Patents

Literature

493 results about "Cyclohexanone oxime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyclohexanone oxime is an organic compound containing the functional group oxime. This colorless solid is an important intermediate in the production of nylon 6, a widely used polymer.

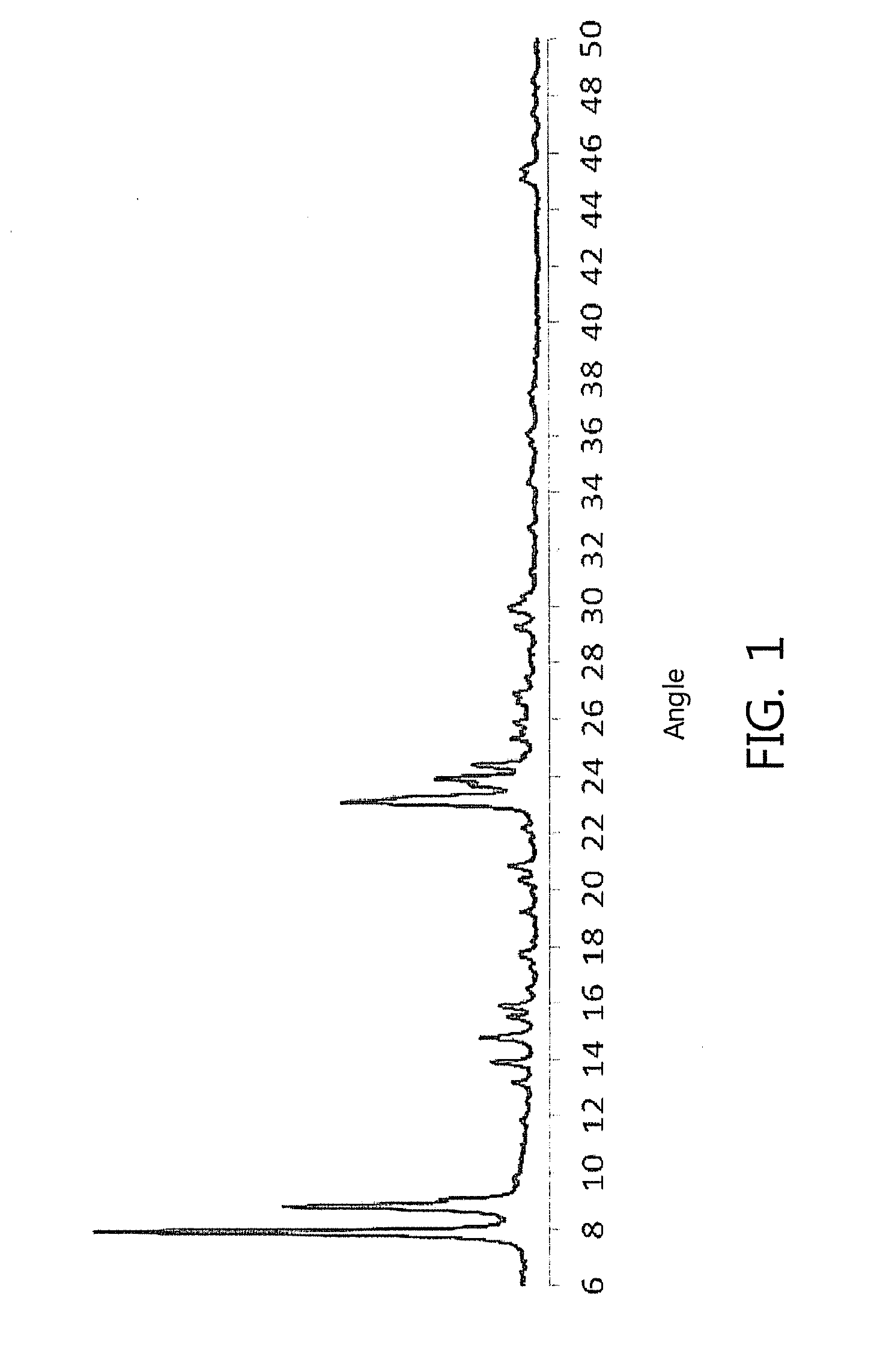

Method for preparing catalyst of containing MFI structured molecular sieve

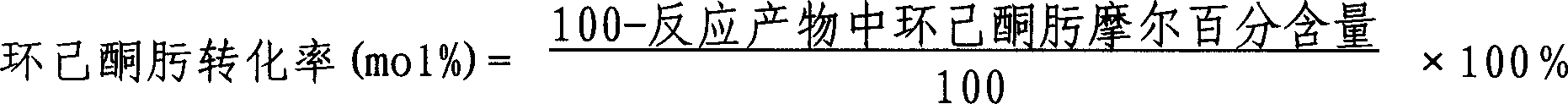

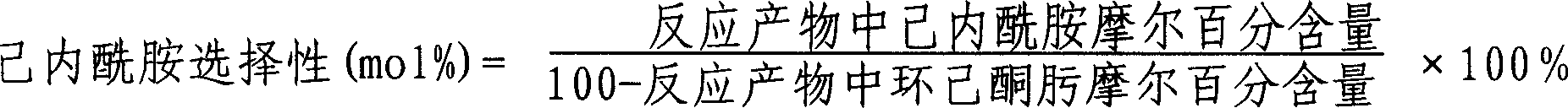

ActiveCN1600428APromote regenerationImprove conversion rateLactams preparationMolecular sieve catalystsBeckmann rearrangementMolecular sieve

A MFI-molecular sieve catalyst for preparing caprolactam from cyclohexanone oxime by gas-phase Beckmann rearrangement is prepared through proportionally mixing MFI-molecular sieve with alkaline silica gel, shaping, drying and calcining. It has high conversion rate and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing epsi-caprolactam

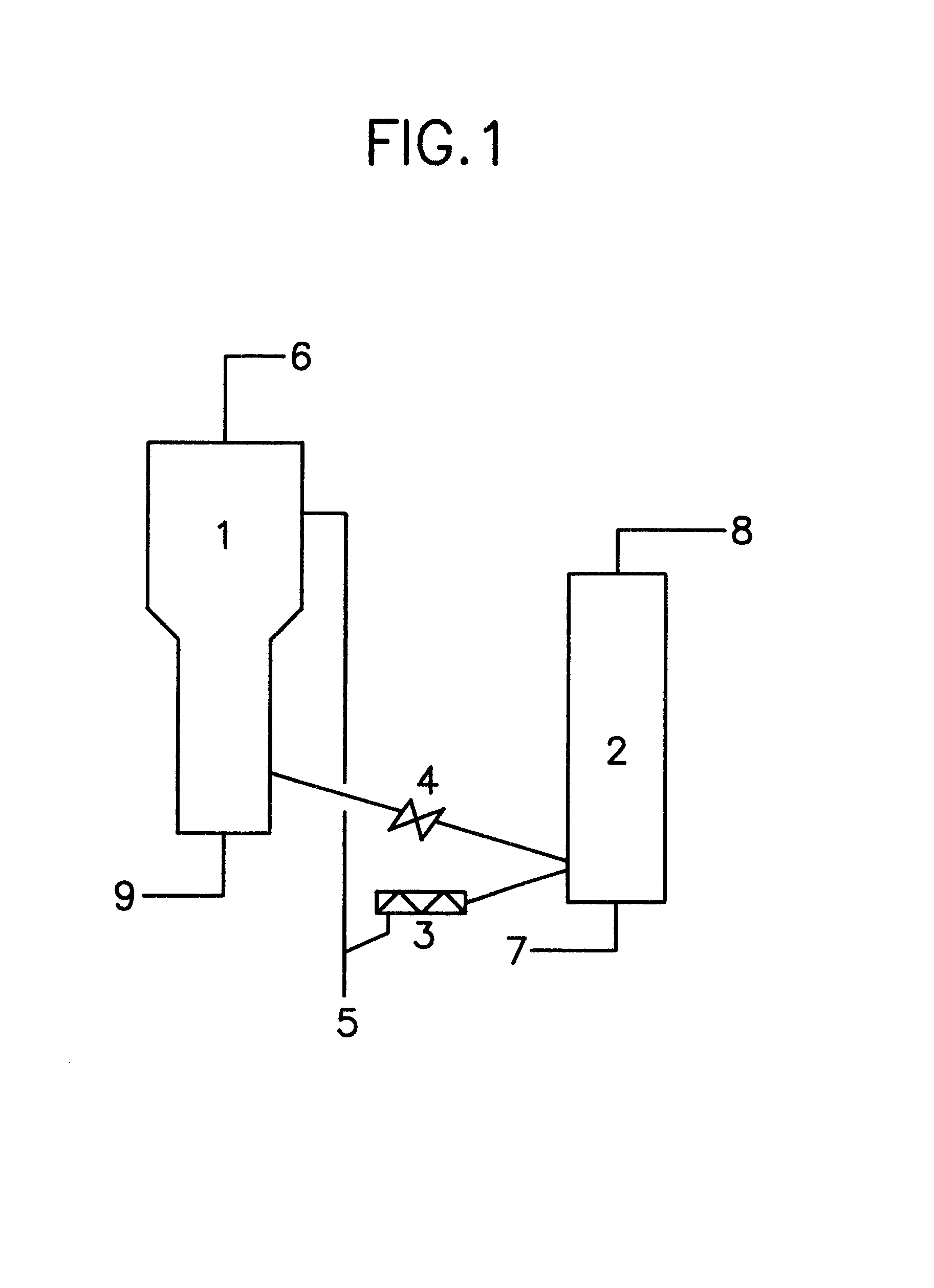

InactiveUS6265574B1High yieldSteadily producedLactams preparationMolecular sieve catalystsBeckmann rearrangementFluidized bed

A process for producing epsi-caprolactam is provided which comprises the steps of subjecting cyclohexanone oxime to a gaseous phase Beckmann rearrangement reaction in a fluidized bed system using a solid catalyst and re-generating the catalyst, wherein said process comprises a step of treating the catalyst with an oxygen-containing gas at an elevated temperature in a re-generation step so that the nitrogen content of the catalyst falls within a range of 10 ppm to 2,500 ppm on its way to the reaction step from the re-generating step. According to the present invention, epsi-caprolactam is produced with a high conversion or a high selectivity without interrupting the rearrangement reaction or the re-generation step.

Owner:SUMITOMO CHEM CO LTD

Method for producing cyclohexanone oxime

InactiveUS6828459B2High yieldOrganic compound preparationOximes preparationCyclohexanone oximeTitanium

A cyclohexanone oxime is produced in a method comprising the step of reacting a cyclohexanone with a hydrogen peroxide and an ammonia in the presence of a titanium silicate and a silicon compound other than the titanium silicate. In the method, the reaction is conducted with suppressing the inactivation of the titanium silicate as a catalyst, to produce the cyclohexanone oxime with a high yield.

Owner:SUMITOMO CHEM CO LTD

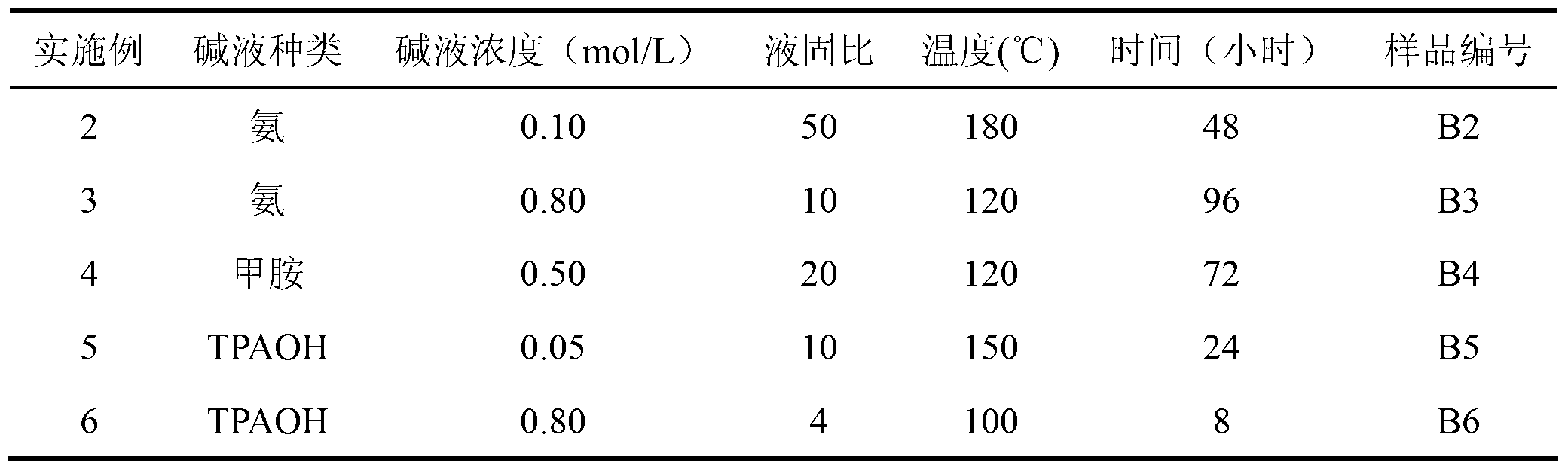

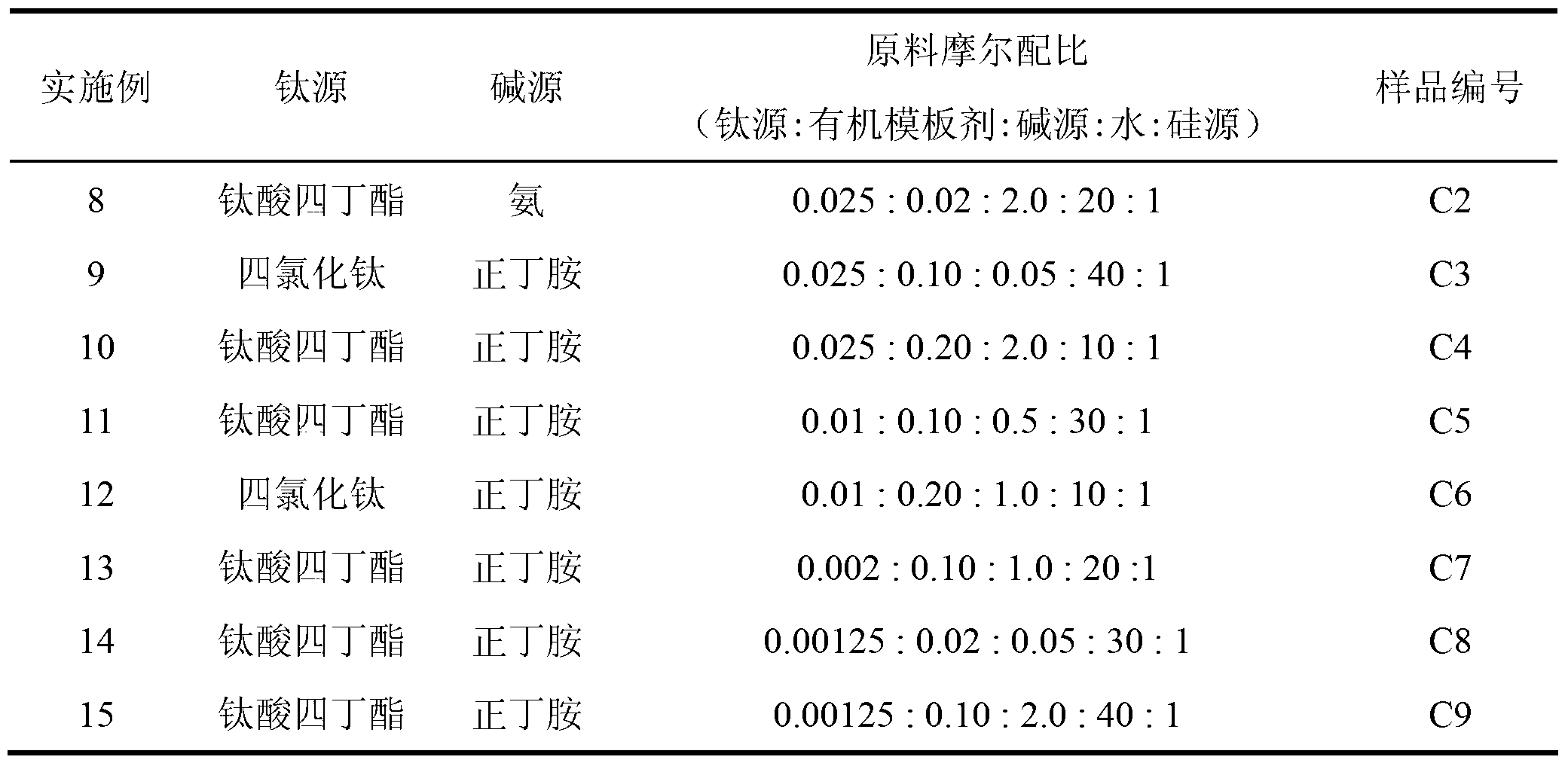

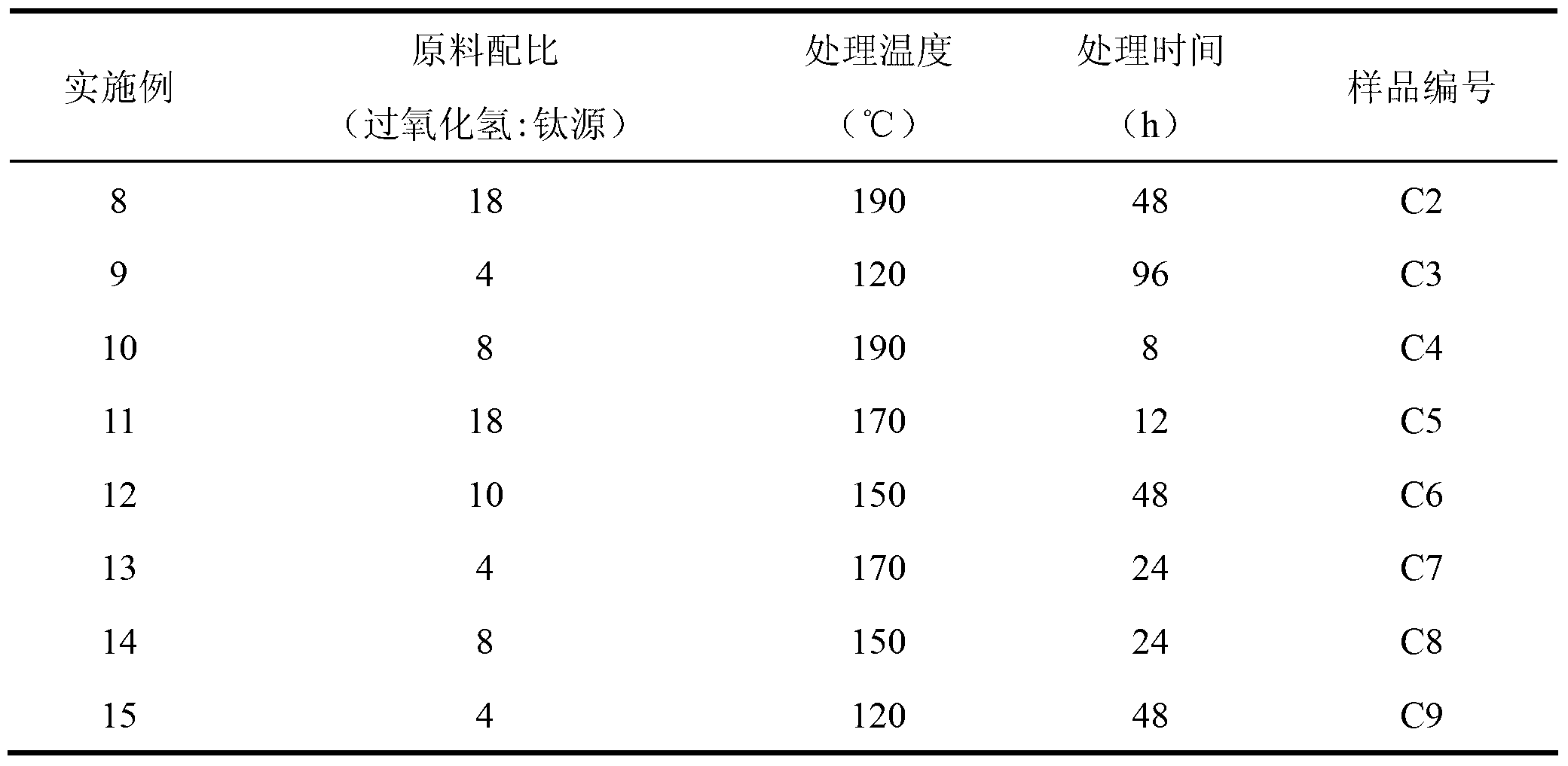

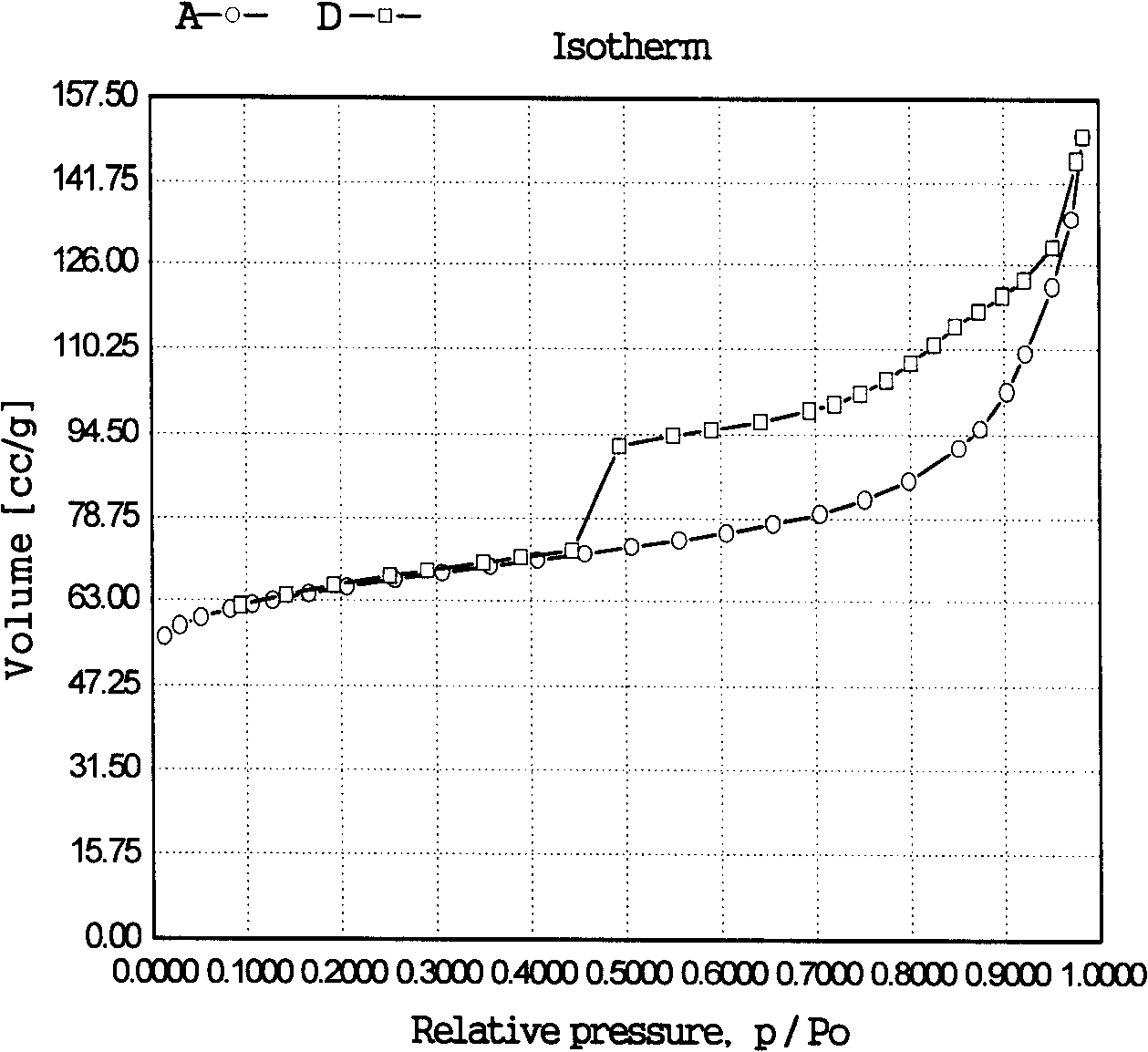

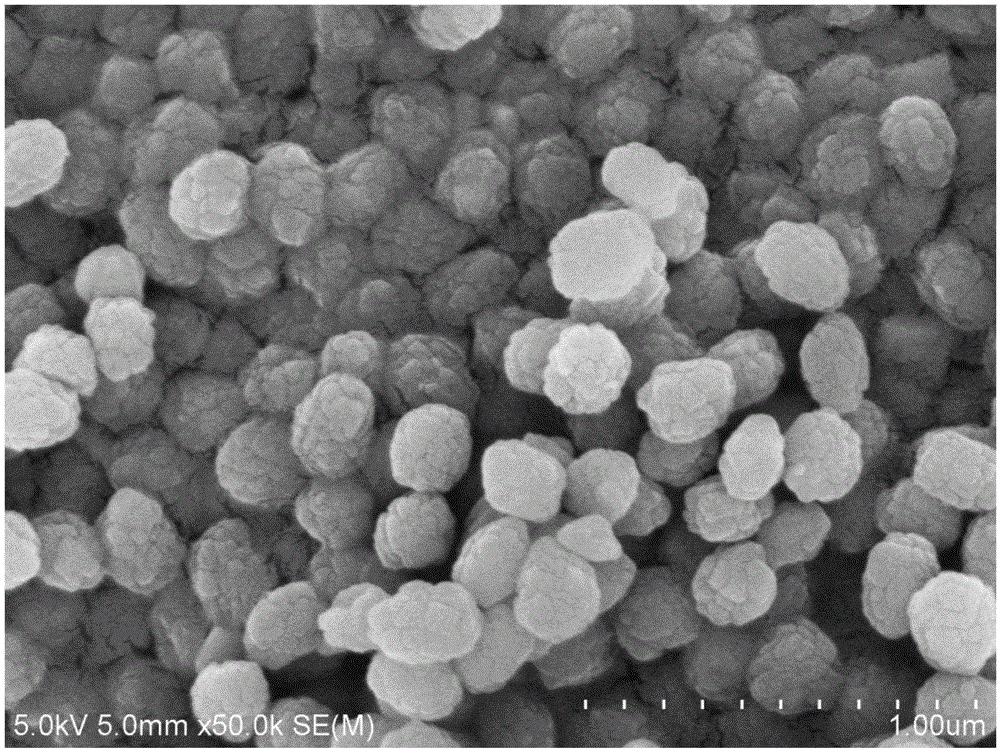

Preparation method of titanium silicalite molecular sieve catalyst with high performance

ActiveCN103214001AImprove performanceCrystalline aluminosilicate zeolitesMolecular sieveCyclohexanone oxime

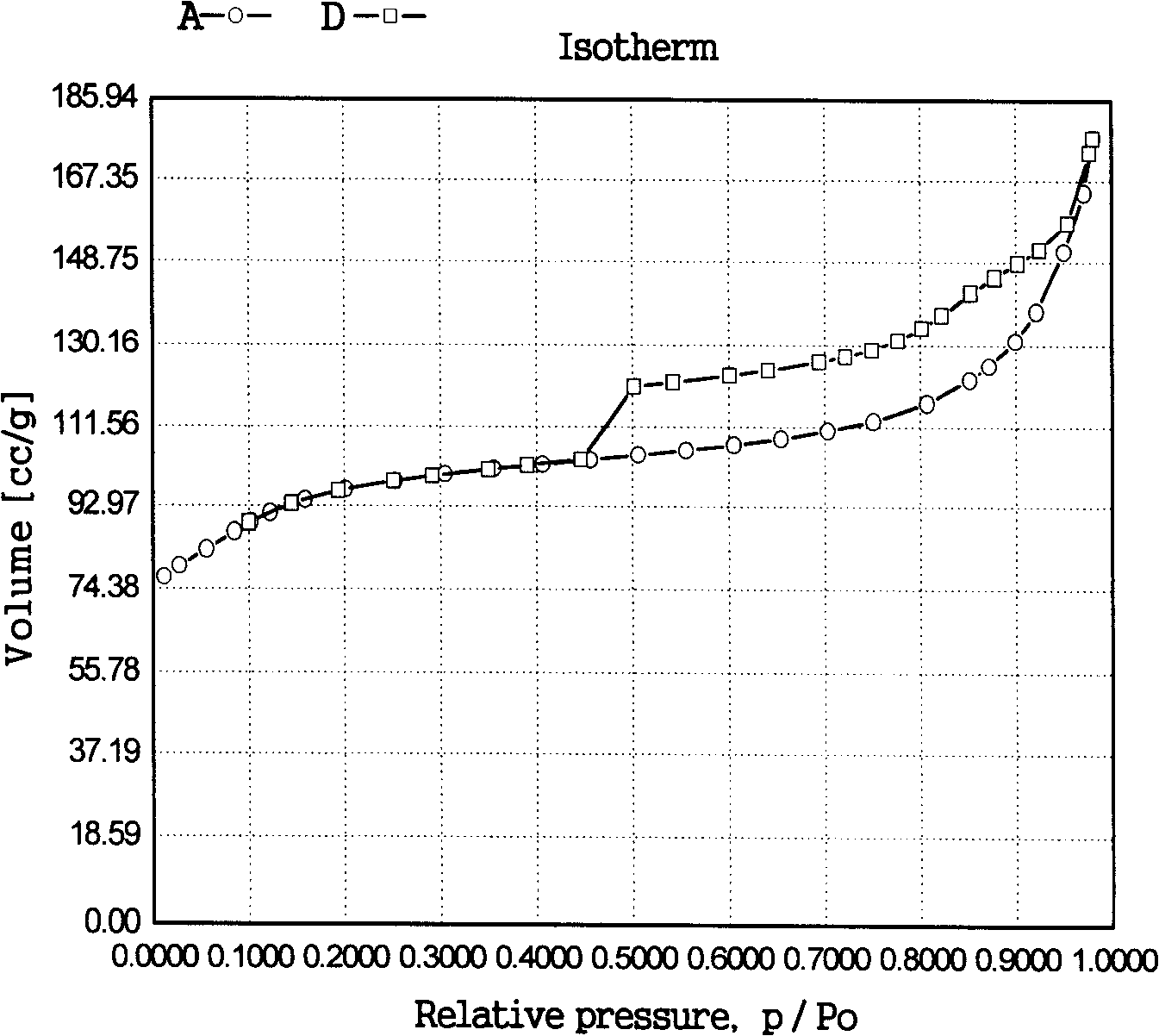

The invention relates to a preparation method of a titanium silicalite molecular sieve catalyst with high performance. The preparation method comprises the following steps of: (1) by taking a silicon source, a titanium source, an organic template and an alkali source as raw materials, synthesizing a micron-sized titanium silicalite molecular sieve A by using a hydrothermal crystallization method; (2) carrying out modification treatment on the titanium silicalite molecular sieve A by using an alkaline solution to obtain a modified molecular sieve B; and (3) preparing a titaniferous modification solution containing the titanium source, the organic template and the alkali source, and carrying out modification treatment on the modified molecular sieve B to obtain the titanium silicalite molecular sieve catalyst C with high performance. By using the preparation method, the problems that the titanium silicalite molecular sieve catalyst prepared in the prior art is high in cost, low in catalytic activity and poor in stability are mainly solved, and the performance of the titanium silicalite molecular sieve catalyst in cyclohexanone-oxime reaction is remarkably improved.

Owner:SHANGHAI NOVEL CHEM TECH

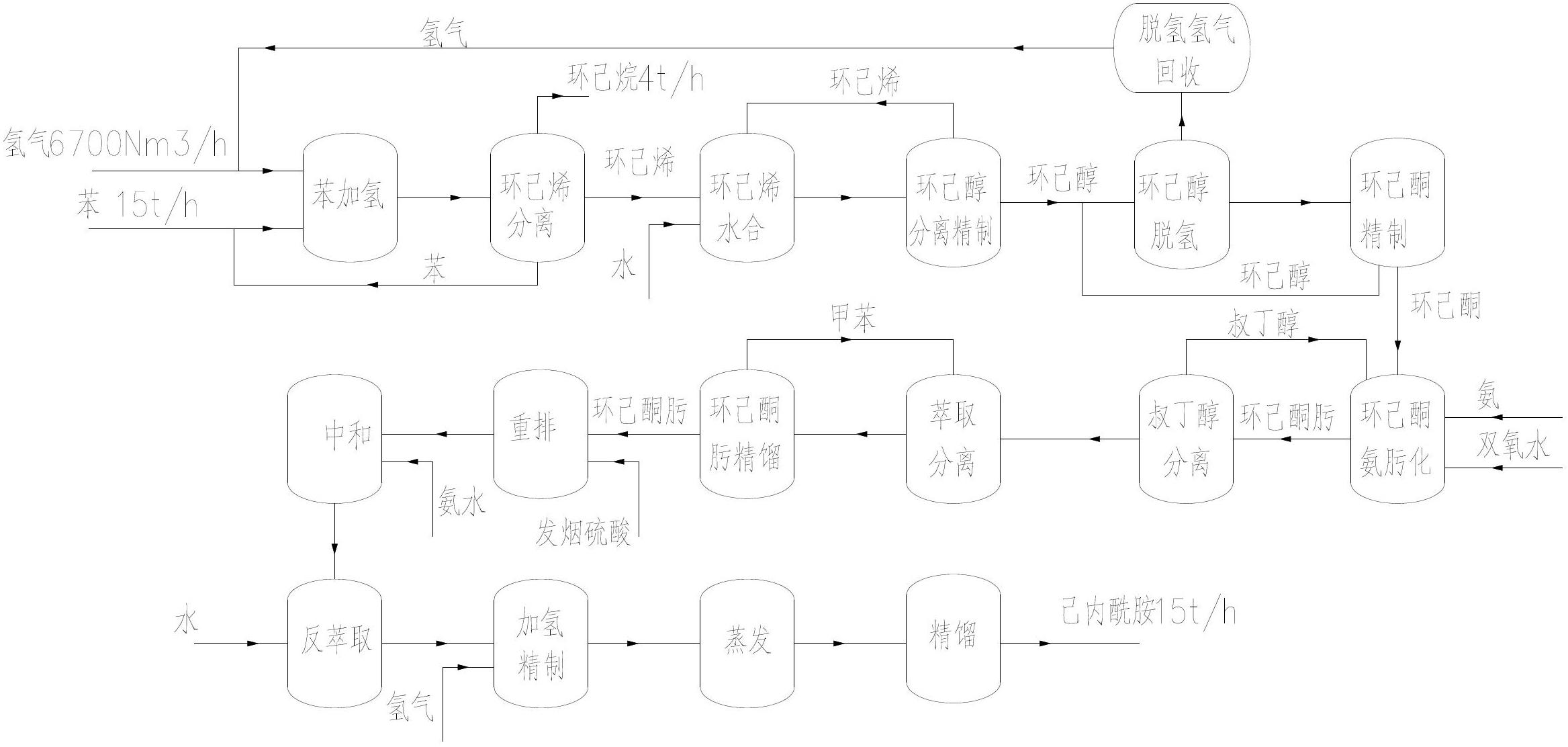

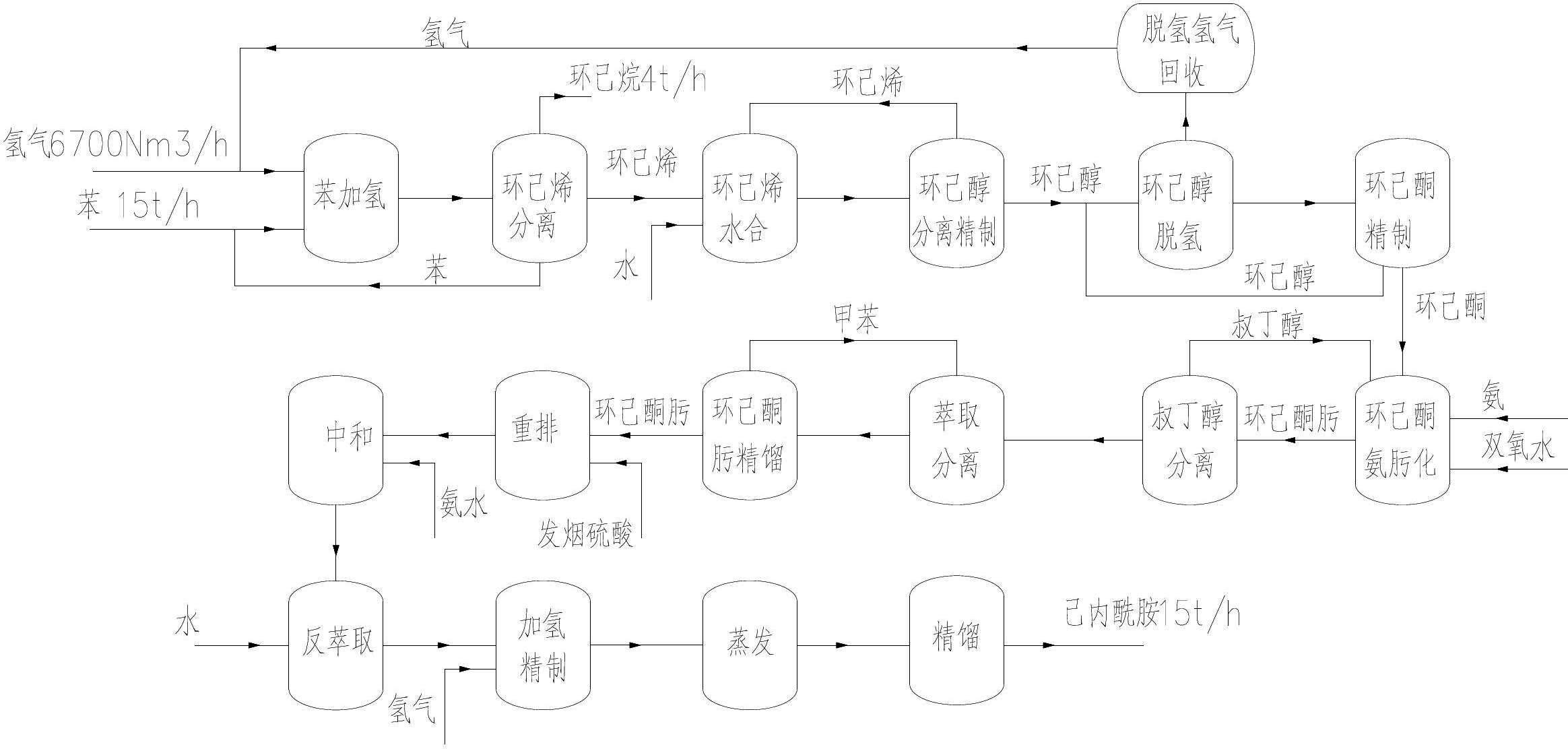

Method for producing caprolactam by taking high-purity benzene as raw material

ActiveCN102675176AAvoid it happening againQuality improvementLactams preparationHydration reactionCyclohexene

The invention provides a method for producing caprolactam by taking high-purity benzene as a raw material, and the method comprises the following steps of: A. preparing cyclohexene from the raw material benzene through hydrogenation; B. separating and purifying cyclohexene; C. carrying out hydration on the cyclohexene for preparing cyclohexanol; D. separating and purifying cyclohexanol; E. carrying out dehydrogenation on cyclohexanol for preparaing cyclohexanone; F. refining cyclohexanone; G. carrying out oximation on cyclohexanone so as to prepare cyclohexanone-oxime; H. refining cyclohexanone-oxime; I. carrying out rearrangement on refined cyclohexanone-oxime so as to prepare caprolactam; and J. refining caprolactam, wherein the high-purity benzene is adopted as a raw material, so that the purity of benzene is more than 99.95%, the sulphur content is less than 5ppm, and the methylbenzene is not more than 100ppm. The method has the beneficial effects that the high-purity benzene is adopted as a raw material, so that the impurity is less, and the product quality is high; the raw material is high in comprehensive utilization rate and low in hydrogen consumption; and the mass of the raw material and intermediate products generated in all the steps of reaction can be strictly controlled, so that the direct commercial value of the intermediate products is fully exerted, and the optimal quality of the product caprolactam can be reached.

Owner:CHINA TIANCHEN ENG +3

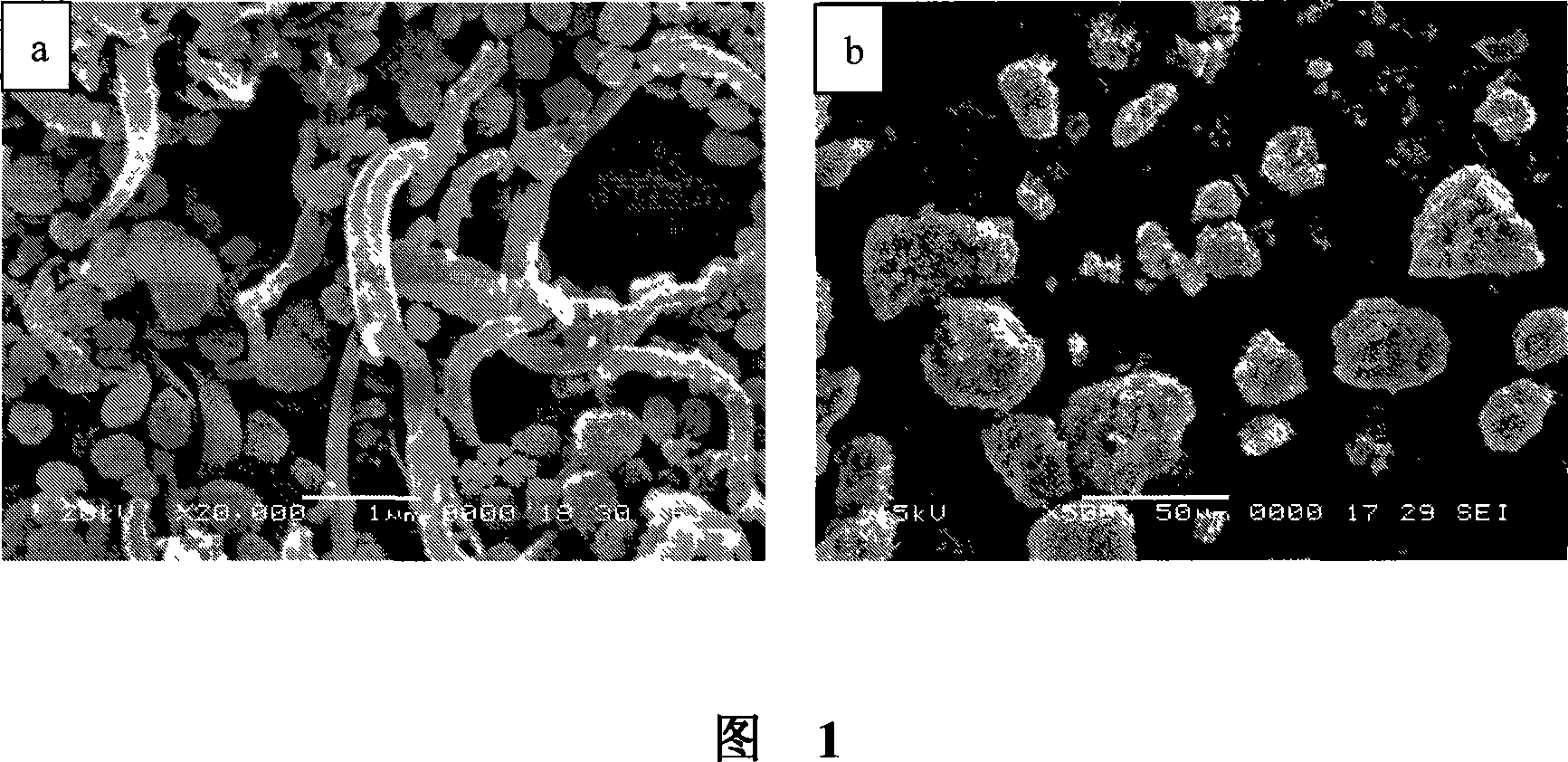

Process for preparing titanium-silicon molecular sieve/nano-carbon fiber fiber composite catalyst

InactiveCN101199941ADoes not affect diffusionDoes not affect catalytic activityMolecular sieve catalystsMicro nanoFiber

The invention relates to a preparation method of composite catalyst of the titanium silicate molecular sieve and the nano-carbon fiber. The composite catalyst of the titanium silicate molecular sieve and the nano-carbon fiber prepared by the method of the invention has strong bonding force between the active component of the titanium silicate molecular sieve and the nano-carbon fiber. Comparing with the industrial micro-nano TS-1 powder (100-500nm), the filtering quality is significantly improved. In the course of using the TS-1 catalyst, the problem of the solution dispersion and separation can be solved; the method is simple and the application range is wide. The catalytic performance of the made composite catalyst is excellent, and can be used for the cyclohexanone ammoximation, the conversion rate of the cyclohexanone and the cyclohexanone oxime selectivity can both reach over 98 percent.

Owner:EAST CHINA UNIV OF SCI & TECH

S-1 full-silicon molecular sieve and preparation method thereof as well as application of S-1 full-silicon molecular sieve in caprolactam preparation

The invention discloses an S-1 full-silicon molecular sieve and a preparation method thereof as well as application of the S-1 full-silicon molecular sieve in caprolactam preparation. The S-1 full-silicon molecular sieve is prepared by the method comprising the following steps: (1) synthesizing a tetrapropylammonium hydroxide template agent; and (2) synthesizing a molecular sieve: carrying out a reaction on tetrapropylammonium hydroxide liquor and tetraethoxysilane and ethanol, filtering, washing with deionized water, drying reaction liquid, roasting, so as to obtain molecular sieve raw powder; adding silica sol, polyethylene glycol 2000, and stronger ammonia water, sesbania powder and activated carbon powder in the molecular sieve raw powder, kneading in a kneader, then carrying out extrusion; roasting, immersing the roasted product in a NH3-NH3NO3 mixing solution and a hydrofluoric acid solution respectively, washing with deionized water, drying, roasting again so as to obtain the S-1 full-silicon molecular sieve. In the invention, the template agent is cheap; the conversion rate of the cyclohexanone and selectivity of the caprolactam are extremely high; a catalyst can be easily and fast regenerated; and the use of concentrated sulphuric acid is avoided, thus the S-1 full-silicon molecular sieve and the preparation method thereof are environment-friendly.

Owner:CHINA TIANCHEN ENG +1

Process for preparing caprolactam by cyclohexanone-oxime gas phase rearrangement

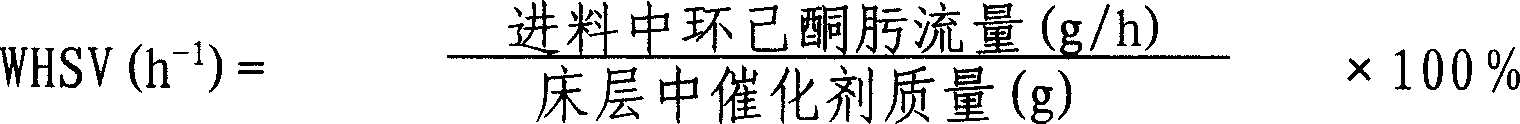

ActiveCN1621405AHigh yieldReduce consumptionLactams preparationBeckmann rearrangementMolecular sieve

The process of preparing caprolactam with cyclohexanone oxime includes the vapor Beckmann rearrangement reaction of cyclohexanone oxime inside one first fixed bed reactor in the presence of MFI structure molecular sieve catalyst; the decomposition and conversion of the reaction side product O-alkyl-epsilon-caprolactim into caprolactam inside one second fixed bed reactor in the presence of MFI structure molecular sieve catalyst and water; and the separation and purification of the reaction effluent. Compared with single vapor Beckmann rearrangement reaction process of cyclohexanone oxime, the present invention has 1-3 % raised caprolactam yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

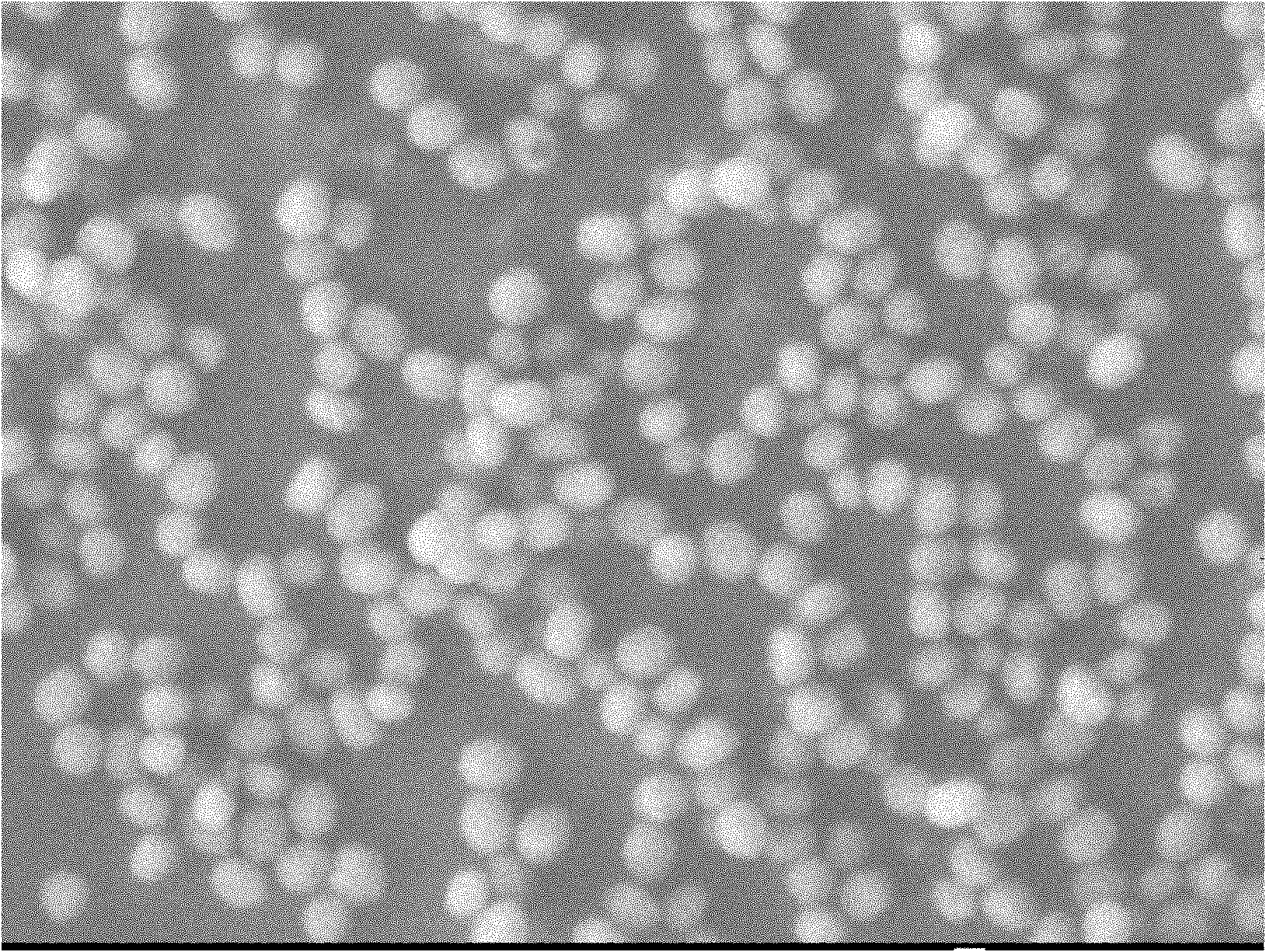

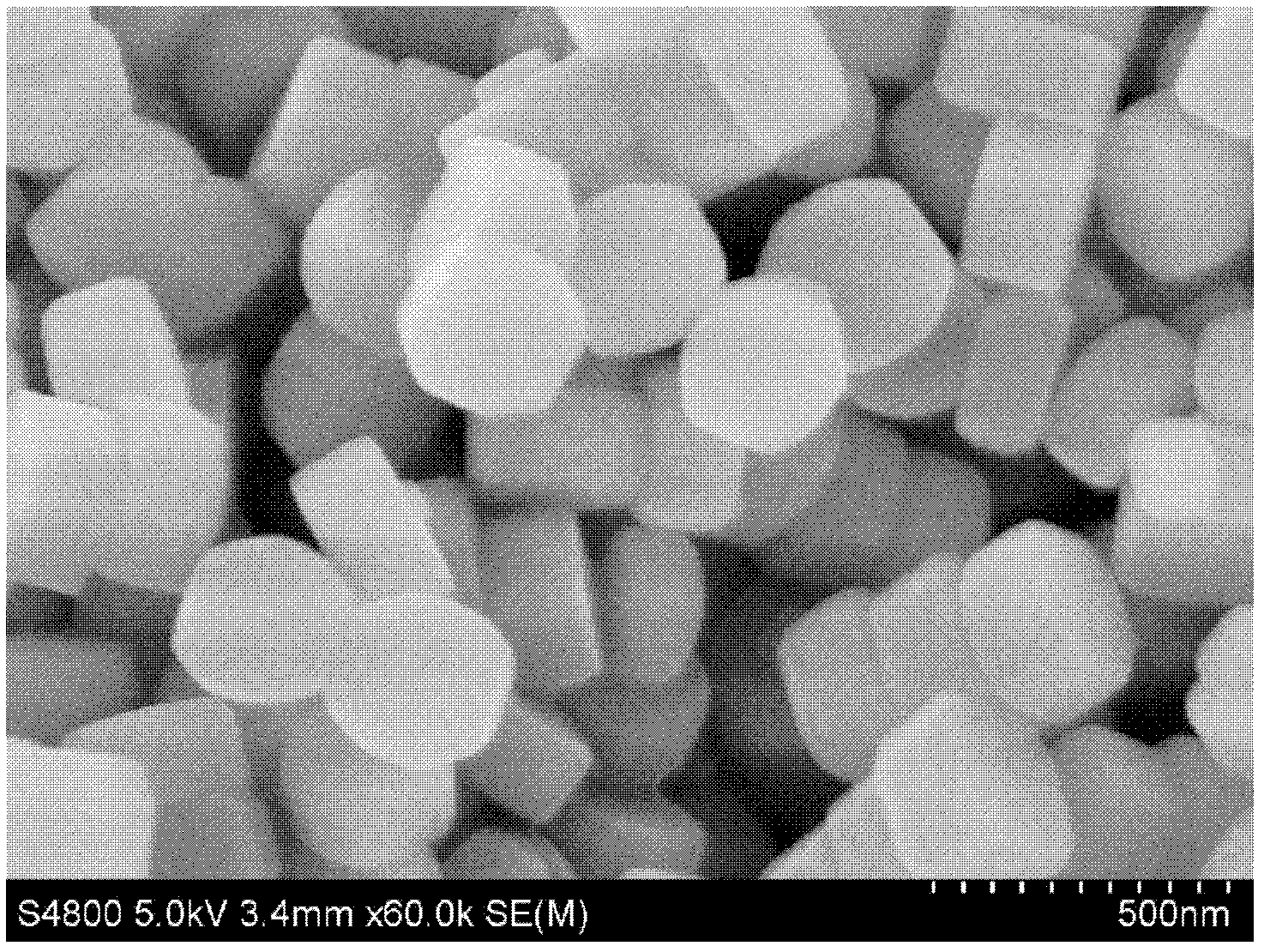

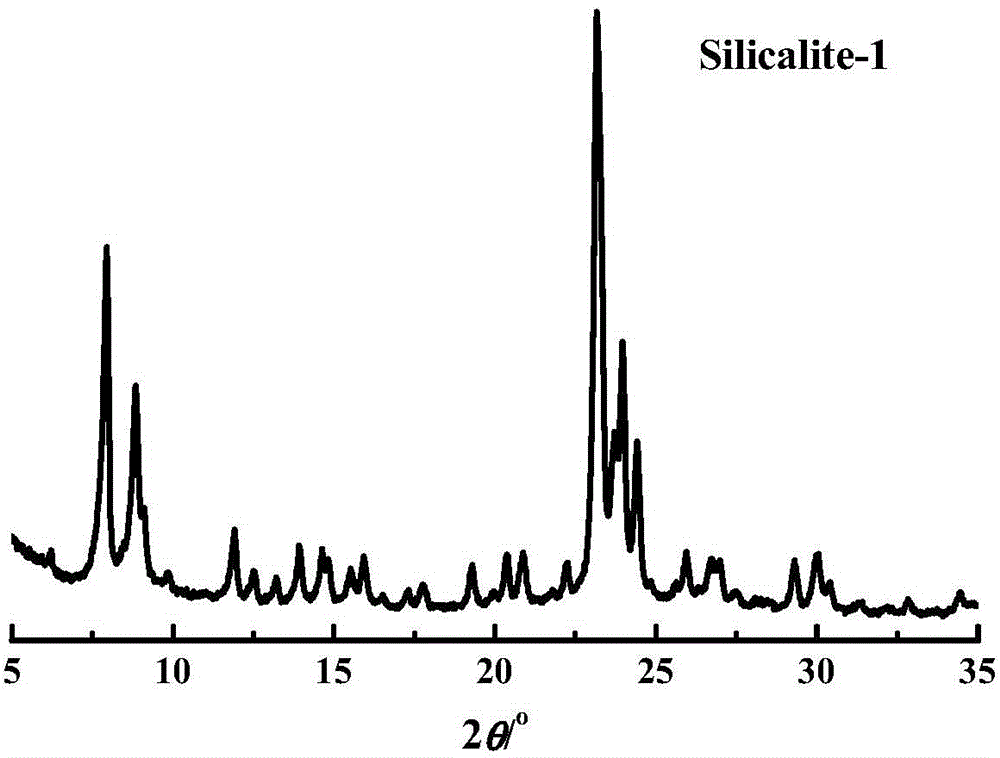

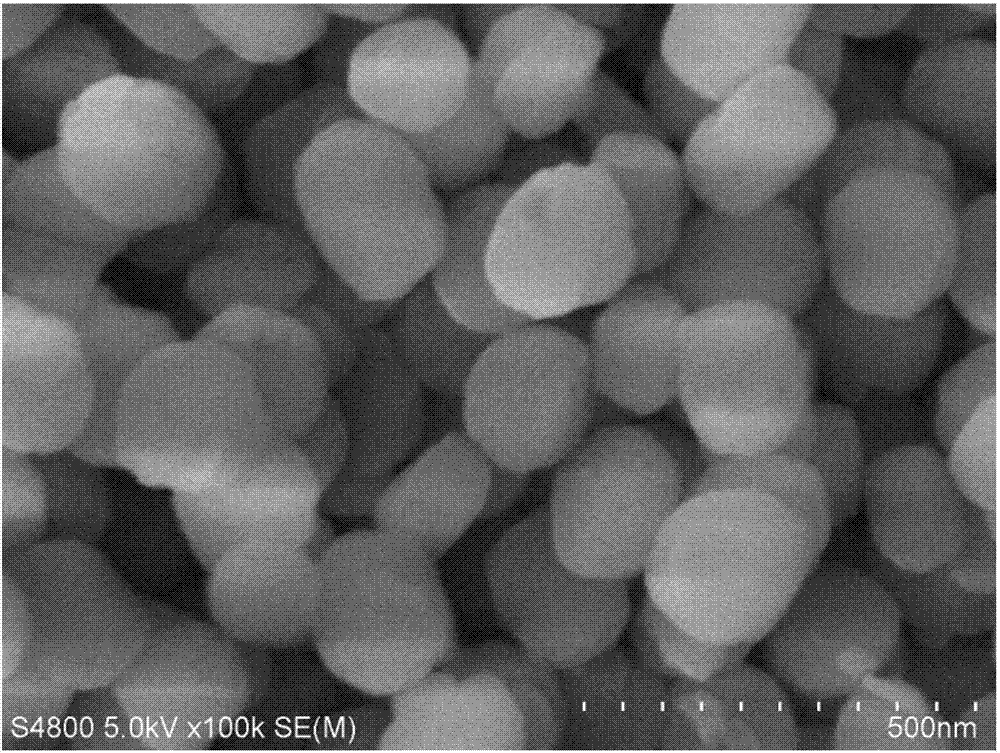

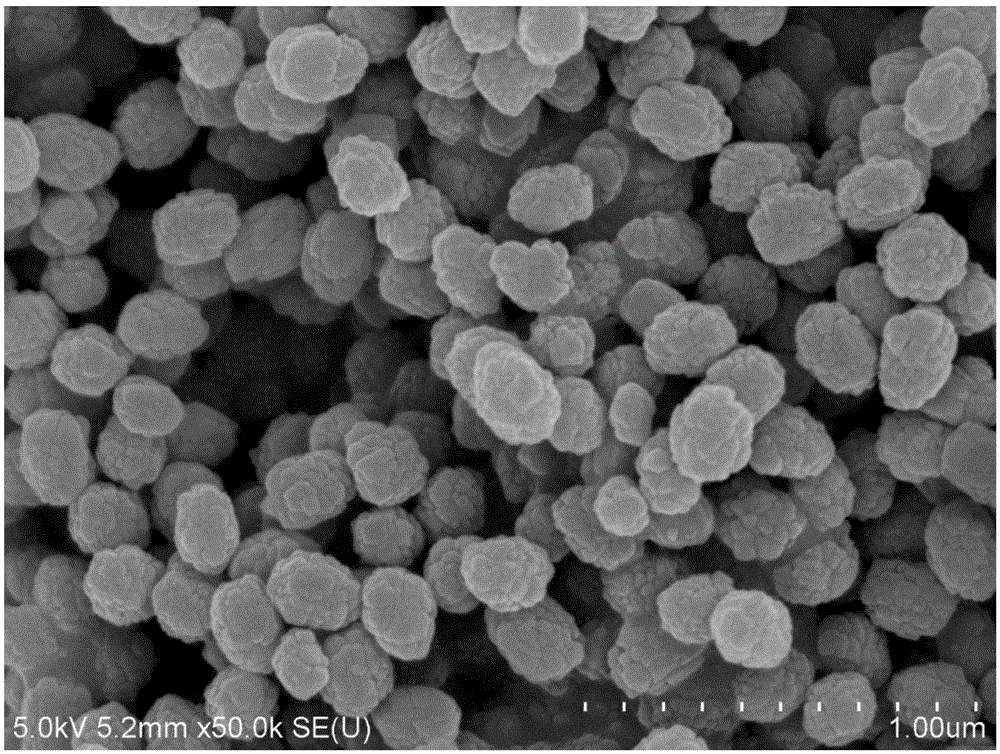

Nanometer all-silicon molecular sieve and its preparation method and use

InactiveCN102432032AHigh crystallinityRegular shapeLactams preparationMolecular sieve catalystsBeckmann rearrangementMass number

The invention provides a nanometer all-silicon molecular sieve. The nanometer all-silicon molecular sieve is prepared from tetrapropylammonium hydroxide, a silicon source, water and amino acids. A mole ratio of the silicon source to tetrapropylammonium hydroxide to water is 1: [0.05 to 0.50]: [15 to 65]. The mass of the used amino acids is 0.5 to 5% of that of the silicon source. A mole number and a mass number of silica represent a mole number and a mass number of the silicon source. The invention also provides a preparation method of the nanometer all-silicon molecular sieve, and a use of the nanometer all-silicon molecular sieve in a cyclohexanone-oxime gas phase beckmann rearrangement reaction. The nanometer all-silicon molecular sieve has a high degree of crystallization, regular morphology and adjustable particle sizes of 40 to 160 nanometers. In a cyclohexanone-oxime gas phase beckmann rearrangement reaction, the nanometer all-silicon molecular sieve shows excellent catalytic activity, selectivity and stability.

Owner:HUNAN UNIV

Synthetic method of siliceous molecular sieve

InactiveCN102515193AIncrease concentrationReduce energy consumptionCrystalline aluminosilicate zeolitesHigh concentrationMolecular sieve

The invention provides a preparation method of a siliceous molecular sieve, in particular to a gelatin crystallization method. The siliceous molecular sieve is synthesized under the condition of a high-concentration organic base template; a silicon source and the high-concentration organic base template, or the silicon source, a titanium source and the high-concentration organic base template are mixed in a certain proportion to prepare the precursor lyosol of the molecular sieve; the lyosol is aged for 1 to 10 h at ambient temperature, so as to obtain precursor lyogel; and the lyogel is put into a high-pressure crystallization kettle to be crystallized for 3 to 7 d at the temperature of 200 DEG C, and then is washed, dried and roasted, so as to obtain the S-1or TS-1 molecular sieve. Through the adoption of the method, the concentration of the template is increased, and a precursor liquid is crystallized in a gel state, so as to improve the productivity of the single kettle and reduce the production cost. S-1 and TS-1 molecular sieve catalysts prepared by using the method are respectively applied to the cyclohexanone-oxime gas phase reaction for preparing caprolactam and the cyclohexanone ammoximation reaction for preparing cyclohexanone oxime, and both achieve better catalytic effects. Therefore, the preparation method has an industrial application value.

Owner:CHINA TIANCHEN ENG +1

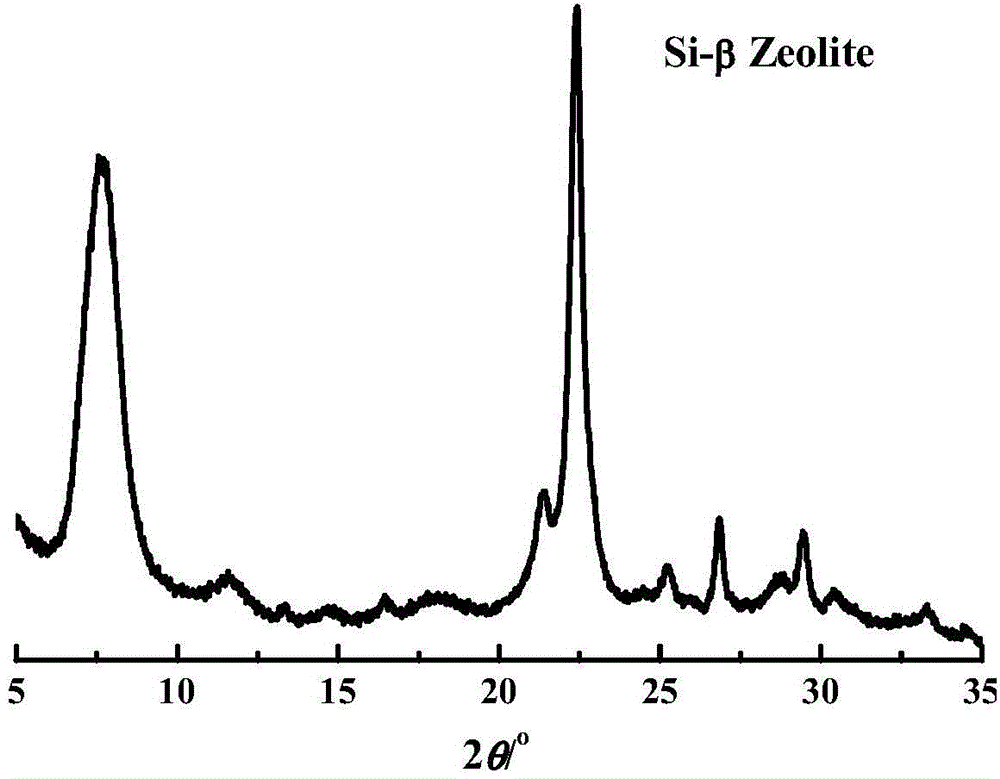

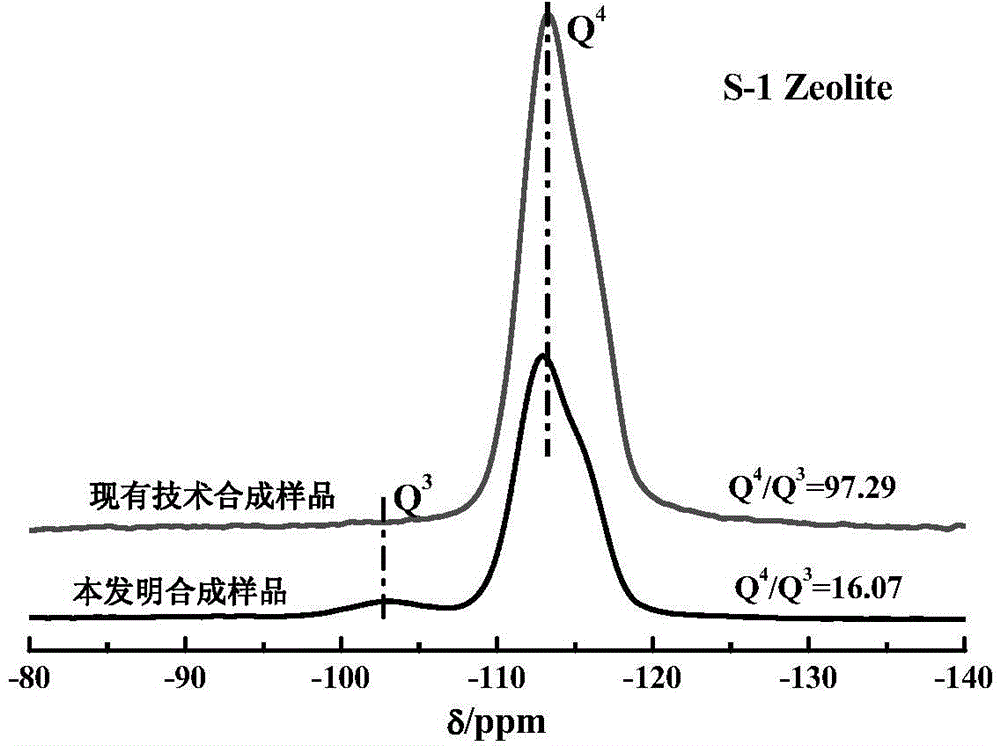

All-silicon molecular sieve and synthetic method thereof

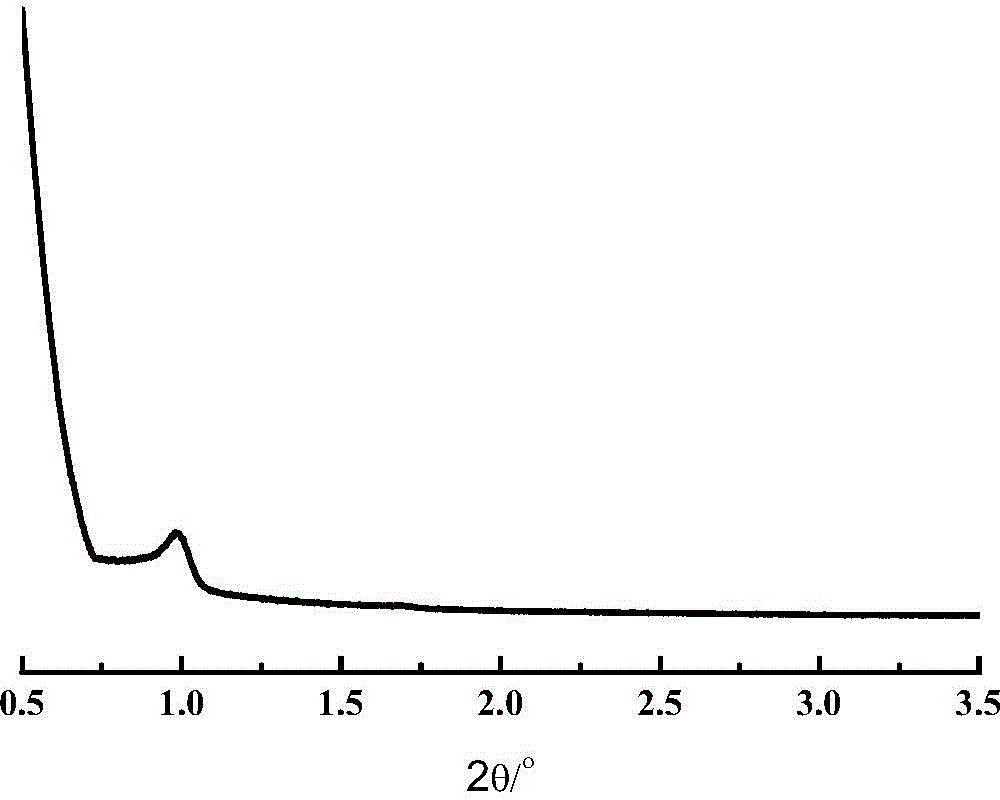

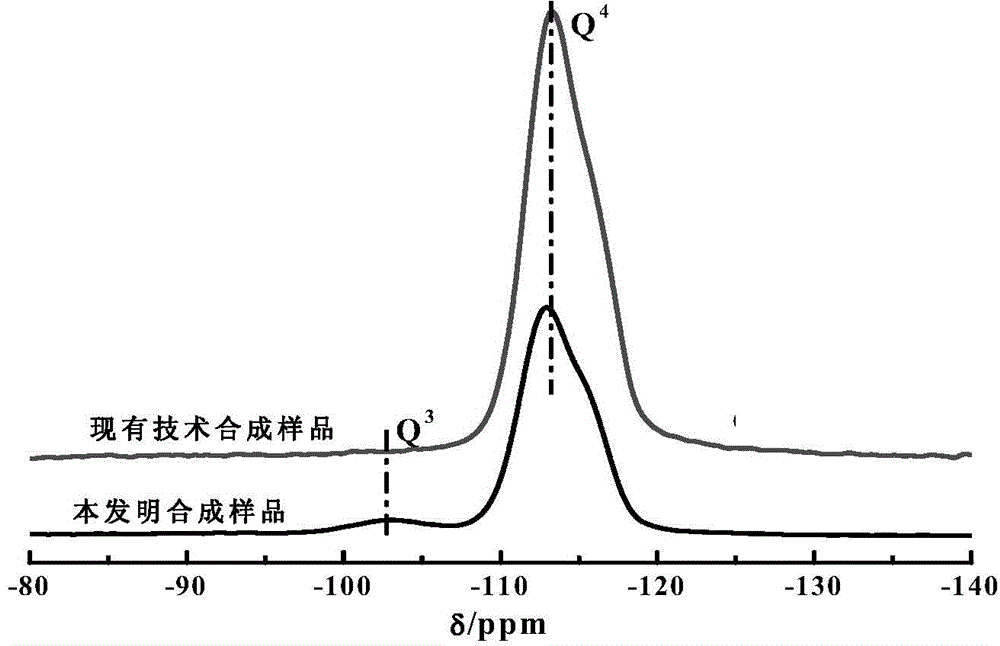

ActiveCN104556087AHigh catalytic activityFlexible adjustment of particle sizeLactams preparationSilicaMolecular sieveBeckmann rearrangement

The invention provides an all-silicon molecular sieve and a synthetic method thereof. Q4 / Q3 of the all-silicon molecular sieve is (10-90):1, wherein Q4 is the peak intensity expressed by the peak height at the chemical shift of -112+ / -2ppm in a 29SiNMR spectrogram of the all-silicon molecular sieve, and Q3 is the peak intensity expressed by the peak height at chemical shift of -103+ / -2ppm in the 29SiNMR spectrogram of the all-silicon molecular sieve. The synthetic method of the all-silicon molecular sieve comprises the following steps: mixing a template agent, an organic silicon source, an inorganic ammonium source and water to be subjected to hydrolytic alcohol removal, aging the obtained product, mixing the aging product with a solid silicon source, crystallizing the mixture in a closed reaction kettle, and recovering the all-silicon molecular sieve. The all-silicon molecular sieve provided by the invention has higher activity in cyclohexanone-oxime beckmann rearrangement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Layered silicate catalysts pillared with metal oxide

InactiveUS6703501B1Speed up the conversion processHigh selectivityLactams preparationMolecular sieve catalystsPorous catalystCyclohexanone oxime

The present invention relates to porous catalysts comprising layered silicate and metal oxides, and a method of preparing epsilon-caprolactam from cyclohexanone oxime using the catalyst. This new catalyst can resolve the environmental and safety problems arising from conventional liquid acid process. Also the present catalyst solves the problem of short lifetime of current solid acid catalysts. Moreover, the present catalyst provides higher selectivity and yield.

Owner:KOREA INST OF SCI & TECH

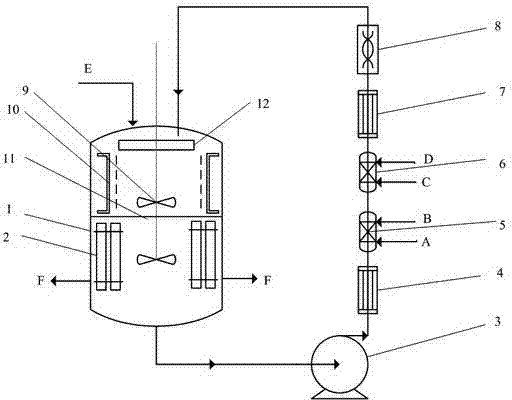

Ammoximation reaction and separation coupling process and device

The invention discloses an ammoximation reaction and separation coupling process which comprises the following steps: continuously adding reaction raw materials and a solvent in different groups outside a reaction kettle into a pipeline reactor for reaction, mixing the components in a mixer, and subsequently feeding the mixture into the reaction kettle for sufficient reaction, wherein the upper part of the reaction kettle is a reaction zone, and the lower part of the reaction kettle is a filtration separation zone; separating a reaction product, namely, cyclohexanone-oxime from a catalyst in the filtration separation zone, feeding the separated cyclohexanone-oxime into a later process, and circulating the catalyst back to the reaction kettle for continuous reaction through equipment such as the pipeline reactor outside the reaction kettle. Backwashing is performed once every 10-300 seconds, so that the continuity of reaction separation is ensured. As the raw materials sufficiently contact the catalyst, the reaction is complete, and the conversion rate of cyclohexanone can be 99.9-100%. The whole set of reaction separation devices is reasonable in arrangement and stable in reaction.

Owner:河北美邦工程科技股份有限公司

Process for producing cyclohexanone-oxime

ActiveCN1683323AHigh catalytic activityImprove conversion rateOximes preparationChemical synthesisMolecular sieve

The liquid phase cyclohexanone-oxime producing process with reaction system comprising cyclohexanone, ammonia and hydrogen peroxide and Ti-MWW molecular sieve as catalyst belongs to the field of organic chemical synthesis. Reactants cyclohexanone, ammonia and hydrogen peroxide are added successively into the reaction system with Ti-MWW molecular sieve as catalyst and solvent through stirring, and heated through heating to obtain the product cyclohexanone-oxime. The present invention has the following obvious advantages: excellent catalytic activity of the Ti-MWW molecular sieve as catalyst, high cyclohexanone converting rate, high cyclohexanone-oxime selectivity, high utilization of hydrogen peroxide, simple post-treatment and environment friendship.

Owner:EAST CHINA NORMAL UNIV

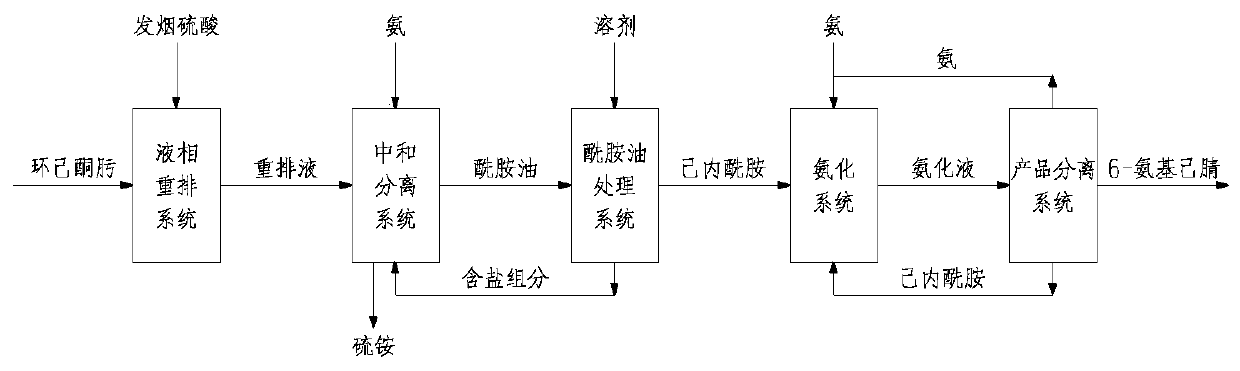

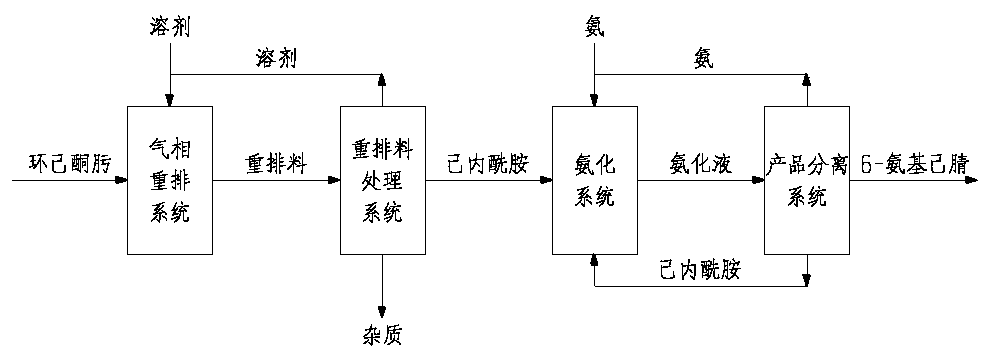

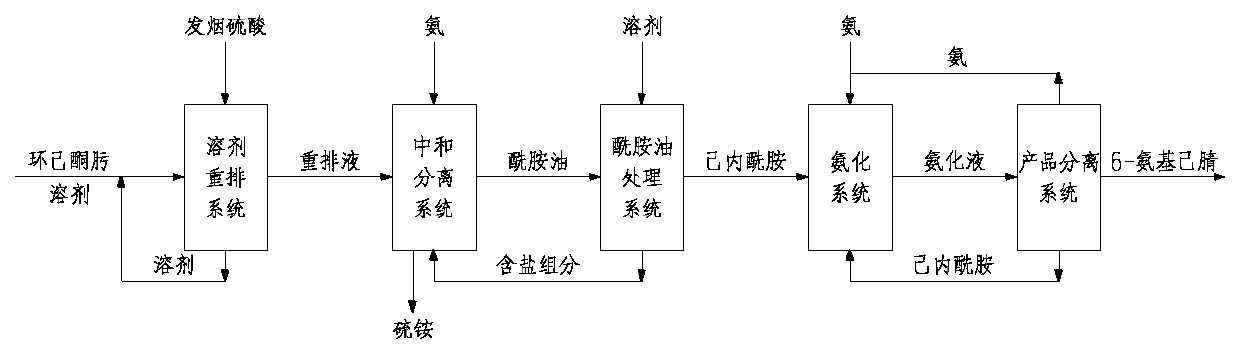

Method for preparing 6-aminocapronitrile from cyclohexanone-oxime

InactiveCN110835311AReduce consumptionReduce processing complexityLactams preparationLactams separation/purificationDistillationIon exchange

The invention discloses a method for preparing 6-aminocapronitrile from cyclohexanone-oxime. The method comprises the following steps: carrying out a rearrangement reaction on cyclohexanone-oxime to obtain a rearranged reaction material; and treating the rearranged reaction material to obtain caprolactam, carrying out an ammoniation dehydration reaction on the caprolactam to obtain an ammoniated dehydrated reaction material, and performing separation to obtain the 6-aminocapronitrile. Compared with the prior art, the method of the invention reduces complex separation and refining processes such as back extraction, ion exchange, hydrogenation, evaporation and distillation required after liquid phase rearrangement of the cyclohexanone-oxime, reduces the processes of crystallization, solventrefining and recovery needed after gas phase rearrangement, and organically combines the caproamide evaporation and rearrangement treatment processes in the ammoniation dehydration reaction process. The steam consumption can be reduced by 2.0-3.0 t / t 6-aminocapronitrile, and the cyclohexanone-oxime consumption is reduced by 20-50 kg / t 6-aminocapronitrile.

Owner:HUNAN BAILI ENGINEERING SCIENCE AND TECHNOLOGY CO LTD

Method for catalysis of pimelinketone oxamidine

ActiveCN101314577AHigh selectivityLow costMolecular sieve catalystsOximes preparationOxidation stateOxygen

The invention discloses a method for catalyzing ammoximation of cyclohexanone. The method comprises the steps as follows: subjecting cyclohexanone, ammonia, oxygen, hydrogen, diluent gas and a solvent to coming in contact with a catalyst. The mole ratio of cyclohexanone, to ammonia, oxygen, hydrogen and diluent gas is 1:(0.1-10.0):(0.1-10.0):(0.1-10.0):(0-100). The mass ratio of the solvent to the catalyst is (20-1000):1. The catalyst is a microporous titanium-silicon material or a compound containing the microporous titanium-silicon material. The composition of the microporous titanium-silicon material is expressed as xTiO2*100SiO2*yEmOn*zE in an oxide form, wherein x ranges from 0.001 to 50.0; the sum of y plus z ranges from 0.005 to 20.0; the ratio of y to z is smaller than 1; E is one or more metal noble metals selected from Ru, Rh, Pd, Re, Os, Ir, P and Au; m and n are numbers required for meeting the oxidation state of the E; and material grains are partially or totally hollow-structured. The method has the advantages of high selectivity of cyclohexanone oxime, high product activity and stability, environment friendliness and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing caprolactam through gas phase Beckmann rearrangement of cyclohexanone-oxime gas

ActiveCN103896839AImprove conversion rateHigh selectivityLactams preparationMolecular sieve catalystsBeckmann rearrangementMolecular sieve

The invention provides a method for preparing caprolactam through gas phase Beckmann rearrangement of cyclohexanone-oxime gas. According to the method, under the condition of rearrangement reaction, cyclohexanone-oxime is in contact with a catalyst, and the catalyst is obtained by the steps of forming a molecular screen with an aluminum-free MFI (Melt Flow Index) structure, and enabling the molecular screen to be in contact with an alkaline buffer solution of a nitrogen-containing compound. The method is high in cyclohexanone-oxime conversion rate, and is capable of realizing long-period and continuous production; the selectivity of caprolactam is capable of reaching 95.8 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing all-silicon micro-mesoporous composite material

ActiveCN104556085AFlexible adjustment of particle sizeLower synthesis costLactams preparationSilicaMolecular sieveAmmonium compounds

The invention relates to a method for synthesizing an all-silicon micro-mesoporous composite material. The method for synthesizing the all-silicon micro-mesoporous composite material comprises the following steps: mixing a template agent, an organic silicon source, an inorganic ammonium source and water, ageing, uniformly mixing with a solid silicon source, crystallizing, and recycling an all-silicon micro-mesoporous composite molecular sieve, wherein the template agent is an organic quaternary ammonium compound, a long-chain alkylammonium compound and optional organic amine. The synthesized all-silicon micro-mesoporous composite material has a high defect site and has high activity when used for converting of cyclohexanone-oxime.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing cyclohexanone-oxime and caprolactam

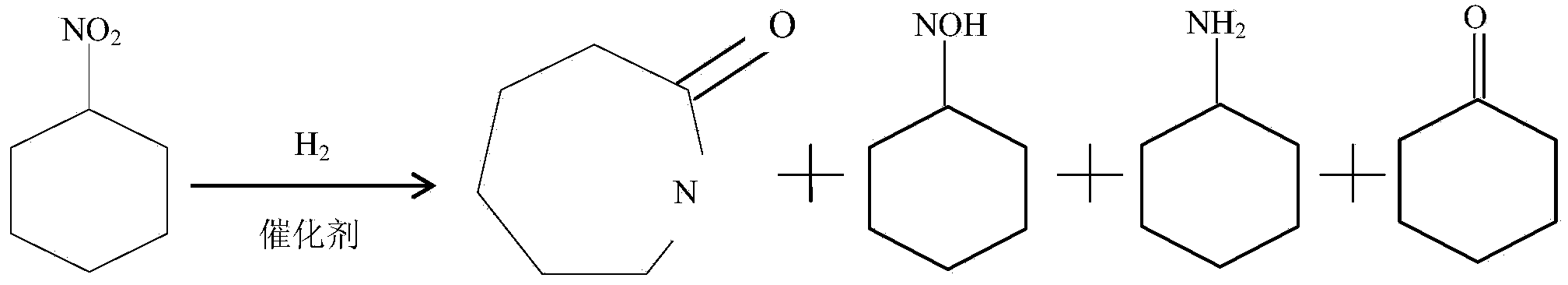

ActiveCN104341318ALow yieldImprove conversion rateLactams preparationOximes preparationGas phaseCyclohexanone oxime

The invention relates to a method for synthesizing cyclohexanone-oxime and caprolactam, particularly a method for synthesizing cyclohexanone-oxime and caprolactam by performing catalytic hydrogenation on nitrocyclohexane used as a raw gas phase. The method has the advantages of high controllability, low cost, environmental protection, higher conversion ratio of raw materials and higher yield, and has industrialization application prospects. The reaction process is simple, no coproduct ammonium sulfate is generated in the reaction process, and no wastewater or waste gas is generated to pollute the environment, and thus, the method is an environment-friendly production technique.

Owner:XIANGTAN UNIV

Method for recovering solvent from ammoximation reaction liquid

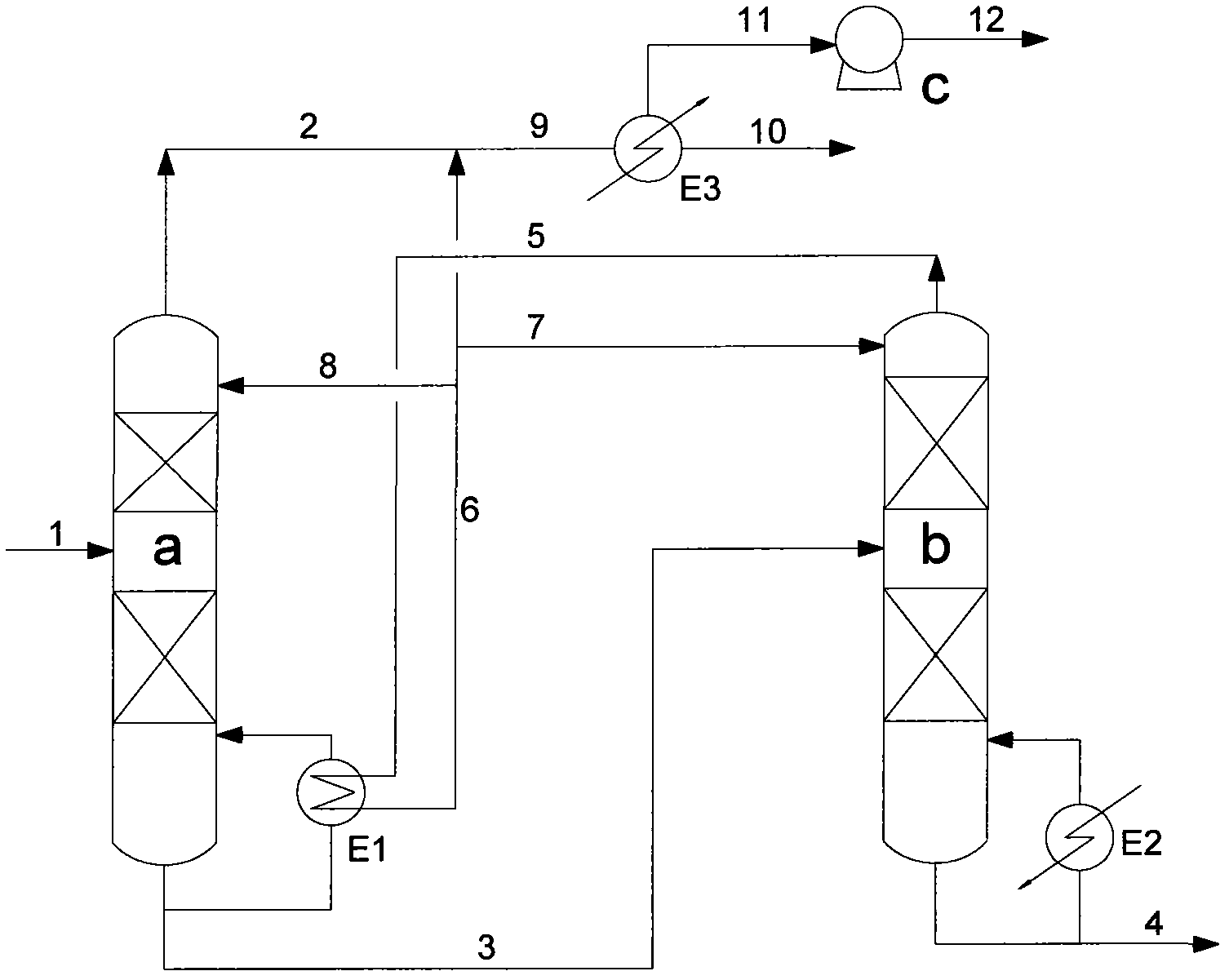

InactiveCN102633676AReduce dosageReduce manufacturing costOximes preparationSolvent vaporPhysical chemistry

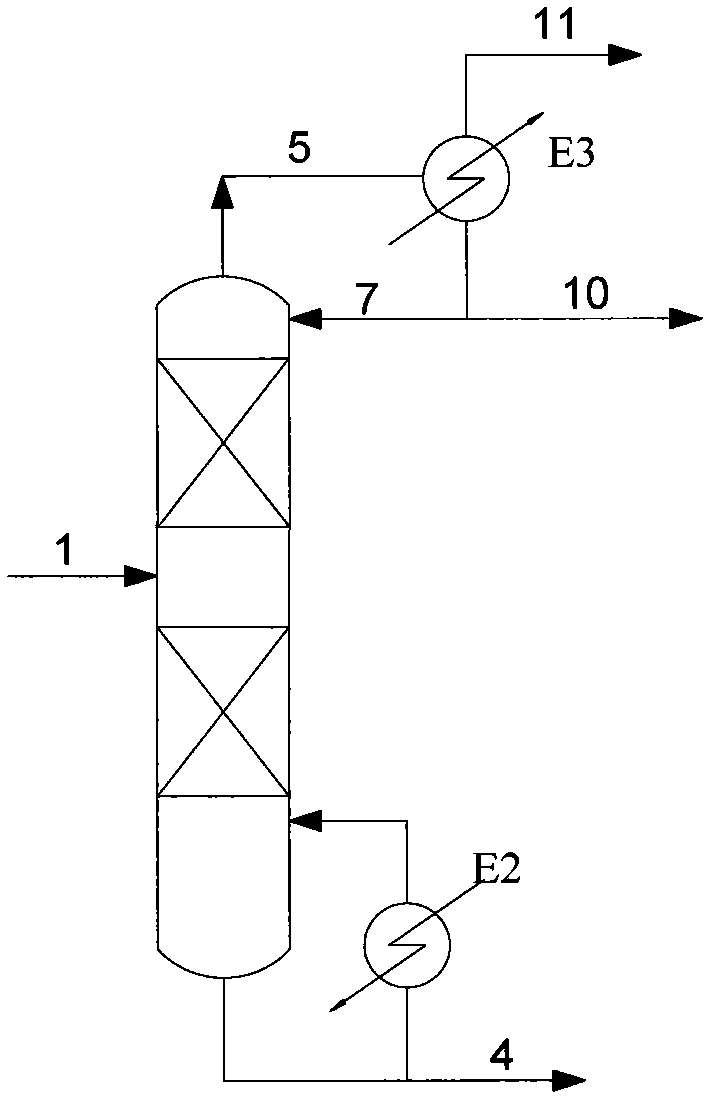

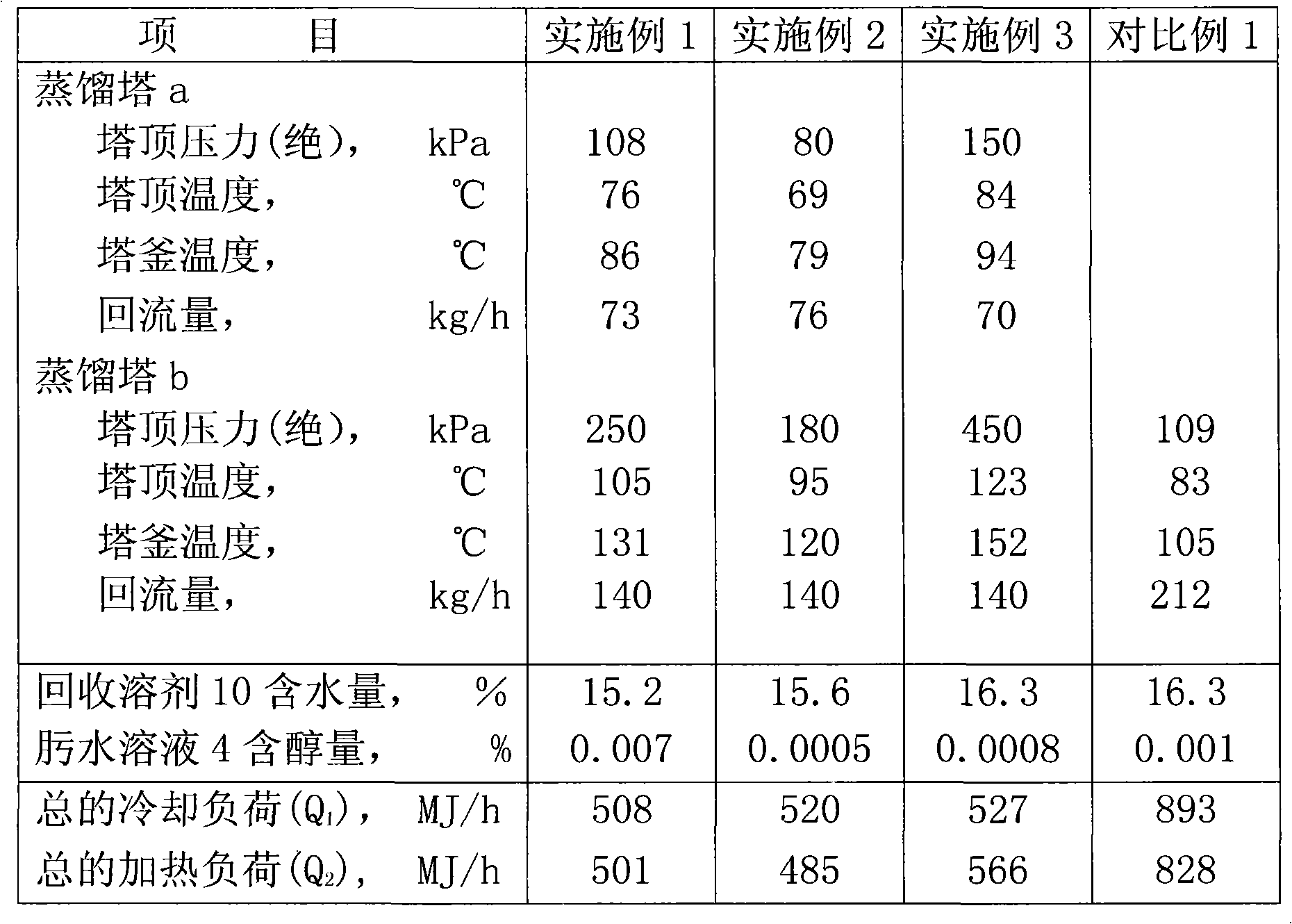

The invention provides a method for recovering a solvent from an ammoximation reaction liquid. The method comprises the following steps: feeding a reaction liquid containing ammonia, the solvent, cyclohexanone oxime, water and cyclohexanone into a primary distillation tower (a), and evaporating out partial solvent containing ammonia and water from a tower top; and feeding materials in a tower kettle into a secondary distillation tower (b), and carrying out pressure distillation by utilizing exterior heat source so as to obtain high-temperature vapor containing the solvent from the tower top and obtain a material containing cyclohexanone oxime, water and cyclohexanone from the tower kettle, wherein the high-temperature vapor containing the solvent serves as the distillation heat source for the primary distillation tower (a). By using the method, the energy consumption for the solvent recovery can be reduced.

Owner:北京凯美信科科技开发有限责任公司

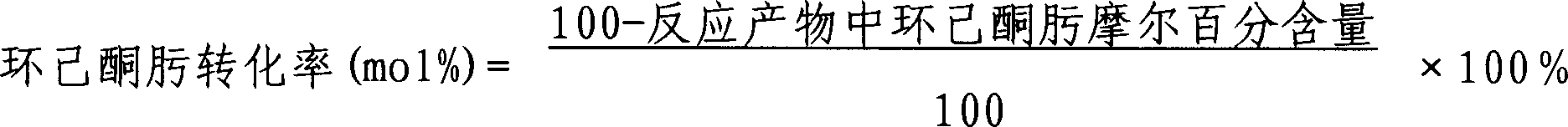

Preparation method of cyclohexanone oxime

ActiveCN101117323AImprove reaction efficiencyAvoid stickingMolecular sieve catalystsOximes preparationCyclohexanone oximeSlurry

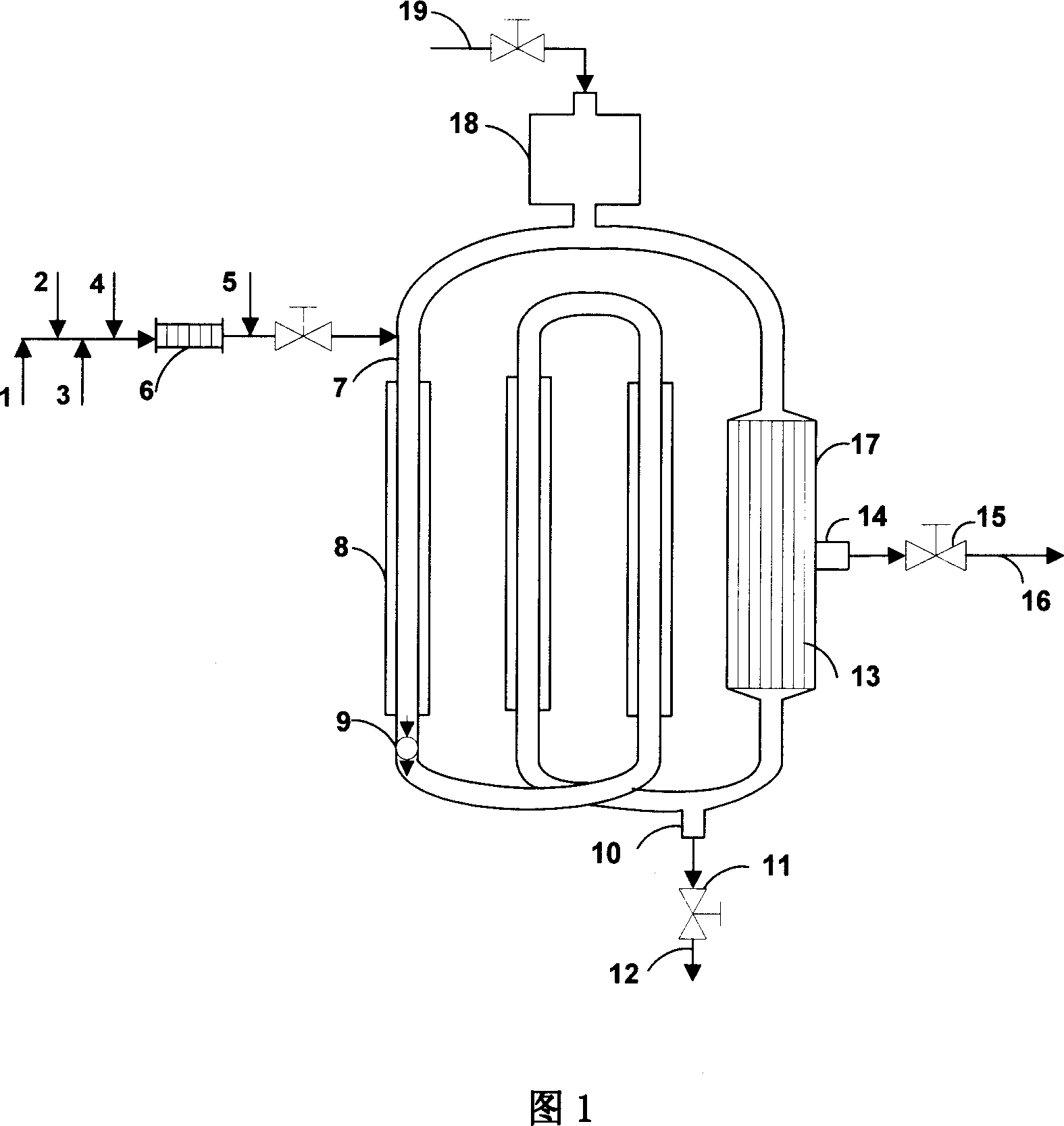

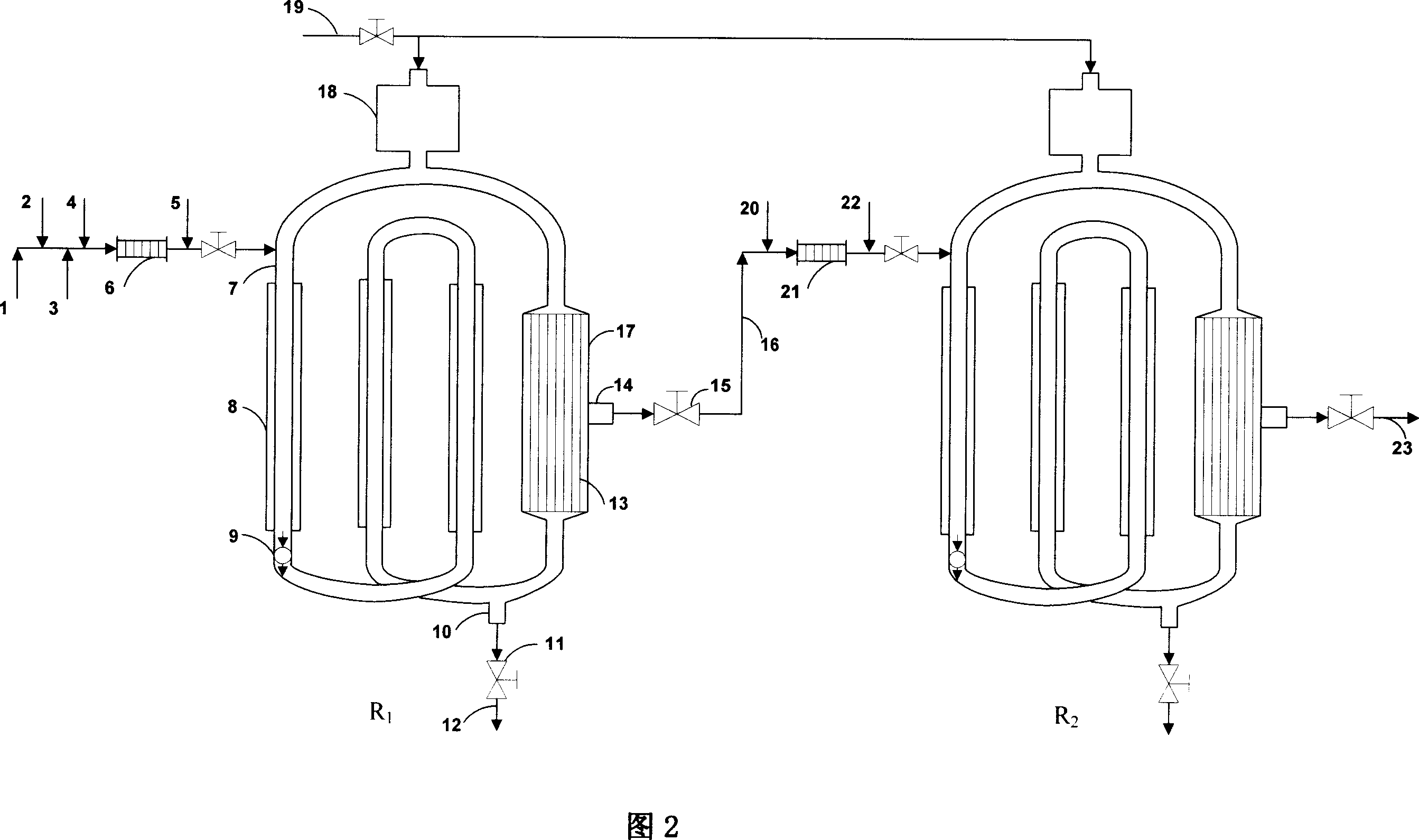

The invention discloses a preparation process for cyclohexanone oxime which is characterized in that the process is carried out continuously and circularly in a loop reactor, wherein the loop reactor consists of a loop and a solid-liquid separating component and makes the reaction slurry comprising catalyzer, ammonia, cyclohexanone, hydrogen peroxide and solvent have an ammoximation reaction in the loop, then the reaction slurry is made a solid-liquid separation by a filtering element in the solid-liquid separating component in a cross-current way, the obtained clear liquid flows out along the radial direction of the filtering element and is reclaimed, the concentrated slurry continues to circulate in the loop.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of epsilon-caprolactam

InactiveCN1896056ASave energyMeet industrial requirementsLactams preparationAlkalinityCyclohexanone oxime

Production of epsilon-glycolylnium is carried out by Beckman rearrangement reacting for cyclohexanone-oxime under the existence of solvent to obtain epsilon-glycolylnium contained mixture, crystalline separating for the mixture to obtain crude epsilon-glycolylnium crystal, dissolving by arene, extracting by water, adsorbing by resin hydrogenation catalyzing to obtain the final product. The value of potassium permanganate is less than 5, extinction value is less 0.05, volatile alkali is less than 0.5meq / kg and alkalinity is less than 0.05meq / kg.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method for Silicate-1 molecular sieve catalyst, catalyst and method for preparing caprolactam

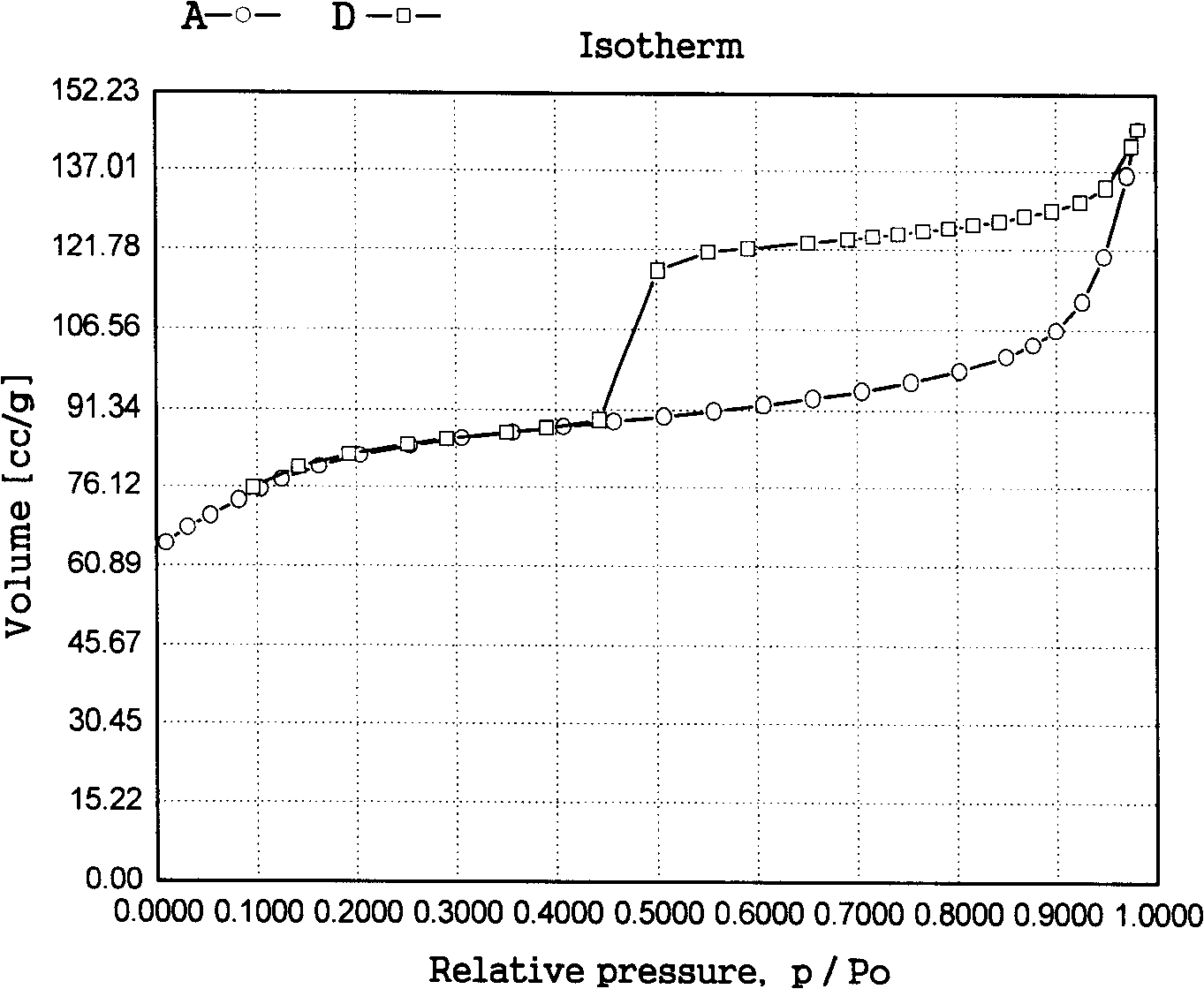

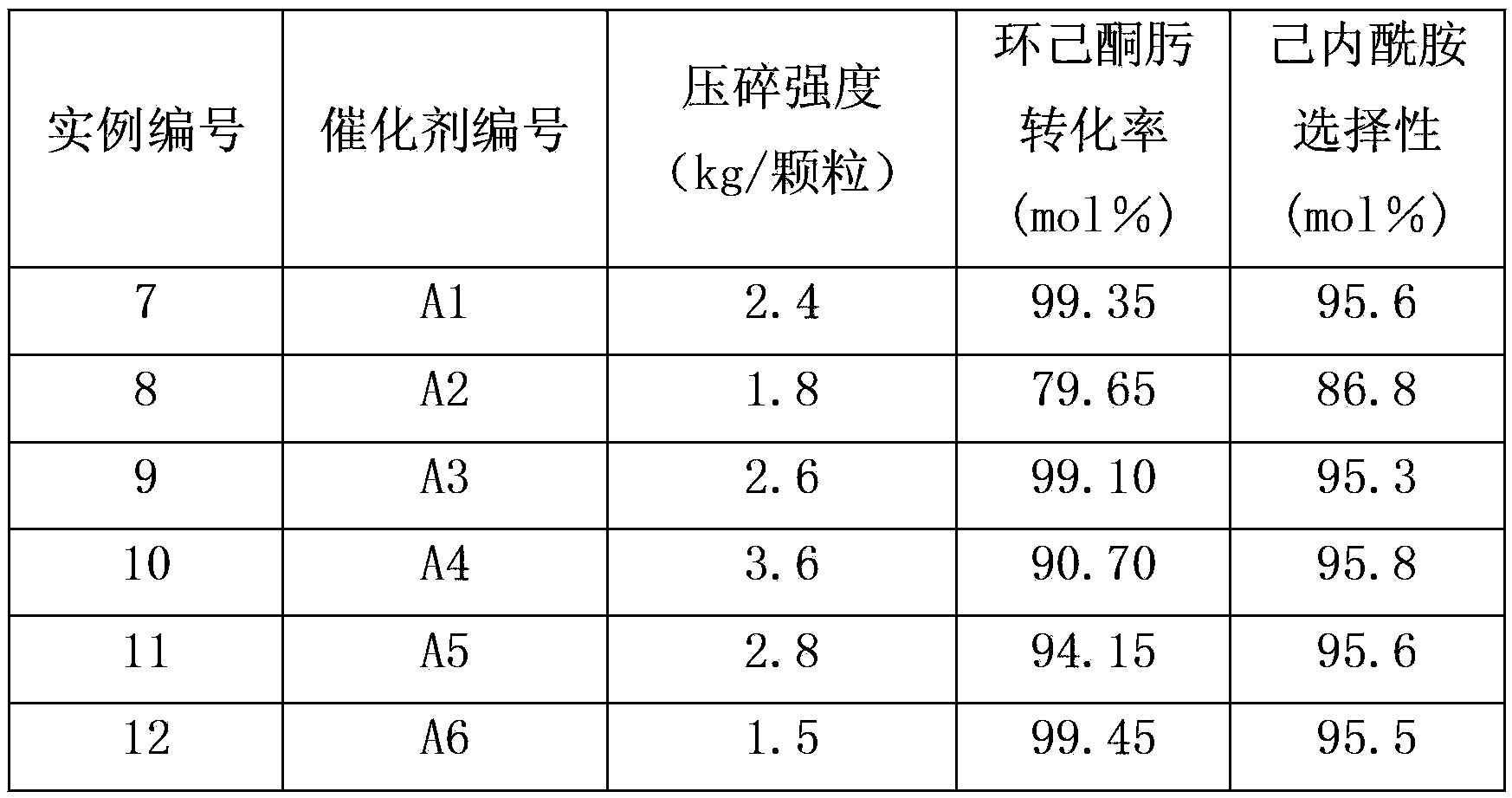

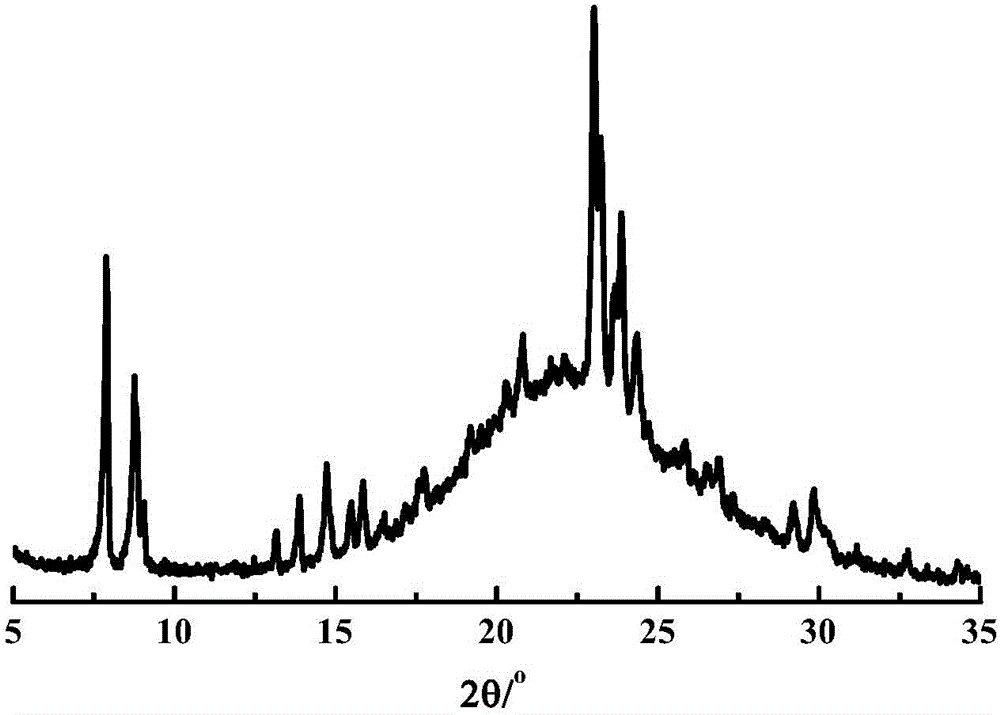

ActiveCN107335464AImprove conversion rateExtend your lifeLactams preparationMolecular sieve catalystsMolecular sieveNitrogen

The invention discloses a preparation method for a Silicate-1 molecular sieve catalyst, the Silicate-1 molecular sieve catalyst prepared by the method and a method for preparing caprolactam from cyclohexanone oxime. The preparation method for the Silicate-1 molecular sieve catalyst comprises the steps: a. mixing a silicon source, a metal ion source, an organic template agent and water, so as to obtain a colloidal mixture; b. subjecting the colloidal mixture obtained in the step a to hydrothermal crystallization, so as to obtain a crystallized product; c. subjecting the crystallized product obtained in the step b to washing and separating treatment, so as to obtain metal ion containing Silicate-1 molecular sieves; and d. subjecting the metal ion containing Silicate-1 molecular sieves obtained in the step c to forming treatment, roasting treatment and aftertreatment by an alkaline buffer solution of a nitrogen containing compound, and carrying out washing, separating and drying, thereby obtaining the Silicate-1 molecular sieve catalyst containing trace metal ions. By adopting the method, the performance of the Silicate-1 molecular sieve catalyst can be effectively changed; and by applying the catalyst to the production of the caprolactam, an unexpected result can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

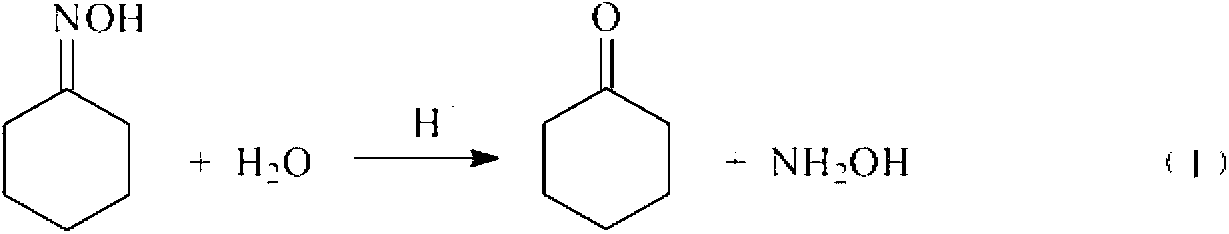

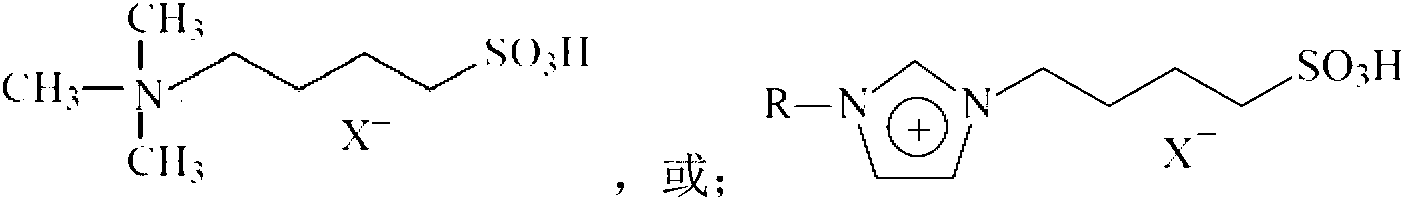

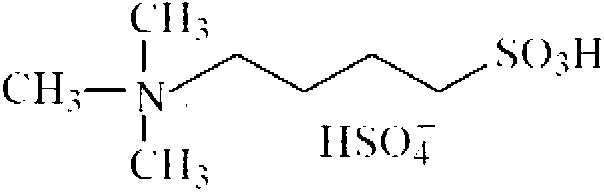

Method for catalyzing hydrolysis reaction of cyclohexanone-oxime in acidic ionic liquid

InactiveCN103073405AOvercoming the disadvantages of being difficult to recycleAvoid pollutionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydroxylamineCyclohexanone oxime

The invention discloses a method for catalyzing a hydrolysis reaction of cyclohexanone-oxime in acidic ionic liquid. The method comprises the following steps of: placing the cyclohexanone-oxime in a reactor, adding an acidic ionic liquid catalyst and deionized water; carrying out constant-temperature stirring reaction for 0.15-4h under the conditions of normal pressure and a temperature of 10-80 DEG C, and separating an organic phase from an inorganic phase in reaction liquid to respectively obtain cyclohexanone and hydroxylamine, wherein the acidic ionic liquid is SO3H-type ionic liquid, the material ratio, namely a mol ratio of the cyclohexanone-oxime to the ionic liquid is 1:(0.16-5.4), and the mol ratio of the deionized water to the ionic liquid is (11-369):1. The method for catalyzing the hydrolysis reaction of the cyclohexanone-oxime in the acidic ionic liquid uses the SO3H-type ionic liquid as a catalyst of the hydrolysis reaction of the cyclohexanone-oxime. Compared with the existing cyclohexanone-oxime hydrolysis route, the method has the advantages that the acidic ionic liquid can be recycled, and the transform ratio of the cyclohexanone-oxime is close to 100 percent.

Owner:HEBEI UNIV OF TECH

Preparation method of aminocaprolactam

ActiveCN101117327AAchieve recyclingHigh selectivityLactams preparationBeckmann rearrangementAcetic anhydride

The invention discloses a preparation process for caprolactam which is characterized in that the acetic anhydride acts as the catalyzer to make a Beckmann rearrangement reaction of cyclohexanone oxime in ionic liquid homogeneous system , then the orgainic solvent is used to extract the ionic liquid and fully transfer the cyclohexanone oxime and the catalyzer into the organic solvent, finally the separation of the cyclohexanone oxime and the catalyzer is realized by the extraction to the solvent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing amide using nonhomogeneous phase oximation rearrangement

ActiveCN1762985ALow costGood economic valueOrganic compound preparationCarboxylic acid amides preparationBeckmann rearrangementReaction temperature

The present invention discloses oximation and rearrangement process of preparing amide with aliphatic and / or cyclic aliphatic ketone as material. The preparation process includes catalytic reaction of ketone, hydrogen peroxide solution and ammonia inside inert solvent to produce ketoxime solution, Beckmann rearrangement of the oil phase product under the action of fuming sulfuric acid, and hydrolysis to neutralize and produce amide. The present invention has shortened technological process, lowered cyclohexyl ketoxime rearranging reaction temperature, lowered sulfuric acid consumption and reduced side product.

Owner:HUBEI JINXIANGNING CHEM ENG TECHENOLOGY CO LTD

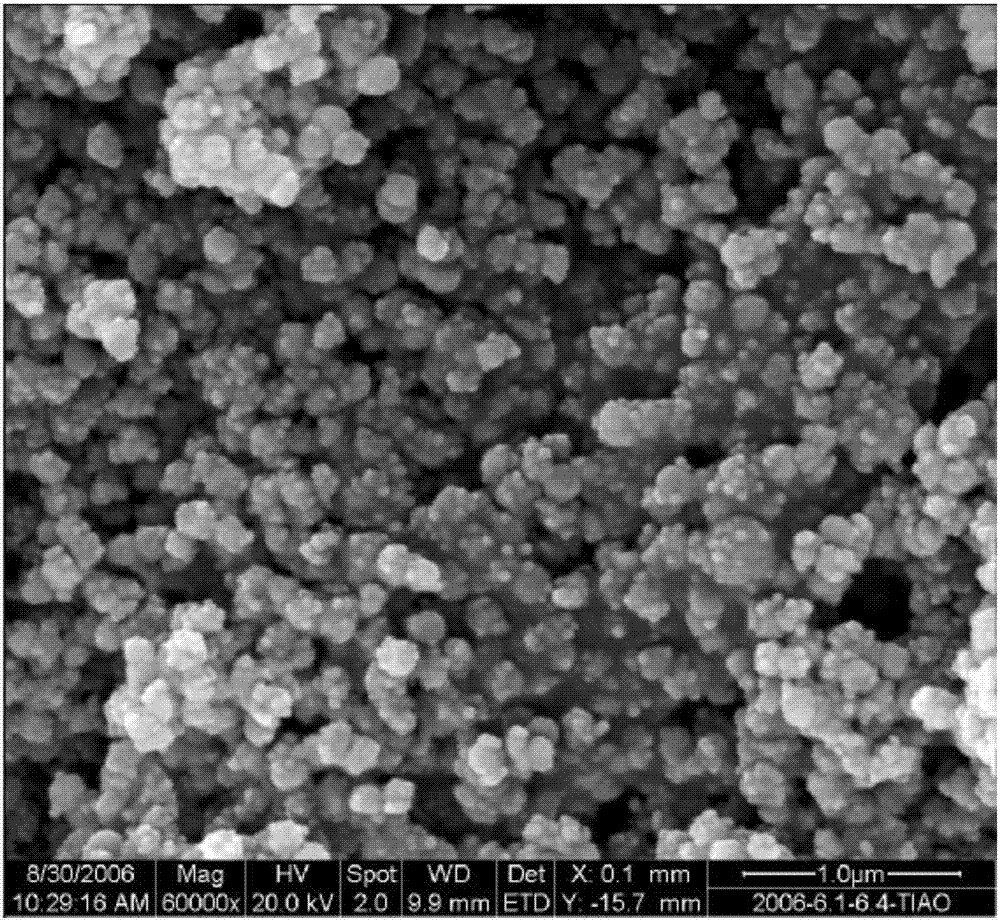

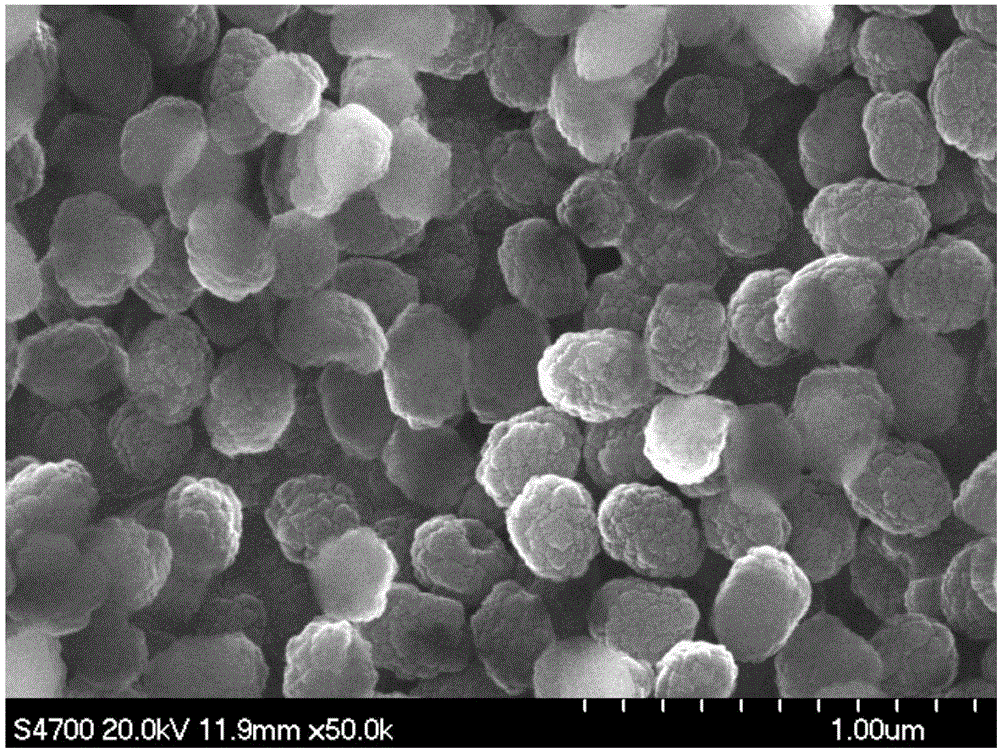

Preparation method of TS-1 titanium silicalite

ActiveCN105197956APromote formationHigh autogenous pressureCrystalline aluminosilicate zeolitesCatalytic oxidationHydrolysis

The invention relates to a preparation method of titanium silicalite and the titanium silicalite prepared by the method. A TS-1 titanium silicalite crystal is prepared from an organic silicon source, an organic titanium source, an organic base template agent and water as raw materials through the steps of hydrolysis, alcoholization, hydrothermal crystallization, washing, roasting and the like; and the form of the TS-1 titanium silicalite crystal can be controlled by adjusting the concentration of the organic base template agent TPAOH in a hydrothermal crystallization reaction mixture and the concentration change in the process of alcoholization. The method has the advantages of easiness in control of process conditions, good repeatability, simple hydrothermal synthesis system ingredients, easiness in separation of hydrolysis products, and the like. The particle size of a TS-1 molecular catalyst prepared by the method provided by the invention is easy to control, and the TS-1 molecular catalyst is in a 'blackberry' form and has a favorable catalytic oxidation function; and in oximation reaction, for example, reaction for preparing cyclohexanone oxime through cyclohexanone ammoximation, the selectivity and catalytic activity of reaction products are obviously increased.

Owner:BEIJING RISUN TECH CO LTD

Method for preparing titanium-silicon molecular sieve and method for preparing cyclohexane oxime by using molecular sieve

ActiveCN102153104AImprove conversion rateHigh selectivityMolecular sieve catalystsOximes preparationMolecular sieveCyclohexanone oxime

The invention provides a method for preparing a titanium-silicon molecular sieve with large particle diameter. The method comprises the following steps of: preparing dispersion liquid of a first-level crystalline particle molecular sieve; adding a flocculating agent and a coagulant aid into the dispersion liquid, and gathering the particles so as to form gathered particle solution; mixing the gathered particle solution and titanium-silicon template synthetic cement; and performing a hydrothermal process. The titanium-silicon molecular sieve prepared by the method has an average particle diameter of more than 5 microns; and when serving as a contact agent for preparing cyclohexane oxime, the titanium-silicon molecular sieve has high conversion rate and selection rate, and has the advantage of easiness for filtering and recycling.

Owner:CHINA PETROCHEM DEVMENT

Titanium-silicalite molecular sieve, method for preparing the same and method for preparing cyclohexanone oxime using the molecular sieve

ActiveUS20130041181A1Enhances ammoximationImprove efficiencyMolecular sieve catalystsOrganic compound preparationMolecular sieveWater baths

The present invention provides a titanium-silicalite molecular sieve and a method for preparing the same. The method includes the steps of preparing a mixture of a titanium source, a silicon source, a metal source selected from IIA to IVA elements and a template agent; heating the mixture to form a gel mixture; heating the gel mixture in a water bath; and calcining the gel mixture after the gel mixture in the water bath to form the titanium-silicalite molecular sieve. The present invention further provides a method for preparing cyclohexanone oxime by using the titanium-silicalite molecular sieve as the catalyst which results in high conversion rate, high selectivity and high usage efficiency of hydrogen peroxide.

Owner:CHINA PETROCHEM DEVMENT

Liquid-phase fixed bed preparation method of cyclohexanone oxime

The invention discloses a liquid-phase fixed bed preparation method of cyclohexanone oxime. The liquid-phase fixed bed preparation method has the characteristic that high-selectivity cyclohexanone oxime combination reaction is carried out on cyclohexanone, hydrogen peroxide, ammonia gas and a tertiary butanol aqueous solution in a fixed-bed reactor under the catalytic action of titanium silicalite molecular sieve, wherein the mass concentration of the hydrogen peroxide is 5%-50%; the mass concentration of the tertiary butanol aqueous solution is 30%-90%; the weight ratio of the cyclohexanone to the hydrogen peroxide to the ammonia gas to the tertiary butanol aqueous solution is 1:(0.35-1.74):(0.19-0.70):3. Compared with the prior art, the liquid-phase fixed bed preparation method of the cyclohexanone oxime is good in selectivity, high in conversion rate, capable of separating reaction liquid without catalyst, simple in process, capable of continuously charging and discharging, environment-friendly and easy for industrial implementation.

Owner:EAST CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com