Touch sensor, preparation method thereof and touch display screen

A touch sensor and touch area technology, which is applied in the field of display screens, can solve the problems of being unsuitable for large-scale promotion and application, the impact of chemical etching environment is large, and the difficulty of reducing the frame, etc., to achieve high metal film uniformity, improve Conductivity, effect of narrow linewidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

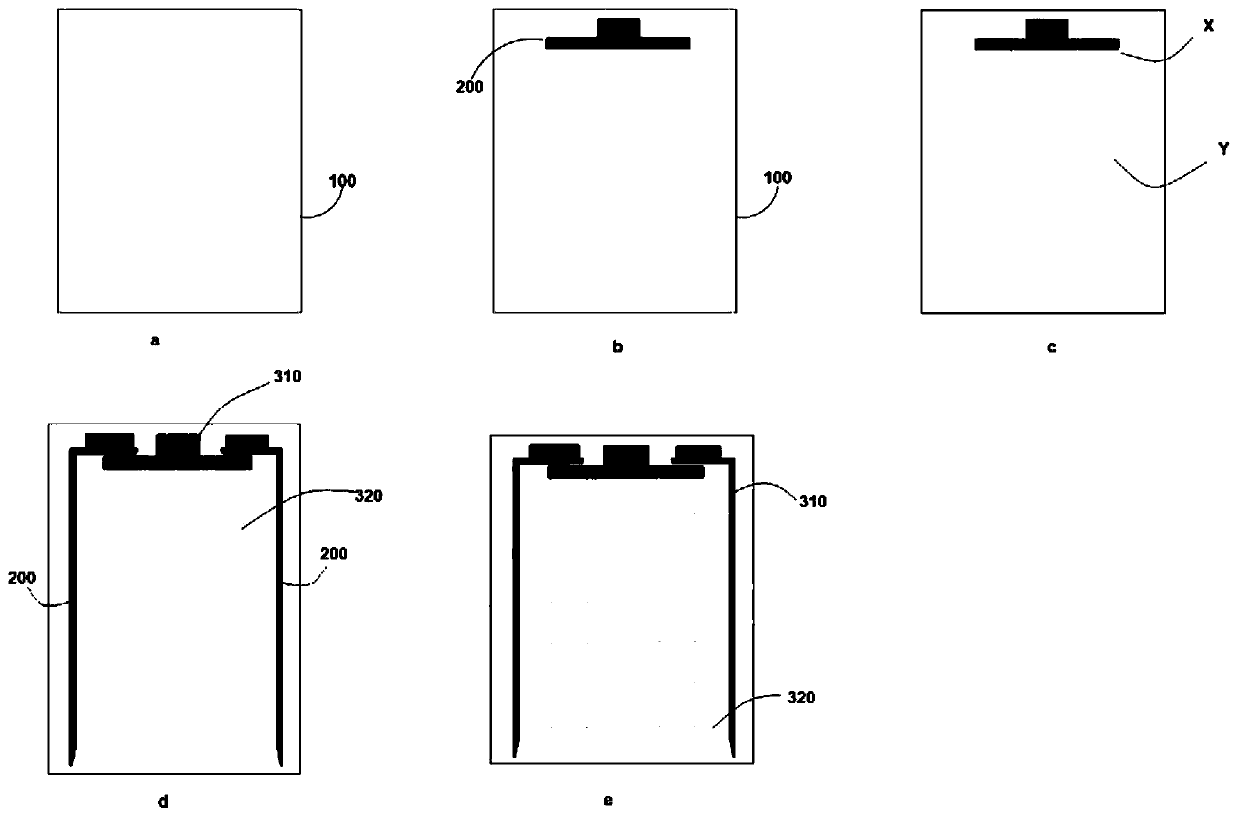

[0027] A method for preparing a touch sensor according to an embodiment of the present invention includes the following steps:

[0028] S101: Provide a substrate, the substrate is a transparent conductive flexible film with a conductive surface, and the conductive surface is silver nanowires or carbon nanotubes;

[0029] The type of substrate is not particularly limited, and a flexible transparent substrate commonly used in the art can be used. The substrate has a conductive surface and can be prepared by depositing a conductive layer on a flexible transparent substrate. For example, the substrate can be prepared by using commercially available CPI ( Colorless Polyimide, colorless polyimide), COP (Cyclo Olefin Polymer, cycloolefin polymer), etc., can deposit carbon nanotubes or nano silver wires on it to form a conductive coating.

[0030] By using silver nanowires or carbon nanotubes as the conductive surface, it is conducive to ink deposition, and then can process thinner me...

Embodiment 1-1~ Embodiment 1-4

[0069] Preparation:

[0070] (1) Provide a substrate, the substrate is a transparent conductive flexible film with two conductive surfaces, the two conductive surfaces are respectively the first conductive surface and the second conductive surface, and the film materials are as shown in Table 1;

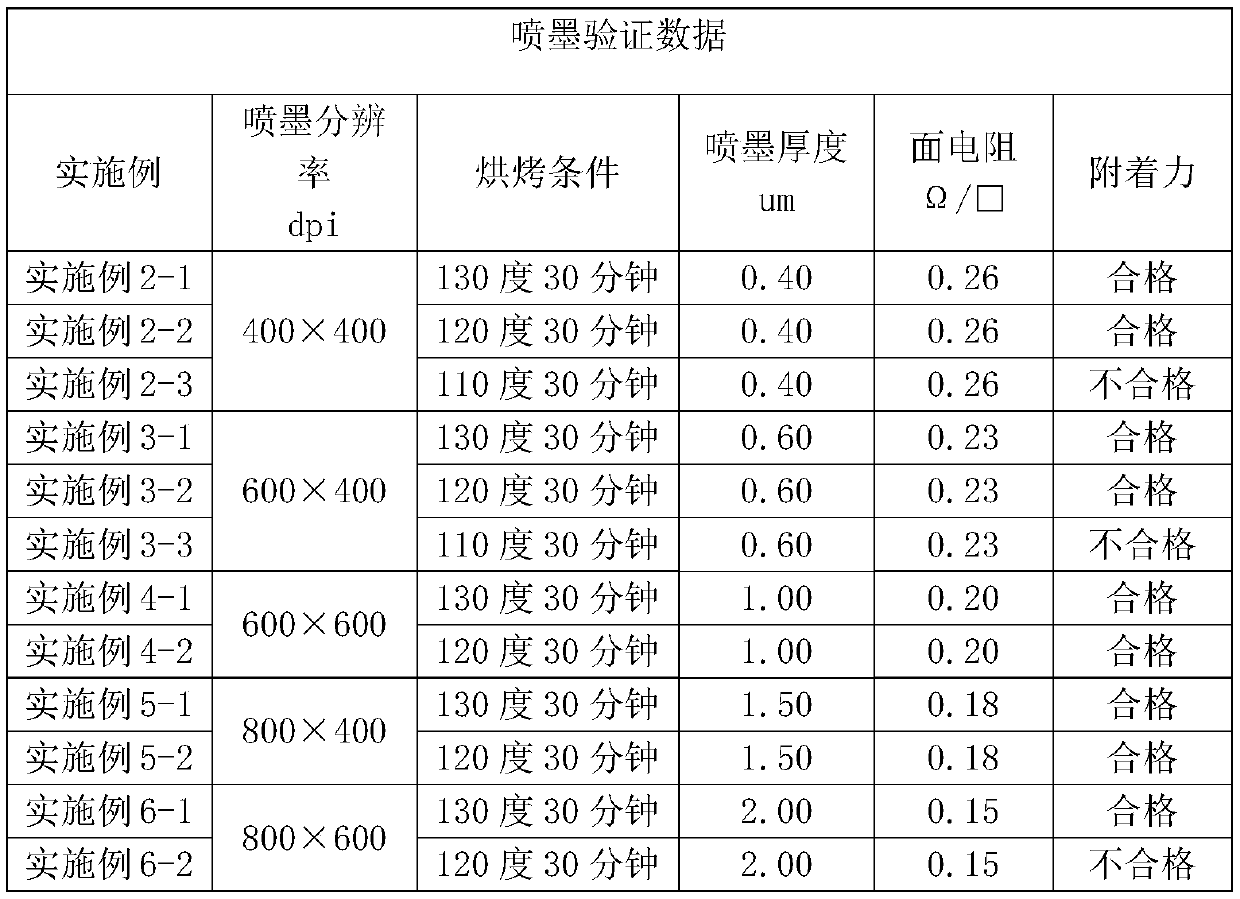

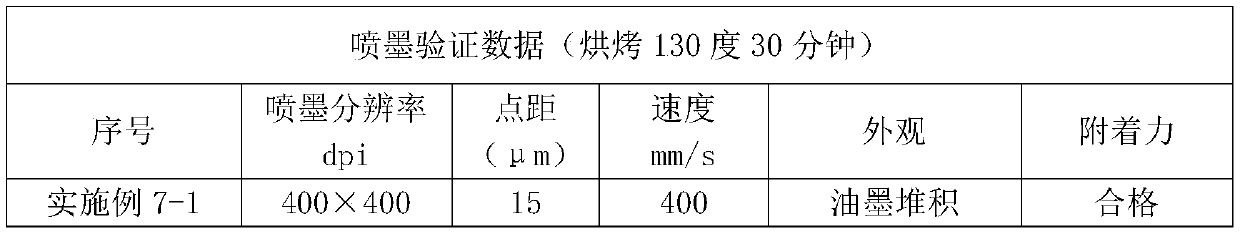

[0071] (2) Inkjet printing, containing nano-silver paste in the ink; inkjet printing ink to the specified area of the first conductive surface of the film (the distance between the nozzle and the film is 20 μm, the speed is 400mm / s, and the ink thickness is 0.4 μm), cured at 130°C for 30 minutes to form a conductive metal area, and the area of the substrate where no conductive metal area is formed is the touch area;

[0072] (3) Laser etching, using laser to etch the conductive metal area and the touch area to form the first graphic circuit, wherein the laser wavelength is 355nm, the laser energy is 0.25W, and the laser speed is 900mm / s;

[0073] (4) Protect the processed circui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com