Patents

Literature

145results about How to "Long lubrication life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

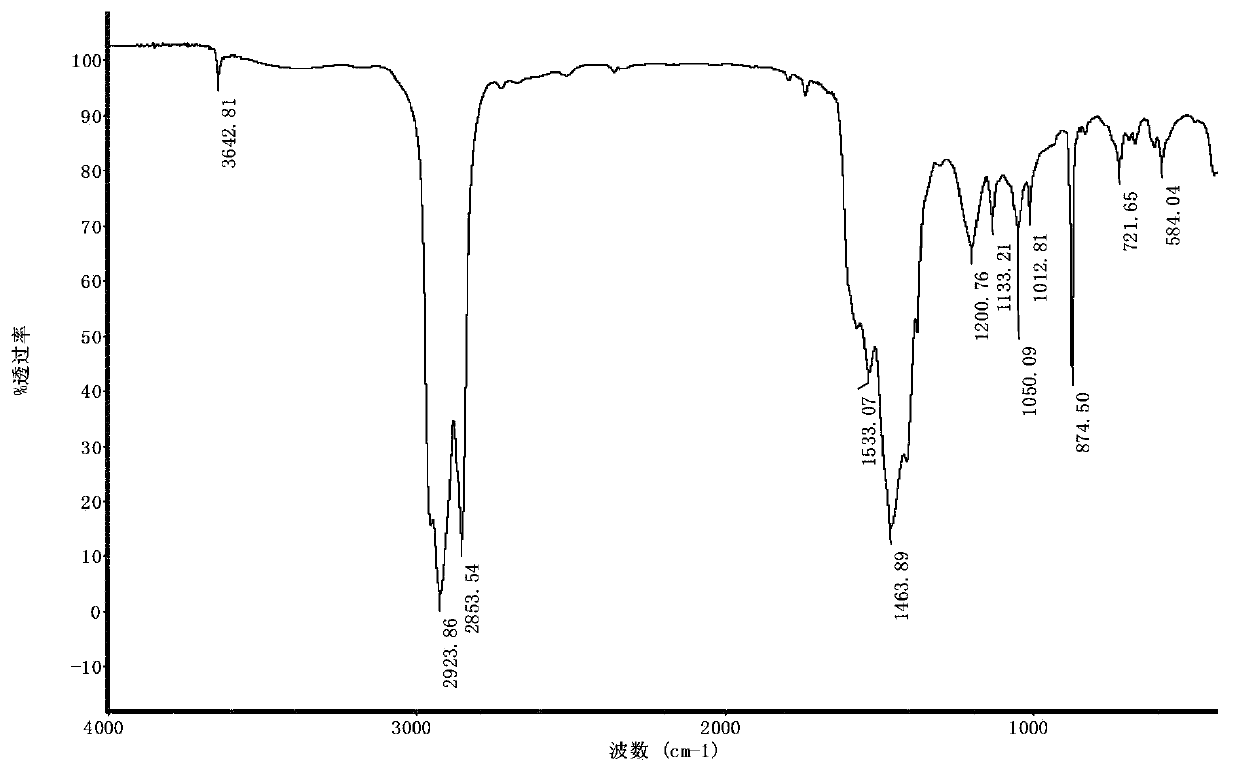

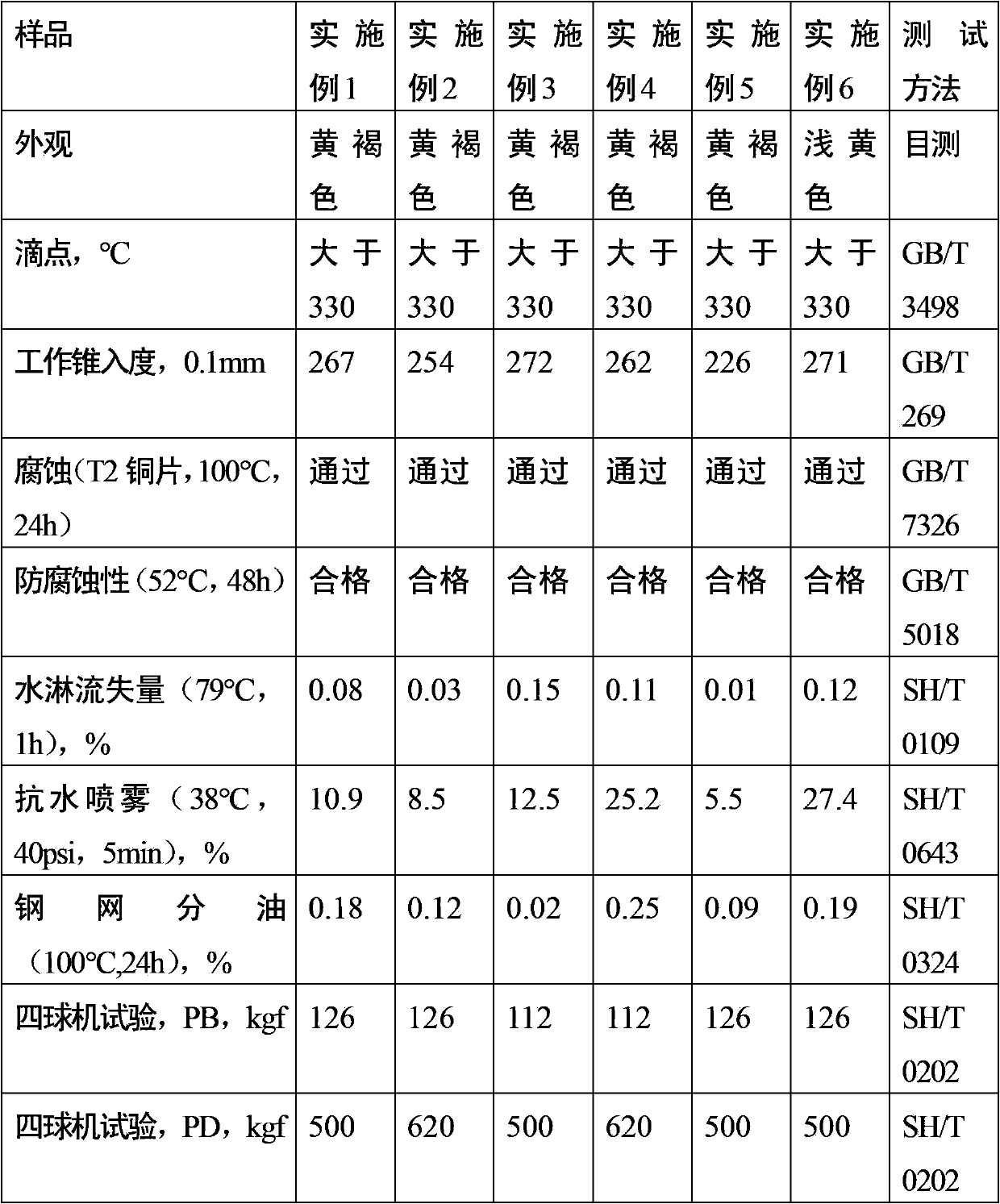

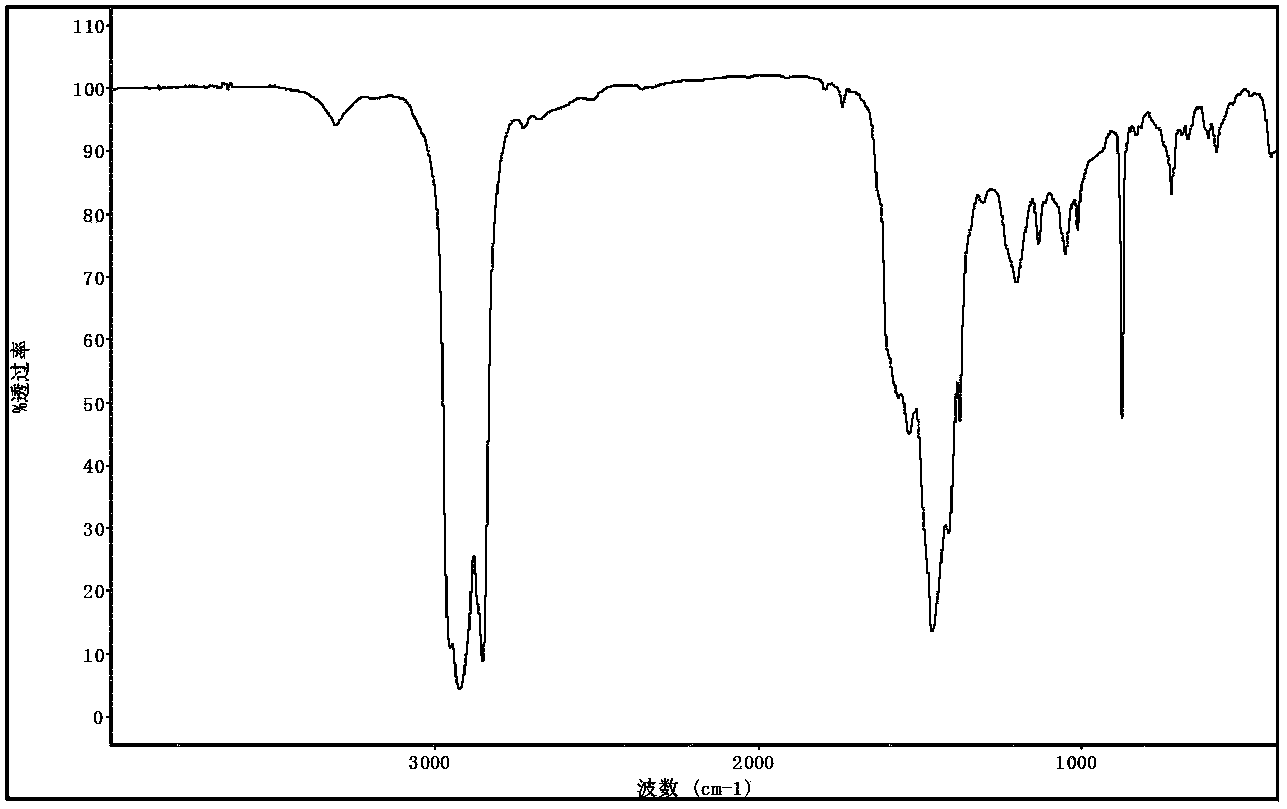

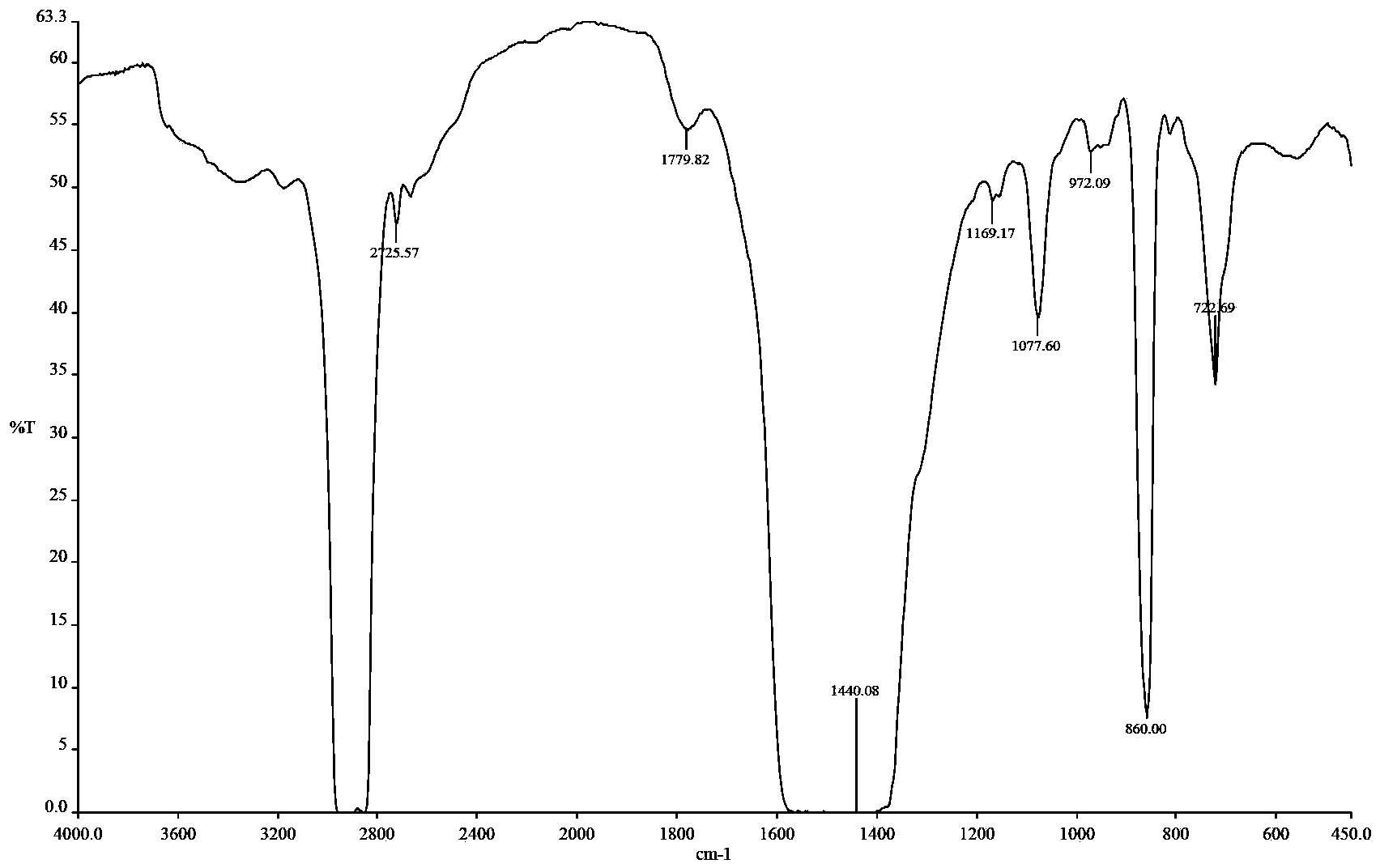

Lubricating grease and preparation method thereof

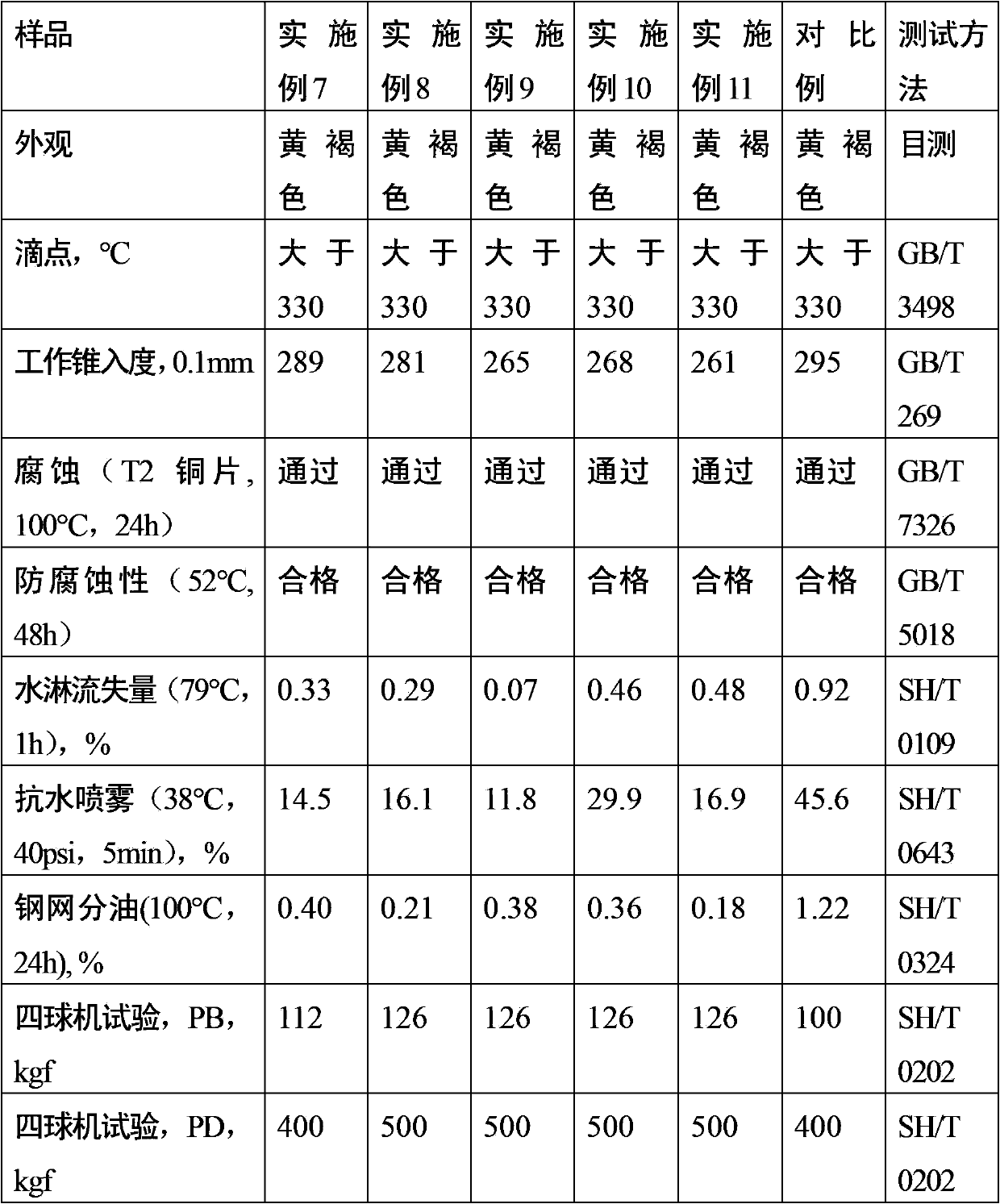

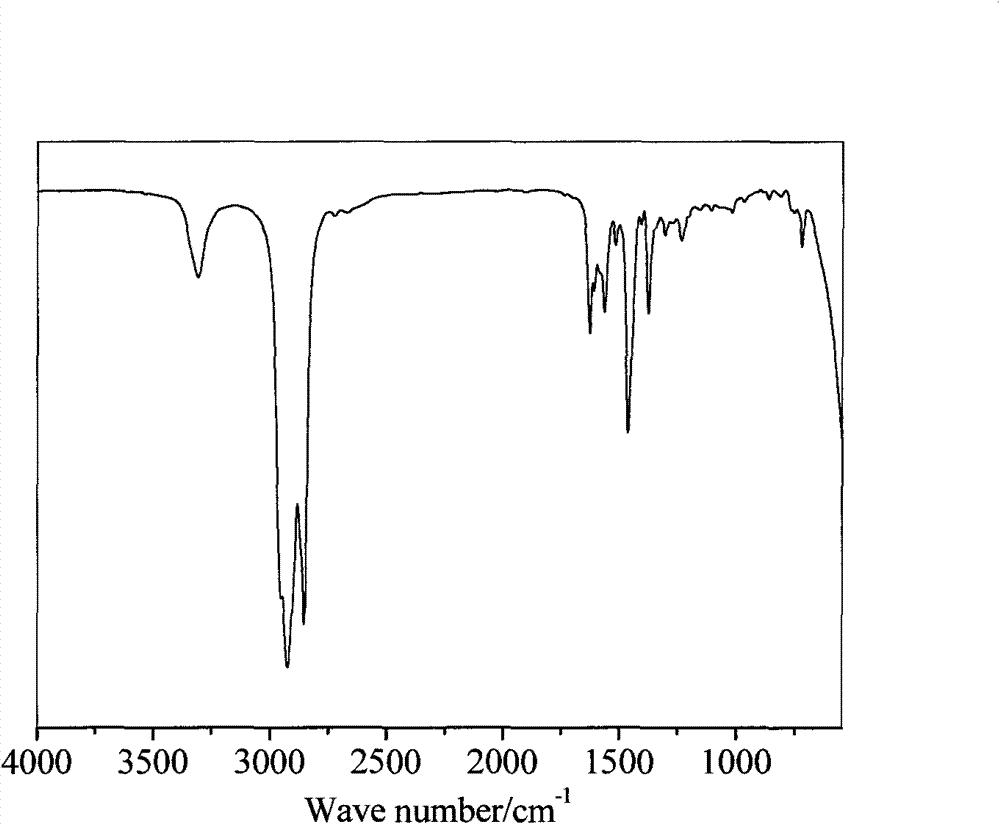

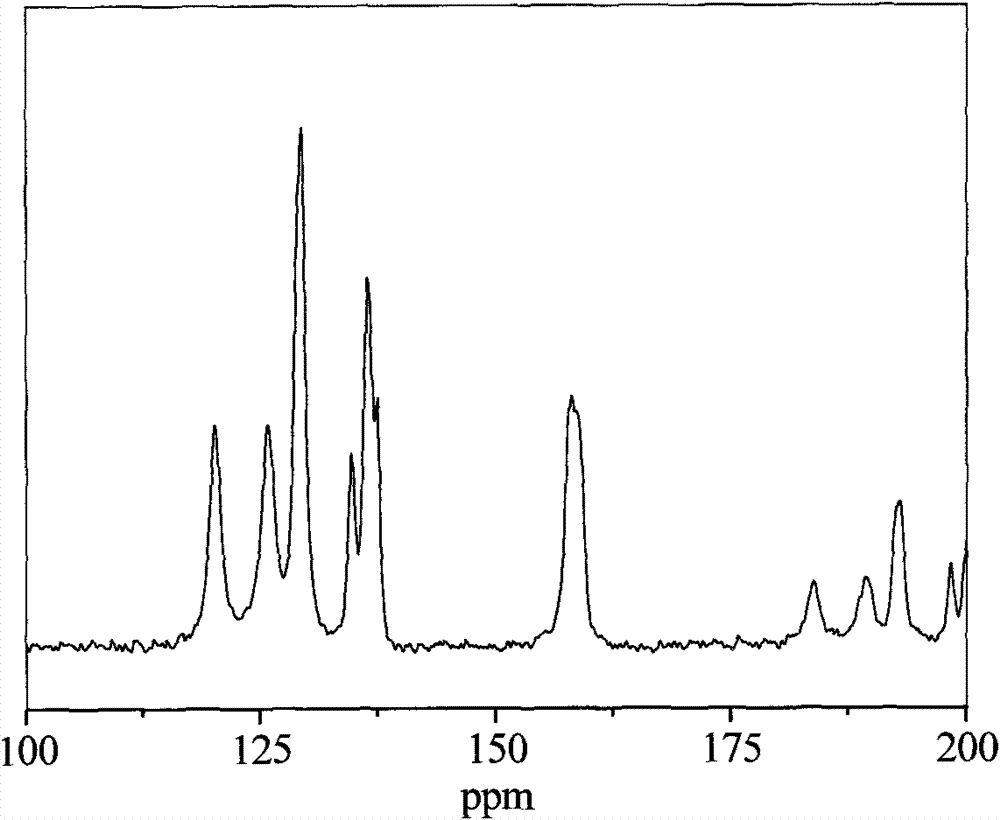

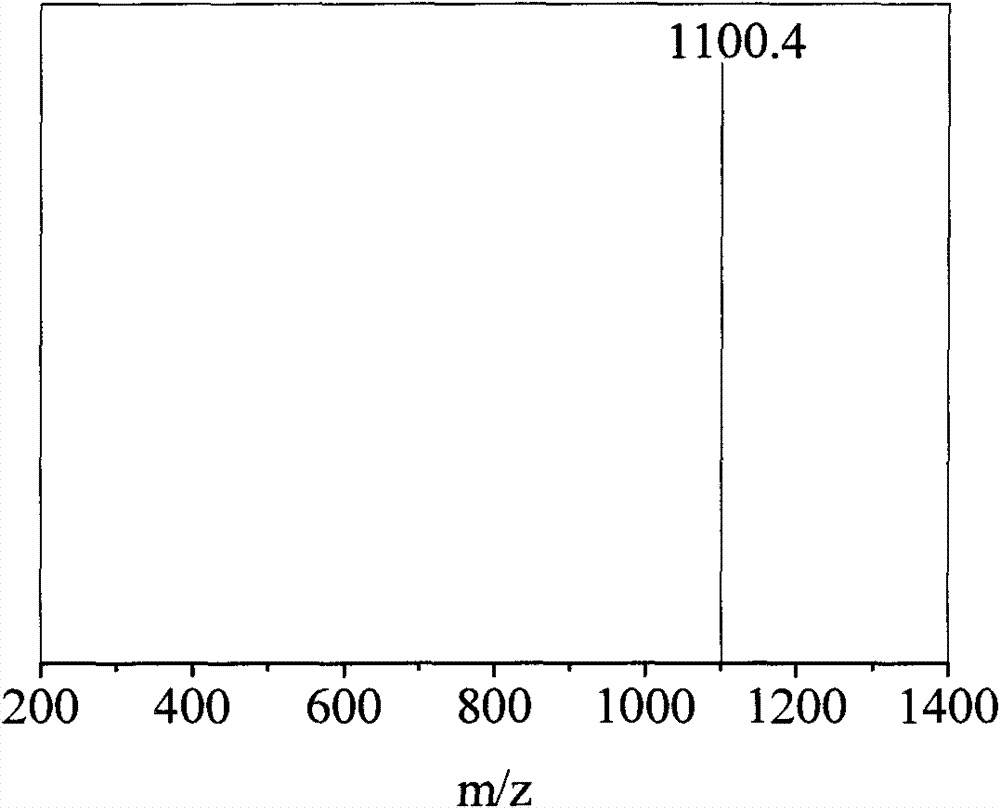

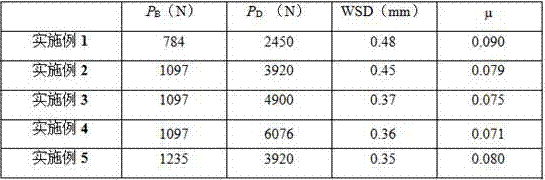

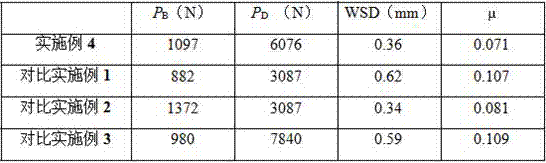

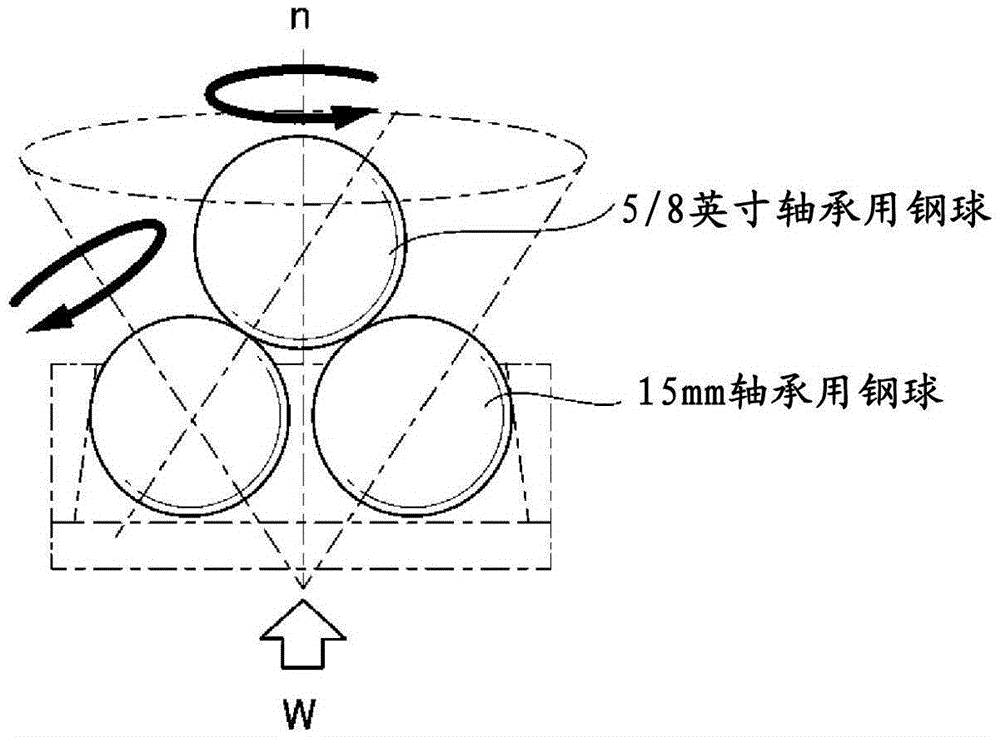

The invention relates to a lubricating grease, comprising 40-95 wt% of a lubricating base oil, 1-59 wt% of a composite zirconium based densifier and 1-59 wt% of bipolyurea; and the composite zirconium based densifier is a compound zirconium soap generated from reaction of higher aliphatic acid, aromatic acid, water and zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the following steps: subjecting the zirconium alkoxide, higher aliphatic acid and aromatic acid to a first contact reaction in lubricating base oil at 60-120 DEG C; then subjecting the mixture obtained from the first contact reaction and water to a second contact reaction at 85-100 DEG C, and heating the products obtained from the second contact reaction for dehydration; and introducing the bipolyurea into the obtained reaction products. The lubricating grease provided by the invention has high drop point, excellent colloidal stability, and excellent extreme pressure wear resistance and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

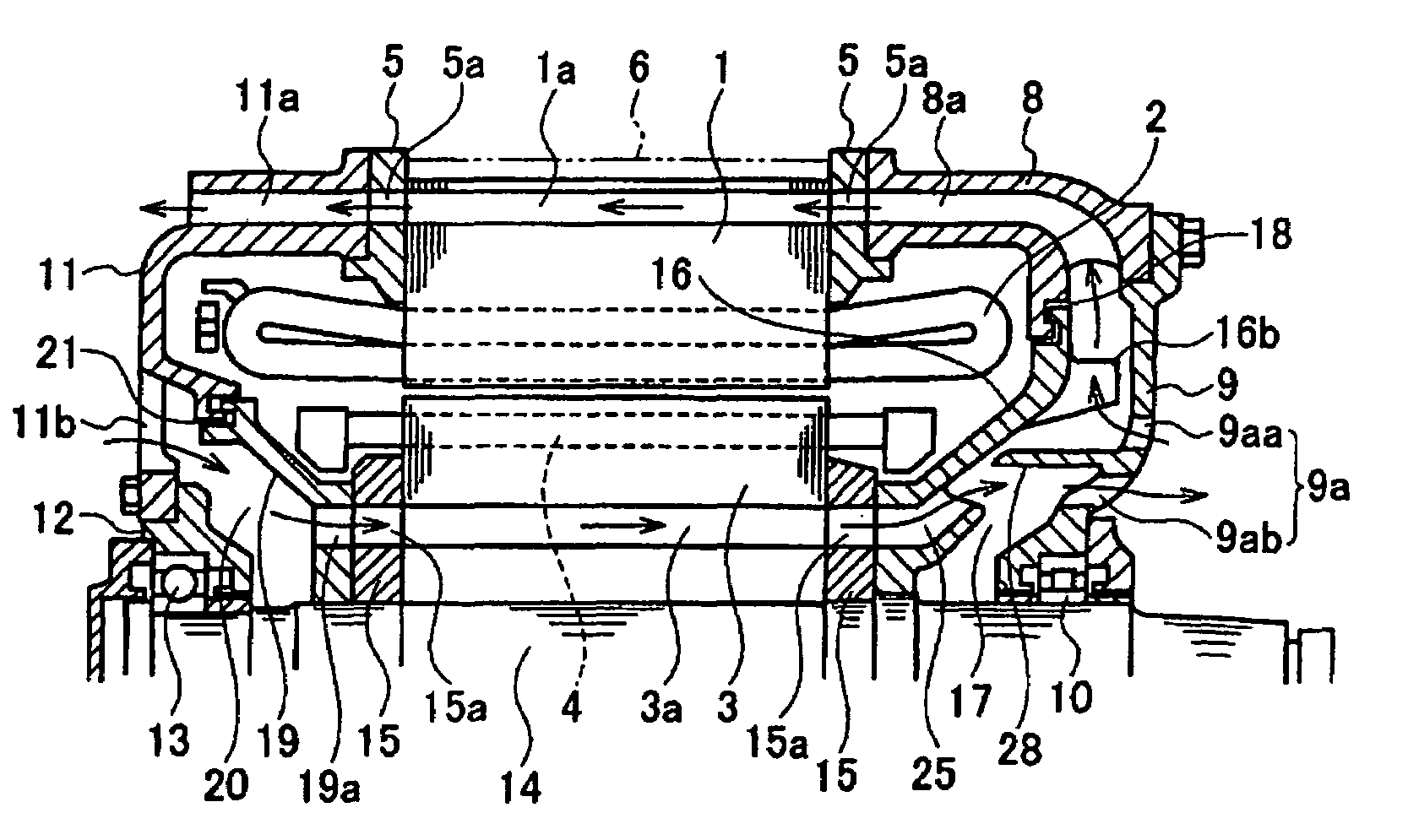

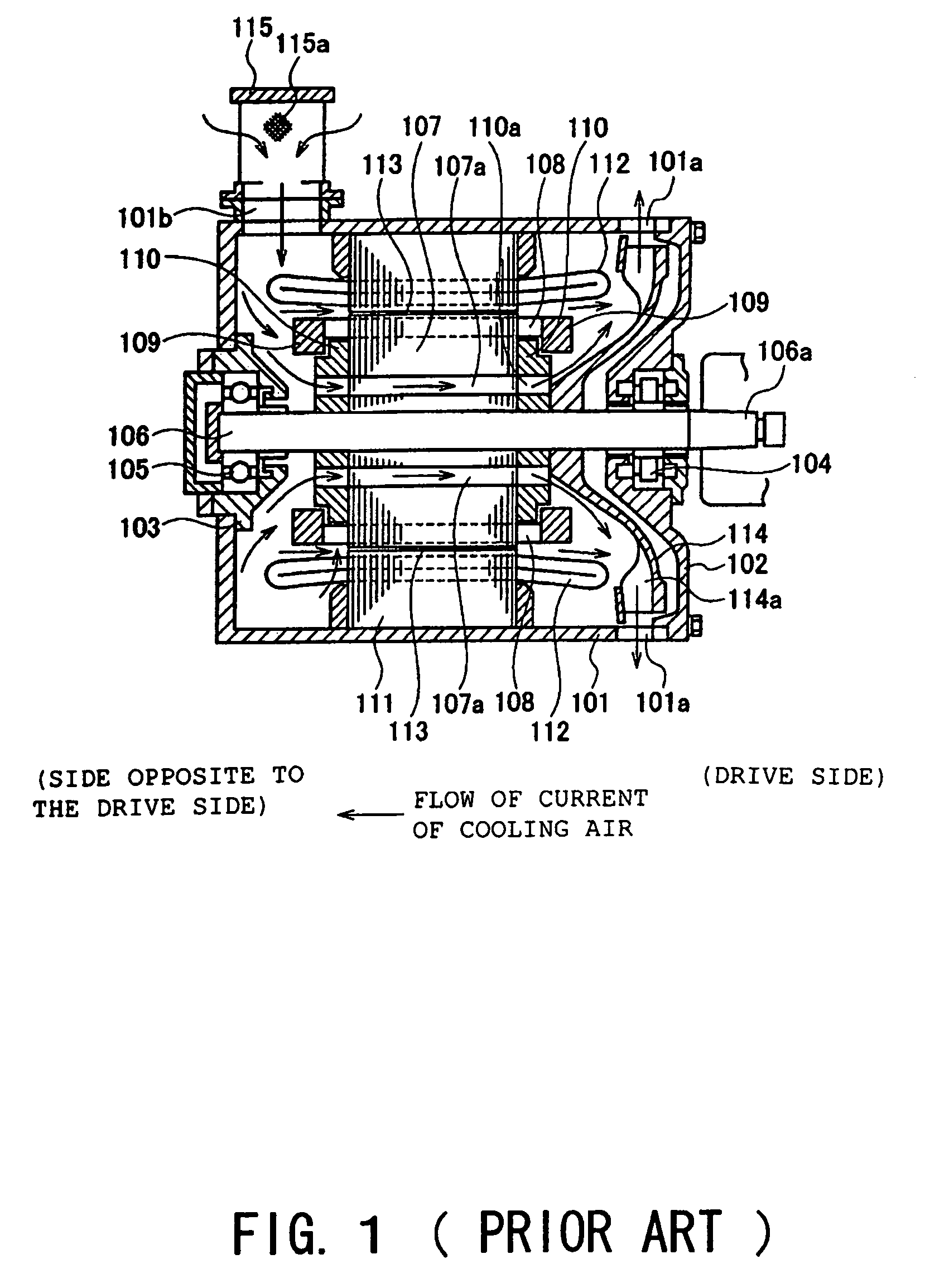

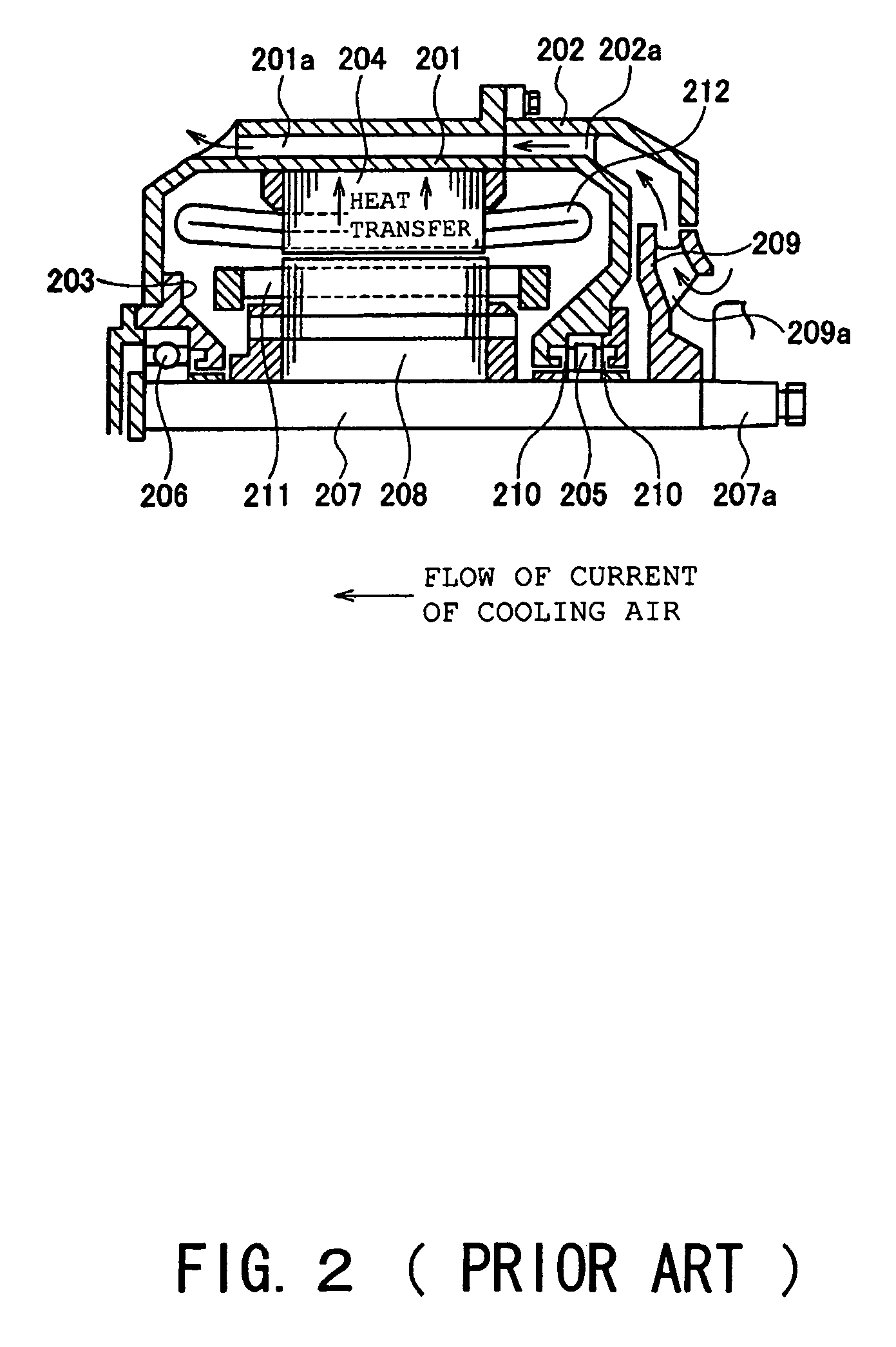

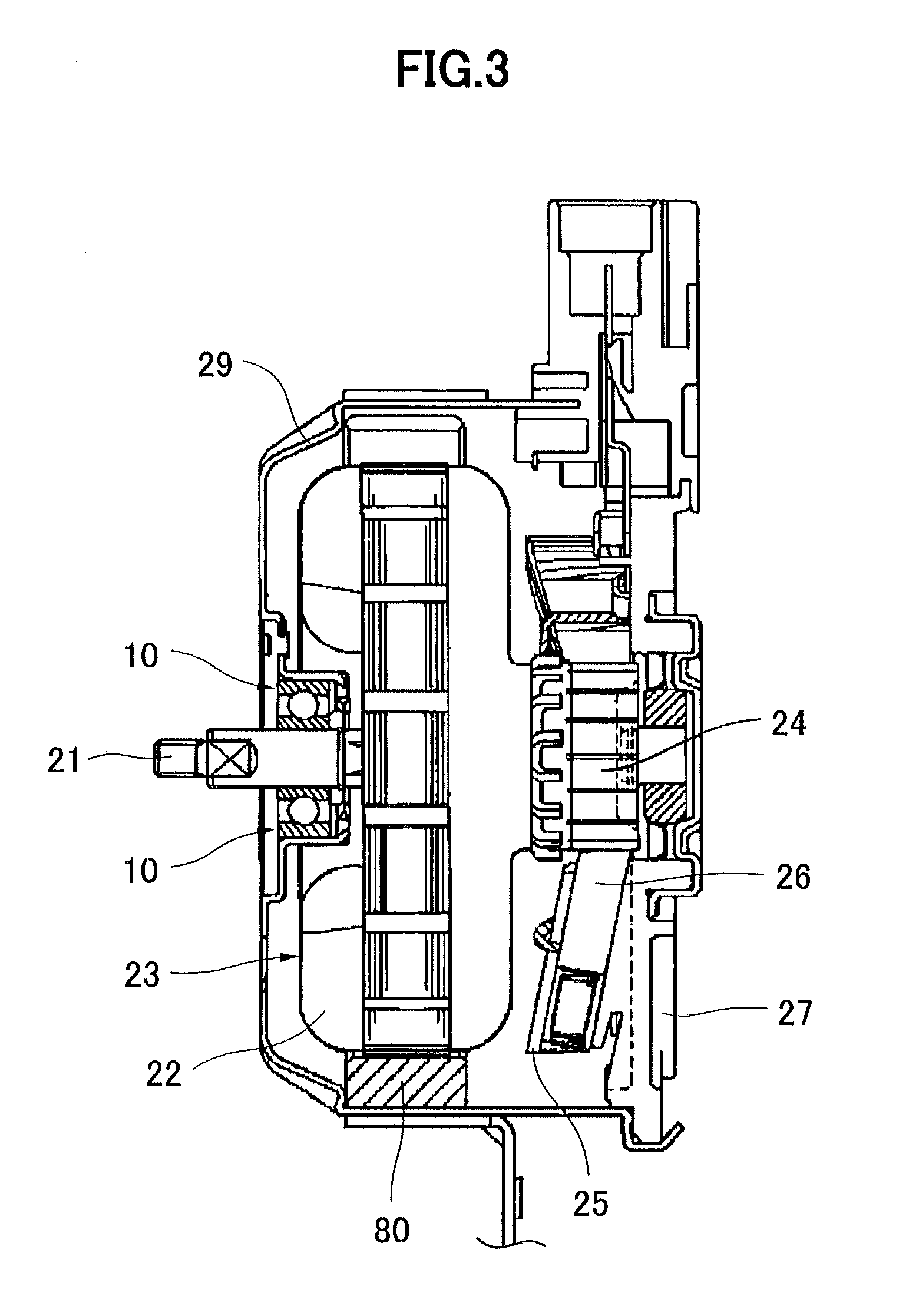

Fully-enclosed fan-cooled motor

ActiveUS7462964B2Increase temperatureLong lubrication lifeMagnetic circuit rotating partsMagnetic circuit stationary partsElectrical and Electronics engineeringStator

A first minute gap (18) is formed between the front end of a ventilation fan (16) and a first bracket (8) and a second minute gap (21) is formed between the front end of a partition member (19) and a second bracket (11); a first aperture (9a) is provided in a location at the inner periphery further inward than the vanes (16b) on the bearing bracket (9); a current of cooling air is formed by introduction of external air by the ventilation fan from this aperture; this current of cooling air is again discharged to the outside through a ventilation passage (8a) of the first bracket and a ventilation passage (1a) on the outer peripheral side of the stator core (1); in addition, a second aperture (11b) is provided in the second bracket (11), a current of cooling air is formed by introduction of external air by the ventilation fan from the second aperture (11b); and this current of cooling air is again discharged to the outside through the ventilation passage (3a) of the rotor core (3), the ventilation passage of the first bracket and the ventilation passage on the outer peripheral side of the stator core.

Owner:KK TOSHIBA

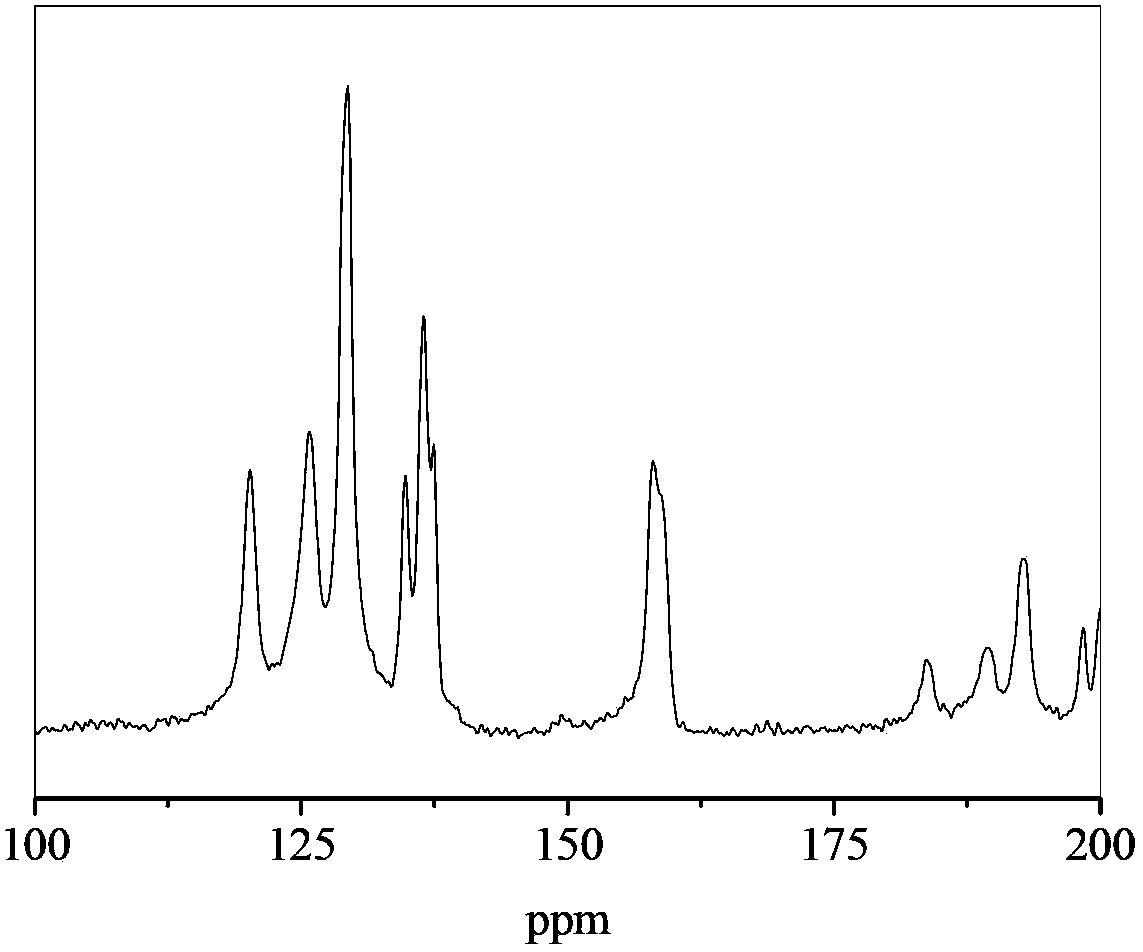

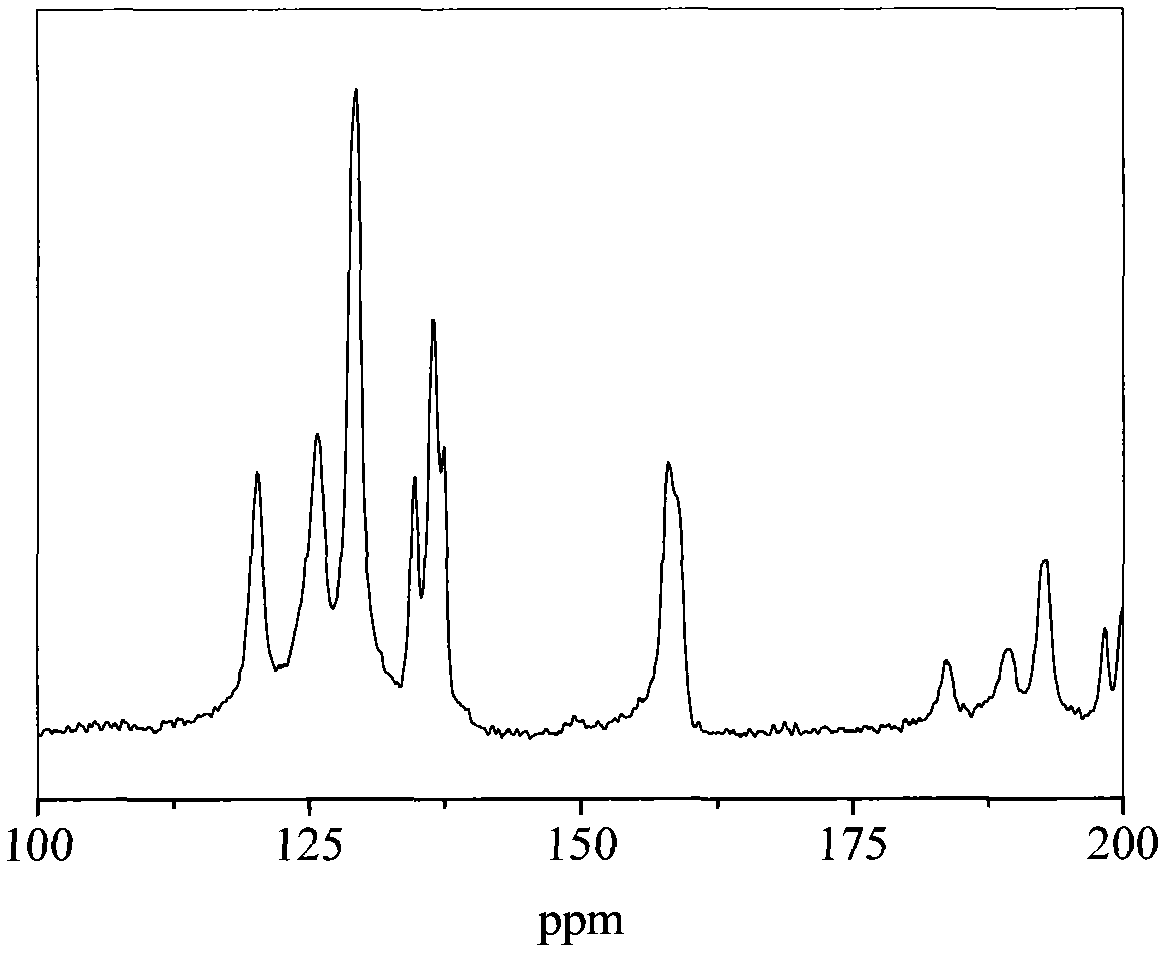

Composite calcium-sulfonate-based tetrapolyurea lubricating grease and preparation method thereof

ActiveCN102453599AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersCorrosionSulfonic acid

The invention discloses a composite calcium-sulfonate-based tetrapolyurea lubricating grease and a preparation method thereof. With the weight of the lubricating grease as a reference, the lubricating grease comprises components of: (1) 10-70% of non-Newtonian fluid calcium sulfonate; (2) 1-10% of higher fatty acid calcium; (3) 1-15% of small-molecule inorganic acid calcium or organic acid calcium; (4) 0.5-30% of tetrapolyurea; and (5) 10-80% of lubricating base oil. According to the lubricating grease, calcium petroleum sulfonate or synthesized calcium sulfonate is adopted as a raw material, and the lubricating oil contains a composite calcium thickening agent and a tetrapolyurea compound. The lubricating grease has excellent extreme pressure wear resistance, ultra-long lubricating life, good adhesion, water resistance, colloid stability, high dropping point, thermal stability, corrosion resistance, and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

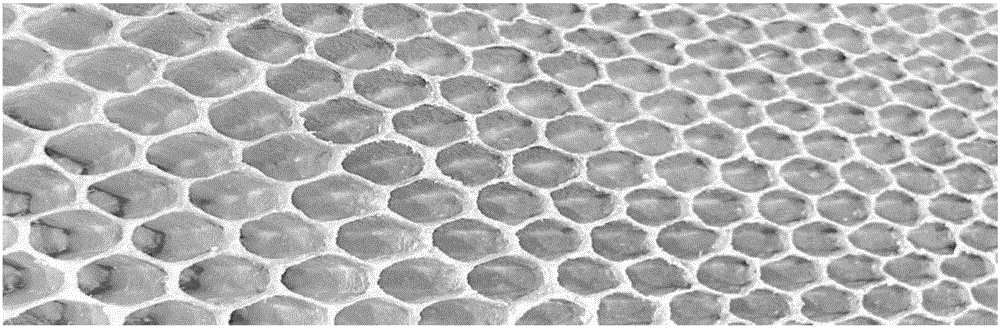

High-temperature alloy base self-lubricating composite material and surface pattern treatment method thereof

InactiveCN101078072AExtended service lifeReduce coefficient of frictionBearing componentsLaser beam welding apparatusSurface patternSuperalloy

A kind of high temperature alloy group self-lubricating compound material and the method to pattern surface of it. The components and the mass percent of them are as following: Ni: 28.8-56.8%, Fe: 10.0-30.0%, Cr: 7.2-14.2%, W: 5.0- 15.0%, C: 3.0-6.0%, Si: 0.8%-1.2%, MoS2: 5.0%-15.0%. The method to pattern it' s surface contains the following steps: The surface of the nickel chromium alloy group self-lubricating compound material sample after being hot pressed and mould will be polished. A gammaray laser will be used to corrase micropore on the surface, the focus of the focusing lens will be adjusted to 40-60mm, the facula diameter at the focus is 0.15- 0.20mm, the impulse duration will be adjusted to 450-500ns, the laser bean will process micropore according to ring shape from outside to inside. The surface after being corrased and polished will be lubricated by daubing the fat of solid layered dry lubricant. The alloy group material not only owns high mechanical strength but also owns high temperature self-lubricating ability. The coefficient of friction can be decreased, the application life can be prolonged, and low attrition abrasion in wide temperature range can also be realized by patterning the surface.

Owner:NANJING UNIV OF SCI & TECH

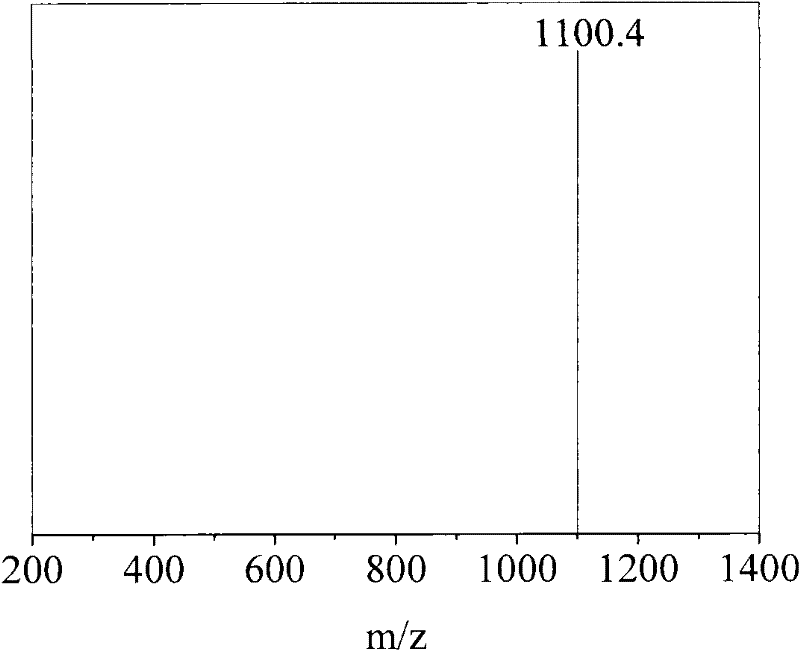

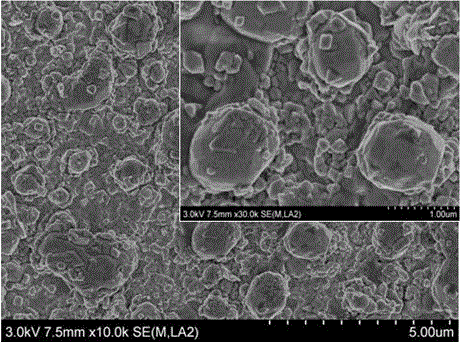

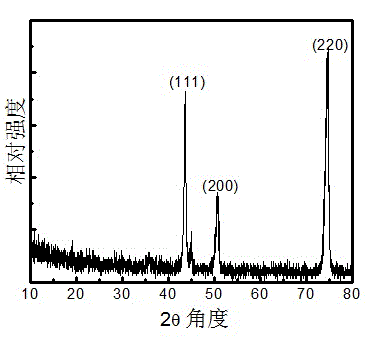

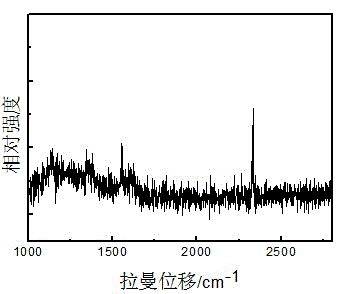

Metal graphene composite material and preparation method thereof

ActiveCN104085150AComposite tightImprove the lubrication effectVacuum evaporation coatingSputtering coatingMetallic materialsThin membrane

The invention provides a metal graphene composite material and a preparation method thereof, relating to the field of materials. The metal graphene composite material comprises a metal substrate, a copper infiltration layer and a graphene film, wherein the metal substrate is in metallurgical bonding with the copper infiltration layer; the graphene film grows on the outer surface of the copper infiltration layer. The preparation method of the metal graphene composite material comprises the following steps: forming the copper infiltration layer on the surface of the substrate, and forming the graphene film on the surface of the copper infiltration layer. According to the metal graphene composite material, because graphene has excellent mechanical property, the lubricating performance of the graphene film on the surface of pure metals or alloys is greatly improved, the friction force on the surfaces of the pure metals or alloys is reduced, and the lubricating life of the pure metals or alloys is prolonged. According to the preparation method of the metal graphene composite material, graphene can grow on large-area metal materials, a copper foil does not need to be corroded, the preparation process is simple, the production cost is low, and industrial production is convenient.

Owner:常熟紫金知识产权服务有限公司

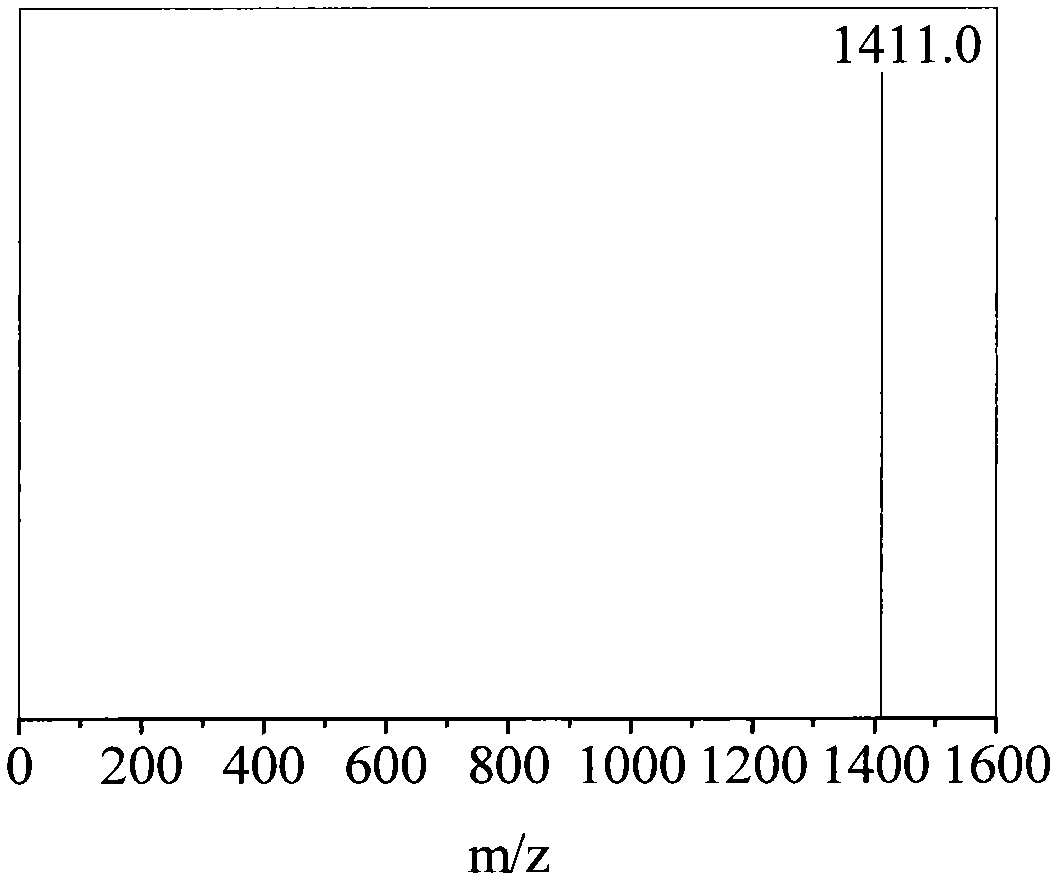

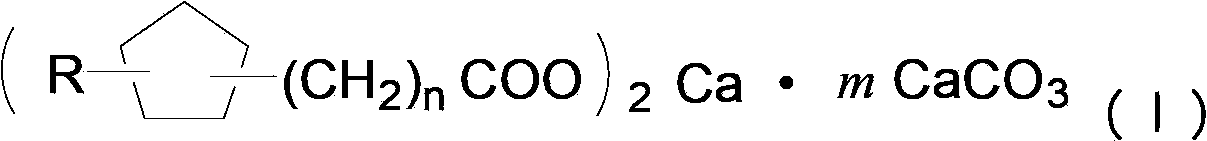

Composite zirconium-based urea bipolymer grease and preparation method thereof

ActiveCN102952604AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersHeat stabilityBase oil

The invention provides composite zirconium-based urea bipolymer grease and a preparation method thereof. The composite zirconium-based urea bipolymer grease comprises: by weight, 1) 1 to 59% of composite zirconium which is produced by a reaction of at least one higher fatty acid, at least one aromatic acid, and an oxide and / or a hydroxide of zirconium, wherein a mole ratio of the at least one aromatic acid to the at least one higher fatty acid is (0.5 to 7): 1, 2) 1 to 59% of a urea bipolymer, and 3) 40 to 95% of lubrication base oil. The composite zirconium-based urea bipolymer grease contains the composite zirconium as a densifier and the urea bipolymer. The composite zirconium-based urea bipolymer grease has excellent extreme pressure wear resistance, a long lubrication life, good water resistance, colloid stability, a high dropping point and good heat stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

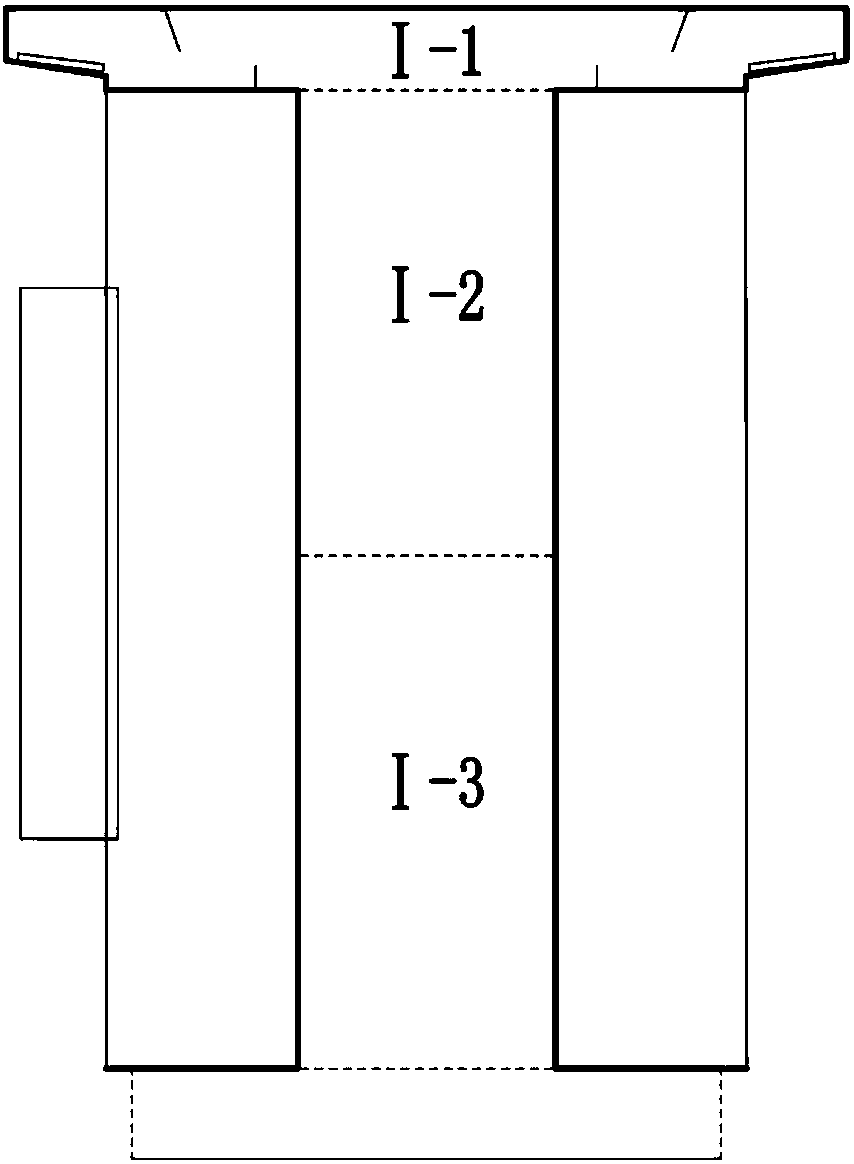

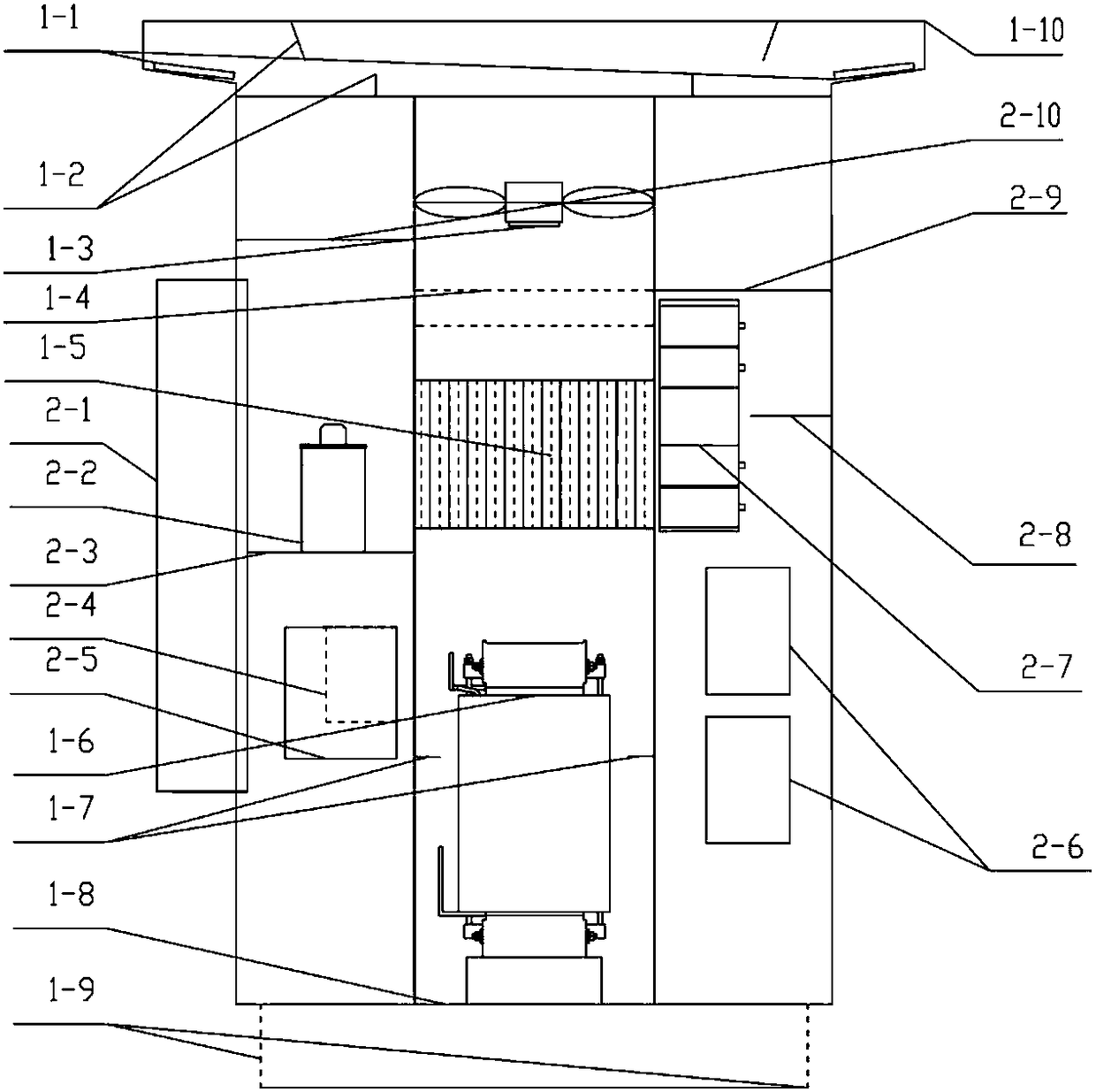

High-power outdoor heat dissipation machine cabinet

PendingCN108495538AImprove impact performanceCompact and reasonable structureCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsPositive pressureWorking temperature

The invention provides a high-power outdoor heat dissipation machine cabinet. The high-power outdoor heat dissipation machine cabinet comprises a core heat dissipation region and an isolation type heat dissipation region, wherein a fin wind channel part of a module heat dissipater is externally arranged in the core heat dissipation region, and modules and single boards are arranged in the isolation type heat dissipation region; a ceiling adopts a lower air inflow manner, so that the waterproof and dustproof functions are simultaneously enhanced; an air flue is ventilated and cooled by virtue of positive pressure blowing of a centrifugal fan, and a rectifying grid is adopted, so that the problem that the axial air flow of the centrifugal fan is not uniform is solved; a device with a relatively protection grade is placed in the isolation type heat dissipation region, an air-heat exchanger is mounted on the rear side of the machine cabinet, and a wind channel partition board is arranged between an internal circulating air inlet and outlet, a heat dissipation path is planned as a double-'U'-shaped loop, heat is transferred to an external heat sink through a copper coil by virtue of thetemperature difference between hot air in the cabinet and an external temperature of the cabinet, air sequentially flows in and out of the whole machine, and the draught fan is arranged at the top ofthe machine cabinet, so that the working temperature is low, and the reliability is high; positive pressure dust prevention is realized in the core heat dissipation region, key devices in the cabinetare not in contact with the environment, so that the disadvantages of air cooling are furthest evaded; and by virtue of a low-cost air flue design, the environmental adaptive capability of an outdoormachine is improved.

Owner:TBEA XIAN ELECTRIC TECH +1

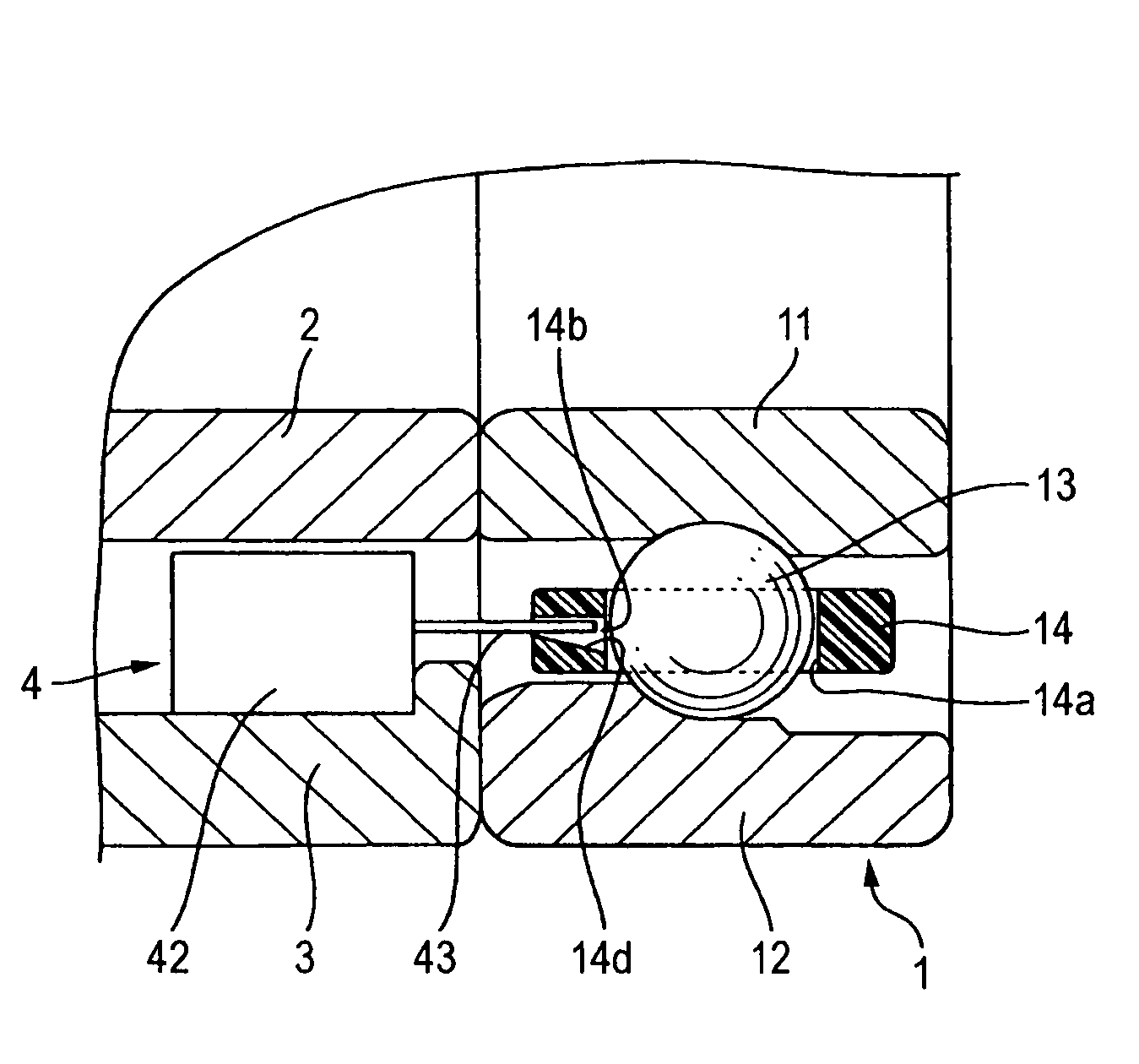

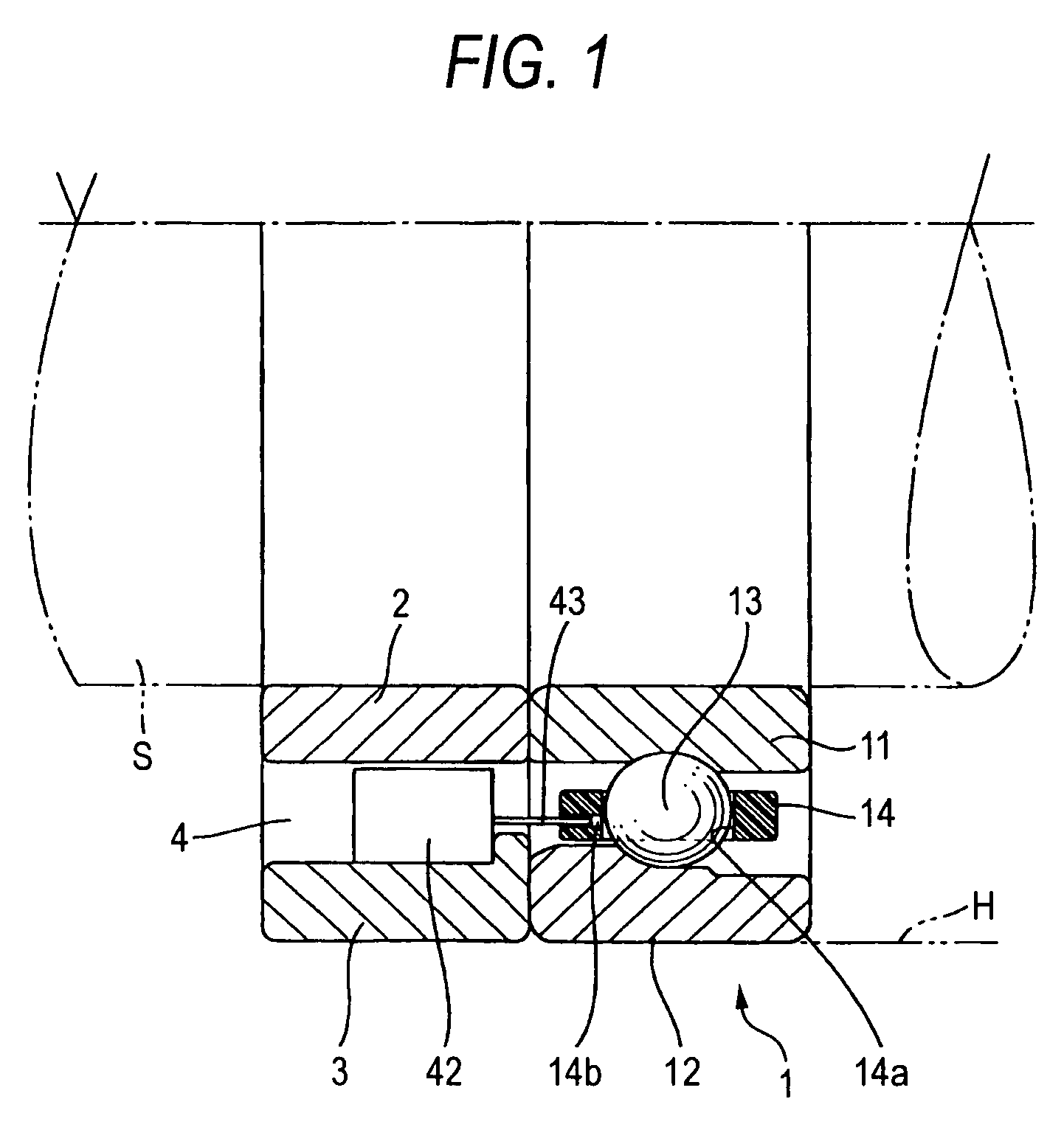

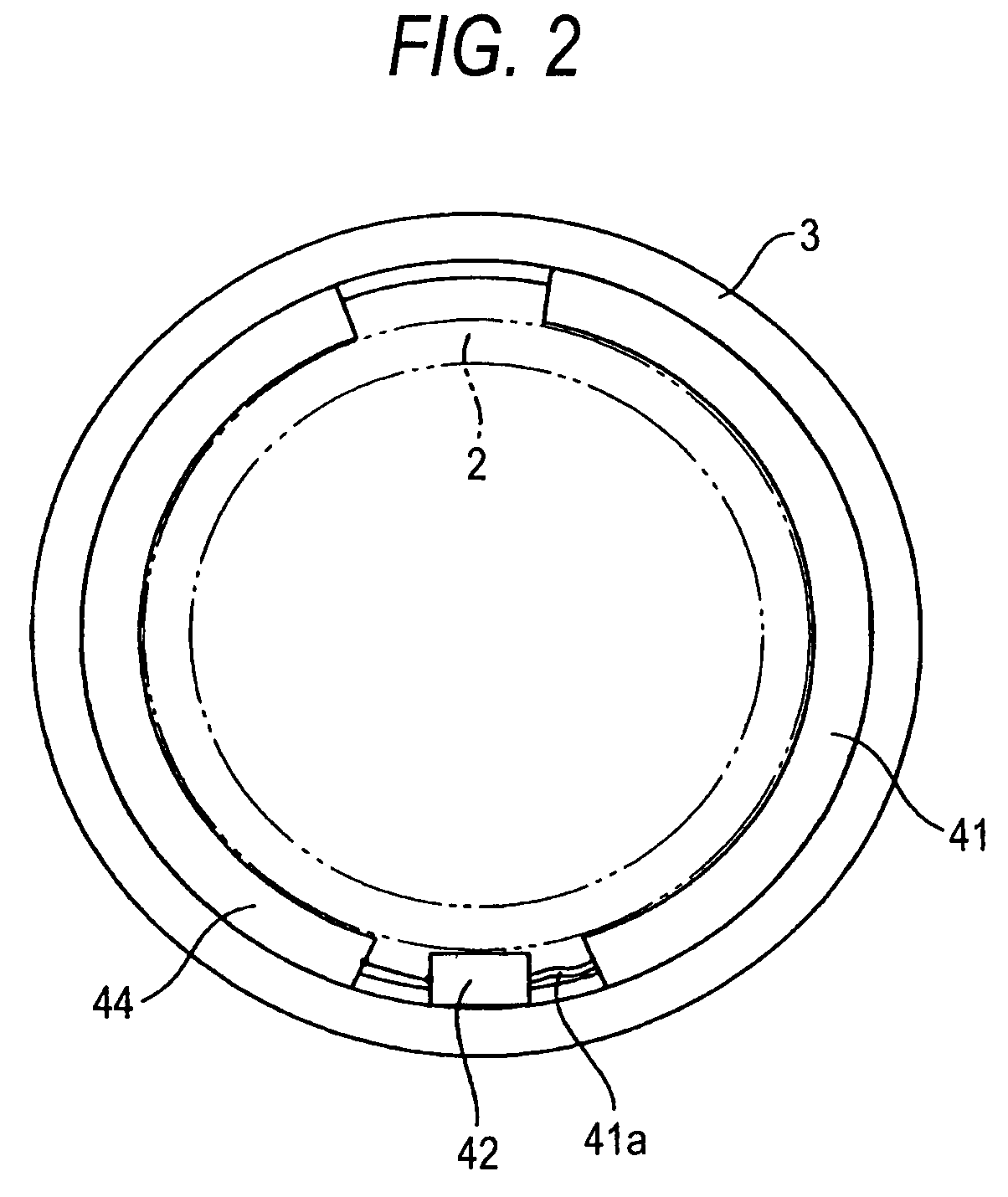

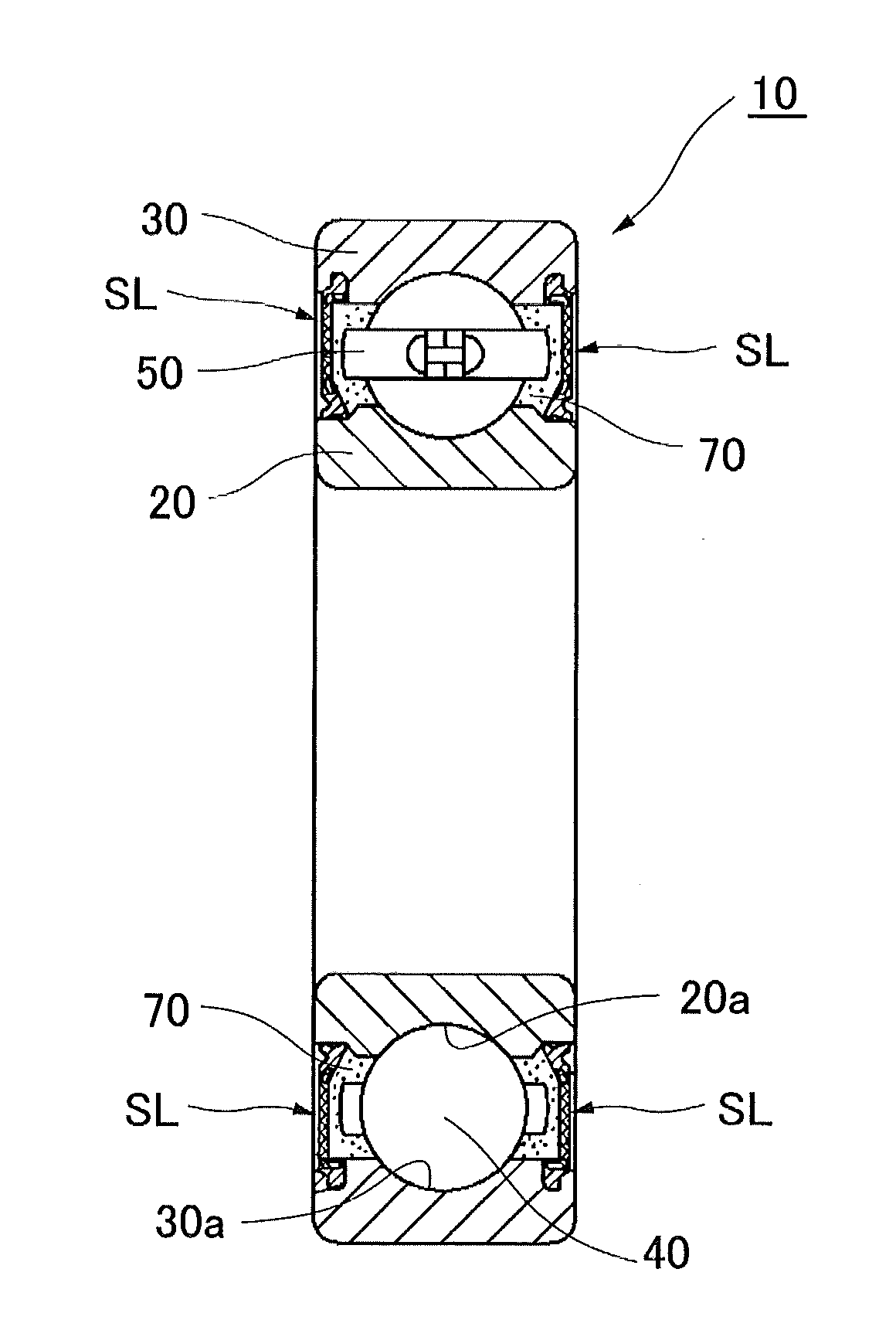

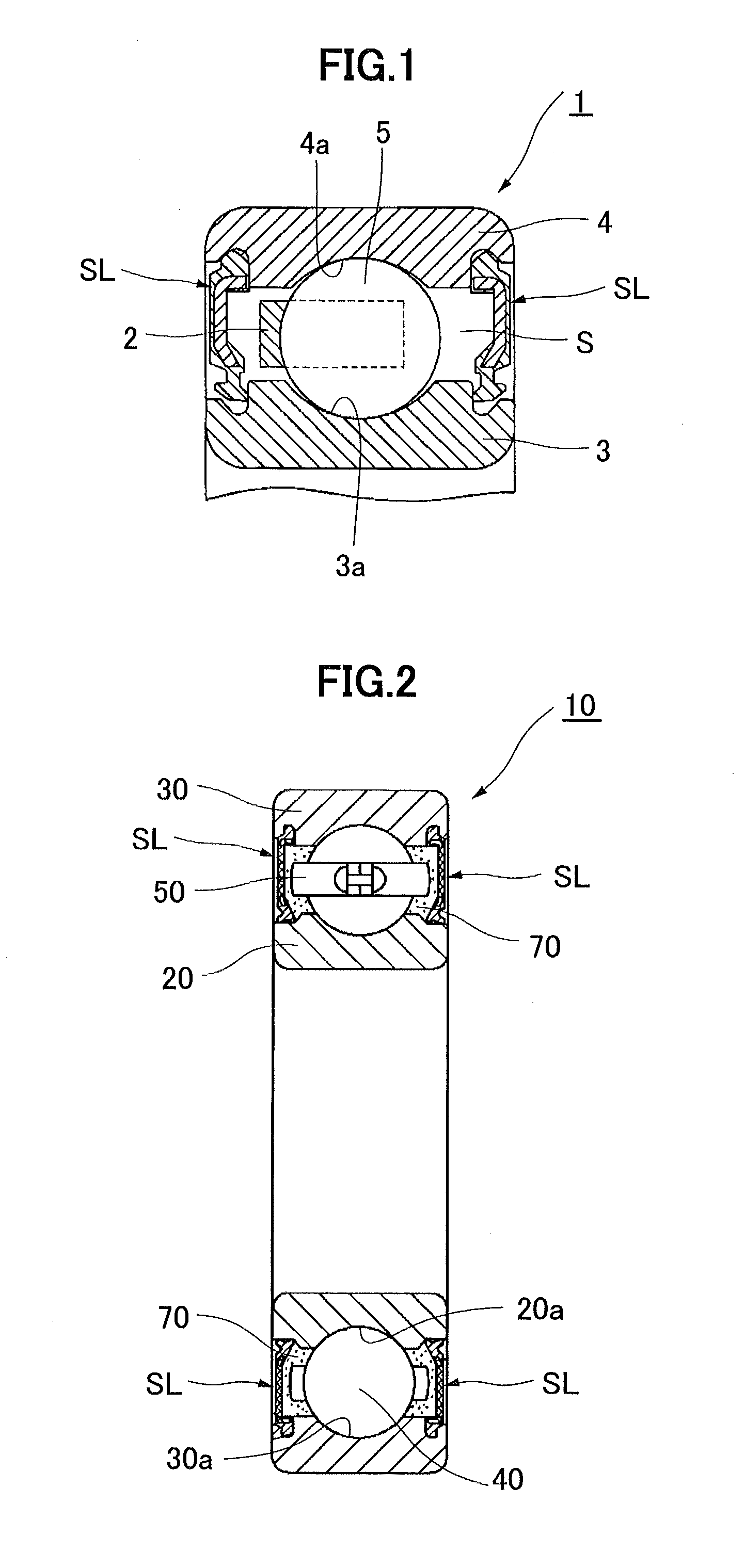

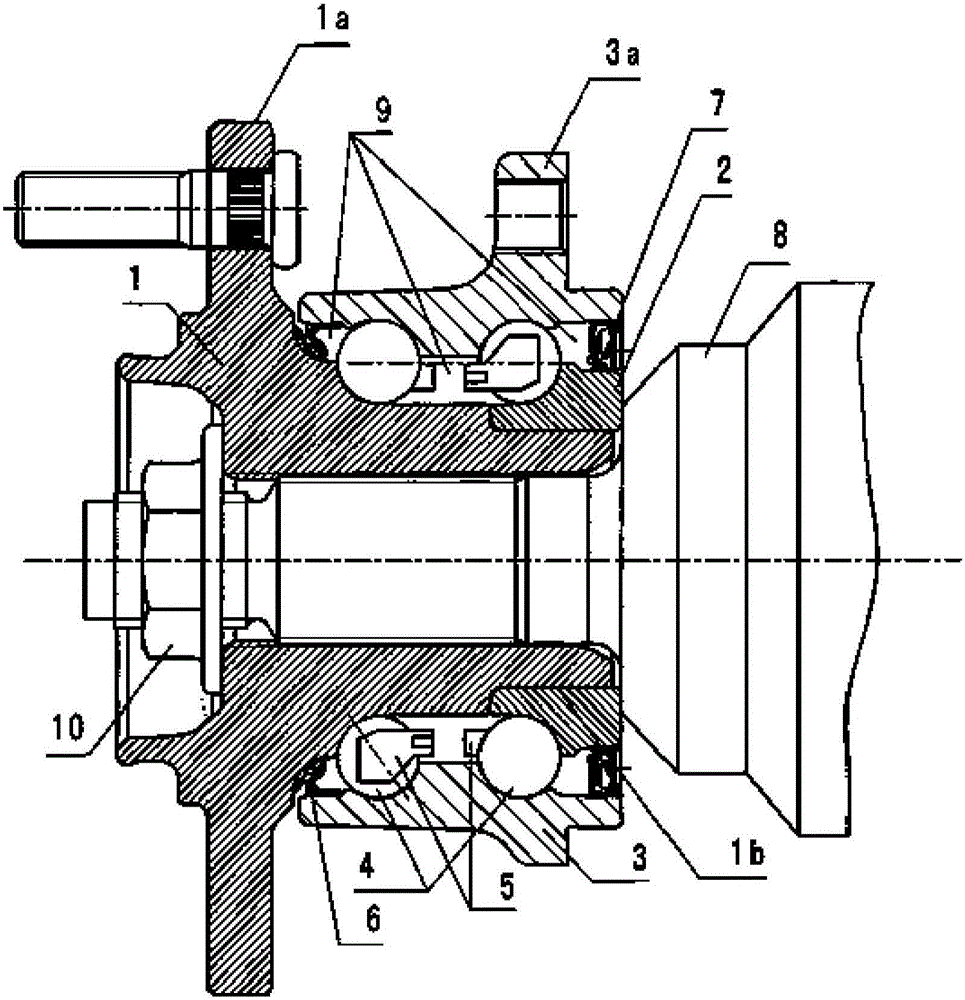

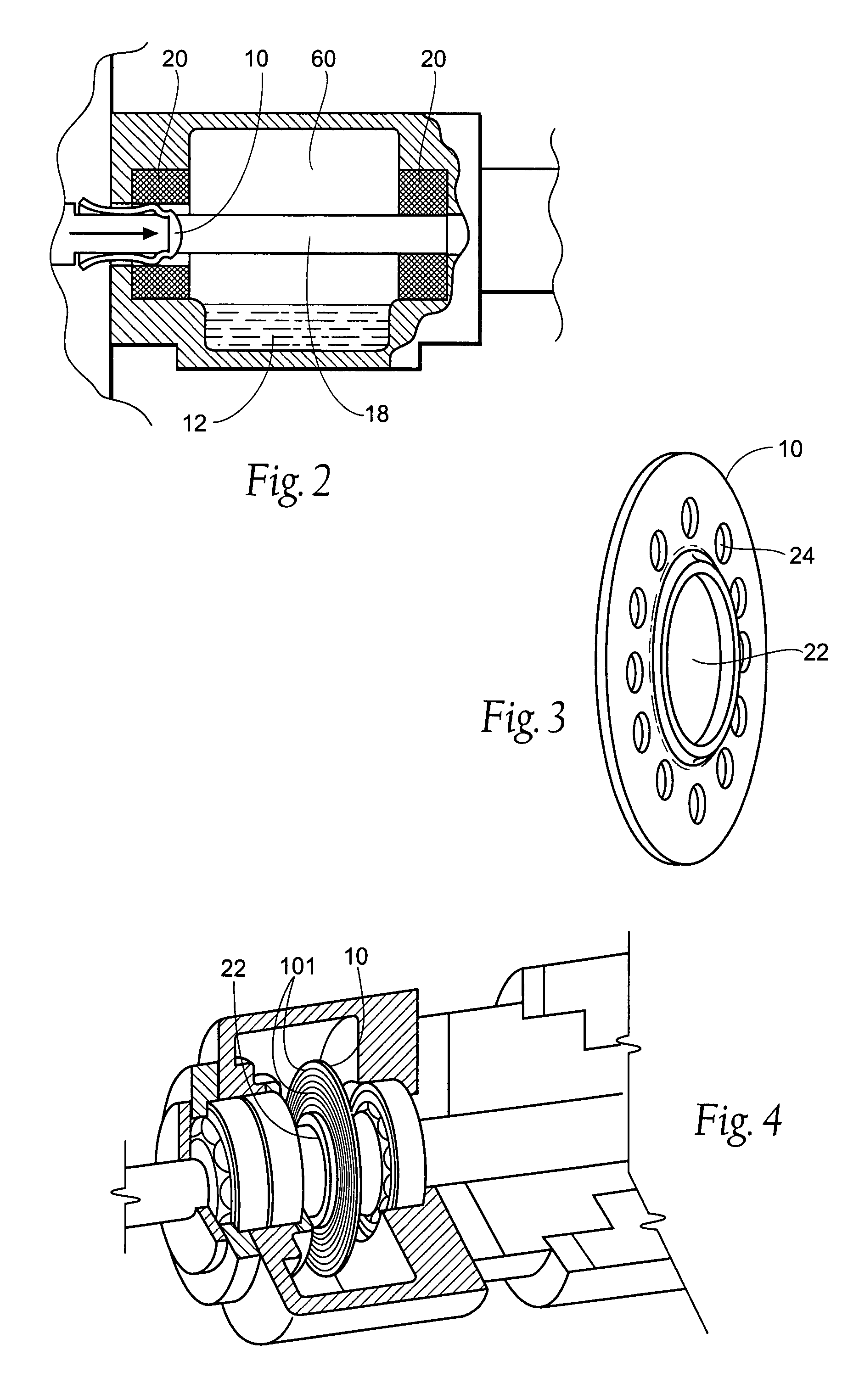

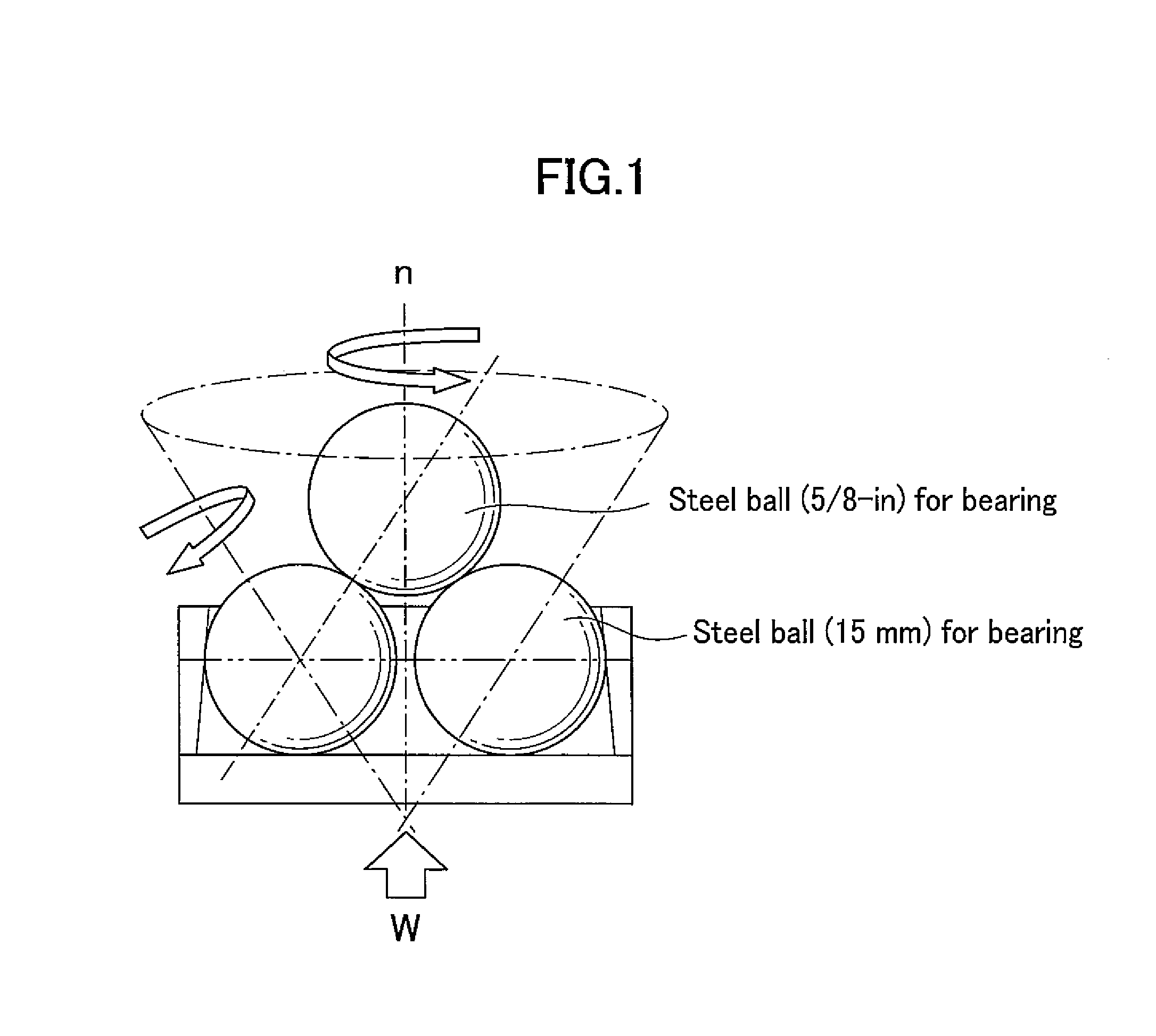

Rolling bearing device

InactiveUS7909513B2Long lubrication lifeLubricating oil is refilled can be extendedRolling contact bearingsShaftsRolling-element bearingCentre of rotation

A groove is formed on one end face side of a cage including a plurality of pockets for holding individually rolling elements which extends circumferentially along a full circumference of the cage about a rotational center thereof and has a bottom portion which communicates individually with the plurality of pockets, and a distal end portion of a nozzle of an oil supply unit is inserted into the groove, whereby the generation of disturbance to airflow and negative pressure in the vicinity of an opening of the nozzle is suppressed when a rolling bearing rotates, so that lubricating oil supplied from the nozzle is allowed to reach the rolling elements in an ensured fashion.

Owner:JTEKT CORP

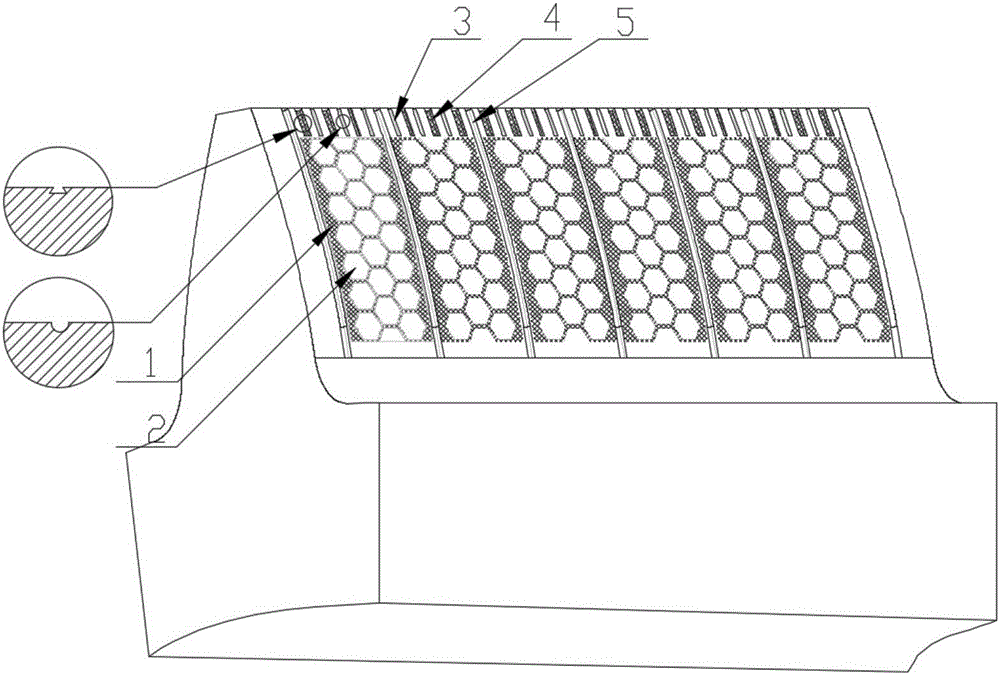

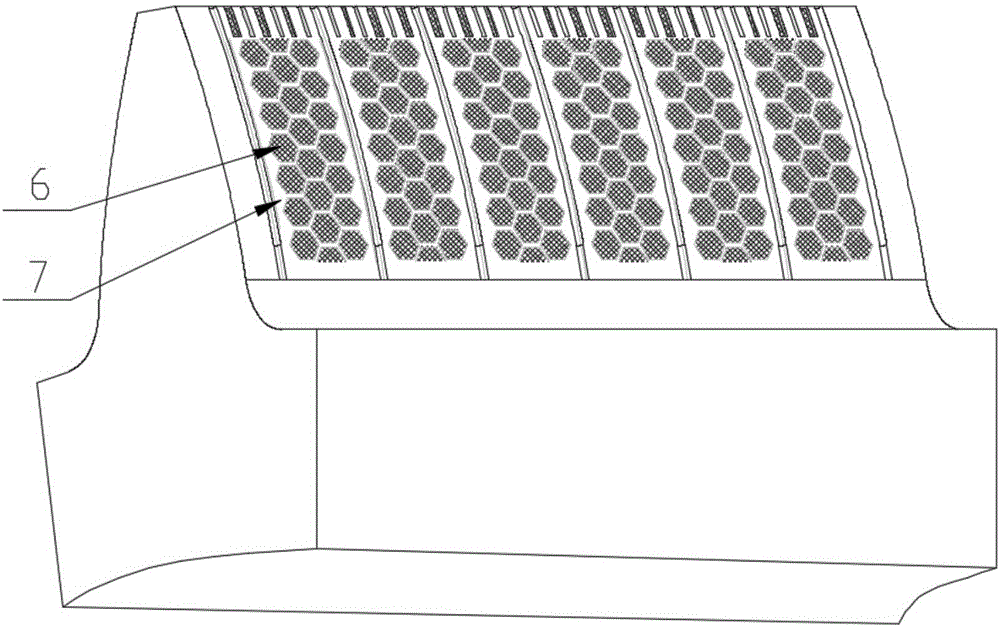

Honeycomb-shaped polygonal self-lubricating gear

InactiveCN106763649AReduce usageGuaranteed StrengthPortable liftingGearing elementsHoneycombEngineering

The invention relates to a honeycomb-shaped polygonal self-lubricating gear. Honeycomb-shaped grooves, strip-shaped grooves, middle strip-shaped chip grooves and top strip-shaped chip grooves are processed in a tooth surface of the honeycomb-shaped polygonal self-lubricating gear; the honeycomb-shaped grooves are positioned in the middle of the tooth surface, and are filled with self-lubricating materials; the strip-shaped grooves are positioned in the top of the tooth surface, and are filled with the self-lubricating materials; and the middle strip-shaped chip grooves and the top strip-shaped chip grooves separately penetrate through the whole tooth surface and are formed in the top of the tooth surface, are distributed in a spaced mode, and are beneficial for chip removal. The invention discloses the honeycomb-shaped polygonal self-lubricating gear which is inspired by a honeycomb shape based on the bionic idea; compared with an existing gear, the honeycomb-shaped polygonal self-lubricating gear has self-lubricating characteristics, does not need to additionally add media such as lubricating oil and lubricating grease, enriches a gear lubricating mode, and can meet normal operation when the gear is under extreme working conditions such as an oil-free working condition and an oil-lack working condition.

Owner:HEFEI UNIV OF TECH

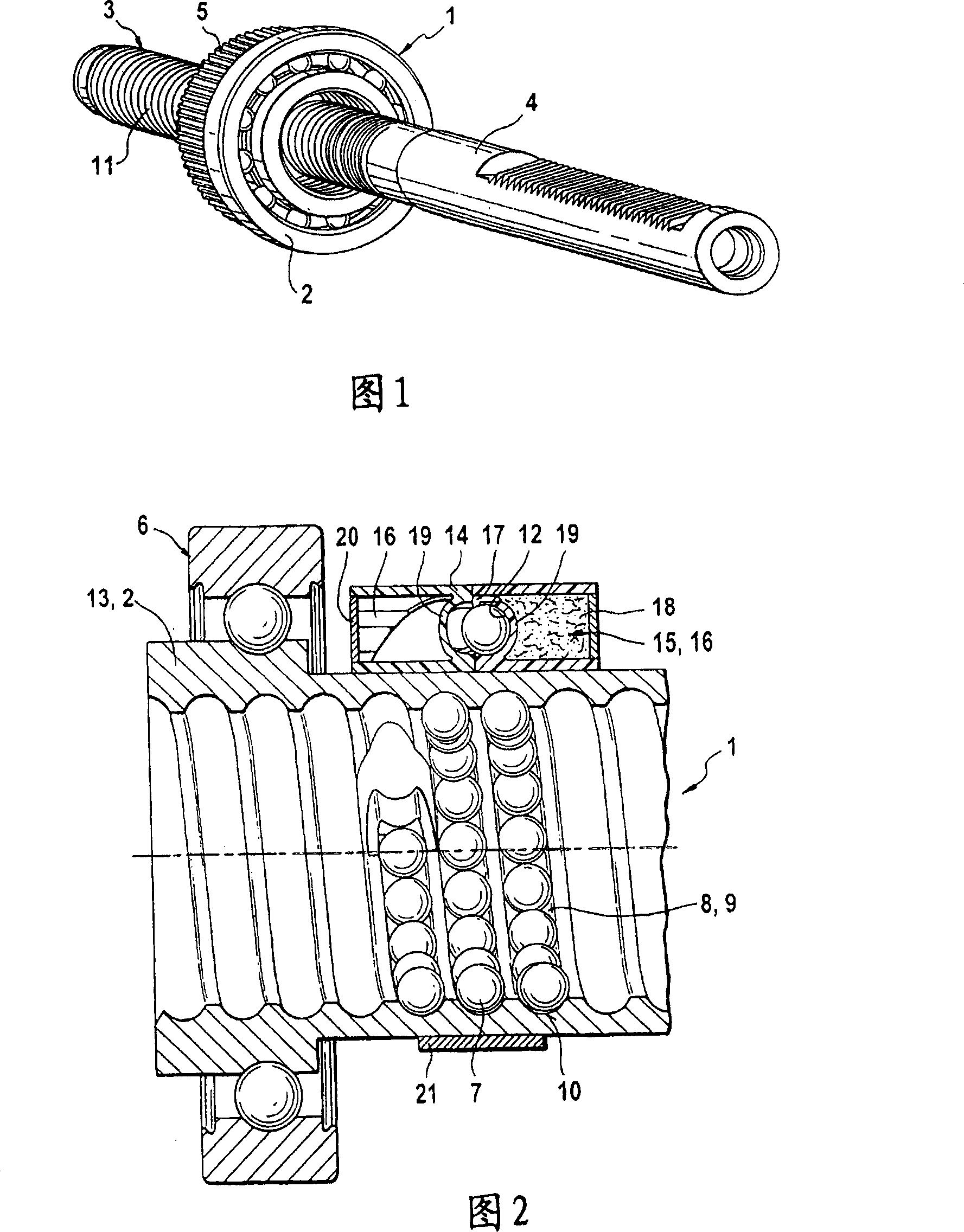

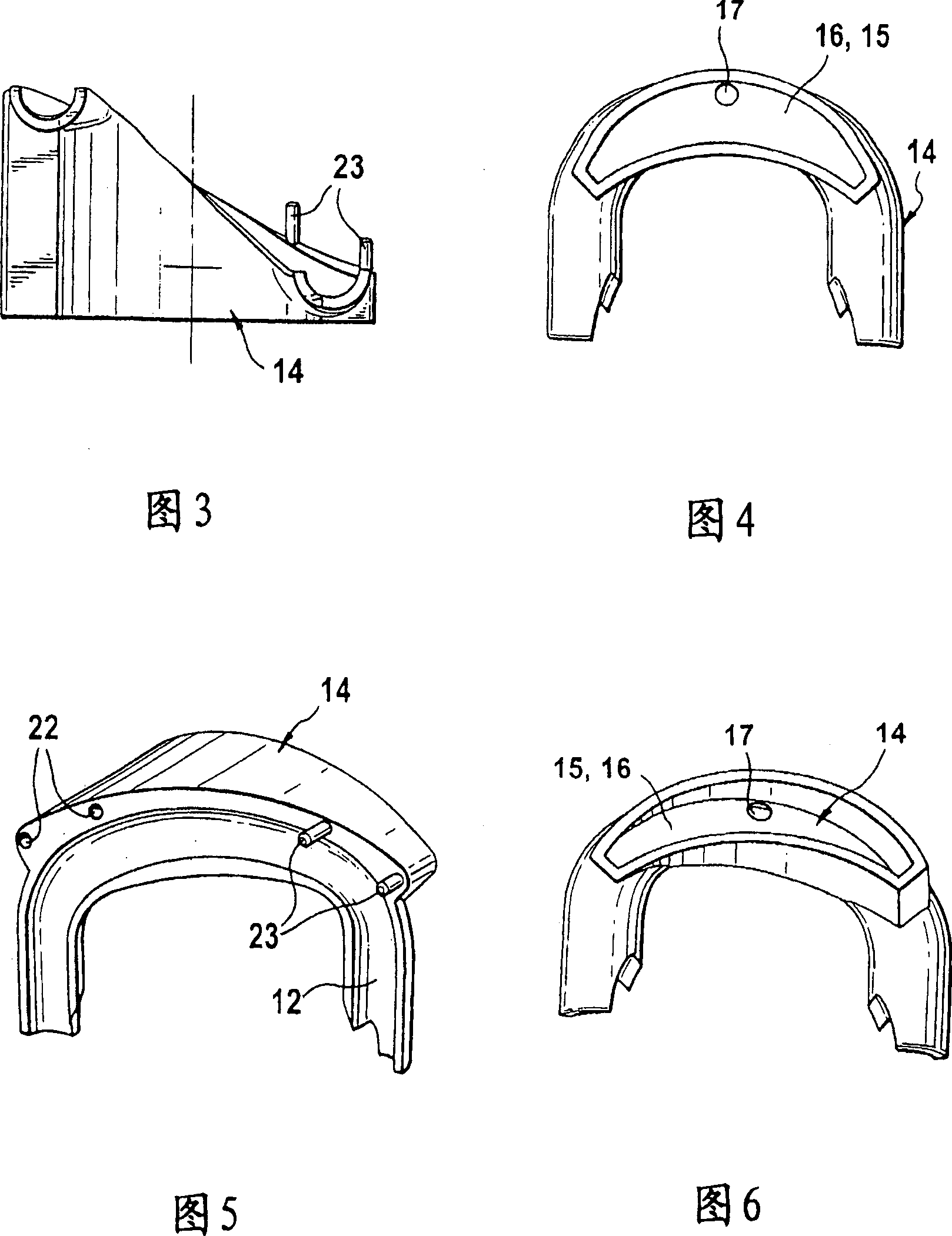

Ball screw

InactiveCN101014784AImplement inputLong lubrication lifeGearingElectrical steeringBall screwEngineering

The invention relates to a ball screw (1) comprising a ball caster spindle (3) and a driven spindle nut (2) arranged thereon. Balls (7) are arranged in a continuously rotatable manner in at least one endless ball channel (8), said ball channel (8) comprising a load section (9) which is wound around the ball caster spindle (3) and defined by ball tracks (10, 11) of the ball caster spindle (3) and the spindle nut (2), and a load-free recycling section (12) which continuously connects the beginning and end thereof. A regreasing device (15) which is arranged on the spindle nut (2) in a rotationally fixed manner supplies lubricant to the ball channel (8) using centrifugal force.

Owner:SCHAEFFLER TECH AG & CO KG

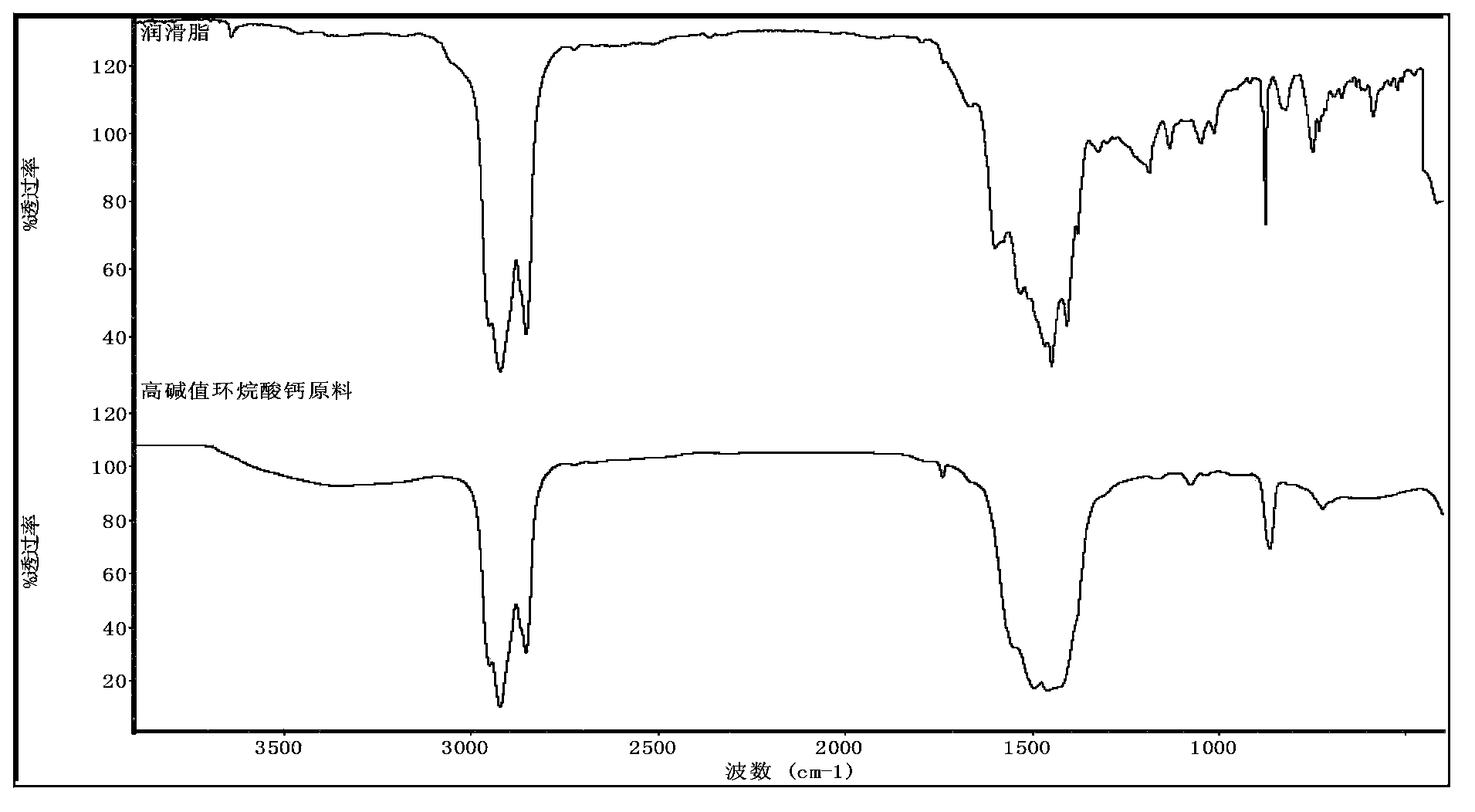

Composite calcium naphthenate-based lubricating grease and preparation method therefor

ActiveCN103627496AGood extreme pressure and anti-wear propertiesLong lubrication lifeLubricant compositionHeat stabilityBase oil

The invention provides a kind of composite calcium naphthenate-based lubricating grease and a preparation method therefor. With the weight of the lubricating grease as a reference, the lubricating grease comprises the following ingredients: 10%-70% of non-Newtonian calcium naphthenate, 1%-10% of calcium salts of high fatty acids, 1%-15% of calcium salts of micromolecule inorganic acids or fatty acids and 10%-80% of lubrication base oil. The lubricating grease employs petroleum calcium naphthenate or synthesized calcium naphthenate as a raw material, and contains composite calcium densifiers. The lubricating grease has good anti-water-spray properties and anti-water spray loss properties, and has good performances of adhesion, extreme pressure antiwear property, colloid stability, high dropping point, heat stability, anti-corrosion and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

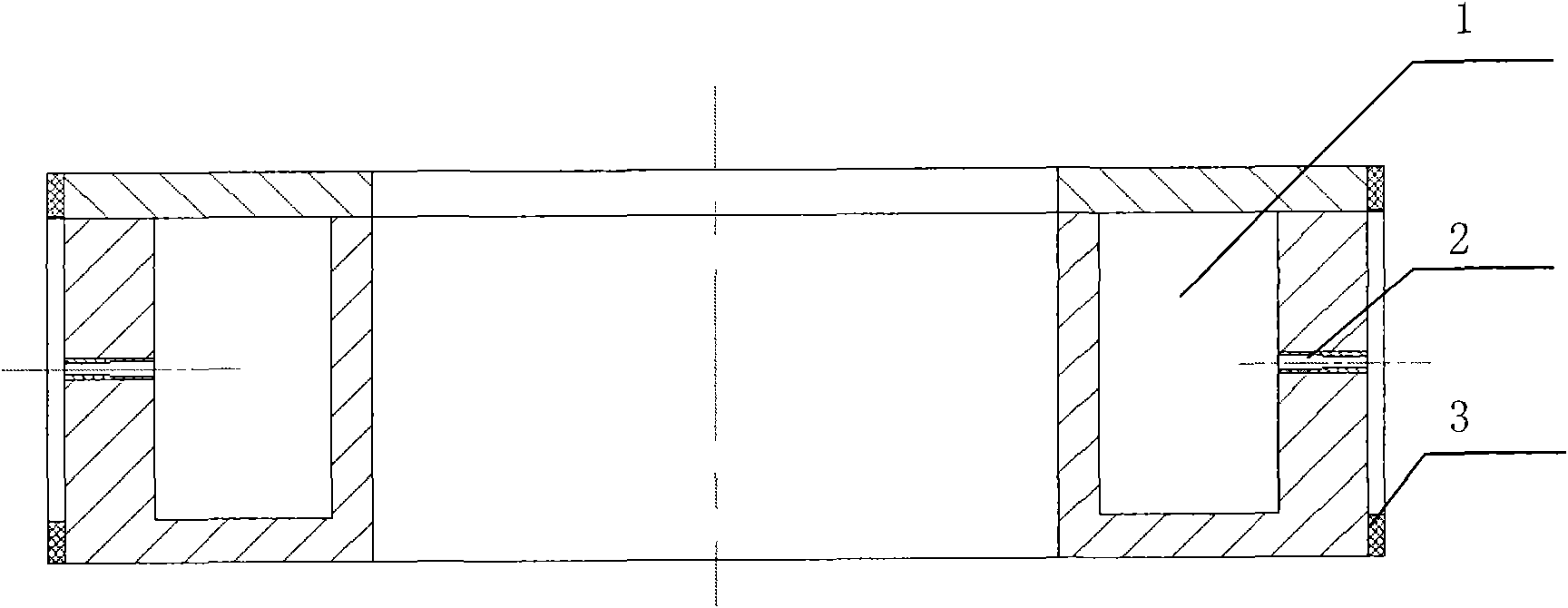

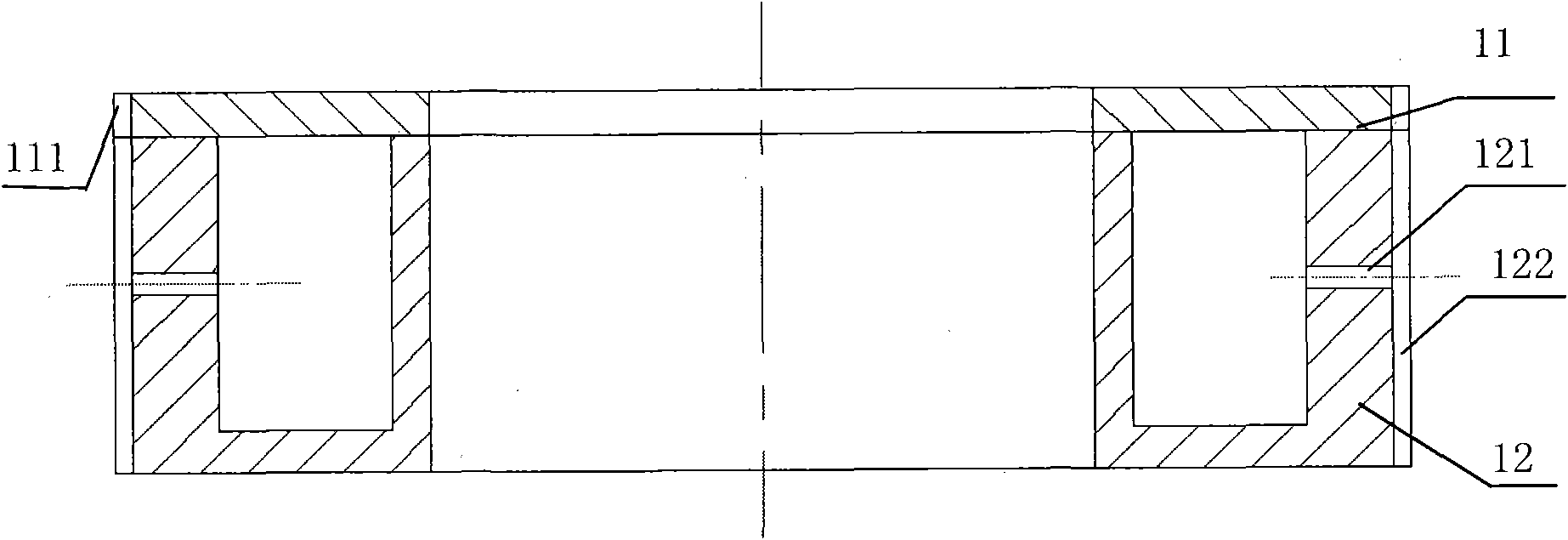

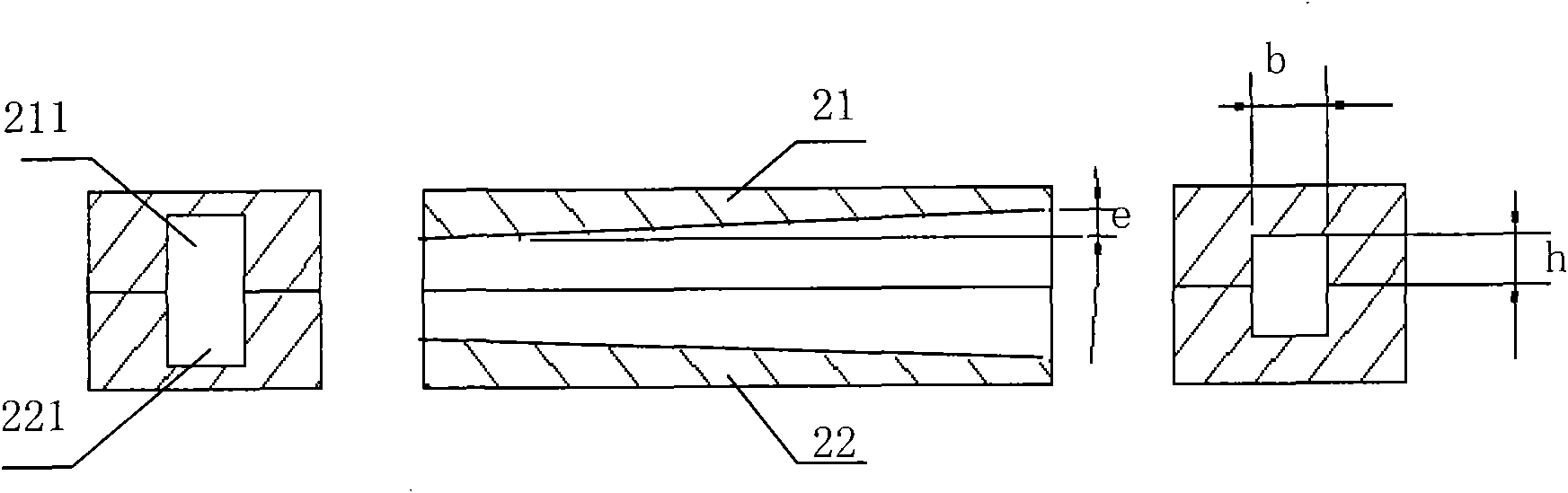

Oil storage and actively oil supply integrated device for space flywheel

InactiveCN101818849AExtended service lifeImprove use reliabilityCosmonautic vehiclesCosmonautic partsAdhesiveFlywheel

The invention discloses an oil storage and actively oil supply integrated device for a space flywheel, which belongs to the technical field of space tribology. The device comprises an oil container, wedge-shaped guide grooves and drainage columns. The oil container comprises a cover plate and a lower oil storage cavity which are connected with each other in an adhering mode by using an adhesive or a mechanical mode; the side wall of the lower oil storage cavity is provided with 4 to 8 radial installing holes; the outer surface of the lower oil storage cavity vertical to the installing holes is provided with drainage holes with the same number as that of the installing holes; the position of the cover plate vertical to the drainage holes is provided with circular holes with the same number and the same size as those of the drainage holes; the wedge-shaped guide grooves are formed in the installing holes in an interference or splicing mode; and the drainage columns are arranged in the drainage holes or the circular holes respectively in the interference or splicing mode. In the same volume, the device of the invention can carry several times more lubricating oil and the utilization ratio of the lubricating oil is close to 100 percent, so that longer lubrication life of a bearing is realized; and the device has the advantages of accuracy, controllability and long acting, effectively prolongs the service life of a flywheel and improves the reliability of the flywheel.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

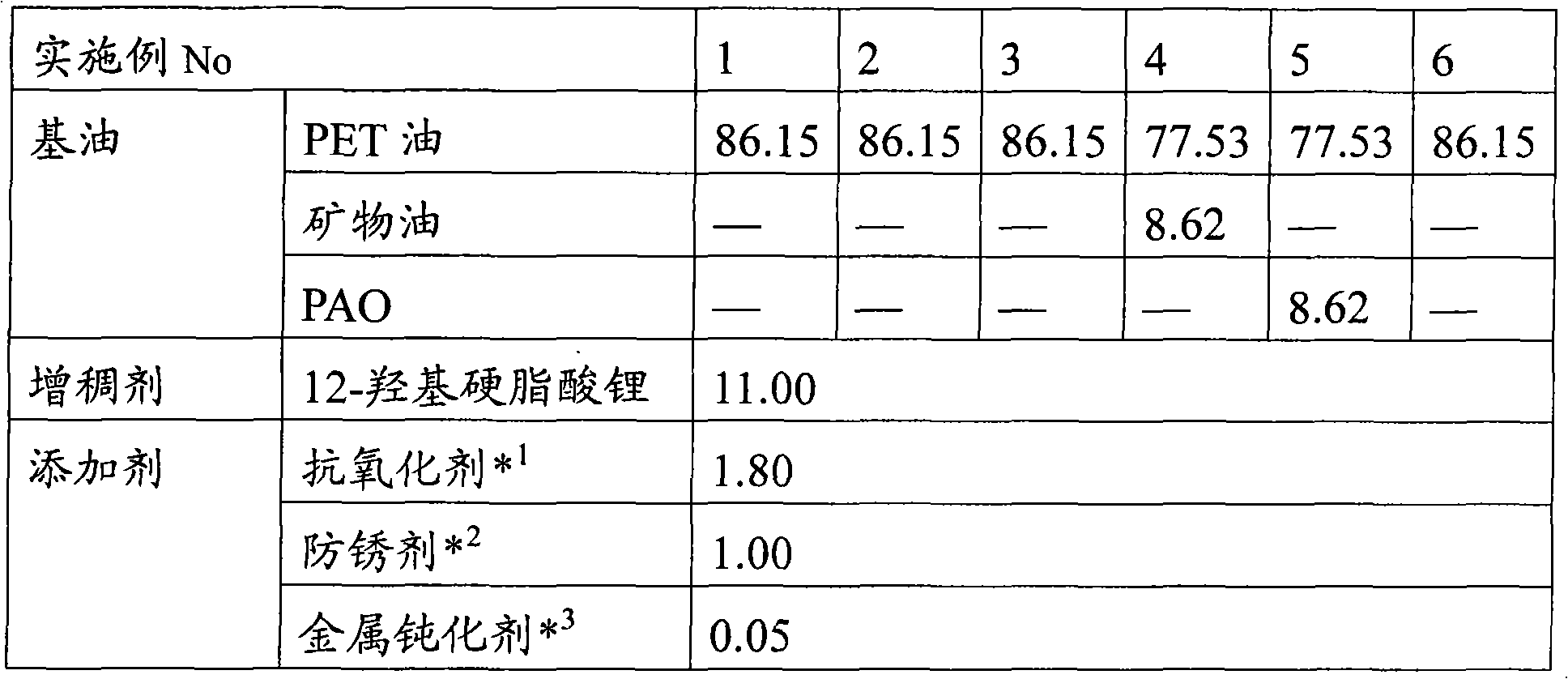

Grease composition and grease-packed rolling bearing

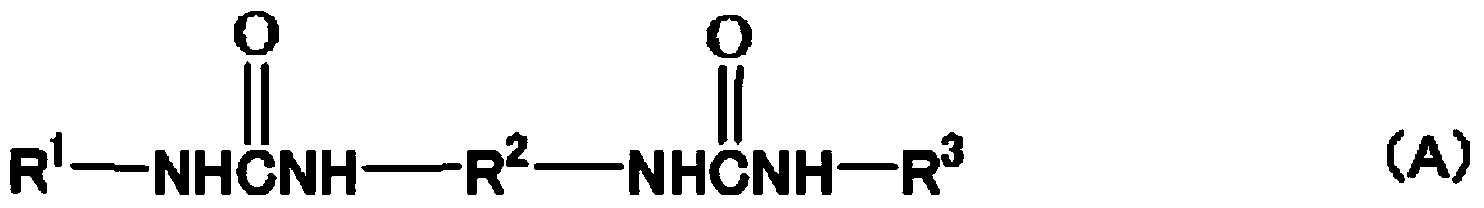

ActiveUS20130331306A1Avoid it happening againExtending bearing lubrication lifeBall bearingsBearing componentsOrganic sulfonic acidSulfonate

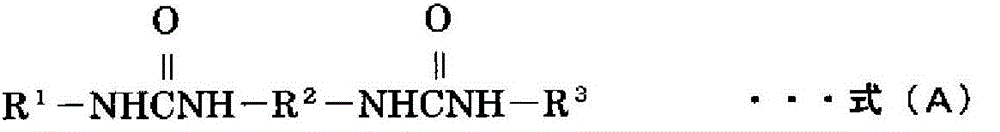

A grease composition for a rolling bearing for a motor to support a rotor of the motor, containing a pentaerythritol ester base oil with a kinematic viscosity at 40° C. of 20 to 55 mm2 / s; 7 to 13 mass % of a diurea thickener represented by formula (A) where each R group is defined; and a rust inhibitor mixture selected from the group consisting of polyol ester type rust inhibitors and organic sulfonate type rust inhibitors. The grease composition can prevent a peculiar noise from being produced at low temperatures, satisfy the low torque performance over a wide temperature range, extend the bearing lubrication life even under the circumstances of high temperature, and exhibit excellent rust inhibiting effect on varnish.

Owner:KYODO YUSHI CO LTD +1

Grease composition and bearing

InactiveCN101321851AImprove overall lifespanImprove the lubrication effectBearing componentsBase-materialsPentaerythritolBase oil

Disclosed is a grease composition containing base oil and a thickening agent, wherein the base oil contains an ester oil which is composed of pentaerythritol and a fatty acid and represented by the general formula (1) below. This grease composition is characterized by containing a pentaerythritol tetraester oil wherein the fatty acid is composed of at least 51-55% by mass of 2-ethylhexane acid and 39-49% by mass of caprylic acid and capric acid in total (provided that the caprylic acid is not less than 30% by mass and the capric acid is 5-10% by mass). Also disclosed is a bearing in which such a grease composition is sealed. C(CH2OCOR<1>)4 (1) (In the formula, R<1> represents a linear and / or branched fatty acid residue having 6-12 carbon atoms.) The grease composition is suitable for rolling bearings under low temperature conditions and exhibits stable lubricity for a long time.

Owner:KYODO YUSHI CO LTD

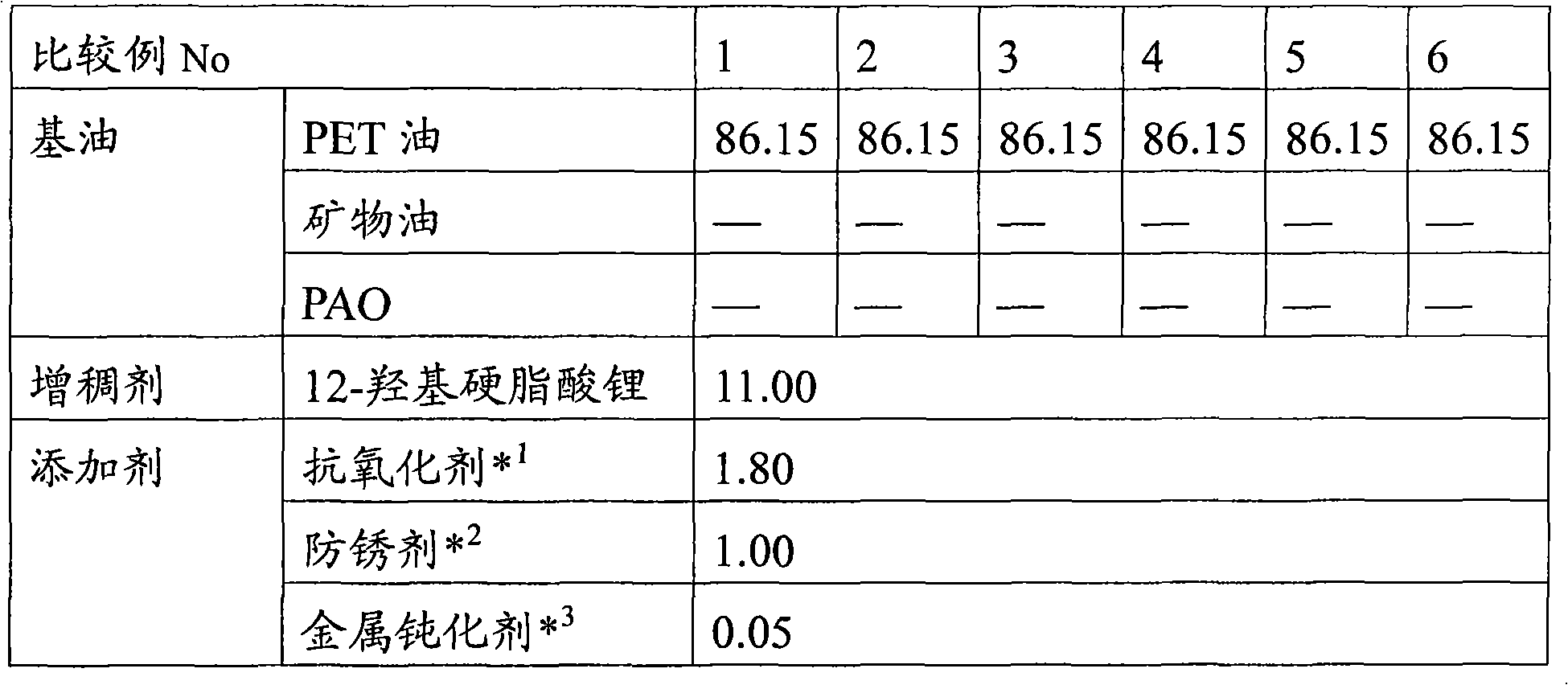

Membrane-grease composite lubrication method

InactiveCN105909962ALong lubrication lifeRealize complementary lubricationGear lubrication/coolingBearing componentsEngineeringPre treatment

The invention provides a membrane-grease composite lubrication method and relates to a lubrication method. The invention aims to solve problems that requirements of high speed high load working condition and changing working conditions cannot be met when prior solid membrane lubrication or grease lubrication is used separately and abrasion is easy to occur and the lubrication effect is poor when the solid membrane is used for lubrication. The method includes performing pre-treatment on work piece surface; processing a solid lubrication membrane on the work piece surface; coating the surface of the solid lubrication membrane with lubrication grease or injecting lubrication grease to the a friction interface of the solid lubrication membrane, so that membrane-grease composite lubrication is realized. According to the invention, the solid lubrication membrane is spaced with grease lubrication, so that abrasion of the solid lubrication membrane is slow down, the solid lubrication membrane is protected and the lubrication service lifetime is prolonged. Mutual complementation in lubrication is realized through the combination of solid membrane lubrication suitable for low-speed heavy duty and a grease lubrication method suitable for high speed low duty. Through solid lubrication membrane carrying, lubrication coordination of lubrication and vibration absorption of the lubrication grease is realized. The lubrication effect is good.

Owner:HARBIN INST OF TECH

Composite zirconium-based hexaurea lubrication grease and its preparation method

ActiveCN103031183AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersHeat stabilityBase oil

The invention provides a composite zirconium-based hexaurea lubrication grease and its preparation method. The lubrication grease comprises 1-59wt% of composite zirconium, 1-59wt% of hexaurea and 40-95wt% of lubrication base oil, wherein the composite zirconium comprises zirconyl higher fatty acid salt and zirconyl acid salt having a low molecular weight. The lubrication grease simultaneously comprises a composite zirconium thickening agent and a hexaurea compound. The lubrication grease has the advantages of excellent extreme-pressure wear resistance, long lubrication life, excellent water resistance, excellent colloid stability, high dropping point, excellent heat stability and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite zirconium-based urea tetramer grease and preparation method thereof

ActiveCN102952605AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersHeat stabilityBase oil

The invention provides composite zirconium-based urea tetramer grease and a preparation method thereof. The composite zirconium-based urea tetramer grease comprises: by weight, 1) 1 to 59% of composite zirconium which is produced by a reaction of at least one higher fatty acid, at least one aromatic acid, and an oxide and / or a hydroxide of zirconium, 2) 1 to 59% of a urea tetramer, and 3) 40 to 95% of lubrication base oil. The composite zirconium-based urea tetramer grease contains the composite zirconium as a densifier and the urea tetramer. The composite zirconium-based urea tetramer grease has excellent extreme pressure wear resistance, a long lubrication life, good water resistance, colloid stability, a high dropping point and good heat stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Layered zirconium phosphate and molybdenum disulfide compound extreme pressure grease and preparation method thereof

InactiveCN107384527AImprove bearing capacity and wear resistanceGood anti-wear performanceAdditivesAntioxidantMolybdenum disulfide

The invention discloses a layered zirconium phosphate and molybdenum disulfide compound extreme pressure grease and a preparation method thereof. The grease comprises the following components by weight percent: 90-96% of base grease, 2.0-7.0% of alpha-layered zirconium phosphate and molybdenum disulfide mixed powder, 1.0-3.0% of an extreme pressure agent and 1.0-2.0% of an antioxidant. The preparation method comprises the following steps: adding 2.0-7.0% of alpha-layered zirconium phosphate and molybdenum disulfide mixed powder, 1.0-3.0% of an extreme pressure agent and 1.0-2.0% of an antioxidant into 90-96% of base grease and then rolling and grinding for 3 times by using a three-roller grinder, thereby acquiring a grease product. The grease disclosed by the invention is capable of promoting the bearing capacity and anti-grinding capacity of the grease. After the grease is mixed with the extreme pressure agent, the grease can meet the rigorous working conditions, such as high impact load.

Owner:TAIYUAN UNIV OF TECH

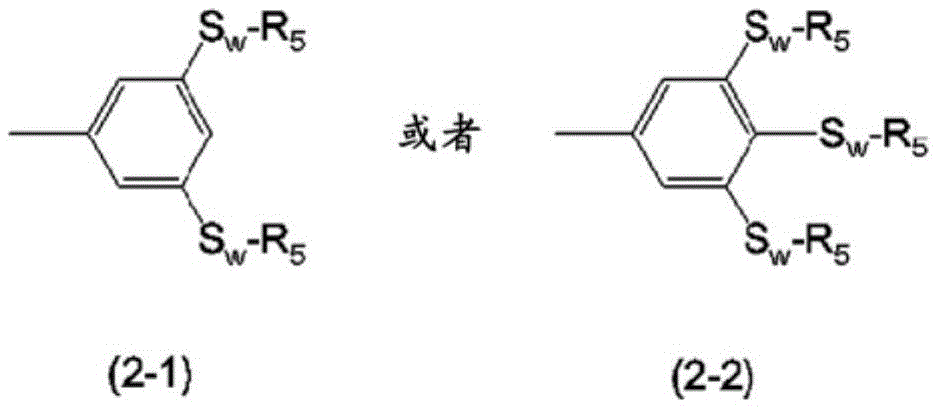

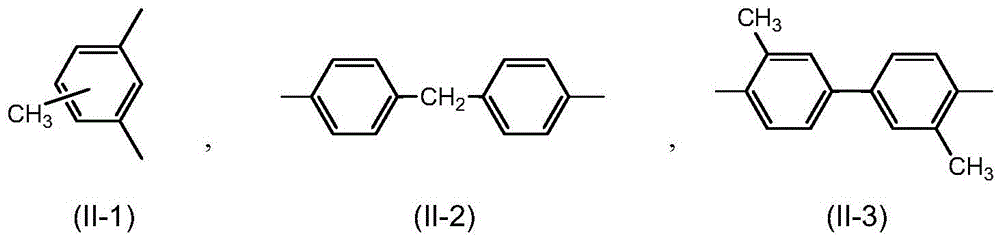

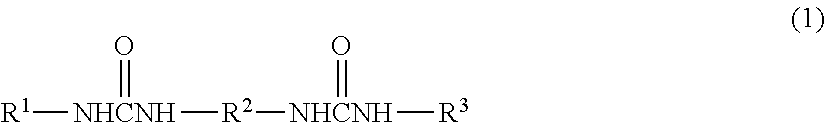

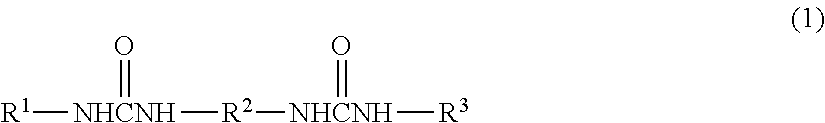

Grease composition

ActiveCN105492582AInhibition of white layer peelingExtended peel lifeThickenersAdditivesBase oilWhite layer

The present invention provides a grease composition which contains a base oil, a thickening agent and an anti-flaking additive such as a compound represented by, for example, formula (1-1), and which suppresses white layer flaking in a rolling bearing. (In the formula, R1 and R4 are each independently a straight chain or branched chain alkyl or alkenyl group having 1-20 carbon atoms.)

Owner:KYODO YUSHI CO LTD +1

Calcium naphthenate base octa-polyurea lubricating grease and preparation method thereof

ActiveCN103571588AGood extreme pressure and anti-wear propertiesLong lubrication lifeLubricant compositionDiamineIsocyanate

The invention provides calcium naphthenate base octa-polyurea lubricating grease and a preparation method thereof. The grease comprises the following components in percentage by the weight of the lubricating grease: (1) 10 to 70% of non-Newtonian calcium naphthenate; (2) 0.5 to 30% of octa-polyurea; (3) 10 to 80% of lubricating base oil. The calcium naphthenate base octa-polyurea lubricating grease is prepared by the following steps: converting non-Newtonian calcium naphthenate and then subjecting the conversion product to carry out reactions with diisocyanate, diamine, and monoamine. The lubricating grease provided by the invention has an excellent extreme pressure anti-wear property and a long lubricating service life, and at the same time has the excellent properties of adhesiveness, waterproofness, colloid stability, high dropping point, thermal stability, corrosion resistance, and salt smog resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

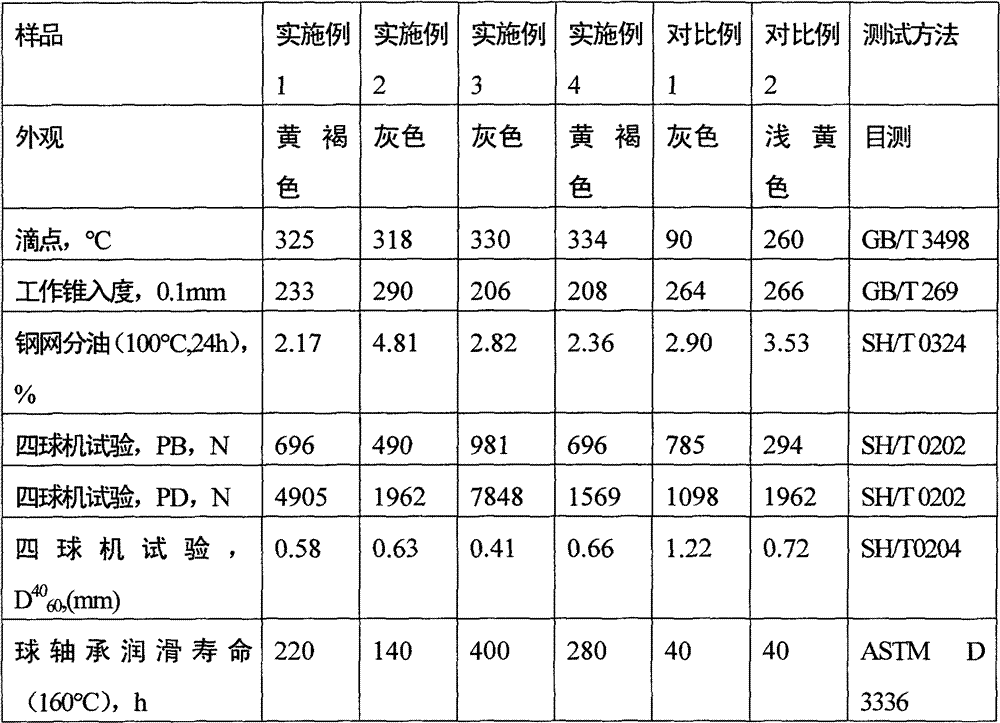

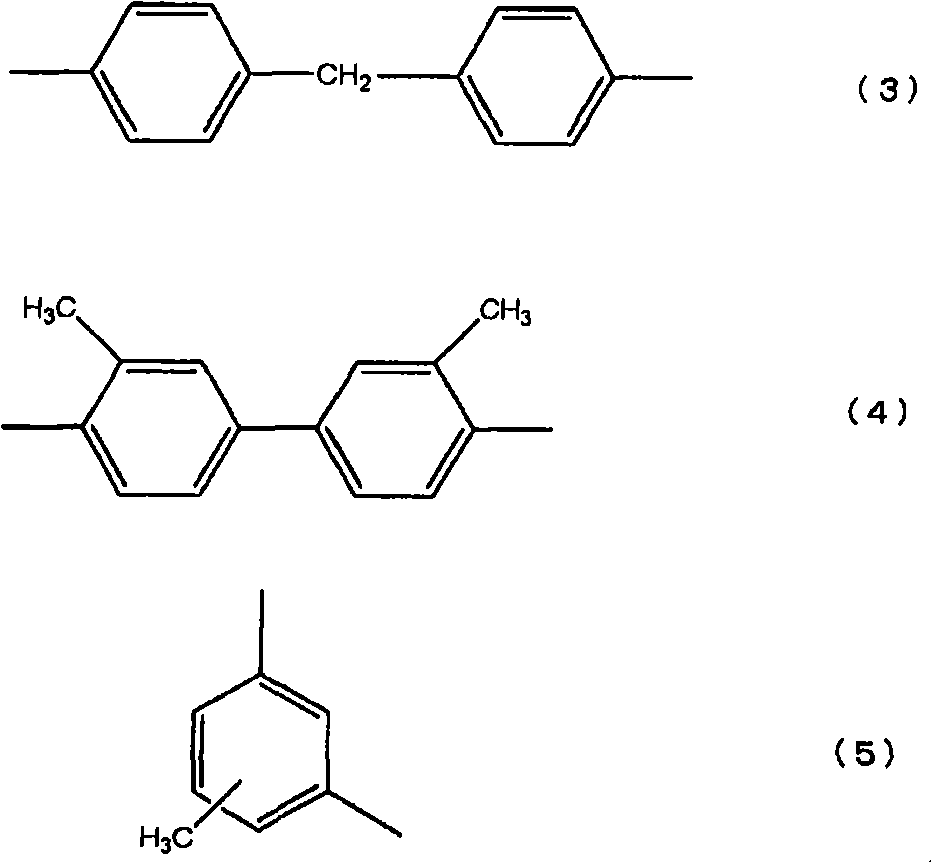

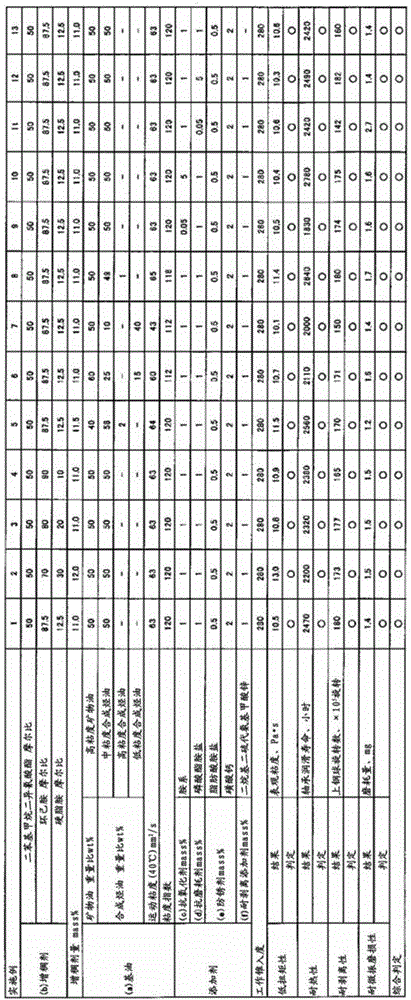

Grease composition and grease-filled wheel bearing

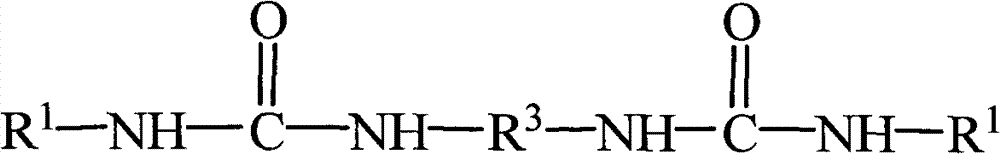

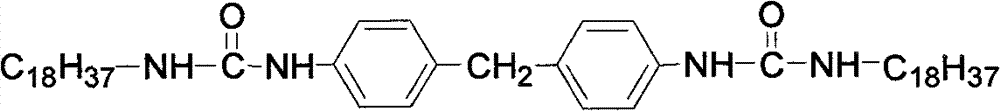

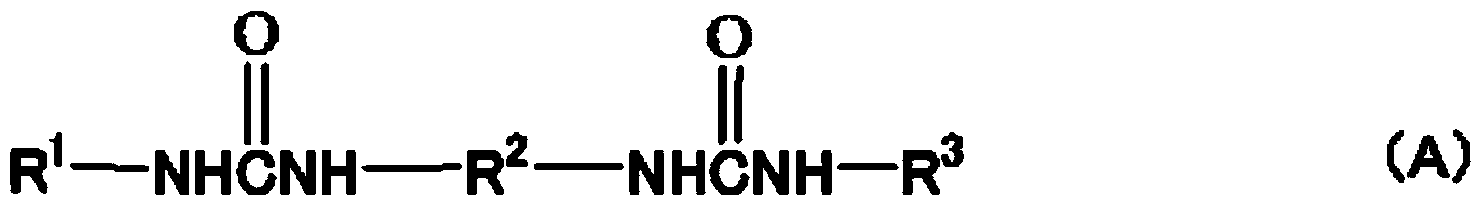

The present invention provides a grease composition for wheel bearings, which contains (a) a base oil which consists of a mineral oil and a synthetic hydrocarbon oil, in which the ratio of the synthetic hydrocarbon oil to the total quantity of the mineral oil and the synthetic hydrocarbon oil is 40-60 mass %, and in which the kinematic viscosity of the mixed oil at 40 DEG C is 40-65 mm2 / s, (b) a thickening agent represented by formula (A), (c) an amine-based antioxidant and (d) an amine phosphate-based wear prevention agent (in the formula, R2 denotes a diphenylmethane group. R1 and R3 may be the same or different and each denote a cyclohexyl group or a straight chain or branched chain alkyl group having 16-20 carbon atoms {the value of (number of cyclohexyl groups) / (number of cyclohexyl groups + number of alkyl groups)} * 100 is 50-90 mol.%).

Owner:KYODO YUSHI CO LTD +1

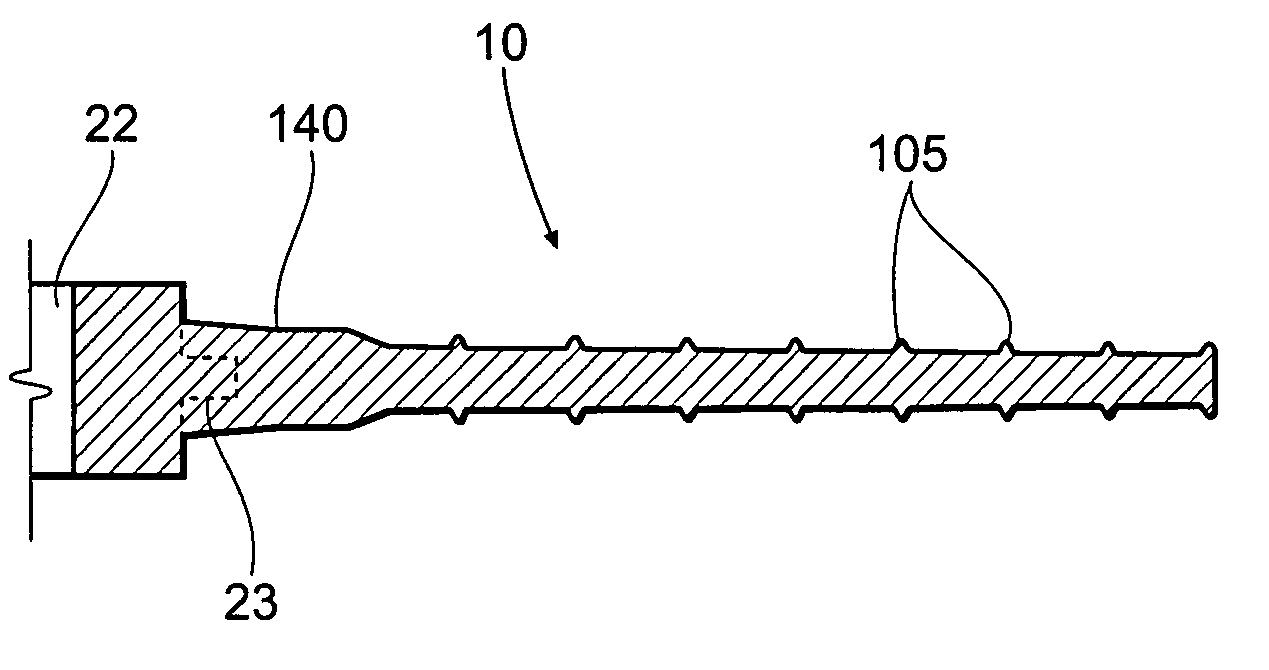

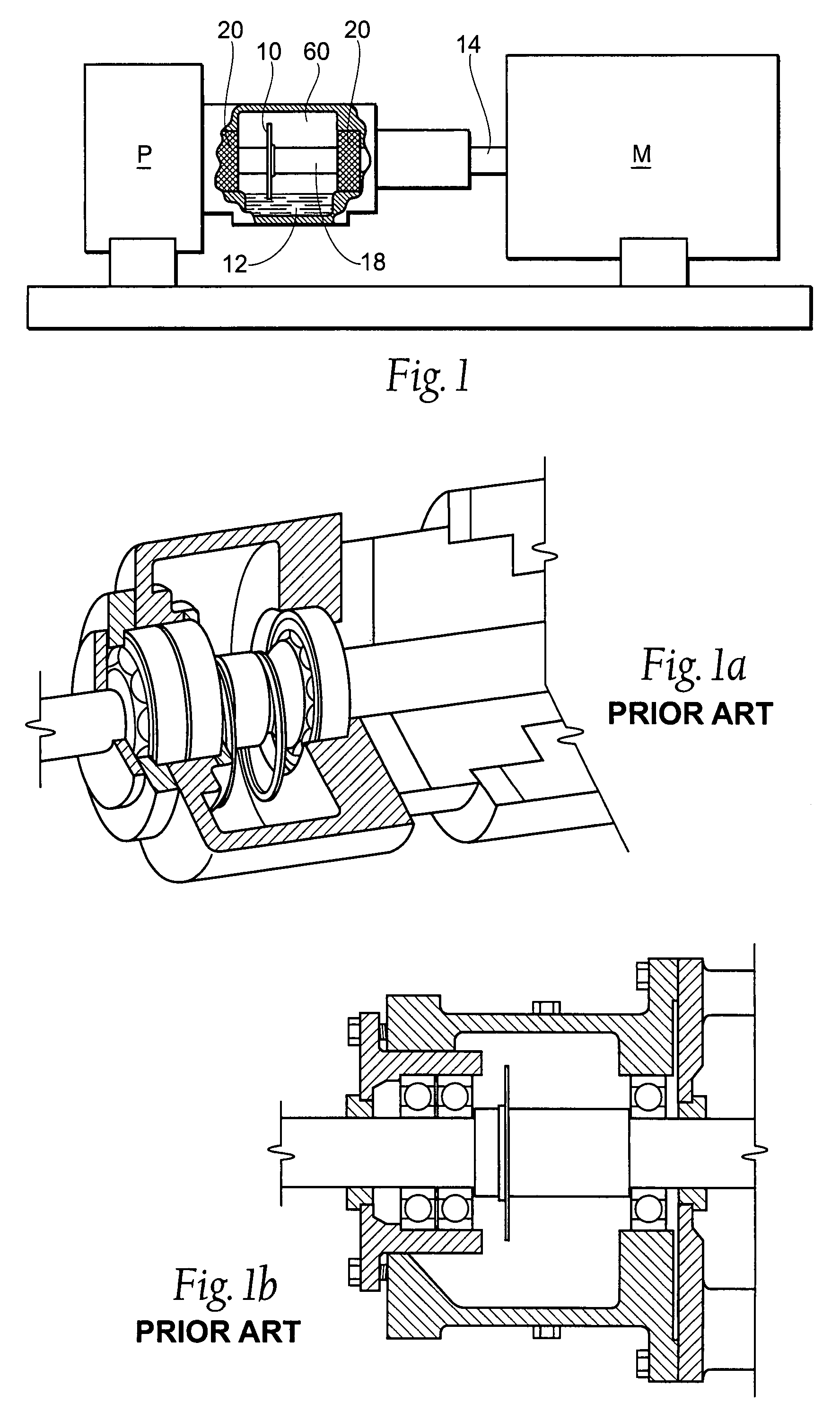

Flinger disc

ActiveUS7862875B2Easy to assemble and disassembleReduce the temperatureDrip or splash lubricationLayered productsEngineeringLubrication

To achieve proper lubrication, a bearing housing or reservoir is filled with a predetermined amount of lubricant. When the machine, of which a bearing is a component, is operated, a flexible flinger disc provides proper lubrication by disturbance of the lubricant.

Owner:TRICO CORP

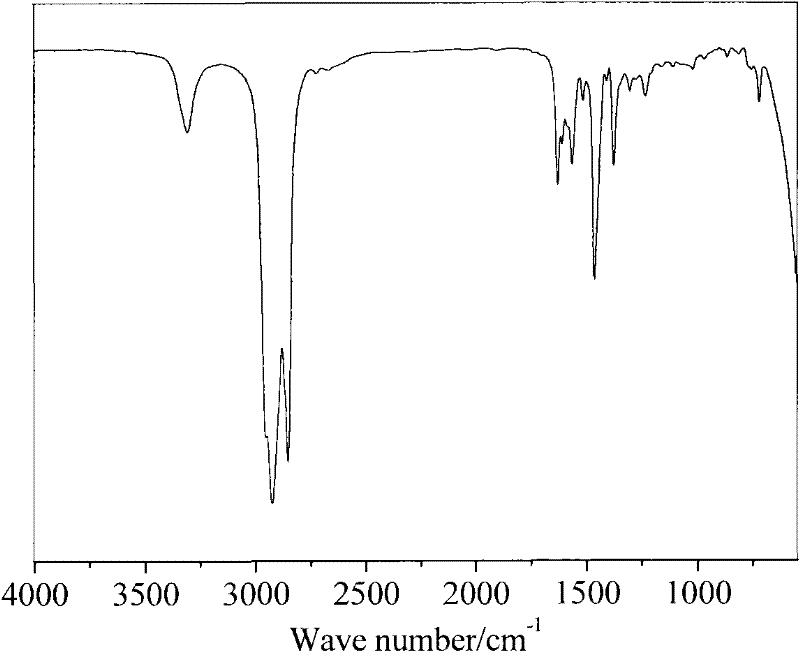

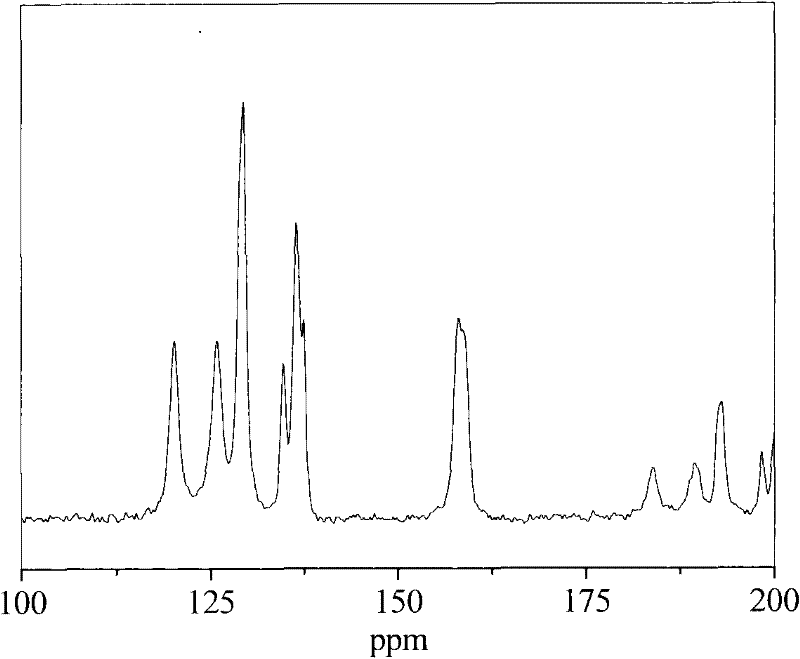

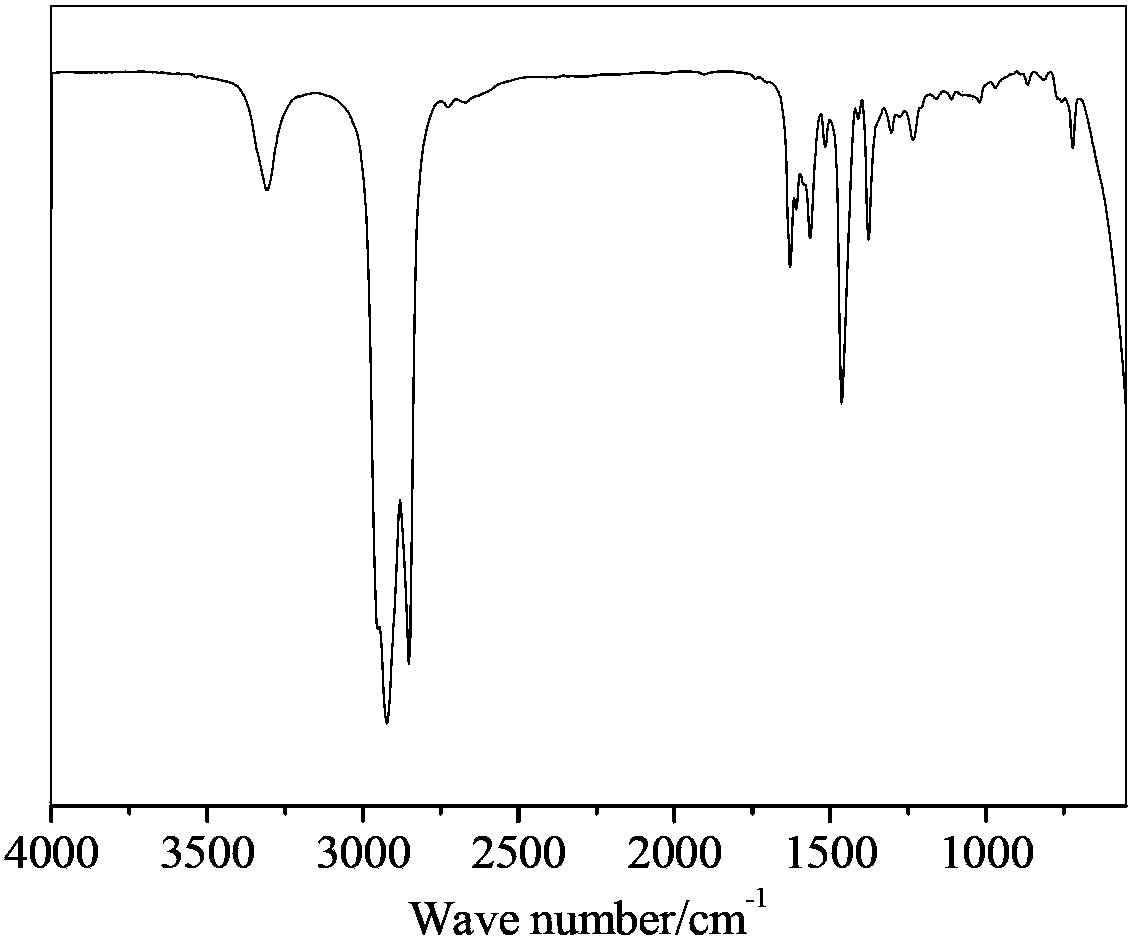

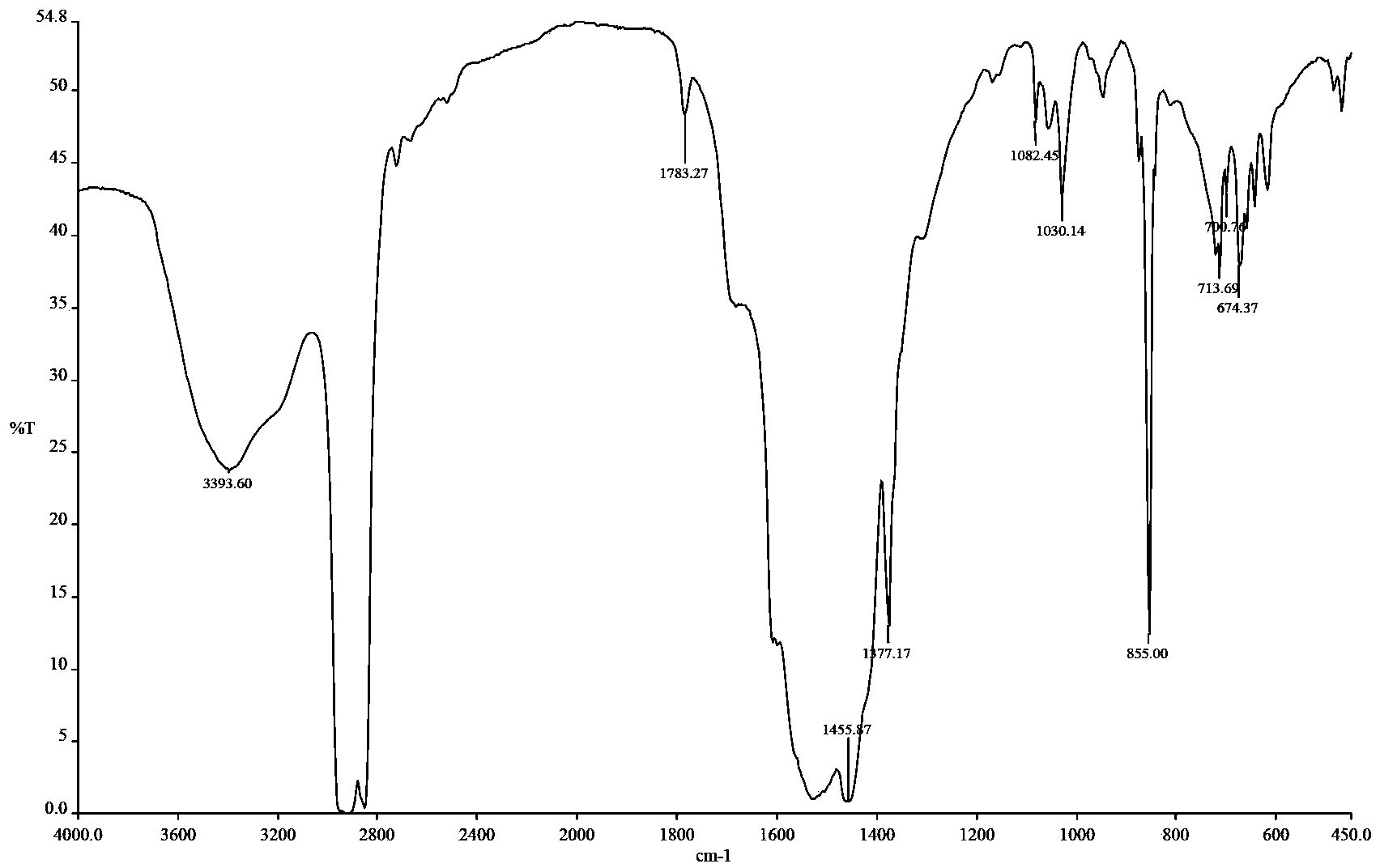

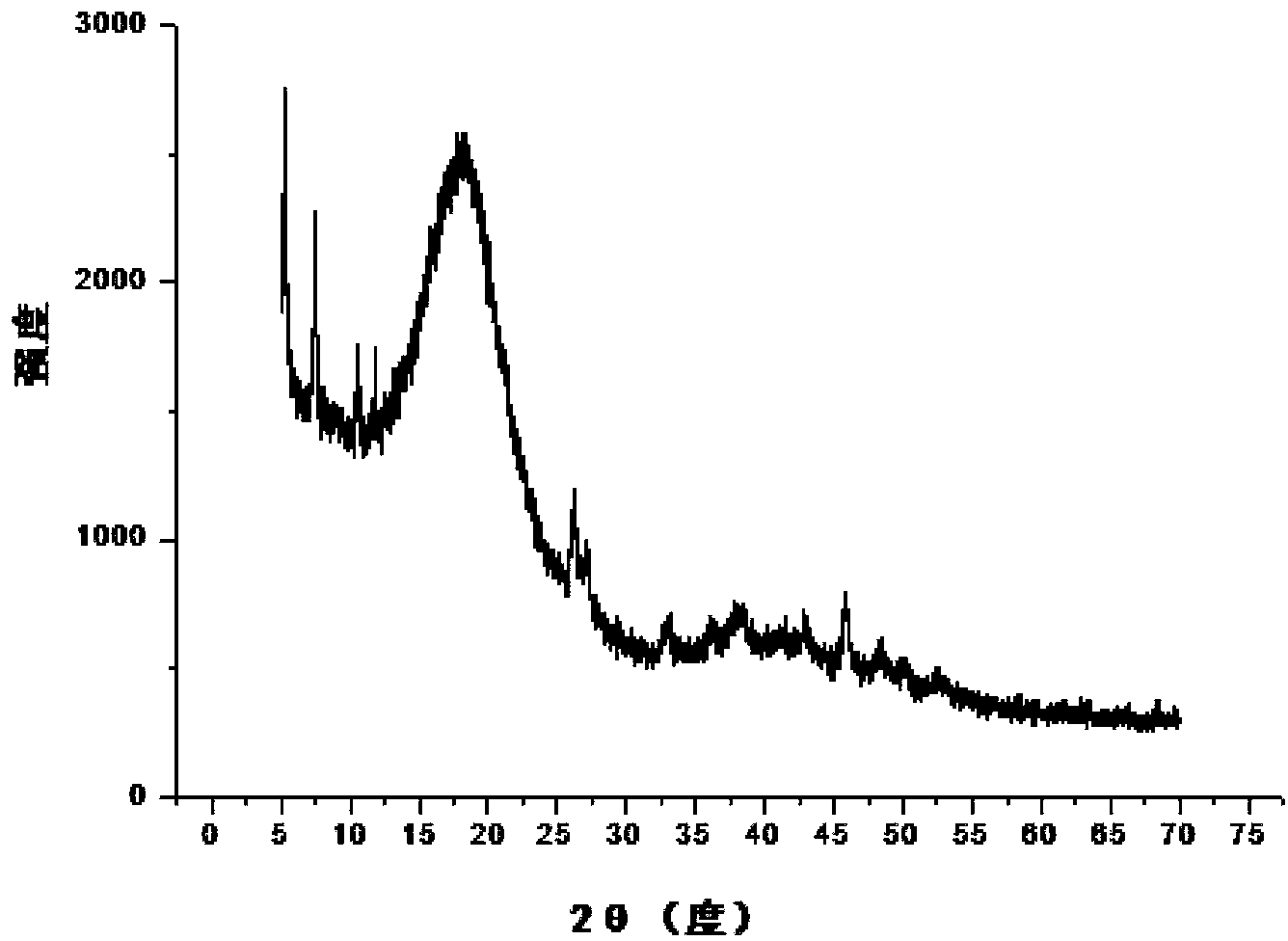

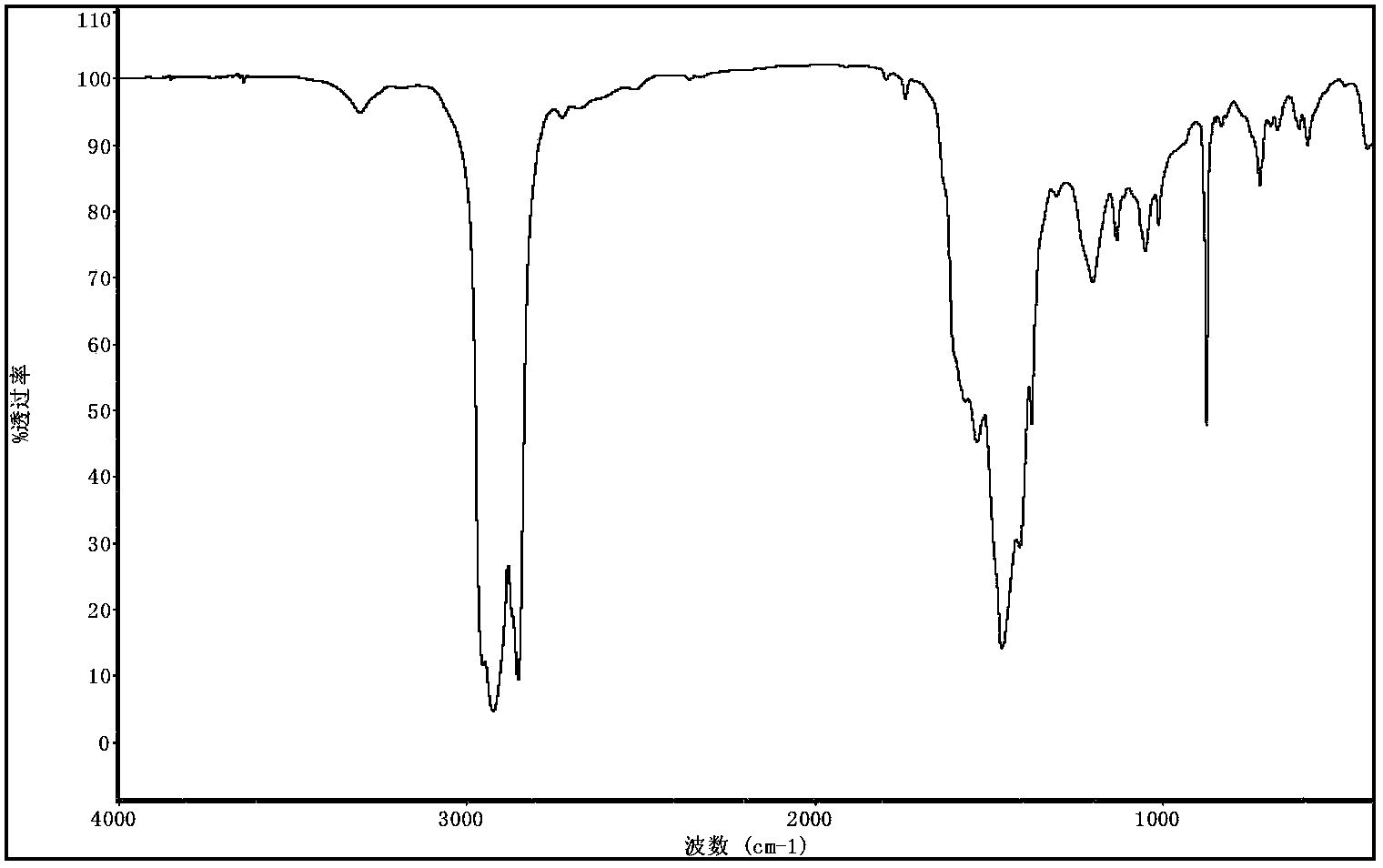

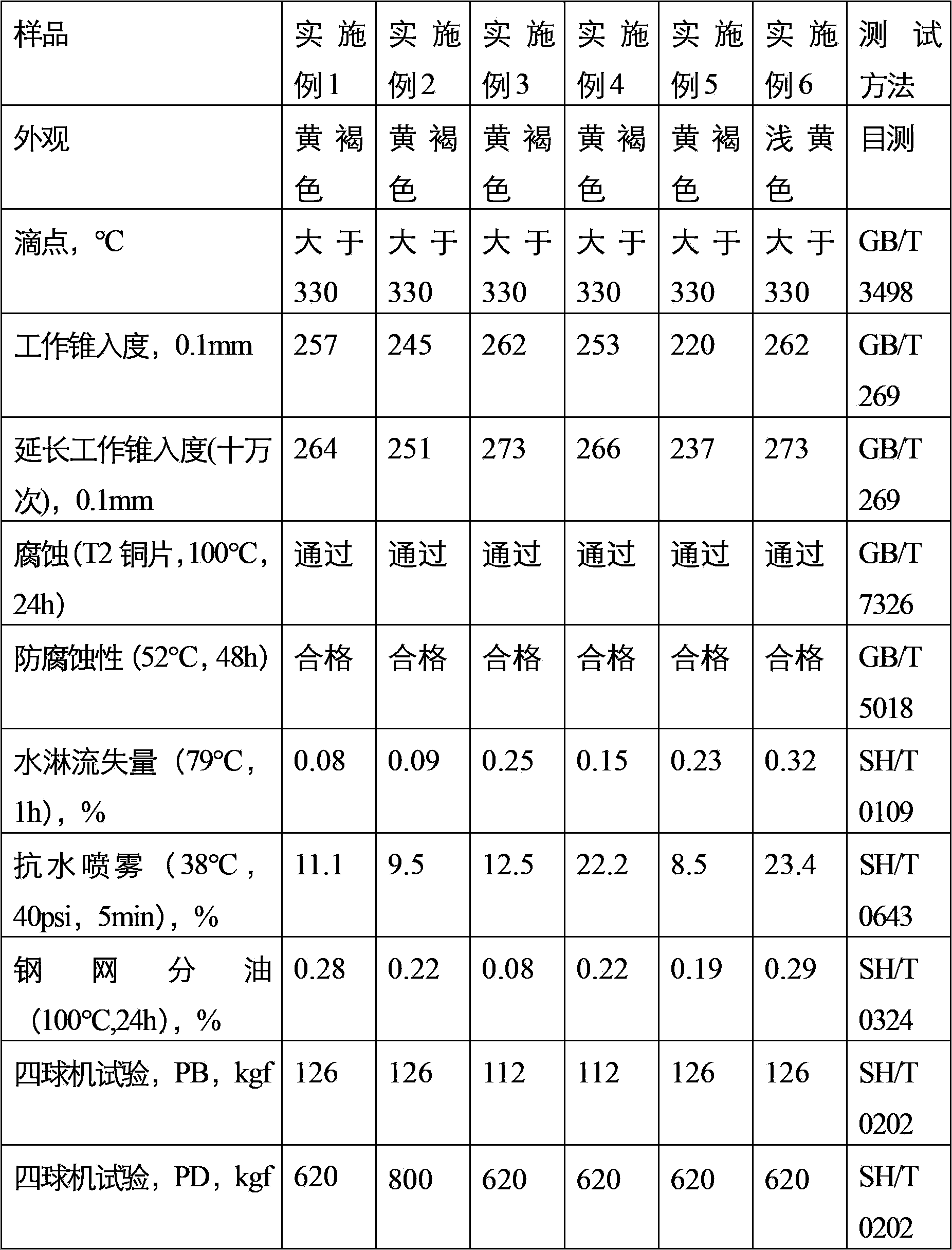

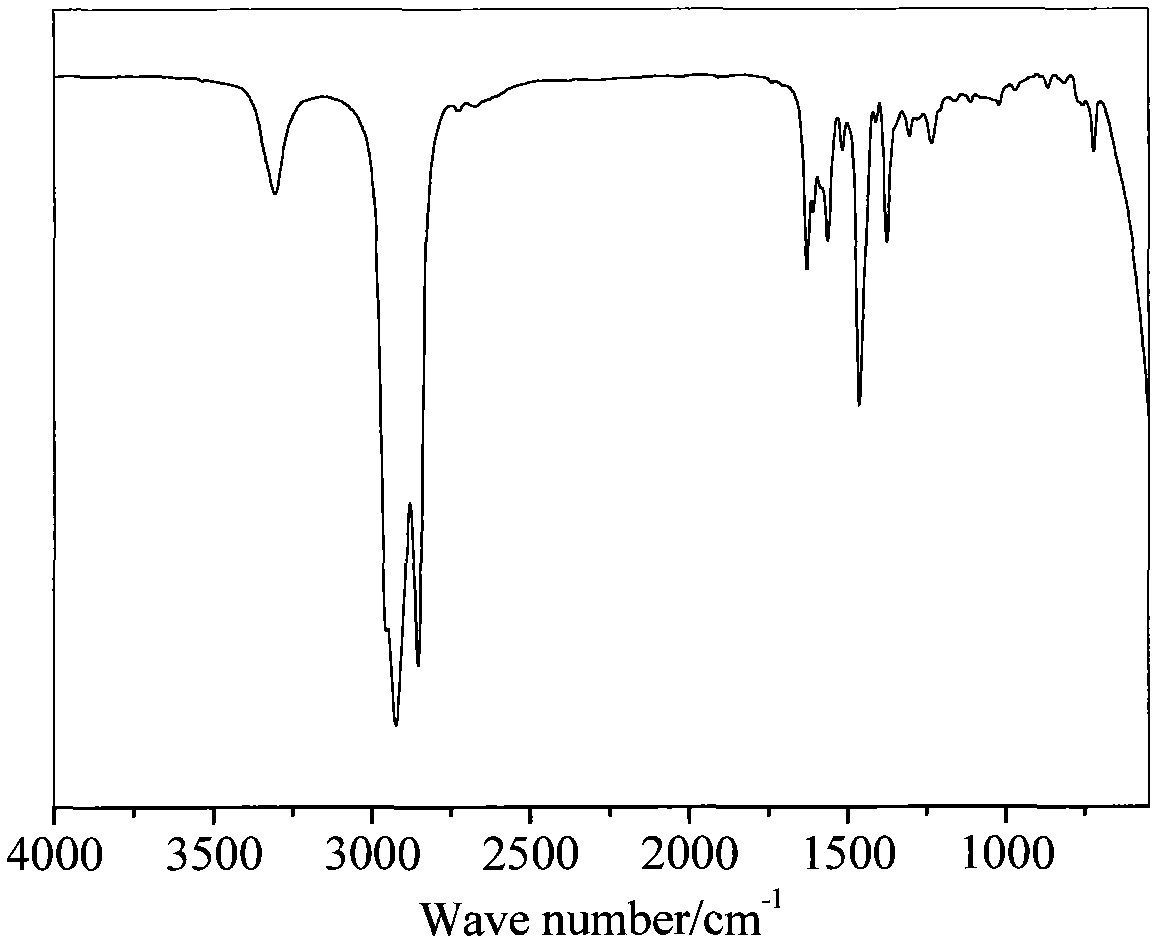

Composite calcium naphthenate-based lubricating grease and preparation method thereof

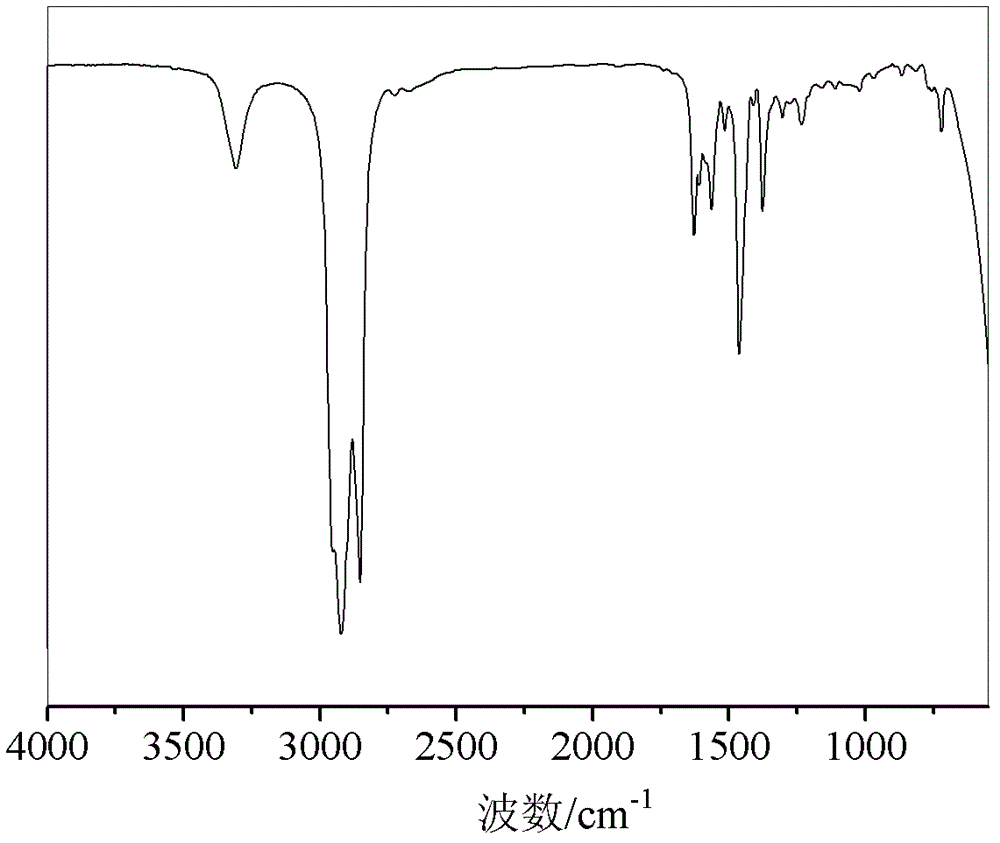

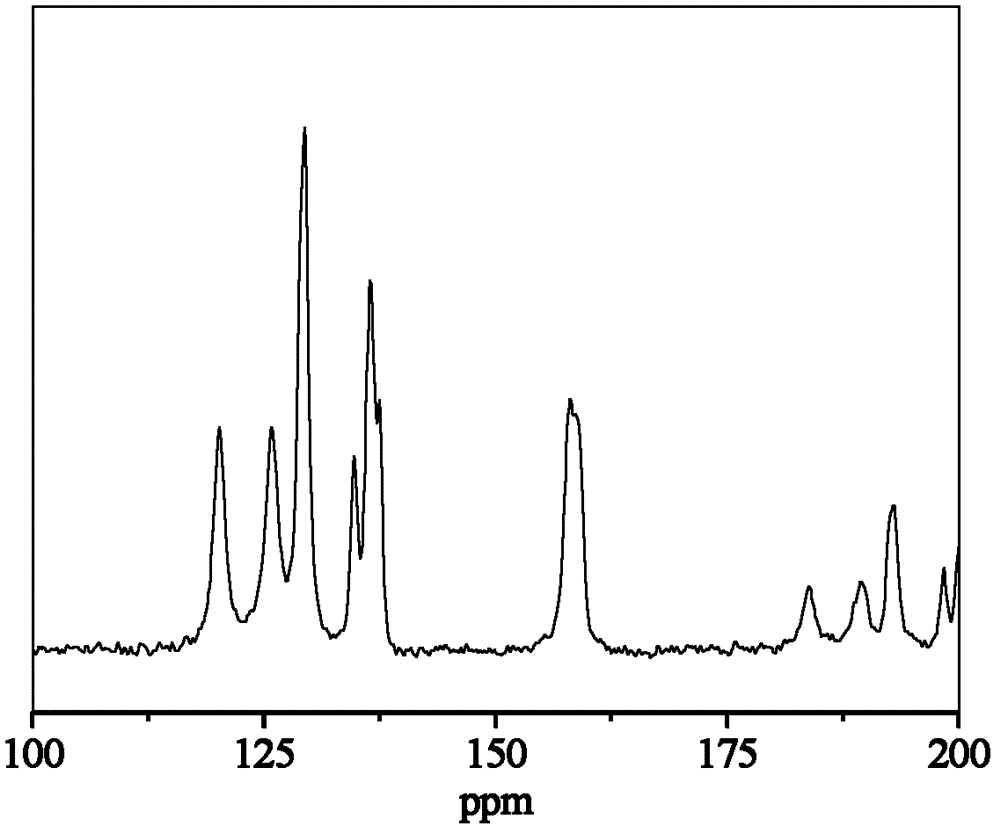

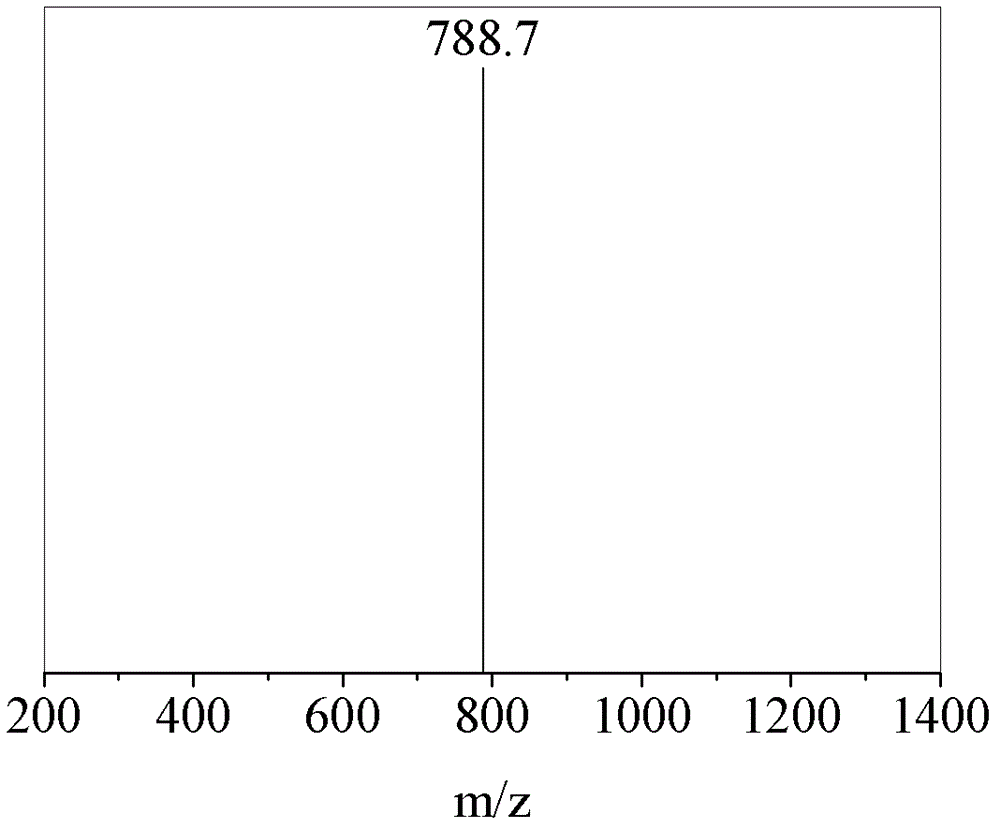

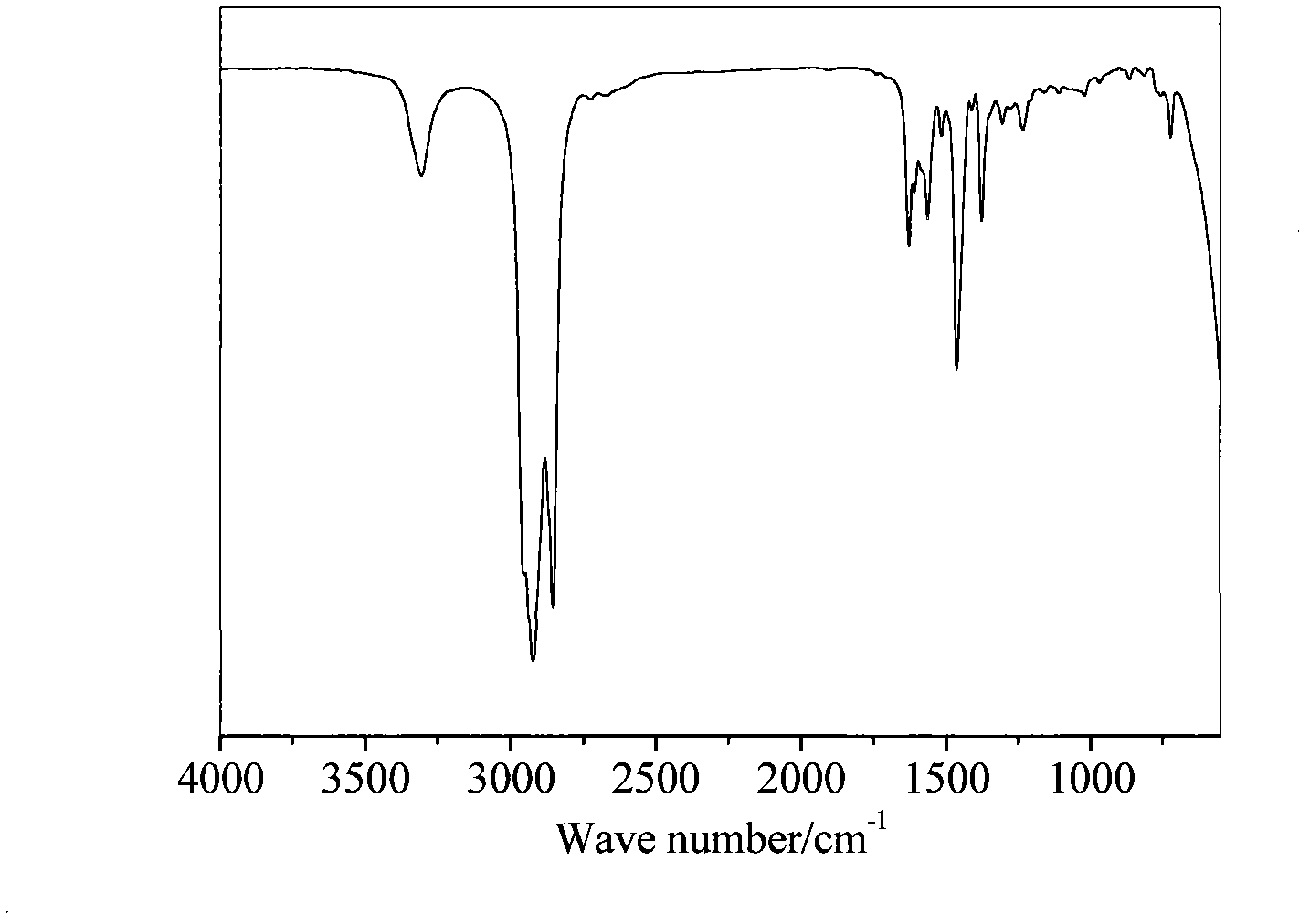

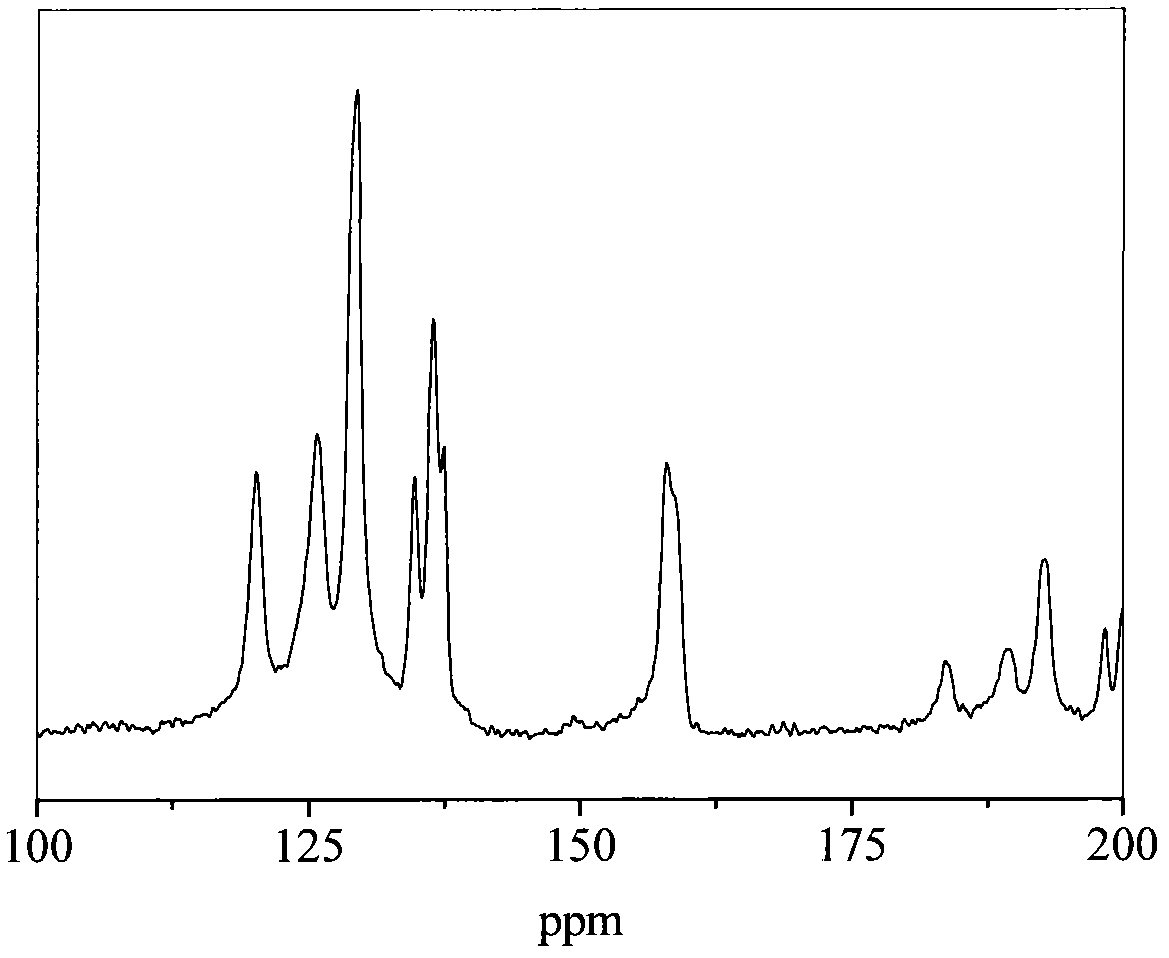

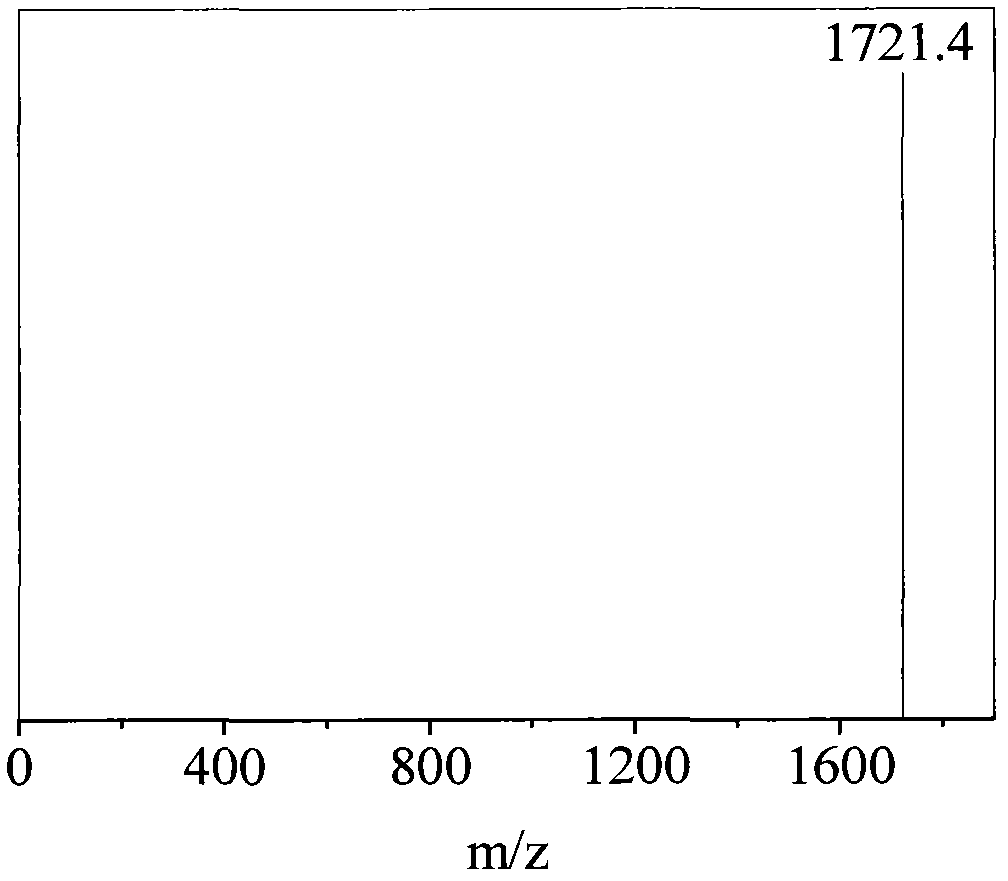

ActiveCN104293449AImprove corrosion resistanceStrong anti-salt spray performanceLubricant compositionSulfonateAragonite

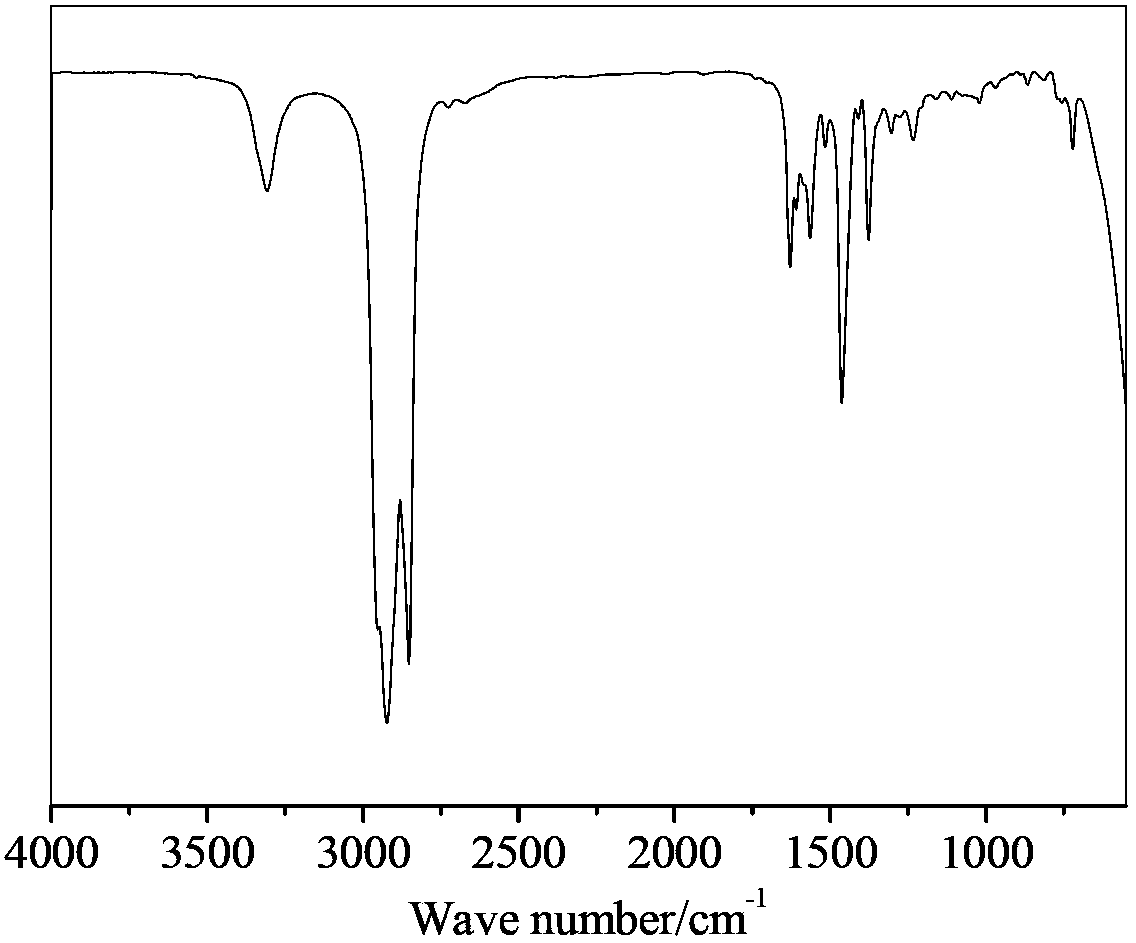

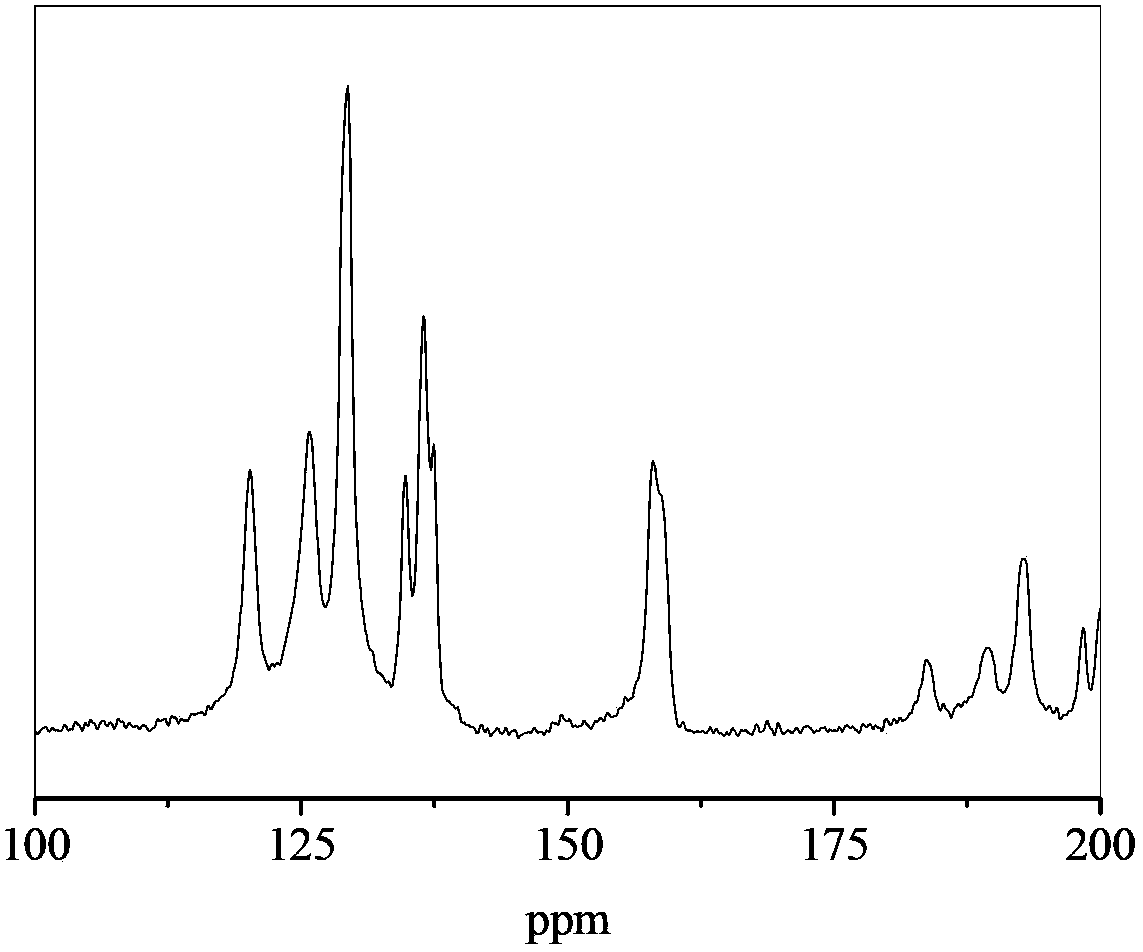

The invention discloses composite calcium naphthenate-based lubricating grease which is characterized by including following components, on the basis of the weight of the lubricating grease, 20-70 wt% of non-Newtonian calcium naphthenate, 1-10 wt% of a calcium salt of a higher fatty acid and 25-70 wt% of a basic oil. An infrared spectrogram of the non-Newtonian calcium naphthenate has a characteristic absorption peak of aragonite-type calcium carbonate. The invention also discloses a preparation method of the composite calcium naphthenate-based lubricating grease and the composite calcium naphthenate-based lubricating grease prepared through the same. The composite calcium naphthenate-based lubricating grease has excellent anti-corrosion property and anti-salt fog property, and has performances comprising a high-temperature-resistant performance, a water-resistant performance, an adhesive performance, a colloid stability and the like, which are better than those of composite calcium sulfonate-based lubricating grease. The composite calcium naphthenate-based lubricating grease has a longer lubricating service life. The preparation method is simple, environmental-protective, low in cost and stable in product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Grease composition

ActiveUS20150232784A1Long lubrication lifeMaintain good propertiesBearing componentsAdditivesOrganic sulfonic acidSulfonate

The invention provides a grease composition for rolling bearings of automotive electrical equipment or automotive auxiliaries, containing a base oil that includes as an essential component an alkyldiphenyl ether oil; a diurea thickener represented by formula (1); an anti-flaking additive including an organic sulfonate rust inhibitor and a load carrying additive; and an antioxidant. In the formula (1), R2 is a bivalent aromatic hydrocarbon group having 6 to 15 carbon atoms; and one of R1 or R3 represents cyclohexyl group and the other represents cyclohexyl group, an alkyl group having 8 to 22 carbon atoms or an aromatic hydrocarbon group having 6 to 12 carbon atoms.

Owner:KYODO YUSHI CO LTD

Calcium naphthenate-based hexapolyurea lubricating grease and preparation method thereof

ActiveCN103571571AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersDiamineIsocyanate

The invention provides calcium naphthenate-based hexapolyurea lubricating grease and a preparation method thereof. On a basis of the lubricating grease weight, the lubricating grease comprises the following components: 1) 10-70% of non-newtonian calcium naphthenate; 2) 0.5-30% of hexapolyurea; 3) 10-80% of lubricating base oil. The calcium naphthenate-based hexapolyurea lubricating grease is obtained by converting newtonian calcium naphthenate, and reacting with diisocyanate, diamine, and monamine. The lubricating grease of the invention has excellent extreme-pressure abrasion resistance and long lubricating life, and also has excellent adhesiveness, water resistance, colloid stability, high dropping point, thermal stability, corrosion resistance, salt mist resistance, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

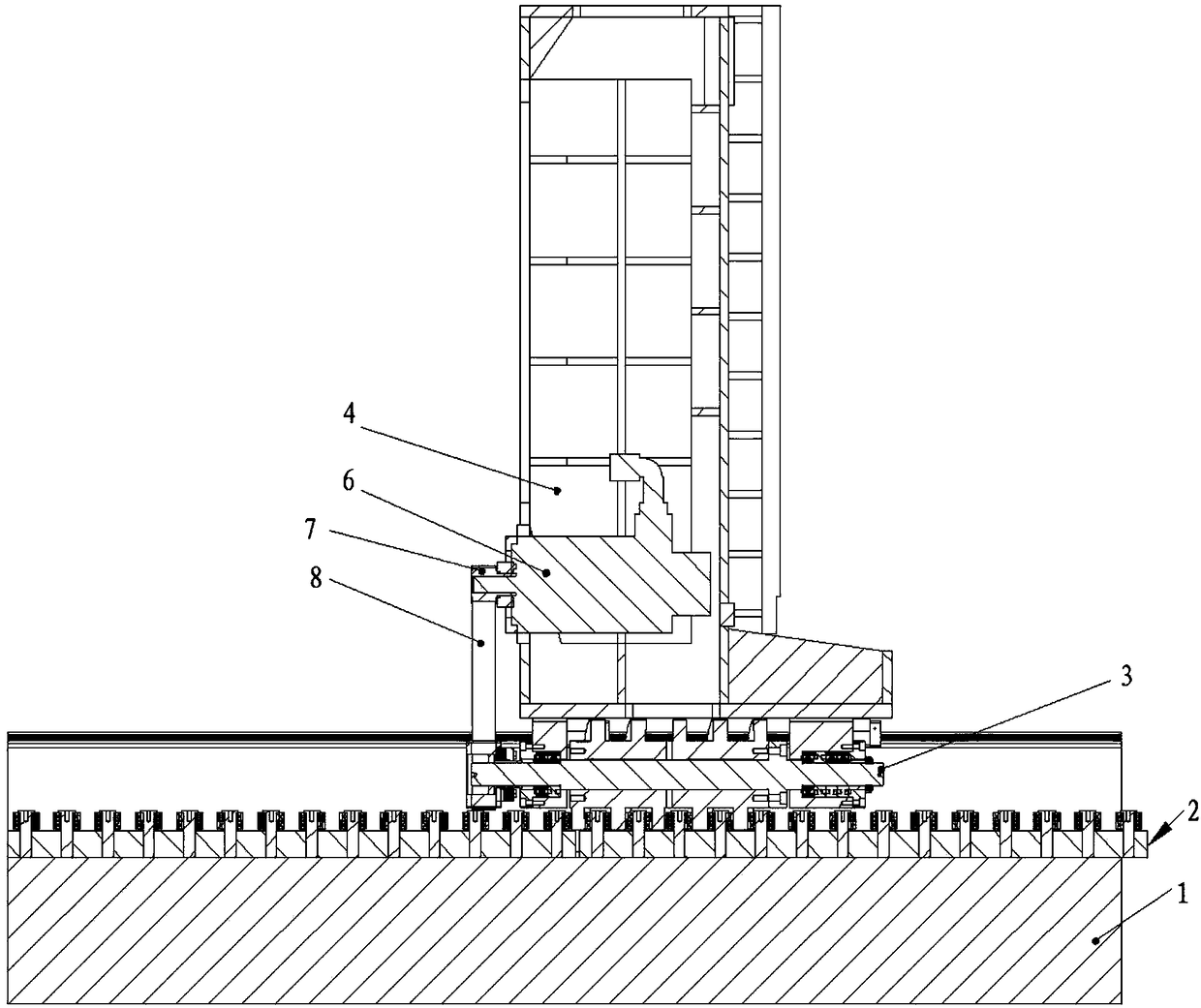

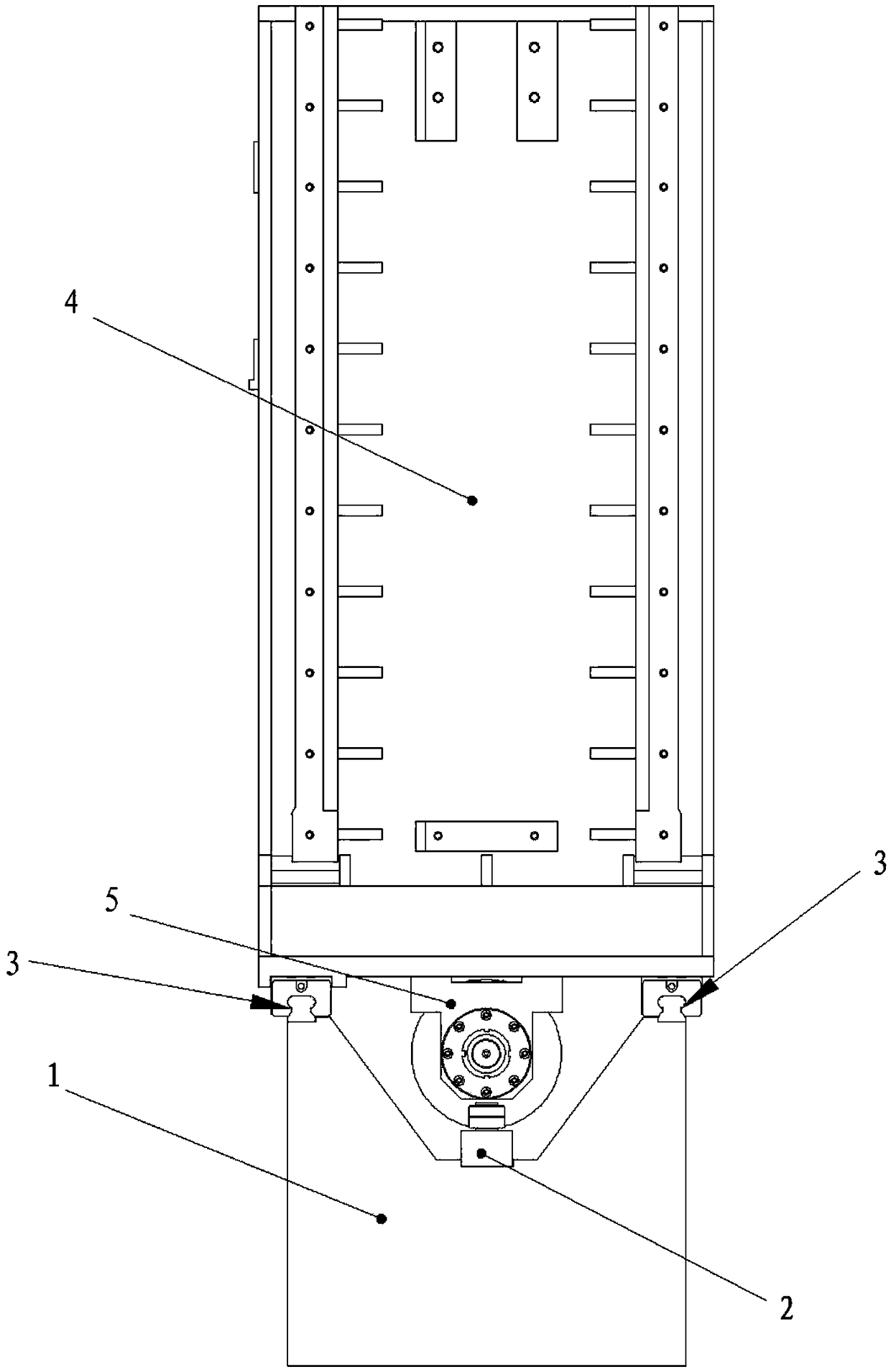

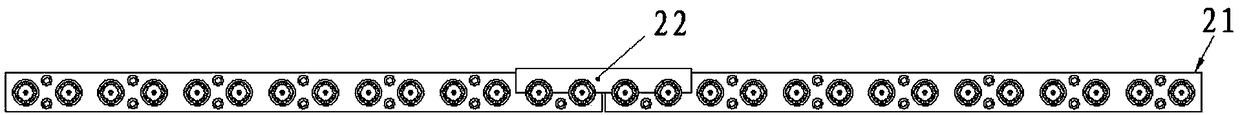

High-precision linear displacement transmission mechanism capable of being lengthened infinitely

The invention discloses a high-precision linear displacement transmission mechanism capable of being lengthened infinitely. The high-precision linear displacement transmission mechanism capable of being lengthened infinitely comprises a base, a roller strip assembly group, linear guide rail pairs, a slide table, a cam assembly group and a servo motor, wherein the roller strip assembly group is mounted on a roller strip mounting base surface of the middle part of the base; the linear guide rail pairs are mounted at the two sides of the top surface of the base; the slide table is mounted on thelinear guide rail pairs; the cam assembly group is mounted on the bottom surface of the slide table through a bearing base; the servo motor is arranged on the slide table; a small belt wheel is mounted on the output shaft of the servo motor; the small belt wheel is connected with an input belt wheel of the cam assembly group through a synchronous belt; and the cam assembly group is in matched transmission with the roller strip assembly group. The high-precision linear displacement transmission mechanism capable of being lengthened infinitely provided by the invention is suitable for long-stroke linear displacement, can be lengthened infinitely, and has the advantages of being high in precision, long in distance, high in displacement seed and low in maintenance cost.

Owner:SHANGHAI HOUCHANG PRECISION MACHINERY CO LTD

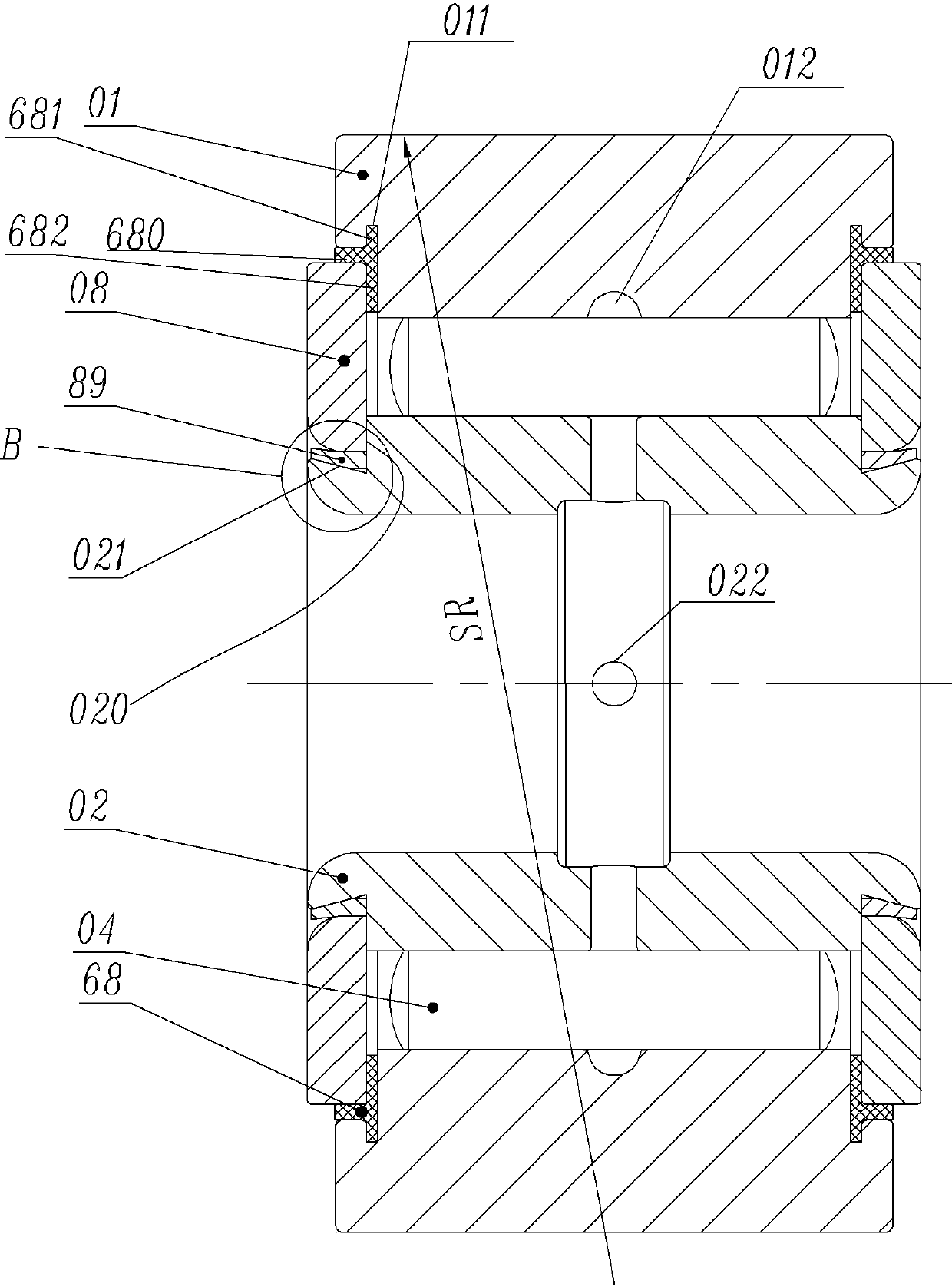

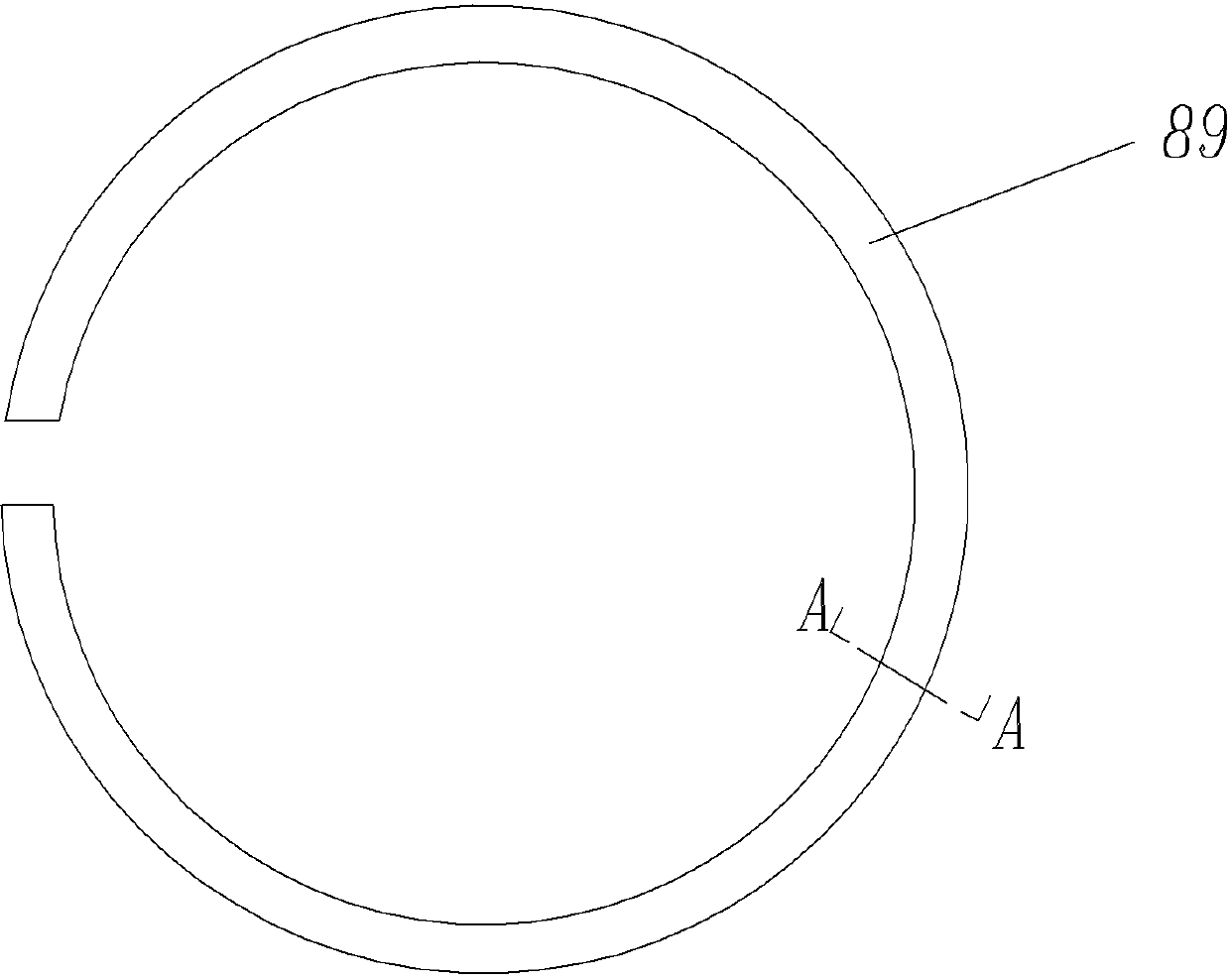

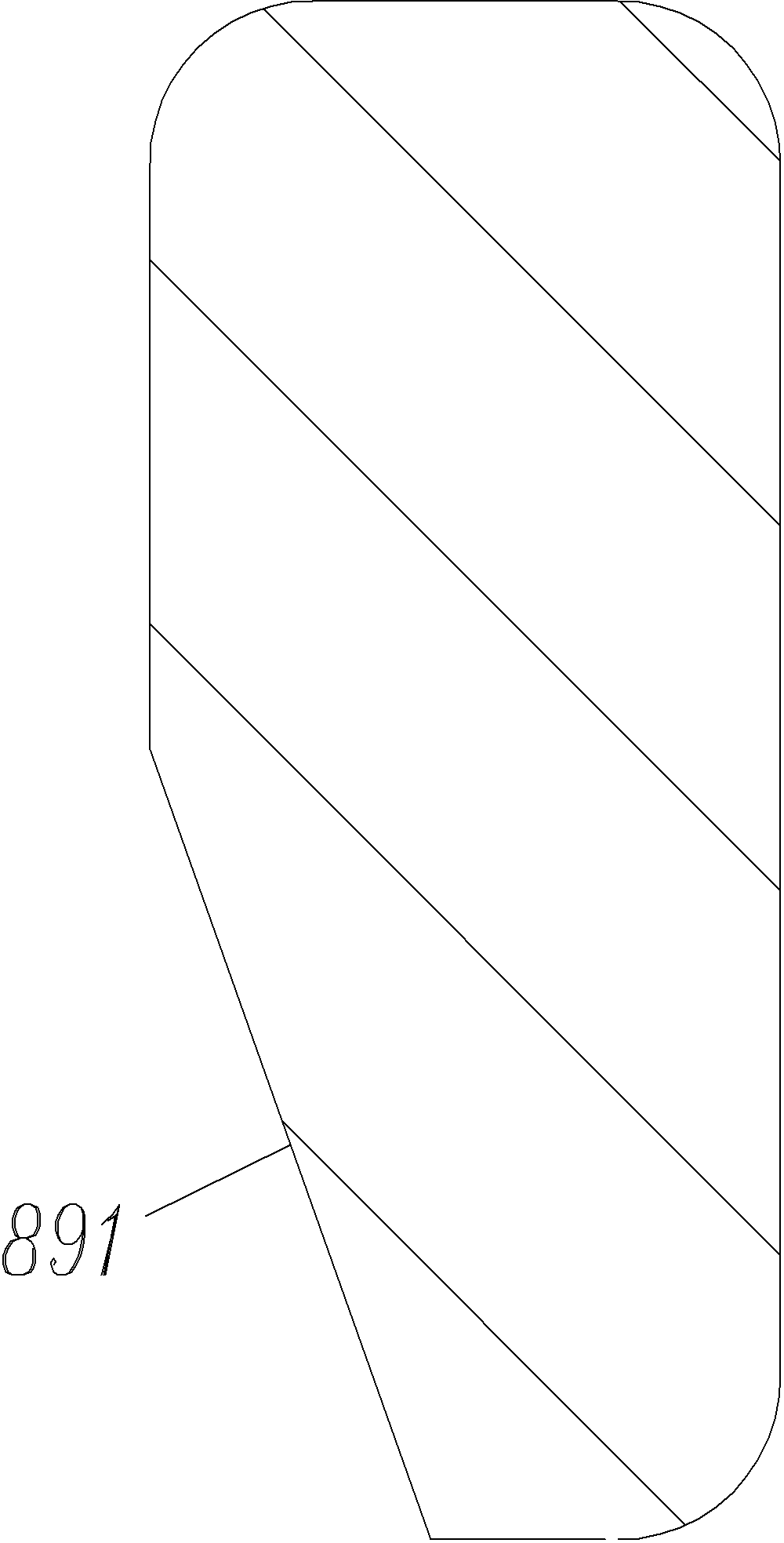

Supporting roller bearing

ActiveCN103122926AAccuracy is not affectedImprove match rateBearing componentsBearingsEngineeringConical surface

The invention discloses a supporting roller bearing which comprises a first ferrule, a second ferrule and a flat check ring, wherein a concave step structure rotatably distributed along the circumferential direction on the corresponding circumferential surface of the first ferrule is arranged at the end part of the first ferrule, which corresponds to an installing position of the flat check ring, the step structure is provided with an annular step surface which is in axial stop matching with the end face of the corresponding flat check ring and a ferrule conical surface rotatably distributed around the circumferential direction of the first ferrule, a snap spring capable of elastically contracting and tensioning along the radial direction for locking the flat check ring is clamped between the ferrule conical surface and the corresponding circumferential surface of the flat check ring, and a snap spring conical surface which is coincidently matched with the ferrule conical surface is arranged on the corresponding circumferential surface of the snap spring. Due to the adoption of a separable structure of the snap spring, the flat check ring and an inner ring, the supporting roller bearing is conveniently assembled and disassembled, and thus the assembly rate can be remarkably increased.

Owner:LUOYANG BEARING RES INST CO LTD

Grease composition for EV/HEV drive motor bearing, and EV/HEV drive motor bearing

InactiveCN103732729ALong lubrication lifeGood fluidity at low temperatureBearing componentsThickenersDrive motorBase oil

Owner:NSK LTD +1

Composite calcium naphthenate lubricating grease and preparation method thereof

ActiveCN103695137AGood extreme pressure and anti-wear propertiesLong lubrication lifeLubricant compositionHeat stabilityBase oil

The invention provides composite calcium naphthenate lubricating grease and a preparation method thereof. The lubricating grease comprises the following components based on the weight of the lubricating grease: 1) 10-70% of non-Newtonian calcium naphthenate, 2) 1-10% of a calcium salt of a higher aliphatic acid, 3) 1-15% of a calcium salt of an aromatic acid, and 4) 10-80% of lube base oil. Calcium petroleum naphthenate or synthetic calcium naphthenate is adopted as a raw material of the lubricating grease. The lubricating grease also comprises a composite calcium densifier. The lubricating grease has excellent water-spraying resistance and water-spraying leaching resistance, and has excellent adhesivity, extreme pressure anti-wear property, colloid stability, high dropping point, heat stability, water resistance, corrosion resistance, salt fog resistance, and other performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite zirconium-based octaurea lubrication grease and its preparation method

ActiveCN103031182AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersHeat stabilityBase oil

The invention provides a composite zirconium-based octaurea lubrication grease and its preparation method. The lubrication grease comprises 1-59wt% of composite zirconium, 1-59wt% of octaurea and 40-95wt% of lubrication base oil, wherein the composite zirconium comprises zirconyl higher fatty acid salt and zirconyl acid salt having a low molecular weight. The lubrication grease simultaneously comprises a composite zirconium thickening agent and an octaurea compound. The lubrication grease has the advantages of excellent extreme-pressure wear resistance, long lubrication life, excellent water resistance, excellent colloid stability, high dropping point, excellent heat stability and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com