Carbon-supported multi-component catalyst and preparation method and application thereof

A multi-component, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the selectivity and yield of benzotriazole products. The rate is not high, there are potential safety hazards, and the quality of products is affected, so as to achieve high industrial application value, reduce catalyst costs, and reduce three wastes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Weigh 0.088gPdCl 2 , 0.132gH 2 PtCl 6 ·6H 2 O, 0.088gCu(NO 3 ) 2 2H 2 O and 0.6g Potassium Citrate are put into there-necked flask; Add 150ml ethylene glycol in flask again and stir about 0.5h at room temperature, obtain precursor solution; Add 5g gac again in the prepared precursor solution, 25 Keep stirring and impregnating at a constant temperature at ℃ for 4 hours; after the impregnation is completed, add 5wt.% KOH / EG solution dropwise to adjust the pH value of the slurry to 10; then raise the temperature to 160°C and keep stirring at a constant temperature for 6 hours; after cooling, filter and use the filter cake Wash with deionized water until neutral; then vacuum-dry at 80°C for about 12 hours. That is, 5.125g of 1%Pd1%Pt0.5%Cu / C catalyst was obtained.

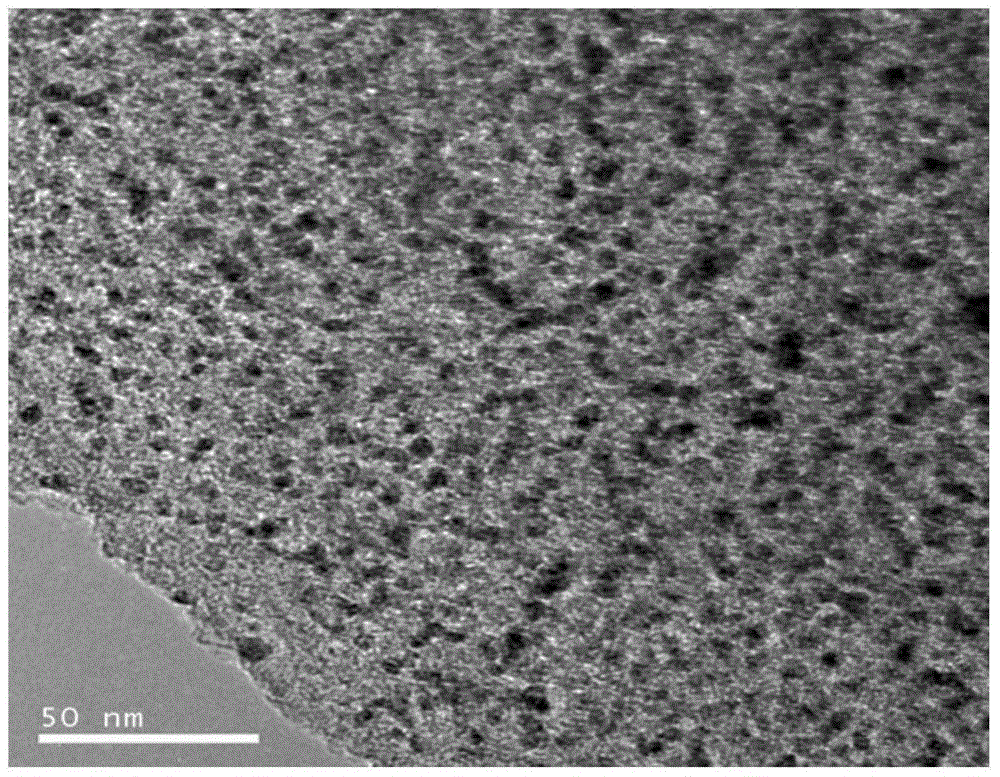

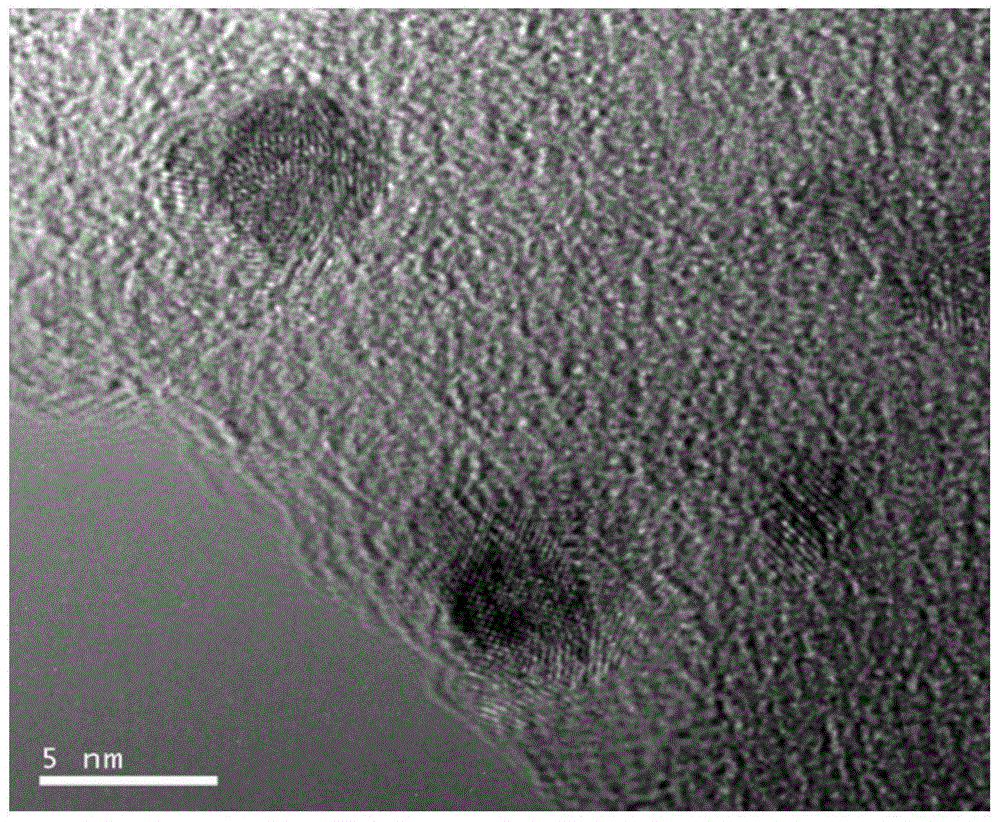

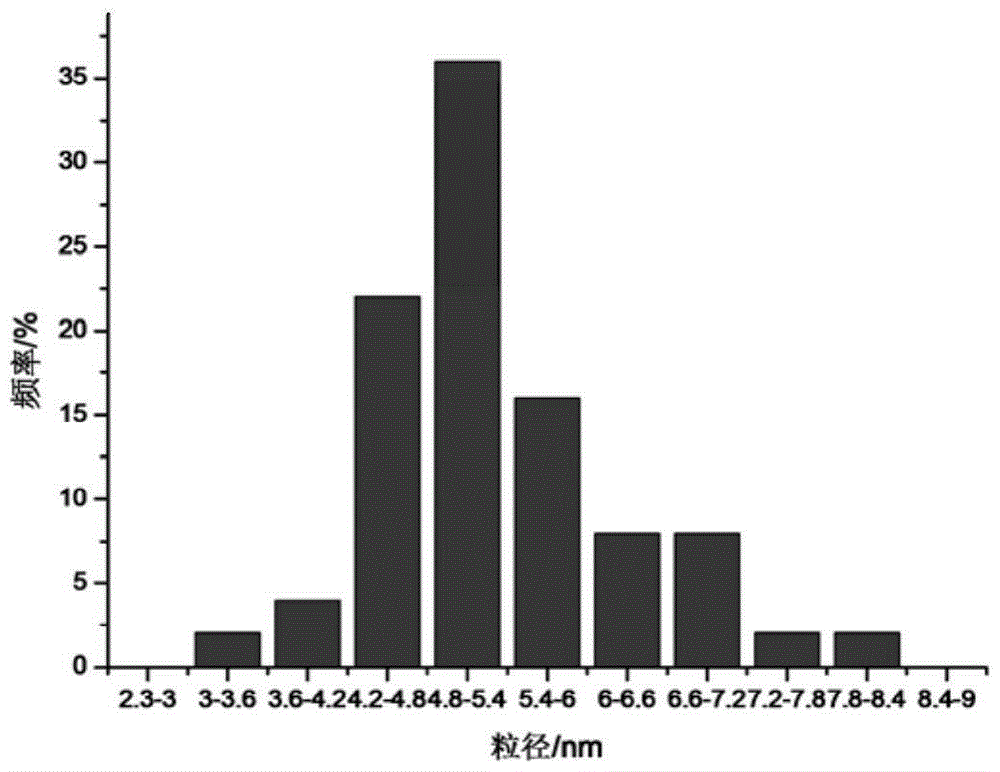

[0052] figure 1 It is the transmission electron microscope characterization figure of the catalyst 50nm scale that the present embodiment makes, from figure 1 It can be seen that the particle size of th...

Embodiment 2

[0056] Weigh 0.066gPdCl 2 , 0.1gH 2 PtCl 6 ·6H 2 O, 0.088gCu(NO 3 ) 2 2H 2 O and 0.5g Potassium Citrate are put into there-necked flask; Add 150ml ethylene glycol in flask again and stir about 0.5h at room temperature, obtain precursor solution; Then add 5g activated carbon in the prepared precursor solution, 25 Keep stirring and impregnating at a constant temperature at ℃ for 4 hours; after the impregnation is completed, add 5wt.% KOH / EG solution dropwise to adjust the pH value of the slurry to 10; then raise the temperature to 160°C and keep stirring at a constant temperature for 6 hours; after cooling, filter and use the filter cake Wash with deionized water until neutral; then vacuum-dry at 80°C for about 12 hours. That is, 5.1 g of 0.75% Pd0.75% Pt0.5% Cu / C catalyst was obtained.

Embodiment 3

[0058] Weigh 0.044gPdCl 2 , 0.066gH 2 PtCl 6 ·6H 2 O, 0.088gCu(NO 3 ) 2 2H 2 O and 0.4g Potassium Citrate are put into there-necked flask; Add 150ml ethylene glycol in flask again and stir about 0.5h at room temperature, obtain precursor solution; Add 5g gac again in the prepared precursor solution, 25 Keep stirring and impregnating at a constant temperature at ℃ for 4 hours; after the impregnation is completed, add 5wt.% KOH / EG solution dropwise to adjust the pH value of the slurry to 10; then raise the temperature to 160°C and keep stirring at a constant temperature for 6 hours; after cooling, filter and use the filter cake Wash with deionized water until neutral; then vacuum-dry at 80°C for about 12 hours. That is, 5.075 g of 0.5% Pd0.5% Pt0.5% Cu / C catalyst was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com