Method for producing caprolactam by taking high-purity benzene as raw material

A technology of caprolactam and raw materials, applied in the field of caprolactam production, can solve the problems of caprolactam production steps not involved, no specific method for quality control, no description of cyclohexanone quality index for caprolactam production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

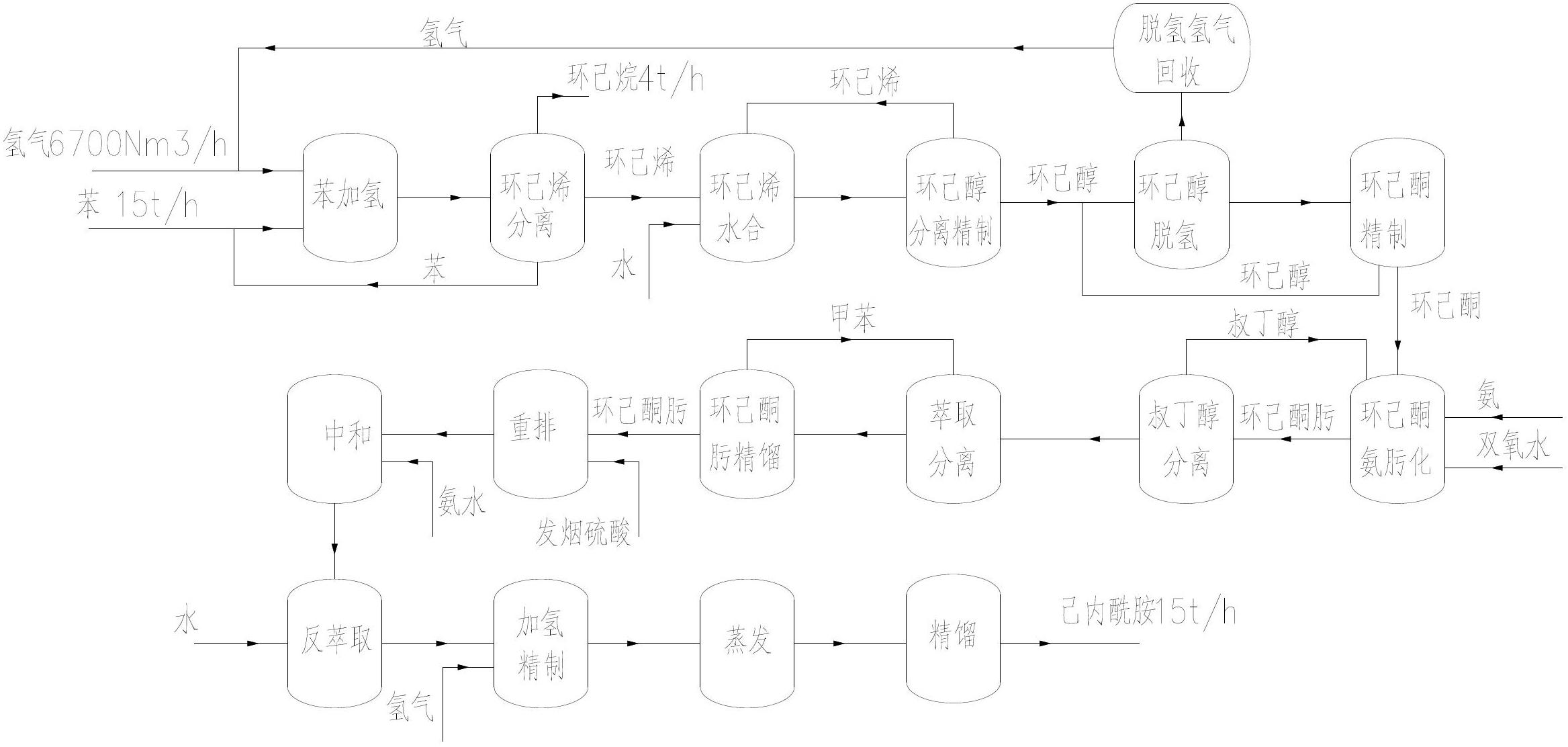

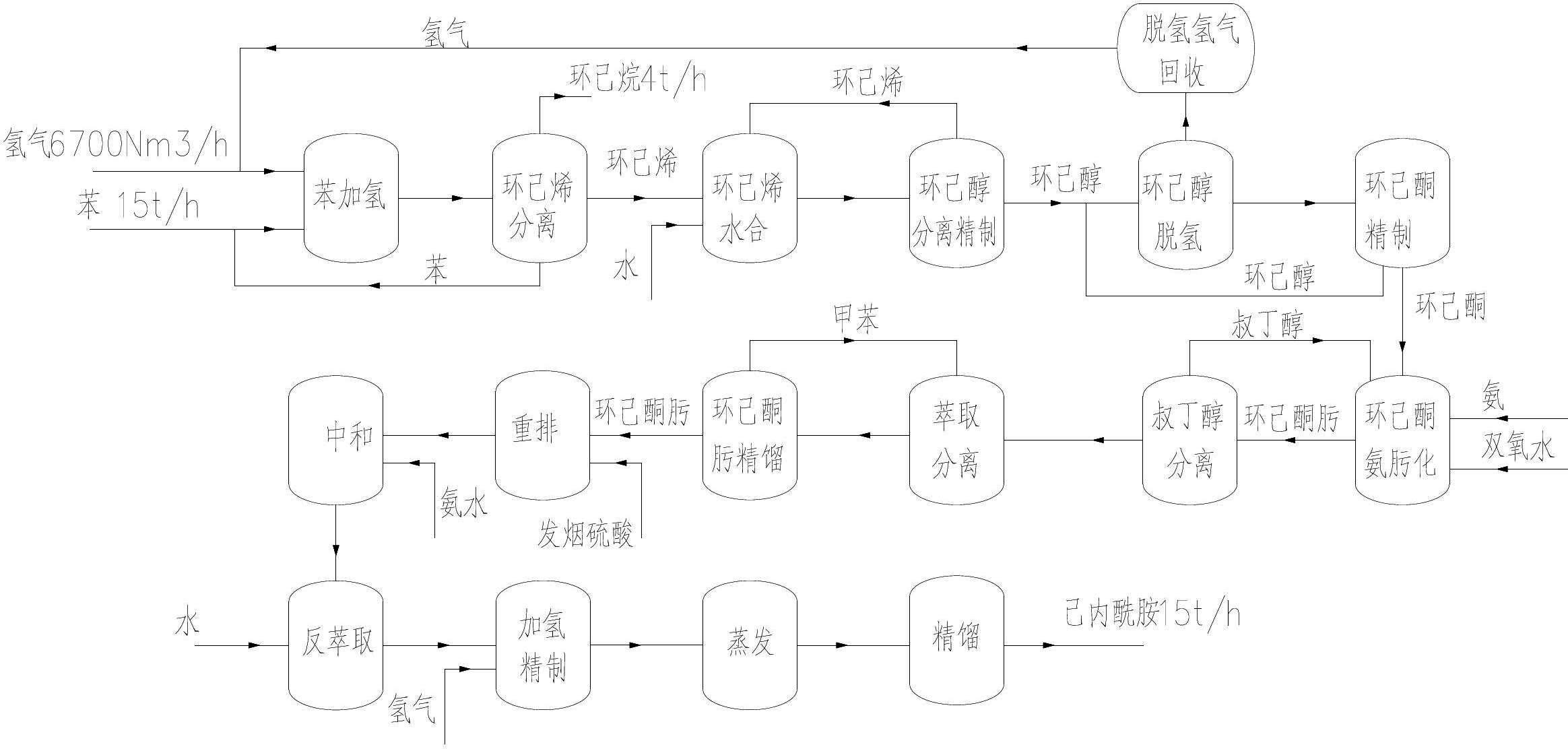

[0068] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. However, the drawings and specific embodiments do not limit the present invention.

[0069] A method for producing caprolactam with high-purity benzene as raw material, which is realized in this way: high-purity benzene with a flow rate of 15t / h enters the benzene hydrogenation reactor through metering and control flow, and hydrogen is introduced at the same time, and the ruthenium-containing catalyst is added in advance In the reactor, the reaction is carried out at a reaction temperature of 145° C. and a pressure of 5 MPaG to generate cyclohexene, and at the same time, some side reactions occur to generate cyclohexane.

[0070] The hydrogenation reaction product passes through the cyclohexene separation unit to separate cyclohexene, cyclohexane and benzene. Benzene is returned to the reactor for continued use; cyclohexane is purified as a by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com