Patents

Literature

36results about How to "Guaranteed basic strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

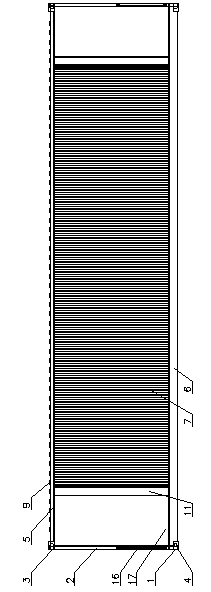

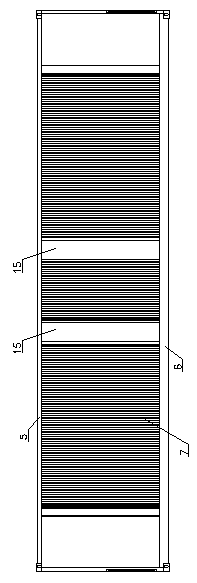

Container type house unit and modularized group building residential building

ActiveCN102304942AGuaranteed basic strengthScientific and reasonable structureBuilding constructionsDwelling buildingEngineeringOperability

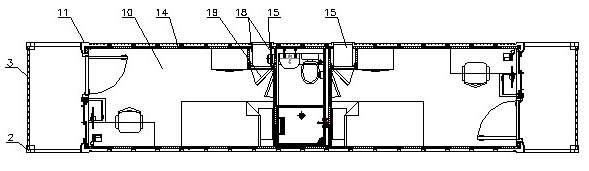

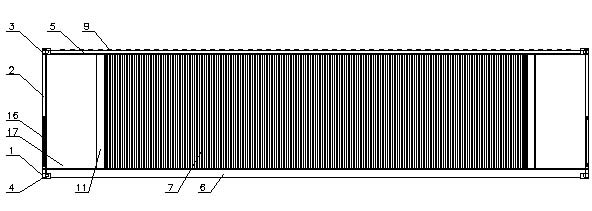

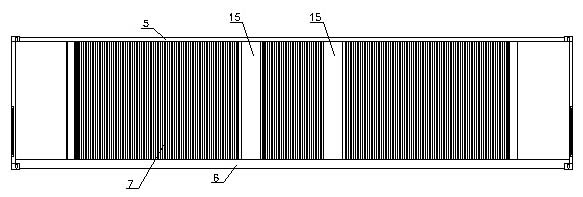

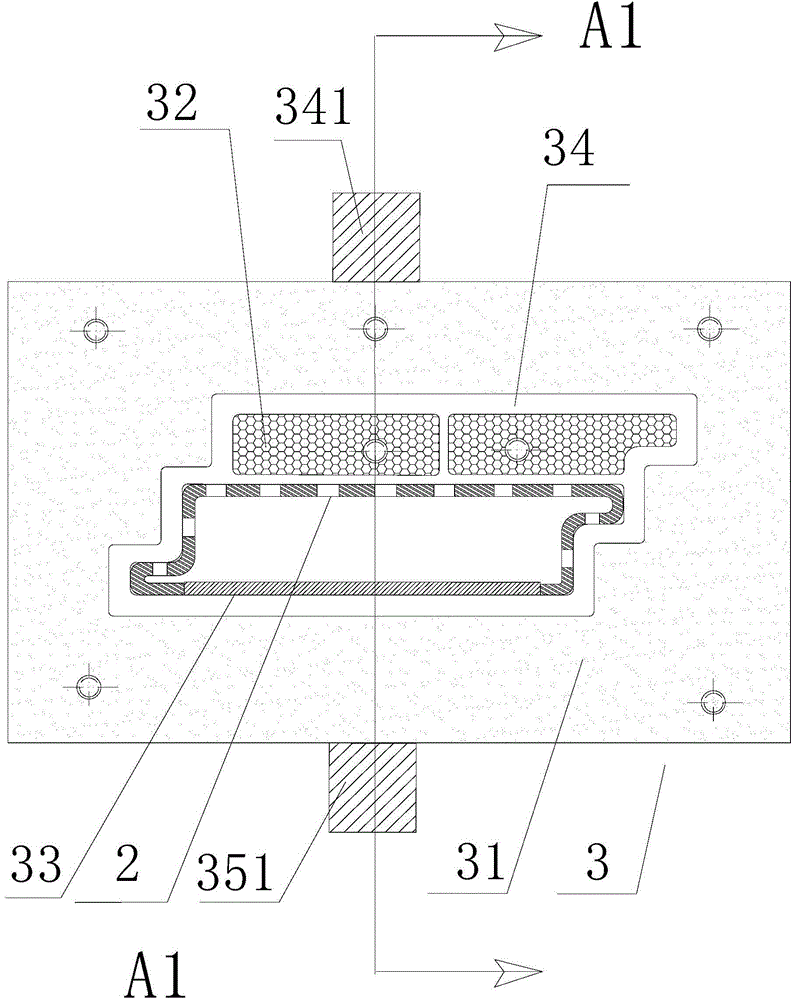

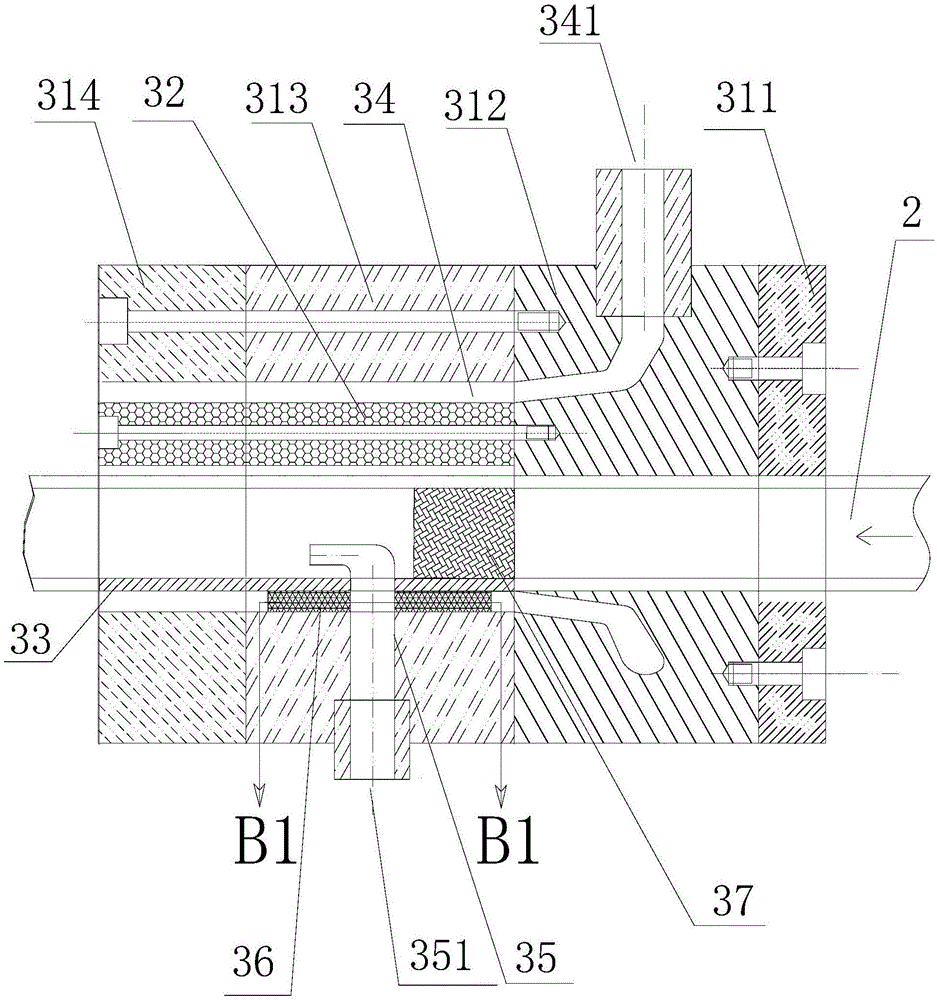

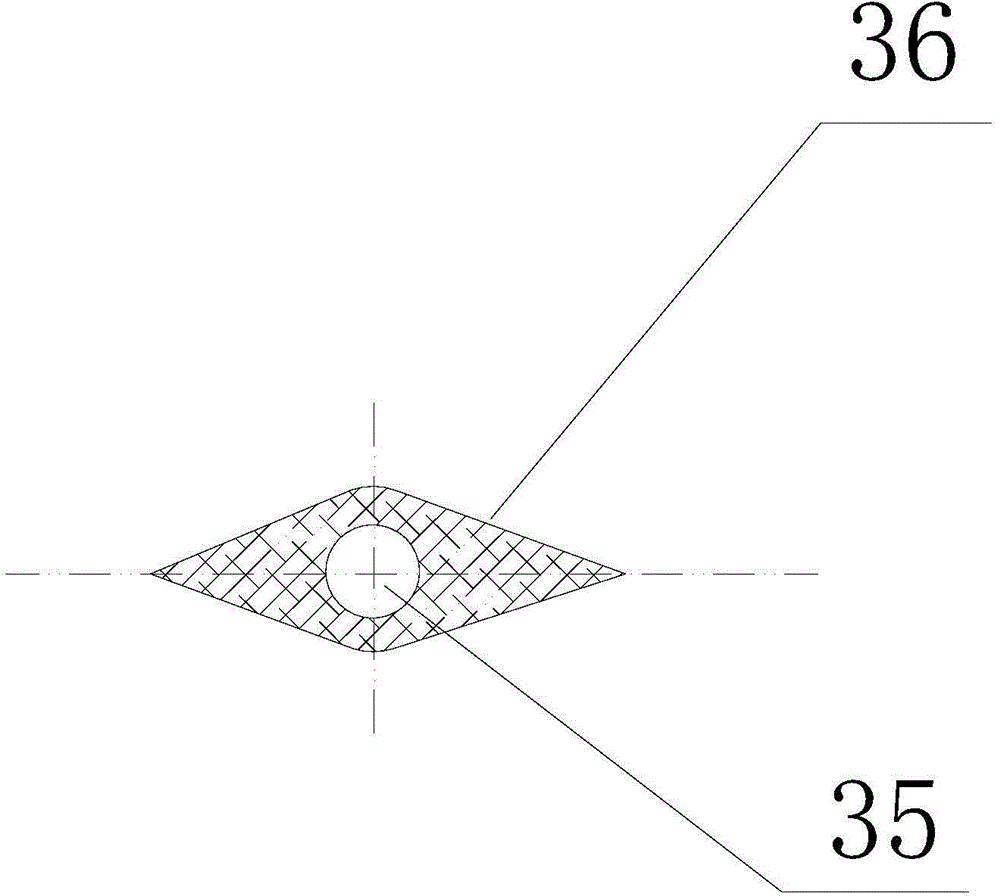

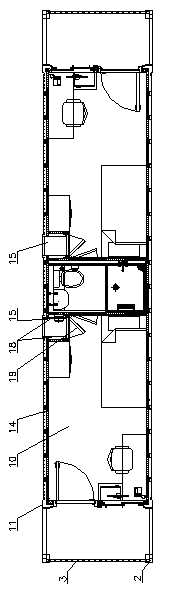

The invention discloses a container type house unit, comprising a container house body, wherein the front end wall and the rear end wall of the container house body are respectively provided with a door (13) for entering the container house body; the front end and the rear end of the of the container house body are respectively provided with a balcony; the balcony and the container house body areformed into a whole; the left side and the right side of each balcony are respectively provided with an access used for the balcony; and side wall on one side of the container house body is provided with a piping shaft (15). In addition, the invention also provides a modularized group building residential building assembled by the container type house unit. According to the container type house unit and the modularized group building residential building formed by the container type house unit, the construction of the original container type residential building is kept, and the basic strength of the container type house is guaranteed. On the basis of the existing container type house, the reliability and the operability of the product can be perfected, the quality of the product is guaranteed, and the container type house unit is suitable for the requirement of industrial production.

Owner:YANGZHOU TONGLEE REEFER CONTAINER

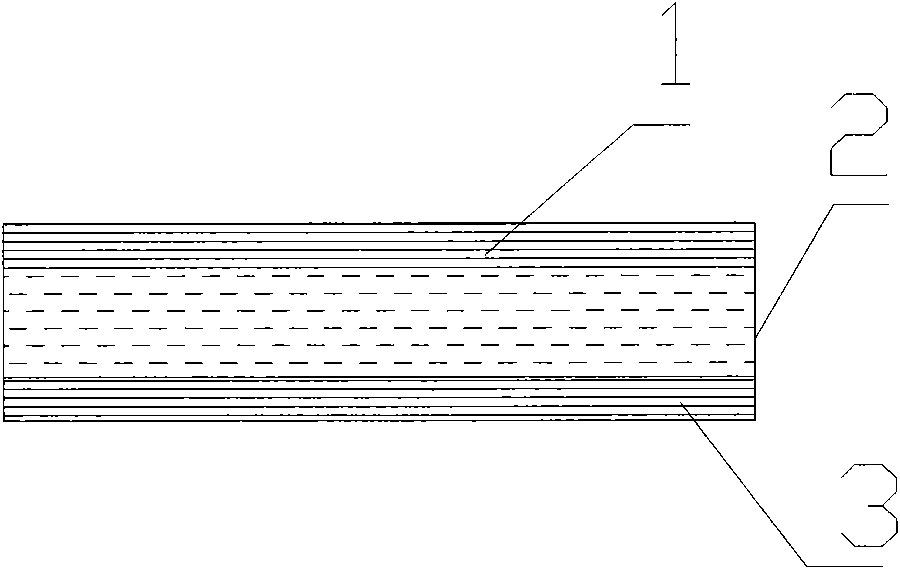

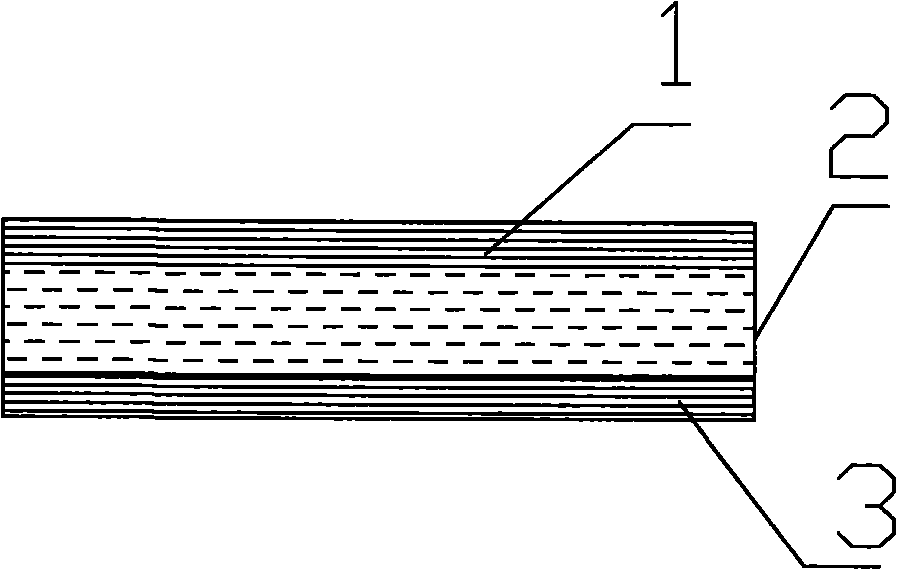

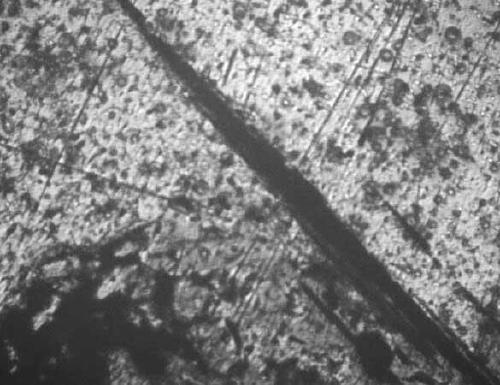

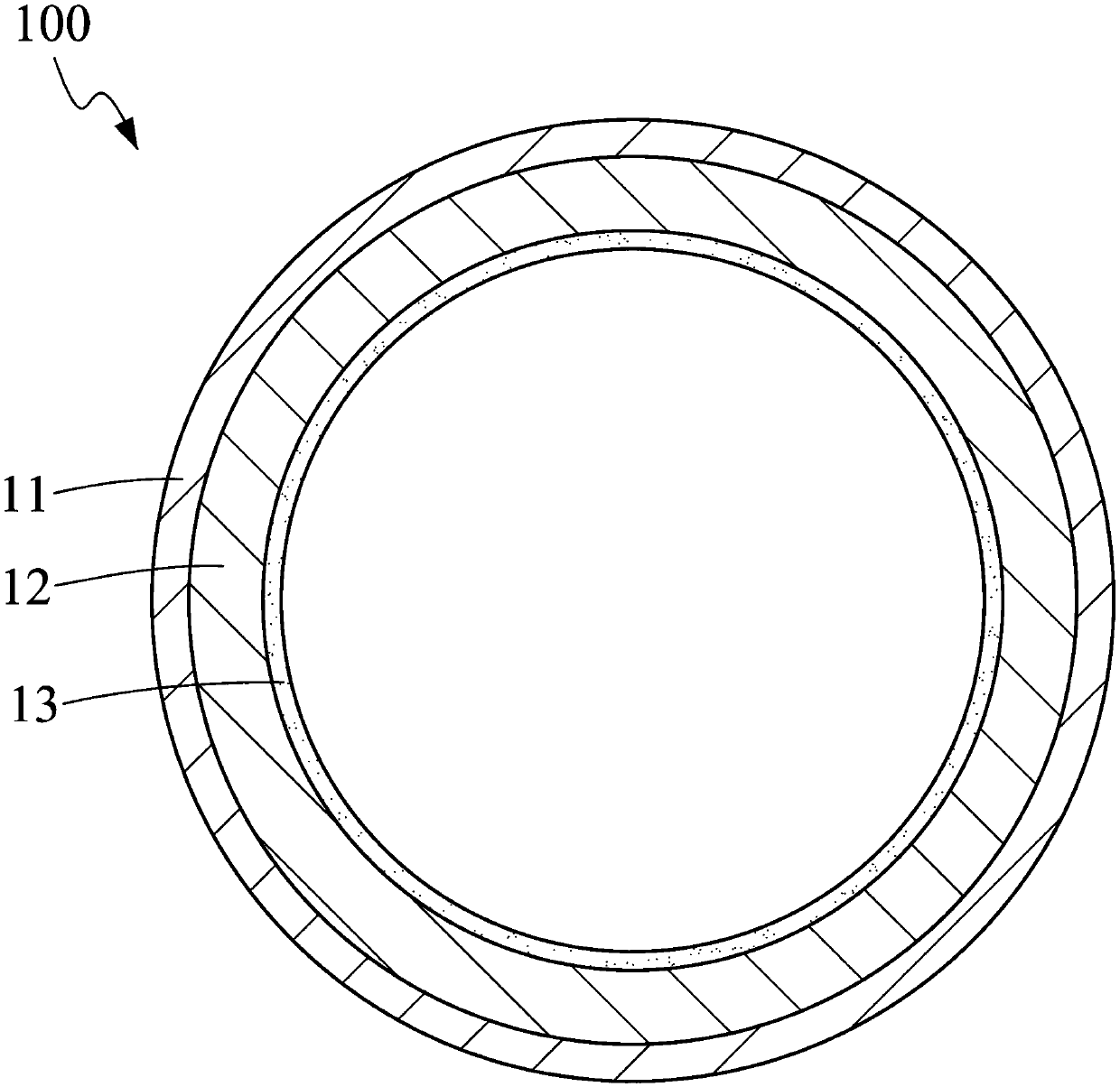

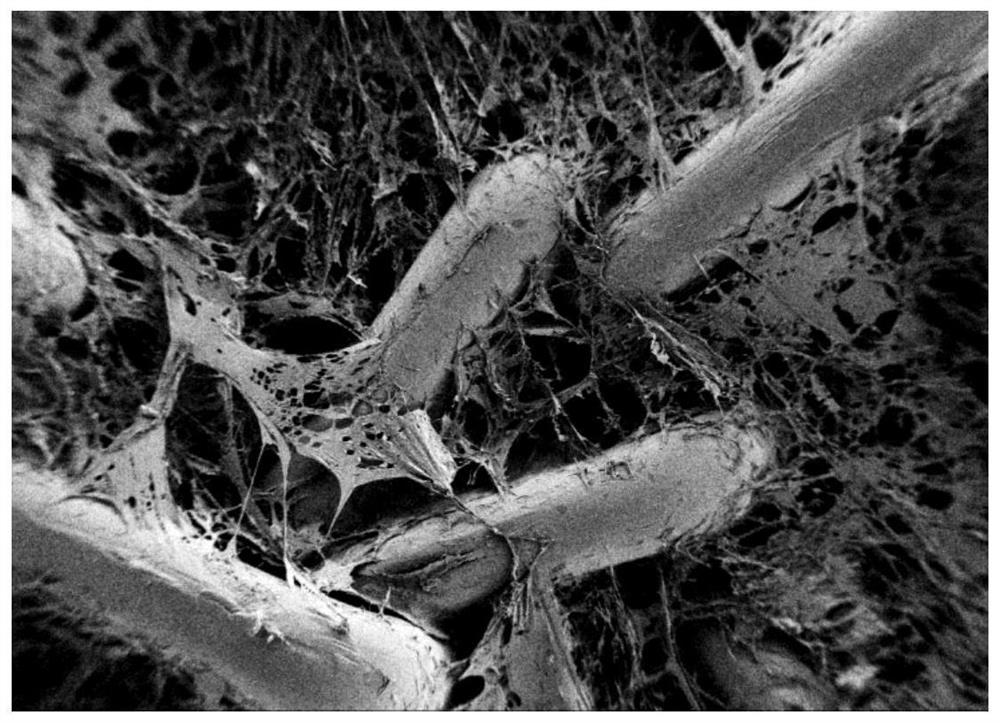

High-strength combination reinforced thermoplastic composite material board

InactiveCN101936449AHigh tensile strengthImprove flexural strengthSheets/panelsGlass/slag layered productsFilament yarnPolypropylene fiber

The invention relates to a thermoplastic composite material, in particular to a high-strength combination reinforced thermoplastic composite material board. The high-strength combination reinforced thermoplastic composite material board has a three-layer structure and comprises an upper fabric layer, a lower fabric layer and an extruding layer, wherein both the upper fabric layer and the lower fabric layer are knitted by combined filament yarns formed by glass fibers and polypropylene fibers; and the extruding layer is arranged between the upper fabric layer and the lower fabric layer and formed by uniformly mixing the long glass fibers and the polypropylene. Compared with a long glass fiber reinforced board, the reinforced polypropylene composite material board improves the tensile strength, bending strength and modulus, impact strength, and the like by more than 80 percent along the glass fiber direction of a fabric. A reinforced polypropylene composite material board by combining a bidirectional fabric with the long glass fiber improves strength, modulus, and the like by more than 60 percent in two same directions with the glass fibers in the fabric. The upper fabric layer and the lower fabric layer of the invention adopt the glass fibers which have flowability compared with the long glass fiber, and a part can be reinforced as required; and a middle layer adopts the long glass fibers, and the basic strength of the board can be ensured.

Owner:江苏纤强复合材料有限公司

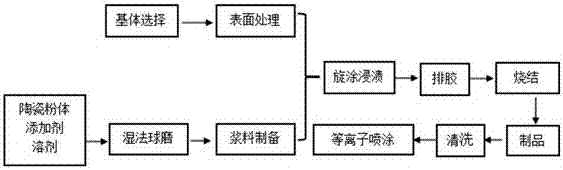

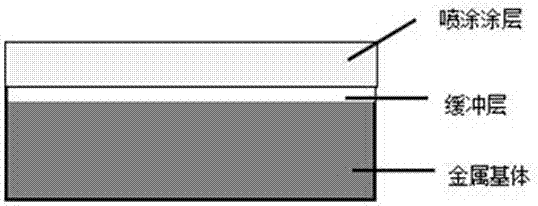

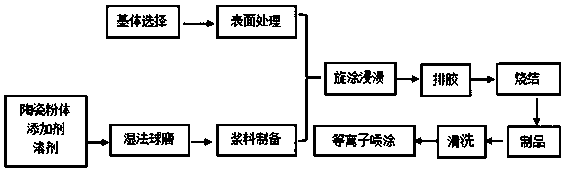

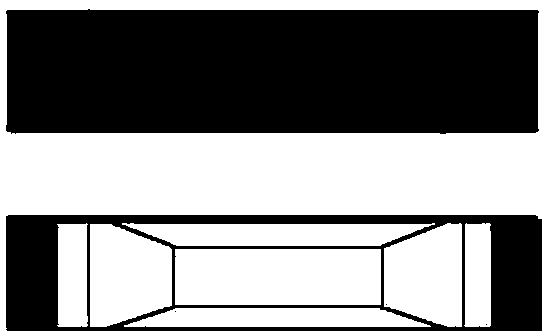

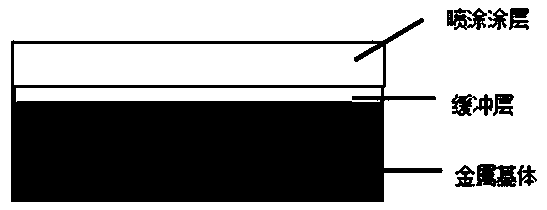

Internal-heated integrated evaporation boat with aluminum oxide porous structure buffering layer

InactiveCN107326330ASolve Oxidation ProblemsHigh bonding strengthVacuum evaporation coatingSputtering coatingPorosityStress relieving

The invention discloses an internal-heated integrated evaporation boat with an aluminum oxide porous structure buffering layer. Surface coatings of the evaporation boat totally comprise two layers. The inner layer is the Al2O3 buffering layer of a loose porous structure, and the outer layer is the compact low-porosity corrosion-resistantAl2O3 coating. Firstly, through a rotary-coating steeping technique, the Al2O3 buffering layer with the thickness being 0.1-0.3 mm is prepared on the surface of a matrix; and then through a plasma spraying technology, the Al2O3 corrosion-resistantlayer with the thickness being 0.5-1 mm is sprayed and prepared on the evaporation boat with the buffering layer. According to the composite technique, the evaporation boat with the Al2O3 coatings of different microstructures is prepared; in service, the buffering layer of the porous structure can achieve the stress relieving effect and can further prevent the problem of matrix oxidization caused by later spraying; and the compact low-porosity Al2O3 coating brings excellent corrosion resistance into play and can be widely applied to the technical field of vacuum evaporation metal thin films.

Owner:FUZHOU UNIV

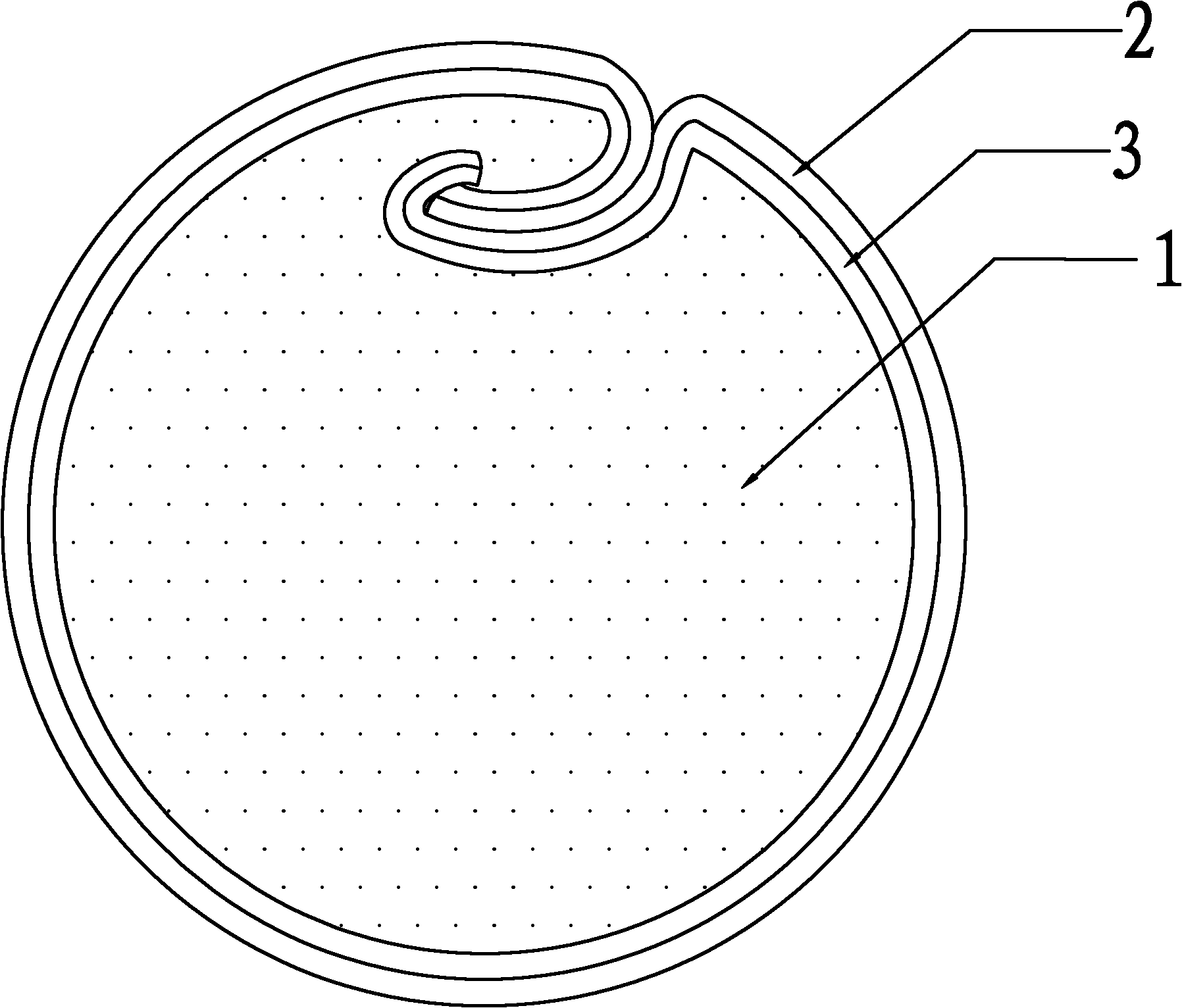

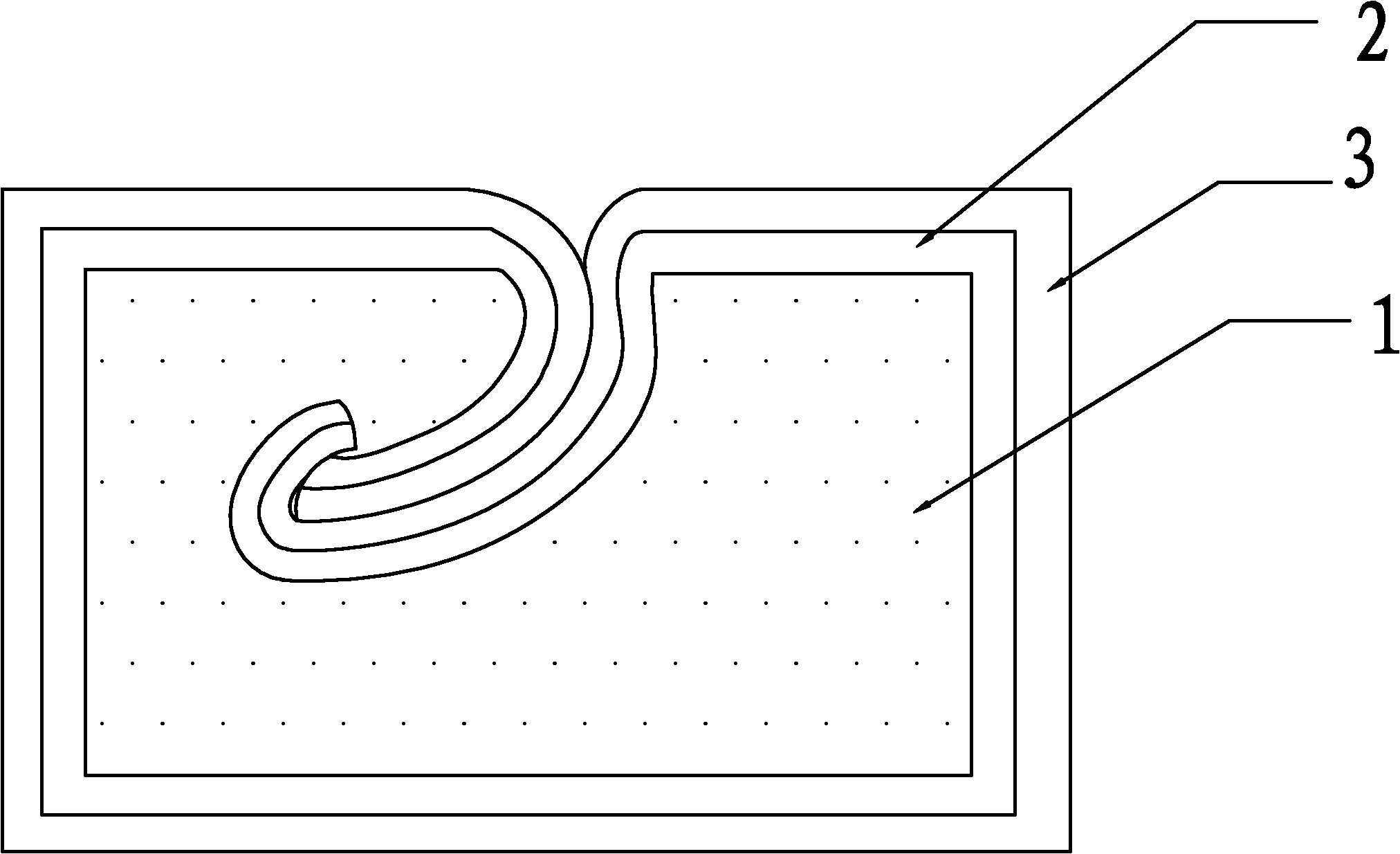

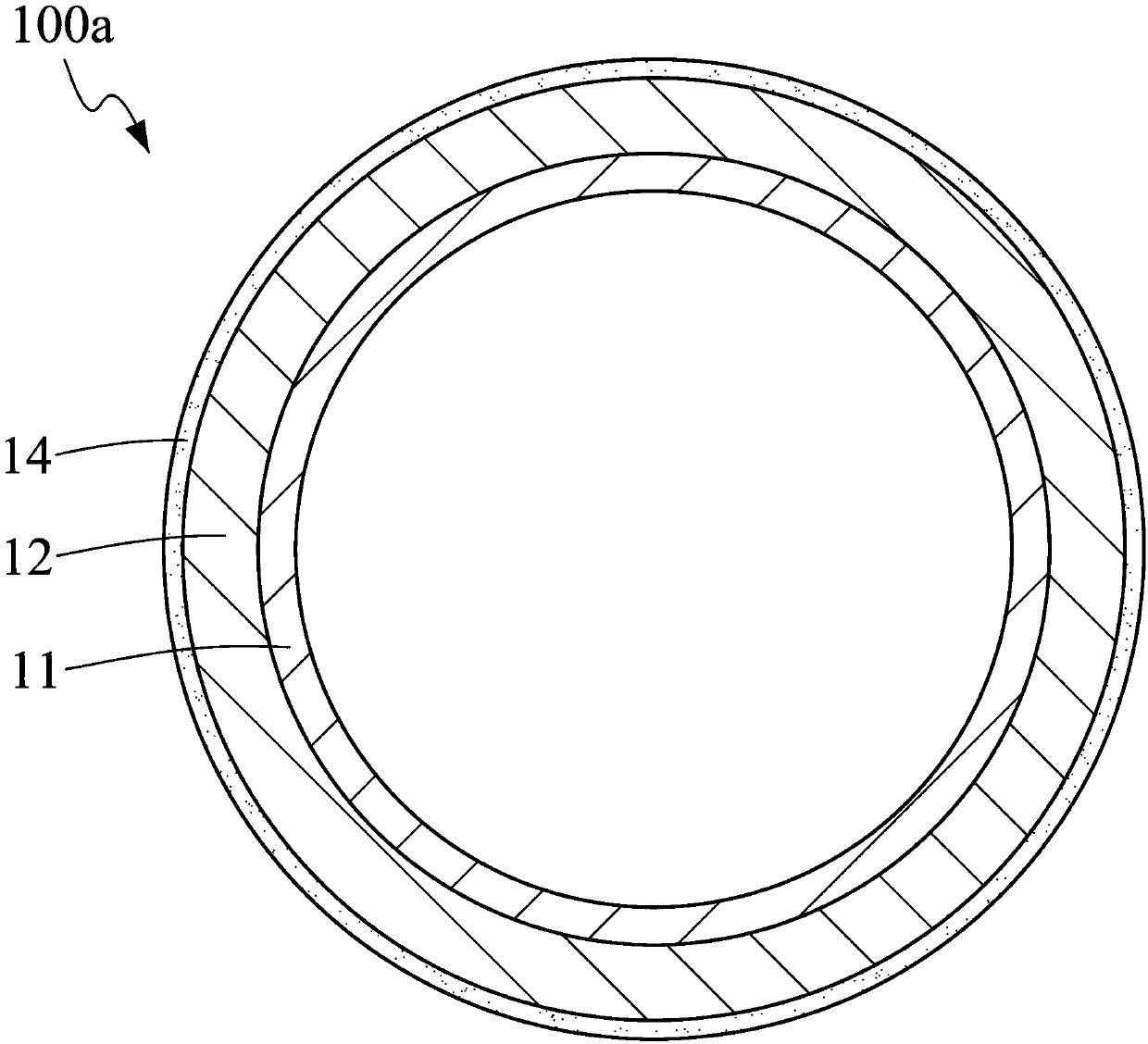

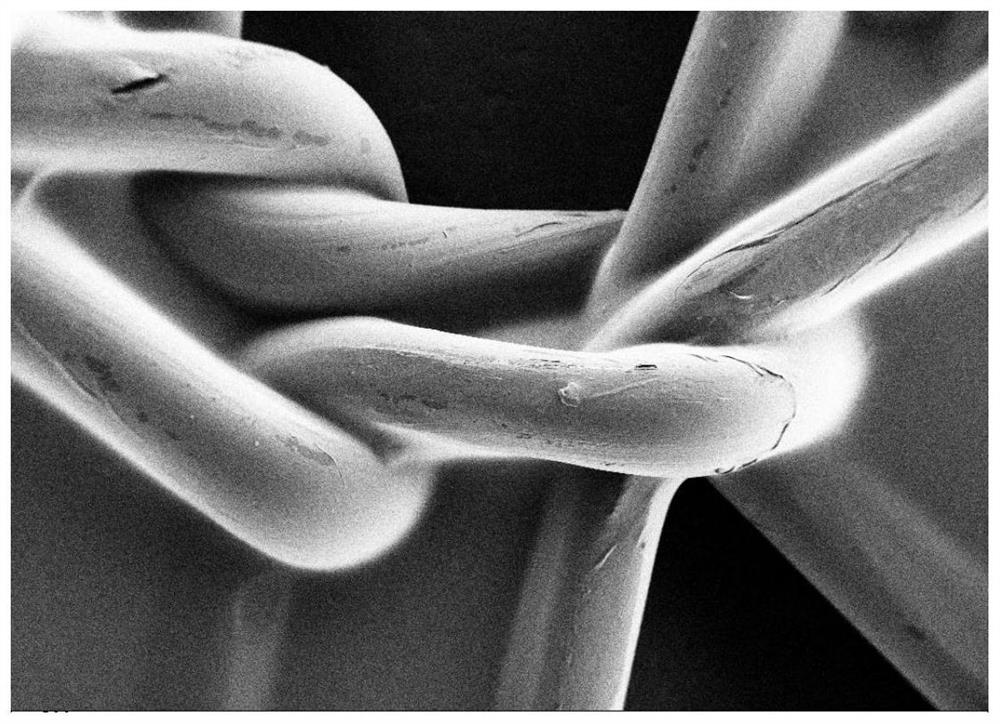

Core-spun yarn and preparation method thereof

InactiveCN102181778AGuaranteed basic strengthGuarantee the breeding effectYarnUltimate tensile strength

The invention relates to a core-spun yarn which comprises a sheath and a core material, wherein the core material is tightly filled in the sheath. The invention is characterized in that the sheath comprises an outer steel sheet layer and an inner metal layer; both sides of the sheath are folded inwards at the joints of the sheath and are extruded and fixed; the melting point of the metal layer is smaller than that of steel; and the thickness of the metal layer is 0.2mm, and the thickness of the steel sheet layer is 0.2mm. The double-layer composite sheath is adopted to lower the melting point of the surface covering layer on the premise of ensuring the basic strength of the core-spun yarn, so that the tape base can be molten within a short time in the molten iron casting process, thereby fully displaying the action of the powder inoculant, ensuring the inoculation effect of the molten iron flow and ensuring the mechanical properties of the iron castings. The invention has the advantages of firm sheath joints, tightly filled powder, regular and symmetric appearance, high working stability, high degree of automation and simple overall structure, and is convenient for maintenance and quick for operation.

Owner:SANXIANG ADVANCED MATERIALS

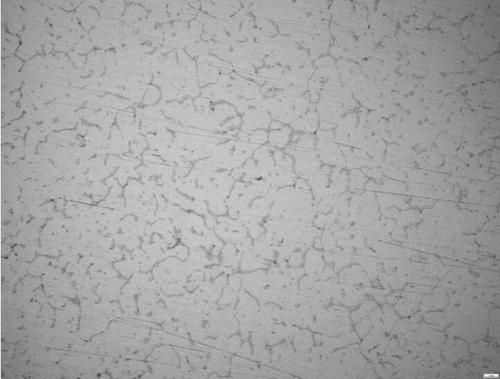

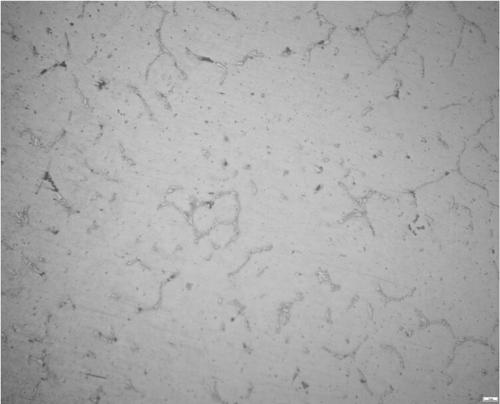

Low carbon, low boron, and high chromium alloy steel and preparation method thereof

InactiveCN108929983AGuaranteed wear resistanceImprove hardenabilityProcess efficiency improvementTungstenAluminium

The invention discloses low carbon, low boron, and high chromium alloy steel and a preparation method thereof which relates to the technical field of alloy steel. The low carbon, low boron, and high chromium alloy steel includes, by weight, 0.05-0.30% of carbon, 1-3.0% of silicon, 0.8-1.3% of manganese, <0.04% of phosphorus, <0.04% of sulfur, 8-13% of chromium, 0.5-2.5% of nickel, 0.1-0.8% of molybdenum, 0.03-0.25% of boron, 0.1-0.3% of aluminum, 0.05-0.2% of tin, 0.3-1.0% of vanadium, 0.1-1.5% of tungsten, 0.05-0.3% of copper, 0.005-0.015% of tantalum, 0.05-0.15% of cobalt, 0.05-0.25% of niobium, 0.8-2.0% of cerium, 0-0.08% of titanium, with the balance being iron and unavoidable impurities. The alloy steel of the invention enables high toughness and impact resistance performance to be ensured, enables wear resistance and hardness to be improved, is easy to control in process, and is suitable for civilian use and promotion.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

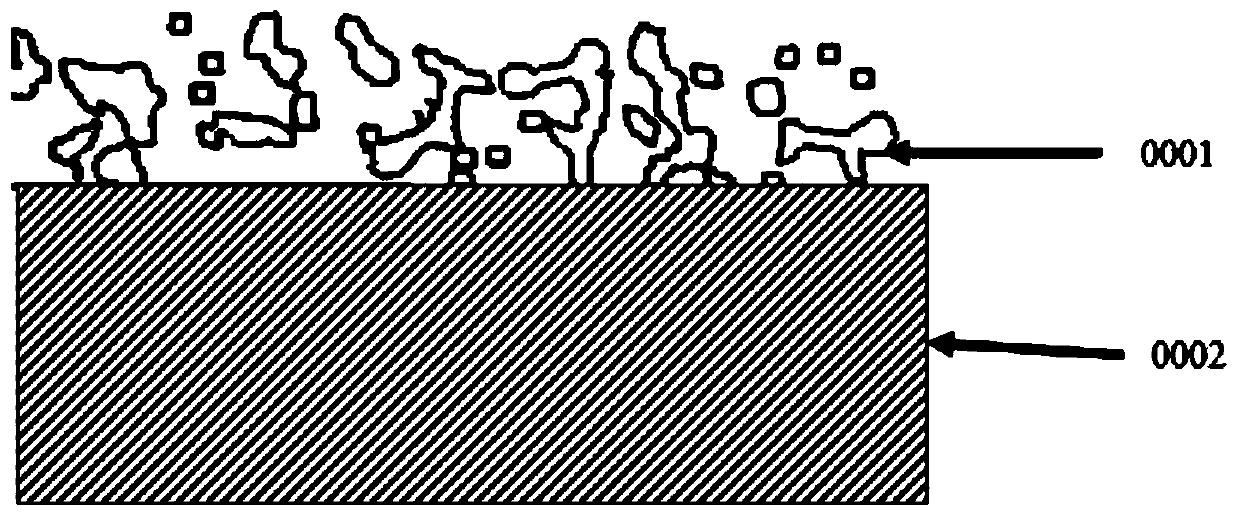

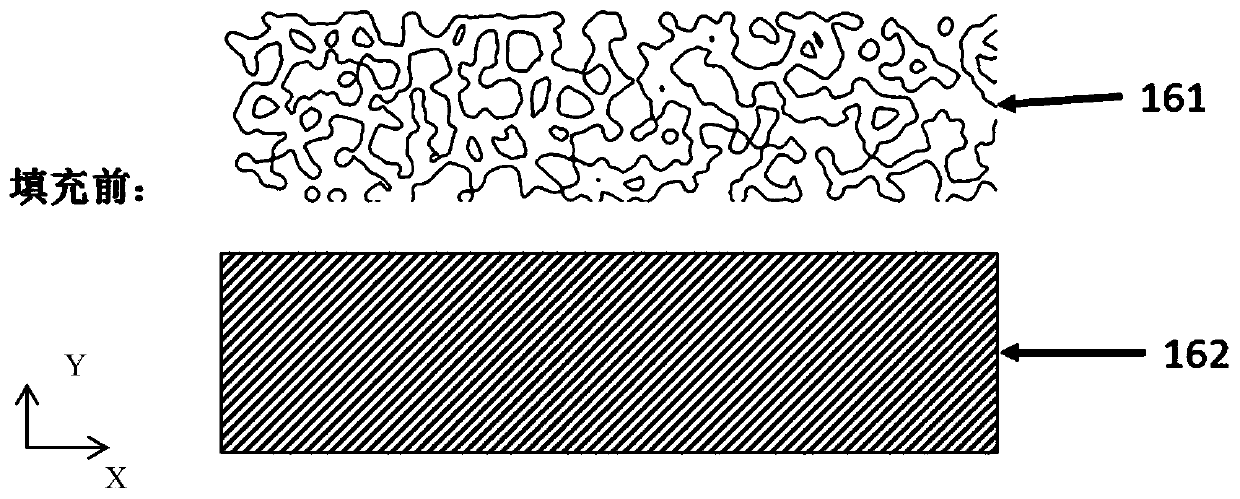

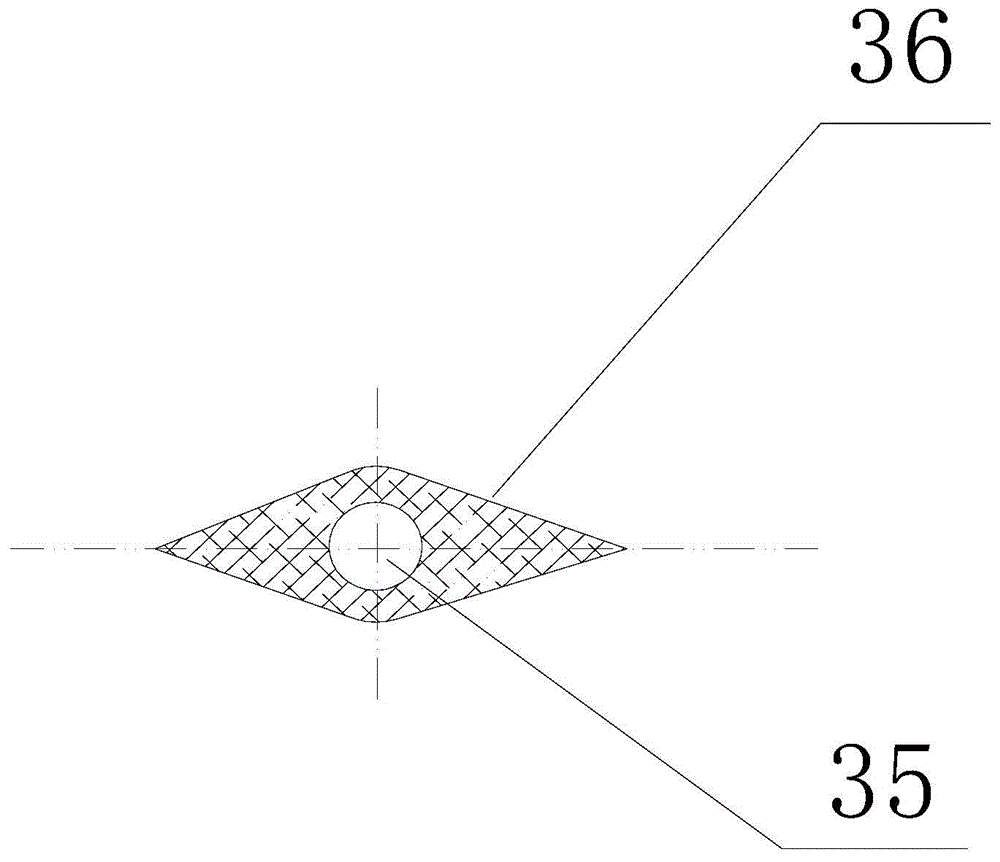

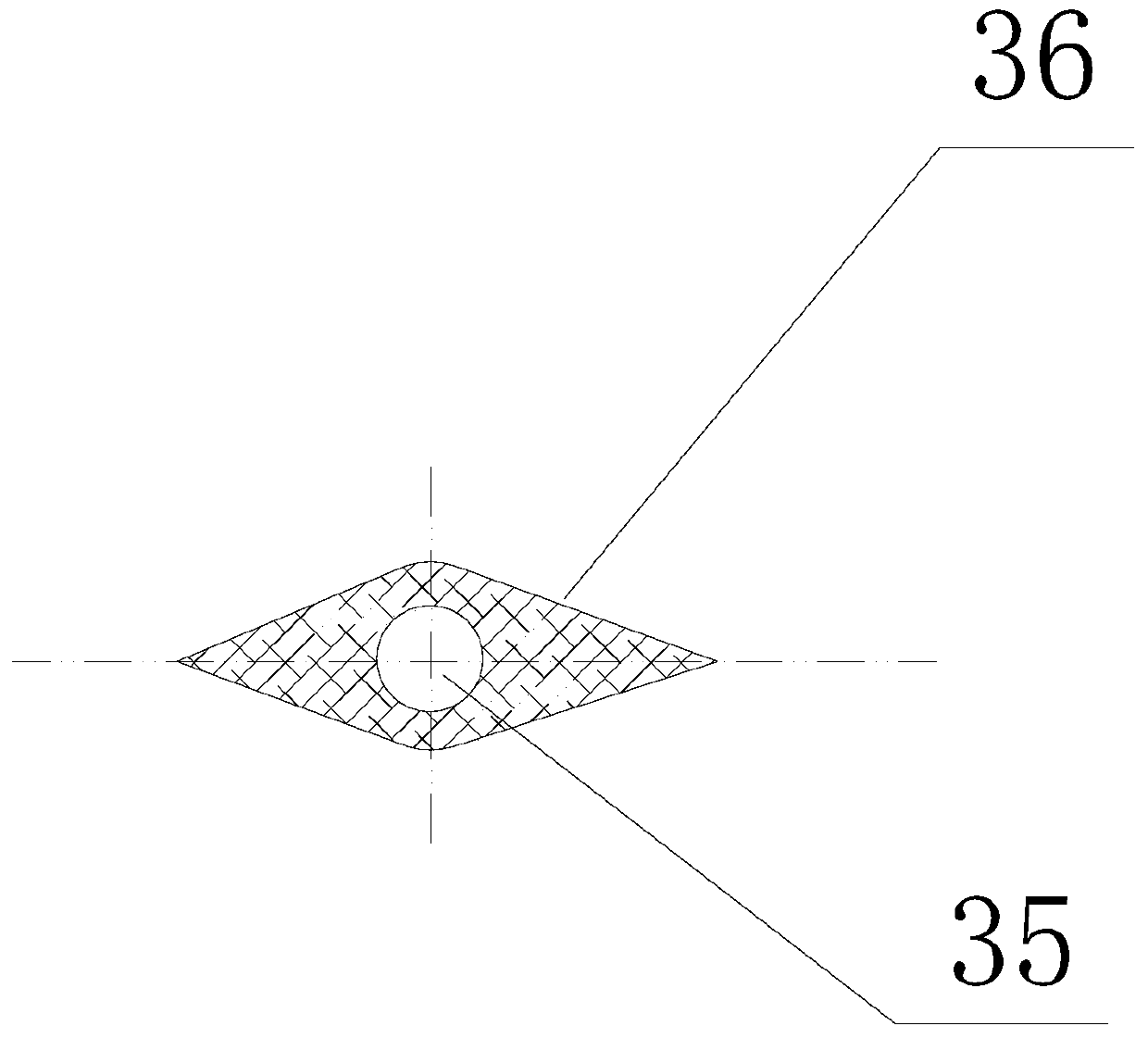

Connection structure of porous surface structure and substrate, preparation method and prosthesis

ActiveCN111449806AReduce thicknessGuaranteed basic strengthDental implantsAnkle jointsProsthesisRelative motion

The invention discloses a connection structure of a porous surface structure and a substrate, a preparation method and a prosthesis. A high polymer material layer is arranged in a gap between the porous surface structure and the substrate, so that the porous surface structure is tightly connected with the substrate, the basic strength of the connecting structure is ensured, the stress shielding phenomenon is improved, and the problem of postoperative osteolysis is solved; wherein a pre-connected complex is arranged on the substrate, the pre-connected complex comprises another porous structureand an intermediate which are connected in advance, the pre-connected complex and the substrate are combined in advance through various methods, and then the substrate with the pre-connected complex is tightly connected with the porous surface structure through a high polymer material layer. Relative movement and even falling between a structure body formed by the high polymer material layer and the porous structure on the surface of the high polymer material layer and the substrate with a smooth surface can be prevented; on the basis of the surface of the porous structure, it can be guaranteed that the surface of the artificial implant prosthesis has excellent bone ingrowth performance, the strength of the substrate is not substantially affected, and the rigidity of the overall compositestructure is optimized to reduce the stress shielding risk.

Owner:YBNX MEDICAL TECH SUZHOU CO LTD

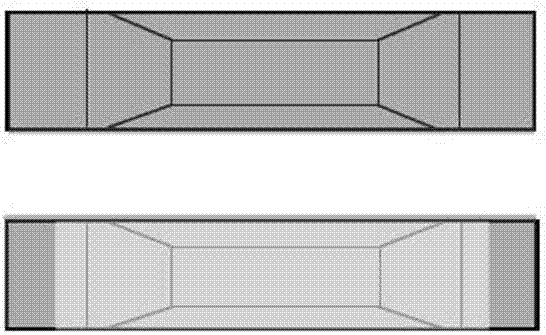

Metal sectional material and wood-plastic co-extrusion moulded composite plate as well as preparation method thereof

ActiveCN105484423AGuaranteed basic strengthReduce steel consumptionBuilding componentsCo extrusionPlastic materials

The application provides a metal sectional material and wood-plastic co-extrusion moulded composite plate. The metal sectional material and wood-plastic co-extrusion moulded composite plate comprises a wood-plastic frame and a metal sectional material, wherein the wood-plastic frame is provided with a first chamber; the metal sectional material is located in the first chamber; the wall surface of the first chamber is bonded with the surface of the metal sectional material; the metal sectional material is provided with a plurality of prefabricated holes; the first chamber of the wood-plastic frame is provided with projections embedding into or penetrating through the prefabricated holes; the projections are integrally moulded with the wood-plastic frame, wherein the wood-plastic frame is made from a foamed wood-plastic material, and the metal sectional material is an open metal sectional material. According to the co-extrusion moulded composite plate provided by the embodiment of the invention, the open metal sectional material is used, and a closed shape is not used, thus ensuring the basic strength of the composite plate, saving the consumption of steel, and creating conditions for realizing compressed air inner-cooling for an extrusion mould.

Owner:BEIJING NEW BUILDING MATERIAL

Making method of edible dinner service

The invention discloses a making method of edible dinner service. The edible dinner service is made from the following components of corn starch, sweet potatoes, potatoes, sunflower oil, egg white, Chinese prickly ash, gelatin and water. According to the making method of the edible dinner service disclosed by the invention, raw materials for making the edible dinner service are completely edible, and besides, the formula of the raw materials is rich in nutrition; the sweet potatoes and the potatoes are used as base materials for preparing pullulan which is matched with the corn starch and fat extracted from the sunflower oil, so that the plasticity, the toughness and the density of the edible dinner service are improved, the basic intensity of the edible dinner service is guaranteed, and the edible dinner service is convenient and durable; chili oil is added, so that the density of the edible dinner service can be improved in a matched manner, the taste of the edible dinner service can be enriched, and waste is avoided.

Owner:QUANJIAO XIANGRUI PLASTIC

Low-carbon low-boron medium-chromium alloy steel, and preparation method thereof

The invention discloses a low-carbon low-boron medium-chromium alloy steel, and a preparation method thereof, and belongs to the technical field of alloy steel manufacturing. The low-carbon low-boronmedium-chromium alloy steel comprises 0.05 to 0.30% of carbon, 1.0 to 3.0% of silicon, 0.8 to 1.3% of manganese, phosphor of 0.04% or lower, sulfur of 0.04% or lower, 3.5 to 7.9% of chromium, 0 to 0.08% of titanium, 0.3 to 2.0% of nickel, 0.1 to 0.5% of molybdenum, 0.03 to 0.25% of boron, 0.1 to 0.3% of aluminium, 0.5 to 1.5% of cerium, 0.02 to 0.1% of tin, 0.3 to 1.0% of vanadium, 0.1 to 1% of tungsten, 0.05 to 0.3% of copper, 0.005 to 0.015% of tantalum, 0.05 to 0.15% of cobalt, 0.05 to 0.25% of niobium, and the balance iron and unavoidable impurities. The hardness of the low-carbon low-boron medium-chromium alloy steel is HRC45-55, the impact energy is 8 to 15J / mm<2>. The preparation method is capable of guaranteeing the high toughness and impact resistance, and improving the wear resistance and hardness, is convenient to control, and is suitable for civil applications and popularization.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

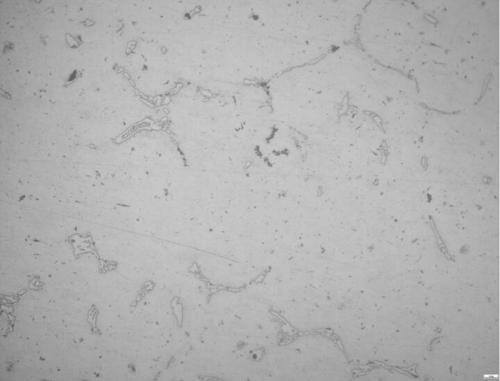

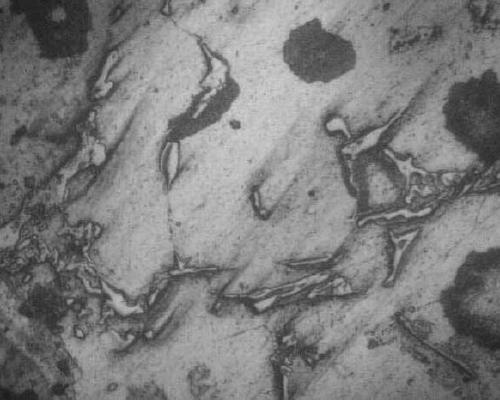

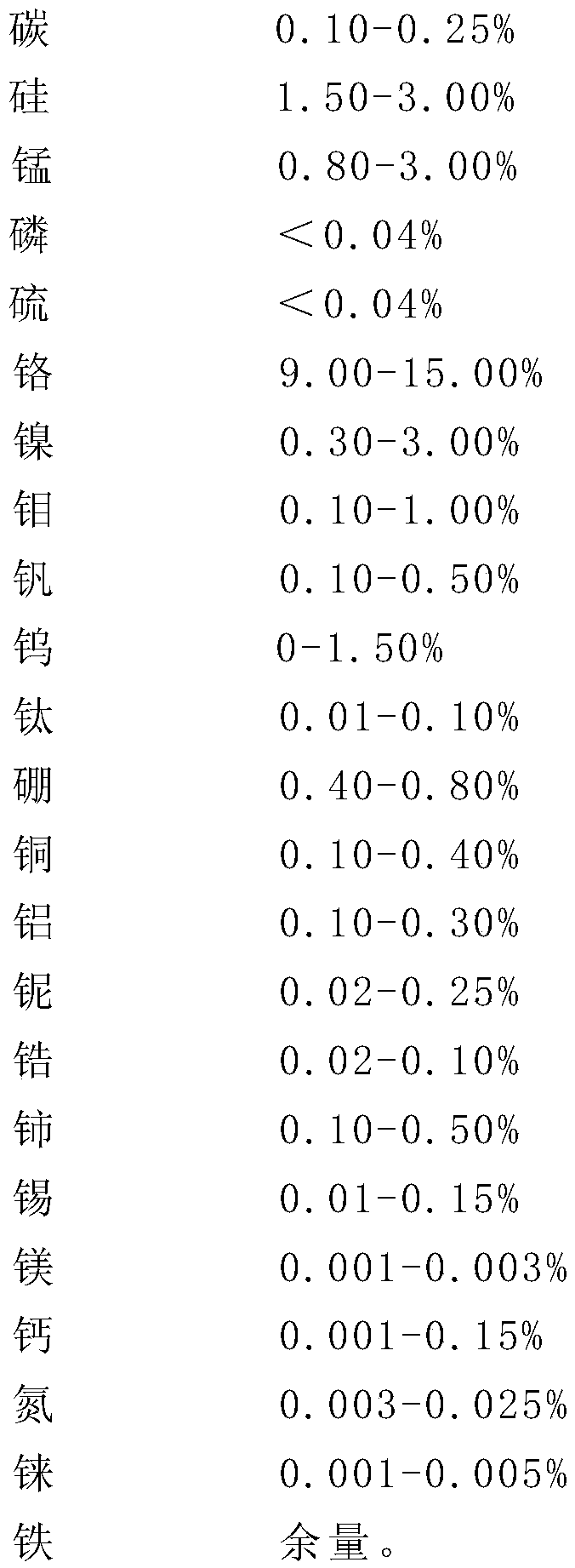

Micro-carbon high-chromium high-boron wear-resistant steel and preparation method thereof

InactiveCN109825778AHinder segregationAvoid hydrogen embrittlementProcess efficiency improvementWear resistantCerium

The invention discloses micro-carbon high-chromium high-boron wear-resistant steel and a preparation method thereof. The prepared wear-resistant steel comprises the following components of, in percentage by weight, 0.10-0.25% of carbon, 1.50-3.00% of silicon, 0.80-3.00% of manganese, less than 0.04% of phosphorus, less than 0.04% of sulfur, 9.00-15.00% of chromium, 0.30-3.00% of nickel, 0.10-1.00%of molybdenum, 0.10-0.50% of vanadium, 0-1.50% of tungsten, 0.01-0.10% of titanium, 0.40-0.80% of boron, 0.10-0.40% of copper, 0.10-0.30% of aluminum, 0.02-0.25% of niobium, 0.02-0.10% of zirconium,0.10-0.50% of cerium, 0.01-0.15% of tin, 0.001-0.003% of magnesium, 0.001-0.15% of calcium, 0.003-0.025% of nitrogen, 0.001-0.005% of rhenium, and the balance iron. The steel not only has the high hardness, also has the characteristics of certain toughness and high wear resistance at the same time.

Owner:陈章华

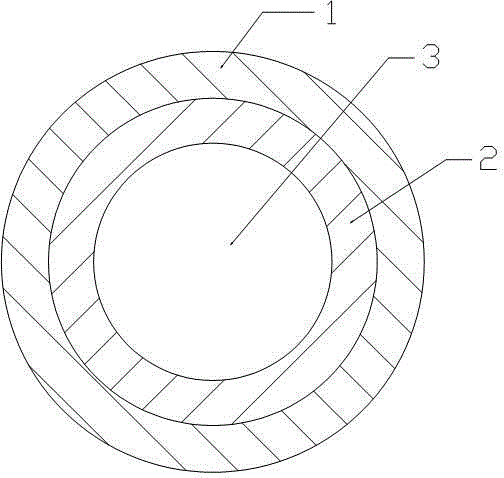

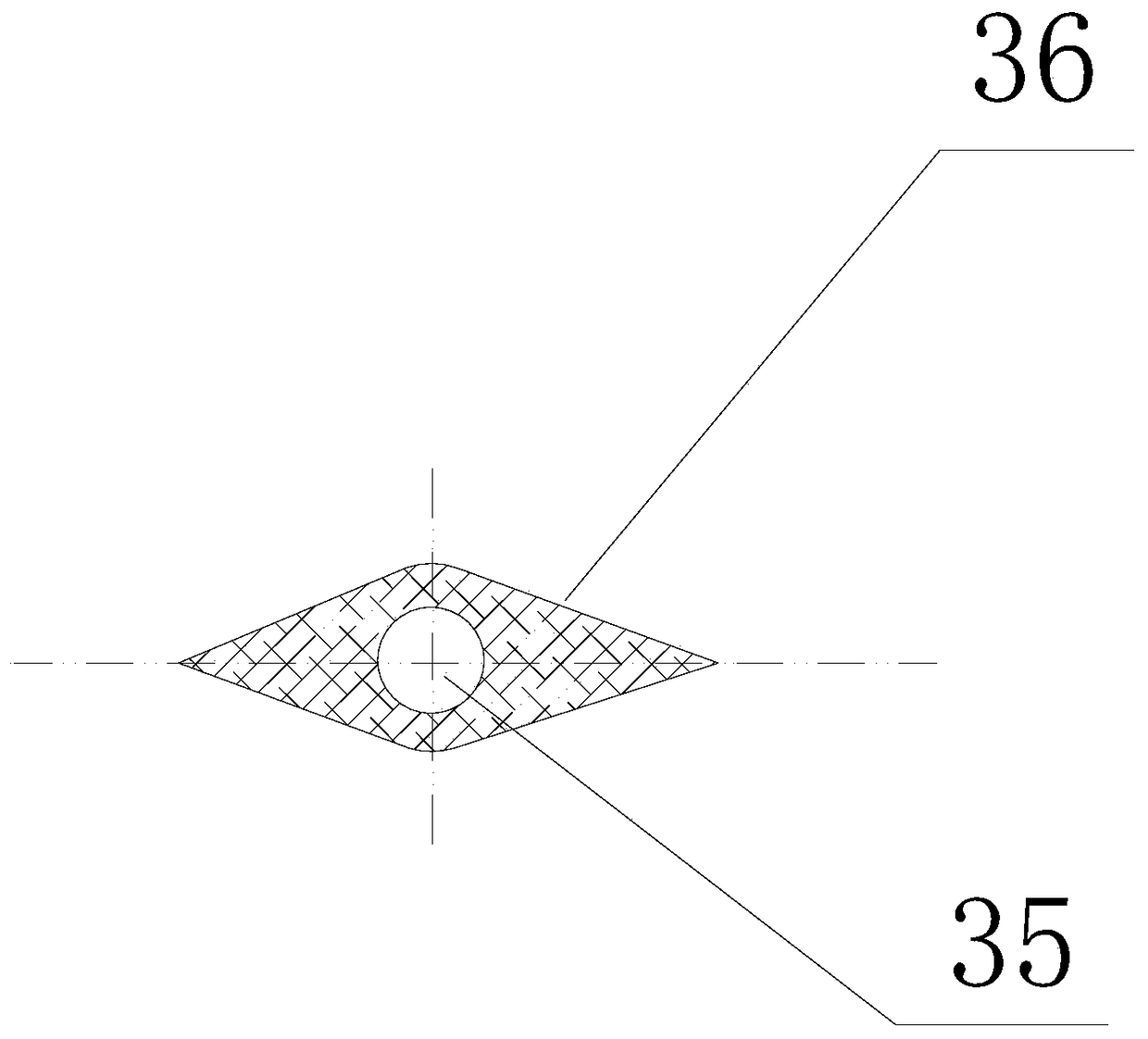

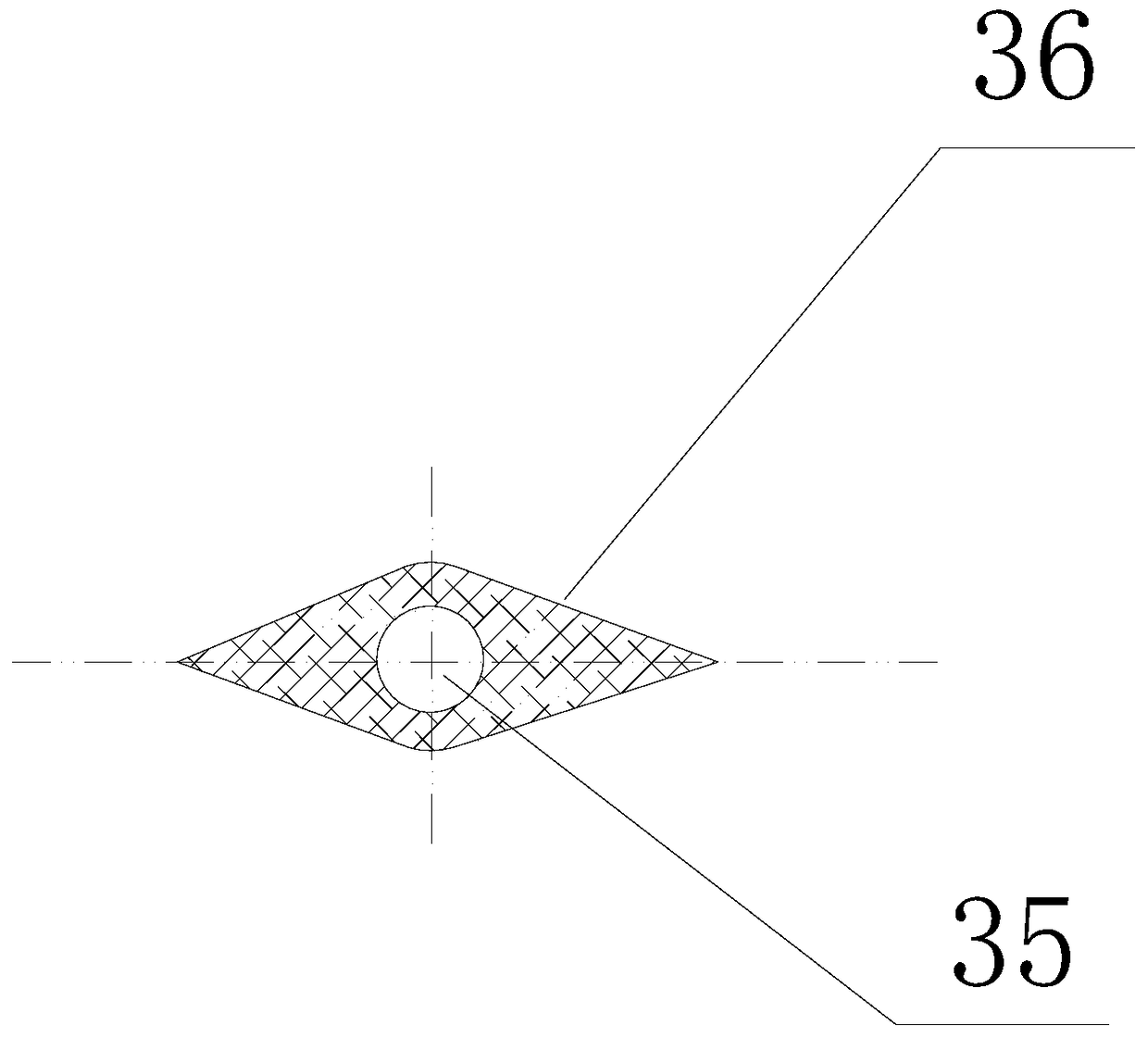

Core-spun yarn

The invention relates to a core-spun yarn, the section of which is circular or rectangular. The core-spun yarn comprises an outer skin and a core material (3), wherein the outer skin comprises an outer strip steel layer (1) and an inner metal layer (2); the metal layer (2) is an aluminum layer; and the core material (3) is formed by uniformly mixing silicon powder and calcium powder. According to the core-spun yarn provided by the invention, as the outer skin comprises the outer strip steel layer and the inner metal layer and is used for preparing the core-spun yarn with the core material, and in a metal-stream inoculation process, the outer strip steel layer ensures the basic strength of the core-spun yarn. As the inner metal layer is the aluminum layer, the melting point of which is lower than that of steel, the melting time of the outer skin is integrally shortened under the condition that the basic strength of the core-spun yarn is ensured. In the molten steel treatment process, the core-spun yarn can be quickly molten to fully exert the effect of a powdery inoculant, so that the strength and toughness of the steel are guaranteed.

Owner:JIANGYIN YURUI METALLURGICAL FURNACE CHARGE

Beverage straw

The invention relates to a beverage straw capable of being produced at low cost. The beverage straw is a hollow tube body with two ends communicated in a penetrating mode, and comprises an aluminum foil tube layer and a paper tube layer, wherein the paper tube layer and the aluminum foil tube layer are overlapped completely inside and outside to be laminated.

Owner:TAIWAN POWER TESTING TECH

Polypropylene composite plate

InactiveCN109747242AHigh tensile strengthImprove flexural strengthGlass/slag layered productsPolypropylene compositesGlass fiber

The invention relates to a thermoplastic composite, in particular to a high-strength combination reinforced thermoplastic composite plate, having a three-layer structure, including upper and lower fabric layers, both woven of combined fiber yarns formed of glass fiber and polypropylene fiber, and an extruded layer formed by mixing well long glass fiber and polypropylene and arranged between the upper and lower fabric layers. Compared with long glass fiber reinforced plates, the unidirectional fabric combination long fiber reinforced polypropylene composite plate has the advantages that tensilestrength, flexural strength and modulus, impact strength and the like are increased by 80% and above in the fabric glass fiber direction; the bidirectional fabric combination long glass fiber reinforced polypropylene composite plate has strength, modulus and the like all increased by 60% and above in the two identical directions of the glass in the fabric. The upper and lower fabric layers are made of glass fiber which is mobile as compared to long glass fiber, and a certain part can be reinforced as required; the intermediate layer is made of long glass fiber so that basic strength of the plate can be guaranteed.

Owner:危华

Co-extrusion molding composite board and preparation method thereof

The present invention provides a co-extrusion molding composite board. The co-extrusion molding composite board comprises a wood plastic frame, a foaming layer and a metal profile; the wood plastic frame is provided with a first cavity; the metal profile has an opening; the metal profile is positioned in the first cavity; the wall surface of the first cavity is bonded to the surface of the metal profile; the foaming layer is put in a space enclosed by the first cavity and the metal profile; the foaming layer is bonded to the wall surface of the first cavity and the surface of the metal profile; and the foaming layer is prepared by foaming materials. According to the composite board, the internal metal profile effectively provides mechanical strength, the metal profile, the foaming layer and the wood plastic frame are composited and integrated, so that the requirement for strength of the wood plastic part is reduced, the foaming technology can be adopted for materials of the wood plastic frame, wood plastic materials are saved, and heat and sound insulation performance of the composite board applied as a wall board is largely improved.

Owner:BEIJING NEW BUILDING MATERIAL

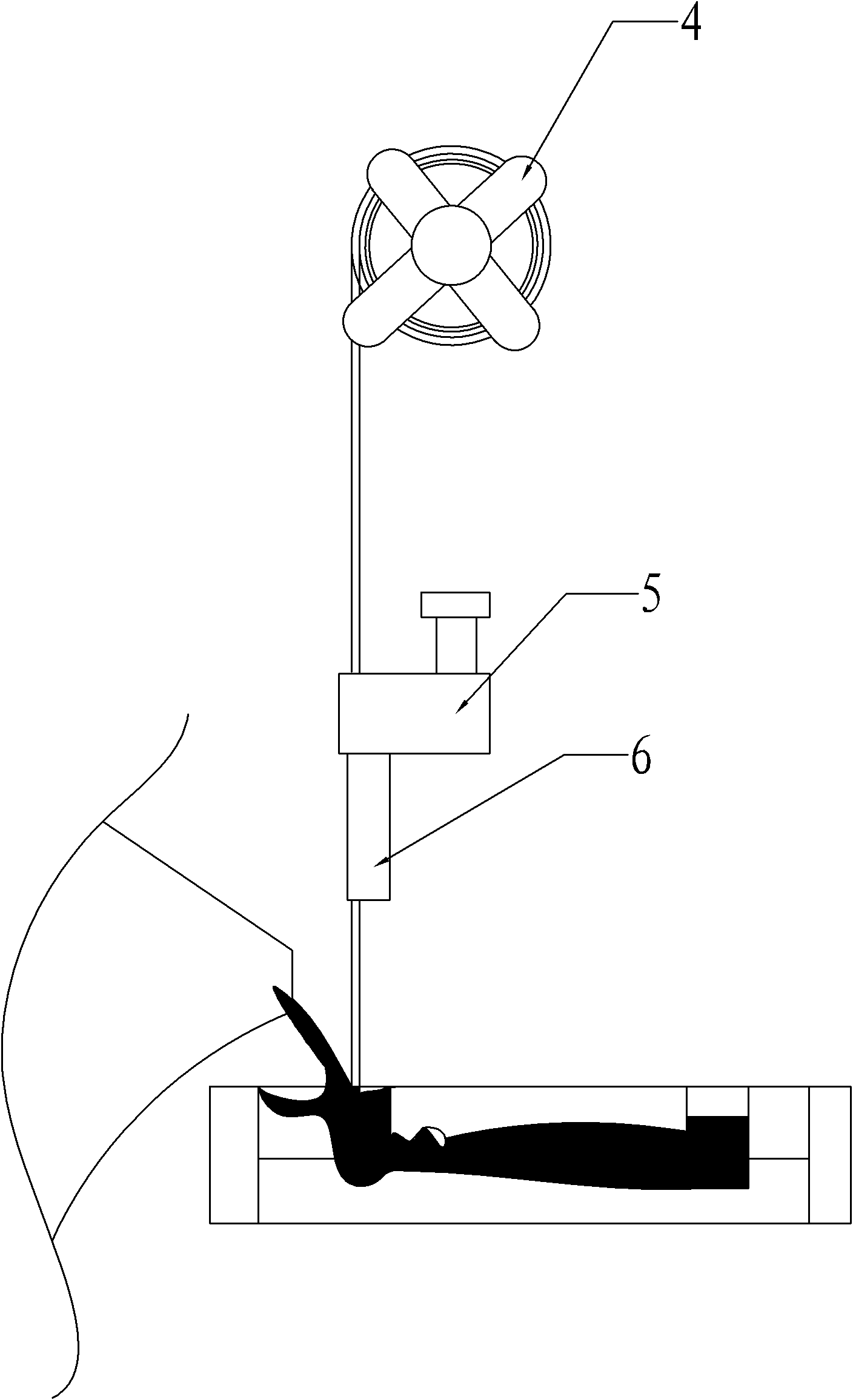

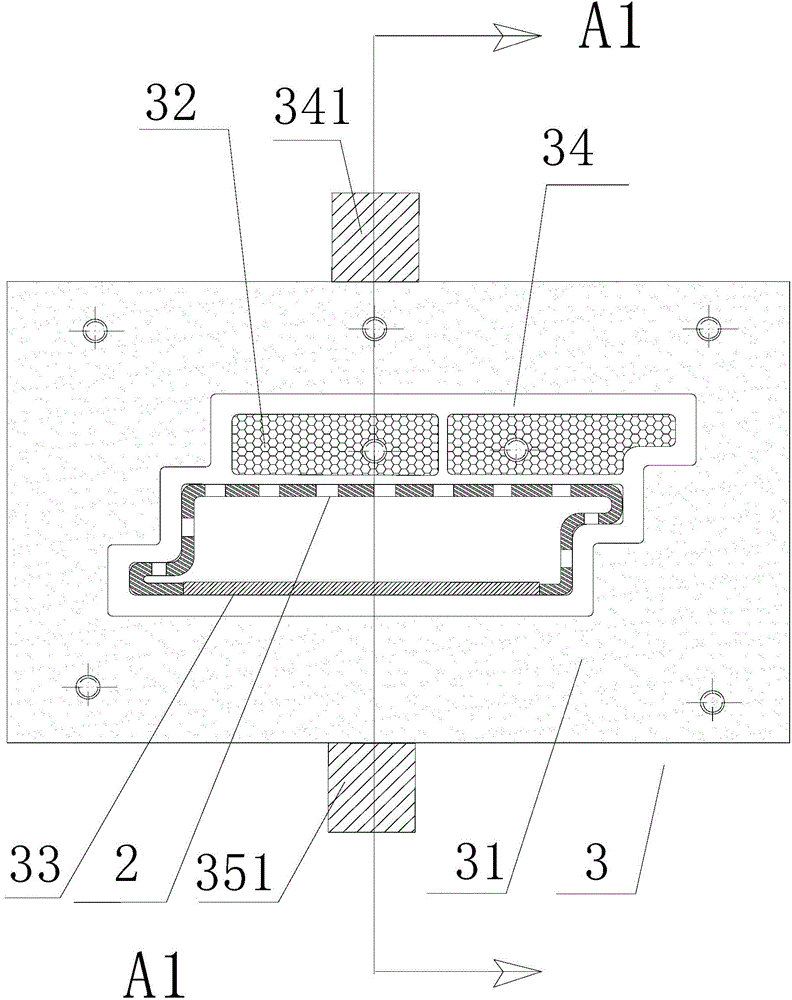

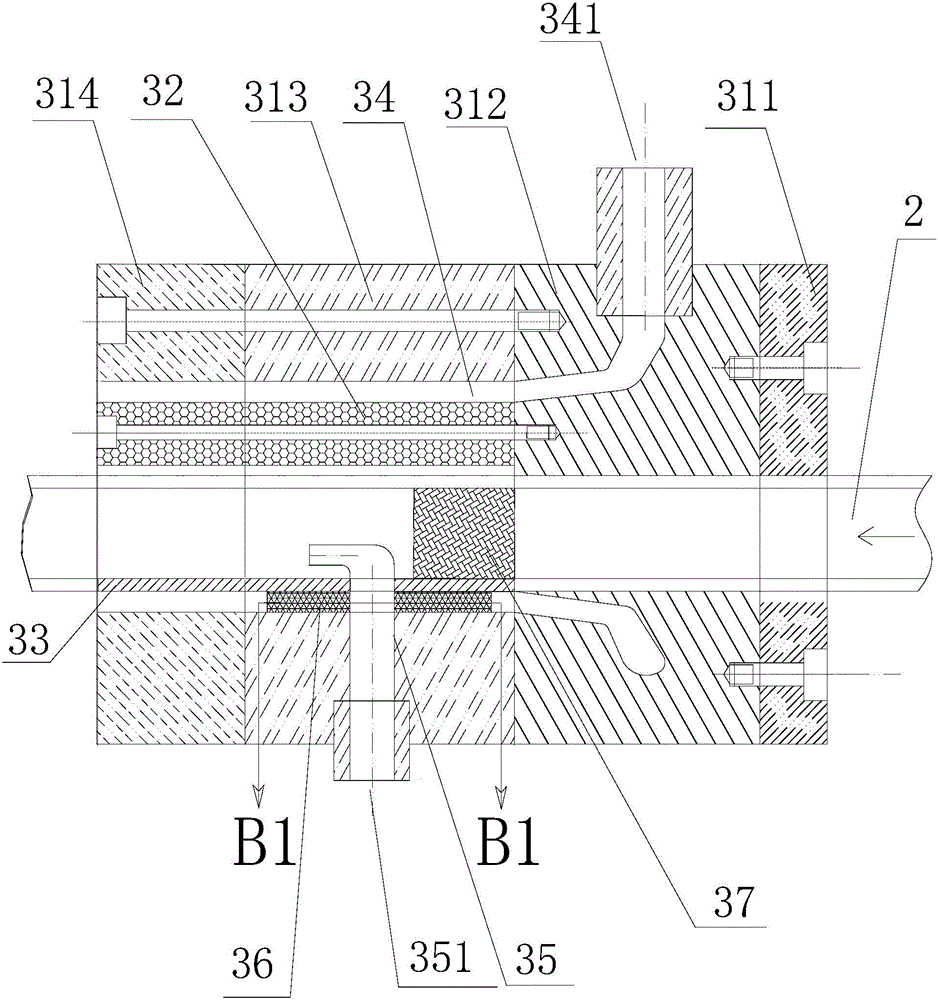

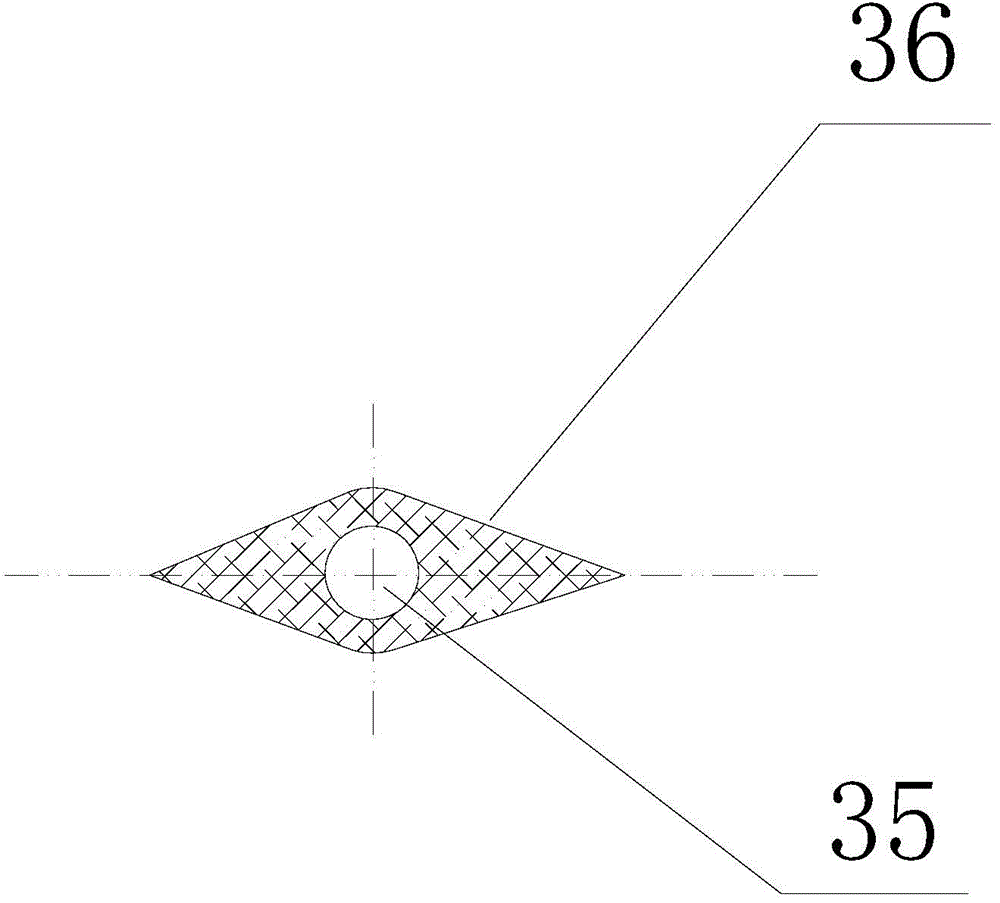

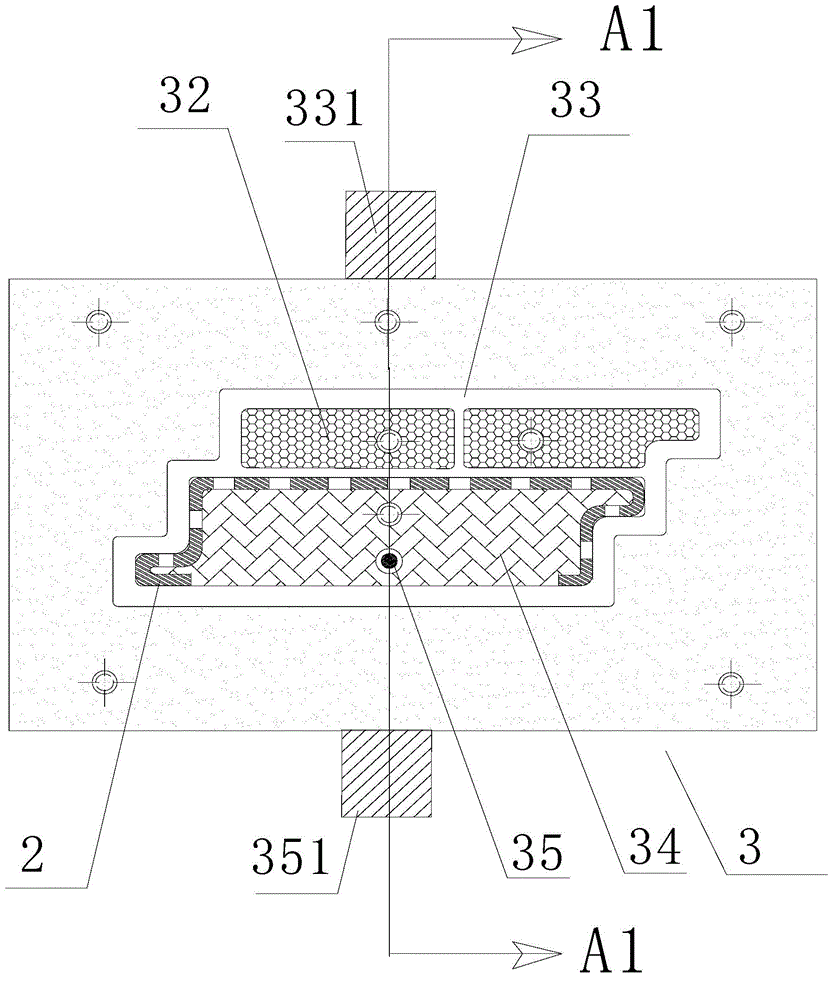

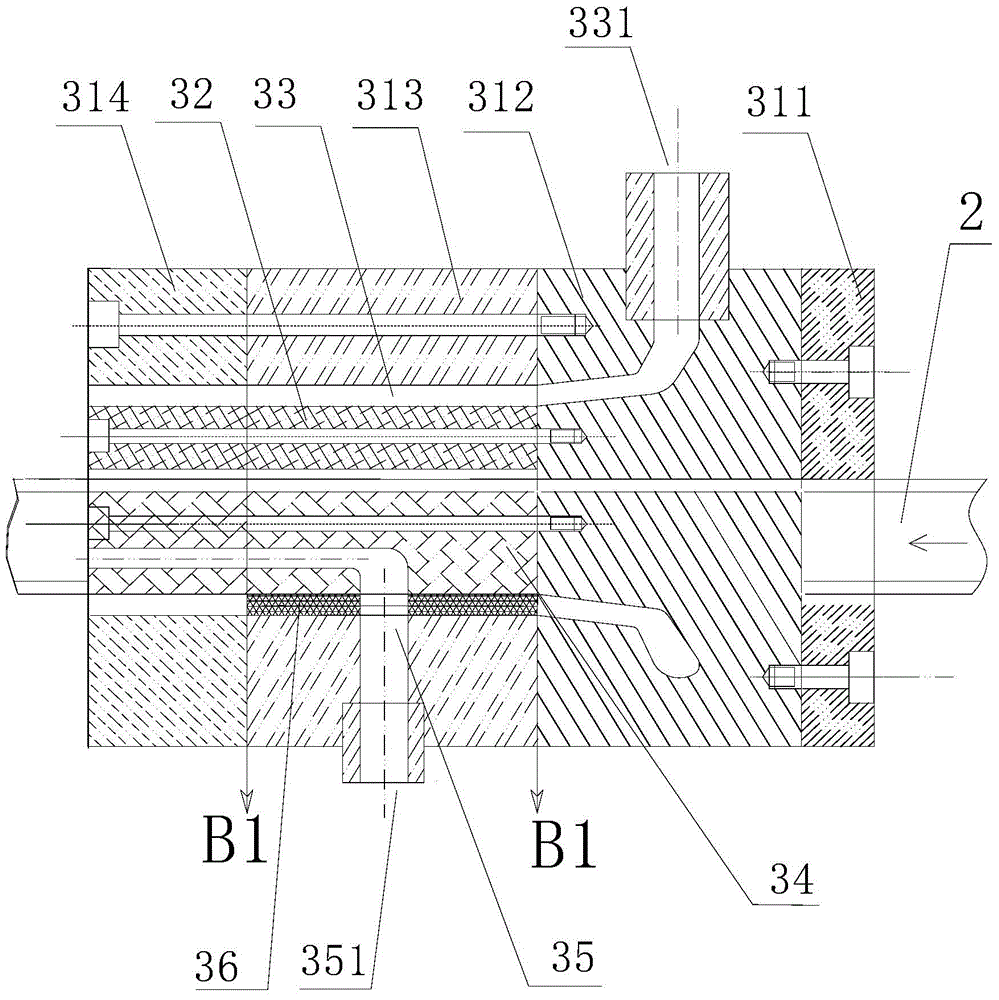

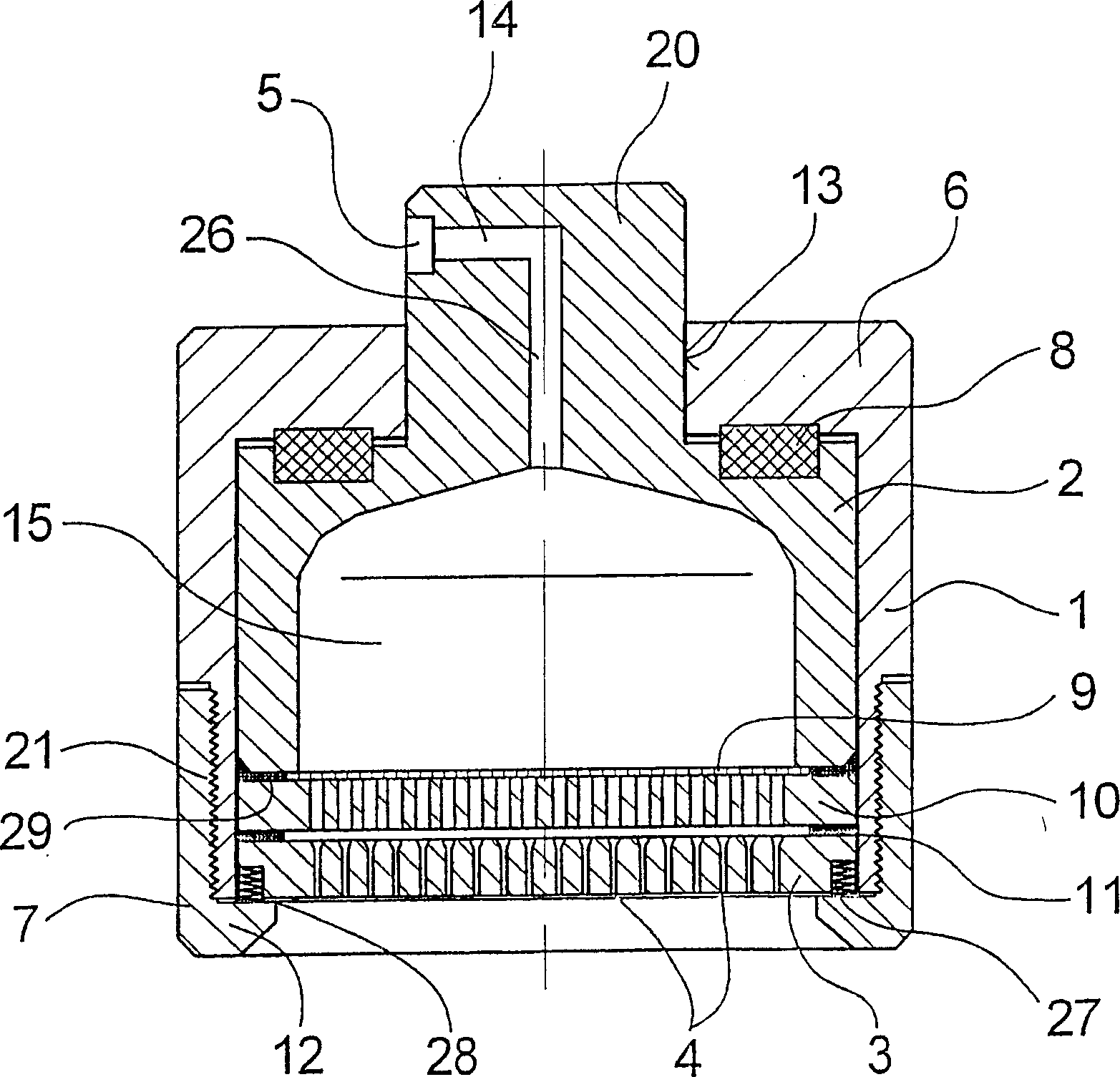

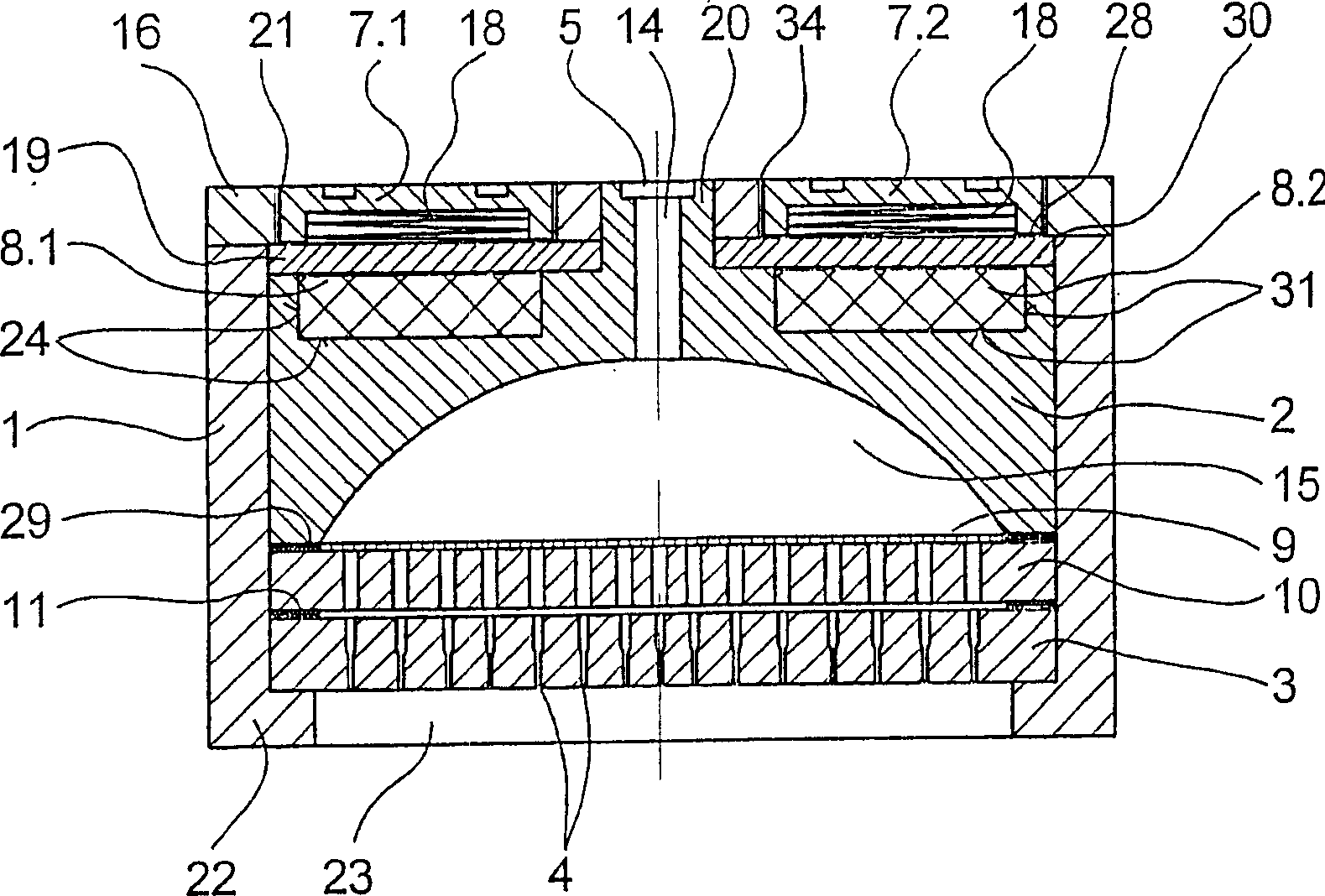

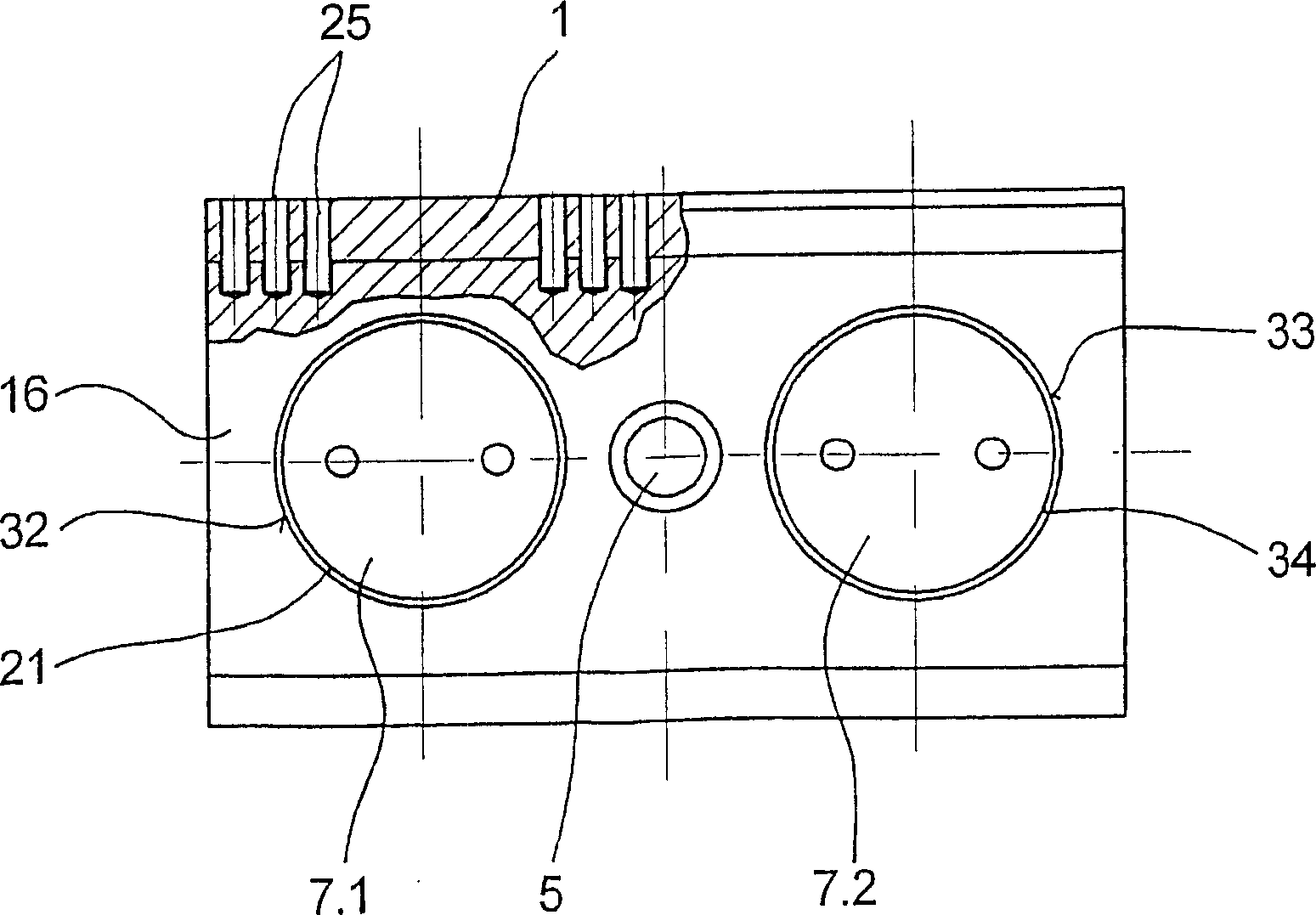

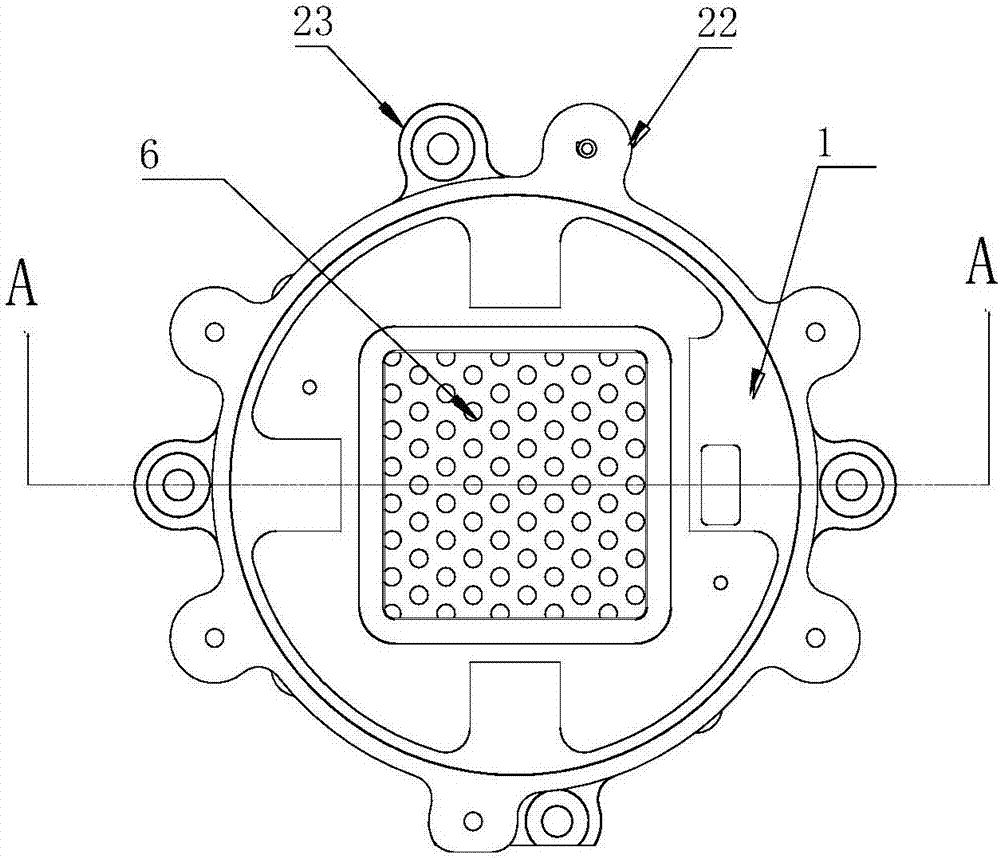

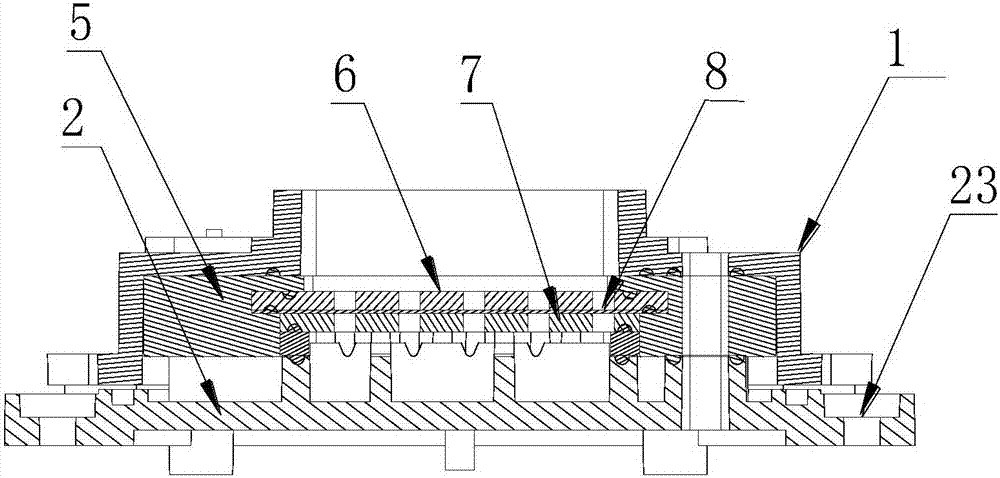

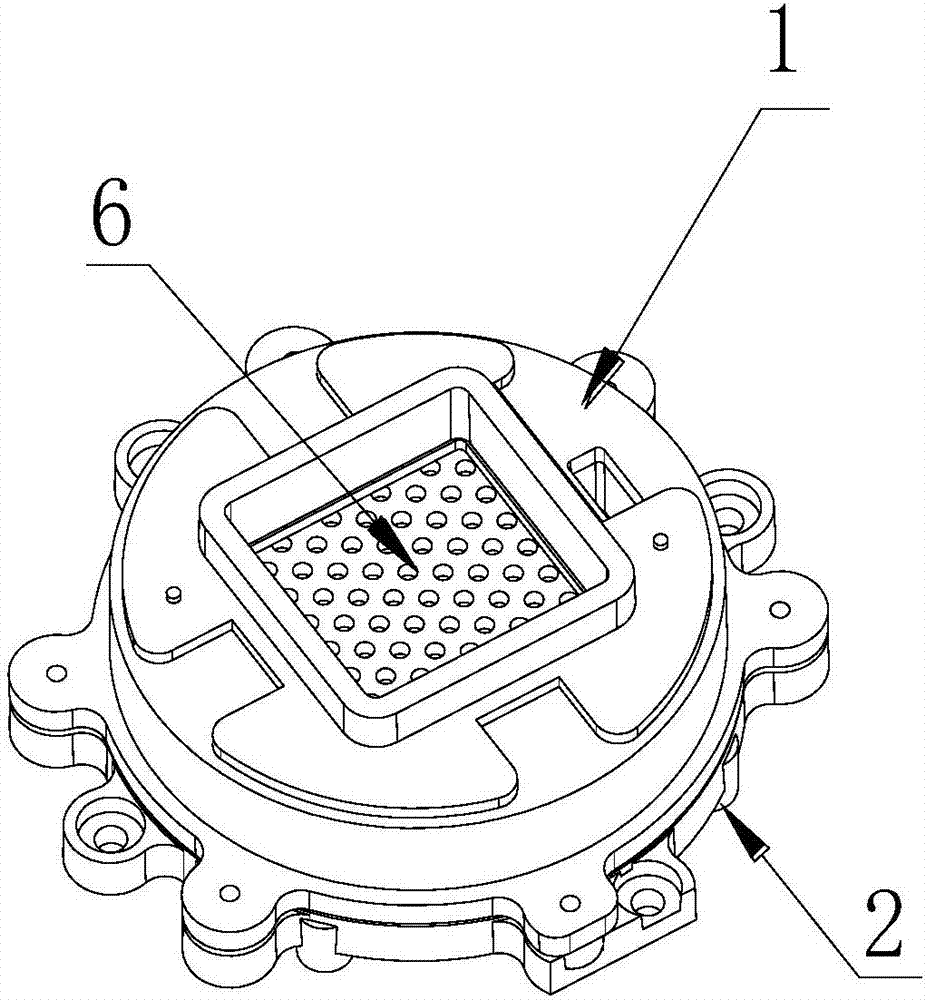

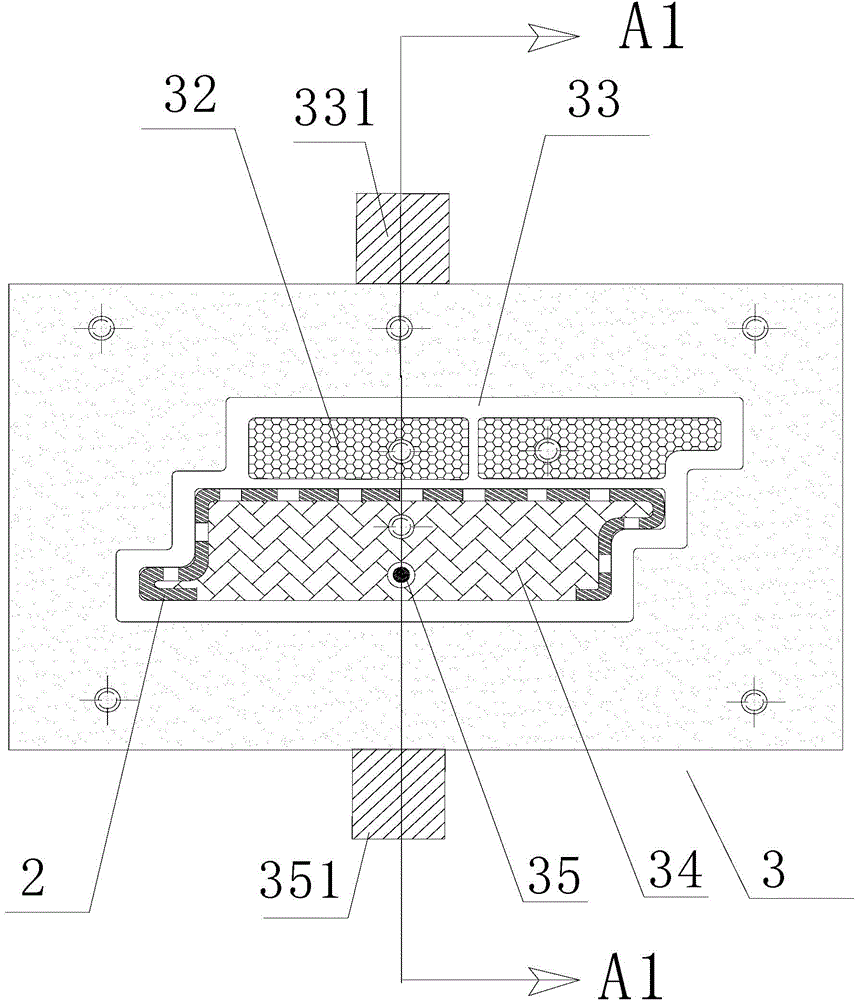

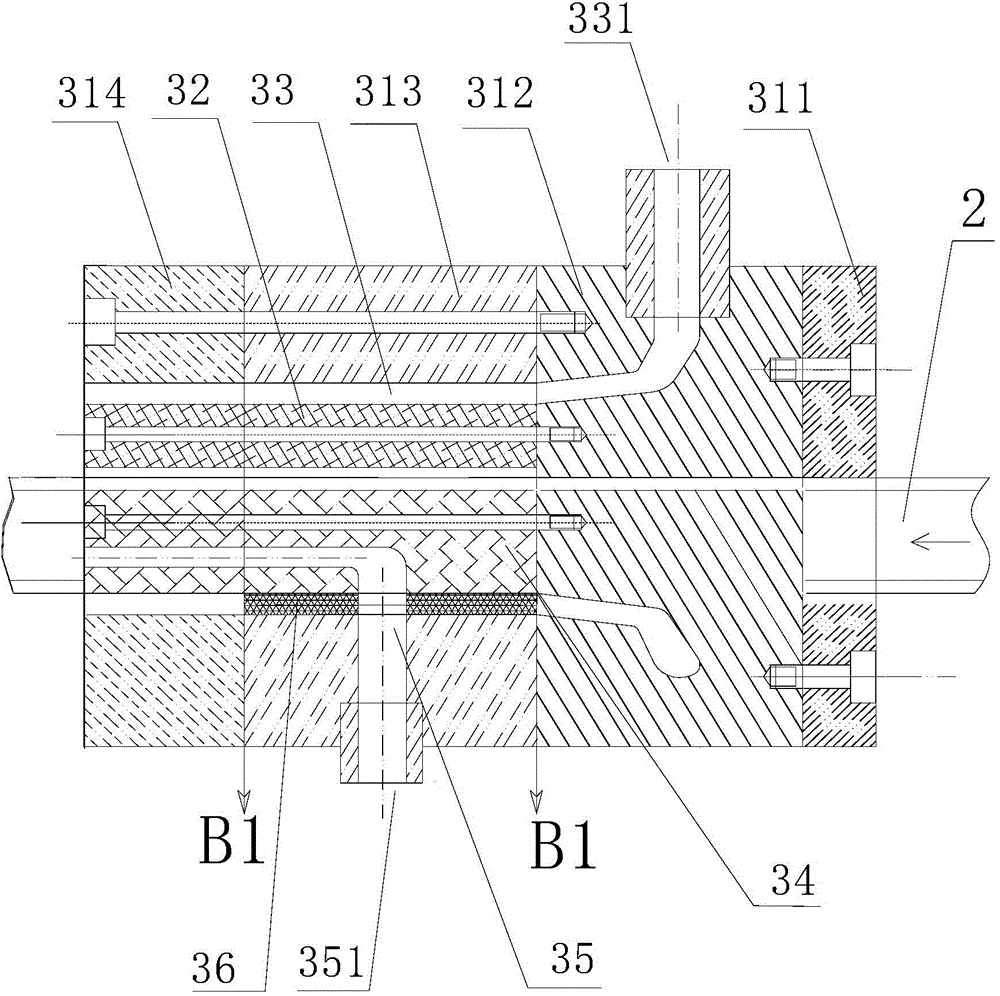

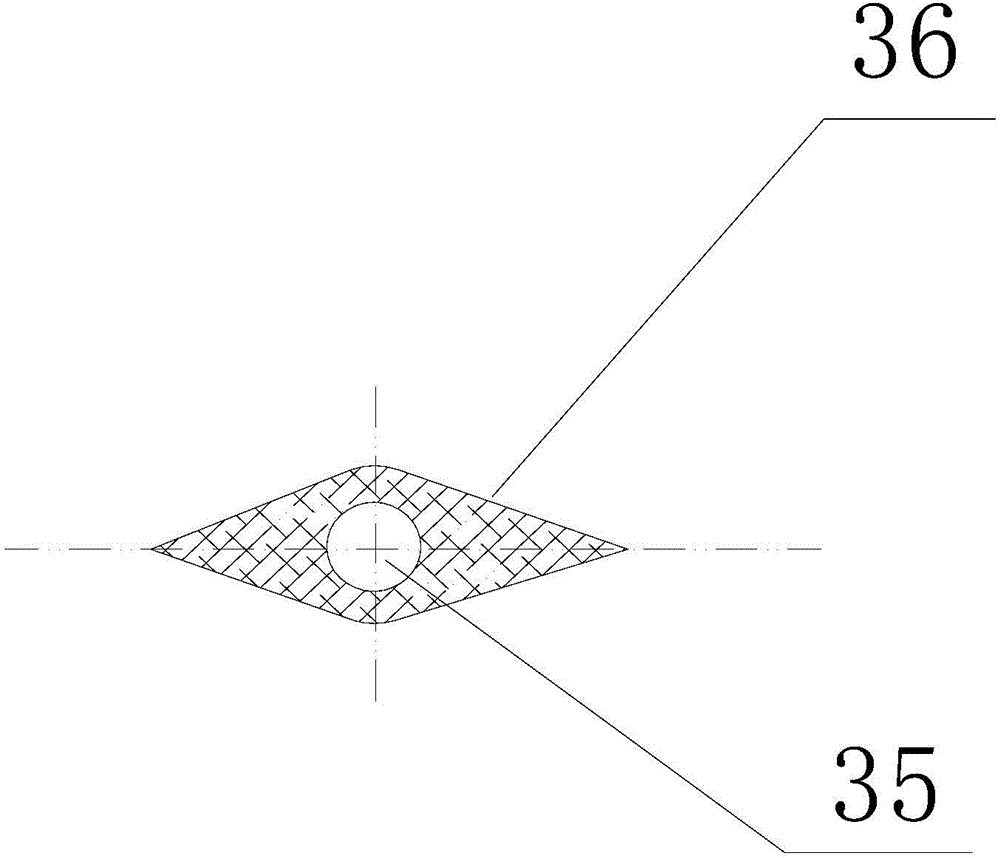

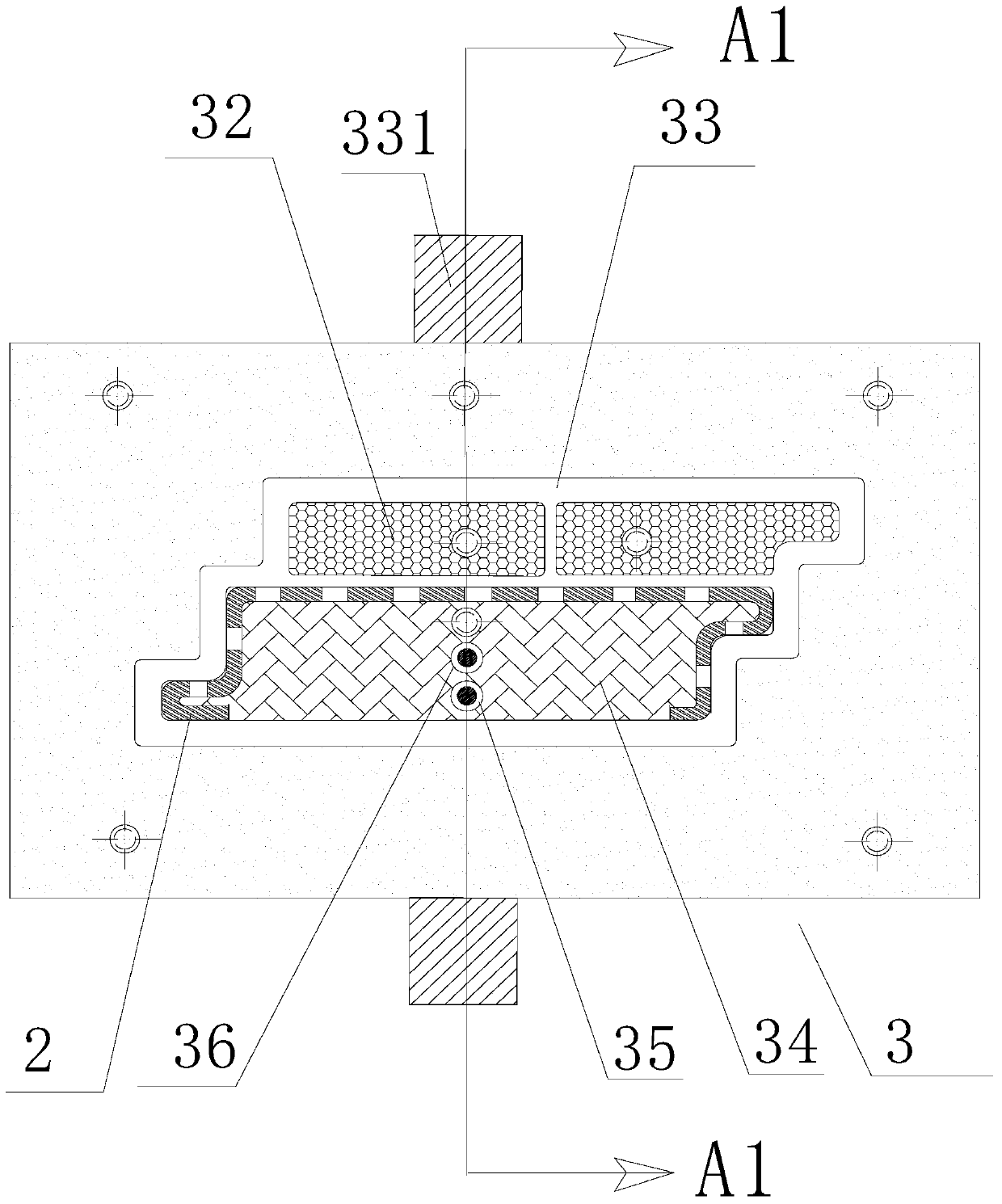

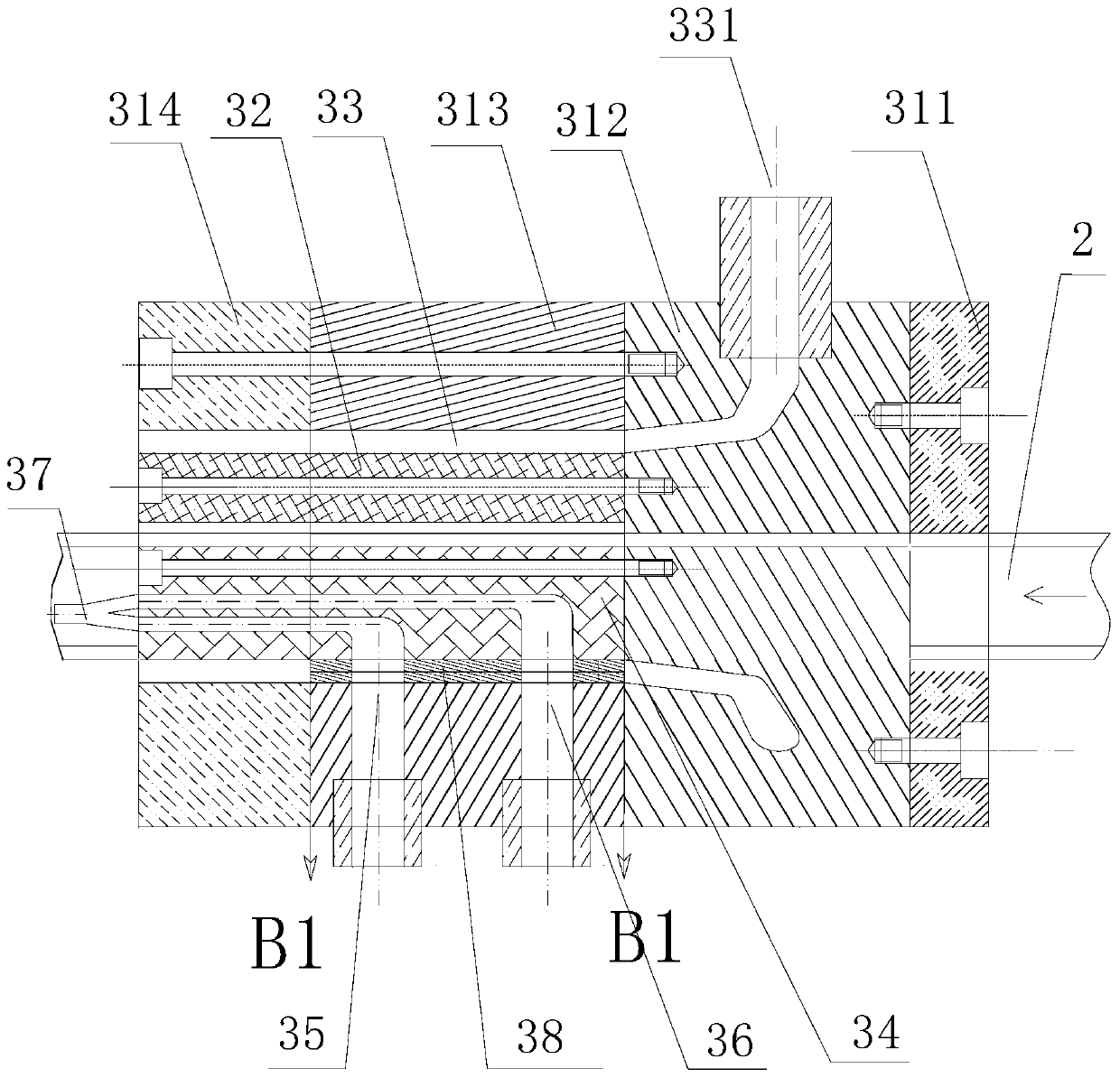

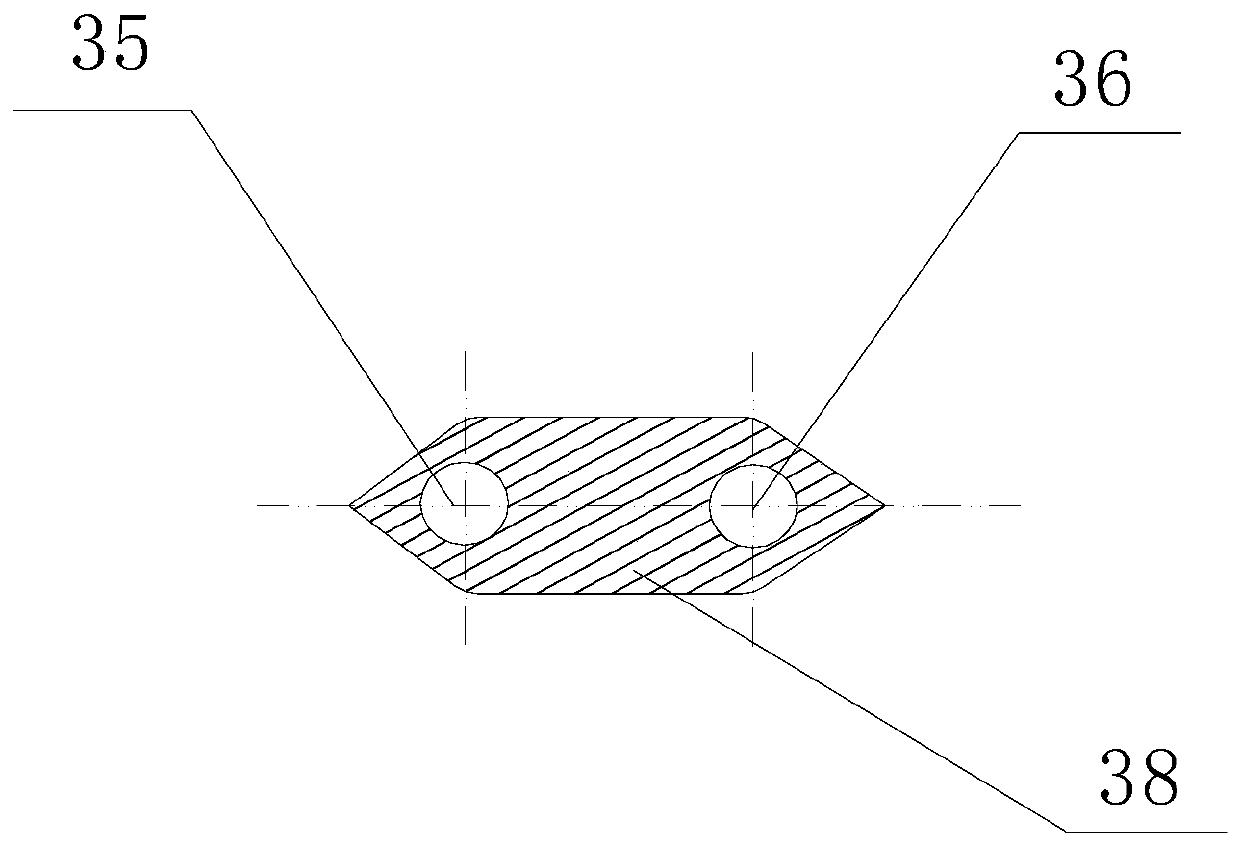

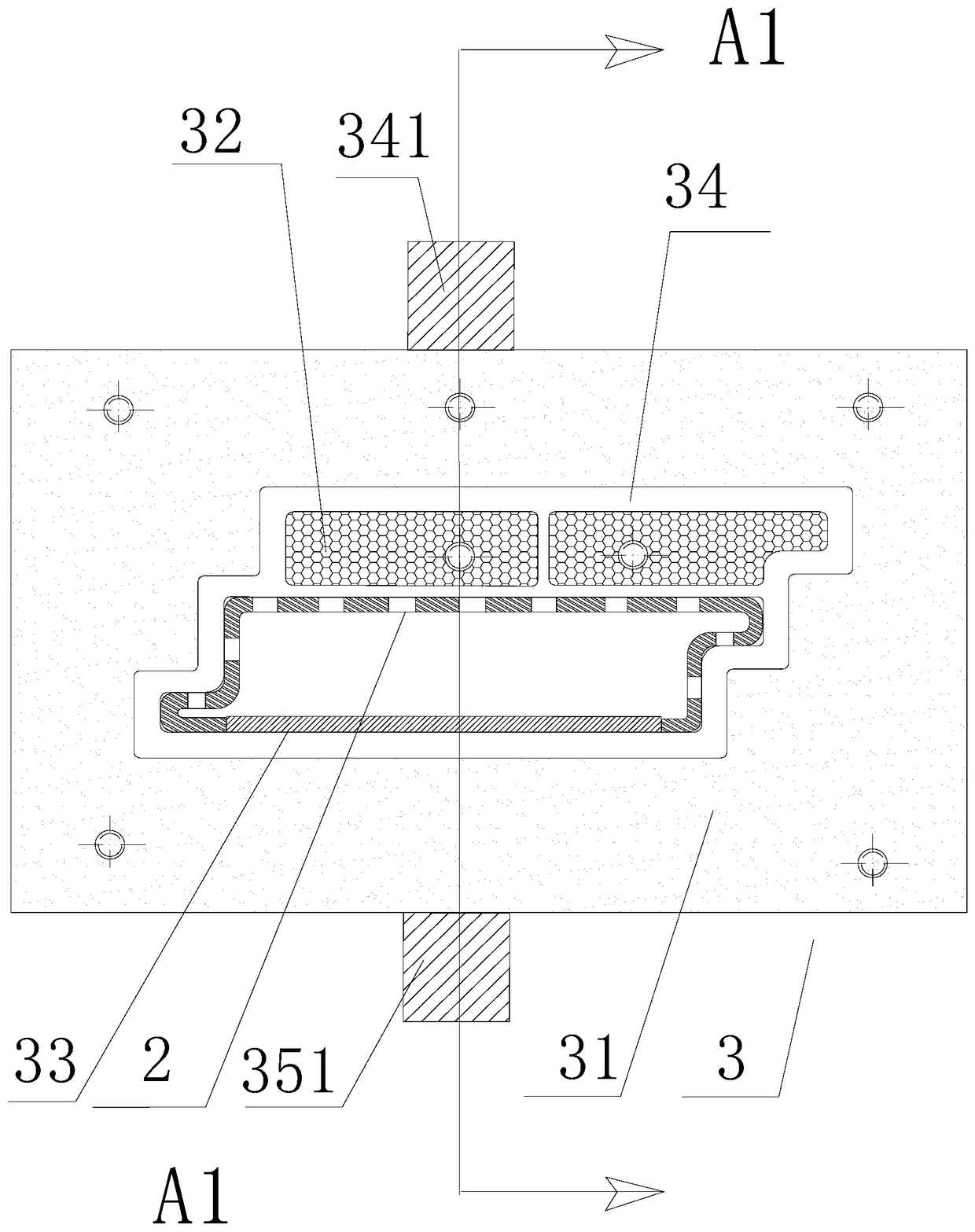

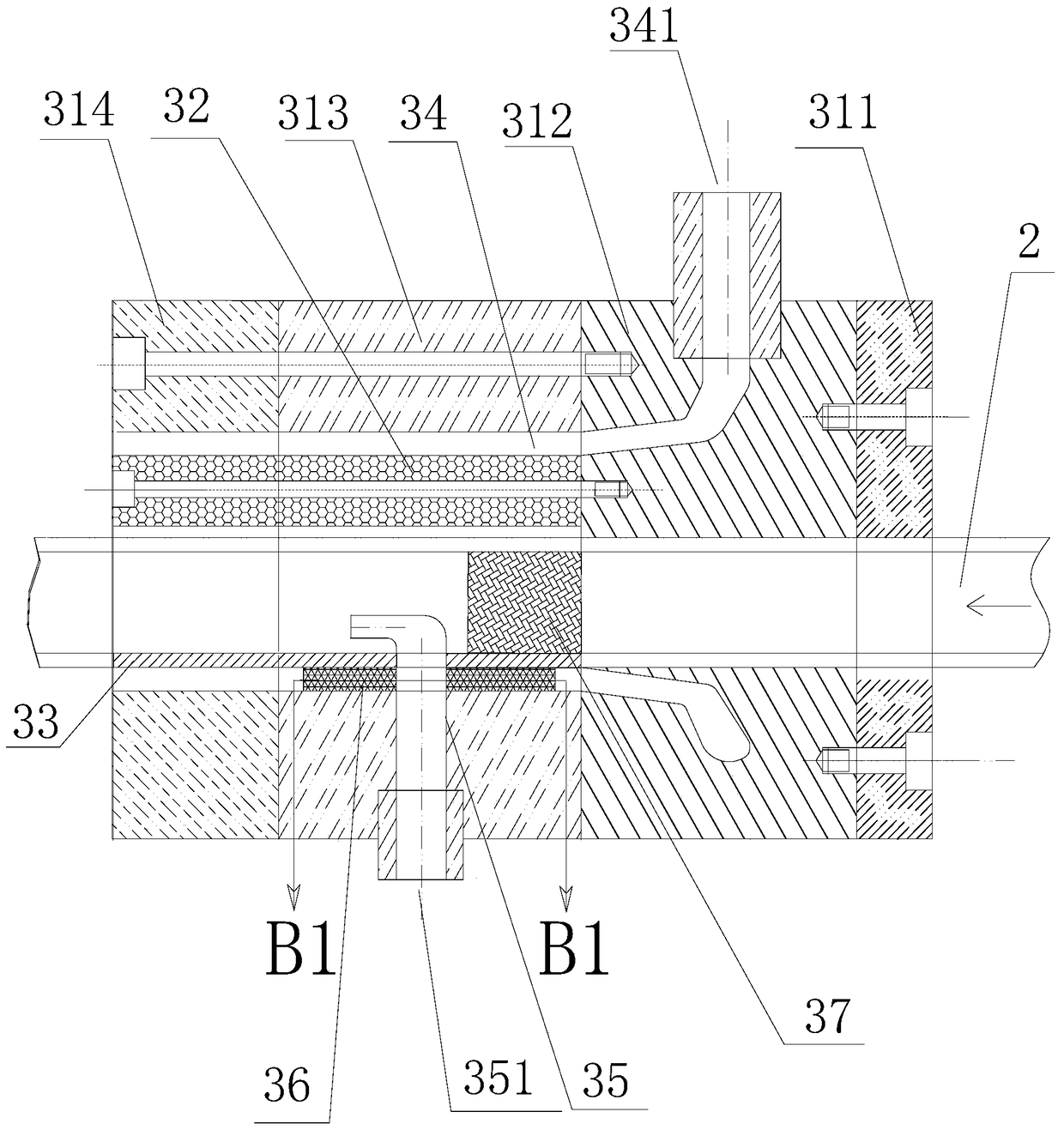

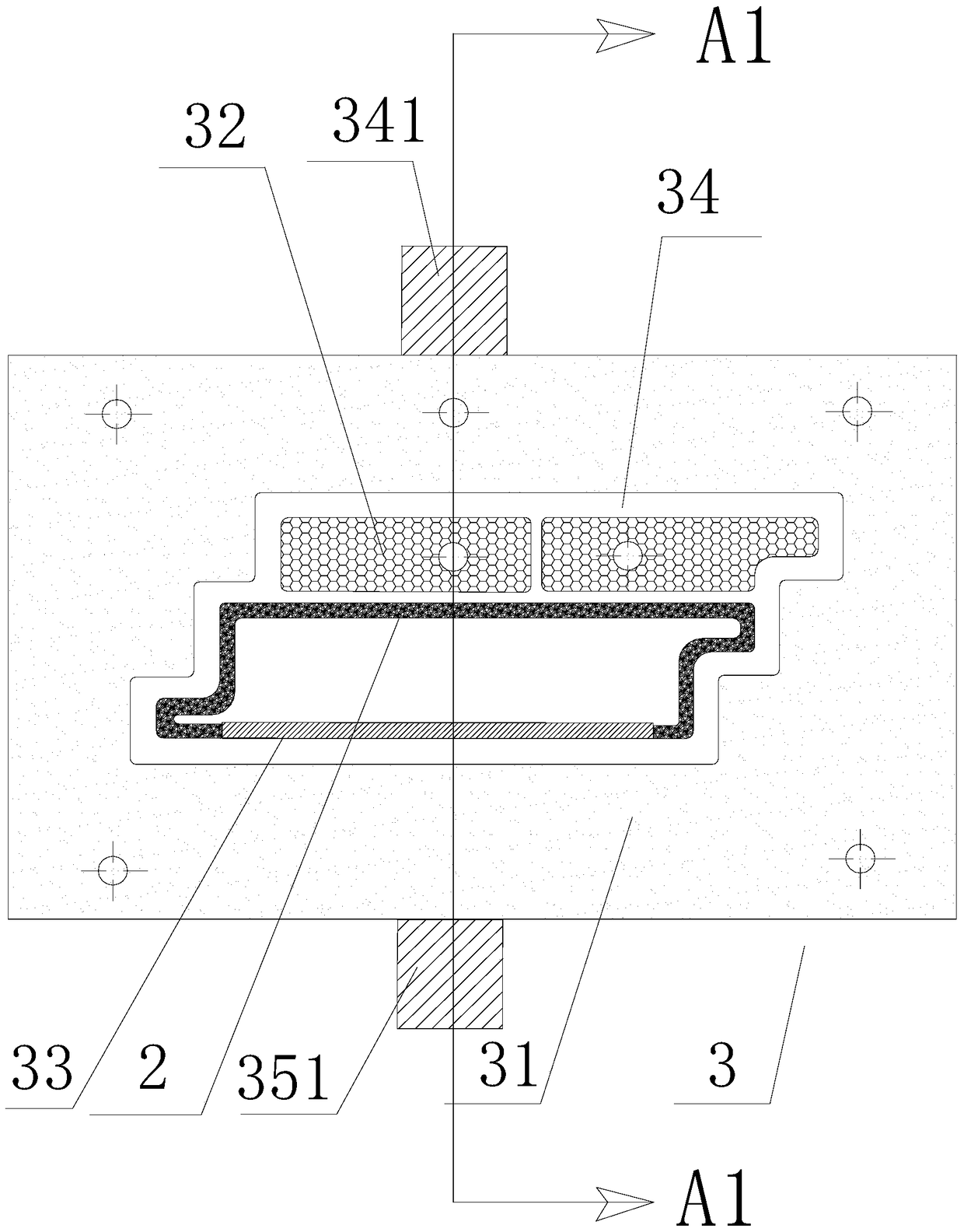

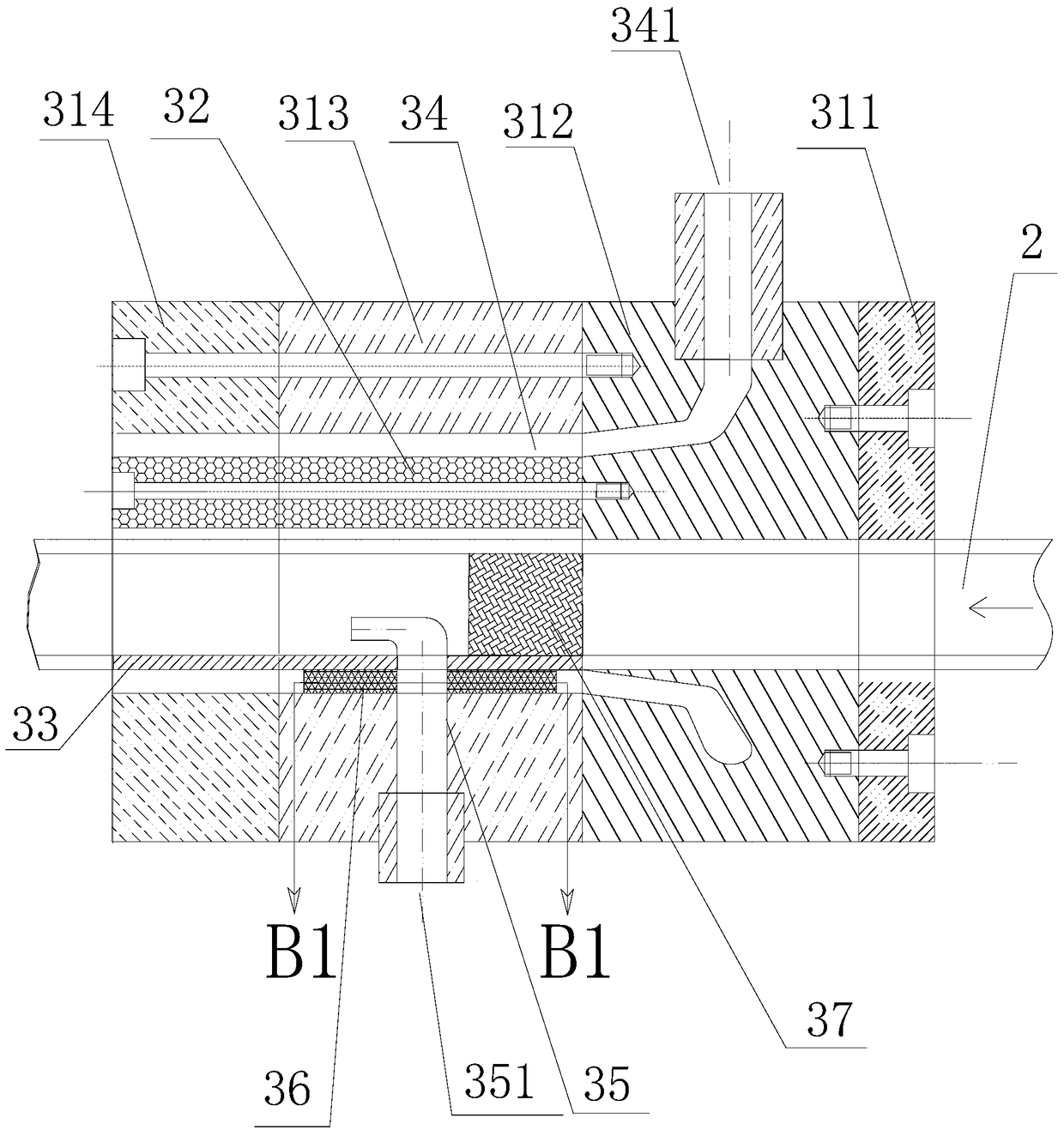

Spinneret

InactiveCN1296530CUniform pressing forceEasy to assemble and disassembleSpinnerette packsThermal expansionMelt spinning

A spinneret assembly for melt spinning a plurality of strand-like filaments, which includes a plurality of internal parts composed of at least one inlet component 2 and a spinneret plate 3 which are braced relative each other in a housing 1 by a supporting means. The inlet component 2 forms a melt inlet 5, and the spinneret plate 3 forms a melt outlet by means of a plurality of spin holes 4. To achieve during operation a self-sealing between the internal parts, the invention provides for arranging an expansion body 8 between the housing 1 and one of the internal parts. The expansion body 8 is formed of a material which has a higher thermal expansion coefficient than the housing material, and it generates, upon being heated, a pressure force inside the housing which provides for a self-sealing bracing of the internal parts.

Owner:SAURER GMBH & CO KG

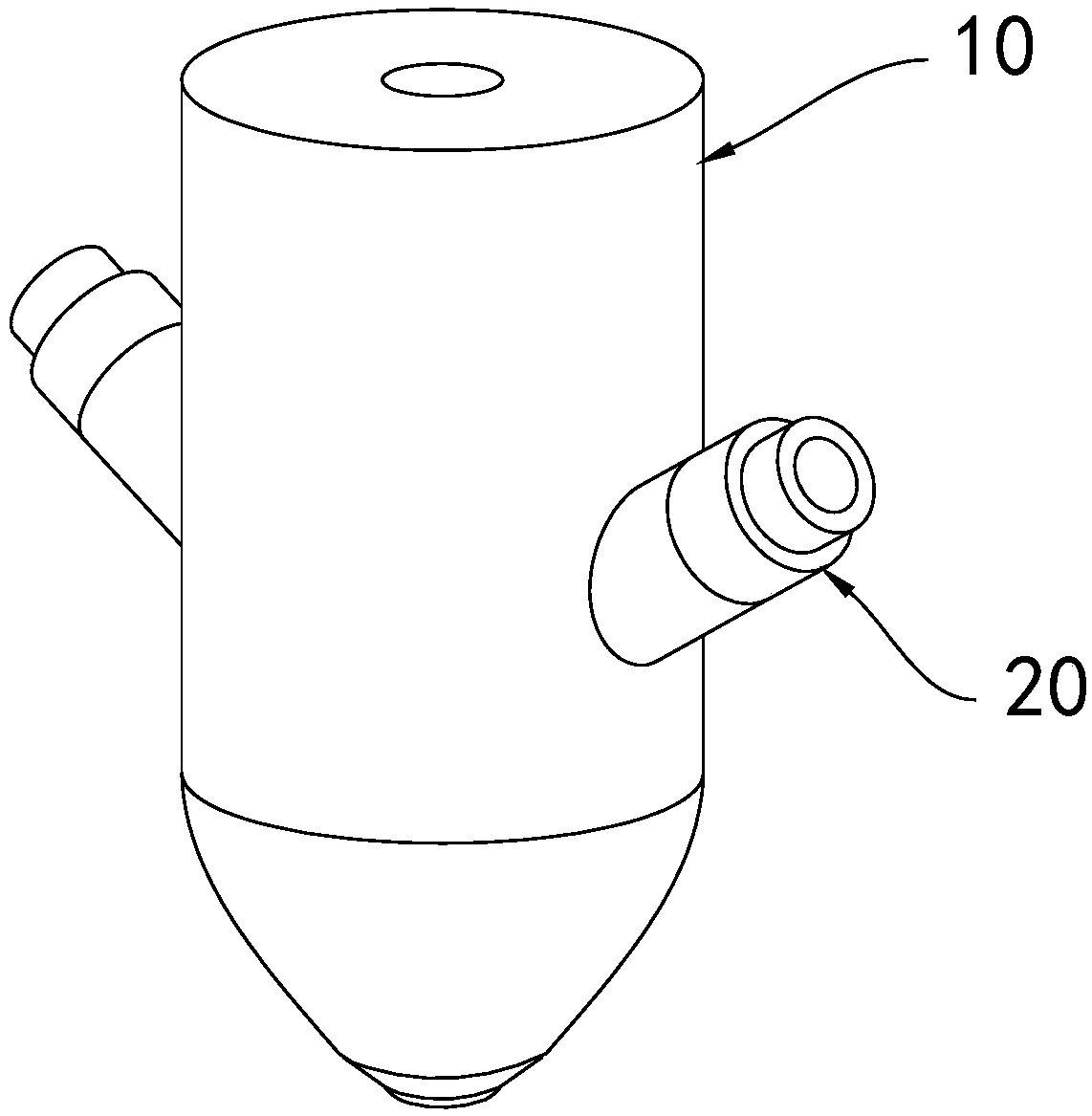

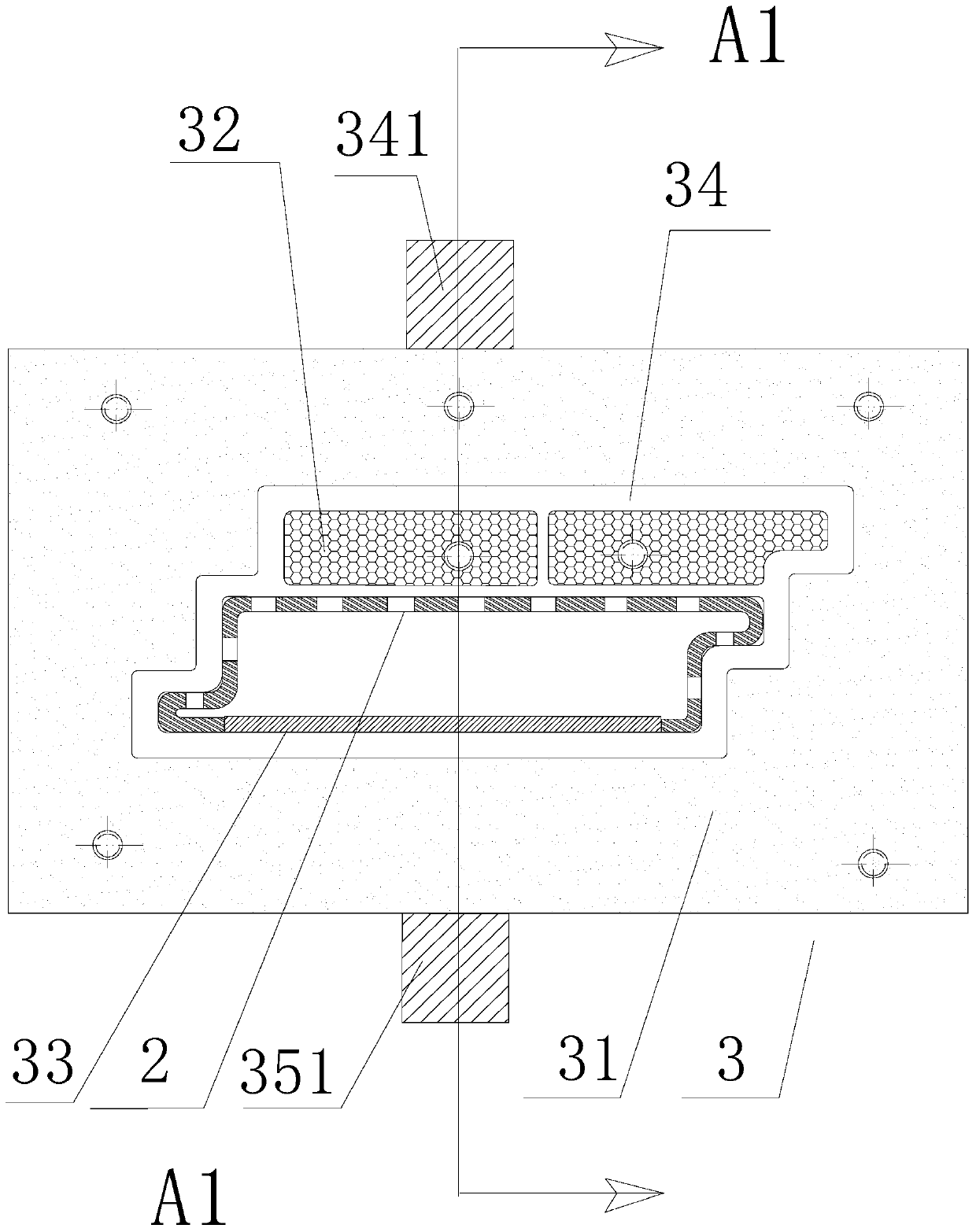

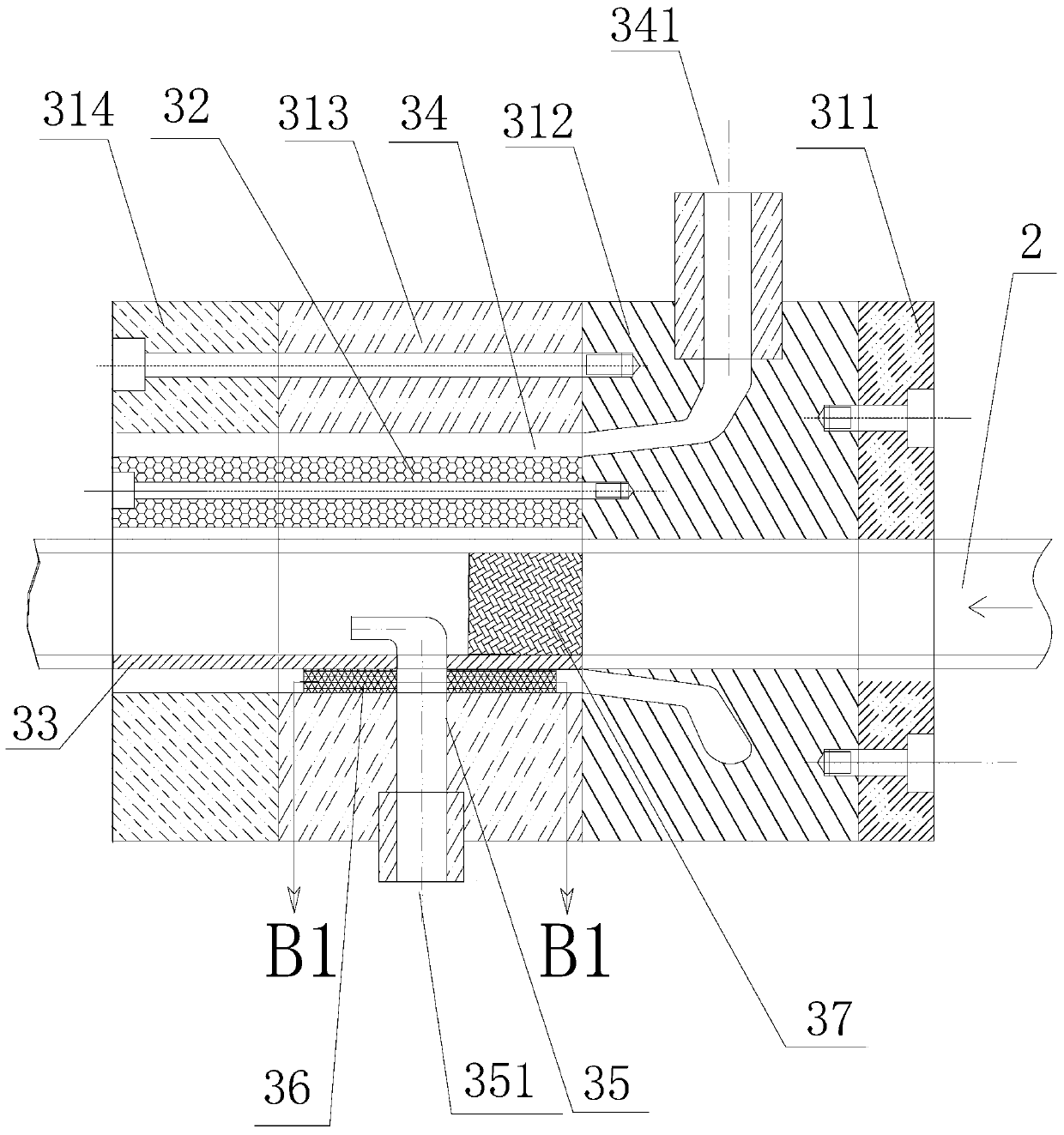

Hydrogen-enriching electrolysis device

PendingCN107512761AIncrease concentrationSimple structureWater/sewage treatment by substance additionWater/sewage treatment apparatusElectrolysisEngineering

The invention discloses a hydrogen-enriching electrolysis device which comprises an upper shell and a lower shell, wherein an opening part is arranged on the upper part of the upper shell; an exhaust port is formed on the lower shell; an upper chamber is arranged in the upper shell; a lower chamber is arranged in the lower shell; an electrode unit is arranged in a chamber structure encircled by the upper chamber and the lower chamber; a sealing pad for separating the upper and lower surfaces of the electrode unit is arranged on the upper part of the electrode unit; the electrode unit comprises a first electrode slice, a second electrode slice and a diaphragm arranged between the first electrode slice and the second electrode slice; a plurality of first through holes are formed on the first electrode slice; and a plurality of second through holes corresponding to the first through holes are formed on the second electrode slice. The invention aims to provide the hydrogen-enriching electrolysis device requiring no water draining and having high hydrogen production efficiency.

Owner:LEEBOW QINGYUAN IND

Low-chrome wear-resistant alloy steel, and preparation method thereof

The invention discloses a low-chrome wear-resistant alloy steel, and a preparation method thereof. The preparation method comprises following steps: technology target value determination, material preparation, melting, sampling and adjusting, casting and moulding, and hot treatment. The low-chrome wear-resistant alloy steel comprises, by weight, 0.25 to 0.35% of carbon, 0.6 to 1.5% of silicon, 0.8to 1.3% of manganese, phosphor<0.04%, sulfur<0.04%, 1 to 3.5% of chromium, 0.1 to 0.5% of nickel, 0.1 to 0.3% of molybdenum, 0.03 to 0.25% of boron, 0.1 to 0.3% of aluminium, 0.1 to 1.2% of cerium, 0.02 to 0.1% of tin, and the balance iron. According to the preparation method, both wear resistance and hardness requirements are satisfied, the toughness is increased greatly, impact resistance is excellent, impact energy is as high as 5 to 8 joules, and cobblestones can be crushed using the low-chrome wear-resistant alloy steel easily.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

Extrusion die for composite sheet material formed by co-extrusion molding of metal section material and wood plastic

An extrusion die for a composite sheet material formed by co-extrusion molding of a metal section material and wood plastic comprises a mold body and a separation plate; the separation plate is arranged in a cavity formed in the mold body, and the metal section material is an opened metal section material; a hollow container is enclosed by the separation plate and the metal section material sent into the cavity, and a gap used for injecting a fused wood plastic foaming material is formed between the container and the mold body; and the extrusion mold is provided with an air channel, and the air channel successively passes through the mold body, the cavity and the separation plate and enters the container space. The extrusion mold in the embodiment is capable of producing the composite sheet material formed through co-extrusion molding of the metal section material and wood plastic, and through the air channel hollow space, too much of the fused wood plastic fluid is prevented from flowing into the hollow space, inner-cooling of the composite sheet material is realized, the cooling shaping efficiency is improved, and thus the production efficiency is improved.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Container type house unit and modularized group building residential building

ActiveCN102304942BGuaranteed basic strengthScientific and reasonable structureBuilding constructionsDwelling buildingContainerizationArchitectural engineering

The invention discloses a container type house unit, comprising a container house body, wherein the front end wall and the rear end wall of the container house body are respectively provided with a door (13) for entering the container house body; the front end and the rear end of the of the container house body are respectively provided with a balcony; the balcony and the container house body areformed into a whole; the left side and the right side of each balcony are respectively provided with an access used for the balcony; and side wall on one side of the container house body is provided with a piping shaft (15). In addition, the invention also provides a modularized group building residential building assembled by the container type house unit. According to the container type house unit and the modularized group building residential building formed by the container type house unit, the construction of the original container type residential building is kept, and the basic strength of the container type house is guaranteed. On the basis of the existing container type house, the reliability and the operability of the product can be perfected, the quality of the product is guaranteed, and the container type house unit is suitable for the requirement of industrial production.

Owner:YANGZHOU TONGLEE REEFER CONTAINER

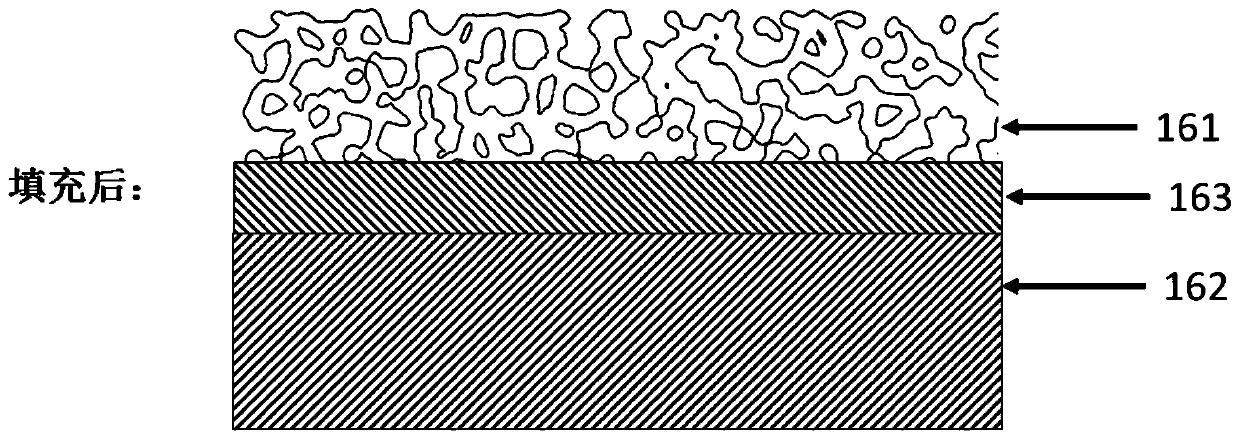

Preparation method of porous hydrogel coating on surface of polypropylene patch

PendingCN114149605AGuaranteed basic strengthHigh strengthCoatingsSodium bicarbonatePolyvinyl alcohol

The invention discloses a preparation method of a porous hydrogel coating on the surface of a polypropylene patch. The preparation method comprises the following steps: ultrasonically cleaning and drying a polypropylene material; putting sodium bicarbonate into the polyvinyl alcohol solution, and slowly stirring until the sodium bicarbonate is completely dissolved; preparing a ferric chloride solution, mixing the ferric chloride solution with the solution, and fully and uniformly stirring to prepare a mixed solution; coating the surface of the dried polypropylene material with the prepared mixed solution, and freezing the polypropylene material at low temperature; finally, the frozen polypropylene material is taken out, unfrozen at room temperature and soaked in deionized water, and the polypropylene material with the porous hydrogel coating on the surface is obtained. The modification method is simple, mild in condition and easy to control. The modified material can keep the mechanical property of a polypropylene body not reduced, and the surface hydrophilicity and anti-inflammatory property of PP can be improved.

Owner:SOUTHEAST UNIV

Extrusion die for composite sheet material formed through co-extrusion molding of wood plastic, foaming layer and metal section material

ActiveCN105437495AImprove thermal insulation performanceGuaranteed basic strengthPlastic materialsMetal

The invention provides an extrusion die for a composite sheet material formed through co-extrusion molding of wood plastic, a foaming layer and a metal section material. The die comprises a die body and a first die core, the first die core is arranged in a cavity formed in the die body, the metal section material is an opened metal section material; the first die core possesses an appearance structure matched with the opened metal section material, and can form a sealed solid body together with the metal section material sent into the cavity through cooperation, and a gap for injecting the fused wood plastic material is reserved between the sealed solid body and the die body; and the extrusion die is provided with a flow channel, and the flow channel successively passes through the die body, the cavity and the first die core and reaches the extrusion end of the die. The extrusion die in the embodiment is capable of producing the composite sheet material which is a composite integral body formed by wood plastic, the metal section material and the foaming layer.

Owner:BEIJING NEW BUILDING MATERIALS PLC

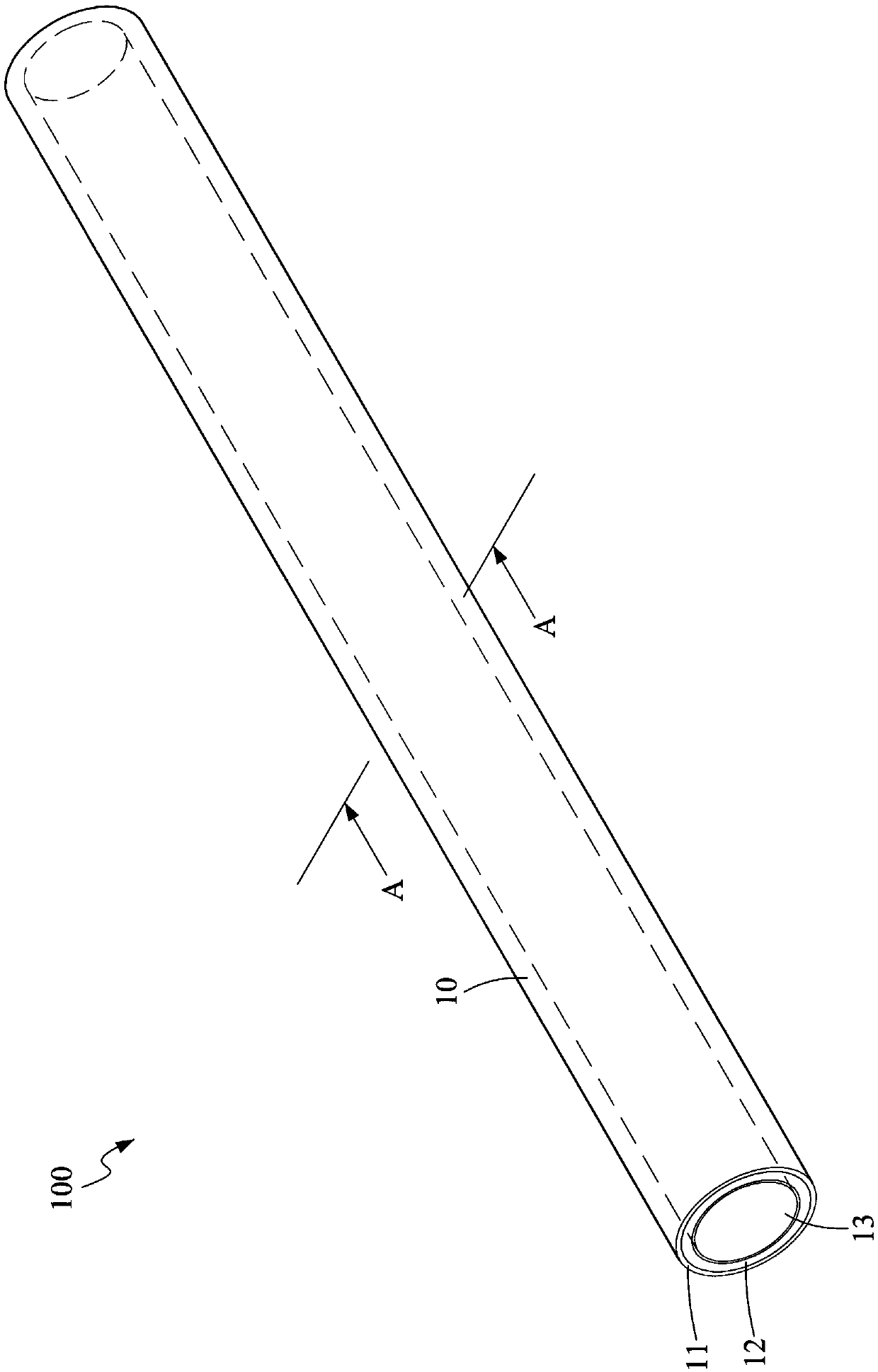

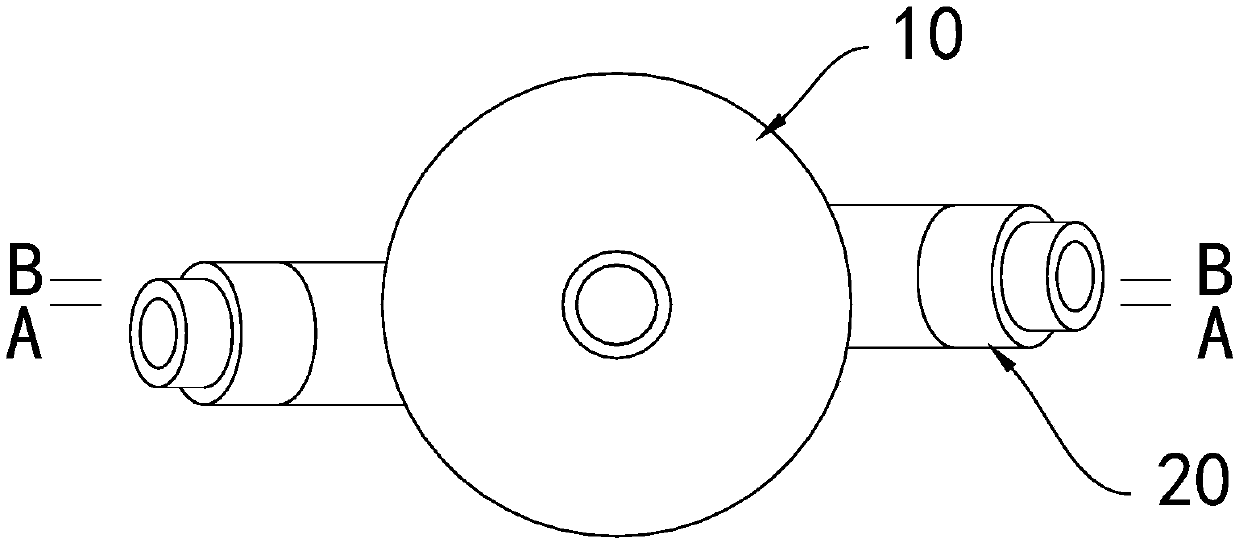

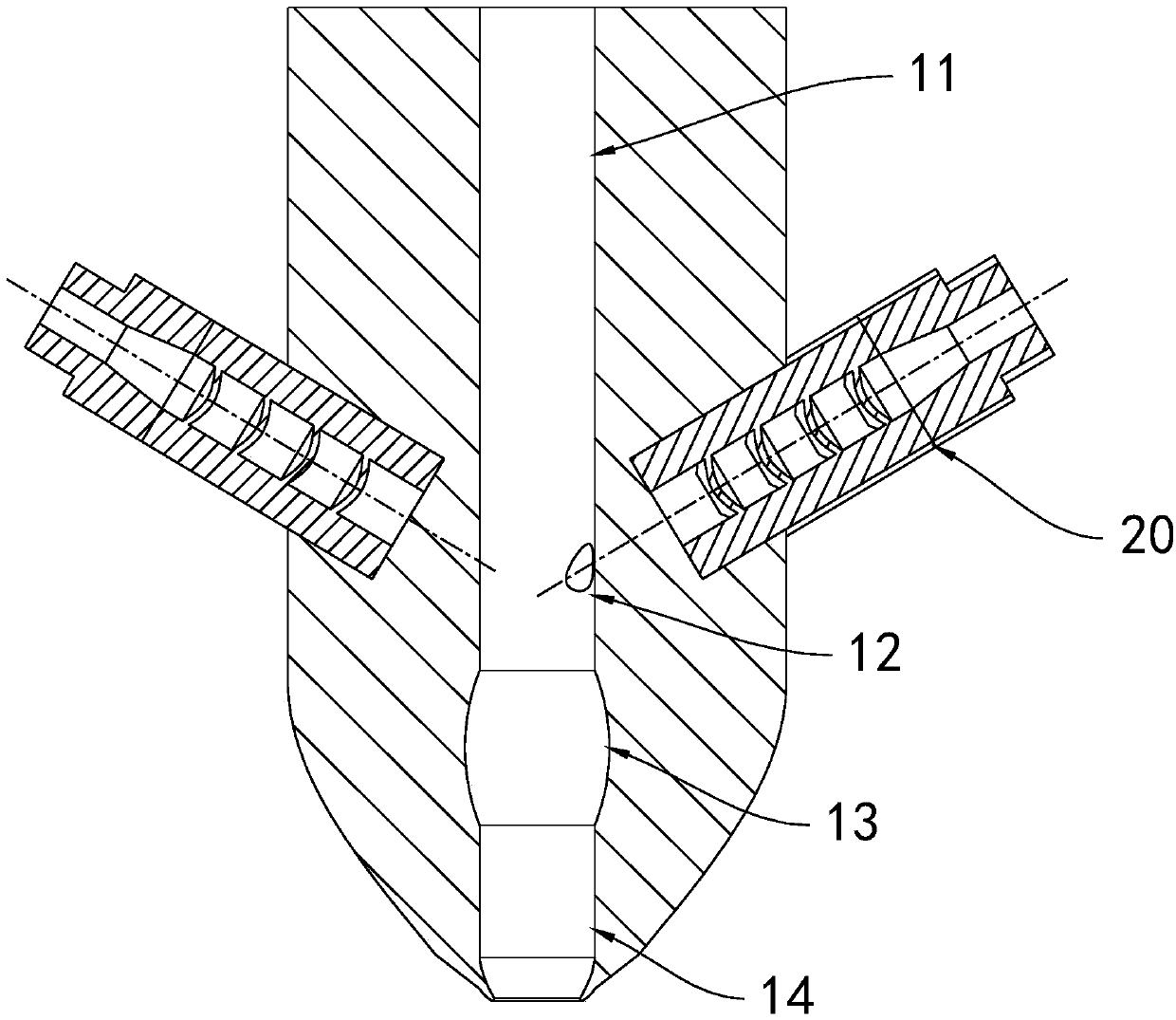

Dissolved air type spinneret

InactiveCN109518285AAvoid enteringUniform surface effectFilament/thread formingAgricultural engineeringTracheole

The invention discloses a dissolved air type spinneret. The spinneret comprises a main pipe body (10), wherein the main pipe body (10) comprises a feeding segment (11), an air inlet segment (12), a slow flow segment (13) and a spinning segment (14) which are sequentially disposed; the air inlet segment (12) is connected to air pipes (20); the inner diameter of the slow flow segment (13) is greaterthan those of the air inlet segment (12) and spinning segment (14). The spinneret has the advantages that spun silk is easy to twist, and the elasticity and the water absorption performance are good.

Owner:湖州鑫瑞辰纺织科技有限公司

A kind of waterproof antibacterial coating cloth and its preparation process

ActiveCN106192440BHas waterproof and antibacterial effectGuaranteed basic strengthTextiles and paperFiberWax

The invention discloses a waterproof antibacterial coating fabric and a preparation technology thereof. The coating fabric comprises a base fabric and a waterproof antibacterial layer sequentially coating the surface of the base fabric. The waterproof antibacterial layer is prepared from, by weight, 50-65 parts of bamboo fiber, 15-25 parts of wasabi, 15-30 parts of wax gourd, 40-55 parts of a polyvinylidene chloride emulsion, 35-45 parts of acrylate copolymer and paraffin compound emulsion, and 10-15 parts of sodium carboxymethylcellulose. The coating fabric achieves the waterproof and antibacterial performance at the same time, the flexibility and mechanical property of the coating fabric are good, the waterproof antibacterial layer uniformly coats the base fabric, the attaching firmness is good, the coating fabric can be still well attached after being used for a long time, and the coating fabric has the long service life.

Owner:ZHEJIANG HUIFENG NEW MATERIALS

A composite sheet formed by co-extrusion of metal profile and wood-plastic and preparation method thereof

ActiveCN105484423BGuaranteed basic strengthReduce dosageBuilding componentsCo extrusionComposite plate

Owner:BEIJING NEW BUILDING MATERIALS PLC

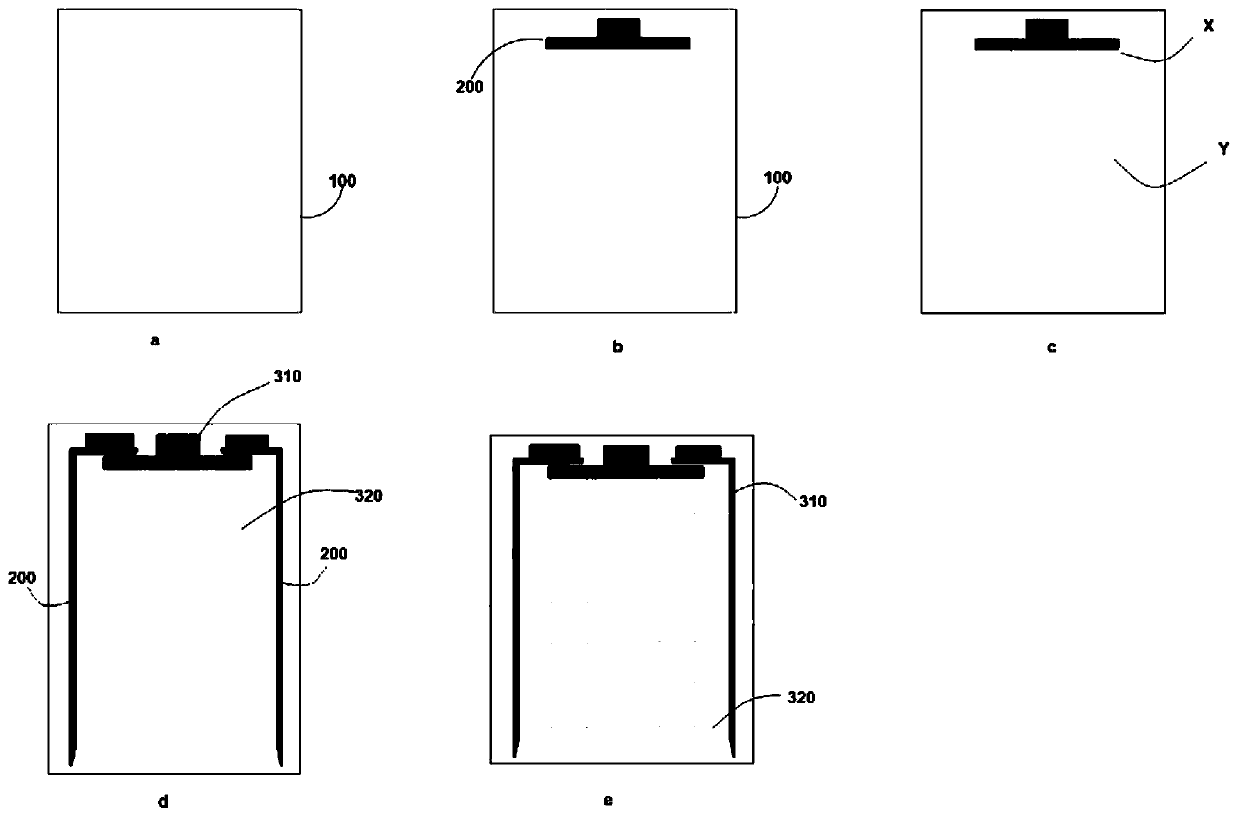

Touch sensor, preparation method thereof and touch display screen

InactiveCN110750171AImprove conduction abilityIncrease line widthInput/output processes for data processingLaser etchingGraphics

The invention relates to a touch sensor and a preparation method thereof, and a touch display screen, the preparation method of the touch sensor comprises the following steps: providing a substrate, the substrate being a transparent conductive flexible film with a conductive surface, and the conductive surface being a silver nanowire or a carbon nanotube; depositing ink in a designated area on theconductive surface of the substrate in an ink-jet printing mode and curing to form a conductive metal area, and the area, where the conductive metal area is not formed, of the substrate being a toucharea; and etching the conductive metal region and the touch region by adopting a laser etching mode so as to respectively form a first graphic circuit and a second graphic circuit which are connectedwith each other in the conductive metal region and the touch region. According to the preparation method of the touch sensor, the flexible foldable touch sensor with an ultra-narrow frame can be processed.

Owner:盈天实业(深圳)有限公司

Waterproof antibacterial coating fabric and preparation technology thereof

ActiveCN106192440AAchieve waterproof effectAchieve antibacterial effectTextiles and paperWaxSodium carboxymethylcellulose

The invention discloses a waterproof antibacterial coating fabric and a preparation technology thereof. The coating fabric comprises a base fabric and a waterproof antibacterial layer sequentially coating the surface of the base fabric. The waterproof antibacterial layer is prepared from, by weight, 50-65 parts of bamboo fiber, 15-25 parts of wasabi, 15-30 parts of wax gourd, 40-55 parts of a polyvinylidene chloride emulsion, 35-45 parts of acrylate copolymer and paraffin compound emulsion, and 10-15 parts of sodium carboxymethylcellulose. The coating fabric achieves the waterproof and antibacterial performance at the same time, the flexibility and mechanical property of the coating fabric are good, the waterproof antibacterial layer uniformly coats the base fabric, the attaching firmness is good, the coating fabric can be still well attached after being used for a long time, and the coating fabric has the long service life.

Owner:ZHEJIANG HUIFENG NEW MATERIALS

An internal heating integrated evaporation boat with alumina porous structure buffer layer

InactiveCN107326330BSolve Oxidation ProblemsHigh bonding strengthVacuum evaporation coatingSputtering coatingPorosityStress relieving

The invention discloses an internal-heated integrated evaporation boat with an aluminum oxide porous structure buffering layer. Surface coatings of the evaporation boat totally comprise two layers. The inner layer is the Al2O3 buffering layer of a loose porous structure, and the outer layer is the compact low-porosity corrosion-resistantAl2O3 coating. Firstly, through a rotary-coating steeping technique, the Al2O3 buffering layer with the thickness being 0.1-0.3 mm is prepared on the surface of a matrix; and then through a plasma spraying technology, the Al2O3 corrosion-resistantlayer with the thickness being 0.5-1 mm is sprayed and prepared on the evaporation boat with the buffering layer. According to the composite technique, the evaporation boat with the Al2O3 coatings of different microstructures is prepared; in service, the buffering layer of the porous structure can achieve the stress relieving effect and can further prevent the problem of matrix oxidization caused by later spraying; and the compact low-porosity Al2O3 coating brings excellent corrosion resistance into play and can be widely applied to the technical field of vacuum evaporation metal thin films.

Owner:FUZHOU UNIV

A kind of co-extruded composite plate and its preparation method

ActiveCN105484373BImprove thermal insulation performanceGuaranteed basic strengthHeat proofingFoam polyurethanesCo extrusion

The present invention provides a co-extrusion molding composite board. The co-extrusion molding composite board comprises a wood plastic frame, a foaming layer and a metal profile; the wood plastic frame is provided with a first cavity; the metal profile has an opening; the metal profile is positioned in the first cavity; the wall surface of the first cavity is bonded to the surface of the metal profile; the foaming layer is put in a space enclosed by the first cavity and the metal profile; the foaming layer is bonded to the wall surface of the first cavity and the surface of the metal profile; and the foaming layer is prepared by foaming polyurethane materials. According to the composite board, the internal metal profile effectively provides mechanical strength, the metal profile, the foaming layer and the wood plastic frame are composited and integrated, so that the requirement for strength of the wood plastic part is reduced, the foaming technology can be adopted for materials of the wood plastic frame, wood plastic materials are saved, and heat and sound insulation performance of the composite board applied as a wall board is largely improved.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Extrusion die for composite board formed by co-extrusion of metal profile and wood plastic

An extrusion die for a composite sheet material formed by co-extrusion molding of a metal section material and wood plastic comprises a mold body and a separation plate; the separation plate is arranged in a cavity formed in the mold body, and the metal section material is an opened metal section material; a hollow container is enclosed by the separation plate and the metal section material sent into the cavity, and a gap used for injecting a fused wood plastic foaming material is formed between the container and the mold body; and the extrusion mold is provided with an air channel, and the air channel successively passes through the mold body, the cavity and the separation plate and enters the container space. The extrusion mold in the embodiment is capable of producing the composite sheet material formed through co-extrusion molding of the metal section material and wood plastic, and through the air channel hollow space, too much of the fused wood plastic fluid is prevented from flowing into the hollow space, inner-cooling of the composite sheet material is realized, the cooling shaping efficiency is improved, and thus the production efficiency is improved.

Owner:BEIJING NEW BUILDING MATERIALS PLC

A kind of preparation method of the composite sheet material that wood-plastic and metal profile co-extrude

ActiveCN105484422BGuaranteed basic strengthReduce dosageBuilding componentsCo extrusionComposite plate

The application provides a composite plate molded by co-extrusion of wood plastics and a metal profile. The composite plate comprises a wood-plastic frame and the metal profile, wherein a first cavity is arranged in the wood-plastic frame; the metal profile is positioned in the first cavity; the wall surface of the first cavity is bonded with the surface of the metal profile; wherein, the wood plastic framework is a foamed wood plastic material layer, and the metal profile is the opening-type metal profile. The composite plate provided by the embodiment has the advantages that the opened metal profile is selected for substituting for the closed metal profile, so that the basic strength of the composite plate is guaranteed, the usage amount of steel is saved, and conditions are created for an extrusion mold to realize internal cooling of compressed air at the same time.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com