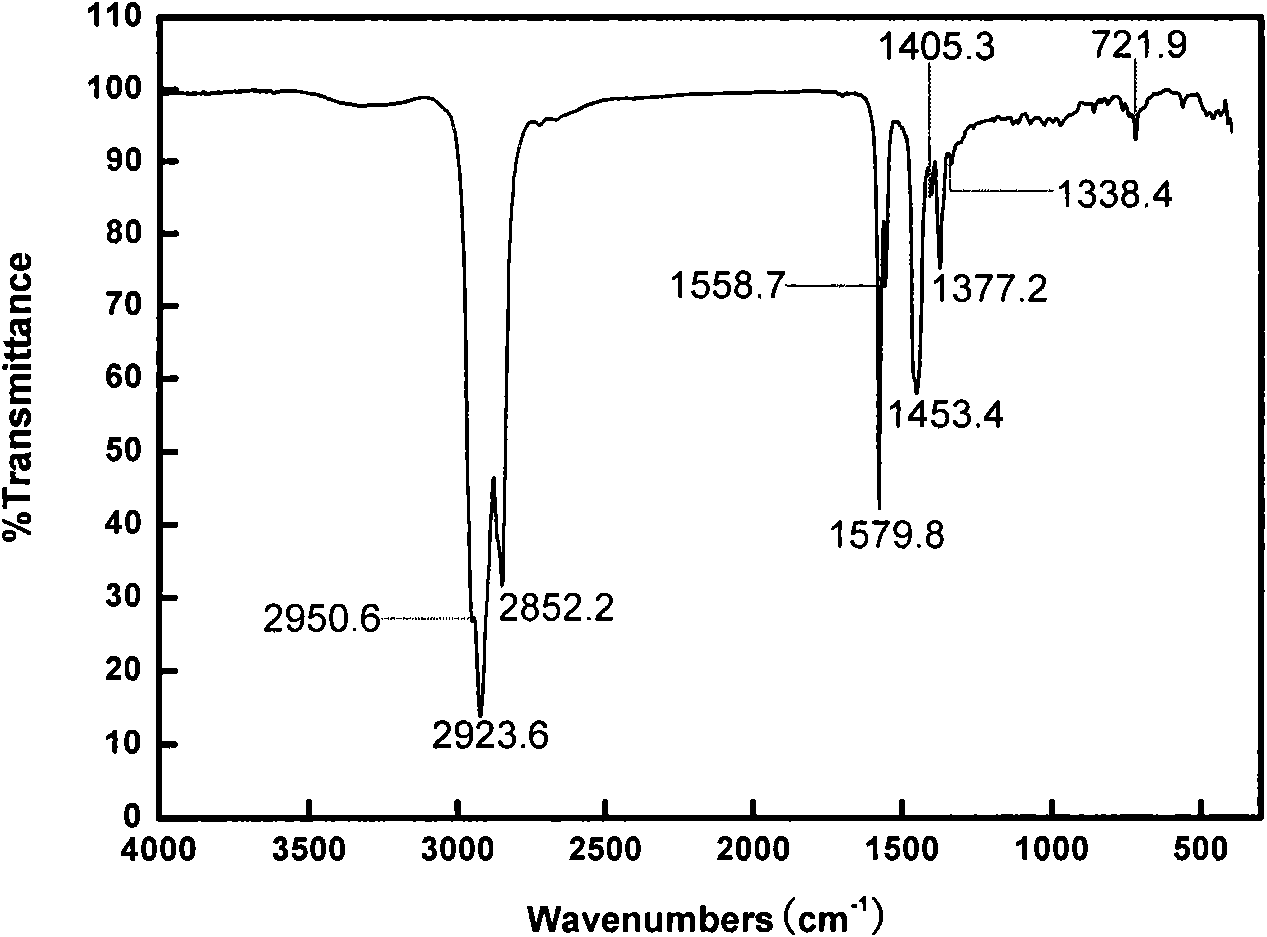

InactiveUS6919301B2Improvement of additive effectEliminate the effects ofBall bearingsBearing componentsChemistryPolyurea

A grease composition with a thickener of a calcium sulfonate complex and a second thickener component in a base oil. The second thickener component may be, for instance, polyurea, a metallic soap, a complex metallic soap or an N-substituted terephthalamic acid metal salt. Alternatively, a grease composition with a thickener of an N-substituted terephthalamic acid metal salt and a second thickener component in a base oil. Furthermore, a grease composition with a thickener component of polyurea and complex metallic soap in an ester oil. Still further, a grease composition with a thickener of polyurea and a complex metallic soap in a base oil.

Owner:NSK LTD

Composite lithium-calcium-based lubricating grease and preparation method

The invention provides composite lithium-calcium-based lubricating grease and a preparation method. The composite lithium-calcium-based lubricating grease consists of lubricating grease base oil, a composite lithium-calcium-based thickener and a surfactant in a mass part ratio of (449-1,722): (69.6-304.8): (2-10), wherein the lubricating grease base oil is at least one of vacuum cut 2 base oil, vacuum cut 3 base oil and vacuum cut 4 base oil; and the composite lithium-calcium-based thickener is a composite thickener consisting of calcium C12 to C24 fatty acid salt, a lithium C2 to C12 fatty diacid salt and lithium borate in mass part ratio of (53.2-238.6):(13.2-53.2):(3.2-13). The invention also provides a method for preparing the composite lithium-calcium-based lubricating grease. The surfactant is added into the composite lithium-calcium-based lubricating grease to produce a synergistic effect with soap molecules for improving the arrangement mode base oil immobilizing capacity of the soap molecules, and thus the dropping point of the lubricating grease is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Ureido lubricating grease and its preparation method

An carbamide-base lubricating grease contains hydrogenated mineral oil, plant oil and carbamide-base thickening agent. Its advantages are high thickening power and dripping point, and low vibration and noise of bearing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite sodium-based lubricating grease and preparation method thereof

ActiveCN104560315AImprove antioxidant capacityImprove high drop pointThickenersSalt resistanceGraphene

The invention discloses composite sodium-based lubricating grease and a preparation method thereof. By the weight of the lubricating grease, the compound sodium-based lubricating grease comprises the following components: 65-95% of lubricating base oil, 5-30% of a composite sodium-based thickener and 0.2-15% of graphene. The composite sodium-based lubricating grease disclosed by the invention has excellent properties such as high temperature resistance, water resistance, adhesivity, colloid stability, extreme pressure antiwear property, long lubricating life, corrosion resistance and salt fog resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame-retardant waterproof ointment incompatible with flame-retardant sheath material and used for filling cable

InactiveCN102708974AExtended shelf lifeFast water absorptionInsulated cablesFibre mechanical structuresChemical industryFilled cable

The invention relates to the technical field of chemical industry and particularly relates to a flame-retardant waterproof ointment incompatible with a flame-retardant sheath material and used for filling a cable. The waterproof ointment is characterized by comprising the following raw material components in percentage by weight: 65-75% of base oil, 4-8% of oil stabilizer, 1-2% of antioxidant, 3-8% of thickener, 3-8% of fire retardant, 3-15% of waterproofing agent and 5-10% of absorptive particles. Compared with the prior art, the flame-retardant waterproof ointment has the following advantages: the quality guarantee period of products is greatly prolonged, the initial water absorption speed is greatly quickened, the initial expansion speed is quicker; the dropping point of the products is higher, the cone penetration is greater, and the thixotropic property is better; and a photoelectric cable made from the flame-retardant waterproof ointment is longer in service life.

Owner:STATE GRID CORP OF CHINA +1

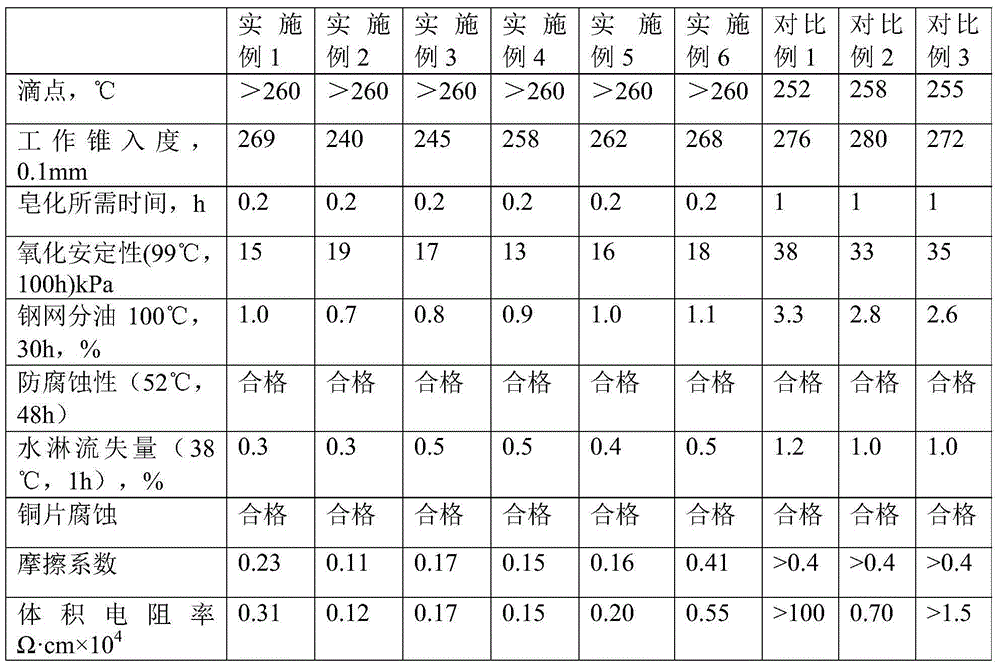

Water-resistant extreme pressure lithium lubricating grease and preparation method thereof

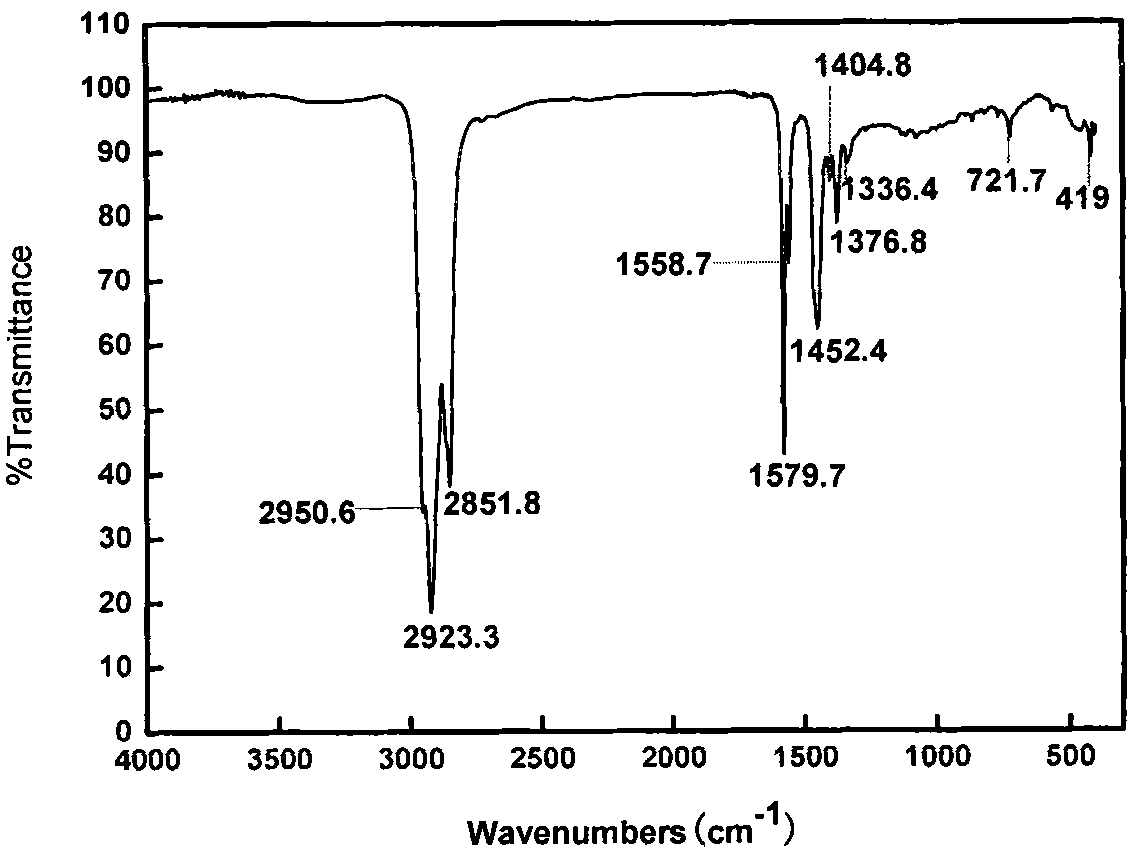

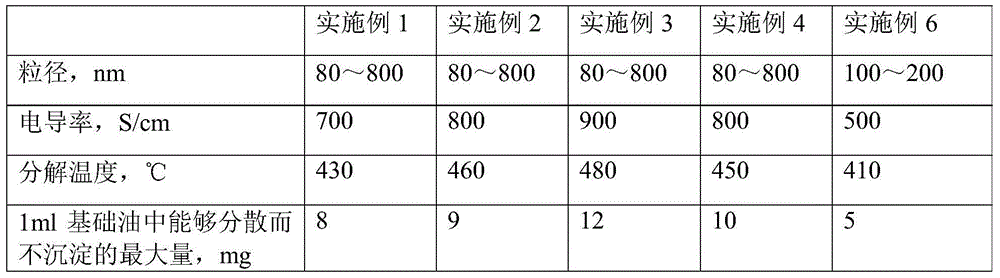

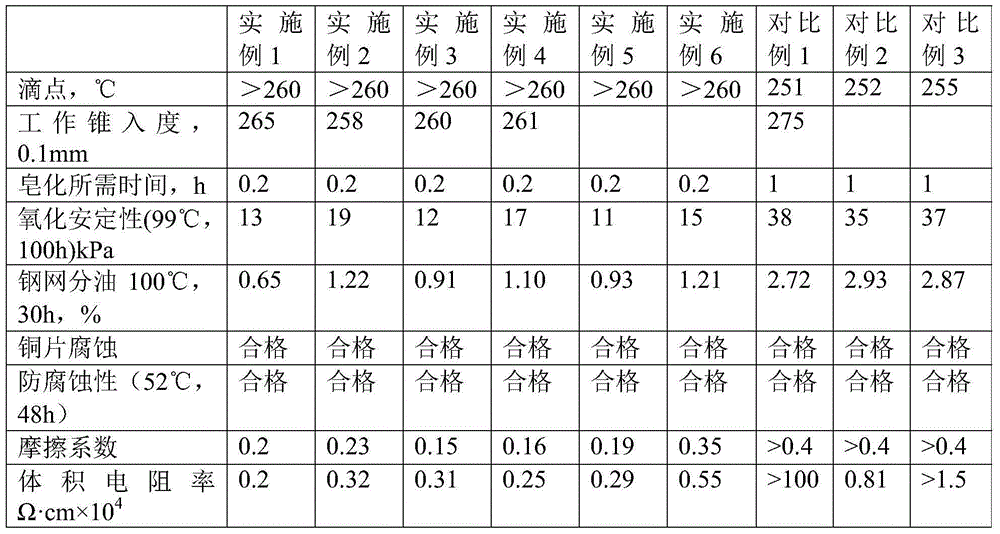

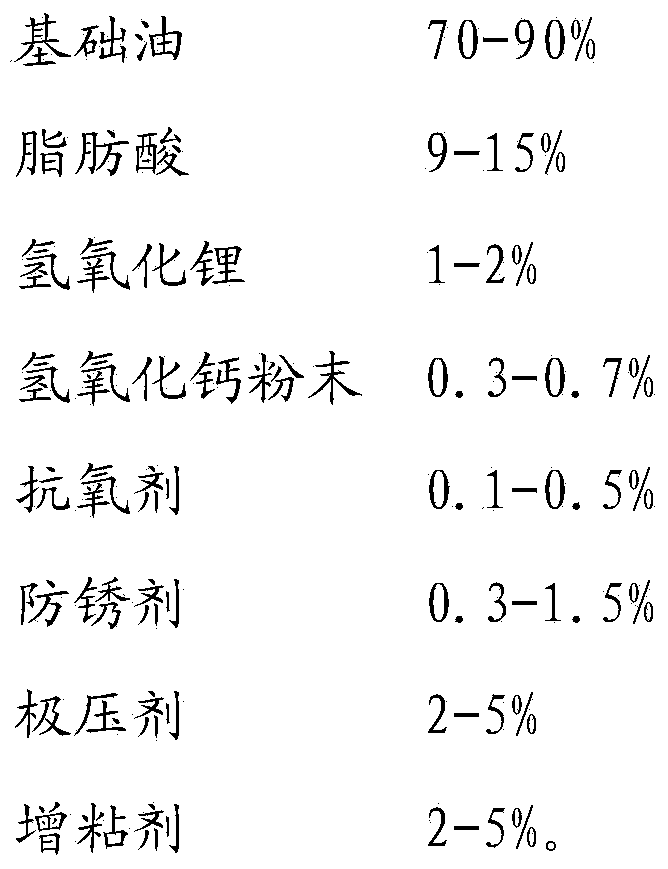

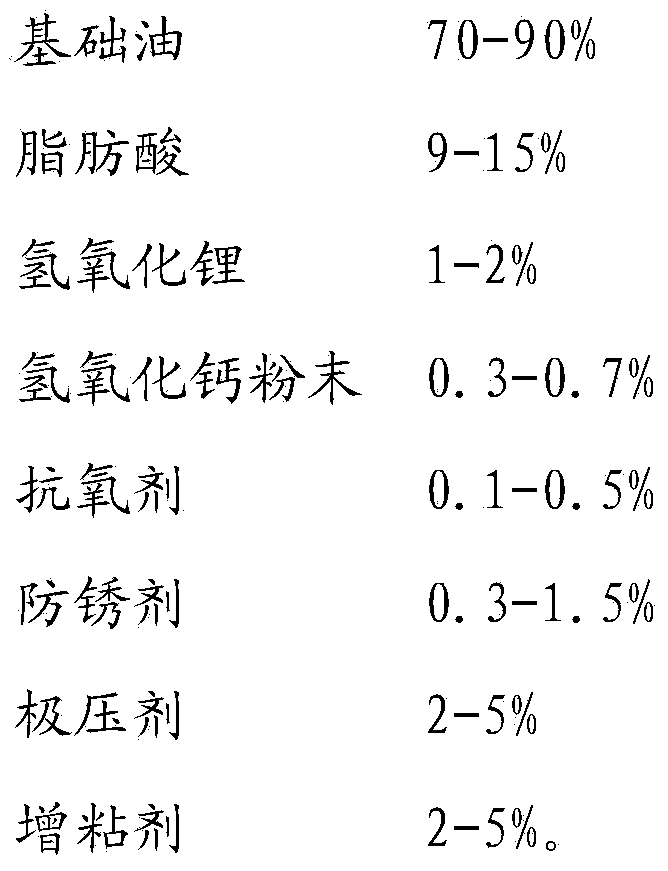

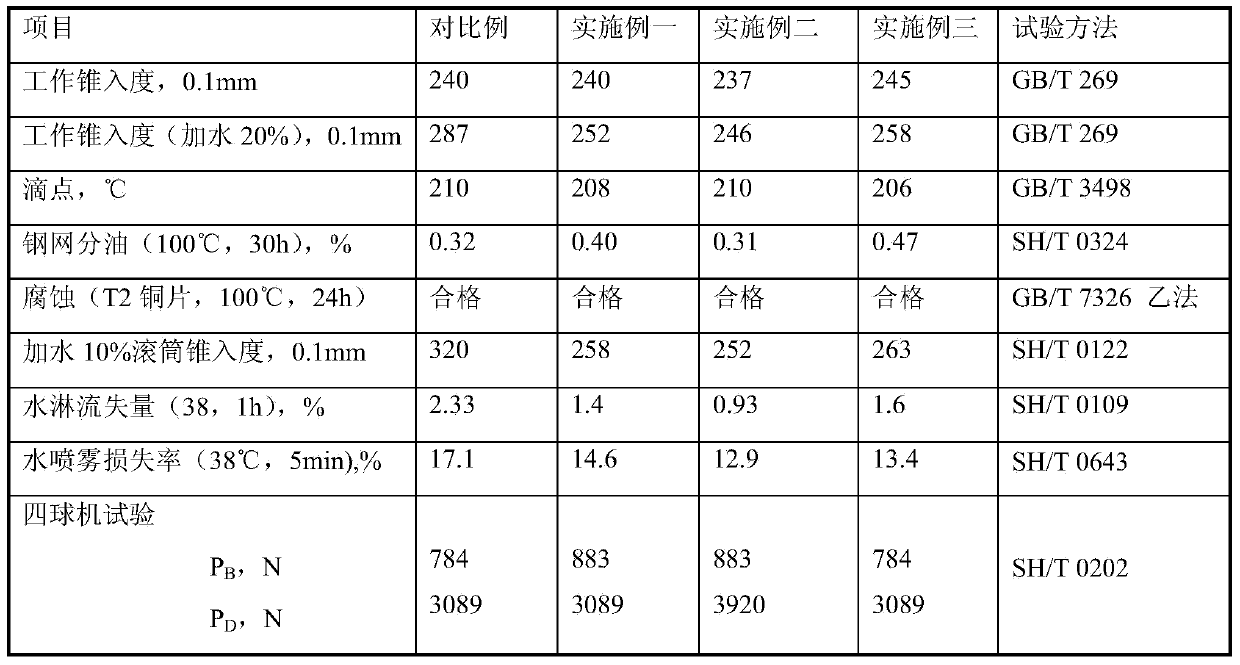

ActiveCN103468357AShorten saponification and dehydration timeDrop point highLubricant compositionLubricationChemistry

The invention relates to lubricating grease and a preparation method thereof, particularly relates to water-resistant extreme pressure lithium lubricating grease and a preparation method thereof, and belongs to the technical field of chemical engineering. The water-resistant extreme pressure lithium lubricating grease comprises the following components by weight percent: 70-90% of base oil, 9-15% of fatty acid, 1-2% of lithium hydrate, 0.3-0.7% of calcium hydroxide powder, 0.1-0.5% of antioxidant, 0.3-1.5% of antirust agent, 2-5% of extreme pressure agent and 2-5% of tackifier. The water-resistant extreme pressure lithium lubricating grease has the beneficial effects that the condition that the water-resistant extreme pressure lithium lubricating grease product has a high dropping point and good shear stability under a general condition is ensured; the product has excellent water-resistance, so that less loss in washing of a lot of water is ensured; the water-resistant extreme pressure lithium lubricating grease can work in the presence of water, is not easily softened to run off, and is good in mechanical stability; the product has excellent anti-rust property and extreme pressure anti-wear property; excellent lubrication of heavy duty equipment under a humid condition can be improved; the lubricating surface is prevented from being rusted.

Owner:JIANGSU LOPALTECH

Composite aluminum soap grease and preparation method thereof

The invention provides composite aluminum soap grease and a preparation method thereof, and belongs to the technical field of lubricating grease preparation. The lubricating grease comprises the following constituents by weight: 5 to 9 percent of C12 to C18 saturated straight-chain fatty acid, 0 to 4 percent of C12 to C18 saturated hydroxy fatty acid, 0.25 to 3 percent of aromatic acid, 0.5 to 1.5 percent of sodium metaaluminate, and 83 to 92 percent of base oil. The preparation method comprises the following steps: adding part of the base oil into a normal-pressure esterifying kettle; stirring; adding the aromatic acid, the C12 to C18 saturated straight-chain fatty acid and the saturated hydroxy fatty acid when the temperature reaches 60 to 80 DEG C; stirring at a constant temperature till the aromatic acid, the C12 to C18 saturated straight-chain fatty acid and the saturated hydroxy fatty acid are dissolved completely; adding the sodium metaaluminate when the temperature reaches 100 to 120 DEG C; saponifying at a low temperature for 1 to 4 hours; saponifying for 1 to 3 hours when the temperature reaches 160 to 180 DEG C; refining for 0.5 to 2 hours when the temperature reaches 200 to 200 DEG C; adding the rest base oil; stirring; cooling; grinding; and degassing to obtain the composite aluminum soap grease. The composite aluminum soap grease prepared by the invention has the advantages of high drop point, favorable mechanical stability and excellent rustproof performance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Composite calcium naphthenate-based lubricating grease and preparation method therefor

ActiveCN103627496AGood extreme pressure and anti-wear propertiesLong lubrication lifeLubricant compositionHeat stabilityBase oil

The invention provides a kind of composite calcium naphthenate-based lubricating grease and a preparation method therefor. With the weight of the lubricating grease as a reference, the lubricating grease comprises the following ingredients: 10%-70% of non-Newtonian calcium naphthenate, 1%-10% of calcium salts of high fatty acids, 1%-15% of calcium salts of micromolecule inorganic acids or fatty acids and 10%-80% of lubrication base oil. The lubricating grease employs petroleum calcium naphthenate or synthesized calcium naphthenate as a raw material, and contains composite calcium densifiers. The lubricating grease has good anti-water-spray properties and anti-water spray loss properties, and has good performances of adhesion, extreme pressure antiwear property, colloid stability, high dropping point, heat stability, anti-corrosion and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Complex aluminum-base lubricating grease and preparation method thereof

ActiveCN104560314AImprove antioxidant capacityImprove high drop pointLubricant compositionSalt resistanceGraphene

The invention discloses complex aluminum-base lubricating grease and a preparation method thereof. On a lubricating grease weight basis, the complex aluminum-base lubricating grease comprises the following components: 65-95 percent of lubricating base oil, 5-30 percent of complex aluminum-base thickening agent and 0.2-15 percent of graphene. The complex aluminum-base lubricating grease provided by the invention has excellent properties such as high-temperature resistance, water resistance, adhesivity, colloid stability, extreme pressure wearability, lubricating life, corrosion resistance and salt fog resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tetra-urea lubricating grease and preparation method thereof

The invention provides a tetra-urea lubricating grease and a preparation method thereof. The tetra-urea lubricating grease comprises lubricating oil basic oil and a tetra-urea thickening agent, and does not contain di-urea thickening agent and fatty acid metal salt. In the preparation method, the tetra-urea lubricating grease is obtained by the reaction of diisocyanate, diamine and monoamine. Compared with the di-urea lubricating grease, the tetra-urea lubricating grease has higher dropping point, better extreme pressure property, colloid stability and shearing stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

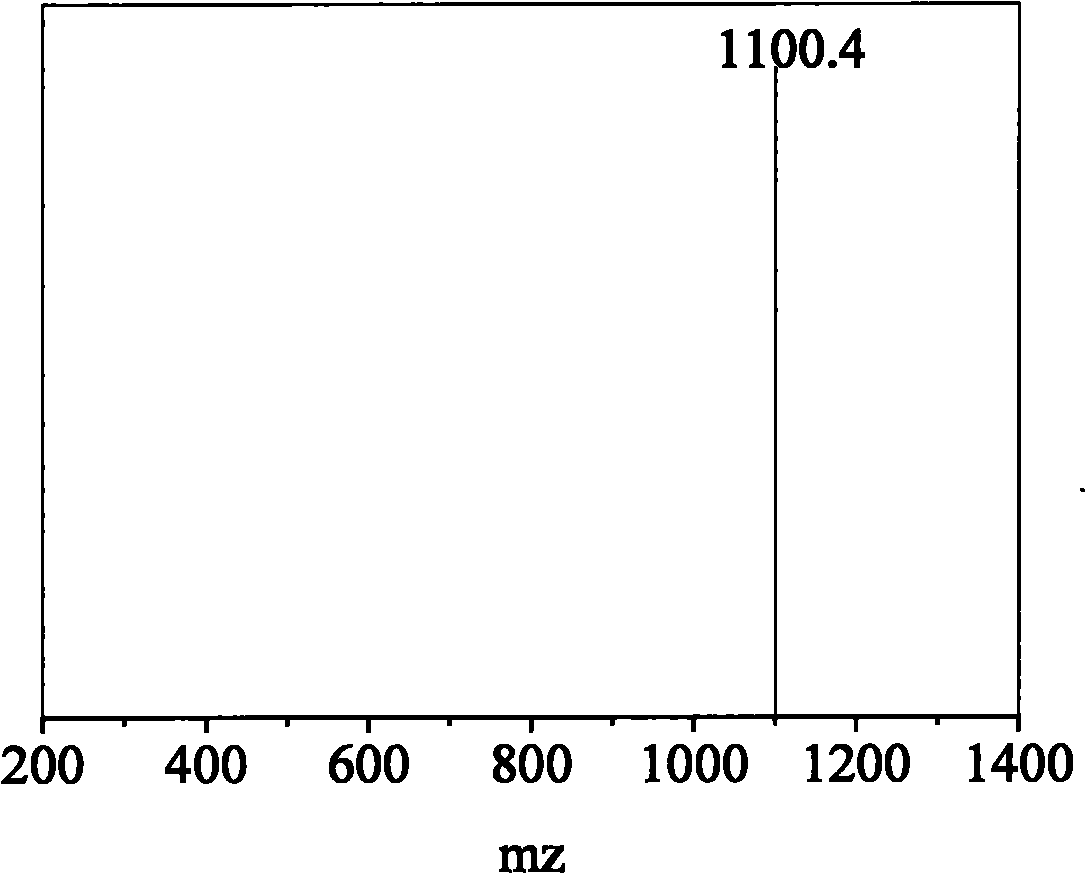

Hydrogen absorption fiber paste for optical fiber composite overhead ground wire (OPGW) optical cable and manufacture method thereof

InactiveCN102778735AGood high and low temperature performanceDrop point highFibre mechanical structuresFiberAntioxidant

The invention relates to hydrogen absorption fiber paste for an optical fiber composite overhead ground wire (OPGW) optical cable. The hydrogen absorption fiber paste comprises, by weight, 75-85% of base oil, 6-10% of gelatinizing agent, 0.3-0.6% of antioxidant, 0.8-1% of viscosity index improver, 1.5-2% of oil distribution inhibitor and 2-5% of hydrogen absorption agent. The base oil is polyalpha-olefin synthesis oil, and the gelatinizing agent is a composite of an organic gelatinizing agent and an inorganic gelatinizing agent. The hydrogen absorption fiber paste has the advantages of adopting the polyalpha-olefin synthesis oil as the base oil so as to enable the fiber paste to have good high-low-temperature performance; improving the stability of a glue body by adding an appropriate amount of silicon-containing (inorganic) glue body into a silicon-free (organic) glue body; having good hydrogen absorption performance by adding an efficient hydrogen absorption agent, removing hydrogen caused by incompatibility of the fiber paste and stainless steel and caused in welding process, reducing defects in optical fiber lattice and loss of optical fiber, and improving transmission performance of the optical fiber.

Owner:JIANGSU NANFANG COMM TECH

Composite barium-based lubricating grease composition and preparation method thereof

The invention discloses a composite barium-based lubricating grease composition and a preparation method thereof. By taking the weight of the lubricating grease as a benchmark, the composite barium-based lubricating grease composition comprises the following components: 65-95% of lubricating base oil, 5-30% of a composite barium-based thickening agent and 0.2-15% of graphene. The composite barium-based lubricating grease has excellent high temperature resistance, water resistance, adhesion, colloidal stability, extreme pressure antiwear property, anti-corrosion property, salt and spray resistance and the like and long lubricating life.

Owner:CHINA PETROLEUM & CHEM CORP +1

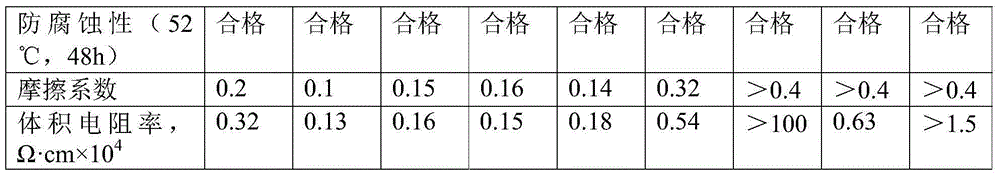

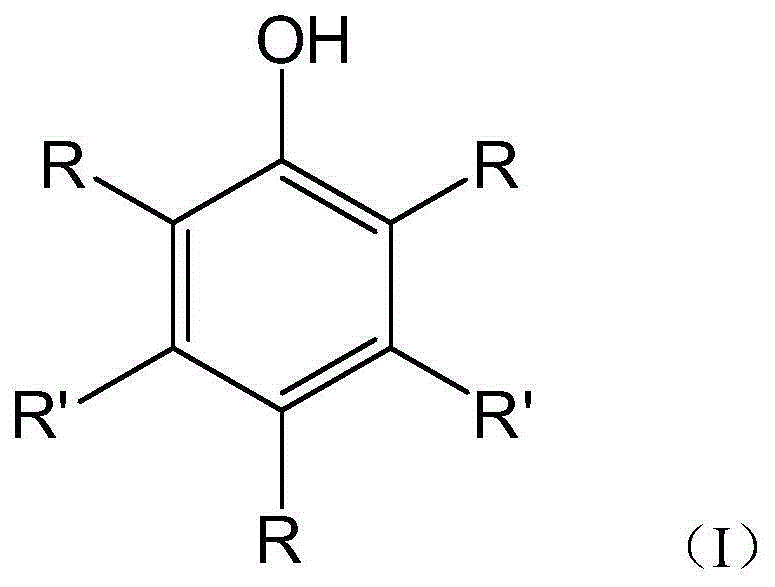

Complex calcium-based lubricating grease and preparing method thereof

ActiveCN106590886ADrop point highGood mechanical stabilityAdditivesHeat stabilityMechanical equipment

The invention provides a complex calcium-based lubricating grease and a preparing method thereof. The lubricating grease comprises 0.01%-1.0% of hindered phenol compound, 5%-35% of complex calcium-based thickening agent and a main amount of lubricating base oil, wherein the structure of the hindered phenol compound is shown in the specifications. According to the complex calcium-based lubricating grease and the preparing method thereof, the complex calcium-based lubricating grease has a high dropping point, good mechanical stability, excellent heat stability, colloid stability, high-temperature oxygen resistance, anti-corrosion performance, anti-water spraying performance, and anti-extreme pressure performance, hardening conditions of the complex calcium-based lubricating grease are improved to some extent, thus the complex calcium-based lubricating grease is capable of being qualified in lubrication of various kinds of motors, electric generators, air blowers, transportation industries, iron and steel enterprises and other various kinds of commercial units, and is especially applicable to lubrication of friction parts of various kinds of mechanical equipment under high-temperature and moist conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Corrosion-resistant zero-shrinkage flame-retardant cable material

InactiveCN110294901AReduce gapIncreased corrosion resistance and insulating propertiesCorrosion resistantSISAL

The invention discloses a corrosion-resistant zero-shrinkage flame-retardant cable material, which is characterized by comprising the following components in parts by weight: 30-40 parts of chlorosulfonated polyethylene rubber; 30 to 40 parts of poly ethylene-propylene methylene rubber; 15-20 parts of polybenzoxazine; 10-15 parts of hydroxyl epoxidized polybutadiene; 12 to 18 parts of a modified graphene oxide- polypyrrole compound; 5-10 parts of polyurea grease; 6-10 parts of a polymer initiator; 5-8 parts of a nano polyelectrolyte layer embedding corrosion inhibitor; 6-9 parts of sisal cellulose; 3-5 parts of reinforced nano microspheres and 3-5 parts of a flame retardant. The cable material has the characteristics of good heat resistance and corrosion resistance, high antistatic performance and high flame retardance with zero deformation, reduces the risk of arc effect and short-circuit fire caused by the cable material, prolongs the service life, and improves the insulation safetyperformance.

Owner:湖南华菱线缆股份有限公司

Cotton picker spindle oil and preparation method thereof

InactiveCN101845354AImprove performanceNo damageAdditivesBase-materialsAgricultural engineeringProcess engineering

The lubricating grease prepared by the invention not only is applicable to cotton picker spindle oil, but also has the advantages of good shear reversibility, high and low temperature, extreme pressure wear resistance, rust resistance, compatibility (with other lipid) and the like and thereby has wide scope of application, can realize very good lubrication action under adverse working conditions,can be widely applied to agricultural machinery, building machinery, railways, ball mills and other equipment as well as steel making, cement, power generation, packaging, chemical engineering, automobile and other industrial fields. Lubricating grease products increasingly develop to the direction of high drop point, high efficiency, long service and environmental friendliness. Ti-based composite resin is just adaptable to the trend of the lubricating grease, now has become the focus of attention in the lubricating grease industry, represents the international advanced level of the lubricating grease, and is a development direction of high-performance lubricating grease variety in the world nowadays.

Owner:新疆五家渠现代石油化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com