ZnS/rGO/CuS nano-photocatalyst and preparation method thereof

A nano-photocatalyst and nano-particle technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as limiting hydrogen production efficiency, easy agglomeration, and small specific surface area of cadmium sulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

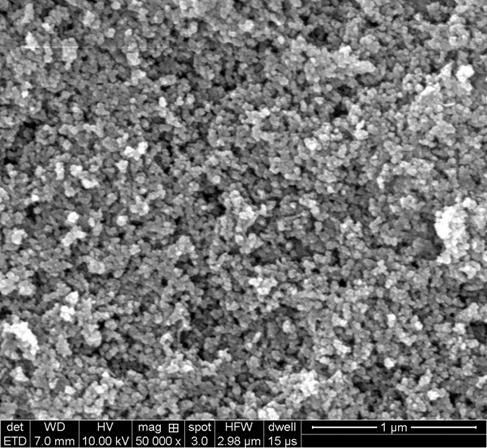

[0021] Weigh 1487.5 mg of zinc nitrate hexahydrate, 8210 mg of 2-methylimidazole, and 1.4 mg of graphene oxide in 25 ml of methanol solution to prepare a 0.2 mol / L GO-ZIF-8 solution, and then ultrasonically disperse for 5 min. The mixture was stirred at a stirring speed of 300 r / min at room temperature for 12 hours, and then centrifuged, and the supernatant was removed. The resulting product was GO-ZIF-8. Then add 225.39 mg of thioacetamide to GO-ZIF-8 and dissolve it in a mixed solution of 20 ml of absolute ethanol and 10 ml of deionized water to prepare a mixture of 0.075 mol / L GO-ZIF-8 and sulfur source Then disperse the solution ultrasonically for 5 minutes, and stir for 20 minutes at a stirring speed of 300r / min at room temperature. Put the above-mentioned mixture into a high temperature polytetrafluoroethylene reactor and react hydrothermally at 120 ℃ for 12 h. After natural cooling After centrifugal separation and drying in an oven at 50 ℃ for 6 h, the product obtained i...

Embodiment 2

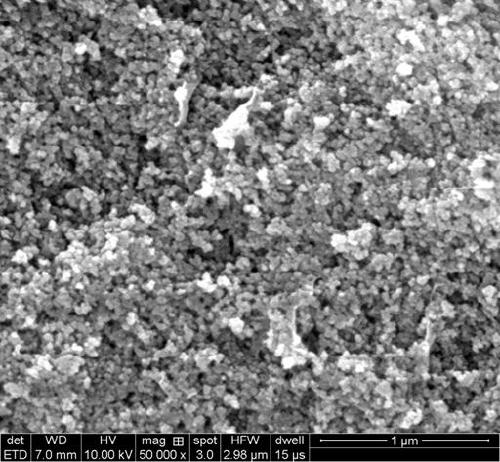

[0025] Weigh 2974.9 mg of zinc nitrate hexahydrate, 8210 mg of 2-methylimidazole, and 3.5 mg of graphene oxide in 25 ml of methanol solution to prepare a 0.4 mol / L GO-ZIF-8 solution, and then ultrasonically disperse for 10 min. The mixture was stirred at a stirring speed of 600 r / min at room temperature for 24 hours, and then centrifuged, the supernatant was removed, and washed with absolute ethanol and deionized water three times. The resulting product was GO-ZIF-8. Then add 225.39 mg of thioacetamide to GO-ZIF-8 and dissolve it in a mixed solution of 20 ml of absolute ethanol and 10 ml of deionized water to prepare a mixture of 0.15 mol / L of GO-ZIF-8 and sulfur source Then disperse the solution ultrasonically for 10 minutes and stir for 30 minutes at a stirring speed of 600 r / min at room temperature. Put the above solution into a polytetrafluoroethylene high-temperature reactor and react hydrothermally at 180 ℃ for 12 h. After natural cooling , Centrifugal separation, and dry...

Embodiment 3

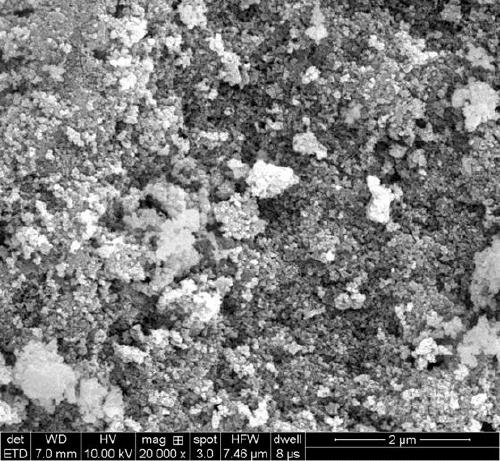

[0029] Weigh 4462.35 mg zinc nitrate hexahydrate, 8210 mg 2-methylimidazole, and 14 mg graphene oxide in 25 ml methanol solution to prepare a 0.6 mol / L GO-ZIF-8 solution, and then ultrasonically disperse for 20 min. It was stirred for 10 h at a stirring speed of 800 r / min at room temperature, and then centrifuged, the supernatant was removed, and washed with absolute ethanol and deionized water for three times. The resulting product was GO-ZIF-8. Then add 225.39 mg of thioacetamide to GO-ZIF-8 and dissolve it in a mixed solution of 20 ml of absolute ethanol and 10 ml of deionized water to prepare a mixture of 0.225 mol / L of GO-ZIF-8 and sulfur source Then disperse the solution ultrasonically for 20 minutes and stir for 20 minutes at a stirring speed of 800 r / min at room temperature. Put the above solution into a high-temperature polytetrafluoroethylene reactor and react hydrothermally at 240 ℃ for 12 h. After natural cooling , Centrifugal separation, and drying in a 80 ℃ oven f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com