Patents

Literature

205results about How to "Reduce on-site construction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

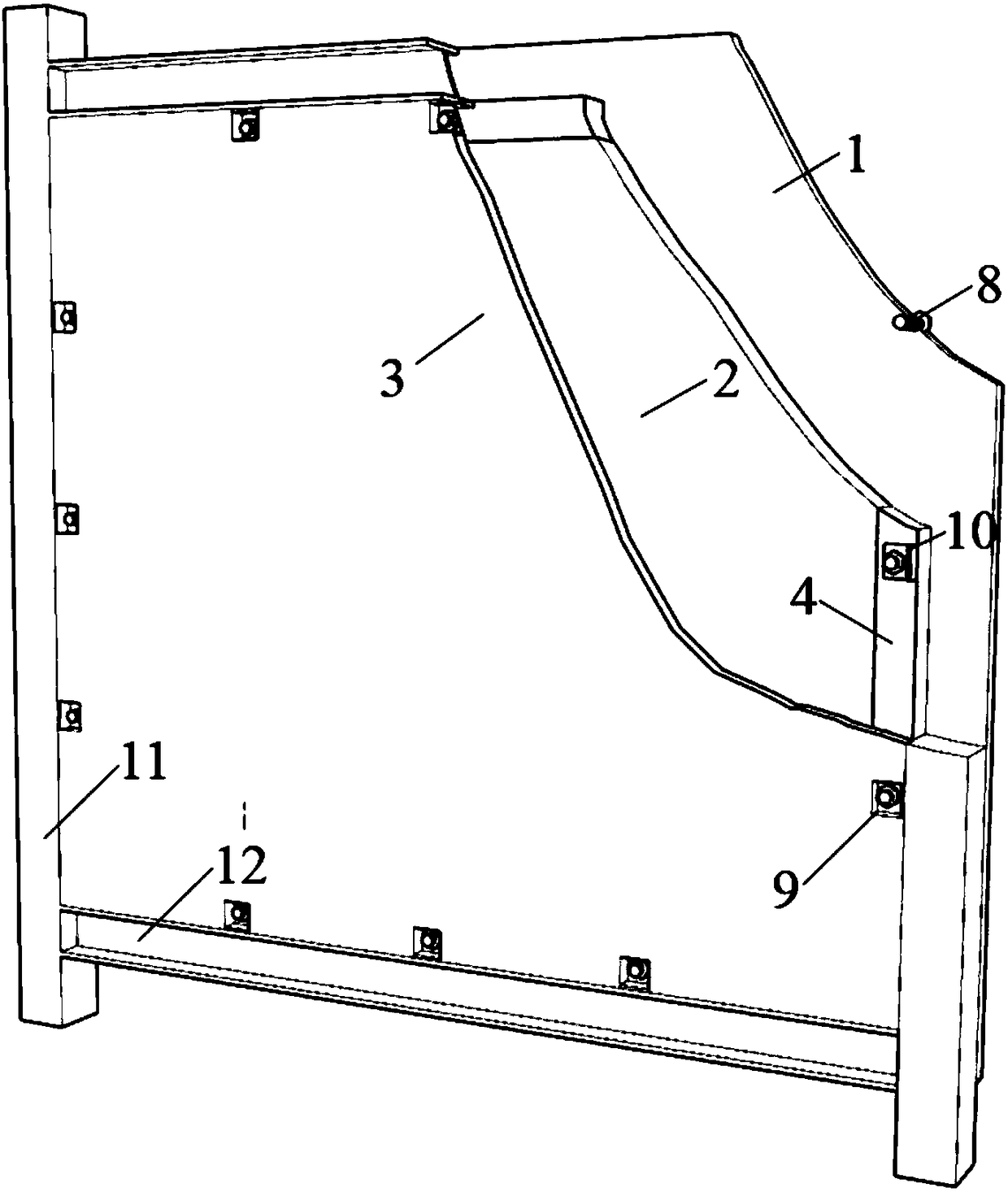

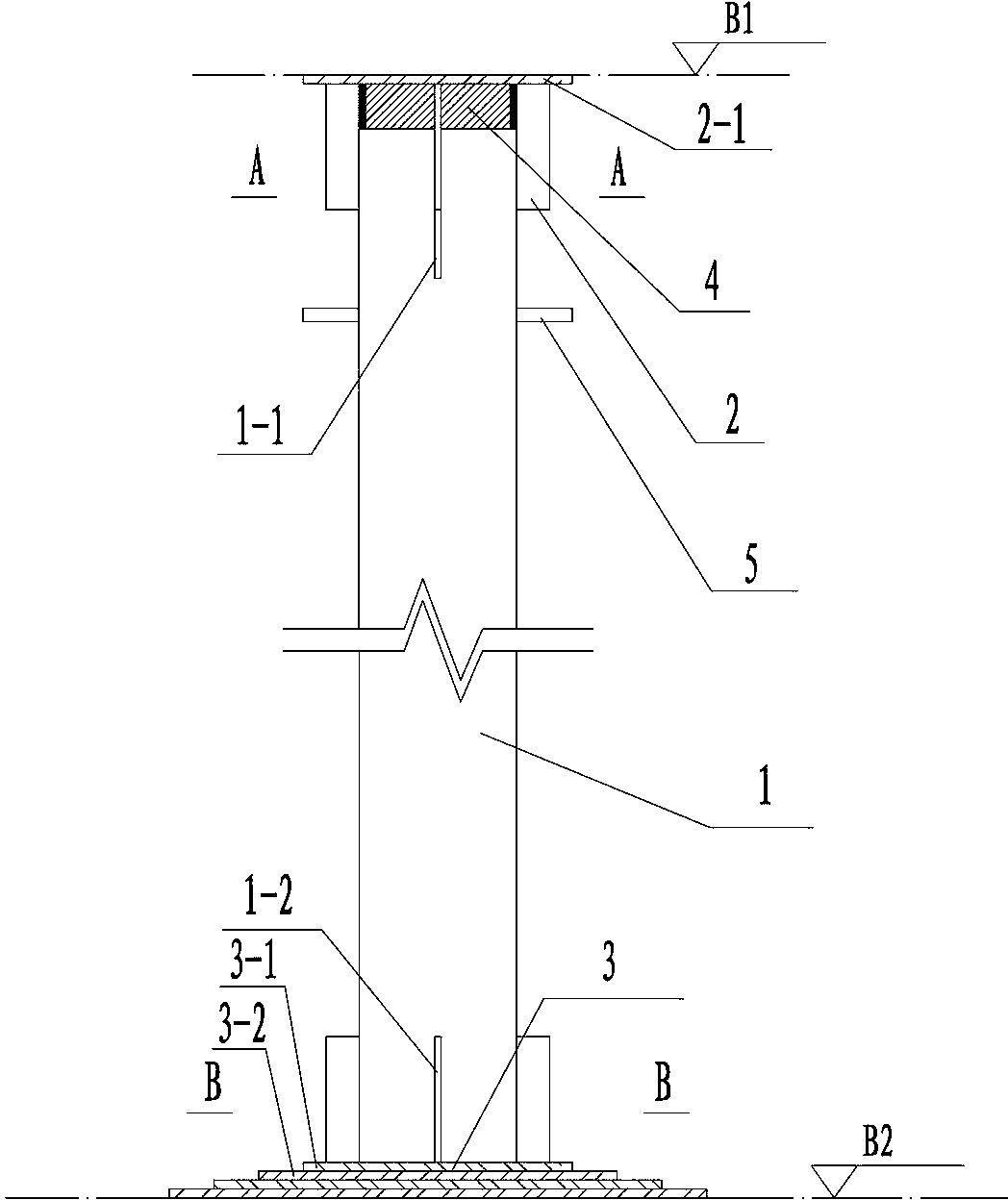

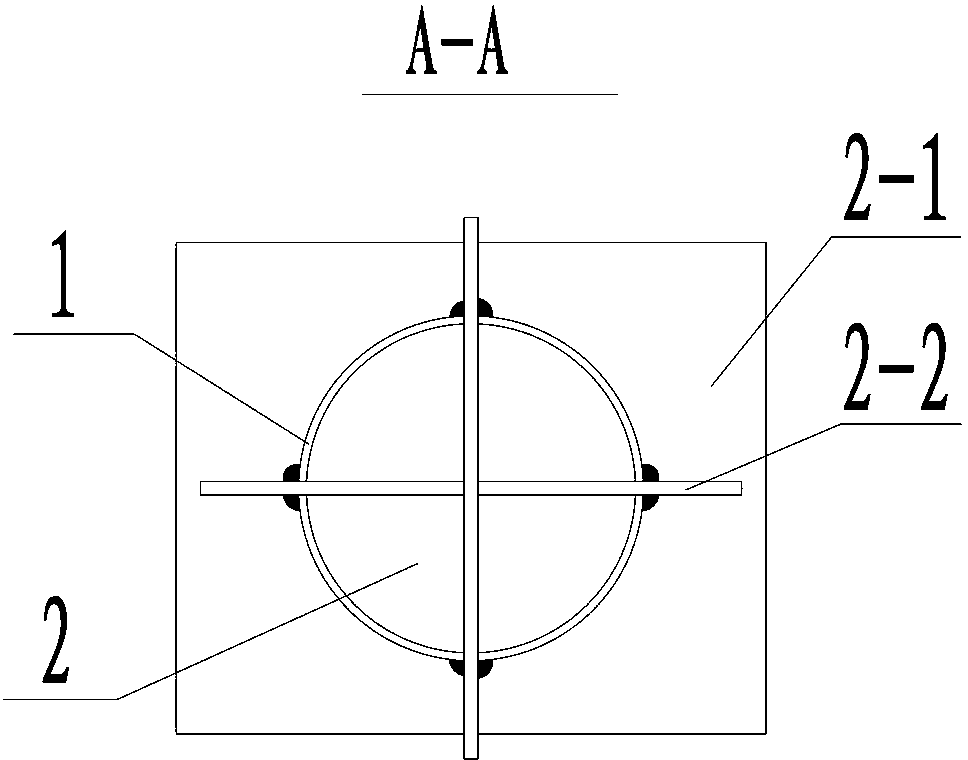

Prefabricated double-column vase bridge pier and assembling construction method thereof

InactiveCN106677056AReduce pollutionReduce the difficulty of on-site construction alignmentBridge structural detailsBridge erection/assemblyBuilding constructionLower degree

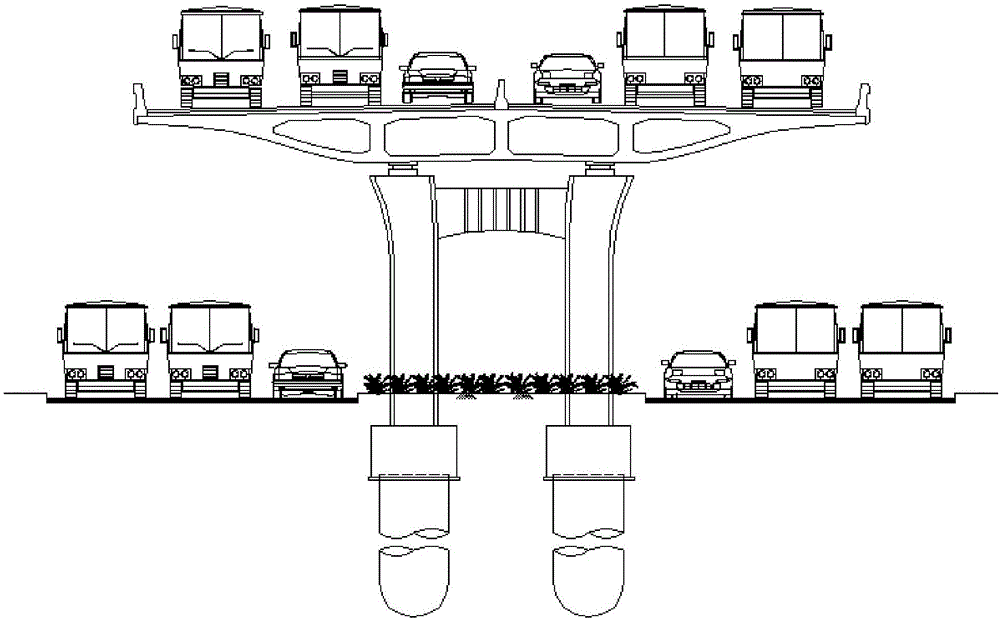

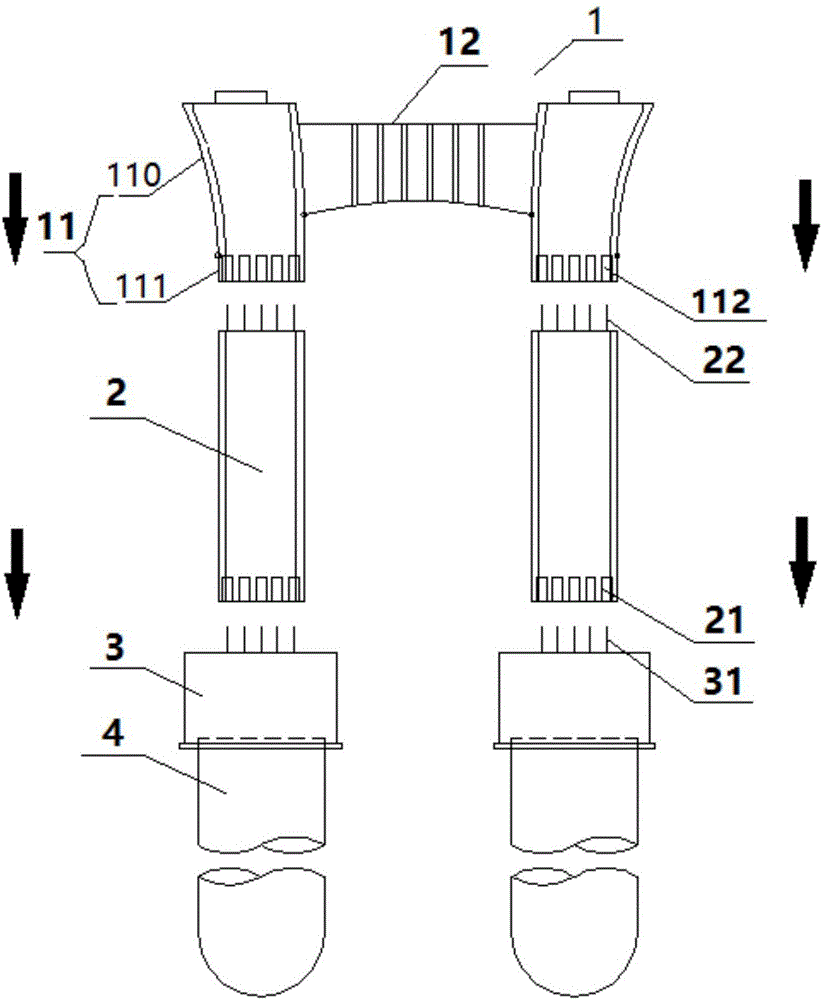

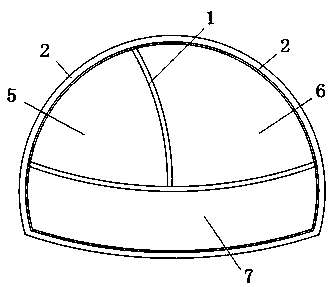

The invention discloses a prefabricated double-column vase bridge pier and an assembling construction method thereof. The prefabricated double-column vase bridge pier comprises two pier body sections and one pier cap section, the pier body sections are bridge pier straight main sections, the pier cap section is a joint of two bridge pier straight and curve transition sections and one tie beam, the two bridge pier straight and curve transition sections are positioned at two ends of the tie beam respectively, and a bridge pier curve section is arranged on the upper portion of each bridge pier straight and curve transition section and gradually transits downwards into a bridge pier straight end section. The double-column vase bridge pier is prefabricated and divided into the pier body sections and the pier cap section, the assembling direction of the bridge pier is uniformly vertical, site construction alignment difficulty is reduced, site construction time is shortened, pollution of site construction to surrounding environments is relieved, and the influence of construction on surround traffic is minimized.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

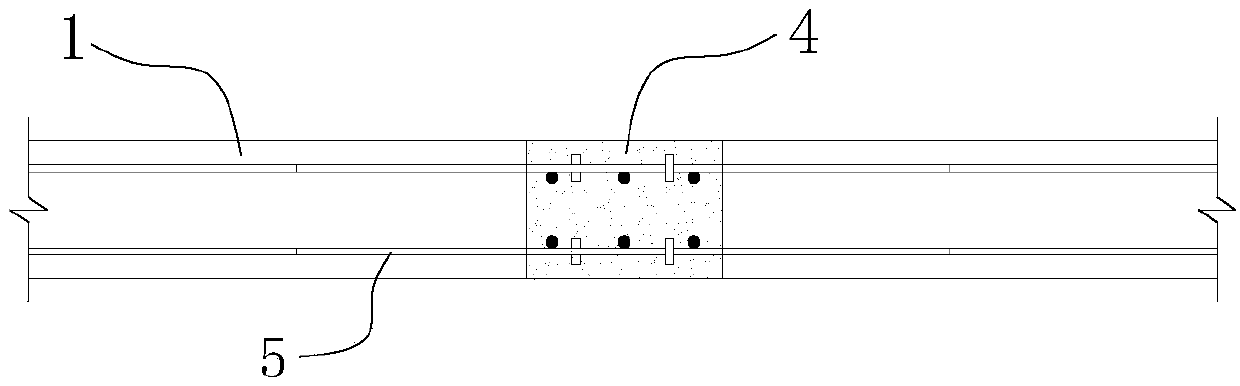

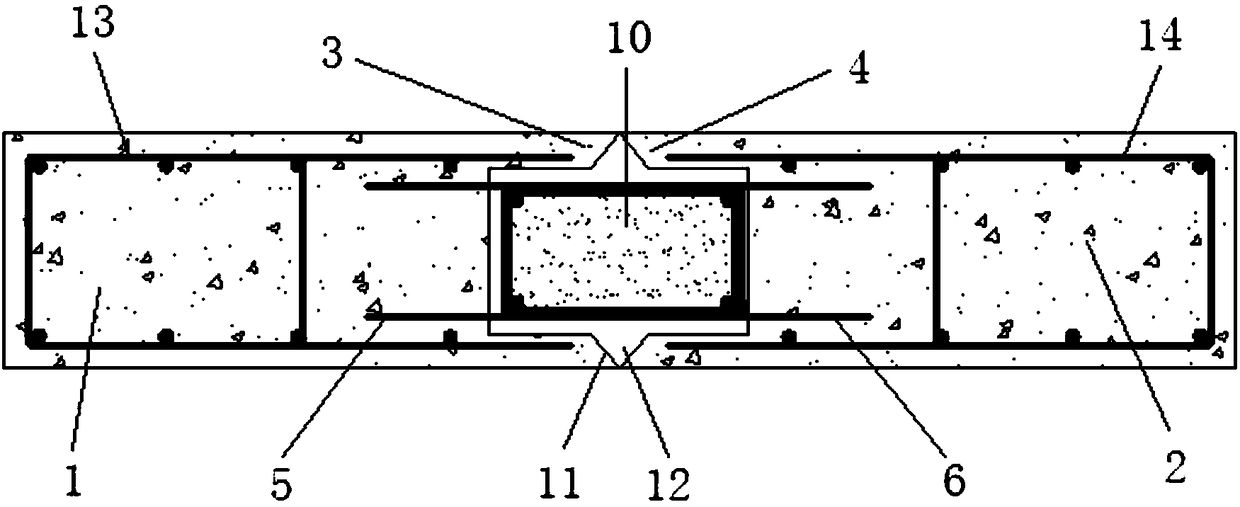

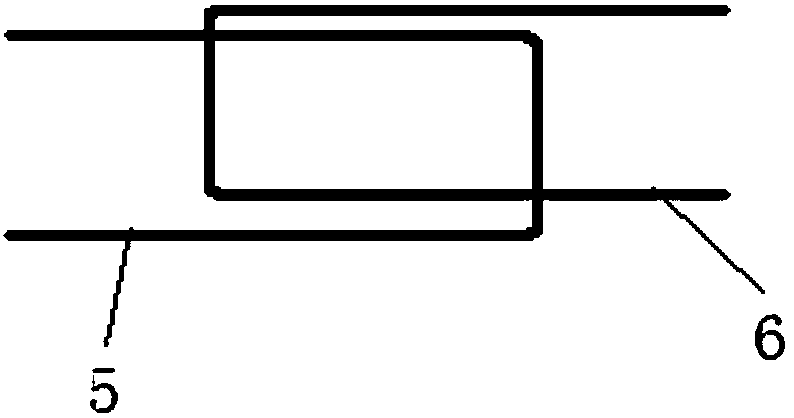

Bridge deck wet joint structure adopting T-head steel bars and construction method of bridge deck wet joint structure

PendingCN107938504AReduce the impactReduce on-site construction timeBridge structural detailsArchitectural engineeringBridge deck

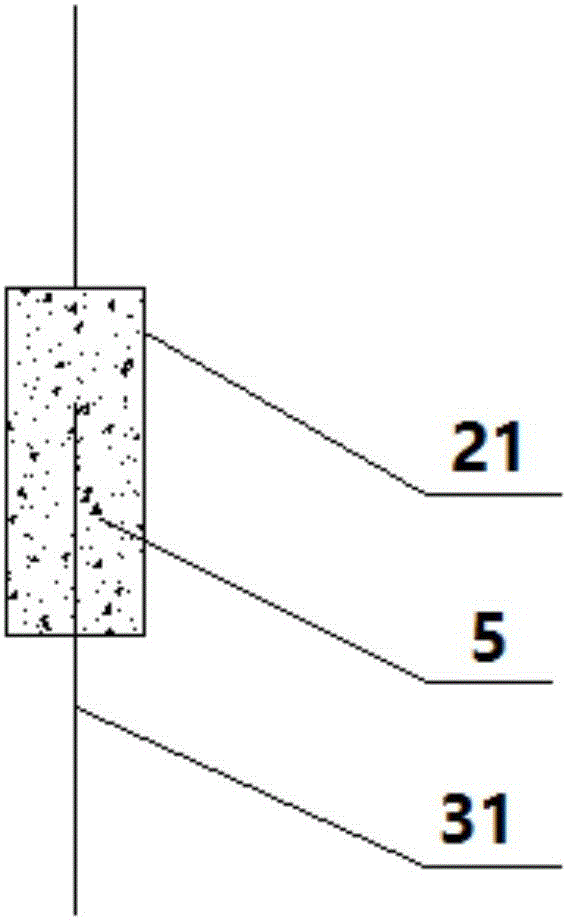

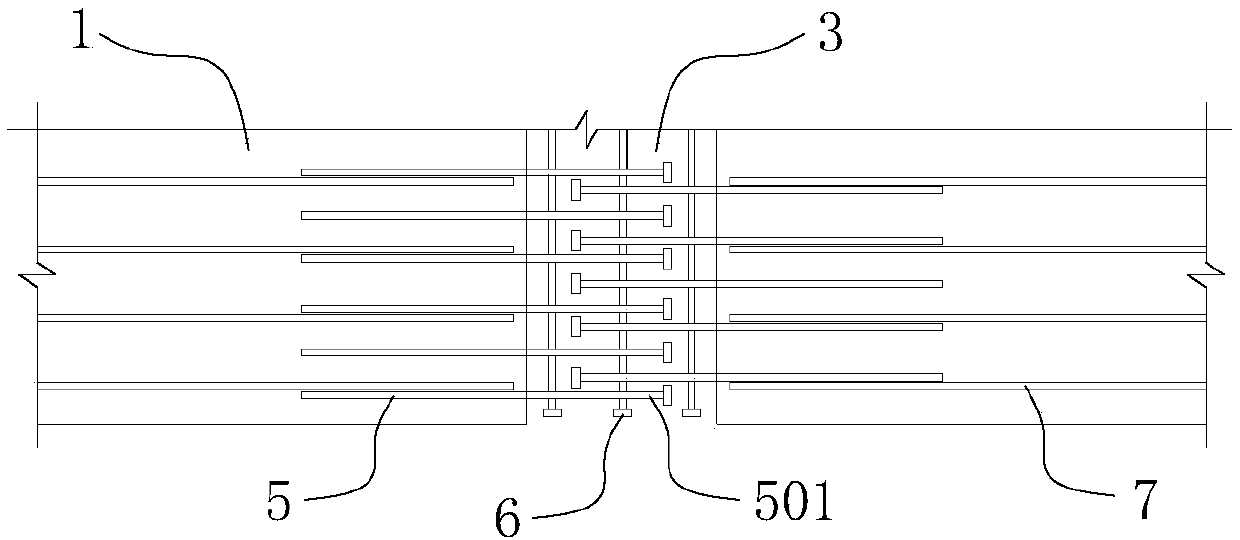

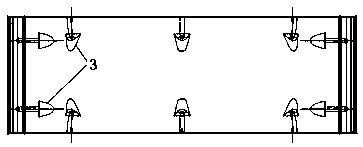

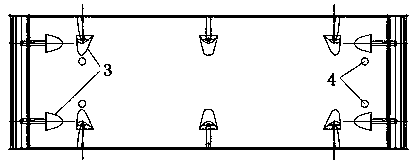

The invention provides a bridge deck wet joint structure adopting T-head steel bars and a construction method of the bridge deck wet joint structure. The bridge deck wet joint structure comprises a plurality of precast concrete bridge decks erected on girders; a plurality of T-head steel bars are pre-buried in the precast concrete bridge decks at the sides close to wet joints; the extending partsof the T-head steel bars are T-head anchoring ends; the T-head anchoring ends between two adjacent precast concrete bridge decks are arranged in a staggered mode; projections of the corresponding T-head anchoring ends have overlapped length; and wet joint concrete is cast in the wet joints in situ, so that two adjacent precast concrete bridge decks can be connected into a whole. The construction method of the bridge deck wet joint structure comprises the steps of pre-burying the T-head steel bars, casting concrete, performing hoisting in place, casting wet joint concrete and the like. The bridge deck wet joint structure simplifies the construction steps, obviously reduces the great welding workload caused by the traditional design, reduces the construction cost, reduces the influence on the existing traffic, improves the construction efficiency, and has wide application prospects.

Owner:CHONGQING UNIV

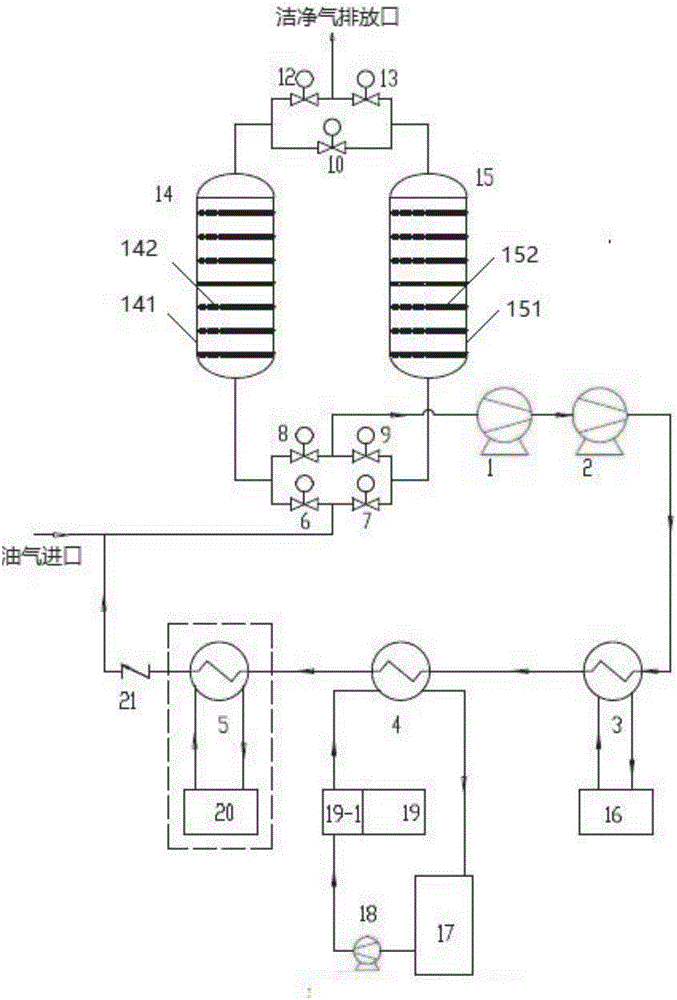

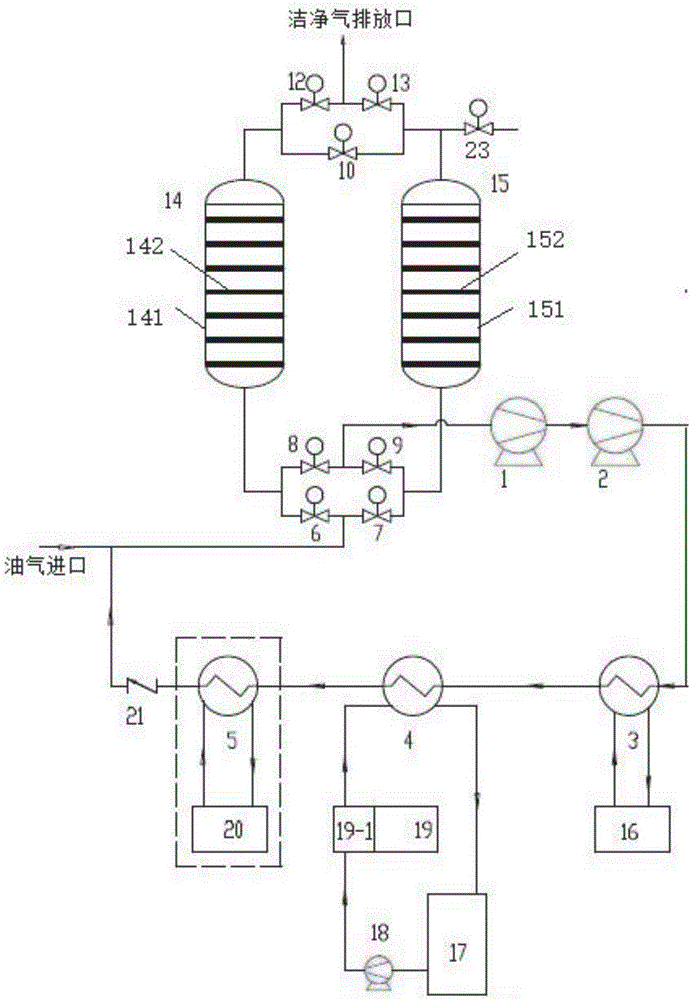

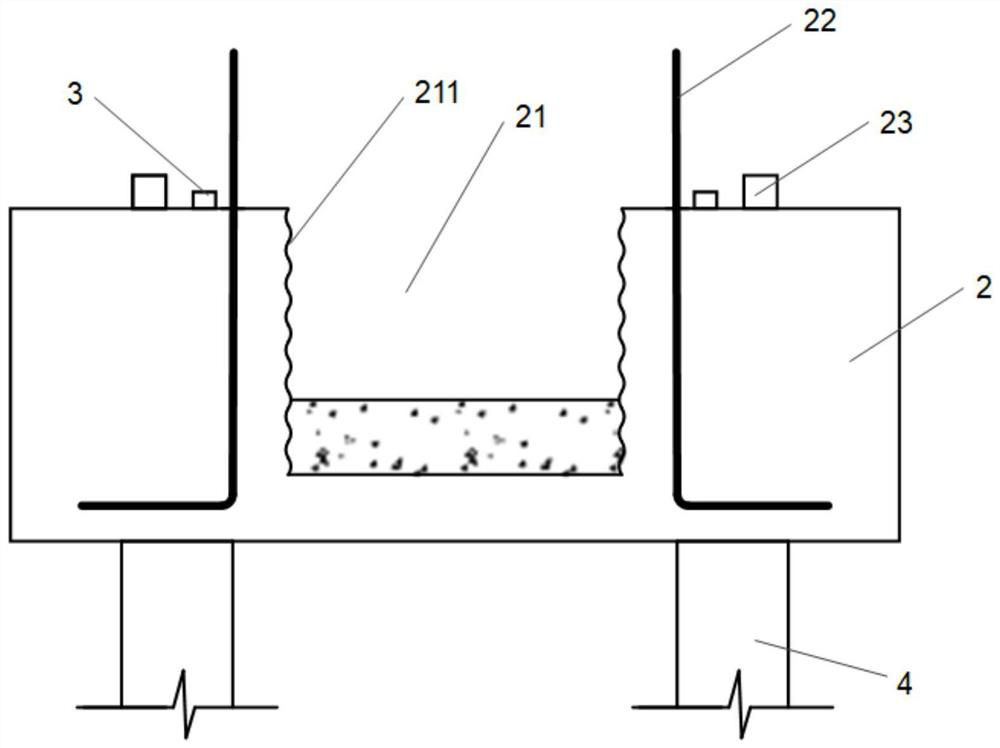

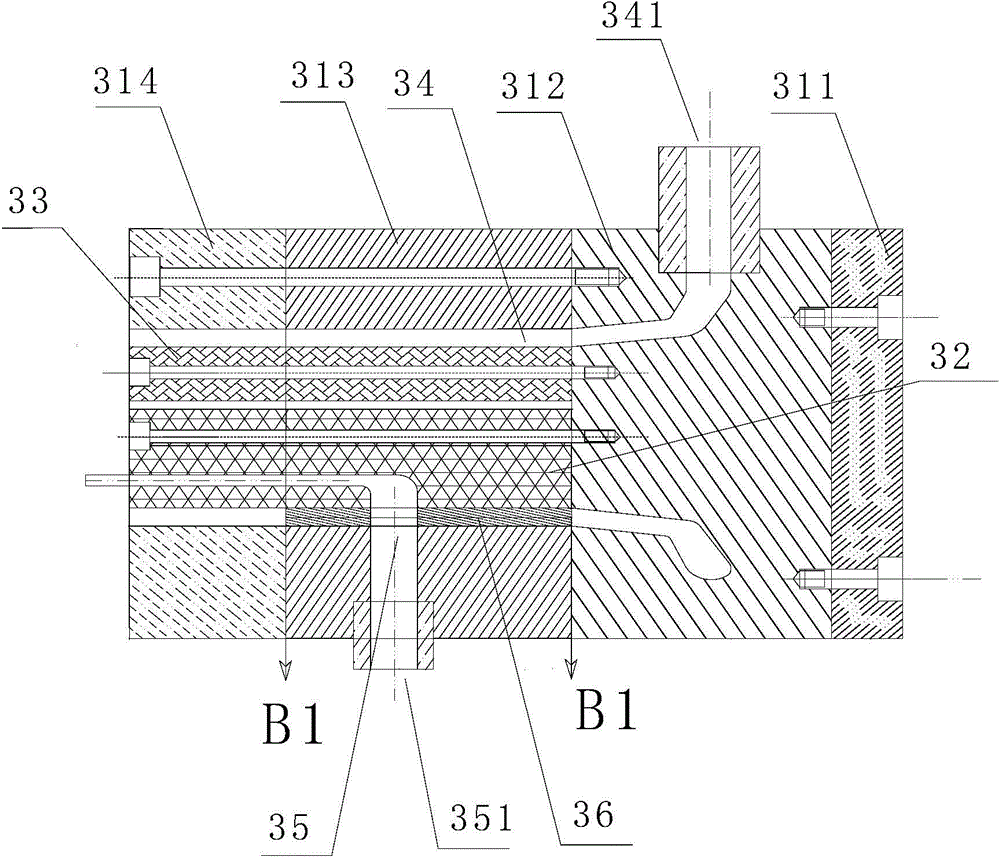

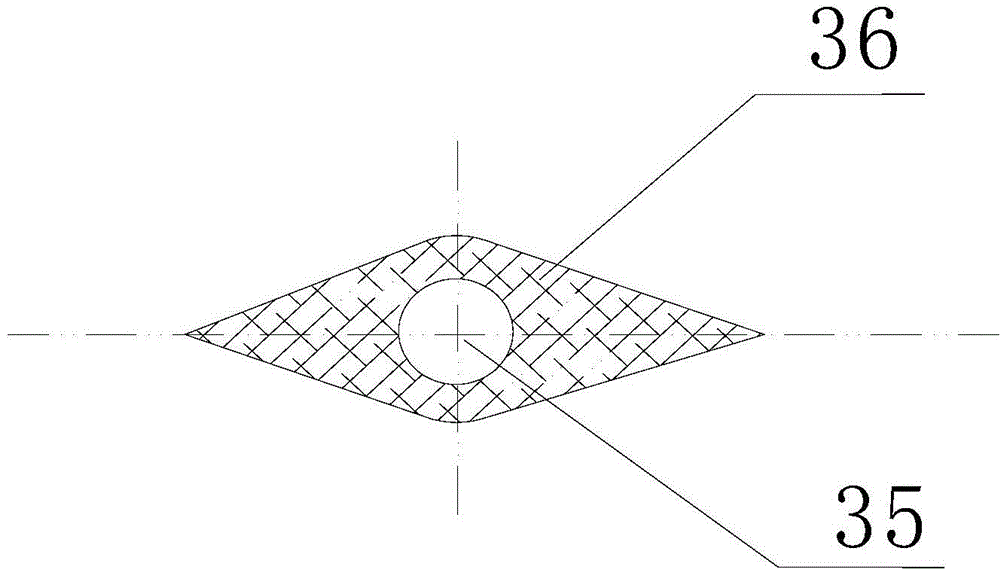

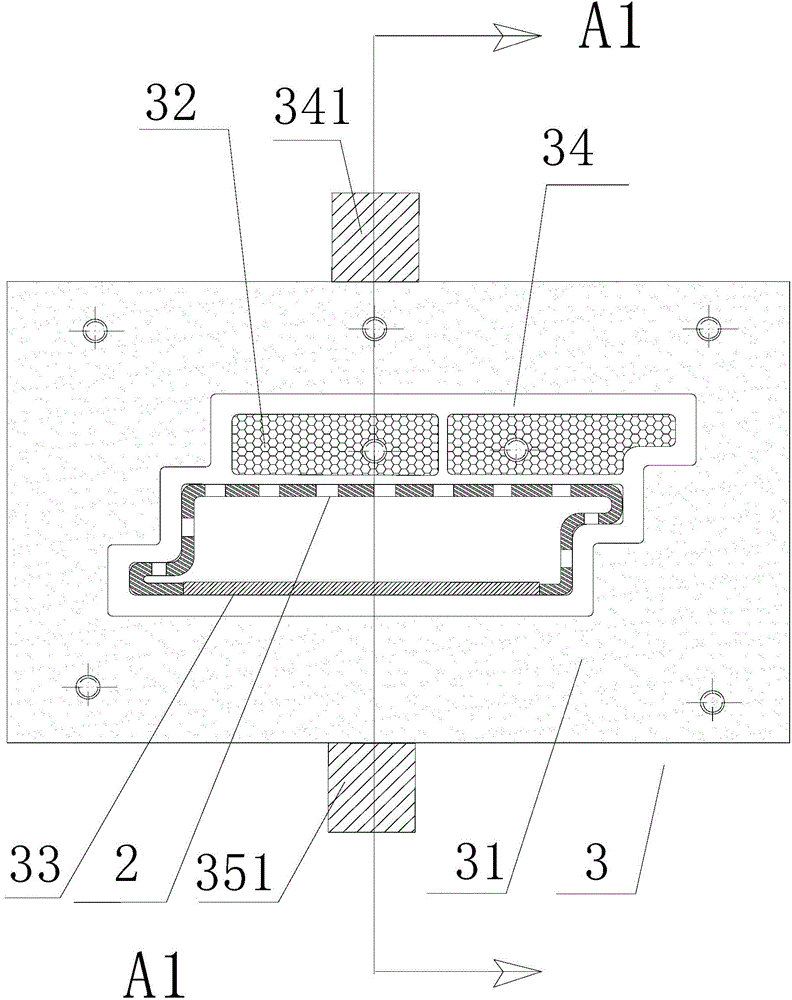

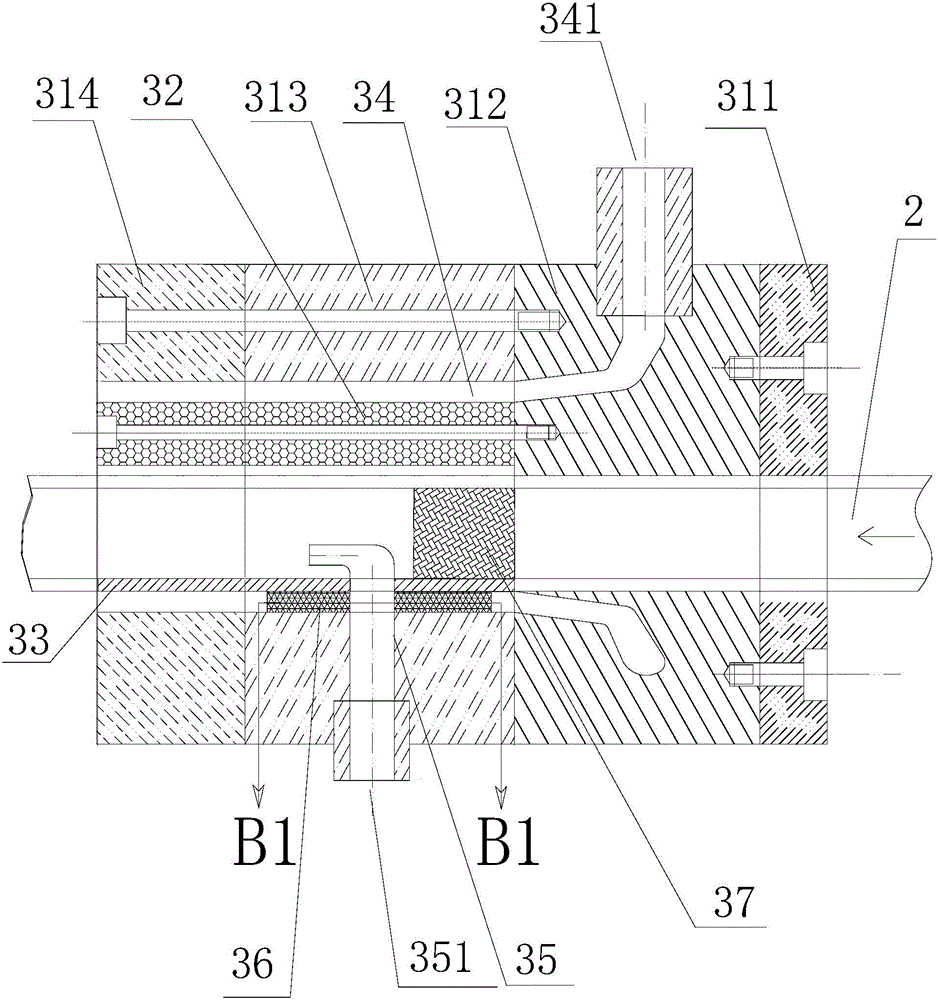

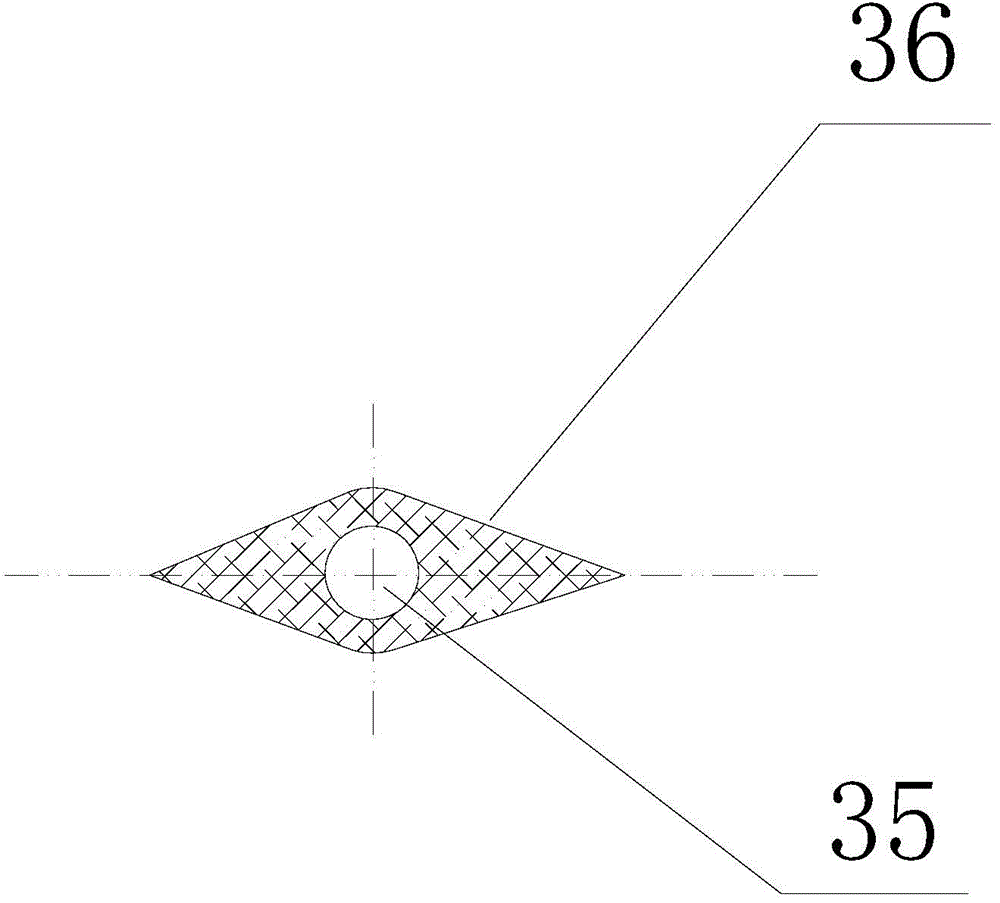

Adsorbing condensing type oil vapor recovery device for effectively preventing adsorption temperature rise and oil vapor recovery method

ActiveCN106731445ALess investmentReduce energy consumptionGas treatmentMultiple-effect/fractional condensationRecovery methodExhaust valve

The invention discloses an adsorbing condensing type oil vapor recovery device for effectively preventing adsorption temperature rise and an oil vapor recovery method. The device comprises an oil vapor inlet, a first valve set, an adsorption tank set, a second valve set, a clean gas exhaust port, a vacuum pump set, a first-level oil vapor condenser, a second-level oil vapor condenser, a third-level oil vapor condenser and a check valve, wherein the first valve set is composed of a gas inlet valve set under the adsorption tank set and a vacuum valve set in parallel connection with each other; the second valve set is composed of an exhaust valve set above the adsorption tank set and a blow-down valve set in parallel connection with each other; the blow-down valve set, the adsorption tank set, the vacuum valve set, the vacuum pump set, the first-level oil vapor condenser, the second-level oil vapor condenser, the third-level oil vapor condenser and the check valve are connected in turn; the check valve is connected with the oil vapor inlet; the oil vapor inlet is connected with the gas inlet valve set, the adsorption tank set, the exhaust valve set and the clean gas exhaust port in turn; a solid-liquid phase variable energy storage substance is filled into the adsorption tank set.

Owner:上海聚宸新能源科技有限公司

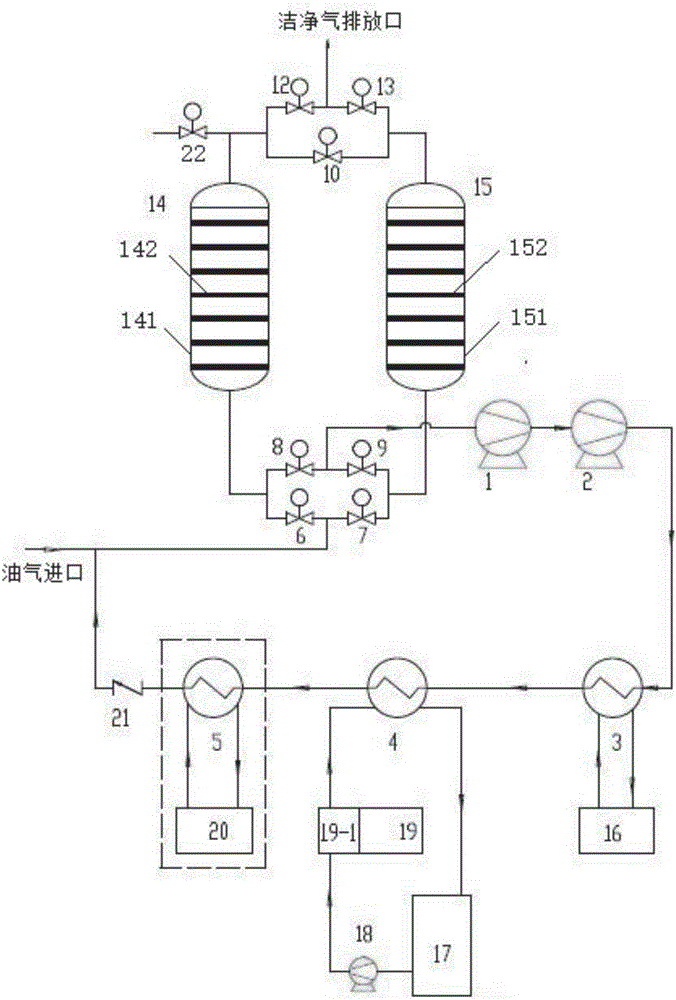

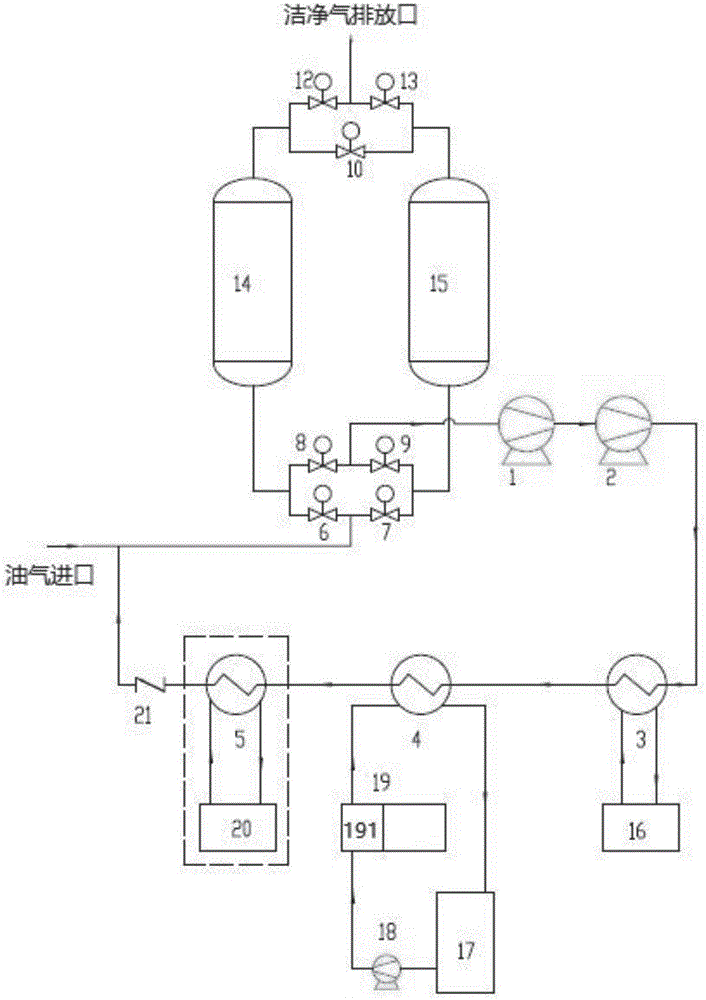

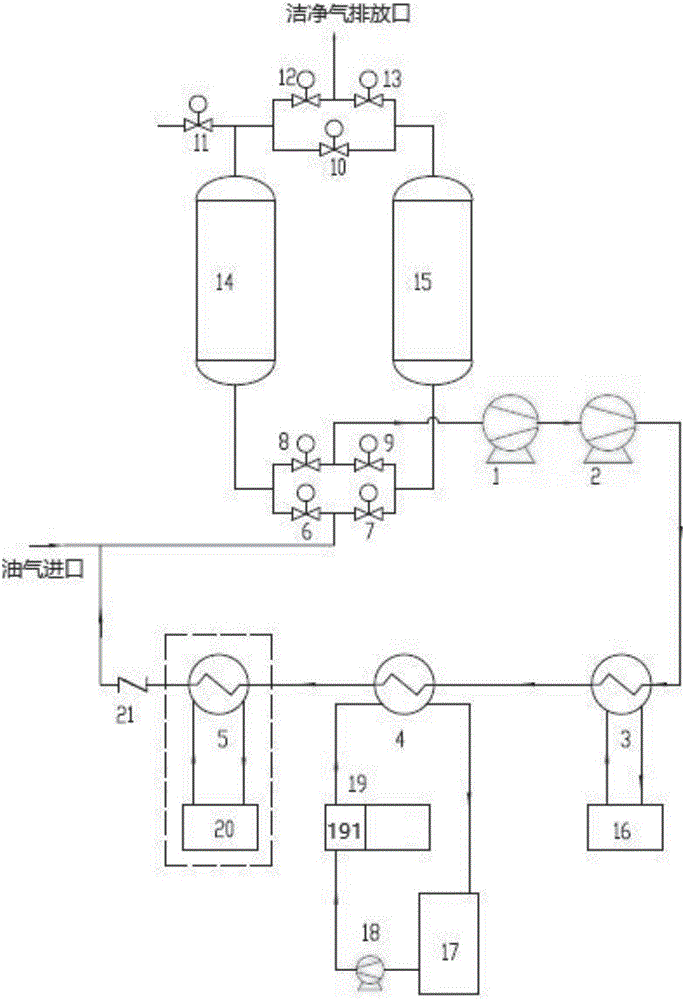

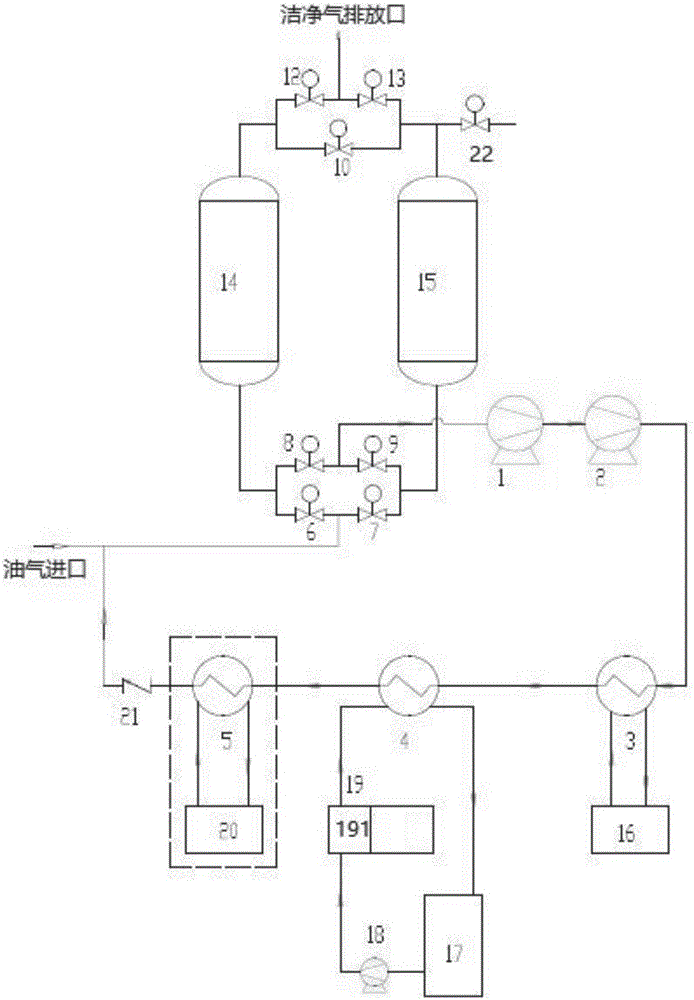

Adsorption and condensation type oil gas recovery device and adsorption and condensation type oil gas recovery process by self-adsorptive heat regeneration

ActiveCN106807179ALess investmentReduce energy consumptionGas treatmentMultiple-effect/fractional condensationInlet valveCheck valve

The invention discloses an adsorption and condensation type oil gas recovery device and an adsorption and condensation type oil gas recovery process by self-adsorptive heat regeneration. The adsorption and condensation type oil gas recovery device by the self-adsorptive heat regeneration comprises an oil gas inlet, a first valve group, a Roots vacuum pump, a dry vacuum pump, a primary oil gas condenser, a secondary oil gas condenser, a tertiary oil gas condenser, a check valve, an adsorption tank group, a second valve group and a clean gas discharge outlet. The first valve group comprises a gas inlet valve group and a vacuum valve group, wherein the gas inlet valve group and the vacuum valve group which are in parallel connection are arranged below the adsorption tank group. The second valve group comprises a gas discharge valve group and a balanced purge valve, wherein the gas discharge valve group and the balanced purge valve are in parallel connection and arranged over the adsorption tank group. The balanced purge valve, the adsorption tank group, the vacuum valve group, the Roots vacuum pump, the dry vacuum pump, the primary oil gas condenser, the secondary oil gas condenser, the tertiary oil gas condenser and the check valve are connected in sequence, and then the check valve is connected with the oil gas inlet. The oil gas inlet is sequentially connected with the gas inlet valve group, the adsorption tank group, the gas discharge valve group and the clean gas discharge outlet.

Owner:上海聚宸新能源科技有限公司

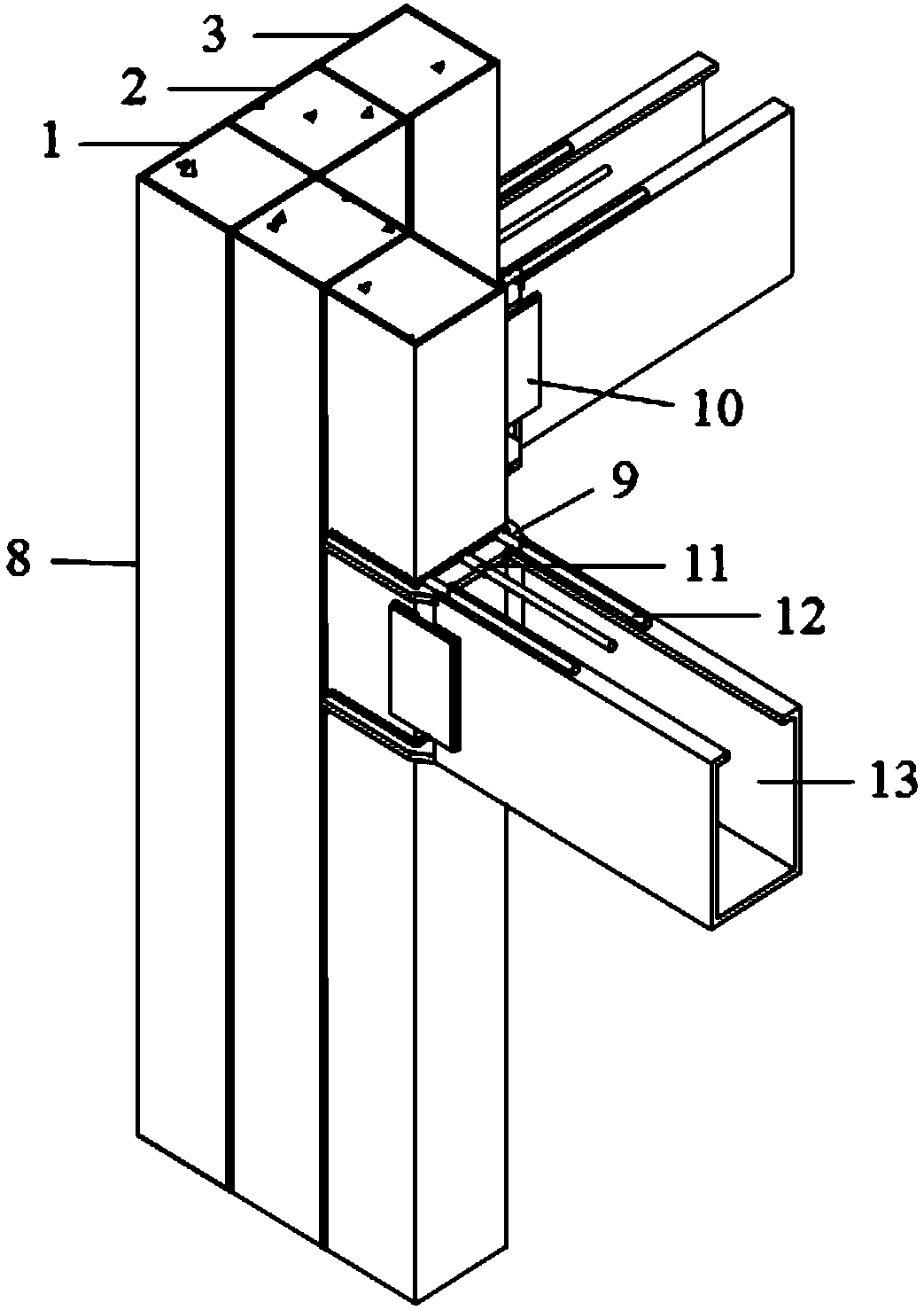

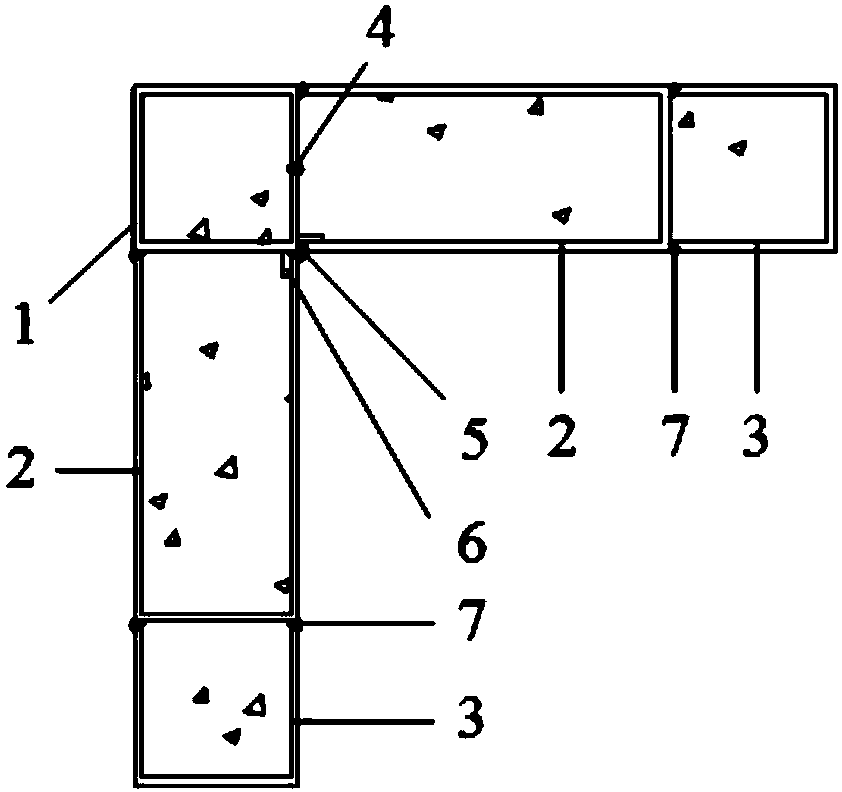

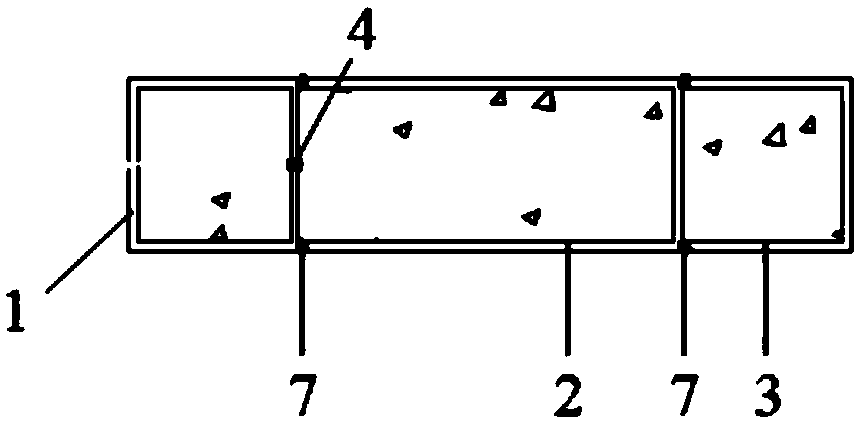

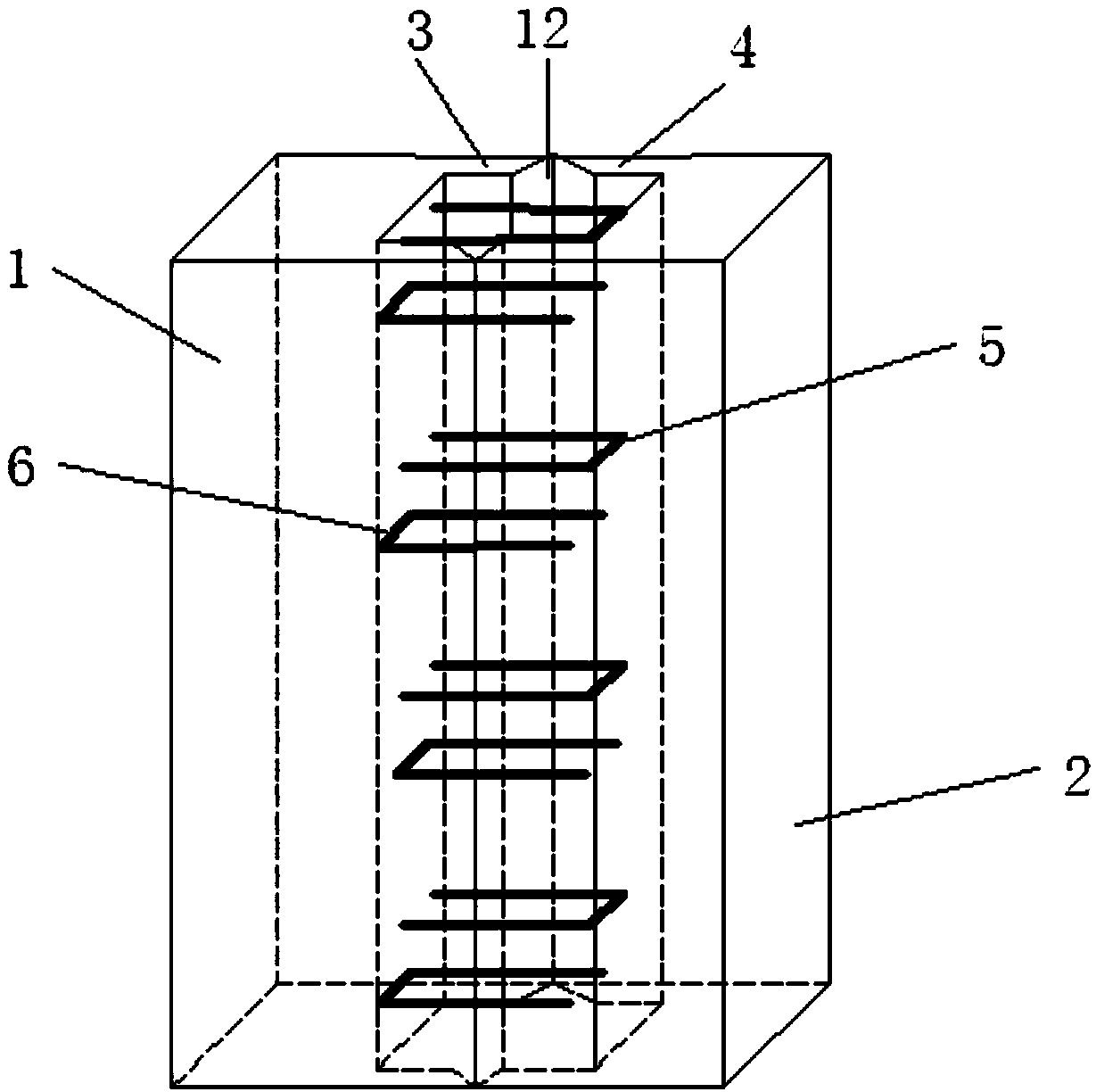

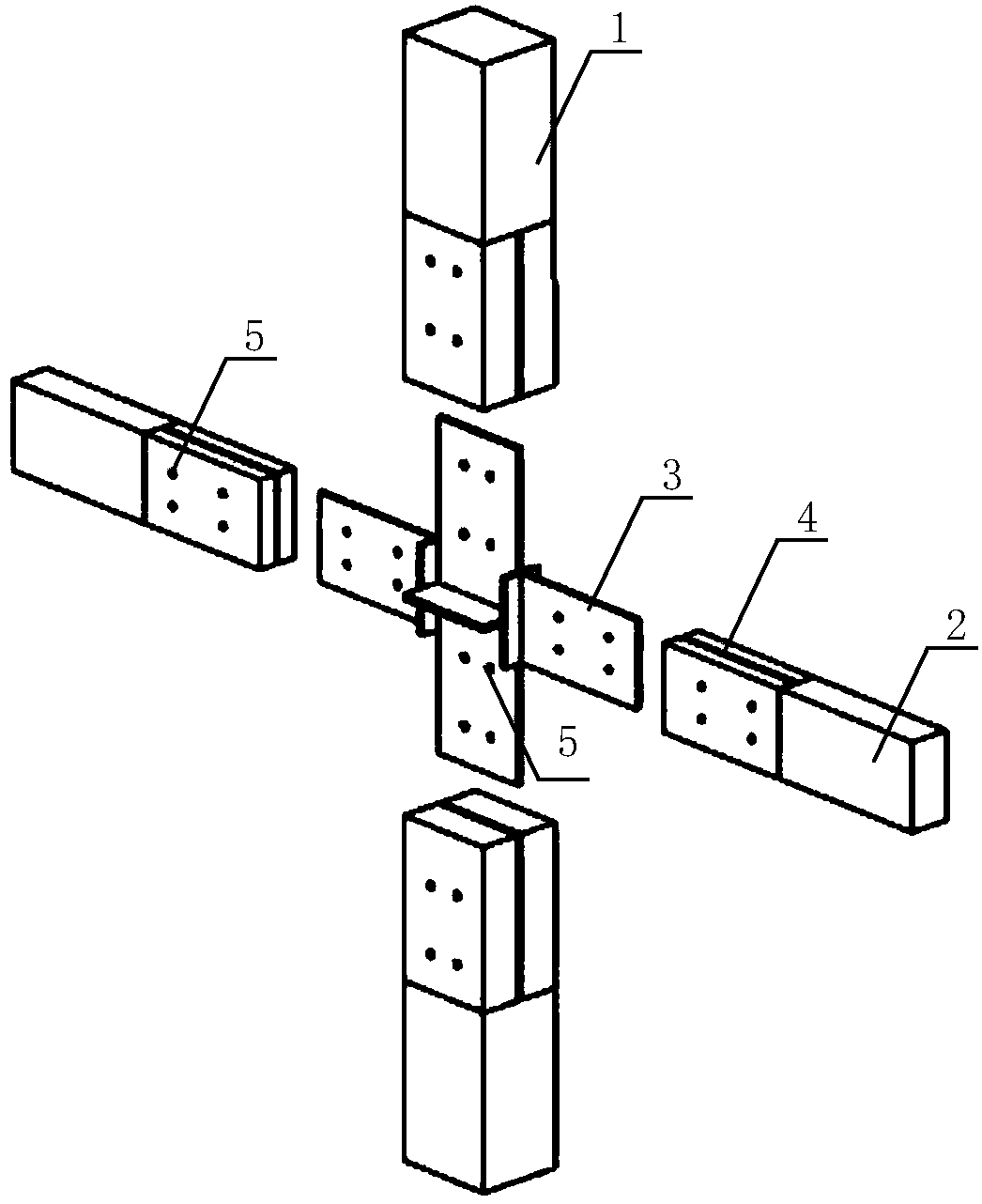

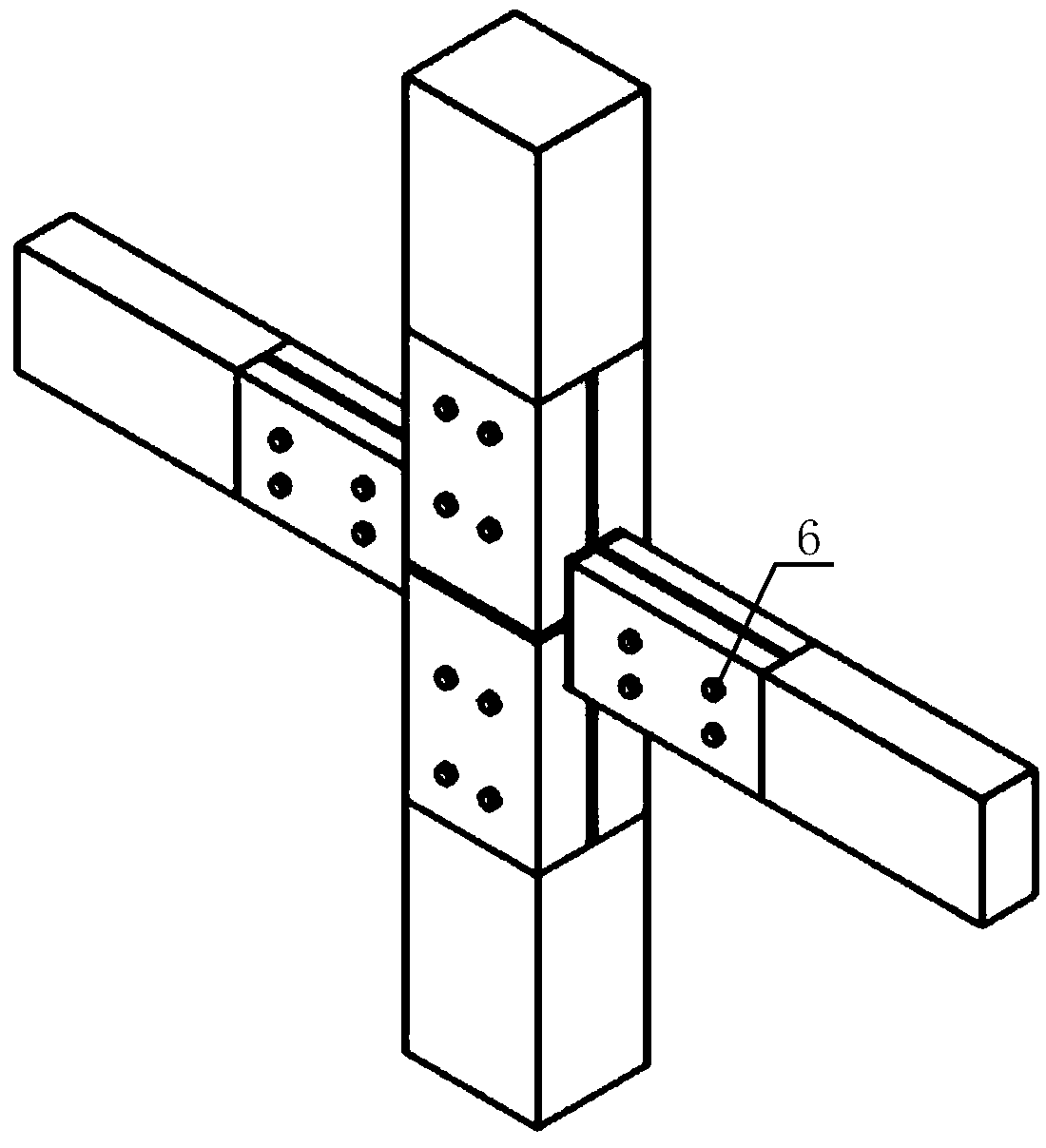

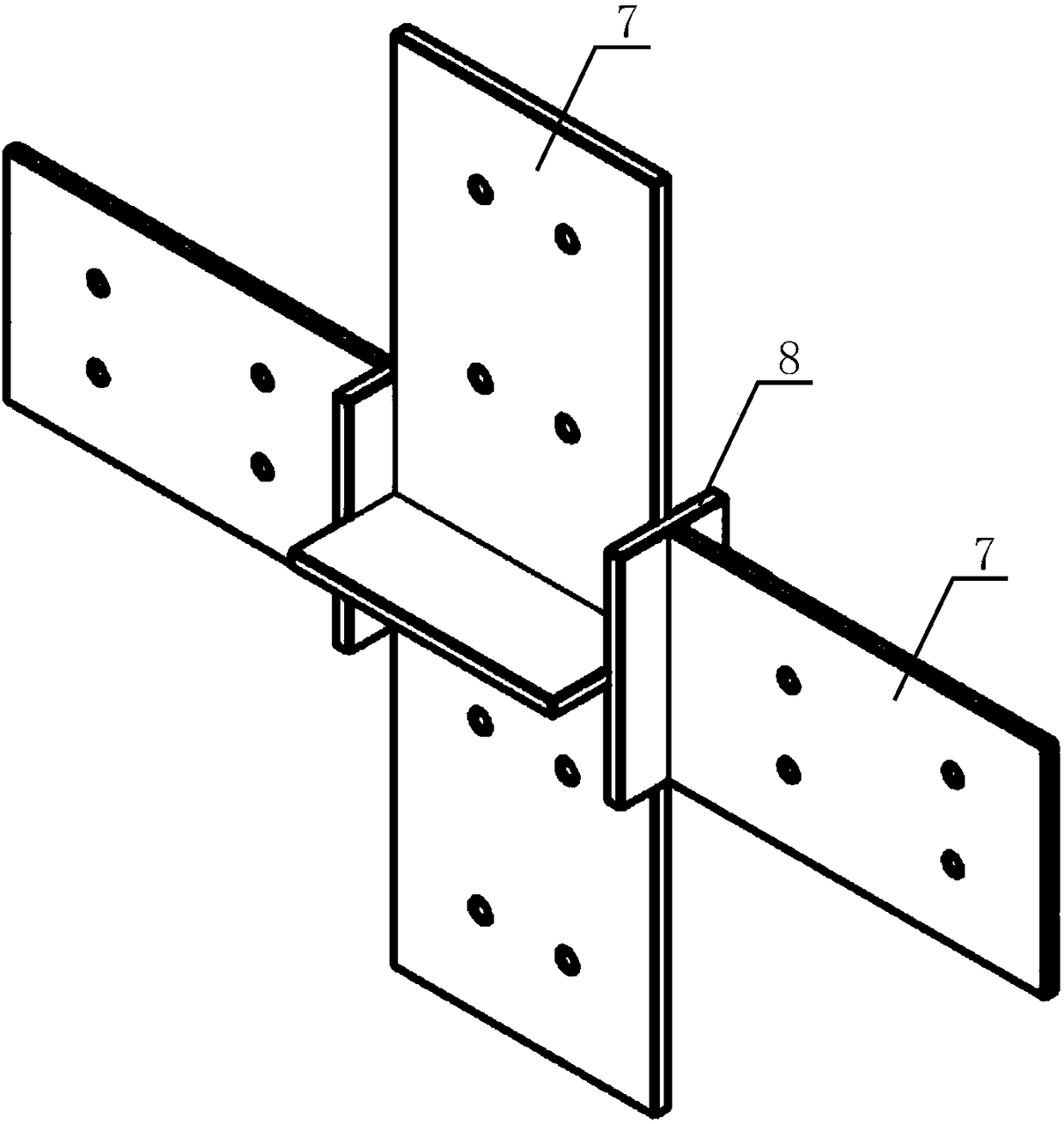

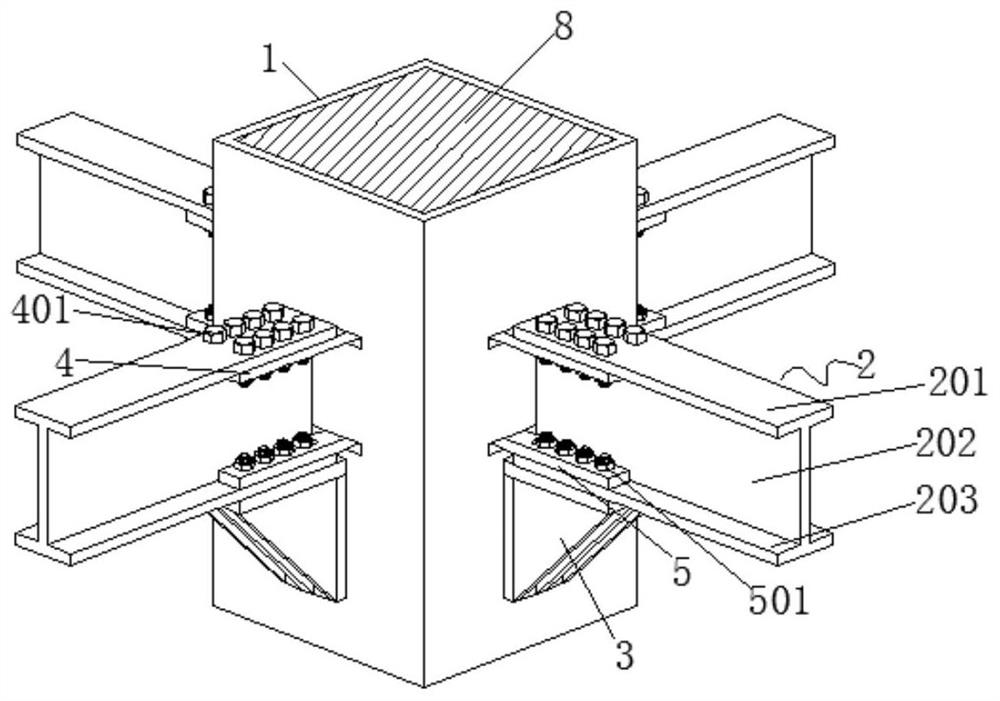

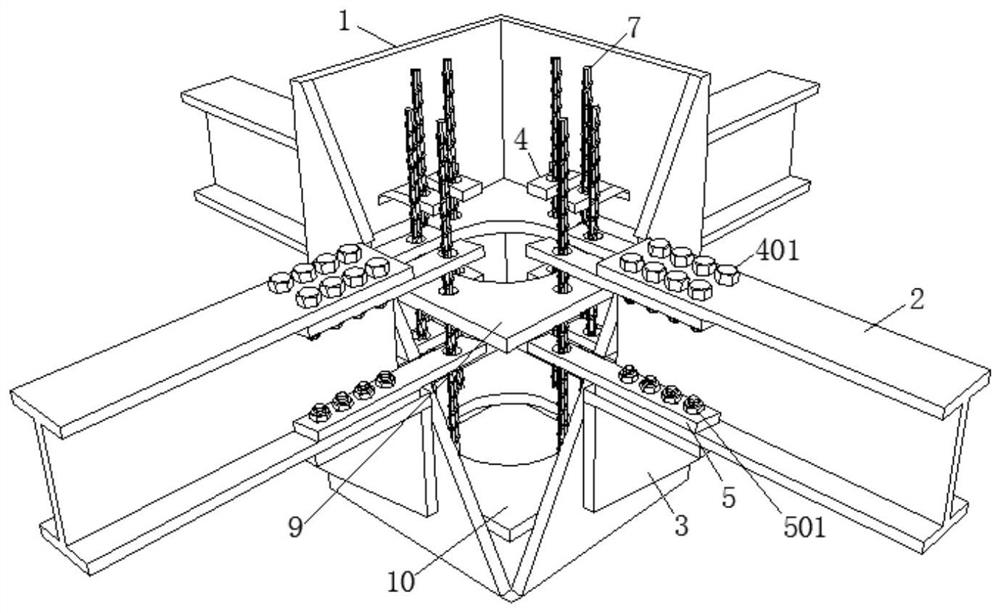

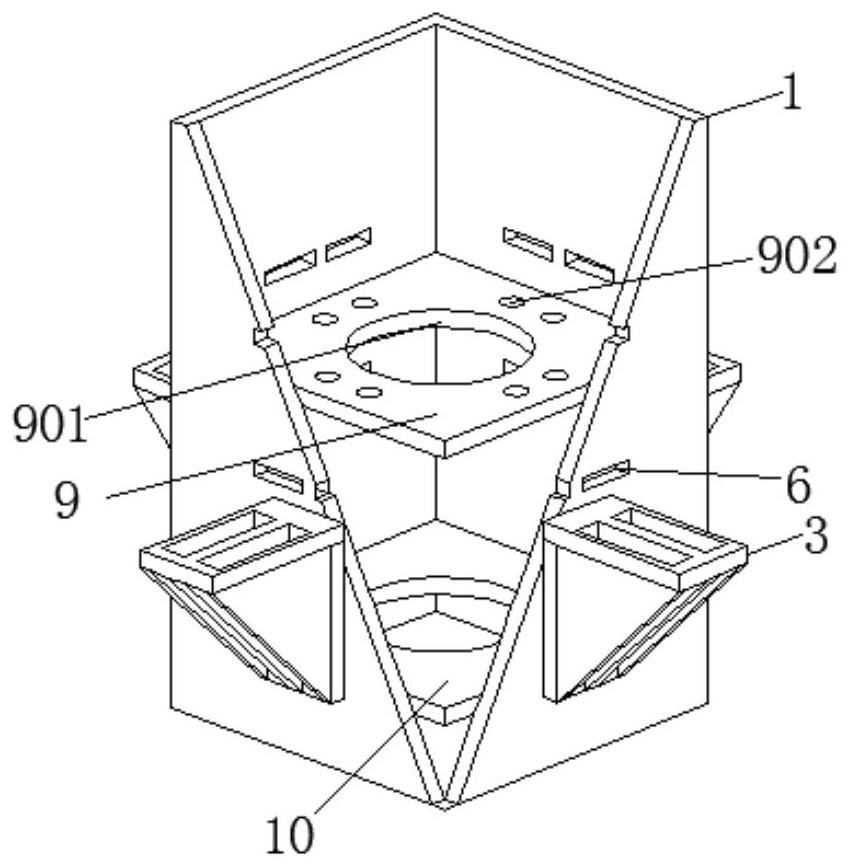

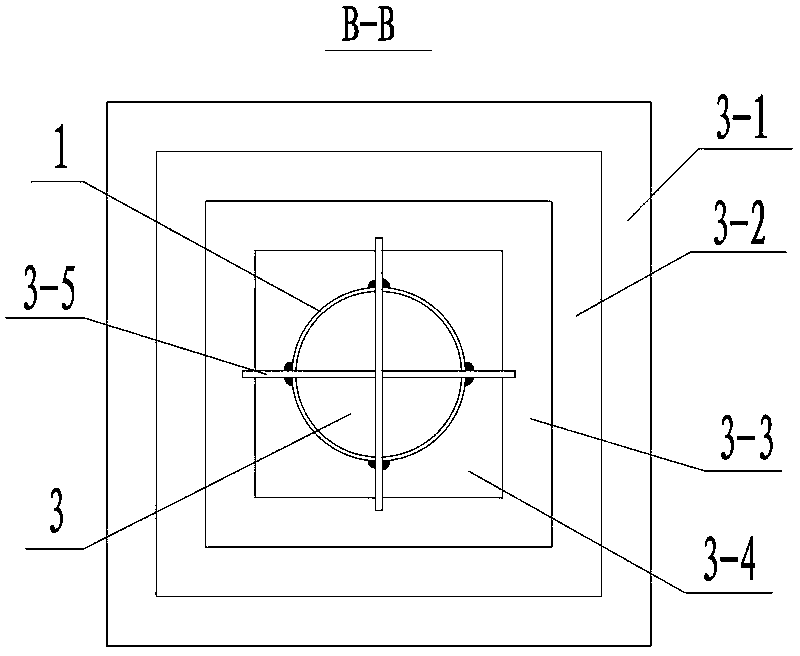

Rigid connection joint of cold-bending multi-cavity steel tube concrete special-shaped column and U-shaped combination beam

PendingCN108104271AImprove utilization efficiencyImprove exposed defectsBuilding constructionsSheet steelEngineering

The invention provides a rigid connection joint of a cold-bending multi-cavity steel tube concrete special-shaped column and a U-shaped combination beam. The machining method is described in that a thin-walled steel plate is machined to be a core column steel tube in cold-bending and welding methods; then, the side surfaces of the core column steel tube is taken as column-rib connection surfaces with the core column steel tube as the center; U-shaped members formed by cold bending are welded; end-column steel tubes are welded with flange connection boards and multiple sleeves; above-mentionedprefabricated members are finished, delivered to the site and welded with negative-bending longitudinal bars; then, the prefabricated members are connected with cold-bending U-shaped steel beams together; next, cavities of steel tubes are filled with concrete in order to manufacture the rigid connection joint of an in-line, L-shaped, T-shaped, or cross-shaped cold-bending multi-cavity steel tube concrete special-shaped column and a U-shaped steel beam. The U-shaped steel beam serves as a template. There is no need to install any template for concrete pouring. The factory prefabrication processcan help reduce construction time. Additionally, the joint is good in mechanical property, convenient in construction and cost-effective and reasonable. The joint has a joint form with a combinationstructure which enjoys a promising application prospect.

Owner:重庆市中科大业建筑科技有限公司

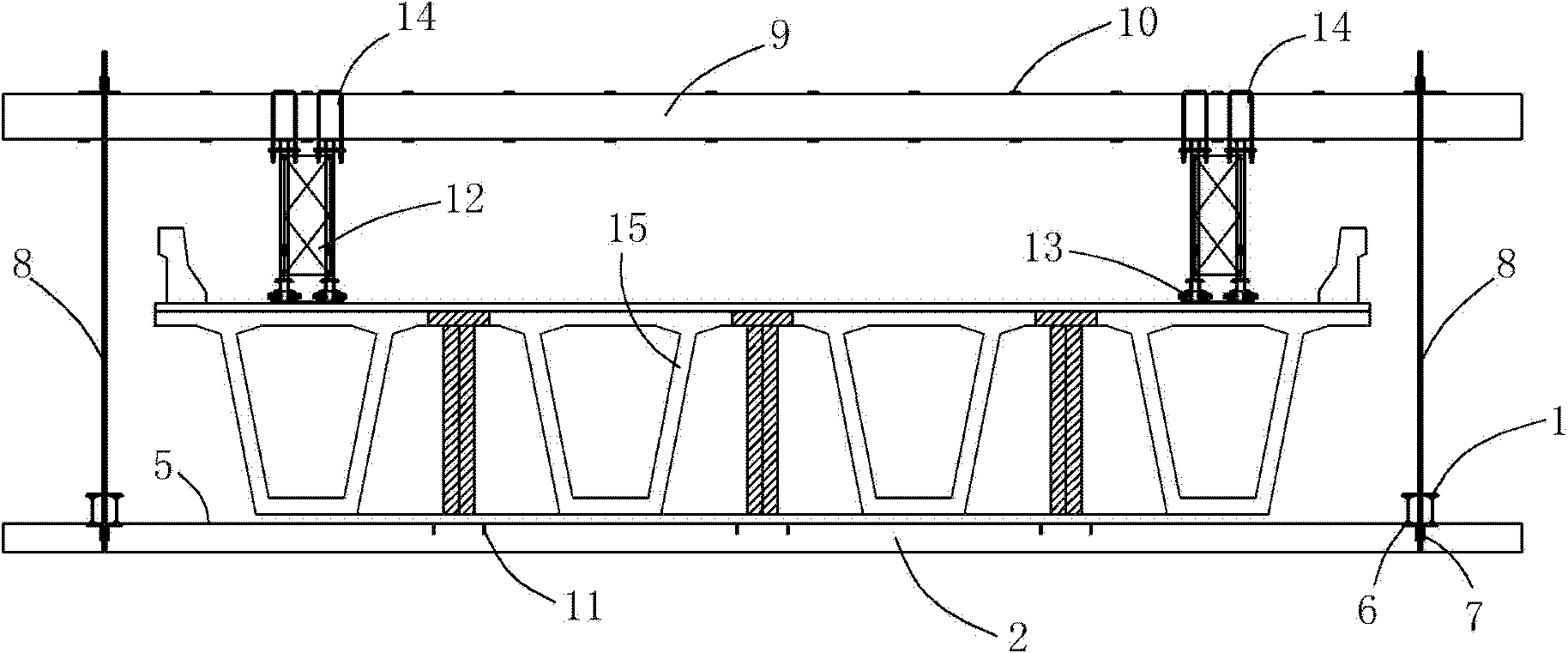

Whole-span prefabricated H-steel-concrete composite beam bridge and construction method

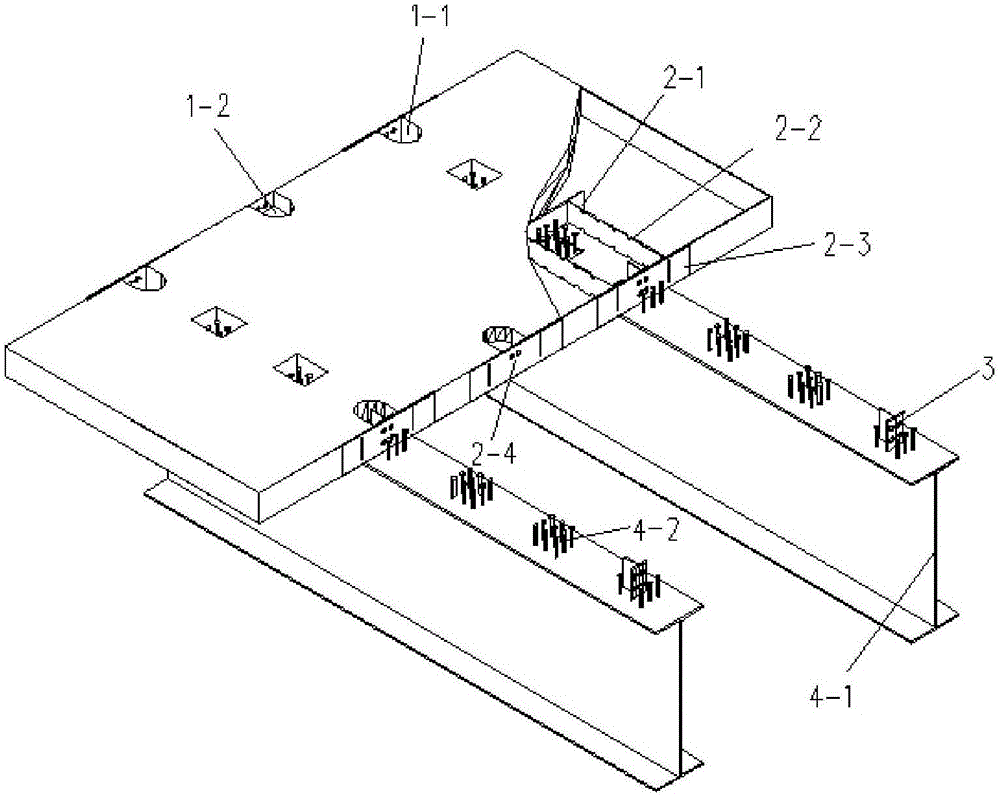

InactiveCN108342973AImprove integritySolve fatigueBridge structural detailsBridge erection/assemblyWelding residual stressBridge deck

The invention discloses a whole-span prefabricated H-steel-concrete composite beam bridge and a construction method. The whole-span prefabricated H-steel-concrete composite beam bridge comprises an H-steel combination and a concrete bridge plate which is poured on the H-steel combination; the H-steel combination comprises H-steels placed in parallel in the bridge width direction; and the whole-span length is the length direction of the H-steels. The whole-span prefabricated H-steel-concrete composite beam bridge has the advantages that the construction of a bridge deck slab is simple and the hoisting weight of the bridge deck slab is light; during making, factory machining and manufacturing procedure does not exist and the later mounting and erecting difficulty is reduced; and meanwhile, as the H-steels can avoid adverse effects such as welding residual stress, more stable mechanical property, better bearing capacity and better durability are obtained; and the making cost can be greatly reduced. Compared with the steel plate girder in the prior art, the whole-span prefabricated H-steel-concrete composite beam bridge has the advantages that the welding or bolting process can be eliminated; construction processes uneasy to control, such as prestressed structure steel strand tensioning and grouting, hollow slab girder hinge joint connection and so on do not exist; the quality of aprofiled-steel composite beam can be effectively guaranteed; and requirements on equipment and technical skills of workers can be reduced.

Owner:CHONGQING JIAOTONG UNIVERSITY

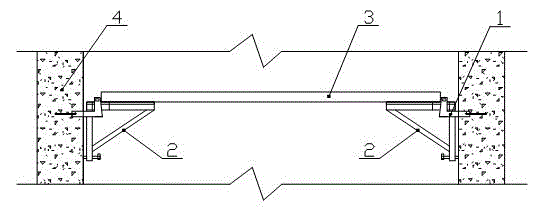

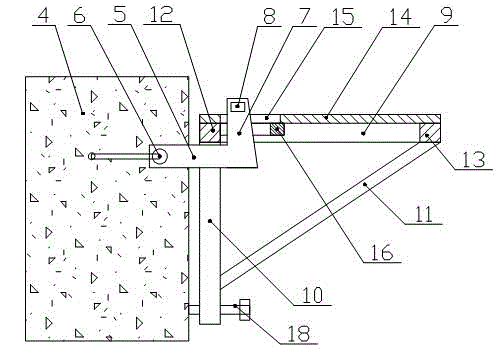

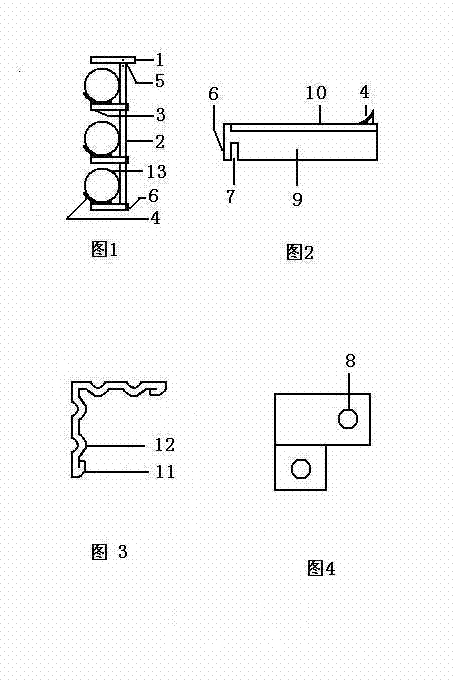

Hanging type stairwell operating platform mechanism and construction method thereof

InactiveCN102979297ALow costQuality improvementScaffold accessoriesBuilding support scaffoldsReinforced concreteEmbedment

The invention relates to a hanging type stairwell operating platform mechanism and a construction method thereof. The hanging type stairwell operating platform mechanism is formed by arrangement of a plurality of unit suspension platforms in a tightly propping way, and the unit suspension platforms consist of a plurality of force-bearing hooks embedded in a reinforced concrete wall of a stairwell, two suspensions hanged on the force-bearing hooks and a platform plate laid on the two symmetric suspensions. The construction method comprises the following steps of: (1) planning the specifications of the suspensions of the platform, determining positions for embedment of the force-bearing hooks, and synchronously embedding the force-bearing hooks during the civil engineering of an elevator shaft; (2) laying the unit suspension platforms level by level by operating personnel from an elevator door on every floor to the inside during the installation process; and (3) sequentially removing the unit suspension platforms from the inner side of the elevator shaft to the elevator doors during the removal process. The hanging type stairwell operating platform is a tool type product which can be produced in a factory, the installation and removal can be performed conveniently, reliable bearing can be realized, demands of multiple applications such as structure construction of concave corners of the elevator shaft or exterior walls and installation, maintenance and safety protection of elevators can be satisfied, and high values of use can be achieved.

Owner:福州市第三建筑工程公司

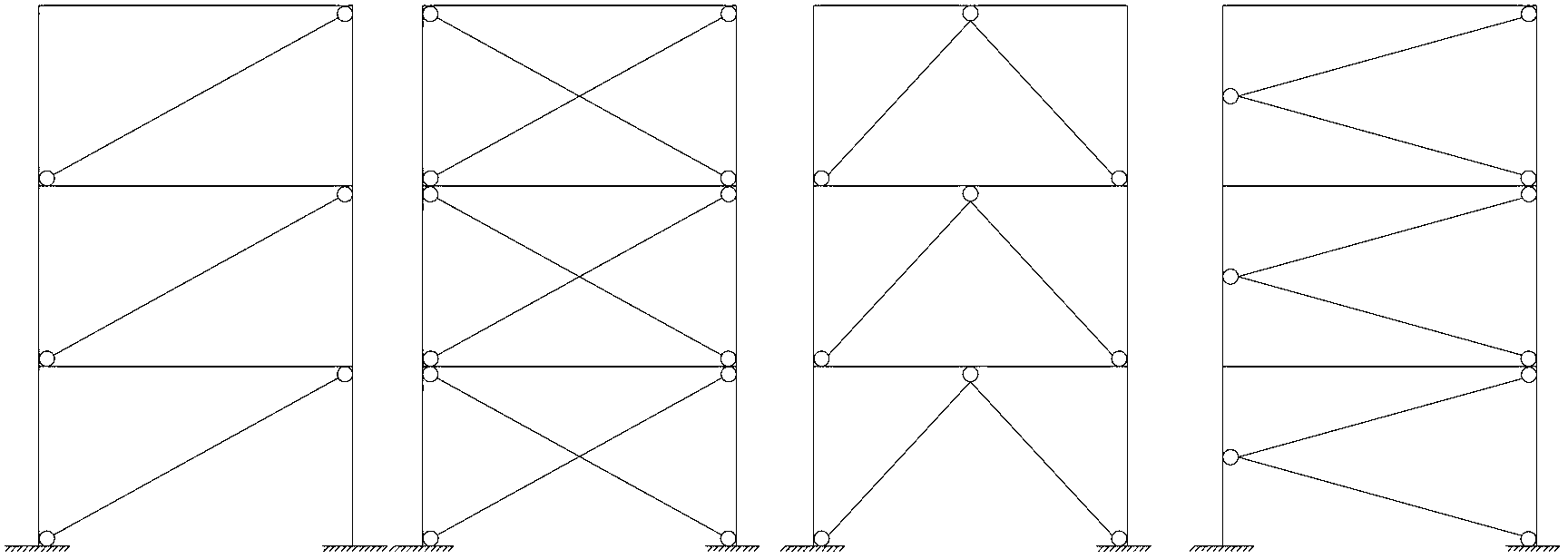

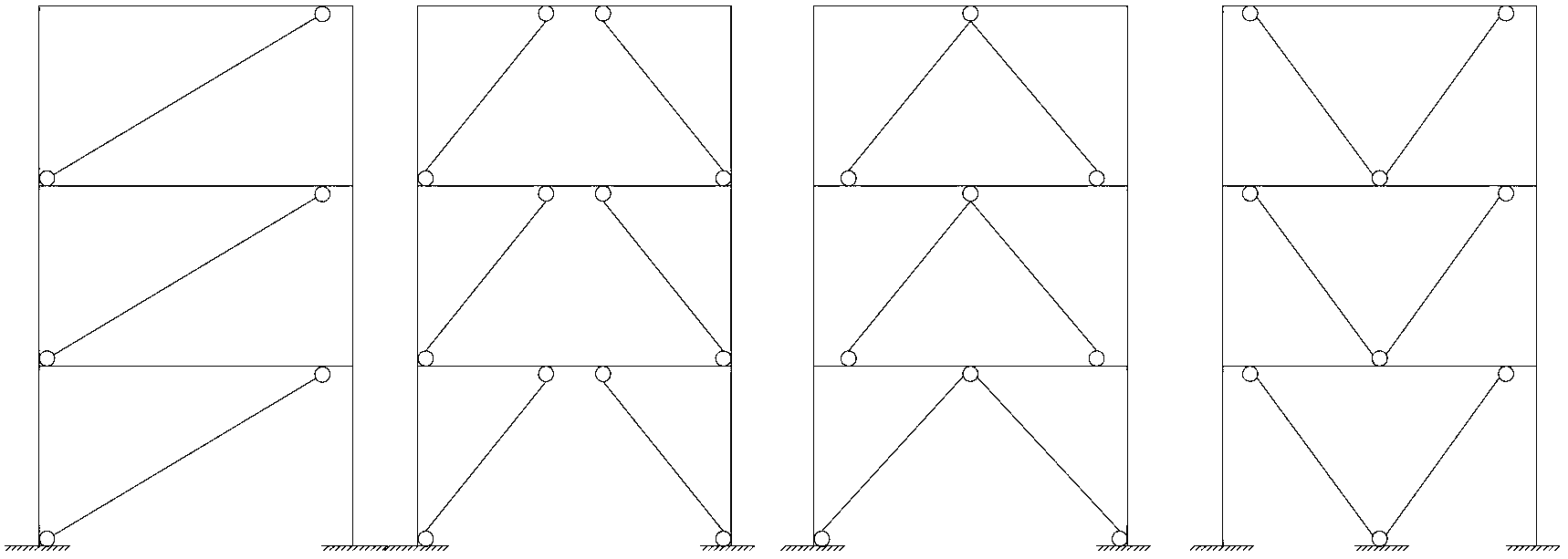

Steel truss support capable of windowing and steel truss barrel structure including same

ActiveCN103233510AImprove lateral force resistanceEliminates shear lag effectsBuilding constructionsEconomic benefitsEngineering

The invention belongs to a steel truss support capable of windowing and a steel truss barrel structure including the same. A node plate (7) is connected with a framed beam (5) and a frame column (6), two ends of a long inclined support (2) are respectively connected with a support rod (8), and the support rod (8) is connected with an end plate (9) and is respectively connected with the framed beam (5) and the frame column (6). A horizontal support (3) is connected with a vertical support (4), the connecting position between the horizontal support (3) and the vertical support (4) is connected with the long inclined support (2), and a short inclined support (1) is respectively connected with the node plate (7) and the long inclined support (2). Connectors of the short inclined support (1), the long inclined support (2), the horizontal support (3), the vertical support (4), the support rod (8) and the end plate (9) are prefabricated by a factory. The steel truss support improves the bearing capacity of the structure by increasing width and thickness of supporting flanges, a window can be arranged at a position where the support is arranged, and the economic benefit and the applicability are improved while steeling using amount is saved.

Owner:江苏瑞成建筑科技有限公司

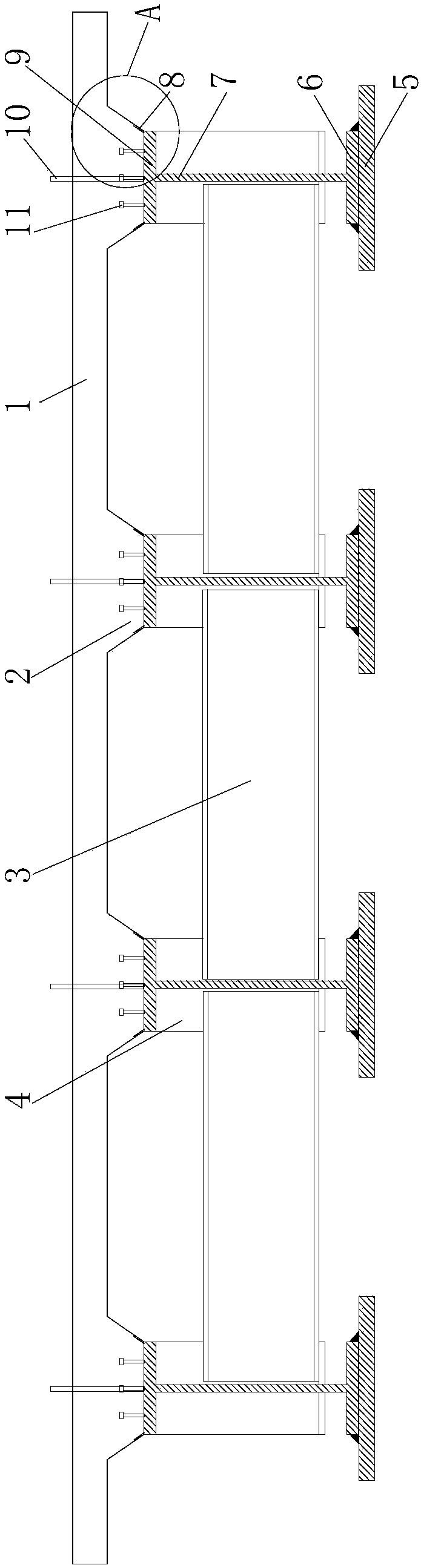

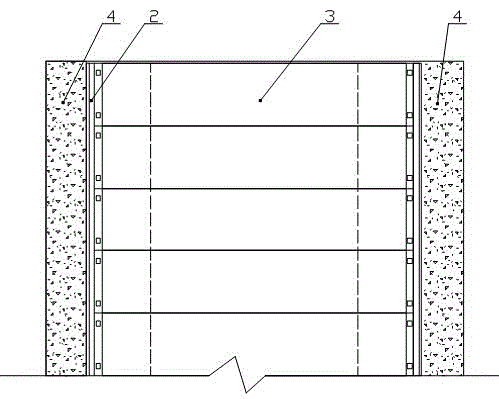

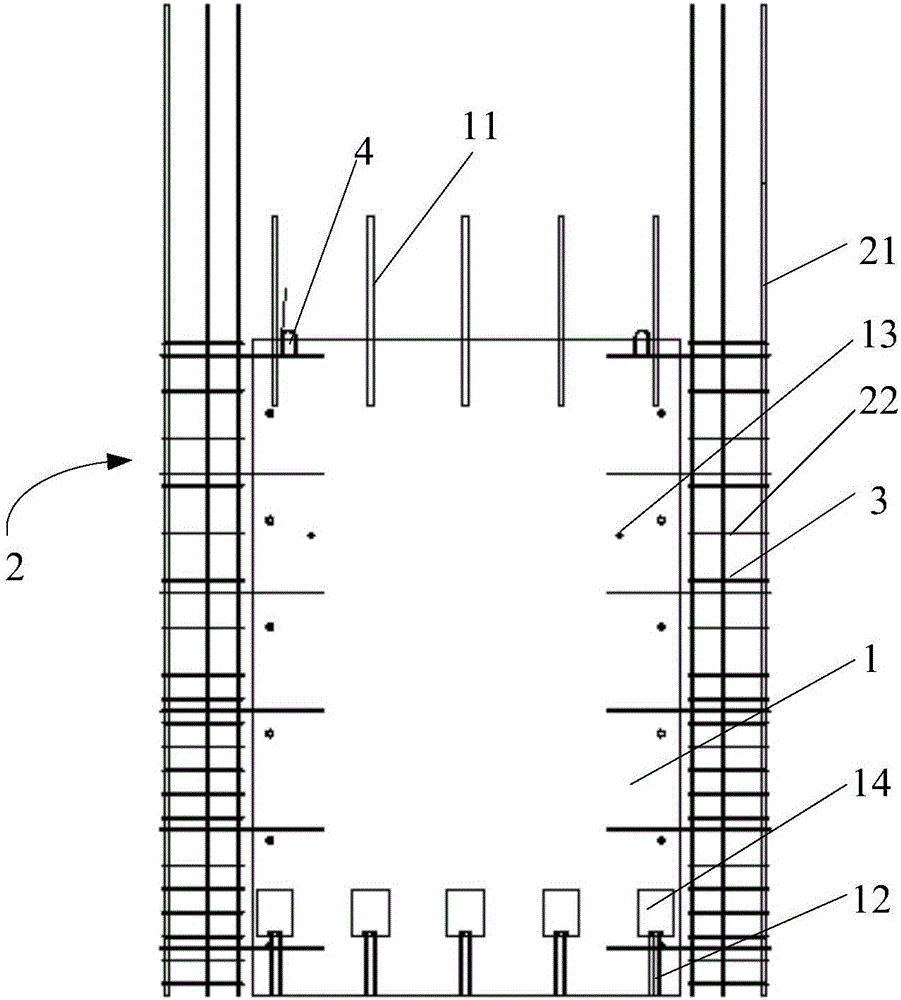

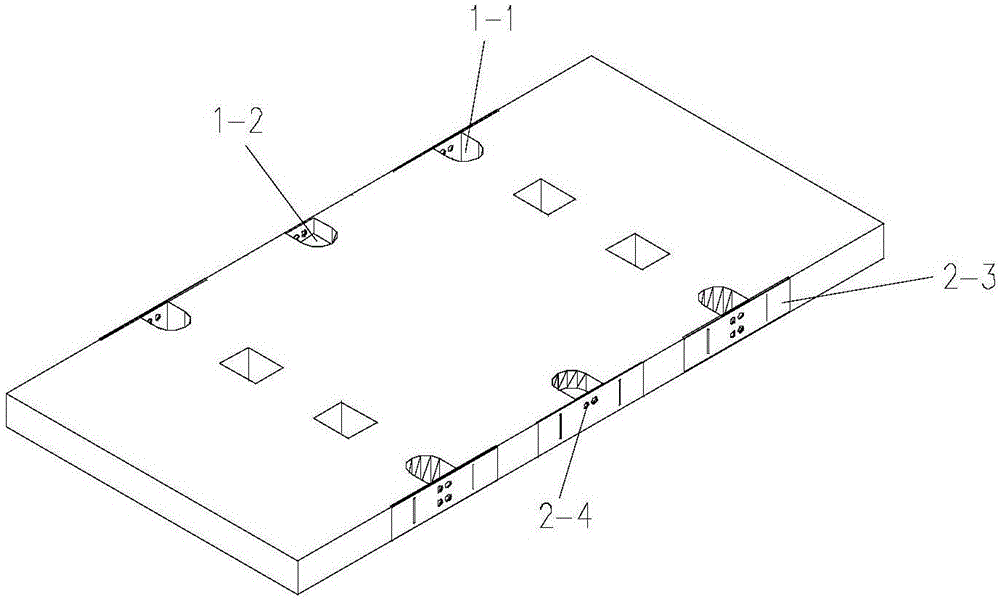

Prefabricated shear wall groove grouting anchor horizontal connection structure

The invention provides a prefabricated shear wall groove grouting anchor horizontal connection structure. The prefabricated shear wall groove grouting anchor horizontal connection structure comprisesa first shear wall and a second shear wall which are laterally arranged side by side, and a first convex plate and a second convex plate are separately disposed on the end faces, facing each other, ofthe first shear wall and the second shear wall. First U-shaped stirrups and second U-shaped stirrups are disposed in a cavity structure in a staggered mode in the vertical direction, wherein the cavity structure is formed by the first and second shear walls and the first and second convex plates in a surrounding mode. Mouth structures formed by overlapping portions of the first and second U-shaped stirrups are provided with reinforcement cages in an inserted mode, and concrete is poured in the cavity structure. Manpower is saved, on-site operation time is reduced and construction is more simple and convenient, the staggered first and second U-shaped stirrups reduce the use of steel bars, and cost is saved; the reinforcement cages inserted in the stirrups improve the shear capacity of theshear walls, the first and second U-shaped stirrups transmit force to the reinforcement cages, and the transmission force is clear, the integrity is improved, and the shear performance is good; and when an earthquake occurs, the reinforcement cages form an embedded column in the shear walls to prevent the shear walls from collapsing.

Owner:SHENYANG JIANZHU UNIVERSITY

Precast concrete shear wall component and construction method thereof

ActiveCN105839836AEliminates lashing workReduce on-site construction proceduresConstruction materialWallsRebarTime cost

The invention discloses a precast concrete shear wall component and a construction method thereof. The precast concrete shear wall component comprises a precast concrete wall panel, embedded column reinforcement cages and protecting shells, wherein the embedded column reinforcement cages are positioned on two sides of the precast concrete wall panel, and the protecting shells sleeve the embedded column reinforcement cages. A plurality of reserved joint bars are arranged above the precast concrete wall panel, and a plurality of reserved bolt holes matched with the reserved joint bars in position are formed below the precast concrete wall panel. Compared with the prior art, the precast concrete shear wall component and the construction method thereof have the advantages that binding the embedded column reinforcement cages on two sides of the precast concrete wall panel on site is omitted, so that on-site construction process steps are decreased and on-site construction time is shortened; on-site connection between the precast concrete wall panel and the bound embedded column reinforcement cages is omitted, so that construction efficiency is improved and construction space is reduced; a construction period is shortened and labor and time costs are saved; construction industrialization and mechanization degree is enhanced, and dependency on increasingly intense labor resource is reduced.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

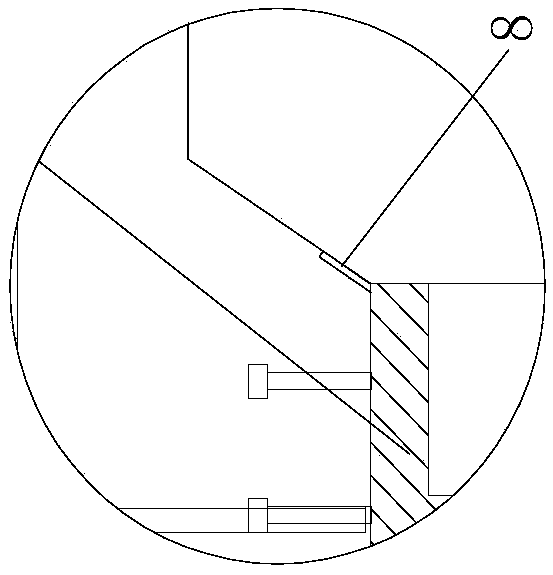

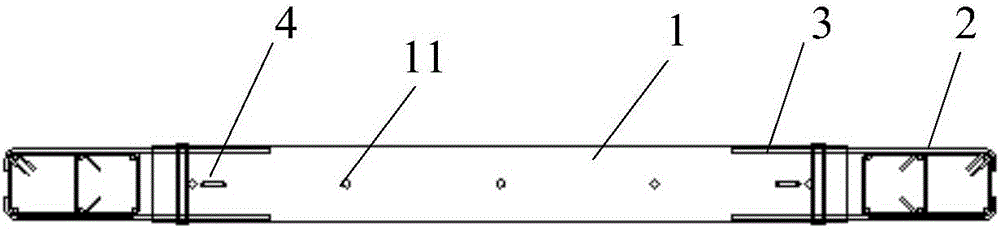

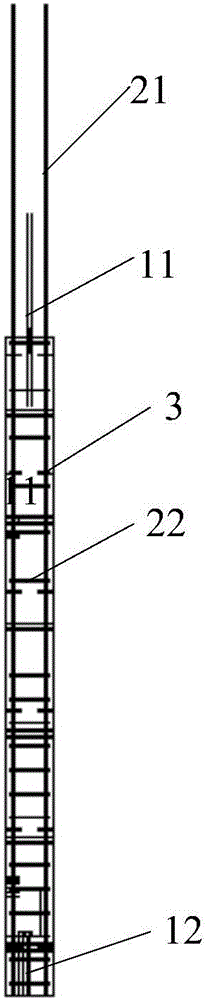

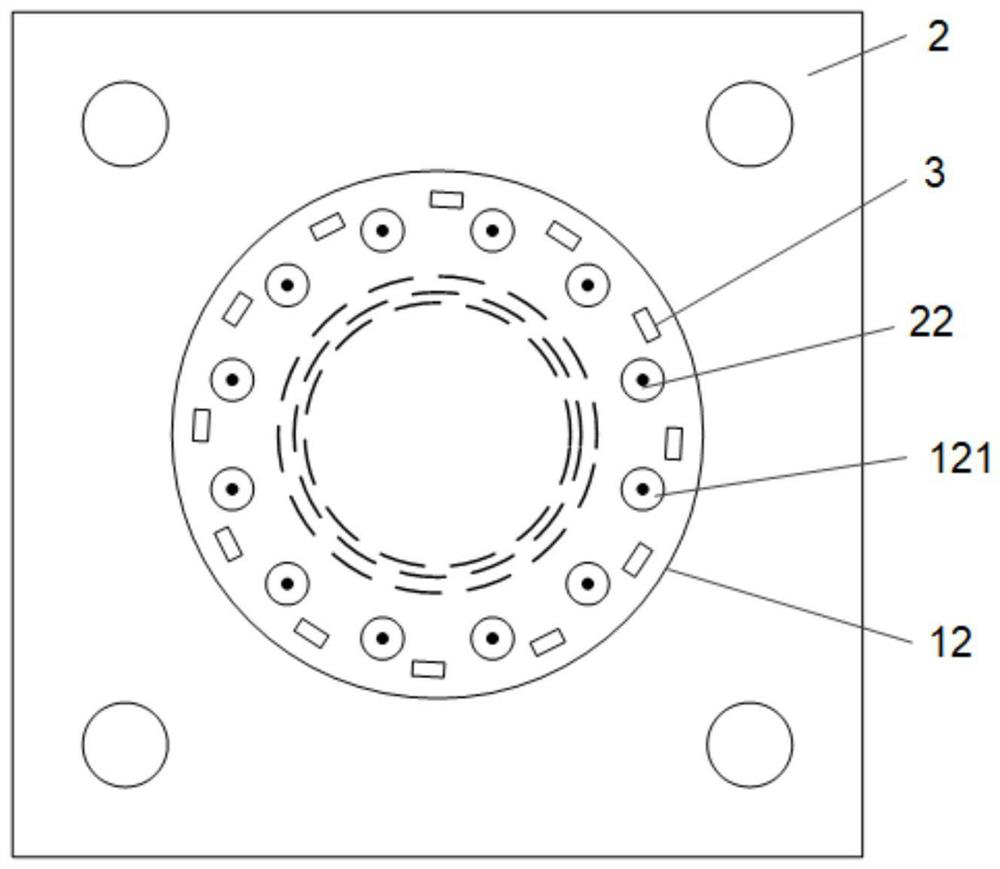

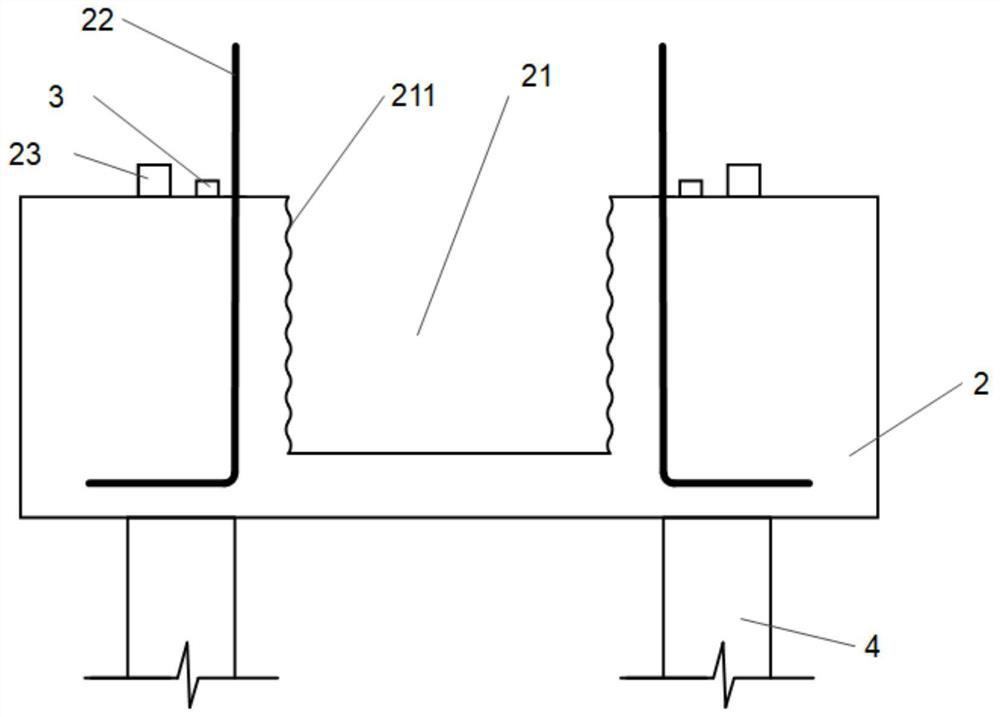

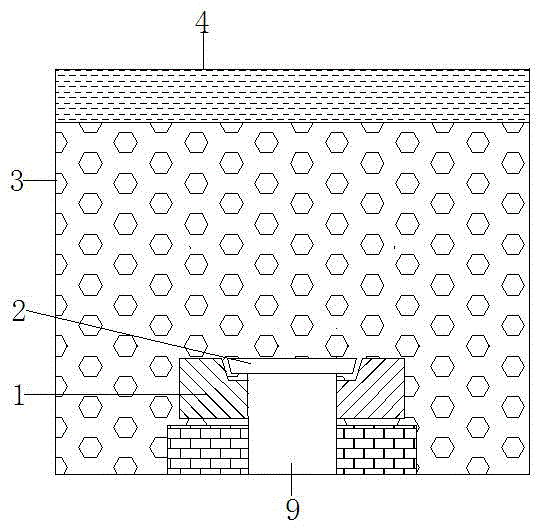

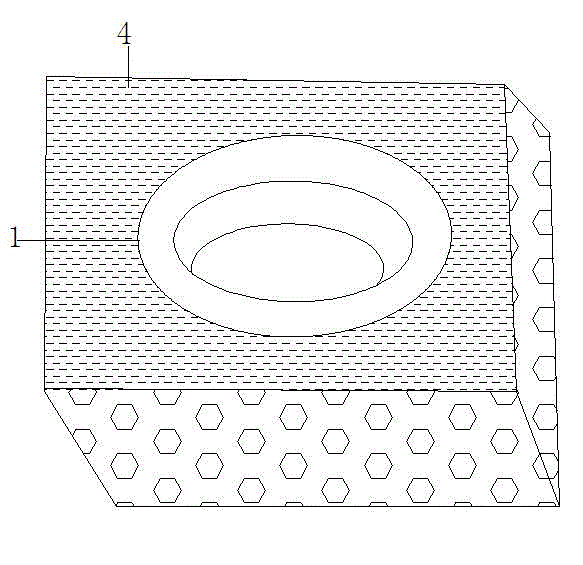

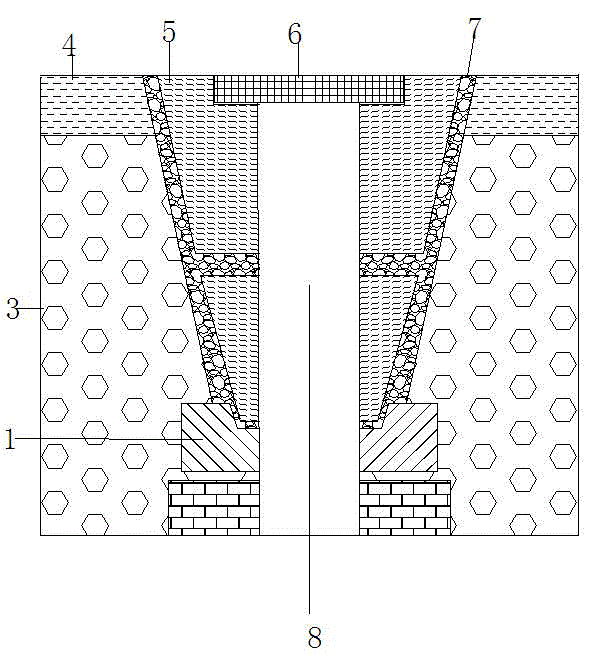

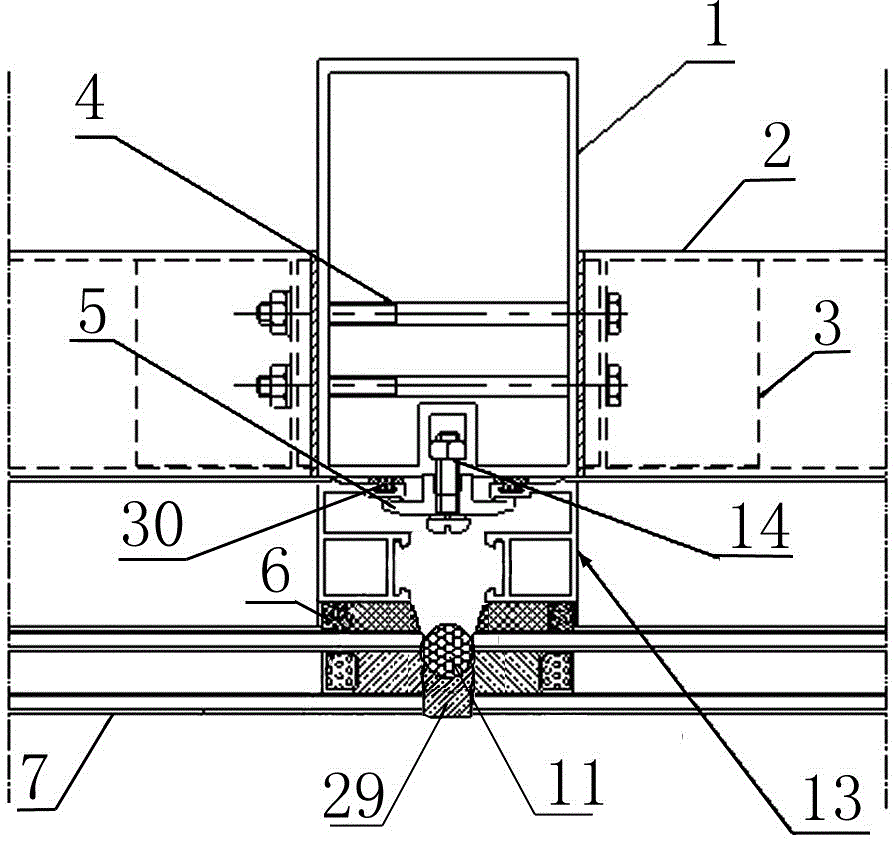

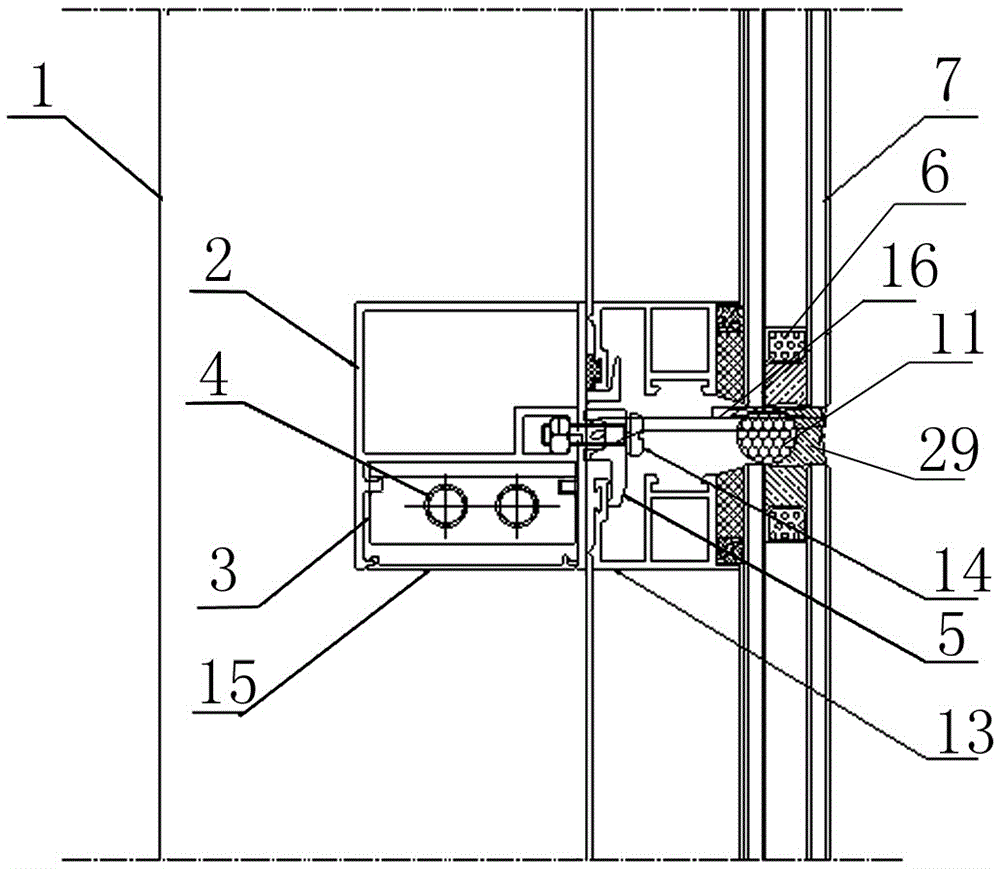

Bearing-socket type prefabricated pier connecting structure and construction method thereof

PendingCN111809510AIncrease the gapNo lack of fullnessBridge structural detailsFoundation engineeringArchitectural engineeringRebar

The invention discloses a bearing-socket type prefabricated pier connecting structure. The structure comprises a prefabricated pier body and a bearing platform, a bearing platform groove is formed inthe bearing platform; a plurality of bearing platform reserved steel bars arranged in the vertical direction are pre-buried in the bearing platform. The prefabricated pier body sequentially comprisesan exposed end, a bearer and an embedding end from top to bottom. The bearer is provided with a plurality of steel bar inserting grooves matched with reserved steel bars of the bearing platform in thecircumferential direction. The free ends of the plurality of bearing platform reserved steel bars are respectively inserted into the steel bar inserting grooves; the outer wall of the embedded end isprovided with a plurality of annularly-protruding stand column shear keys. The embedded end is embedded into the groove of the bearing platform; the lower surface of the bearer is placed on the uppersurface of the bearing platform; grouting materials are poured into the steel bar inserting grooves and the bearing platform grooves. The volume of the grouting material can be adopted to calculate the pouring amount of the grouting material, a gap between the bearing platform and the prefabricated pier body is large, the phenomenon of non-fullness does not exist, splicing construction is easy, the construction error-tolerant rate is high, and the defects that in the prior art, potential safety hazards exist, and the grouting fullness degree is not easy to check can be overcome.

Owner:SHANGHAI INST OF TECH

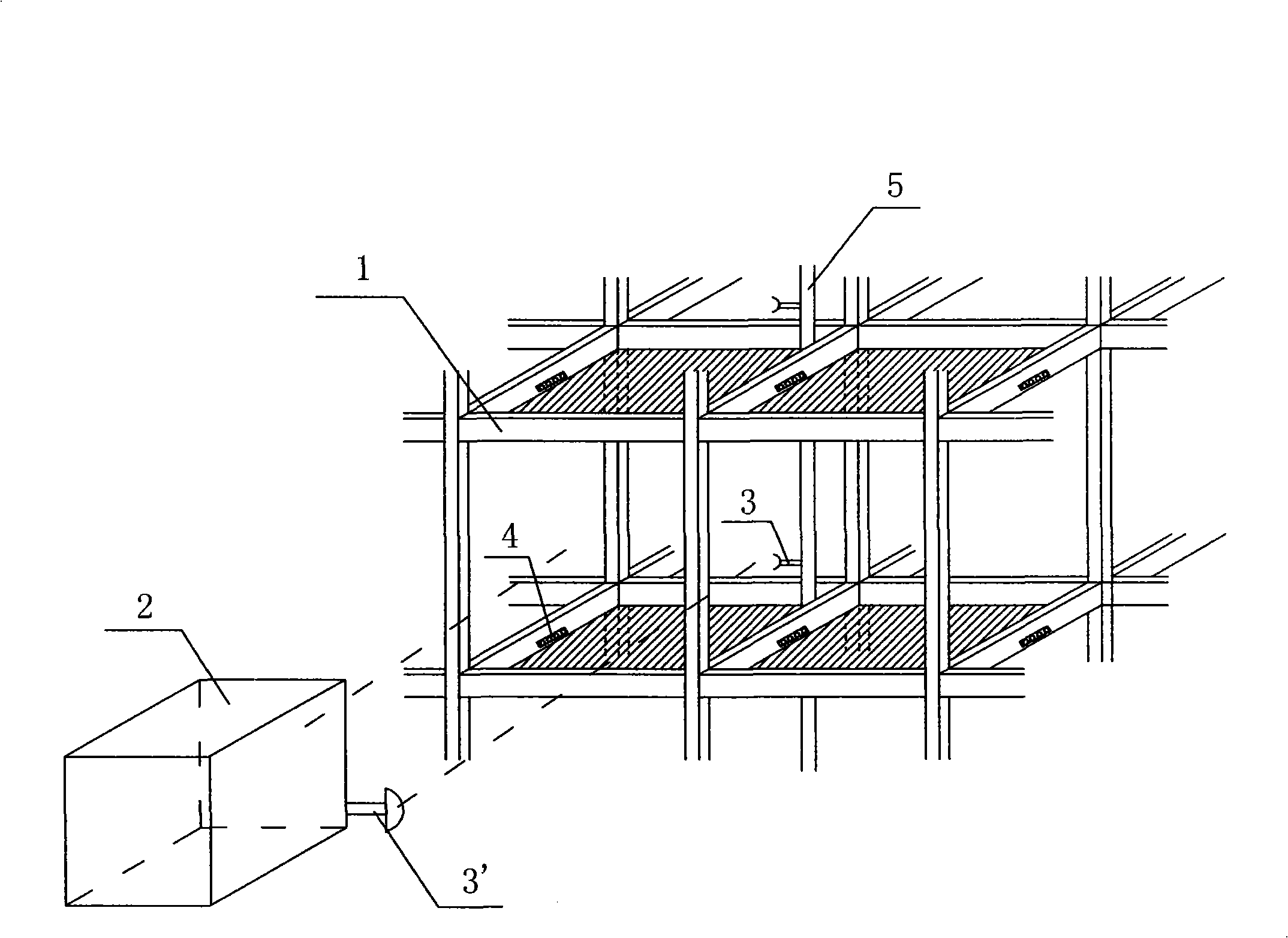

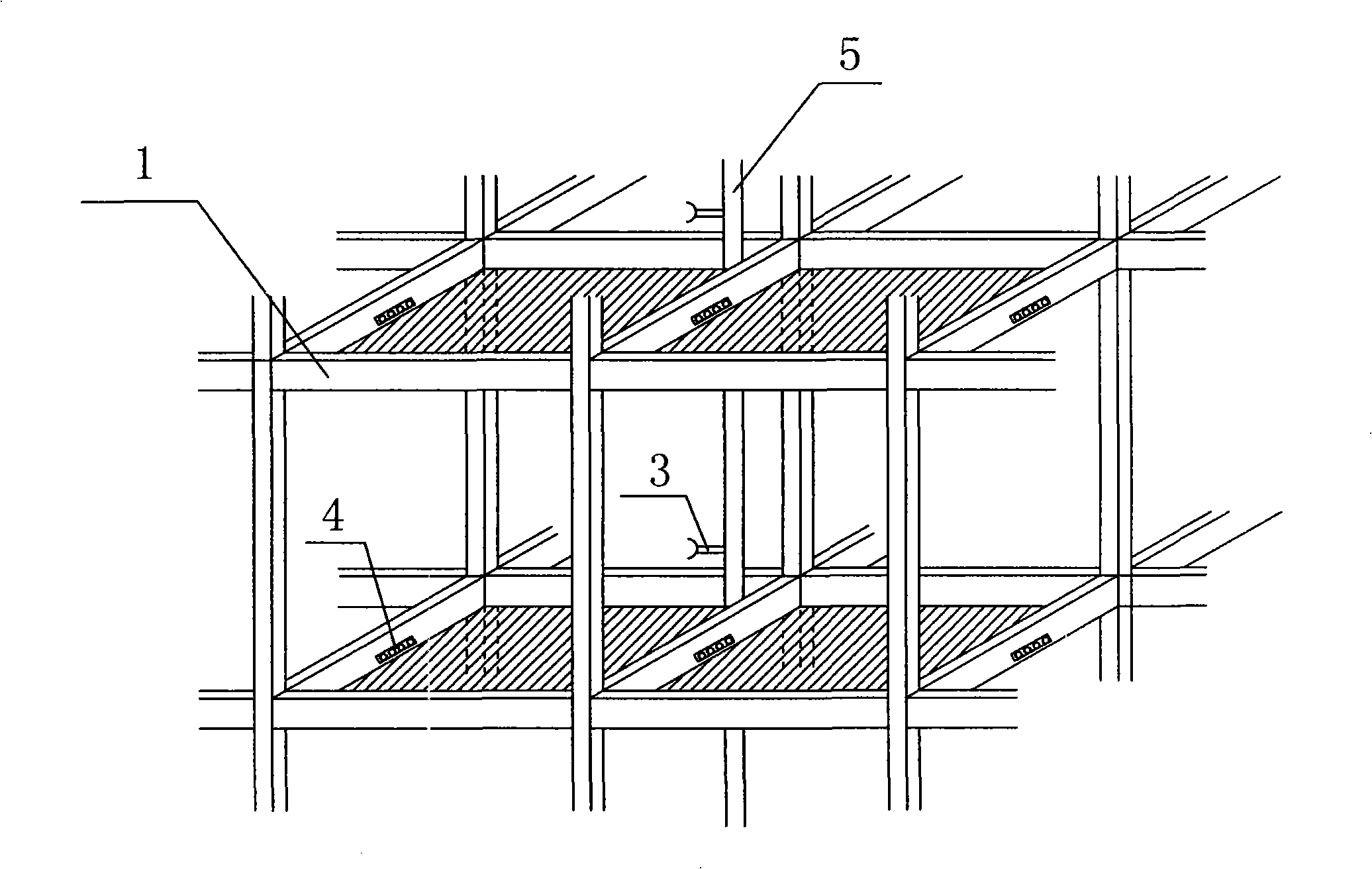

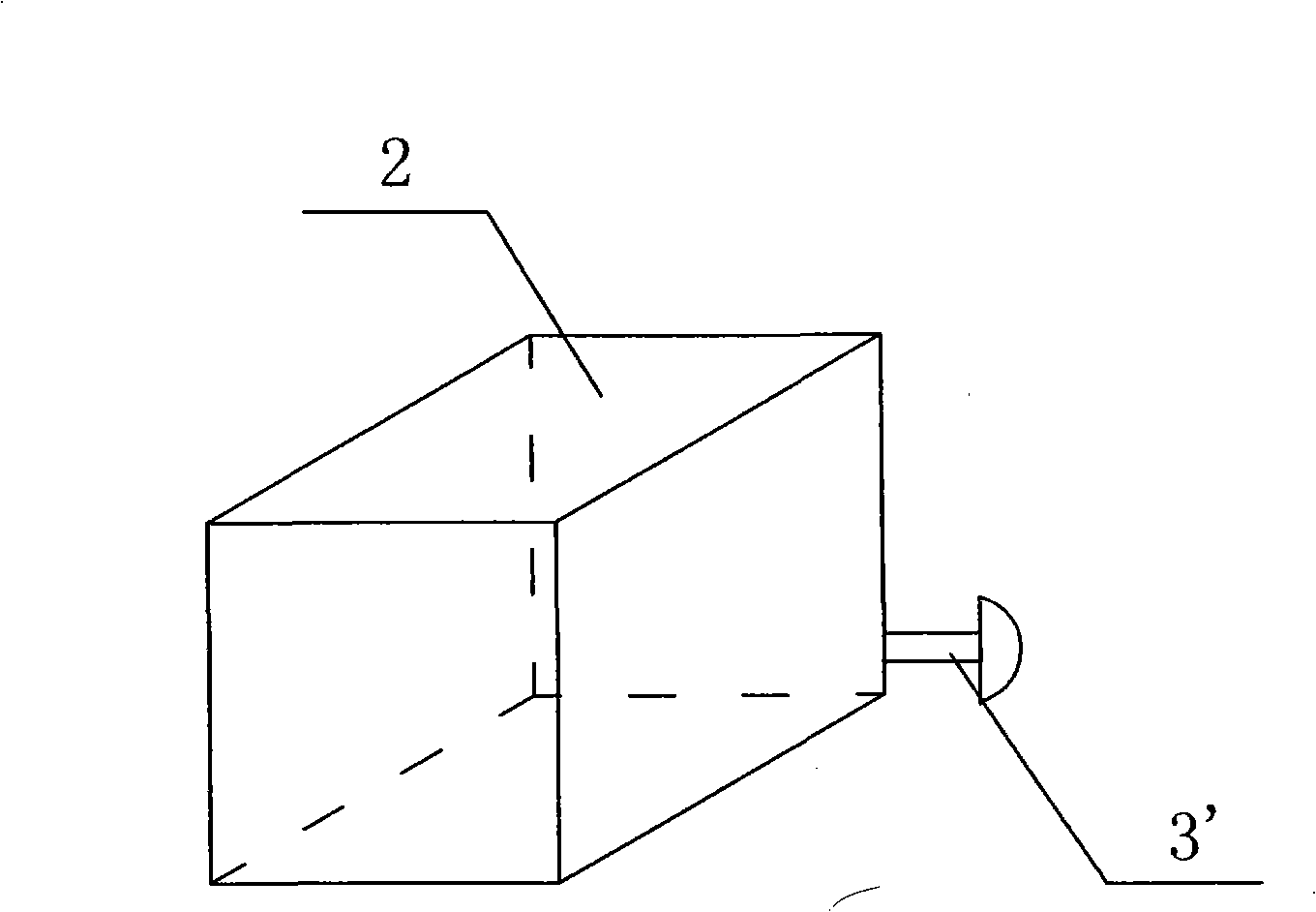

New framed building and construction procedure thereof

InactiveCN101285324AReduce on-site construction timeLow costBuilding constructionsElectricityEnergy source

The invention discloses a novel frame building structure and a method for building the same. The structure of the novel frame building comprises a frame body, a space unit, mother interfaces of water, electricity, gas, communication and ventilation arranged on a pipeline route, son interfaces of water, electricity, gas, communication and ventilation arranged outside the space unit and a fixing mechanism. The space unit taken as a whole body is fixed by the fixing mechanism and arranged inside the frame body, and the space unit is detachable; mother interfaces and son interfaces of water, electricity, gas, communication and ventilation are interconnected. A building built according to the structure and the construction method can realize the independent construction and decoration of rooms and the frame body, and rooms taken as a whole body can be moved without damage, thereby facilitating the movement, saving construction time and energy sources and reducing pollution.

Owner:李乃华

Prefabricated inspection well and road construction method involving inspection well

ActiveCN103603373AReduce labor usage and road costShorten construction timeArtificial islandsSewerage structuresEngineeringSubgrade

The invention relates to an inspection well, in particular to a prefabricated inspection well and a road construction method involving the inspection well. The road construction method involving the inspection well includes the following steps of (1) arranging a base with an opening, (2) installing a bottom cover on the base, wherein the position of the bottom cover can be determined, (3) normally laying a road bed and a road surface on the bottom cover, (4) prefabricating the inspection well, (5) determining the position of the bottom cover, (6) smoothly cutting the road surface until the bottom cover is exposed and taking out the bottom cover, (7) placing the prefabricated inspection well, and (8) wholly or partially replacing, maintaining and recycling the prefabricated inspection well. The road construction method has the advantages that labor and road manufacturing cost are effectively reduced, road on-site construction time is shortened, the situation that the road surface is uneven due to uneven sediment of the surrounding of the inspection well is effectively avoided, flatness of the road surface is improved, road construction quality is improved, maintenance time of the inspection well is substantially shortened, and the inspection well can be recycled.

Owner:于有为

Combined type protection shed frame and construction method thereof

ActiveCN102425123AReduce the amount of on-site constructionReduce distractionsBuilding repairsTrack maintainenceBridge deckCross over

The invention discloses a combined type protection shed frame and a construction method thereof. The combined type protection shed frame is characterized in that a bearing structure located on the top surface of a bridge is arranged; the top surface of the bridge is taken as a bearing foundation by bearing longitudinal girders in the bearing structure; bearing cross girders crossing over the bridge are supported by the bearing longitudinal girders; a steel-structure frame located at the bottom part of the bridge is arranged; frame longitudinal girders in the steel-structure frame are suspended below the bearing cross girders through suspenders, and are located at both sides of the bridge; and frame cross girders in the steel-structure frame are suspended at the bottom parts of the frame longitudinal girders. The combined structure of the combined type protection shed frame disclosed by the invention is entirely borne on a bridge deck, and foundations do not need to be constructed at both sides of the existing railroad line, thereby, the on-site construction quantity of the existing railroad line is greatly reduced, the construction risk is lowered, the potential safety hazards areeliminated, and the interference on the normal operation of the existing railroad line is effectively reduced.

Owner:THE FIRST ENG CO LTD OF CTCE GRP

Connecting joint of fabricated concrete composite wall with built-in thermal insulation layer and light steel frame

PendingCN108277887AImprove seismic performanceHigh design strengthWallsHeat proofingThermal insulationSteel frame

The invention belongs to the technical field of connecting and manufacturing of wall joints in building structure engineering and particularly relates to a connecting joint of a fabricated concrete composite wall with a built-in thermal insulation layer and a light steel frame. The composite wall is mounted in a semi-embedded mode, and the built-in thermal insulation layer and inner sheet concreteare embedded into the light steel frame. Beam columns of the light steel frame are externally wrapped with outer sheet concrete. Compared with a traditional fabricated wall, the wall can serve as a structural force-bearing component, transmits loads with the frame beam columns, and participates in house structural force bearing, the house bearing capacity and anti-seismic capacity are improved, wallboards are wrapped with the frame beam columns, and thus steel corrosion is effectively reduced. The joint of the composite wall and the frame achieves bolted connection by means of the methods that bolts are pre-buried into the composite wall and connecting angle steel is welded to the frame structure beam columns, the structure form of the joint is simple, connecting is reliable, constructionis easy, the joint is applied to practical engineering, the building period can be effectively shortened, and the joint is suitable for being applied and popularized in low-rise and high-rise light steel frame structures.

Owner:BEIJING UNIV OF TECH

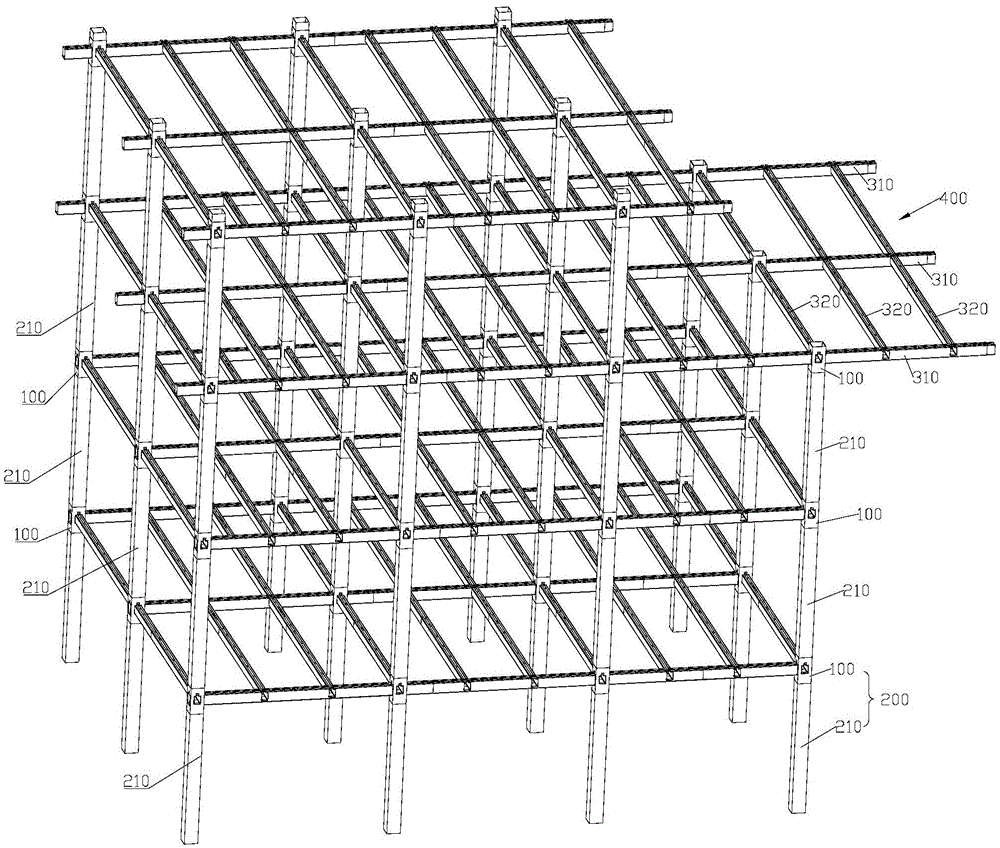

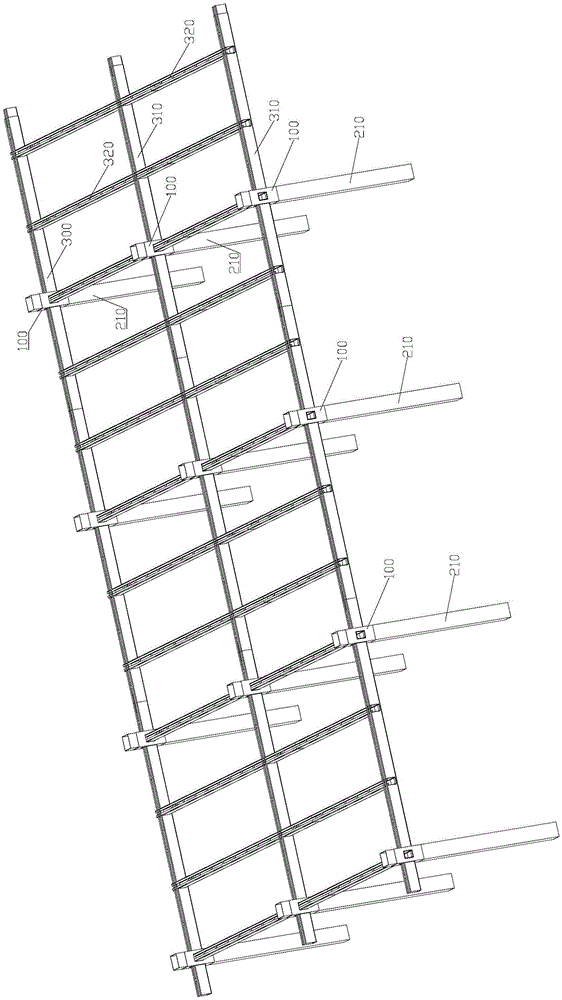

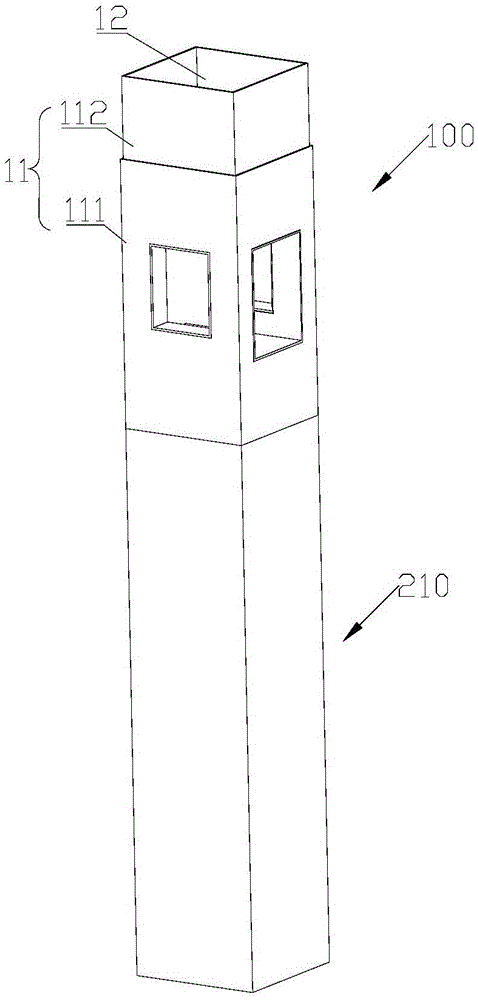

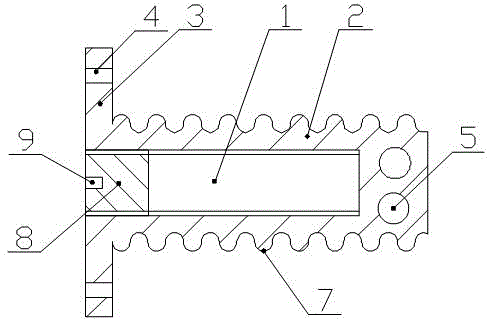

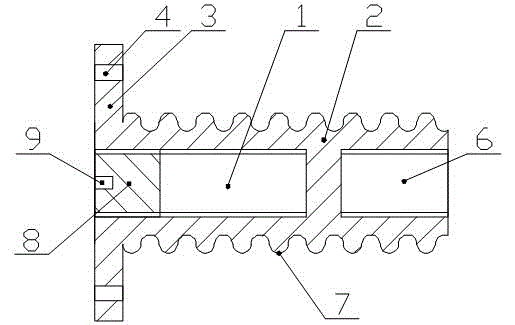

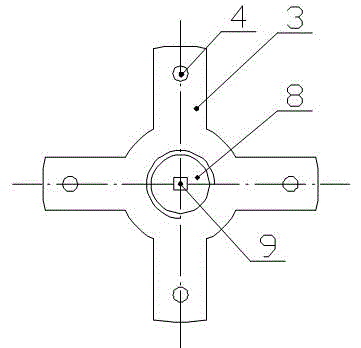

Steel structure

ActiveCN106049677AUniform appearanceSimple structureBuilding constructionsEngineeringUltimate tensile strength

The invention discloses a steel structure. The steel structure is characterized by comprising stand columns and beams; the stand columns comprise supporting columns and bracket structures; the supporting columns comprise supporting column pipe cavities; the bracket structures comprise sleeves which are provided with sleeve walls; the sleeve walls define sleeve cavities; first through holes penetrating through the sleeve walls are formed in the sleeve walls; the first through holes communicate with the sleeve cavities, and the sleeve walls are connected with the supporting columns; the beams comprise outer sleeves which are provided with outer sleeve walls; the outer sleeve walls define outer sleeve cavities; the outer sleeve walls are inserted into the supporting column pipe cavities from the first through holes; and the ends of the outer sleeve pipe walls are located in the supporting column pipe cavities or penetrate through the sleeves and protrude out of the sleeve walls. The structure principle of the steel structure is applied to a steel structure so as to solve the problems of beam continuity, structure fixing and node strength. The condition of beam top concrete pouring grooves is ingeniously used for welding, and the problem of steel structures is completely solved.

Owner:李新华

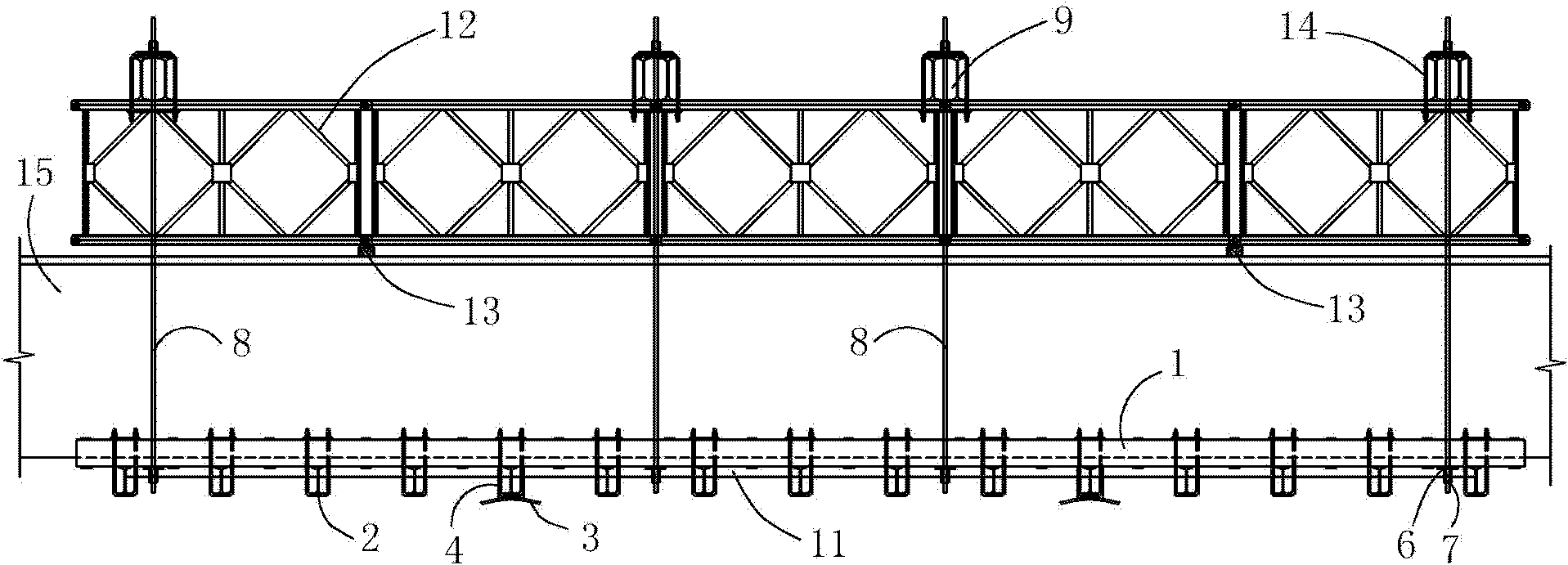

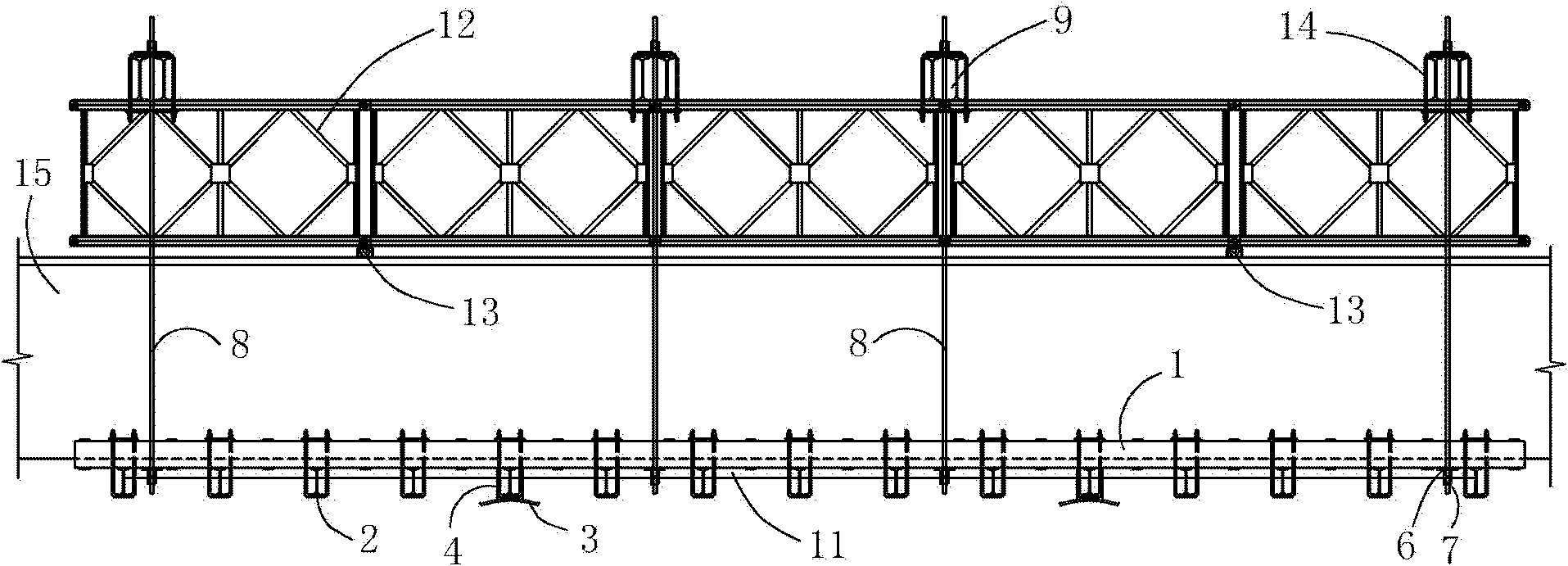

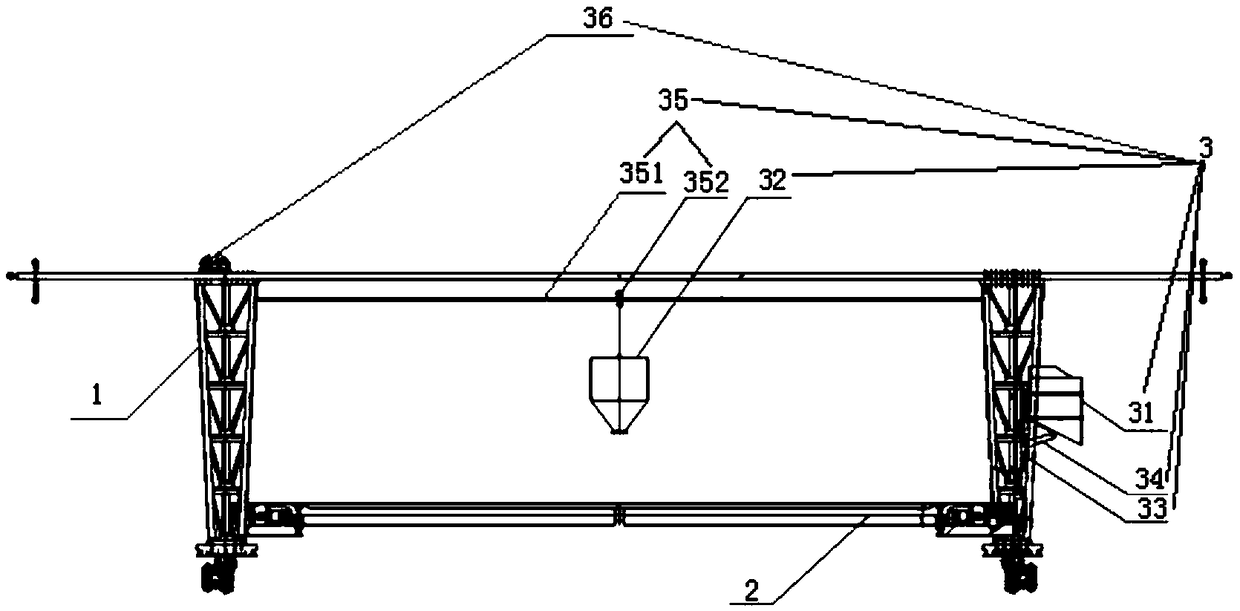

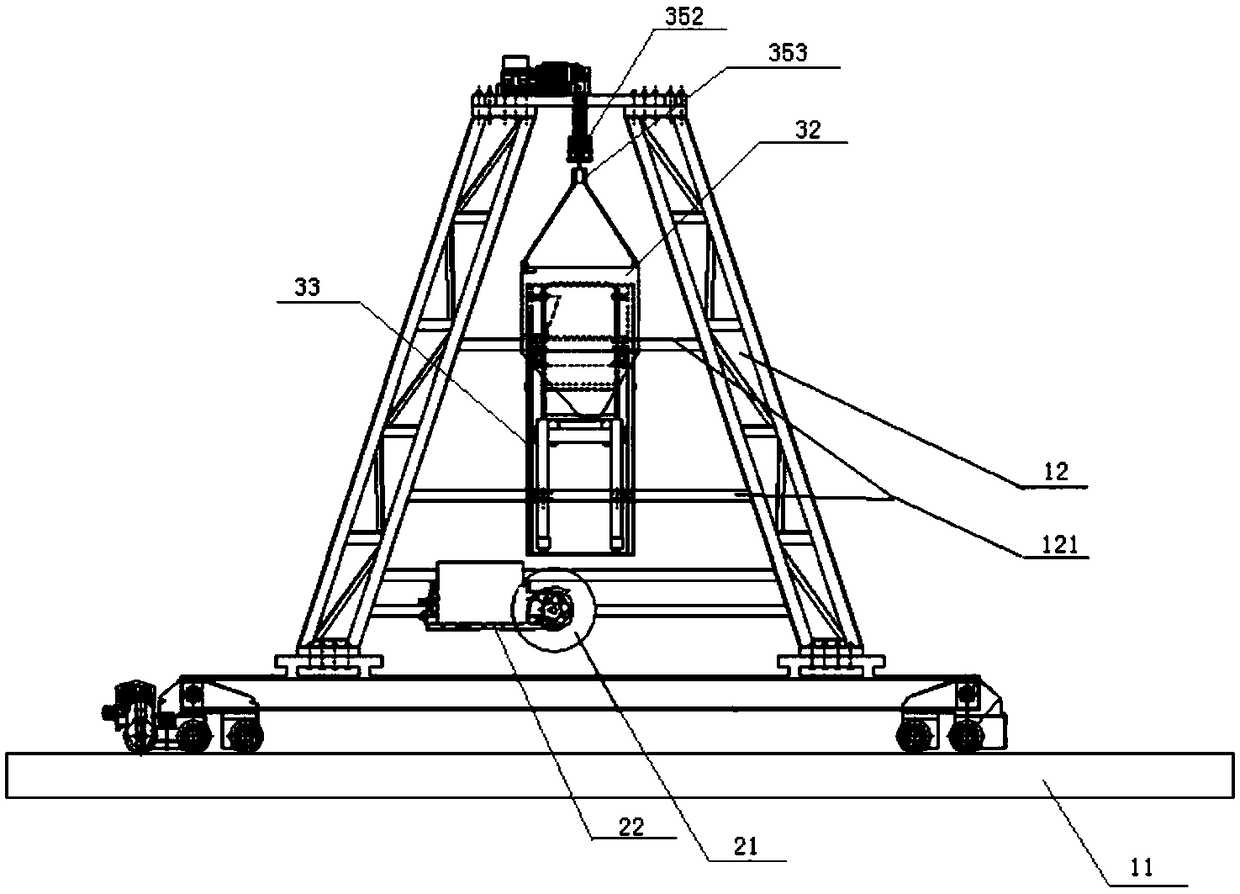

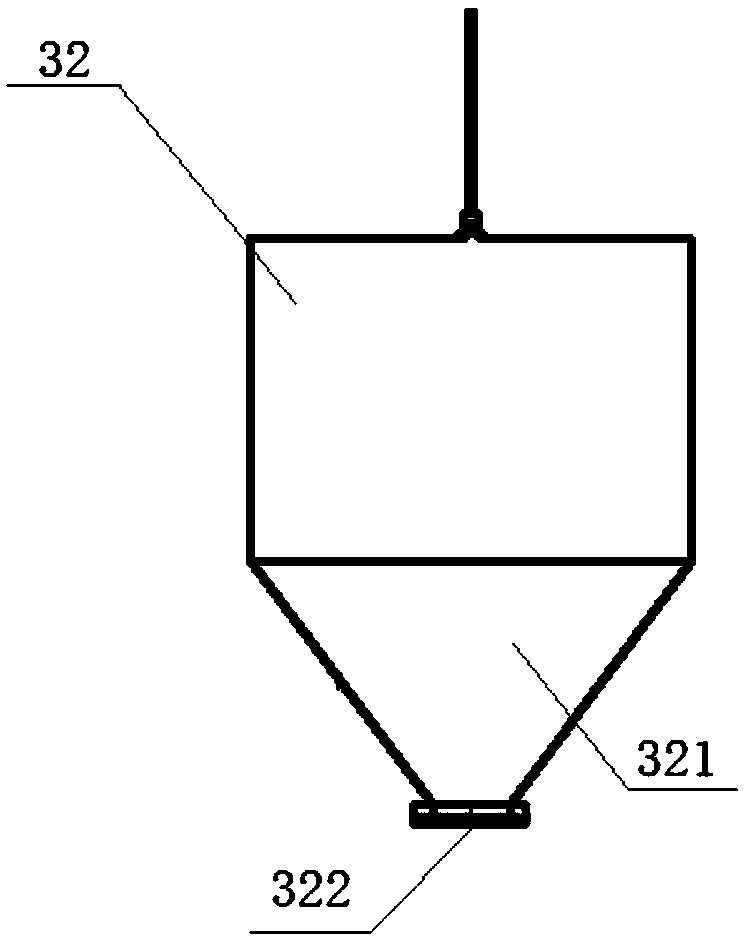

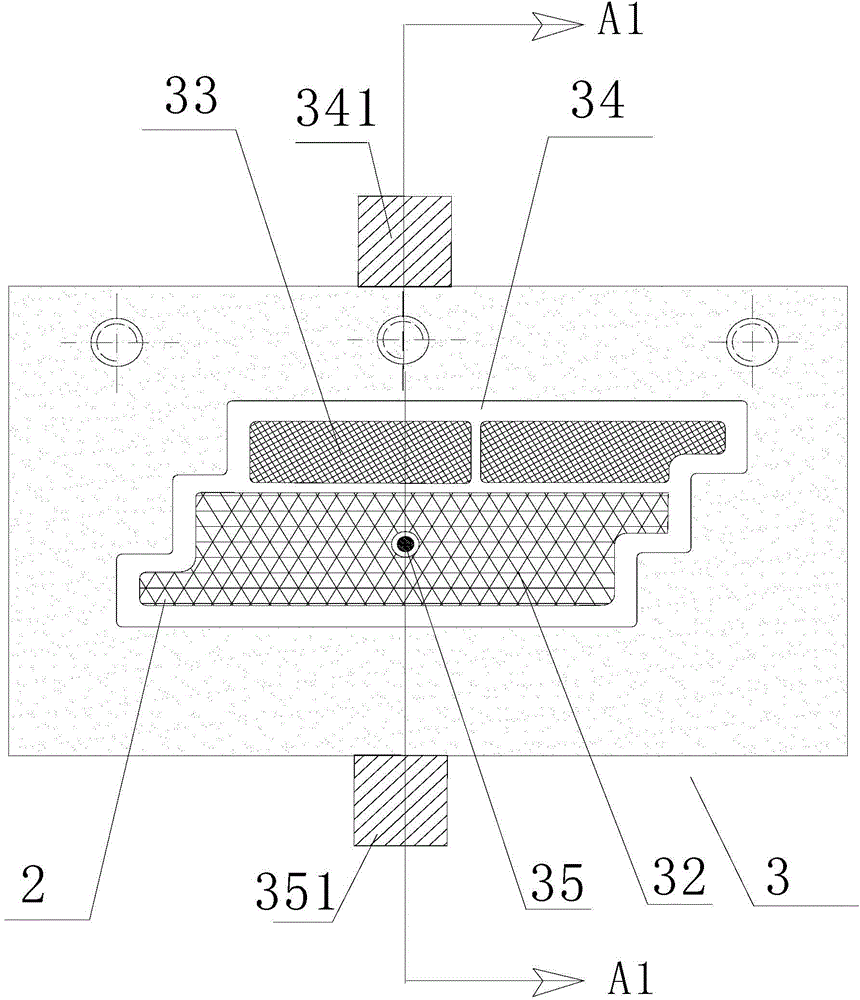

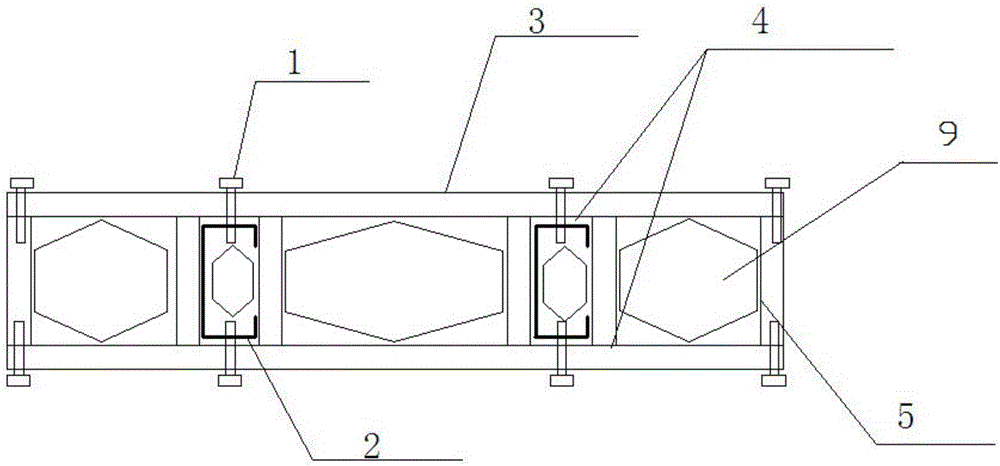

Steel bridge deck prefabricated paving equipment

ActiveCN109306649AReduce construction proceduresReduce the impactBridge structural detailsBridge erection/assemblyBridge deckPortal frame

The invention discloses steel bridge deck prefabricated paving equipment. The steel bridge deck prefabricated paving equipment can change the traditional steel bridge deck pavement construction procedure and technology. The steel bridge deck subjected to sand blasting and anti-rust coat and tack coat spraying can be paved with asphalt concrete in a factory, and is conveyed to a construction site for bridge deck assembling after forming. After assembling, the SMA asphalt mixture and other surface materials can be directly paved on the steel bridge deck. On-site construction procedures are reduced, construction difficulty is lowered, influence on construction by weather is avoided, and steel bridge paving quality and efficiency are effectively improved. The steel bridge deck prefabricated paving equipment comprises a walking machine frame and a paving mechanism, and is provided with a moving material cabin. The walking machine frame comprises a moving portal frame, a guide rail and the like. The paving mechanism comprises a spiral material arranging machine, an ironing plate and an ironing plate lifting device. The moving material cabin comprises a vertical lifting material cabin anda horizontal paving material cabin.

Owner:CHANGAN UNIV

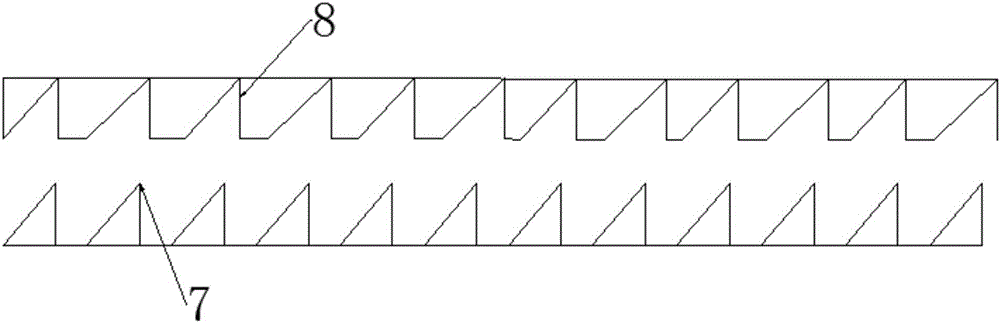

Composite plate formed by co-extruding wood, plastics and foaming layer and preparation method thereof

ActiveCN105421650AEfficient thermal insulation and sound insulation effectImprove physical strengthBuilding componentsGlass fiberComposite plate

The invention provides a composite plate formed by co-extruding wood, plastics and a foaming layer. The composite plate comprises a wood and plastic framework and the foaming layer. The wood and plastic framework is provided with a first cavity. The first cavity is filled with the foaming layer, and the foaming layer is bonded to the wall face of the first cavity, wherein the foaming layer is made from foaming materials, and raw materials of the foaming layer do not contain wood powder, wood fibers, glass fibers or basalt fibers. According to the composite plate formed through co-extrusion, the foaming layer does not contain wood powder, wood fibers, glass fibers or basalt fibers, the foaming effect can be 490 Kg / m<3> or below or even reaches 238 Kg / m<3>, and an efficient heat-preserving, heat-insulating and sound-insulating effect is achieved.

Owner:BEIJING NEW BUILDING MATERIALS PLC

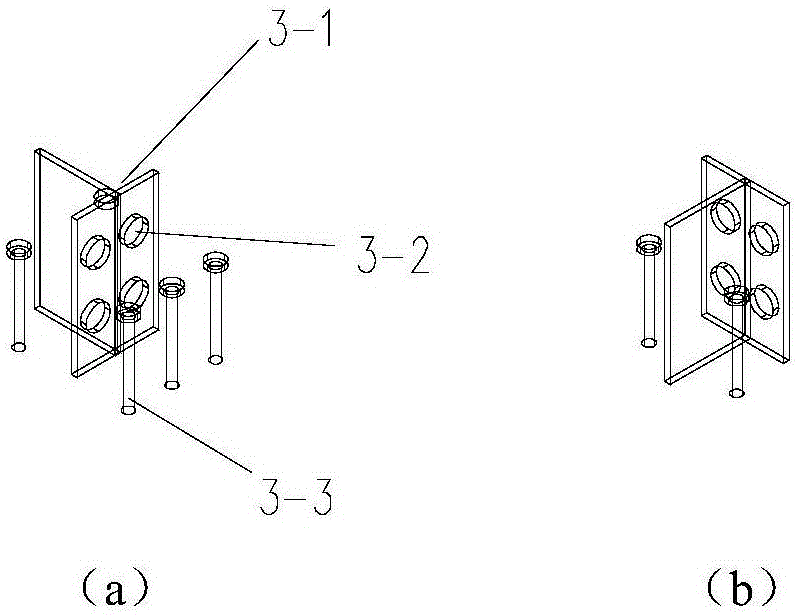

Node connecting structure for assembled bamboo wood beam column

PendingCN108222289ABeam-column connection structure is stableEasy to install on siteBuilding constructionsSteel platesBending moment

The invention discloses a node connecting structure for an assembled bamboo wood beam column. The structure comprises a rectangular side column, a rectangular beam, a steel filling plate and split bolts, wherein the steel filling plate is formed by welding an H-shaped steel plate and a wing plate; a bolt hole is formed in the net section of the wing plate; notches and bolt holes are formed in theend parts of the rectangular side column and the rectangular beam; the dimensions of the notches are consistent with those of a corresponding inserting part of the wing plate; the rectangular side frame comprises an upper side column and a lower side column, and the upper side column, the lower side column and the rectangular beam are connected and fixed to the steel filling plate through the split bolts. By way of node connection mode of the steel filling plate of the bamboo wood structure, the node connection of the bamboo wood structure has the characteristics of a semi-rigid node, can better bear the bending moment and the shearing force of the node and form a more stable mechanism system, and has the characteristics of high node rigidity, firm connection, high industrial degree and convenience in field construction.

Owner:NANJING UNIV OF TECH

Metal sectional material and wood-plastic co-extrusion moulded composite plate as well as preparation method thereof

ActiveCN105484423AGuaranteed basic strengthReduce steel consumptionBuilding componentsCo extrusionPlastic materials

The application provides a metal sectional material and wood-plastic co-extrusion moulded composite plate. The metal sectional material and wood-plastic co-extrusion moulded composite plate comprises a wood-plastic frame and a metal sectional material, wherein the wood-plastic frame is provided with a first chamber; the metal sectional material is located in the first chamber; the wall surface of the first chamber is bonded with the surface of the metal sectional material; the metal sectional material is provided with a plurality of prefabricated holes; the first chamber of the wood-plastic frame is provided with projections embedding into or penetrating through the prefabricated holes; the projections are integrally moulded with the wood-plastic frame, wherein the wood-plastic frame is made from a foamed wood-plastic material, and the metal sectional material is an open metal sectional material. According to the co-extrusion moulded composite plate provided by the embodiment of the invention, the open metal sectional material is used, and a closed shape is not used, thus ensuring the basic strength of the composite plate, saving the consumption of steel, and creating conditions for realizing compressed air inner-cooling for an extrusion mould.

Owner:BEIJING NEW BUILDING MATERIAL

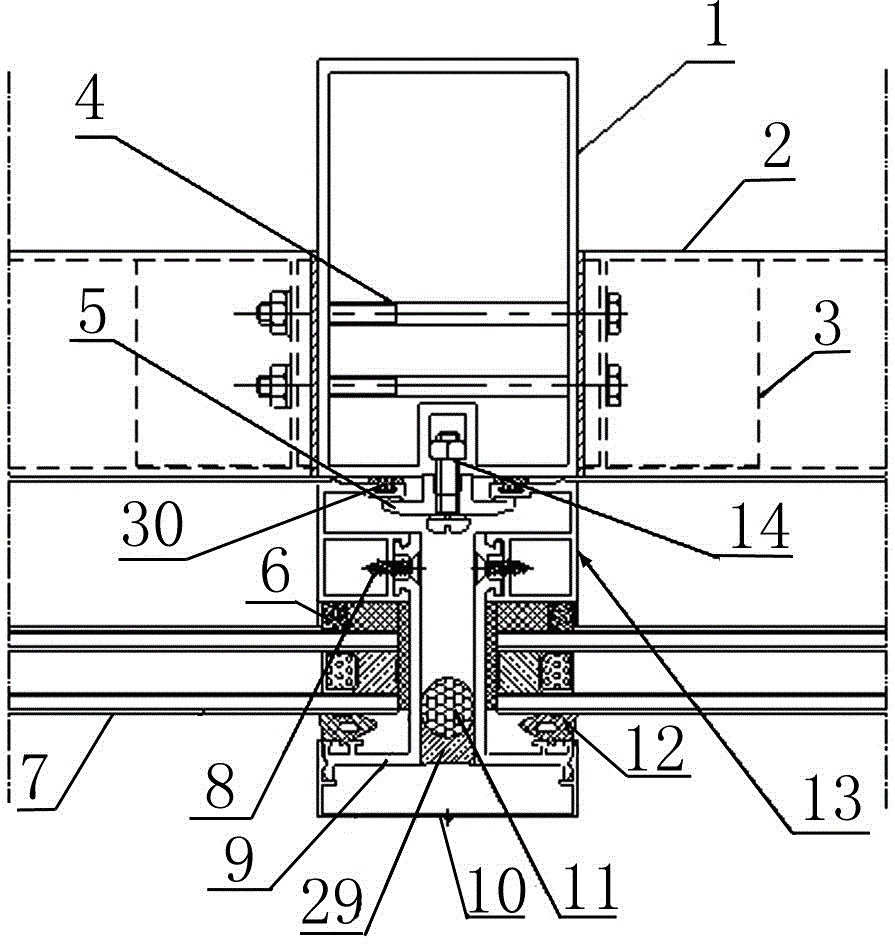

Full-bolt socket and spigot type beam column connecting structure of fabricated steel concrete

InactiveCN112323975AReduce the accuracy of construction requirementsHave stabilityBuilding constructionsEngineeringSteel columns

The invention provides a full-bolt socket and spigot type beam column connecting structure of fabricated steel concrete. The beam column connecting structure comprises a steel column, a plurality of I-shaped beams, supporting pieces and connecting pieces, wherein the plurality of I-shaped beams, the supporting pieces and the connecting pieces are arranged on the steel column, the steel column is provided with a hollow cavity for concrete pouring, a plurality of fixing steel bars are arranged in the hollow cavity, the supporting pieces are arranged below the I-shaped beams and connected with the I-shaped beams through bolts, one ends of the connecting pieces are connected with the I-shaped beams through bolts, the other ends of the connecting pieces are inserted into the hollow cavity of the steel column to be connected with the fixing steel bars, and finally concrete is poured for fixing. By means of the combination of steel concrete connection and bolt connection, the beam-column joint has the stability of welding type connection, the construction precision of full-bolt type installation is also reduced, the construction process is simple, and the efficiency is high.

Owner:广州建筑产业研究院有限公司 +1

Curtain wall exposed and hidden frame connecting auxiliary frame, curtain wall system and construction method thereof

InactiveCN106284779ASimple structureReasonable designWallsMutual transformationStructural engineering

The invention relates to a curtain wall exposed and hidden frame connecting auxiliary frame, a curtain wall system and a construction method thereof. The connecting auxiliary frame comprises two strip-shaped auxiliary frame units of mirror symmetry and a transforming auxiliary frame detachably connected with the auxiliary frame units; the transforming auxiliary frame comprises two strip-shaped exposed frame press plate units and strip-shaped decorative buckling covers, wherein the strip-shaped exposed frame press plate units are arranged in a mirror symmetry and correspondingly connected with the auxiliary frame units. The cross section of the exposed frame press plate units is in a J shape and comprises a vertical plate and a transverse plate, wherein a clamping strip connected with a connecting slide groove in a matched mode is arranged at the upper end of the vertical plate, a second through clamping groove is formed in the outer end of the upper surface of the transverse plate in the length direction, and a third through clamping groove is formed in the side face of the outer end of the transverse plate in the length direction, and the decorative buckling covers are connected with the third through clamping grooves in the two exposed frame pressing plate units through convex strips on the two side walls. The connecting auxiliary frame is simple in structure and reasonable in design and is combined with the exposed frame press plate units to achieve mutual transformation between an exposed frame glass curtain wall and a hidden frame glass curtain wall.

Owner:中标建设集团股份有限公司

Adjustable support and construction method thereof

The invention provides an adjustable support and a construction method thereof. The adjustable support is arranged between a basement ceiling and the ground and is formed by a main force transfer component, the upper part of the main force transfer component is connected with an adjustable head component, the lower end of the main force transfer component is connected with a load dispersing component, the main force transfer component comprises a vacancy filling part, a jack ejector rod on a jack ejector base of the main force transfer component is in contact connection with the adjustable head component which has a linear upward movement trail on the main force transfer component, the vacancy filling part consists of four valve ring vacancy blocks, the inner diameter and the outer diameter of the vacancy filling part are equal to those of the main force transfer component, the vacancy filling part is inlaid between the main force transfer component with the adjusted supporting height and the adjustable head component. All parts are prefabricated in a factory, and are assembled, adjusted, fixed and erected in site. The adjustable support assists large-scale overhang steel structures or large-span steel structure in constructing, so that the tedious condition of overlapping a scaffold is avoided; the height of the head component of the adjusted support is adjustable, so that the problem that supporting stand columns cannot be erected due to the fact that the absolute length of the supporting stand columns is greater than the interlayer spacing of a basement is solved; the adjustable support can be conveniently detached, transferred and reused.

Owner:CHINA CONSTR FIRST DIV STEEL STRUCTUREENG

Floor formed by combining cold-formed thin-wall C-shaped steel and straw plates and manufacturing method

InactiveCN106149939AIncrease stiffnessImprove bearing capacityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesCold formedAdhesive

The invention discloses a floor formed by combining cold-formed thin-wall C-shaped steel and straw plates and a manufacturing method. The combination floor is made from the two straw plates and the two pieces of cold-formed thin-wall C-shaped steel in a combination mode; the cold-formed thin-wall C-shaped steel is arranged between the straw plates, the straw plates and the cold-formed thin-wall C-shaped steels are bonded through high-strength structural adhesive, the high-strength structural adhesive forms the solidified bonded face, self-tapping screws for fixing the straw plates and the cold-formed thin-wall C-shaped steel are arranged at the solidified bonded face, sealing strips are arranged on the sides of the two straw plates and connected with the straw plates through screws, a plurality of rib strips are arranged on the connecting faces of the cold-formed thin-wall C-shaped steel, and a plurality of barbs are arranged on the connecting faces of the straw plates and engaged with the rib strips; the rigidity and the bearing capacity of a pure steel floor and a pure wood floor are improved, and the actual engineering requirements are met; the floor can be manufactured in a plant, site assembly is carried out, and the site construction time is largely shortened; the floor is compared with a traditional concrete floor ceiling and the like, and the self weight is small, the whole construction cost is low, the bearing capacity is high, and the ductility is good.

Owner:CHINA MCC17 GRP

Assembly type light pipeline hanger

The invention relates to an assembly type light pipeline hanger. The assembly type light pipeline hanger is composed of a fixed cross beam, a connecting hanging beam, a pipeline support beam and a connector, wherein the fixed cross beam, the connecting hanging beam and the pipeline support beam are pressed into a roll rim through a galvanized coil and are respectively processed by a right angle beam material with a strengthening groove; the connector is made of a square material, two sides are connected so as to form a right angle, the outer edge size of the connector is equal to the interior angle size of the right angle beam material, and the centre transverse line positions of the two sides of the connector are connected with connecting holes; the vertical plane of one end of the pipeline support beam is connected with a connecting pin, a connecting groove is arranged at the adjacent position of the connecting pin, and the depth of the connecting groove does not exceed a half of the height of the plane; and the width of the connecting groove is matched with the thickness of the right angle beam material after molding, and the horizontal plane of the other end of the pipeline support beam is provided with a pipeline positioning platform. The assembly type light pipeline hanger provided by the invention can be respectively configured according to the technical parameters of a bearing pipeline, and assembly and fixation are carried out by bolts.

Owner:王晶华

Prefabricated supporting pipe piece inverted 'T'-shaped excavation method and temporary supporting structure adopted by urban shallow buried large-section tunnel

PendingCN109681233AReduce one-time disturbance areaThe construction method is simpleUnderground chambersTunnel liningSocial benefitsEconomic benefits

The invention belongs to the technical field of urban underground engineering and particularly relates to a prefabricated supporting pipe piece inverted 'T'-shaped excavation method and a temporary supporting structure adopted by an urban shallow buried large-section tunnel. The temporary supporting structure comprises prefabricated temporary vertical supporting pipe pieces and temporary transverse supporting pipe pieces, wherein the middle partition wall of an upper left step is formed by splicing and erecting the temporary vertical supporting pipe pieces; an inverted arch of the upper left step is formed by splicing and erecting the temporary transverse supporting pipe pieces; an inverted arch of an upper right step is formed by splicing and erecting the temporary transverse supporting pipe pieces; and each temporary vertical supporting pipe piece is provided with a grouting hole. According to the prefabricated supporting pipe piece inverted 'T'-shaped excavation method and the temporary supporting structure adopted by the urban shallow buried large-section tunnel, the temporary supporting structure does not drop to the bottom by adopting temporary vertical supports, and the temporary vertical supports are closed with temporary transverse supports to form an innovative inverted 'T'-shaped excavation method; and an upper step is divided into the upper left step and the upper right step for two-step excavation, and an area of the one-time remolding to a tunnel face soil body is reduced. The construction method provided by the invention has the advantages of simple step, strong operability as well as remarkable economic benefit and social benefit and saves the land.

Owner:JINAN URBAN CONSTR GRP +2

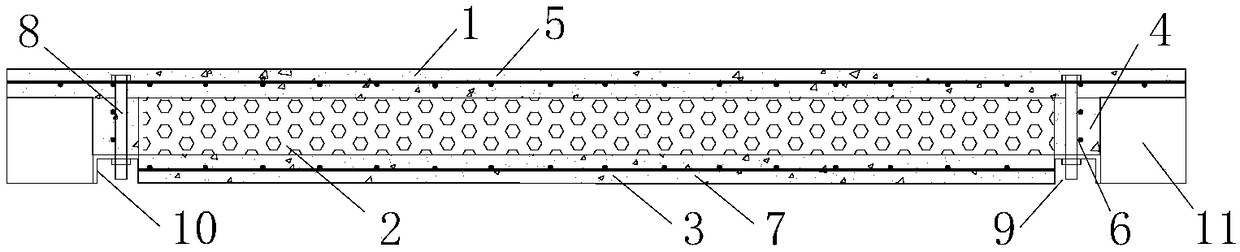

Seam bolt connection type prefabricated concrete bridge deck and prefabricating method

ActiveCN106087741AFast constructionSpeed up prefabricationBridge structural detailsBridge erection/assemblyRear quarterSheet steel

The invention provides a seam bolt connection type prefabricated concrete bridge deck and a prefabricating method. The prefabricating method comprises the following steps: erecting a steel main girder and mounting a concrete bridge deck, wherein a bridge deck connection steel plate is mounted when the concrete bridge deck is prefabricated, an outer edge plate is mounted on the outer side of a connection rabbet, an inner edge plate and a side plate with a hole are mounted in the concrete bridge deck and a main girder connection part is welded on the steel main girder, and the main girder connection part is connected with the outer edge plate through a high-strength bolt; and then constructing a bridge deck shearing force rabbet and the connection rabbet. The seam bolt connection type prefabricated concrete bridge deck is simple in structure and relatively high in prefabricating and splicing degree; field construction time is shortened and a construction period is shortened; and prefabricating production and field assembling connection of structural parts can be realized better.

Owner:CHANGAN UNIV

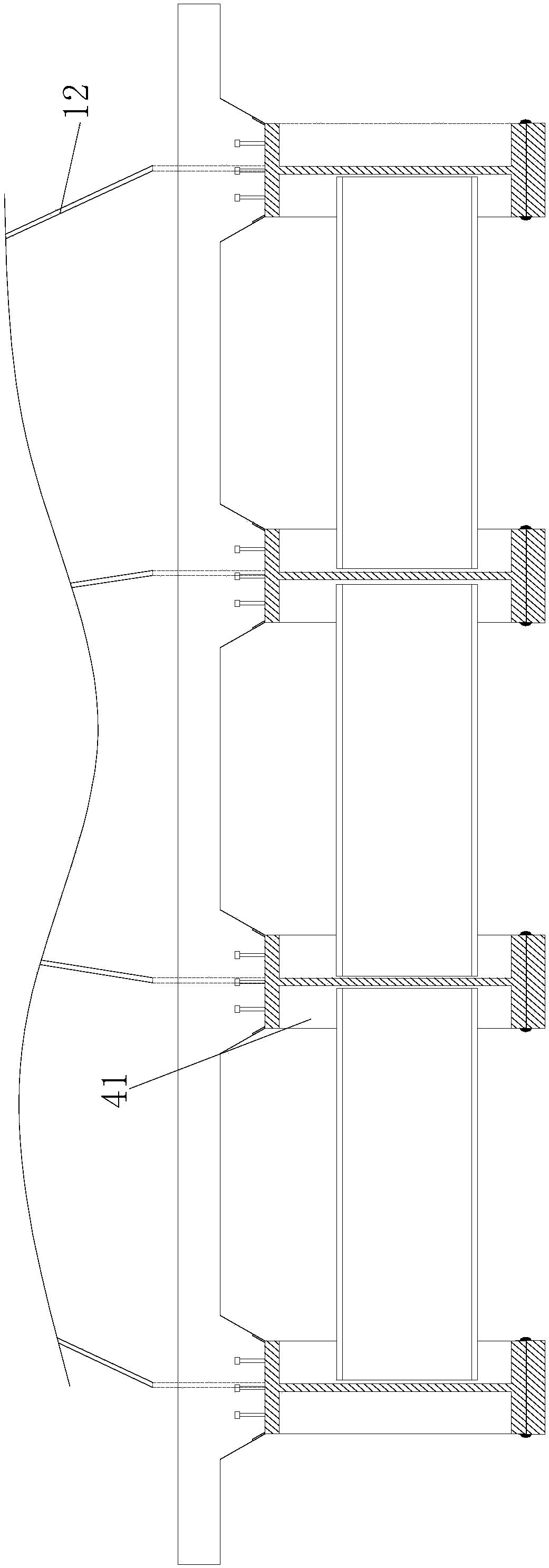

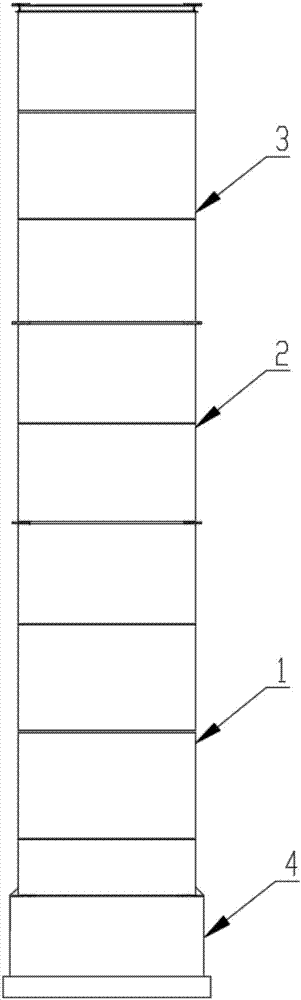

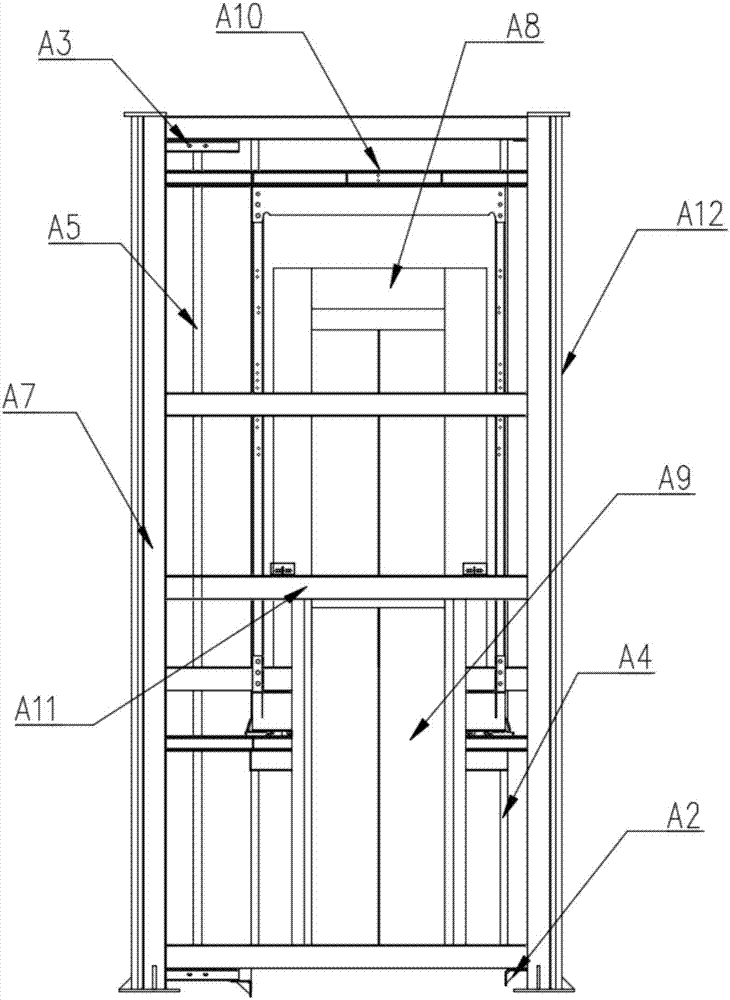

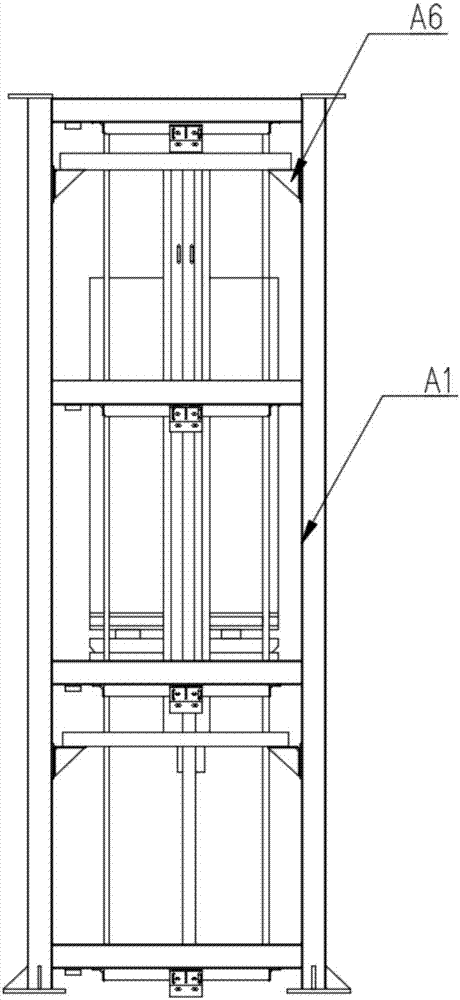

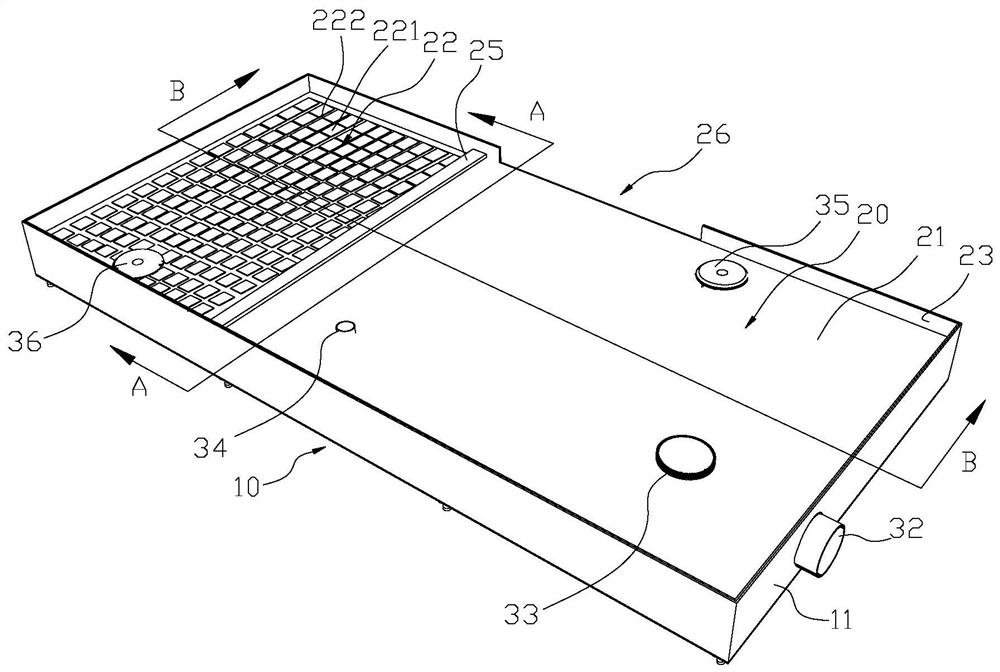

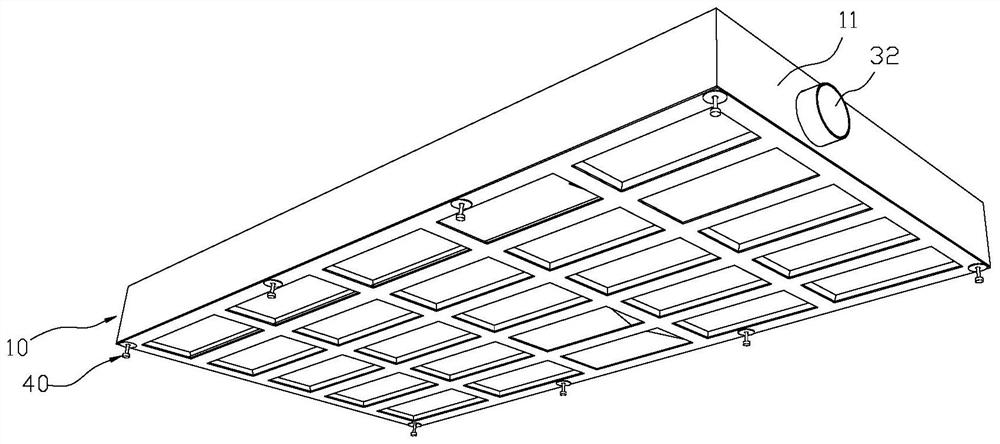

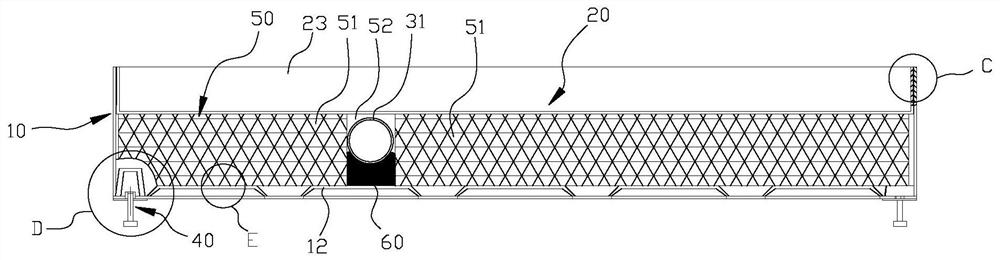

Integral fast-assembly type steel-structure elevator

InactiveCN107032213AOvercome live productionOvercoming complexityElevatorsBuilding liftsFixed frameEngineering

The invention discloses an integral fast-assembly type steel-structure elevator. The integral fast-assembly type steel-structure elevator is composed of a first-segment modular section, a middle modular section and a top modular section, wherein the first-segment modular section is composed of a first-segment frame, a first main guide rail support, a first shared guide rail support, a first main guide rail, a first counterweight guide rail, a lift car fixing frame support, first-segment frame stand columns, a lift car assembly, a first landing door system, lift car fixing frames, first-segment frame cross beams and first outer decorations; the middle modular section is composed of a middle frame, a second main guide rail support, a second shared guide rail support, a second main guide rail, a second counterweight guide rail, a second landing door system, a middle frame cross beam and second outer decorations; and the top modular section is composed of a top frame, a third main guide rail support, a third shared guide rail support, a third main guide rail, a third counterweight guide rail, a traction machine beam, a traction machine, a counterweight frame, a third landing door system, a counterweight frame fixing frame, a top frame cross beam and third outer decorations. According to the integral fast-assembly type steel-structure elevator, the three modular sections are assembled in a factory, so that the on-site construction time is greatly saved, and small influence is caused to the outgoing and life of residents.

Owner:SHANDONG FUJI ZHIYU ELEVATOR

Embedded cylindrical nut anchor bed and use method thereof

The invention relates to an embedded cylindrical nut anchor bed and a use method thereof. The embedded cylindrical nut anchor bed comprises a cylindrical body with a first inner threaded hole, wherein the front end part of the cylindrical body is provided with a positioning flange part which is provided with a positioning hole, and the rear end part of the cylindrical body is closed and is provided with a round hole connected with a structural reinforcing steel bar; or the rear end part of the cylindrical body is provided with a second threaded hole in threaded connection with the structural reinforcing steel bar. The use method comprises the following steps of: (1) arranging a plug screw into the inner threaded hole inside at the front end part of the embedded cylindrical nut anchor bed by using a tool; (2) connecting the rear end part of the embedded cylindrical nut anchor bed with the structural reinforcing steel bar; (3) jacking the positioning flange part on a template and fixing the positioning flange part on the wood template by using iron screws or self-tapping screws; and (4) pouring concrete into the wood template, detaching the wood template after the concrete is set, and when an external structure is in need of the embedded cylindrical nut anchor bed, arranging the external structure in the first inner threaded hole in a screw joint manner.

Owner:福州市第三建筑工程公司

Chassis system

PendingCN112695976AImprove construction efficiencyReduce on-site construction timeSewerage structuresDomestic plumbingAutomotive engineeringManufacturing engineering

The invention discloses a chassis system which is used for being arranged on the structural ground of a toilet. The chassis system comprises a box body, a pipeline system and a chassis, wherein the upper end of the box body is open; the pipeline system is arranged in the box body; the chassis is packaged at the upper end of the box body; and the connector end of the pipeline system extends out of the box body or the chassis to be used for being connected with an external pipeline. According to the chassis system, the pipeline system is packaged in the box body through cooperation of the box body and the chassis, so that the chassis and the pipeline system are integrated together through the box body, and then functional components for decorating the ground of the toilet can be assembled in advance in a factory; and when the ground of the toilet needs to be decorated, only the chassis system prefabricated in the factory needs to be directly placed on the structural ground of the toilet, the procedures of on-site pipeline arrangement, chassis erection and the like are not needed, and then the construction efficiency is improved.

Owner:TIANJIN DAYIN BUILDING MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com