Method for extracting indium from indium-rich smoke dust by using oxygen pressure technology

A soot and indium-rich technology, which is applied in the direction of improving process efficiency, can solve the problem of low yield of indium extraction, and achieve the effects of high direct yield of indium, good promotion value, and strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

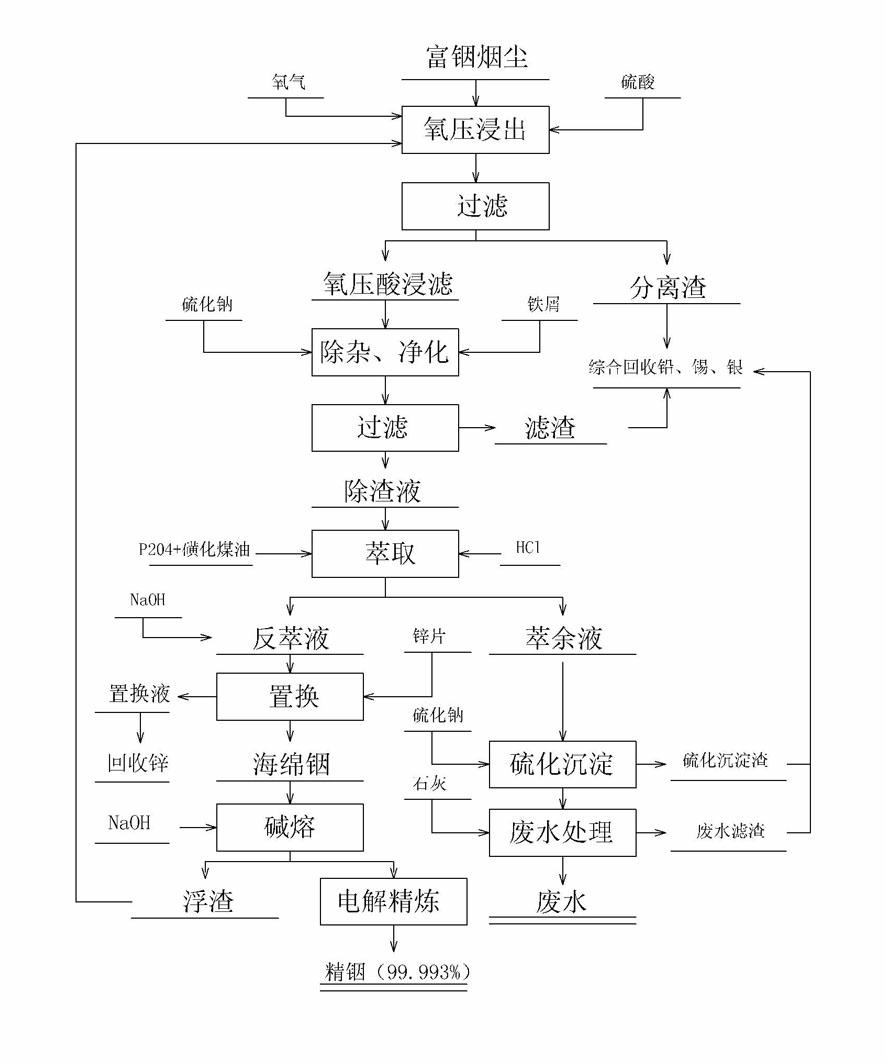

Method used

Image

Examples

Embodiment 1

[0051] Lead electrolysis dross is fumed to enrich indium soot composition (wt,%): In 11.44, Zn 2.06, Pb24.86, Fe 0.33, As 0.89, Sb 1.45.

[0052] Take 150Kg of the above-mentioned raw material, grind the sample preparation until the particle size is 120 mesh, add 10% H 2 SO 4 The solution was mixed and placed in a closed high-pressure reactor, and the control conditions were: reaction temperature 160°C, reaction oxygen pressure 0.6MPa, reaction time 4.0h; after the reaction, the reactor was cooled and opened safely after pressure release, and the slurry Liquid-solid separation is carried out, the filter residue is washed once with hot water at 80°C, and then returned to the lead recovery system for treatment, and the filtrate is sent for impurity removal and extraction. The filter residue was sampled and analyzed: 0.014% indium, 68.18% lead, 2.63% tin; filtrate: 0.426g / L indium, 0.020g / L lead, 3.35g / L zinc. In the leaching reaction, the In leaching rate is 97.31%, the Sn lea...

Embodiment 2

[0058] The raw material composition of indium-rich soot of lead-tin reverberatory furnace is (wt,%): In 0.287, Zn 1.36, Pb16.71, Fe 0.89, As 1.91, Sb 0.64, SiO 2 5.65, Cd 0.32, Sn 7.62.

[0059] Take 1Kg of the raw material that has been pulverized and prepared to a particle size of 120 mesh, and add H with a mass percentage concentration of 30% according to the liquid-solid ratio of 4:1. 2 SO 4 The solution was mixed and placed in a closed high-pressure reactor, and the reaction conditions were controlled as follows: reaction temperature 120°C, reaction oxygen pressure 0.8Mpa, reaction time 2h; after the reaction was completed, the reactor was cooled, and the pressure was released, and the material was safely opened. The slurry was separated from liquid to solid, and the filter residue was washed twice with hot water at 70°C, weighed and analyzed. The slag contains 0.008% indium, 56.38% lead, and 35.06% tin; the filtrate contains 0.48g / L indium and 0.012g / L lead. Based on ...

Embodiment 3

[0063] Get 200Kg of the raw materials used in Example 1, sample preparation and pulverization to a particle size of 110 mesh, add 15% H in mass percent concentration according to the reaction liquid-solid ratio 5:1 2 SO 4 The solution was slurried and placed in a closed titanium autoclave. The reaction control conditions were: temperature 180°C, oxygen pressure 1.5MPa, time 3h; after the reaction, the reaction kettle was cooled, and the pressure was released, and the slurry was liquid-solidified. Separation, the filter residue is washed twice with hot water at 80°C, and then returned to the lead recovery system for processing, and the filtrate is sent for impurity removal and extraction. The filter residue was sampled and analyzed: 0.012% indium, 55.67% lead, 34.86% tin; filtrate: 0.457g / L indium, 0.014g / L lead, 1.35g / L zinc. In the leaching reaction, the In leaching rate is 97.48%, the Sn leaching rate is 0.95%, the Pb leaching rate is 0.41%, and the Zn leaching rate is 98.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com