Preparation method of TS-1 titanium silicalite

A titanium-silicon molecular sieve, TS-1 technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of long hydrothermal crystallization time, poor experiment repeatability, complex reaction system, etc., and achieve easy control of particle size and low cost , The effect of simplifying the reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

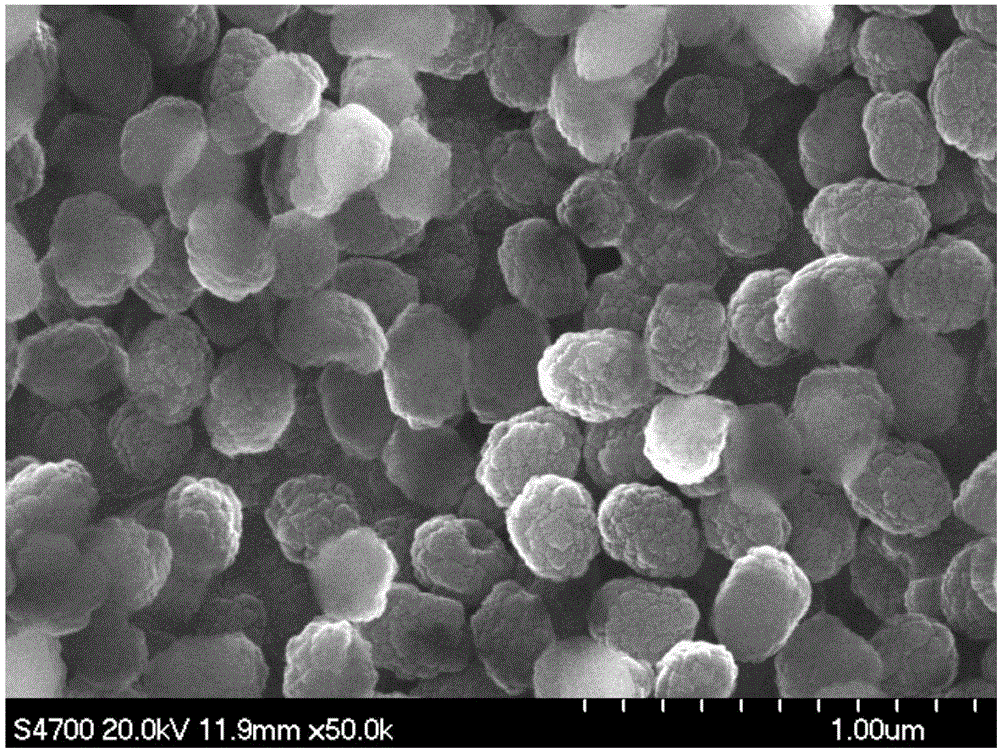

Embodiment 1

[0044] Organic silicon source and organic titanium source are TEOS and TEOT respectively

[0045] first hydrolysis

[0046] SiO in Si source in proportion (molar ratio) 2 : TiO in titanium source 2 : Template agent: H 2 O is 1:0.05:0.22:25, prepare the reaction mixture solution: first add TEOT to TEOS and mix evenly, slowly add the mixed solution of TEOS and TEOT to the template agent under vigorous stirring: H 2 O ratio of 0.22:25 (SiO 2 The molar ratio is 1) in the diluted TPAOH aqueous solution. After all the dropwise addition, the reaction mixture was hydrolyzed at 35°C for 5 hours;

[0047] second step alcohol

[0048] After hydrolyzing the titanium silicon treated in the previous step, the temperature of the reaction mixture solution was raised to 80°C, and the alcohol was removed for 4 hours. According to the calculation, deionized water was added dropwise during the alcohol removal process to ensure that the concentration of the template agent in the reaction mix...

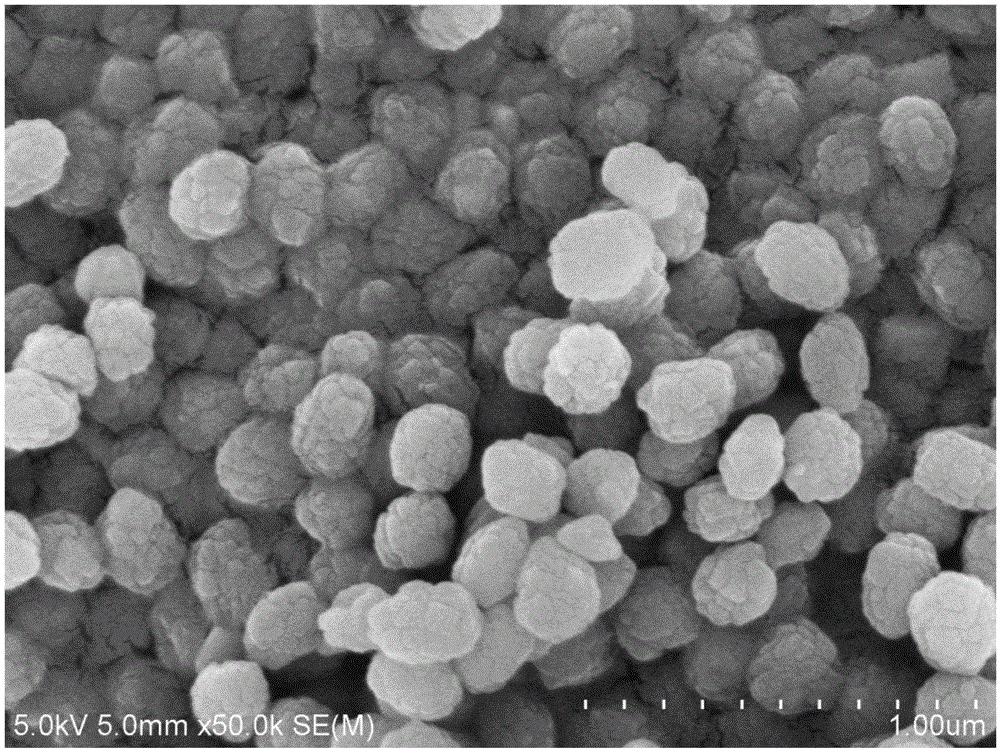

Embodiment 2

[0055] Organic silicon source and organic titanium source are TEOS and TEOT respectively

[0056] first hydrolysis

[0057] SiO in Si source in proportion (molar ratio) 2 : TiO in titanium source 2 : Template agent: H 2 O is 1:0.04:0.25:20, prepare the reaction mixture solution: first add TEOT to TEOS and mix evenly, slowly add the mixed solution of TEOS and TEOT to the template agent under vigorous stirring: H 2 O ratio of 0.25:20 (SiO 2 The molar ratio is 1) in the diluted TPAOH aqueous solution. After all the dropwise addition, the reaction mixture was hydrolyzed at 45°C for 3 hours;

[0058] second step alcohol

[0059] Heat up the reaction mixture solution after hydrolyzing the titanium silicon treated in the previous step to 75°C, and chase the alcohol for 5 hours. According to the calculation, add deionized water dropwise during the alcohol chase to ensure that the concentration of the template agent in the reaction mixture solution is basically unchanged. In ter...

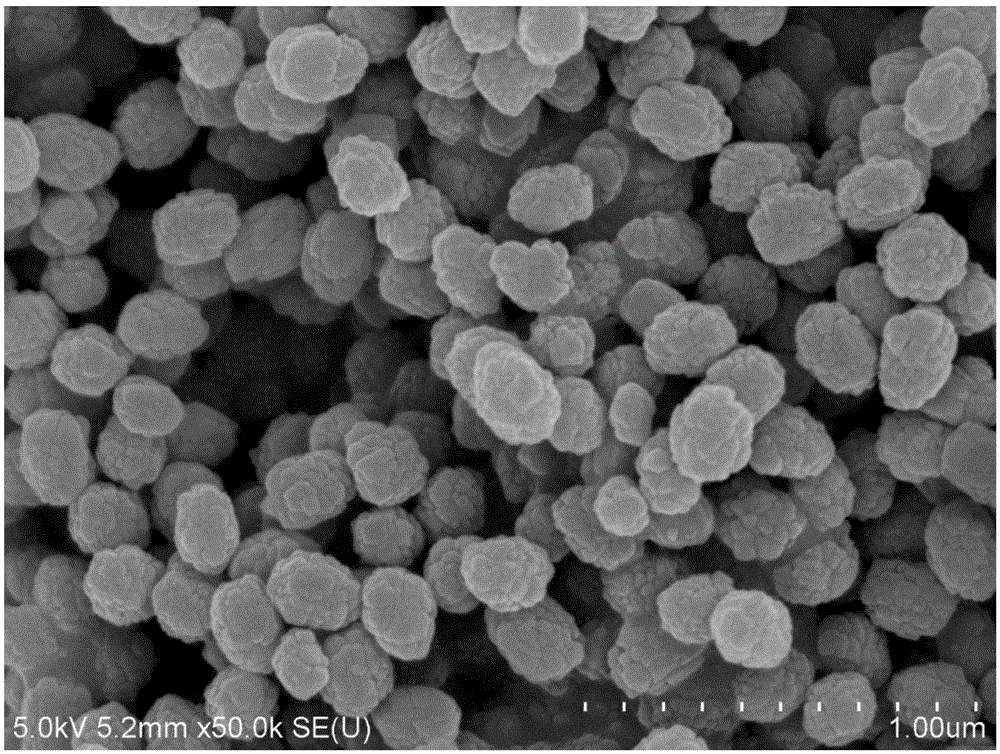

Embodiment 3

[0066] The organic silicon source and the organic titanium source are tetrabutyl orthosilicate and tetrabutyl titanate (TBOT), respectively.

[0067] first hydrolysis

[0068] SiO in Si source in proportion (molar ratio) 2 : TiO in titanium source 2 : Template agent: H 2 O is 1:0.04:0.245:19, prepare the reaction mixture solution: first add TBOT to tetrabutyl orthosilicate and mix evenly, slowly add the mixed solution of TBOT and tetrabutyl orthosilicate to the template under vigorous stirring Agent:H 2 O ratio of 0.245:19 (SiO 2 The molar ratio is 1) in the diluted TPAOH aqueous solution. After all the dropwise addition, the reaction mixture was hydrolyzed at 60°C for 3 hours;

[0069] second step alcohol

[0070] After hydrolyzing the titanium silicon treated in the previous step, the temperature of the reaction mixture solution was raised to 90°C, and the alcohol was removed for 4 hours. According to the calculation, deionized water was added dropwise during the alco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com