Patents

Literature

482results about How to "Simple reaction system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid acid catalyst and reaction technique for synthesis of allantoin

InactiveCN101347739AHigh activityImprove stabilityOrganic chemistryMolecular sieve catalystsRare-earth elementSolid acid

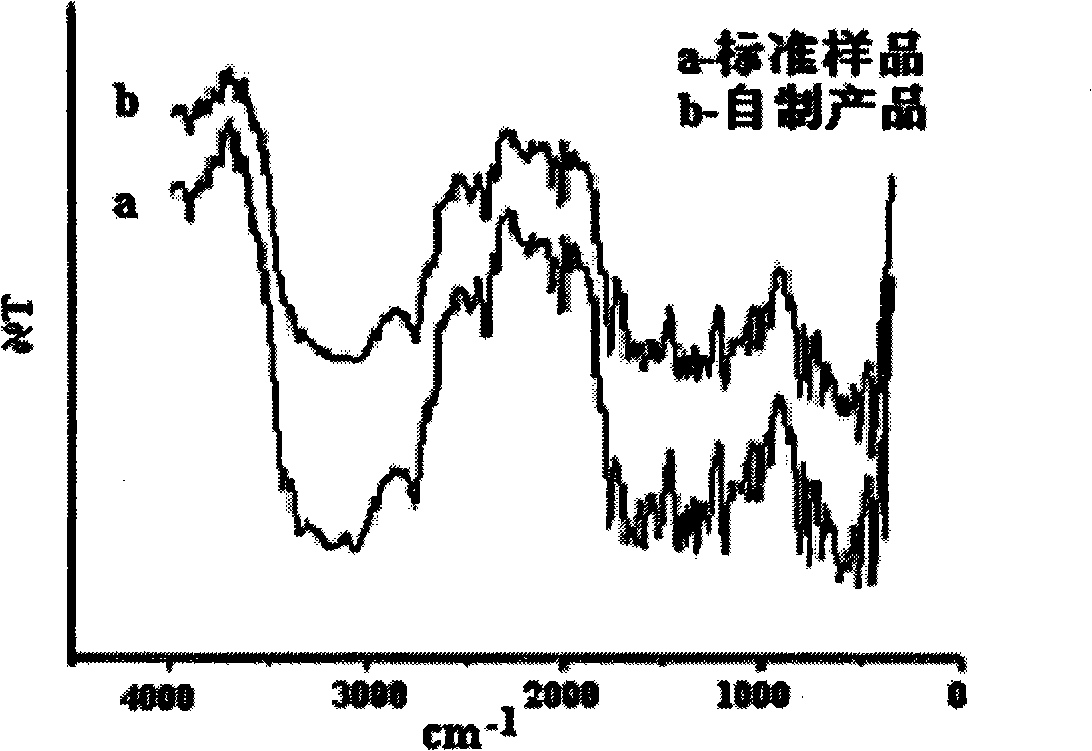

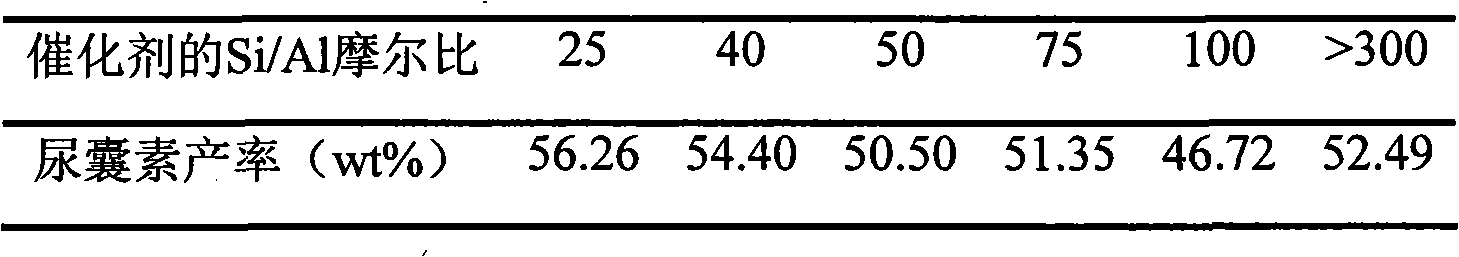

The invention relates to a catalyst for synthesis of allantoin by the reaction of glyoxylic acid and urea and a corresponding reaction process. The catalyst is the solid acid catalyst and takes one or the combination of more of oxides and molecular sieves of IVB to VIB elements as a carrier, or a complex which is composed of one or the combination of more of the oxides and the molecular sieves of IVB to VIB elements and one or the combination of more of the oxides of IB, IIB, VIIB, VIIIB and rare earth element as the carrier, and the carrier is carried out the impregnation supporting, the drying and the calcination by using inorganic strong acid or ammonium salt solution thereof for the preparation. The use of the catalyst can synthesize an allantoin product by one-step reaction of the glyoxylic acid and the urea in an atmospheric pressure tank reactor. The catalyst of the invention has the advantages of high activity and stability, recyclable property, no corrosion of the device and environmental pollution, etc. The synthesis reaction process of the allantoin has the advantages of simple process, less using amount of the catalyst, short reaction time and high yield of the allantoin, etc.

Owner:HUNAN UNIV

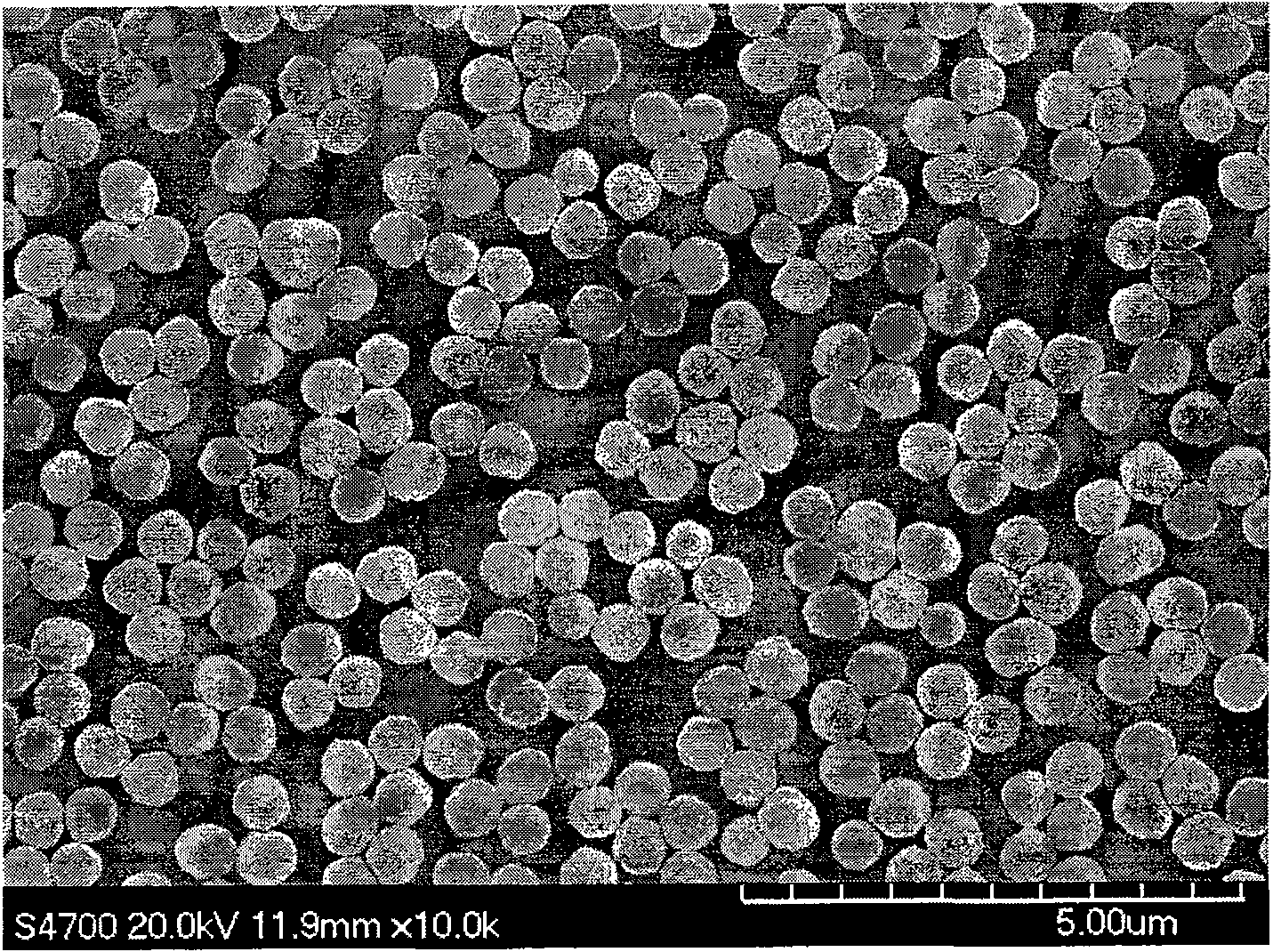

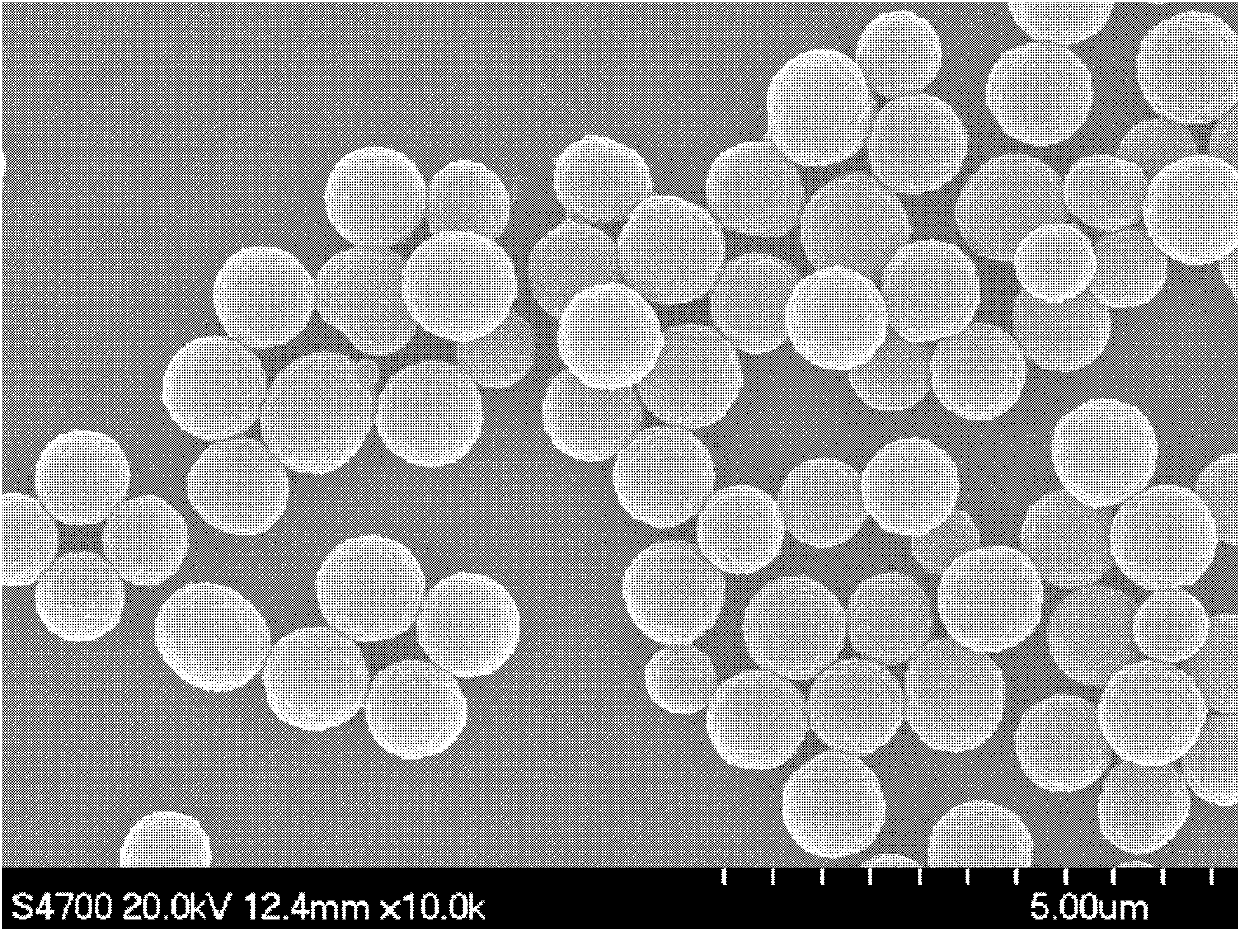

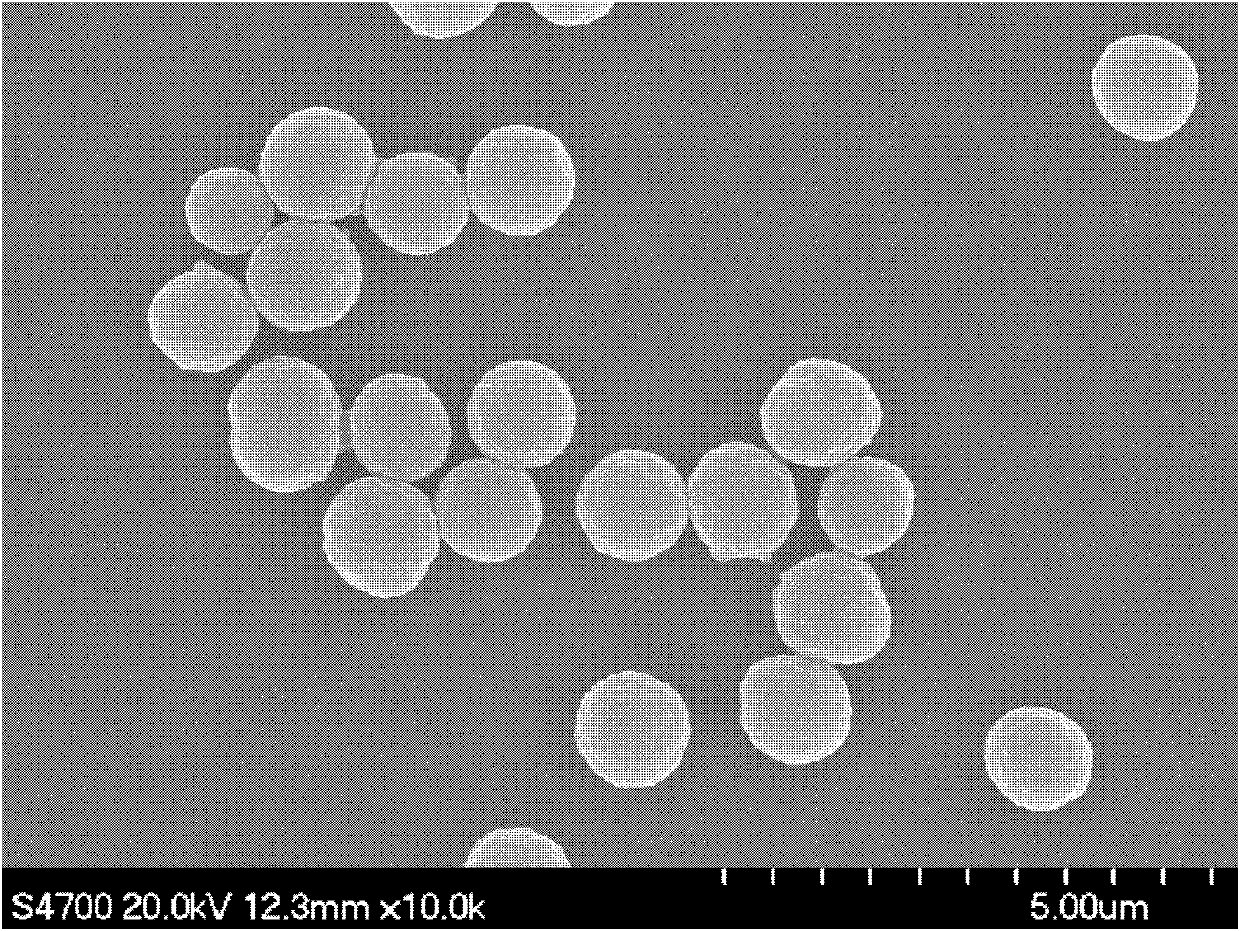

Copolymerization reaction method for styrene/maleic anhydride

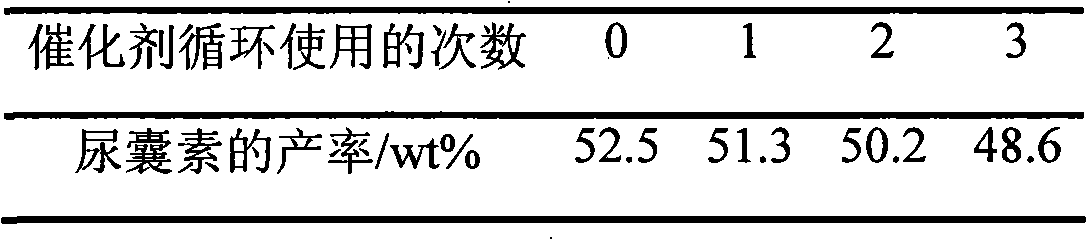

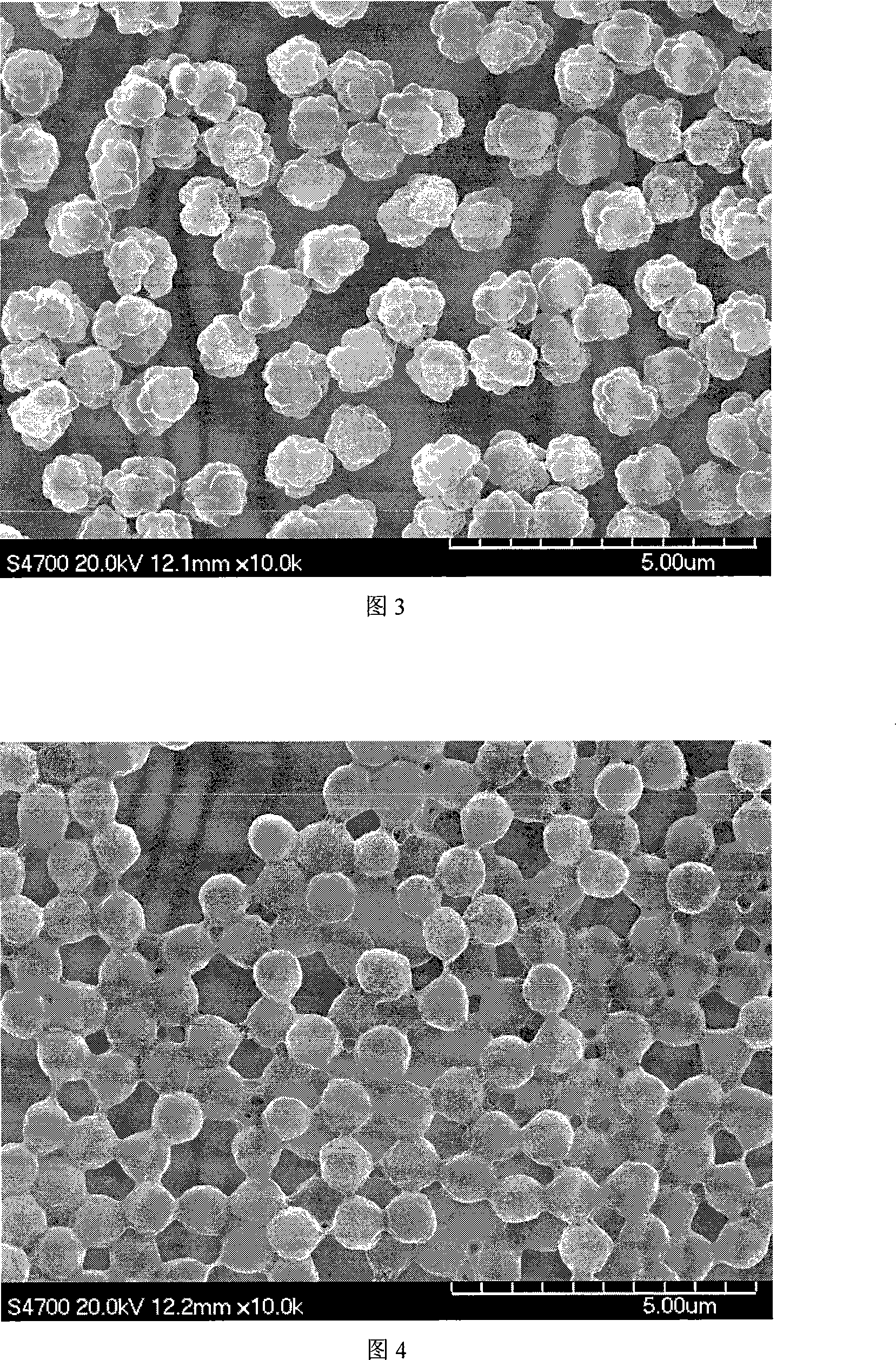

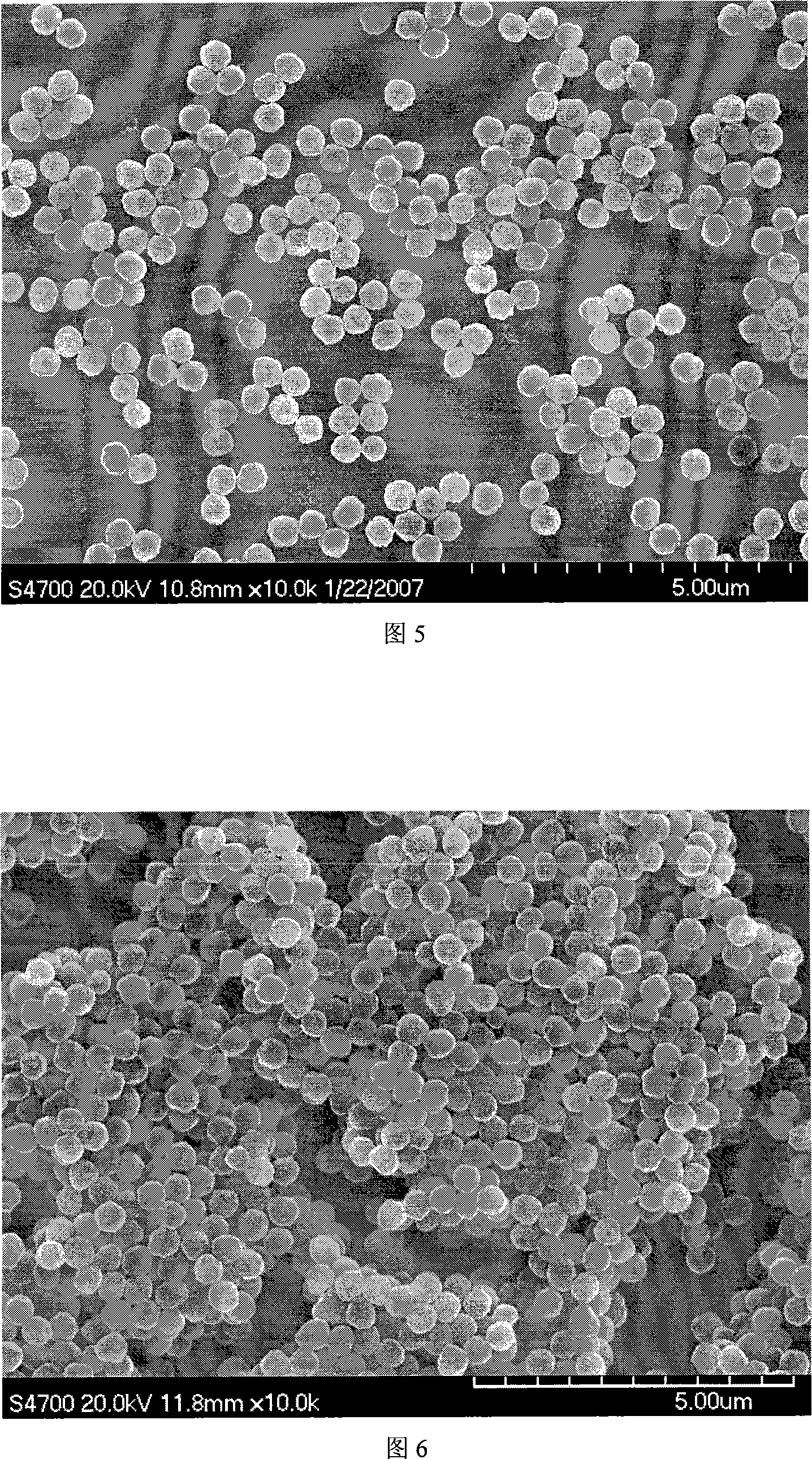

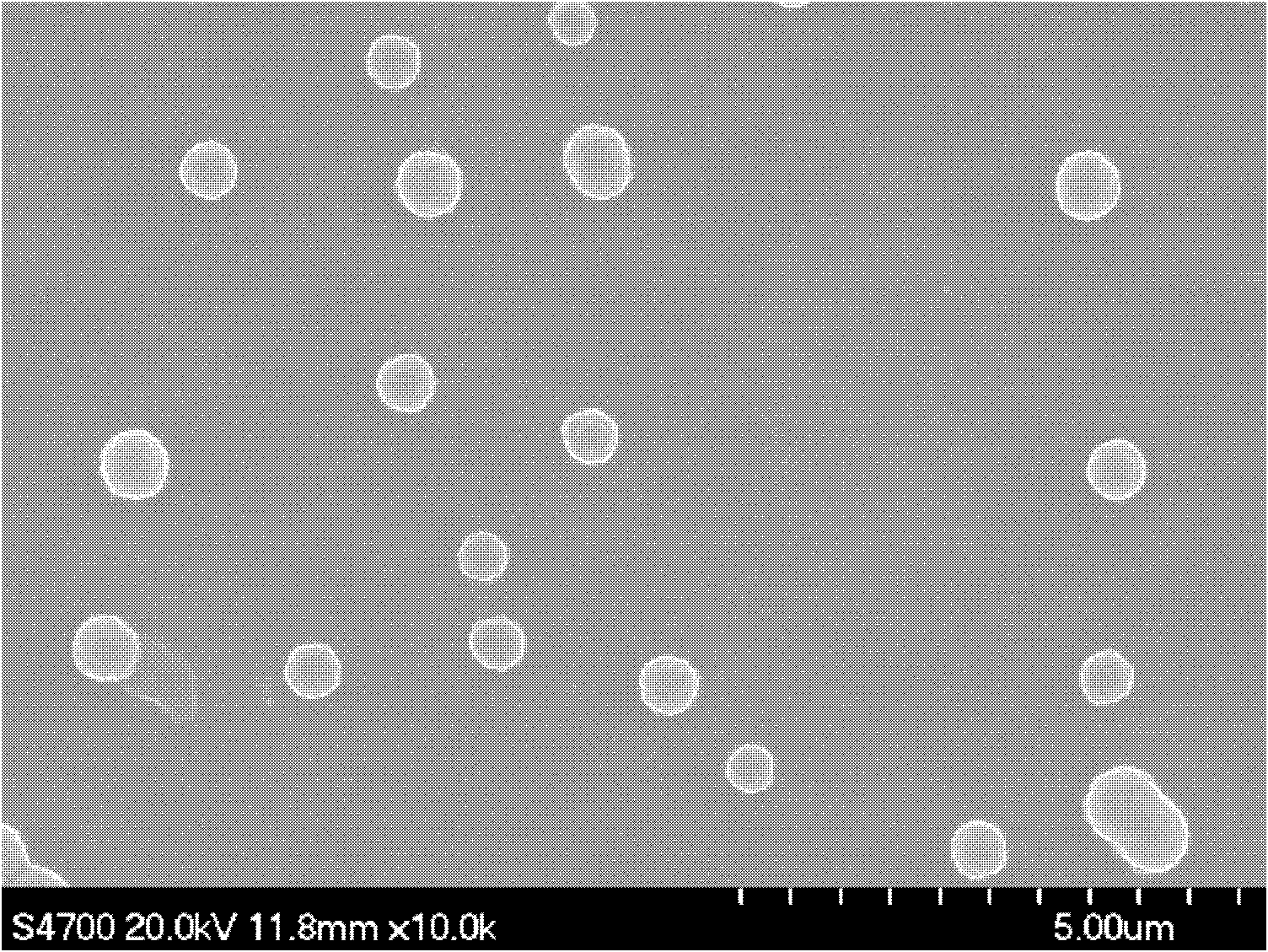

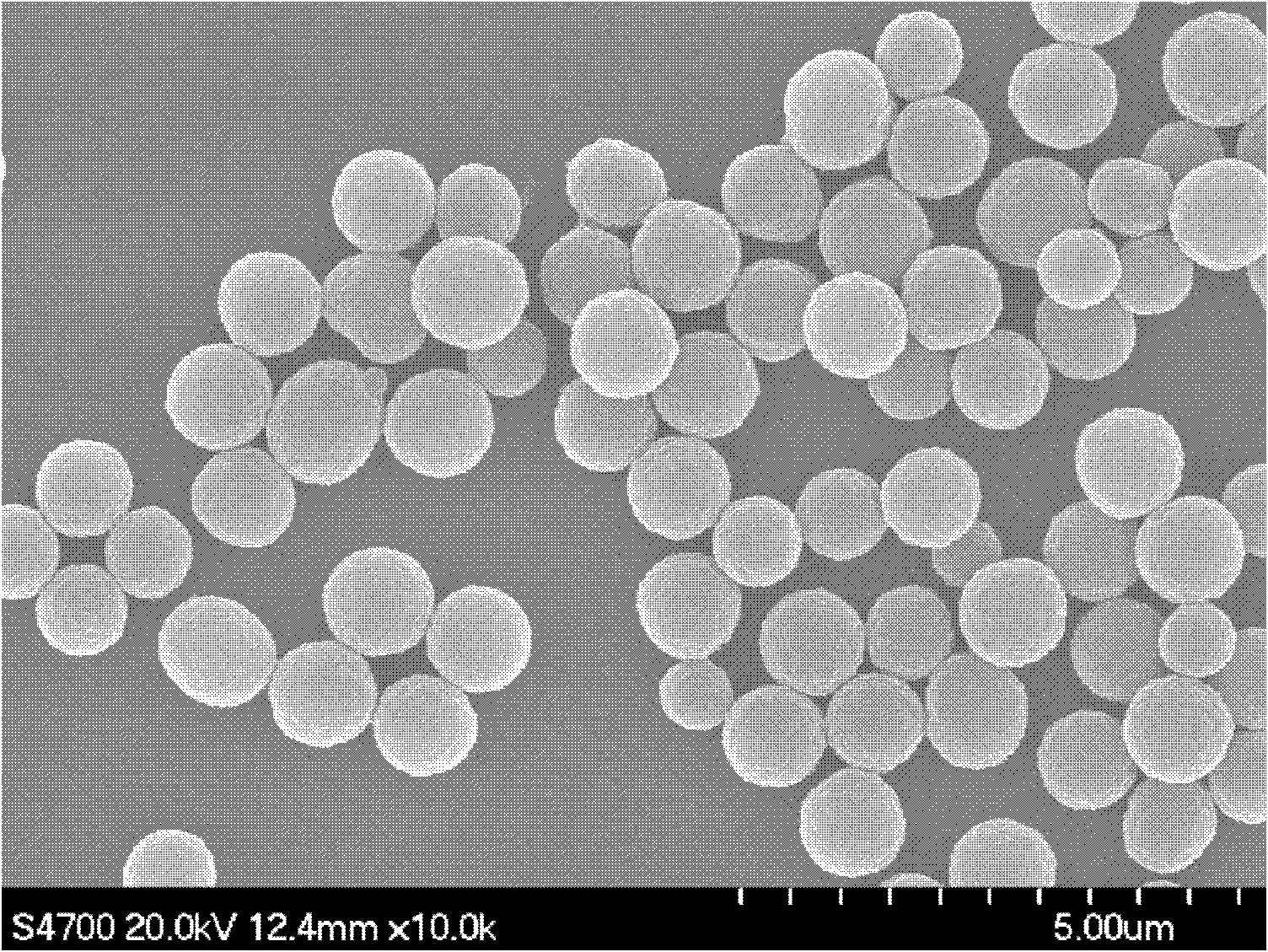

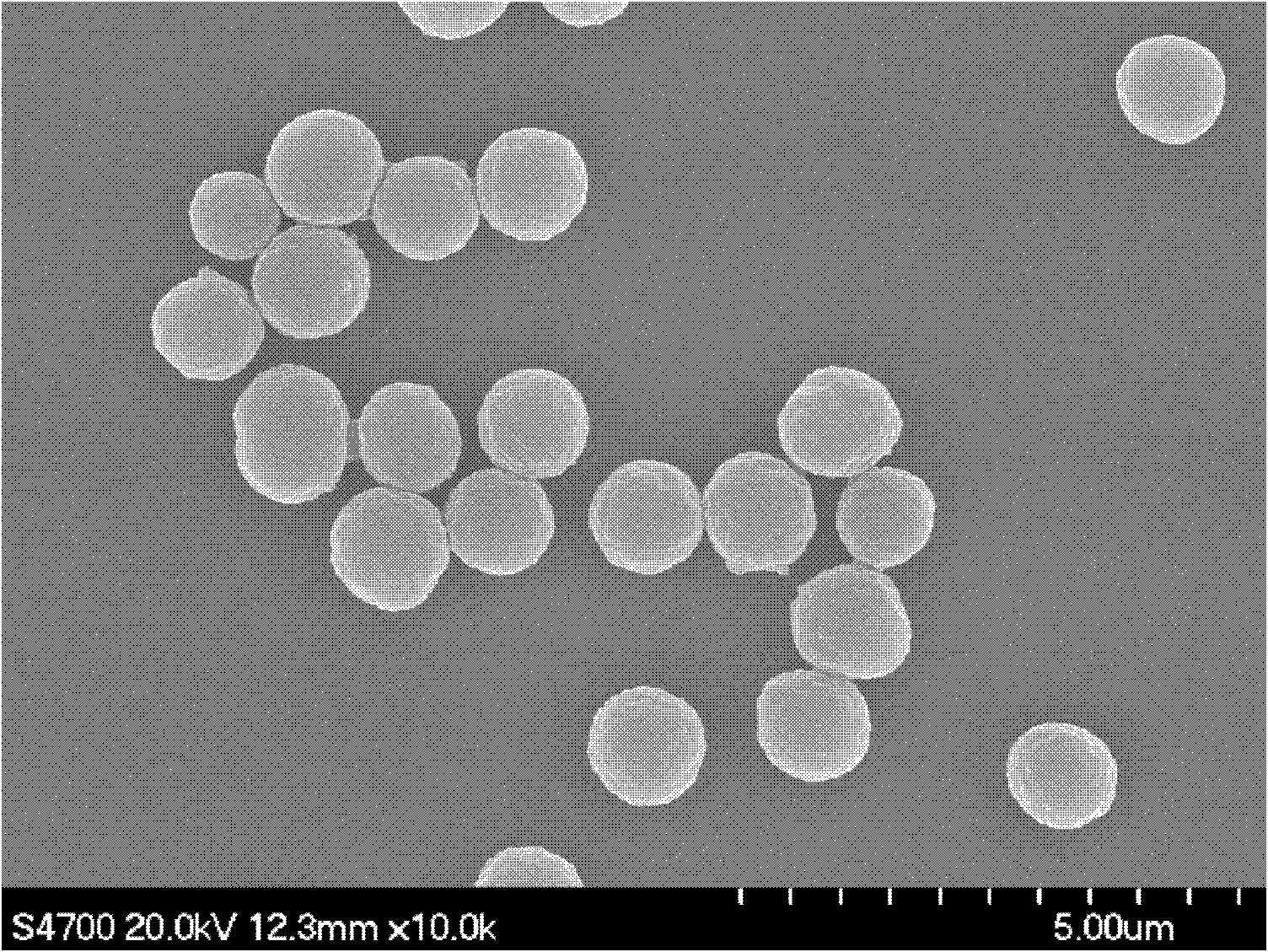

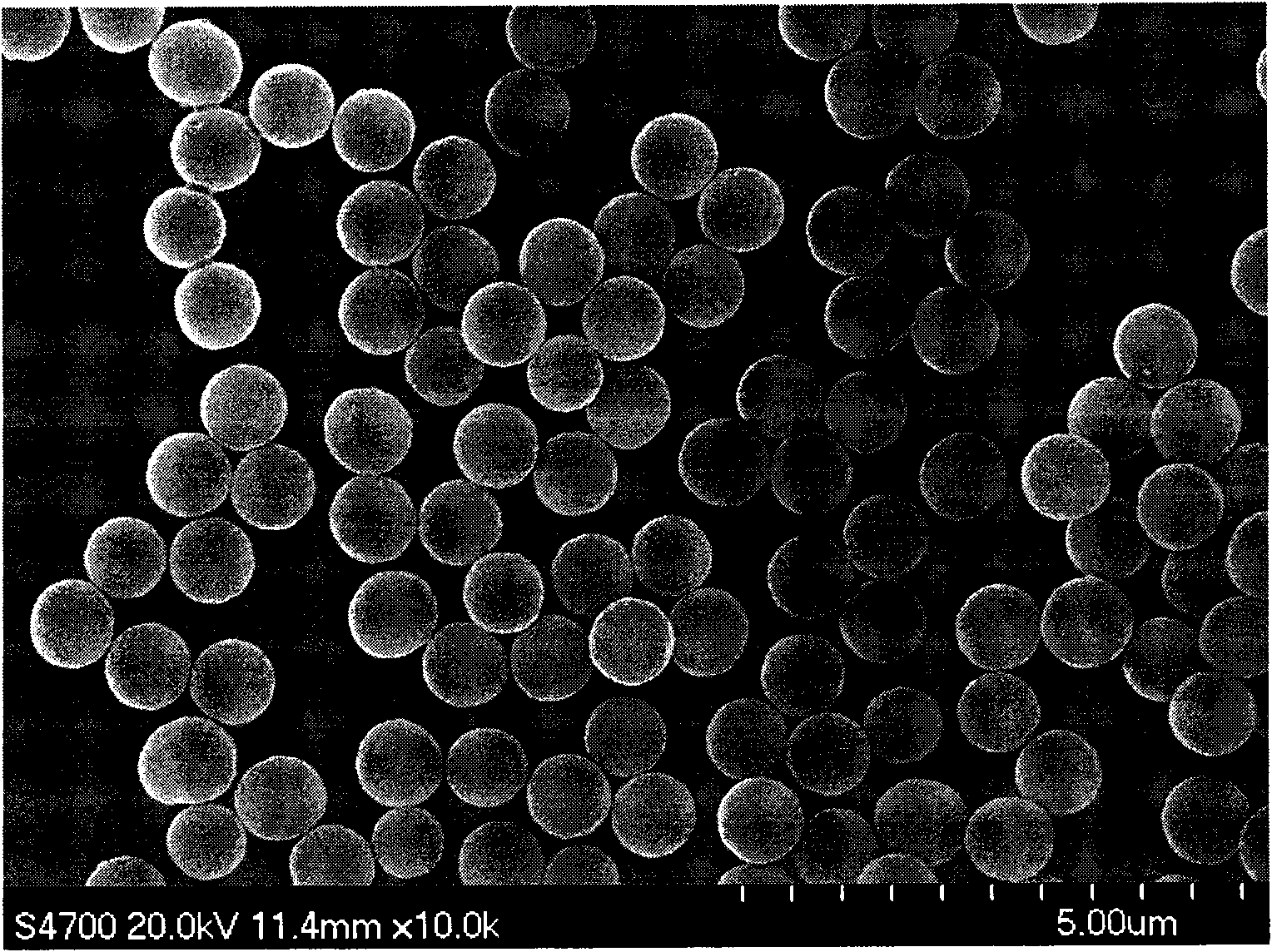

A copolymerization method of phenylethene / maleic anhydride belongs to polymer preparation technical field, for resolving the defect caused by stabilizer in traditional disperse polymerization system, which comprises under nitrogen gas protection, dissolving monomer Man and St, inducer organic hyperoxide or azocompound of suitable ratio in organic acid alkyl ester, the mixture of aromatics and organic acid alkyl ester or the mixture of ketone and alkane to react for 1 / 4-12h at 60-90 DEG C to obtain the disperse system of polymer microballoon, wherein the average particle diameter of microballoon in the disperse system is 90-1715mm, the disperse factor is 1.04-1.004 and the number average molecular weight is 80000-300000g / mol. The invention has the advantages of eliminated stabilizer, simple process, low cost, clean polymer microballoon or particle surface, controllable particle diameter, controllable shape and narrow granularity distribution.

Owner:BEIJING UNIV OF CHEM TECH

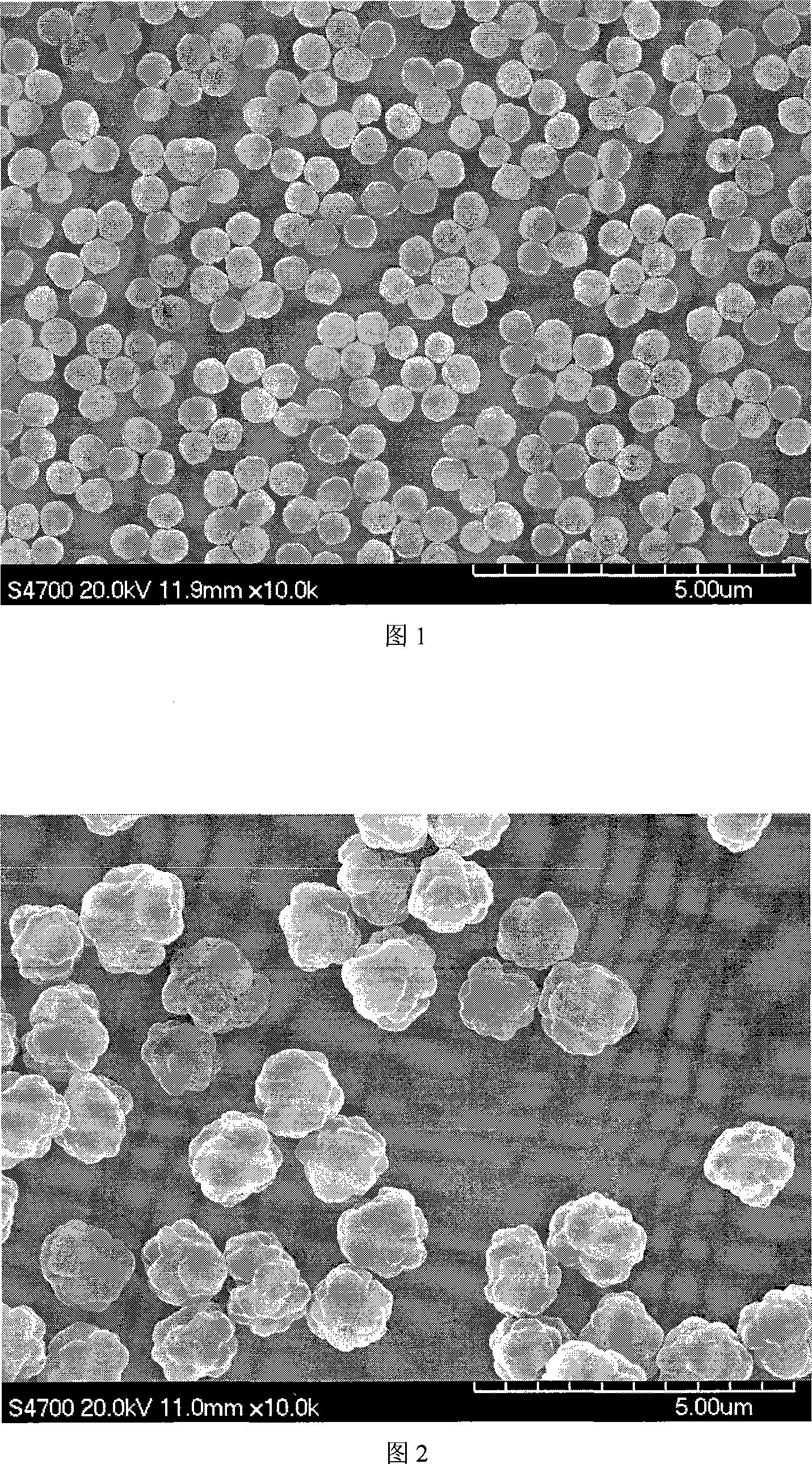

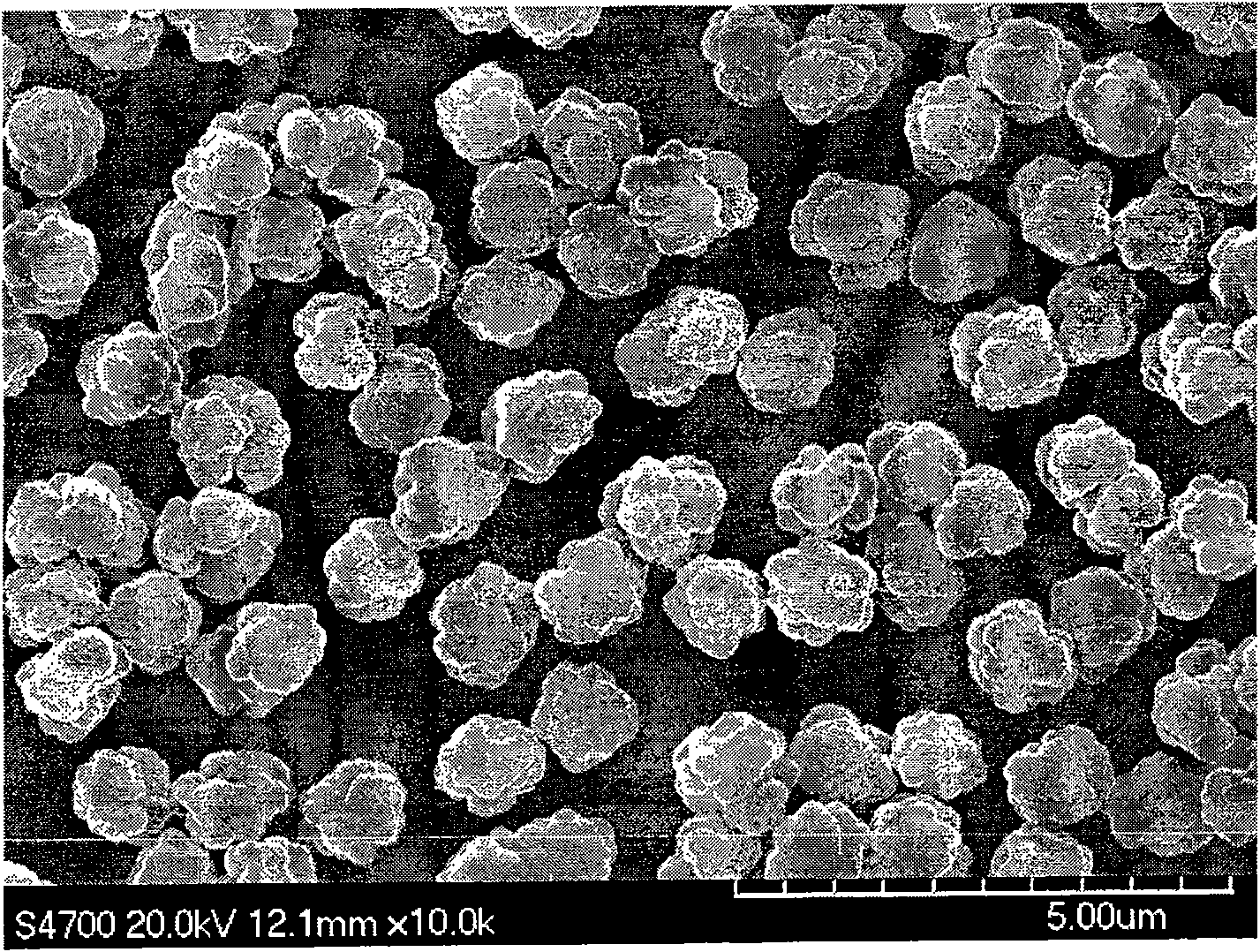

Novel method for performing copolymerization reaction of dicyclopentadiene and maleic anhydride

The invention discloses a novel method for performing a copolymerization reaction of dicyclopentadiene and maleic anhydride, and belongs to the technical field of copolymers. The method comprises the following steps of: under the protection of nitrogen, adding monomers and an initiator into an organic medium and dissolving, reacting for 2 to 12h at the temperature of between 60 and 90 DEG C to obtain a self-stabilizing dispersion system of monodisperse microspheres of an alternating copolymer, and performing centrifugal separation, and drying to obtain a white solid of the dicyclopentadiene / maleic anhydride alternating copolymer, wherein the reaction monomers are the dicyclopentadiene and the maleic anhydride, and the molar ratio of the two monomers is 5:1-1:5; the medium is a mixed solvent of organic acid alkyl ester and organic alkane, and the organic acid alkyl ester accounts for 30 to 70 volume percent of the mixed solvent; and a chemical structure is that: R1 is a hydrogen atom, C1-C5 alkyl, phenyl or benzyl, and R2 is C1-C5 alkyl. A stabilizer and a costabilizer are not required to be added, the reaction system is simple, and a product is easy to separate; and polymer microspheres have smooth and clean surfaces, uniform particle sizes, controllable appearances, and high dispersibility.

Owner:BEIJING UNIV OF CHEM TECH

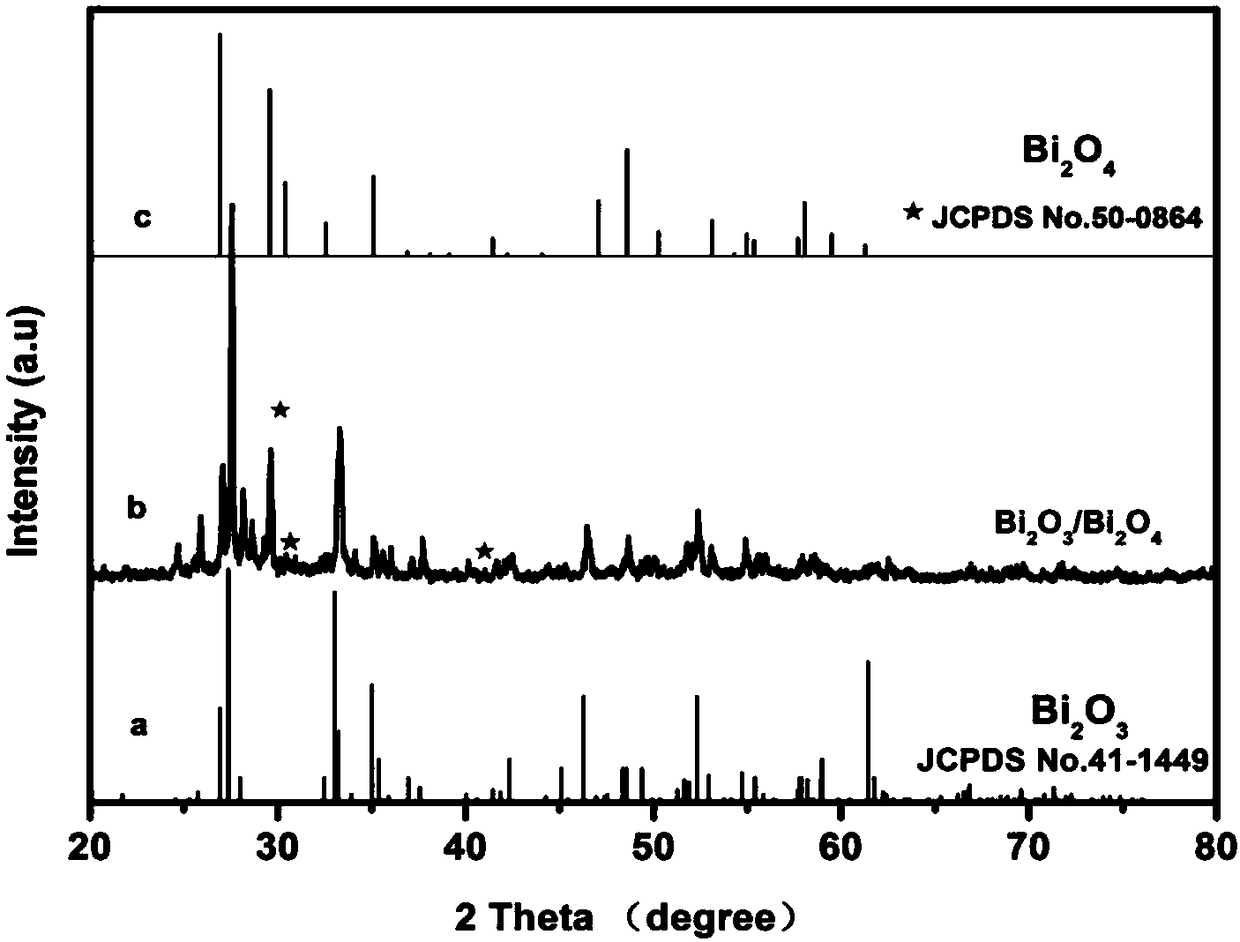

Bismuth oxide/bismuth tetraoxide heterojunction photocatalyst, preparation method and use thereof

ActiveCN108273492AOvercoming the disadvantage of low photocatalytic activityReduce typesWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionMuffle furnace

The invention provides a preparation method and use of a Bi2O3 / Bi2O4 phase heterojunction photocatalyst. The preparation method comprises the following steps: firstly, mixing 2.8 g of bismuth salt with 0-1.87 g of alkali uniformly to prepare a paste; then, placing a mixture into a muffle furnace and calcining at 100-450 DEG C for 0.5-4.0 h; washing a calcined substance with deionized water; and drying at 60 DEG C to obtain earthy yellow to reddish brown solids which are the Bi2O3 / Bi2O4 heterojunction photocatalyst. The Bi2O3 / Bi2O4 phase heterojunction photocatalyst prepared in the invention isused for degrading organic pollutants in water, and has higher visible light catalyzing activity than a commercial Bi2O3 photocatalyst.

Owner:YUNNAN UNIV

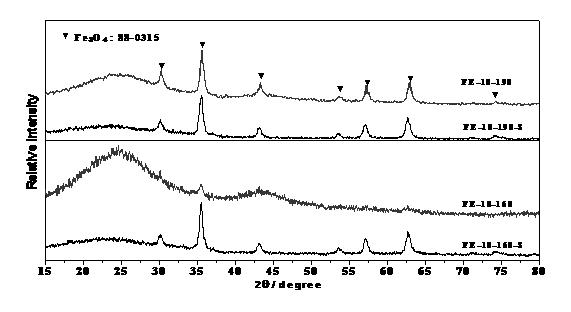

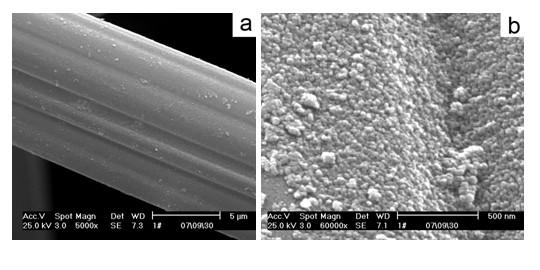

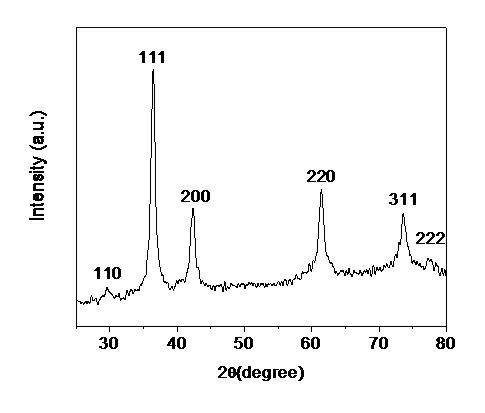

Magnetic separation type composite adsorbing material and preparation method thereof

InactiveCN101940910ASmall grainHigh degree of crystallinityOther chemical processesFiberActivated carbon

The invention relates to a magnetic separation type composite adsorbing material which is prepared from nano Fe3O4 and active carbon fiber. The ferriferous oxide nano composition fiber material is synthesized by using conventional organic solvent as the reaction medium under the control of a simple low temperature solvent thermal system. The magnetic separation type composite adsorbing material can be used as a magnetic separation type adsorbing material for adsorbing organic or inorganic pollutants to purify waste water.

Owner:FUZHOU UNIV

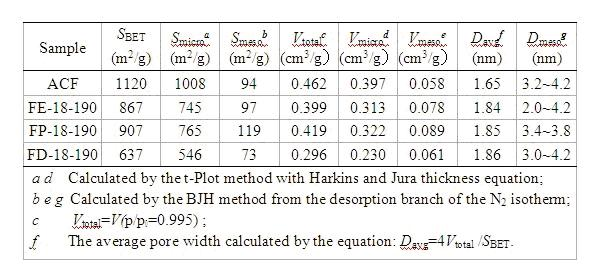

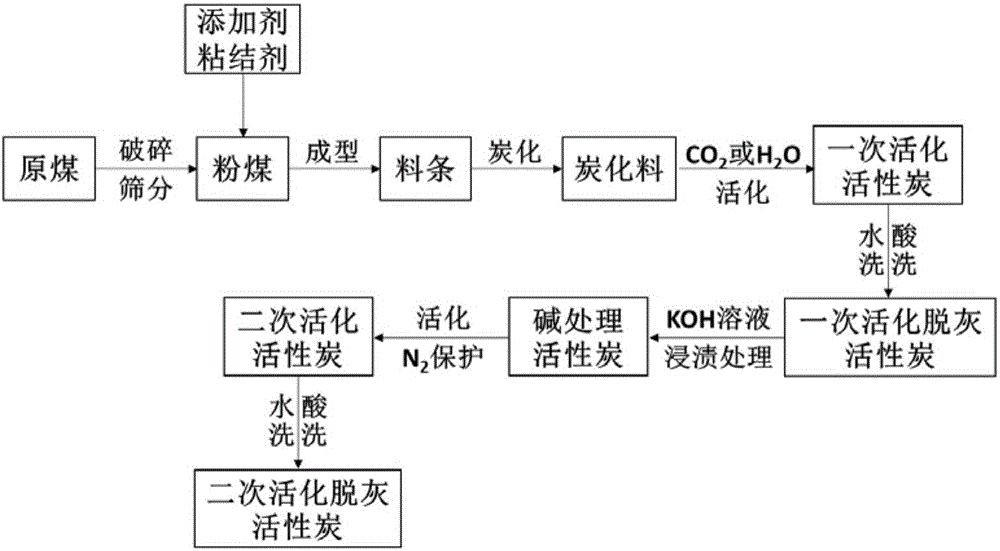

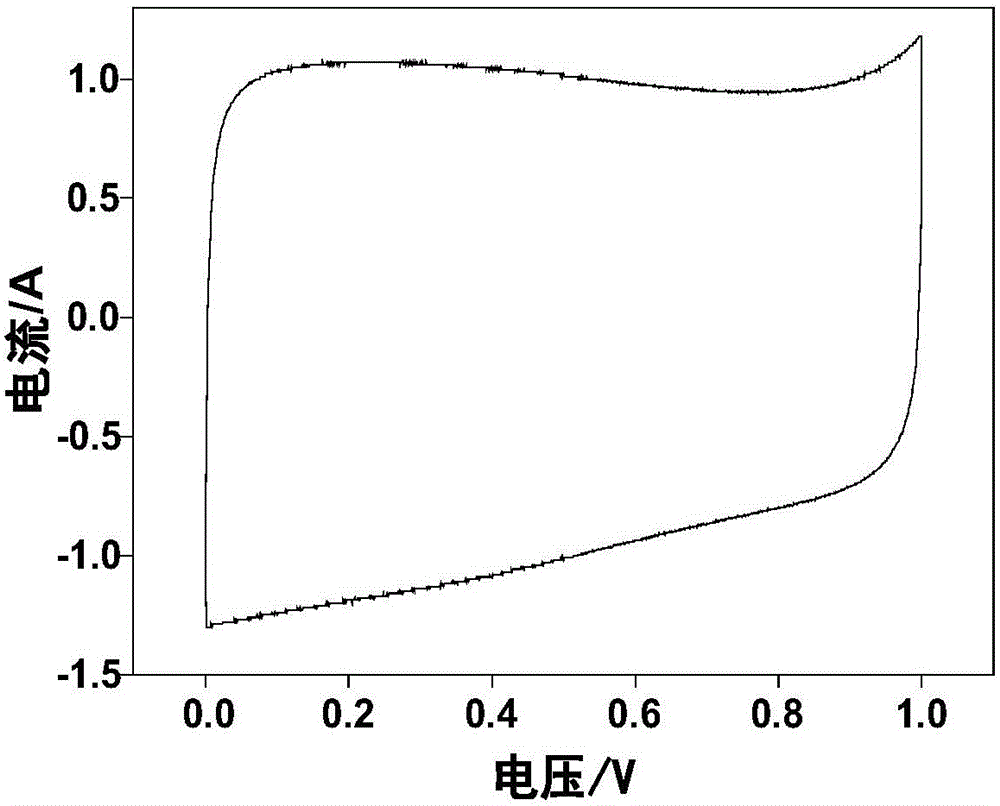

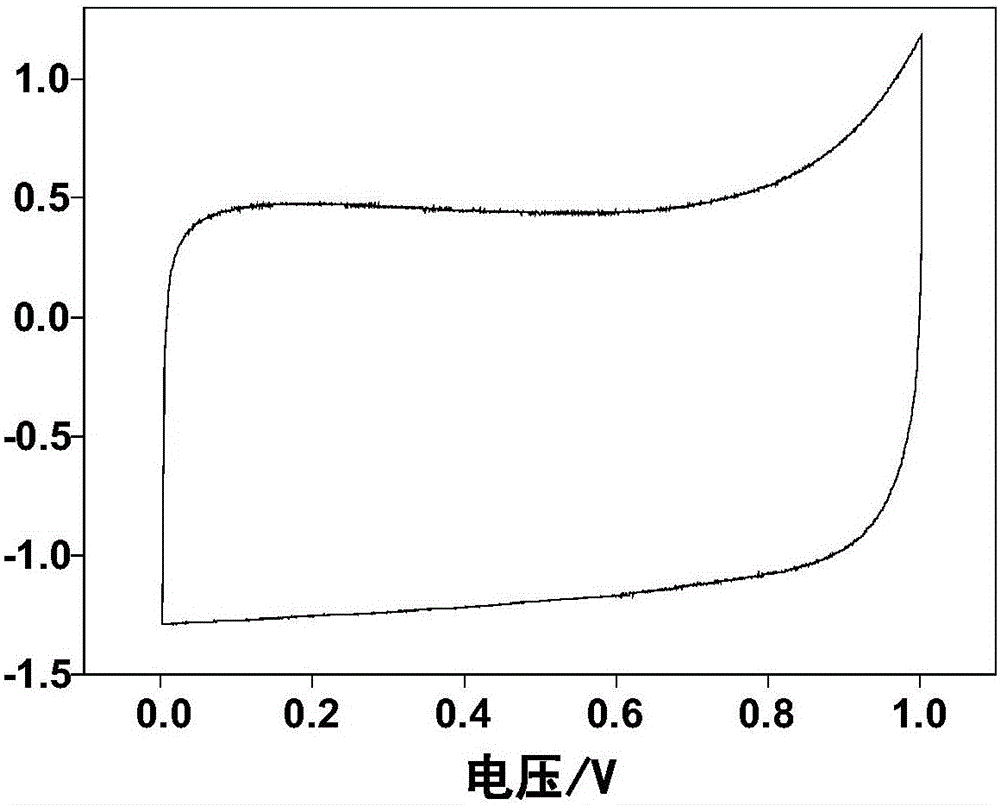

Two-step activation preparation method of activated carbon and application thereof in supercapacitor

The invention discloses a two-step activation preparation method of activated carbon and application thereof in a supercapacitor. The method comprises the following steps that blind coal is smashed and sieved, and an additive and a binder are added to be stirred; the mixture is added into a muffle furnace to be carbonized and then, shifted into a tubular activating oven, activated gas is introduced to be activated; diluted hydrochloric acid is used for acid pickling, filtering is performed, then, distilled water is used for washing, and a KOH solution is used for dipping; one-time activated carbon is placed into the activating oven, and protective gas is introduced to be activated; diluted hydrochloric acid is used for acid pickling, filtering is performed, then, distilled water is used for washing till pH is 7, and then drying is performed; reactivated de-ashing activated carbon is uniformly mixed with ethylene and polytetrafluoroethylene after being ground, the mixture coats foamed nickel, and after drying is performed, tabletting is performed to prepare the supercapacitor. Blind coal is adopted as a raw material, reaction conditions are mild, on the basis of the conventional activated carbon production technology, reactivation and de-ashing are performed, the synthesis cost is greatly lowered, and the huge application and popularization potential is achieved in the field of activated carbon for the high-performance supercapacitor.

Owner:CHINA UNIV OF MINING & TECH

Preparation method of glycolide

ActiveCN103242287AShorten production timeReduce production processOrganic chemistryAcetic acidOligomer

The invention discloses a preparation method of glycolide. According to the preparation method, high purified glycolic acid crystal is taken as a raw material, and high-purity high-yield glycolide crystal can be synthetized through a series of steps such as dehydration polycondensation, melt phase polycondensation, depolymerization reaction and recrystallization purification. Glycolic acid oligomer is generated through glycolic acid polycondensation, and almost all the glycolic acid oligomers are depolymerized for preparing the glycolide under the action of a high efficient catalyst, the usage amount of the catalyst is low, the preparation technology is simple, the yield is high and the preparation method has industrial production potential.

Owner:WUHAN UNIV

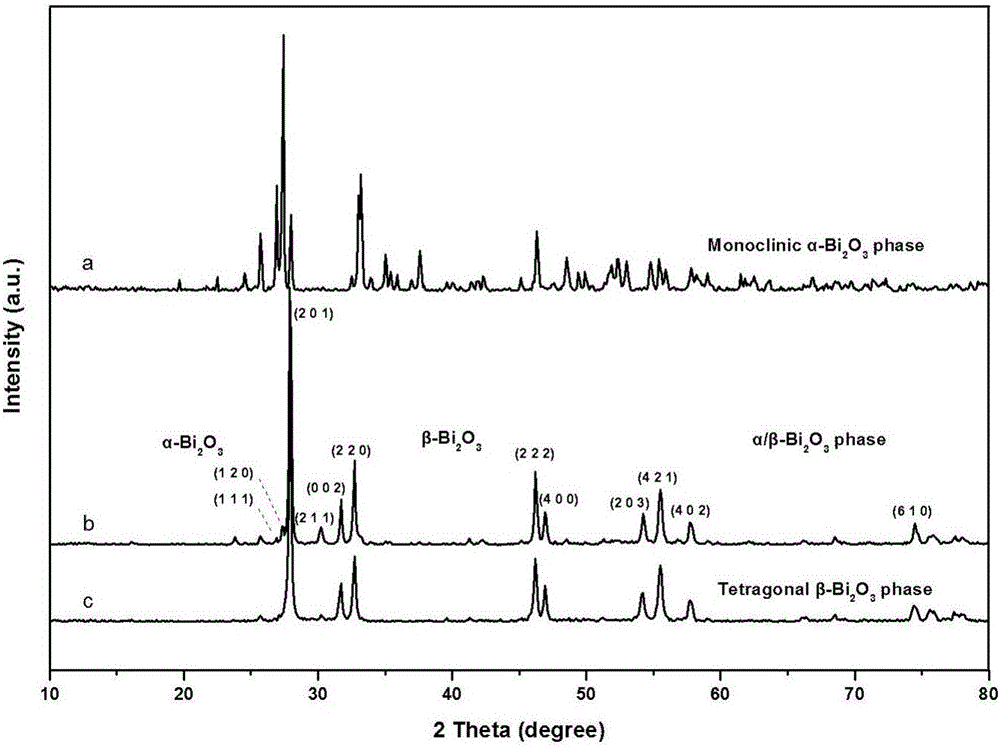

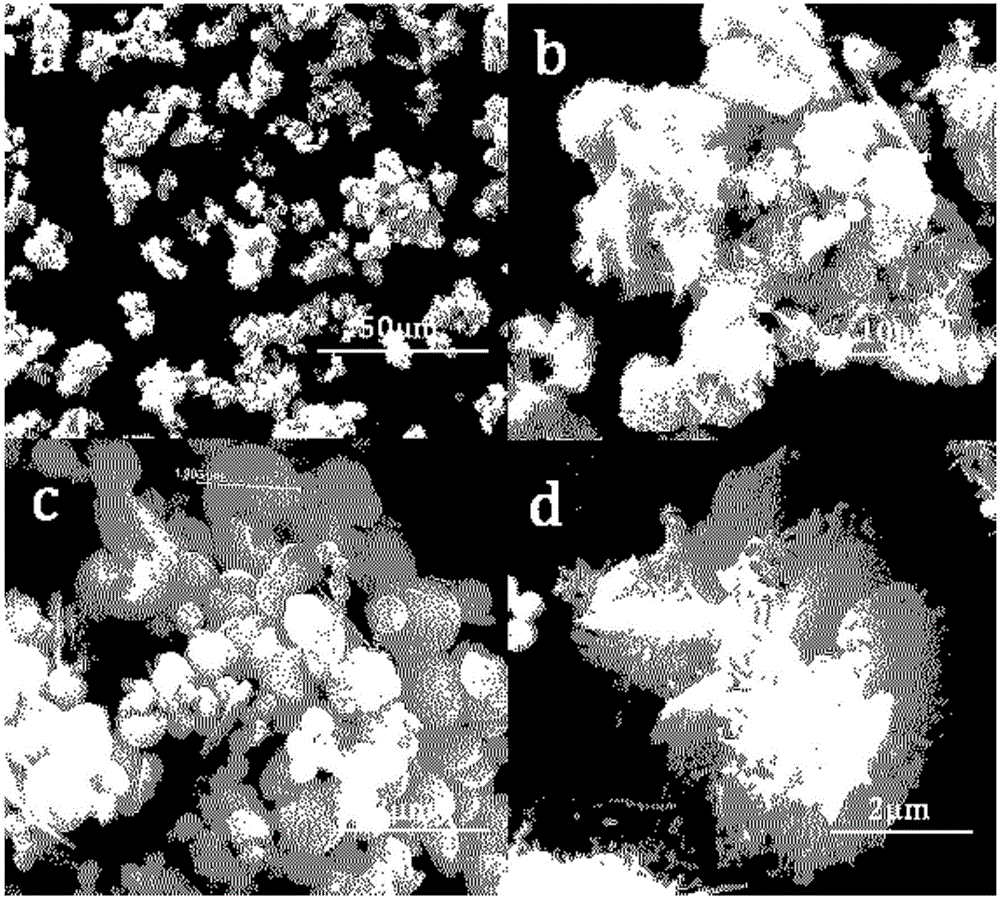

Alpha/beta-bismuth oxide phase heterojunction photocatalyst as well as preparation method and application thereof

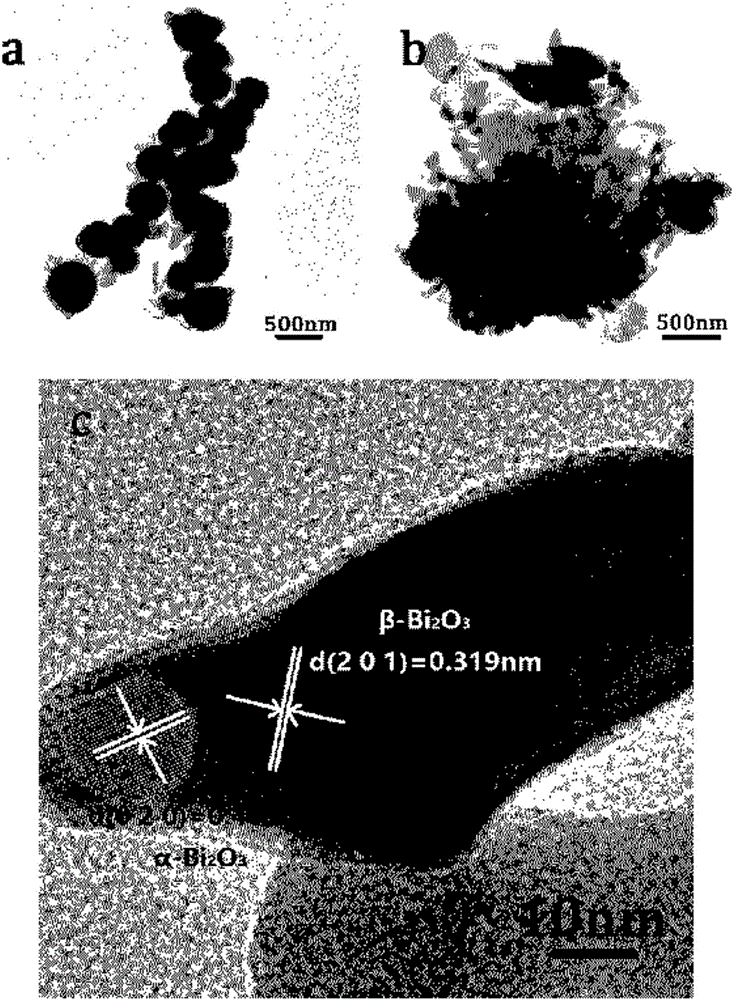

ActiveCN106732524AEfficient degradationEfficient removalWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionSource material

The invention provides an alpha / beta-Bi2O3 phase heterojunction photocatalyst as well as a preparation method and application thereof. The method comprises the following steps: firstly dissolving 2-4mmol of a bismuth source material in 70mL of a reductive solvent, magnetically stirring for 30 minutes under the room temperature, then adding 0-2.0mL of aniline into the solution, and continuing to stir for 10 minutes; transferring the mixed solution into a reactor, putting the mixed solution in a drying oven for carrying out solvothermal reaction for 8-12 hours at the temperature of 150-180 DEG C to obtain a bismuth-based precursor; washing, drying and grinding the precursor, putting the precursor in a muffle furnace for calcining for 0.5-2.0 hours at the temperature of 300 DEG C to obtain yellowish green powder which is the alpha / beta-Bi2O3 phase heterojunction photocatalyst. The prepared alpha / beta-Bi2O3 phase heterojunction photocatalyst is used for degrading organic pollutants in water; compared with commercial TiO2 (P25), pure-phase alpha-Bi2O3 and pure-phase beta-Bi2O3 photocatalysts, the alpha / beta-bismuth oxide phase heterojunction photocatalyst has higher visible-light catalytic activity.

Owner:YUNNAN UNIV

Method for copolymerization of alpha-methyl styrene (AMS) and maleic anhydride (MAn)

The invention provides a method for preparing an alternating copolymer of alpha-methyl styrene (AMS) and maleic anhydride (MAn), belonging to the high molecular precipitation polymerization field. The method comprises the following steps: taking the mixed solution which is formed by respectively mixing organic acid alkyl ester or ketone with alkane as reaction medium, taking organic peroxide or azo compound as an initiator to initiate monomer AMS to copolymerize MAn and preparing the copolymer microsphere of the AMS and MAn; wherein, the copolymer microsphere features uniform grain diameter and monodispersity. The method has simple process and can synthesize good dispersion system featuring uniform grain diameter and even dispersion.

Owner:BEIJING UNIV OF CHEM TECH

Synthetic method of high molecular weight (HMW) alternating copolymer of styrene and maleic anhydride

A synthetic method of a high molecular weight (HMW) alternating copolymer of styrene and maleic anhydride belongs to the high molecular precipitation polymerization field. The copolymer obtained by the current methods for preparing the copolymer of the styrene and maleic anhydride has smaller molecular weight or has higher requirements on equipments and processes. The synthetic method comprises the following steps: taking organic acid alkyl ester or mixed solvent of ketone and alkane as a polyreaction medium, taking organic peroxide or azo compound as an initiator to initiate monomer maleic anhydride to react with the styrene and obtaining the HMW alternating copolymer of styrene and maleic anhydride through precipitation polymerization. The method has simple process and simple post treatment of synthesized copolymer, and has the characteristics of being low in cost and environment-friendly, etc.

Owner:BEIJING UNIV OF CHEM TECH

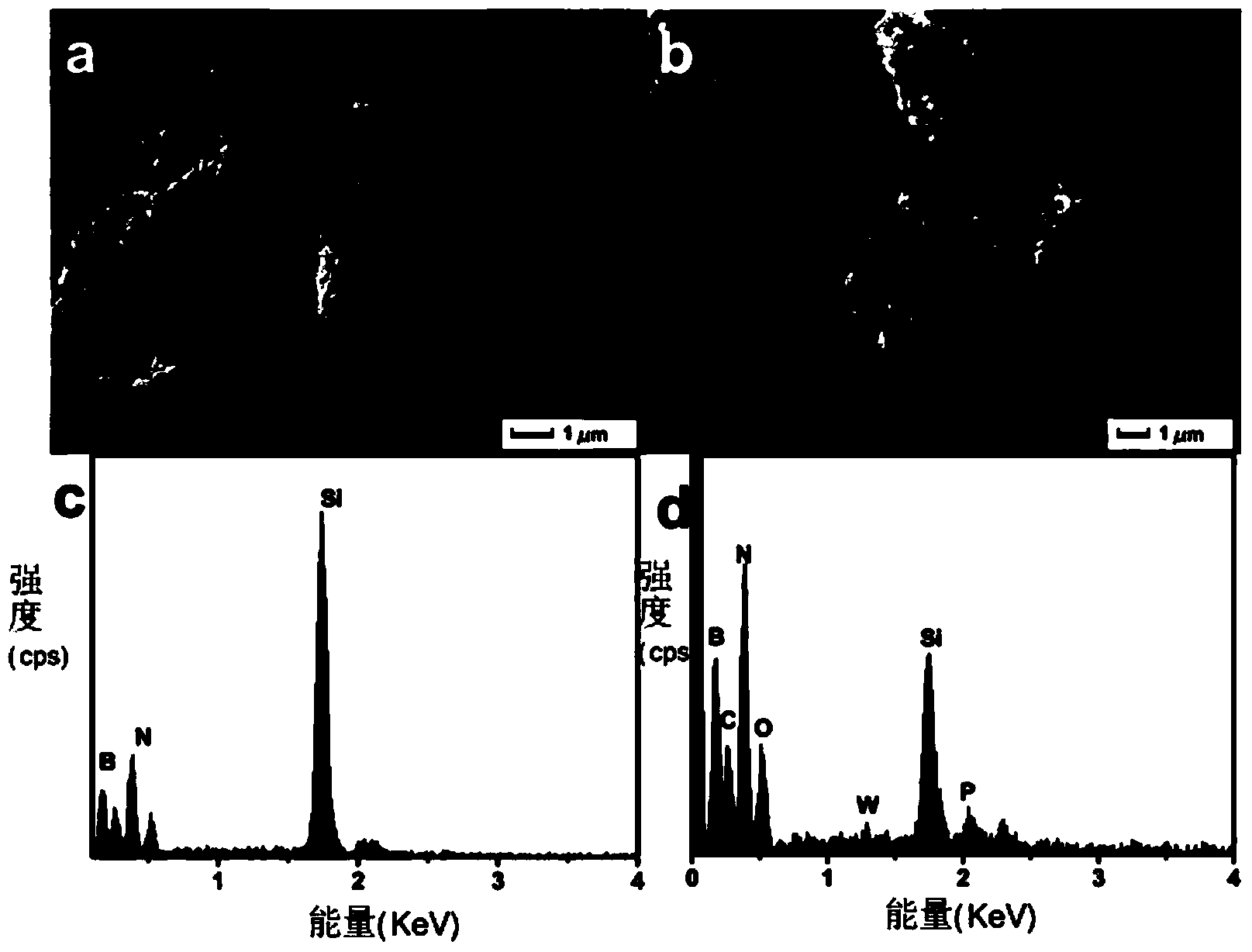

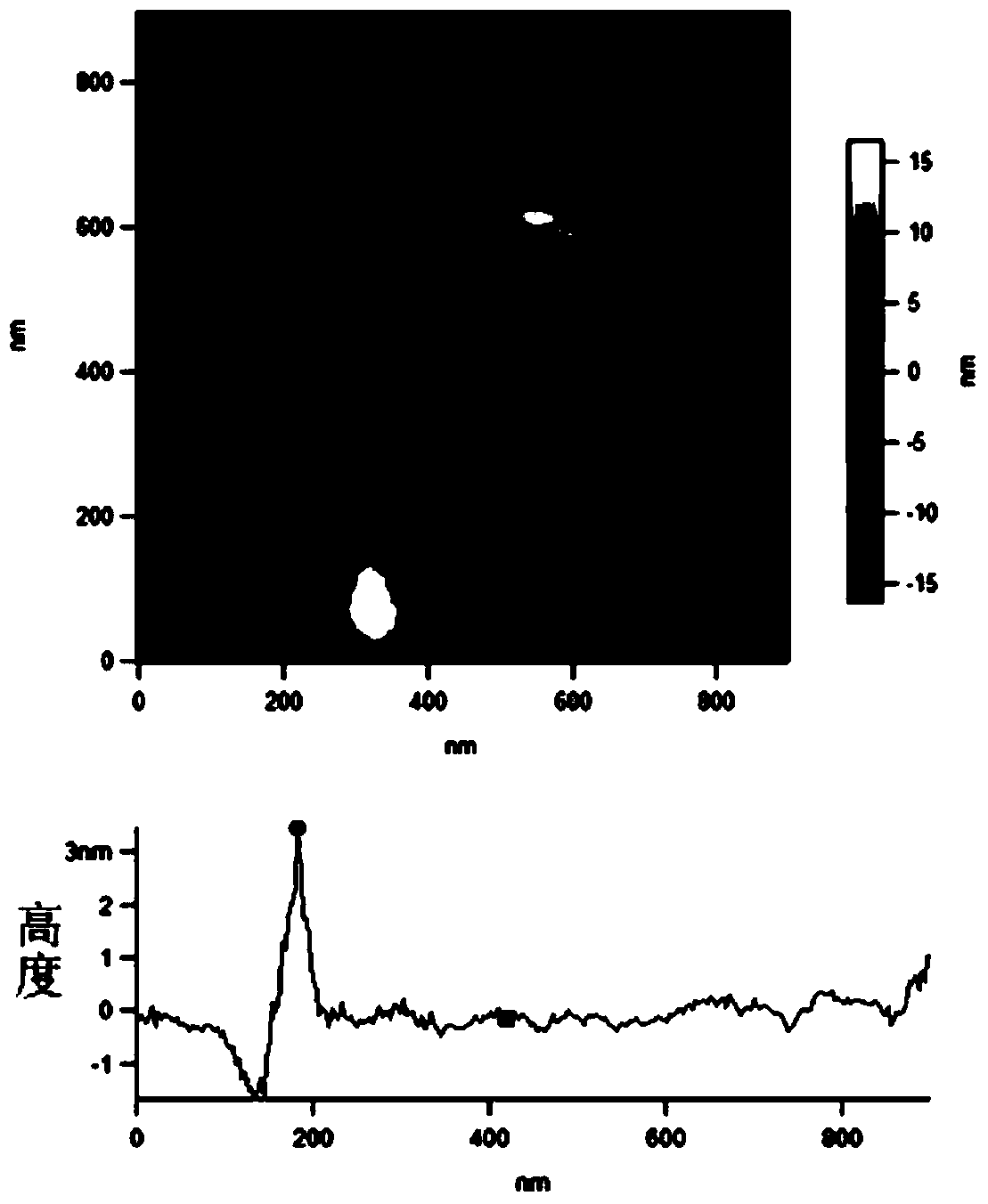

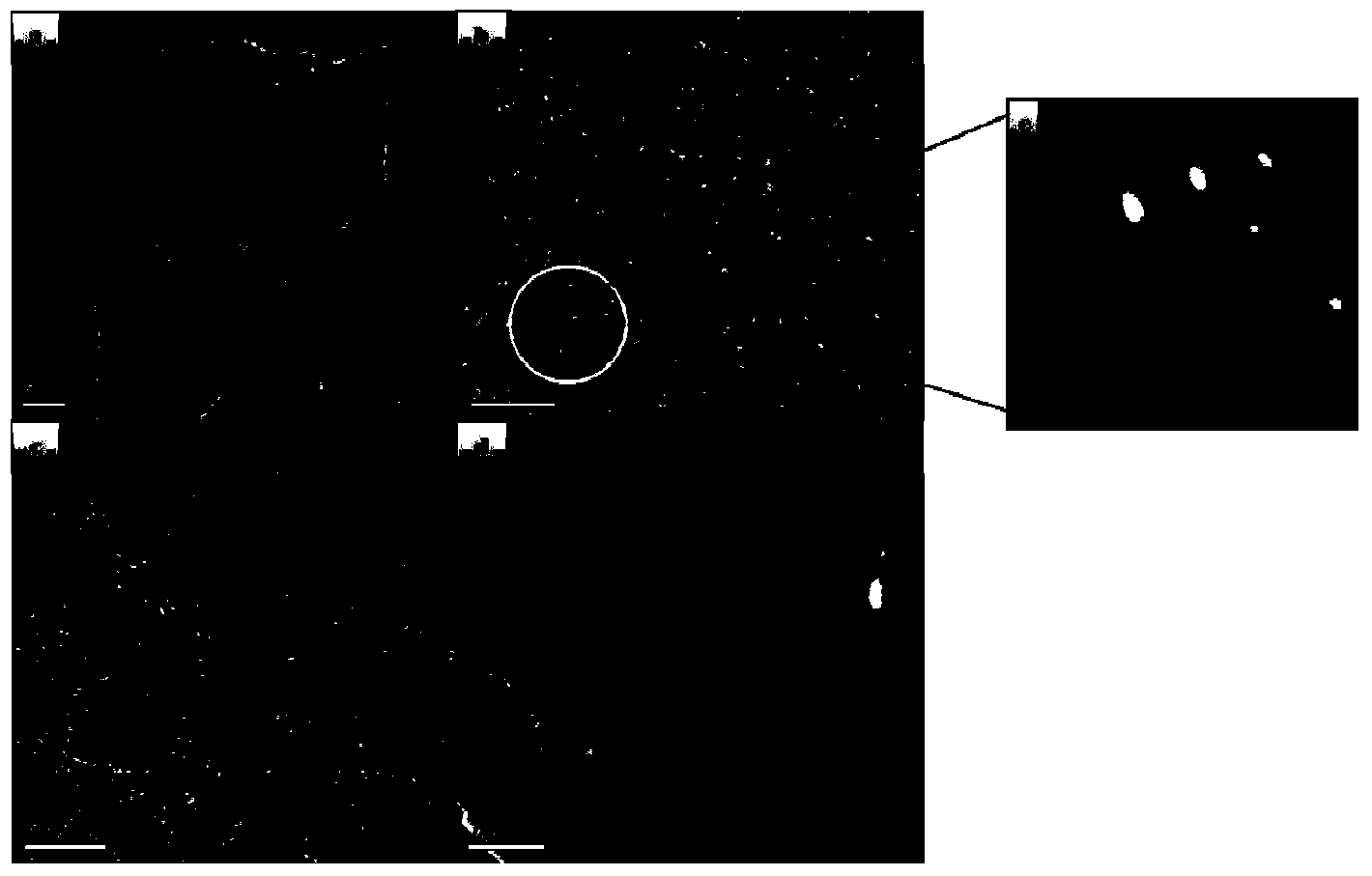

Preparation method of graphene-like boron nitride loading ionic liquid catalyst and application thereof

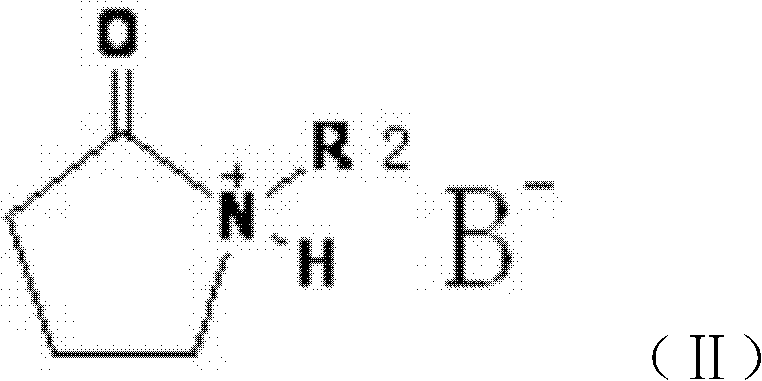

ActiveCN103736521AHigh activityEasy to useOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsQuaternary ammonium cationBoron nitride

The invention discloses a preparation method of a graphene-like boron nitride (G-BN) loading ionic liquid (IL) catalyst. The catalyst takes graphene-like boron nitride as a carrier, and an ionic liquid is carried in a solid state to the catalyst which is synthesized on graphene-like boron nitride, wherein the graphene-like boron nitride is a single-layer or less-layer boron nitride, the ionic liquid is a metal-matrix polyacid ionic liquid, and the molecular formula thereof is Q2 [M6O19], where M is a central atom which is tungsten and molybdenum, Q is a cation which is a quaternary phosphonate cation(I) or a quaternary ammonium cation (II), and R1, R2, R3 and R4 are linear chain alkyls. The catalyst disclosed by the invention has the advantages of having high sulfur removal efficiency, short reaction time, simple reaction system, mild reaction conditions, easy separation and convenient recycling and requiring no pressurization equipment.

Owner:JIANGSU UNIV

Method for degrading formaldehyde pollutant with catalyzing wet oxidation process

InactiveCN101844827AHigh activityMild reaction conditionsWater/sewage treatment by oxidationHigh concentrationIndustrial waste water

The invention provides a method for degrading high-concentration formaldehyde pollutant with a catalyzing wet oxidation process by adopting metal-metal oxide as a catalyst. The formaldehyde pollutant water solution with the mass concentration of 100 to 10000 mg / L is arranged into a high-pressure reactor, metal-metal oxide compound catalyst is added into the reactor, oxygen or air is used as an oxidant, the formaldehyde pollutant is removed through the oxidation reaction, the reaction temperature is 60 to 200 DEG C, the reaction pressure is 0.5 to 3MPa, pH value of the reaction solution is 2 to 10, and the reaction time is 0.5 to 8 hours. The reaction condition by adopting the method to process the formaldehyde waste water is moderate, the cost is low, the removal rate of total organic carbon of formaldehyde containing the formaldehyde reaches more than 90 percent, secondary pollution does not exist, and the method is applicable to the degradation of the formaldehyde pollutant in the industrial waste water and has promising industrialized application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for generating 5-hydroxymethylfurfural by using ionic liquid catalysis

InactiveCN101812039AEasy to separateEasy to purifyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventHydroxymethylfurfural

The invention discloses a method for generating 5-hydroxymethylfurfural by using ionic liquid catalysis, which comprises the following steps: dissolving a reaction substrate into an organic solvent, and adding ionic liquid in an amount of 5 to 20 percent based on the total mole of the reaction substrate; and reacting the mixture for at least 2 hours at the temperature of between 70 and 120 DEG C under the protection of inert gas, namely neutralizing the reaction solution, and filtering, drying and distilling the reaction product to obtain the 5-hydroxymethylfurfural. The reaction system shows the characteristic of homogeneous reaction during catalytic dehydration, and has high catalytic activity and selectivity; and the using amount of a catalyst can be optimized to trace so as to improve the reaction conversion rate, reduce the use of other organic solvent and additive, reduce the cost and facilitate the separation and purification of the reaction product at the same time.

Owner:TIANJIN UNIV

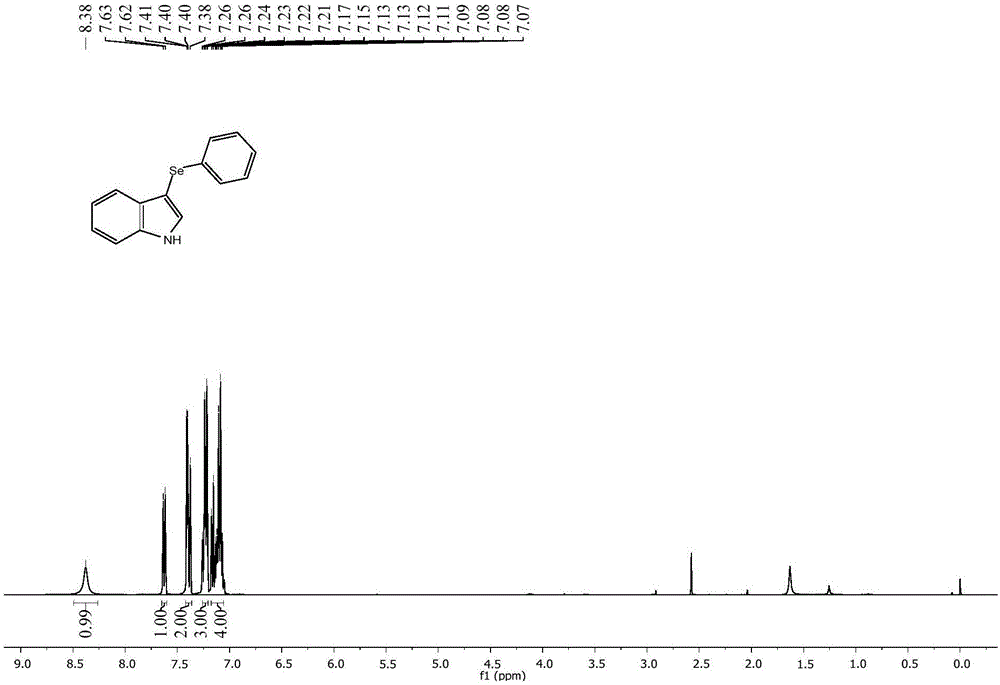

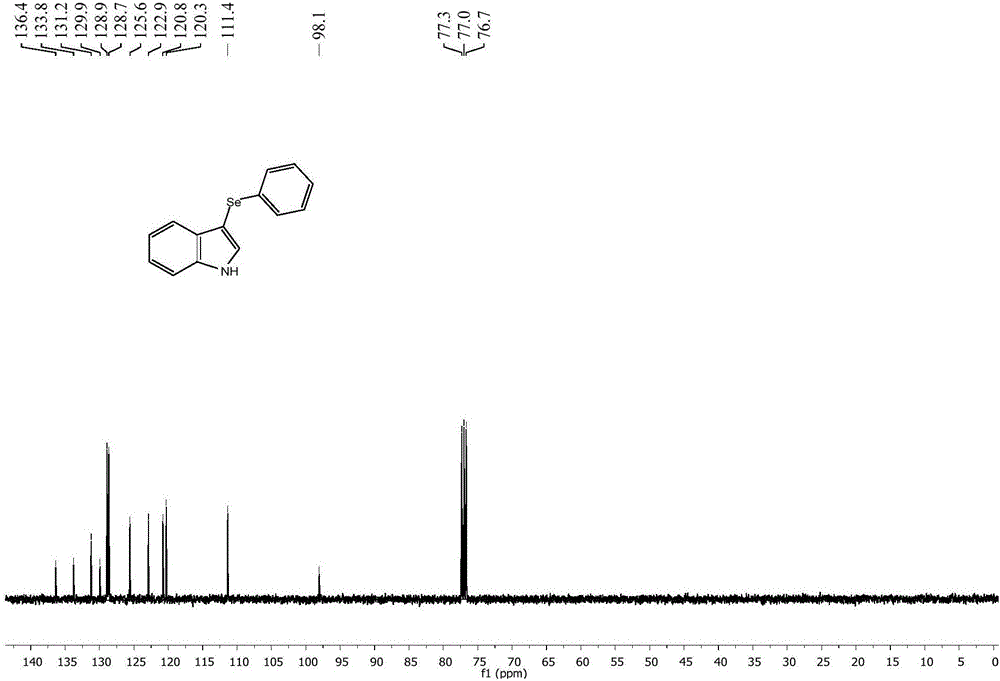

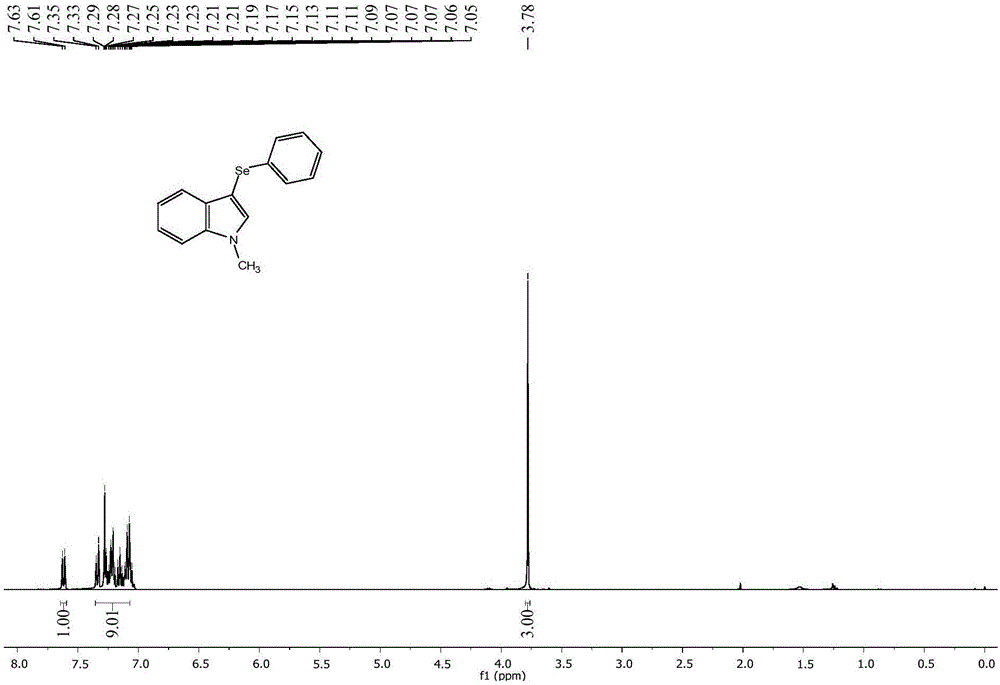

Electrochemical preparation method for 3-selenium aryl indole compounds

InactiveCN106544692AGood reaction selectivityHigh yieldElectrolysis componentsElectrolytic organic productionOrganic synthesisSodium iodide

The innveiton discloses an electrochemical preparation method for 3-selenium aryl indole compounds, and belongs to the technical field of electrochemical organic synthesis. The preparation method comprises the following steps of: sequentially adding electrolyte, sodium iodide, indole compounds, diselenium aromatic ether compounds and an electrolytic solvent into an electrolytic tank without a diaphragm; inserting an anode and a cathode; stirring and electrifying, reacting under a constant-current condition; and after reaction is completed, carrying out organic extraction on an electrolyte solution by use of an organic solvent, and separating and extracting to obtain the 3-selenium aryl indole compounds. According to the electrochemical preparation method disclosed by the invention, an anode electrode is used as a platinum electrode or a net-shaped glass-state carbon electrode (RVC electrode), the cathode is a nickel net or a net-shaped glass-state carbon electrode (RVC electrode) or platinum, the yield is high, selectivity is good, and a metal catalyst does not need to be additionally added, so that a catalyst which is poisonous, dear and complex to prepare is effectively prevented from being used, a reaction system is simple and effective, and the electrochemical preparation method is environmentally friendly. The method disclosed by invention is operated under normal pressure at a normal temperature, and is simple and safe.

Owner:SOUTH CHINA UNIV OF TECH

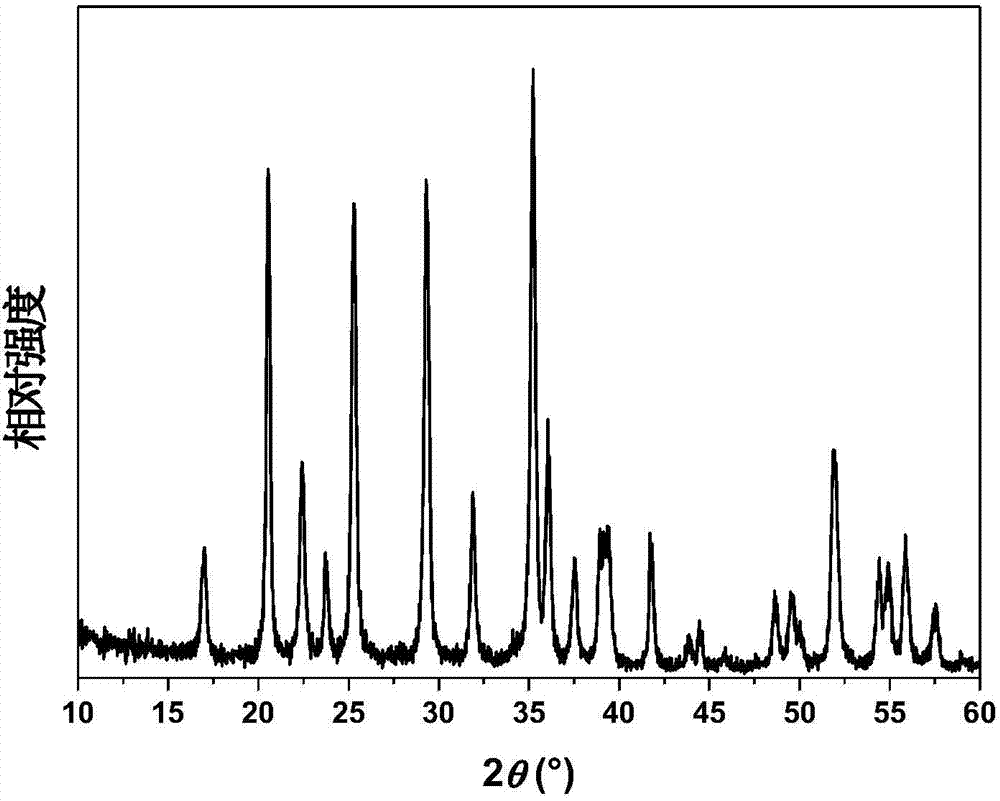

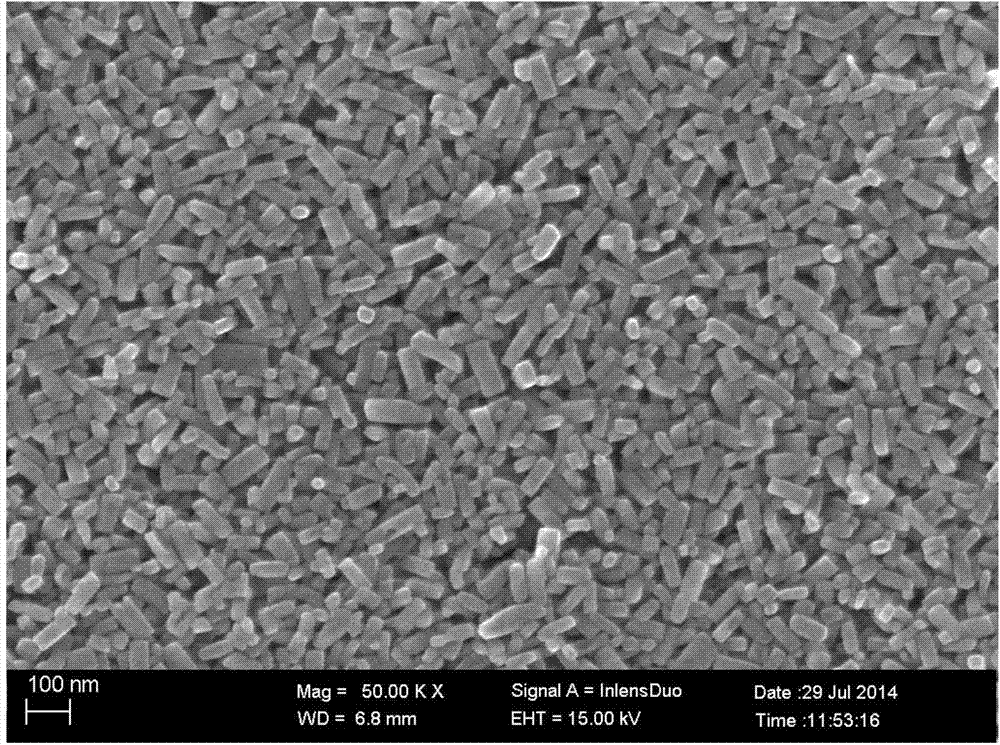

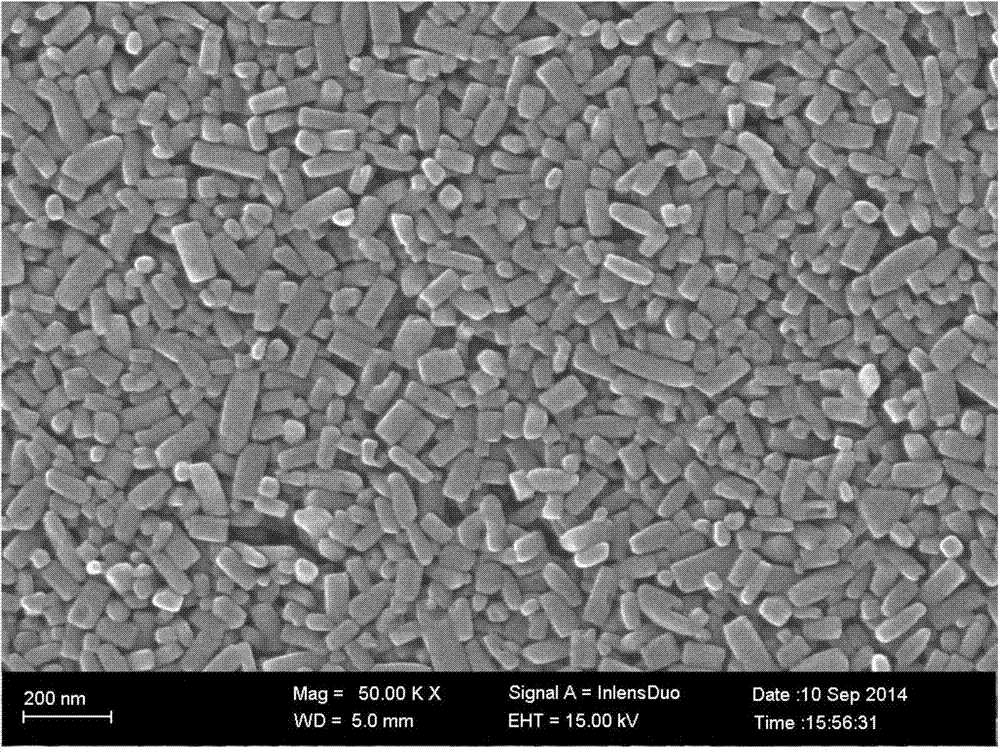

Nanorod-like lithium manganese phosphate anode material and preparation method thereof

InactiveCN104766972ASimple reaction systemProcess parameters are easyMaterial nanotechnologyCell electrodesSolventSucrose

Belonging to the lithium ion battery material technical field in the field of new energy materials, the invention in particular relate to a nanorod-like lithium manganese phosphate anode material and a preparation method thereof. The method includes: taking ethylene glycol and water as the reaction solvent, synthesizing lithium manganese phosphate by a solvothermal technique, and then mixing the lithium manganese phosphate with sucrose to synthesize a carbon-coated lithium manganese phosphate anode material. The method provided by the invention has the characteristics of simple reaction system, easily controllable process parameters, short process, low preparation cost, and easy mass production, and further expands the research work of the lithium manganese phosphate preparation field. The product obtained in the invention has the advantages of high purity, small size, good particle dispersibility, thus being conducive to effective contact of an electrode material and an electrolyte solution, shortening the lithium ion diffusion distance, and improving the rate performance of the lithium ion battery. The lithium manganese phosphate anode material has a low carbon content, and a small amount of carbon coating can improve the material electronic conductivity and also ensures that the lithium ion battery with the product as the anode material can acquire high energy density.

Owner:TSINGHUA UNIV

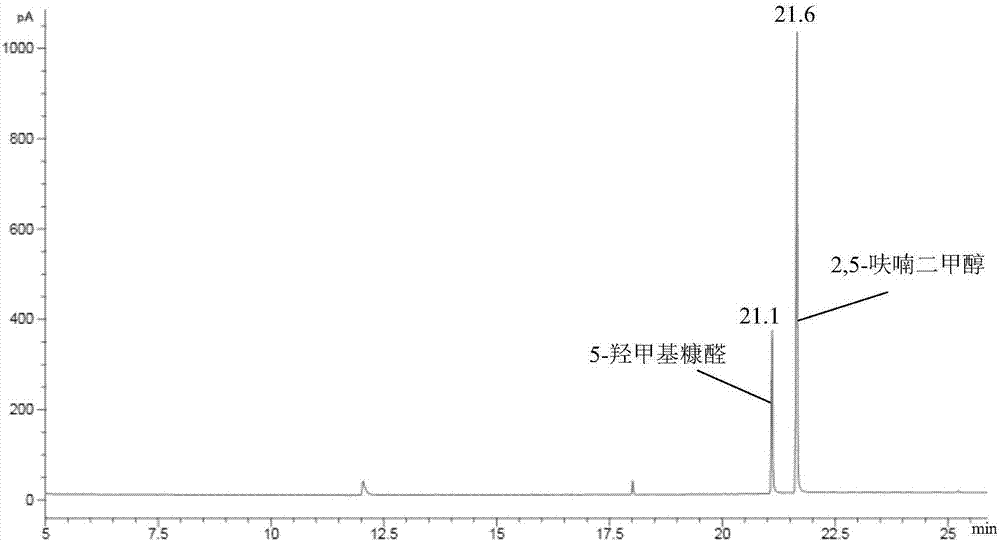

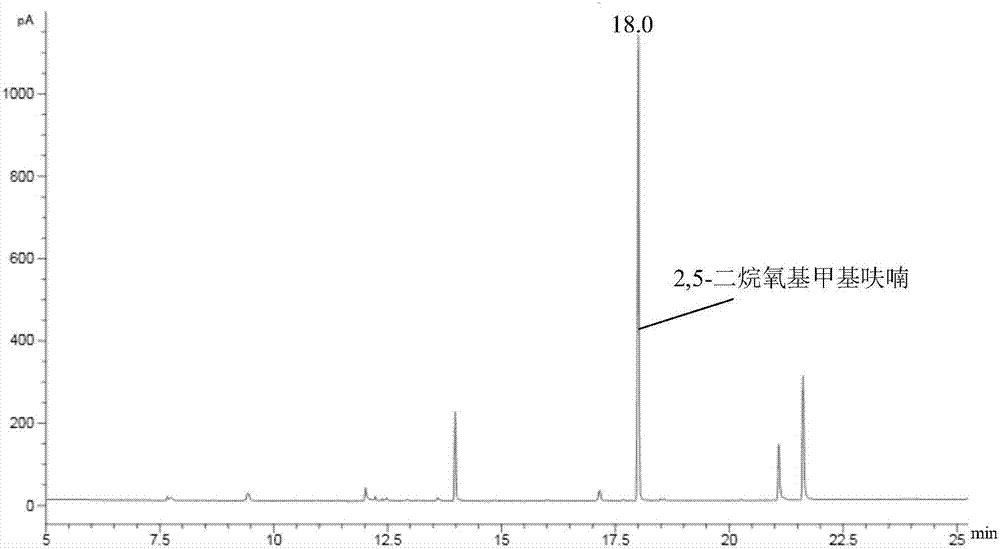

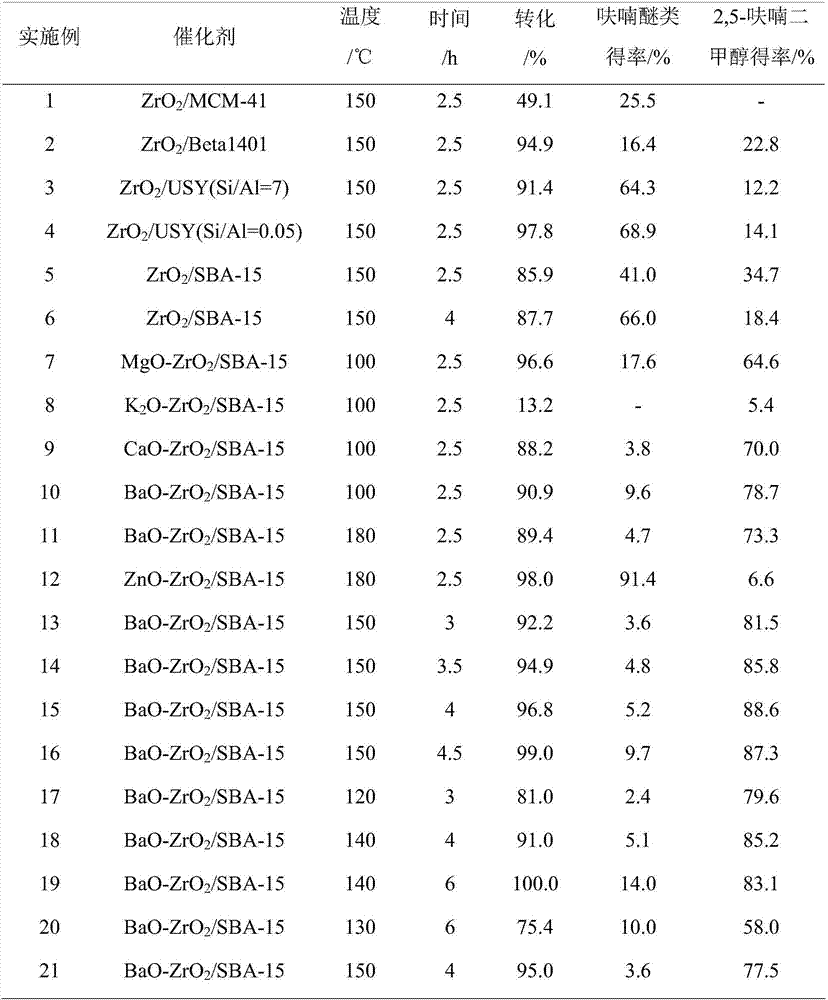

Synthetic method of 2,5-furan dimethanol and etherified product of 2,5-furan dimethanol

The invention discloses a synthetic method of 2,5-furan dimethanol and an etherified product of 2,5-furan dimethanol and relates to 2,5-furan dimethanol. The synthetic method comprises the following steps of: adding organic alcohol into a reaction substrate; putting the obtained mixture as a raw material in a high pressure reaction kettle; adding a certain amount of a molecular sieve supported catalyst; and performing a heating reaction to obtain 2,5-furan dimethanol and the etherified product of 2,5-furan dimethanol. By using alcohol as a hydrogen donor and a reaction substrate, no external hydrogen source does not needed. By adjusting the acid-base property of a catalyst through an active metal component, 2,5-furan dimethanol can be obtained by selectively catalyzing transfer hydrogenation of 5-hydroxymethylfurfural or 2,5-dialkoxyl methyl furan is obtained by further etherification. The catalyst is cheap and easily available and good in repeatability, no excessively hydrogenated product exists, and the whole reaction is hydrogenated in a hydrogen environment, and the synthetic method has relatively strong operating safety of industrial production and very good industrial application potential.

Owner:XIAMEN UNIV

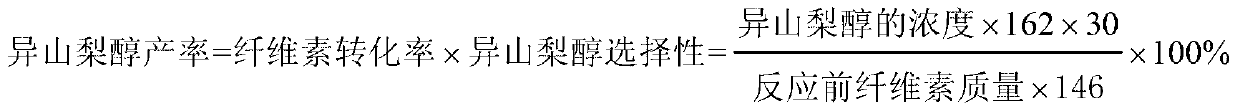

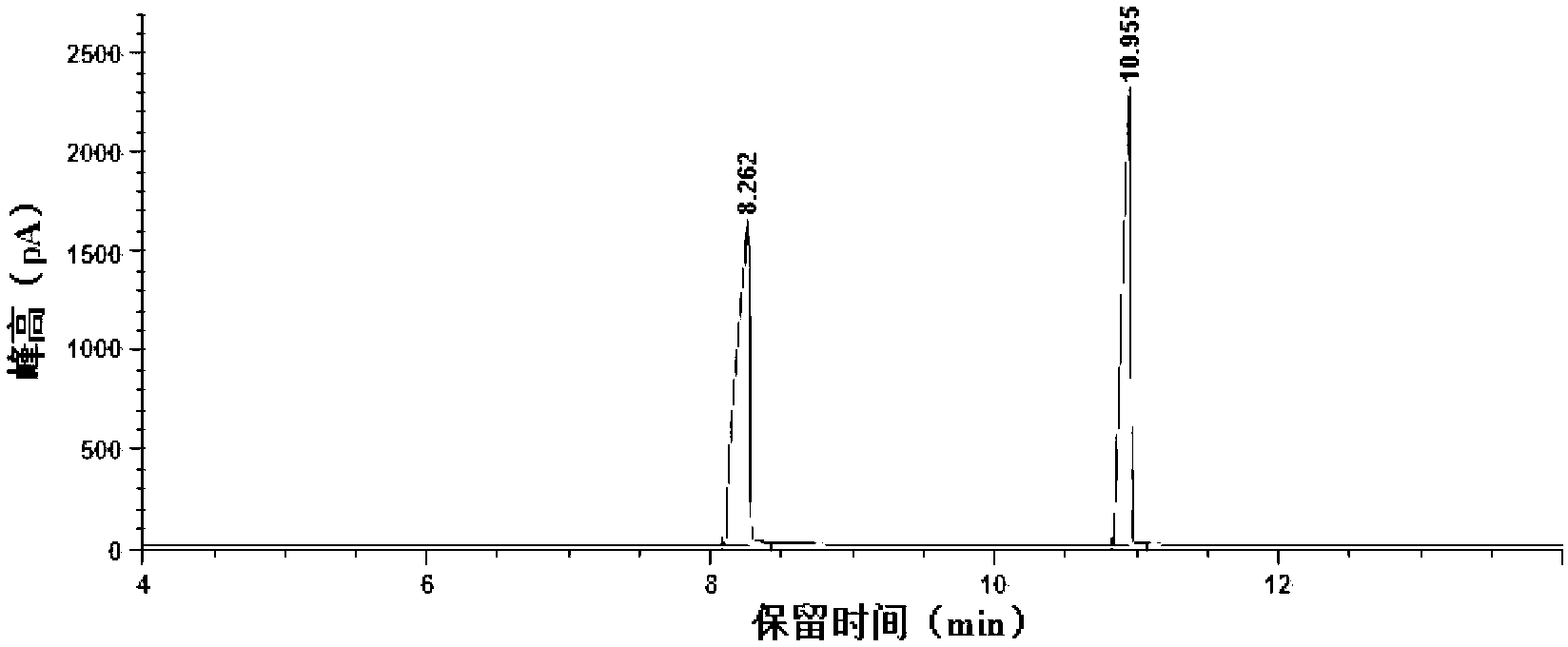

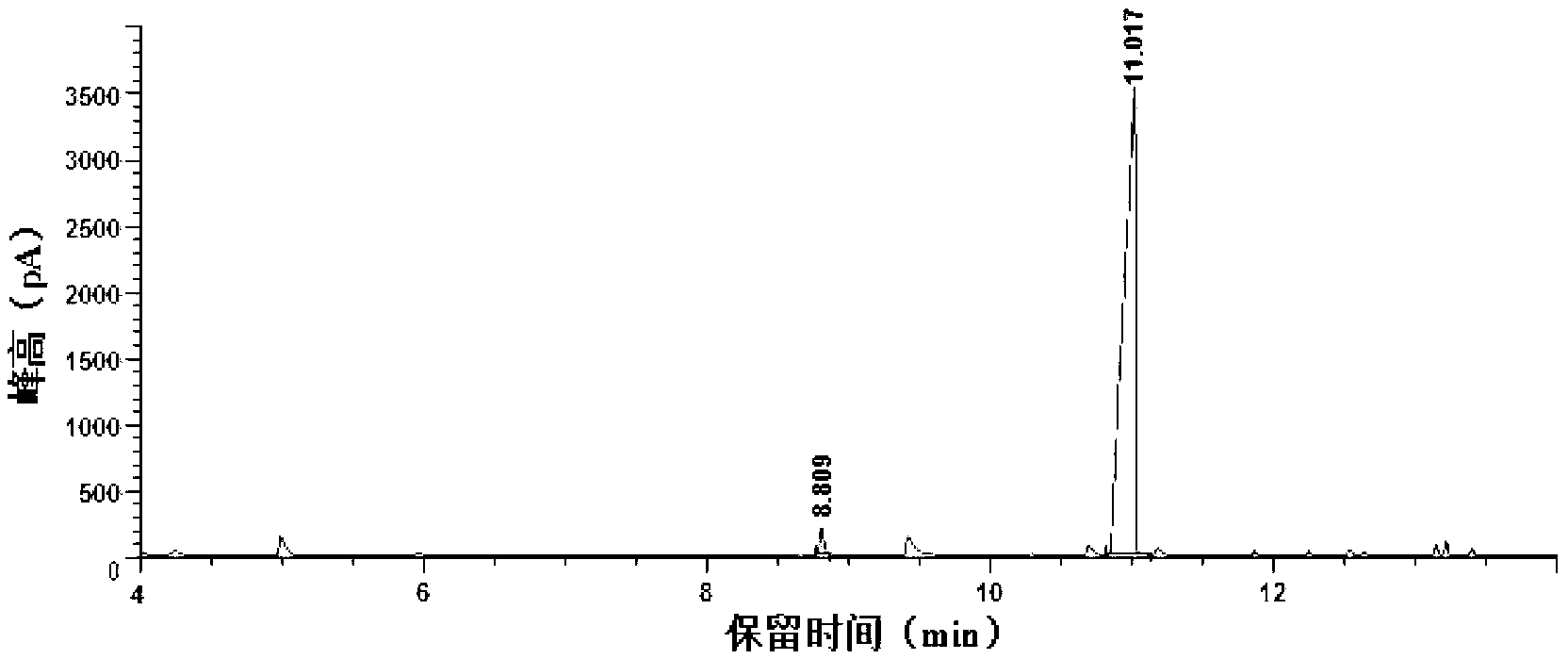

Method for preparing isosorbide based on cellulose

The invention relates to the technical field of fine chemical engineering and discloses a method for preparing isosorbide based on cellulose. The method comprises the following steps of: adding a cellulose raw material into an airtight high-pressure reactor containing enough water, wherein the reaction pressure is 1-12 MPa, and the reaction temperature is 180-300DEG C; and carrying out hydrolysis, hydrogenation and hydration reactions in water for 0.5-48 hours in the presence of a catalyst to obtain the isosorbide. The catalyst is a metal / solid acid bifunctional catalyst and has the addition amount of 0.03-2.0g / g cellulose. The method disclosed by the invention has low corrosion to equipment as no inorganic liquid acid needs to be added, and is low in cost, simple in reaction system and easy to industrialize; and the catalyst is long in service life and free of loss.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

Method for preparing ethyl levulinate based on solid superacid catalysis and furfuryl alcohol alcoholysis

InactiveCN103274942ALow costEasy to separateOrganic compound preparationCarboxylic acid esters preparationAlcoholEthyl ester

The invention discloses a method for preparing ethyl levulinate based on solid superacid catalysis and furfuryl alcohol alcoholysis, and relates to ethyl levulinate. The method comprises the steps of adding furfuryl alcohol, a catalyst and a reaction solvent to a reaction kettle, reacting, and obtaining ethyl levulinate. The catalyst is selected from at least one of solid superacid of SO4<2-> / TiO2, SO4<2-> / ZrO2, SO4<2-> / Fe2O3, SO4<2-> / SnO2, and SO4<2-> / Al2O3, or at least one of solid superacid of S2O8<2-> / TiO2, S2O8<2-> / ZrO2, S2O8<2-> / Fe2O3, S2O8<2-> / SnO2, and S2O8<2-> / Al2O3; the reaction solvent is ethyl alcohol; and reaction conditions are that the temperature is 100-150 DEG C, the rotating speed is 300-500 rpm (revolutions per minute), the time is 0.5-2.5h, a mass ratio of furfuryl alcohol to solid superacid is (1-4):1, and a mass ratio of furfuryl alcohol to ethyl alcohol is (0.01-0.2):1.

Owner:XIAMEN UNIV

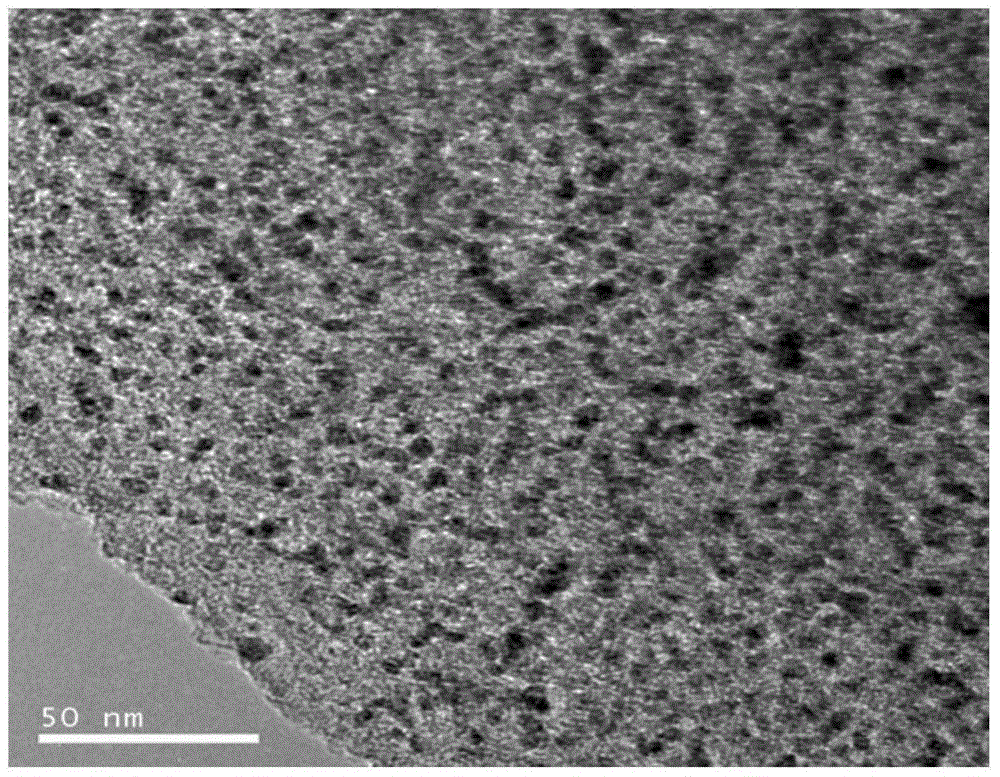

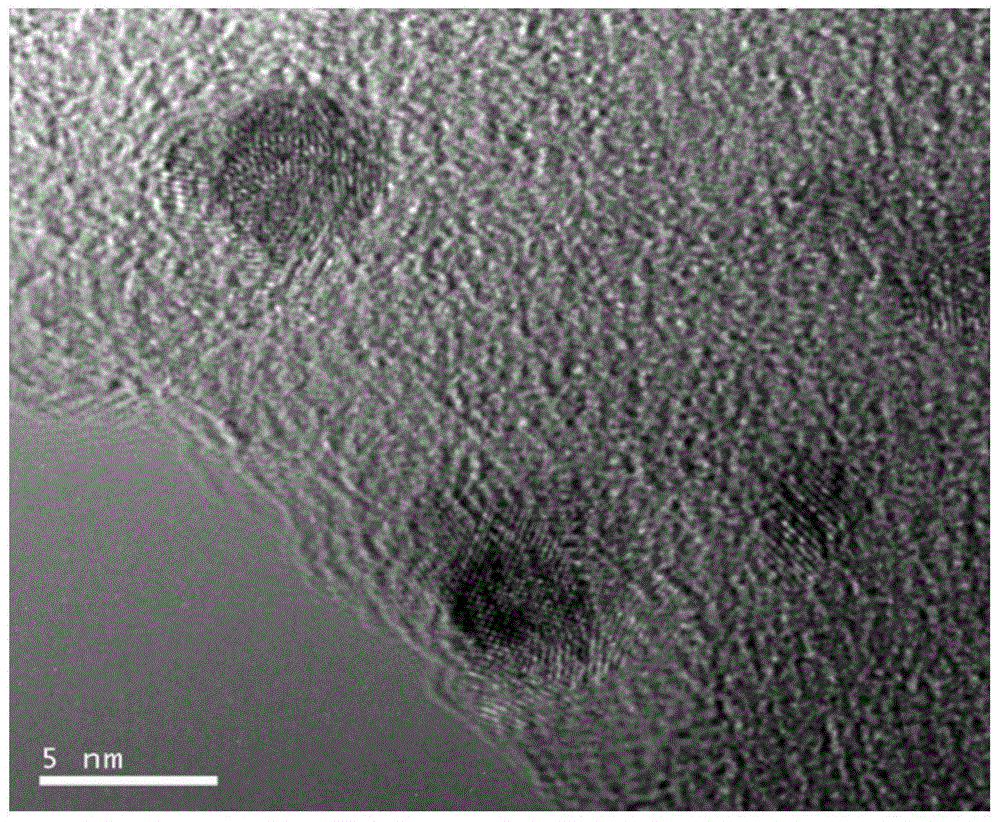

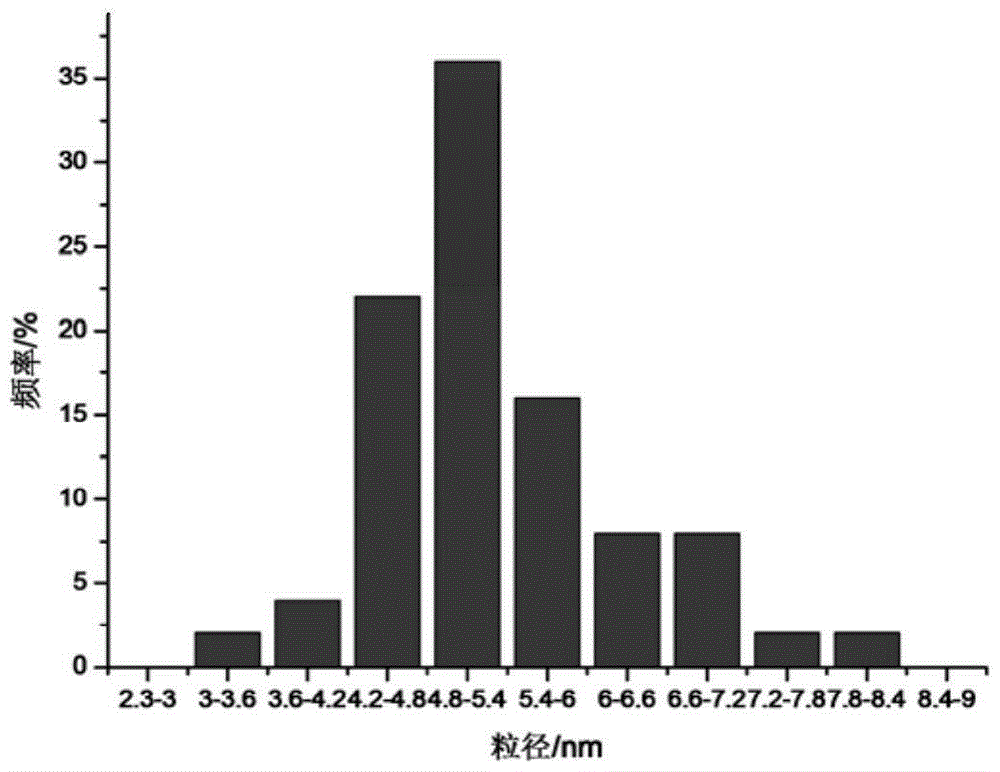

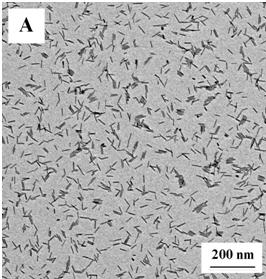

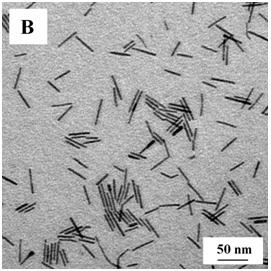

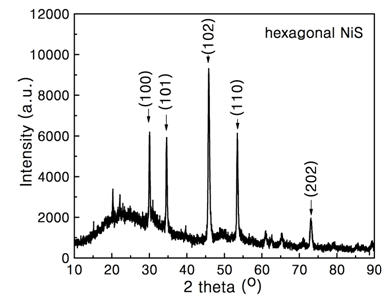

Method for synthesizing nickel sulfide nanorods through solid-liquid phase reaction and prepared nanorods

InactiveCN102198960ASmall sizeSimple reaction systemNanotechnologyNickel sulfidesChemical reactionDiameter ratio

The invention discloses a method for synthesizing nickel sulfide nanorods through solid-liquid phase reaction and the prepared nickel sulfide nanorods. The method comprises the following steps of: heating a mixture of an acetylacetone nickel solid, alkyl sulfhydryl and octadecene to the temperature of between 250 and 340 DEG C in a dry reactor, keeping the temperature for 15 to 45 minutes, and separating to obtain target products, namely the nickel sulfide nanorods. The nickel sulfide nanorods have regular nanorod-like structures, the average diameter of 4 to 5nm, the length of 25 to 70nm and the length-diameter ratio of 4 to 12. The nickel sulfide nanorods with smaller sizes, uniform appearances and hexagonal phase structures are synthesized through the solid-liquid phase chemical reaction at a low temperature under normal pressure, the process is simple, reaction time is short, and the method is suitable for mass production.

Owner:NANJING NORMAL UNIVERSITY

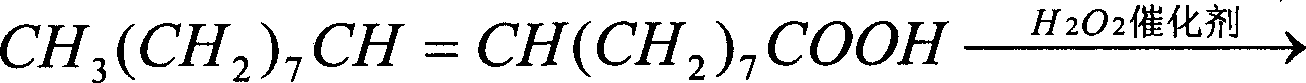

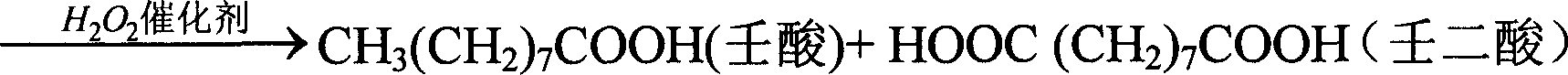

Process for preparing azelaic acid by oleic acid phase transfer catalytic oxidation

InactiveCN1566064AHigh reaction conversion rateHigh selectivityOrganic compound preparationCarboxylic compound preparationCatalytic oxidationSolvent

The invention discloses a process for preparing azelaic acid by oleic acid phase transfer catalytic oxidation, which is realized by the action of tungsten doped multiple acid catalyst through hydrogen peroxide oxidation, the catalyst can be circulated after recovering in the whole process. The oleinic acid is fed through 30%-70% hydrogen dioxide for oxidation reaction at 60-105 deg. C, the reacting time being 6.0-12.0 hours.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Copolymerization reaction method for styrene/maleic anhydride

A copolymerization method of phenylethene / maleic anhydride belongs to polymer preparation technical field, for resolving the defect caused by stabilizer in traditional disperse polymerization system, which comprises under nitrogen gas protection, dissolving monomer Man and St, inducer organic hyperoxide or azocompound of suitable ratio in organic acid alkyl ester, the mixture of aromatics and organic acid alkyl ester or the mixture of ketone and alkane to react for 1 / 4-12h at 60-90 DEG C to obtain the disperse system of polymer microballoon, wherein the average particle diameter of microballoon in the disperse system is 90-1715mm, the disperse factor is 1.04-1.004 and the number average molecular weight is 80000-300000g / mol. The invention has the advantages of eliminated stabilizer, simple process, low cost, clean polymer microballoon or particle surface, controllable particle diameter, controllable shape and narrow granularity distribution.

Owner:BEIJING UNIV OF CHEM TECH

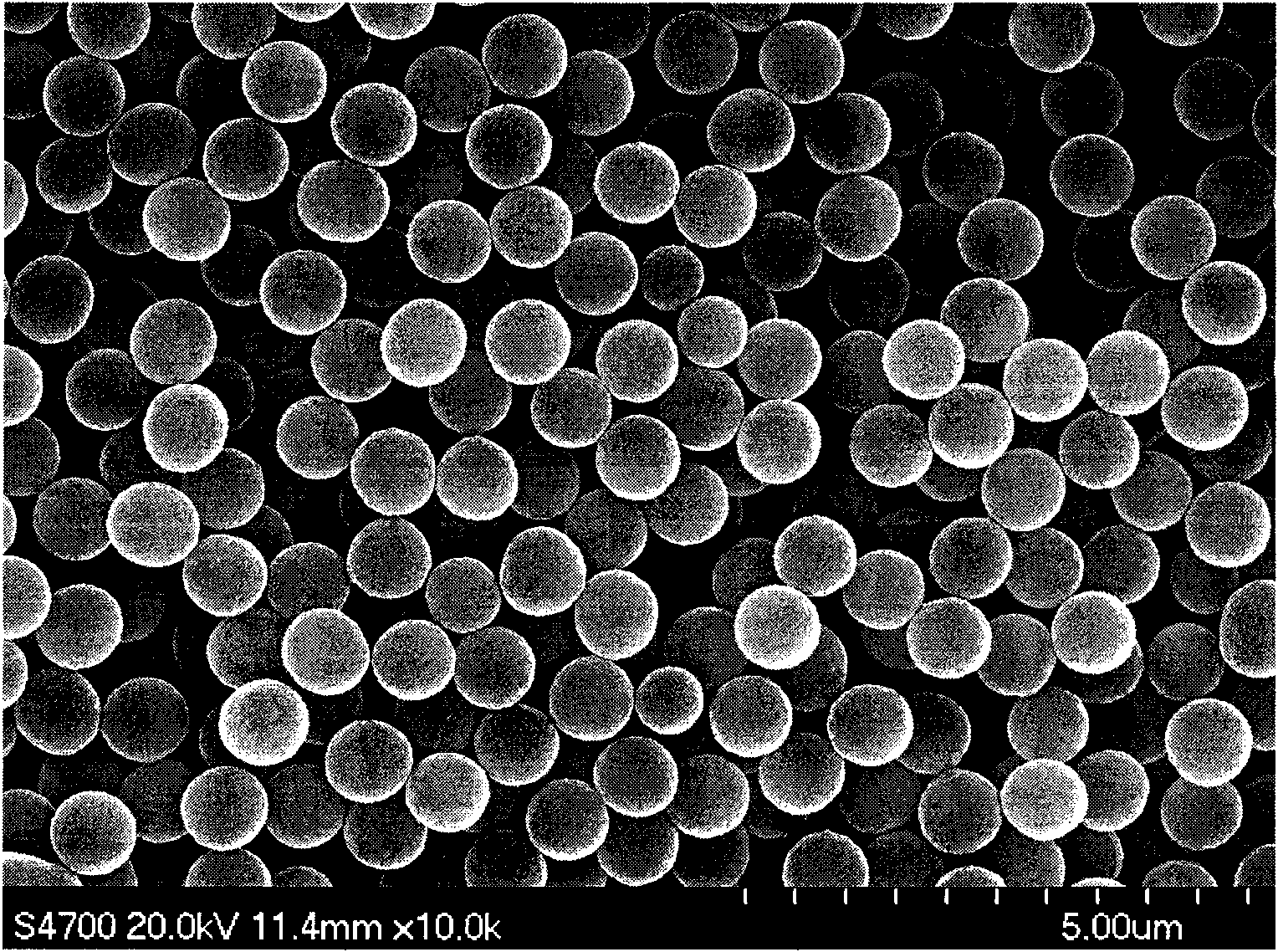

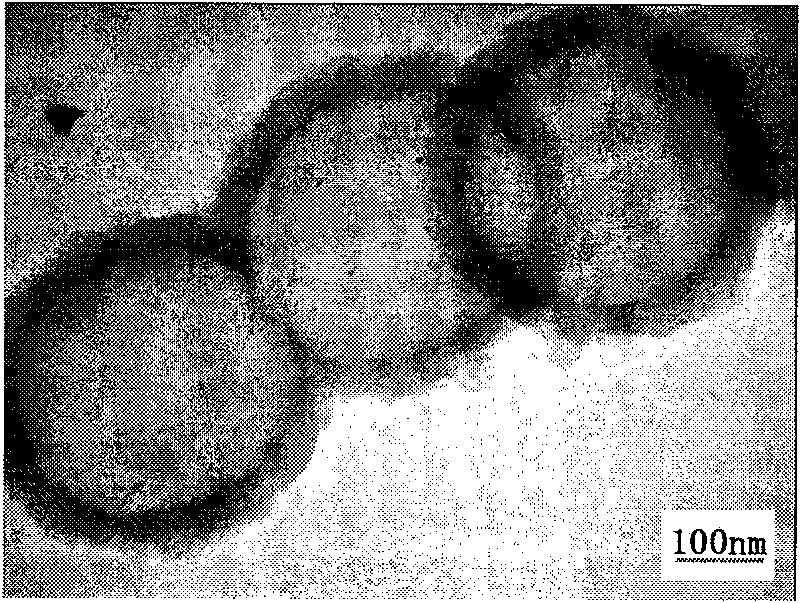

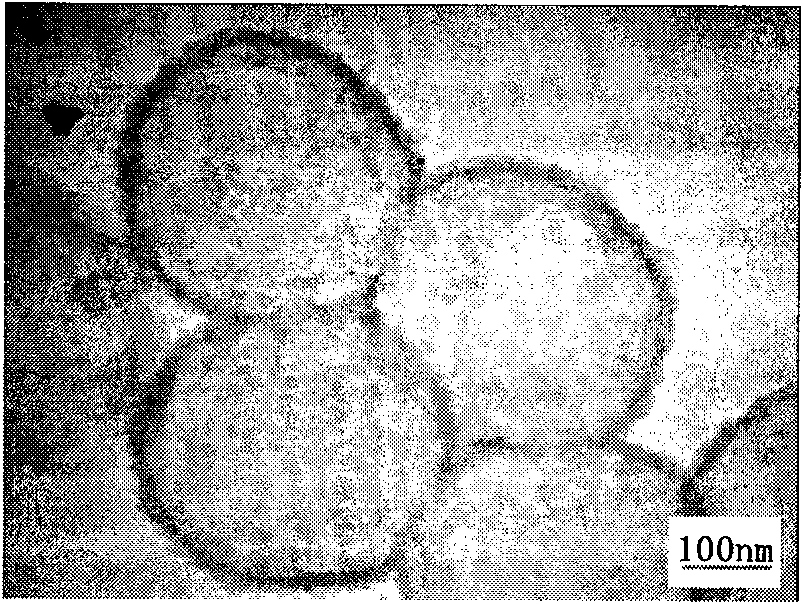

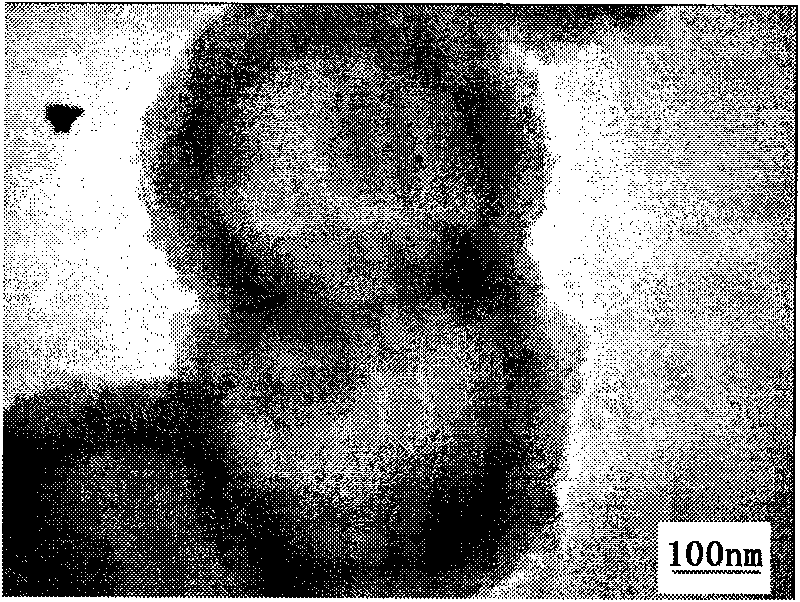

A metal/ polymer composite particle and method of preparing the same

InactiveCN101550213ASimple reaction systemSimple process controlPolymer compositesConductive materials

The present invention relates to a metal / polymer composite particle and method of preparing the same, and the outer layer (lamella) is metal and the inner layer (nucleus) is organic polymer. More specifically, the lamella is conductive metal layer and the metal includes but not limited to Cu, Ag, Au and Pt etc. the organic polymer particles used as composite particle nucleus can be hollow polymer balls, sphere wall of the organic polymer balls has a certain intensity and the surface contains a large amount of reactivity groups, and metal / polymer composite particles can be obtained on deposition metal layer of the surface after amination modification. The metal / polymer composite particles can be used for preparing conductive materials and conductive particles used as conductive adhesive etc.

Owner:BEIJING UNIV OF CHEM TECH

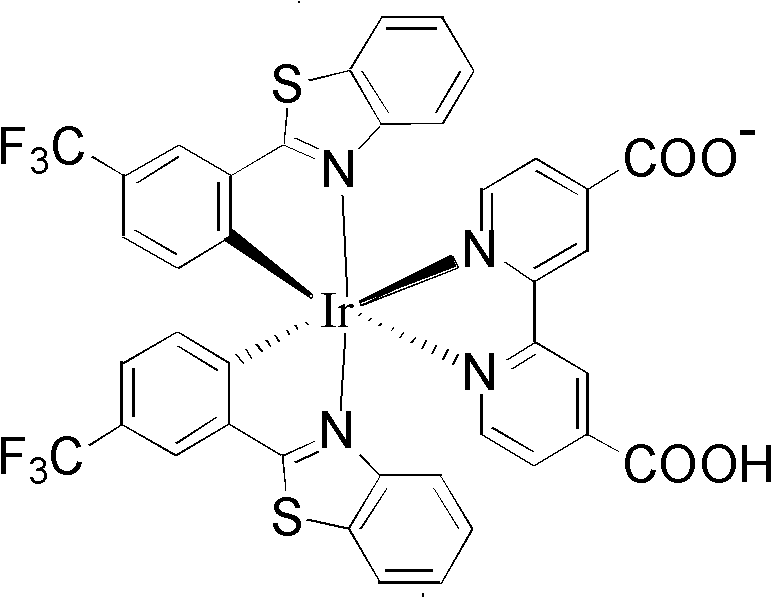

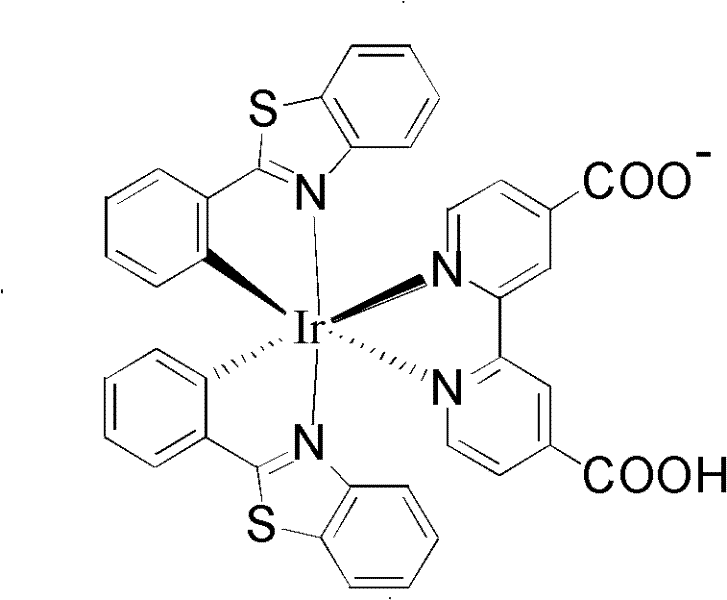

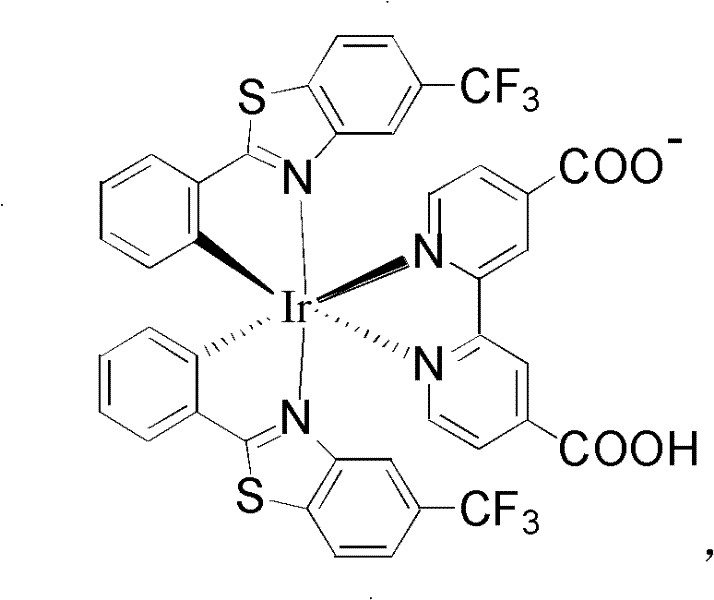

Iridium complex, preparation method of iridium complex, method for catalyzing and reducing water by using visible light and dye-sensitized solar cell

InactiveCN102491989ASimple reaction systemLow costLight-sensitive devicesSolid-state devicesSolventTrifluoromethyl

The invention provides an iridium complex, which has a visible light reactivity and can be used for rapidly preparing hydrogen through reduction by catalyzing water by using visible light. The invention further provides a preparation method of the iridium complex, a method for preparing hydrogen by catalyzing and reducing the water by using the visible light by means of the iridium complex and a dye-sensitized solar cell containing the iridium complex. The iridium complex comprises a chemical formula of Ir(L)2Hbpdc, wherein L is 3-trifluoromethyl-2-phenyl benzothiazole, 2-phenyl benzothiazole, 2-phenyl-5-(trifluoromethyl) benzothiazole or 4-N,N dimethyl-phenyl-5-(trifluoromethyl) benzothiazole, and Hbpdc is 4-carboxyl-4'-carboxylate-2,2'-bipyridyl. The preparation method of the iridium complex comprises the steps of: dissolving iridium trichloride and L in a first solvent, reacting to obtain an intermediate product Ir2(L)4Cl2, and reacting the intermediate product with 4-4'-dicarboxylic acid-2,2'-bipyridyl and sodium carbonate to obtain the iridium complex.

Owner:NANJING UNIV

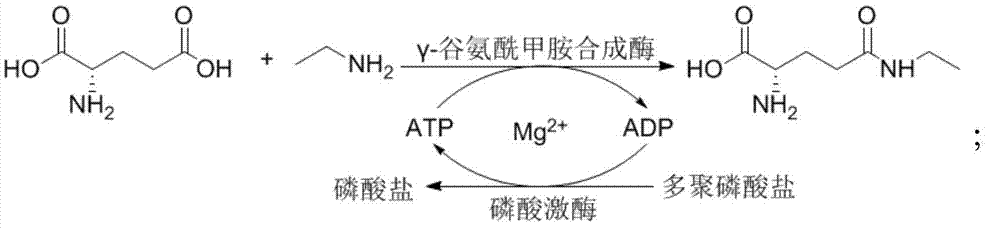

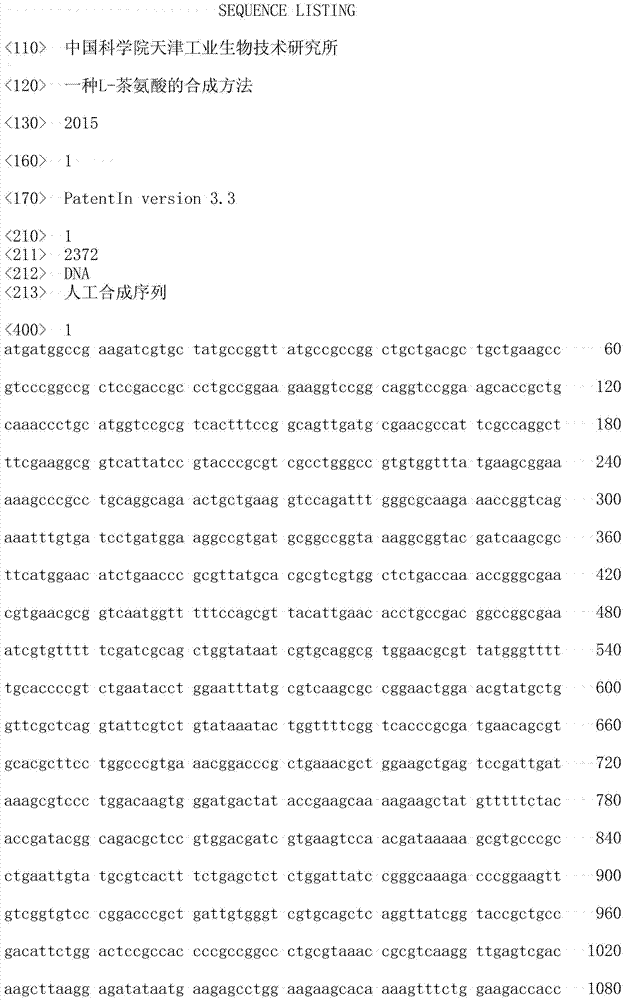

Synthetic method of L-theanine

The invention relates to the technical field of bioengineering and in particular relates to a synthetic method of L-theanine. The method comprises the following step of synthesizing L-theanine by taking gamma-glutamyl-methylamine synthetase and phosphokinase as catalysts and L-sodium glutamate and ethylamine hydrochloride as substrates. The method can be used for producing a lot of cloned expression proteins as catalysts by taking L-sodium glutamate and ethylamine hydrochloride which are relatively low in price as the initial raw materials, and has the advantages of being mild in reaction condition, strong in specificity, high in reaction conversion rate, simple and convenient to operate, low in requirement on reaction equipment, small in environmental pollution and the like.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

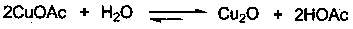

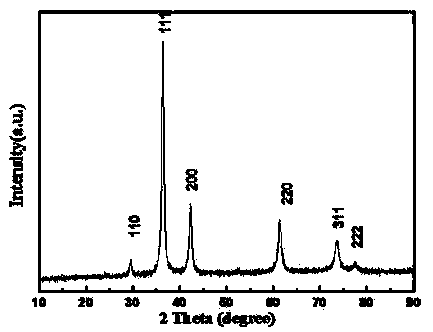

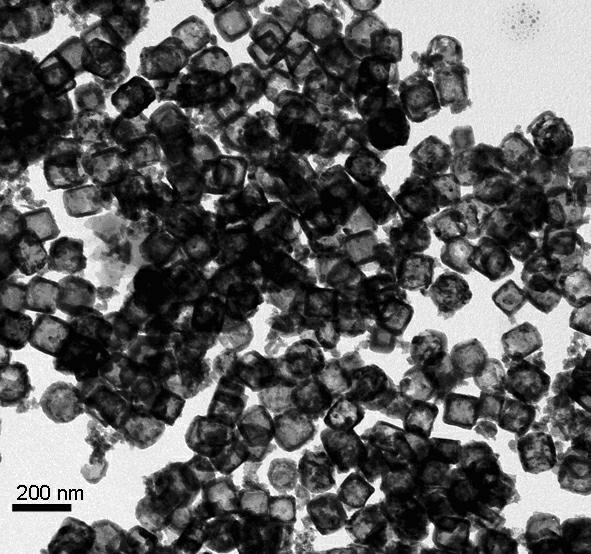

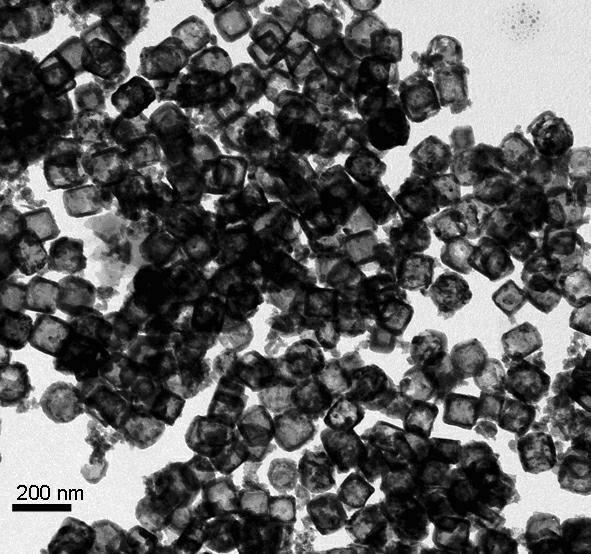

Preparation method of cuprous oxide hollow nanometer cubes

InactiveCN102557106ASimple reaction systemThe synthesis process is simpleNanotechnologyCopper oxides/halidesPolyolAlcohol

The invention discloses a preparation method of cuprous oxide hollow nanometer cubes. According to the preparation method, a chemical reducing method is adopted, polyhydric alcohol is used as solvents and reducing agents, cuprous diacetone is reduced at high temperature, the cuprous oxide hollow nanometer cubes are obtained, the edge length of the obtained cuprous oxide hollow nanometer cubes is about 150nm, and the wall thickness is about 20nm. The preparation method has the advantages that the process is simple, any surfactants do not need to be added, the operation is simple and convenient, the cost is low, and the preparation method is suitable for mass production.

Owner:HUAIYIN TEACHERS COLLEGE

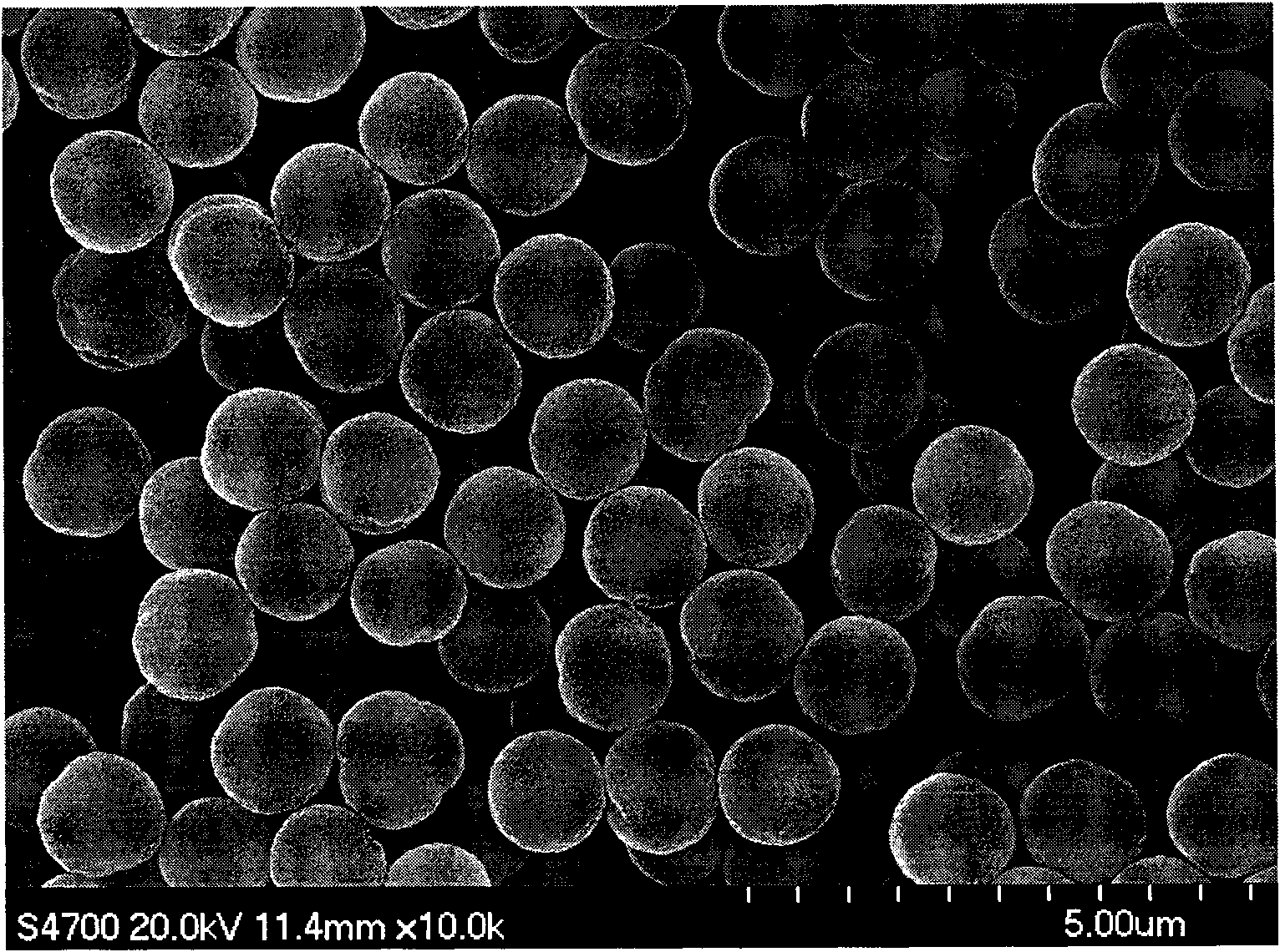

Novel method for performing copolymerization reaction of dicyclopentadiene and maleic anhydride

InactiveCN102212166AEasy to separateSelf-stabilizing dispersion polymerization process system is simpleAlkaneChemical structure

The invention discloses a novel method for performing a copolymerization reaction of dicyclopentadiene and maleic anhydride, and belongs to the technical field of copolymers. The method comprises the following steps of: under the protection of nitrogen, adding monomers and an initiator into an organic medium and dissolving, reacting for 2 to 12h at the temperature of between 60 and 90 DEG C to obtain a self-stabilizing dispersion system of monodisperse microspheres of an alternating copolymer, and performing centrifugal separation, and drying to obtain a white solid of the dicyclopentadiene / maleic anhydride alternating copolymer, wherein the reaction monomers are the dicyclopentadiene and the maleic anhydride, and the molar ratio of the two monomers is 5:1-1:5; the medium is a mixed solvent of organic acid alkyl ester and organic alkane, and the organic acid alkyl ester accounts for 30 to 70 volume percent of the mixed solvent; and a chemical structure is that: R1 is a hydrogen atom, C1-C5 alkyl, phenyl or benzyl, and R2 is C1-C5 alkyl. A stabilizer and a costabilizer are not required to be added, the reaction system is simple, and a product is easy to separate; and polymer microspheres have smooth and clean surfaces, uniform particle sizes, controllable appearances, and high dispersibility.

Owner:BEIJING UNIV OF CHEM TECH

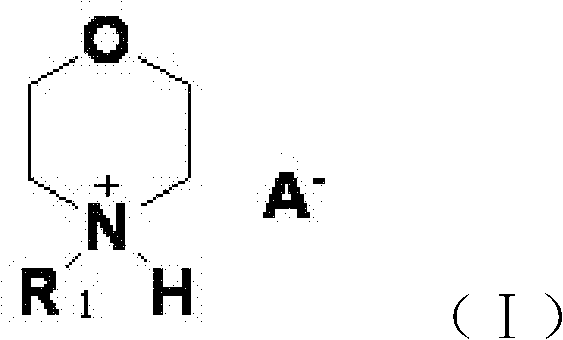

Synthetic method of nitrogen-heterocyclic substituted thieno[3,2-d]thiazole as well as derivatives of same

ActiveCN108822135AMild reaction conditionsSimple reaction systemOrganic chemistryPromotion effectPhotochemistry

The invention mainly relates to a synthetic method of nitrogen-heterocyclic substituted thieno[3,2-d]thiazole as well as derivatives of same. In the invention, with oxime ester, methyl nitrogen-heterocyclic ring and sulfur simple substance being raw materials, researching on a three-component cyclization reaction is carried out under promotion effect by an organic solvent, and a benzothiophene multiheterocyclic derivative is synthesized through intermolecular cyclization under a gentle condition. The synthetic method is free of transition metal catalysis and supplies a new approach for synthesizing benzothiophene compounds. The method also has advantages such as simple reaction system, gentle reaction conditions, less reaction equipment, simple experimental operations and above-average yield; and the product is a potential luminescent materials.

Owner:XIANGTAN UNIV

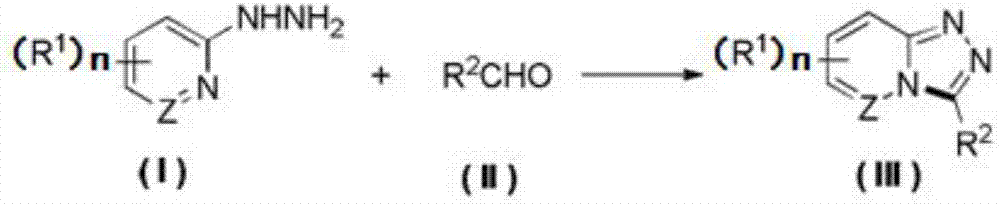

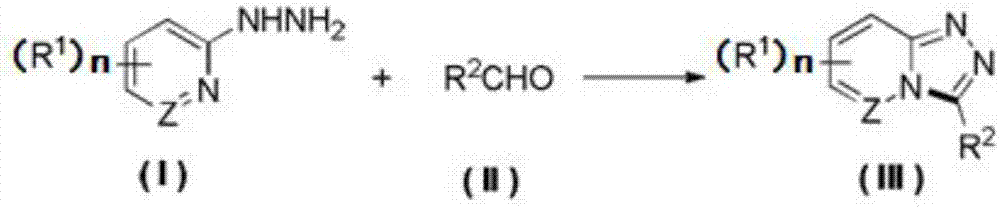

Synthesis method of 1,2,4-triazolohetercyclic compound

ActiveCN107474047AHigh yieldSimple reaction systemOrganic chemistryElectrolysis componentsSynthesis methodsHydrogen molecule

The invention provides a method for synthesizing a 1,2,4-triazolohetercyclic compound. The method comprises the following steps: dissolving a 2-hydrazinohetercyclic compound (I) and an aldehyde compound (II) into acetonitrile A; stirring at 25 DEG C to 80 DEG C and reacting for 1h to 8h; then adding tetrabutylammonium tetrafluoroborate, acetonitrile B and water; taking a graphite carbon rod as an anode and a platinum sheet as a cathode; switching on a power supply and electrifying for 3h to 8h, wherein the current strength is 15mA / mmol to 30mA / mmol according to the amount of substance of the aldehyde compound (II); carrying out post-treatment on a reaction solution to obtain the product 1,2,4-triazolohetercyclic ring compound (III). The method has the advantages of simple reaction system, easiness for obtaining raw materials and high total yield; the 2-hydrazinohetercyclic compound and the aldehyde compound are subjected to electrochemical catalysis to obtain the 1,2,4-triazolohetercyclic compound in one step; only one water molecule and one hydrogen molecule are removed and the atomic economy is extremely high; the formula is shown in the description.

Owner:ZHEJIANG UNIV OF TECH

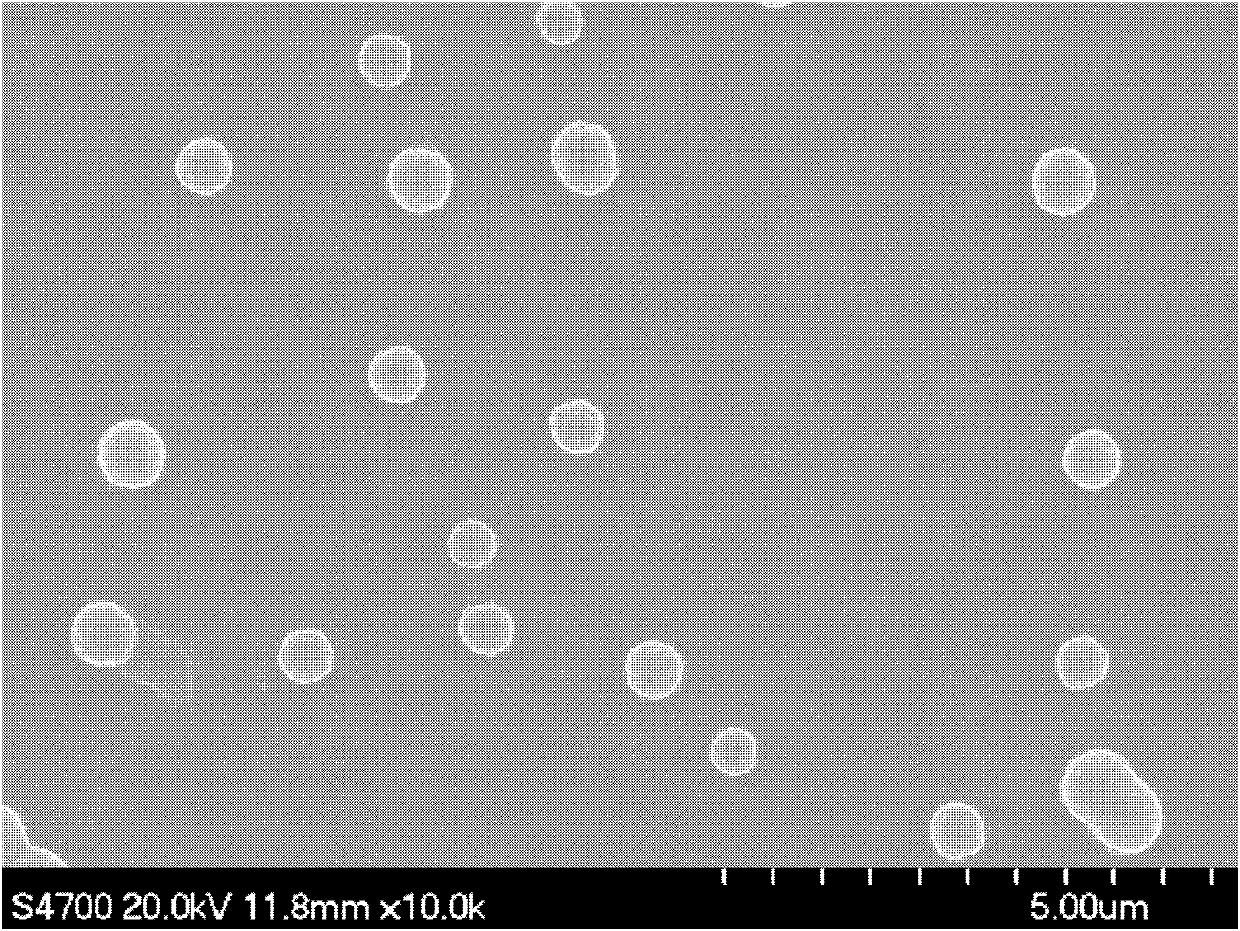

Preparation method of graded spherical cuprous oxide hollow nano particle

InactiveCN103466681ASimple reaction systemReduce manufacturing costMaterial nanotechnologyCopper oxides/halidesHydrazine compoundCopper salt

The invention discloses a preparation method of a graded spherical cuprous oxide hollow nano particle. The preparation method of the graded spherical cuprous oxide hollow nano particle is characterized by comprising the following steps of: (1) dissolving copper salt in water, (2) dropwise adding a mixed aqueous solution of hydrazine hydrate and acetate at 5-40 DEG C under a stirring condition, and (3) after dropwise adding, continuing stirring for 10-30min at 5-40 DEG C, centrifuging, washing with water, performing vacuum drying, and obtaining the graded spherical cuprous oxide hollow nano particle, wherein a molar concentration of Cu<2+> is 0.1-4mol / L, and a molar ratio of acetate (CH3COO<->) to hydrazine hydrate (N2H4) to copper salt (Cu<2+>) is (1-3):(0.5-4):1. According to the method, a reaction system is simple, raw materials are cheap and easy to obtain, and the method produces no hazardous waste, meets a green production concept, is simple in process route, easy and simple to operate, mild in reaction condition, short in reaction time and high in efficiency, and is suitable for mass production.

Owner:HENAN NORMAL UNIV

Carbon-supported multi-component catalyst and preparation method and application thereof

ActiveCN105214686AEasy to prepareHigh metal dispersionOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPlatinumActivated carbon

The invention provides a carbon-supported multi-component catalyst and a preparation method thereof. The catalyst is prepared from a carrier and metal active components loaded on the carrier. The carrier is activated carbon. The metal active components comprise palladium, platinum and a transition metal element assistant. Based on the mass of the carrier, namely, the activated carbon, the capacity of palladium ranges from 0.5 wt% to 5.0 wt%, the capacity of platinum ranges from 0.5 wt% to 5.0 wt%, and the capacity of the transition metal element assistant ranges from 0.1 wt% to 2.5 wt%. Meanwhile, the mass ratio of palladium to platinum is 1:0.5-2.0. The catalyst can be applied to catalytic hydrogenation for synthesis of benzotriazole ultraviolet absorbent. The preparation method of the catalyst is easy and convenient, the catalytic activity is high, the selectivity and yield of target products are high, good stability is achieved, and meanwhile three wastes generated in the hydrogenation process are fewer.

Owner:ZHEJIANG UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthetic method of nitrogen-heterocyclic substituted thieno[3,2-d]thiazole as well as derivatives of same Synthetic method of nitrogen-heterocyclic substituted thieno[3,2-d]thiazole as well as derivatives of same](https://images-eureka.patsnap.com/patent_img/0135faca-9d05-4b46-b338-73f7227e6c08/HSA0000169964320000011.png)

![Synthetic method of nitrogen-heterocyclic substituted thieno[3,2-d]thiazole as well as derivatives of same Synthetic method of nitrogen-heterocyclic substituted thieno[3,2-d]thiazole as well as derivatives of same](https://images-eureka.patsnap.com/patent_img/0135faca-9d05-4b46-b338-73f7227e6c08/HSA0000169964320000012.png)

![Synthetic method of nitrogen-heterocyclic substituted thieno[3,2-d]thiazole as well as derivatives of same Synthetic method of nitrogen-heterocyclic substituted thieno[3,2-d]thiazole as well as derivatives of same](https://images-eureka.patsnap.com/patent_img/0135faca-9d05-4b46-b338-73f7227e6c08/HSA0000169964320000021.png)