Honeycomb-shaped polygonal self-lubricating gear

A honeycomb-shaped, polygonal technology, used in the lubrication of engines, belts/chains/gears, components with teeth, etc., can solve the problems of serious wear of self-lubricating materials, short life of self-lubricating gears, and difficult to control oil output. , to achieve the effect of improving lubrication life, increasing gear life, and improving high temperature conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

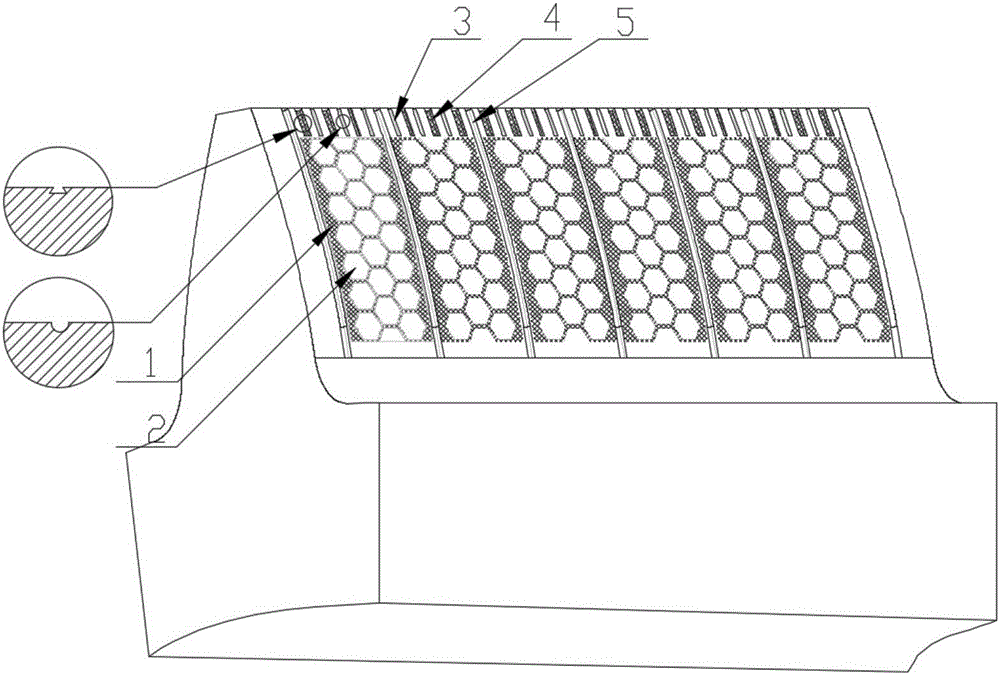

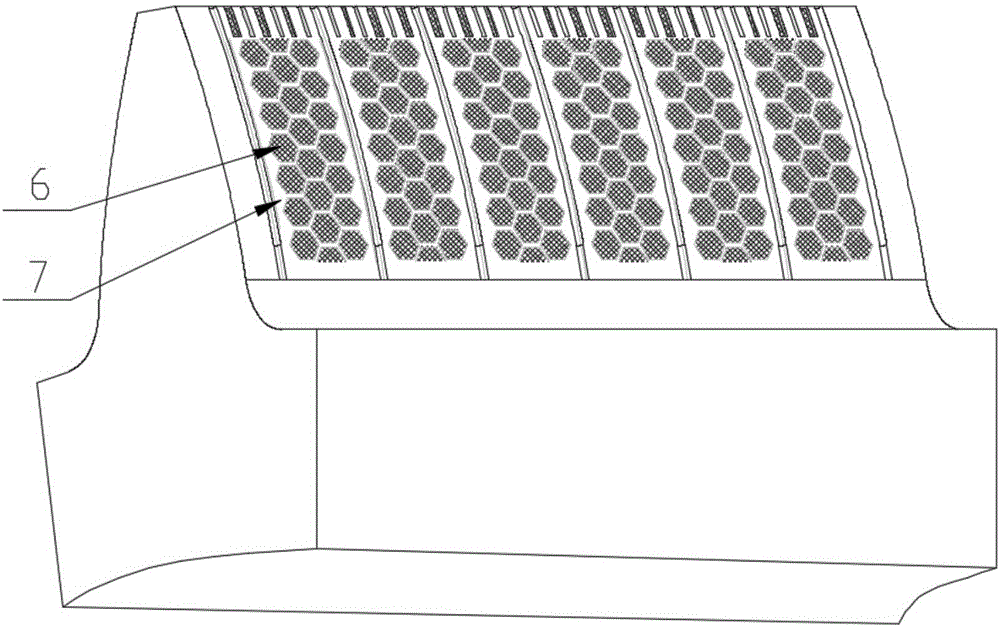

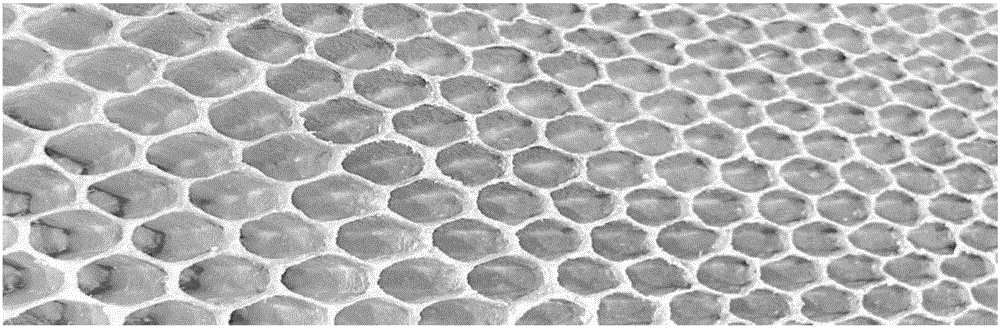

[0021] see figure 1 and figure 2 , the gear tooth surface adopts the electrochemical method to process the honeycomb pattern, figure 1 figure 2 The black shaded part on the middle tooth surface is the metal-based self-lubricating material.

[0022] The metal-based self-lubricating material is clad in the strip groove 4 on the top of the tooth surface, the top strip chip removal groove 3 is spaced from the strip groove 4, and the wear debris generated during the gear meshing process can be Discharge from the top strip flute 3. On both sides of the self-lubricating material 1 of the driving gear, there is also the middle strip-shaped chip removal groove 5 spanning the entire tooth surface, and the grinding debris generated during the internal meshing process of the tooth surface is discharged in this way. The unprocessed area left on the tooth side is to ensure the strength of the gear and prevent fatigue fracture. The tooth root adopts a transitional design to effectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com