Patents

Literature

342results about How to "Effective separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

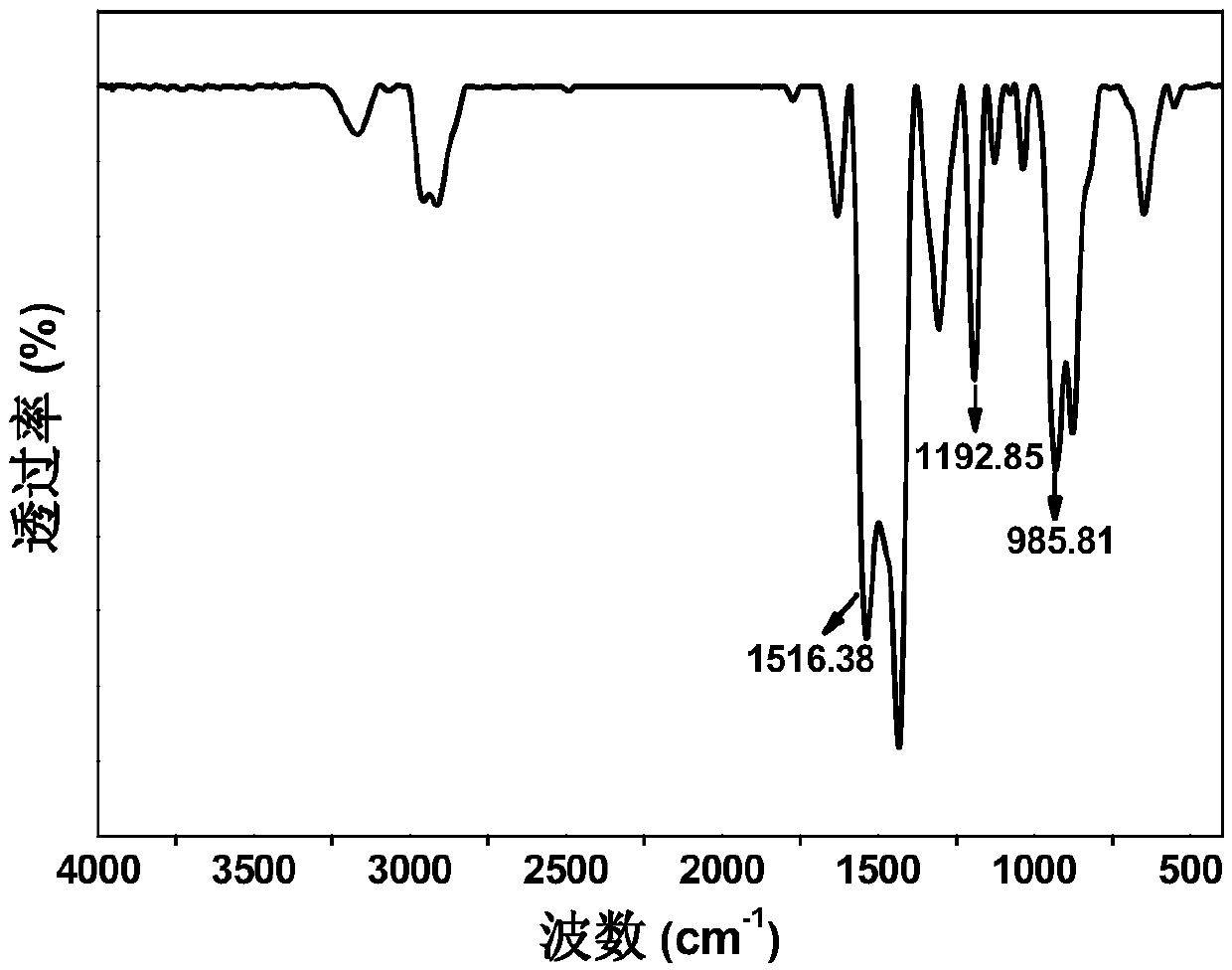

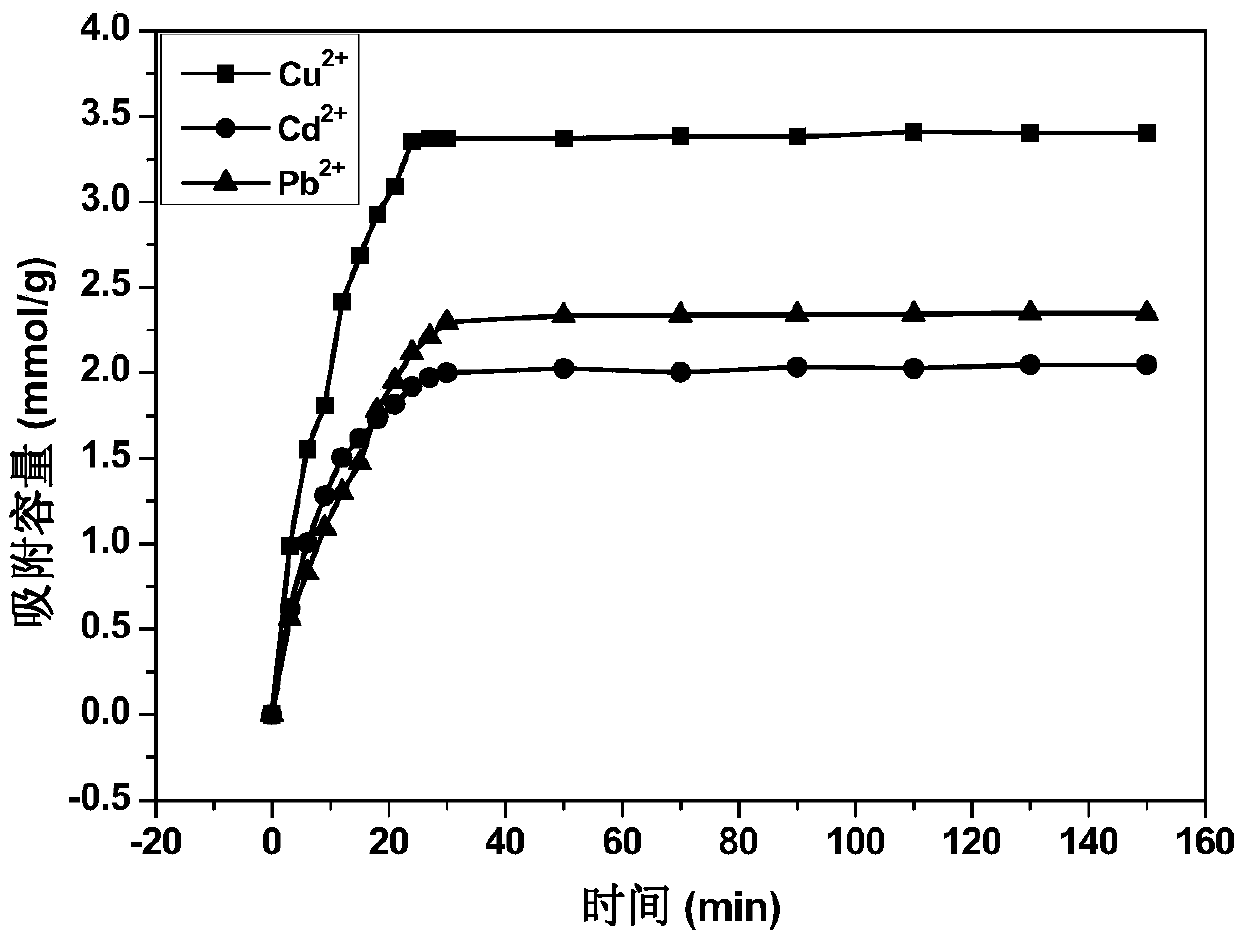

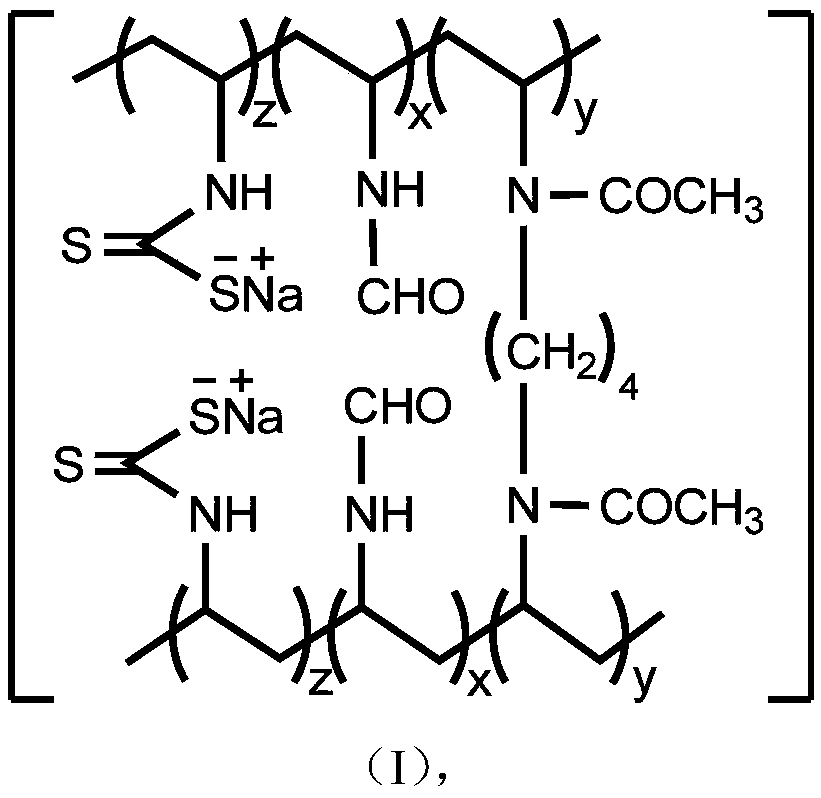

High-adsorptivity heavy metal ion chelating agent containing dithiocar-bamate structure and preparation method thereof

ActiveCN105498726AEffective separationBroad application prospectsOther chemical processesWater contaminantsIonMetal ion sequestering

The invention relates to a high-adsorptivity heavy metal ion chelating agent containing a dithiocar-bamate structure and a preparation method thereof. The chelating agent has a structure shown in a formula (I). The heavy metal ion chelating agent has a stable gel network framework structure, has easy water-absorbing swelling property and does not produce secondary pollution to a water body, meanwhile stronger coordination and chelation effects exist between dithiocarbamate groups and heavy metal ions, and accordingly rapid and effective separation of multiple types of heavy metal ions can be achieved, such as such as Cu<2+>, Cd2<2+>, Ni<+> and Hg2<2+>. (shown in the description).

Owner:SHANDONG UNIV

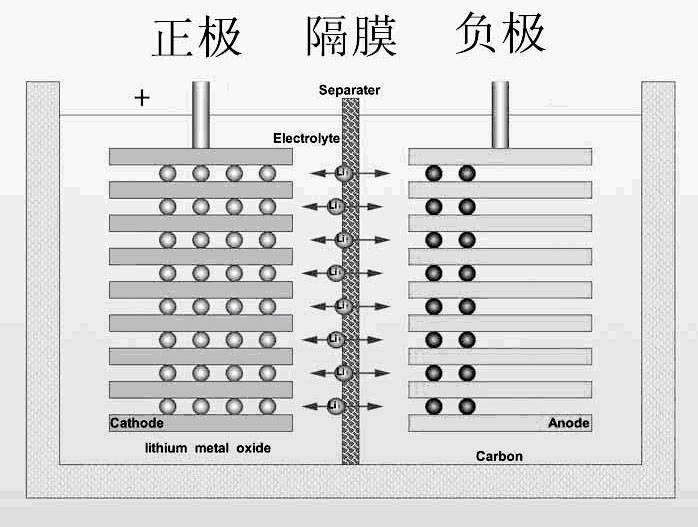

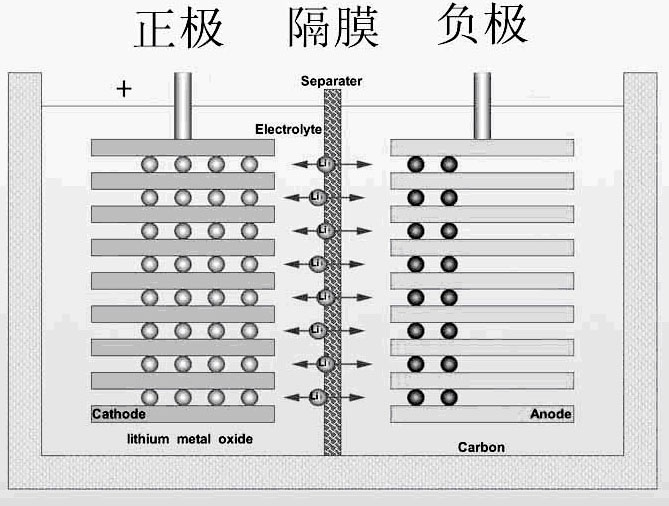

High-safety aqueous and organic mixed lithium ion battery

InactiveCN102055029AImprove power characteristicsAvoid burnsFinal product manufactureCell electrodesPower batteryElectrical battery

The invention belongs to the technical field of batteries, particularly to a high-safety aqueous and organic mixed lithium ion battery. The invention applies the ion embedded-disembedded mechanism adopted by the organic lithium ion battery to the mixed system with the separation of organic electrolyte and aqueous electrolyte, and ions of embedded reaction are lithium ions. In the high-safety aqueous and organic mixed lithium ion battery, the anode adopts the aqueous embedded compound material containing lithium ions, the cathode adopts the cathode material of the organic lithium ion battery, the electrolyte solution adopts the separated organic and aqueous electrolytes containing lithium ions, and a separating membrane adopts a lithium ion exchange membrane containing a waterproof layer. The charge-discharge process only relates to the transference of the ion between the cathode and the anode, and the features of the lithium ion battery of rocking chair type are still reserved. The high-safety aqueous and organic mixed lithium ion battery has higher work voltage than the common aqueous lithium ion battery and higher power performance than the common organic lithium ion battery. The high-safety aqueous and organic mixed lithium ion battery has the characteristics of long circulating service life, high power, safety, low cost and no environment pollution, and is particularly suitable to be used as the ideal power battery of the electric automobile.

Owner:FUDAN UNIV

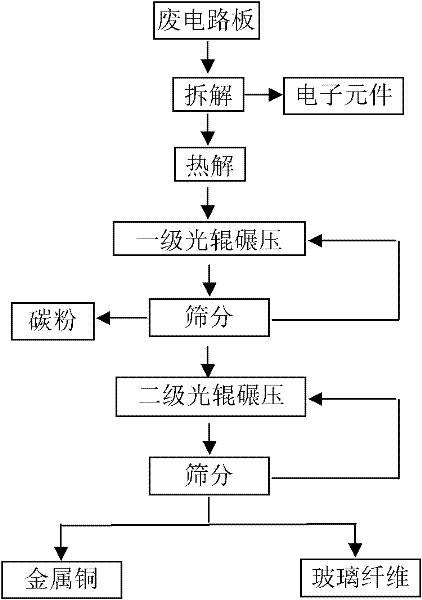

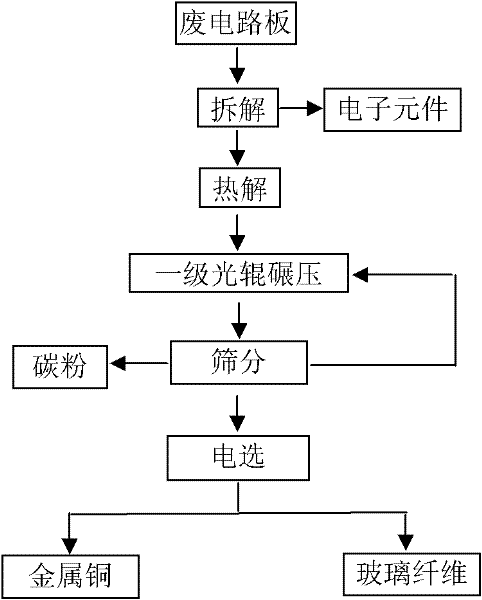

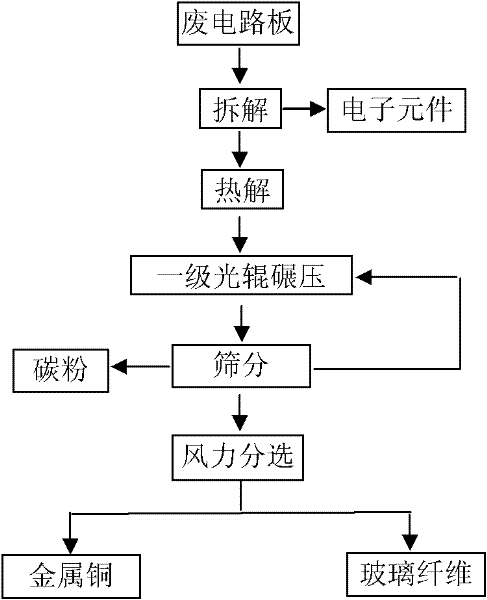

Method for separation and recovery of metal and nonmetal in waste printed circuit board

InactiveCN102350429AEffective separationAvoid destructive crushingSolid waste disposalProcess efficiency improvementElectricityPrinted circuit board

The invention belongs to the field of recovery and utilization of waste printed circuit boards, and specially, relates to a method for separation and recovery of metal copper and a glass fiber cloth in a waste printed circuit board. The method comprises the following steps that putting an electric element-free waste circuit board into a pyrolysis furnace to carry out pyrolysis treatment, wherein a resin for bonding a glass fiber cloth and a metal layer is pyrolyzed into carbon, carrying out treatment on the residues obtained by the previous step by a two-stage smooth roll rolling technology, and carrying out screening to obtain a carbon powder, metal and glass fiber concentrate. In the invention, a first-stage rolling process aims at shedding pyrolytic carbon between a glass fiber cloth and a metal layer, wherein each layer of the electric element-free waste circuit board is completely separated from other layers of the electric element-free waste circuit board and carbon powder is separated out after screening; and a second-stage rolling process aims at crushing devastatingly the glass fiber cloth and rolling up the metal layer which is flexible into a roll, so that through screening, metal-nonmetal separation is realized. In addition, metal and nonmetal in a mixture obtained by the first-stage rolling process and screening can be separated out directly by an electric separation method or a pneumatic preparation method. Through the combination of pyrolysis and physical processes, the method provided by the invention realizes high-efficiency separation of metal and nonmetal from a waste circuit board, and finally, realizes the purpose of eco-friendly resource recovery of waste circuit boards.

Owner:DALIAN UNIV OF TECH

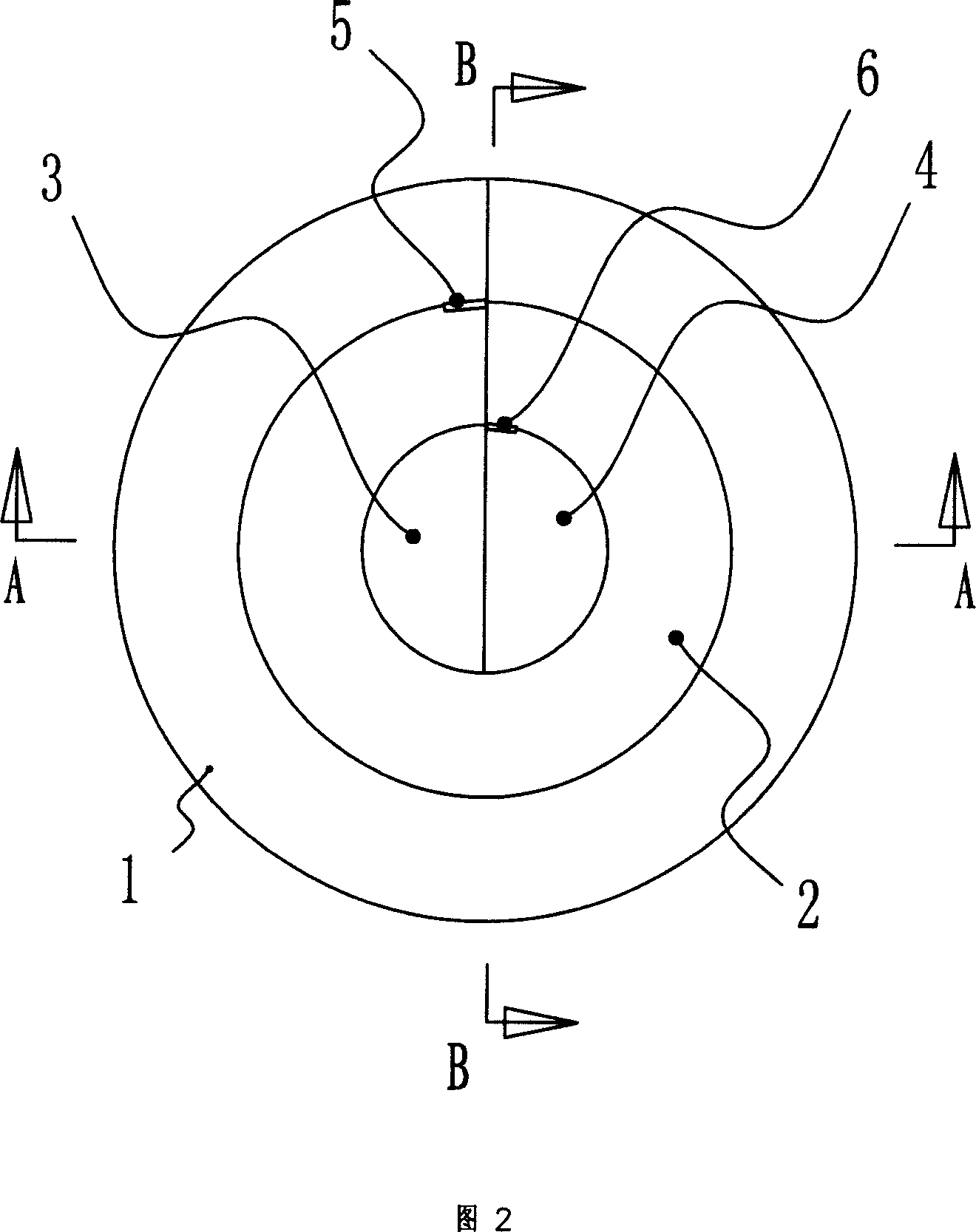

Micro-plastic floatation separation device and application thereof

InactiveCN107364041AImprove separation efficiencyEffective separationPlastic recyclingSolventEngineering

The invention discloses a micro-plastic flotation separation device. The micro-plastic flotation separation device comprises a liquid storage pond, a reactor, a first-level density separation pond, a second-level density separation pond and a filter all of which sequentially communicate with one another, wherein a pipeline for communicating the liquid storage pond with the reactor is provided with a valve and a pump; the reactor is internally provided with a stirrer, and the reactor conducts water sample aeration through an air pump I; and the filter is internally provided with a filter film, and an outlet pipeline of the filter is provided with an air pump II. The micro-plastic flotation separation device can achieve flotation separation of micro-plastic for different environment samples and has the beneficial effects that the separation efficiency is high, filtrate used for flotation can be recycled, and adopted solvents are environmentally friendly.

Owner:HOHAI UNIV

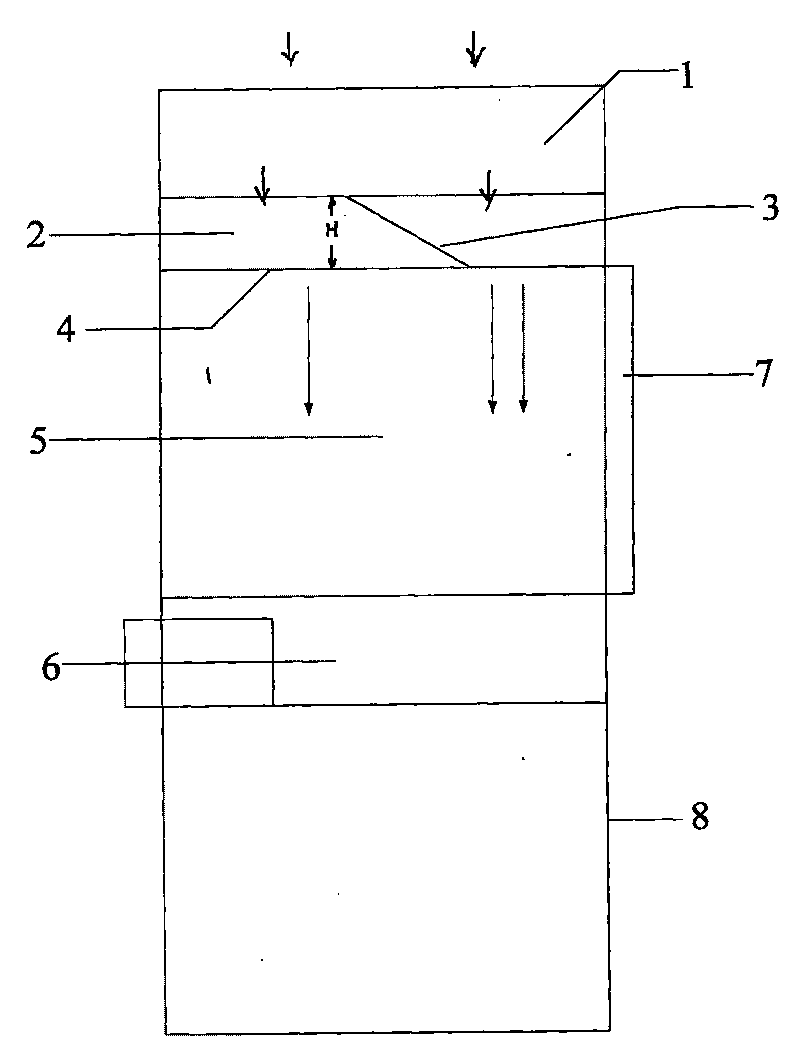

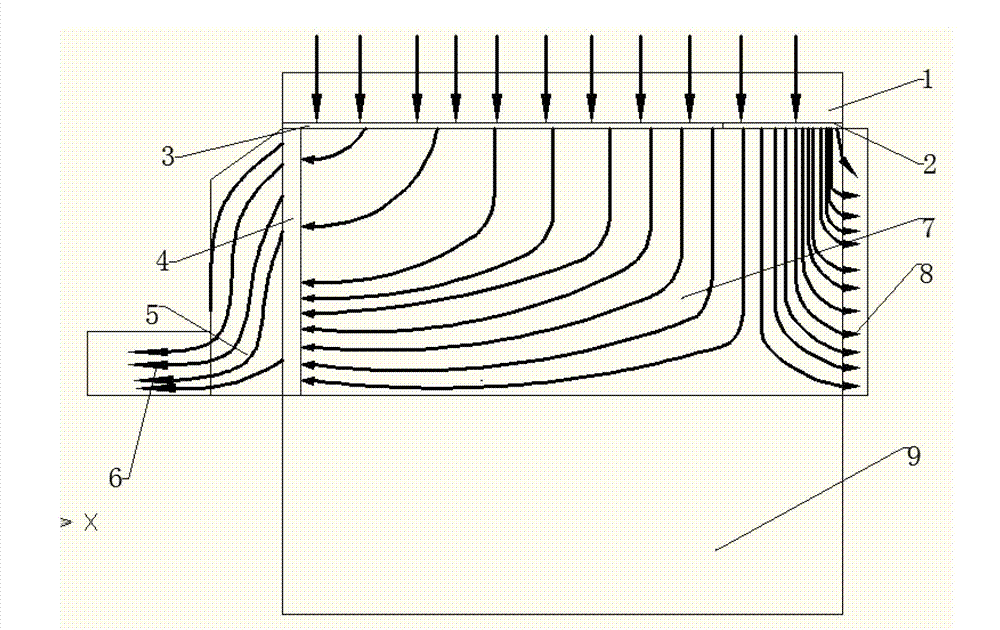

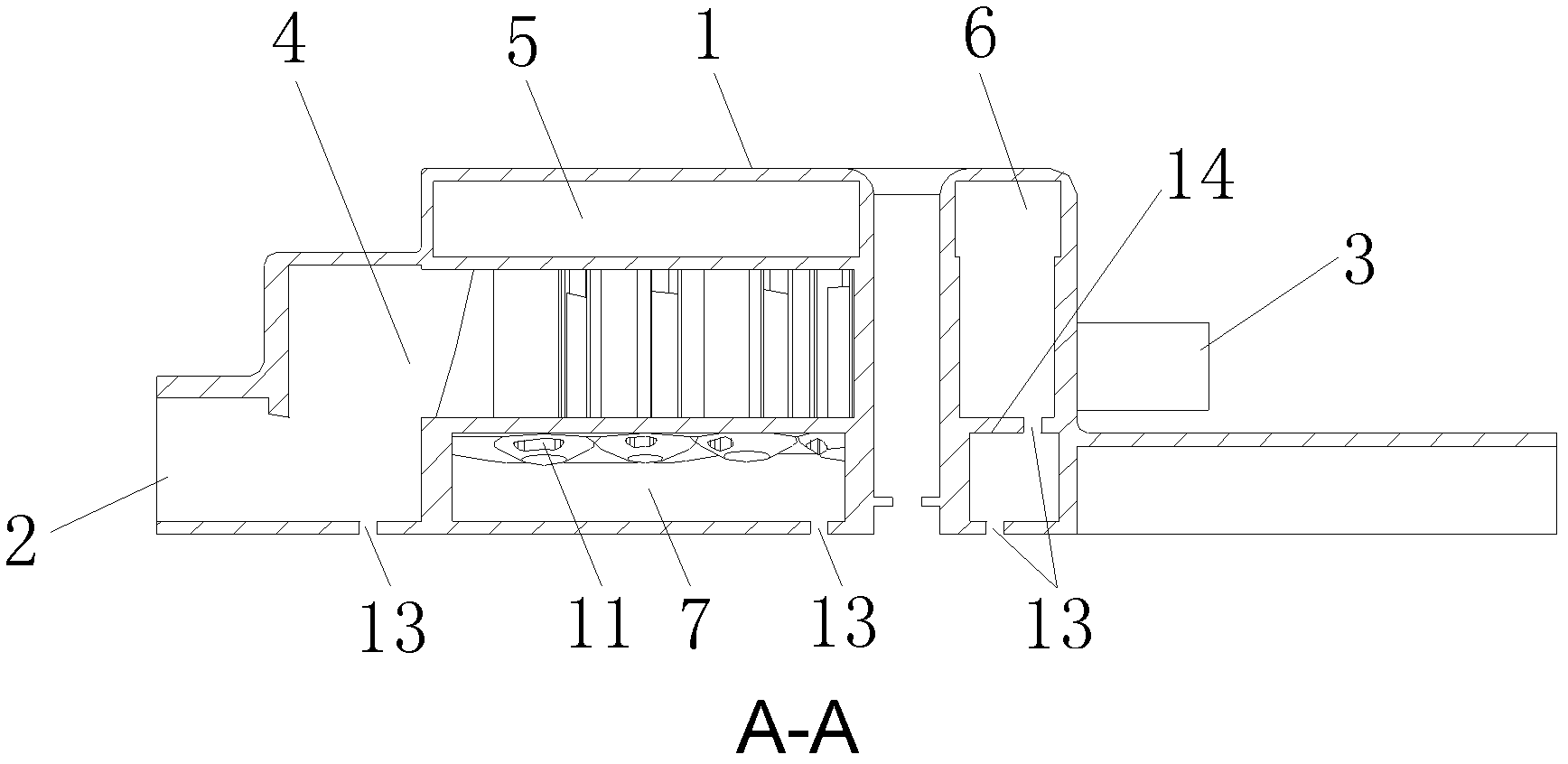

Air wall sealing type double positive pressure purification workbench

InactiveCN101711999AReduce dust particlesEasy adjustmentEnclosures/chambersLaboratory benches/tablesEngineeringPositive pressure

The invention discloses an air wall sealing type double positive pressure purification workbench which comprises an air inlet system, and a flow guide and pressure division area is arranged below the air inlet system, wherein the bottom of the flow guide and pressure division area is provided with a flow diffusion plate, and a working cavity is arranged below the flow diffusion plate and communicated with an air suction system; the height of the flow guide and pressure division area is 40-60mm, and a flow guide and pressure division plate is arranged in the flow guide and pressure division area; the flow guide and pressure division plate is obliquely arranged in the flow guide and pressure division area and divides the flow guide and pressure division area into a front area and a rear area with trapezoidal cross sections; the front area with the trapezoidal cross section is in a form that an air inlet end is large, and an air outlet end is small, and the rear area with the trapezoidal cross section is in a form that the air inlet end is small, and the air outlet end is large. The workbench has reasonable structure and can effectively guarantee the clean class of the working cavity and the safety of operating personnel.

Owner:NANTONG UNIVERSITY

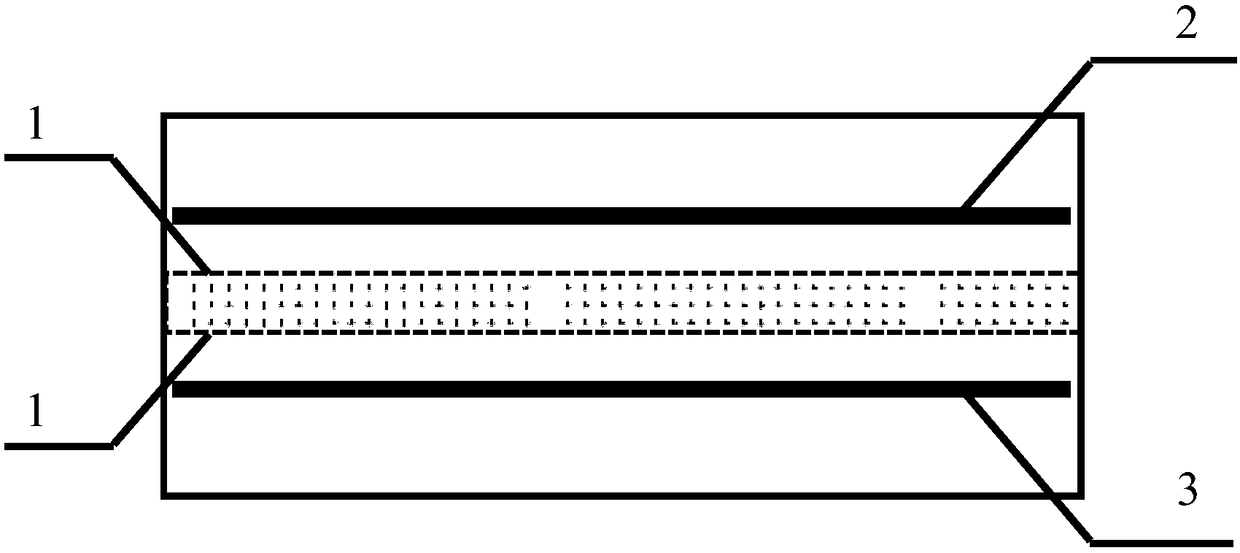

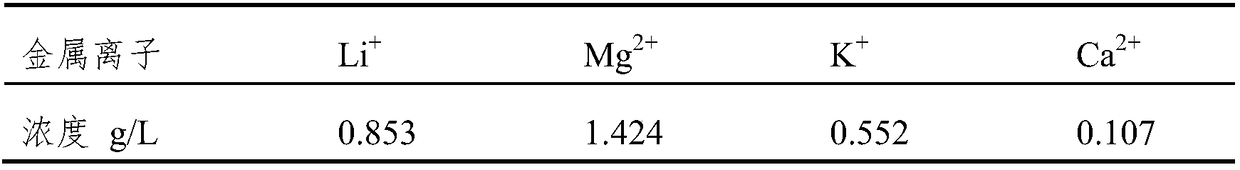

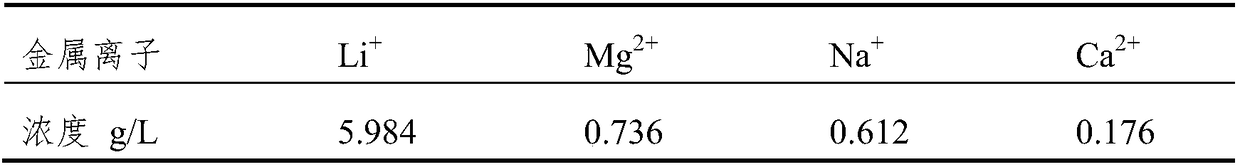

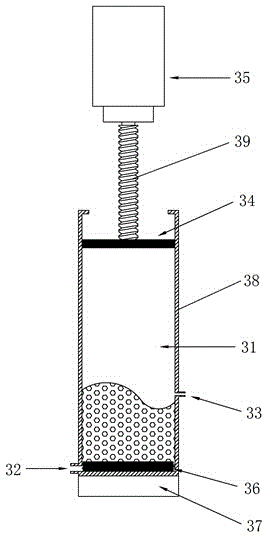

Method and device for separating lithium from lithium-containing solution

The invention provides a method and a device for separating lithium from a lithium-containing solution. The method comprises the following steps: dividing an electrolytic cell into an anode chamber, an organic phase chamber and a cathode chamber by adopting an ion exchange membrane; and transferring lithium ions in the lithium-containing solution inside the anode chamber to a lithium enrichment solution inside the cathode chamber by virtue of an organic phase in the organic phase chamber under the effect of an external voltage, wherein the organic phase is an organic reagent which can selectively have chemical reaction with the lithium ions in the lithium-containing solution; the device comprises the electrolytic cell; the electrolytic cell is divided into the anode chamber, the organic phase chamber and the cathode chamber by adopting the iron exchange membrane; and the organic phase chamber is positioned between the anode chamber and the cathode chamber. Compared with the prior art which has low separation efficiency on the lithium irons and the other metal irons in the lithium-containing solution, the method and the device for separating the lithium from the lithium-containing solution, provided by the invention, can be used for treating a lithium-containing solution which has a relatively high magnetism to lithium ratio.

Owner:CENT SOUTH UNIV

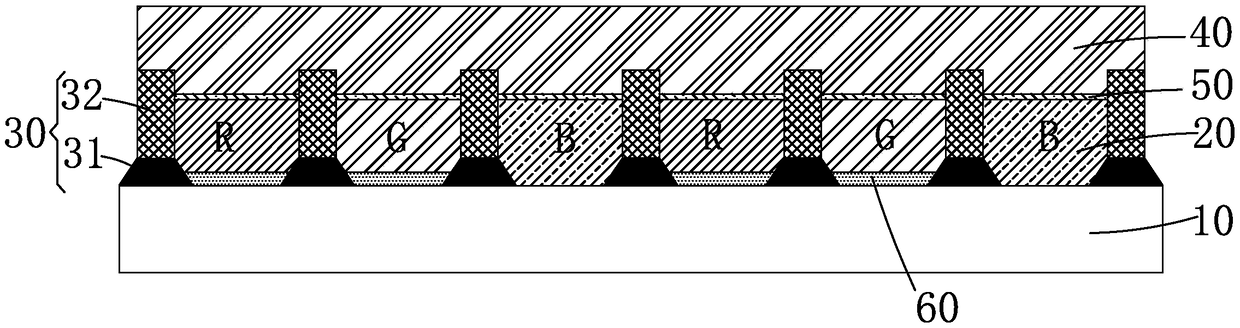

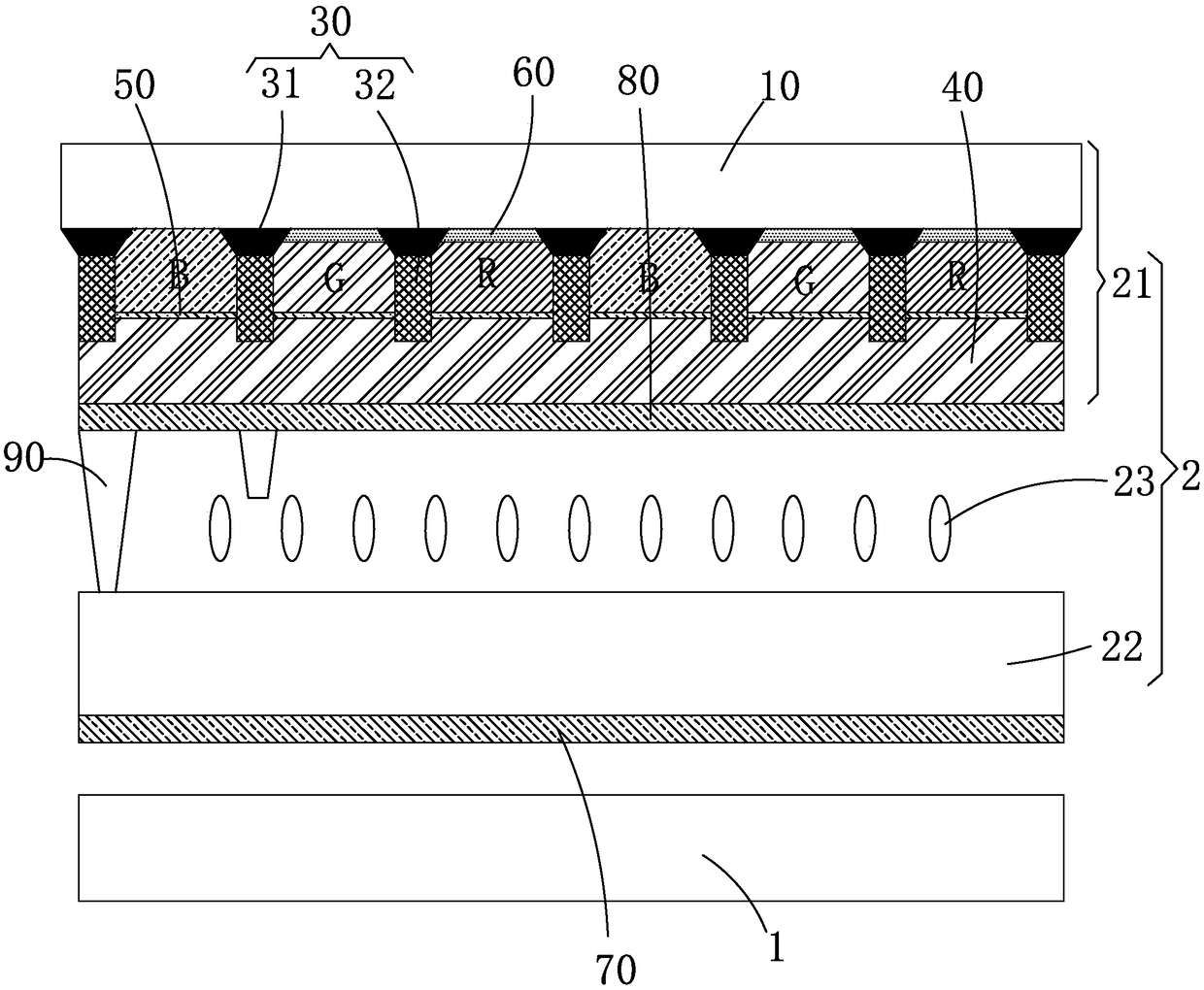

Color filter substrate and liquid-crystal display device

InactiveCN109375410AIncrease profitAvoid mixing colorsNon-linear opticsLiquid-crystal displayQuantum dot

The invention provides a color filter substrate and a liquid-crystal display device. The color filter substrate comprises a substrate base plate, multiple quantum dot filtering units arranged on the substrate base plate in an arrayed way and retaining walls arranged on the substrate base plate and located among the quantum dot filtering units. Each retaining wall comprises a black matrix layer arranged on the substrate base plate and a reflection layer arranged on the black matrix layer, wherein the thickness of each retaining wall is greater than that of each quantum dot filtering unit, and the reflection layer can reflect light irradiated to the surface of the reflection layer into the quantum dot filtering units for secondary utilization. The phenomenon is avoided that light penetratesinto other quantum dot filtering units to cause color mixture while the light utilization rate is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

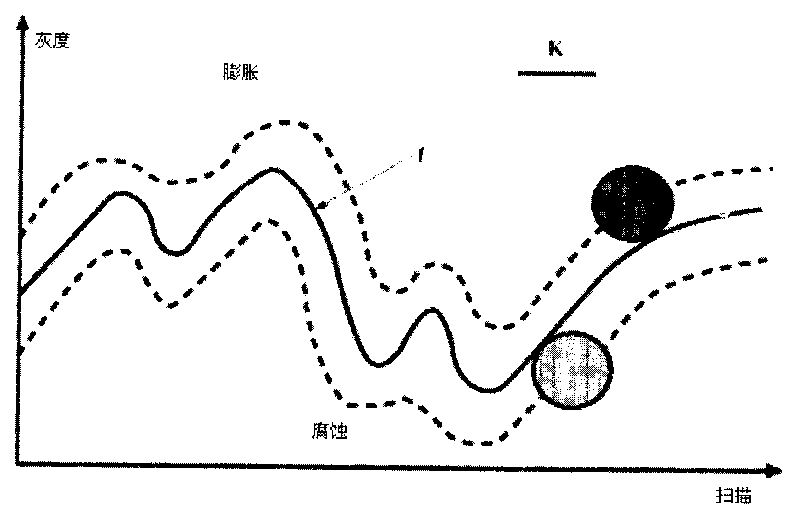

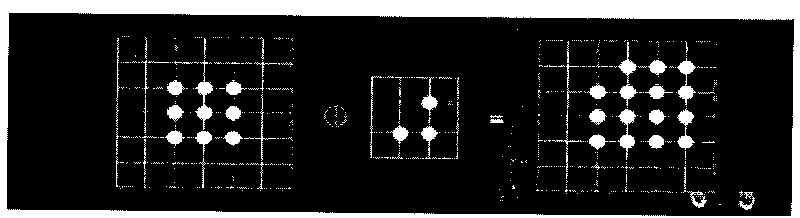

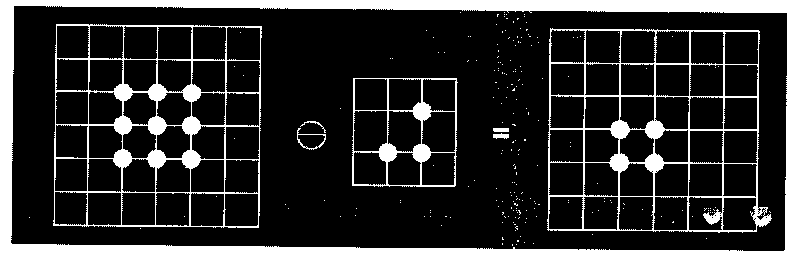

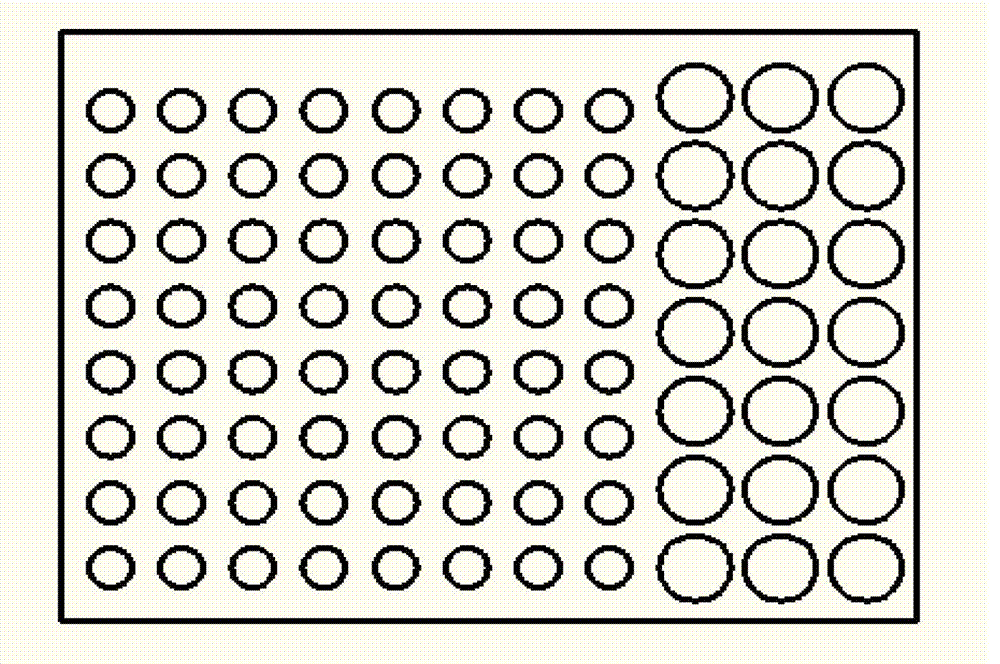

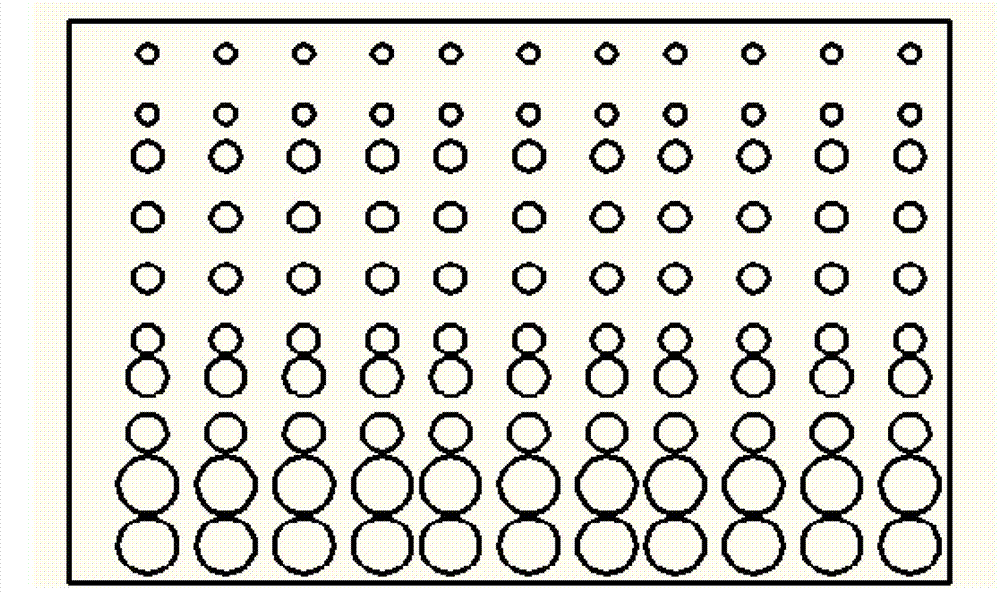

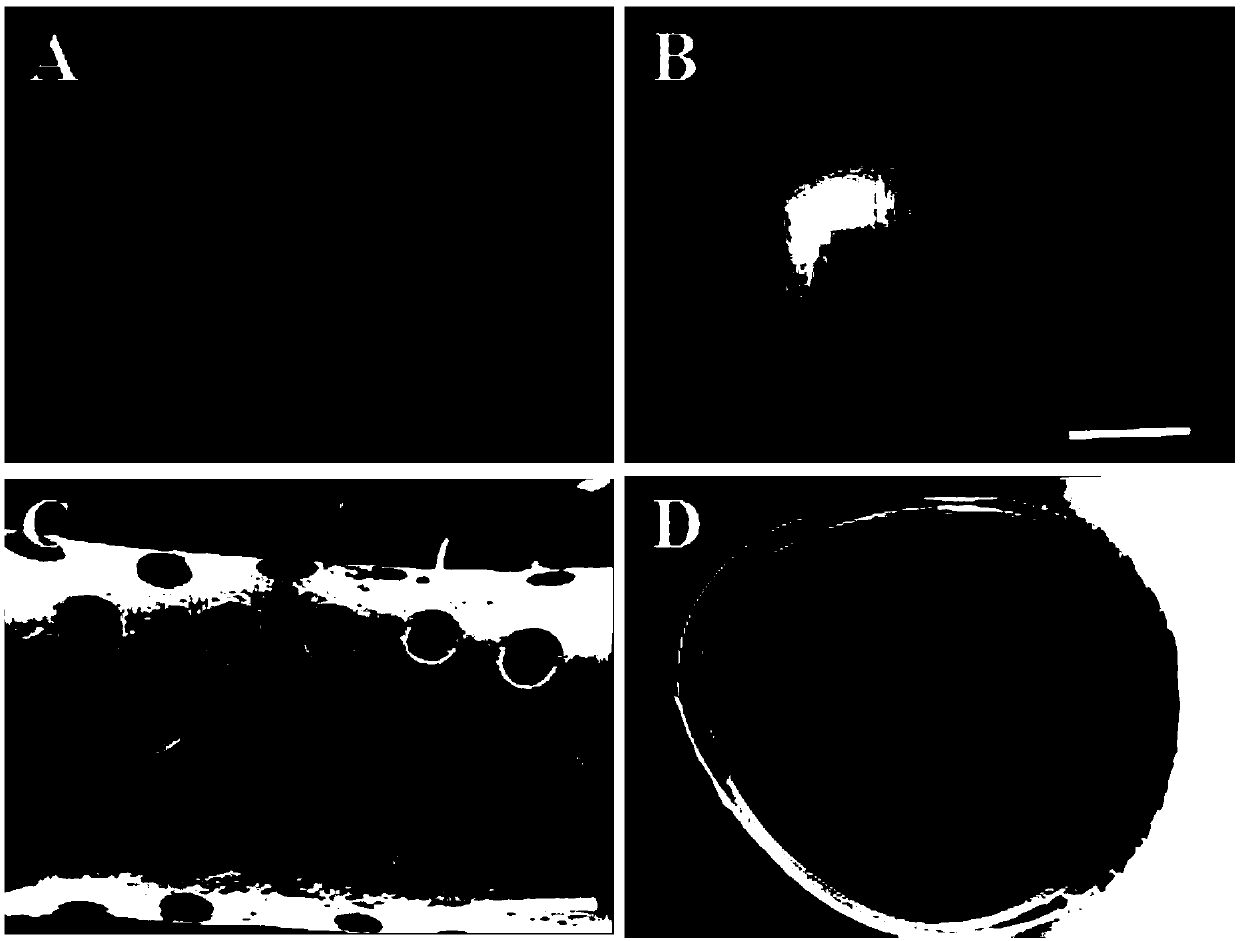

Morphology based method for separating cells

InactiveCN101692282AEffective separationEfficient separationImage analysisStructuring elementMarked graph

The invention provides a morphology based method for separating cells. The method comprises the following steps: 1) regions are marked, wherein a binary image of a cell image segmentation result is marked based on the morphology to obtain marked value of each adhering region; 2) a monomer cell is extracted, 2.1) a region is extracted; and 2.2) firstly, a marked graph existing adhering regions is found out, a round structure with the size of structure element of 1 is selected and expanded, and expansion is stopped when the boundary of the marked graph exceeds the boundary of an adhering graph, and the size of the marked graph is a whole of the monomer cell in adhering cells; and 3) a reconstructed new binary image set is traversed, attribution of each monomer is determined, and an image set is established according to an coordinate and area information. The method can effectively separate adhering cells, and prepares for accurate calculation on morphological parameters of the cells.

Owner:ZHEJIANG UNIV OF TECH

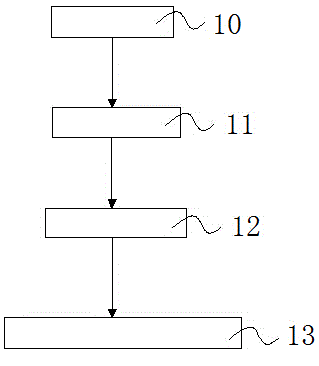

Porous membrane and preparation method thereof

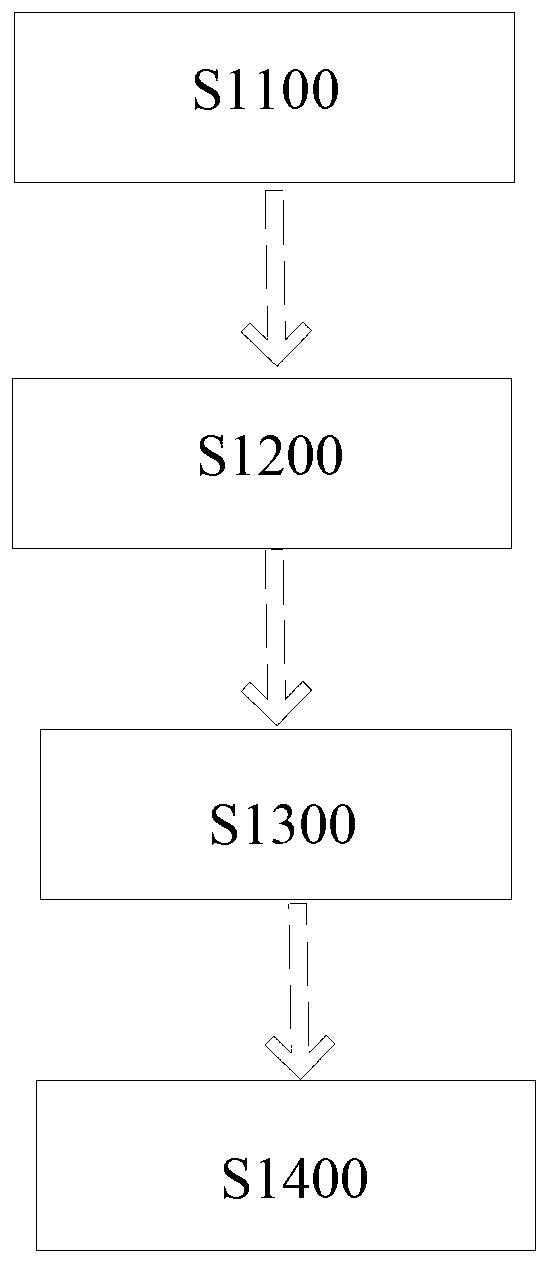

The invention discloses a porous membrane and a preparation method thereof. According to the method, the porous membrane is prepared from the following required raw materials in parts by weight: 1 to 50 parts of nano cellulose, 20 to 50 parts of inorganic pore forming agent and 30 to 79 parts of diamine monomer and dianhydride monomer. The method comprises the following steps of: S1200 monomer polymerization; S1300 membrane forming; heat treatment; S1400 inorganic pore forming agent removing; and drying. The mechanical performance of the porous membrane prepared by using the method is improved significantly.

Owner:BEIJING NANO ACE TECH CO LTD

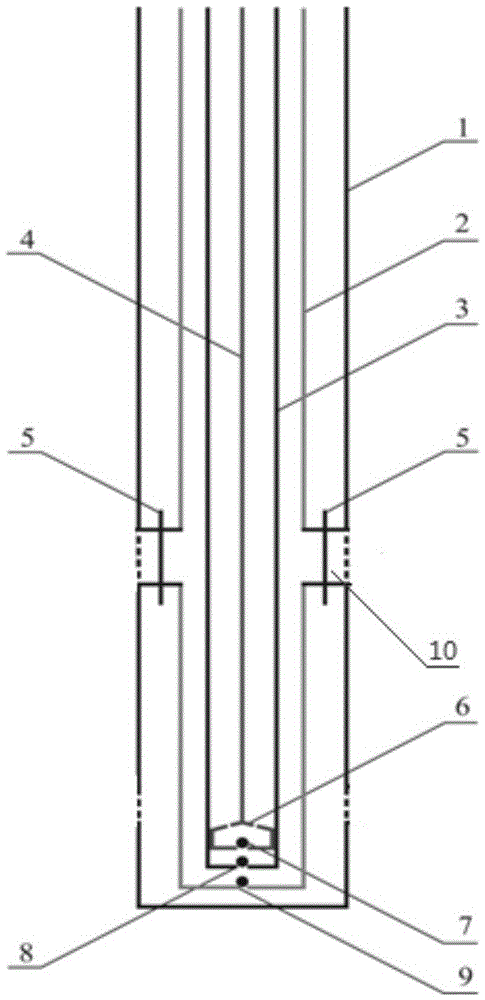

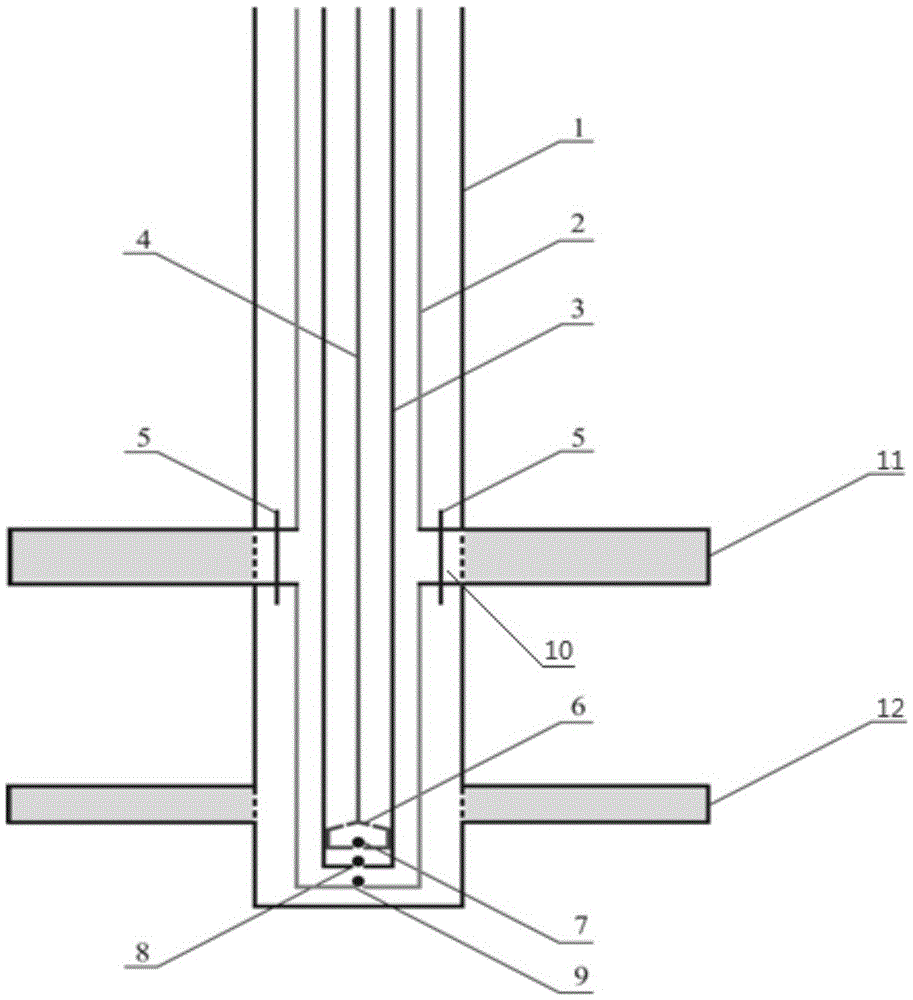

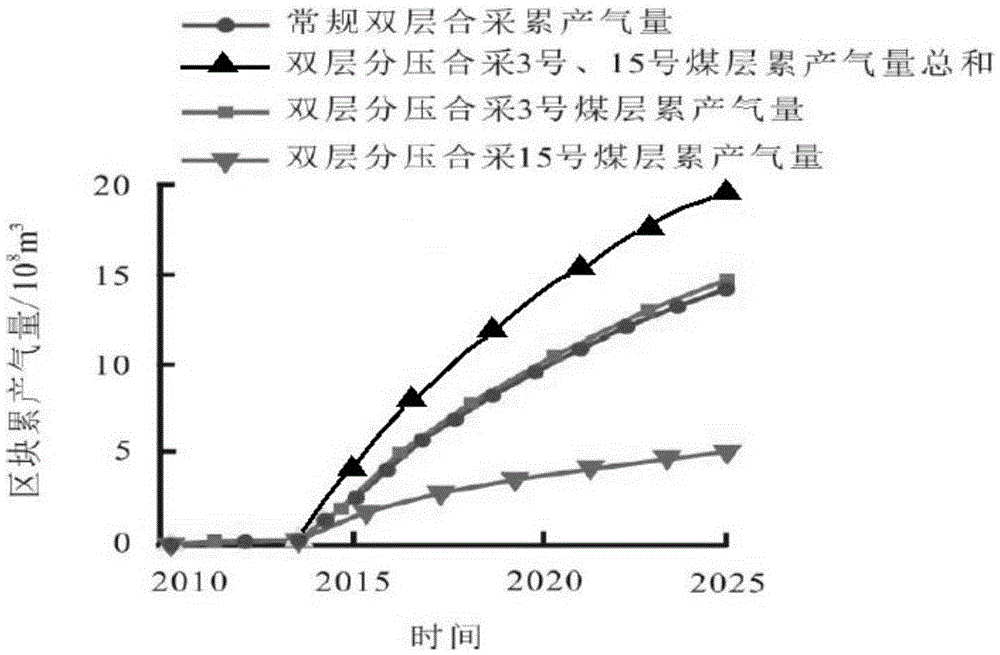

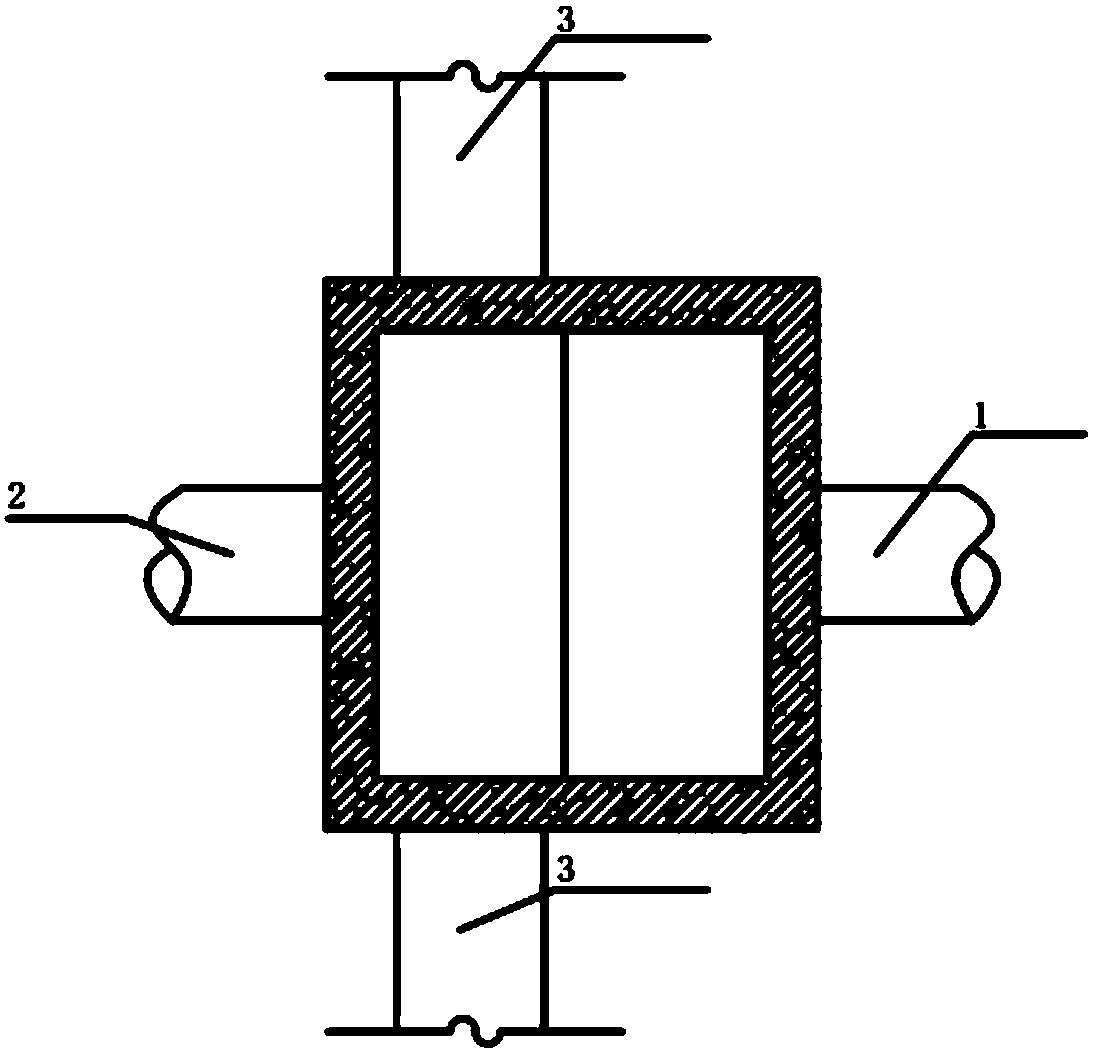

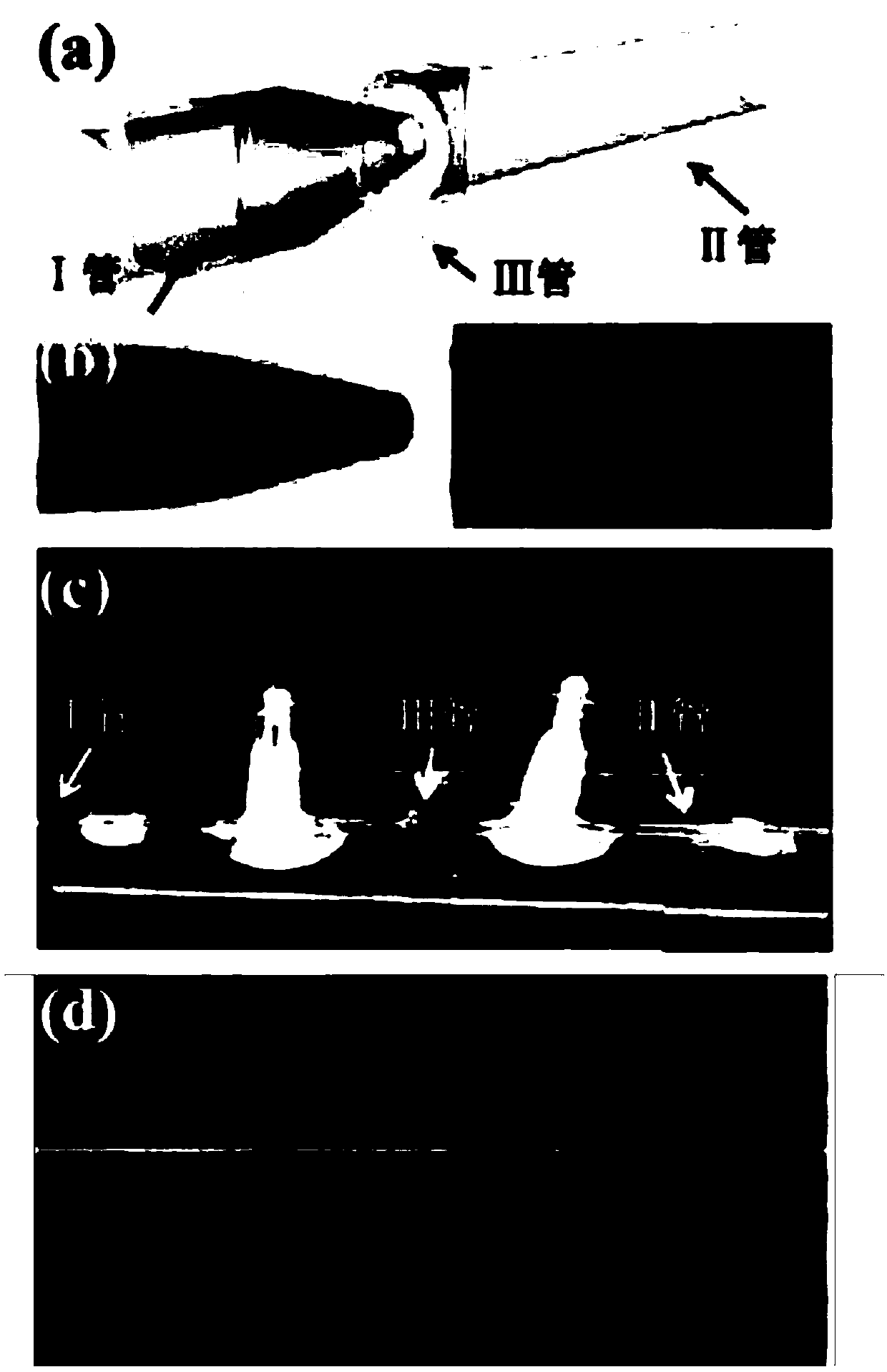

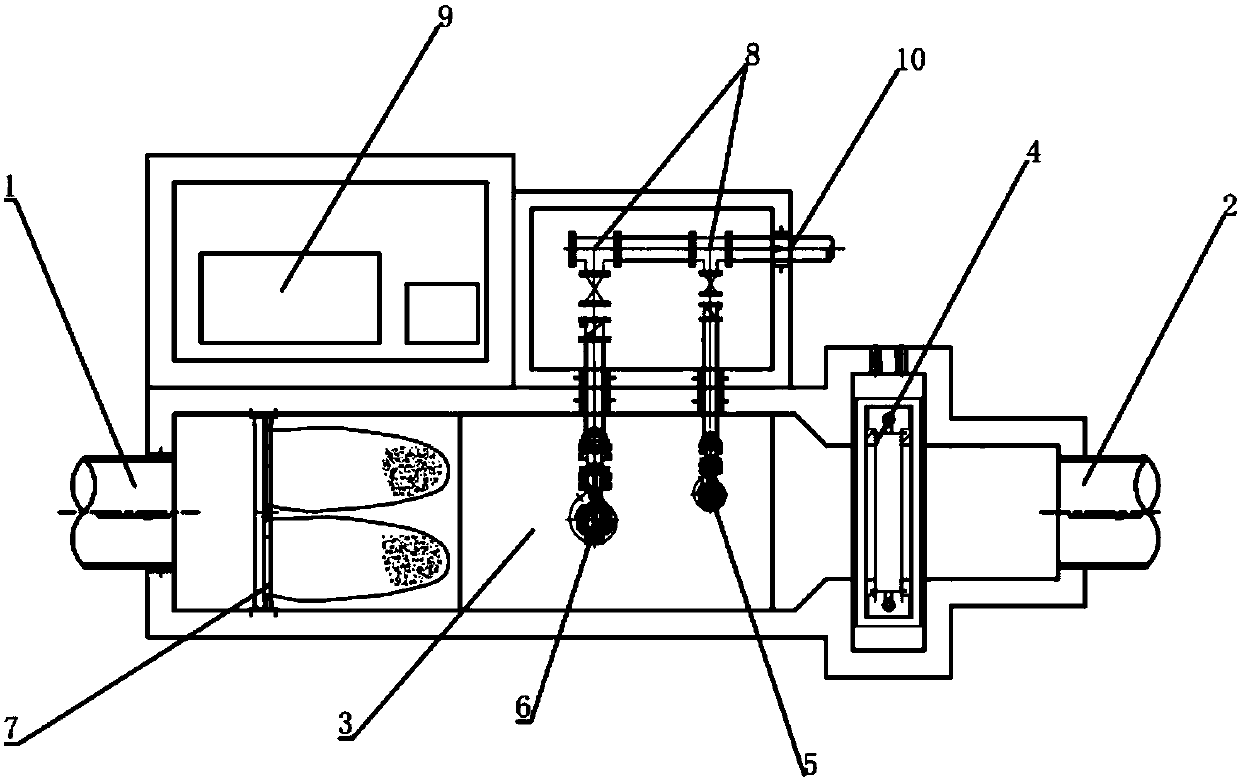

Vertical-well double-layer partial-pressure commingling method and device for coalbed methane

The invention relates to a vertical-well double-layer partial-pressure commingling method and device for coalbed methane. The method includes the steps that a pipe is arranged in the well, and three isolated channels including the first channel, the second channel and the third channel are arranged in the pipe; the side wall of the first channel and the side wall of the second channel are communicated with two coal beds respectively, gas of the two coal beds is discharged to a well opening through the first channel and the second channel respectively, liquid of the two coal beds flows to the bottom of the first channel and the bottom of the second channel respectively, and gas-liquid separation is achieved in the well; one-way valves are arranged between the first channel and the second channel and between the second channel and the third channel, and the liquid of the two coal beds is jointly drawn out of the well while accumulated liquid in the well bottom is avoided. According to the method and device, the gas and the water generated by the upper coal bed and the lower coal bed are jointly mined and jointly drawn through the single well, gas-liquid separation is carried out at the well bottom, the gas is drawn through a gas path, the liquid is drawn through a liquid path, pressure systems of the two coal beds are separated, interlayer interference generated during exploitation is reduced, and the gas yield is effectively increased.

Owner:SOUTHWEST PETROLEUM UNIV +1

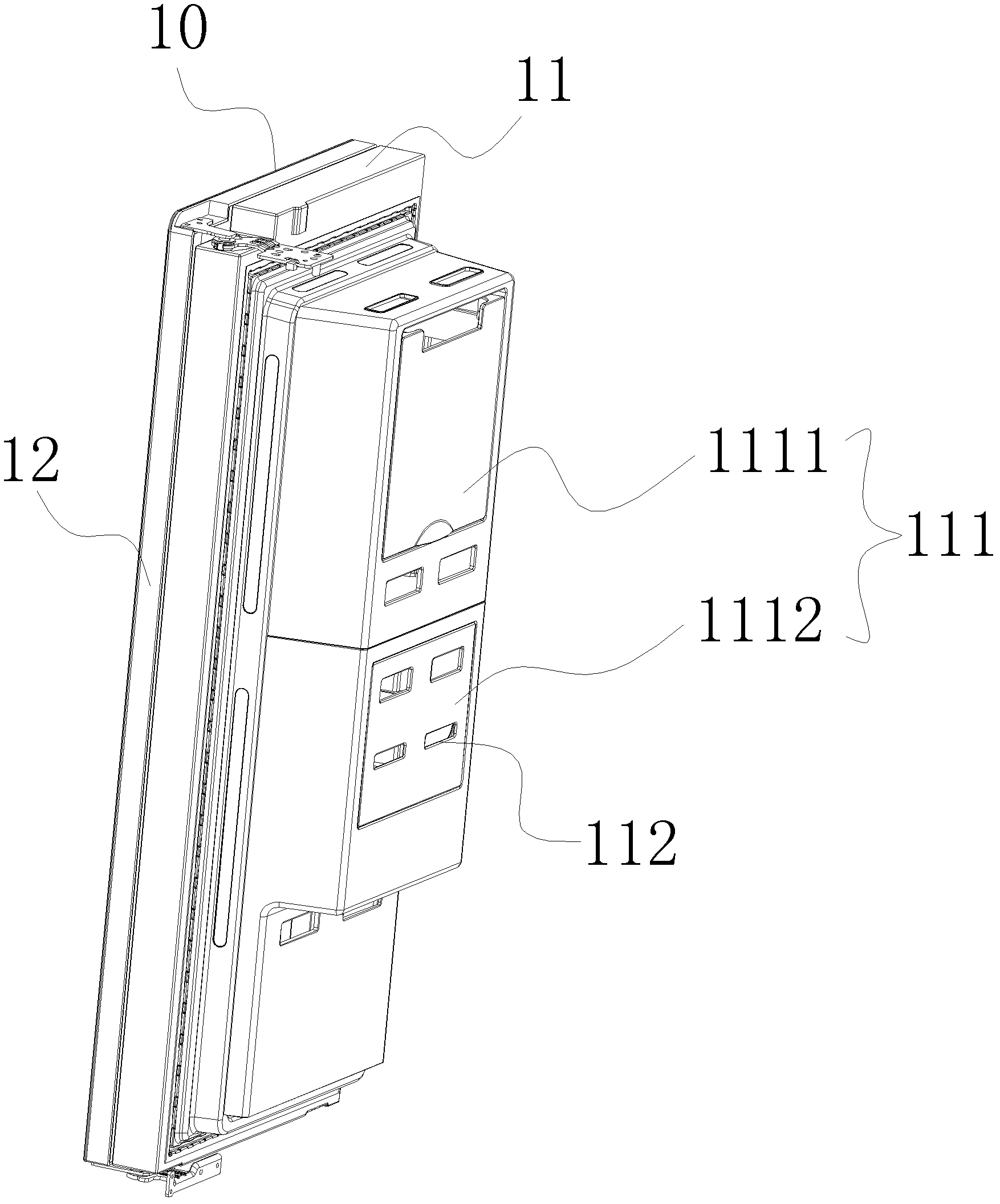

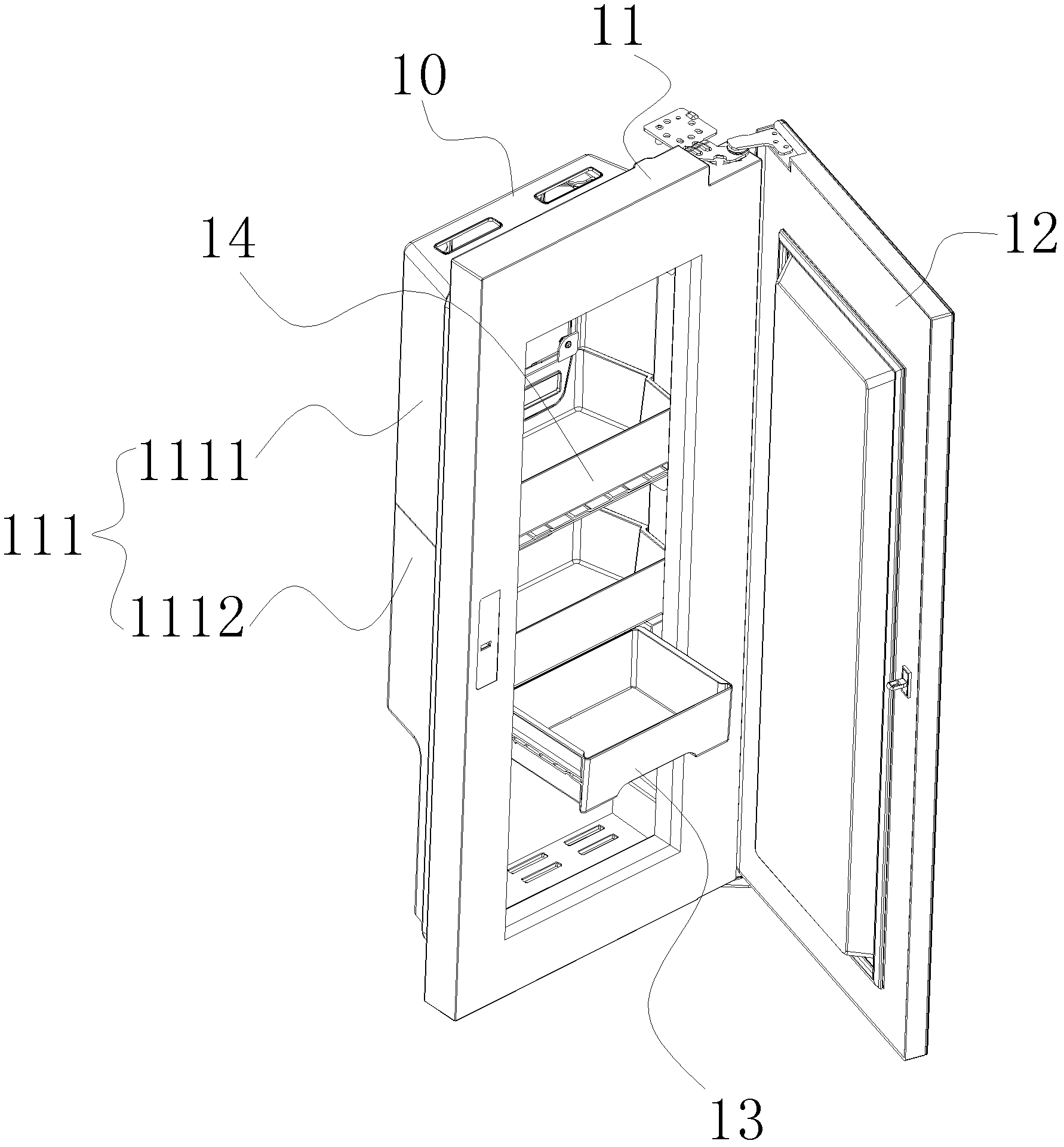

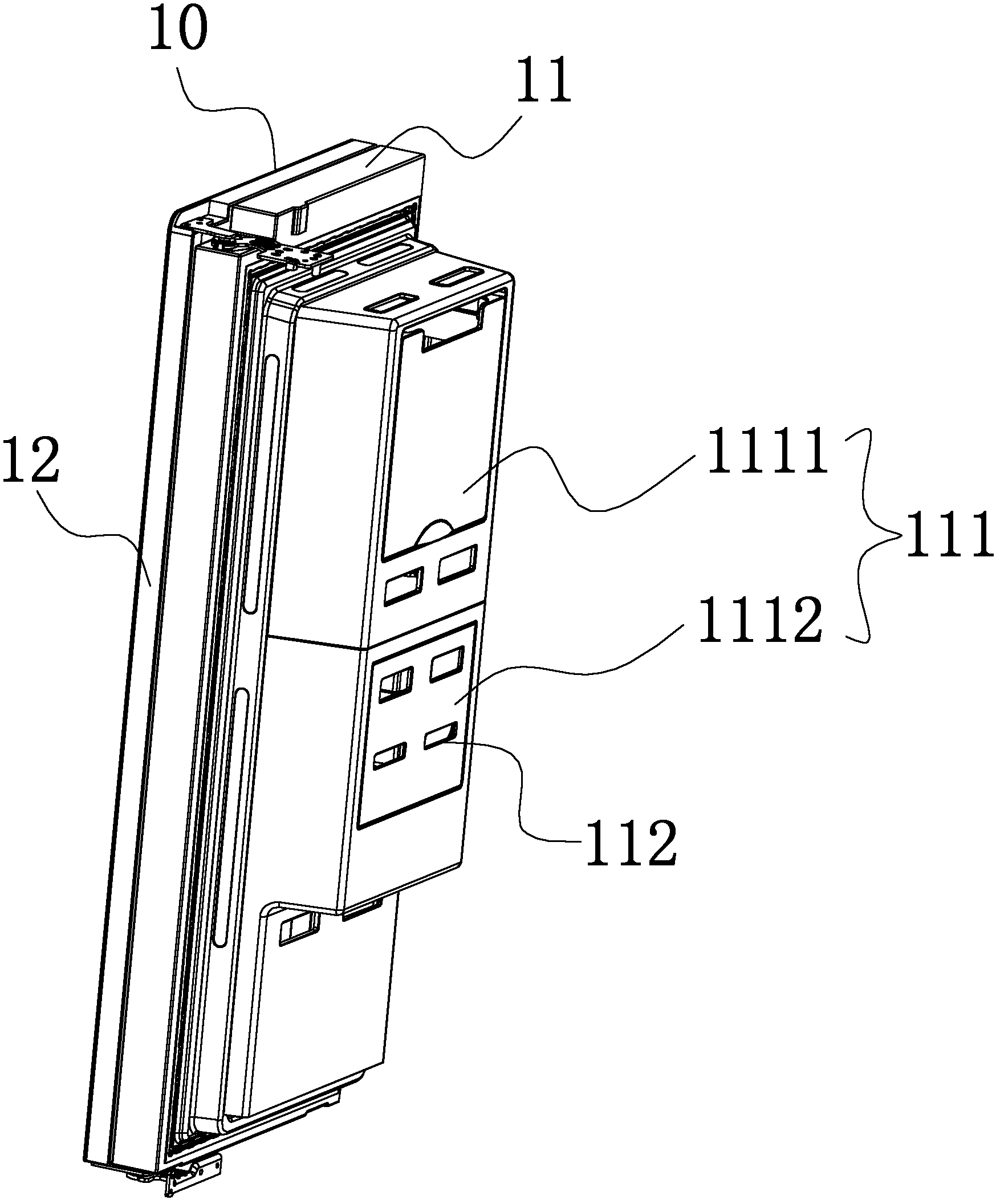

Refrigerator door body and refrigerator with same

InactiveCN102494480AReduce energy consumptionEffective separationDomestic cooling apparatusLighting and heating apparatusRefrigerator carCooling capacity

The invention discloses a refrigerator door body and a refrigerator with the same. The refrigerator door body comprises a first door body and a second door body, wherein the first door body comprises a frame and a door liner; the door liner is connected with the rear surface of the frame to define a storage room; drawers are installed in the storage room and can be pulled out of and pushed into the storage room; and the second door body is pivotally installed on the first door body to open and close the storage room. The refrigerator door body has the following beneficial effects that: after the drawers are installed in the refrigerator door body, the goods can be effectively separated to maintain goods independence and airtight space can be simultaneously formed, thus meeting the storage requirements of special goods; and the first door body and the second door body are arranged to form the storage room structure and the whole refrigerator door body is unnecessary to be opened when the goods in the storage room are taken out, thus reducing cooling capacity losses and refrigerator energy consumption.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Manufacturing method of bi-polar transistor array isolated by double shallow slots

ActiveCN101339921AAvoid makingSolve the problem that injection cannot inject large concentrationSemiconductor/solid-state device manufacturingBit lineTransistor array

The invention relates to a manufacturing method of a two shallow isolation (dual-STI) bipolar transistor array. The method is characterized in that an selective epitaxial method is avoided in the manufacturing method; a deeper STI is made and formed on a first conductive type underlay; an easy diffused second conductive type atomic materials equably deposit and are contained on the side wall and at the bottom of the STI; the easy diffused second conductive type atomic materials which are deposited near a STI notch are removed. Annealing causes that the second conductive type atomics in the materials to be spread to bit lines, so as to form a second conductive type heavy doping of the bit lines; later, the bit lines which are connected with each other by the diffuse of the second conductive type atomics are separated by etching, so as to ensure that the electricity among bit lines is not communicated; separate bipolar transistors are formed above the separate bit lines by ion injection and photoetching. The transistors on the same bit lines are separated by a lighter STI. The method of the invention also comprises the manufacturing method of a gated phase-change memory based on the two shallow isolation (dual-STI) bipolar transistors.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

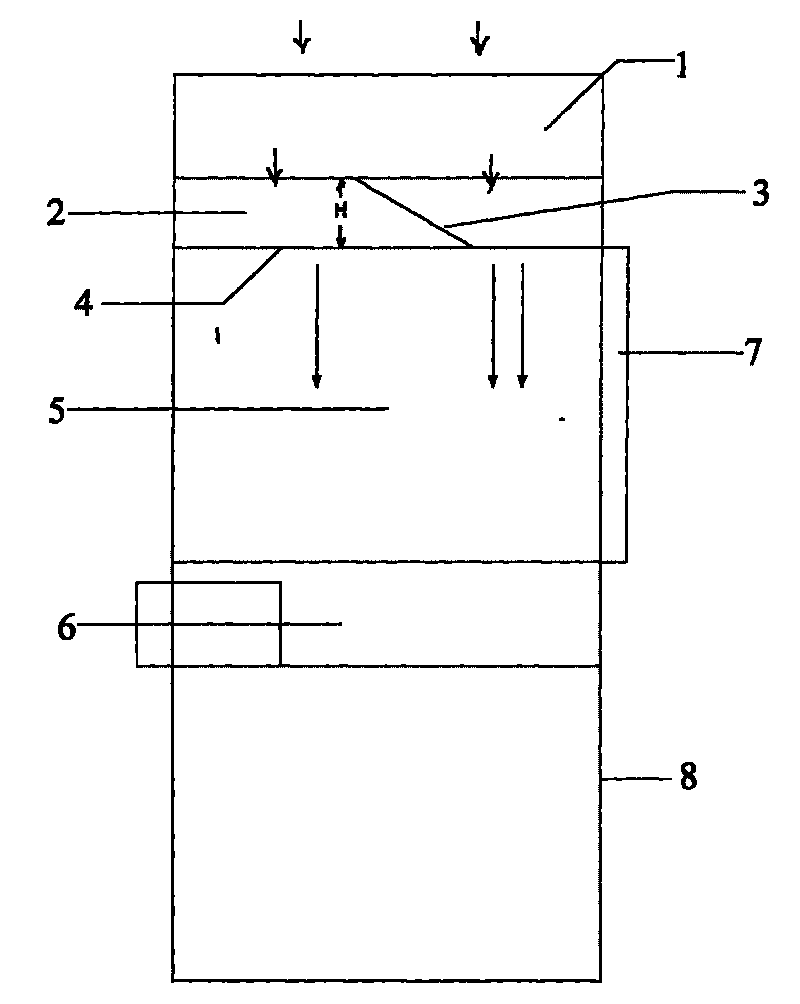

Double-layer-flow purification working table

InactiveCN103170376AEffective separationAvoid harmDust-free enclosuresWork benchesPositive pressureAtmospheric pressure

The invention relates to a double-layer-flow purification working table which comprises an air intake system and an air discharging system, wherein an air diffusion plate is arranged below the air intake system; a working chamber is arranged below the air diffusion plate; large holes are formed along the transverse direction on the front side of the air diffusion plate; small holes are formed along the transverse direction at other parts of the air diffusion plate; the air discharging system comprises an air collecting plate which is positioned inside the working chamber and is vertically arranged; the holes in the air collecting plate are increased gradually from top to bottom; an air collecting hood is installed on the outer side of the air collecting plate; the lower part of the air collecting hood is connected with an air discharging device through an air discharging tube; the air flow inside the working chamber is collected by the air collecting hood after horizontally passing through the air collecting plate and is discharged out by the air discharging device through the air discharging tube. By adopting a mutation hole mode, two positive pressure areas are formed at the working chamber, wherein the air pressure on one side close to working personnel is greater than the air pressure on the inner side; the air discharging system is put on the inner side of the working chamber; and by adopting a gradual change hole mode, the air flow inside the working chamber is collected by the air collecting hood after horizontally passing through the air connecting plate, and the phenomenon that the air flow rebounds below the working chamber is avoided.

Owner:NANTONG UNIVERSITY

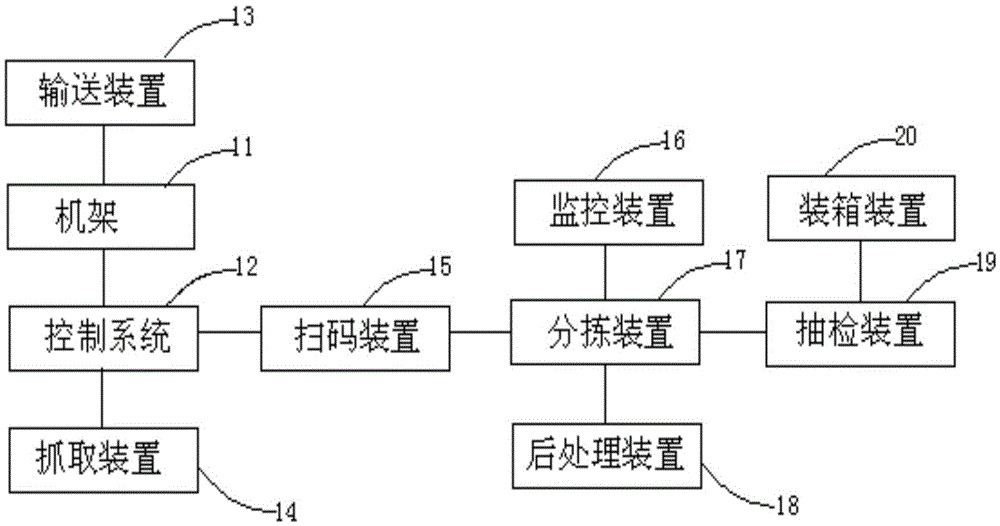

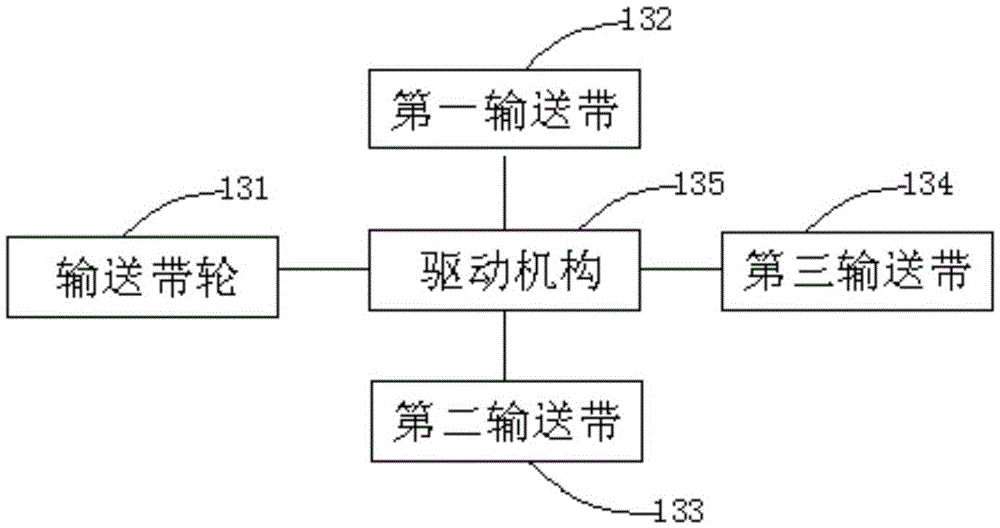

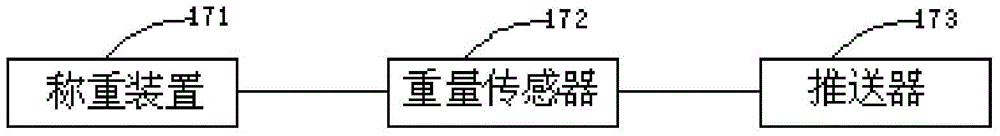

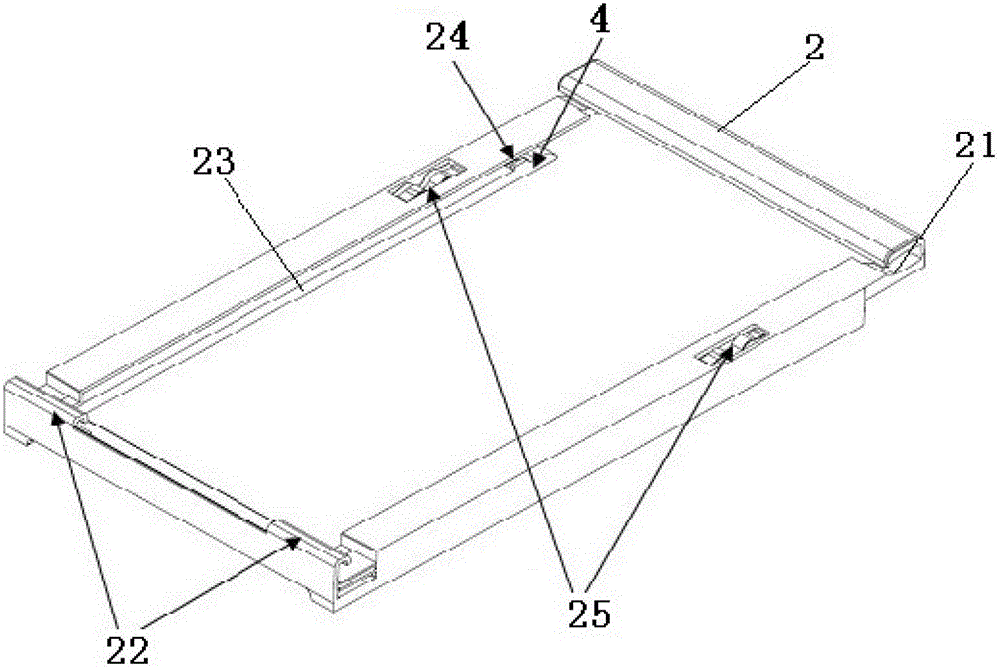

Automatic sorting and encasement equipment

InactiveCN105620831AHigh degree of automationEffective separationPackaging automatic controlSortingAgricultural engineeringEngineering

The invention provides automatic sorting and encasement equipment which comprises a machine frame, a control system, a conveying device, a grabbing device, a code scanner, a monitoring device, a sorting device, an aftertreatment device, a spot-checking device and an encasement device. Multiple monitoring on agricultural product quality is achieved, full-automatic spot-checking is achieved, qualified agricultural products and unqualified agricultural products are effectively separated, and labor efficiency is improved.

Owner:冯贵良

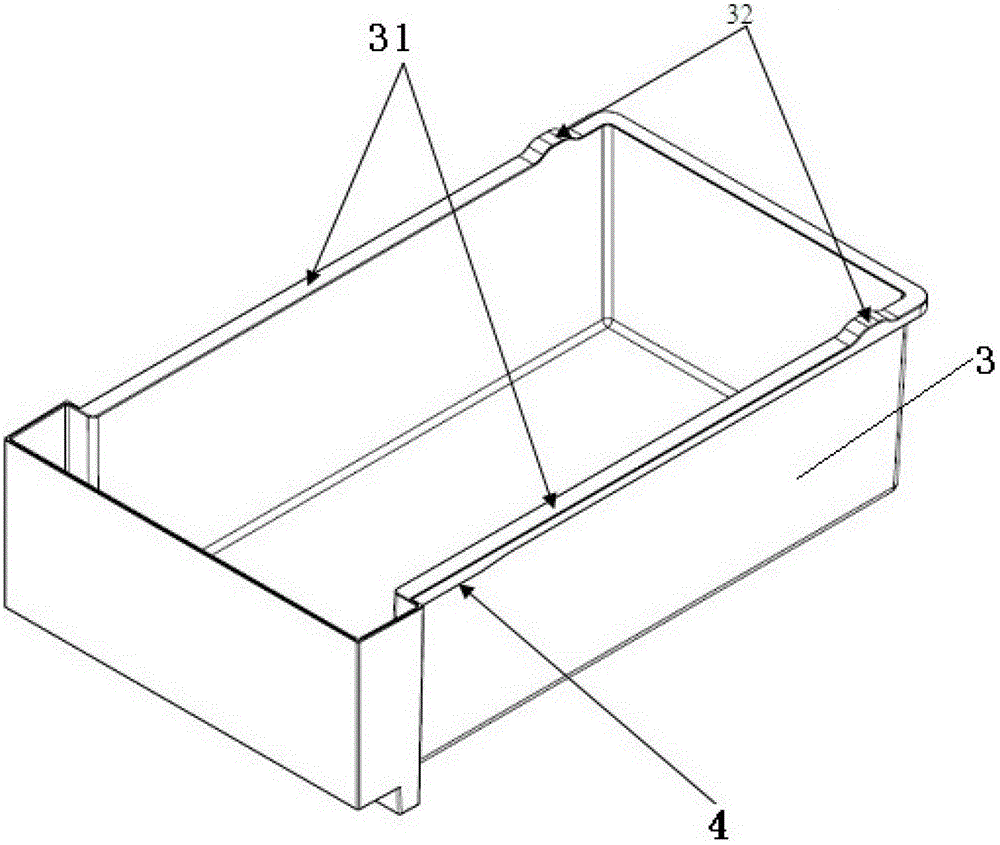

Suspended storage box for refrigerator

The invention discloses a suspended storage box for a refrigerator. The suspended storage box comprises a shelf, wherein a mounting seat is arranged on the shelf and a storage box is suspended on the mounting seat. According to the suspended storage box, the storage box is assembled and guide rails are automatically formed through the structures of the mounting seat and the shelf without other structural parts. A customer can enable the storage box to slide in the left and right directions of the shelf according to the own usage habit, so that small-capacity objects can be better stored or products with special effects can be effectively separated from commodities so as to be kept fresh and healthy. In addition, the position of the storage box can be adjusted up, down, left and right so as to guarantee that other objects can be conveniently stored. Under the condition that the structure function can be realized, the storage box is simple and convenient to assemble, so that the low cost is guaranteed.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

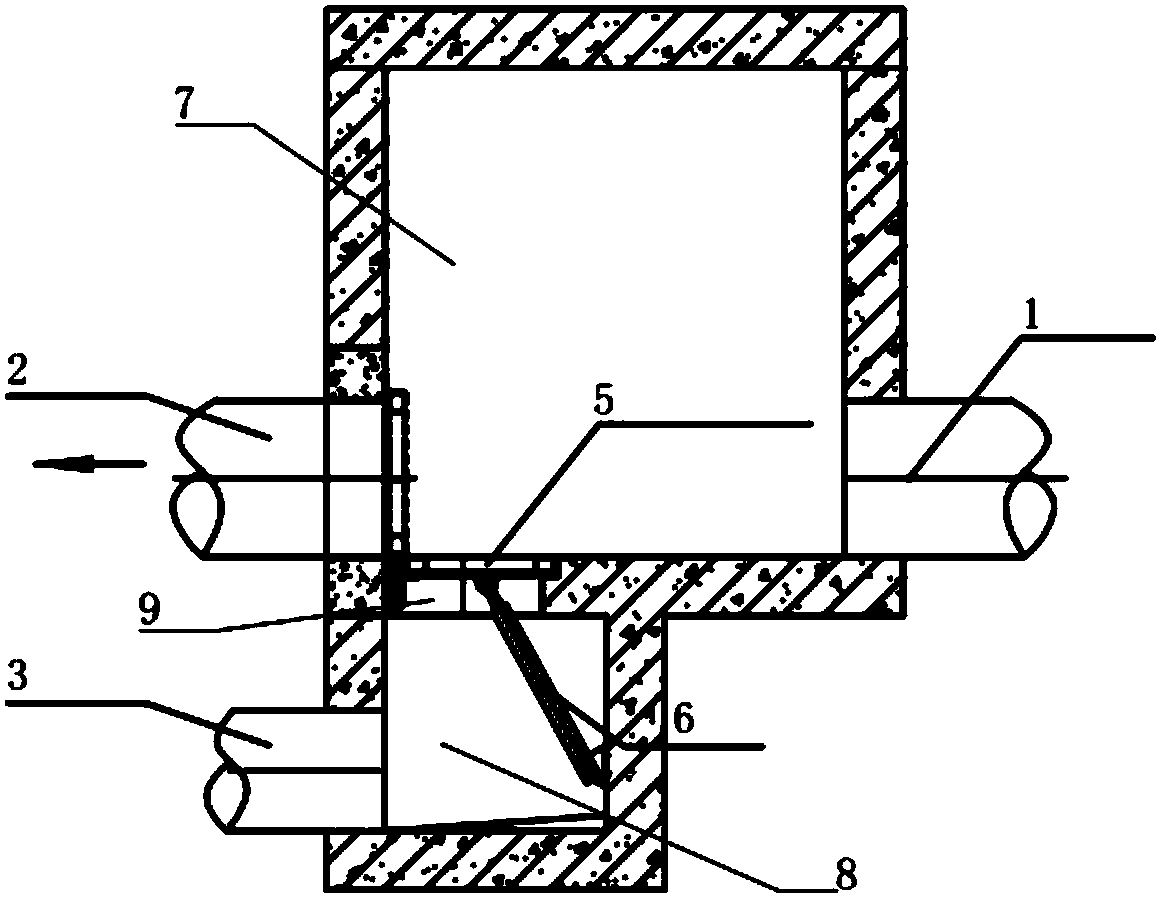

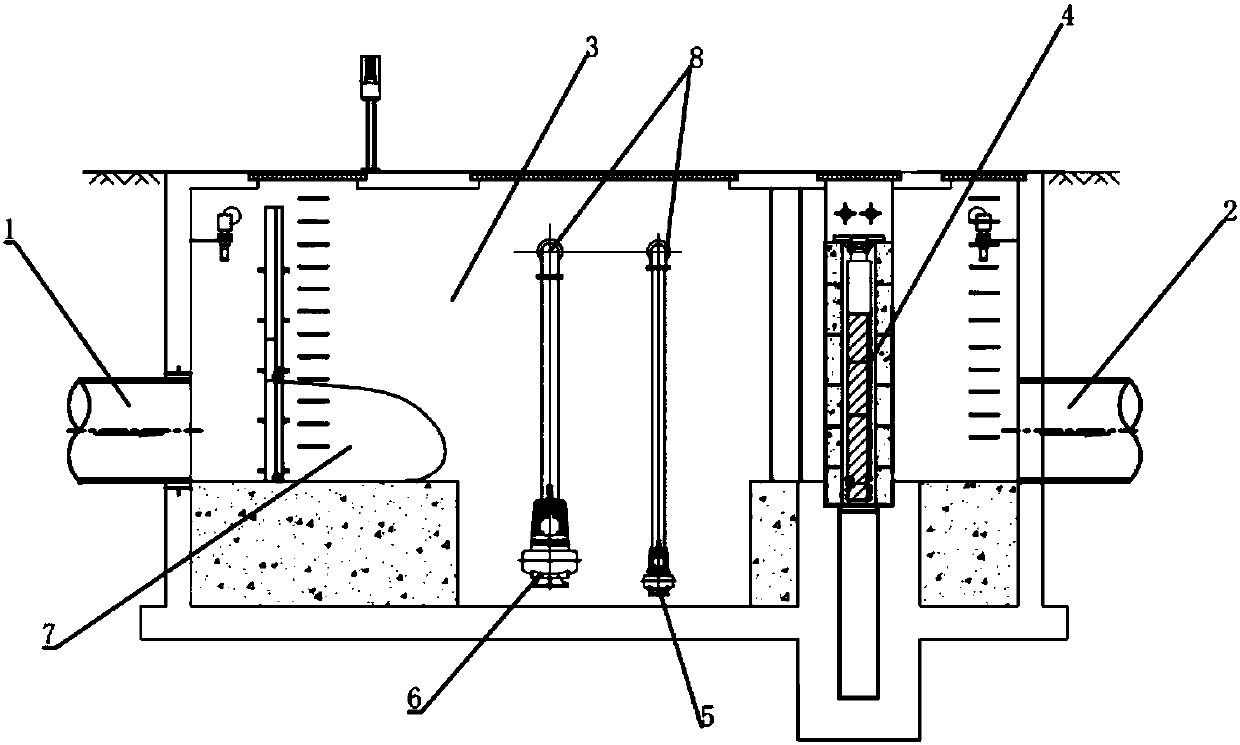

Distributing well with double flaps sluice gate and drainage system and drainage control methods thereof

InactiveCN107761900AReasonable dischargeEnsure flood safetyFatty/oily/floating substances removal devicesSewerage structuresPipeline transportWater quality

The invention discloses a distributing well with a double flaps sluice gate and a drainage system and a drainage control methods thereof, which is of an intelligent drainage effect. Reasonable water discharging is achieved by reasonably controlling the opening of a double flaps sluice gate of the drainage system through a control system, sewage and initial rainwater are enclosed to a storing and regulating facility to the most extent, while flood discharging is guaranteed. The drainage control methods comprise a water level method, a water quality method, a water quality-water level method, atime method, a total amount method, a rainfall method, a time-water level method, a total amount-water level method, and a rainfall-water level method. The phenomenons of water current cannot be limited in a intercepting sewer, and clean water and later rainwater are sent to a sewage treatment plant through an intercepting sewer of the prior art are effectively solved by the regulating of the methods. The sewage is enclosed to the storing and regulating facility to the most extent, and cleaner water is discharged to natural water body by reasonably controlling discharging routes of the sewage,the initial rainwater and the mid-term and later rainwater.

Owner:WUHAN SHENGYU DRAINING SYST

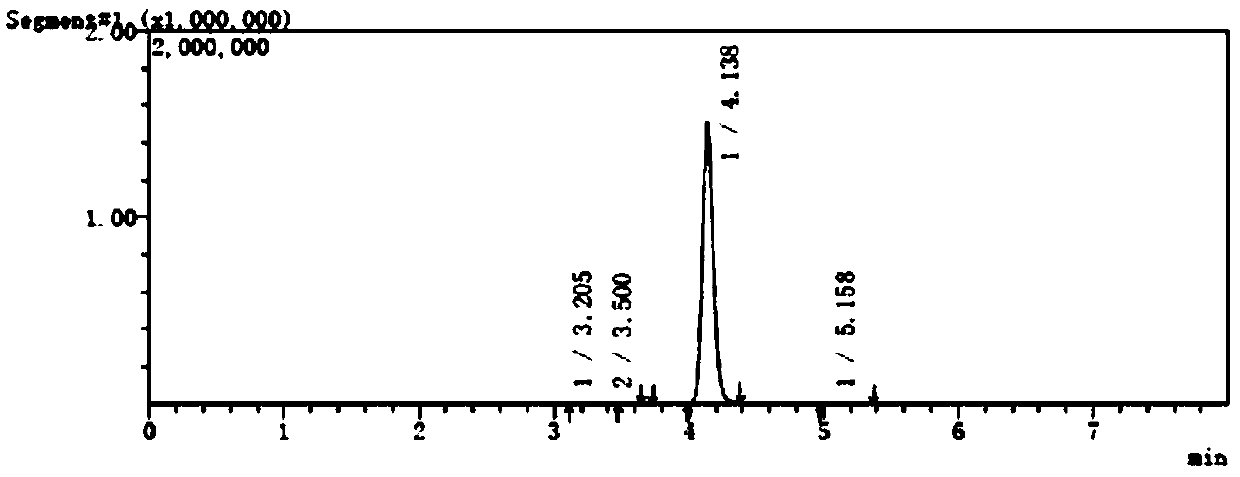

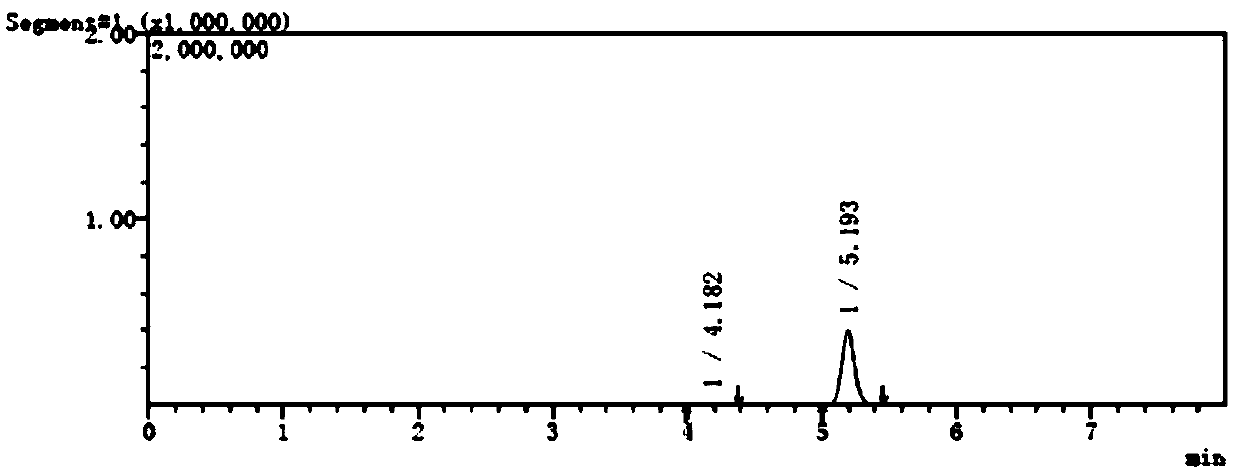

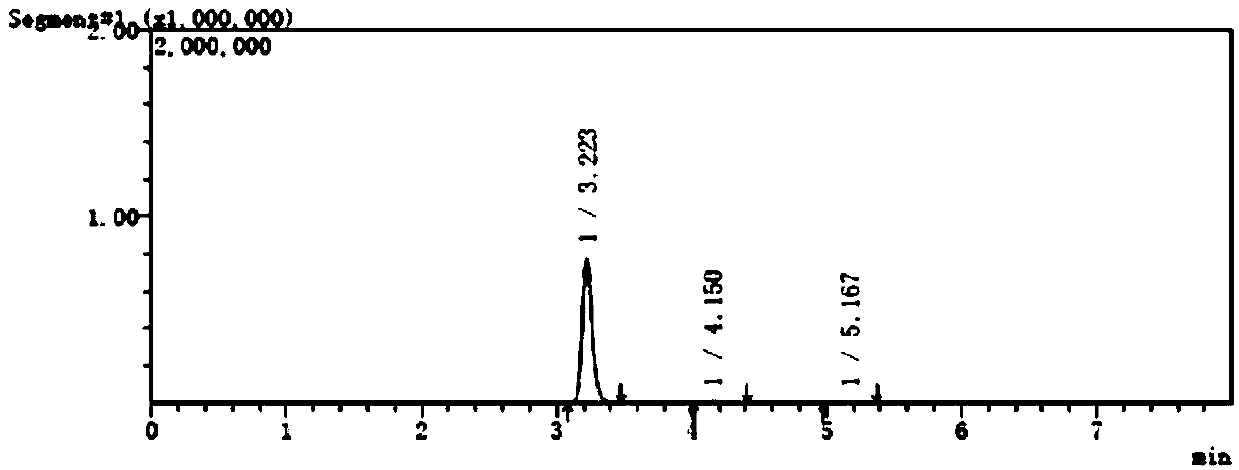

Method for analyzing genotoxic impurities in pantoprazole sodium and starting raw materials of pantoprazole sodium

ActiveCN110487918AEffective separationAccurate quantitative determinationComponent separationBenzimidazoleChemistry

The invention belongs to the field of pharmaceutical analytical chemistry, and particularly relates to two methods for analyzing and measuring potential genotoxic impurities in pantoprazole sodium anda synthetic starting material 5-difluoromethoxy-2-mercapto-1H-benzimidazole thereof. According to the method, octadecylsilane chemically bonded silica is used as a stationary phase, and a mass spectrometry detector is used for analysis and determination; the mobile phase is an aqueous solution containing acetonitrile, methanol and organic ammonium salt; the structural types of the potential genotoxic impurities comprise halogenated methylpyridine compounds, azaaryl N-oxides, N-acylated aminobenzene compounds, aromatic amines compounds and nitrobenzene compounds. According to the method, the effective separation of potential genotoxic impurities in pantoprazole sodium and synthesis starting raw materials of pantoprazole sodium can be realized, the genotoxic impurities can be accurately andquantitatively determined; the method is high in sensitivity and specificity; the experimental operation is simple, convenient and rapid, and the method has important significance for quality controland medication safety of pantoprazole sodium.

Owner:INST OF MATERIA MEDICA AN INST OF THE CHINESE ACAD OF MEDICAL SCI

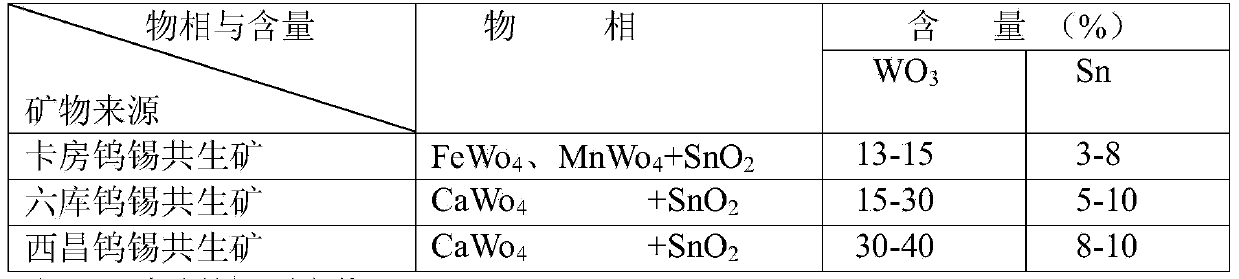

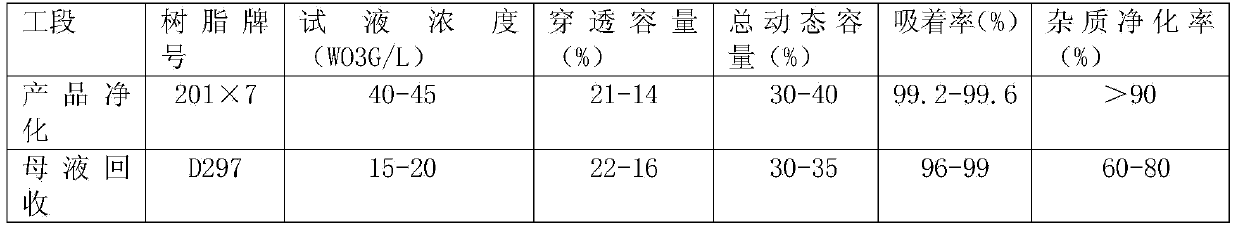

Method for producing tungsten and tin chemical products through chemical metallurgical separation of tungsten-tin paragenic ore

InactiveCN103725879AGuaranteed high oxidationGuaranteed stabilityProcess efficiency improvementLiquid wasteTin dioxide

The invention belongs to the field of chemical metallurgical technology, and particularly relates to a method for producing tungsten and tin chemical products directly from tungsten-tin paragenic ore by use of the chemical metallurgical technology. The method comprises the steps of grinding the tungsten-tin paragenic ore serving as a raw material, and performing acidolysis by use of nitric acid to obtain tungsten-tin mixed slag; dissolving the tungsten-tin mixed slag with ammonia water to obtain ammonium tungstate and tin slag; after the ammonium tungstate enters the solution, performing ion-exchange purification with anion gel resin and desorption with ammonium chloride or ammonia water to obtain high-purity ammonium paratungstate; with lignite as a reducing agent and a non-metal mineral as a stabilizer, performing reduction stabilization of the tin slag, and leaching out the tin with sulfuric acid; performing liquid-phase oxidation and dehydration drying to obtain tin dioxide; performing corresponding after-treatment on the waste gas and waste liquid generated in the preparation process. The method provided by the invention can be used for effectively producing tungsten and tin chemical products at the same time, avoids resource waste and can guarantee the quality of the tin products and relatively low cost as well as the quality of the tungsten products.

Owner:戴元宁

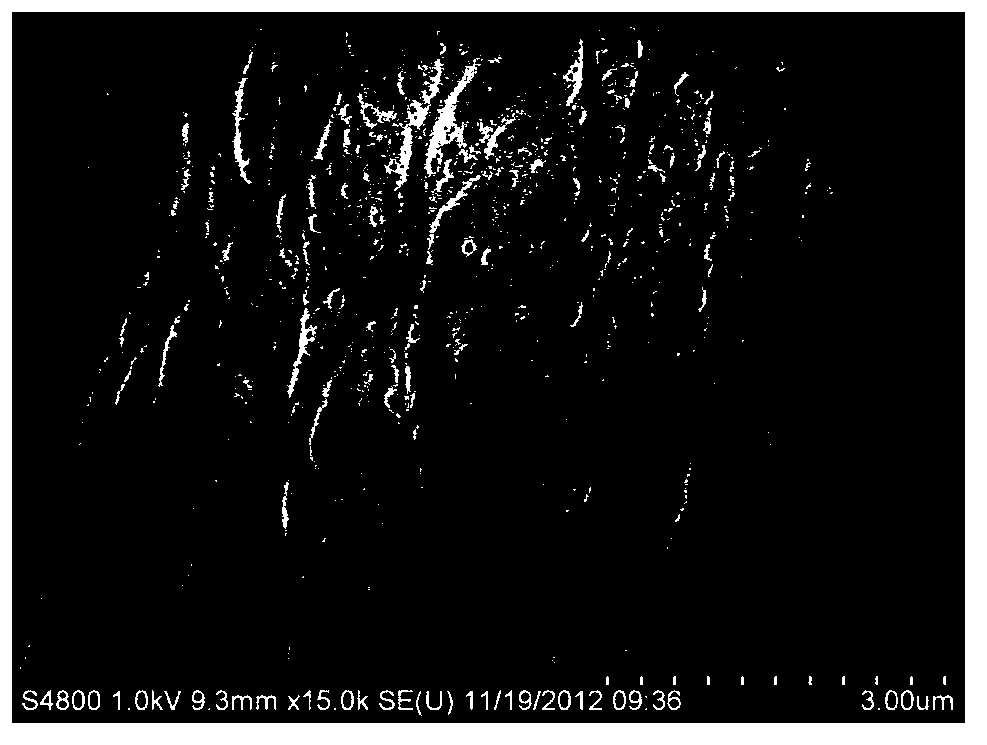

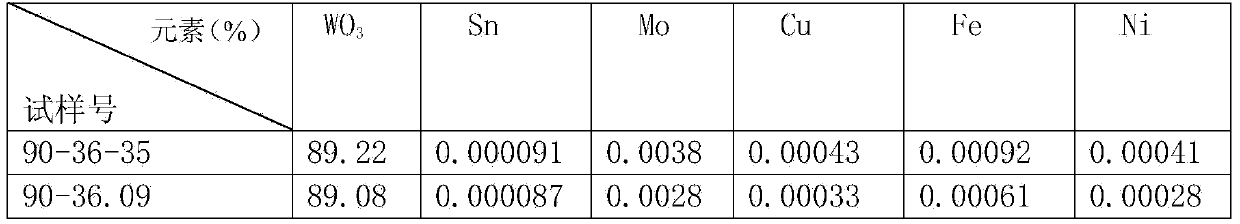

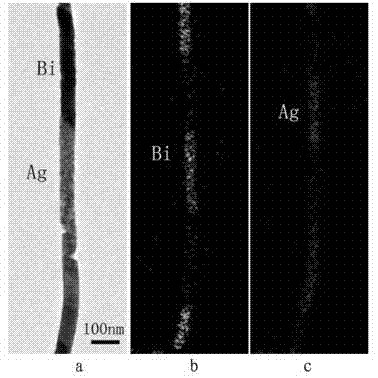

Silver-bismuth superlattice nanowire array and preparation method and application thereof

InactiveCN103088388AAvoid condensationEffective separationMaterial nanotechnologyPreparing sample for investigationDiameter ratioBismuth nanowire

The invention discloses a silver-bismuth superlattice nanowire array and a preparation method and application thereof. The array is formed by arranging one-dimensional superlattice nanowires which are formed by alternately connecting silver nanowires and bismuth nanowires in holes of an alumina template with a gold film coated on one surface, wherein the thickness of the gold film is 200-400nm, the linear diameter of the silver nanowires is 55-65nm, the silver nanowires are 100-200nm long, the linear diameter of the bismuth nanowires is 55-65nm, and the bismuth nanowires are 65nm-2mum long. The method comprises the following steps of firstly obtaining a through hole alumina template with a hole diameter of 55-65nm through a two-step anodic oxidation method, then plating the gold film on one surface of the through hole alumina template, next, placing the alumina template with one side plated with the gold film in silver electrolyte, electro-depositing for 25-35s at direct-current voltage of 0.4-0.6V, then placing the alumina template in bismuth electrolyte, and electro-depositing for 45-600s at direct-current voltage of 0.9-1.3V so as to prepare the silver-bismuth superlattice nanowire array. The silver-bismuth superlattice nanowire array can be used for testing the relationship between the length-diameter ratio and the melting characteristic of the bismuth nanowire.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

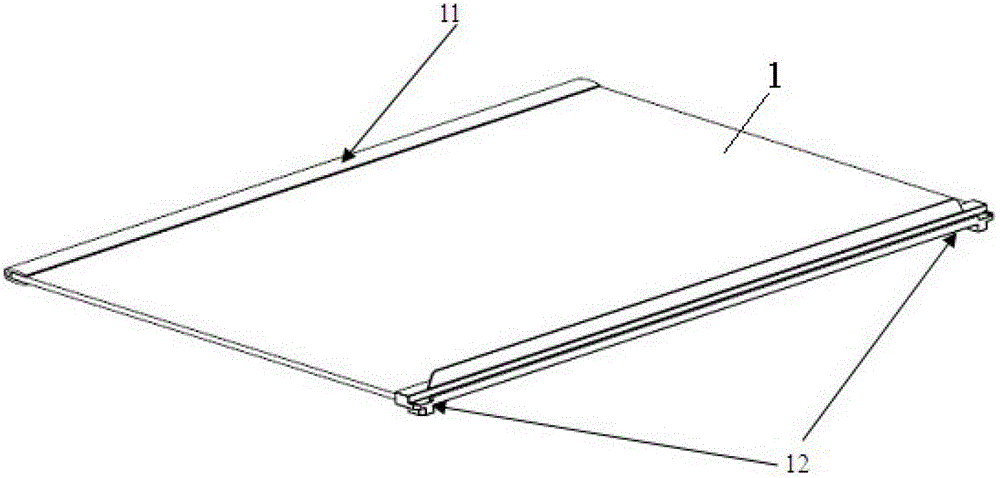

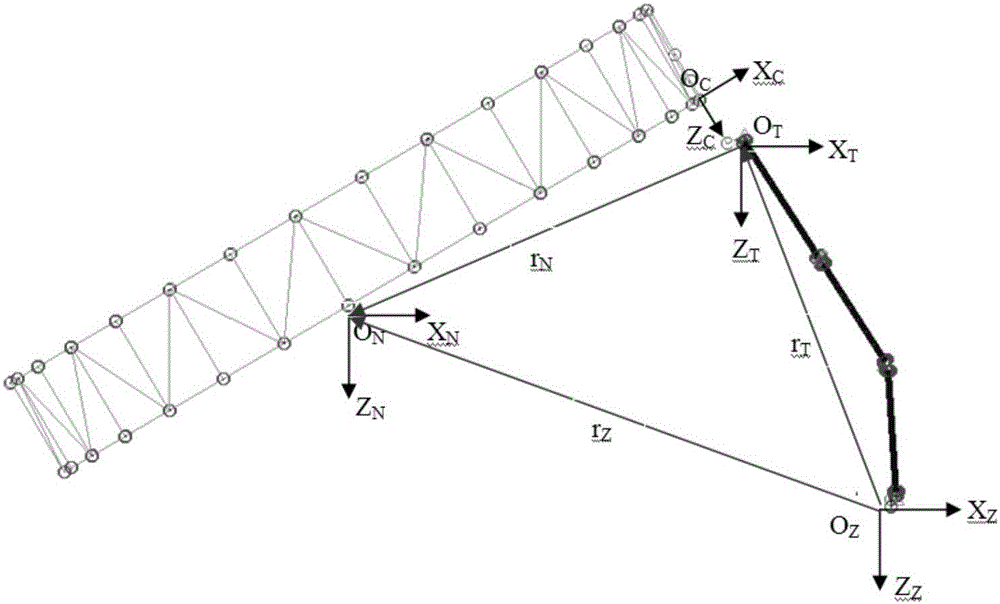

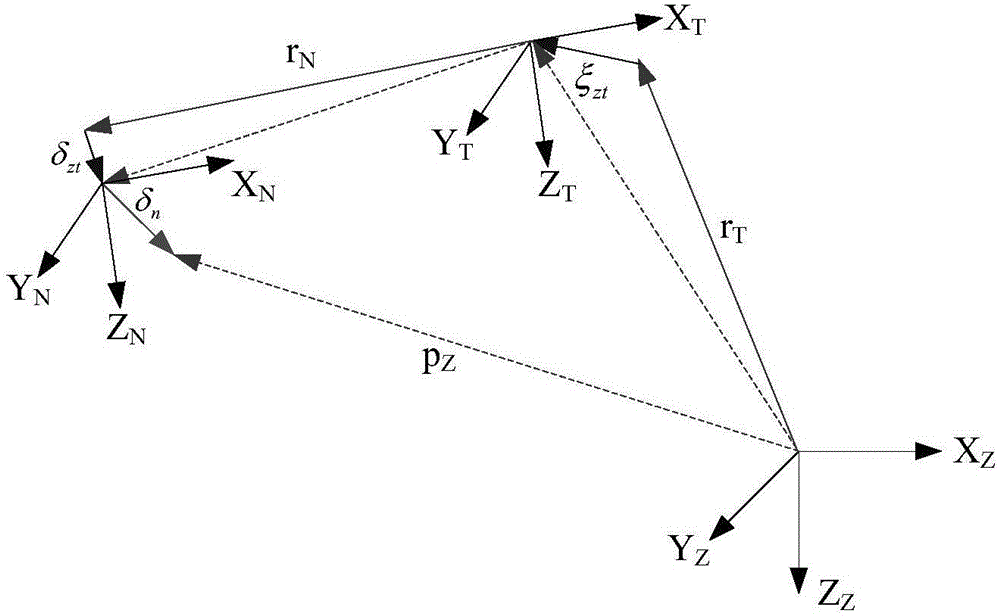

Dynamics modeling method for obtaining antenna on-track vibration influence

ActiveCN105843074AEffective separationEfficient separationSimulator controlAttitude controlEngineering

The invention discloses a dynamics modeling method for obtaining antenna on-track vibration influence. The dynamics modeling method includes the steps of taking annular antennas and all expanded arms for supporting the annular antennas in a whole-spacecraft system as substructures, establishing rigid-flexible coupling dynamic equation set for the whole-spacecraft system, calculating the modality coordinate array of the expanded arms with the annular antennas and the modality coordinate array of the annular antennas, establishing an attitude control model to simulate attitude control for the whole-spacecraft system, and calculating the annular antenna vibration response according to the attitude control simulation result. The annular antenna vibration response includes integral involved position change, of the expanded arms with the annular antennas, supposing with the self position change of the annular antennas, wherein the integral involved position change of the expanded arms with the annular antennas is solved by the modality coordinate array of the expanded arms with the annular antennas, and the self position change of the annular antennas is solved by the modality coordinate array of the annular antennas. The invention belongs to the technical field of antenna on-track vibration.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

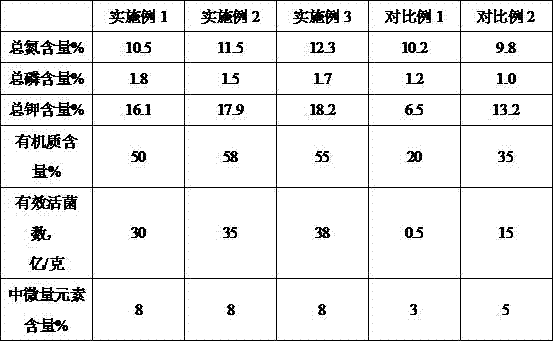

Biological water soluble fertilizer and preparation method thereof

InactiveCN107540471AImprove qualityEffective separationBio-organic fraction processingOrganic fertiliser preparationFreeze-dryingPhosphate

The invention discloses biological water soluble fertilizer and a preparation method thereof, which belongs to the technical field of fertilizer. The fertilizer is prepared by mixing urea, monoammonium phosphate, potassium sulfate, ammonium molybdate, potassium fulvic acid, calcium ammonium nitrate, amino acid powder, borax, an anti-caking agent, ferrous sulfate, manganese sulfate, a chelating agent, fermentation freeze drying powder and garlic polysaccharide according to a given weight ratio. The water soluble fertilizer is not only rich in nutrition and high in nutrition content, but also good in biological activity and capable of effectively preventing the diseases and insect pests of crops.

Owner:成都云图控股股份有限公司

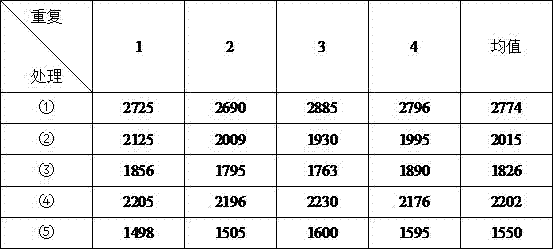

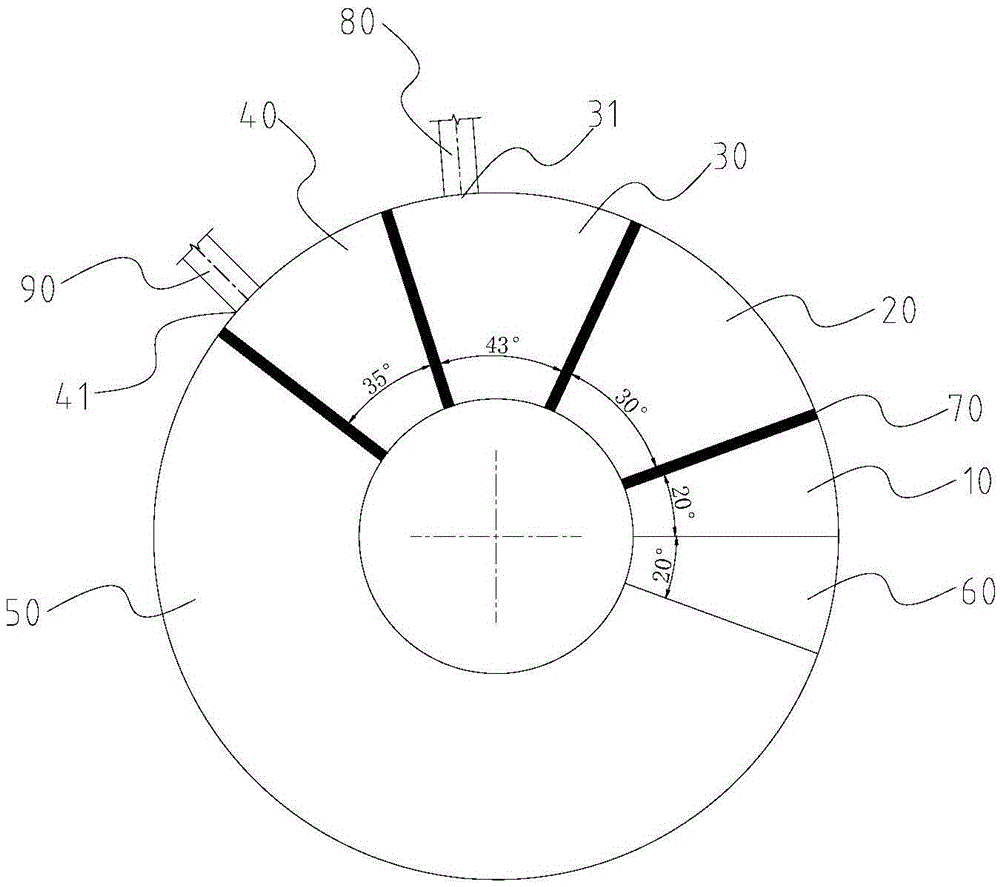

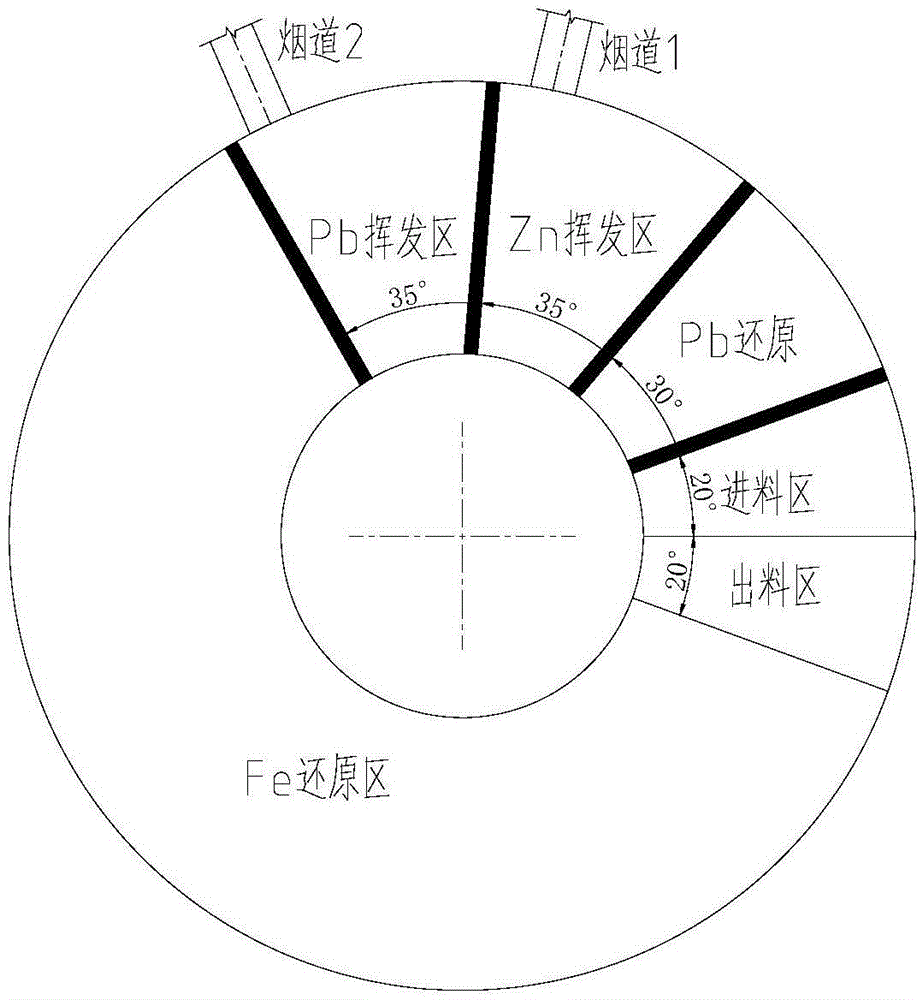

Rotary hearth furnace for processing lead-zinc-containing melting slag

ActiveCN105648228AEffective separationSolve problems that cannot be effectively usedFurnace typesProcess efficiency improvementSlagIron reduction

The invention provides a rotary hearth furnace for processing lead-zinc-containing melting slag. A feeding region, a lead reducing region, a zinc volatilization region, a lead volatilization region, an iron reduction region and a discharging region are sequentially formed in the rotary hearth furnace in the raw material moving direction, wherein a partition wall is respectively arranged between the feeding region and the lead reducing region, between the lead reduction region and the zinc volatilization region, and between the lead volatilization region and the iron reduction region; the zinc volatilization region is provided with a first smoke gas outlet; the lead volatilization region is provided with a second smoke gas outlet; the feeding region is provided with a feeding opening; the discharging region is provided with a discharging opening. When the rotary hearth furnace is used, lead, zinc and iron in the lead-zinc-containing melting slag can be singly separated.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

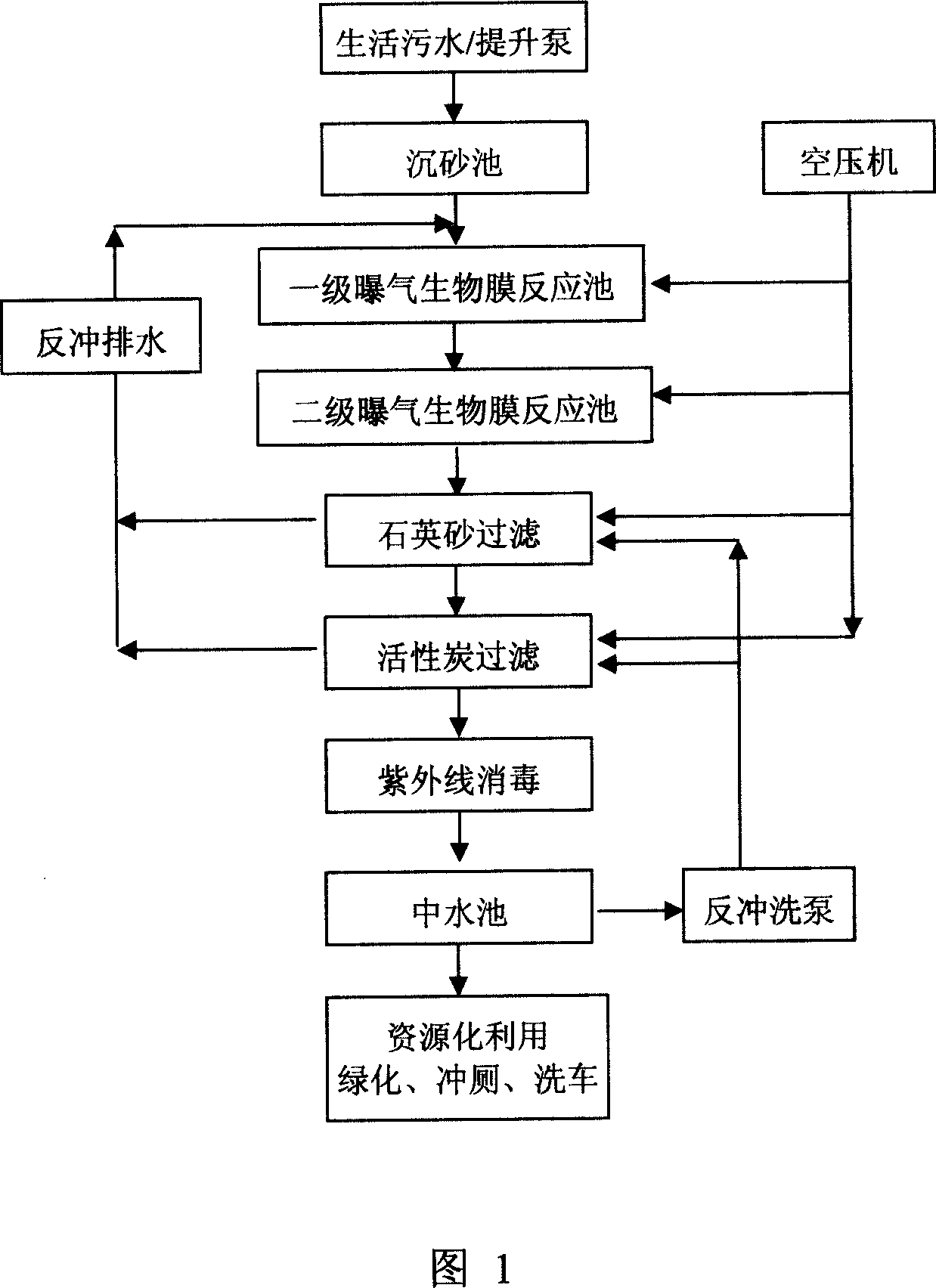

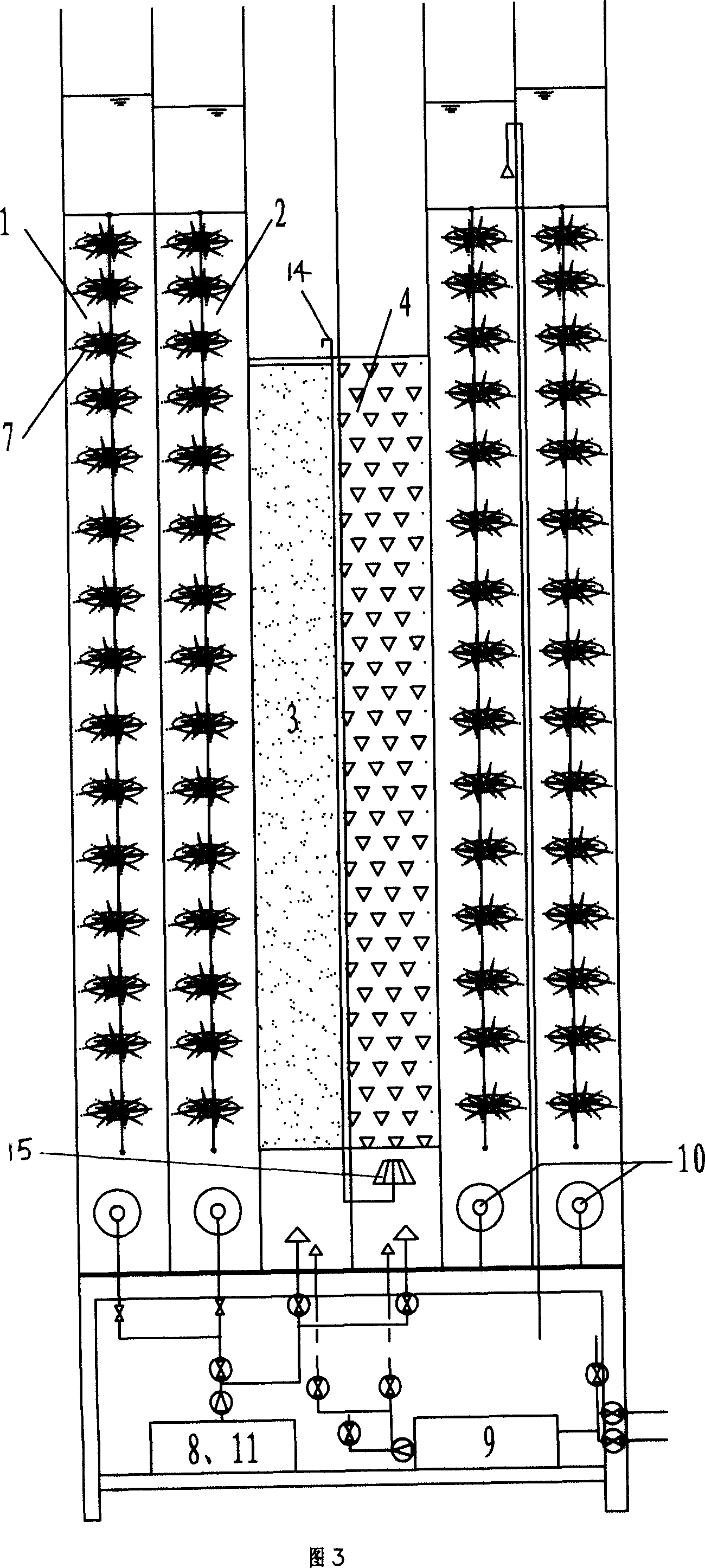

Domestic sewage resource treatment process and device with zero discharge of biological sludge

InactiveCN101033106AAchieving zero emissionsEffective separationTreatment using aerobic processesMultistage water/sewage treatmentSuspended particlesSludge

This invention relates to a process technology for resourcedizing life sewage, in which, a sewage pump lifts sewage to a sand deposition basin for eliminating sand and suspending particles, a first and second level aeration bio-film reaction basin realizes degradation of organic materials and nitration of ammonia nitrogen and reduces mud by optimizing the growing period and environment of microbes, a quartz sand filter basin eliminates suspended substances in the second level aeration biofilm reaction basin, an active carbon filter eliminates perculiar smell and chroma so as to reduce concentration of organics and suspended materials, a disinfection system system controls target of microbes and a mid-water basin stores the processed mid-water, which integrates the first and second levels of aeration bio-film reaction basin, the quartz sand filter basin and an active carbon basin to reduce occupied areas.

Owner:董文艺

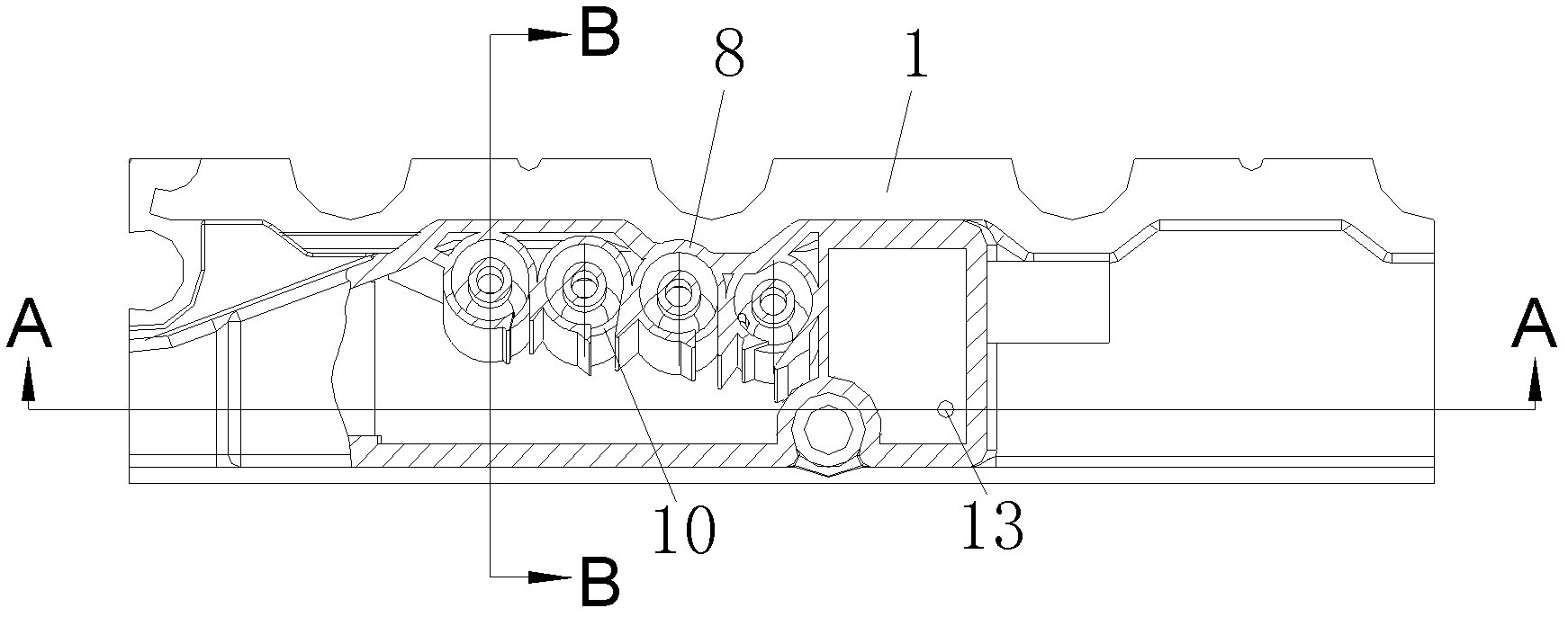

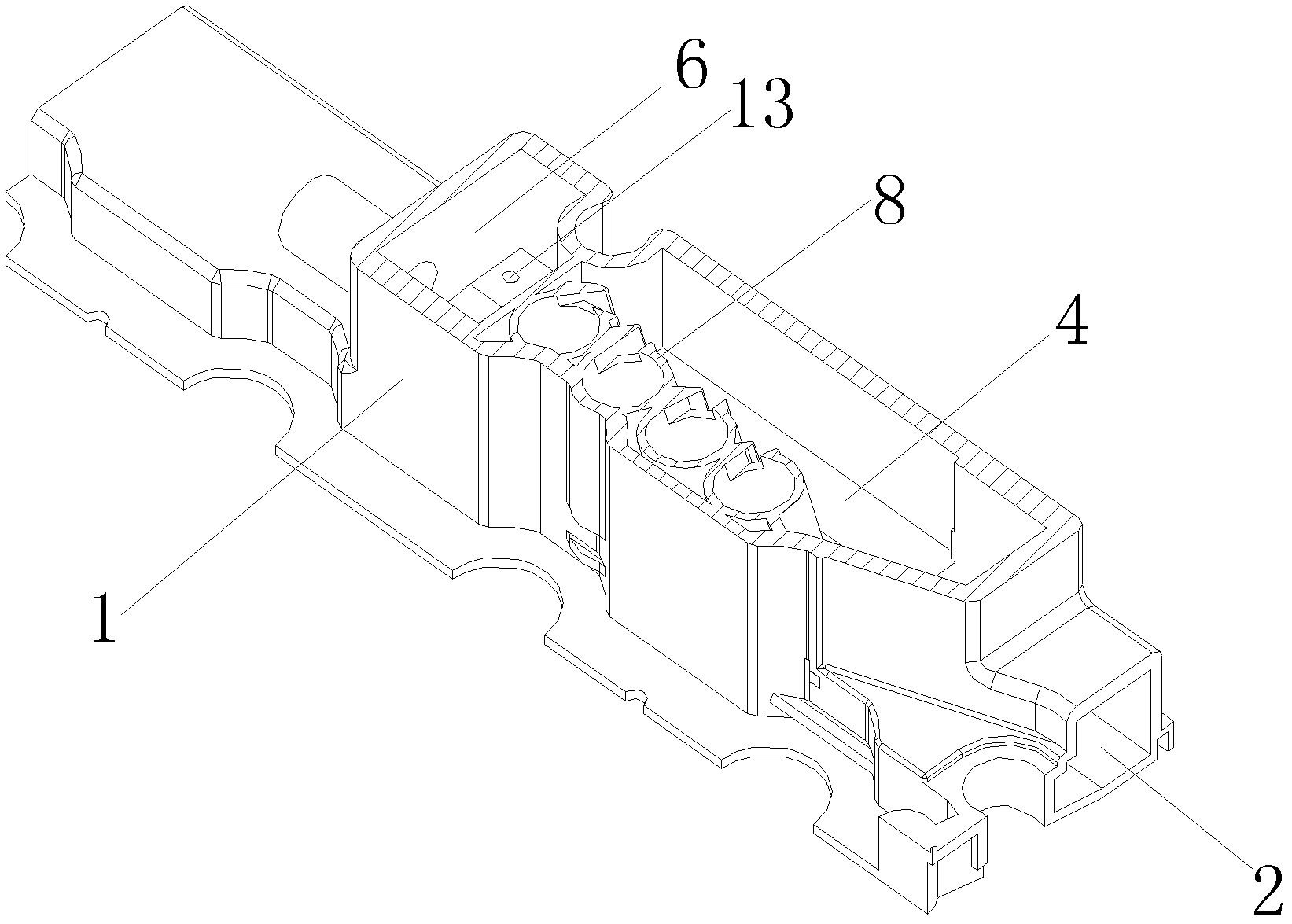

Gas-oil separator

InactiveCN102588041AEasy to separateEffective separationMachines/enginesCrankcase ventillationOil separationEngineering

The invention discloses a gas-oil separator and relates to the technical field of automobile engines, solving the problem of poor gas-oil separation efficiency. The gas-oil separator comprises a separator shell, wherein a gas-oil separation cavity is arranged in the separator shell; one end of the gas-oil separation cavity is communicated with a gas-oil air inlet, and the other end of the gas-oil separation cavity is communicated with an air outlet cavity; a cyclone gas-oil separator is arranged in the gas-oil separation cavity; and the upper end of the cyclone gas-oil separator is provided with an air outlet communicated with the air outlet cavity, the side face of the cyclone gas-oil separator is provided with an air inlet, and the lower end of the cyclone gas-oil separator is provided with an oil outlet. The gas-oil separator provided by the invention is applied to various automobiles and acts as a gas-oil separation mechanism of a ventilating device in an engine crankcase.

Owner:GREAT WALL MOTOR CO LTD

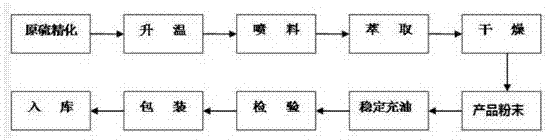

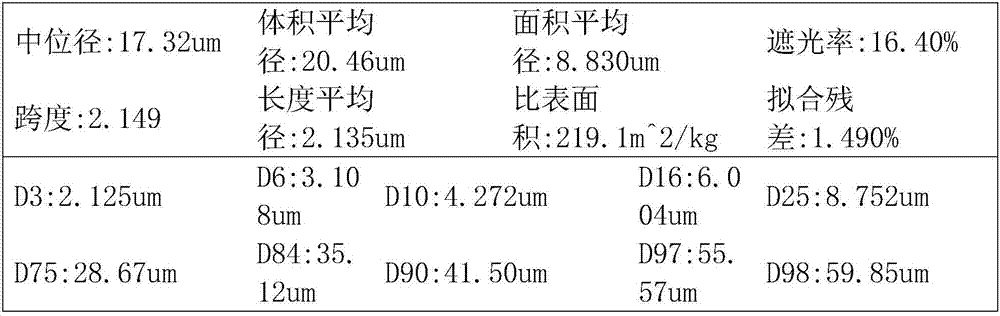

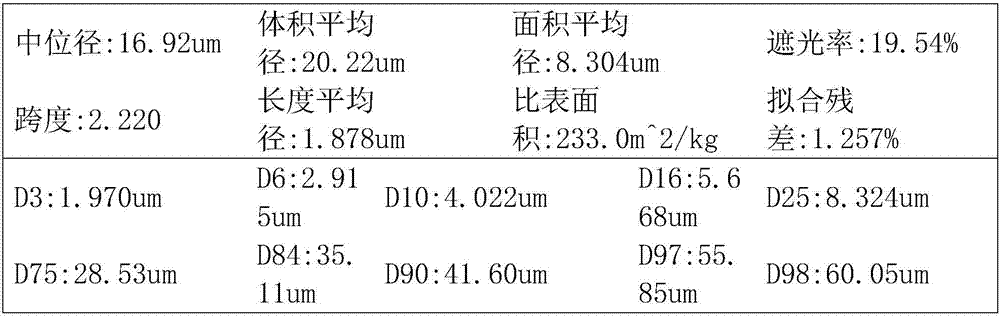

Method for preparing insoluble sulfur through blocking molecular chain of quenching polymerization product of sulfur monomer

InactiveCN107200309AImprove thermal stabilityGood dispersionSulfur preparation/purificationSulfur productLiquid state

The invention discloses a method for preparing insoluble sulfur through blocking molecular chain of a quenching polymerization product of a sulfur monomer. The method specifically comprises the following steps: (1) melting and heating raw material sulfur into a flowing state and heating liquid-state sulfur for gradual gasification, so as to form sulfur steam; (2) spraying the sulfur steam obtained by gasification in step (1) into a pot with a spraying head, pressurizing quenching liquid to spray out atomized liquid drops, performing atomization contact on the atomized liquid drops and the sulfur steam to complete an addition reaction of two ends of the molecular chain and cooling, so as to obtain an intermediate containing the insoluble sulfur; (3) soaking the intermediate containing the insoluble sulfur obtained in step (2) into carbon disulfide for continuous extraction and stabilization; (4) transforming the materials into a dryer for drying; (5) charging extending oil specially used for rubber, so as to form an insoluble sulfur product. The sulfur steam is in full contact with the highly atomized quenching liquid, the insoluble sulfur is made into powder once, and the insoluble sulfur product is formed after extraction, drying, oil charging and secondary stabilization, therefore, the heat stability is improved.

Owner:QINGDAO UNIV OF SCI & TECH

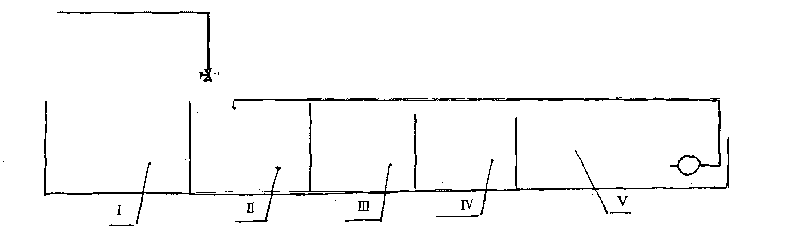

Courtyard-style landscape wetland

InactiveCN101759296ATo achieve the purpose of purificationAdjustable hydraulic retention timeSustainable biological treatmentBiological water/sewage treatmentEutrophicationAquatic animal

The invention relates to a courtyard-style landscape wetland, which consists of a nitrobacteria pond, a plant filtering bond, an aquatic plant settling pond, a conversion pond and an aquatic animal or fish pond. The wetland is mainly applied to the design of urban landscape water areas, the eutrophication control of the landscape water areas and an ecological purified circulating system of the purification of the front of inlets of various cities, parks, river banks or lake banks, families, parks and hotels. The sewage can be purified by the actions of precipitation, adsorption, nitration, denitrification and the like, thus the pollution load is reduced.

Owner:KUNMING UNIV OF SCI & TECH

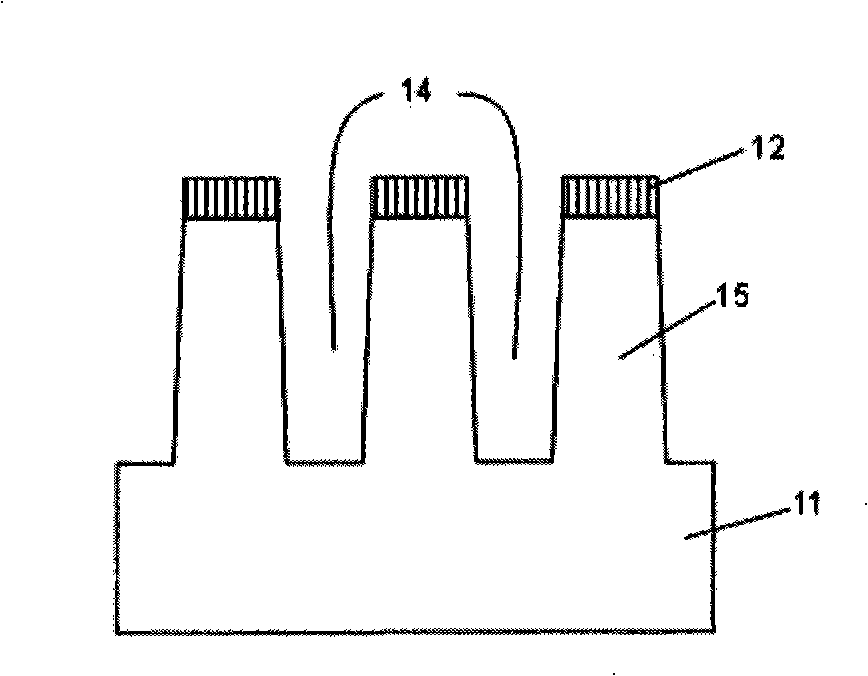

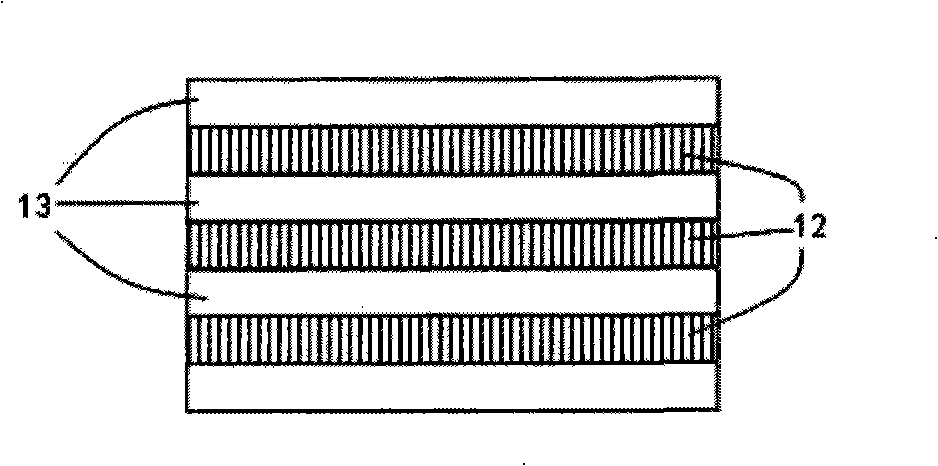

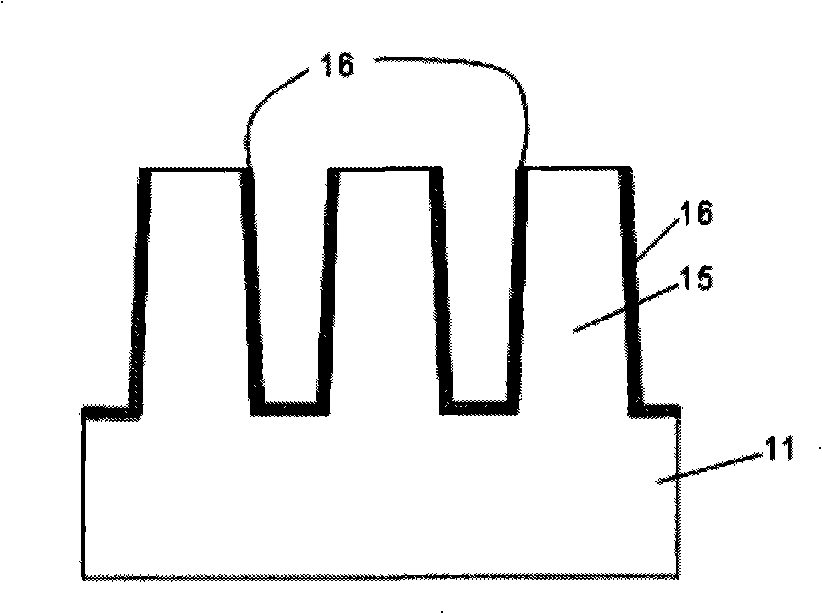

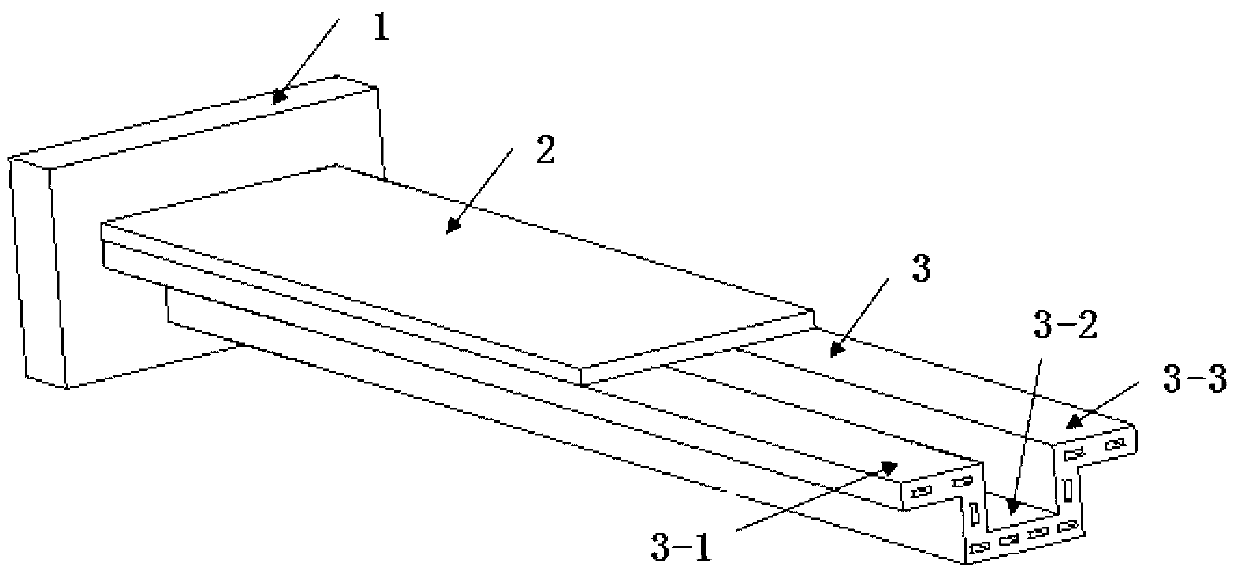

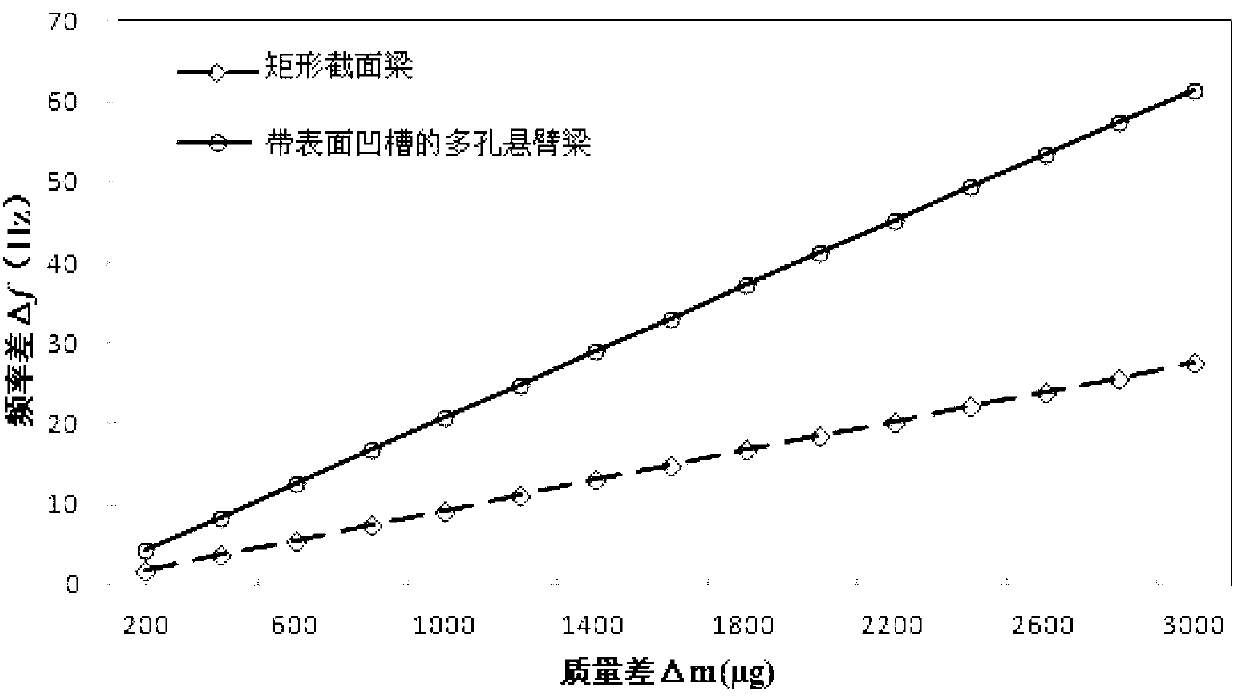

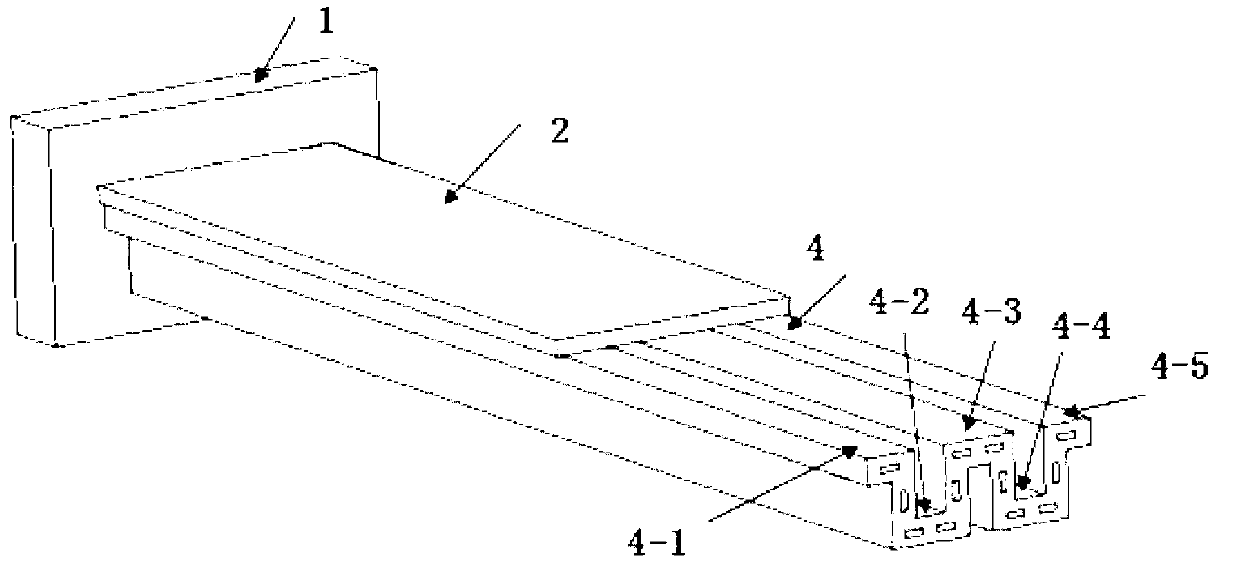

Multipurpose micro-mass sensor of porous cantilever structure

InactiveCN102967351AHigh sensitivity per unit areaImprove stabilityWeighing apparatus using elastically-deformable membersWeighing by absorbing componentElectricityCell growth

A multipurpose micro-mass sensor of a porous cantilever structure belongs to the technical field of multipurpose detection sensors. The micro-mass sensor is characterized in that the upper surface of a porous cantilever which is connected with a fixed block is connected with a piezoelectric film, and the areas of the extension part of the cantilever are a plurality of different detection areas with the same sensitivity. The mass of a detected object is accurately calculated according to the data output of the piezoelectric film. The induction of the porous cantilever can realize the following functions: (a) the plurality of detection areas are effectively isolated; (b) the sensitivities of all the positions in the detection areas are highly consistent with each other, so that the position sensitivity of a test result is reduced; and (c) specific examples show that compared with a conventional planar type sensor structure, the multipurpose micro-mass sensor has the sensitivity which can be increased by 187% at most. The multipurpose micro-mass sensor has the characteristics of simplicity in structure, wide measurement scope, good uniformity, high sensitivity and the like, and thus can be widely applied to gas / liquid concentration measurement and the measurement of cell growth and microorganism, such as bacteria or virus and the like.

Owner:DALIAN UNIV OF TECH

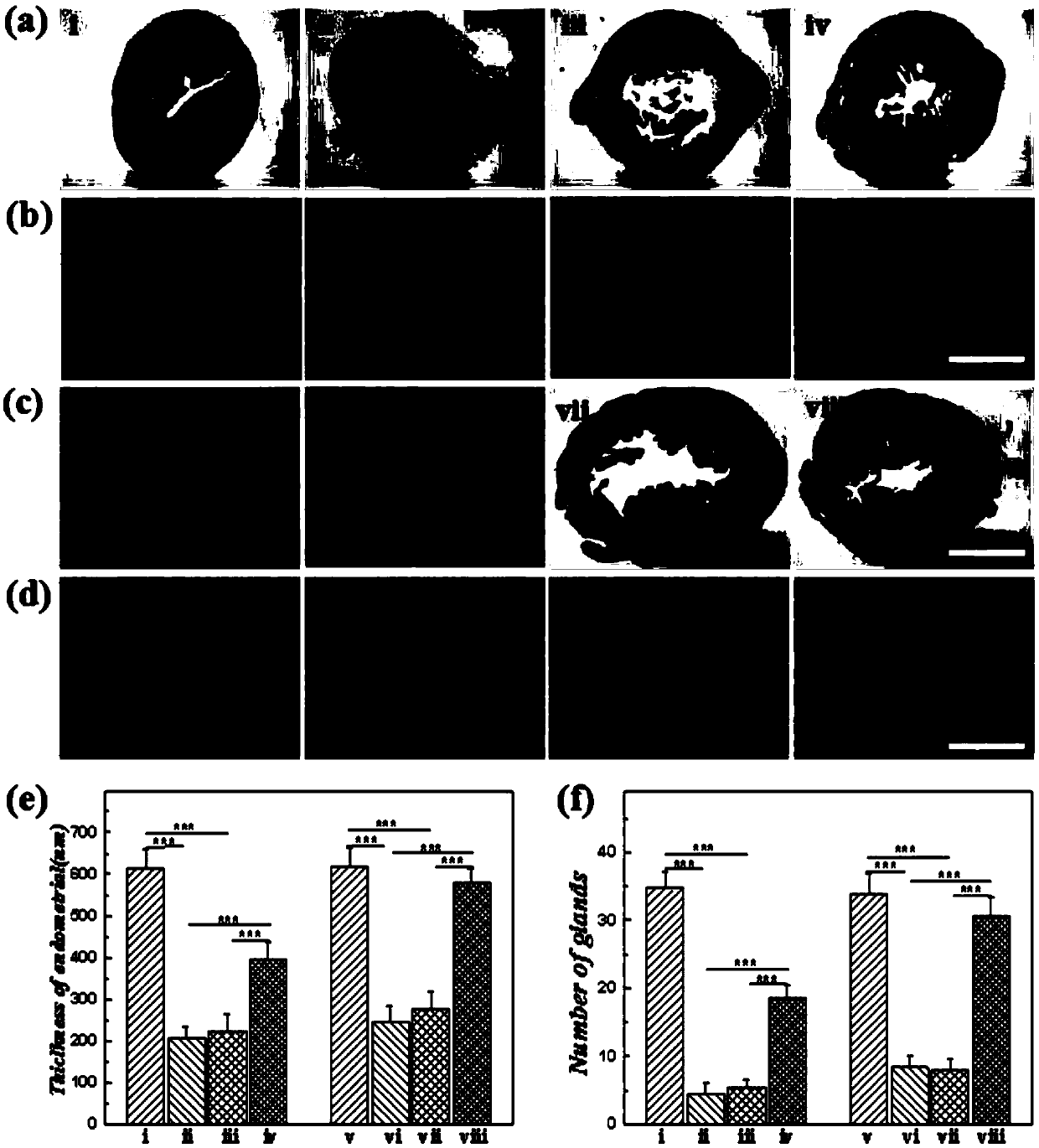

Three-dimensional porous stent and preparation method and application thereof

ActiveCN109091705AModerate pore sizeGood biocompatibilityAdditive manufacturing apparatusProsthesisTissue repairEmulsion

The invention discloses a three-dimensional porous stent. The three-dimensional porous stent is made from composite biomaterials consists of degradable natural biomaterials and degradable artificiallysynthesized macromolecule materials. The three-dimensional porous stent has a three-dimensional orderly porous structure in which holes are homogeneous, mutually penetrated and regular in distribution, and the hole diameter is 80-350[mu]m. The invention further discloses a preparation method and application of the three-dimensional porous stent. According to the method disclosed by the invention,the advantages of an emulsion microflow control technique and the advantages of the composite biomaterials are combined. The three-dimensional porous stent disclosed by the invention has favorable biocompatibility and biodegradability and has the characteristics that the hole diameter is appropriate, the holes are mutually penetrated, and the three-dimensional porous stent is degradable and compressible, can be shaped and can be used for performing drainage effectively, and good space is provided for medicine delivery and slow release, cell growth and metabolism and tissue repair; the proportion of ingredients of the compound materials and the holes in concentrated distribution can guarantee that the three-dimensional porous stent has favorable compression and resilience properties like sponge, so that the three-dimensional porous stent can better adapt to the shape of the uterine cavity or the shape of other positions needing prevention of adhesion, and the effect of effectively preventing the adhesion can be achieved.

Owner:南京恒华生物发展有限公司

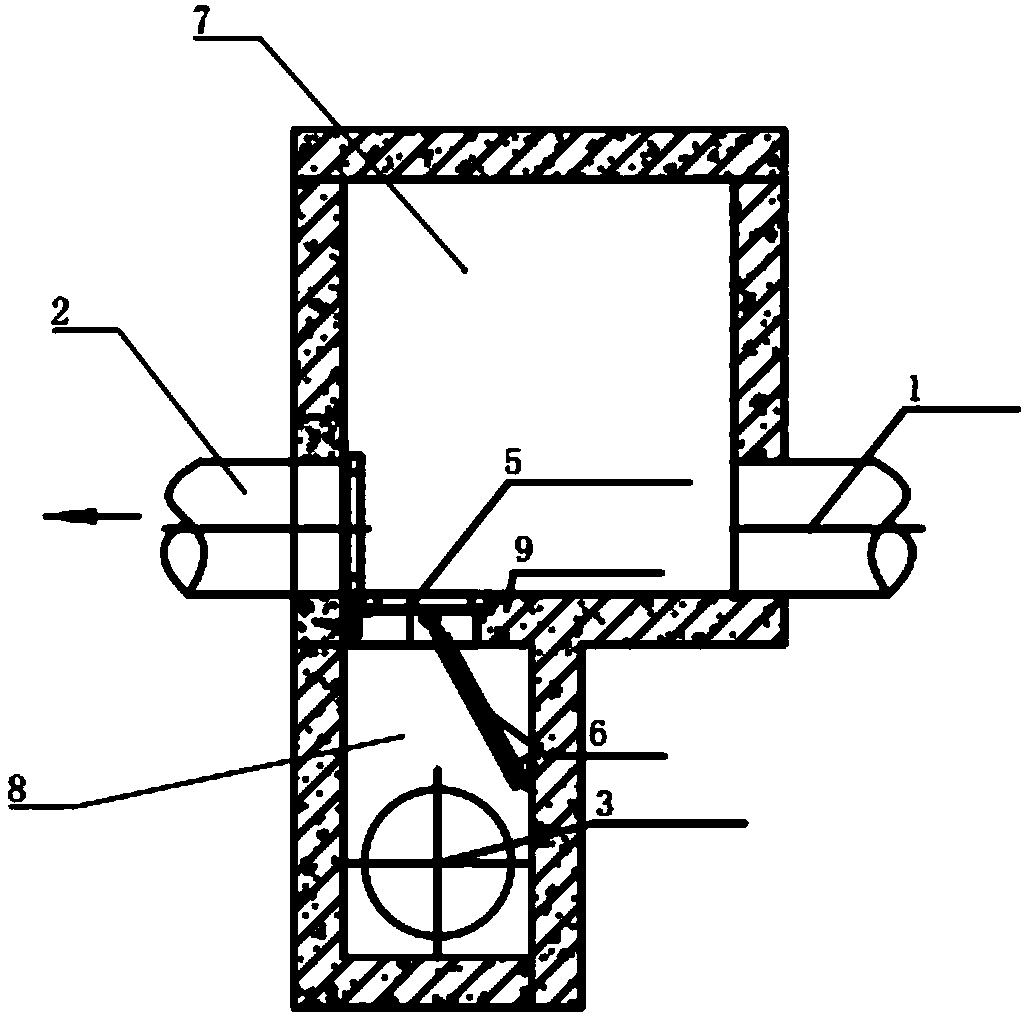

Water draining system with hydraulic downwards-open check gate and pump draining function and water draining control method

PendingCN107587580AReasonable arrangementReasonable dischargeSewerage structuresGeneral water supply conservationHigh elevationWater quality

The invention discloses a water draining system with a hydraulic downwards-open check gate and the pump draining function and a water draining control method. The water draining system is provided with a rainy-day submersible sewage pump, a sunny-day submersible sewage pump and the hydraulic downwards-open check gate; according to the liquid level height of water bodies in a well body of a flow dividing well or the water quality of water bodies in the well body of the flow dividing well, whether submersible sewage pumps work or not and the hydraulic downwards-open check gate is started or notcan be judged, and reasonable distribution of the water bodies is thus achieved. The water bodies with different water levels and / or water qualities can also be reasonably drained, and therefore the maximum governance effect is achieved. The water draining system is particularly suitable for the condition that a pipe extending to a sewage treatment plant is located at the high elevation and cannotbe drained in a gravity mode; as the submersible sewage pumps are arranged in the water draining system, water bodies with the poor quality in the well body of the flow dividing well are drained to the sewage treatment plant in a pump-draining mode, and during emergency flood discharging, sewage can also be drained to natural water bodies through a water outlet.

Owner:WUHAN SHENGYU DRAINING SYST

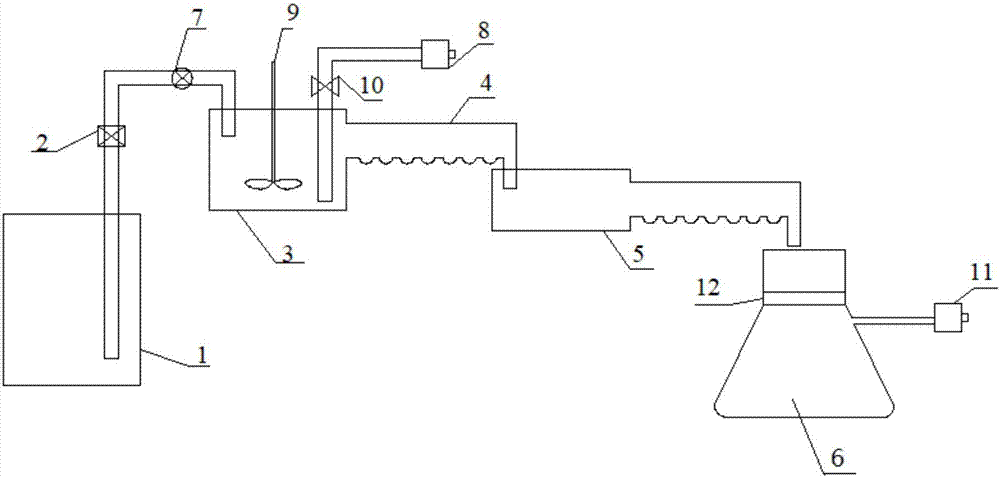

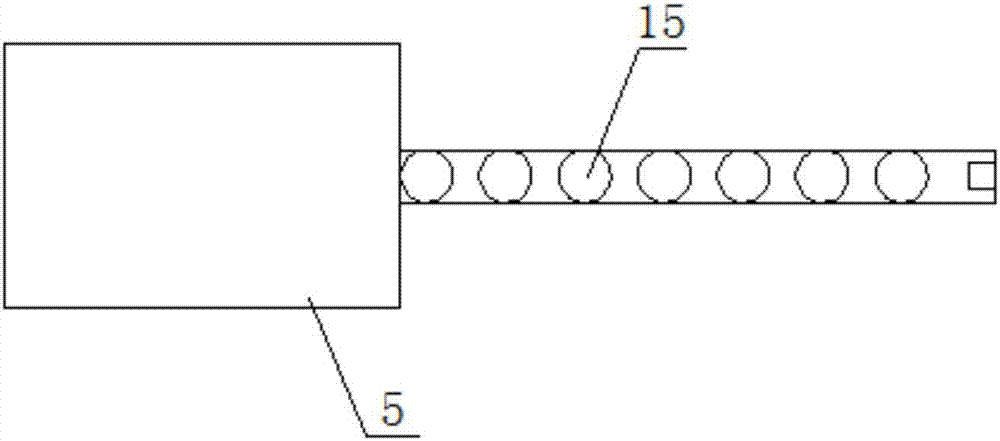

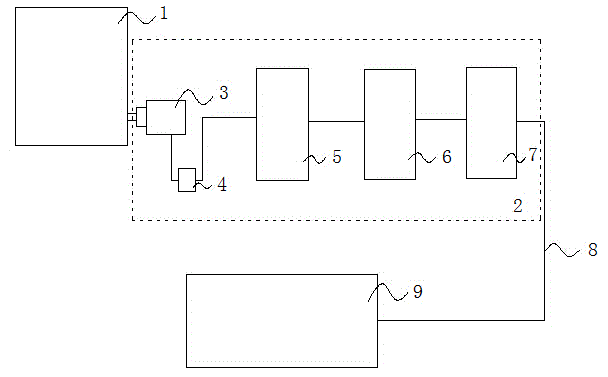

Online transformer oil chromatography monitoring system based on vacuum stirrer

InactiveCN104897816AEffective separationImprove degassing efficiencyComponent separationChromatography columnComputer data processing

The invention discloses an online transformer oil chromatography monitoring system based on a vacuum stirrer. The system comprises a data acquisition unit and a master control computer data processing and fault diagnosis system, wherein the data acquisition unit comprises an oil-gas separator, a chromatographic column, a gas sensor and a CPU (central processing unit), wherein a sampling end of the oil-gas separator is connected with a transformer, an output end of the oil-gas separator is connected to the chromatographic column through a cold trap, an output end of the chromatographic column is connected to the gas sensor, and an output end of the gas sensor is connected to the CPU; the data acquisition unit is connected to the master control computer data processing and fault diagnosis system through a communication network; a vacuum mixing and vibrating degassing device is arranged in the oil-gas separator; a carrier gas generating module is arranged in the data acquisition unit. According to the online transformer oil chromatography monitoring system, a conventional carrier-gas cylinder is replaced with the carrier gas generating module, stable carrier gas is provided for the monitoring system, the data accuracy of the monitoring system is guaranteed, frequent replacement of the carrier-gas cylinder is avoided, and the use is very convenient.

Owner:云南电网有限责任公司文山供电局

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com