Patents

Literature

830results about How to "Realize recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

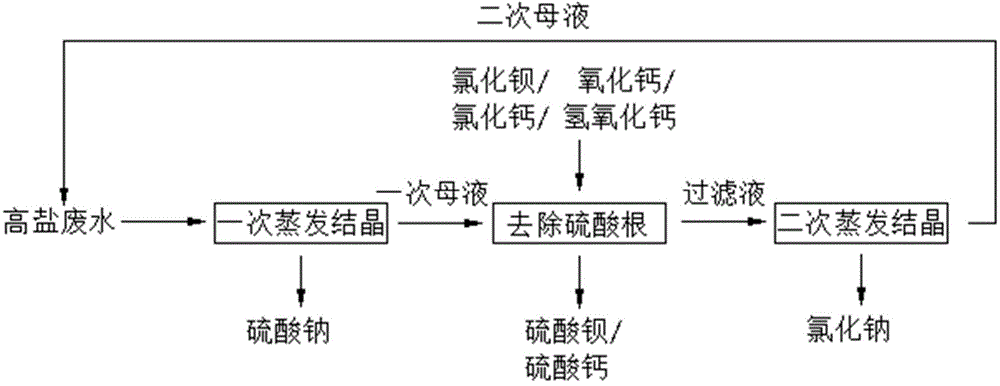

Recycling method of high-salinity wastewater

ActiveCN104591464AProcess conditions are stableEasy to industrializeMultistage water/sewage treatmentEnergy based wastewater treatmentChemistryCoal chemical industry

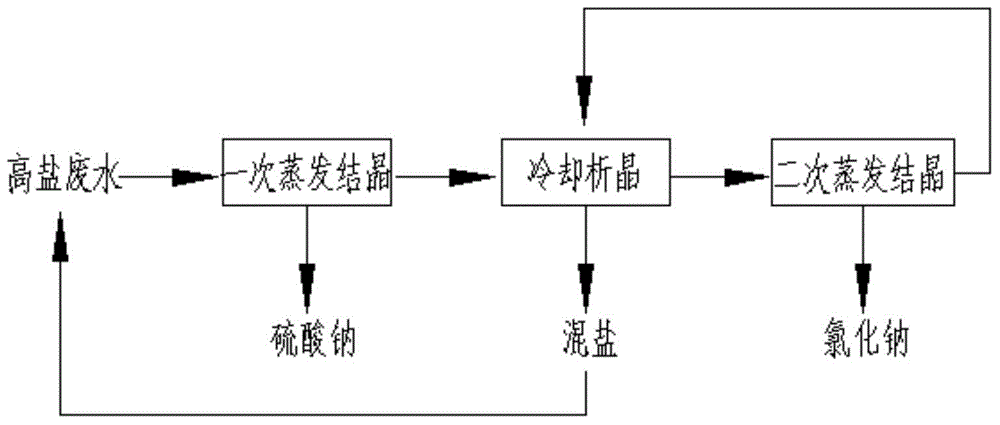

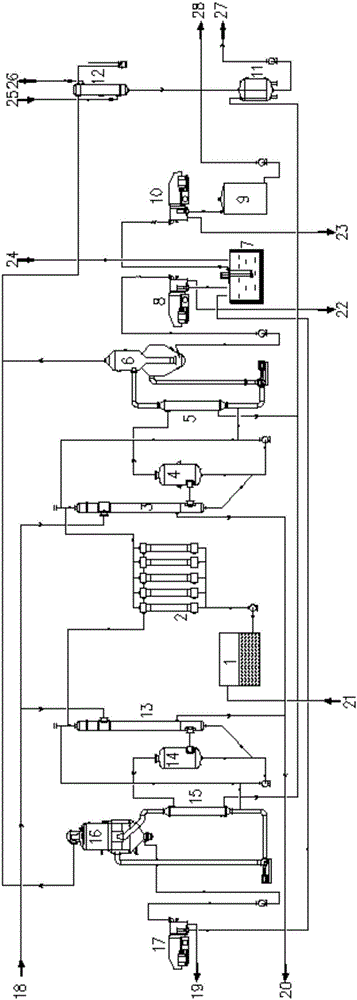

The invention discloses a recycling method of high-salinity wastewater. Sodium sulfate and sodium chloride are recycled through three steps of primary evaporative crystallization, cooling crystallization and secondary evaporation crystallization. According to the method disclosed by the invention, sodium sulfate and sodium chloride in the high-salinity wastewater of coal chemical industry can be effectively recycled; the method is simple and stable in technological conditions; industrial popularization is facilitated; the recycled sodium sulfate and sodium chloride meet the quality requirements of industrial products, and can be directly recovered and applied mechanically or sold as byproducts, so that the target of treating the high-salinity wastewater is reached; the requirements of the current environment-friendly situation are met; waste is changed into treasures; resource utilization of salts is achieved; and benefits of factories are improved.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP +1

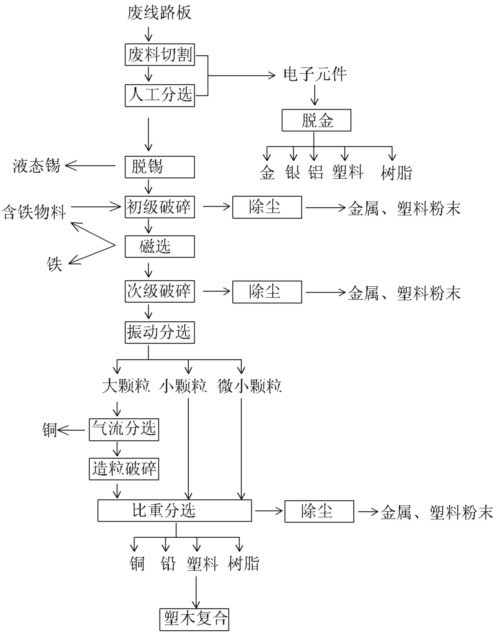

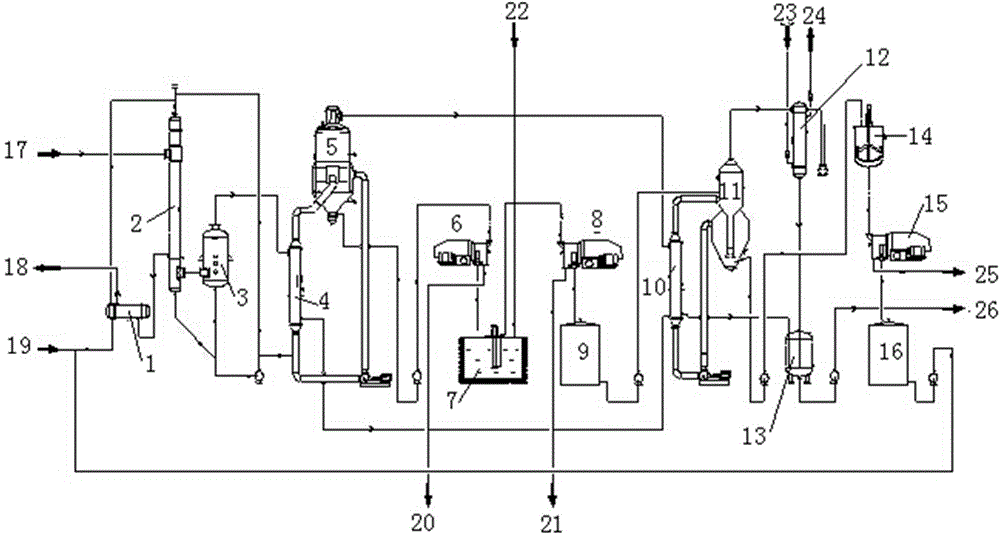

Recycling processing technology for waste circuit board

ActiveCN102671916ARealize recyclingEfficient separationWaste processingSolid waste disposalSpecific gravityScrap

The invention discloses a recycling processing technology for a waste circuit board and relates to the recycling processing technology for waste resources. The recycling processing technology comprises the following steps of: cutting wastes; manually separating; removing gold; removing tin; primarily crushing; magnetically separating; secondarily crushing; separating by vibrating; separating through airflow; crushing pellets; separating according to specific gravity; compounding plastic and wood; and lastly, respectively recycling the matters, such as gold, silver, aluminum, iron, tin, copper, lead, plastic and resins, thereby reusing the matters. The recycling processing technology has the advantages that: (1) the flow line production operation is realized, the degree of automation is high and the yield is high; (2) compared with the traditional processing method, the recycling processing technology effectively reduces the emission of toxic gas and water and improves the environmental protection index; and (3) various matters in the waste circuit board are more effectively separated, the noble metal is recycled, the recycling of resources is realized, the mineral resource exploitation and wood felling are indirectly reduced, and the energy consumption and pollution during the processes of mineral resource exploitation and metallurgy processing are reduced.

Owner:NINGBO HUILONG MACHINERY CO LTD

Waste solution mercury removal adsorbent, preparation method and application method thereof

ActiveCN103623771ARealize recyclingTo achieve the purpose of mercury removalOther chemical processesWater/sewage treatment by sorptionLiquid wasteSorbent

Owner:SHANGHAI JIAO TONG UNIV

Metal, ceramic powder and polymer mixture used for manufacturing metal and ceramic products and method for hydrolyzing and removing polymer from moldings

The invention discloses a polymer material, metal and ceramic powder mixture used for manufacturing metal, ceramic and compound (mixed) material (material component) products and a method for hydrolyzing and removing polymer materials from moldings. The mixture comprises the following materials in volume ratio: 40-70% of material components and 60-30% of polymer material adhesives (being composed of the following materials in mass ratio: 50-95% of main materials that can be hydrolyzed and removed at a relatively low temperature, 46-4.5% of ancillary materials that can be thermally removed at a relatively high temperature and 4-0.5% of additives); the mixture is used for molding by mixing, banburying, squeezing and granulating; main polymer materials are hydrolyzed and removed from molded green bodies at a relatively low temperature, auxiliary polymer materials and additives are thermally removed at a relatively high temperature, and the green bodies are sintered to obtain target products. The polymer material and the method have the advantages that adhesive removing is low in temperature and short in time, and the catalyst is water; removed materials are reusable by recycling, condensing and separating, and are environment-friendly; after molding, pouring gate and flow passage rejecting materials can be repeatedly recycled; the product cost is lowered.

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

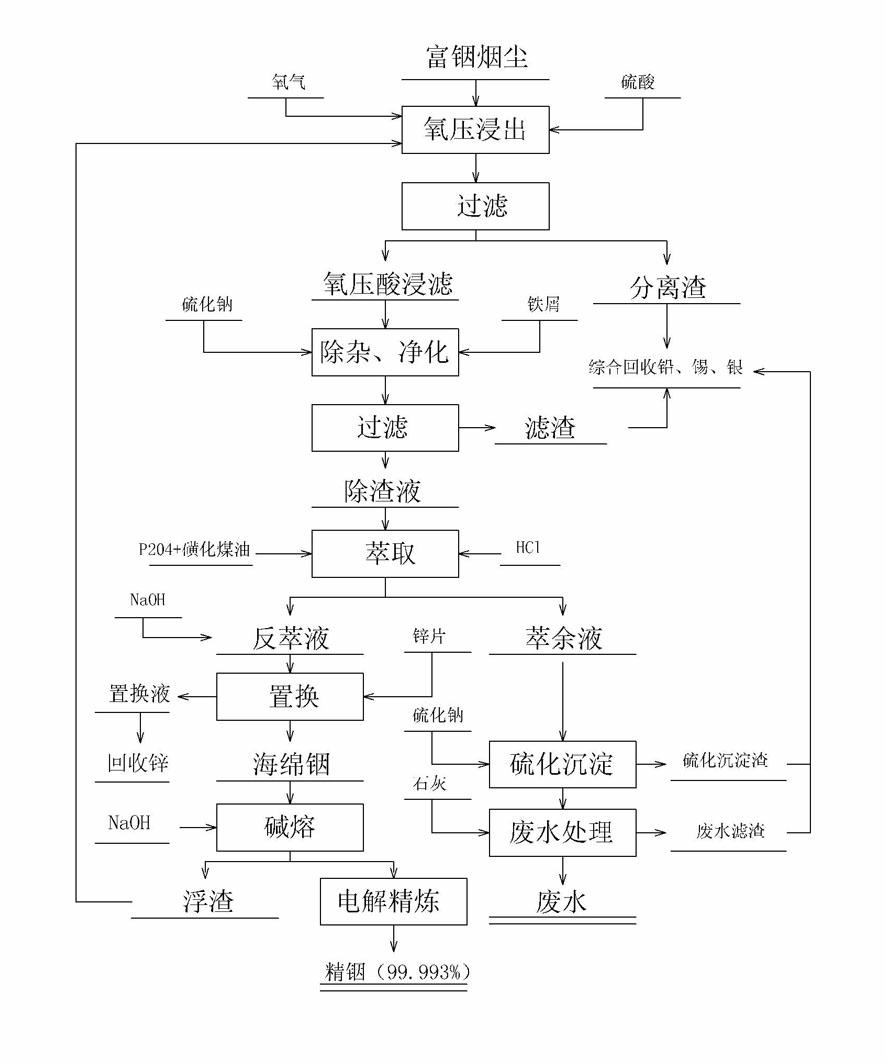

Method for extracting indium from indium-rich smoke dust by using oxygen pressure technology

The invention provides a method for extracting indium from indium-rich smoke dust by using an oxygen pressure technology. The method is characterized by comprising the following steps of: carrying out leaching indium extraction of the difficult-to-handle indium-rich smoke dust of a Pb-Sn reverberatory furnace by adopting a wet-process metallurgical oxygen pressure acid leaching technology, and highly enriching and recycling valuable metals in the raw material; and purifying to remove impurities of leachate, and carrying out extraction, replacement and electrolytic refining, thereby obtaining greater than 99.995% of electrical indium products. The technology method has the advantages that the indium leaching rate of the indium-rich smoke dust of the Pb-Sb reverberatory furnace and the enrichment rate of the valuable metals can be obviously increased, and the comprehensive recycling effect can be achieved, thereby waster water of indium smelting can be discharged up to the standard after being processed with low cost, the environmental pollution in the indium extraction process is eliminated. In the process, the leaching rate of the indium is more than 97%, leaching residues containless than 0.01% of indium, the enrichment rate of plumbum, tin, bismuth and zinc is more than 98%, the quality of refined indium products is more than 99.995%, and plumbum enriching slag containing greater than 60% of Pd is obtained. The technical scheme can independently form a system, can also be used for improving and perfecting old technologies and has higher popularization and application value.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Recovery processing method of high salinity wastewater containing sodium chloride and sodium sulfate

InactiveCN104973726AHigh purityMeet quality requirementsEnergy based wastewater treatmentMultistage water/sewage treatmentResource utilizationSULFATE ION

The invention discloses a recovery processing method of high salinity wastewater containing sodium chloride and sodium sulfate, and belongs to the field of industrial wastewater treatment. According to the recovery processing method, sodium chloride and sodium sulfate are recycled via primary evaporative crystallization, removing of sulfate ions via adding of materials and generation of precipitations, and secondary evaporative crystallization. The recovery processing method can be used for effective recovery of sodium chloride and sodium sulfate in coal chemical industry high salinity wastewater; process conditions are simple and stable; the recovery processing method is convenient for industrialized popularization; recovered sodium chloride and sodium sulfate are capable of satisfying quality requirements of industrial-grade products, and can be recycled and reused directly or be sold as by-products; processing of high salinity wastewater is realized; environmental requirements are satisfied; waste is changed into valuables; salt resource utilization is realized; and factory income is increased.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

Processing method of salt-free dyeing through activated dye

InactiveCN102899929AIncrease the adsorption rateImprove adsorption capacityDyeing processInorganic saltsOrganic solvent

The invention relates to a processing method of salt-free dyeing through activated dye, which includes the steps of: (1), acid pickling and enzyme washing of cotton fabric after the pretreatment of scouring and bleaching; (2) mixing water with organic solvent at volume ratio of (1:4)-(1:9) to form a mixed solution, and then adjusting the pH value of the mixed solution; and (3)dyeing the pretreated cotton fabric in 20-30 DEG C activated dye by using the mixed solution, then carrying out water scrubbing, acid pickling, soaping, hot-water scrubbing, color fixing and softening on the dyed cotton fabric, and finally recovering the solvent. With the processing method, the adsorption rate and the equilibrium adsorption amount of the activated dye are improved, and environmental and ecological problems caused when large quantity of inorganic salt is used are completely solved. In the dyeing process, the input of inorganic salt is omitted, so the operational techniques and the labor intensity in the dyeing process are effectively simplified and the production cost is reduced. Through a solvent recovery system, the solvent contained in the dyeing residue of the hydrosolvent is recovered for cycle use. Therefore, the recovery and the recycling of the resource are realized, the production cost is saved and the pollution to the environment is alleviated.

Owner:DONGHUA UNIV +1

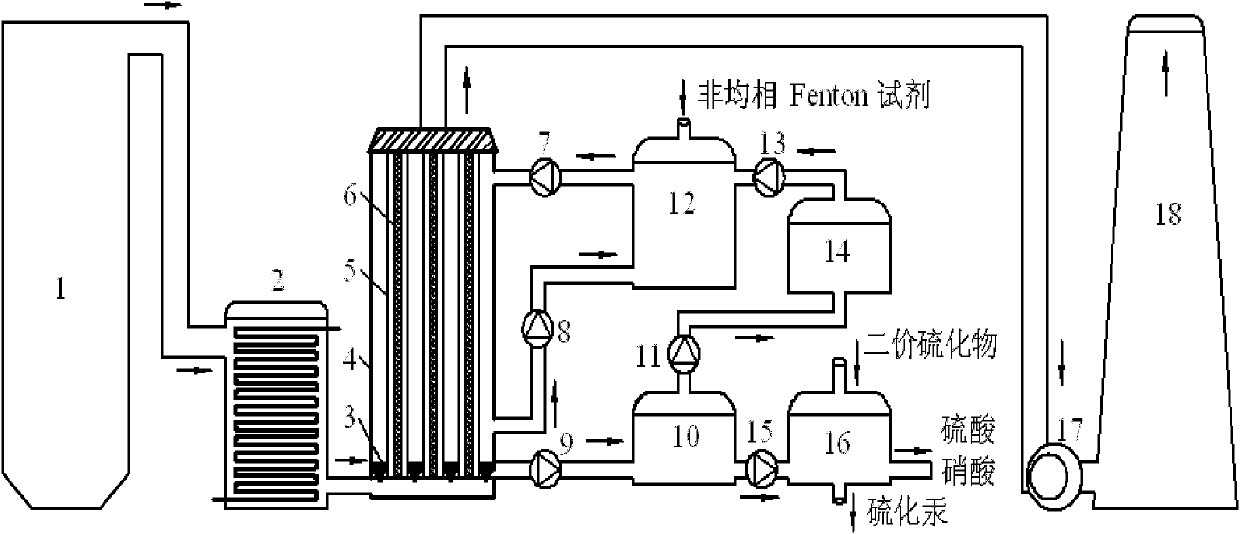

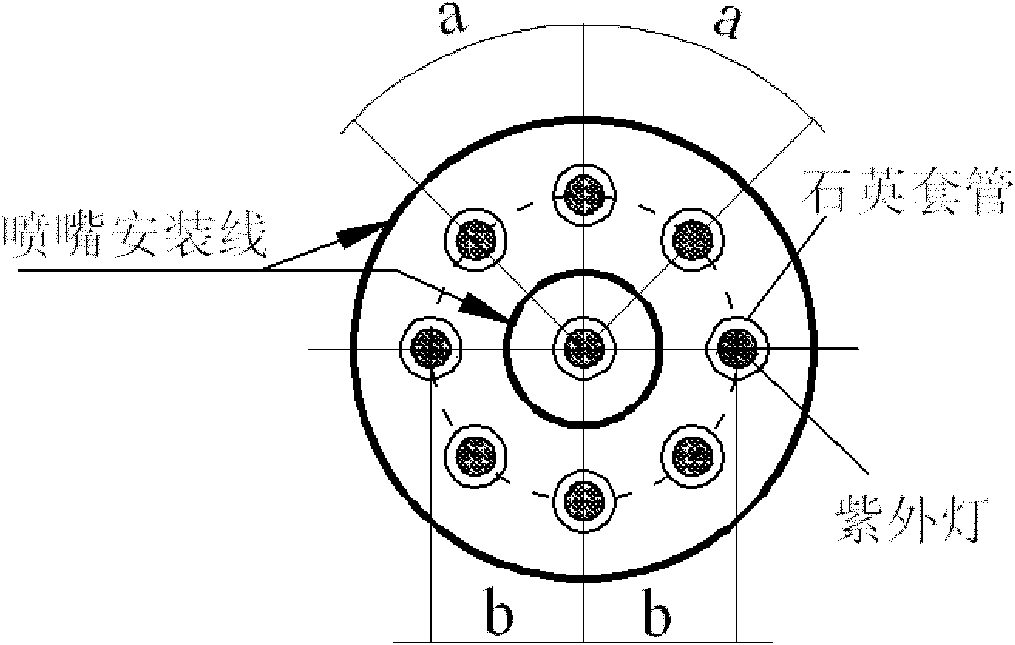

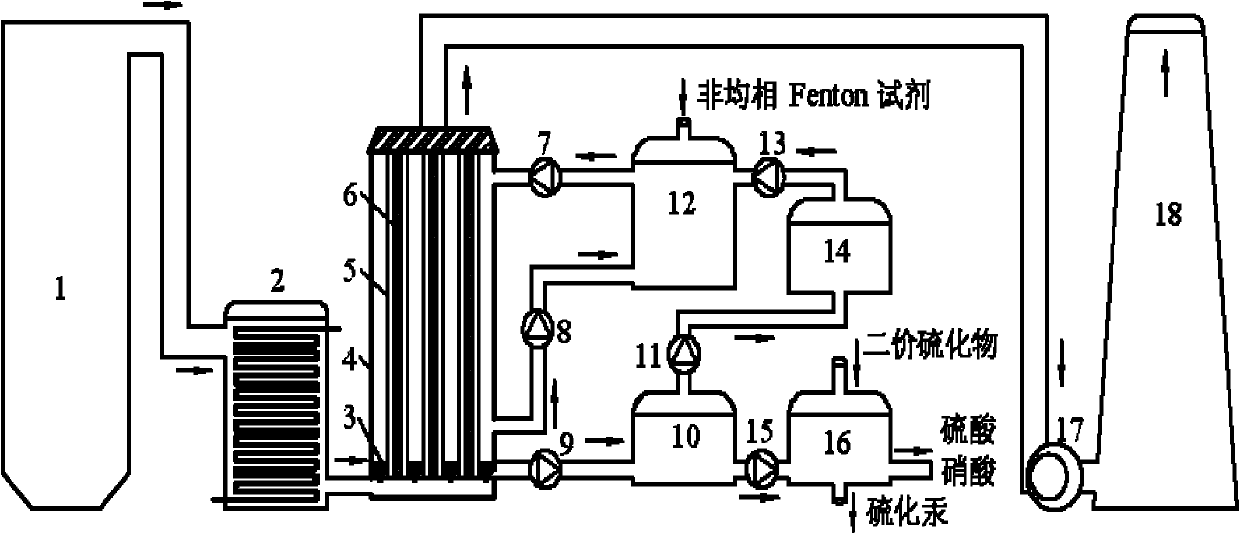

Heterogeneous-Photo-Fenton-based integrated smoke gas purification system

InactiveCN102166471ANo secondary pollutionImprove oxidation capacityDispersed particle separationAir quality improvementHydroxyl radicalPollution

The invention discloses a heterogeneous-Photo-Fenton-based integrated smoke gas purification system. The smoke gas purification system generates a hydroxyl radical (.OH) with strong oxidizability by using heterogeneous Photo-Fenton to oxidize SO2, NO and Hg0 in the smoke gas into H2SO4, HNO3 and Hg2<+> respectively, wherein the H2SO4, the HNO3 and the Hg2<+> are fixed in solution; after reaction,a solid catalyst in mixed solution can be recycled through simple primary precipitation separation; a small amount of Hg2<+> in the solution can be generated into insoluble HgS by adding the same mole ratio of S2<->, and then the HgS is recycled through secondary precipitation separation; and the remaining sulfuric acid and nitric acid solution can be used as an industrial raw material to be further recycled. The whole integrated desulfuration, denitration and demercuration processes generate no secondary pollution, so the heterogeneous-Photo-Fenton-based integrated smoke gas purification system has a very good application prospect.

Owner:SOUTHEAST UNIV

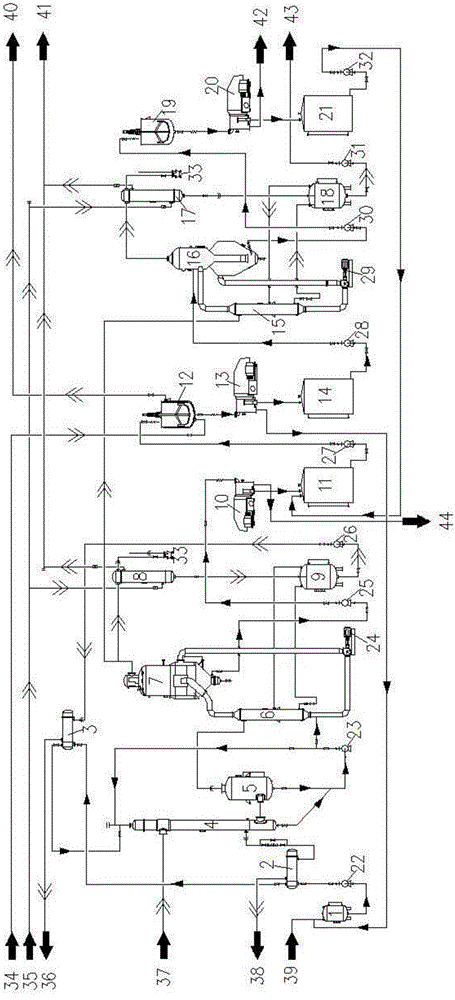

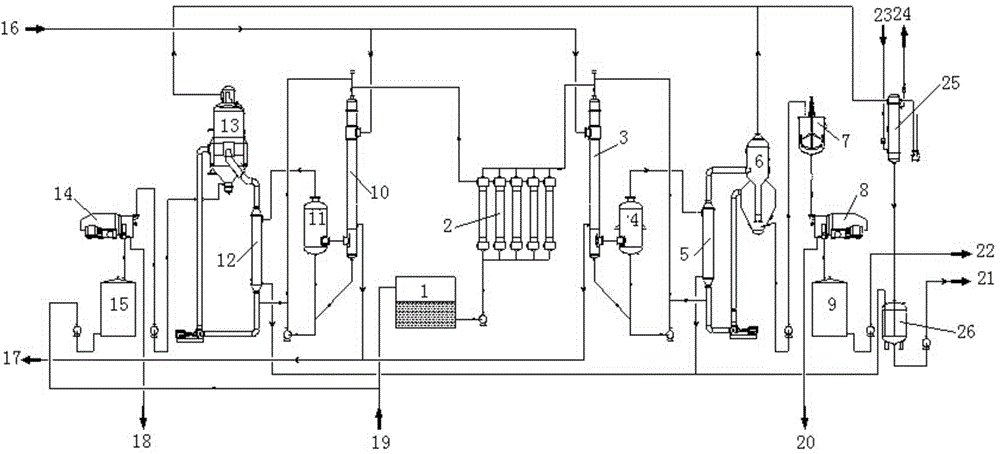

Sewage treatment and regeneration cyclic utilization device and sewage treatment and regeneration cyclic utilization method

InactiveCN102674628AImprove the efficiency of sewage treatmentTo achieve the effect of double treatmentSludge treatment by de-watering/drying/thickeningWater/sewage treatment by irradiationCapacitanceElectrolysis

The invention relates to a sewage treatment and regeneration cyclic utilization device, which is provided with a biochemical system, an electrolysis system, a membrane biological reactor (MBR) system and a deep processing system. A sewage treatment and regeneration cyclic utilization method comprises the following steps of (1) biochemical treatment; (2) electrolysis; (3) MBR system filtering; (4) capacitance desalting and sterilization; and (5) sludge treatment. The device and the method can overcome the defects that in the existing sewage regeneration technology, the quality of the regeneration water is poor, the water consumption water quality requirements are difficult to meet, the investment is high, the operation cost is high, the secondary pollution is caused on the environment, and the like. The sewage discharge can be reduced, the utilization efficiency of the water is improved, meanwhile, the regeneration and the reutilization on the sludge are realized, and the harm possibly caused by the sludge to the environment is eliminated.

Owner:BOYING XIAMEN SCI & TECH

Recycling method for high-salinity wastewater containing sodium chloride and sodium sulfate

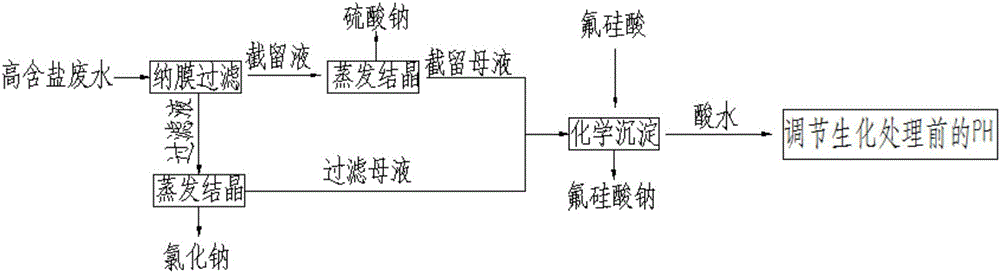

InactiveCN105110536AReduce processing costsRealize resource utilizationWater/sewage treatment by centrifugal separationWater contaminantsAcid waterWastewater

The invention discloses a recycling method for high-salinity wastewater containing sodium chloride and sodium sulfate and belongs to the field of wastewater treatment. The method comprises: filtering wastewater through a nanofiltration membrane; performing evaporative crystallization on filtrate through the nanofiltration membrane to obtain sodium chloride and filtered mother liquor; performing evaporative crystallization on retained liquor which does not pass through the nanofiltration membrane to obtain sodium sulfate and retained mother liquor; mixing the filtered mother liquor with the retained mother liquor to obtain a mixture and adding fluosilicic acid into the mixture; and stirring sufficiently the mixture to obtain sodium fluosilicate by filtering. Filtered acid water is used in pH value adjustment of a system before biochemical treatment.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

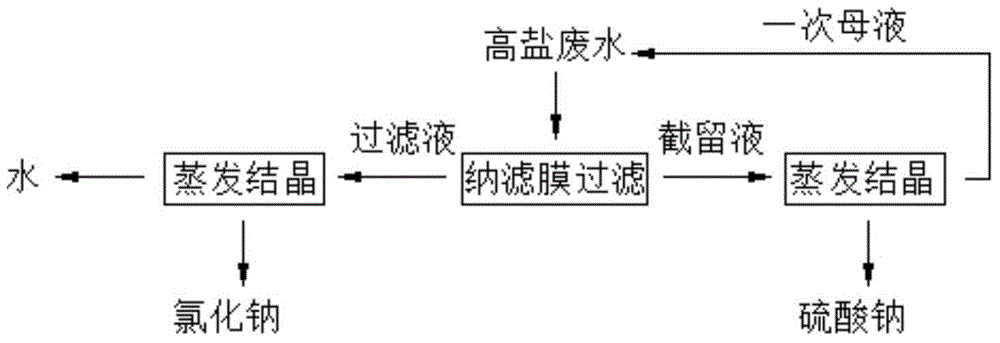

Method for recycling high-salt waste water containing sodium chloride and sodium sulfate

InactiveCN104961285AHigh purityMeet quality requirementsAlkali metal sulfite/sulfate purificationEnergy based wastewater treatmentIndustrial waste waterNanofiltration

The invention discloses a method for recycling high-salt waste water containing sodium chloride and sodium sulfate, and belongs to the field of industrial waste water treatment. The method comprises the steps of filtering by a nanofiltration membrane, evaporating and crystallizing filtrate penetrating through the nanofiltration membrane to obtain sodium chloride, evaporating and crystallizing trapped fluid which cannot penetrate through the nanofiltration membrane to obtain sodium sulfate, returning a primary mother solution to the system, and mixing the primary mother solution with raw materials to be continuously recycled. By adopting the method, sodium sulfate and sodium chloride in the high-salt waste water can be effectively recycled, a purpose of treating the high-salt waste water can be realized, and the current environmental-protection demand can be satisfied, waste can be converted into treasure, the recycling of salts can be realized, and the benefit of factories can be increased.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

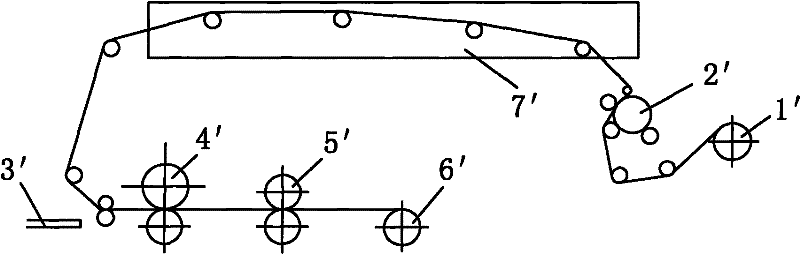

Control system and method for printing paper or coating film

InactiveCN102173193ASimplify operating proceduresImprove processing efficiencyRotary pressesPrinting press partsControl systemEngineering

The invention discloses a control system and a control method for printing paper or coating a film. The control system at least comprises a film unreeling device, a film gluing unit, a single-sheet unreeling device, a compounding unit, a film cutting device and a single-sheet delivery device. The control method at least comprises steps of feeding, gluing, compounding and reeling. The film coating, a film surface secondary pressing process, curing and cold foiling, and a laser transfer process are integrated, the operating procedures are simplified, the technological processing efficiency is improved, the additional value of a product is improved, a compound transfer process can be completed, the transferred film can be recycled, the cost is saved and the environment is protected.

Owner:东莞市博森印刷器材有限公司

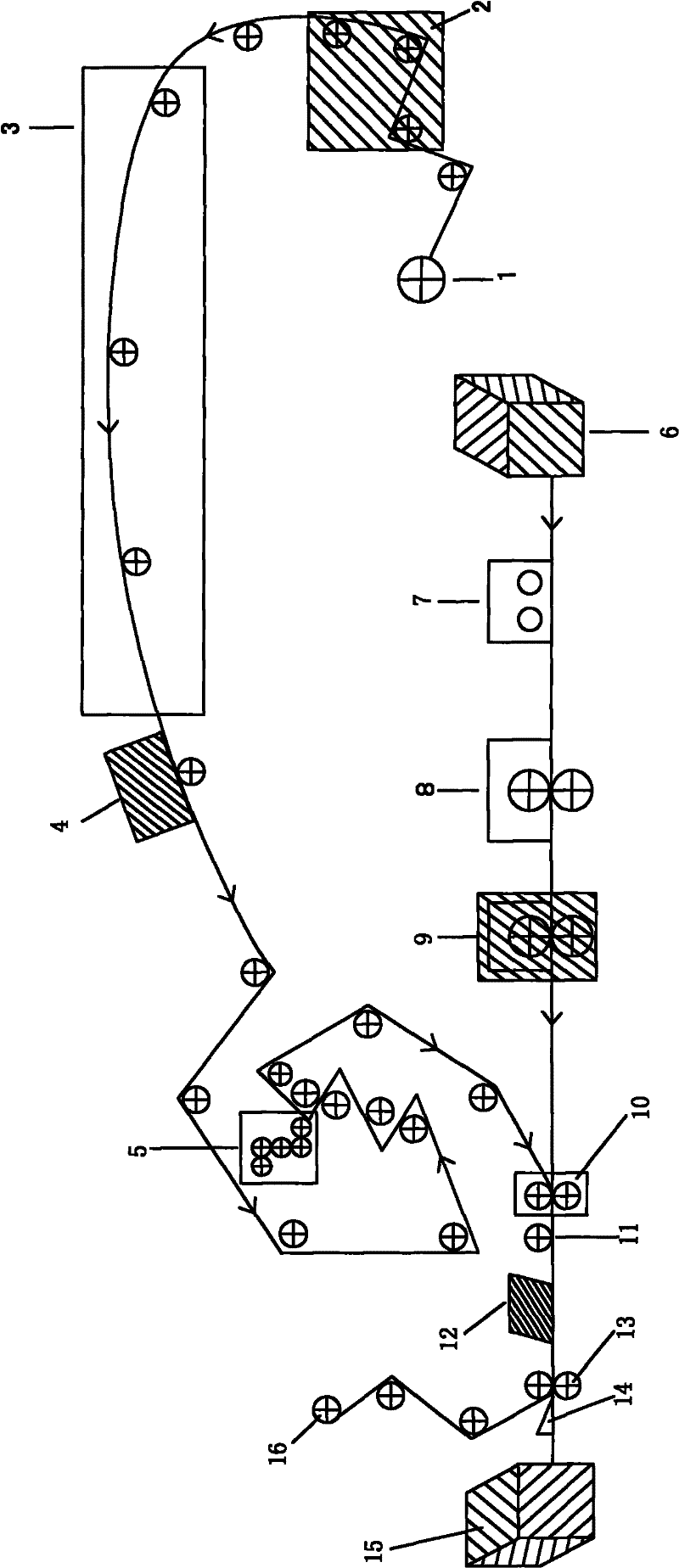

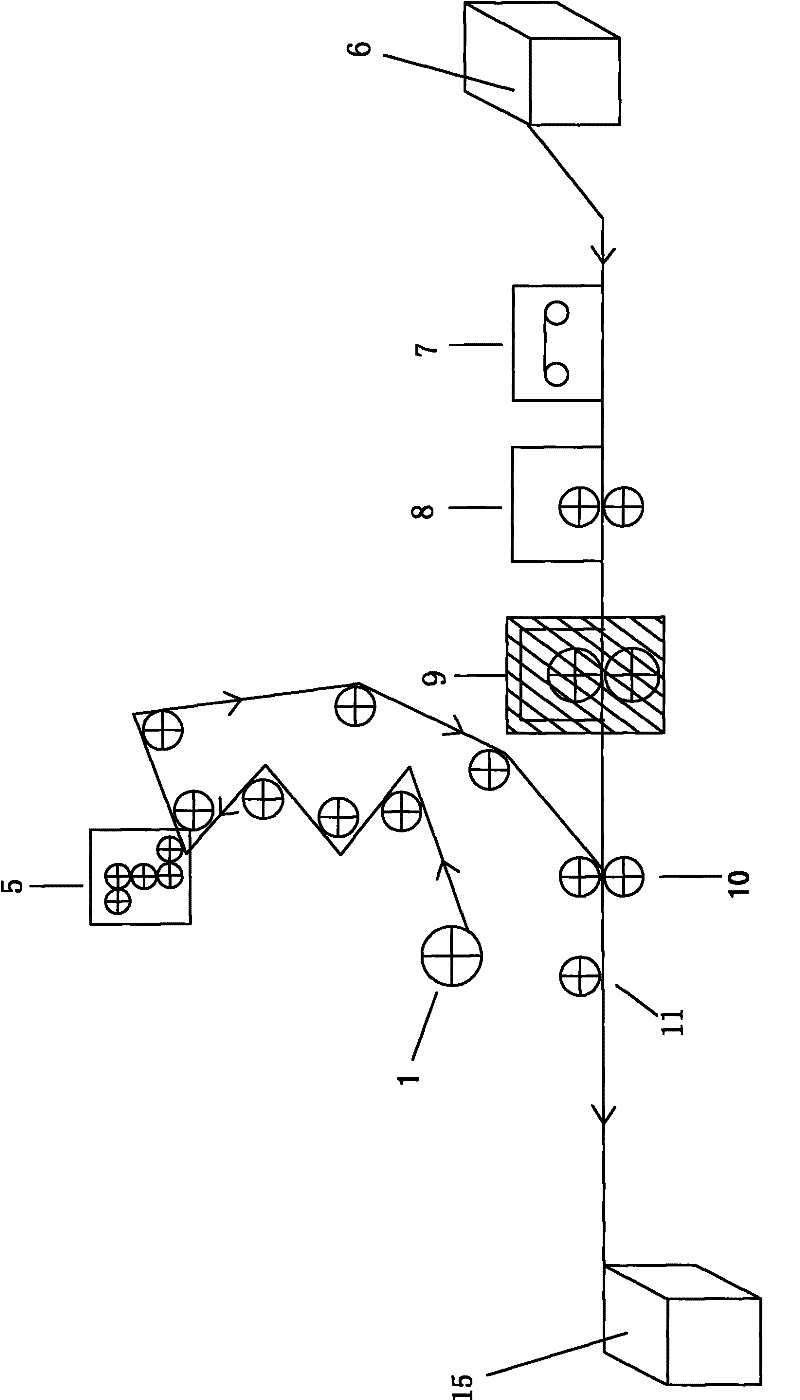

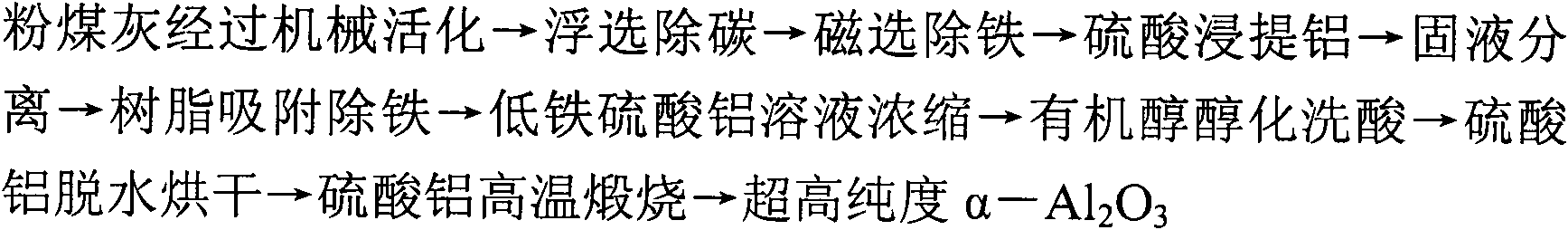

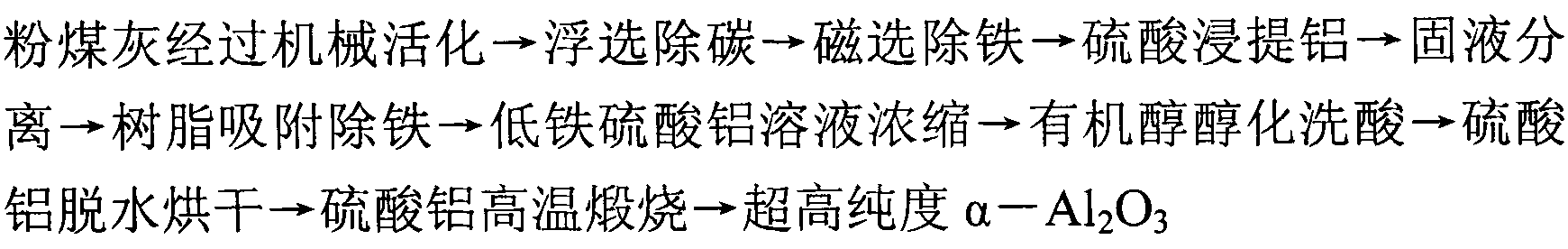

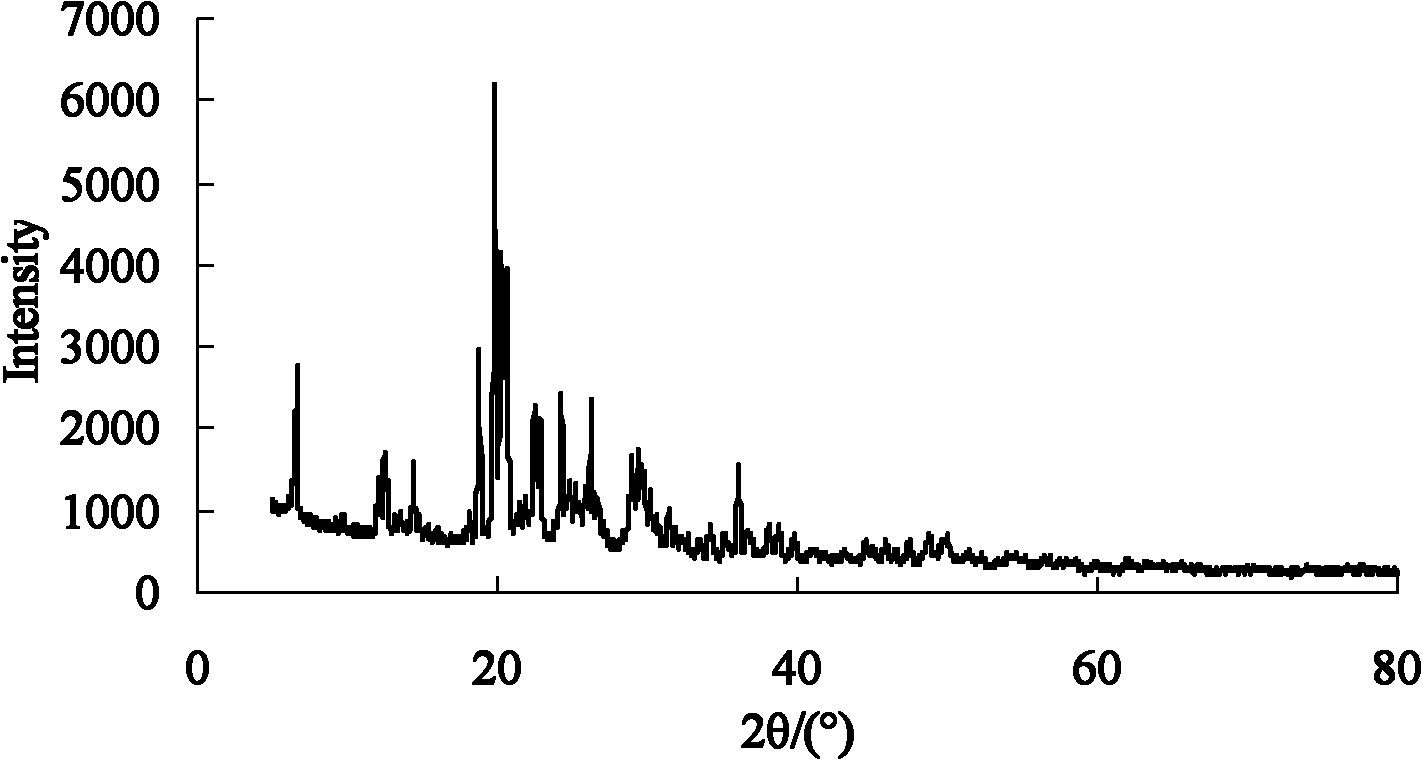

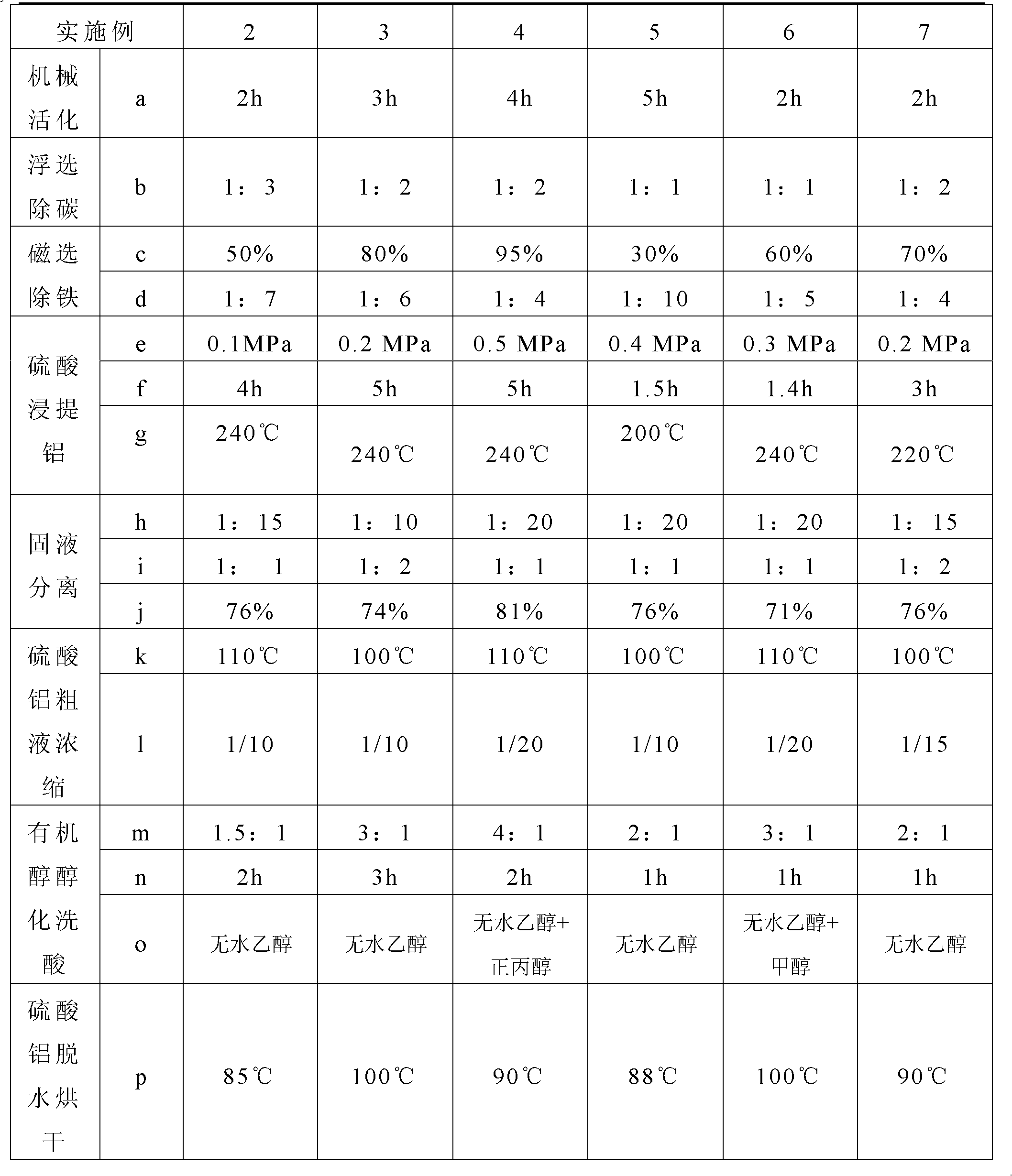

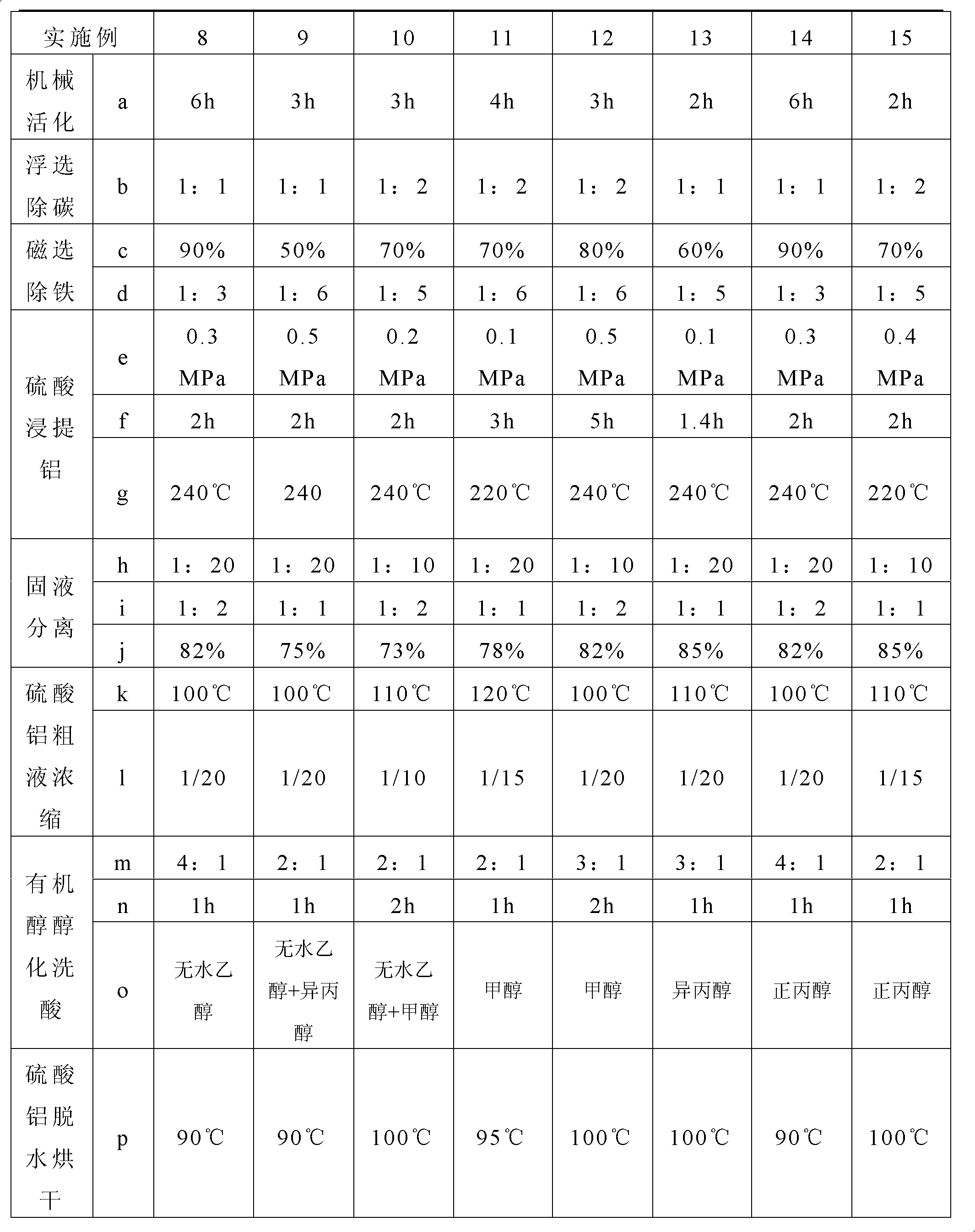

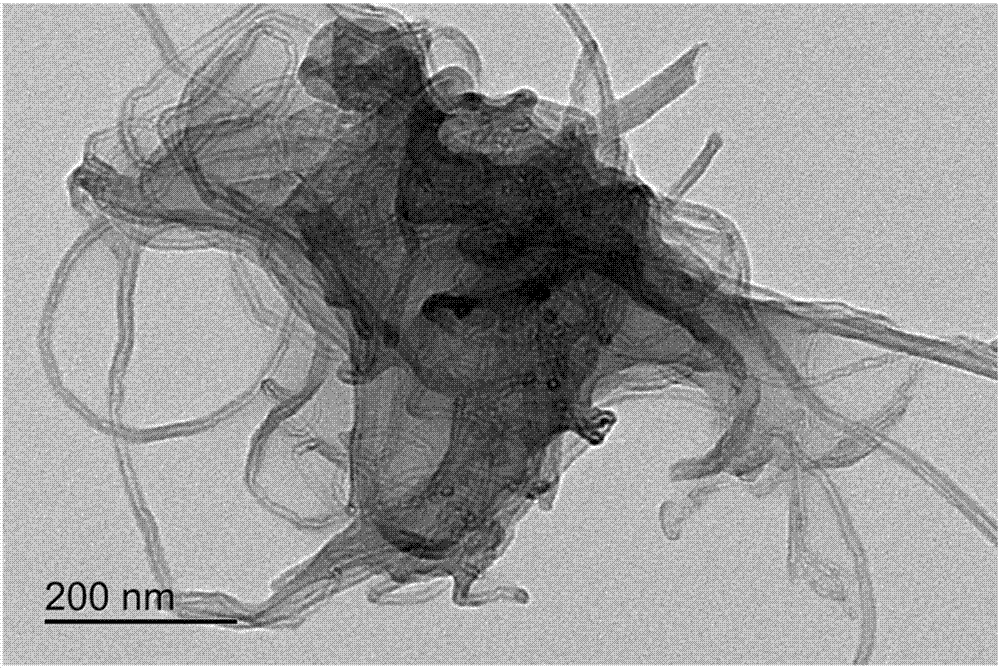

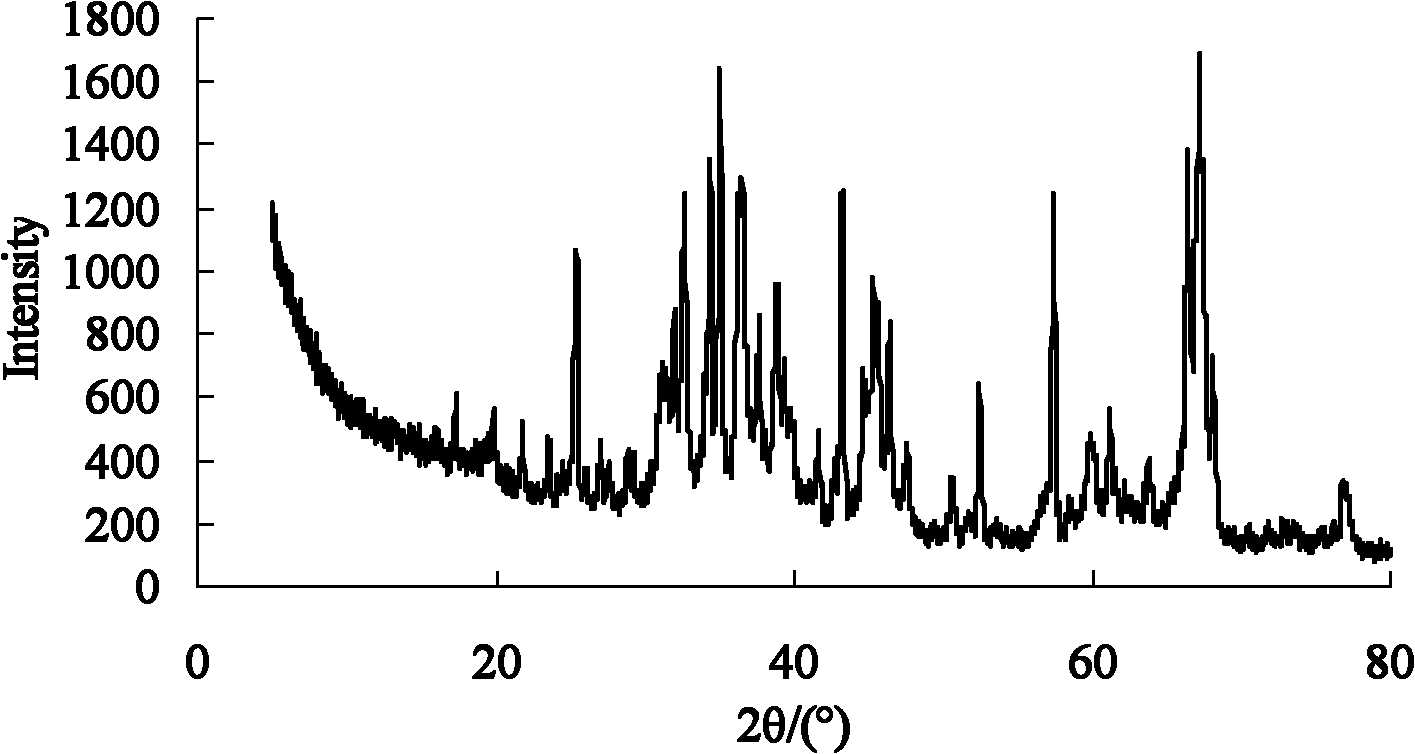

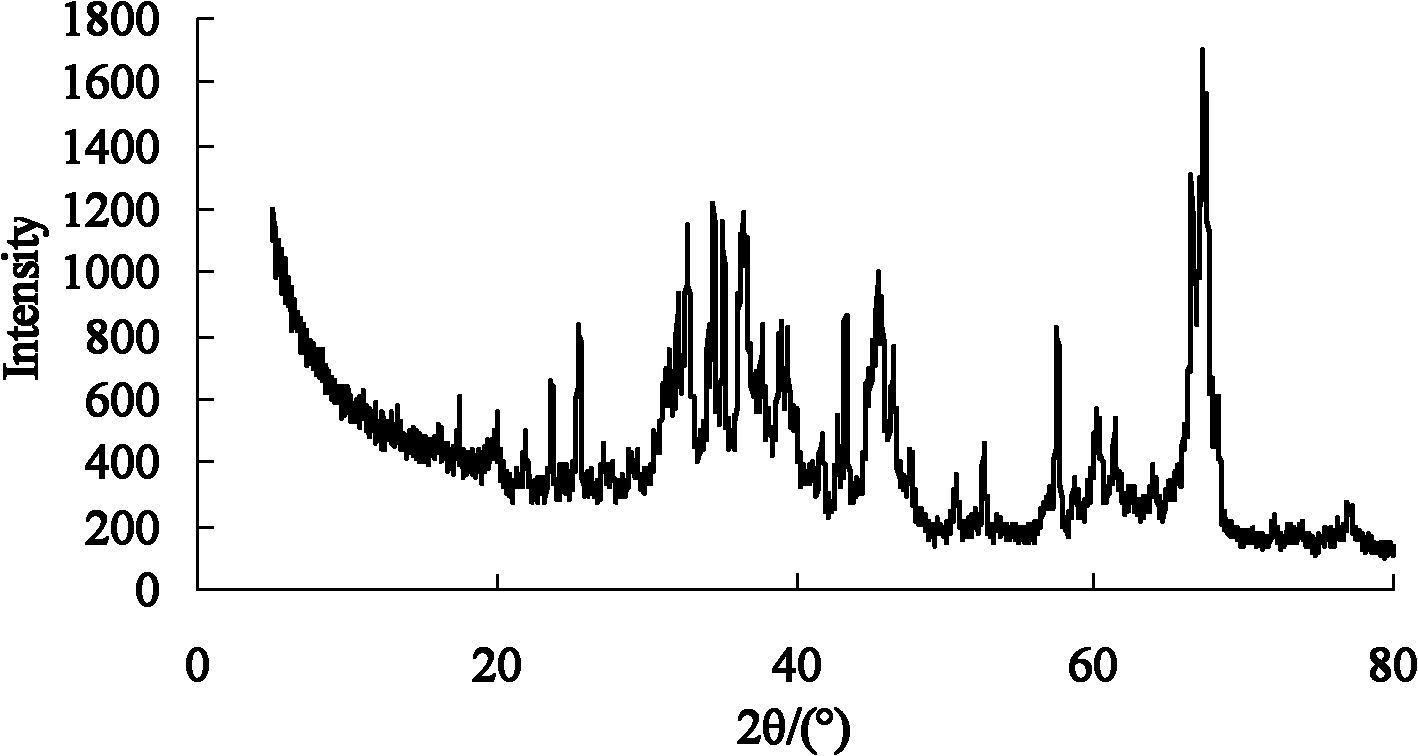

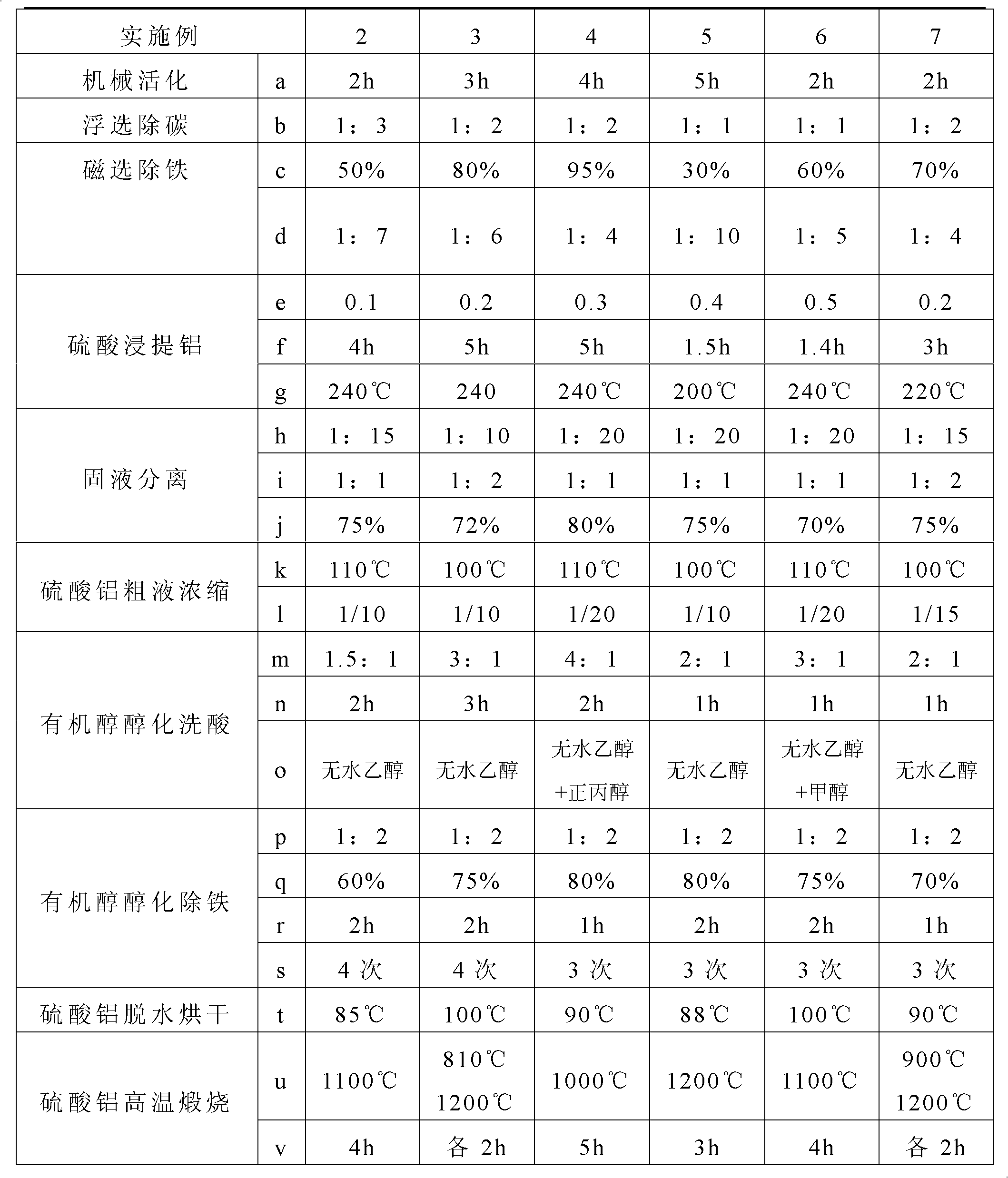

Process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina

InactiveCN102101686AReduce energy consumptionEasy to operatePigmenting treatmentSolid waste disposalAcid washingBiological activation

The invention discloses a process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina. In the process method, mechanical activation, flotation decarbonization, magnetic separation iron removal sulfuric acid aluminum lixiviation, solid-liquid separation, resin absorption iron removal, low-iron aluminum sulfate concentration, organic alcohol alcoholization acid washing, aluminum sulfate dehydration drying and aluminum sulfate high-temperature calcination are carried out on the coal ash so as to obtain ultra-high purity alpha-Al2O3, wherein the content of the Fe2O3 in the ultra-high purity alpha-Al2O3 is less than 2 ppm. By using the process method, the complicated purification problem that intermediate aluminum sulfate in the process of coal ash reclamation is necessarily subjected to a called Bayer circulation process is avoided, thereby simplifying the process flow, reducing the energy consumption, reducing the resource consumption and solving the technical problem of over-large secondary residue quantity accumulation. The process method has the advantages that the extraction efficiency is high, and the circulation recovery of organic alcohol and sulfuric acid and comprehensive utilization of byproducts such as resin and the like are achieved. In the invention, the process is simple, the process flow is short, the production process is easy to control, the content of the impurity in the product is low, and the quality of the product is stable.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

Method for producing ultra-high purity aluminium sulfate from fly ash

InactiveCN102020303AReduce energy consumptionEasy to operateSolid waste disposalAluminium sulfatesAluminium saltsSulfuric acid

The invention discloses a method for producing ultra-high purity aluminium sulfate from fly ash, which comprises the following steps: mechanically activating fly ash, decarbonizing by floatation, removing iron by magnetic separation, extracting aluminium with sulfuric acid, separating solids from liquid, removing iron by resin adsorption, concentrating the low-iron aluminium sulfate solution, washing acid by alcoholization with organic alcohol, and dehydrating and drying the aluminium sulfate to obtain the ultra-high purity aluminium sulfate in which the content of Fe is lower than 0.2ppm. The ultra-high purity aluminium sulfate is better than the strictest technical requirements for Solid Type II First-Grade (low-iron product) and Solid Type III (high-aluminium low-iron fine product) in HG / T2225-2001 Industrial Aluminium Sulfate and Class I Solid (for drinking water) in HG2227-2004 Water Treatment Agent-Aluminium Sulfate. The invention has the advantages of simple technique, short procedure, easily controlled production process, high aluminium extraction yield, low production cost, low impurity content in the product and stable product quality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

Sludge curing material for comprehensively utilizing phosphorous gypsum

The invention discloses a sludge curing material for comprehensively utilizing phosphorous gypsum. The sludge curing material consists of the following materials in percentage by weight: 20%-60% of phosphorous gypsum, 5%-25% of coal ashes, 10%-30% of mineral powder, 8%-25% of limestone and 0.2%-3% of an activator. According to the sludge curing material, the waste phosphorous gypsum is used as the main material and supplemented with industrial waste such as the mineral powder, the coal ashes as well as limestone or cheap materials, thereby realizing recycling the industrial waste, and lowering environmental pollution; meanwhile, sludge curing production cost is lowered, quality of a sludge curing product is improved, engineering construction application such as road foundation and foundation filler is realized, needs of aggregate for building are lowered, and therefore, construction material cost and transportation cost are lowered.

Owner:JIANGSU NATURE WAY TECH

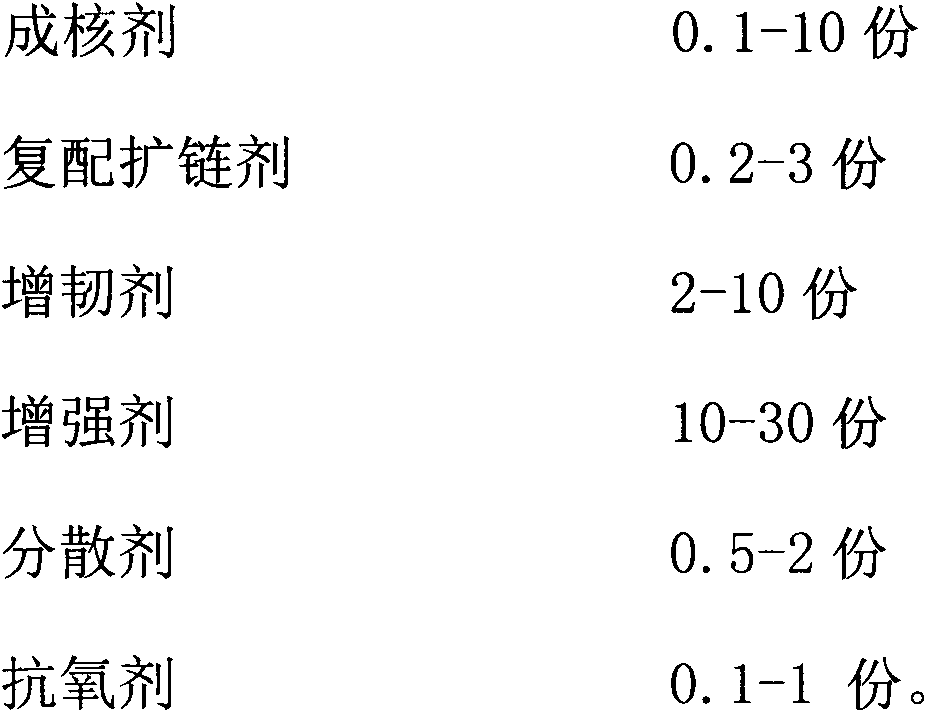

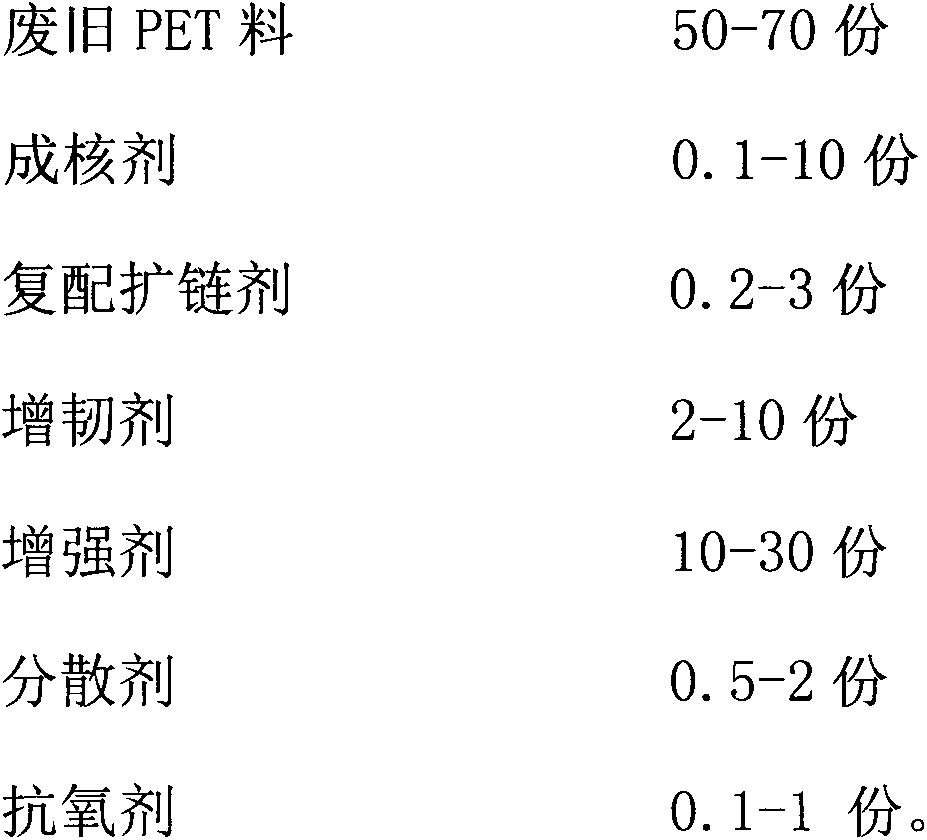

Waste PET (Polyester) heat-proof tackifying and reinforcing composite material and preparation process thereof

InactiveCN103146159AThe preparation process is simple and convenientGood mechanical propertiesPolyesterAntioxidant

The invention discloses a waste PET (Polyester) heat-proof tackifying and reinforcing composite material and a preparation process thereof. The preparation raw materials of the waste PET heat-proof tackifying and reinforcing composite material include a waste PET material, a nucleating agent, a compound chain extender, a toughening agent, a reinforcing agent, a dispersant and an antioxidant. When the waste PET heat-proof tackifying and reinforcing composite material is prepared, a first mixture formed by mixing the waste PET material and the toughening agent is added from a main feed port, the nucleating agent, the compound chain extender, the dispersant and the antioxidant are added from a powder side beside the main feed port in a feeding way, and the reinforcing agent is added from the feed port positioned at an extruder side, so that a small amount of powdery auxiliary agent and a main material can be uniformly mixed and the quality of a finished material is enhanced in such a unique charging way. The preparation process of the waste PET heat-proof tackifying and reinforcing composite material, which is disclosed by the invention, has the advantages of simple process and easiness for industrialization; and the waste PET heat-proof tackifying and reinforcing composite material disclosed by the invention has the advantages of high crystallization rate, high heat-proof temperature and excellent mechanical property.

Owner:江苏中再再生资源有限公司

Synthetized diesel oil

This invention relates to synthetic diesel oil, which is produced by: (1) mixing isooctyl nitrate 30 wt.%, cyclohexylamine 30 wt.%, ferrocene 30 wt.%, and zinc peroxide 10 wt.% to obtain composite additive; (2) mixing fossil-grade diesel oil 10-40 parts and the composite additive 0.3-2 parts to obtain mother diesel oil; (3) mixing 200# solvent oil 10-30 parts and lightweight aviation kerosene 5-20 parts to obtain modified 200# solvent oil; (4) mixing fatty acid methyl ester or C9 10-60 parts, the mother diesel oil and the modified 200# solvent oil to obtain the synthetic diesel oil. The synthetic diesel oil has such advantages as low cost, simple process and abundant raw materials, and can be used for replacing standard fossil-grade diesel oil.

Owner:固安中德利华石油化学有限公司

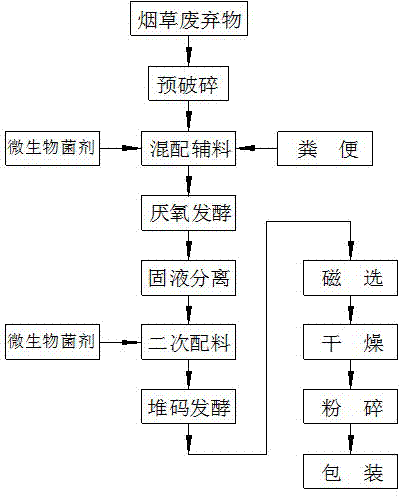

Process for producing marsh gas and bioorganic fertilizer by utilizing tobacco waste

InactiveCN102887754ASolve the problems that plague tobacco farmersSolve puzzlesBio-organic fraction processingWaste based fuelSocial benefitsMicrobial agent

The invention discloses a process for producing marsh gas and bioorganic fertilizer by utilizing tobacco waste. The process comprises the following steps of: a, primary crushing; b, auxiliary material blending; c, anaerobic fermentation; d, solid-solution separation; e, secondary feed proportioning; f, stacking and fermentation; g, magnetic concentration; h, drying; i, pulverization; and j, packaging. According to the process, through carrying out the anaerobic fermentation and aerobic fermentation after a microbial agent is added into the tobacco waste, the marsh gas which is higher in value and the high-quality bioorganic fertilizer are produced; the recycle of resources is realized; the waste is changed into the valuable; the difficult problem of the tobacco waste, which puzzles a tobacco grower for a long term, is really solved; and the process is better in economic benefit and social benefit.

Owner:云南海利实业有限责任公司

Method of preparing chromium oxide using wet reducing potassium bichromate or sodium bichromate

InactiveCN1410357AShort processEasy to operateChromium trioxideAlkali metal oxides/hydroxidesSodium bichromateL&D process

A process for preparing Cr2O3 by wet reduction of potassium (or sodium) bichromate includes such steps as preparing the aqueous solution of potassium (or sodium) bichromate, thermal pressure reactionon reducer to obtain hydrate of chromium oxide, filtering, drying filter cake, high-temp. calcining under protection of inertial gas, and cooling. Its advantages are short period, low cost and high output rate (more than 95%).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

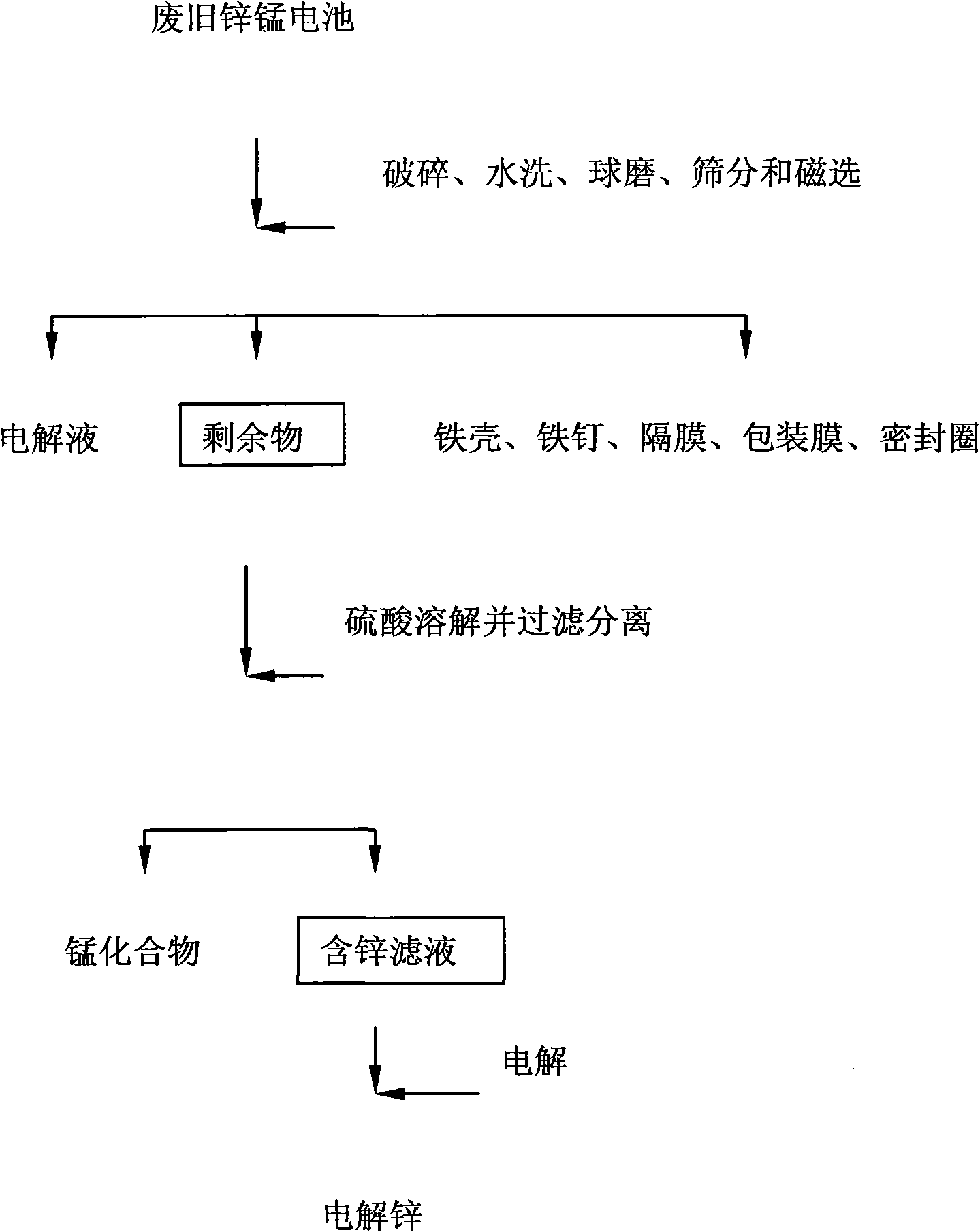

Recycling method of waste zinc-manganese battery

InactiveCN101673829ASolve environmental problemsRealize recyclingReclaiming serviceable partsWaste accumulators reclaimingManganeseEnvironmental engineering

The invention relates to a recycling method of a waste zinc-manganese battery, comprising the following steps: (1) the battery is broken and electrolyte is recovered; (2) iron and organic matters areseparated from washing broken matters; (3) separated remnants are dissolved by acid; (4) zinc is recovered from filtrate. The method can recycle zinc-manganese dry batteries and basic zinc-manganese batteries, thereby not only solving the environmental-protection problem caused by the waste batteries, but also realizing reclamation of valuable substances in the waste batteries. The process has high economic and social value; in the process flows, the used equipment is simple, and valuable substances have good separation effect, and the generation amount of secondary pollutants in the recyclingprocess is small, harmless treatment can be carried out, and the process has advancement on technology; the process method can be easily applied to scale production. The recycling method is simple, economic and practical, has easy operation and can recycle the waste zinc-manganese battery in a large scale.

Owner:SOUTH CHINA NORMAL UNIVERSITY

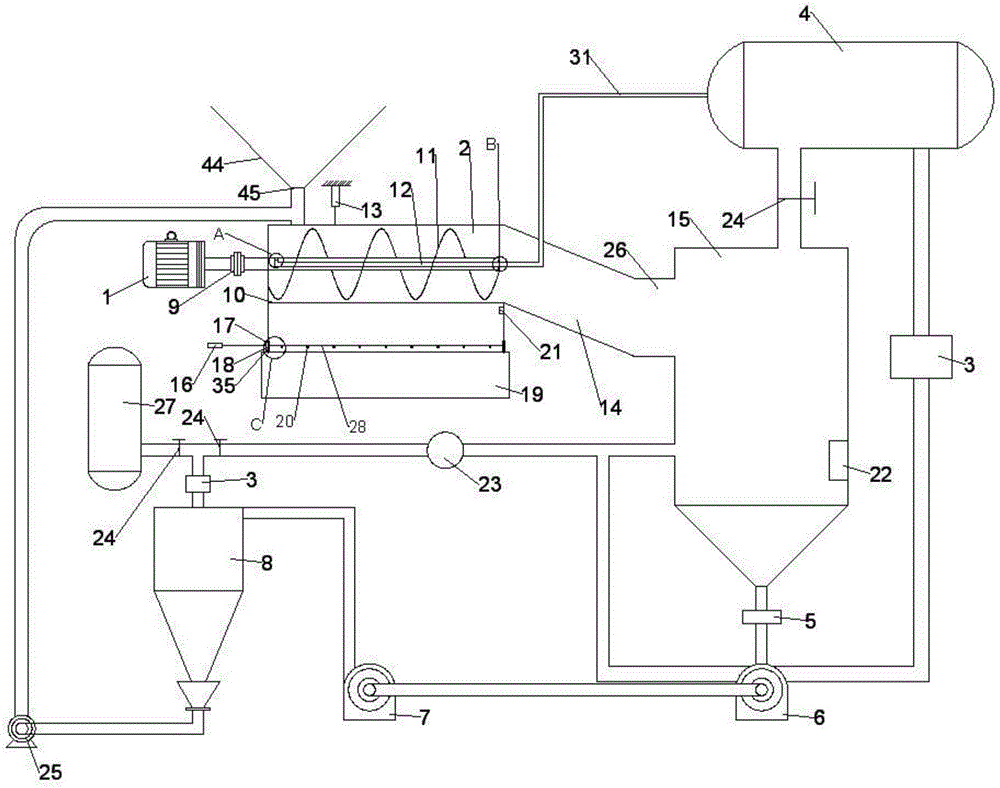

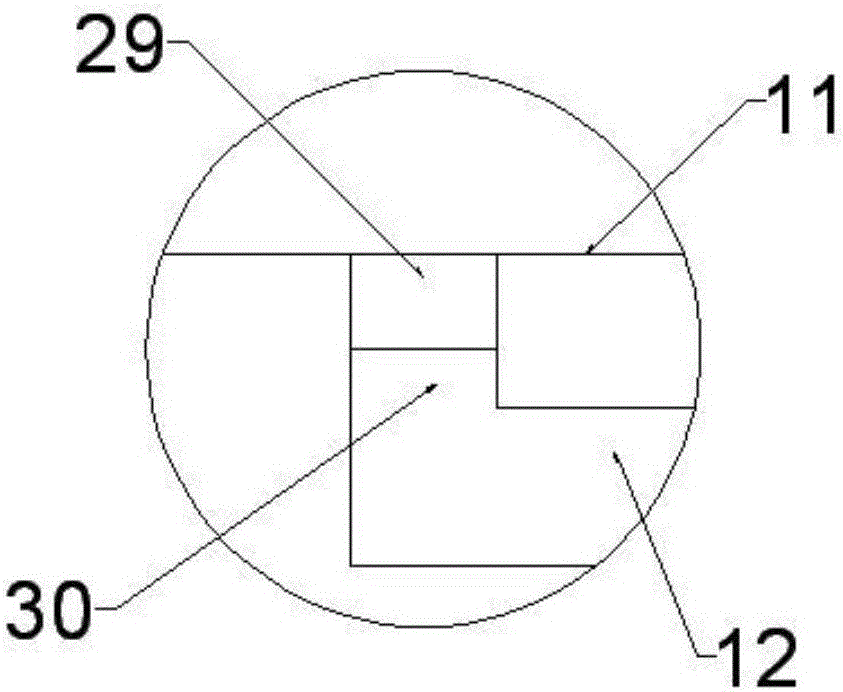

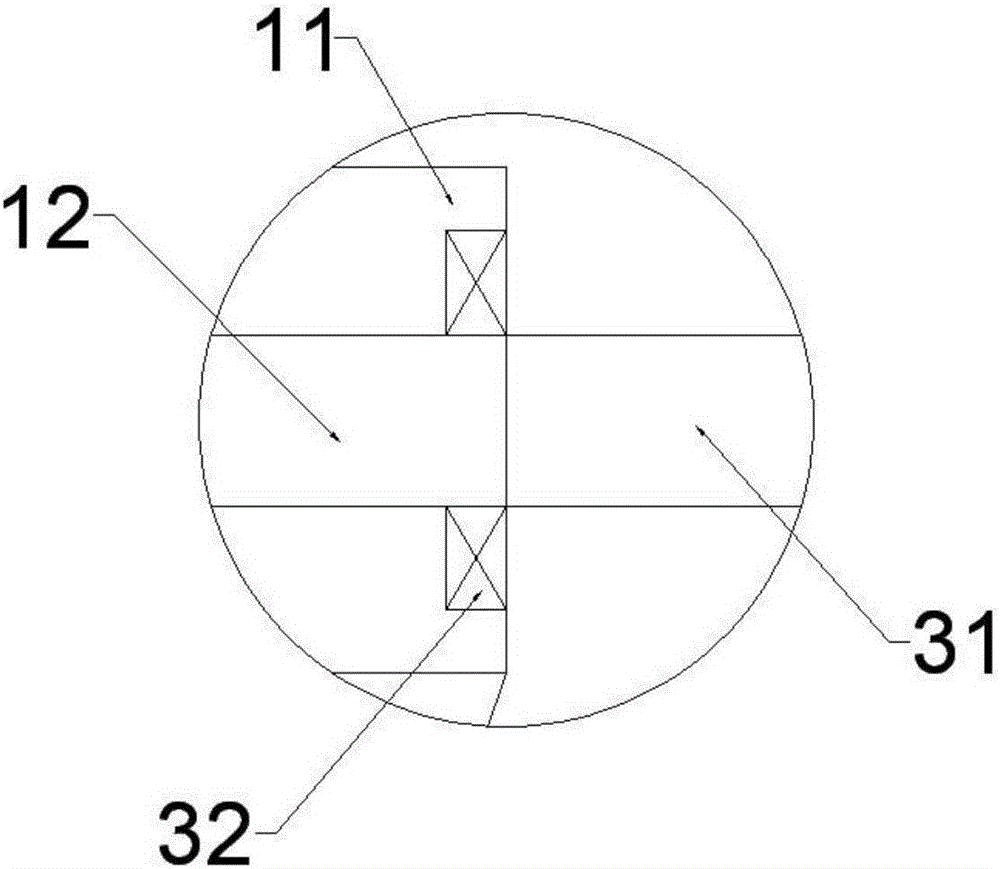

Copious cooling pulverizer and working method thereof

InactiveCN106111289AGuarantee that the mesh meets the requirementsEasy to collectGrain treatmentsLiquid nitrogen containerNitrogen gas

The invention relates to a cryogenic pulverizer and its working method, comprising a motor, a hopper, a material pre-cooling room, a material freezing room, a low-temperature mill, an induced draft fan, a cyclone separator, a bag filter, a liquid nitrogen tank and a compressor. Machine, the cryogenic pulverizer of the present invention and its working method, use liquid nitrogen to cool and freeze the material to be pulverized so as to achieve the brittleness required for the pulverization of the material, rich in resources and easy to separate, colorless, odorless and non-toxic gas, to avoid In addition, nitrogen is also a good anti-oxidant, which can prevent the finished powder material from being oxidized and deteriorated, and realize the recycling of nitrogen. In addition, the cooling capacity of the finished powder material is fully utilized to reduce energy consumption. save resources.

Owner:菏泽市花王高压容器有限公司

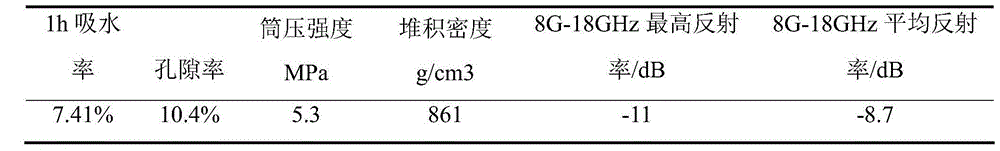

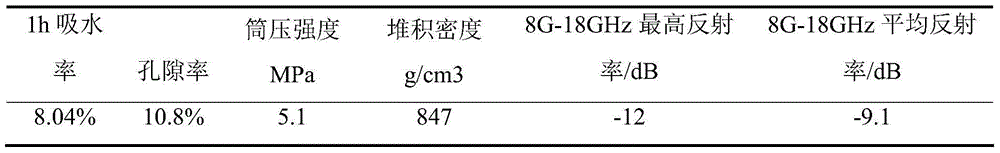

Wave-absorbing lightweight aggregate and preparation method

The invention relates to a wave-absorbing lightweight aggregate and a preparation method. The method includes following steps: 1) employing water, shale, civil domestic sludge and fly ash as raw materials, mixing the raw materials to obtain a rough material; 2) carrying out a one-step moulding process to obtain rough material balls; 3) first pre-burning and first roasting: carrying out a drying process, a first pre-burning process and a first roasting process to the rough material balls; 4) first cooling: slowly cooling and rapidly cooling the roasted rough material balls to obtain a semi-finished product of the lightweight aggregate; 5) second moulding: carrying out a water-saturating process to the semi-finished product of the lightweight aggregate, wrapping a fly ash layer or a shale layer on the semi-finished product and air-drying the semi-finished product; 6) carrying out a second pre-burning process and a second roasting process to obtain a shell semi-molten aggregate; 7) carrying out a second cooling process to obtain a core porous aggregate; 8) constructing a shell structure: wrapping a graphitic layer on the core porous aggregate, carrying out a heat-preservation process and a cooling process to obtain the wave-absorbing lightweight aggregate. The wave-absorbing lightweight aggregate can effectively improve strength performance and wave-absorbing performance of a lightweight aggregate and can improve combination performance between the lightweight aggregate and a concrete.

Owner:WUHAN UNIV OF TECH

Preparation of coated sand by use of phosphate inorganic binder and molding method thereof

ActiveCN104289661AGood collapsibilityRealize recyclingFoundry mouldsFoundry coresGranularityWater vapor

The invention discloses preparation of coated sand by the use of a phosphate inorganic binder and a molding method thereof. Preparation of the coated sand comprises the following steps: uniformly mixing the phosphate inorganic binder and quartz sand; heating and drying to a semi-dry state; adding calcium stearate with the granularity being 600 meshes and uniformly mixing; and drying and cooling so as to obtain the phosphate inorganic binder coated sand which is in a dry arenaceous state. During molding of the coated sand, the coated sand undergoes hydration only by high temperature steam, the binder is dissolved, sand grains are connected, and finally hot-air is blown for drying and curing molding. The hardening speed is fast. During preparation and curing molding of the coated sand, smell or any harmful gas or substance is not generated. The sand mould has low gas-forming property, is harmless to the health of workers, causes no pollution to the environment and is energy-saving and environmentally friendly. The coated sand provided by the invention has characteristics of high strength, high temperature resistance, low gas evolution, no curing agent required for molding and good storage stability.

Owner:HUBEI UNIV OF TECH +1

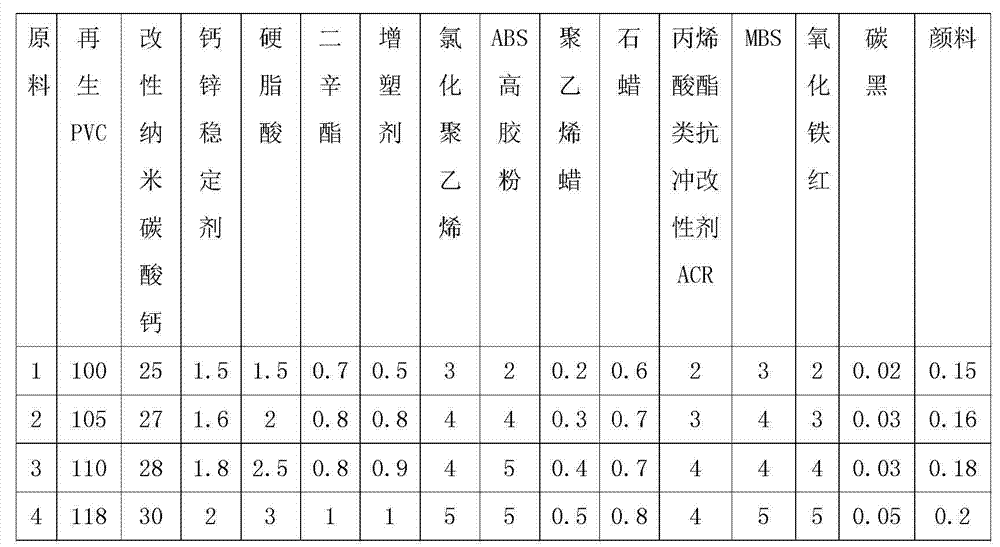

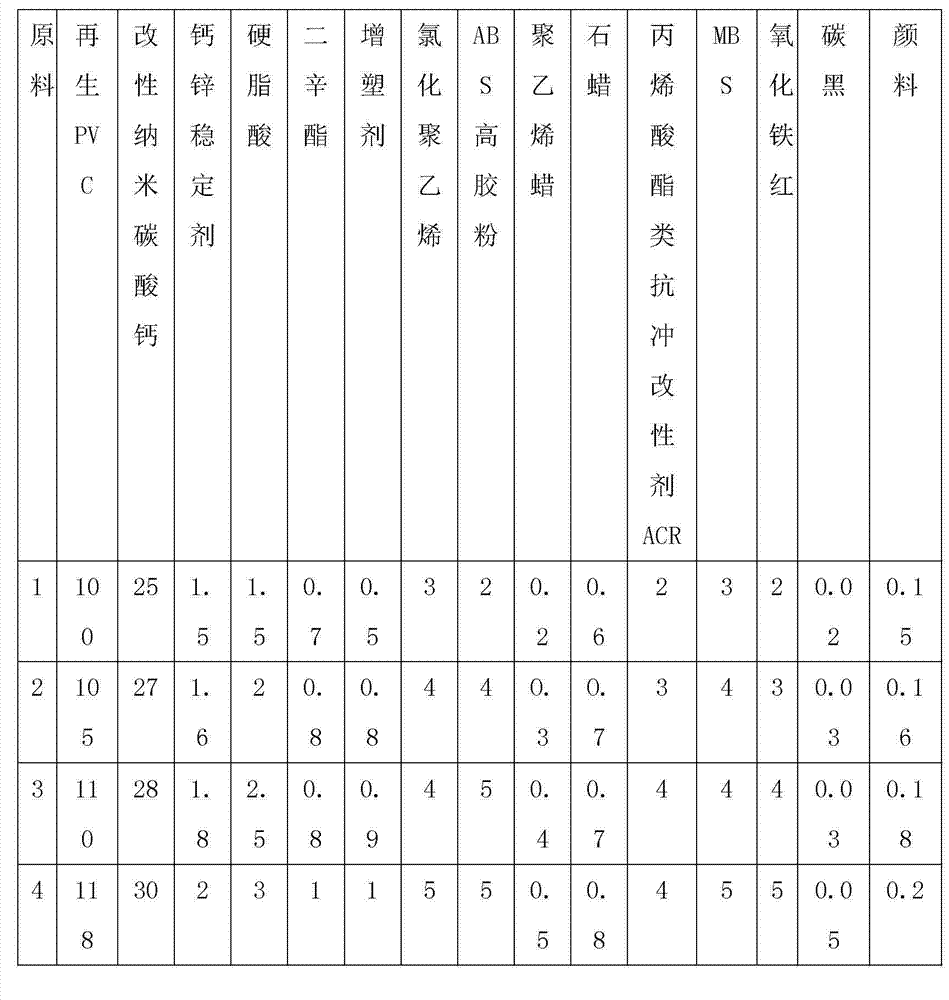

Color glass-reinforced plastic profile material made from novel reclaimed material

The invention discloses a color glass-reinforced plastic profile material made from a novel reclaimed material. The color glass-reinforced plastic profile material is made from raw materials, such as recycled PVC (polyvinyl chloride), modified nano calcium carbonate, a calcium zinc stabilizer, stearic acid, di-n-octyl phthalate, plasticizer, chlorinated polyethylene, ABS (acrylonitrile-butadiene-styrene) high rubber powder, polyethylene wax, paraffin, acrylate impact modifier ACR, MBS (methyl methacrylate), iron oxide red, carbon black and a pigment. According to the color glass-reinforced plastic profile material, the calcium zinc stabilizer substitutes a lead salt stabilizer, so that the color glass-reinforced plastic profile material is safer and harmless and does not affect the health of human bodies. A waste glass-reinforced plastic profile material or an unqualified glass-reinforced plastic profile material is effectively utilized, so that the reutilization of the glass-reinforced plastic profile material is realized, a large number of raw materials are also saved in a production process, white pollution is reduced, our natural environment is more protected, and the policy requirements of energy conservation and environment friendliness are met. The profile material made from the recycled PVC has all the characteristics of the profile material made from the raw materials as well as the characteristics of smoother surface, better density, better toughness and the like.

Owner:SHUCHENG ANTAI PLASTIC PROD

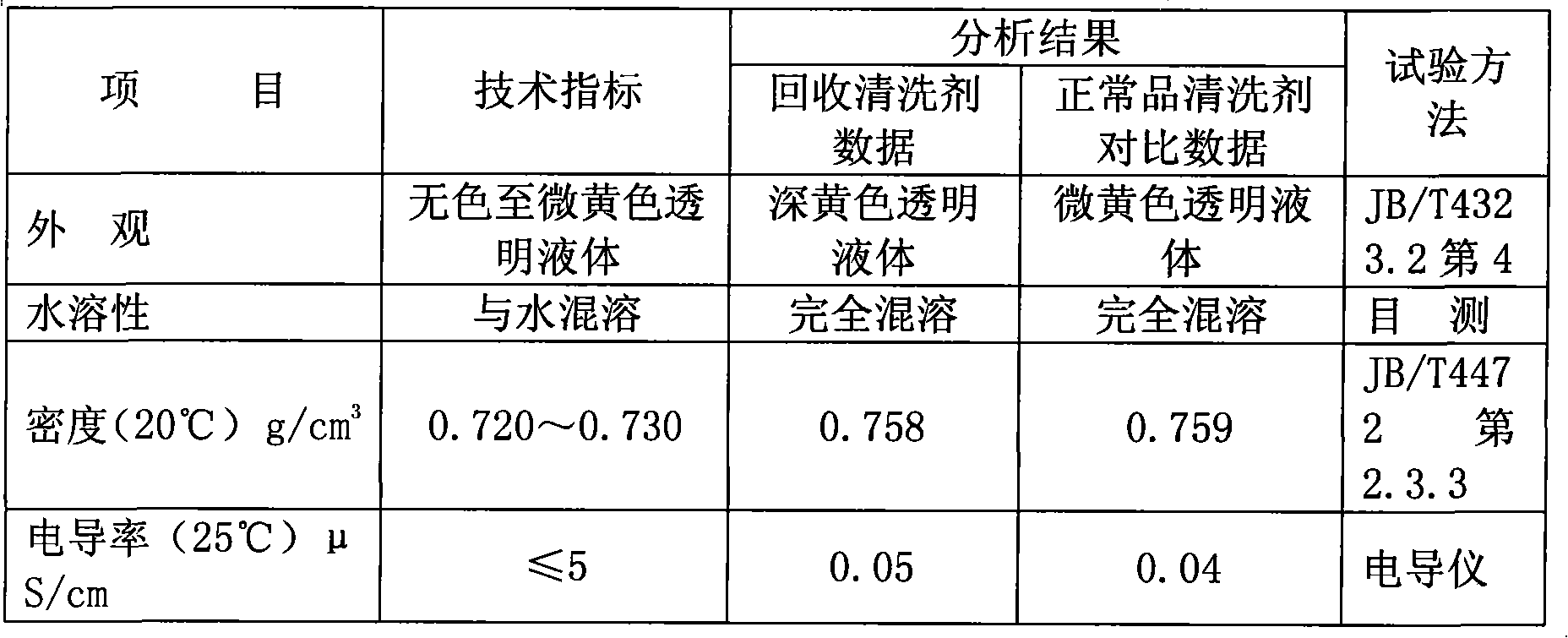

Cyclic renewable water-based cleaning agent and cyclic renewing technology

The invention relates to a long-life cyclic renewable water-based cleaning agent and cyclic renewing technology, which can infiltrate into the micron gap to realize the cleaning without water. The water-based cleaning agent comprises the following components by weight percentage: alkane and isoalkane 23-92%, biodegradable activator complexes surfactant 5-15%, antistatic agent 0.001-0.5%, corrosion inhibitor 0.1-12%, cosolvent 1-30%. The long-life cyclic renewable water-based cleaning agent is used for cleaning the tin indium oxide corrosion resistance, surface to be cleaned and residue in the deep-layer micron crack without dissolving and swelling function on various colloidal materials. The cleaning agent is not poisonous without chemicals and components inhibited in international and domestic, with very low conductivity, neutral pH value and good stability.

Owner:深圳市科玺化工有限公司

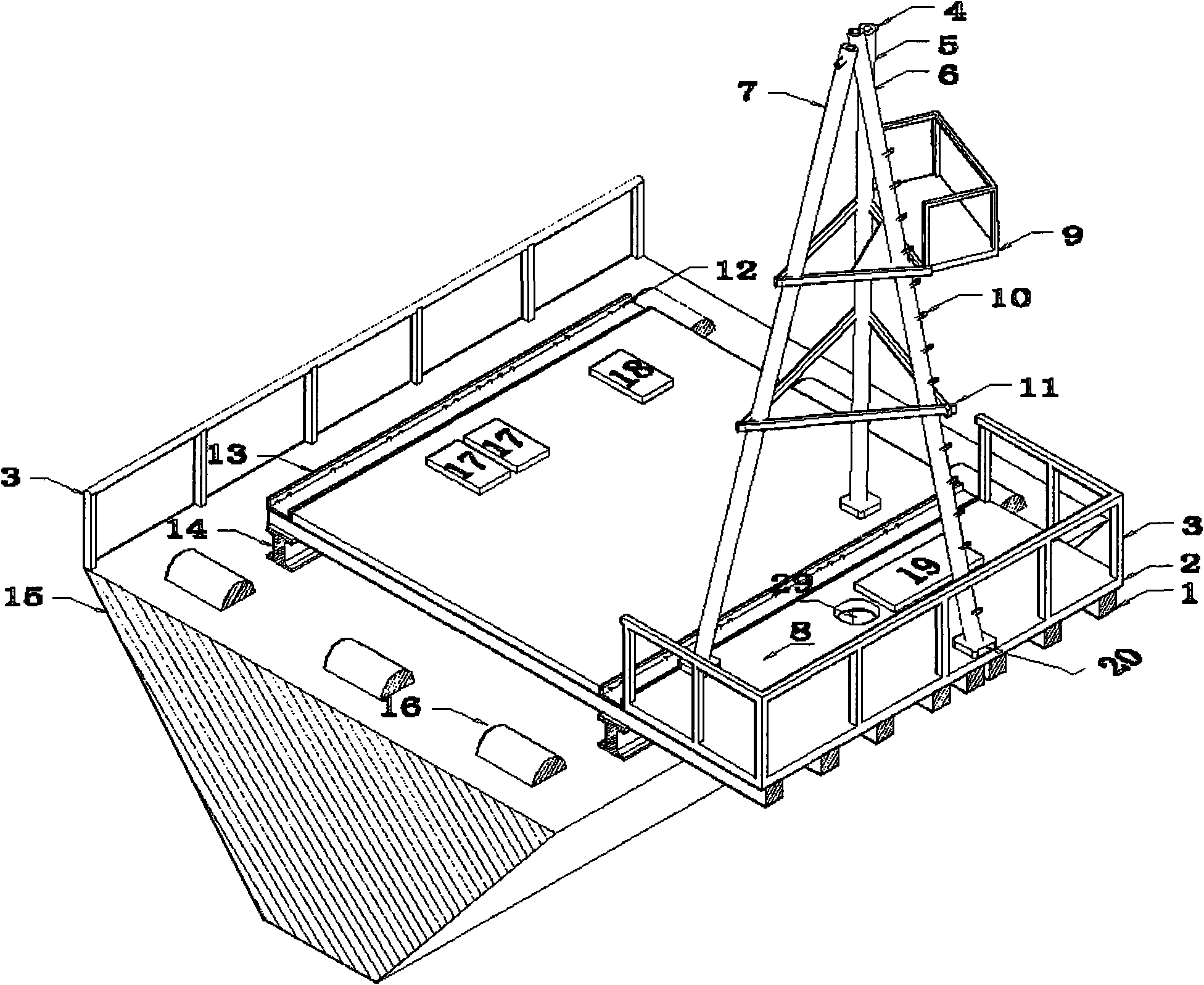

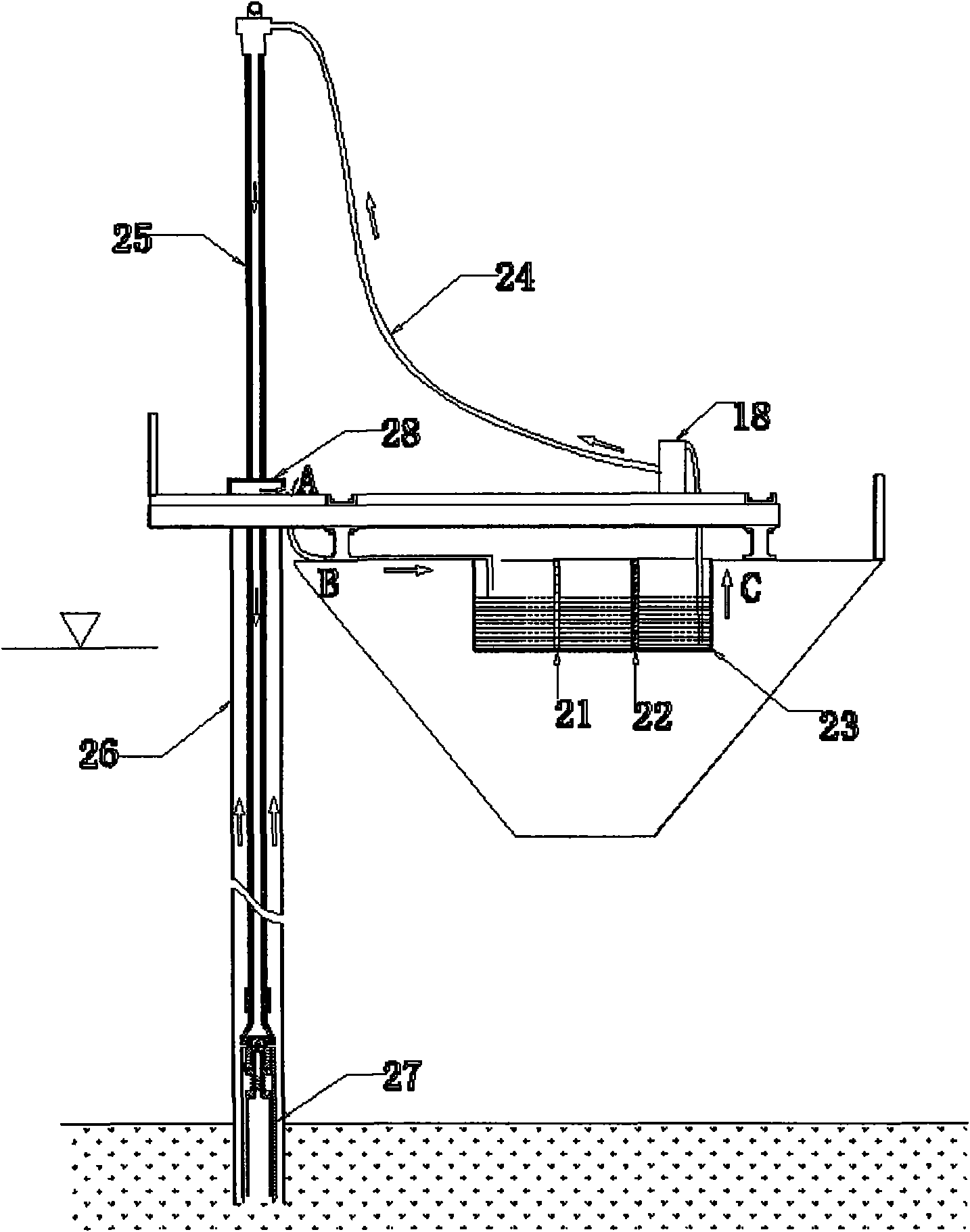

Unilateral cantilever type water survey platform system

InactiveCN101643110AStructural standardizationLow costFloating buildingsUnderwaterMarine engineering

The invention discloses a unilateral cantilever type water survey platform system, comprising a working boat, a unilateral cantilever survey platform, a boring tower and equipment. The working boat isprovided with a plurality of windlasses, at least two shaped steels are arranged on the deck of the working boat, a plurality of supports are arranged on the shaped steels in a crossing way and extends out one side of the boat body, floor board and channel steel are laid on the supports, wherein the position of channel steel corresponds to the position of the shaped steel, the channel steel is infixed connection with the support and the shaped steel, and the parts of the support and the floor board, extending out the boat body, are the working area cantilever sides. The boring tower is arranged on the unilateral cantilever survey platform. The equipment, comprising the boring tower inside the working area cantilever side and the slurry pumps on the boat body, is arranged on the survey platform. The invention is simple, has low cost, and can be used for geotechnical coring, sampling and in situ testing when exploring underwater, thereby ensuring exploration goes smoothly under any environments and conditions.

Owner:CCCC THIRD HARBOR CONSULTANTS +1

Method for recovering sulfur and iron resources through reducing and decomposing titanium white waste slag green vitriol by sulfur

ActiveCN102431976ARealize recyclingEliminate pollutionDispersed particle separationSulfur-trioxide/sulfuric-acidAdditive ingredientSlag

The invention discloses a method for recovering sulfur and iron resources through reducing and decomposing titanium white waste slag green vitriol by sulfur, which is characterized in that firstly, the titanium white waste slag green vitriol is dried for 5 to 40 minutes at 120 to 400 DEG C in inert atmosphere, crystal water in the titanium white waste slag is removed, then, the dried titanium white waste slag is added into a reaction vessel with the temperature being 200 to 700 DEG C, gaseous sulfur with the mold percentage being 1 to 50 percent is introduced in the reducing mixed atmosphere to take reduction reaction with the titanium white waste slag for 0.1 to 3 hours, the obtained ferrous sulfide residue is mixed with effective ingredients of ferrous sulphate in the anhydrous titaniumwhite waste slag according to a mol ratio of 0.2 to 2:3, the materials are roasted for 0.1 to 4 hours in the weak oxidizing atmosphere at the temperature being 500 to 1000 DEG C through being uniformly ground, the generated sulfur dioxide tail gas returns the first work station, the brought heat is used for the reaction of the first work station, and the obtained solid slag materials can replace the lime for directly neutralizing the titanium white waste acid and the acid waste gas or can be used as raw materials for producing ferric oxide series pigments and for steel plants.

Owner:SICHUAN UNIV

Novel reclamation method of electroplating sludge

InactiveCN102701549ARealize recyclingImprove stabilitySludge treatmentWaste water treatment from metallurgical processIonHeavy metals

The invention relates to a novel reclamation method of electroplating sludge, belonging to the technical field of chemical and environmental science. The method takes the electroplating sludge as raw material, right amount of iron source is supplemented into the raw material, agricultural waste rice hulls treated by activating are added into the raw material, the reclamation for the electroplating sludge can be realized under the conditions of mild water heat, ventilation and proper alkaline condition, and porous loaded type ferrite new material is obtained. The novel reclamation method is energy-saving and high in efficiency, and can realize regenerating cyclic utilization of solid waste; the obtained porous loaded type ferrite new material is high in stability, difficult in dissolution of heavy metal ions and free from secondary pollution, and can be used for efficiently removing mercury ion in water; furthermore, the porous loaded type ferrite new material has good magnetism, thus being convenient to recover, separate and recycle, and achieving the aim of controlling waste by waste. The process route is high in efficiency, simple, mild and low in energy consumption, and does not easily generate secondary pollution; and the needed device is simple, convenient to operate, easy in control of conditions and low in production cost.

Owner:JIANGNAN UNIV

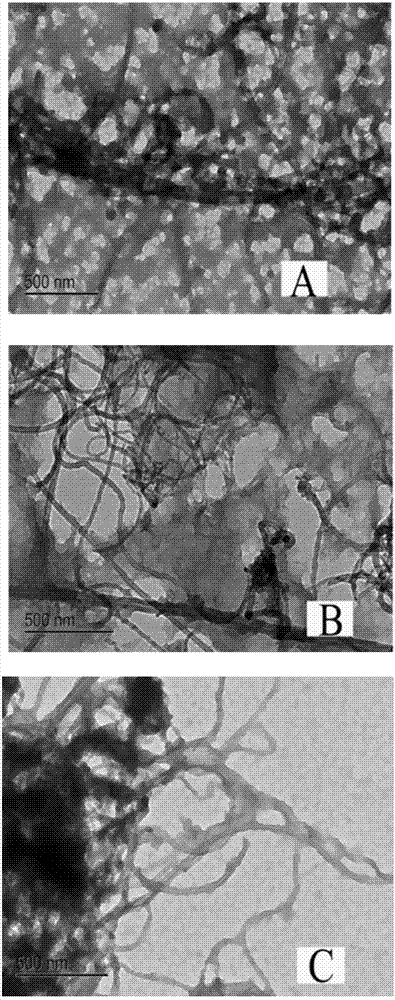

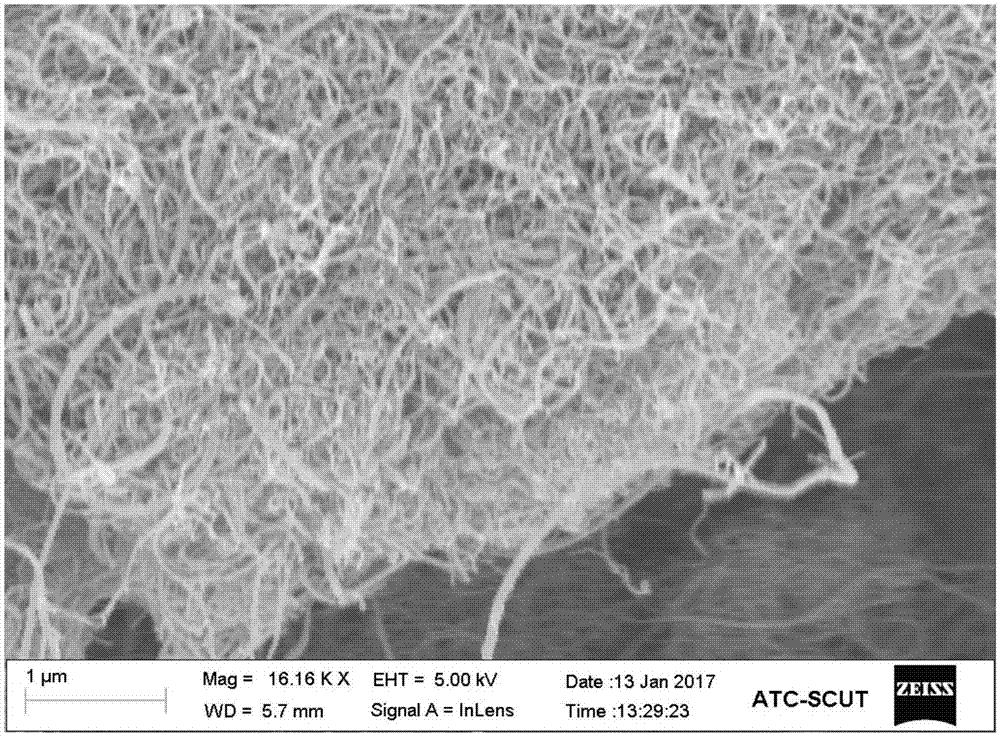

Lignin-based hard carbon/carbon nanotube composite material and preparation method and application thereof in negative electrode materials of lithium ion batteries

ActiveCN107959006ALarge specific surface areaHigh degree of graphitizationCell electrodesSecondary cellsOrganic solventCarbon nanotube

The invention belongs to the technical field of negative electrode materials of lithium ion batteries and discloses a lignin-based hard carbon / carbon nanotube composite material and a preparation method and application thereof in the negative electrode materials of the lithium ion batteries. The preparation method includes steps: respectively ultrasonically dispersing lignin and carbon nanotubes into organic solvent aqueous solution, mixing, adding alkali for adjusting pH to alkaline, and ultrasonically uniformly dispersing; adding acid for adjusting pH to 1-4, standing, and separating to obtain a lignin / carbon nanotube compound; adding the compound and an activating agent into water, heating, well stirring, heating and drying to obtain a lignin-based hard carbon / carbon nanotube compositematerial precursor; carbonizing the precursor to obtain the lignin-based hard carbon / carbon nanotube composite material. A surface area range of the lignin-based hard carbon / carbon nanotube compositematerial prepared according to the method is 500-3000m<2> g<-1>, activation time is 0.5-6h, and the lignin-based hard carbon / carbon nanotube composite material can be applied to the negative electrodematerials of the lithium ion batteries.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing metallurgical-grade aluminum oxide by coal ash

InactiveCN102020300AEasy industrial iron removalHigh extraction rateSolid waste disposalAluminium oxides/hydroxidesHigh pressureRaffinate

The invention discloses a method for producing metallurgical-grade aluminum oxide by coal ash, comprising the following steps: mechanically activating the coal ash, adding water for performing flotation to remove the black which is not completely burnt; removing ferric oxide by magnetic separation; adding concentrated sulphuric acid in raffinate of the coal ash to perform reaction under high temperature and high pressure for 1-6h; after reaction, adding water, heating up and boiling, filtering, obtaining aluminum sulfate raw liquor, evaporating and concentrating the raw liquor, cooling, and obtaining concentrated solution of aluminum sulfate; adding organic alcohol, filtering; adding water for dissolving filter cake, adding the organic alcohol, dissolving ferric sulfate, separating out aluminum sulfate, filtering, and obtaining aluminum sulfate filter cake, drying at 70-100 DEG C, burning at a temperature more than 800-1200 DEG C, and obtaining the metallurgical grade Al2O3 of which content of Fe2O3 is less than 0.02%. The method avoids that secondary intermediates gamma-Al2O3 must be obtained by burning and purified by Bayer circulation, the method is simple in technology, easy to control, high in extraction rate of the aluminum oxide, low in production cost, low in product impurity content and steady in quality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com