Anode of high-energy lithium/thionyl chloride battery and preparation method of anode

A thionyl chloride battery, high-energy technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve problems such as increasing internal resistance, reducing battery load capacity, etc., to increase reaction sites, increase capacity and working voltage. , the effect of increasing the capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

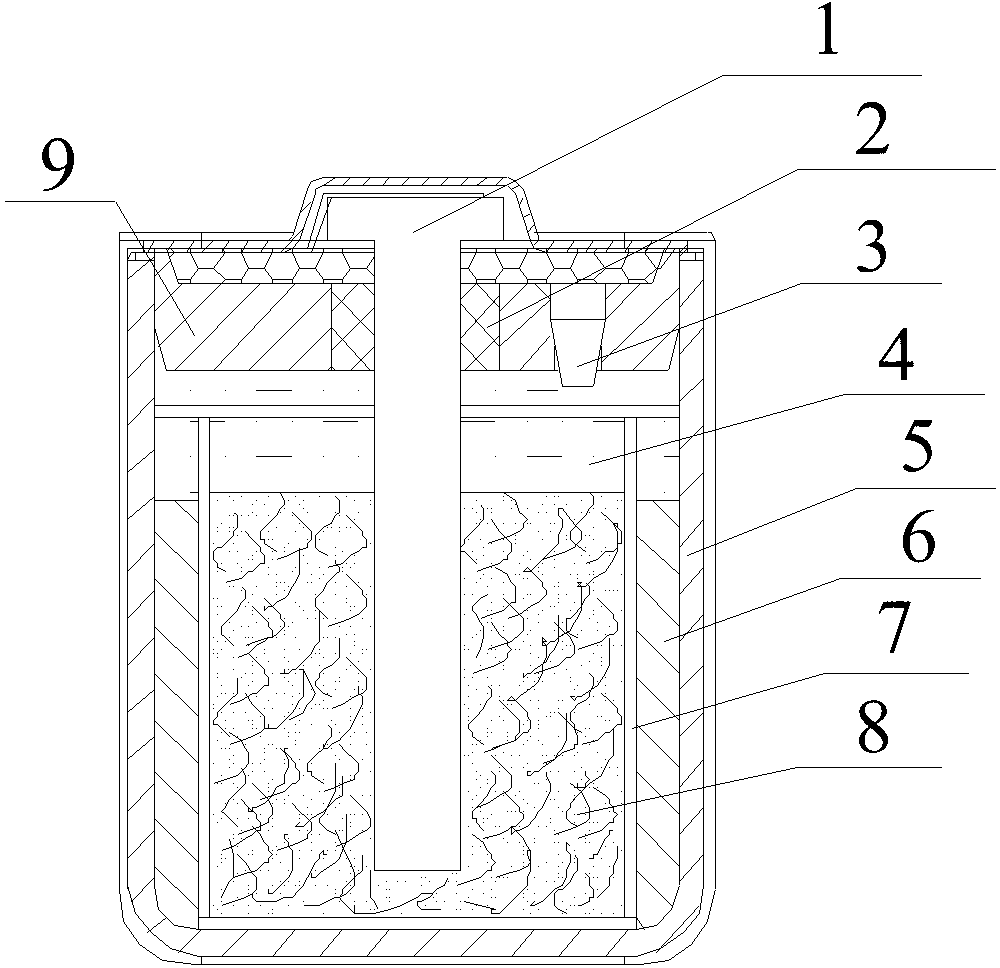

Image

Examples

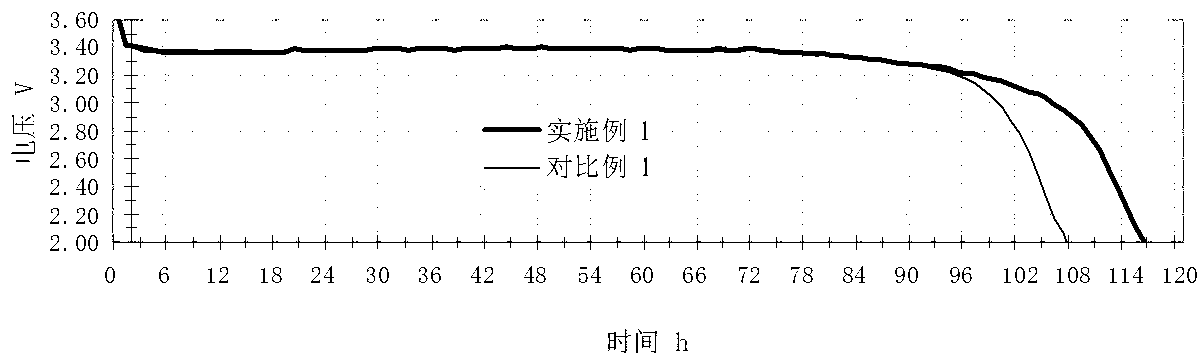

Embodiment 1

[0029] This embodiment provides a positive electrode of a high-energy lithium / thionyl chloride battery. The positive electrode is composed of 10 g of acetylene black, 1.2 g of polytetrafluoroethylene emulsion, 57 g of absolute ethanol, and 0.8 g of conductive carbon fiber. The diameter of carbon fiber is 7μm~11μm, and the length is 1~3mm. PTFE emulsion is 60% water emulsion. Acetylene black was battery grade, and absolute ethanol was analytically pure.

[0030] The present embodiment also provides the preparation method of the positive electrode of high-energy lithium / thionyl chloride battery, and it comprises the following steps:

[0031] 1) Mixing powder: Mix 10g acetylene black, 1.2g polytetrafluoroethylene emulsion, 57g absolute ethanol, and 0.8g conductive carbon fiber to form a paste;

[0032] 2) Carbon bag molding: Extrude the above paste into a cylinder with an extruder and a molding die;

[0033] 3) Initial drying: Dry the obtained cylinder at a drying temperature ...

Embodiment 2

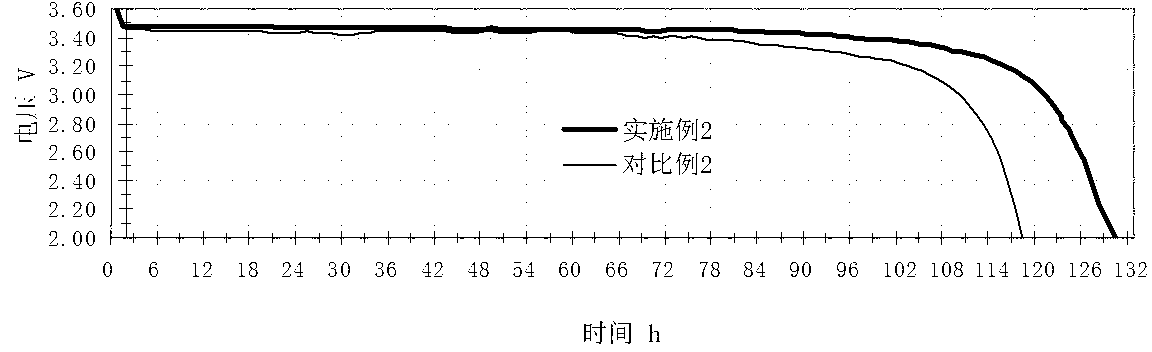

[0041] Embodiment 2 is substantially the same as Embodiment 1, except that the positive electrode of this embodiment is composed of 10 g of acetylene black, 1.0 g of polytetrafluoroethylene emulsion, 55 g of absolute ethanol, and 0.9 g of conductive carbon fiber. Other preparation methods are the same as in Example 1, and a high-energy lithium / sub-battery (model ER14505) is produced.

[0042] The discharge capacity test of the ER14505 high-energy lithium / sub-battery was performed at room temperature with a constant resistance of 200Ω to 2.0V. The results are as follows: image 3 . Depend on image 3 It can be seen that the discharge capacity of the ER14250 high-energy lithium / sub-battery is 2.11Ah.

Embodiment 3

[0044] Embodiment 3 is substantially the same as Embodiment 1, except that the positive electrode of this embodiment is composed of 10 g of acetylene black, 0.9 g of polytetrafluoroethylene emulsion, 56 g of absolute ethanol, and 1.0 g of conductive carbon fiber. Other preparation methods are the same as in Example 1, and a high-energy lithium / sub-battery (model ER26500) is produced.

[0045] The discharge capacity test of the ER26500 high-energy lithium / sub-battery was carried out at room temperature at a constant current of 50 mA to 2.0V. The results are as follows: Figure 4 . Depend on Figure 4 It can be seen that the discharge capacity of the ER26500 high-energy lithium / sub-battery is 6.4Ah.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com