Synthetic method of L-theanine

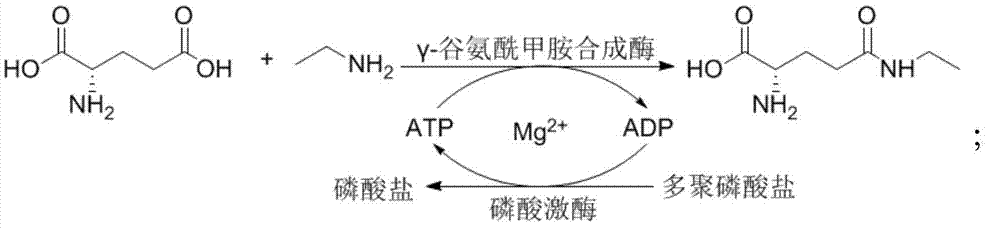

A synthesis method, theanine technology, applied in the field of bioengineering, can solve the problems of unfavorable industrial production, complex reaction system and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 enzymatic method catalyzes the synthesis of L-theanine

[0042] Into a 50mL reaction bottle, sequentially add final concentrations of 100mM sodium glutamate, 100mM ethylamine hydrochloride, 150mM magnesium chloride hexahydrate, 75mM sodium hexametaphosphate, 5mM adenosine triphosphate (ATP) and 75mM imidazole buffer (pH 8.0) , add water to dissolve so that the final volume is 10 mL, adjust the reaction pH to 7.0 with 5M sodium hydroxide solution, add 50 mg γ-glutamine synthetase and 40 mg phosphokinase. After reacting at 37° C. and 200 rpm for 24 h, samples were taken for HPLC analysis.

[0043] The detection method is: TAG; UV 210nm detection; mobile phase: ammonium acetate buffer (5 mM, pH 6.0) / methanol=25 / 75, v:v.

[0044] The results showed that the conversion rate of L-theanine was 93%, and the ee value was >99%.

Embodiment 2

[0045] Embodiment 2 enzymatic method catalyzes the synthesis of L-theanine

[0046] In the 100mL reaction bottle, add successively the final concentration of 200mM sodium glutamate, 200mM ethylamine hydrochloride, 150mM magnesium chloride hexahydrate, 75mM sodium hexametaphosphate, and 5mM adenosine triphosphate disodium (ATP), add water to dissolve to make the final volume 50mL, The pH of the reaction was adjusted to 7.0 with 5M sodium hydroxide solution, and 250 mg of γ-glutamine synthetase and 200 mg of phosphokinase were added. The reaction was carried out at 37° C. under mechanical stirring, and the reaction pH was maintained at 7.0 with 2M sodium hydroxide solution during the reaction. After reacting for 7 hours, samples were taken for HPLC analysis and the detection method was the same as in Example 1.

[0047] The results showed that the conversion rate was 90%, and the ee value was >99%.

Embodiment 3

[0048] Embodiment 3 enzymatic method catalyzes the synthesis of L-theanine

[0049] In the 100mL reaction bottle, add successively the final concentration of 400mM sodium glutamate, 400mM ethylamine hydrochloride, 300mM magnesium chloride hexahydrate, 150mM sodium hexametaphosphate, 5mM adenosine disodium triphosphate (ATP), add water to dissolve to make the final volume 50mL, The pH of the reaction was adjusted to 7.0 with 5M sodium hydroxide solution, and 250 mg of γ-glutamine synthetase and 200 mg of phosphokinase were added. React at 37°C under mechanical stirring. During the reaction, use 2M sodium hydroxide solution to maintain the reaction pH at 7.0. After 1 hour of reaction, add 250mg of γ-glutamine synthetase and 200mg of phosphokinase. After reacting for 24 hours, samples were taken for HPLC analysis, and the detection method was the same as in Example 1.

[0050] The results showed that the conversion rate was 80%, and the ee value was >99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com