Method for preparing beta-type aluminum hydroxide

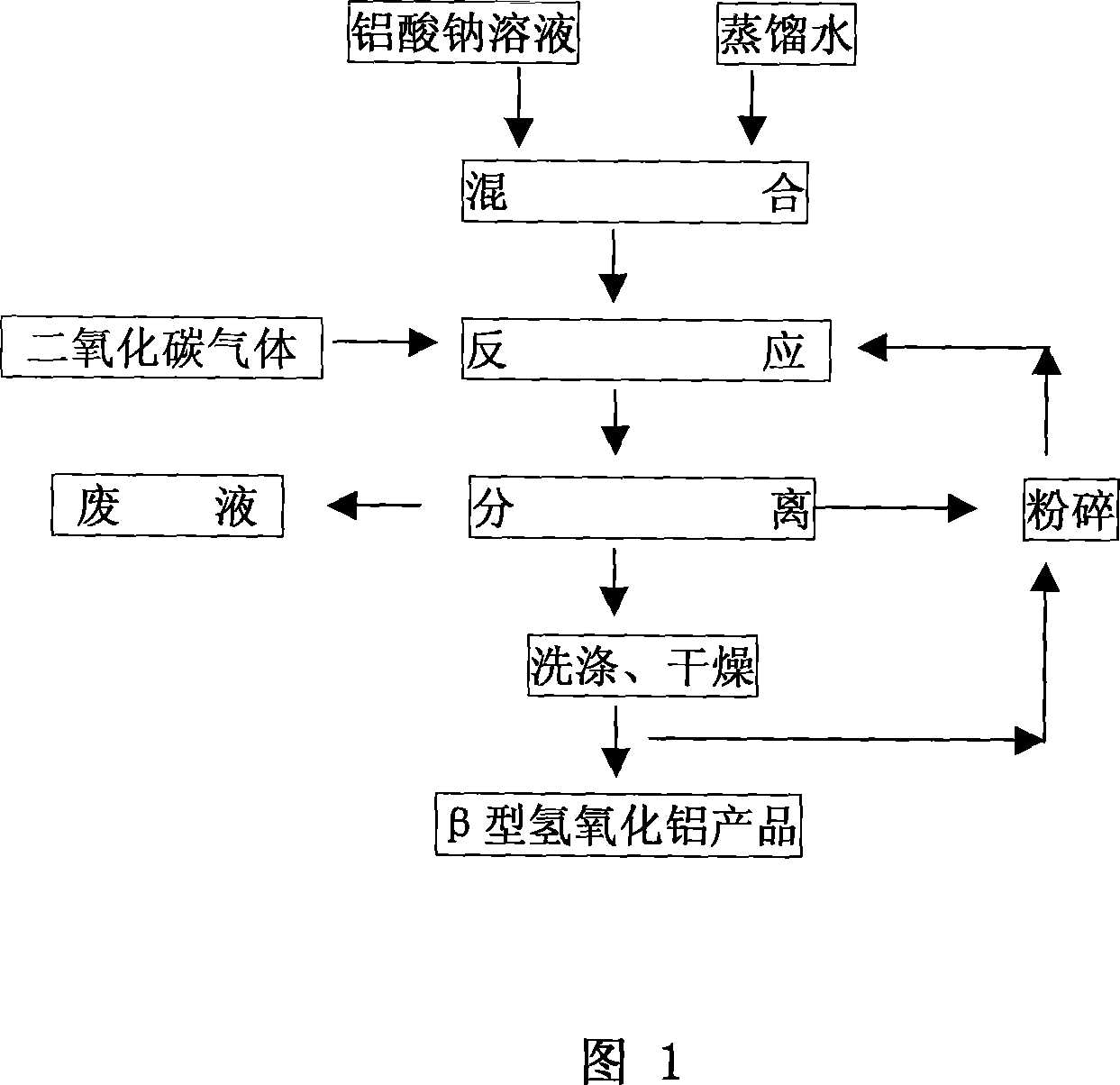

A technology of aluminum hydroxide and aluminum oxide, which is applied in the field of preparation of β-type aluminum hydroxide, can solve the problems of low concentration of aluminum oxide in sodium aluminate solution, difficulty in product particle size control, and complicated decomposition system, so as to facilitate industrial implementation, The operation process is easy to master and the production process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

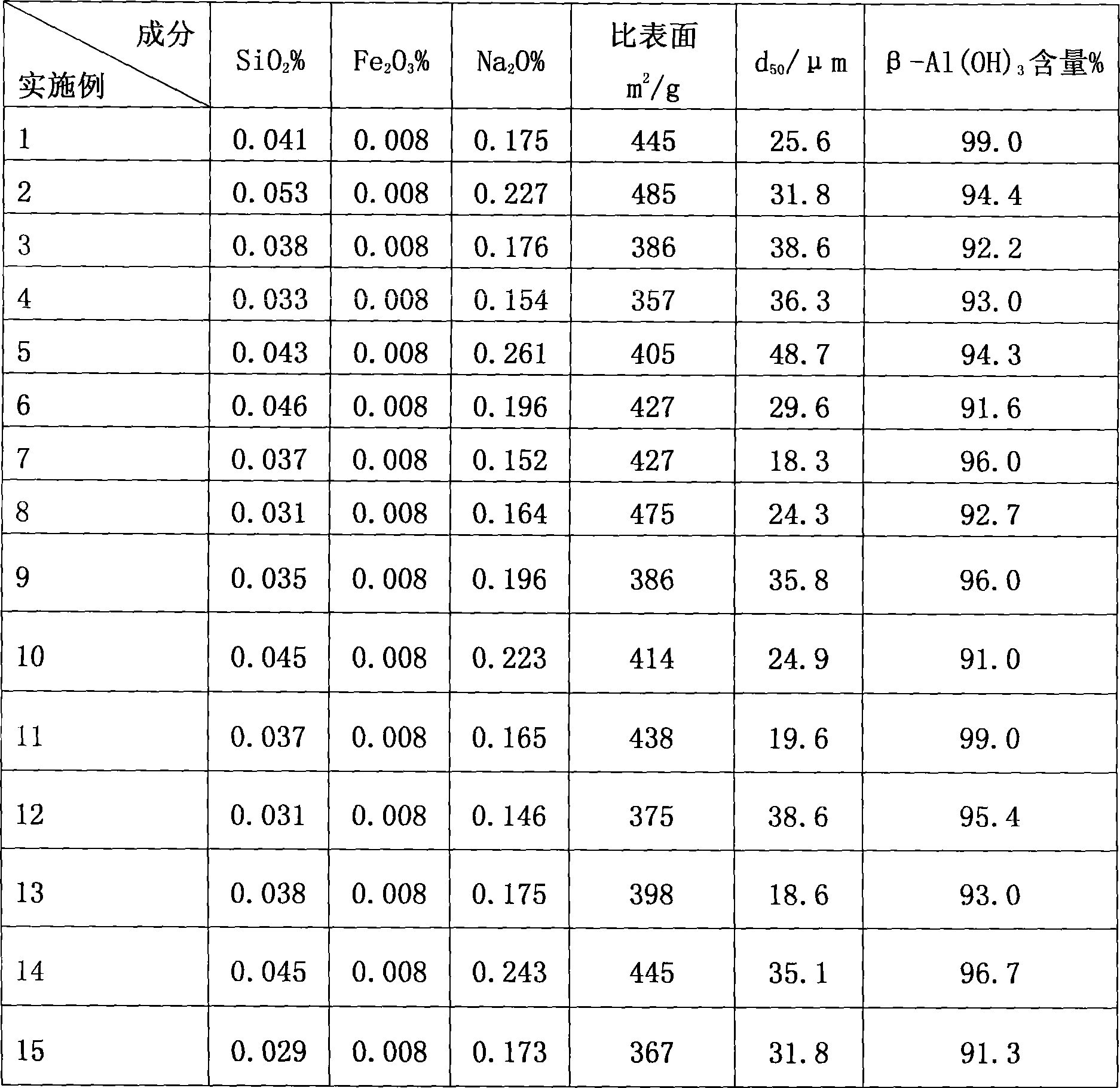

[0018] Sodium aluminate refined solution obtained by soda lime sintering method, its composition is alumina content 110g / l, αk1.44, dilute with distilled water to alumina content 50.3g / l, add 7kg / m 3 β-type aluminum hydroxide seeds of the solution, particle size d of β-type aluminum hydroxide seeds 50 2.5μm, through the concentration of 36% carbon dioxide gas, ventilation speed of 40m 3 / hour·m 3 solution, decompose for 70 minutes, the decomposition rate is 90%, and the decomposed slurry is subjected to liquid-solid separation, washing and drying to obtain β-type aluminum hydroxide with a purity of 99.0% and a specific surface area of 445m 2 / g, d 50 is 25.6 μm, and its physical and chemical results are shown in Table 1.

Embodiment 2

[0020] Sodium aluminate refined solution obtained by soda lime sintering method, its composition is alumina content 110g / l, αk1.44, dilute with distilled water to alumina content 50.3g / l, add 1kg / m 3 β-type aluminum hydroxide seeds of the solution, particle size d of β-type aluminum hydroxide seeds 50 0.5μm, through the concentration of 36% carbon dioxide gas, the ventilation speed is 30m 3 / hour·m 3 solution, decompose for 90 minutes, the decomposition rate is 93%, and the decomposed slurry is subjected to liquid-solid separation, washing and drying to obtain β-type aluminum hydroxide with a purity of 94.4% and a specific surface area of 485m 2 / g,d 50 is 31.8 μm, and its physical and chemical results are shown in Table 1.

Embodiment 3

[0022] Sodium aluminate refined solution obtained by soda lime sintering method, its composition is alumina content 110g / l, αk1.44, dilute with distilled water to alumina content 50.3g / l, add 4kg / m 3 β-type aluminum hydroxide seeds of the solution, particle size d of β-type aluminum hydroxide seeds 50 10.6μm, through the concentration of 36% carbon dioxide gas, ventilation speed of 40m 3 / hour·m 3 solution, decompose for 70 minutes, the decomposition rate is 90%, and the decomposed slurry is subjected to liquid-solid separation, washing and drying to obtain β-type aluminum hydroxide with a purity of 92.2% and a specific surface area of 386m 2 / g,d 50 is 38.6 μm, and its physical and chemical results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com