Patents

Literature

120results about How to "Guaranteed mechanical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

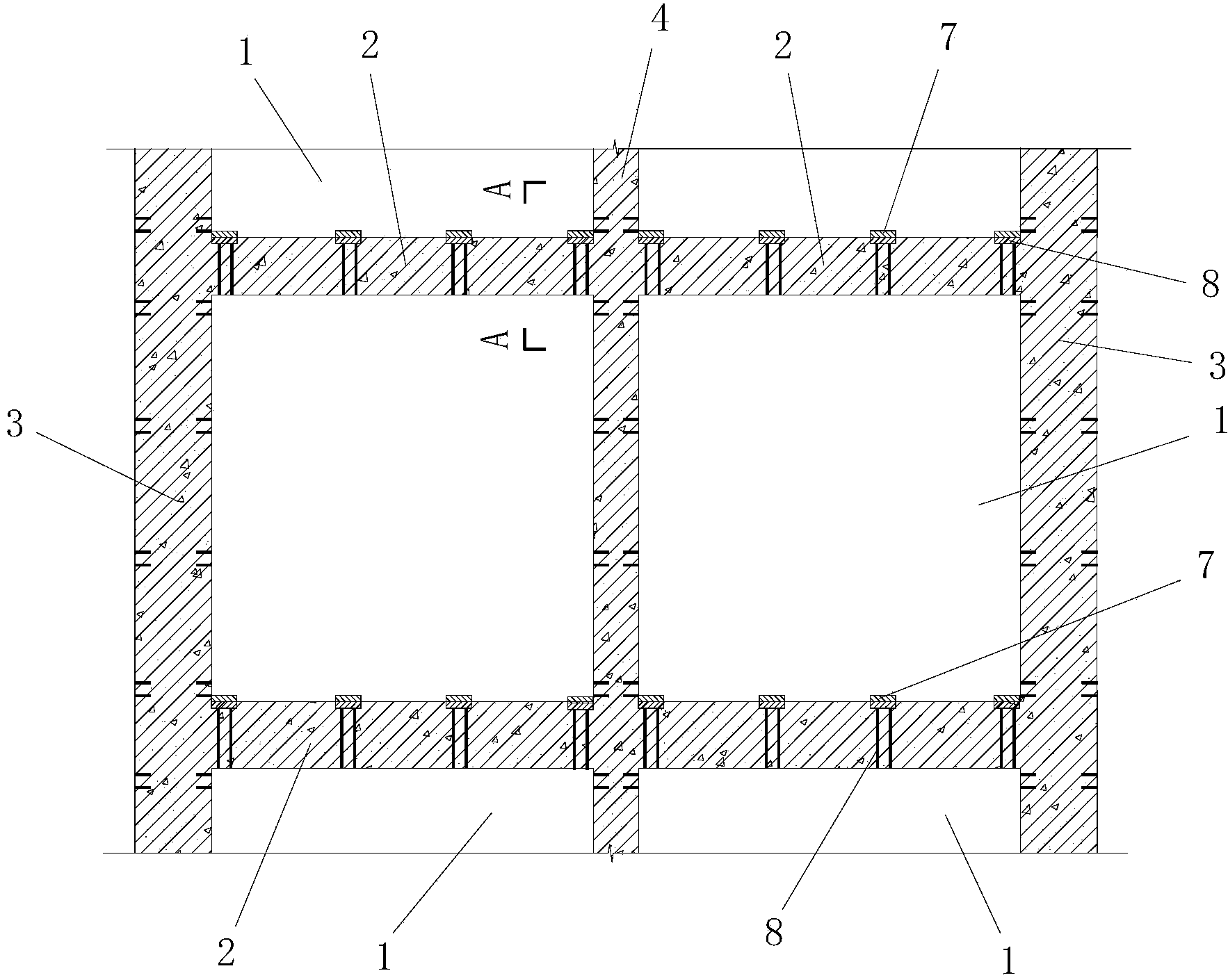

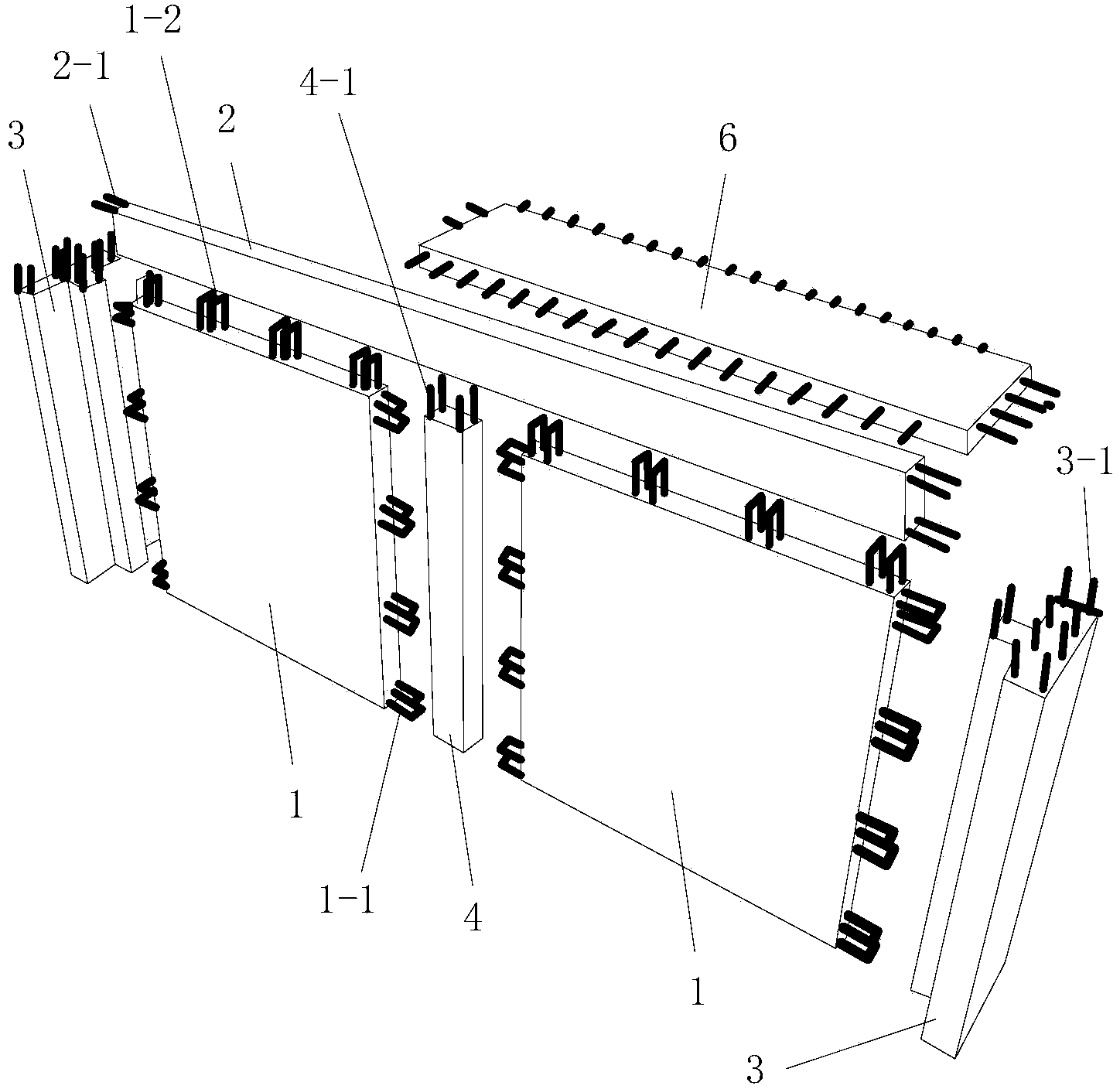

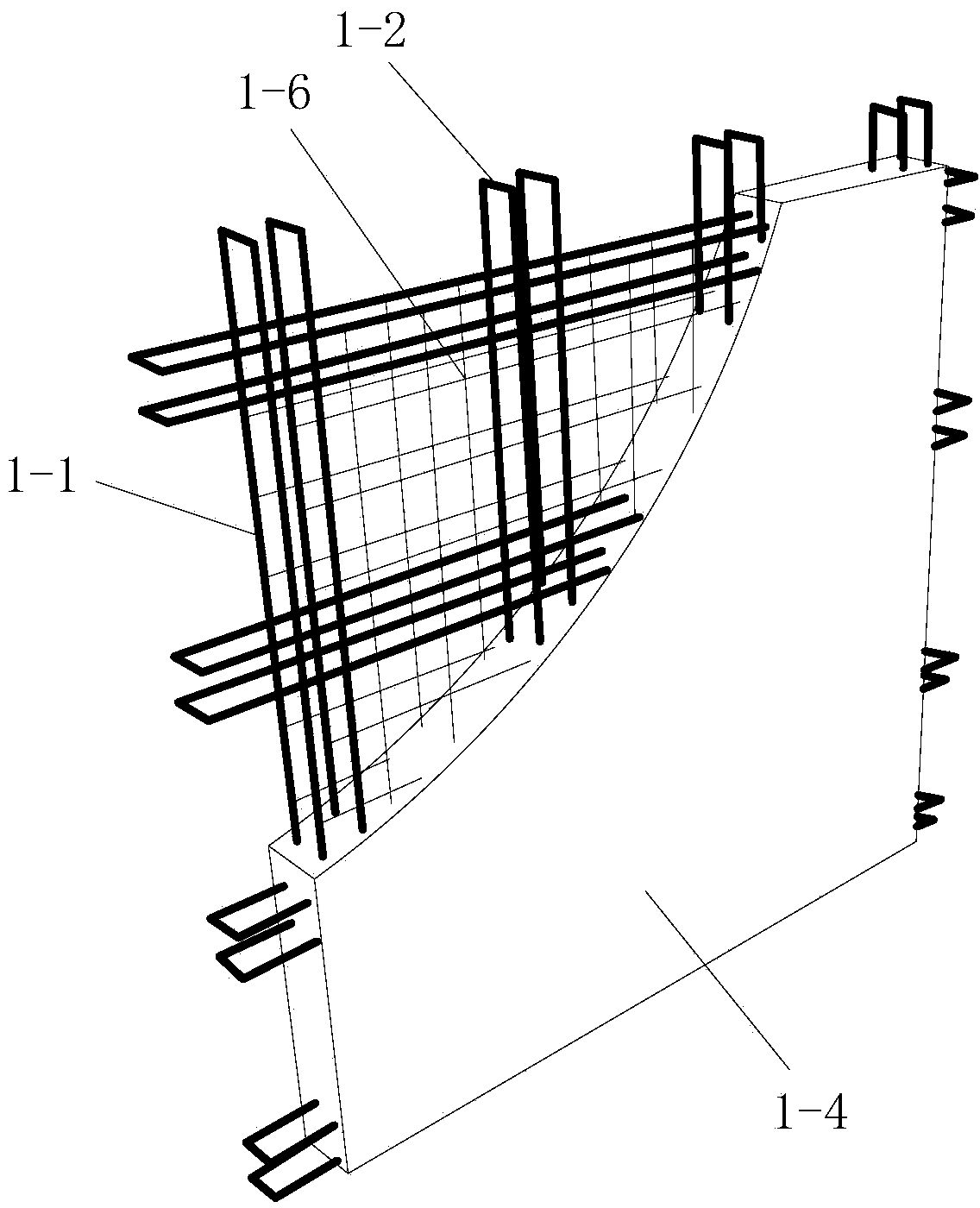

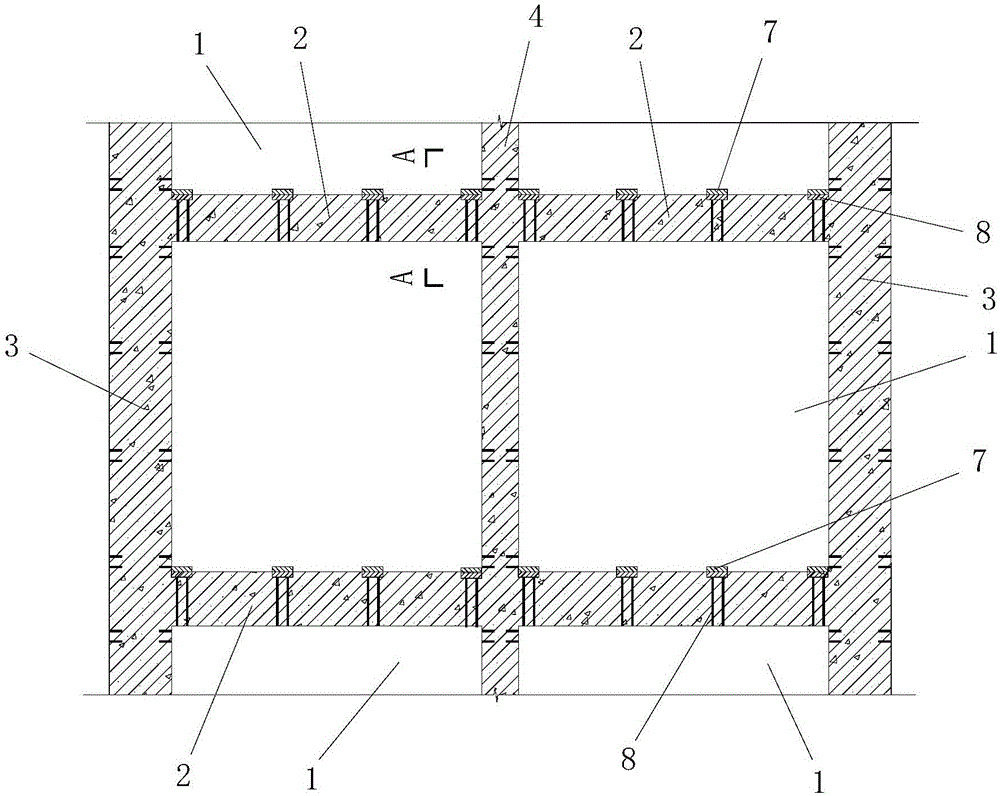

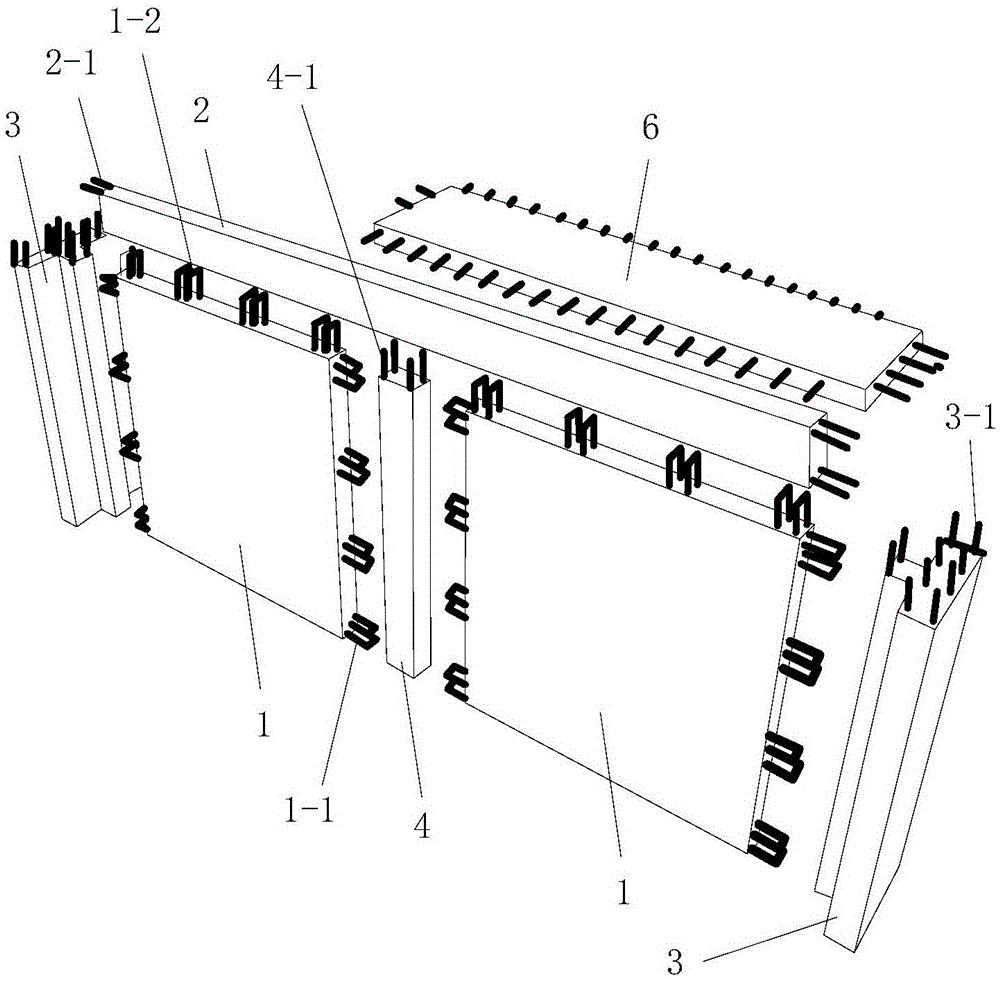

Assembled type gridding shearing wall structural system and construction technology of assembled type gridding shearing wall structural system

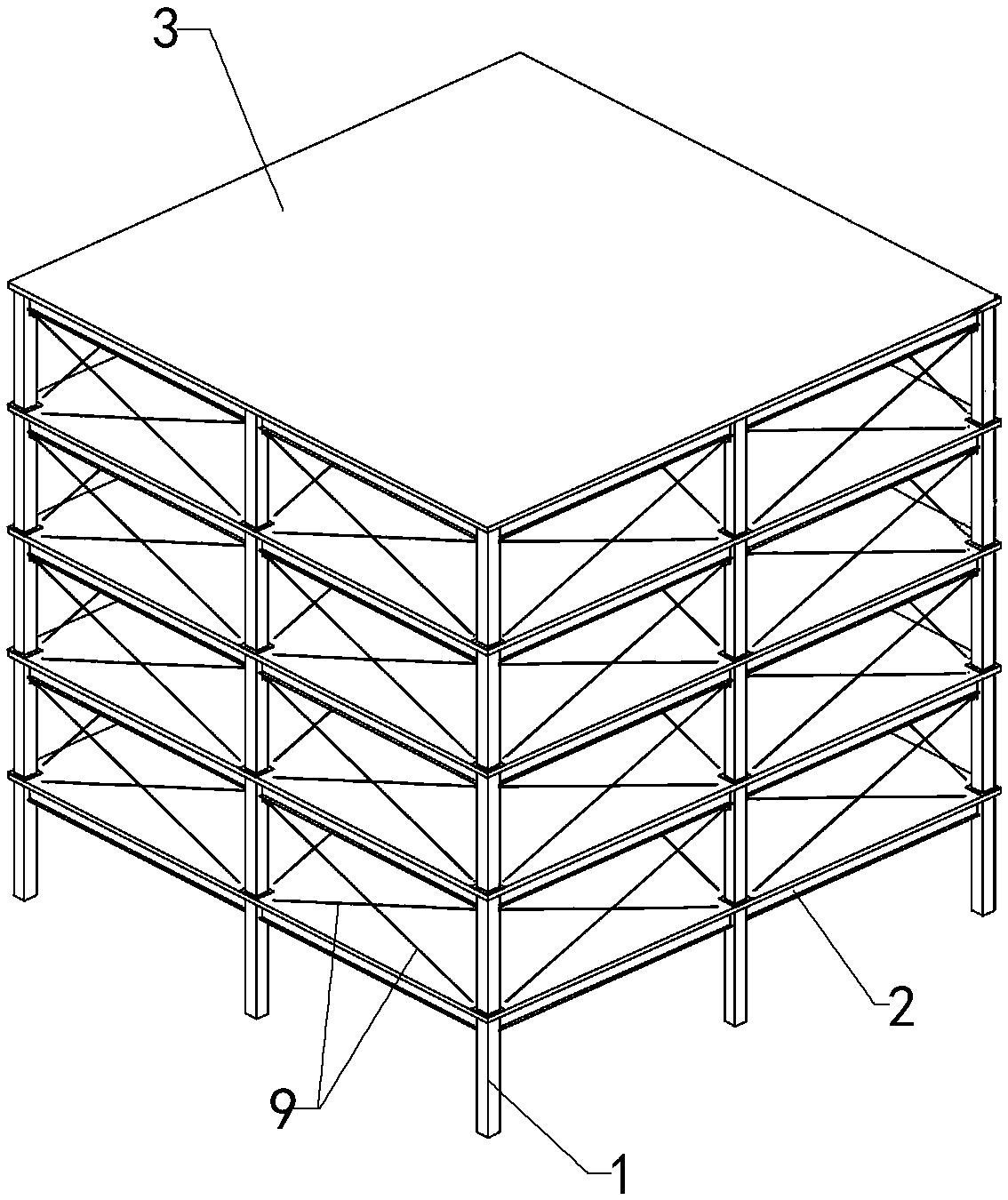

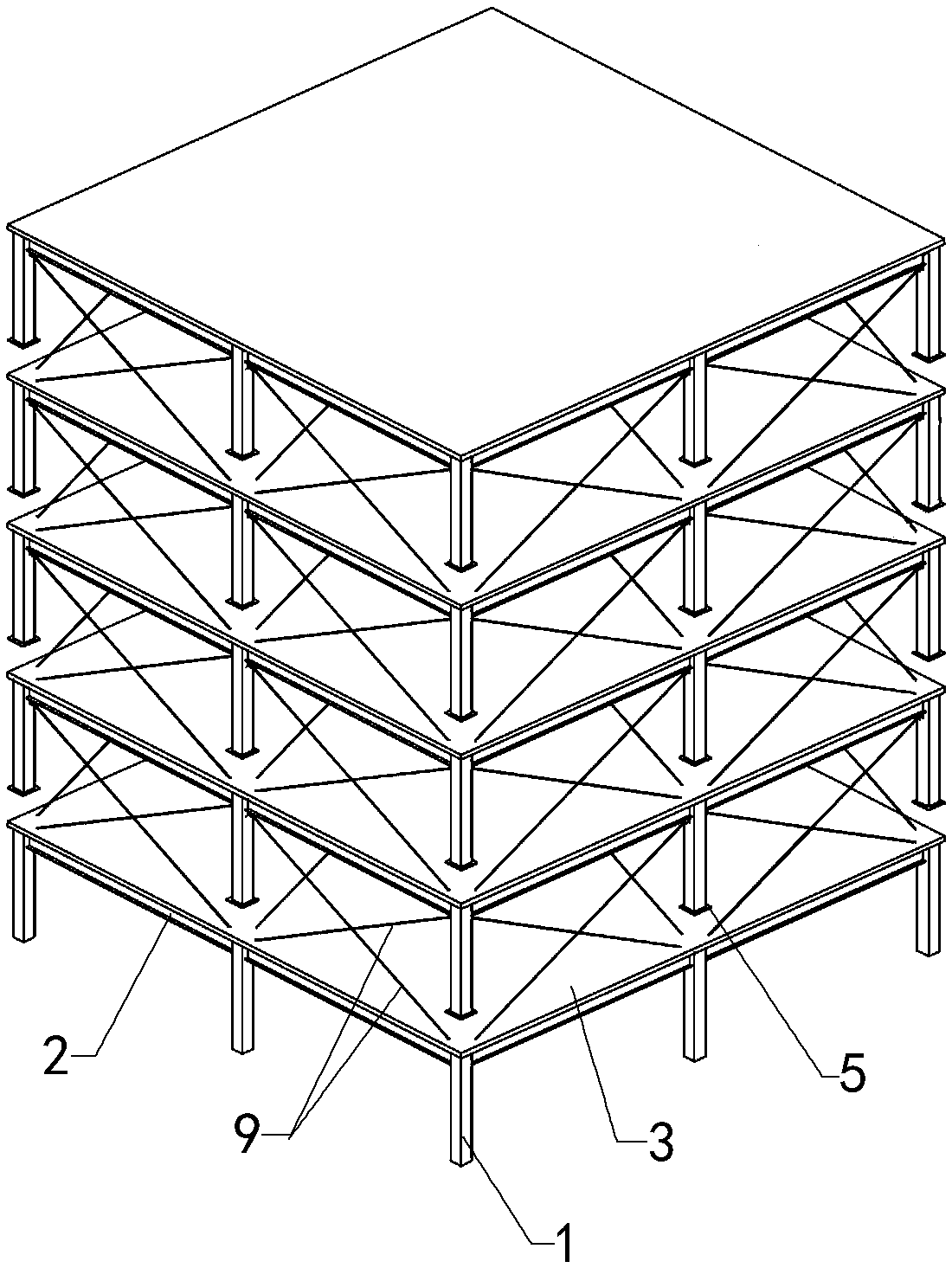

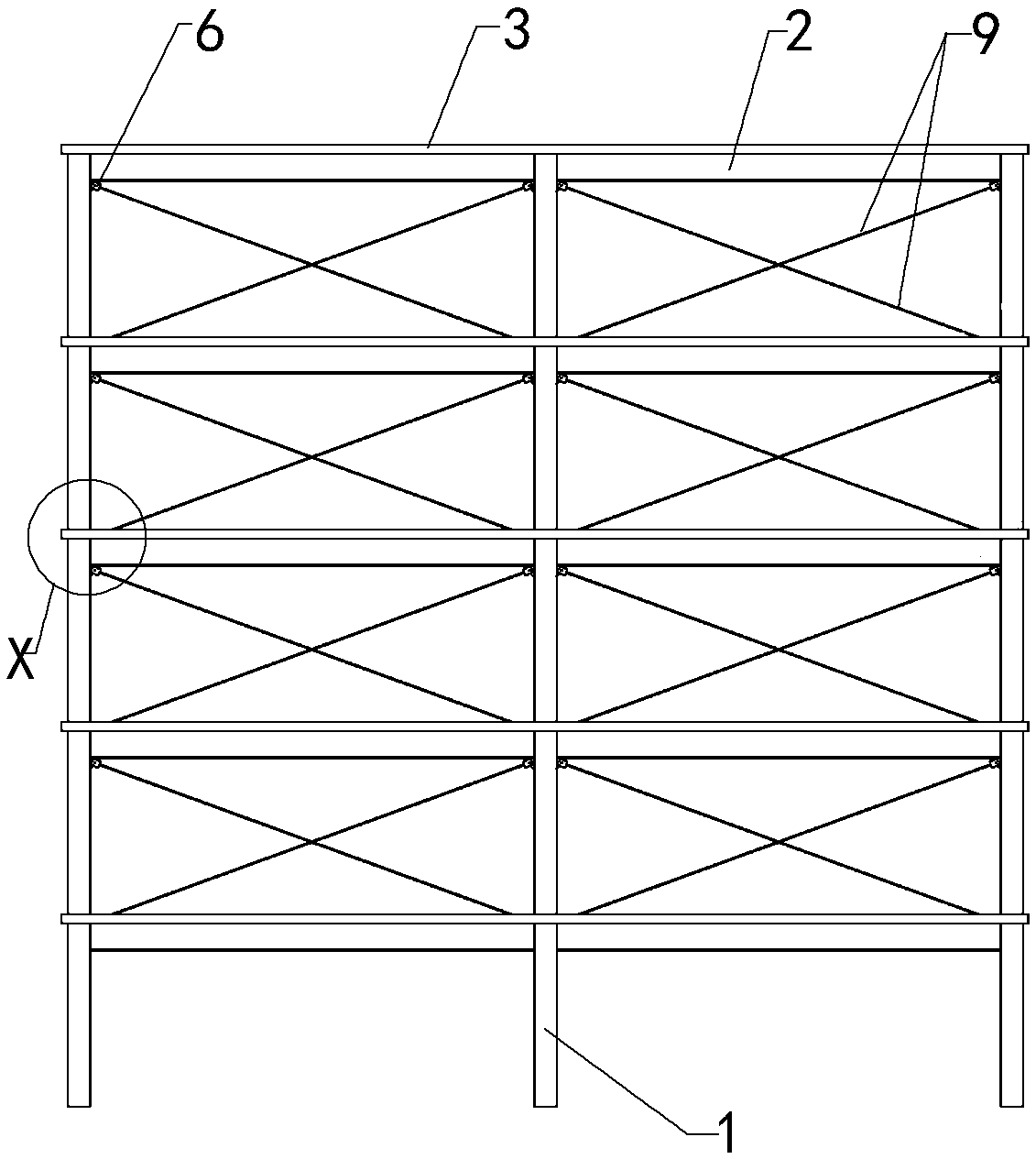

ActiveCN103924711ASimple structureLow input costWallsBuilding material handlingVertical edgeEngineering

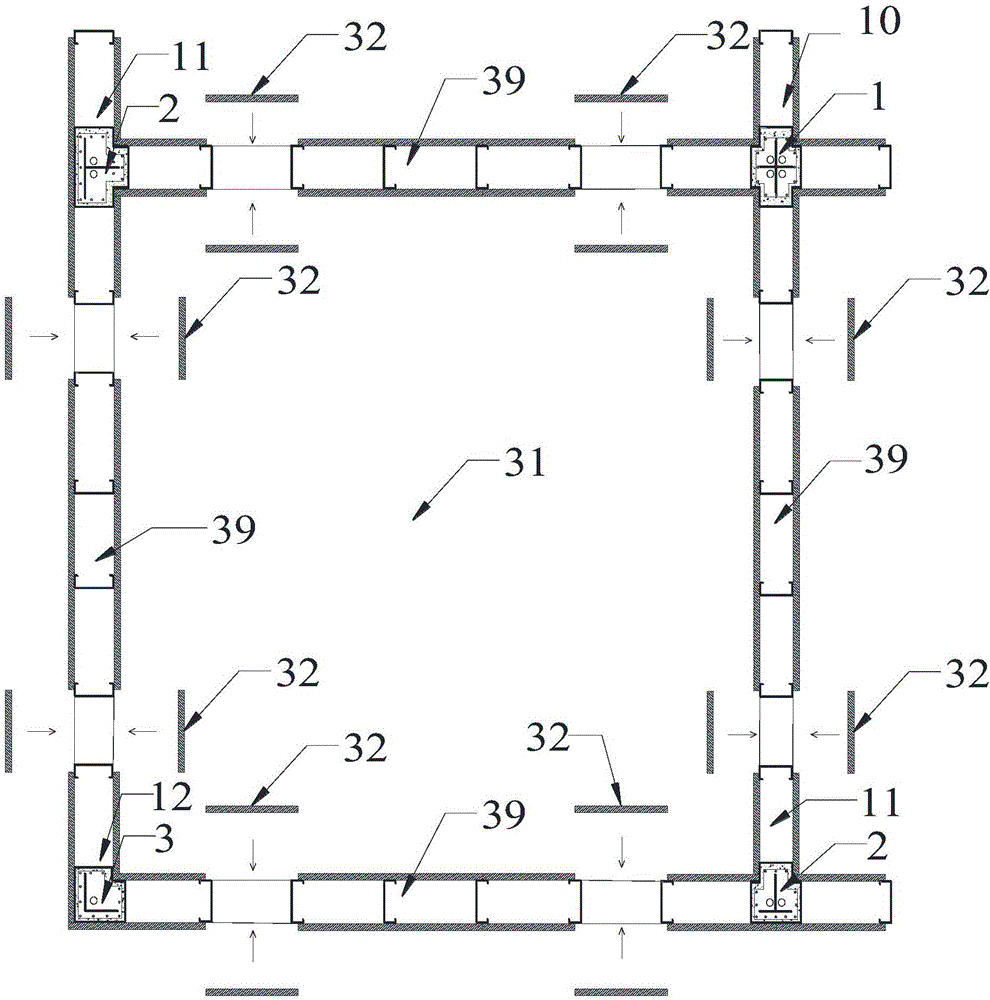

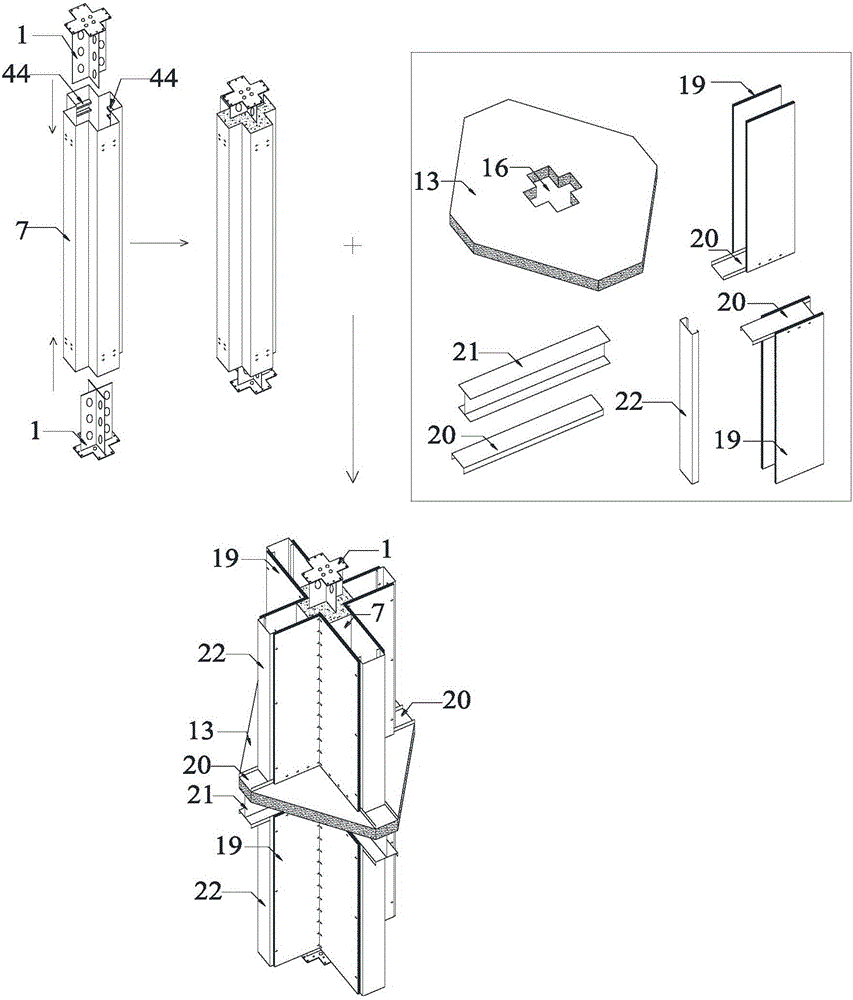

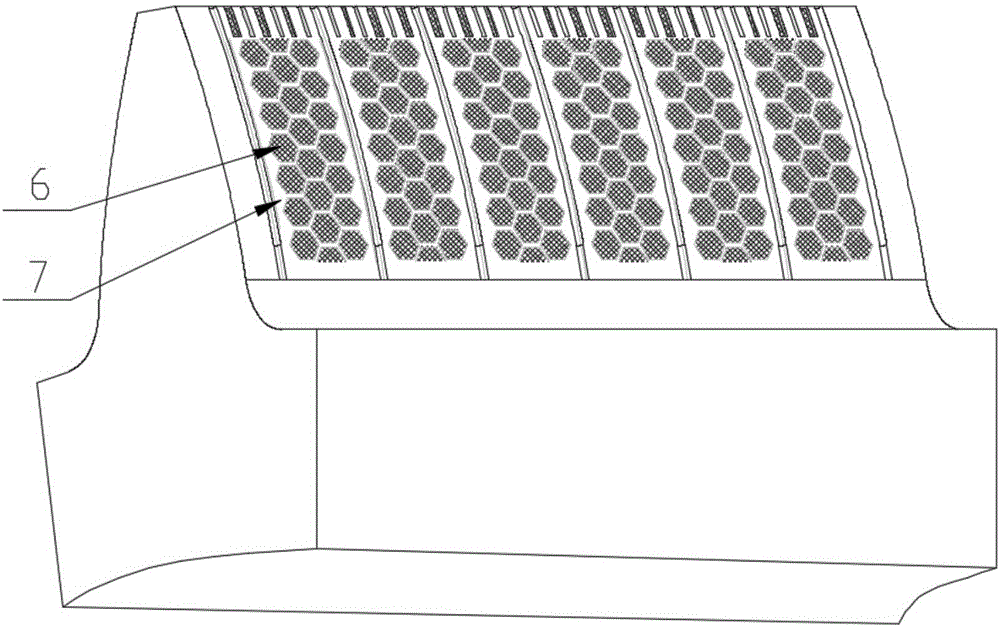

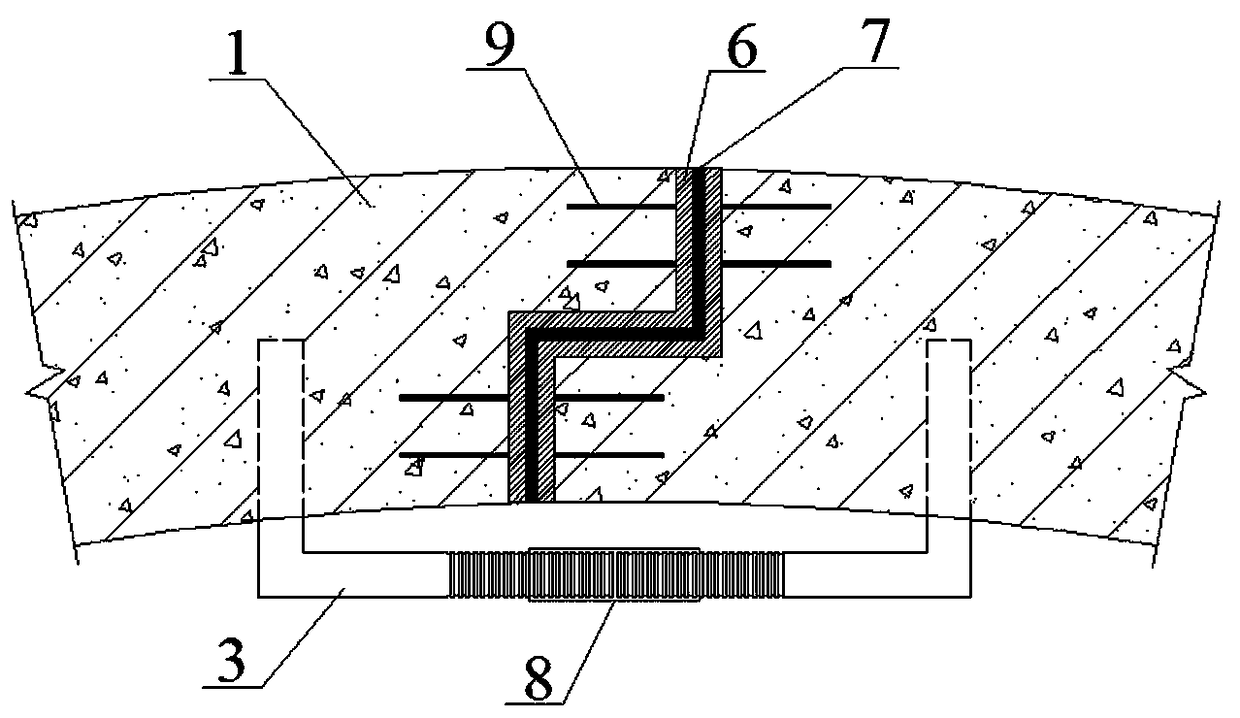

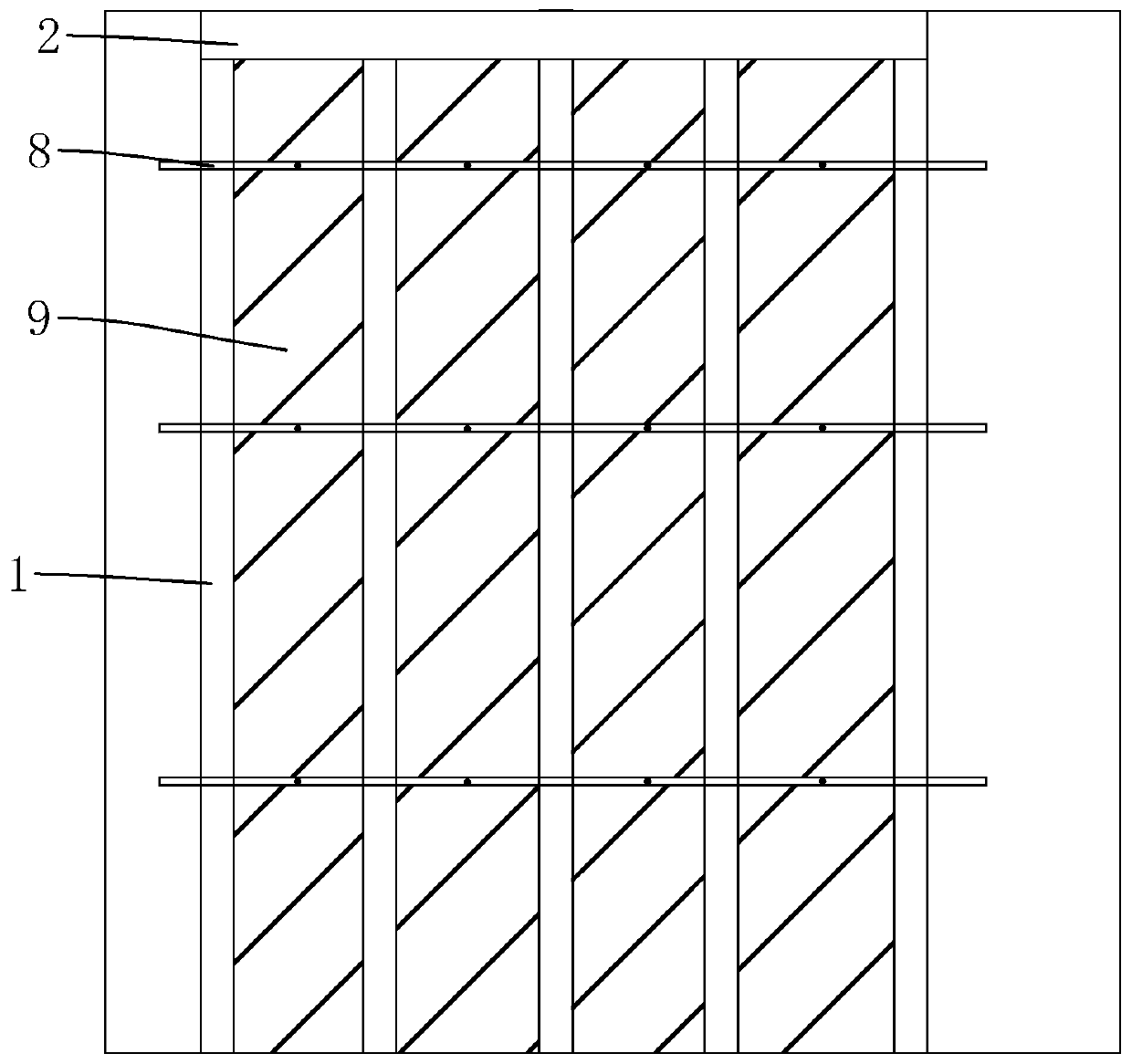

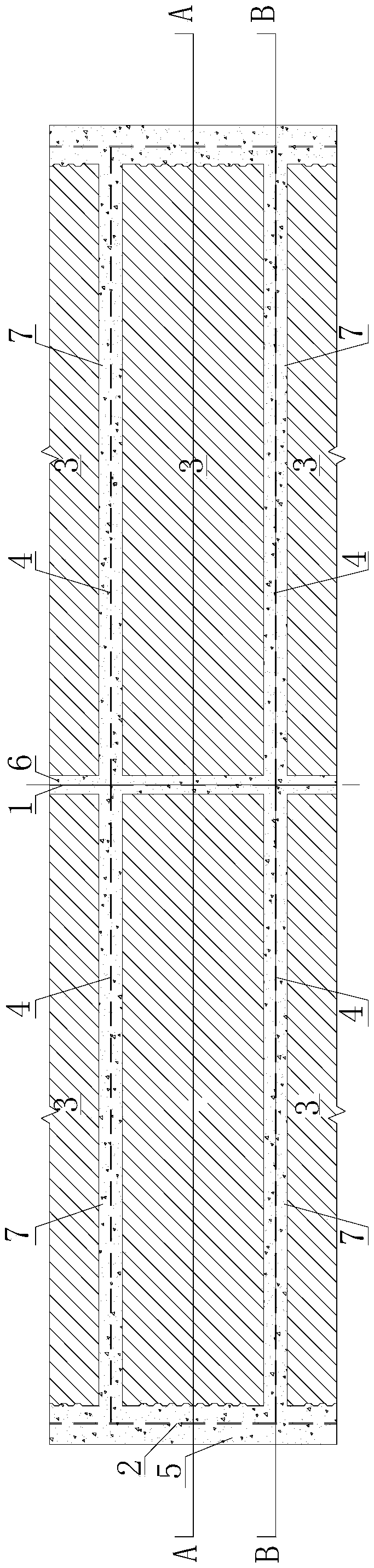

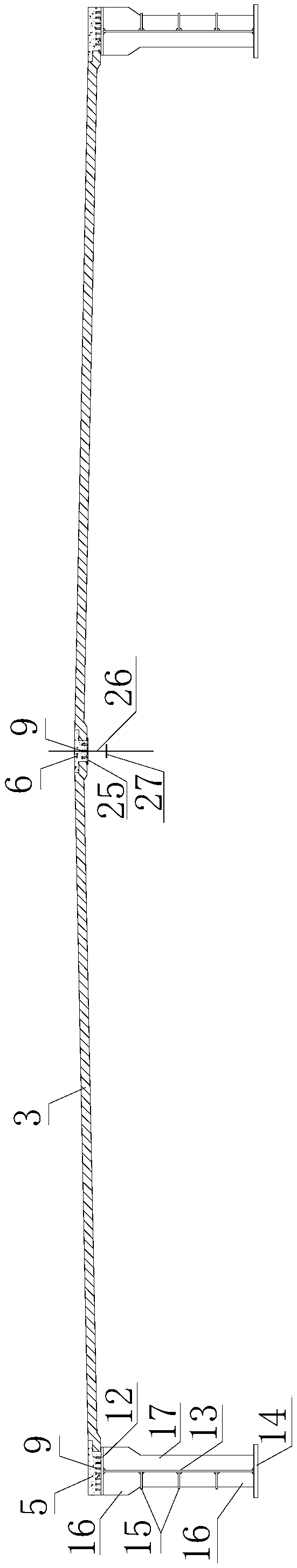

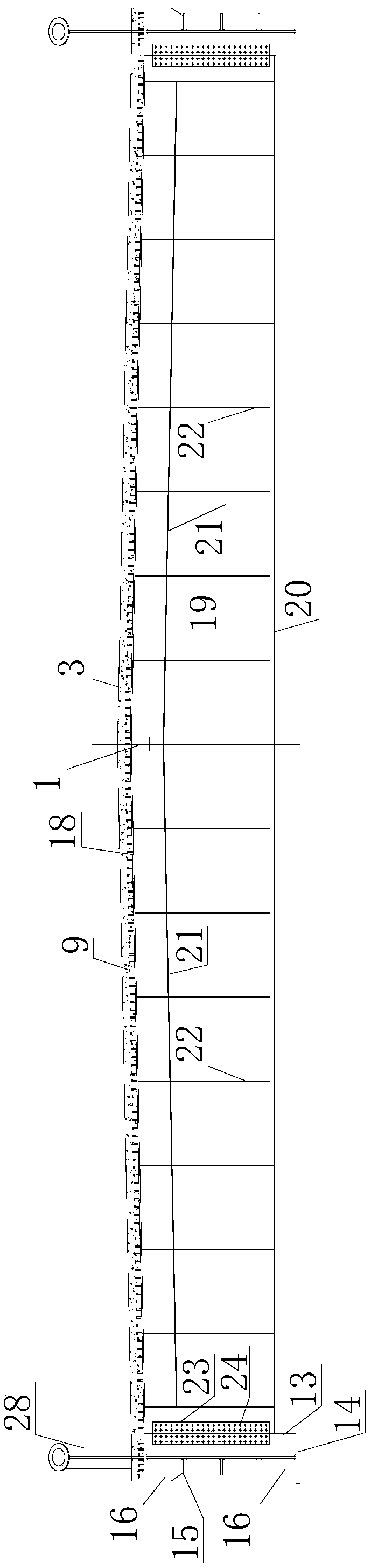

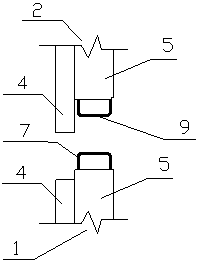

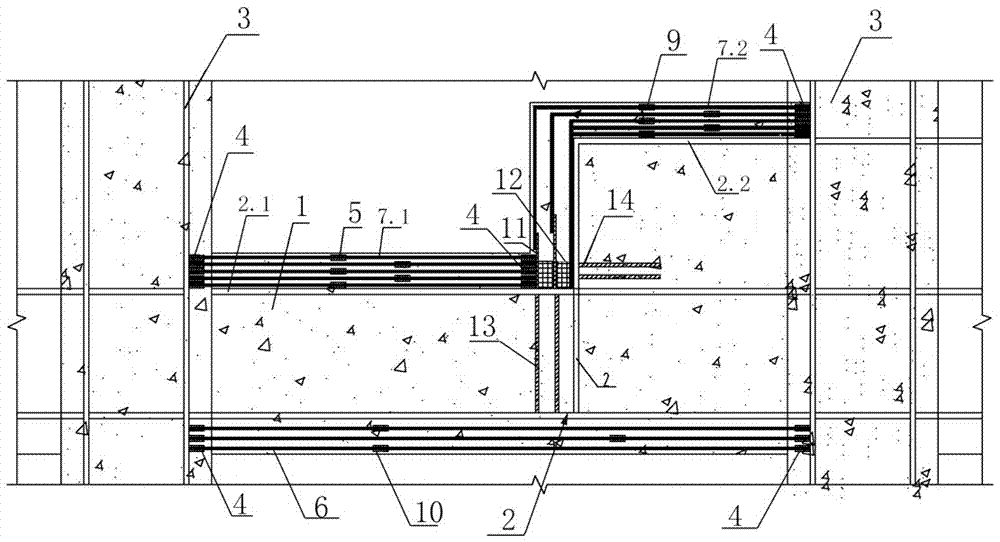

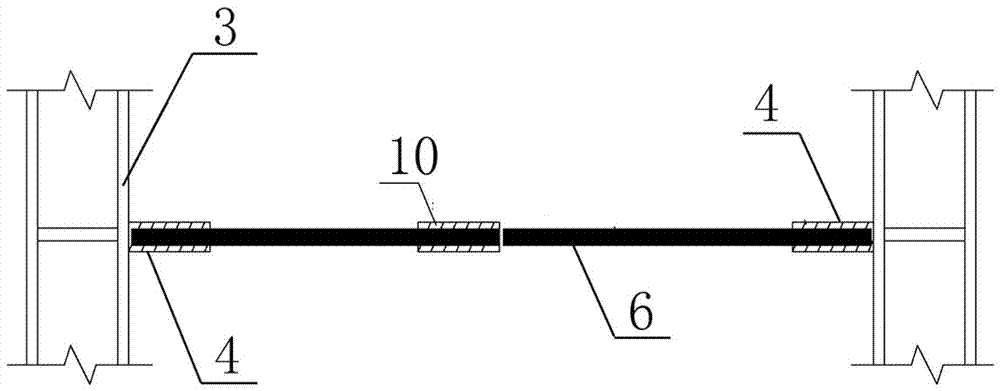

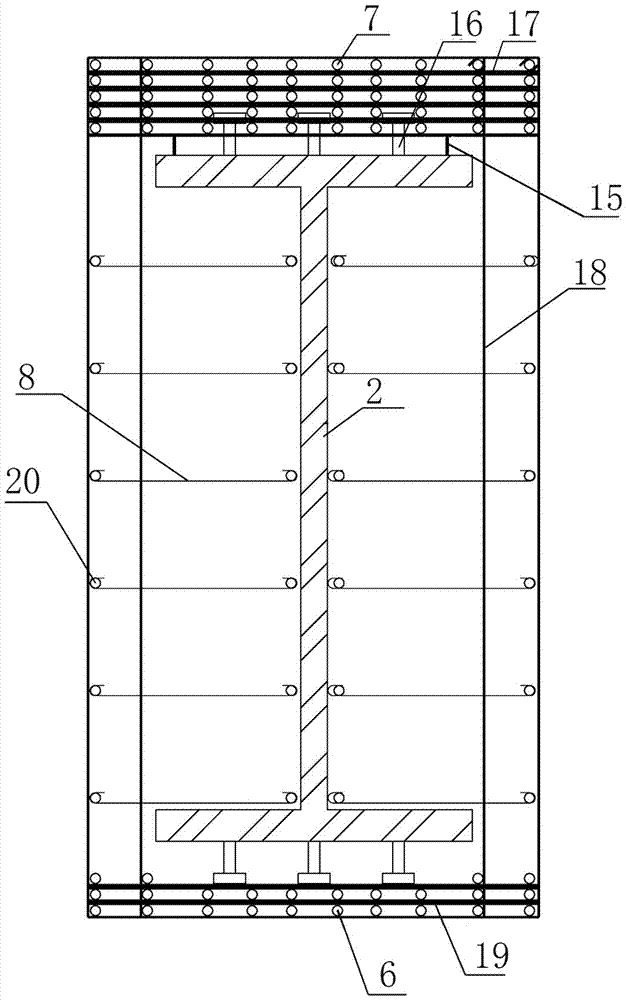

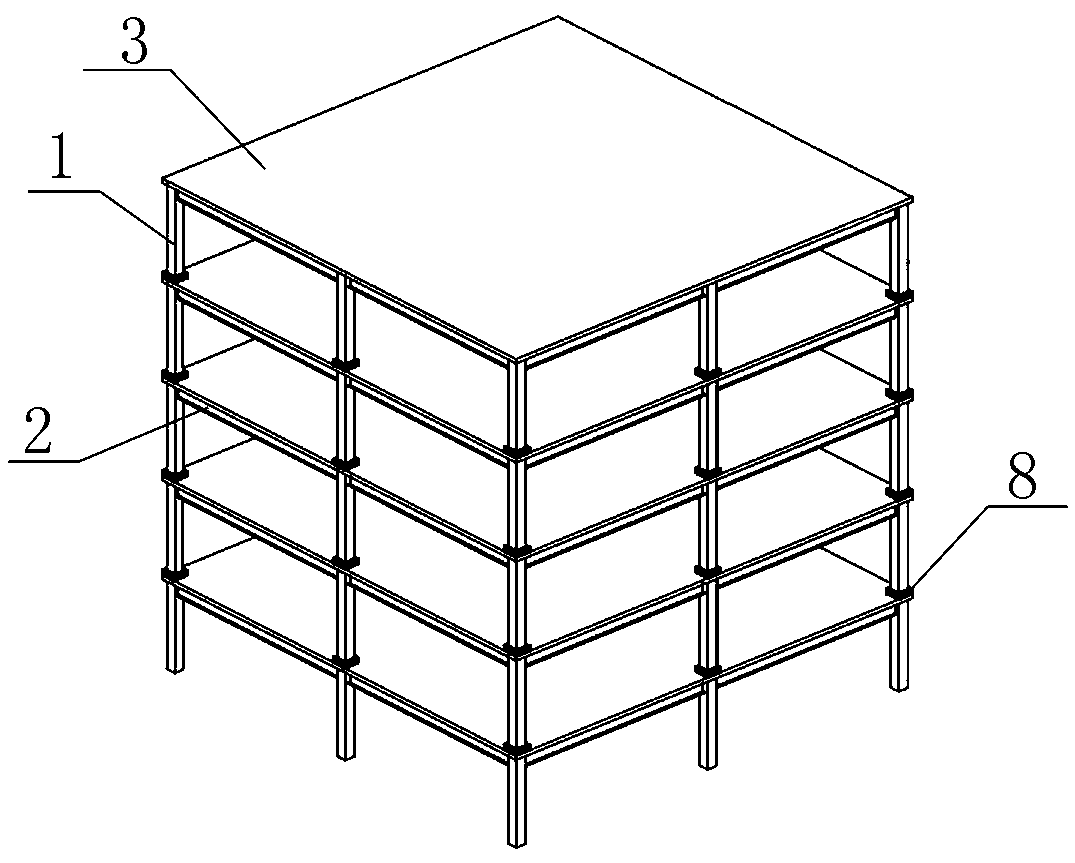

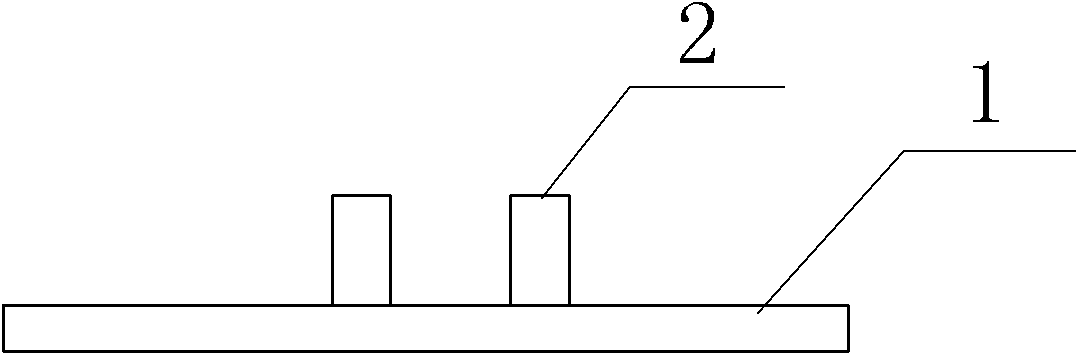

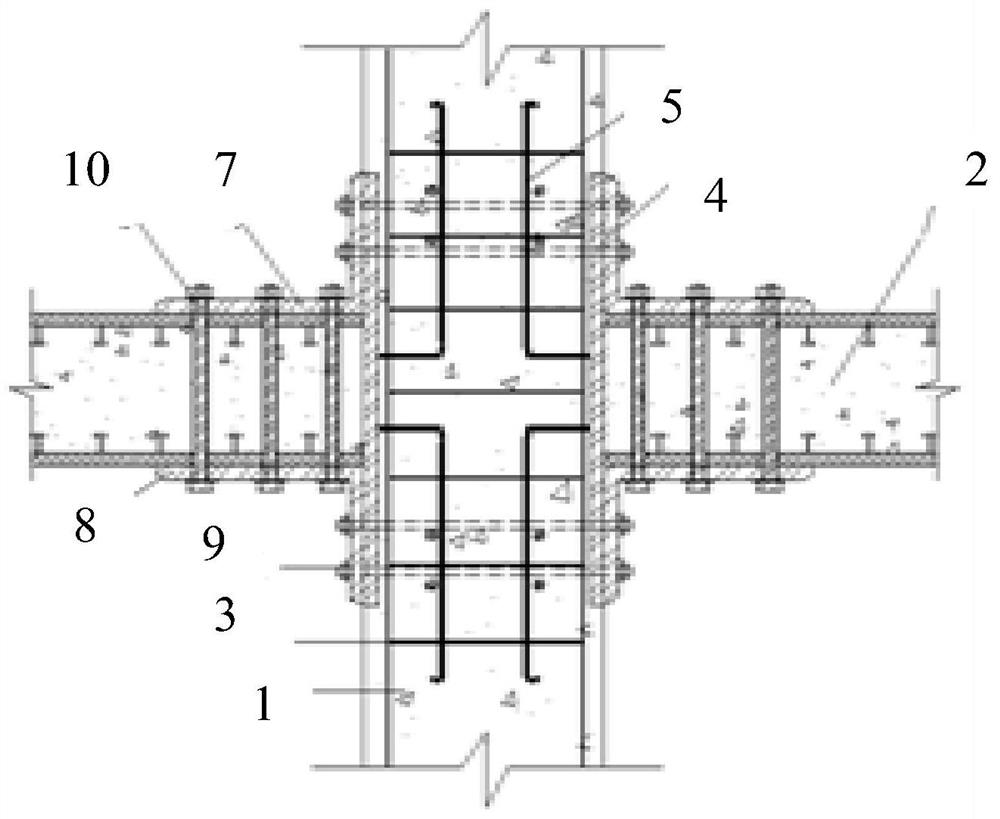

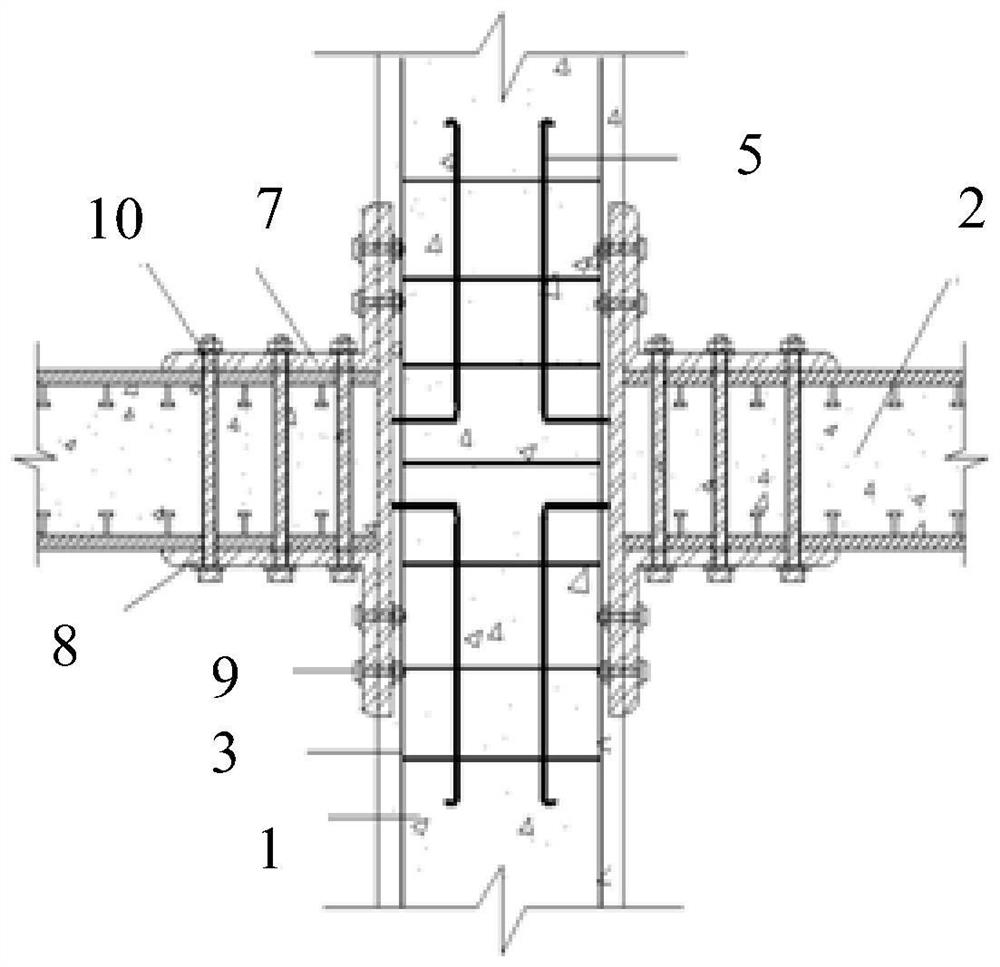

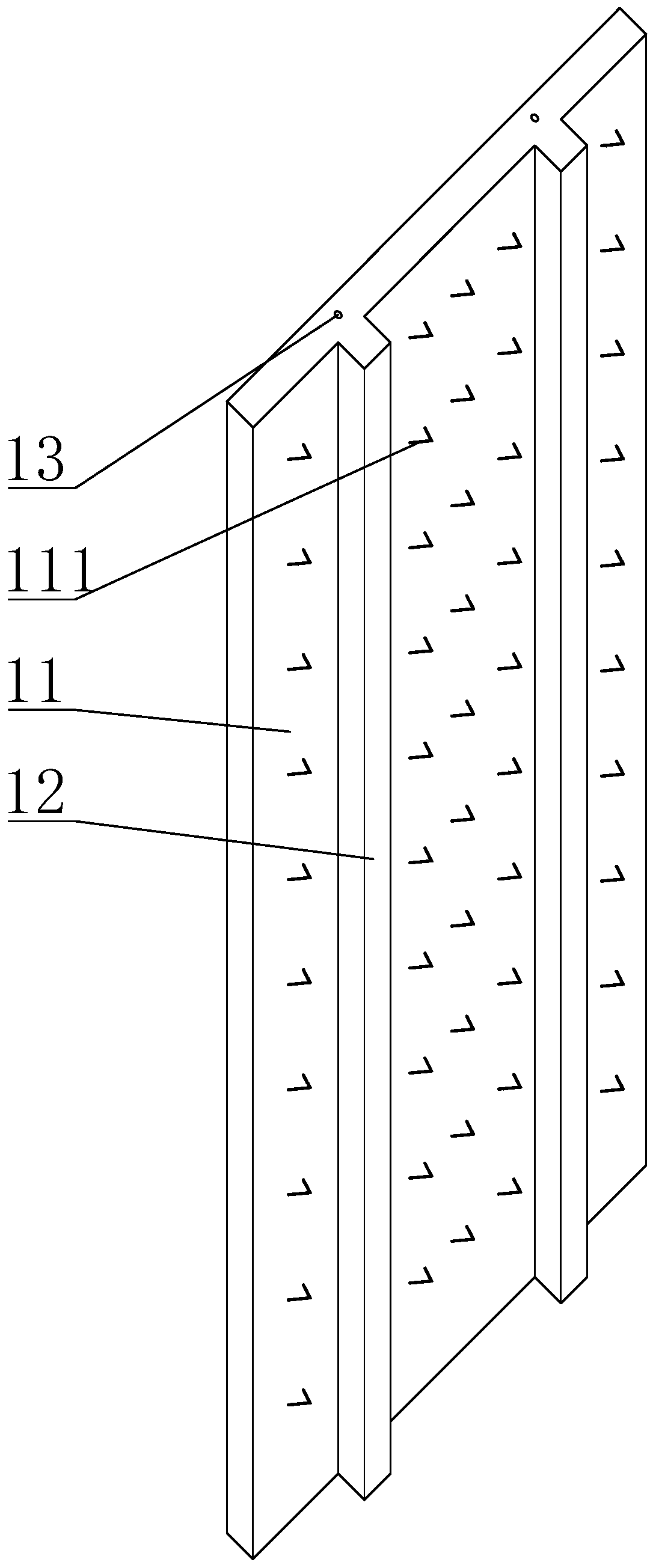

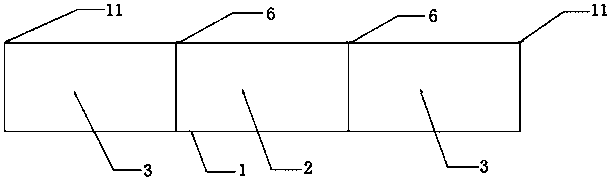

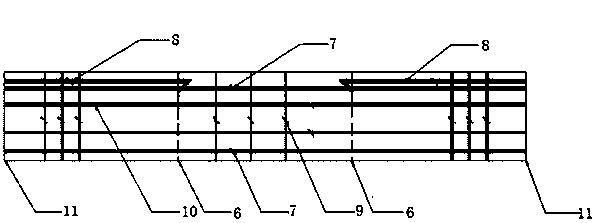

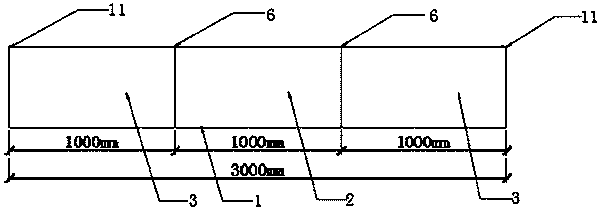

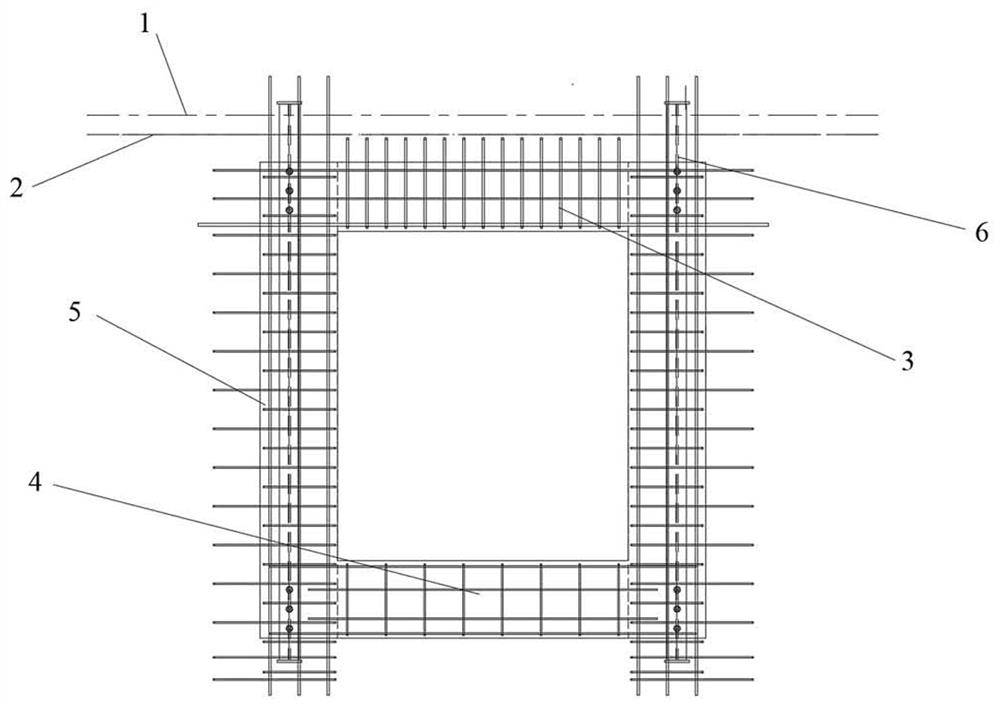

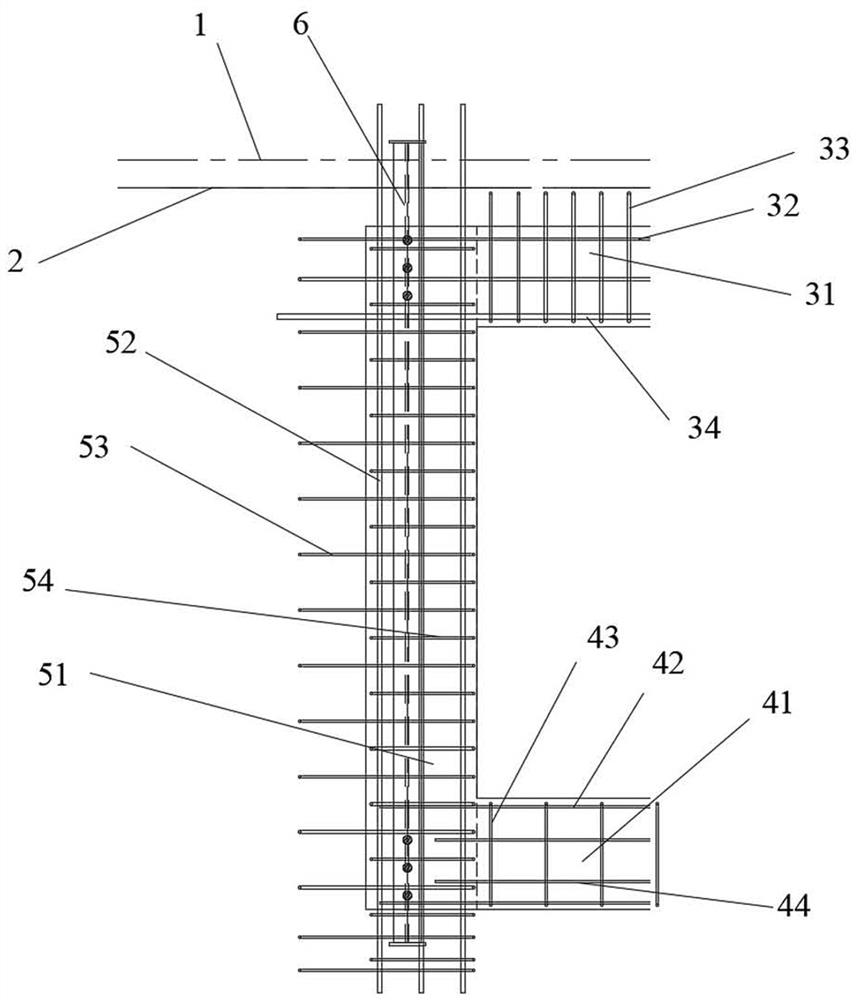

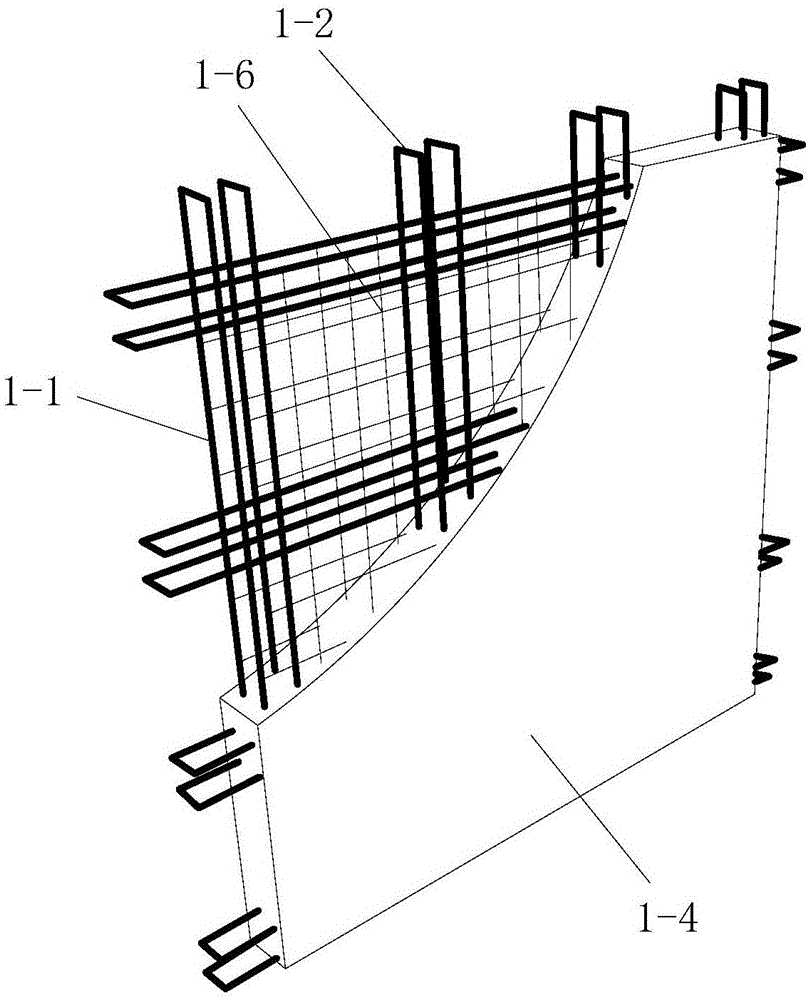

The invention discloses an assembled type gridding shearing wall structural system which comprises a plurality of shearing wallboards arranged from top to bottom. Each shearing wallboard comprises a shearing wall body, upper restraining hidden beams and two vertical edge restraining components, the shearing wall body is formed by a plurality of prefabricated gridding shearing wall main bodies in a spliced mode, every two adjacent prefabricated gridding shearing wall main bodies are connected through a connecting hidden column, and rectangular boxes on the internal framework of each prefabricated gridding shearing wall main body are respectively provided with a rectangular heat preservation board in an inlaid mode. A construction technology of the assembled type gridding shearing wall structural system includes the steps of (1) carrying out measuring and setting-out, (2) hoisting the prefabricated gridding shearing wall main bodies, (3) constructing the upper restraining hidden beams, the connecting hidden columns and the vertical edge restraining components, (4) constructing the shearing wallboard on the upper layer, and (5) repeating the steps till the construction process of the multiple shearing wallboards is completed. The assembled type gridding shearing wall structural system and the construction technology are reasonable in design, convenient to construct, low in investment cost and good in use effect, and multiple problems in traditional assembling of an integrated shearing wall structure can be effectively solved.

Owner:东莞市建安住宅工业有限公司

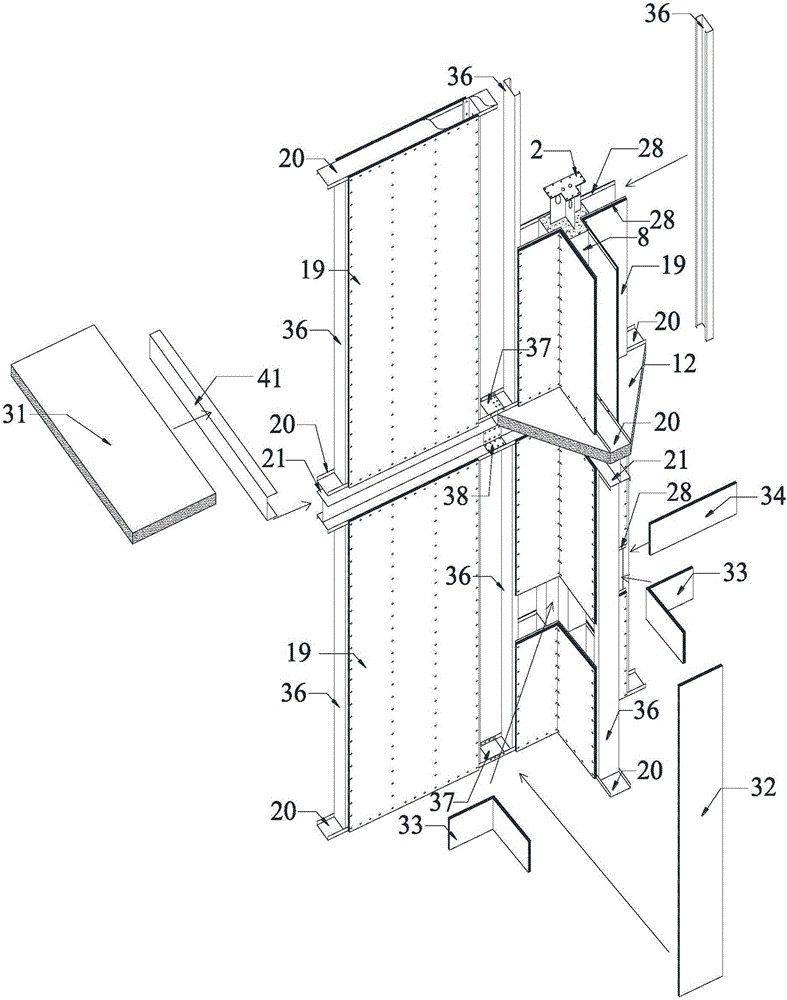

Multilayer cold-formed steel integrally prefabricated house and splicing method thereof

ActiveCN105696817AReduce on-site construction workloadHigh degree of industrializationBuilding material handlingDwelling buildingFloor slabEngineering

Owner:SOUTHEAST UNIV

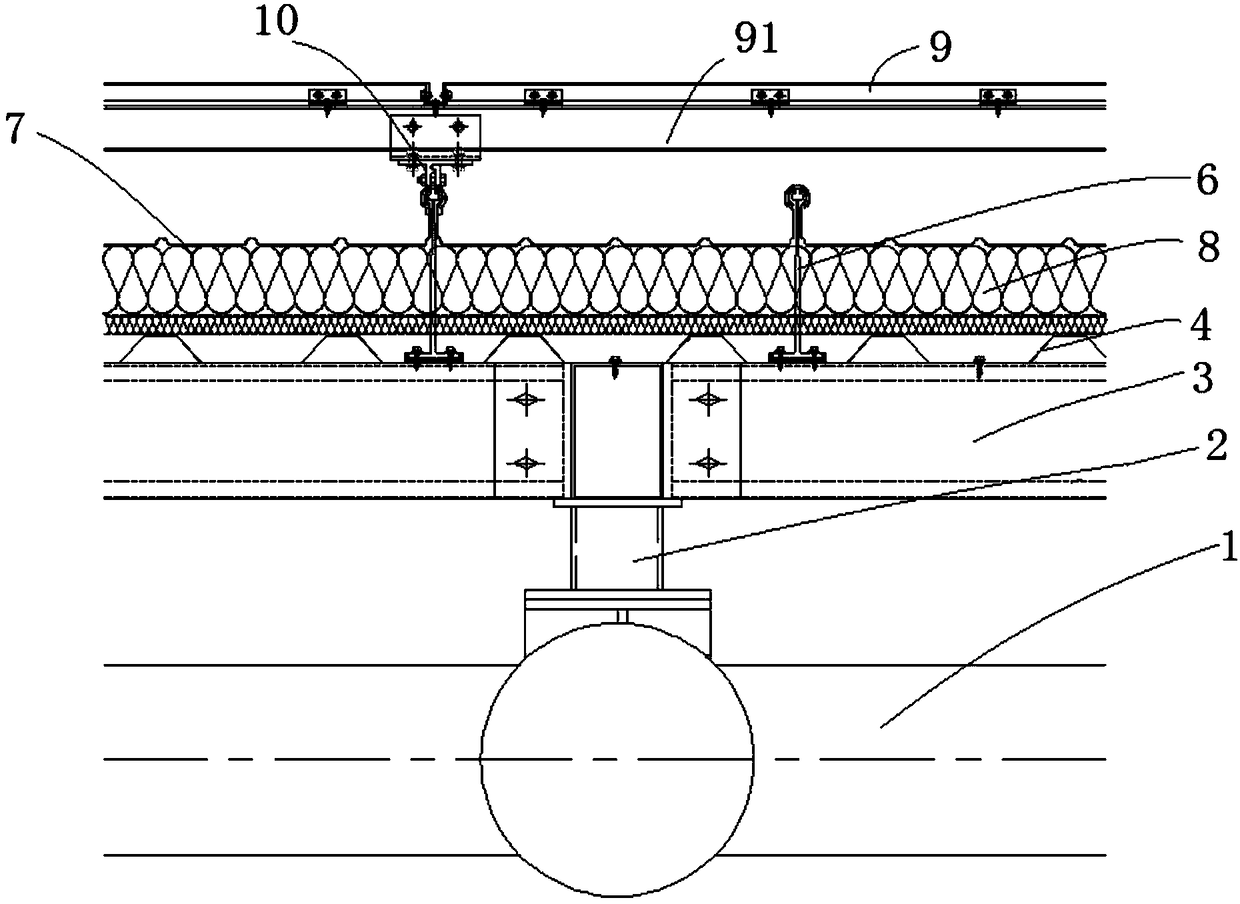

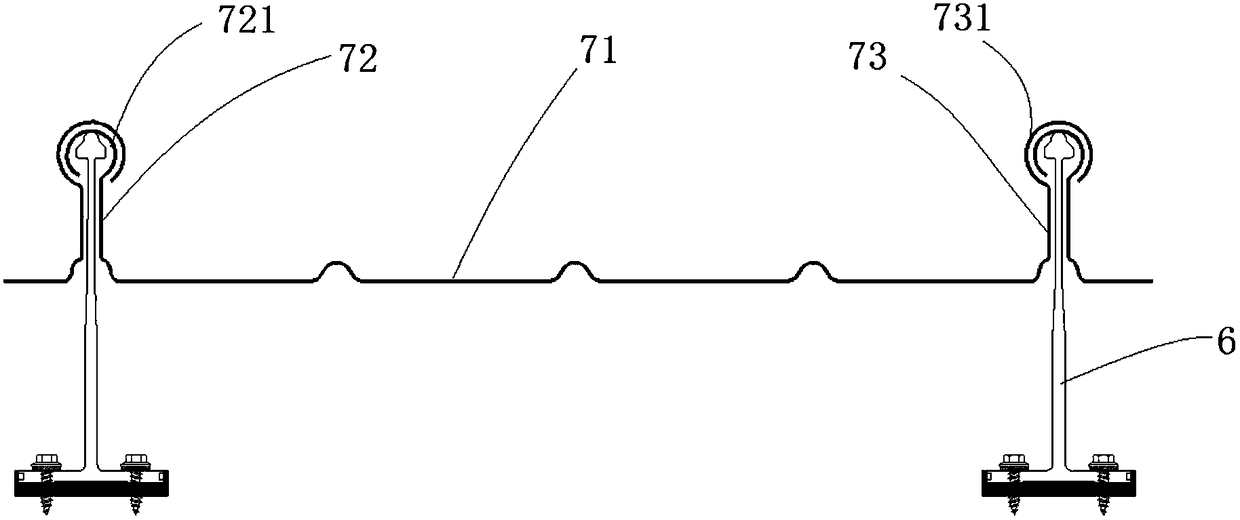

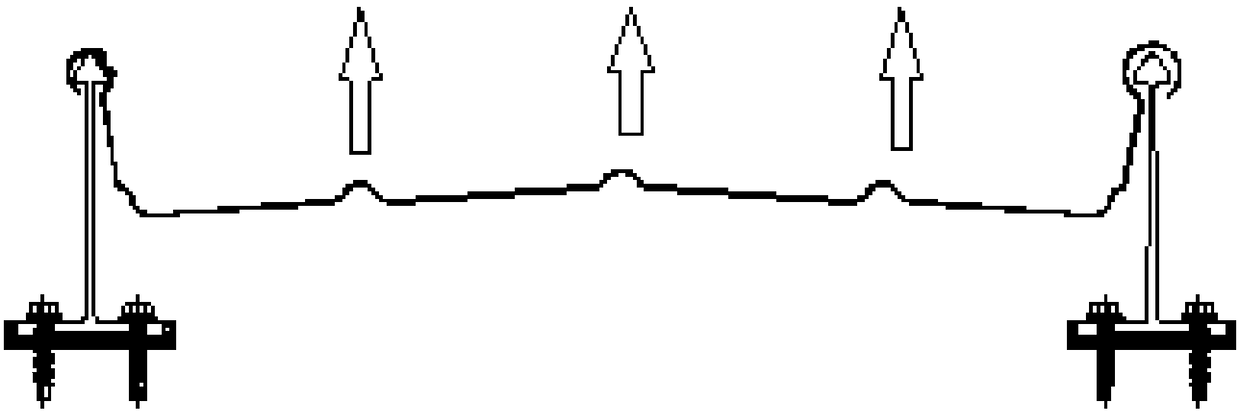

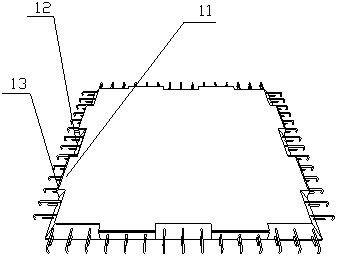

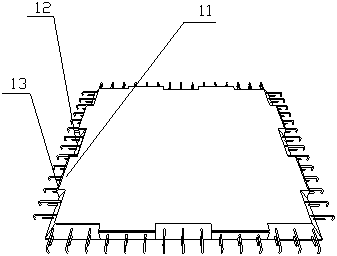

Anti-typhoon and anti-leakage metal roof system

PendingCN108590007AAvoid fatigue damageNo stress concentration problemsBuilding roofsRoof covering insulationsThermal insulationEngineering

The invention discloses an anti-typhoon and anti-leakage metal roof system. The metal roof system sequentially comprises a main steel structure, main roof purline, secondary roof purline, pressed steel bottom plates and purline laid on the pressed steel bottom plates from top to bottom. A plurality of fixed seats are fixed to the purline at intervals, concave roof plates which are engaged with thefixed seats are arranged between the fixed seats, and multiple layers of sound-insulation and vapor-proof thermal insulation materials are laid on the pressed steel bottom plates. The fixed seats include fixed supporting seats and panel engaging plates, wherein the purline is fixedly connected with the lower ends of the fixed supporting seats; the panel engaging plates are fixedly connected withthe fixed supporting seats, and small angles are formed between the panel engaging plates and the fixed supporting seats in the length direction of the roof plates so that the panel engaging plates and the fixed supporting seats can rotate relatively; and panel engaging parts are formed in the upper parts of the panel engaging plates, and the panel engaging parts and both side edges of the roof plates form engaging connection. The anti-typhoon and anti-leakage metal roof system solves the problems that a traditional metal roof system with vertical lockrands has low wind resistance, and is prone to leaking and prone to producing expansion deformation damage, and the safety of upper supporting facilities is affected.

Owner:CENT INT GROUP +1

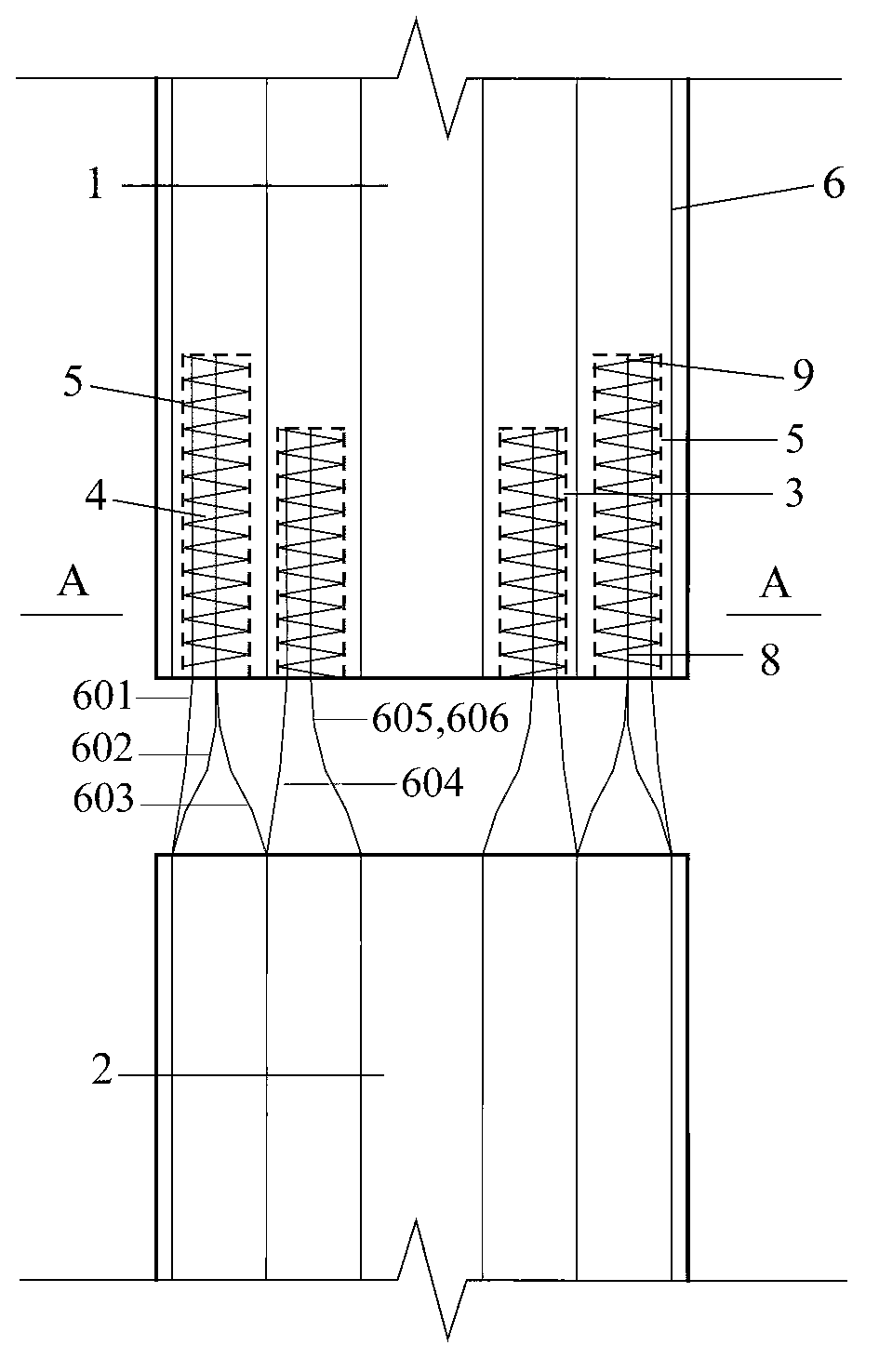

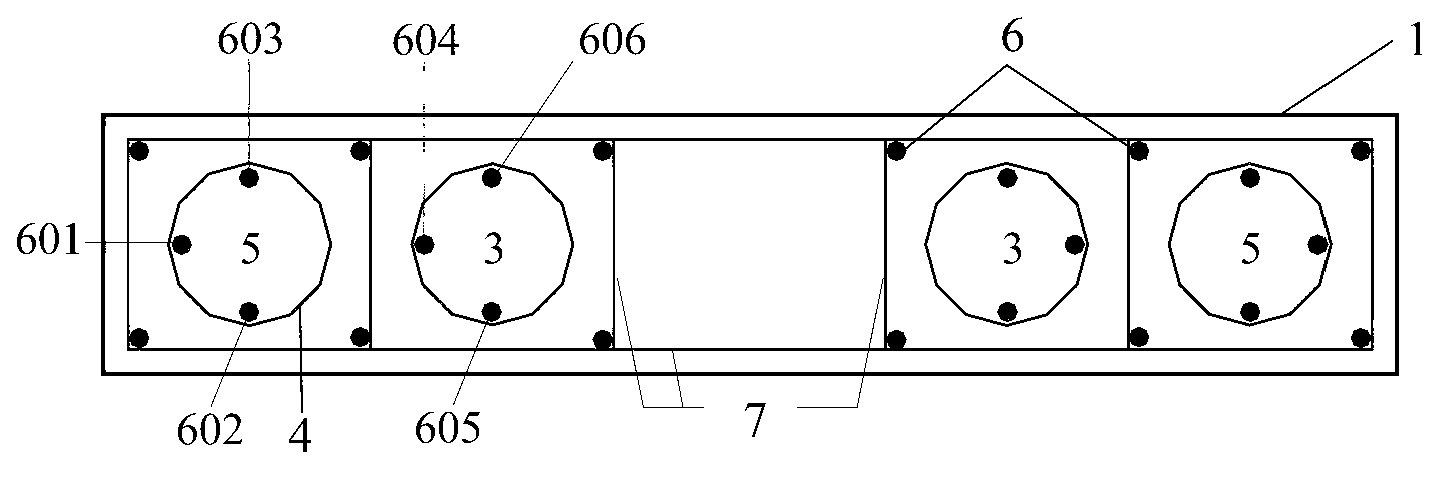

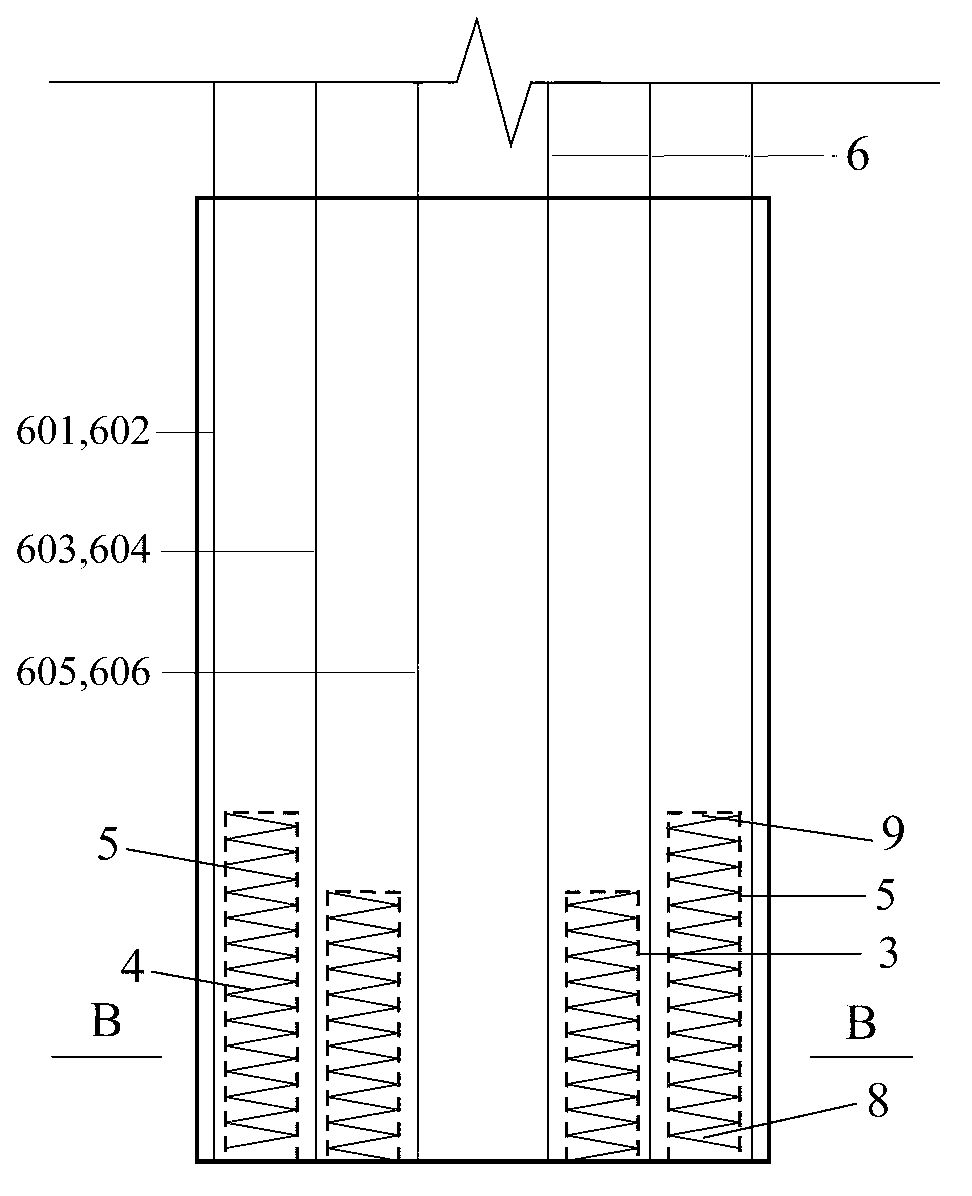

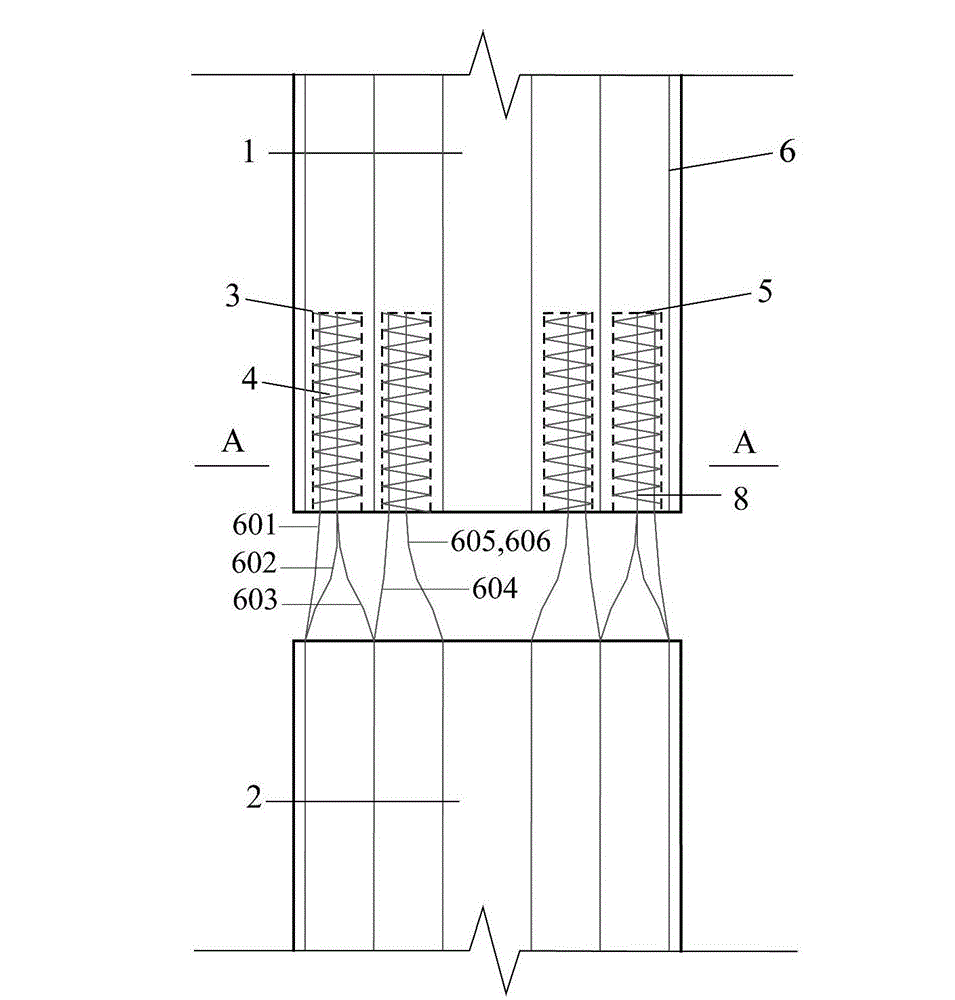

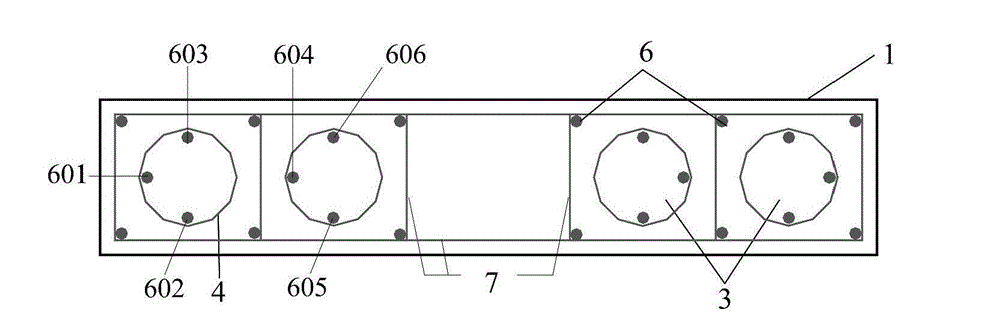

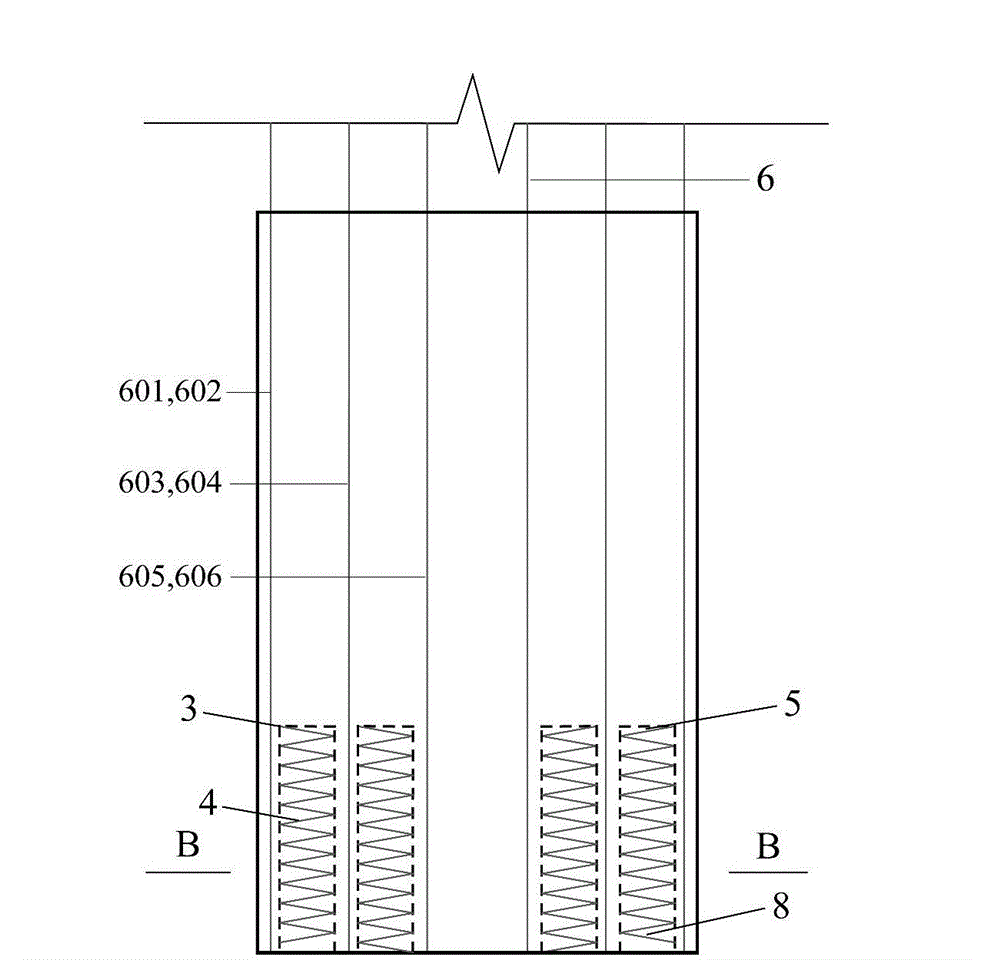

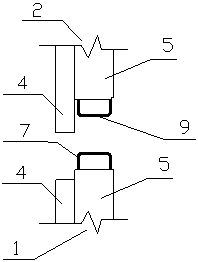

Prefabricated assembling whole type shear wall connected with staggered-height vertical steel bar

The invention provides a prefabricated assembling whole type shear wall connected with a staggered-height vertical steel bar, comprising an upper-layer wall body and a lower-layer wall body, wherein the two ends of the bottom of the upper-layer wall body are provided with a first reserved hole and a second reserved hole, which are vertical; the vertical height of the second reserved hole is 1.2-1.5 times as much as the vertical height of the first reserved hole; a spiral stirrup which is as high as the first reserved hole and the second reserved hole is respectively pre-buried in each one of the first reserved hole and the second reserved hole; vertical steel bars at the inner side of an edge member of the lower-layer wall body are bundled by groups; a plurality of combined steel bar bundles are respectively inserted into the first reserved hole and the second reserved hole; and concrete mortar materials are filled between the steel bar bundles and the first reserved hole, and between the steel bar bundles and the second reserved hole. According to the prefabricated assembling whole type shear wall, the concrete of a pressed region can be effectively restricted and the prefabricated assembling whole type shear wall can be used for overlapping the vertical steel bars in a prefabricated shear wall system.

Owner:SOUTHEAST UNIV

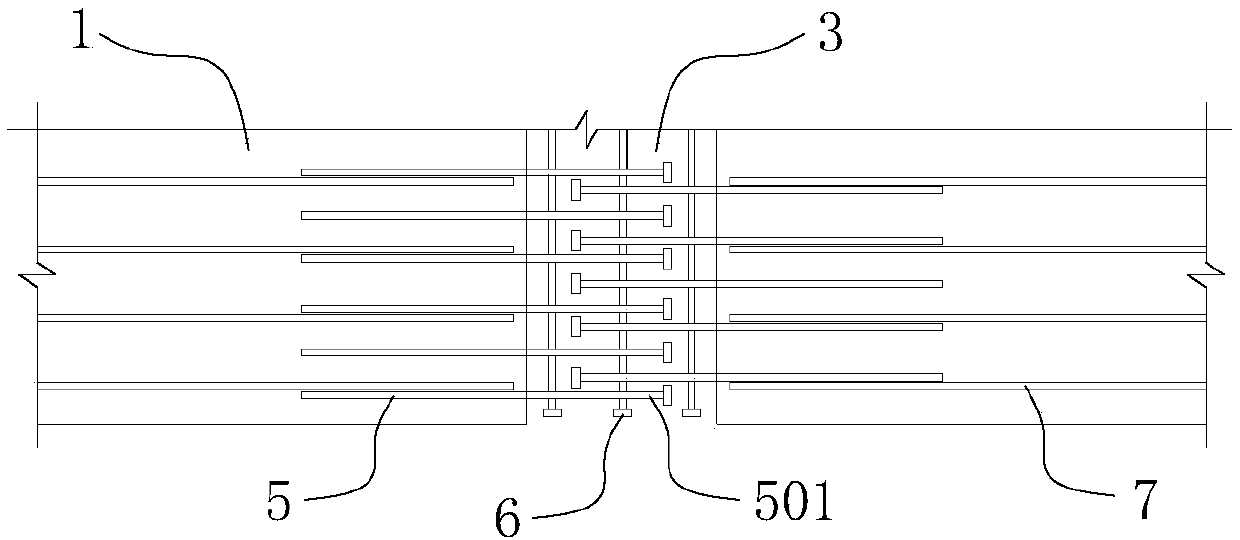

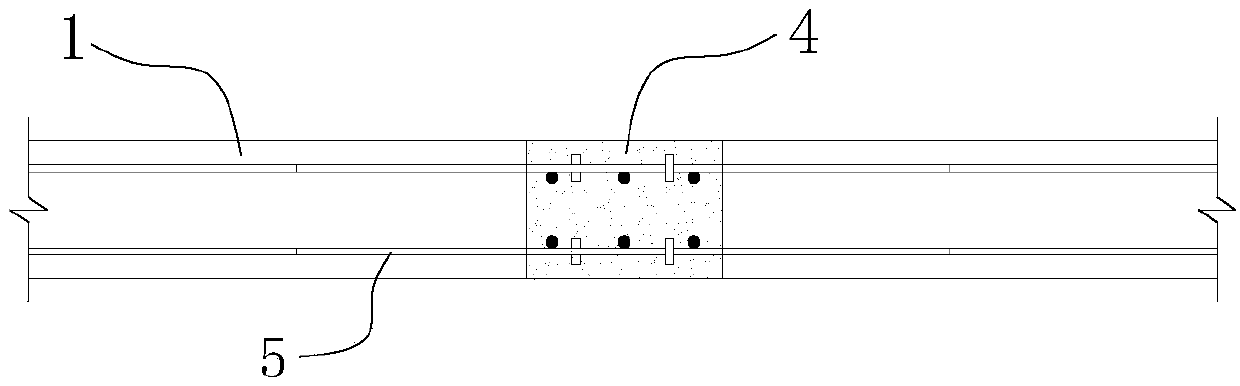

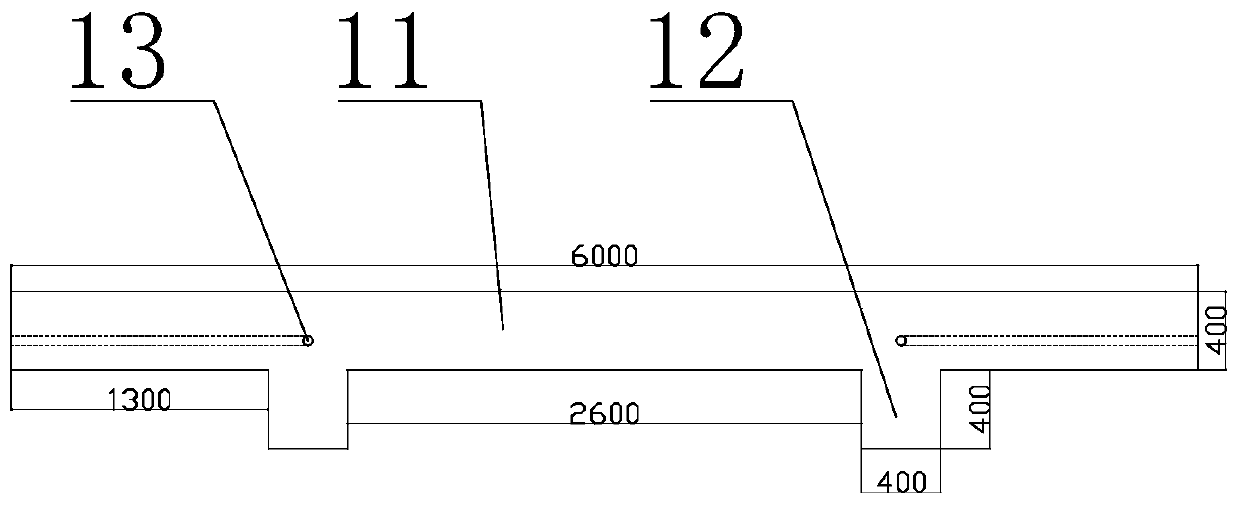

Bridge deck wet joint structure adopting T-head steel bars and construction method of bridge deck wet joint structure

PendingCN107938504AReduce the impactReduce on-site construction timeBridge structural detailsArchitectural engineeringBridge deck

The invention provides a bridge deck wet joint structure adopting T-head steel bars and a construction method of the bridge deck wet joint structure. The bridge deck wet joint structure comprises a plurality of precast concrete bridge decks erected on girders; a plurality of T-head steel bars are pre-buried in the precast concrete bridge decks at the sides close to wet joints; the extending partsof the T-head steel bars are T-head anchoring ends; the T-head anchoring ends between two adjacent precast concrete bridge decks are arranged in a staggered mode; projections of the corresponding T-head anchoring ends have overlapped length; and wet joint concrete is cast in the wet joints in situ, so that two adjacent precast concrete bridge decks can be connected into a whole. The construction method of the bridge deck wet joint structure comprises the steps of pre-burying the T-head steel bars, casting concrete, performing hoisting in place, casting wet joint concrete and the like. The bridge deck wet joint structure simplifies the construction steps, obviously reduces the great welding workload caused by the traditional design, reduces the construction cost, reduces the influence on the existing traffic, improves the construction efficiency, and has wide application prospects.

Owner:CHONGQING UNIV

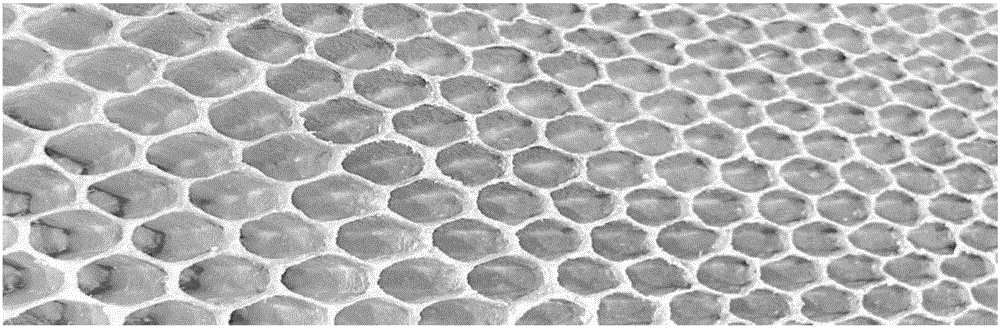

Honeycomb-shaped polygonal self-lubricating gear

InactiveCN106763649AReduce usageGuaranteed StrengthPortable liftingGearing elementsHoneycombEngineering

The invention relates to a honeycomb-shaped polygonal self-lubricating gear. Honeycomb-shaped grooves, strip-shaped grooves, middle strip-shaped chip grooves and top strip-shaped chip grooves are processed in a tooth surface of the honeycomb-shaped polygonal self-lubricating gear; the honeycomb-shaped grooves are positioned in the middle of the tooth surface, and are filled with self-lubricating materials; the strip-shaped grooves are positioned in the top of the tooth surface, and are filled with the self-lubricating materials; and the middle strip-shaped chip grooves and the top strip-shaped chip grooves separately penetrate through the whole tooth surface and are formed in the top of the tooth surface, are distributed in a spaced mode, and are beneficial for chip removal. The invention discloses the honeycomb-shaped polygonal self-lubricating gear which is inspired by a honeycomb shape based on the bionic idea; compared with an existing gear, the honeycomb-shaped polygonal self-lubricating gear has self-lubricating characteristics, does not need to additionally add media such as lubricating oil and lubricating grease, enriches a gear lubricating mode, and can meet normal operation when the gear is under extreme working conditions such as an oil-free working condition and an oil-lack working condition.

Owner:HEFEI UNIV OF TECH

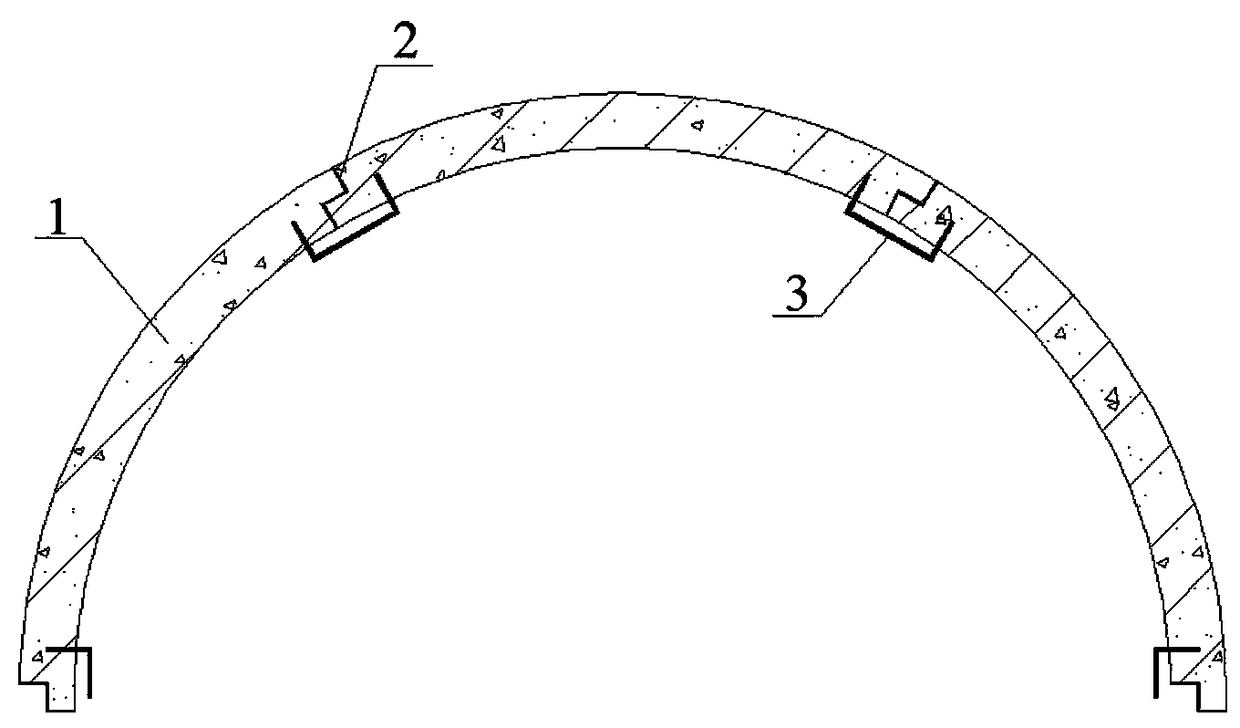

Pipe segment joint type shield tunnel structure

PendingCN109026063ARealize assembly positioningImprove assembly efficiencyUnderground chambersTunnel liningEngineeringFlange

The invention discloses a pipe segment joint type shield tunnel structure which comprises a pipe segment body. The structure is characterized in that a half of side flanges of the pipe segment body are concaved, the other half of the side flanges of the pipe segment body protrude, the adjacent pipe segment bodies are supported mutually through bump interlocking; the pipe segment body is provided with pre-buried right-angle bolts, and the right-angle bolts are connected through a bolt sleeve; a pre-buried steel plate is arranged at the side flange of the pipe segment body. The waterproof structure is composed of a steel plate putty water stop at the pipe segment side flange joint and a GB / SR water stop at the inner side of the pipe segment circumference of the circular seam. The joint is simple in type, construction is convenient, no bolt hand hole is formed, the waterproof effect is good, pipe segment staggering can be reduced, and the splicing quality can be improved.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Prefabricated integral type shear wall

The invention discloses a prefabricated integral type shear wall. The prefabricated integral type shear wall comprises an upper wall body and a lower wall body; cylindrical reserved holes are vertically formed in two ends of the bottom of the upper wall body; vertical spiral stirrups with same heights are arranged in the reserved holes; exhaust vents which are communicated with the outside are formed in the top ends of the reserved holes; grouting holes which are communicated with the outside are formed in the lower parts of the reserved holes; vertical steel bars at the inner sides in edge constructional elements in the lower wall body extend out of the top of the lower wall body and then are bundled in groups, and the multiple grouped steel bar bunches are respectively inserted into the corresponding reserved holes till to be up to the tops of the reserved holes; and concrete mortar is filed between each steel bar bunch and each reserved hole. The prefabricated integral type shear wall has the advantages of being capable of reducing the construction difficulty of overlapping joint of the steel bar bunches, effectively restricting concrete in a compressive zone and being used for the overlapping joint among the vertical steel bars in a prefabricated integral type concrete shear wall system.

Owner:SOUTHEAST UNIV

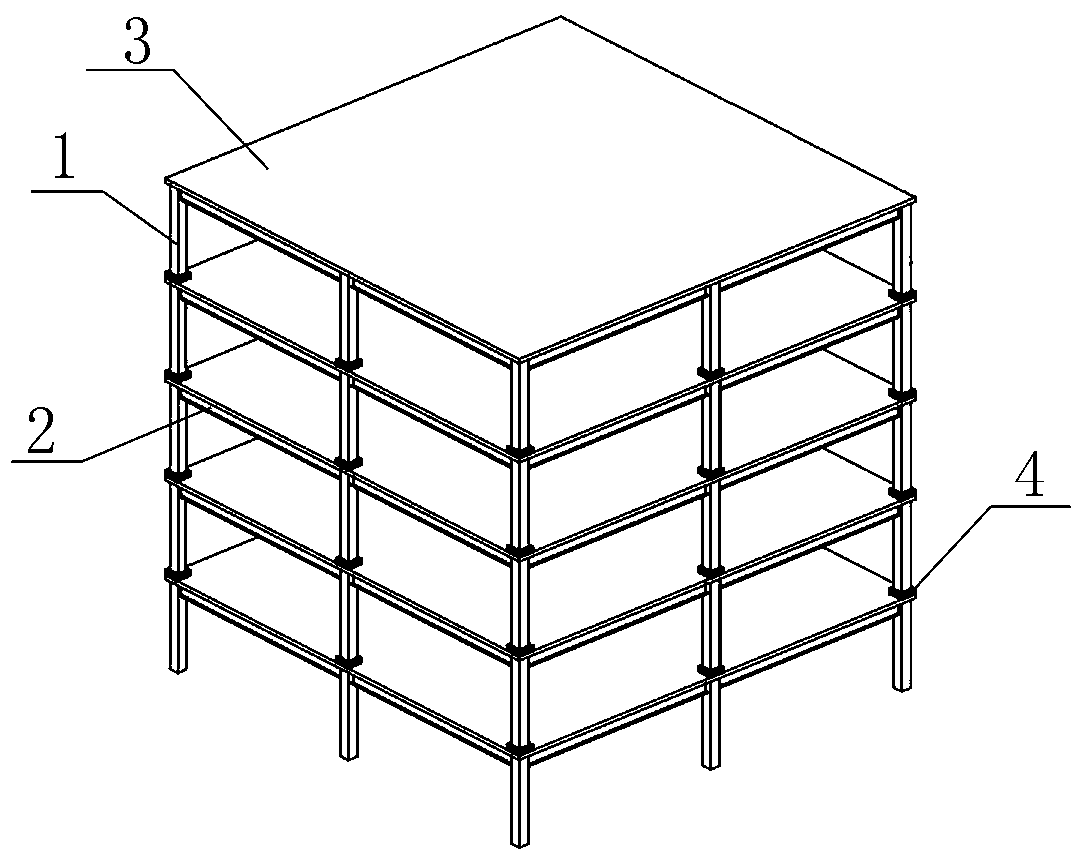

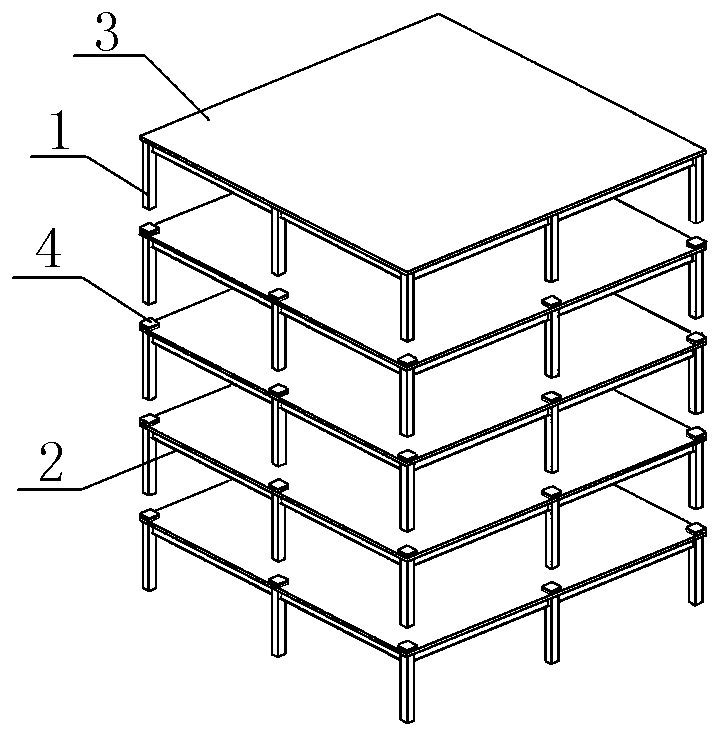

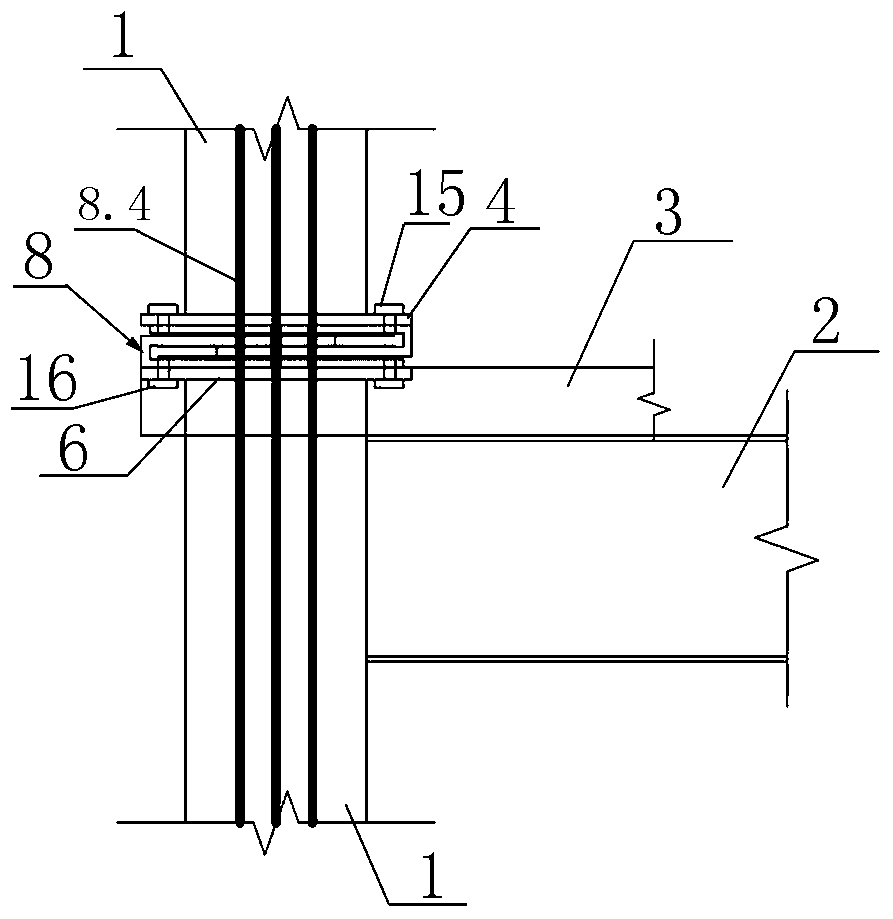

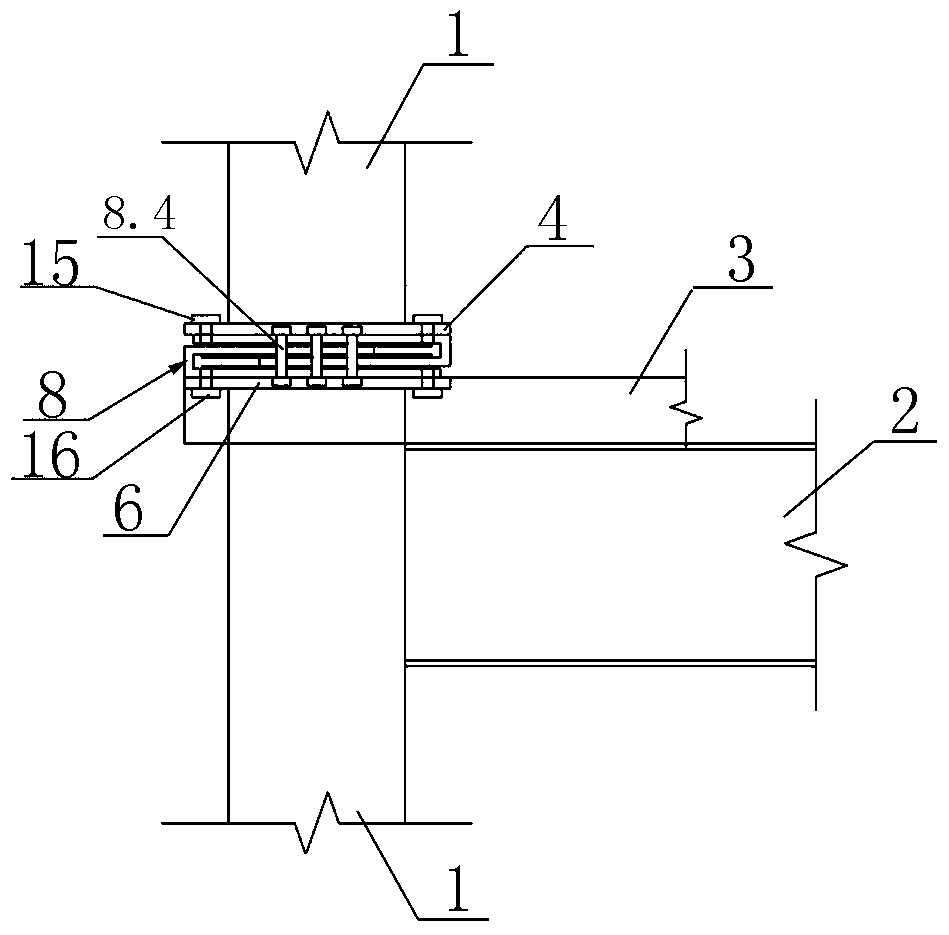

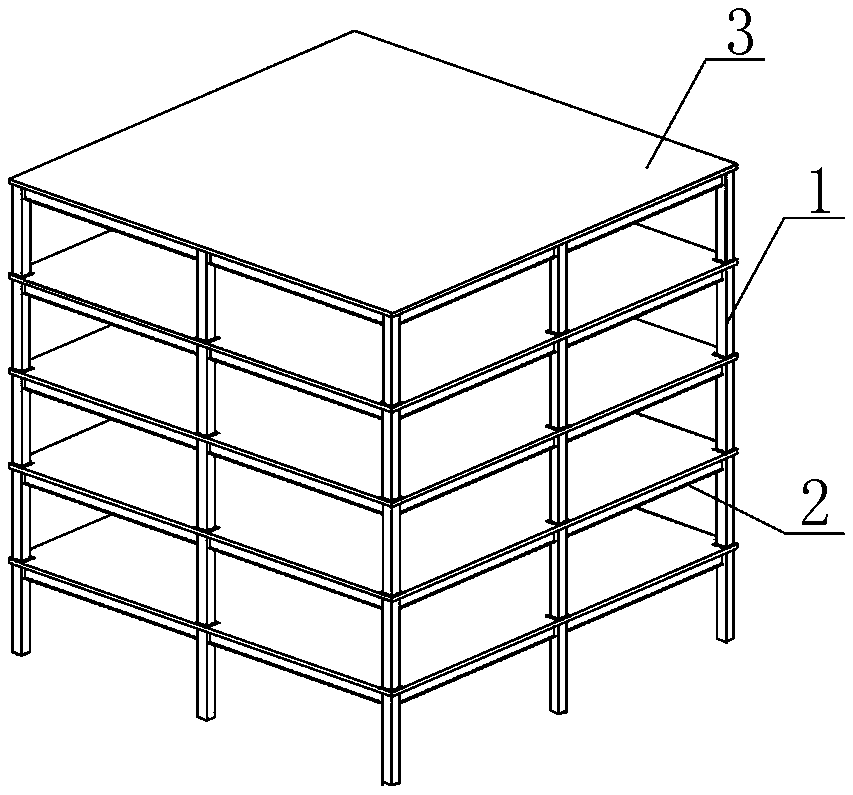

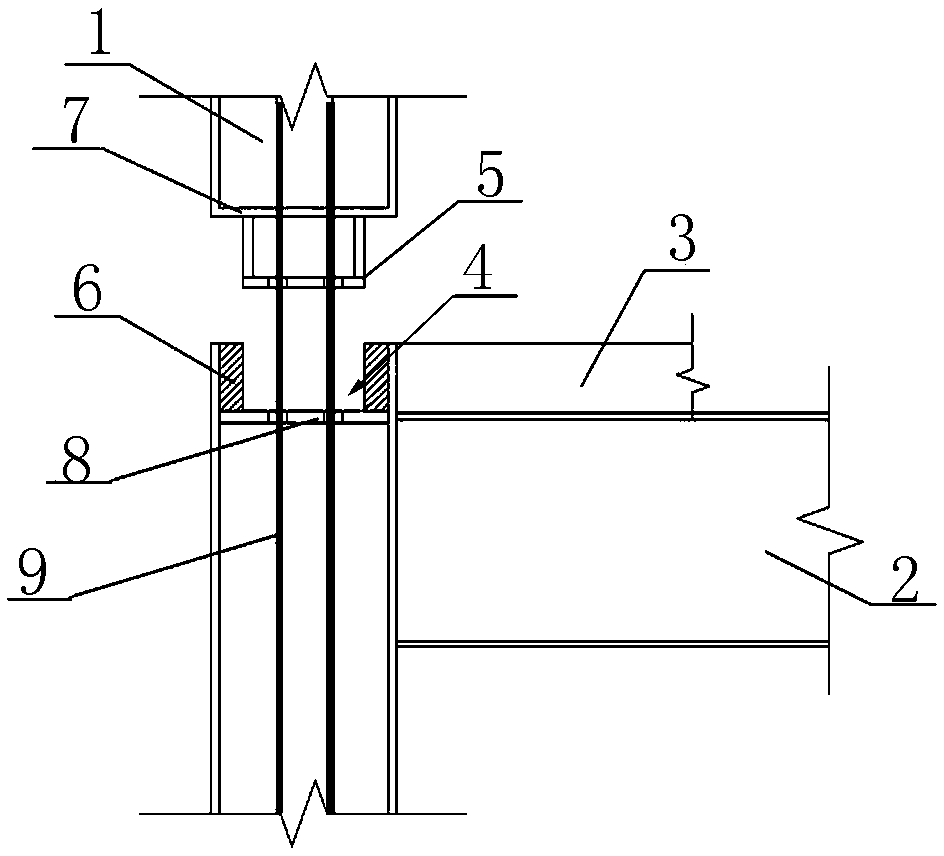

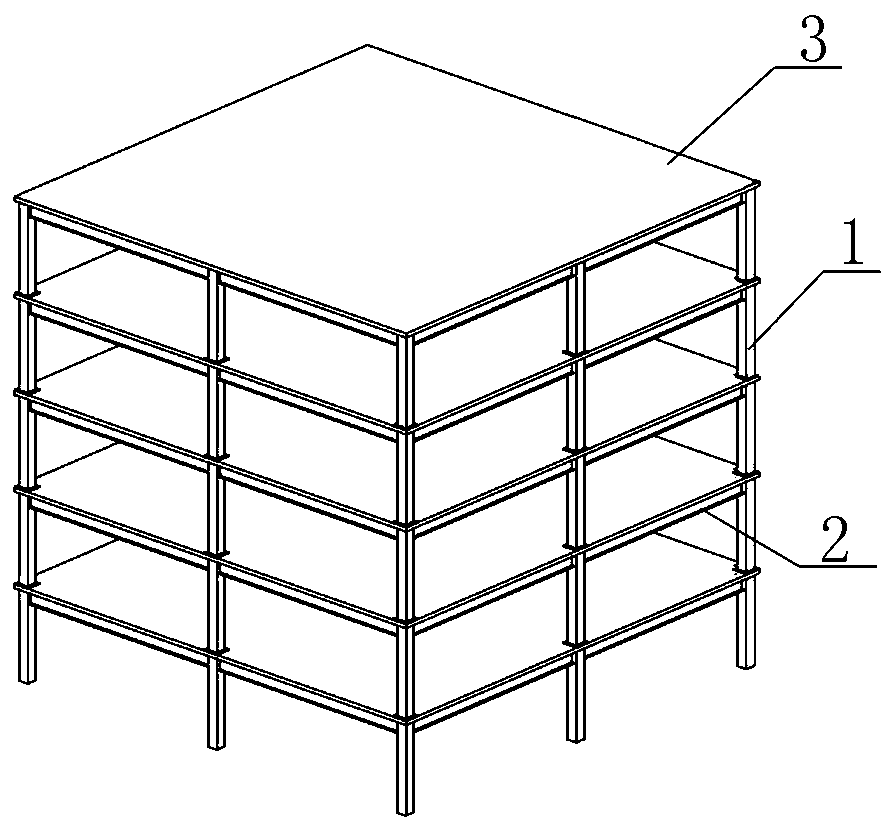

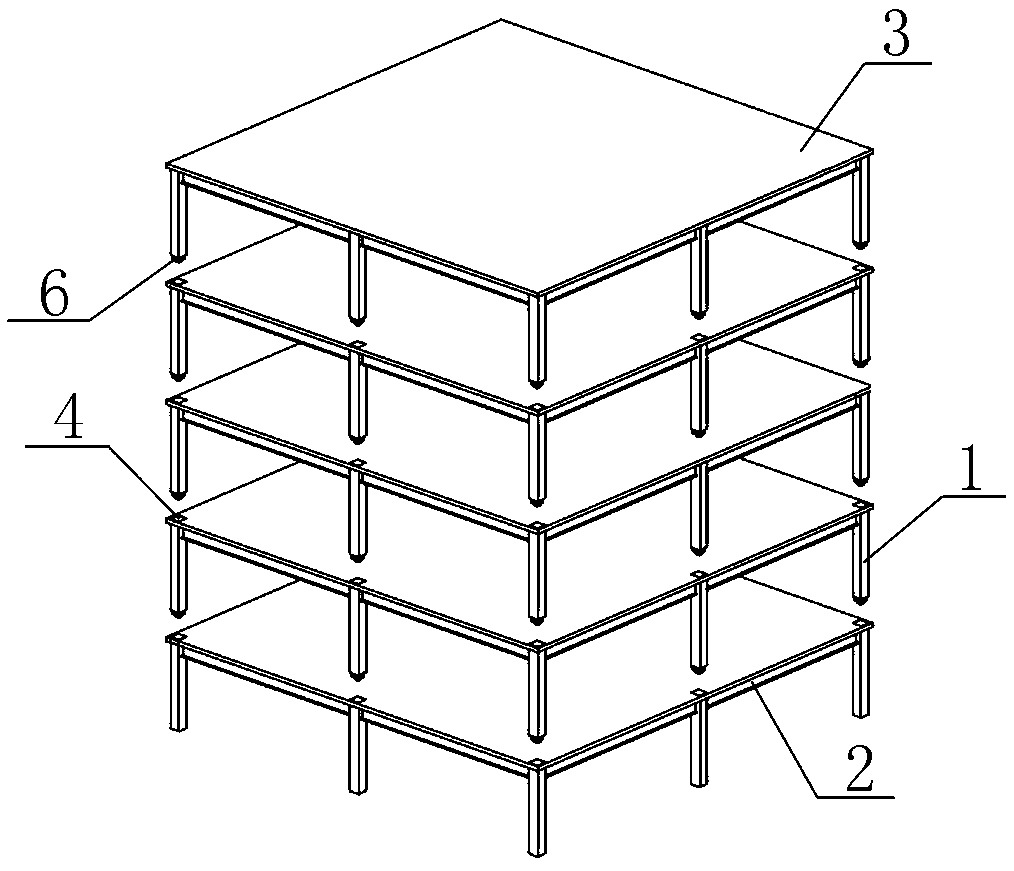

Prestressed support friction damping assembled steel structure system and design method thereof

ActiveCN110528679ANo pollution in the processImprove construction efficiencyProtective buildings/sheltersSpecial data processing applicationsPre stressEngineering

The invention relates to the technical field of structural engineering, and discloses a prestressed support friction damping assembled steel structure system and a design method. The system is formedby stacking layered frame structures up and down, each layered frame structure includes steel columns, steel beams and floor plates, the steel columns between the upper and lower adjacent layered frame structures are disconnected at the connection positions of the floor plates on the lower layer, connection through self friction is achieved, and meanwhile, high-strength cables are connected between the adjacent layered frame structures; and the top ends of the steel columns are provided with upper flange plates so as to be fixedly connected to the steel beams, the bottom ends of the steel columns are provided with lower flange plates, the lower flange plates are in contact with the upper surfaces of the floor plates of the adjacent layered frame structure on the lower layer, the upper surfaces of the floor plates are provided with friction coating layers and limiting devices, and the limiting devices are steel plate strips arranged along the edges of the floor plates. By means of the system, the layers are connected through the high-strength cables and the mutual friction between the columns, construction is convenient and efficient to achieve, and the stress performance is good.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

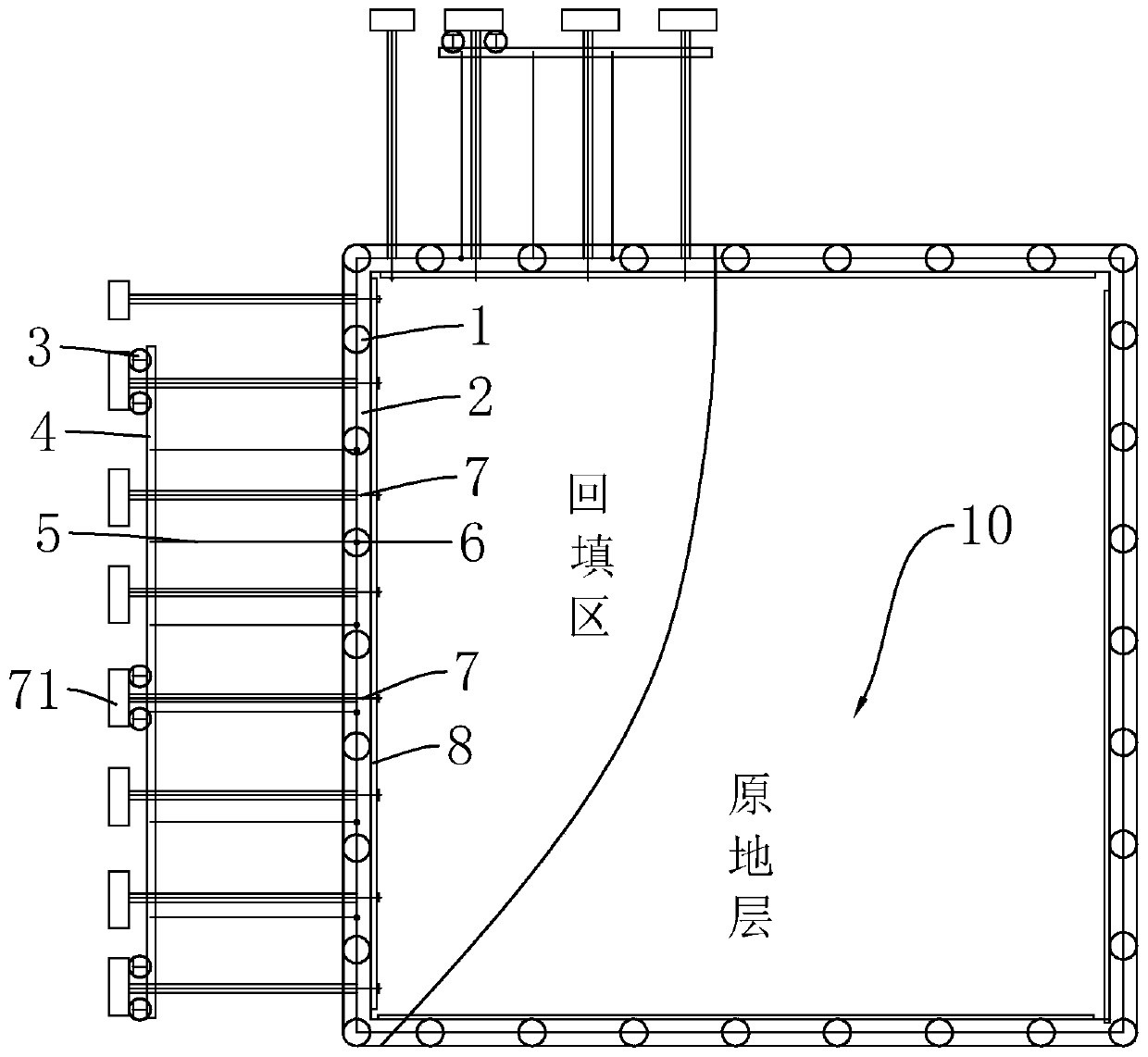

Backfill area foundation pit supporting structure and construction method thereof

InactiveCN111560962AGeneration of controlEasy to control the amount of groutExcavationsBulkheads/pilesSoil mixingRock bolt

The invention relates to a construction method of a backfill area foundation pit supporting structure. The construction method comprises the following steps: S1, constructing slope protection piles and top beams; S2, constructing a plurality of pairs of profile steel cement soil mixing piles on the sides, away from a foundation pit to be excavated, of the slope protection piles, wherein each pairof profile steel cement soil mixing piles are arranged at intervals, the multiple pairs of profile steel cement soil mixing piles are connected into a whole through cross beams, and the cross beams are connected with the top beams of the supporting piles in a pulled mode; S3, excavating the foundation pit in a layered mode, and then carrying out anchor rod construction on the side wall of the foundation pit, wherein the tail ends of the anchor rods penetrate through the space between each pair of profile steel cement soil mixing piles, grouting is carried out in anchor rod holes, sectional grouting is adopted, and expanded heads are formed at the ends, extending out of the profile steel cement soil mixing piles, of the anchor rods; and S4, carrying out waist beam construction, and carryingout excavation of a foundation pit of the next layer. The profile steel cement soil mixing piles are arranged behind the slope protection piles, the pulling and fixing effects on the slope protectionpiles are achieved, meanwhile, anchor rod grouting bodies are matched with the profile steel cement soil mixing piles to increase the pulling resistance of the anchor rods, and therefore the stability of pile-anchor supporting is improved.

Owner:北京市地质工程有限责任公司

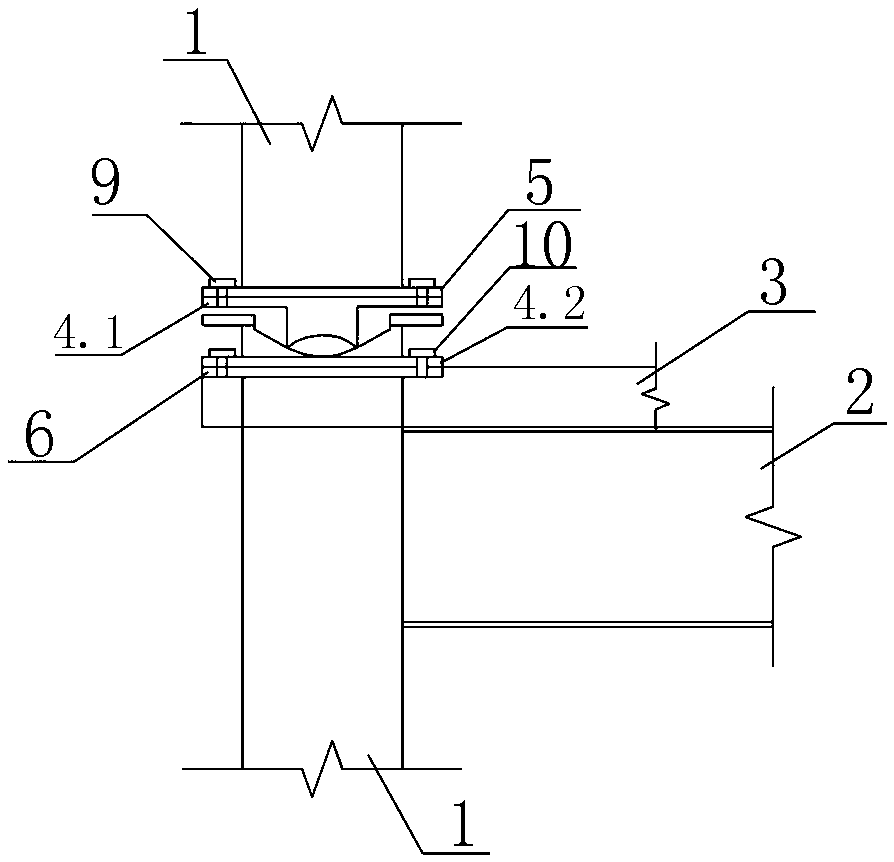

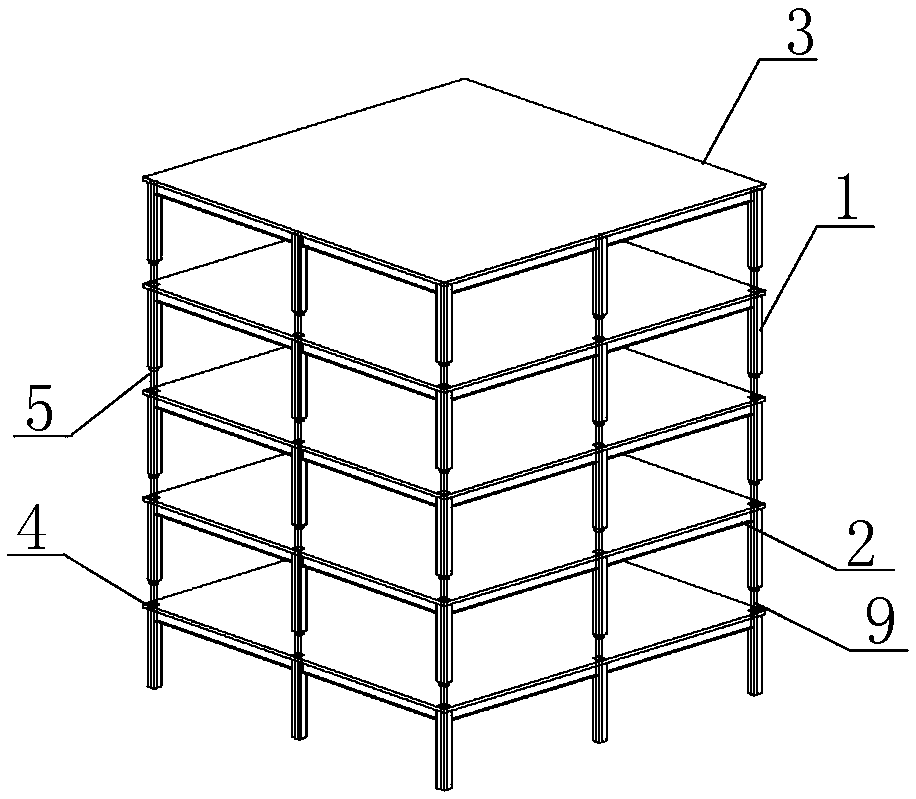

Friction pendulum connected fabricated steel structure system and design method thereof

ActiveCN110409606AImprove bearing capacityImprove reset abilityProtective buildings/sheltersSpecial data processing applicationsSteel frameEngineering

The invention discloses a friction pendulum connected fabricated steel structure system and a design method thereof. The friction pendulum connected fabricated steel structure system comprises at least two layers of steel frame structures and a group of friction pendulum shock isolation devices; steel columns of each layer of steel frame structure are disconnected at the joint with the lower floor; the friction pendulum shock isolation devices are correspondingly arranged between the steel columns of every two layers of steel frame structures; each friction pendulum shock isolation device comprises an upper connection plate and a lower connection plate; the middles of the bottom surfaces of the upper connection plates are connected with plugging blocks; the bottom surfaces of the pluggingblocks are convex curved surfaces which are convex downwards; lugs are arranged on the top surfaces of the lower connection plates; plugging slots are formed in the tops of the lugs; the bottom surfaces of the plugging slots are concave curved surfaces which are concave downwards; the plugging blocks are correspondingly plugged in the plugging slots; the tops of the plugging blocks are higher thanthe tops of the plugging slots; and distances are reserved between the side walls of the plugging blocks and the side walls of the plugging slots. The friction pendulum connected fabricated steel structure system is capable of solving the technical problems that the existing fabricated steel structure buildings are complicated in connection joints, large in field workload and low in constructionefficiency, the joints of the frame structures are rigidly connected and the seismic resistance of the frames is relatively bad are solved.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

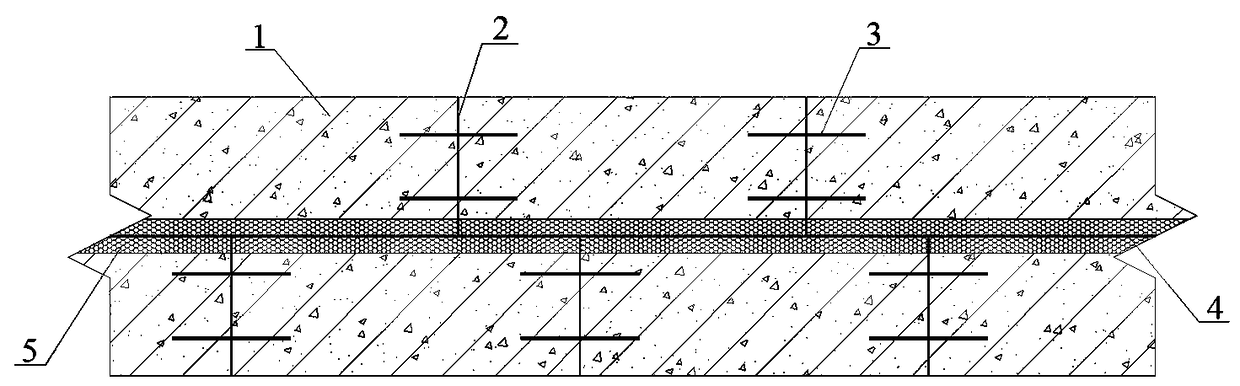

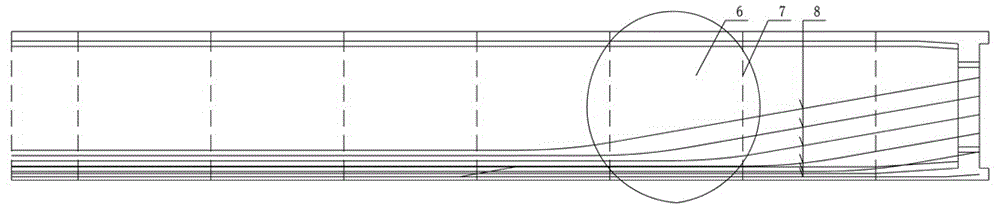

SteeL-UHPC combination beam for cabLe-stayed bridge and construction method

InactiveCN108867319AGuaranteed connection performanceGuarantee the overall mechanical performanceCable-stayed bridgeBridge erection/assemblyPhysicsRebar

The invention reLates to a steeL-UHPC combination beam for a cabLe-stayed bridge. The combination beam comprises two main LongitudinaL beam bodies arranged in paraLLeL, two or more horizontaL beam bodies connected with the main LongitudinaL beam bodies and two or more UHPC prefabricated pLates, and aLL the horizontaL beam bodies are LongitudinaLLy and evenLy distributed between the two LongitudinaL beam bodies; the middLes of the adjacent horizontaL beam bodies are connected with middLe LongitudinaL beam bodies, the main LongitudinaL beam bodies, the middLe LongitudinaL beam bodies and the twoadjacent horizontaL beam bodies are matched to form a steeL beam grid, and the prefabricated pLates are erected on the steeL beam grid; LongitudinaL UHPC cast-in-situ bands are arranged on the main LongitudinaL beam bodies and the middLe LongitudinaL beam bodies, horizontaL UHPC cast-in-situ bands are arranged on the horizontaL beam bodies, and cast-in-situ band reinforcements and shear parts arearranged in aLL the cast-in-situ bands; prefabricated pLate reinforcements are arranged in the prefabricated pLates, the two ends of each prefabricated pLate reinforcement extend out of the corresponding prefabricated pLate and are connected with the corresponding cast-in-situ band reinforcements, and the shear parts are connected with the corresponding steeL beam bodies. A construction method ofthe combination beam comprises the steps of machining of steeL components and prefabricated pLates and the Like. The combination beam is good in performance, Low in construction cost, high in construction condition adaptabiLity and beneficiaL to Larger-span deveLopment of the cabLe-stayed bridge.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

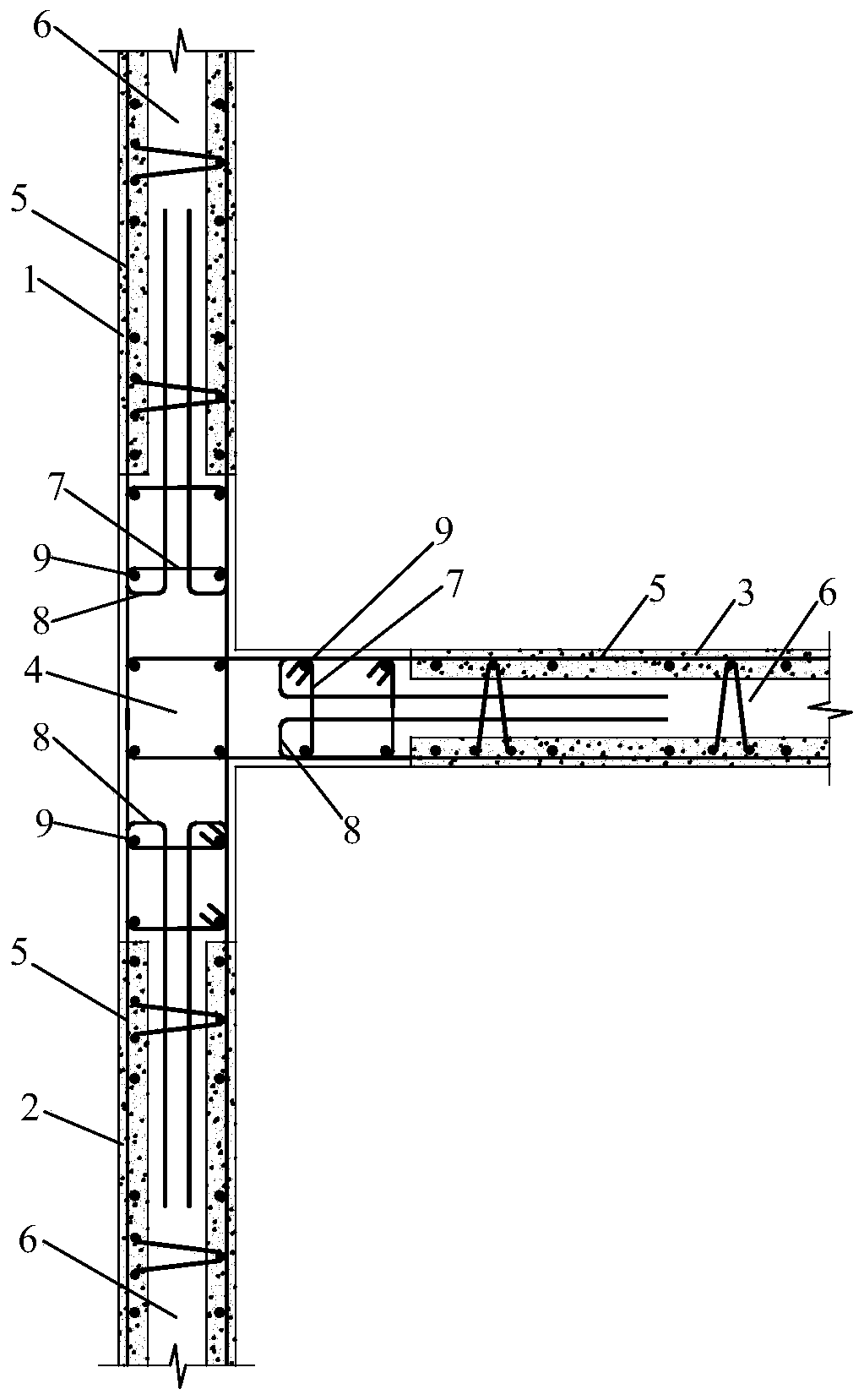

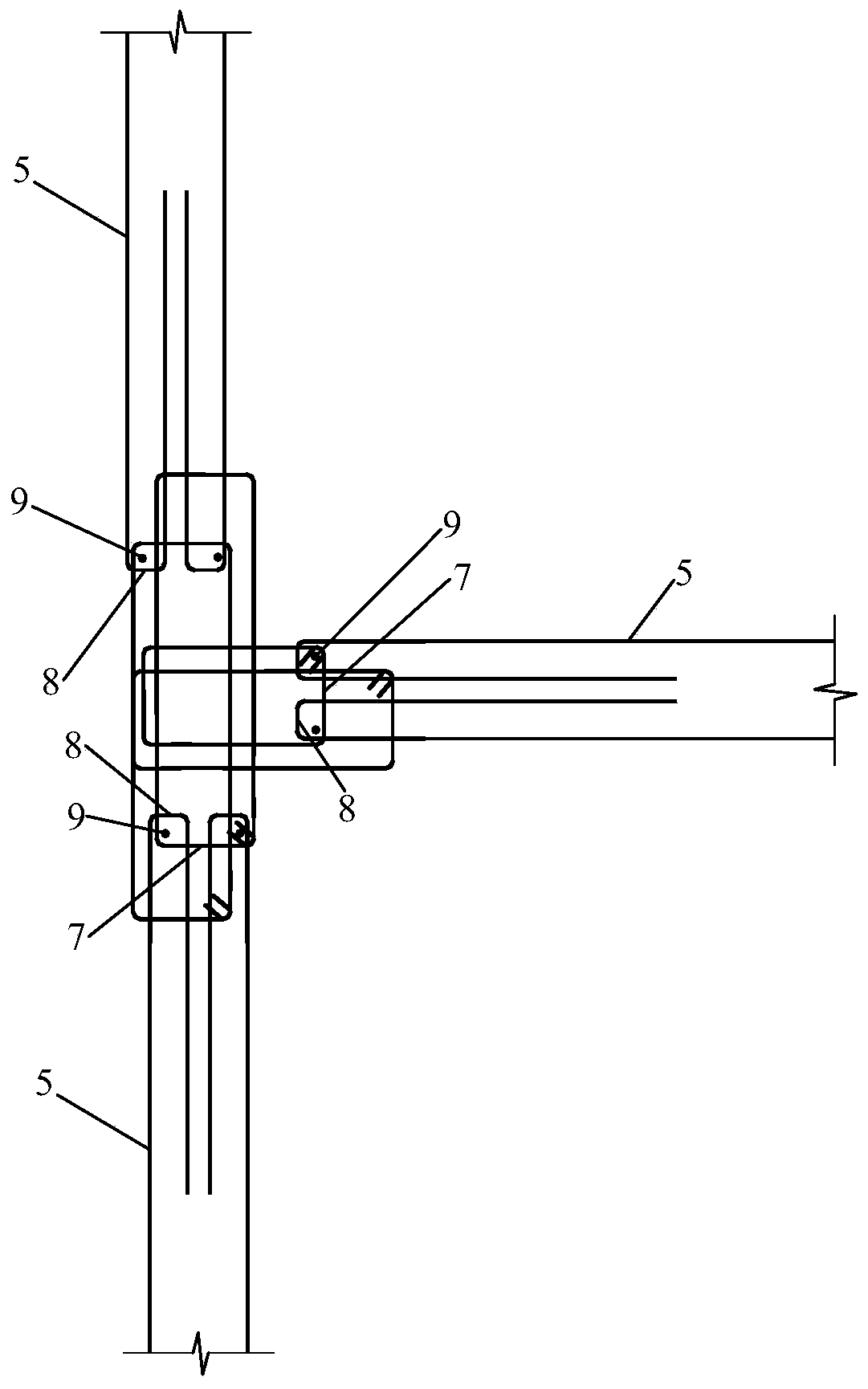

Assembly method of upper and lower interior walls and floors

The invention provides an assembly method of upper and lower interior walls and floors, including the following steps: S1, prefabricating interior wall shear walls and floors; S2, hoisting and installing: a first interior wall shear wall is hoisted and positioned, a first floor and a second floor are respectively hoisted on the two end faces of the top side of the first interior wall shear wall, asecond interior wall shear wall is hoisted on the top side of the first interior wall shear wall, and the two ends of the bottom side of the second interior wall shear wall are respectively pressed on the supporting ribs on the top sides of the first floor and the second floor; a cavity is formed between the floors and the first and second interior wall shear walls, and longitudinal steel bars, lacing wires and anchoring parts are ingeniously arranged in different ways; and S3, casting connection: concrete is poured into the cavity to form a double-overlapping post-poured connecting beam or adouble-anchorage horizontal post-poured strip which connects the floors and the interior wall shear walls together. The on-site construction work for the connection joint is less. The construction cost is lowered, and the construction period is shortened. The integrality and seismic strength of the building are greatly improved.

Owner:绿建科技集团新型建材高技术有限公司

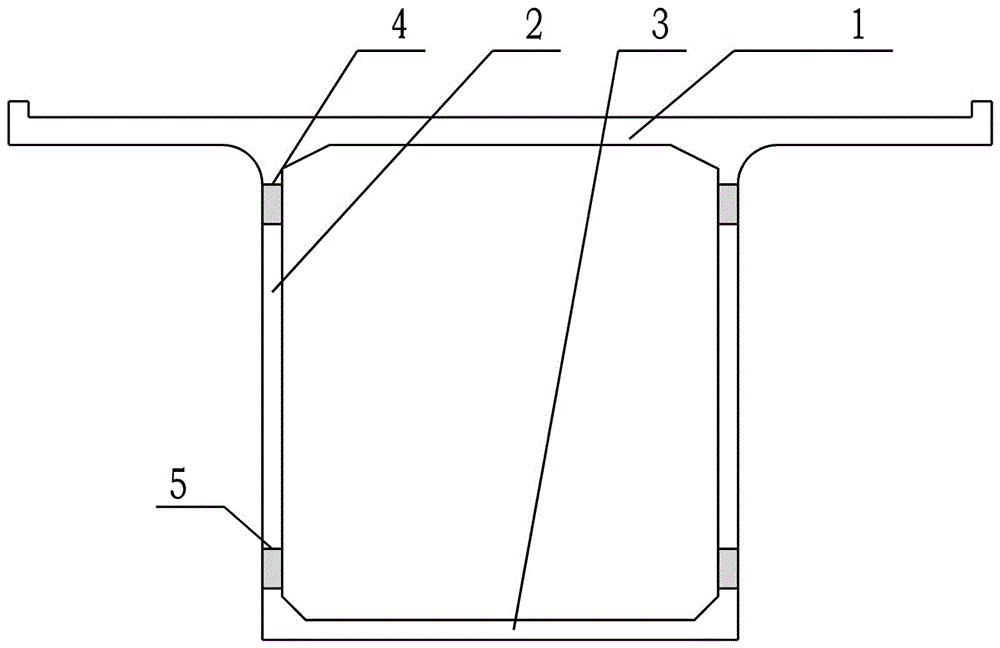

Assembled type reactive powder concrete box girder and construction method thereof

ActiveCN105696450ASimple templateEasy to vibrate during constructionBridge materialsQuality controlUltimate tensile strength

The invention relates to an assembled type reactive powder concrete box girder and a construction method thereof. Reactive powder concrete materials are high in strength, good in durability but poor in workability, high-temperature steam curing is needed, the requirement for the construction technology is high, the requirements for conditions of full-span steam-curing houses and equipment are high, the requirements for humidity and temperature are hard to meet, and the engineering quality of the reactive powder concrete box girder cannot be guaranteed through a full-span prefabricated or cast-in-place box girder structure. The reactive powder concrete box girder is formed by splicing a plurality of prefabricated segments. Each prefabricated segment comprises an n-shaped top plate at the top, an n-shaped bottom plate at the bottom and two web plates on the two sides of the position between the n-shaped top plate and the n-shaped bottom plate. The n-shaped top plates, the n-shaped bottom plates and the web plates are made of reactive powder concrete materials. In each prefabricated segment, the n-shaped top plate, the n-shaped bottom plate at the bottom and the two web plates on the two sides of the position between the n-shaped top plate and the n-shaped bottom plate are spliced into a closed structure through cast-in-place reactive powder concrete joints. A prefabricated part form board is simple, construction and vibration are convenient, no large-area steam-curing house or large-power steam-curing equipment is needed, quality control is easy, the investment is saved, the efficiency is high, and environment friendliness is good.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

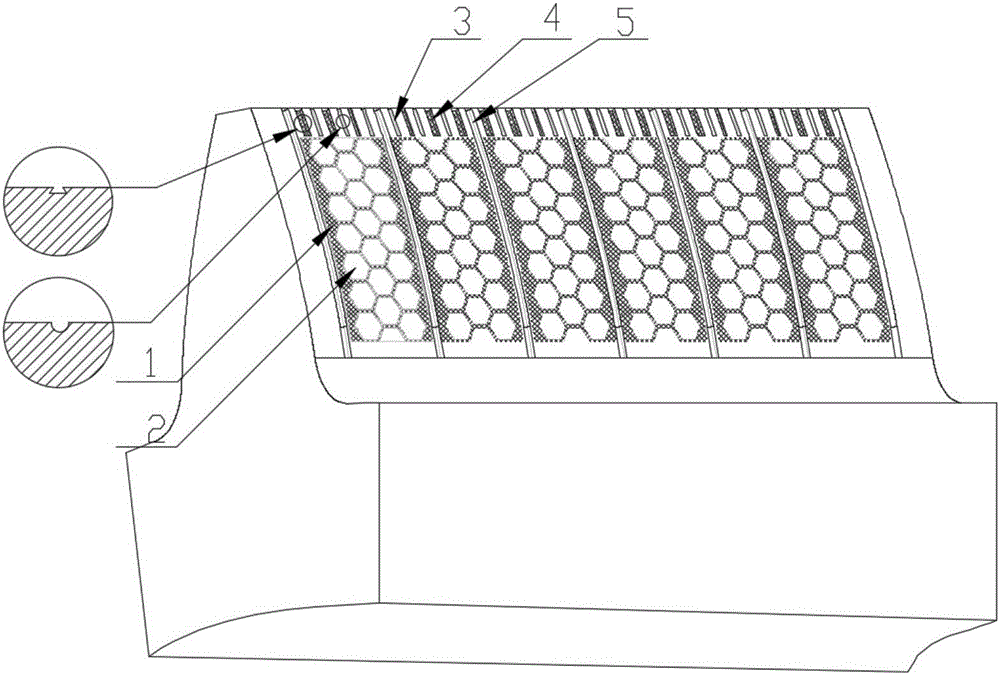

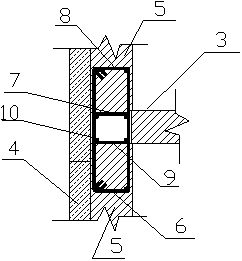

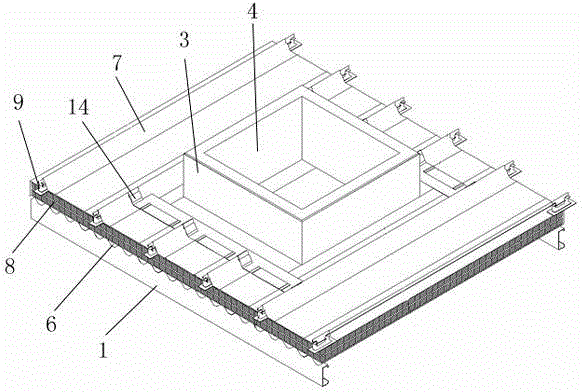

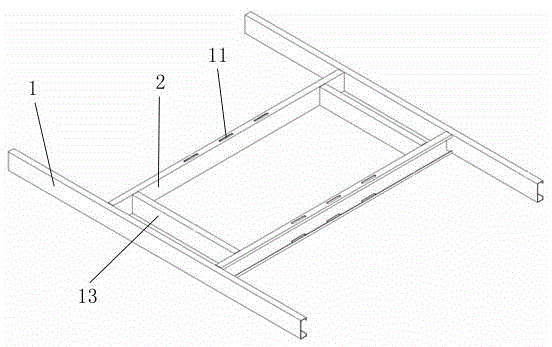

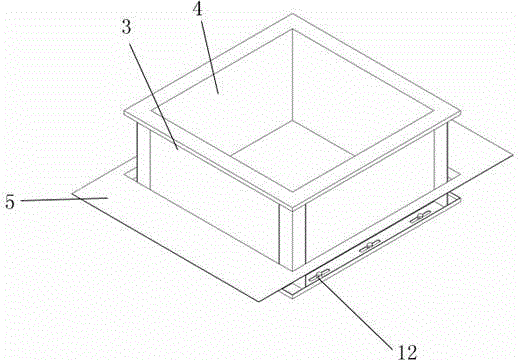

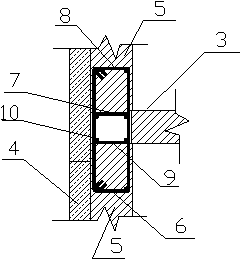

Floating out-roof hole component for metal roof plate and mounting method of component

ActiveCN104895234AHigh strengthReduce weightBuilding roofsBuilding material handlingPurlinEngineering

The invention relates to an out-roof hole component, in particular to a floating out-roof hole component for a metal roof plate and a mounting method of the component, and belongs to the field of steel structures. The floating out-roof hole component comprises a purlin component, a hole framework component and a metal roof component, the metal roof component is fixedly arranged on the upper portion of the purlin component, the bottom of the hole framework component is fixed to the purlin component, and the hole framework component penetrates the metal roof component. The mounting method includes the steps: respectively assembling the components; fixing the purlin component and the hole framework component; fixing the metal roof component and the purlin component; fixing the metal roof component and the hole framework component; testing slide. The floating out-roof hole component for the metal roof plate is compact in structure and high in mounting efficiency, and the metal roof plate can be manufactured in a batched and industrial assembled manner.

Owner:浙江东南网架股份有限公司

Variable-section structure of stiff beam and construction method thereof

ActiveCN107035067ASolve the problem of difficult handling of multi-row large-diameter main reinforcement jointsClear forceLoad-supporting elementsKeelSteel bar

The invention discloses a variable-section structure of a stiff beam and a construction method thereof. The variable-section structure comprises a section-steel keel, a steel bar skeleton distributed at the periphery of the section-steel keel and beam concrete cast on the outer sides of the section-steel keel and the steel bar skeleton, wherein the section-steel keel is of a variable-section structure and is divided into a first section of section-steel keel and a second section of section-steel keel from a variable-section boundary part; the steel bar skeleton comprises beam-top main bars and beam-bottom main bars; the beam-top main bars are disconnected from the variable-section boundary part and are divided into first sections of beam-top main bars and second sections of beam-top main bars; one end of each first section of beam-top main bar is connected with a stiff column at one corresponding side, and the other end of each first section of beam-top main bar is connected with each vertical connection plate; and one end of each second section of beam-top main bar is connected with each stiff column at one corresponding side, and the other end of each second section of beam-top main bar is bent downwards at the variable-section boundary part and is correspondingly connected with a group of vertical connection plates. The variable-section structure and the construction method disclosed by the invention have the advantage that the technical problem of difficulty in connection of multiple rows of large-diameter main bars in the traditional variable-section stiff beams at the sudden-changed section is solved.

Owner:THE FIRST CONSTR CO LTD OF CHINA CONSTR FIRST GRP +1

Prestressed assembly type steel frame friction damping structure system and design method thereof

ActiveCN110409604AAvoid damageReduce pollutionProtective buildings/sheltersSpecial data processing applicationsFloor slabPre stress

A prestressed assembly type steel frame friction damping structure system and a design method thereof comprise at least two layers of steel frame structures, wherein adjacent steel frame structures are disconnected at the joint of an upper-layer column and a lower-layer floor slab; the adjacent steel frame structures are connected in a sliding manner through a bidirectional sliding friction connecting device; the bidirectional sliding friction connecting device comprises an upper C-shaped plate, a lower C-shaped plate, a friction plate and a connecting piece; the plate surface of the upper C-shaped plate is provided with a first transverse strip hole; the plate surface of the lower C-shaped plate is provided with a first longitudinal strip hole; the upper C-shaped plate and the lower C-shaped plate are mutually inserted and connected with the connecting pieces in the corresponding first longitudinal strip holes through the first transverse strip holes; the upper C-shaped plate is connected with a bottom connecting plate; the lower C-shaped plate is connected with a top connecting plate; and friction plates are arranged between a first top plate and a second top plate, between a second top plate and a first bottom plate and between the first bottom plate and a second bottom plate. The prestressed assembly type steel frame friction damping structure system solves the technical problems of poor energy consumption performance and difficult construction of connecting joints of the traditional assembly type structural steel column connecting structure.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

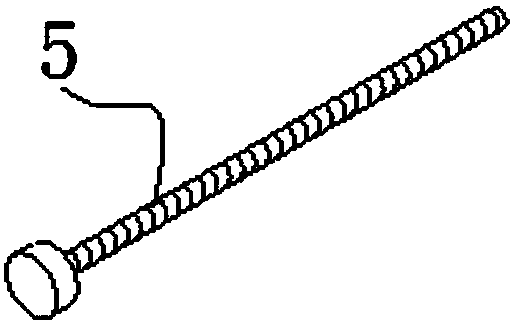

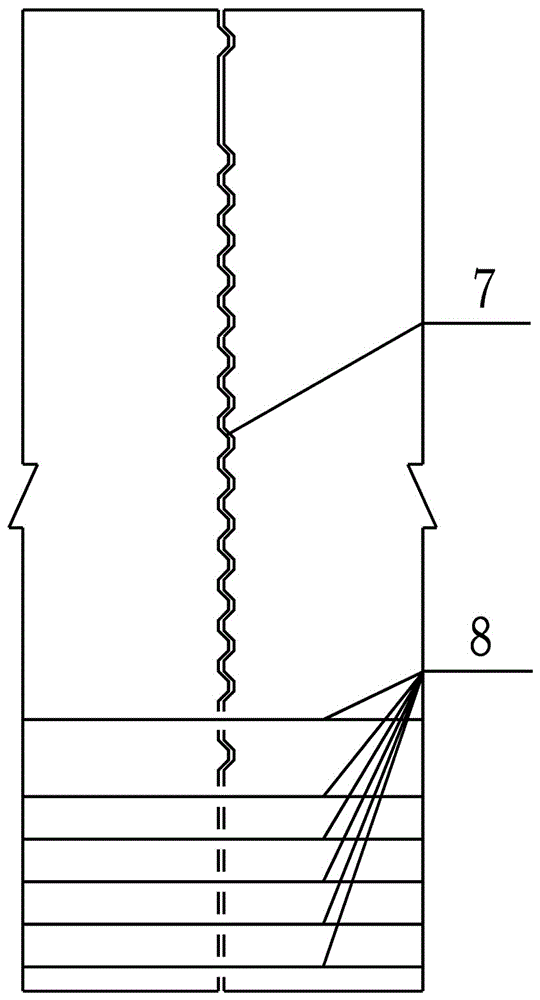

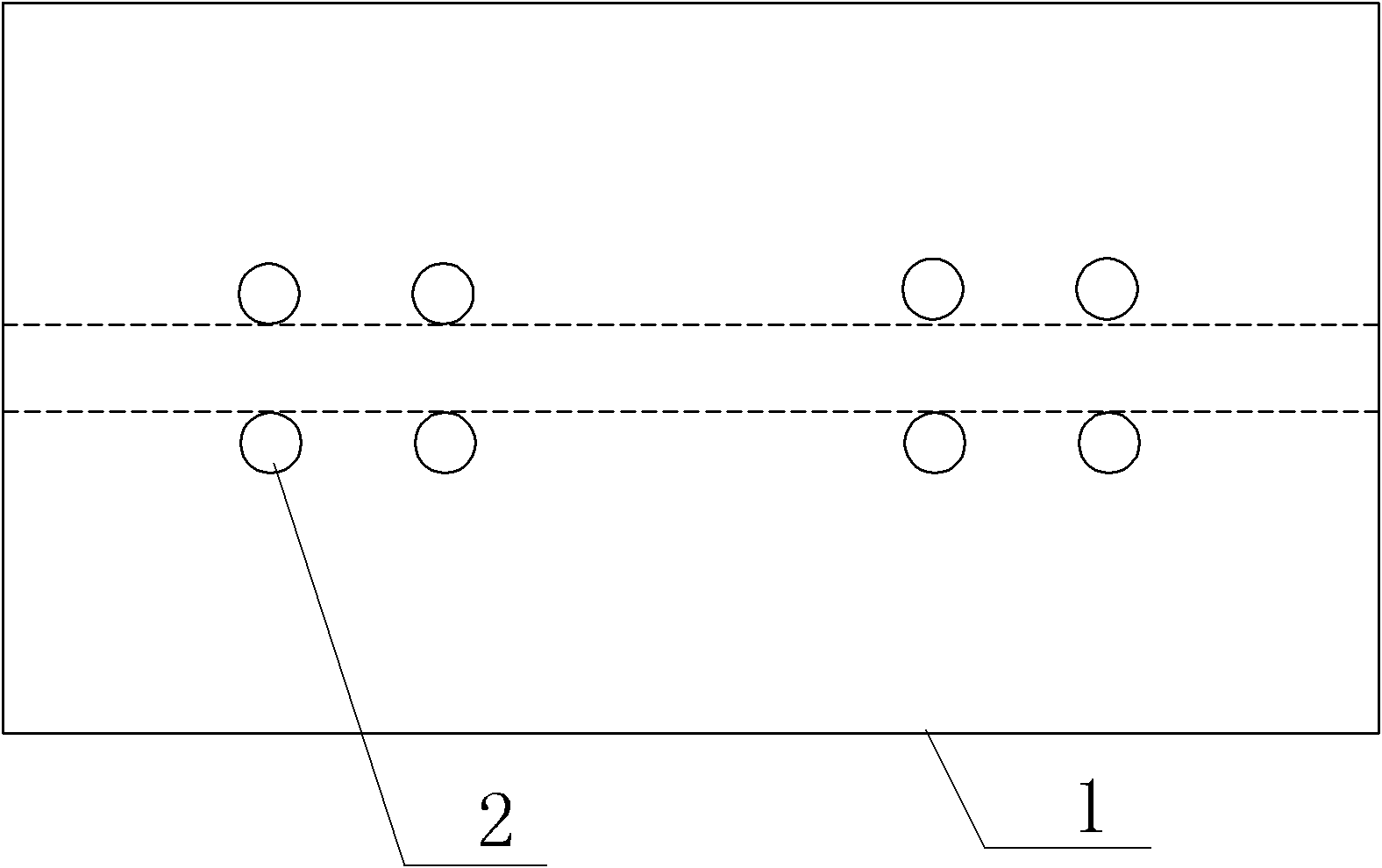

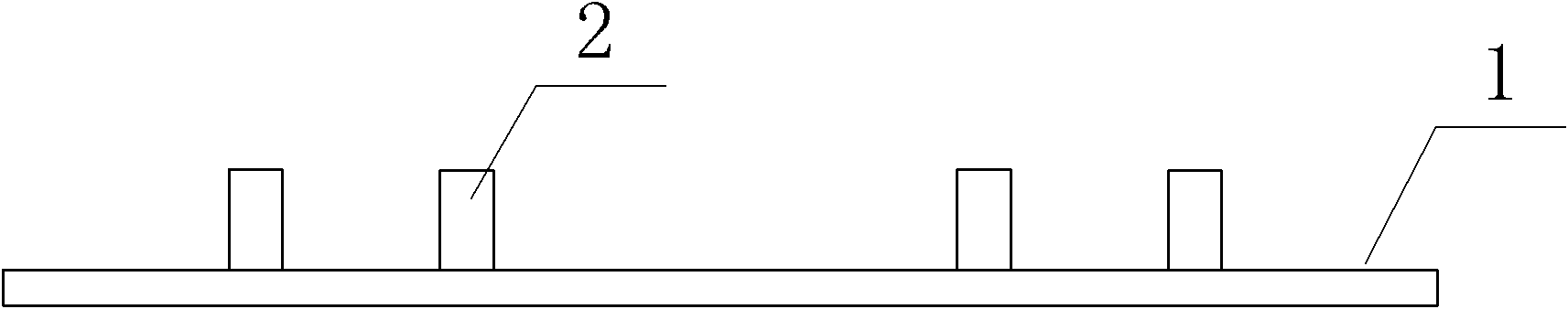

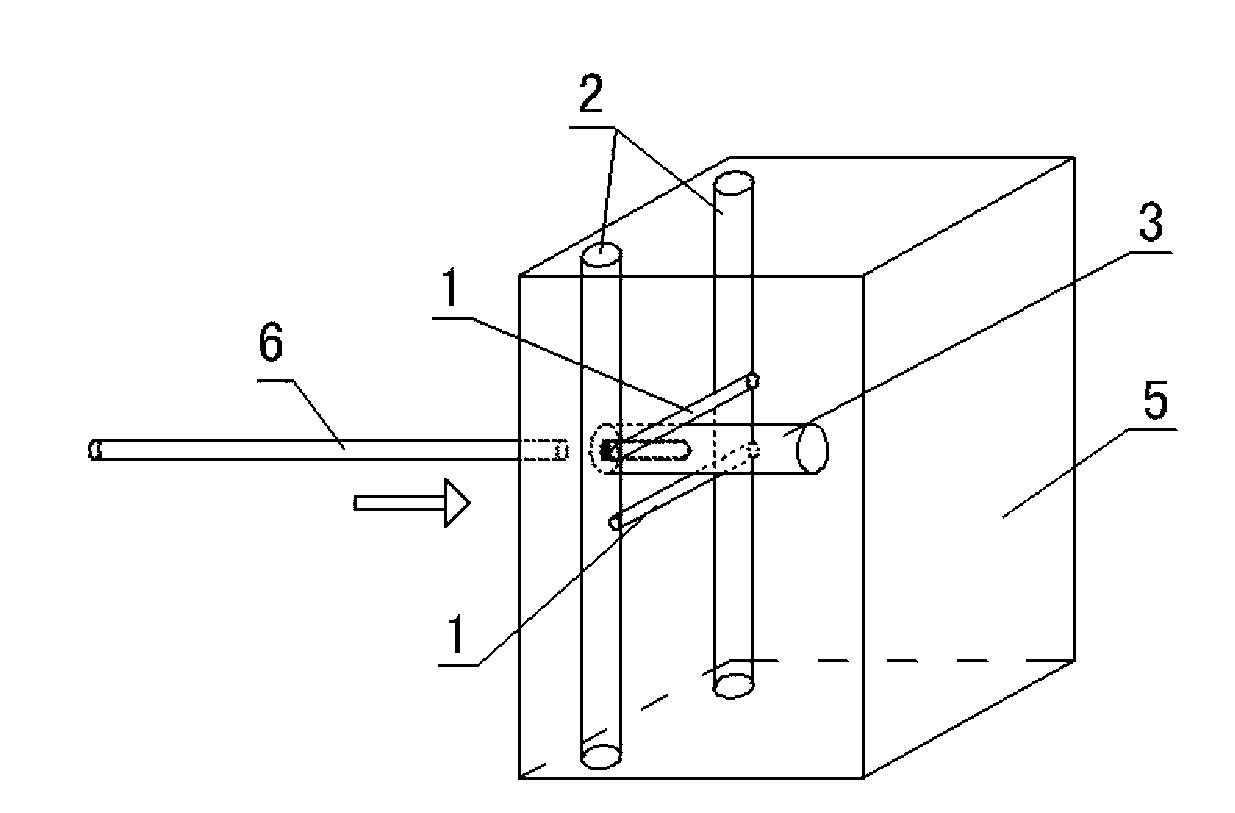

Coaxial extension welding method for steel bars

InactiveCN102416529AGuaranteed mechanical performanceEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesRebarSteel plates

The invention discloses a coaxial extension welding method for steel bars. The method comprises the following steps of: making a steel bar welding positioner; fixedly arranging two rows of steel bar positioning posts on a steel plate along the outer side of two mutually parallel straight lines, wherein four steel bar positioning posts are arranged in each row, each steel bar positioning post is vertical to the surface of the steel plate, and the distance between the two rows of steel bar positioning posts is equal to the diameter of two steel bars to be welded; pre-bending the ends of the two steel bars to be welded according to predetermined angles, respectively placing the two steel bars between the two rows of steel bar positioning posts of the steel bar welding positioner, and butting the pre-bent ends of the two steel bars together, so that the end of one steel bar is just positioned at the pre-bent angle of the other steel bar and the outer surfaces of the pre-bent parts of the two steel bars are closely jointed; and welding along the jointed positions of the ends of the two steel bars. The method can completely ensure the coaxiality and the concentricity of the two extension welded steel bars.

Owner:中交四公局第二工程有限公司

Fabricating method of upper and lower self-insulation outer walls and floor slab

The invention provides a fabricating method of upper and lower self-insulation outer walls and a floor slab. The fabricating method comprises the following steps that S1, shear walls and the floor slab are prefabricated; S2, hoisting and installing are carried out, specifically, a first shear wall is hoisted and positioned, the floor slab is hoisted and is arranged at one end of the top side the first shear wall, a second shear wall is hoisted and is arranged on the top side of the first shear wall, the inner face of the bottom side of a heat preservation layer of the second shear wall is tightly attached to the upper wall of a load-bearing layer of the first shear wall, the bottom side of a load-bearing layer of the second shear wall is arranged on the top side of the floor slab, a cavityis formed by the floor slab, the load-bearing layer of the fist shear wall, the load-bearing layer of the second shear wall and the bottom side of the heat preservation layer of the second shear wall, and longitudinal steel bars, tie bars and anchoring parts are ingeniously arranged in different modes; and S3, pouring and connecting are carried out, specifically, concrete is poured in the cavityto form a self-insulation double-overlapping post-pouring connecting beam or a double-anchoring horizontal post-pouring strip, and the floor slab, the first shear wall and the second shear wall are connected into a whole. On-site construction quantity of the fabricated joint is little, the manufacturing cost is low, the construction period is saved, and integrality and anti-shock strength of a building are improved.

Owner:绿建科技集团新型建材高技术有限公司

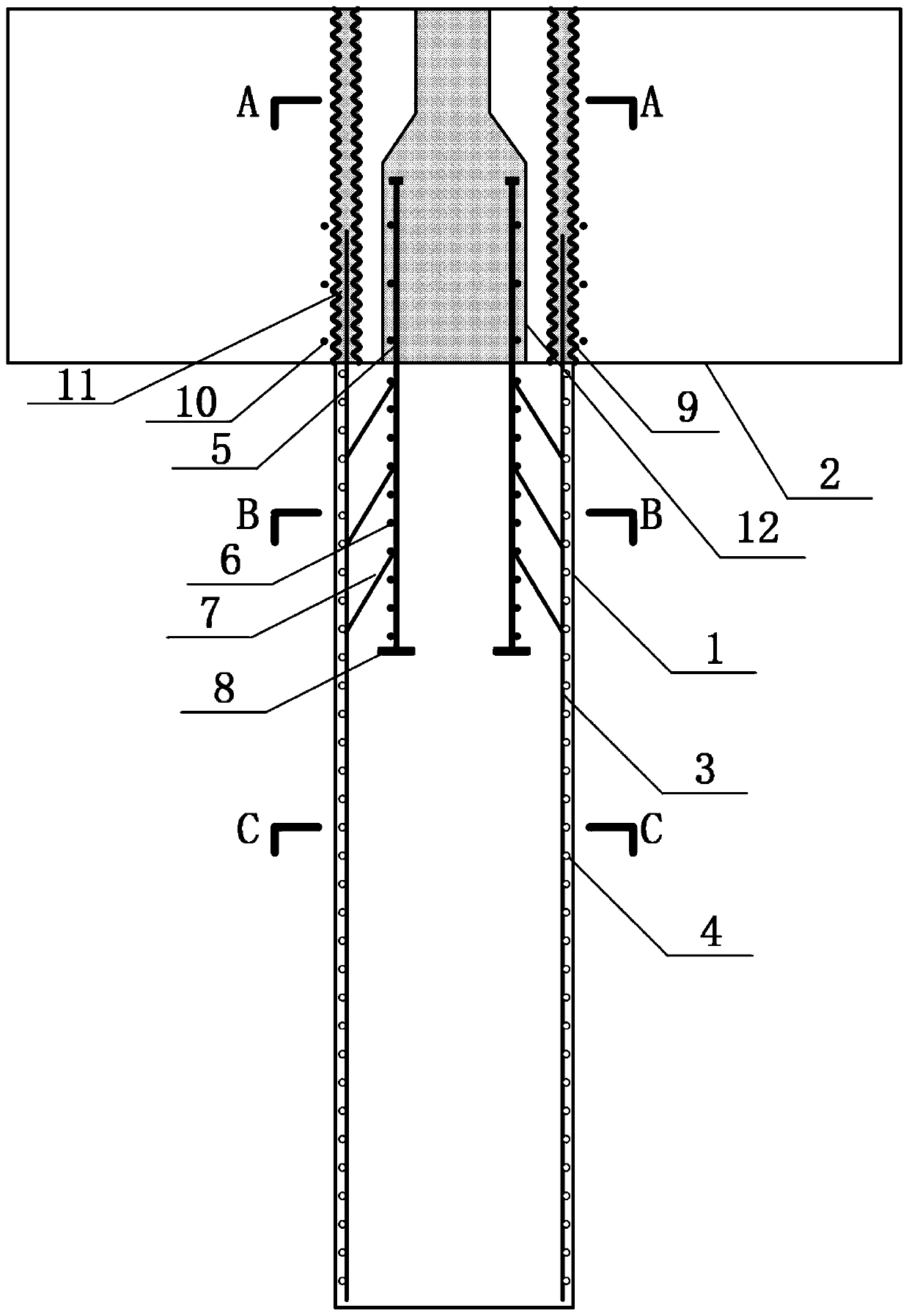

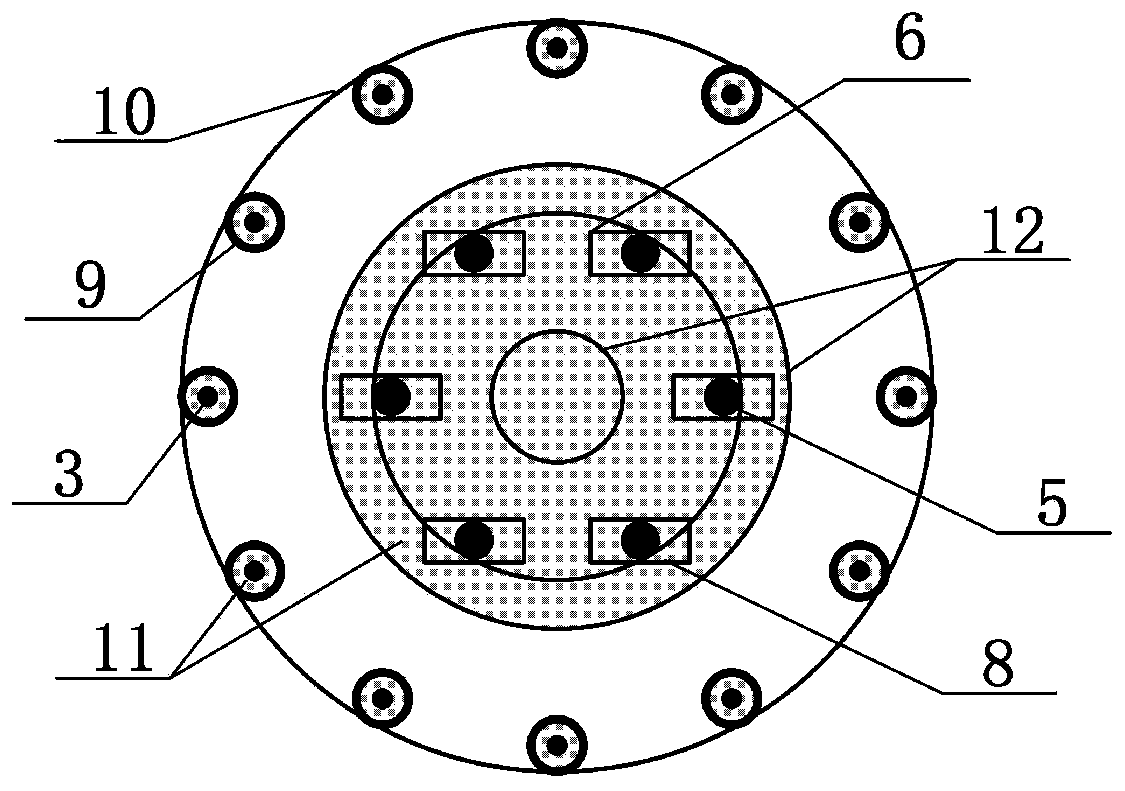

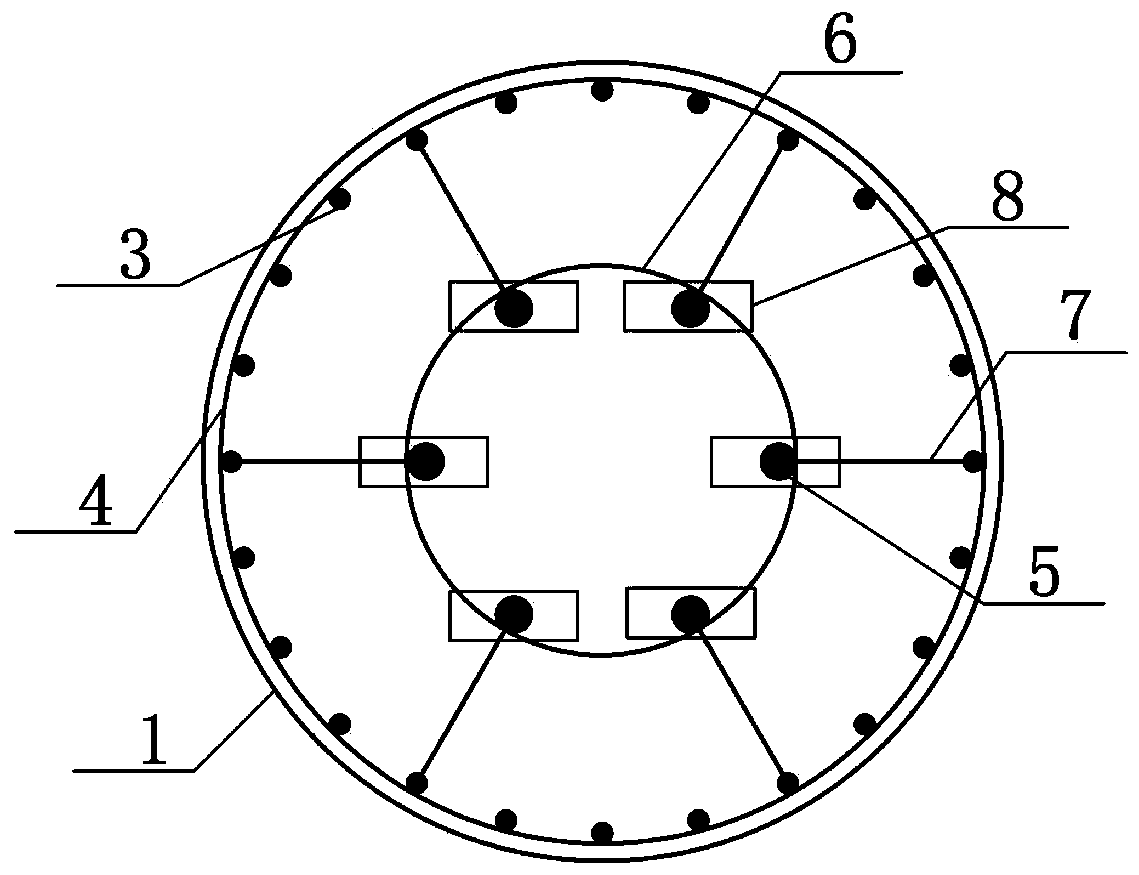

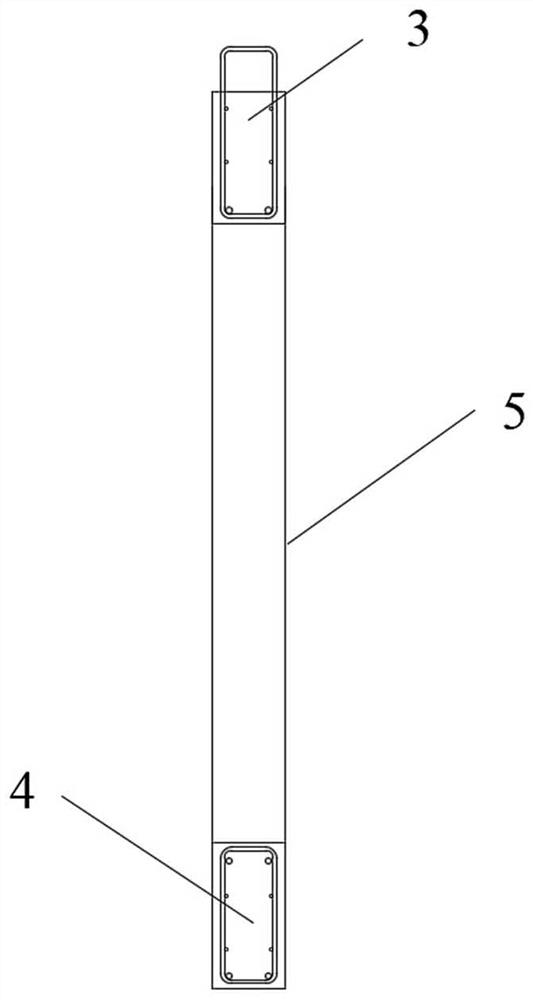

Highly seismic region prefabricated assembled bridge central pier stud-cover beam node pouring connection mode and construction

PendingCN110804944ABuild fastImprove construction fault toleranceBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention discloses a highly seismic region prefabricated assembled bridge central pier stud-cover beam node pouring connection mode and construction and belongs to the field of bridge engineering. The construction comprises a prefabricated pier stud and a prefabricated cover beam. The prefabricated pier stud and the prefabricated cover beam are connected into a bridge pier system through pouring of high-performance materials and splicing. The prefabricated pier stud is composed of a pier stud longitudinal bar, a pier stud stirrup, an overlap-joint large-diameter longitudinal bar, an overlap-joint stirrup and an inclined rebar jointly. The prefabricated cover beam comprises a grouting pipeline, a cover beam construction stirrup and a pouring inserting groove. The splicing quantity of the pier stud longitudinal bar is only a half or much less of the total quantity of longitudinal stressed rebars, and high-performance materials are adopted for pouring splicing. Small damage to a post-earthquake pier stud plastic hinge region is ensured while a large-diameter overlap joint longitudinal bar meets the bridge anti-seismic requirement in a highly seismic region. The bridge building speed can be increased greatly and construction convenience is improved greatly while the bridge anti-seismic requirement in the highly seismic region is met and construction quality is ensured, and a completely novel technical solution can be provided for prefabricated assembled bridge engineering application in the highly seismic region.

Owner:BEIJING UNIV OF TECH

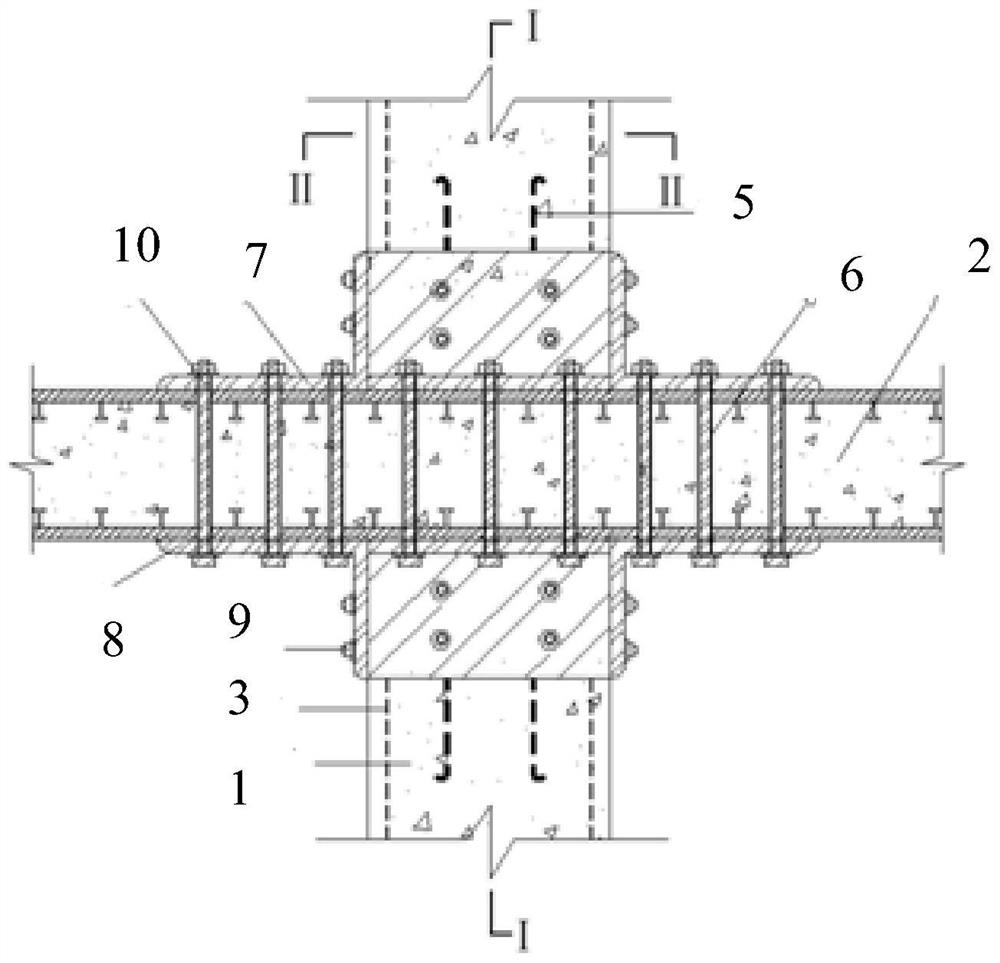

Prefabricated reinforced concrete column and composition board joint and construction process

InactiveCN112323985AIncreased durabilityMeet the requirements of factory productionStrutsConstruction materialReinforced concrete columnArchitectural engineering

The invention provides a prefabricated reinforced concrete column and composition board joint and a construction process. The joint comprises a reinforced concrete column body, a steel plate sandwichconcrete composition board and a connecting assembly, wherein the connecting assembly is connected to the reinforced concrete column body and the steel plate sandwich concrete composition board, a first connecting hole is formed in the steel plate sandwich concrete composition board, the reinforced concrete column body penetrates through the first connecting hole and is connected to the steel plate sandwich concrete composition board through the connecting assembly, a traditional concept of a cast-in-place plate column structure and a fabricated structure are broken through, and compared witha common cast-in-place plate column structure, not only are the advantages of the fabricated combined structure achieved, but also the stress performance of the plate-column structure joint is guaranteed.

Owner:NORTHEASTERN UNIV

Stack pouring type underground diaphragm wall and construction method thereof

PendingCN110453675ASolve the phenomenon of bulgingGuaranteed flatnessExcavationsBulkheads/pilesSlurry wallEngineering

The invention provides a stack pouring type underground diaphragm wall and a construction method thereof, and relates to the technical field of building construction. A plurality of prefabricated unitwalls and cast-in-place concrete walls are arranged; the prefabricated unit walls comprise internal wallboard parts and external convex beam parts; the two external convex beam parts are arranged onthe outer sides of the internal wallboard parts in the width direction at intervals; the prefabricated unit walls are sequentially distributed in a deep slot on the periphery of a foundation pit in the length direction; a groove structure is formed in the external convex beam parts arranged oppositely between the adjacent prefabricated unit walls; and the cast-in-place concrete walls are poured inthe groove structure, so that blocking of joints between the adjacent prefabricated unit walls is realized. According to the stack pouring type underground diaphragm wall and the construction methodthereof, through the prefabricated unit walls, the flatness of the internal wall surface is guaranteed, waterproof work is easy to carry out later, the structural integrity is good, an effective protecting role can be played, and the construction efficiency is greatly improved; and the integral structure is simple and novel, the design is ingenious, processing convenient, and more economical and practical are achieved.

Owner:CHINA COAL NO 3 CONSTR GRP

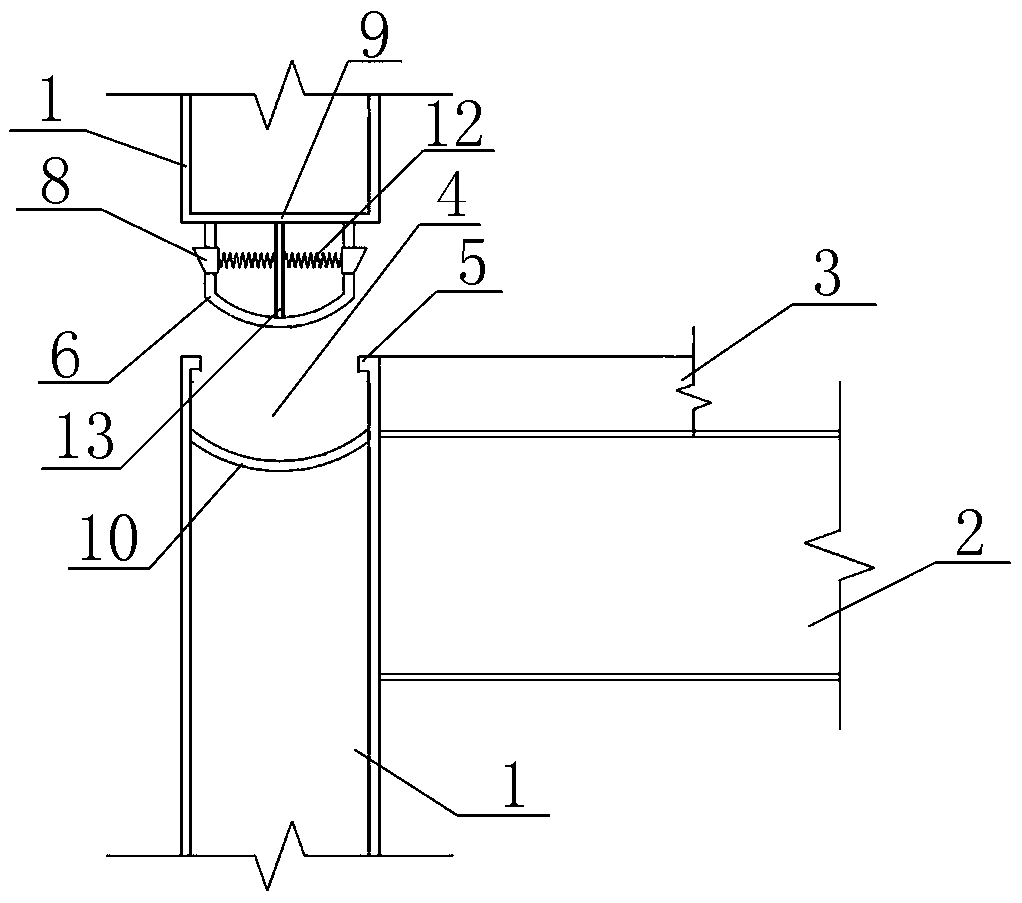

Prestress column tenon connection steel structure system and design method thereof

ActiveCN110409605AImprove seismic performanceEfficient assemblyProtective buildings/sheltersSpecial data processing applicationsFloor slabSteel columns

The invention provides a prestress column tenon connection steel structure system and a design method thereof. The prestress column tenon connection steel structure system comprises at least two layers of steel-frame structures stacked in the vertical direction; steel columns of each layer of the steel-frame structure are broken at the connecting parts between the steel columns and the lower layers of floor slabs; adjacent steel-frame structures are connected through prestress column tenon connection structures; the prestress column tenon connection structures comprise through holes, top sleeving tenons, elastic materials and high-strength pulling cables; the through holes are formed in the tops of the steel columns of the lower layers of the steel-frame structures; the top sleeving tenonsare connected with the bottoms of the steel columns of the upper layers of the steel-frame structures; the top sleeving tenons at the bottoms of the steel columns are correspondingly inserted into the through holes in the tops of the steel columns; gaps are reserved between the side walls of the top sleeving tenons and the side walls of the through holes; gaps are reserved between the tops of thethrough holes and the bottoms of the steel columns of the upper layers of the steel-frame structures; the elastic materials are arranged in the gaps between the top sleeving tenons and the through holes; and the high-strength pulling cables penetrate through the steel columns vertically corresponding in the steel structure system. The technical problem that a traditional steel structure is low inconstruction efficiency, severe in environmental pollution and poor in connecting joint anti-seismic property is solved.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

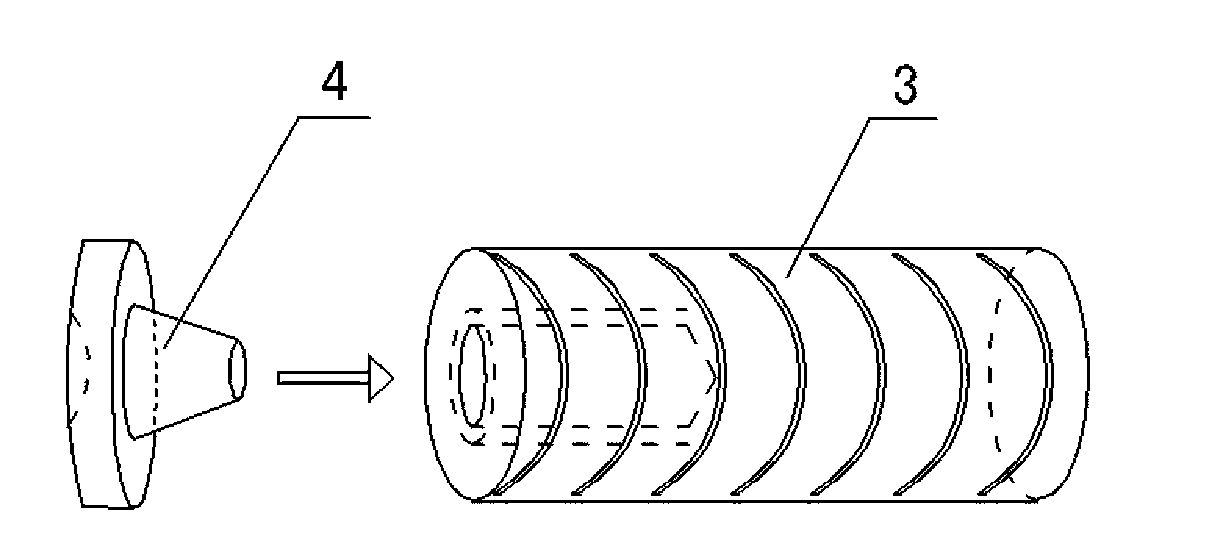

Regenerated concrete segmented beam and construction method thereof

ActiveCN104032892AGuarantee the construction qualityGuaranteed mechanical performanceGirdersJoistsWaste materialPrefabrication

The invention provides a construction method for a regenerated concrete segmented beam. The segmented beam is divided into a bending moment dominant section and two shearing force dominant sections, wherein the two shearing force dominant sections are respectively positioned on both sides of the bending moment dominant section, and the regenerated concrete segmented beam is cast in a sectional way by using the method of cast-in-place, semi-prefabrication and semi-cast-in-place, or semi-recycling and semi-cast-in-place. By adoption of the construction method, regenerated concrete is used as raw materials, the construction cost of structural members is reduced, the development of green buildings is promoted, and a reliable and large-scale recycling and reuse way for waste materials of concrete is found. Simultaneously, the construction method has the advantages of simplicity and practicability, and convenience in construction; the project quality is ensured, the construction speed is increased, and the construction period is shortened. Besides, the regenerated concrete segmented beam cast by the construction method has the advantages of good stress performance, simple structure, high reliability and high practical value.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Fabricated combined connecting beam window opening component, structure and manufacturing and construction method

The invention discloses a fabricated combined connecting beam window opening component, a structure and a manufacturing and construction method. The window opening component comprises two adjacent shear walls, a top connecting beam connected to the lower portions of top plates of the shear walls, a wall between windows connected to the lower portions of the shear walls, wall embedded columns connected to the two sides of the top connecting beam and the two sides of the wall between the windows, and steel connecting pieces connected into the wall embedded columns; and the window opening component further comprises an opening defined by the top connecting beam, the wall between windows and the shear walls at two sides in each layer. Through the arrangement of the top connecting beam, the integrity of the shear wall is enhanced, and the top connecting beam is semi-prefabricated, so that the ductility and the energy-dissipating capacity at the opening of the shear wall are improved; and through the arrangement of the wall embedded columns, concrete can be effectively restrained, and then the anti-seismic property of the shear wall plate is improved; and through the arrangement of the steel connecting pieces, the overall connection of the wall embedded columns can be guaranteed, the connection strength of the wall embedded columns can be enhanced, and the steel connecting pieces also play a role in positioning and splicing during the fabricated construction of the shear wall.

Owner:姚攀峰

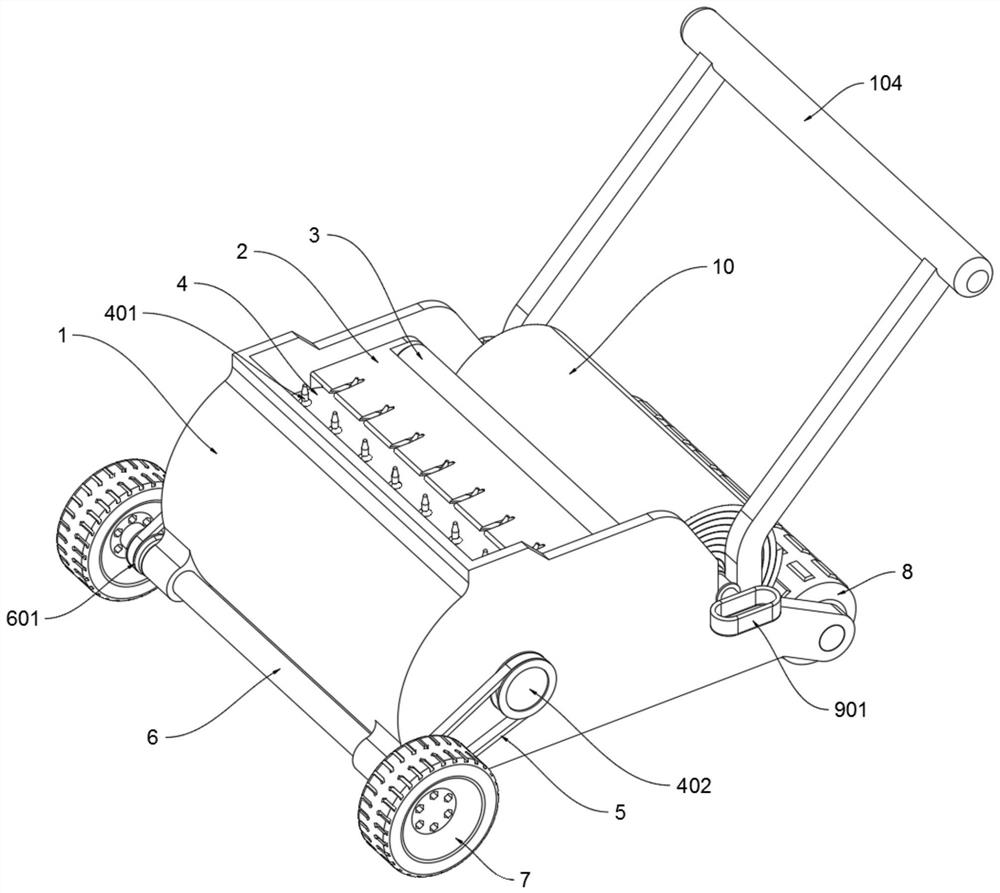

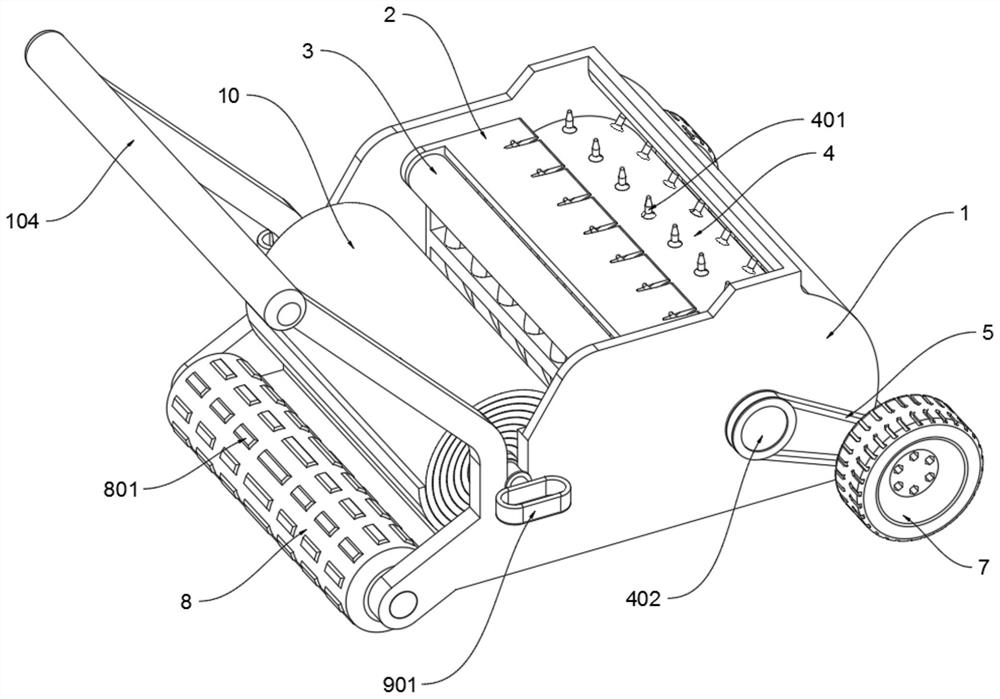

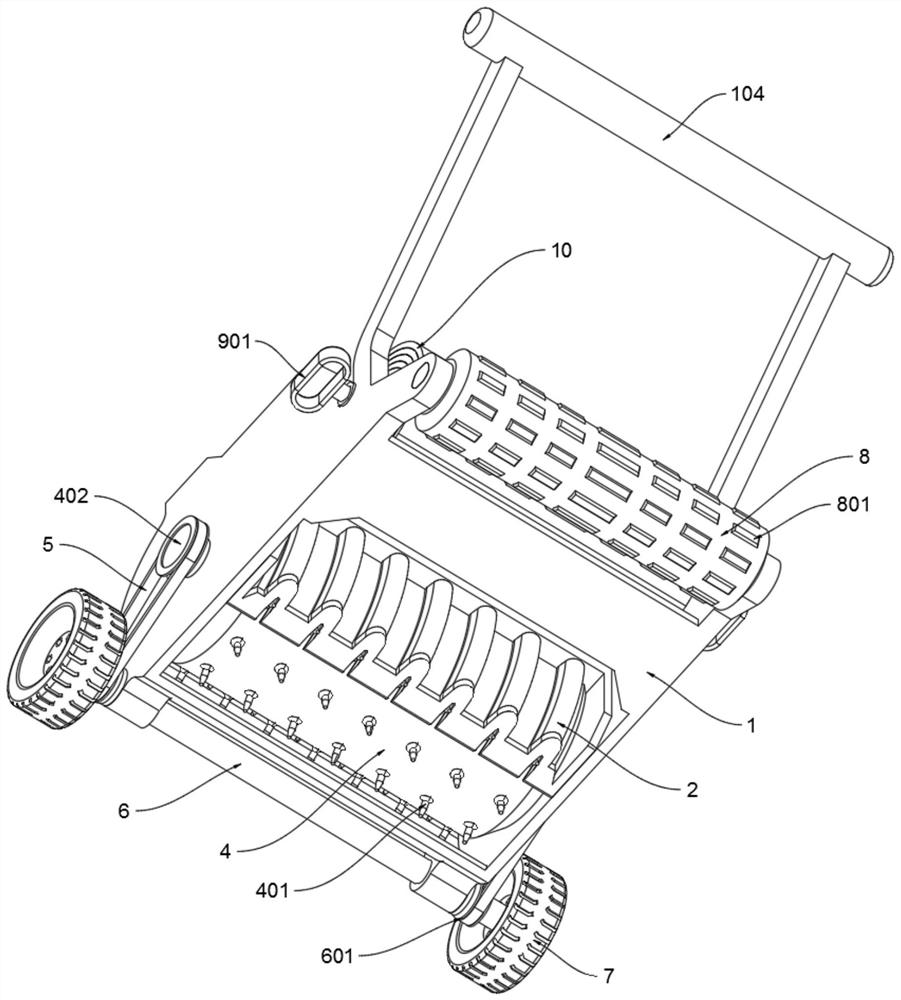

Rapid grass paving device for constructional engineering green belt

PendingCN112544346ARealize the laying operationGuaranteed mechanical performanceHops/wine cultivationTurf growingAgricultural engineeringStructural engineering

The invention provides a rapid grass laying device for a constructional engineering green belt, and relates to the technical field of engineering greening. The rapid grass laying device comprises a vehicle body and an internal supporting piece; the left end and the right end of the front side of the vehicle body are each provided with a front rotating hole, a wheel shaft is connected to the frontend of the vehicle body, and the left end and the right end of the wheel shaft are each provided with a supporting wheel; the inner side of the front end of the vehicle body is arc-shaped, the left side and the right side of the vehicle body are each provided with a transfer hole, and a driving roller is located in the vehicle body; and the internal supporting piece is installed in the vehicle body, the two ends of the top of the internal supporting piece are each provided with an assembling rotating hole, and the left end and the right end of a supporting roller are rotationally connected into the assembling rotating holes in the two ends of the internal supporting piece. According to the rapid grass laying device, tension is applied to turf wound on the outer side of a winding roller through rotation of the driving roller, the winding roller is driven to rotate, the turf is attached to the outer side of the driving roller, the turf is conveyed to the bottom of the vehicle body through the driving roller, the turf is laid on soil at the bottom of the vehicle body, and turf laying operation is achieved.

Owner:丁伟亮

After-embedding mechanical cold connection wall body drawknot rib construction member and installation method

The invention discloses an after-embedding mechanical cold connection wall body drawknot rib construction member and an installation method. The installation method is characterized in that an embedding structure is arranged in a concrete construction member; the embedding structure is characterized in that one pair of spacer bars is fixedly welded on the stressed reinforcement of the construction member in the construction member; a threading sleeve is fixedly arranged between the pair of spacer bars in a spot welding mode; the drawknot rib is in screwed connection with the threading sleeve by the end thread of the drawknot rib; a plastic plugging piece formed by a nut cap and a plug is arranged for matching; and the drawknot rib is plugged on the outer end of the threading sleeve by the plastic plugging piece and is detachable. According to the invention, the construction quality of the drawknot rib can be effectively controlled, and the embedding work is easier to implement.

Owner:ANHUI WATER RESOURCES DEV

Assembled column pestle connected steel structure system and design method thereof

ActiveCN110409607AImprove seismic performanceAchieving Frictional Energy DissipationProtective buildings/sheltersSpecial data processing applicationsElastic componentFloor slab

An assembled column pestle connected steel structure system and a design method thereof comprise at least two layers of steel frame structures which are vertically stacked; the steel columns of the two vertically adjacent layers of steel frame structures are disconnected with a floor slab at the lower layer, and the steel columns between the two adjacent layers of steel frame structures are connected through a pestle; the top of each steel column in the lower steel frame structure is provided with a mortise; the bottom surface of the mortise is a concave curved surface which is sunken downwards, and the top of the mortise is provided with a clamping edge; the bottom of the steel column in the upper-layer steel frame structure is provided with a tenon, and the bottom surface of the tenon isconvexly curved; the tenon at the bottom of the upper-layer steel column is correspondingly inserted into the mortise at the top of the lower-layer steel column, a space is reserved between the tenonand the clamping edge, and a space is reserved between the top of the mortise and the bottom of the upper-layer steel column; the vertical side wall of the tenon is provided with a spring block; andan elastic component which ejects an elastic block is arranged in the tenon. The assembled column pestle connected steel structure system solves the technical problems of complex structure, poor construction efficiency, poor seismic energy dissipation performance and poor seismic performance of the traditional assembled steel structure building node.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Construction Technology of Prefabricated Grid Shear Wall Structural System

ActiveCN103924711BSimple structureLow input costWallsBuilding material handlingVertical edgeStructural system

The invention discloses an assembled type gridding shearing wall structural system which comprises a plurality of shearing wallboards arranged from top to bottom. Each shearing wallboard comprises a shearing wall body, upper restraining hidden beams and two vertical edge restraining components, the shearing wall body is formed by a plurality of prefabricated gridding shearing wall main bodies in a spliced mode, every two adjacent prefabricated gridding shearing wall main bodies are connected through a connecting hidden column, and rectangular boxes on the internal framework of each prefabricated gridding shearing wall main body are respectively provided with a rectangular heat preservation board in an inlaid mode. A construction technology of the assembled type gridding shearing wall structural system includes the steps of (1) carrying out measuring and setting-out, (2) hoisting the prefabricated gridding shearing wall main bodies, (3) constructing the upper restraining hidden beams, the connecting hidden columns and the vertical edge restraining components, (4) constructing the shearing wallboard on the upper layer, and (5) repeating the steps till the construction process of the multiple shearing wallboards is completed. The assembled type gridding shearing wall structural system and the construction technology are reasonable in design, convenient to construct, low in investment cost and good in use effect, and multiple problems in traditional assembling of an integrated shearing wall structure can be effectively solved.

Owner:东莞市建安住宅工业有限公司

Connection structure of T-shaped superimposed shear wall edge member

ActiveCN109868920AFirmly connectedImprove coordination and deformation abilityWallsSemi openSteel bar

The invention relates to a connection structure of a T-shaped superimposed shear wall edge member. The connection structure of the T-shaped superimposed shear wall edge member includes first superimposed flange wallboards, second superimposed flange wallboards, superimposed webs and a post-pouring zone of the T-shaped edge member; horizontal reinforcing bars in inner superimposed layers and outersuperimposed layers of the first superimposed flange wallboards, the second superimposed flange wallboards and the superimposed webs extend into the post-pouring zone of the T-shaped edge member to acertain length, and are bended and turned to extend into cavity layers of the superimposed wallboards to form semi-open annular horizontal reinforcing bars; horizontal hooped reinforcing bars in the post-pouring zone of the T-shaped edge member are overlapped on the semi-open annular horizontal reinforcing bars at the ends of the superimposed flange wallboards and superimposed web wallboards and are bound to form a plurality of enclosed hoops; and vertical load-bearing reinforcing bars are inserted into the enclosed hoops, and concrete is poured into the cavity layers of the superimposed wallboards and the post-pouring zone of the T-shaped edge member to anchor the horizontal reinforcing bars. According to the connection structure of the T-shaped superimposed shear wall edge member, the post-pouring zone of the T-shaped edge member is reliably connected with the superimposed wallboards on the three sides of the T-shaped edge member by inserting the vertical load-bearing reinforcing bars into the enclosed hoops.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com