A metal/ polymer composite particle and method of preparing the same

A polymer and cross-linked polymer technology, applied in the field of metal/polymer composite particles, can solve the problems of large specific gravity of composite metal particles, reduced electrical conductivity, reduced mechanical properties, etc., and achieves recyclable toxicity, easy separation, and excellent electrical conductivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

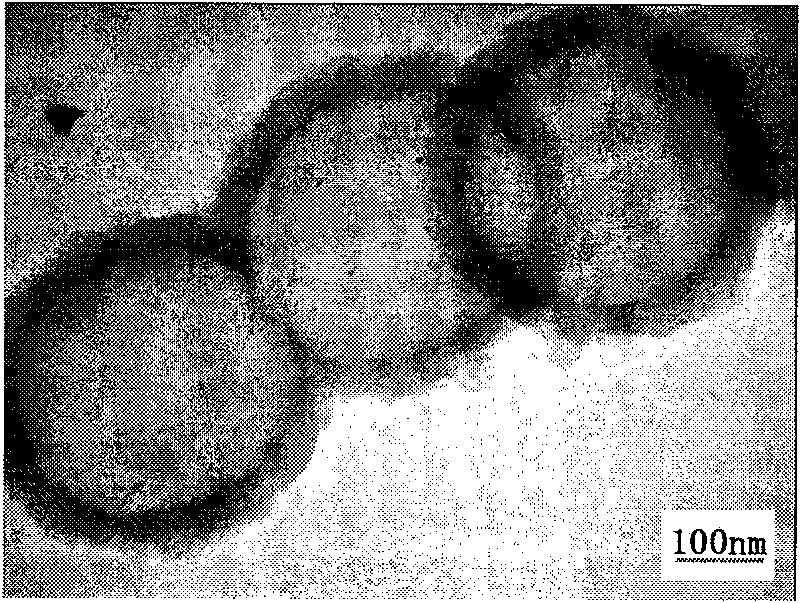

[0053] PMV and total monomer mass ratio 1: 1, MAn and DVB molar ratio 1: 1, wherein PMV 3g, MAn 1.56g, DVB-551.44g; Initiator is AIBN, 0.06g; Medium is butyl acetate and normal Heptane, butyl acetate 70vol.-%, n-heptane 30vol.-%, respectively 56ml and 24ml. Adopt water bath heating, react 10 hours under the temperature of 75 ℃, remove PMV inner core with acetone, obtain polymer hollow microsphere average particle diameter (d), microsphere wall thickness (d '), polymerization yield (C p ), the results are shown in Table 1, and the transmission electron microscope photos of polymer hollow microspheres are shown in figure 1 . Take 0.3 g of dried hollow microspheres and 0.3 g of ethylenediamine; the medium is tetrahydrofuran, 20 mL. Under magnetic stirring, react at room temperature for 30 minutes to obtain hollow polymer microspheres after amination. The infrared spectra of hollow polymer microspheres before and after amination are shown in Figure 10 . Take 0.2 g of hollow m...

Embodiment 2

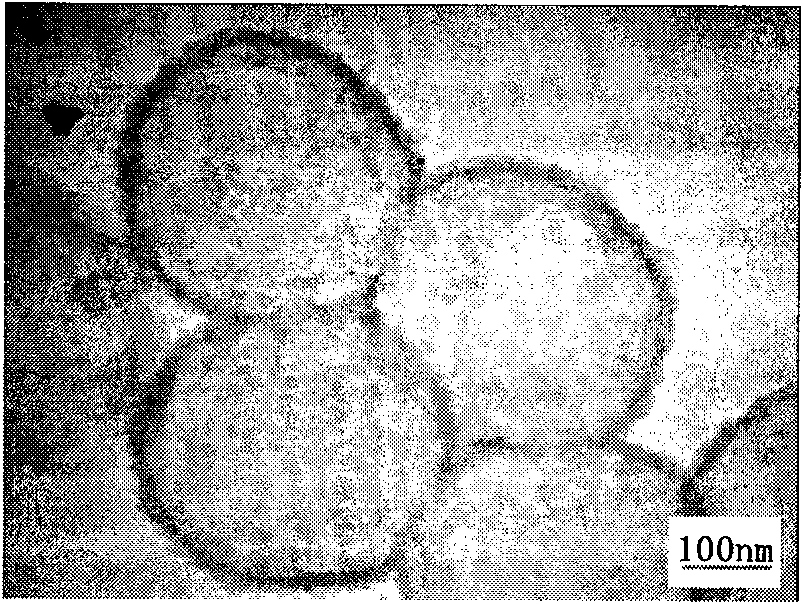

[0055] PMV and total monomer mass ratio 4:1, MAn and DVB molar ratio 1:1, wherein PMV 12g, MAn 1.56g, DVB-551.44g; Initiator is AIBN, 0.06g; Medium is butyl acetate and normal Heptane, butyl acetate 70vol.-%, n-heptane 30vol.-%, respectively 56ml and 24ml. Adopt water bath heating, react 10 hours under the temperature of 75 ℃, remove PMV inner core with acetone, obtain polymer hollow microsphere average particle diameter (d), microsphere wall thickness (d '), polymerization yield (C p ), the results are shown in Table 1, and the transmission electron microscope photos of polymer hollow microspheres are shown in figure 2 . Take 0.3 g of dried hollow microspheres and 0.3 g of propylenediamine; the medium is ethanol, 20 mL. Under magnetic stirring, react at room temperature for 30 minutes to obtain aminated polymer hollow microspheres. Take 0.2 g of hollow microspheres after amination, disperse them in 25 ml of deionized water, add 4×10 -2 M silver nitrate solution 1ml, 9.1m...

Embodiment 3

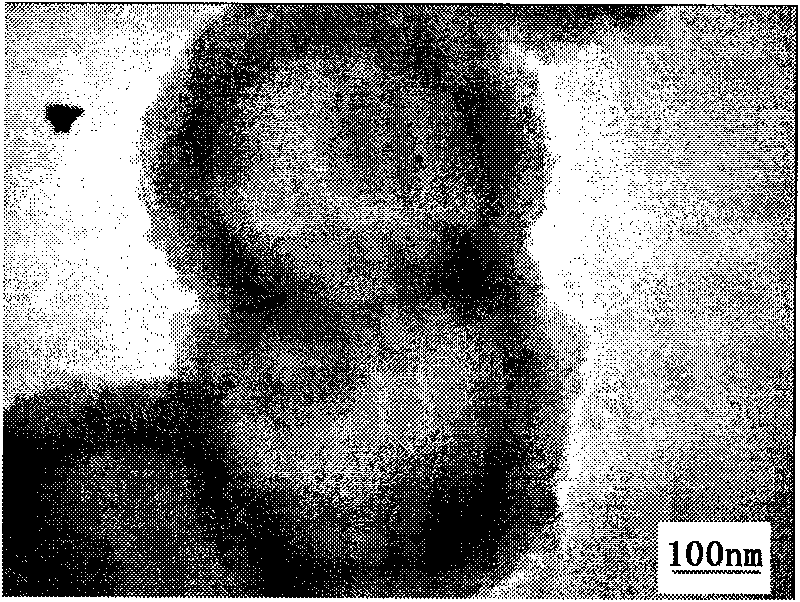

[0057] PMV and total monomer mass ratio 1: 4, MAn and DVB molar ratio 1: 1, wherein PMV0.75g, MAn 1.56g, DVB-551.44g; Initiator is AIBN, 0.06g; Medium is butyl acetate and N-heptane, butyl acetate 70vol.-%, n-heptane 30vol.-%, respectively 56ml and 24ml. Adopt water bath heating, react 10 hours under the temperature of 75 ℃, remove PMV inner core with acetone, obtain polymer hollow microsphere average particle diameter (d), microsphere wall thickness (d '), polymerization yield (C p ), the results are shown in Table 1, and the transmission electron microscope photos of polymer hollow microspheres are shown in image 3 . Take 0.3 g of dried hollow microspheres and 0.3 g of ethylenediamine; the medium is tetrahydrofuran, 20 mL. Under magnetic stirring, react at room temperature for 30 minutes to obtain aminated polymer hollow microspheres. Take 0.2 g of hollow microspheres after amination, disperse them in 25 ml of deionized water, add 4×10 -2 M silver nitrate solution 1ml, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com