Full-automatic sample thermal desorption and liquid phase micro-enriching device

A fully automatic, sample technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of easy residues in the syringe, easy blockage of the injection needle, short life, complicated manual operation methods, etc. The effect of less dosage and short enrichment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

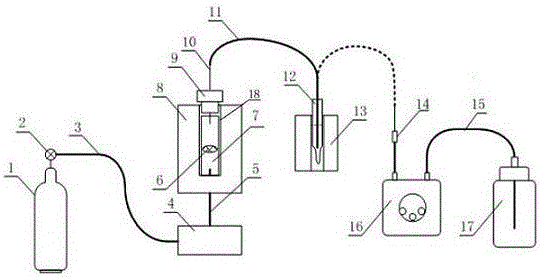

[0013] Such as figure 1 As shown, the fully automatic sample thermal desorption and liquid phase micro-enrichment device provided by the present invention includes a heating device, a condensation device and an enrichment device. The heating device includes a heating body 8, and a heating tank 18 is arranged in the heating body 8 , the heating tank 18 is provided with a quartz sample tube 7, a high-temperature Teflon pad 9 is arranged on the mouth of the quartz sample tube 7, a stainless steel tube 5 is arranged between the heating body 8 and the quartz sample tube 7, and one end of the stainless steel tube 5 is located at In the quartz sample tube 7, the other end of the stainless steel tube 5 is connected with a micro-flow controller 4, the micro-flow controller 4 is connected with a nitrogen cylinder 1, and the high-temperature Teflon pad 9 is provided with a needle 10, a needle 10 One end of the needle is set in the quartz sample tube 7, the other end of the needle 10 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com